Supercritical once-through boiler capable of firing eastern Junggar coal

A supercritical once-through furnace and furnace technology, which is applied to steam generation, lighting and heating equipment, etc., can solve the problems of long-term, safe and complete combustion of power station boilers, and achieve the effect of saving huge investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

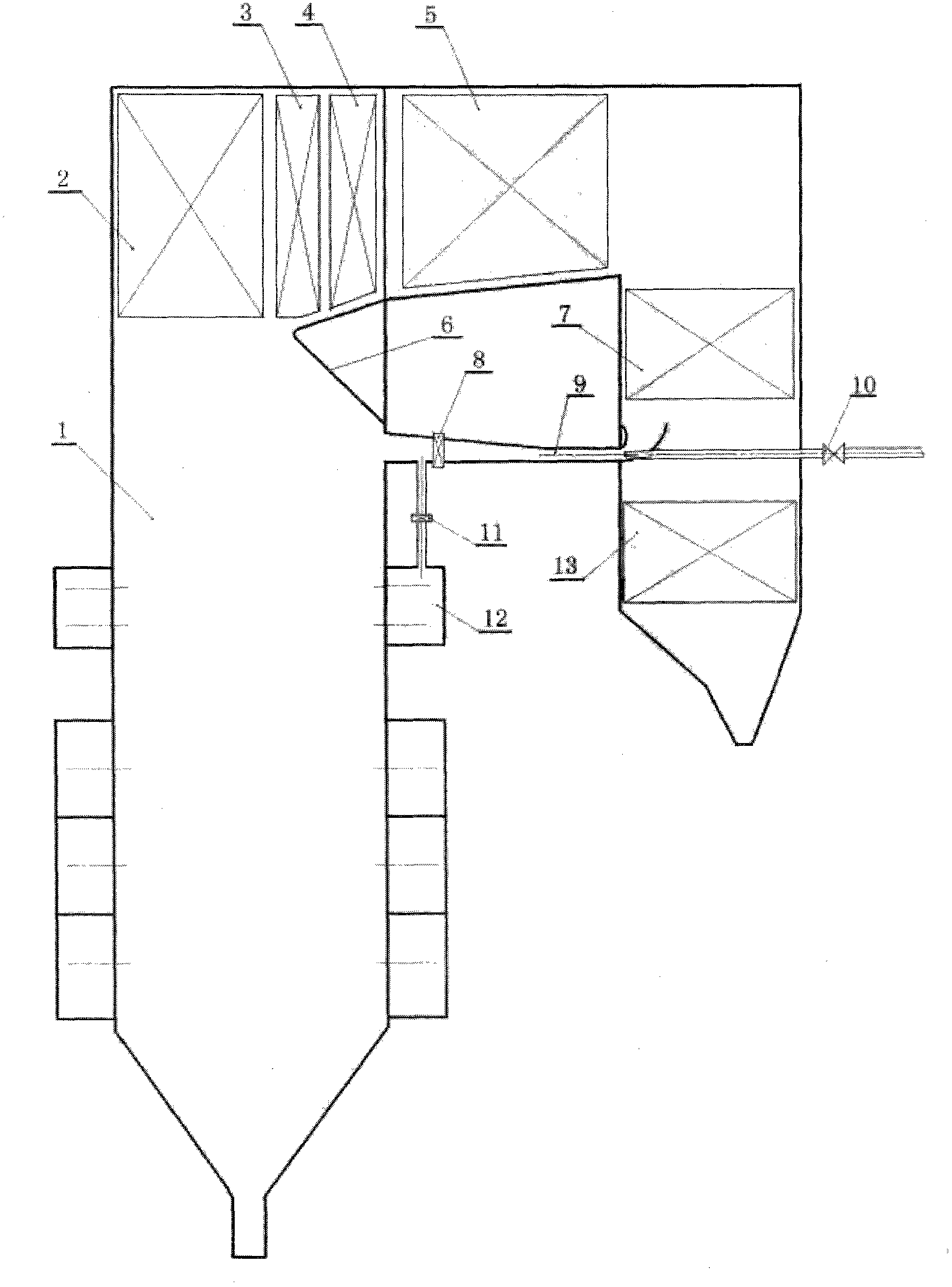

[0035] Example 1: Supercritical DC Furnace ∏ Type Furnace Scheme Using Zhundong Coal

[0036] Combine now figure 1 Taking a 600MW level primary reheat Π-type utility boiler with main steam temperature / reheat steam temperature 571°C / 569°C as an example to illustrate the optimal way to realize the invention.

[0037] The supercritical once-through furnace for burning Zhundong coal in the present invention comprises a furnace and a burner (1), a partition superheater (2), a panel superheater (3), a high-temperature superheater (4), and a high-temperature reheater (5) ), folding smoke angle (6), low-temperature reheater (7), air-smoke ejector shut-off baffle (8), temperature-regulating air-smoke ejector (9), injector hot primary air adjustment baffle (10 ), injector deactivation protection cooling wind baffle (11), separated secondary air wind box (12), economizer (13); use very low furnace volume exothermic intensity; in boiler, low load and / or high temperature When the contami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com