High-parameter waste incineration boiler with reheating function

A waste incineration, high-parameter technology, applied in incinerators, preheating, combustion chambers, etc., to achieve the effects of improving sealing, improving parameters, and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

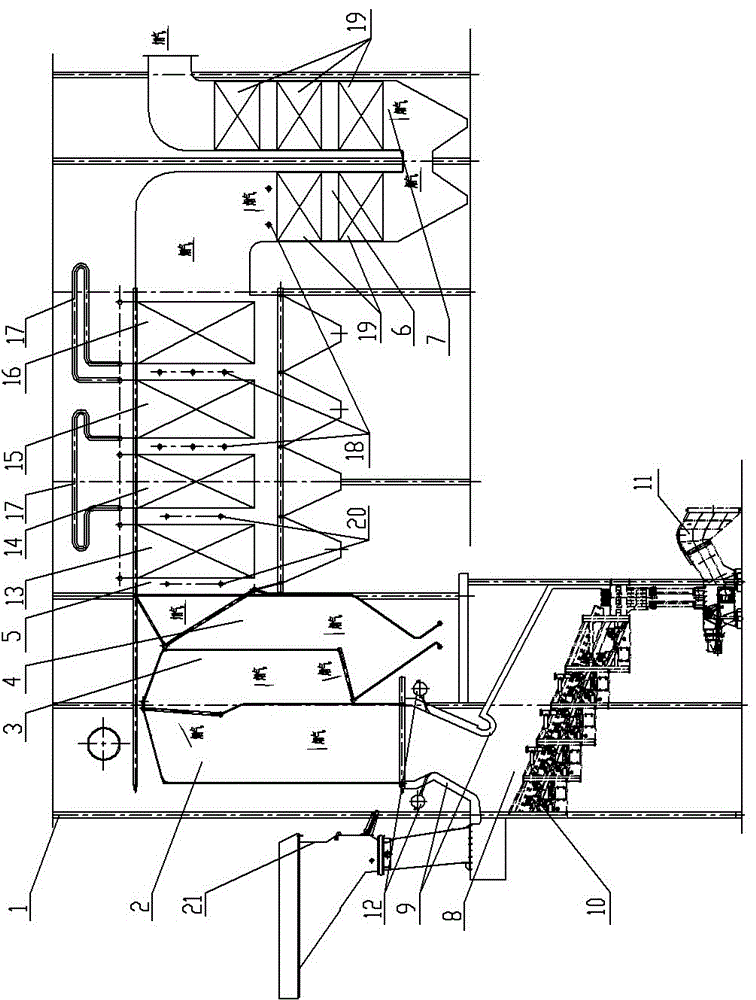

[0017] See figure 1 As shown, a high-parameter waste incineration boiler with reheating includes a bracket 1, on which a connected first vertical channel 2, a vertical combustion chamber 1 3, a vertical combustion chamber 2 4, and a horizontal Flue 5, tail vertical flue 1 6 and tail vertical flue 2 7, the bottom of the first vertical passage 2 is connected to the furnace 8, the furnace 8 is provided with front and rear arches 9, the bottom of the furnace 8 is provided with a fire grate 10, and the lower end of the fire grate 10 A slagging device 11 is provided, a secondary air channel 12 is provided at the front and rear arches 9, and refractory castables are provided at the water wall of the high temperature zone of the first vertical channel 2, so that the hot flue gas with a flue gas temperature above 850°C can flow in the furnace Stay within 2 seconds or more to effectively suppress the generation of dioxins. The other parts of the first vertical channel and the water wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com