Method for recycling the afterheat of continuous blowdown extension tank and device thereof

A technology of sewage expansion and waste heat recovery, which is applied to chemical instruments and methods, separation methods, preheating, etc., can solve problems such as affecting the environment, heat loss, white fog, etc., and achieve heat saving, efficient operation, and improvement of the working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

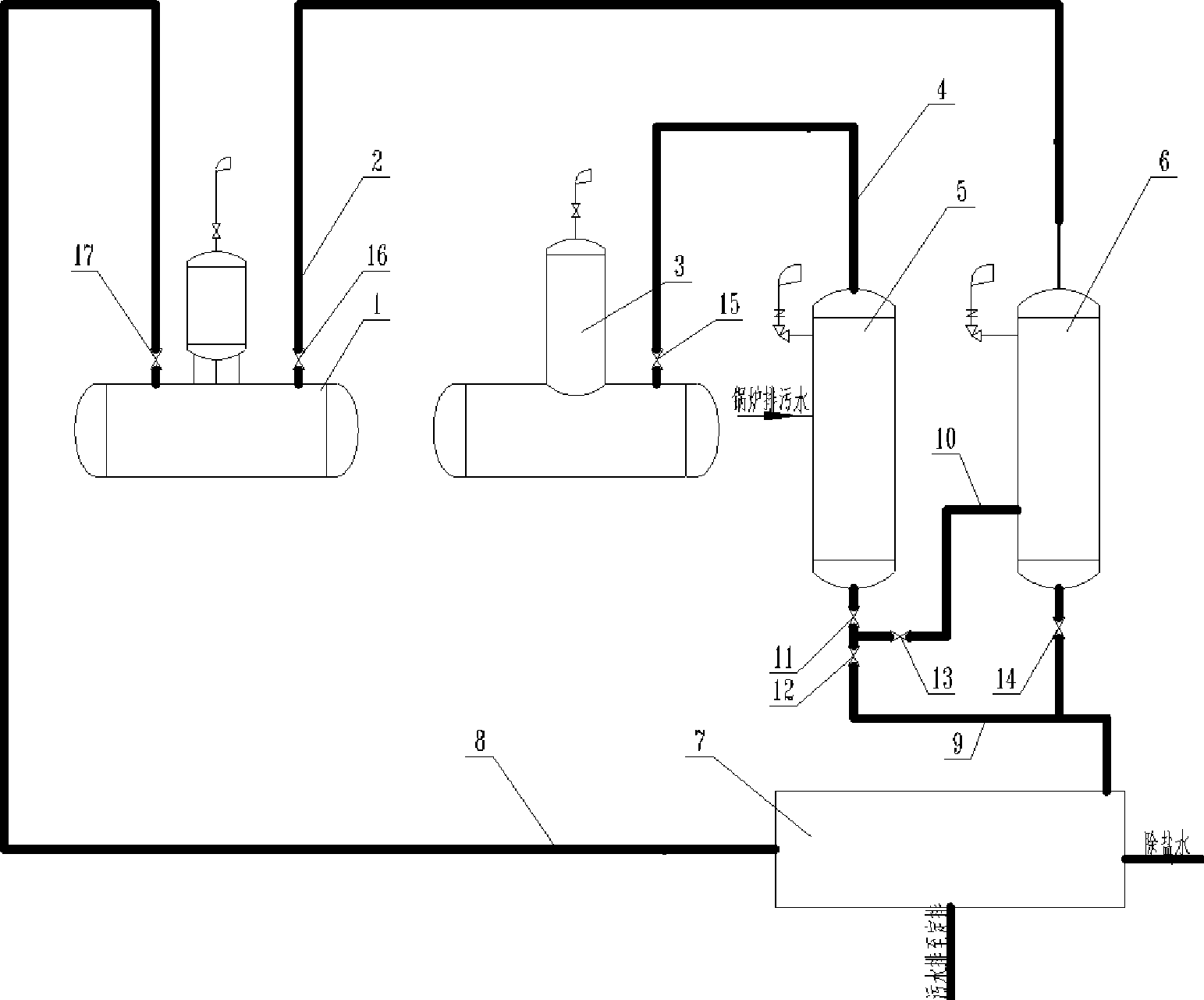

[0010] Embodiment of the present invention: connect the secondary steam outlet and the soft water outlet of the first-level continuous blowdown expansion vessel 5 and the second-level continuous blowdown expansion vessel 6, and connect the atmospheric deaerator 1 and the pressure deaerator 3 through pipelines 2 and 4 respectively The hot water after expansion of the first-level continuous blowdown expansion vessel 5 and the second-level continuous blowdown expansion vessel 6 enters the raw water preheater 7 through the pipeline 8 for heat exchange, and then sends the desalted water into the atmospheric deaerator through the pipeline 9 1 Reuse of waste heat. After the heat exchange, the boiler blowdown water is directly discharged to the fixed discharge expansion vessel. Valves 11, 12, 13, 14 are respectively installed between the pipelines 9, 10, a valve 15 is installed on the pressure deaerator 3, and valves 16, 17 are installed on the atmospheric deaerator 1. Under normal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com