Device for recovering waste heat and supplying steam through multistage dilatation flashing

A steam and flash evaporation technology, which is applied in the field of high-temperature waste heat utilization, can solve the problems of heat absorption affecting heat generating devices, high operating costs, and long distances between hot spots of production and hot spots of consumption, etc., and achieves insensitivity to heat load fluctuations and automatic adjustment of production The effect of stable steam volume and steam pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

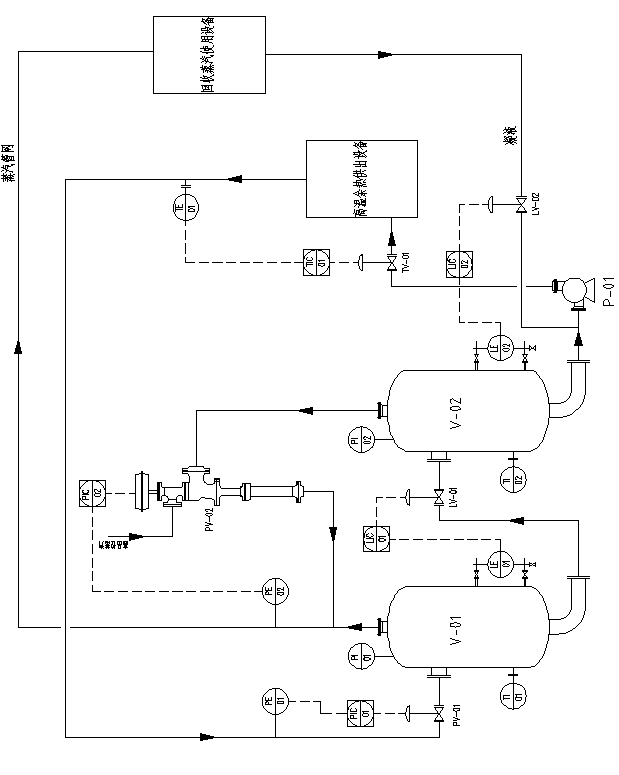

[0032] figure 1 Structural block diagram of waste heat recovery and steam supply device for secondary expansion flash evaporation, including: primary flash tank V-01, secondary expansion flash tank V-02, hot water circulation pump P-01, hot water pipe network Pressure regulating valve PV-01, steam injection heat pump PV-02, hot water main pipe temperature control system TIC-01 (including temperature regulating valve TV-01 and temperature transmitter TE-01), primary flash tank V-01 The liquid level control system LIC-01 (including liquid level regulating valve LV-01 and liquid level transmitter LE-01) is installed on the top, and the liquid level control system LIC-02 ( Including liquid level regulating valve LV-02 and liquid level transmitter LE-02), all devices are connected by pipelines, in which water (or low-pressure steam or steam-water mixture) is used as the heat carrier, and hot water is preferred Heat carrier, safe and stable.

[0033] As a further improvement, temp...

Embodiment 2

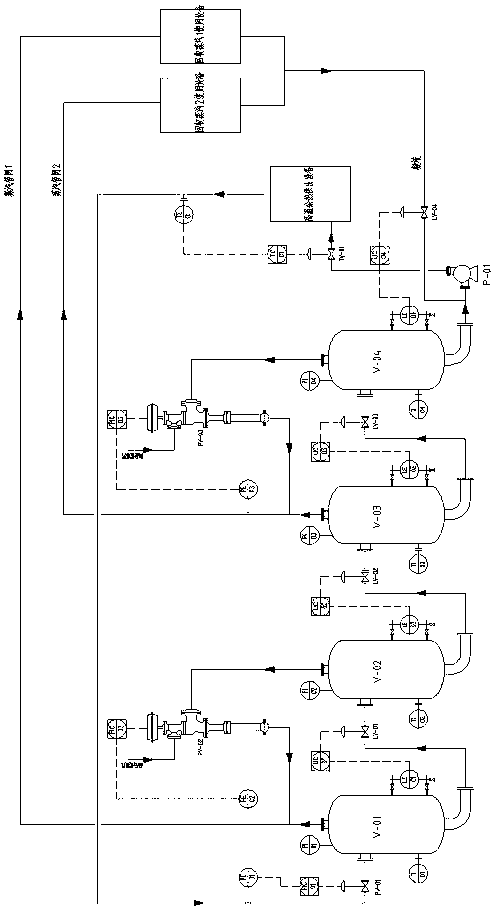

[0043] figure 2 Schematic diagram of the simplified structure for recovering waste heat and supplying steam for four-stage expansion flash evaporation, including: one-stage flash tank V-01, two-stage expansion flash tank V-02, three-stage flash tank V-03, four-stage expansion Flash tank V-04, hot water circulation pump P-01 (multiple equipment can be used according to process characteristics), including pressure regulating valve PV-01, steam injection heat pump PV-02, including steam injection heat pump PV-03, Each flash tank is equipped with a liquid level control system: liquid level control system LIC-01 (including liquid level control valve LV-01 and liquid level transmitter LE-01), LIC-02 (including liquid level control valve LV-02 and liquid level transmitter LE-02), LIC-03 (including liquid level control valve LV-03 and liquid level transmitter LE-02), LIC-04 (including liquid level control valve LV-04 and Liquid level transmitter LE-02), hot water main pipe tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com