Chain boiler plant for burning multi-biomass fuels

A biomass fuel and chain boiler technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of chain boiler load instability, boiler load adjustment difficulties, etc., to achieve the effect of easy boiler load and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

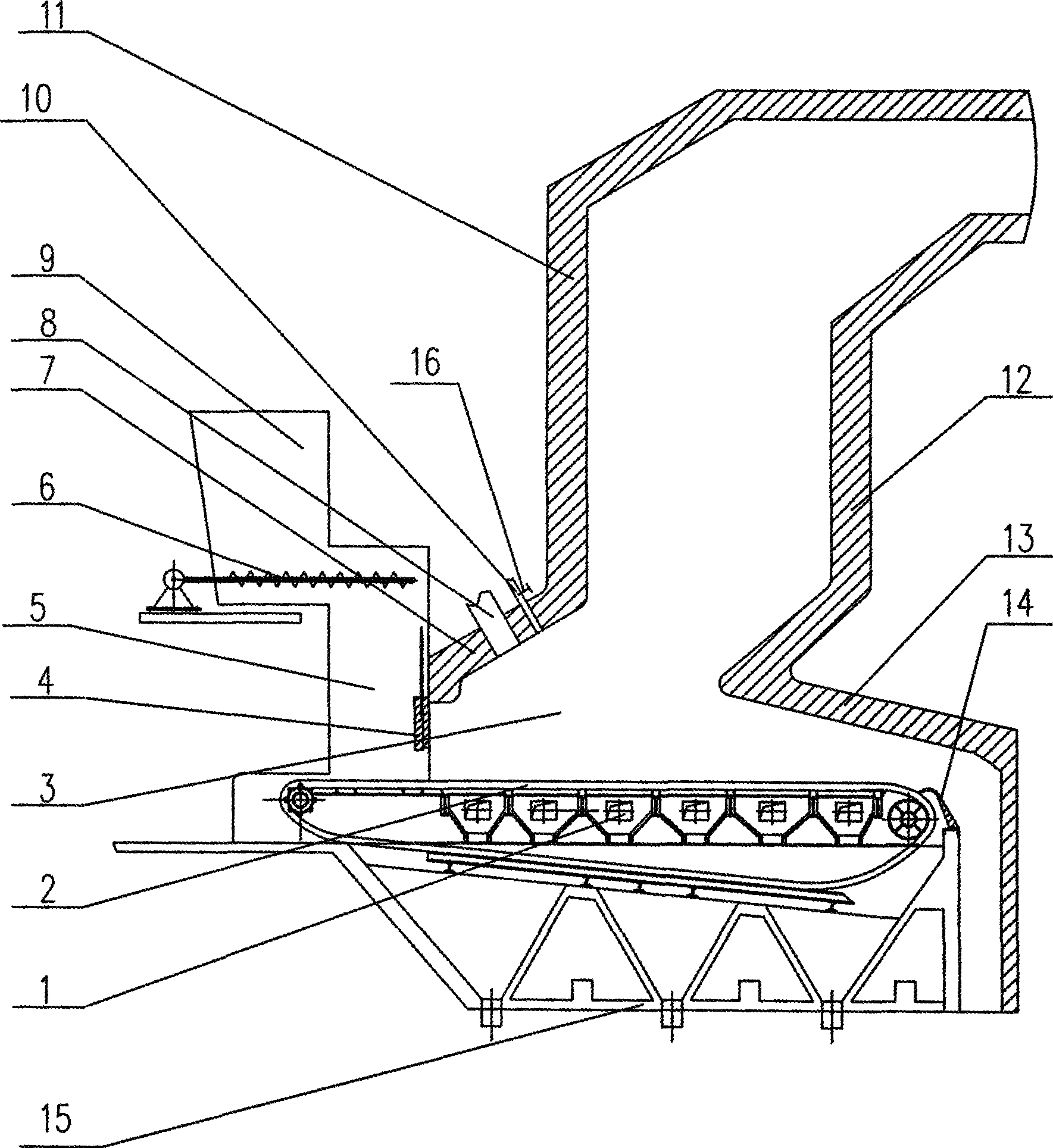

[0007] Specific implementation mode one: as figure 1 As shown, the chain boiler device for burning multiple biomass fuels in this embodiment includes a boiler base 15, a fire grate 2, a front arch 7, a rear arch 13, a front wall 11, a rear wall 12, a biomass baffle 4, Reamer 6, biomass upper hopper 9, biomass lower hopper 5 and air distribution chamber 1, the lower end of the biomass upper hopper 9 communicates with the upper end of the biomass lower hopper 5, and the biomass upper hopper 9 is connected to the biomass The joint of the lower hopper 5 is horizontally equipped with a hinged dragon 6, the air distribution chamber 1 is arranged on the fire grate 2, and the fire grate 2 is arranged on the upper end of the boiler base 15, the front wall 11, the front arch 7, the biomass lower hopper 5, The fire grate 2, the rear arch 13, and the rear wall 12 enclose the furnace 3, and the biomass baffle 4 is located between the front arch 7 and the fire grate 2 and is arranged in the...

specific Embodiment approach 2

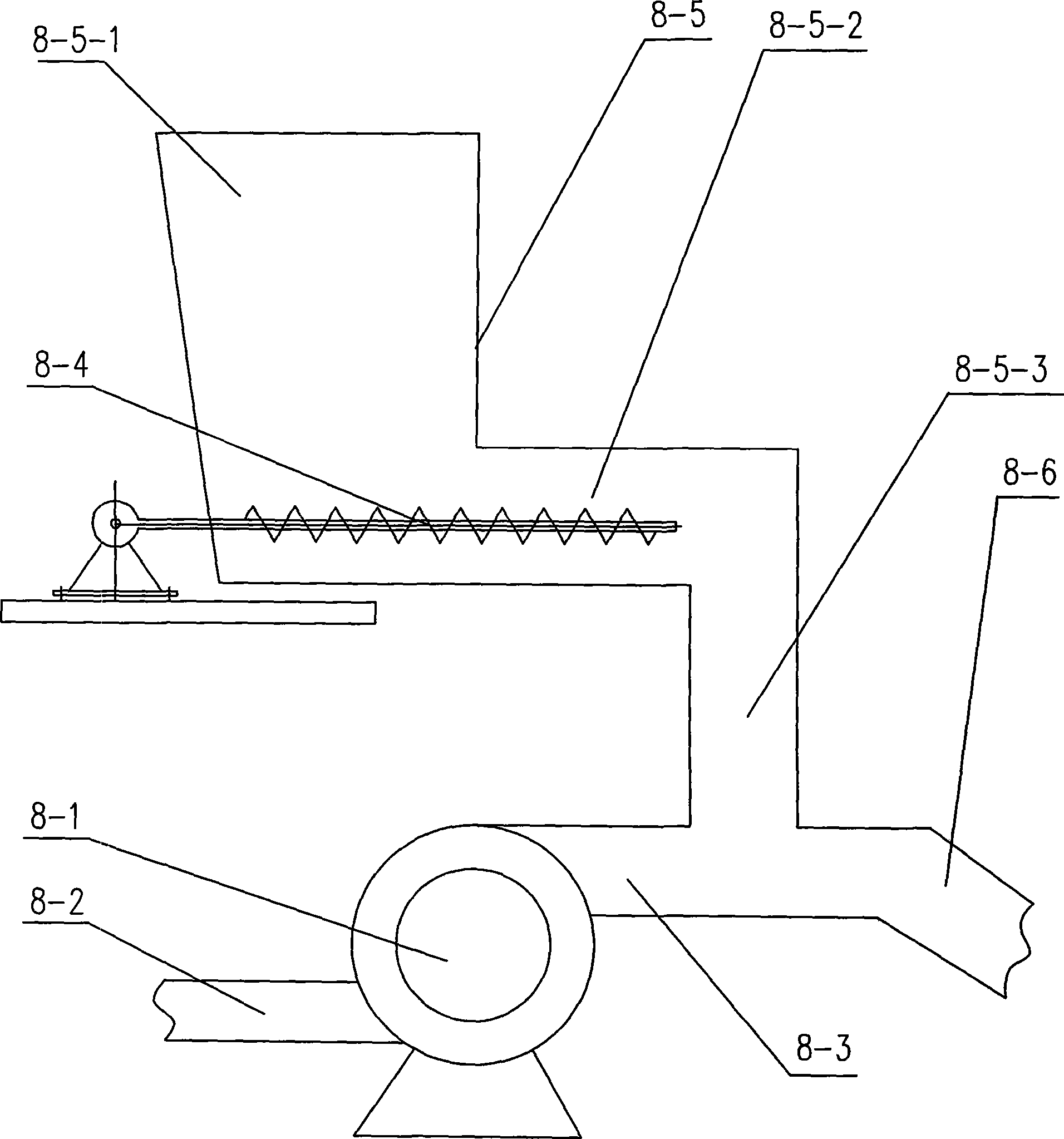

[0009] Specific implementation mode two: as figure 1 and figure 2 As shown, the arched biomass spout device 8 in this embodiment consists of a feeding fan 8-1, a feeding air inlet pipe 8-2, a feeding air outlet pipe 8-3, a feeding hinge 8-4, and a powdery biomass hopper. 8-5 and arched biomass spout 8-6, the powdery biomass hopper 8-5 is composed of upper hopper 8-5-1, horizontal section 8-5-2 and lower hopper 8-5-3, The lower end of the upper hopper 8-5-1 communicates with the upper end of the lower hopper 8-5-3 through the horizontal section 8-5-2, and the feeding hinge 8-4 is horizontally arranged in the horizontal section 8-5-2. The air inlet pipe 8-2 communicates with the feeding fan 8-1, the feeding fan 8-1 communicates with the feeding air outlet pipe 8-3, and the lower end of the lower hopper 8-5-3 and the feeding air outlet pipe 8-3 are all connected with the upper arch. The biomass spout 8-6 communicates, and the biomass spout 8-6 on the arch communicates with the...

specific Embodiment approach 3

[0010] Specific implementation mode three: as figure 1 As shown, the boiler device in this embodiment further includes a slag stopper 14, and the slag stopper 14 is installed between the rear end of the fire grate 2 and the boiler base 15. The slag stopper 14 prevents ash from entering the bottom of the fire grate. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0011] working principle:

[0012] Biomass fuel (such as wood branches, wood blocks, etc.) drops from the silo to the hinge dragon 6 through the biomass upper hopper 9, and two to three hinge dragons are arranged along the width direction of the boiler, and the biomass fuel is pushed to the biomass through its rotation. In the material lower hopper 5, the biomass fuel will fall on the fire grate 2 through the biomass lower hopper 5. Blocked by the biomass baffle plate 4, the rotating fire grate 2 takes away a certain thickness of block biomass fuel. Biomass fuel enters the furnace 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com