Recycled two-phase flow flowmeter calibrating platform of wet steam

A technology of flowmeter and calibration table, applied in liquid/fluid solid measurement, measurement device, instrument, etc., can solve the problems of high pressure and high temperature steam danger, no wet steam, difficult recovery of wet steam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

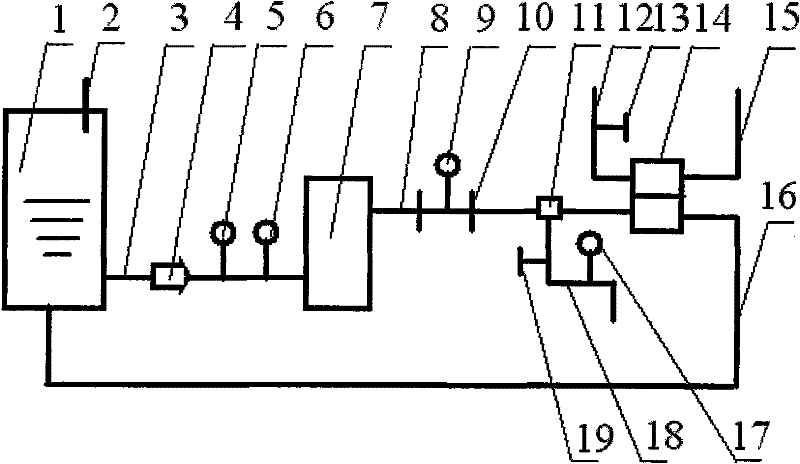

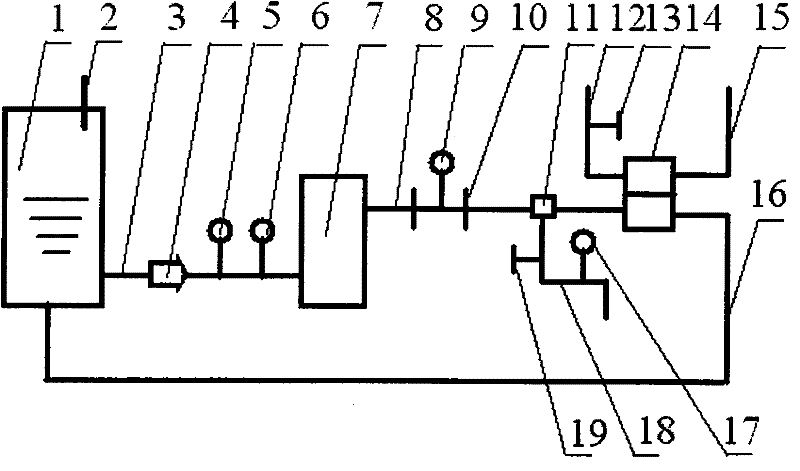

[0020] now attached figure 1 The present invention is further described:

[0021] This embodiment is a recovery type wet steam two-phase flow flowmeter calibration platform, which is used to calibrate the flow and dryness of the wet steam two-phase flow flowmeter.

[0022] This embodiment is composed of a stable water supply unit, a steam generation unit, a calibration unit and a waste heat recovery unit in sequence. The stable water supply unit includes a heat storage tank 1 , an air pipe 2 , a boiler feedwater pipe 3 , a gear pump 4 , a feedwater flow meter 5 and a feedwater conductivity meter 6 . The steam generating unit is a once-through boiler 7 without a steam drum. The calibration unit includes a steam supply pipe 8 , a meter to be inspected 9 , a meter inspector 10 , a water sampler 11 , a water sample conductivity meter 17 , a sampling water pipe 18 and a sampling water regulating valve 19 . The waste heat recovery unit includes a cooling heat exchanger 14 , a coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com