Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Avoid scour wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler water wall air film protection device

Provided is a boiler water wall air film protection device. A plurality of tuyeres are arranged obliquely in an upstream boiler wall of high-temperature flame and flue gas coal dust airflow in the boiler water wall area and each tuyere communicate with an air flue arranged on the outer side of a hearth. Air is jetted into the hearth through the tuyeres, airflow forms an air curtain between the downstream portion of the flame and high-temperature flue gas flow and a water wall along the flue gas and the air curtain is towards the water wall under pushing of the flame and the high-temperature flue gas to form an air isolation layer, on the one hand, the action of the air curtain can push the wall-eroding coal dust airflow or flame to the center of the cross section of the hearth, so that erosive wear and corrosion to the water wall from the wall-eroding coal dust airflow or flame are avoided, and on the other hand, the air curtain is turned to the downstream water wall area under the action of the upstream high-temperature flame and flue gas, a layer of oxidizing atmosphere protection film is formed on the downstream water wall area, and the problem of high-temperature corrosion of the water wall is solved fundamentally.

Owner:XIAN THERMAL POWER RES INST CO LTD

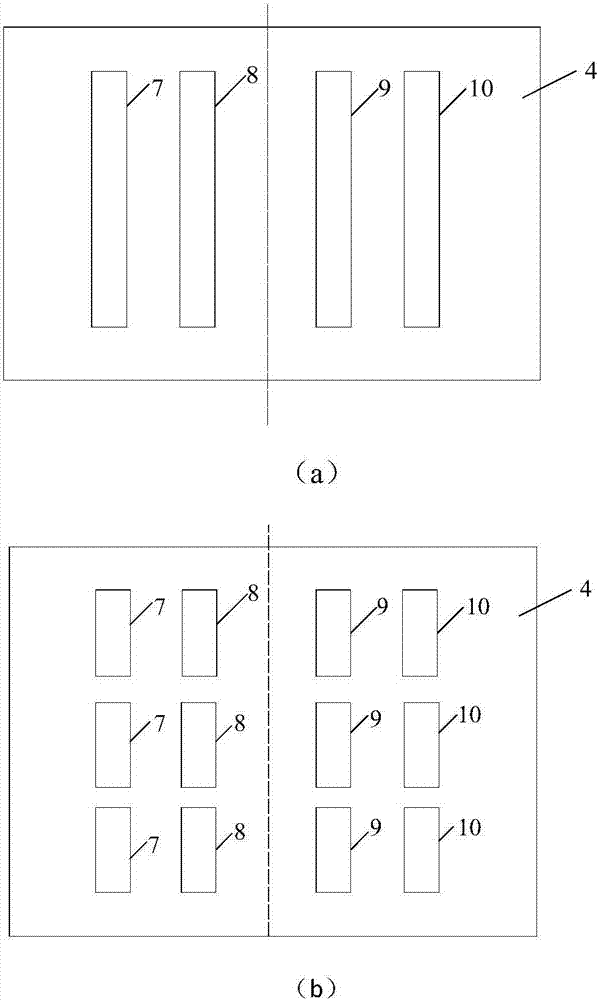

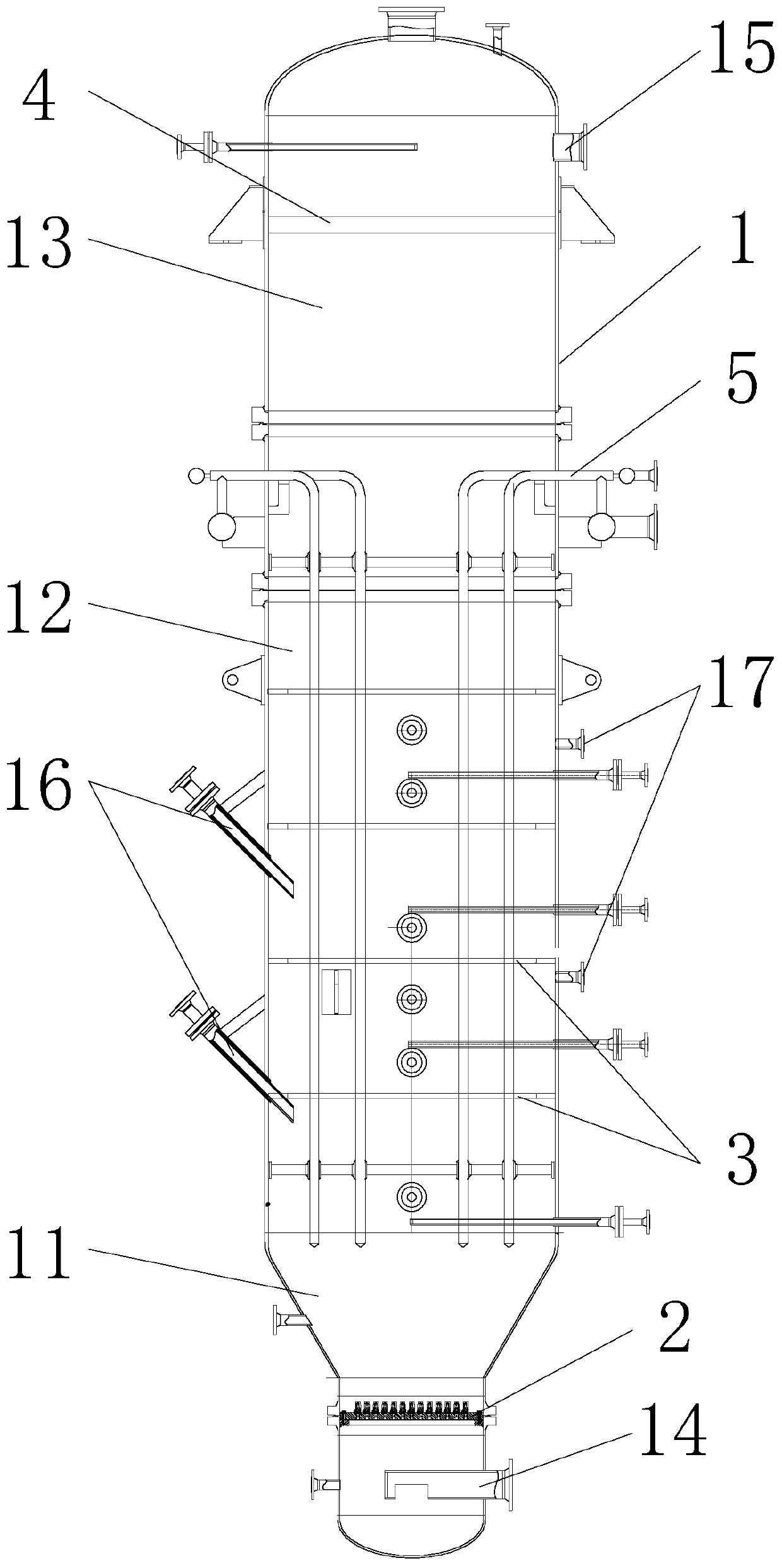

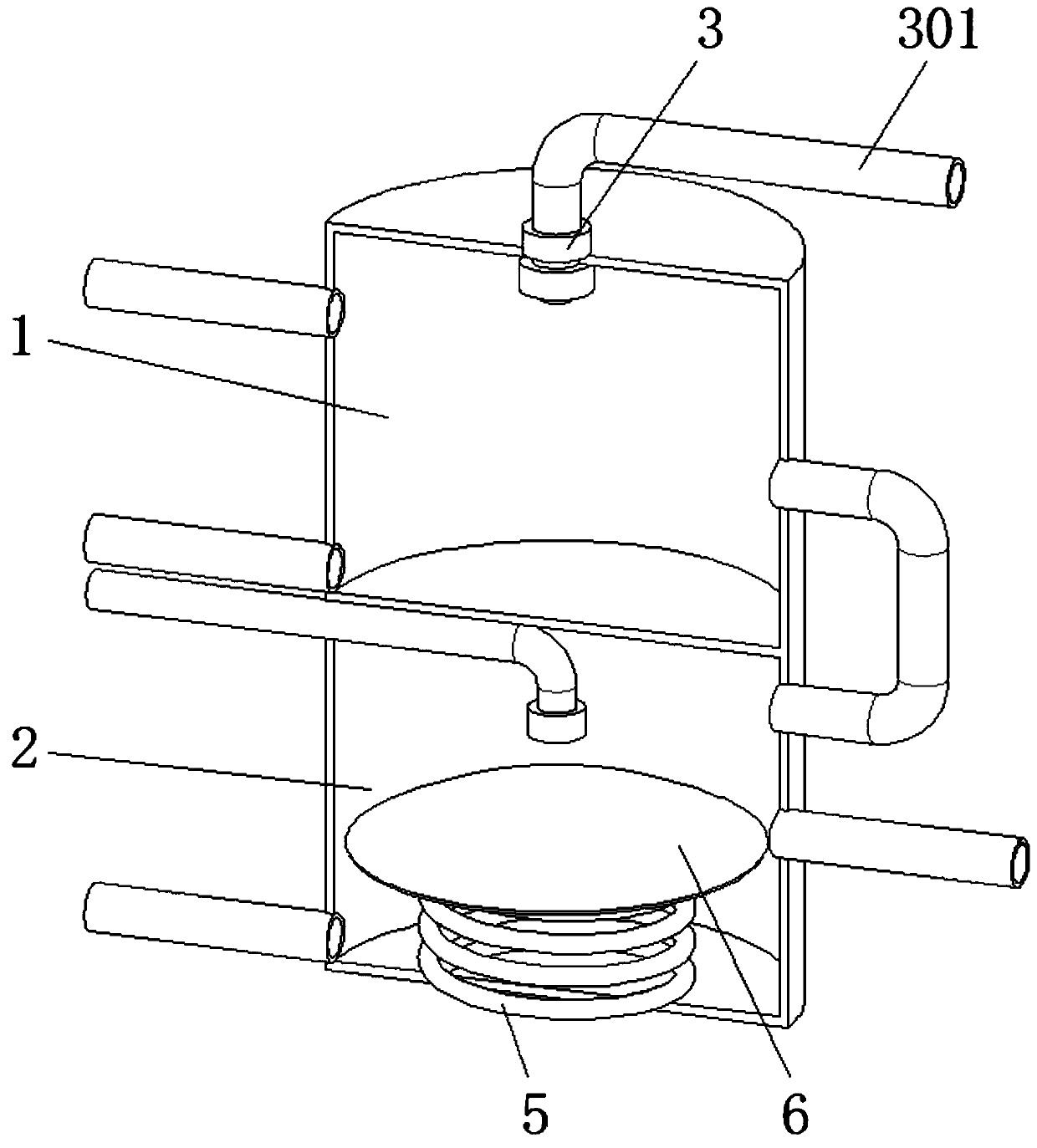

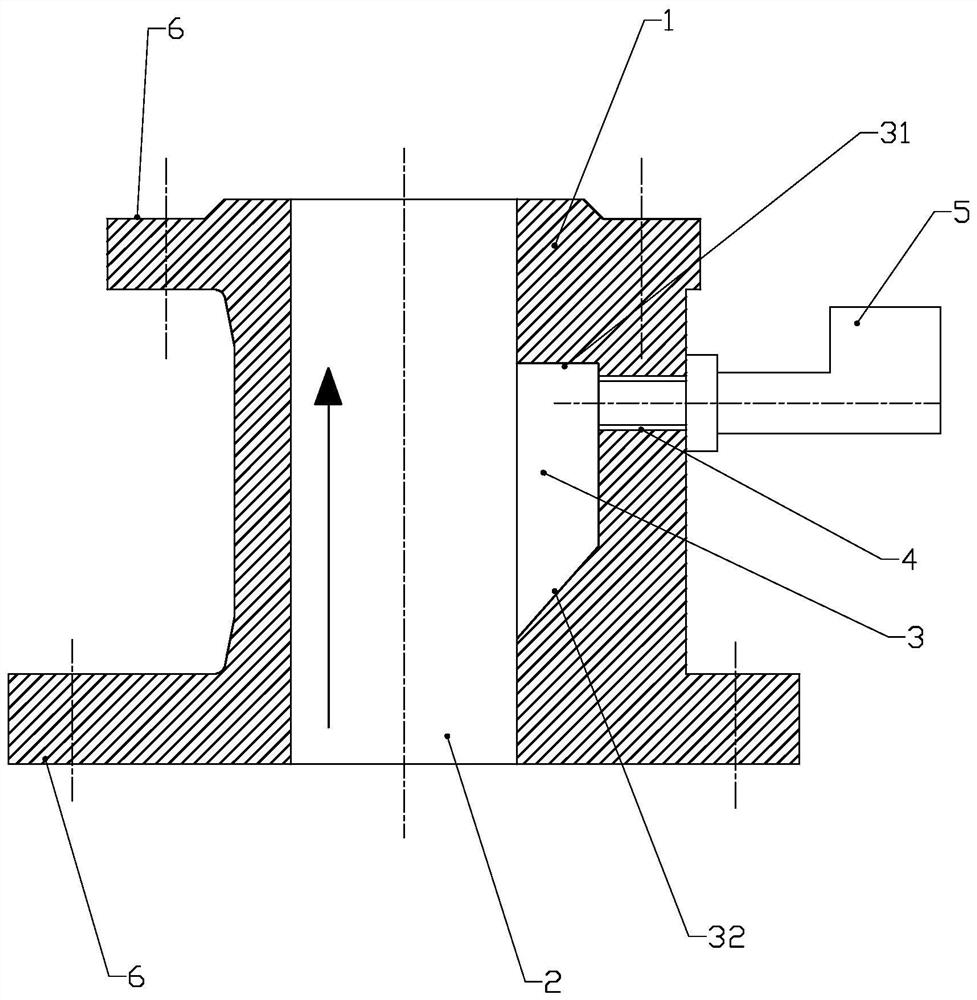

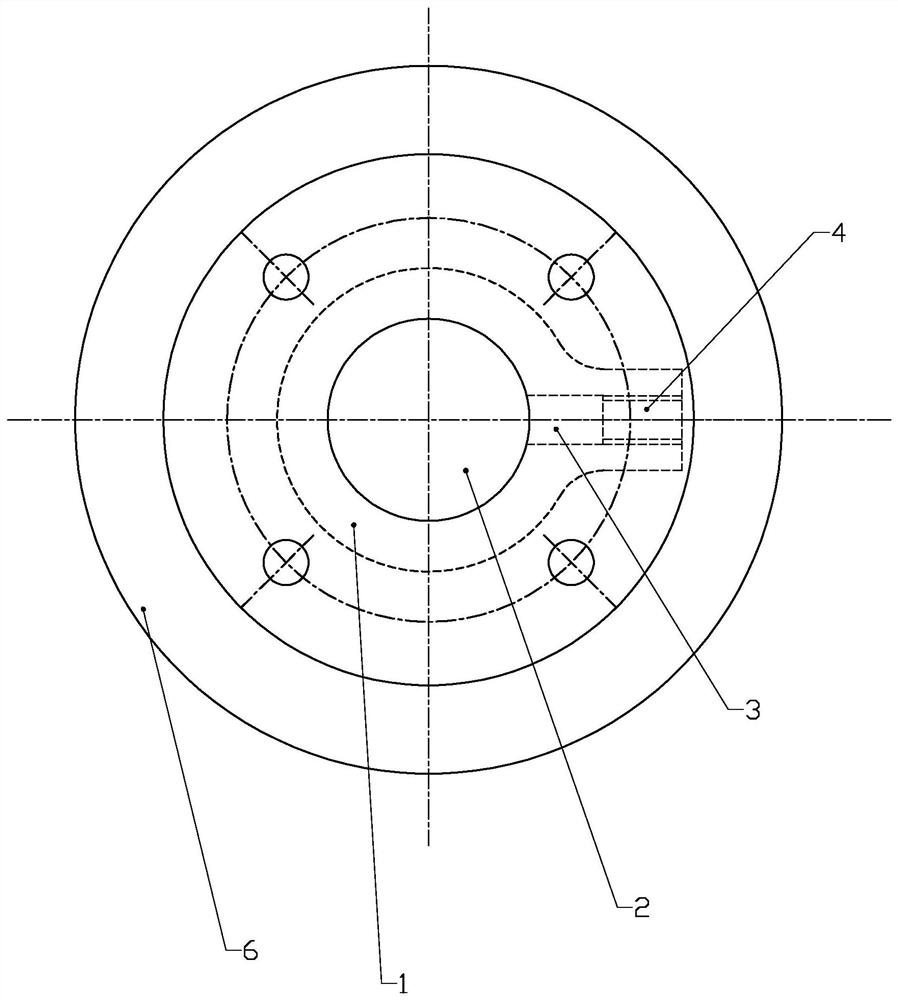

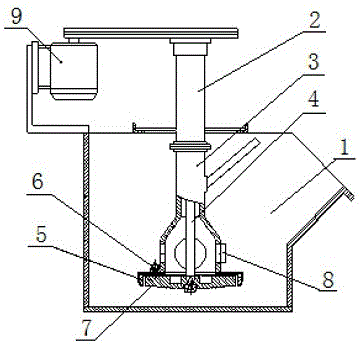

Gas distributor for ash agglomerating fluidized-bed gasification furnace

InactiveCN102827644AAvoid scour wearAvoid Vibration FractureGranular/pulverulent flues gasificationFluidized bed gasifierEngineering

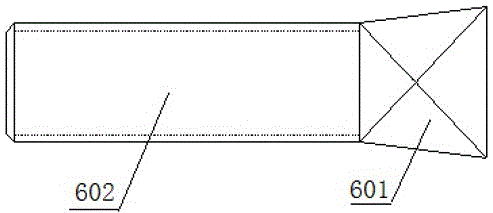

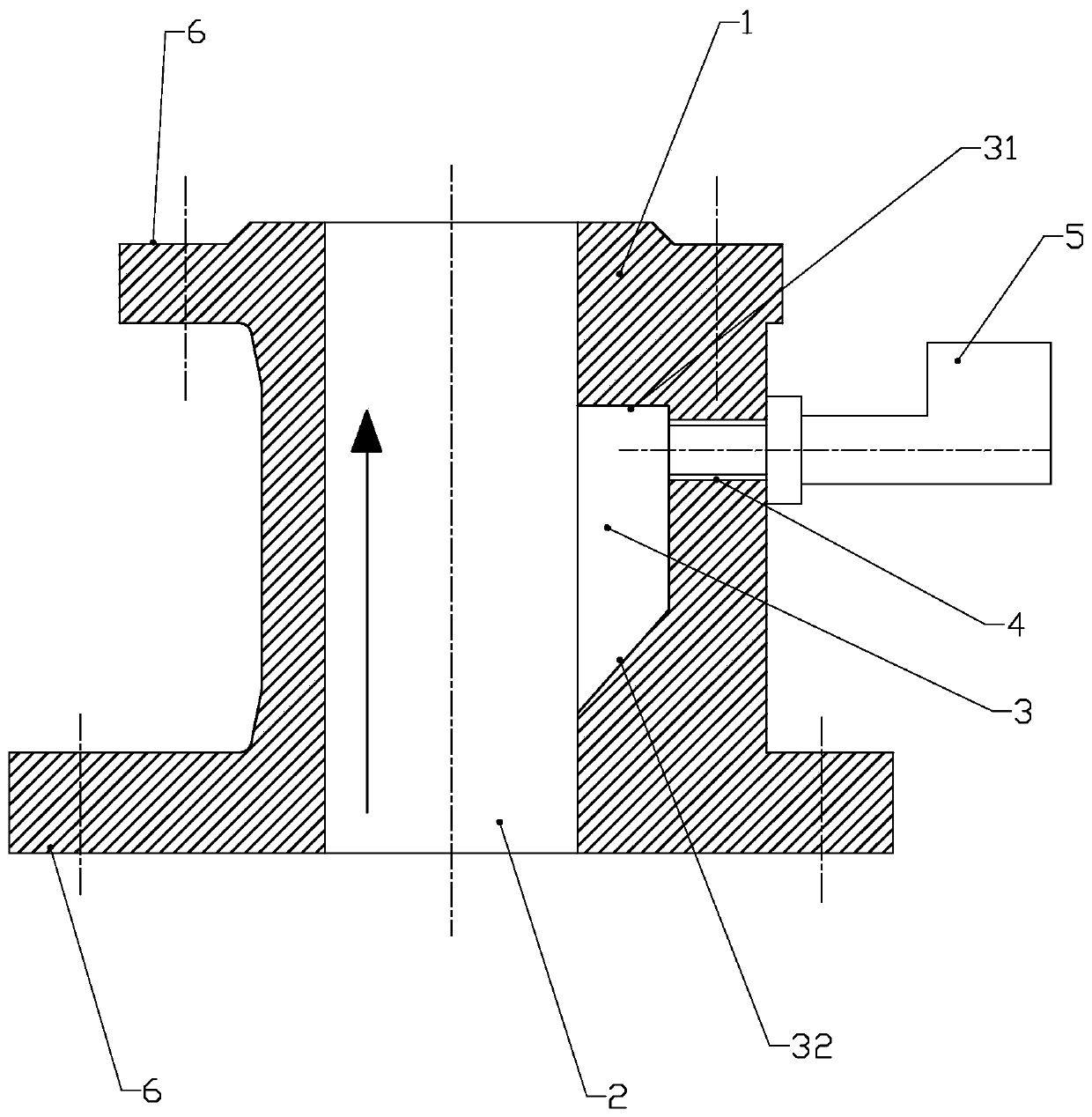

The invention provides a gas distributor for an ash agglomerating fluidized-bed gasification furnace. The gas distributor comprises a gasification furnace shell, a tapered distribution plate, at least three distributed injection pipes, a slagging pipe and a gas inlet pipe of a gas chamber, wherein one end of the slagging pipe is connected to the bottom of the tapered distribution plate, and is open, and the other end of the slagging pipe penetrates through the gasification furnace shell, and is connected with a gasification agent gas source. The gas distributor is characterized in that one end of each distributed injection pipe is connected to the lower part of the tapered distribution plate, and is open, and the other end of each distributed injection pipe penetrates through the gasification furnace shell, and is connected with the gasification agent gas source; and openings of the distributed injection pipes in the tapered distribution plate are symmetrically and uniformly distributed about the center of the slagging pipe. The gas distributor is high in fluidization performance, adapted to long-cycle running, simple in structure and applicable to a large-sized fluidized-bed gasification furnace.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

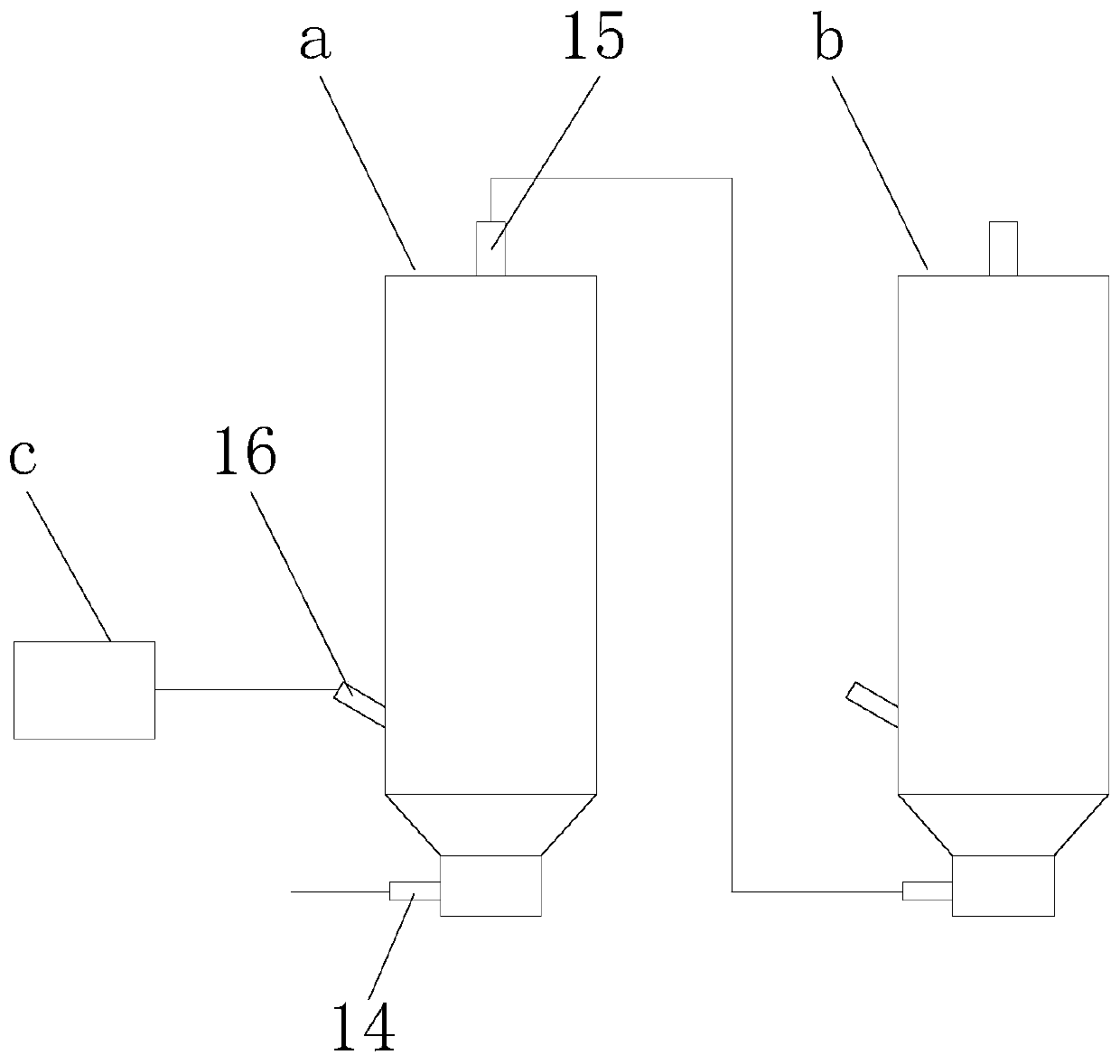

High-temperature solid particle heat exchange system

PendingCN111735332AReduce heat lossImprove heat transfer efficiencySolar heating energySolar heat storagePower cycleEngineering

The invention discloses a high-temperature solid particle heat exchange system. Gas is taken as an intermediate heat exchange medium between high-temperature particles and a power cycle working medium, and the intermediate heat exchange medium is used for heat exchange between the high-temperature particles and the power cycle working medium, so that the technical problems of low heat exchange efficiency, serious abrasion of a heat exchange surface and the like of a particle heat exchanger are effectively solved. According to the high-temperature solid particle heat exchange system, leaked particles in the particle lifting process are recycled through pneumatic conveying, a solution is provided for heat recycling of the conveyed gas, low-temperature particles leaked in a particle lifting system or other conveying systems are conveyed into a low-temperature particle storage tank through a pneumatic conveying device, the low-temperature particle storage tank is a positive-pressure storage tank, and after the conveyed gas of the pneumatic conveying device is continuously input, positive pressure is formed in the tank, heat exchange gas in the particle / gas heat exchanger is effectivelyprevented from flowing back into the low-temperature particle storage tank, the pressure of the low-temperature particle storage tank is balanced through a check valve, the conveyed gas is guided into the particle / gas heat exchanger, waste heat of the low-temperature particle storage tank is recycled, and the particle heat loss is effectively reduced.

Owner:浙江高晟光热发电技术研究院有限公司

Top oblique insert type spray gun, preparation method and using method for air blowing slag accretion

The invention discloses a top oblique insert type spray gun for air blowing slag accretion. A connecting section comprises a metal connecting pipe and a connecting part, a gun body section comprises a metal main pipe, a gun body section refractory castable lining and a gun body section V-shaped anchoring part, and a nozzle section comprises a metal spray pipe, a nozzle section refractory castable lining and a nozzle section V-shaped anchoring part. The metal spray pipe and the metal main pipe are in welded communication, and an included angle alpha formed by the metal spray pipe and the metal main pipe is greater than 0 degree and less than 180 degrees. A diffuse type nozzle facing to the molten iron surface during air blowing is arranged in the nozzle section refractory castable lining, and a through hole which corresponds to the diffuse type nozzle and communicates with the diffuse type nozzle in the radial direction is formed in the side wall of the upper half portion of the metal spray pipe in the radial direction. Advantages of the top gun air blowing auxiliary deslagging technology and advantages of the molten iron jar air brick ventilation auxiliary deslagging technology are highly gathered, all kinds of disadvantages existing in conventional top gun air blowing or air brick ventilation are fully overcome, and the comprehensive purposes of reducing deslagging iron losses, shortening deslagging time, prolonging the service life of a molten iron jar and the air blowing slag accretion spray gun and lowering deslagging process cost are realized.

Owner:武汉钢铁有限公司

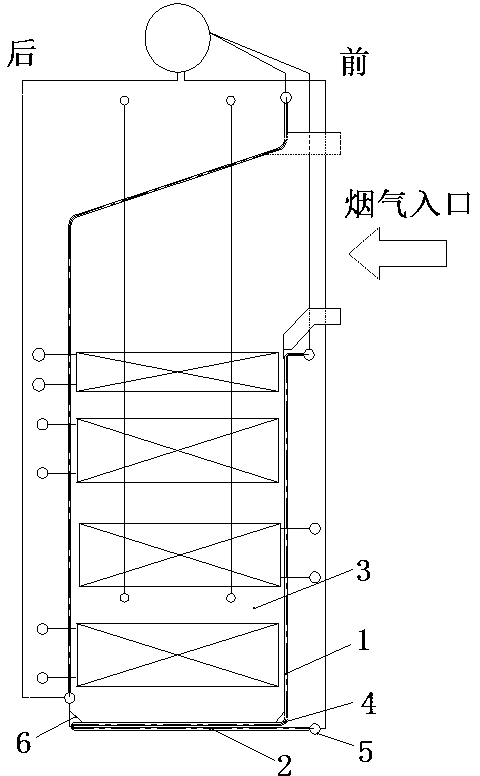

Flue-gas purifying system for boiler

PendingCN106390724AAvoid poisoningAvoid scour wearGas treatmentDispersed particle filtrationAir preheaterFlue gas

The invention discloses a flue-gas purifying system for a boiler. The flue-gas purifying system comprises a mixed reaction tower and a dust and nitrate filter which are communicated. The flue-gas purifying system is characterized in that flue gas is firstly desulfurized by the mixed reaction tower, then is dedusted and denitrified by the dust and nitrate filter, and the flue-gas flow is firstly dedusted and then is denitrified when passing through the dust and nitrate filter. Therefore, the flue gas is purified according to the sequence of desulfurization, dedusting and denitrification, so that the generation of NH4HSO4 in denitrification of the flue gas is avoided, further ash blocking of an air preheater and corrosion of equipment are avoided, and the catalyst poisoning caused by alkali metal and dust particles in the flue gas is avoided to guarantee the efficiency of denitrifying reaction.

Owner:FUJIAN LONGKING

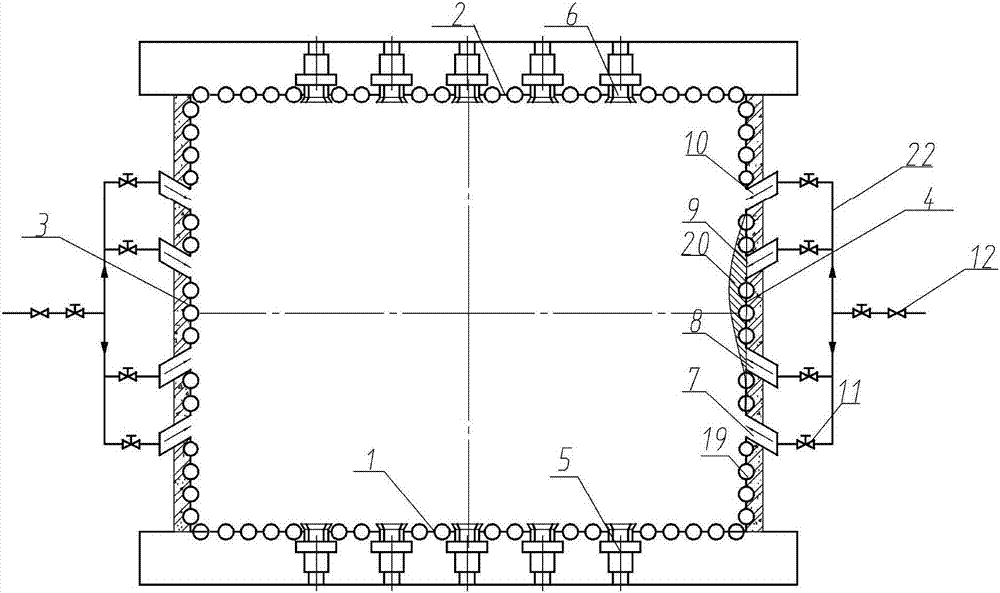

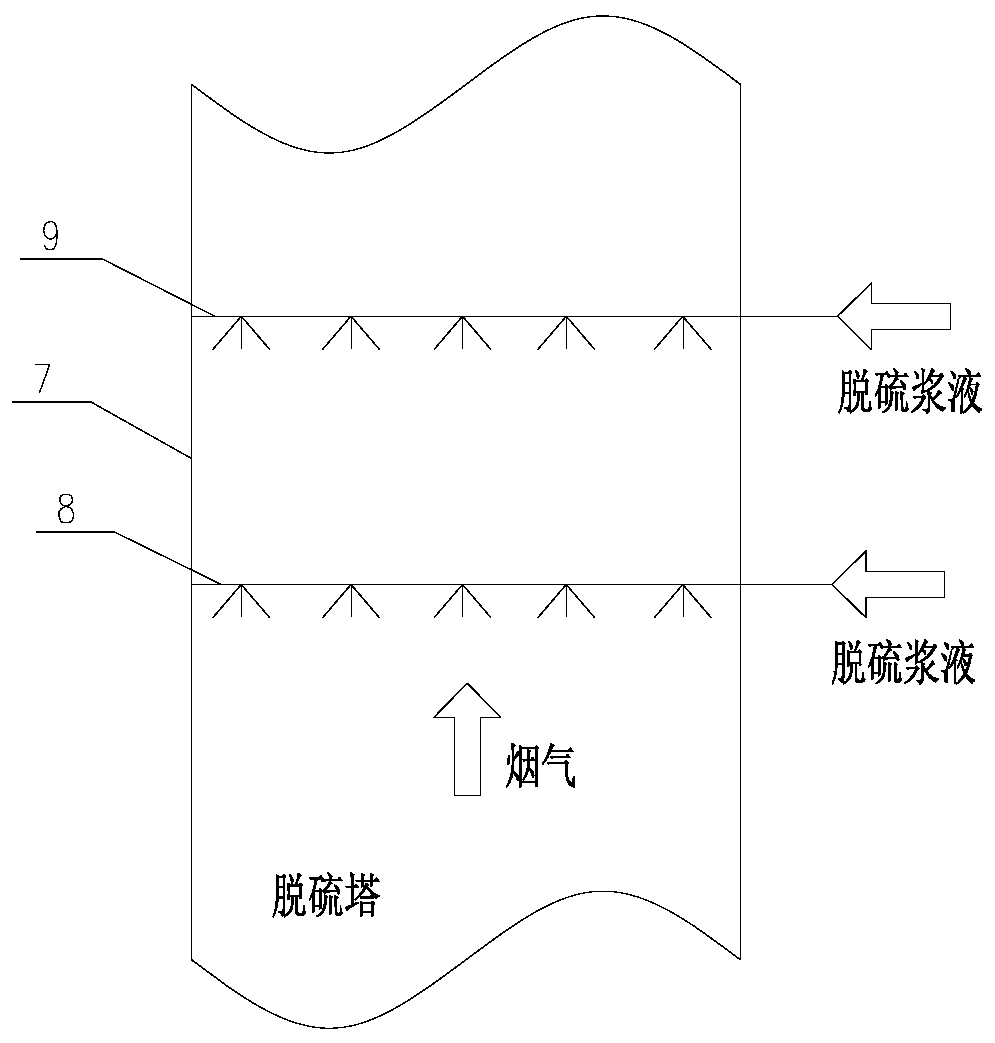

Desulfurization slurry spraying device

PendingCN110270215ANo short circuitSolve escape phenomenonGas treatmentUsing liquid separation agentSlurryEngineering

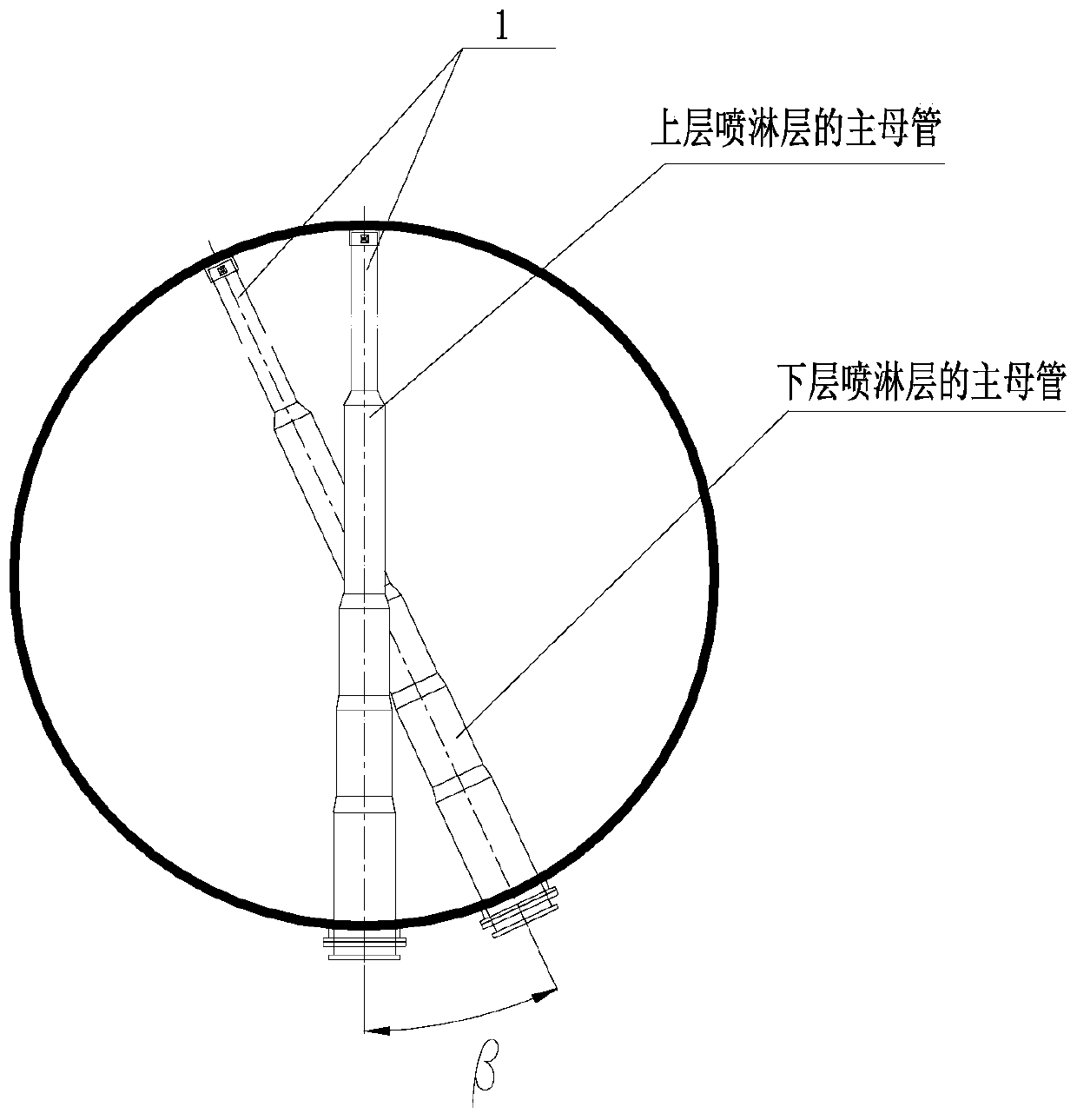

The invention provides a desulfurization slurry spraying device. The desulfurization slurry spraying device is composed of two or more layers of spraying layers, wherein the spraying layers are sequentially distributed in a desulfurization tower from top to bottom, the spraying layers comprise primary mother tubes, supporting beams, secondary mother tubes, branches, first nozzles and second nozzles, the primary mother tubes are supported by the supporting beams, two ends of each supporting beam are fixed to a tower wall of the desulfurization tower, the corresponding secondary mother tubes are connected with two sides of each primary mother tube, the corresponding branches are connected with two sides of each secondary mother tube, the tail ends of the branches are connected with nozzles, the nozzles comprise the first nozzles or the second nozzles, each two adjacent spraying layers are composed of an upper-layer spraying layer and a lower-layer spraying layer, and an included angle beta of downward projections of the corresponding primary mother tube of each lower-layer spraying layer and the corresponding primary mother tube of the corresponding upper-layer spraying layer exists. By means of the spraying device, the phenomenon of escape of smoke along a wall can be solved basically, the desulfurization rate and the dust removal rate are improved, a liquid-gas ratio can be reduced appropriately, and more strict requirements of environmental protection can be met.

Owner:浙江菲达环保科技股份有限公司 +2

High-pressure difference sleeve adjusting valve

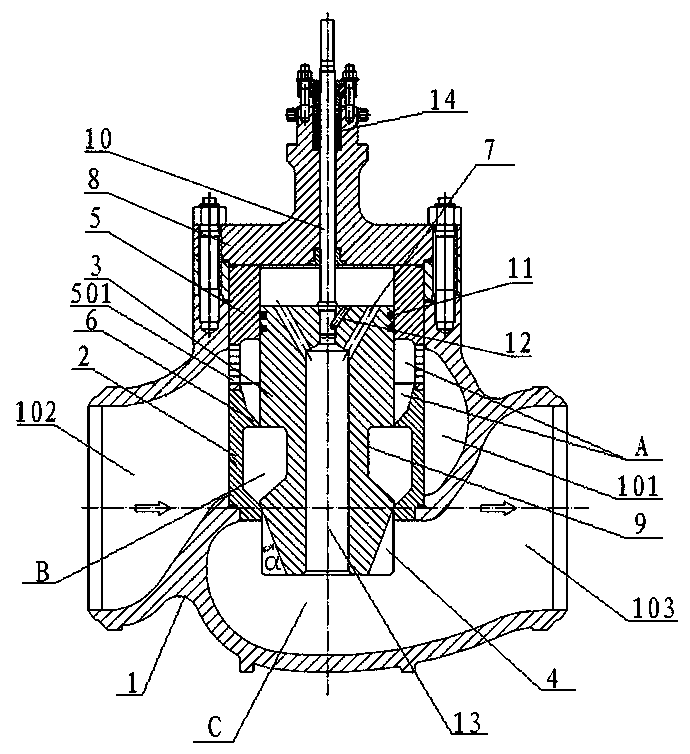

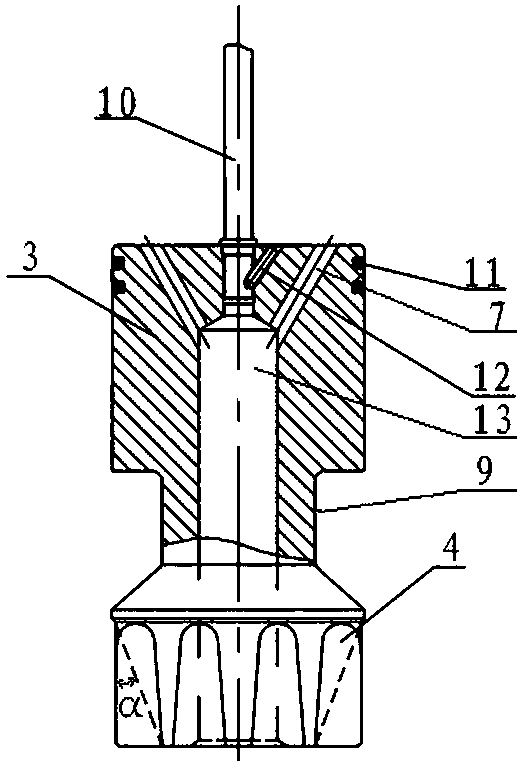

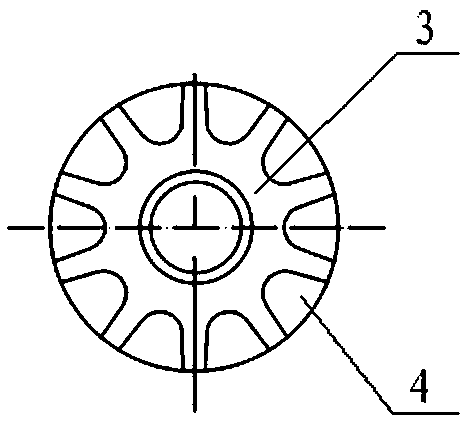

PendingCN108825867AEliminate erosionRealize multi-level step-downValve members for absorbing fluid energyLift valveThree stageEngineering

The invention discloses a high-pressure difference sleeve adjusting valve. The high-pressure difference sleeve adjusting valve comprises a valve body, a valve cover and a valve inner piece which is arranged in the valve body and the valve cover. The valve inner piece further comprises a valve cage, a valve seat, a valve rod and a valve element. The valve element is fixedly connected with the lowerend of the valve rod. The valve cage and the valve seat are overlapped up and down and are of a sleeve structure relative to the valve element. A first medium pressure reducing buffer space is reserved between the valve cage and the upper segment of the valve element, a second medium pressure reducing buffer space is reserved between the valve seat and the lower segment of the valve element, andthe three-stage pressure reducing adjusting valve is formed with a third medium pressure reducing buffer space. According to the high-pressure difference sleeve adjusting valve, by means of the firstmedium pressure reducing buffer space, the second medium pressure reducing buffer space and the third medium pressure reducing buffer space, multi-stage pressure reducing is achieved, the phenomenon that the sealing face of the valve is prone to being scoured by high-speed medium fluid and erosion is caused is eliminated, and the problems that the sealing face is blown damage, inner leaking and erosive abrasion are caused, and the noise is large and other problems are avoided.

Owner:SICHUAN BINDA VALVE CO LTD +2

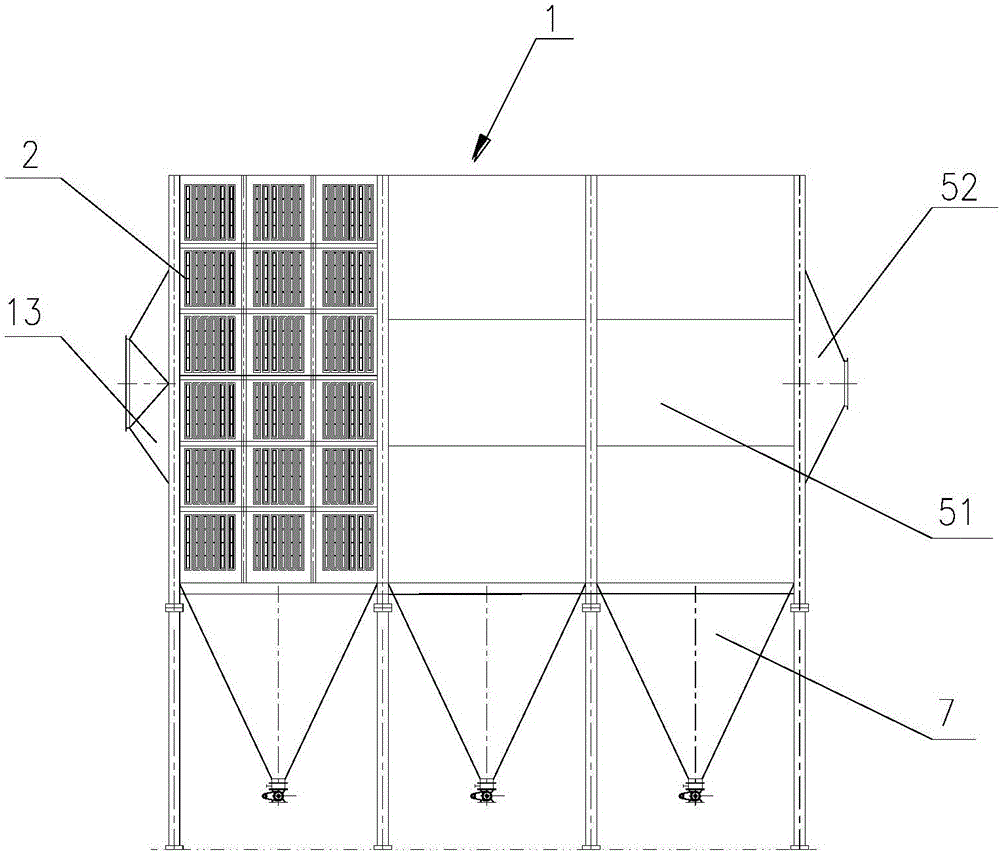

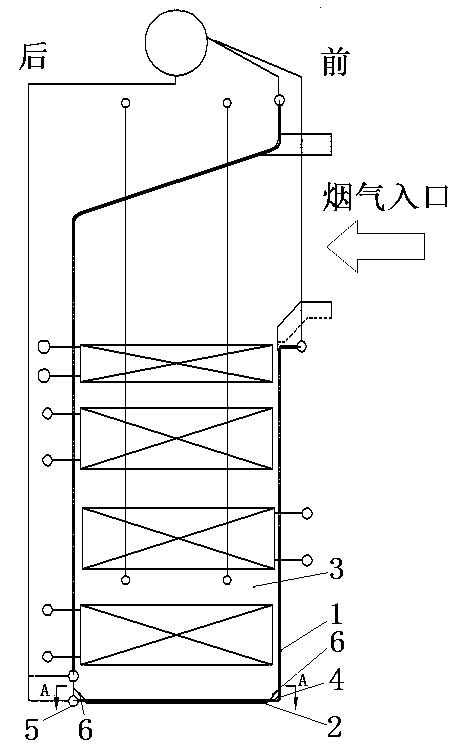

Dust removal and denitration integrated equipment for flue gas and filter box of dust removal and denitration integrated equipment

PendingCN106268314AAvoid scour wearImprove denitrification efficiencyGas treatmentDispersed particle filtrationFlue gasEngineering

The invention discloses dust removal and denitration integrated equipment for flue gas. The dust removal and denitration integrated equipment comprises a shell. A filter box is arranged in the shell and is provided with a dust removal portion and a denitration portion, and the flue gas can be denitrated by the denitration portion after dust in the flue gas is removed by the dust removal portion. The dust removal and denitration integrated equipment has the advantages that most alkali metal particles and the dust in the flue gas are removed before denitration reaction is carried out, and accordingly catalyst poisoning due to the alkali metal particles in the flue gas can be prevented; erosive wear of the denitration portion due to the dust in the flue gas can be prevented, accordingly, the denitration efficiency of the denitration portion can be improved, and the service life of the denitration portion can be guaranteed. The invention further discloses the filter box of the dust removal and denitration integrated equipment.

Owner:FUJIAN LONGKING

Process for manufacturing integral fine crystal alumina ceramic bend pipe

The invention belongs to the ceramics field, in particular to a fabrication technology of an entire aplite aluminum oxide ceramics bent pipe, which has the technical scheme that an aplite aluminum oxide ceramics straight pipe is arranged on a U-shaped mould which is matched with the aplite aluminum oxide ceramics straight pipe, the straight pipe and the mould are contacted by lines and are matched by clearance, the height of the mould is 1 / 2 to 3 / 4 of the diameter of the ceramics bent pipe, the straight pipe and the mould are arranged in a shuttle kiln, and the straight pipe is slowly embedded in the mould under gravity action after the ceramics straight pipe is softened. The invention has advantages that the aplite aluminum oxide ceramics bent pipe has no aperture and is comparatively smooth in the process of transporting power, and scouring abrasion in the pipe nipple connector during operation is avoided; the bent pipe is an entirety, no obstacle exists in the transporting process, the self wear-resisting property of the aluminum oxide is good, with little abrasion, the service life of an aluminum oxide elbow is prolonged, and operational maintenance frequency of the device is reduced, which brings better economic benefit to users.

Owner:JINGANG NEW MATERIALS

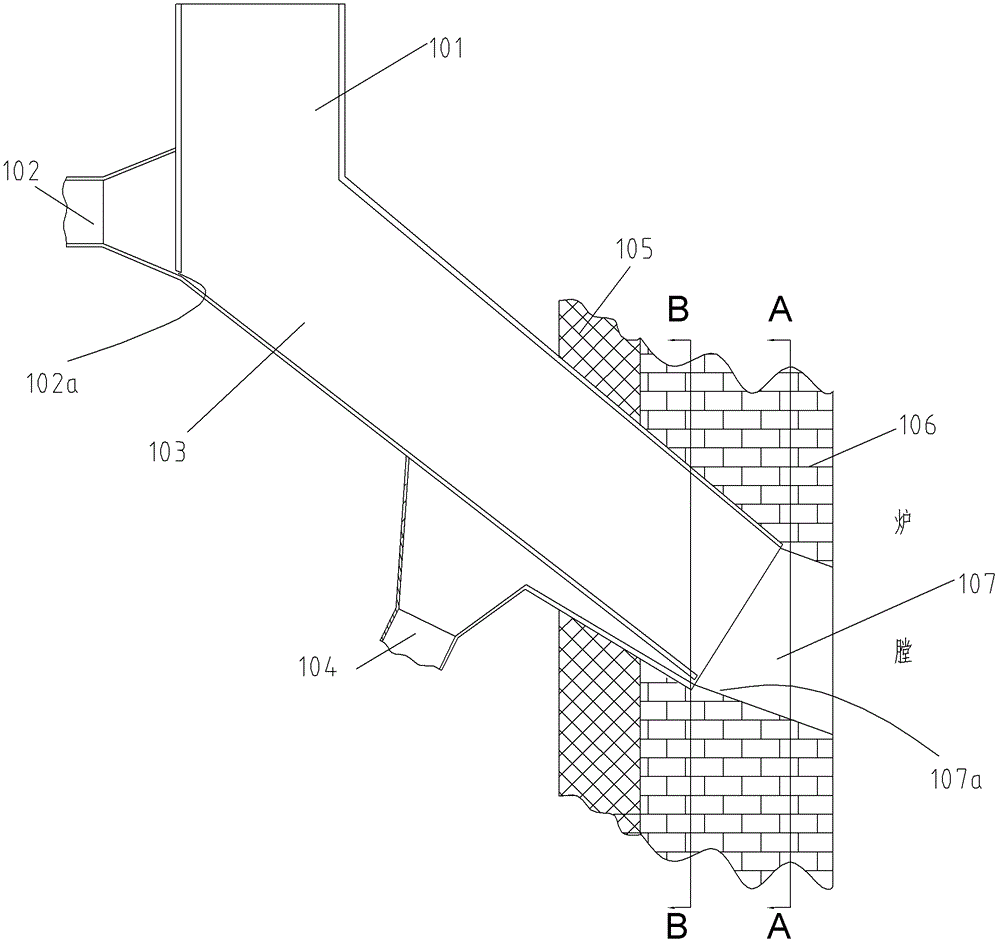

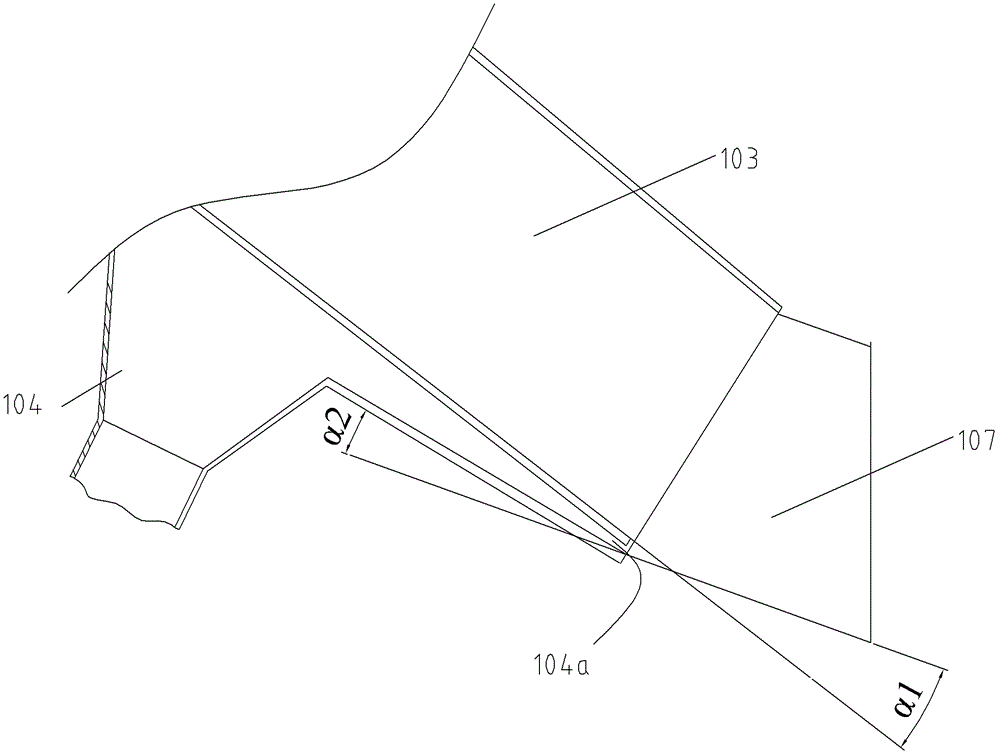

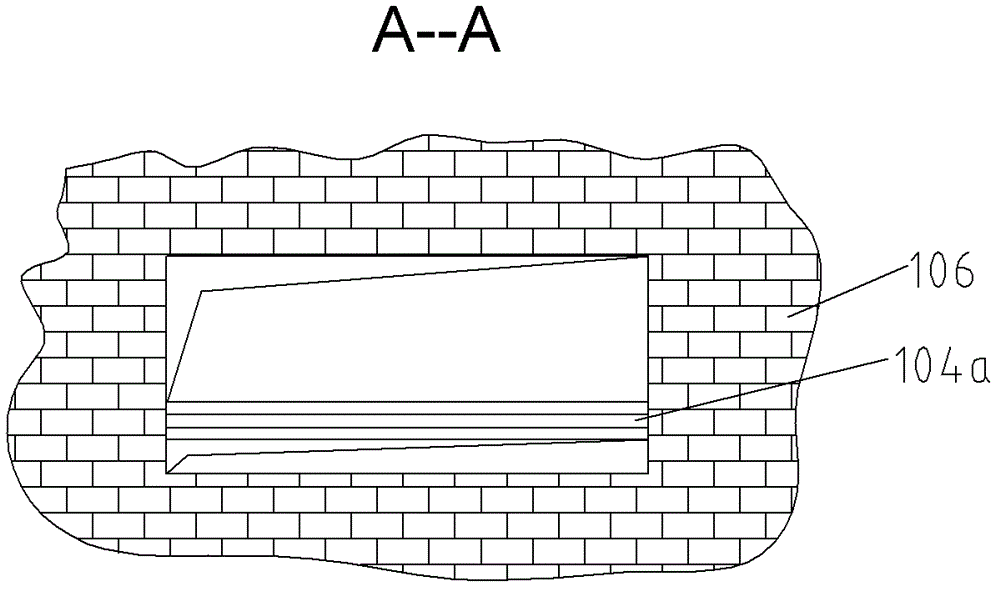

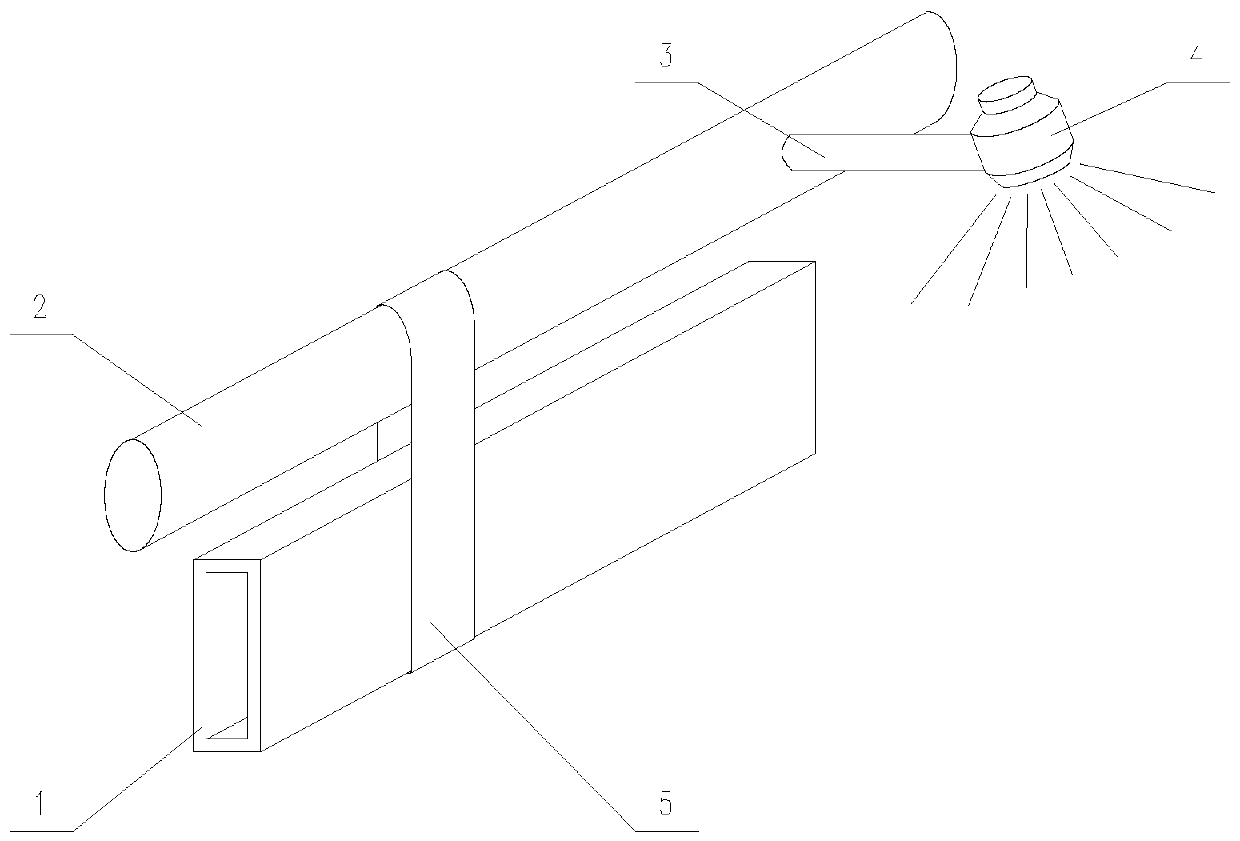

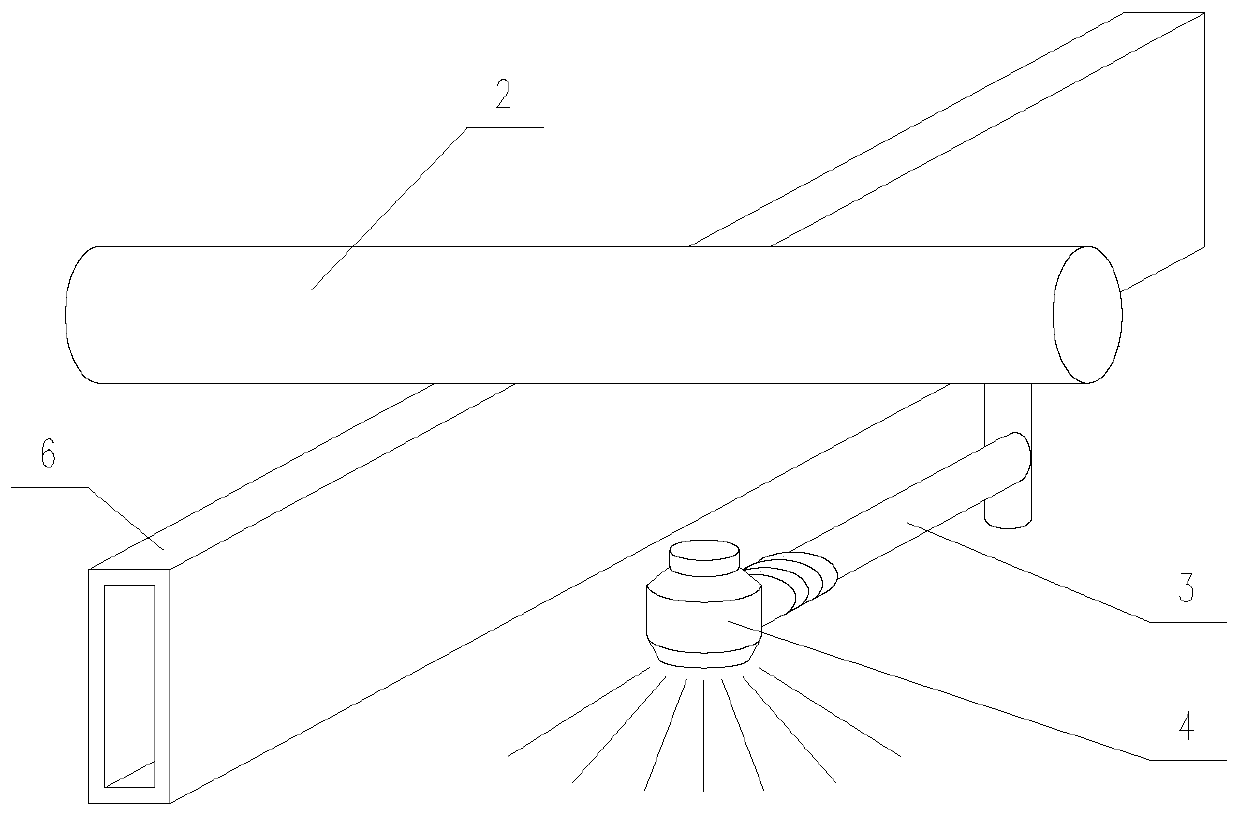

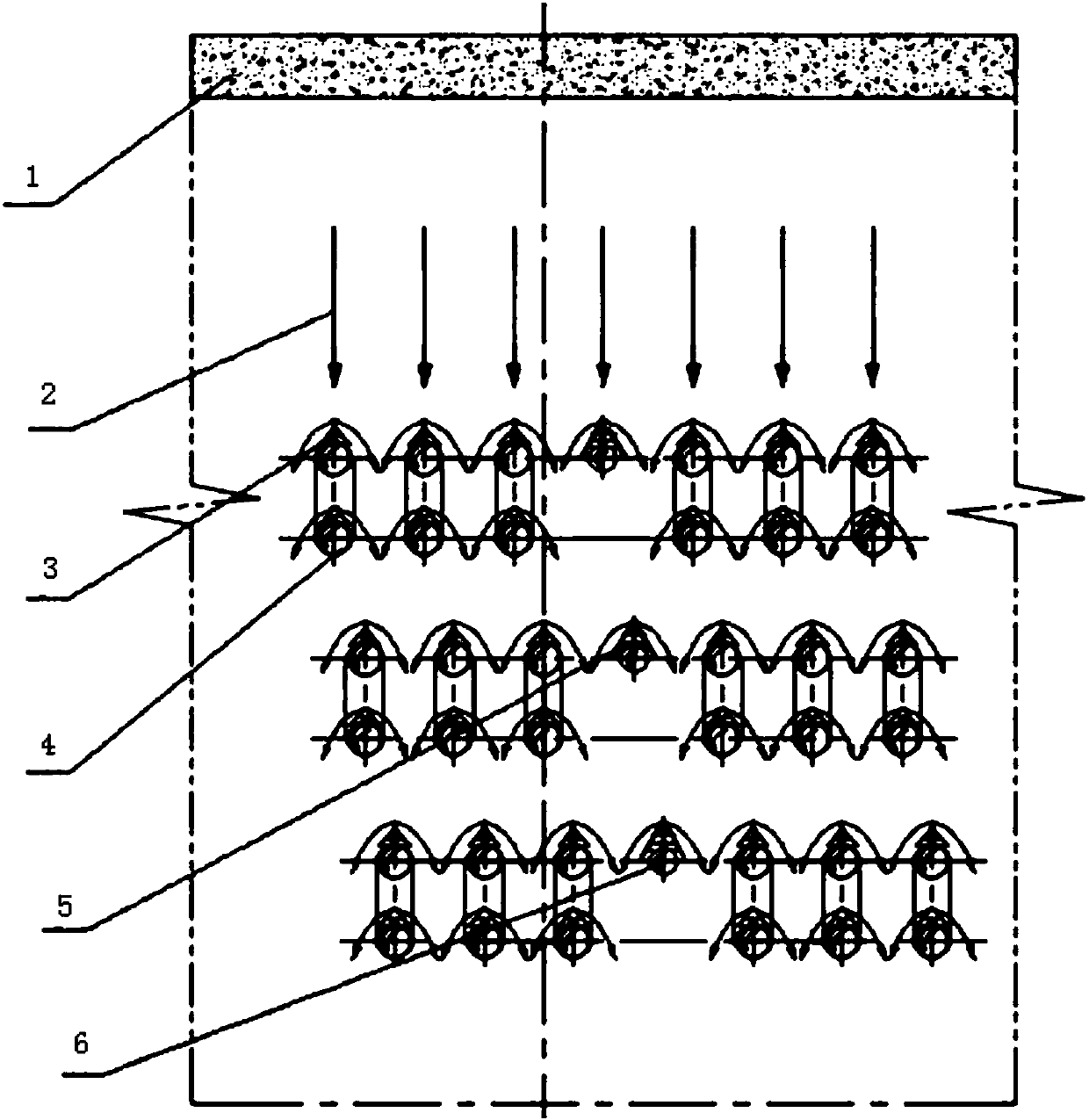

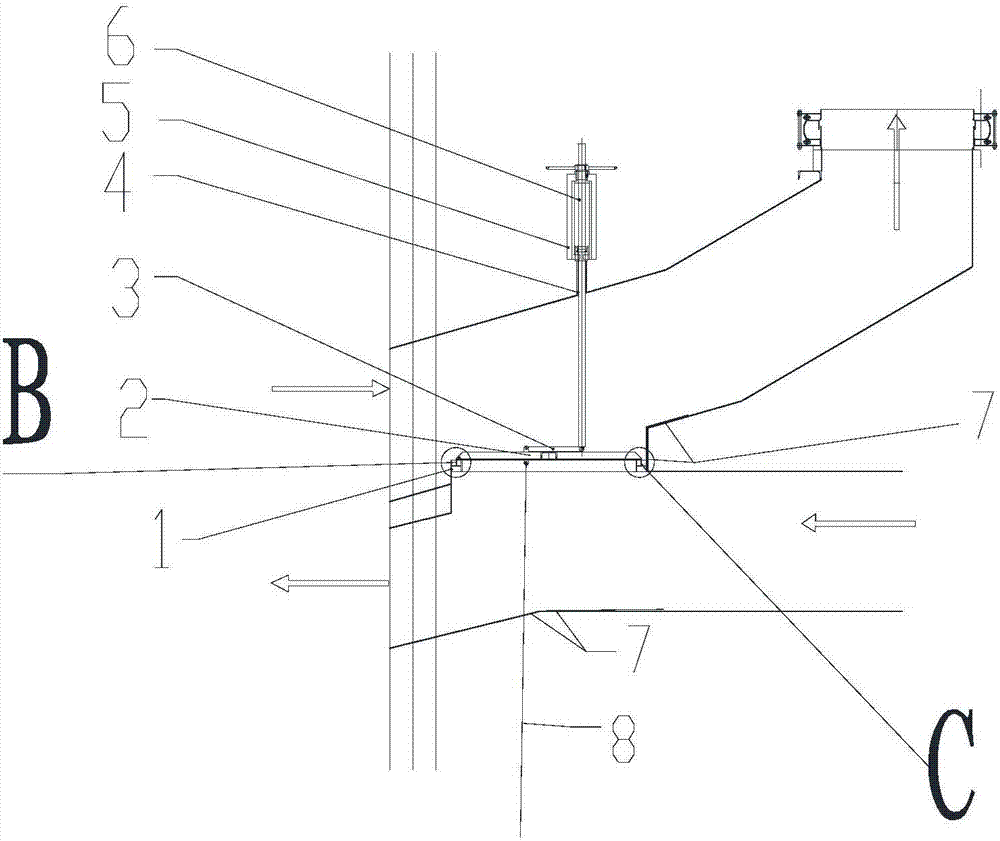

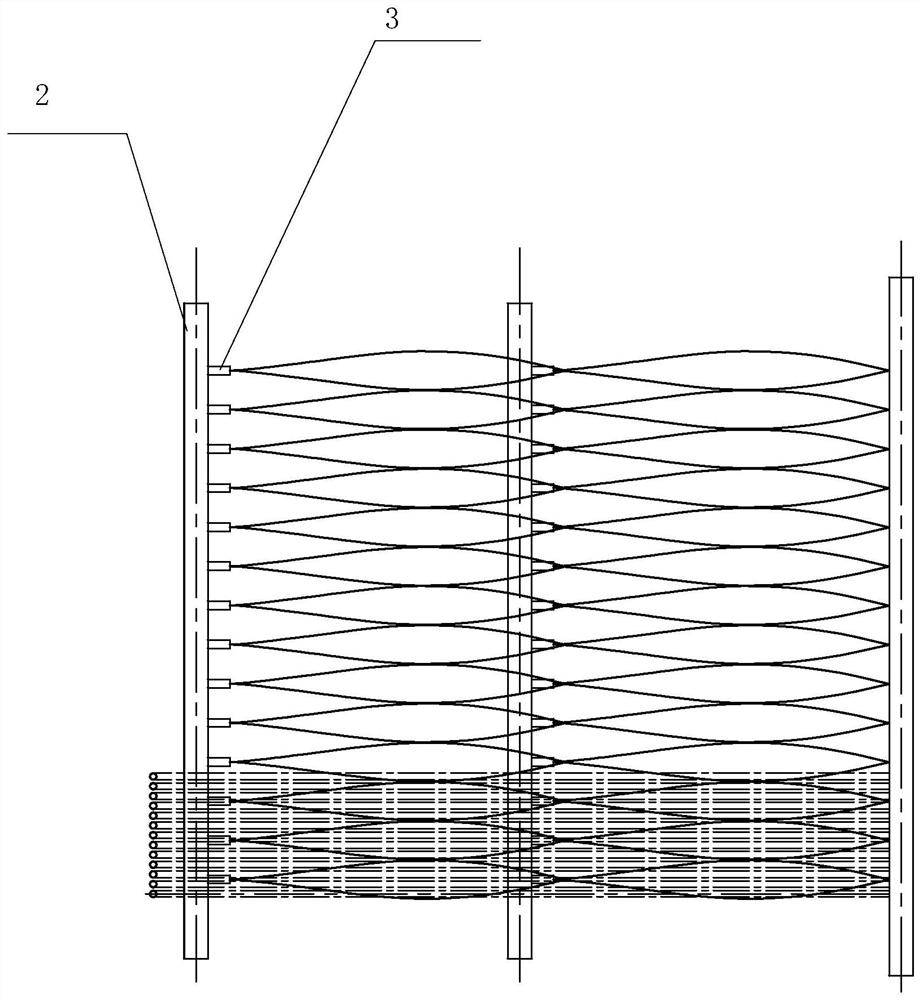

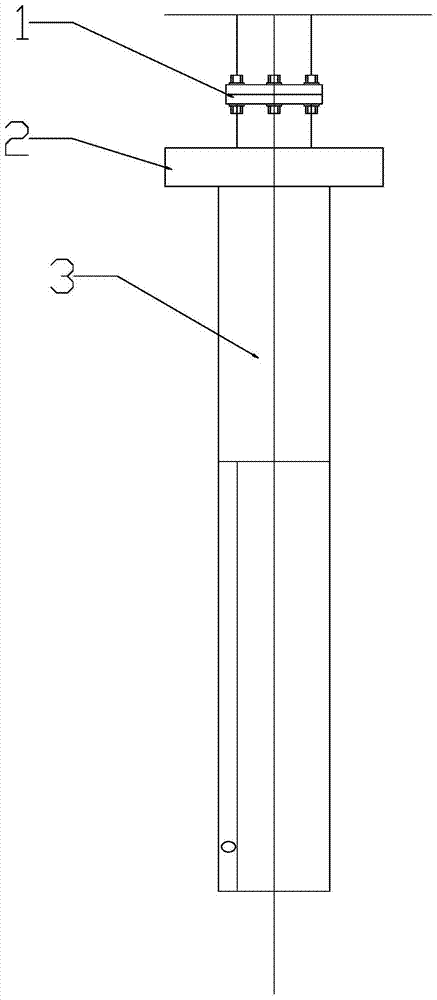

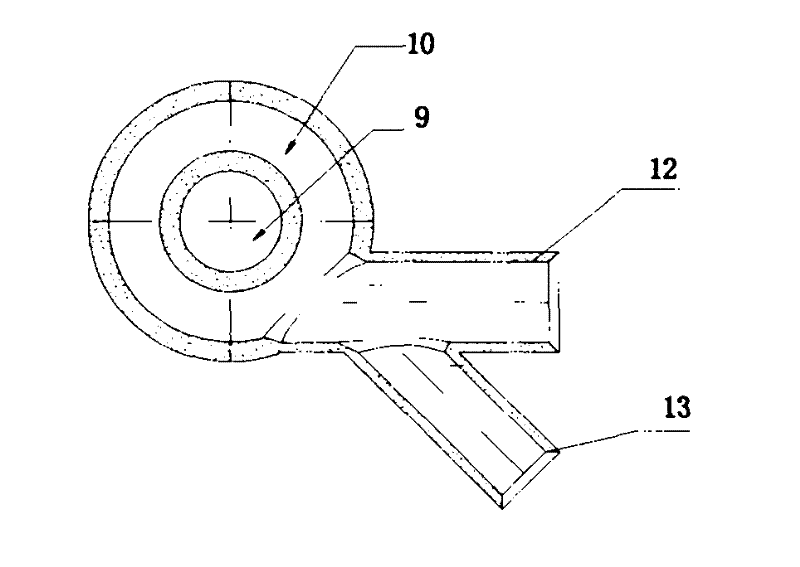

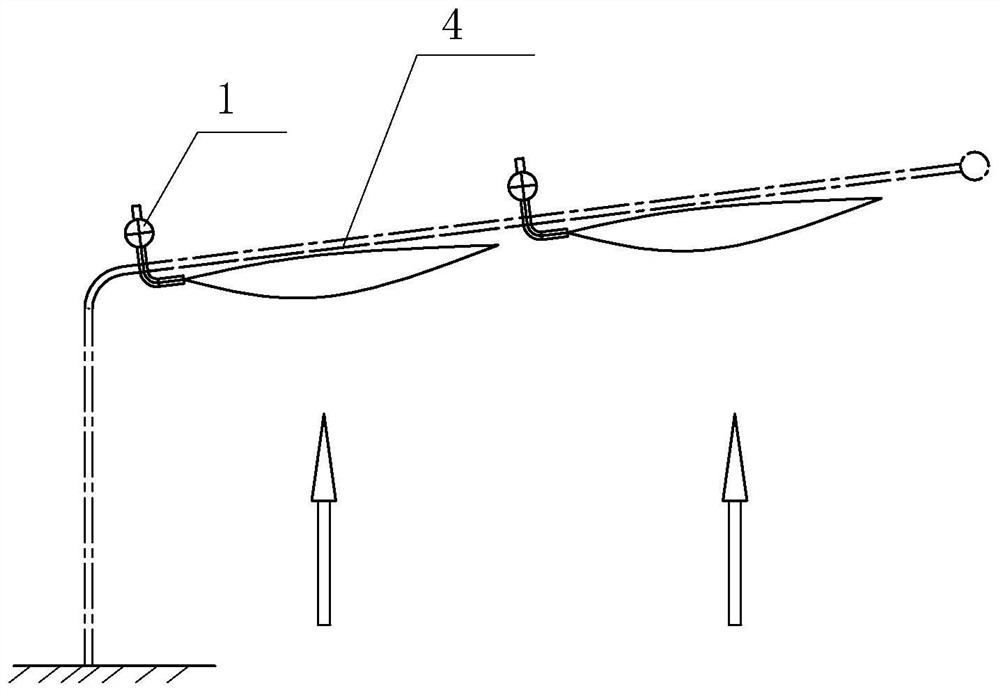

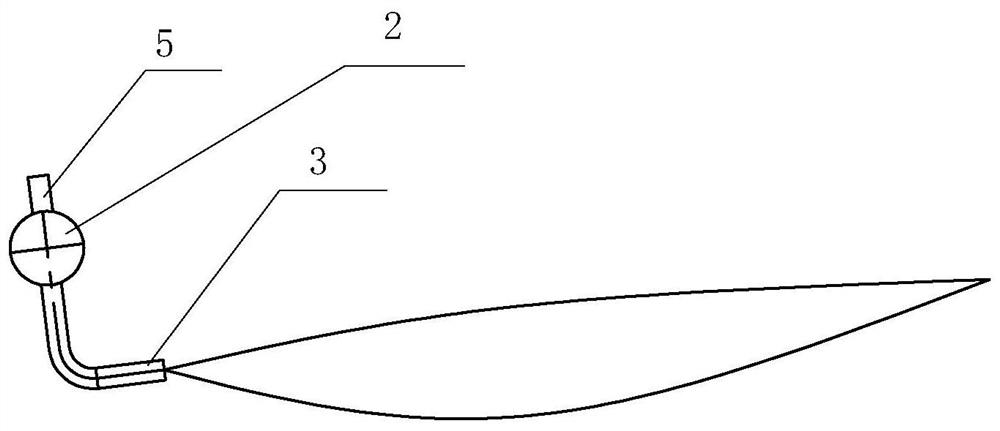

Blanking port integrated blanking device for biomass fuel circulating fluidized bed boiler

ActiveCN102563631BAvoid scour wearImprove liquidityFluidized bed combustionApparatus for fluidised bed combustionEngineeringBiomass fuels

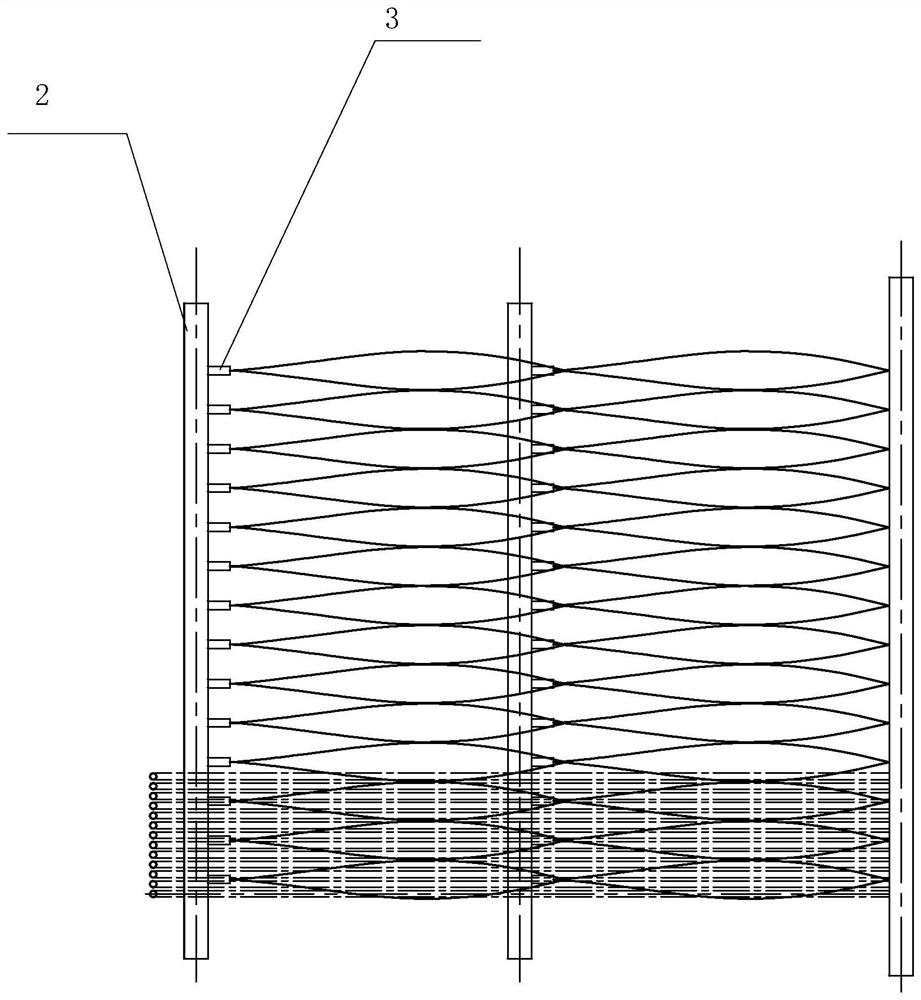

The invention discloses a blanking port integrated blanking device for a biomass fuel circulating fluidized bed boiler. The blanking port integrated blanking device comprises an open-jointed pipe, a flow guide pipe, a disturbance air pipe and a material spreading air pipe; an air chamber of the disturbance air pipe is communicated with the open-jointed pipe; the flow guide pipe is inserted into the boiler wall of the boiler and a castable layer and then is directly communicated with the hearth of the boiler; the pipe orifice of the flow guide pipe, which is communicated with the hearth of the boiler is a blanking port; an air chamber of the material spreading air pipe is communicated with the corner of the open-jointed pipe, which is connected with the flow guide pipe; the communication part of the air chamber of the material spreading air pipe and the corner is a material spreading air spray port which is formed in the lower part of the air chamber of the material spreading air pipe; and the flow direction of air entering the flow guide pipe from the material spreading air spray port is the same as the downward inclined direction of the flow guide pipe. Moreover, hot secondary air flows through a disturbance air spray port to form disturbance air which can disturb and loosen agglomerated biomass fuels so as to fulfill the aim of dispersing the materials, and the reverse fleeing of the fuels in the hearth can be prevented. The blanking device can effectively guarantee the flowability and continuity of the biomass fuels in the falling process.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Novel stripping element tight connecting device

The invention relates to a novel stripping element tight connecting device. A stripping steam vertical pipe passes through a cone-shaped baffle plate, and the stripping element tight connecting device is tightly connected with the stripping steam vertical pipe and the cone-shaped baffle plate. The stripping element tight connecting device comprises a compressing baffle plate, a connecting plate, a compressing ring, a silk screen, a sleeve and ceramic fibers, wherein the inner side face of the compressing baffle plate is fixedly connected with the stripping steam vertical pipe, the upper end of the connecting plate is fixedly connected with the compressing baffle plate, the lower end of the connecting plate is fixedly connected with the compressing ring, the compressing ring extends into the sleeve, the silk screen is located below the compressing ring and meanwhile is arranged on the top of a circular gap between the sleeve and the stripping steam vertical pipe, the ceramic fibers are filled in the circular gap below the silk screen, the sleeve is fixedly connected with the cone-shaped baffle plate, and the circular gap is formed between the lower end opening of the sleeve and the stripping steam vertical pipe. According to the technical scheme, not only can the free swelling deformation between the cone-shaped baffle plate and the stripping steam vertical pipe be ensured, but also the device has the sealing effect and can be used for effectively preventing the stripping steam vertical pipe from being worn through.

Owner:LUOYANG ZHIDA PETROCHEM ENG

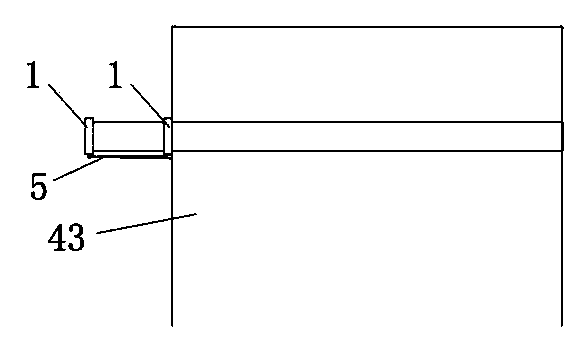

Novel pipeline supporting mode

PendingCN111408259ASmall footprintAvoid scour wearGas treatmentDispersed particle separationGlass fiberClassical mechanics

The invention provides a novel pipeline supporting mode. The mode comprises a parallel supporting beam, and an FRP slurry spraying main pipe is arranged on the outer surface of the upper end of the parallel supporting beam; the FRP slurry spraying main pipe and the parallel supporting beam are arranged in parallel; a saddle and an FRP winding are arranged on the outer surfaces of the FRP slurry spraying main pipe and the parallel supporting beam; the position, close to the rear end, of the outer surface of the FRP slurry spraying main pipe is fixedly connected with FRP slurry spraying branch pipes. The other end of each FRP slurry spraying branch pipe is fixedly connected with a nozzle. According to the structure of the device, the occupied space of the parallel supporting beams is small;the installation height of the nozzles does not need to be integrally reduced, the spraying branch pipes do not need to be additionally provided with elbows or descend, only the angles of the nozzleson the two sides of the parallel supporting beam need to be adjusted, the machining problem of the glass fiber reinforced plastic branch pipes is solved, the erosive wear problem of the supporting beams is avoided, and meanwhile the fracture risk problem of the FRP slurry spraying main pipe is solved.

Owner:DATANG ENVIRONMENT IND GRP

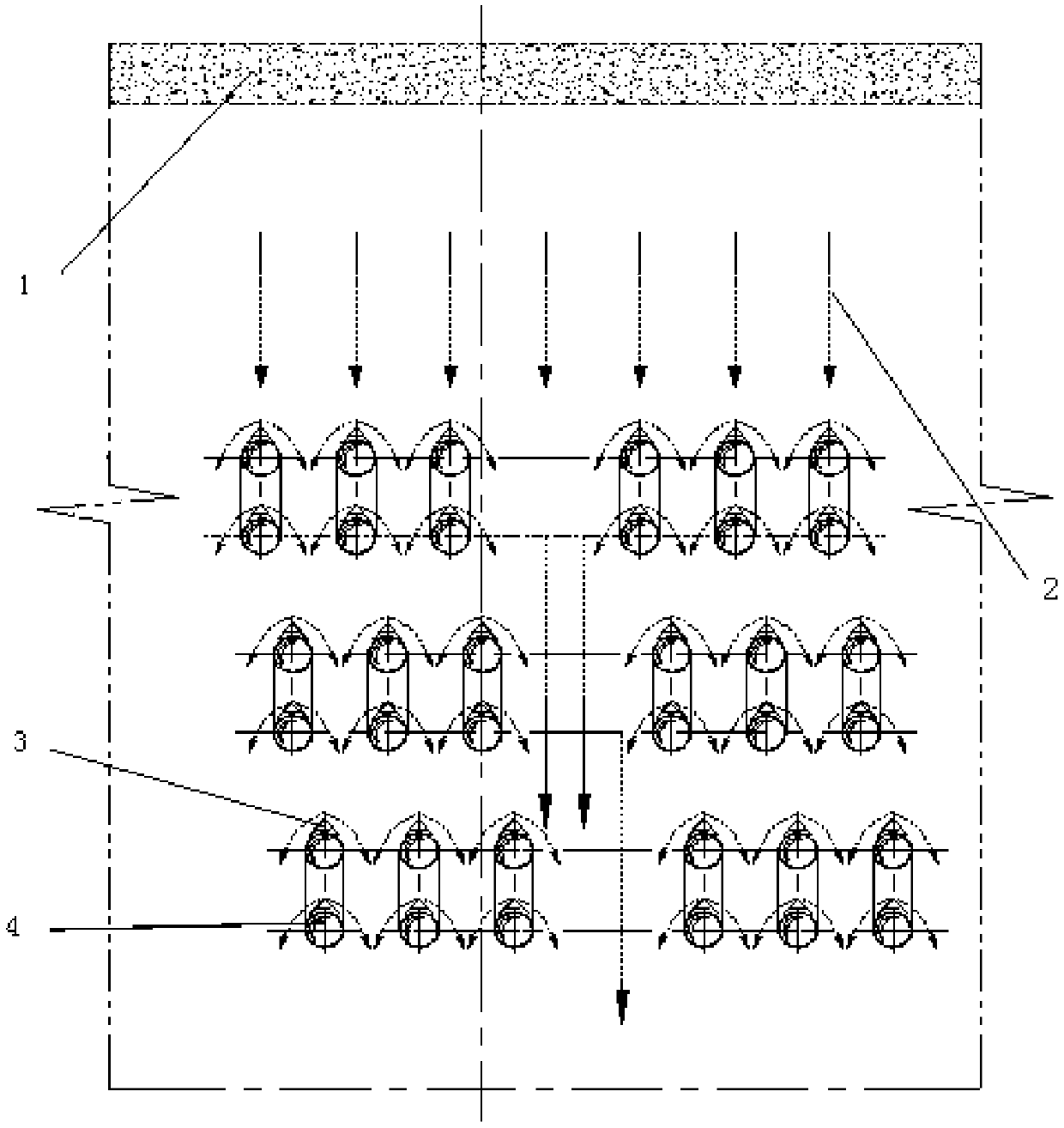

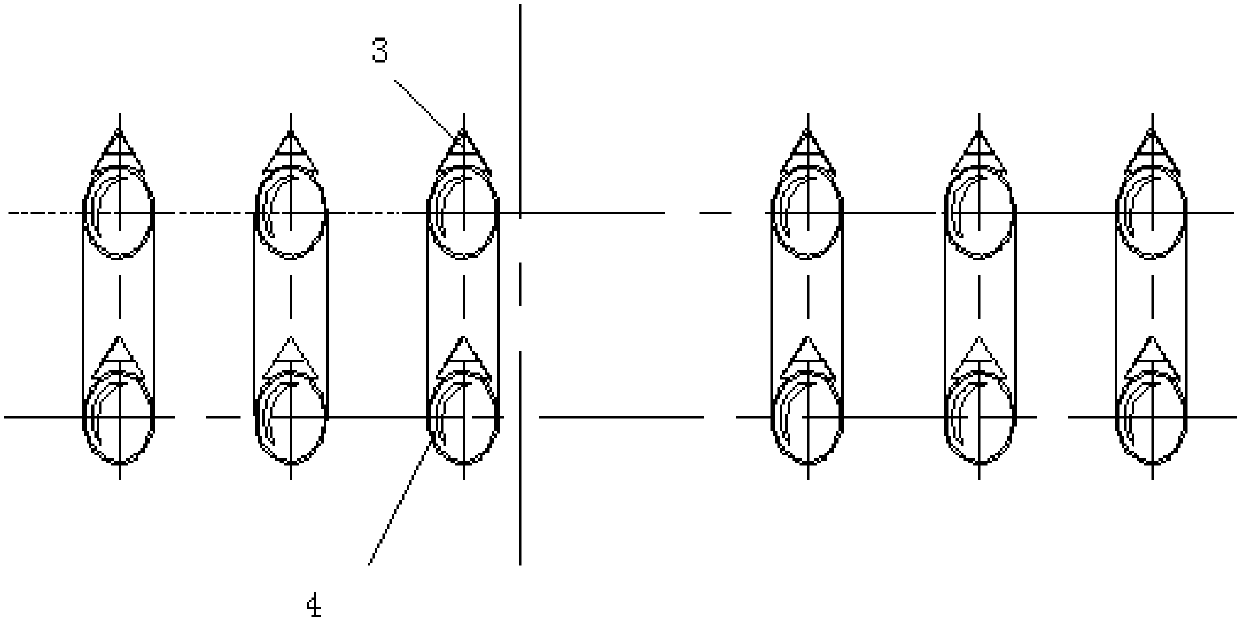

Pulverized coal pyrolyzing furnace with material homogenizing and pressure bearing structure

PendingCN107841329AShorten speedExtend your lifeSpecial form destructive distillationEngineeringCoal pyrolysis

The invention relates to a pulverized coal pyrolyzing furnace with a material homogenizing and pressure bearing structure. The pulverized coal pyrolyzing furnace with the material homogenizing and pressure bearing structure mainly comprises a furnace body, radiant pipes and the material homogenizing and pressure bearing structure, wherein the multiple layers of radiant pipes are arranged in a furnace chamber so as to form an empty area; the material homogenizing and pressure bearing structure is arranged in the empty area, and comprises a support part, a distributing cap and a connecting part;the support part is arranged along a horizontal direction; the head part of the distributing cap is in a circular arc shape; the bottom part of the distributing cap is arranged on the support part; the connecting part is fixed onto a furnace wall and is connected with two ends of the support part through pin shafts so as to fix the support part onto the furnace wall. According to the pulverized coal pyrolyzing furnace with the material homogenizing and pressure bearing structure provided by the invention, the material homogenizing and pressure bearing structure is arranged in the empty area,so that pulverized coal is homogenized and buffered, and the collision loss of equipment and the furnace body caused by the pulverized coal is reduced; meanwhile, a furnace operation pressure bearingability of the furnace body is improved, and an effect on stabilizing the furnace body is achieved.

Owner:北京神雾电力科技有限公司

Tee-joint switching device for boiler denitration

ActiveCN106871148AEffective isolationEnvironmentally friendly ultra-low emissionsEmission preventionDispersed particle separationEngineeringEconomizer

The invention provides a tee-joint switching device for boiler denitration. The tee-joint switching device comprises a frame and a sealing baffle. The frame is located among the connection position of an inlet and an outlet of a flue of a denitration reactor, a flue of a low-temperature coal economizer or air pre-heater and a flue of a high-temperature coal economizer or air pre-heater. The sealing baffle is arranged on the frame, located at one end of the connection position of the inlet and the outlet of the denitration reactor and hinged to the frame. The sealing baffle can move vertically with the connection position of the inlet and the outlet of the flue of the denitration reactor as the axis, and thus the tee-joint switching device can be opened and closed.

Owner:冯力燕

Low-value silicon powder recycling system

The invention discloses a low-value silicon powder recycling system, comprising a low-value silicon powder reactor, wherein the low-value silicon powder reactor comprises a reactor body, the reactor body is mainly formed by a gas distribution section located at the lower part, a reaction section located at the middle, and a gas-solid separation section located at the upper part, the gas distribution section comprises a feed gas distributor located below the reaction section and a feed gas inlet formed in the lower side of the feed gas distributor, the gas-solid separation section is provided with a synthesis gas outlet, the reaction section is provided with a silicon powder inlet and a heating device, and a reaction gas distributor is further arranged in the reaction section. The low-valuesilicon powder recycling system disclosed by the invention reduces the speed of gas flow in the reactor, so that low-value silicon powder can fully react with feed gas, reaction time is prolonged, the recovery rate of the low-value silicon powder is improved, the condition that the low-value silicon powder is treated as solid waste is avoids, raw material waste is reduced, and production cost islowered.

Owner:SICHUAN YONGXIANG POLY SILICON

Front wall heating surface structure of CDQ (Coke Dry Quenching) waste heat boiler

InactiveCN103307590AIncrease heat absorptionImprove water cycle safetyBoiler water tubesAbsorption capacityWater circulation

The invention discloses a front wall heating surface structure of a CDQ (Coke Dry Quenching) waste heat boiler. In order to solve the problem of water circulation faults of a conventional water-cooled wall of a CDQ waste heat boiler, the front wall heating surface structure of the CDQ waste heat boiler comprises a water-cooled wall section and a lateral washing section; a pipe at the water-cooled wall section extends to the interior of a gas duct at the tail part of a waste heat boiler to form the lateral washing section; the axial line of a pipe at the lateral washing section forms an inclined angle of not larger than 30 degrees with the horizontal plane; and one end of the pipe at the lateral washing section is communicated with the pipe at the water-cooled section, and the other end is fixed on a lower interconnecting box close to a front wall or a rear wall. The pipe on the water-cooled wall of the front wall of the CDQ waste heat boiler extends to the interior of the gas duct at the tail part of the waste heat boiler to form the lateral washing section, so that the heat absorption capacity of the front wall heating surface is increased, and the water circulation safety of the front wall heating surface is improved.

Owner:CHANGSHA BOILER PLANT

Desulfurization and denitrification device for steel sintering flue gas

PendingCN110124489AGuaranteed smoothAvoid cloggingGas treatmentDispersed particle separationFlue gasSpray nozzle

The invention relates to the technical field of flue gas desulfurization and denitrification equipment, and discloses a desulfurization and denitrification device for steel sintering flue gas. The device comprises a denitrification chamber, a desulfurization chamber, an atomizing nozzle and a liquid inlet pipe; spoilers are fixedly arranged on the inner wall of the liquid inlet pipe; a cavity is formed in the atomizing nozzle; a through groove is formed in the atomizing nozzle; electric heating wires are fixedly arranged inside the through groove and the cavity; and a spring is fixedly arranged on the bottom surface of the desulfurization chamber. According to the desulfurization and denitrification device for steel sintering flue gas, a urea solution generates turbulence and rotates alongthe surfaces of the spoilers when passing through the spoilers, and the solution forms a vortex-like flow in the liquid inlet pipe, so that separated crystals cannot be attached to the pipe wall, andthen smoothness of the nozzle is ensured. Meanwhile, the urea solution is heated by the electric heating wires when reaching the nozzle, so that the separated crystals are dissolved in the solvent again, and blockage of the nozzle is further avoided.

Owner:陈炜健

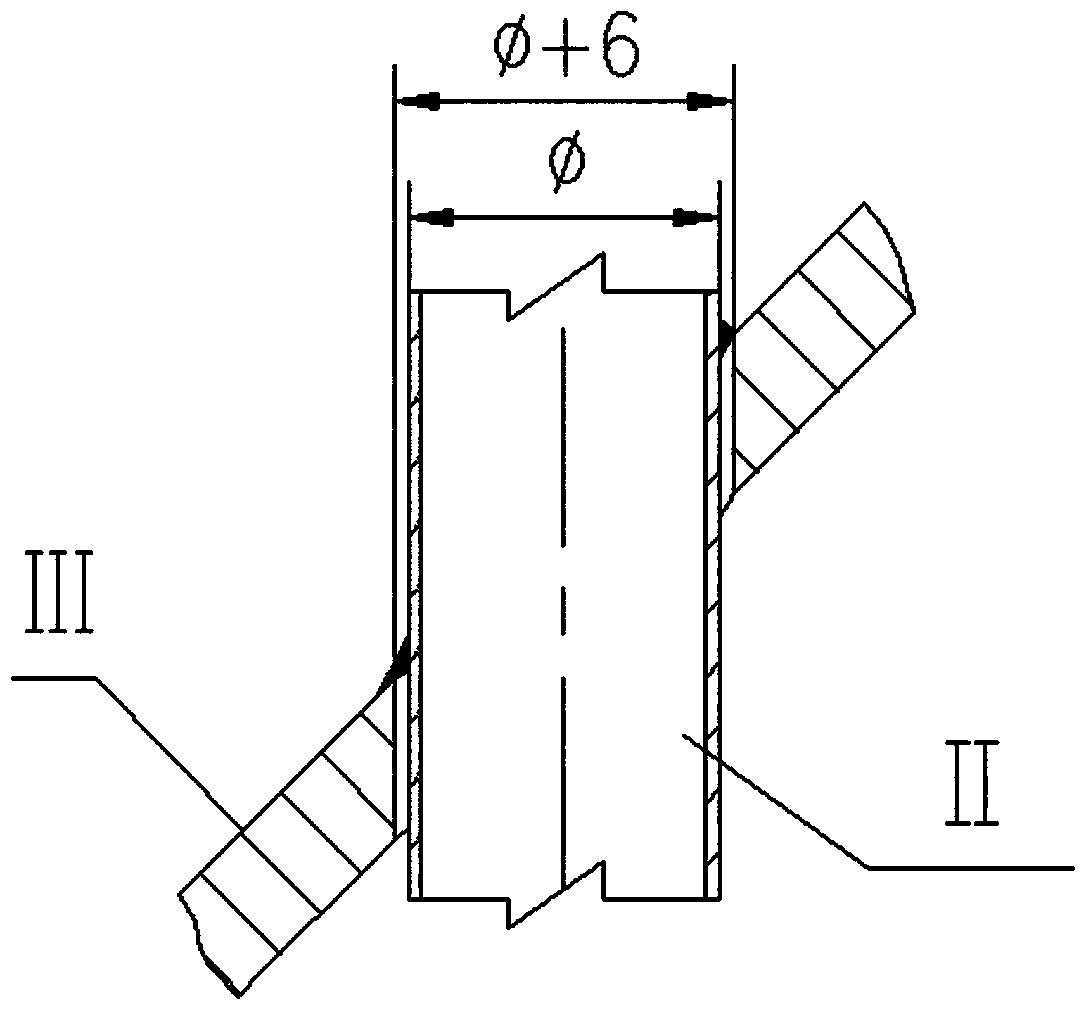

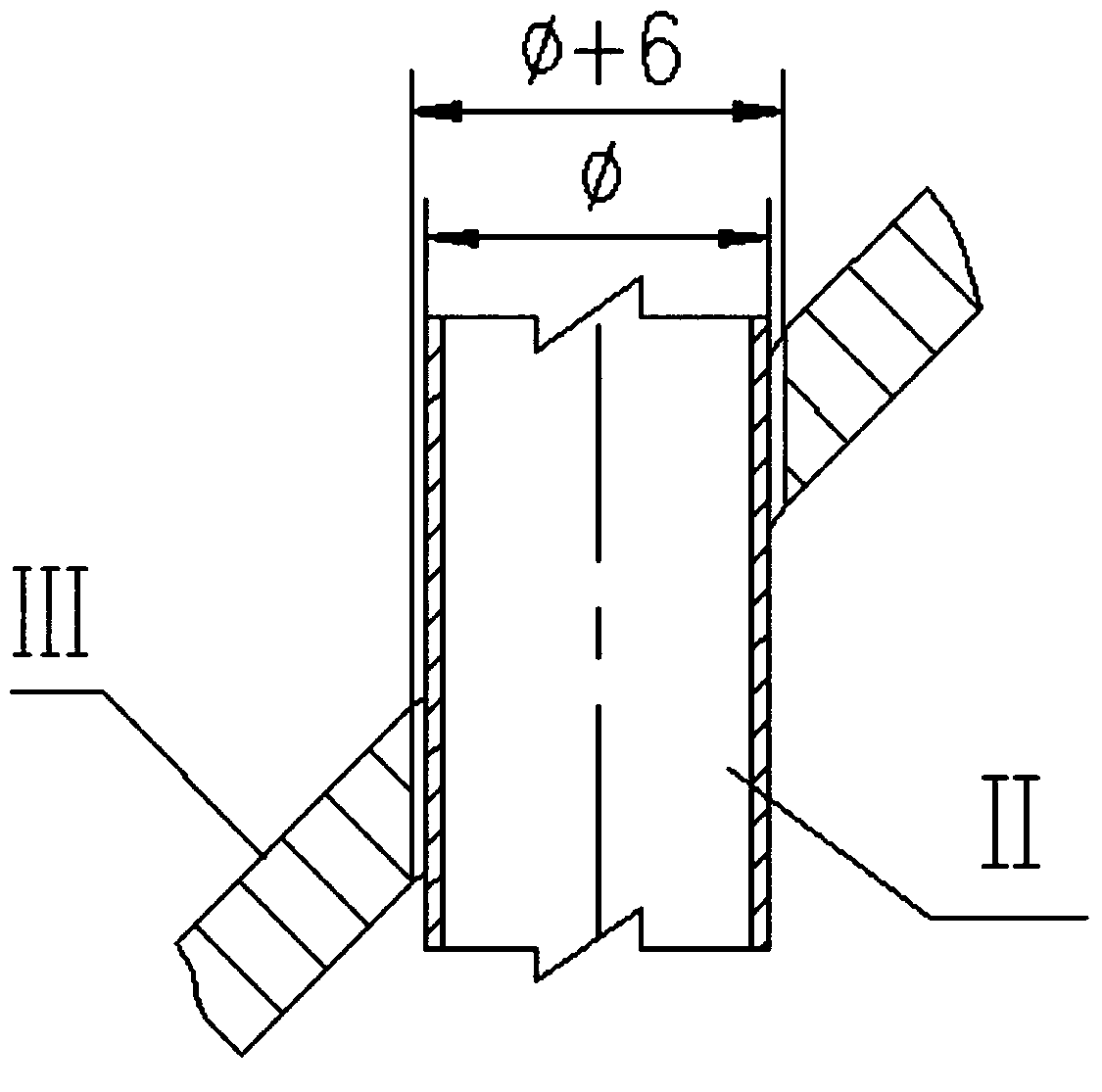

A connection structure and method for a powder conveying channel

ActiveCN110921332BAvoid the problem of crushed pipesAvoid risk of leakageBulk conveyorsExpansion jointPipe

The invention discloses a connection structure and method for a powder conveying channel. The connection structure includes an inner cylinder, an outer cylinder, an inner cylinder anti-wear block, and an inner cylinder receiving ring. The inner and outer cylinders nested in each other are set to realize the connection of the two joints with lined pipes. A radial expansion gap is reserved between the inner and outer cylinders and the lined pipes, and an expansion joint is reserved between the ends of the two joints with lined pipes. , to avoid the problem that the lined pipe expands and expands and radially expands to cause the pipe to be damaged, and the inner cylinder is provided with an anti-wear block at the expansion joint between the ends of the two lined pipes to prevent the powder from being transported from the reserved expansion Seam erosion and wear; when the inner and outer cylinder casing structures are installed, an appropriate amount of powder to be conveyed is poured into the annulus formed by the outer cylinder and the lower section liner pipe, and the inner cylinder is inserted into the outer cylinder to seal the gap, avoiding powder The risk of body leakage from expansion gaps and expansion joints is eliminated, and the reliable and efficient connection of channels is realized.

Owner:SHAANXI YANCHANG PETROLEUM GRP

High-temperature acidic flue gas deacidification device arranged in garbage incinerator

ActiveCN110624375ADoes not cause cokingReduce corrosionGas treatmentDispersed particle separationFlue gasSorbent

The invention relates to a high-temperature acidic flue gas deacidification device arranged in a garbage incinerator. The high-temperature acidic flue gas deacidification device comprises: a base, which is slidably arranged at the upper part of a third channel in the incinerator, wherein a first through hole is formed in the middle part of the base and is arranged corresponding to the flowing direction of high-temperature acidic flue gas; and a plurality of carriers, which are detachably mounted on the base in sequence, wherein the surface of each carrier is fixedly connected with an adsorbent, and a gap allowing the high-temperature acidic flue gas to pass through is reserved between every two adjacent carriers. When the high-temperature acidic flue gas flows through the first through hole in the base and passes through the gaps among the carriers, the adsorbent can react with the high-temperature acidic flue gas, so corrosion of the high-temperature acidic flue gas to a heat exchanger on a horizontal flue is greatly reduced. Due to the fact that the adsorbent is fixedly connected to the carriers, the adsorbent cannot be separated from the carriers and attached to the heat exchanger, so the phenomenon of serious coking on a heat exchange pipeline cannot be caused, and serious erosive wear to the heat exchange pipeline after the adsorbent becomes hard particles is avoided.

Owner:SOUTH CHINA UNIV OF TECH

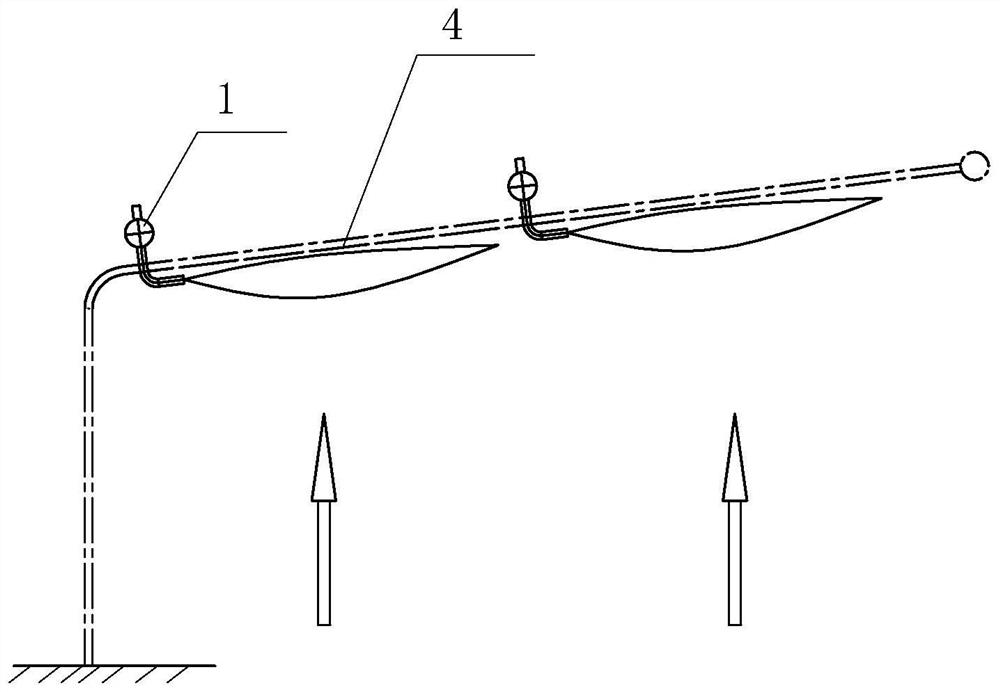

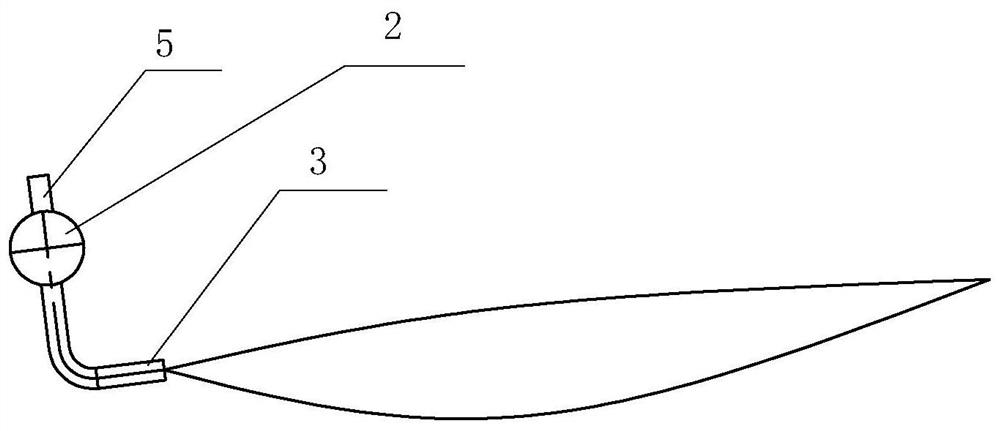

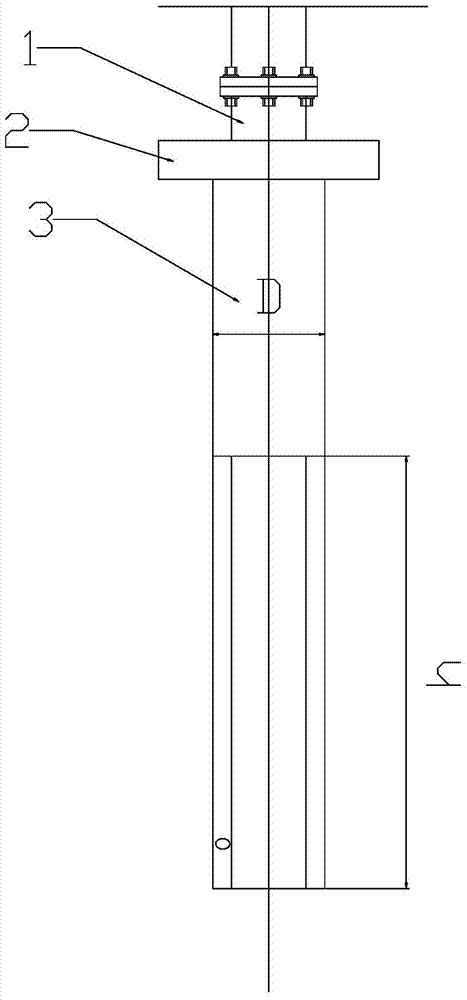

A kind of method for smoke screen protection of boiler flue gas side

A method for smoke screen protection on the flue gas side of a boiler. It solves the problem that the specific heating surface of the existing boiler is easily corroded and worn. It includes the following steps: determining the area to be protected by the smoke screen; setting the air curtain device; according to the formula: finding the unknown n, that is, determining the number of protection pipes arranged according to the area to be protected by the smoke screen. The beneficial effect of the present invention is that the smoke protection layer is formed on the heating surface or specific area to be protected by the air curtain device, and the heating surface or the specific area is protected by the protection of the protective layer, so as to avoid direct contact with the smoke and avoid The occurrence of erosion wear and corrosion greatly prolongs the safe operation period of the equipment, thereby improving the stability and continuity of the boiler or device, making the product long service life.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

A high-temperature acid flue gas deacidification device installed in a garbage incinerator

ActiveCN110624375BDoes not cause cokingReduce corrosionGas treatmentDispersed particle separationFlue gasSorbent

The invention relates to a high-temperature acidic flue gas deacidification device arranged in a garbage incinerator. The high-temperature acidic flue gas deacidification device comprises: a base, which is slidably arranged at the upper part of a third channel in the incinerator, wherein a first through hole is formed in the middle part of the base and is arranged corresponding to the flowing direction of high-temperature acidic flue gas; and a plurality of carriers, which are detachably mounted on the base in sequence, wherein the surface of each carrier is fixedly connected with an adsorbent, and a gap allowing the high-temperature acidic flue gas to pass through is reserved between every two adjacent carriers. When the high-temperature acidic flue gas flows through the first through hole in the base and passes through the gaps among the carriers, the adsorbent can react with the high-temperature acidic flue gas, so corrosion of the high-temperature acidic flue gas to a heat exchanger on a horizontal flue is greatly reduced. Due to the fact that the adsorbent is fixedly connected to the carriers, the adsorbent cannot be separated from the carriers and attached to the heat exchanger, so the phenomenon of serious coking on a heat exchange pipeline cannot be caused, and serious erosive wear to the heat exchange pipeline after the adsorbent becomes hard particles is avoided.

Owner:SOUTH CHINA UNIV OF TECH

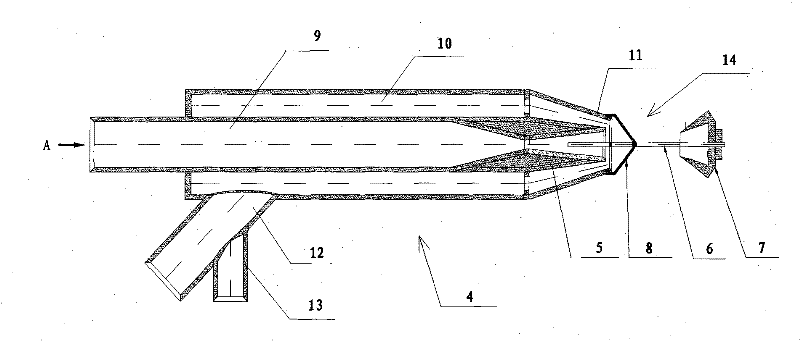

Plug-in type molten iron slag blowing spray gun

The invention discloses a plug-in molten iron slag slag blowing spray gun, which comprises a connecting section and a spray gun main body connected in sequence, and a splash-proof disk perpendicular to the spray gun main body is connected between the connecting section and the spray gun main body. The centerline plane of the main body is a symmetric plane, and damper vanes are symmetrically arranged. The splash-proof disc includes a core tube, and a metal disc perpendicular to the core tube is arranged on the outer wall of the core tube. The surface is uniformly welded with V-shaped anchors, and the lower surface of the metal disc and the V-shaped anchors are poured and wrapped with refractory castable linings. The main body of the spray gun includes a core tube, and the outer wall of the core tube is provided with damping fins plate, the damper fin includes a metal anchor member vertically welded on the outer wall of the core tube and a refractory castable lining wrapped on the outer wall of the core tube and the metal anchor member of the wing plate; Convenience, stable operation, less erosion and wear on the molten iron tank wall, low iron loss during slag removal, and short slag removal time.

Owner:武汉钢铁有限公司

A slurry type pressure taking pipe

The invention discloses a slurry-type pressure-taking pipe, which belongs to the pressure-taking pipe. Its structure includes a pressure-taking pipe body. The pressure taking groove is connected with the main channel, and the pressure taking pipe body outside the pressure taking groove is provided with a pressure taking instrument connection port, the pressure taking instrument connection port is connected with the pressure taking groove, and the pressure taking instrument connection port is connected with a pressure taking instrument. pressure instrument. Compared with the prior art, the slurry-type pressure-taking pipe of the present invention effectively solves the problems of scouring and wear of pressure-taking instruments and blockage of pressure-taking ports in a slurry environment.

Owner:SHANDONG ZHANGQIU BLOWER

Smoke power-type wet desulphurization ultrasonic atomization device and application thereof

ActiveCN101920162BImprove desulfurizationAvoid negative effects such as increased power consumptionDispersed particle separationResonant cavitySpray nozzle

The invention discloses a smoke power-type wet desulphurization ultrasonic atomization device comprising a nozzle body and a resonant cavity, wherein the resonant cavity is arranged at the front end of the nozzle body through a centre rod. The device is characterized in that the nozzle body comprises a smoke channel and a slurry channel, wherein the slurry channel is sleeved outside the smoke channel, and an outlet of the smoke channel is a Venturi tube. In the invention, smoke exhausted from the tail of a boiler is used as a medium, by utilizing the smoke which needs to be desulfurized originally is used as the medium, the device is not only beneficial to the desulfurization of the smoke medium, but also avoids the negative effect that the power consumption of a fan is increased due to the increase of the smoke amount of a desulfurization system because other media are introduced; and the smoke reaches the supersonic velocity at the outlet of the Venturi tube, and is mixed with the slurry at the outlet of the slurry channel and drives slurry to be conveyed into the resonant cavity along the centre rod to resonate to generate ultrasonic waves, therefore, the ultrasonic atomizationis realized. The structure can improve the slurry atomization performance, reduce the desulfurization cost and improve the desulfurization efficiency.

Owner:SOUTH CHINA UNIV OF TECH

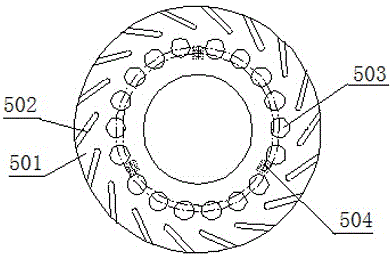

Flotation machine with integrated bolts and cover board

The invention discloses a flotation machine with integrated bolts and cover board. The flotation machine comprises a trough body, a bearing body, an air cylinder, a main shaft, a cover board, tapered square-head bolts and an impeller, wherein three cast iron brackets are arranged on the back part of a hollow disk; tapered square holes are formed in the cast iron brackets; the sizes of the tapered square holes are matched with those of the tapered square heads; the positions of the tapered square holes correspond to those of ear holes in the air cylinder; the tapered square heads of the tapered square-head bolts are arranged in the tapered square holes of the cast iron brackets and are locked through lock nuts; and a polyurethane layer is sprayed on the surface of each cast iron bracket, so that the tapered square heads are buried into the polyurethane layers. The tapered square heads of the tapered square-head bolts are buried into polyurethane; the tapered square heads do not directly contact ore pulp when working and are not easily abraded; and the cover board is not easy to fall off, so that the flotation machine has the advantages of abrasive resistance and long service life.

Owner:GUANGXI GAOFENG MINE IND +1

Slurry type pressure tapping pipe

The invention discloses a slurry type pressure tapping pipe, and belongs to a pressure tapping pipe. The pressure tapping pipe structurally comprises a pressure tapping pipe body, wherein a hole formed in the middle of the pressure tapping pipe body is a main flow channel, a pressure tapping groove is formed in the inner wall of the pressure tapping pipe body, the pressure tapping groove is communicated with the main flow channel, a pressure tapping instrument connecting port is formed in the pressure tapping pipe body on the outer side of the pressure tapping groove, the pressure tapping instrument connecting port is communicated with the pressure tapping groove, and a pressure tapping instrument is connected to the pressure tapping instrument connecting port. Compared with the prior art,the slurry type pressure tapping pipe effectively solves the problems that a pressure tapping instrument is eroded and abraded and a pressure tapping opening is blocked in the slurry environment.

Owner:SHANDONG ZHANGQIU BLOWER

Method for smoke screen protection at smoke side of boiler

The invention discloses a method for smoke screen protection at the smoke side of a boiler. The problem that a specific heating surface of an existing boiler is prone to being corroded and abraded is solved. The method comprises the following steps of determining an area to be subjected to smoke screen protection; arranging an air curtain device; and solving an unknown number n according to a formula, namely, determining the number of arranged protection tubes according to the area to be subjected to smoke screen protection. The method has the beneficial effects that a smoke protection layer is formed on a heating surface or a specific area needing to be protected through the air curtain device, and the heating surface or the specific area is protected through protection of the protection layer, so that direct contact with smoke is avoided, erosive wear and corrosion are avoided, the safe operation period of equipment is greatly prolonged, the stability and continuity of the boiler or the device are improved, and the service life of the product is long.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

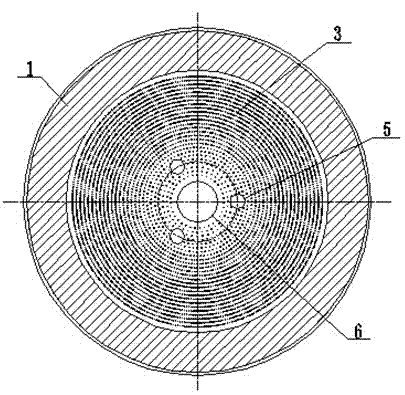

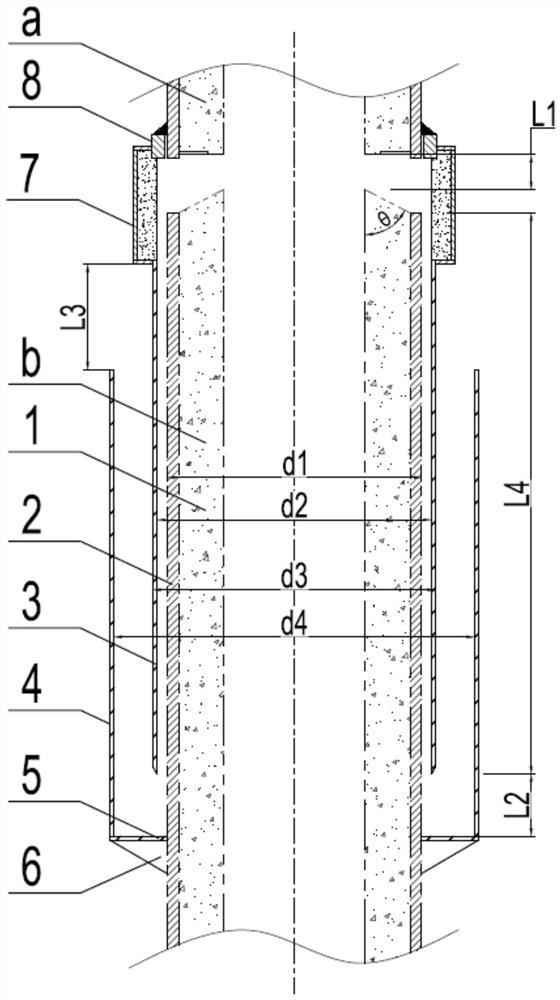

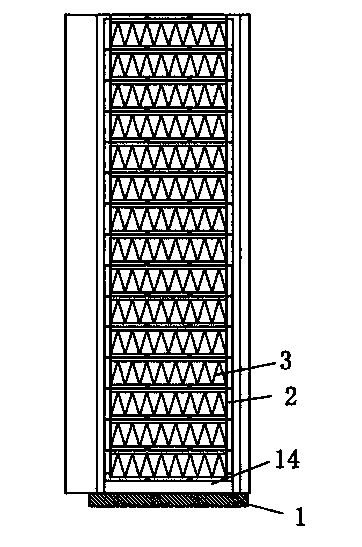

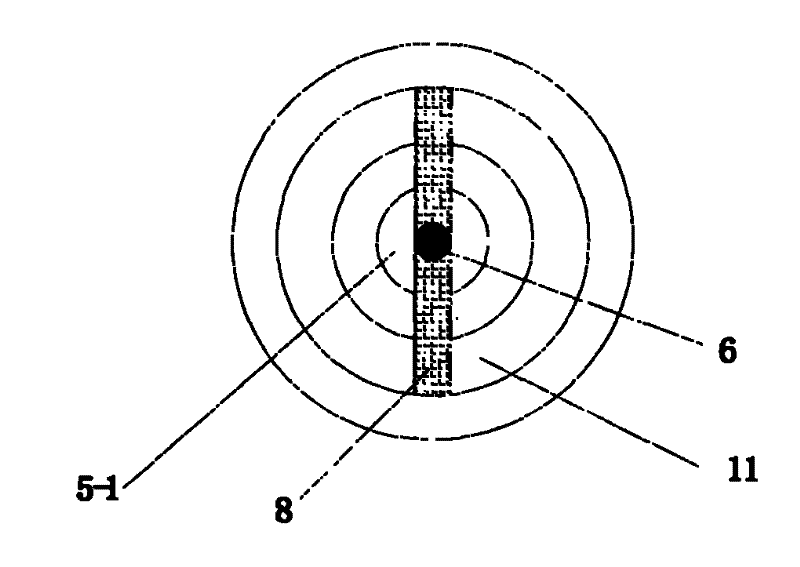

Hearth temperature water-cooling control device for large circulating fluidized bed boiler

InactiveCN105588121AExtended service lifeGuaranteed tightnessFluidized bed combustionApparatus for fluidised bed combustionEngineeringSteam drum

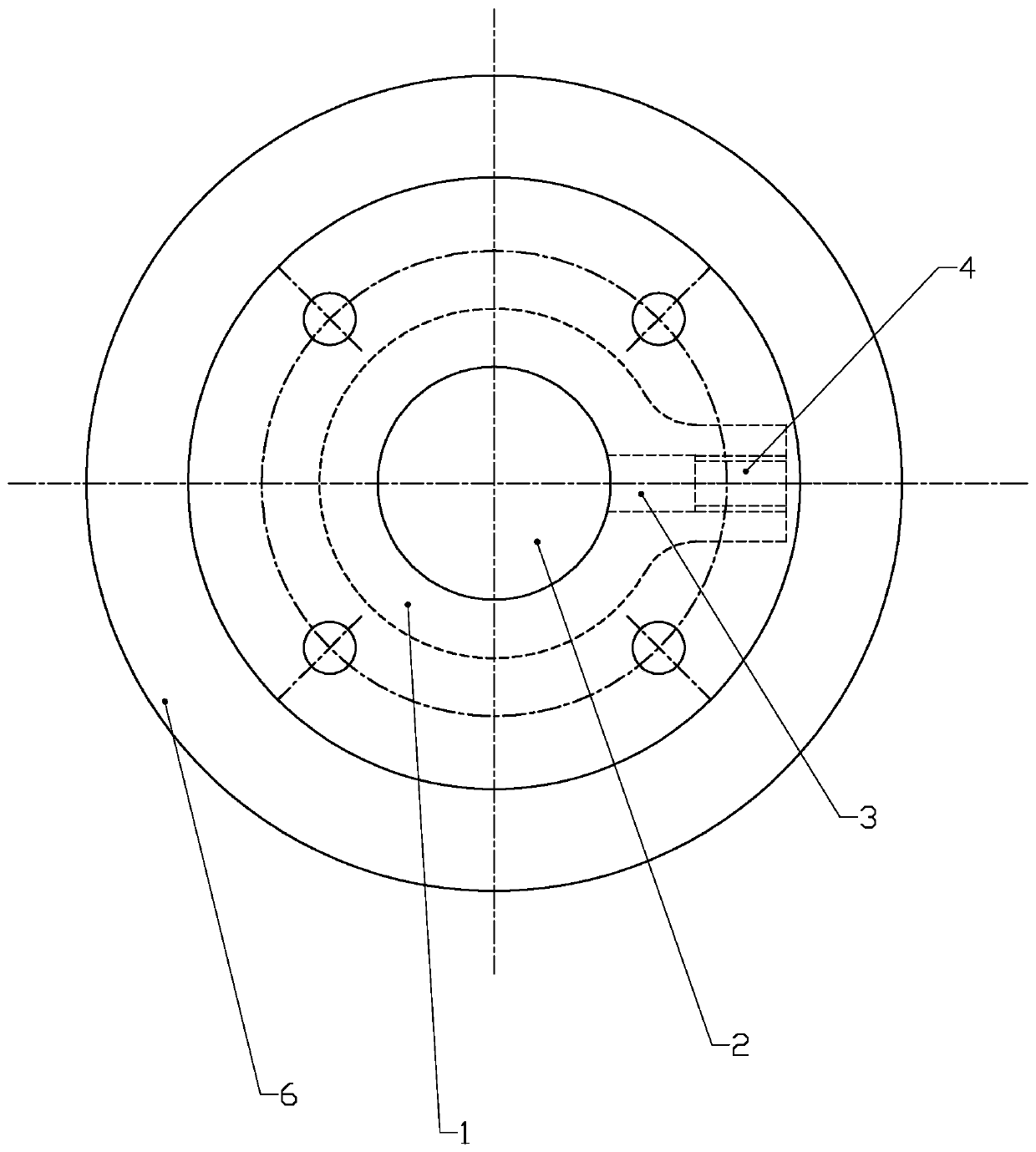

The invention discloses a hearth temperature water-cooling control device for a large circulating fluidized bed boiler. By the adoption of the hearth temperature water-cooling control device for the large circulating fluidized bed boiler, the problem that the hearth temperature of a circulating fluidized bed boiler is slightly higher and difficult to control is solved. The hearth temperature water-cooling control device for the large circulating fluidized bed boiler comprises a hearth, a water-cooling partition wall, a steam pocket, connecting pipes, an upper header and a lower header, wherein the water-cooling partition wall, the steam pocket, the connecting pipes, the upper header and the lower header are located in the hearth. The hearth comprises a hearth roof, a front wall, a rear wall, a left side wall and a right side wall, wherein a rectangular cylinder is formed by the front wall, the rear wall, the left side wall and the right side wall. The water-cooling partition wall comprises a plurality of heat exchange pipes, abrasion-proof fins and flat steel, wherein the heat exchange pipes are arranged on the same plane in parallel, the flat steel is welded between every two adjacent heat exchange pipes, and the heat exchange pipes and the flat steel are arranged linearly; the abrasion-proof fins are welded to the two sides of each heat exchange pipe. The water-cooling partition wall horizontally extends to the middle of the hearth and vertically penetrates through the hearth. The upper end and the lower end of the water-cooling partition wall communicate with the upper header and the lower header correspondingly. The upper header and the lower header communicate with the steam pocket through the connecting pipes, and a circulation loop is formed. One side of the water-cooling partition wall is fixedly connected to the middle of the front wall of the hearth and is perpendicular to the front wall, and the other side of the water-cooling partition wall horizontally extends to the middle of the hearth.

Owner:SHANXI GUOFENG COAL POWER CO LTD +1

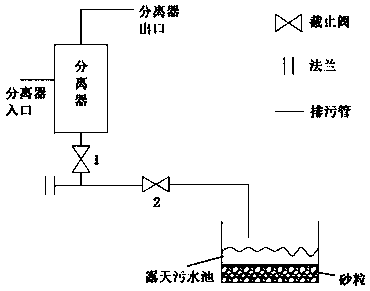

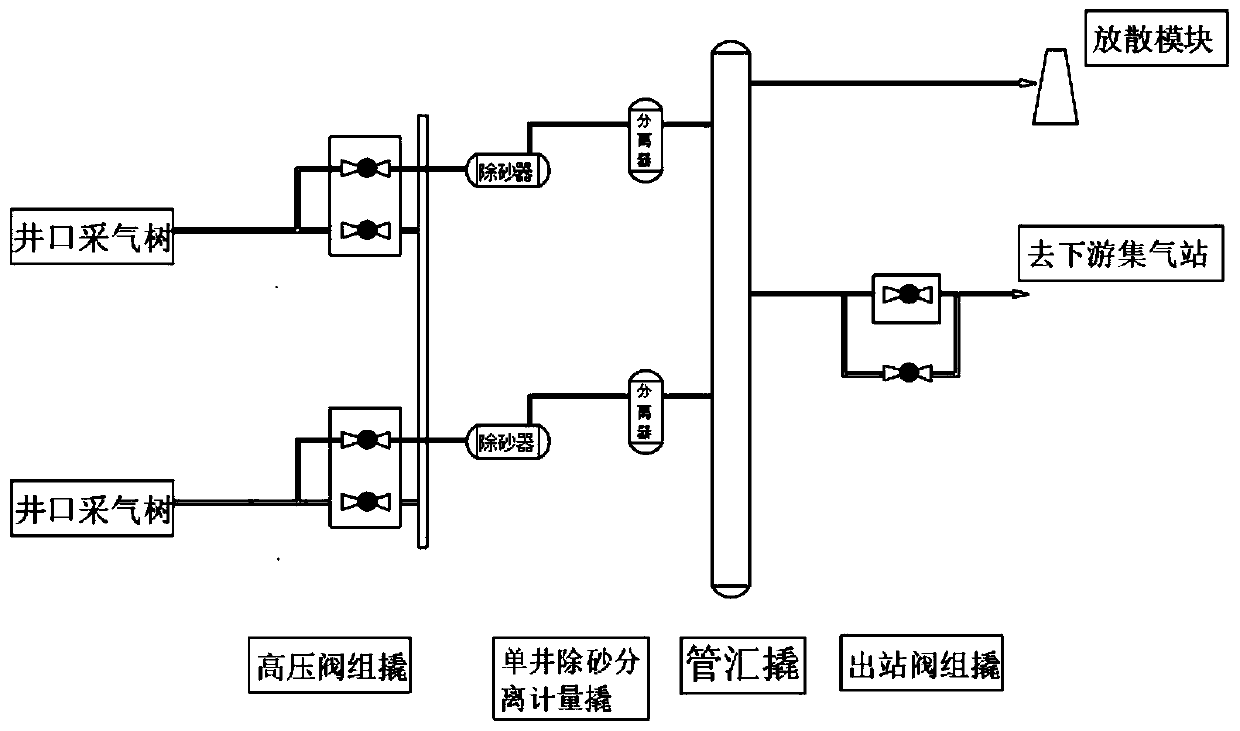

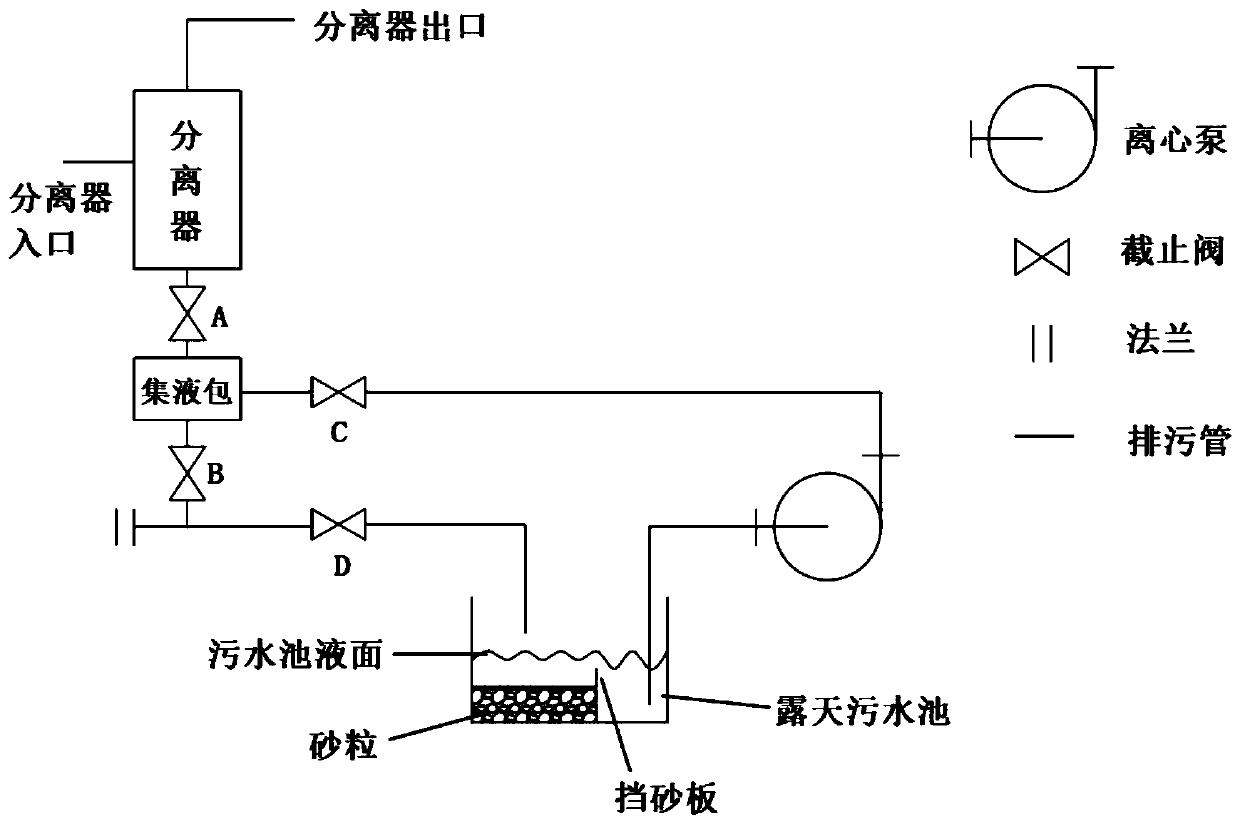

Novel separation measurement sled pollution discharge system and method for shale gas field

The invention discloses a novel separation measurement sled pollution discharge system and method for a shale gas field. The novel separation measurement sled pollution discharge system comprises a shale gas separator, a liquid collecting pack, a sewage pool, and a centrifugal pump, wherein the liquid collecting pack is a sealed container; liquid level meters are arranged on the shale gas separator and the liquid collecting pack; a sand blocking plate is arranged in the sewage pool, and is used for dividing the sewage pool into a sand settling zone and a contaminated zone; a liquid dischargingopening is formed in the bottom of the shale gas separator; a liquid inlet I is formed in the top of the liquid collecting pack; a liquid discharging opening of the shale gas separator is connected with a liquid inlet I of the liquid collecting pack through a vertical pipeline I; a valve A is arranged on the pipeline I; a liquid outlet is formed in the bottom of the liquid collecting pack, and isconnected with the sand settling zone through a pipeline II; a valve B and a valve D are arranged on the pipeline II; the contaminated zone is connected with an entrance of the centrifugal pump through a pipeline III; an exit of the centrifugal pump is connected with a liquid inlet II of the liquid collecting pack through a pipeline IV; and a valve C is arranged on the pipeline IV. Through the adoption of the novel separation measurement sled pollution discharge system disclosed by the invention, the erosion rate of the pollution discharge pipeline can be reduced, and the operation safety ofthe equipment is guaranteed.

Owner:SOUTHWEST PETROLEUM UNIV

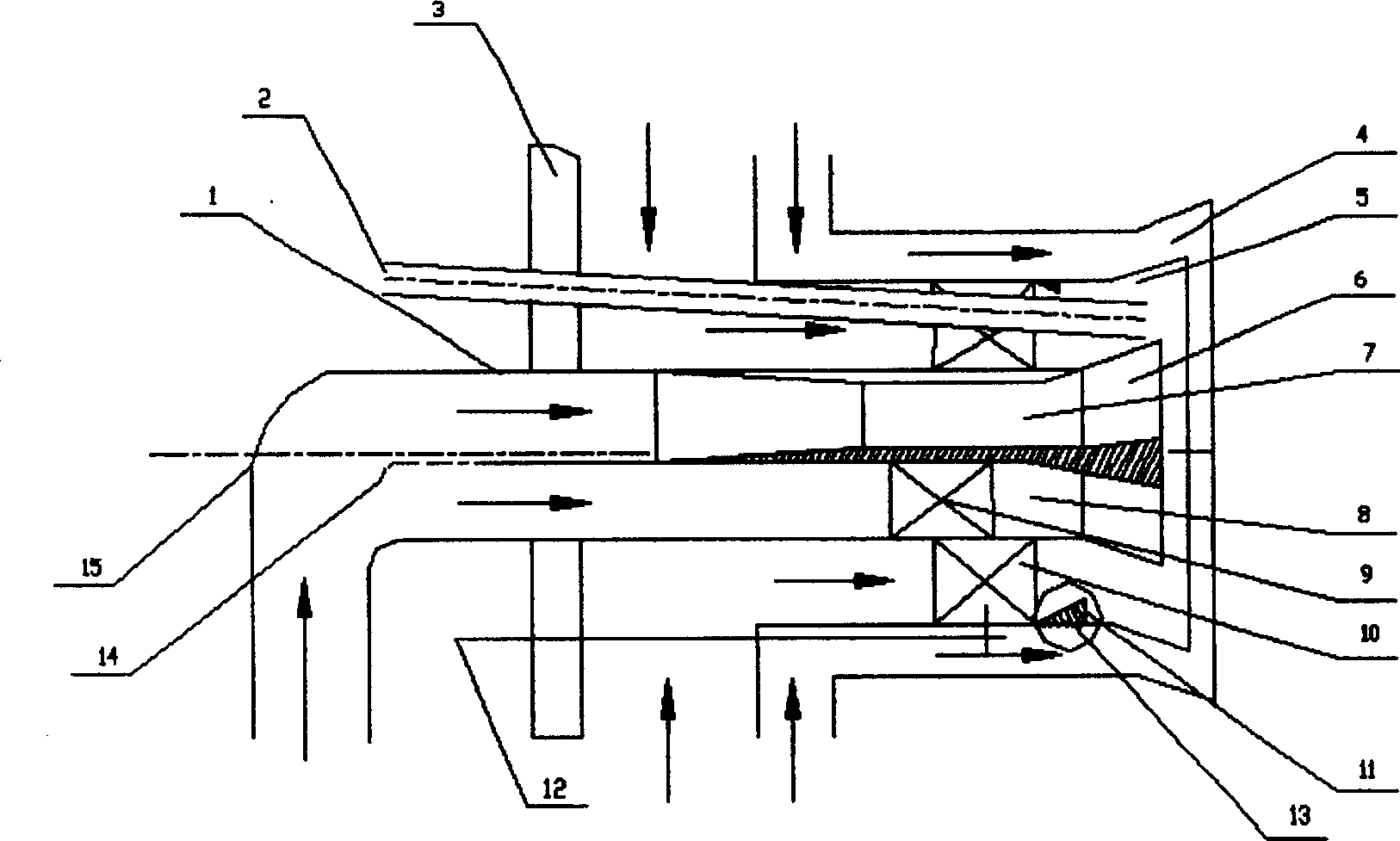

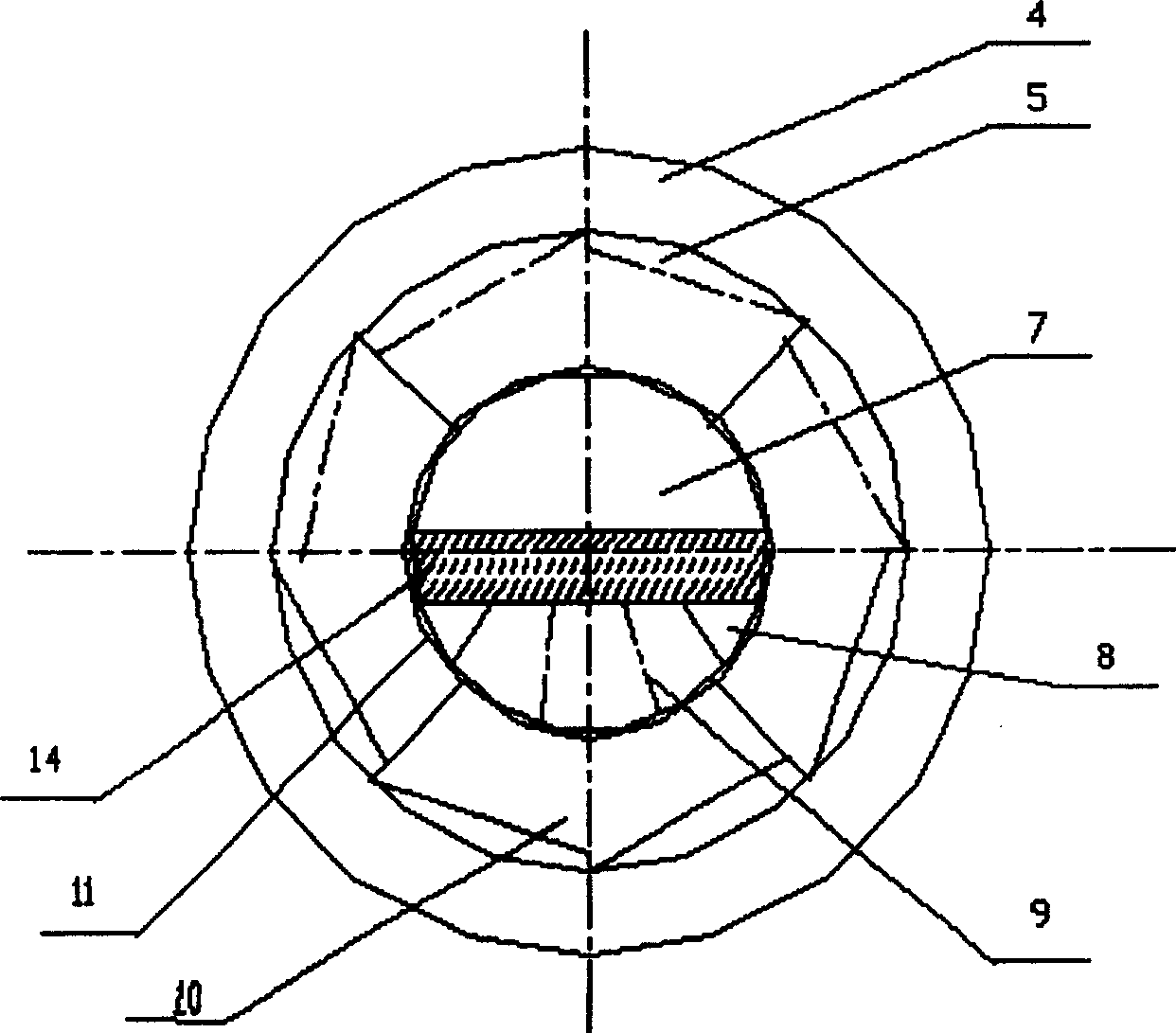

Circularly swirling coal powder burn device with various concentration coal powder pipe

InactiveCN1279313CAvoid DC FlashingReduce the number of minor repairsPulverulent fuel combustion burnersFly ashPowder burn

The utility model relates to a circular swirl thick and thin coal powder burner, which relates to a swirl pulverized coal combustion device. In the present invention, a separation partition is arranged in the primary air pulverized coal pipe to divide the primary air pipe into the upper and lower thick and light pulverized coal pipelines, and a reducer for uniform pulverized coal flow is arranged in the concentrated pulverized coal pipeline. A wedge-shaped body is formed between the bottom and the separating partition; fixed swirl vanes are set in the light coal powder pipeline at the lower part of the primary air duct, and movable and adjustable swirl vanes are set in the secondary air duct, and A rotating body with curved grooves on the inner surface is arranged on the wall surface of the front end of the swirl vane of the secondary air duct. The invention can effectively reduce the NO of pulverized coal furnace x emissions without significantly increasing the carbon content of fly ash; at the same time, when burning low-volatile pulverized coal, it effectively solves the problems of low-load ignition and stable combustion, and reduces the resistance and wear of the primary air duct, thereby improving the service life of the combustion equipment and equipment performance costs.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com