Supercritical hydrothermal combustion device suitable for high-viscosity fuel

A supercritical water and combustion device technology, applied in lighting and heating equipment, mining fluids, boreholes/well components, etc., can solve problems such as high energy consumption and large pollution, achieve high heat energy utilization, save energy, prevent The effect of high temperature burning or even explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

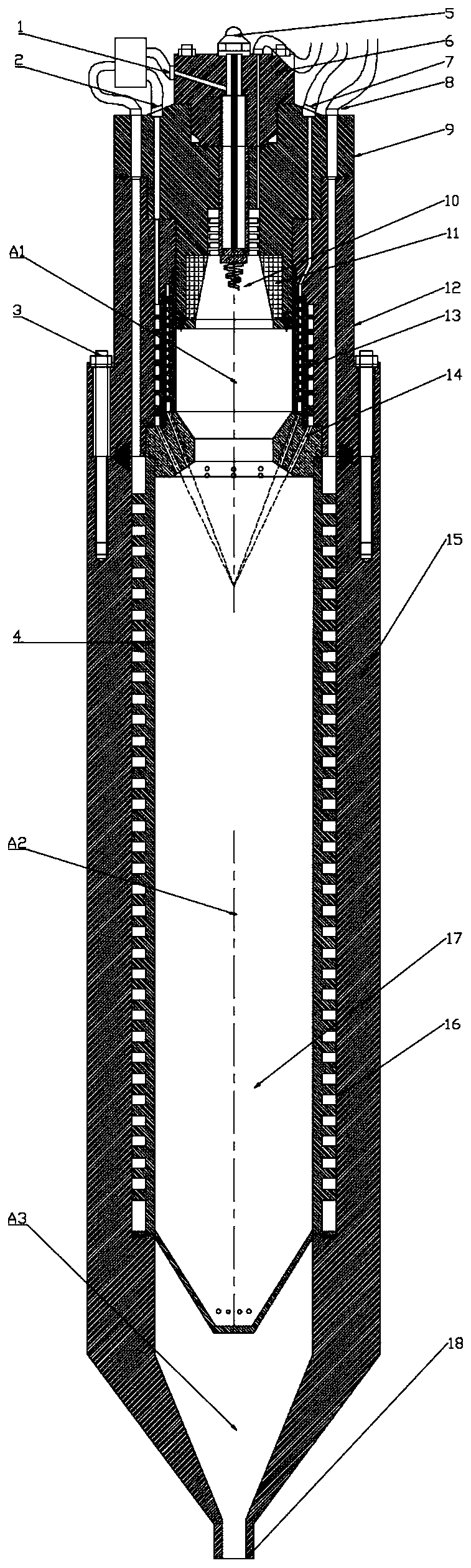

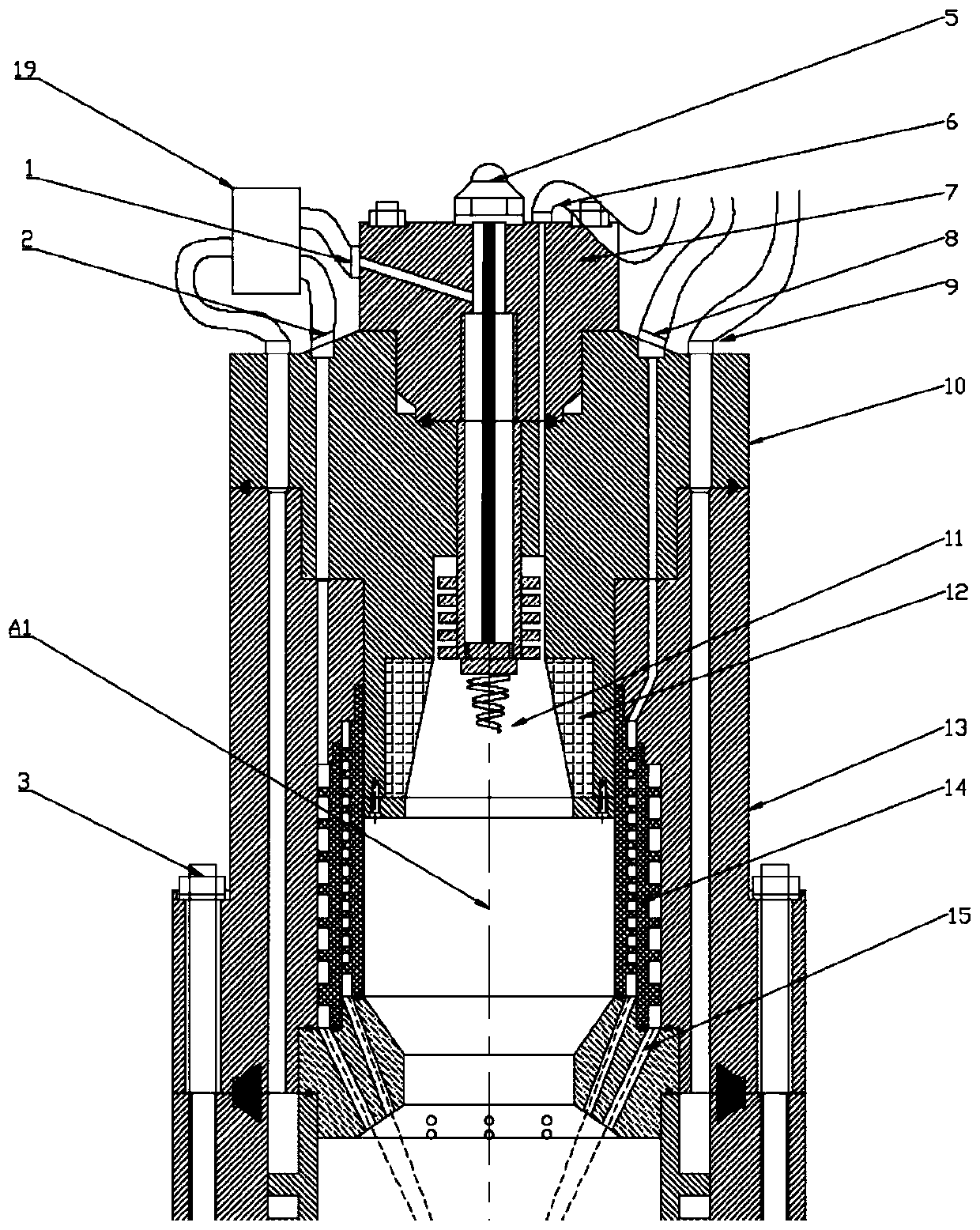

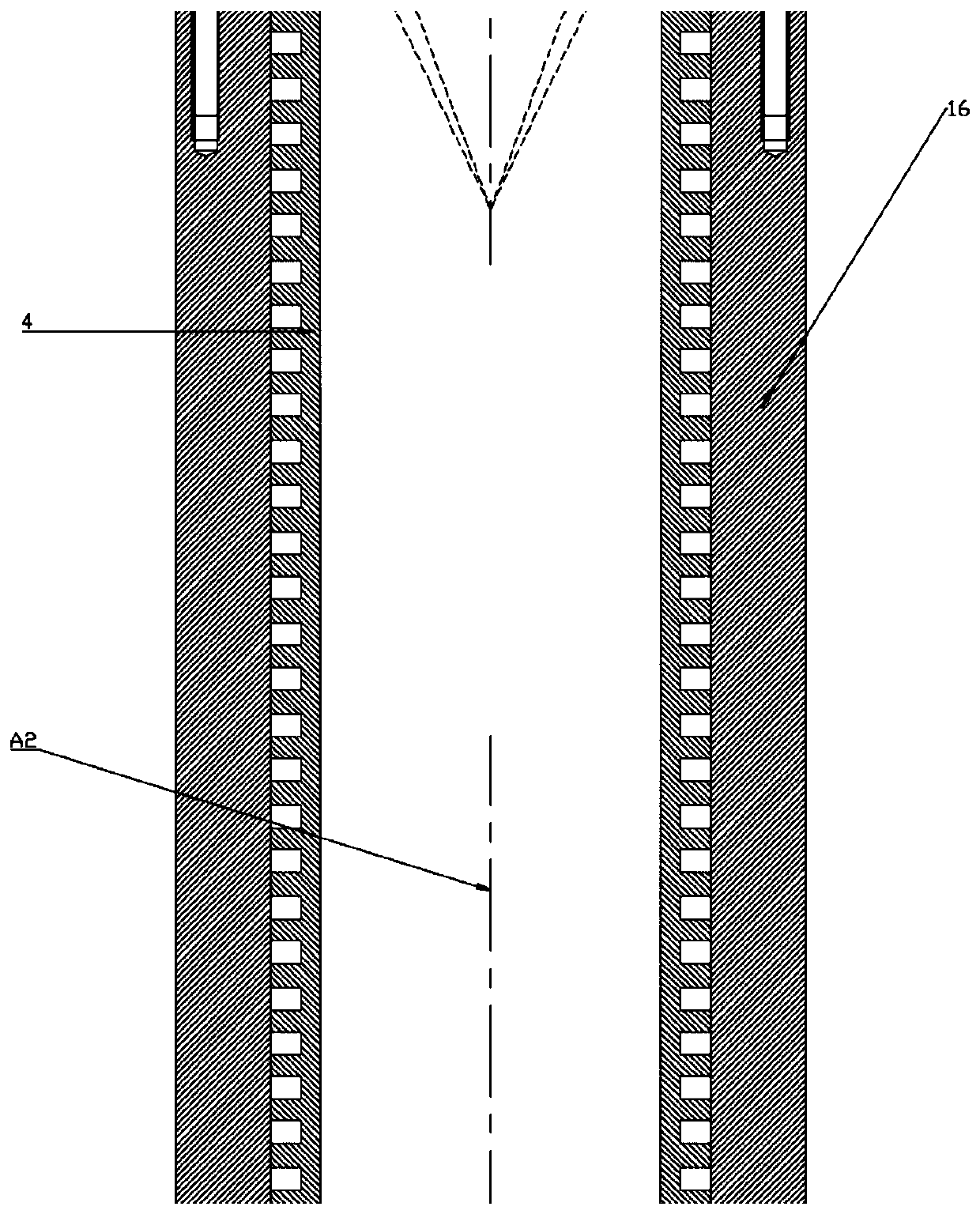

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is a supercritical hydrothermal combustion device suitable for high-viscosity fuel, which can use crude oil, diesel oil, gasoline, coal slurry or ethanol as fuel, and the device is mainly composed of four main components connected and assembled by bolt groups 3 in sequence : upper end cover 7, middle end cover 10, stable combustion chamber main body one 13 and combustion chamber main body two 16.

[0030] Among them, the upper end cover 7 is provided with a primary fuel inlet 1, a high-energy heating rod 5, and a primary oxidant inlet 6, and the middle end cover 10 is provided with a secondary fuel inlet 2, a secondary oxidant inlet 8, and a reactant primary nozzle 11, And can further set up the cold fuel inlet 9, the reactant primary nozzle 11 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com