Manufacturing clamp for induction electric heater of liquid collection tank of gas-liquid separator

A technology of gas-liquid separation device and liquid collection tank, which is applied in the direction of lighting and heating equipment, refrigerators, refrigeration components, etc., and can solve the problems of limited heat exchange, damage to lubricating oil, small contact area between electric heater and liquid collection tank, etc. problems, to achieve the effect of convenient maintenance and replacement, enlarged contact area, uniform and effective heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

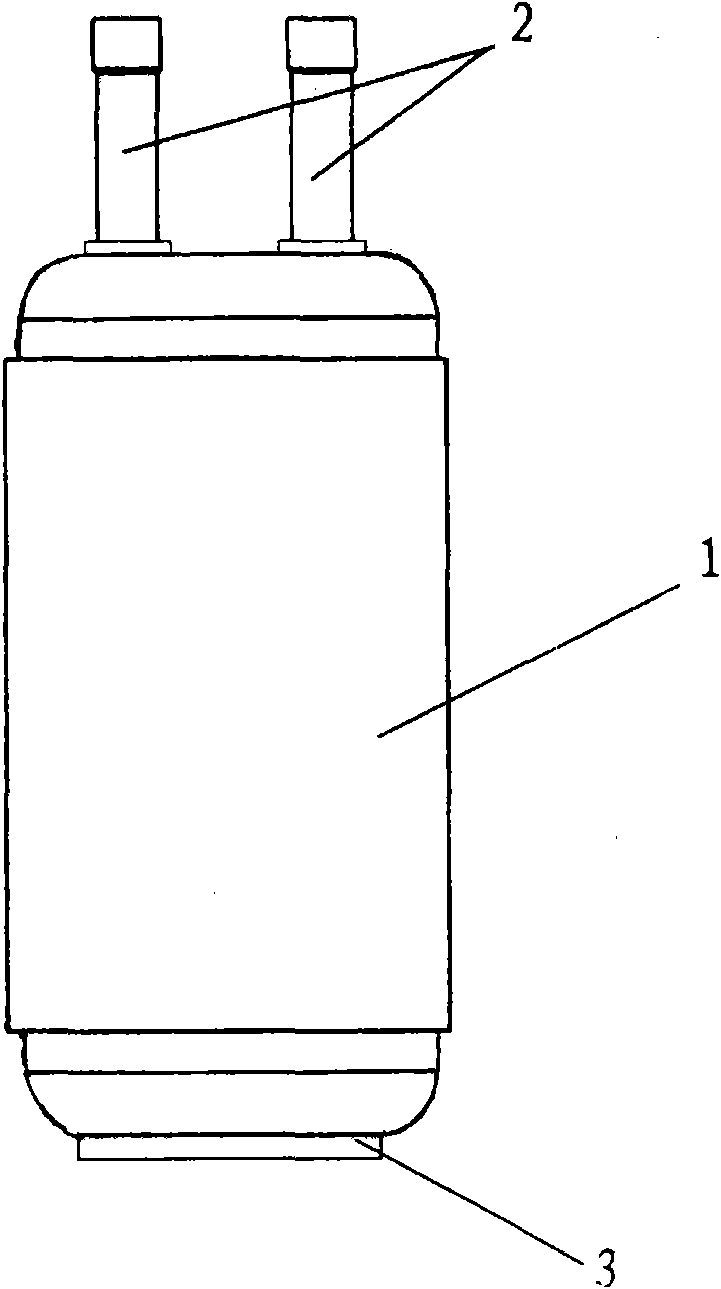

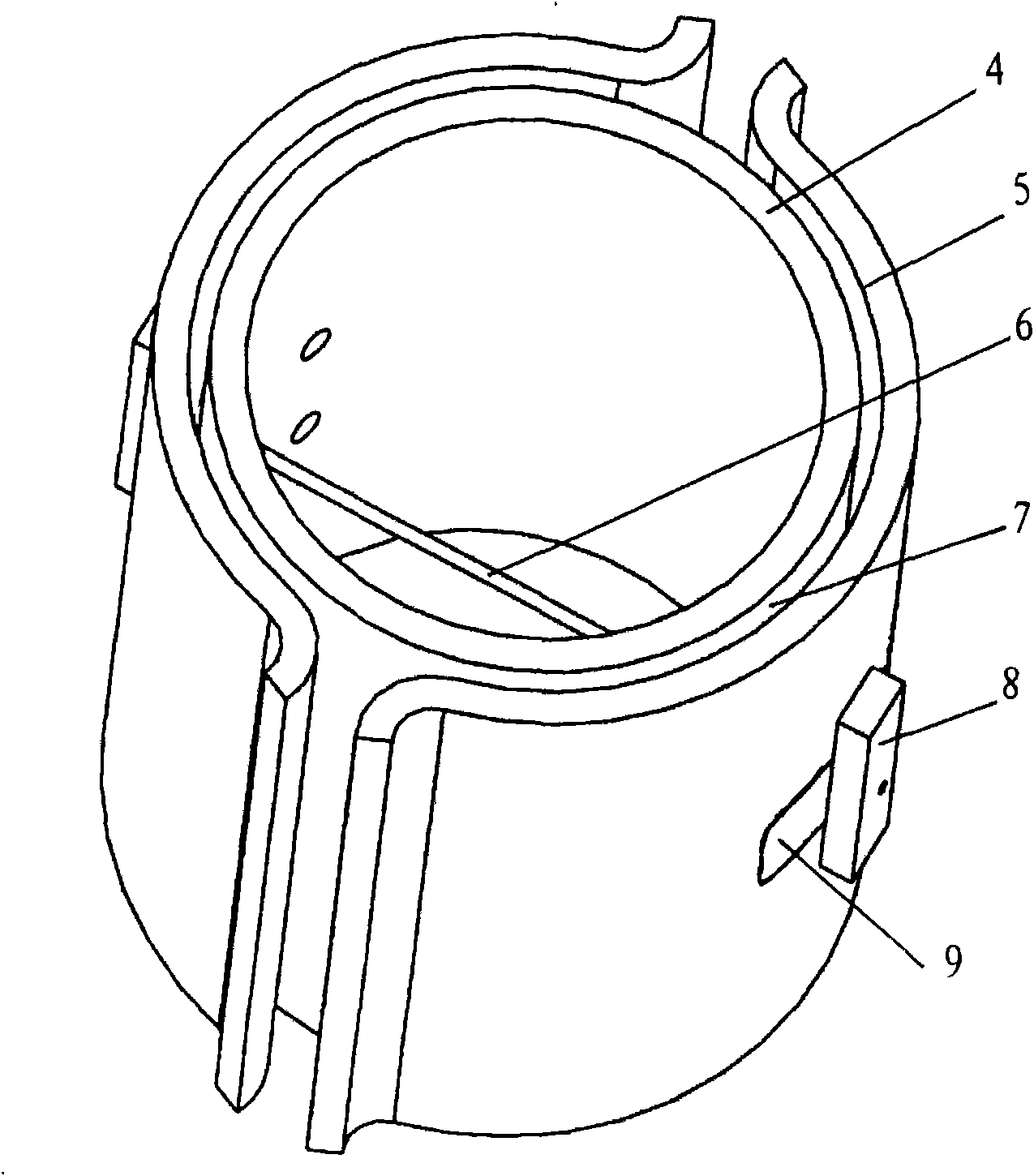

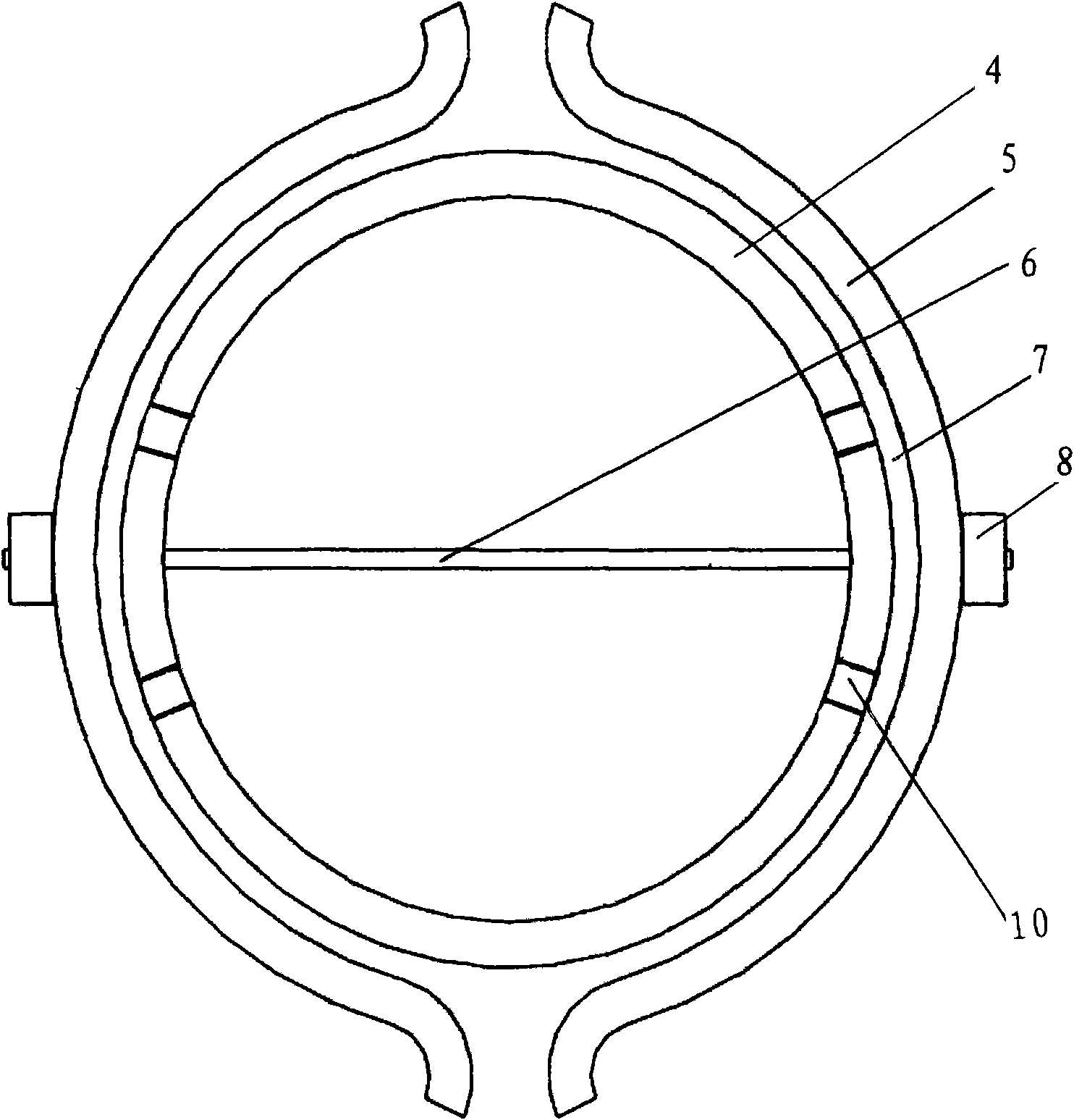

[0026] The production clamp for the induction electric heater of the liquid collection tank of the gas-liquid separation device of the present invention will be further described in conjunction with the accompanying drawings. figure 2 It shows the jig structure for making the induction electric heater of the gas-liquid separation device liquid collection tank of the present invention, image 3 A cross-sectional view showing the fabrication jig for an induction electric heater, Figure 4 It shows the state that the induction electric heater is installed on the liquid collection tank of the gas-liquid separation device.

[0027] As shown in the figure, the production jig for the induction electric heater of the liquid collection tank of the gas-liquid separation device involved in the present invention is composed of a cylindrical inner cylinder 4 and a curved surface shell 5, and two symmetrical curved surface shells 5 are fixed inside by metal threaded rods 6 On the outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com