Comprehensive recovery method and system of condensation water and dead steam

A recovery method and recovery system technology, which is applied in the field of comprehensive recovery of condensed water and exhaust steam, can solve the problems of waste of water resources, waste of secondary soda water resources, and failure to recover heat energy, and achieve the effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

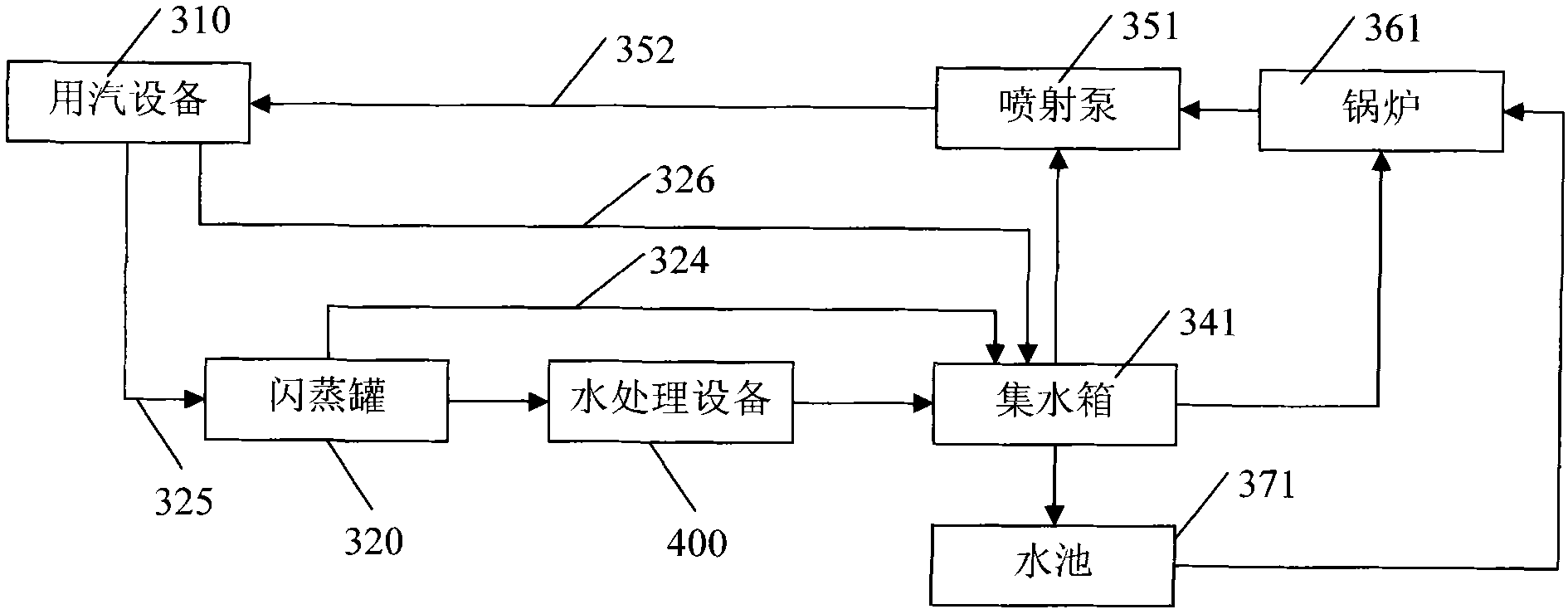

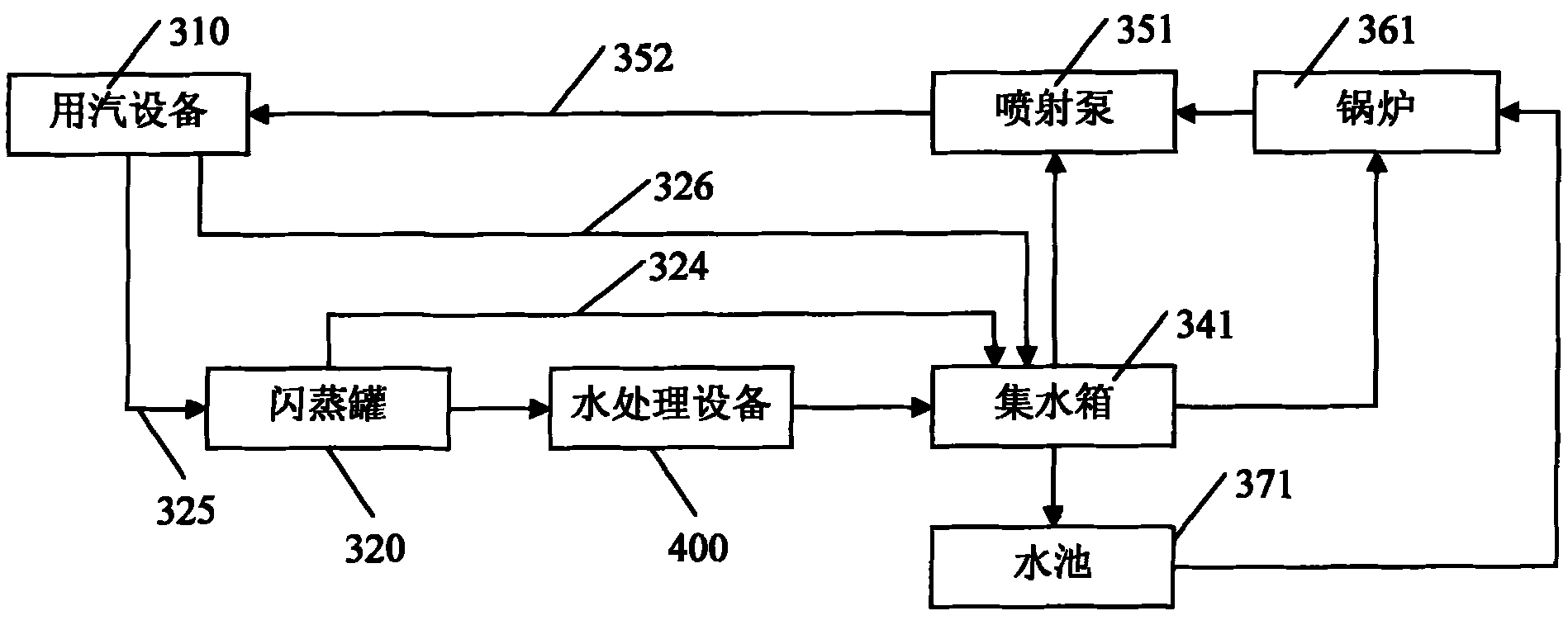

[0039] A kind of comprehensive recovery method of condensed water and exhaust steam of the present invention is as figure 1 As shown, the condensed water discharged from the steam-consuming equipment 310 is transported to the flash tank 320 through the inverted bucket trap for flash evaporation, part of the condensed water becomes secondary steam, and part of it is discharged; the exhaust steam discharged from the steam-consuming equipment 310 is passed through The exhaust steam pipe 326 is guided below the condensed water level of the water collecting tank 341, so that the condensed water can fully absorb the heat of the exhausted steam.

[0040] The condensed water discharged from the flash tank 320 enters the water treatment step through the condensed water pipe 325 . The water treatment step includes temperature adjustment, pretreatment, secondary treatment and mixing steps carried out in sequence.

[0041] In the temperature adjustment step, the condensed water is spraye...

Embodiment 2

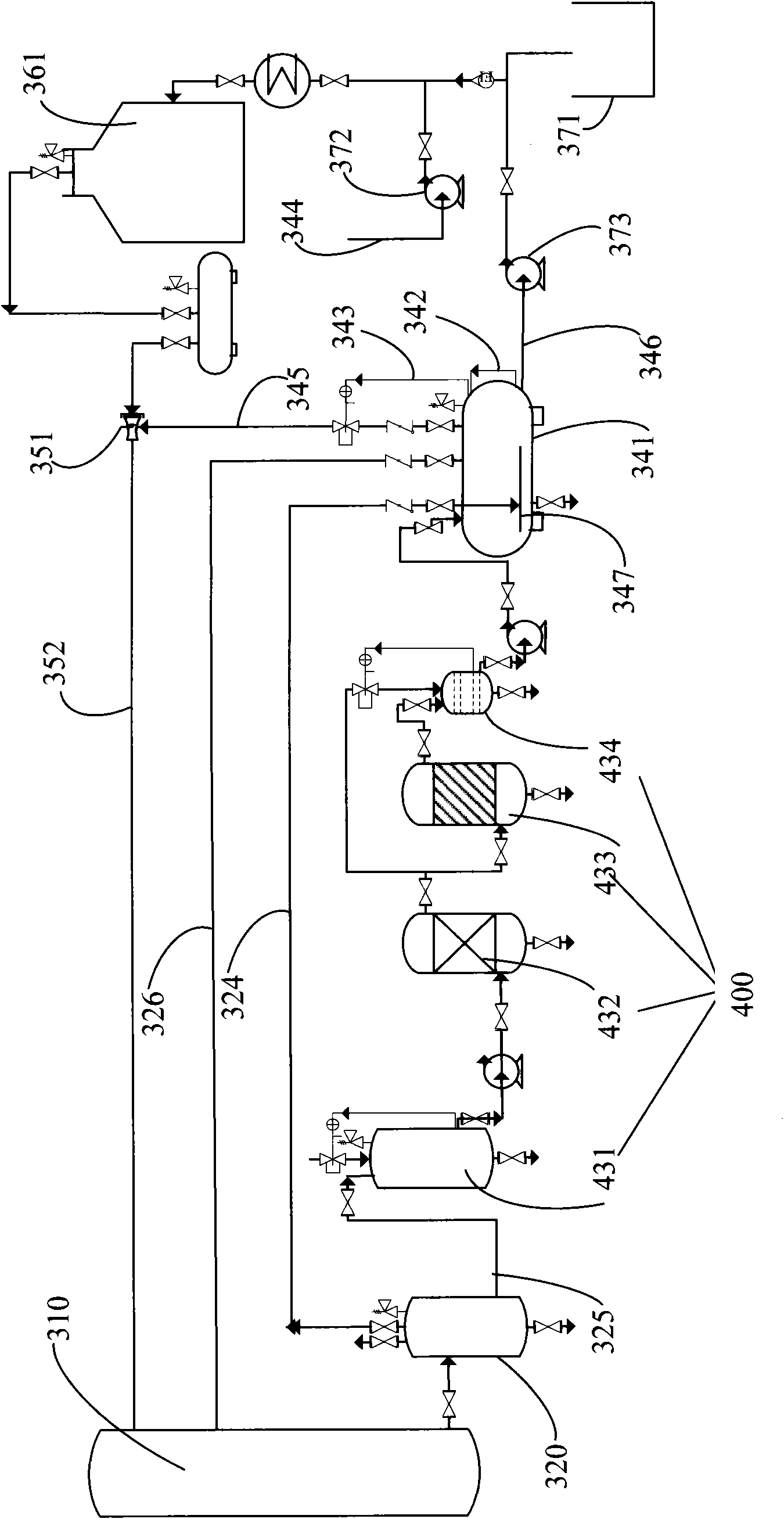

[0052] A comprehensive recovery system for condensed water and exhaust steam of the present invention such as figure 2 Shown are exhaust steam pipe 326 , flash tank 320 , secondary steam pipe 324 , condensate water pipe 325 , water treatment equipment 400 , water collection tank 341 and jet pump 351 . The water treatment equipment 400 includes a temperature regulating tank 431, a pretreatment tank 432, a secondary treatment tank 433 and a mixing tank 434,

[0053] The exhaust steam pipe 326 is connected to the steam consuming equipment 310 and the flash tank 320, the secondary steam pipe 324 is connected to the flash tank 320 and the water collection tank 341, and the condensed water pipe 325 is connected to the flash tank 320 and the temperature regulating tank 431. The warm tank 431 , the pretreatment tank 432 , the secondary treatment tank 433 and the mixing tank 434 are connected in sequence, and the mixing tank 434 is connected to the water collection tank 341 . The wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com