Circulating fluidized bed boiler for combustion papermaking waste residue and sludge

A circulating fluidized bed and papermaking waste slag technology, used in fluidized bed combustion equipment, incinerators, steam boilers, etc. The effect of ash and material return is smooth, and the effect of avoiding high temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

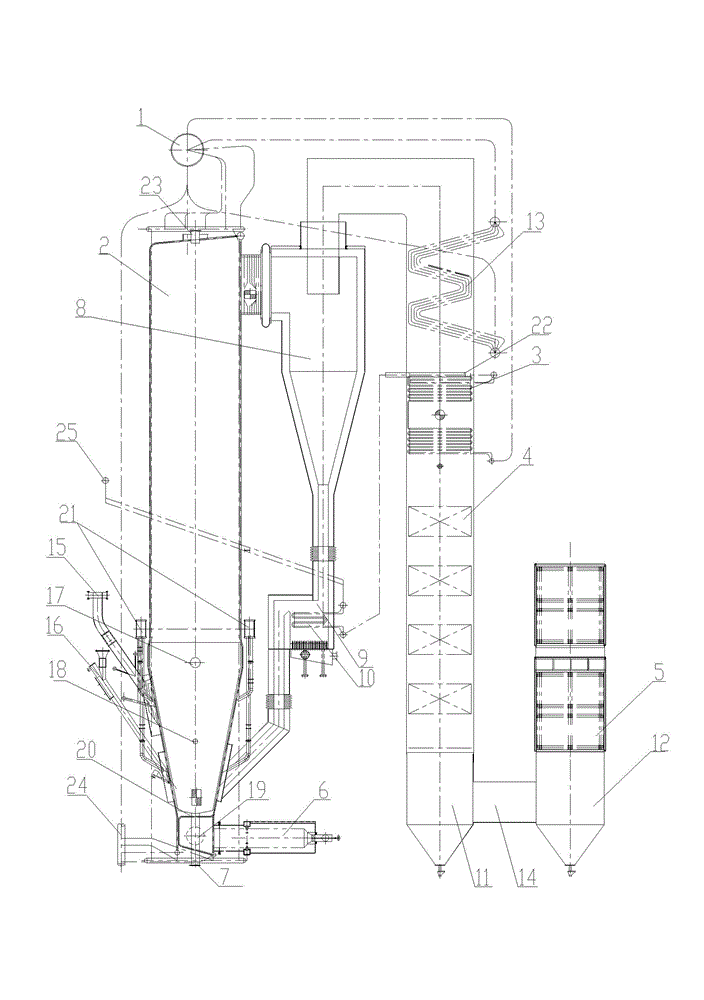

[0013] See figure 1 , which includes a drum 1, a furnace 2, a low-temperature superheater 3, an economizer 4, an air preheater 5, a feeding device, and an under-bed ignition device 6. The bottom of the furnace 2 is provided with an under-bed ignition device 6 and a slag discharge pipe 7 , the feeding device is located in the middle and lower part of the furnace 2, the top of the furnace 2 is supported by a drum 1, the furnace is connected to the flue, and the flue is equipped with a low-temperature superheater 3, an economizer 4, and an air preheater 5. The upper part of the furnace 2 The side outlet is connected to the upper side inlet of the high-temperature adiabatic volute cyclone separator 8, the top outlet of the high-temperature adiabatic volute cyclone separator 8 is connected to a flue, and the lower part of the high-temperature adiabatic volute cyclone separator 8 is connected to a return box 9, An external high-temperature superheater 10 is arranged in the return bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com