Method for preparing crosslinkable polyethylene cable material

A technology for cross-linking polyethylene and cable materials, which is applied in the field of preparing cross-linkable polyethylene cable materials, can solve the problems of uneven grafting, insufficient surface properties of products, and difficulty in ensuring uniform chemical reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

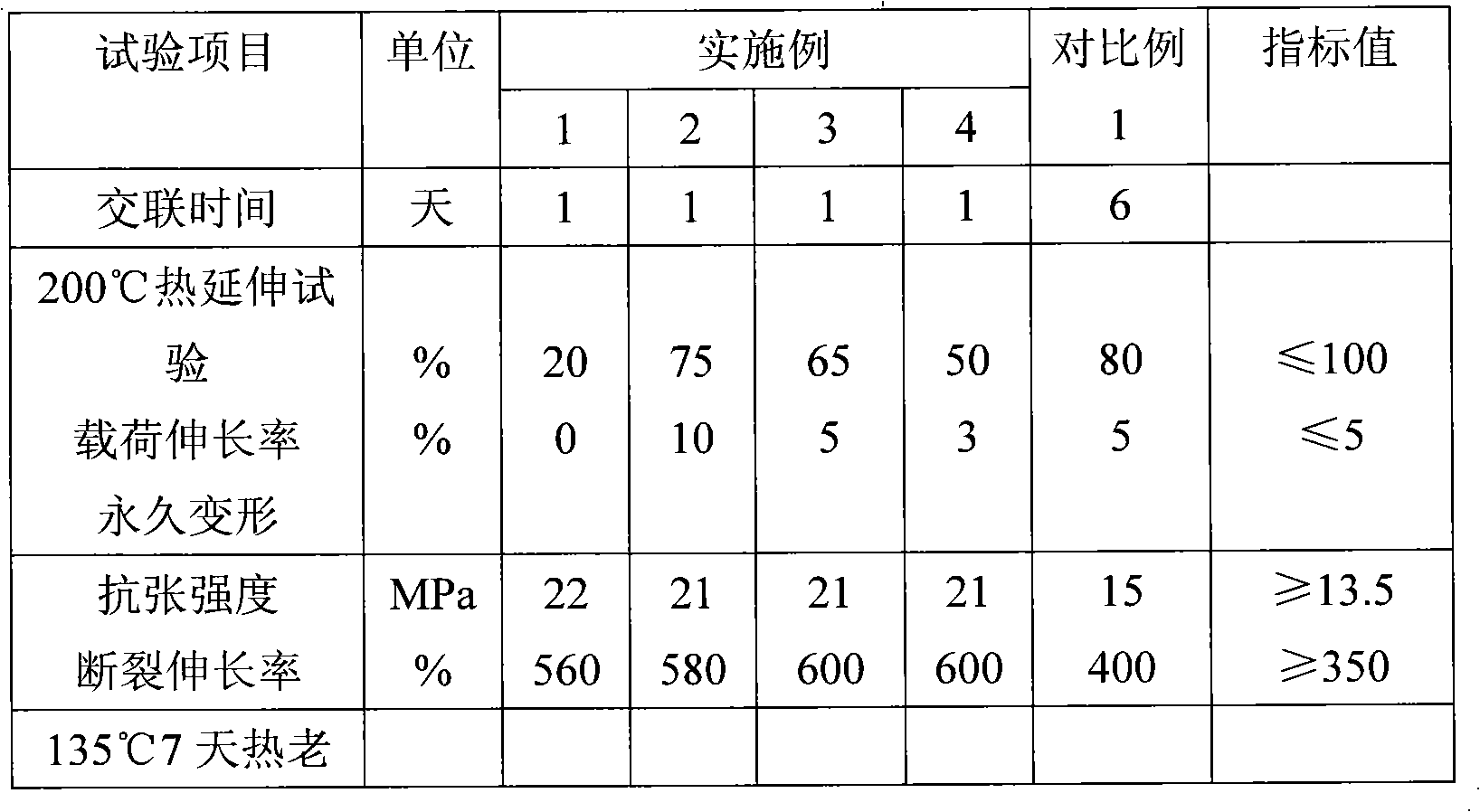

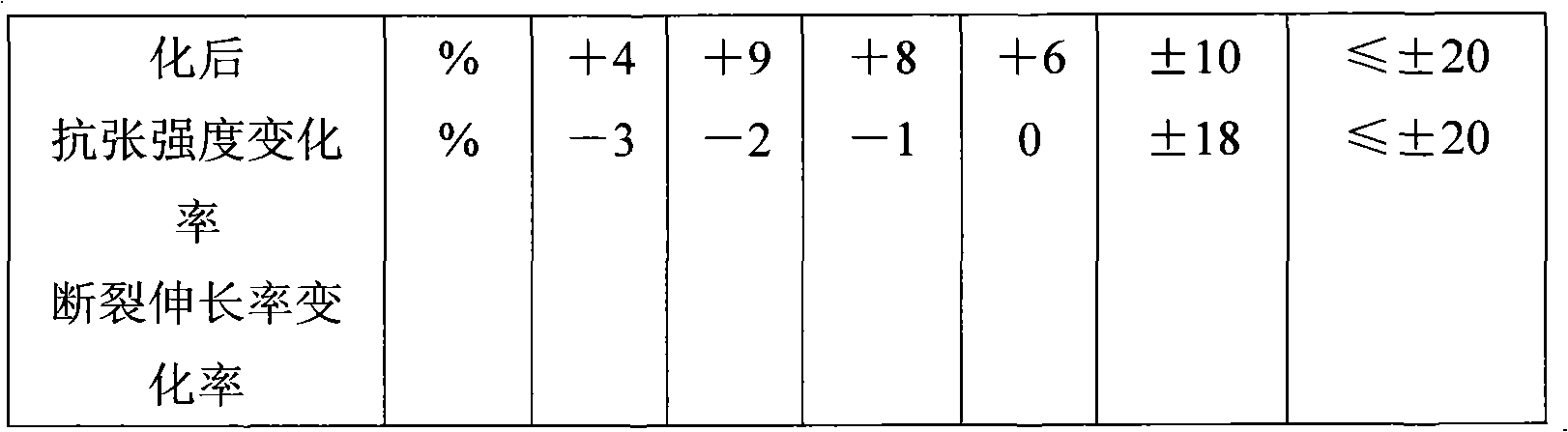

Examples

Embodiment 1

[0024] Put into 95 parts of polyethylene (Yangzi Petrochemical, 7042 brand), 5 parts of vinyltriethoxysilane, 0.1 part of dicumyl peroxide, 0.1 part of dilauric acid in a high-speed mixer with a speed of 100 rpm Dibutyltin, 0.1 part of phenylacetic acid, 0.05 part of antioxidant 1010, 0.05 part of antioxidant 168, 0.1 part of antioxidant and anti-copper agent, 0.5 part of polyethylene wax, mixed for 20 minutes, then added to the twin-screw extruder Exiting machine, the temperature of each zone of the extruder is: zone 1 120°C, zone 2 160°C, zone 3 190°C, zone 4 210°C, zone 5 215°C, zone 6 220°C, head 220°C, melt granulation to get a A cross-linkable polyethylene cable material.

Embodiment 2

[0026] In the high-speed mixer of 100rpm, the rotation speed is to drop 75 parts of polyethylene (Yangzi Petrochemical, 7042 brand), 20 parts of ethylene-vinyl acetate copolymer (EVA, Korea 1828 brand), 1.0 parts of vinyltriethoxysilane, 2 parts of dicumyl peroxide, 1 part of dibutyltin dilaurate, 1 part of p-aminophenylacetic acid, 0.5 parts of antioxidant 1010, 0.5 parts of antioxidant and anti-copper agent, 2 parts of polyethylene wax , mixed for 20 minutes, and then added to the twin-screw extruder, the temperature of each zone of the extruder is: 120°C in the first zone, 160°C in the second zone, 190°C in the third zone, 210°C in the fourth zone, 215°C in the fifth zone, 220°C in the sixth zone, The machine head is 220°C, and melted and granulated to obtain a cross-linkable polyethylene cable material.

Embodiment 3

[0028] 55 parts of polyethylene (Yangzi Petrochemical, 7042 brand), 20 parts of polyethylene (Yangzi Petrochemical, 2426H brand), 20 parts of ethylene-vinyl acetate copolymer (EVA, Korean 1828 brand) were put into a high-speed mixer with a speed of 100 rpm. ), 2 parts of vinyltriethoxysilane, 0.2 part of dicumyl peroxide, 0.5 part of dibutyltin dilaurate, 0.5 part of p-methoxyphenylacetic acid, 0.2 part of antioxidant 1010, 0.2 parts of anti-oxidation and anti-copper agent, 0.5 parts of polyethylene wax, mixed for 20 minutes, and then added to the twin-screw extruder. The fourth zone is 210°C, the fifth zone is 215°C, the sixth zone is 220°C, and the machine head is 220°C. Melt and granulate to obtain a cross-linkable polyethylene cable material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com