Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

267 results about "Wet steam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet steam is a mixture of steam and liquid water. It exists at a saturation temperature containing more than 5% water. It is said to be a two-phase mix: steam contains droplets of water that have not changed phase.

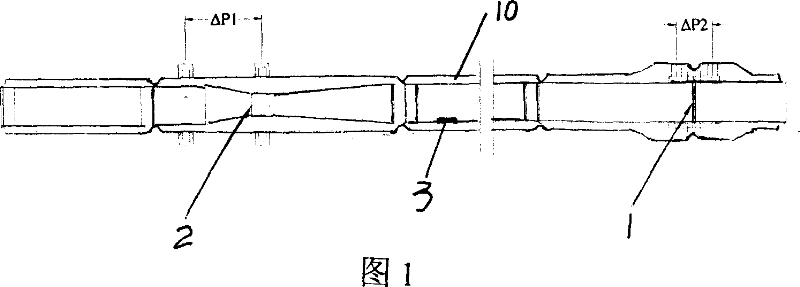

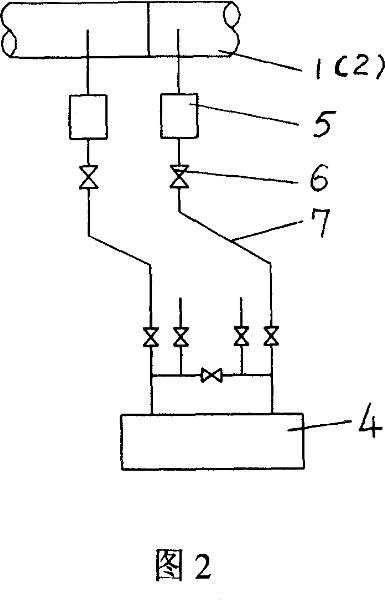

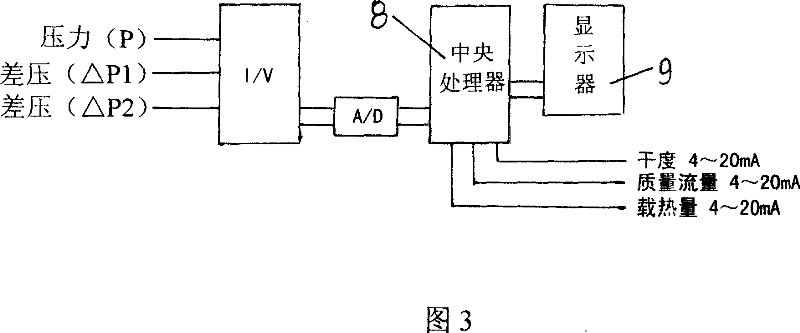

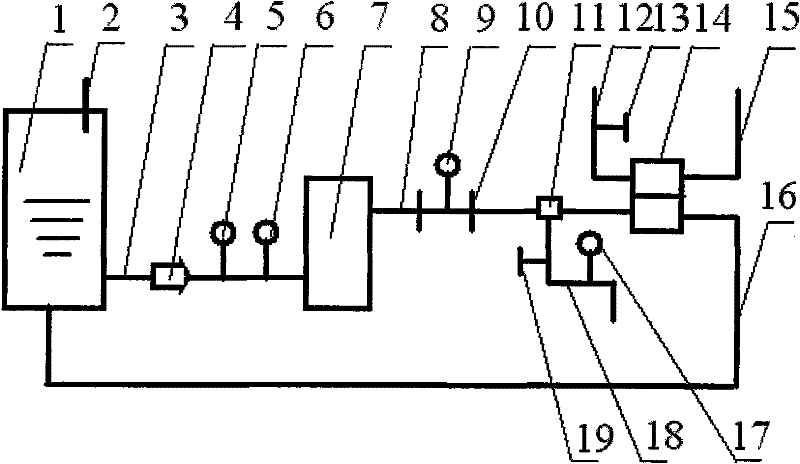

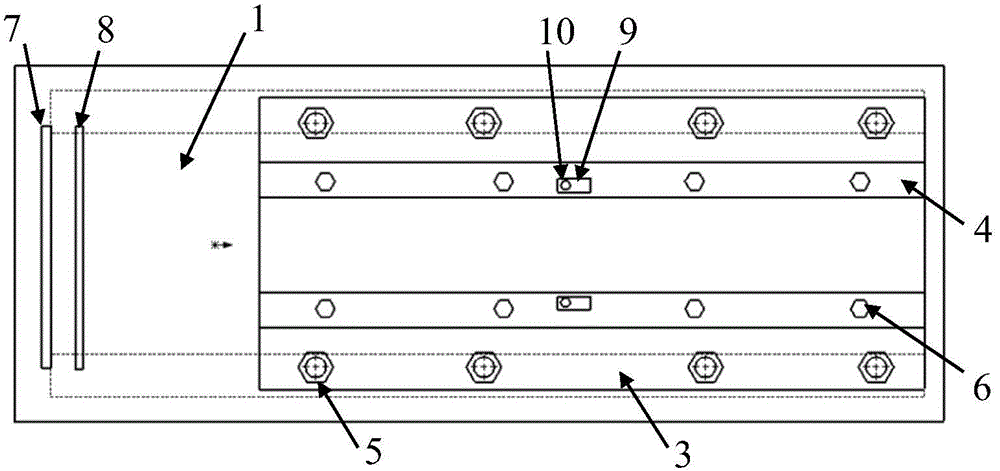

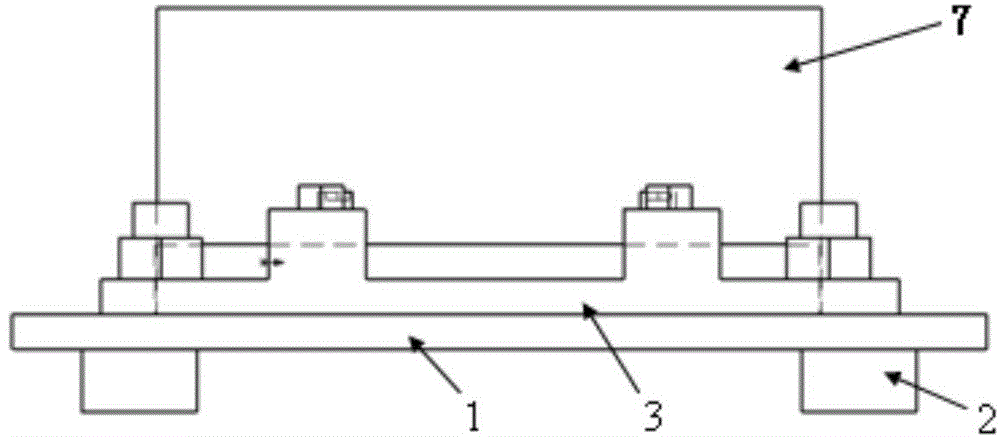

Combined device for measuring wet steam flow and dryness and measuring method thereof

InactiveCN101038188AMaterial moisture contentVolume/mass flow by differential pressureMeasurement deviceDifferential pressure

The present invention discloses a combined type measuring device of the steam flow and the degree of dryness and the measuring method thereof. The device uses the standard pore plate, the classical Venturi pipe as a one-time measuring element. Standard signals is transformed and transmitted by the high-precision pressure sensor and the intelligent differential pressure transmitter, and the standard 4~20mA signals are transformed into 1~5 V pressure signals through I / V and then the signals are input into the high-speed data collecting card. At last, the density of the saturated vapour and the saturated water, the specific enthalpy, the latent heat of vaporization are calculated in the central processing unit by invoking the IAPWS-IF97 formula module of the steam and water property according to the pressure signals, thus, the degree of dryness, the quality flow, the carried heat are calculated. At the same time, the quality flow and the carried heat are in cumulate calculation, and the important parameters are storied in the database in time. Comparing to that of the traditional calculating formula IF-67, the calculating precision of the present invention has been improved more than 10 times and the iterative calculating precision is high and the calculation speed is improved 4~12 times.

Owner:长春锅炉仪表程控设备股份有限公司

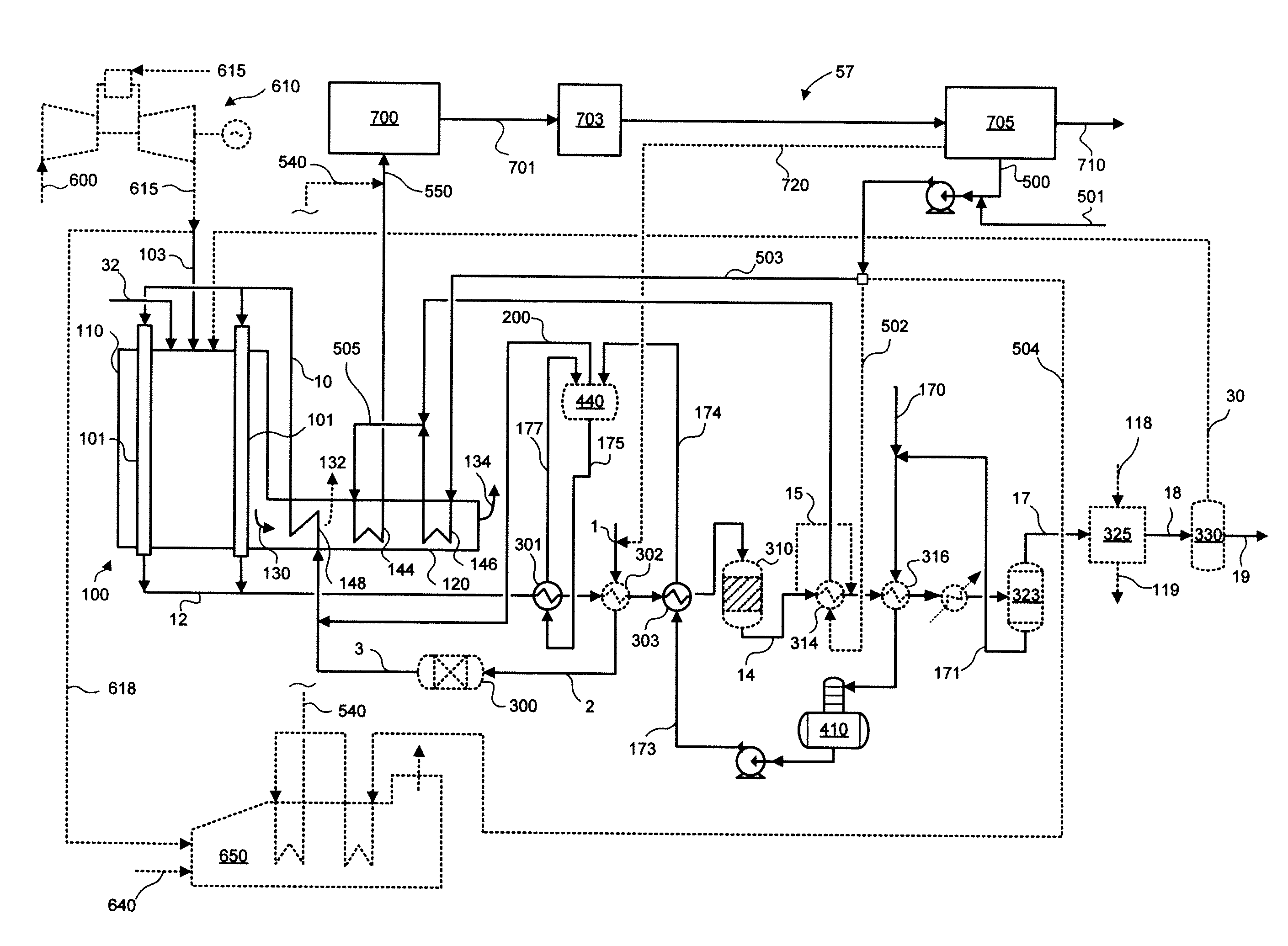

Integrated Hydrogen Production and Hydrocarbon Extraction

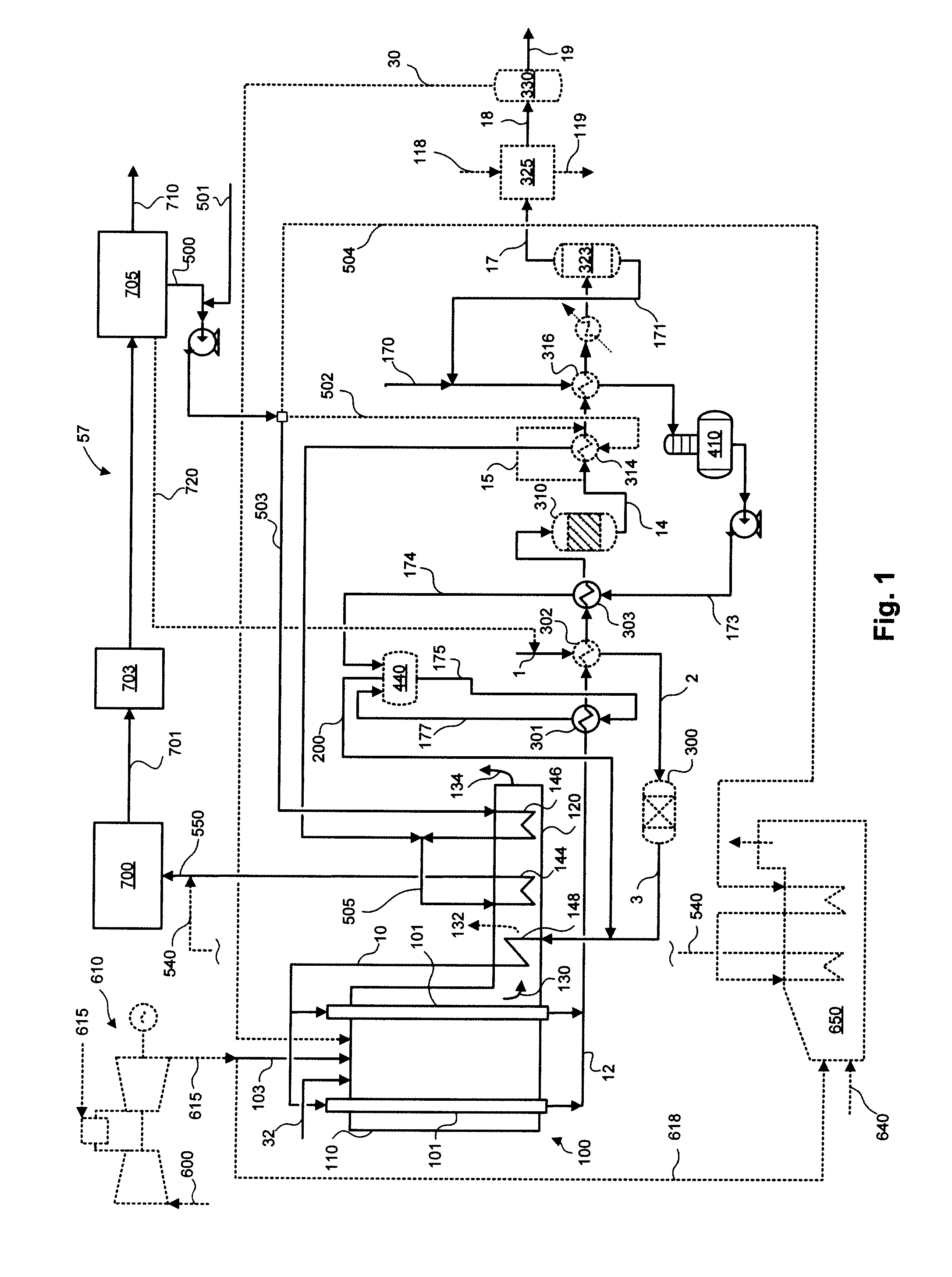

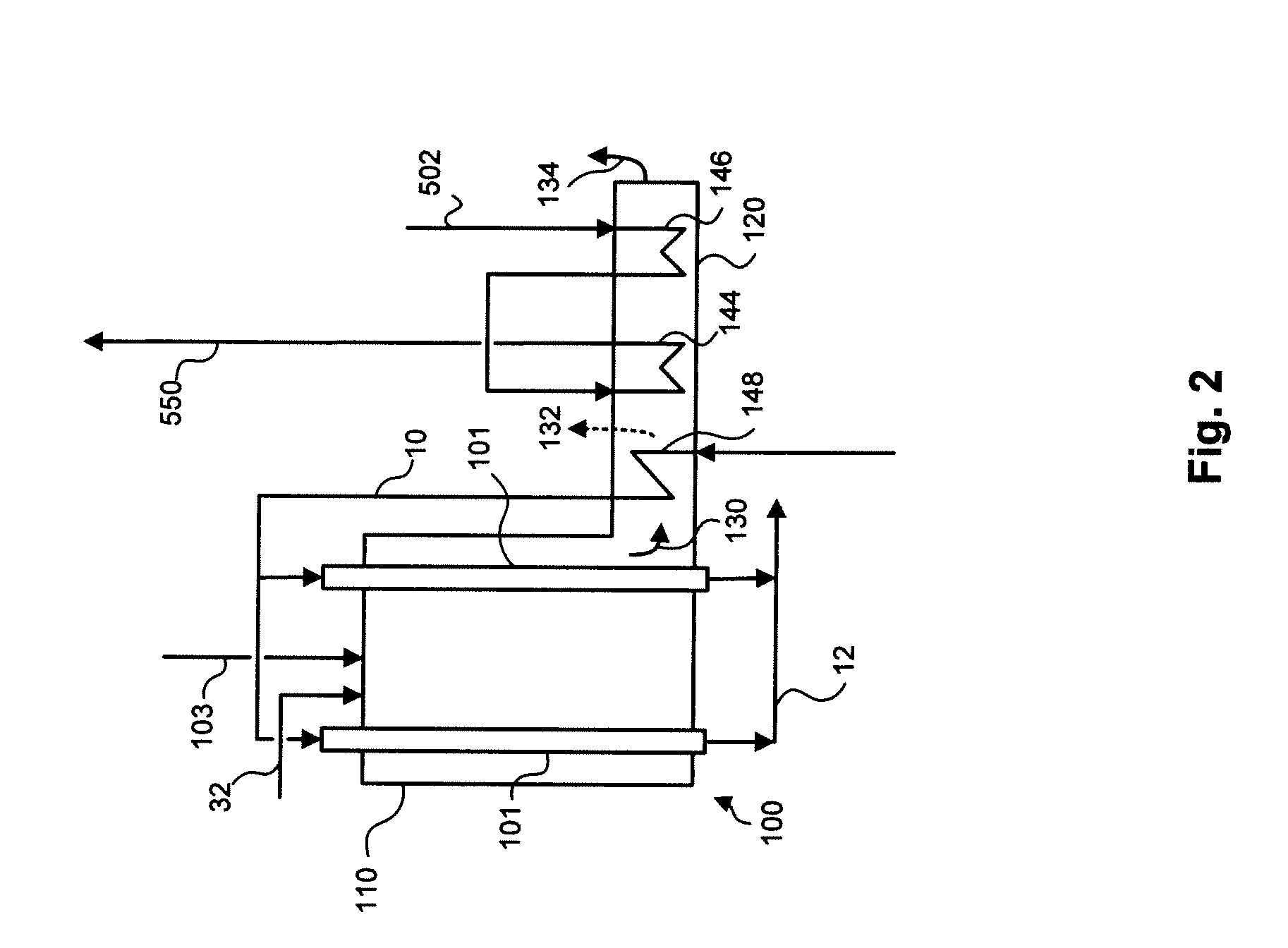

Reformer and method for producing hydrogen and steam where steam is used for steam-assisted extraction of heavy hydrocarbons. Steam is injected into a hydrocarbon-containing reservoir. Hydrocarbons are extracted from the reservoir along with produced water. Hydrogen is produced in a catalytic steam hydrocarbon reformer. Combustion product gas from the reformer is used to generate wet steam in a once-through steam generator from produced water recycled from the reservoir. The wet steam is used for the steam-assisted extraction of heavy hydrocarbons. The reformer has a heat exchanger section where a heat exchanger is suitable for processing the produced water by once-through steam generation and is suitable for mechanical cleaning.

Owner:AIR PROD & CHEM INC

Method and apparatus for measuring multiple parameters of steam

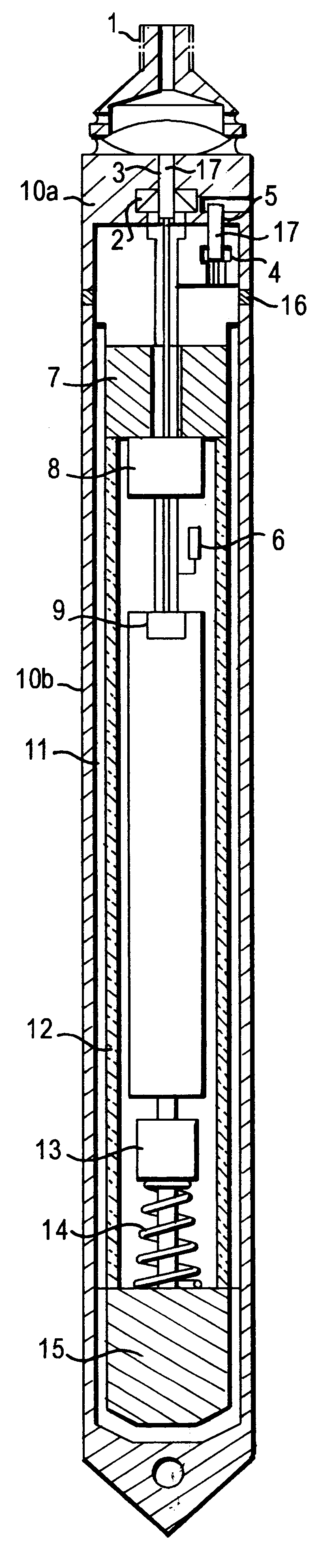

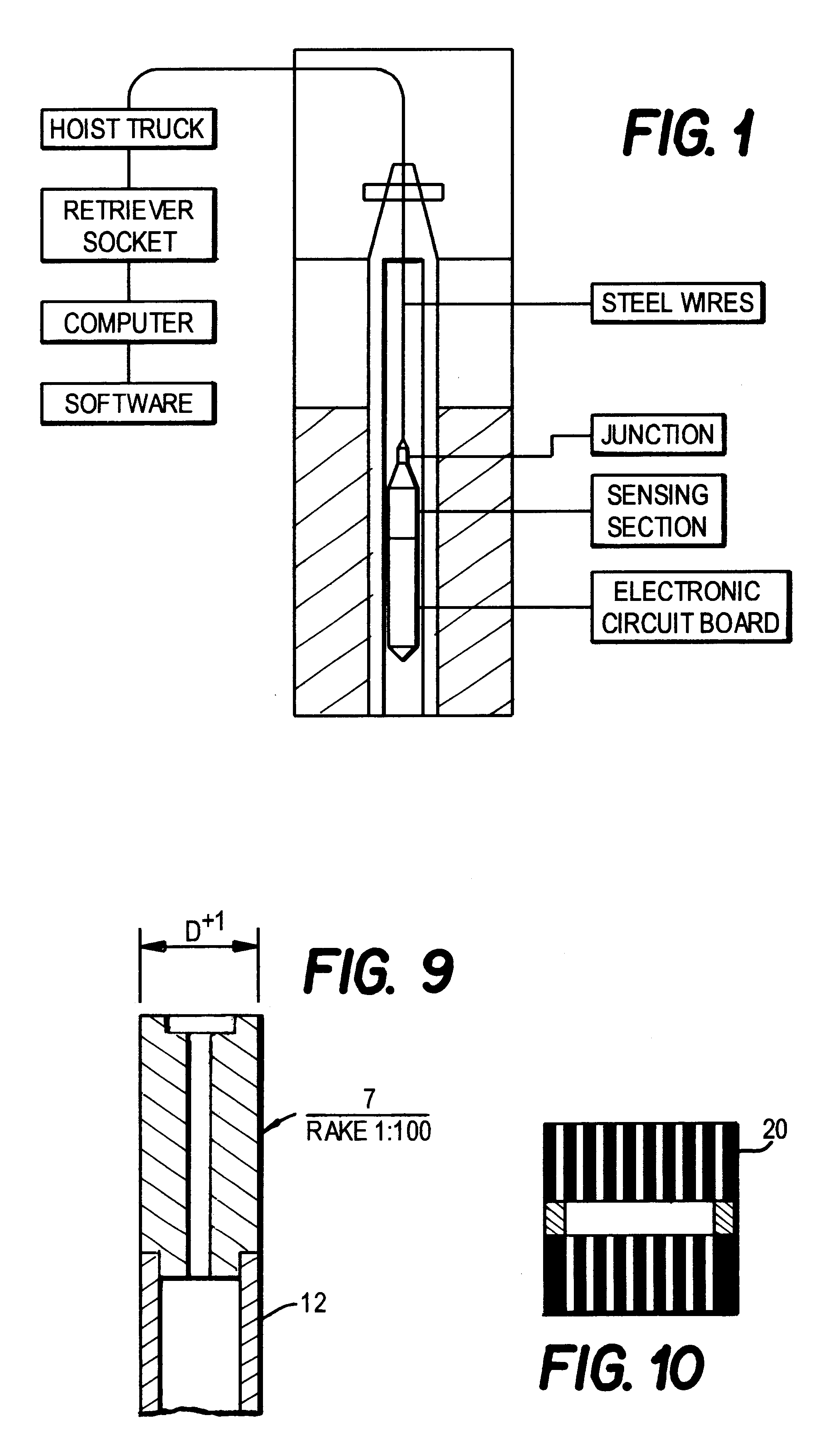

A method and an apparatus are disclosed for the measurement of the aridity, temperature, flow rate, total pressure, still pressure, and kinetic pressure of steam at a downhole location within a well through which wet steam is flowing. The apparatus comprises a series of fiber optic sensors that are mounted on sections of a shell assembly. The apparatus is lowered into a well to different downhole locations, and measures the multiple parameters of steam at different locations and heights. The data can be stored on board for subsequent analysis at the surface when the apparatus is retrieved from the well. The apparatus is very reliable, accurate, and of long-life in harsh environments.

Owner:PHOTOSONIC

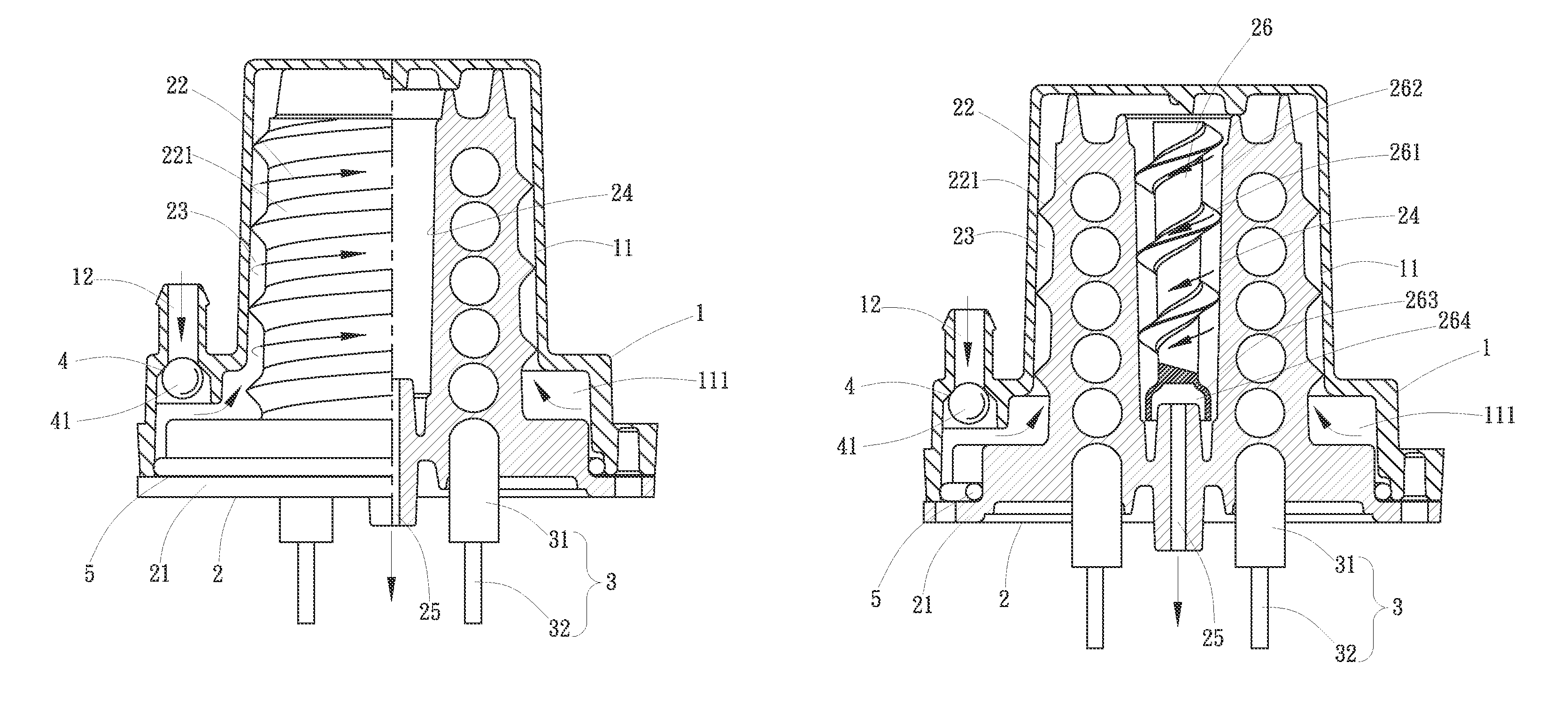

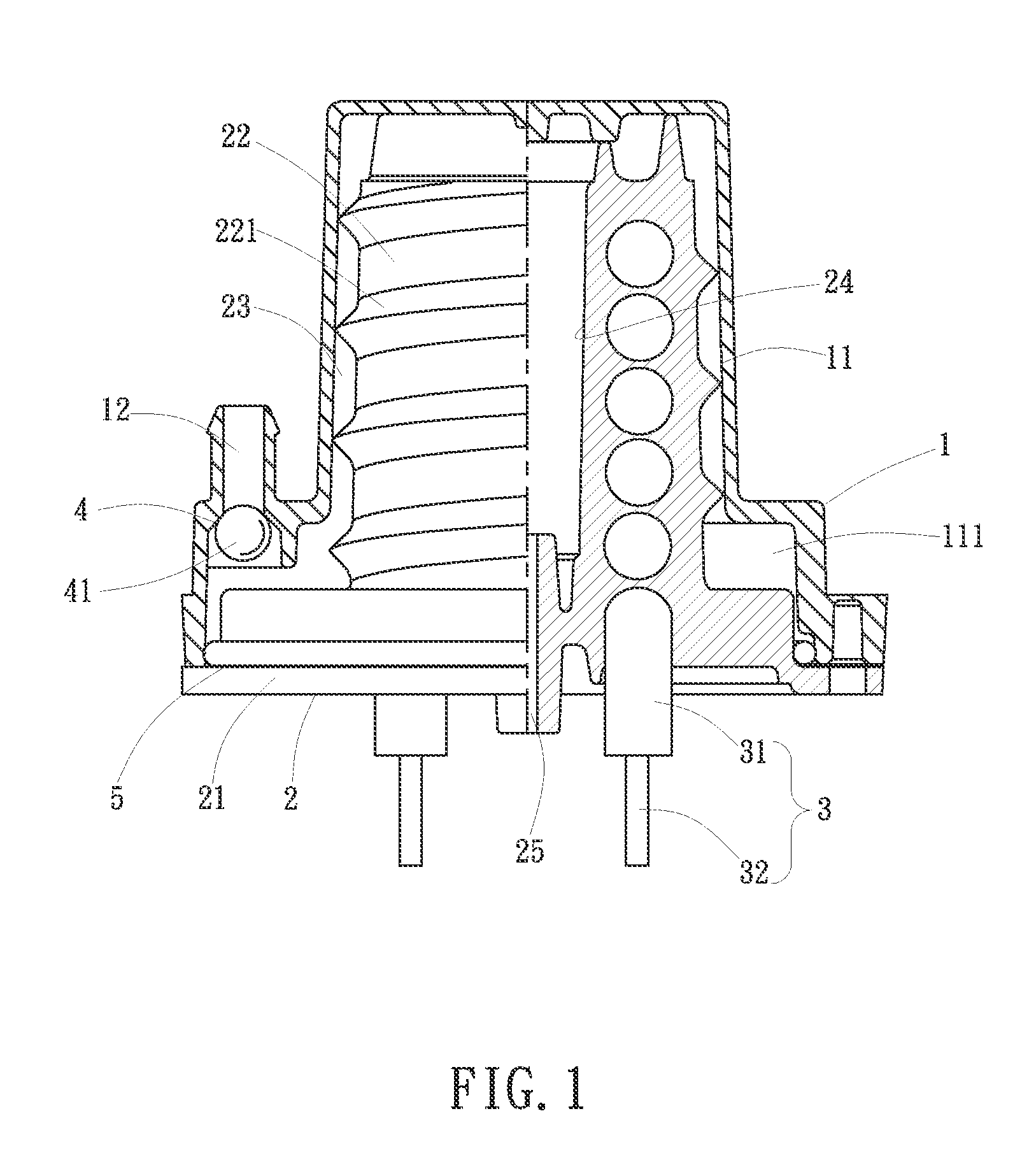

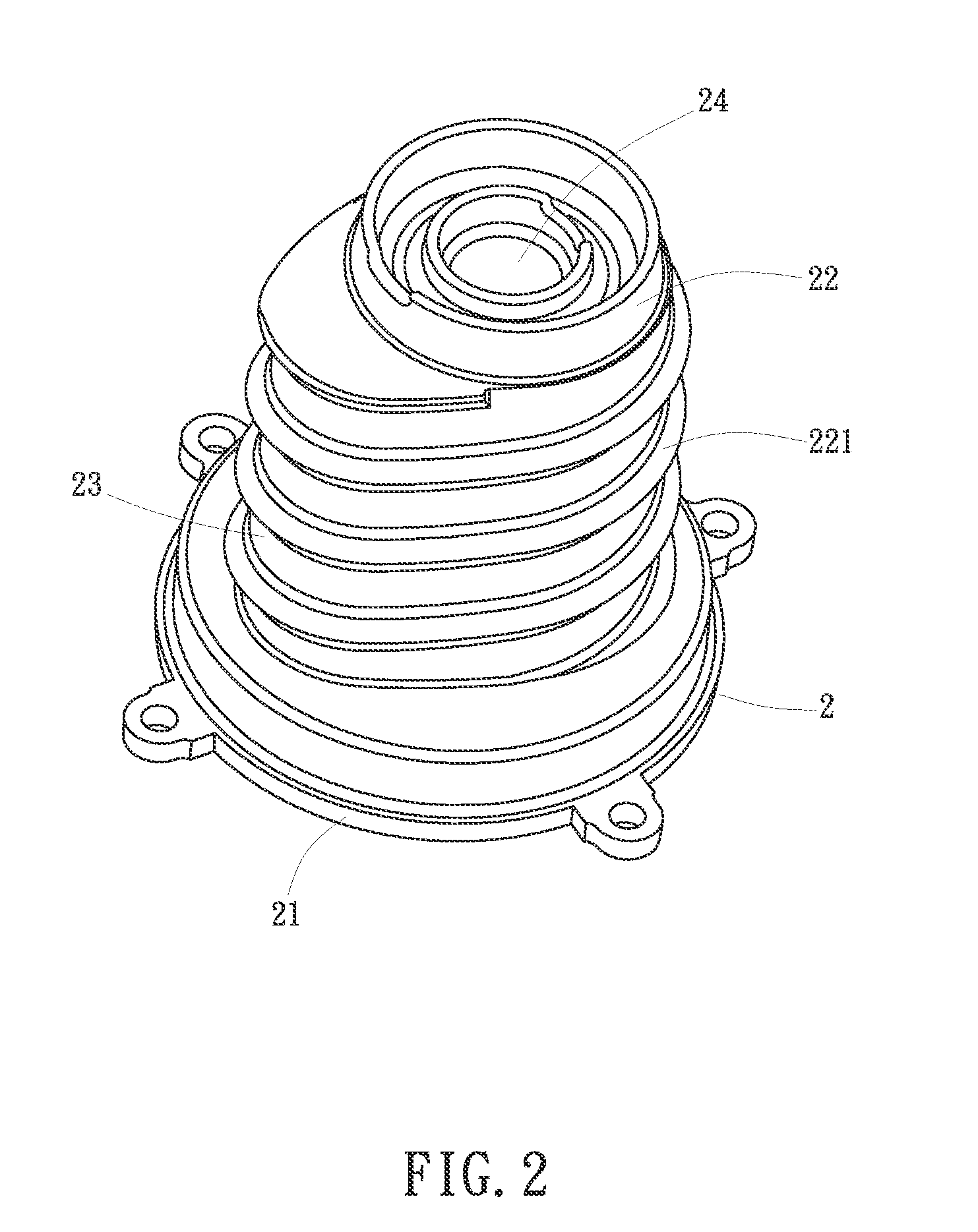

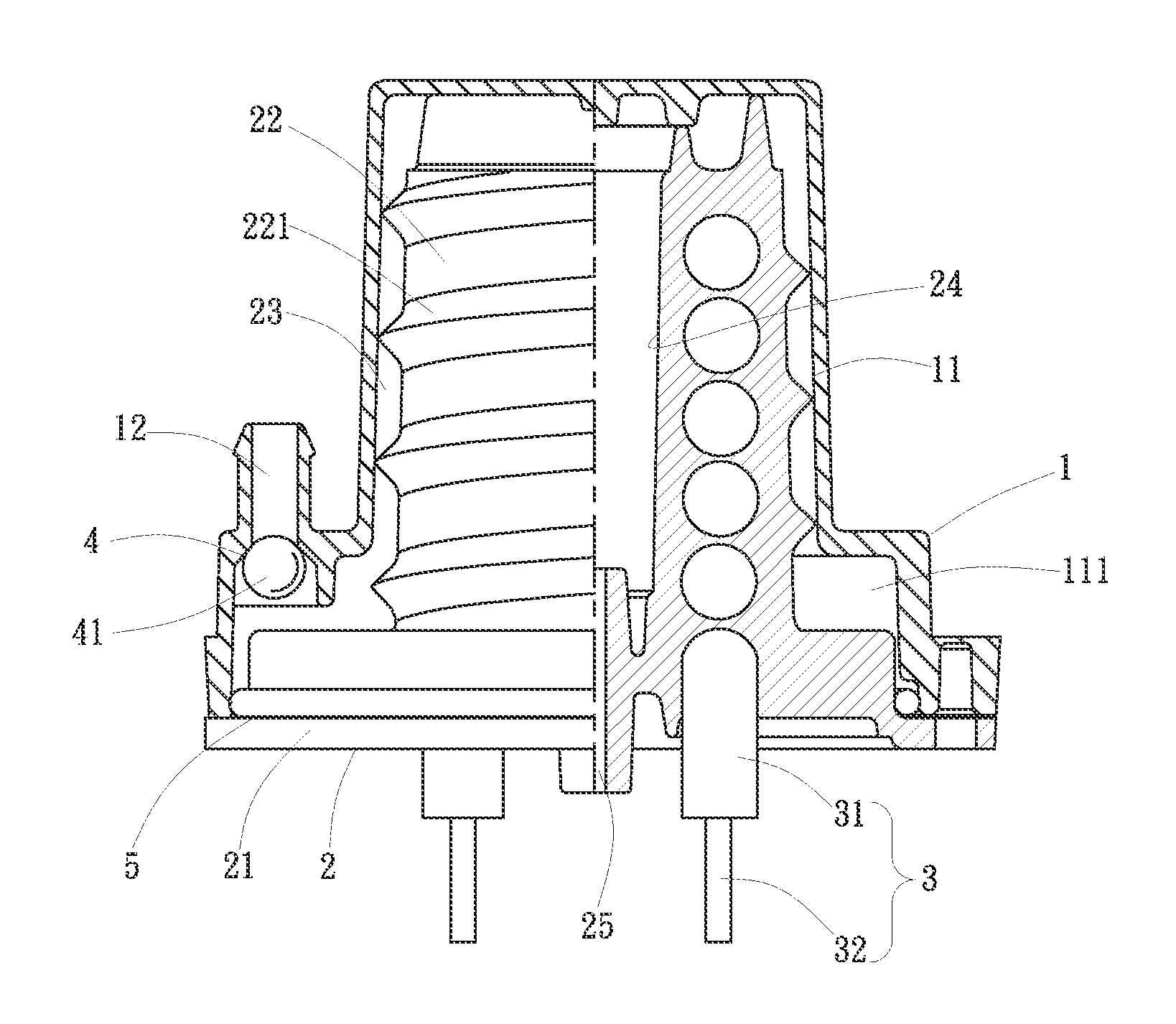

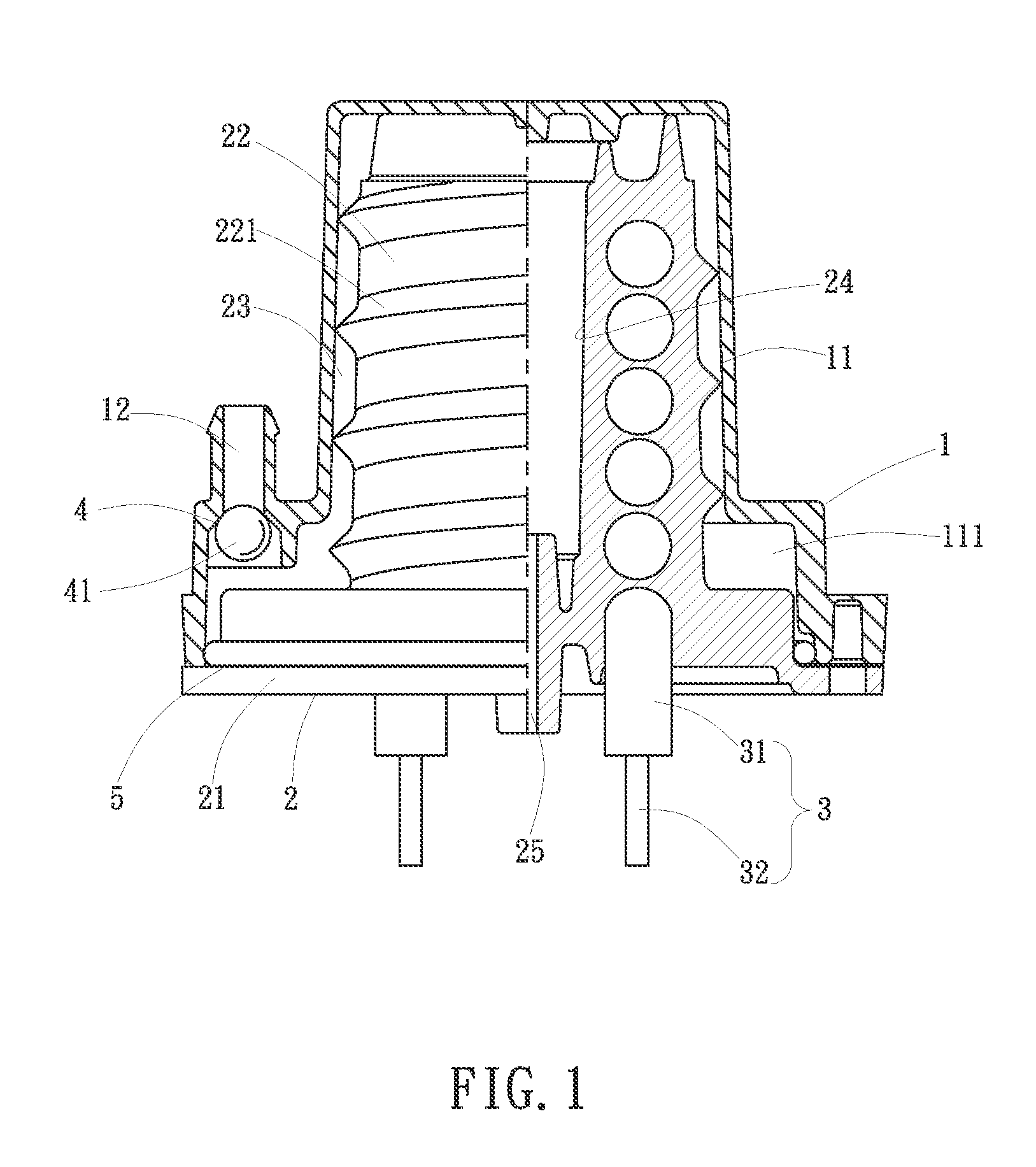

Steam generator

InactiveUS8554063B2Increase contact areaIncrease heatSteam generation heating methodsSpray nozzlesElectricityWet steam

A steam generator includes a housing, a heating unit, an electrothermal unit and a one-way valve. The housing has a chamber and a water inlet. The heating unit includes a heating portion extending into the chamber. The heating portion has a first spiral channel thereon. One end of the heating portion is formed with a vaporization room and a steam outlet. The vaporization room has a second spiral channel therein to extend the time that the water and the wet steam pass through the heating unit so as to provide a complete heating and vaporizing function. Besides, by the one-way valve coupled to the water inlet, the steam generator of the present invention is simple in structure and cost-effective, providing an automatic water supply and re-heating function.

Owner:ZWEITA INT

Steam generator

InactiveUS20110280553A1Increase contact areaIncrease heatSteam generation heating methodsSpray nozzlesElectricityWet steam

A steam generator includes a housing, a heating unit, an electrothermal unit and a one-way valve. The housing has a chamber and a water inlet. The heating unit includes a heating portion extending into the chamber. The heating portion has a first spiral channel thereon. One end of the heating portion is formed with a vaporization room and a steam outlet. The vaporization room has a second spiral channel therein to extend the time that the water and the wet steam pass through the heating unit so as to provide a complete heating and vaporizing function. Besides, by the one-way valve coupled to the water inlet, the steam generator of the present invention is simple in structure and cost-effective, providing an automatic water supply and re-heating function.

Owner:ZWEITA INT

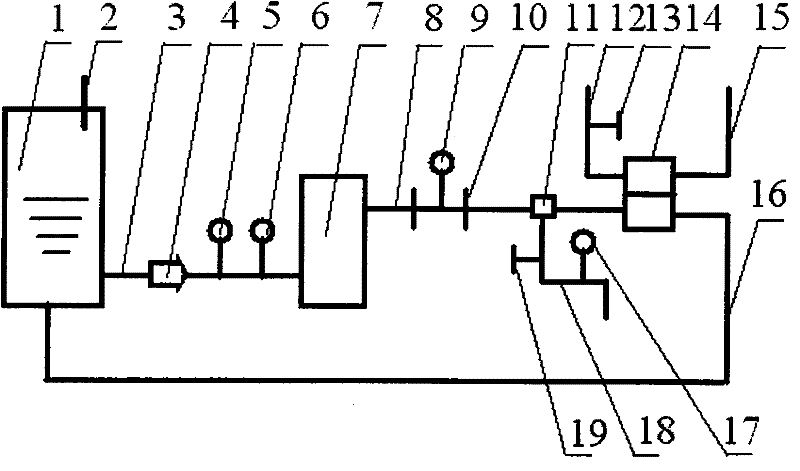

Wet steam flow instrument and measuring method

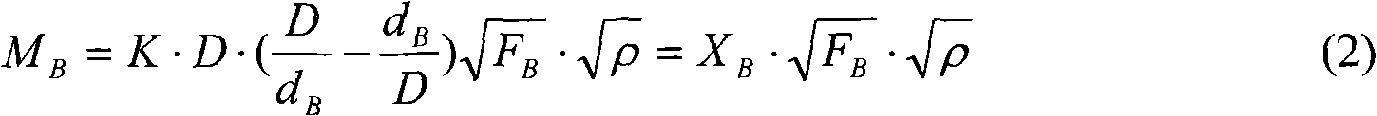

InactiveCN101839738AMaterial moisture contentIndirect mass flowmetersVena contracta diameterWet steam

The invention discloses a wet steam flow instrument and a measuring method. An orifice plate flow meter and a uniform speed tube kinemometer are connected in series on a wet steam pipeline; a pressure gauge is arranged in the wet steam pipeline between the flow meter and the kinemometer, a dryness flow processor is placed in an instrument box, and a support rod of the instrument box is welded on the outer wall of the wet steam pipeline; and a steam thermal physical property database and a steam flow dryness mathematical model are placed in the flow dryness processor. The measuring method comprises the following steps of: acquiring a fluid dynamic-static pressure difference signal delta Pk on a differential pressure transmitter of the flow meter, a fluid pressure signal P of the pressure gauge and a dry saturated steam flow rate Ug of the kinemometer through the dryness flow processor; obtaining a saturated water density rho1 and dry saturated steam density rhog through the flow dryness processor; and performing combined solution on the steam flow dryness mathematical model consisting of a void fraction alpha equation, a steam dryness x equation, a steam density rho equation and a flow meter flow G equation to obtain steam quality flow and steam dryness to be solved in the wet steam pipeline. The measuring method has the advantage of high wet steam measuring precision.

Owner:南通东华炉业有限公司 +1

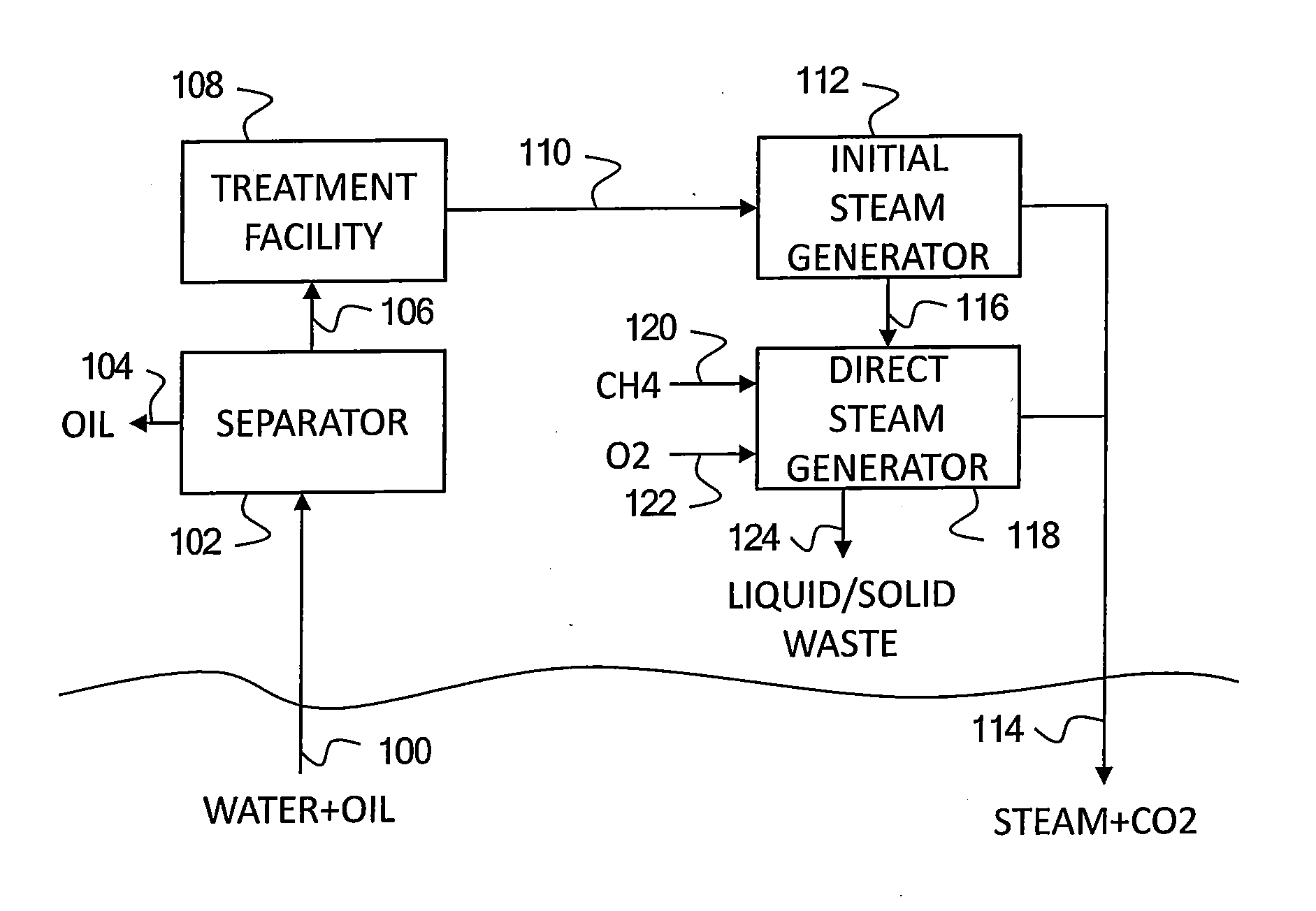

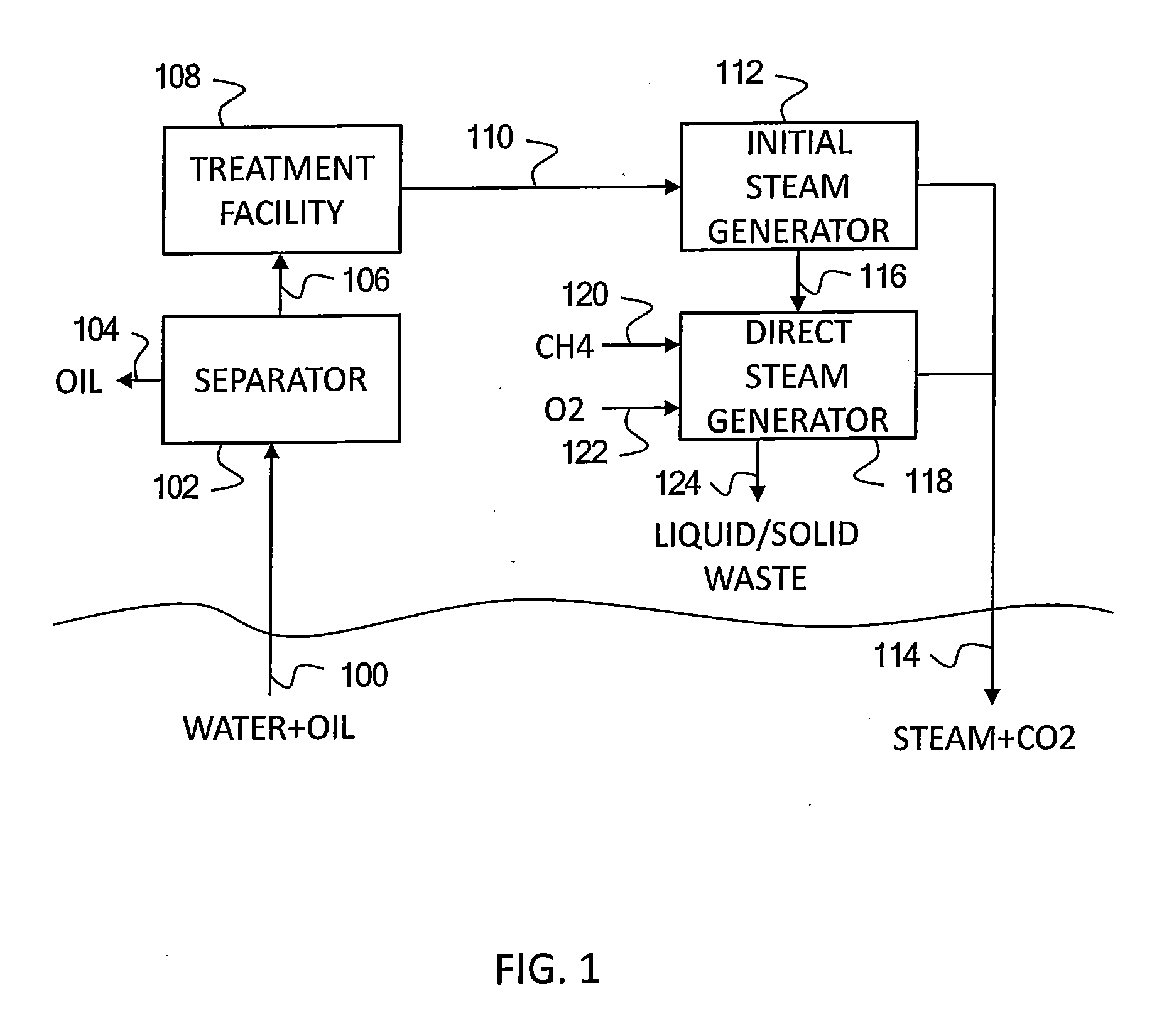

Direct steam generation of boiler blowdown

Systems and methods generate steam from produced water by passing the produced water through first and second steam generators coupled together. The first steam generator produces wet steam in which a liquid effluent with impurities of the produced water passes to the second steam generator. The second steam generator combusts fuel and oxidant in direct contact with the liquid effluent. The first and second steam generators limit fouling and waste while providing a combined steam output that may include combustion products from only the second steam generator.

Owner:CONOCOPHILLIPS CO

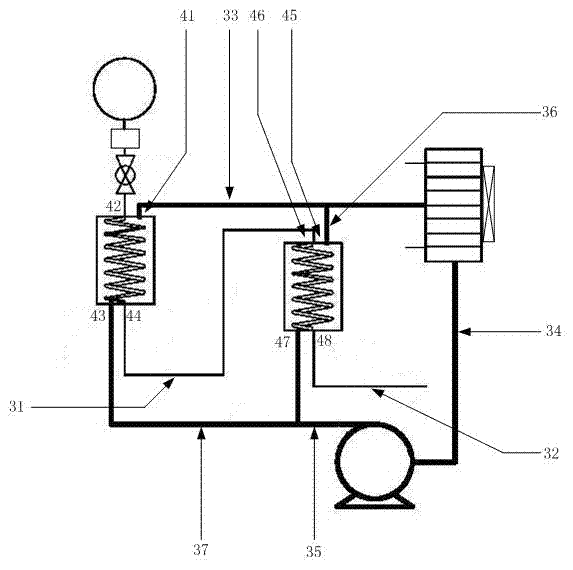

Experimental device for two-phase heat transfer characteristic research and method for measuring wet steam dryness

ActiveCN104330436AAvoid tightnessReduce experiment costMaterial heat developmentWet steamEngineering

The invention discloses an experimental device for two-phase heat transfer characteristic research and a method for measuring wet steam dryness. The experimental device comprises a steam boiler, a first steam-water mixer, an experimental body and a first water injection system for providing cooling water, wherein both the first water injection system and the steam boiler are communicated with the first steam-water mixer; the first steam-water mixer is communicated with the experimental body; the cooling water provided by the first water injection system is mixed with wet steam provided by the steam boiler in the first steam-water mixer and then the mixture flows into the experimental body. The experimental device for the two-phase heat transfer characteristic research has the characteristics that the steam boiler is adopted to provide high-temperature and high-pressure steam instead of a traditional electric heating manner, the wet steam provided by the steam boiler and the cooling water by the first water injection system are mixed reasonably to realize the experimental working conditions of high flow, high pressure and high dryness, and the problems of insulating sealing and critical boiling are avoided because the experimental device has no pre-heating section and the experimental body also does not need to be heated.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

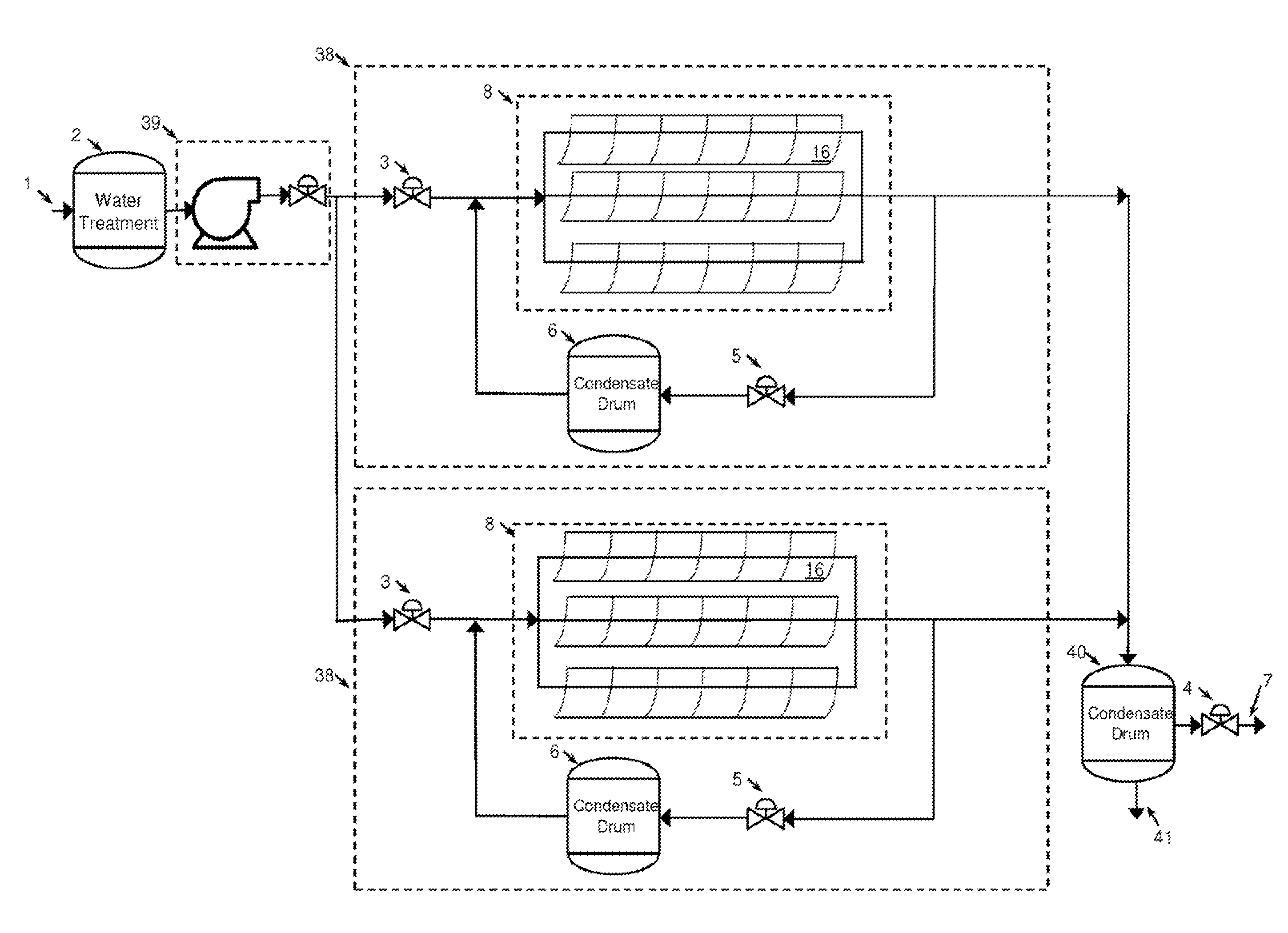

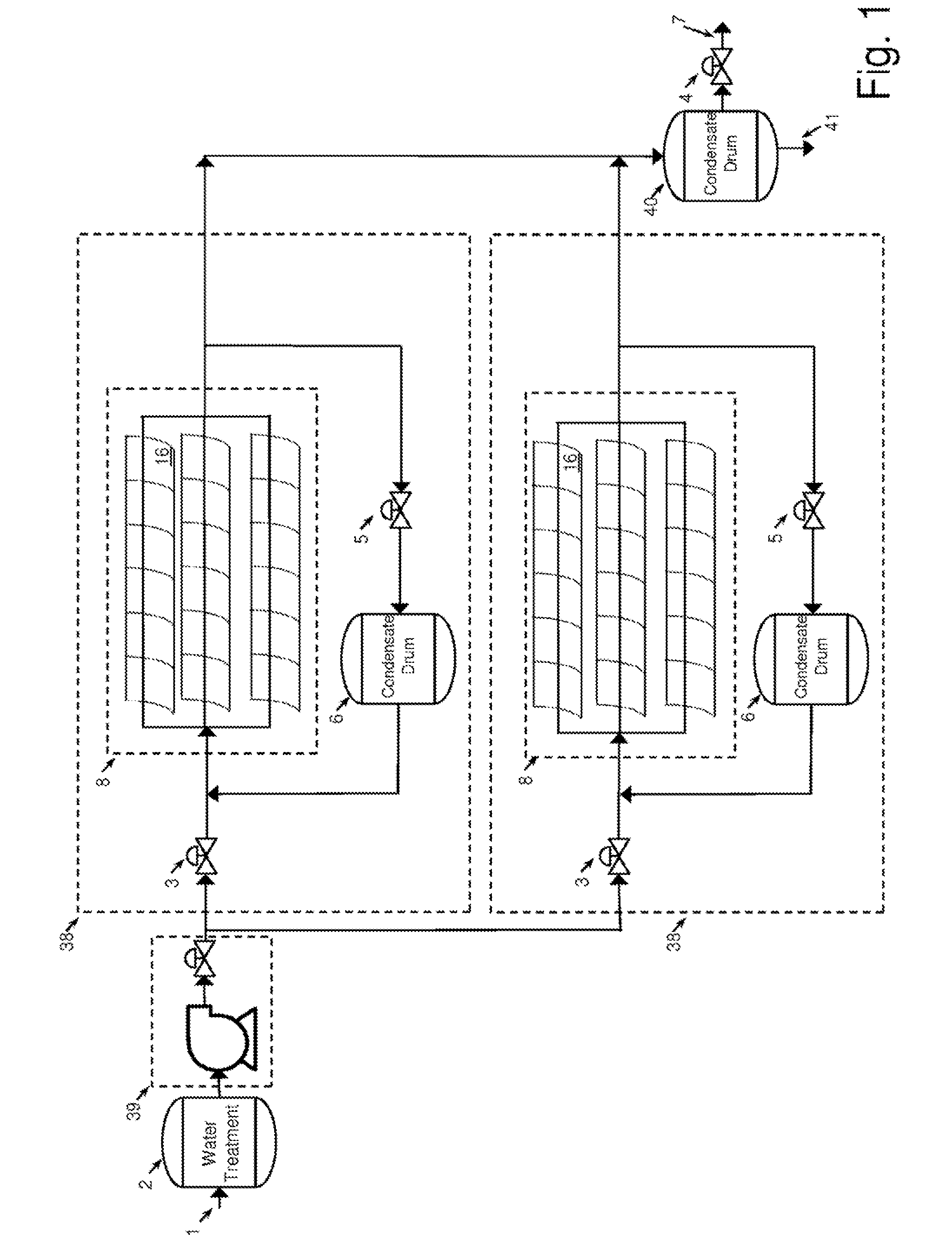

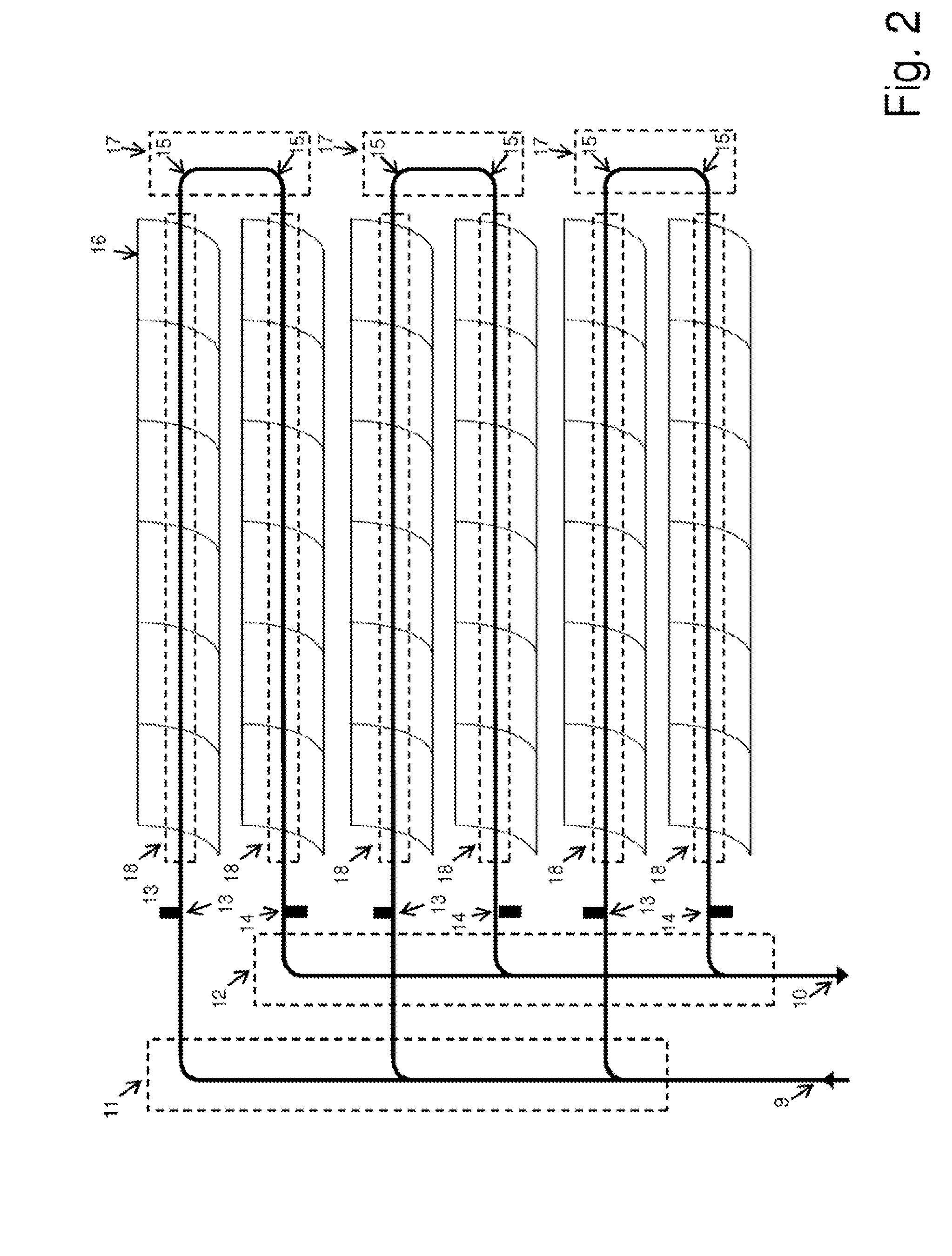

Direct solar steam generation

ActiveUS20140326234A1Improve performanceImprove efficiencySolar heating energyGeneral water supply conservationThermal energyDesalination

Solar energy generates steam in a “once-through” configuration without recirculation, with closely managed steam quality, to produce wet steam from high-contaminant feed water without scaling or fouling. Feed water is pressurized, preheated, and evaporated in a series of pipes exposed to concentrated solar energy to produce a water-steam mixture for direct distribution to an industrial process such as enhanced oil recovery or desalination. Water flow rates are managed based on measurements of solar energy and steam production to manage variations in the solar energy. Steam generator piping system uses continuous receiver pipe that is illuminated by segmented parabolic mirrors enabled to track the sun. Provisions for steam generator piping recurring maintenance are provided. Thermal energy from hot condensate and / or from low quality steam is recaptured and warms inlet water.

Owner:GLASSPOINT SOLAR

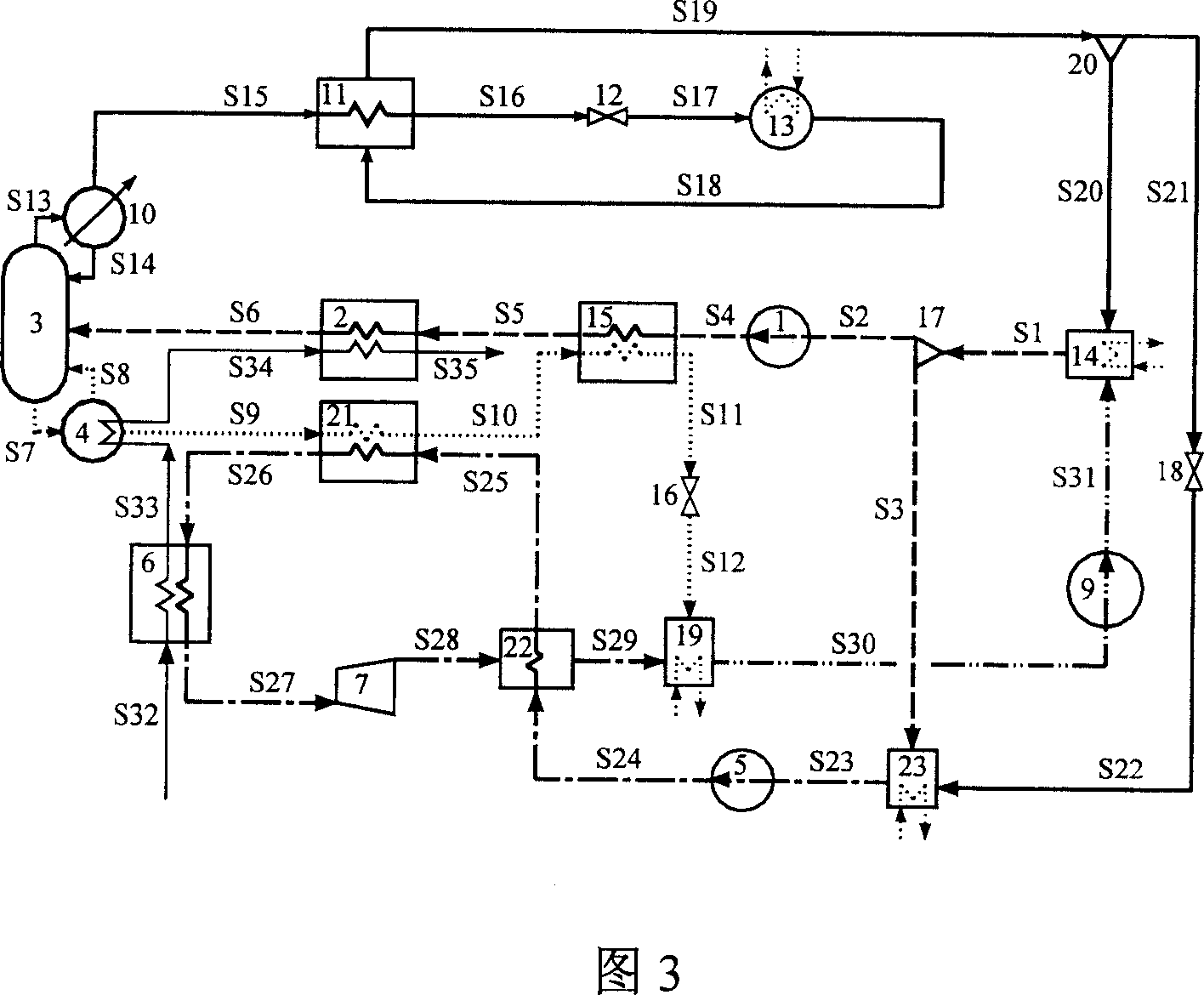

Method and system of producing superheated steam

ActiveCN103162282AStable temperatureStability requirementSteam generation heating methodsFluid removalSoftened waterWet steam

The invention provides a method and a system of producing superheated steam. The method of producing the superheated steam comprises the following steps: A. qualified softened water is introduced to a steam-injection boiler to produce wet steam with the temperature of 350 DEG C and dryness of 75%; B. steam-water separation is carried out on the wet steam, and saturated water and dry steam with dryness of above 99% are separated out; and C. the dry steam is introduced into a secondary steam heater to be heated, and superheated dry steam with the superheat degree of 30-40 DEG C is obtained. The system of producing the superheated steam comprises the steam-injection boiler used for producing the wet steam, a steam-water separator connected with the steam-injection boiler, and a steam heating boiler connected with the steam-water separator, wherein the steam-water separator comprises a steam outlet and a saturated water outlet, and the steam heating boiler is independent from the steam-injection boiler. The method and the system of producing superheated steam produce the superheated steam with the superheat degree of 10 DEG C, fully utilize the heat of separated water, and reduce the processing amount of the separated water.

Owner:PETROCHINA CO LTD

Flowing wet steam wetness measuring system and method

The invention discloses a flowing wet steam wetness measuring system and a measuring method. The flowing wet steam wetness measuring system comprises a sampling inlet section, an over-hot steam source, a steam mixing device, an over-hot steam inlet section and a mixed steam outlet section, wherein the sampling inlet section is used for sampling wet steam; the over-hot steam source is used for supplying over-hot steam; the steam mixing device is used for mixing wet steam and over-hot steam; the inlet end of the over-hot steam inlet section is connected with the over-hot steam source; the inlet end of the mixed steam outlet section is connected with the steam mixing device; the outlet ends of the sampling inlet section and the over-hot steam inlet section are both connected with the steam mixing device; both the over-hot steam inlet section and the mixed steam outlet section are provided with pressure acquisition devices, flow acquisition devices and temperature acquisition devices; a pressure acquisition device is arranged on the sampling inlet section; the sampling inlet section and the over-hot steam inlet section are further provided with flow adjusting valves near the inlet ends. The flowing wet steam wetness measuring system is accurate and reliable in measurement result, the wetness of flowing wet steam under different wetness conditions can be measured in real time, the system is simple in structure, and the equipment cost is low.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

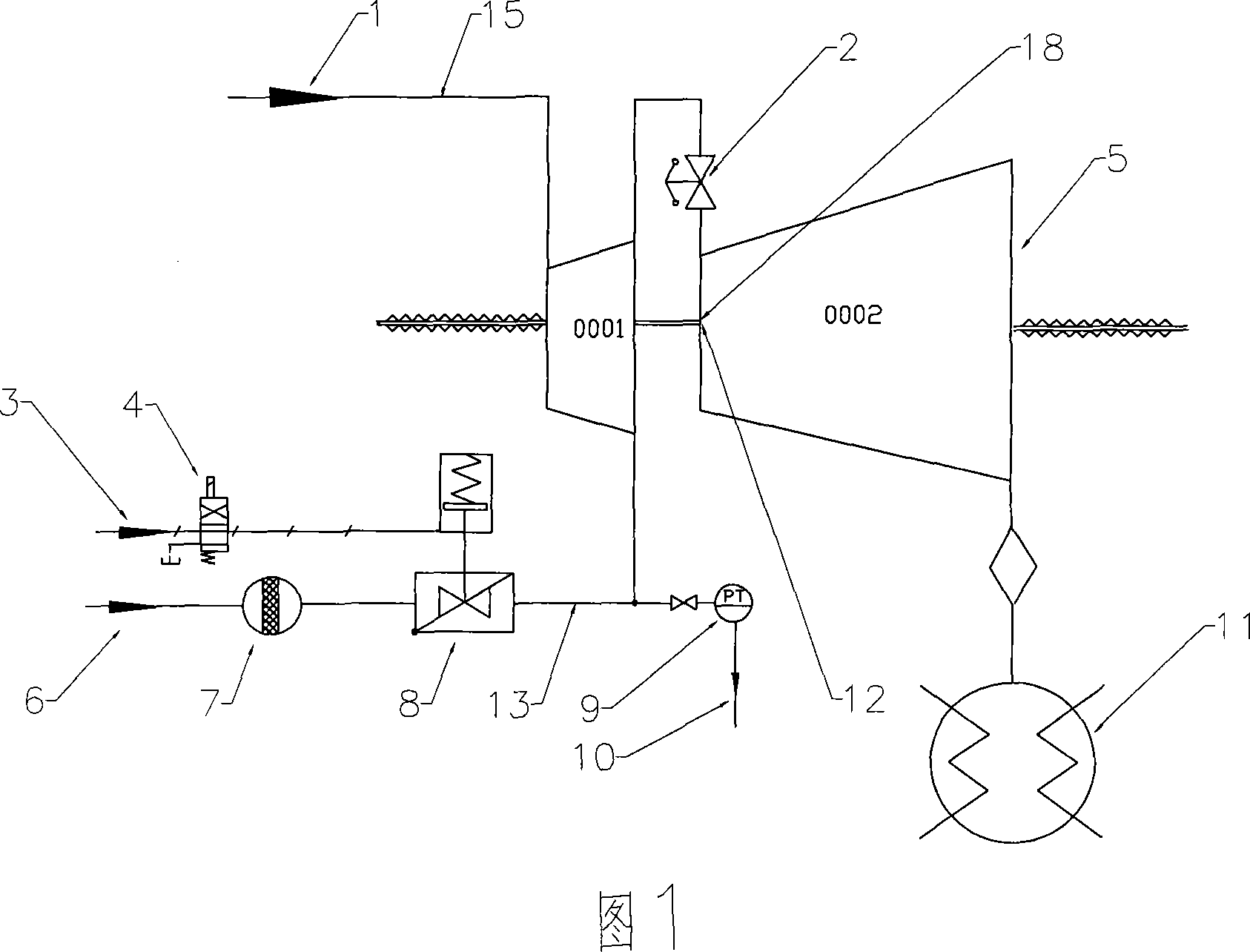

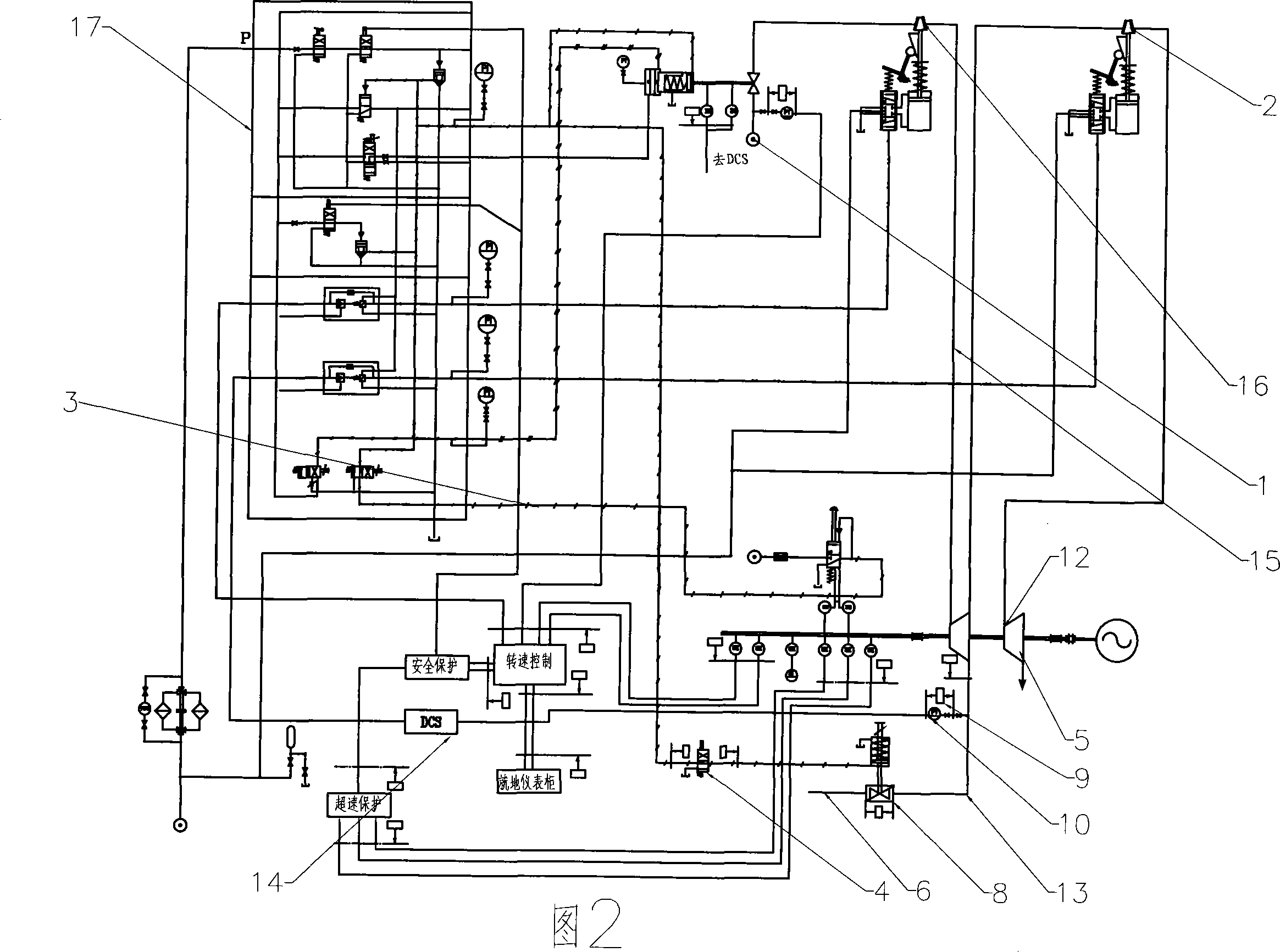

Exhaust heat steam turbine air-supplementary regulation system and its control method

ActiveCN101235732AAchieve self-regulationGuaranteed uptimeEngine componentsSteam engine plantsWet steamControl signal

The invention discloses a residual heat utilization steam turbine steam complementing adjusting system and a control method, which comprises an adjustable steam complementing adjusting steam valve, a pressure steam turbine, a transducer, a steam-water separator and an adjustor, a steam complementing hole is arranged on the interpolar position of a steam turbine, a steam complementing pipeline is connected on the steam complementing hole, a steam-water separator is arranged on the steam complementing pipeline, the adjustable steam complementing adjusting steam valve is arranged on the steam complementing pipeline between the steam-water separator and the steam complementing hole, executing signals of the adjustable steam complementing adjusting steam valve are connected with the adjuster output control signals, a pressure transducer is arranged on the steam complementing pipeline, the steam complementing signals of the pressure transducer is connected with the adjuster pressure output signals. Steam complementing steam firstly passes through the steam-water separator, and wet steam is conversed to be dry steam to reduce waterworn. The residual heat utilization steam turbine steam complementing adjusting system which is got by the invention effectively solves the problem which exists in the existing technique, the system achieves automatic adjustment of steam complementing when a steam complementing system which is stably operated is guaranteed. Thereby residual heat utilization is led to be the highest.

Owner:HANGZHOU ZHONGNENG STEAM TURBINE POWER CO LTD

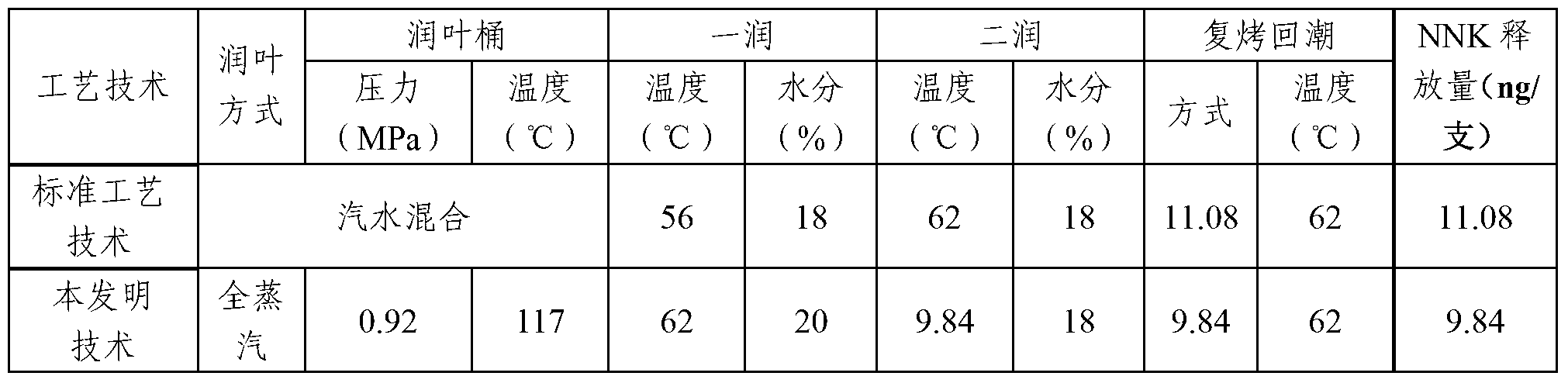

Leaf tobacco processing method capable of selectively reducing release amount of NNK (Nitrosamine) in cigarette smoke

InactiveCN103238915AReduce releaseThe method is feasible and practicalTobacco preparationProcess specificationWet steam

The invention discloses a leaf tobacco processing method capable of selectively reducing a release amount of NNK (Nitrosamine) in cigarette smoke. The leaf tobacco processing method comprises the steps of: firstly, preheating wet leaf barrel, and charging when circulatory hot wind is at 80 DEG C to 120 DEG C; then adjusting a hot steam valve and a wet steam valve based on the positions of the processed leaf tobacco, and respectively controlling a temperature and a moisture content of the wet leaf tobacco; and finally, processing by adopting full steam at a temperature which is accordance with the technical requirements of YC / T146-2010 Leaf Tobacco Threshing and Redrying Process Specification. The method has obvious effects of selectively reducing the release amount of the NNK in the cigarette smoke, achieves the reduction amplitude of 11.20-38.21%, has good repeatability, is applicable to the practical threshing and redrying production, expands the leaf tobacco processing technology of reducing harmful components in the cigarette smoke, and has relatively good practical significance and reference function for harm reduction and tar reduction in the industry.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Work-cold joint supplied cross still state straight and reverse coupling heating power circulation system and method

ActiveCN1948864AImprove effective utilizationReduce irreversible lossEnergy efficient heating/coolingClimate change adaptationLiquid stateCoupling

The invention includes the following steps: heating the ammonia water working medium to a saturated liquid state and then being separated into strong ammonia steam and weak ammonia water; using the condensated strong ammonia steam as the refrigerating output and generate the strong ammonia wet steam; mixing the weak ammonia water after the power positive circulating work with the strong ammonia wet steam and then being condensated to be the fundamental concentration ammonia water working medium.

Owner:中科思道(南京)储能技术有限公司

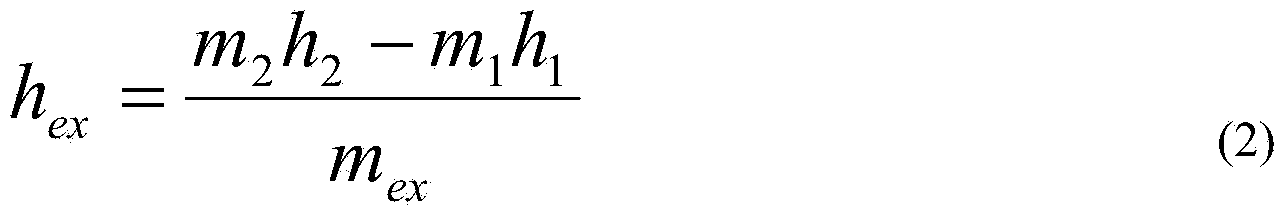

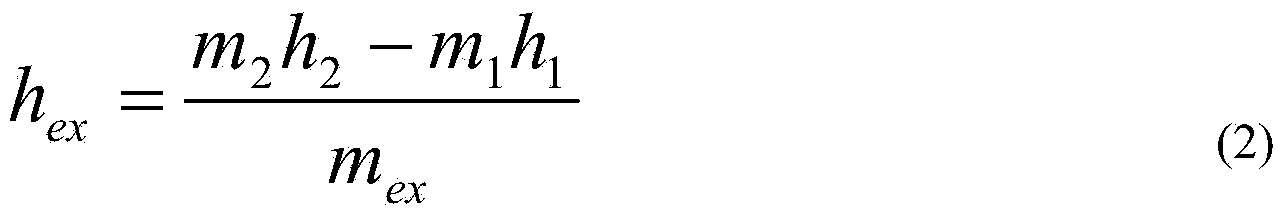

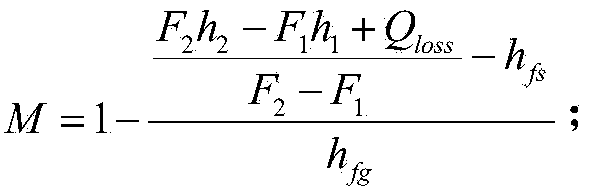

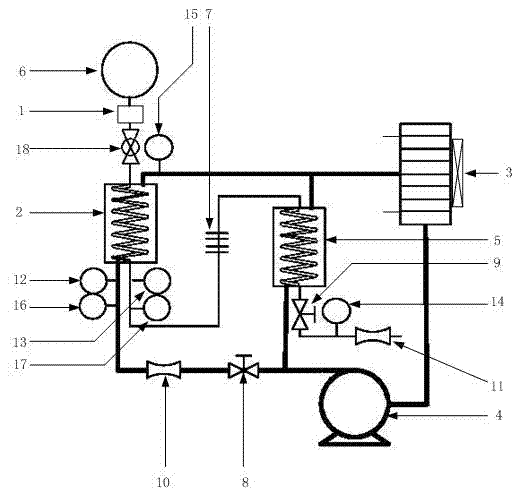

Online wet steam dryness gauge

ActiveCN103207210AEasy to track and controlConvenient Control Track ControlMaterial moisture contentWet steamEngineering

An online wet steam dryness gauge comprises a sampler, a heat exchanger, a water tank, a centrifuge, a cooler, a first sampling branch, a second sampling branch, a first cooling branch, a second cooling branch and a third cooling branch. The sampler, the heat exchanger, the water tank, the centrifuge and the cooler are connected by the first sampling branch, the second sampling branch, the first cooling branch, the second cooling branch and the third cooling branch. The online wet steam dryness gauge further comprises a first enthalpy measuring device, a second enthalpy measuring device, a first flow measuring device, a second flow measuring device and a data processing module, wherein the first enthalpy measuring device is used for measuring enthalpy at a medium outlet of the heat exchanger, the second enthalpy measuring device is used for measuring enthalpy a cooling water inlet and a cooling water outlet, the first flow measuring device is mounted on the second sampling branch, the second flow measuring device is mounted on a second secondary branch, and the data processing module is connected with the first enthalpy measuring device, the second enthalpy measuring device, the first flow measuring device and the second flow measuring device. By the gauge, pressure on a sampling side and a cooling side can be measured and calculated in real time, and real-time wet steam dryness can be provided.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

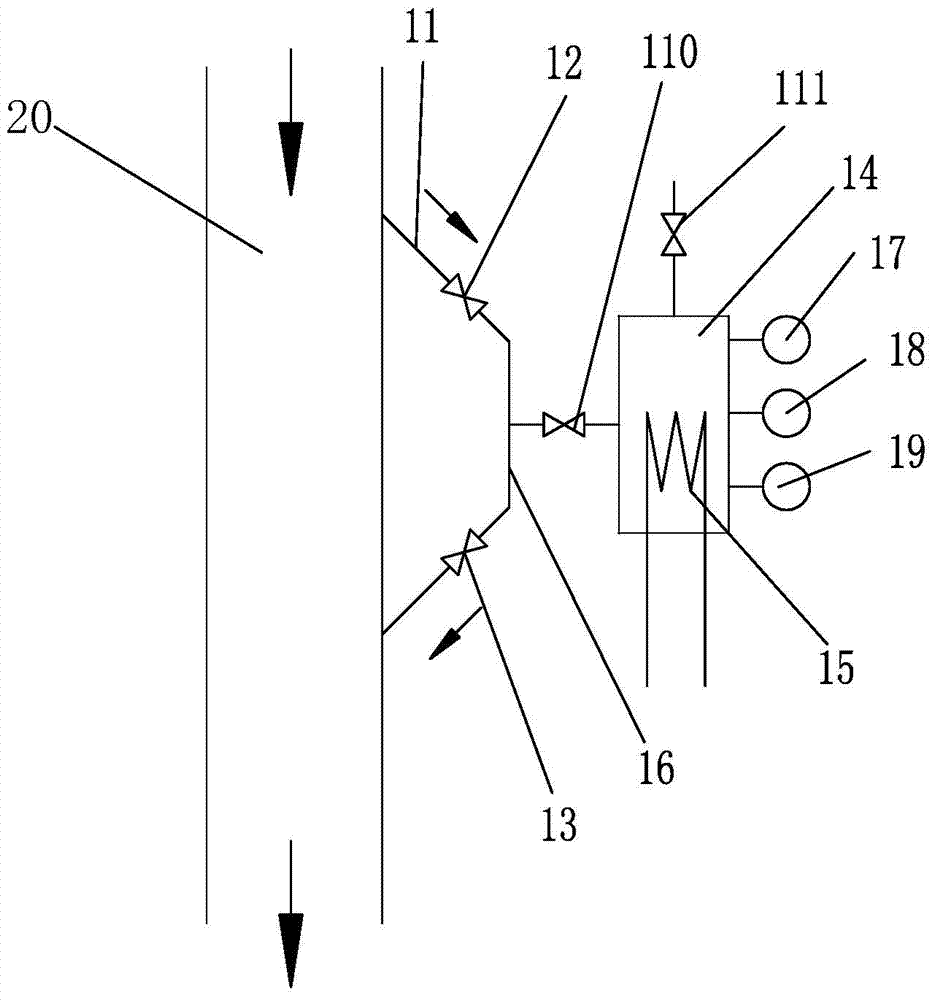

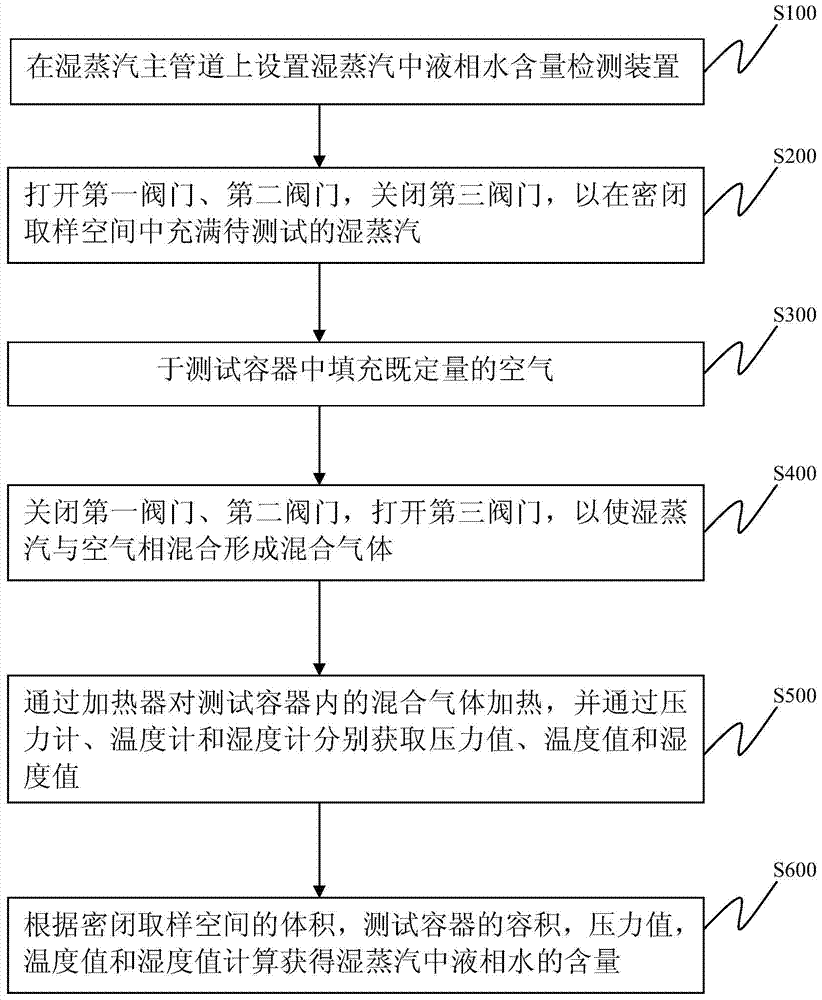

Liquid-phase water content detection device and liquid-phase water content detection method for wet steam

ActiveCN103592199AEasy to testDoes not affect measurement accuracyMaterial analysisWet steamEngineering

The invention relates to a liquid-phase water content detection device for wet steam. The liquid-phase water content detection device for the wet steam is arranged on a main wet steam pipeline and comprises a bypass pipeline, a first valve, a second valve, a test container and a heater, wherein the bypass pipeline is communicated with the main wet steam pipeline; the first valve and the second valve are arranged on the bypass pipeline; a set fixed quantity of air is filled in the test container; the heater is connected with the test container; the bypass pipeline between the first valve and the second valve forms a closed sampling space through a third valve; a pressure meter, a thermometer and a hygrometer are arranged on the test container; the test container is communicated with the closed sampling space through the third valve. The invention further provides a liquid-phase water content detection method for the wet steam. According to the liquid-phase water content detection device and the liquid-phase water content detection method, a state of tested gas can be measured on line, and only simple conventional accessory equipment is needed; the test process is simple and feasible; furthermore, calculation of heat is not needed; the heat dissipation loss cannot affect the measurement precision; the liquid-phase water content detection device and the liquid-phase water content detection method are suitable for the wet steam with various pressure levels.

Owner:CHINA IPPR INT ENG

Measuring method and measuring device for liquid drop particles in wet-steam region

InactiveCN104297112AStrong penetrating powerSimple structureMaterial analysis using sonic/ultrasonic/infrasonic wavesParticle size analysisHigh concentrationSonification

The invention relates to a measuring method and a measuring device for liquid drop particles in a wet-steam region. An ultrasonic excitation signal acquires ultrasonic signals with three different frequencies by adopting a mode of superposing waves; the processing and analyzing process of the ultrasonic signals in a computer comprises the following steps: performing fast Fourier transform on the obtained signals to obtain ultrasonic signal amplitudes with three frequencies, and calculating to obtain sound attenuation coefficients; obtaining particle diameter values of the liquid drop particles according to the relationship between the measured particle diameter values of the liquid drop particles and the ratio of the sound attenuation coefficients with three frequencies; likewise, obtaining a volume concentration value according to the relationship between the volume concentration value and the sound attenuation coefficients, and obtaining a humidity value of wet steam according to the conversion relationship between the volume concentration and the humidity. The measuring device is simple in structure and low in cost; compared with the measuring method for the wet steam by adopting other principles, the measuring method disclosed by the invention has the advantages that ultrasonic waves have strong penetrating power; an ultrasonic transducer can normally work in a severe environment; online measurement of particles sizes, volume concentration and humidity of the liquid drop particles in the wet steam region with higher concentration at the final stage of a low-pressure cylinder can be realized without precision correction.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Steam dryness modulating system

ActiveCN106227279AAchieve humidificationAchieve dehumidificationTobacco preparationHumidity controlProduction lineWet steam

A steam dryness modulating system comprises a steam generator, a gas collecting tank and three branches connected between the steam generator and the gas collecting tank in parallel, wherein the steam generator in the branch I is directly connected with the gas collecting tank to be in a normally opened state, a humidifying device is arranged in the branch II, a dehumidification device is arranged in the branch III, and a gas outlet pipe of the gas collecting tank is connected with a gas using device and is provided with a dryness meter. The steam dryness modulating system is characterized in that the steam of the branches converge in the gas collecting tank, the branch II and the branch III are switched according to a steam dryness value actually measured by the dryness meter, the steam leading amount is adjusted through a valve, and dry and wet steam mixing of different proportions can be achieved. In addition, automatic detection and control of steam dryness can be achieved by adding a signal controller. The united online pipeline steam dryness meter is applied to the system, and online real-time detection of the steam quality of the key working section of a tobacco shred production line can be achieved. Good steam quality can not only guarantee the tobacco shred processing quality, but also improve the energy utilization rate, and the service life of the valve and the device can be effectively prolonged.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

Steam compressor arrangement

InactiveCN101737332AIncrease temperatureEfficient use ofClimate change adaptationSteam useThermal energyWet steam

A steam compressor arrangement comprises the following components: a positive displacement compressor for compressing the steam which is sucked into a reaction space and is used as a gas phase object fluid and discharging to a discharging tube with a preset discharging pressure; a liquid guiding mechanism for guiding the liquid phase objective fluid into the reaction space or a suction space of the compressor; and a dehydrator which is configured on the discharging tube and separates liquid phase part from the objective fluid discharged from the compressor, wherein, the liquid guiding mechanism guides the liquid phase object fluid with enough amount for the following states: namely, the heat is consumed as latent head of vaporization, which is used for vaporizing the liquid phase object fluid; the heat is the residual heat which is in the energy given from the compressor to the object fluid and is after energy consumption for increasing the pressure of the gas phase object fluid sucked by the compressor to the discharging pressure; and furthermore the object fluid is discharged from the compressor with a state that one part of the object fluid is liquid phase wet steam. Therefore the excessive temperature increase of the compressor is prevented, and the output of the compressor is furthest used as the steam energy.

Owner:KOBE STEEL LTD

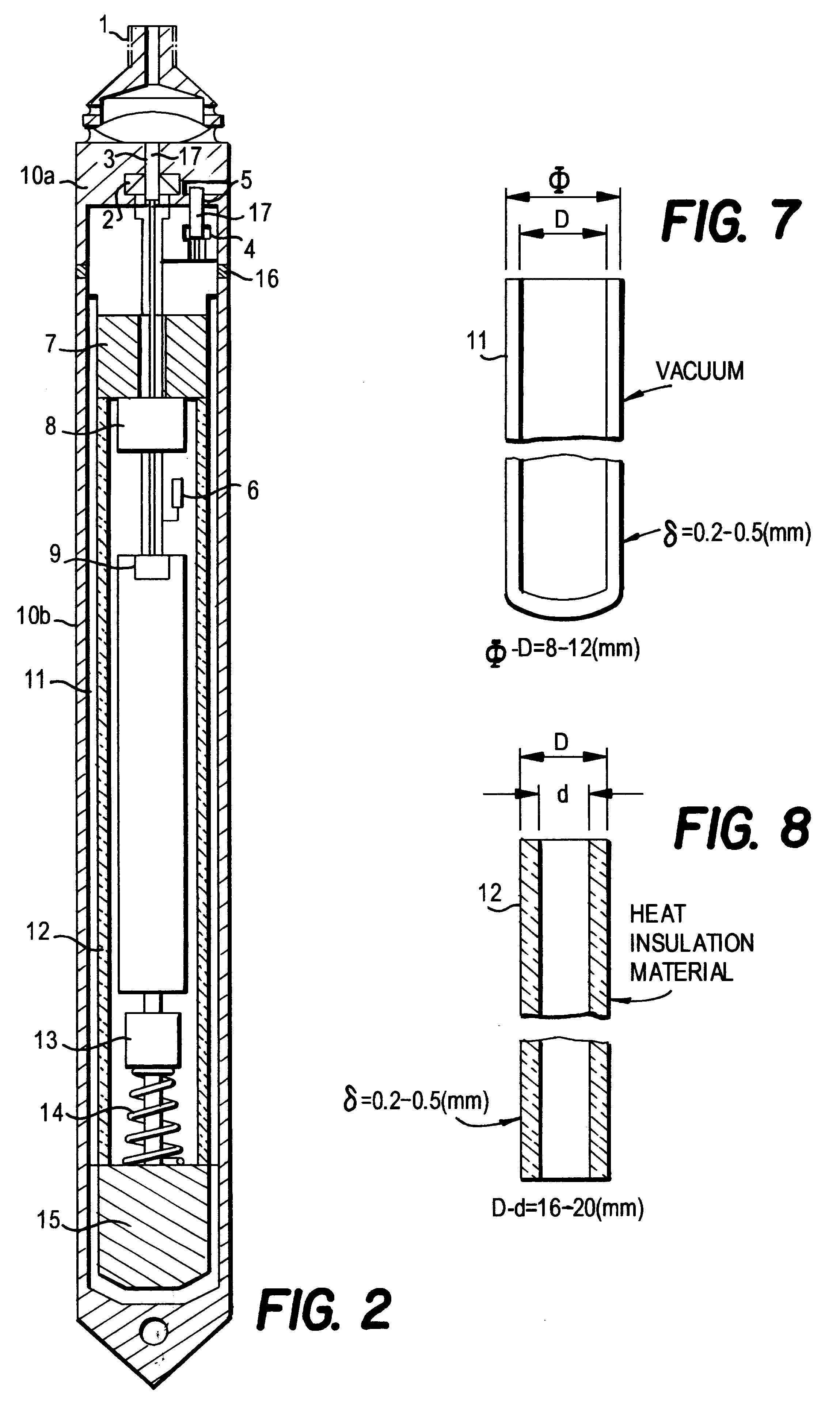

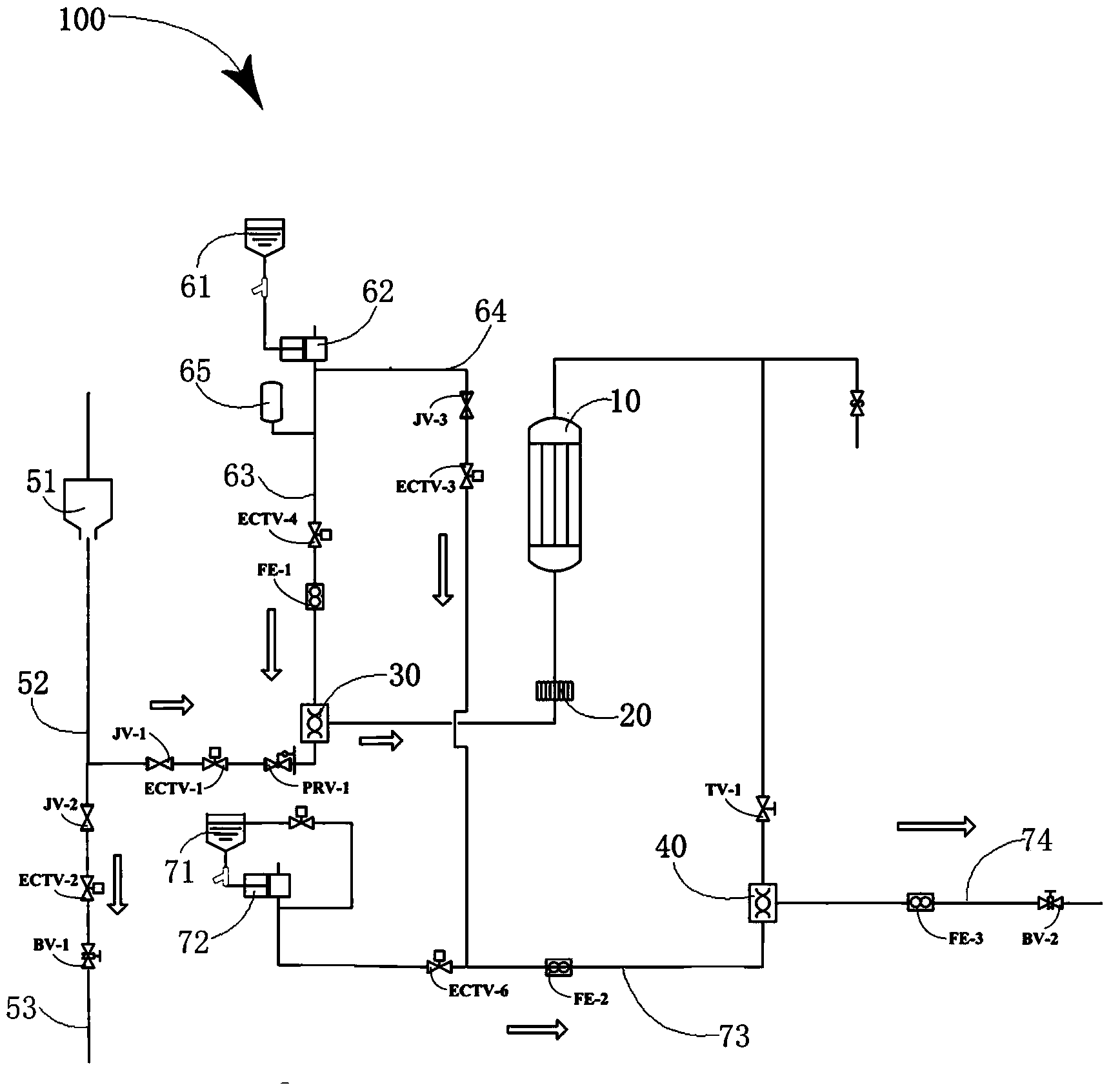

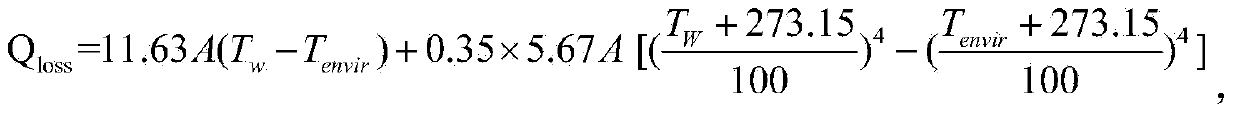

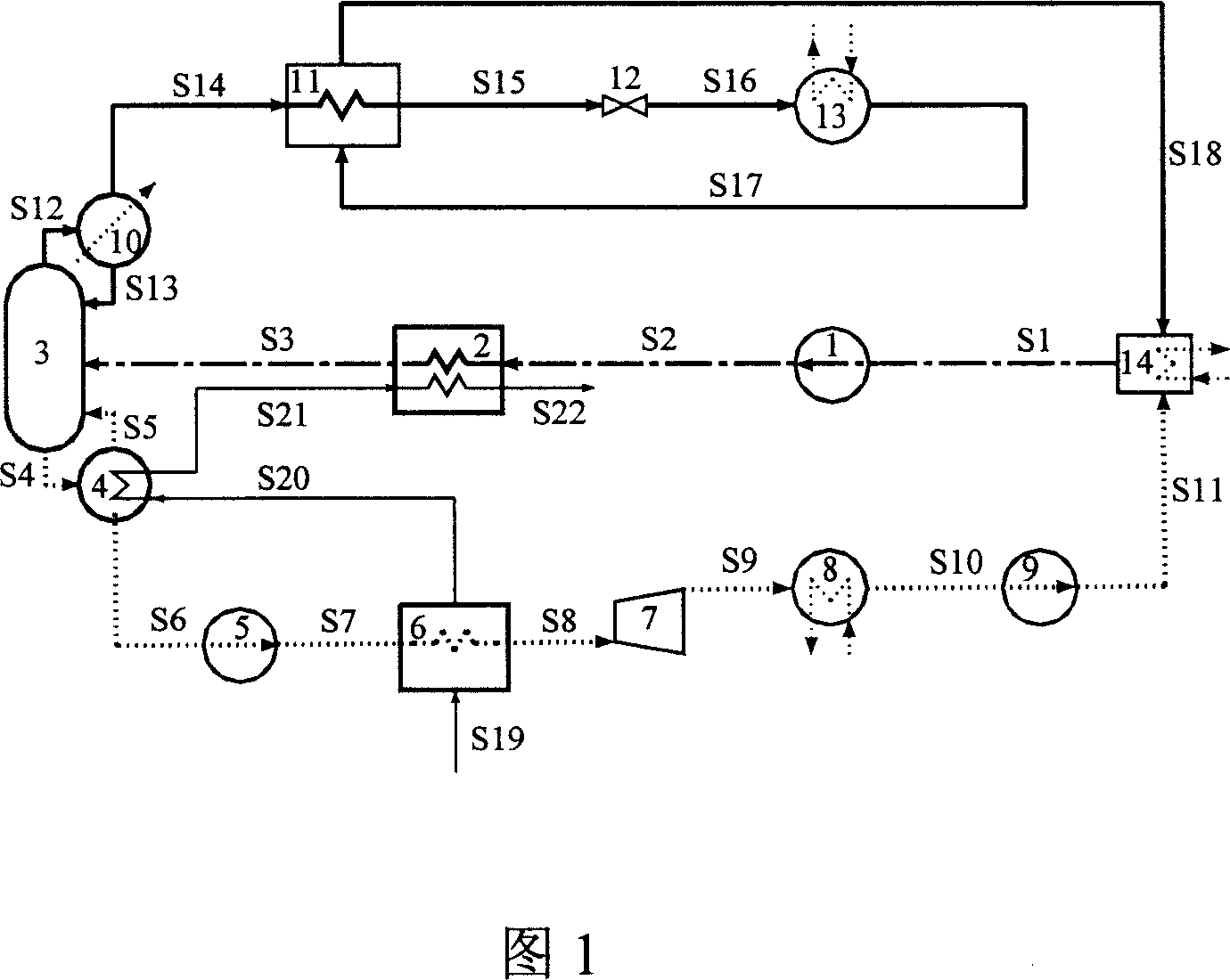

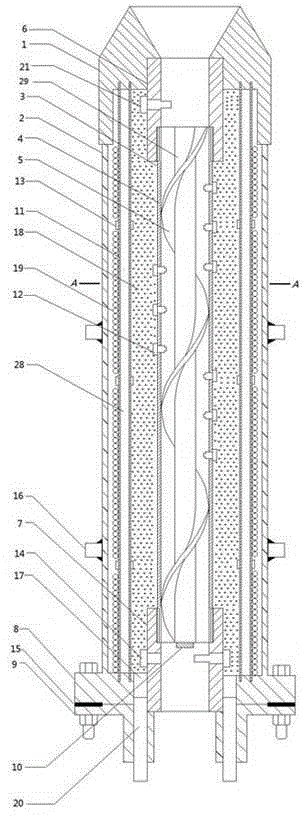

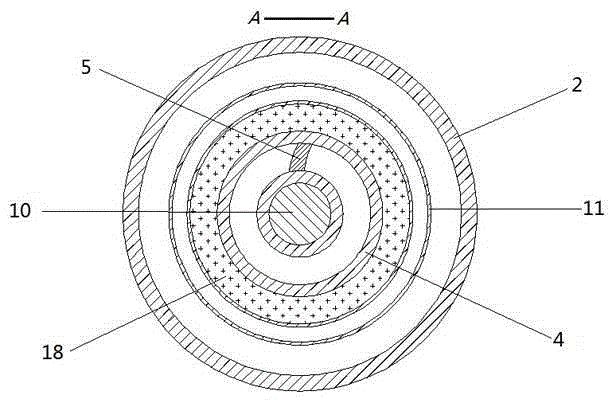

Soft measurement method based on variable-boundary segmentation energy balance, multifunctional wet steam measuring needle and wet steam heat absorption measurement and control device

ActiveCN103185735AGuaranteed absorptionNo heat lossMaterial heat developmentMaterial moisture contentElectricityProcess mechanism

The invention relates to a soft measurement method based on variable-boundary segmentation energy balance, a multifunctional wet steam measuring needle and a wet steam heat absorption measurement and control device. The multifunctional wet steam measuring needle is characterized by consisting of an electric heating rod, an electric heating rod sleeve with uniform and screw pitch-equal convex spiral ribs, a multifunctional wet steam measuring needle outer wall tube, a front sensor seat and a rear sensor seat. The wet steam heat absorption measurement and control device consists of an isothermal sleeve, temperature measuring points distributed on the inner wall and the outer wall of the isothermal sleeve at equal distances and computer online measurement and control equipment. The multifunctional wet steam measuring needle is put in the wet steam heat absorption measurement and control device and is wholly pressed and fixed by an outer sleeve, an outer sleeve flange cover and an outer sleeve flange disc; based on the flowing and heating process mechanism analysis of wet steam in the structure, a soft measurement model and an online calibration model of measurement results are established; and the whole equipment is simple in structure and is suitable for various measurement fields in relation to wet steam two-phase flow, in particular to the measurement of exhaust steam humidity of a condensing turbine.

Owner:杨善让

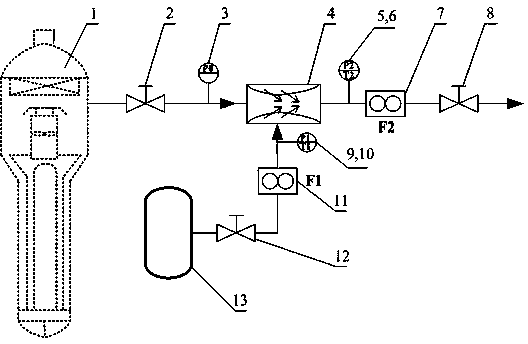

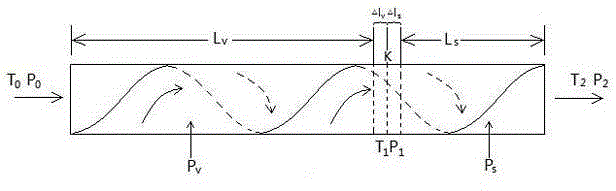

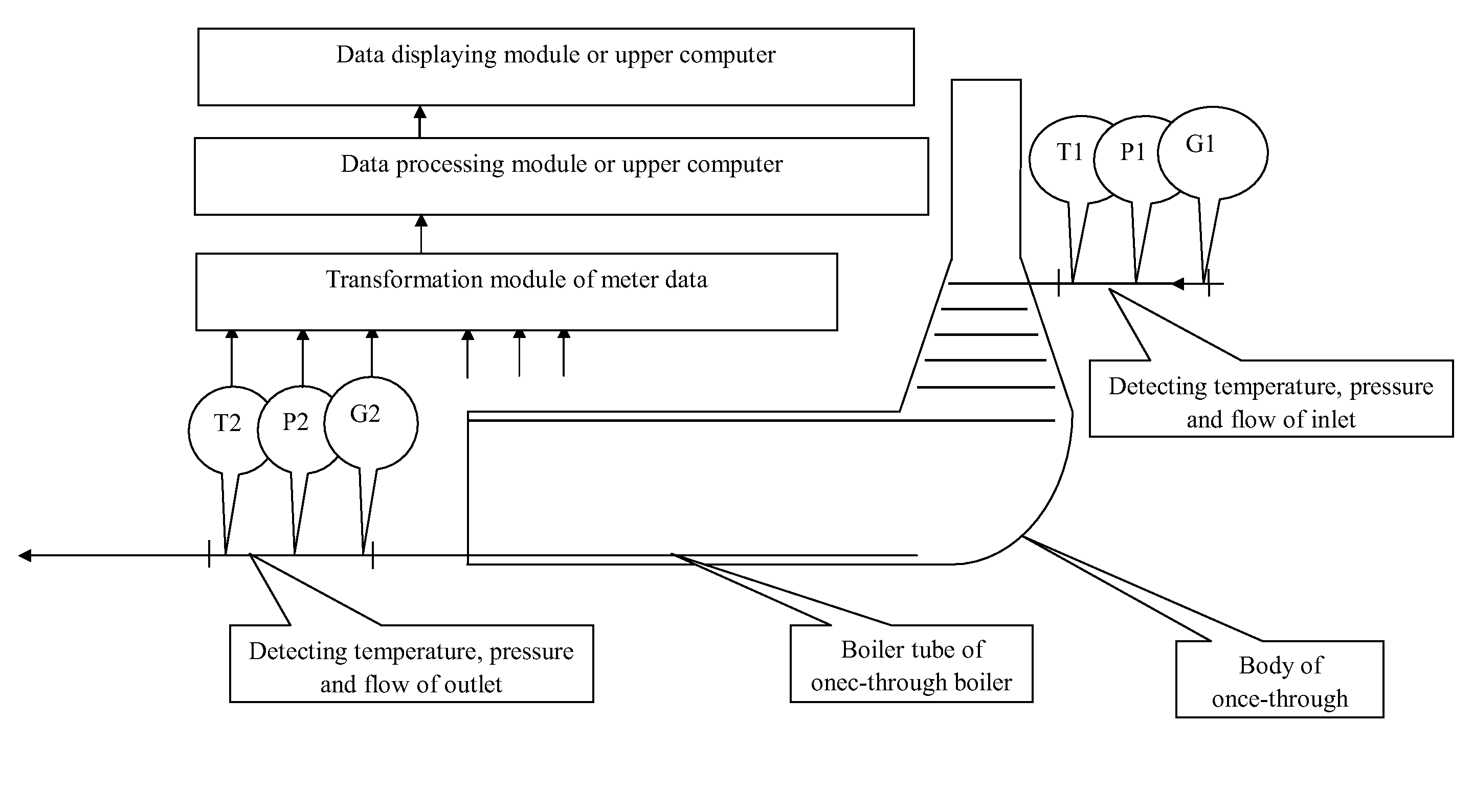

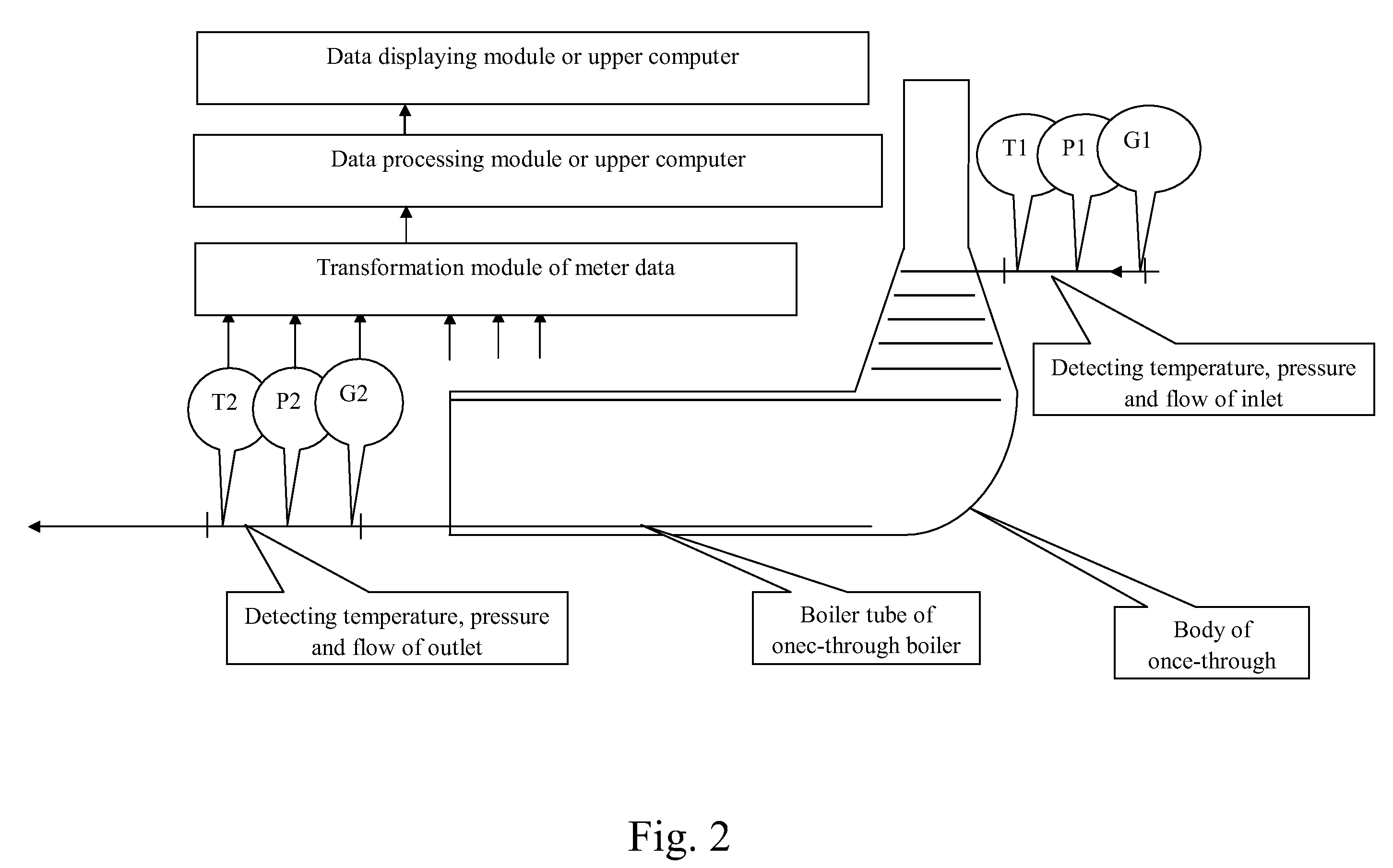

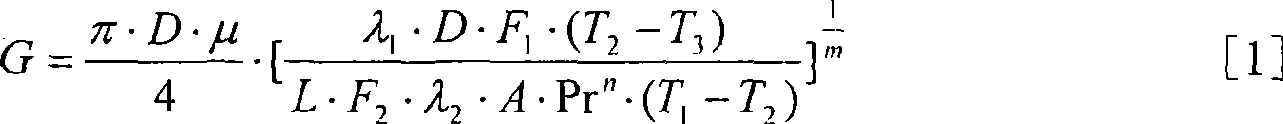

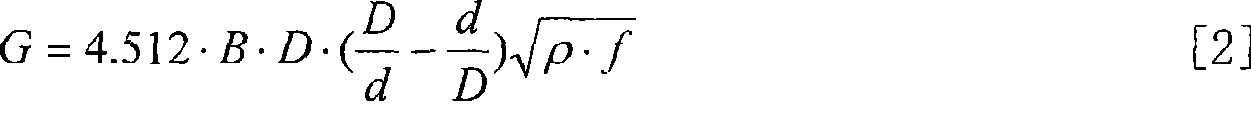

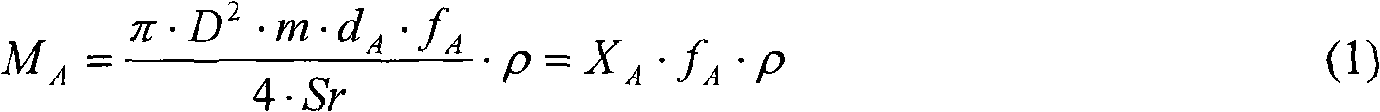

Method of detecting dryness of wet steam of a once-through steam injection boiler and a detecting apparatus therefor

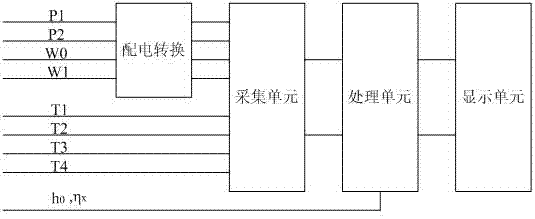

InactiveUS20090217736A1Economic benefitImprove securityVolume/mass flow measurementMaterial moisture contentData displayWet steam

A method of detecting the dryness of wet steam of a once-through steam injection boiler, comprises:first, by detecting and / or calculating, obtaining volume flow of wet steam, corresponding volume flow of saturated liquid, and corresponding volume flow of saturated vapour; andthen obtaining the dryness of wet steam of the once-through steam injection boiler, X, according to the following relationship equation:X=;wherein are the volume flow of wet steam, the corresponding volume flow of saturated liquid, and the corresponding volume flow of saturated vapour respectively.A detecting apparatus for detecting dryness of wet steam of a once-through steam injection boiler, specifically comprises: a data detecting module 1, a data processing module 2, and a data displaying module 3, wherein the data processing module 2 connects the data detecting module 1 and the data displaying module 3.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

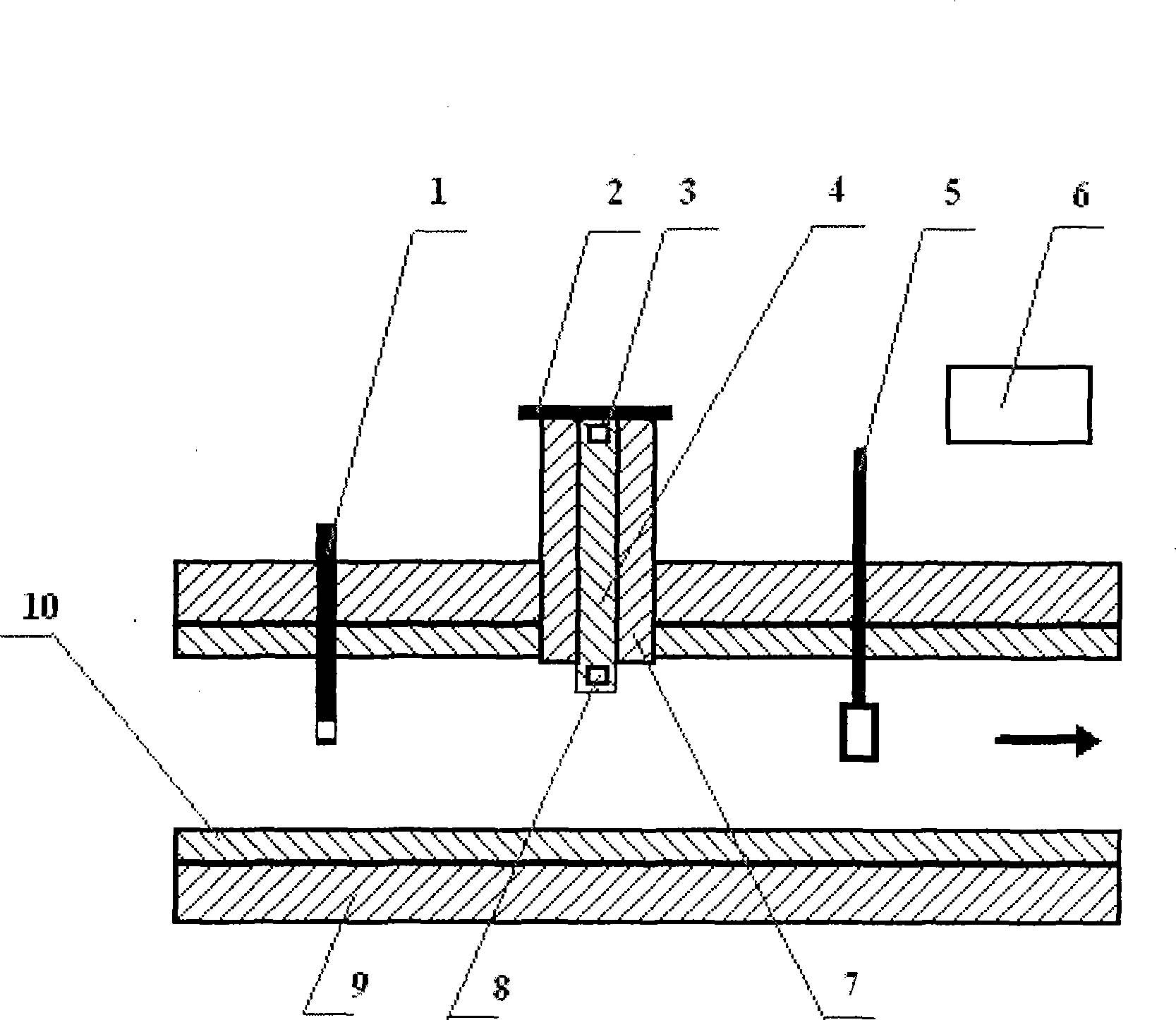

Temperature flow-type steam quality measurement device and measurement method

The invention discloses a temperature flow-type steam quality measurement device and a measurement method thereof, comprising a temperature sensor, a flowmeter, a heat transfer rod, a thermal sleeve and a steam quality processor. The heat transfer rod (4) is installed on the wall of a steam pipe (10); a steam temperature sensor (1) and a target-type flowmeter (5) are respectively arranged at the two sides of the heat transfer rod; and the outer surface of the heat transfer rod (4) is sleeved with a thermal sleeve (7). A hot end temperature sensor (8) is internally embedded at the hot end of the heat transfer rod (4), and the hot end directly contacts with the steam in the steam pipe; a cold end temperature sensor (3) is internally embedded at the cold end of the heat transfer rod (4), and the cold side is fixed with a cooling fin (2) and contacts with the ambient air. The invention derives the steam flow in the steam pipe according to the steam temperature in the steam pipe, the hot end temperature of the heat transfer rod, and the cold end temperature of the heat transfer rod, and then combines the steam flow in the steam pipe with the steam flow which is measured by the target-type flowmeter, and finally calculates the wet steam quality in the steam pipe. The invention has the advantages of high measurement accuracy, and good stability and reliability.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD +1

Spraying process of water erosion resisting coating for water turbine vanes

The spraying process of water erosion resisting coating for water turbine vanes includes repair welding, sand blasting, spraying transition layer, applying pore sealing agent and vane protecting steps. It has high binding strength between the coating and vane surface resulting in coating life as long as four years and without peeling, leads to low use cost and is suitable for vanes operating in wet steam area and last stage vanes operating in low load condition.

Owner:MUDANJIANG AIDI ELECTRICAL POWER TECHN

Recycled two-phase flow flowmeter calibrating platform of wet steam

InactiveCN102230817AAdjustable qualityAdjustable steam drynessTesting/calibration apparatusWaste heat recovery unitGear pump

The invention provides a recycled two-phase flow flowmeter calibrating platform of wet steam, which is characterized in that a heat storage box of a stable water supply unit is communicated with a concurrent boiler through a boiler feed pipe; a gear pump, a water feed flowmeter and a water feed conductivity meter are arranged on the boiler feed pipe in sequence; a concurrent boiler of a steam-generating unit is communicated with a cooling heat exchanger by a steam supply pipe; a detected meter, a meter detector and a water sampler are arranged on the steam supply pipe in sequence; a cooling heat exchanger of a waste heat recovery unit is connected with the heat storage box by a water inlet tube of the heat storage box; the water sampler is communicated with a sampling water pipe; and the sampling water pipe is connected with a water sample conductivity meter and a sampling water regulating valve. The calibrating platform can provide the wet steam for calibration and the wet steam for the calibration can regulate mass flow rate and steam dryness. A high-accuracy wet steam standard flowmeter and a standard dryness meter are arranged on the calibrating platform, thus being capable of executing high-accuracy calibration on the detected meter. The wet steam for the calibration can be used for recycling fluids and waste heat, thus reducing the operating cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

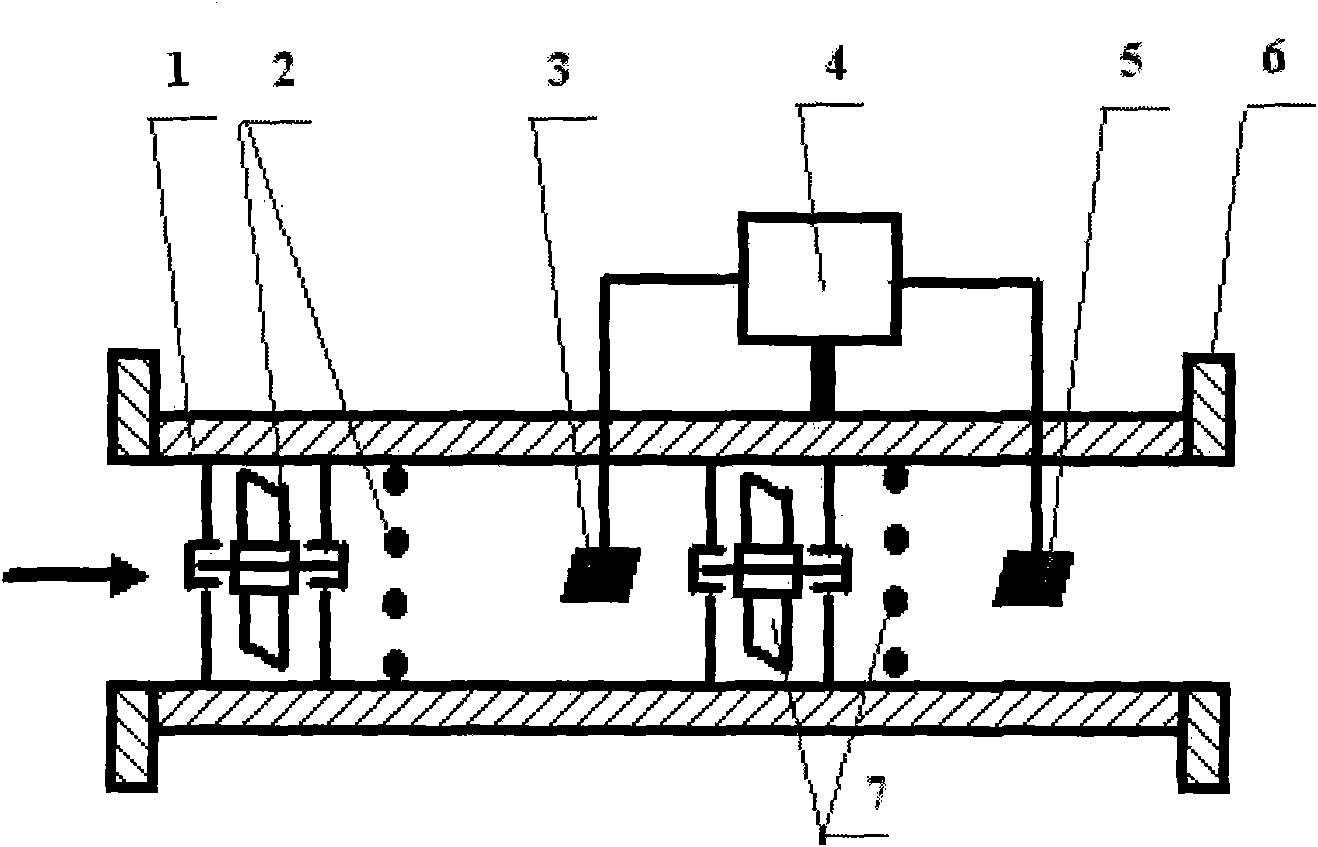

Flow measurement device and method of gas-liquid multi-phase flow

InactiveCN101672676AHigh measurement accuracySimple structureVolume flow measuring devicesIndirect mass flowmetersMeasurement deviceWet steam

The invention discloses a flow measurement device of gas-liquid multiphase flow, used for measuring the flow of wet steam in heterogeneous distribution. The flow measurement device is characterized inthat a homogeneous rectifier A, a flow meter sensor A, a homogeneous rectifier B and a flow meter sensor B are arranged in a straight-way pipe sequentially, and a numeral display meter in which a flow processing program of the gas-liquid multiphase flow is arranged is fixed outside the straight-way pipe. The invention also discloses a method for measuring the flow of wet steam in heterogeneous distribution by the flow measurement device of gas-liquid multiphase flow, and the method comprises the following steps: acquiring flow characteristic signals of the A flow meter sensor and the B flow meter sensor; and simultaneously working out the flow of the wet steam in heterogeneous distribution by mass conservation equation of the A flow meter sensor and the B flow meter sensor. The inventionnot only can measure the flow quality of gas-liquid multiphase flow but also has the advantages of high measurement accuracy, good stability and reliability, simple structure and low manufacturing cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

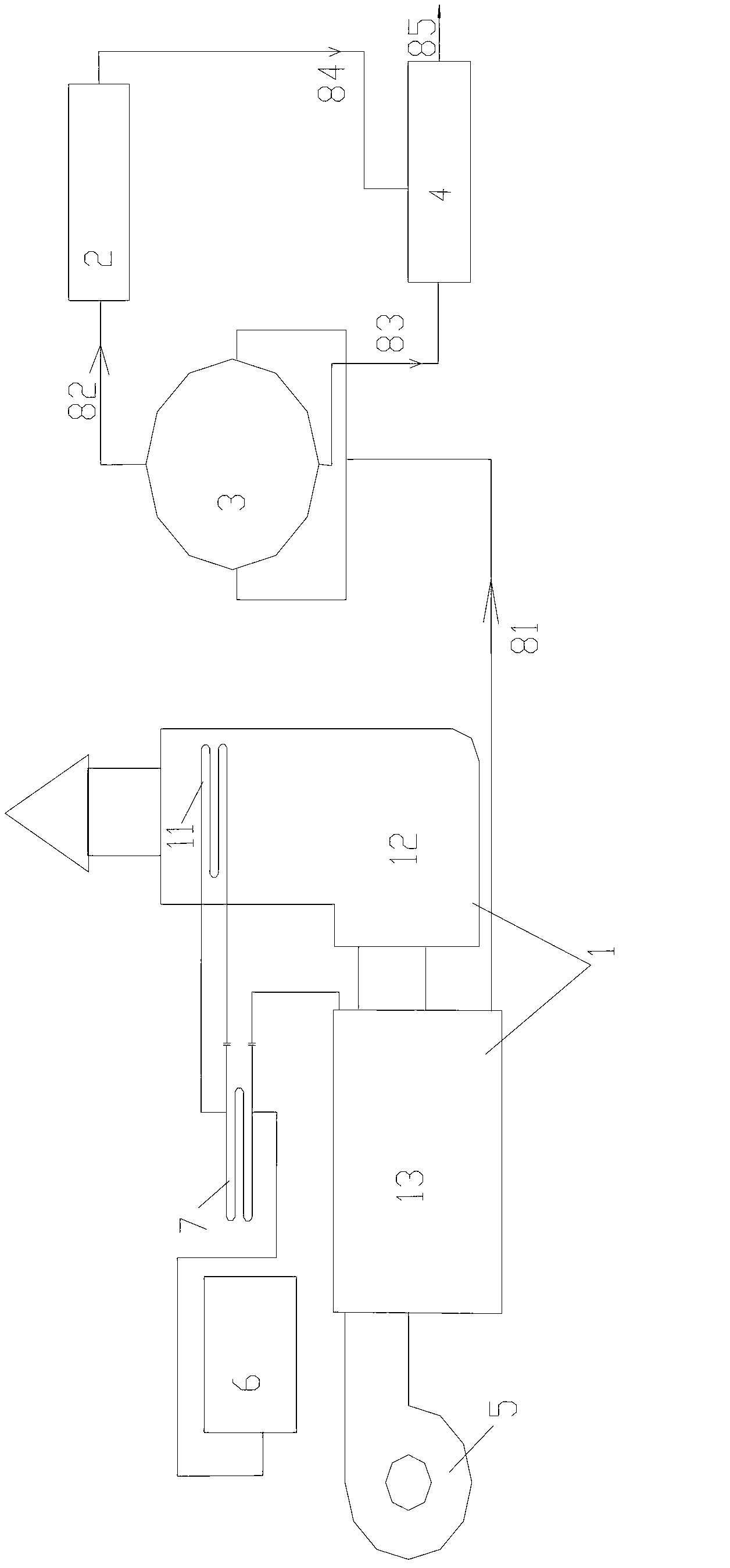

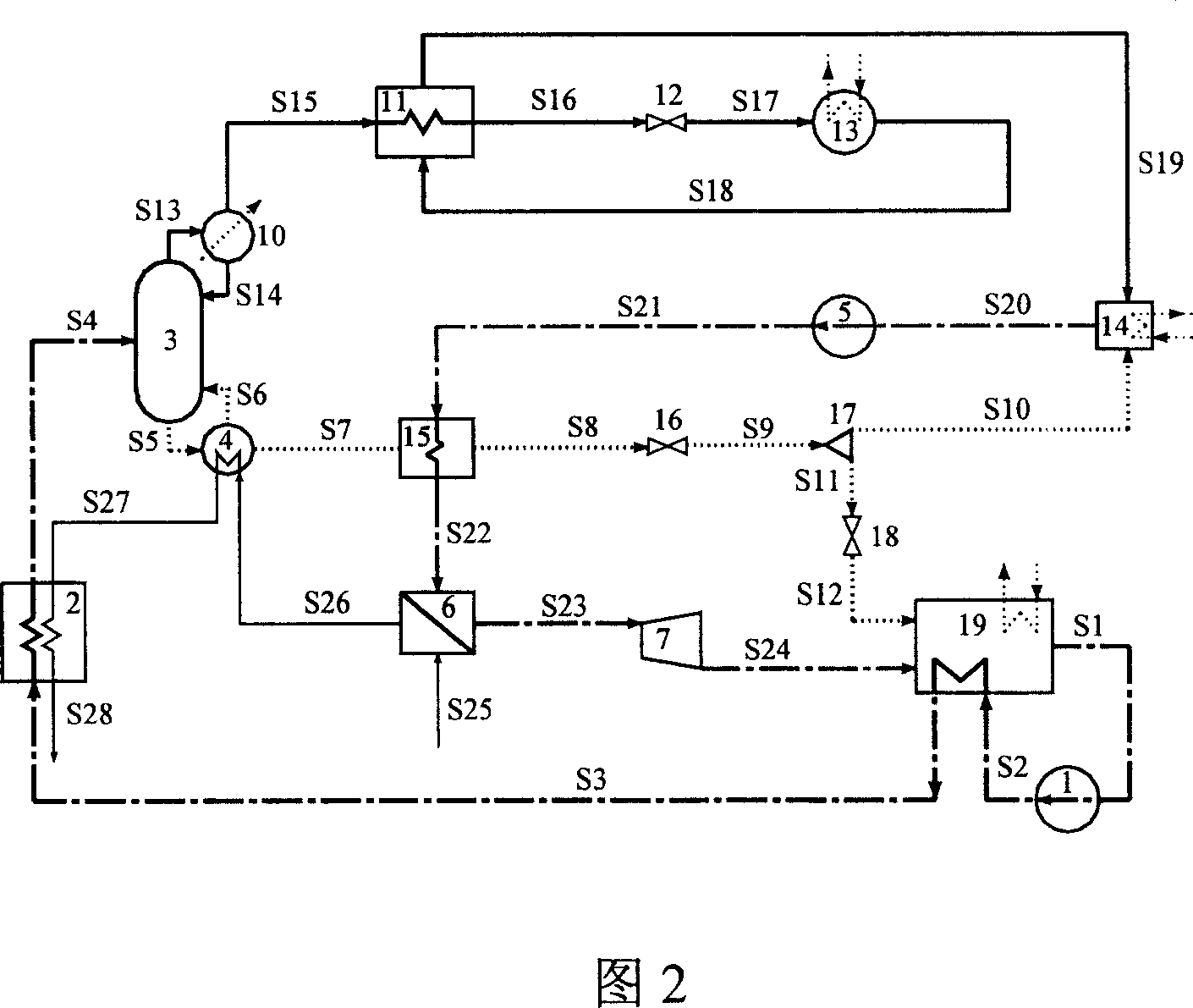

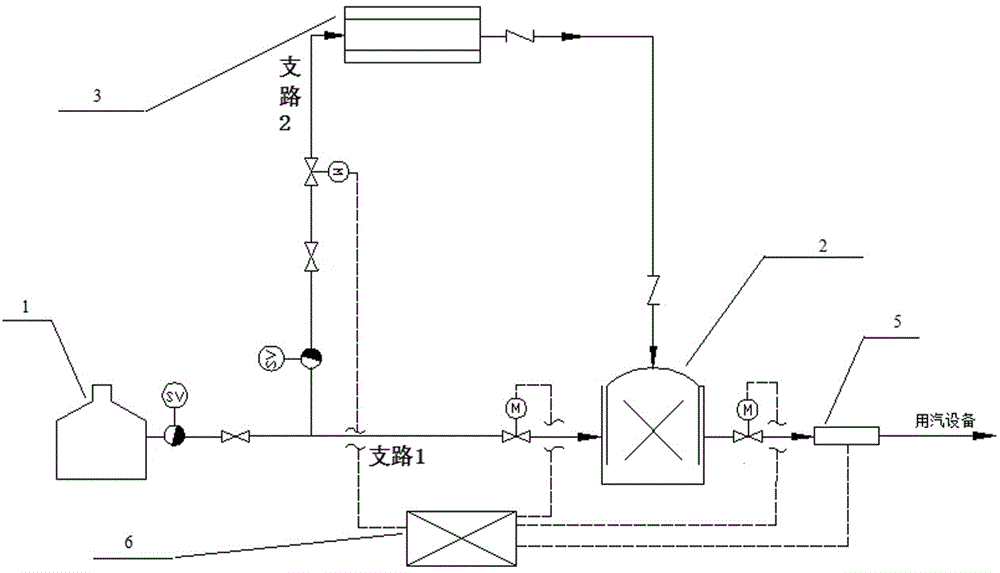

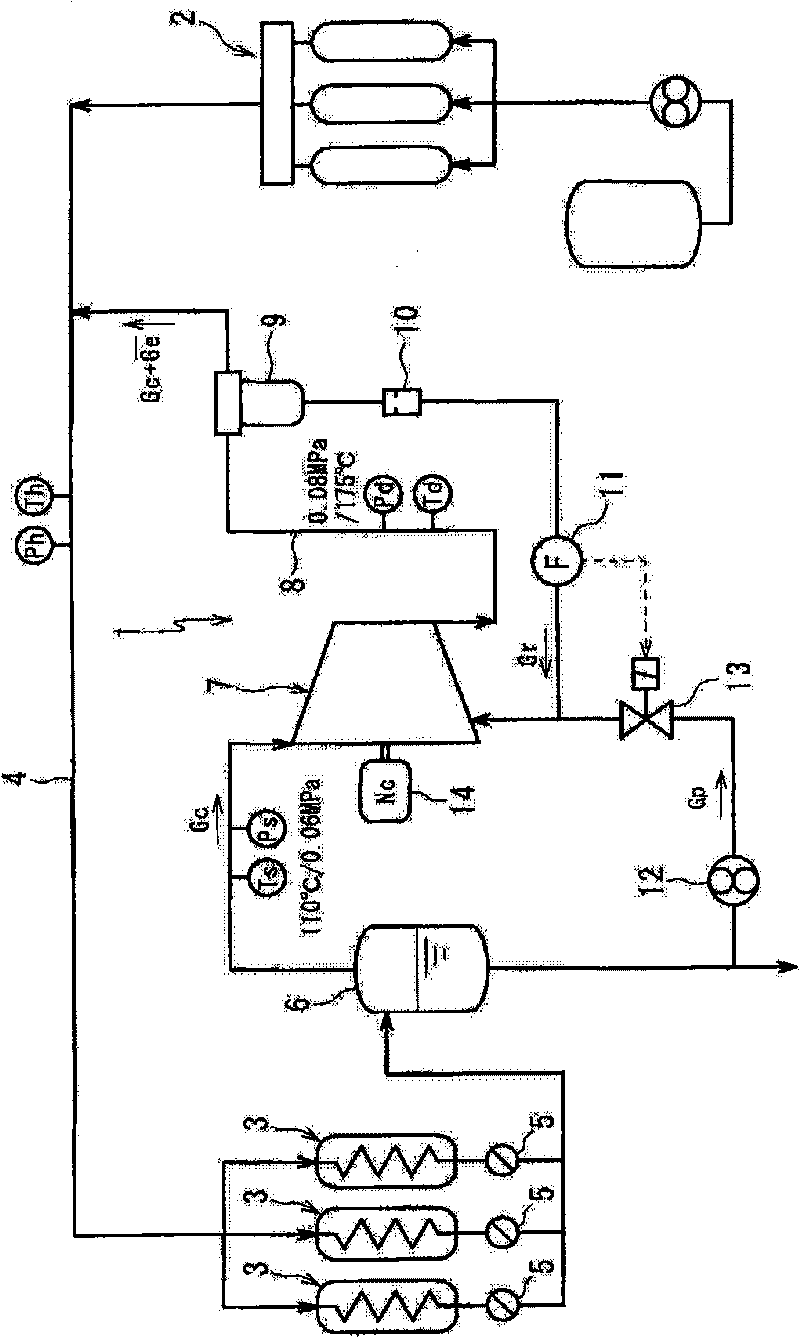

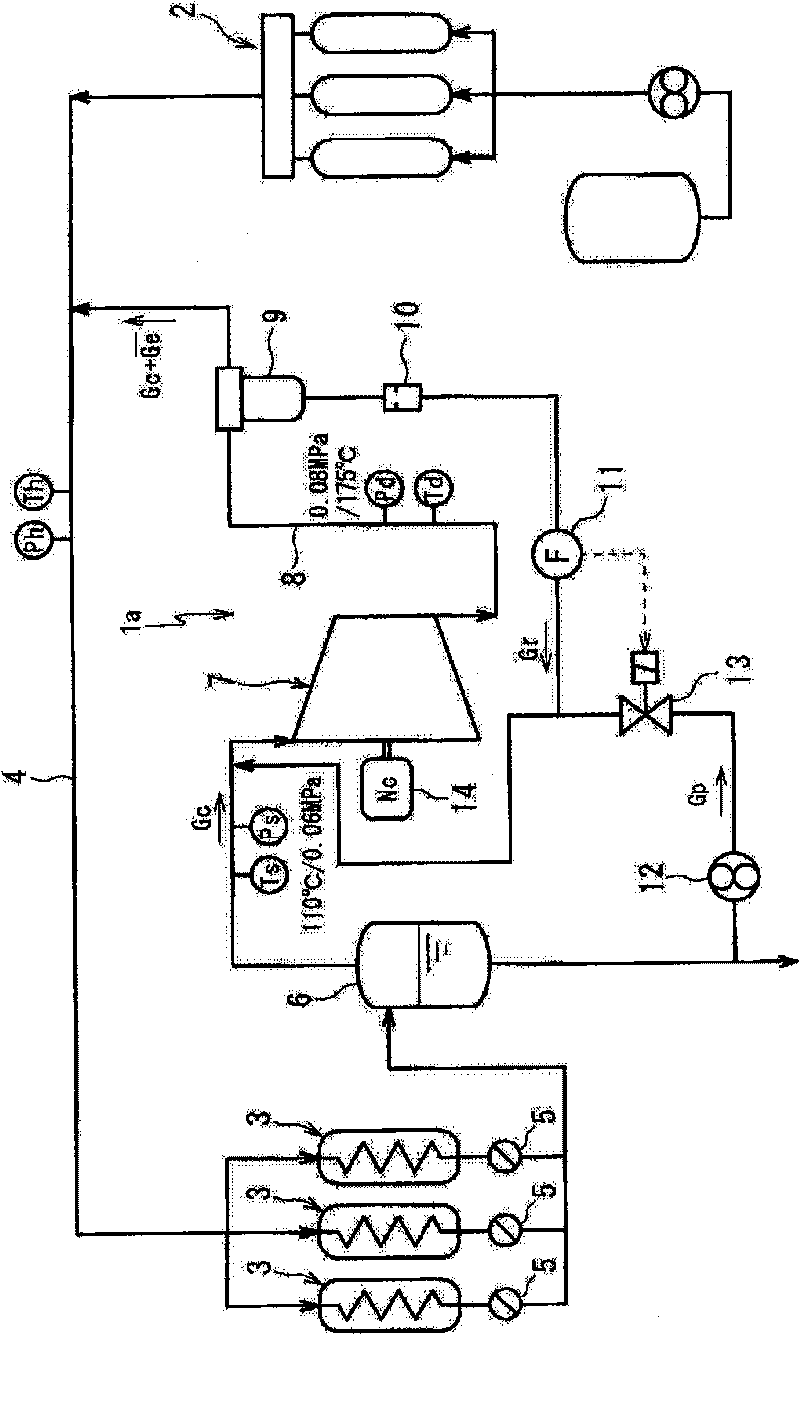

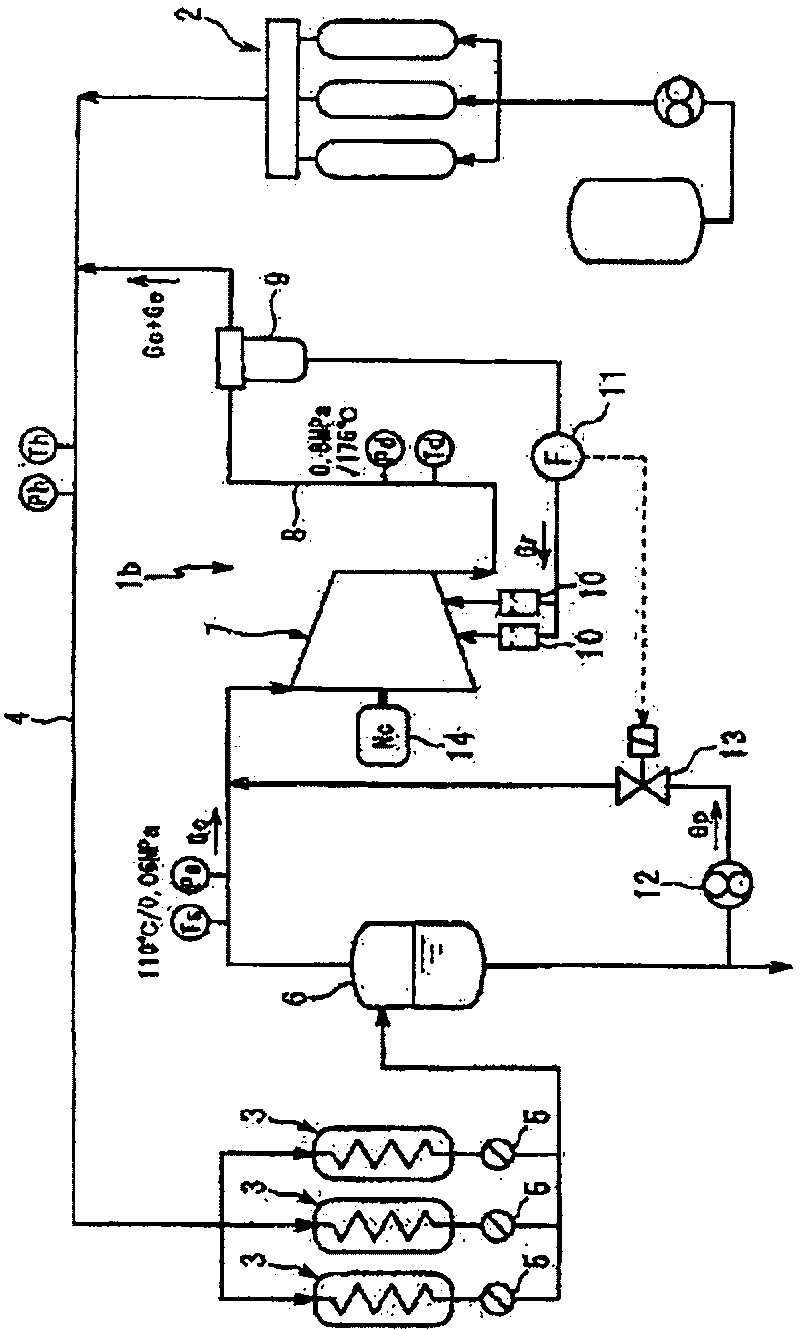

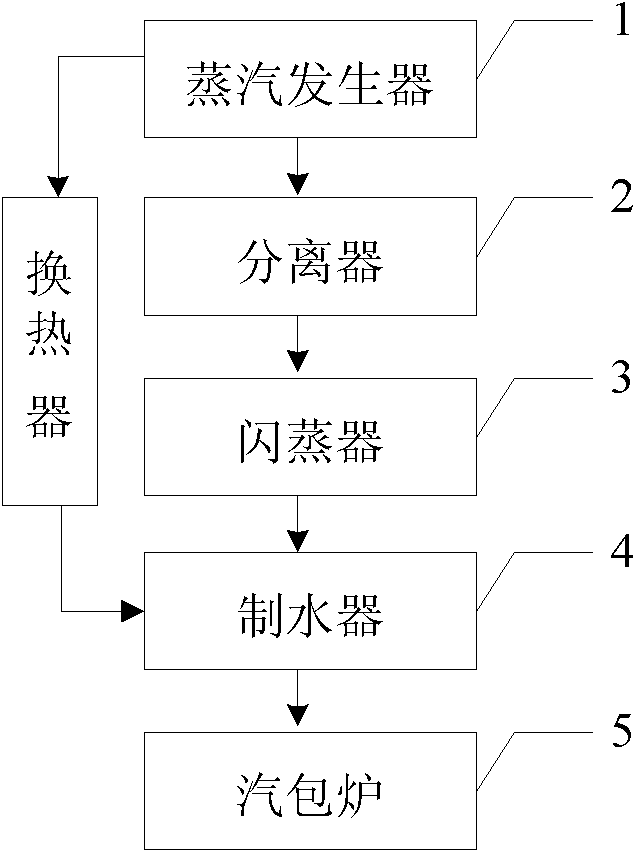

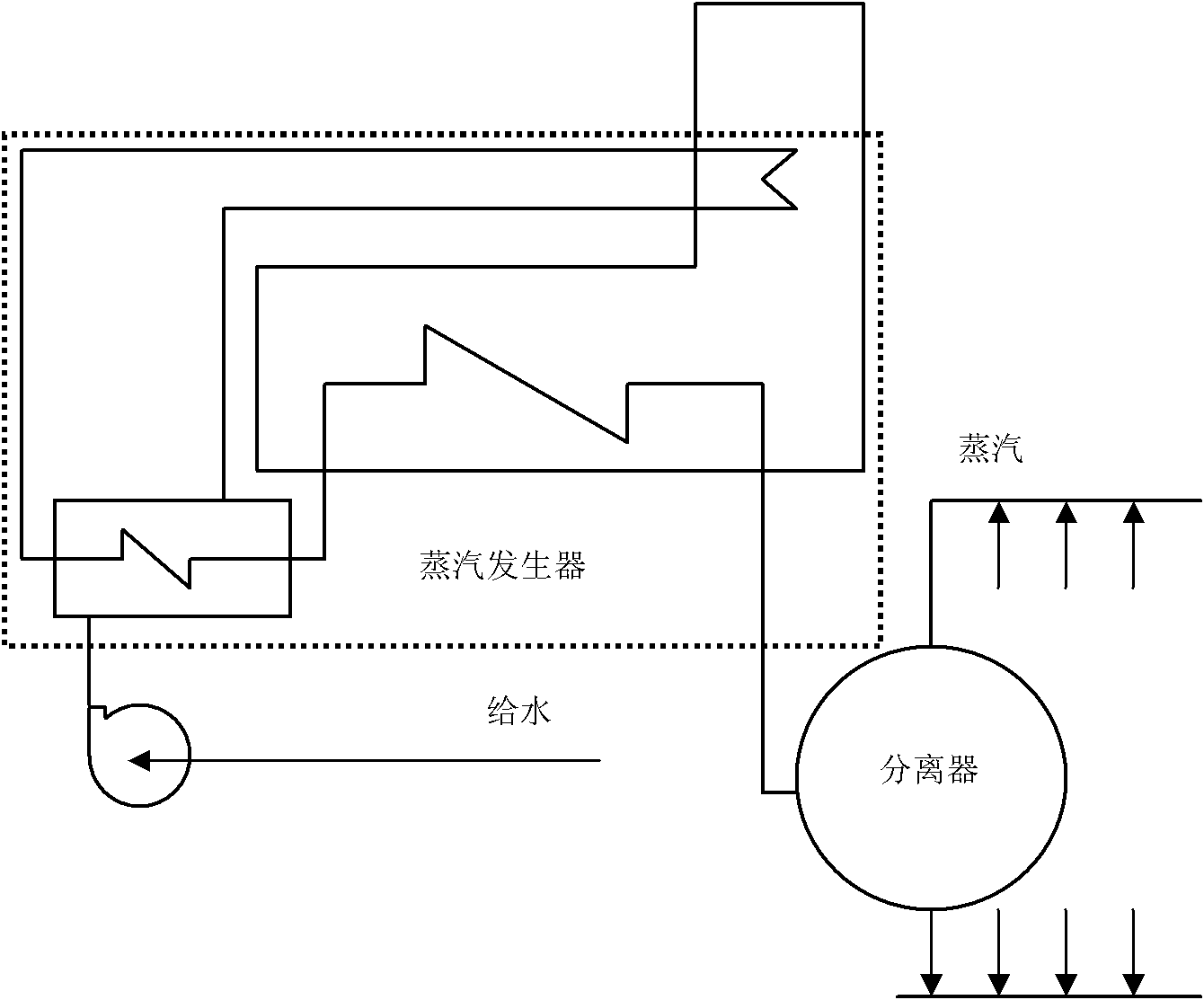

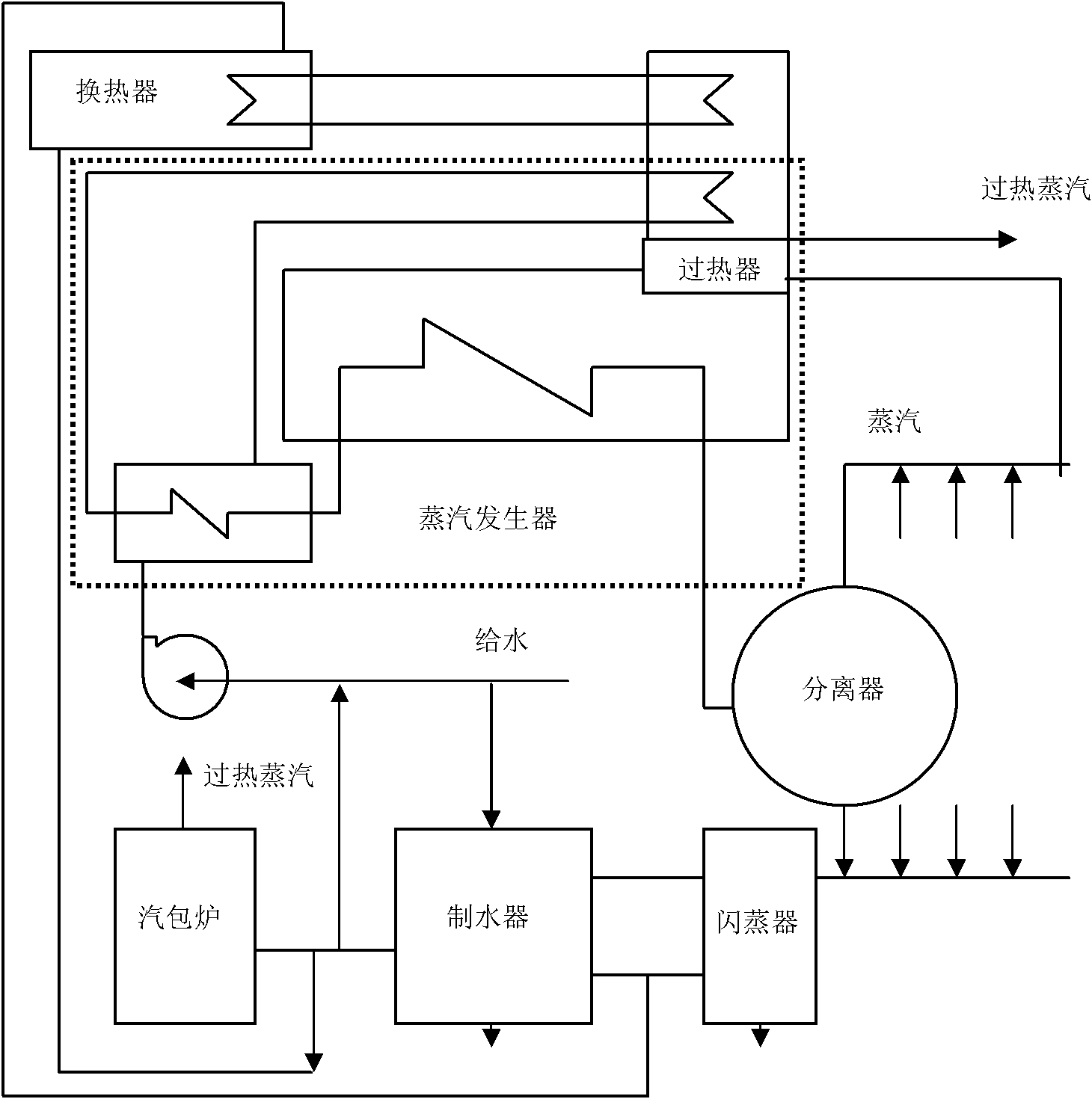

SAGD (steam assisted gravity drainage) wet steam injection station system, boiler water recycling method thereof

ActiveCN102720474AImprove utilizationOvercome efficiencyFluid removalMultistage water/sewage treatmentHigh concentrationWet steam

The invention provides an SAGD (steam assisted gravity drainage) wet steam injection station system, and a boiler water recycling method thereof. The system comprises a steam generator and a separator, wherein the separator is used for separating high-dryness steam and high-temperature saline water output by a boiler; the system also comprises a flash evaporator, a water maker, a drum boiler and a heat exchanger; the flash evaporator is connected with the separator for carrying out flash evaporation treatment on the high-temperature saline water separated by the separator so as to generate wet steam and high-concentration saline water; the water maker is connected with the flash evaporator for carrying out evaporative desalination treatment on the high-concentration saline water generated by the flash evaporator so as to generate product water by the wet steam generated by the flash evaporator; the drum boiler is connected with the water maker for heating the product water generated by the water maker to form overheat steam, and the heat exchanger is respectively connected with the water maker and the steam generator for recovering smoke afterheat generated by the steam generator as a supplied heat source of the water maker for carrying out evaporative desalination treatment. According to the wet steam injection station system, energy and water can be saved and the utilization of heat can be improved.

Owner:PETROCHINA CO LTD

Large-diameter high-speed liquid jet impact test device

InactiveCN104535440APrevent violent movementPrevent tamperingMaterial strength using repeated/pulsating forcesLiquid jetWet steam

The invention discloses a large-diameter high-speed liquid jet impact test device which comprises a test bed rack, a jet power device, a power bracket device, a liquid jet device, a sample clamping device and an observation device, wherein the jet power device is positioned on the rear side of the test bed rack and is clamped by the power bracket device; the liquid jet device is positioned in front of the jet power device and is fixed on the test bed rack by virtue of a bolt, a liquid nozzle rack is arranged at the front end of the liquid jet device, and a sleeve rack through which only a nylon rod is allowed to penetrate is arranged at the rear end of the liquid jet device; the sample clamping device is positioned in front of the liquid jet device, and a rectangular groove is formed in the middle of the device and is used for clamping the sample; and the observation device is used for observing the speed and diameter of liquid jet. The device can be used for researching notch damage generated by different materials under the impact of high-speed drops of different diameters, the analysis experiment result can guide material selection of wet-steam region steam turbine vanes and other mechanical parts which operate in a water erosion environment, and the test device has significant academic value for further researching the liquid-solid high-speed impact mechanism.

Owner:XI AN JIAOTONG UNIV

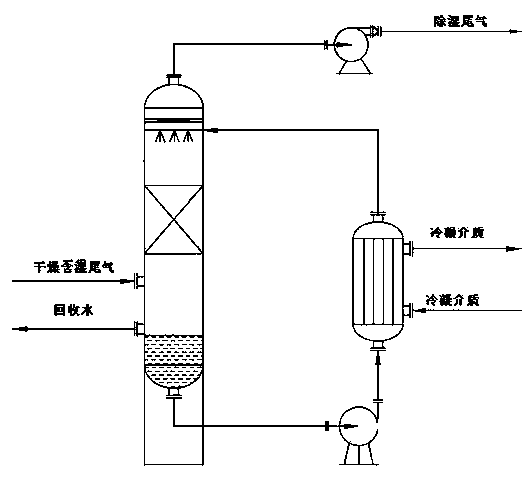

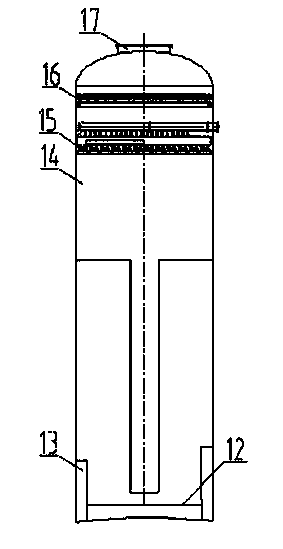

Tail gas separation tower

ActiveCN103657353AAchieve clean separationAvoid the disadvantage of containing impuritiesUsing liquid separation agentTransportation and packagingWet steamPhysical chemistry

The invention relates to a novel dried water-containing tail gas separation tower which can cleanly separate water in the dried water-containing tail gas. The separation tower consists of an area I for washing, cooling, condensation and absorption and an area II for negative-pressure flashing. By the conditional exchanging, transferring and circulating of heat quantity and quality between the area I for washing, cooling, condensation and absorption and the area II for negative-pressure flashing area, the novel dried water-contained tail gas separation tower can realize clean separation of wet steam and incondensable process gas in the dried water-contained tail gas.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

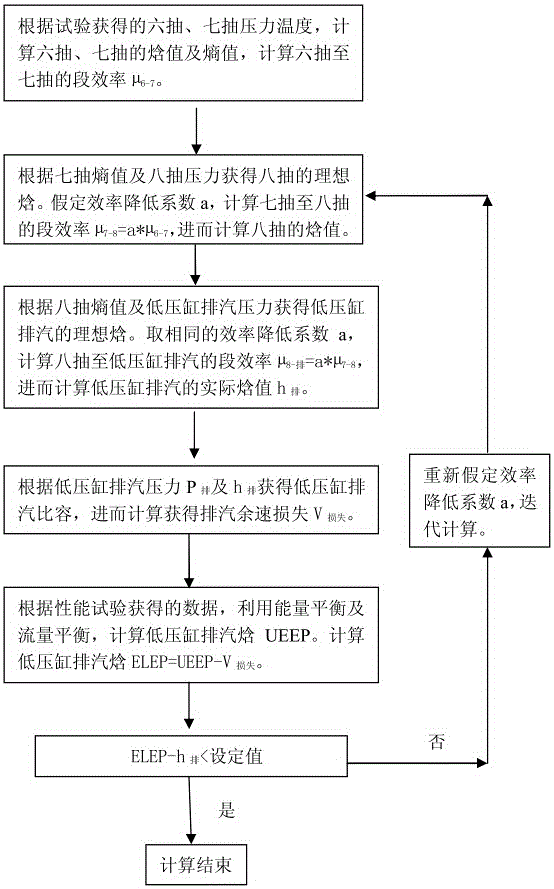

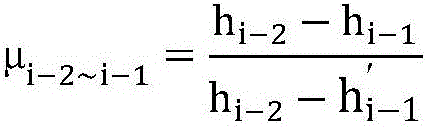

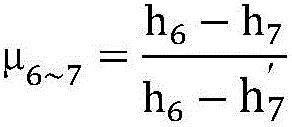

Method for calculating efficiency of low-pressure cylinder of thermal power plant steam turbine

The invention relates to a method for calculating the efficiency of a low-pressure cylinder of a thermal power plant steam turbine. The conventional method for calculating the efficiency of the low-pressure cylinder at present is low in precision. The method comprises the following steps: (1) calculating steam extraction pressure from high to low, supposing that a first steam extraction point in a wet steam state is i, calculating enthalpy values and entropy values of the steam extraction points i-1 and i-2 according to pressure and temperature which are acquired by a performance test, and calculating section efficiency [mu](i-2 to i-1) of i-2 to i-1; (2) supposing that the efficiency reduction coefficient is a, i.e. the section efficiency [mu](i-2 to i-1) of i-2 to i-1 is [mu]i-1 to i= a*[mu](i-2 to i-1); (3) calculating an actual enthalpy value of the point i; (4) calculating the steam discharging enthalpy h(steam discharging) of the low-pressure cylinder; (5) calculating the steam discharging leaving velocity loss V(leaving velocity loss) of the final stage; (6) calculating an enthalpy value UEEP of the unit mass of steam discharged by the low-pressure cylinder; and (7) calculating the efficiency of the low-pressure cylinder. The method is easy to operate and high in calculation precision.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Systems and methods for determining steam turbine operating efficiency

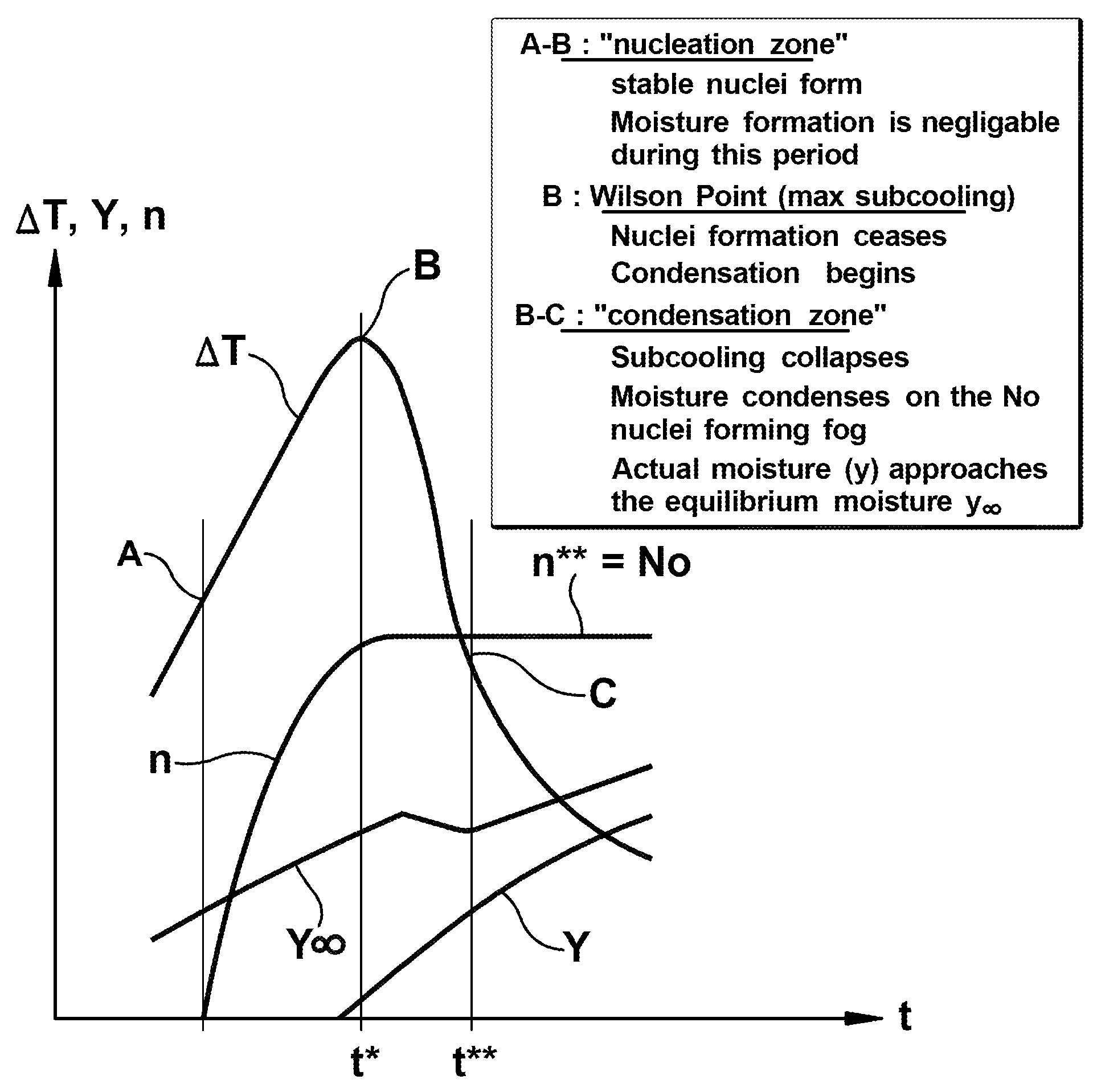

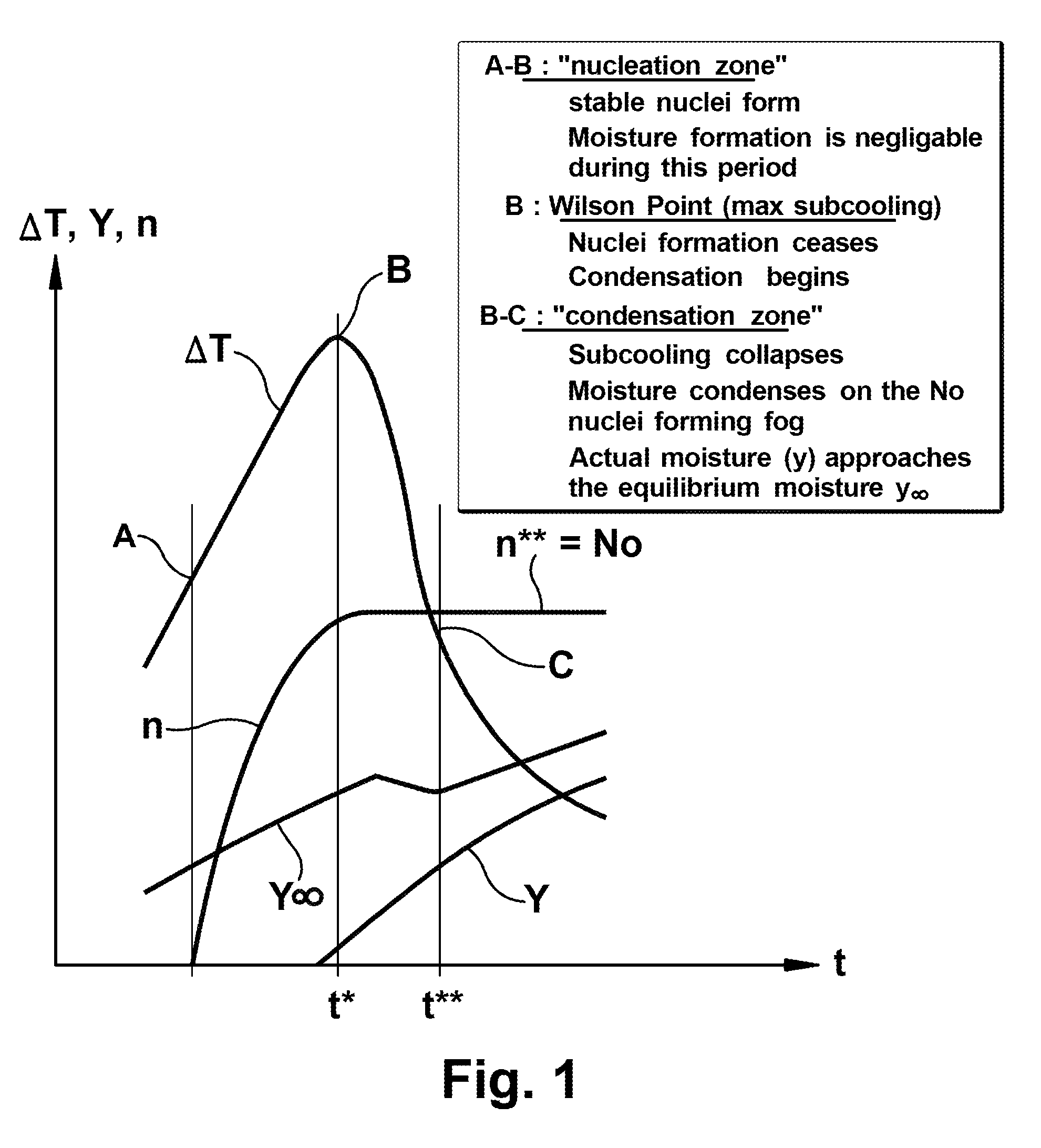

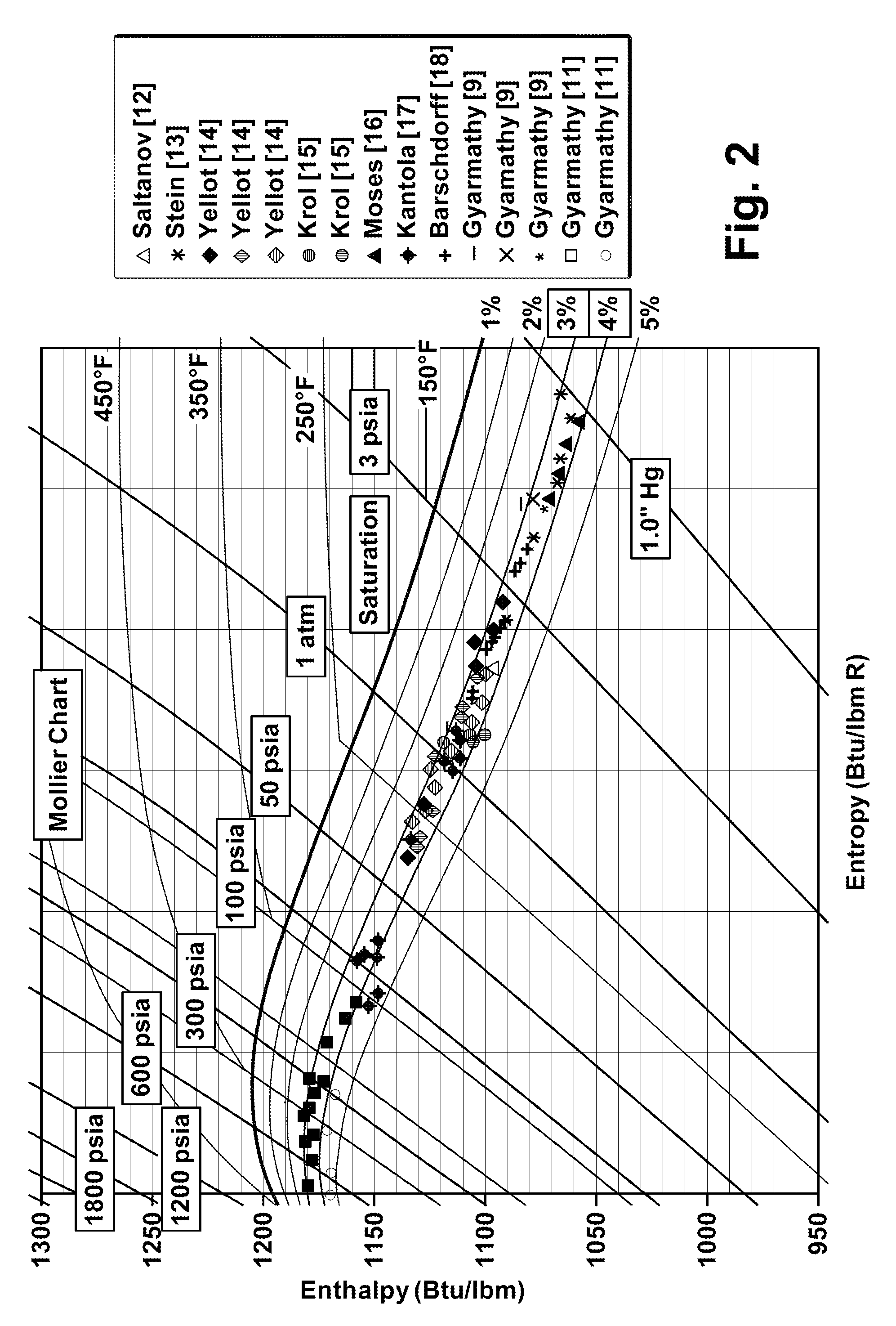

A method for calculating moisture loss in a steam turbine operating under wet steam conditions. The method may include the steps of: 1) assuming equilibrium expansion, calculating a flow field initialization to determine initial pressure values, initial expansion rate, initial velocity values at an inlet and an exit of each of a plurality of bladerows in the steam turbine, and initial enthalpy values through each of the plurality of bladerows in the steam turbine; 2) using the initial pressure values, the initial velocity values, and the initial enthalpy values, calculating an initial subcooling ΔT value through each of the plurality of bladerows of the steam turbine; 3) calculating an Wilson Point critical subcooling ΔT value through each of the plurality of bladerows of the steam turbine required for spontaneous nucleation to occur based on the initial pressure value and the initial expansion rate; and 4) comparing the initial subcooling ΔT values to the Wilson Point critical subcooling ΔT values to determine where spontaneous nucleation occurs through the plurality of bladerows of the steam turbine.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com