Soft measurement method based on variable-boundary segmentation energy balance, multifunctional wet steam measuring needle and wet steam heat absorption measurement and control device

A technology of wet steam and segmental energy, which is applied in the field of online measurement of wet steam two-phase flow, which can solve the problems of inaccurate measurement of mass flow, inability to realize long-term on-line monitoring, inability to give absolute humidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

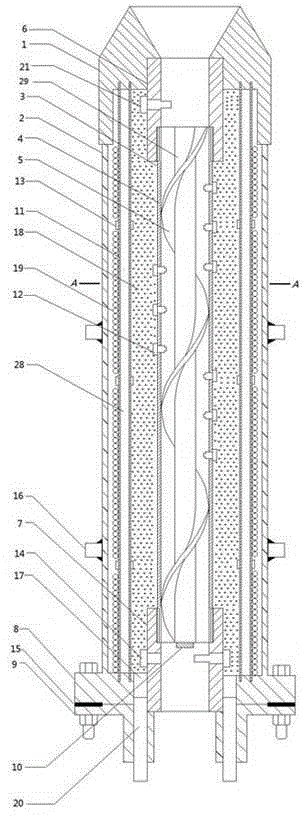

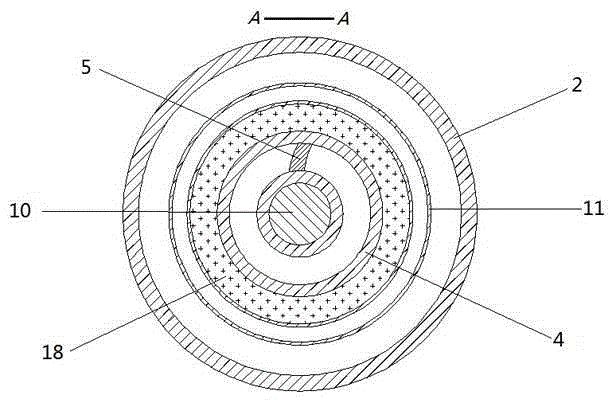

[0044] Now, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0045] refer to figure 1 with figure 2 , the multifunctional wet steam probe of the present invention comprises an electric heating rod 10, an electric heating rod casing 29 with a uniformly pitched outwardly convex spiral rib 5, a multifunctional wet steam probe outer wall tube 4, a front sensor seat 6 and Rear sensor seat 7. The electric heating rod 10 and the inner cavity of the electric heating rod sleeve 29 are connected by an interference fit, and the top surface of the uniform and equal-pitch convex spiral rib 5 on the electric heating rod sleeve 29 is connected to the outer wall of the multifunctional wet steam probe. The inner wall of the tube 4 is connected with an interference fit, the inlet of the outer wall tube 4 of the multi-functional wet steam probe is connected with the front sensor seat 6 with an interference fit, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com