Leaf tobacco processing method capable of selectively reducing release amount of NNK (Nitrosamine) in cigarette smoke

A technology for processing cigarette smoke and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of reducing the NNK content of cigarette smoke, achieve the effect of reducing the release amount, the effect is obvious, and the method is feasible and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

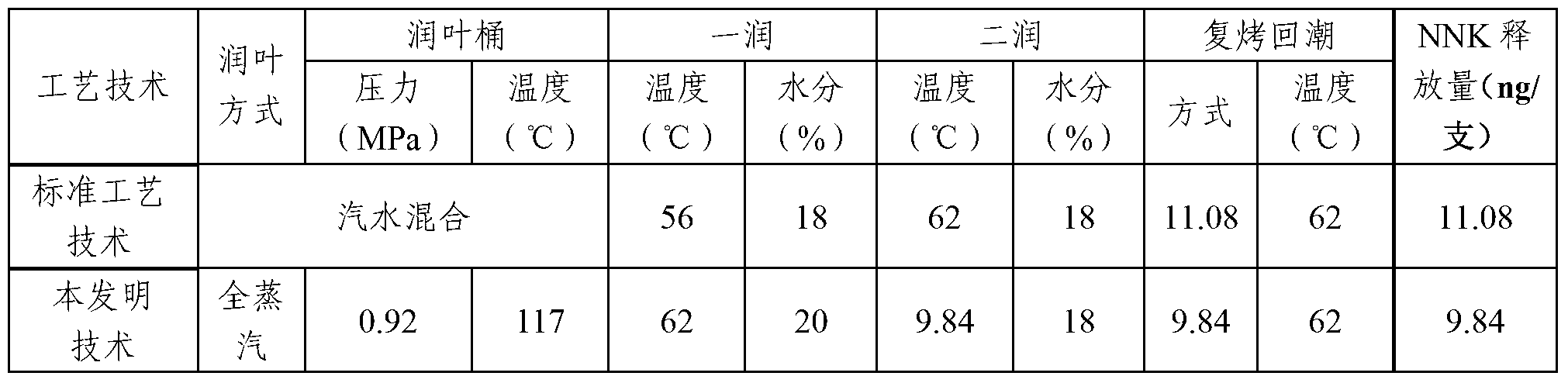

[0019] The 2011 Kunming K326BSF tobacco leaves were processed by "YC / T146-2010 Tobacco Leaf Threshing and Rebaking Process Specification" (referred to as the standard process technology) and the technical method of the present invention, and 200g of samples were taken at the packaging place every 30min, 10 times in total, and mixed evenly. In order to prepare for the determination of NNK release in the smoke of tobacco leaf samples.

[0020] The cigarette samples are conditioned under the conditions specified in GB / T16447-2004 "Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products", and the cigarettes are smoked under the conditions specified in GB / T16450-2004 "Definition and Standard Conditions of Smoking Machines for Routine Analysis". GB / T23228—2008 "Determination of Tobacco-specific N-Nitrosamines in Total Particulate Matter in Mainstream Cigarette Smoke by Gas Chromatography-Thermal Analysis Method" Determination of NNK release in smoke of K3...

Embodiment 2

[0025] Respectively adopt "YC / T146-2010 Tobacco leaf threshing and redrying process specification" and the technical method of the present invention to process 2011 Kunming Hongda C3F tobacco leaves, take 200g samples at the packing place every 30min, and mix them evenly for 10 times in order to prepare for measuring the tobacco leaf samples NNK release in smoke.

[0026] The cigarette samples are conditioned under the conditions specified in GB / T16447-2004 "Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products", and the cigarettes are smoked under the conditions specified in GB / T16450-2004 "Definition and Standard Conditions of Smoking Machines for Routine Analysis". GB / T23228—2008 "Determination of Tobacco-specific N-Nitrosamines in Total Particulate Matter in Mainstream Cigarette Smoke by Gas Chromatography-Thermal Analysis Method" Determination of NNK release in processed tobacco leaves 2011 Kunming Hongda C3F smoke.

[0027] The results show...

Embodiment 3

[0031] Respectively adopt "YC / T146-2010 Tobacco leaf threshing and redrying process specification" and the technical method of the present invention to process 2011 Kunming Yunyan 87X2F tobacco leaves, take a sample of 200g at the packing place every 30min, and mix them evenly for 10 times in order to prepare for the determination of tobacco leaf sample tobacco leaves. The amount of NNK released in the air.

[0032] The cigarette samples are conditioned under the conditions specified in GB / T16447-2004 "Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products", and the cigarettes are smoked under the conditions specified in GB / T16450-2004 "Definition and Standard Conditions of Smoking Machines for Routine Analysis". GB / T23228—2008 "Determination of Tobacco-specific N-Nitrosamines in Total Particulate Matter in Mainstream Cigarette Smoke by Gas Chromatography-Thermal Analysis Method" Determination of NNK release in smoke of processed tobacco leaves 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com