Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1305results about "Feed water supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low Grade Heat Recovery from Process Streams for Power Generation

InactiveUS20120031096A1Improve efficiencyImproves flexibility in designFeed water supplySteam engine plantsVapor liquidWorking fluid

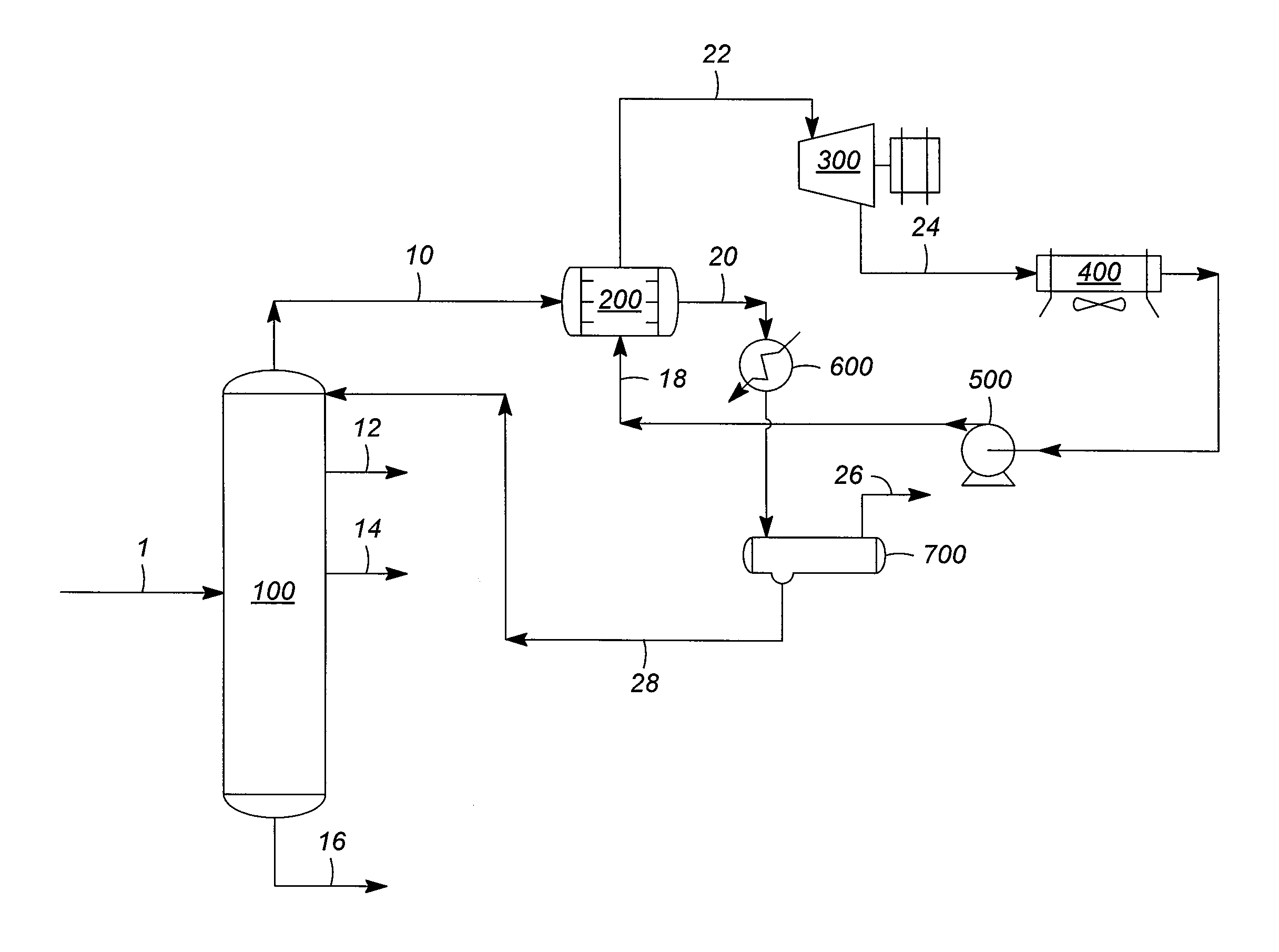

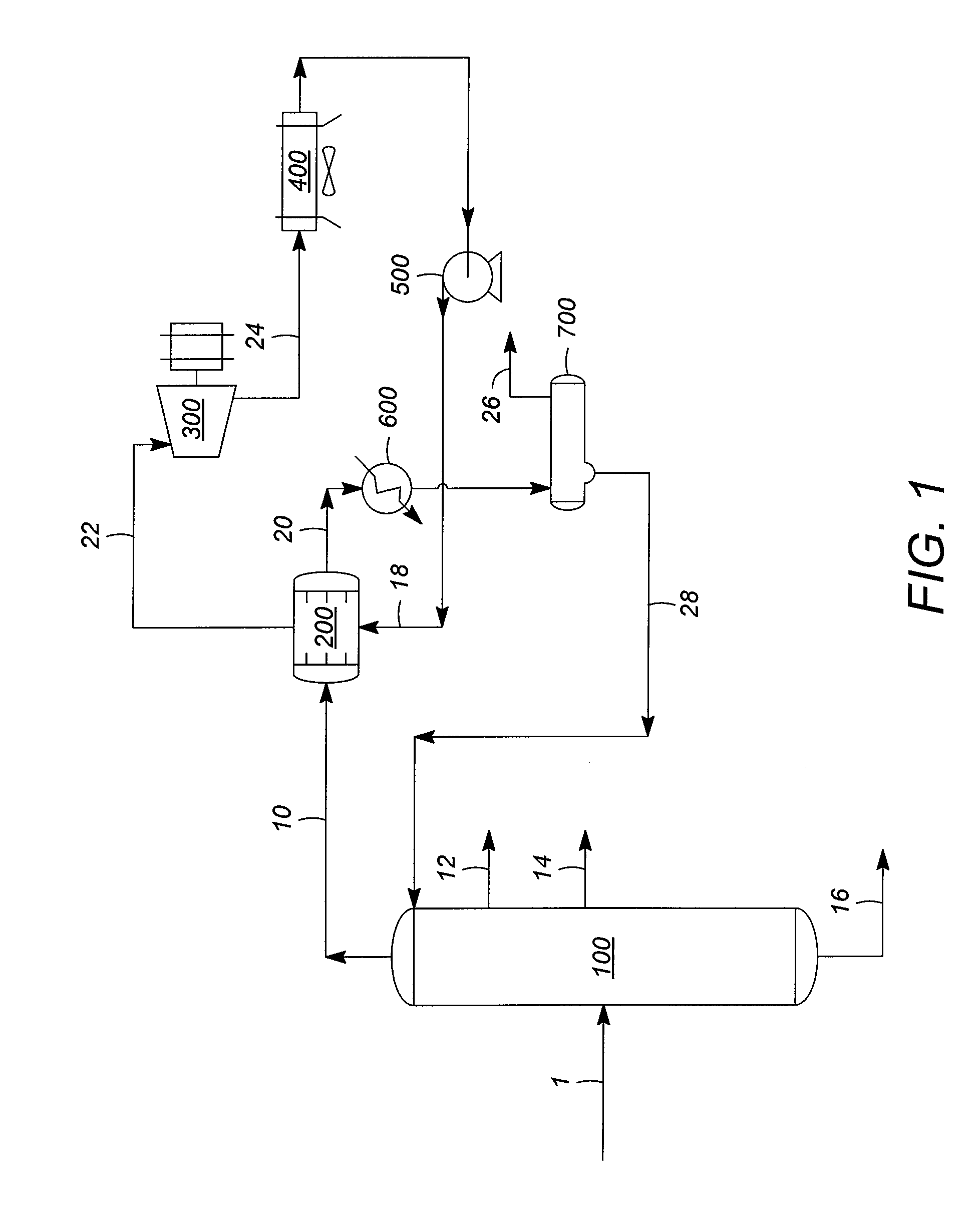

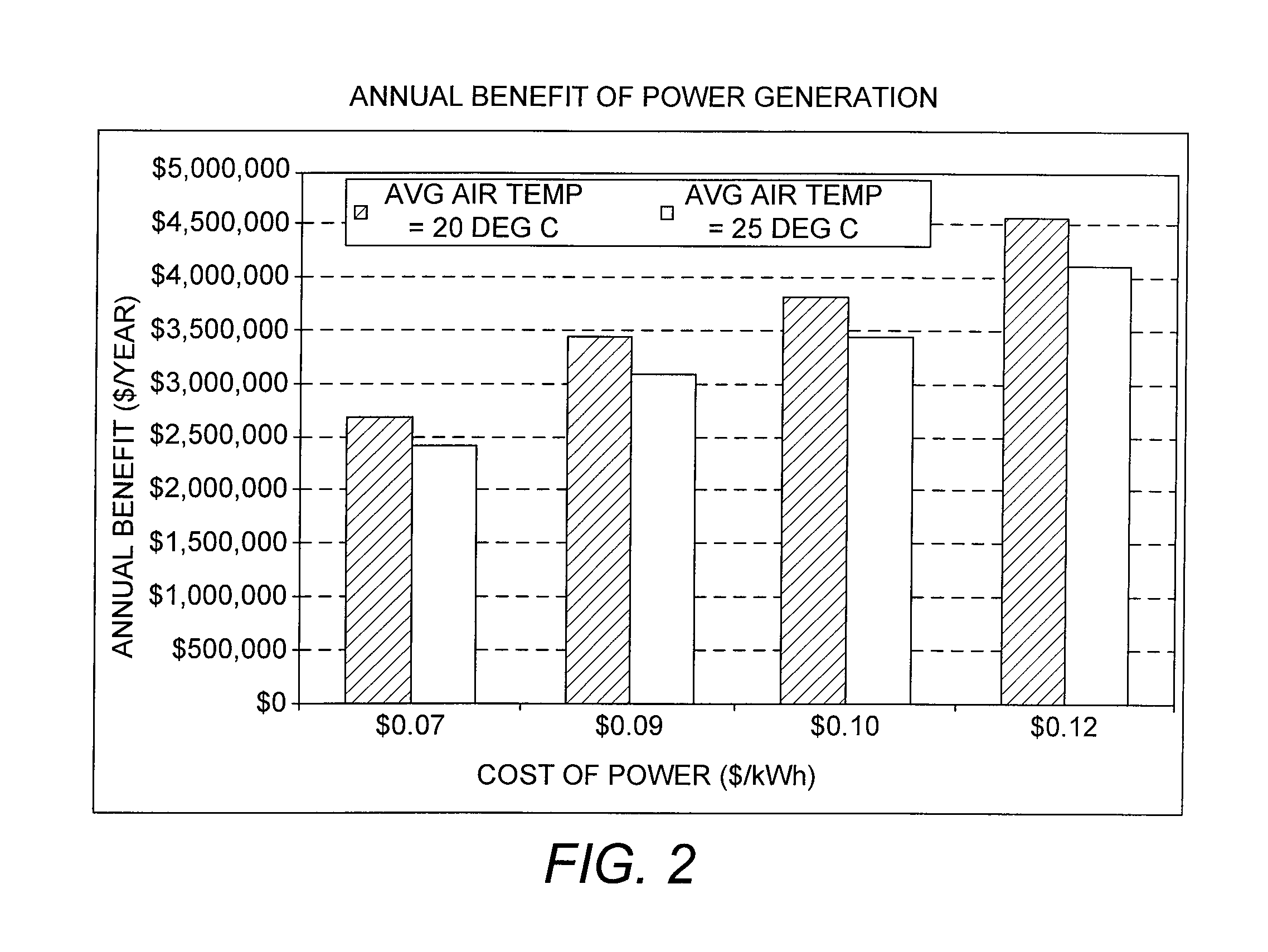

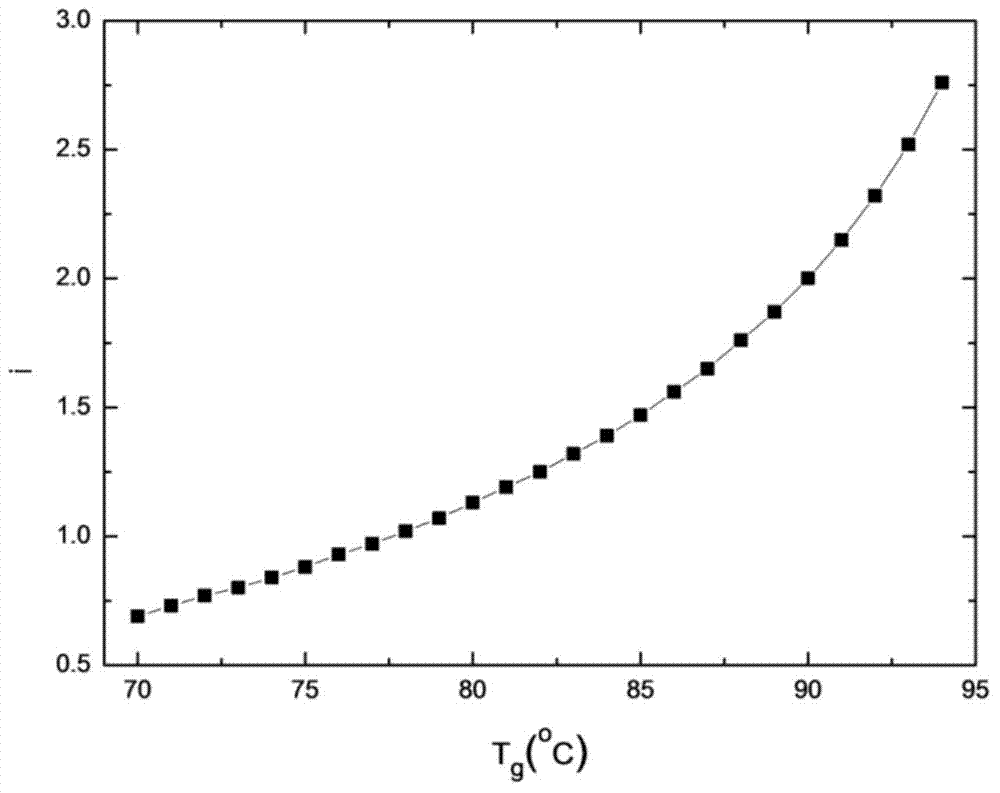

Methods are described for generating electrical power from low grade heat sources from refining and petrochemical processes, including overhead vapors from vapor-liquid contacting apparatuses such as distillation columns, absorbers, strippers, quenching towers, scrubbers, etc. In many cases, these overhead vapors exit the apparatuses at a temperature from about 90° C. (194° F.) to about 175° C. (347° F.). Rather than rejecting the low temperature heat contained in these vapors to cooling air and / or cooling water, the vapors may instead be used to evaporate an organic working fluid. The vapors of the working fluid may then be sent to a turbine to drive a generator or other load.

Owner:UOP LLC

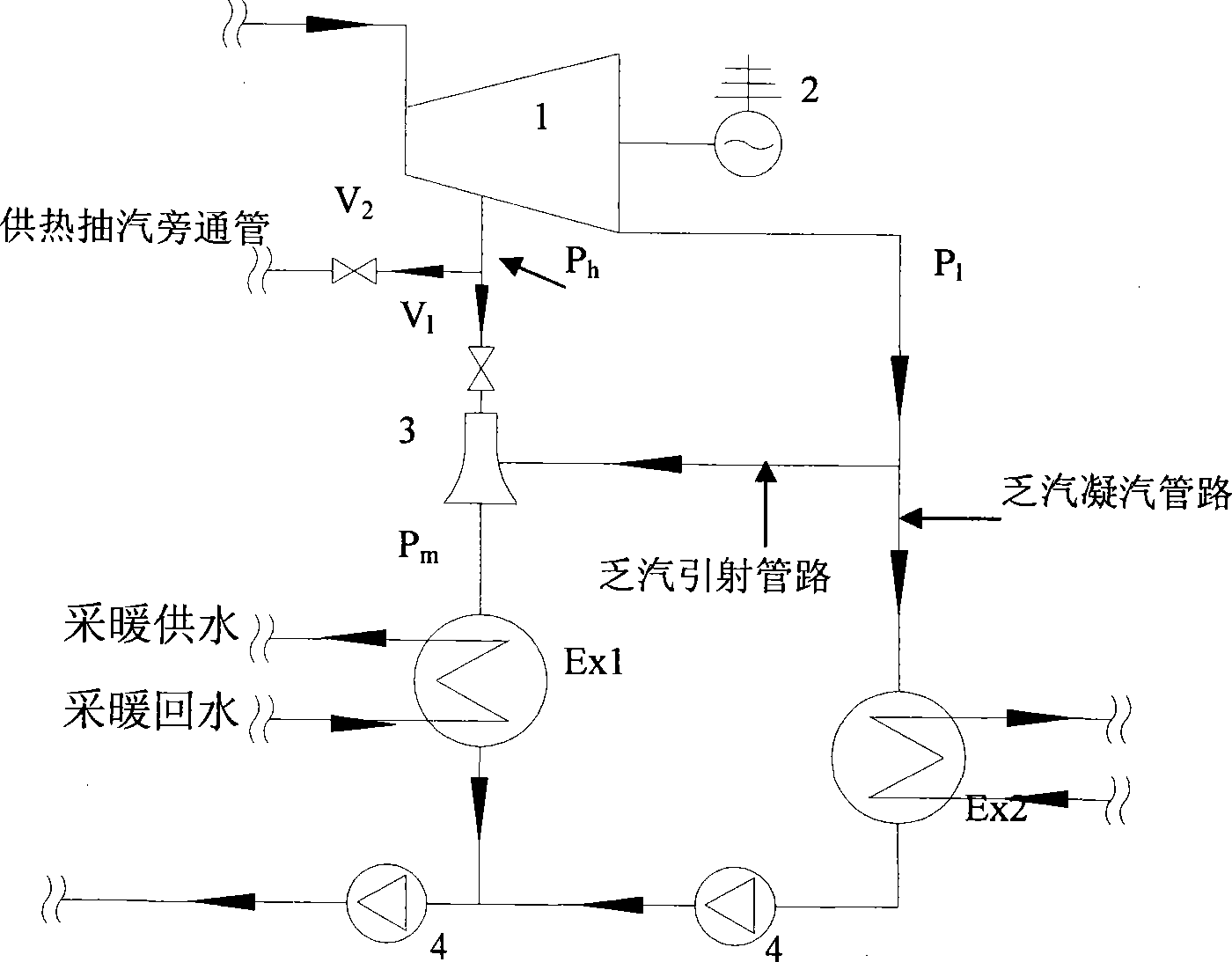

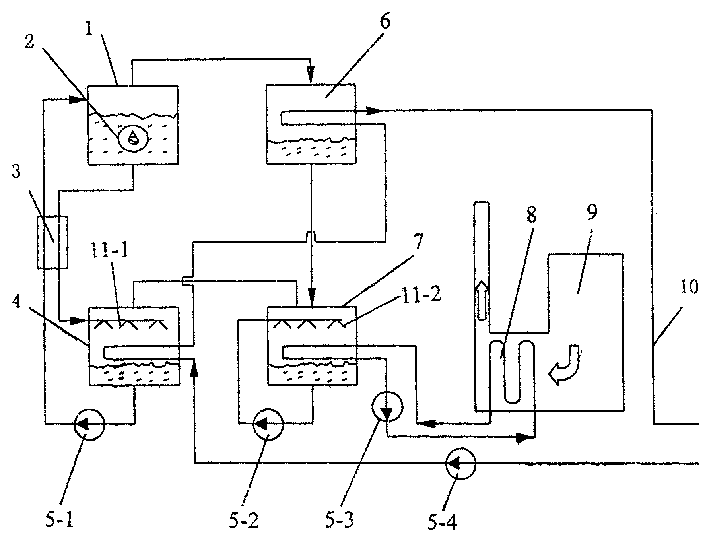

Steam jet type heat pump heat distribution system for recovering thermal power plant condensing residual heat

InactiveCN101240909AEasy to manufactureImprove heat transfer effectFeed water supplyEnergy efficient heating/coolingLow voltageCore component

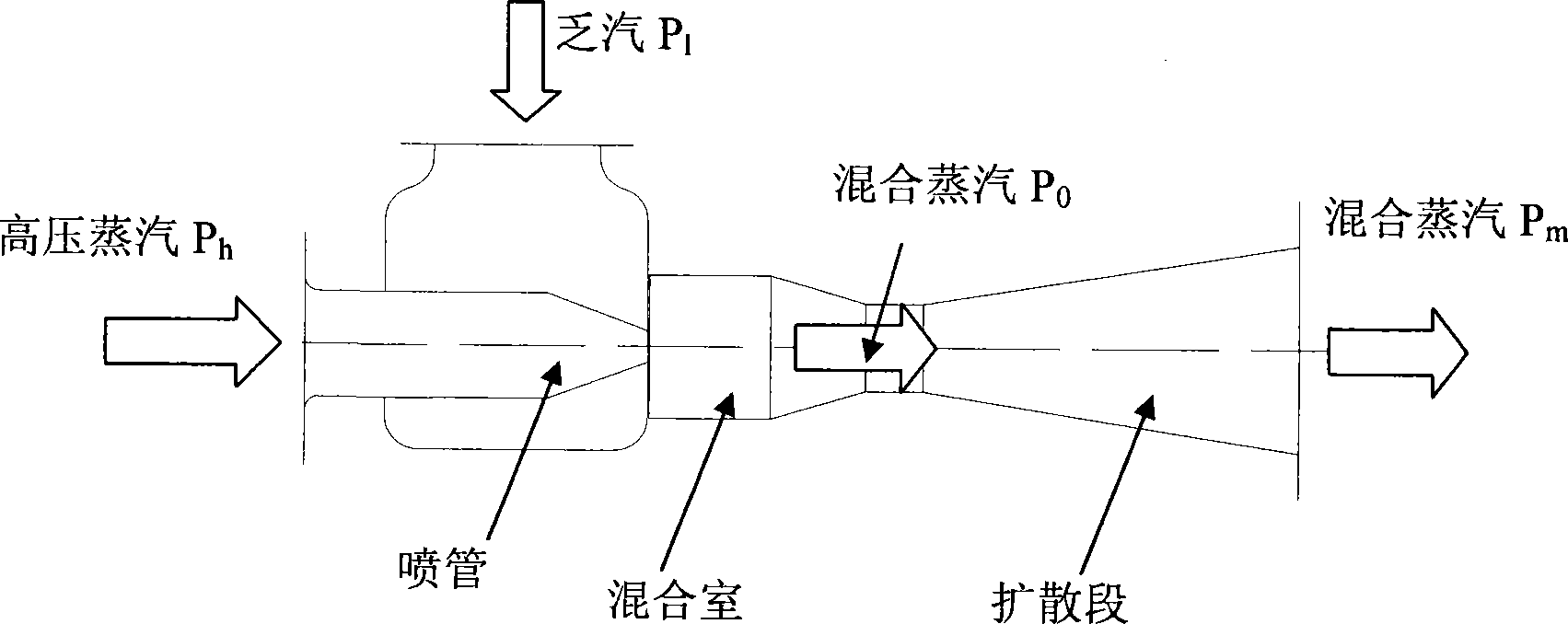

The present invention provides a steam injection heatpump heating system. The technical solution is that the system is composed of a steam injector, a high voltage steam pipeline, a low voltage steam pipeline, a throttling gear and a bypass connecting pipe. The high voltage steam enters in the heat exchanger heaing backwater after injecting lower steam turbine voltage condensing in low temperature, this realises waste heat recovery in low temperature condensing steam of the steam turbine. The core component is the steam injector, the high voltage heat supplying pumping is used as high-velocity jet acceleratively formed in the injecting tube of the working steam, and lower voltage steam turbine is rolled in the mixing room as injected flow, mixing steam in the expanding section of the steam injector is decelerately compressed in a certain back pressure, then sending to the heat interchanger for heating backwater, a certian back pressure mixing steam condenses to water after heat releasing in the exchanger, returning to the backwater system of electrical factory, completing thermal circuit of the combined heat and power generation set.

Owner:TSINGHUA UNIV

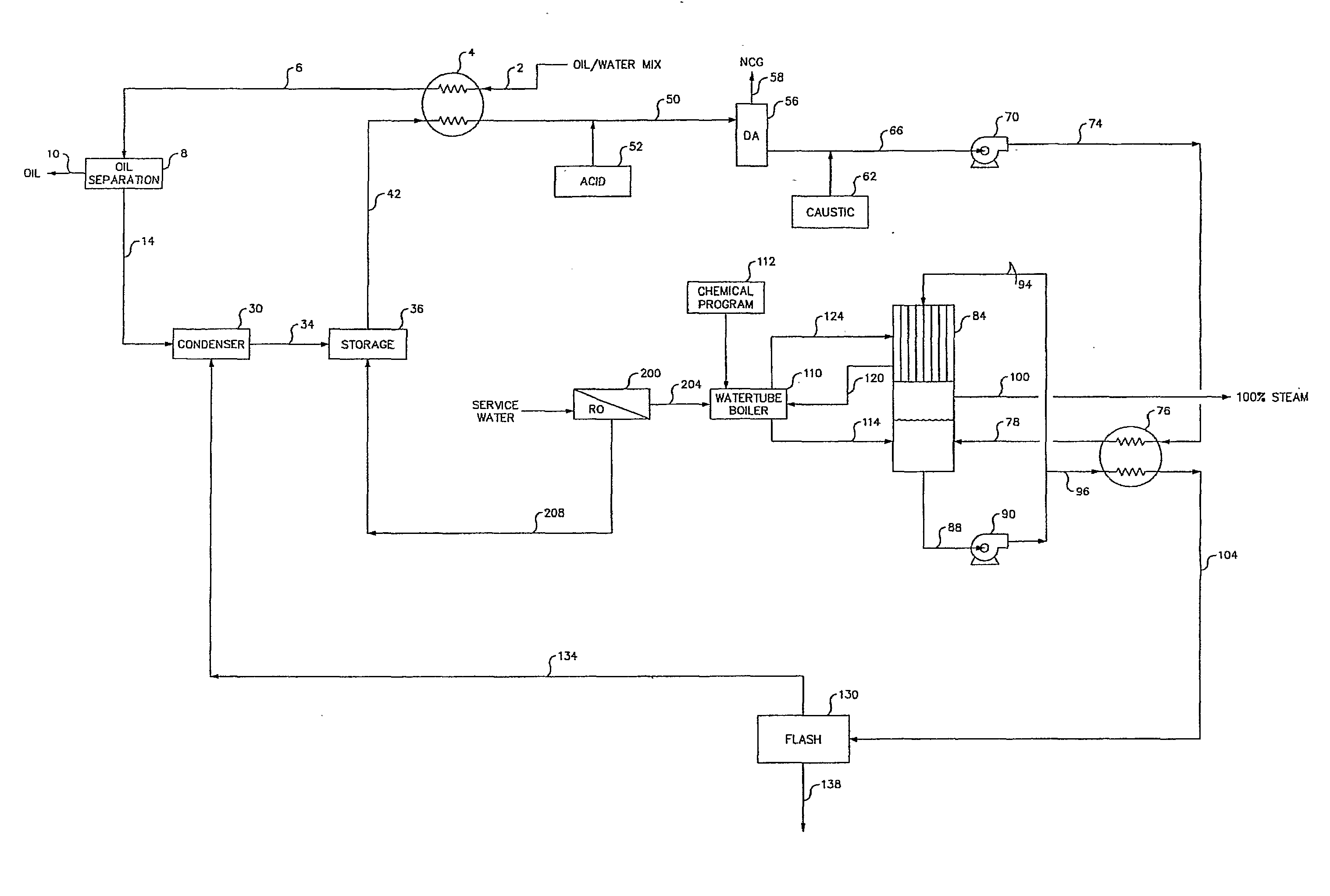

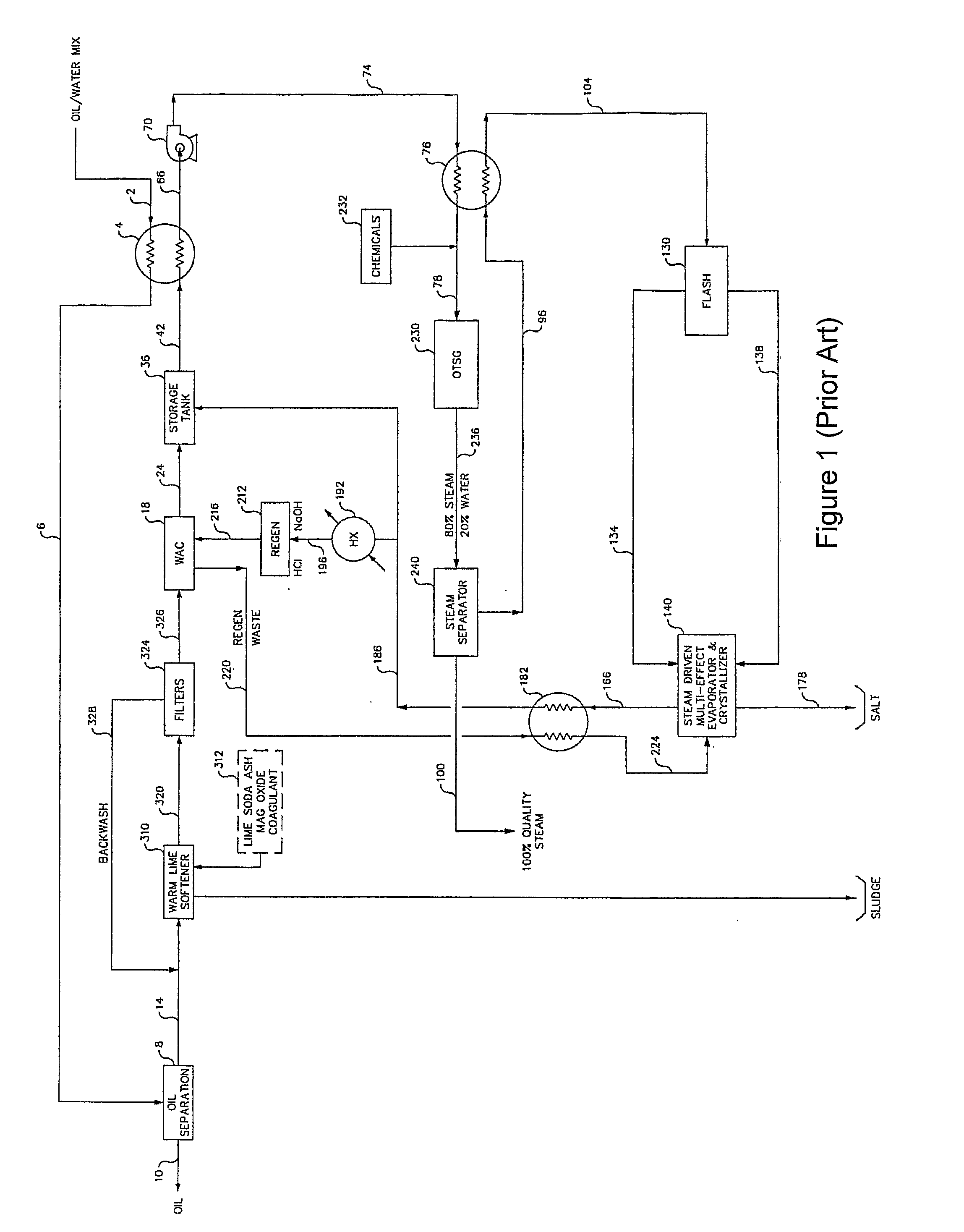

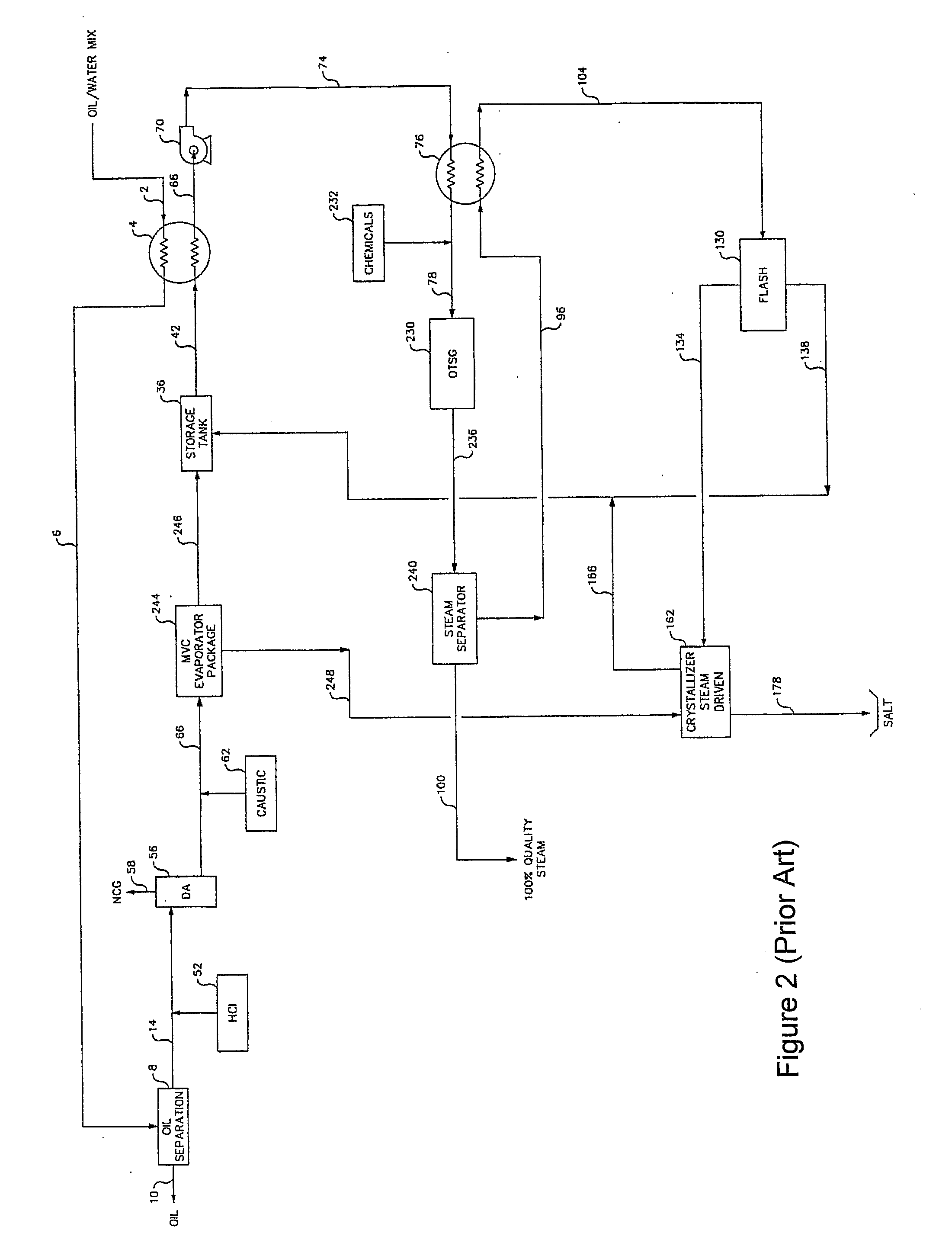

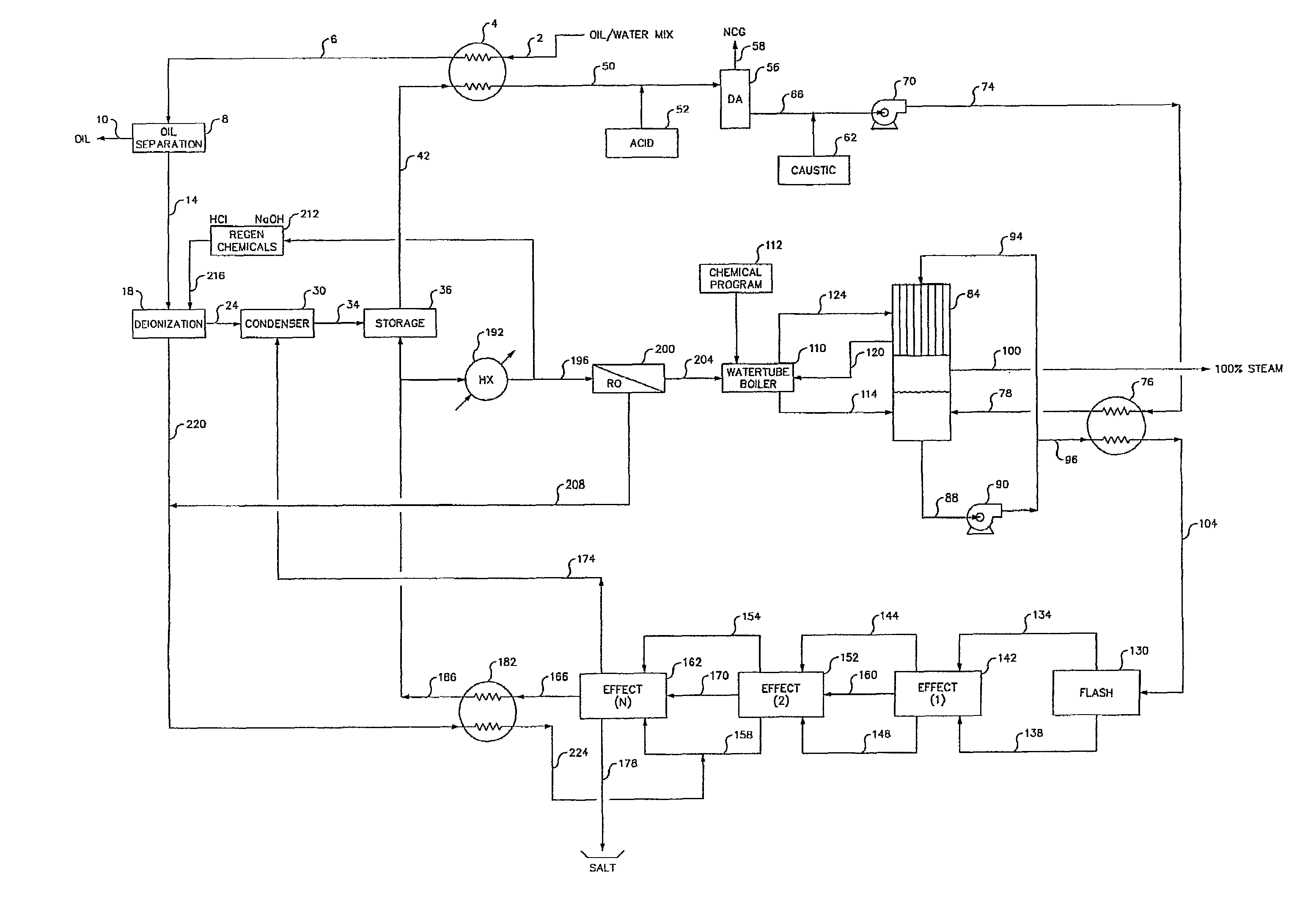

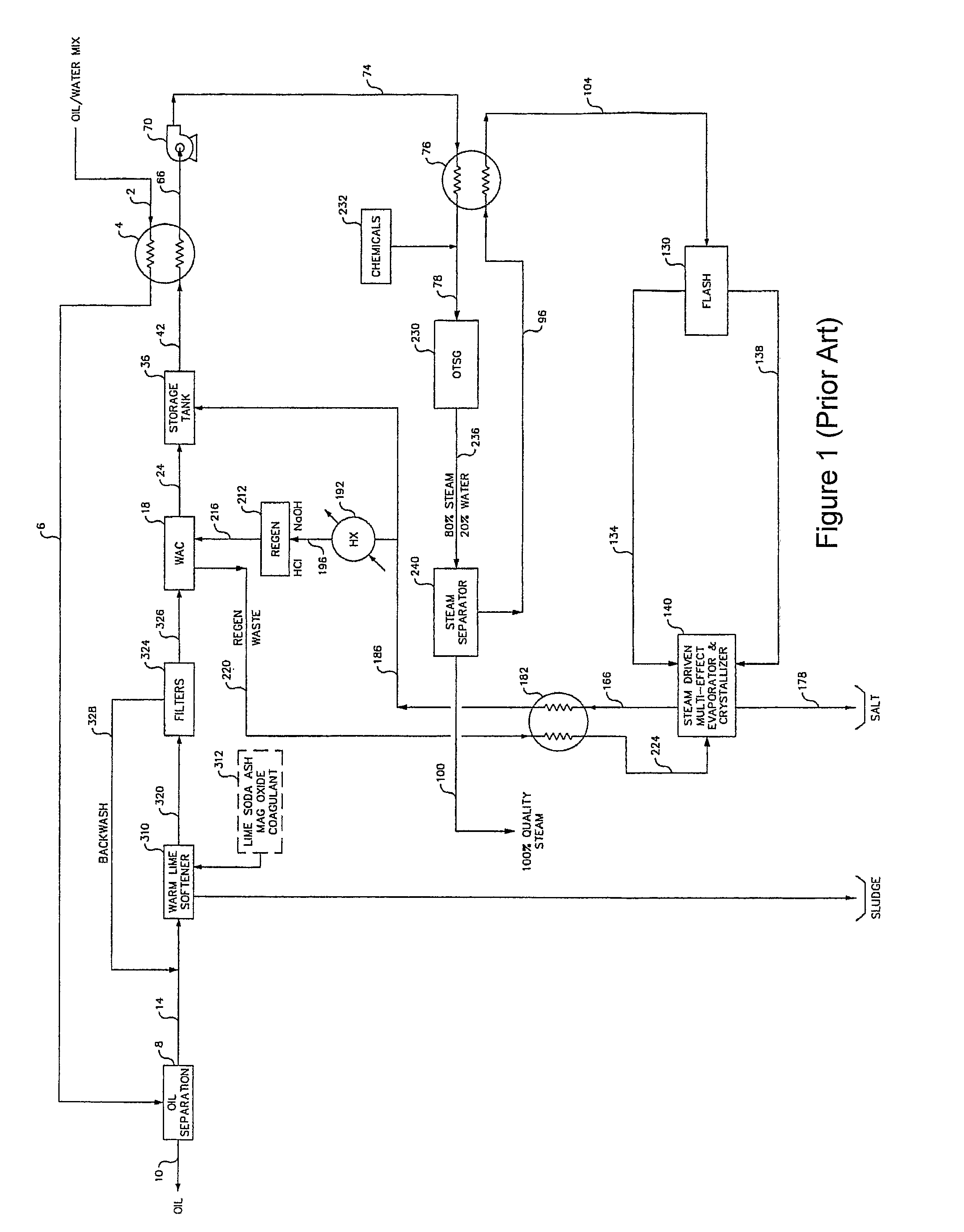

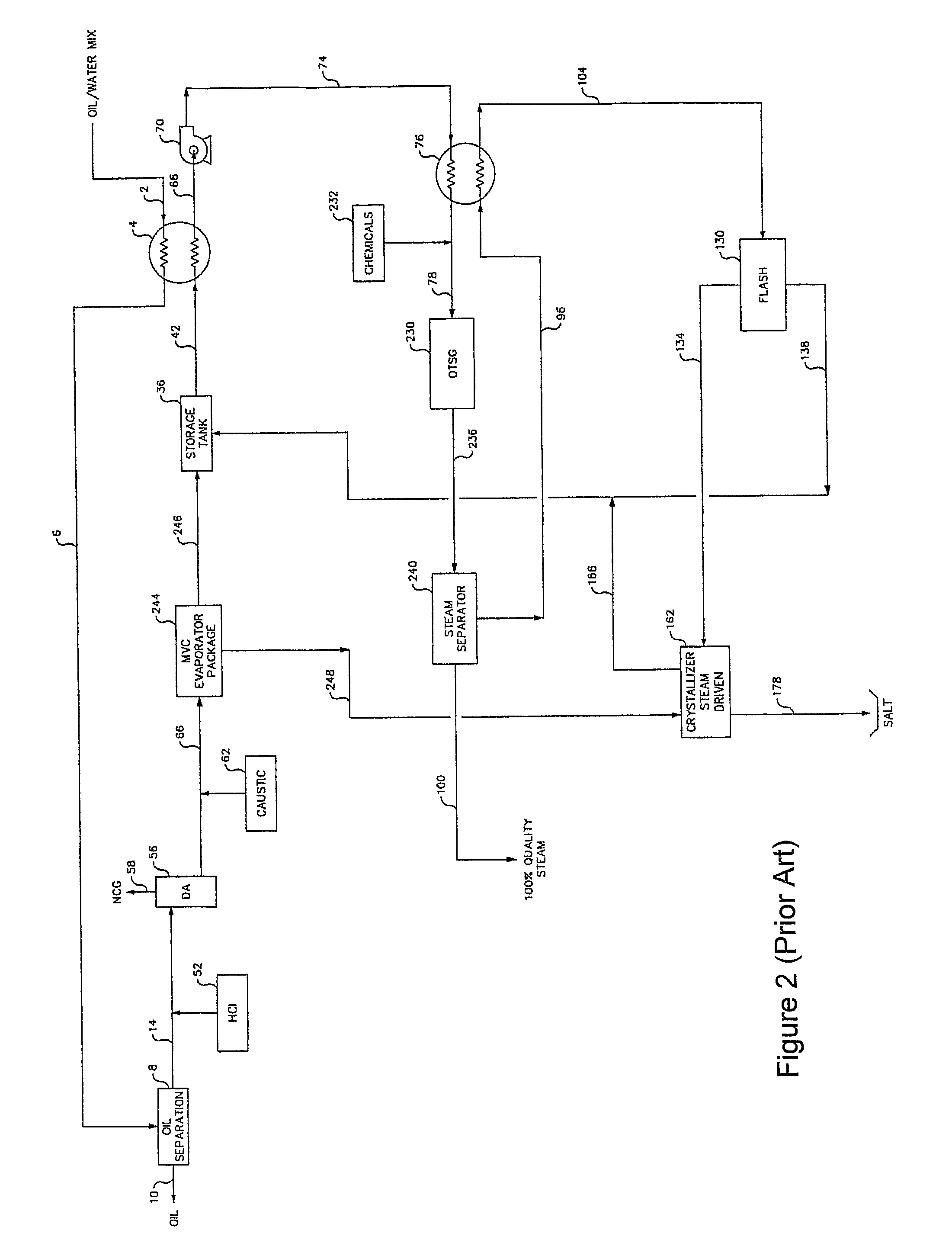

Method for Production of High Pressure Steam from Produced Water

InactiveUS20080110630A1Average power consumptionMinimize waste generationDrying using combination processesSolid sorbent liquid separationChemical treatmentDistillation

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

Method for production of high pressure steam from produced water

InactiveUS7591309B2Drying using combination processesSolid sorbent liquid separationChemical treatmentWater flow

An evaporation based method for generation of high pressure steam from produced water in the heavy oil production industry. De-oiled produced water is processed through a high pH / high pressure evaporator driven by a commercial watertube boiler. The vapor produced by the evaporator is suitable for the steam assisted gravity drainage (SAGD) method being utilized by heavy oil recovery installations, without the use of once through steam generators that require extensive chemical treatment, and without requiring atmospheric distillation, which requires high power consuming compressors. Evaporator blowdown may be further treated in a crystallizing evaporator to provide a zero liquid discharge (ZLD) system and, with most produced waters, at least 98% of the incoming produced water stream can be recovered in the form of high pressure steam.

Owner:AQUATECH INT LLC

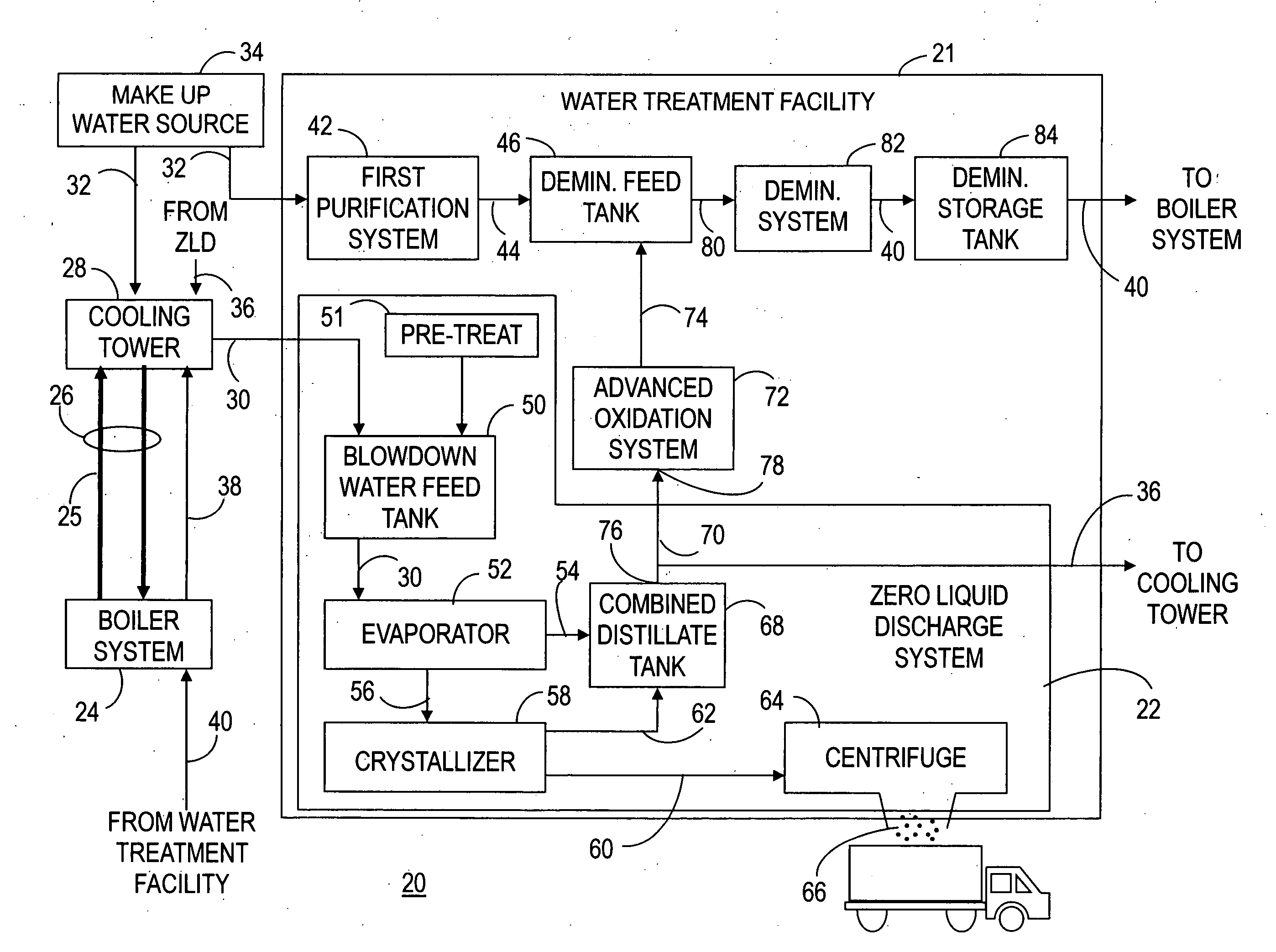

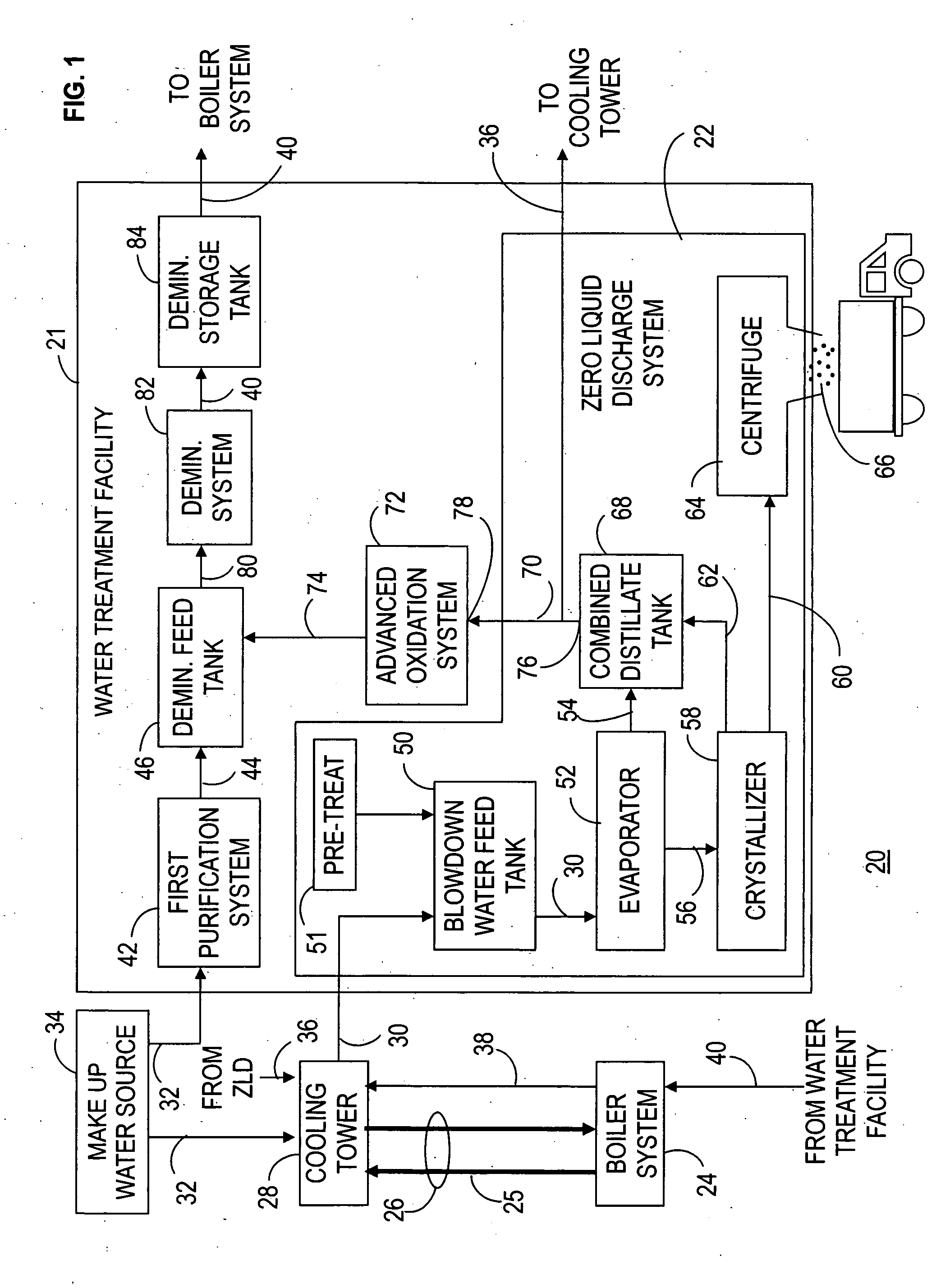

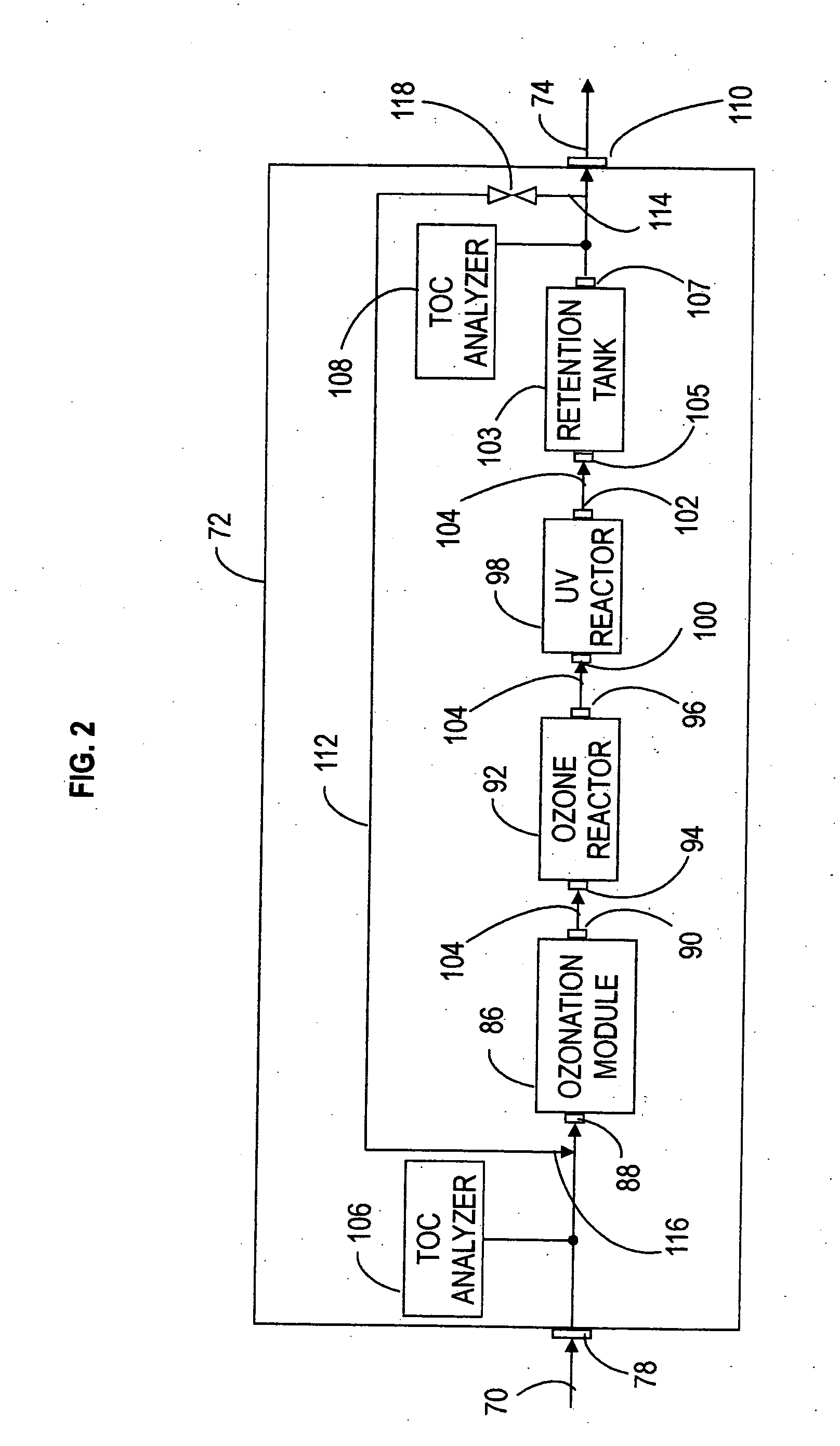

System and method of reducing organic contaminants in feed water

InactiveUS20070125719A1Reducing organic contaminantEfficient implementationWater treatment parameter controlWater/sewage treatment by irradiationHigh concentrationPower station

A zero liquid discharge (ZLD) power plant (20) includes an advanced oxidation system (72) for reducing contaminants in source water (70) to form feed water (40) for a boiler (24). The system (72) includes an ozonation module (86) for applying high concentration ozone to the source water (70) to form a mixed stream (104), an ozone reactor (92) in which the mixed stream is retained (104) under pressure, an ultraviolet reactor (98) downstream from the ozone reactor (92) for enhanced contaminant reduction, and a retention tank (103) downstream from the reactor (98). In one configuration, the source water (70) is evaporator distillate from an evaporator (52) that recycles cooling tower blowdown 30. The system (72) achieves organic contaminant reduction at total organic carbon (TOC) levels of less than three hundred parts per billion.

Owner:ARIZONA PUBLIC SERVICE

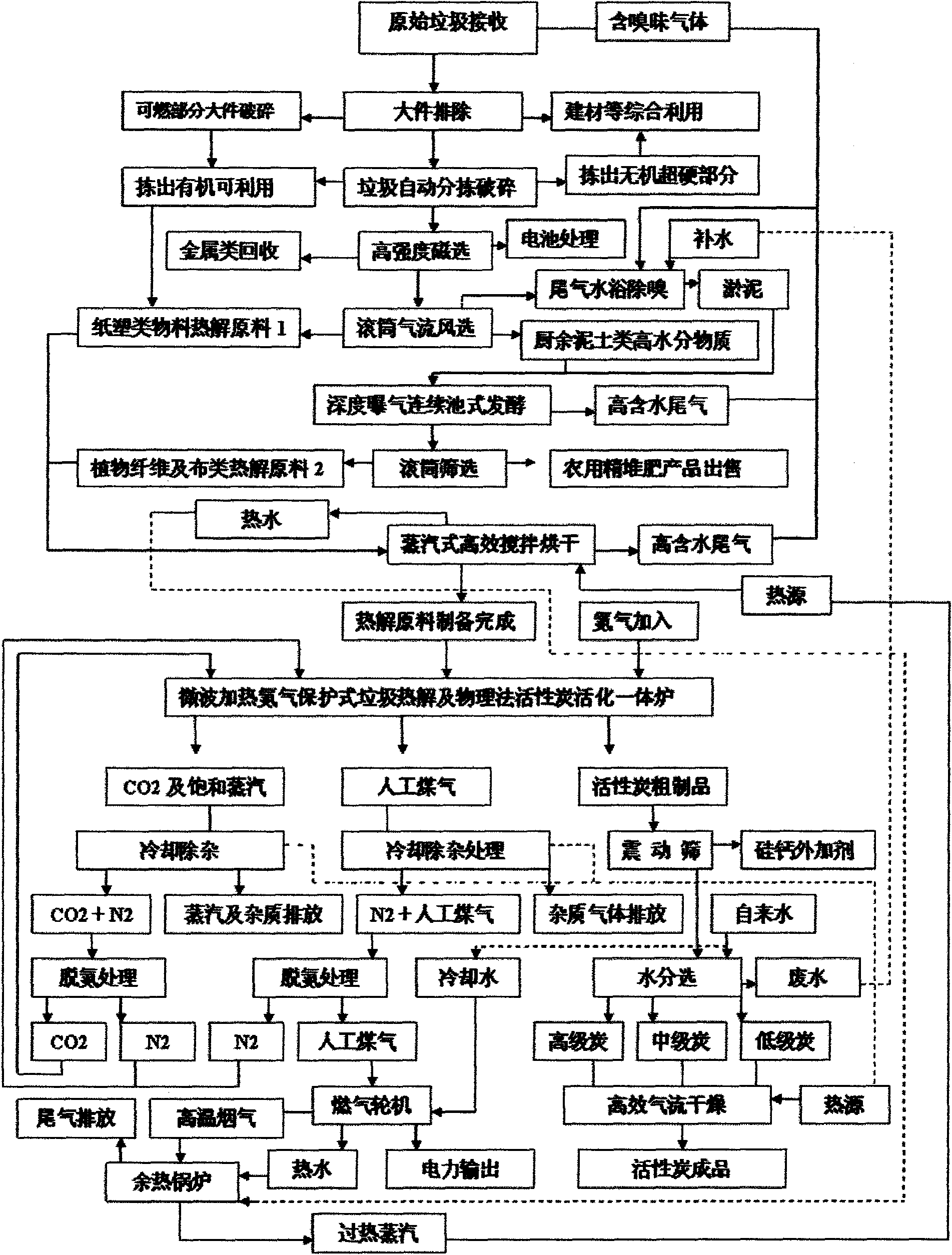

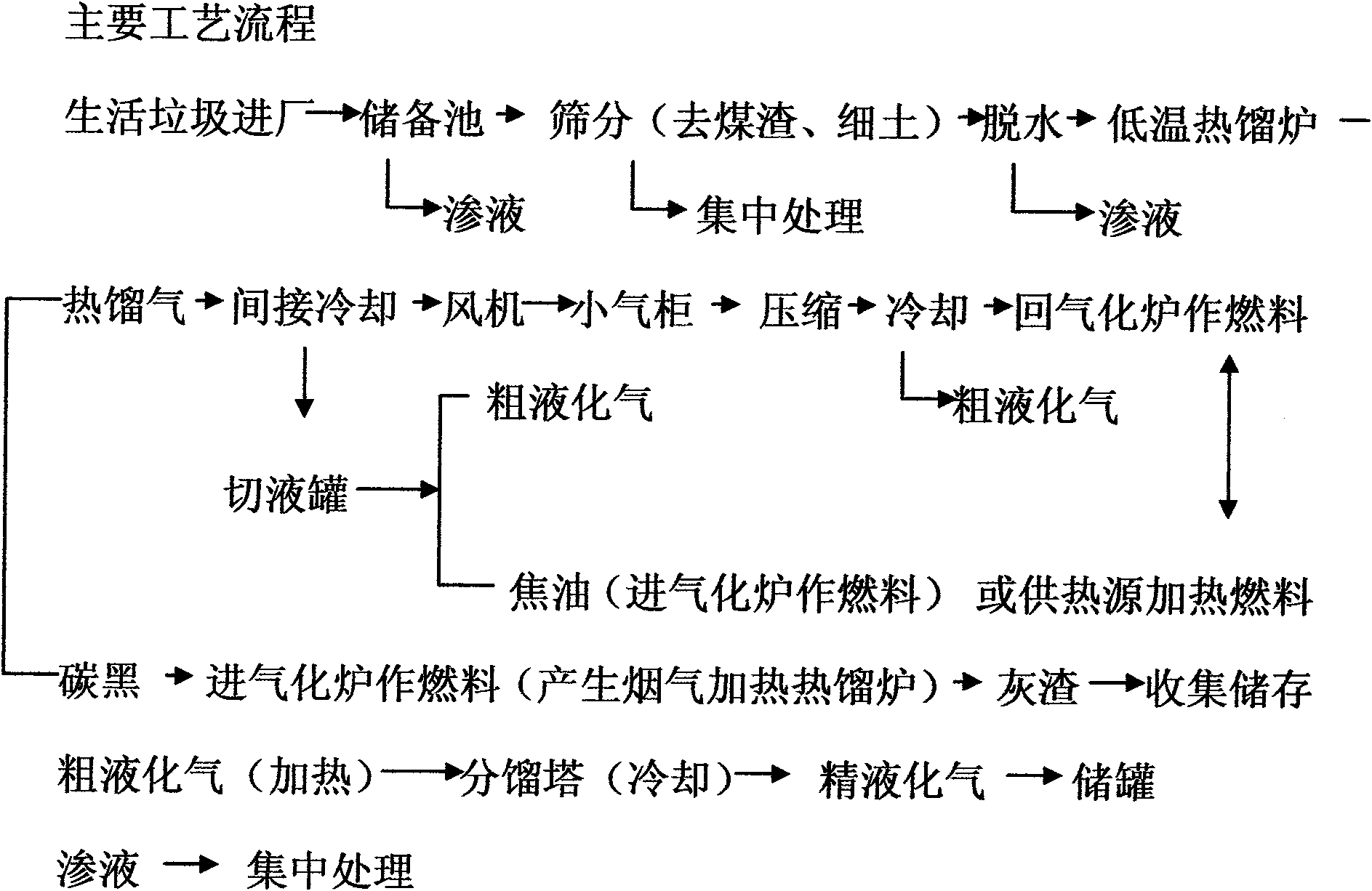

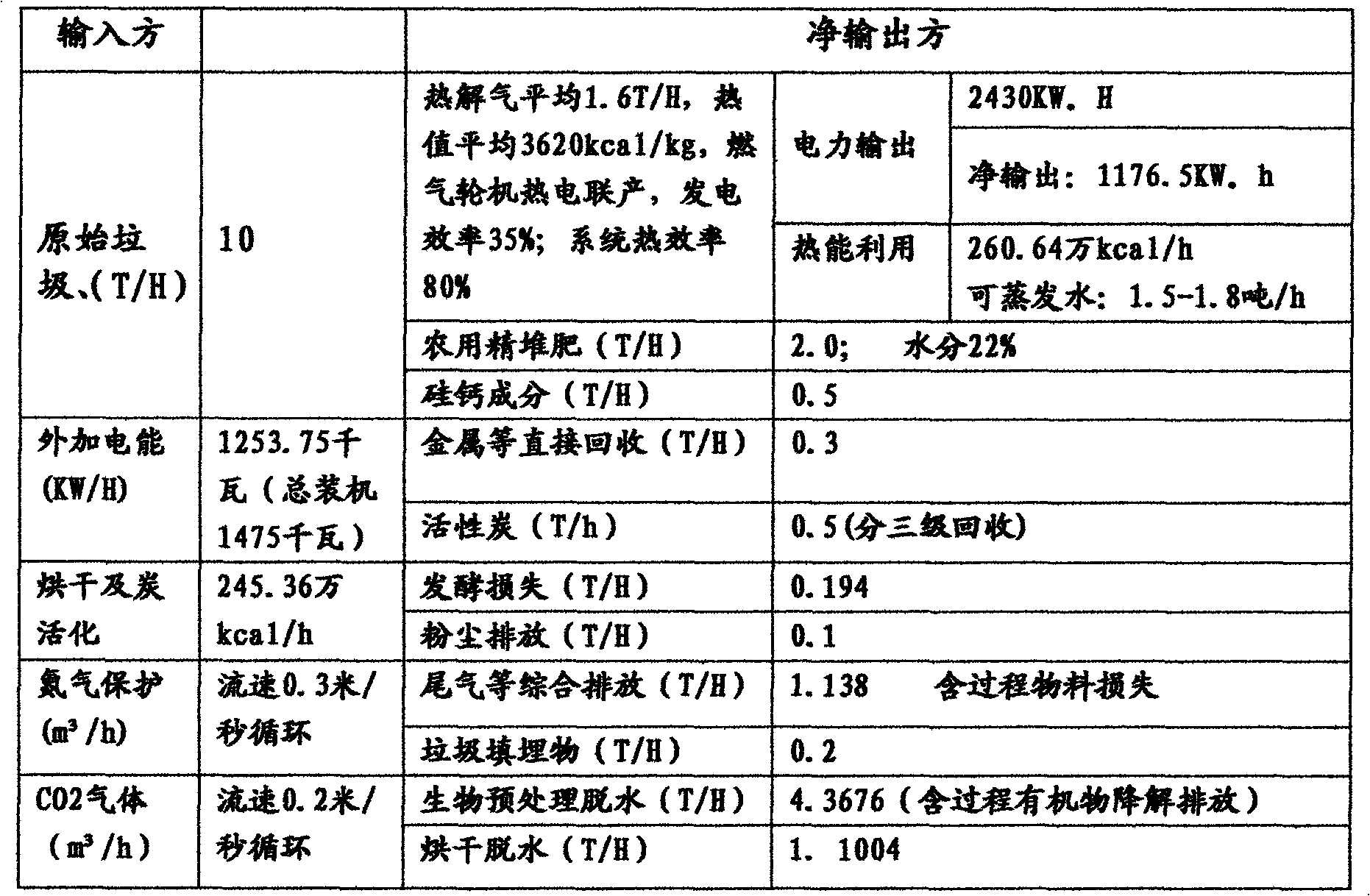

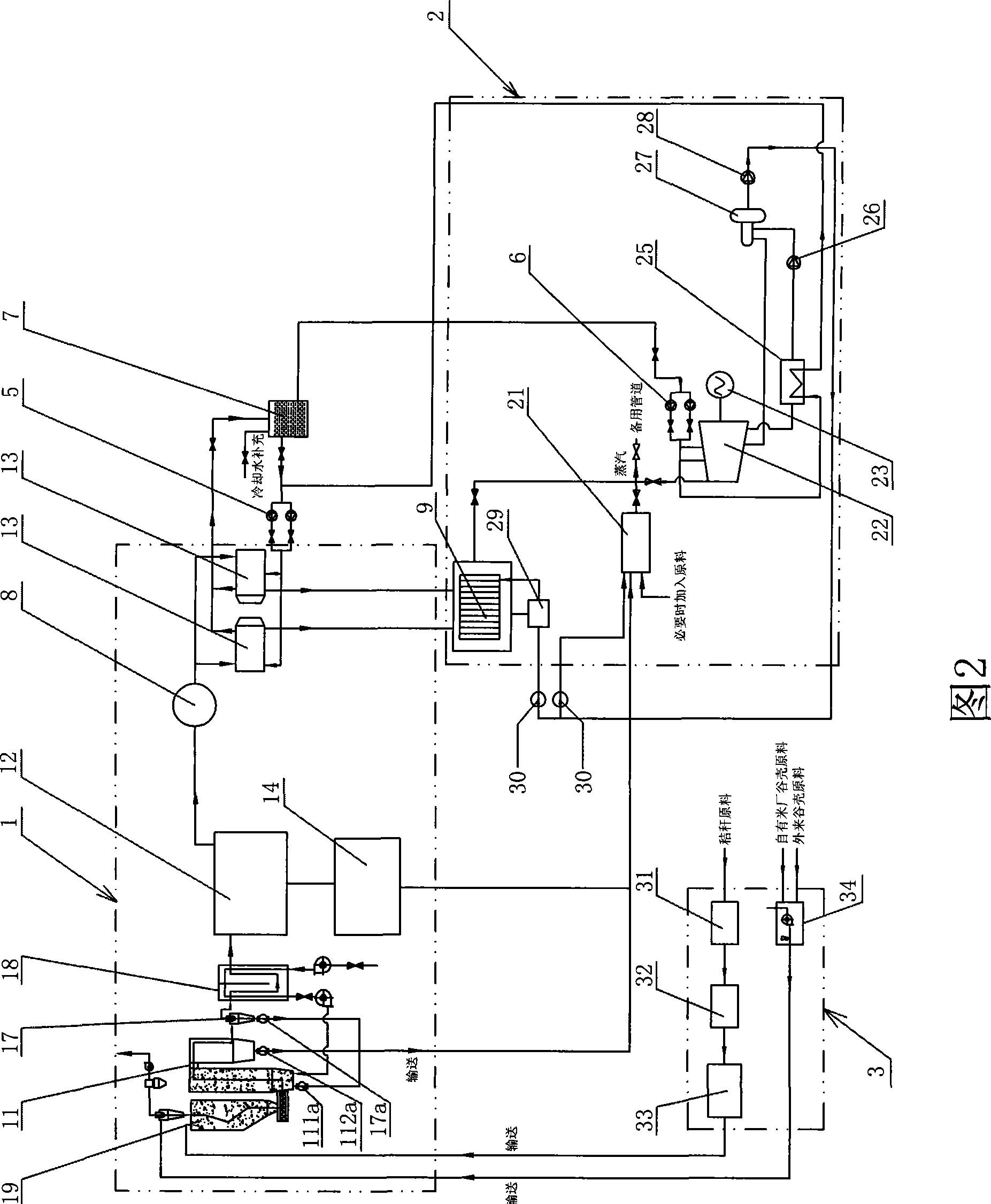

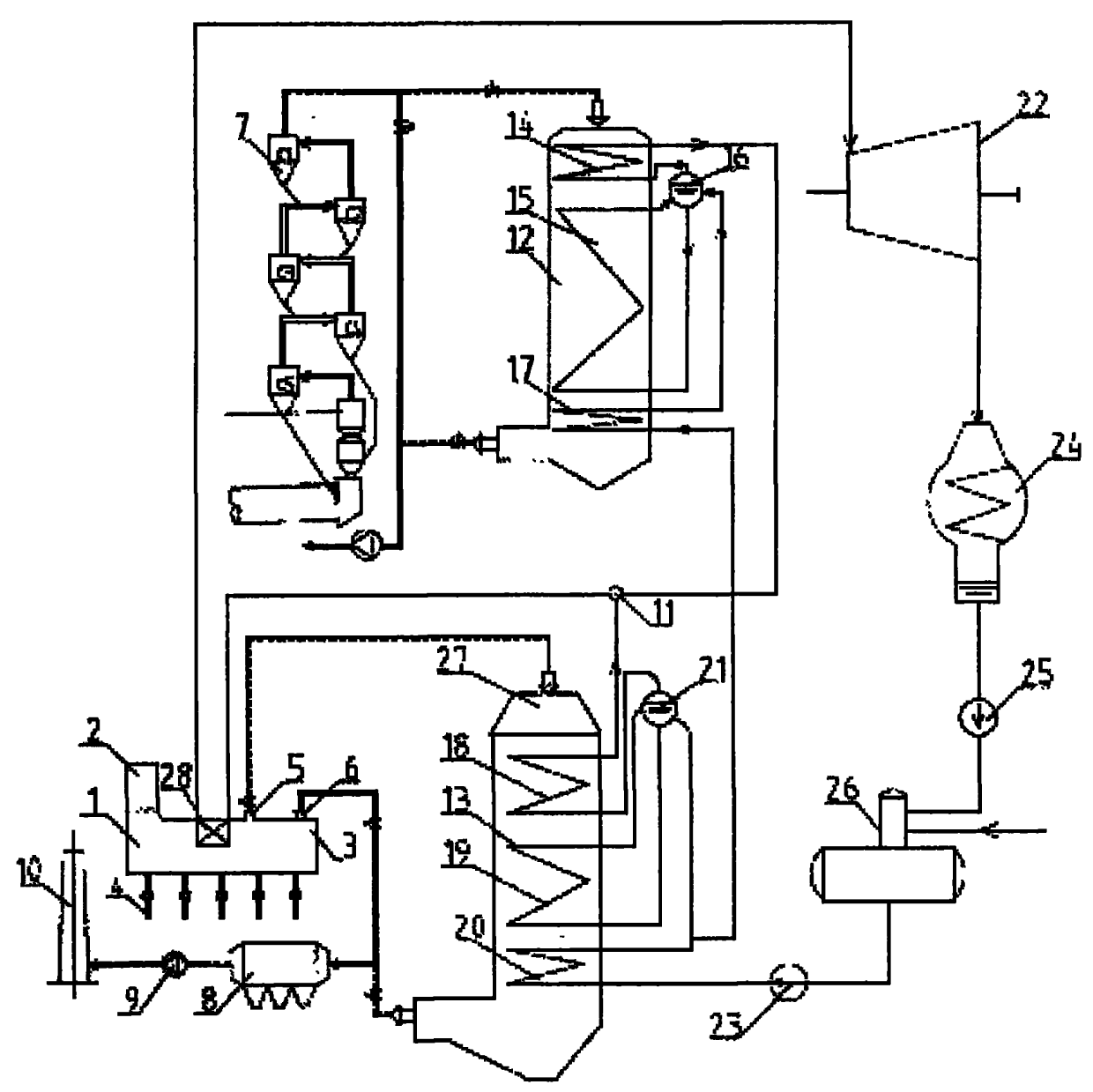

Technological method of comprehensive utilization of separation and pyrolysis treatment of garbage

InactiveCN101618392AAchieve harmless disposal rateReduce energy consumptionDrying solid materials with heatCarbon compoundsEvaporationOxygen

The invention relates to a technological method of comprehensive utilization of separation and pyrolysis treatment of garbage, which solves the problem of comprehensive utilization of separation pretreatment and pyrolysis gas in the process of separation treatment of garbage. The method comprises the following steps: separating and crushing the garbage for secondary classification; classifying the available components in the garbage into three classes, wherein the first class comprises paper, plastic and the like which are used as pyrolysis raw materials 1, the second class comprises the mixture of soil, kitchen wastes and the like, and the third class comprises the mixture of rag, fresh branches, vines and the like; chopping the mixture of the third class, and mixing the chopped mixture of the third class with the mixture of the second class; treating the mixture of the second class and the mixture of the third class by aerobic fermentation, and using penetrant for direct back-spraying and evaporation in high-temperature regions; treating the obtained product by secondary sieving to obtain pyrolysis raw materials 2; mixing and drying the pyrolysis raw materials 1 and the pyrolysis raw materials 2; condensing the generated steam to obtain hot water which back flows into a waste heat boiler of a power generating system to be used as supplemental water; commercializing and recovering the pyrolysis raw materials; and burning the obtained combustible gas for power generation. The invention has the advantages of high recovery rate, low energy consumption and no pollution caused by discharge.

Owner:SHEN ZHEN A MART IND

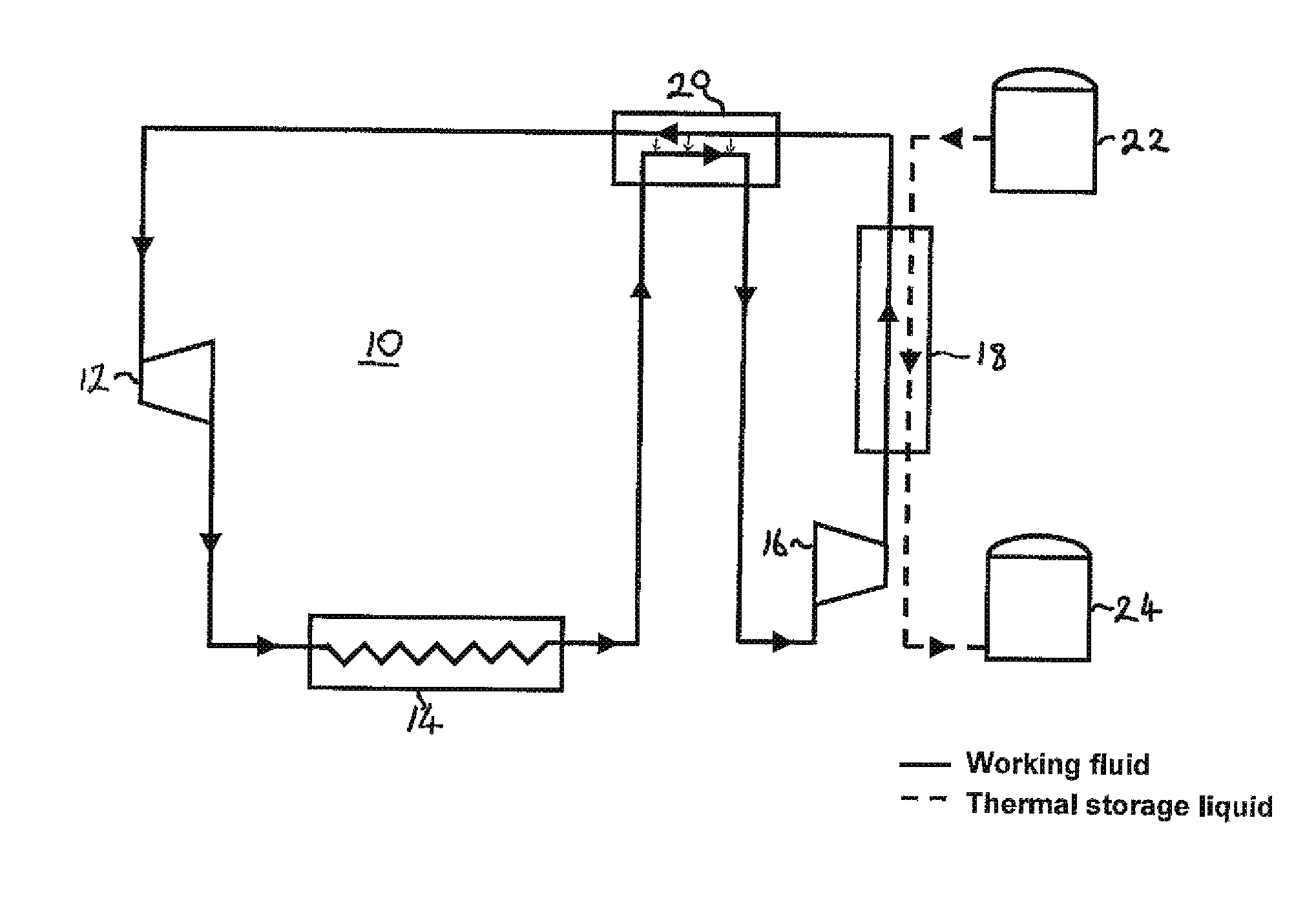

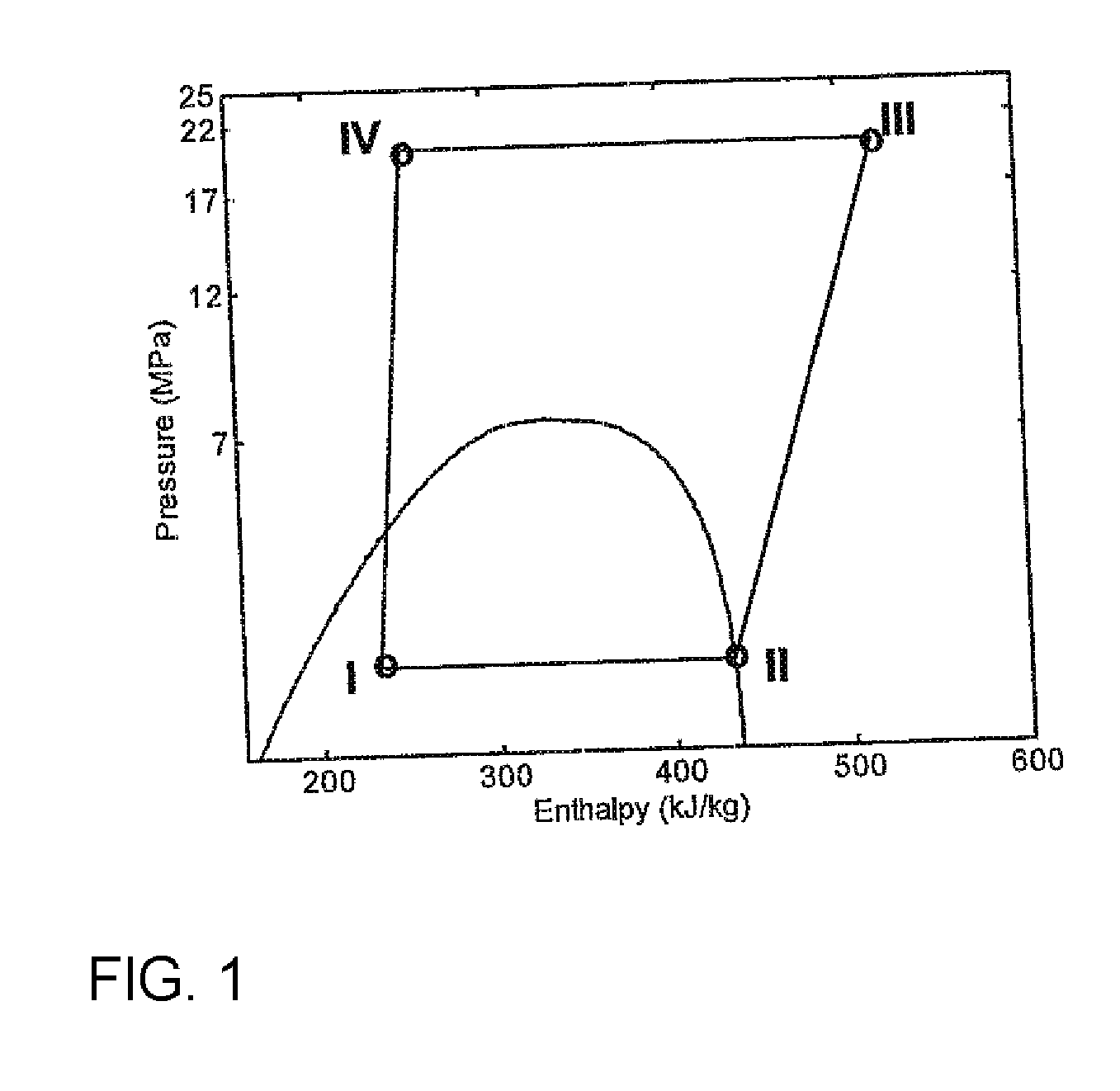

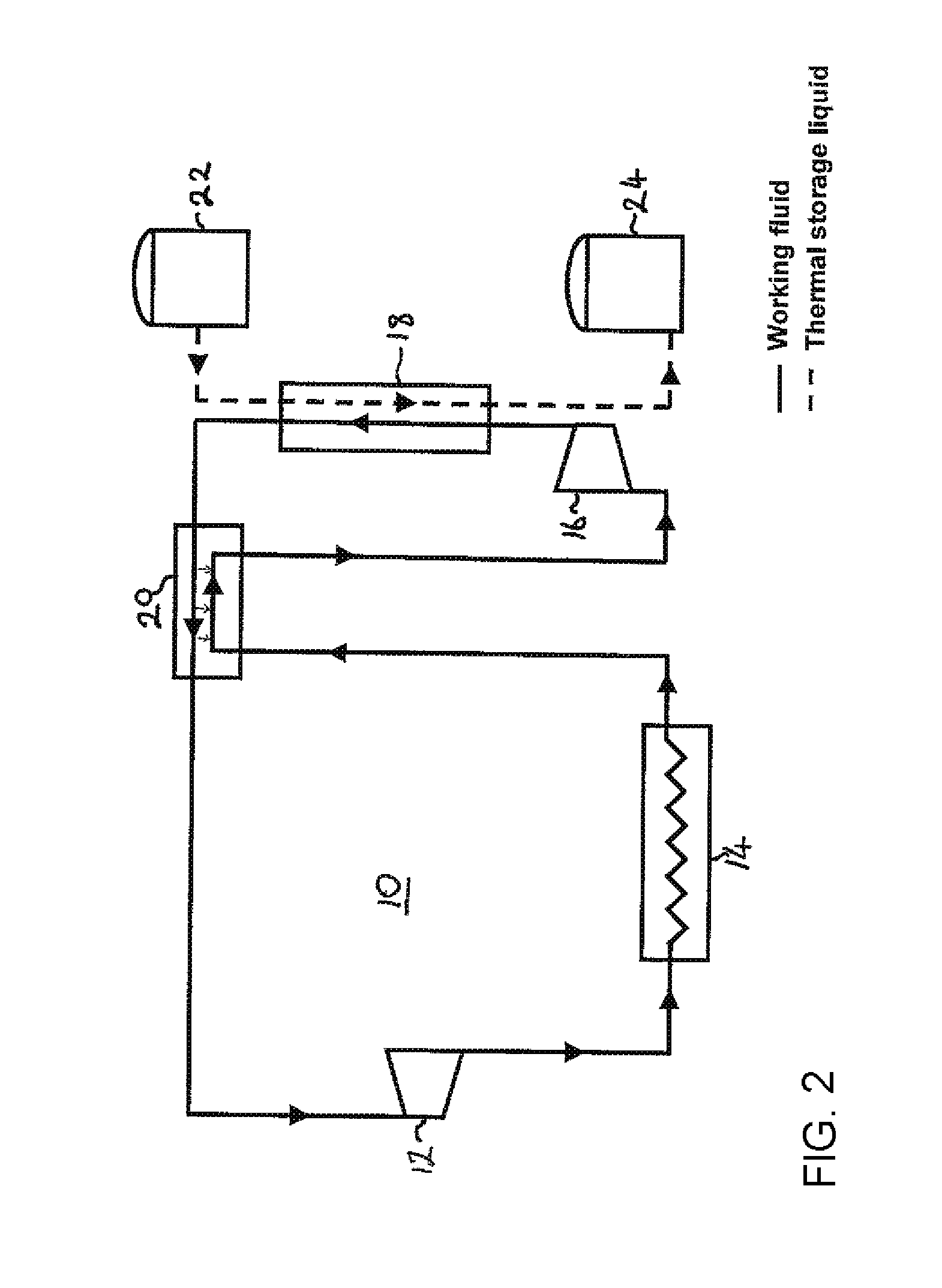

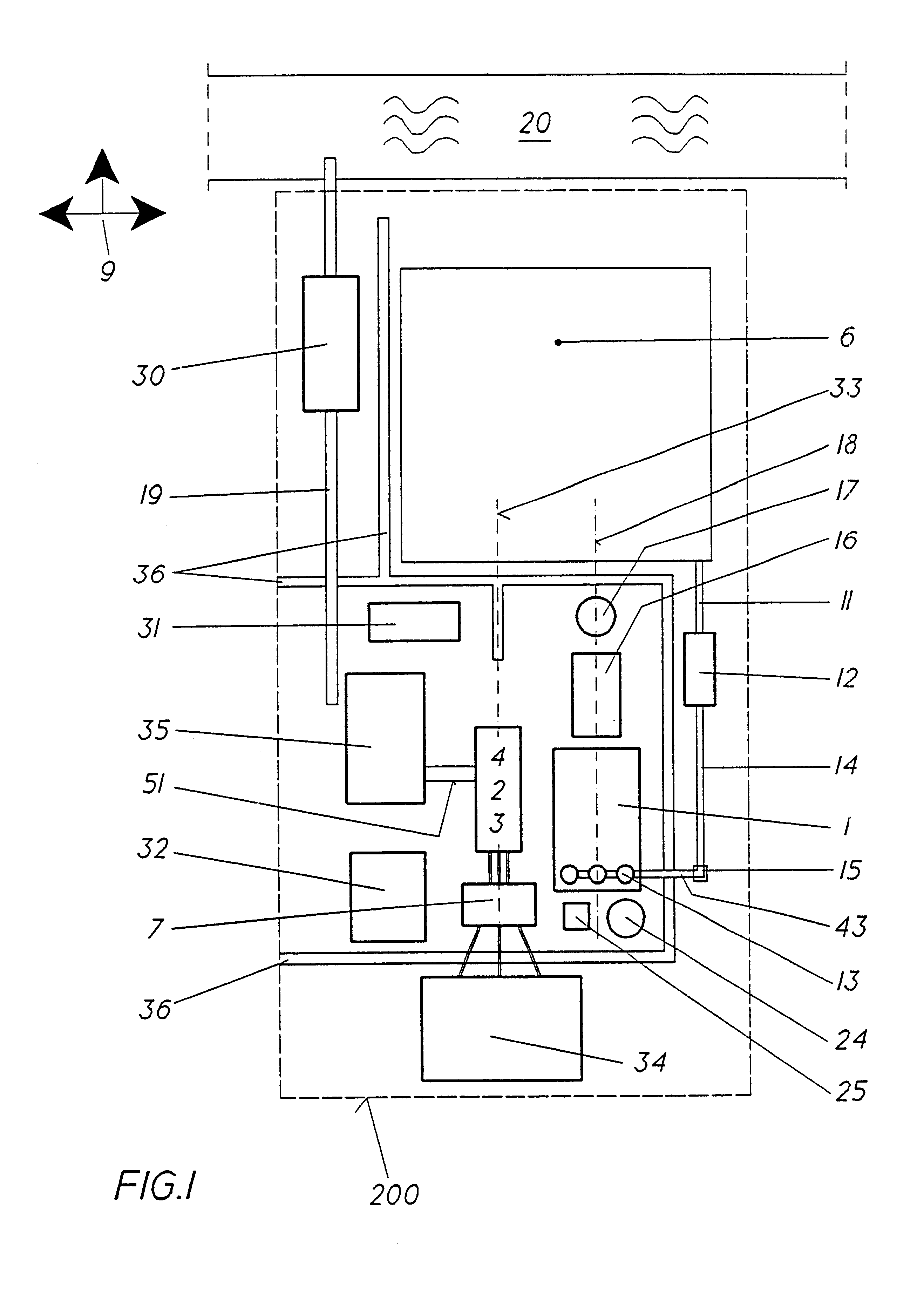

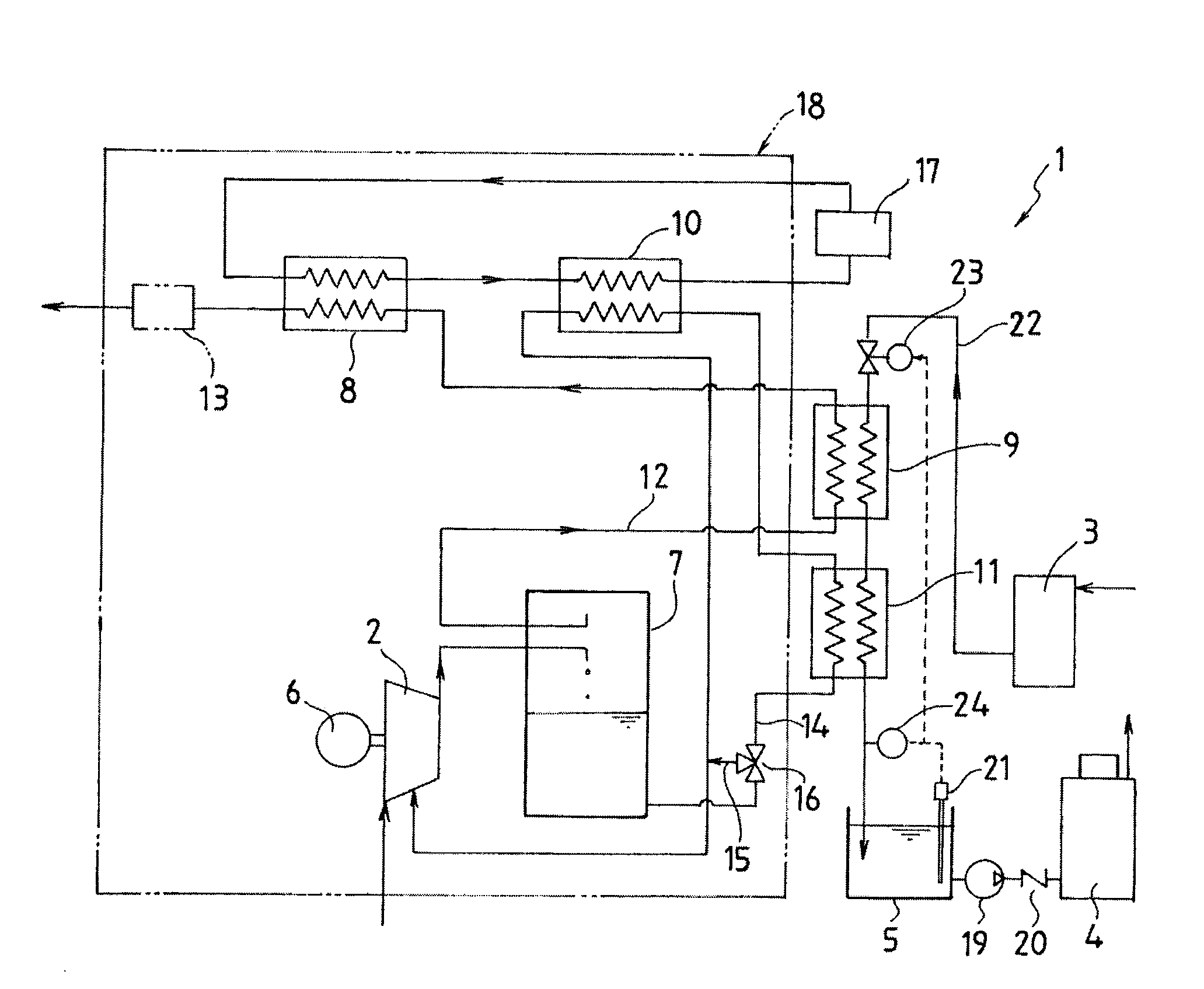

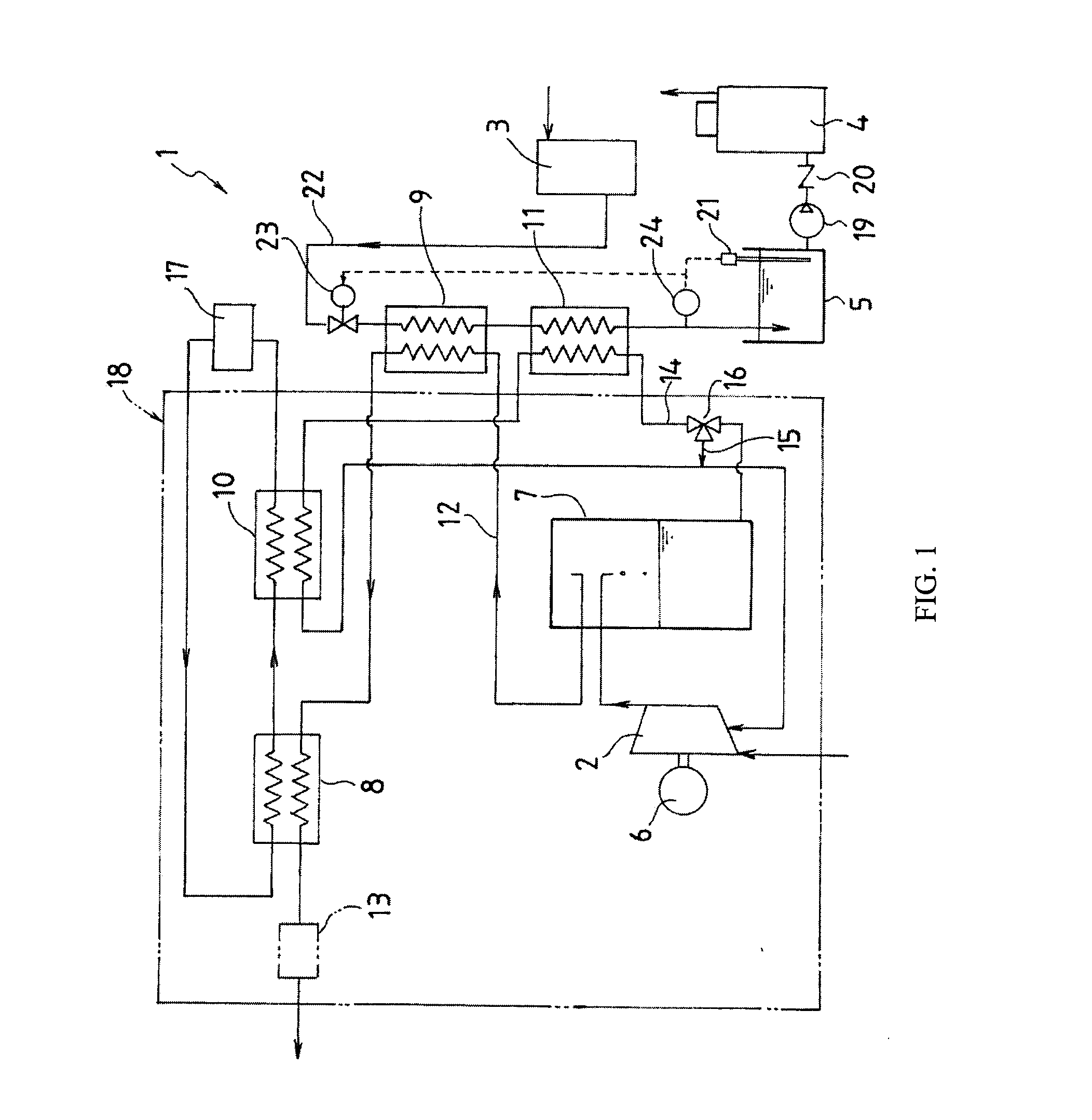

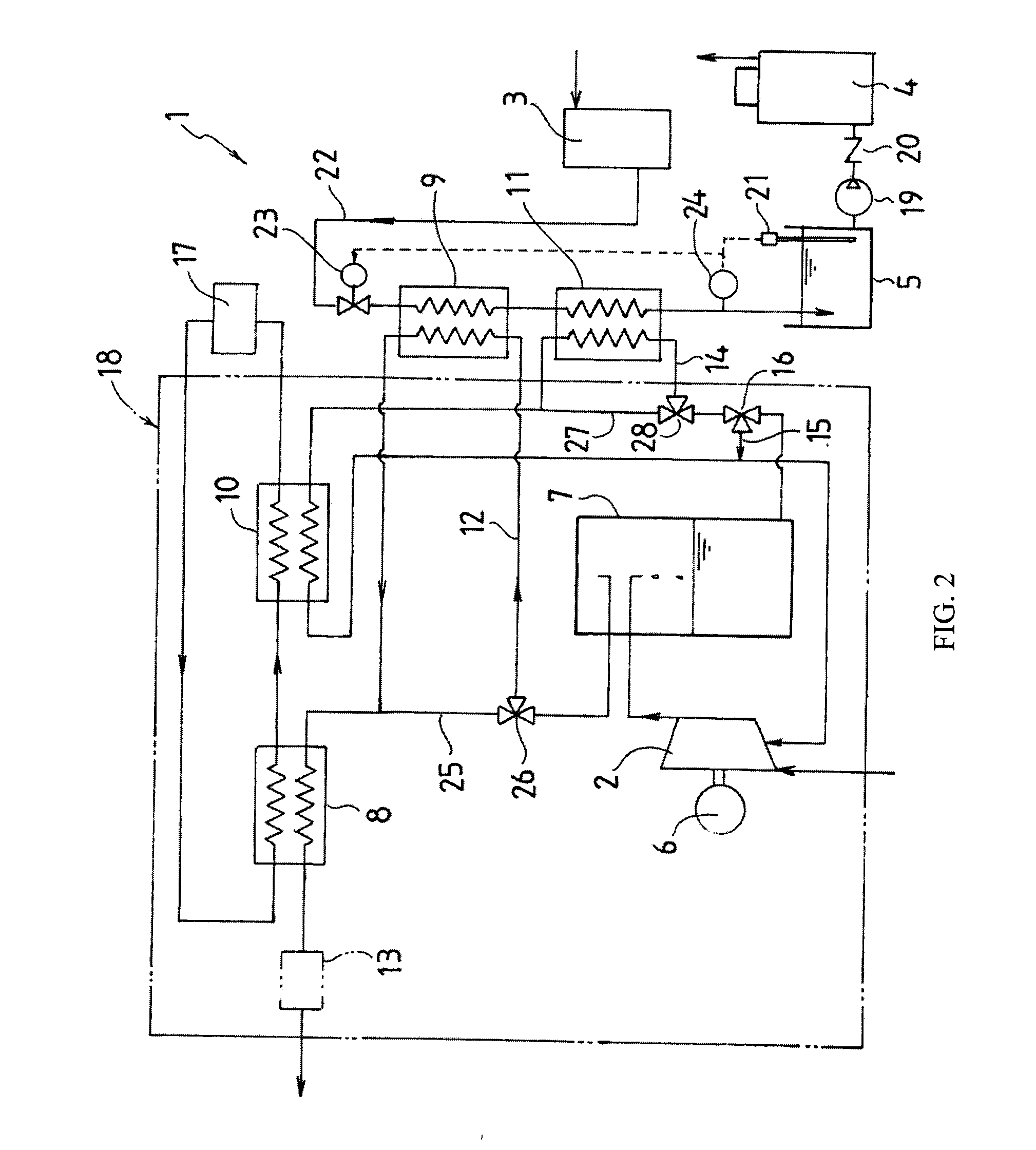

Thermoelectric energy storage system having an internal heat exchanger and method for storing thermoelectric energy

InactiveUS20120222423A1Minimized in sizeMaximizes workFeed water supplySteam accumulatorsThermal energyWorking fluid

Exemplary embodiments are directed to a thermoelectric energy storage system (TEES) and method for converting electrical energy into thermal energy to be stored and converted back to electrical energy with an improved round-trip efficiency are disclosed. The TEES includes a working fluid circuit for circulating a working fluid through a first heat exchanger and a second heat exchanger, a thermal storage medium circuit for circulating a thermal storage medium, the thermal storage medium circuit having at least one hot storage tank coupled to a cold storage tank via the first heat exchanger. The arrangement maximizes the work performed by the cycle during charging and discharging for a given maximum pressure and maximum temperature of the working fluid.

Owner:ABB RES LTD

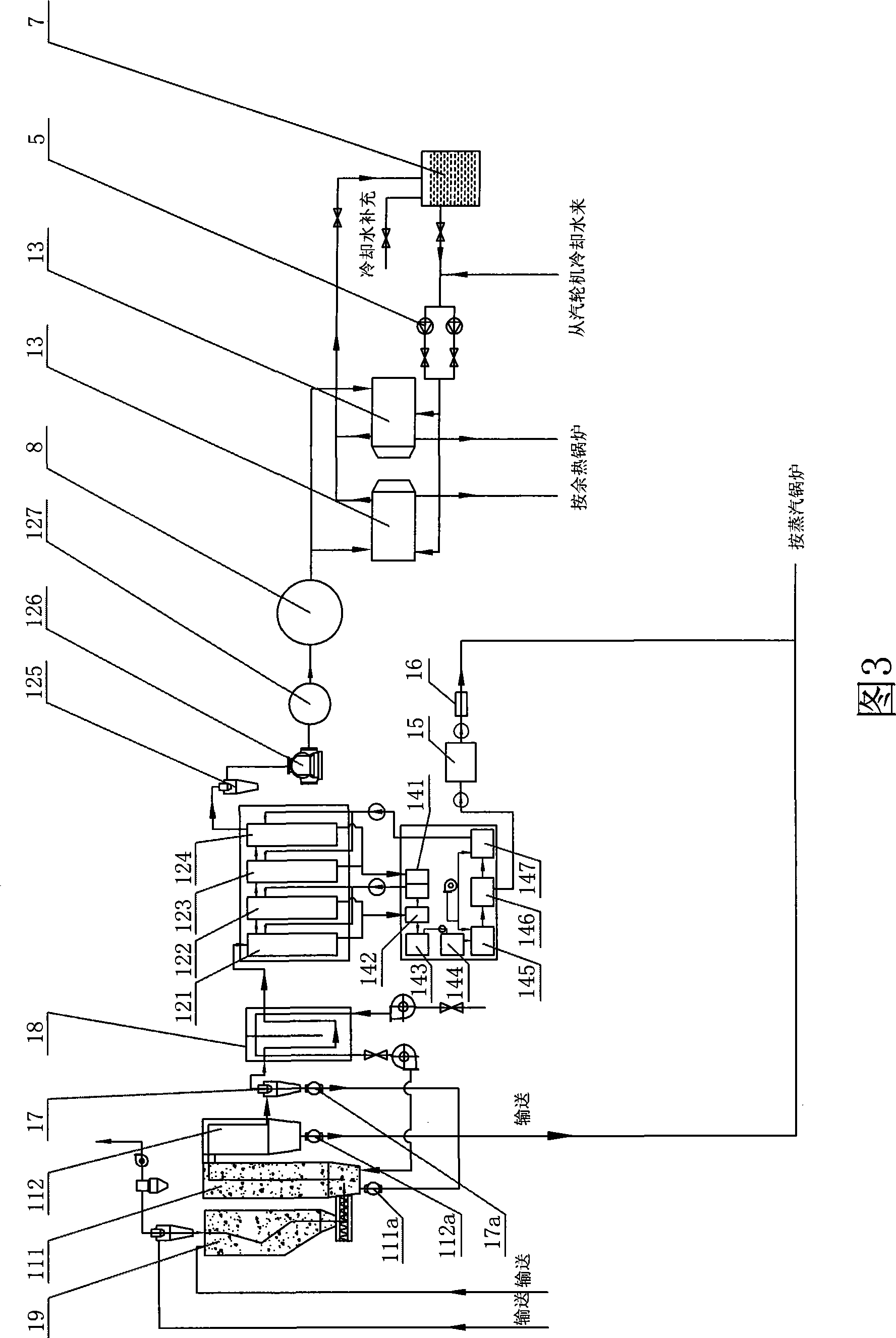

High-moisture-content lignite predrying method and system integrated with thermal power plant

InactiveCN102353237AWith drying capacityKeep dryDrying solid materials with heatFeed water supplyThermal energyFluidized bed drying

The invention discloses a high-moisture-content lignite predrying method and system integrated with a thermal power plant. In the method, lignite is dried by using hot air as a fluidizing agent and a drying medium in a fluidized bed dryer; and a heater is built in the fluidized bed dryer to supply partial heat for drying. The lignite predrying system integrated with the thermal power plant comprises the fluidized bed dryer, the heater built in the dryer, a deduster, a gas-gas heat exchanger, a gas-water heat exchanger, an air heater and a fan. According to the system, waste heat in the system and low-grade heat energy in the power plant are fully utilized to dry the lignite. By applying the method and the system disclosed by the invention, the moisture content of the lignite fed into a furnace can be reduced, the heat loss of a boiler due to exhaust gas can be reduced, and the efficiency of the lignite boiler is increased; the low-grade heat energy and waste heat resources in the thermal power plant are fully utilized, so that the consumption of high-grade energy sources in a drying process is reduced, and the power generation efficiency of a lignite power plant is increased.

Owner:XI AN JIAOTONG UNIV

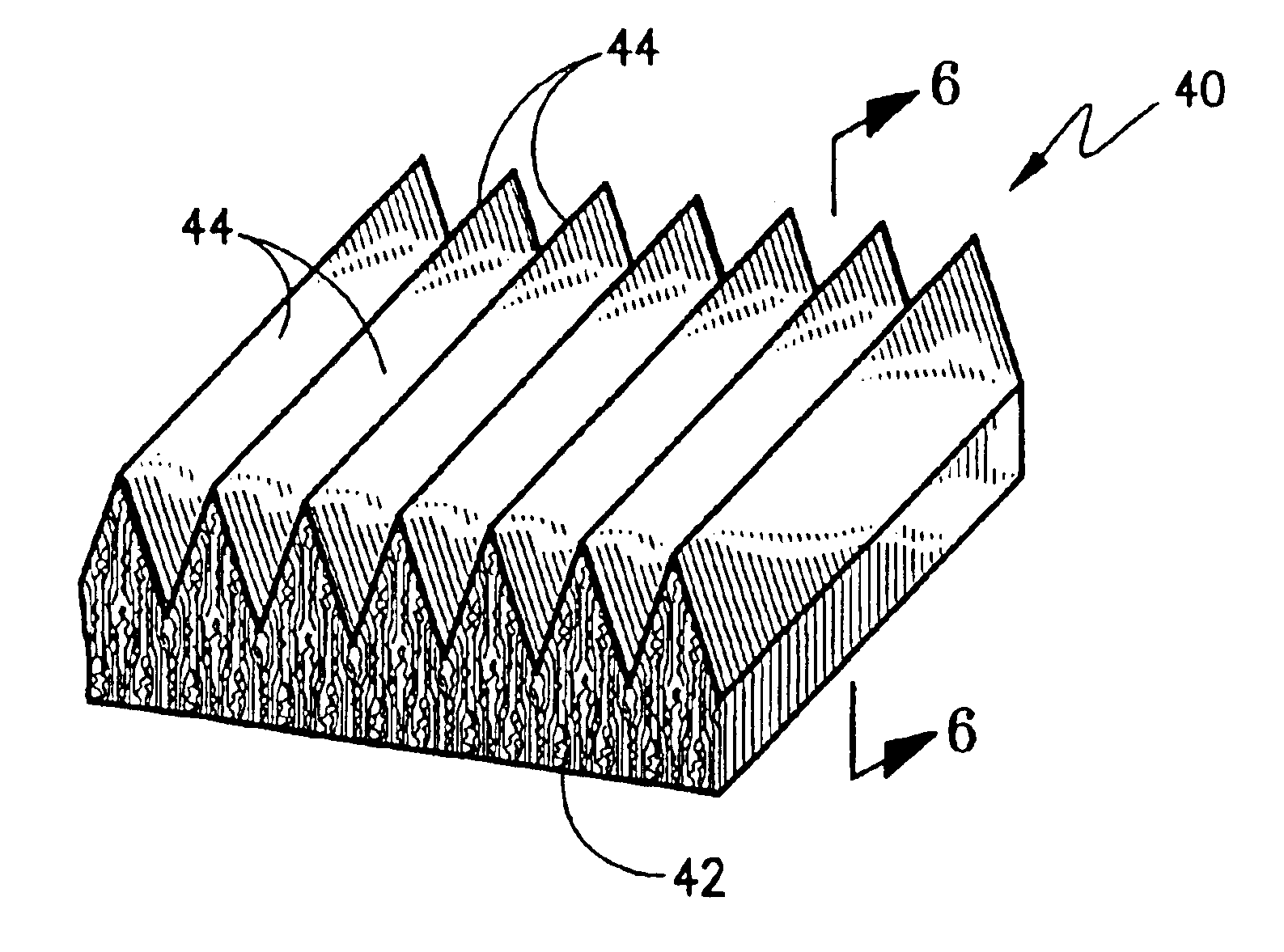

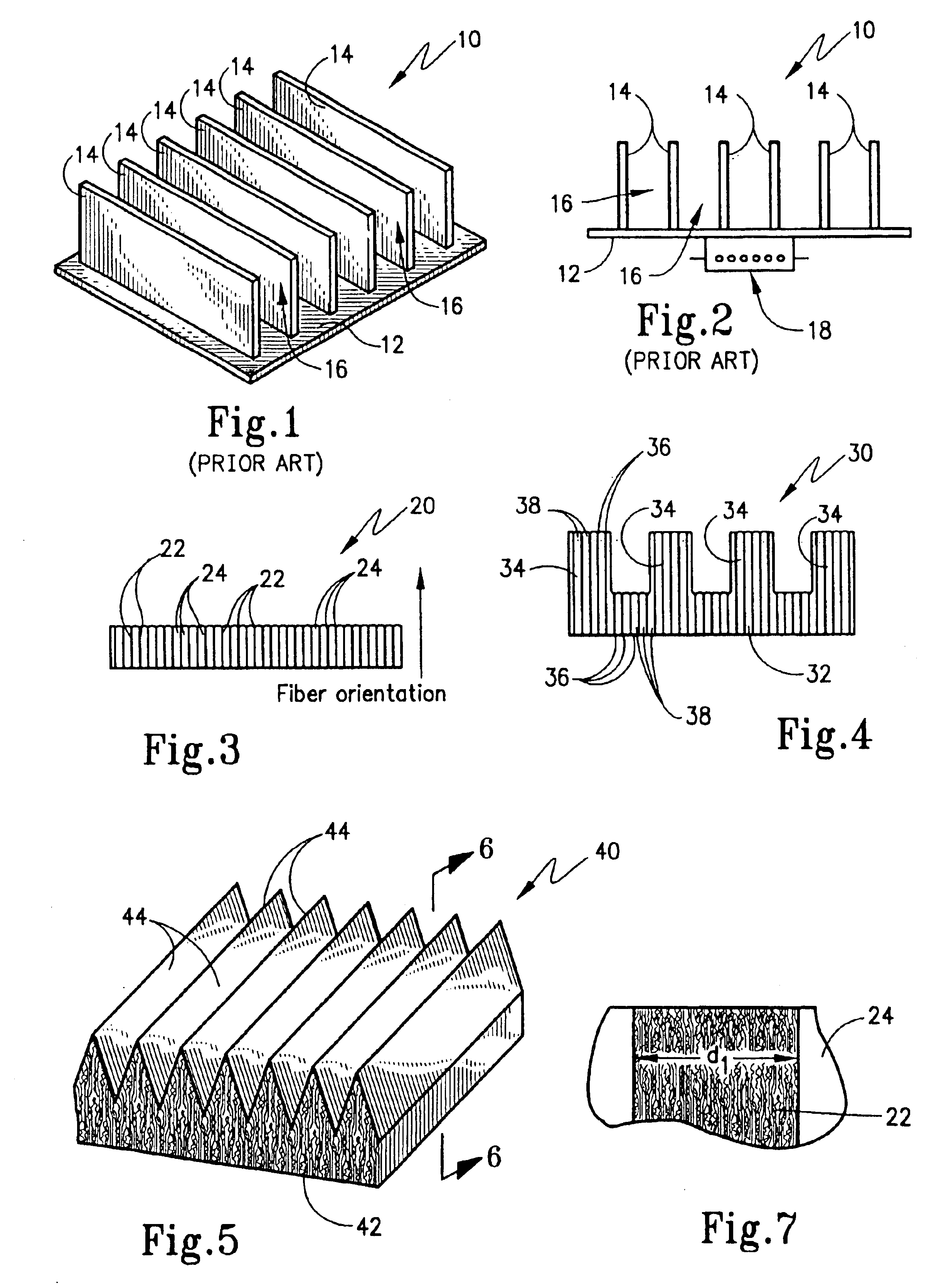

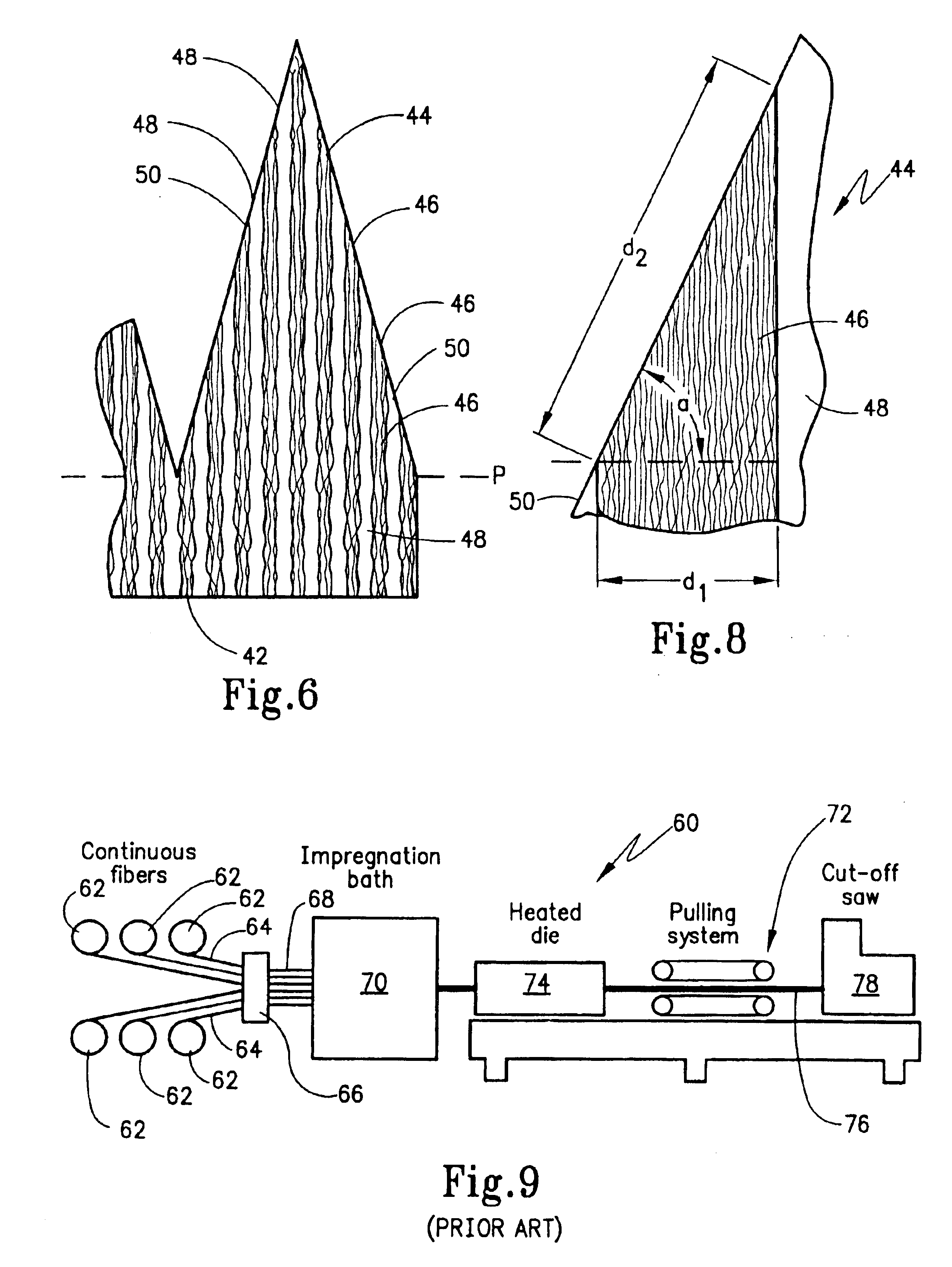

Thermal management material, devices and methods therefor

InactiveUS6844054B2Low costImprove thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesThermal energyFiber

The present invention provides thermal devices, materials and methods for use in transferring heat from heat sources. One embodiment comprises a thermal transfer body that has first and second end portions and includes a thermally anisotropic material that conducts more thermal energy in a longitudinal direction than in a direction transverse thereto, wherein at least one of the first and second end portions includes a projection having a surface area oriented obliquely to the longitudinal direction. Multiple projections may be provided of various geometries, such as pyramids, cones, triangular prismoids and domes. The thermally anisotropic material may include an ensemble of longitudinally thermally conductive fibers, such as carbon fibers derived from precursors such as petroleum or coal pitch, which may be embedded in a support matrix of various materials.

Owner:THERMO COMPOSITE LLC

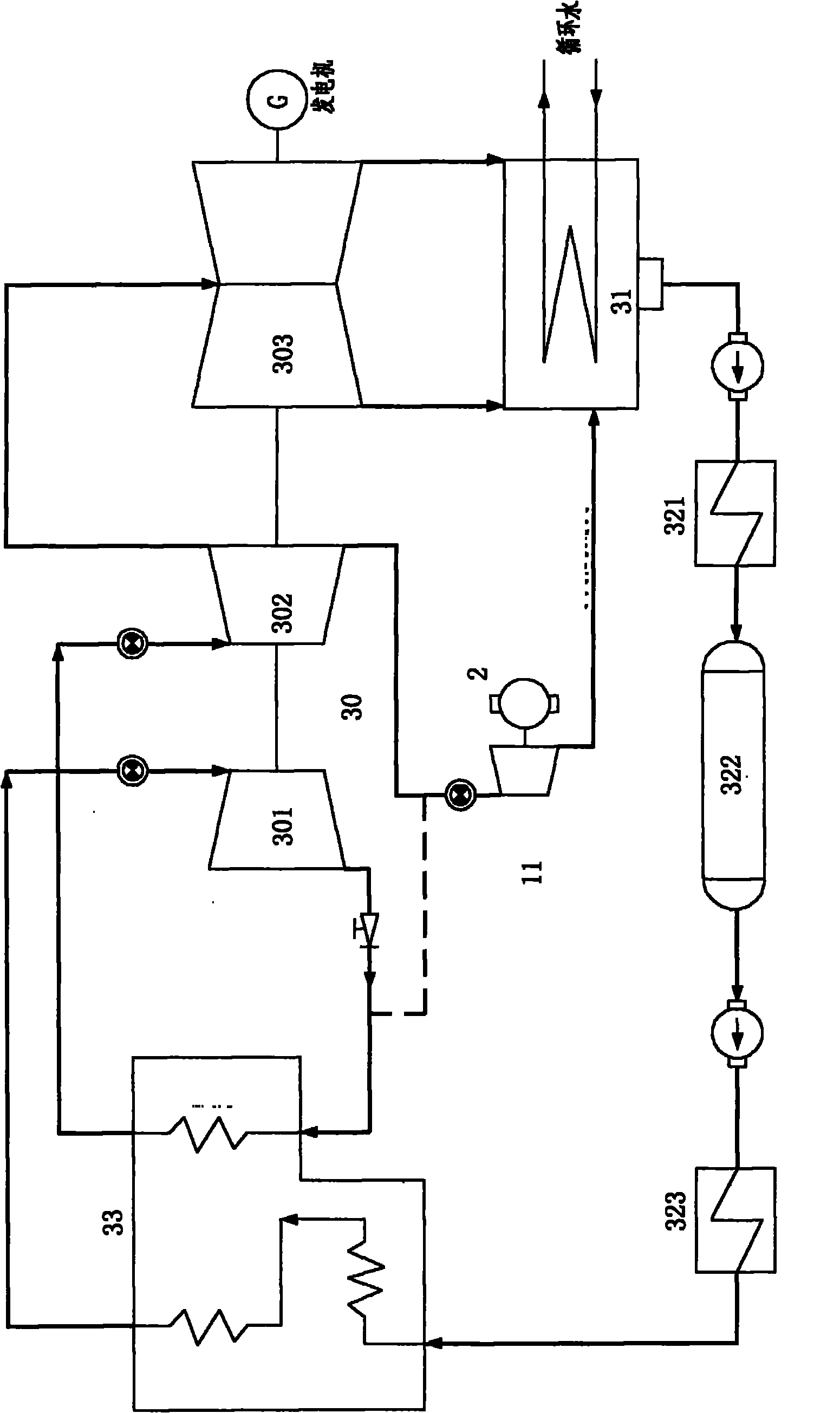

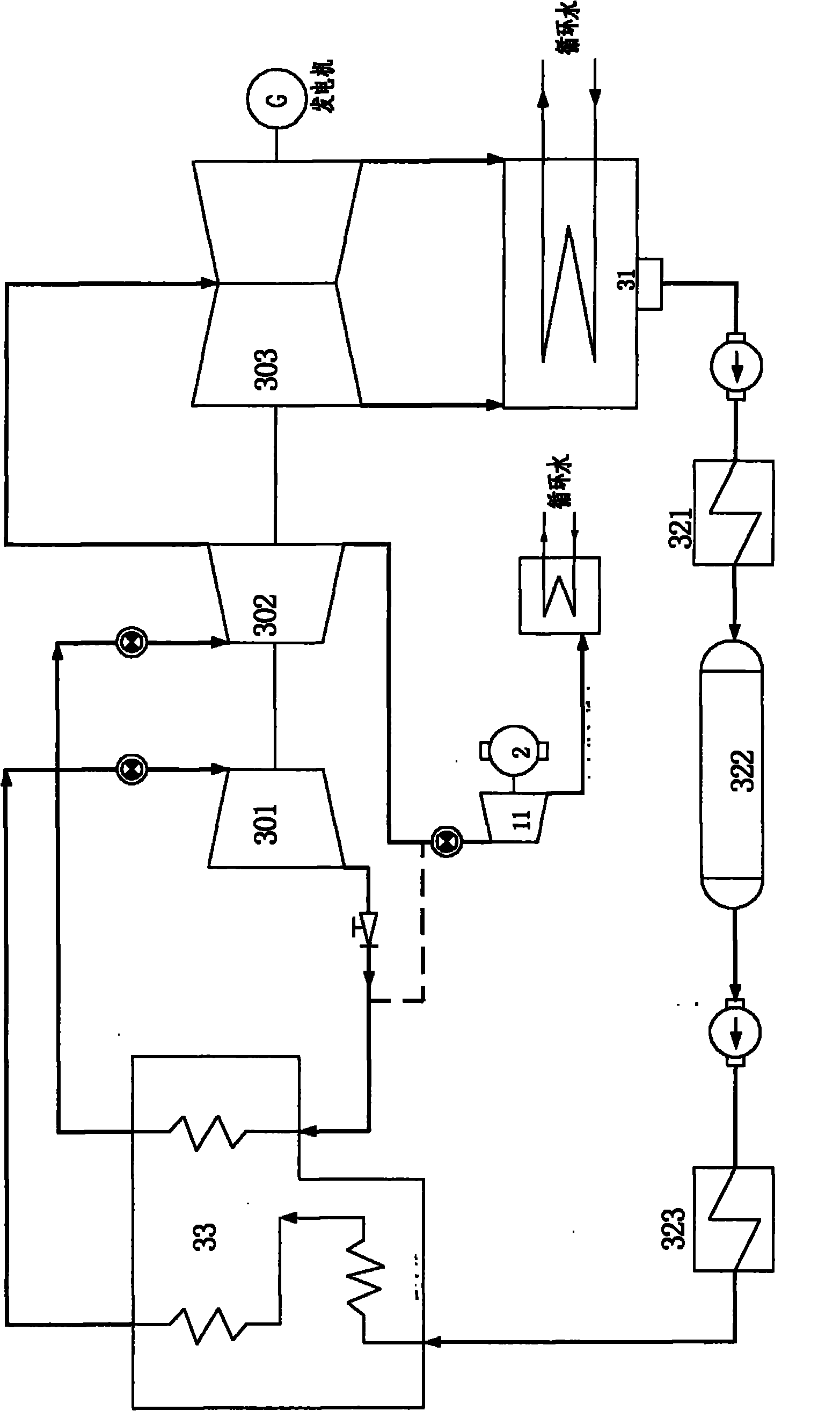

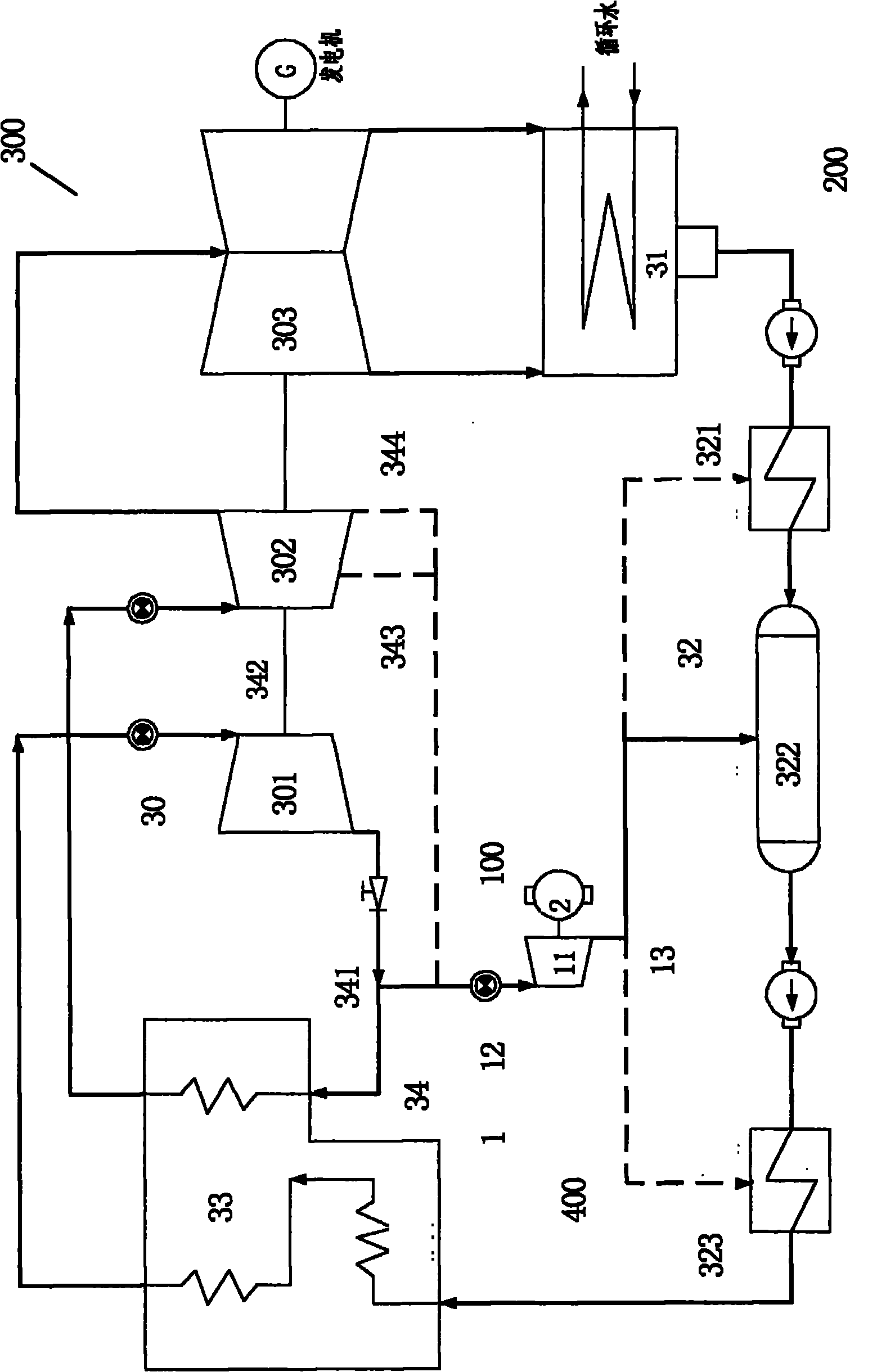

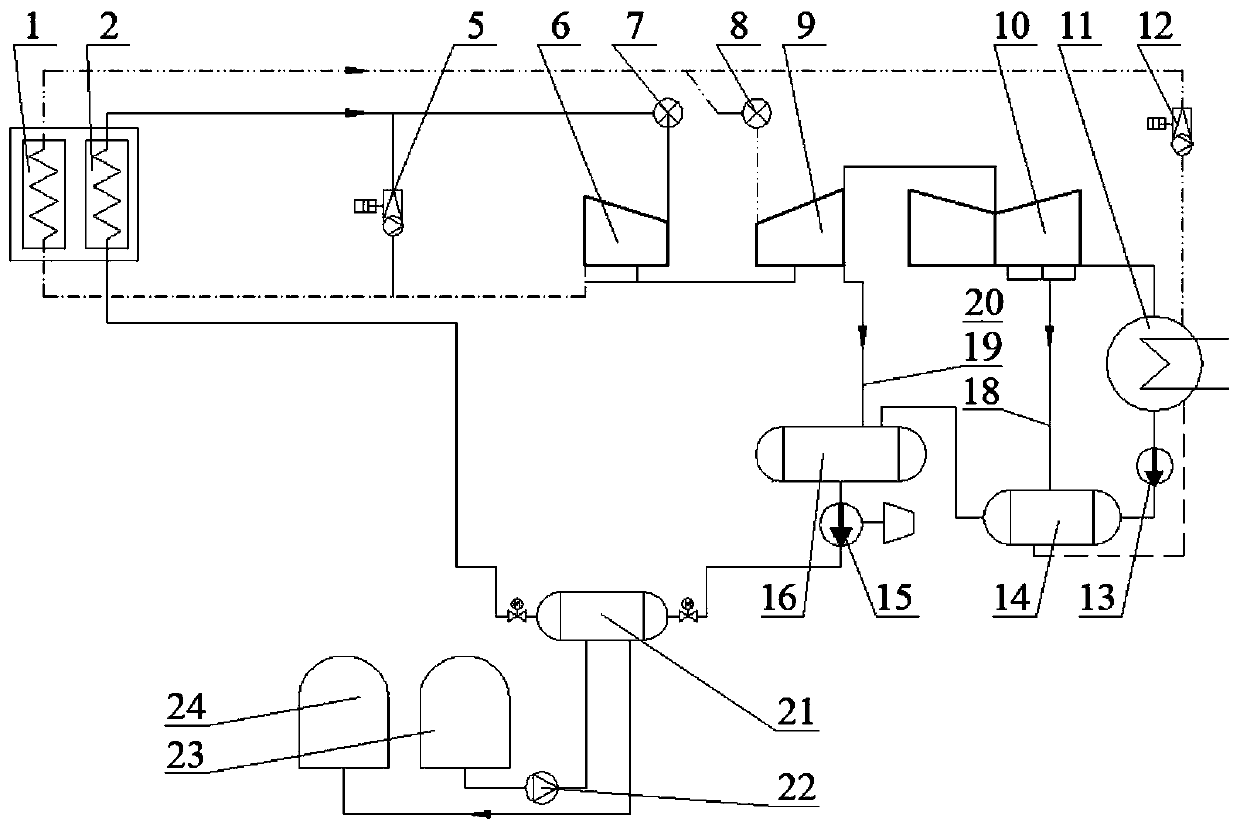

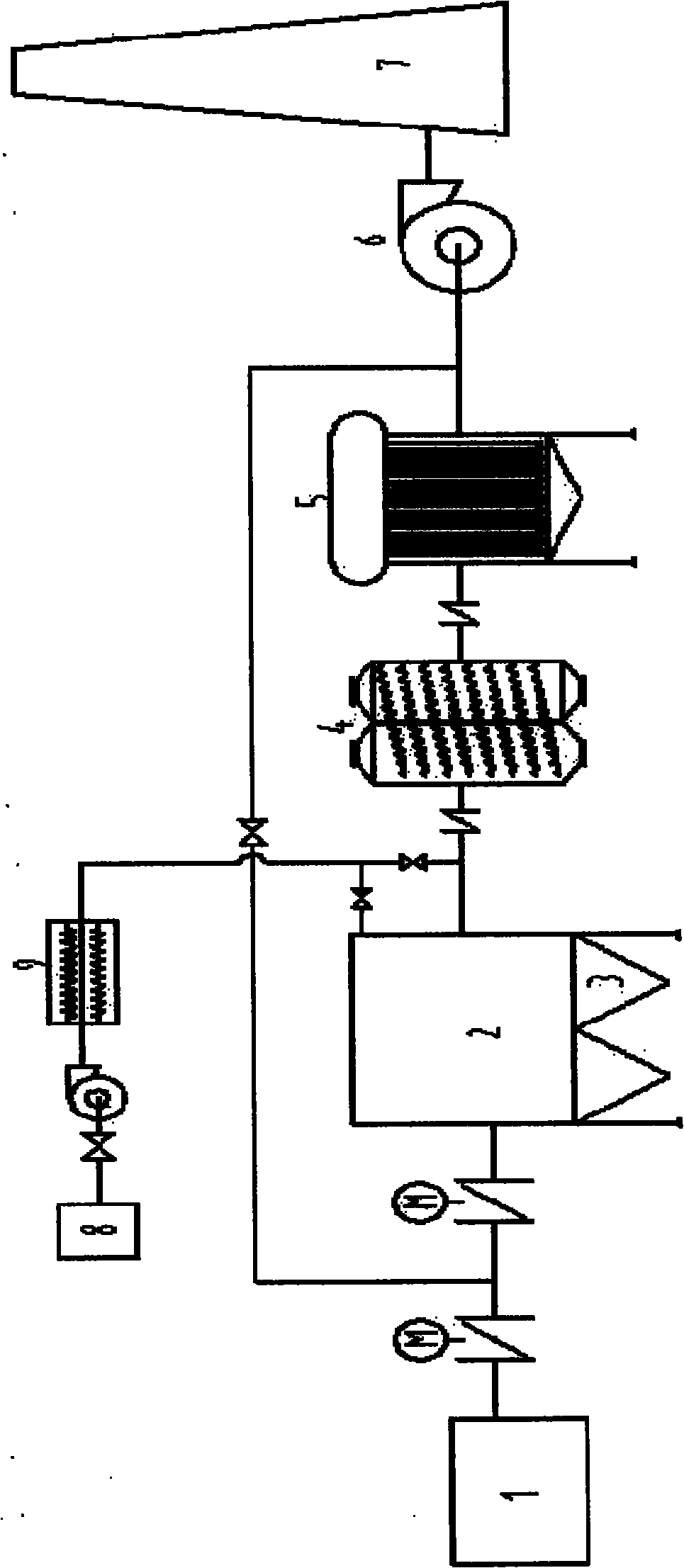

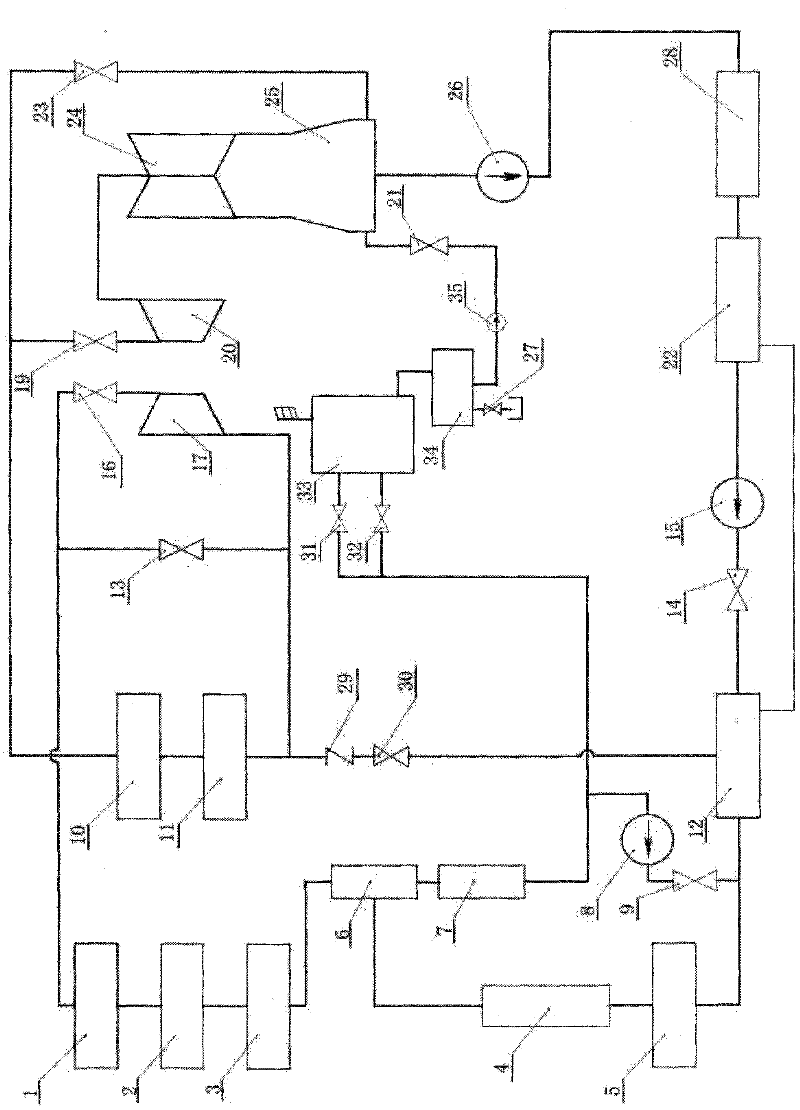

Small turbine system in power plant and thermal cycle system in power plant containing same

InactiveCN101899999ASave electricityImprove power supply efficiencyFeed water supplyEnergy industryPower stationEngineering

The invention provides a small turbine system in a power plant for recovering the exhaust steam heat to the thermal cycle system in the power plant. The system comprises a backheating-type small turbine unit and a driven device driven by the backheating-type small turbine unit. The backheating-type small turbine unit comprises a small turbine, a small turbine admission pipe system and a small turbine exhaust pipe system. The small turbine admission pipe system is arranged on the upstream of the small turbine and receives steam source from the thermal cycle system in the power plant; the small turbine exhaust pipe system is arranged on the downstream of the small turbine; the exhaust steam of the small turbine exhaust pipe system enters to the backheating unit of the thermal cycle system in the power plant so that the exhaust heat is recovered. The invention further provides a backheating system and a thermal cycle system in the power plant containing the small turbine system in the power plant. The systems can greatly improve the power supply efficiency of the unit.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

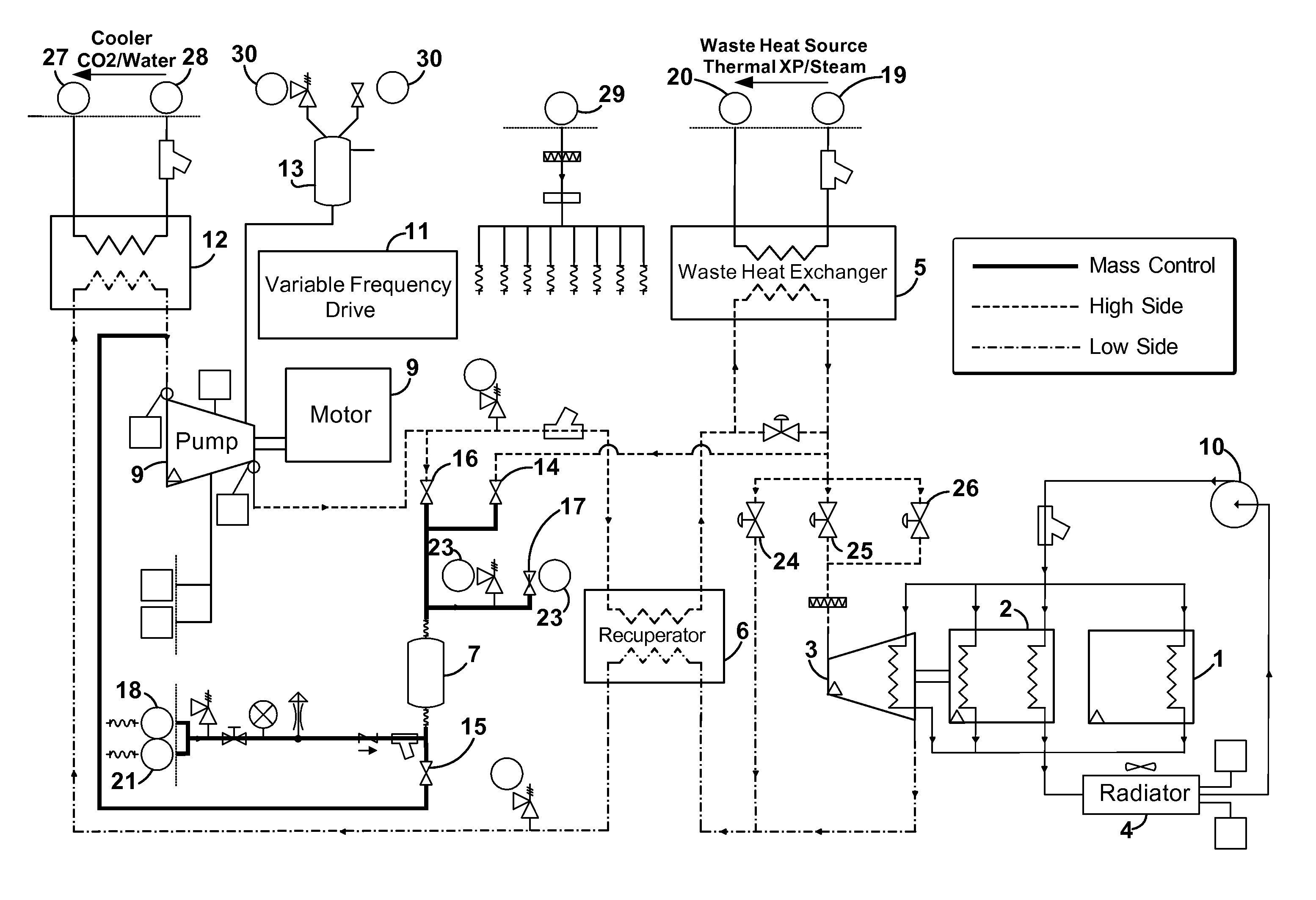

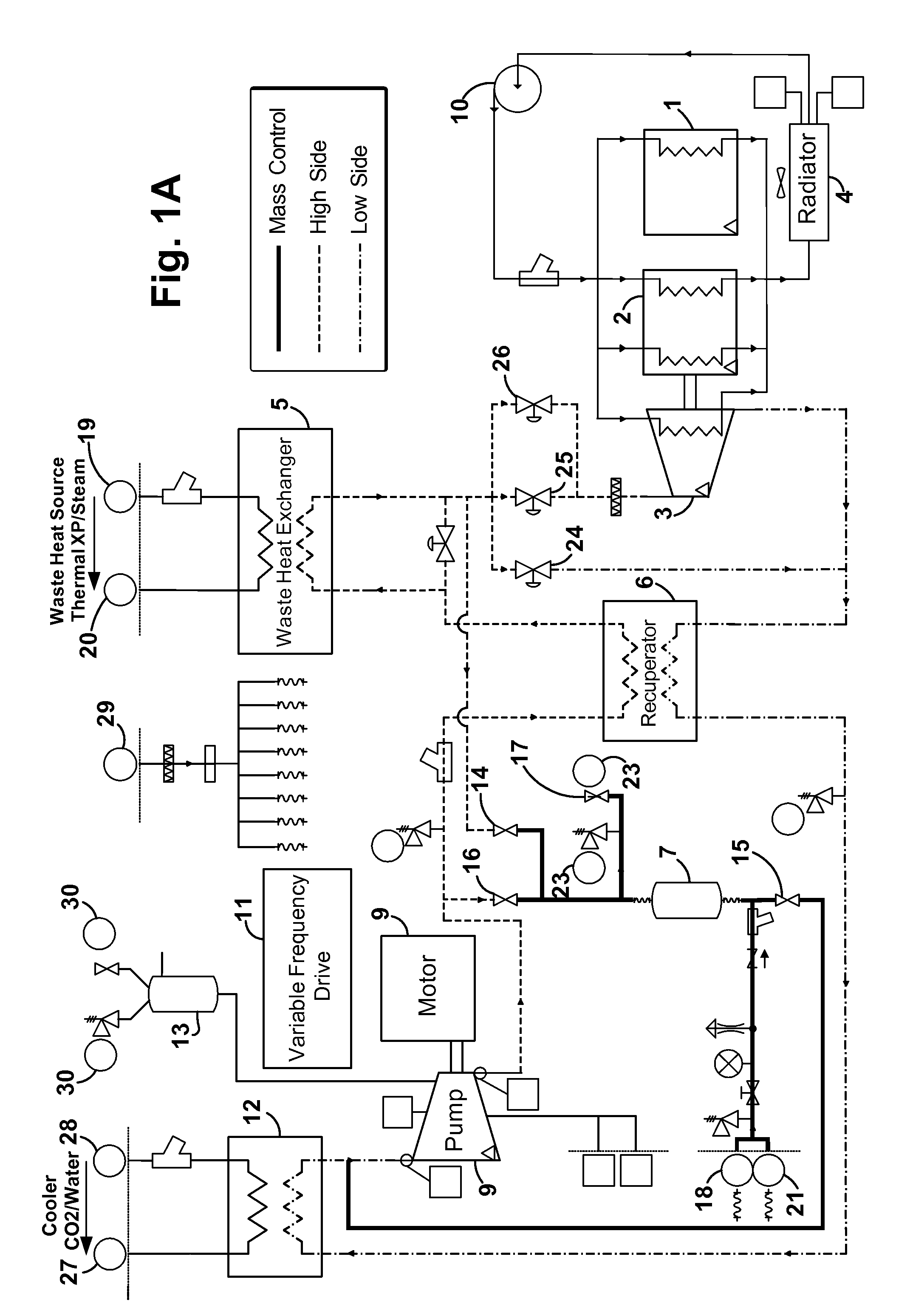

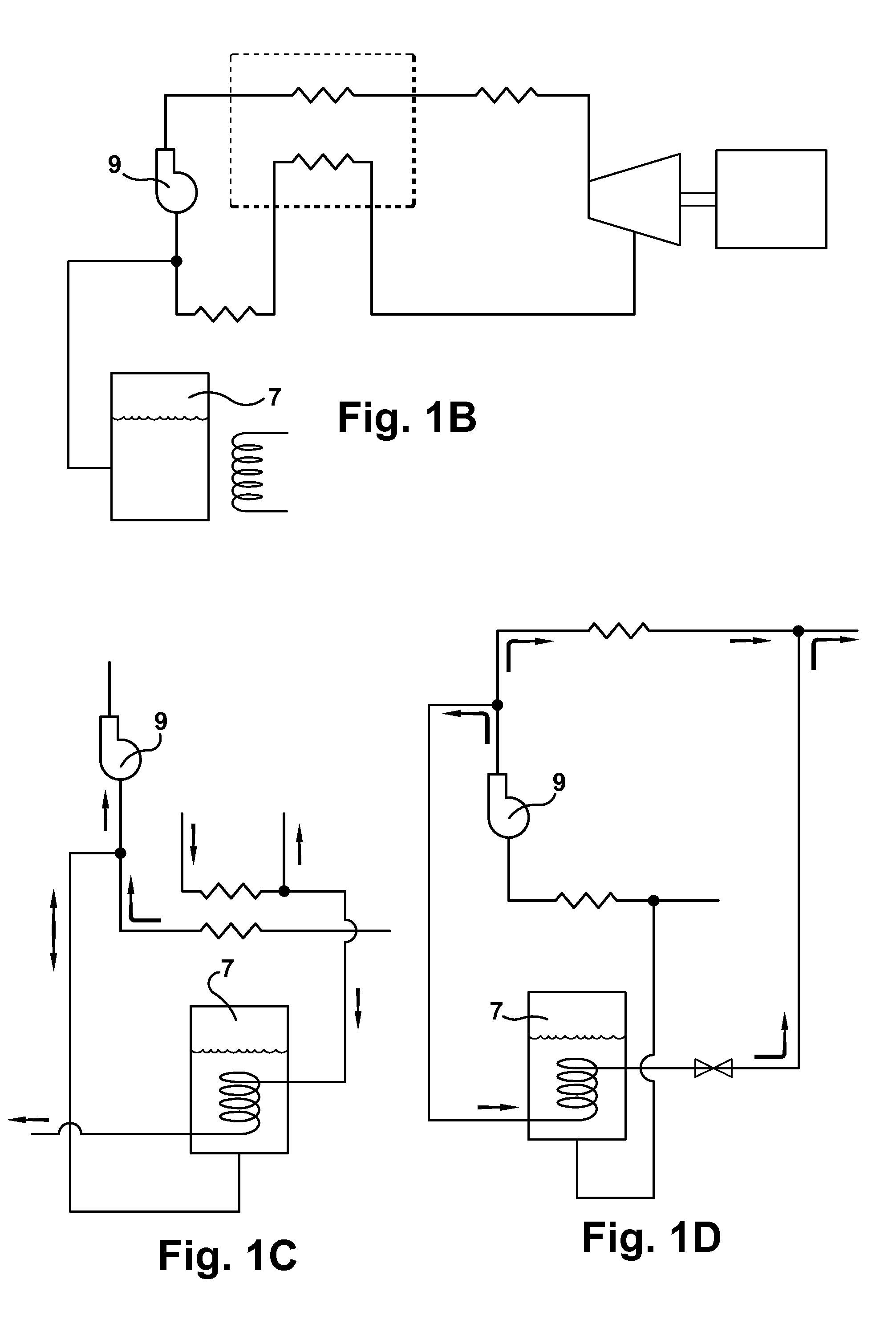

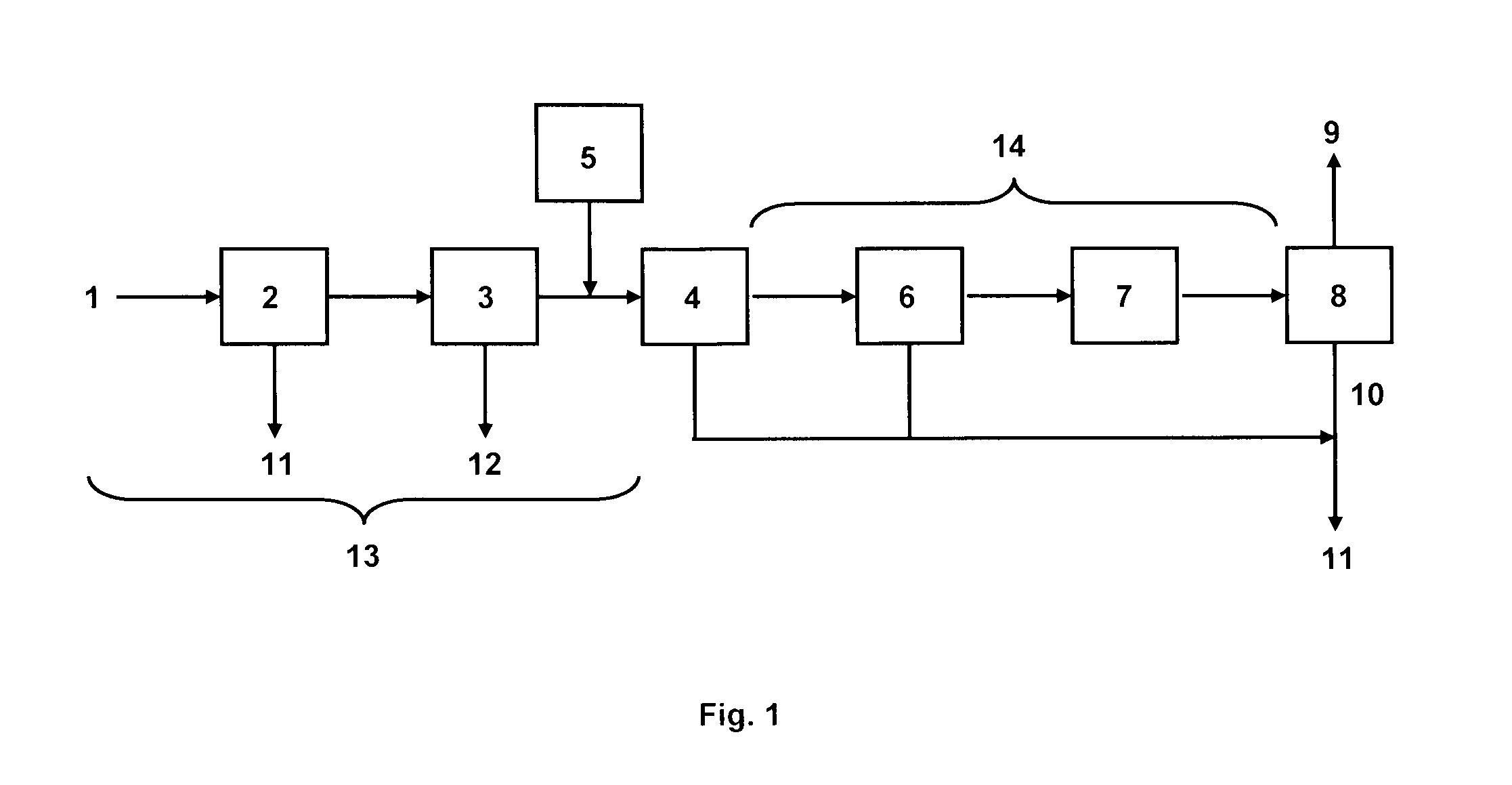

Thermal energy conversion method

A waste heat recovery system, method and device executes a thermodynamic cycle using a working fluid in a working fluid circuit which has a high pressure side and a low pressure side. Components of the system in the working fluid circuit include a waste heat exchanger in thermal communication with a waste heat source also connected to the working fluid circuit, whereby thermal energy is transferred from the waste heat source to the working fluid in the working fluid circuit, an expander located between the high pressure side and the low pressure side of the working fluid circuit, the expander operative to convert a pressure / enthalpy drop in the working fluid to mechanical energy, a recuperator in the working fluid circuit operative to transfer thermal energy between the high pressure side and the low pressure side of the working fluid circuit, a cooler in thermal communication with the low pressure side of the working fluid circuit operative to control temperature of the working fluid in the low side of the working fluid circuit, a pump in the working fluid circuit and connected to the low pressure side and to the high pressure side of the working fluid circuit and operative to move the working fluid through the working fluid circuit, and a mass management system connected to the working fluid circuit, the mass management system, method and device having a working fluid vessel connected to the low pressure side of the working fluid circuit and configured to passively control an amount of working fluid mass in the working fluid circuit.

Owner:ECHOGEN POWER SYST +1

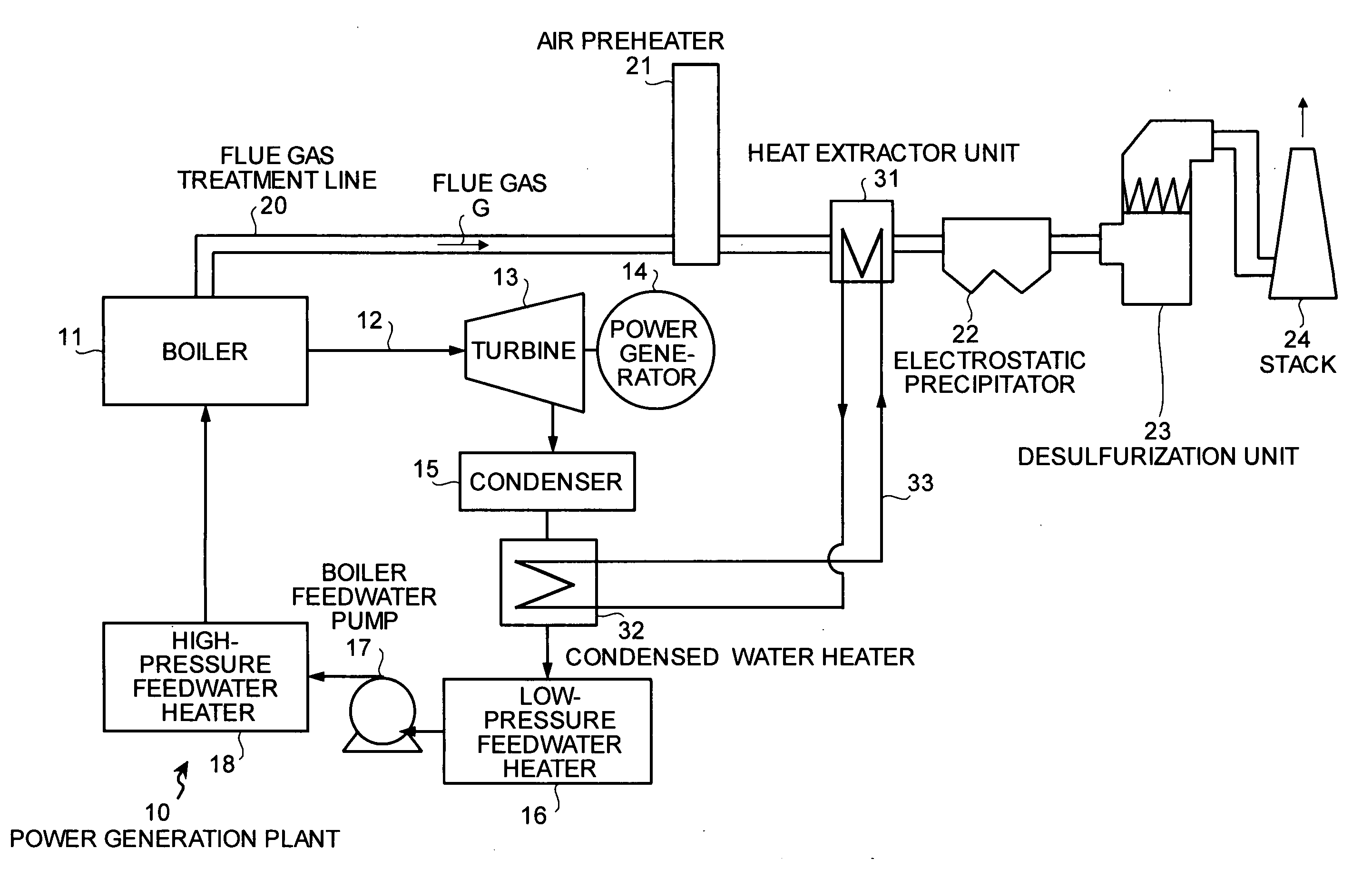

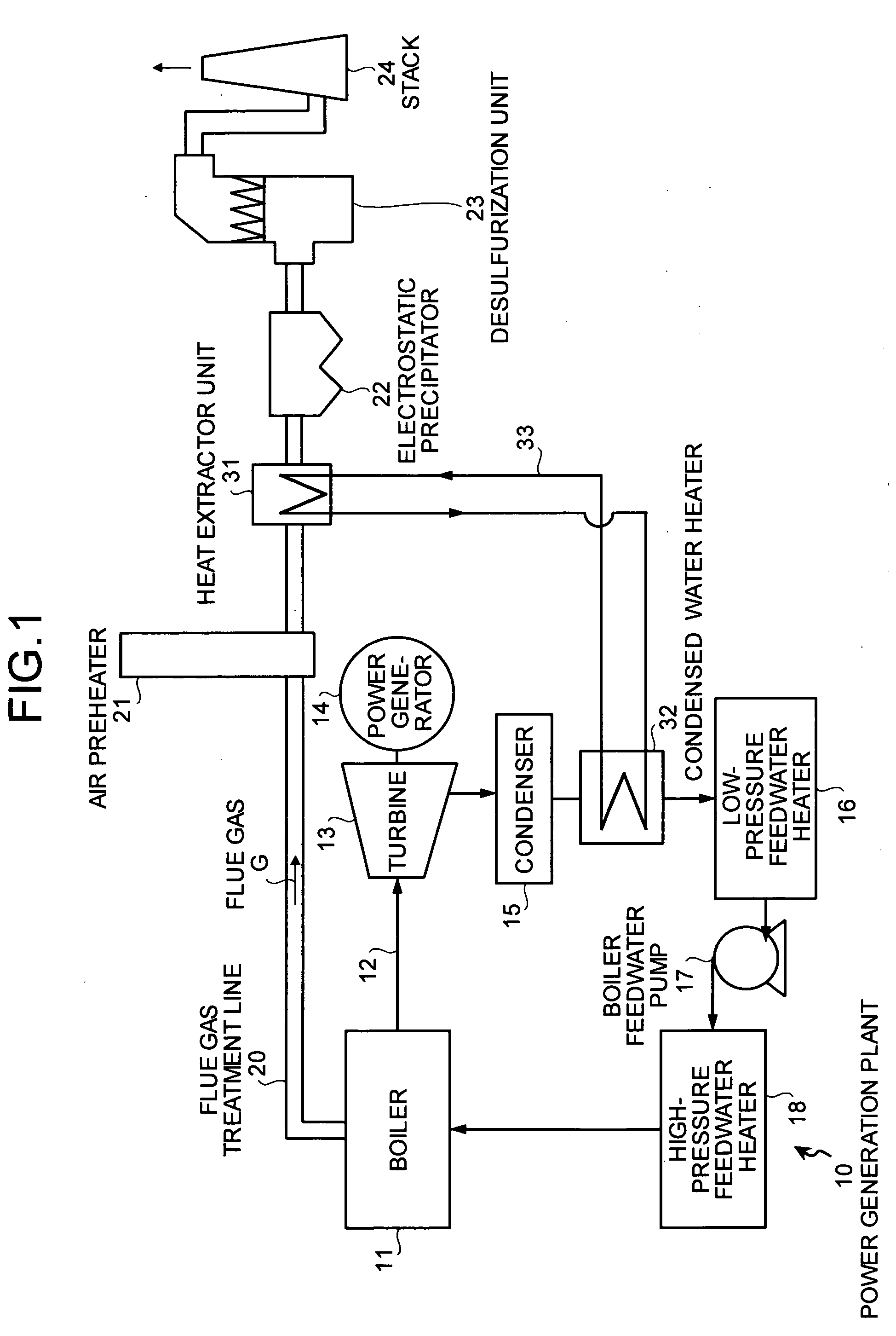

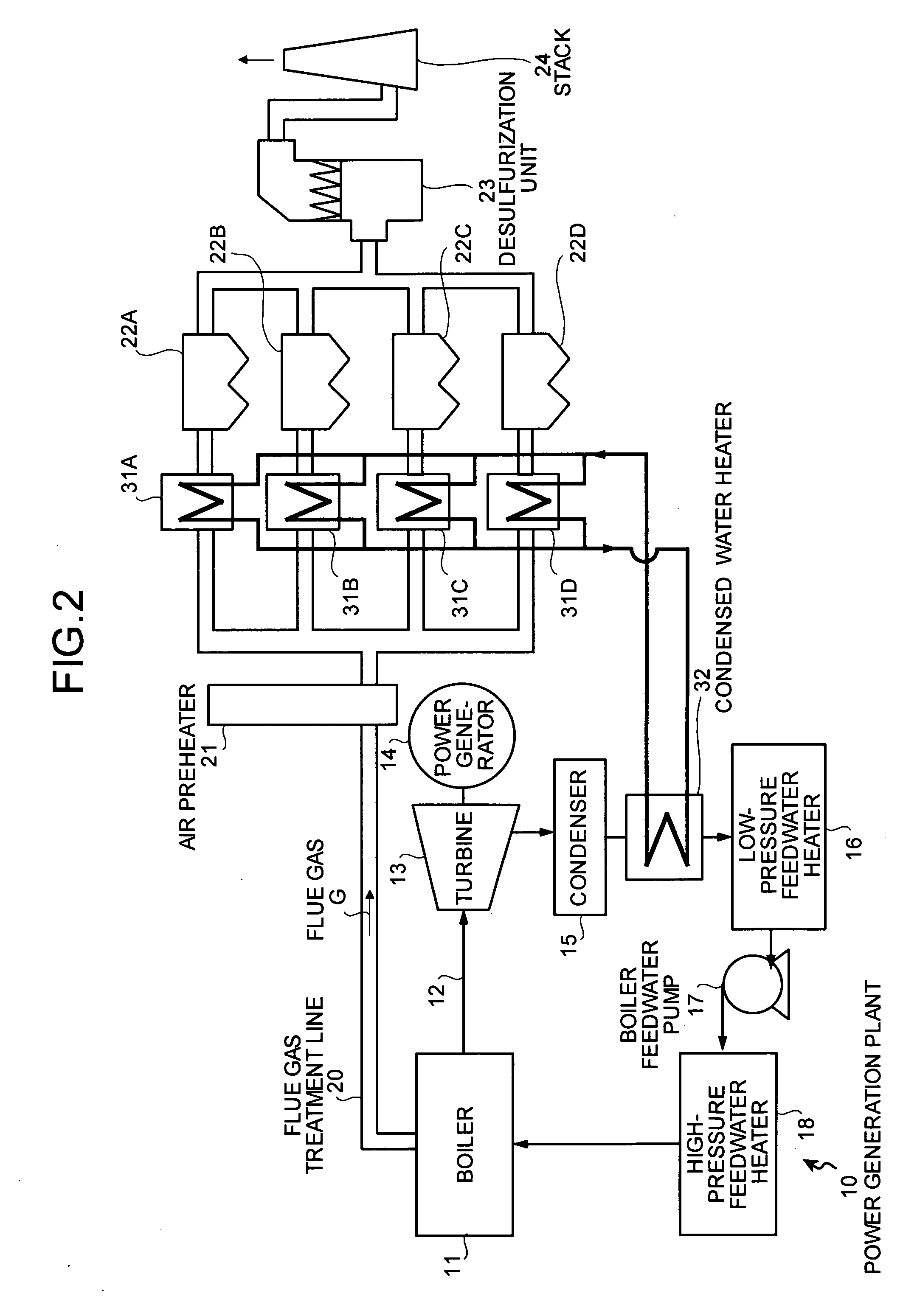

Heat recovery equipment

Heat recovery equipment recovers heat from flue gas. The heat recovery equipment includes a power generation plant that drives a steam turbine by superheated steam produced in a boiler, and an exhaust-gas treatment line that treats flue gas output from the boiler. The exhaust-gas treatment line includes a first air preheater, a heat extractor unit, and a dry electrostatic precipitator. The power generation plant includes a condensed water line. The condensed water line includes a condenser, a condensed water heater, and a low-pressure feedwater heater. The condensed water heater heats water condensed by the condenser with the heat recovered by the heat extractor unit.

Owner:MITSUBISHI POWER LTD

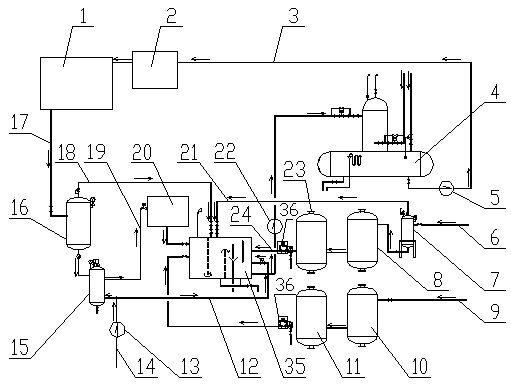

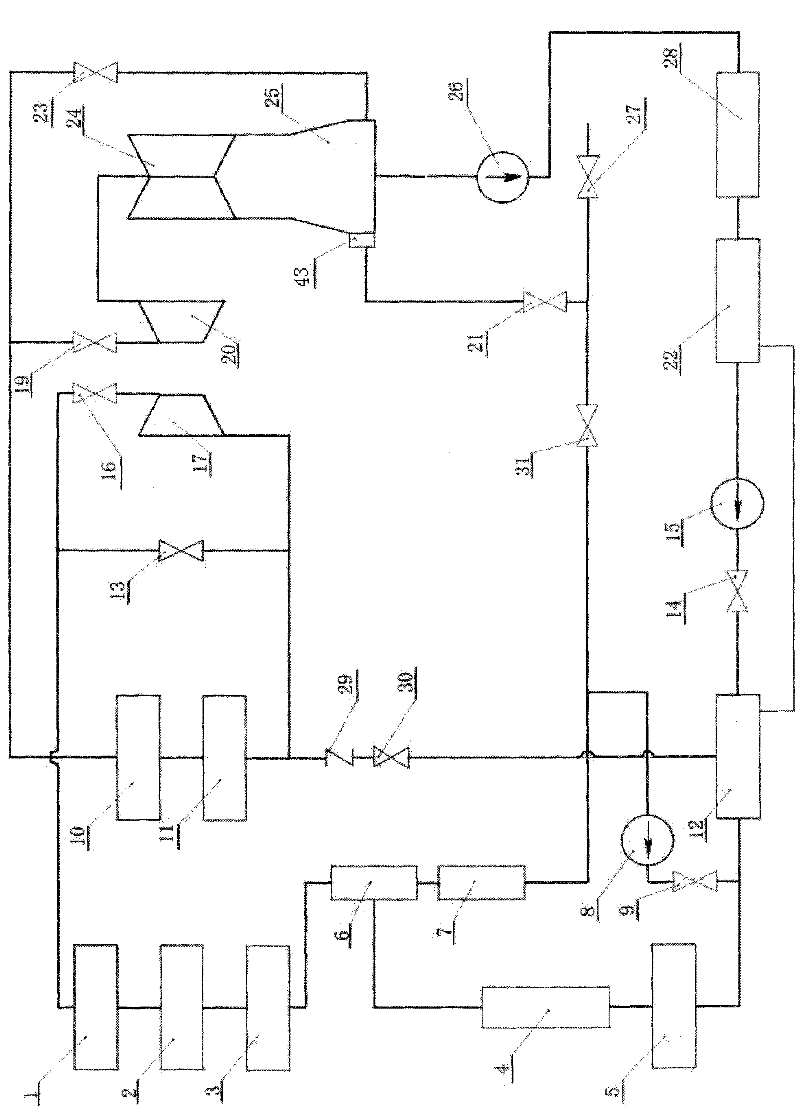

Combined heat and power generation full-condensation afterheat recovery technology

InactiveCN108317579AGuaranteed temperatureReduce dosageFeed water supplySteam useCogenerationTemperature difference

The invention provides a method for directly feeding primary network returned water in the steam condenser as condensed water and a method for reducing the water outlet temperature of the condensed water of a steam condenser step by step, increasing the water supply temperature of a primary network step by step and improving the power generation efficiency and the heat supply effect. The method comprises a thermal power plant steam extraction heat supply system, a returned water temperature adjusting system, a thermal power plant steam condenser cooling water system and a high-temperature-difference heat supply primary pipe network.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

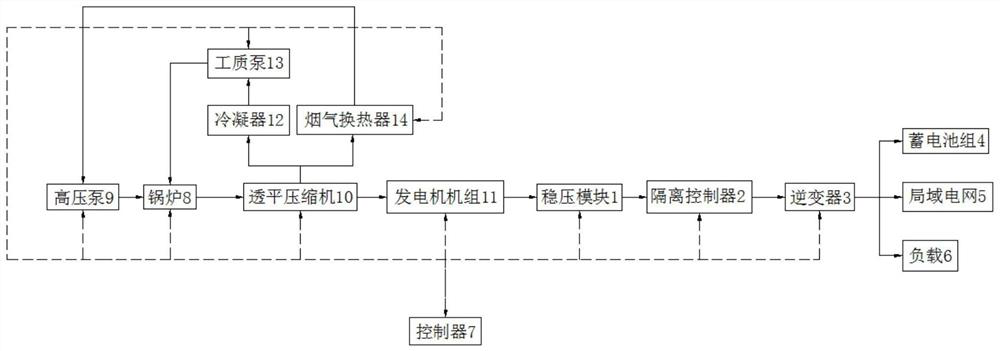

Organic Rankine cycle power generation system for oil field waste heat

PendingCN111911255ATake advantage ofImprove powerFeed water supplyPump controlOrganic Rankine cycleProcess engineering

The invention discloses an organic Rankine cycle power generation system for oil field waste heat. The organic Rankine cycle power generation system involves a turbine compressor, a power generator set, a voltage stabilizing module, an isolation controller and an inverter, wherein a boiler is used for receiving the oil field waste heat, and enabling an organic working medium to absorb heat from waste heat flow in the boiler to generate steam with certain pressure and temperature, a gas inlet of the turbine compressor is connected to a gas outlet of the boiler, and the generator set is used forreceiving high-pressure gas from the turbine compressor and pushing blades of the generator set to rotate, so that the generator set generates electric energy. According to the organic Rankine cyclepower generation system for the oil field waste heat, the controller intelligently controls the operation of each equipment, so that the oil field waste heat is utilized more sufficiently, and throughpressurization and acceleration of the steam, the electric quantity of electric energy generated by the steam to the generator set can be increased, and great economic benefits are generated.

Owner:WUHAN UNIV OF TECH

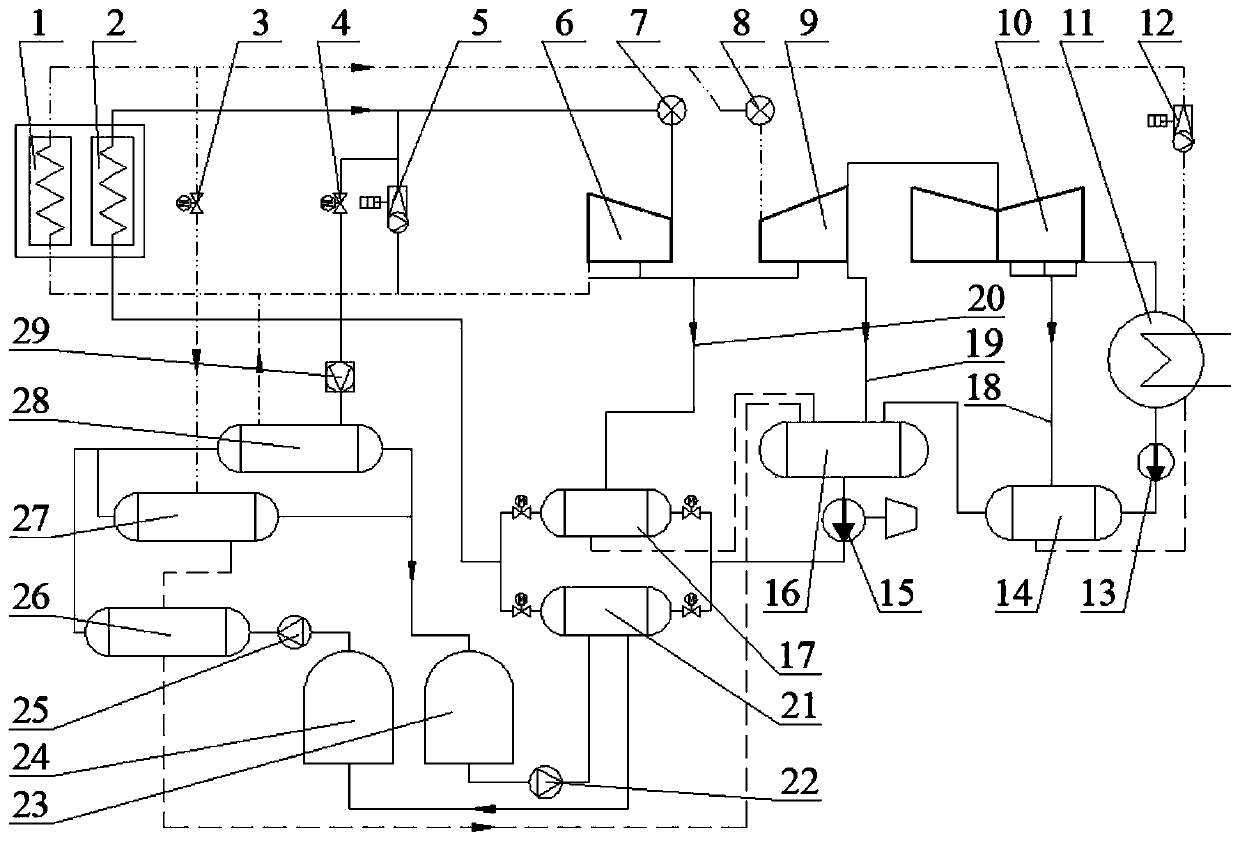

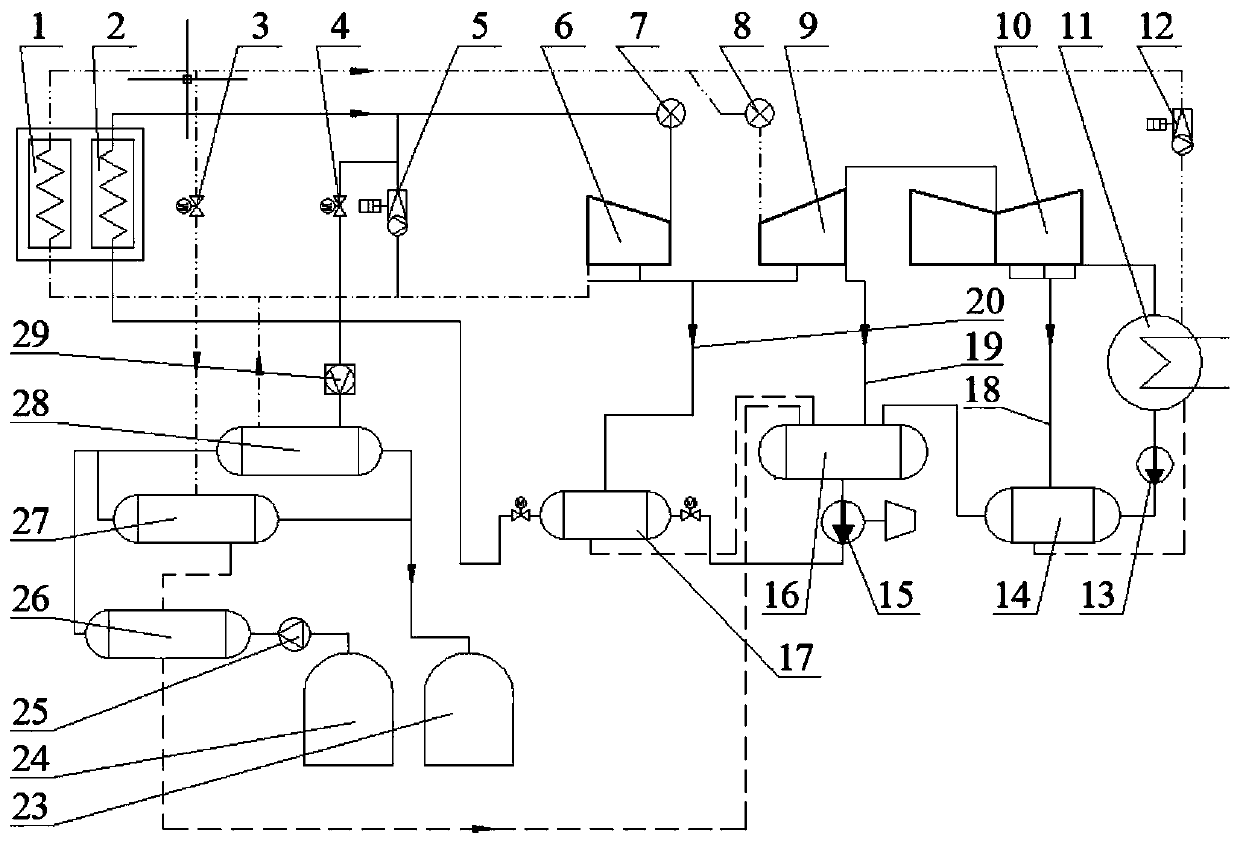

Deep peak shaving system of thermal power plant

PendingCN110006026AImprove operational efficiencyImprove economyLiquid degasificationHeat storage plantsSteam pressureSteam condensation

The invention discloses a deep peak shaving system of a thermal power plant. The deep peak shaving system comprises a superheater, a reheater, a high-pressure cylinder, a reheating steam electric regulating valve, a main steam electric regulating valve, a medium-pressure cylinder, a low-pressure cylinder, a condenser, a condensation water pump, a low-pressure heating water feeding heat exchanger,a water feeding pump set, a deaerator, a high-pressure heating water feeding heat exchanger, a steam turbine low-pressure steam extraction system, four-stage extraction, a steam turbine high-pressuresteam extraction system, a high-temperature molten salt water feeding heat exchanger, a high-temperature molten salt pump, a high-temperature molten salt storage tank, a low-temperature molten salt storage tank, a low-temperature molten salt pump, a molten salt preheater, a steam condensation type heat exchanger, a steam non-condensation type heat exchanger, a steam pressure reduction device and the like. According to the system, the molten salt heat storage technology is utilized, redundant steam heat is stored during load reducing peak shaving of a unit, in the process of load increasing peak shaving of the unit, high-temperature molten salt is used for heating high-pressure fed water to reduce steam extraction of a steam turbine, the output of the steam turbine is increased, the heat efficiency of the unit is improved, and the flexible and deep peak shaving of the thermal power plant is realized.

Owner:BEIJING UNIV OF TECH

Method for recycling flue gas waste heat of thermal power plant boiler

InactiveCN102454980AImprove recycling efficiencyImprove work efficiencyCombustion processFeed water supplyAir preheaterEngineering

The invention discloses a method for recycling flue gas waste heat of a thermal power plant boiler. A first heat exchanger is connected in parallel to an air pre-heater of a boiler exit flue, the heat exchange medium input / output end of the first heat exchanger is connected with a high-pressure condensed water heater through a flow control valve, and the high-pressure condensed water is heated, so that steam extraction of high-quality steam of a steam turbine is reduced. By the method, the recycling efficiency of the exhaust waste heat of the boiler is effectively improved, the work efficiency of the boiler and the steam turbine is improved, the energy consumption of power generation is reduced, and good economic benefits and social benefits are obtained.

Owner:上海成信设施科技有限公司 +1

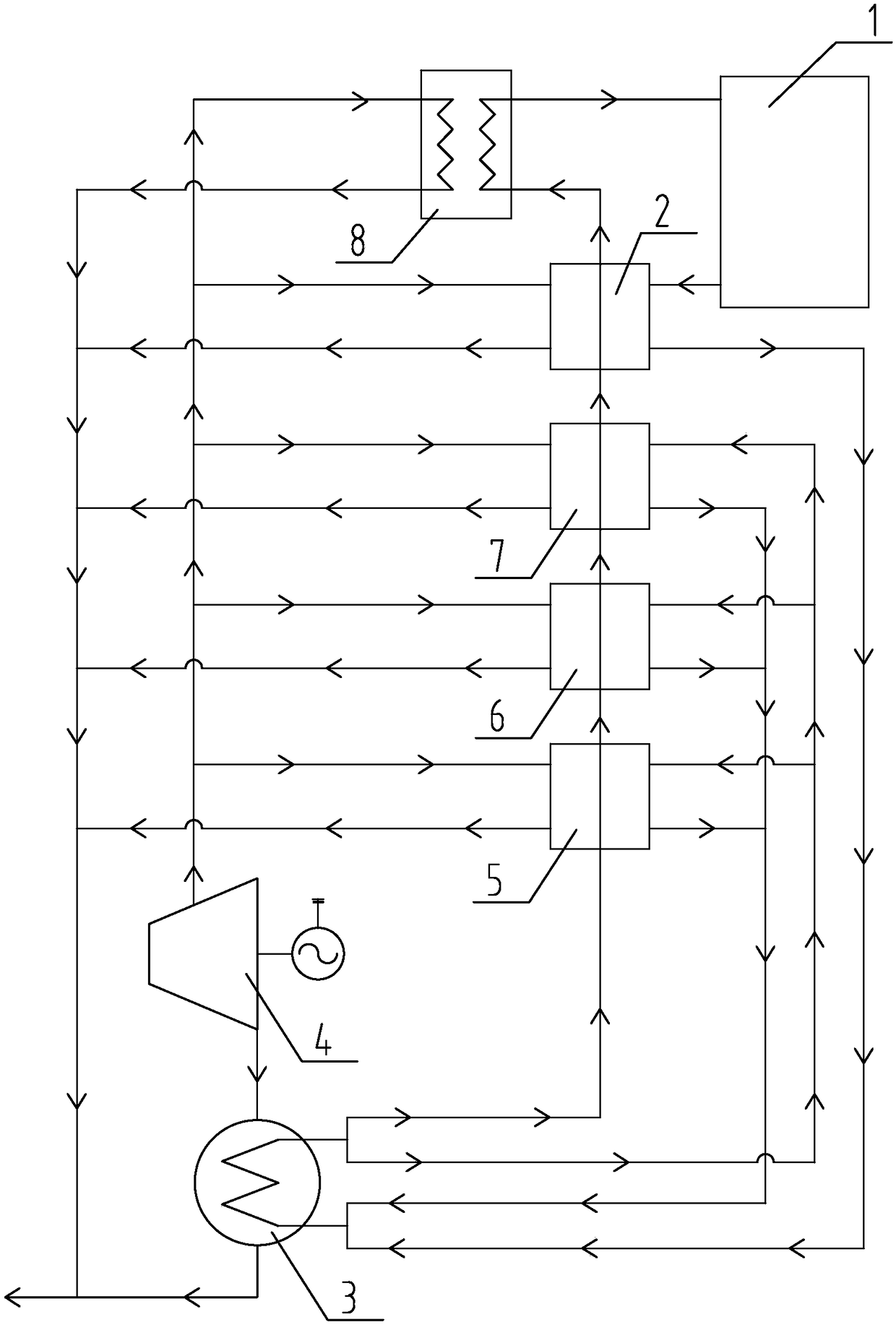

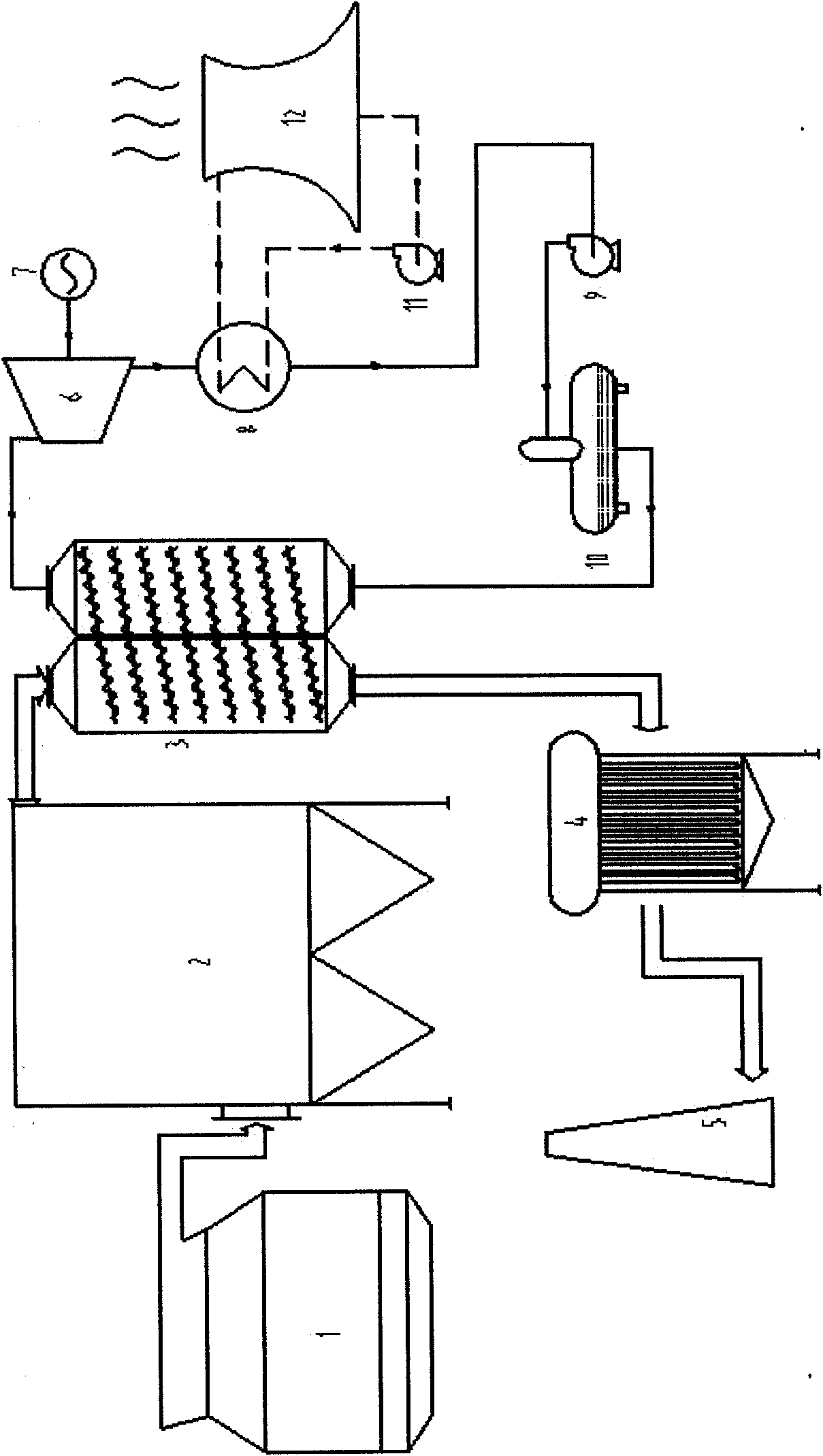

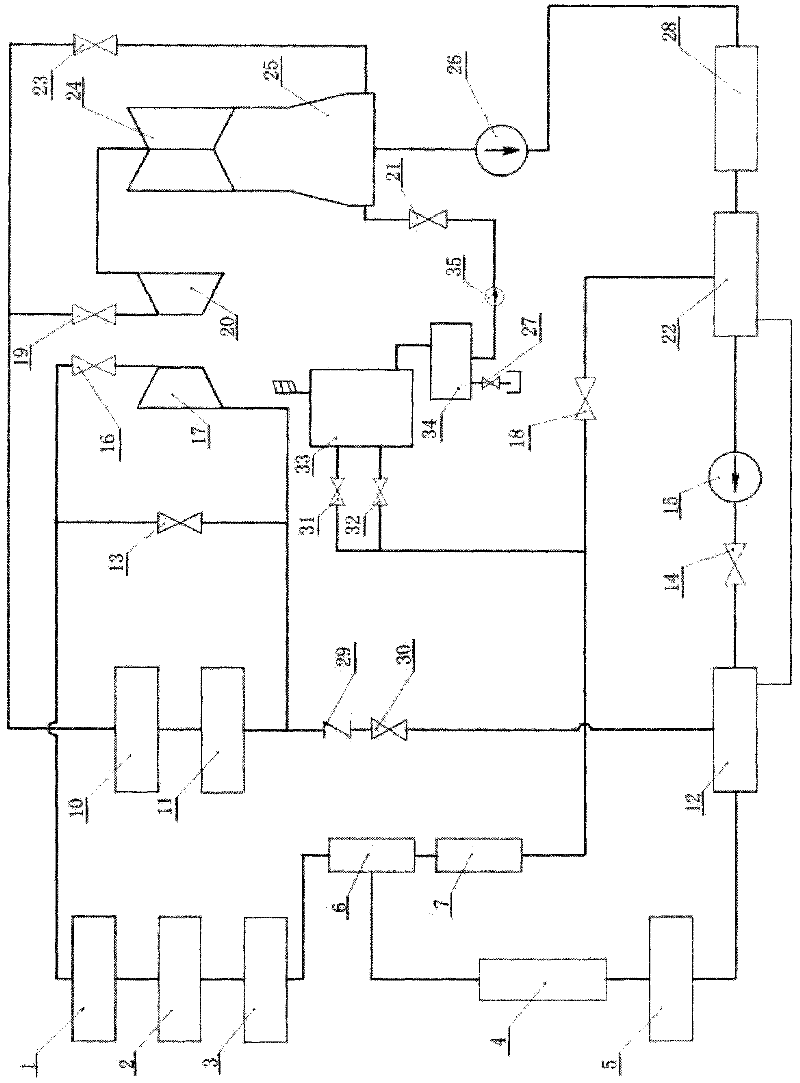

Integrated waste heat generating and heating system and process flow thereof

InactiveCN101852555AAvoid paralysisLow running costValve arrangementsDispersed particle filtrationFiberHeat conducting

The invention discloses a waste heat generating equipment system and a waste heat generating process. The system comprises a ceramic fiber dust collector (2), a rapid heat conducting heat-pipe waste heat boiler (3), a rapid heat conducting heating device (4), a steam replenishing and condensing steam turbine (6), a condenser (8), a condensing water pump (9) and a vacuum deaerator (10), wherein ceramic fiber dust collector (2) is arranged at a waste heat outlet end; the rapid heat conducting heat-pipe waste heat boiler (3) bears a steam preparing device for power generation; the rapid heat conducting heating device (4) is arranged on the smoke inlet of a boiler; medium and high-pressure main steam generated by a rapid heat conducting heat-pipe waste heat boiler is mixed and enters the steam replenishing and condensing steam turbine (6) through a pipeline; low-pressure steam enters the steam replenishing and condensing steam turbine (6) through a steam replenishing pipeline; waste steam on the tail part of the steam turbine enters the condenser (8); condensed water enters the vacuum deaerator (10) through the condensing water pump (9) and a pipeline; water from which oxygen is removed in the deaerator enters the heat-pipe waste heat boiler (3) through a water supply pump of the boiler; and low-temperature smoke discharged from the back end of the boiler is delivered into the rapid heat conducting heating device (4). The waste heat utilization ratio of the integrated system is enhanced by over 60 percent on average, so unit energy consumption of an enterprise is greatly lowered, the problem of unstable running of the system due to dust blocking of the boiler and wearing of a heat exchange tube in a medium and low temperature waste heat generating system is solved and comprehensive generating efficiency is enhanced by over 30 percent.

Owner:童裳慧

Heat supply device capable of recovering aqueous vapour in fuel gas, fuel oil boiler flue gas

InactiveCN1414288AImprove efficiencyEmission reductionHeat pumpsFeed water supplyFlue gasAbsorption heat pump

The present invention discloses heat supply device for recovering latent heat of aqueous vapour in flue gas of fuel oil and fuel gas boiler fume, it includes boiler, condensation heat exchanger, heatsupply pipe and absorption heat pump composed of generator, solution exchanger, absorber, evaporator, condenser and connecting pipe; a part of the said condensation exchanger is set up in gas flue ofthe said boiler and its extended part is set up in the evaporator of absorption heat pump, the said heat supply pipe passes through the condense and the absorber of the said absorption heat pump.

Owner:TSINGHUA TONGFANG CO LTD

Boiler water replenishing system capable of collecting waste heat and condensed water

ActiveCN102607014AHydration does not affectReduce consumptionFeed water supplyExpansion tankBoiler blowdown

The invention discloses a boiler water replenishing system capable of collecting waste heat and condensed water. A boiler blowdown pipe of a boiler is connected with a blowdown expansion tank, a steam outlet of the blowdown expansion tank is connected into a hot water tank through a blowdown flash steam pipe, a blowdown water pipe of the blowdown expansion tank is connected into a continuous-discharge heat exchanger which is further connected with a softened water feeding pipe, the softened water feeding pipe is connected with a water softening station through a water supply pump, the softened water feeding pipe for the continuous-discharge heat exchanger is connected with a boiler secondary energy saver prior to being connected into the hot water tank, and the hot water tank is connected with a hot water outlet pipe which is sequentially connected with a circulating pump, a heat deaerator and a boiler water feeding pump prior to being connected into a boiler water inlet. The boiler water replenishing system has the advantages that centralized use of the waste heat and the condensed water is achieved, steam consumption of the deaerator is reduced, waste heat absorption effect is enhanced, connection of the deaerator is simplified, pollution of the heat and the condensed water to the environment is reduced, and water replenishing for the boiler is unaffected when heat exchange equipment fails.

Owner:CHINA TOBACCO HENAN IND

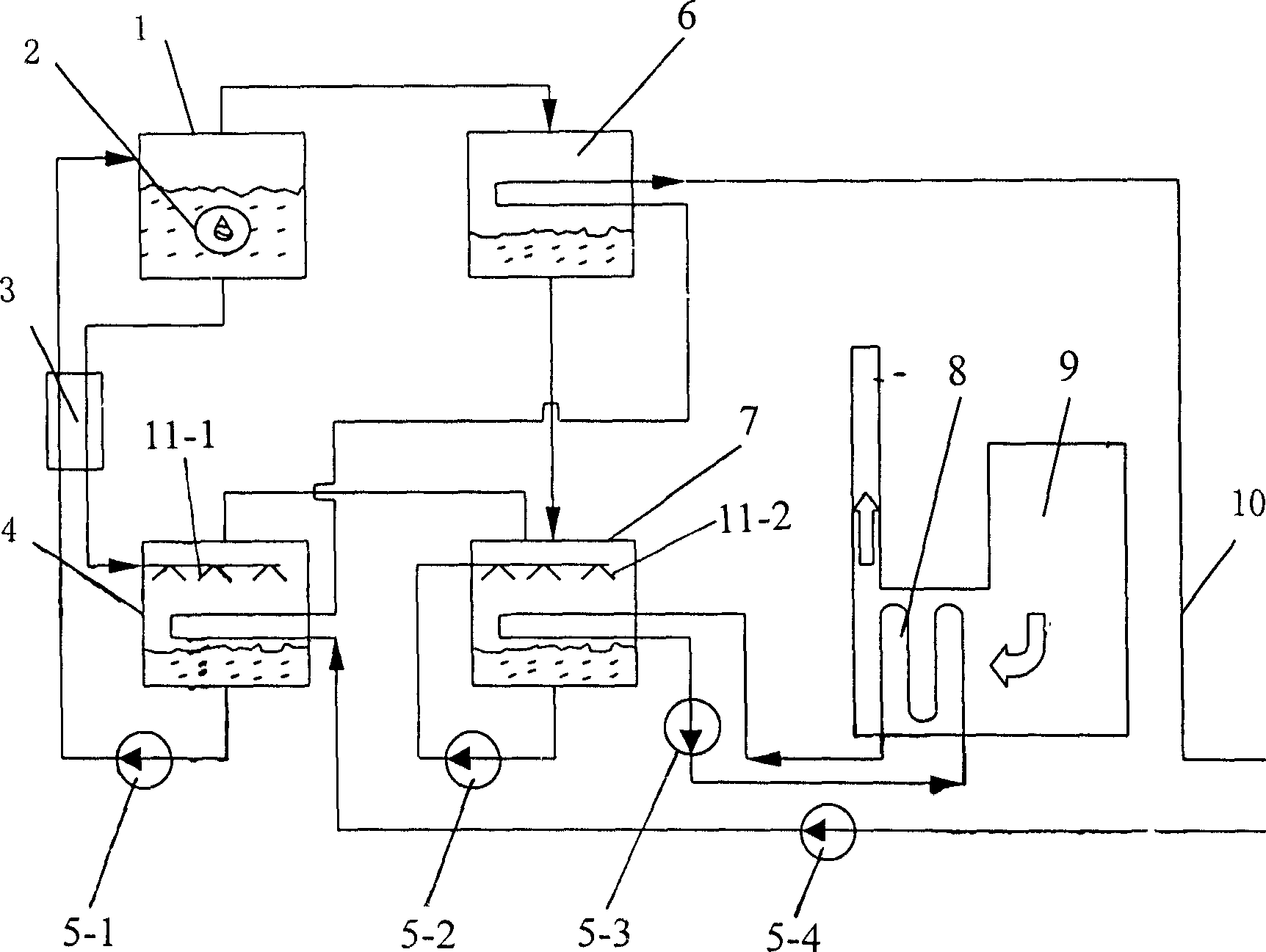

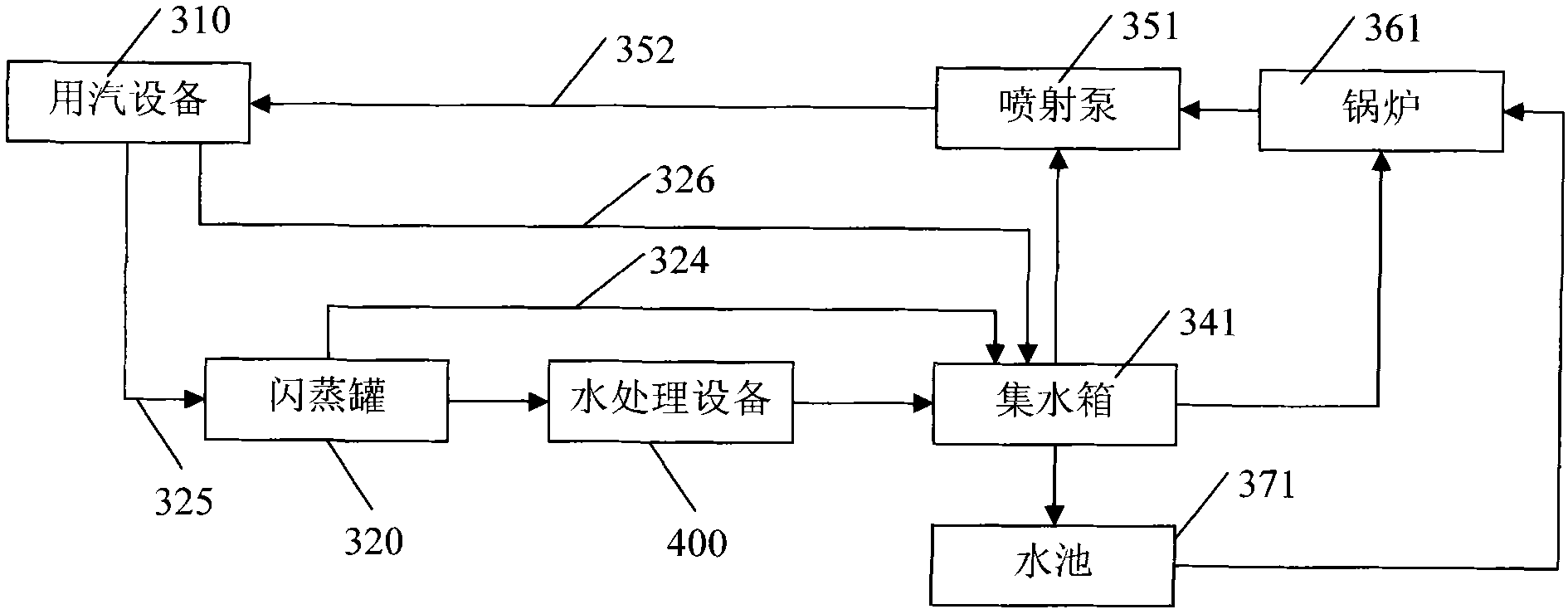

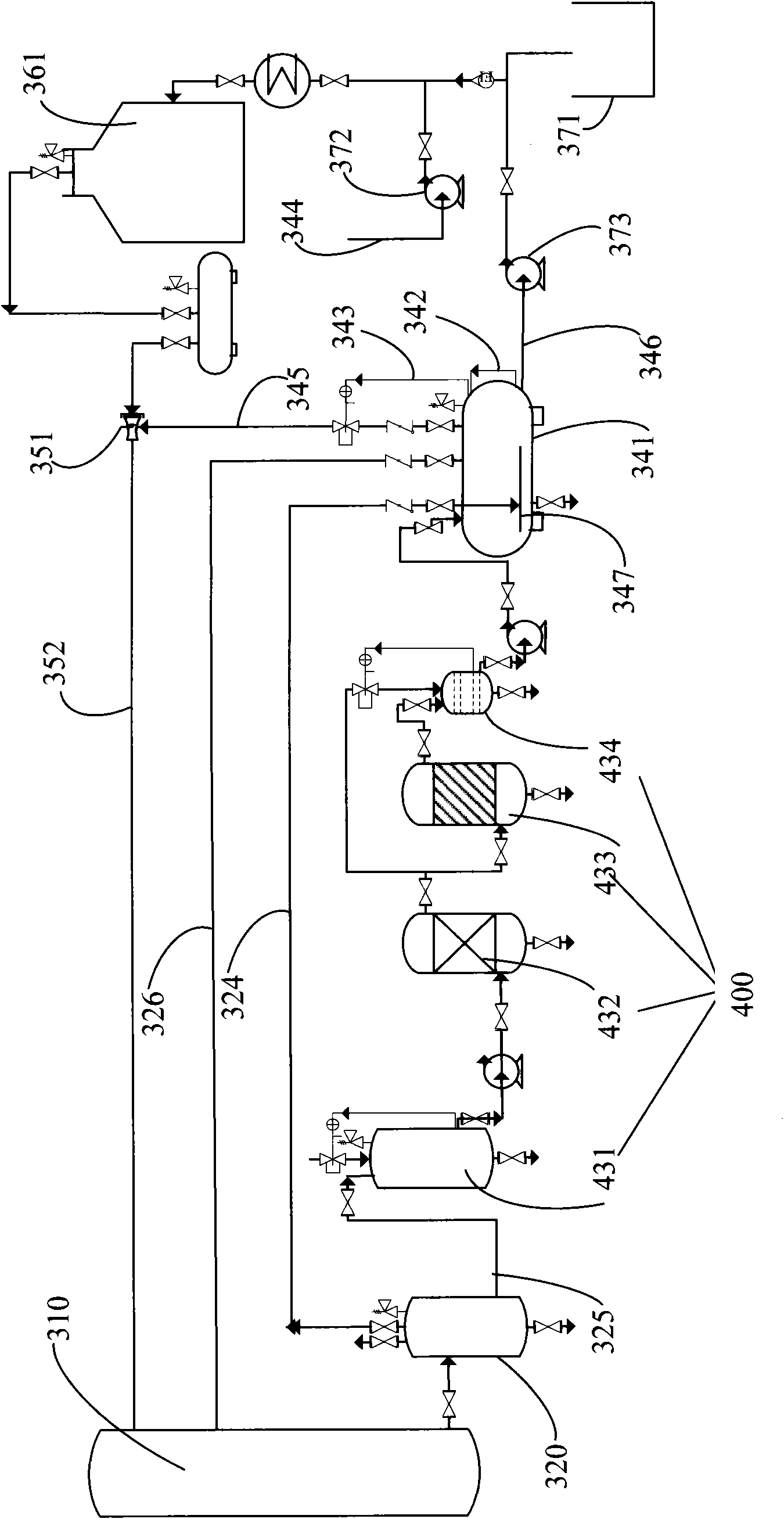

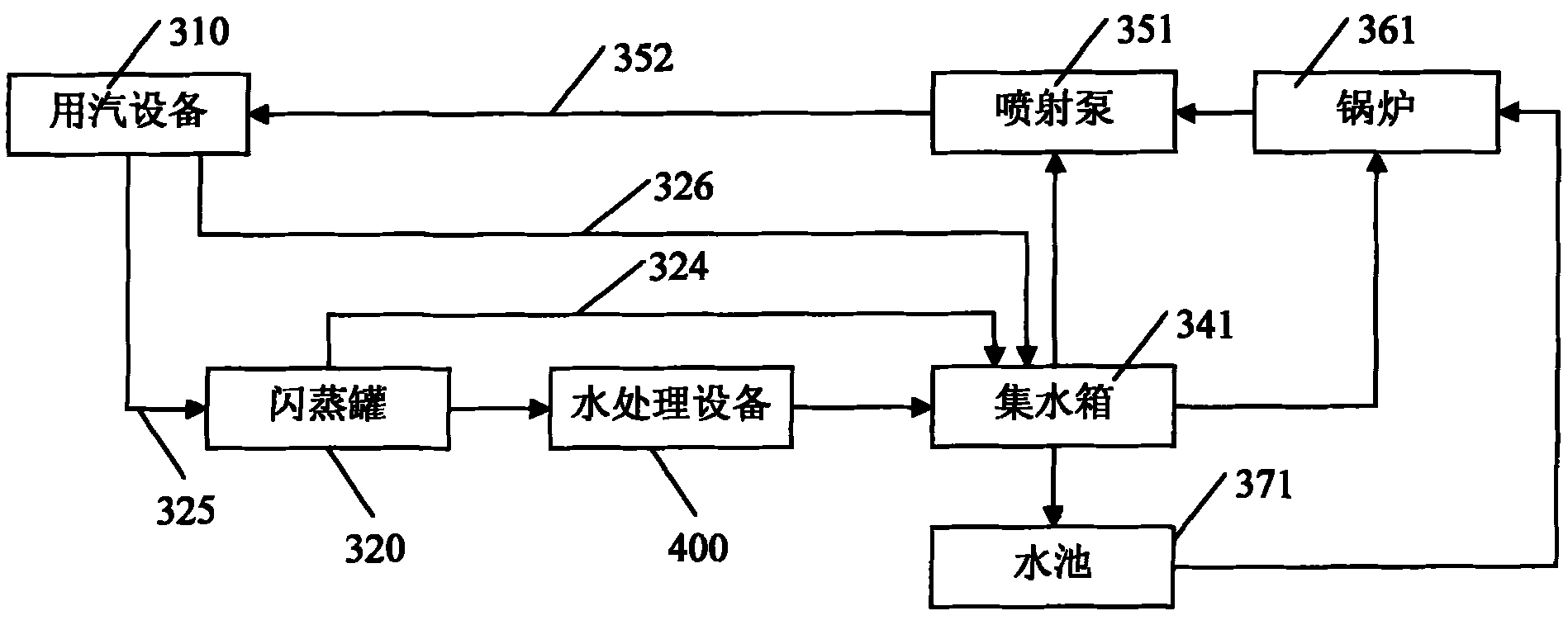

Comprehensive recovery method and system of condensation water and dead steam

InactiveCN101793390AAvoid damageAvoid heat lossFeed water supplyMultistage water/sewage treatmentRecovery methodWater saving

The invention discloses a comprehensive recovery method and a system of condensation water and dead steam. The method comprises the following steps: (1) transmitting the condensation water discharged by steam-consuming equipment to a flash drum to be performed with flash evaporation to obtain flash steam, and transmitting the flash steam and the dead steam discharged by the steam-consuming equipment to be below the liquid level of the condensation water in a water collecting tank; (2) transmitting the residual condensation water after flash evaporation to water processing equipment to be treated, and discharging to the water collecting tank to feed water for a boiler; (3) transmitting the condensation water in the water collecting tank to the boiler; and (4) when steam pressure in the water collecting tank exceeds the warning value, transmitting the steam in the water collecting tank to the steam-consuming equipment through a main boiler steam pipe by an injection pump. The temperature of the condensation water is lowered after flash evaporation, and then the condensation water is processed by the water processing equipment to prevent high temperature from damaging the water processing equipment; and meanwhile, the flash steam is directly recovered to the water collecting tank so as to take away most parts of heat of the condensation water, thus avoiding heat loss to the utmost degree, and realizing energy and water saving.

Owner:广东省特种设备检测院顺德分院

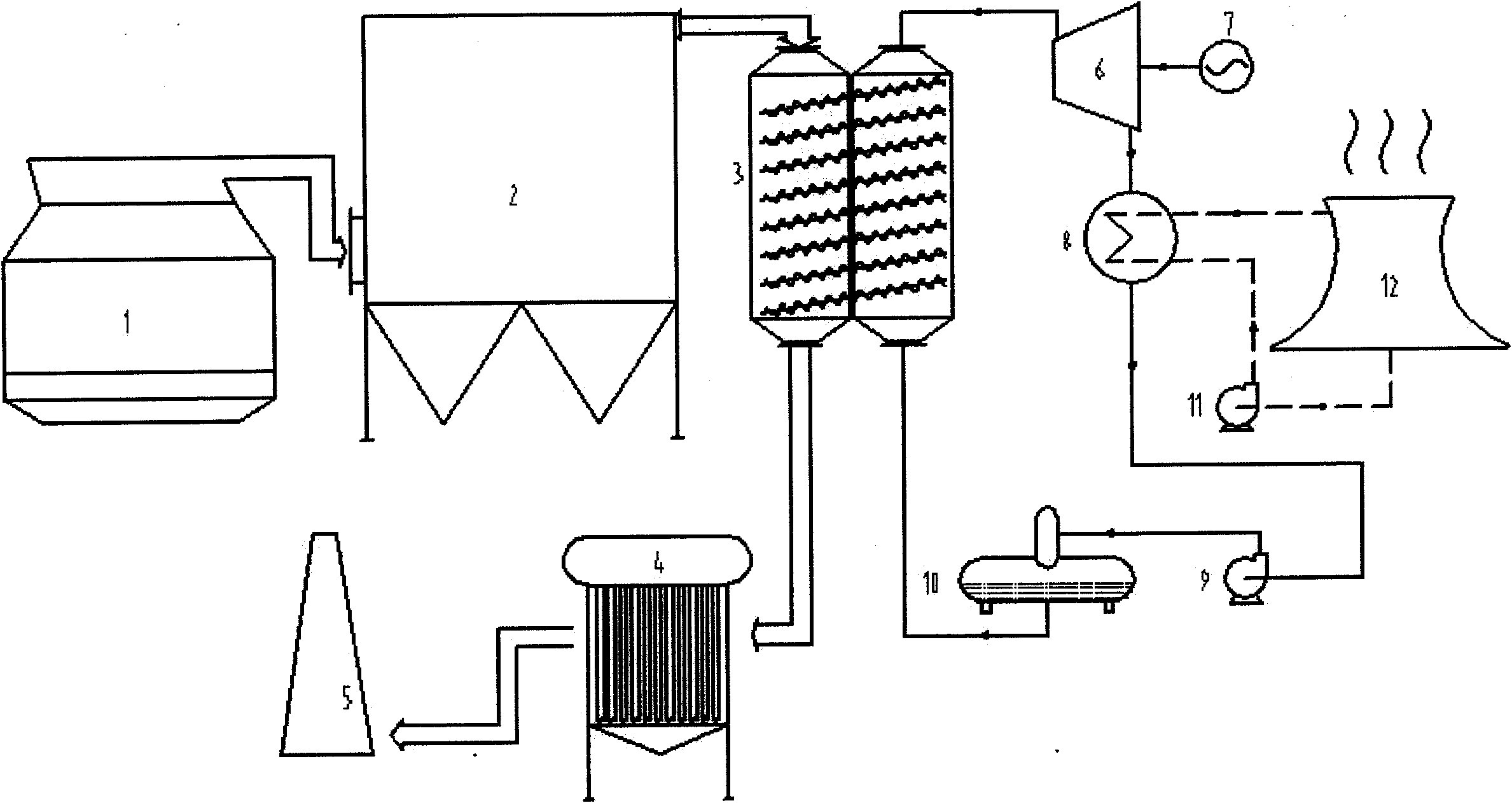

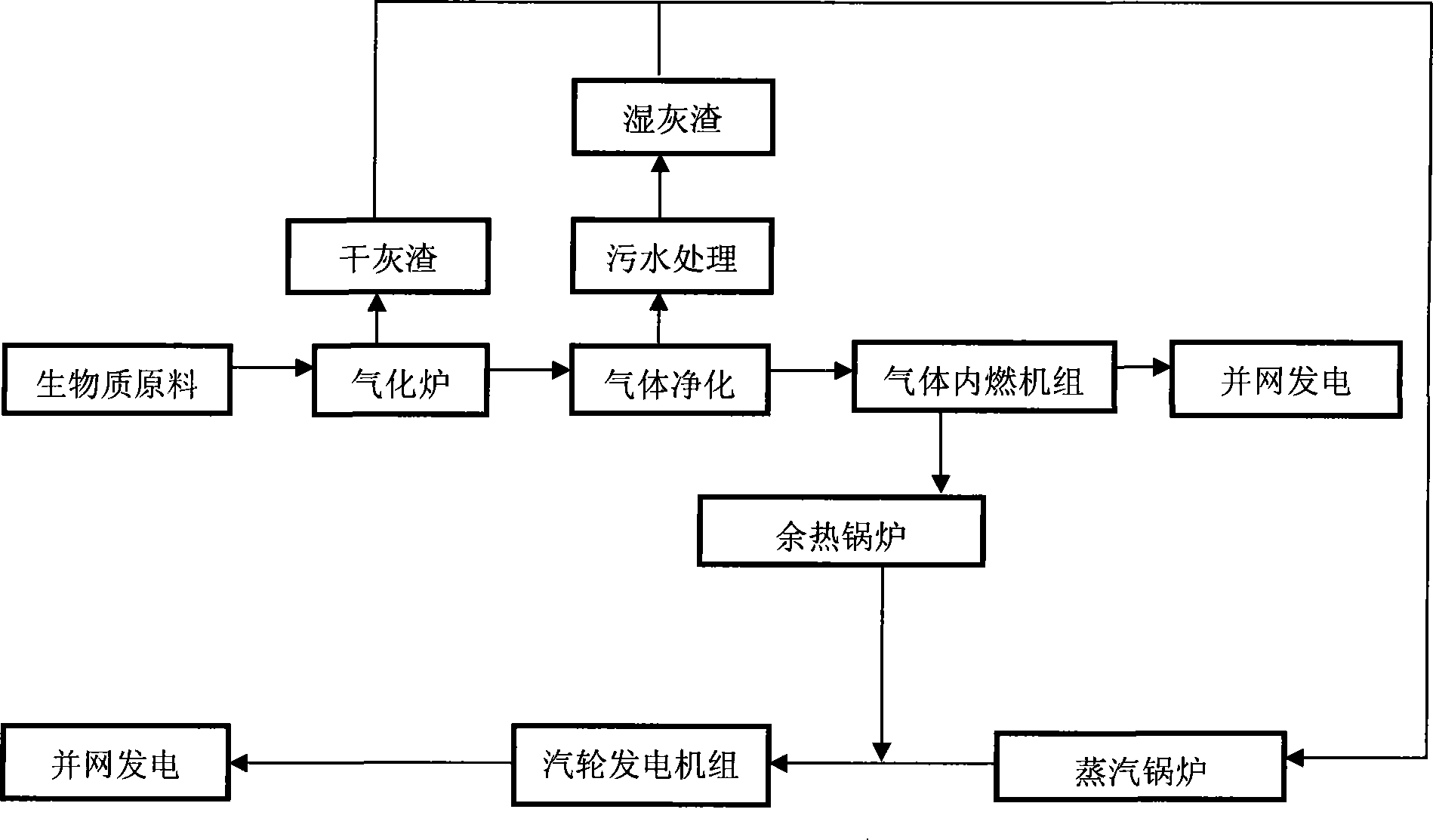

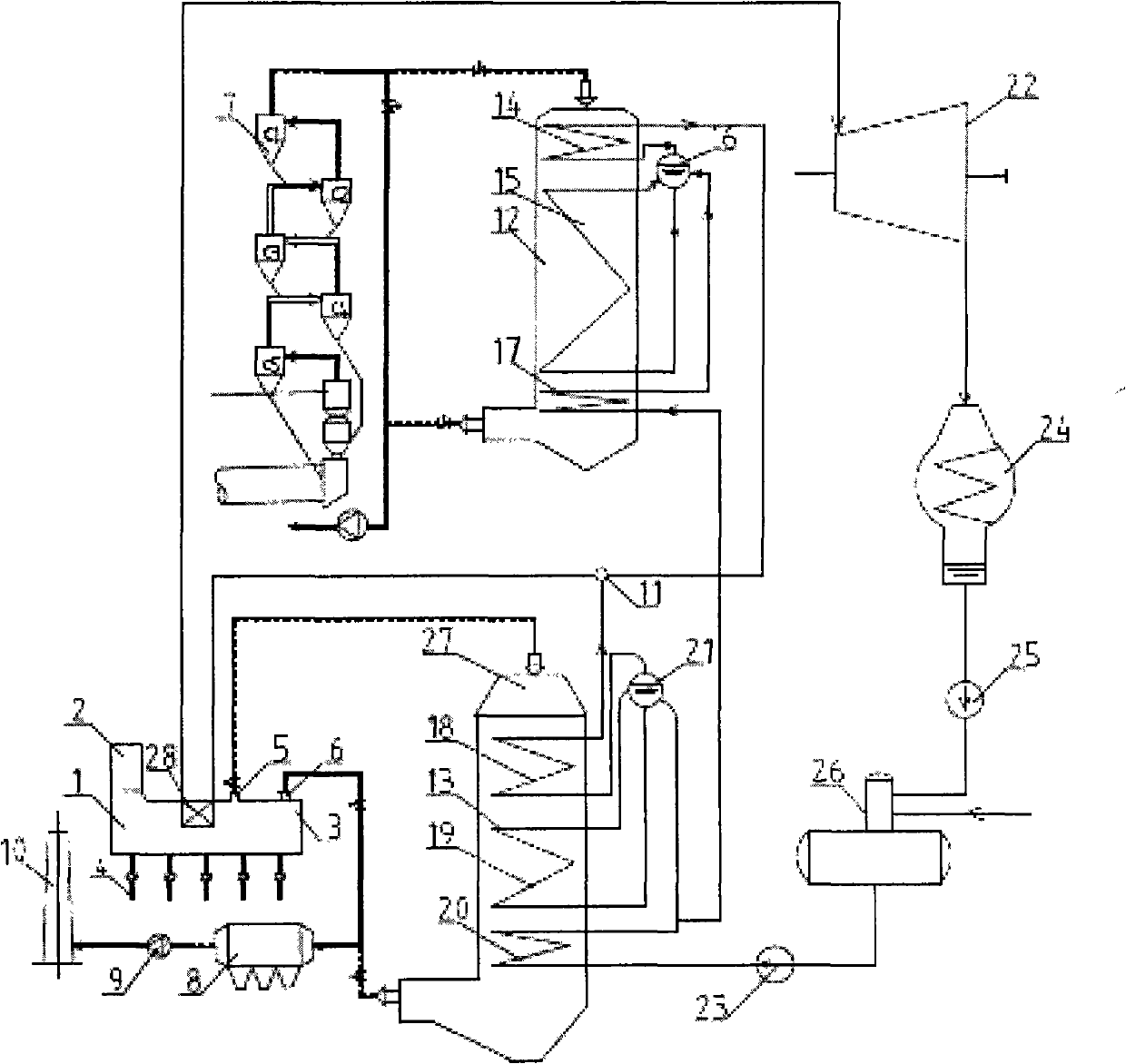

Biomass energy circulation electrification technique as well as generating system thereof

InactiveCN101251045ATake advantage ofImprove power generation efficiencyInternal combustion piston enginesFeed water supplyThermal energyInternal combustion engine

The invention provides a biomass energy IGCC technology which is characterized in that the technology comprises the following steps that: (1) the biomass raw material is gasified to be converted into the combustible gas which is dedusted and decoked as well as purified and is sent to a gas internal-combustion engine to generate electricity; (2) the biomass raw material or the clinker generated in the gasification and power generation process in the step 1 or the mixture of the two is sent to a steam boiler to be burnt in order to generate the superheated steam; the exhaust heat of the gas internal-combustion engine of the step 1 is inlet to an exhaust-heat boiler to generate the superheated steam; (3) the superheated steam generated by the steam boiler and the exhaust-heat boiler of the step 2 is sent to a turbonator set. The biomass energy IGCC technology takes full advantage of the heat energy and the product generated by each processing step in the biomass energy gasification and power generation process and generates electricity circularly, thereby greatly raising the power generation efficiency, taking full advantage of waste materials and lowering the running cost. The invention also discloses a power generation system for realizing the biomass energy IGCC technology.

Owner:黄家笙 +1

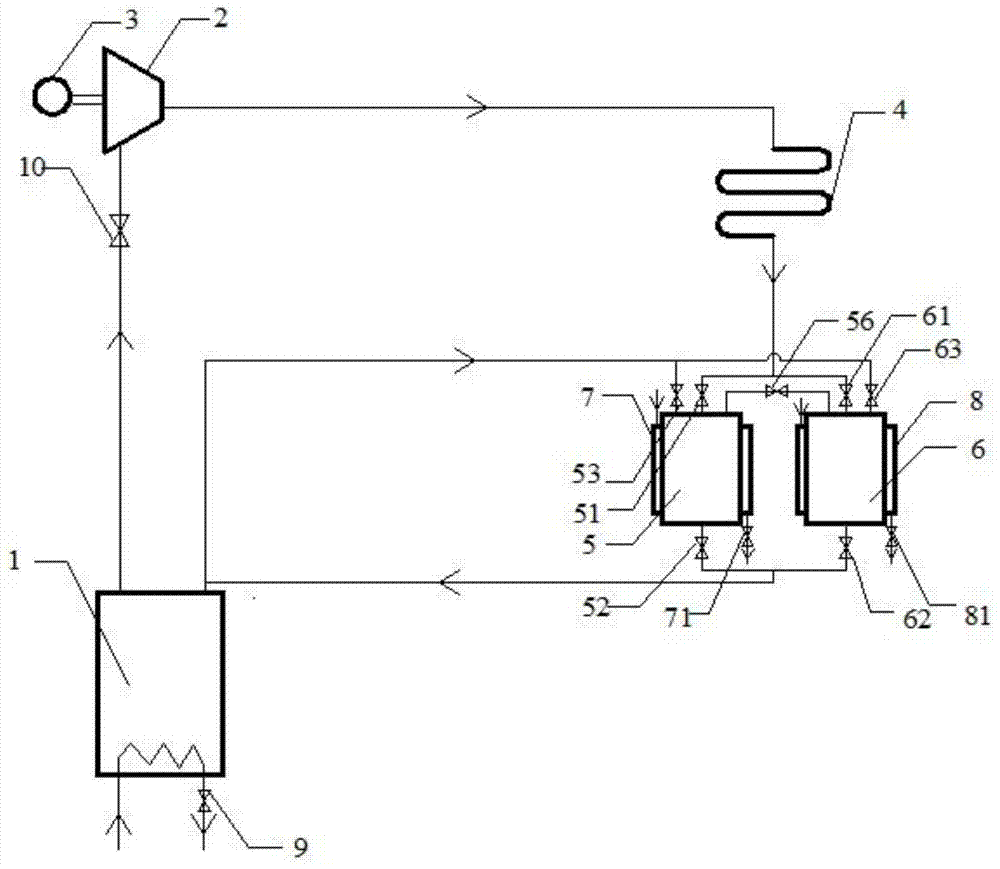

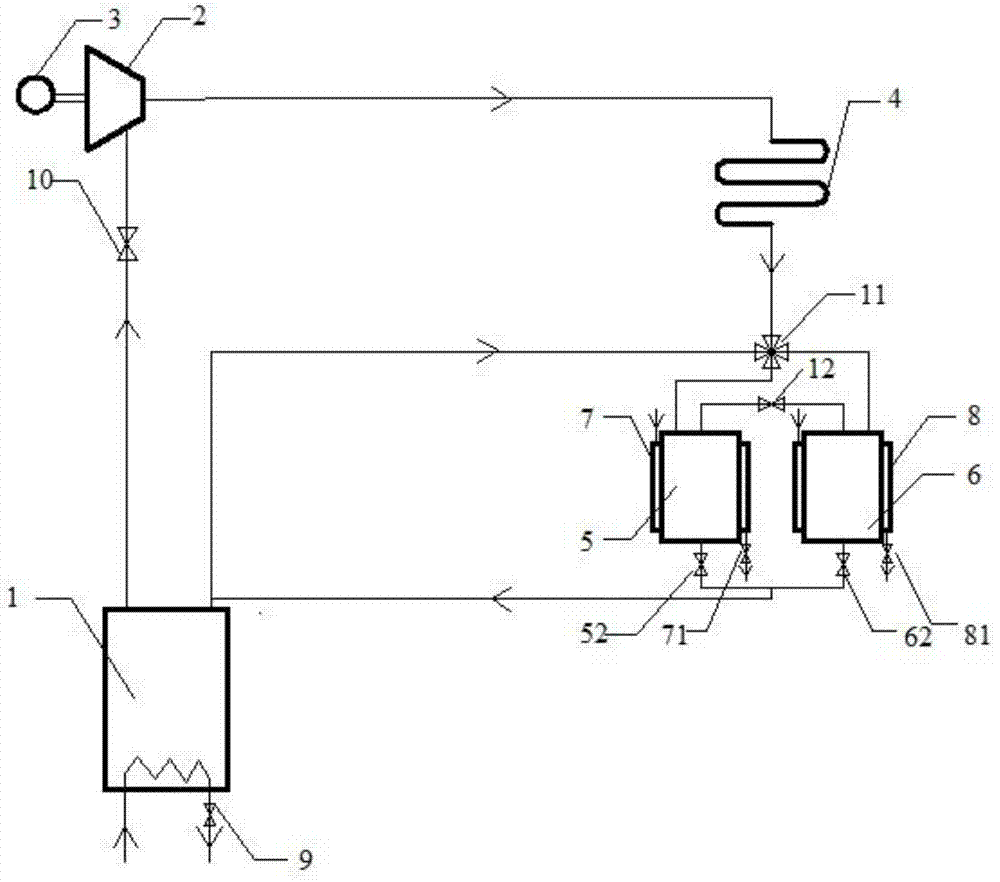

Non-pump type organic Rankine cycle method and device for power generation

InactiveCN104121046AReduce heat loadFew moving partsFeed water supplySteam engine plantsOrganic Rankine cycleEngineering

The invention discloses a non-pump type organic Rankine cycle method and device for power generation. High-temperature high-pressure working medium steam which is generated by a boiler is used for pressurizing liquid working media and conveying the liquid working media, then liquid working media to be conveyed in a next cycle are pre-pressurized, and energy of the high-temperature high-pressure working medium steam is sufficiently used for improving power generation efficiency of a system. The device comprises the boiler, an expansion machine, a generator, a condenser and a liquid storing device. The liquid storing device comprises two or more liquid storing tanks which are connected in parallel and matched. Each liquid storing tank is respectively communicated with the boiler, the condenser and the other matched liquid storing tank through control valves. The boiler is sequentially connected with the expansion machine, the generator, the condenser and the liquid storing device in series to form a loop, and the steam in the expansion machine expands and does work to drive the generator to generate power. According to the device, non-pump cycle of the system is achieved, the number of moving parts is reduced, and moving performance is more stable and reliable. Energy using of the system is more economical and reasonable, thermal loads of cooling water are reduced, and net power generation efficiency is greatly improved.

Owner:ZHEJIANG UNIV

Pump-free direct current furnace starting system capable of recycling working medium and heat comprehensively

The invention relates to a pump-free direct current furnace starting system capable of recycling a working medium and heat comprehensively, and provides a direct current furnace starting system which is used for a supercritical direct current furnace without a starting furnace water circulation pump at a power station and can recycle the working medium and heat comprehensively. According to the invention, during the starting period of the direct current furnace, three high-pressure heaters at the side of a turbine are utilized as a water heat exchanger, heat is emitted in echelon by the starting of the drainage with high enthalpy, pressure is reduced, thus the enthalpy is reduced to be suitable for the safe recovery by a deaerator; double control logic of the high-pressure heater by a machine set DCS (data conversion system) with special design ensures each high-pressure heater to complete the starting whole process of the direct current furnace and a heat regenerative system working pattern safely and economically under two different working patterns; the working medium and heat can be recycled comprehensively by each starting working condition and starting whole process, and therecycled effect is superior to the direct current furnace starting system with a starting furnace water circulation pump; and the maintaining expense of the infrastructural construction investment and operation can be reduced greatly by the starting furnace-free circulation pump and a subsystem thereof.

Owner:章礼道

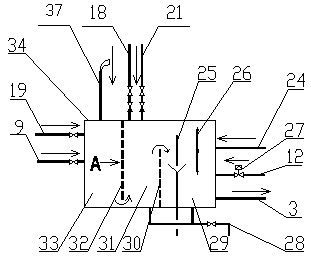

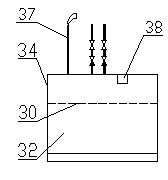

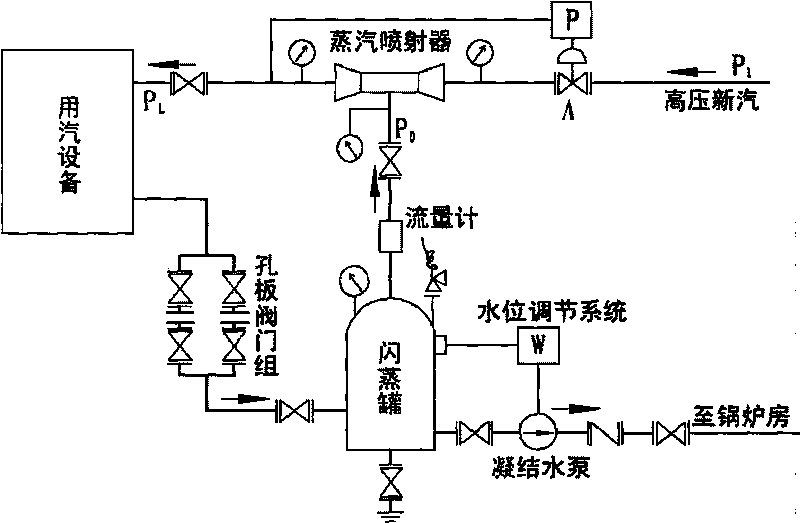

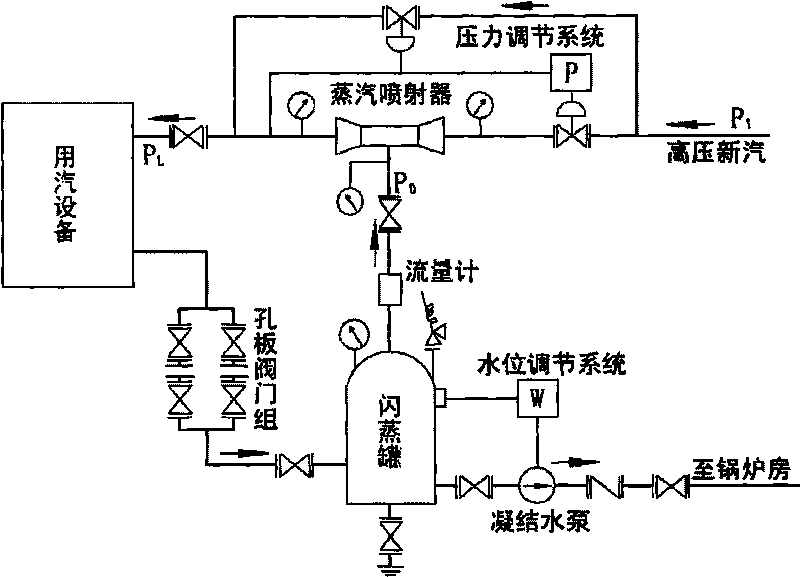

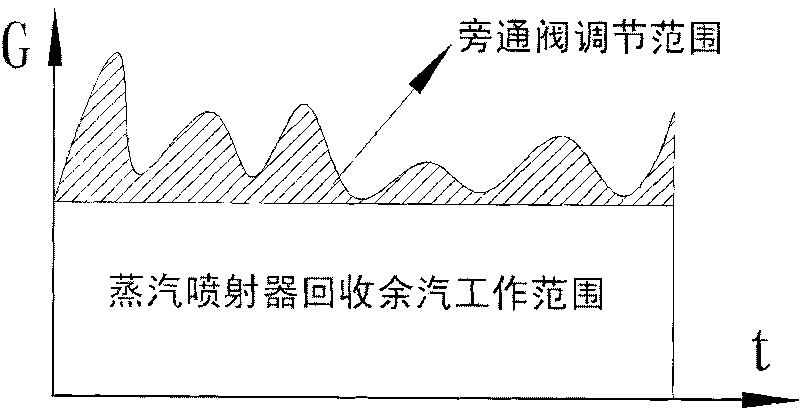

Steam jet waste steam recycling device and steam jet waste steam recycling system

InactiveCN101706038AMeet load demandSupply process steam optimizationFeed water supplyPipeline systemsSteam pressureEngineering

The invention discloses a steam jet waste steam recycling device. In the device, the steam inlet end of a steam ejector is connected with a bypass with an adjustment valve; and at least two steam ejectors are connected in parallel. Two or more steam jet waste steam recycling devices are connected in series to form a waste steam recycling system; the steam pressure parameter of one suite of device is higher than that of the other suite; high-pressure process steam generated by the device with the higher steam pressure parameter is divided into two paths for output, wherein one path is connected with each steam equipment needing to use the pressure, while the other path is connected with the steam inlet end of the other device with the lower steam pressure parameter to be used as the admitted steam of the other device. The device and the system disclosed by the invention can enable the steam jet waste steam recycling system to make the steam ejectors work stably under the condition of relatively larger load fluctuation, simultaneously achieve relatively better energy-saving effect, meet requirements on the process pressure PL and flow rate GL at any time and ensure the process steam equipment to rationally run with assured quality and quantity.

Owner:CHONGQING GIENT ENERGY SAVING TECH

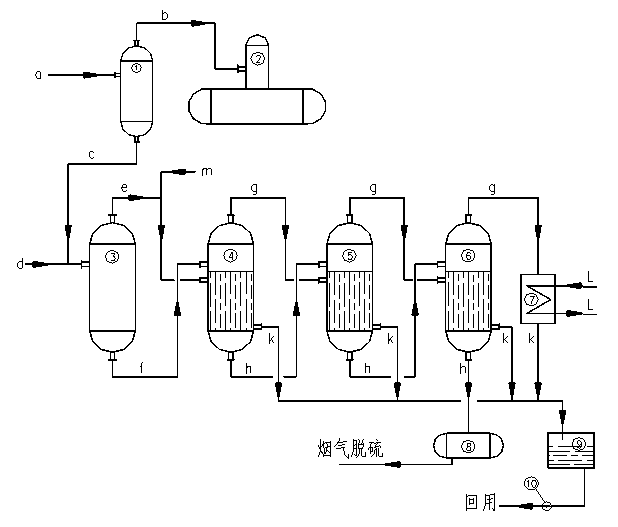

Comprehensive utilization method of thermal power plant boiler wastewater

The invention provides a comprehensive utilization method of thermal power plant boiler wastewater. The comprehensive utilization method comprises the following process steps: (1) continuous boiler wastewater goes into a continuous blowdown flash tank for reduced-pressure flashing; secondary steam generated after flashing is guided out of the upper part of the continuous blowdown flash tank and into a deaerator; (2) the hot wastewater at the bottom of the continuous blowdown flash tank is guided into a boiler periodic blowdown flash tank for further reduced-pressure flashing together with regular boiler wastewater; (3) the secondary steam generated by flashing from the periodic blowdown flash tank serves as a heat source and is guided into a low-temperature multiple-effect evaporator group, and bottom salt-containing wastewater also goes into the low-temperature multiple-effect evaporator group as the evaporated liquid; (4) the condensed water generated by the low-temperature multiple-effect evaporator group and the steam condensed water out of a cooler are collected to a condensed water tank by use of a condensation header and then fed into a boiler water supply system by use of a condensed water pump to be recycled; a thickened liquid generated by performing multiple-effect evaporation on the salt-containing wastewater is recycled into a thickened liquid recovery tank and then fed into a wet boiler flue gas desulphurization system used as a desulfurizing agent for desulphurization.

Owner:CHINA CEC ENG

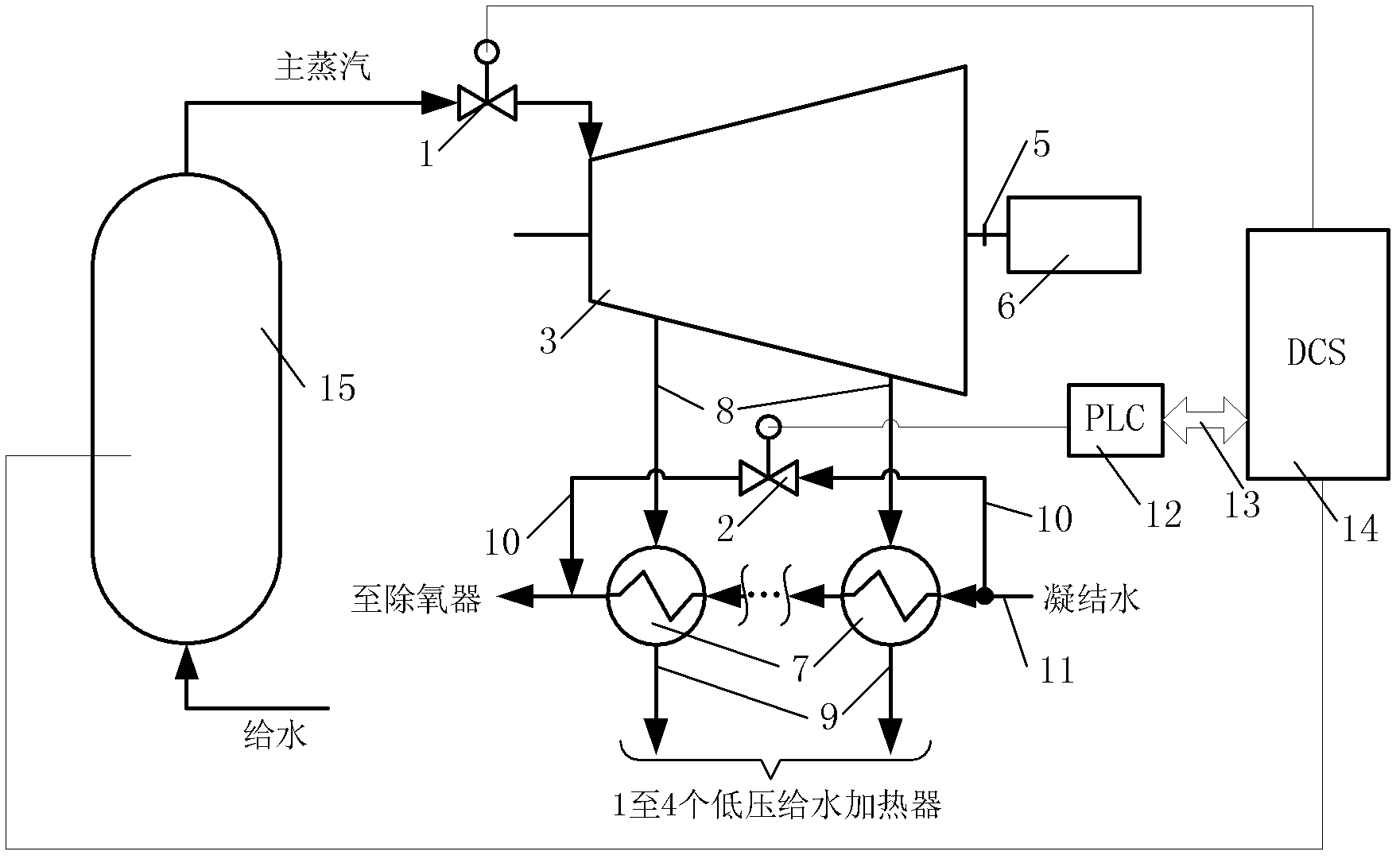

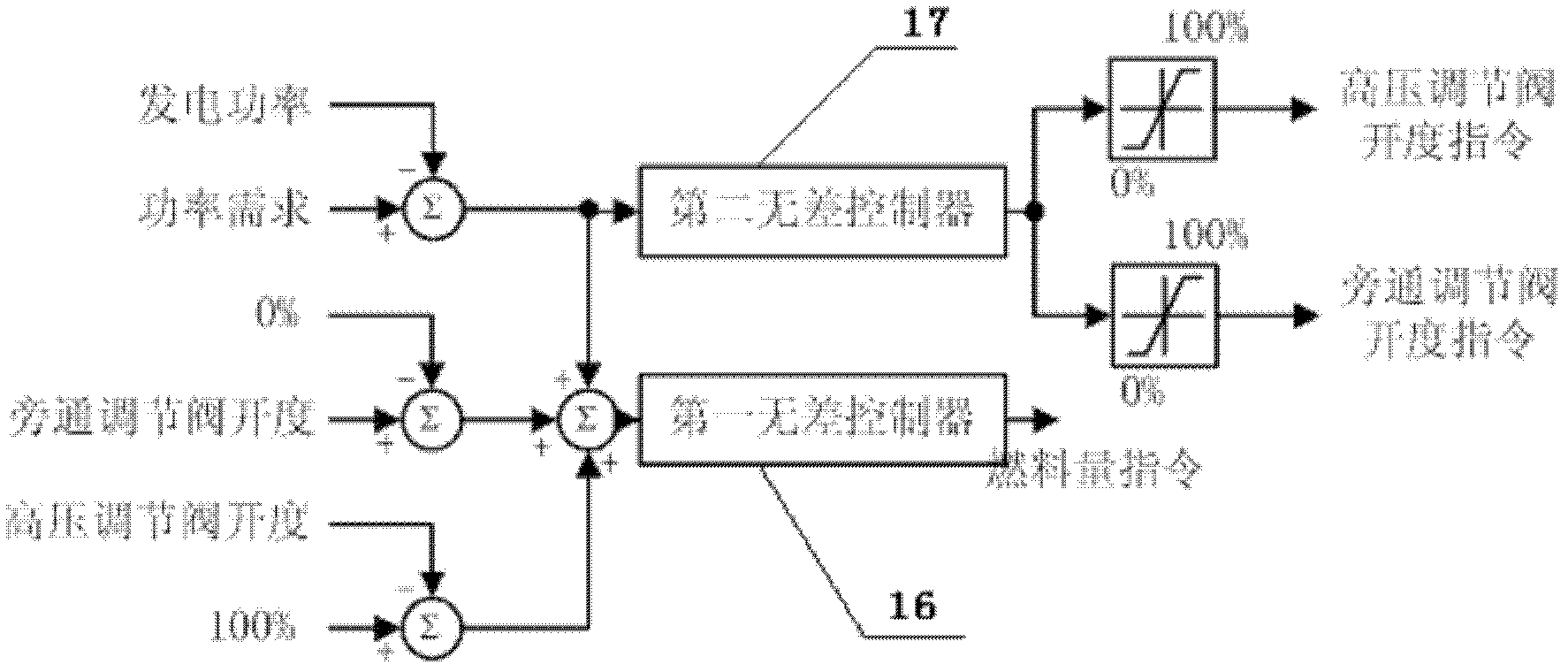

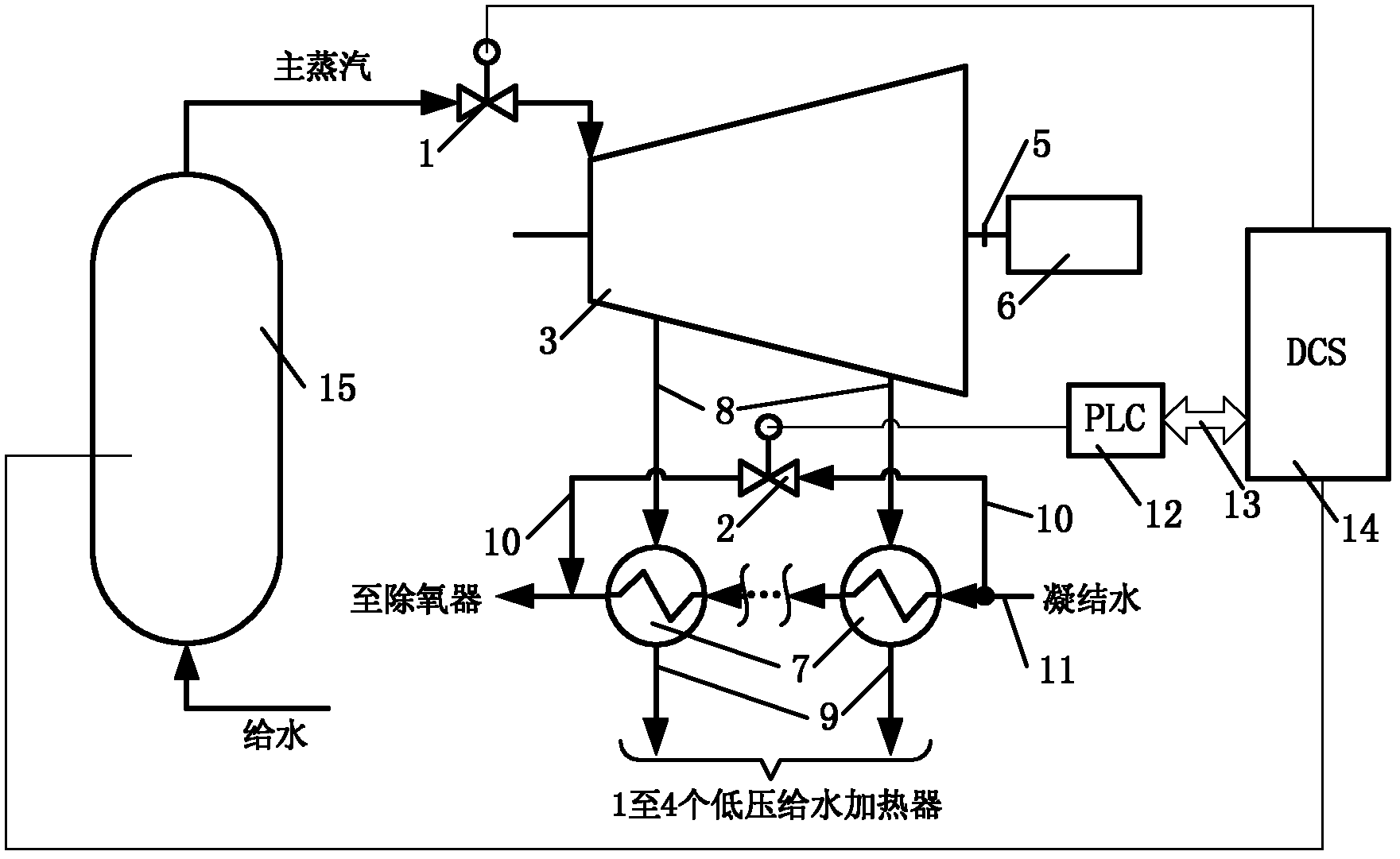

Energy-saving quick power regulating system of thermal generator set and method

ActiveCN102588938AQuick adjustment of powerDoes not affect the water levelFuel supply regulationLiquid degasificationDistribution controlControl system

Disclosed are an energy-saving quick power regulating system of a thermal generator set and a method. The system comprises a distribution type control system, a PLC (programmable logic control) unit and a low-pressure heater condensate bypass regulating system, the PLC unit is connected with the distribution type control system by a bidirectional interface, and the low-pressure heater condensate bypass regulating system is in communication connection with the PLC unit. The method includes that opening of a bypass regulating valve is reduced by the PLC unit when load needs to be quickly added, and the opening of a fully opened high-pressure regulating valve is reduced by the PLC unit via the distribution control system when the load needs to be reduced quickly. Unnecessary loss is avoided on the premise of guaranteeing safety and stability of the system, the requirement of a power grid on power regulating speed of the set is met, and quick power regulation and economical running of the thermal generator set are realized.

Owner:XIAN THERMAL POWER RES INST CO LTD

Pure medium-low temperature waste heat generating system in cement kiln

InactiveCN101793467AIncrease temperatureIncrease enthalpyFeed water supplyIncreasing energy efficiencySuperheaterDeaerator

The invention relates to a pure medium-low temperature waste heat generating system in a cement kiln. The invention is characterized in that an AQC boiler is arranged at the kiln head to generate low-temperature low-pressure steam; an SP boiler is arranged at the kiln tail to generate low-temperature low-pressure steam; the low-temperature low-pressure steam generated by the two waste heat boilers are mixed by a steam distributor and then goes into a common high-temperature superheater arranged in the front end of a grate cooler at the kiln head, the low-temperature low-pressure steam generated by the AQC boiler and the SP boiler is superheated into high-temperature high-pressure steam and then goes into a condensing steam turbine, the dead steam after the action of the steam turbine goes into a condenser, condensation water goes into a vacuum deaerator through a condensation water pump and a pipeline to deoxidize, and the deoxidized water goes into the AQC boiler and the SP boiler through a boiler feed pump. By reasonably using the waste steam temperature in the cement kiln and carrying out the cascading use of the waste steam heat based on the temperature, the invention reduces or avoids the entropy phenomena, and enables the temperature of the superheated steam at the inlet of the steam turbine to be raised, thereby realizing the pure medium-low temperature waste heat generating system in the cement kiln, of which the generating capacity is improved.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

Production of steam and its application to enhanced oil recovery

InactiveUS20110005751A1Easy to handleLess substanceDrying using combination processesFeed water supplySULFATE IONCeramic membrane

The invention relates to a method for producing steam comprising the successive steps of:providing feedwater containing carbonate and / or sulfate ions;adding a crystallizing reagent able to react with carbonate and / or sulfate ions to the feedwater, in order to produce carbonate and / or sulfate crystals;filtering the feedwater with a ceramic membrane to produce a permeate stream;supplying the permeate stream to a boiler; andgenerating steam in the boiler.The invention also relates to an installation adapted for implementing said method, as well as to a process for extracting hydrocarbons from a subterranean formation using the abovementioned method for producing steam.

Owner:TOTAL PUTEAUX FR

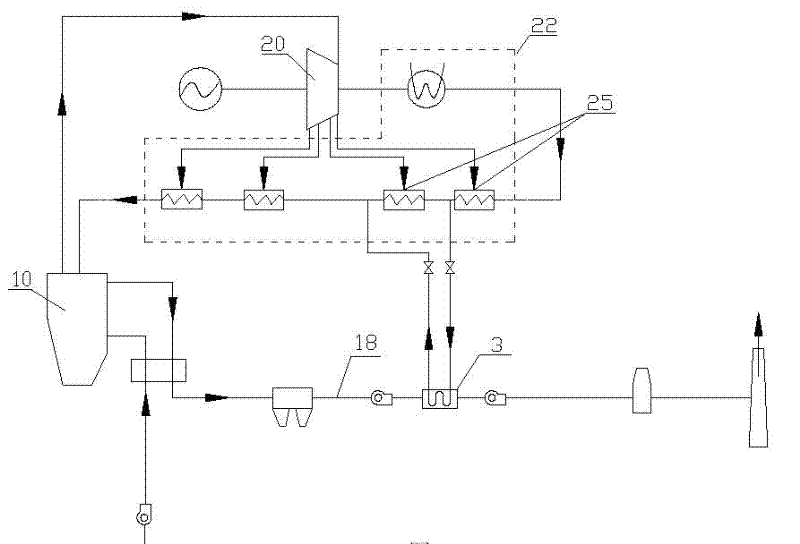

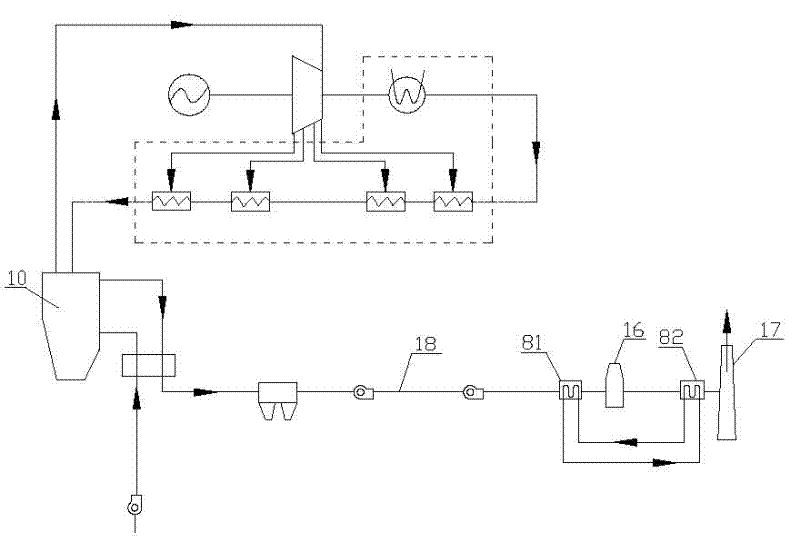

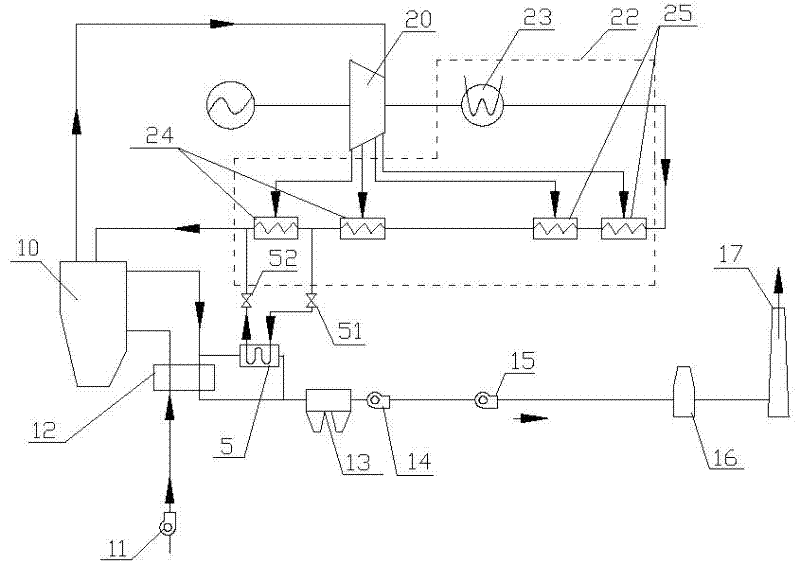

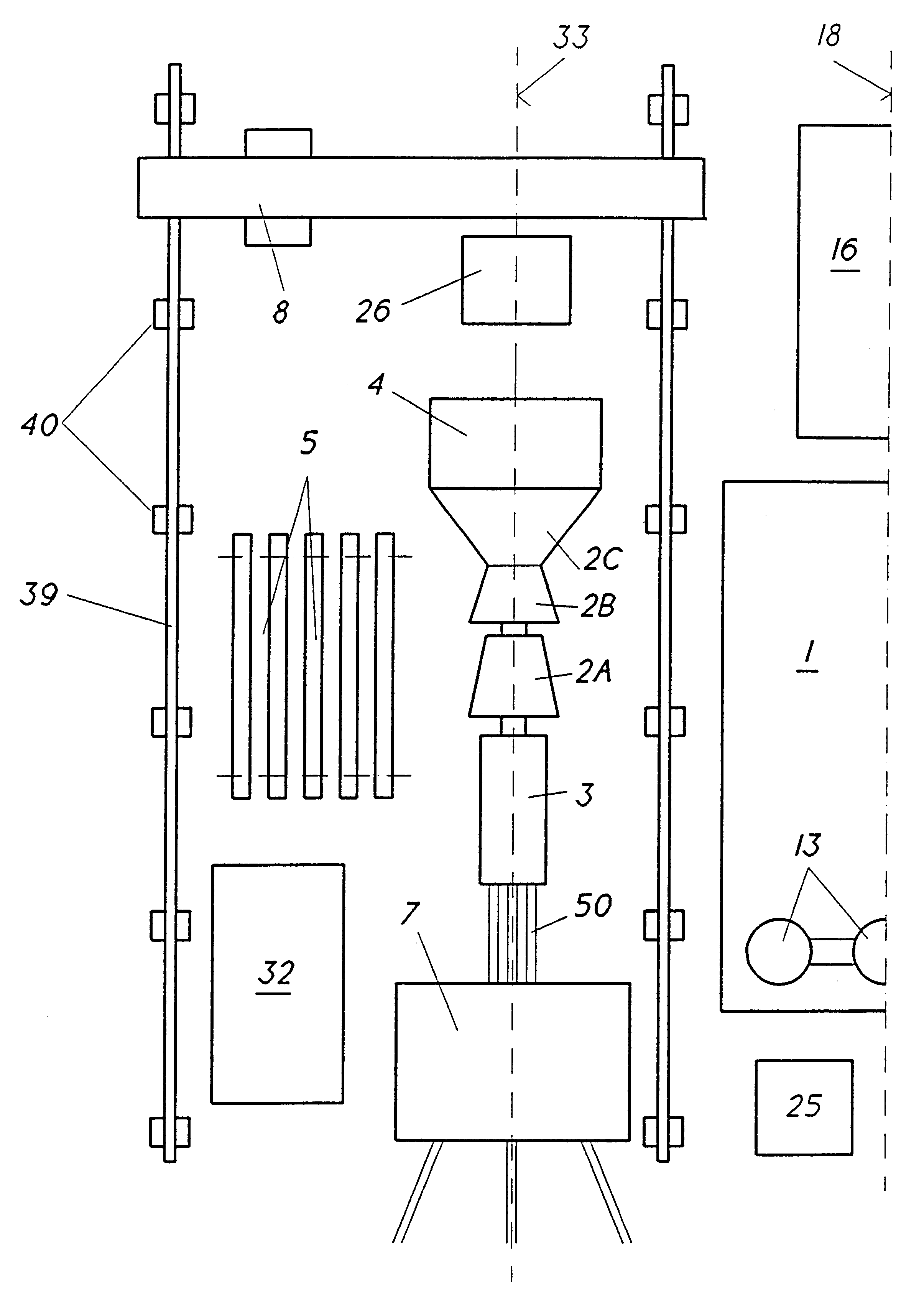

Steam power plant

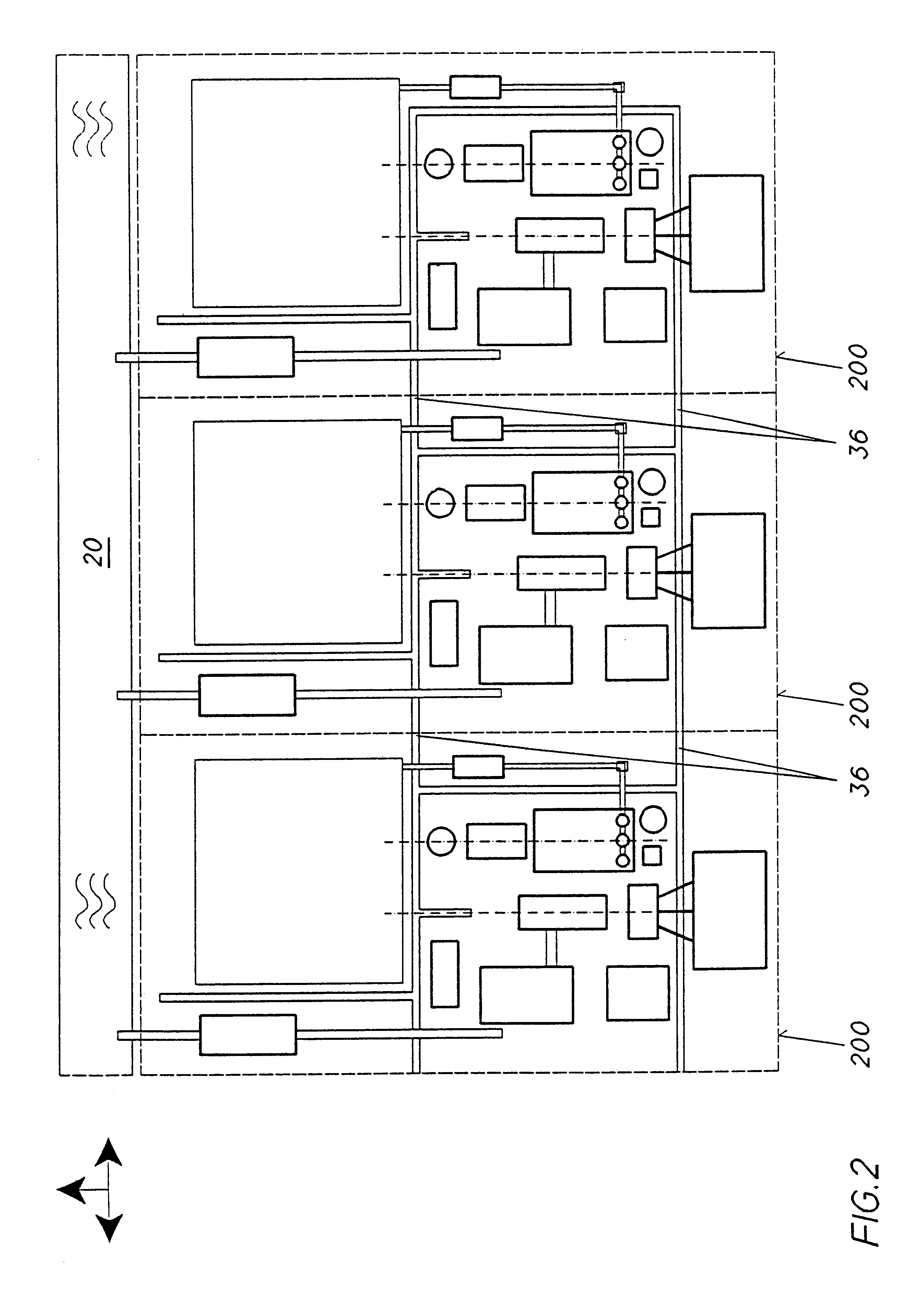

The invention relates to a steam power plant which consists essentially of a steam generator (1), a turbo group comprising a condensing steam turbine (2) and generator (3), a water-cooled condenser (4) and a bled-steam-heated preheating system. In said steam power plant all components, including the fuel storage area (6), are situated at ground level and in the open air. The turbo group (2, 3) and the condenser (4), the preheating system with associated pumps and the transformers (7) are arranged such that a gantry crane is able to pass over them. The steam generator (1), flue gas cleaning system (16) and the chimney (17) are positioned in a row along a common flue gas axis (18) and the turbo group (2, 3) arranged in the immediate vicinity and parallel thereto. As seen from the main wind direction (9), the coal storage area (6) is positioned downwind from the turbo group (2, 3) and the steam generator (1).

Owner:GENERAL ELECTRIC TECH GMBH

Heat recovery system

InactiveUS20120090340A1Heat recoverySteam generation heating methodsCentral heating with accumulated heatEngineeringChiller

A heat recovery system includes a first air cooler for cooling compressed air from a compressor, a first oil cooler for cooling a lubricant from the compressor, and a second air cooler and / or a second oil cooler serving as a heat recovering heat exchanger. The second air cooler heats water with the heat of the compressed air to be fed to the first air cooler. In contrast, the second oil cooler heats water with the heat of a lubricant to be fed to the first oil cooler.

Owner:MIURA COMPANY LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com