Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Eliminate erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

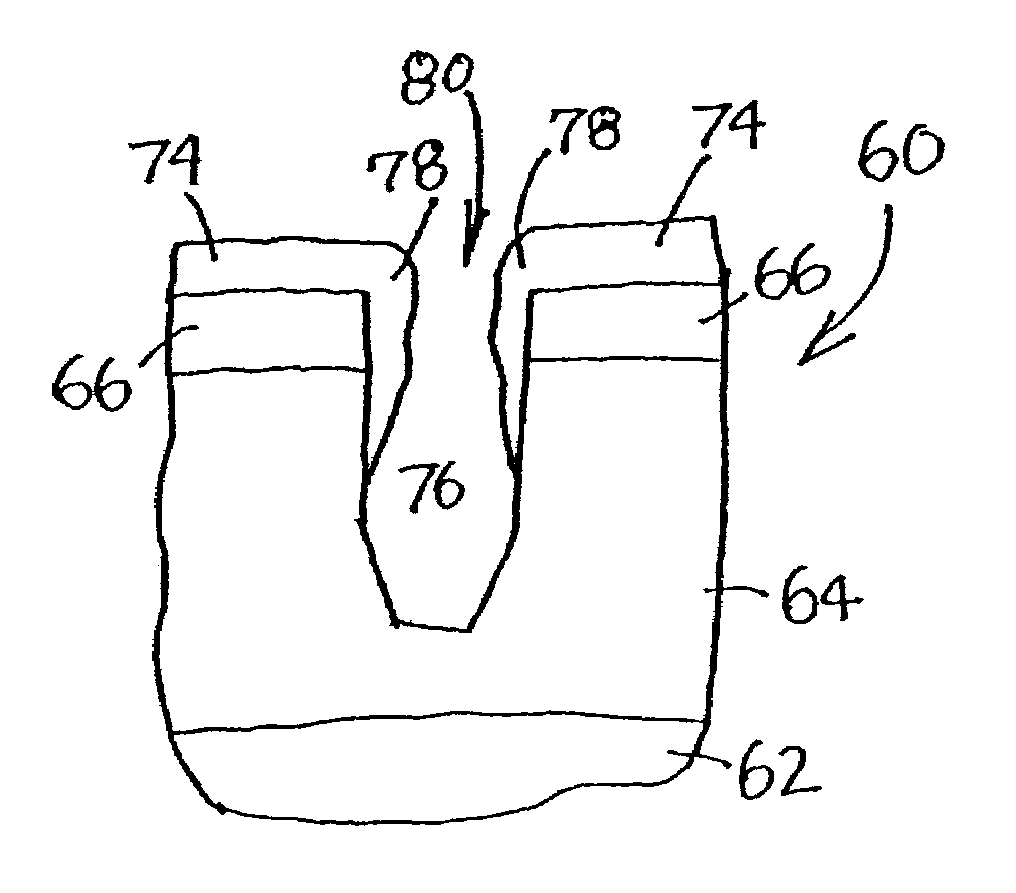

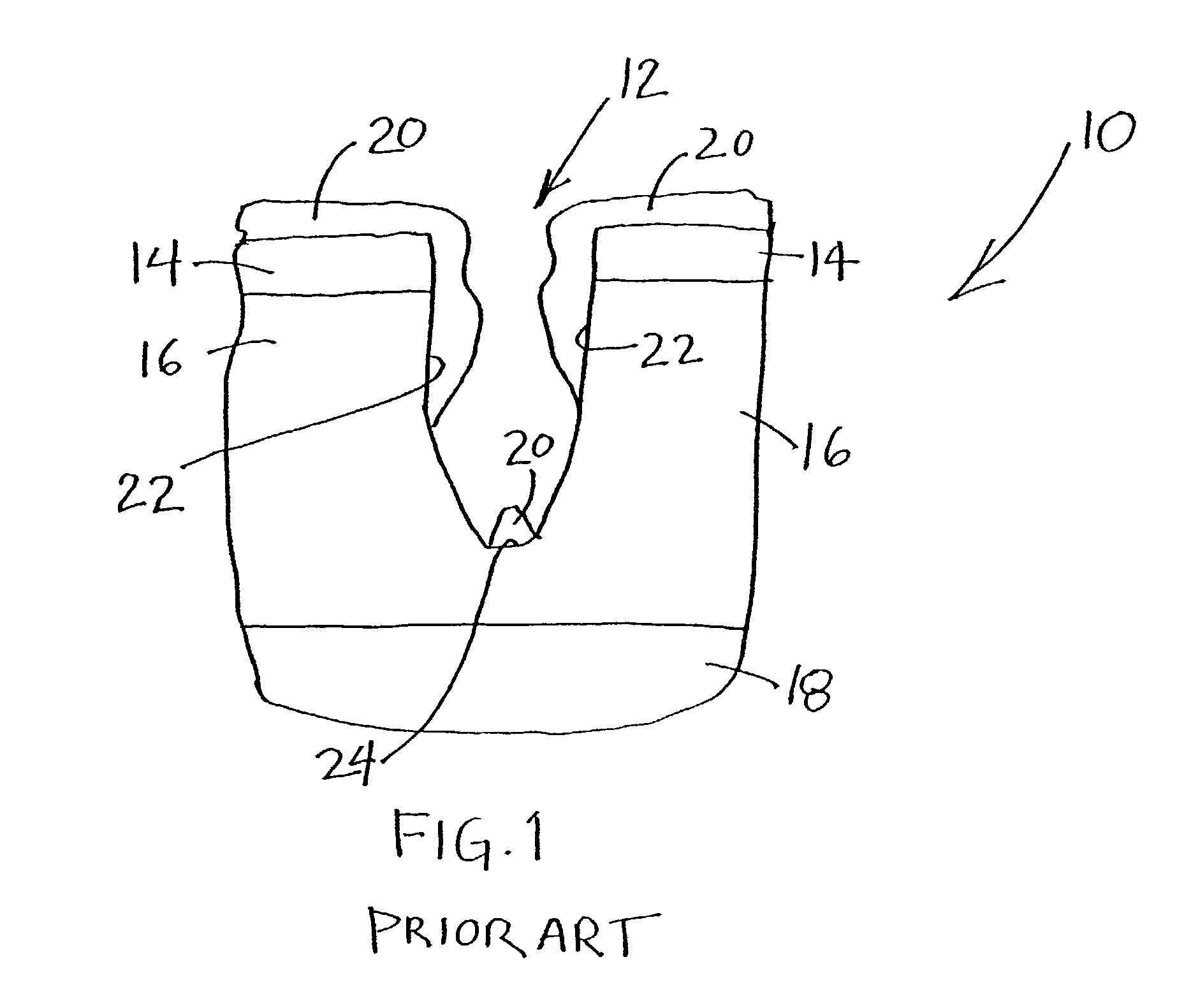

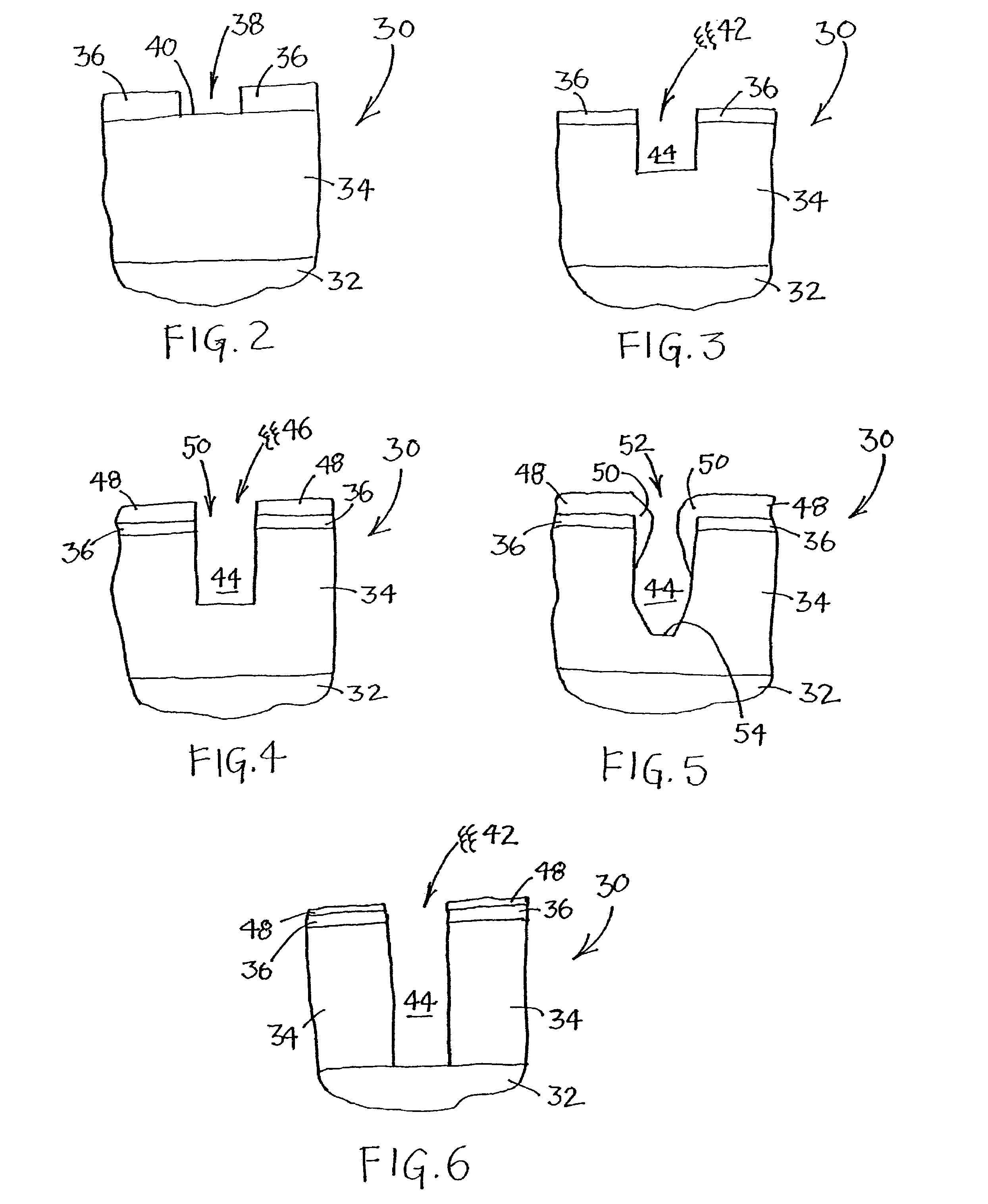

Satiation devices and methods for controlling obesity

Satiation devices for controlling obesity and methods of implanting same are configured to create a small satiation pouch in the proximal portion of the stomach with a narrow passage leading into the lower portion of the stomach. The small satiation pouch is configured to collect a small amount of masticated food from the esophagus and the narrow passage delays emptying of the food from the satiation pouch into the larger part of the stomach, thereby causing a feeling of fullness.

Owner:TRANSENTERIX

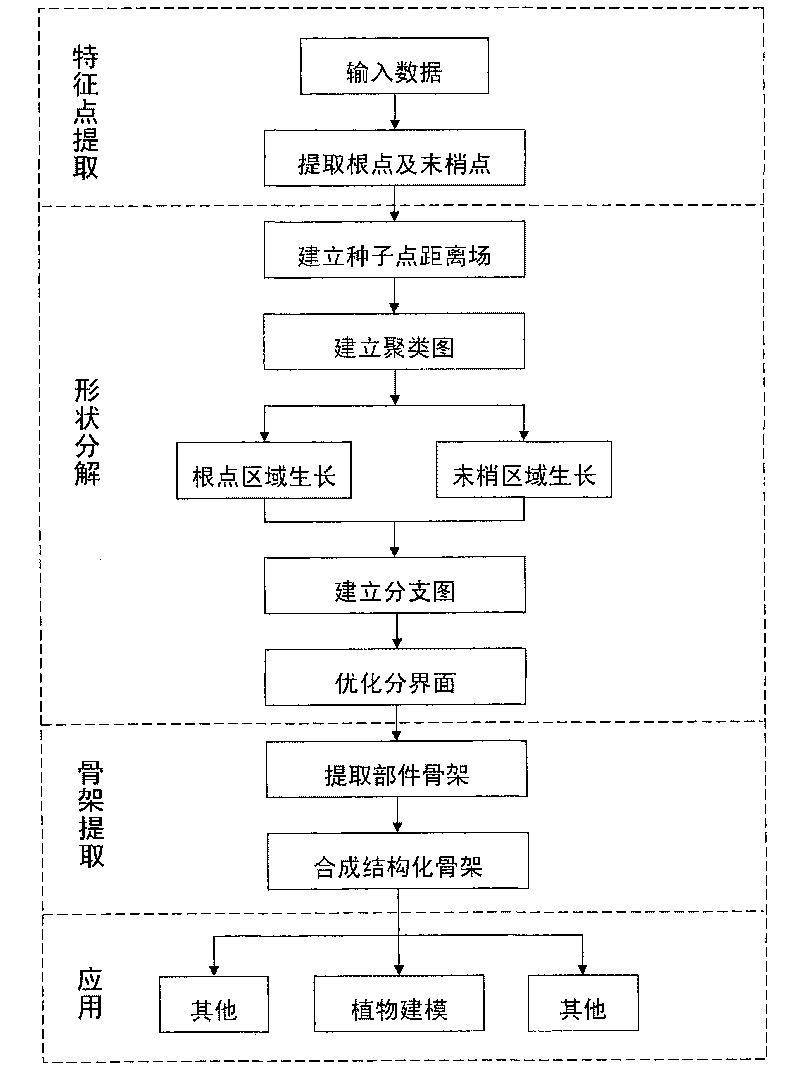

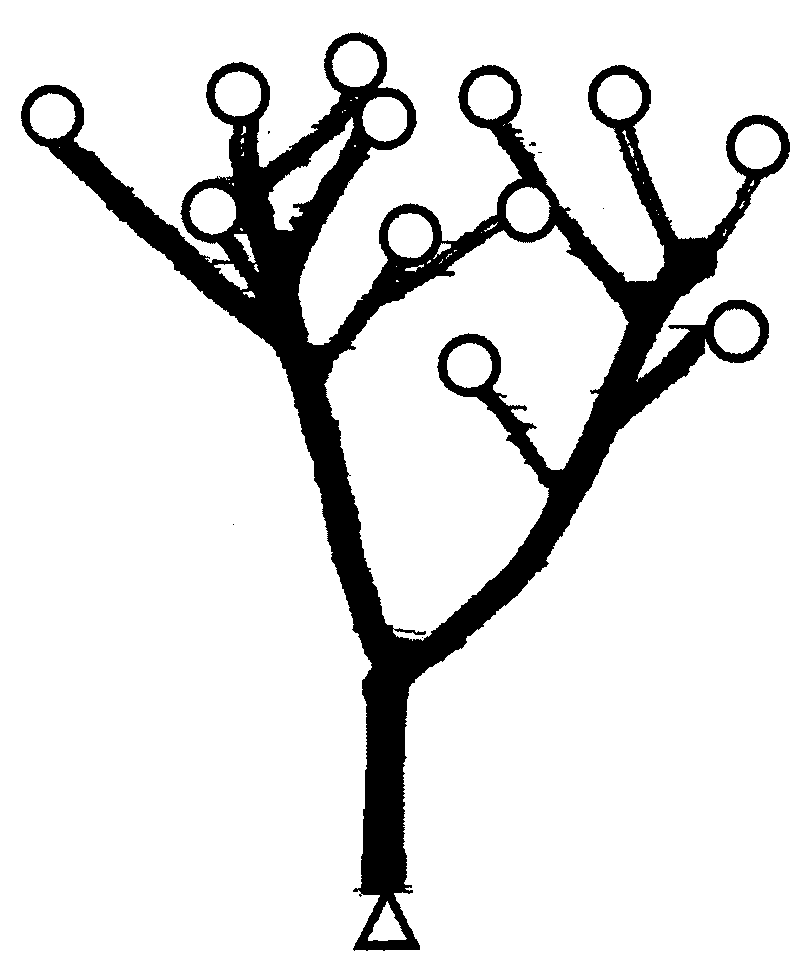

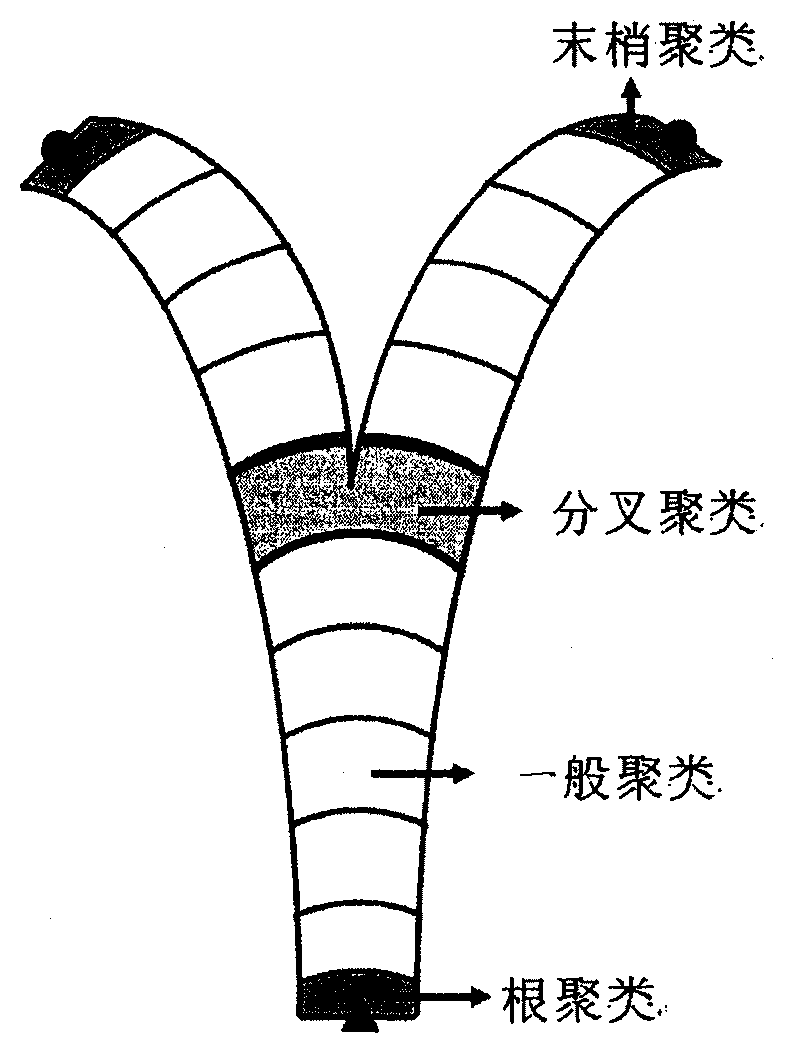

Three-dimensional framework fast extraction method based on branch feathers

The invention provides a three-dimensional framework fast extraction method based on branch feathers, which comprises the following steps: firstly, automatically extracting root points and tip end points of a tree type voxel model; then, carrying out seed point distance conversion on the root points and the tip end points of the voxel model; automatically judging the branching feathers and optimizing cutting surfaces according to the growth strategy of regions from the root points or the tip end points; decomposing an object into meaningful components with reasonable delimitation between components; and finally, extracting voxel component frameworks and connecting the voxel component frameworks into a structural framework of the object. The framework fast extraction method based on branch feathers is fast and effectively, and the structural integral frameworks maintain topological structures of the original voxel model, and can not generate fracture and redundant complicated branches. The actual plant model construction is carried out on the basis of the framework, the actual scanning data can be processed, and the invention has the anti-noise capability and has high reconstruction accuracy. The test on a plurality of data sets proves that the invention is applicable to bodies with annular structures and can process surface voxel models and solid voxel models.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

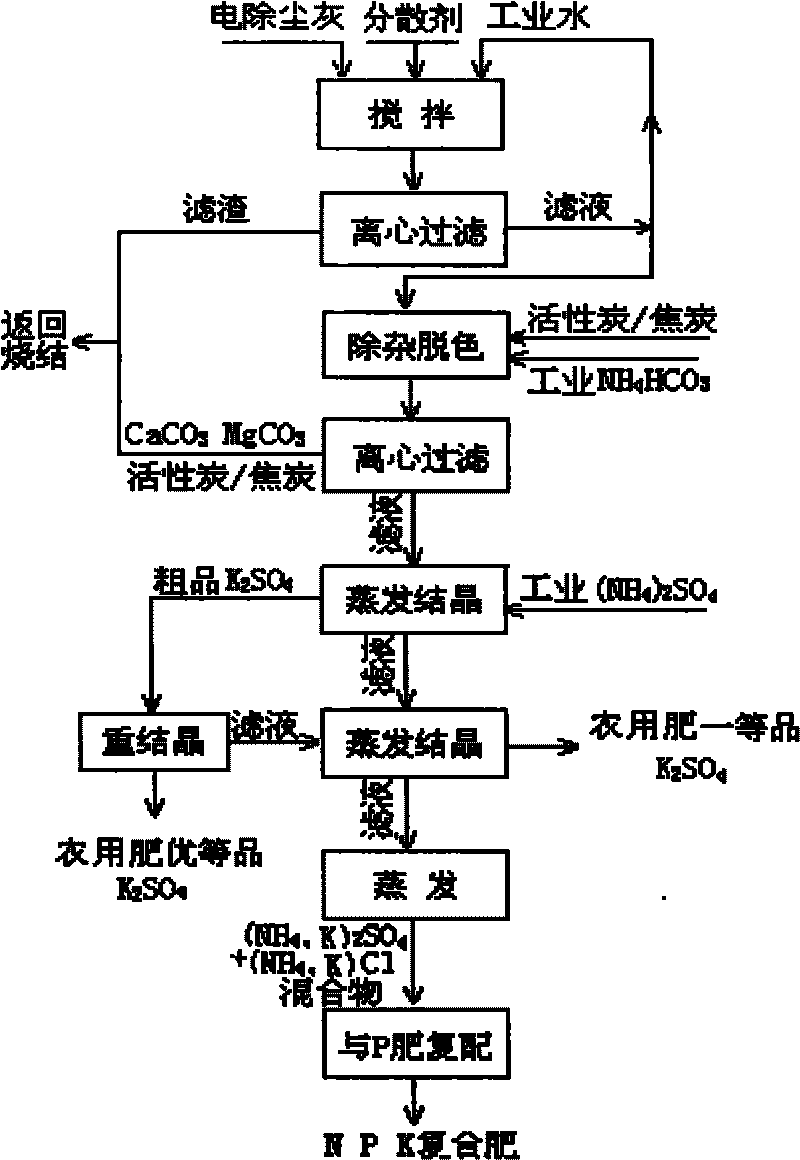

Method for recovering potassium elements from sintering ashes of steel and iron works and preparing potassium sulfate

ActiveCN101723410AEliminate erosionExtended service lifeAlkali metal sulfites/sulfatesPotassium fertilisersEvaporationImpurity

The invention discloses a method for recovering potassium elements from sintering ashes of steel and iron works and preparing potassium sulfate. The method comprises the following main steps of: A. removing potassium by adopting a circulating industry washing leaching solution mode, and carrying out solid-liquid separation on suspension liquid by adopting a centrifugal filtration or centrifugal precipitation mode; B. adding NH4HCO3 into the potassium removing solution for removing impurities, and adding active carbon or industrial coke powder for decoloration; and C. adding industrial (NH4)2SO4 for evaporation and crystallization to prepare the potassium sulfate. The invention can completely eliminate corrosion caused by circulating gathering of alkali metal of potassium, sodium and the like in the iron-making blast furnace and the adverse effects on sintering electric dedusting system efficiency and the like when the sintering ashes are reused as ingredients directly, and simultaneously realize high-efficiency recycling of the potassium resource.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

Method to eliminate striations and surface roughness caused by dry etch

InactiveUS7153779B2Reduce resist etch rateAvoid erosionDecorative surface effectsSemiconductor/solid-state device manufacturingMetallurgyNitrogen

A plasma etch process for forming a high aspect ratio contact opening through a silicon oxide layer is disclosed. The silicon oxide layer is plasma etched using etch gases that include at least one organic fluorocarbon gas. At least one etch gas is used that includes one or more nitrogen-comprising gases to deposit a surface polymeric material during the etching for maintaining a masking layer over the silicon oxide layer. The method of the invention achieves a complete and anistropic etching of a contact opening having a high aspect ratio and the desired dimensions.

Owner:MICRON TECH INC

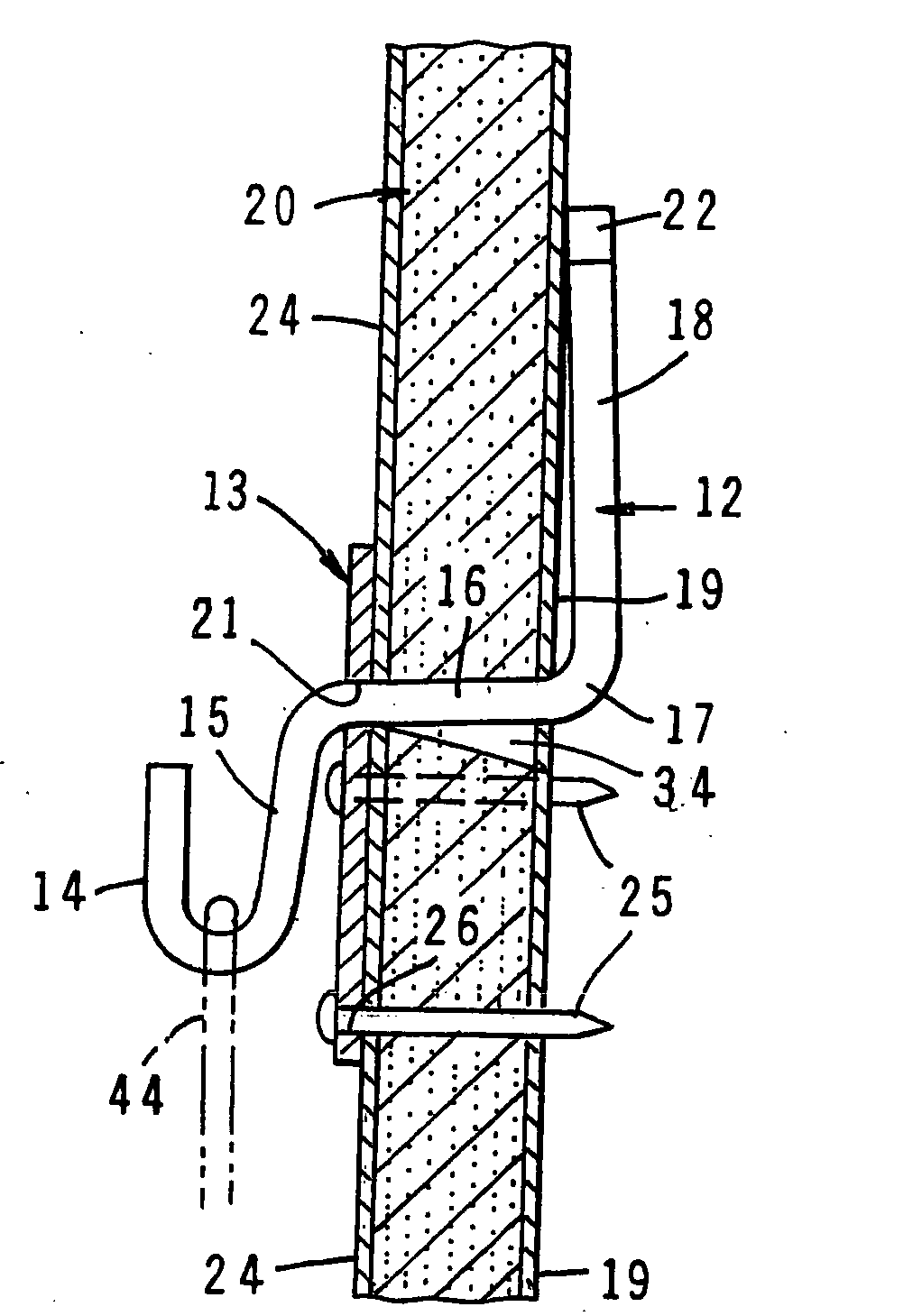

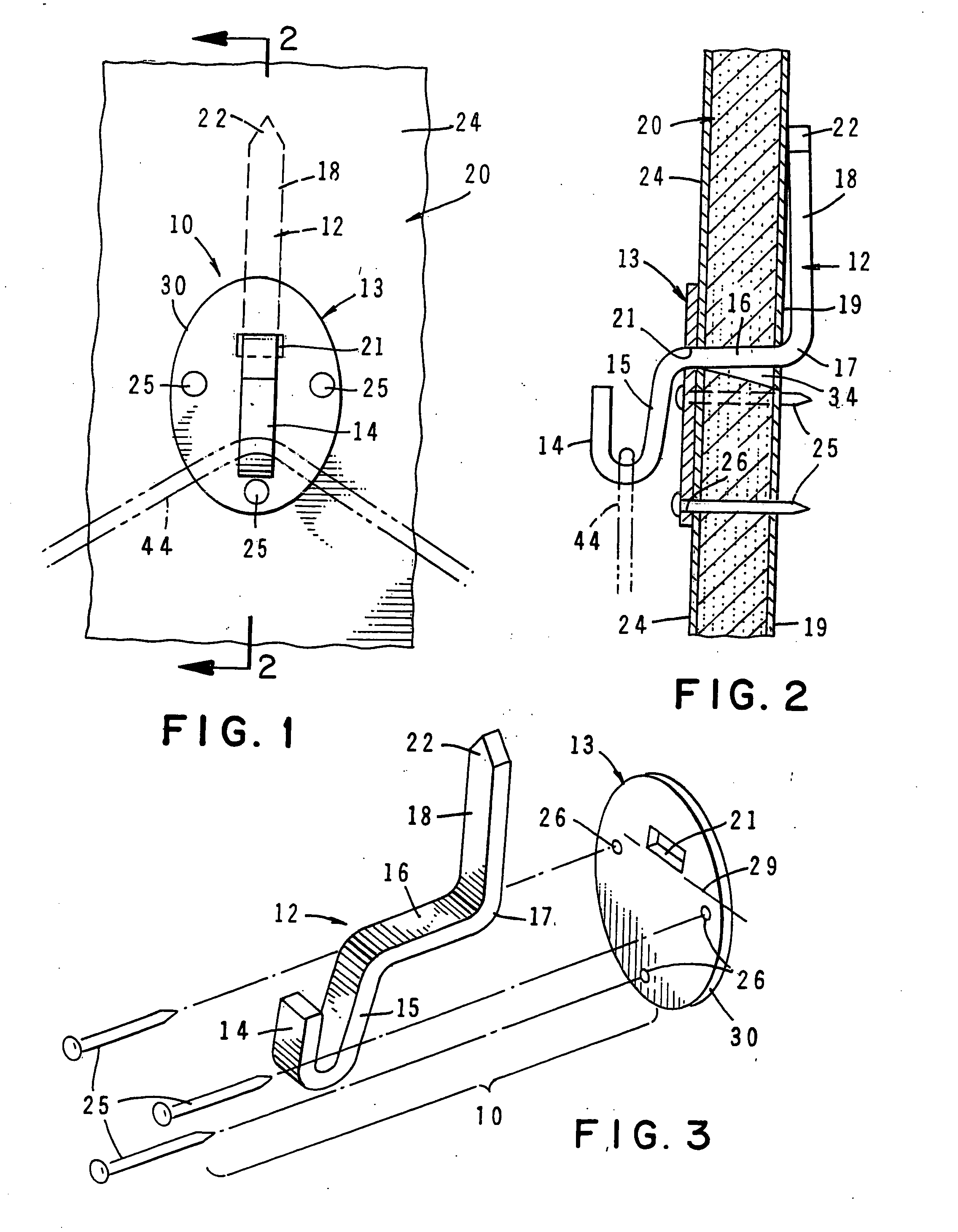

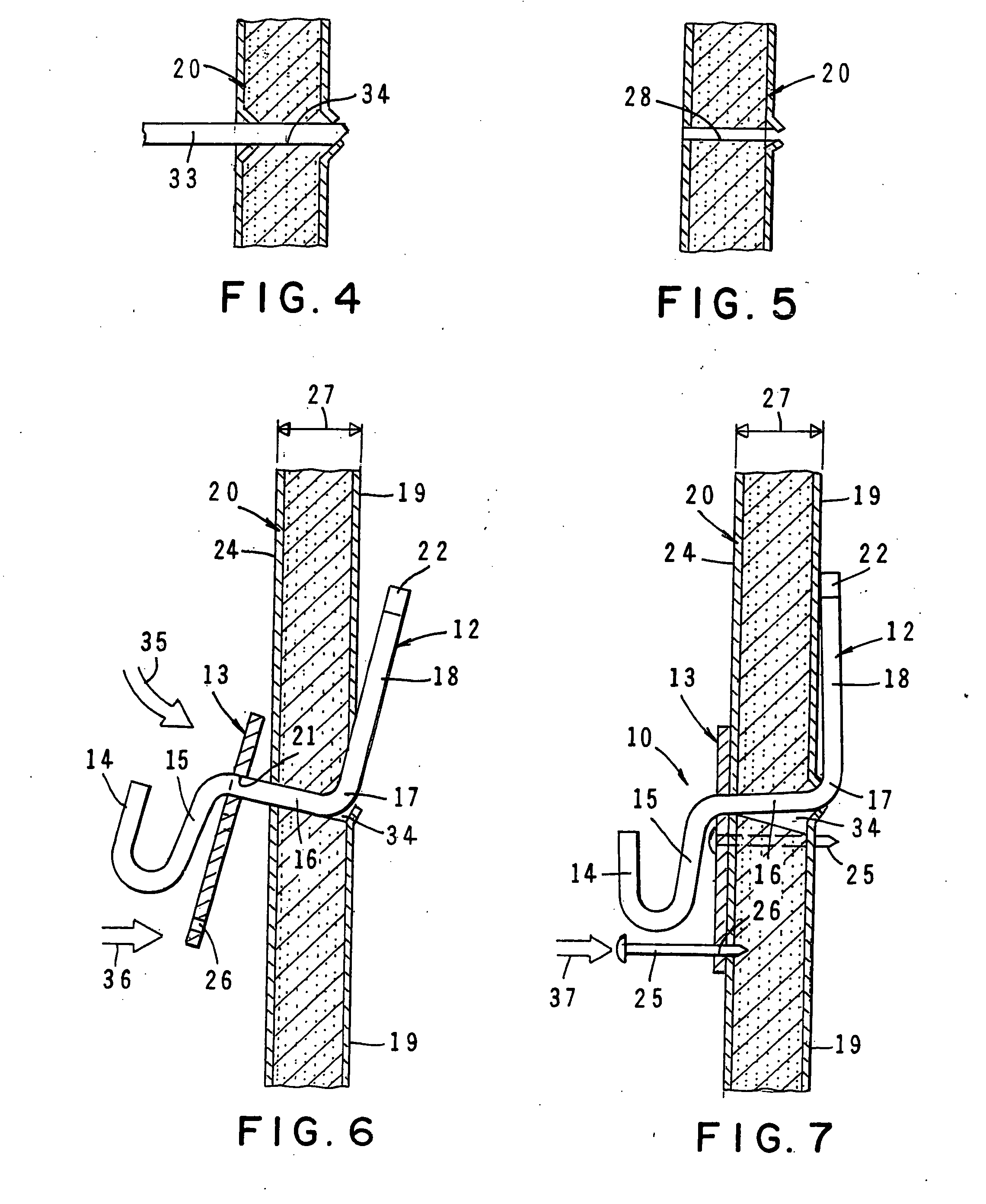

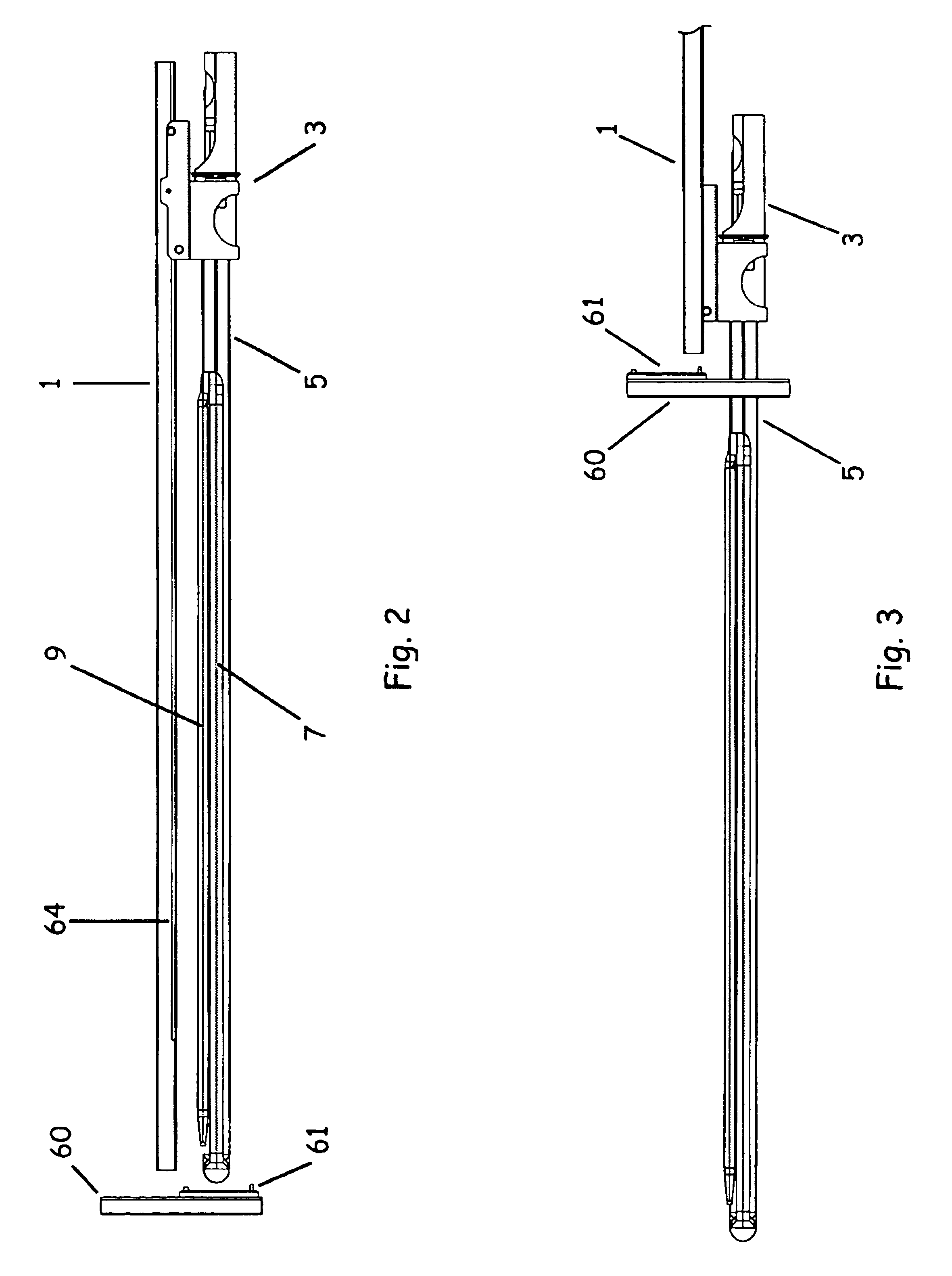

Wall hanger assembly

InactiveUS20040159766A1Eliminate erosionEliminate deteriorationPicture framesCurtain suspension devicesClothes hangerFastener

A hanger device in an assembly of a clip and a support member for installation upon a wallboard. The clip is formed as one piece, having an upturned arm, a downwardly turned leg and a horizontally oriented extension member connecting the two together. A hook is mounted on leg and a pointed end is provided on the terminal end of the arm. An opening is formed in support member so as to mate geometrically to the rectangular cross section of extension member to prevent turning of clip after installation of device in wallboard. A plurality of spaced-apart apertures is provided in the support member for insertion of fasteners to attach support member to the wallboard. The device of the invention carries much more weight than do the present state-of-the art hangers.

Owner:SKORKA RICHARD

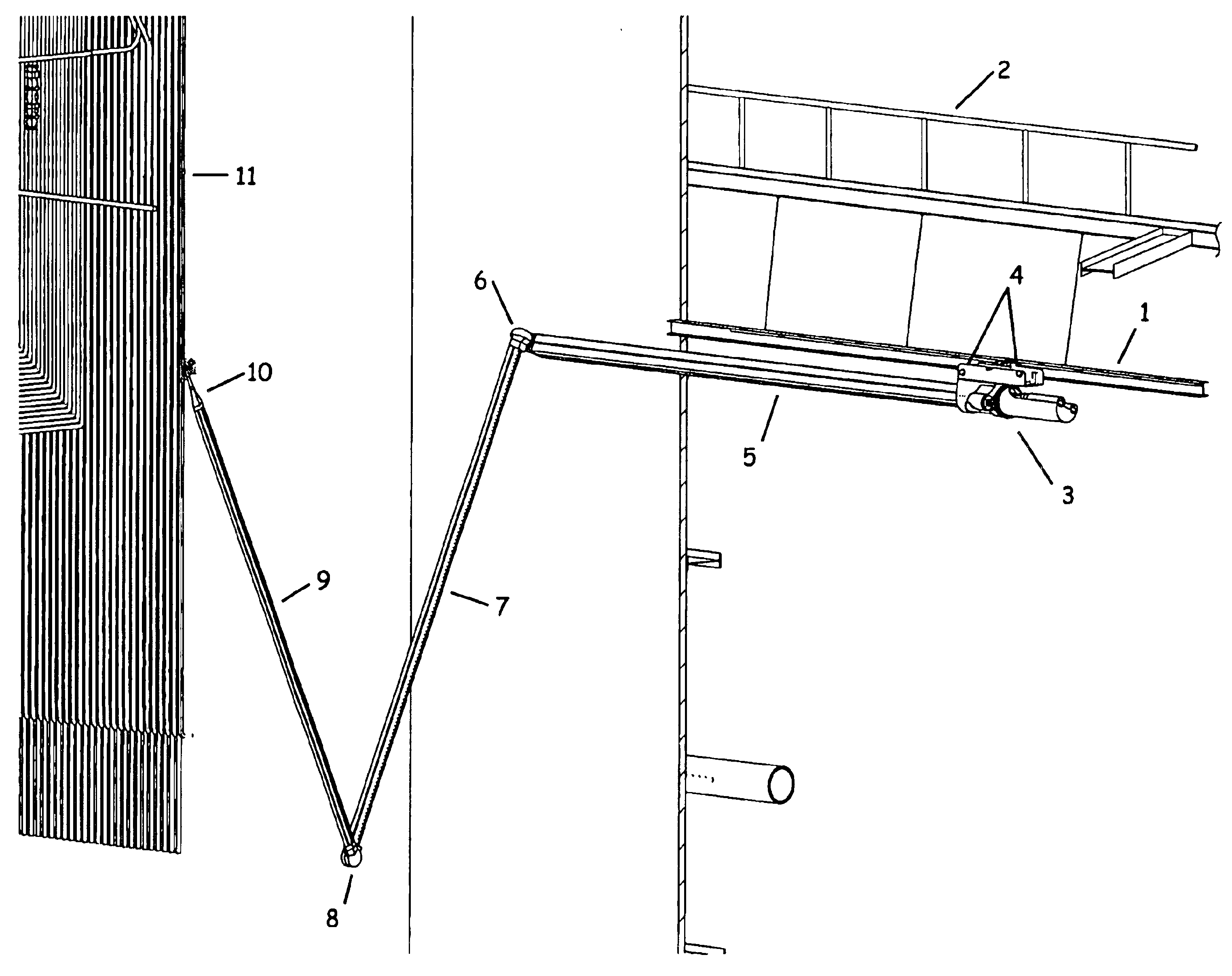

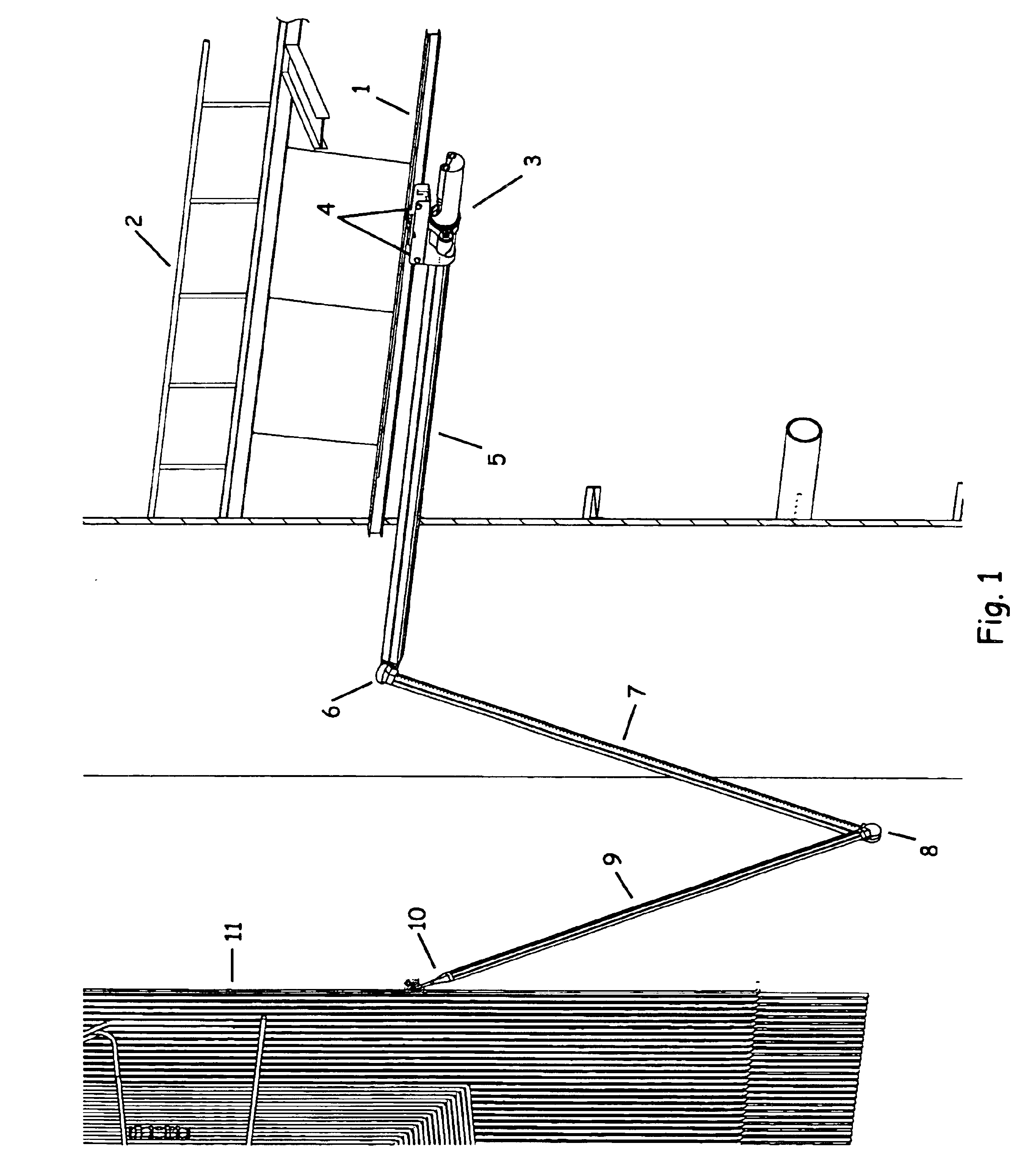

Method and apparatuses to remove slag

ActiveUS7204208B2Eliminate tube damageEliminate erosionMechanical cleaningPressure cleaningFiberCarbon fibers

A robotic apparatus for the cleaning and maintenance of coal fired boilers, which is designed to operate in the high temperature environment of the combustion gasses to effectively clean and remove slag deposits of the boiler heat transfer surfaces by use of a precision directed, low pressure, low flow rate water stream. The robotic cleaning apparatus is comprised of lightweight carbon fiber structural elements, attached to the exterior of the boiler, and cooled by annular pressurized water sheaths impingent on a thin metal skin covering the lightweight structural elements. Multiple articulated joints allow for complete access to the heat transfer surfaces of the boiler. A variety of payloads can be delivered to specific points within the boiler, including imaging systems, cutting, and welding apparatuses. A mathematical state space control matrix allows for optimal positioning and feedback control of motions.

Owner:KURION INC

Gas-fed hollow cathode keeper and method of operating same

ActiveUS20080047256A1Reduce erosionWeaken energyMachines/enginesOptical signallingIon bombardmentHigh pressure

A gas-fed hollow cathode keeper can reduce ion bombardment erosion by expelling gas through the keeper faceplate. The expelled gas effectively creates a high-pressure “shield” around the keeper such that bombarding ions suffer energy-reducing collisions before impacting the keeper. If the bombarding ion energy is reduced enough, the erosion is eliminated since sputtering is a threshold phenomenon.

Owner:RGT UNIV OF MICHIGAN

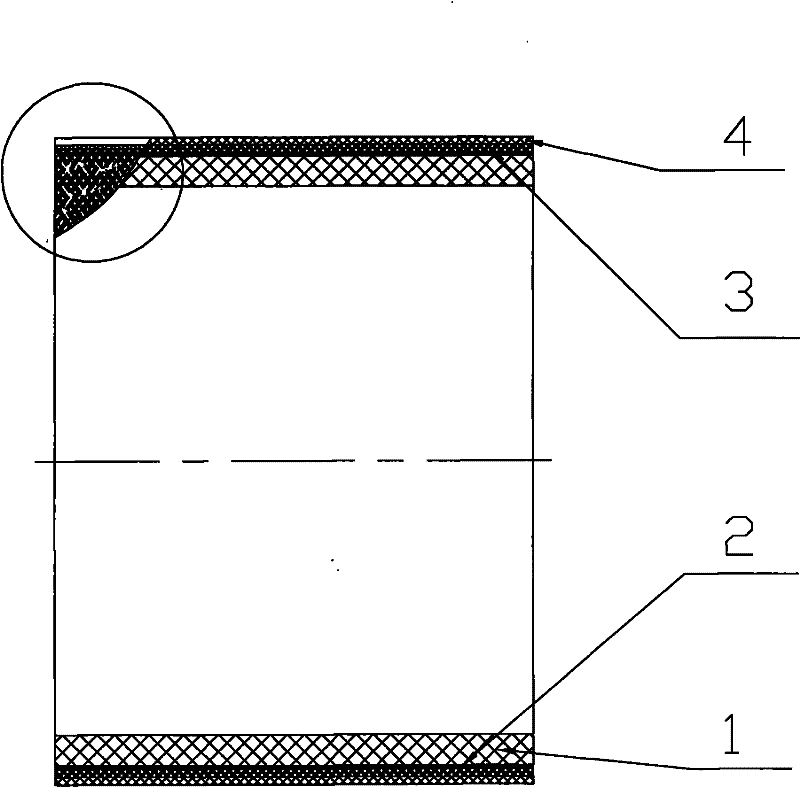

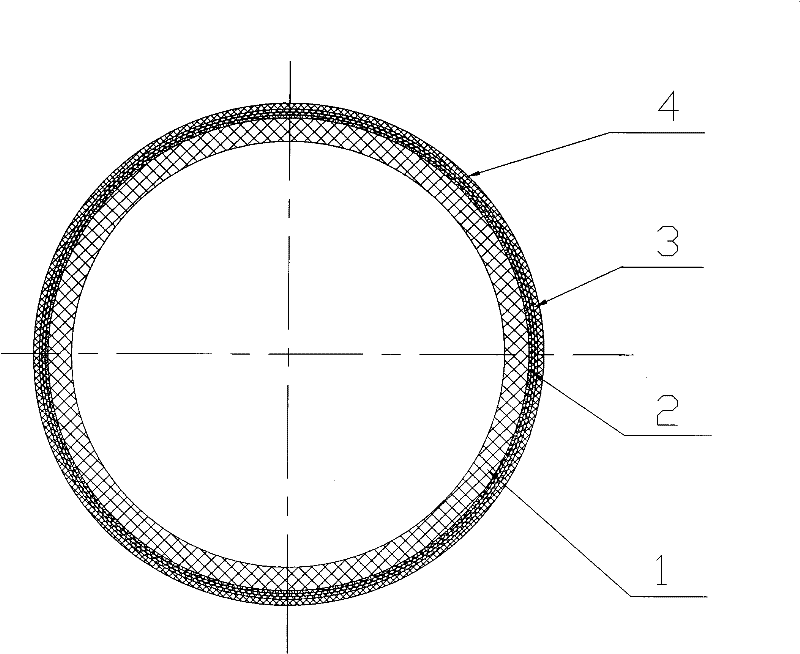

Side packaging structure of electronic module

ActiveCN103187370AGuaranteed normal operationExcellent adhesionSemiconductor/solid-state device detailsSolid-state devicesElectrical polarityEngineering

The invention discloses a side packaging structure of an electronic module, which comprises an upper substrate, a lower substrate and a sealing frame, wherein the sealing frame is arranged at the peripheries of the upper substrate and the lower substrate in a surrounding manner, and forms a containing space with the upper substrate and the lower substrate. A main body of the sealing frame is made of a silicone layer, so that a waterproof effect of an external packaging structure is improved greatly; an opportunity that moisture permeates into the electronic module via the side packaging structure is reduced; and the side packaging structure can avoid damage from an internal polar solvent or a plastic agent by virtue of the characteristic of silica gel.

Owner:PROLOGIUM TECH +1

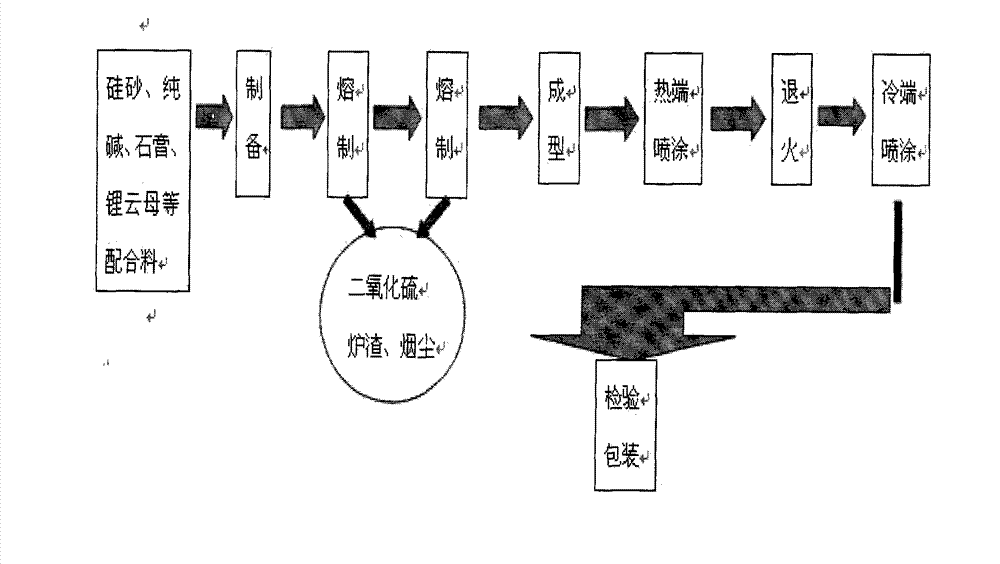

Fabrication method of beer bottle

The invention relates to a beer bottle and a fabrication method thereof. The beer bottle is fabricated by taking desulfurization gypsum of a thermal power plant as a raw material. According to the beer bottle and the fabrication method, a by-product, namely the desulfurization gypsum, for flue gas desulfurization of the thermal power plant serves as a clarifying agent to substitute fluorite and anhydrous sodium sulphate, so that the cost is lowered effectively, corrosion to fire-resisting materials is reduced, the service life of a kiln is prolonged, emission of fluoride is decreased, and pollution to an atmosphere is reduced. The desulfurization gypsum of the thermal power plant substitutes partial toxic raw materials, including fluoride such as the fluorite, so that the glass melting and clarification capacity can be improved, the glass component structure can be changed, the melting temperature and melt viscosity can be reduced, the thermal expansion coefficient can be reduced, the glass transparency can be enhanced, the thermal shock resistance and acid resistance of a product can be improved, and the glass strength can be improved; in addition, the corrosion of the clarifying agent such as the fluorite to the kiln is eliminated, volatilization of fluoride is reduced, atmosphere pollution is avoided, and an environment is protected.

Owner:青岛崂玻玻璃制品有限公司

Method and apparatus for a high efficiency ultraviolet radiation source

InactiveUS20050035711A1Improve efficiencyEfficient productionWater/sludge/sewage treatmentSolid cathode detailsCapacitanceElectrical resistance and conductance

An efficient, intense ultraviolet radiation source is disclosed that uses electrodes, external to the UV-generating plasma, to eliminate electrode erosion. High-frequency electrical energy is coupled to the UV-emitting plasma capacitively. The electrodes are attached to the glass envelope in such a way as to minimize or eliminate resistive or capacitive losses. The intense ultraviolet radiation source can be generated by applying a continuous or pulsed / gated high-frequency voltage to the glass envelope via the external electrodes. Electrode erosion is eliminated as a reason for lamp failure and the peak intensity that can be generated without damage is greatly increased.

Owner:ABQ ULTRAVIOLET POLLUTION SOLUTIONS

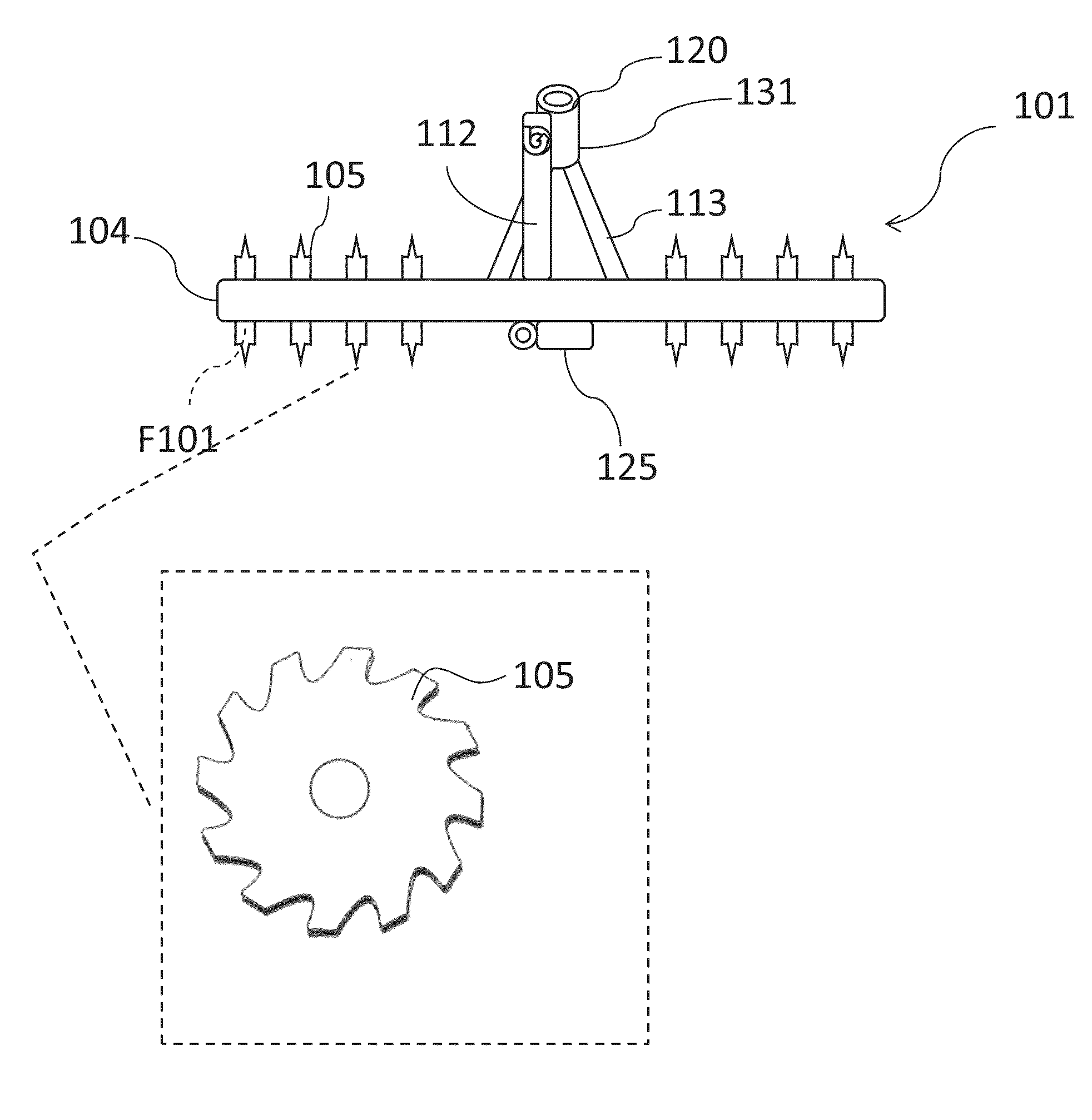

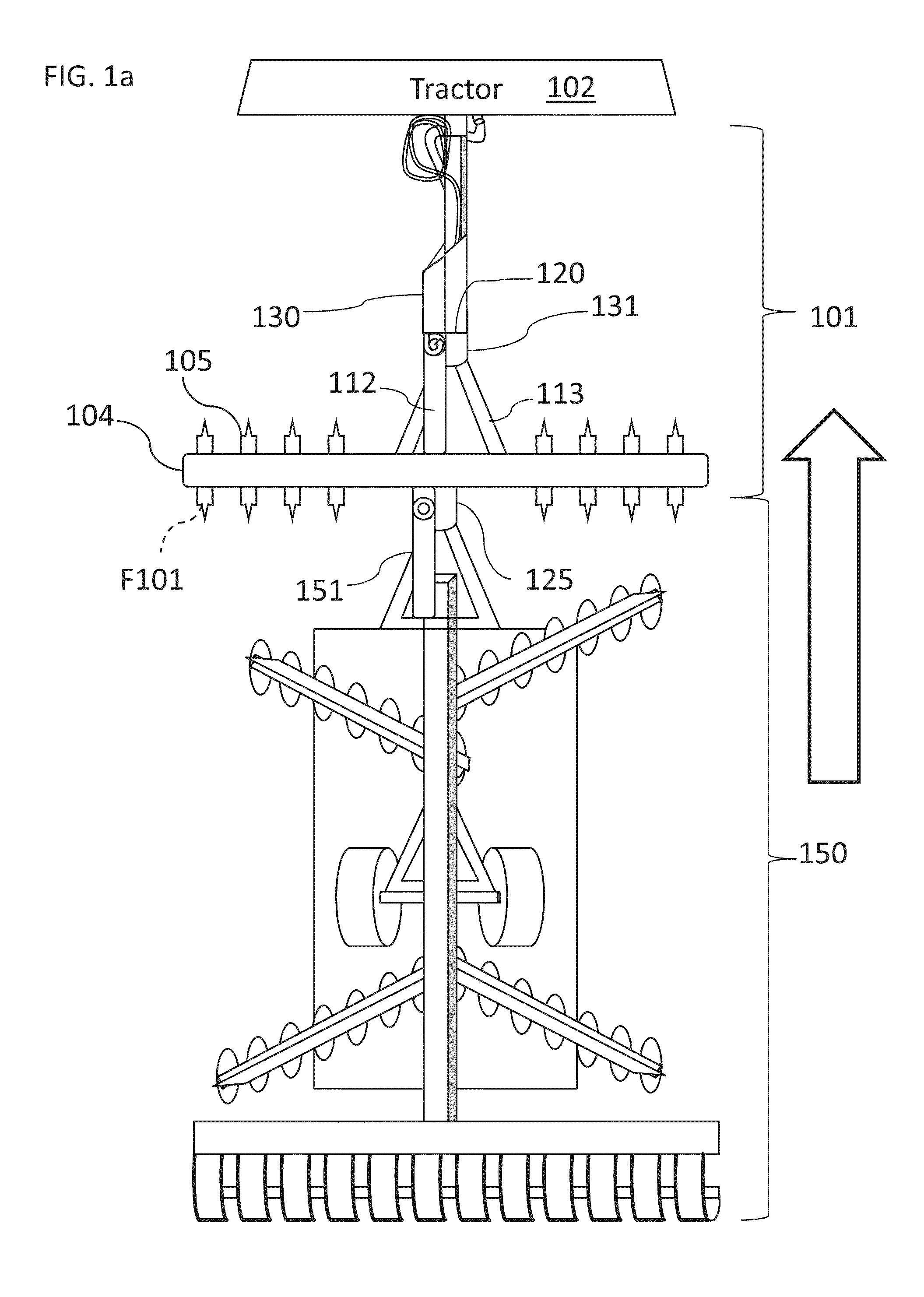

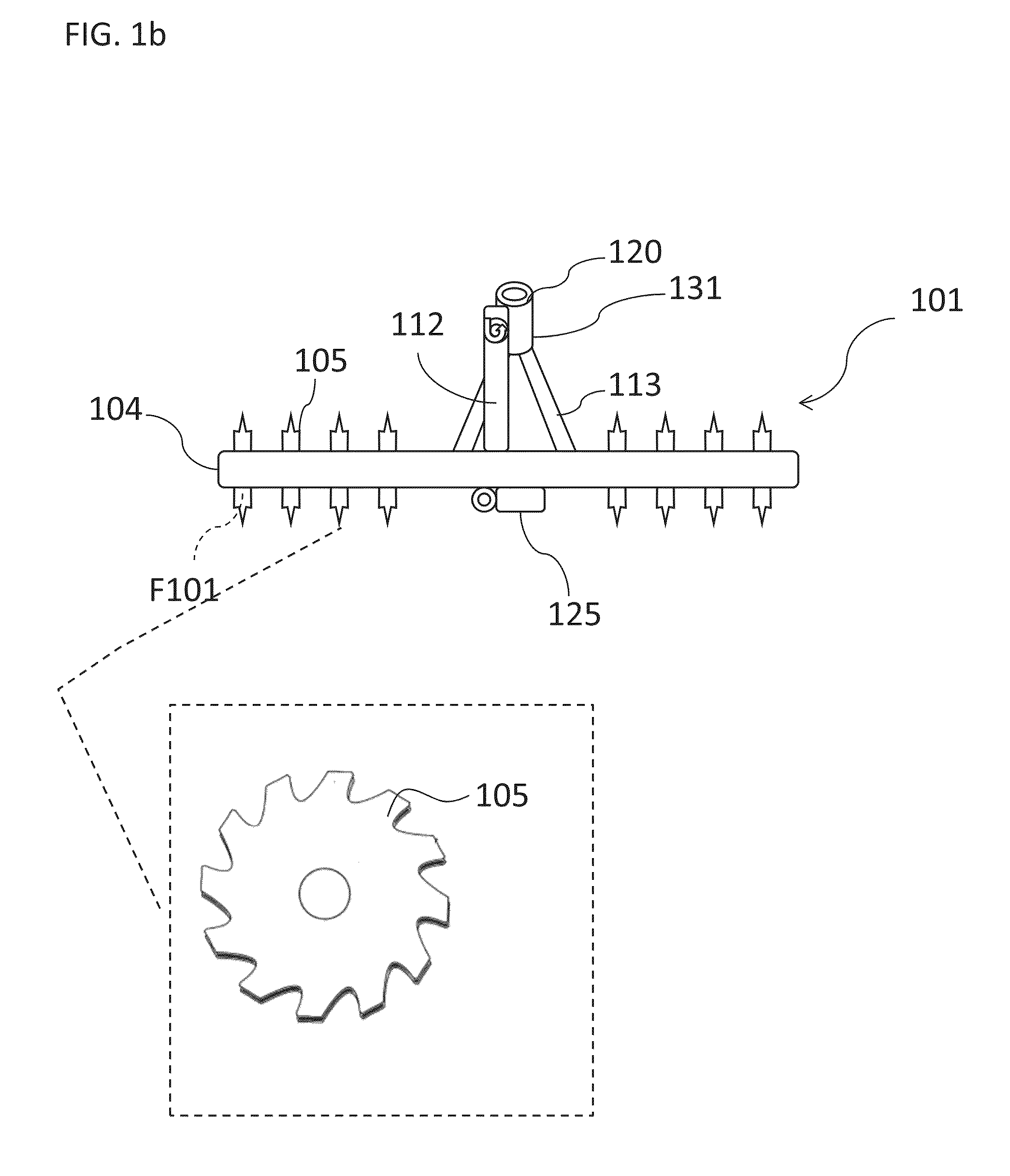

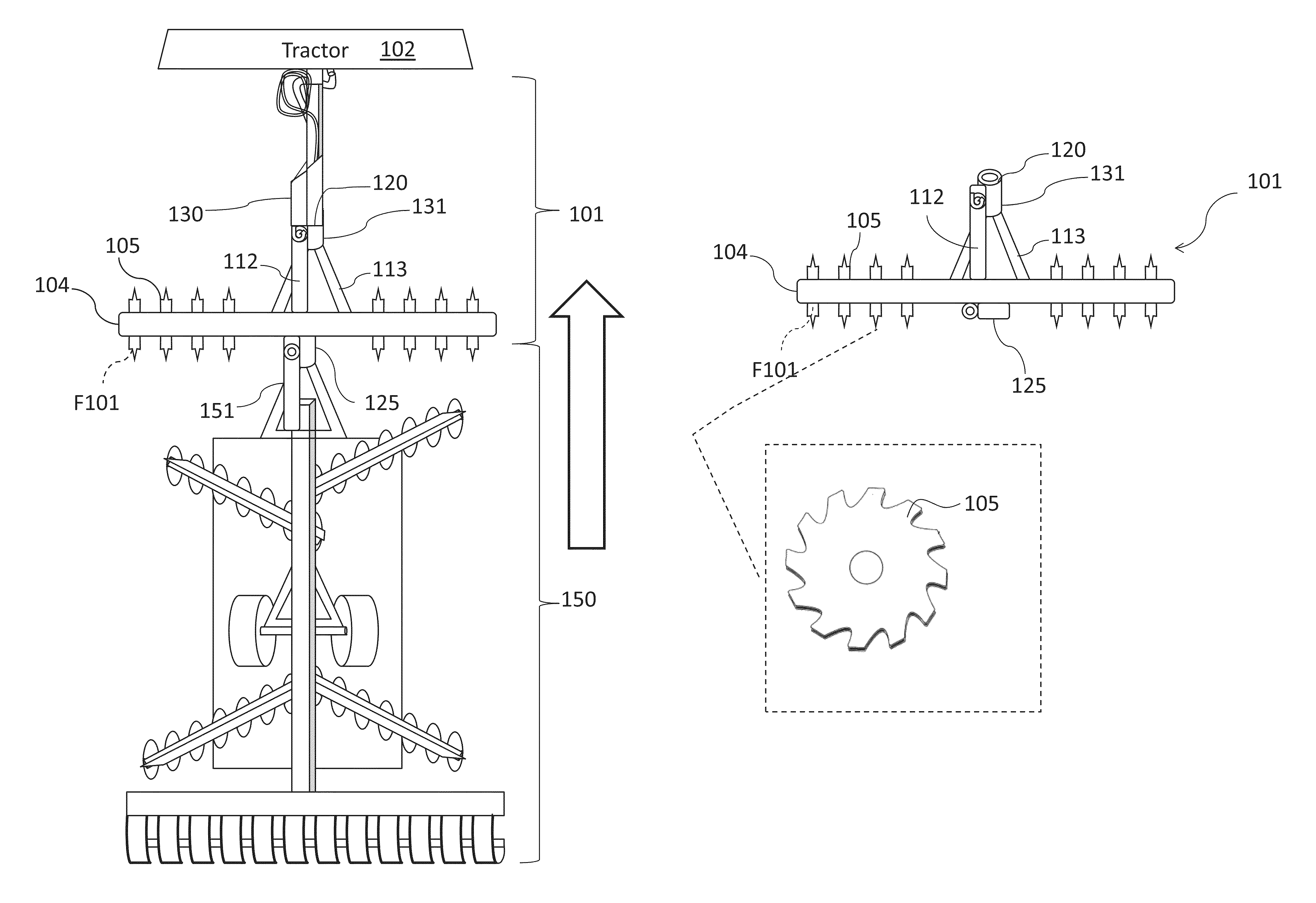

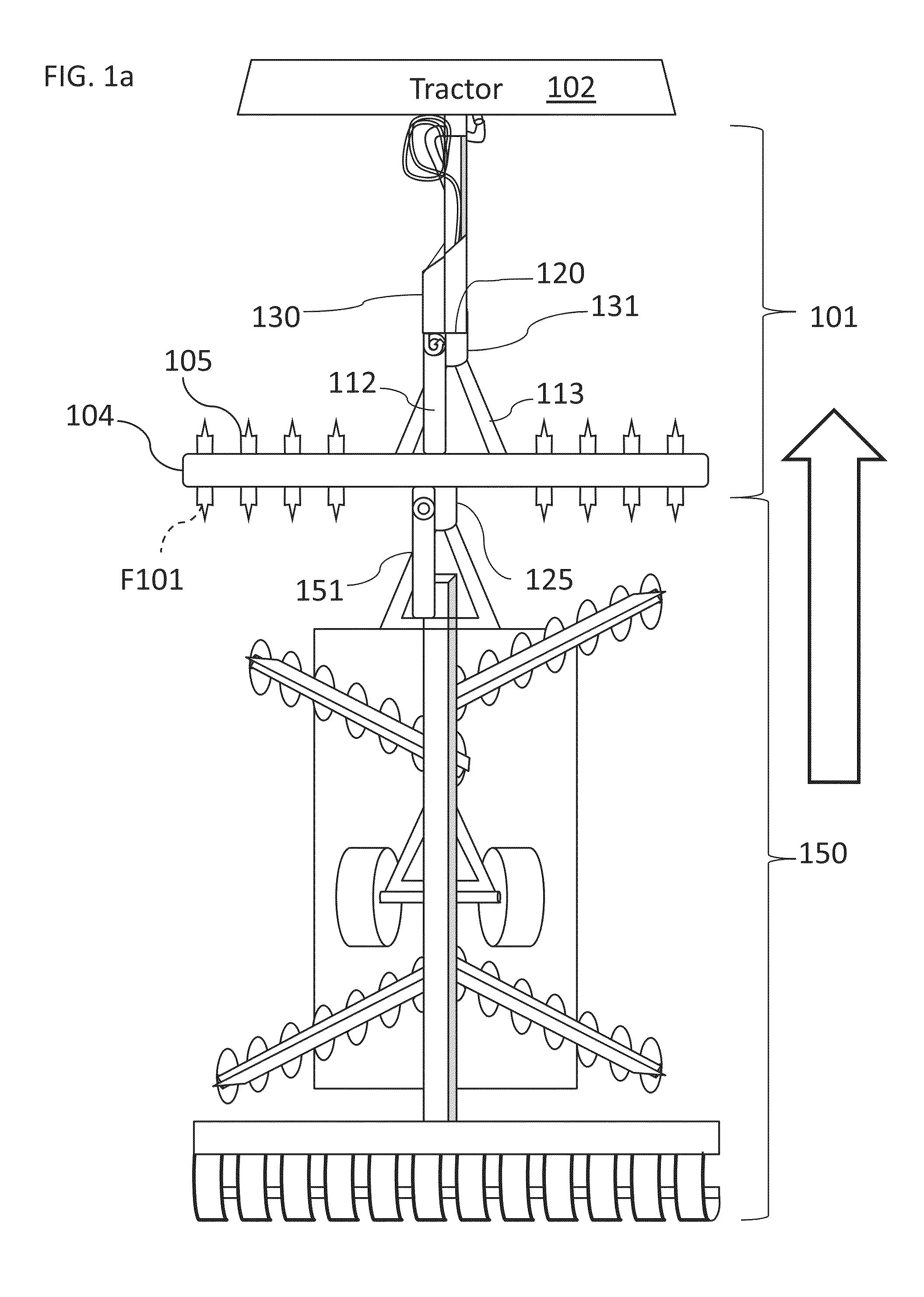

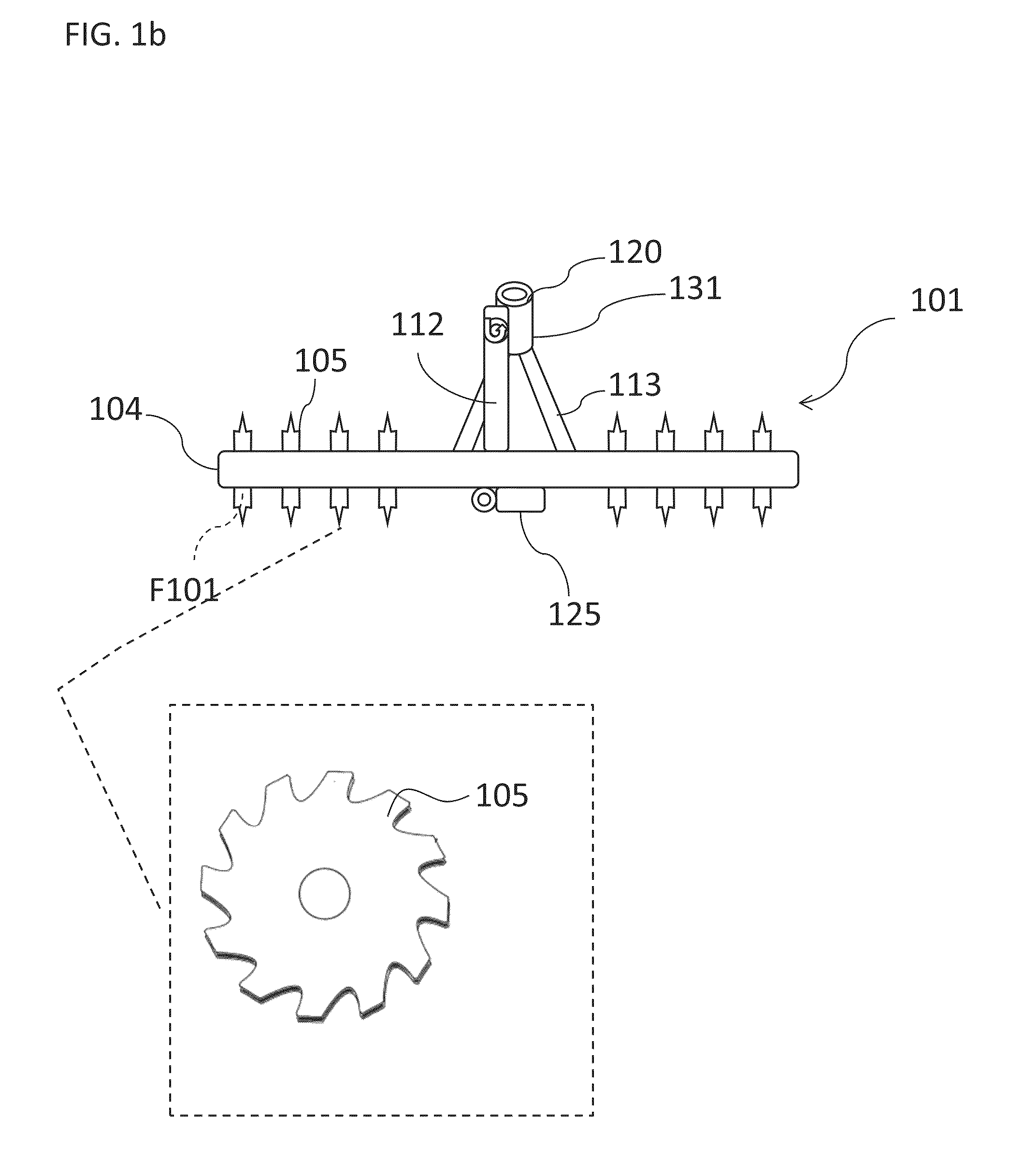

Tillage system

InactiveUS20140123885A1Prevent soil erosionSmoothen the soil surfaceSpadesLiquid fertiliser distributionSpring forceAgricultural engineering

An add-on tillage system is adapted to be mounted on an agricultural device to enhance tilling ability. The add-on tillage system includes a tilling unit with a common tool bar having attached thereto a first set of a plurality of tilling tines or coulters adapted to produce deep grooves in a tilled field. Means are provided for adjusting spacing between the tines or coulters, tilling tines or coulters up and down as a group being loaded by spring force, compressed air pistons or hydraulically actuated rams. A first mount is adapted to receive a tongue with hydraulic operations for mounting to a tractor. A second mount is adapted to receive a tongue with hydraulic mount to an agricultural device adapted to be pulled by the tractor. The add-on tillage system tills surface soil for a clean appearance, providing improved rain / irrigation water absorption, eliminating water run-off and erosion.

Owner:NANCE JOHN D

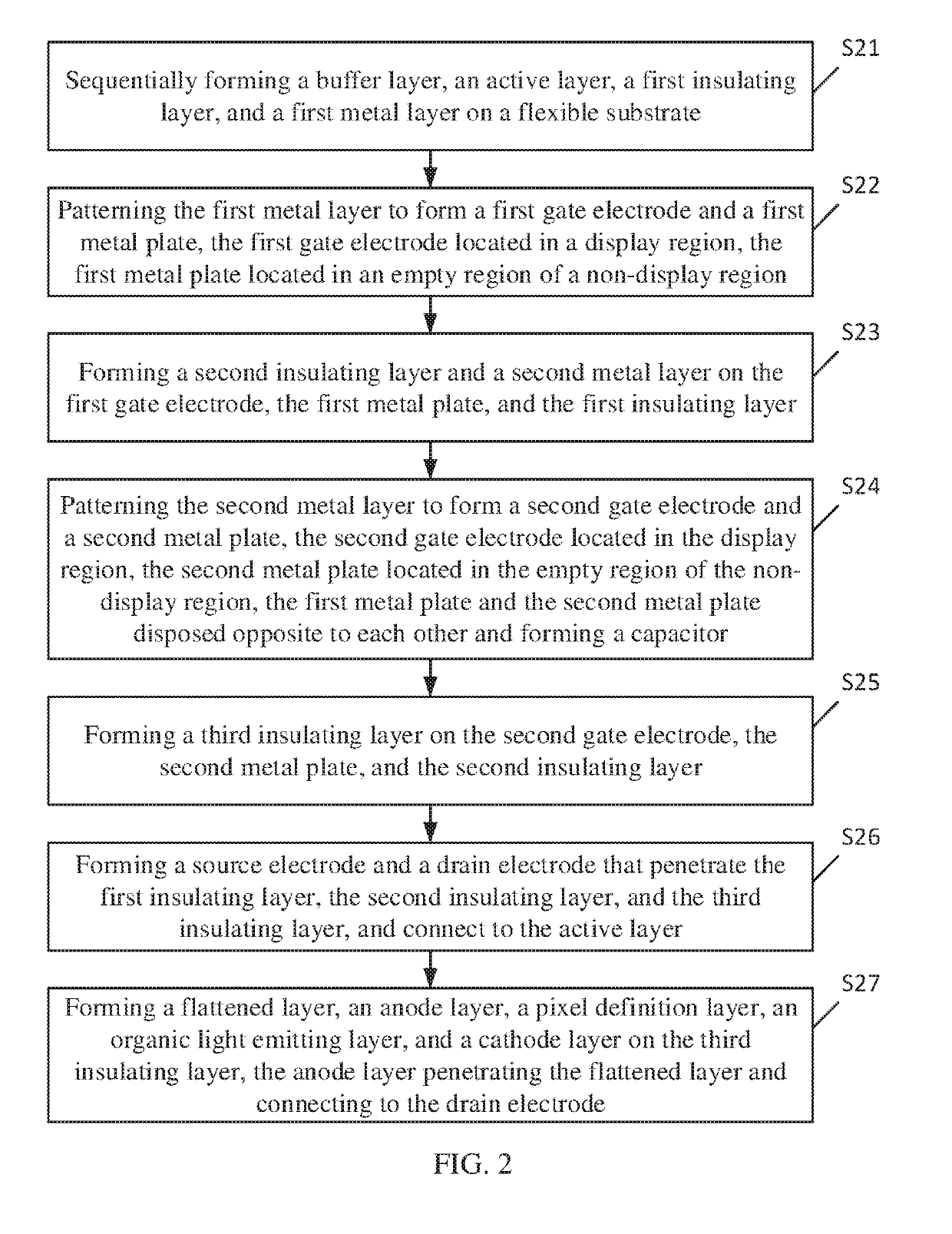

Flexible display panel and manufacturing method thereof

ActiveUS20190165072A1Efficiently improving a yield rate of the flexible display panelsEliminate erosionFinal product manufactureSolid-state devicesEngineeringFlexible display

A flexible display panel includes a display region and a non-display region. Capacitors are added to an empty region of the non-display region. The capacitors have ability to buffer a release of electrostatic charges, thereby reducing damage to inner devices and metal wiring film layers caused by the electrostatic charges and protecting the metal wiring film layers from being damaged and destroyed by the electrostatic charges during manufacturing active thin-film transistors of the flexible display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Solar cell based on nano-onion-carbon composite anode buffer layer

ActiveCN106098944ALower contact barrierHigh hole mobilitySolid-state devicesSemiconductor/solid-state device manufacturingCarbon compositesOrganic solar cell

The invention, which belongs to the organic semiconductor thin-film solar battery field, discloses a solar cell based on a nano-onion-carbon composite anode buffer layer. On the basis of an ortho type structure, the solar cell comprises a substrate (1), a transparent conductive anode ITO (2), a composite anode buffer layer (3), an optical active layer (4), a cathode buffer layer (5), and a metal cathode (6), wherein the layers are arranged successively from bottom to top. The composite anode buffer layer is formed based on compounding of a conductive polymer PEDOT:PSS, a micromolecule material F4-TCNQ, and a nano onion carbon material. The conductive polymer PEDOT:PSS is doped with the micromolecule material F4-TCN with a certain proportion and a high-conductivity nano onion carbon material, so that the photoelectric conversion efficiency of the device is improved, the air stability of the organic thin-film solar cell is enhanced, and the service life is prolonged.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Rotating mechanical seal

InactiveUS6845985B2Damage to sealing surfacePrevent leakageEngine sealsSealingEngineeringMechanical engineering

A rotating mechanical seal with a sliding ring, characterized by the sliding ring (5) being attached by way of an O-ring (6) on a shaft (1) of a compressor and rotating with the shaft (1) and by a non-rotating backing ring (4) being provided which is attached by way of an O-ring (3) to a housing (2) of the compressor so as to be gas-tight wherein the sliding ring (5) and backing ring (4) are pressed one against another by a spring (8) to form a seal and slide one upon the other, wherein one of the rings (4,5) is made of a carbon and silicon carbide composite material and the other of a silicon carbide material.

Owner:EAGLE INDS

Underwater inflatable flexible solar concentrator and photovoltaic power generation system thereof

ActiveCN106949639AMeet energy demandSmall footprintPhotovoltaic supportsSolar heating energyNew energyLight energy

The invention provides an underwater inflatable flexible solar concentrator applied to an underwater working device and a photovoltaic power generation system thereof and belongs to the technical field of new energy application. At a non-working state, the underwater inflatable flexible solar concentrator is accommodated in an accommodation box at the top end of the underwater operation device. The underwater inflatable flexible solar concentrator is composed of an inflatable flexible solar concentrator body, a solar cell array, a control platform, a lifting rope and the like. During work, the underwater inflatable flexible solar concentrator inflates the concentrator body and pulls the concentrator body to a specific position of underwater operation by adjusting the lifting rope to enable the solar cell array to be located on the focal plane of the concentrator body. Parallel light is refracted in water through the concentrator body and converged on the solar cell array to convert light energy into electric energy. The electric energy is stored in the control platform through a storage battery, and the using electric power needed by the underwater operation device is obtained after the electric energy passes through an inverter. Charging and discharging of the storage battery, energy supply of the underwater operation device and winding and unwinding of the lifting rope are all achieved through control of the control platform.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

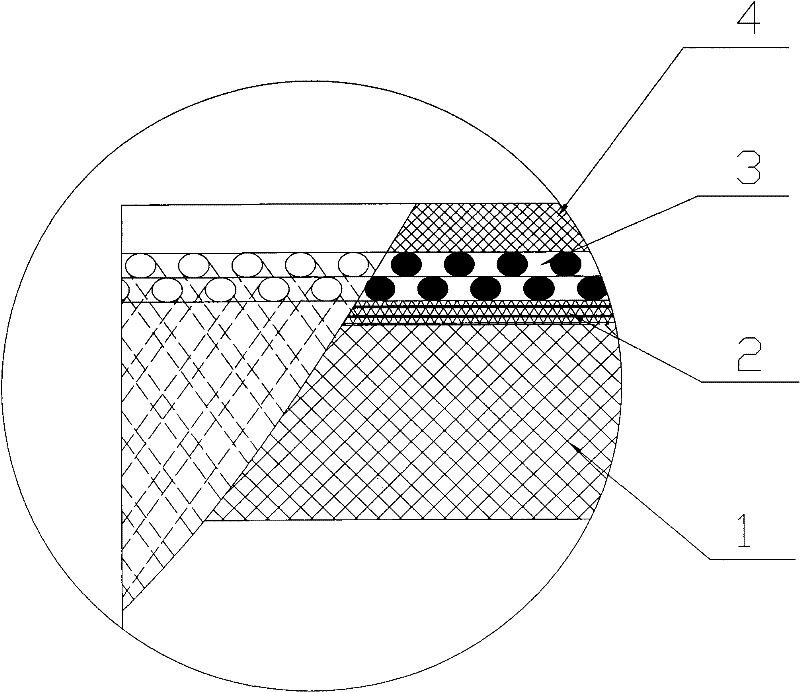

Novel structure for polyethylene reinforced compound pipe

The invention discloses a novel structure for a polyethylene reinforced compound pipe and belongs to the technical field of pipes. The novel structure for the polyethylene reinforced compound pipe comprises a substrate pipe, a metal reinforced layer, a fiber reinforced layer and an outer wall, wherein at least one metal reinforced layer and at least one fiber reinforced layer are arranged; specially used glues are heated and are used for integrally adhering the substrate pipe to the fiber reinforced layer, adhering the fiber reinforced layer to the metal reinforced layer and adhering the metal reinforced layer to the metal reinforced layer; the fiber reinforced layer is arranged at an equidistant interval, in the form of forming an inclined angle of 0-10 degrees between the fiber reinforced layer and the axial line of the pipe; an inclined angle between the metal reinforced layer and the axial line of the pipe is 54-70 degrees; the metal reinforced layer has a steel wire bidirectional crossed wound structure; the steel wire is a spring steel wire; and the diameter of the steel wire is 0.3-2.5 millimeters. The novel structure for the polyethylene reinforced compound pipe has the advantages of reasonable structure design, strong wear-resisting decay resistance and high loading capacity. Compared with a traditional pipe, the novel structure for the polyethylene reinforced compound pipe has the advantages that the loading capacity of the pipe is increased by 2-3 times, a steel pipe in a specific application field can be replaced by the polyethylene reinforced compound pipe, the application range is wide and the service life is long.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

Traditional Chinese medicine biological preparation for promoting female reproductive health and preparation method thereof

PendingCN110478477AGrowth inhibitionInhibition of reproductionHydrolysed protein ingredientsAnthropod material medical ingredientsPropolisIrritation

The invention relates to a traditional Chinese medicine biological preparation for promoting female reproductive health and a preparation method thereof. The traditional Chinese medicine biological preparation comprises radix sophorae flavescentis, fructus cnidii, gallnut, aloe, radix angelica sinensis, cortex phellodendri, safflower, semen cuscutae, roselle, cranberry, propolis, lysozyme, mentholand soybean peptide. The traditional Chinese medicine biological preparation has the advantages that the traditional Chinese medicine biological preparation adopts pure natural traditional Chinese medicine components, is free of irritation to the vagina mucosa, does not destroy the clean environment of the vagina, removes the vagina peculiar smell, eliminates itching, inflammation and erosion, nourishes the vagina, has the functions of bacteriostasis, bacterium resistance, virus resistance and the like, can inhibit the growth and reproduction of bacteria, can be used for repairing the vaginalmucosa and the cervical injury, and also can promote elasticity and tightness restoration of the vagina, protect the ovary, improve the immunity of organisms and promote the female reproductive health.

Owner:王其兵

Magnetic Pulse Formed Vehicle Driveshaft and Method of Making Same

InactiveUS20130236244A1Simple processEliminate electric erosionClutchesYielding couplingEngineeringInductor

A method of forming a sliding spline-type joint using magnetic pulse forming technology includes providing a female driveshaft member and a splined insert having inwardly formed splines. A male driveshaft member is provided having outwardly formed splines engageable with the insert. A mandrel is provided having outer ribs similar to the outer spline profile of the male driveshaft member. An inductor is provided which is energized to create a pulse magnetic field. The insert is placed over the mandrel. The female driveshaft member is disposed over the insert, and both are placed inside the inductor. The inductor is energized to deform a portion of the female driveshaft member over the insert to form an array of crimps for permanently connecting the female driveshaft member with the insert. The male driveshaft member is engaged into the insert to provide a sliding spline-type of slip joint.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Steel-making method of experimental induction furnace

InactiveCN102321783AShort processing timeFlexible operationElectric furnaceSteelmakingFixed position

The invention relates to a steel-making method of an experimental induction furnace, comprising the following steps of: electrifying and completely melting solid metal charge in a furnace; blowing oxygen into the furnace from a furnace top by adopting a fixed position manner or a gradual water-cooling oxygen lance position lowering manner; slagging; changing bottom blowing gas flow rate when top blowing oxygen is 15-16min; when mass percent of carbon in molten steel is less than 0.1%, stopping top oxygen supply; and removing slag in the furnace, then carrying out aluminium deoxidation, alloying and tapping according to type of steel which is made. The invention has the characteristics that: processing time is short, operation is flexible and effective; decarbonization, degasification, dephosphorization and sulphur impurity removal are carried out on molten metal in the induction furnace, molten iron can be rapidly smelted into steel, and great benefit is provided for expanding metallurgy function of the induction furnace and controlling variety, composition and product quality; good condition is provided for preferentially dephosphorizing during steelmaking, end phosphorous content is reduced to 0.010-0.0045wt%, environmental pollution and corrosion to lining of the induction furnace which are caused by solid cosolvent such as fluorite and the like can be eliminated.

Owner:武钢集团有限公司

Multilayer interconnection substrate, semiconductor device, and solder resist

InactiveCN101047159AHigh modulus of elasticityThe modulus of elasticity is sufficientPrinted circuit detailsSemiconductor/solid-state device detailsGlass fiberResist

A multilayer interconnection substrate includes a resin laminated structure in which plural build-up layers are laminated, each of the plural build-up layers comprising an insulation layer and an interconnection pattern, and first and second solder resist layers provided on a top surface and a bottom surface of the resin laminated structure, wherein each of the first and second solder resist layers includes a glass cloth.

Owner:FUJITSU LTD

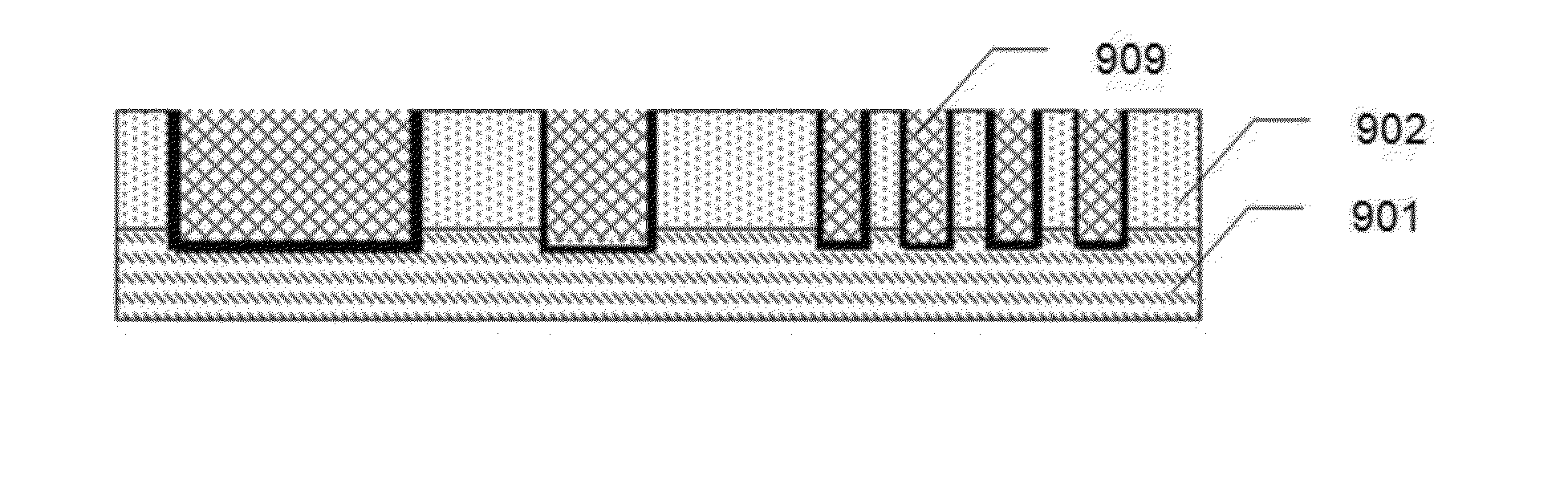

Method of forming copper interconnects

ActiveUS20160276169A1Effective thickness is minimized and avoidedUniform resistivitySemiconductor/solid-state device manufacturingCopper interconnectDielectric layer

A method of forming copper interconnects includes: depositing a dielectric layer on a silicon wafer substrate; forming vias and / or trenches in the dielectric layer; next, depositing a barrier layer and a copper seed layer sequentially from bottom to up on the dielectric layer; depositing a copper layer on the copper seed layer, and performing an annealing process; then performing a multi-step polishing process to remove bulk coppers and stopping at the barrier layer; performing a planarization process to remove the barrier layer on the surface of the dielectric layer, a portion of the dielectric layer, and a portion of the copper in the vias and / or trenches to form the copper interconnects in the dielectric layer.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Preparation method of ultrathin neodymium-iron-boron permanent magnet surface protective coating

ActiveCN112725751ASolve the problem of magnetic performance degradationMagnetic does not affectVacuum evaporation coatingSputtering coatingSurface cleaningCopper

The invention discloses a preparation method of an ultrathin neodymium-iron-boron permanent magnet surface protective coating. The method comprises the steps that direct current magnetron sputtering coating is performed on a neodymium-iron-boron magnet subjected to surface cleaning treatment to obtain a neodymium-iron-boron magnet with a copper gradient coating deposited on the surface; surface pretreatment is performed on the obtained neodymium-iron-boron magnet with the copper layer deposited on the surface, and then a nickel-based coating is applied to obtain the neodymium-iron-boron magnet with the Cu-Ni combined coating deposited on the surface; in the sputtering process, power supplies of a Cu-Sn target and a Cu target are turned on, and the Cu-Sn target and the Cu target are sputtered at the same time; the initial power of the Cu-Sn target is 120 W and is gradually reduced according to the speed of 3-5 W / min in the sputtering process until the Cu-Sn target is turned off; and the power of the Cu target is 150 W and is always kept unchanged, and the time is 1.5-3.0 hours. The ultrathin permanent magnet combines the advantages that a prepared film layer is deposited firmly and is compact and resistant to corrosion due to the fact that acid pickling pretreatment is not required in a magnetron sputtering technology, and the problem that the magnetic performance is reduced due to the fact that an acid pickling solution and an electroplating solution erode a matrix structure in the surface treatment process of the permanent magnet is solved.

Owner:TAIYUAN UNIV OF TECH

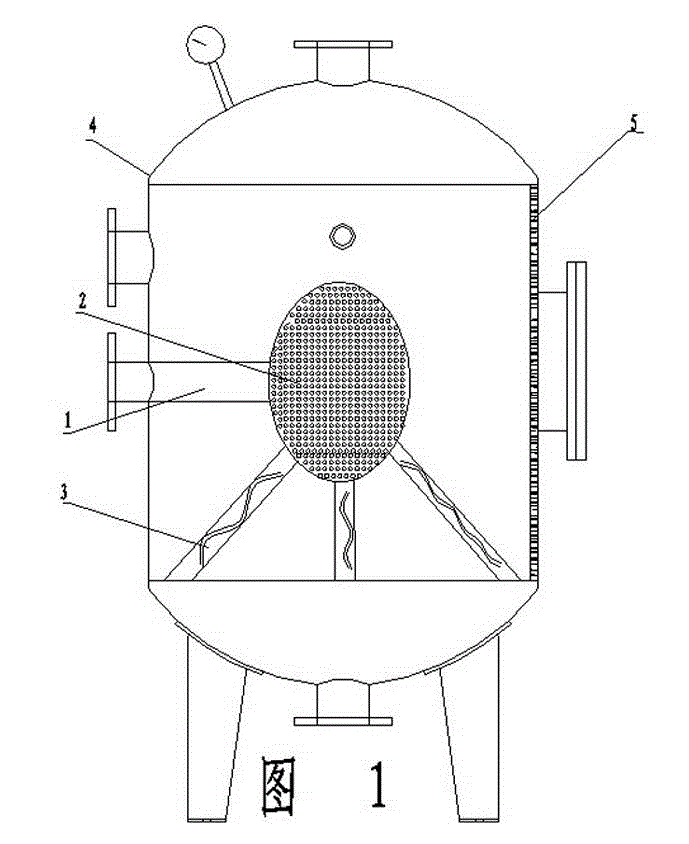

Noise-reduced and cavitation-prevented gas storage tank

InactiveCN104565797AAvoid impactReduce vibrationContainer filling methodsPressure vesselsEngineeringGas holder

The invention discloses a noise-reduced and cavitation-prevented gas storage tank. The noise-reduced and cavitation-prevented gas storage tank comprises a gas inlet pipe, a damping chamber, three elastic devices and a gas storage tank, wherein the gas inlet pipe is connected with the gas storage tank and is located in the middle of the gas storage tank, an opening of the gas inlet pipe corresponds to the center of the damping chamber, the damping chamber is suspended to the center of the gas storage tank through the elastic devices, and a damping layer is attached to the internal wall of the gas storage tank; the damping chamber is an elliptical microporous chamber and is made from impact-resistant and eolation-resistant metal, the caliber of the damping chamber is twice that of the gas inlet pipe, the three elastic devices are flat-steel bracing wires, are located at the bottom of the tank body so as to support the damping chamber and are of triangular distribution, and the damping layer is made from rubber-covered slag wool. The noise-reduced and cavitation-prevented gas storage tank has the characteristics of noise damping and reducing, cavitation prevention, simple structure, economical efficiency and practicability, high efficiency and environment-friendliness, safety and reliability and the like.

Owner:HARBIN HONGWANZHI SCI & TECH DEV

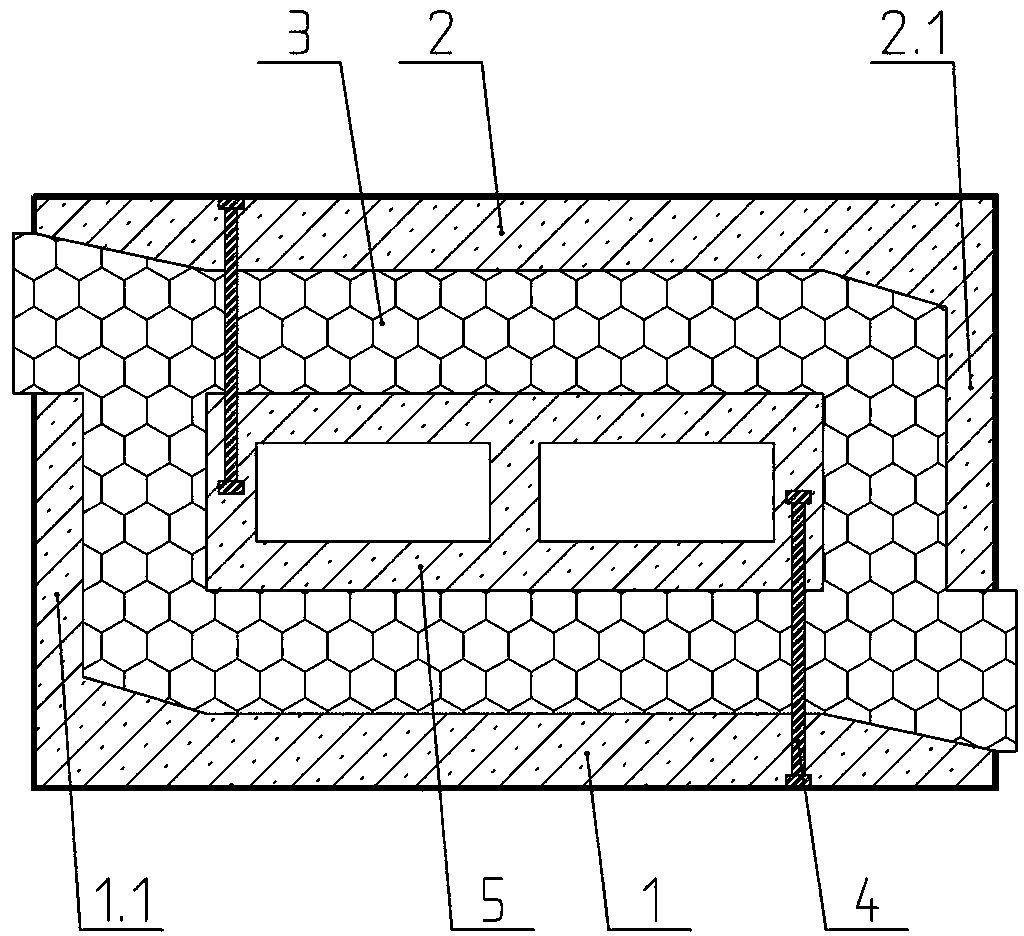

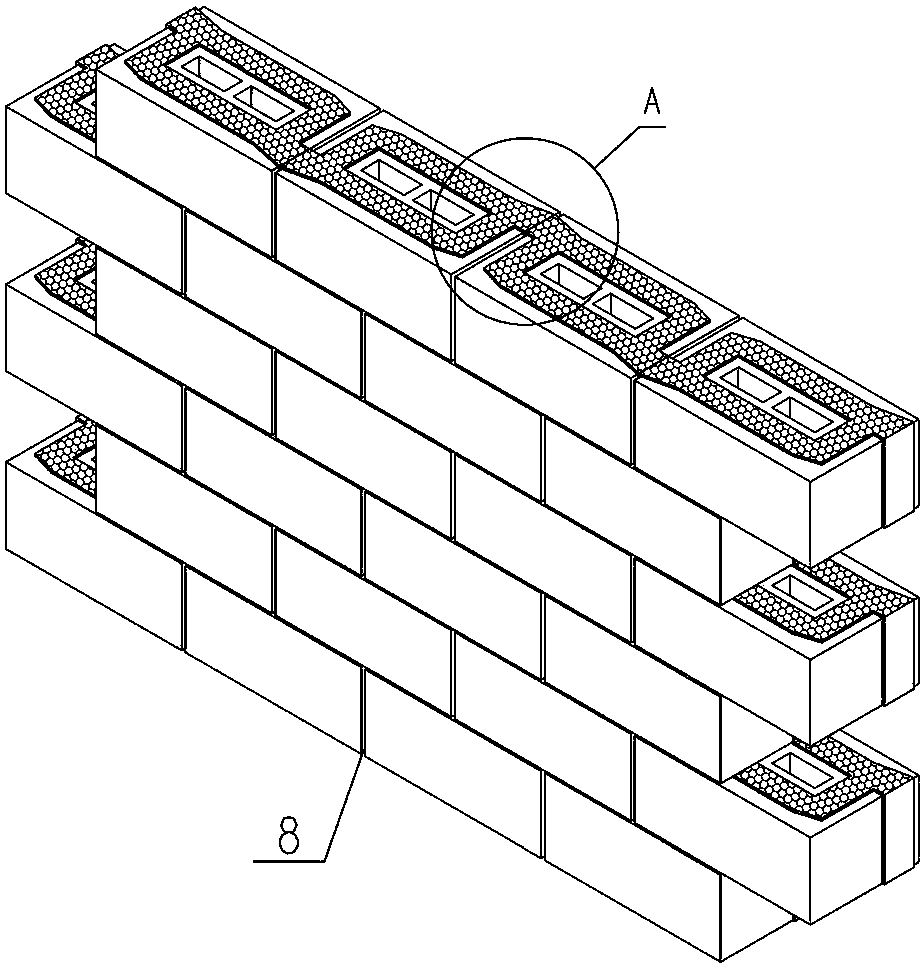

All-obstruction bridge concrete composite self-heat-preservation integrated building block

ActiveCN104278790ASynchronous lifespanLife SynchronizationConstruction materialStructural engineeringConcrete composites

Owner:刘立才

Tillage system

InactiveUS9320189B2Prevent soil erosionSmoothen the soil surfaceSpadesHarrowsSpring forceAgricultural engineering

An add-on tillage system is adapted to be mounted on an agricultural device to enhance tilling ability. The add-on tillage system includes a tilling unit with a common tool bar having attached thereto a first set of a plurality of tilling tines or coulters adapted to produce deep grooves in a tilled field. Means are provided for adjusting spacing between the tines or coulters, tilling tines or coulters up and down as a group being loaded by spring force, compressed air pistons or hydraulically actuated rams. A first mount is adapted to receive a tongue with hydraulic operations for mounting to a tractor. A second mount is adapted to receive a tongue with hydraulic mount to an agricultural device adapted to be pulled by the tractor. The add-on tillage system tills surface soil for a clean appearance, providing improved rain / irrigation water absorption, eliminating water run-off and erosion.

Owner:NANCE JOHN D

Pneumatic opposite acting plunger pump

ActiveCN106640577AReasonable liquidityImprove drainage capacityPositive displacement pump componentsPiston pumpsBarrel ShapedEngineering

The invention discloses a pneumatic opposite acting plunger pump which comprises a pump body. The left side and the right side of an inner cavity of the barrel-shaped pump body are each provided with a set of plungers, and an upper water outlet and a lower water inlet are machined in the upper side and the lower side of the middle of the pump body respectively. A flange and a driving mechanism are mounted at the ends of the left side and the right side of the pump body respectively. The plungers on the left side and the right side of the pump body and the driving mechanism have the same structure; the left plungers comprise piston rods, belleville springs I, bolt plugs and belleville springs II, and the belleville springs I, the bolt plugs and the belleville springs II sequentially penetrate through the ends of the right sides of the piston rods. According to the pneumatic opposite acting plunger pump, by means of reasonable water pump cylinder design, the water suction and drainage capacity of a water pump is amplified, an opposite double-plug mode is adopted, the flowing property of water is reasonable, energy consumption loss is reduced, blocking is not likely to happen, and the failure probability is reduced.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Steel belt embedded type ultra-high molecular weight polyethylene compound pipe

InactiveCN102242835AExtended service lifeReasonable structural designRigid pipesAdhesiveCross-linked polyethylene

The invention discloses a steel belt embedded type ultra-high molecular weight polyethylene compound pipe and belongs to the technical field of pipes. The steel belt embedded type ultra-high molecular weight polyethylene compound pipe is provided with a substrate pipe, wherein slots, the thickness and width of which are matched with the thickness and width of steel belts, are uniformly arranged on periphery of an outer wall of the substrate pipe; the steel belts are embedded into the slots; steel wires are spirally wrapped and wound on the steel belts along the direction vertical to the axial direction of the substrate pipe; a polyethylene pipe with a molecular weight above 250 ten thousand units, which is used for wrapping a strip spiral wound radial cross-linked polyethylene stretching rubber belt or wrapping a hot melting PE (polyethylene) plastic, is taken as the outer wall; the thickness of the steel belts is 0.5-3 millimeters; a distance between the slots is 10-20 millimeters; the steel belts are wrapped by the hot melting adhesives coated with high molecular weight polyethylene; the steel wires are spring steel wires with diameters of 0.8-2.5 millimeters; and the polyethylene with the molecular weight above 250 ten thousand units is taken as a raw material of the substrate pipe. The steel belt embedded type ultra-high molecular weight polyethylene compound pipe has the advantages of reasonable structure design, strong wear-resisting decay resistance, high loading capacity, wide application range and long service life.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

Deck sewage collection and treatment device used for large ship

ActiveCN108854189AEasy to classifySpeed up filteringAuxillariesWater treatment installationsMarine engineeringSewage

The invention relates to the field of sewage collection and treatment devices used for large ships, in particular to a deck sewage collection and treatment device used for a large ship and aims to provide the deck sewage collection and treatment device used for the large ship which can collect sewage after a large ship deck is flushed and avoid serious pollution of a water body of a sea area wherethe large ship is located. The deck sewage collection and treatment device used for the large ship is characterized by comprising a base, universal wheels, rollers, large bearings, a supporting rod,a hose, a first one-way valve, a cylinder, a piston, a small guiding rod, a small spring, a connecting pipe and the like; the universal wheels are connected with the right side of the bottom of the base. The deck sewage collection and treatment device used for the large ship can conveniently collect and treat the sewage which is generated after the large ship deck is flushed, so that convenient for workers to eliminate corrosion of seawater to the large ship deck and cleanness and sanitation of the large ship deck is maintained.

Owner:新昌县昱康环保机械有限公司

Magnetic pulse formed vehicle driveshaft and method of making same

InactiveUS9028164B2Eliminate erosionSimplify a driveshaft sliding spline-type slip jointClutchesYielding couplingInductorSlip joint

A method of forming a sliding spline-type joint using magnetic pulse forming technology includes providing a female driveshaft member and a splined insert having inwardly formed splines. A male driveshaft member is provided having outwardly formed splines engageable with the insert. A mandrel is provided having outer ribs similar to the outer spline profile of the male driveshaft member. An inductor is provided which is energized to create a pulse magnetic field. The insert is placed over the mandrel. The female driveshaft member is disposed over the insert, and both are placed inside the inductor. The inductor is energized to deform a portion of the female driveshaft member over the insert to form an array of crimps for permanently connecting the female driveshaft member with the insert. The male driveshaft member is engaged into the insert to provide a sliding spline-type of slip joint.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Traditional Chinese medicine biological agent acting on female reproductive system and preparation method of traditional Chinese medicine biological agent

PendingCN110613839AClear vaginal odorEliminate itchingHydroxy compound active ingredientsPeptide/protein ingredientsSodium hyaluronateReproductive system

The invention relates to a traditional Chinese medicine biological agent acting on a female reproductive system and a preparation method of the traditional Chinese medicine biological agent. The traditional Chinese medicine biological agent is prepared from raw materials as follows: recombinant humanized collagen, hydrolyzed collagen, sodium hyaluronate, cranberries, glossy privet fruits, semen cuscutae, radix sophorae flavescentis, fructus cnidii, flos carthami, fructus kochiae, cortex phellodendri, garden burnet roots, borneol, menthol and polyhexamethylene biguanidine hydrochloride. The traditional Chinese medicine biological agent has the benefits as follows: the traditional Chinese medicine biological agent is prepared from pure natural traditional Chinese medicine ingredients, can eliminate pruritus, inflammation and erosion and nourish vagina, has functions of inhibiting bacteria and resisting bacteria and viruses, has no irradiation to vagina mucosa, cannot damage clean environment in the vagina, clears peculiar smell of the vagina, can inhibit growth and reproduction of bacteria, can repair vagina mucosa and cervix uteri injury and also can promote recovery of elasticity and tightness of the vagina, protect the ovary, improve the immunity of the organism and nurse the female reproductive system.

Owner:田兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com