Device for testing model with three-dimensional gradient nonuniform loading structure

A technology for structural models and test devices, which is applied to the testing, measuring devices, instruments, etc. of machines/structural components, which can solve the problem of inability to perform three-dimensional gradient non-uniform loading of models, inability to perform three-dimensional loading of non-uniform gradient distributions, and inability to perform model gradients. Non-uniform three-dimensional loading and other problems, to achieve the effect of flexible and convenient assembly, high rigidity and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

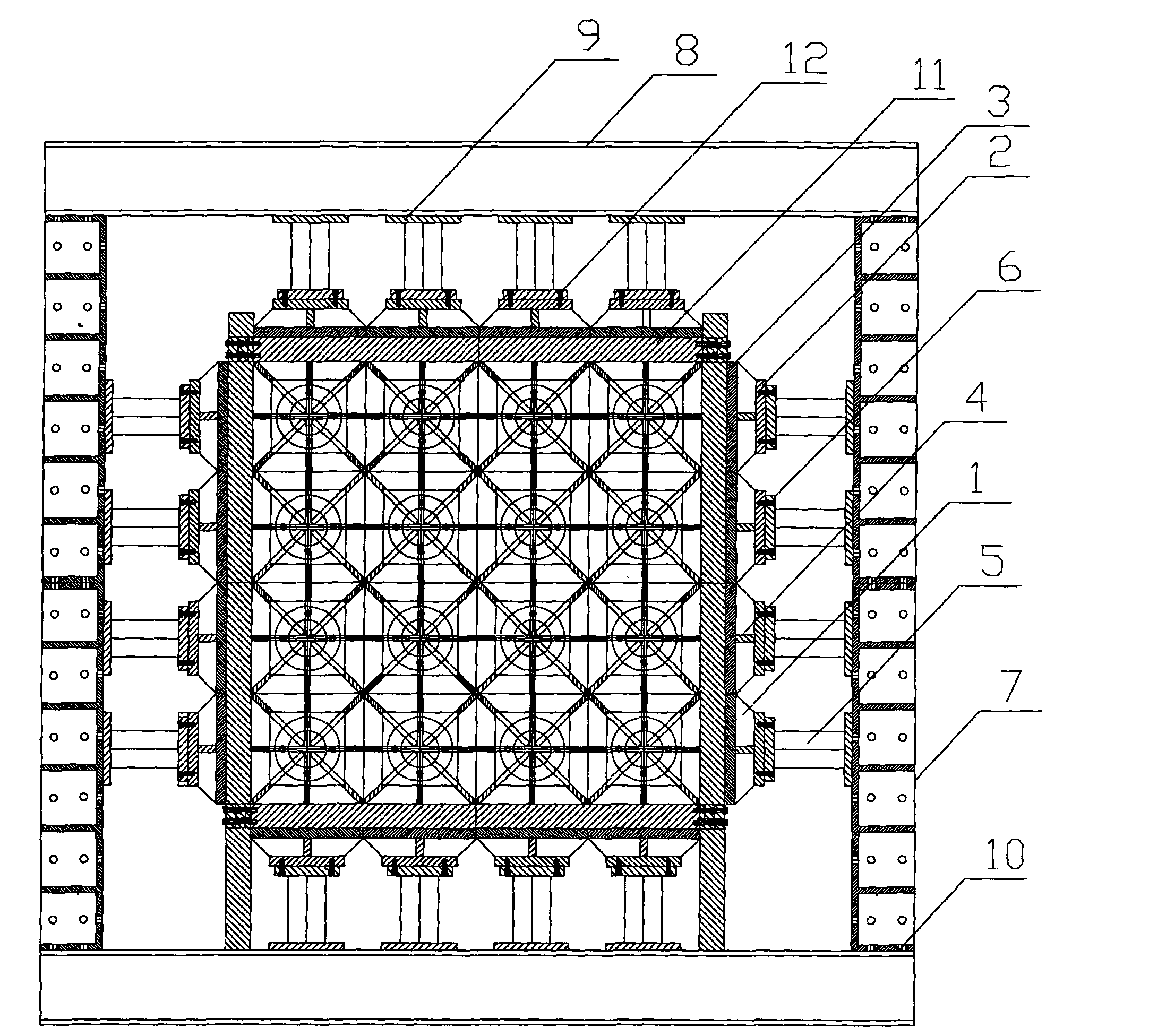

[0034]In Fig. 1, the three-dimensional gradient non-uniform loading structural model test device is composed of a table-shaped gradient non-uniform loading device and a loading reaction device. The loading reaction device is connected with the non-uniform loading device with a gradient gradient inside, and the gradient loading module of the non-uniform gradient loading device is closely attached to the surface of the test model.

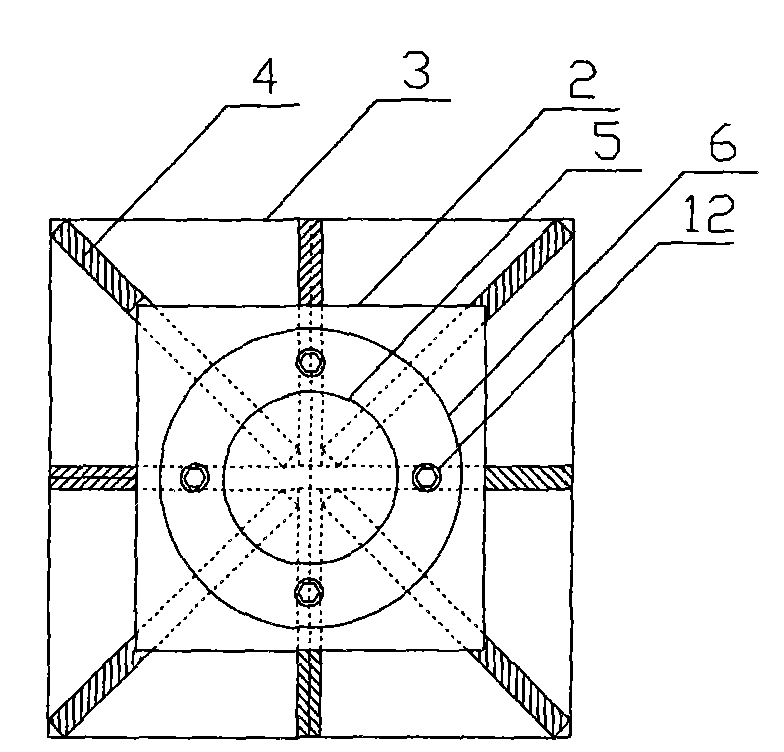

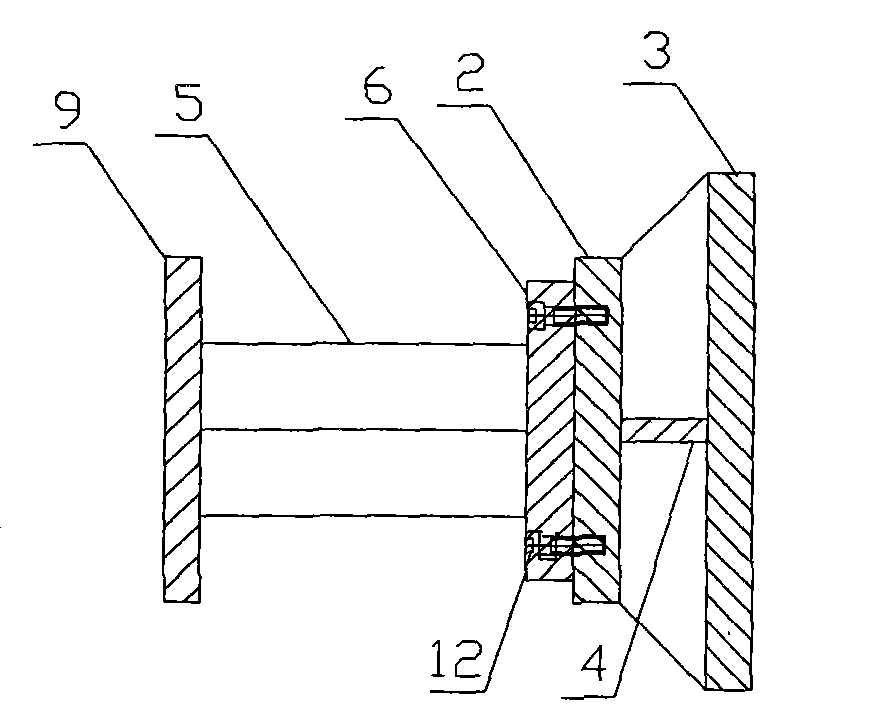

[0035] Among them, the platform-shaped gradient non-uniform loading device is divided into six loading areas, and each loading area is composed of sixteen platform-shaped gradient loading modules 1 and sixteen jack loaders 5 with a design tonnage of 20 tons. The entire test model is composed of Ninety-six bench-shaped gradient loading modules 1 and ninety-six jack loaders 5 with a design tonnage of 20 tons are composed. Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com