Front wall heating surface structure of CDQ (Coke Dry Quenching) waste heat boiler

A waste heat boiler and coke CDQ technology, which is applied in the direction of boiler water pipes, etc., can solve the problems of slag pipe deviation from nucleate state boiling, overheating of pipes, burning and bursting of pipes, and affecting boiler safety. , Increase heat absorption, improve the effect of water cycle safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

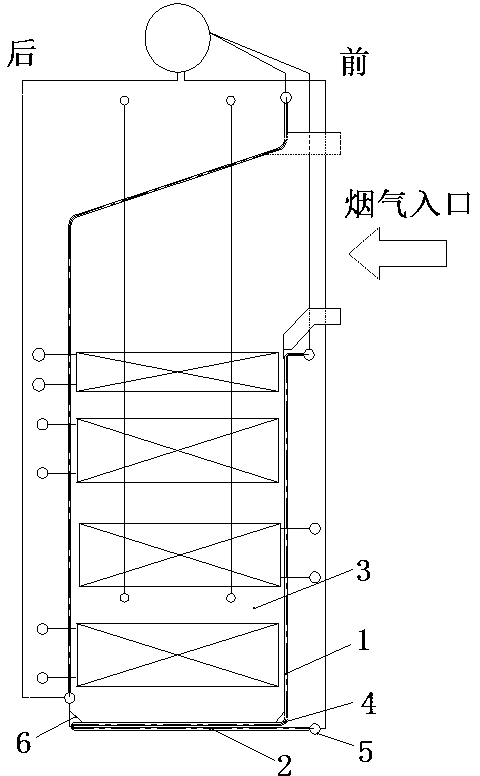

[0022] A front wall heating surface structure of a CDQ waste heat boiler, such as figure 1 As shown, including the water-cooled wall section and the transverse flushing section. The water-cooled wall pipes on the heating surface of the front wall extend into the tail flue of the waste heat boiler to form a transverse scour section, which is used to increase the heat absorption of the heating surface of the front wall and improve the safety of water circulation. The pipes in the transverse flushing section are made of light pipes arranged in the form of serpentine pipes. The arrangement of the pipes adopts a combination of horizontal arrangement and 15° inclined arrangement, which has a compact structure and can effectively prevent the stratification of steam and water in the pipe. One end of the transverse flushing section is connected to the water-cooled wall section through an elbow, and the other end of the transverse flushing section is connected to the lower header, whic...

Embodiment 2

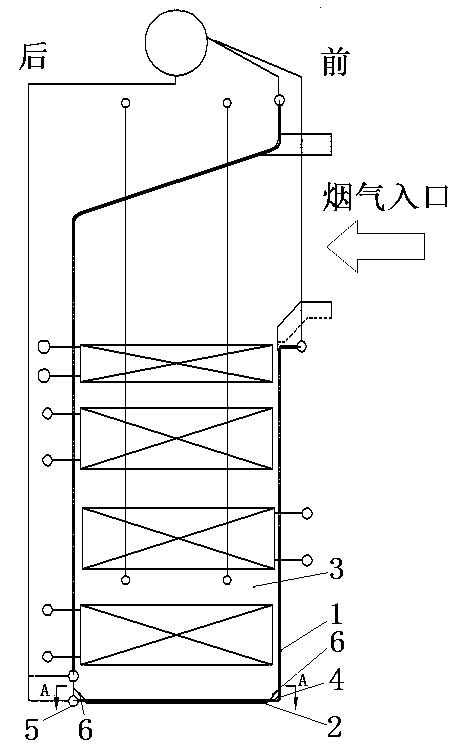

[0024] A front wall heating surface structure of a CDQ waste heat boiler, such as figure 2 , as shown in 3, with figure 1 The embodiment shown is similar, the difference is that the horizontal flushing section is arranged horizontally with a single row of finned tubes, which has high heat exchange efficiency and compact structure. One end of the transverse flushing section is connected to the water-cooled wall section through an elbow, and the other end of the transverse flushing section is connected to the lower header, which is arranged close to the rear wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com