Low-nitrogen efficient energy-saving high temperature and high pressure circulating fluidized bed boiler

A circulating fluidized bed, high-efficiency and energy-saving technology, applied in the field of boiler equipment, can solve the problems of large initial investment in equipment, increased operating costs of enterprises, and long transformation period, so as to achieve stable and reliable operation, reduce plant power consumption, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

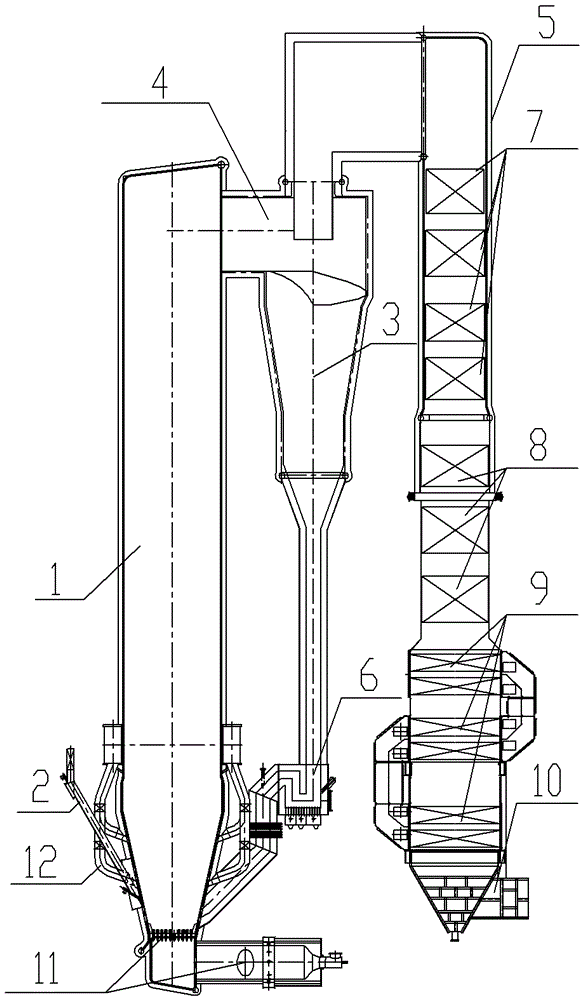

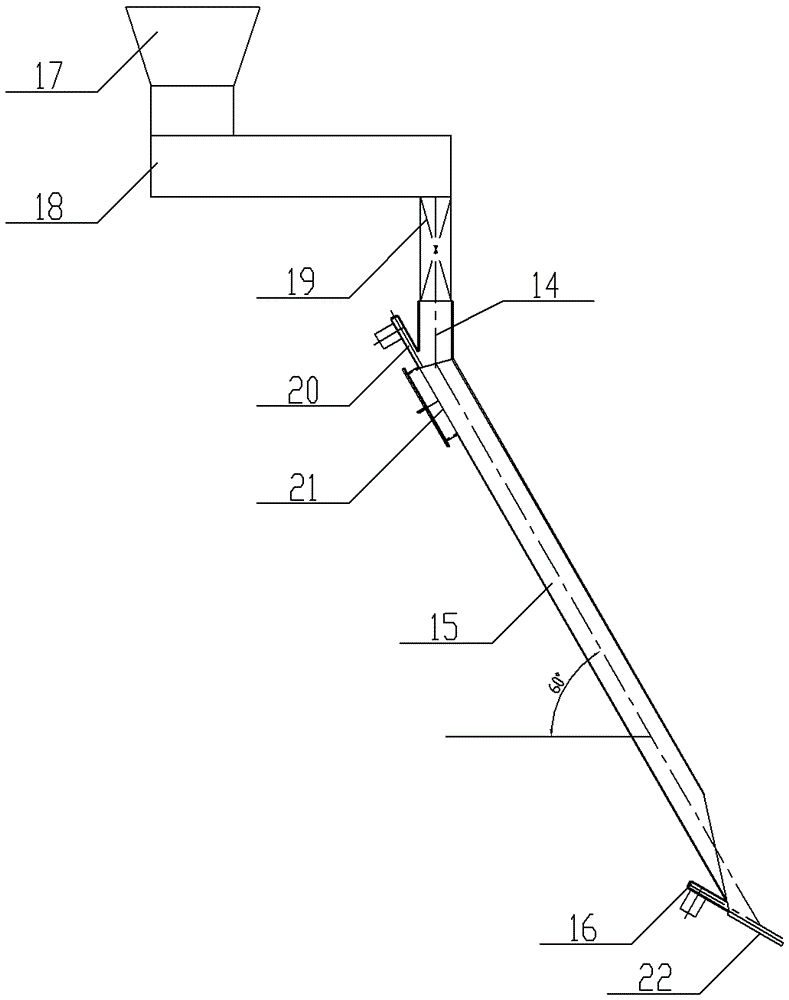

[0025] See Figure 1 to Figure 7 As shown, a high-temperature, high-pressure, low-nitrogen, high-efficiency and energy-saving circulating fluidized bed boiler includes a furnace 1, the lower end of the furnace 1 is provided with a coal feeding system 2 and a secondary air system, the upper end of the furnace 1 is connected to a separation system 3, and the separation system 3 Including the separator inlet flue 23 and the cyclone separator 24, the ammonia injection denitrification system 4 in the furnace is arranged between the furnace 1 and the cyclone separator 23, the separator inlet flue 23 is connected to the furnace 1, and the upper end inlet of the cyclone separator 24 is connected to the tail The flue 5, the return system 6 is installed between the lower outlet of the cyclone separator 23 and the lower end of the furnace 1, and the tail flue 5 is provided with a superheater 7, an economizer 8 and a preheater 9 and is connected to the outlet flue 10; A secondary air syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com