Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127results about How to "Prevent high temperature corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

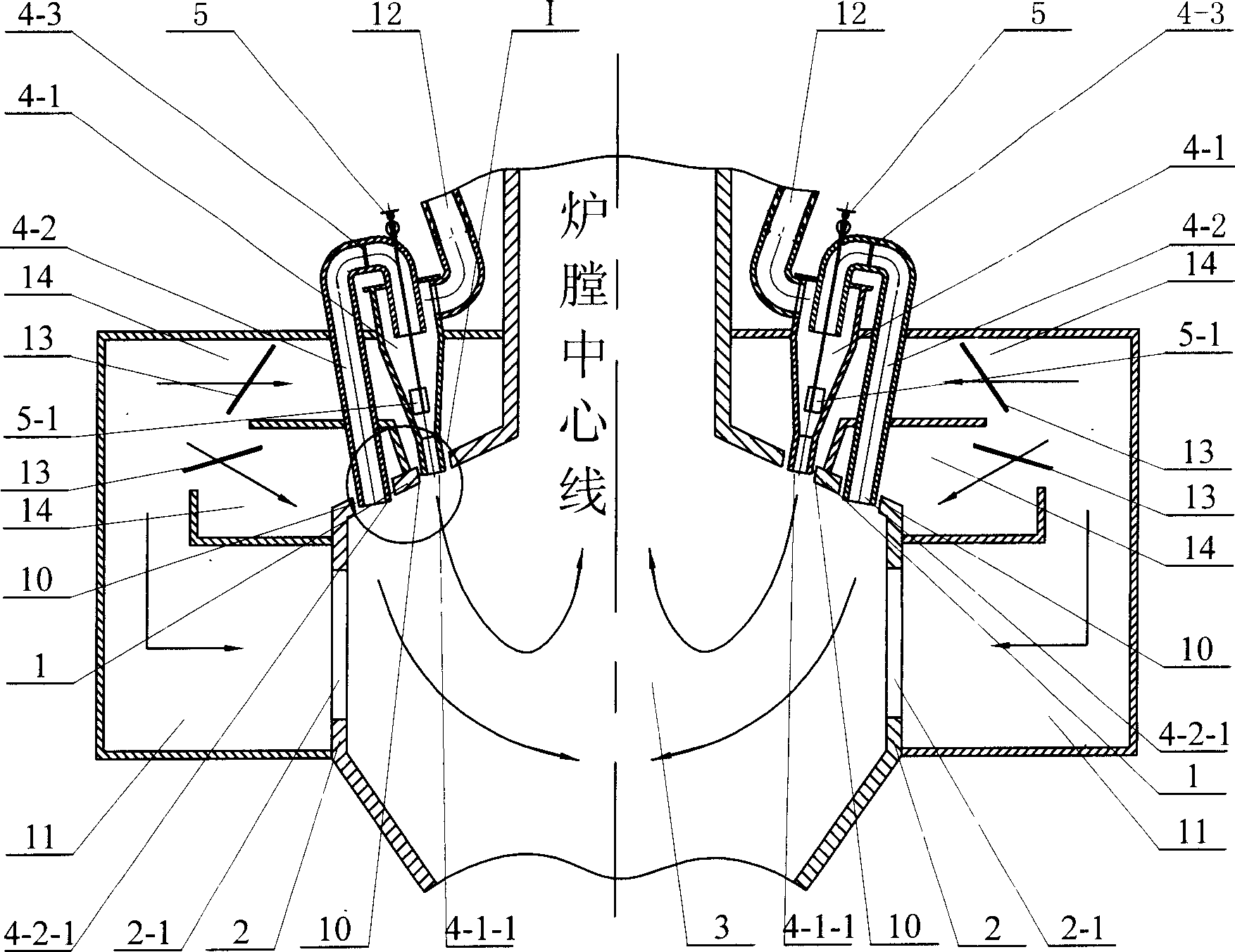

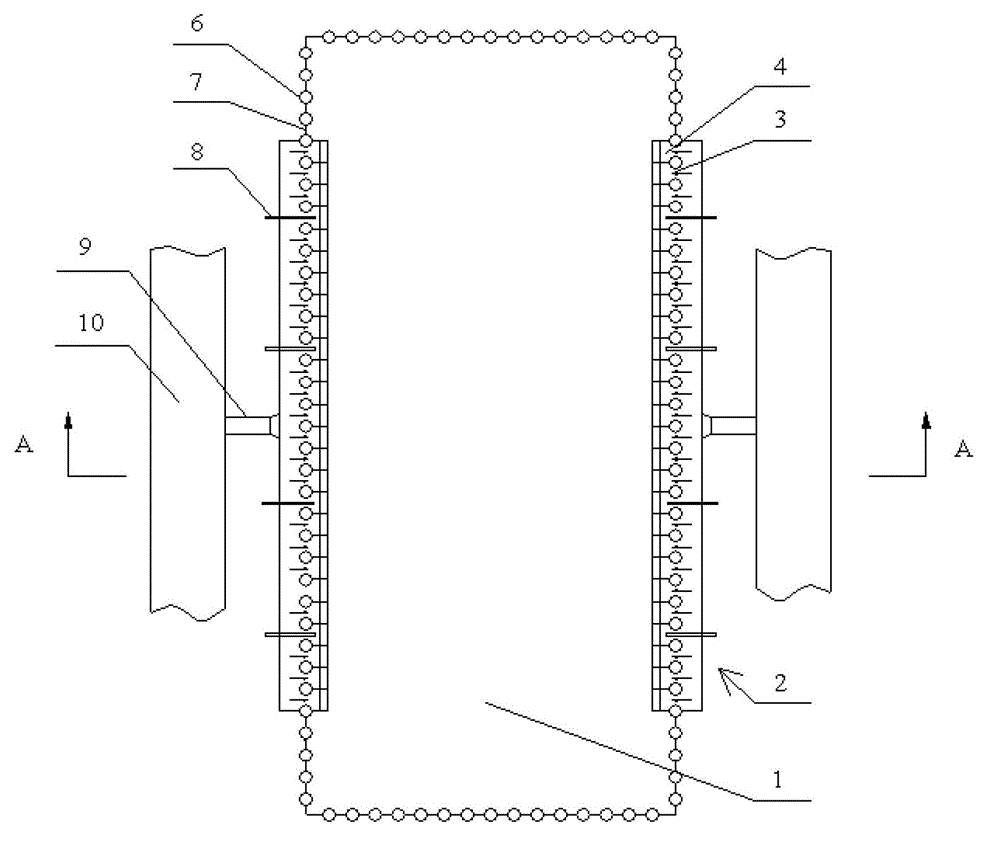

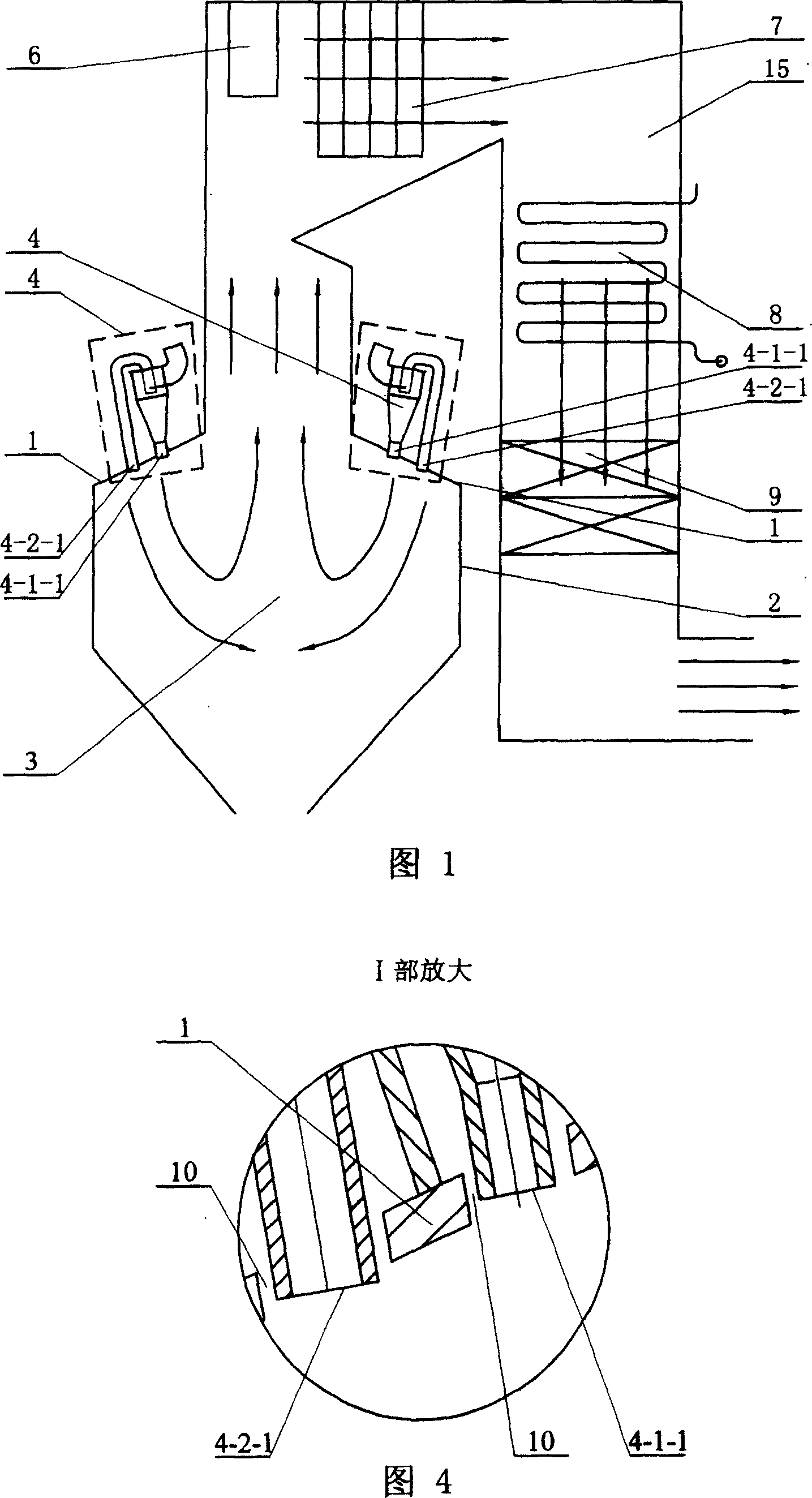

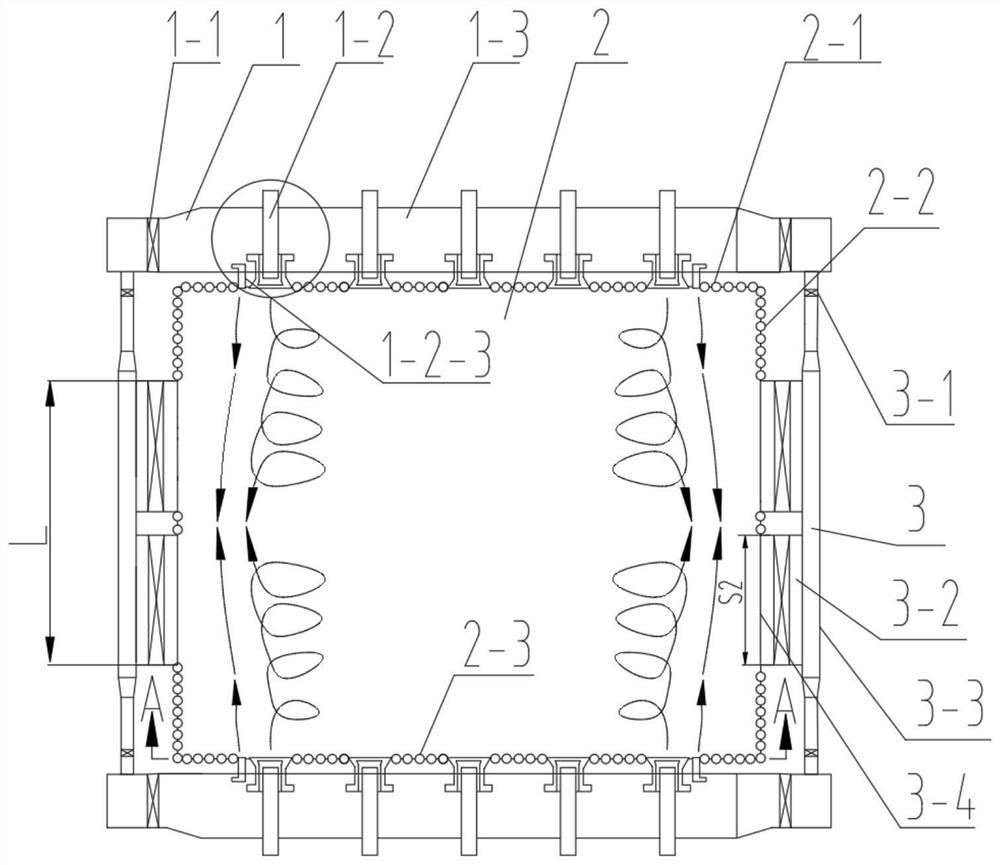

Near-wall air device for preventing high-temperature corrosion of water-cooled wall of power station boiler

InactiveCN101706110AReduce resistanceOvercome the shortcoming of fast wind speed attenuationCasings/liningsAir volumeCombustor

The invention discloses a near-wall air device for preventing the high-temperature corrosion of the water-cooled wall of a power station boiler, which comprises an air duct, a regulating valve, a near-wall air box, near-wall air unit nozzles, a fuel component on-line monitor and a speed measuring device, wherein the direction of the near-wall air is parallel to the axis of a pipe of the water-cooled wall, the resistance along the course is small and the air speed reduction is slow; only one layer of near-wall air nozzles is required to be arranged in a burner area and the system structure is simple; and the nozzles are flexibly arranged, the nozzle cooling condition is good, the operational air volume is small and the stability is high. Thus, the device is suitable to be promoted for preventing the high-pressure corrosion of the water-cooled walls of power station boilers.

Owner:XI AN JIAOTONG UNIV +1

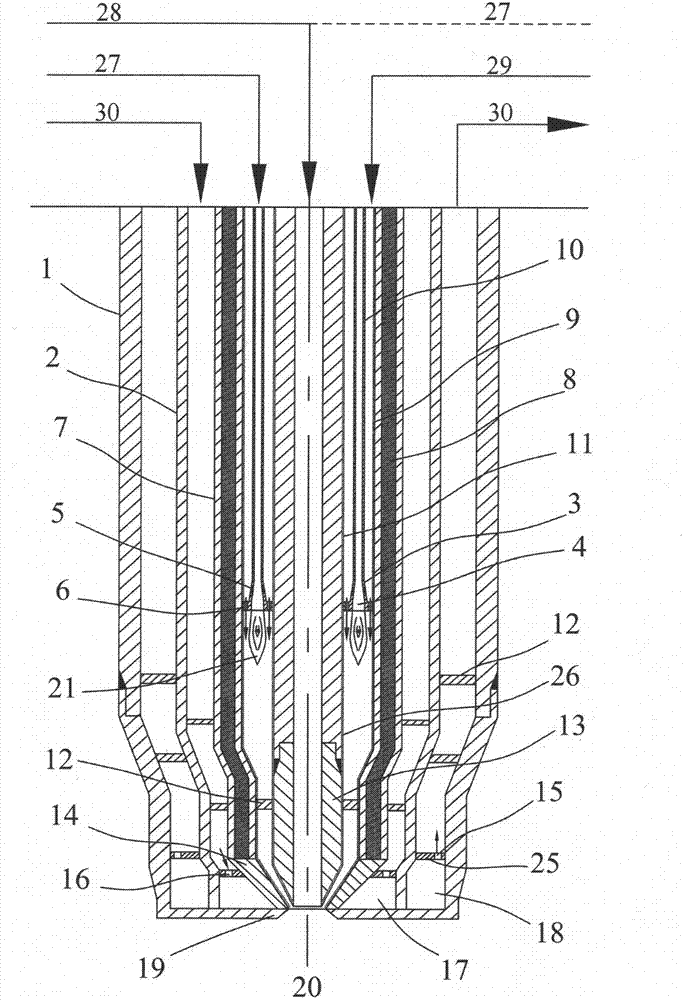

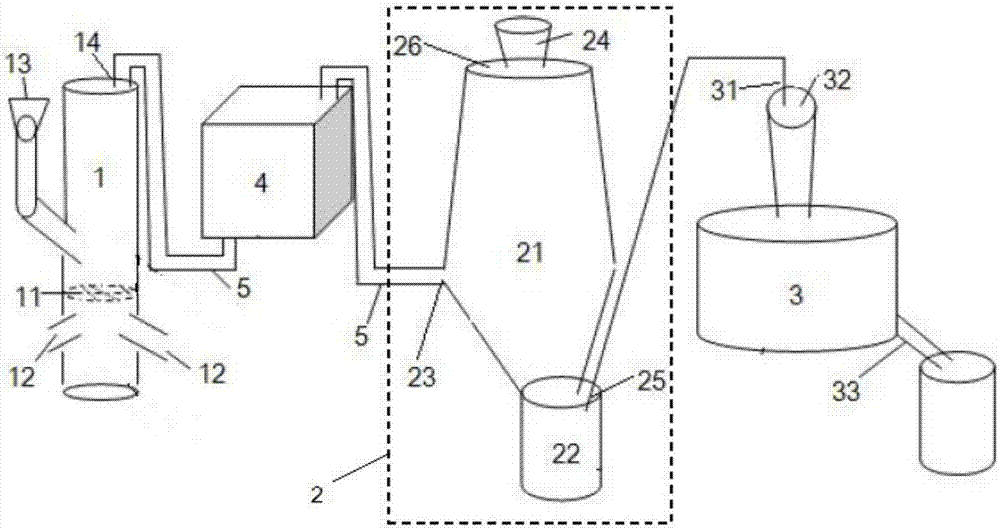

Combined-type thermal-oxidation igniting process nozzle for gasifying solid powder fuel

ActiveCN102767827ASimple structureEasy to manufacture and maintainBurnersIndirect carbon-dioxide mitigationEngineeringOxygen

The invention provides a combined-type thermal-oxidation igniting process nozzle for gasifying solid powder fuel. The combined-type thermal-oxidation igniting process nozzle for gasifying the solid powder fuel is characterized by comprising a central passage, a thermal-oxidation spray gun fuel passage circularly shaped is uniformly arranged outside the central passage, a side gasifying agent inlet is reserved on the outer wall of the thermal-oxidation spray gun fuel passage, a thermal-oxidation spray gun burner is arranged inside the thermal-oxidation spray gun fuel passage, and a gasifying agent spraying nozzle is arranged on the head portion of the thermal-oxidation spray gun burner. An outer metal wall of a thermal-oxidation passage coaxial with the central passage is arranged outside the thermal-oxidation spray gun fuel passage, an inner metal wall of a cooling jacket is coaxially arranged outside of the outer metal wall of the thermal-oxidation passage, and an outer metal wall of the cooling jacket is coaxially arranged outside the inner metal wall of the cooling jacket via a middle tube wall of the cooling jacket. By the aid of the combined-type thermal-oxidation igniting process nozzle for gasifying the solid powder fuel, defects in the prior art are overcome, a start working nozzle and the process nozzle are integrated, and the whole igniting process of a gasification furnace is simplified. The combined-type thermal-oxidation igniting process nozzle for gasifying the solid powder fuel has the advantages of multiple functions, wide applications, long service life and the like.

Owner:SHANGHAI BOILER WORKS

Ascending pipe heat exchange device for raw gas of coke oven

ActiveCN103436272AImprove insulation effectReduce lossesEnergy inputStationary tubular conduit assembliesSaline waterFlue gas

The invention discloses an ascending pipe heat exchange device for the raw gas of a coke oven, and belongs to the technical field of recycling utilization of raw gas afterheat. The ascending pipe heat exchange device for the raw gas of the coke oven comprises a flue gas inlet flange arranged at the lower end of the ascending pipe heat exchange device, a flue gas outlet flange arranged at the upper end of the ascending pipe heat exchange device, an inner barrel, a middle barrel and an outer barrel, wherein an inner sandwich layer is formed between the inner barrel and the middle barrel, desalted water or nitrogen or air is fed into the inner sandwich layer, and an outer sandwich layer is formed between the middle barrel and the outer barrel and is a closed thermal insulating layer. The ascending pipe heat exchange device can be used for ensuring a heat exchange effect, effectively, safely and reliably recycling the raw gas afterheat, ensuring the safe and economic operation of the coke oven and a heat exchanger under severe working conditions and meanwhile solving the problem of narrow adaptation of a conventional heat exchanger in starting and stopping processes.

Owner:江苏龙冶节能科技有限公司

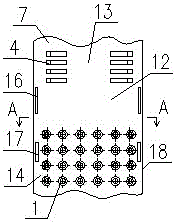

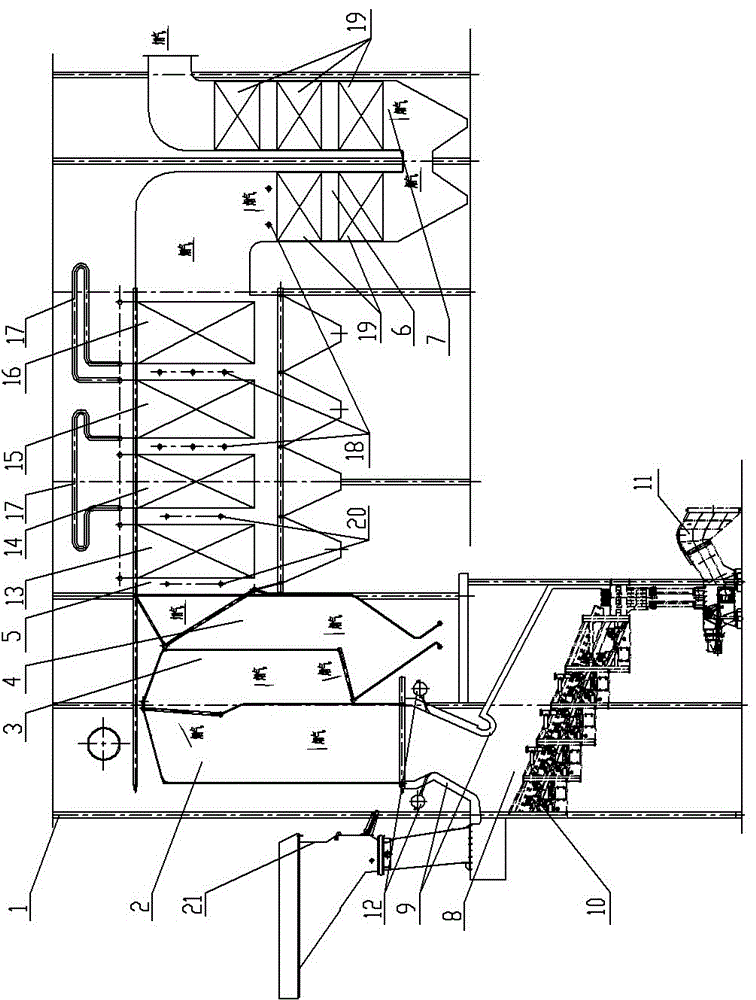

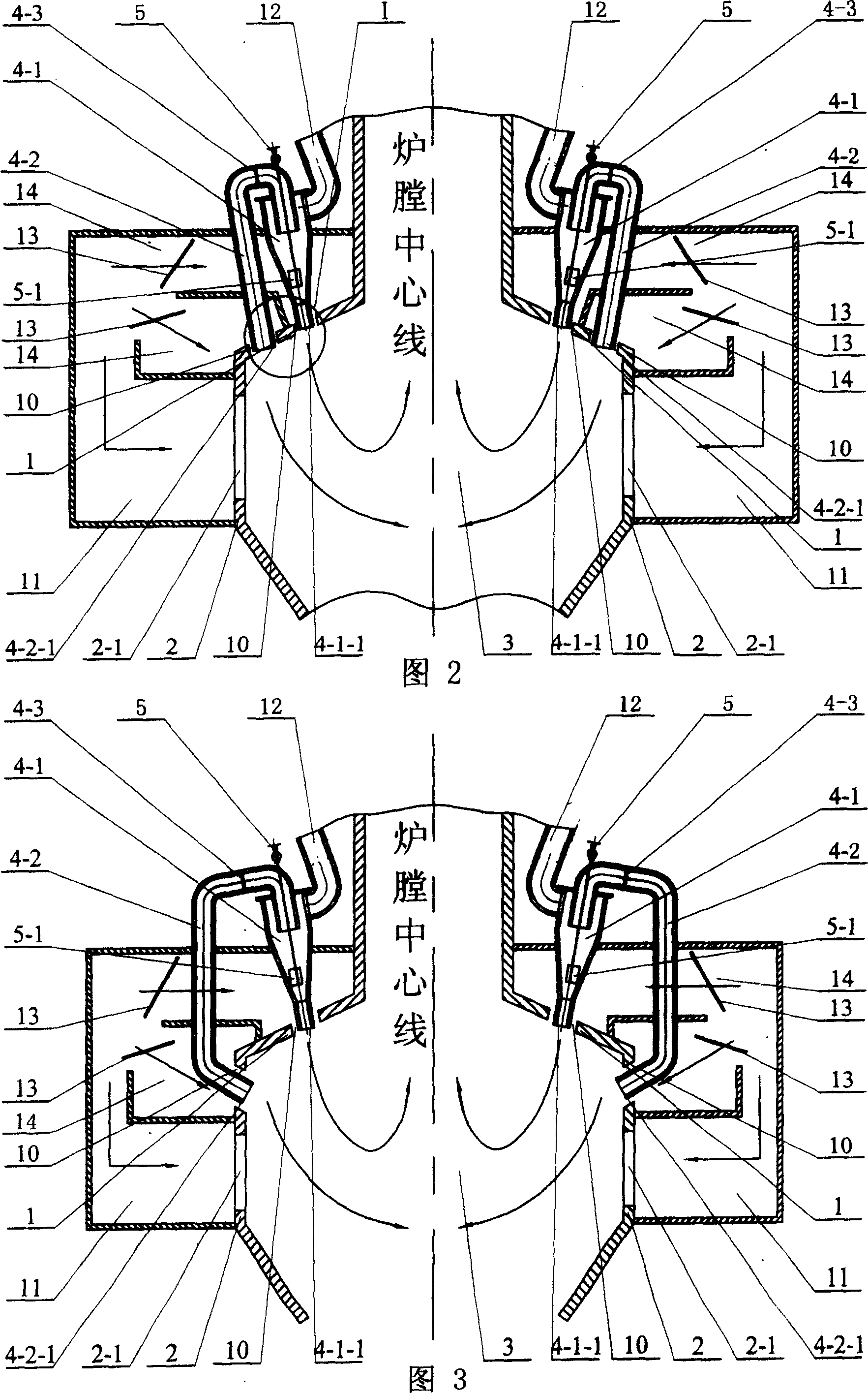

W-shape flame furnace with gradation coal burner

ActiveCN1707160AHigh melting temperaturePrevent high temperature corrosionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

The present invention is one W-shaped flame furnace with dense and dilute coal powder combustion and relates to one kind of burning plant. The improved W-shaped flame furnace includes furnace arch, side wall, hearth formed with the furnace arch and the side wall, and burner. The burner includes dense coal powder flow flame nozzle in the center of the hearth and dilute coal powder flow flame nozzle near the side wall. The present invention has greatly raised ash melting temperature to avoid slagging of the water cooled wall and prevent high temperature corrosion while reaching the aims of timely igniting and stable combustion.

Owner:HARBIN INST OF TECH

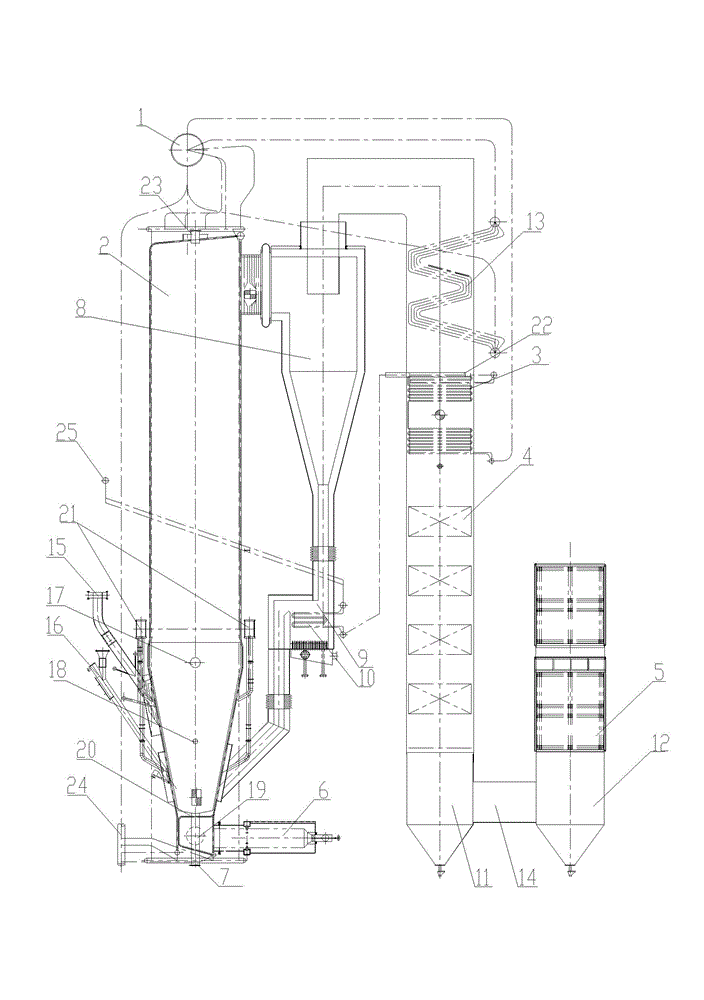

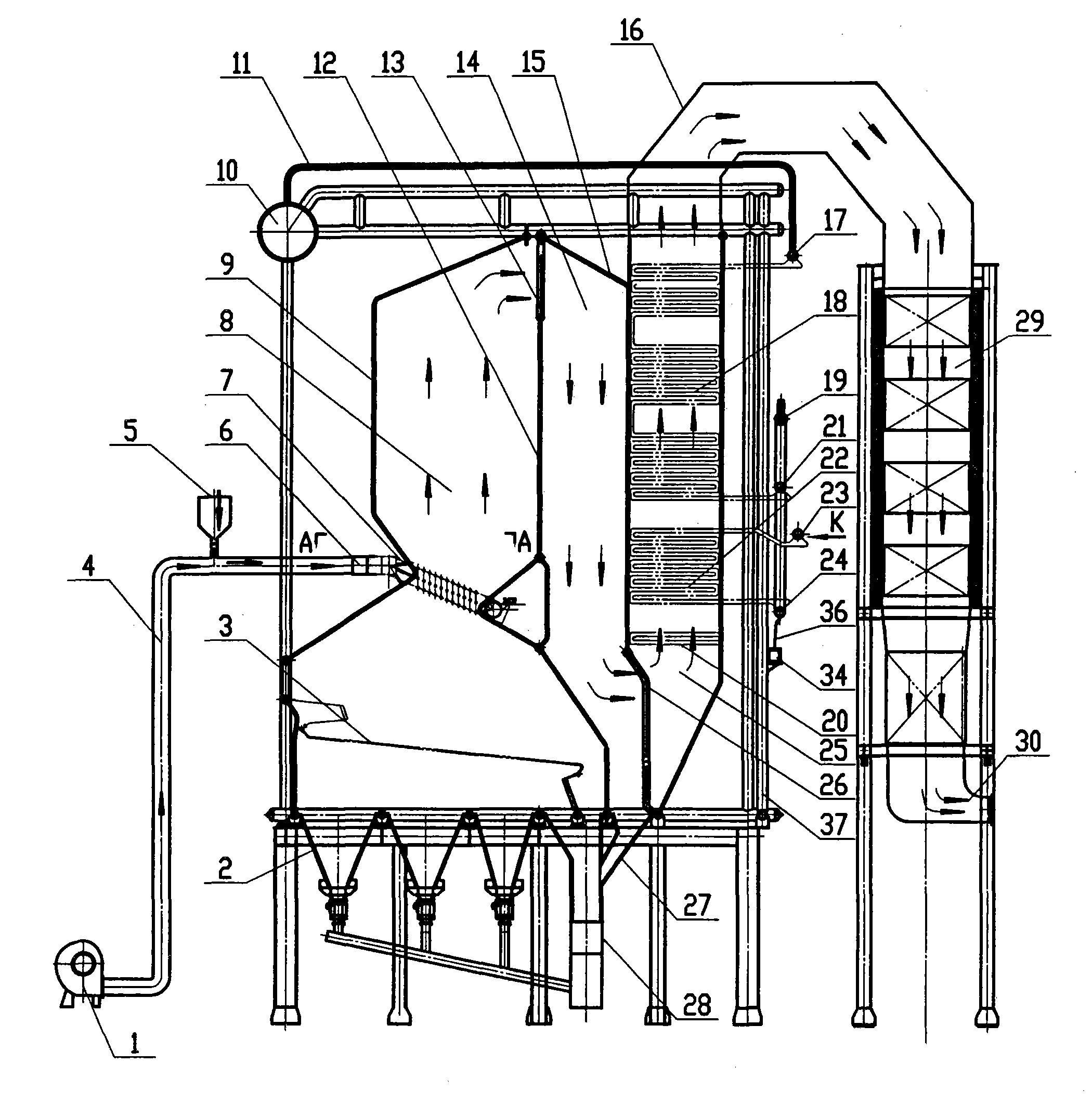

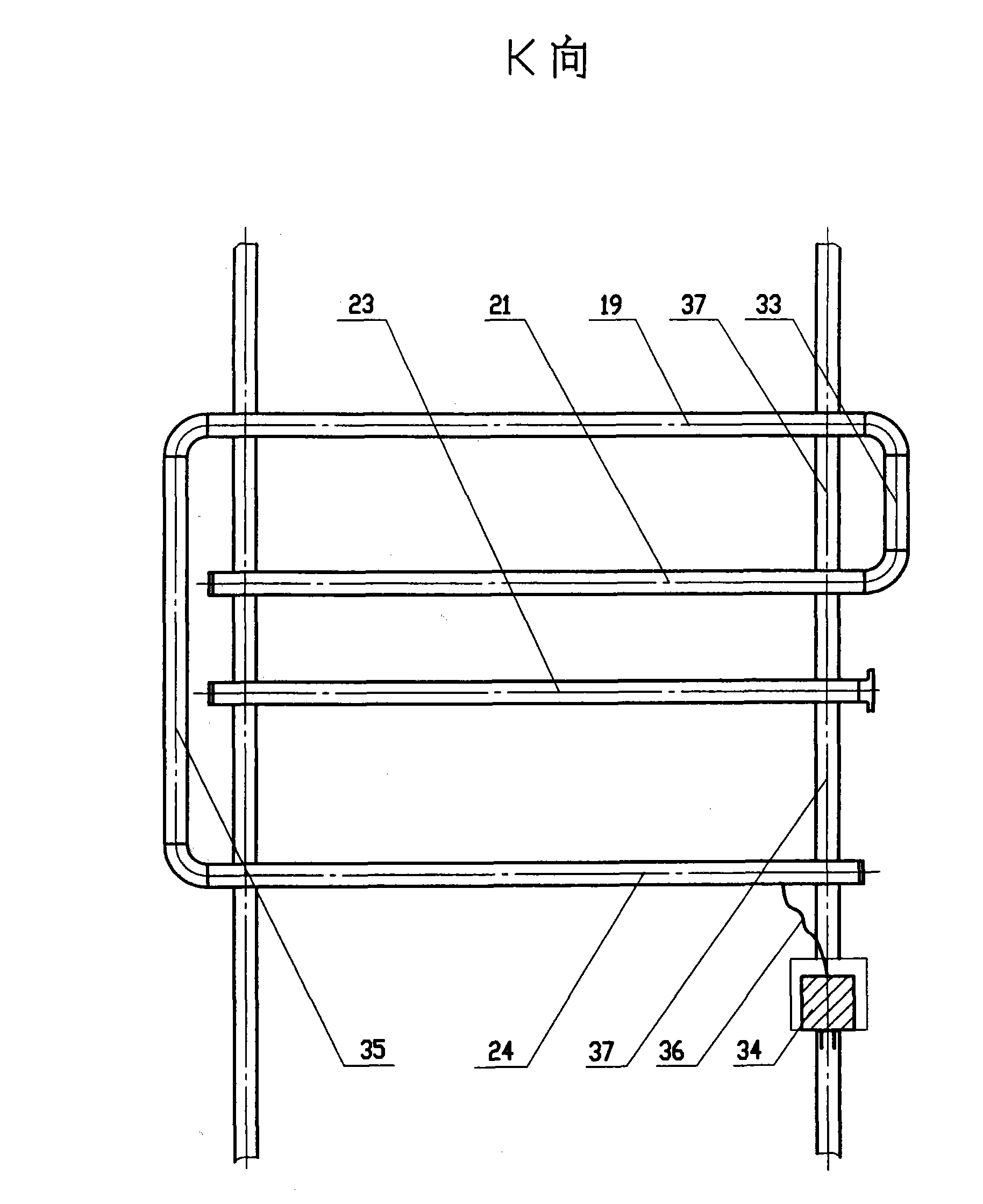

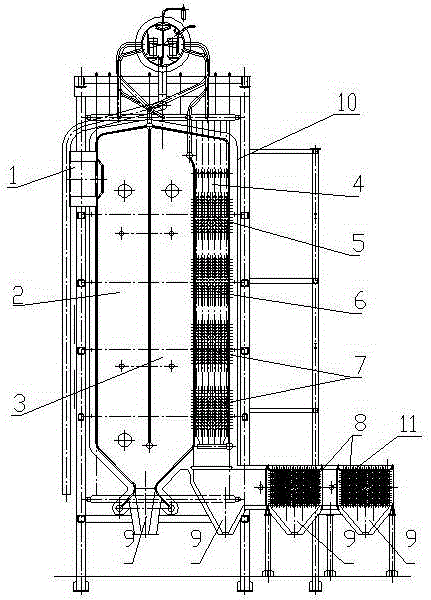

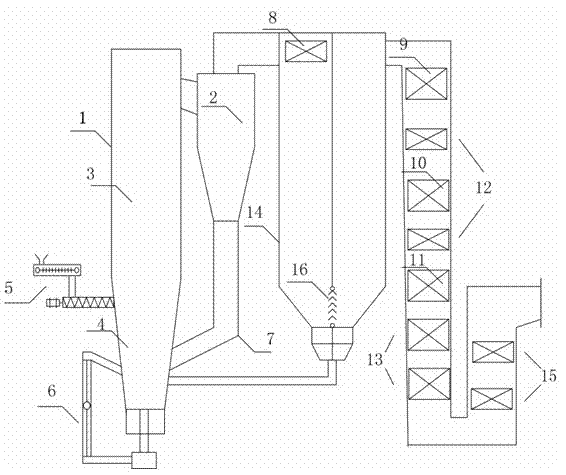

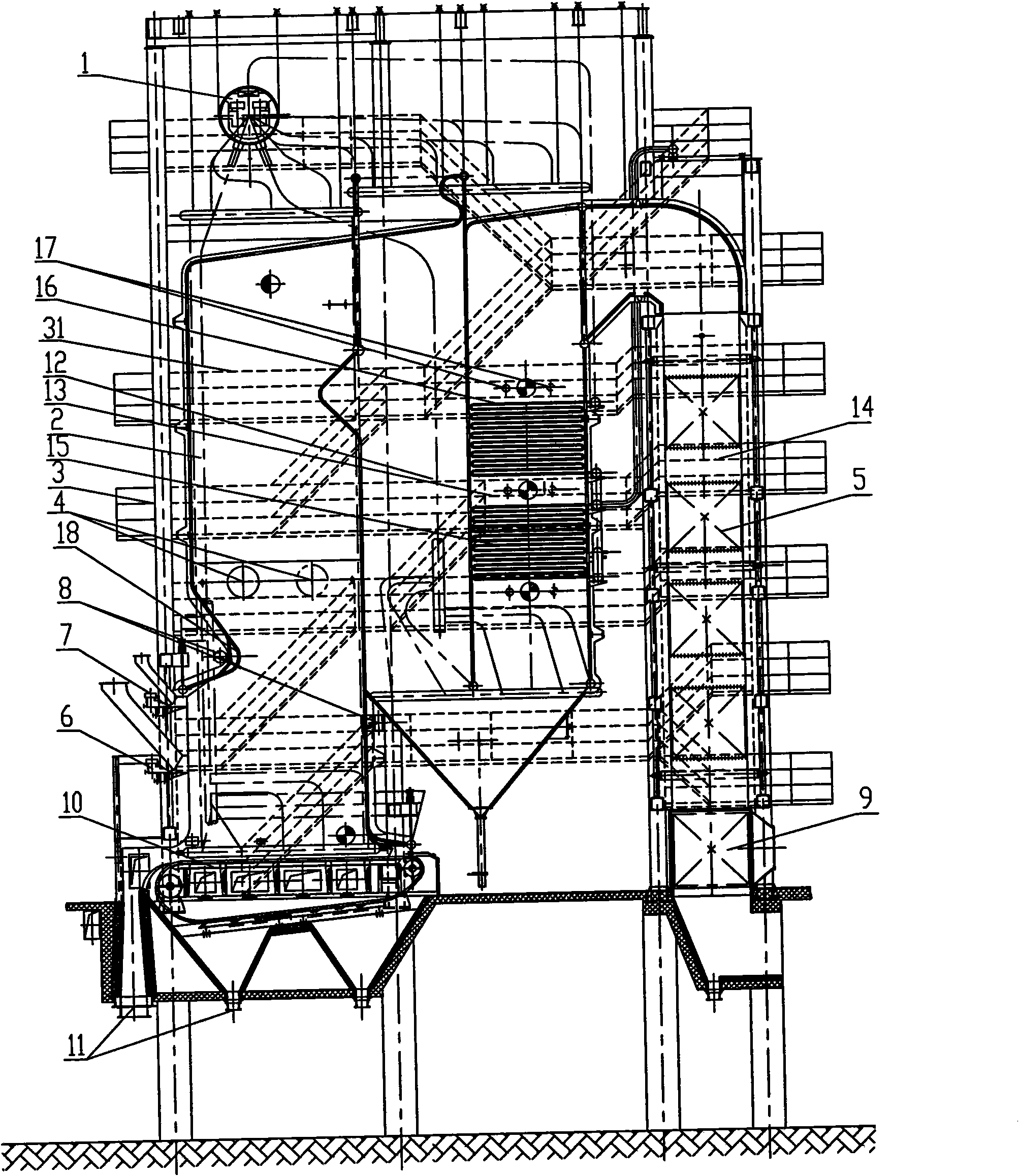

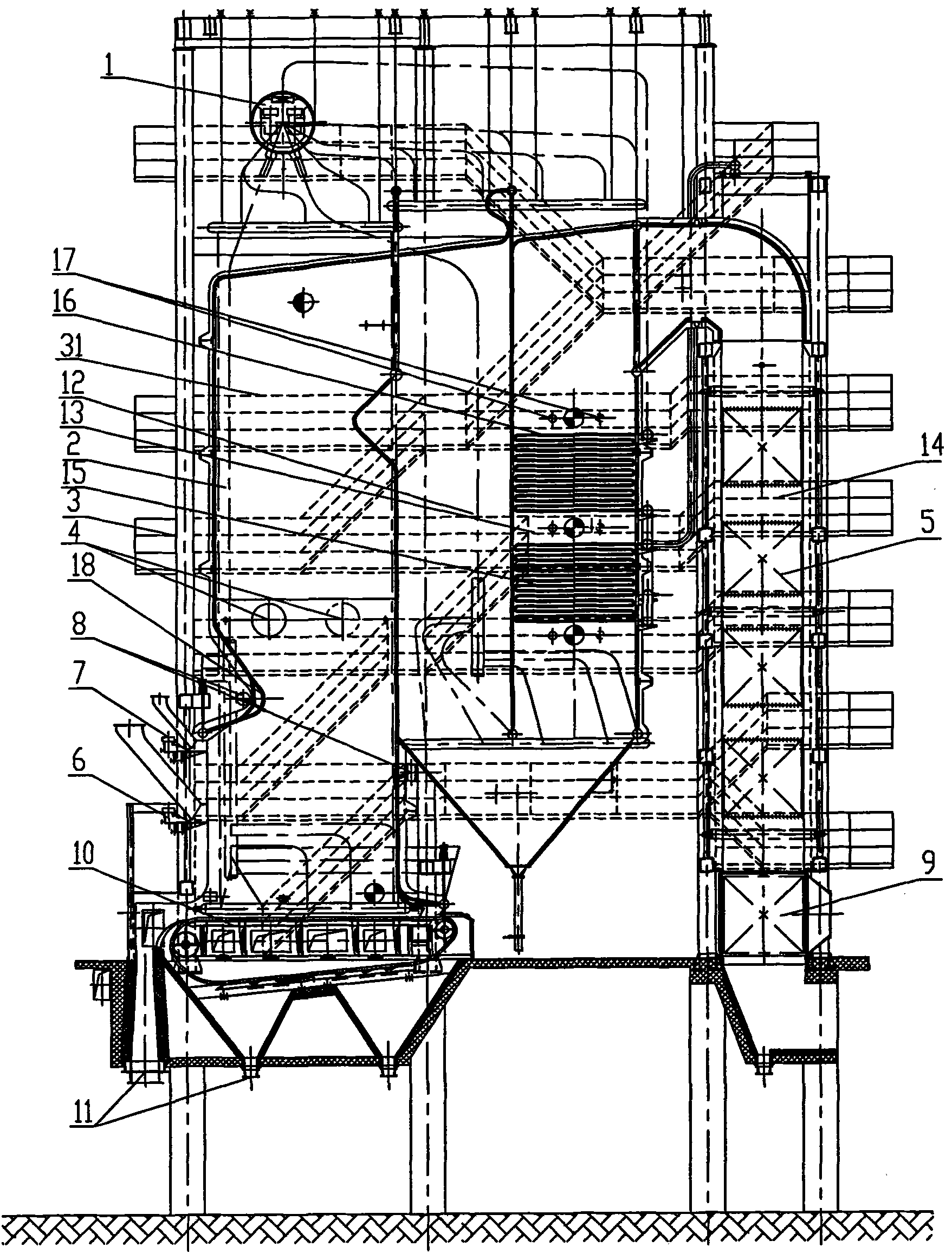

Circulating fluidized bed boiler for combustion papermaking waste residue and sludge

ActiveCN102721046APrevent high temperature corrosionNot susceptible to high temperature corrosionFluidized bed combustionIncinerator apparatusAir preheaterThermal insulation

The invention provides a circulating fluidized bed boiler for combustion papermaking waste residue and sludge. The circulating fluidized bed boiler returns materials smoothly and is enough in output and insusceptible to high temperature corrosion of a high temperature superheater and a low temperature superheater and low temperature corrosion of an air preheater, and the superheaters and a coal economizer cannot accumulate dust easily. The technical scheme is that the circulating fluidized bed boiler comprises a boiling drum, a hearth, the low temperature superheater, the coal economizer, the air preheater, a feeding device and an ignition device under a bed. The ignition device under the bed and a deslagging pipe are arranged at the bottom of the hearth, the feeding device is located on the half lower portion of the hearth, the boiling drum is supported at the top of the hearth, the hearth is communicated with a flue, and the low temperature superheater, the coal economizer and the air preheater are arranged in the flue. The circulating fluidized bed boiler is characterized in that inlets of a high temperature thermal insulation volute cyclone separator are bilaterally symmetrically connected to an outlet of a rear wall of the upper portion of the hearth, and an outlet positioned at the top of the high temperature thermal insulation volute cyclone separator is connected with the flue.

Owner:WUXI HUAGUANG BOILER

Face-fired boiler advanced denitration burning method

ActiveCN106247320AReduce concentrationLower emission valueCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlue gasHearth

The invention discloses a face-fired boiler advanced denitration burning method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of turbulent burners in each of layers of turbulent burners arranged on a front wall and a rear wall and is burnt, secondary air is introduced through secondary air nozzles of the turbulent burners, over fire air is introduced through one or more layers of over fire air nozzles on the front wall and the rear wall, the primary air and the secondary air on the front wall and the rear wall are oppositely introduced, the excess air coefficient range of the main burning area of the turbulent burners is 0.5-1.05, and the fire coal undergoes low oxygen burning; the excess air coefficient range of the over fire area of the over fire air nozzles is 1.05-1.3, and oxygen rich burning is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over fire layer to reduce nitrogen oxides in flue gas in high temperature environment in the hearth and inhibit generation of new nitrogen oxides. The face-fired boiler advanced denitration burning method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

W-firing boiler advanced denitration combustion method

ActiveCN106247321AReduce concentrationLower emission valueFluegas recirculationIndirect carbon-dioxide mitigationHearthEngineering

The invention discloses a W-firing boiler advanced denitration combustion method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of main combustors on boiler arches of a front wall and a rear wall and is combusted, secondary air and under-arch secondary air are respectively introduced through secondary air nozzles and under-arch secondary air nozzles, exhaust gas wind is introduced through exhaust gas wind nozzles on the front wall and the rear wall, one or two layers of over-fire air are introduced through over-fire air nozzles, the excess air coefficient range of a main combustion area is 0.7-1.05, and the fire coal undergoes low oxygen combustion; the excess air coefficient range of an over-fire area is 1.05-1.3, and oxygen rich combustion is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over-fire air layer to reduce nitrogen oxides in flue gas and inhibit generation of new nitrogen oxides. The W-firing boiler advanced denitration combustion method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

Boiler decoking agent

The invention discloses a liquid decoking agent for coal fired boiler, falling into the technical field of coal fired boiler clean combustion and environmental protection control. The liquid decoking agent comprises a decoking agent 0.5-5 wt%, an oxidant 5-25 wt%, a combustion-supporting catalyst 1-10 wt%, an anticorrosion agent 5-30 wt% and water in balance. The decoking agent can promote combustion and falling of coke-layer matter; the oxidant nitrate can release oxygen gas under high temperature, to promote combustion of different positions of dust and carbon; the combustion-supporting catalyst, potassium permanganate and manganese oxide, can act as oxygen atom reaction carrier under high temperature and catalyze combustion of coal powder; and the anticorrosion agent, modified nano-alumina or nano-magnesia, can convert low-melting-point compound in coke layer into loose high-melting-point compound, which facilitates removal of coked layer and prevention of high-temperature corrosion, and after long-term use, the nano-alumina or nano-magnesia will be attached to a heated surface to form a micro-scale anticorrosion layer.

Owner:SNTO TECH GRP

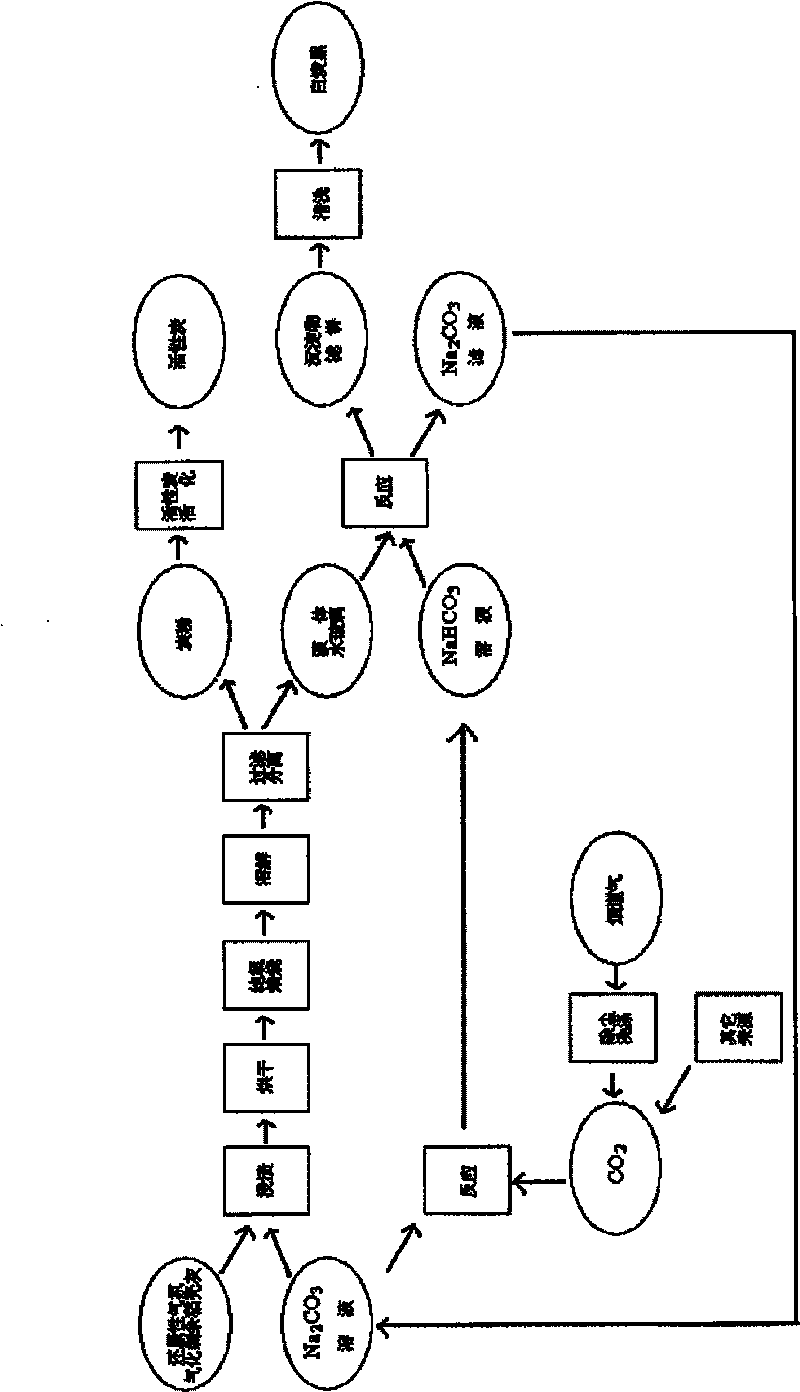

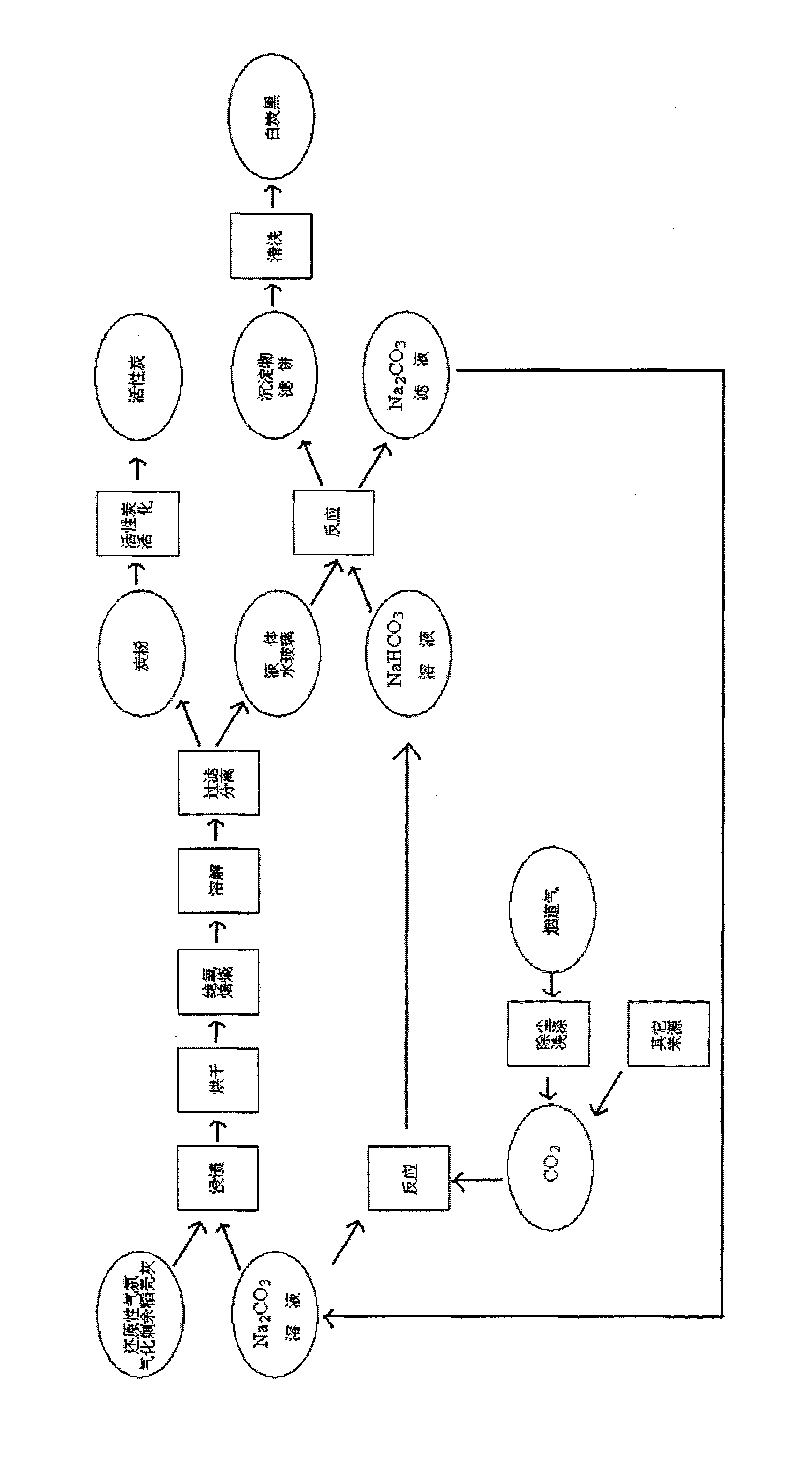

Method for producing white carbon black and active carbon by using residual rice hull ash after gasification

InactiveCN101704526AGood effectGood impregnation absorption performanceSilicaSilicon dioxidePermeation

The invention provides a method for producing white carbon black and active carbon by using residual rice hull ash after gasification, which comprises the following steps of: performing alkali solution impregnation, drying and roasting on the residual rice hull ash after the gasification, which serves as a raw material, to obtain a mixture of powdery water glass and carbon powder; adding water into the mixture to dissolve the mixture and boiling the mixture to obtain a water glass solution and the carbon powder; performing the reaction of the water glass solution and soluble alkali metal acid carbonate to obtain silicon dioxide hydrate; filtering the silicon dioxide hydrate; washing and drying a precipitate to obtain the white carbon black; and washing and activating filter residue of the carbon powder to obtain the active carbon, wherein an alkali solution can be recycled. In the method, silicon dioxide in raw materials can well react with alkali, the impregnating absorption performance is good, the uniform permeation is achieved quickly, and the drying link can be switched immediately, so that the large silo capacity for storing impregnated rice hull ash is unnecessary; the anoxic roasting temperature is low, so that the high-temperature corrosion of a furnace body is avoided; the alkali solution can be recycled, so that the loss of chemical raw materials is reduced; the intermediate product powder, which is the mixture of the water glass and the carbon powder, is easy to be separated and filtered; and a prepared white carbon black product is high in purity and strong in activity.

Owner:李洪锡 +2

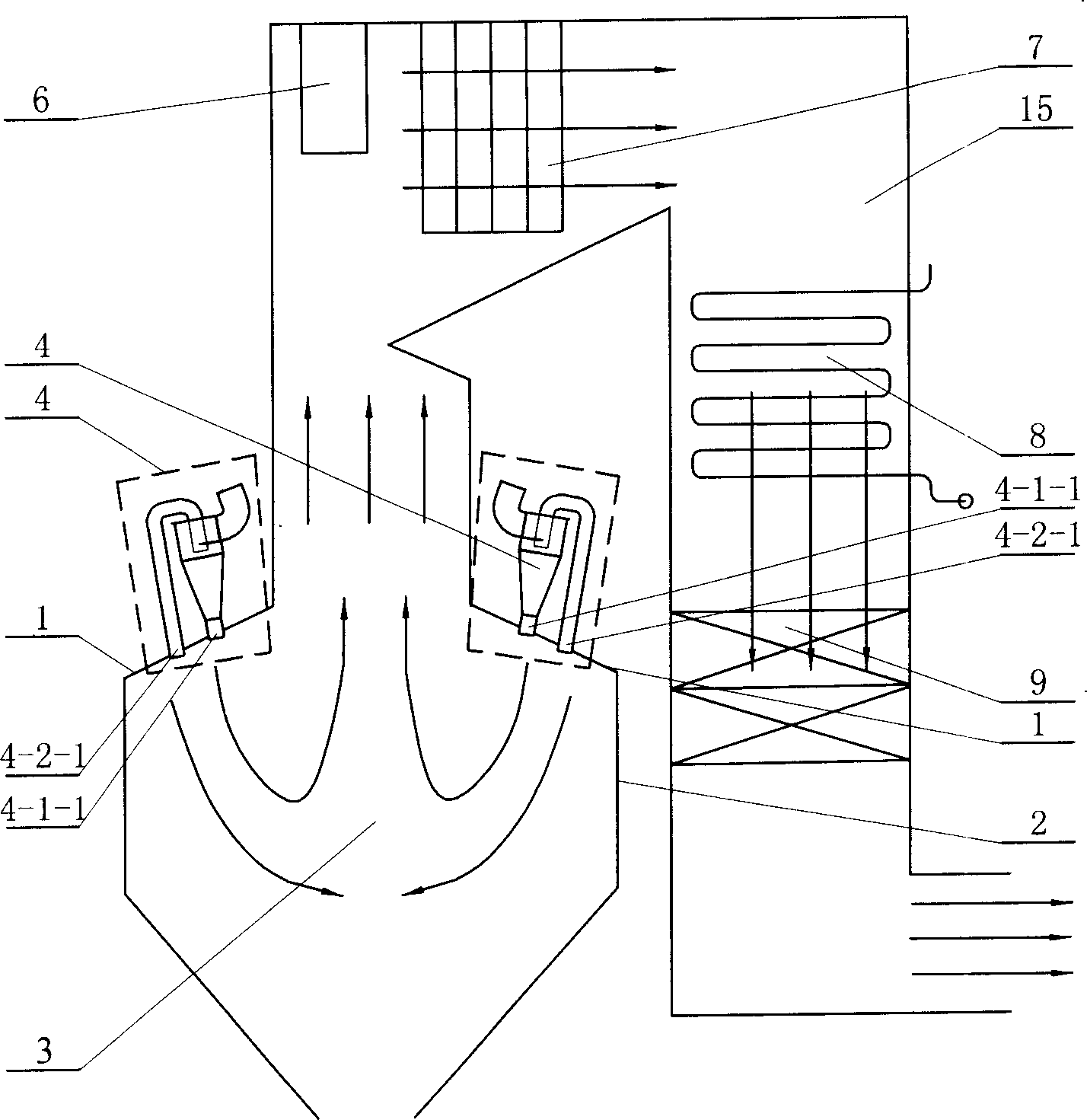

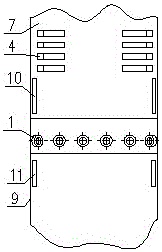

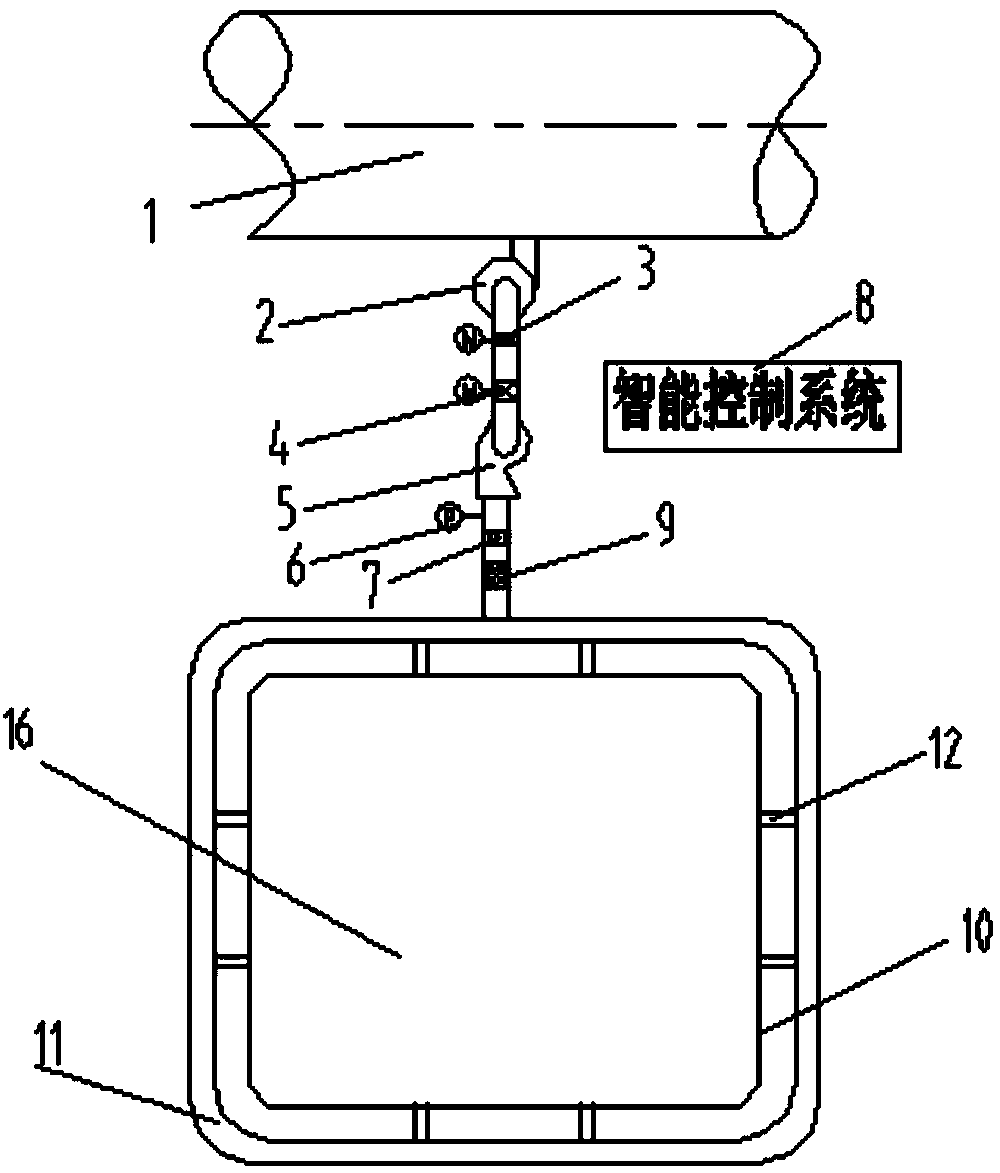

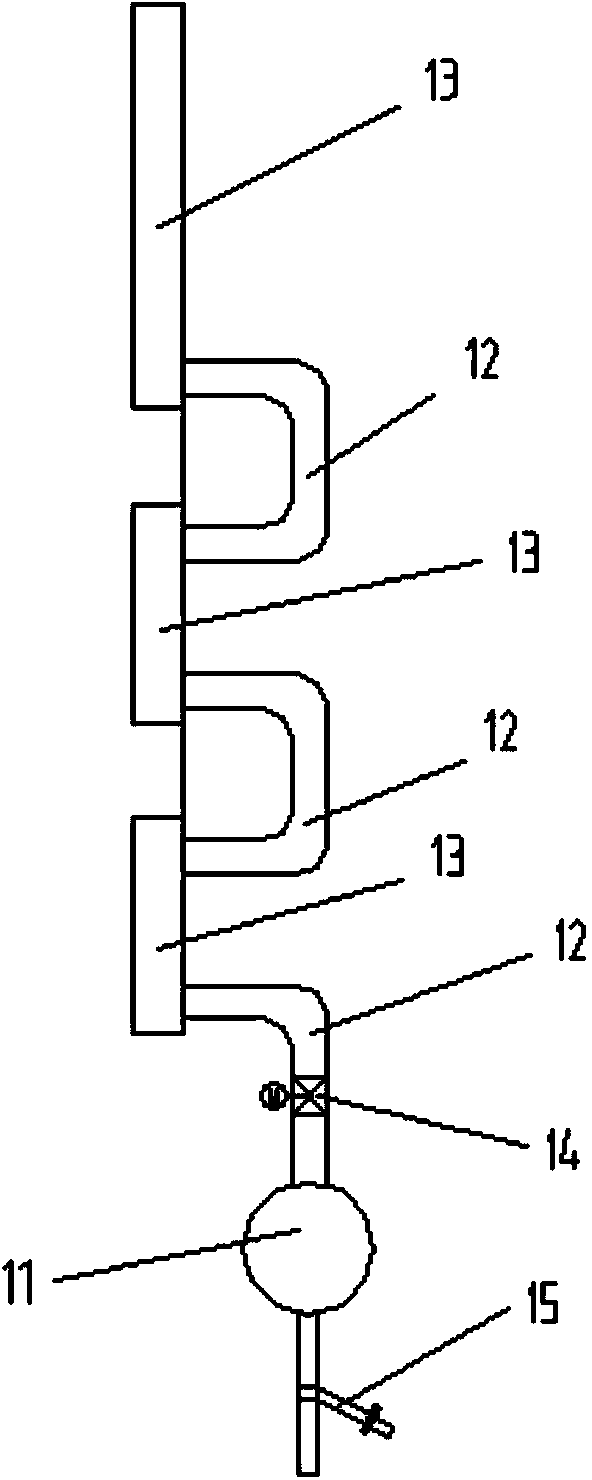

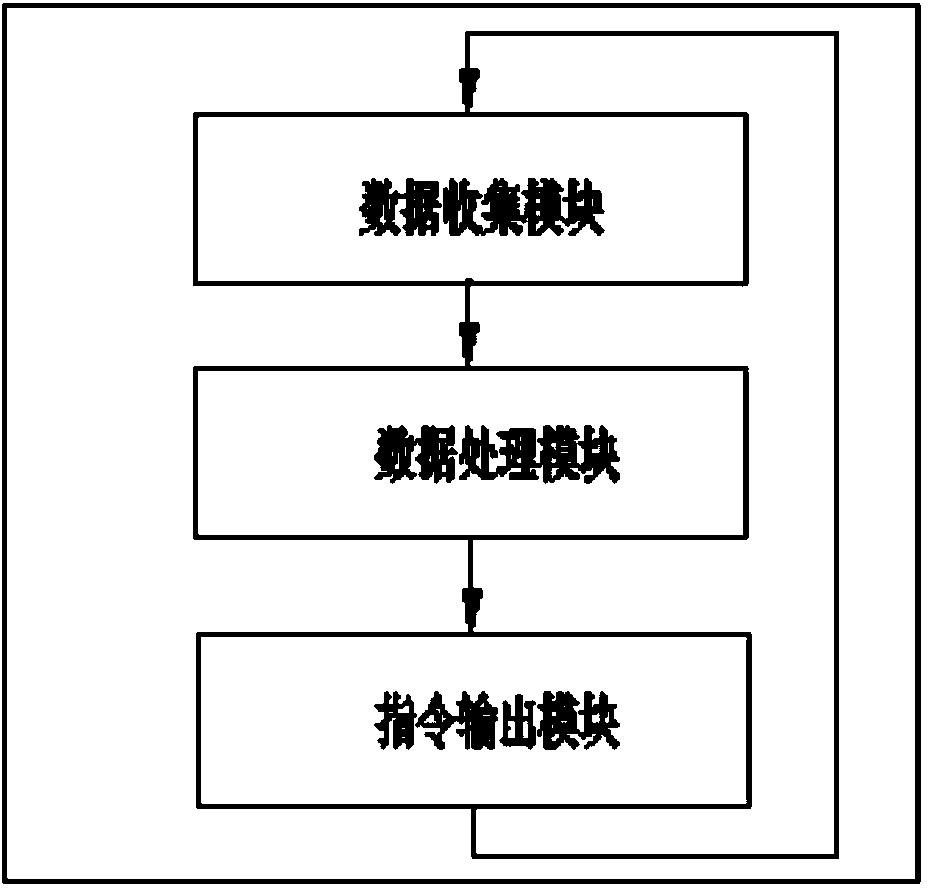

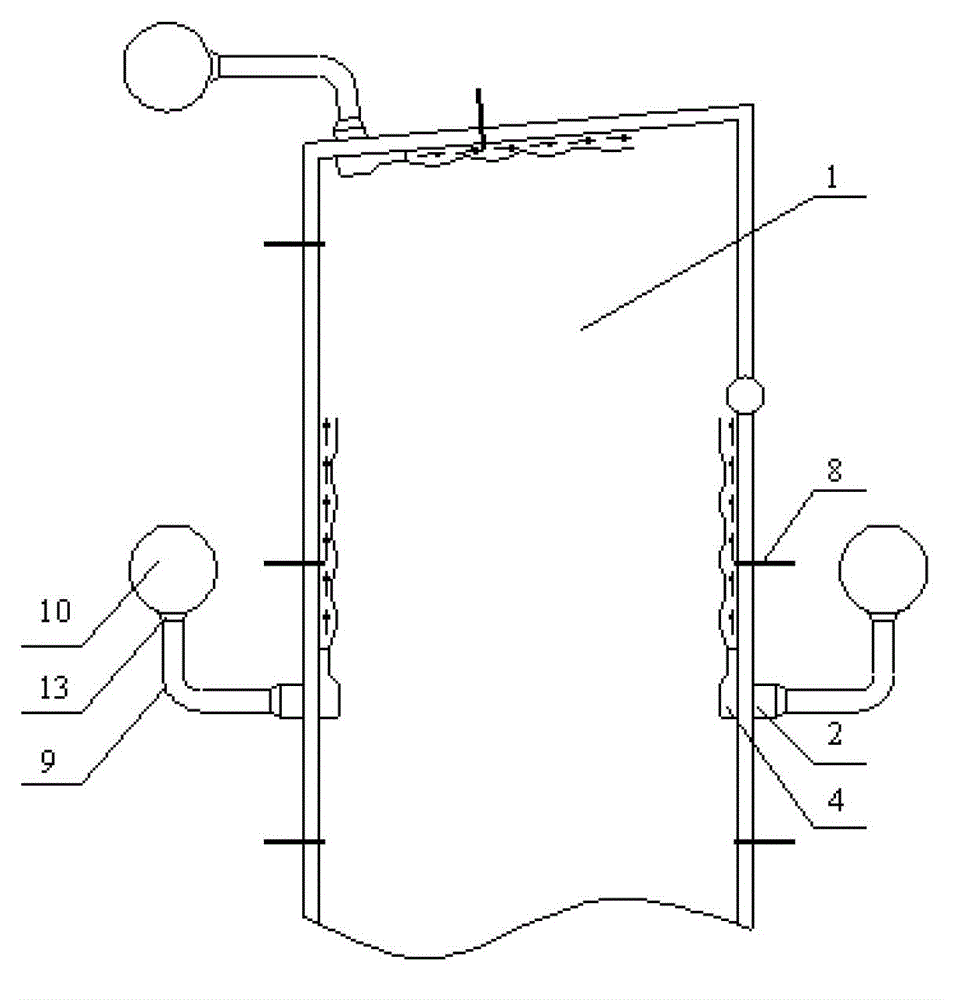

Intelligent water wall high temperature corrosion preventing system suitable for large power station boiler and method

ActiveCN103712233AReduce intensityBurning has no effectCasings/liningsPower stationMeasurement device

The invention relates to an intelligent water wall high temperature corrosion preventing system suitable for a large power station boiler and a method. The system can be adjusted in real time according to the change of the operating conditions of the boiler to prevent a water wall from high temperature corrosion, operating personnel involvement is not needed, and the high temperature corrosion is intelligently prevented. The system comprises a pressurizing pipeline communicated with an air pre-heater outlet hot secondary air box, a booster fan is arranged on the pressurizing pipeline and is communicated with an annular air box of surrounding a protection wall, the annular air box is communicated with branch air boxes through connecting air boxes, and the branch air boxes are communicated with ventilation grooves in the boiler wall. An air flow adjusting device is arranged on the pressurizing pipeline, and the air flow adjusting device comprises an isolation baffle, a master adjusting baffle, an air flow measuring device and a pressure sensor and further comprises a branch adjusting baffle of the connecting air boxes. An intelligent control system adjusts the opening and closing degree of each baffle in the air flow adjusting device according to the operating state of the boiler, and the air flow is controlled to prevent the water wall from the high temperature corrosion.

Owner:STATE GRID CORP OF CHINA +1

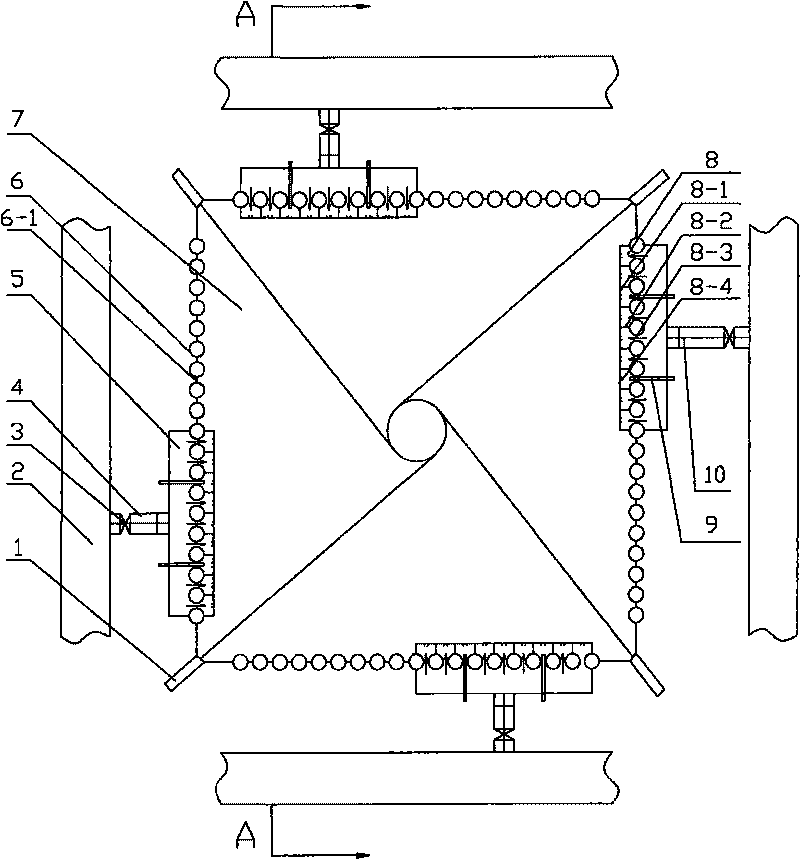

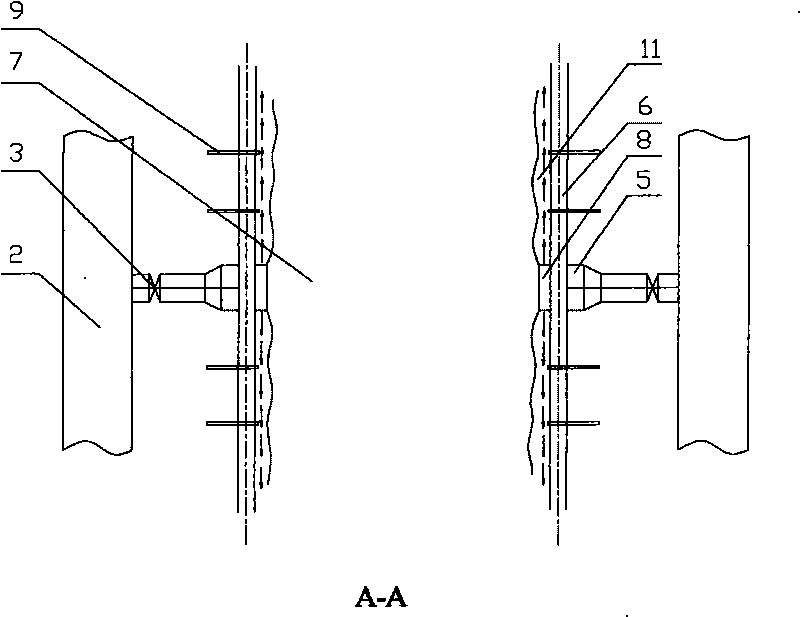

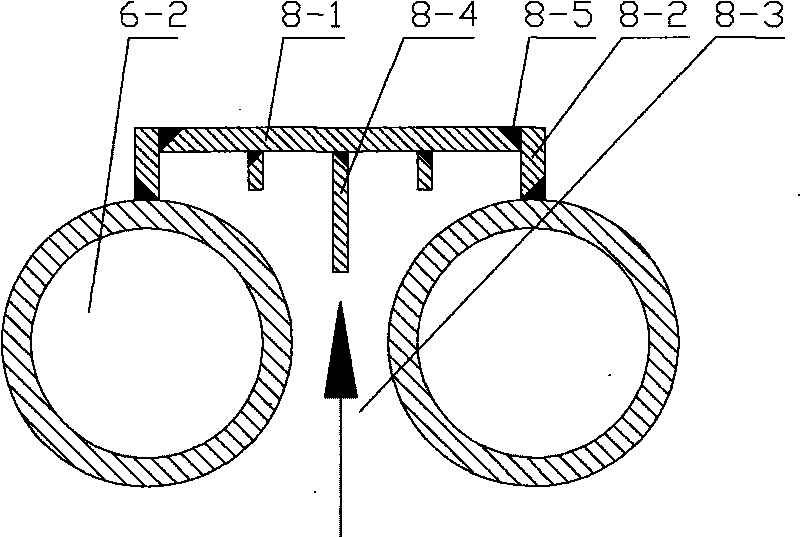

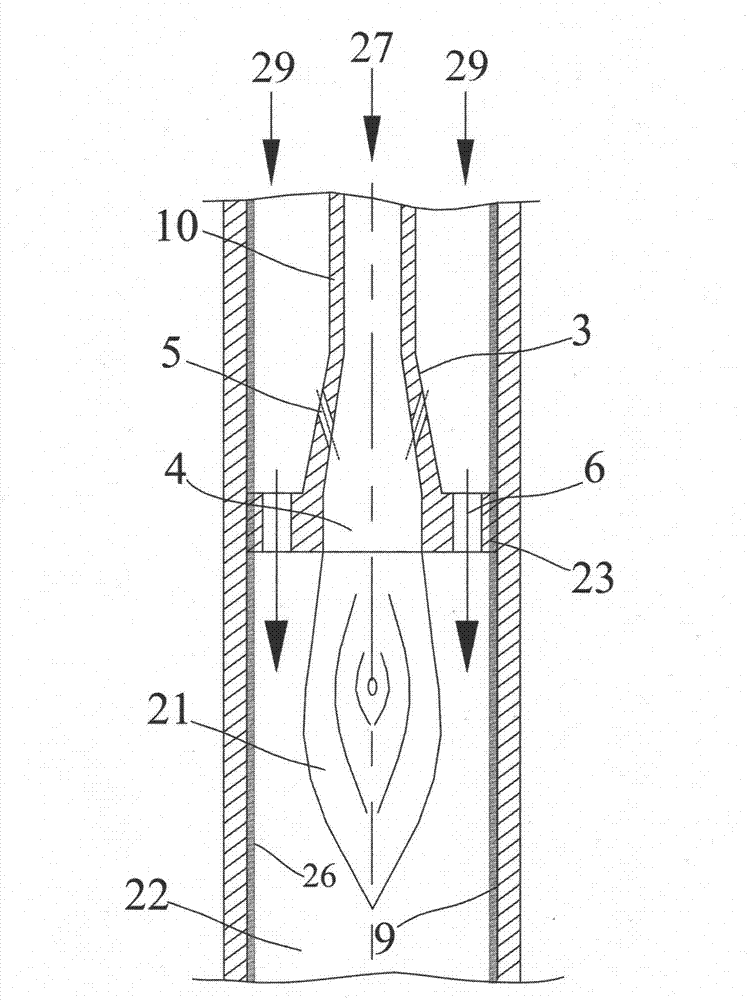

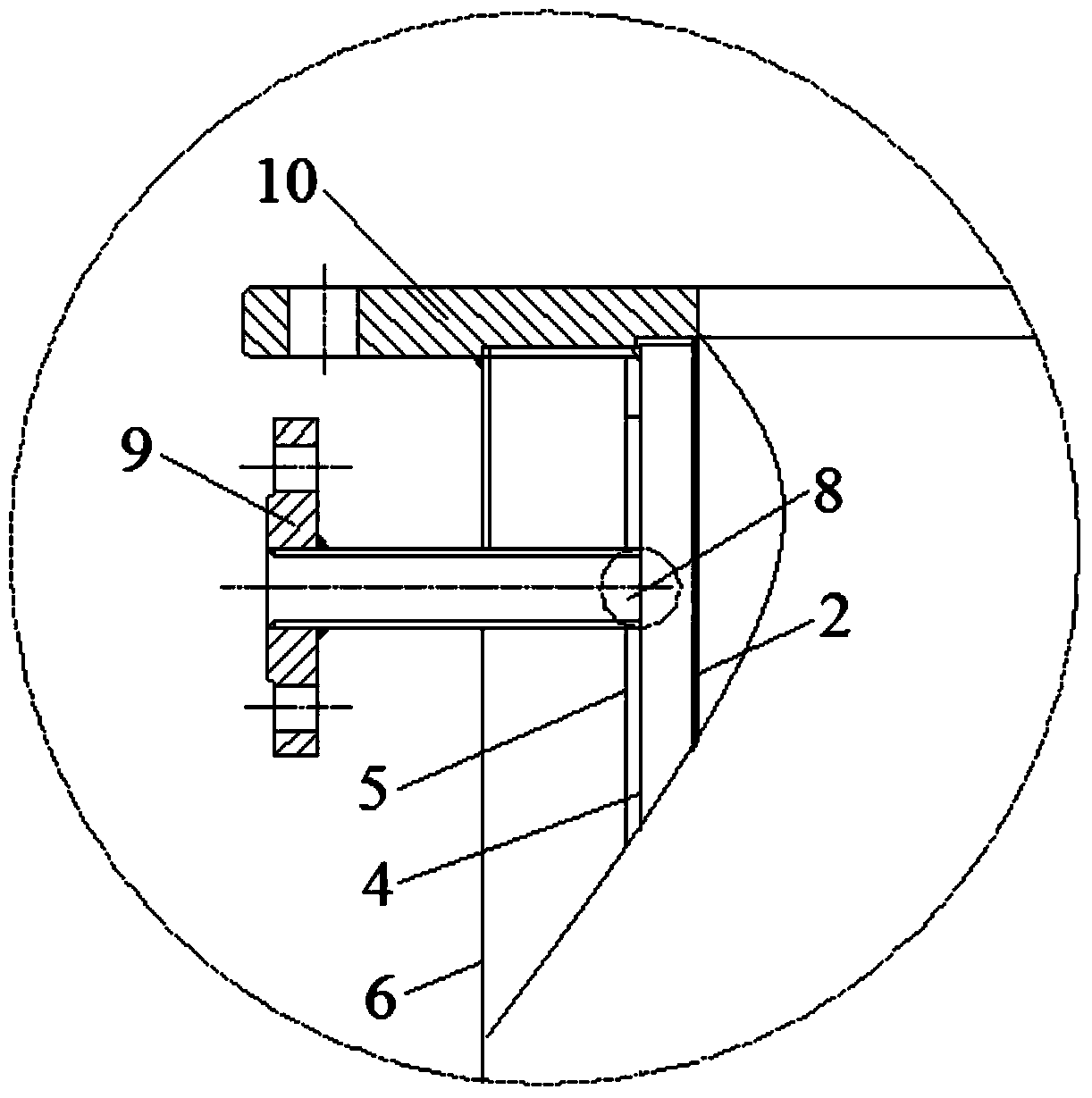

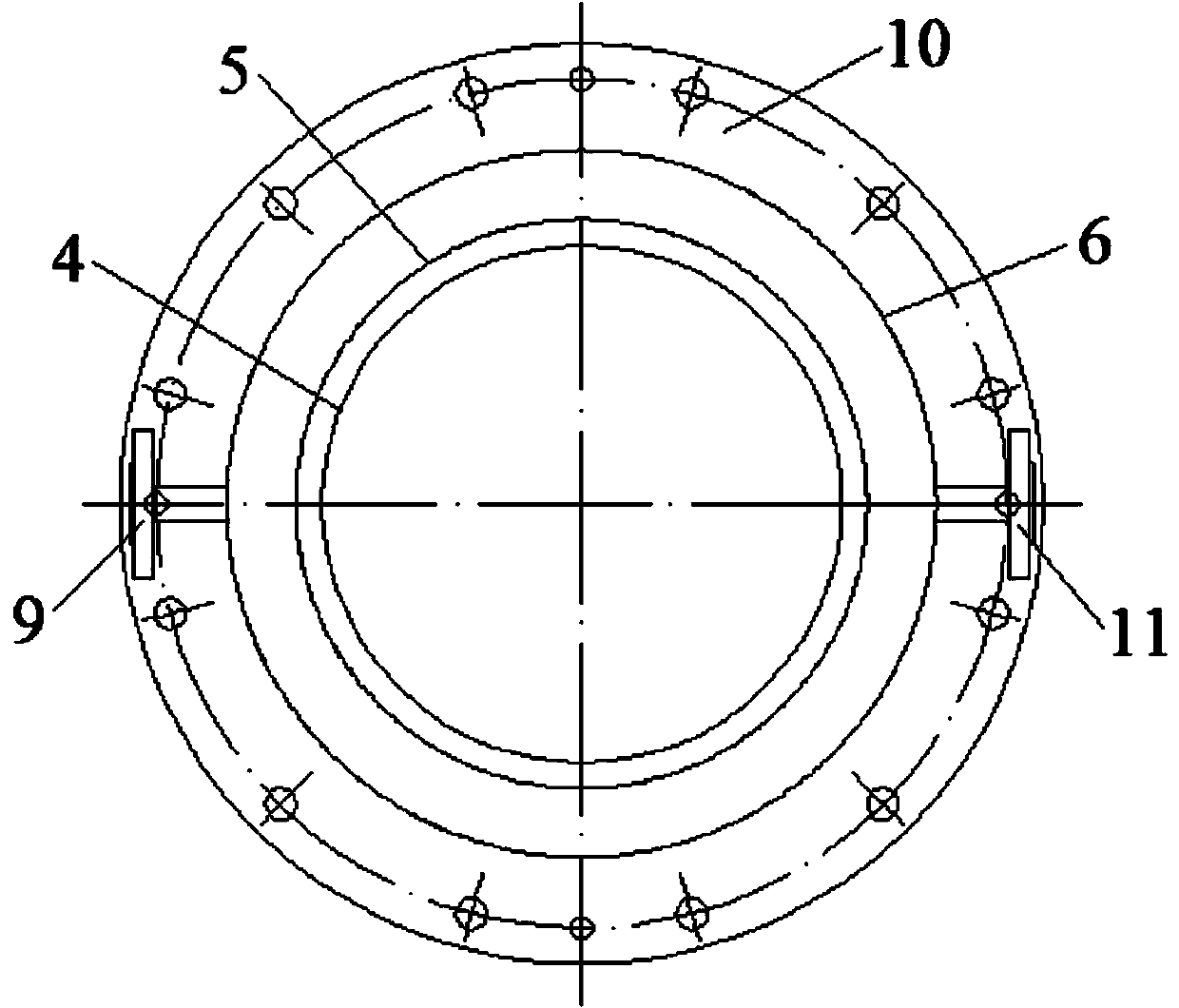

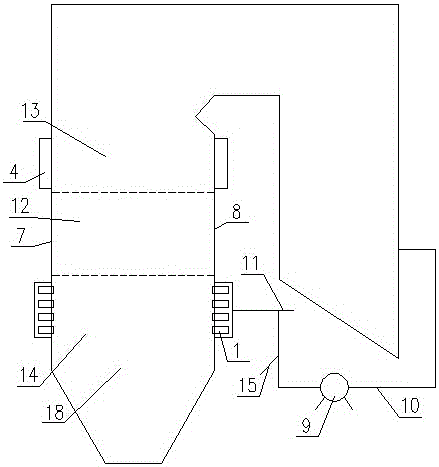

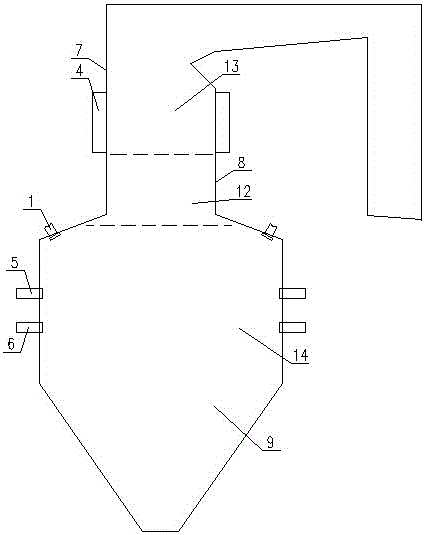

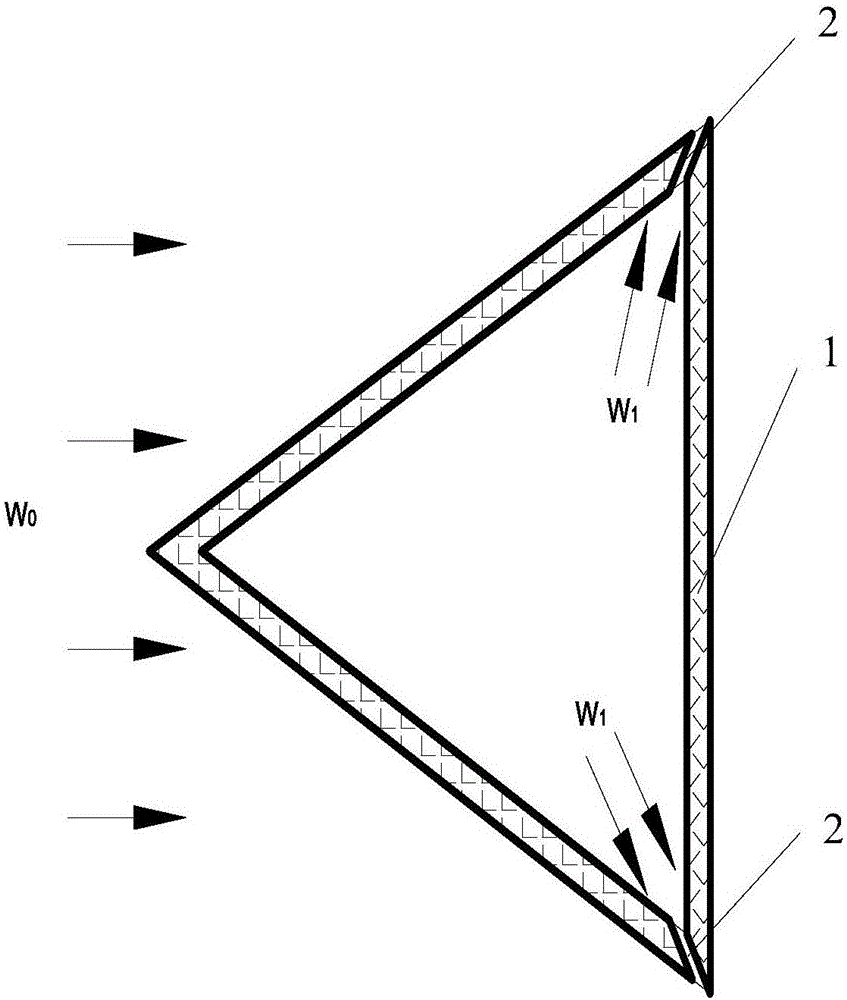

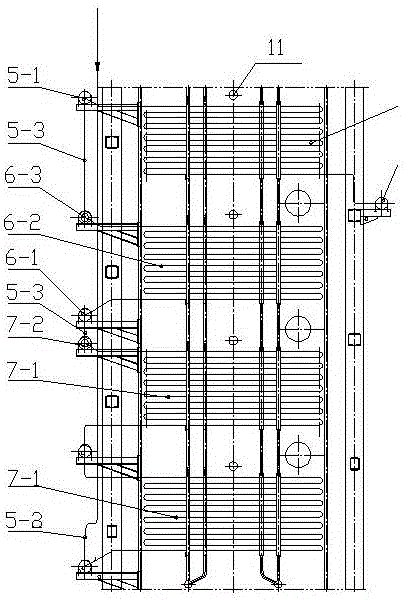

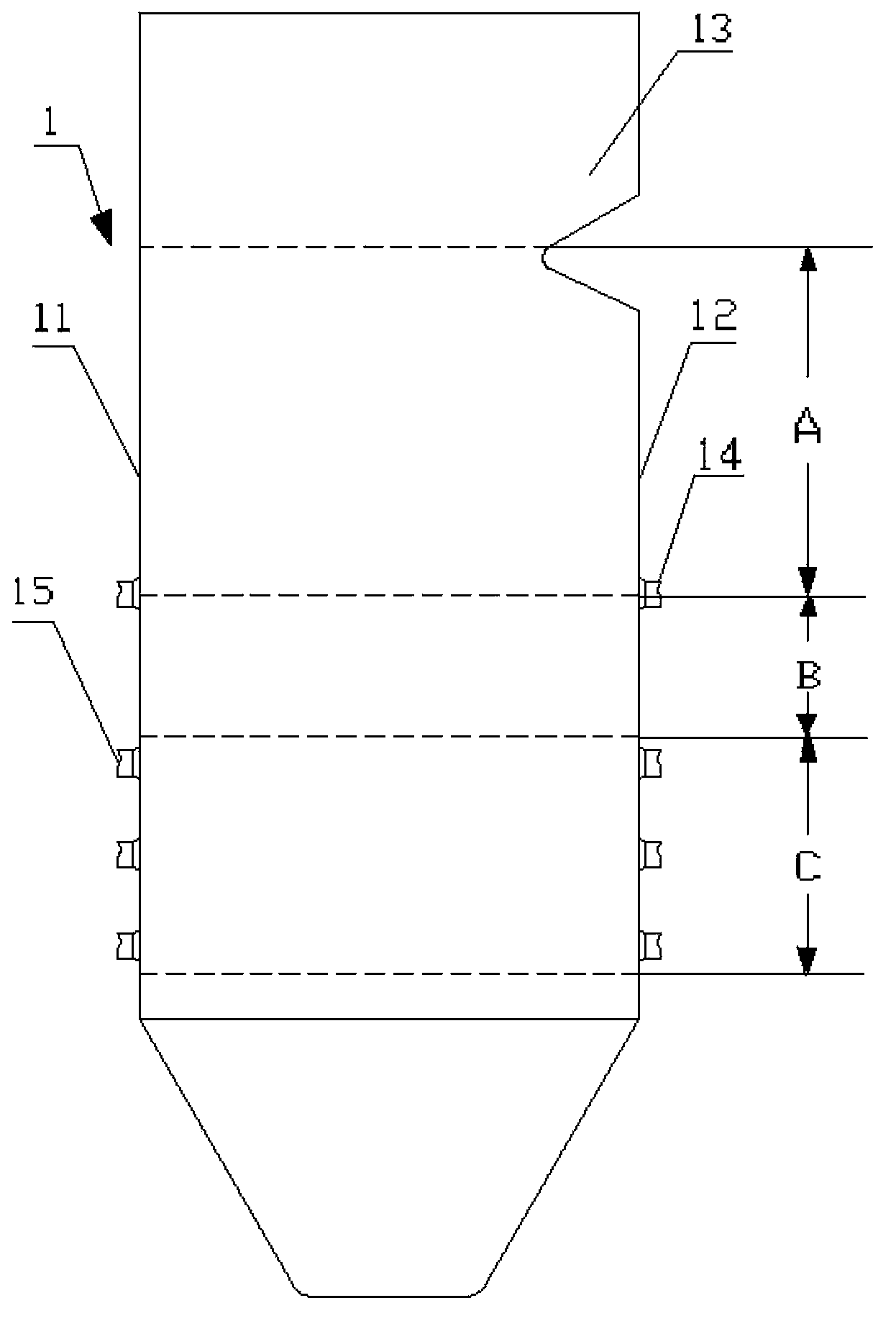

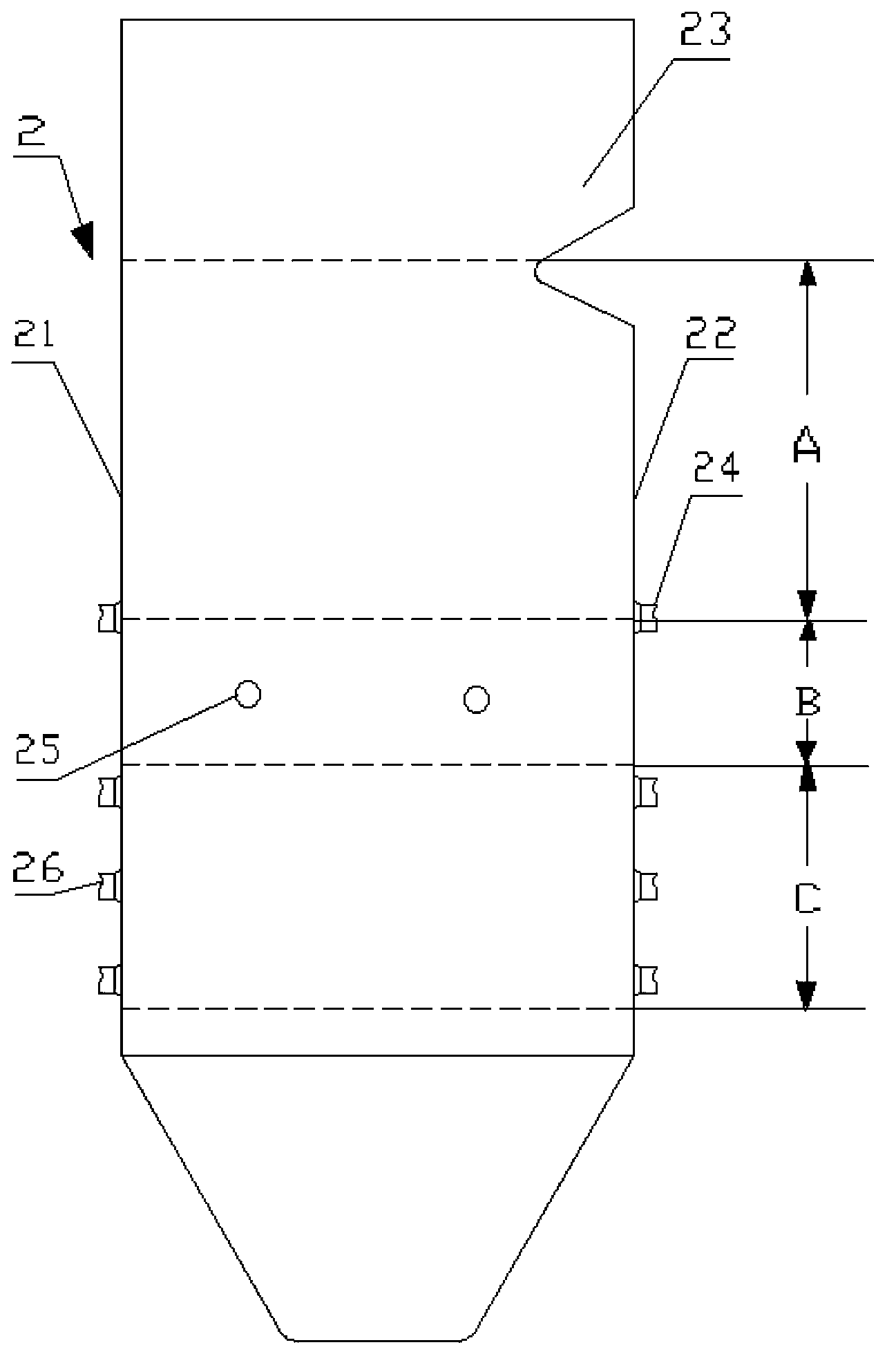

Adherence air device for preventing high-temperature corrosion of water cooling wall of refuse burning boiler

ActiveCN102980176ALow flow resistanceLong conveying distanceCasings/liningsNon-combustible gases/liquids supplyEngineeringHigh-temperature corrosion

The invention discloses an adherence air device for preventing high-temperature corrosion of a water cooling wall of a refuse burning boiler. The adherence air device comprises an adherence air box and an adherence air nozzle, wherein one end of the adherence air box is connected with the adherence air nozzle; the other end of the adherence air box is connected with an air pipe; the adherence air nozzle comprises a nozzle fin, a front baffle, a bottom baffle, a water cooling wall pipe and a water cooling wall fin; the front baffle is composed of an inlet baffle, a reducing baffle and an outlet baffle; a blowing slit is formed on the outlet baffle; and a water cooling wall slit is formed by taking down the water cooling wall fin between two corresponding adjacent water cooling wall pipes. The adherence air nozzle adopts a reducing design, smoke is sprayed out from one side of a main smoke direction, and the adherence air direction is the same as the axial direction of the water cooling wall pipe; and with an injection area, the device realizes stable and reliable formation, little flow resistance, long conveying distance and large protection range. The device does not need multi-layer arrangement, causes little influence on the burning heat transfer of the original boiler, and effectively solves the problem of high-temperature corrosion of the water cooling wall of the refuse burning boiler.

Owner:SOUTH CHINA UNIV OF TECH

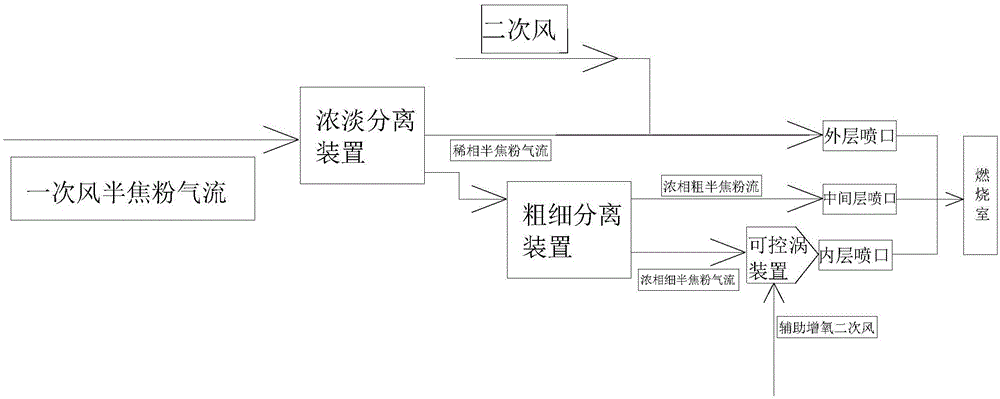

Method for burning gasified semi-coke particles by concentrated-dilute and coarse-fine deep separation and controlled vortex stable combustion technologies

InactiveCN106556007AFire stablePrevent high temperature corrosionFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberSlag

A method for burning gasified semi-coke particles by concentrated-dilute and coarse-fine deep separation and controlled vortex stable combustion technologies is characterized in that low-rank coal primary air semi-coke powder flow carrying gasified semi-coke is subjected to concentrated-dilute separation to obtain concentrated-phase semi-coke powder flow and dilute-phase semi-coke powder flow; the concentrated-phase semi-coke powder flow is subjected to coarse-fine separation to obtain concentrated-phase coarse semi-coke powder flow and concentrated-phase fine semi-coke flow; the dilute-phase semi-coke powder flow and secondary air are mixed, and the mixture is guided into an outer-layer nozzle of a combustion chamber; and the concentrated-phase fine semi-coke powder flow and the concentrated-phase coarse semi-coke powder flow are guided into an inner-layer nozzle and an intermediate-layer nozzle of the combustion chamber respectively and then sprayed into the combustion chamber, a controlled vortex bluff body device and an auxiliary aeration secondary air nozzle are mounted in the inner-layer nozzle of the combustion chamber, and during ignition, the concentrated-phase fine semi-coke powder flow sprayed by the inner-layer nozzle of the combustion chamber is ignited at first. The method can effectively improve ignition, combustion and burn-out characteristics of gasified semi-coke, reduces pollutant discharge and can effectively prevent a furnace wall from slag-bonding and a water wall from high-temperature corrosion.

Owner:CHONGQING UNIV

Liquid coke inhibitor

InactiveCN102329676AReduce dust accumulationHas cleaning effectFuel additivesBULK ACTIVE INGREDIENTOxygen

The invention discloses a liquid coke inhibitor, and belongs to the technical field of clean coal combustion. Main active ingredients of the liquid coke inhibitor are an organic surfactant and nitrate. When the organic surfactant is at high temperature, an organic polymer compound has a dirt cleaning effect, and the organic polymer compound is reacted at high temperature to generate a large number of air bubbles so as to make coke blocks loose. The nitrate can generate microexplosion and release oxygen at high temperature, can continuously release oxygen in a range from low temperature to high temperature to make soot formation and carbon deposition layers on different parts loose and contribute to more fully combusting pulverized coal; metal ions in the nitrate can promote low melting point compounds in a coke layer to be converted into loose high melting point compounds, which can contribute to removing a coking layer and prevent high temperature corrosion.

Owner:SNTO TECH GRP

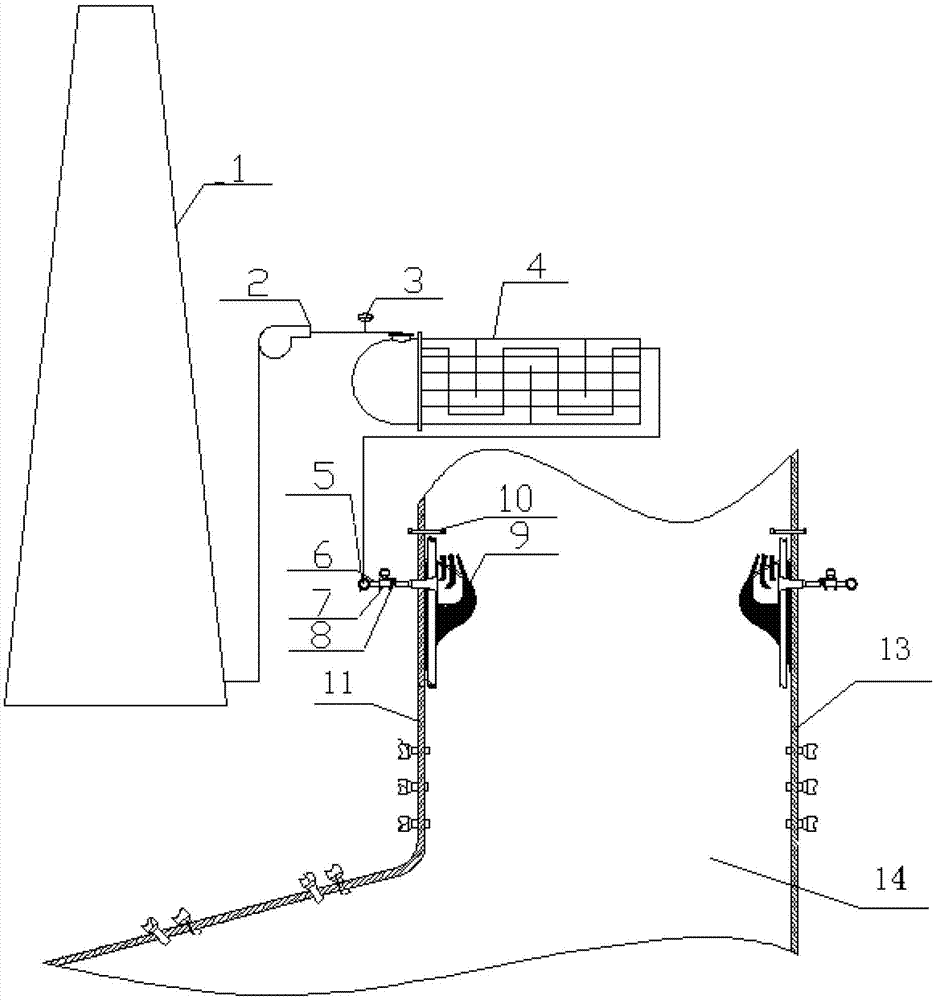

Wall-attached air system for preventing high temperature corrosion of water cooled wall of garbage incinerator

The invention discloses a wall-attached air system for preventing high temperature corrosion of a water cooled wall of a garbage incinerator. A wall-attached air supply device comprises a chimney, a slag pump, a controllable heat exchanger, an air pipe and an air duct which are connected in sequence through pipelines. Necking devices are wall-attached air bellows symmetrically arranged on the inner front wall and the inner rear wall of a first flue; the corresponding surfaces of the two wall-attached air bellows are streamline-type curved surfaces; the arc line of the lower curved surface of the streamline-type curved surfaces and the wall surfaces of the front wall and the rear wall are in smooth transition; the included angle between the air outlet angles of the air outlets of the wall-attached air bellows relative to the wall surfaces of the front wall and the rear wall is 170-175 DEG; and air blown by the air outlets forms an airstream layer along the inner wall surfaces of the front wall and the rear wall and ascends along the water cooled wall, so that the oxidizing atmosphere is guaranteed, the temperature of areas near the water cooled wall is relatively reduced, and the high temperature corrosion is prevented. The streamline-type curved surfaces of the wall-attached air bellows can reduce wear of unburned particles on the water cooled wall and prevent combustion of the unburned particles in the positions close to the wall.

Owner:SOUTH CHINA UNIV OF TECH

Biomass preventing corrosion of superheater and garbage power generation boiler

The invention discloses a biomass preventing the corrosion of superheater and a garbage power generation boiler, belonging to power generation equipment using renewable sources as fuel. The garbage power generation boiler comprises a boiler body, characterized in that: a circular secondary air box is arranged around a furnace arc part of a hearth and the spacing between a front arc and a rear arc is appropriately shortened; a limestone powder funnel is arranged at a secondary air main, limestone powder is fully mixed with smoke gas under the driving of secondary air so as to reduce the content of chlorine in the smoke gas; a shaft flue I, a shaft flue II and a shaft flue III are arranged sequentially at a high-temperature smoke gas outlet of the hearth, a superheater pipe is arranged inside the shaft flue II and controlled within 800 DEG C; a box body for fixing a zinc spelter is arranged at a descending pipe wall which is adjacent to a high-temperature superheater inlet header and a low-temperature superheater outlet header, and the zinc spelter is connected with the high-temperature superheater inlet header or the low-temperature superheater outlet header via conducting wires; the garbage power generation boiler has obvious effect in preventing the corrosion of the superheater, prolongs the service life of the superheater and includes low cost, simple and convenient construction and maintenance.

Owner:朴显泽 +2

Boiler water wall air film protection device

Provided is a boiler water wall air film protection device. A plurality of tuyeres are arranged obliquely in an upstream boiler wall of high-temperature flame and flue gas coal dust airflow in the boiler water wall area and each tuyere communicate with an air flue arranged on the outer side of a hearth. Air is jetted into the hearth through the tuyeres, airflow forms an air curtain between the downstream portion of the flame and high-temperature flue gas flow and a water wall along the flue gas and the air curtain is towards the water wall under pushing of the flame and the high-temperature flue gas to form an air isolation layer, on the one hand, the action of the air curtain can push the wall-eroding coal dust airflow or flame to the center of the cross section of the hearth, so that erosive wear and corrosion to the water wall from the wall-eroding coal dust airflow or flame are avoided, and on the other hand, the air curtain is turned to the downstream water wall area under the action of the upstream high-temperature flame and flue gas, a layer of oxidizing atmosphere protection film is formed on the downstream water wall area, and the problem of high-temperature corrosion of the water wall is solved fundamentally.

Owner:XIAN THERMAL POWER RES INST CO LTD

Secondary air offset whirl pulverized coal burner for W flame boiler

ActiveCN105423294AGood for early ignitionImprove flame stabilityPulverulent fuel combustion burnersCombustion apparatusCombustion chamberSlag

Disclosed is a secondary air offset whirl pulverized coal burner for a W flame boiler. The problems of high NOx discharge amount, high fly ash combustible matter content, slag-bonding to water walls of front and back walls of a lower combustion chamber and high temperature corrosion of the W flame boiler which is provided with an existing whirl pulverized coal burner on an arch are solved. A circular ring inner secondary air stop block in the circumferential direction is added in inner secondary air on a dividing cylinder of primary air and inner secondary air of the whirl pulverized coal burner; the angle of the circular ring inner secondary air stop block in the circumferential direction is 180 degrees; a circular ring outer secondary air stop block in the circumferential direction is added in outer secondary air on a dividing cylinder of the inner secondary air and the outer secondary air; the angle of the circular ring outer secondary air stop block in the circumferential direction is 180 degrees; the boundary line in the diameter direction of the circular ring inner secondary air stop block and the circular ring outer secondary air stop block is parallel to the front and back walls of the boiler; the circular ring inner secondary air stop block and the circular ring outer secondary air stop block are mounted on one side close to the center of a combustion chamber. The secondary air offset whirl pulverized coal burner is used for the W flame boiler.

Owner:HARBIN INST OF TECH

Method for spraying and preparing high temperature sulfidation resistant alloy layer on the surface of cast iron

InactiveCN101575693ASufficient binding strengthHigh bonding strengthMolten spray coatingWire rodSulfidation

The invention belongs to the technical field of metal surface spray and provides a method for spraying and preparing a high temperature sulfidation resistant alloy layer on the surface of cast iron. The method includes the following steps of: (1) pre-treating the surface of a cast iron workpiece before spraying, and exposing the clean and coarsening metal surface of the workpiece; (2) adopting a subsonic speed oxyacetylene flame hot spray method to spray prime coat on the surface of the cast iron workpiece, wherein the prime coat adopts nickel aluminum compound powder; and (3) adopting a high speed arc wire spray method to spray an FeCrAl working layer on the surface of the cast iron workpiece. The technique of the invention is characterized by simple and convenient operation and strong applicability, can save high alloy material and is convenient for promotion and use. Compared with the overall high temperature sulfidation resistant material, the cast iron part prepared by means of the method is low in cost, has excellent resistance to high temperature sulfidation and favorable wearing resistance, and can strikingly improve the service life of the cast iron part in a high temperature sulfidation environment.

Owner:HENAN POLYTECHNIC UNIV

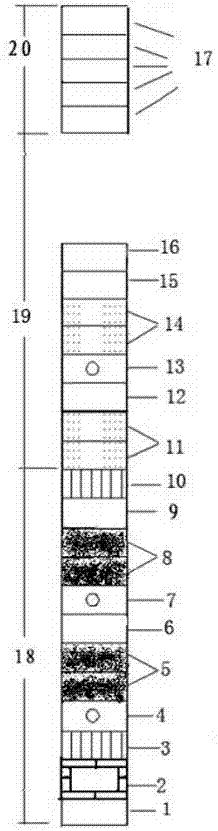

High-parameter waste incineration boiler with reheating function

ActiveCN105953231AImprove sealingHigh thermal efficiencyCasings/liningsSteam superheatersSpray coatingEconomic benefits

The invention relates to waste incineration boilers used for power generation and steam supply, in particular to a high-parameter waste incineration boiler with a reheating function. According to the high-parameter waste incineration boiler with the reheating function, the heat efficiency of the boiler and the overall power generation efficiency of a power plant can be effectively improved, so that the economic benefits of the power plant are greatly increased. The high-parameter waste incineration boiler comprises a hearth. The hearth sequentially communicates with a first perpendicular channel, two perpendicular reburning chambers, a horizontal flue and tail perpendicular flues. A reheater, a high-temperature superheater, a medium-temperature superheater and a low-temperature superheater are sequentially arranged in the horizontal flue. The reheater is provided with a spraying coating or is made of an anti-corrosion material. The tail perpendicular flues are each internally provided with coal economizers.

Owner:WUXI HUAGUANG BOILER

Vertical single-drum refuse-incinerating waste heat boiler

InactiveCN102748742AImprove sealingGuaranteed no air leakageSteam superheatersSteam boilersCooling chamberSuperheater

The invention relates to a vertical single-drum refuse-incinerating waste heat boiler, mainly comprising a high-temperature smoke inlet, a front cooling chamber, a rear cooling chamber, a vertical well flue, a super-heater, a tube box type economizer and a drum; the boiler provided by the invention utilizes a diaphragm type water-cooling wall smoke cooling chamber, a diaphragm type water-cooling wall enclosure vertical-well flue, and a steel tube box type economizer; all smoke channels are in sealed welding structures; sealing property of the boiler is high to ensure that airs do not leak out from the boiler, and harmful gas in smoke does not leak. Because the smoke cooling chamber is arranged in front of the super-heater, high-temperature smoke passes through the cooling chamber at first, and then flows into the super-heater so as to reduce temperature of inlet smoke of the super-heater, and prevent the super-heater from high temperature corrosion by chlorine-containing gas generated by burning refuses.

Owner:TAIYUAN BOILER GROUP

Low-NOX air-coal-powder optimized burner group

ActiveCN102927560AEmission reductionImprove combustion efficiencyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorSlag

The invention provides a low-NOX air-coal-powder optimized burner group. Burners are arranged at four corners of a hearth. A secondary air I nozzle, a micro-oil ignition primary air nozzle I, an offset secondary air nozzle, an oil air chamber, a concentrated primary air nozzle, a secondary air I nozzle, an oil air chamber, a concentrated primary air nozzle, a secondary air I nozzle, an offset secondary air nozzle, a light primary air nozzle, a secondary air I nozzle, an oil air chamber, a light primary air nozzle, a secondary air I nozzle and an above-fire air nozzle are distributed in layered mode in the height direction from the bottom to the top. A primary air anti-tangential circle and a secondary air I tangential circle are arranged on the same layer, the diameter of the secondary air I tangential circle is larger than that of the primary air anti-tangential circle, and offset secondary air is closer to a water cooling wall compared with secondary air I. The low-NOX air-coal-powder optimized burner group has the advantage of being low in NOX emission, preventing slag-bonding in the hearth, preventing the hearth from being corroded at high temperature, and effectively protecting the water cooling wall.

Owner:山东智信电力科技有限公司

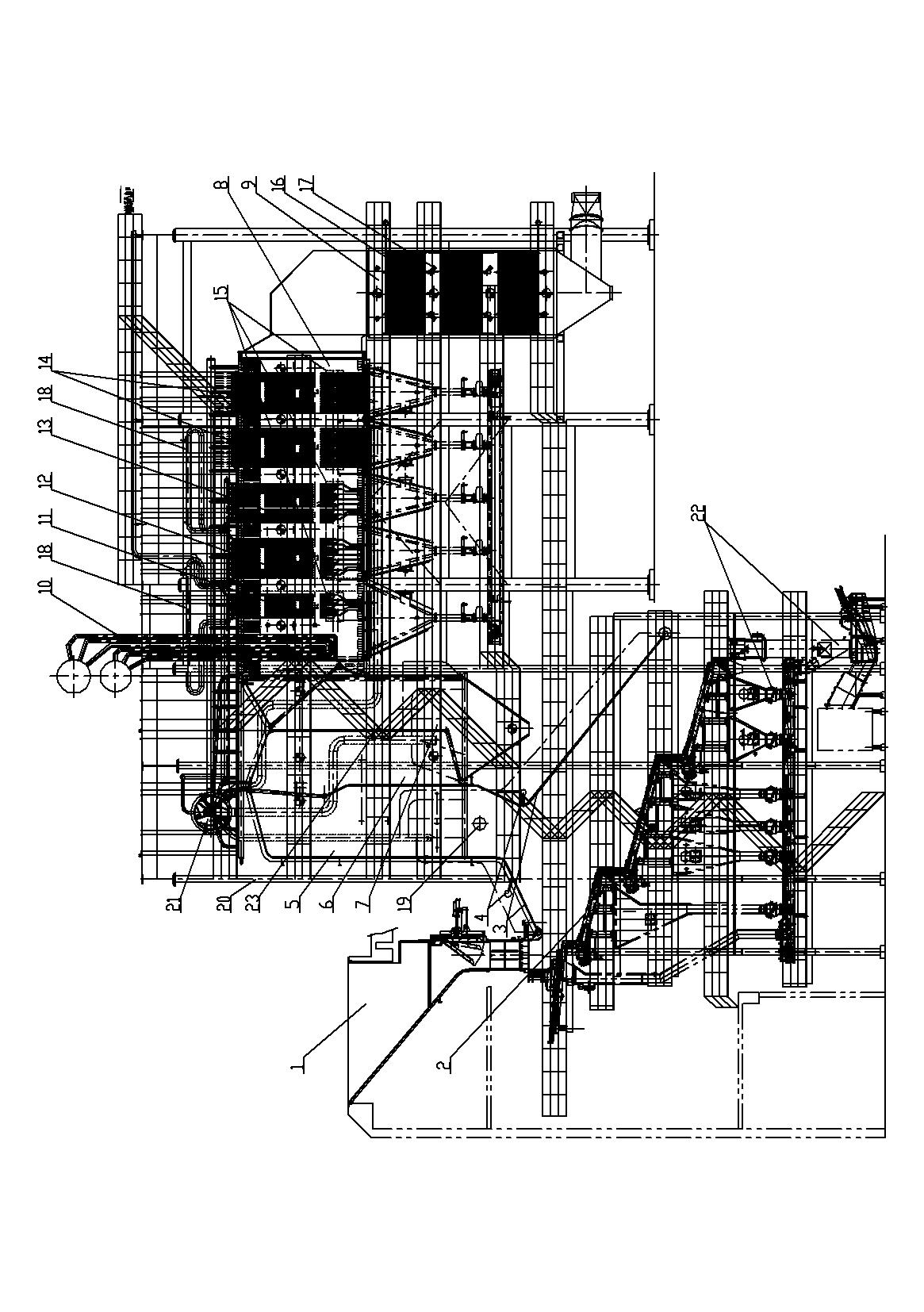

System and method for fluidized bed gas production, gas-based reduction and electric steelmaking coupling

PendingCN107299175AImprove matchReduce consumptionShaft furnaceProcess efficiency improvementSteelmakingFluidized bed

The invention relates to a system and a method for fluidized bed gas production, gas-based reduction and electric steelmaking coupling. The system comprises a fluidized bed, a gas-based reduction device and an electric furnace, wherein the fluidized bed comprises an air distribution plate, a gas blowing hole, a fluidized bed material cabin and a coal gas outlet; the gas-based reduction device comprises a vertical furnace and a iron tank which are connected with each other; the vertical furnace comprises a coal gas inlet and an oxidized block cabin; the coal gas inlet is connected with the coal gas outlet; the iron tank comprises a reduced iron outlet; the electric furnace comprises a reduced iron inlet, an electric furnace cabin and a steel outlet; and the electric furnace reduced iron inlet is connected with the reduced iron outlet of the iron tank. Through coupling processes of fluidized bed gas production-direct gas-based reduction-electric steelmaking coupling, the process of cooling, washing, dust collection and further heating of a coal gas produced by using the fluidized bed is avoided, system investment is reduced, sensible heat of the coal gas is sufficiently utilized, energy consumption of coal gas heating of the vertical furnace is reduced, relatively optimal parameters are screened, the complete-flow optimal process is explored, and optimal coupling of production parameters of equipment is achieved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

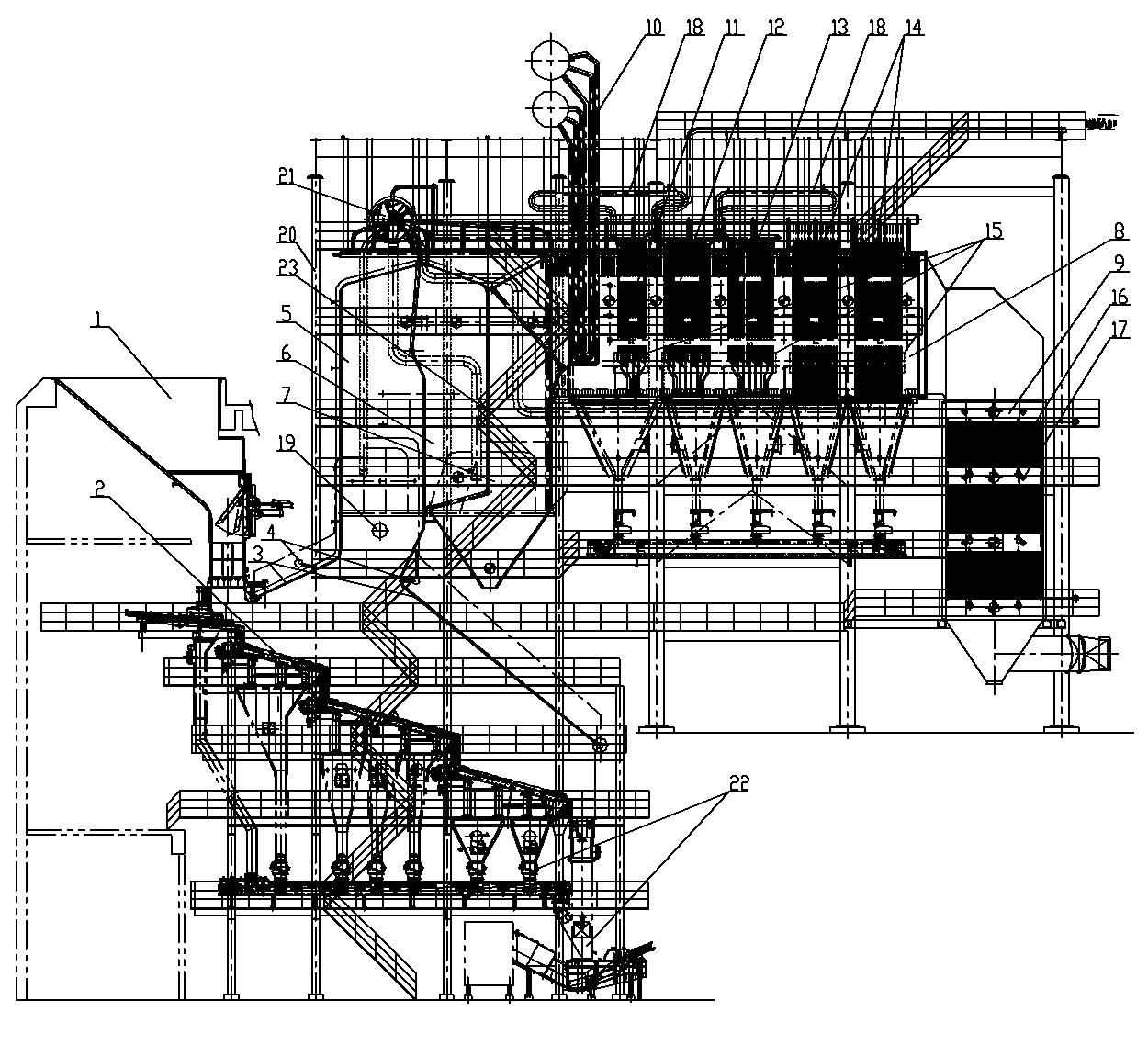

High-temperature air combustion intensifying device and method applicable to low heating value mixed garbage

ActiveCN102878569AIncineration is stable enoughFully stable combustionIncinerator apparatusCombustion chamberSlag

The invention discloses a high-temperature air combustion intensifying device and method applicable to low heating value mixed garbage, wherein a low-temperature preheater is arranged on the rear side of a U-shaped tail part flue; a garbage feeding opening is arranged on the side wall of the lower part of a furnace chamber; the side wall of the upper part of the furnace chamber is connected with the upper part of a cyclone separator; the bottom part of the cyclone separator is connected with the upper end of a back feeder; the lower end of the back feeder is connected with the side wall of the lower part of the furnace chamber; the upper end of the cyclone separator is connected with the upper part of the front side of a U-shaped combustion chamber; the lower end of the U-shaped combustion chamber is connected with the side wall of the lower part of the furnace chamber; the lower end of the furnace chamber is connected with the side wall of the lower part of the furnace chamber through a water-cooled cold slag sorting and back feeding device; and the upper part of the rear side of the U-shaped combustion chamber is connected with the upper part of the front side of the U-shaped tail part flue. The method utilizing the high-temperature air to intensify the low heating value garbage mixed combustion is more suitable for the domestic characteristics that the garbage has complicated components, high moisture and low heating value, has wider fuel application range, and is more sufficient and stable in combustion, the garbage can be purely combusted without the need of coal, the energy consumption is reduced, and the operating economy is improved.

Owner:ZHEJIANG UNIV

Waste incineration boiler

ActiveCN102322640ANot easy to accumulate dustImprove cleanlinessIncinerator apparatusAir preheaterEngineering

The invention provides a waste incineration boiler, which ensures that a conventional waste incineration boiler is less in dust stratification, convenient in soot cleaning and difficult in leakage, and the operation and maintenance costs of the boiler are reduced. The waste incineration boiler comprises a furnace chamber, a furnace grate and a horizontal flue, wherein the furnace chamber is positioned above the furnace grate; a boiler barrel is arranged above the furnace chamber; a front-back arch is arranged on the lower part of the furnace chamber; secondary air is arranged on the front-back arch, and faces the furnace grate; and an air preheater, an overheater and an evaporator are arranged in the horizontal flue. The waste incineration boiler is characterized in that: the furnace chamber is connected with a vertical burn-out chamber, three vertical flues, the horizontal flue and a tail part vertical flue in turn; a coal economizer is arranged in the tail part vertical flue; a rapping apparatus is arranged on a pipeline of the air preheater, the overheater and the evaporator which are arranged in the horizontal flue; and a shockwave or steam sootblower is arranged in the tail part vertical flue.

Owner:WUXI HUAGUANG BOILER

Wall-attached wind nozzle, boiler and boiler system

The invention discloses a wall-attached wind nozzle, a boiler and a boiler system. The wall-attached wind nozzle ejects over fire air, is arranged on a wall of the boiler, and comprises a wind inlet channel inserted in the wall of the boiler; the wind inlet channel is communicated with an over fire air source; the wall-attached wind nozzle further comprises an exhaust channel communicated with a wind inlet channel; and the exhaust channel ejects wall-attached wind operated along the wall of mounting the wall-attached wind nozzle. The over fire air ejected by the exhaust channel of the wall-attached wind nozzle can be operated along the wall to form the wall-attached wind so as to form an oxide protection layer on the surface of the wall to prevent a reductive environment from causing high-temperature corrosion to the wall. Moreover, the over fire air is operated along the wall without disturbing an airflow in a hearth and causing the influence on a daily operation mode of the boiler.

Owner:YANTAI LONGYUAN POWER TECH

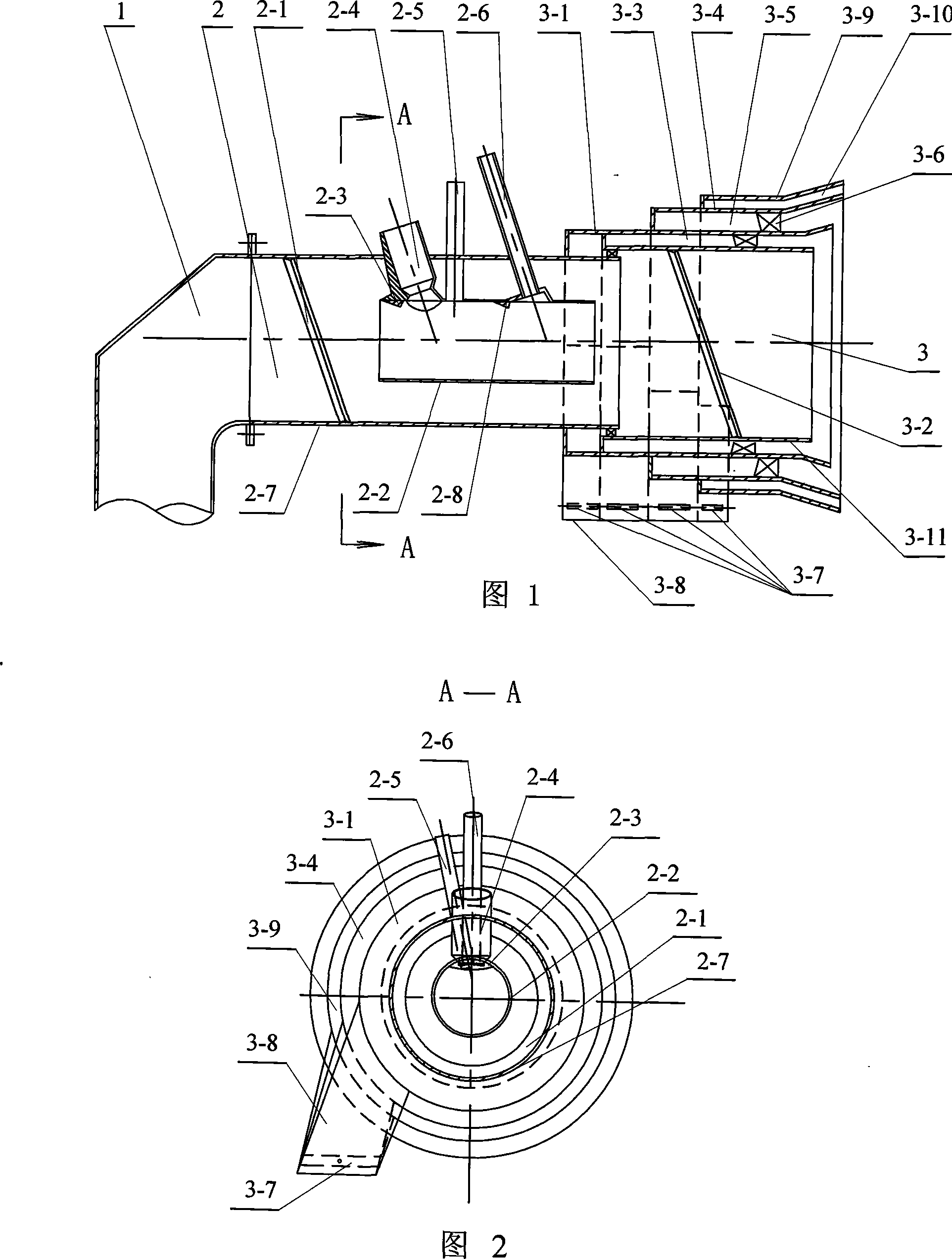

Little oil ignited swirling pulverized coal combustion device

InactiveCN101187470AAvoid wastingEmission reductionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir volumePollutant emissions

A low-oil-consumption ignition swirling pulverized coal burning device relates to a pulverized coal burning device. The invention aims to solve the problems of large oil consumption, energy waste, and high pollutant discharge of a coal-fired boiler existing in the burning device in the coal-fired boiler of power plants. An inlet end of an inner wall swirling wind cover (3-1) in the invention is connected with an outlet end of an external pipe (2-7), a passage exit in a duct (3-8) is respectively connected with the inner wall swirling wind cover (3-1), a swirling outer secondary wind cover (3-4) and a direct secondary wind cover (3-9), and the passage exist in the duct (3-8) is respectively provided with an air volume regulation plate (3-7). The invention has the advantage of reasonable structure, design and arrangement. The invention burns pulverized coal by using a small amount of oil, oil and gas, natural gas or coal gas, which can save ignition energy, and reduces the discharge of pollutant. The device of the invention has higher safety and reliability properties, which can save 40%-90% fuel oil compared with the prior art.

Owner:HARBIN INST OF TECH

W-shape flame furnace with gradation coal burner

ActiveCN1333199CHigh melting temperaturePrevent high temperature corrosionCombustion using gaseous and pulverulent fuelLiquid fuel feeder/distributionCombustorEngineering

The present invention is one W-shaped flame furnace with dense and dilute coal powder combustion and relates to one kind of burning plant. The improved W-shaped flame furnace includes furnace arch, side wall, hearth formed with the furnace arch and the side wall, and burner. The burner includes dense coal powder flow flame nozzle in the center of the hearth and dilute coal powder flow flame nozzle near the side wall. The present invention has greatly raised ash melting temperature to avoid slagging of the water cooled wall and prevent high temperature corrosion while reaching the aims of timely igniting and stable combustion.

Owner:HARBIN INST OF TECH

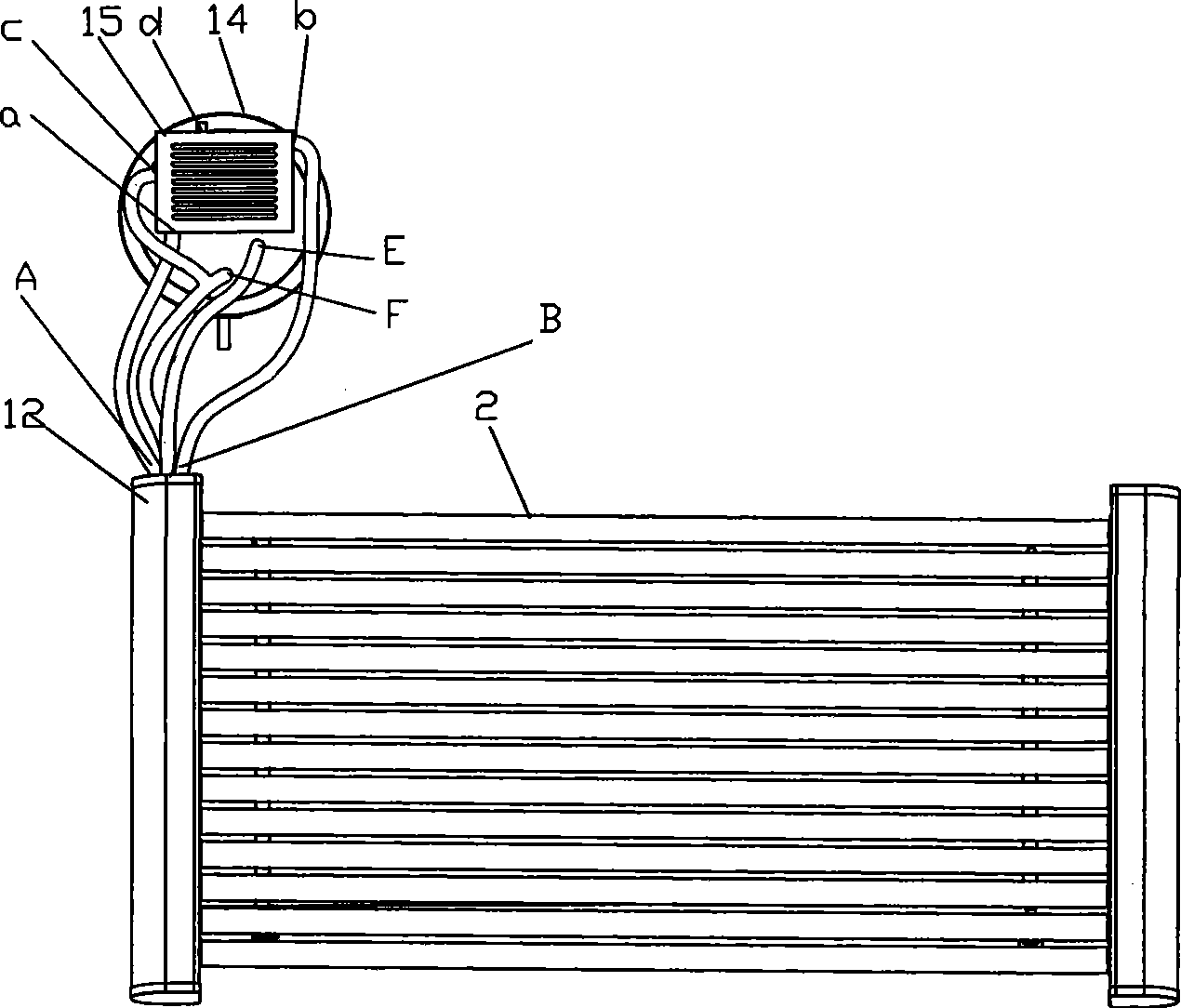

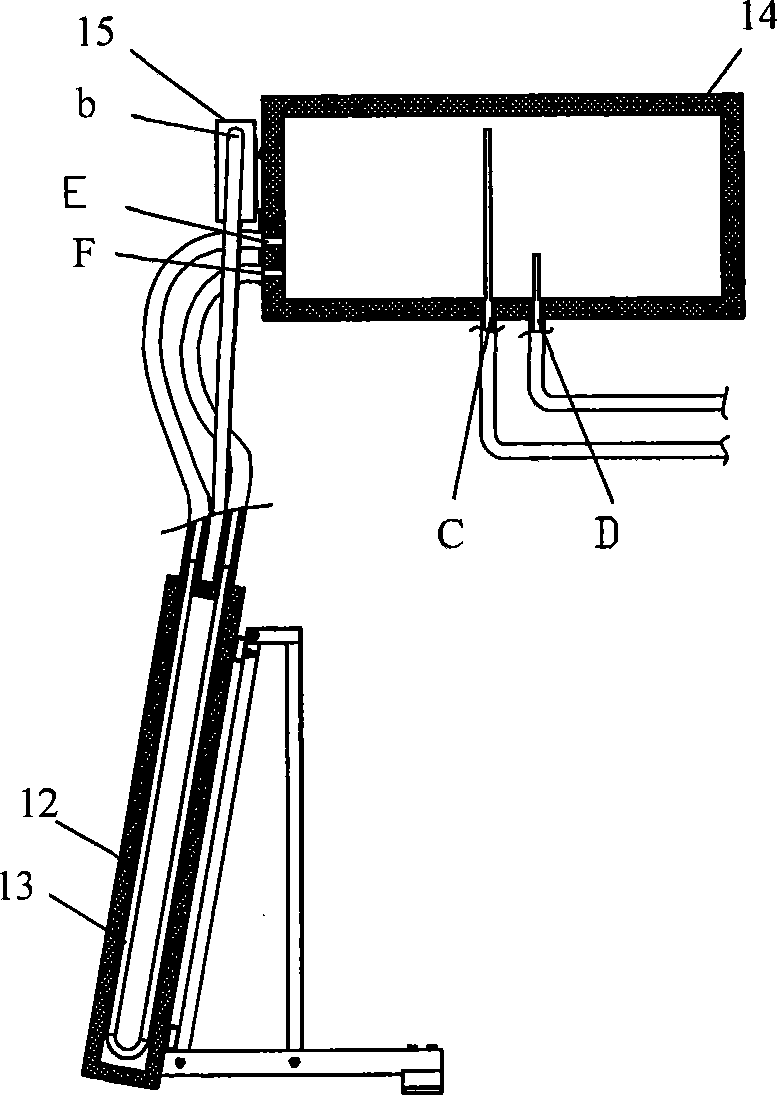

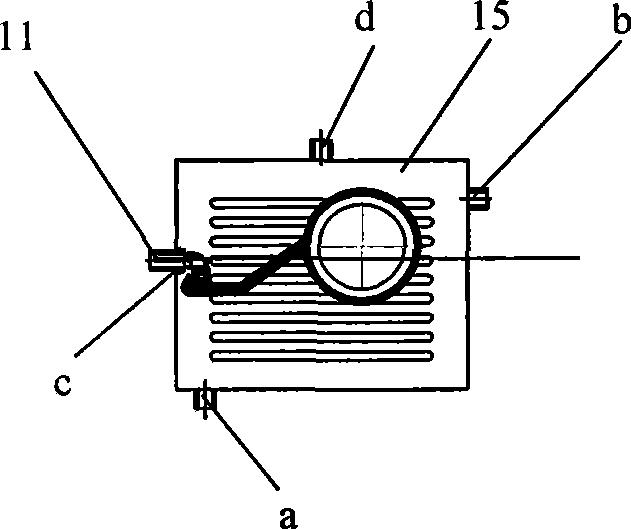

Solar water heater with functions of fluid supply and heat dissipation

InactiveCN101520240AGuarantee the safety of usePrevent high temperature corrosionSolar heating energySolar heat devicesWater sourceSolar water

The invention relates to a solar water heater, which belongs to the technical field of solar application. The water heater comprises a collector and a hot water storage tank, wherein the collector is provided with a fluid supply port and a reflux port. The solar water heater is characterized by comprising a fluid supply radiation tank; the fluid supply radiation tank is provided with a water supply inlet, a fluid supply inlet and a reflux inlet higher than the fluid supply port, and the upper part of the fluid supply radiation tank is provided with an exhaust overflow port; the water supply inlet is connected with a water source through a connection control device; and the fluid supply inlet and the reflux inlet are connected with corresponding ports of the collector respectively so as to form a heat dissipation circulation loop. The solar water heater felicitously and organically combines fluid supply and heat dissipation together so as to supply water and effectively solve the problem of overheat, thereby ensuring use safety of the solar water heater.

Owner:A O SMITH CHINA WATER HEATER CO LTD

Boiler for derived fuel RDF, waste plastics RPF and waste wood of combustion of refuses

ActiveCN101852422AAvoid cokingHigh volatile contentCasings/liningsSteam boilersRefuse-derived fuelSocial benefits

The invention discloses a boiler for derived fuel RDF, waste plastics RPF and waste wood of combustion of refuses, mainly comprising a hearth, a burnout chamber, a superheater chamber and a rear flue duct, wherein the burnout chamber, the superheater chamber and the rear flue duct are successively connected behind the hearth; a drum is arranged above the hearth, and a reverse chain fire grate is arranged on the lower part of the hearth; slag trapping and ash discharging equipment is arranged below the reverse chain fire grate; the front wall of the lower part of the hearth is provided with a waste wood spray seeding device and a refuse derived fuel RDF and waste plastics RPF spray seeding device which are communicated with the inner part of the hearth, and the waste wood spray seeding device is arranged below the refuse derived fuel RDF and waste plastics RPF spray seeding device. In the invention, the steam produced by using refuse derived fuel RDF, the waste plastics RPF and the waste wood to be combusted in a boiler is used for generating electricity and supplying steam. The invneiton has the social benefit of saving energy and reducing environmental pollution and has favourable economic benefit.

Owner:ZHEJIANG WEIMING ENVIRONMENT PROTECTION

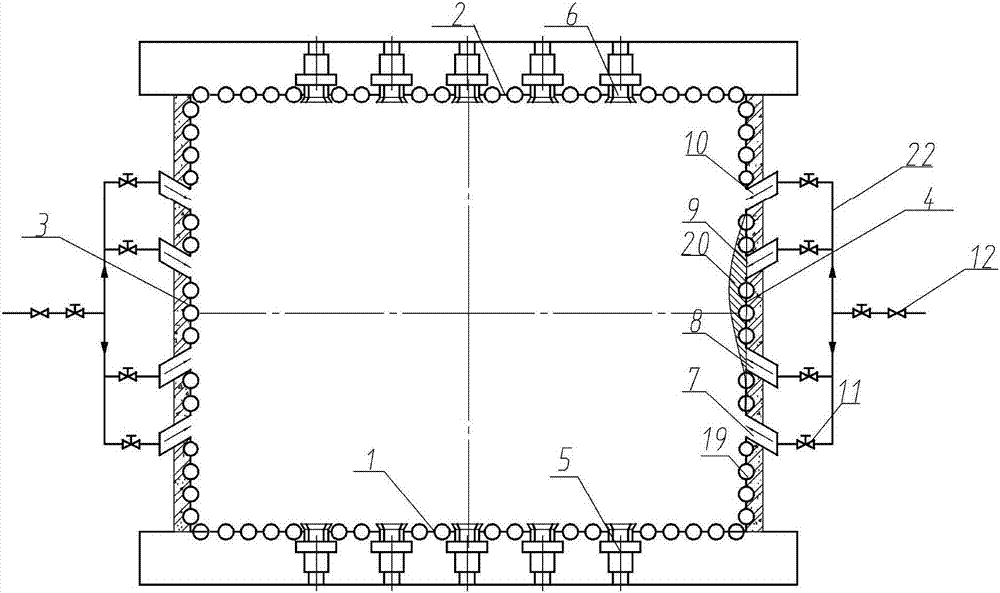

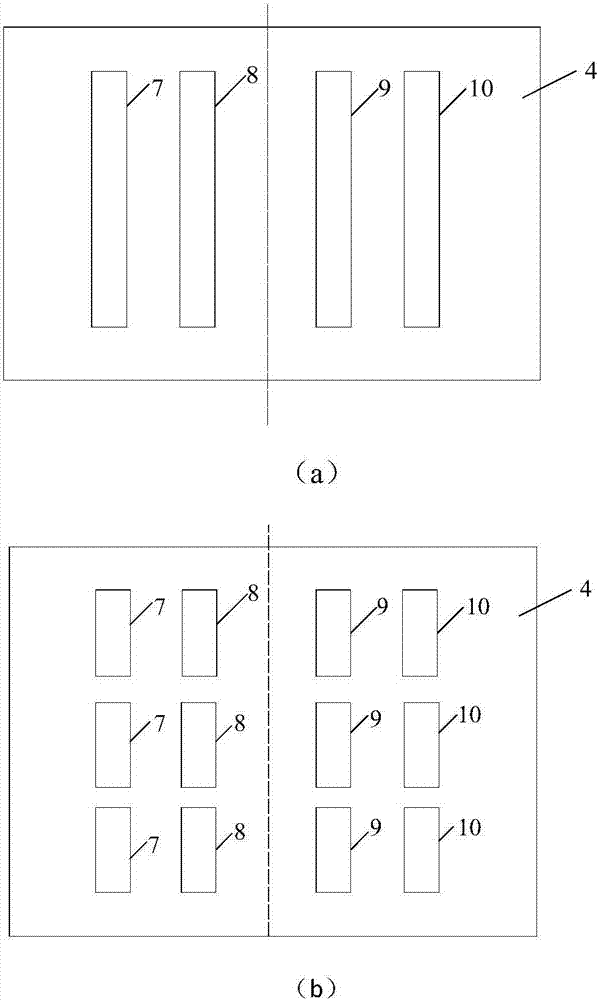

Device for preventing high-temperature corrosion of water cooling wall of combustion boiler and boiler corrosion prevention method

ActiveCN113776047ASolve different high temperature corrosion areasPrevent high temperature corrosionIndirect carbon-dioxide mitigationAir/fuel supply for combustionCombustion systemEngineering

The invention discloses a device for preventing high-temperature corrosion of a water cooling wall of a combustion boiler and a boiler corrosion prevention method, relates to the device for preventing high-temperature corrosion of the water cooling wall of the boiler and the boiler corrosion prevention method, and aims to solve the problem that a central powder feeding rotational flow pulverized coal burner is used in a front and rear wall main combustion area of an existing boiler. The device comprises a combustion system, a hearth and two groups of close-to-wall air systems, wherein the hearth comprises a front wall, a rear wall and two side walls; the combustion system comprises two secondary air doors, two secondary air boxes, multiple combustors and multiple over-fire air ports; and the front wall, the rear wall and the two side walls form a boiler body. The method is implemented according to the following steps: 1, ventilation is conducted in the secondary air boxes; 2, wall-attaching wind is added to the side walls; and 3, the high-temperature corrosion prevention direct-current air in the first step and the wall-attaching wind in the second step act jointly, so that the high-temperature corrosion phenomenon of the water cooling wall is prevented, and the purpose of the invention is achieved. The invention belongs to the field of boilers.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com