Ascending pipe heat exchange device for raw gas of coke oven

A technology of tube heat exchange and raw gas, which is applied in the heating of coke ovens, the discharge device of retort gas, and coke ovens. Achieve good heat insulation effect, avoid pollution and prevent high temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

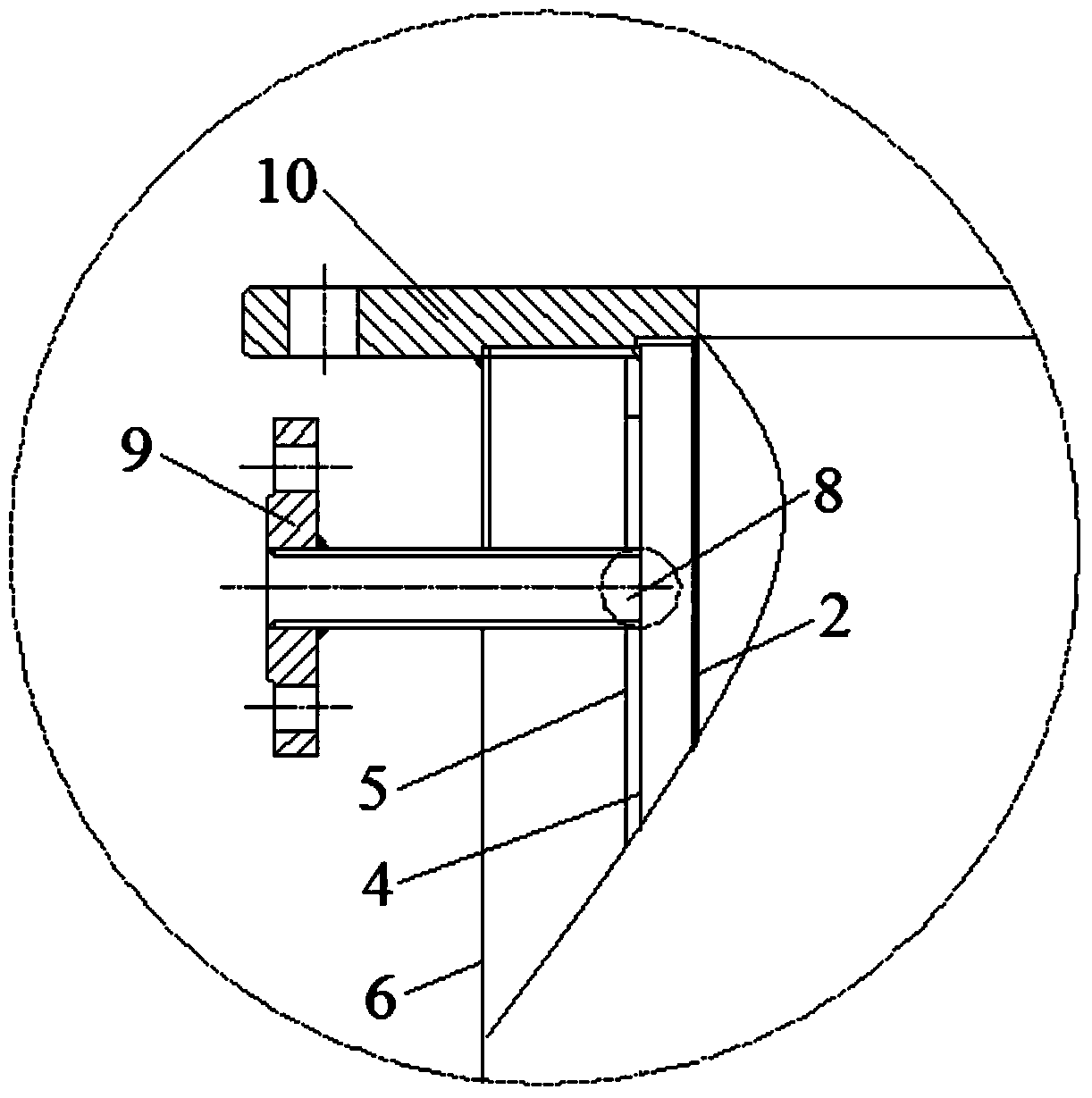

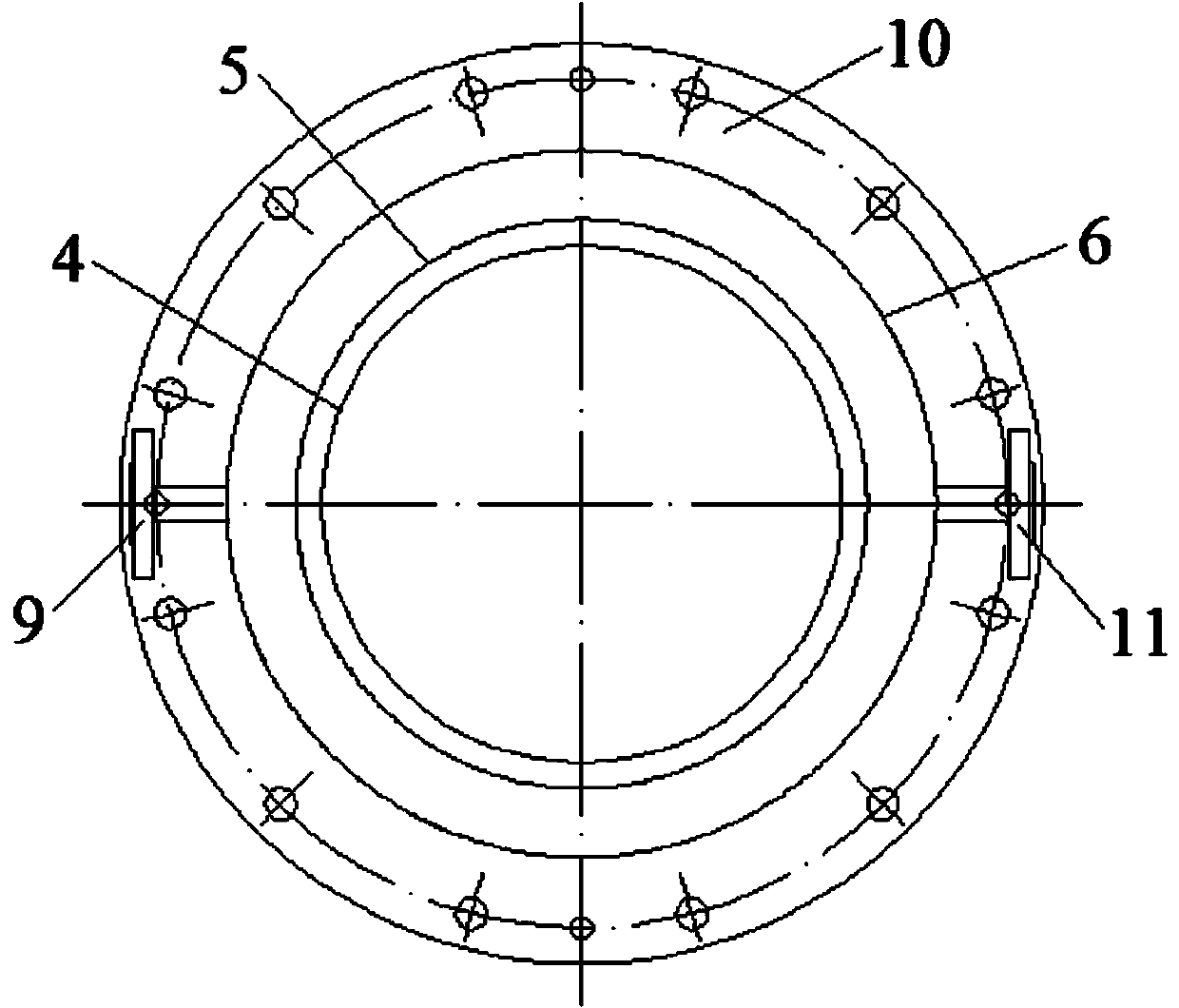

[0033]A heat exchange device for a coke oven waste gas riser in this embodiment includes a flue gas inlet flange 1, a flue gas outlet flange 10, an inner cylinder 4, a middle cylinder 5, an outer cylinder 6, an expansion joint 7, and a water inlet interface. Flange 11 and water outlet flange 9, flue gas inlet flange 1 is arranged at the lower end of the riser heat exchange device, and flue gas outlet flange 10 is arranged at the upper end of the riser tube heat exchange device. The heat exchange is completed in the riser heat exchange device, which ensures a good heat exchange effect. An inner interlayer is formed between the inner cylinder 4 and the middle cylinder 5, and demineralized water is introduced into the inner interlayer, and an outer interlayer is formed between the middle cylinder 5 and the outer cylinder 6, and the outer interlayer is a sealed thermal insulation layer, and the inner cylinder 4 is similar to a tube. And plate heat exchanger, compared with the trad...

Embodiment 2

[0036] The basic structure of a coke oven waste gas riser heat exchange device in this embodiment is the same as that in Embodiment 1, except that an inner interlayer is formed between the inner cylinder 4 and the middle cylinder 5 in this embodiment, and the inner interlayer passes through the inner layer. Nitrogen gas is introduced as a heat exchange medium; the temperature-resistant and wear-resistant material 2 provided on the inner wall of the inner cylinder 4 is refractory brick, and the materials of the inner cylinder 4, the middle cylinder 5 and the outer cylinder 6 are all cast alloys.

Embodiment 3

[0038] The basic structure of a coke oven waste gas riser heat exchange device in this embodiment is the same as that in Embodiment 1, except that an inner interlayer is formed between the inner cylinder 4 and the middle cylinder 5 in this embodiment, and the inner interlayer passes through the inner layer. Enter air as heat exchange medium; the temperature-resistant and wear-resistant material 2 provided on the inner wall of the inner cylinder 4 is refractory ceramics, and the materials of the inner cylinder 4, the middle cylinder 5 and the outer cylinder 6 are all cast alloys.

[0039] The heat exchange device for the riser pipe of the coke oven waste gas of the present invention overcomes various drawbacks under the condition of absorbing various experiences and lessons, and can effectively, safely and reliably recover the waste heat of the waste gas. In order to better understand the content of the present invention, the working principle of the present invention is now giv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com