Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1473results about "Steam generation plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

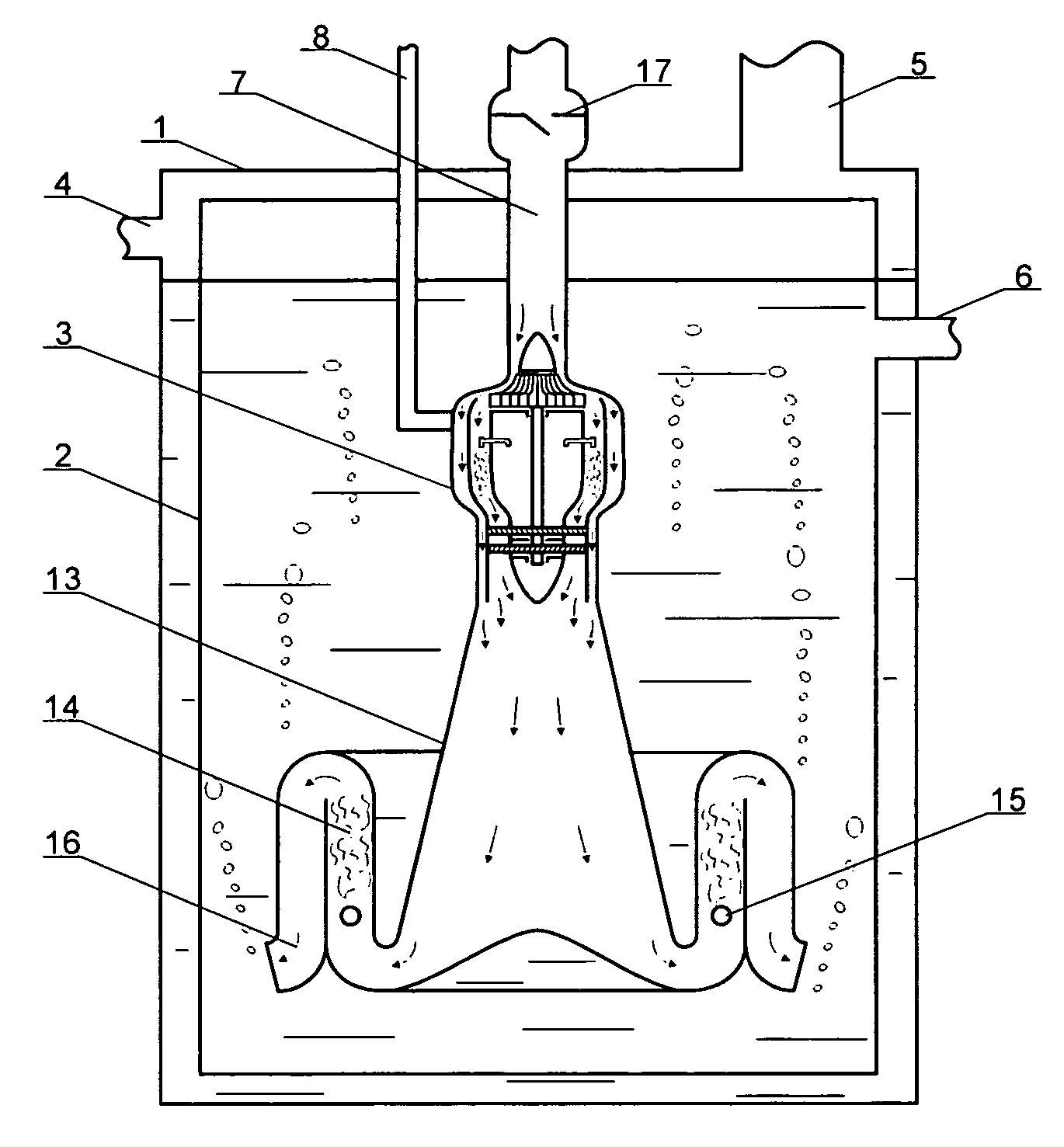

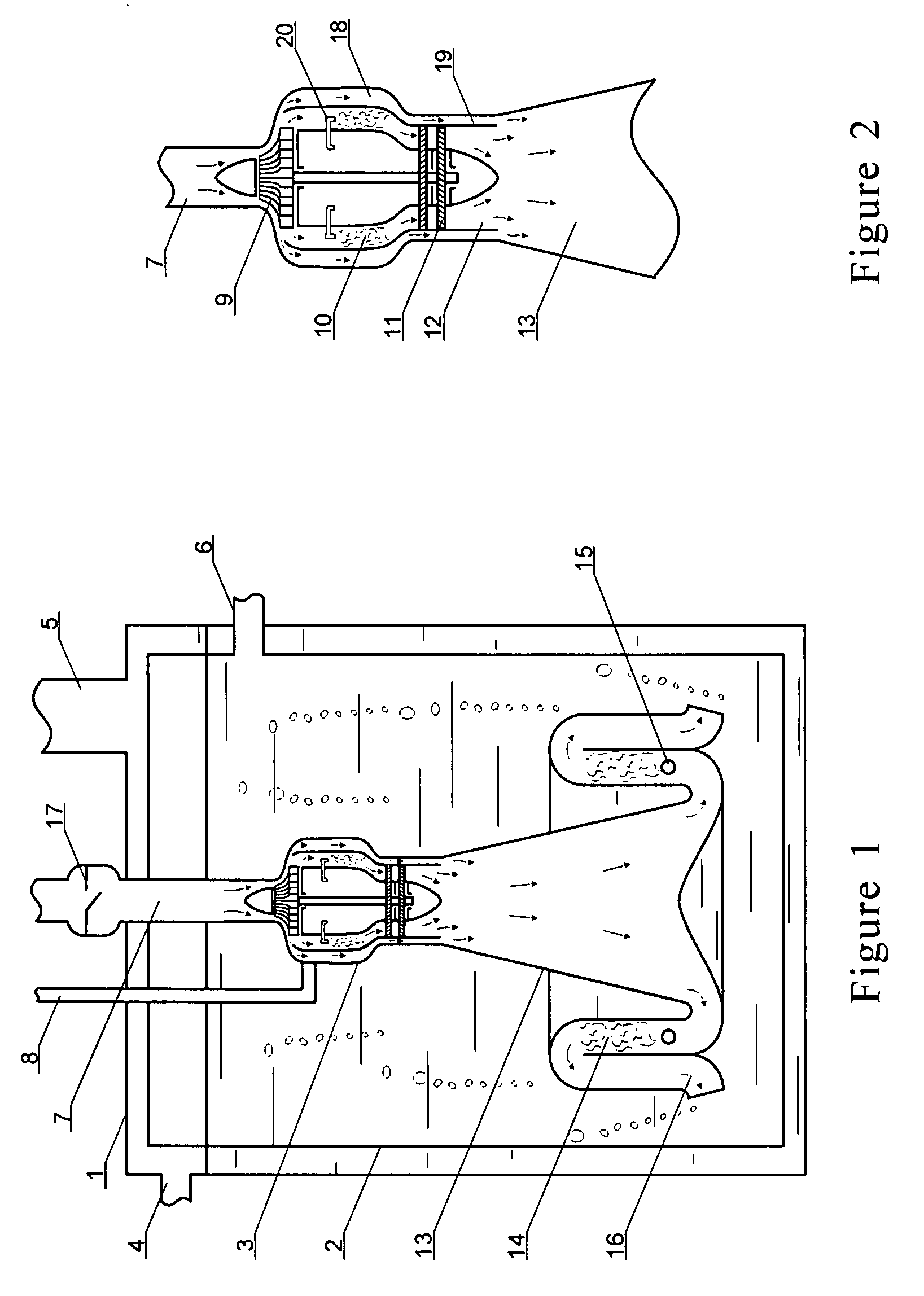

Method and device of turbine submerged combustion boiler

InactiveUS20080035078A1Improve energy efficiencySteam generation using pressureGas turbine plantsComing outHigh energy

The invention is about a submerged combustion method and the device; in details, it is a submerged combustion method and the device utilizing turbine heat engine principle. In the invention, turbine power combustion means is used and substituted conventional submerged combustion system that must equip air blowing means. The high temperature gases generated from the combustion within the turbine power combustion means will do works on turbine, which will drive the air compressor means of the turbine power combustion means to induce air for combustion, and will drive the second-time complete combustion of high temperature gases and the complement fuel, and then the gases will come out from water bottom against tank water pressure and carry out heat interchange with tank water. The turbine submerged combustion boiler device of the invention need not equip air blowing means additionally which would consume energy. So it has high energy efficiency and a simple system structure. And it has features of high heat interchange rate, stable long term heat efficiency, environmental protection, etc.

Owner:LI WEICHENG

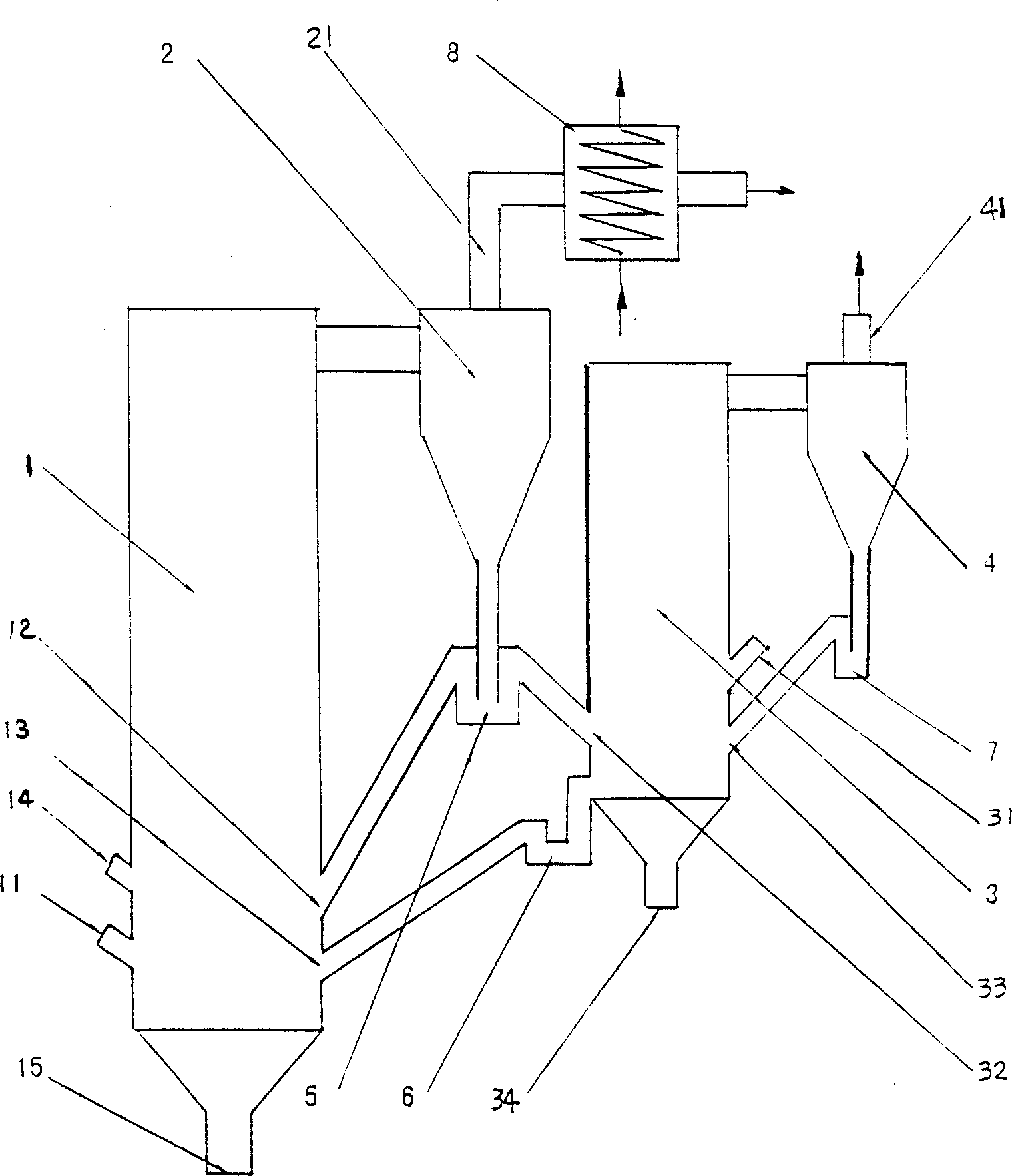

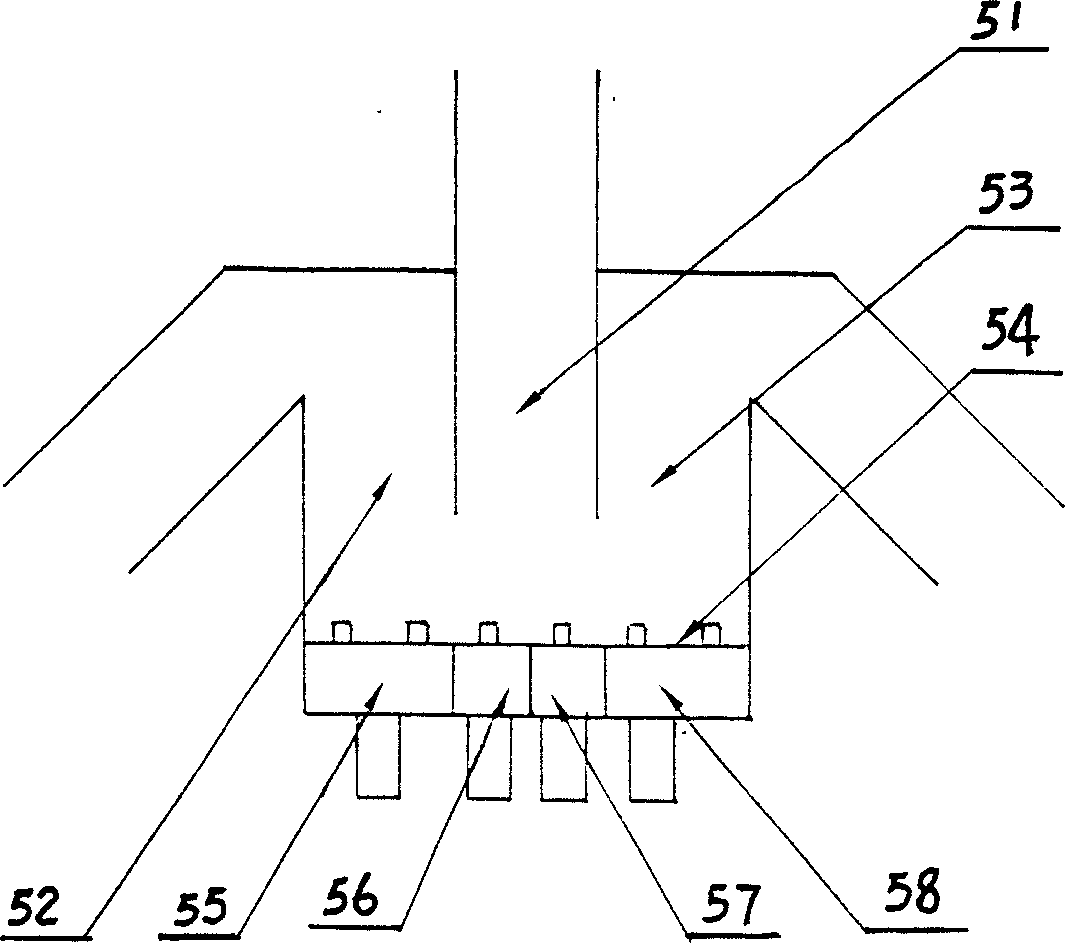

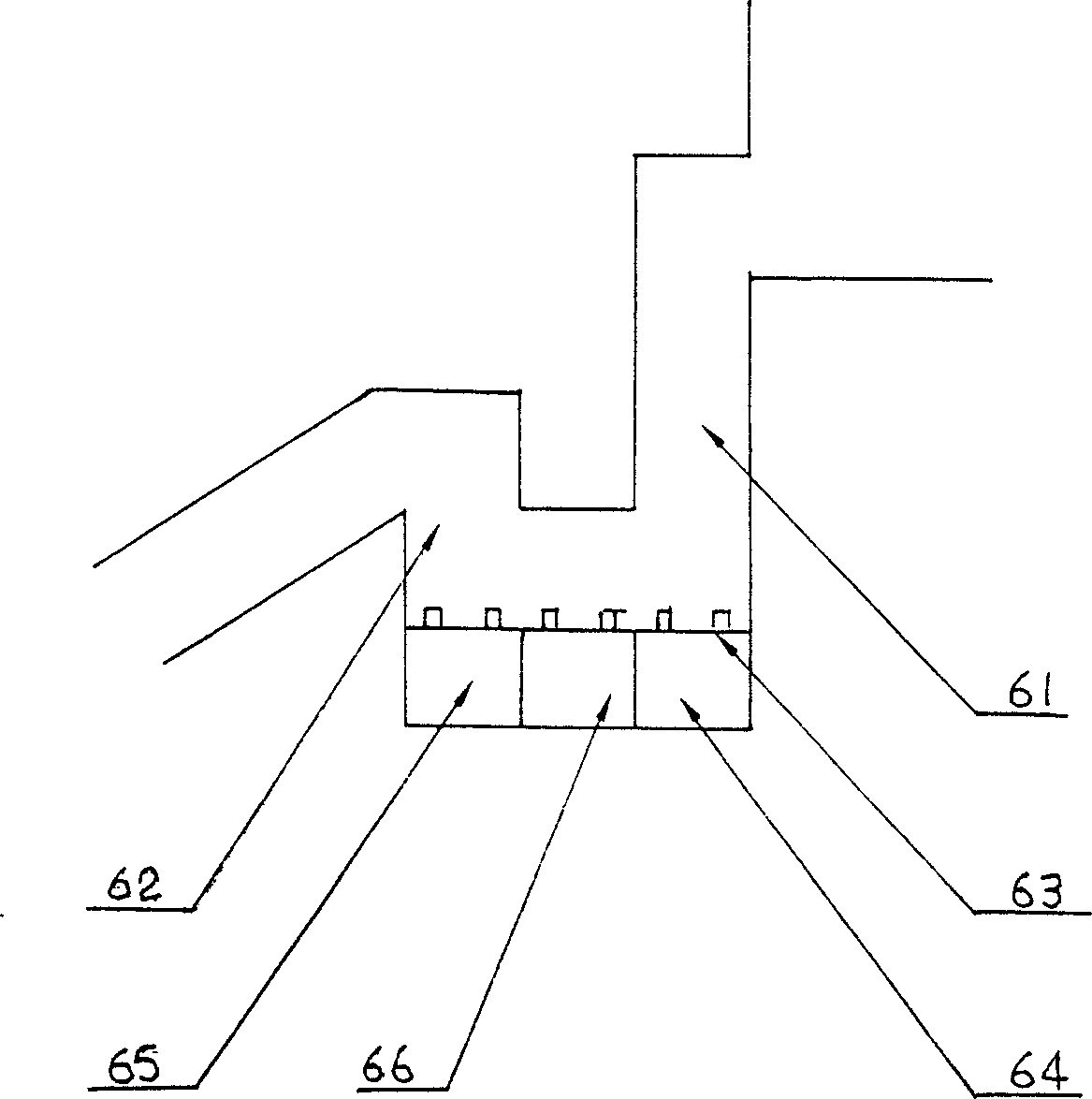

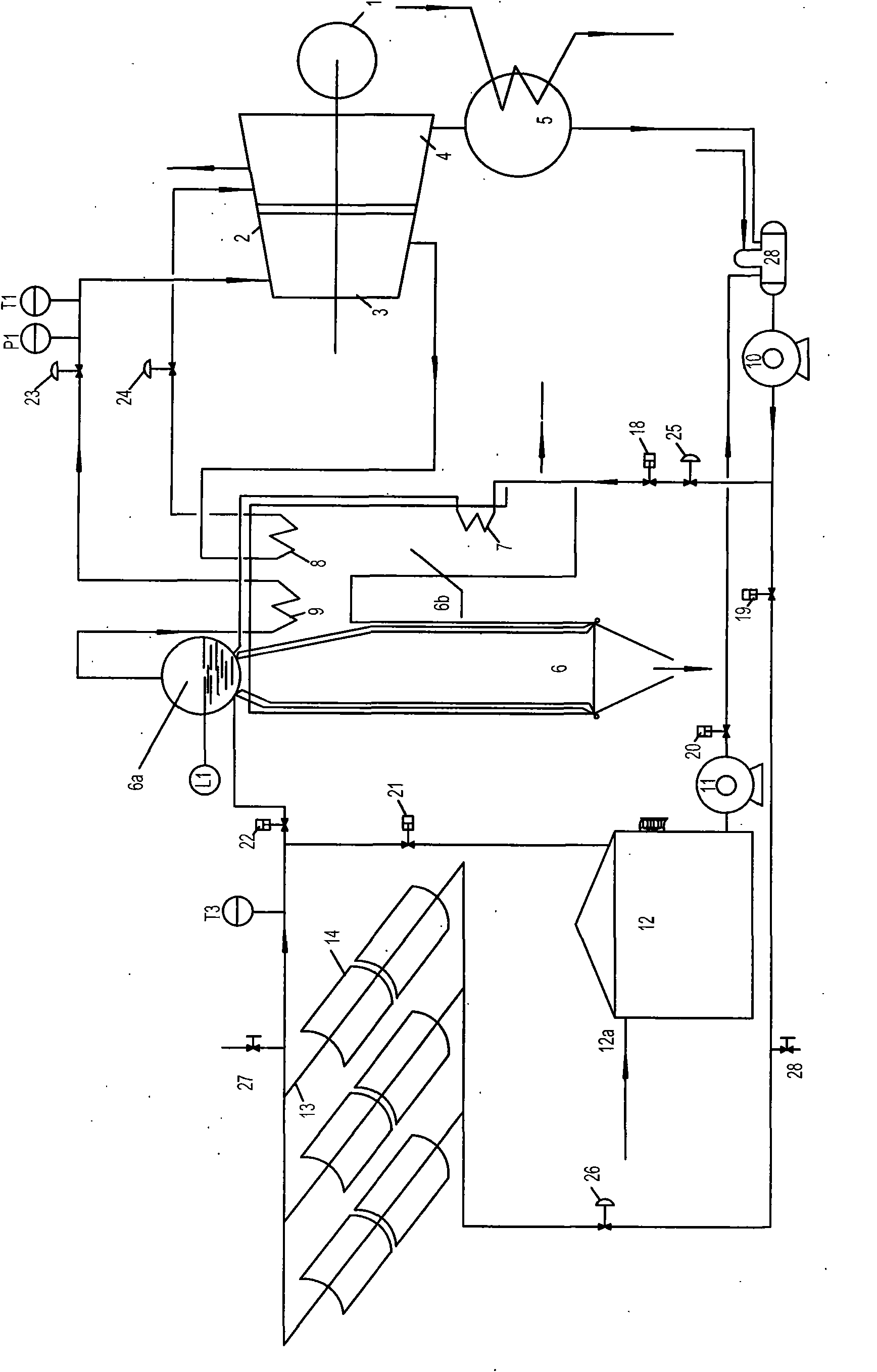

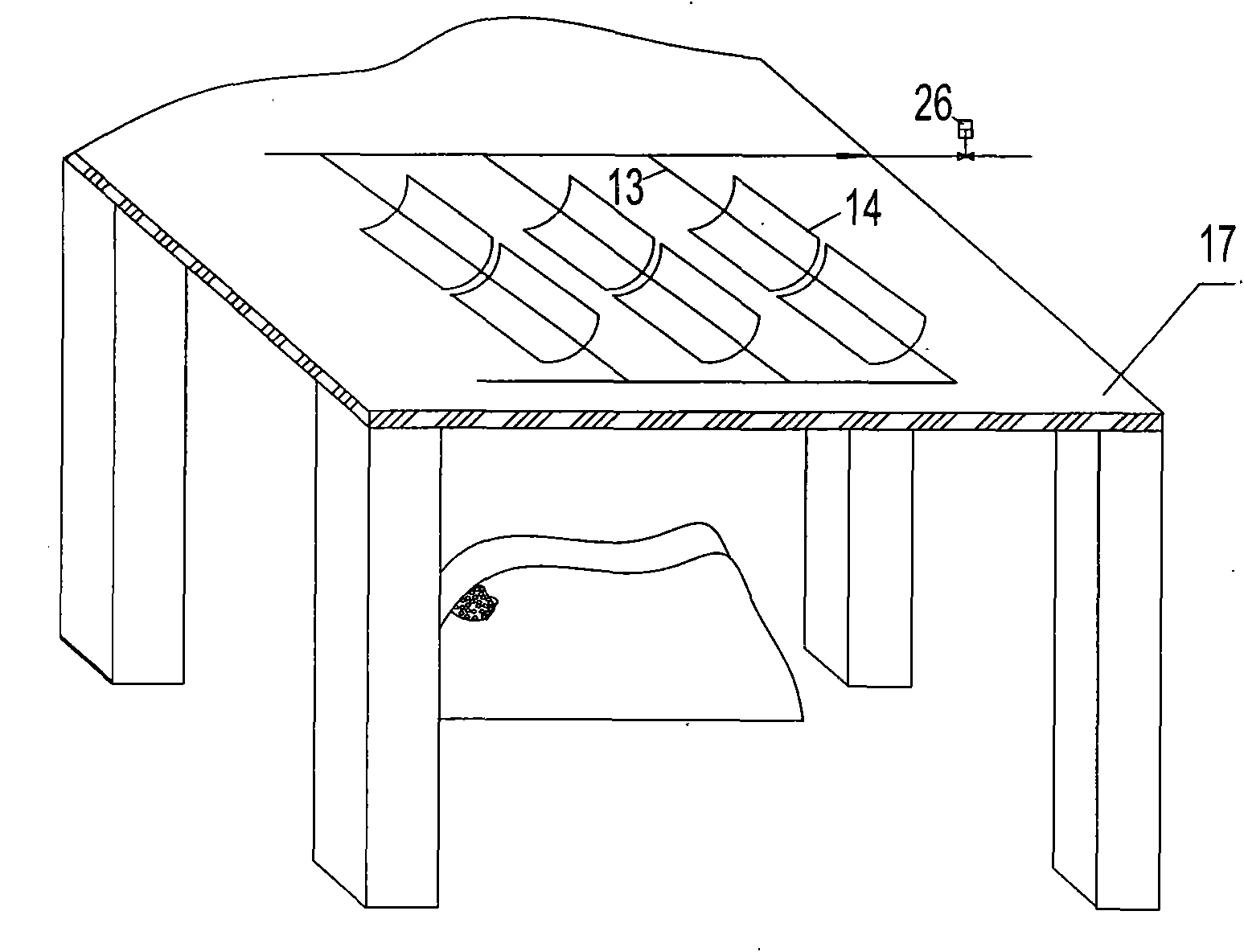

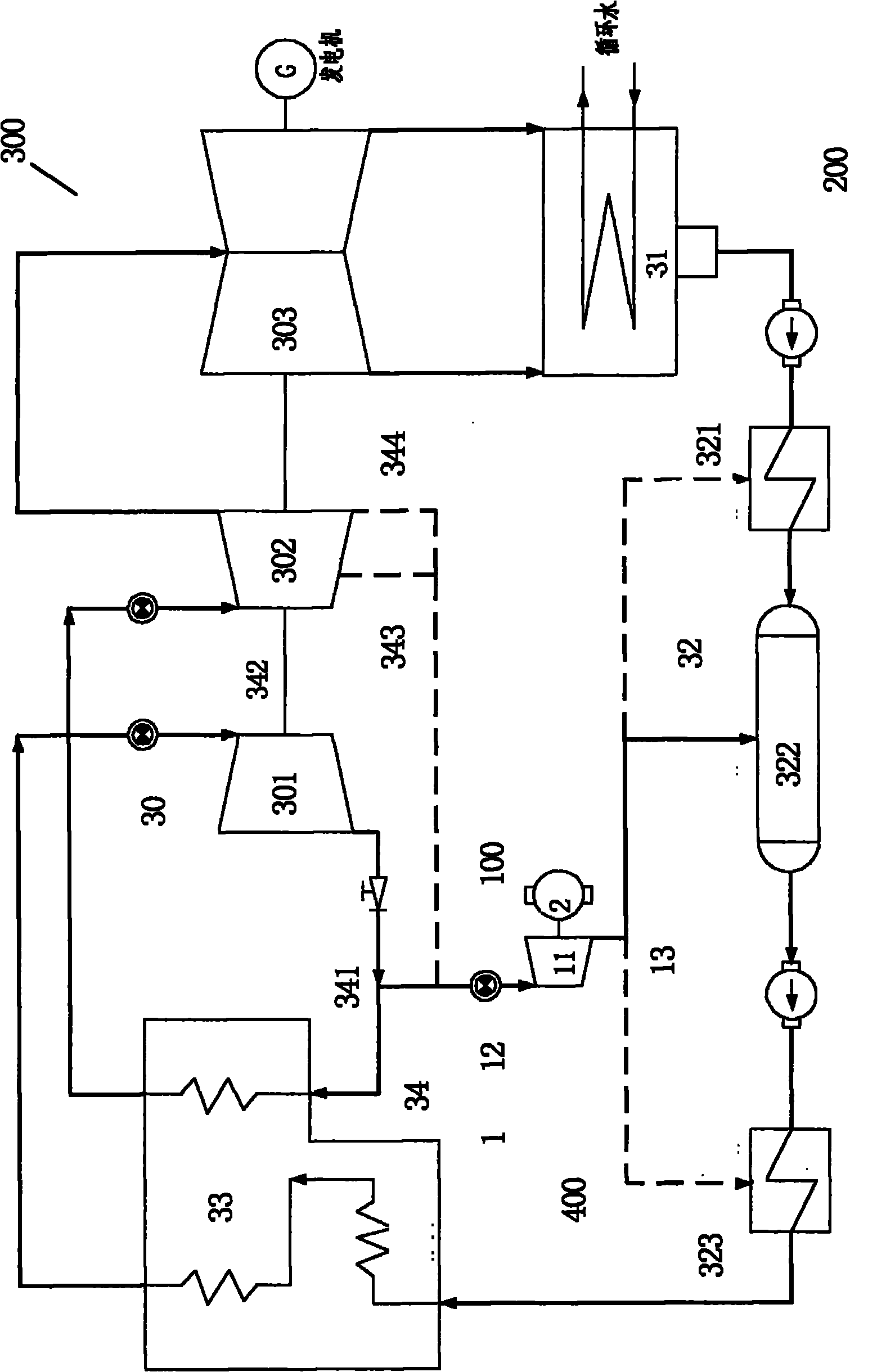

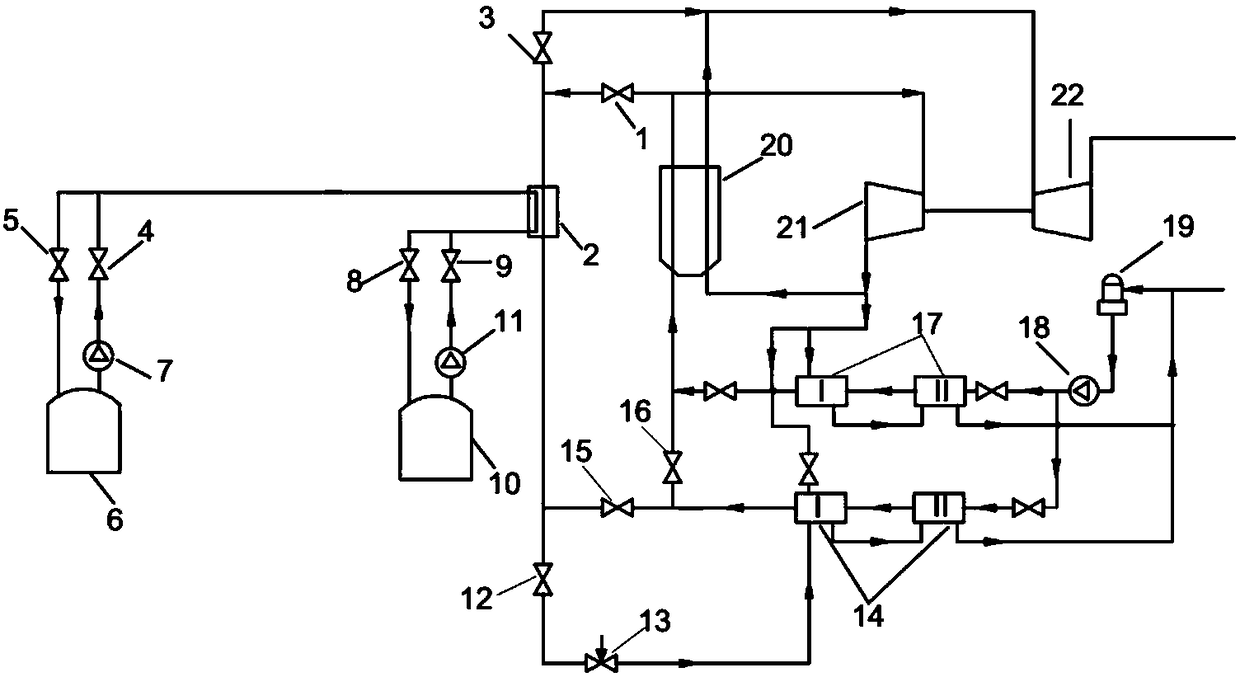

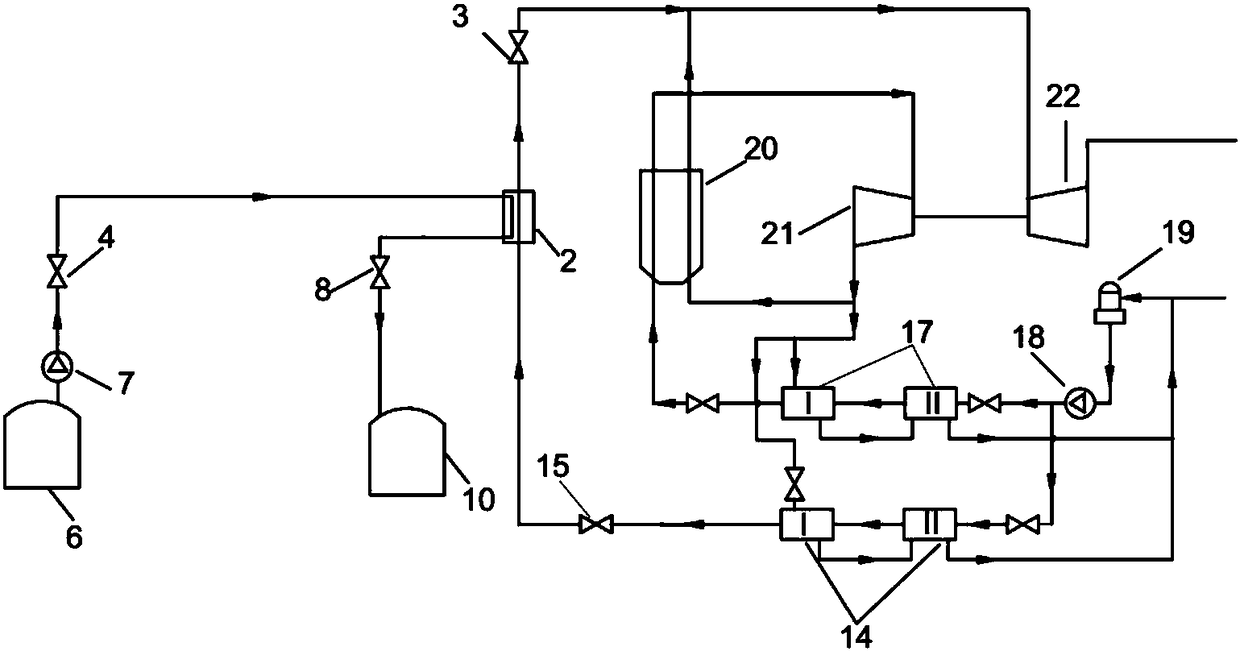

Coal gas-steam combined production method and apparatus of double-circulation fluidized bed

InactiveCN1754945AStable productionDwell time is easy to controlSteam generation plantsGranular/pulverulent flues gasificationCombustion chamberAlternative fuels

The invention relates to coal gas-steam cogeneration method and opposite furnace. Wherein, fuel burns in combustion chamber to generate smoke gas, the latter enters heat exchanger after cyclone separator to generate steam; some cycle dust collected by cyclone separator returns to chamber, other enters vaporizer; fuel takes pyrogenic gasification reaction to generate coal gas with reacted product back to chamber; the cogeneration furnace has double-cycle fluidized bed loop, wherein, the burning loop composes of a chamber, a smoke gas separator, and a refeeding device; the gasification loop composes of a gasification room, a coal gas separator, and a refeeding device; two loops are coupled by hot dust allocator and refeeding device. The running mode is flexible, and also fit to treat carbon-containing waste.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

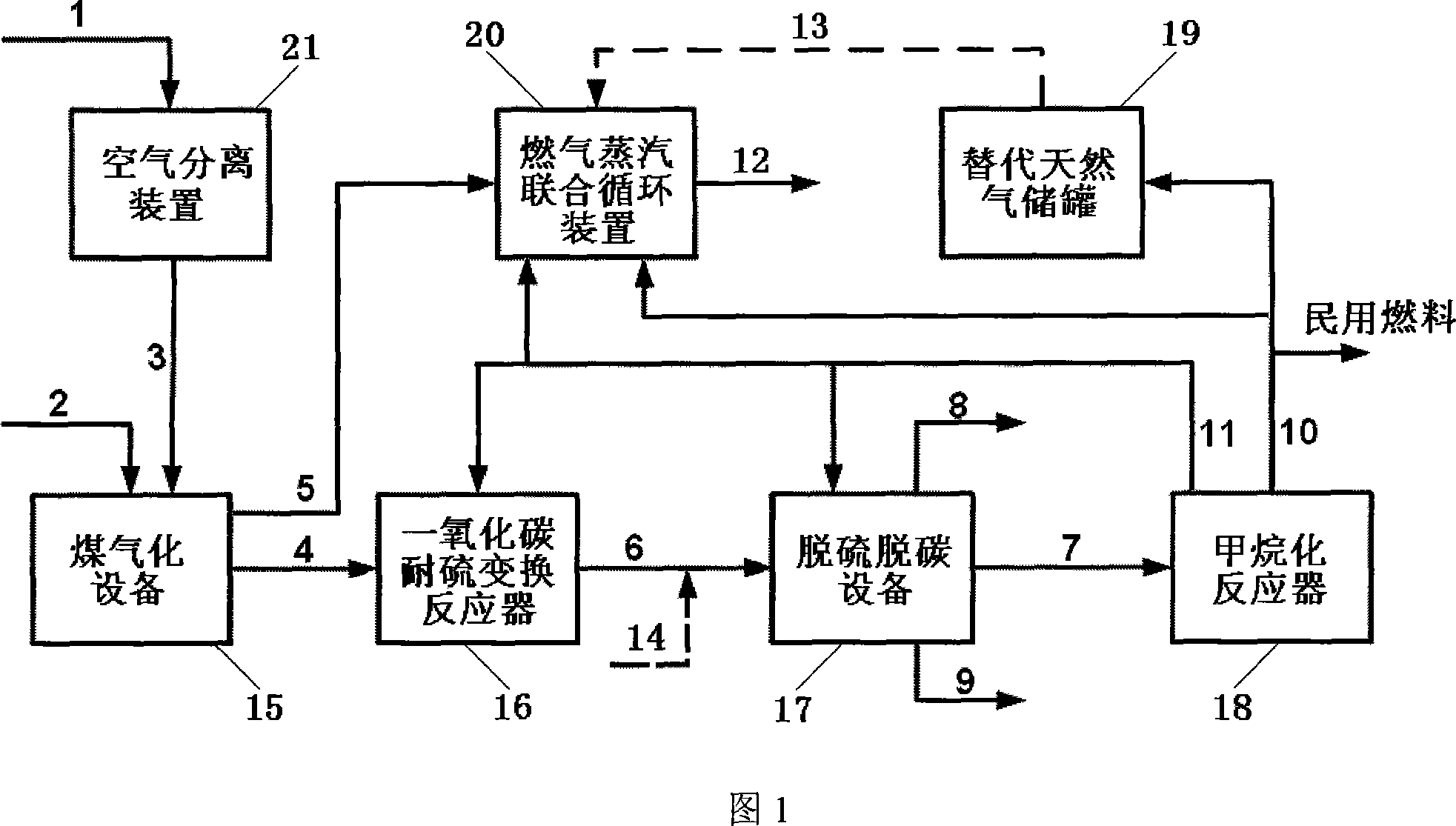

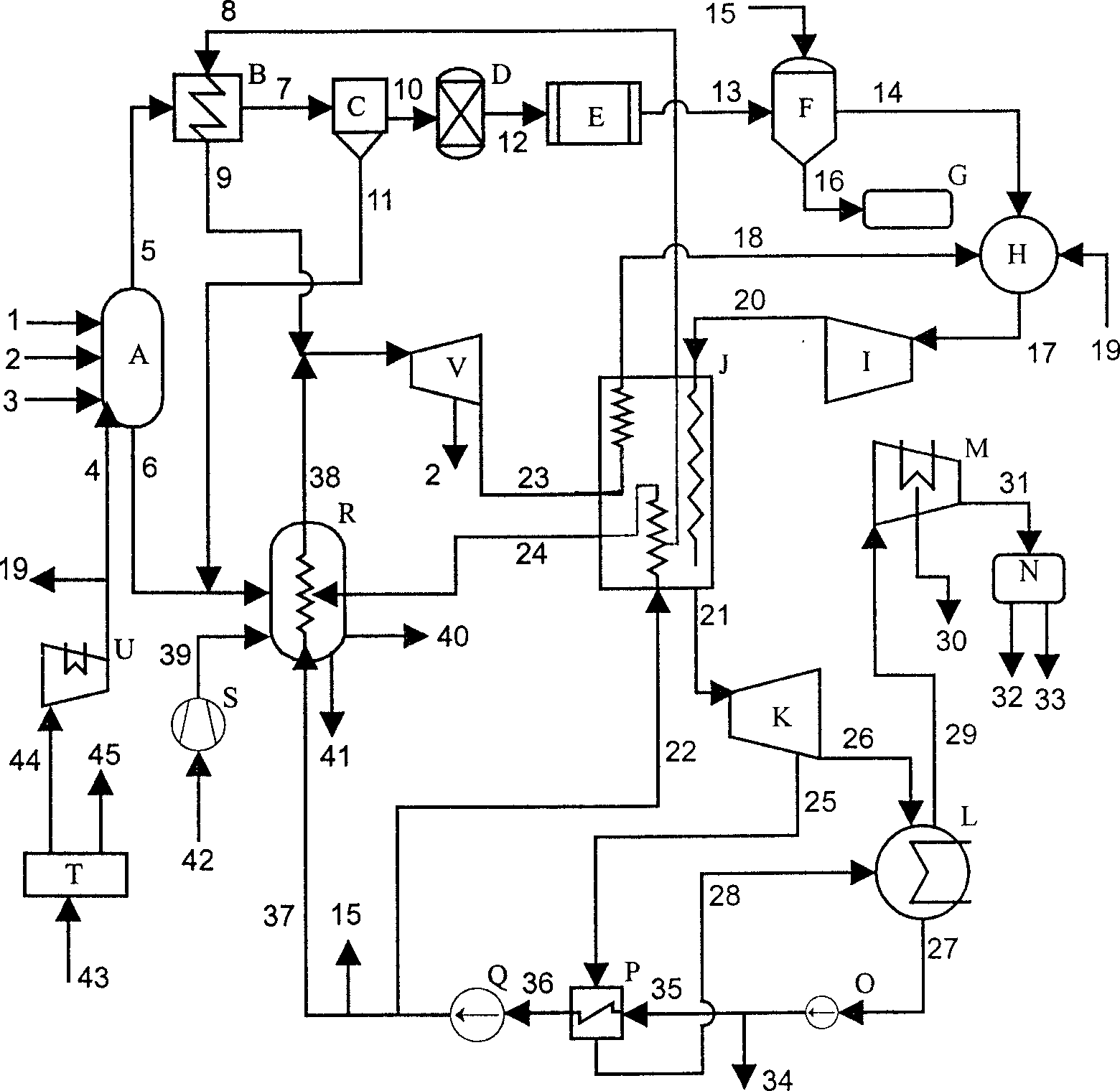

Combined system and process for producing electric-substituted natural gas based on coal gasification and methanation

ActiveCN101074397AEfficient and clean utilizationEfficient use ofCombustible gas chemical modificationCombustible gas purificationMethanationSlurry

An electric-substituting natural gas combined system and process based on coal gasification and methanation are disclosed. The process is carried out by delivering oxygen, powdered coal or water-gas slurry into gasified apparatus, recovering for crude gasified gas by wet heat, delivering into sulfur-resisting carbon monoxide carbon reactor, adjusting hydrogen-carbon ratio, entering into desulfurizing decarbonizer, recovering elementary sulfur while enriching carbon dioxide, delivering synthetic gas into methane reactor to generate substituted natural gas as domestic gas partially, entering into gas and steam combined circulator partially, and entering into substituted natural gas storage tank partially. It integrates coal gasified, methanation and gas steam combined circulation together, it's efficient and clean, has better utilizing rate, no CO2 discharge and need for changing gas turbine or load.

Owner:TSINGHUA UNIV

Solar power generation method and system taking biomass boiler as auxiliary heat source

ActiveCN101968041ASolve the problem of antifreeze in winterHigh thermal efficiencySolar heating energyFrom solar energyWater storage tankEngineering

The invention discloses a solar power generation method and a solar power generation system taking a biomass boiler as an auxiliary heat source. The system comprises a solar condensation heat collecting device, a biomass boiler device and a steam turbine generator system, wherein the solar condensation heat collecting device takes water as a medium and is combined by adopting medium-pressure solar vacuum heat collecting pipes in a series-parallel matrix; the outlet of the solar condensation heat collecting device is communicated with the bottom of a steam pocket of the biomass boiler; and the steam outlet of the steam pocket of the biomass boiler is connected with a cylinder of a steam turbine generator. A de-aerator and a water supply pump are connected in series in the water inlet pipeline of the solar condensation heat collecting device. A steam re-heater is connected in series in the connected pipeline of the steam outlet of the steam pocket of the biomass boiler and the cylinder of the steam turbine generator; the steam re-heater is connected to the cylinder of the steam turbine generator; and the steam re-heater is placed in a flue of the biomass boiler. A water supply tank is a desalting water storage tank, and the desalting water storage tank is connected with the de-aerator through the water supply pump and connected with the outlet of the solar condensation heat collecting device through a first control valve.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

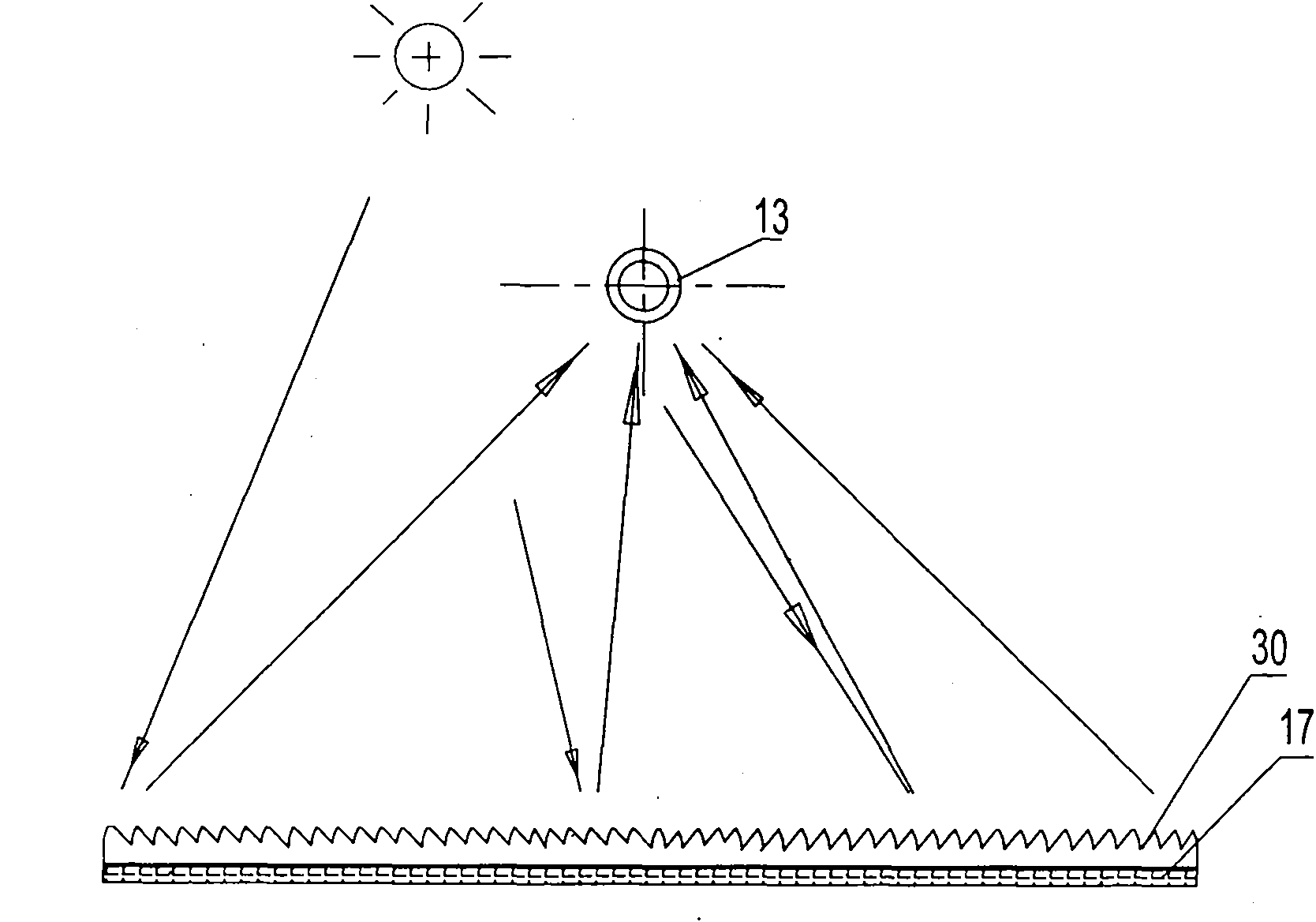

Solar concentration plant for the production of superheated steam

InactiveUS20080302314A1Easy to controlReduce riskSolar heating energySuperheating controlHeliostatEvaporation

A solar concentration plant which uses water / steam as a heat-carrying fluid, in any thermodynamic cycle or system for the exploitation of process heat, which is comprised of an evaporation subsystem, where saturated steam is produced under the conditions of pressure of the system, and a superheater subsystem through which the steam reaches the required conditions of pressure and temperature at the turbine inlet, and in which an attemperation system (10) may be incorporated, these being physically separated and interconnected by means of a drum (5) in which the separation of water and steam takes place, and in which a strategic control of the pointing of the field of heliostats (1) towards either of the subsystems (evaporator or superheater) may be carried out, with individual or group pointing of the heliostats, in such a way that they jointly control both the pressure within the drum (5) and the outlet temperature of the superheated steam (11).

Owner:ABENGOA SOLAR NEW TECH SA

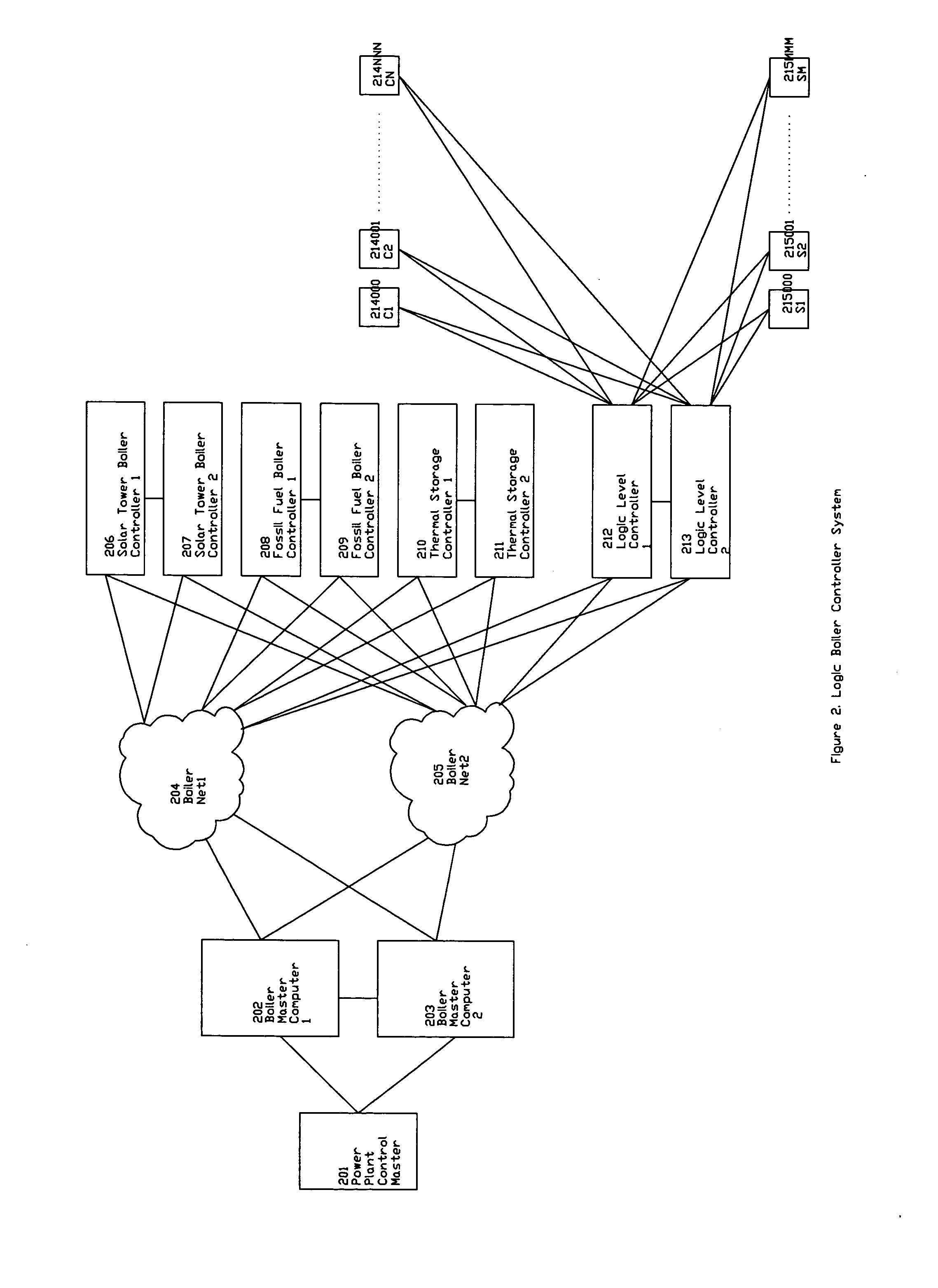

Concentrate solar thermal energy electric power plant logic boiler

A logic boiler that consists of a concentrated solar energy boiler, a thermal storage system, and a traditional fossil fuel boiler is replacement of the traditional fossil fuel boiler in a power plant for solar thermal electric power generation. The thermal storage system or fossil fuel boiler compensates the output steam of the solar energy boiler to provide on demand, reliable and regulated steam for steam turbine. The controls sequences provide results that maximize the output of the solar boiler while provide the regulated and fast responded steam to the turbine. The control sequences also provide an algorithm to store excessive thermal energy from the solar energy boiler into the thermal storage system. The power plant sees the logic boiler as a conventional boiler without knowing the details of working sequences between the solar boiler and fossil fuel boiler or thermal storage.

Owner:ZHU YANONG

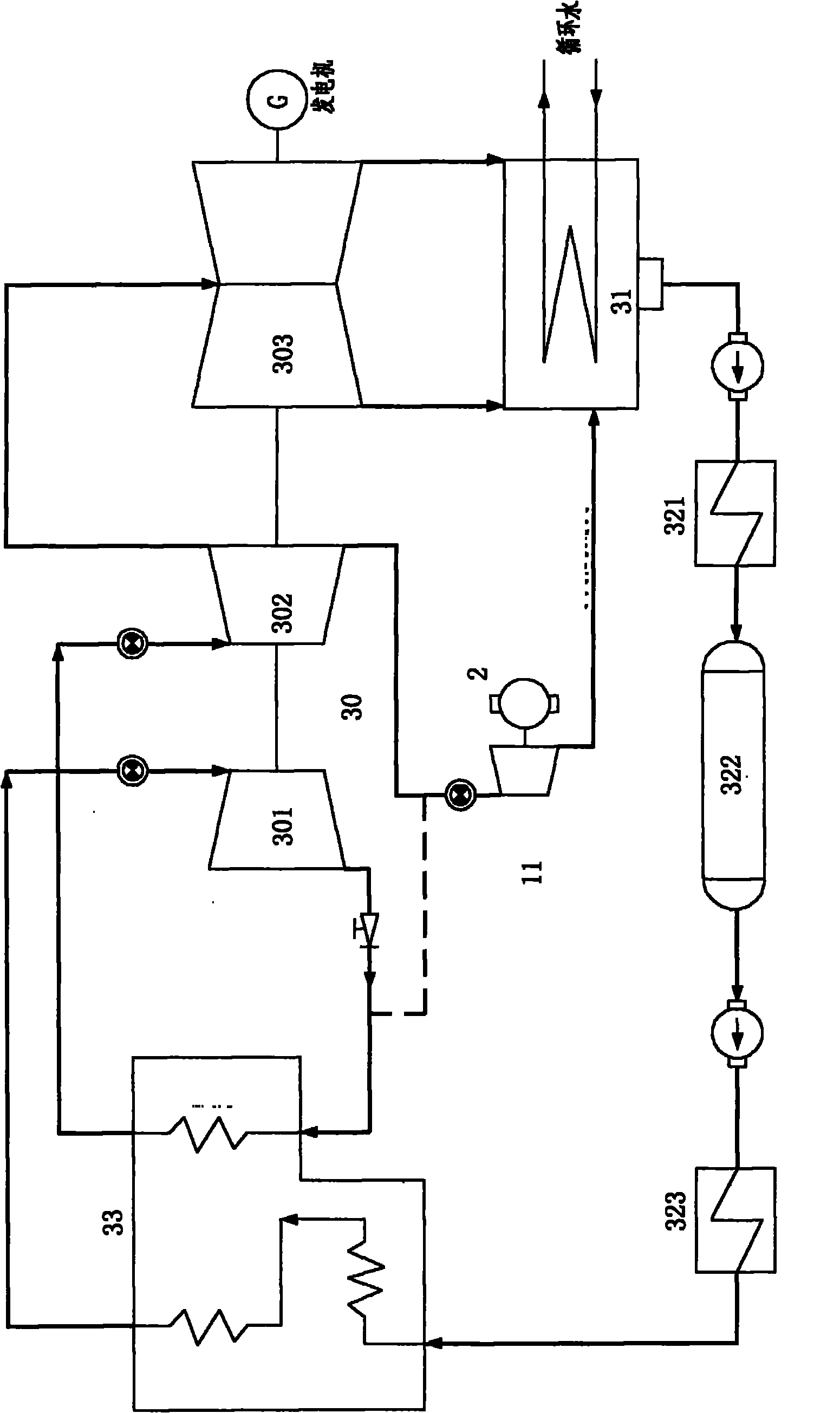

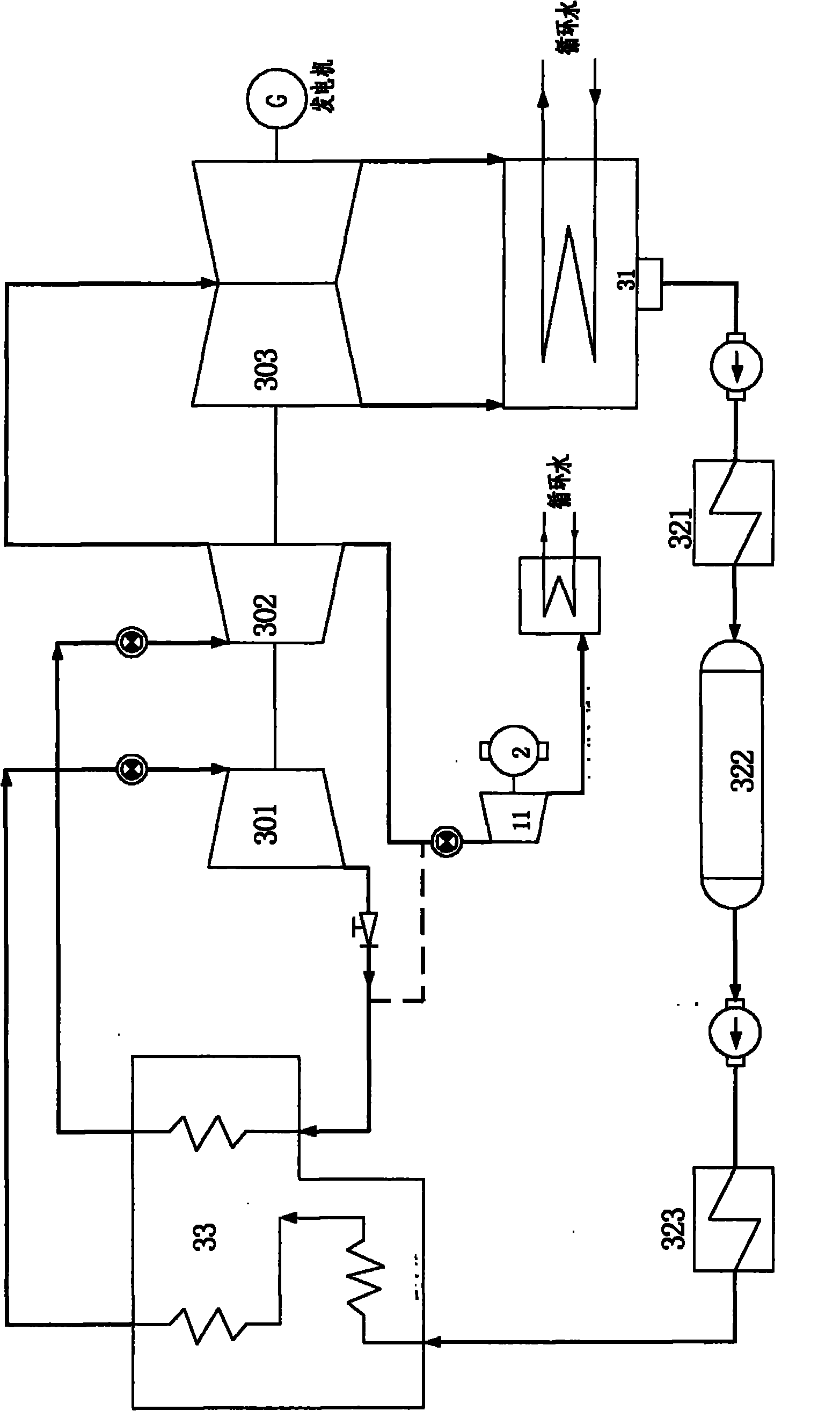

Small turbine system in power plant and thermal cycle system in power plant containing same

InactiveCN101899999ASave electricityImprove power supply efficiencyFeed water supplyEnergy industryPower stationEngineering

The invention provides a small turbine system in a power plant for recovering the exhaust steam heat to the thermal cycle system in the power plant. The system comprises a backheating-type small turbine unit and a driven device driven by the backheating-type small turbine unit. The backheating-type small turbine unit comprises a small turbine, a small turbine admission pipe system and a small turbine exhaust pipe system. The small turbine admission pipe system is arranged on the upstream of the small turbine and receives steam source from the thermal cycle system in the power plant; the small turbine exhaust pipe system is arranged on the downstream of the small turbine; the exhaust steam of the small turbine exhaust pipe system enters to the backheating unit of the thermal cycle system in the power plant so that the exhaust heat is recovered. The invention further provides a backheating system and a thermal cycle system in the power plant containing the small turbine system in the power plant. The systems can greatly improve the power supply efficiency of the unit.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

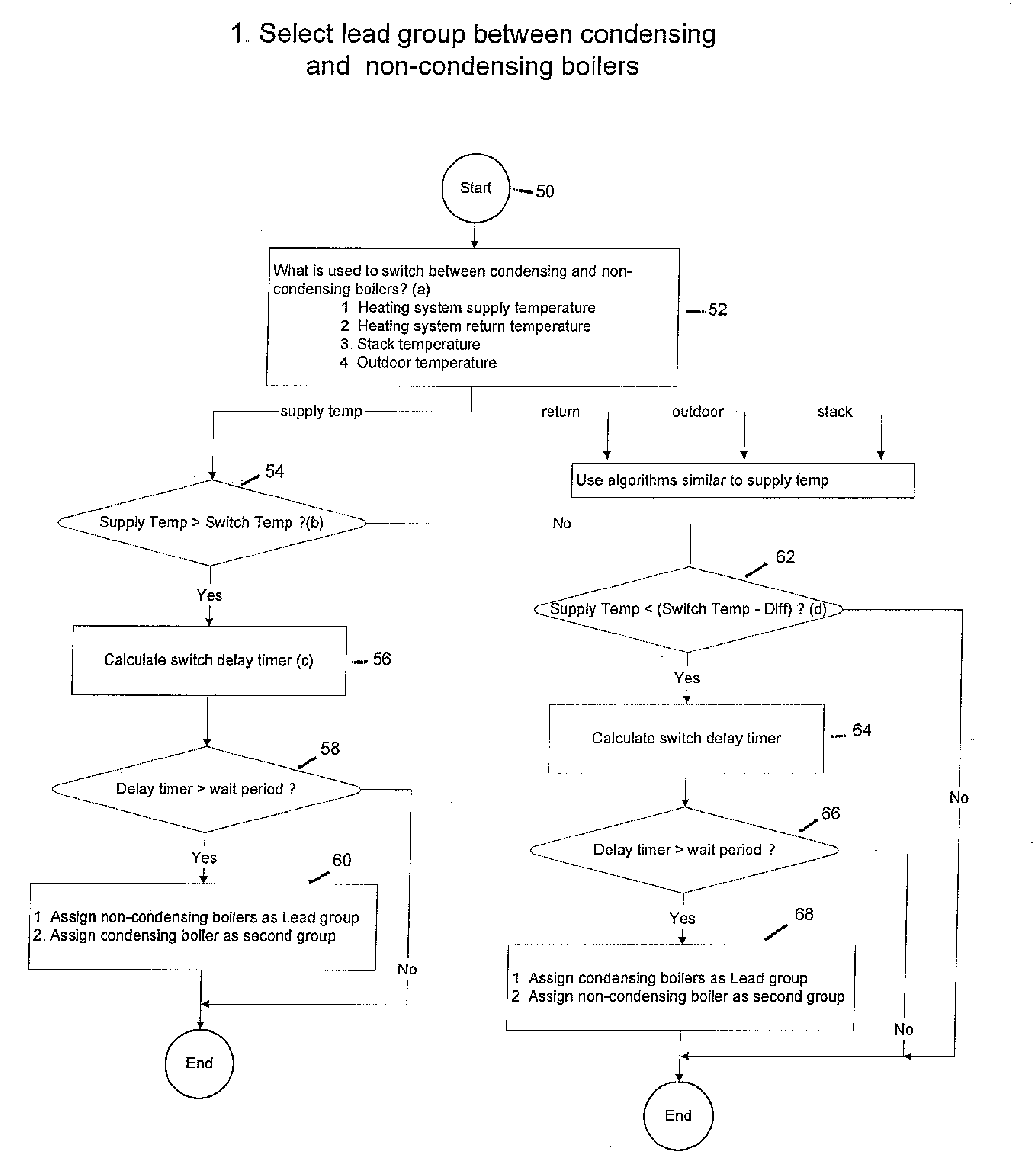

Optimizing multiple boiler plant systems with mixed condensing and non-condensing boilers

ActiveUS20100006042A1Maintaining overall heating plant efficiencyImprove efficiencyBoiler controlSteam generation plantsBoiler plantIndependent group

A system is provided to optimize multiple boiler plant systems having mixed condensing and non-condensing boiler groups. The system advantageously employs the independent groups of boilers depending on preset conditions under control of a system control unit. The preset conditions are checked against operating conditions of the boiler plant, and a system control unit controls which of the groups of boilers is the lead and which is secondary. In some instances, both groups of boilers may be utilized under heavy load. Further, effective switching between groups and within groups is also provided to minimize unnecessary repetitive boiler operation.

Owner:HEAT TIMER

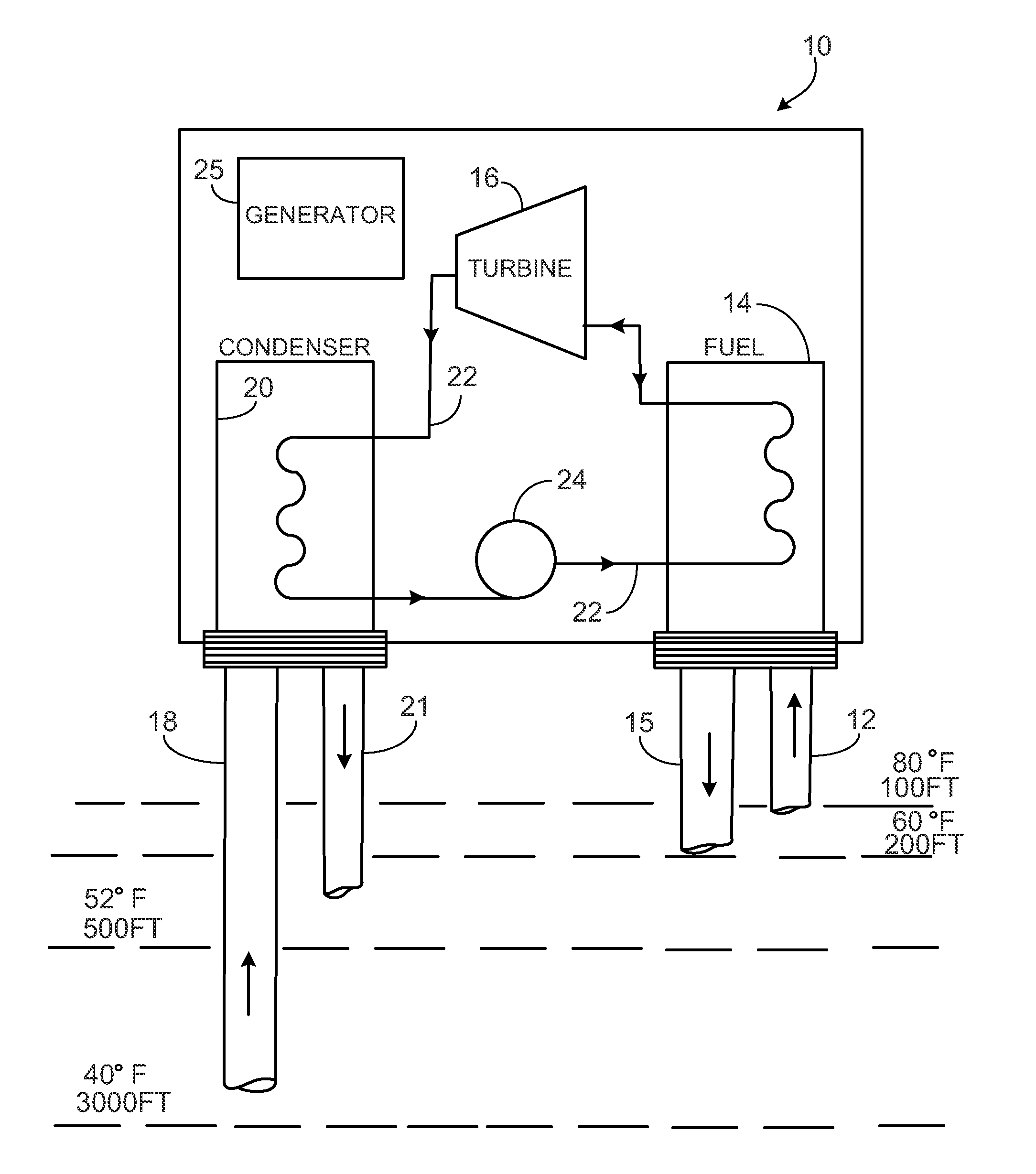

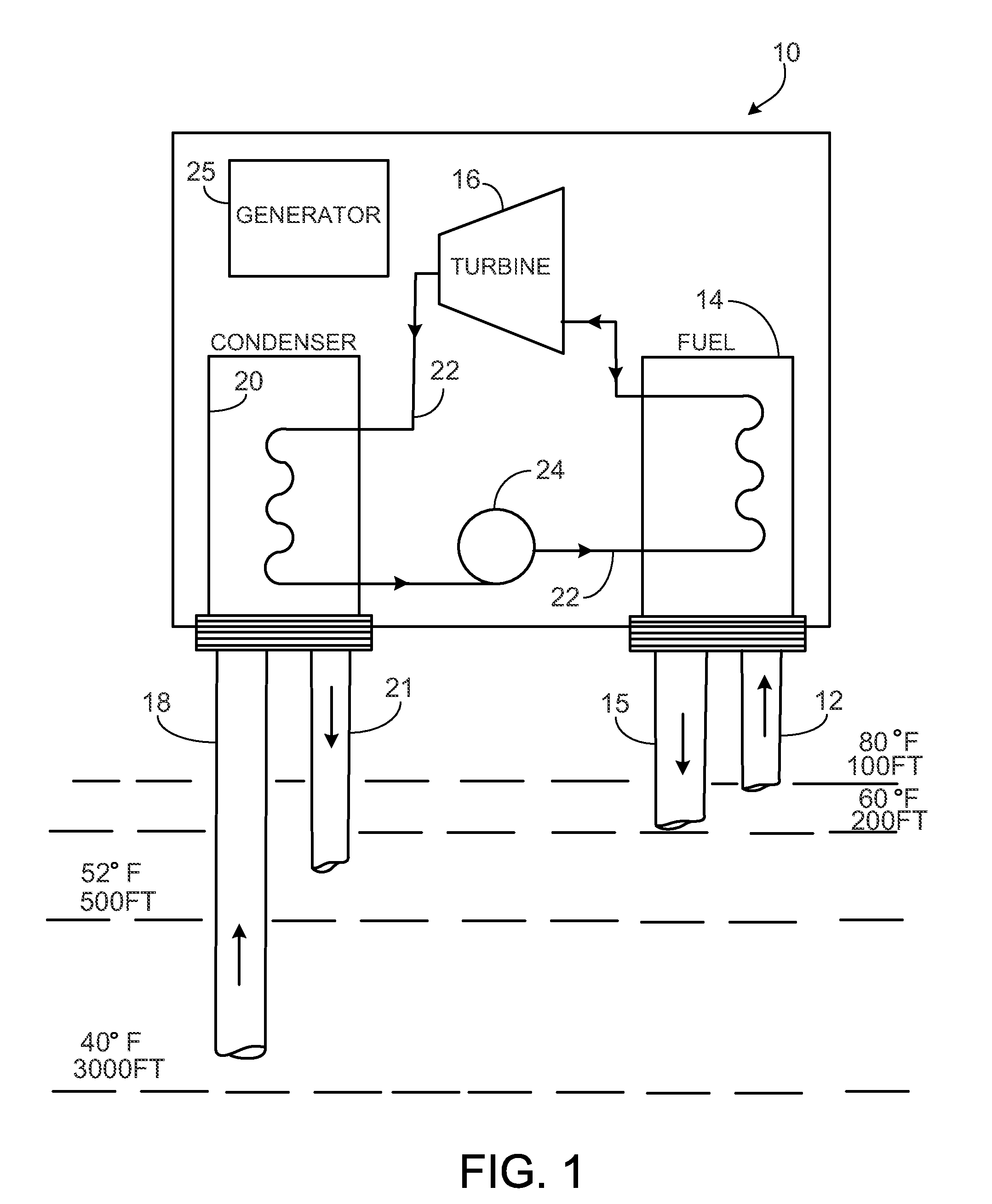

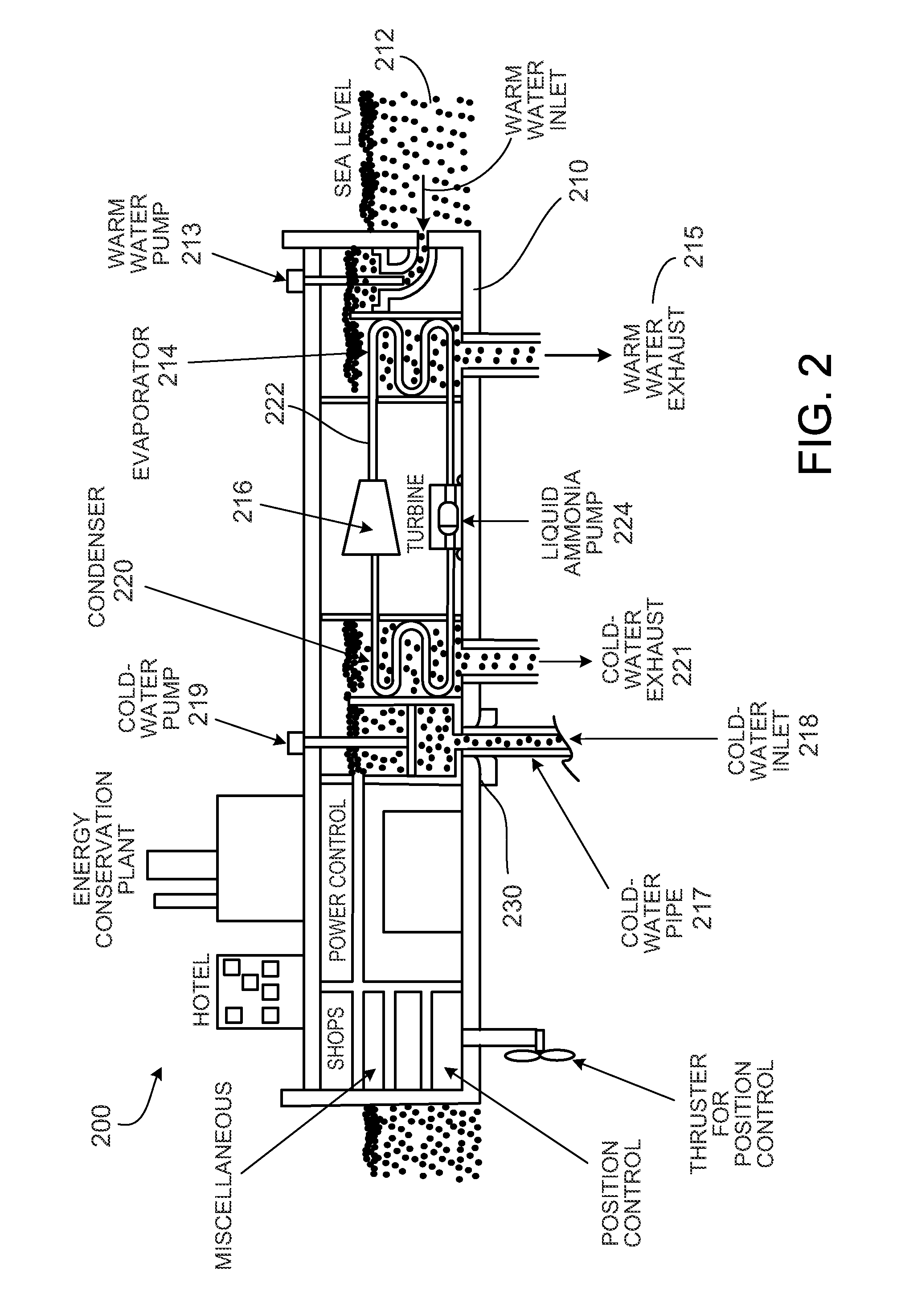

Industrial Ocean Thermal Energy Conversion Processes

InactiveUS20120073291A1Increase net efficiencyShorten construction timeSteam generation plantsSteam engine plantsThermal energyOcean thermal energy conversion

A combined OTEC and steam system having an OTEC power generation system including a multistage condensing system in fluid communication with a cold water system and a steam system comprising a steam condenser, wherein the steam condenser is in fluid communication with the cold water system.

Owner:THE ABELL FOUND INC

On-line monitoring method and device for a fossil fuel converter apparatus

InactiveUS20070184556A1Sound scientific basisSatisfies of ash contentFuel supply regulationSolid fuelsMaterial balanceEnergy balanced

An online monitoring method and device for a fossil fuel converter apparatus. The method monitors fuel compositions in real time by measuring operating data of the converter apparatus and comprises the following steps: determining reactant compositions and number of variables thereof; determining fuel compositions and number of variables thereof; determining compositions of incomplete products and number of variables thereof; determining relationship between the fuel compositions and calorific value; establishing an equation set involving the fuel compositions, the reactant compositions and the resultants compositions, according to energy balance relationship and material balance relationship in the combustion process; providing given conditions for independent relationships concerning variables in the above equation set; measuring boiler operating data and assigning the variables in the above equation set; and finding the solution to the equation set and obtaining real-time monitoring data of the converter apparatus.

Owner:WANG ZHEN

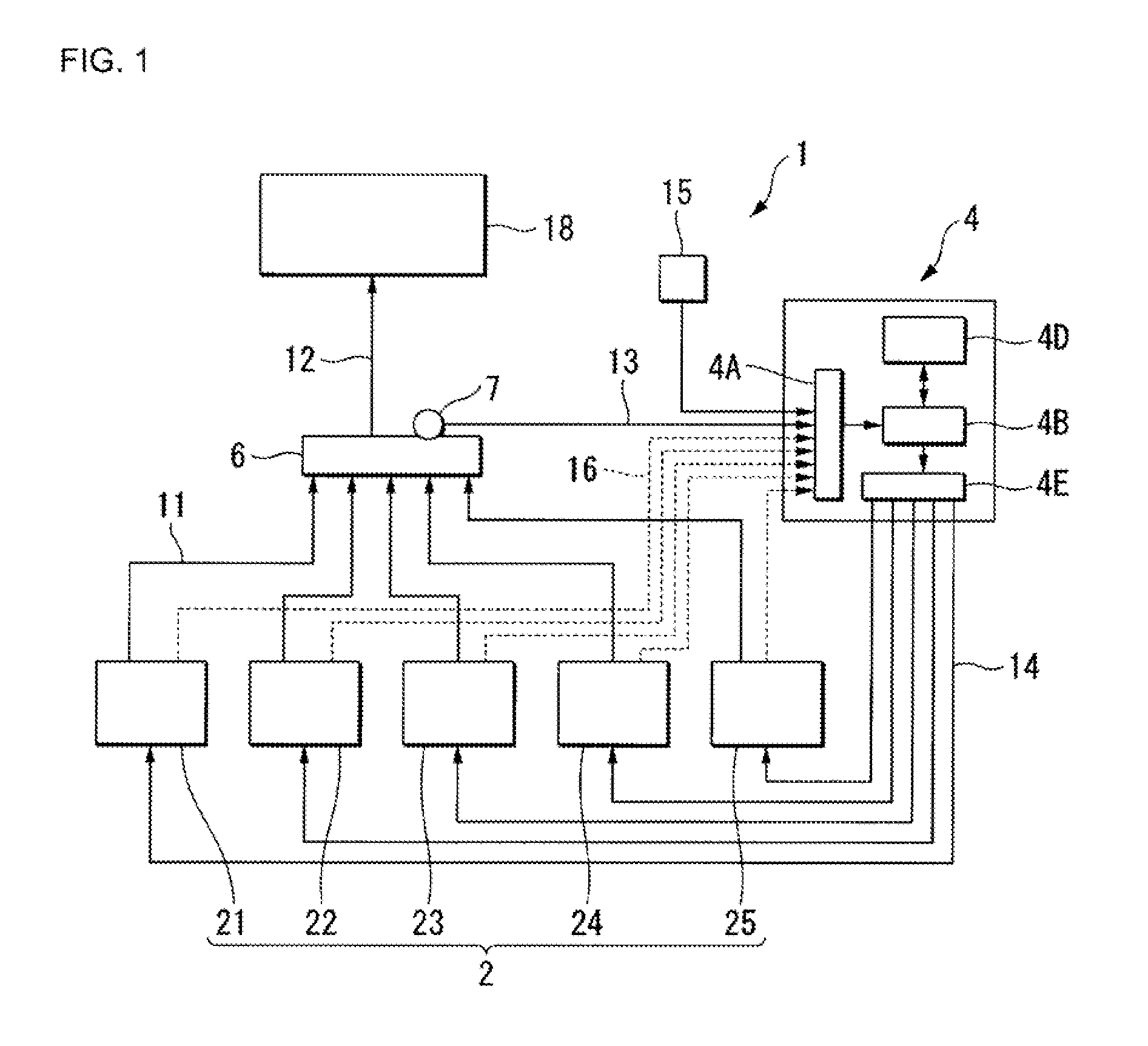

System, program product, and related methods for global targeting of process utilities under varying conditions

ActiveUS20100030547A1Precise definitionSimple designBoiler controlSteam generation plantsElectric power systemProcess conditions

Systems, program product, and methods to optimize energy management for a site including a combined steam heat and electrical power system, is provided. A system, for example, can include a computer including memory, and energy utility modeling program product stored in the memory. The system can rigorously target, without manual iteration, for multiple utility commodity targets to include their global minimum and maximum requirements or capabilities, individually, or subject to other target objectives, due to varying process conditions. The system can also obtain the supply and demand best and worst case scenarios due to varying process conditions for a given process or cluster of processes. The system can also provide such data subject to other supply and demand objectives, and can further provide a range of commodity requirements or capabilities subject to user selected values for other commodity requirements or capabilities.

Owner:SAUDI ARABIAN OIL CO

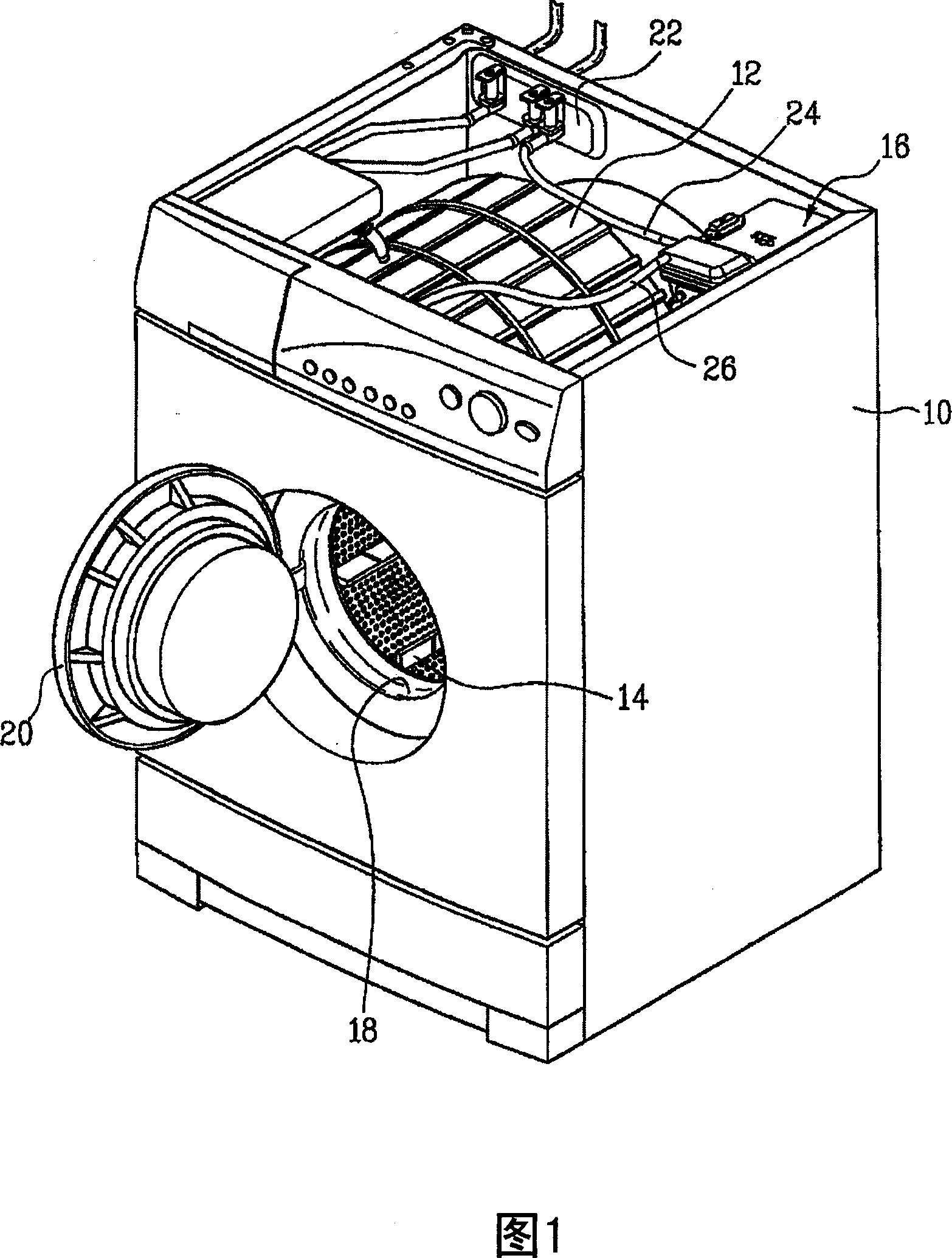

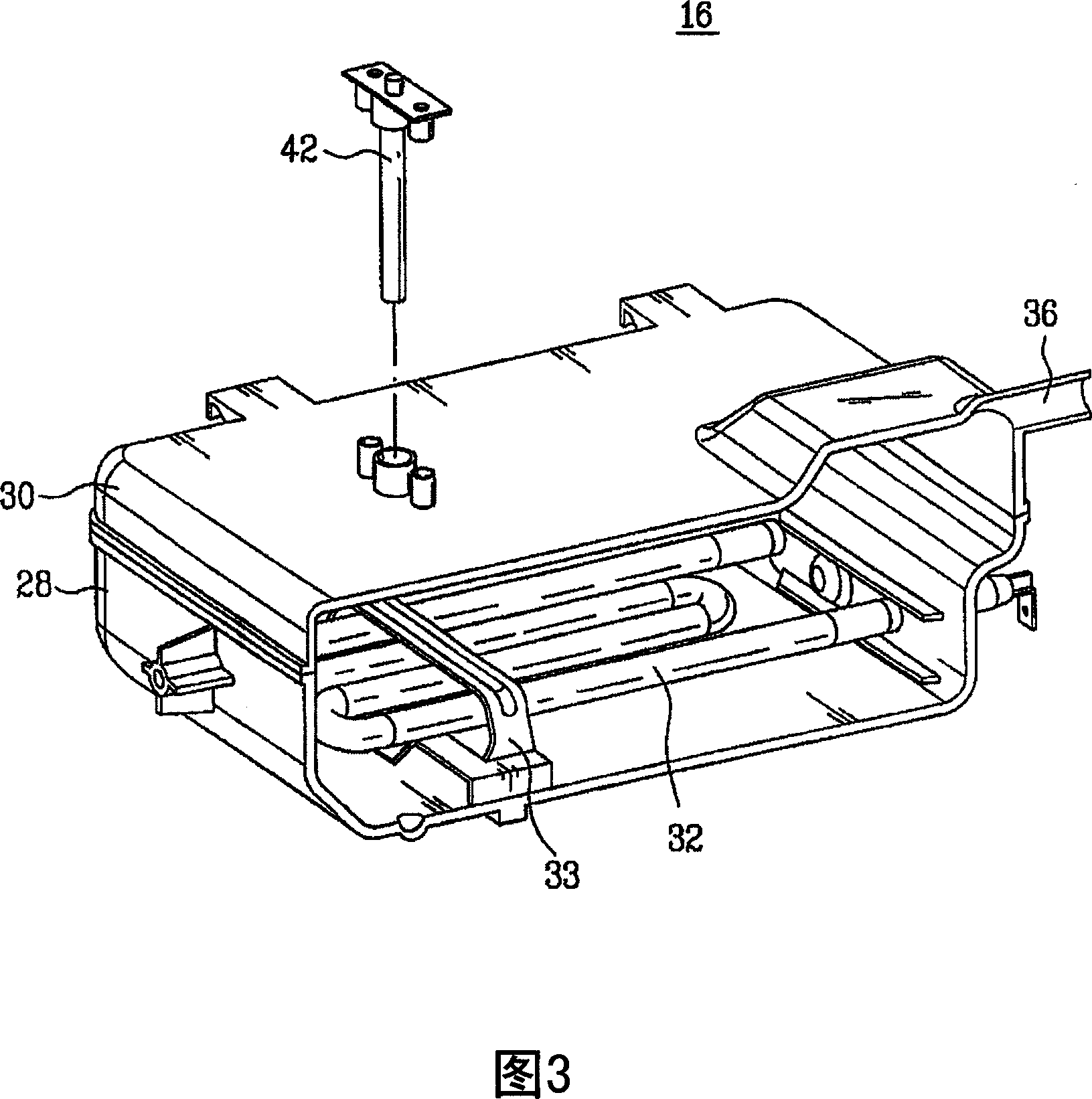

Steam generator and drum type washing machine with the same

ActiveCN101024915AImprove production efficiencySmall sizeSteam generation heating methodsOther washing machinesEngineeringSteam generation

The invention discloses a steam generator and a drum-type washing machine with the steam generator. The present invention relates to a steam generator. More particularly, the present invention relates to a steam generator which has a compact design to enhance efficiency, and to a drum-type washing machine with this steam generator. The steam generator includes a heater that heats water to generate steam; a lower case that holds water for steam generation, having a heater holding part in which the heater is vertically oriented in the heater holding part, and an upper case coupled to an upper portion of the lower case to form a predetermined space. The invention provides a drum-type washing machine with the steam generator.

Owner:LG ELECTRONICS INC

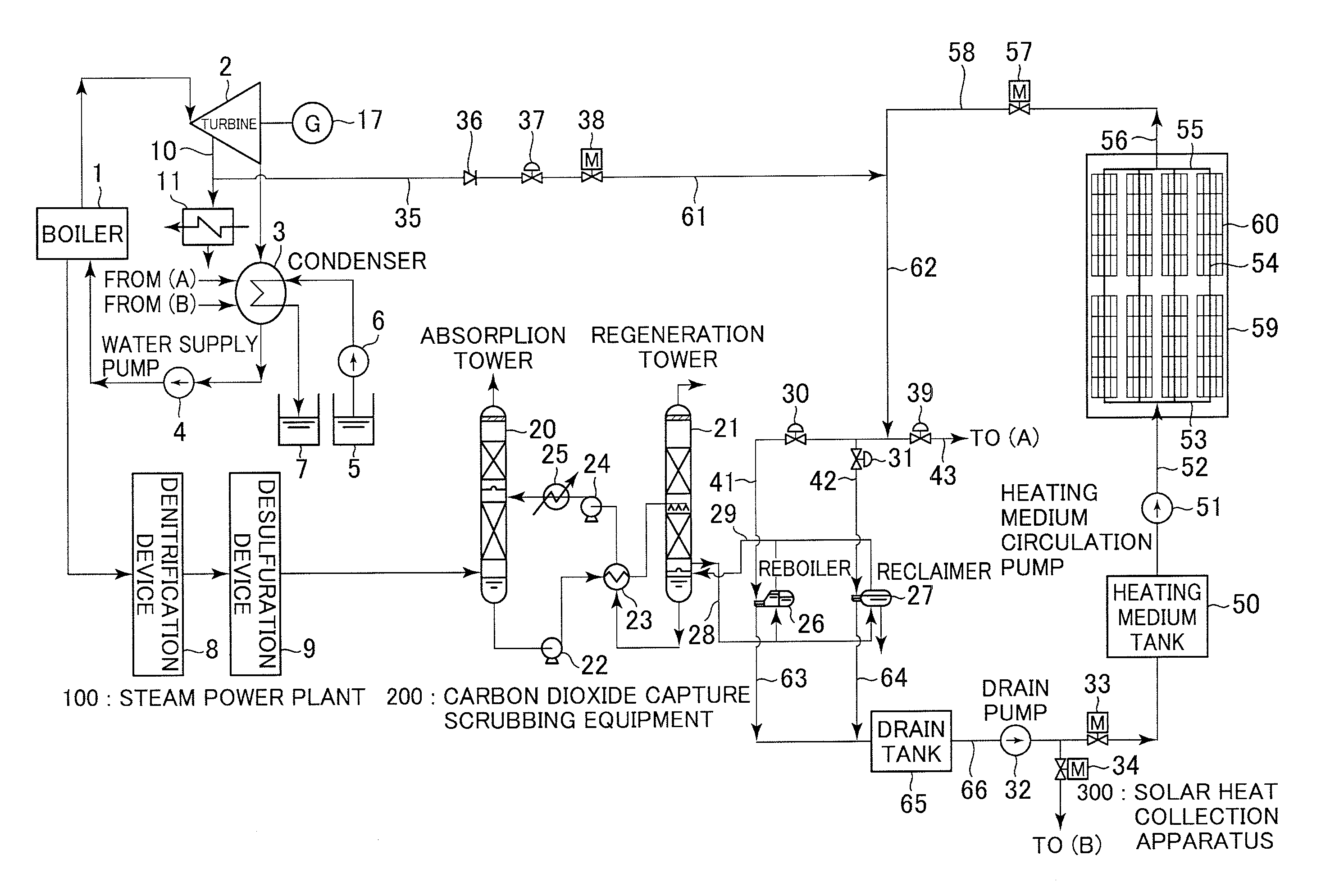

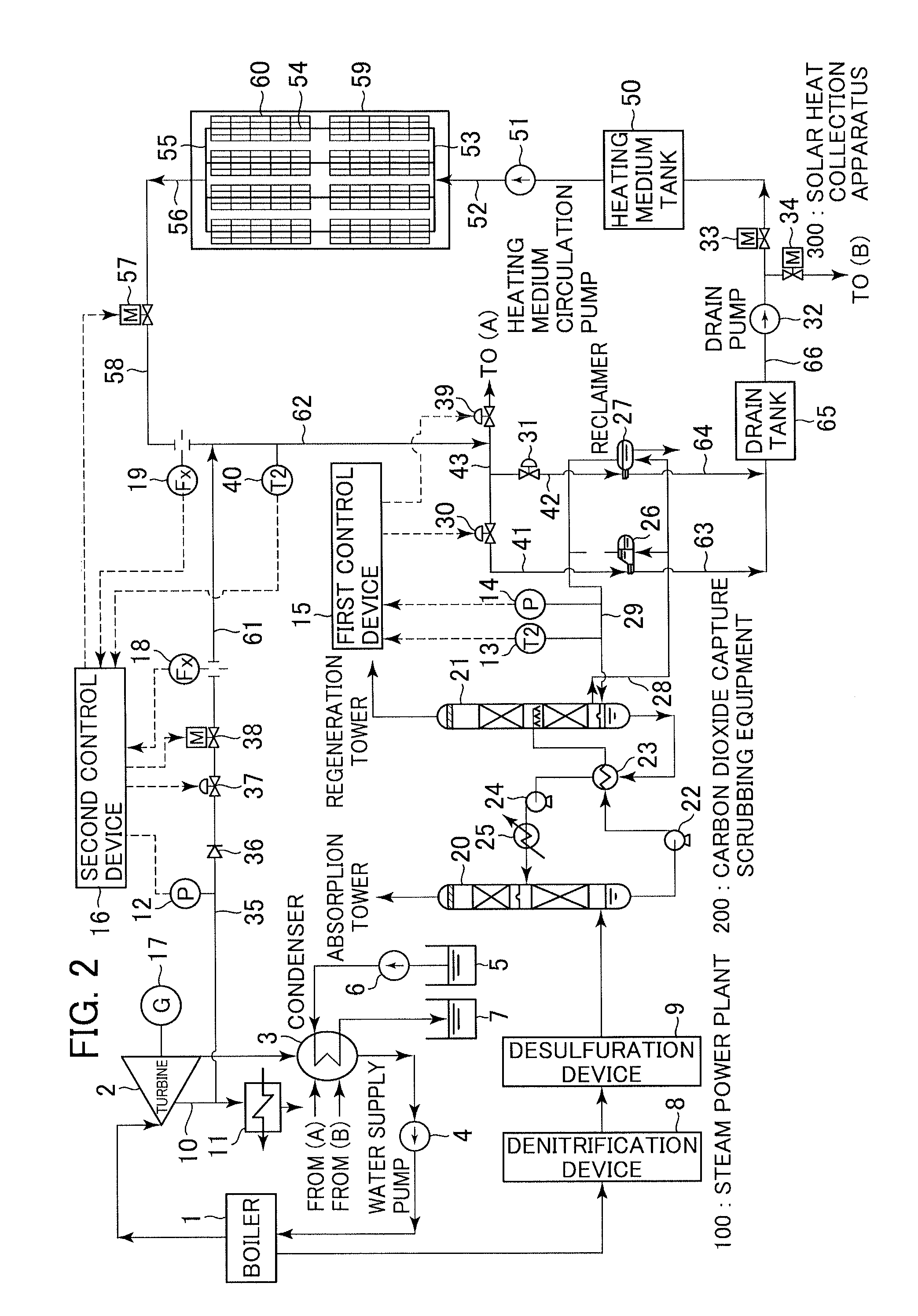

Thermal Power Plant with Carbon Dioxide Capture Scrubbing Equipment

InactiveUS20120192564A1Reduce energy costsImprove efficiencyAuxillary drivesCarbon compoundsReboilerEngineering

A thermal power plant includes carbon dioxide capture scrubbing equipment that suppresses reductions in the efficiency and output of a steam turbine, and, at the same time, reduces variations in the amount of steam supplied from a solar heat collection apparatus to a reboiler and variations in the temperature and pressure of reboiler generated steam, and stably carries out reactions for separating carbon dioxide from an absorbent by heating. The thermal power plant includes the carbon dioxide capture scrubbing equipment for capturing carbon dioxide from a boiler exhaust gas and the solar heat collection apparatus. Steam generated by the solar heat collection apparatus is supplied to the reboiler provided for a regeneration tower of the carbon dioxide capture scrubbing equipment.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

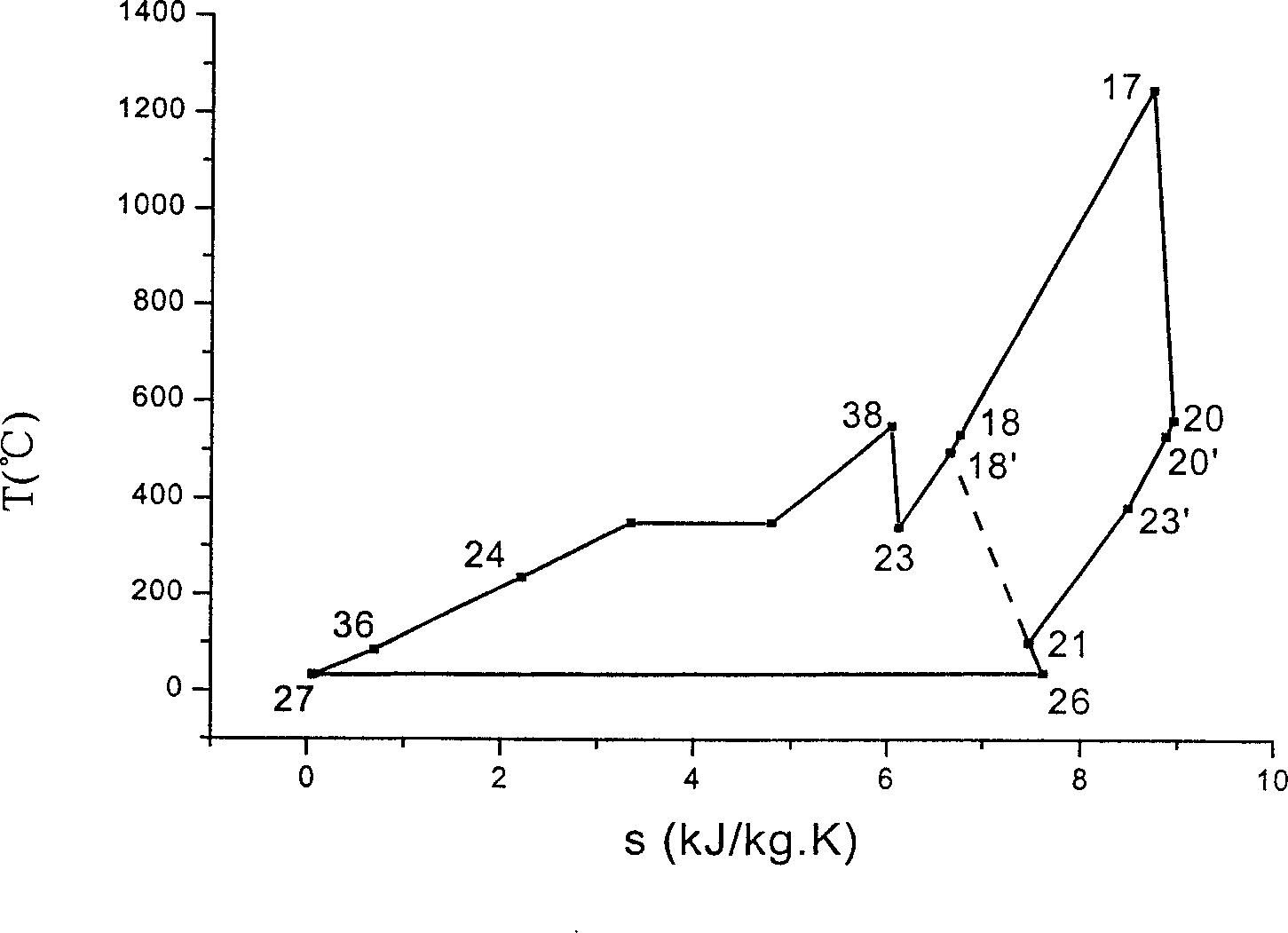

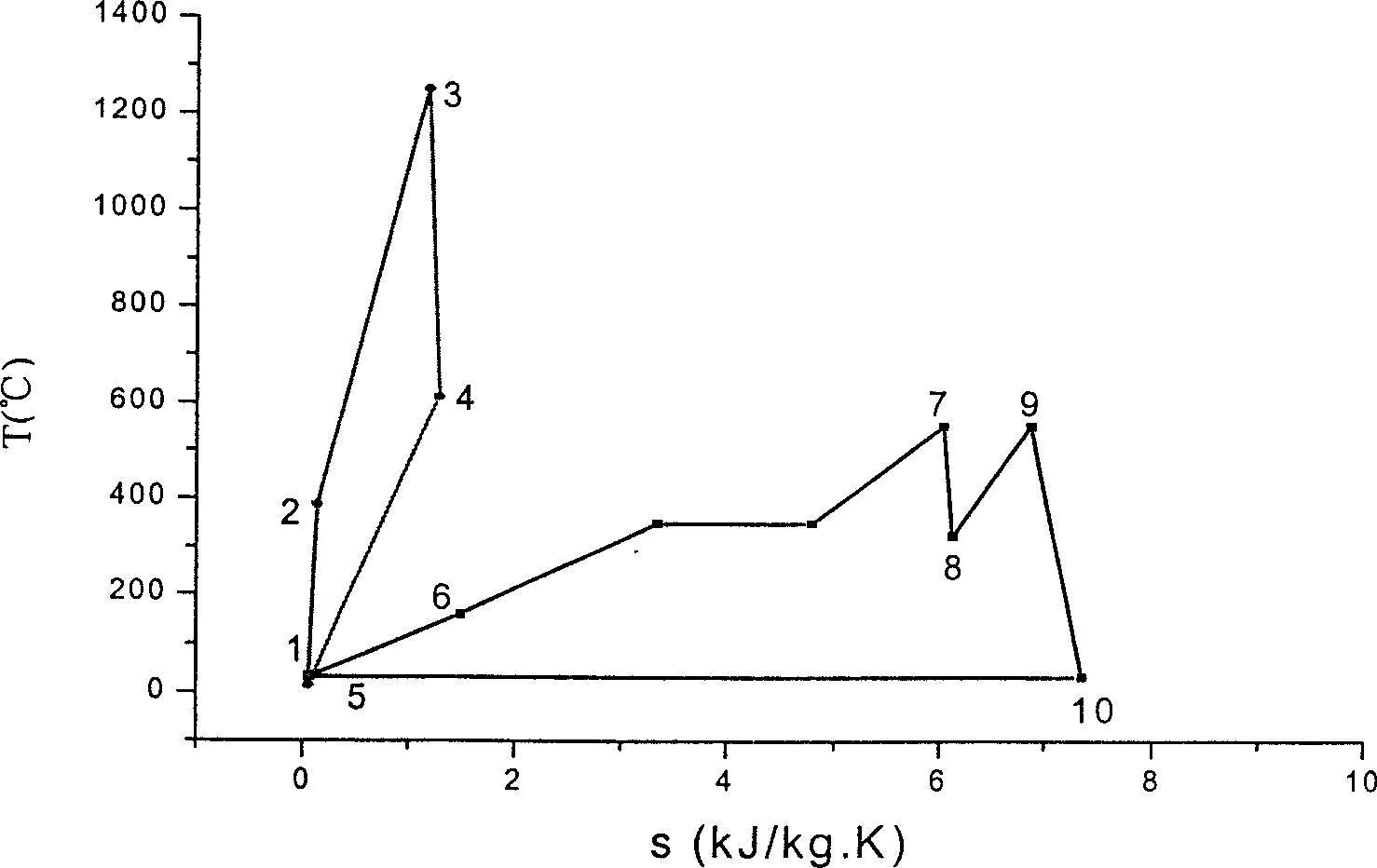

Inside and outside burning coal integrative combined cycle generation system and method

InactiveCN1521446AAchieve efficiencyPromote environmental protectionGas turbine plantsSteam generation plantsEngineeringHigh pressure

The invention relates to an external and internal fire coal integrated combination circulation power generating system and process thereof, the power generating system comprises gasification sub-system, power circulation subsystem and carbon dioxide reclamation subsystem. The process according to the invention includes heating up in external-burning mode in the low-temperature stage of the endothermic process in thermodynamic cycle, obtaining the energy through portion coal gasification, and using internal-burning mode heating up in high temperature stage, obtaining the coal gas energy through portion coal gasification. The advantages of the invention are high heat efficiency, environmentally friendliness and good economy property.

Owner:中科思道(南京)储能技术有限公司

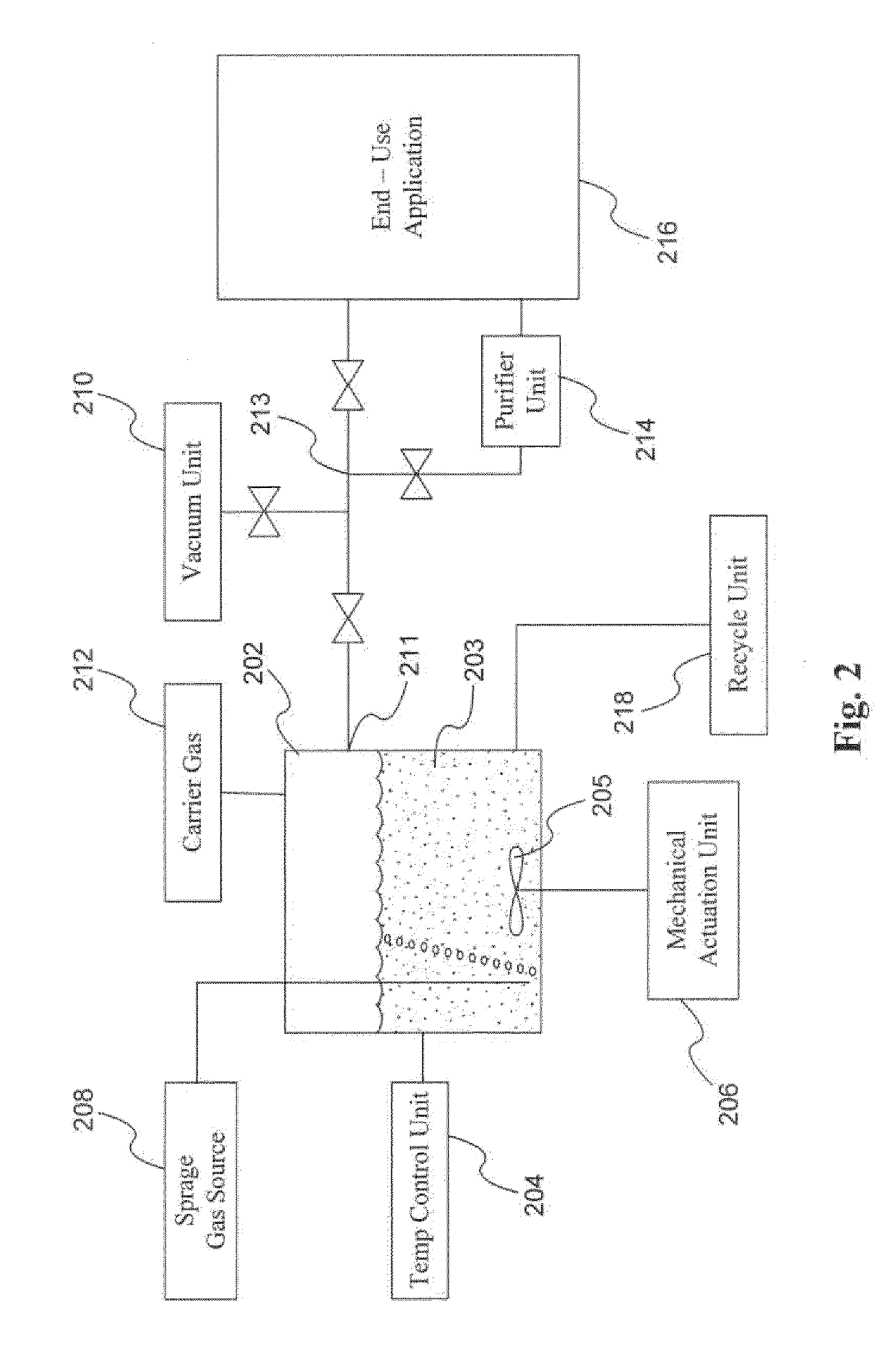

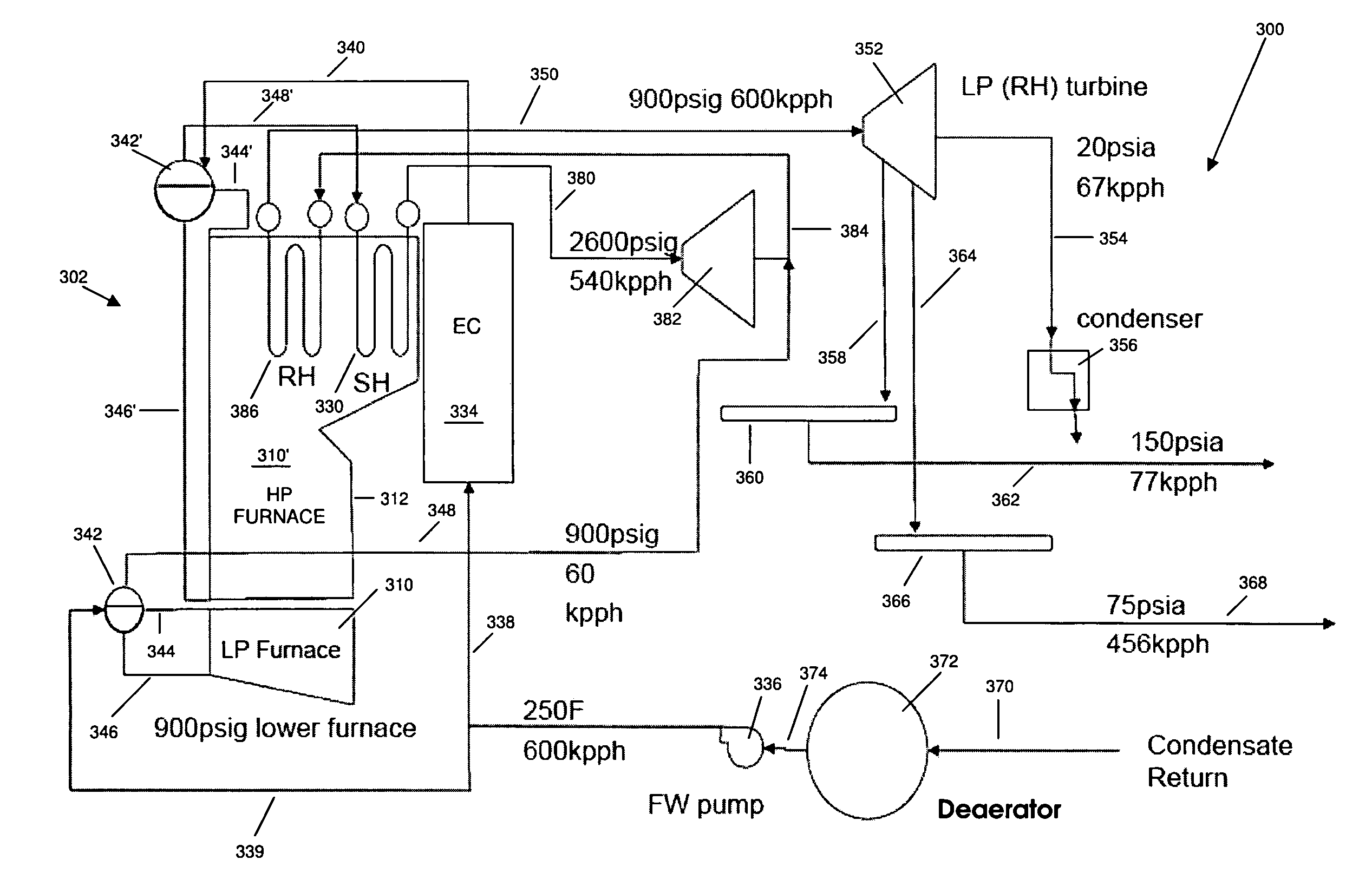

Ionic liquid mediums for holding solid phase process gas precursors

InactiveUS20090320771A1Reduce developmentRapid even transferOther chemical processesSteam generation plantsIonSolid phases

Ionic fluid mixtures are described that include an ionic liquid and a solid-phase material. The ionic liquid and the solid-phase material are selected to convert the solid-phase material into a gas phase material at a temperature that is lower than a conversion of the ionic liquid into a gas phase ionic material. In addition, methods of supplying a gaseous precursor to an application are described. These methods include providing a mixture of an ionic liquid and a solid-phase starting material, heating the mixture to a temperature that vaporizes at least a portion of the solid-phase starting material into the gaseous precursor, and transporting the gaseous precursor from the mixture to the application that utilizes the gaseous precursor.

Owner:MATHESON TRI GAS

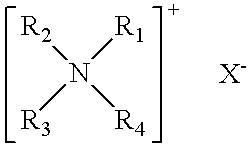

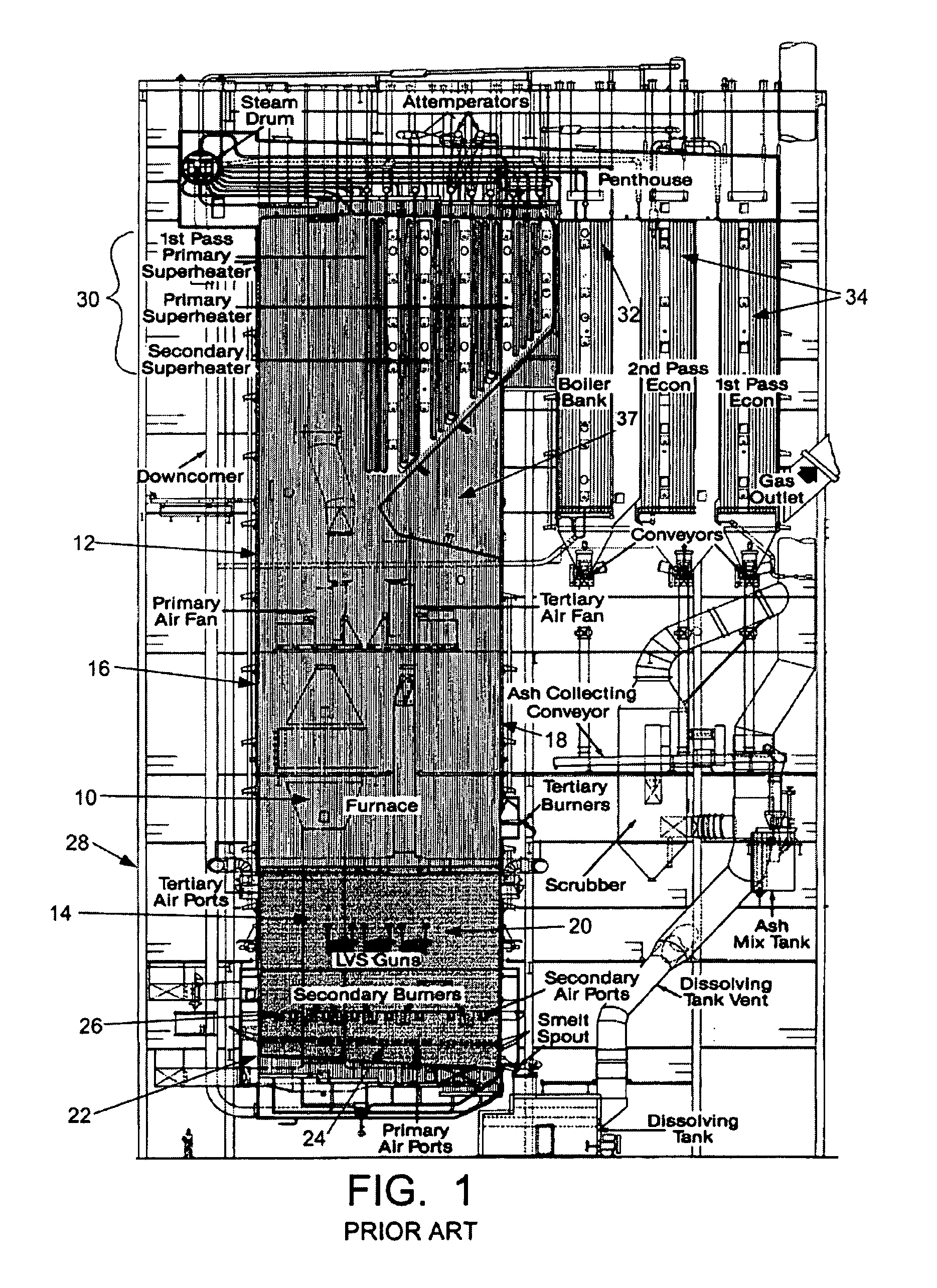

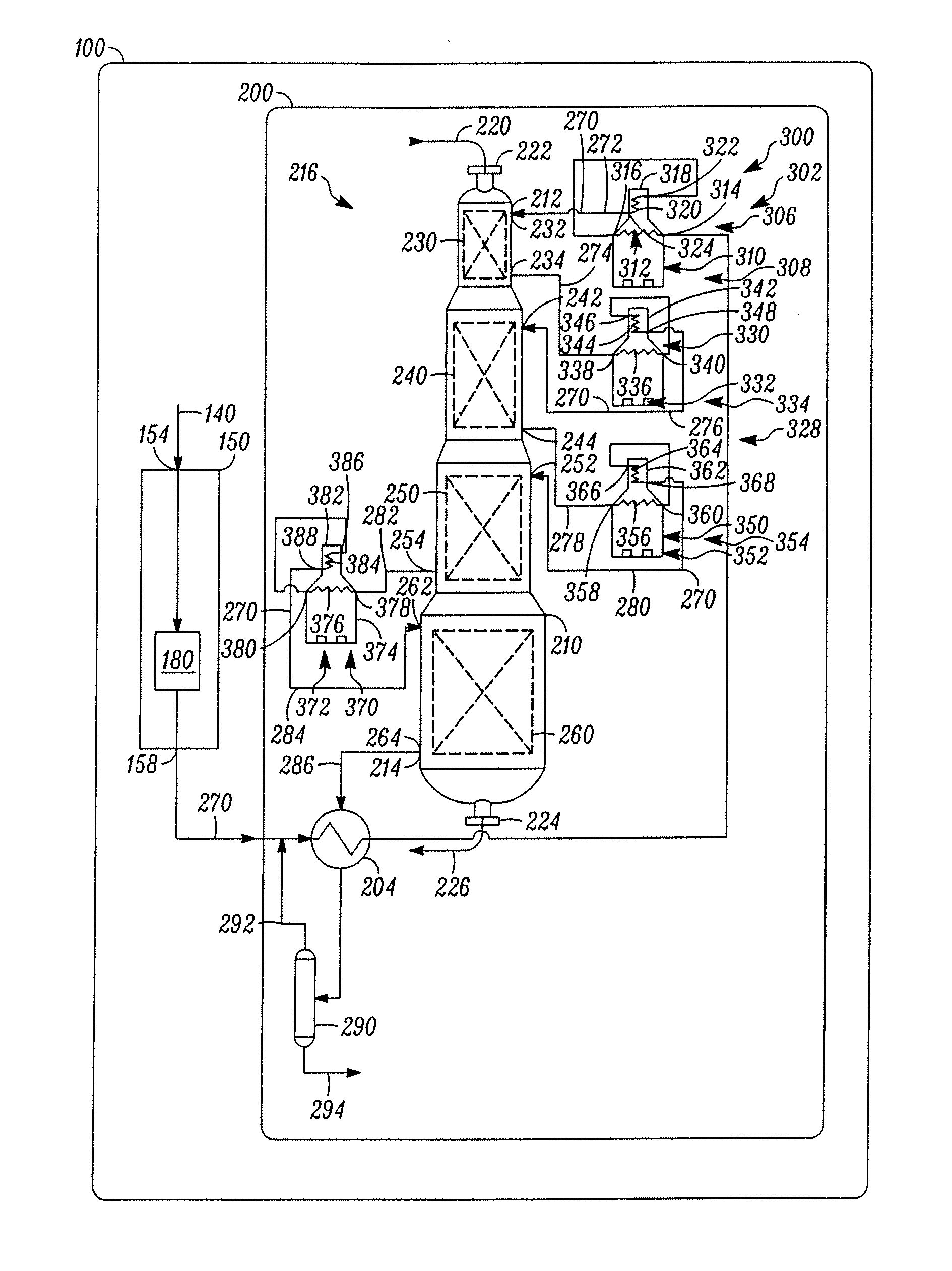

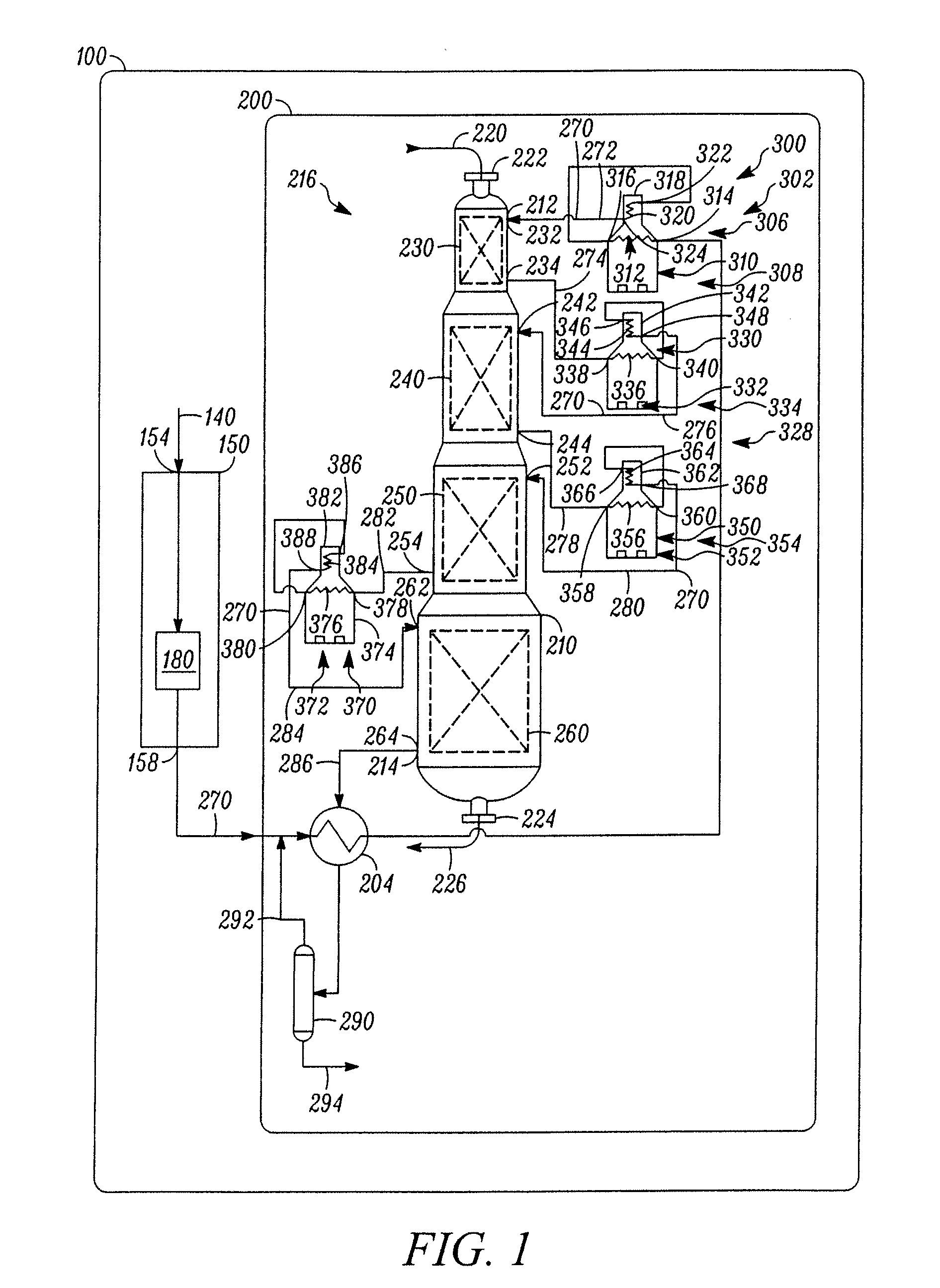

Enhanced steam cycle utilizing a dual pressure recovery boiler with reheat

InactiveUS20090241860A1Increase generationThe material is lowSuperheating controlFood processingBoiler furnaceEngineering

An enhanced steam cycle utilizing a dual pressure recovery boiler with reheat allows a large increase in electrical generation with various turbine cycles while overcoming traditional lower furnace material limitations. A dual pressure designed recovery boiler furnace is provided with a lower furnace and an upper furnace. The lower furnace is operated at a lower temperature to prevent or reduce corrosion of the lower furnace wall tubes caused by the reducing environment. The lower furnace can be either a low pressure natural circulation steam generating (drum) system or economizer. Unlike the lower furnace, the upper furnace is not exposed to a reducing environment and is therefore not as susceptible to severe corrosion rates. The upper furnace is operated at higher temperatures and pressures which permit implementation of higher efficiency reheat steam cycles. The upper furnace thus operates as a high pressure natural circulation steam generating (drum) system, or as a once-through supercritical steam generating system. The dual pressure recovery boiler can thus be coupled to a variety of condensing, non-condensing or a combination of condensing and non-condensing turbine cycles to provide a large increase in electrical generation.

Owner:THE BABCOCK & WILCOX CO

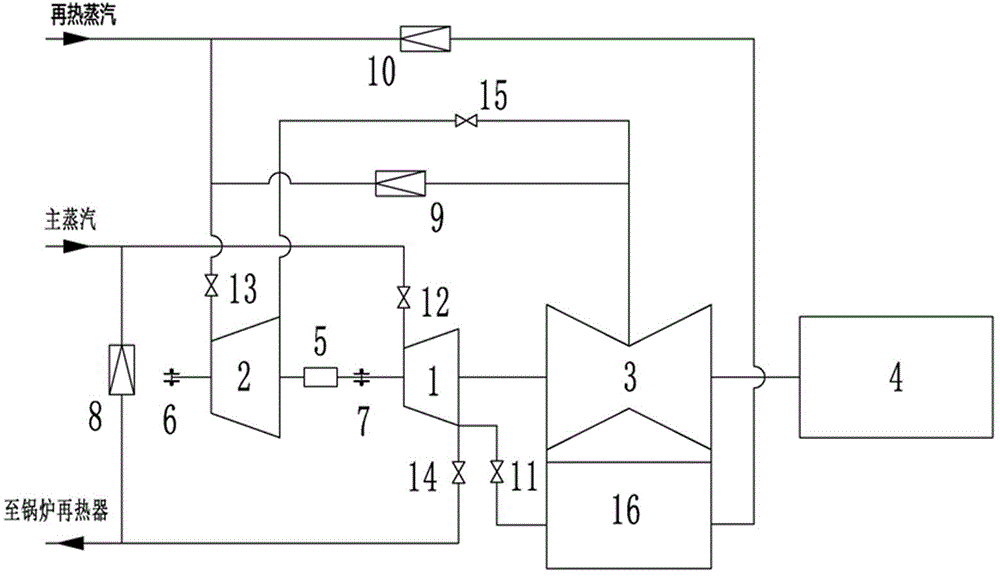

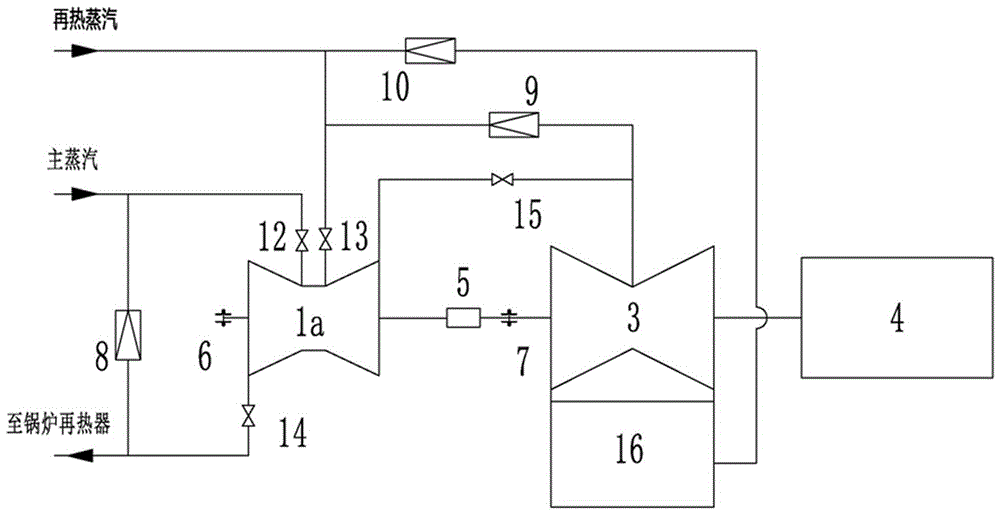

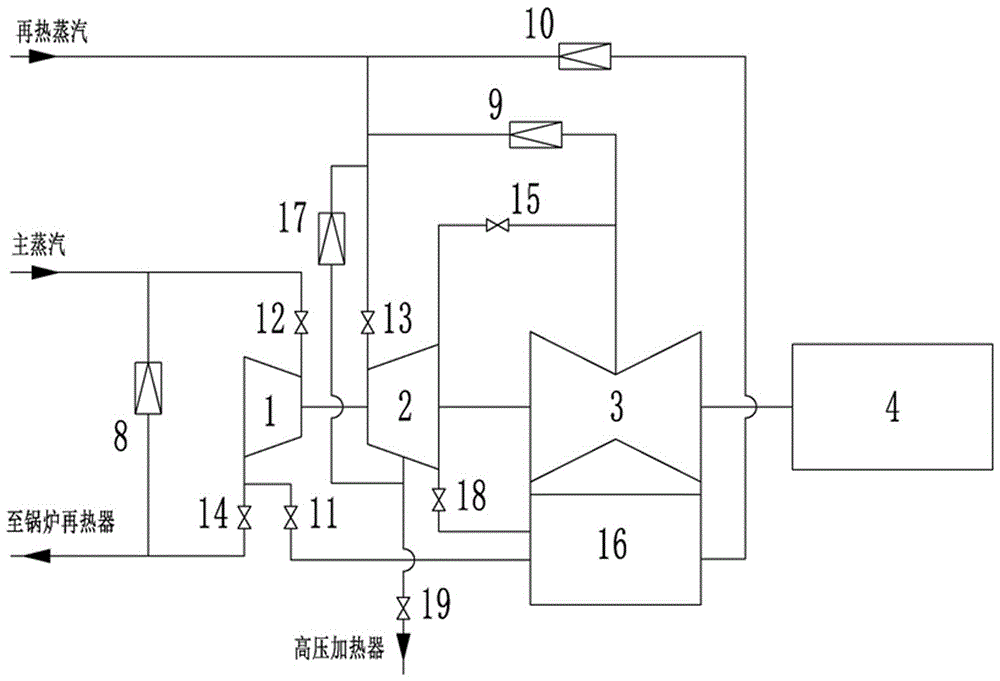

Turbine with deep peak regulation function and thermodynamic system

The invention relates to the field of thermal power generation, in particular to a turbine with a deep peak regulation function and a thermodynamic system. The turbine comprises an intermediate-pressure cylinder, a synchronous automatic clutch, a high-pressure cylinder, a low-pressure cylinder, an intermediate-pressure by-pass valve and the like, wherein the intermediate-pressure cylinder, the synchronous automatic clutch, the high-pressure cylinder and the low-pressure cylinder are connected with one another through a coupler and connected with a power generator through the output end of a low-pressure rotor. During deep peak regulation of a unit, a high-pressure steam inlet regulation valve and an intermediate-pressure steam inlet regulation valve are closed, the intermediate-pressure cylinder is cut off through the synchronous automatic clutch, the high-pressure cylinder is vacuumized through a vent valve, a high-pressure by-pass valve and the intermediate-pressure by-pass valve of the unit are opened, steam from a boiler directly enters the low-pressure cylinder for acting, the unit is maintained to operate with low power output, and the purpose of deep peak regulation of the unit is achieved.

Owner:山西漳电科学技术研究院(有限公司) +2

Water softener regeneration

ActiveUS20100193444A1Reduce the temperatureCation exchanger materialsIon-exchanger regenerationWater useSoftened water

A new process for ion exchange softening of water used in Once-Through Steam Generators (OTSGs) by recovering and using the salt content of the blowdown water from the OTSG to regenerate the softener resin is provided, thus eliminating the cost for commercial regenerant salt that would otherwise be needed. Further, the very high purity of the salt recovered in the blowdown inherently results in the production of softened water with hardness leakage levels that are an order of magnitude lower than can be attained using commercial salt, thus reducing scale deposit potential and improving operating efficiency and reliability of the OTSG.

Owner:PUROLITE CORP

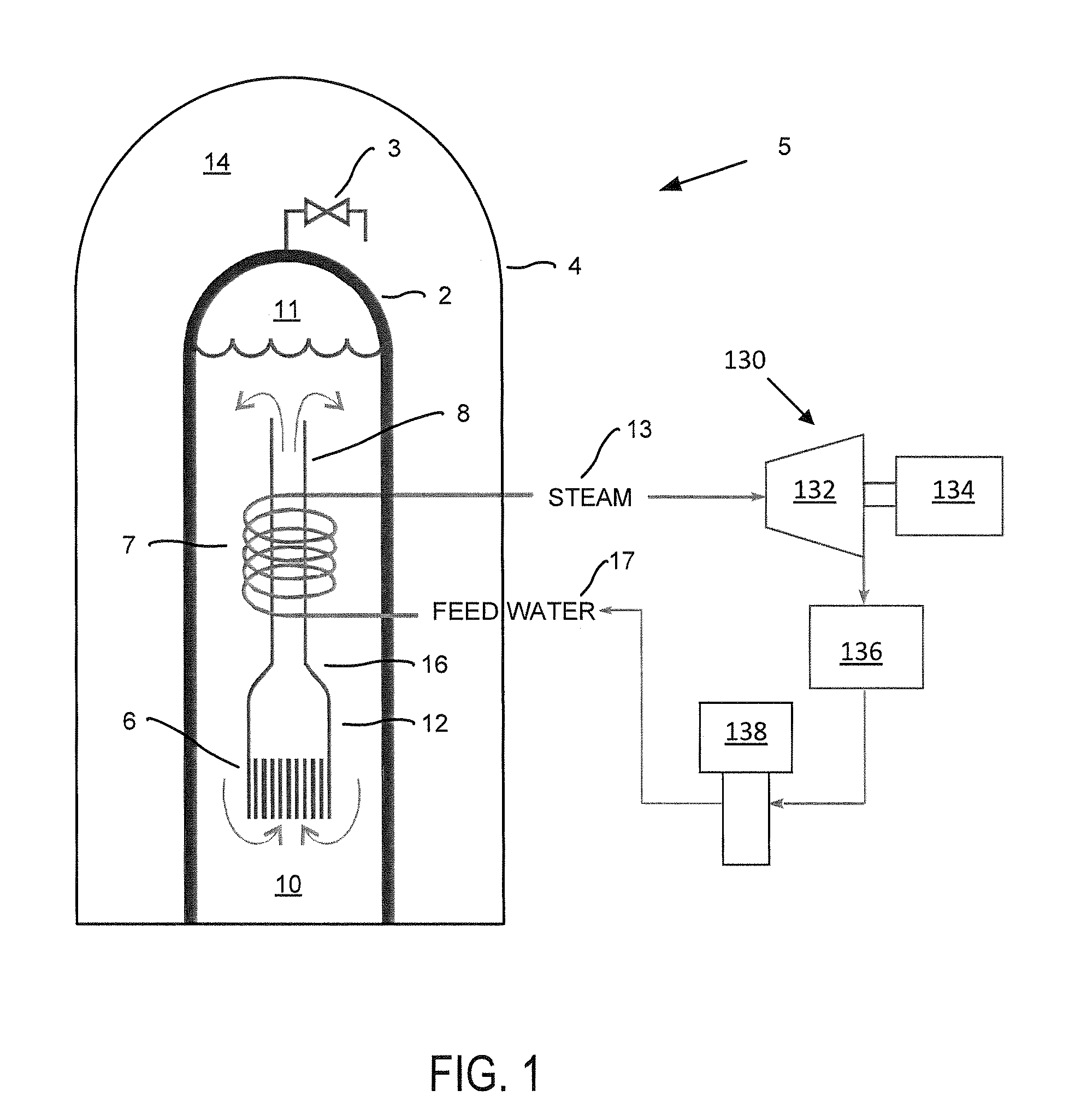

Helical coil steam generator

ActiveUS20120111287A1Redundant operationSteam generation heating methodsMetal-working apparatusSteering wheelHelical coil

A steam generator includes a lower integrated tubesheet and plenum (ITP) configured to receive feedwater and a first set of heat transfer tubes fluidly coupled to a plurality of stubs protruding from a first side of the lower ITP. A second set of heat transfer tubes fluidly couples to plurality of stubs protruding from a second side of the lower ITP. The first set of heat transfer tubes is coiled in a substantially clock-wise direction, and the second set of heat transfer tubes is coiled in a substantially counter-clockwise direction. The steam generator further includes an upper ITP fluidly coupled to the first and second set of heat transfer tubes, wherein the feedwater entering the lower ITP is converted to steam in the first and second sets of heat transfer tubes. The upper ITP is configured to transport the steam away from the steam generator.

Owner:NUSCALE

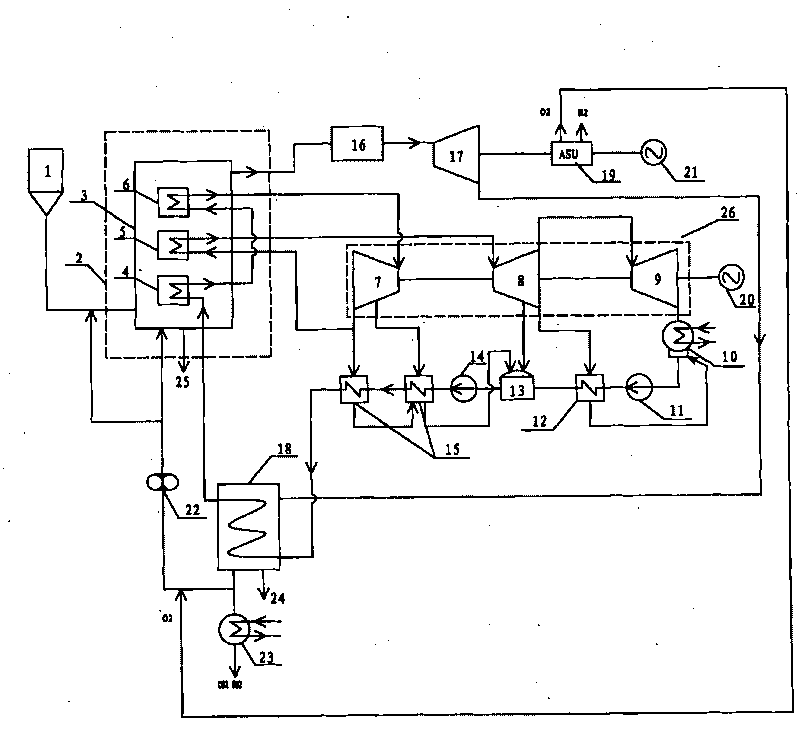

Combined cycle generation system of high-pressure oxygen-enriched combustion fluidized bed

InactiveCN101761915ASmall sizeHigh outputFluidized bed combustionSteam generation plantsLiquid waterTrapping

The invention relates to a combined cycle generation system of a high-pressure oxygen-enriched combustion fluidized bed, which is used for solving the problem of economy of oxygen-enriched combustion. The invention has the technical scheme that the combined cycle generation system of the high-pressure oxygen-enriched combustion fluidized bed comprises a working medium circulating system, an oxygen gas supply and flue gas recirculation system and a fuel conveying device, wherein the overall process of the whole system from the oxygen preparation of air separation, the combustion and the heat exchange of a boiler, the work applying of a high-pressure gas turbine until the CO2 trapping of flue gas is persistently finished at high pressure, and the compression energy consumption and the decompression loss are greatly reduced. The invention can condense water in the flue gas which is unserviceable originally in combustion at normal pressure into liquid water, thereby utilizing the released latent heat of vaporization, which lowers the flue gas loss to about 1%, enhances the efficiency of the boiler greatly and can also enhance the output of the gas turbine by about 3-5%. Because of high pressure in an exhaust-heat boiler, liquid-state CO2 can be obtained only by cooling the flue gas to about 25 DEG C through cooling water. Compared with a normal-pressure oxygen-enriched combustion mode adopting multistage compression and refrigeration, the energy saving of the invention is larger.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

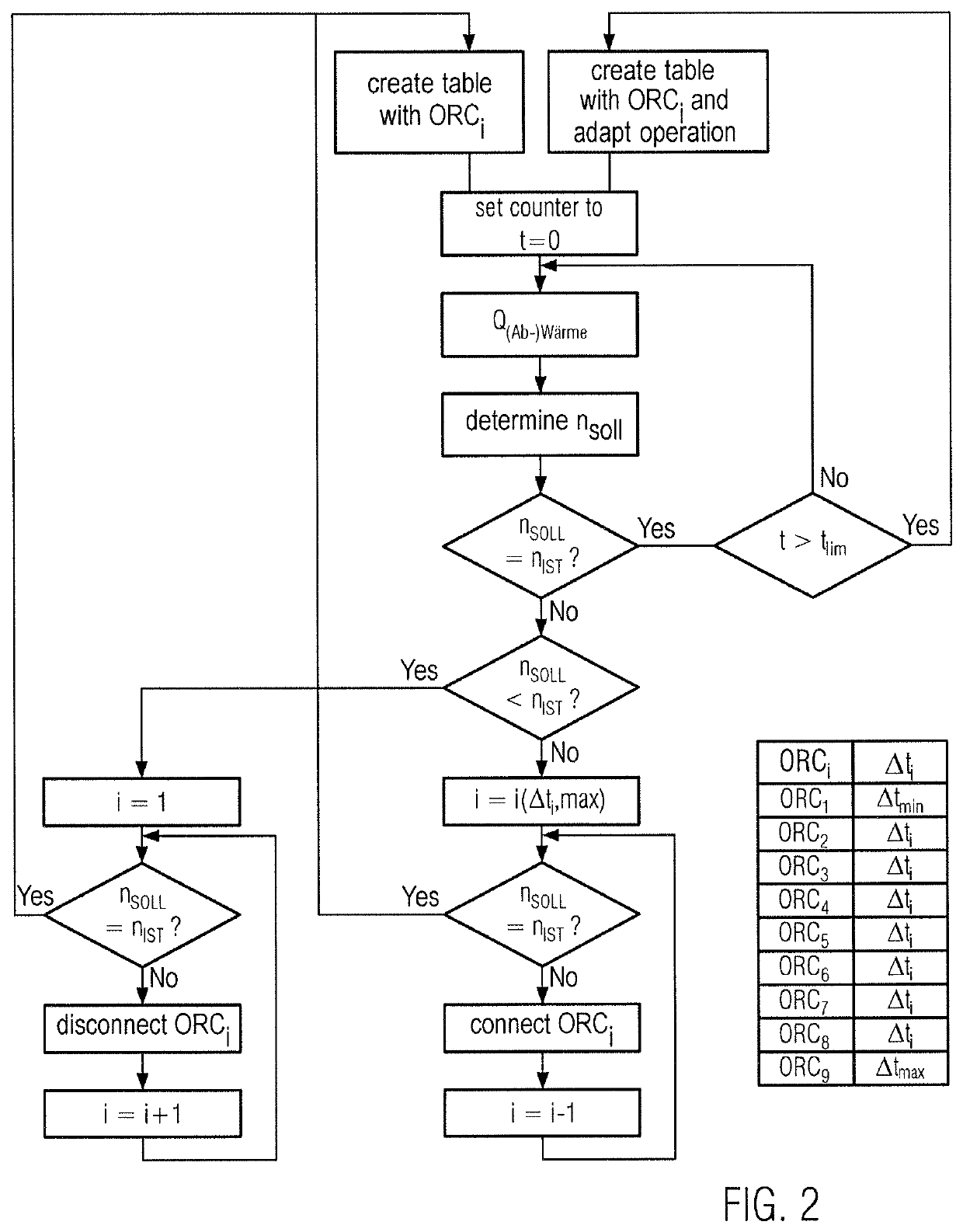

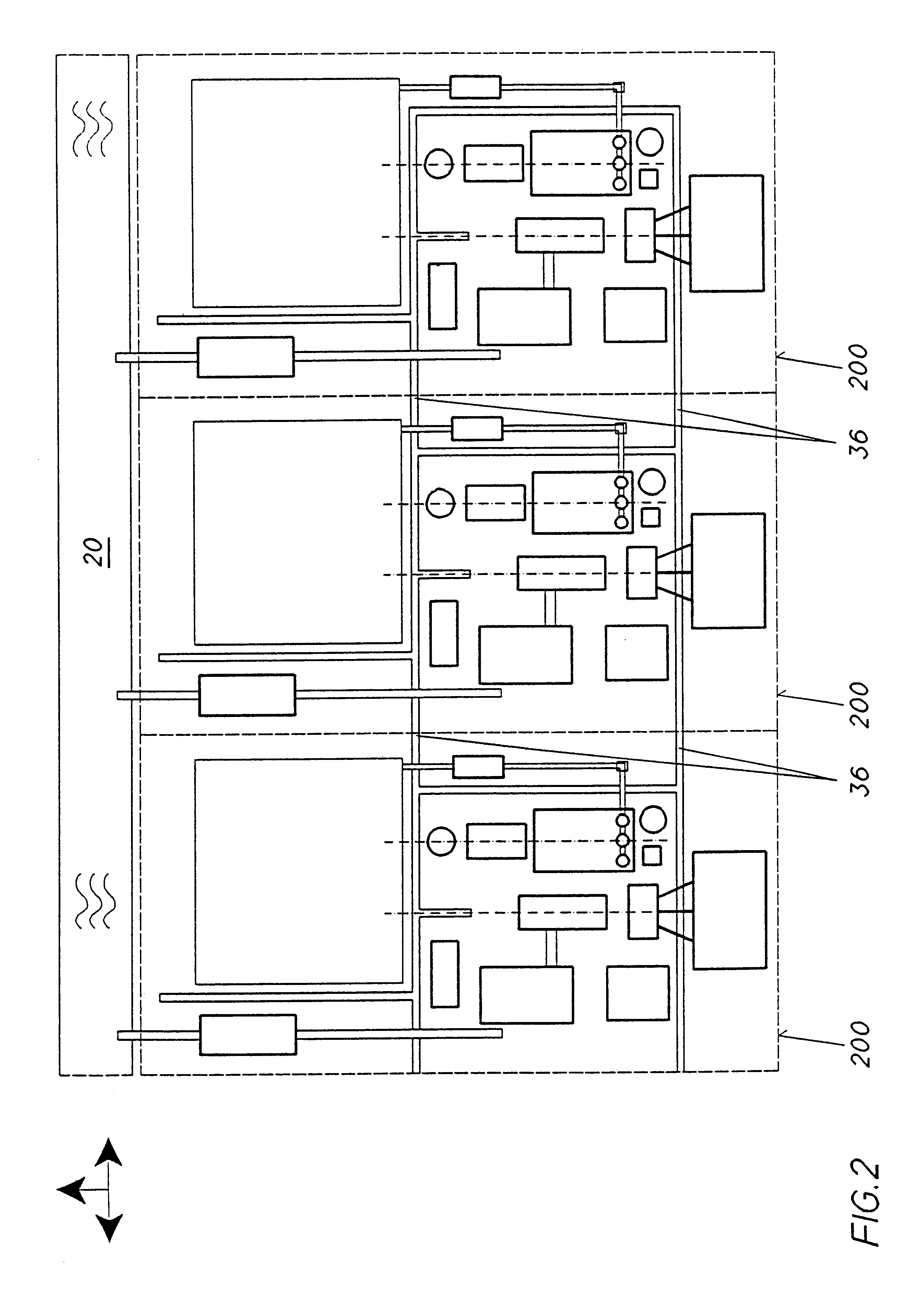

ORC stack-system control

ActiveUS10570782B2Long operationPromote conversionSteam generation plantsSteam engine plantsControl theoryRunning time

The invention relates to a method for controlling ORC stacks with a total number ntot of individually operable ORC modules, said method comprising the following steps: determining the running time remaining until the next servicing time for each operable ORC module respectively; determining a target number nsoll of ORC modules to be operated; comparing said target number nsoll to an actual number nist of currently operated ORC modules; when nsoll>nist, connecting a number nsoll−nist of ORC modules that corresponds to the difference between the target number and the actual number, where the ORC modules with the longest remaining running times of the ORC modules currently not being operated are connected; and / or when nsoll<nist, disconnecting a number nist−nsoll of ORC modules that corresponds to the difference between the actual number and the target number, where the ORC modules with the shortest remaining running times of the ORC modules currently being operated are disconnected; and / or when nsoll=nist, connecting the ORC module with the longest remaining running time Δt1 of the ORC modules not currently being operated, and disconnecting the ORC module with the shortest remaining running time Δt2 of the ORC modules currently being operated, if Δt1>Δt2.

Owner:ORCAN ENERGY AG

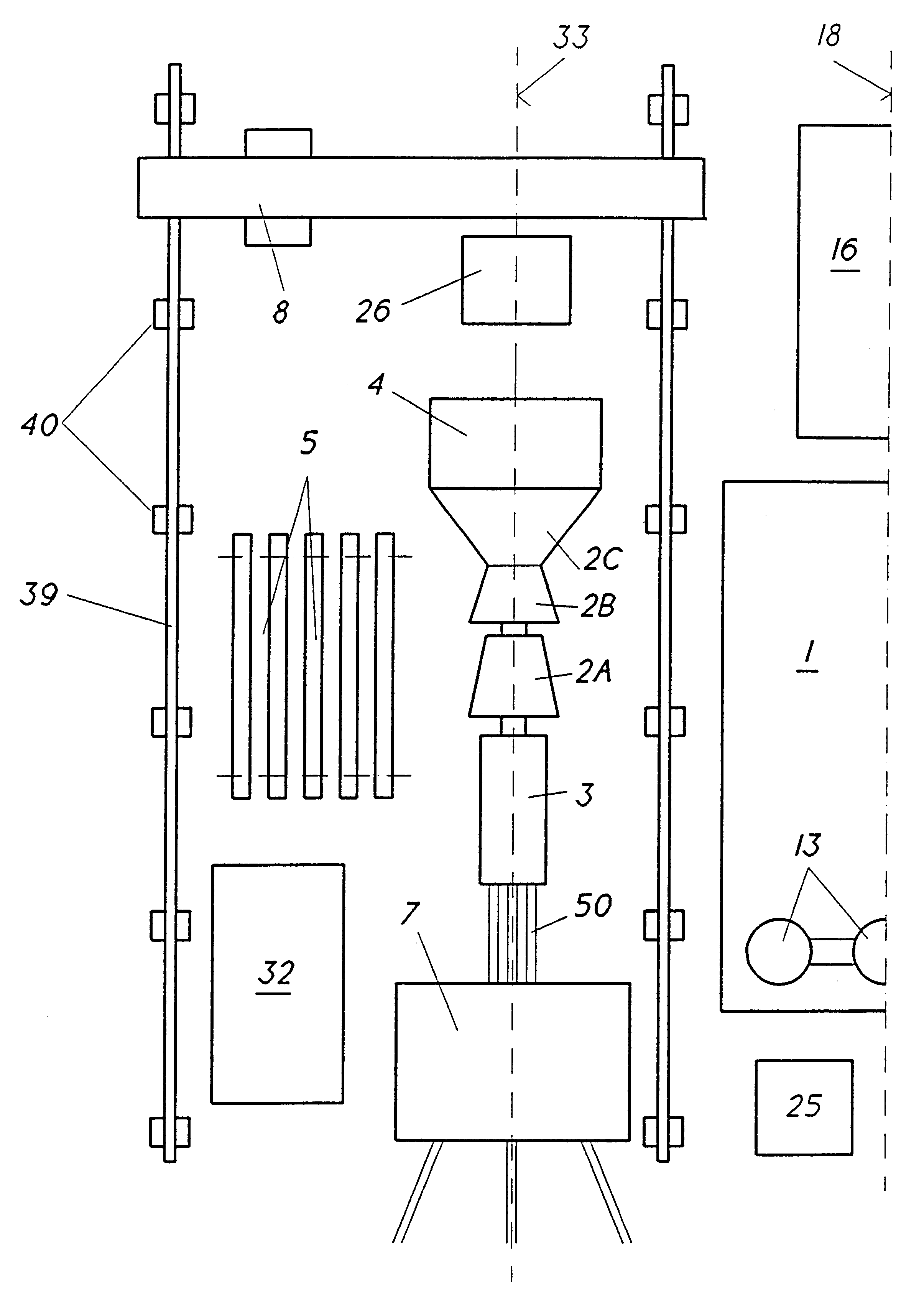

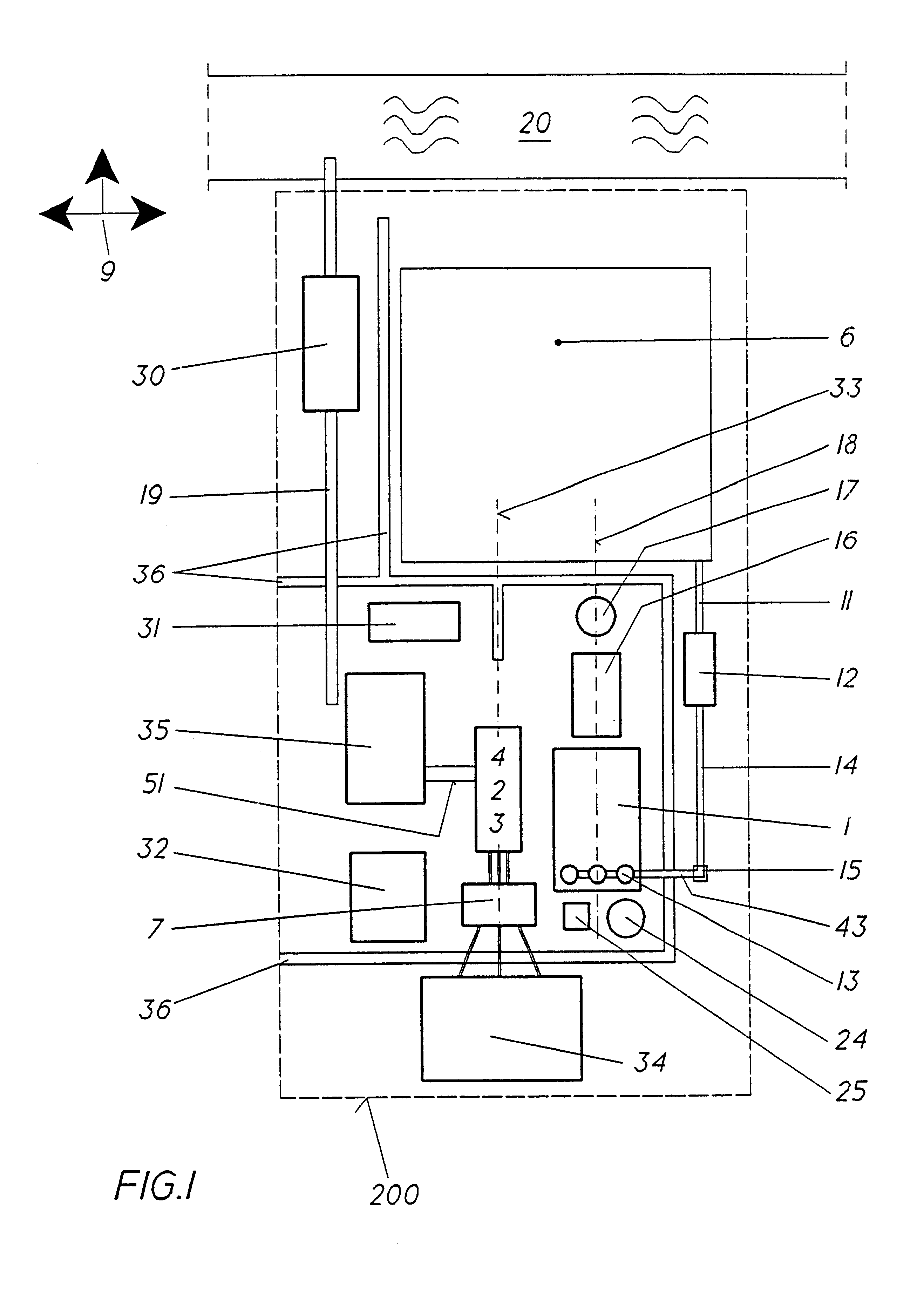

Steam power plant

The invention relates to a steam power plant which consists essentially of a steam generator (1), a turbo group comprising a condensing steam turbine (2) and generator (3), a water-cooled condenser (4) and a bled-steam-heated preheating system. In said steam power plant all components, including the fuel storage area (6), are situated at ground level and in the open air. The turbo group (2, 3) and the condenser (4), the preheating system with associated pumps and the transformers (7) are arranged such that a gantry crane is able to pass over them. The steam generator (1), flue gas cleaning system (16) and the chimney (17) are positioned in a row along a common flue gas axis (18) and the turbo group (2, 3) arranged in the immediate vicinity and parallel thereto. As seen from the main wind direction (9), the coal storage area (6) is positioned downwind from the turbo group (2, 3) and the steam generator (1).

Owner:GENERAL ELECTRIC TECH GMBH

Control program, controller, and boiler system

ActiveUS20110162593A1Reduce necessityInhibit start-and-stop lossSampled-variable control systemsComputer controlControl subjectsCombustion

The present invention relates to a control program, a controller, and a boiler system that are related to a boiler group including a plurality of boilers controlled in combustion at stepwise combustion positions. It is well suitable, in a control program for conducting control on a boiler system that includes a boiler group having a plurality of boilers which can be controlled in combustion quantity at stepwise combustion positions and in which at least one of the combustion positions is assumed to be a high-efficiency combustion position and that is configured to be controlled in combustion based on an increase / decrease in desired loads, that in the case of increasing a quantity of combustion in the boiler group, after a high-efficiency combustion shift signal that makes the shift to the high-efficiency combustion position is output to all of the boilers subject to high-efficiency control by which control is conducted on the basis of combustion at the high-efficiency combustion position, a control signal may be output that makes the shift to a higher combustion position than the high-efficiency combustion positions for any one of the high-efficiency control subject boilers.

Owner:MIURA COMPANY LIMITED

Fired heater for a hydrocarbon conversion process

ActiveUS8282814B2Low costShorten the timeThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonEngineeringInlet manifold

One exemplary embodiment of the present invention can be a fired heater for a hydrocarbon conversion process. The fired heater includes inlet and outlet headers or manifolds, a set of heater tubes with each heater tube having an inlet and an outlet, at least one restriction orifice adjacent the inlet of at least one heater tube. The restriction orifice may be within the inlet manifold and adjacent the inlet of a heater tube, or between the inlet manifold and the inlet to the heater tube. A process may include passing a hydrocarbon stream through the fired heater described herein during the course of operating a hydrocarbon conversion process.

Owner:UOP LLC

Steam microwave oven and cooking method thereof

ActiveCN102705879AIncrease profitRealize the heating functionDomestic stoves or rangesElectrical heating fuelMicrowave ovenEngineering

The invention discloses a steam microwave oven and a cooking method thereof.. The steam microwave oven comprises a microwave oven body, a water tank, a water pump and a steam generator, wherein the microwave oven body comprises a magnetron connected with a cavity through a waveguide assembly; one end of the steam generator is connected with the water tank through the water pump, and the other end of the steam generator is arranged in the cavity; a heating pipe is arranged in the cavity; a water tank is arranged on a bottom plate of the steam microwave oven through a connecting plate, and the bottom plate is arranged at the bottom of the cavity; and the water pump is arranged on the bottom plate. The steam microwave oven further comprises a heating wire which is arranged at the top of the cavity. The steam generator comprises a water inlet pipe, a steam generator shell, a first heating pipe, a first temperature controller, a second heating pipe, a second temperature controller and a temperature sensor, wherein one end of the water inlet pipe is connected with the water pump. The steam microwave oven can not only achieve the function of cooking with steam and microwave simultaneously, but also achieve the functions of cooking with steam and barbecuing simultaneously, thereby having the characteristic of wide application range.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

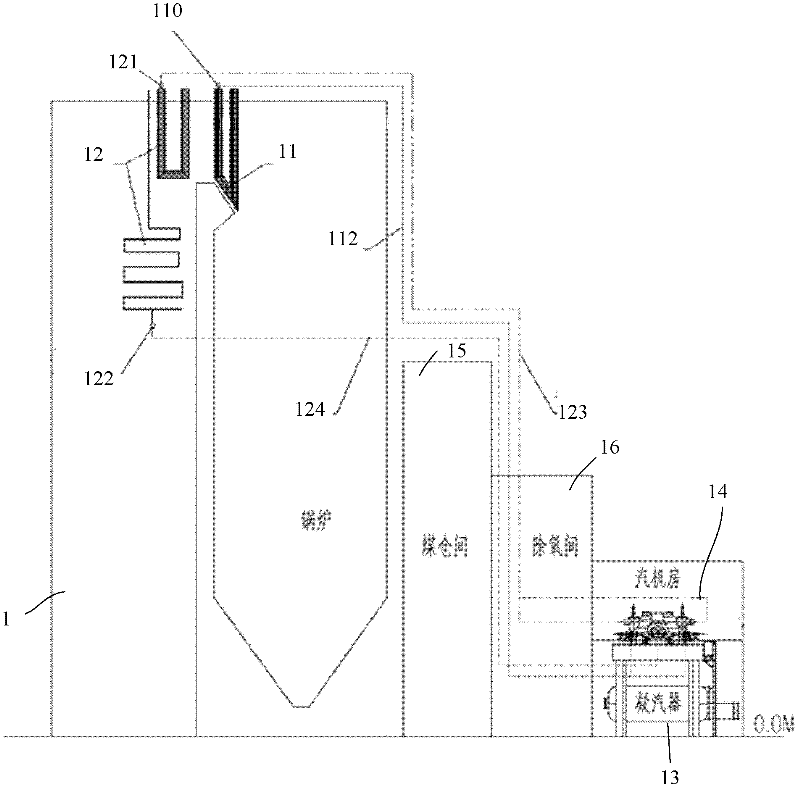

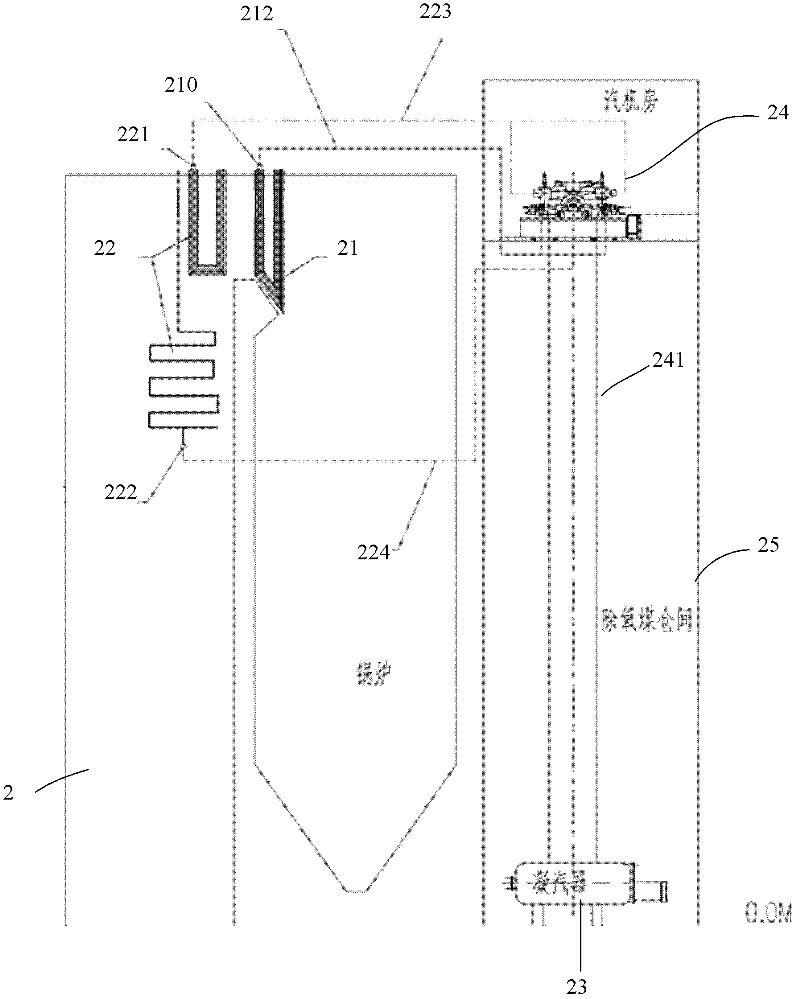

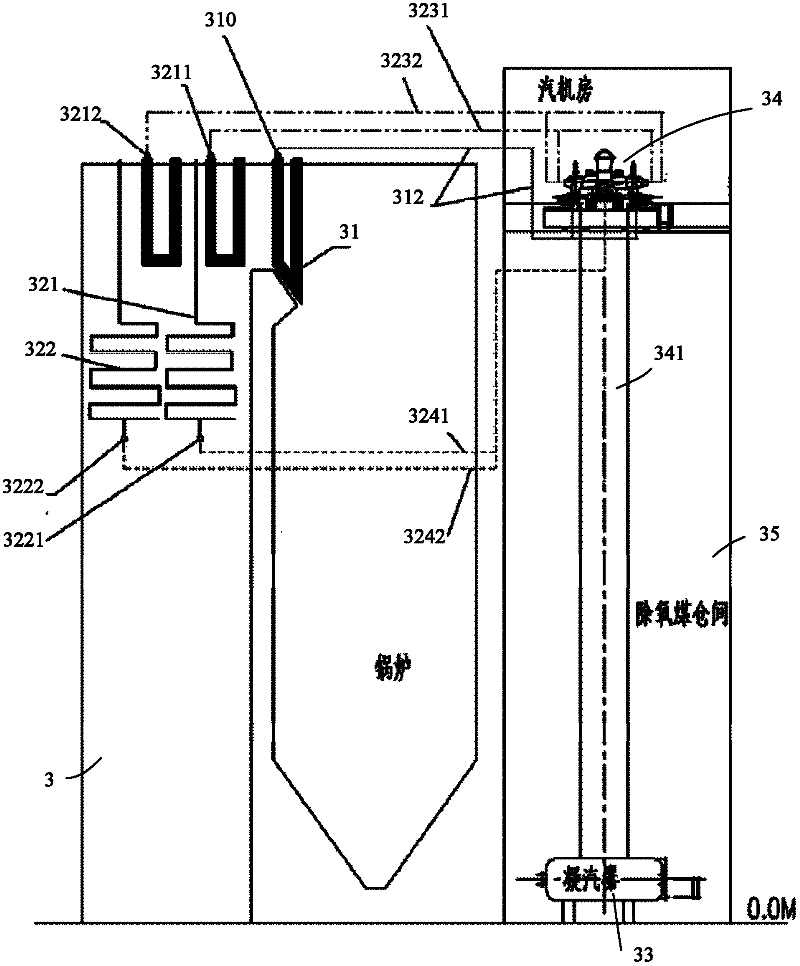

Single-shaft steam turbine generator unit

InactiveCN102230398AImprove efficiencyReduce resistanceSteam generation plantsSteam engine plantsEngineeringSuperheater

The invention discloses a single-shaft steam turbine generator unit. The lengths of a main steam pipeline and / or a reheating steam pipeline can be obviously shortened. The single-shaft steam turbine generator unit comprises a steam turbine generator and a boiler and is characterized in that the steam turbine generator is arranged near the superheater outlet header of the boiler to cause the connecting pipeline of the boiler and a steam turbine to be short enough; and the elevation of the steam turbine at least exceeds the elevation of the superheater outlet header by above 50%. The steam turbine generator adopts an elastic foundation and is supported by a steam turbine house civil engineering structure.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

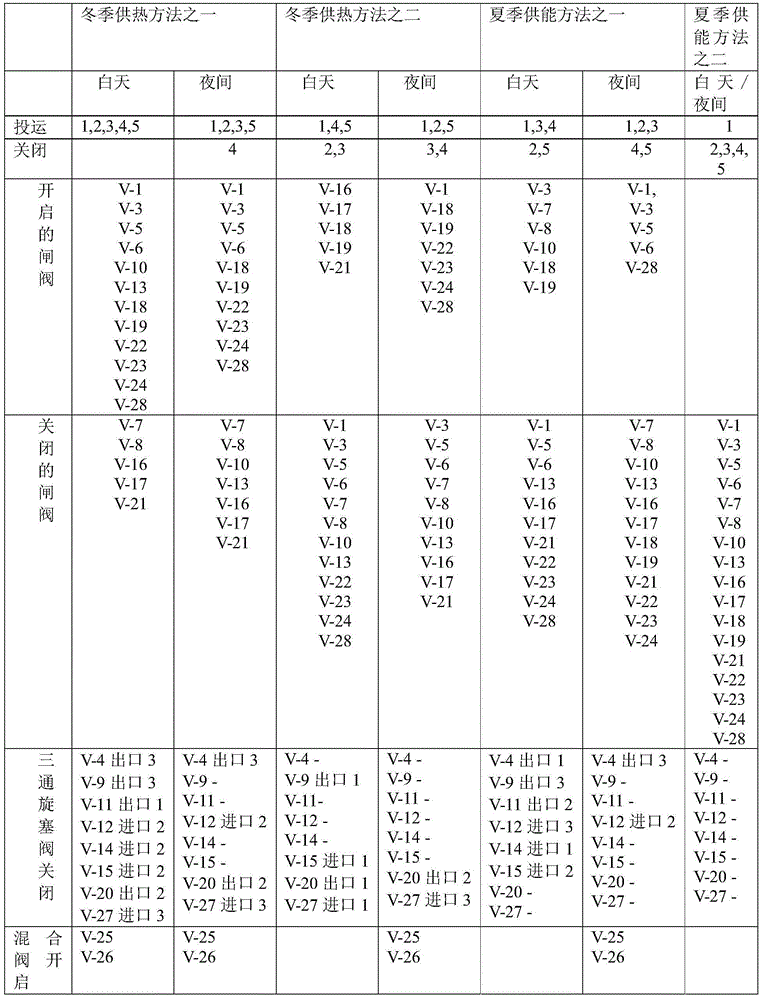

Auxiliary solar energy carbon-dioxide-capturing and heating integrated system and method thereof

ActiveCN104154521AMeet with heatMeet electricity demandSolar heat devicesClimate change adaptationPressure reductionElectric power

The invention discloses an auxiliary solar energy carbon-dioxide-capturing and heating integrated system and method thereof. The integrated system is mainly composed of a coal-fired power generation subsystem, a steam extraction pressure reduction temperature reduction circulation subsystem, a carbon dioxide capturing subsystem, a solar energy heat collection subsystem and a heat supplying subsystem. The subsystems are connected with a valve mainly through a heat exchanger and related pipelines to form the integrated system. To meet the heat supply requirements of the coal-fired power generation subsystem, the carbon dioxide capturing subsystem and the heat supplying subsystem at different times in different seasons, the solar energy heat collection quantity is supplied for different subsystems through an output end valve control mode. The system can maintain dual effects of power plant power output and carbon dioxide emission reduction in summer, and the heat supplying area is increased on the basis of achieving carbon dioxide emission reduction of a coal-fired power plant in winter. The integrated system can achieve renewable energy utilization and power plant carbon dioxide capturing at the same time, and large-scale application of the domestic solar energy utilizing and carbon dioxide capturing technology is strongly promoted.

Owner:TIANJIN UNIV

Fossil-Fuel Heated Continuous Steam Generator

InactiveUS20080257282A1Simple structureWater circulationFuel injection apparatusCombustion chamberEngineering

The invention relates to a fossil-energy heated continuous steam generator, whereby the at least one combustion chamber, viewed in the flow direction of the hot gases, is divided into at least two throughflow segments, formed by evaporator heating surfaces, whereby the evaporator heating surfaces each comprise steam generation tubes welded to each other in a gastight manner and pressurized in parallel with a flow medium. According to the invention, said generator is suitable for operation with high fresh steam parameters, such as for example, steam temperatures of approximately 700° C., with a simple construction and particularly simple assembly, whereby a throughflow segment, arranged after the first through flow segment, viewed in the direction of flow of the hot gases, forms the first evaporator stage for the flow medium, such that the injection of particularly cold flow medium can occur in the region of maximum heating.

Owner:SIEMENS AG

Low NOx water heater with serpentined air entry

A fuel-fired low NOx water heater extending along a vertical axis has a radiant fuel burner disposed in its combustion chamber. The entire burner combustion air quantity is delivered to the burner from outside the combustion chamber via a horizontally serpentined flow path extending through an internal portion of the water heater. This serpentined air inflow path configuration causes a substantial portion of particulate matter in the incoming combustion air to be removed therefrom before entering and potentially clogging the burner.

Owner:RHEEM MFG CO

Fused salt heat accumulating peak regulating system for heat-engine plant heating by means of main steam

PendingCN108548168AGet the most out of your utilizationImprove economyLiquid degasificationSteam generation plantsEngineeringHigh pressure

The invention relates to a fused salt heat accumulating peak regulating system for a heat-engine plant heating by means of main steam and belongs to the technical field of heat accumulating peak regulating of heat-engine plants. The system comprises a main steam regulating valve, a high pressure steam-fused salt heat exchanger, a reheated steam regulating valve, a high temperature fused salt tank,a high pressure fused salt pump, a low temperature fused salt tank, a low temperature fused salt pump, a throttling valve, a high pressure heater, a water delivery pump, a deaerator, a boiler, a highpressure cylinder and a medium pressure cylinder. When the electrical load is reduced, the utilization ratio of the boiler is fully exerted; a fused salt heat accumulating system is additionally arranged to store heat of residual stem of the boiler in the high temperature fused salt through the high pressure steam-fused salt heat exchanger; in the electrical peak stage, the high temperature fusedsalt is extracted from the fused salt tank to be fed to the high pressure steam-fused salt heat exchanger again to heat the boiler feed water and generate high temperature high pressure steam and issent to a turbine to increase the generating capacity of the turbine and play a peak regulating role on a unit. Residual steam generated by the boiler can be recovered when the electrical load is relatively low, so that the utilization ratio and the operating safety of the boiler are improved, and the purpose of being energy-saving is achieved.

Owner:BEIJING UNIV OF TECH

Popular searches

Submerged flame steam boilers Steam generation using hot heat carriers Feed-water heaters Hot gas positive displacement engine plants Combined combustion mitigation Solar heat systems Steam superheaters Steam generation using solar heat Solar thermal energy generation Solar heat collector controllers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com