Steam dryness modulating system

A modulation system and steam technology, applied in the control/regulation system, humidity control, tobacco preparation, etc., can solve the problems of unstable control, unstable steam moisture content, physical quality and sensory quality that do not meet the requirements of process standards, etc. Achieve the effects of reducing raw material consumption and energy consumption in the process, improving equipment operation efficiency and stability, and improving product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

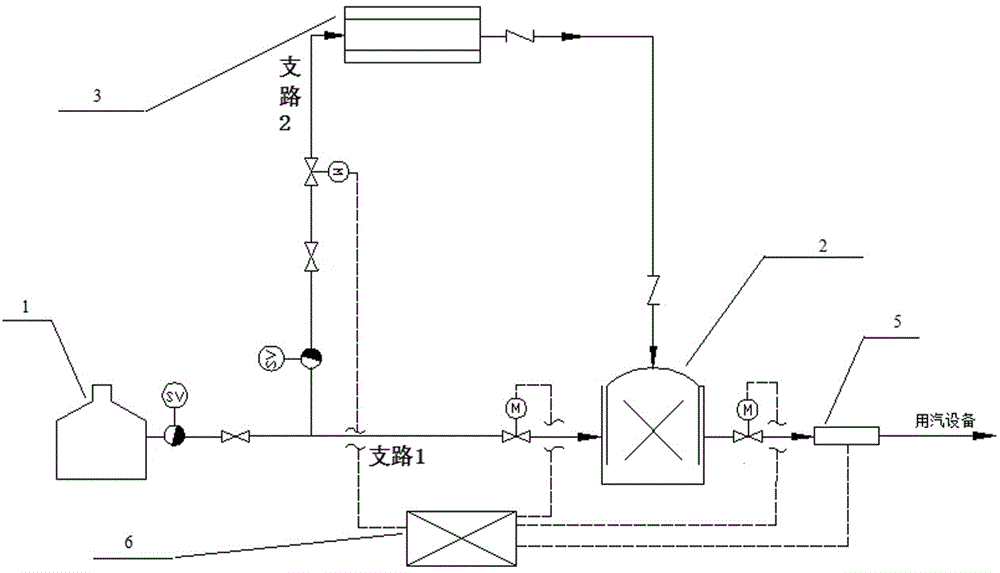

[0023] like image 3 As shown, the passage is composed of branch Ⅰ and branch Ⅱ. The main purpose is to reduce the dryness of the steam. Part of the steam from the steam generator is desuperheated and humidified through the desuperheater, and the other part directly leads to the gas collecting tank and The steam from the desuperheater is combined. The steam coming out of the gas collecting tank is first measured by the dryness meter, and then enters the steam using equipment.

Embodiment 2

[0025] like Figure 4 As shown, the passage is composed of branch Ⅰ and branch Ⅲ, the main purpose is to increase the dryness of the steam, part of the steam enters the steam-water separator to increase the dryness of the steam, and is combined with the steam from the steam generator in the gas collecting tank. confluence. The steam coming out of the gas collecting tank is first measured by the dryness meter, and then enters the steam using equipment.

[0026] Through the selection of various equipment, pipes, pipe fittings and valves of the pipeline steam dryness regulation and measurement system, a detailed pipeline steam dryness modulation measurement system has been established, such as figure 1 shown. The system is composed of steam generator, desuperheater, steam-water separator, gas collecting tank, dryness meter, signal controller and supporting steam pipeline.

[0027] The detection and effective control of steam dryness can be realized through the above technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com