Noise-reduced and cavitation-prevented gas storage tank

A gas storage tank and anti-cavitation technology, which is applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of large pressure difference, influence on the surrounding environment, loud noise, etc., and achieve noise reduction , reduce vibration, and relieve tank wall erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

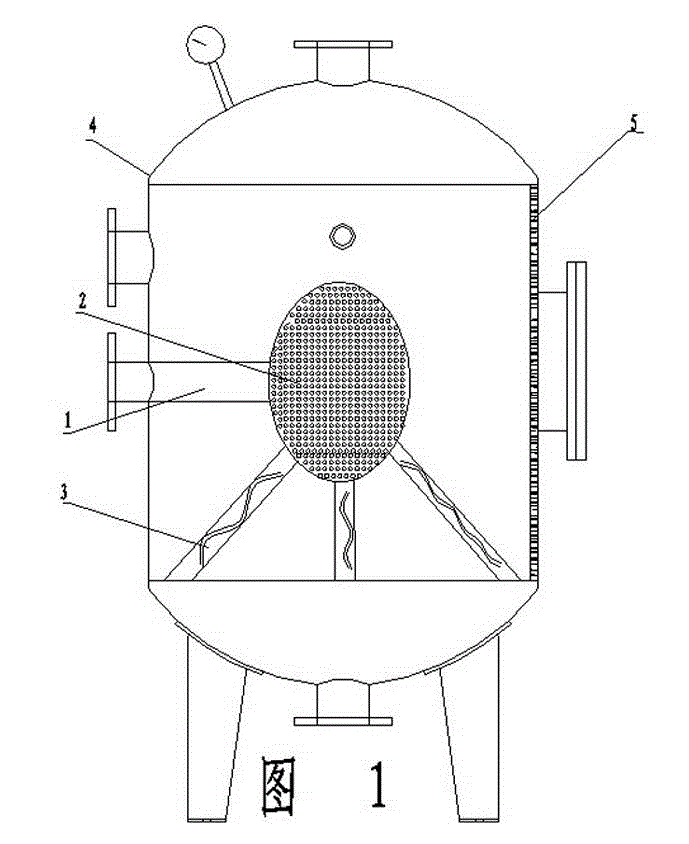

[0019] Such as figure 1 As shown, a noise reduction and anti-cavitation gas storage tank includes an air intake pipe 1, a shock absorption chamber 2, an elastic device 3, an air storage tank 4, and a shock absorption layer 5, and is characterized in that: the air intake pipe 1 and the air storage tank 5 is connected and located in the middle of the gas storage tank, the inlet pipe 1 corresponds to the center of the shock absorbing chamber 2, the elastic device 3 supports the shock absorbing chamber 2 in the center of the gas storage tank, and the shock absorbing layer 5 is attached to the inner wall of the gas storage tank 4.

Embodiment 2

[0021] The shock-absorbing chamber 2 is an oval microporous chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com