High temperature corrosion resisting low NOx vortex burning device

A high-temperature corrosion and combustion device technology, which is applied in the direction of burning with various fuels, burners, and burning with block fuels and liquid fuels, can solve problems such as high-temperature corrosion, reduce the generation of NOx, prolong the transit time, The effect of suppressing the production of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

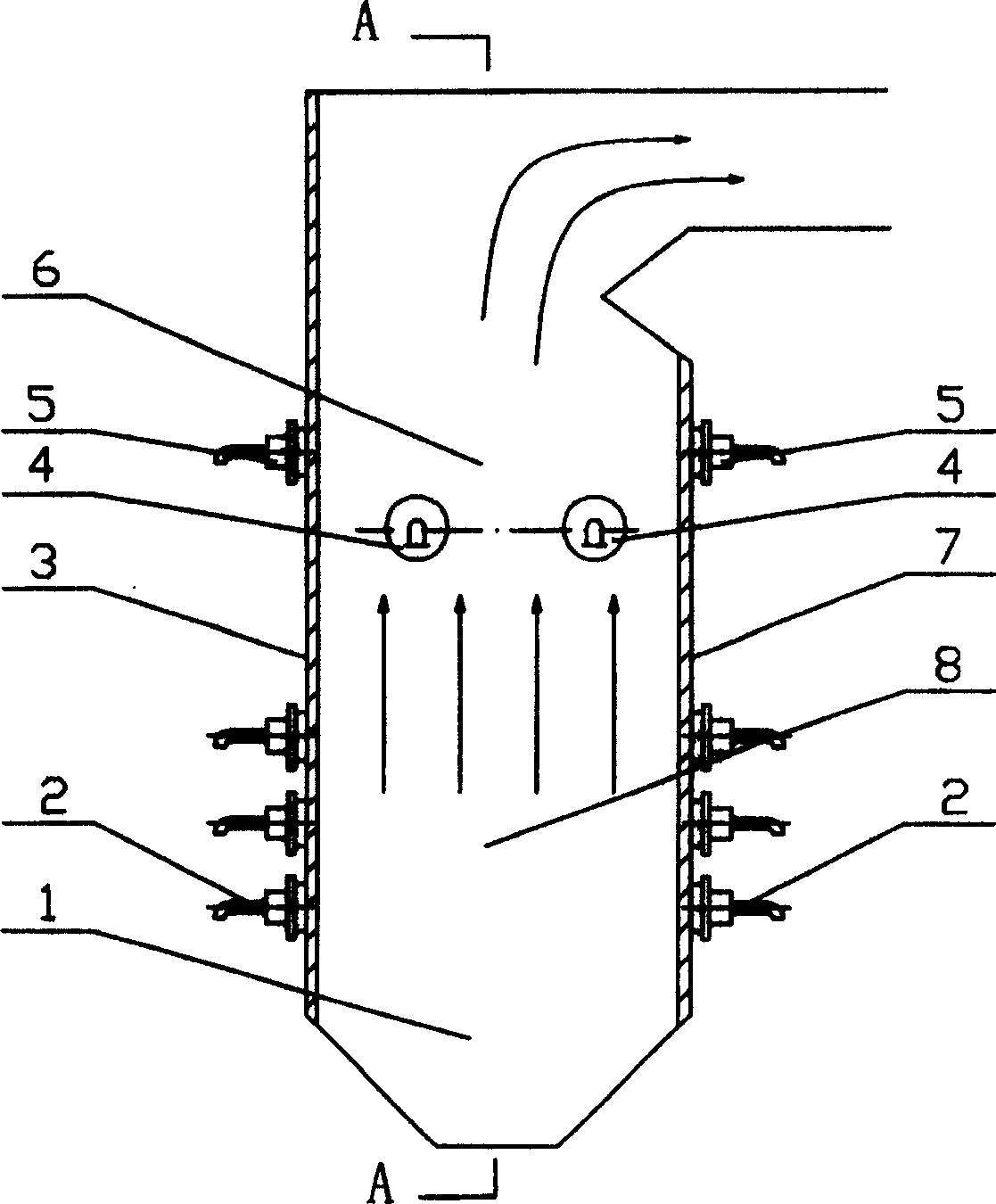

[0007] Specific implementation mode one: (see figure 1 , Figure 4 ) This embodiment consists of a furnace 1, a plurality of central powder feeding swirl pulverized coal burners 2, a front wall 3, a side wall OFA (overburned air) nozzle 4, a swirling OFA (overfired air) nozzle 5, and a burnout zone 6. The rear wall 7, the main combustion area 8 and two side walls 9; the furnace 1 is formed between the front wall 3, the rear wall 7 and the two side walls 9, and the side wall OFA (overfired air) nozzle 4 is set in the furnace The upper part of the two side walls 9 in 1, the furnace 1 area where the pulverized coal burner 2 is located is the main combustion zone 8 in the center of the side wall OFA (burned out air) nozzle 4, and the side wall OFA (burned out air) The furnace 1 area where the wind) nozzle 4 and the swirl OFA (overburned air) nozzle 5 are located is the burnout zone 6, and a plurality of central powder-feeding swirl pulverized coal burners 2 are respectively arran...

specific Embodiment approach 2

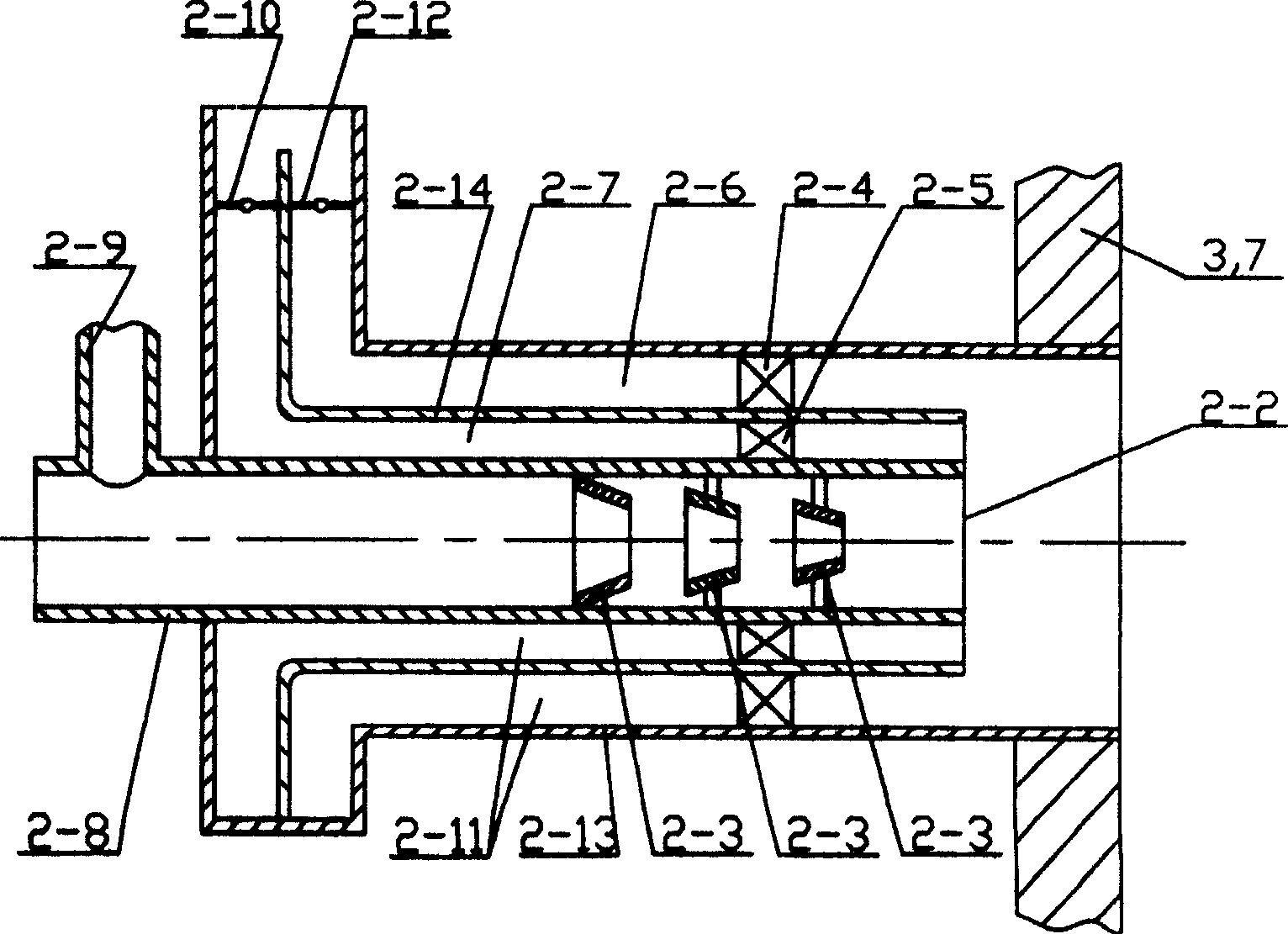

[0008] Specific implementation mode two: (see figure 2 ) The central powder feeding swirl pulverized coal burner 2 of the present embodiment consists of a burner 2-2, three conical separation rings 2-3, an outer swirl 2-4, an inner swirl 2-5, a primary Air duct 2-8, powder delivery pipeline 2-9, inner air door baffle 2-10, outer air door baffle 2-12, burner shell 2-13 and barrel-shaped partition 2-14, the burner shell The body 2-13 is fixedly connected with the front wall 3 or the rear wall 7, the primary air duct 2-8 is arranged at the center of the burner housing 2-13, and the primary air duct 2-8 is located in the burner housing 2-13 One end is the burner 2-2, the powder conveying pipeline 2-9 is arranged on the outside of the burner housing 2-13, the powder conveying pipeline 2-9 is fixedly connected with the primary air pipe 2-8, and the primary air pipe 2-8 is provided with There are three conical separation rings 2-3, and the diameters of the three conical separation ...

specific Embodiment approach 3

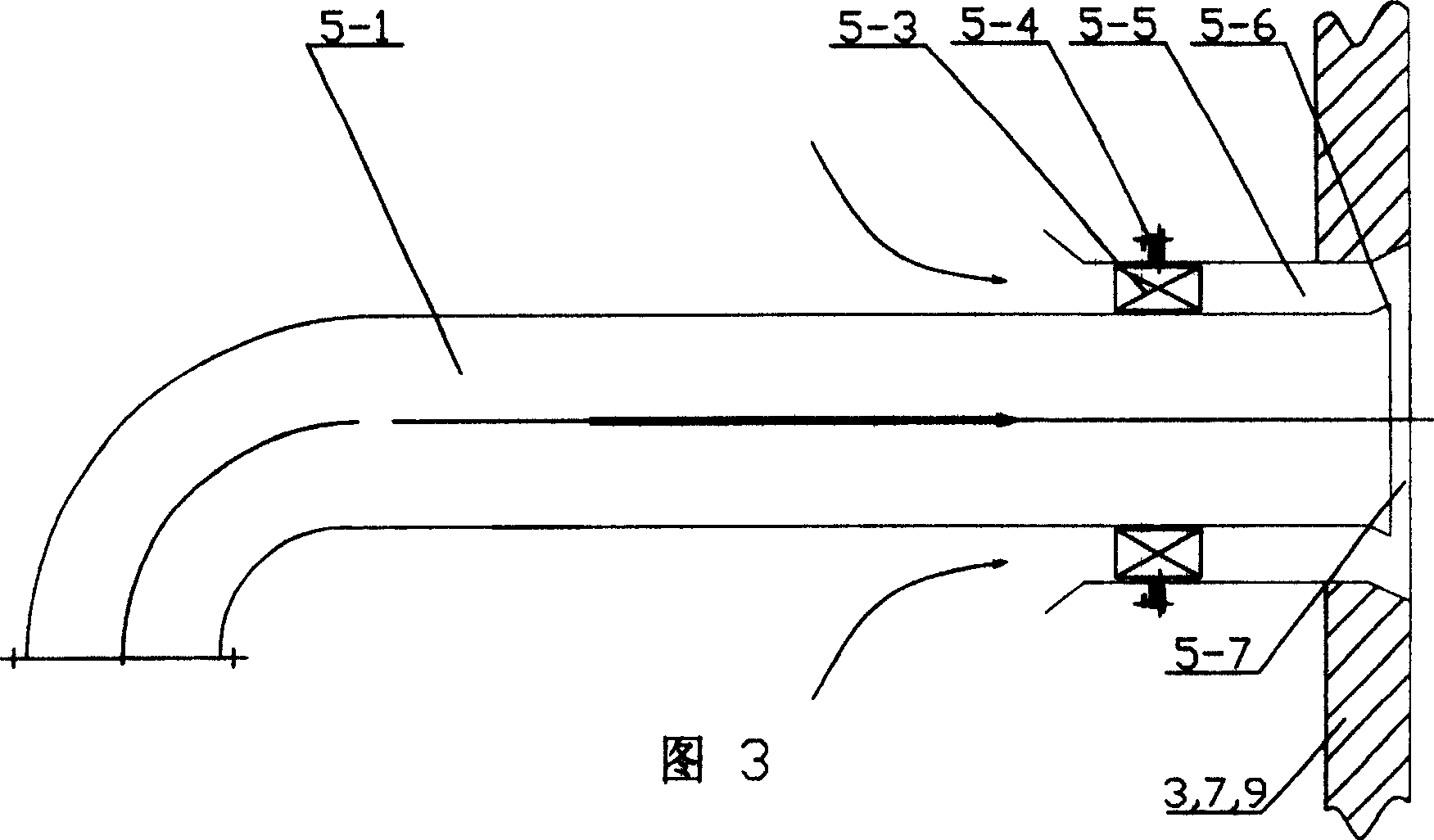

[0009] Specific embodiment three: (see Fig. 3) the swirl OFA (overburned air) nozzle 5 of the present embodiment is composed of a central secondary air duct 5-1, a swirler 5-3, a damper baffle plate 5-4, and a secondary air duct 5-1. The air channel 5-5 is composed of the central secondary air nozzle 5-6 and the secondary air nozzle 5-7. The central secondary air channel 5-1 is fixed on the front wall 3, the rear wall 7 or the side wall 9, and the secondary air The spout 5-7 is arranged on the side of the central secondary air spout 5-6 of the central secondary air duct 5-1, and a cyclone 5 is fixed between the secondary air spout 5-7 and the central secondary air duct 5-1 -3, the damper baffle plate 5-4 is arranged on the outside of the secondary air nozzle 5-7 on one side of the cyclone 5-3, and a secondary air outlet 5-7 is formed between the secondary air outlet 5-7 and the central secondary air duct 5-1. Secondary air duct 5-5. The airflow entering the central secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com