Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2362 results about "Cross-linked polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cross-linked polyethylene, commonly abbreviated PEX, XPE or XLPE, is a form of polyethylene with cross-links. It is used predominantly in building services pipework systems, hydronic radiant heating and cooling systems, domestic water piping, and insulation for high tension (high voltage) electrical cables. It is also used for natural gas and offshore oil applications, chemical transportation, and transportation of sewage and slurries. PEX is an alternative to polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC) or copper tubing for use as residential water pipes. There has always fire risks of metallic plumbing systems. PEX is safer than other system.

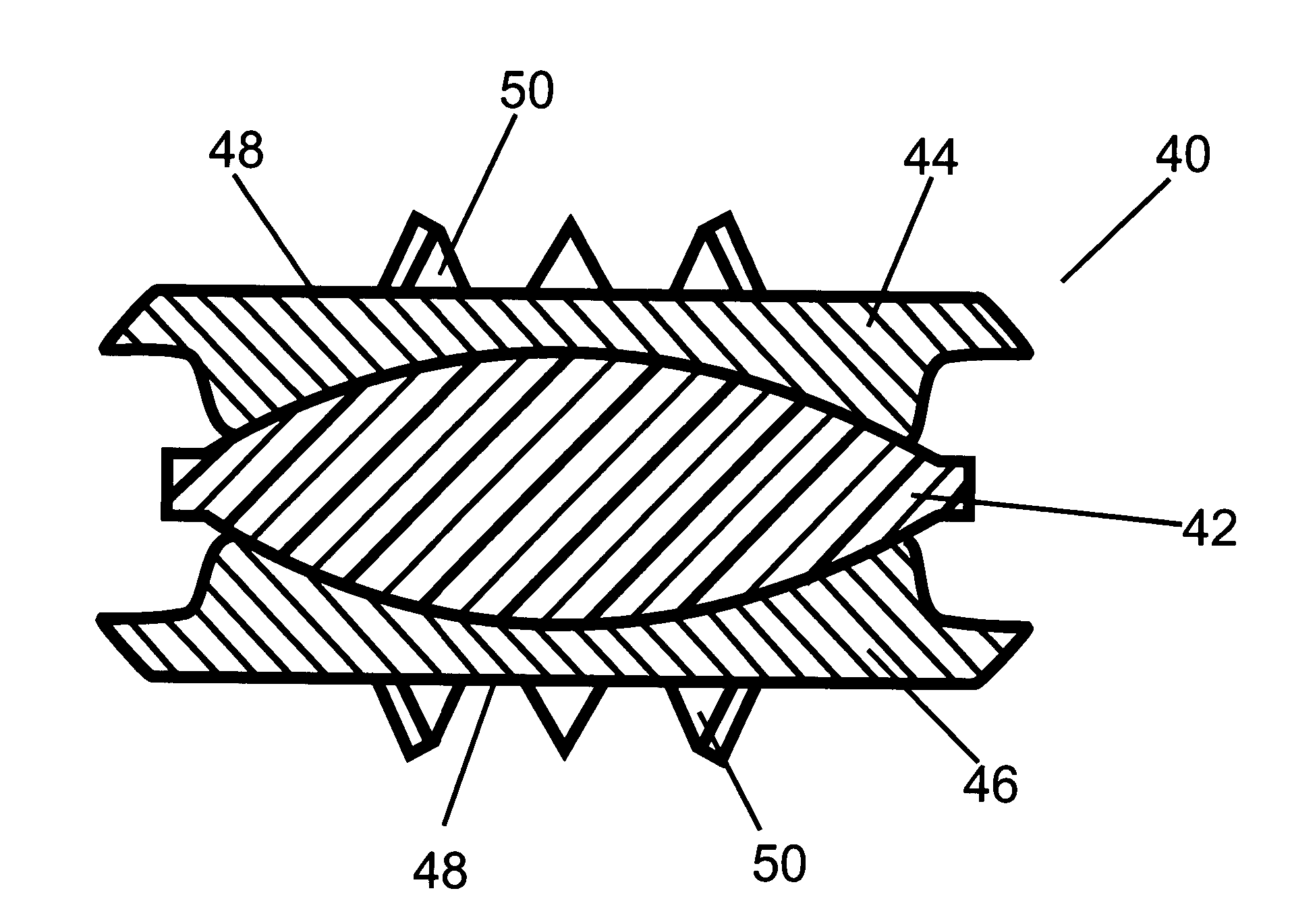

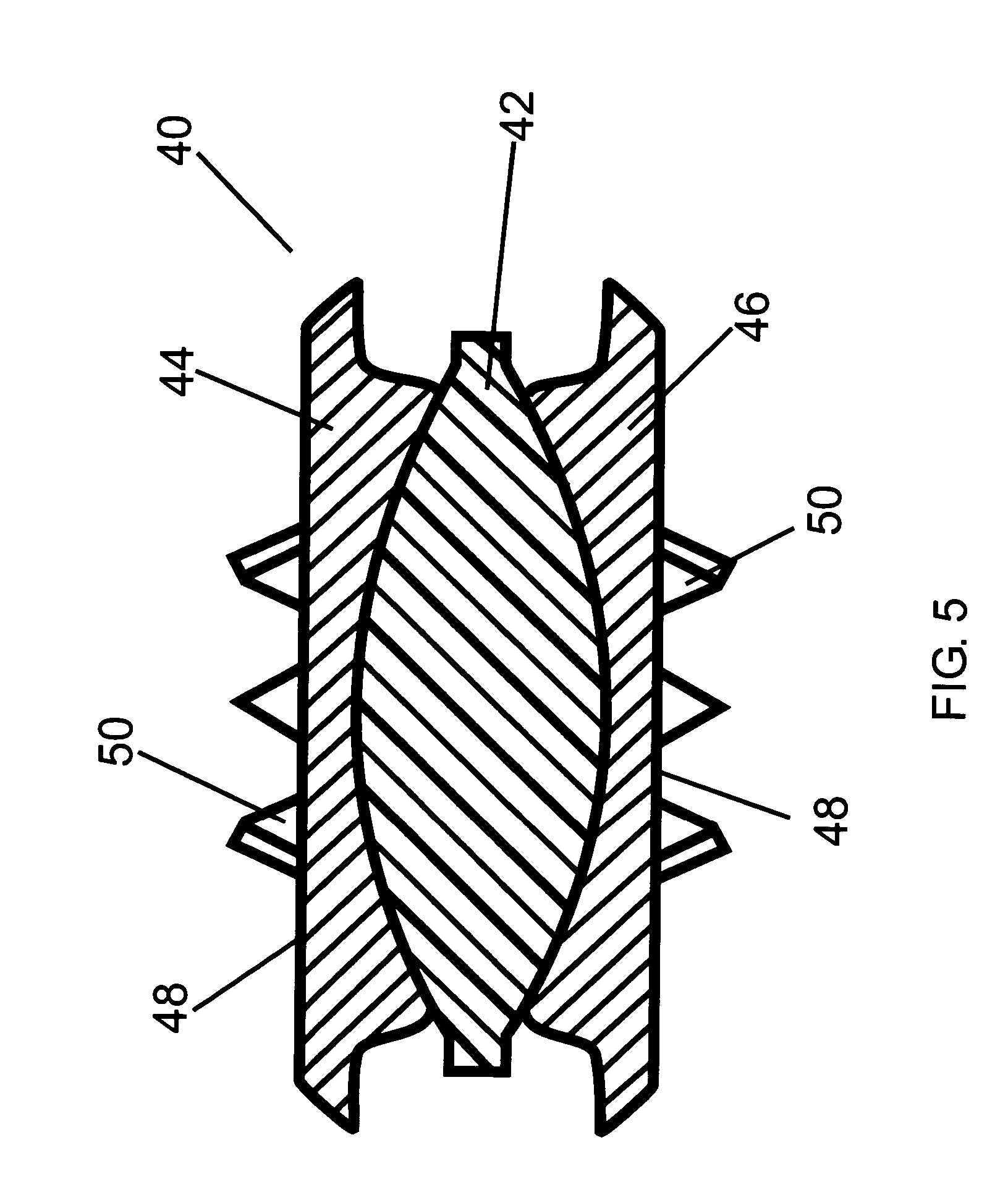

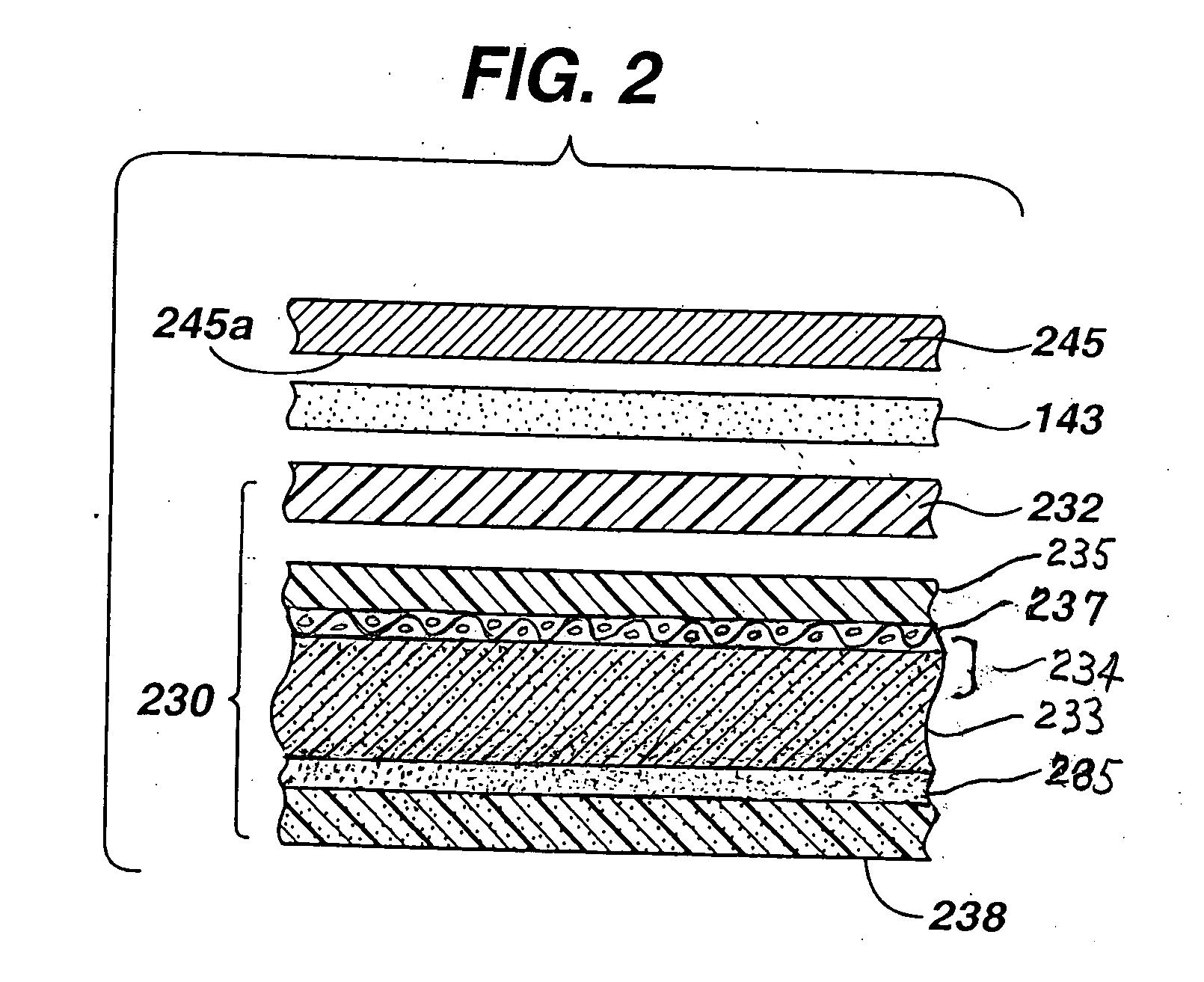

Reinforced, laminated, impregnated, and composite-like materials as crosslinked polyvinyl alcohol hydrogel structures

InactiveUS6855743B1High mechanical strengthIncrease modulusFibre treatmentSynthetic resin layered productsPorosityCross-link

Reinforced, laminated, impregnated, and materials with composite properties as cross linked polyvinyl alcohol hydrogel structures in bulk or cellular matrix forms that can take essentially any physical shape, or can have essentially any size, degree of porosity and surface texture. They have a wide range of physical properties, unusual and unique combinations of physical properties and unique responses to stress fields, which allows for their use in many end use applications.

Owner:HYDROMEDICA

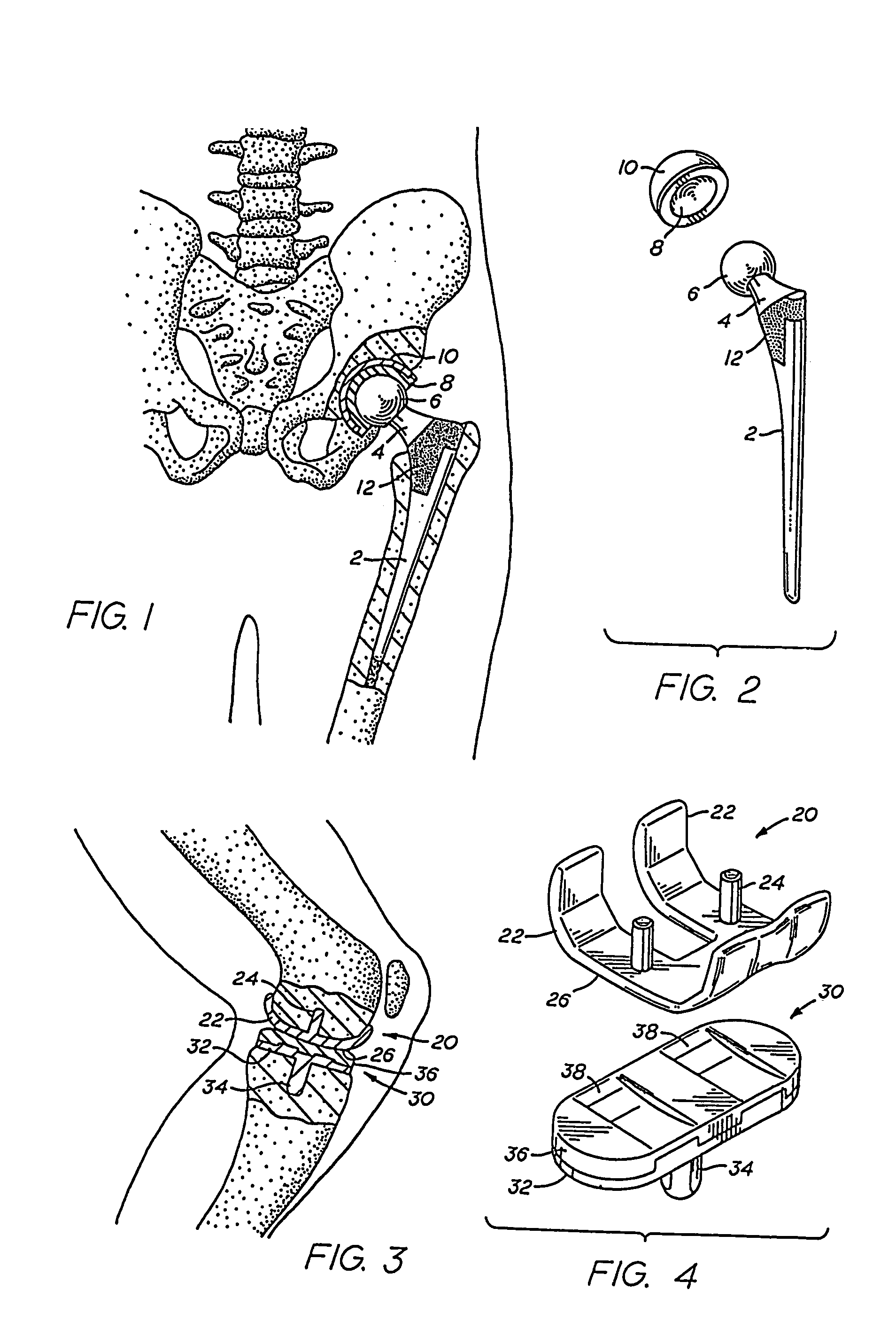

Prosthetic devices employing oxidized zirconium and other abrasion resistant surfaces contacting surfaces of cross-linked polyethylene

Orthopedic implants which include the components of zirconium or zirconium-based alloys having surfaces coated with oxidized zirconium or alternatively, other orthopedic implants comprising abrasion resistant surfaces contacting surfaces of cross-linked polyethylene are disclosed. Such implants provide low friction, highly wear resistant coatings especially useful in artificial joints, such as hip joints, knee joints, elbows, etc., but also useful in other implant devices as well. The implants also find use as vertebral disc prostheses.

Owner:SMITH & NEPHEW INC

High modulus crosslinked polyethylene with reduced residual free radical concentration prepared below the melt

InactiveUS6852772B2Improve diffusivityHigh-frequency sonicationImpression capsAnkle jointsPolymer scienceCross-linked polyethylene

The present invention provides an irradiated crosslinked polyethylene containing reduced free radicals, preferably containing substantially no residual free radical. Disclosed is a process of making irradiated crosslinked polyethylene by irradiating the polyethylene in contact with a sensitizing environment at an elevated temperature that is below the melting point, in order to reduce the concentration of residual free radicals to an undetectable level. A process of making irradiated crosslinked polyethylene composition having reduced free radical content, preferably containing substantially no residual free radicals, by mechanically deforming the polyethylene at a temperature that is below the melting point of the polyethylene, optionally in a sensitizing environment, is also disclosed herein.

Owner:THE GENERAL HOSPITAL CORP +1

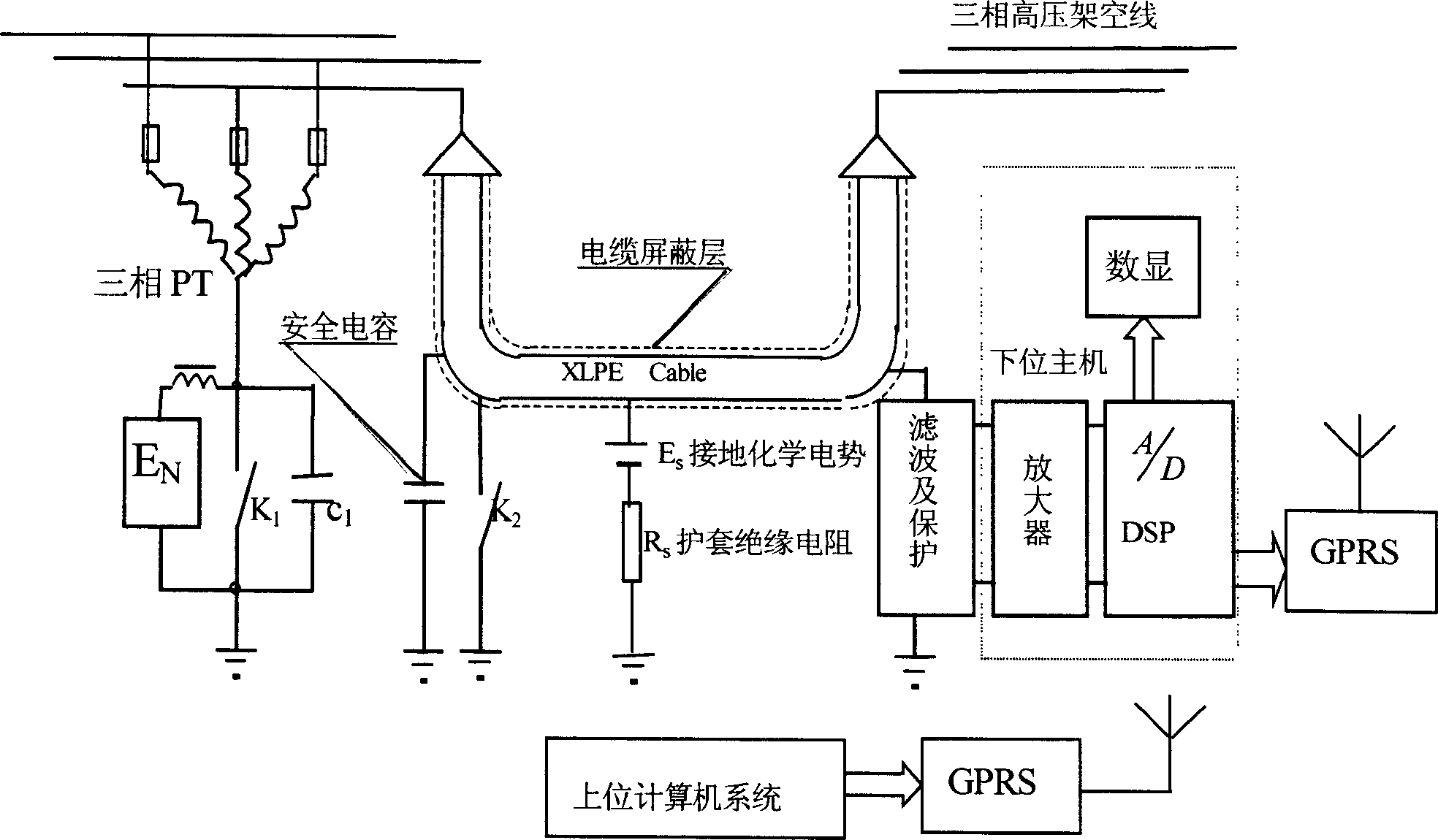

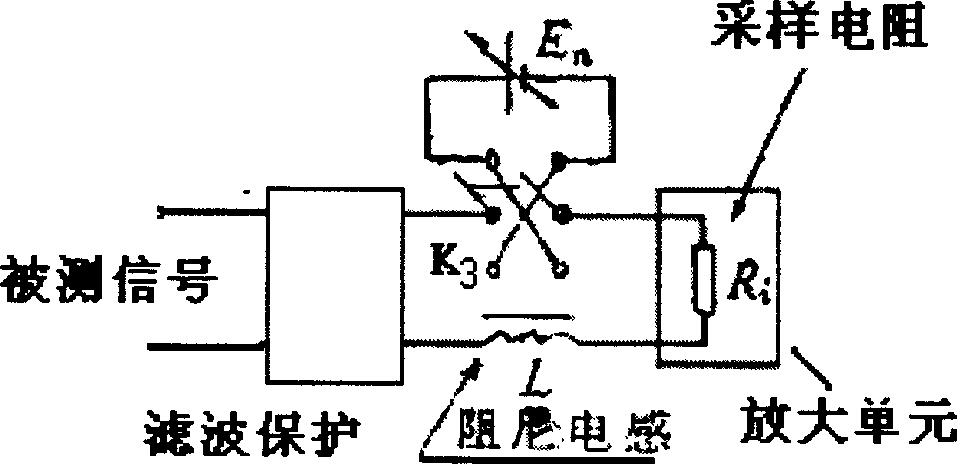

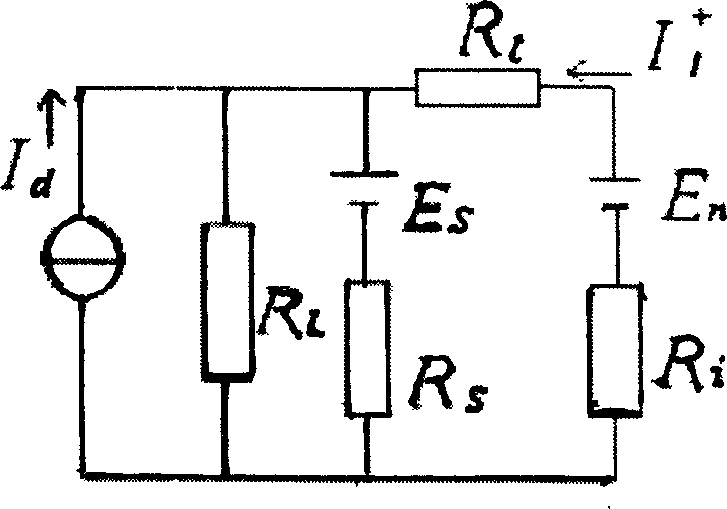

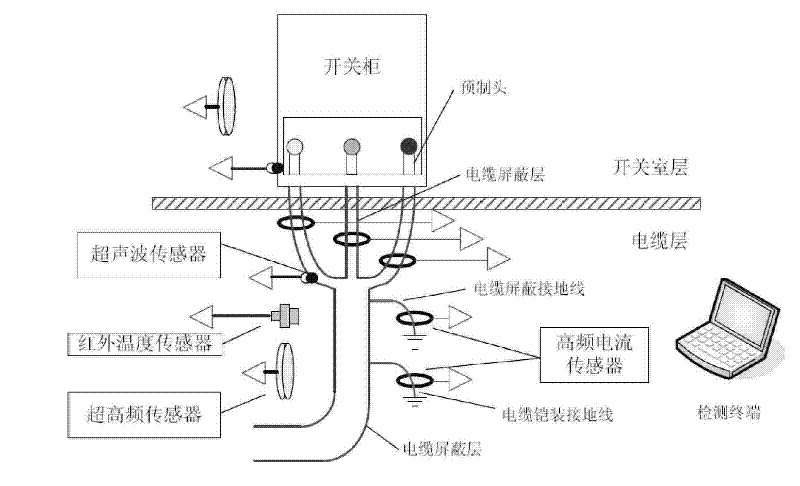

Insulating state on-line monitoring method of cross-linked PE cable

InactiveCN1834673AAvoid Breakdown AccidentsResistance/reactance/impedenceFault locationCross-linkElectrical resistance and conductance

The invention discloses online monitoring method of the insulation state method for crossing polyethylene insulated power cable that adopts DC superposing method to take online testing for the three phase XLPE power cable. After gaining the parameters, GPRS would send it to host computer, which would take analysis to the data and judge the insulation state. The invention realizes unattended operation online monitoring and wireless remote controlling and measuring.

Owner:XI AN JIAOTONG UNIV

Sequentially cross-linked polyethylene

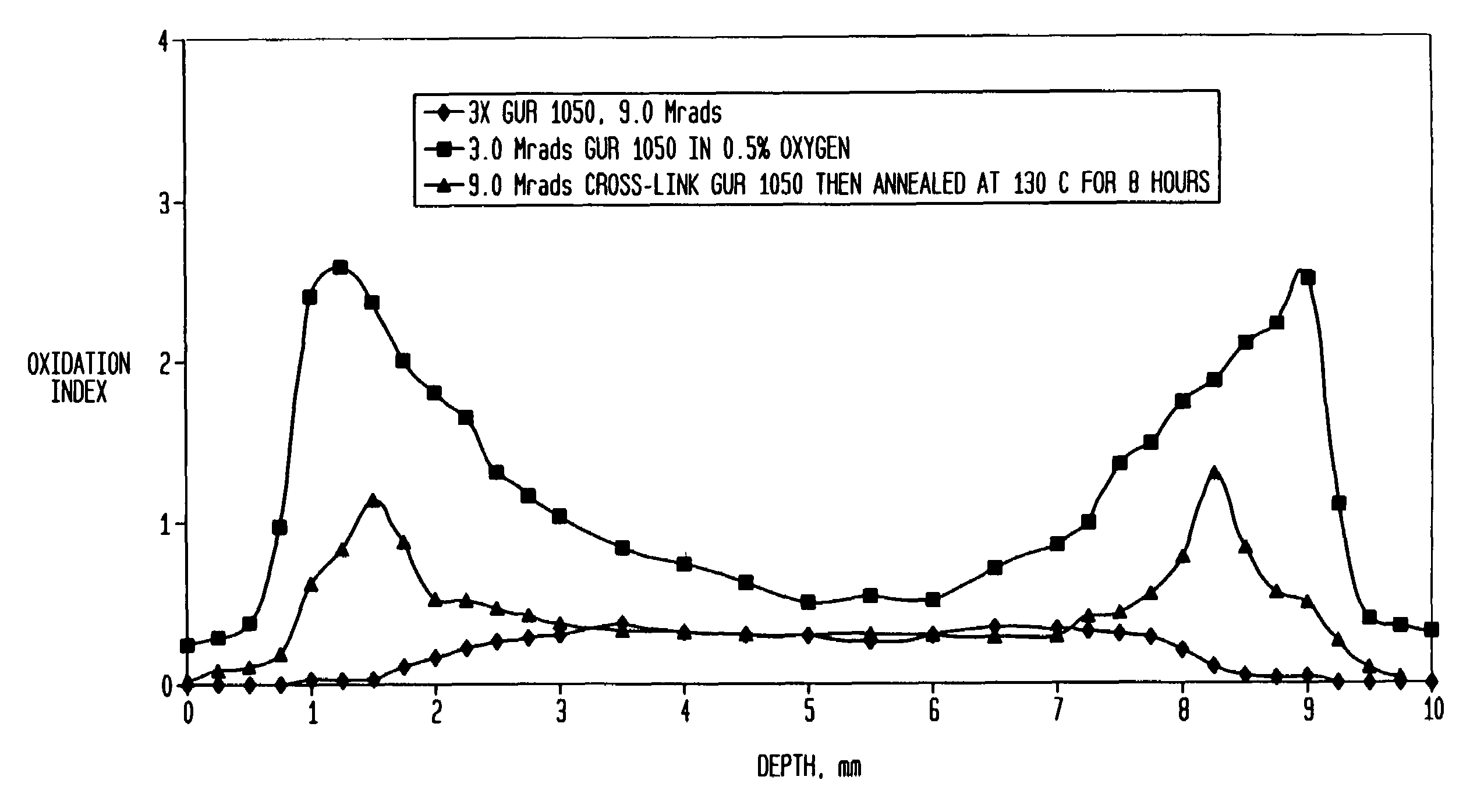

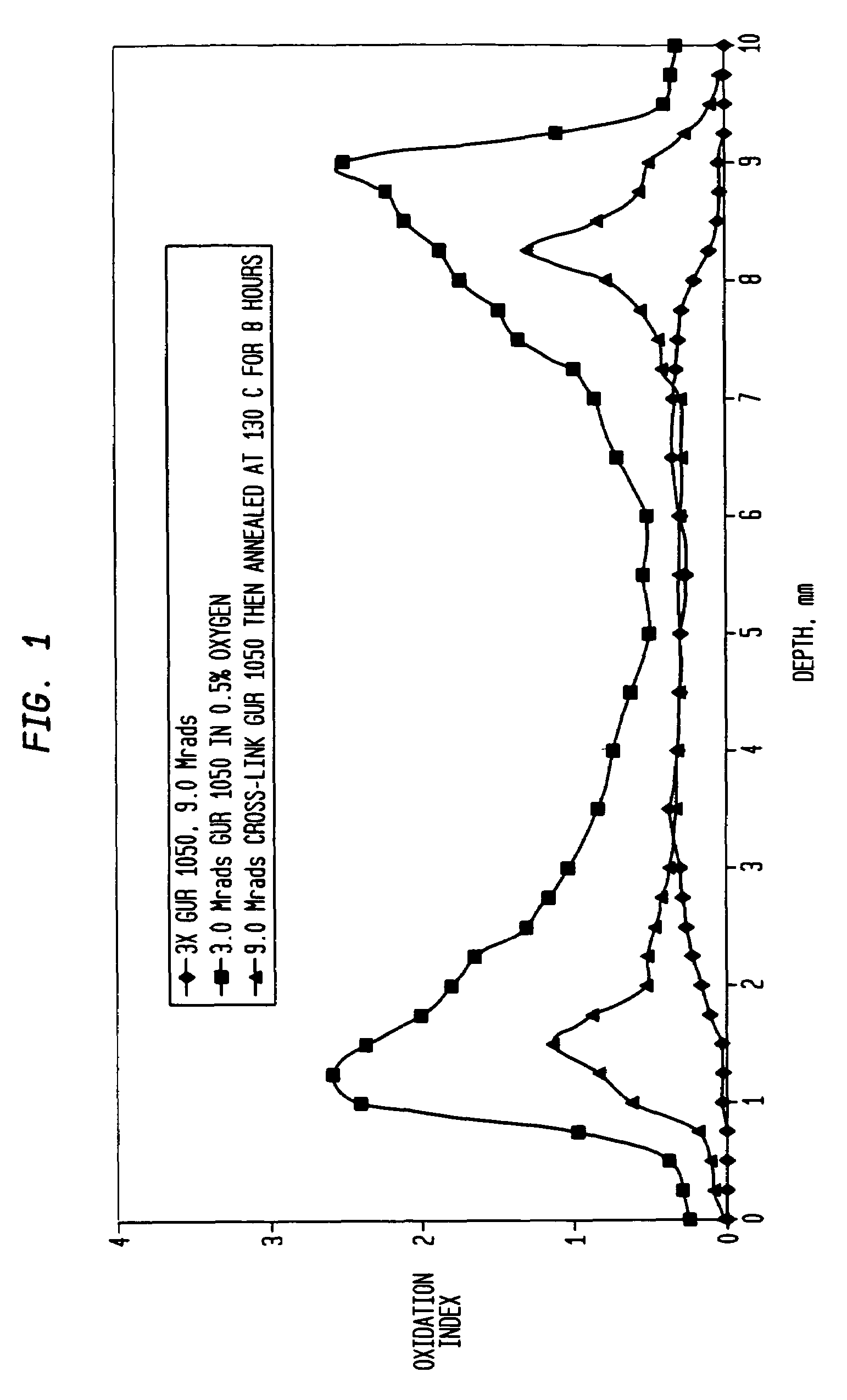

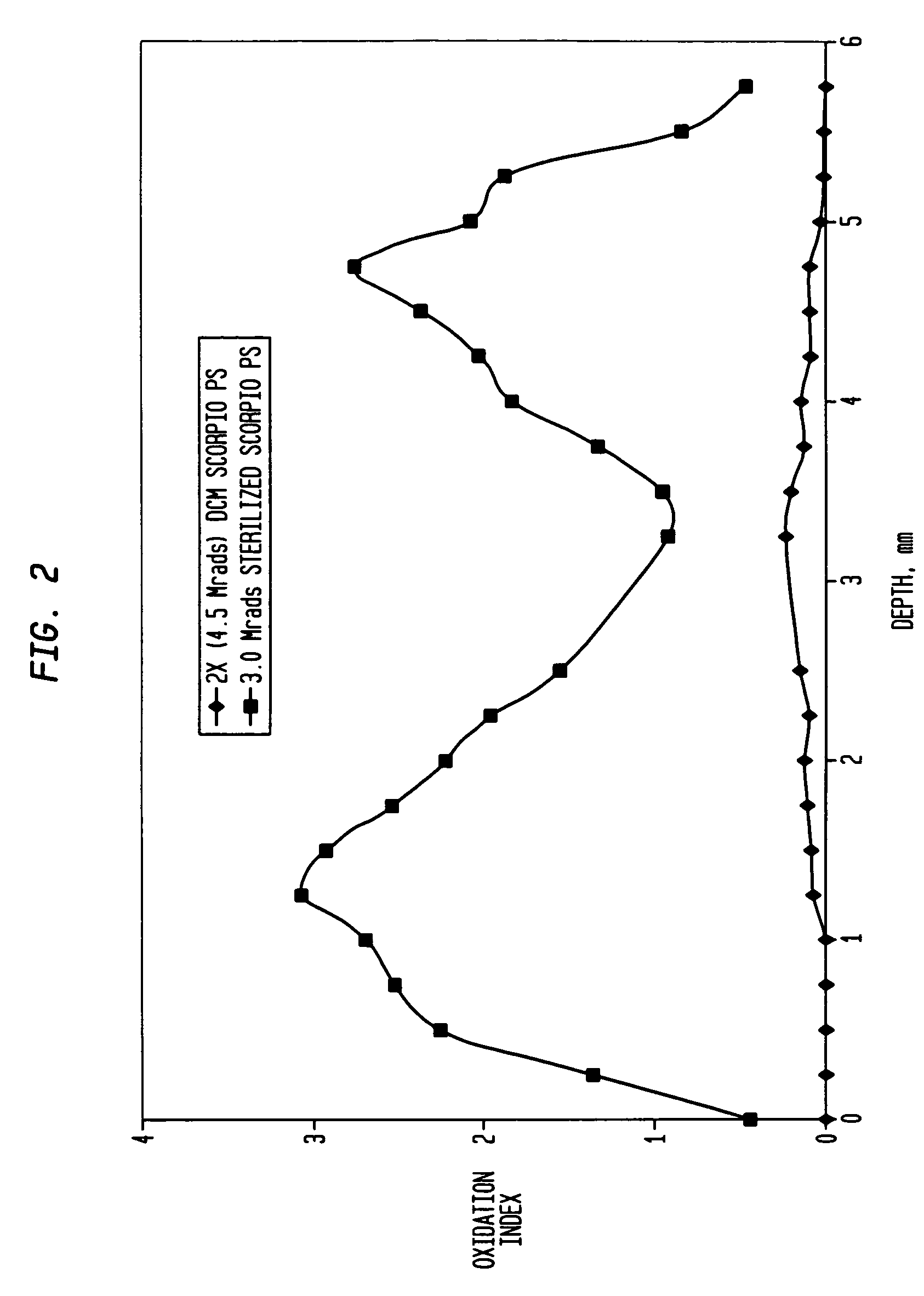

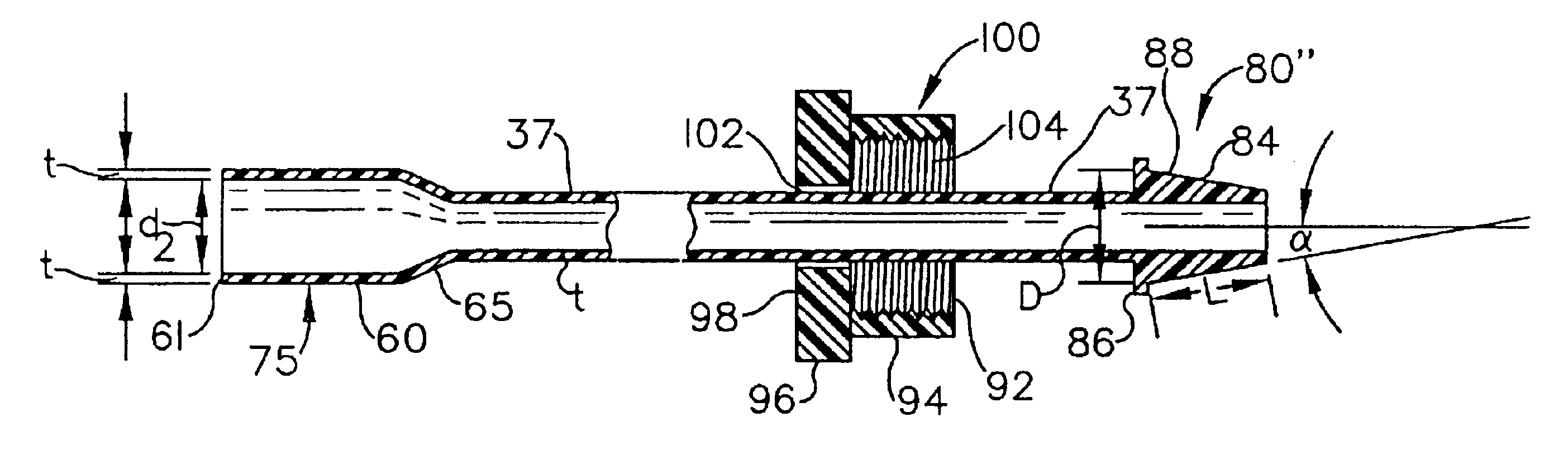

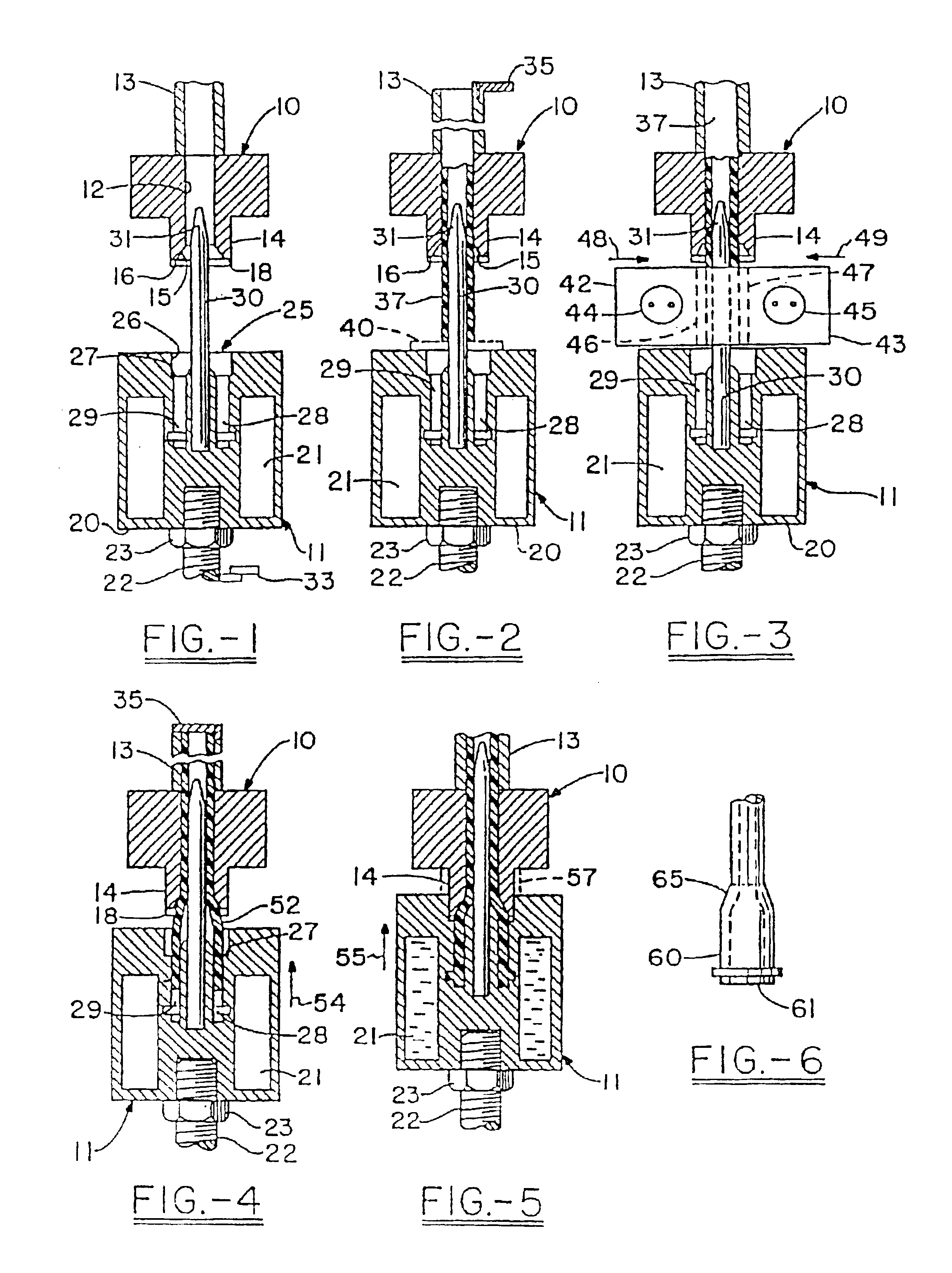

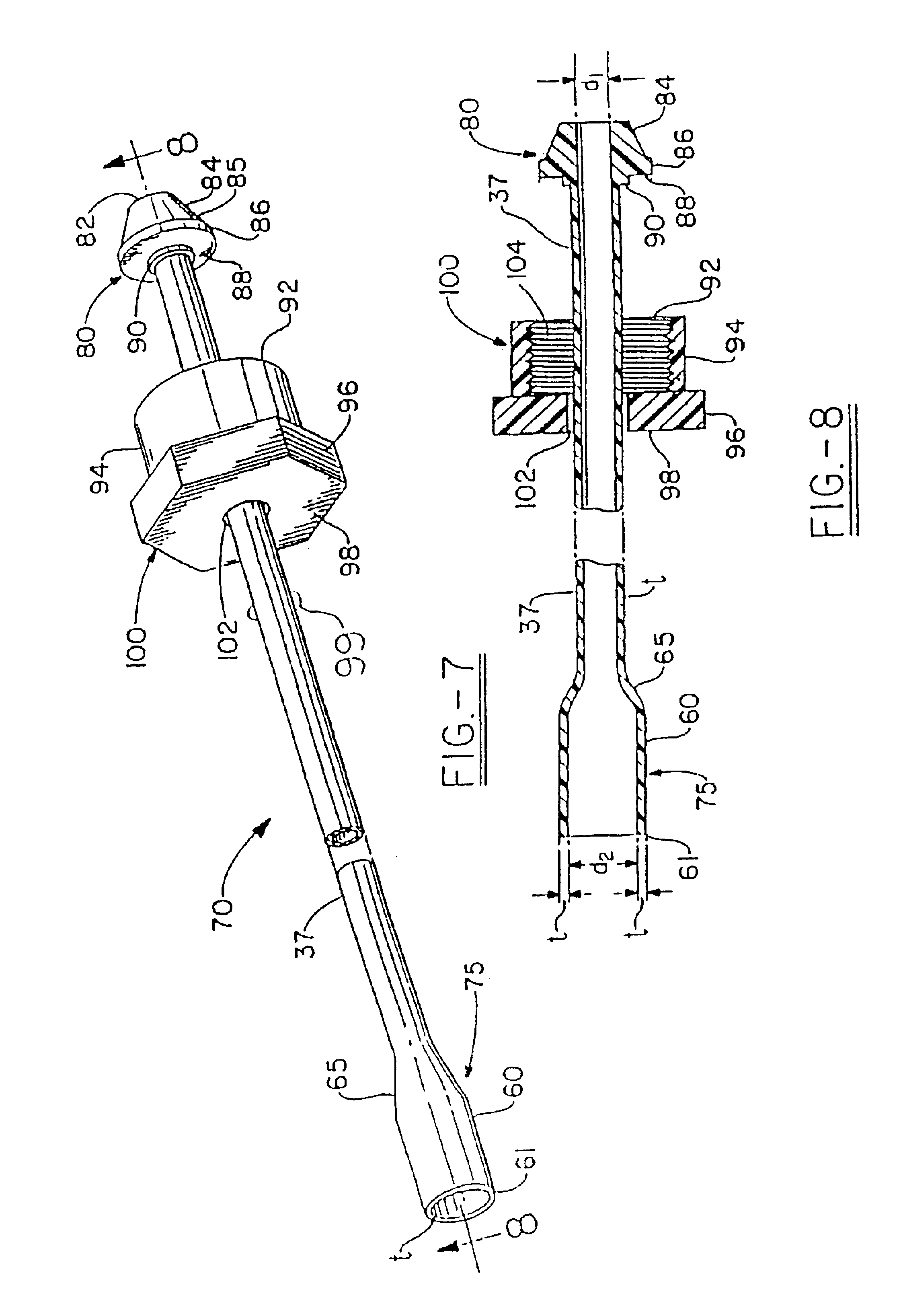

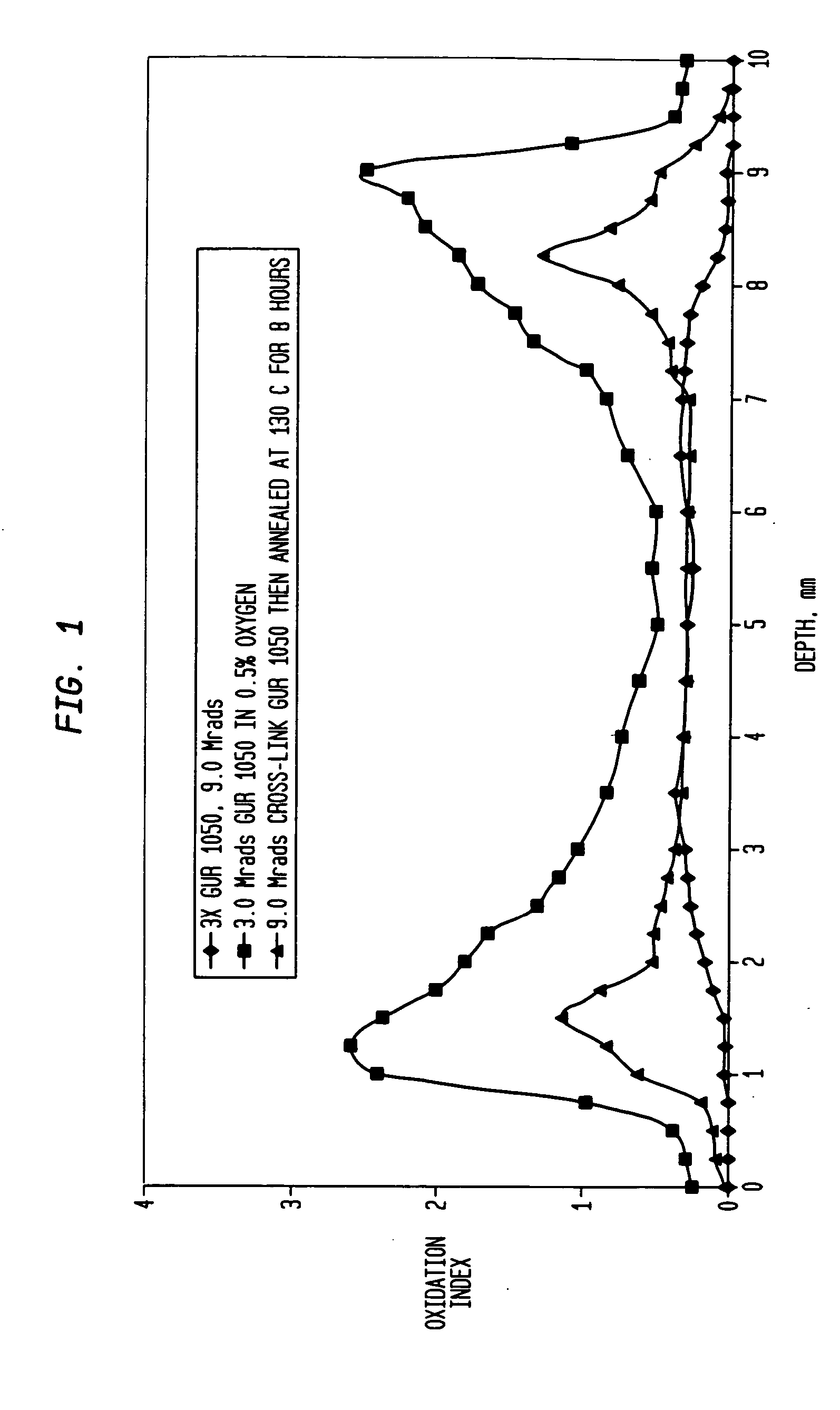

A method of producing an improved polyethylene, especially an ultra-high molecular weight polyethylene utilizes a sequential irradiation and annealing process to form a highly cross-linked polyethylene material. The use of sequential irradiation followed by sequential annealing after each irradiation allows each dose of irradiation in the series of doses to be relatively low while achieving a total dose which is sufficiently high to cross-link the material. The process may either be applied to a preformed material such as a rod or bar or sheet made from polyethylene resin or may be applied to a finished polyethylene part. If applied to a finished polyethylene part, the irradiation and annealing must be accomplished with the polyethylene material not in contact with oxygen at a concentration greater than 1% oxygen volume by volume. When applied to a preform, such as a rod, the annealing of the bulk polymer part of the rod from which the finished part is made must take place on the rod before the implant is machined therefrom and exposed to oxygen.

Owner:HOWMEDICA OSTEONICS CORP

Fluoropolymer composite tube and method of preparation

InactiveUS6517657B1High strengthLamination ancillary operationsSynthetic resin layered productsAdhesiveX-ray

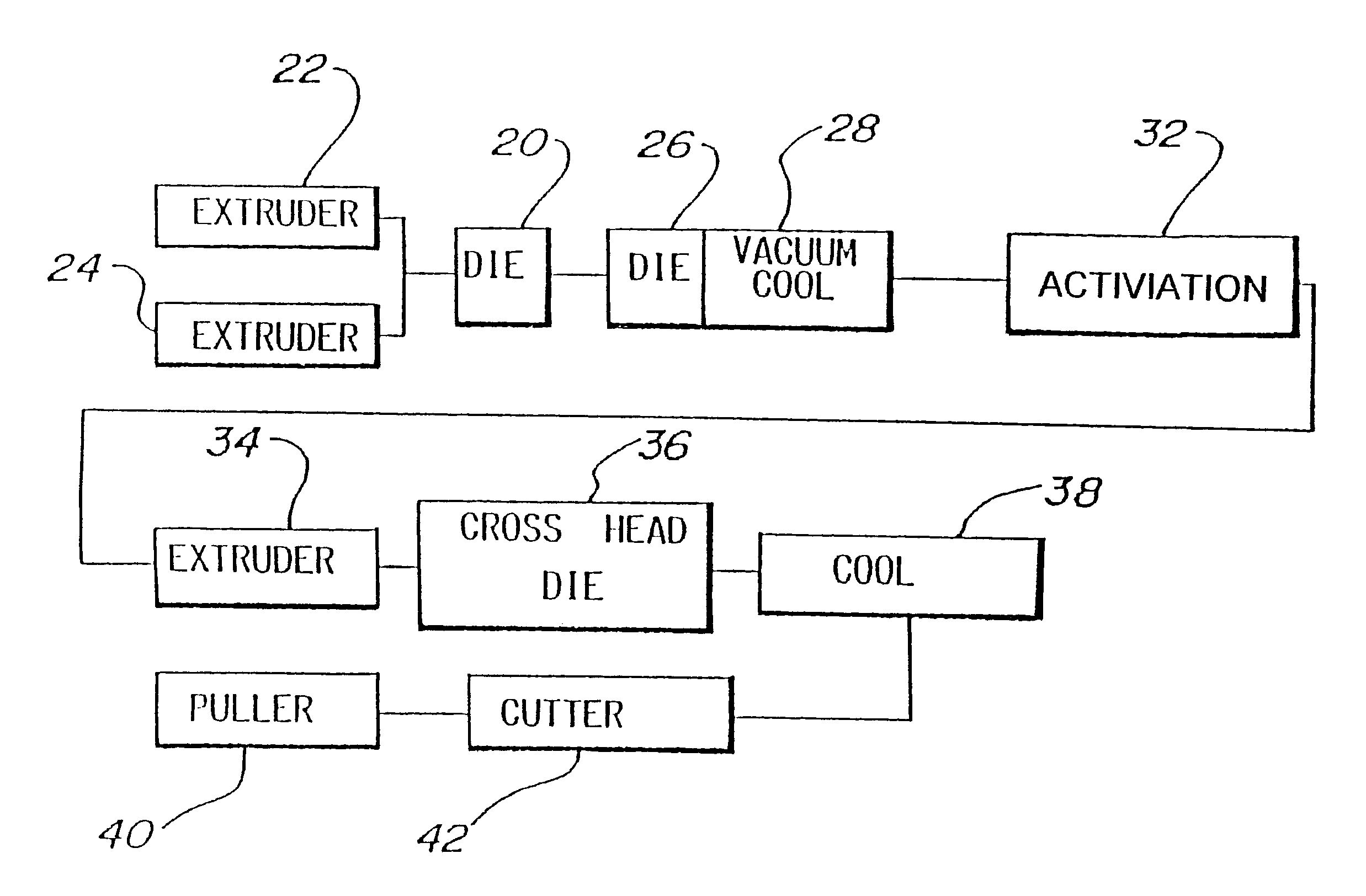

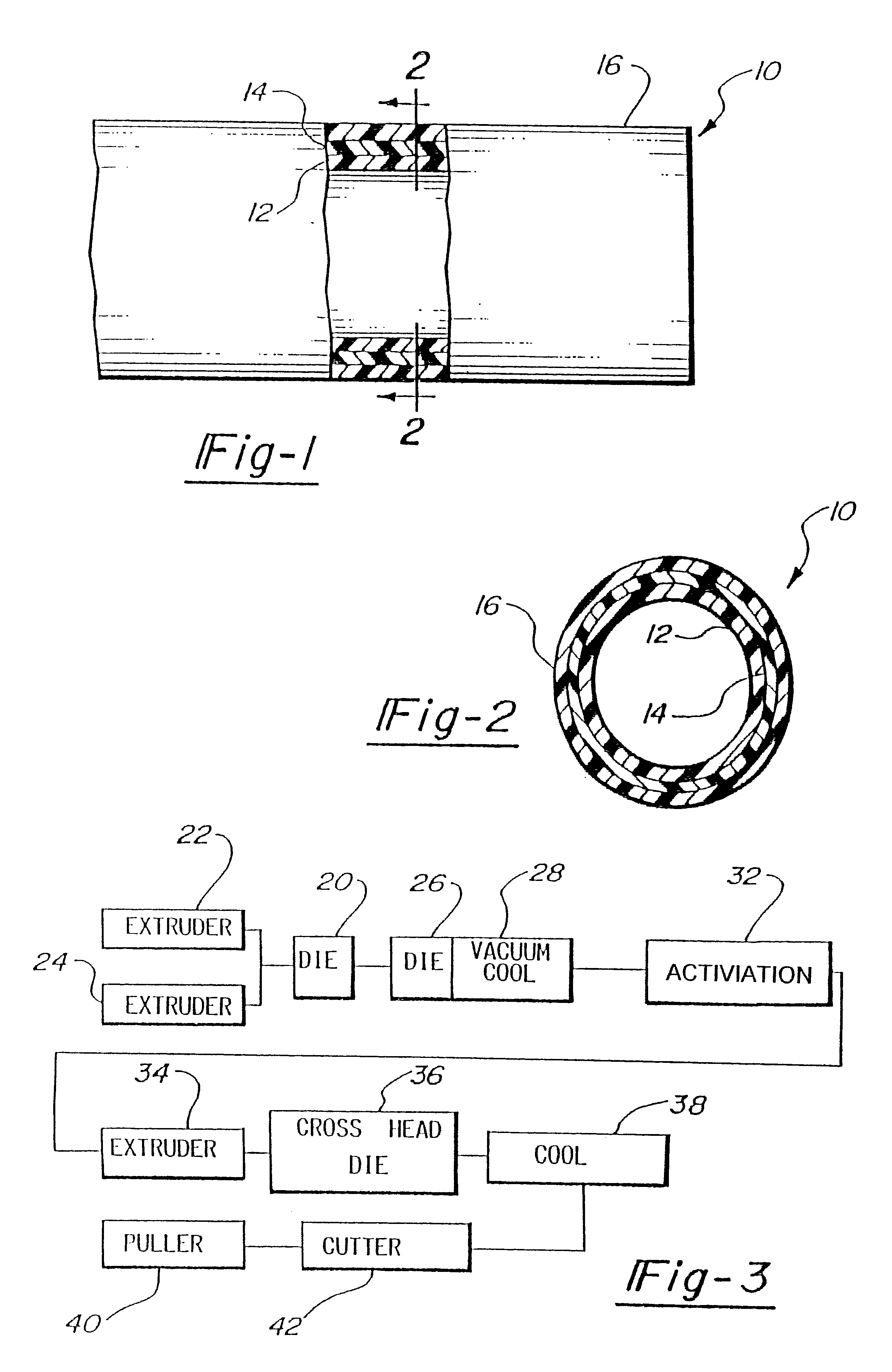

Described herein is a method of preparing a fluoropolymer composite comprising the steps of activating the fluoropolymer substrate and thereafter applying a layer of a different polymer to the activated fluoropolymer substrate. The activation step can be described as a mixed gas plasma discharge or an electrically formed plasma. Also described herein are other methods of surface activation including exposure to excimer laser, gamma rays, x-ray flux, electron beam, sodium naphthalate bath, coupling or curing agents, and others. In particular, described is a fuel pipe comprised of an inner fluorocarbon layer having electrostatic discharge resistance and hydrocarbon evaporative emission resistance chemically bonded to an outer layer of a cross-linked polyethylene polymer. There is no need for additional adhesives. Fluoropolymer layers have excellent chemical resistance.

Owner:MARTINREA IND INC

Electrical Cable Having Crosslinked Insulation With Internal Pulling Lubricant

ActiveUS20100236811A1Reduce tensionHigh viscosityPlastic/resin/waxes insulatorsBottlesElectrical conductorPower cable

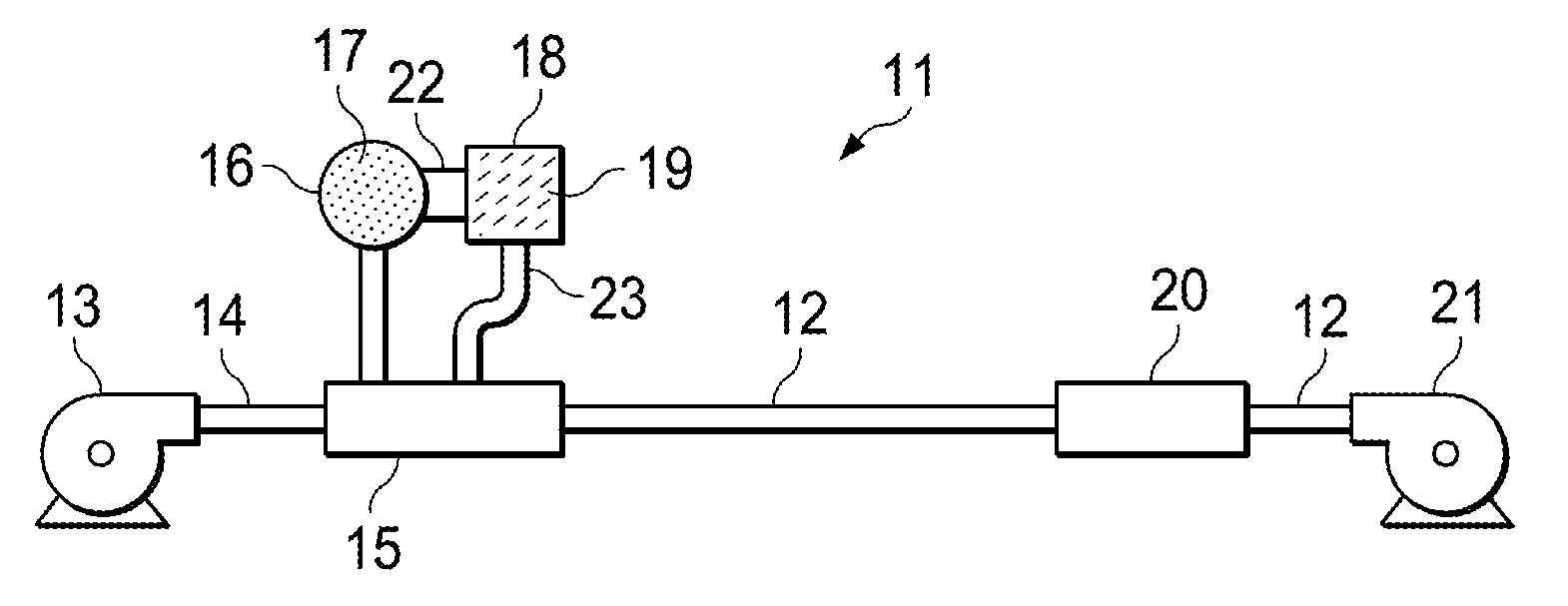

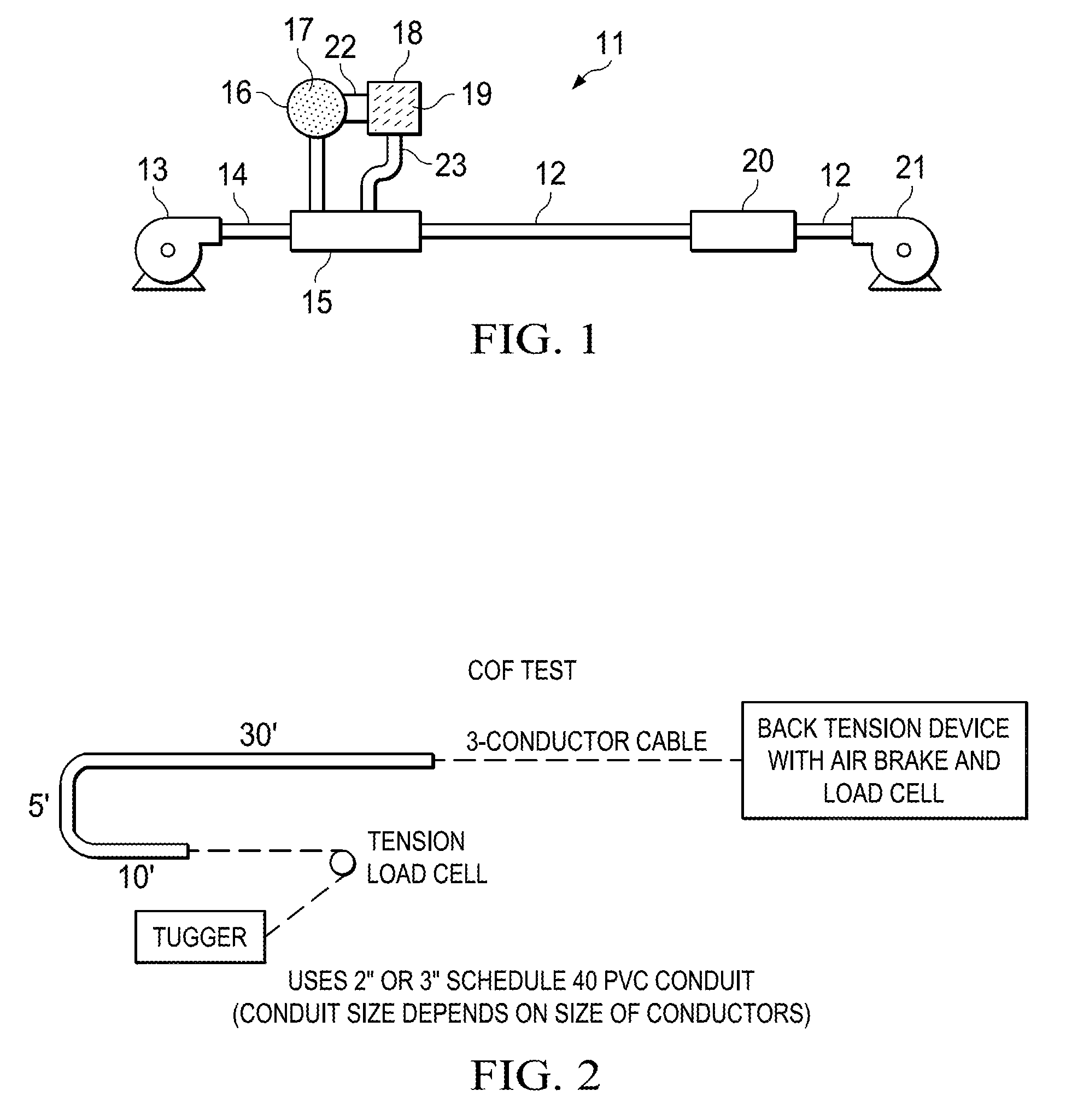

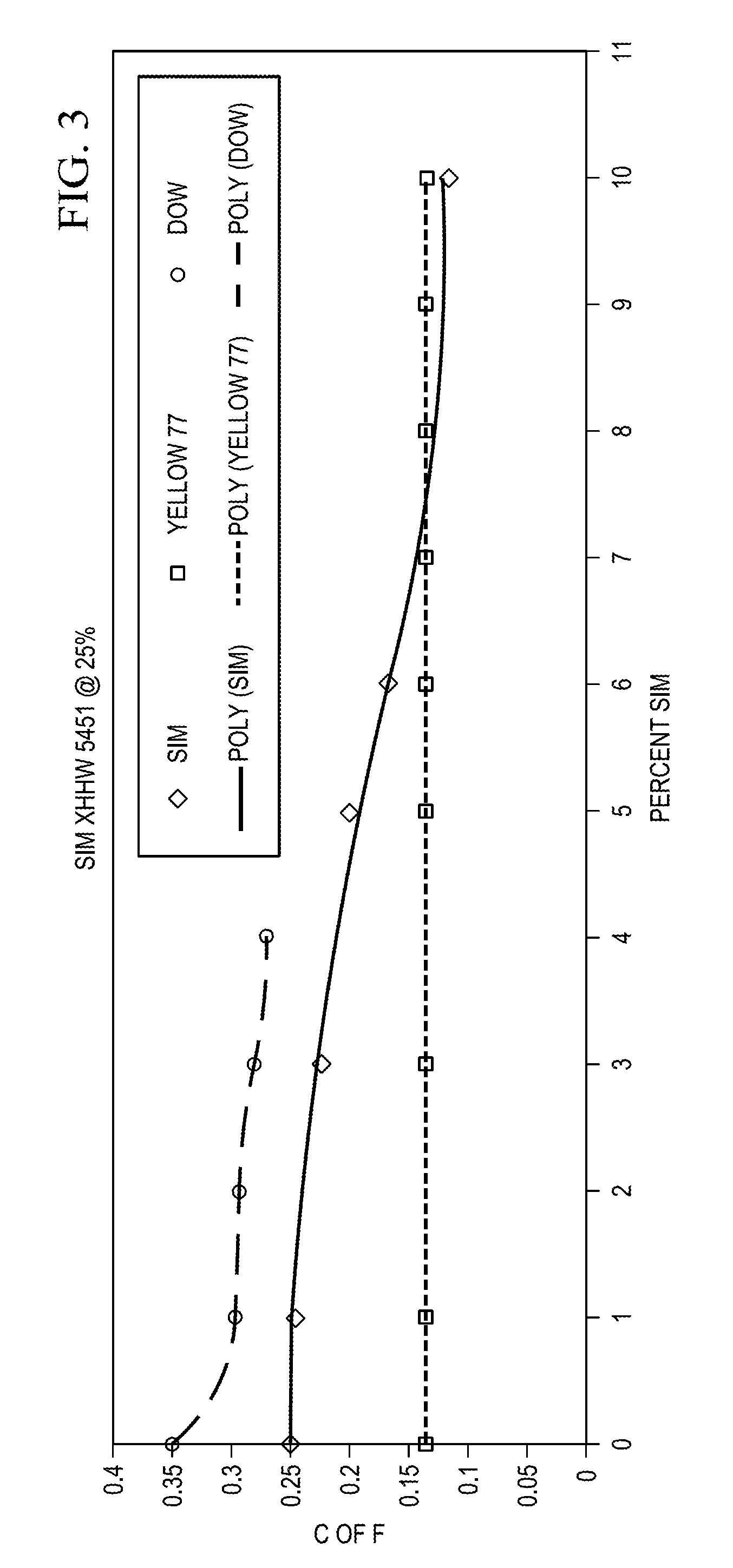

Electrical power cable having a reduced surface coefficient of friction and required installation pulling force, and the method of manufacture thereof, in which the central conductor core, with or without a separate insulating layer, is surrounded by a sheath of crosslinked polyethylene. A high viscosity, high molecular weight silicone based pulling lubricant or fatty acid amide pulling lubricant is incorporated by alternate methods with the polyethylene to form a composition from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

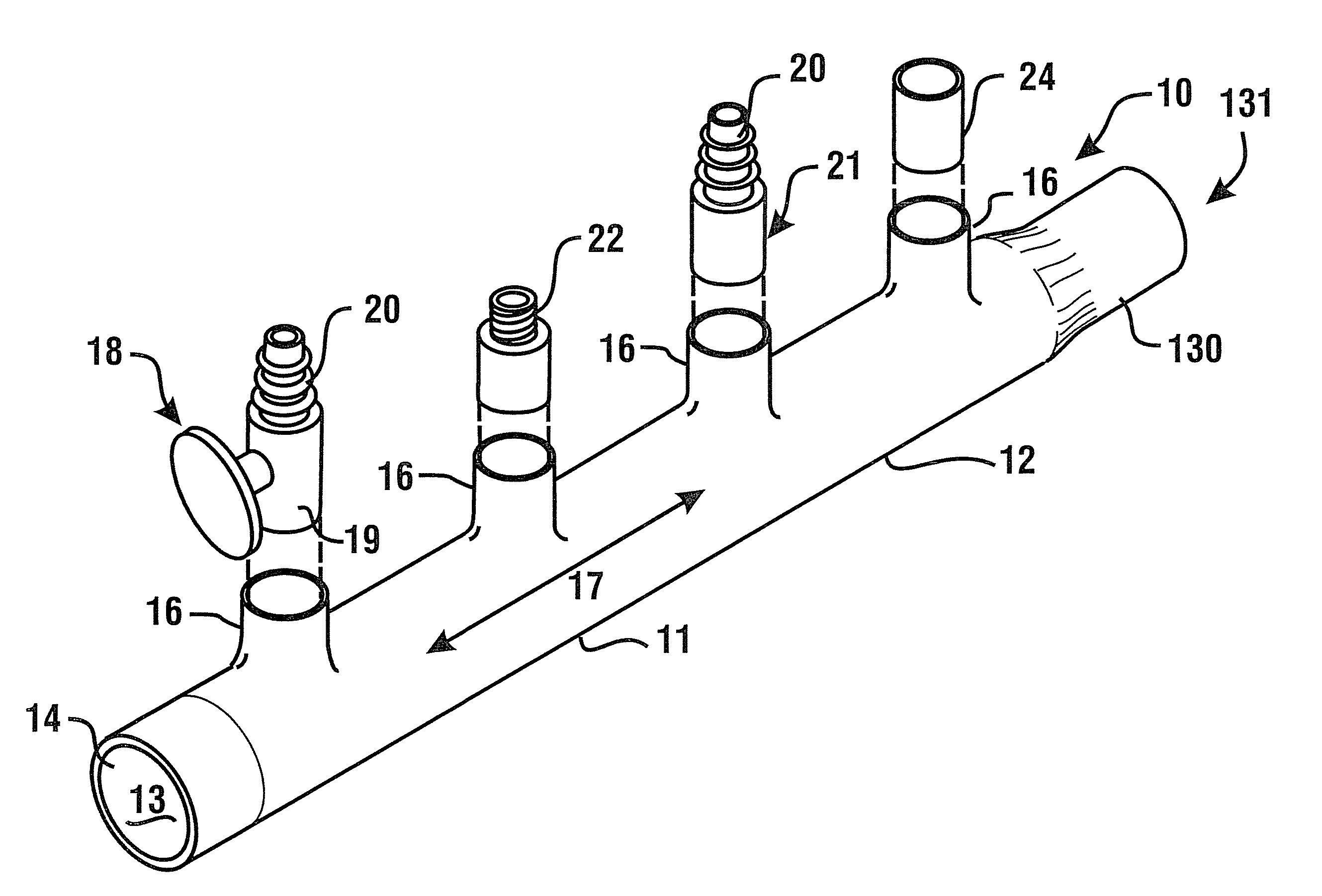

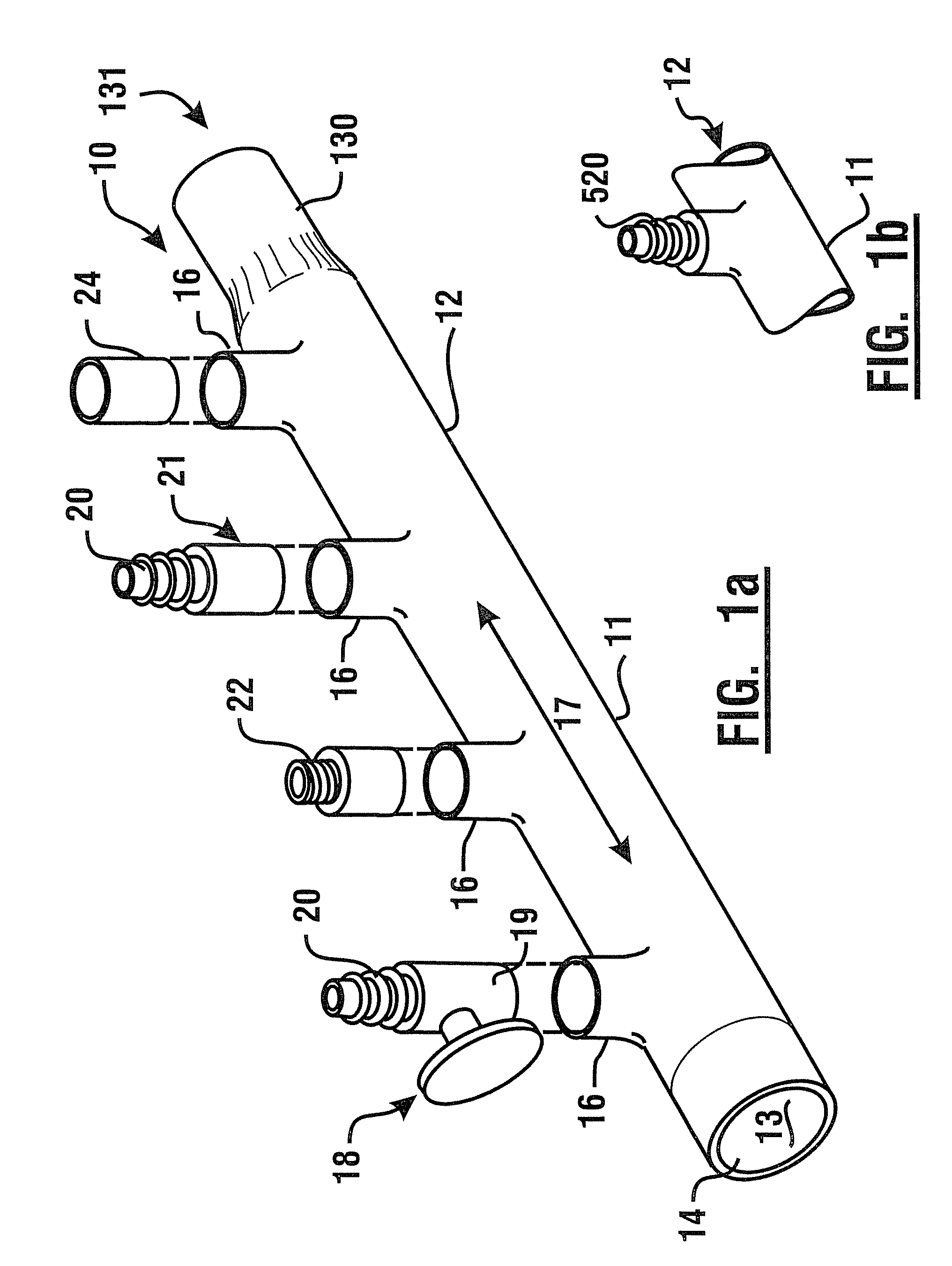

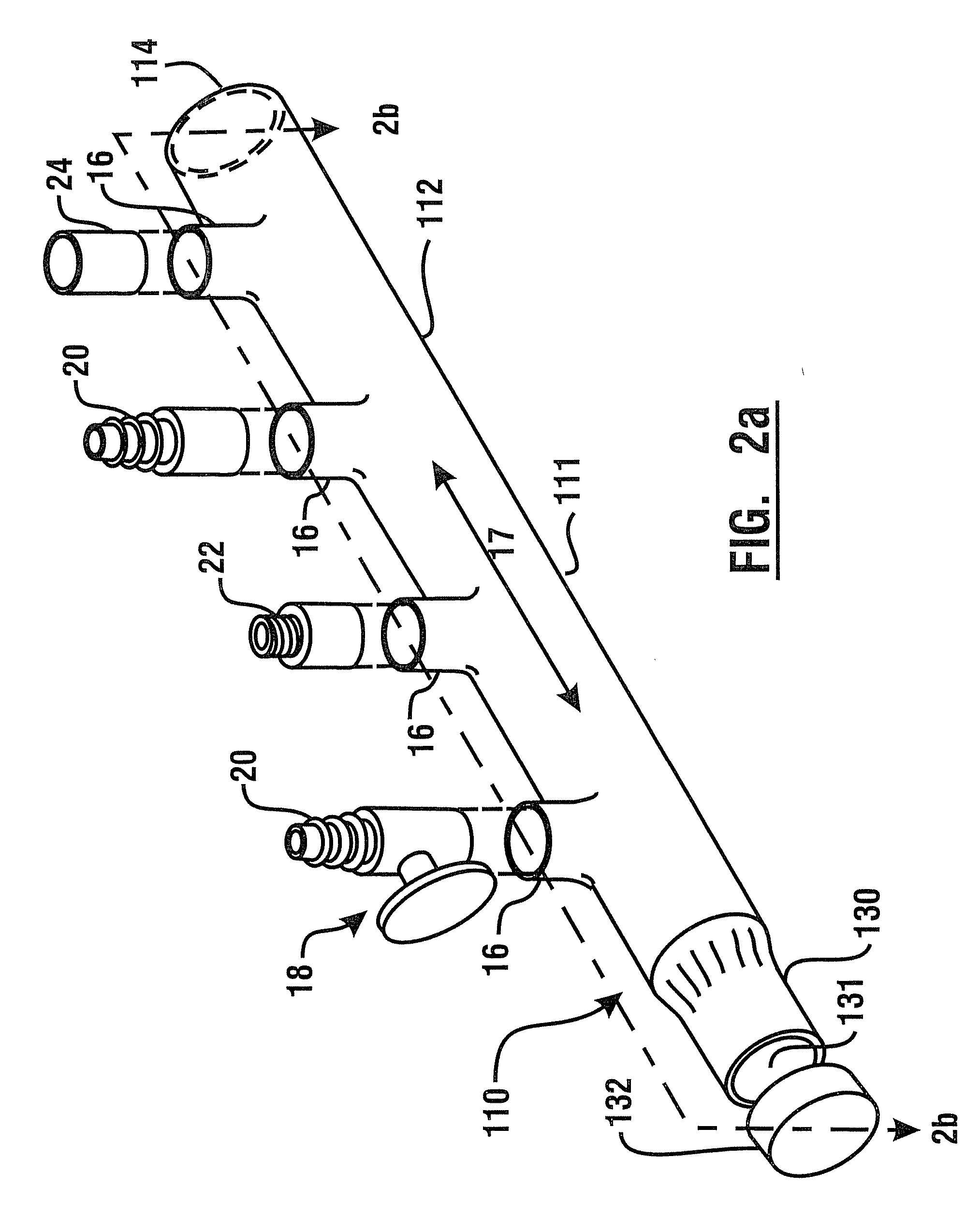

Water Manifold System And Method

InactiveUS20080276998A1Easily in buildingImprove scalabilityLighting and heating apparatusDomestic plumbingChlorinated polyvinyl chlorideEngineering

A system for distributing water within a building operates to distribute water from a pressurized water supply source to devices that receive water, such as faucets, toilets, showers, sprinklers, and hot water heating devices. The system includes at least one manifold which may be of unitary molded plastic construction and comprised of chlorinated polyvinyl chloride (CPVC). The manifold includes an entry port and a plurality of outlet ports which are also referred to as sockets. The sockets are configured to receive fitting inserts of various types that include water line connectors. The sockets are also configured to accept standard plastic water conduits therein in cemented relation. The water line connectors may include metallic connectors such as barbed fittings, which can be used to connect the manifold and crosslinked polyethylene (PEX) pipe in nonthreaded relation. Manifolds may be connected together to provide suitable distribution arrangements.

Owner:LUBRIZOL ADVANCED MATERIALS INC

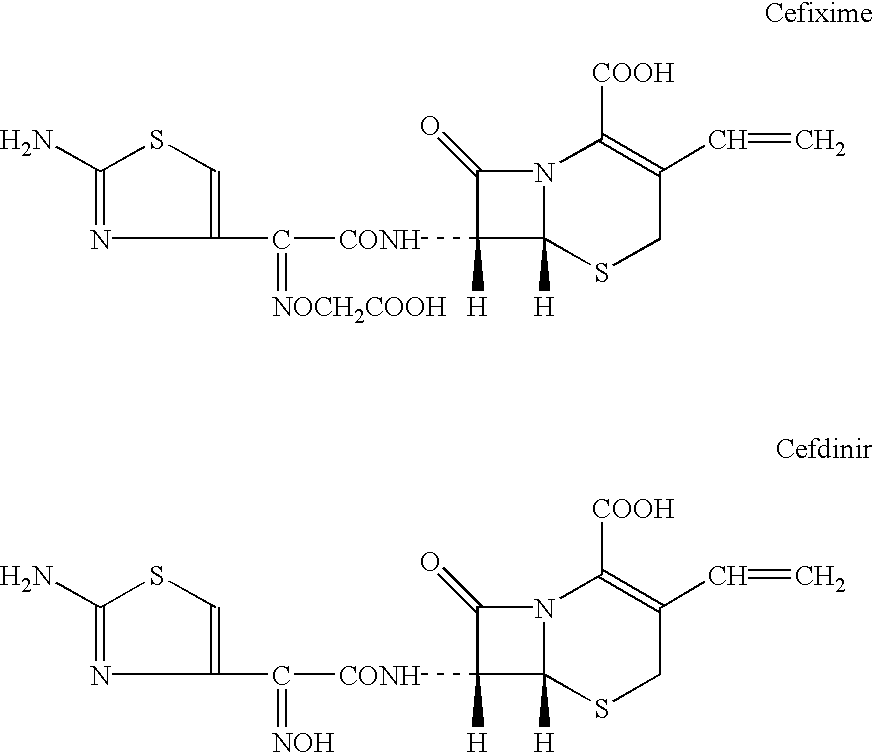

Beta-lactam antibiotic-containing tablet and production thereof

InactiveUS6423341B1Antibacterial agentsOrganic active ingredientsLow-substituted hydroxypropylcelluloseEngineering

This invention provides beta-lactam antibiotic-containing tablets capable of being orally taken either as such owing to their being small-sized, hence still easily swallowable, or, in the case of administration to the aged encountering some difficulty in swallowing, in the form of dispersions resulting from easy self-disintegration upon being dropped into water in a glass as well as a method of producing the same. The tablets of this invention comprise, on the per-tablet basis, 60-85% by weight of a beta-lactam antibiotic, 1-10% by weight of low-substituted hydroxypropylcellulose and / or crosslinked polyvinylpyrrolidone as a disintegrator, and 0.5-2% by weight of a binder. Granules to be compressed for tableting are prepared using water or an aqueous solution of ethanol or the like.

Owner:ASTELLAS PHARMA INC

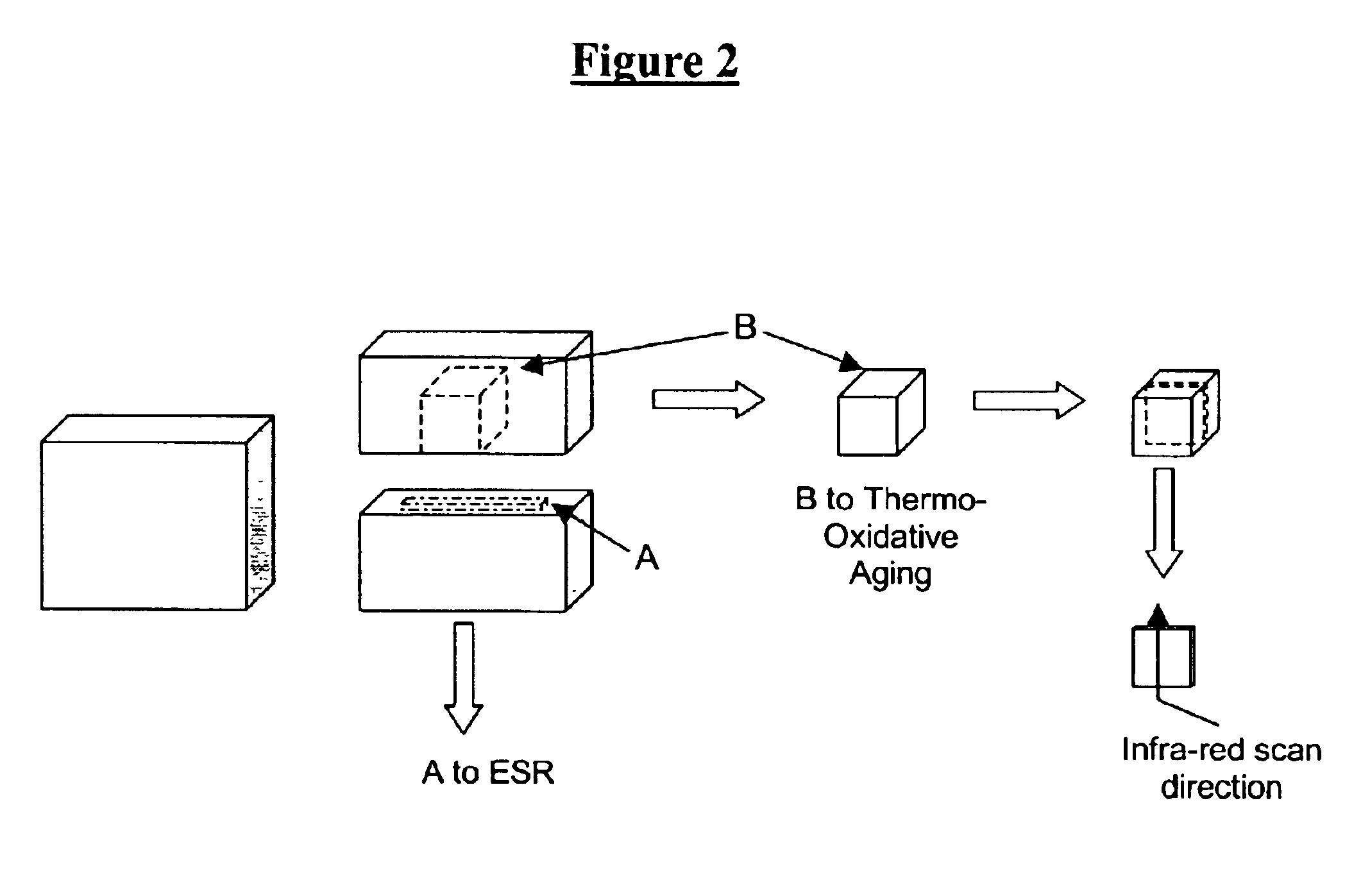

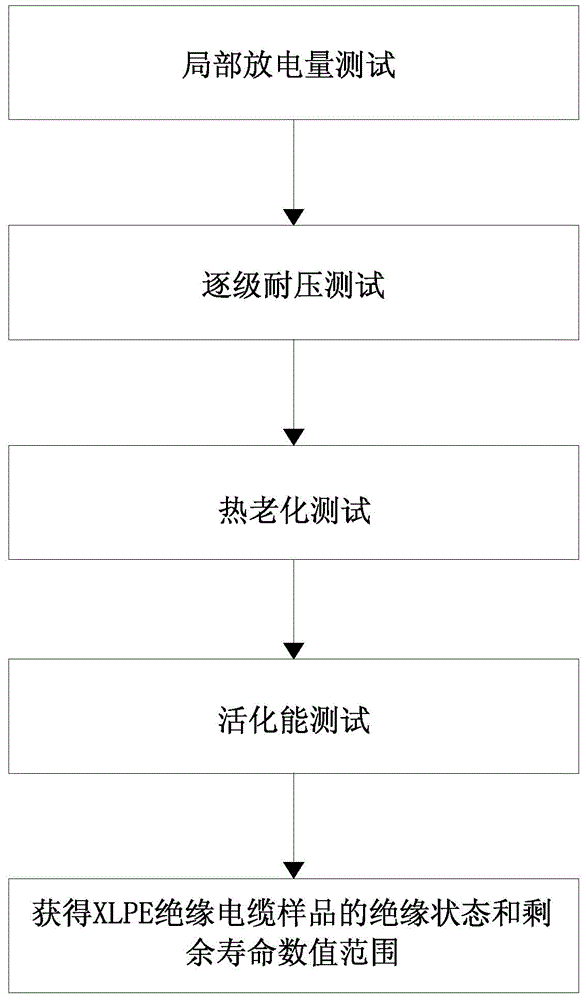

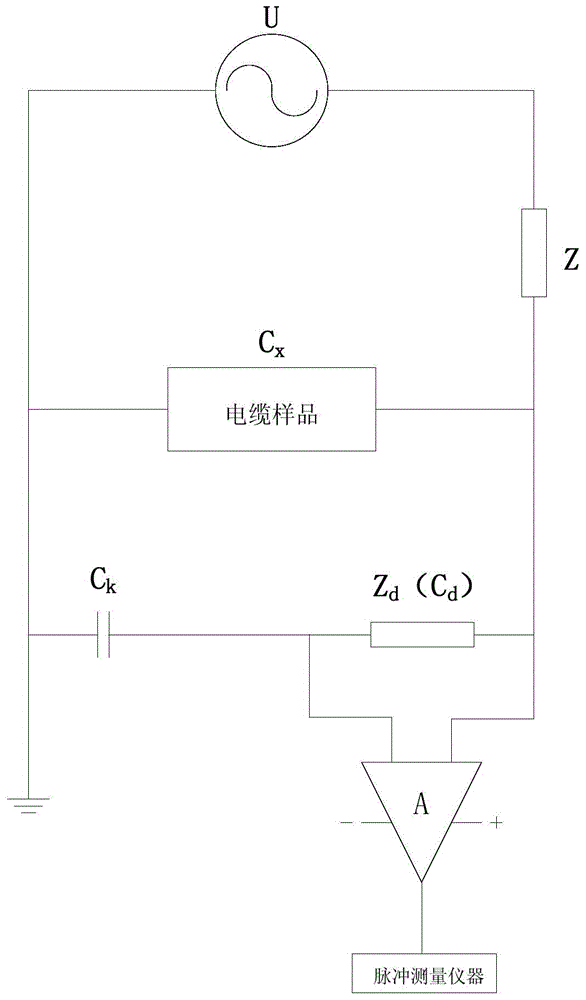

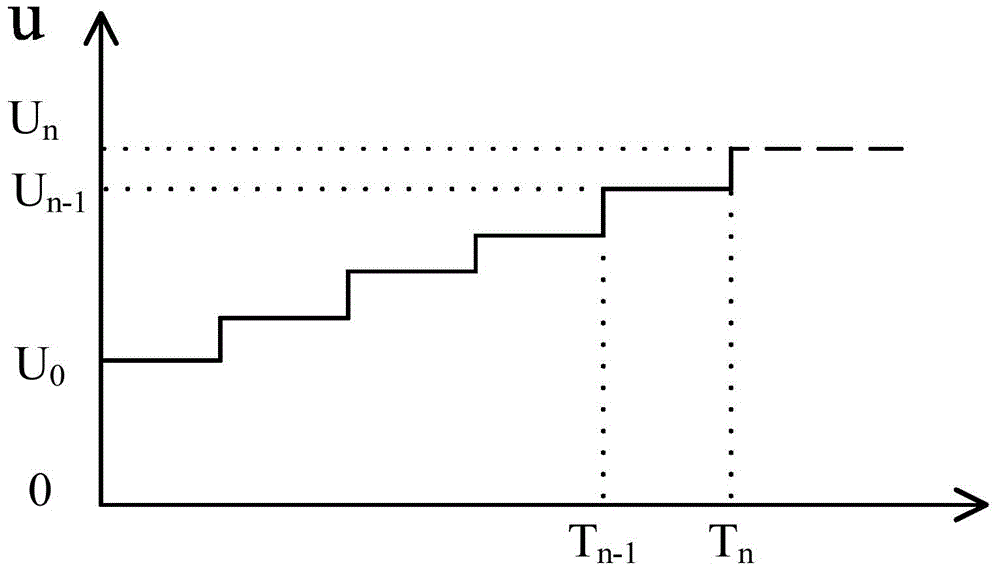

Insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties

The invention discloses an insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties. An insulating cable is an XLPE (Cross Linked Polyethylene) insulating cable. The method comprises a partial discharging amount test, a gradual layer voltage-resisting test, a thermal aging test and an activating energy test; an insulating state of an XLPE insulating cable sample is obtained according to a partial discharging amount calculated by he partial discharging amount test; a residual service life numerical value range of the XLPE insulating cable sample is obtained according to testing results of the gradual layer voltage-resisting test, the thermal aging test and the activating energy test. The method can integrate a plurality of indexes of cable aging evaluation, and combines macroscopic and microscopic change conditions, so that the residual service life data of the cable is completely analyzed in the three aspects of physical performances, chemical performances and electric performances, and the method has important guiding meanings on line modification and power grid planning.

Owner:SOUTH CHINA UNIV OF TECH

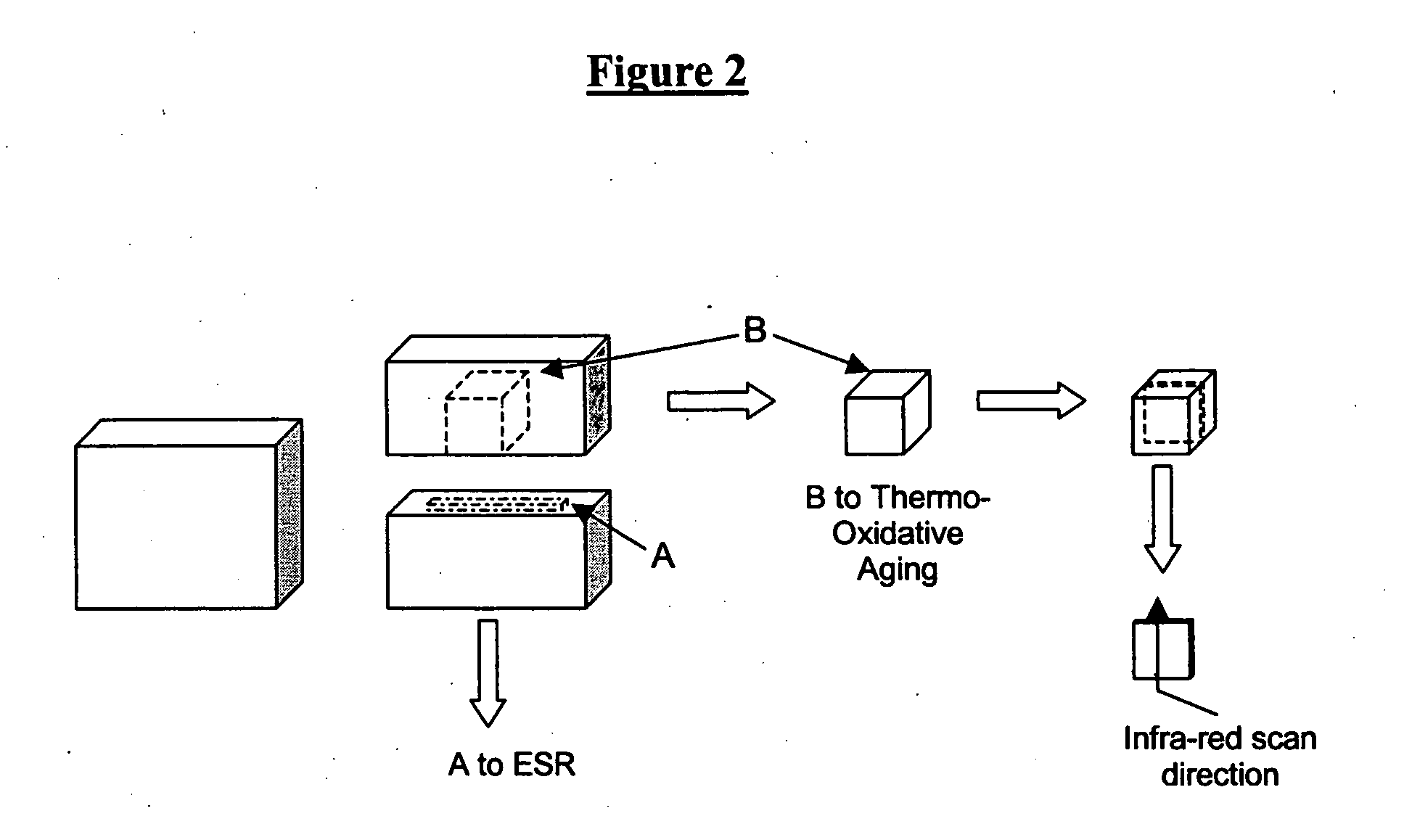

High modulus crosslinked polyethylene with reduced residual free radical concentration prepared below the melt

InactiveUS20050124718A1Reduced free radical concentrationReduced residual free radical contentSurgical adhesivesAnkle jointsPolymer scienceCross-linked polyethylene

The present invention provides an irradiated crosslinked polyethylene containing reduced free radicals, preferably containing substantially no residual free radical. Disclosed is a process of making irradiated crosslinked polyethylene by irradiating the polyethylene in contact with a sensitizing environment at an elevated temperature that is below the melting point, in order to reduce the concentration of residual free radicals to an undetectable level. A process of making irradiated crosslinked polyethylene composition having reduced free radical content, preferably containing substantially no residual free radicals, by mechanically deforming the polyethylene at a temperature that is below the melting point of the polyethylene, optionally in a sensitizing environment, is also disclosed herein.

Owner:THE GENERAL HOSPITAL CORP +1

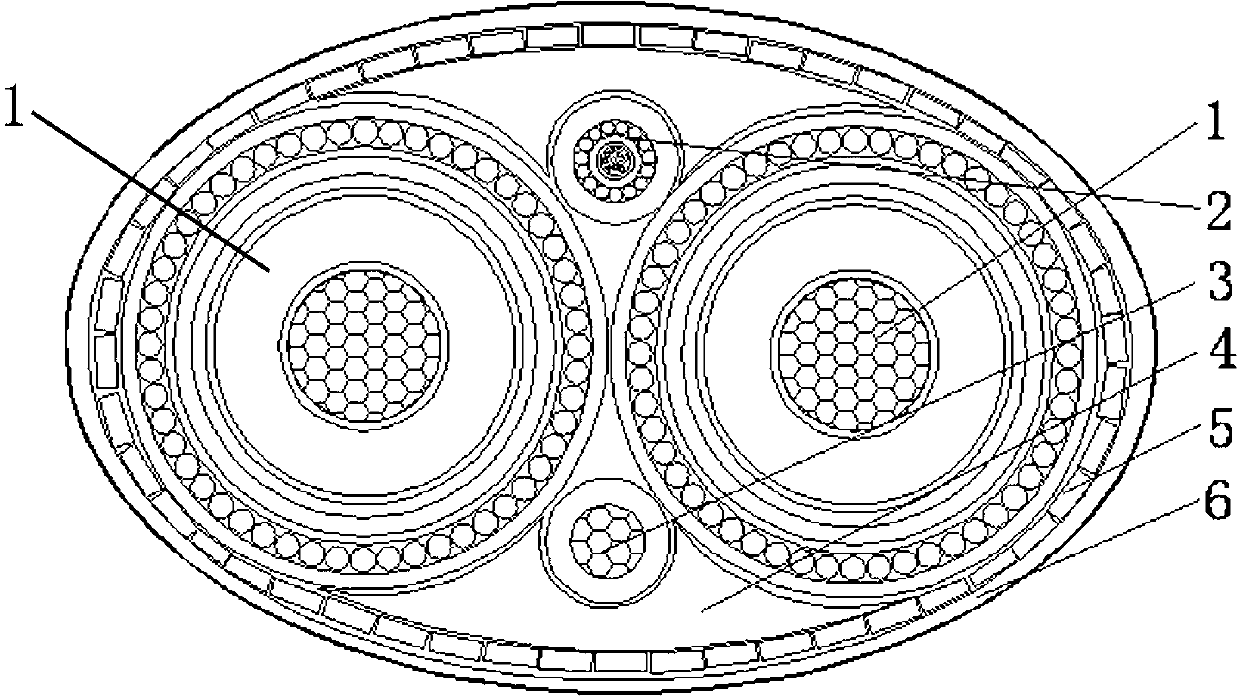

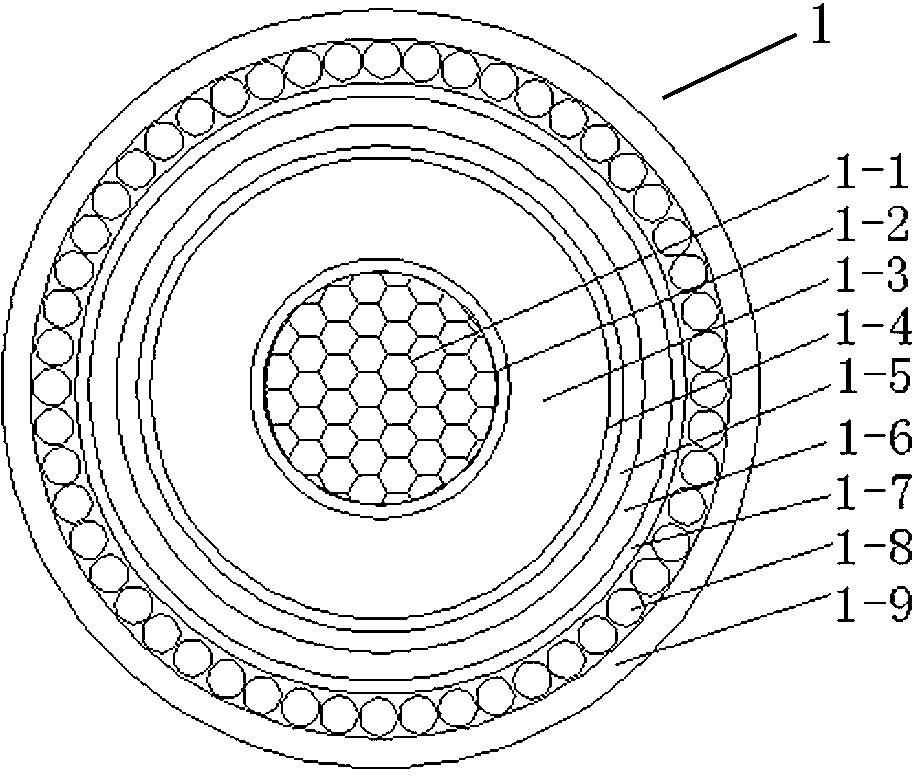

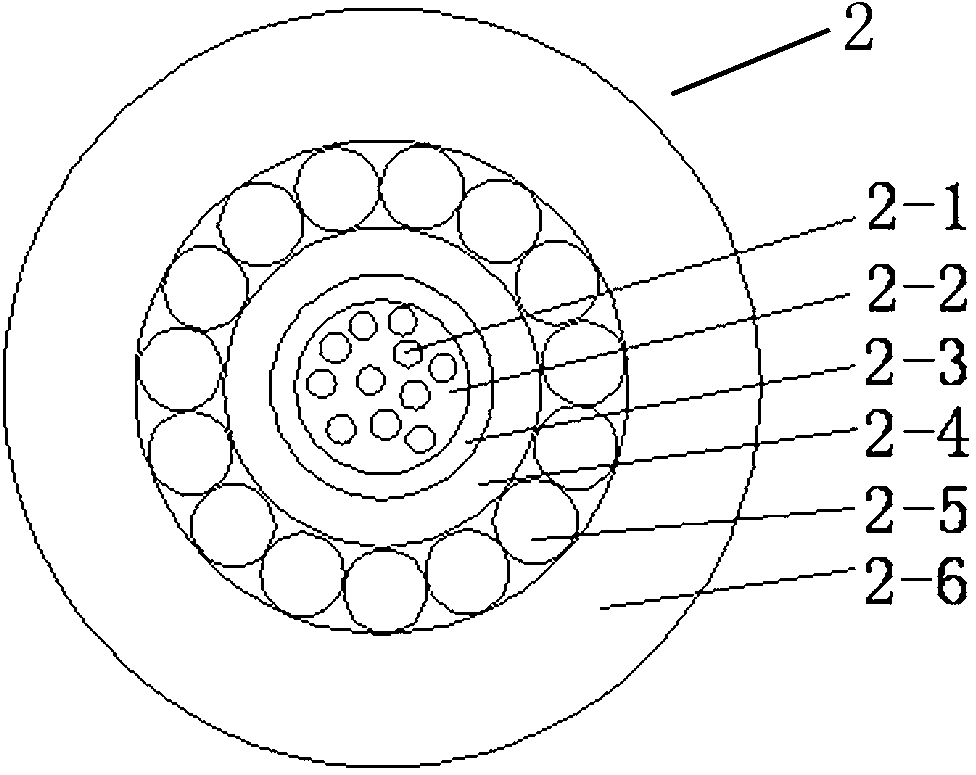

Ultrahigh pressure cross linked polyethylene insulated flexible direct-current optical fiber composite submarine cable

ActiveCN103000292AImprove workplaceImprove work field strength in insulation work fieldCommunication cablesOcean bottomUltra high pressure

The invention discloses an ultrahigh pressure cross linked polyethylene insulated flexible direct-current optical fiber composite submarine cable and relates to a direct-current cable. The ultrahigh pressure cross linked polyethylene insulated flexible direct-current optical fiber composite submarine cable is particularly used in large-power remote submarine power transmission in a flexible direct-current power consumption system of the vacuum control switch (VCS) current-switching technology and grid-tied connection among new energy alternating current systems of aperiodic operating wind power generation, tidal power generation and the like. The ultrahigh pressure cross linked polyethylene insulated flexible direct-current optical fiber composite submarine cable comprises direct-current cables, an optical fiber unit, a grounding feeder, filling strips, a main armor layer and an outer protective layer, wherein the two direct-current cables are respectively arranged on the left side and the right side, the optical fiber unit is arranged above the middle of the two direct-current cables, the grounding feeder is arranged under the middle portion of the two direct-current cables, and the cable is formed in a flat-supporting non-stranding mode; cable forming gaps are filled through arc-shaped filling strips; the direct-current cables, the optical fiber unit and the grounding feeder form the cable and then are armored through the main armor layer, the outer protectively layer is arranged on the surface of the main armor layer, anti-corrosion insulating glue is coated on each layer of polypropylene rope, and high-strength self-adhesive tapes are twisted outside the anti-corrosion insulating glue.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Polyolefin connectors

A one-piece polyolefin connector or polymeric blend connector with the characteristics of a polymer having the specific density of between 0.90 and 0.96 g / cc capitalizing on the aspect ratio of the connector and angularity of the sealing surface in combination for use in applications less physically demanding than those for use with crosslinked polyethylene material.

Owner:MERCURY PLASTICS LLC

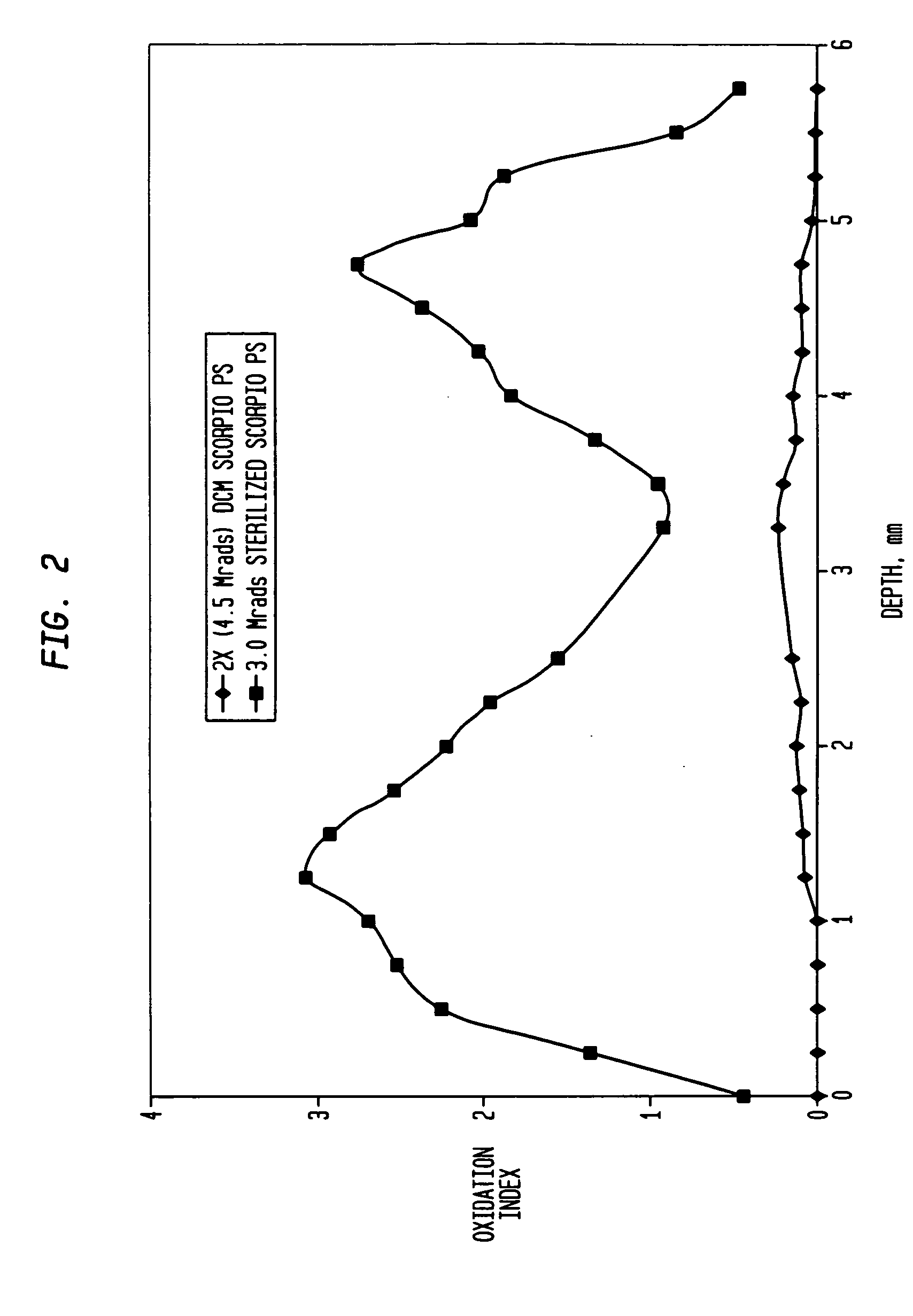

Sequentially cross-linked polyethylene

A method of producing an improved polyethylene, especially an ultra-high molecular weight polyethylene utilizes a sequential irradiation and annealing process to form a highly cross-linked polyethylene material. The use of sequential irradiation followed by sequential annealing after each irradiation allows each dose of irradiation in the series of doses to be relatively low while achieving a total dose which is sufficiently high to cross-link the material. The process may either be applied to a preformed material such as a rod or bar or sheet made from polyethylene resin or may be applied to a finished polyethylene part. If applied to a finished polyethylene part, the irradiation and annealing must be accomplished with the polyethylene material not in contact with oxygen at a concentration greater than 1% oxygen volume by volume. When applied to a preform, such as a rod, the annealing of the bulk polymer part of the rod from which the finished part is made must take place on the rod before the implant is machined therefrom and exposed to oxygen.

Owner:HOWMEDICA OSTEONICS CORP

Polymer composition comprising cross-linked polyethylene and methods for making the same

The invention provides a polymer composition comprising cross-linked polyethylene having a non-polar biocompatible lipid disposed in at least a portion of the free volume of the polyethylene. The invention further provides methods for making the polymer composition.

Owner:DEPUY PROD INC

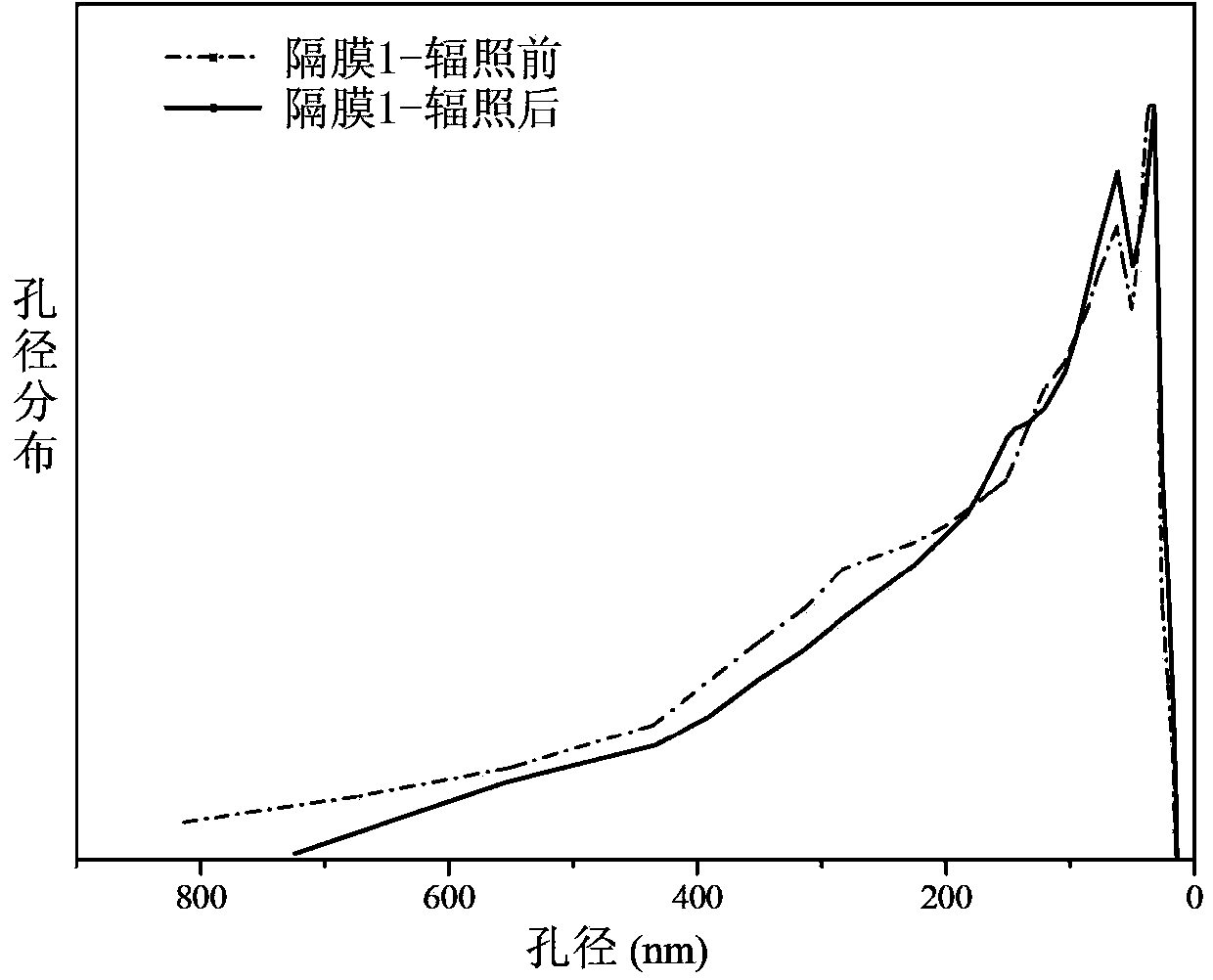

Irradiation cross-linking lithium-ion battery diaphragm and preparation method thereof

ActiveCN103421208AImprove securityLow closed cell temperatureCell component detailsCross-linkPolymer science

The invention discloses a preparation method of an irradiation cross-linking polyethylene porous diaphragm. According to the method, the polyethylene porous diaphragm is soaked in and adsorbs a volatile solvent containing initiator and cross-linking agent to lead initiator and cross-linking agent into the surface and the interior of the polyethylene porous diaphragm, and is then treated with irradiation cross-linking underwater or under the protection of inert gas, and a locally cross-linked diaphragm is obtained by controlling the cross-linking condition. The irradiation cross-linking lithium-ion battery diaphragm has the advantages that the tensile strength and the hydrophily are greatly improved; the high-temperature hot-shrinkage rate is greatly reduced; the defect of low membrane rupture temperature is overcome; the membrane rupture temperature is greatly raised while the normal hole closing of the diaphragm is guaranteed; the hole closing temperature of the diaphragm is 120 to 140 DEG C; the membrane rupture temperature is raised to be higher than 160 DEG C.

Owner:ZHEJIANG UNIV +2

Highly cross-linked and wear-resistant polyethylene prepared below the melt

InactiveUS20070043137A1Improve diffusivityHigh-frequency sonicationCross-linked polyethyleneWear resistant

The present invention provides irradiated crosslinked polyethylene containing reduced free radicals, preferably containing substantially no residual free radical. Processes of making crosslinked wear-resistant polyethylene having reduced free radical content, preferably containing substantially no residual free radicals, by mechanically deforming the irradiated PE either with or without contact with sensitizing environment during irradiation and annealing the post-irradiated PE at a temperature that is above the melting point of the PE, are also disclosed herein.

Owner:THE GENERAL HOSPITAL CORP +1

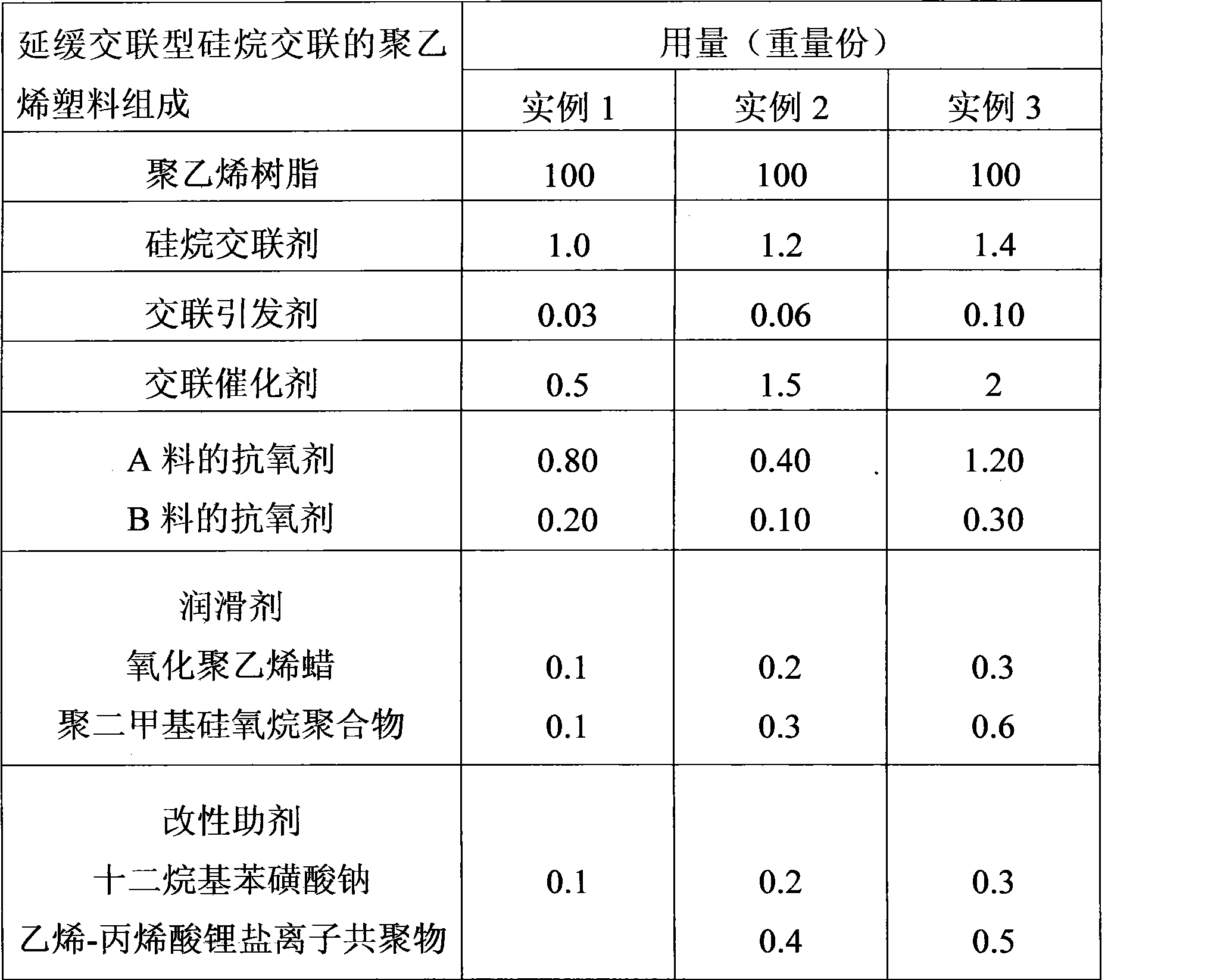

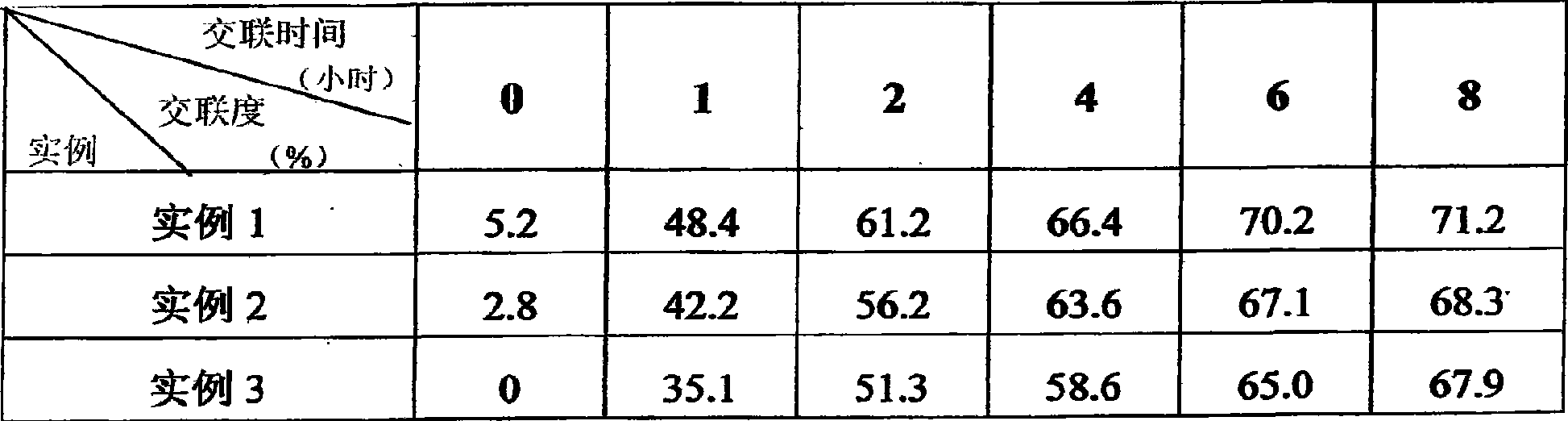

Delayed cross-linked type silicane cross-linked polyethylene plastic

ActiveCN101531783AReduce occurrenceExtended cleaning cyclePlastic/resin/waxes insulatorsRigid pipesCross-linkCross-linked polyethylene

Owner:上海高分子功能材料研究所

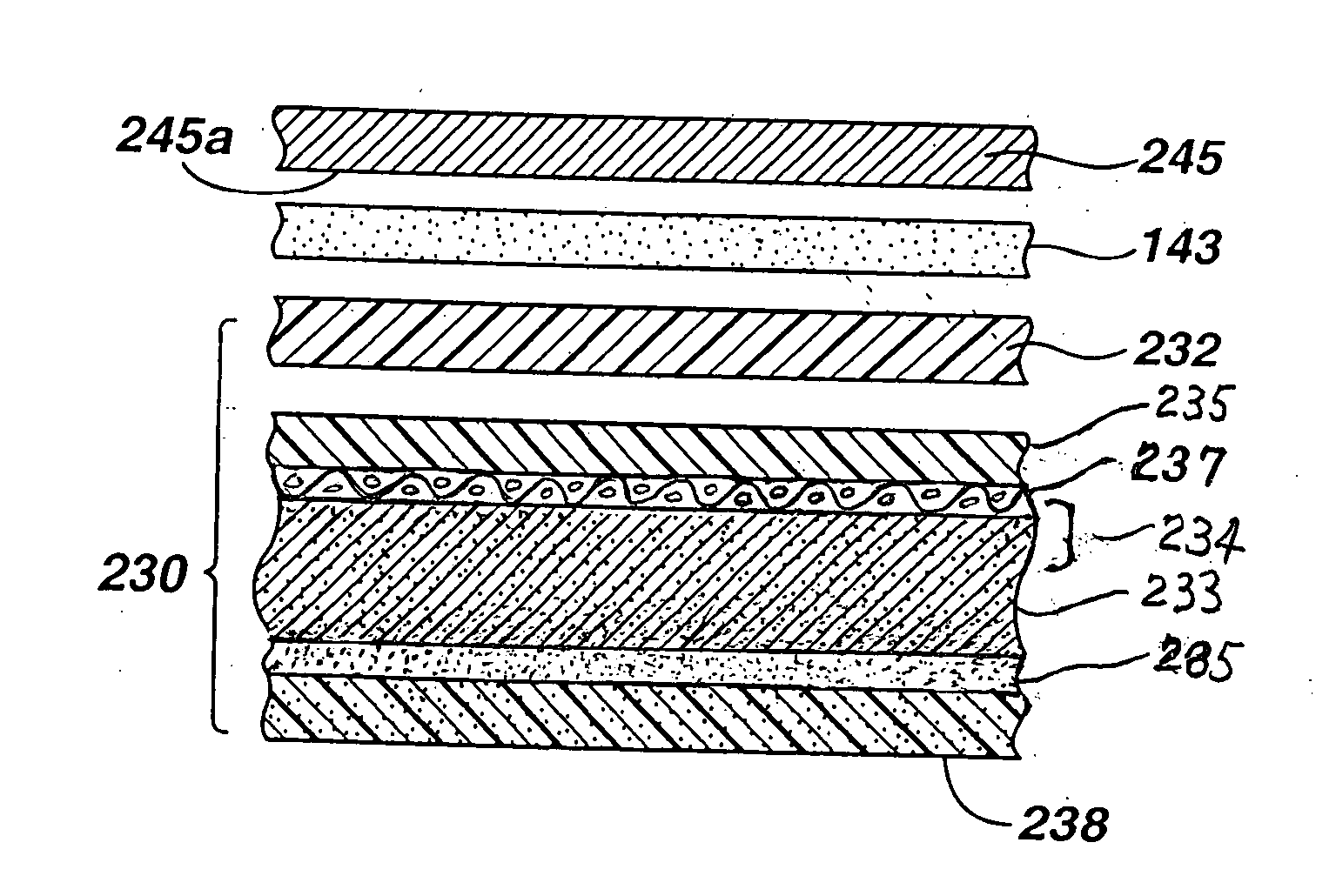

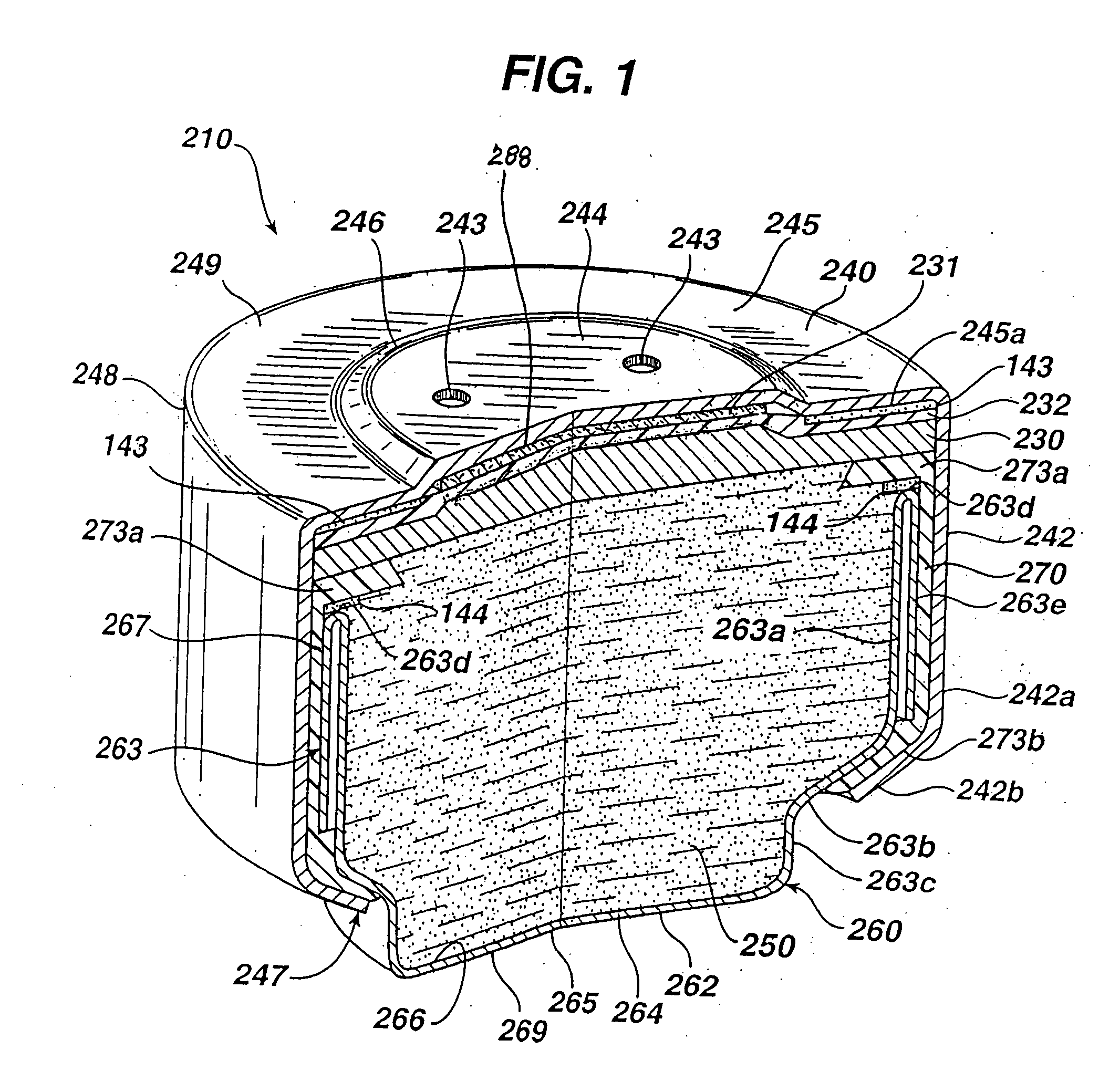

Zinc/air cell

InactiveUS20070224495A1Improve ionic conductivityResists deterioration in ionic conductivityFuel and primary cellsNon-aqueous electrolyte accumulator electrodesPolyvinyl alcoholButton battery

A zinc / air depolarized cell wherein the anode comprises zinc particles, aqueous alkaline electrolyte, and aqueous alkaline electrolyte within said anode casing; a cathode within said cathode casing; and an electrolyte permeable separator between said cathode and anode; and a glue comprising crosslinked polyvinylalcohol, preferably crosslinked with a boron containing compound, said glue located between the separator and a side of said cathode to adhesively bond the separator to the cathode. The cell may be in the form of a button cell. The glue provides a strong adhesive bond between the separator, desirably of microporous polypropylene, and the cathode. The glue promotes ionic conductivity at the separator / electrode interface even when the zinc / electrolyte ratio within the anode is elevated.

Owner:DURACELL U S OPERATIONS

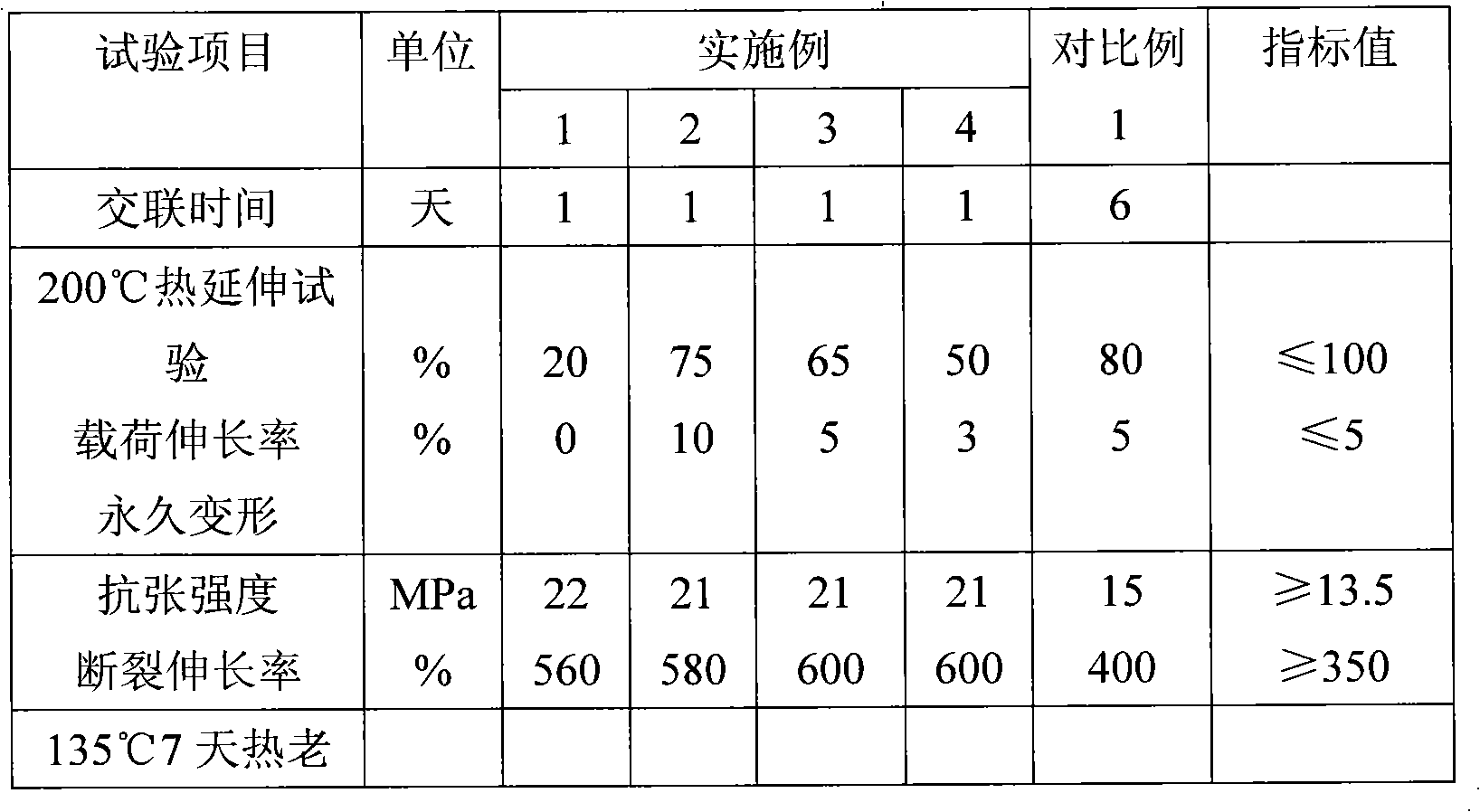

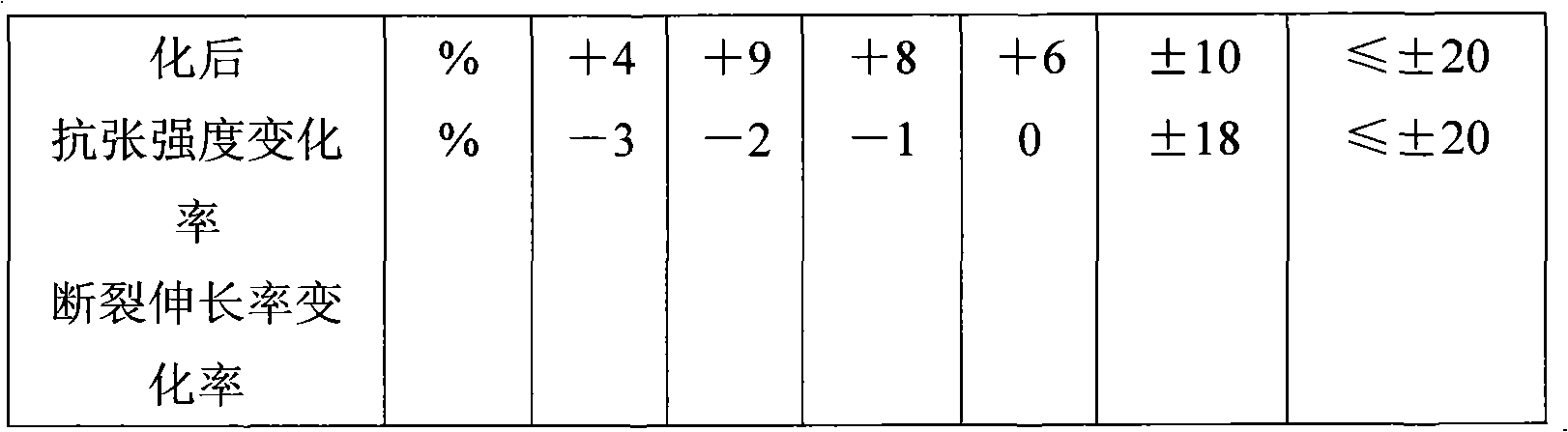

Room-temp, silane cross linked polyethylene plastic and its preparation method

An ordinary-temp silane cross-linked polyethylene plastics used for insulating layer of electric cable and plastic tube is prepared from polyethylene resin, silane cross-linking agent, metal passivating agent, cross-linking catalyst, carrier and antioxidizing agent through preparing the silane grafted material, preparing mother material of catalyst, mixing them together, extruding out for shaping, and laying aside for 1-3 days.

Owner:上海高分子功能材料研究所

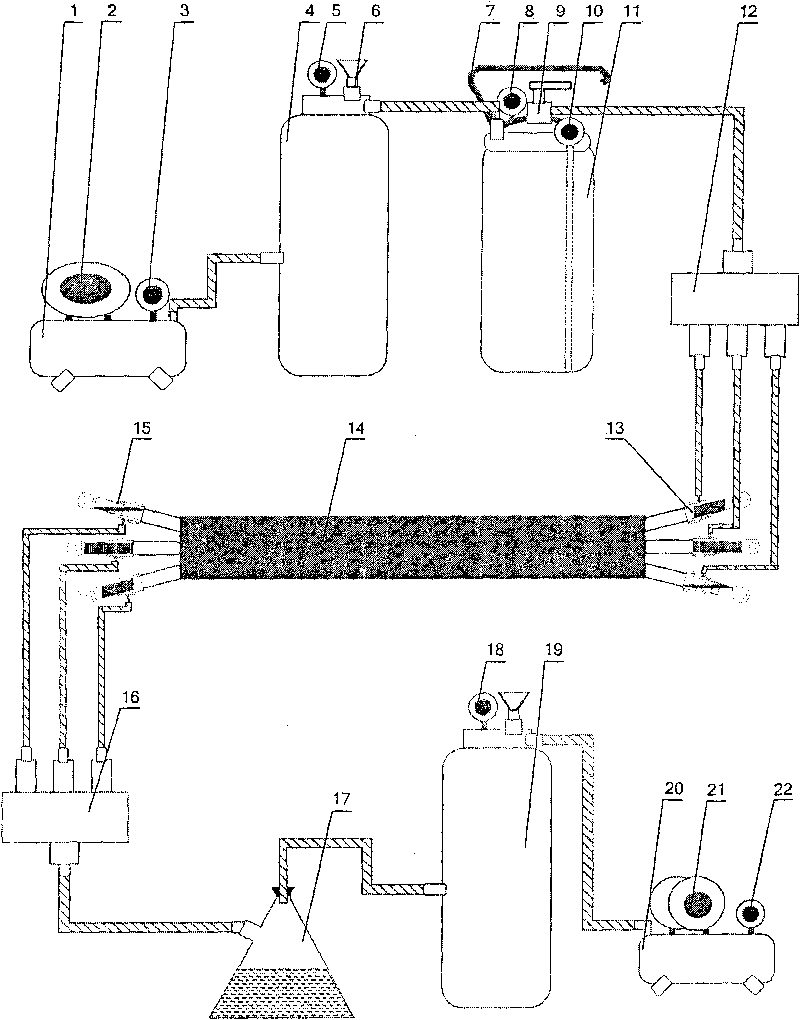

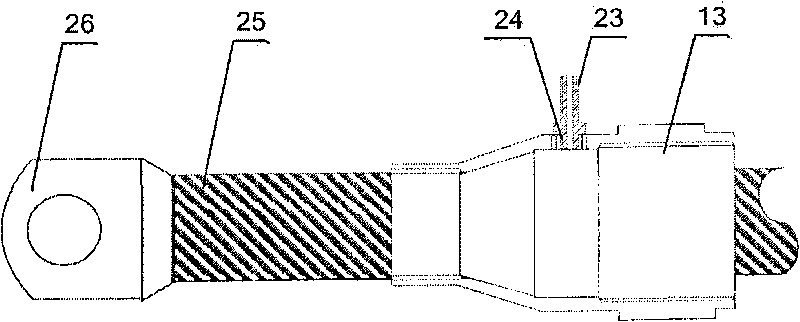

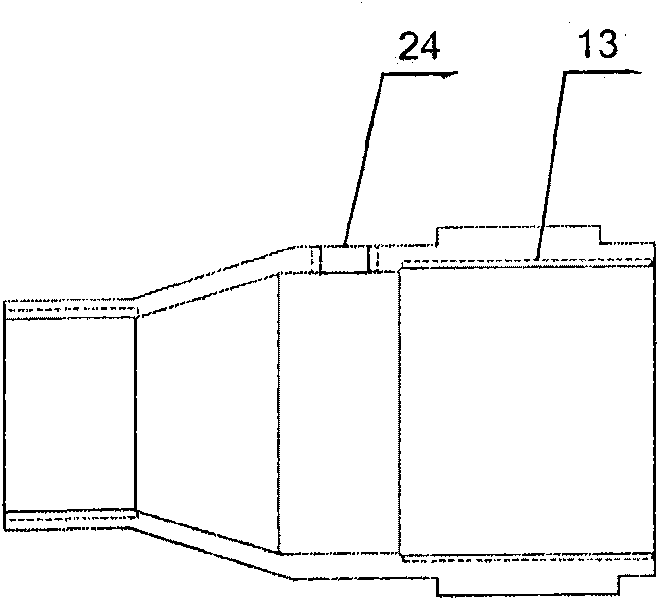

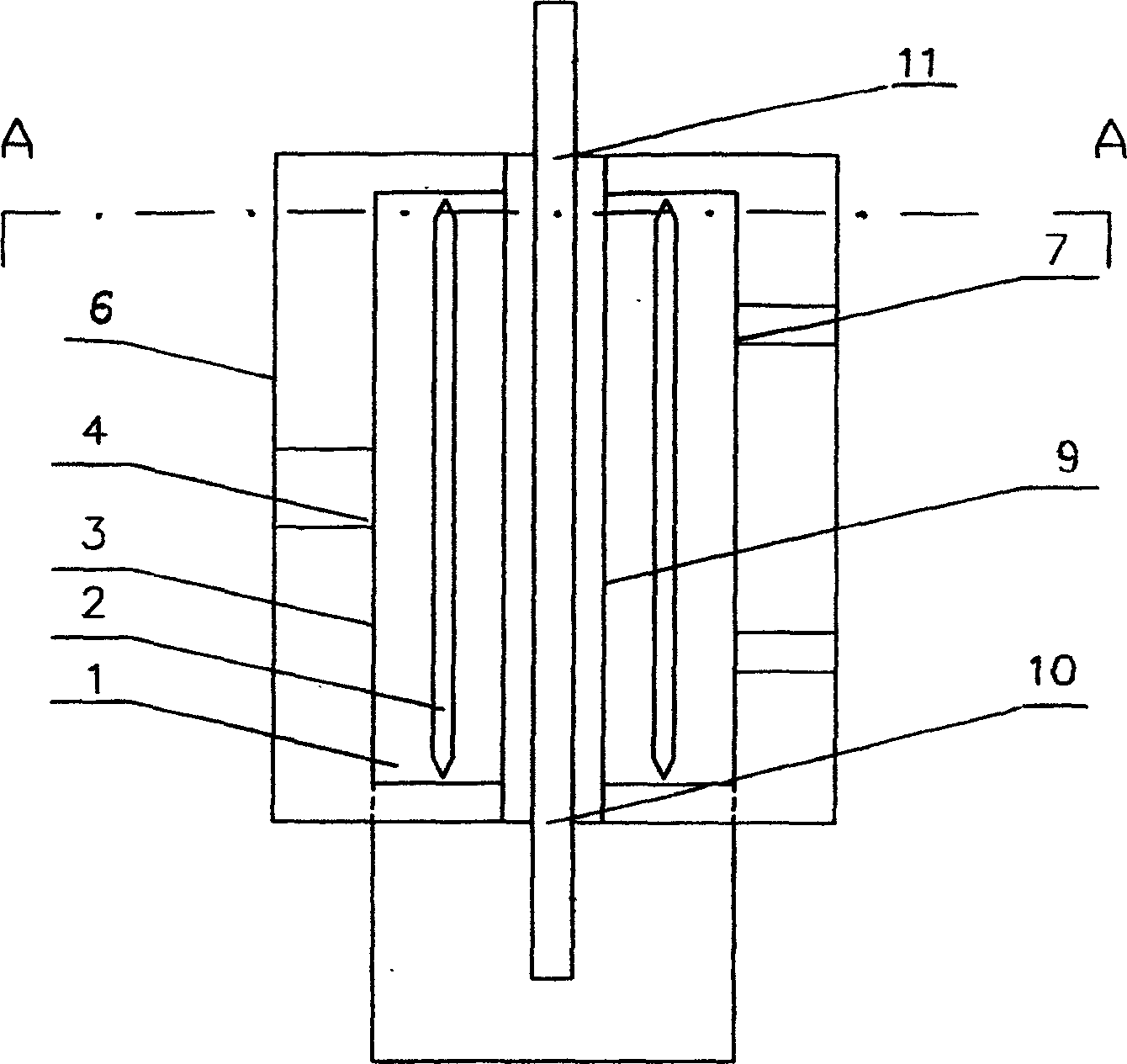

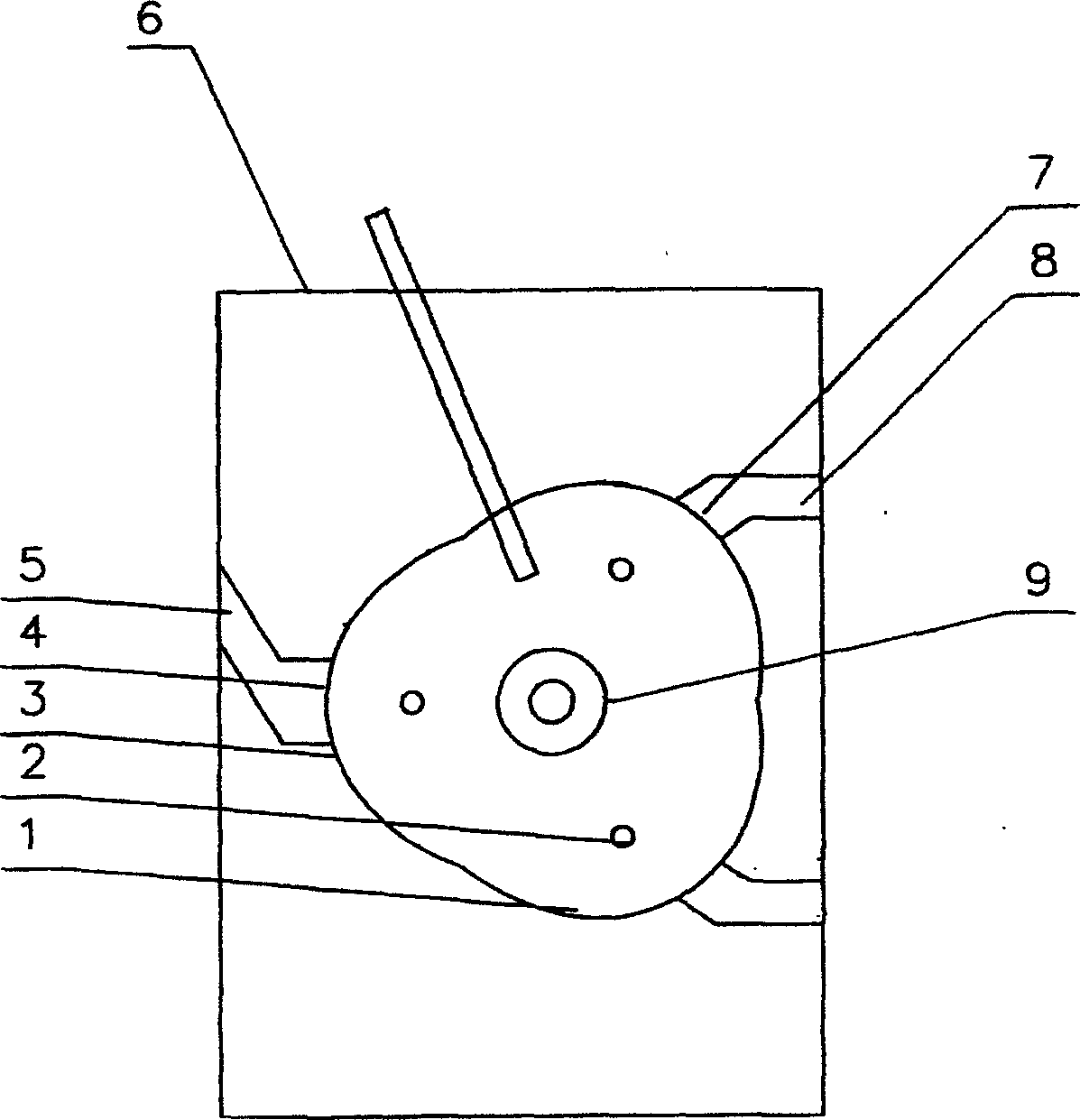

Electrified repair device for cross-inked polyethylene power cable and electrified repair method thereof

ActiveCN101728792AEnsure safetyLow costApparatus for repairing insulation/armouring cablesVacuum pumpingPower cable

The invention discloses an electrified repair device for a cross-inked polyethylene power cable and an electrified repair method thereof. The device is characterized in that the device comprises a repair hydraulic pressure injection system, a vacuum pumping system as well as repair liquid adapters (13, 15) and taps (12, 16) which are positioned at both ends of a cable, wherein the repair liquid adapter (13) at one end of the cable is connected with the repair hydraulic pressure injection system through the tap (12), and the repair liquid adapter (15) at the other end of the cable is connected with the vacuum pumping system through the tap (16); the repair hydraulic pressure injection system is that an air compressor (1), a gas water-absorbing tank (4) and a repair liquid tank (11) are orderly connected with the tap (12) and the repair liquid adapter (13); and the vacuum pumping system is that the repair liquid adapter (15), the tap (16), a residual liquid collection bottle (17), a filtering tank (19) and a vacuum aspirator (20) are orderly connected.

Owner:SICHUAN UNIV

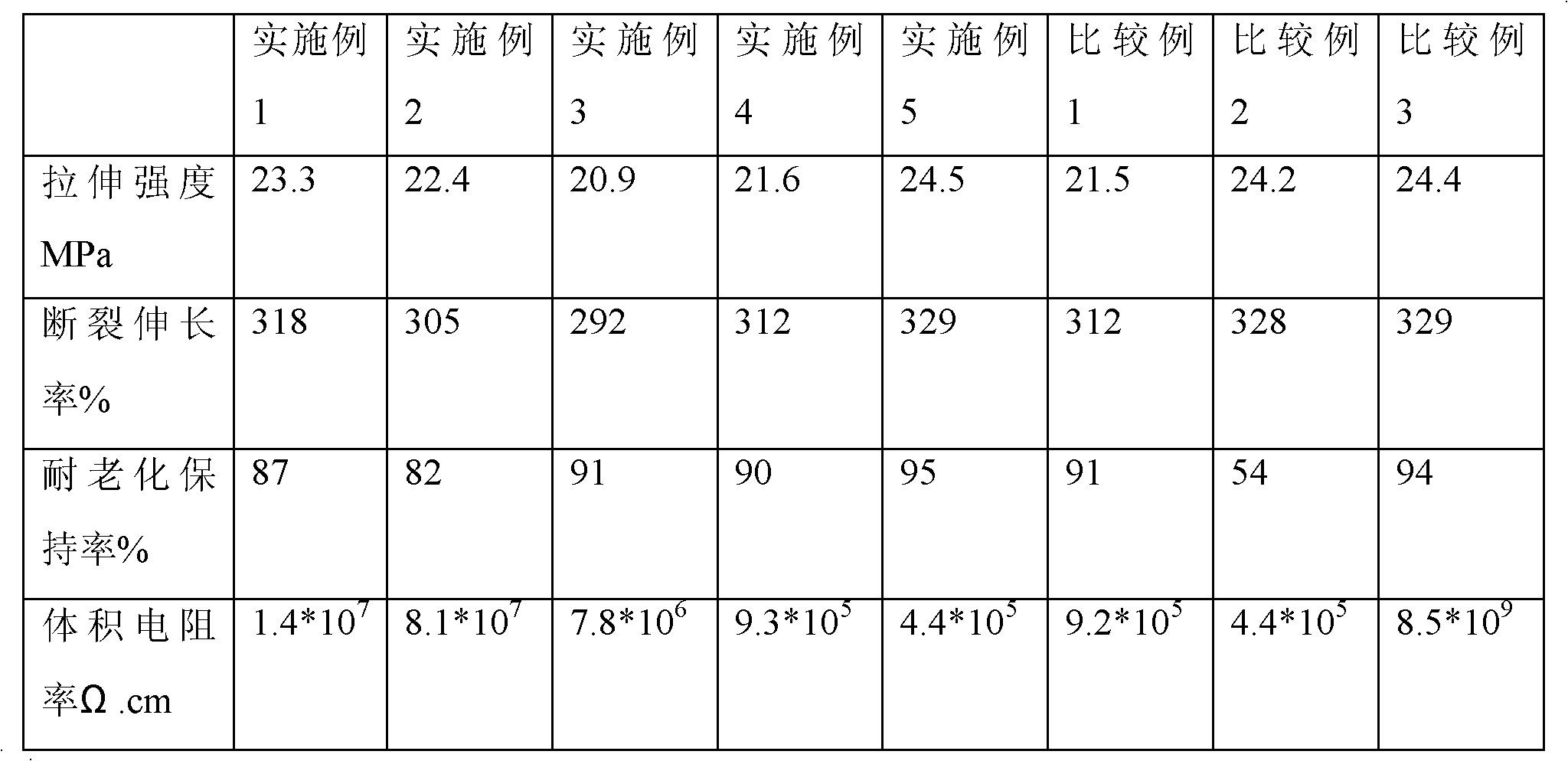

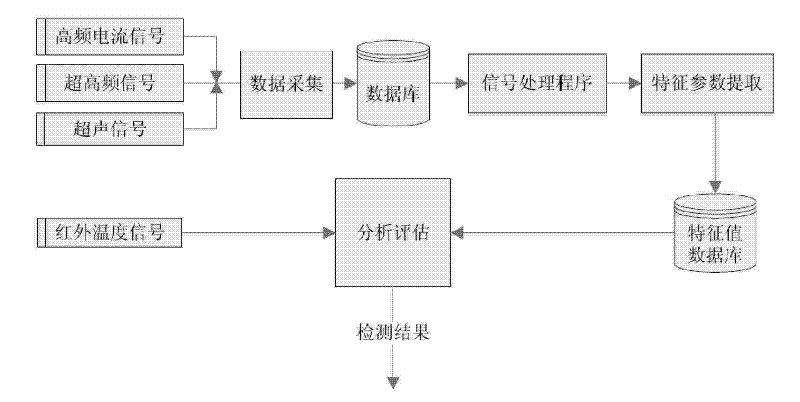

Weather-proof flame retardation antistatic crosslinking polyethylene tubing, preparation method and application

InactiveCN102993537AGood weather resistanceStrong persistenceGeneral water supply conservationRigid pipesLow-density polyethyleneAntistatic agent

The invention belongs to the high-molecular plastic modification technology and processing technology field, and relates to a crosslinking polyethylene tubing, a preparation method and an application. The tubing comprises the following components by weight: 100 parts of low density polyethylene, 0.5-1.2 parts of anti-oxidant, 0.3-0.6 parts of assisted anti-oxidant, 8-15 parts of fire retardant, 0-5 parts of flame retardation synergistic agent, 0.8-1.5 parts of antistatic agent, 1.2-1.6 parts of cross-linking agent, 0.8-1.2 parts of coupling agent, 0.8-1.2 parts of dispersant, 0.2-0.5 parts of catalyst and 0-12 parts of additive. Compared with the prior art, the tubing has advantages of stable flame retardation and antistatic property, fireproof and explosion-proof capability, aging resistance, long usage life, light weight, convenient transport and installation. The weather-proof flame retardation antistatic crosslinking polyethylene tubing used for mining is suitable for pipelines of water supply, air exhaust, air compress, gunniting and gas discharge under a coal mine well, the usage is safety and environmental protection.

Owner:嘉兴林鑫管业科技股份有限公司

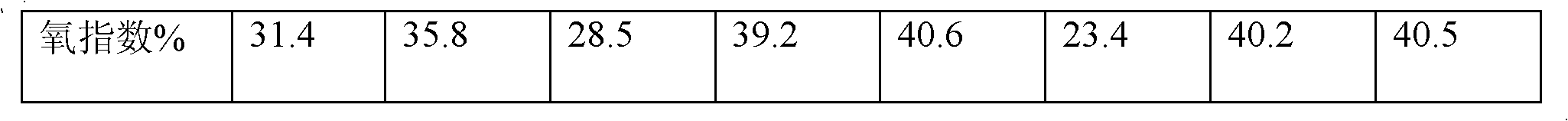

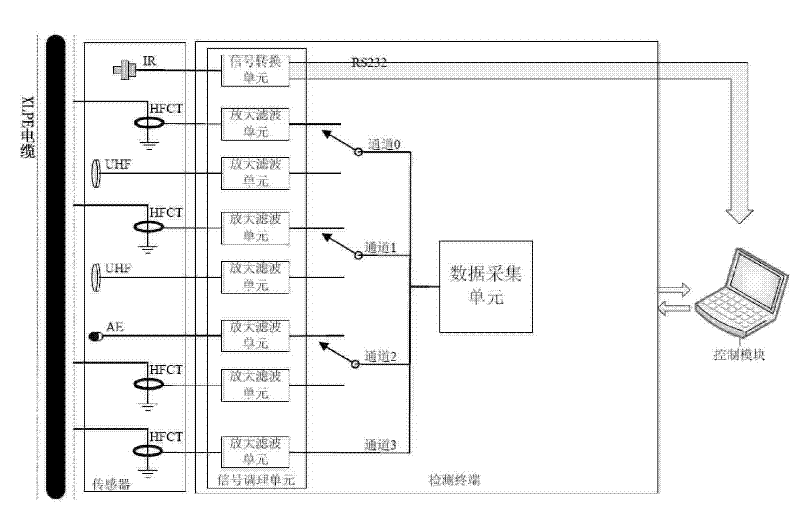

Portable cable local discharge detection device

ActiveCN101750573ACompact structureConvenient mobile detectionTesting dielectric strengthPower cableSignal-to-noise ratio (imaging)

The invention relates to a portable cable local discharge detection device in the technical field of electric power detection. The portable cable local discharge detection device comprises a sensor, a detection terminal and a control module, wherein the input end of the sensor is connected with an electric cable for detection, the output end of the sensor is connected with the detection terminal for transmitting an analog sensing signal, and the control module is connected with the detection terminal for receiving the analog sensing signal and outputting a control instruction and a detection result. The invention has compact structure, convenient mobile detection because a box body is provided with a wheel structure, high working efficiency, higher sensitivity and signal to noise ratio, and can be applied to effectively detecting local discharge of a cross linked polyethylene (XLPE) cable on site by comprehensively applying four detection methods of a high-frequency current method, an ultrahigh frequency method, an ultrasonic method and an infrared temperature method.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

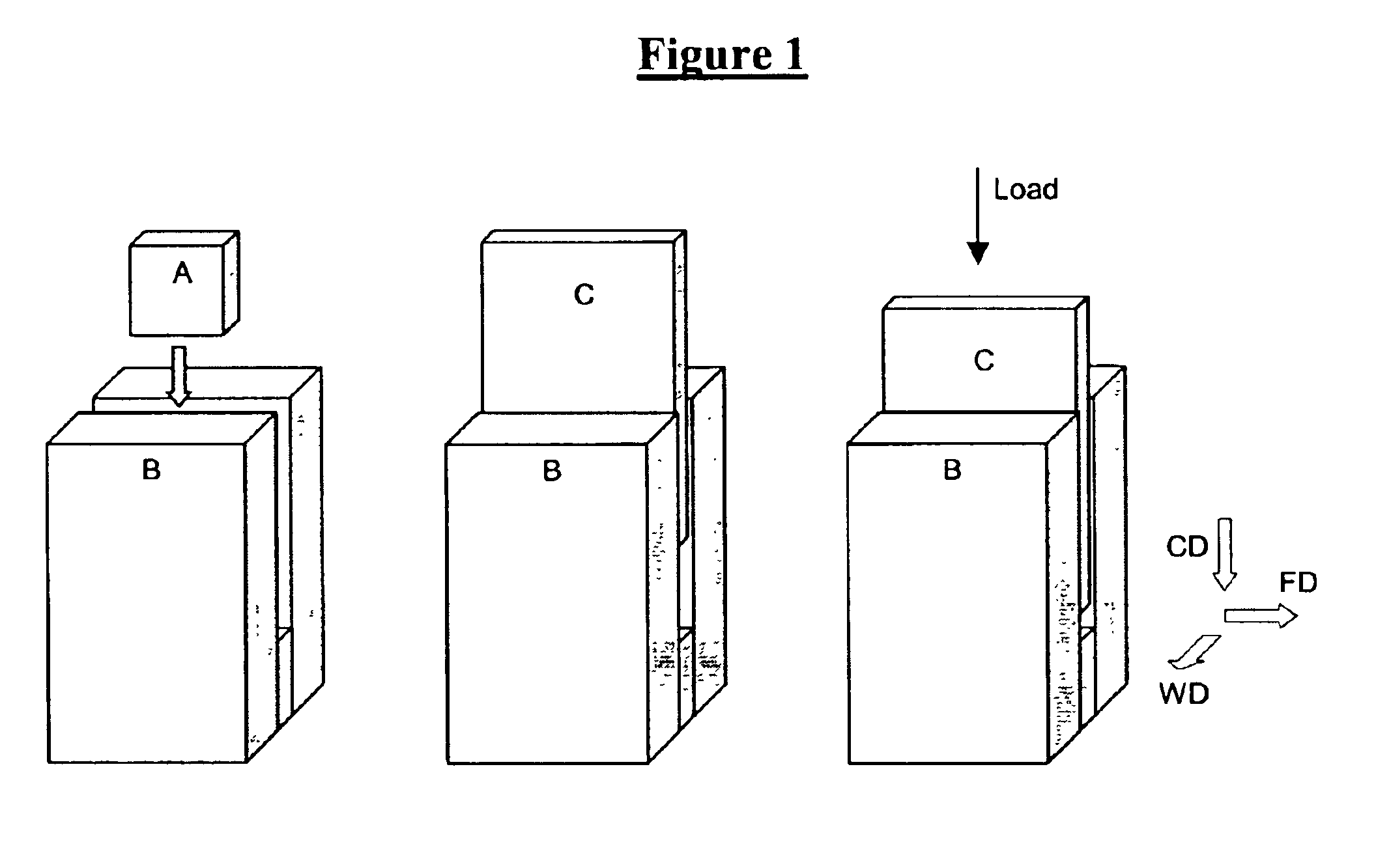

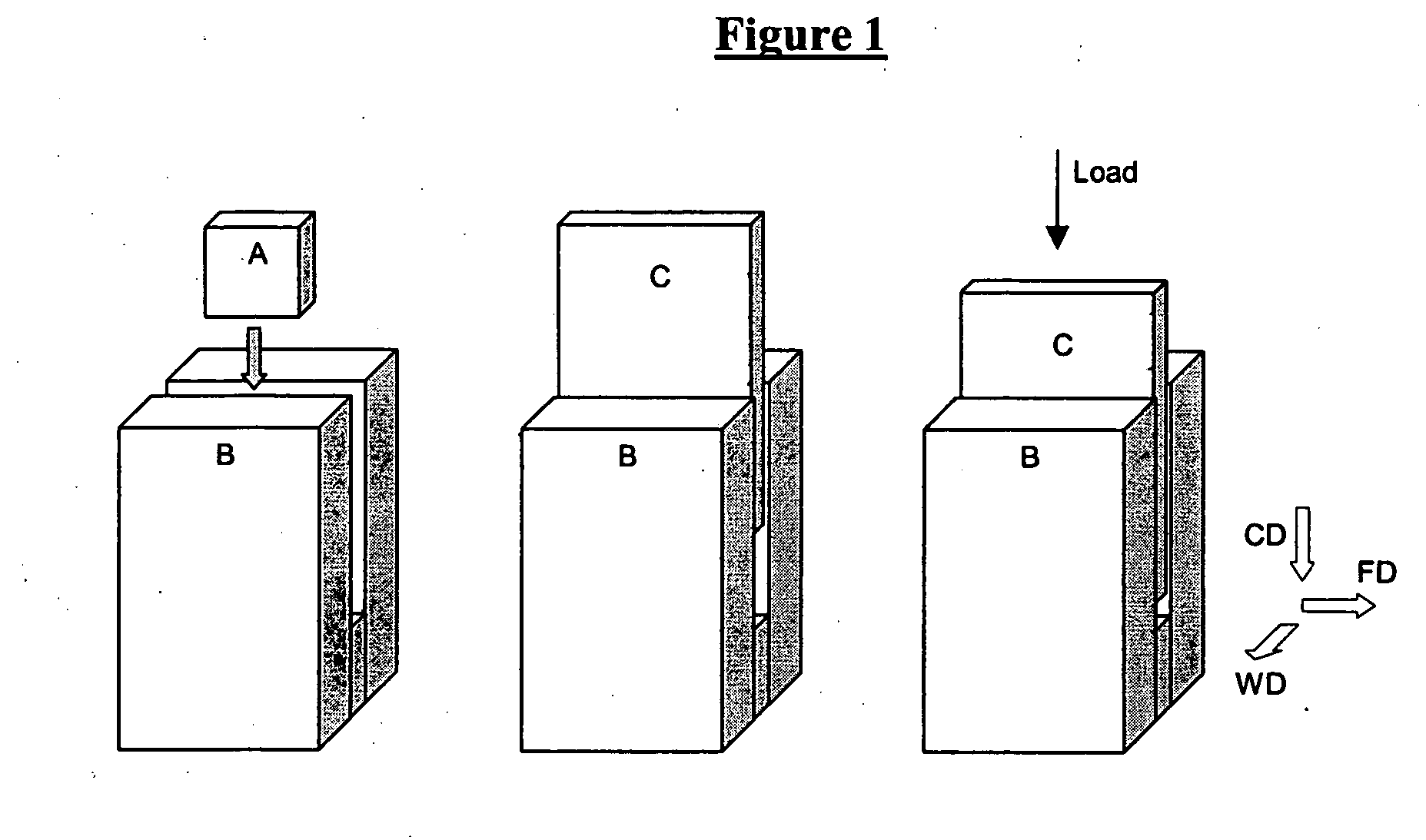

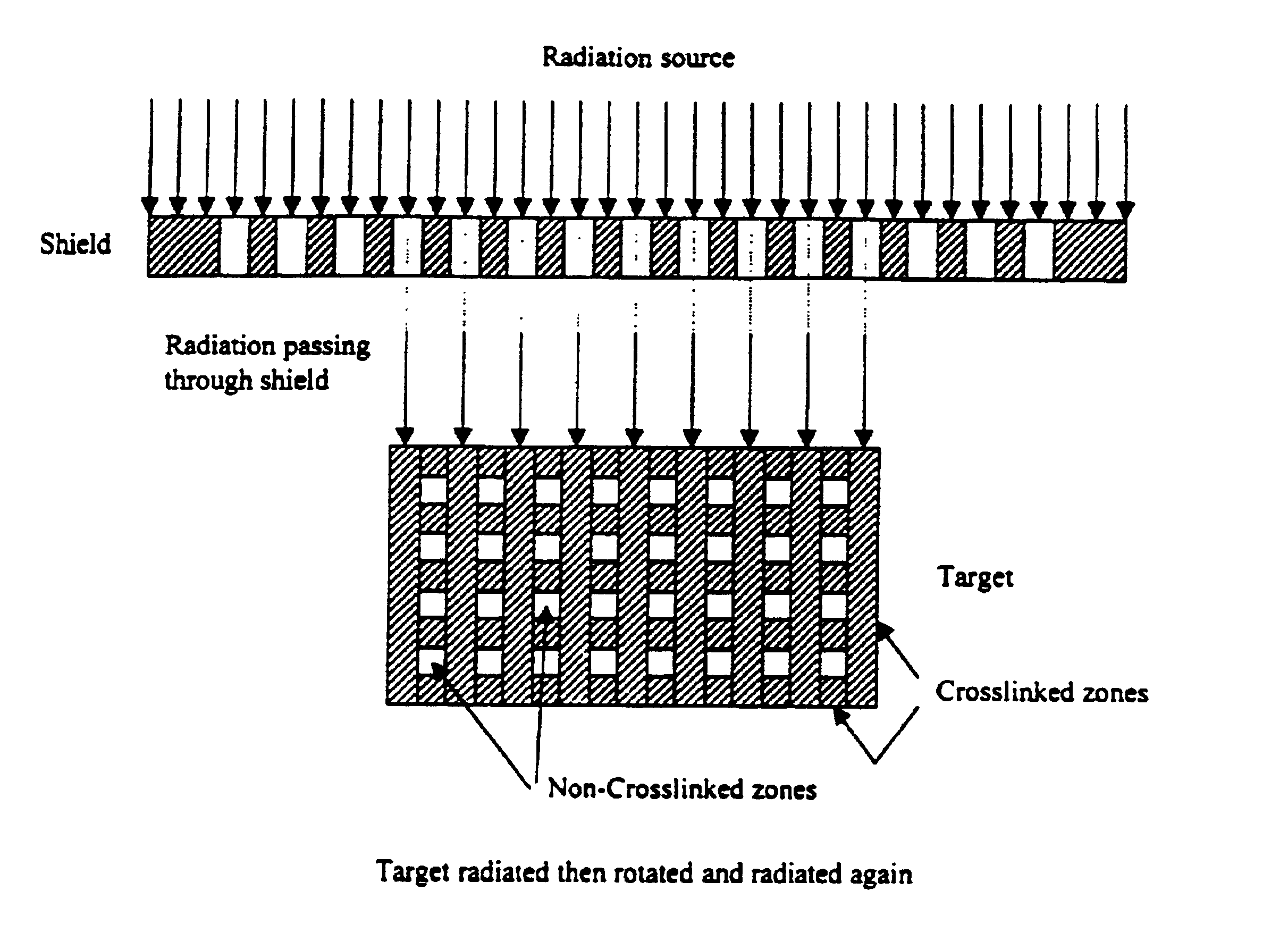

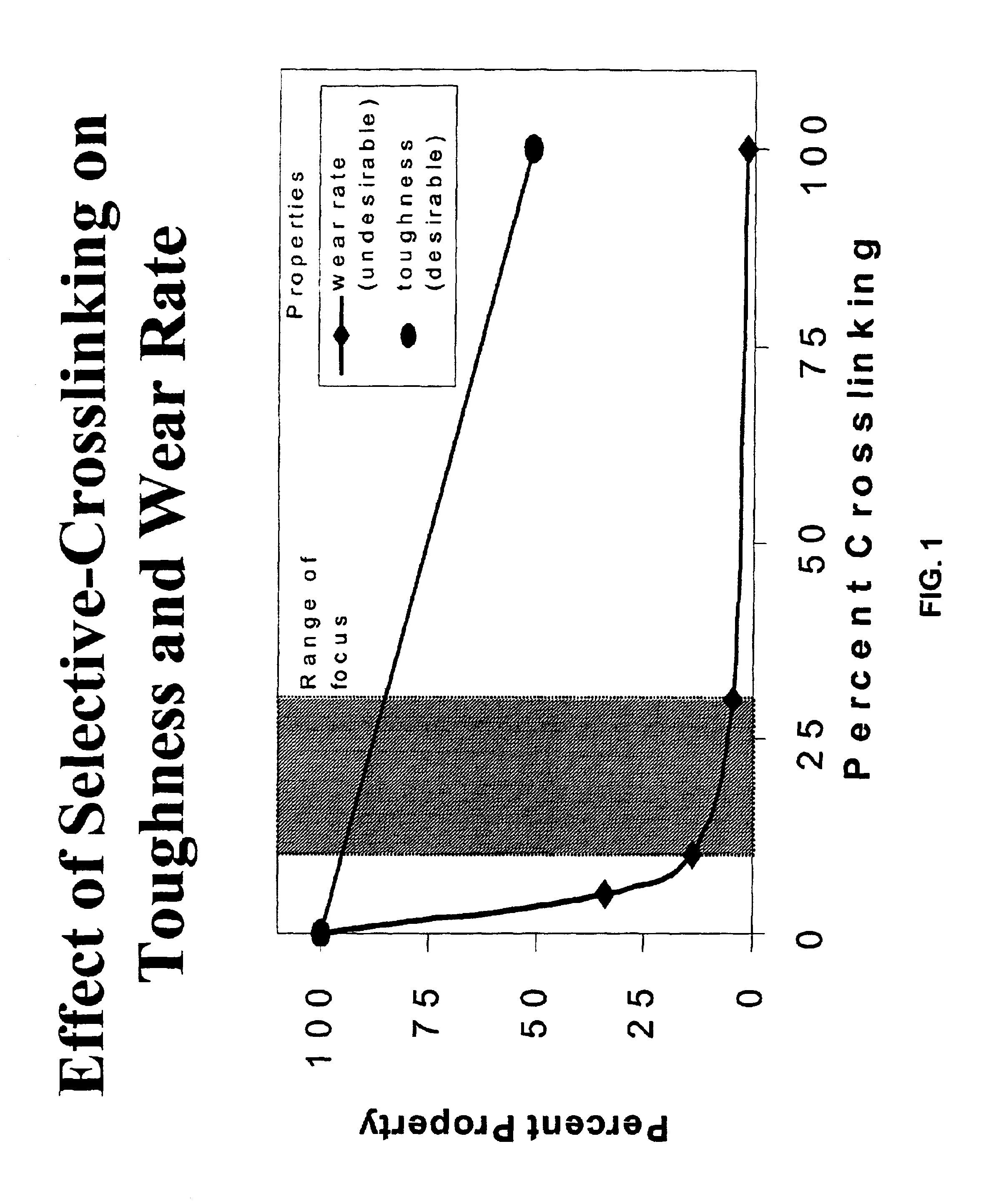

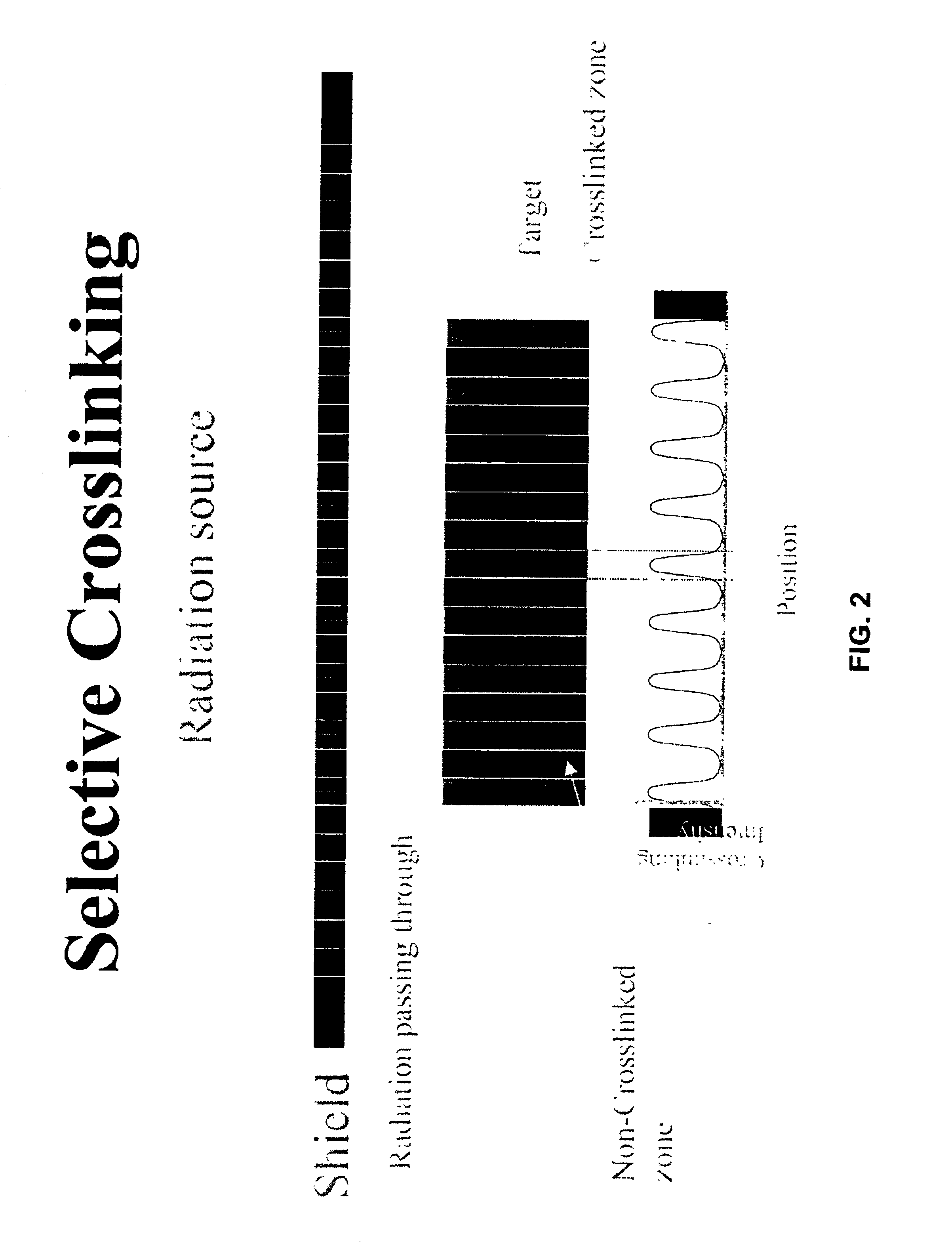

Methods for preparing selectively cross-linked polyethylene orthopedic devices

InactiveUS6849224B2Improve wear characteristicsLimited amountDiagnosticsSurgical needlesCross-linkCross-linked polyethylene

An improved prosthetic medical device having improved wear resistance and toughness is provided in the present application. A method is provided to selectively cross-link the polymeric matrix comprising the medical device by employing an interrupting means such as a mask, wire mesh or chopper wheel placed in between the medical device and irradiation source. In addition, the medical device may be translated while being irradiated to further effect the selective cross-linking. The present invention also provides for an injection molding process wherein a prosthetic medical device is formed in a single step, then selectively cross-linked.

Owner:HOWMEDICA OSTEONICS CORP

Compound danshen oral disintegrant tablet and its preparation method

The present invention relates to a compound salvia oral disintegrant tablet capable of being disintegrated quickly in oral cavity to release medicine. It composition includes the salvia root extract, notoginseng total saponin, borneol and excipient, and its disintegration time is within 40 sec, in which the excipient includes filling agent, disintegrant, glidant and corrective. Its filling agent is of microcrystalline cellulose, its dose is 40%-90% of total weight of the prescription, and the disintegrant is selected from sodium carboxymethylstarch, cross-linked carboxymethylcellulose sodium, cross-linked polyvinylpyrrolidone and low-substituted hydroxypropyl cellulose, and its dose is 5%-25% of total weight of prescription.

Owner:BEIJING BOERDA BIO TECH DEV

Method for judging aging state of cross linked polyethylene (XLPE) cable insulation water tree

InactiveCN102778638AAccurate judgmentLow frequency conductivityTesting dielectric strengthActivation energyTest sample

The invention relates to a method for comprehensively accessing and diagnosing aging degree of a cable insulation water tree by testing data such as insulation dielectric loss peak, low frequency conductivity, lamella thickness change and group disappearance of a cable. The method can accurately judge insulation performance of a cross linked polyethylene (XLPE) cable from the microscopic view, and especially can effectively access insulation aging state of the cable producing the water tree. The aging degree of the cable insulation water tree is high when a cable insulation test sample has the following characteristics: the activation energy corresponding to the loss peak a at a low frequency position is appropriately equal to 0.14eV, the change of the electric conductivity of low frequency of 0.1Hz s is largest along with the aging time, the methyl group value cannot be observed at the position of 2700cm<-1>, the lamella thickness is smaller than 54.34*10-10m, and the like.

Owner:CHINA ELECTRIC POWER RES INST

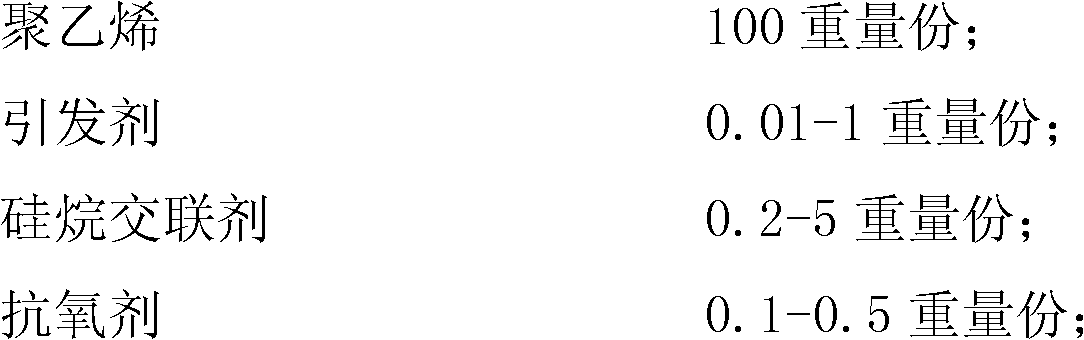

Silane cross-linked polyethylene insulating material and production method thereof

InactiveCN102532664AEvenly dispersedIncrease the degree of cross-linkingPlastic/resin/waxes insulatorsSilanesAntioxidant

The invention provides a silane cross-linked polyethylene insulating material composition, which comprises a material A and a material B, wherein the material A is composed of the following components in parts by weight: 100 parts of polyethylene, 0.01-1 parts of initiator, 0.2-5 parts of silane cross-linking agent, and 0.1-0.5 parts of antioxidant; the material B is composed of the following components in parts by weight: 100 parts of polyethylene, 0.5-5 parts of catalyst, 0.01-5 parts of processing aid, and 0.1-0.5 parts of antioxidant; and the material A is mixed and extruded by a reciprocating single-screw extruder.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

Infrared irridiation crosslinked polyethylene plastic for pipe, wire and cable and its preparing method

ActiveCN1749303AHigh mechanical strengthImprove heat resistanceTubular articlesCross-linkPolymer science

The polyethylene plastic consists of polyethylene resin 100 weight portions, peroxide as cross-linking agent 0.2-2.5 weight portions, antioxidant 0.01-1.5 weight portions, auxiliary cross-linking agent 0.01-10 weight portions, lubricant 0.1-5 weight portions, and stuffing 0-80 weight portions. All the materials are mixed fully, the mixture is pelletized in an extruder at 80-190 deg.c, and the pelletized product is dried to water content less than 200 ppm and stored inside vacuum packing bag. When used, the pelletized material is extruded into pipe, wire or cable coating and hot radiation cross-linked in special infrared irradiation equipment to form cross-linked polyethylene product with excellent mechanical performance and heat performance.

Owner:上海高分子功能材料研究所

Method for preparing crosslinkable polyethylene cable material

The invention discloses a preparation method of crosslinkable polyethylene cable material, which includes the steps and the following components are represented in proportion by weight: throwing polyethylene 75-95 proportion by weight, ethylene-vinyl acetate copolymer 0-20 proportion by weight, unsaturated silicone hydride 1.0-5 proportion by weight, free radical evocating agent 0.1-0.5 proportion by weight, organotin catalyst 0.1-1 proportion by weight, organic acid compound 0.1-1 proportion by weight, anti-oxidant 0.1-0.5 proportion by weight, anti-copper agent 0.1-0.5 proportion by weight, and lubricant 0.5-2 proportion by weight into the high speed mixing machine with rotary speed at 80-120 rpm for mixing 15-25 minutes, and then adding the mixture into the double-screw extruder, melting and prilling for obtaining crosslinkable polyethylene cable material. The method provided by the invention mixes all the material and dispersing uniformly, and then executes grafting reaction, thereby realizing more uniform grafting reaction and guaranteeing homogeneity of the crosslinking process, in addition, the invention uses organic acid compound which remarkably improves catalysis function of organotin catalyst, and improves crosslinking speed of silicone hydride, and overcomes the defect that the conventional silicone hydride crosslinked plastic can be linked only in warm water or steam environment with long time cooking, thereby saving production cost for manufacturer considerably. The crosslinkable polyethylene cable material obtained according to the invention is extruded by plastic cable extrusion machine unit for obtaining cable insulation layer, and is placed under the condition of 23 DEG C. with 50% humidity for one day naturally, then the crosslinking process is finished, moreover the product can pass performance indexes of hot extension performance test, dynamics test and aging characteristic test according to the national standard request.

Owner:SHANGHAI JIAO TONG UNIV

Composite bracket made of multialdehyde sodium alginate crosslinked calcium polyphosphate/chitosan and preparation and use thereof

InactiveCN101301491AGood biocompatibilityPromote degradationPharmaceutical non-active ingredientsProsthesisDefect repairBiocompatibility Testing

The invention discloses a composite frame of multi-aldehyde sodium alginate cross-linked polyethylene / chitosan for bone or cartilage repair and treatment, as well as preparation and application of the material of the framework. The framework is made from Calcium polyphosphate, chitosan and multi-aldehyde sodium alginate. As organic matrix multi-aldehyde sodium alginate cross-linked chitosan derived from nature which is the main component of the composite frameworks of the invention, therefore the composite framework is safe and non-toxic, has good biocompatibility and biodegradability, and cell identificaton signal existed on the surface provides physical support and the best chemical environment for bone or cartilage regeneration and reconstruction, the network structure makes the mechanical properties improved greatly. In addition, the components of the inorganic strengthened calcium polyphosphate are consistent with those of human bone tissue, has the property of activity which promotes bone or cartilage growth and the controllable degradation. The composite of the invention can be used as defect repair of bone or cartilage and tissue engineering, drug delivery carrier.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com