Residual heat recovery system of sewage water of coke dry quenching boiler

A waste heat recovery system and boiler blowdown technology, applied in chemical instruments and methods, liquid degassing, separation methods, etc., can solve problems such as safety hazards, heat loss, etc., and achieve the effect of large heat exchange temperature difference and high heat recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

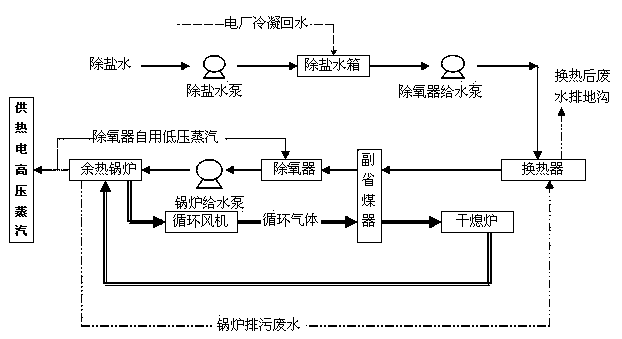

[0021] In this embodiment, the desalinated water after the deaerator is fed to the water pump first passes through the heat exchanger, then through the auxiliary economizer, and then the deaerator is arranged in series, such as figure 1 As shown; by adding a sewage heat exchanger, the desalted water sent to the auxiliary economizer by the deaerator feedwater pump is used as the cooling medium for heat exchange with the sewage, and the desalinated water is returned to the deaerator for deaeration , so that the temperature of the desalted water entering the deaerator increases due to the recovery of the heat of the sewage, which can reduce the amount of steam required for thermal deaeration

[0022] In the system composed of waste heat boiler, desalinated water pump, desalted water tank, deaerator feed water pump, sub economizer, deaerator, circulating fan and waste heat boiler in the traditional system, a heat exchanger is added. The heat exchanger uses desalinated water as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com