Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121 results about "Boiler blowdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler blowdown is water intentionally wasted from a boiler to avoid concentration of impurities during continuing evaporation of steam. The water is blown out of the boiler with some force by steam pressure within the boiler. Bottom blowdown used with early boilers caused abrupt downward adjustment of boiler water level and was customarily expelled downward to avoid the safety hazard of showering hot water on nearby individuals.

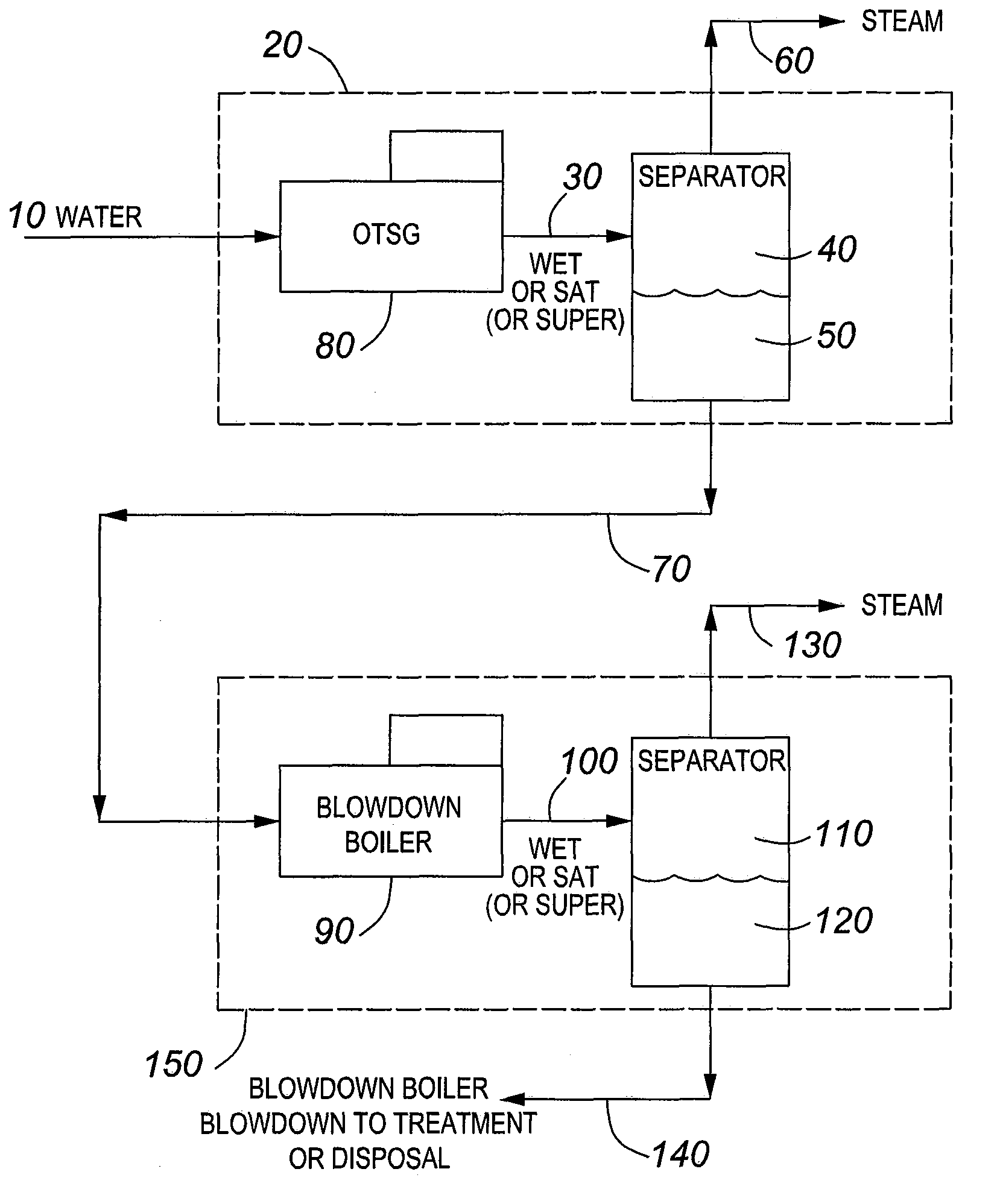

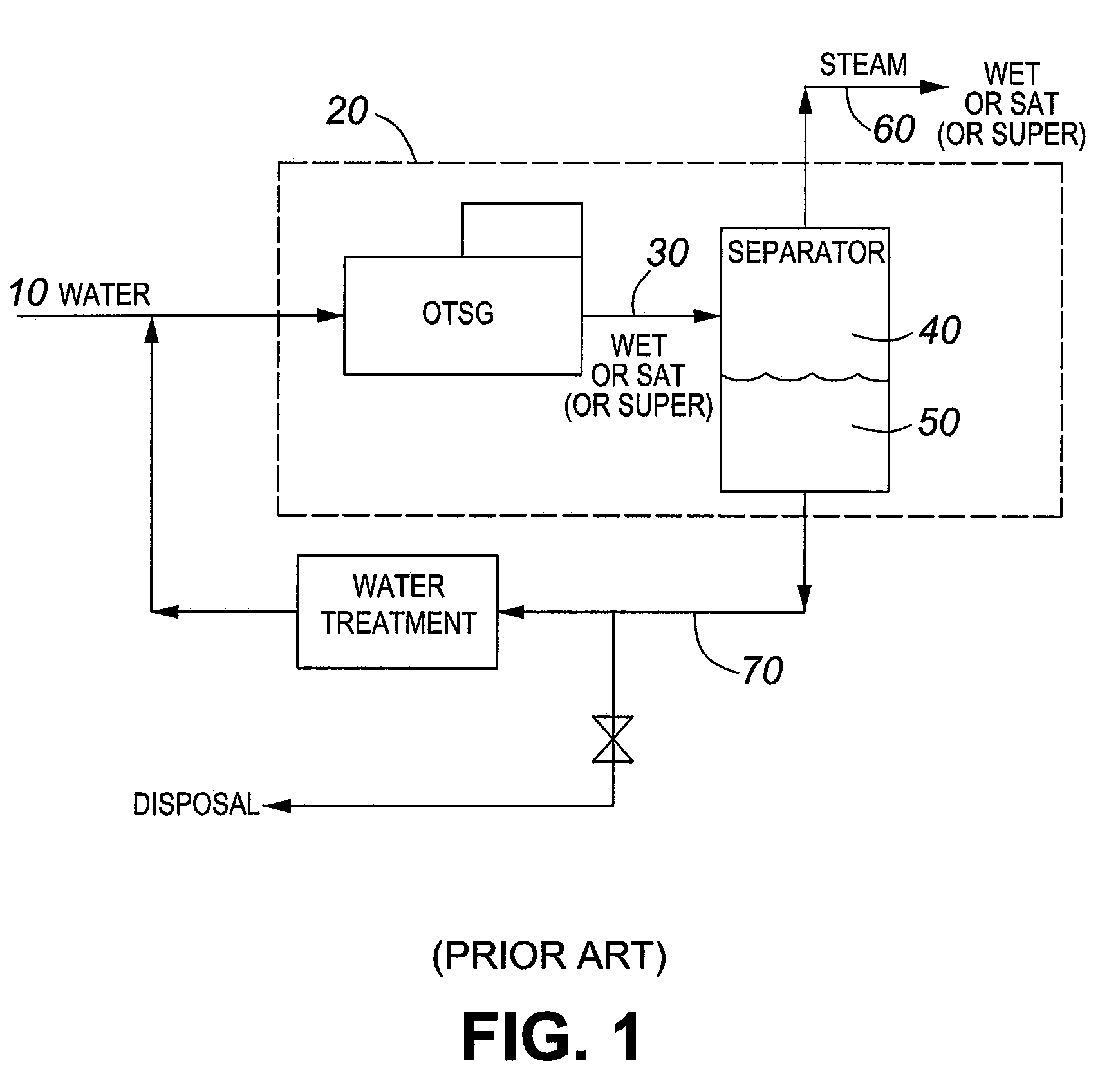

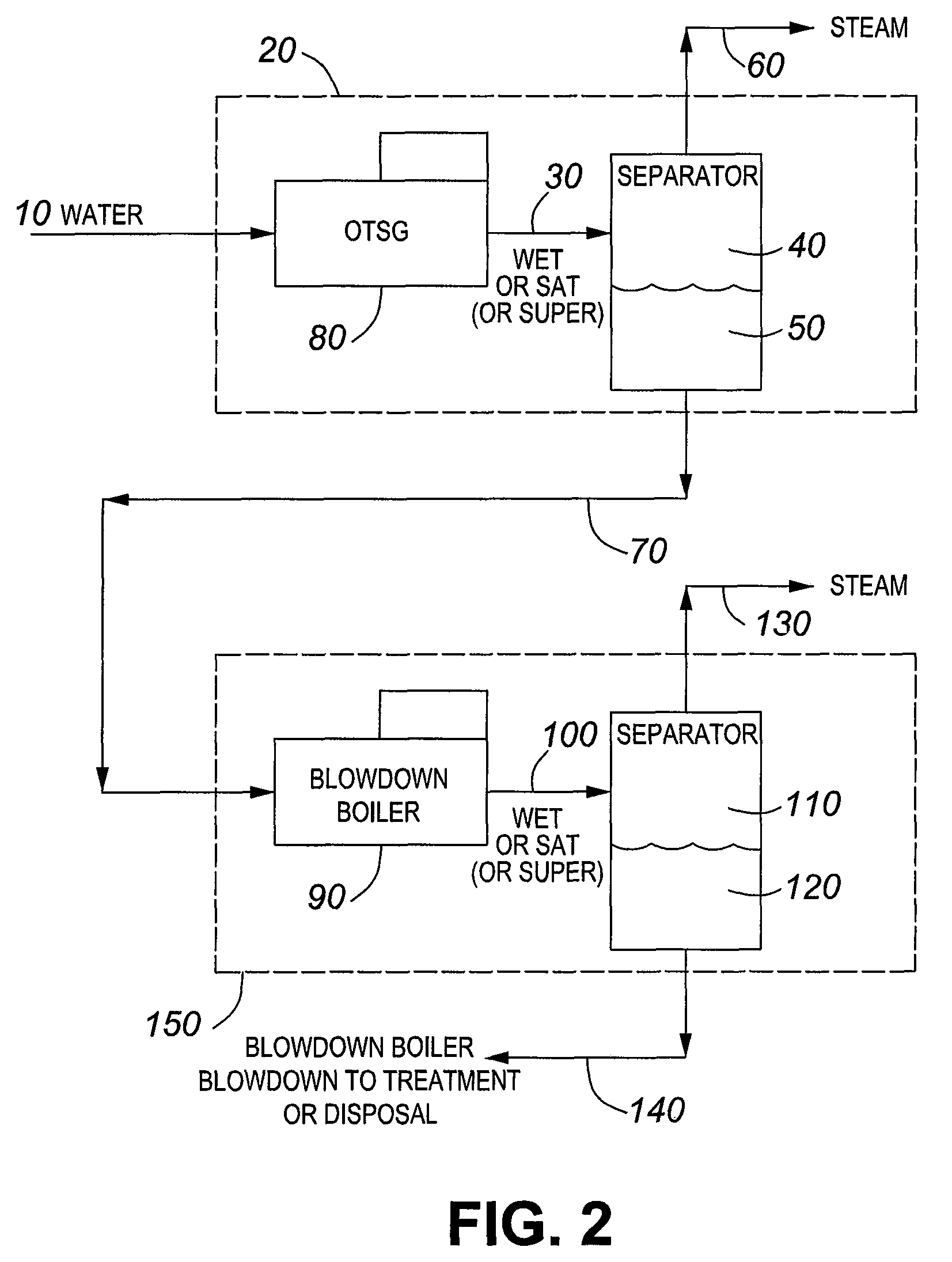

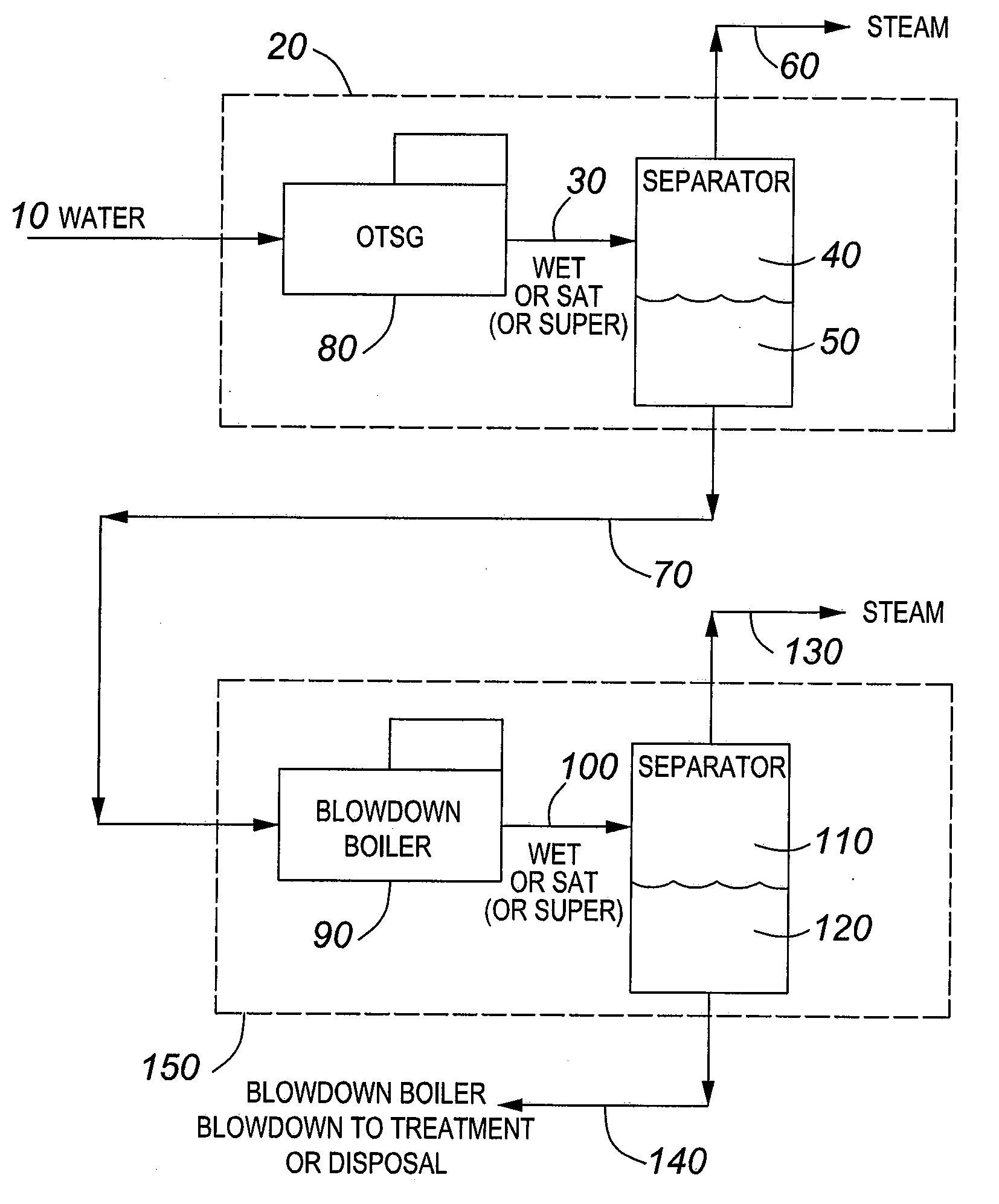

Method and apparatus for steam generation

ActiveUS8166925B2Reduce in quantityIncrease volumeWater circulationFuel injection apparatusBoiler blowdownHardness

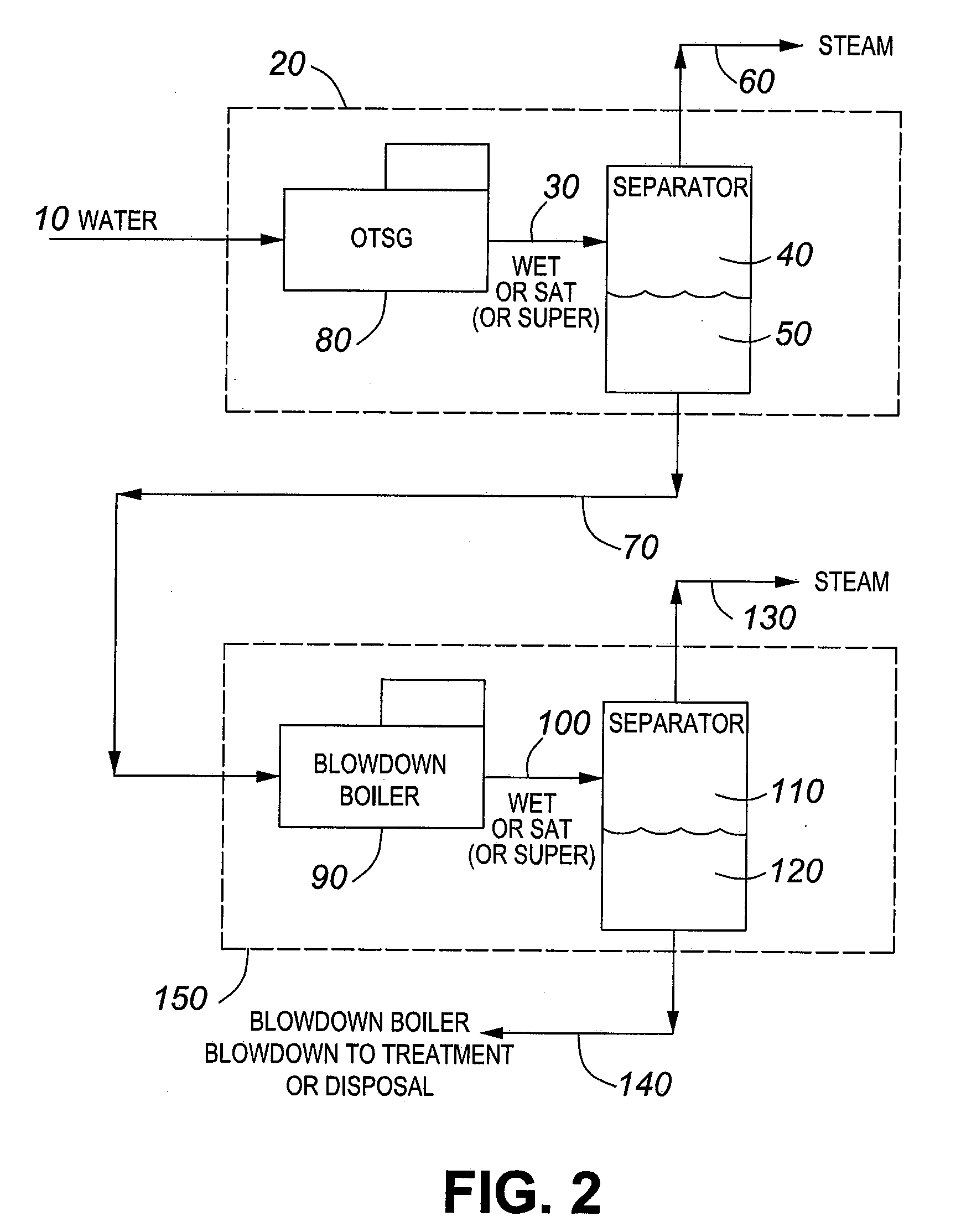

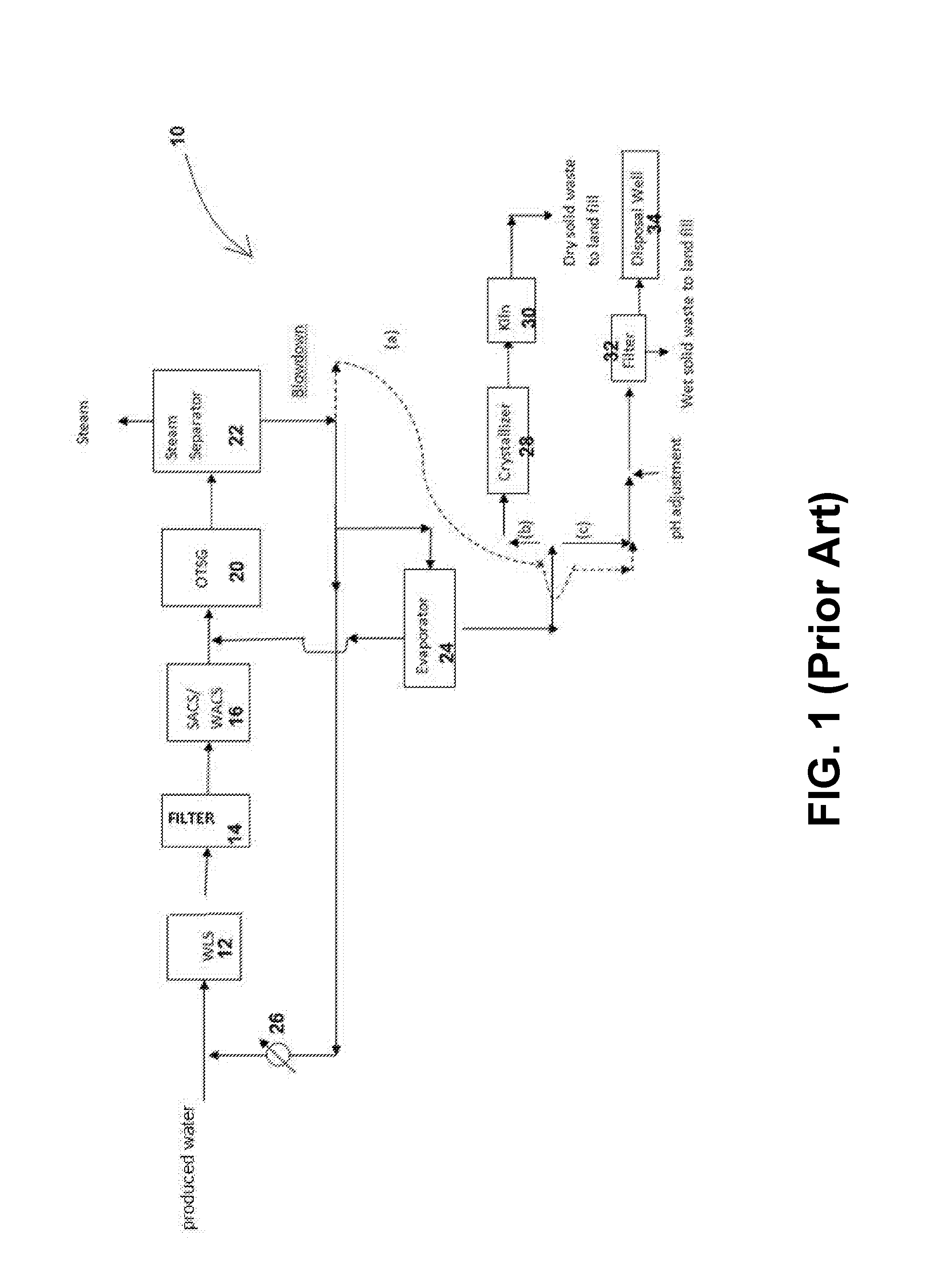

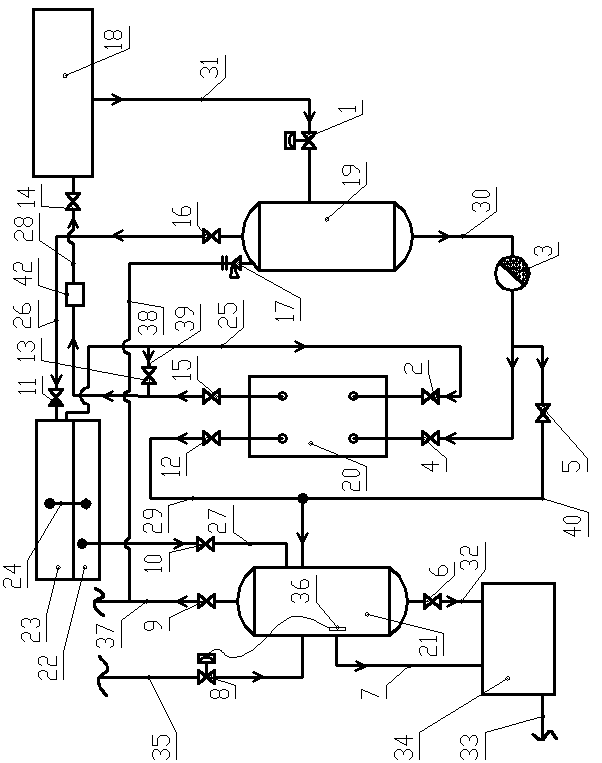

A method, apparatus, and system and operation of surface equipment to generate steam while reducing the quantity of boiler blowdown and thereby increasing the amount of feedwater that is re-used or re-cycled in generating said steam. The present invention teaches that, on a sustained basis, the blowdown stream at the outlet of a once-through steam generator can be routed to the inlet of a second once-through steam generator that is in series with the first, that blowdown stream can be used to generate additional steam in the second once-through steam generator and further reduce the amount of blowdown, and that this can be accomplished without need of any treatment that reduces hardness or silica levels of the blowdown stream prior to its entering or during its entry into the inlet of the second once-through steam generator. The output of this second steam generator is a substantially dry saturated steam vapor stream and, complementarily, a blowdown stream whose mass rate has been reduced substantially from that of the blowdown stream exiting the first steam generator.

Owner:FCCL PARTNERSHIP

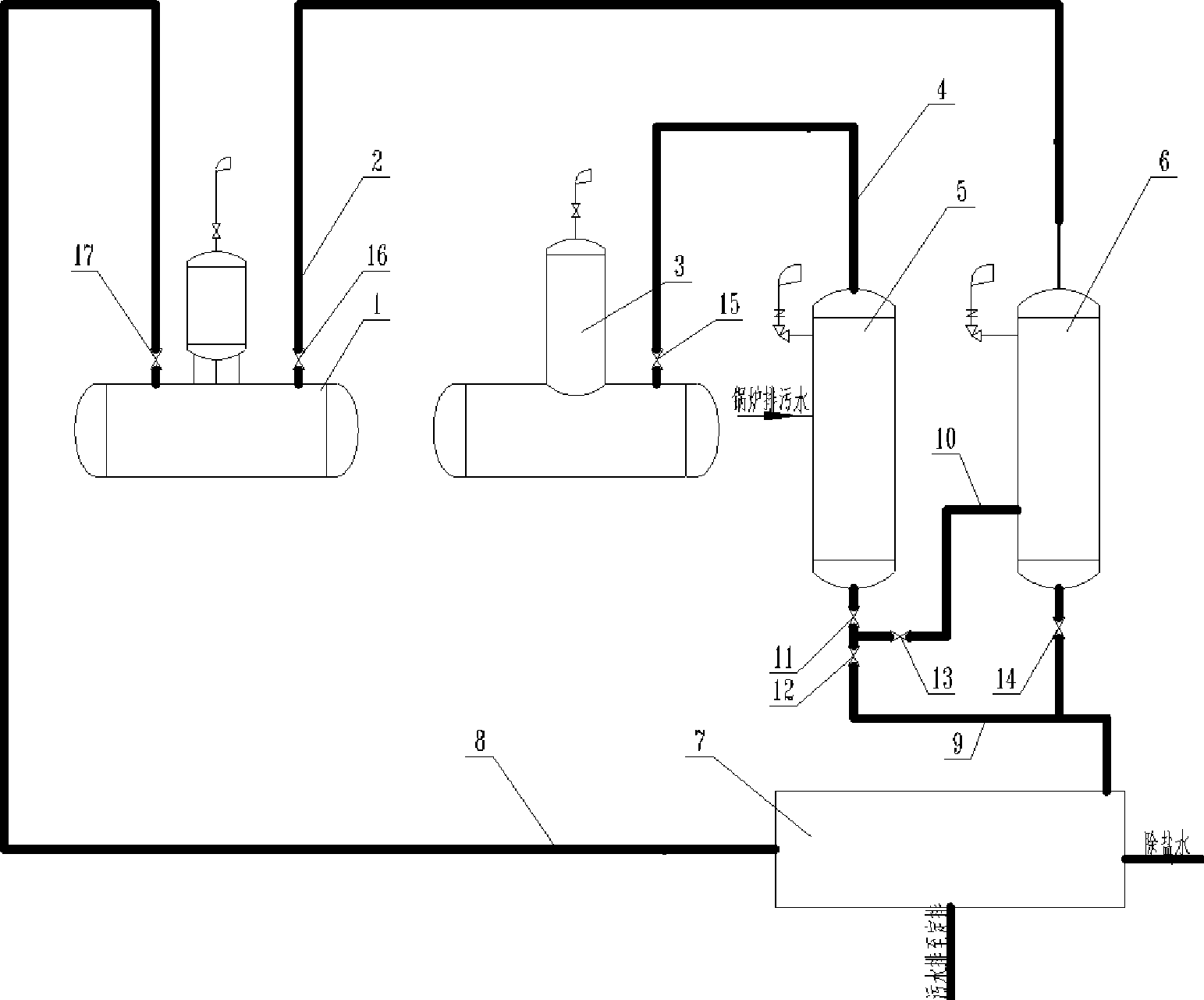

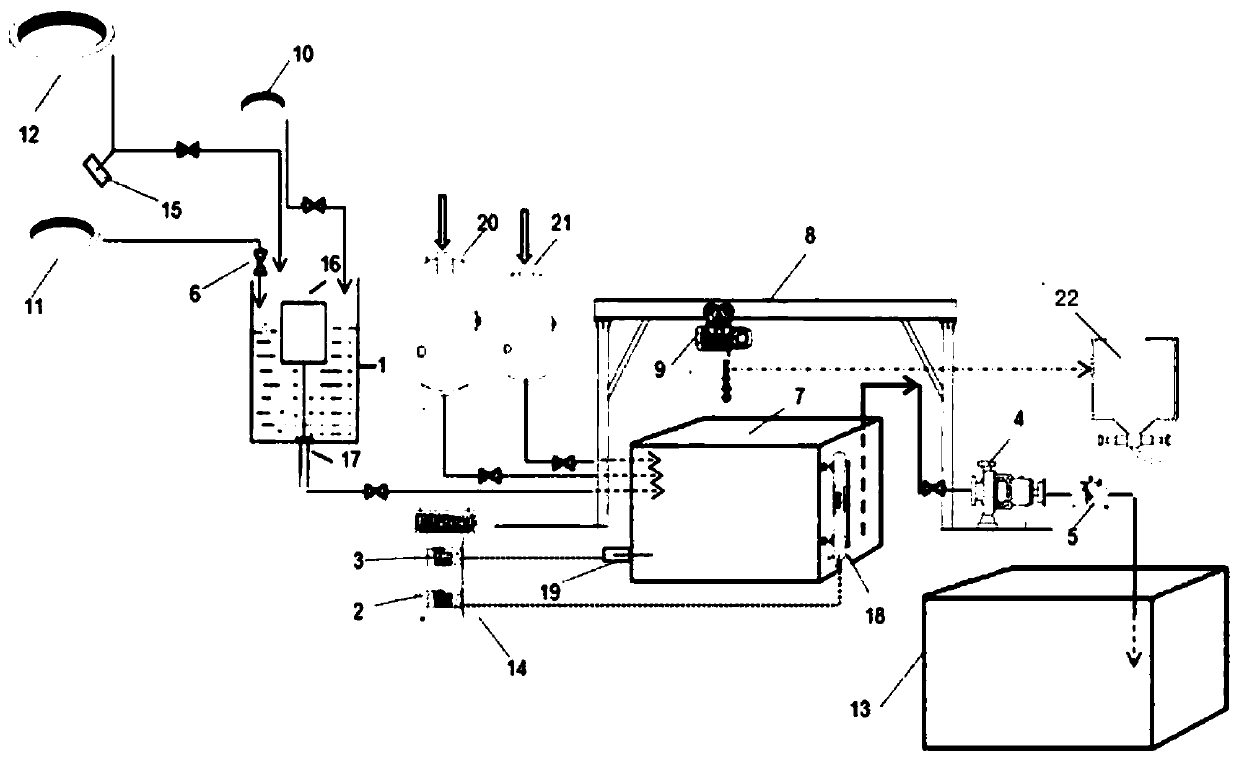

Boiler water replenishing system capable of collecting waste heat and condensed water

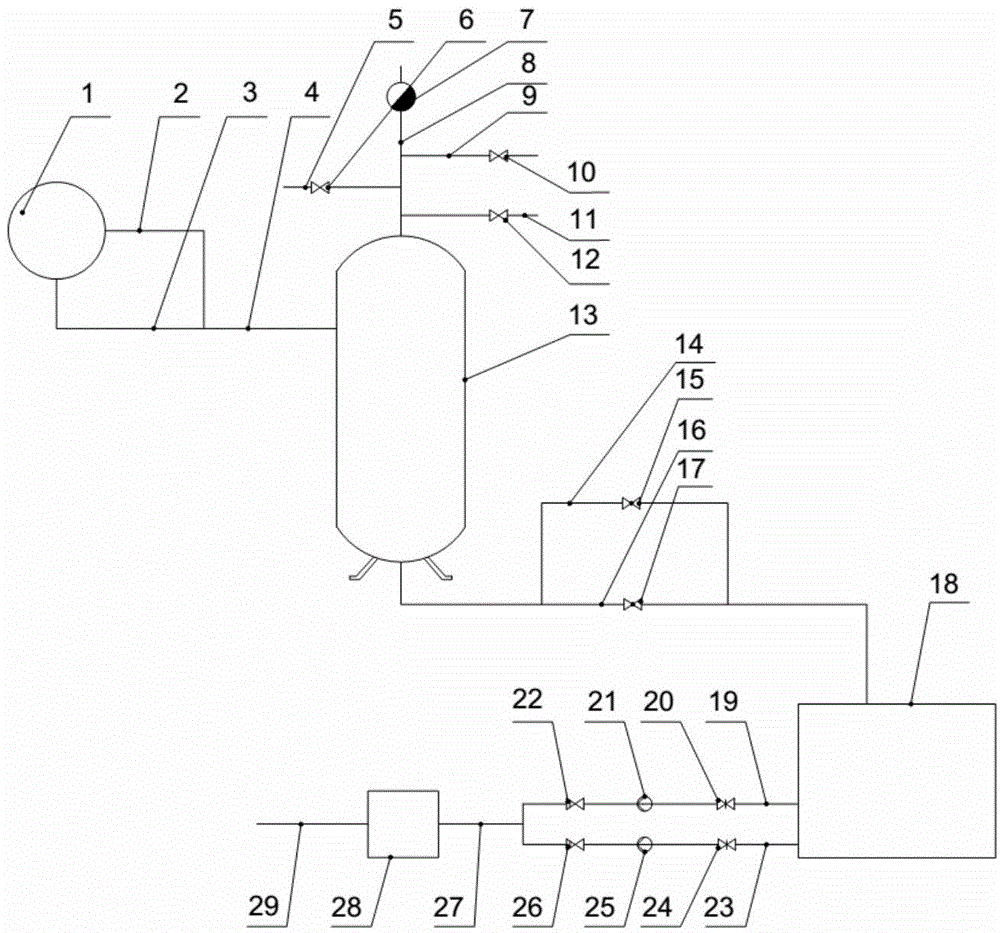

ActiveCN102607014AHydration does not affectReduce consumptionFeed water supplyExpansion tankBoiler blowdown

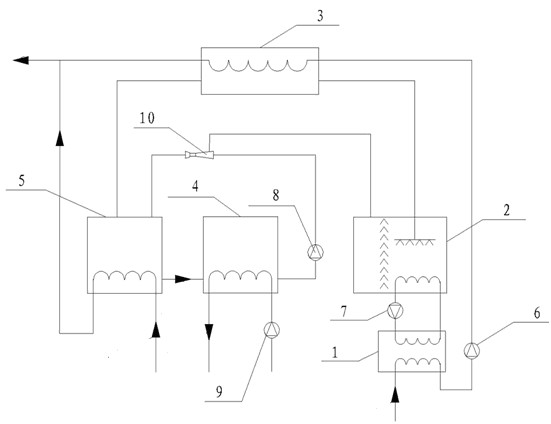

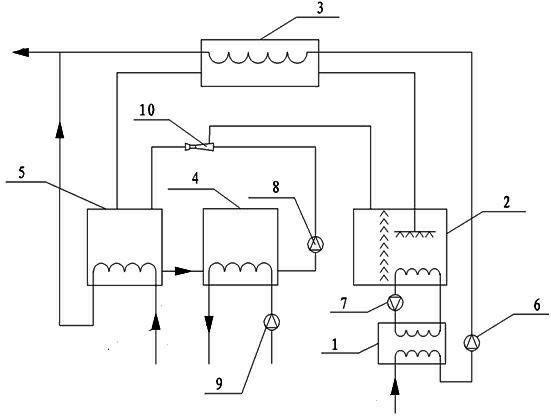

The invention discloses a boiler water replenishing system capable of collecting waste heat and condensed water. A boiler blowdown pipe of a boiler is connected with a blowdown expansion tank, a steam outlet of the blowdown expansion tank is connected into a hot water tank through a blowdown flash steam pipe, a blowdown water pipe of the blowdown expansion tank is connected into a continuous-discharge heat exchanger which is further connected with a softened water feeding pipe, the softened water feeding pipe is connected with a water softening station through a water supply pump, the softened water feeding pipe for the continuous-discharge heat exchanger is connected with a boiler secondary energy saver prior to being connected into the hot water tank, and the hot water tank is connected with a hot water outlet pipe which is sequentially connected with a circulating pump, a heat deaerator and a boiler water feeding pump prior to being connected into a boiler water inlet. The boiler water replenishing system has the advantages that centralized use of the waste heat and the condensed water is achieved, steam consumption of the deaerator is reduced, waste heat absorption effect is enhanced, connection of the deaerator is simplified, pollution of the heat and the condensed water to the environment is reduced, and water replenishing for the boiler is unaffected when heat exchange equipment fails.

Owner:CHINA TOBACCO HENAN IND

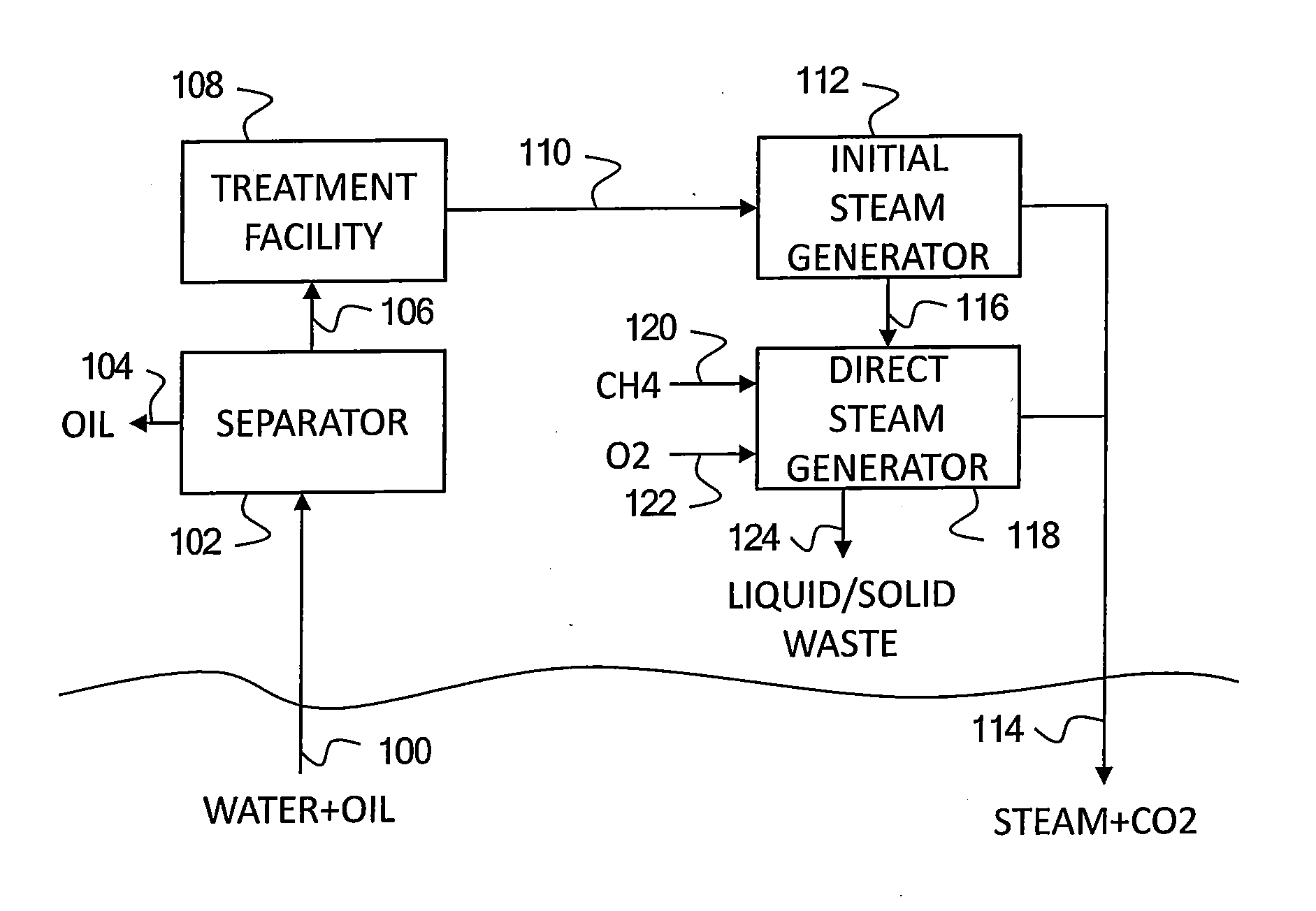

Direct steam generation of boiler blowdown

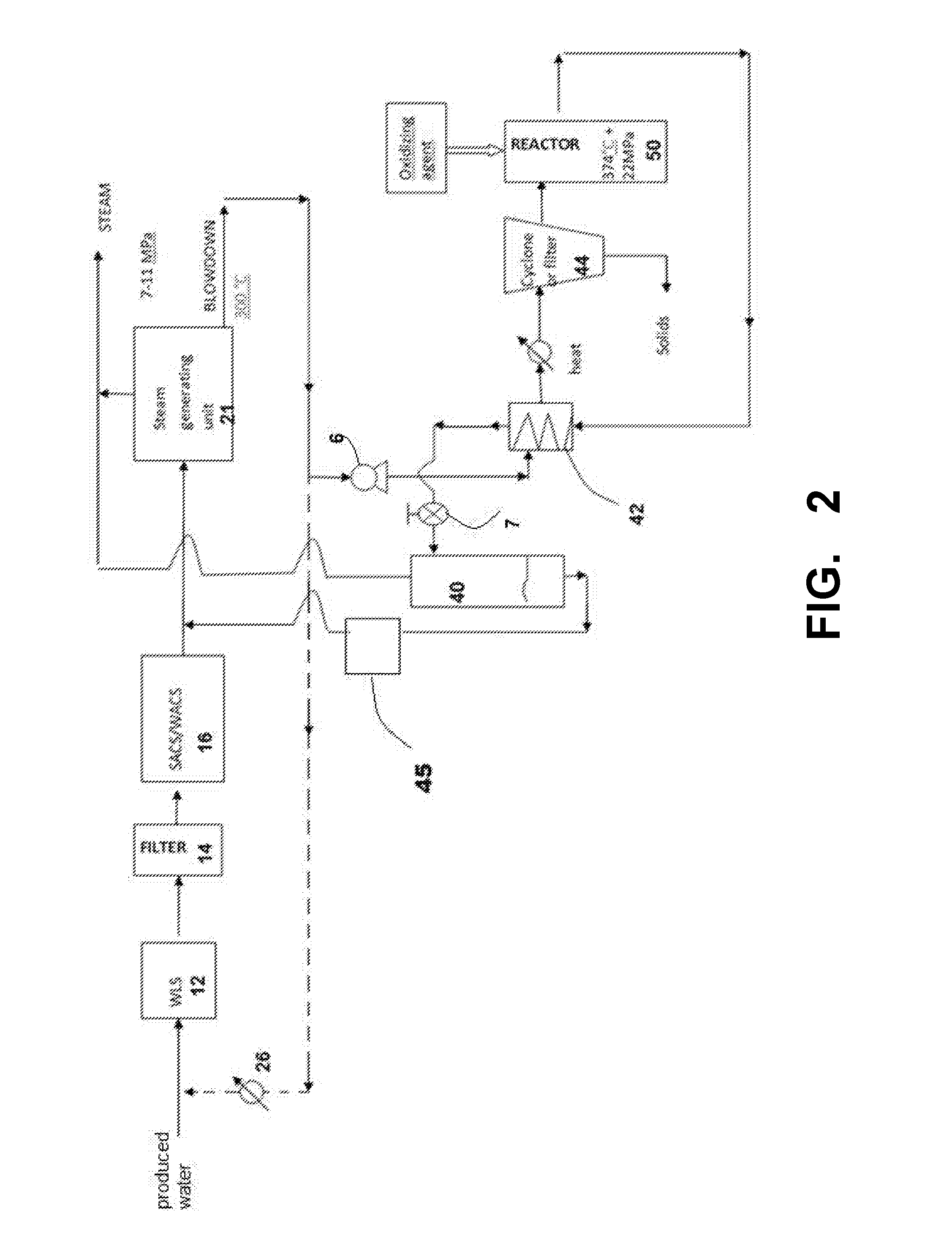

Systems and methods generate steam from produced water by passing the produced water through first and second steam generators coupled together. The first steam generator produces wet steam in which a liquid effluent with impurities of the produced water passes to the second steam generator. The second steam generator combusts fuel and oxidant in direct contact with the liquid effluent. The first and second steam generators limit fouling and waste while providing a combined steam output that may include combustion products from only the second steam generator.

Owner:CONOCOPHILLIPS CO

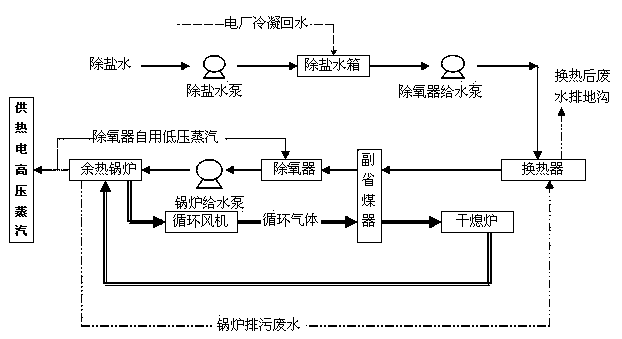

Residual heat recovery system of sewage water of coke dry quenching boiler

InactiveCN103388817ALarge heat transfer temperature differenceImprove heat recovery effectLiquid degasificationBoiler blowdownEngineering

The invention relates to a residual heat recovery system of sewage water of a coke dry quenching boiler. The system is characterized in that a sewage water heat exchanger is additionally arranged, desalting water which is delivered to an auxiliary coal saver by a water feed pump of a deaerator is used as a cooling medium to exchange heat with the sewage water nearby, and then the heat-exchanged desalting water is delivered to the deaerator to be deaerated. The system has the advantages that the problem of quantity distribution of water entering the heat exchanger and the auxiliary coal saver is avoided, and the operation and the control are convenient; the temperature of the desalting water entering the heat exchanger is minimum, the heat exchange temperature difference is high, and the heat recovery effect is good; the temperature of air at an inlet of the coke dry quenching boiler is controlled to 115 DEG C to 135 DEG C, and the temperature of actual running is controlled to about 125 DEG C and has a space of 10 DEG C from the maximum temperature, so the adjusting capability is high; and in addition, the quantity of circulating air is higher, so the temperature of the water entering the auxiliary coal saver is raised by about 8 DEG C in comparison with the temperature of the previous arrangement, the effect on the temperature of circulating air is little, and the running parameters of a coke dry quenching groove and the boiler are controlled within the specified range.

Owner:广西华锐工程设计有限公司

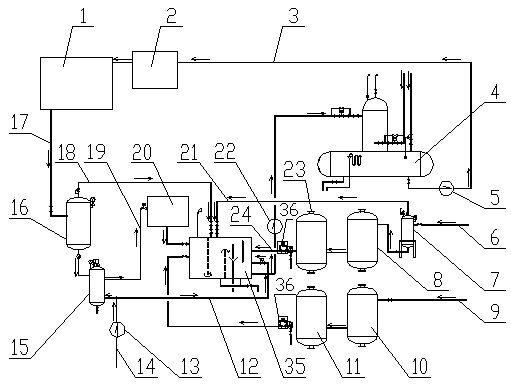

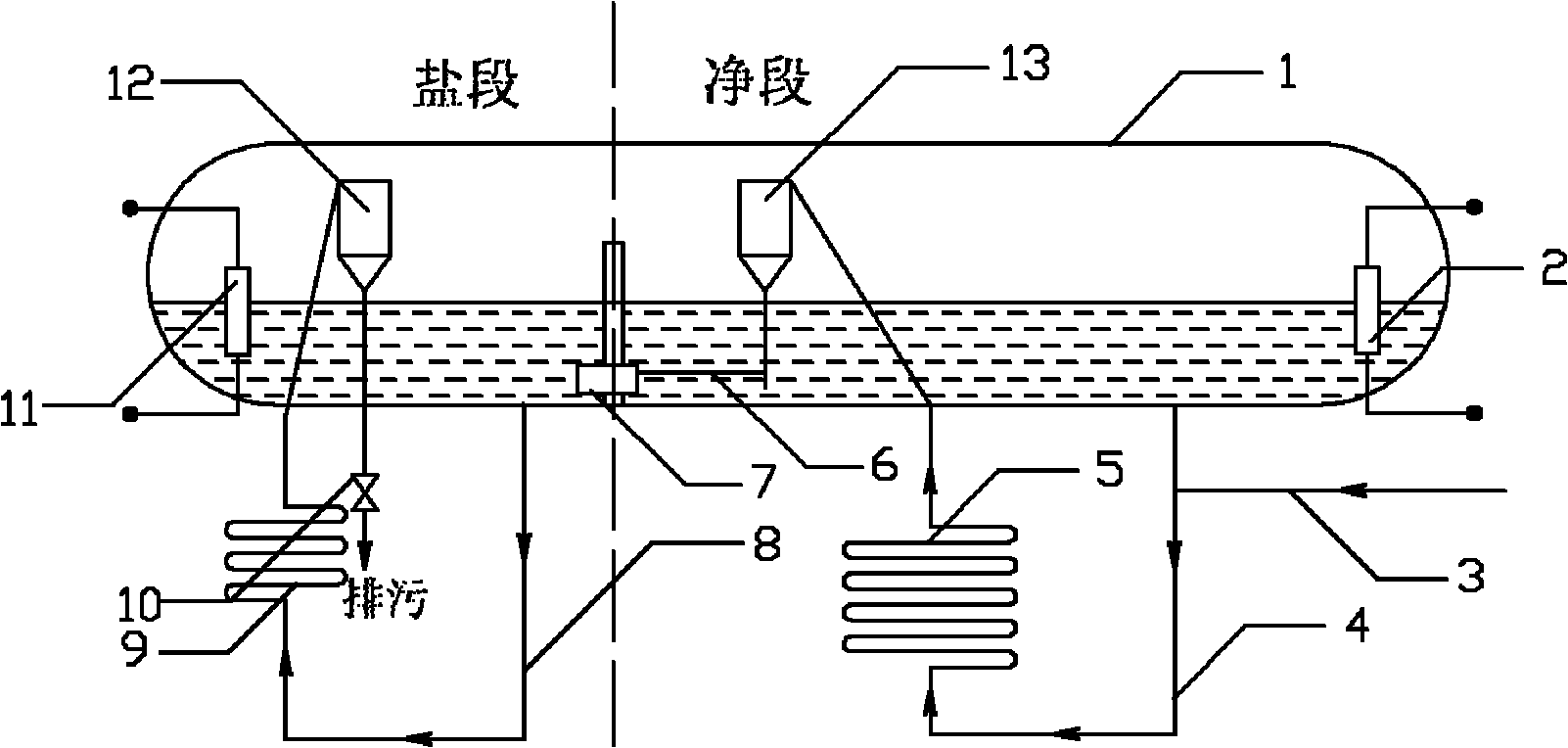

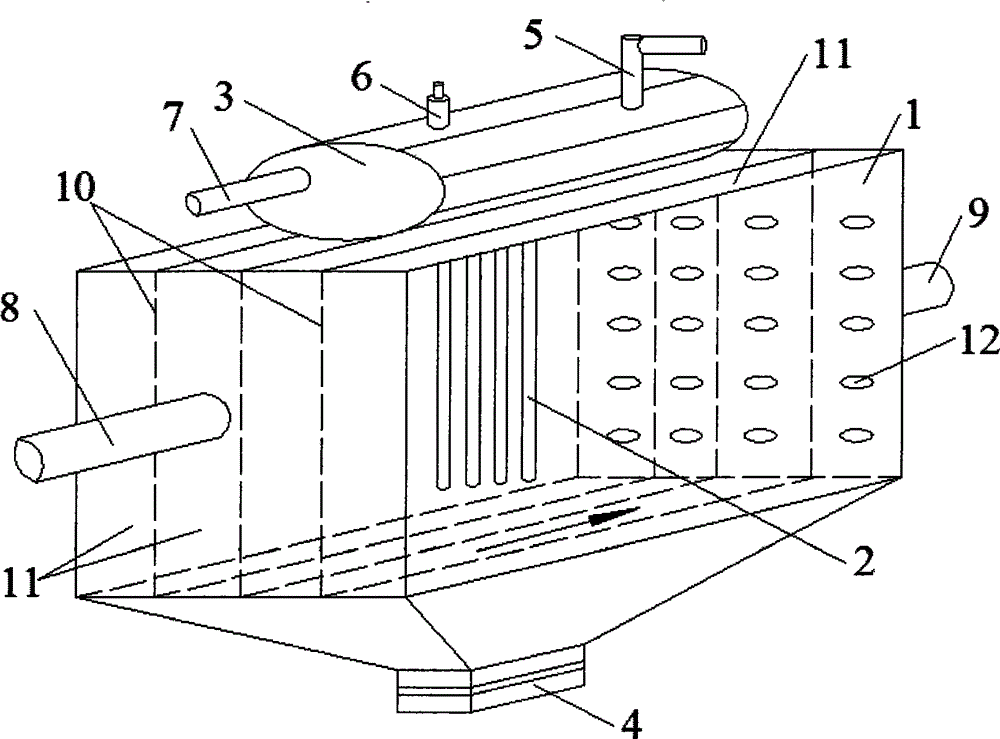

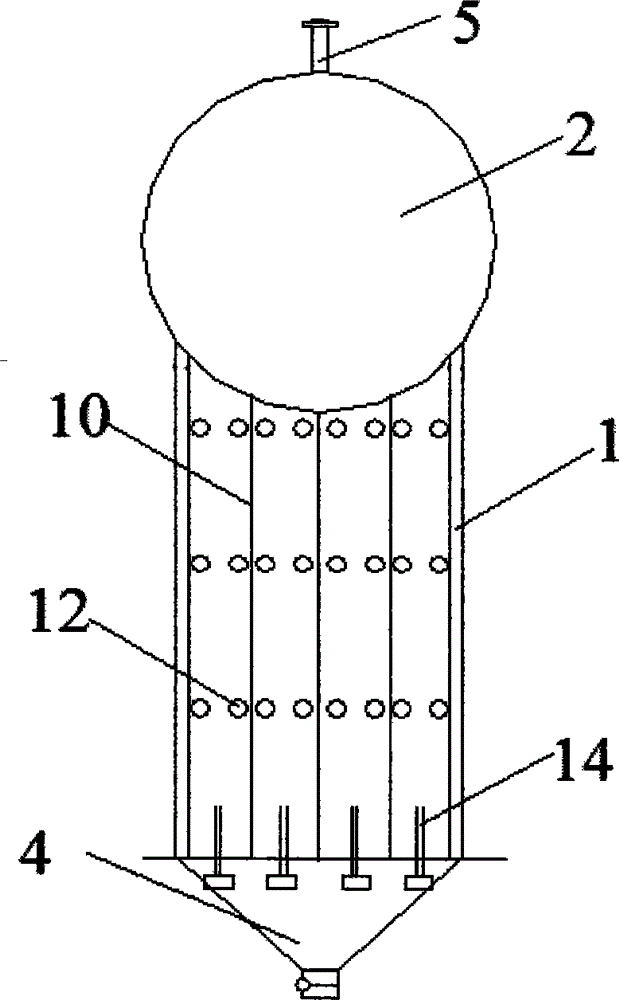

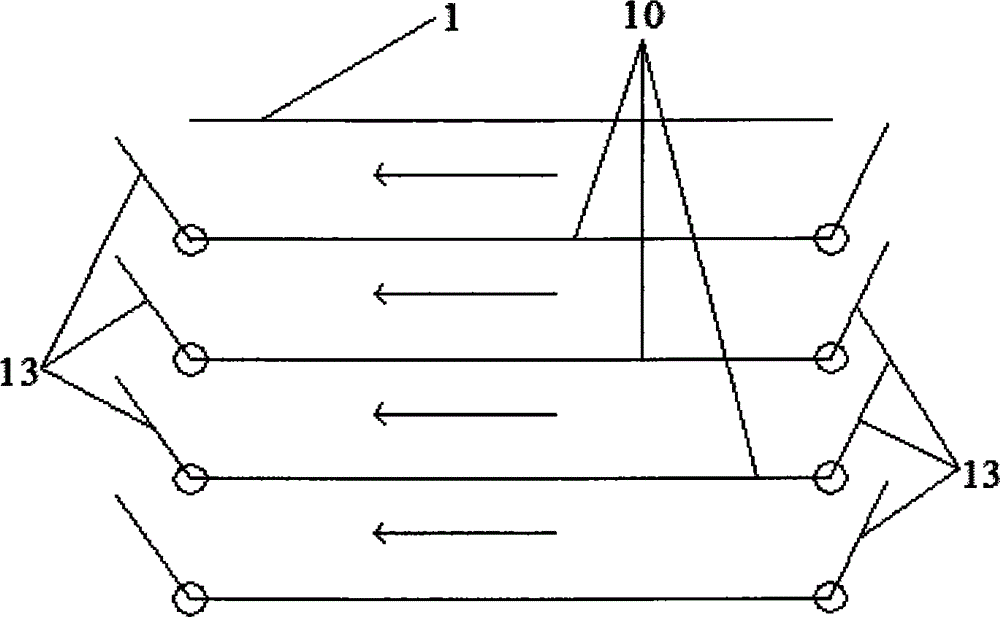

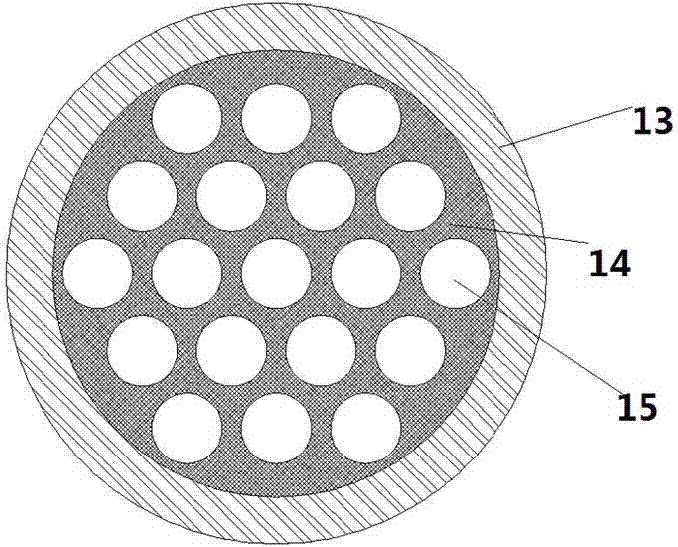

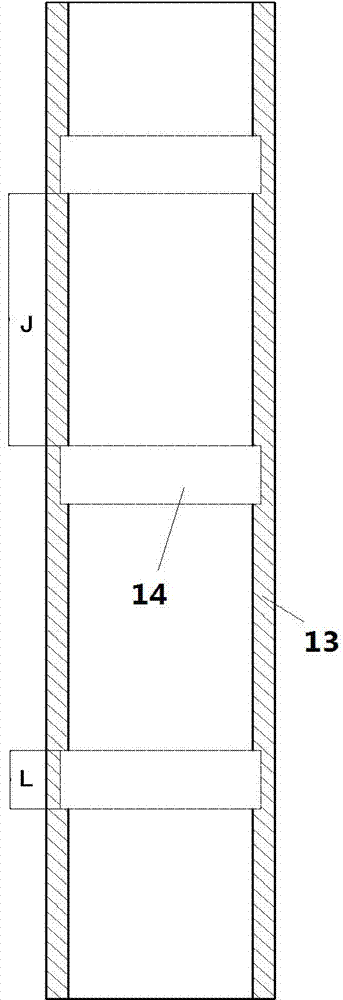

Natural circulating steam injection boiler fed with high salt-containing softened water and water circulating method

ActiveCN101979917ASmooth circulationReduced hydrodynamic safetyBoiler drums/headersBoiler cleaning apparatusBoiler blowdownSoftened water

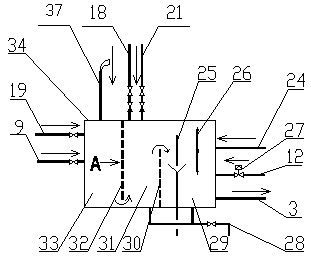

The invention discloses a natural circulating steam injection boiler fed with high salt-containing softened water and a water circulating method, and belongs to the fields of natural circulating steam pocket water power technology and stage evaporation technology. A steam pocket is divided into a net section and a salt section, boiler feed water is directly introduced into a vertical down pipe of the net section of the steam pocket, and the evaporation heating surface of the net section is arranged on the heating surface of a hearth. The feed water of the salt section of the steam pocket is supplied by the boiler water of the net section, the evaporation heating surface of the salt section is arranged in a flue at the tail of the boiler, and the sewerage is directly led out by a steam-water separation device on the salt section of the boiler. The blow-down rate of the boiler is 5 to 15 percent, and the evaporation capacity of the salt section is 5 to 40 percent of the total evaporation capacity. Under the same blow-down rate, the boiler water of the net section and salt section heating surfaces of the boiler has low salt content; the heating surfaces have good corrosion resistance, hydrodynamic characteristic and safe heat transfer; and the heating surface of the salt section is convenient for overhauling. The fuel of the boiler can be coal, oil, natural gas and other combustible solids, and is suitable for high-capacity thick oil thermal recovery steam injection boilers.

Owner:TSINGHUA UNIV

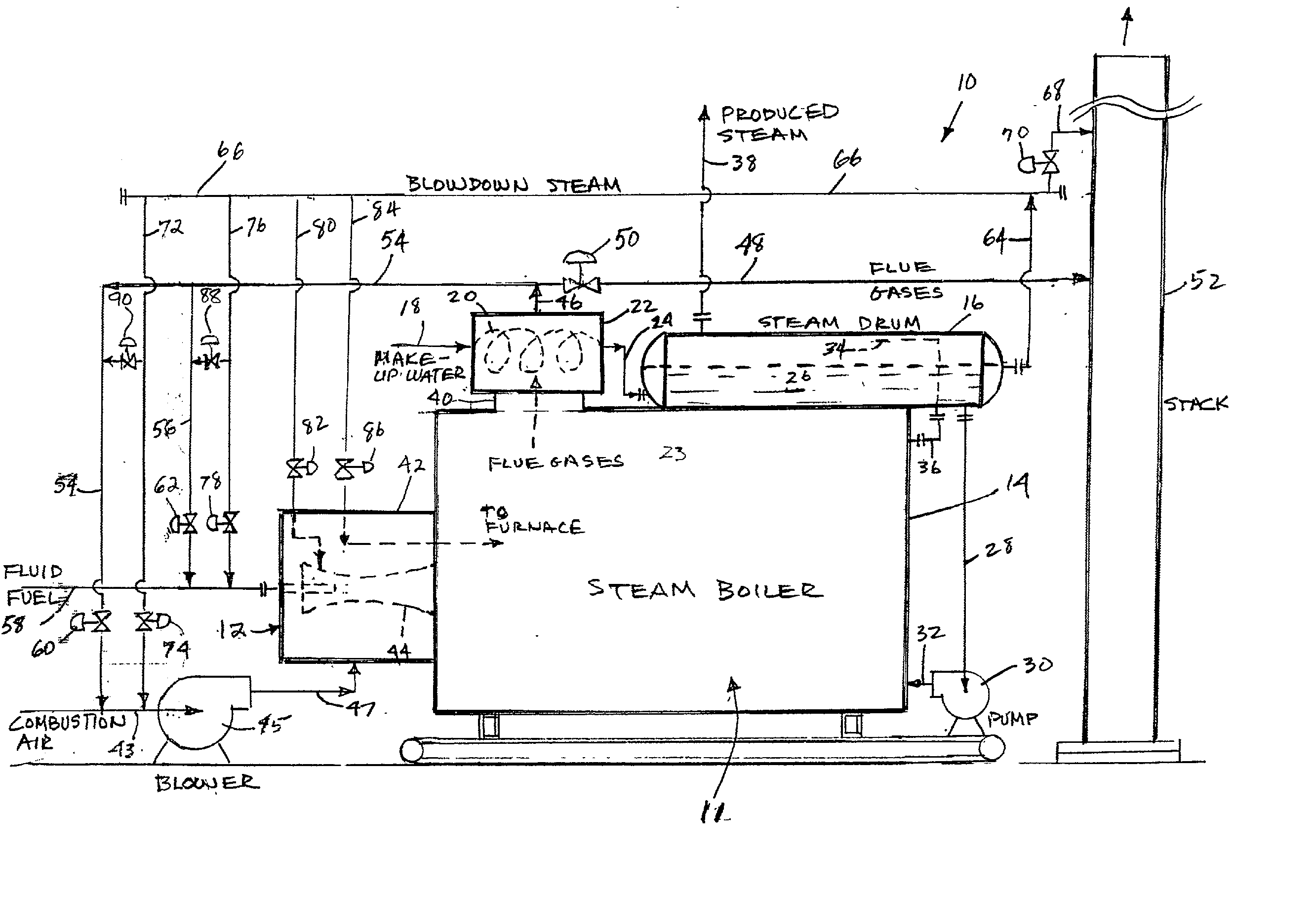

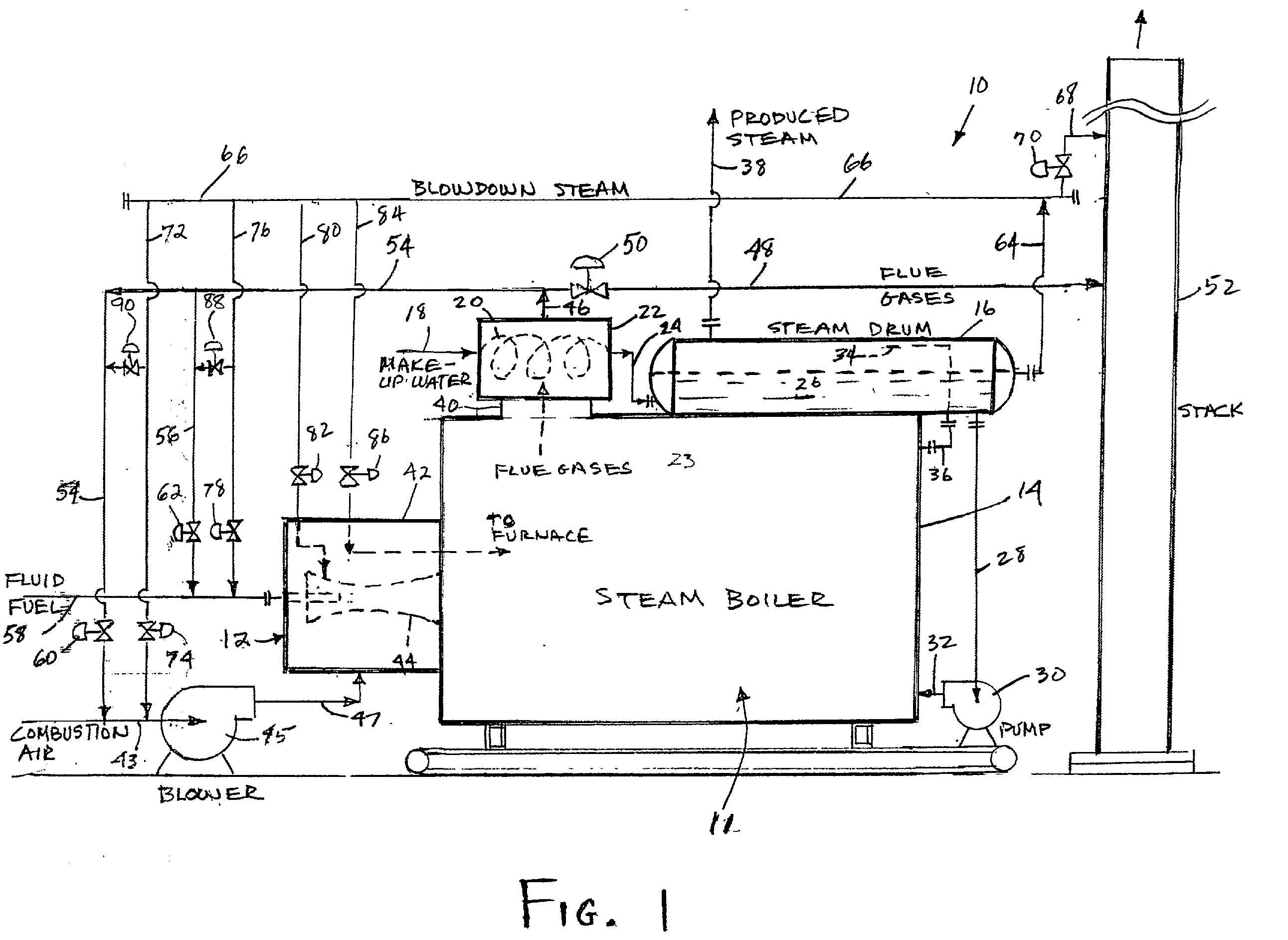

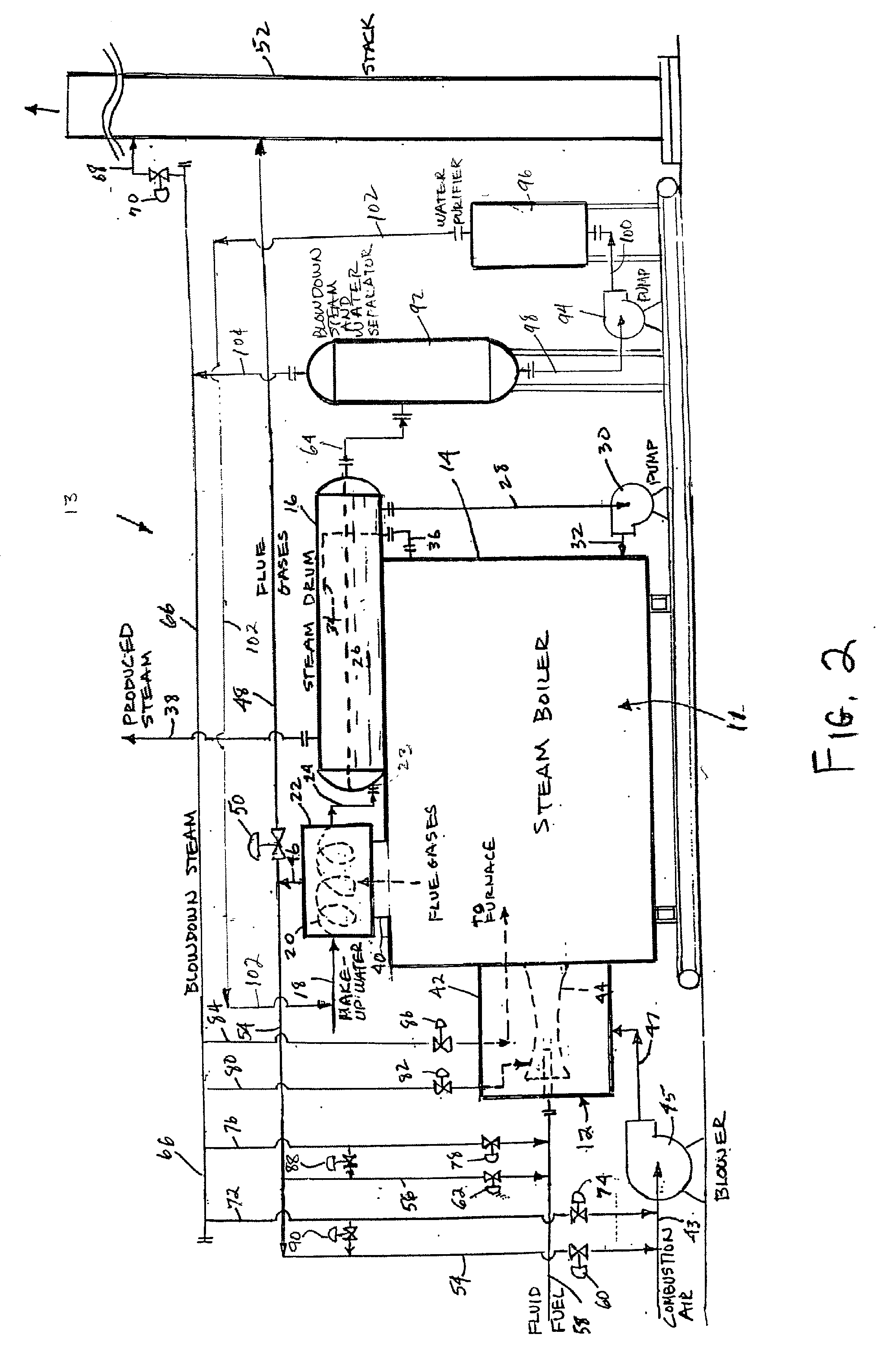

Method and apparatus for steam generation

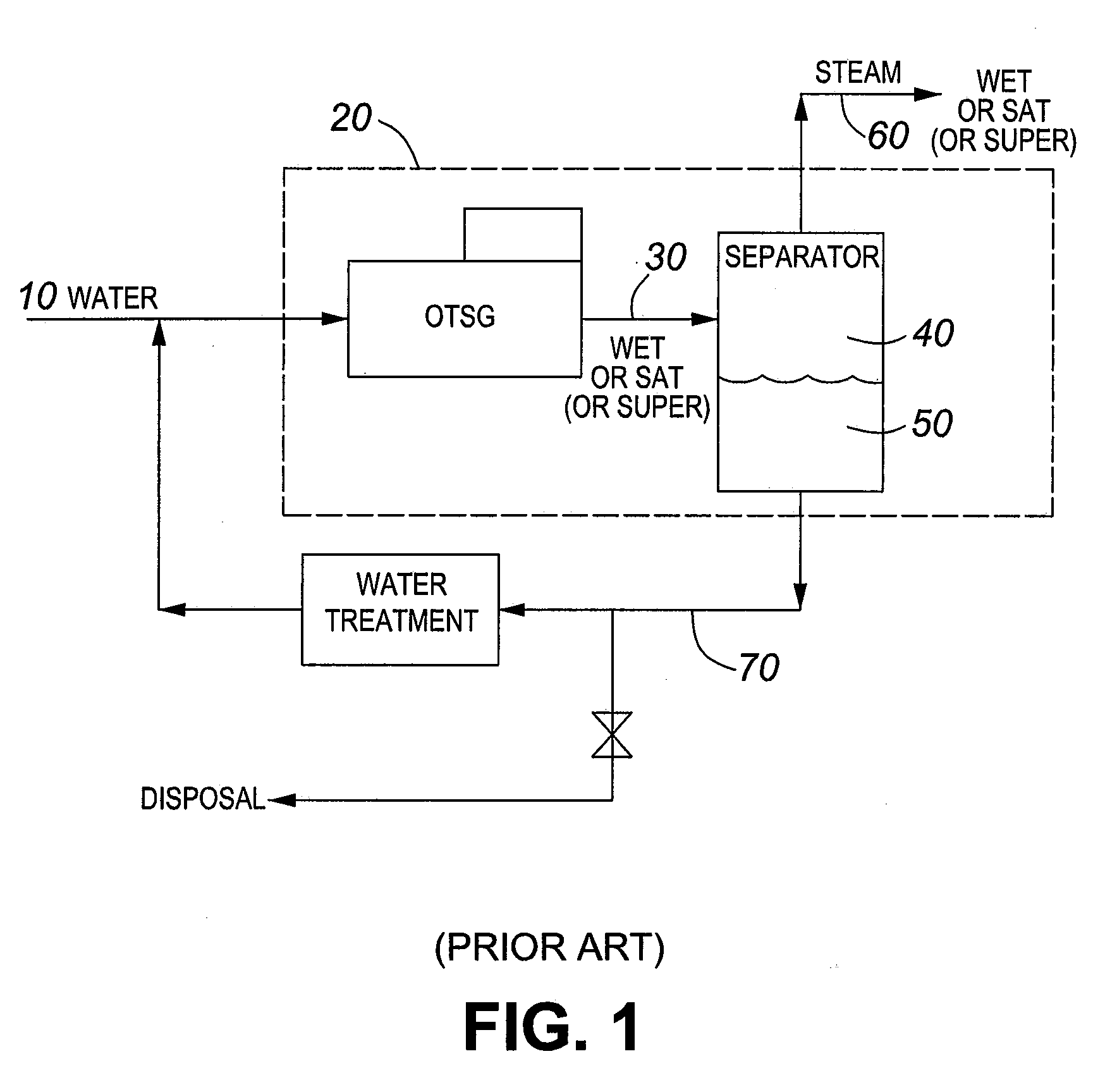

ActiveUS20090133643A1Reduce in quantityIncrease volumeWater circulationSteam separation arrangementsBoiler blowdownHardness

A method, apparatus, and system and operation of surface equipment to generate steam while reducing the quantity of boiler blowdown and thereby increasing the amount of feedwater that is re-used or re-cycled in generating said steam. The present invention teaches that, on a sustained basis, the blowdown stream at the outlet of a once-through steam generator can be routed to the inlet of a second once-through steam generator that is in series with the first, that blowdown stream can be used to generate additional steam in the second once-through steam generator and further reduce the amount of blowdown, and that this can be accomplished without need of any treatment that reduces hardness or silica levels of the blowdown stream prior to its entering or during its entry into the inlet of the second once-through steam generator. The output of this second steam generator is a substantially dry saturated steam vapor stream and, complementarily, a blowdown stream whose mass rate has been reduced substantially from that of the blowdown stream exiting the first steam generator.

Owner:FCCL PARTNERSHIP

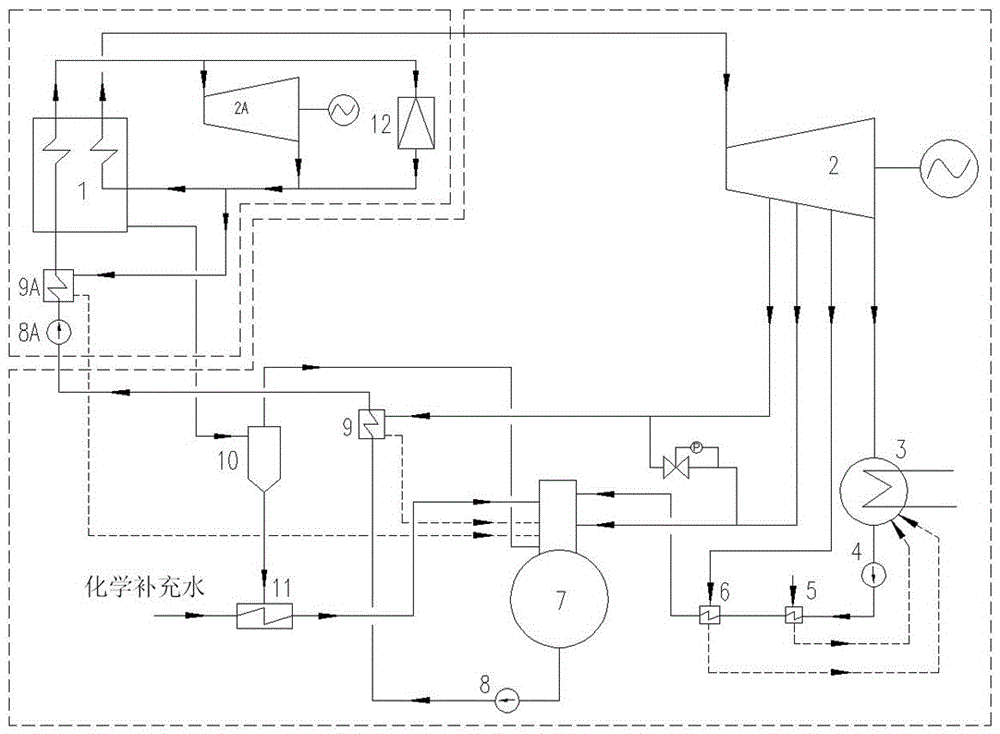

Coal gas power generation system for steel mills

InactiveCN106321175AImprove working abilityGuaranteed uptimeSteam engine plantsPower capabilityBoiler blowdown

A coal gas power generation system for steel mills comprises a low-voltage power generation system and a boiler blowdown system, wherein the low-voltage power generation system mainly consists of a turbo generator set, a condenser, a condensate pump, a steam seal heater, a low-pressure heater, a deaerator, a feed pump and a primary high-pressure heater; the boiler blowdown system mainly consists of a blowdown flash vessel and a sewage heater; and the coal gas power generation system further comprises a gas-fired boiler and a high-voltage power generation system, and the high-voltage power generation system mainly consists of a back-pressure turbo generator set. According to the coal gas power generation system, the ultrahigh-pressure gas-fired boiler is adopted to produce ultrahigh steam with higher quality, so that the power capability of steam is improved. According to the coal gas power generation system, as the turbo generator set adopts a back-pressure turbine of which the exhaust steam parameters meet the demands on reheating of the gas-fired boiler and the inlet steam parameters of an original medium-temperature medium-pressure steam turbine, and normal operation of an original medium-temperature medium-pressure turbo generator set is guaranteed without dismantlement.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Blowdown heat recovery

ActiveUS6938583B2Provide controlPreserving thermal energyBoiler cleaning apparatusMachines/enginesThermal energyBoiler blowdown

A method of recovering heat energy during blowdown of a steam boiler is described wherein thermal energy is recovered both from flash steam produced by blowdown water and the blowdown water itself. The flash steam is preferably condensed in the feedwater (or any open vented water tank) so as to recover the water volume of the flash steam in addition to its heat energy.

Owner:WOOD STEWART J

Intelligent blowdown boiler

InactiveCN104949098AAvoid wastingRealize automatic online monitoringBoiler cleaning apparatusEnergy industryThermal energyAutomatic control

The invention provides an intelligent blowdown boiler which comprises an automatic control blowdown system. The automatic control blowdown system is automatically controlled according to the amount of steam generated by the boiler and the amount of water input into the boiler. The water supply amount and the generated steam amount of each boiler are monitored in real time, so that the dynamic relation of the water supply amount and the generated steam amount is obtained, whether the blowdown system of the boiler works normally or not is judged, and waste of a large amount of heat energy waste caused by faults of the blowdown system of the boiler is avoided.

Owner:张雪原

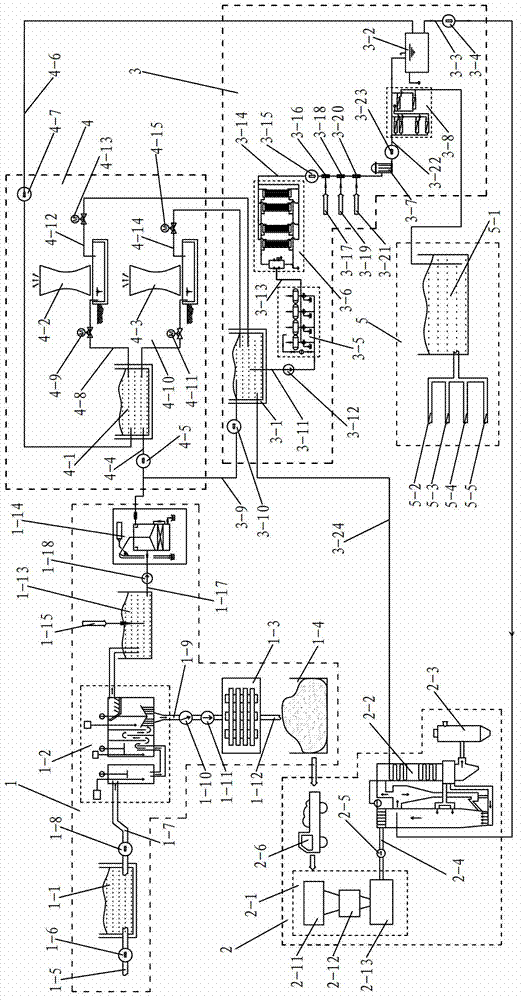

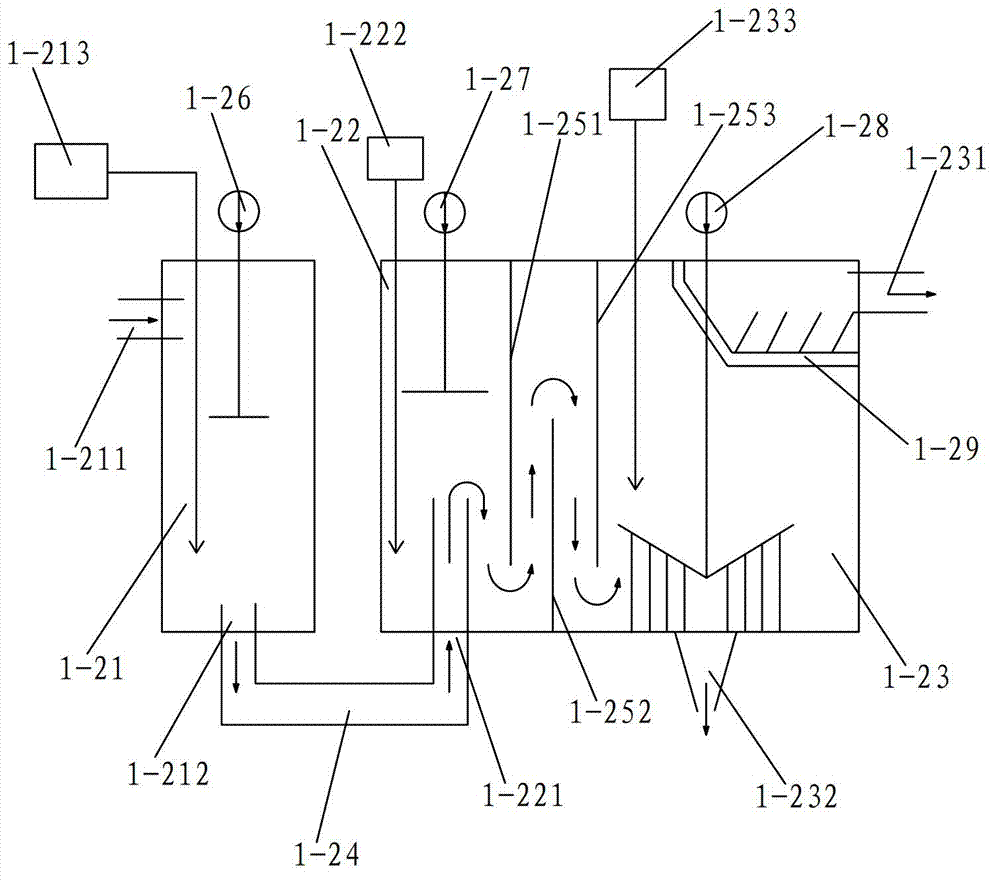

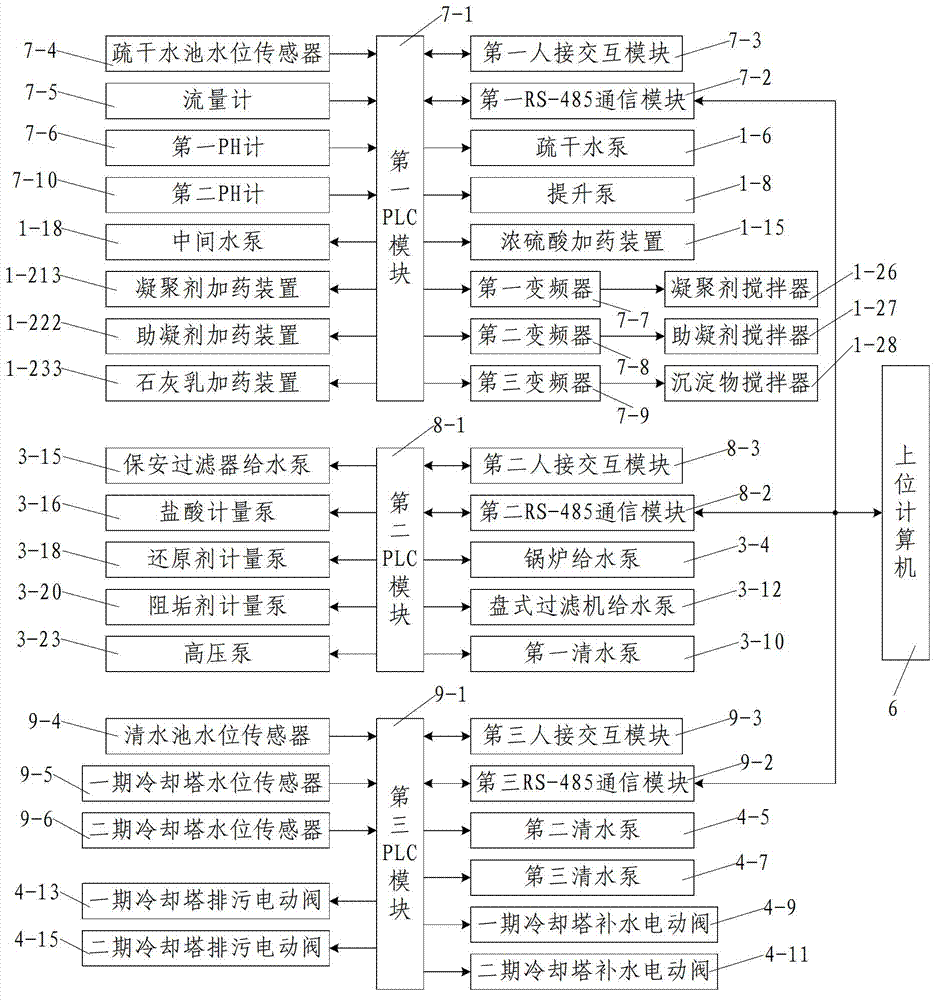

A system and a method for recycling coal mine drainage and power plant waste water with zero discharge

ActiveCN103288243ACompact structureNovel and reasonable designSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentEnvironmental resistanceCooling tower

The present invention discloses a system and a method for recycling coal mine drainage and power plant waste water with zero discharge. The system comprises a coal mine drainage low-speed decarbonization treatment system, a sludge utilizing system, a boiler blowdown water recycling system, a clean water utilizing system and a concentrated drainage utilizing system. The coal mine drainage low-speed decarbonization treatment system mainly comprises a low-speed decarbonization treatment device; the boiler blowdown water recycling system mainly comprises a disc filter, an ultrafiltration water purifier, a security filter and a reverse osmosis water purifier; and the clean water utilizing system comprises a clean water reservoir, a first stage cooling tower and a second stage cooling tower. The method comprises steps of: 1, coal mine drainage low-speed decarbonization treatment; 2, sludge utilizing; 3, boiler blowdown water treatment and recycling; 4, clean water untlizing; and 5, concentrated drainage utilizing. According to the invention, the system and the method are novel and reasonable in design with zero discharge of both solid waste and waste water, energy-saving, environmental friendly, very practical, and high in promotion value; and recycling of waste water and full utilization of sludge can be achieved.

Owner:嘉兴笼列电子商务有限公司

Compound deoxygenation corrosion inhibitor for boiler water supply and preparation method thereof

InactiveCN107352610AAvoid corrosionOvercome the disadvantage of low oxygen removal efficiencySpecific water treatment objectivesWater/sewage treatment by degassingLiquid productBoiler blowdown

The invention provides a compound deoxygenation corrosion inhibitor for boiler water supply. The deoxygenation corrosion inhibitor includes a variety of organic components, all the components cooperate and can achieve rapid and effective removal of dissolved oxygen from boiler water, and overcome the shortcoming of low deoxygenation efficiency of single deoxidant. The deoxygenation corrosion inhibitor obtained by adjusting the organic alkalizer content can be applied to ordinary pressure, medium-pressure and high-pressure boilers, and has wide application range. Oxime and hydrazide have strong reducibility, can quickly remove dissolved oxygen from boiler water, and at the same time can generate a layer of dense black ferroferric oxide passivation film on the boiler inner wall so as to prevent further corrosion of the boiler. The deoxygenation corrosion inhibitor provided by the invention has no need for ammonia water to serve as the pH regulator, and avoids ammonia corrosion. The deoxygenation corrosion inhibitor provided by the invention is composed of all-organic components, does not introduce inorganic impurities or reaction by-products, does not affect the boiler blowdown and steam quality, and is a liquid product, and has the advantages of no toxicity, no flash point, and safe and convenient use and operation.

Owner:SHENYANG DREAMLAND ENVIRONMENTS TECH

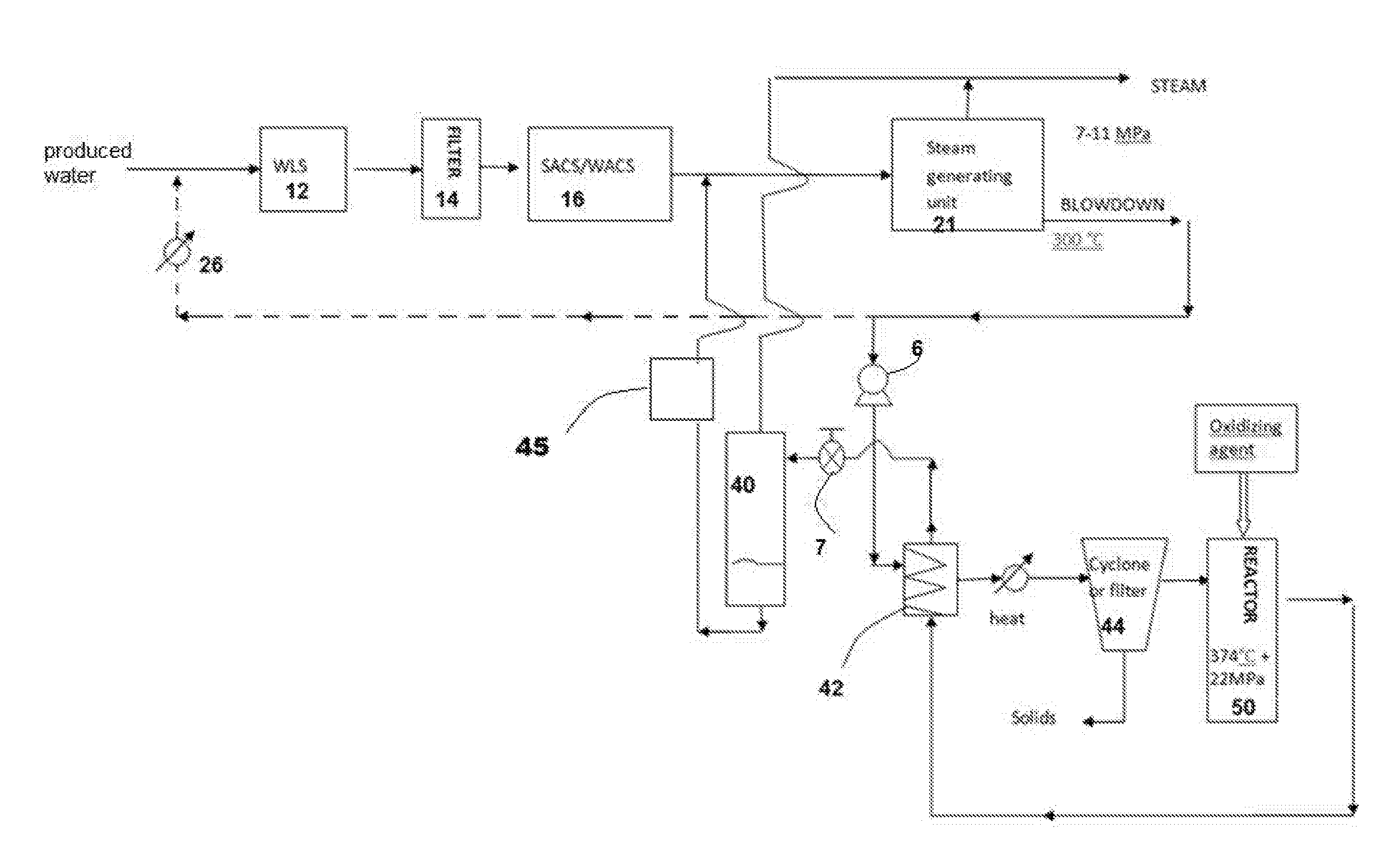

Blowdown recycle method and system for increasing recycle and water recovery percentages for steam generation units

InactiveUS20160244346A1Waste water treatment from quariesSpecific water treatment objectivesSolubilityBoiler blowdown

A boiler blowdown recycle method and system for increasing recycle and water recovery percentages for steam generation units used in thermal hydrocarbon recovery processes such as SAGD and CSS methods. Blowdown from a steam generating unit is elevated to supercritical temperatures and pressures, and an oxidizing agent added, thereby oxidizing organic and inorganic compounds in the blowdown and simultaneously reducing solubility of inorganics within the blowdown allowing them to precipitate out or be more easily separated therefrom, leaving a purified stream.

Owner:HUSKY OIL OPERATIONS

Method and device for improving thermal circulation efficiency

InactiveCN102620478AReduce coal consumptionReduce consumptionHeat pumpsSteam useBoiler blowdownNuclear power

Provided are a method and a device for improving thermal circulation efficiency. The method sends dead steam of a turbine into a condenser to exchange heat with coolant water in the condenser, temperature of the coolant water in an evaporator is decreased, the dead steam condensed and cooled flows into the condenser and then flows into a steam generator or a boiler to be warmed and pressurized, high temperature steam exhausted from the boiler or pumped from the turbine enters a generator to enable solution in the generator to be generated, generated coolant steam flows into the condenser, condensed coolant further enters the evaporator to be evaporated again and injected into the generator through an absorption circulation pump and an injection pump, and generated thick absorption liquid flow into an absorber and then enters the generator again with the coolant steam through the absorption circulation pump and the injection pump. The invention further comprises the device for improving thermal circulation efficiency of thermal power plants or nuclear power plants. The method and the device can reduce running cost, improve thermal circulation efficiency and have no pollution on the environment.

Owner:HUNAN CHUANGHUA LOW CARBON ENVIRONMENTAL PROTECTION TECH

Method for recycling the afterheat of continuous blowdown extension tank and device thereof

InactiveCN101446410AGuaranteed uptimeReduce heatLiquid degasificationFeed-water heatersBoiler blowdownWorking environment

The invention discloses a method for recycling the afterheat of a continuous blowdown extension tank and a device thereof. Secondary steam discharged by a second stage continuous blowdown extension tank (6) is connected to an air deaerator (1) by a pipeline (2). Secondary steam discharged by a first stage continuous blowdown extension (5) is connected to a pressure deaerator (3) by a pipeline. The first stage continuous blowdown extension (5) and the second stage continuous blowdown extension tank (6) pass through drainage water of a boiler, the capacity of which is expanded, go into a raw water preheater, change heat with demineralized water, and then send demineralized water into the air deaerator (1) for reusing afterheat. The invention greatly reduces heat loss, increases utilization rate of soft water, provides guarantee for efficient running of boiler water, reduces running cost and maintenance cost, and improves working environment.

Owner:GUIYANG AL-MG DESIGN & RES INST

Methods of utilizing boiler blowdown for reducing NOX

The present invention provides improved methods of reducing NOx emissions in the flue gases produced by a steam boiler fired by a fluid fuel and combustion air burner and including a steam drum provided with make-up water from which produced steam and blowdown steam are withdrawn. In accordance with the invention at least a portion of the blowdown steam is combined with the fluid fuel or combustion air or both.

Owner:JOHN ZINK CO LLC

Boiler blow down system

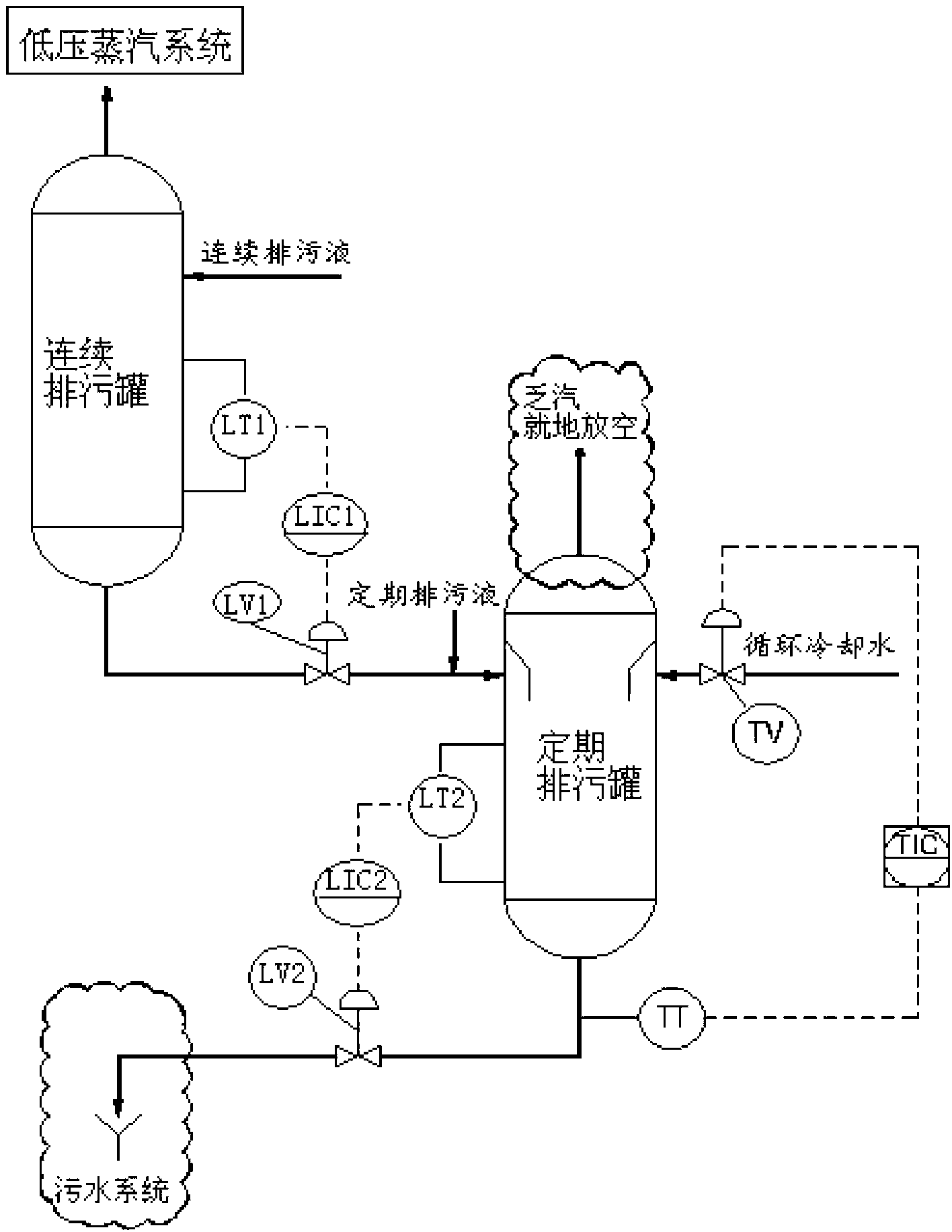

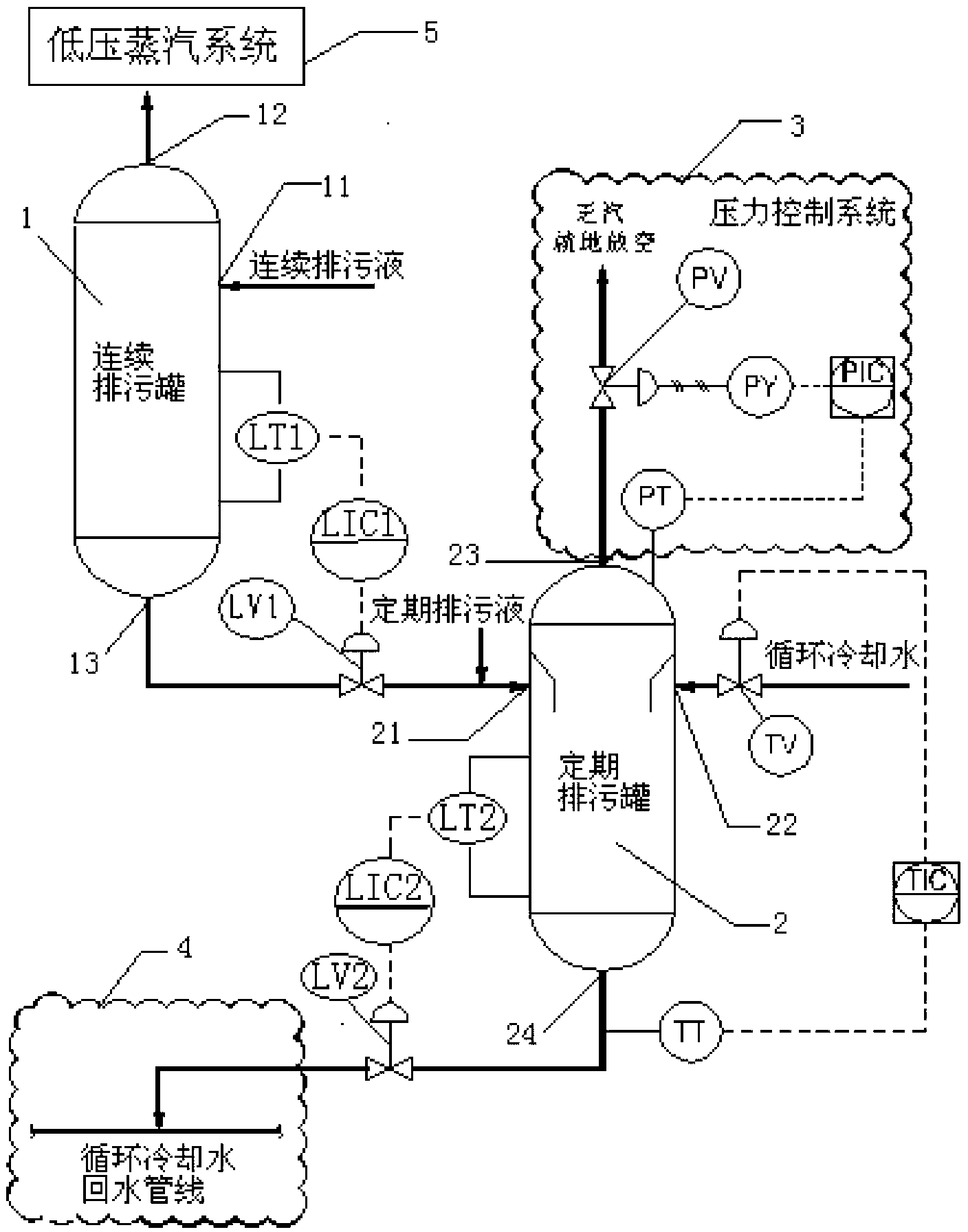

ActiveCN103307591AReduce wasteIncrease the amount of condensateBoiler cleaning apparatusBoiler blowdownControl system

The invention relates to a boiler blow down system which comprises a continuous blow down tank, a periodic blow down tank, a pressure control system and a recirculated cooling water return pipeline, wherein as for the continuous blow down tank, a tangential input port is used for inputting continuous blow down liquid, an output port at the top is used for outputting low-pressure steam, and an output port at the bottom is used for outputting bottom condensate into the periodic blow down tank; as for the periodic blow down tank, a first tangential input port is used for inputting the bottom condensate and the periodic blow down liquid of the continuous blow down tank, a second tangential input port is used for inputting recirculated cooling water, the output port at the top is used for discharging the low-pressure exhaust steam into atmosphere through the pressure control system, and the output port at the bottom is used for discharging tank bottom condensed water into the recirculated cooling water return pipeline; the pressure control system is arranged at the top of the periodic blow down tank and used for controlling the operating pressure of the periodic blow down tank and discharging low-pressure exhaust steam; and the recirculated cooling water return pipeline is arranged at the bottom of the periodic blow down tank and used for recovering tank bottom condensed water of the periodic blow down tank. The boiler blow down system can reasonably recycle the periodic blow down condensed water, which reduces water resource waste and boosts corporate profitability.

Owner:BEIJING PETROCHEM ENG

Boiler blow-down water heat energy utilization system

ActiveCN104033880AReduce the temperatureTemperature double heatingSteam generation heating methodsLiquid degasificationWater softeningBoiler blowdown

The invention discloses a boiler blow-down water heat energy utilization system which comprises a water softening station, a boiler, a flash tank, a heat exchanger and a cooling tank. The water softening station comprises a water softener and a water tank, the water softener is connected with the water tank through a soft water outlet tube, and the water softener is connected with a backwash water outlet tube. The heat exchanger is connected with a boiler water supply tube, a cooling tank water inlet tube, a flash tank connecting tube and a water tank outlet tube. The boiler is connected with a boiler water supply tube and a boiler blowdown tube. The top of the flash tank is connected with the water tank through a water tank connecting tube, and the bottom of the flash tank is connected with the heat exchanger through the flash tank connecting tube. The cooling tank is connected with the heat exchanger through the cooling tank water inlet tube, and the bottom of the cooling tank is connected with a cooling tank blowdown tube. The side wall of the cooling tank is connected with an overflow tube, and the overflow tube is connected with a sewage pool. According to the boiler blow-down water heat energy utilization system, boiler blow-down water is used for heating boiler inlet water, flash steam is used for heating water in a hot water tank, so that the temperature of the boiler blow-down water is lowered, the temperature of the boiler inlet water is dually heated, and heat energy needed by the boiler is saved.

Owner:CHINA TOBACCO HENAN IND

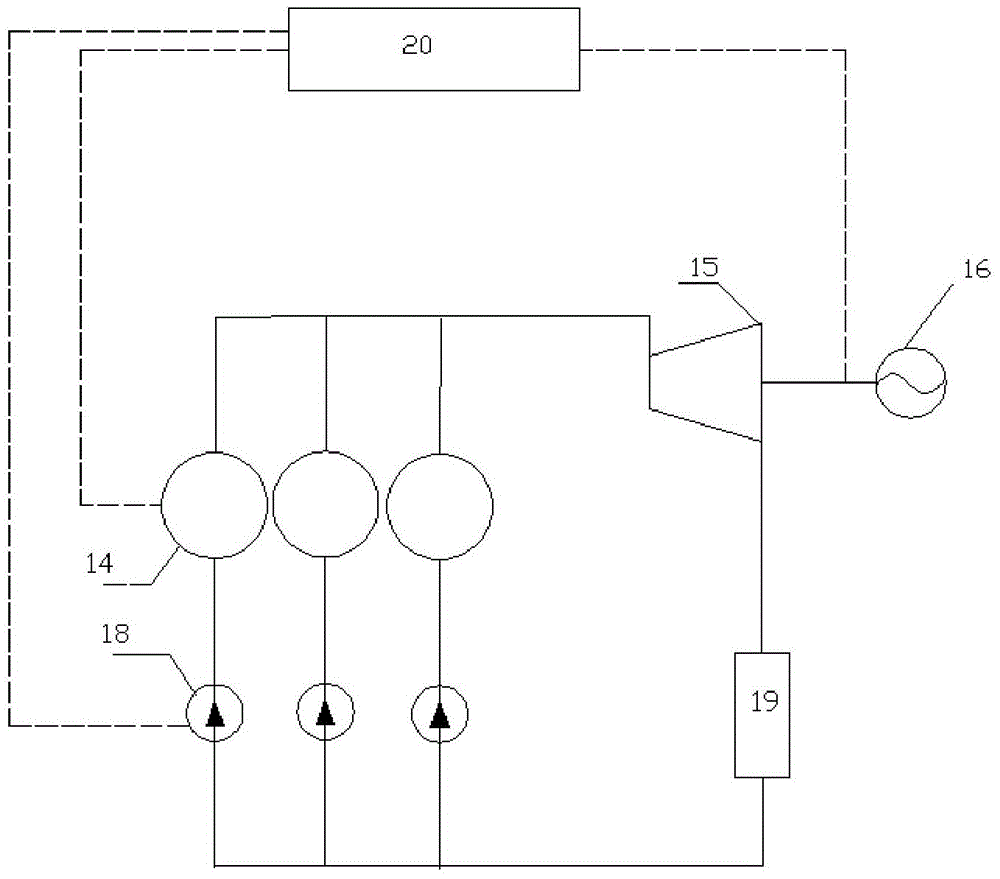

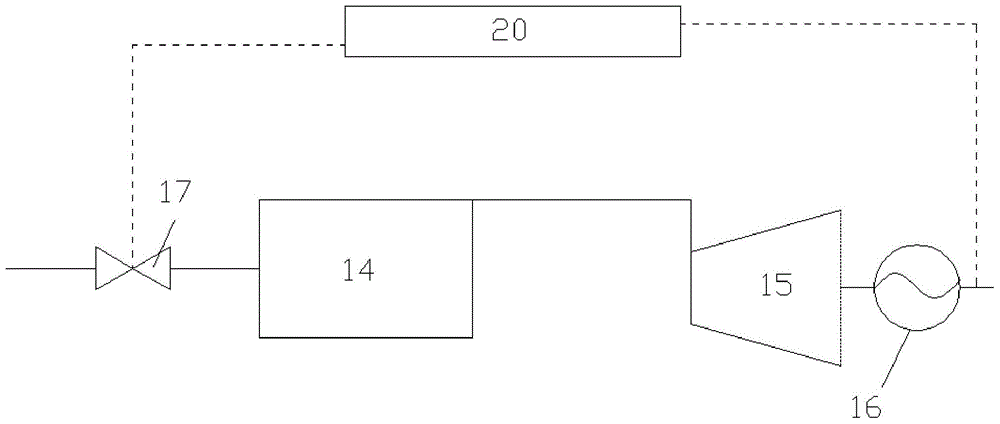

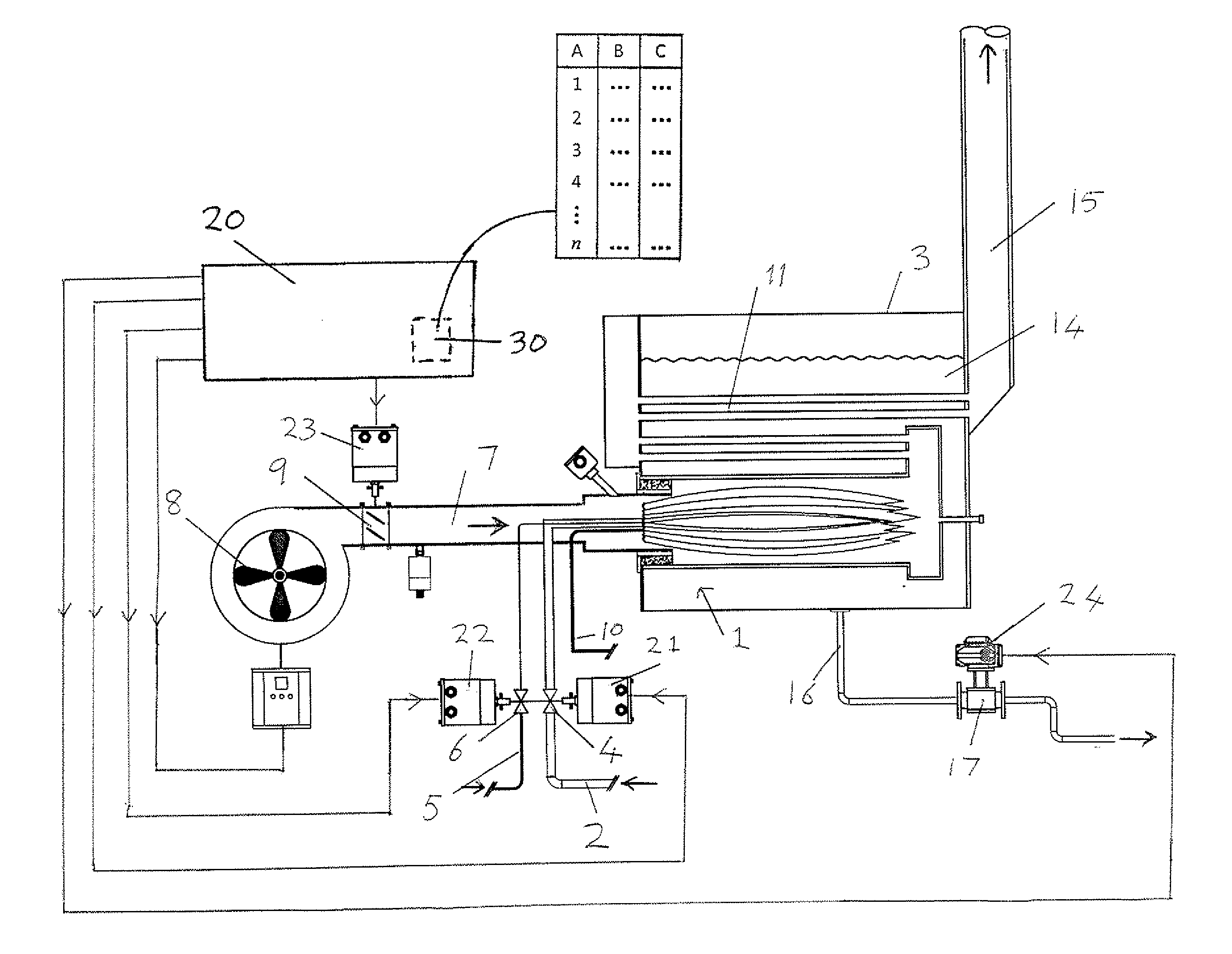

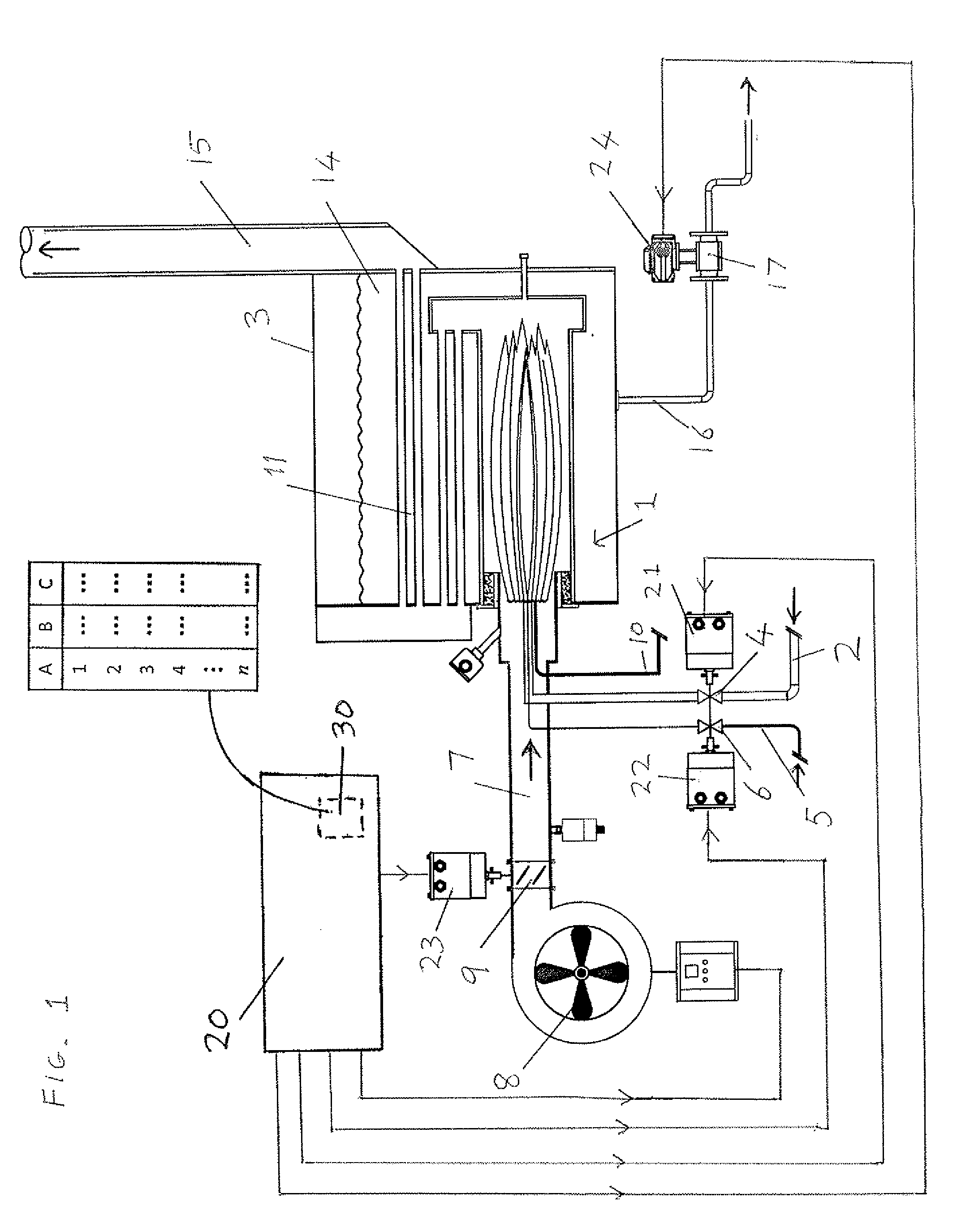

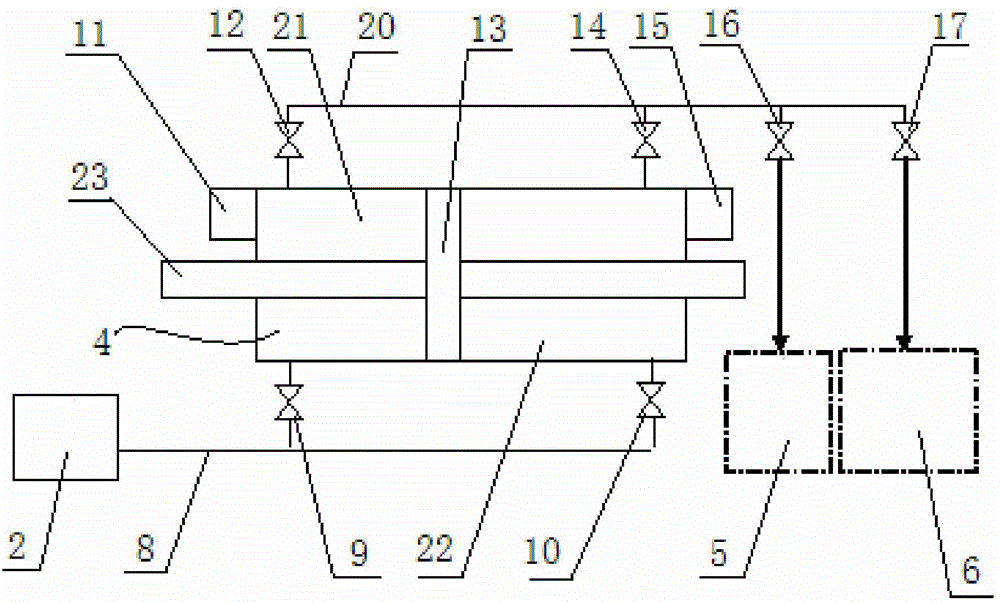

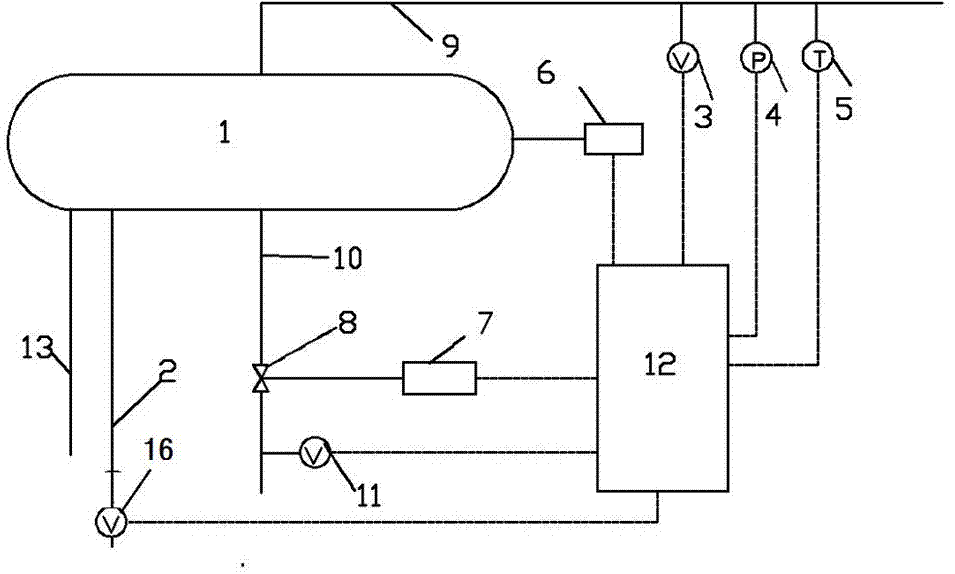

Control of blowdown in steam boilers

InactiveUS20140102382A1Reduce heat lossReduce wasteBoiler cleaning apparatusMachines/enginesProduction rateBoiler blowdown

Blowdown of a pressurised steam boiler heated by a burner 1 and including a blowdown flow control valve 17 is controlled by opening the control valve in response to receiving a control signal from a control unit 20 to allow water to leave the boiler. The control unit receives one or more signals indicative of the steam production rate of the boiler and adjusts the amount of blowdown in dependence upon the aggregate steam production.

Owner:AUTOFLAME ENG

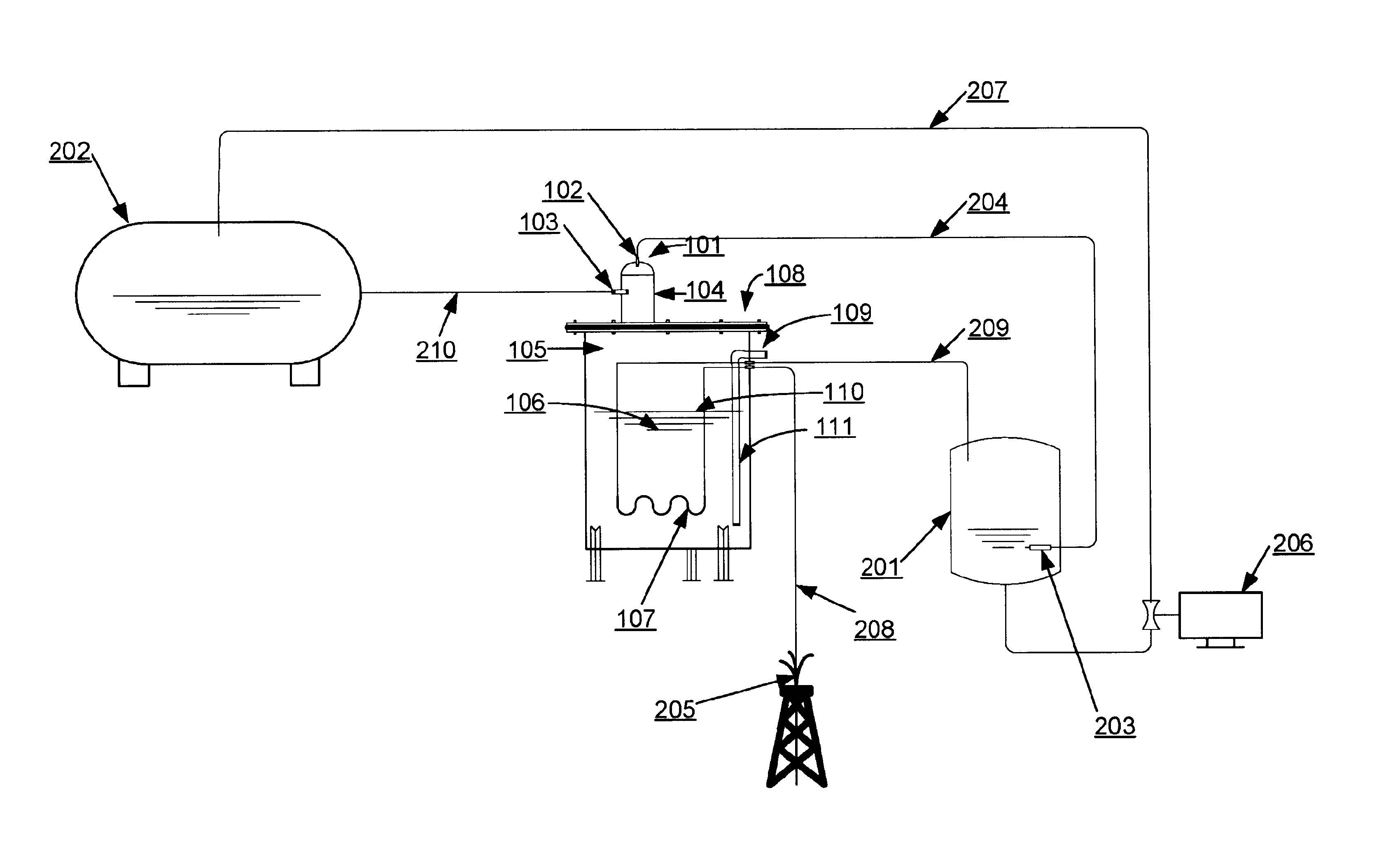

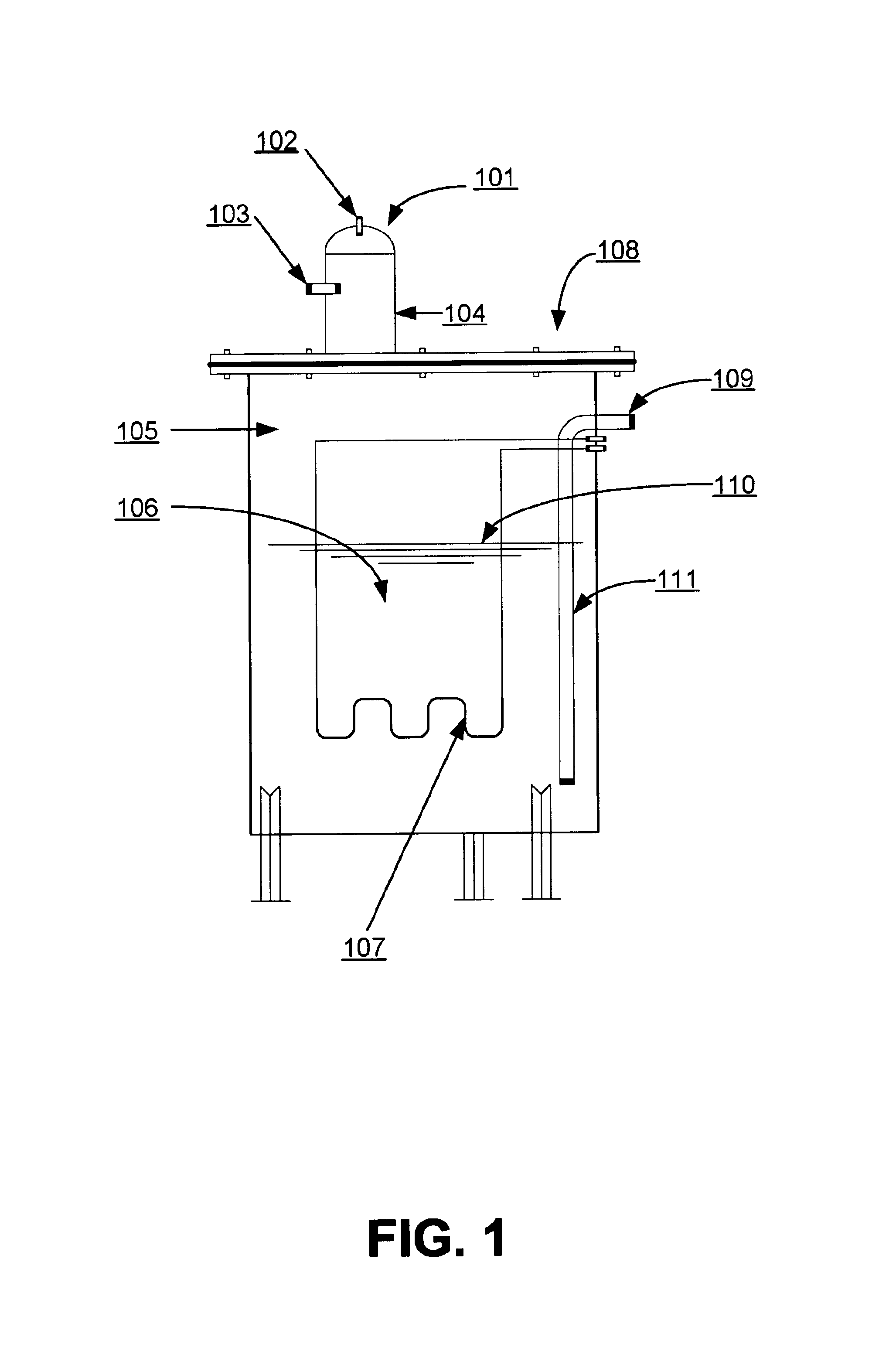

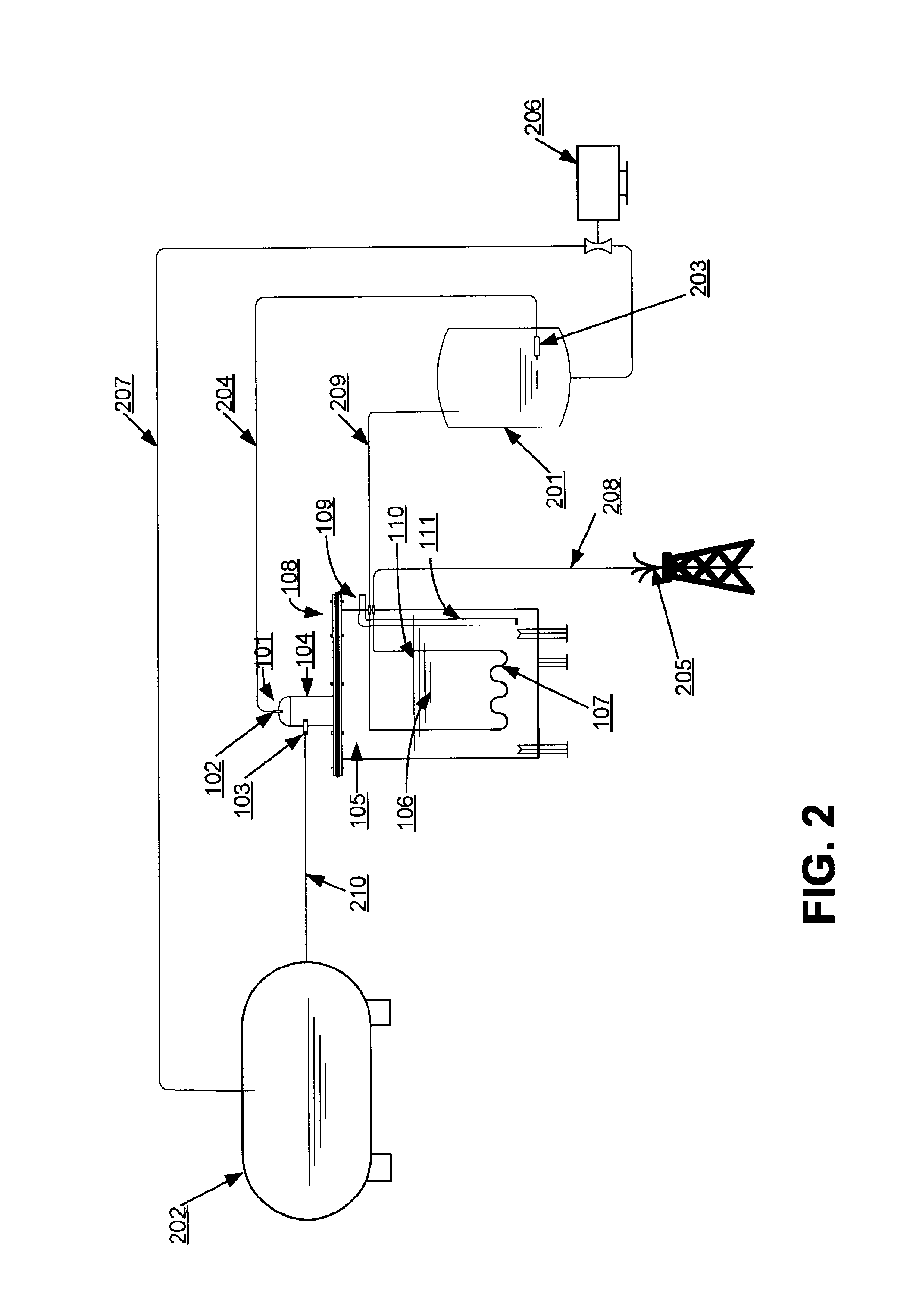

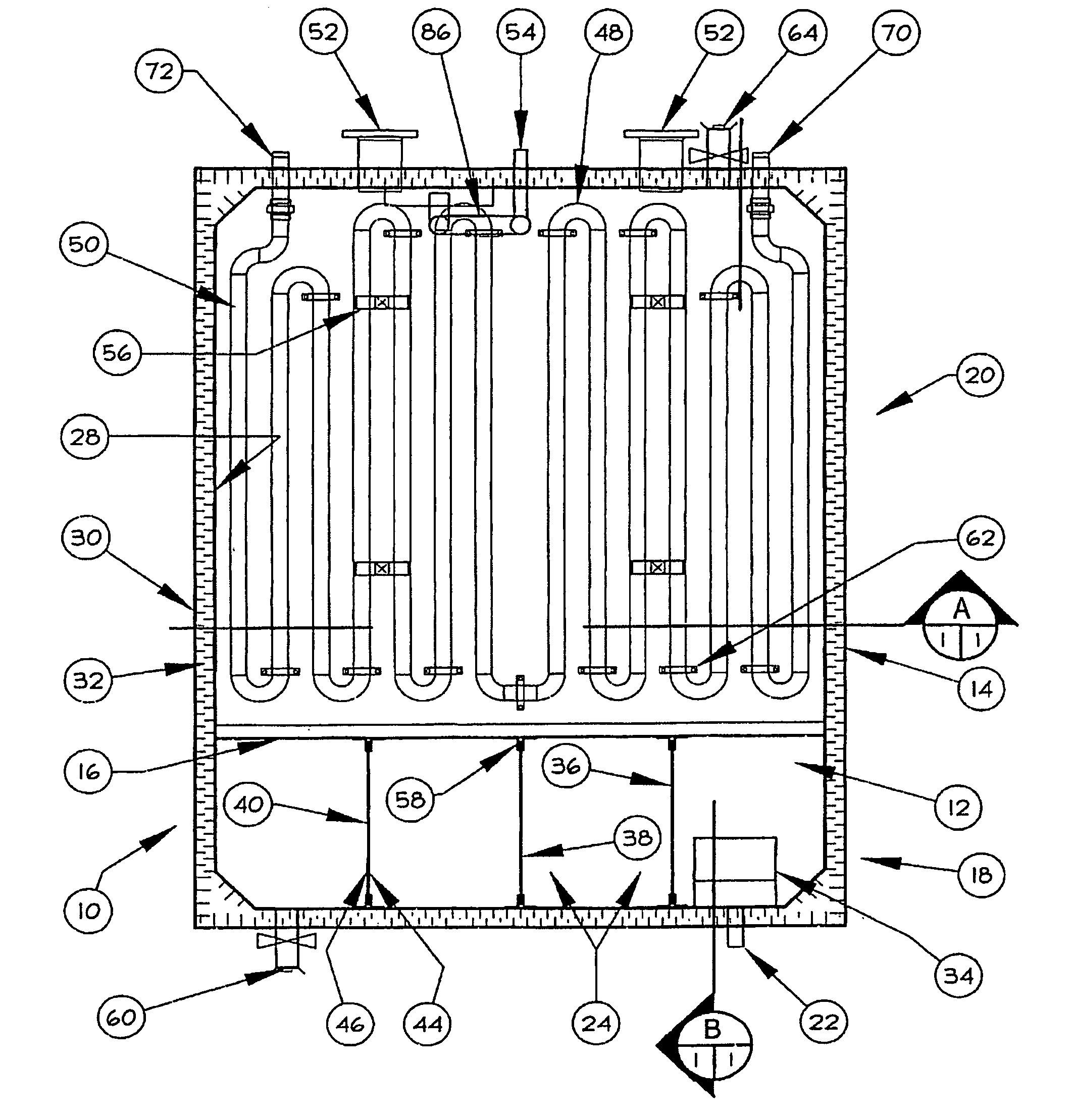

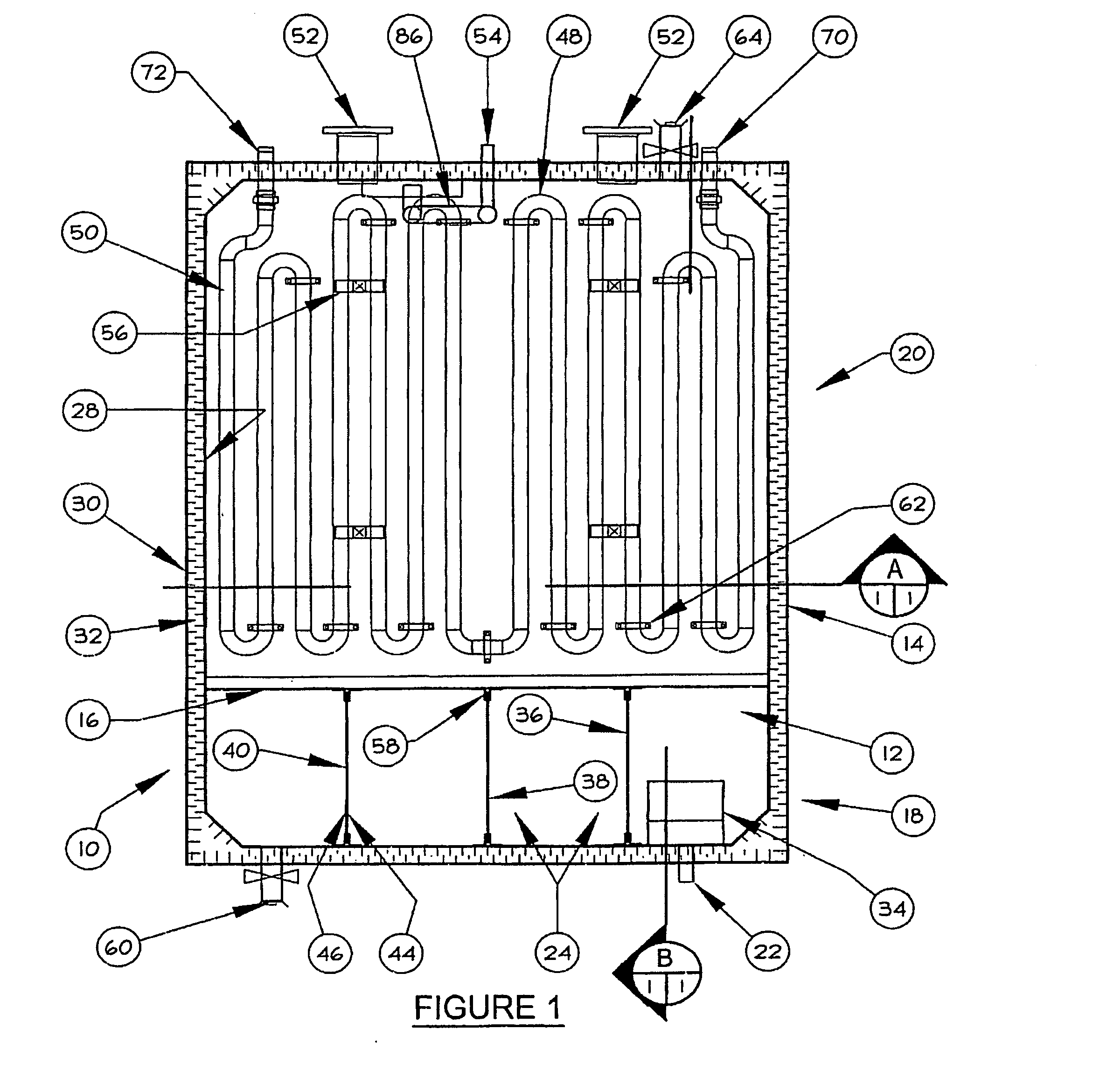

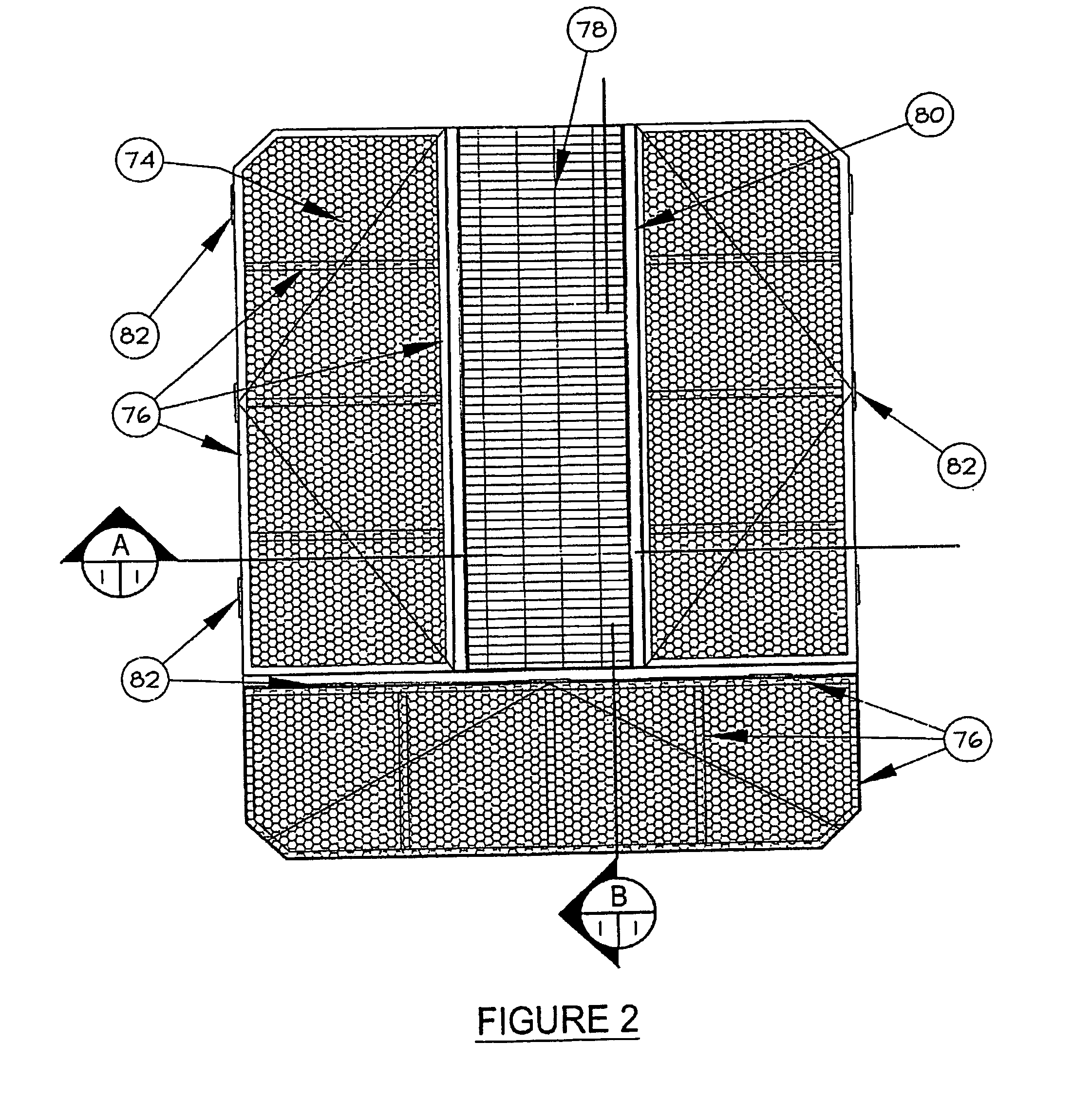

Settling and evaporation tank apparatus, method and system

InactiveUS20070181262A1Increase evaporation rateLower Level RequirementsSedimentation tanksSettling tanks heating/coolingBoiler blowdownWater treatment system

An apparatus, method and system for treating contaminated water. The apparatus comprises a tank with a dividing member dividing the tank into a settling region and an evaporation region. The settling region comprises an inlet, weir means, and an outlet, and the evaporation region comprises an inlet and heat application means, the settling region outlet in fluid communication with the evaporation region inlet. The method comprises allowing contaminated water to encounter the weir means, producing contaminants and cleaned water, and transporting the cleaned water to the evaporation region, where the heat application means apply heat to the cleaned water allowing evaporation of the cleaned water. The water treatment system comprises a settling sub-system for receiving contaminated water from a source and allowing contaminants to settle out of the contaminated water, producing cleaned water, and an evaporation sub-system in fluid communication with the settling sub-system for receiving the cleaned water and enabling evaporation of the cleaned water. Preferably, the system further comprises a boiler blowdown sub-system in fluid communication with the evaporation sub-system, wherein an adjacent boiler is allowed to vent boiler contents into the evaporation sub-system during boiler blowdown.

Owner:R&B OILFIELD RENTALS

Energy-saving scale inhibiting and removing anticorrosion compound medicament for steam boiler and preparation method of medicament

InactiveCN103922491ADecrease increaseHigh molecular weightTreatment using complexing/solubilising chemicalsSludgeTannin

The invention discloses an energy-saving scale inhibiting and removing anticorrosion compound medicament for a steam boiler and a preparation method of the medicament. The preparation method comprises the following steps of preparing an organic component: weighing the following components in parts by weight: 15-35 parts of lignin, 5-20 parts of sodium alga acid, 0.5-2.5 parts of sodium humate, 1.5-3.5 parts of sodium tannin, 1.5-3.5 parts of modified starch, and 2.5-5.5 parts of glycol derivative, so as to obtain the organic component; preparing an inorganic component: weighing the following components in parts by weight: 2.5-5.5 parts of sodium hydroxide, and 5-17 parts of trisodium phosphate, so as to obtain the inorganic component; mixing the organic component with the inorganic component so as to obtain the compound medicament for the steam boiler. According to the medicament, the blowdown rate of the boiler can be lowered, water scale can be effectively prevented from generating, the old scale in the system can be dissolved and converted into sludge to be removed through pollution discharge, the sludge is in flow condition, so as not to block a meter and a valve, any on-going corrosion in the system can be inhibited, 100% pure neutral steam can be guaranteed to be produced, and priming of the steam boiler is prevented.

Owner:WEIFANG GLAN GREEN

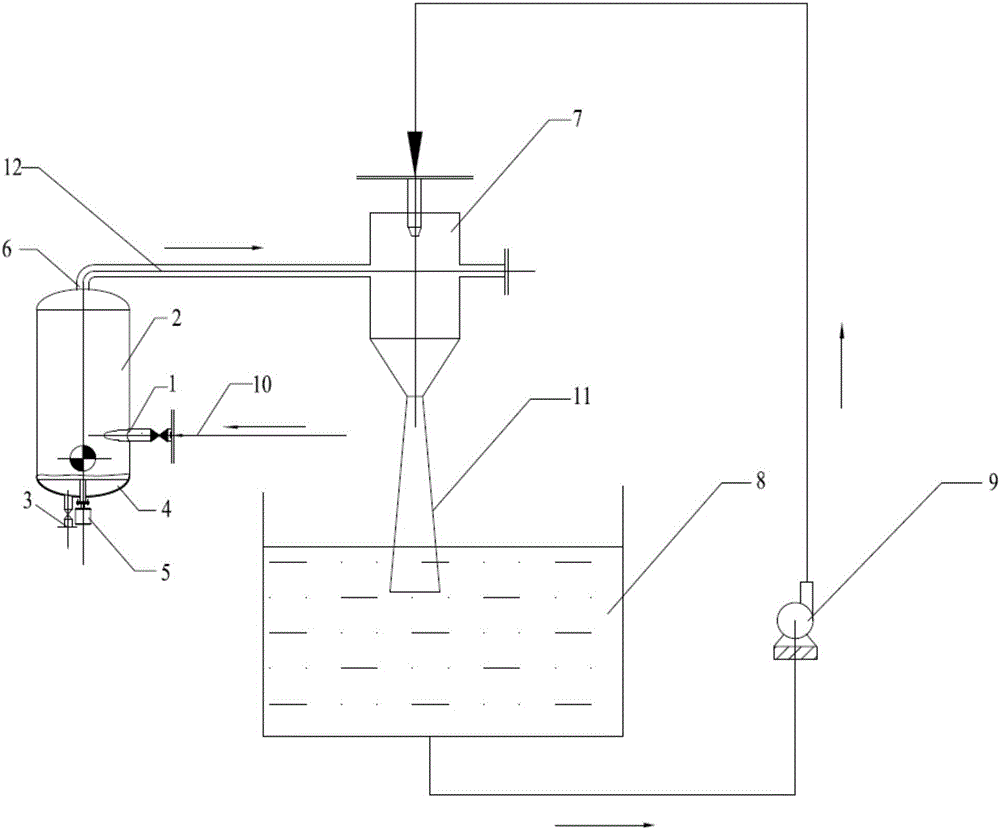

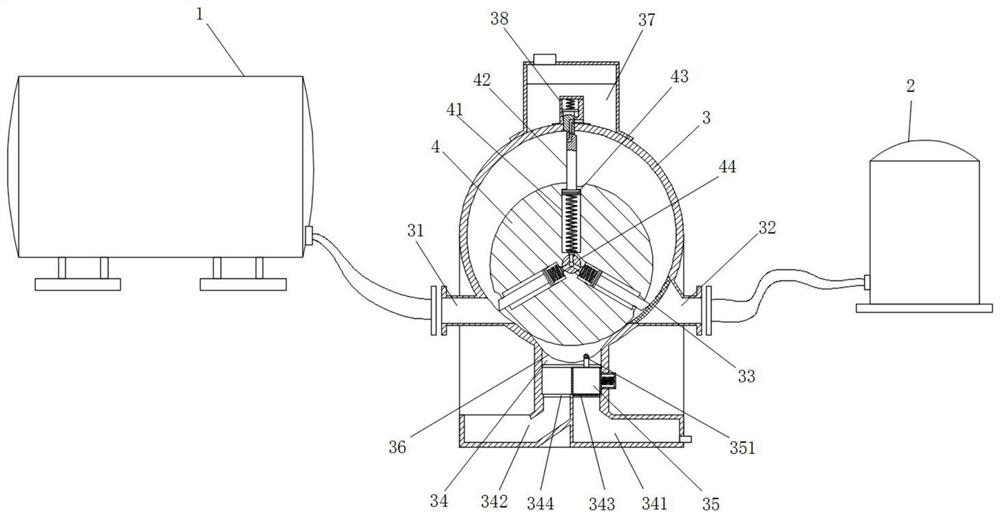

Pollution discharge, water and energy saving, recovery and separation device and method of steam injection boiler

InactiveCN105864743AReduce labor intensitySignificant water savingFeed water supplySpecific water treatment objectivesBoiler blowdownPotassium

The invention discloses a pollution discharge, water and energy saving, recovery and separation device and method of a steam injection boiler and relates to the technical field of boiler equipment. The device comprises a pollution discharge tank, a water blaster, a water-jet pump, a rotary discharging machine and a boiler water filling pool. High-temperature, high-pressure and high-salinity boiler water from a boiler pollution discharge pipe tangentially enters the pollution discharge tank, expands and depressurizes inside the tank, and generates a large amount of steam through flash evaporation; due to the function of the water-jet pump, the water blaster is kept in a negative pressure state from minus 100 kPa to minus 50 kPa; steam generated inside the pollution discharge tank is sucked in through the water blaster and dissolved in cold water from the water-jet pump, heats the cold water and is stored in the boiler water filling pool to be recycled; and the high-salinity water is separated from steam under the effects of flash evaporation and rotation, stored in the bottom of the pollution discharge tank, and discharged out of the tank through the rotary discharging machine, so that crystallized potassium, sodium and other saline materials or alkaline materials are prevented from adhering to the wall of the pollution discharge tank. The pollution discharge, water and energy saving, recovery and separation device can be used in cooperation with the steam injection boiler, and the steam injection boiler can be a fluidized bed boiler, a pulverized coal furnace, a grate furnace, a gas-fired boiler or an oil fired boiler.

Owner:TSINGHUA UNIV

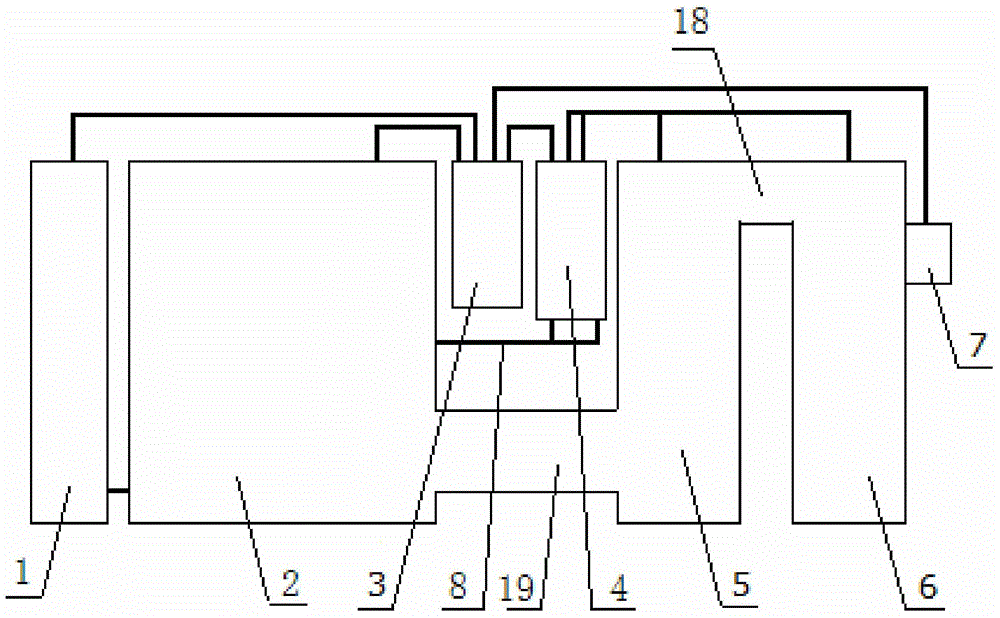

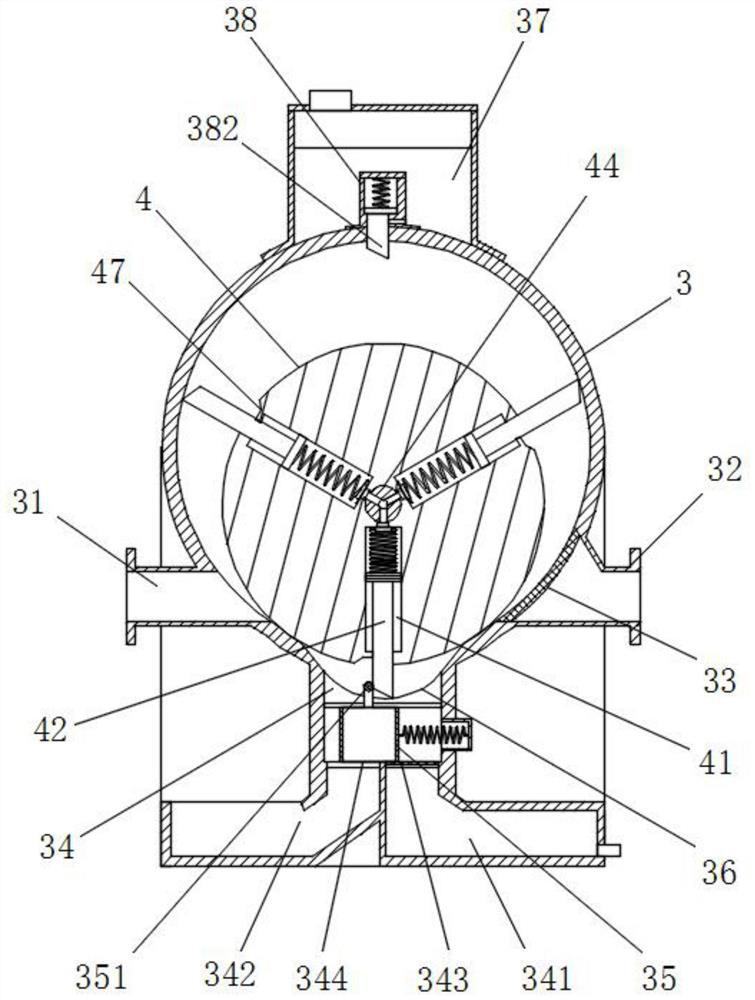

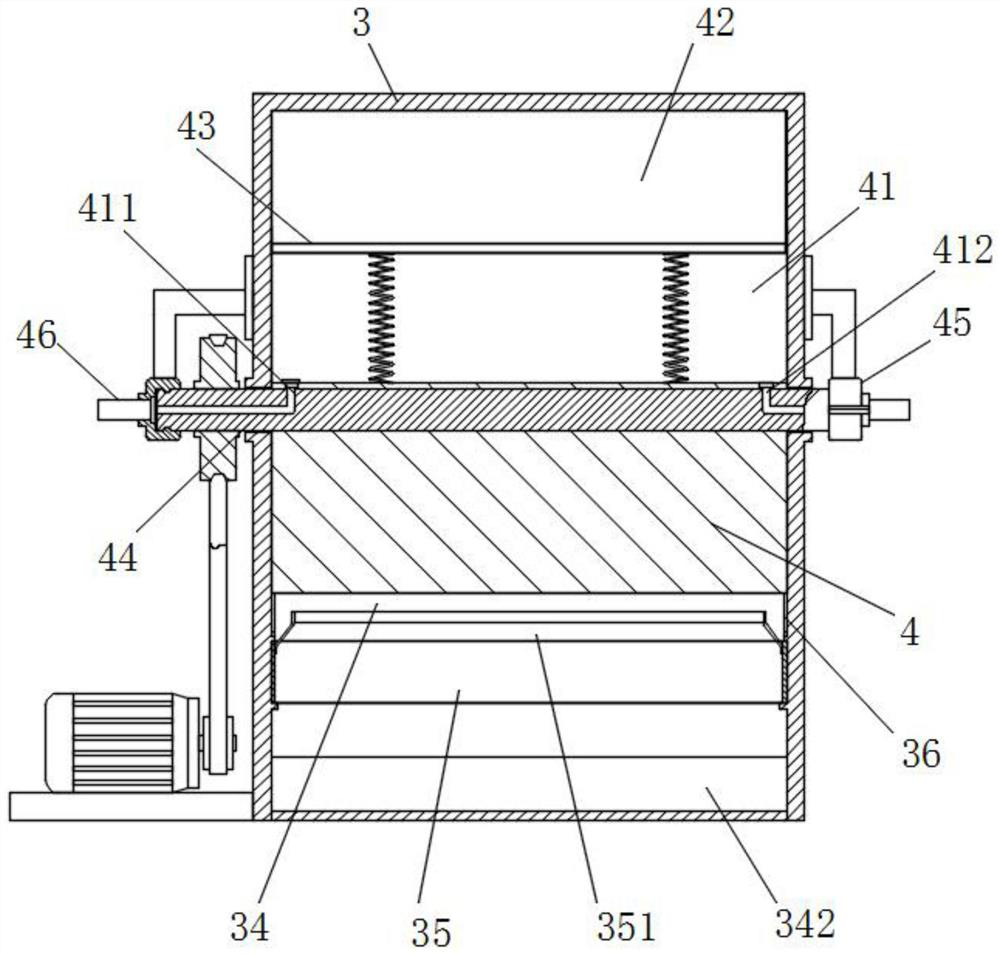

Boiler blow-down water storage and allocation device and usage method thereof

ActiveCN104930493AImplement alternate storageRealize distributionFluid heatersBoiler cleaning apparatusWater storageBoiler blowdown

The invention relates to the field of industrial boilers, in particular to a boiler blow-down water storage and allocation device and a usage method thereof. The boiler blow-down water storage and allocation device comprises a water storage vat and a water diversion pipe. A piston is arranged in the water storage vat. The piston divides the interior of the water storage vat into two airtight and volume-variable water storage spaces. A blow-down water pipe is communicated with the two water storage spaces in the water storage vat through two branches. The two water storage spaces in the water storage vat are connected with the water diversion pipe arranged outside the water storage vat through pipelines. The output end of the water diversion pipe is communicated with different devices needing supply of the blow-down water through two branches. According to the boiler blow-down water storage and allocation device, supply of blow-down water among all the devices can be effectively adjusted in the process of treating the boiler blow-down water.

Owner:DANDONG BLUESKY ENVIRONMENT PROTECTION BOILERS

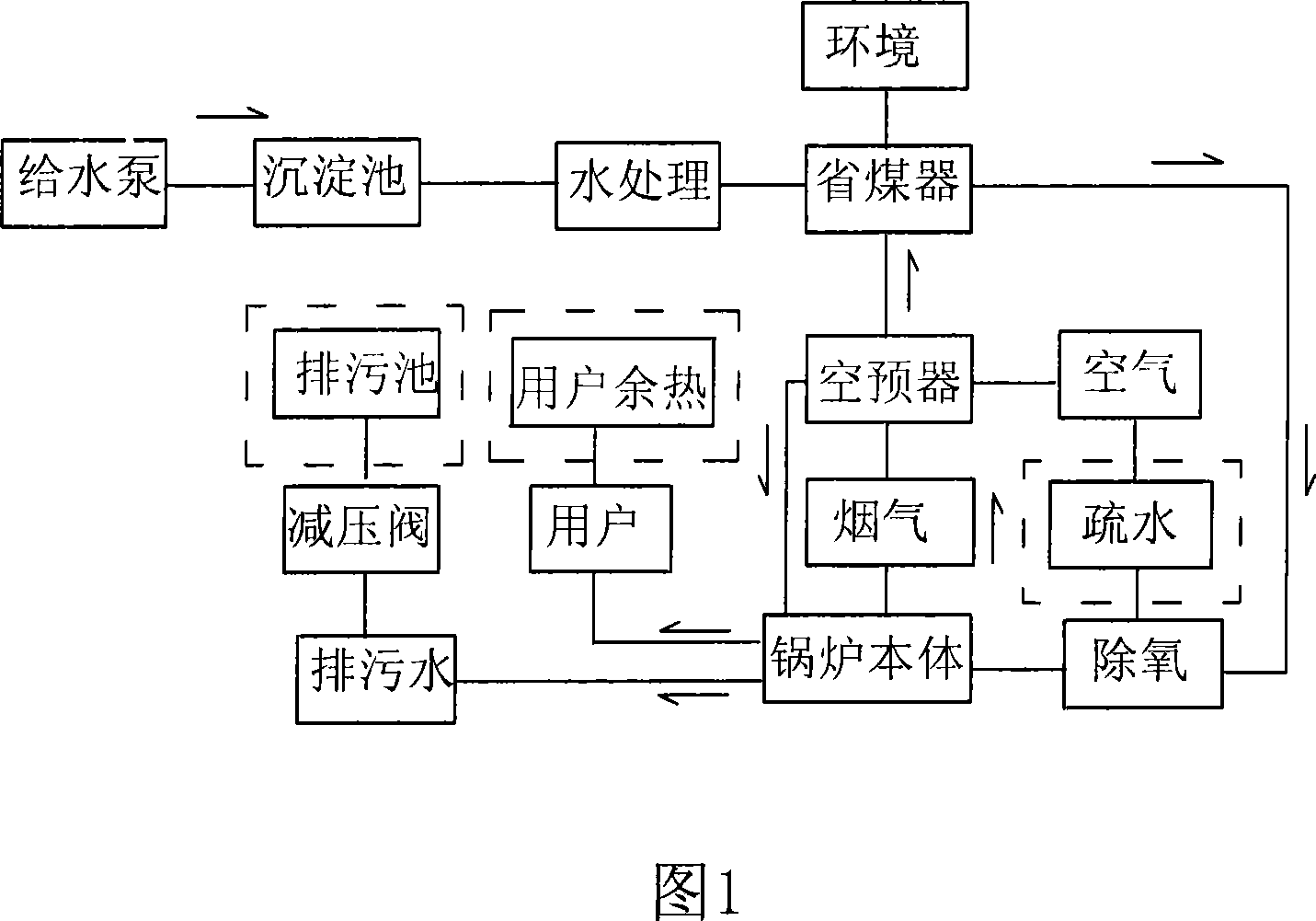

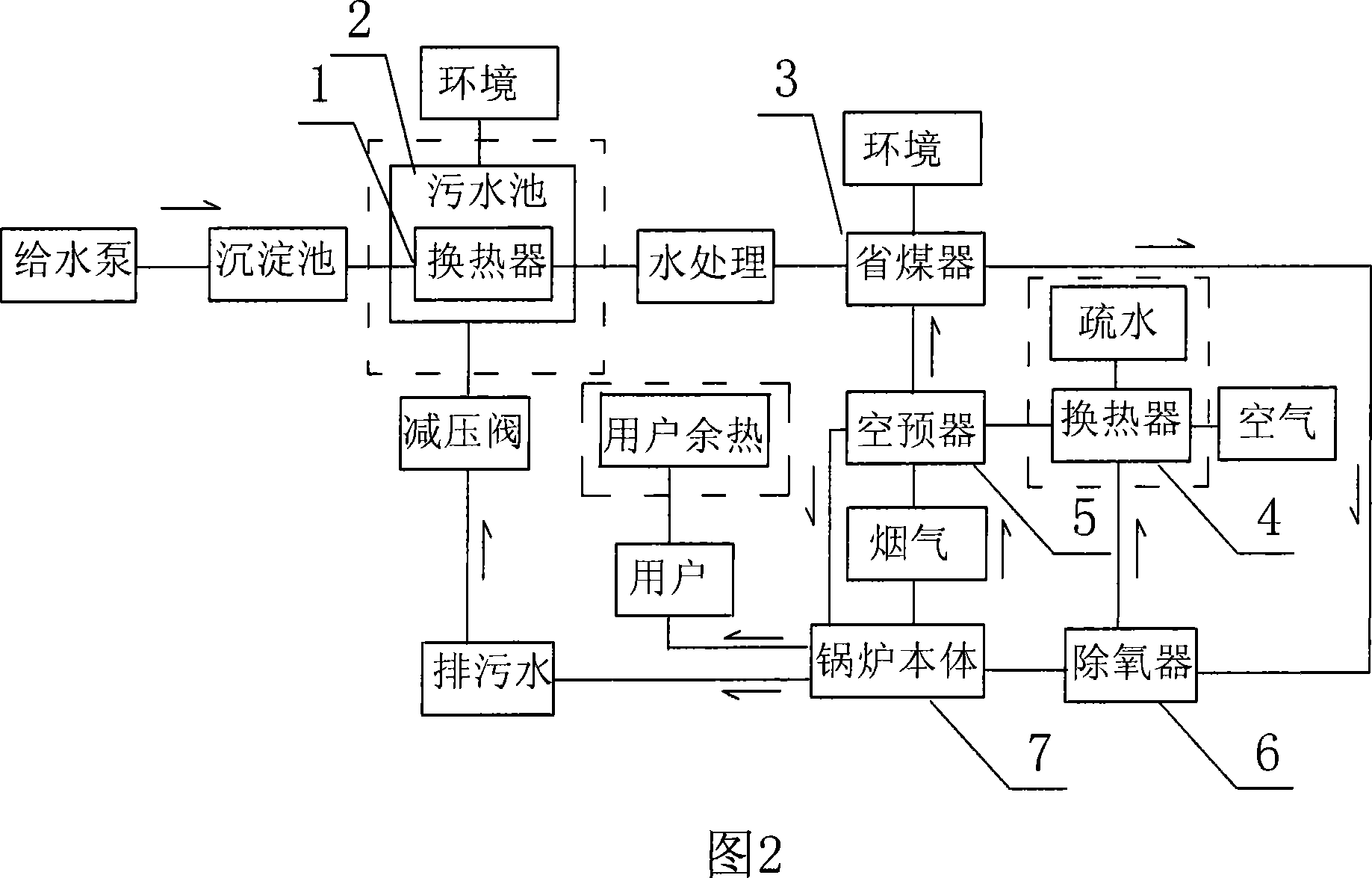

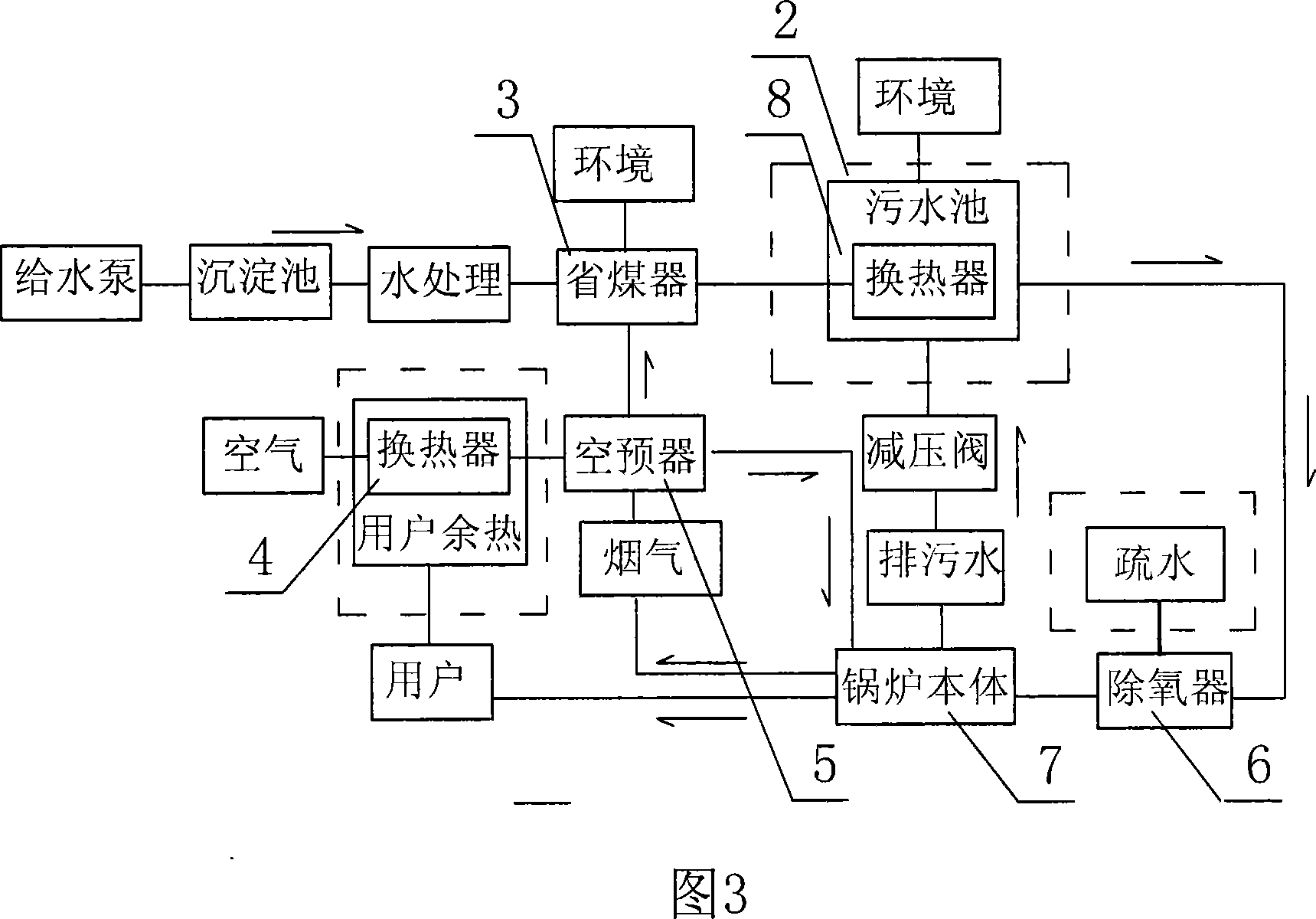

Discrete low grade residue heat recovery boiler high temperature water-supply and air preheater system

InactiveCN101055073AGuaranteed uptimeSteam generation using hot heat carriersFeed-water heatersAir preheaterBoiler blowdown

The present invention discloses a boiler high temperature water feeding and air preheating system for reclaiming dispersed low grade residual heat which includes a pollution discharge pool (2), a coal economizer (3), an air preheater (5) and a boiler furnace (7). The pollution discharge pool (2) is buried with a pipe heat exchanger (1) connected to the tap water in front of the coal economizer (3), or the pollution discharge pool (2) is mounted with a water-water heat exchanger (8) after the boiler water enters the coal economizer (3) and before a deaerator (6); a heat exchanger (4) disposed at the user residual heat place is connected to the air preheater (5) in the front of the boiler furnace (7). The invention is a boiler high temperature water feeding and air preheating system for reclaiming dispersed low grade residual heat which can realize the boiler blowdown heat reclamation, and can reclaim the low grade energy exhausted to environment from the system on the base that the components of the thermoelectric boiler are running steadily.

Owner:HUNAN UNIV

Device and method for removing ash in smoke box of waste heat boiler

The invention discloses a device for removing ash in a smoke box of a waste heat boiler. The device comprises the smoke box. Heat absorbing pipes are arranged inside the smoke box, a steam pressure pocket is arranged on the top of the smoke box, an ash discharge outlet is formed in the bottom of the smoke box, a steam exhaust pipe, a safety valve and a one-way water inlet pipe are arranged on the top of the steam pressure pocket, the water inlet pipe is connected with the heat absorbing pipes inside the smoke box, a high-temperature smoke inlet pipe is connected onto a side surface of the smoke box, a smoke outlet pipe is connected to the side surface, which is opposite to the side surface connected with the smoke inlet pipe, of the smoke box, partition plates which are parallel to a smoke movement direction are arranged inside the smoke box, an internal space of the smoke box is divided into at least two chambers by the partition plates, chamber doors are arranged at two ends of each chamber, and ash flushing pipes are arranged in each chamber and are connected with blowdown pipelines and blowdown valves of the boiler. According to the technical scheme, the device for removing the ash has the advantages that the ash can be removed without stopping the boiler, and accordingly the work efficiency can be improved; vibration and the like on the smoke box can be omitted when the ash is removed, accordingly, the smoke box can be prevented from being damaged, and the service life of the smoke box can be prolonged.

Owner:汪家权

Phosphorus-free treatment agent for boiler water as well as preparation and application of treatment agent

ActiveCN110697915AGood dispersionStable and suitable viscosity average molecular weightSpecific water treatment objectivesScale removal and water softeningAcryditeBoiler blowdown

The invention relates to a phosphorus-free treatment agent for boiler water as well as preparation and application of the treatment agent. The treatment agent is prepared from the following raw material components in percentages by mass: 16-30% of modified polyaspartic acid, 10-20% of N-(3,4-dihydroxyphenethyl)acrylamide, 10-16% of a pH regulator, 3-8% of a deoxidant, 2-6% of a film-forming auxiliary agent, and the balance of deionized water. The treatment agent is prepared by the following steps: adding the deionized water into a reaction kettle according to the mass percentage content, adding the modified polyaspartic acid and the N-(3,4-dihydroxyphenethyl)acrylamide, performing full and uniform stirring, sequentially adding the deoxidant, the film-forming auxiliary agent and the pH regulator, performing heating to 50-65 DEG C, performing constant-temperature stirring for 20-30 min, and performing natural cooling to room temperature to obtain the treatment agent. In practical application, when the treatment agent is prepared, the components are calculated and added according to an actual water volume of a boiler, and the addition amount is 10-20 g / t. Compared with the prior art,the treatment agent provided by the invention is applied to medium and high-pressure boiler water systems, overcomes various negative effects caused by the use of a phosphate, reduces the blowdown rate of the boiler, saves energy, and has a good application prospect.

Owner:汇科琪(天津)水质添加剂有限公司

Compound boiler scale and corrosion inhibitor as well as preparation method and application of thereof

ActiveCN107176703AGood scale resistanceReduce corrosionSpecific water treatment objectivesScale removal and water softeningBoiler blowdownHigh pressure

The invention provides an organic polymer scale inhibitor in a compound boiler scale and corrosion inhibitor. Particularly, poly(aspartic acid) has a good scale inhibition function on calcium carbonate and magnesium hydrate and has good biodegradability, no impurities are introduced into a boiler system, the clinical salt content of boiler water is increased, and the boiler blowdown rate is reduced; an organic polymer dispersant has a dispersion function and can stabilize calcium and magnesium ions in water and inhibit formation of silica scale, ferric scale, cooper scale and magnesium scale; the corrosion inhibitor has very high reductivity, a black Fe3O4 passivation film can be formed on the surface of the inner wall of a boiler, and the boiler is prevented from being further corroded. According to the compound boiler scale and corrosion inhibitor, negative influences of trisodium phosphate are eliminated, the discharge capacity is effectively reduced, and environment burden is reduced. A water treatment agent is applied to low-pressure, medium-pressure and high-pressure boilers by adjusting the pH value, inhibiting scaling and preventing corrosion, pH of boiler water is effectively buffered, the hydrogen brittleness phenomenon caused by excessive acid and alkali in the boiler is prevented, and boiler metal is protected.

Owner:SHENYANG DREAMLAND ENVIRONMENTS TECH

Boiler blow-off wastewater recovery treatment equipment

PendingCN113979582AAvoid destructionImprove sexual functionSpecific water treatment objectivesTreatment involving filtrationBoiler blowdownWater flow

The invention discloses boiler blow-off wastewater recovery treatment equipment, and relates to the technical field of boiler wastewater treatment. The boiler blow-off wastewater recovery treatment equipment comprises a boiler discharge system and a periodic blow-off expanding device, wherein a continuous blow-off expanding device is arranged in the boiler discharge system, high-temperature and high-pressure boiler blow-off water is firstly discharged into the continuous blow-off expanding device, and then is discharged into the periodic blow-off expanding device through the continuous blow-off expanding device, and the blow-off water is subjected to flash evaporation in the periodic blow-off expanding device to generate steam. According to the conventional recovery scheme, steam generated by a periodic blow-off expanding device exchanges heat with water in a newly-arranged steam-water heat exchanger. According to the invention, a heat exchange filtering device is arranged on a pipeline from the blow-off water flow of a continuous blow-off expanding device to a periodic blow-off expanding device, so that when a boiler continuous blow-off system goes wrong or a boiler has a safety accident, the heat exchange filtering device is in a running stopping state, and the damage to the steam heat exchanger body caused by excessive flash steam quantity of the periodic blow-off expanding device is avoided.

Owner:青岛海湾化工设计研究院有限公司

Boiler blow-down water comprehensive utilization device

InactiveCN105737133AAchieve recyclingAvoid pollutionCombustion processBoiler cleaning apparatusThermal energyBoiler blowdown

The invention provides a boiler blow-down water comprehensive utilization device. One end of a first pipeline and one end of a second pipeline are connected with a boiler. The other end of the first pipeline and the other end of the second pipeline are connected with one end of a third pipeline. The other end of the third pipeline is connected with a blow-down flash tank. One end of a fifth pipeline is connected with the blow-down flash tank. The other end of the fifth pipeline is provided with a drain valve. One end of a fourth pipeline, one end of a sixth pipeline and one end of a seventh pipeline are all connected with the fifth pipeline. The other end of the fourth pipeline, the other end of the sixth pipeline and the other end of the seventh pipeline are provided with a first adjusting valve, a second adjusting valve and a third adjusting valve correspondingly. One end of a ninth pipeline is connected with the blow-down flash tank. The other end of the ninth pipeline is connected with a cooling tank. A second ball valve is mounted on the ninth pipeline. One end of an eleventh pipeline is connected with the cooling tank, and the other end of the eleventh pipeline is connected with one end of a twelfth pipeline. A second gate valve, a second pump and a second check valve are mounted on the eleventh pipeline. The other end of the twelfth pipeline is connected with one end of a raw water filtering basin. The other end of the raw water filtering basin is connected with a thirteenth pipeline. By adopting the boiler blow-down water comprehensive utilization device, recycling of hot waste water can be realized, pollution is avoided, and thermal energy is saved.

Owner:GUANGXI UNIV

Component feedback automatic control boiler blowdown system

InactiveCN107084382AReduce lagExcellent pollution controlBoiler cleaning apparatusBoiler controlHysteresisAutomatic control

The invention provides an automatic control boiler blowdown system. The system conducts automatic control according to the steam quantity generated by boilers and the water quantity input into the boilers. The boilers are subjected to regular blowdown. A central diagnosis monitor automatically sets the blowdown quantity according to the ratio of the steam mass to the water mass input into the boilers. According to the automatic control boiler blowdown system, by monitoring the input water quantity and the generated steam quantity of all the boilers in real time, the dynamic ratio relation between the input water quantity and the generated steam quantity is obtained; according to the dynamic proportion relation, the blowdown quantity of the boilers is automatically calculated; and according to the blowdown quantity, the blowdown time and speed are adjusted. The automatic control boiler blowdown system automatically calculates the blowdown quantity, so that compared with the prior art, the hysteresis property caused by automatic control in the prior art is reduced, and optimal blowdown control can be achieved.

Owner:ZHONGBEI UNIV

Comprehensive recycling system for coke dry quenching wastewater

PendingCN111517380ASolving RecyclingDifficult to collectCoke quenchingMixing methodsBoiler blowdownWater storage tank

The invention discloses a comprehensive recycling system for coke dry quenching wastewater, and belongs to the field of energy conservation and environmental protection. The system is characterized inthat cooling water for cooling three water seals of a dry quenching furnace, boiler blow-off wastewater and sampling cooling water are connected into a water storage tank arranged on the ground through a buffer water tank and a pipeline; after boiler blow-down water in the water storage tank is mixed and cooled by water seal cooling water, a liquid level interlocking device arranged in the waterstorage tank controls a centrifugal pump to pump the wastewater into the circulating water pool for reuse, the water storage tank is arranged beside the fly ash silo, and a coke breeze grab bucket isarranged at the upper part of the water storage tank to periodically clean out coke breeze at the bottom of the tank and place the coke breeze in the fly ash silo. The system solves the problems of cyclic utilization of coke dry quenching wastewater and difficult collection of coke powder, and realizes the purposes of energy conservation and environmental protection of coke dry quenching.

Owner:LINHUAN COKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com