Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1505results about "Volume flow measuring devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

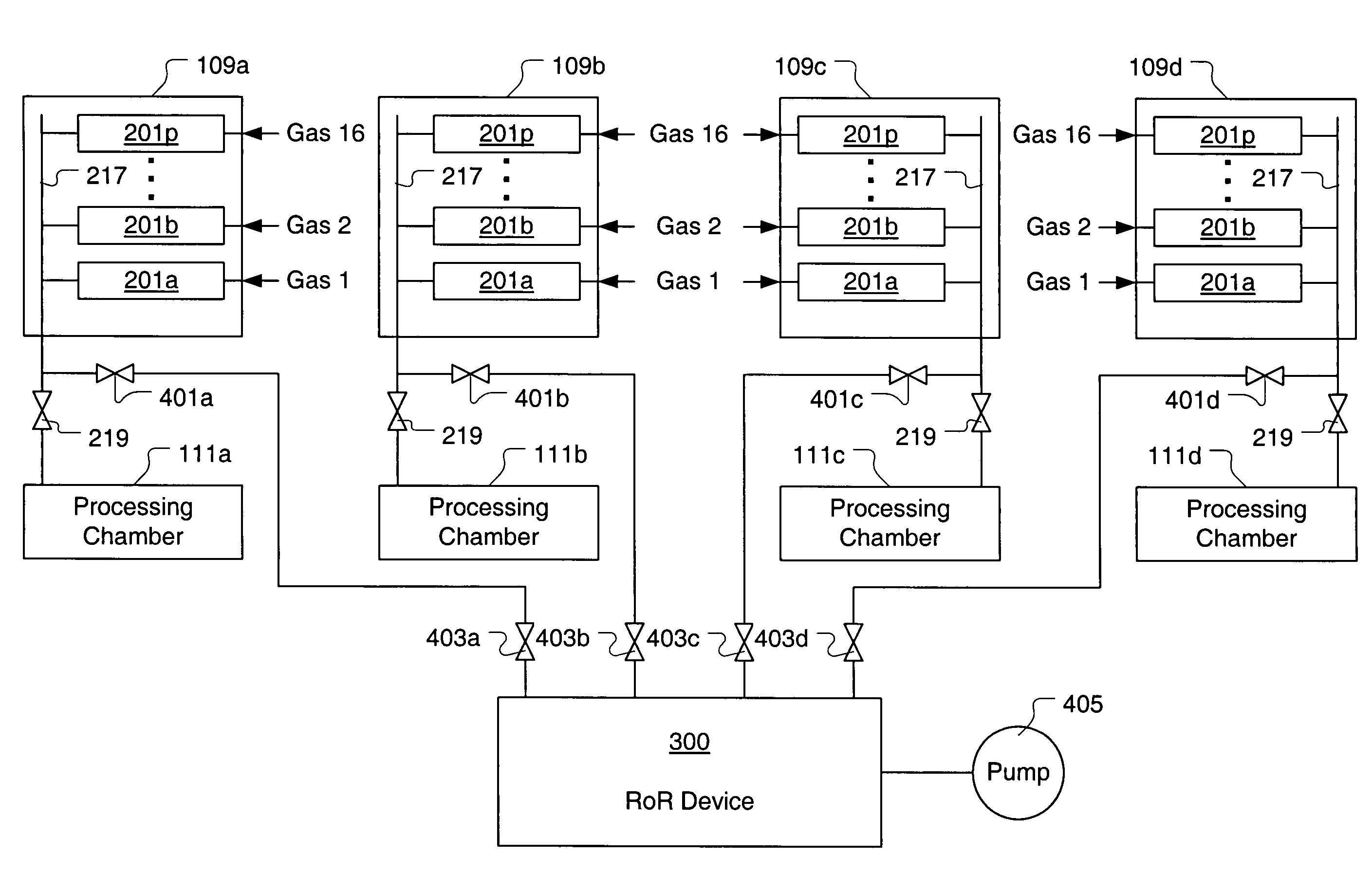

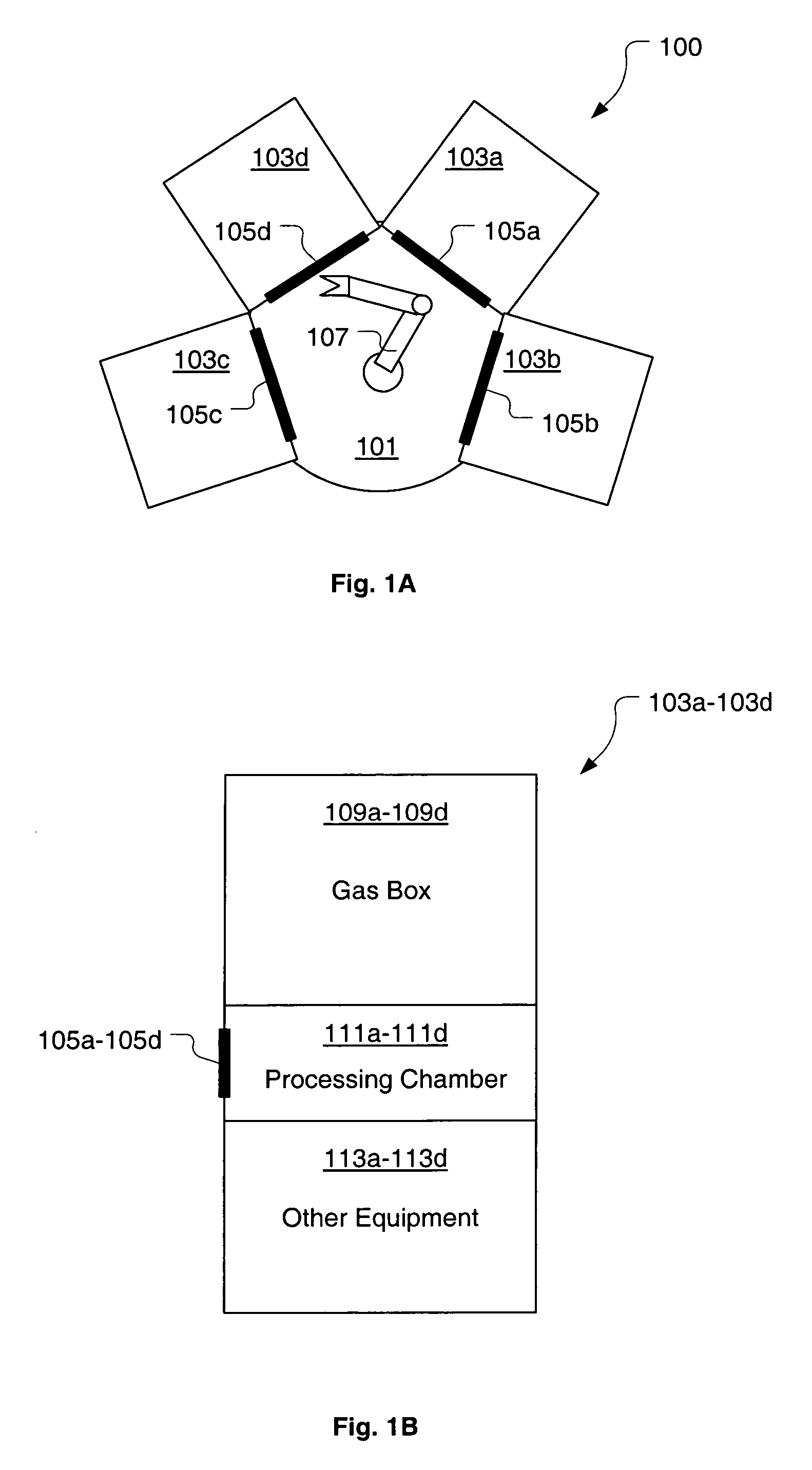

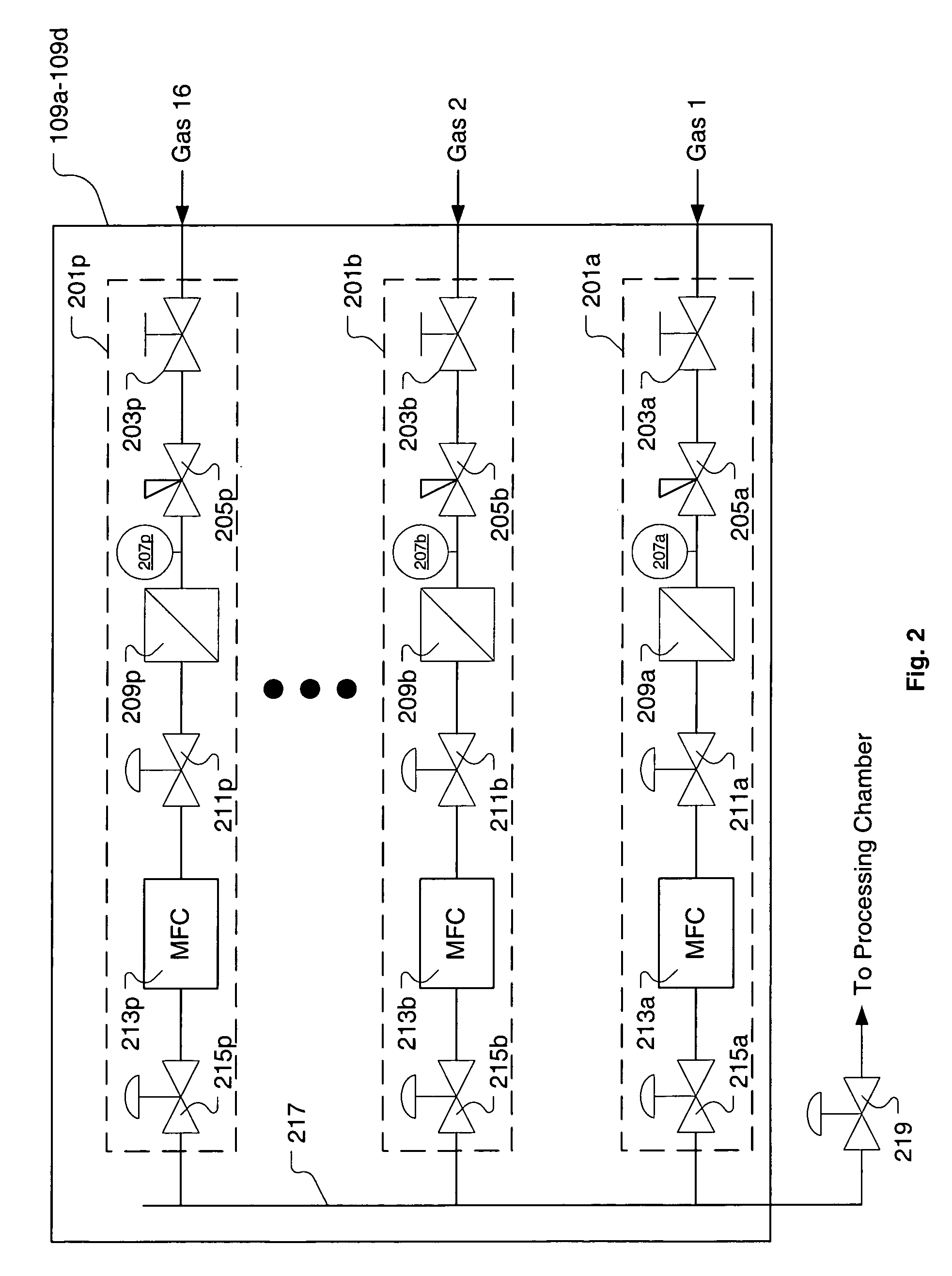

System and method for gas flow verification

A gas flow rate verification apparatus is provided for shared use in a multiple tool semiconductor processing platform. The gas flow rate verification apparatus is defined to measure a pressure rate of rise and temperature within a test volume for determination of a corresponding gas flow rate. The apparatus includes first and second volumes, wherein the second volume is larger than the first volume. The apparatus also includes first and second pressure measurement devices, wherein the second pressure measurement device is capable of measuring higher pressures. Based on the target gas flow rate to be measured, either the first or second volume can be selected as the test volume, and either the first or second pressure measurement device can be selected to measure the pressure in the test volume. Configurability of the apparatus enables accurate measurement of gas flow rates over a broad range and in an time efficient manner.

Owner:LAM RES CORP

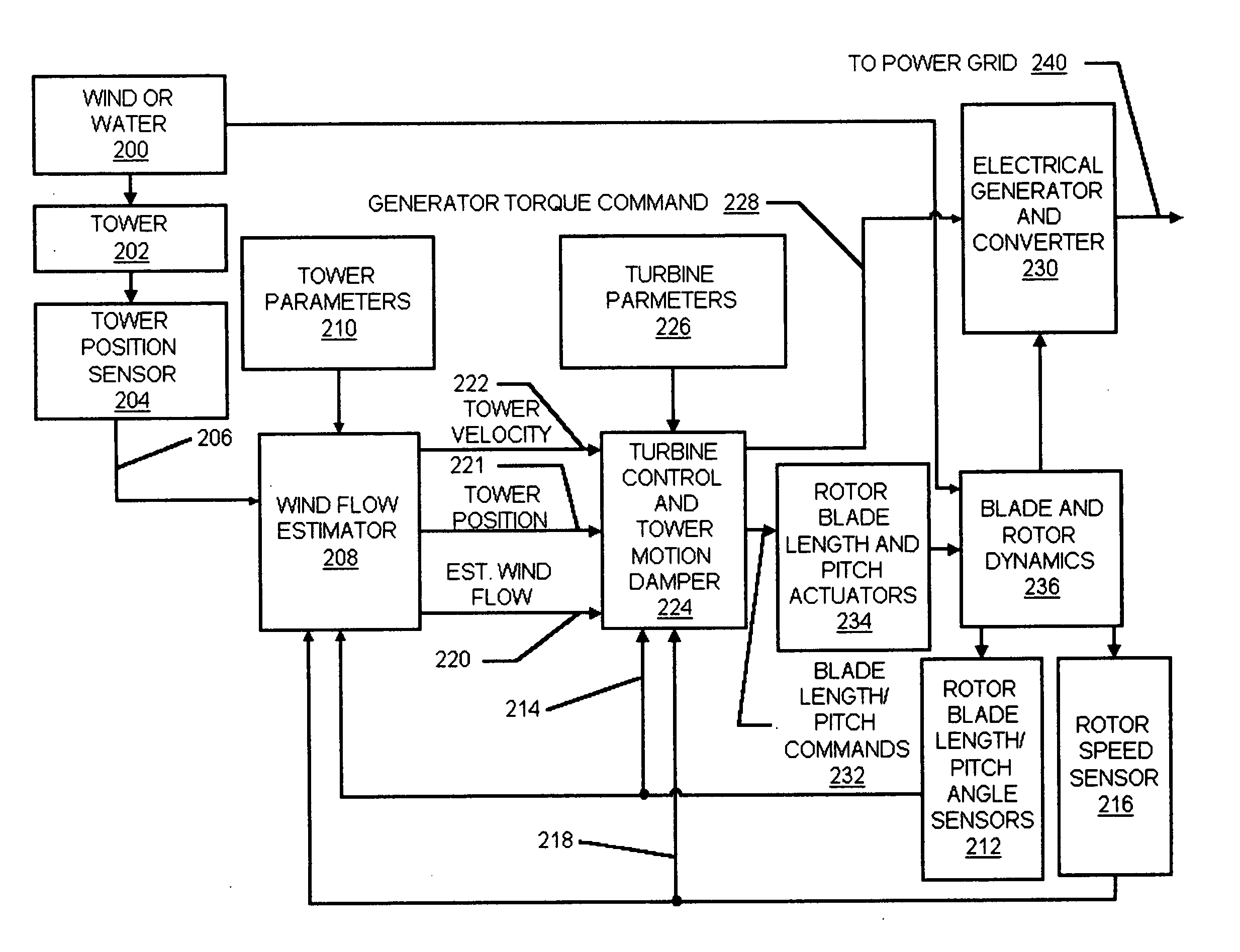

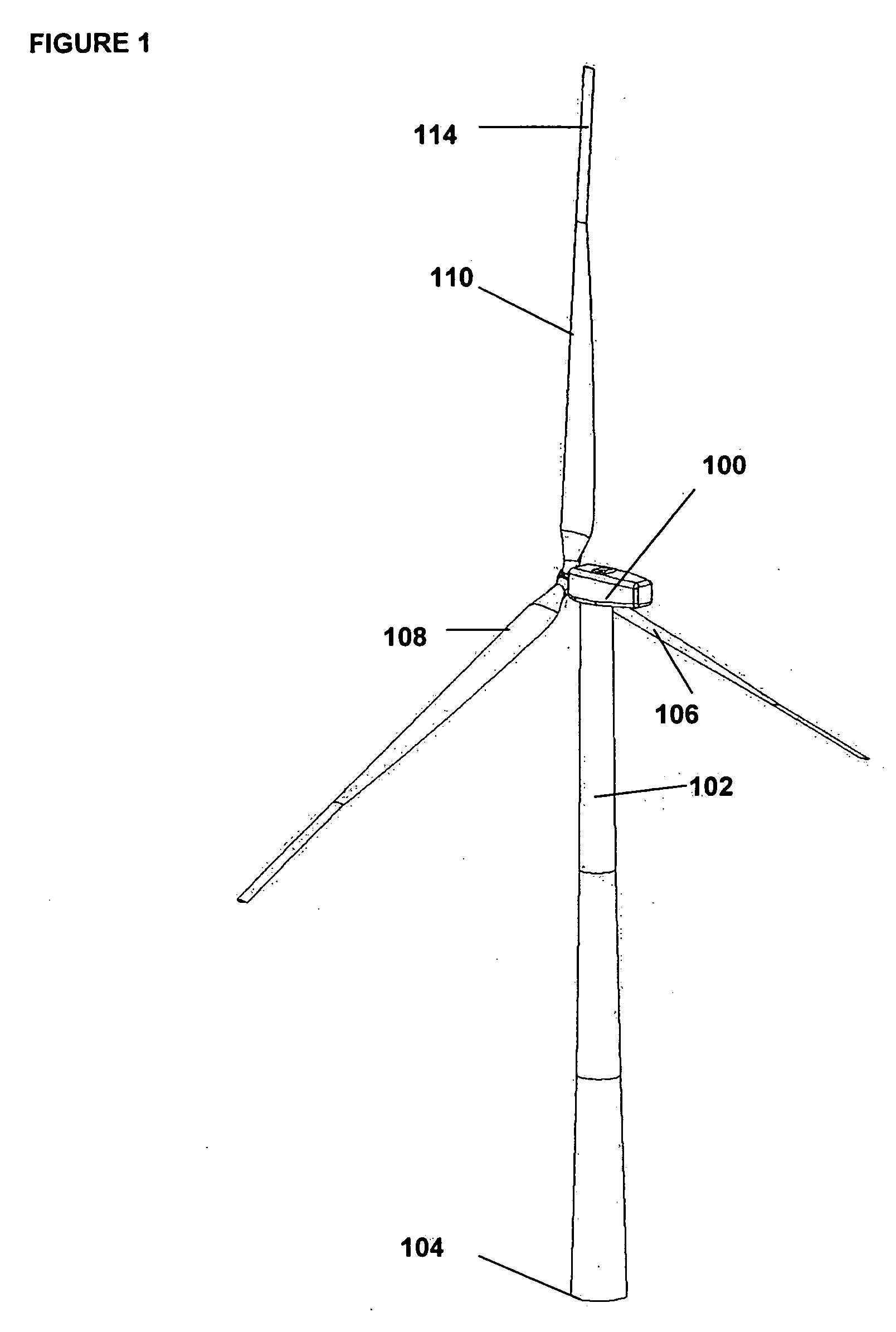

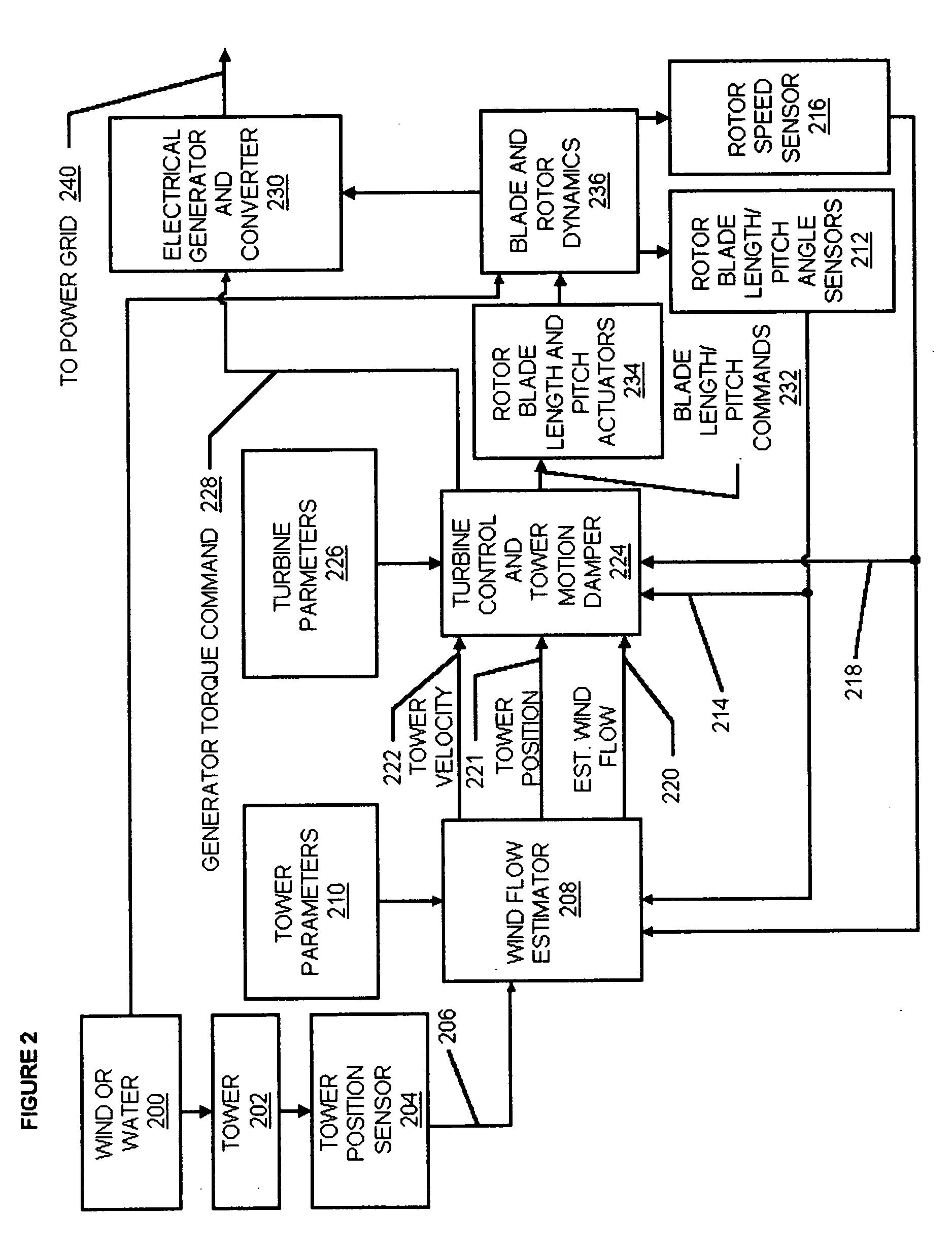

Wind flow estimation and tracking using tower dynamics

A turbine control system for a variable speed electrical generator in a wind turbine mounted atop a support tower. The wind turbine converts wind energy into a driving torque applied to the generator. The control system includes a turbine support tower position sensor and may also include other tower acceleration and velocity sensors. A wind flow estimator uses the measured motion, generator rotation rate and blade pitch angle to predict wind flow over the swept area of the turbine's rotor, and the tower motion. The predicted wind flow and motion is used in the turbine control system to properly adjust its operating point, to tune the controller, to control the rotor rotation rate, and to damp tower oscillations.

Owner:UNITED TECH CORP

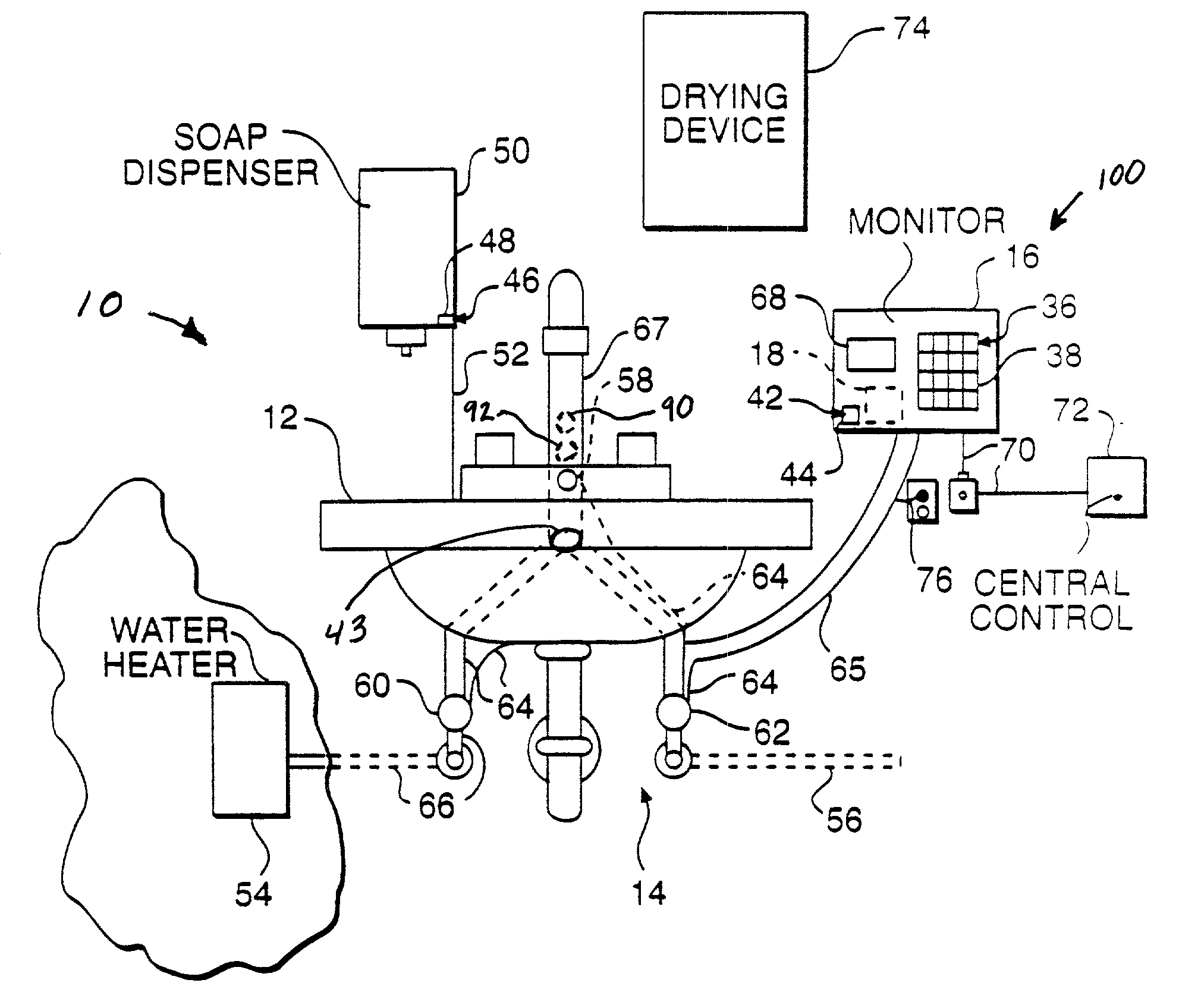

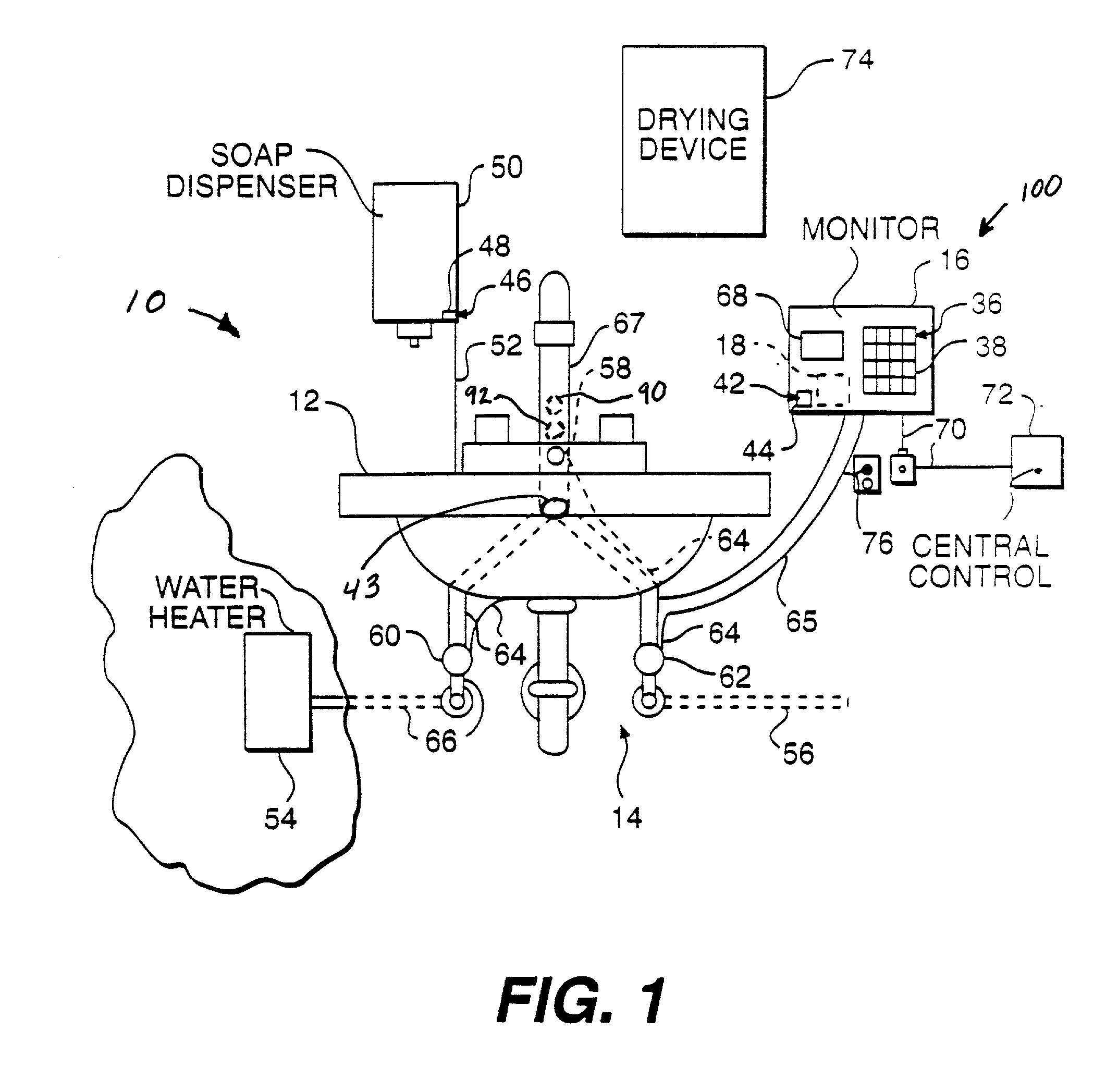

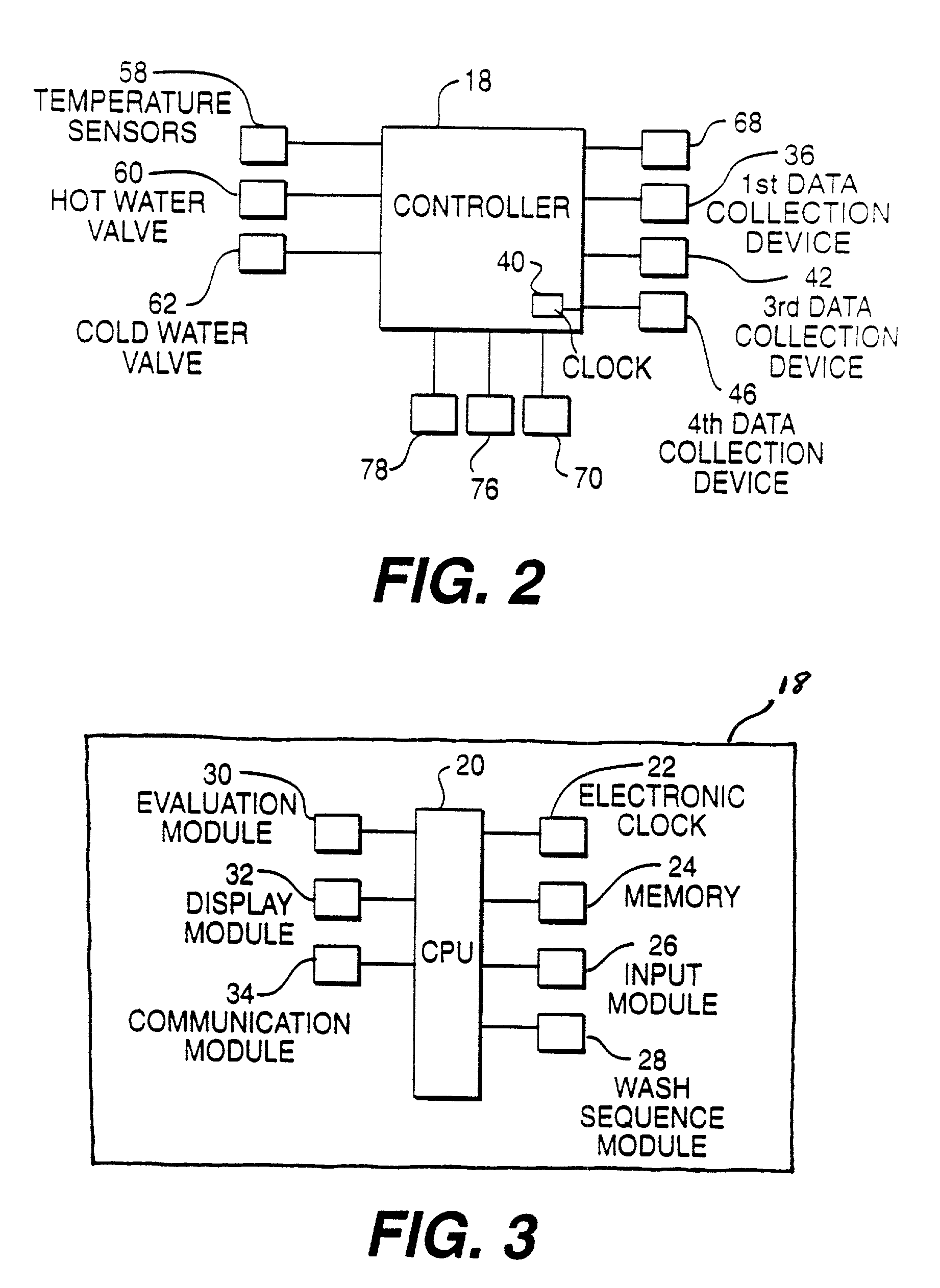

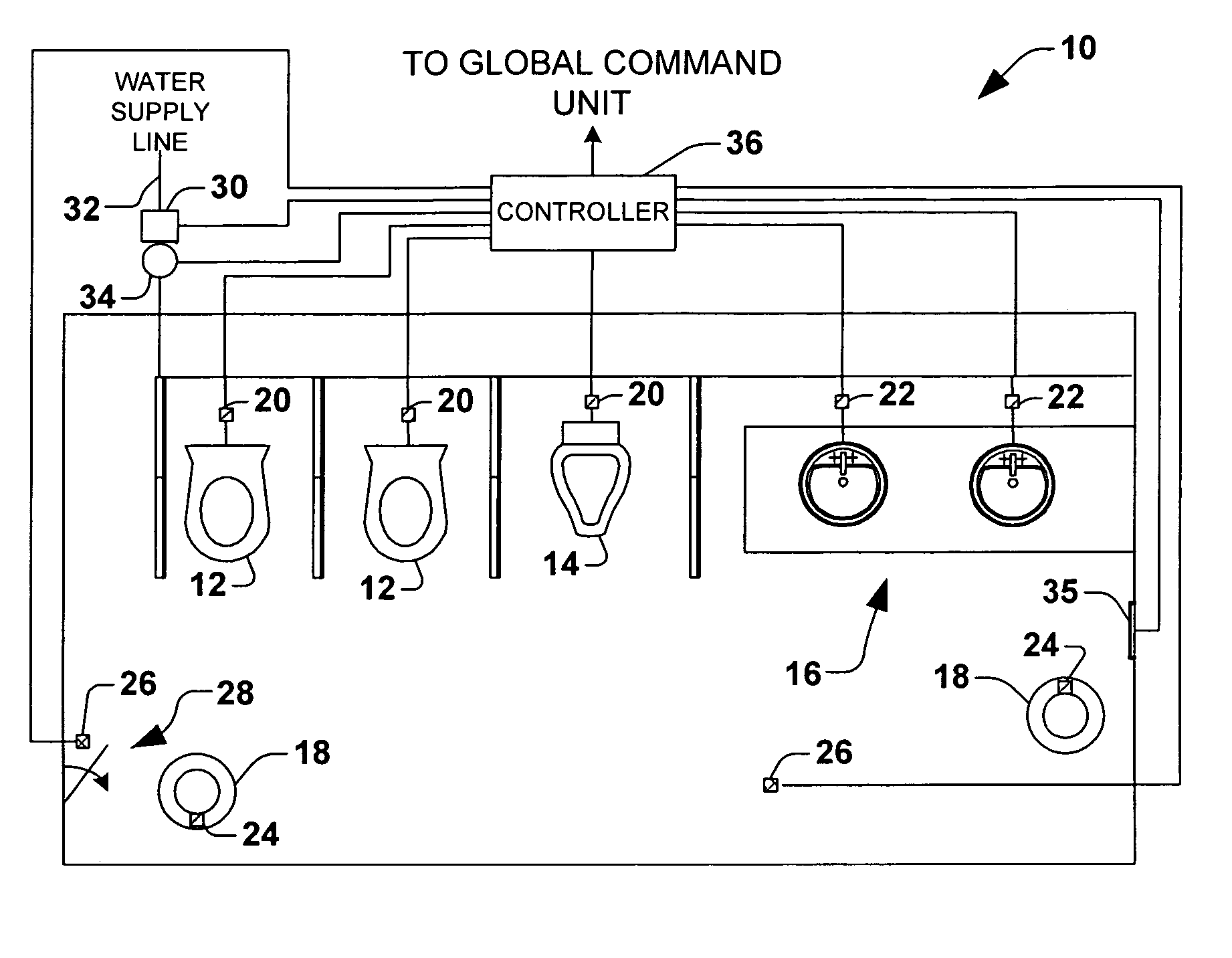

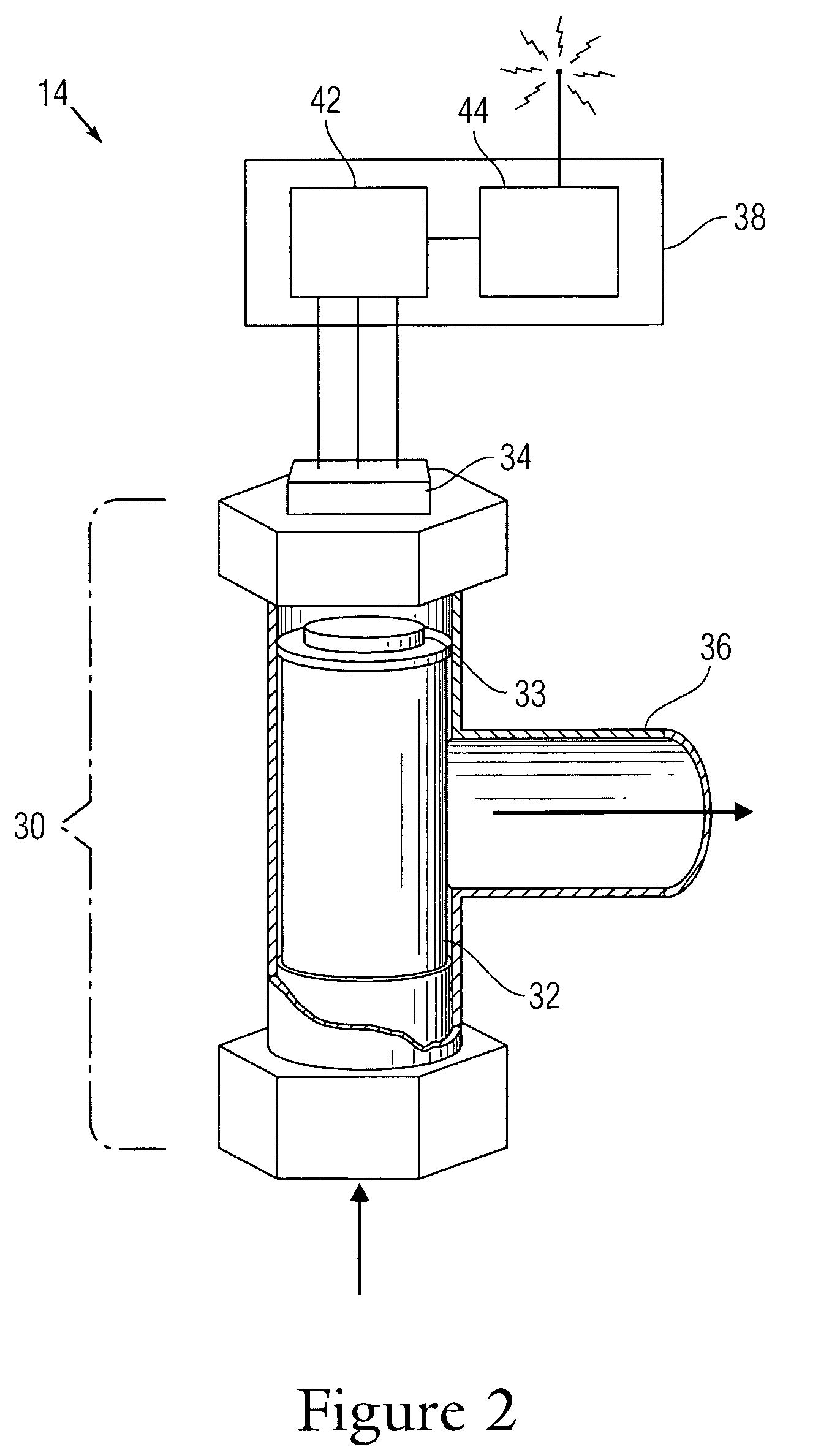

System for controlling operation of a sink

InactiveUS20020019709A1Registering/indicating time of eventsVolume/mass flow measurementWireless controlControl valves

A system for controlling operation of a sink may include a valving device adapted to be coupled to plumbing of the sink to selectively allow water to flow into a basin of the sink. The valving device can be configured to be actuated in response to a wireless control signal. The system may also include a valve controller for controlling operation of the valving device. The valve controller may be configured to provide the wireless control signal to actuate the valving device. Also provided are systems for monitoring and controlling operation of a sink, and methods of controlling operation of a sink.

Owner:COMPLIANCE CONTROL

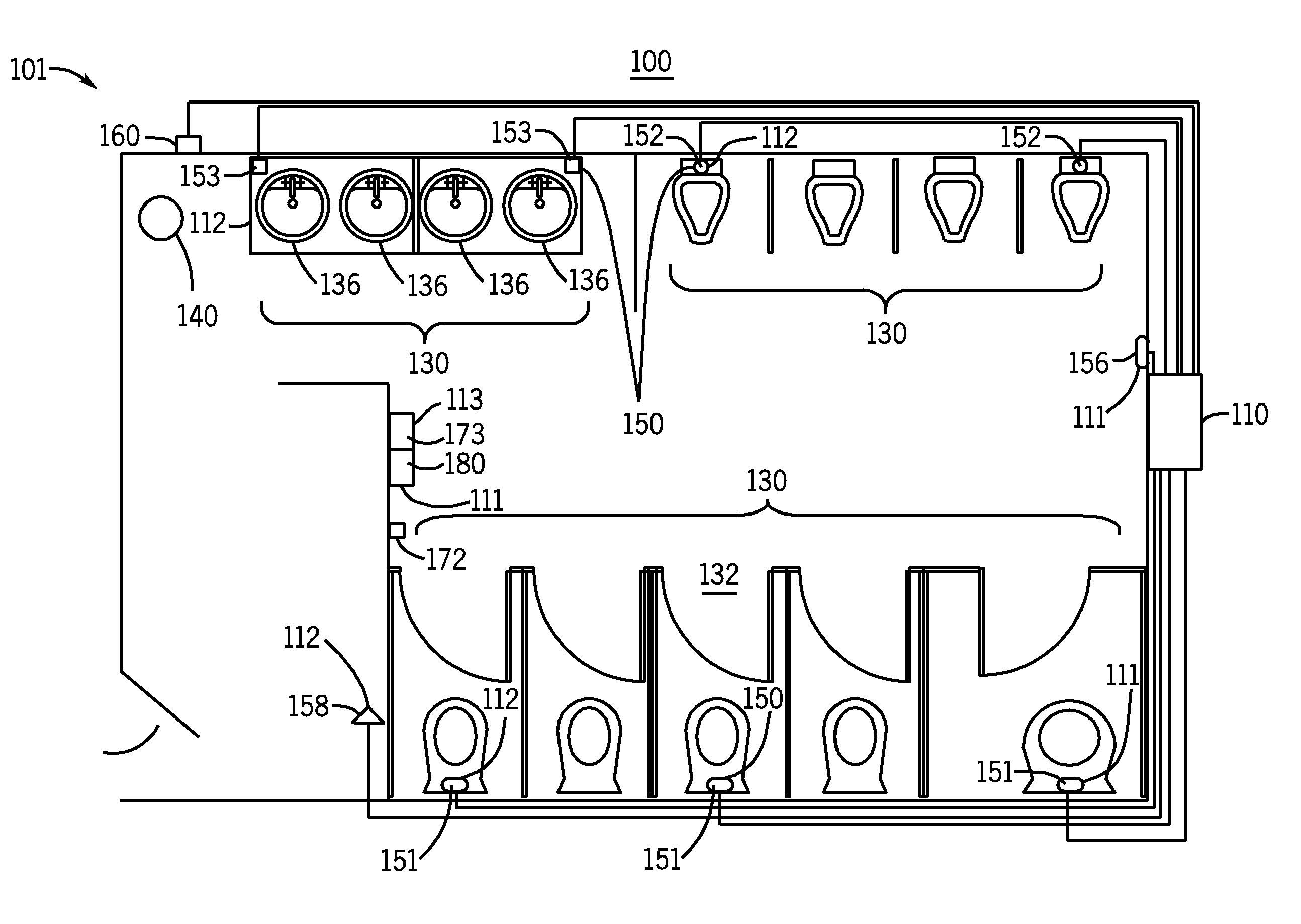

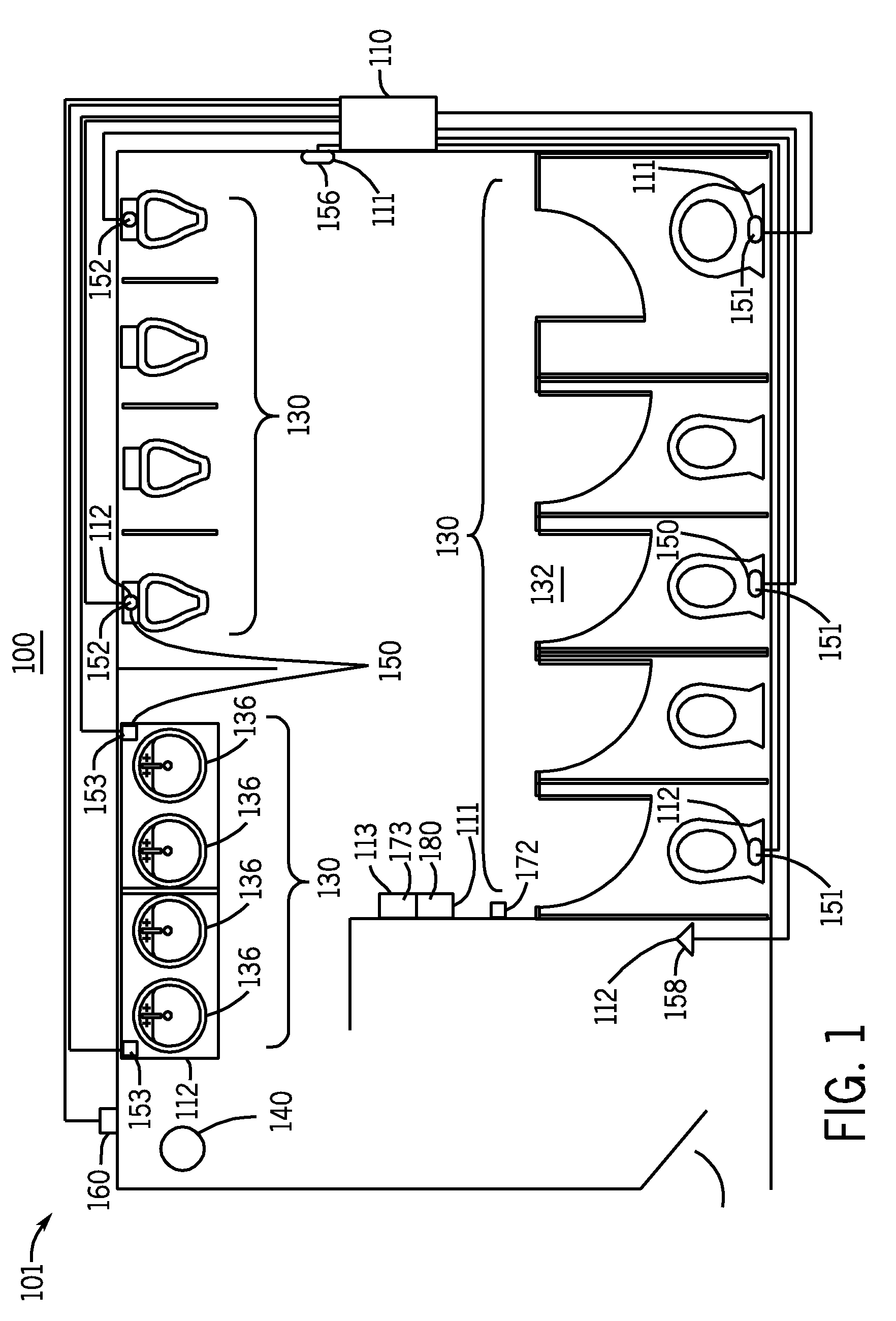

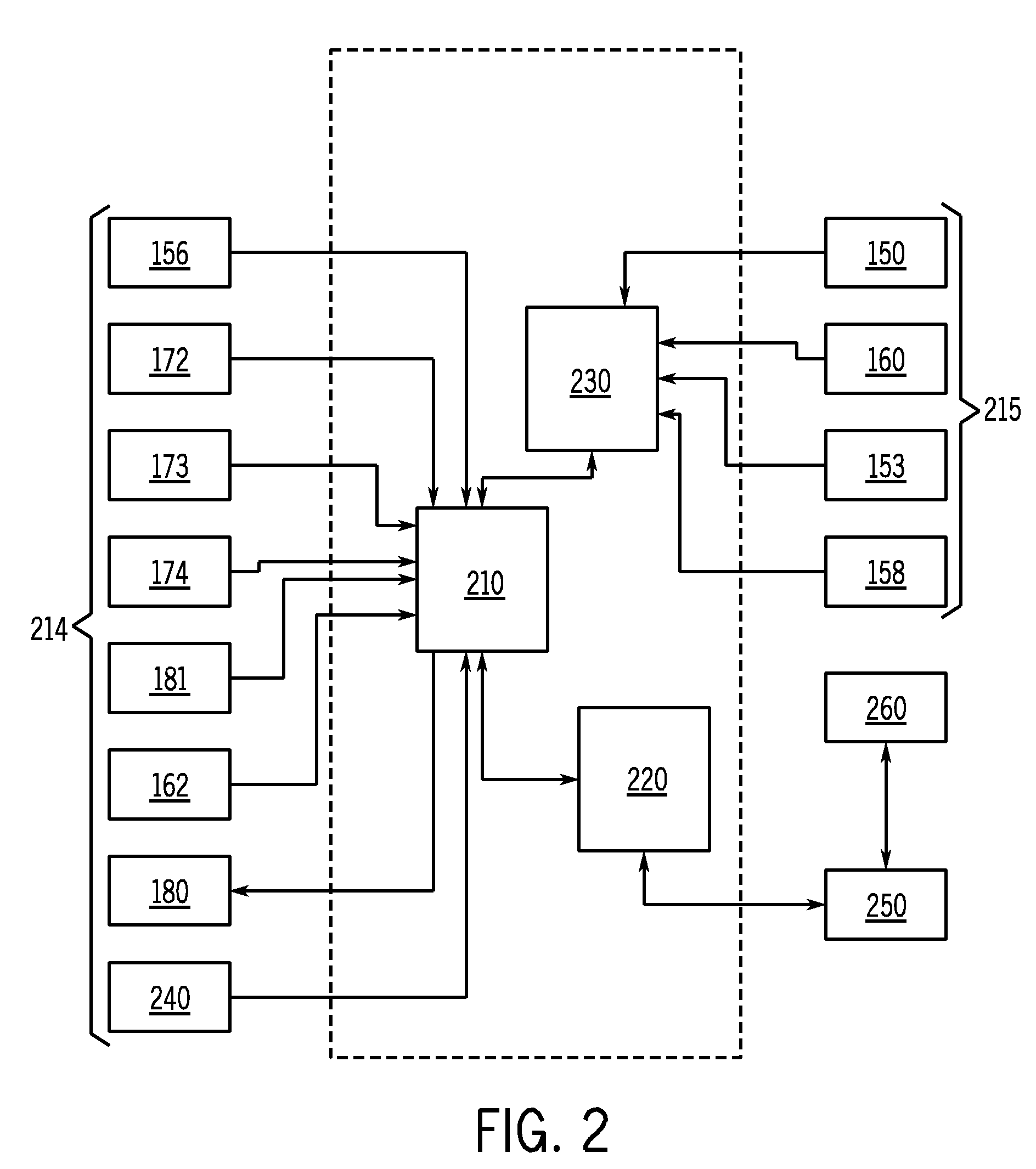

Restroom convenience center

ActiveUS20090119142A1Easy to useHigh trafficVolume/mass flow measurementHolders and dispensersState dependentMonitoring system

A restroom monitoring system for monitoring attributes of fixtures within a restroom using sensors. Additional attributes are determined from the monitored attributes. Consumable usage levels are estimated based on predetermined consumption levels associated with usage states of the fixtures. The restroom monitoring system provides an indication of the need for replenishment of consumables based on the monitored attributes of the fixtures. In addition, restroom monitoring system may provide additional information regarding the restroom attributes to a service provider, a manager or a user.

Owner:SLOAN VALVE COMPANY

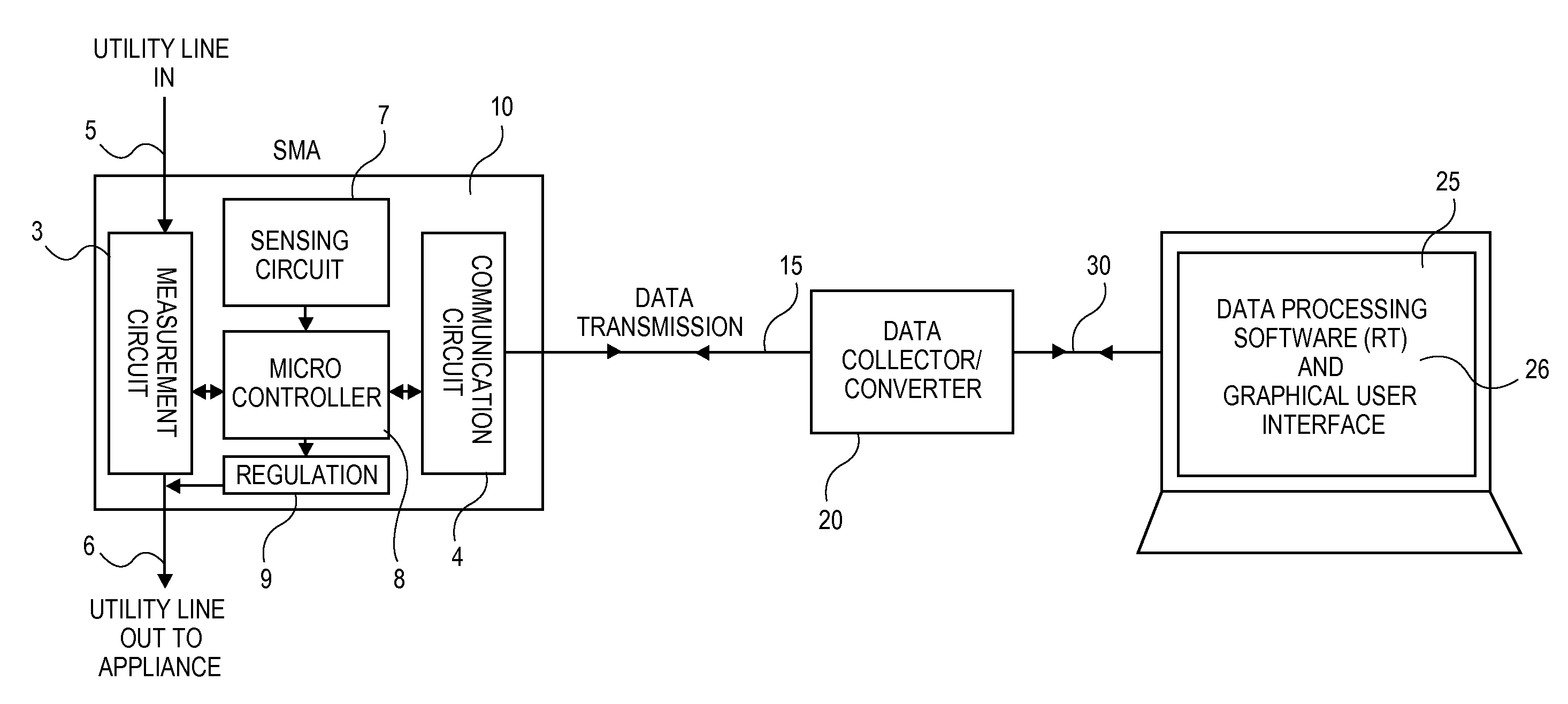

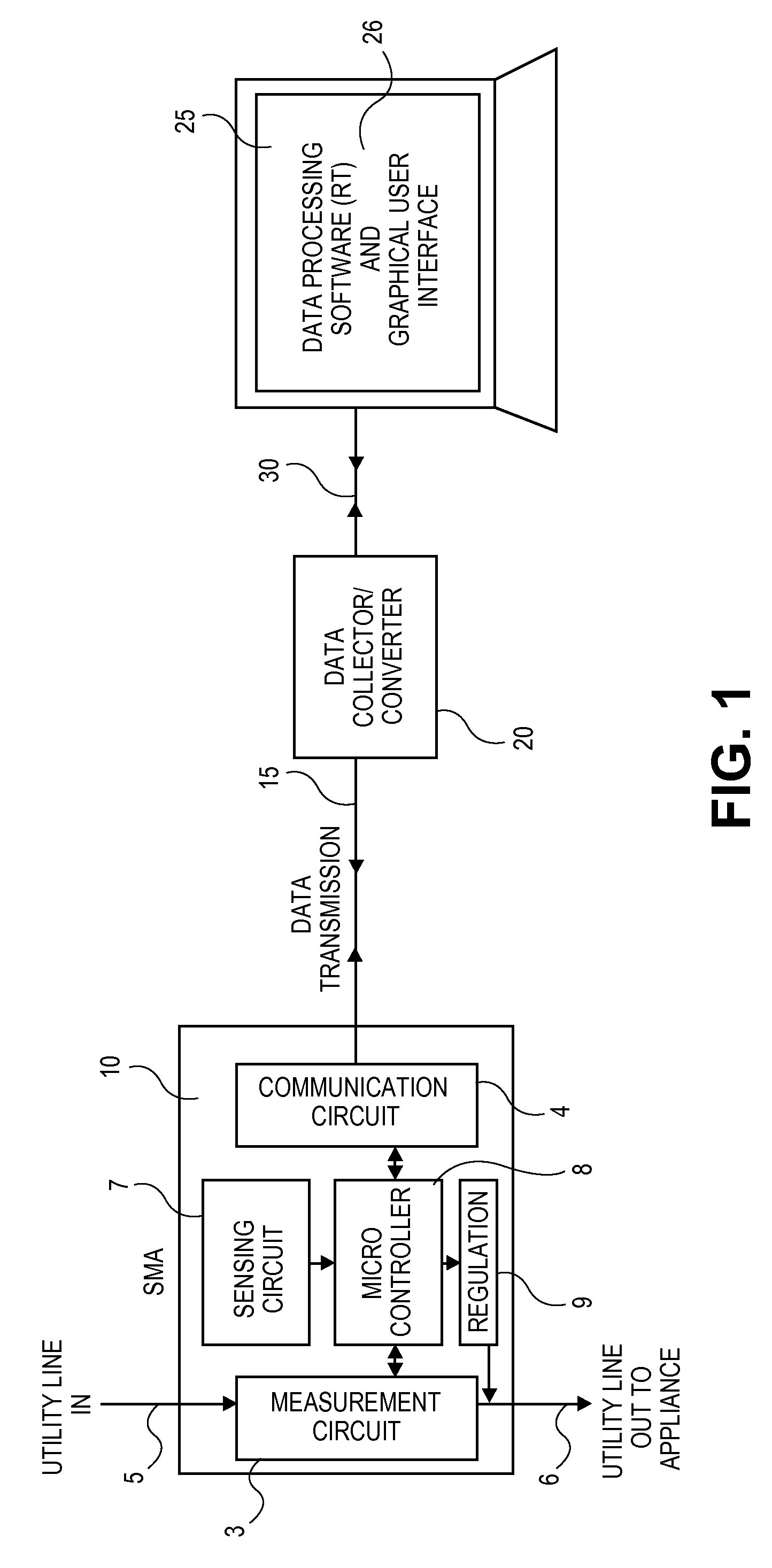

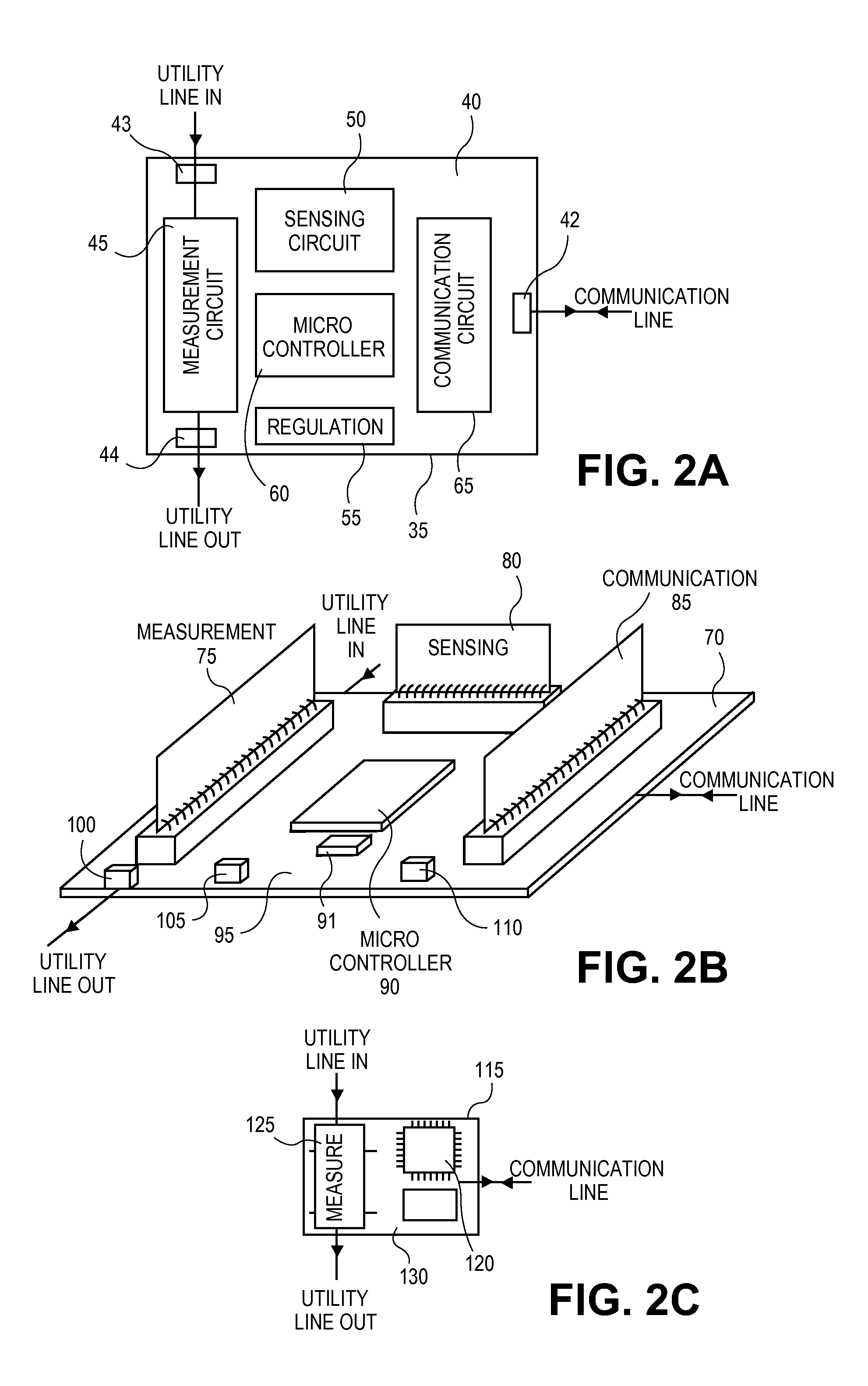

Optimizing Utility Usage by Smart Monitoring

InactiveUS20110082599A1Not cause excessive noiseStreamline data collectionLevel controlVolume/mass flow measurementUnique identifierSmart surveillance

A system for optimizing utility usage is described. The system comprises a monitoring device adapted to be connected to a utility point, a utility consuming device and a central processing unit (CPU). The monitoring device is configured to regulate utility usage information of the utility consuming device and is further configured to assign a unique identifier to the monitoring device. The monitoring device comprises a measurement circuit for measuring utility usage information, wherein the measurement circuit is coupled to the utility point. The monitoring device is configured to communicate with the CPU, wherein the monitoring device is configured to transmit utility usage information of the utility consuming device to the CPU on the unique identifier and wherein the monitoring device is configured to receive utility usage information of the utility consuming device and wherein the CPU is configured to process the utility usage information based on the unique identifier.

Owner:SHINDE MAKARAND +2

Flow rate compensation for transient thermal response of hot-wire anemometers

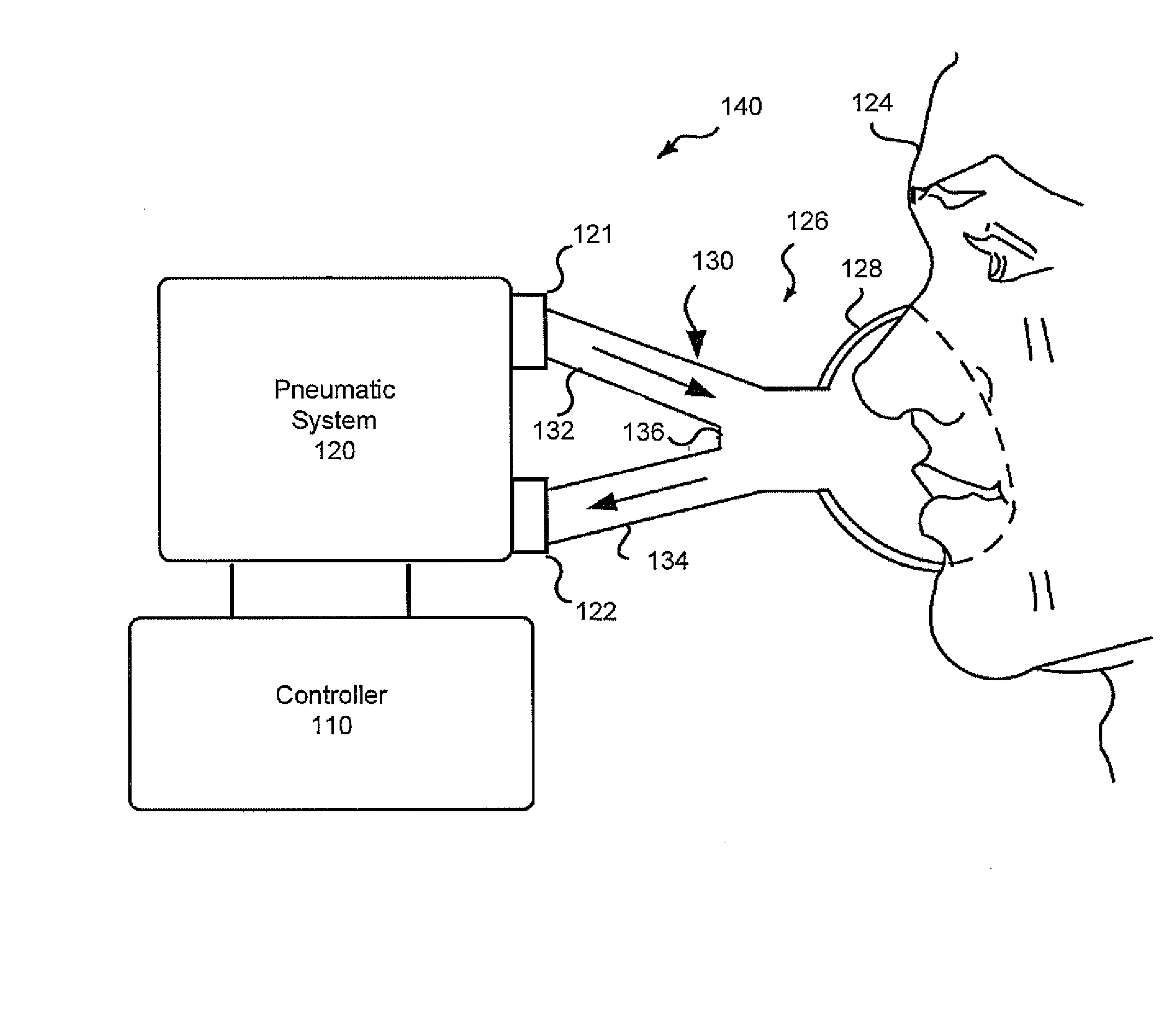

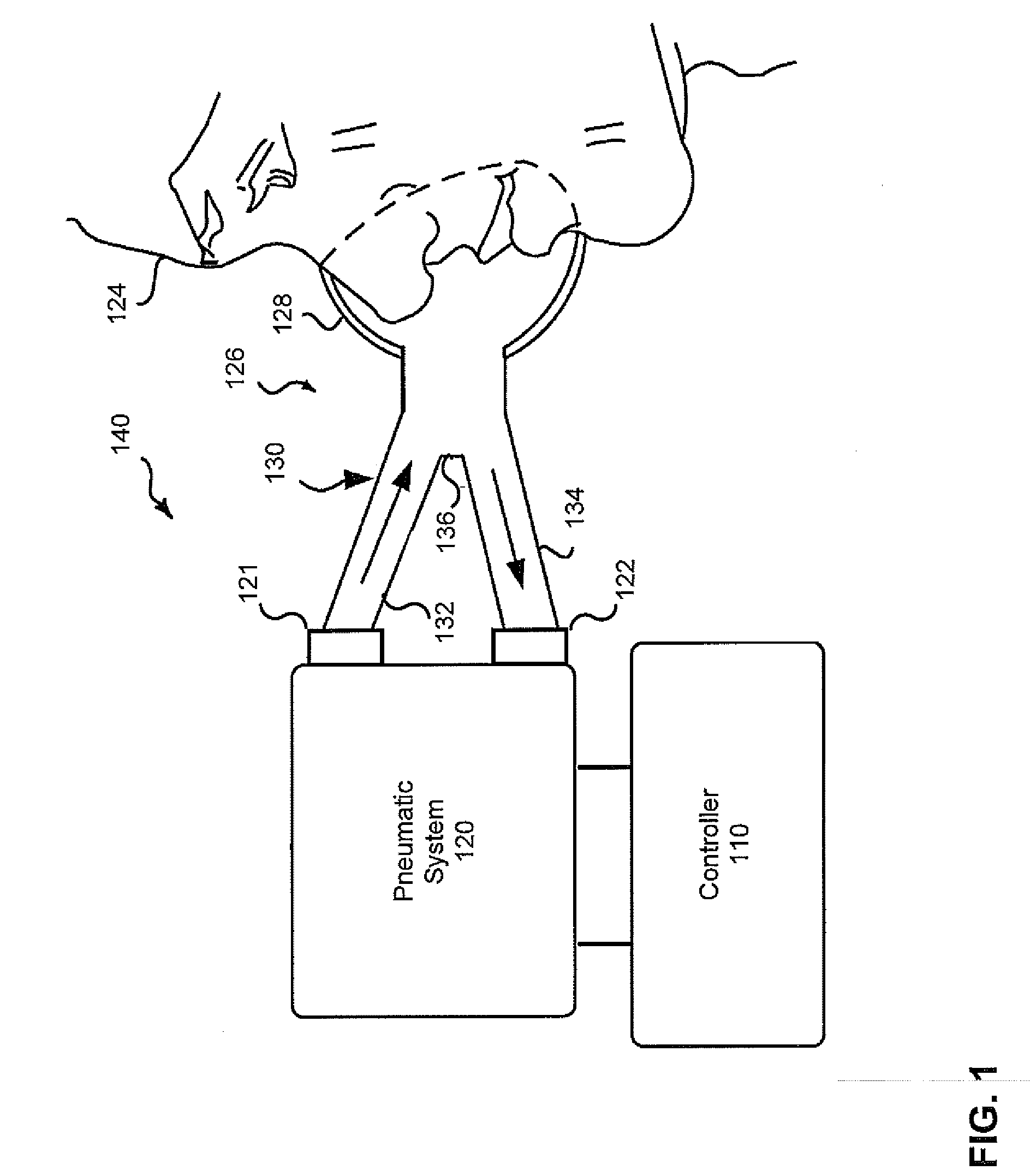

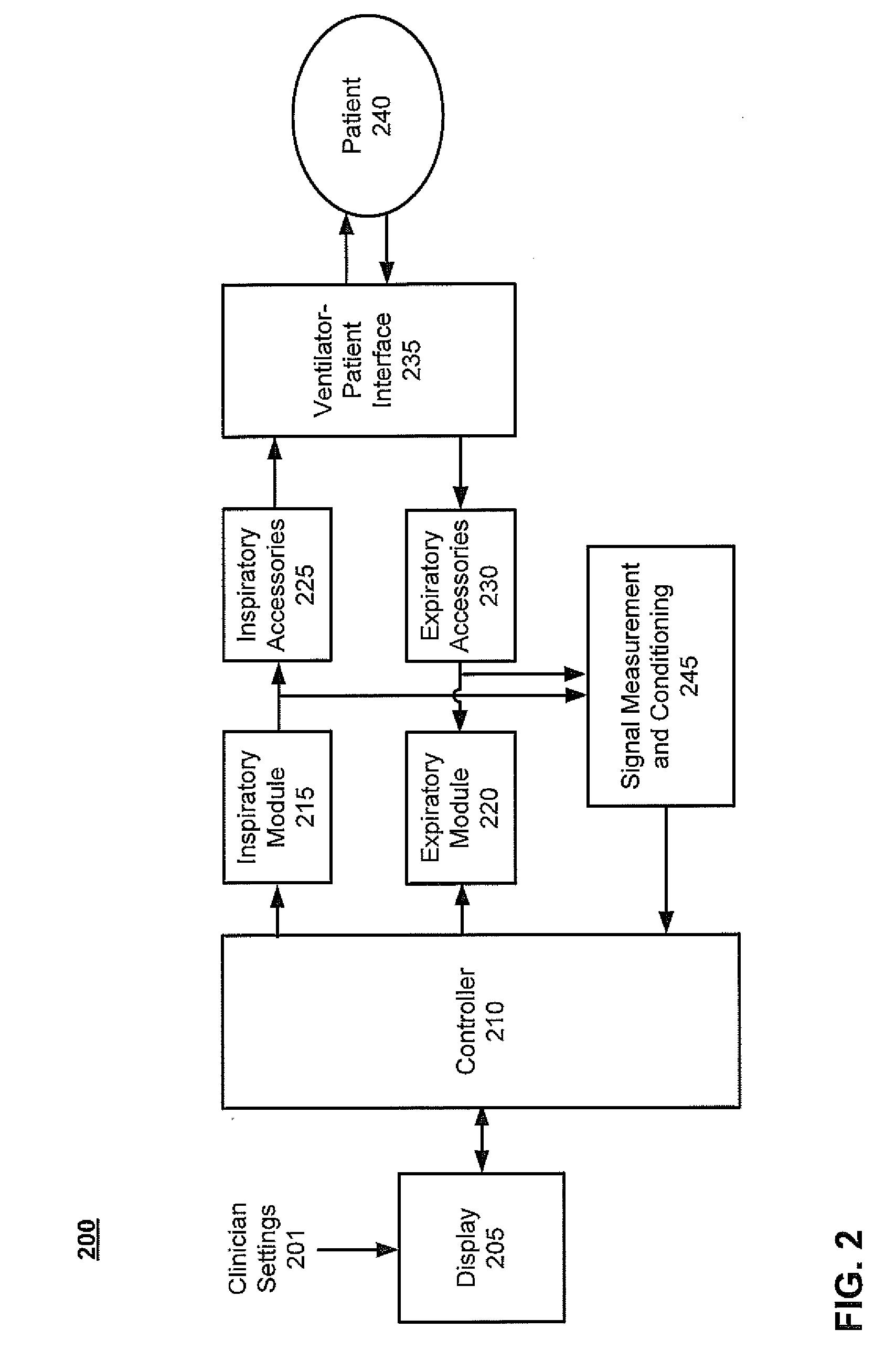

ActiveUS20100218765A1Operating means/releasing devices for valvesVolume/mass flow by thermal effectsEngineeringOxygen

Systems and methods are described for application of a transitory corrective modification to a hot-wire anemometer flow voltage and / or calculated flow rate to compensate for transient thermal response of the anemometer during a change in mixture of a mixed gas being measured. According to one embodiment a method of applying the transitory corrective modification is provided. An output signal of an exhalation flow sensor of a medical ventilator is received. The flow sensor includes a hot-wire anemometer. The output signal is indicative of a rate of flow of expired gas by a patient. Transient thermal response of the hot-wire anemometer is compensated for by applying a corrective modification to the output signal or a value based thereon. The corrective modification is based at least in part on a fraction of inspired oxygen (FiO2) being supplied by the medical ventilator to the patient.

Owner:TYCO HEALTHCARE GRP LP

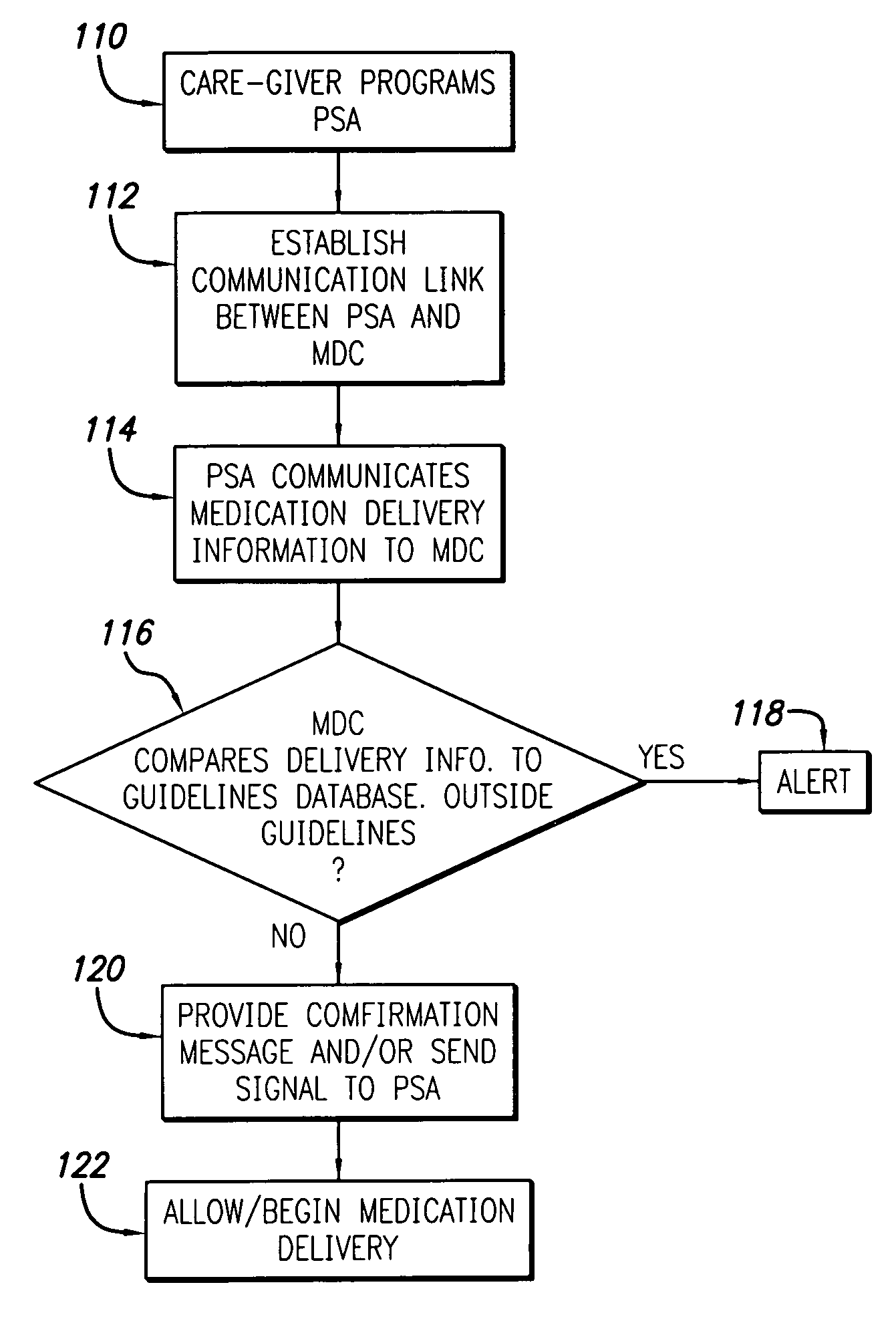

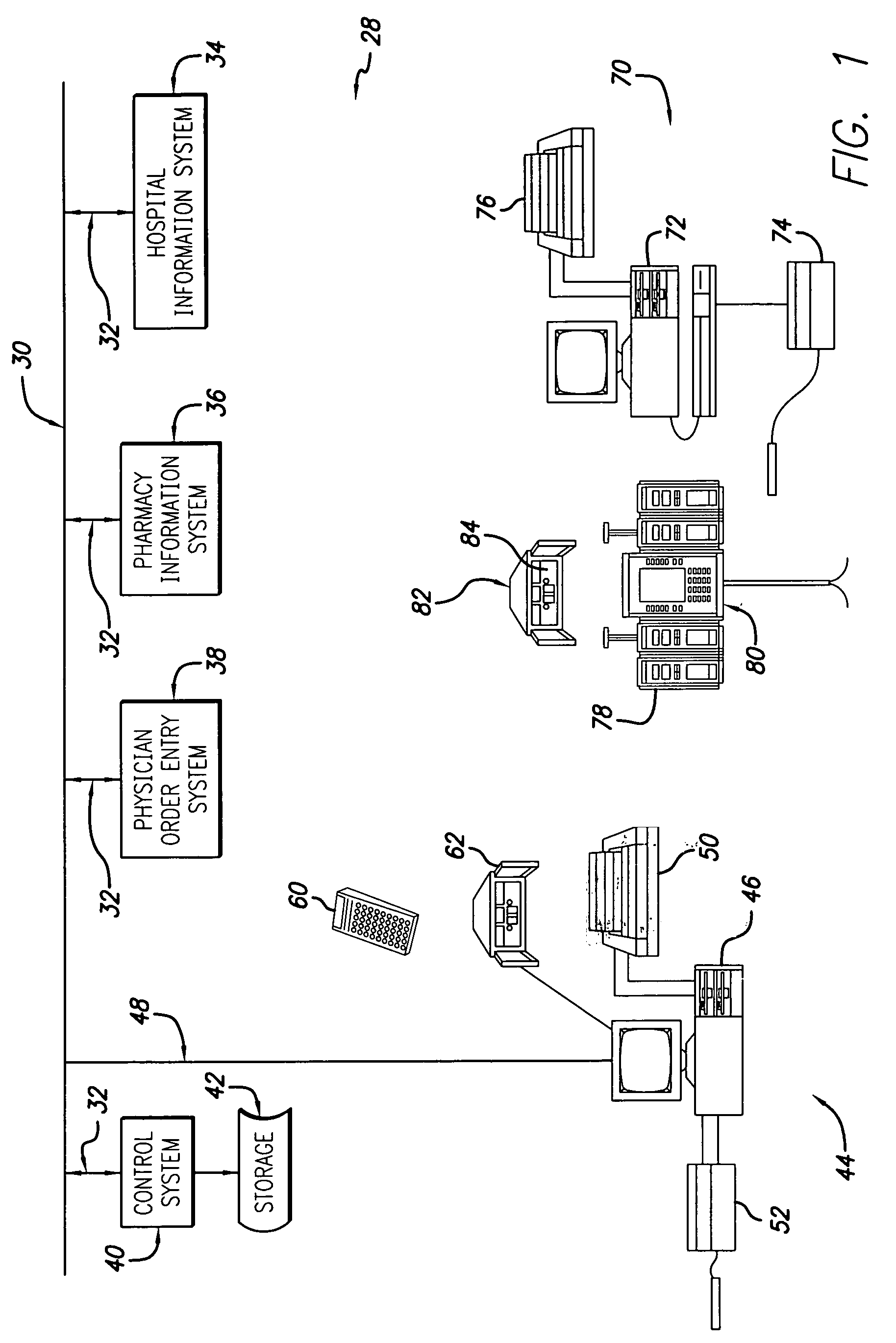

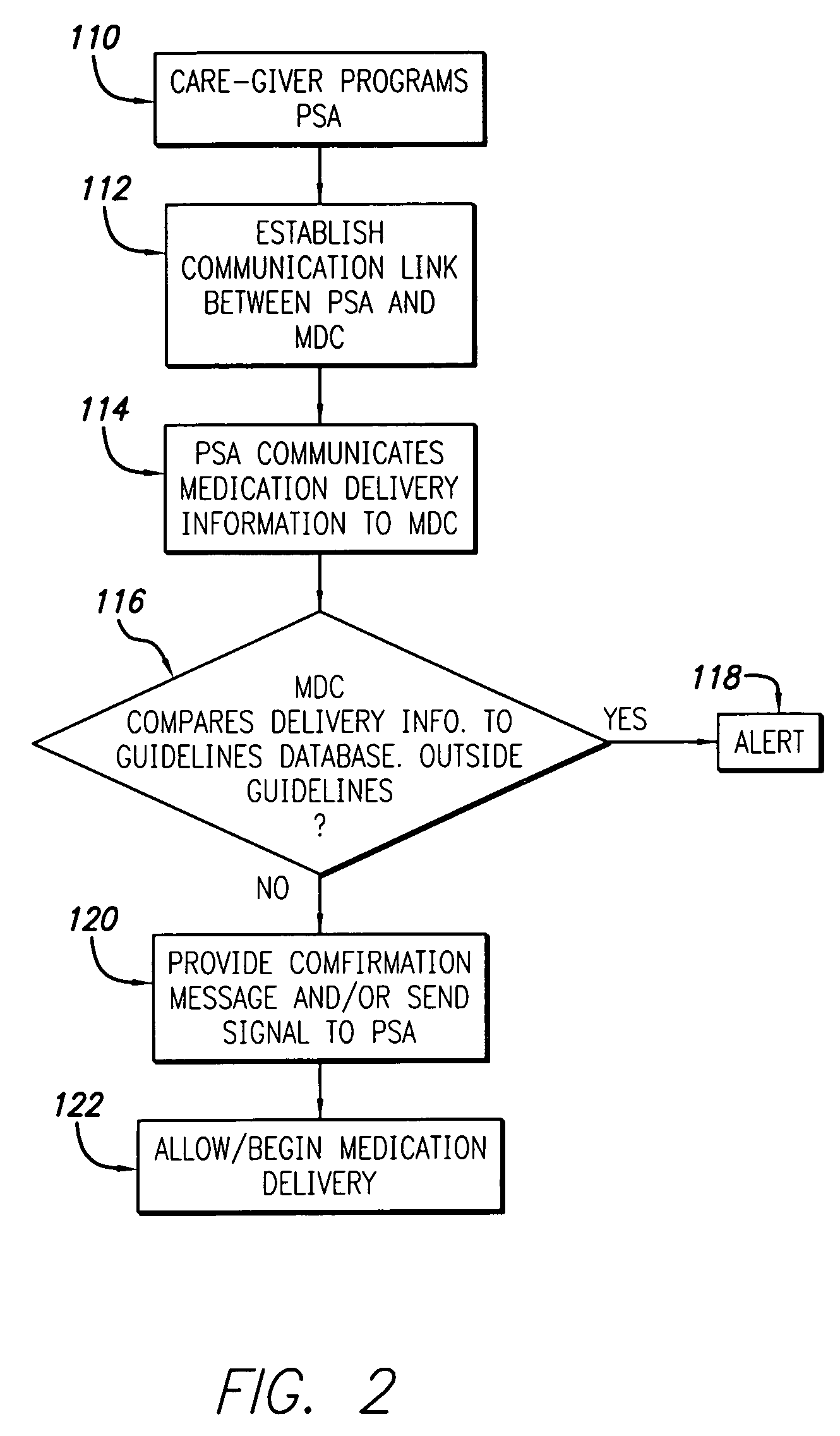

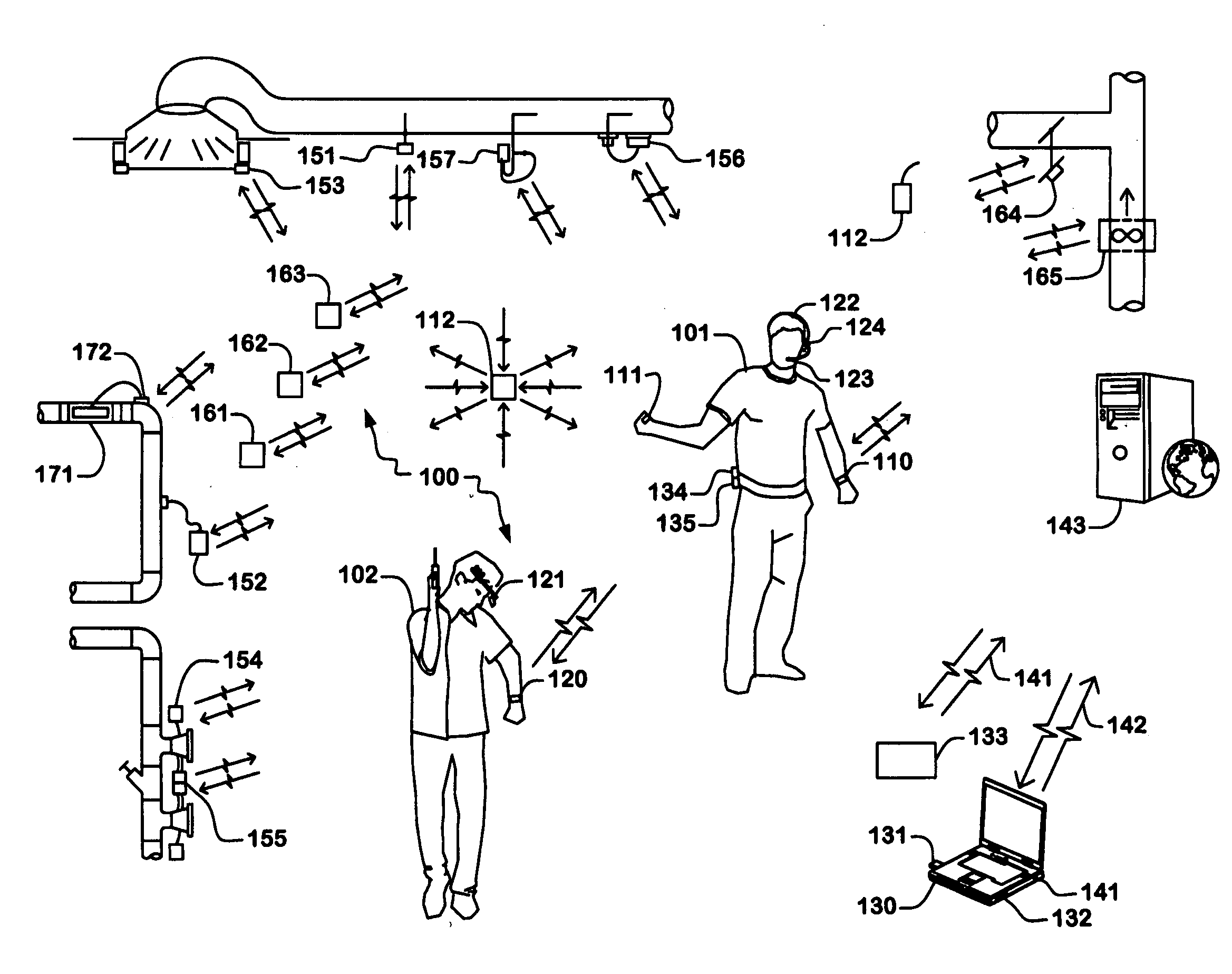

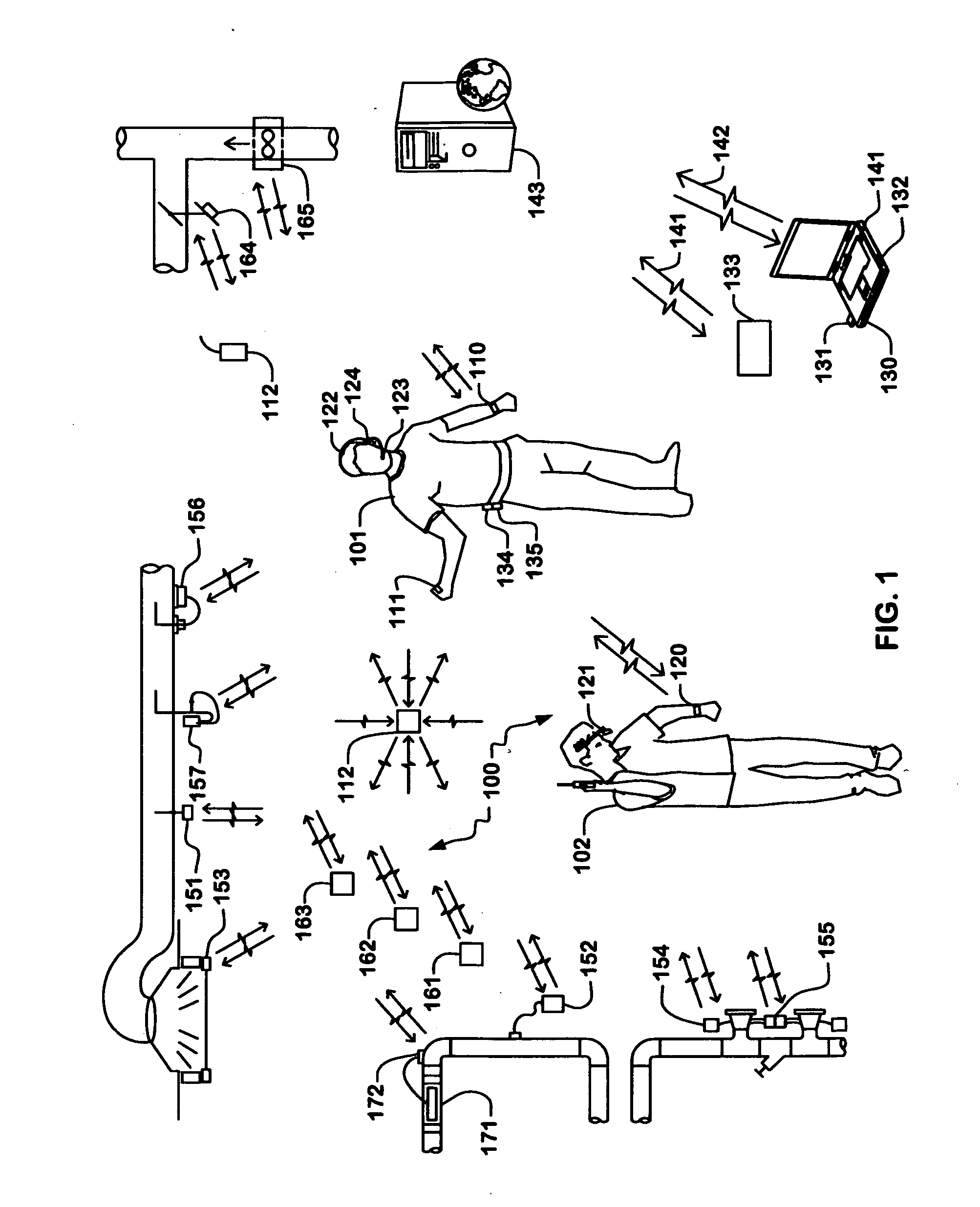

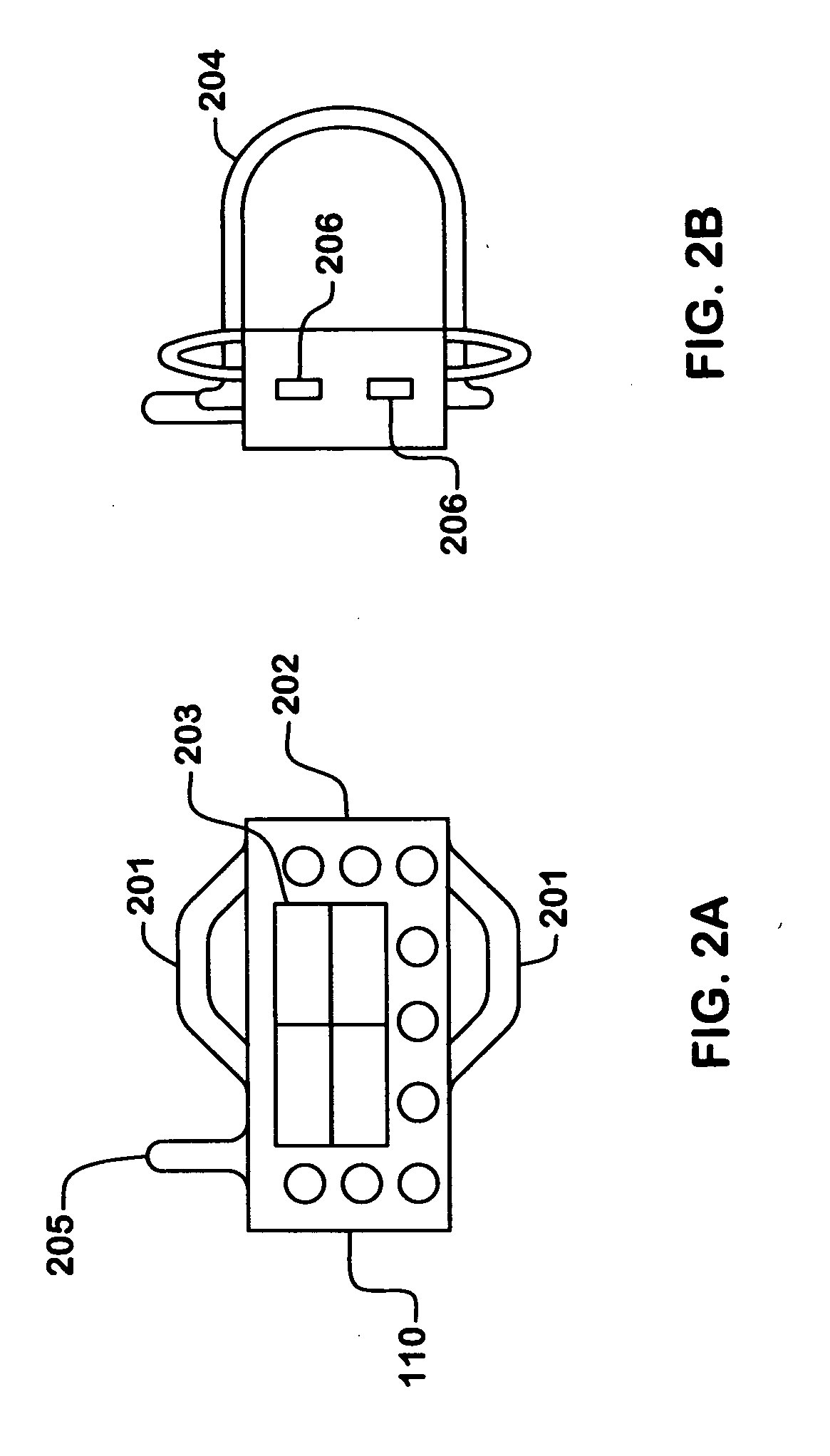

Medication management system

A system and method for confirming that a medication administration device has been programmed with the correct medication administration parameters. A medical database carrier is used compare medication delivery parameters entered into a medication administration device to institutionally established guidelines or more widely accepted protocols to ensure that the medication is delivered in accordance to those guidelines. The medical database carrier may also be configured to communicate information regarding medication delivery and other patient information between a control system in communication with the care-giving facility's other information systems and a patient specific asset such as an infusion pump. The medical database carrier may be a smartcard, a PDA such as a Palm™ Pilot, laptop computer, pager, mobile phone, or other device capable of storing, processing and communicating information. The system may use either wired or wireless connections to communicate information between the components of the system.

Owner:CAREFUSION 303 INC

Wireless sensors system and method of using same

ActiveUS20120046792A1Improve understandingAct quicklySpace heating and ventilationTemperatue controlEngineeringWater temperature

An apparatus, system, and methods for measuring environmental parameters are disclosed. The apparatus, system, and methods can be used for a variety of applications, including HVAC air balancing and building commissioning. The system includes a variety of wireless sensing modules and wearable modules for control, display, and storage. Parameters measured include air and water temperature, pressure, velocity, and flow. Also included are sensors for light intensity, CO concentrations, and CO2 concentrations.

Owner:EVERGREEN TELEMETRY LLC

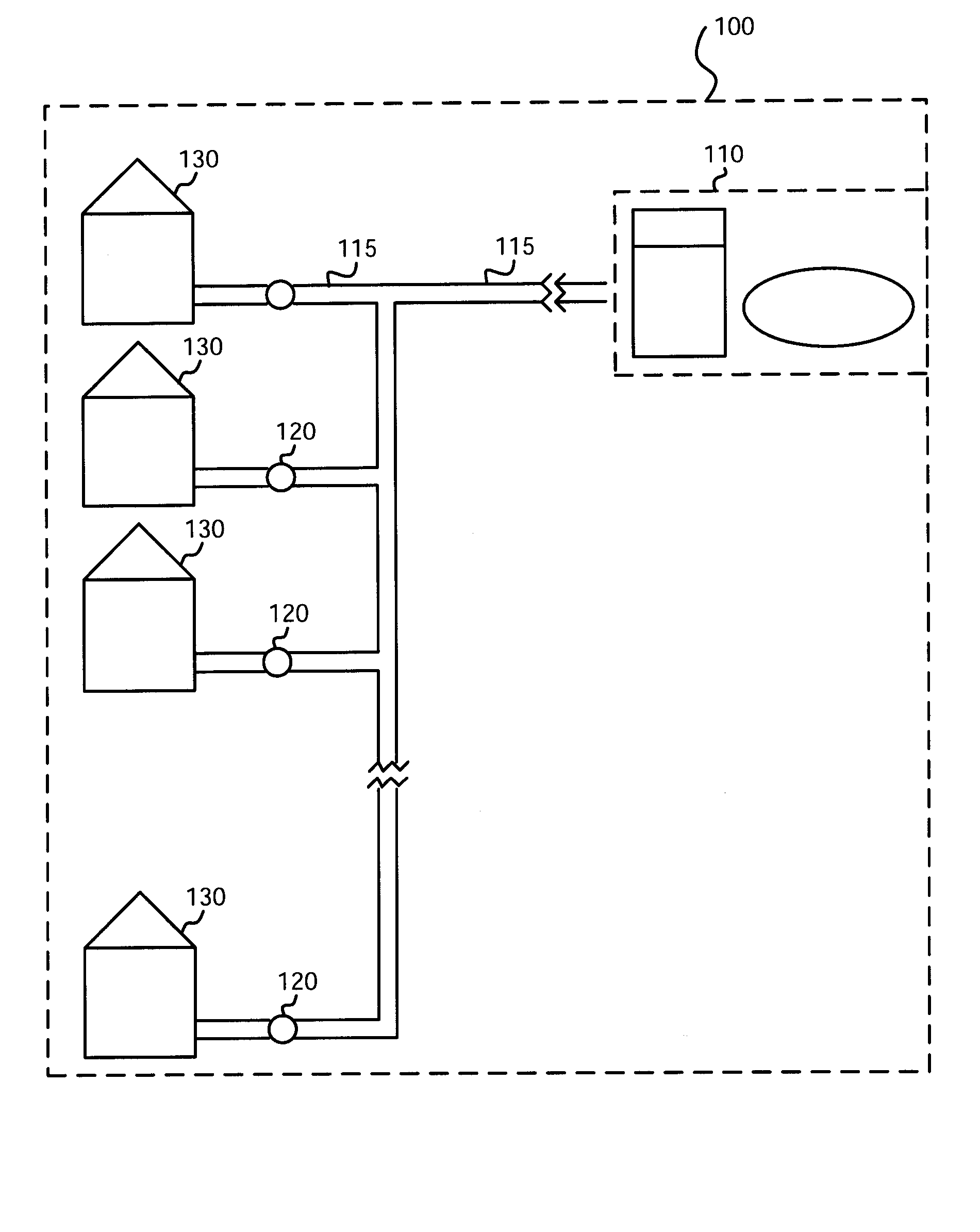

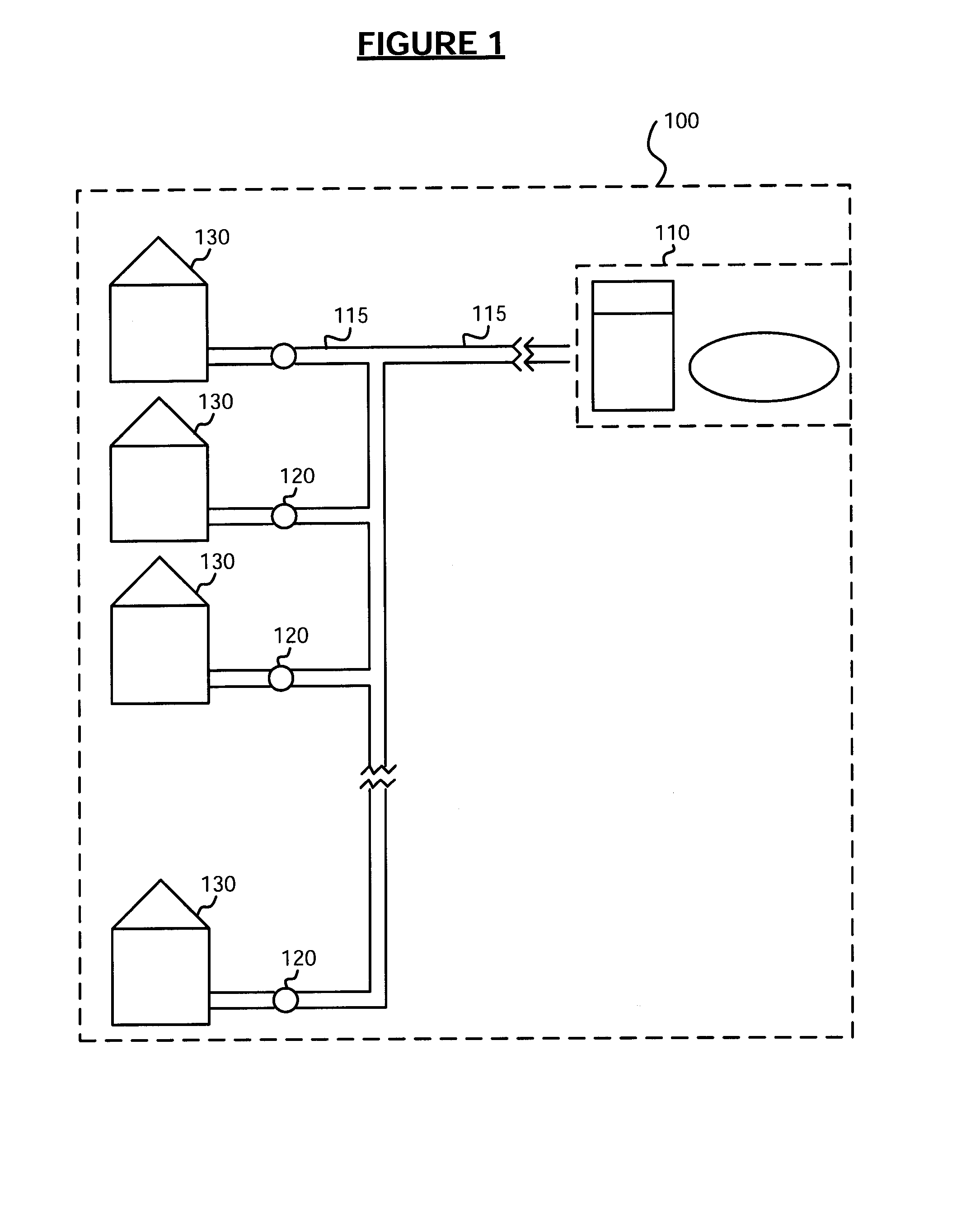

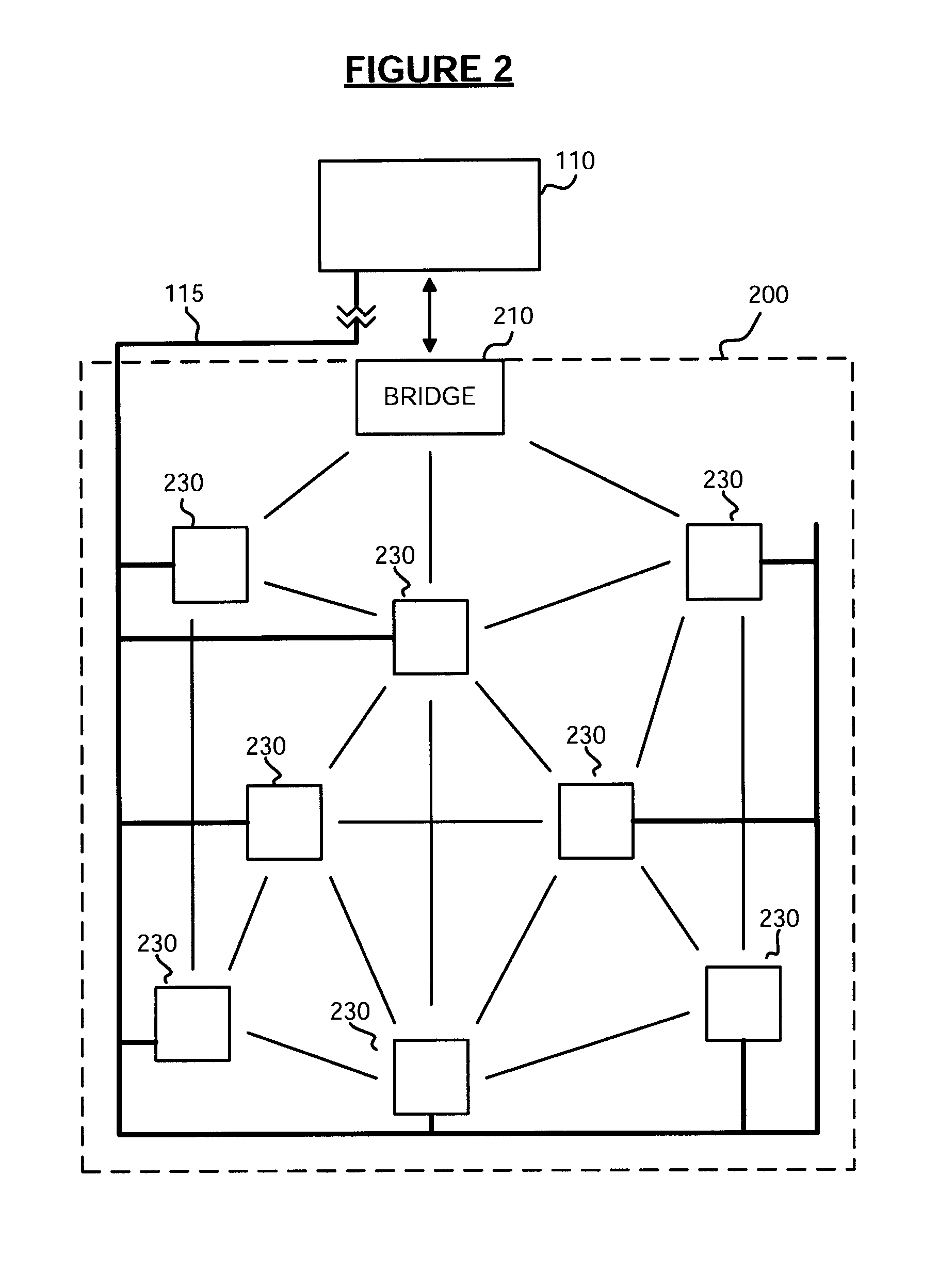

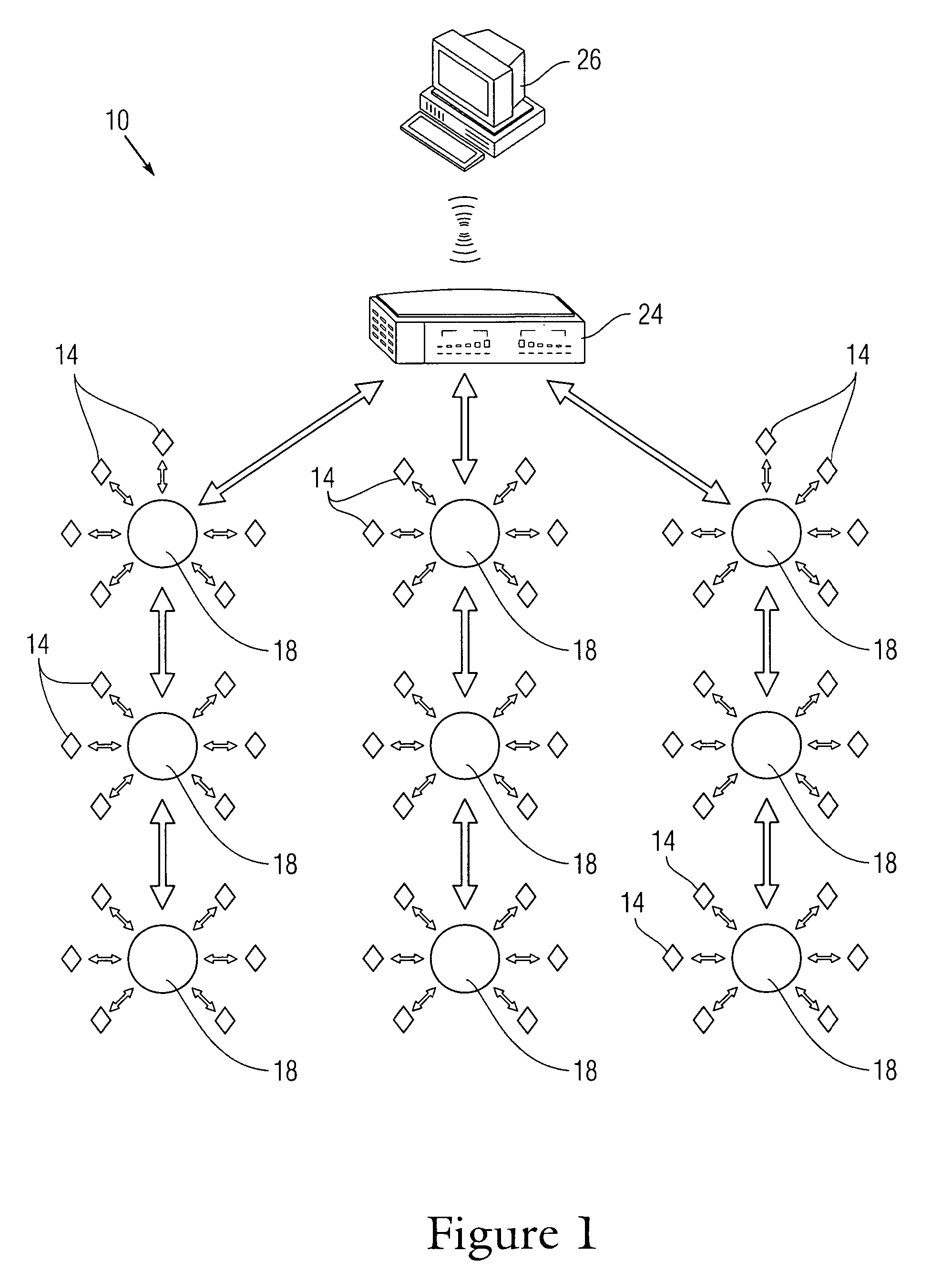

Systems and methods for remote utility metering and meter monitoring

ActiveUS20070284293A1Electric signal transmission systemsVolume/mass flow measurementTransceiverMechanical energy

A remote water meter monitoring system is provided. A mesh network-type transceiver unit is coupled to a water meter housing having a water counting mechanism inside to transmit water consumption information as well as other sensor information, such as backflow detection, water pressure, and water metrics (e.g., residual chlorine and temperature) to a central server system via a bridge device and a corresponding mesh network. Mechanical energy from the water flowing through the water meter housing is converted to electrical energy via an energy conversion unit. An electrically powered shut off valve is remote addressable via the transceiver unit.

Owner:MUELLER INT LLC

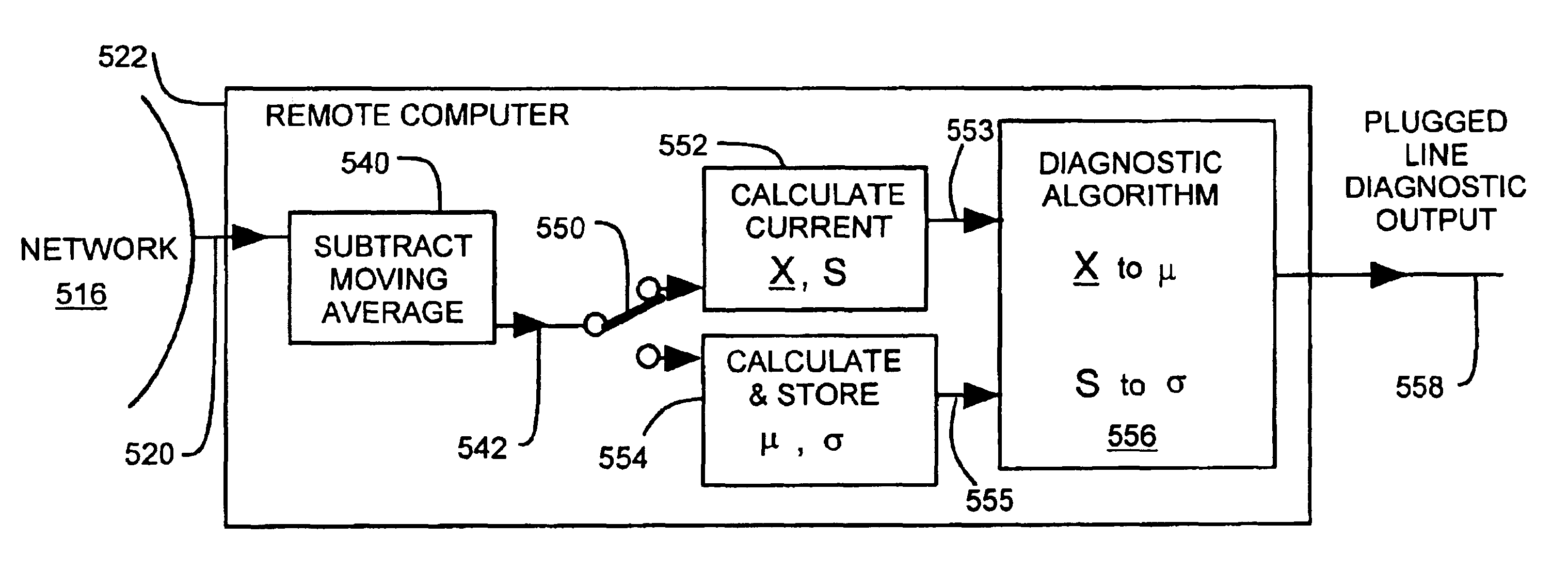

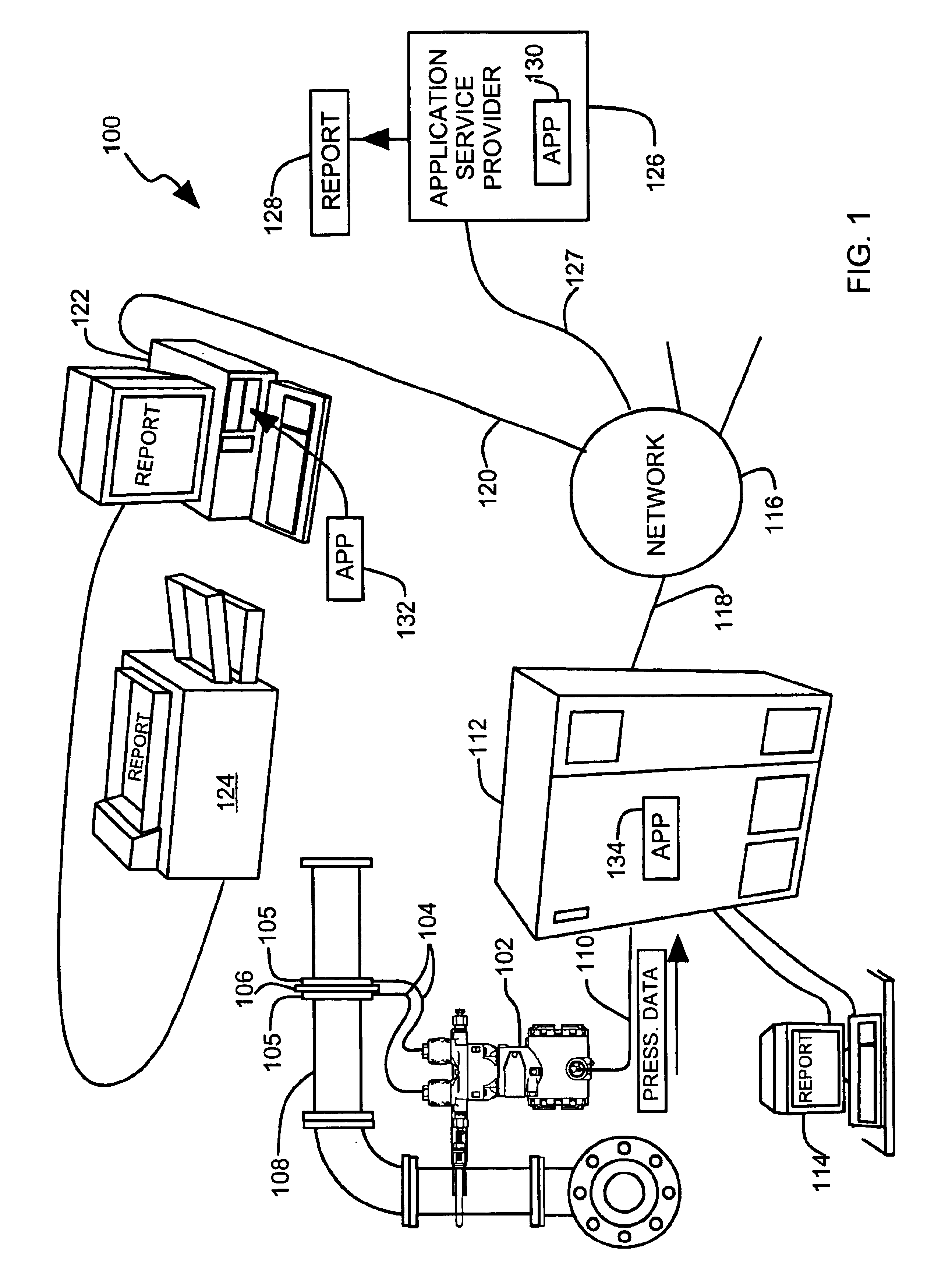

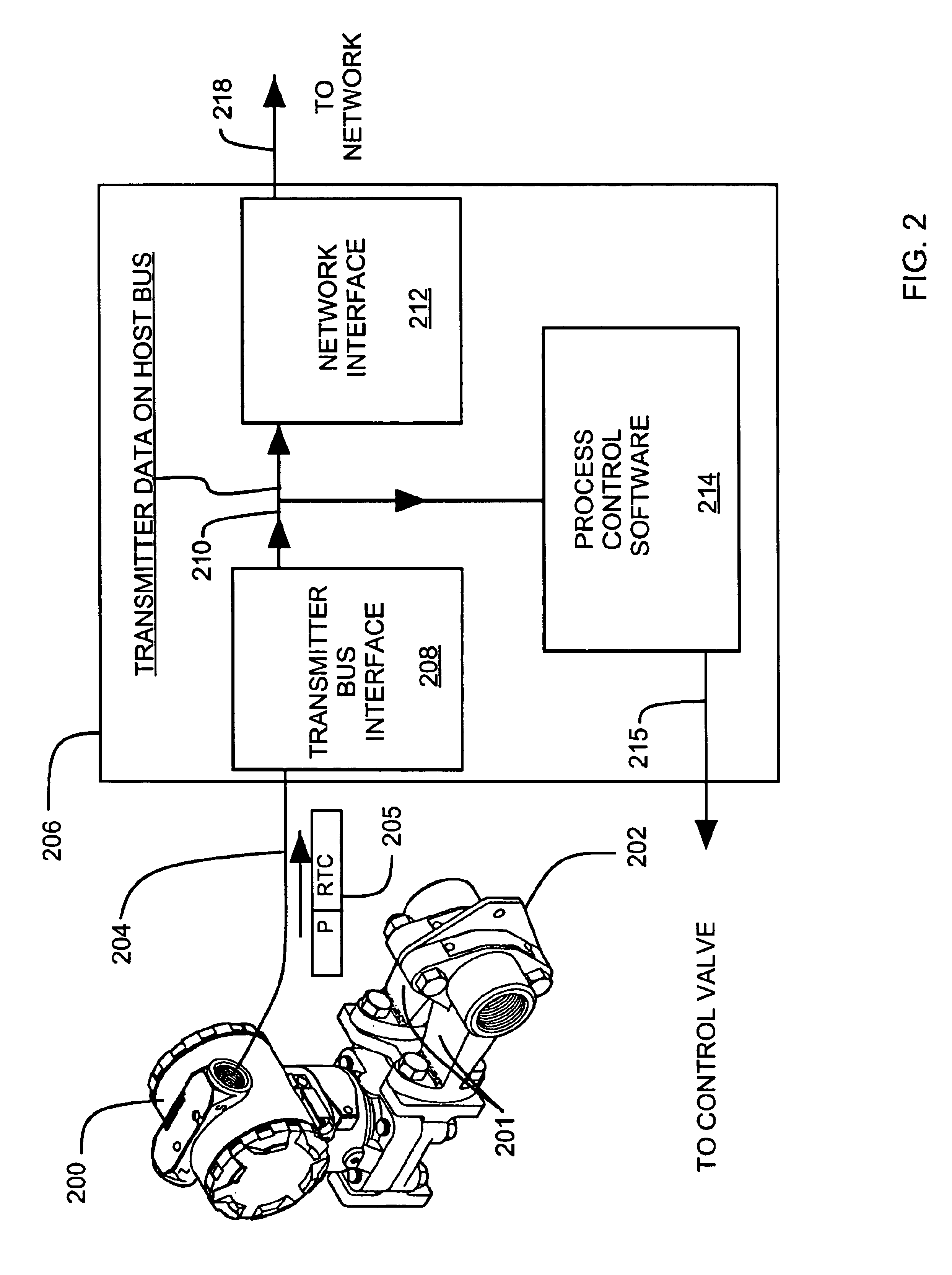

Flow diagnostic system

InactiveUS6907383B2Sampled-variable control systemsFlow control using electric meansMoving averageReal-time clock

A flow diagnostic system for a flow sensing element and impulse lines. A pressure transmitter coupled to the impulse lines provides digital pressure data to a control system. The control system provides the pressure data and real time clock readings to a diagnostic application. The diagnostic application calculates a difference between current pressure data and its moving average. A condition of the primary element or impulse lines is diagnosed from a current pressure data set relative to an historical data set. The diagnostic application is downloadable from an application service provider (ASP). The application can run on the control system, a remote computer or the ASP. A diagnostic report is preferably provided.

Owner:ROSEMOUNT INC

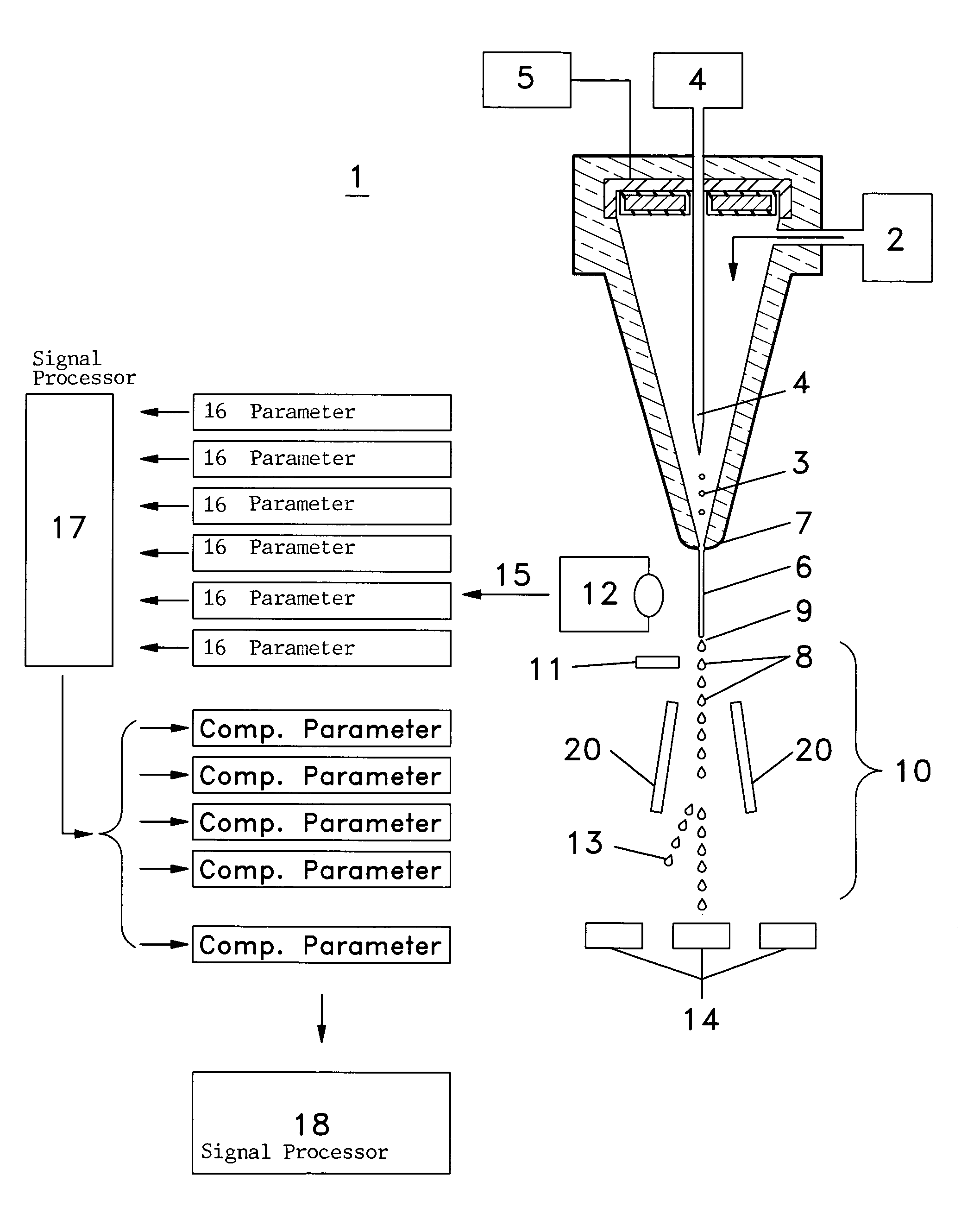

Transiently dynamic flow cytometer analysis system

InactiveUS7024316B1Good compensationShort transition timeFlow propertiesVolume/mass flow measurementHigh rateComputer science

A flow cytometry apparatus and methods to process information incident to particles or cells entrained in a sheath fluid stream allowing assessment, differentiation, assignment, and separation of such particles or cells even at high rates of speed. A first signal processor individually or in combination with at least one additional signal processor for applying compensation transformation on data from a signal. Compensation transformation can involve complex operations on data from at least one signal to compensate for one or numerous operating parameters. Compensated parameters can be returned to the first signal processor for provide information upon which to define and differentiate particles from one another.

Owner:BECKMAN COULTER INC

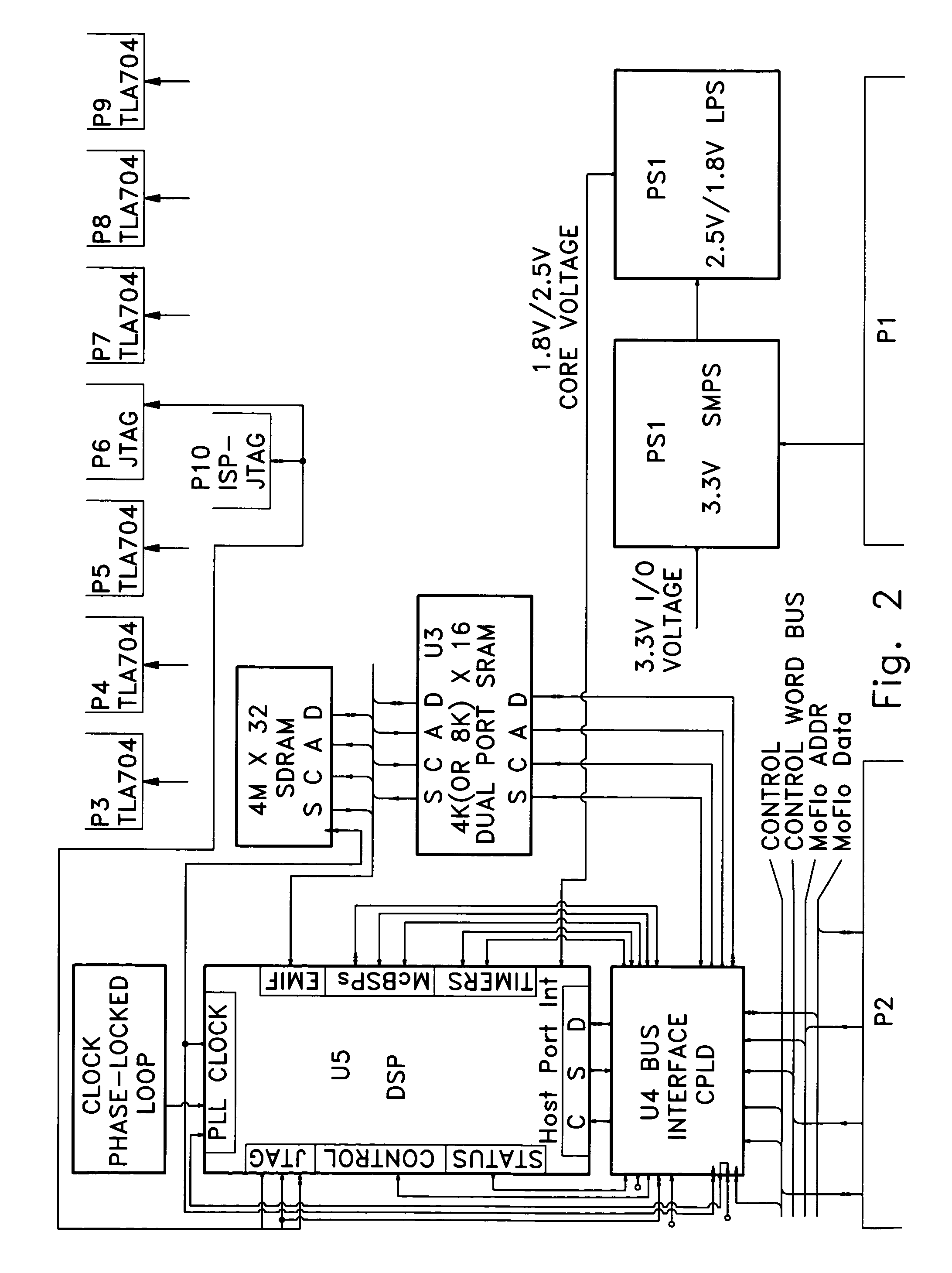

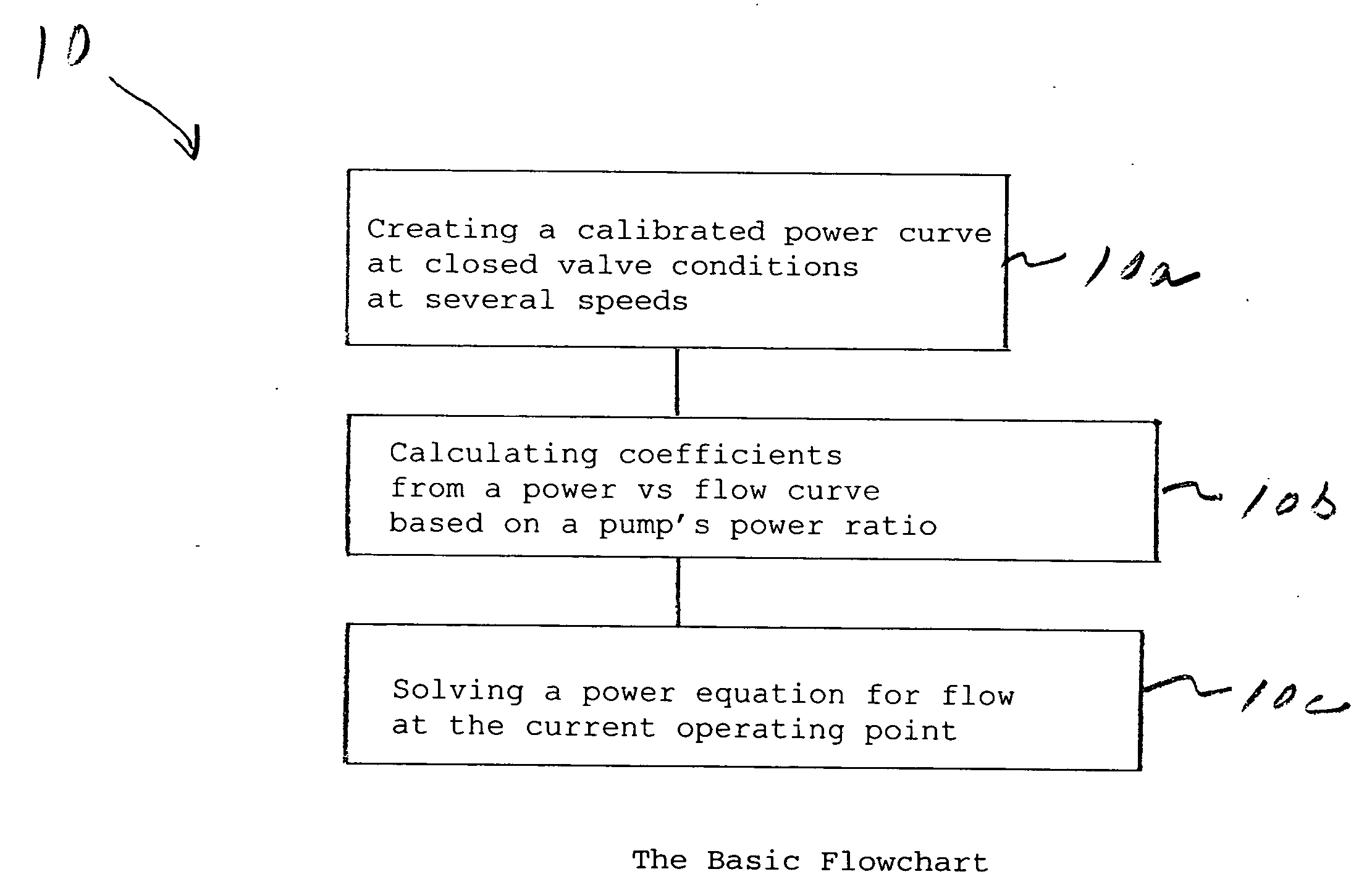

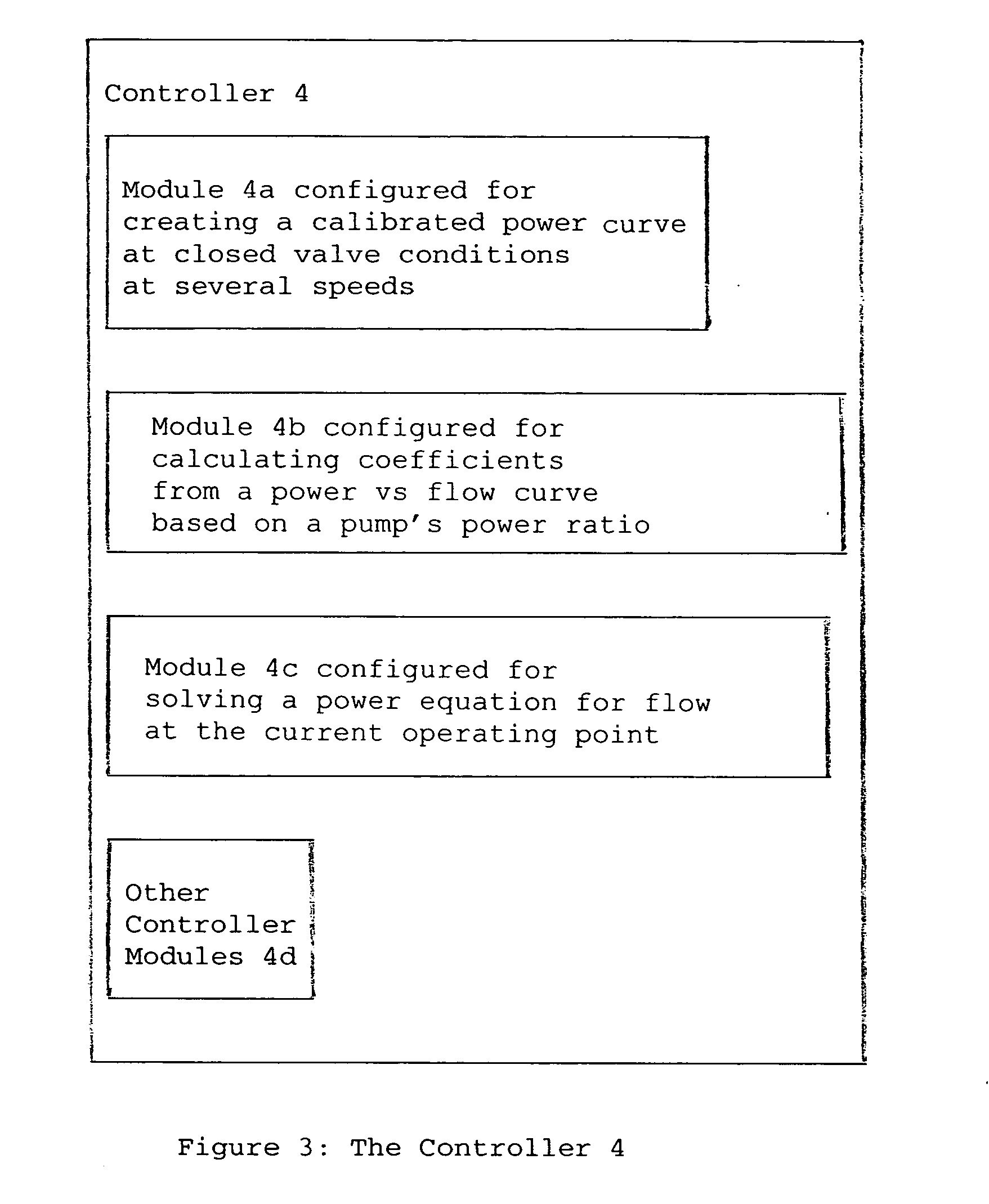

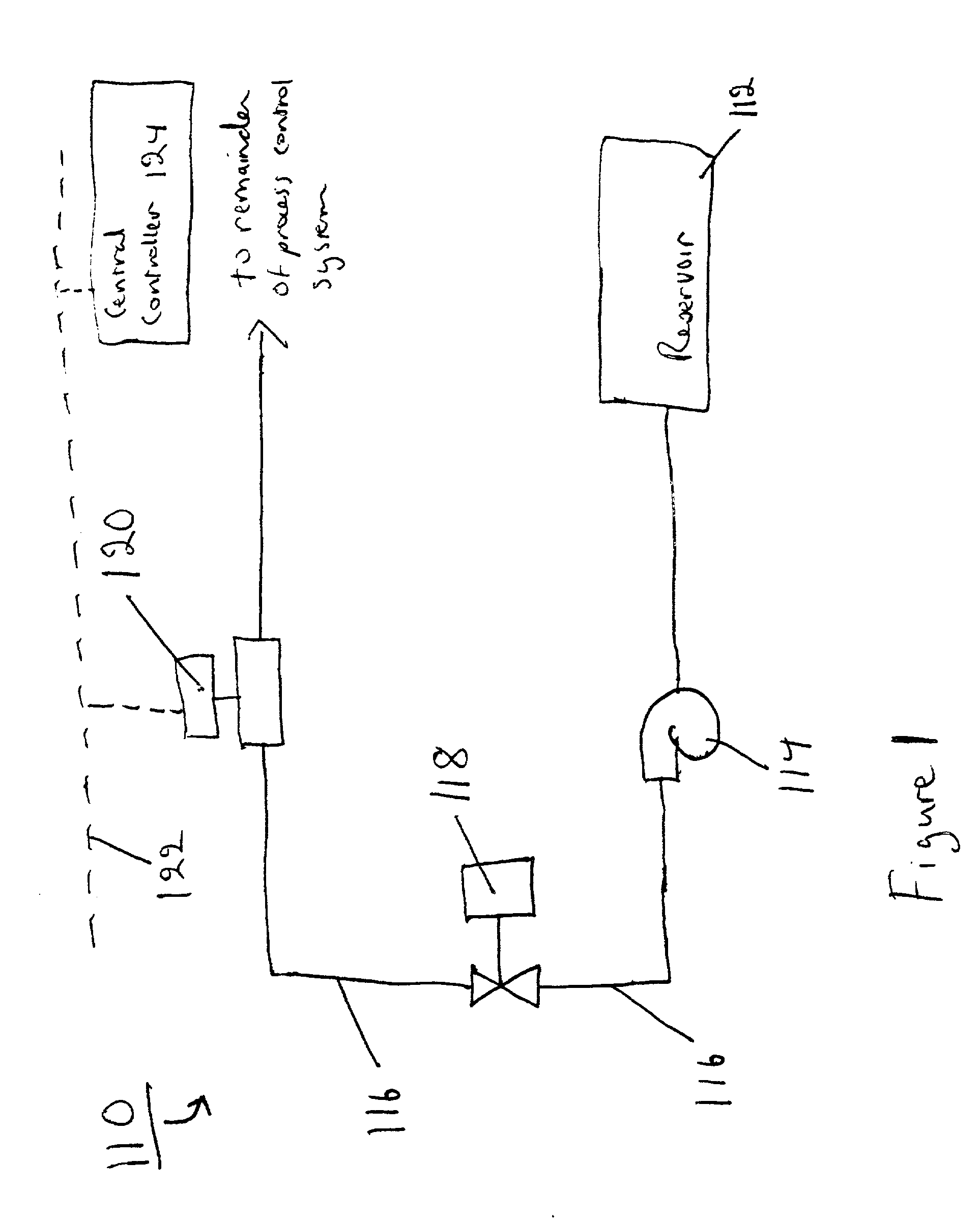

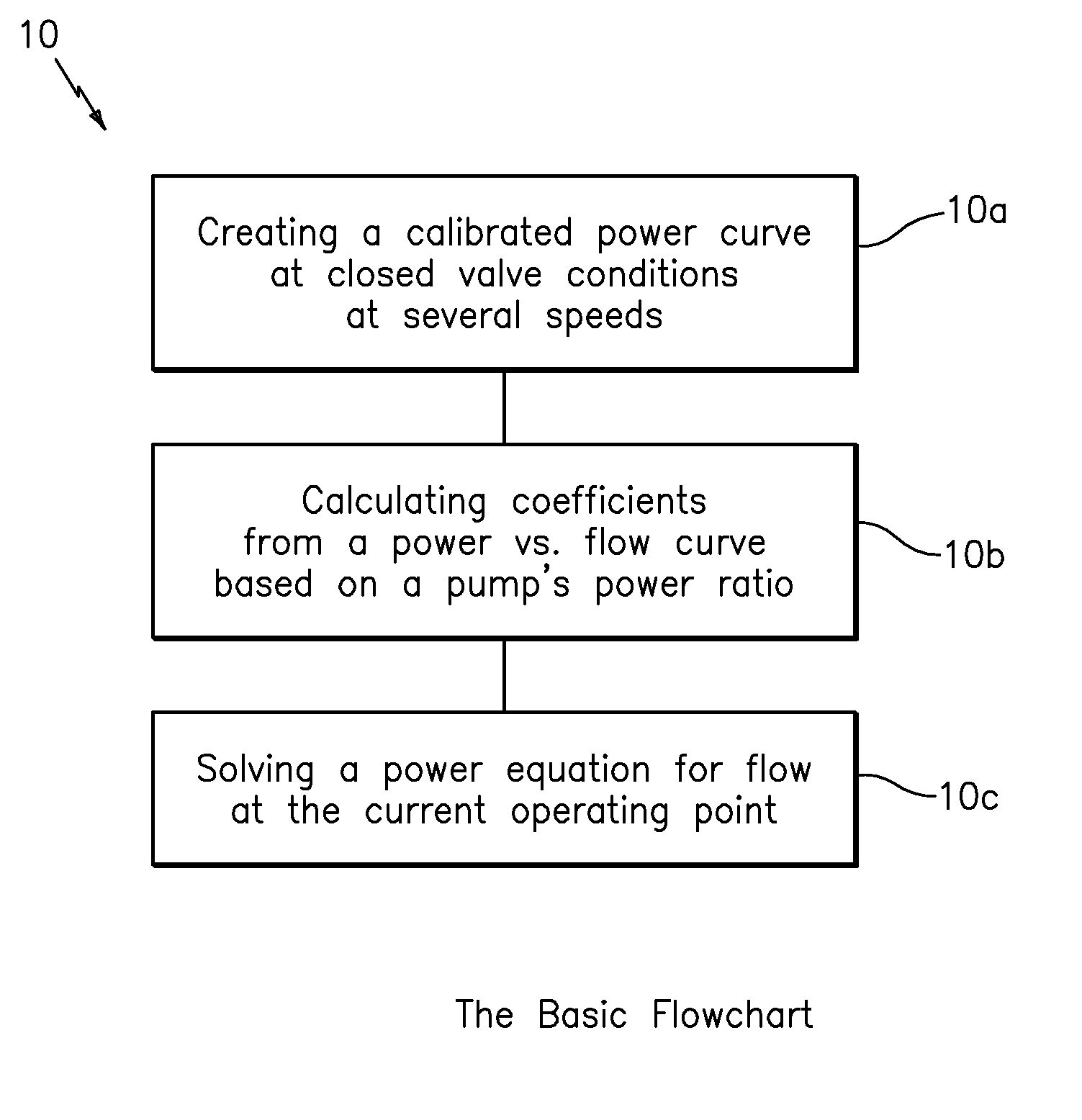

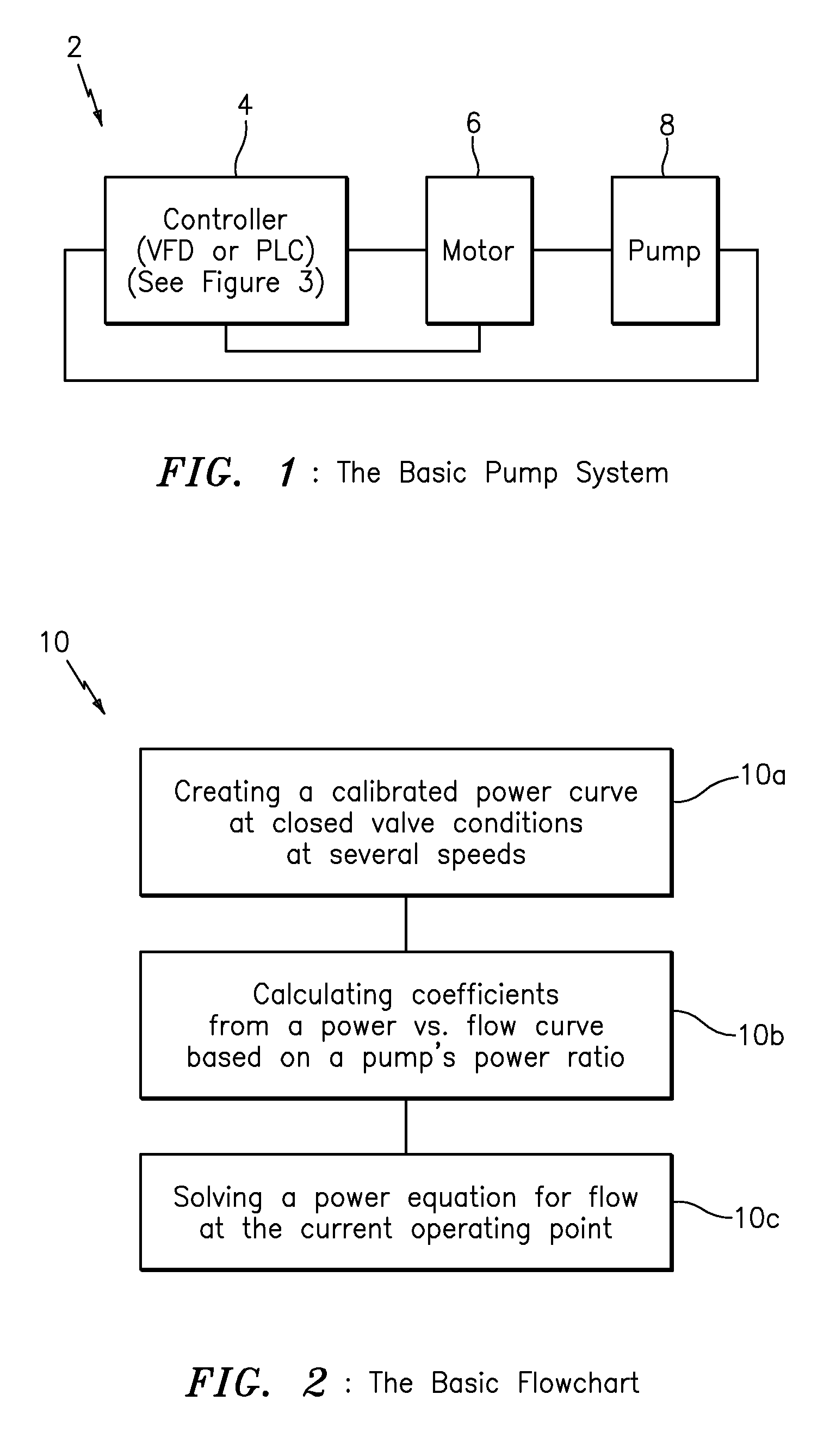

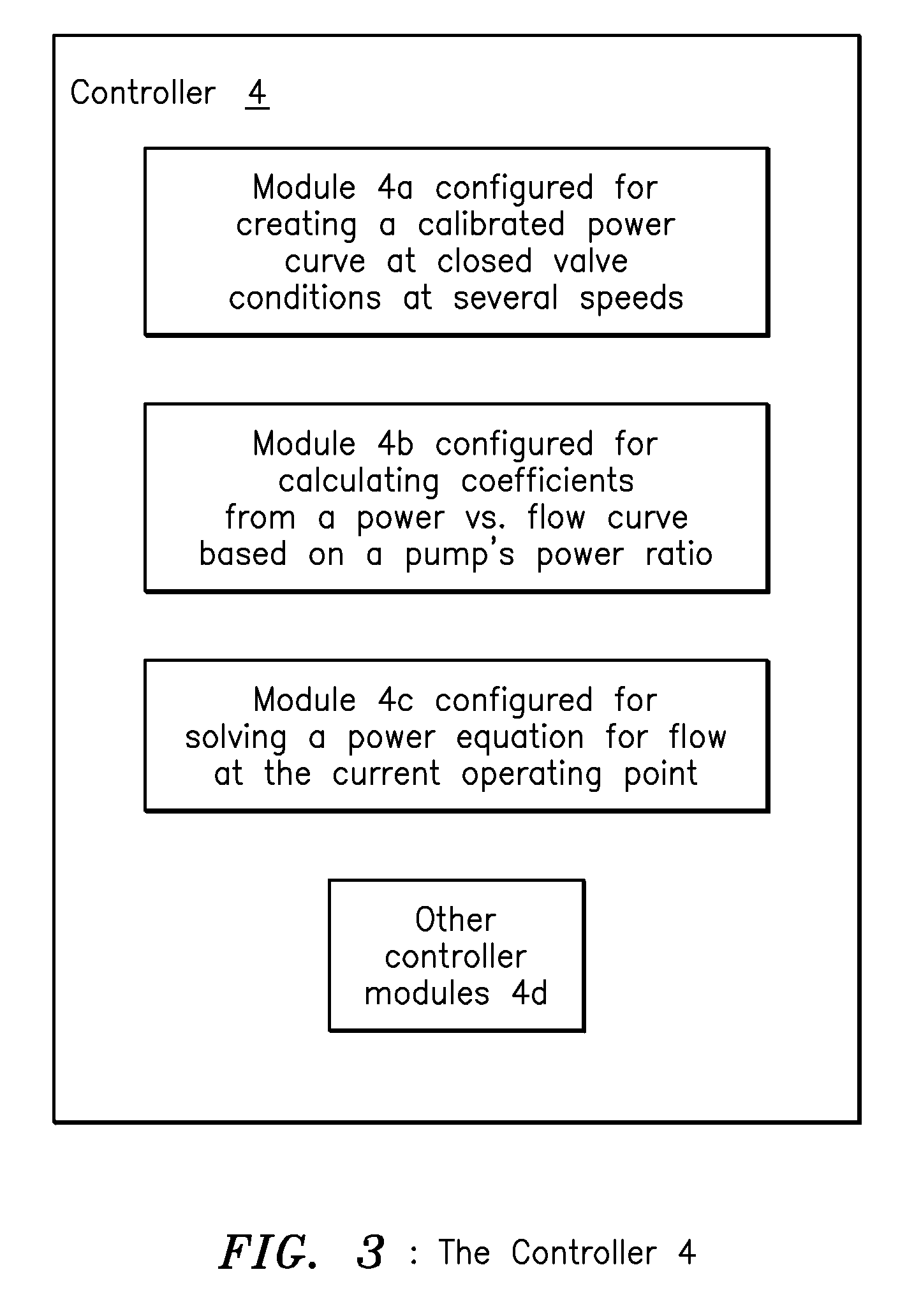

Method for determining pump flow without the use of traditional sensors

ActiveUS20070212210A1Testing/calibration apparatusAmplifier modifications to reduce noise influenceOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

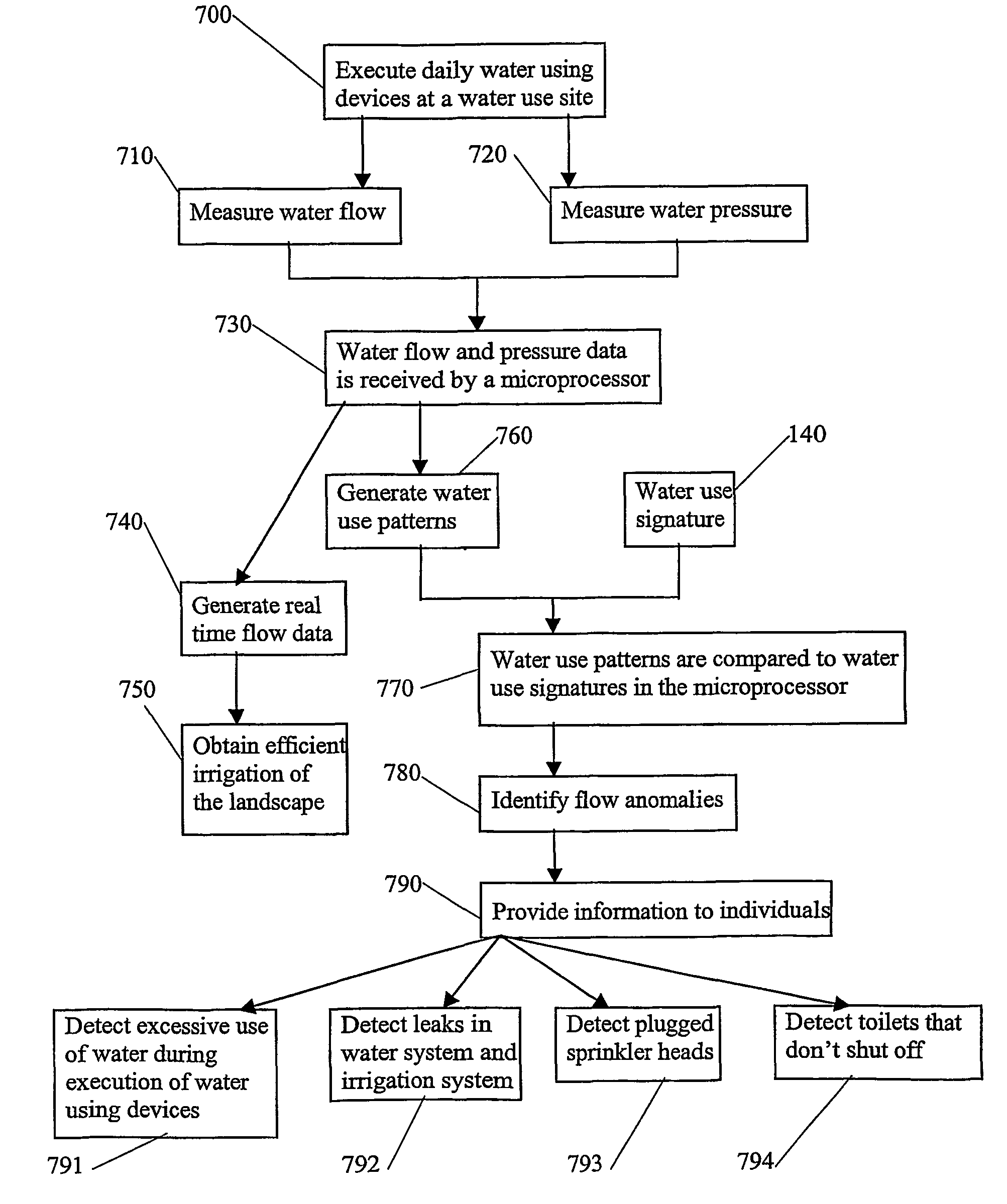

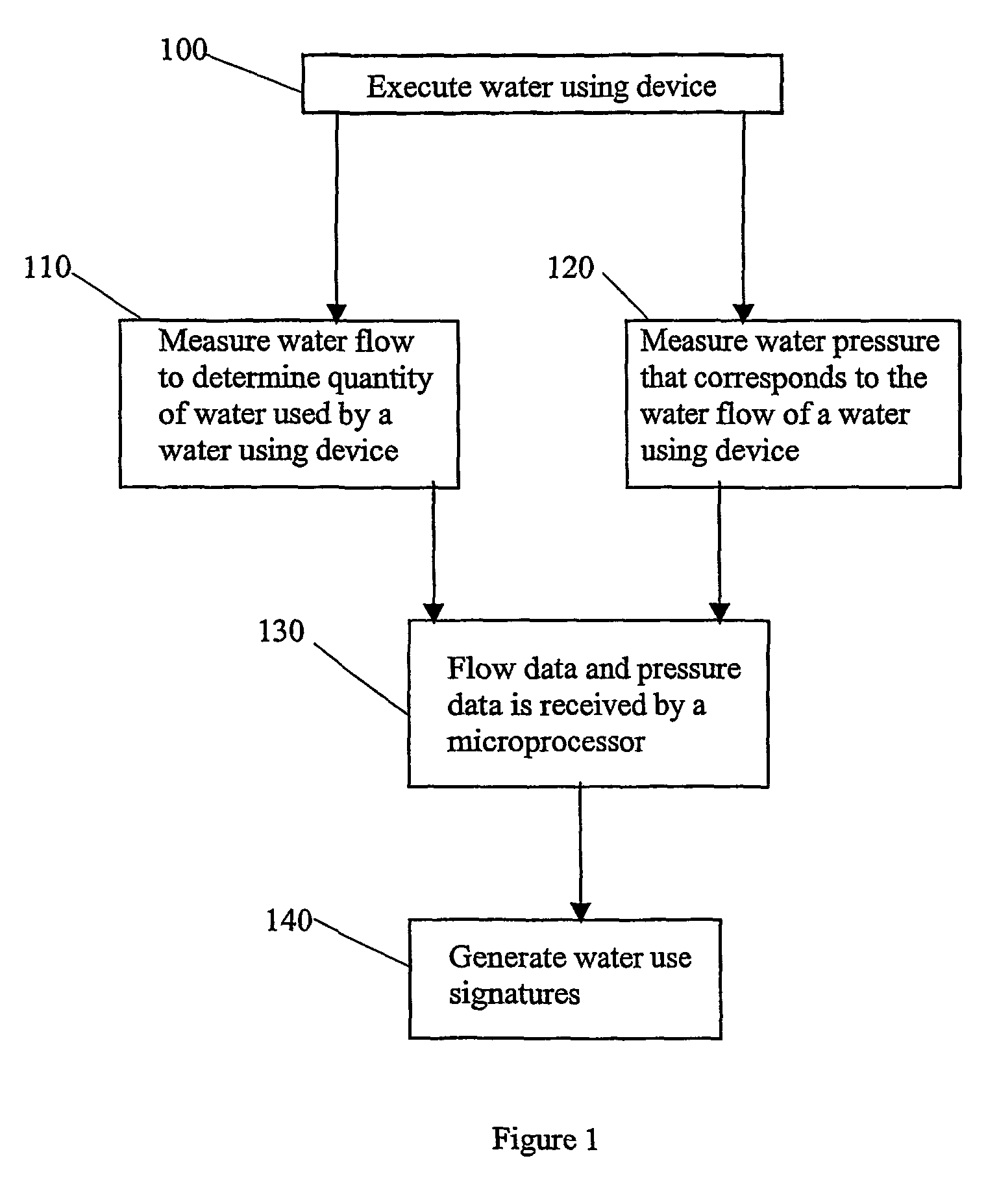

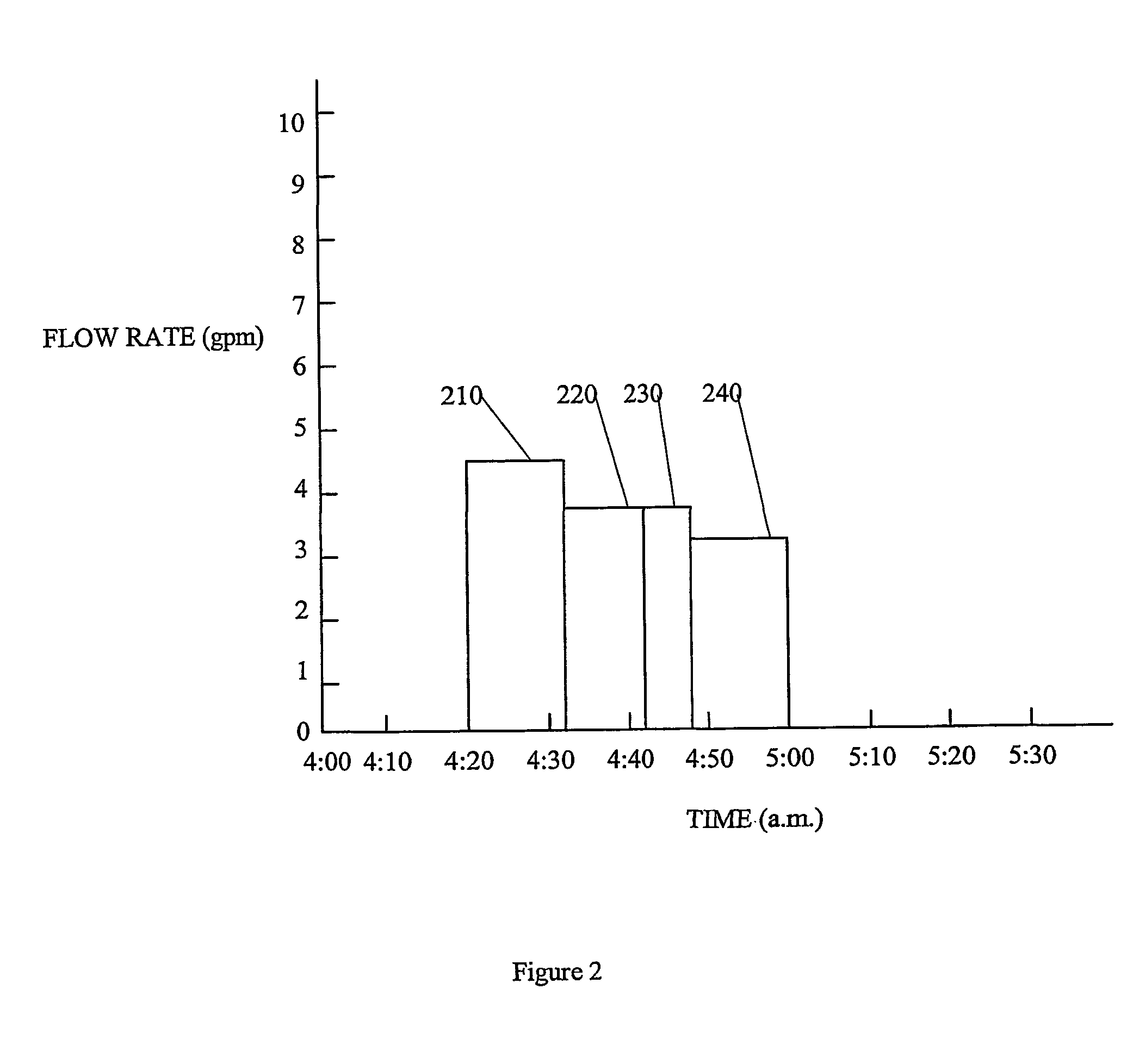

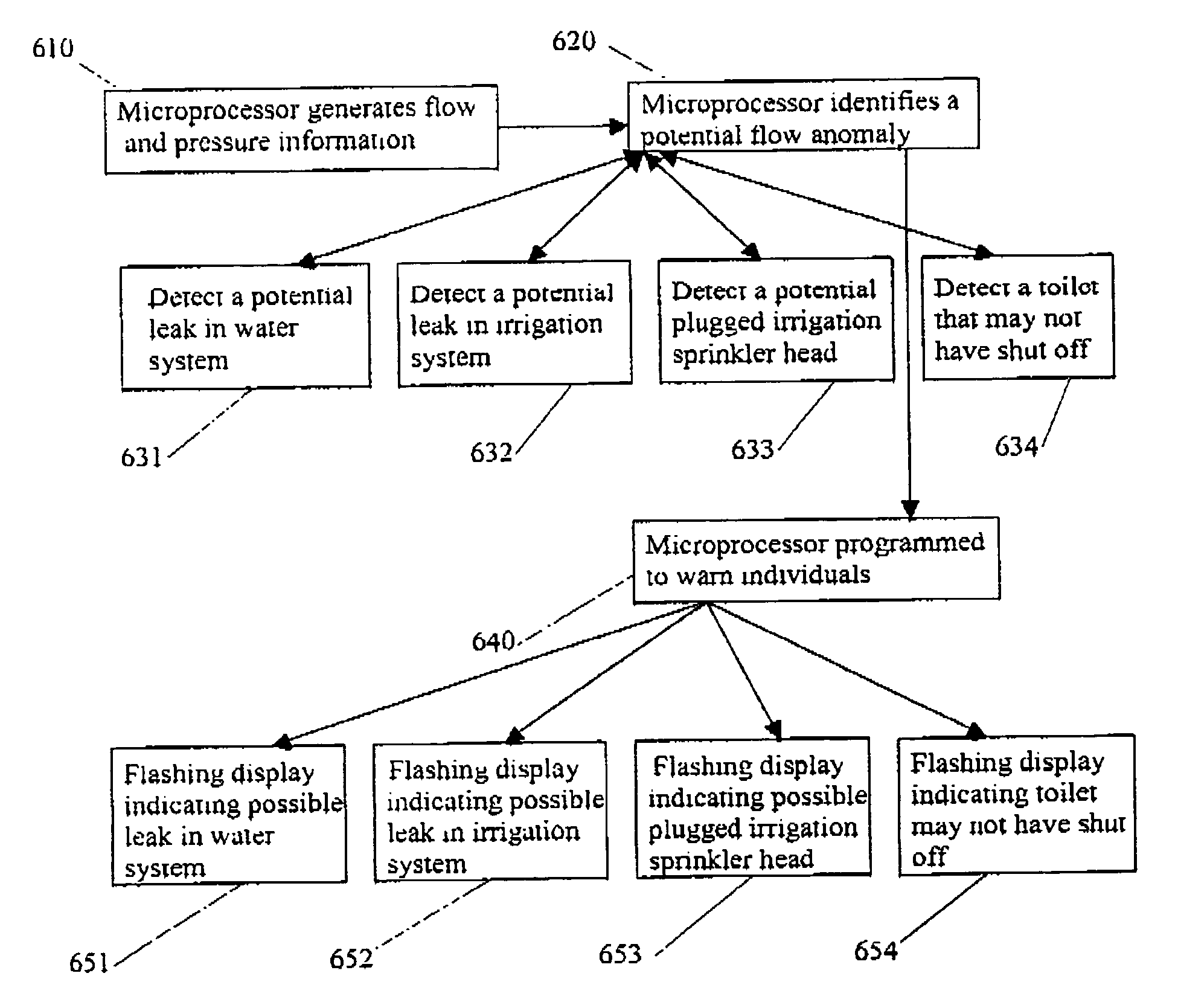

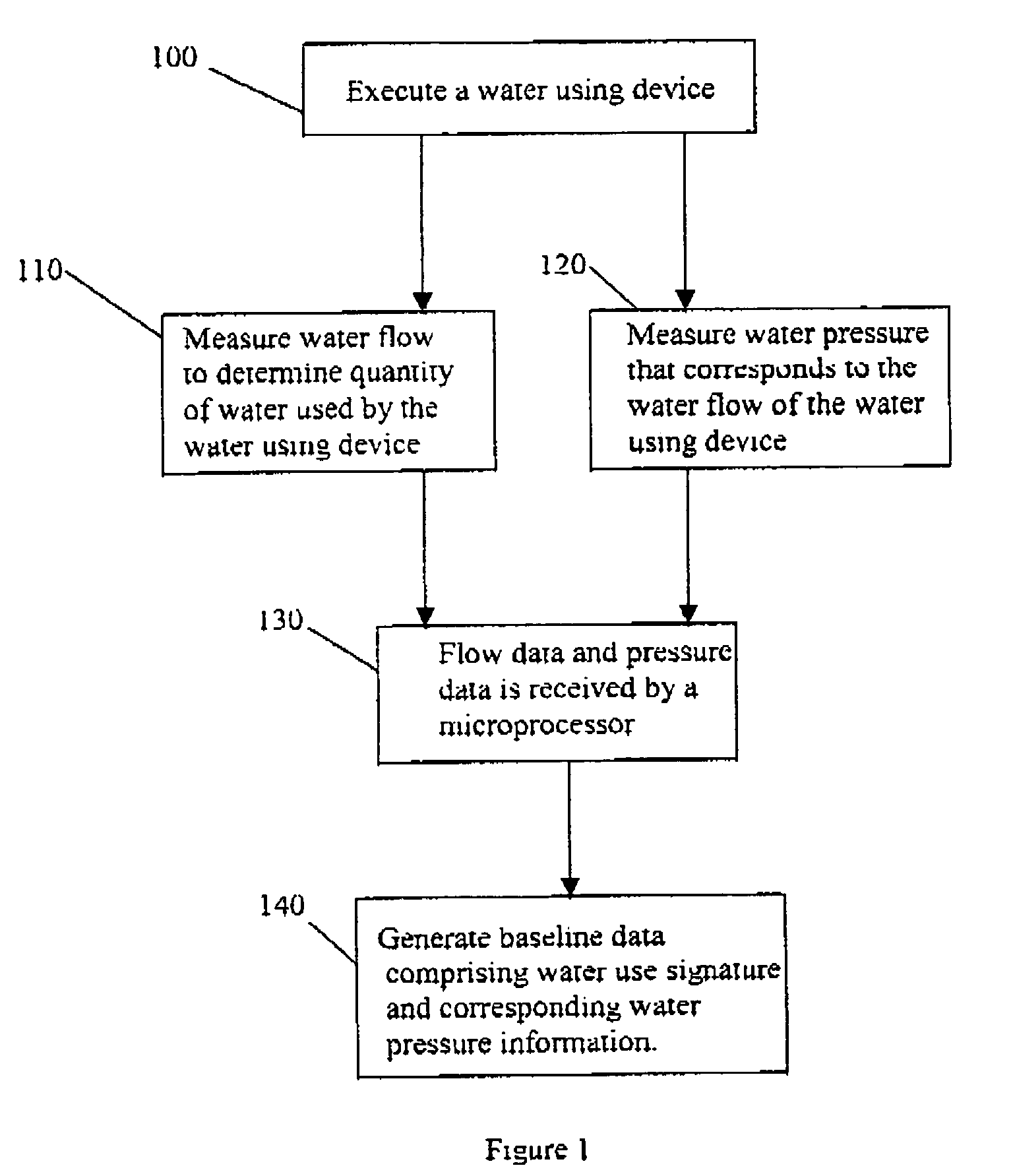

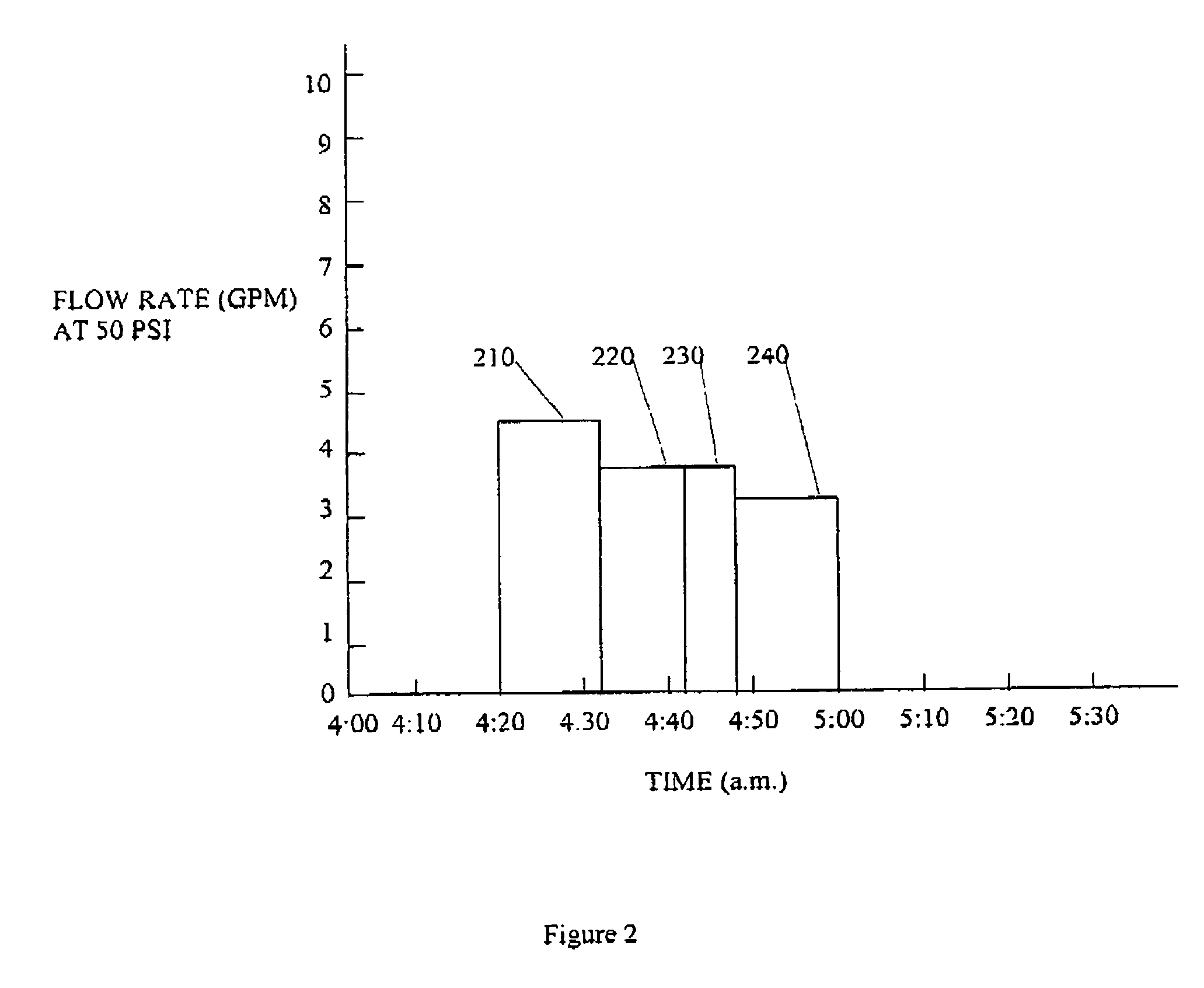

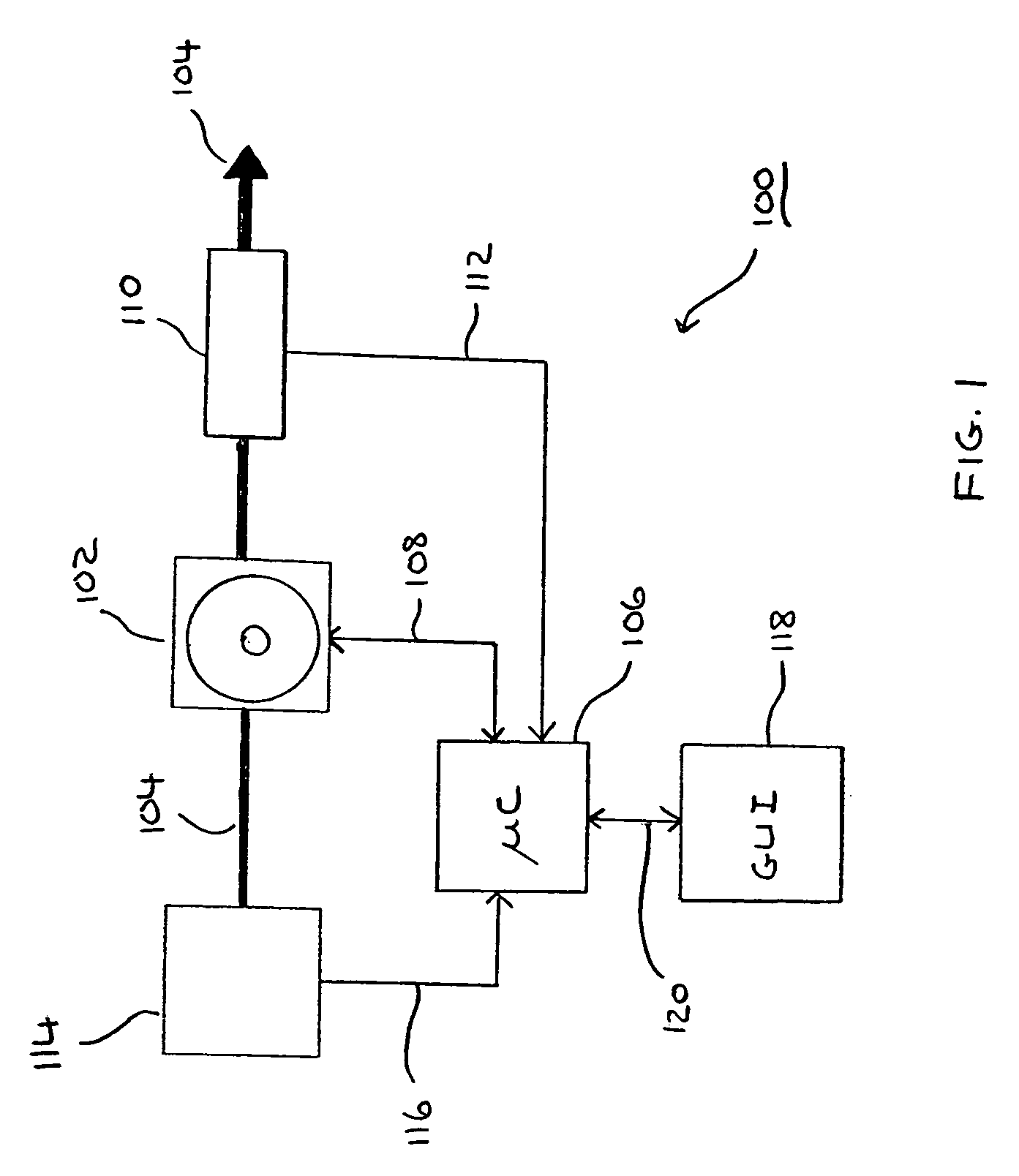

Methods and apparatus for using water use signatures in improving water use efficiency

InactiveUS6963808B1Reduce wasteImprove efficiencyMeasurement of fluid loss/gain rateGeneral water supply conservationWater useWater-use efficiency

The present invention provides systems and methods that identify a flow anomaly to an operator or other person by: executing a first device of a plurality of water using devices; receiving flow data on a quantity of water used by the first device during a time period required to generate a first water use signature from the first device; comparing a future water use pattern against the first water use signature to identify a flow anomaly with the first device; and providing information regarding the flow anomaly to the person. Identifying anomalies can be useful in numerous ways, including discovering problems that need fixing, reducing waste, and even calculating appropriate irrigation application rates.

Owner:AQUA CONSERVATION SYST

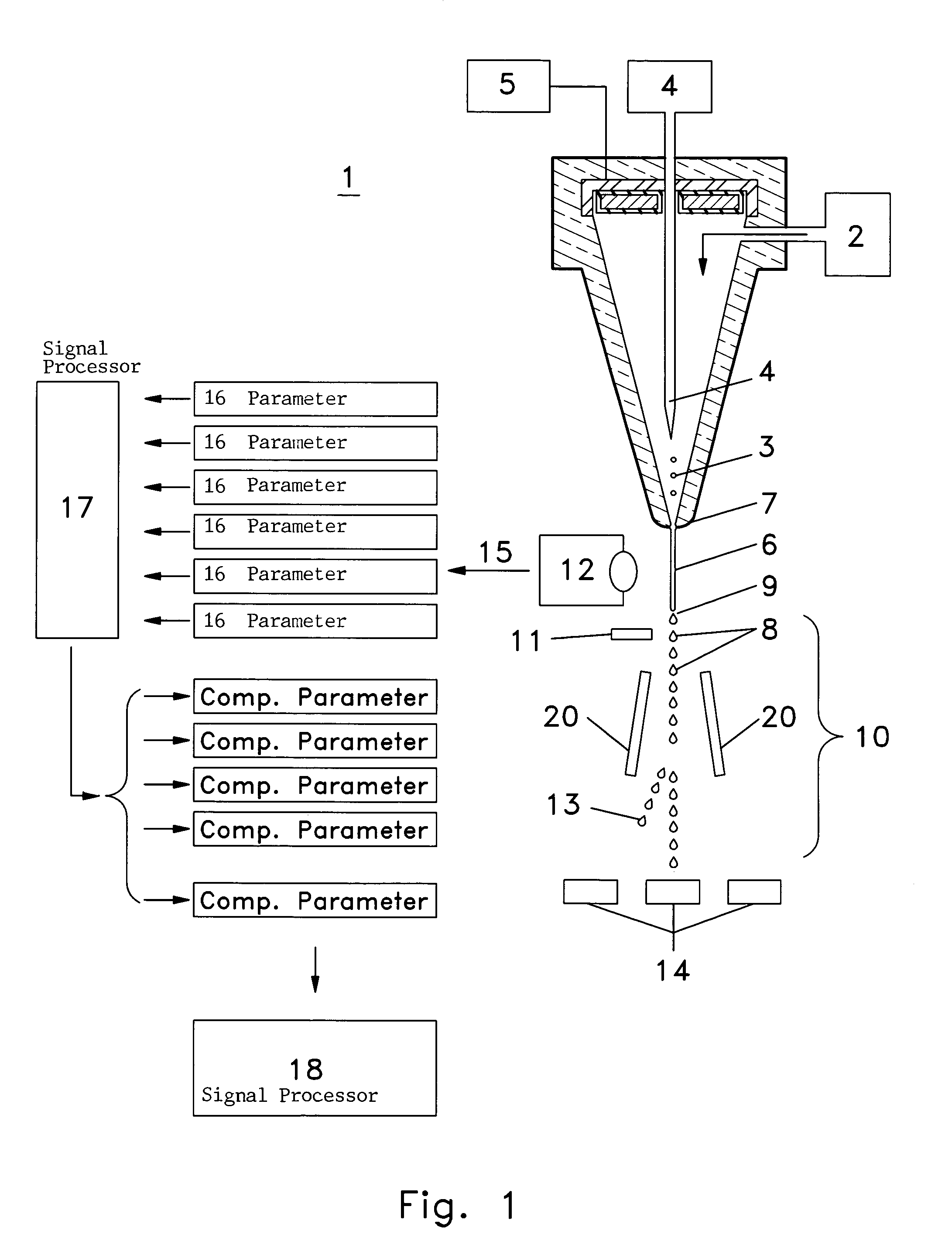

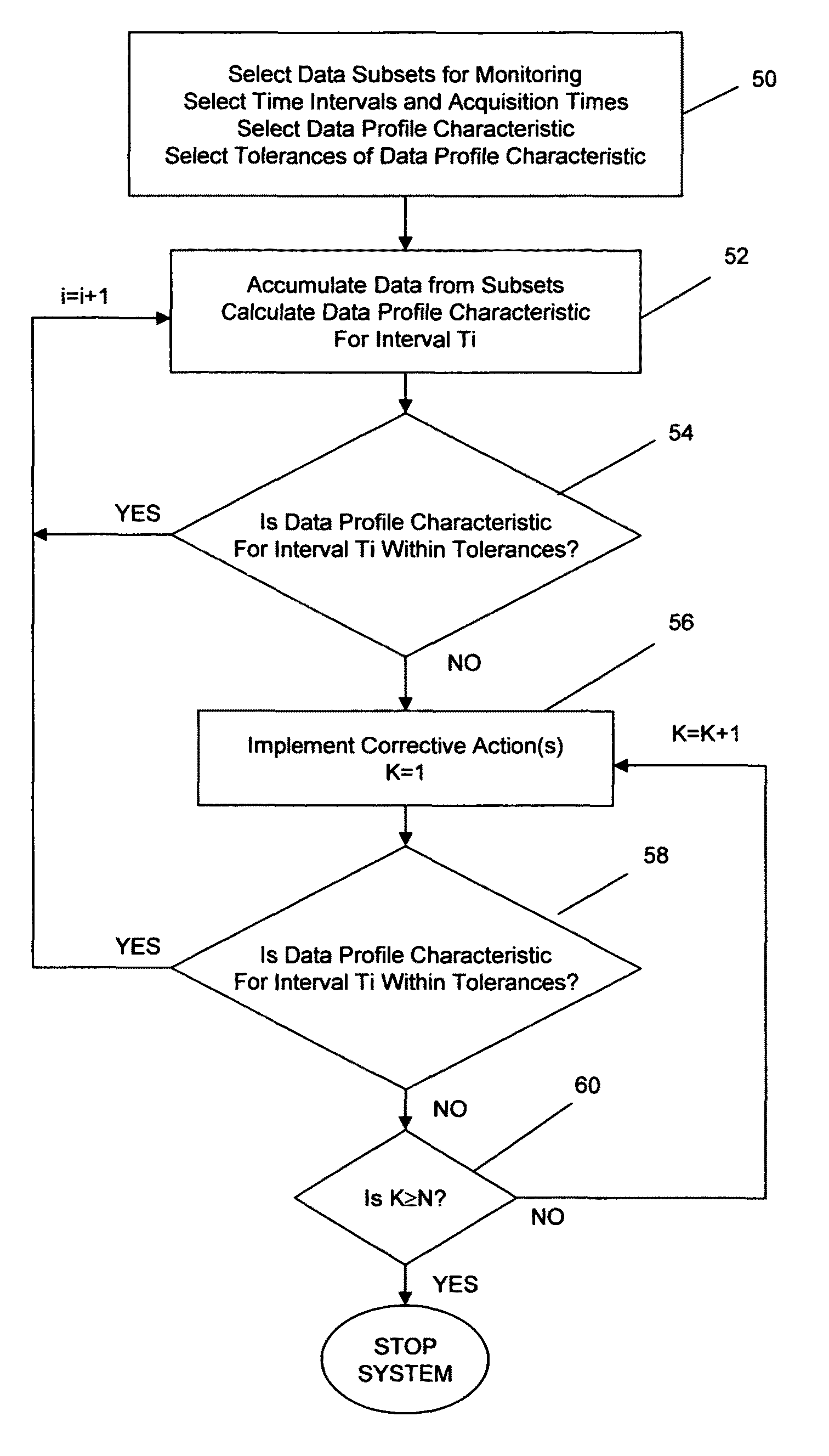

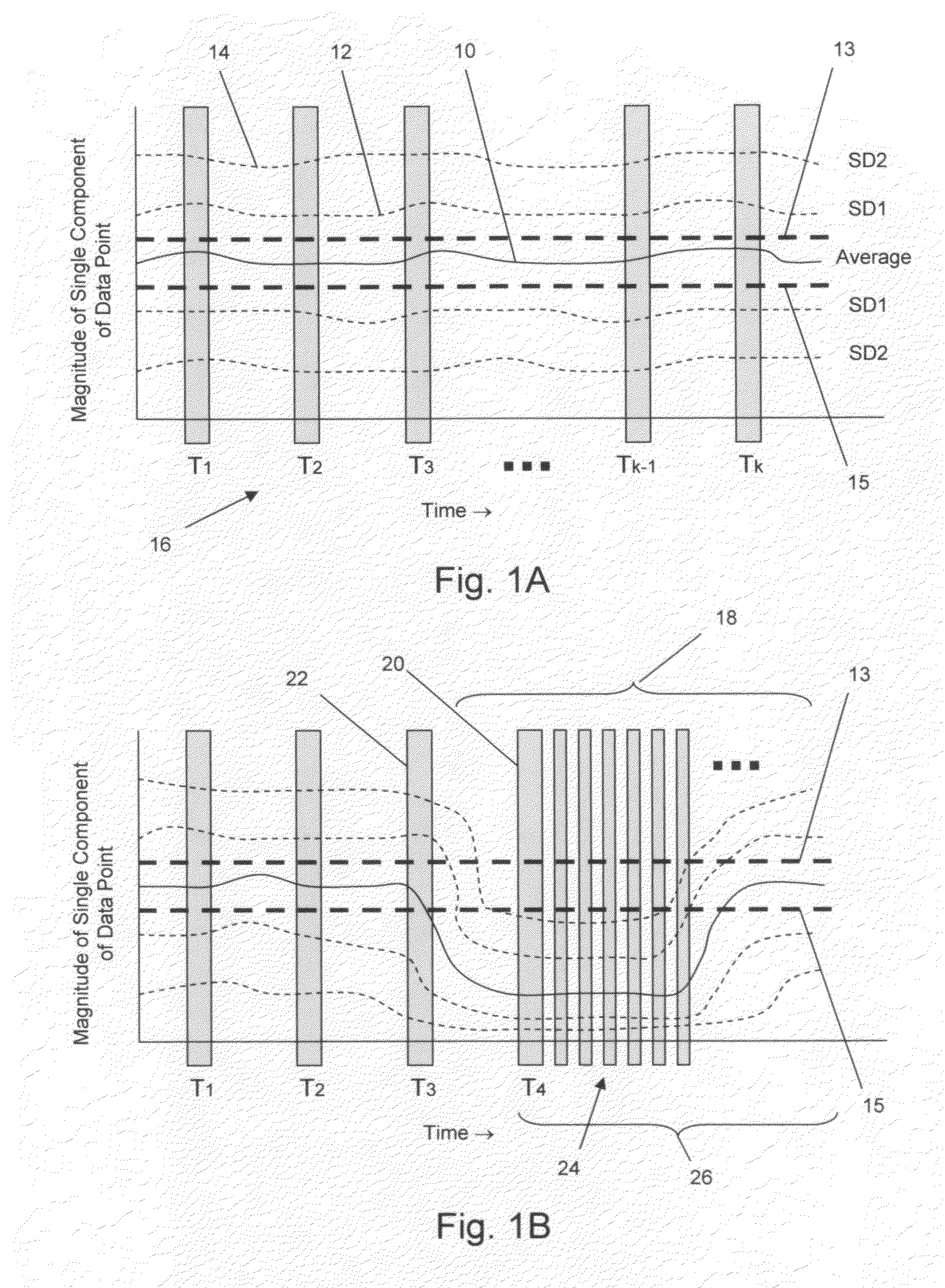

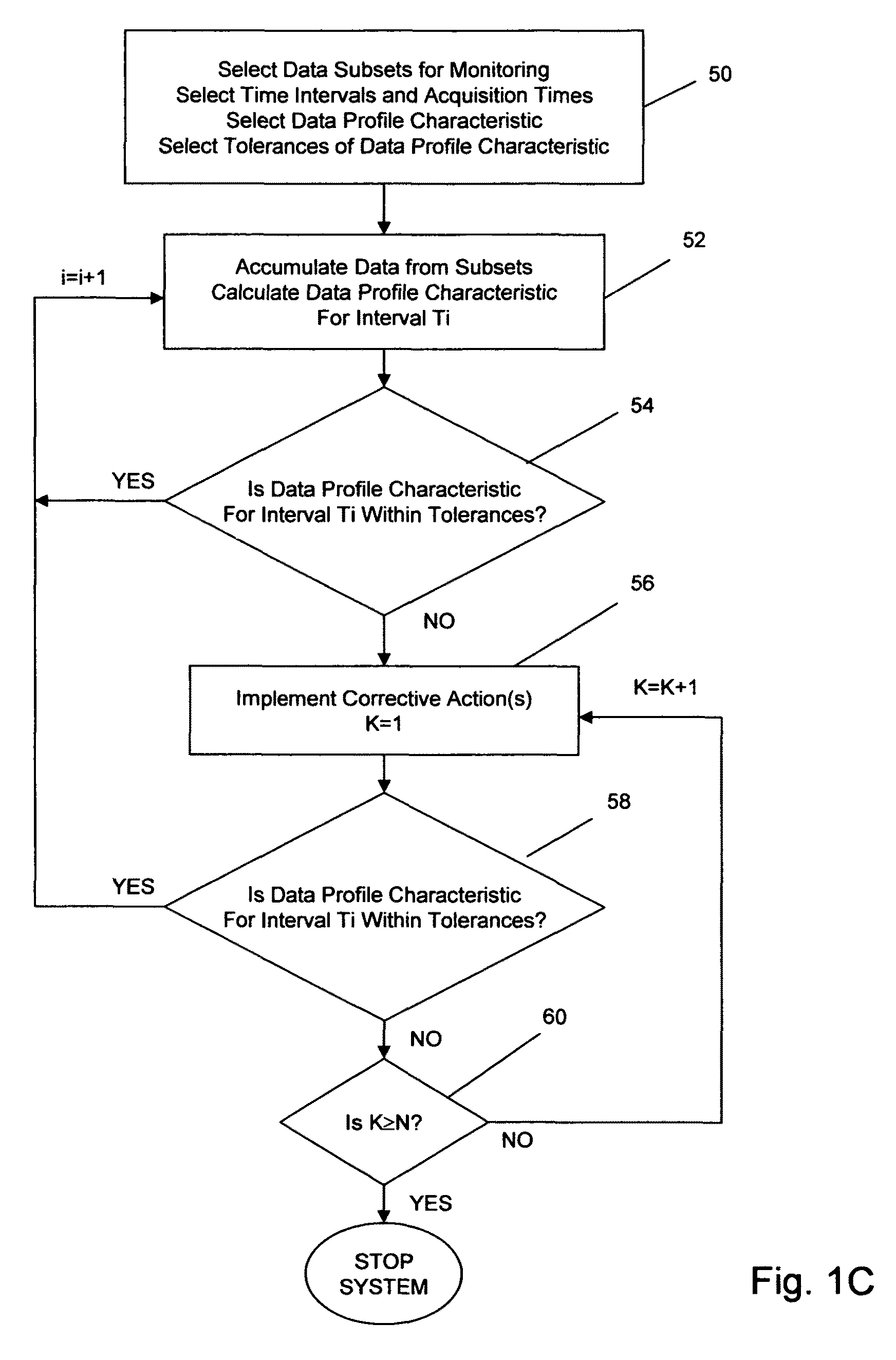

High throughput flow cytometer operation with data quality assessment and control

ActiveUS8140300B2Digital data processing detailsVolume/mass flow measurementParticle sortingData acquisition

The invention provides a flow system and method for reliable multiparameter data acquisition and particle sorting. In accordance with the invention, a flow system assesses changes in the pattern of data collected in successive time intervals and actuates one or more corrective actions whenever the changes exceed predetermined limits. The present invention overcomes problems associated with collecting data and sorting and enumerating particles in flow cytometry systems that operate for prolonged periods or that must accommodate samples that vary widely in quality.

Owner:BECTON DICKINSON & CO

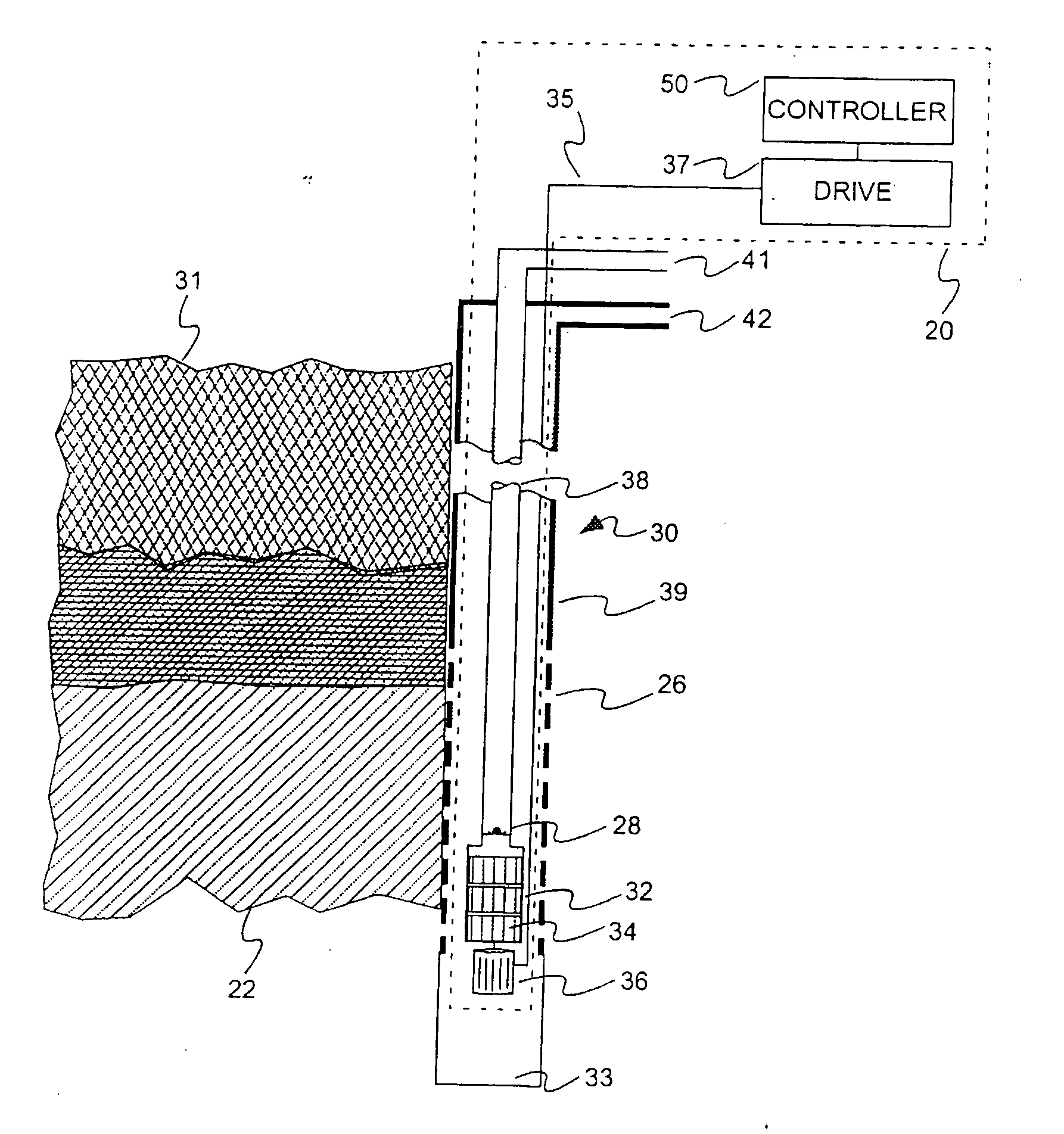

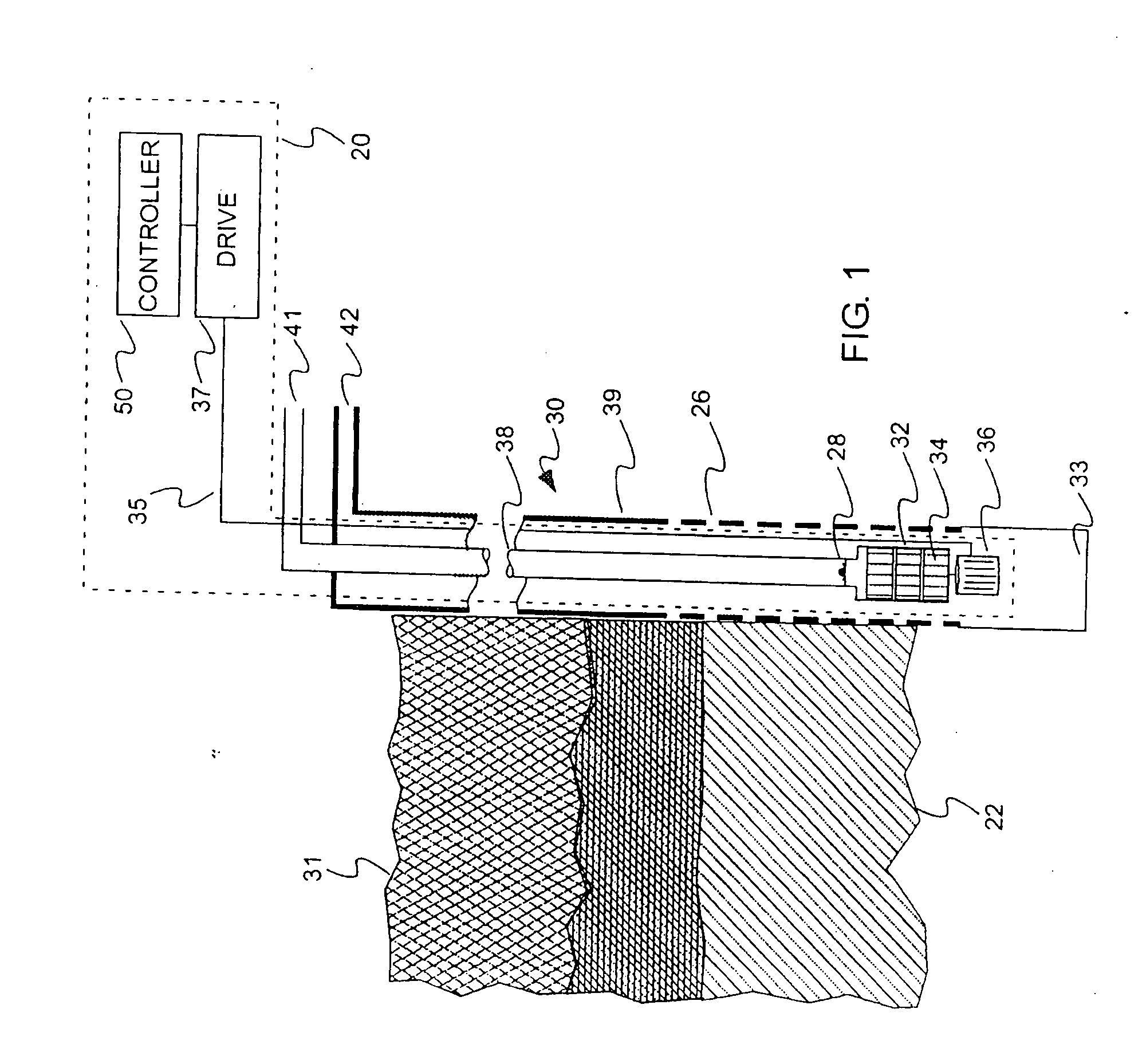

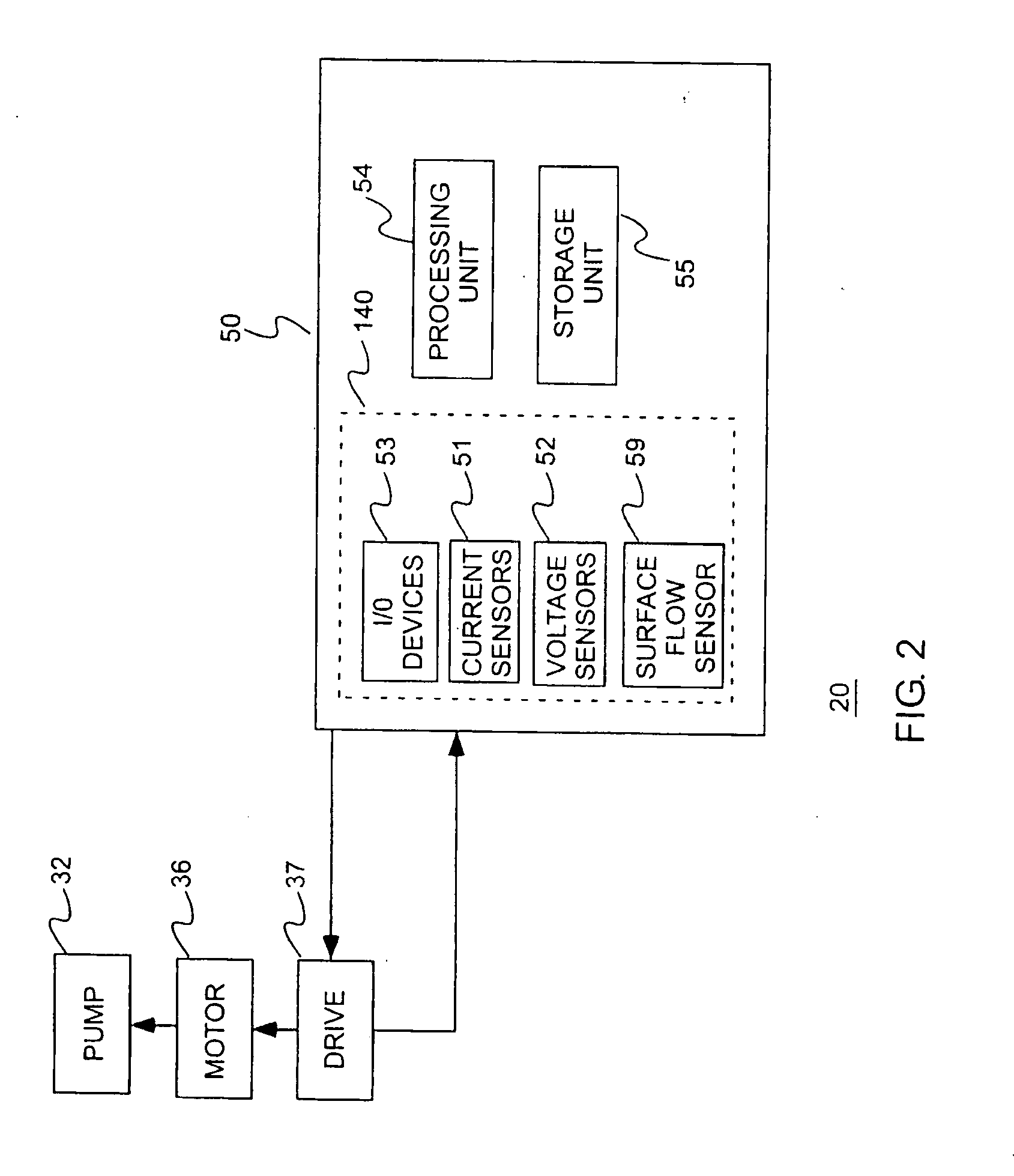

Determination And Control Of Wellbore Fluid Level, Output Flow, And Desired Pump Operating Speed, Using A Control System For A Centrifugal Pump Disposed Within The Wellbore

ActiveUS20080067116A1Enhance market appealBroad possible marketLevel controlWind motor controlEngineeringSystem parameters

A method and apparatus for determining a fluid level and / or output flow during operation of a centrifugal pump, are provided, which may be used for production of gas and / or oil from a well, and include a vector feedback model to derive values of torque and speed from signals indicative of instantaneous current and voltage drawn by the pump motor, a pump model which derives values of the fluid flow rate and the head pressure for the pump from torque and speed inputs, a pumping system model that derives, from the estimated values of the pump operating parameters, an estimated value of fluid level and other pumping system parameters. Controllers responsive to the estimated values of the pumping system parameters control the pump to maintain fluid level at the pump input, near an optimum level, or within a safe operating range and / or output flow from the pump.

Owner:UNICO LLC

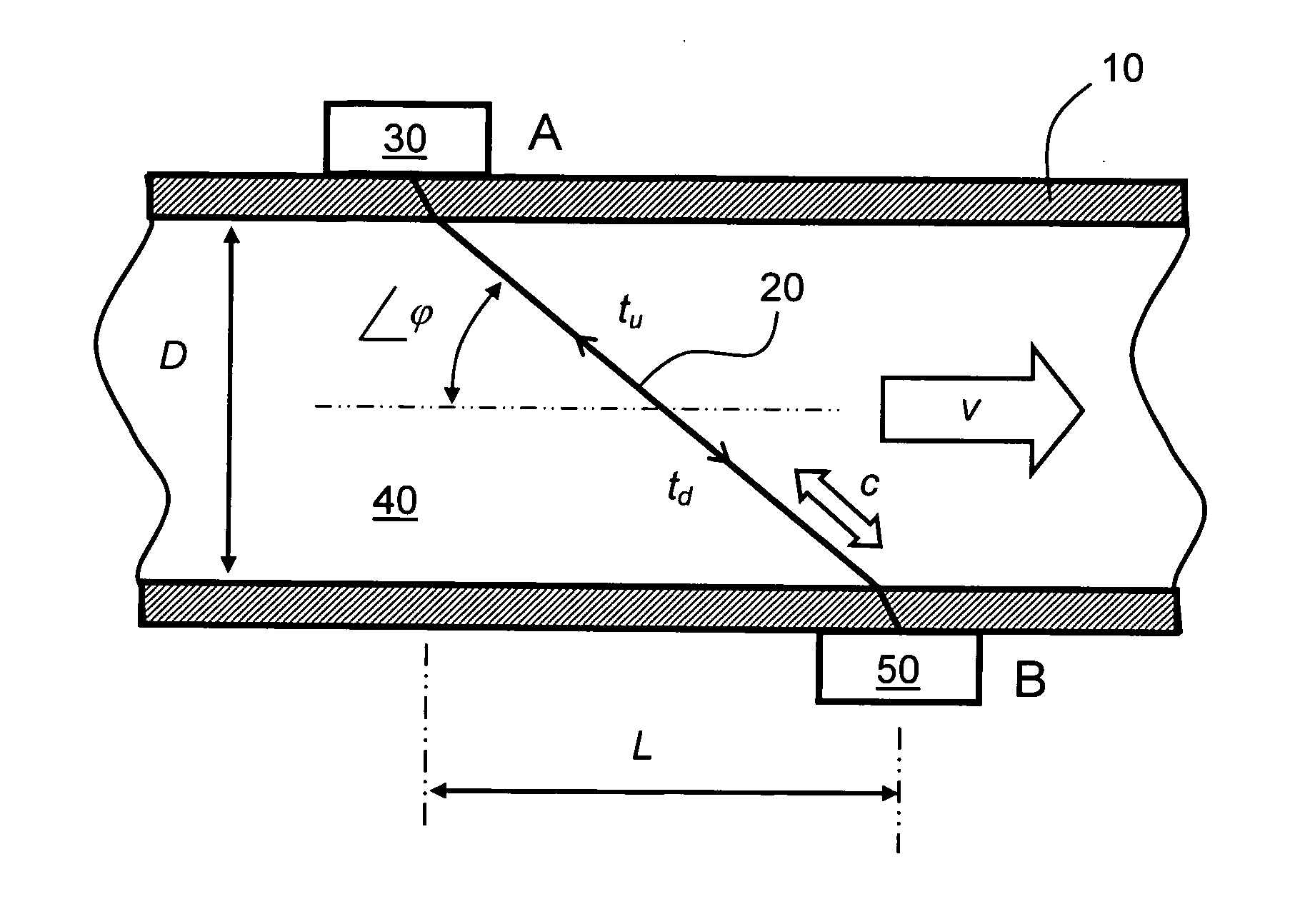

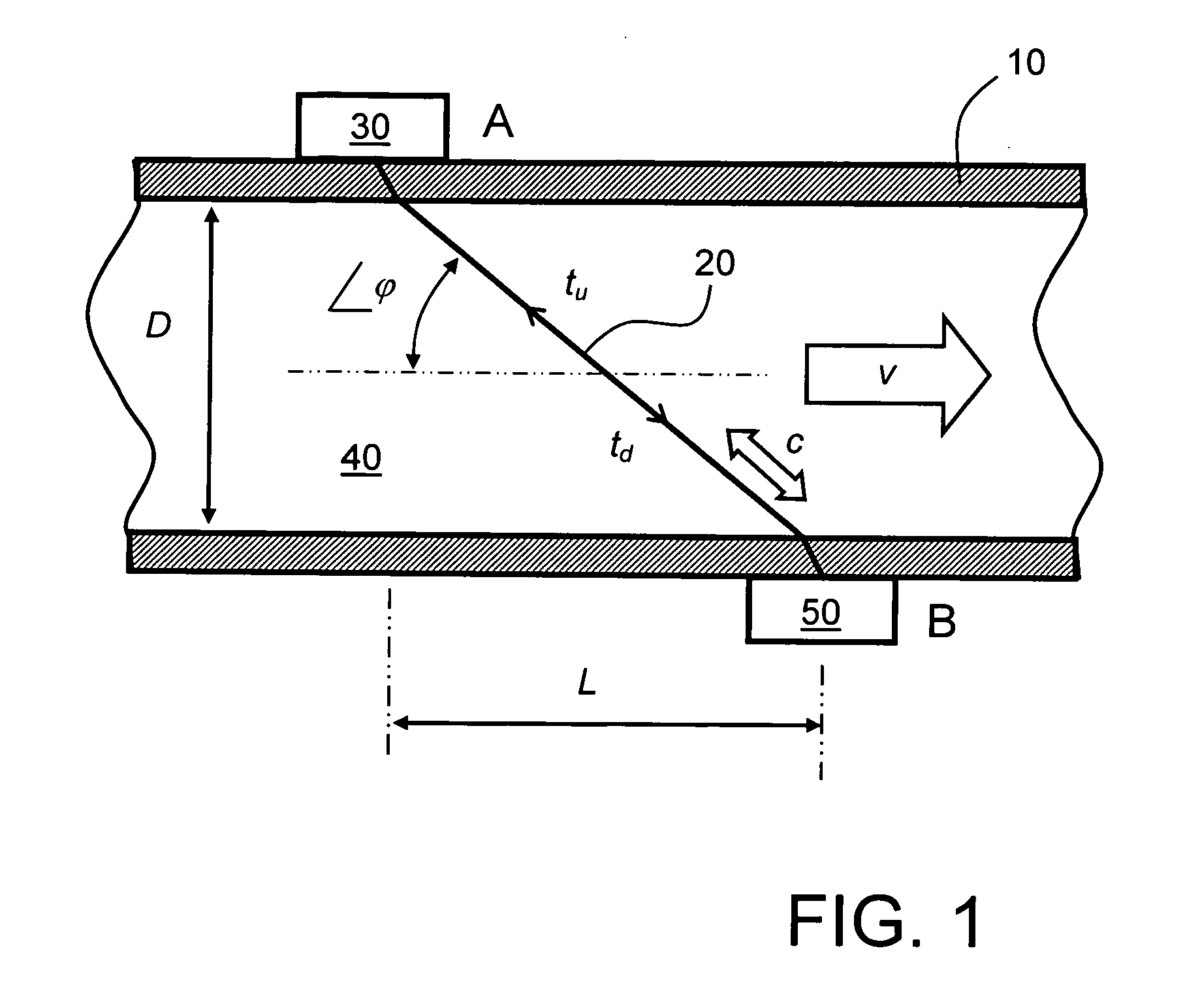

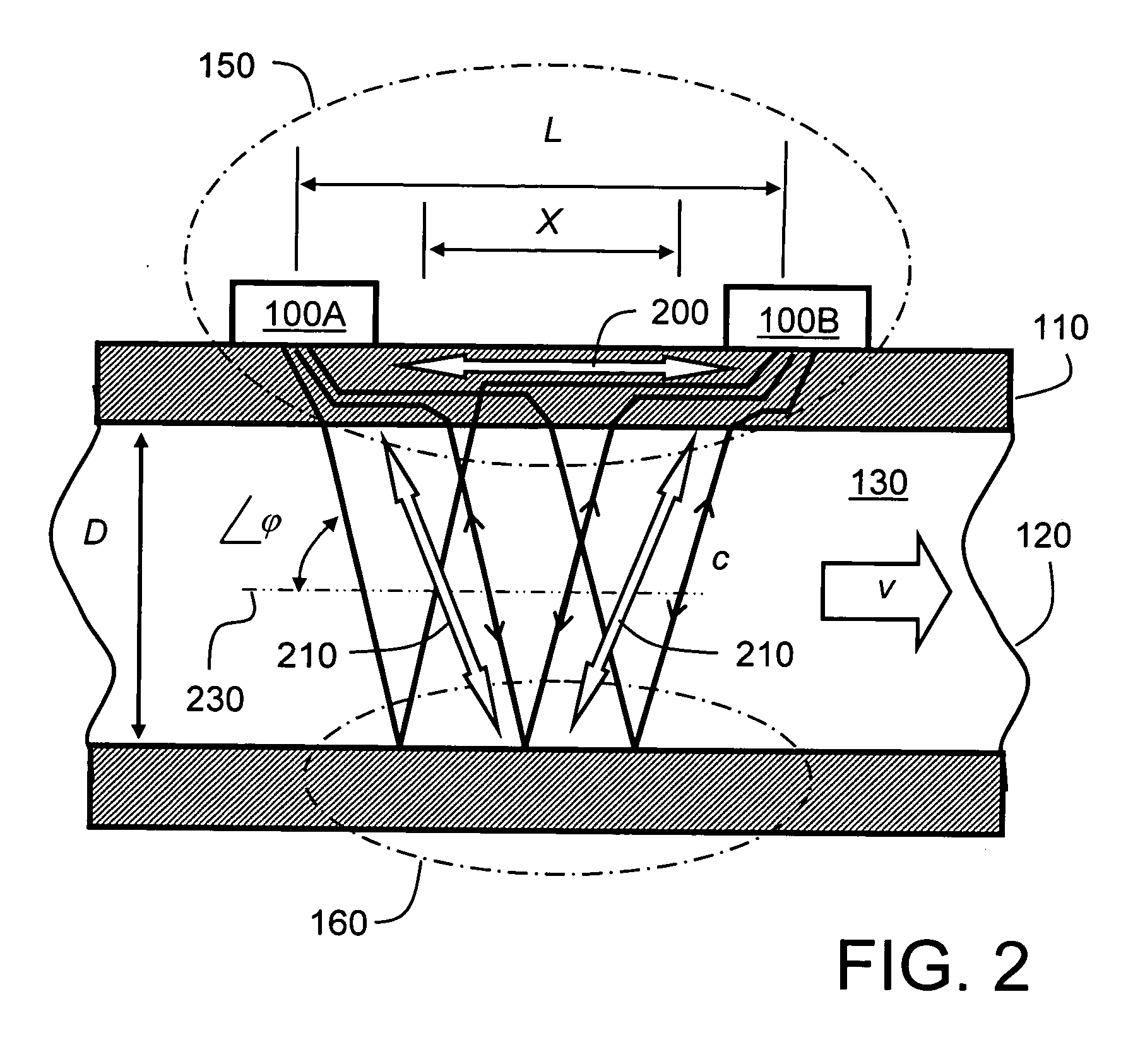

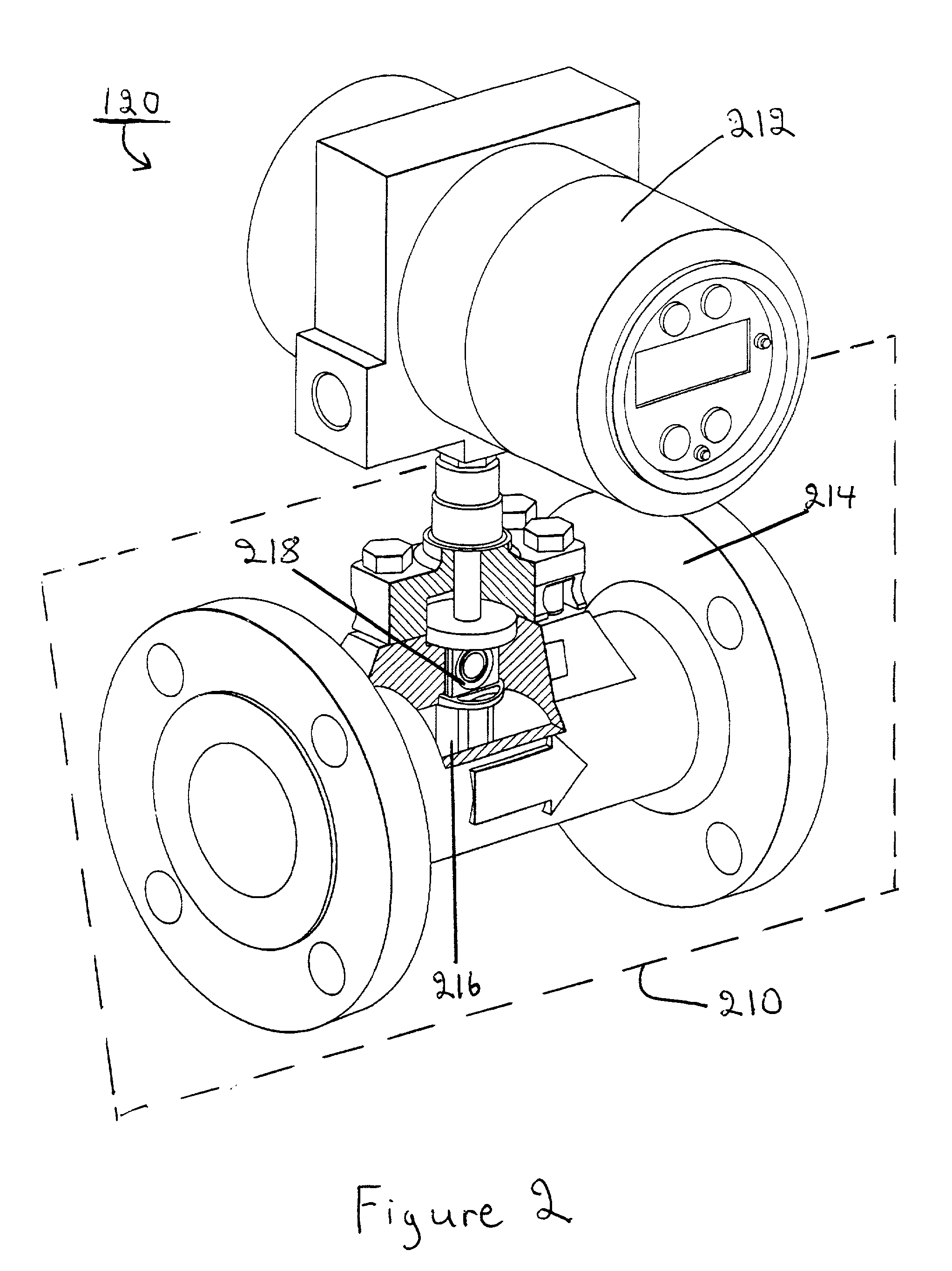

Flow measuring apparatus

ActiveUS20110271769A1Reliable and accurate measurementImprove energy transferFlow propertiesVolume flow measuring devicesPropagation timeUltrasonic radiation

A flow measuring apparatus (300, 500) measures a fluid flow (130) within a conduit (120) including a wall (110). The apparatus (300, 500) includes a transducer arrangement including at least two transducers (100A, 100B) for alternately emitting and receiving ultrasonic radiation through the conduit wall (110) and the flow (130). The apparatus (300, 500) also includes a signal processing arrangement (310) for generating signals to excite the transducer arrangement (100A, 100B) and for processing received signals provided by the transducer arrangement (100A, 100B) for generating output signals from the signal processing arrangement (310) indicative of properties of the flow. The transducer arrangement (100A, 100B) in cooperation with the conduit (120) provides a first path (200) for Lamb-wave ultrasonic radiation coupling directly from a first of the at least two transducers (100A, 100B), to a second of said at least two transducers to generate a first received signal. The transducer arrangement (100A, 100B) in cooperation with the conduit (120) provides at least one second path (210) for ultrasonic propagation along the wall (100) via Lamb waves coupling to at least a portion of the flow (130) from a first of the at least two transducers (100A, 100B) to a second of the at least two transducers (100A, 100B) to generate a second received signal. The signal processing arrangement (310) determines from said first and second received signals ultrasonic radiation propagation time periods through the first path (200) and through the at least one second path (210), and to perform computational operations on the propagation time periods to determine properties of the flow including, but not limited to, at least one of: fluid flow velocity (v) in the conduit (120), a sound velocity (c) through the fluid (130).

Owner:XSENS

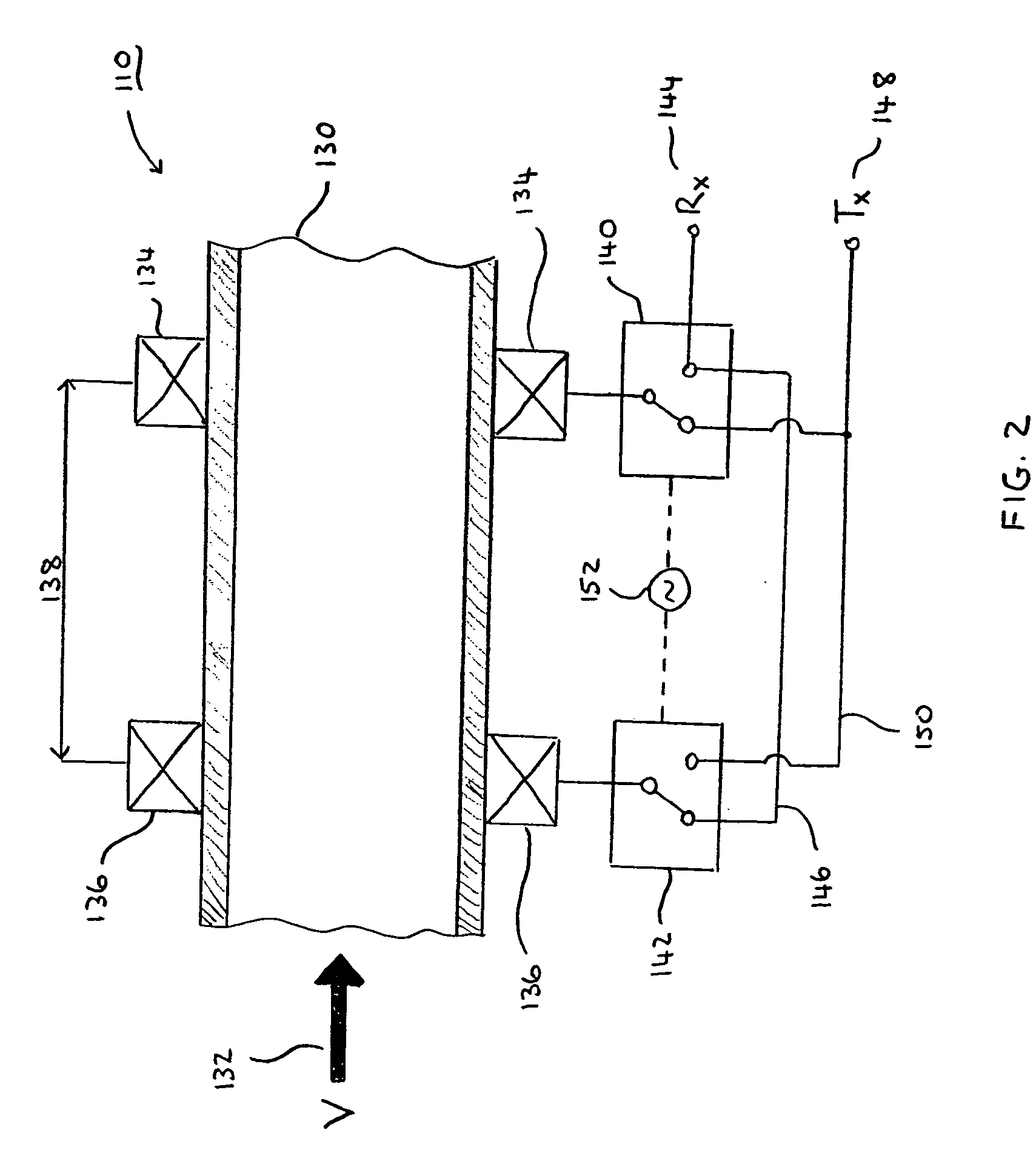

Methods and apparatus for using water use signatures and water pressure in improving water use efficiency

InactiveUS7330796B2Measurement of fluid loss/gain rateGeneral water supply conservationBaseline dataWater use

A method to identify a water flow anomaly in a system having first and second water using devices to generate baseline data that preferably has water use signatures and corresponding water pressure information regarding the water using devices; comparing the baseline data with actual water usage signatures and corresponding actual water pressure information to identify a flow anomaly with the water using devices; and providing information on the flow anomaly to an individual. It is especially contemplated that baseline data are generated for multiple devices coupled to a common water supply system, with baseline data from two or more water using devices compared against future water use patterns of the same devices. Apparatus to accomplish these tasks is preferably housed in an irrigation controller, which may be advantageously coupled to a flow meter.

Owner:AQUA CONSERVATION SYST

Ultrasonic liquid flow controller

ActiveUS20050288873A1Operating means/releasing devices for valvesFlow propertiesTime domainSonification

An ultrasonic flow meter includes a conduit, a first ultrasonic transducer, a second ultrasonic transducer, and a controller. The first ultrasonic transducer is disposed at a first position about a first portion of the conduit to transmit a first ultrasonic signal and to receive a second ultrasonic signal. The second ultrasonic transducer is disposed at a second position about a second portion of the conduit that is spaced apart from the first position along a length of the conduit to transmit the second ultrasonic signal and to receive the first ultrasonic signal. The controller is configured to cross-correlate the first and second received ultrasonic signals and generate a resulting time-domain signal, analyze the resulting time-domain signal to determine a difference in transit time between the first and second received ultrasonic signals, and calculate a rate of flow of a fluid in the conduit based upon the determined difference.

Owner:BROOKS INSTRUMENT

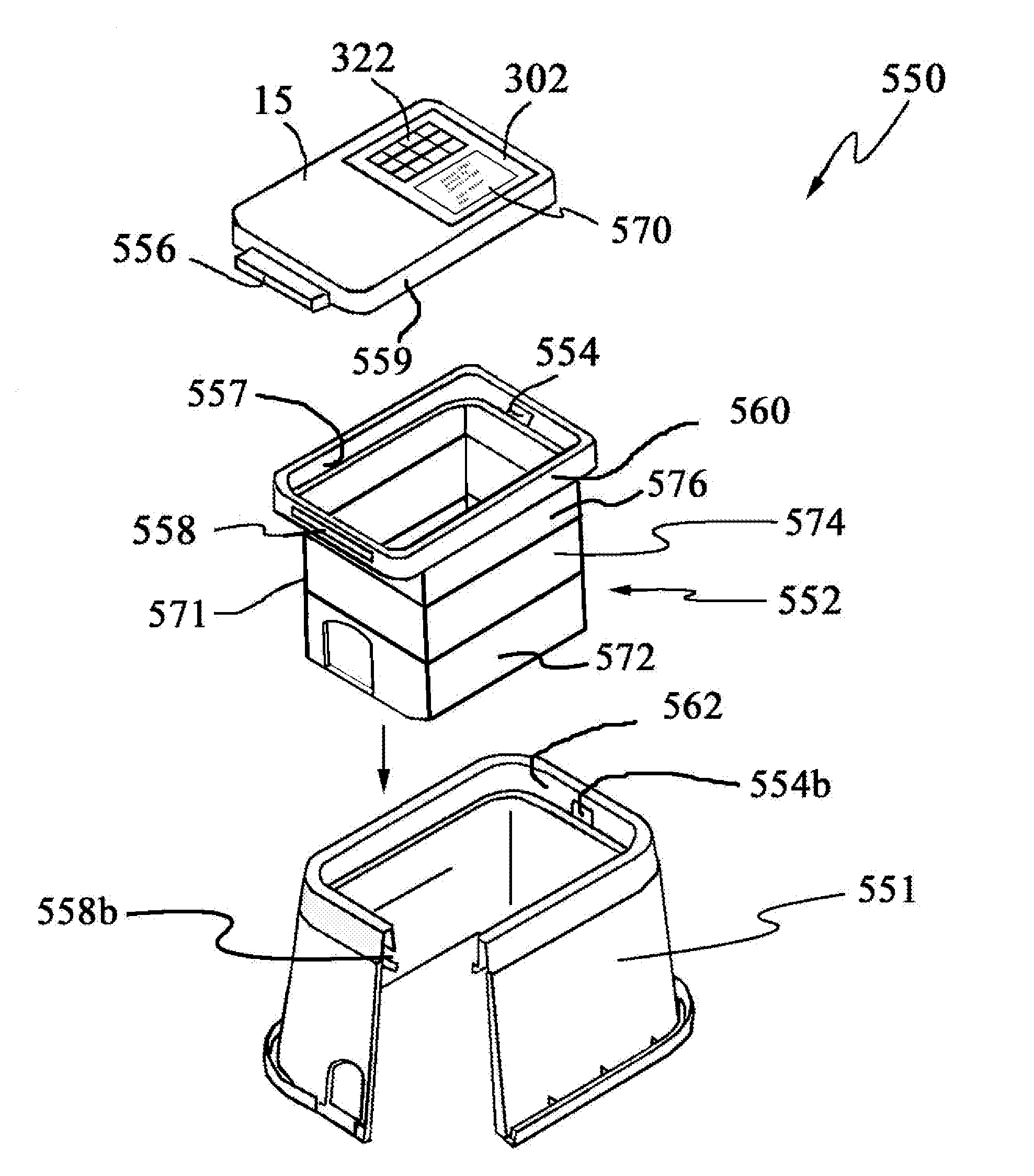

Configurable Smart Utility Meter Box

InactiveUS20080150750A1Avoid flowElectric signal transmission systemsMeasurement apparatus componentsEngineeringSmart meter

The invention relates to a meter box for housing a utility meter and configured for associating a customer service line to a utility service line. The meter box may be configured to fit within an existing meter box and may be configured with side sections in a telescopic arrangement. Flow control components at an input of the meter box prevent backflow.The meter box comprises an electronic module that includes a variety of selectable features including datalogging, AMR, environmental monitoring, and resource monitoring. A remote monitor is provided for allowing a customer to view selected data including consumption data, pressure, pH, temperature, warnings, remote turnoff, and provide secured bill paying services. Imaging / audio components provide visual and audio data which may include an image of an analog readout for a meter register, images of the metering environment, and sound data for metering environment.

Owner:PARRIS EARL H +1

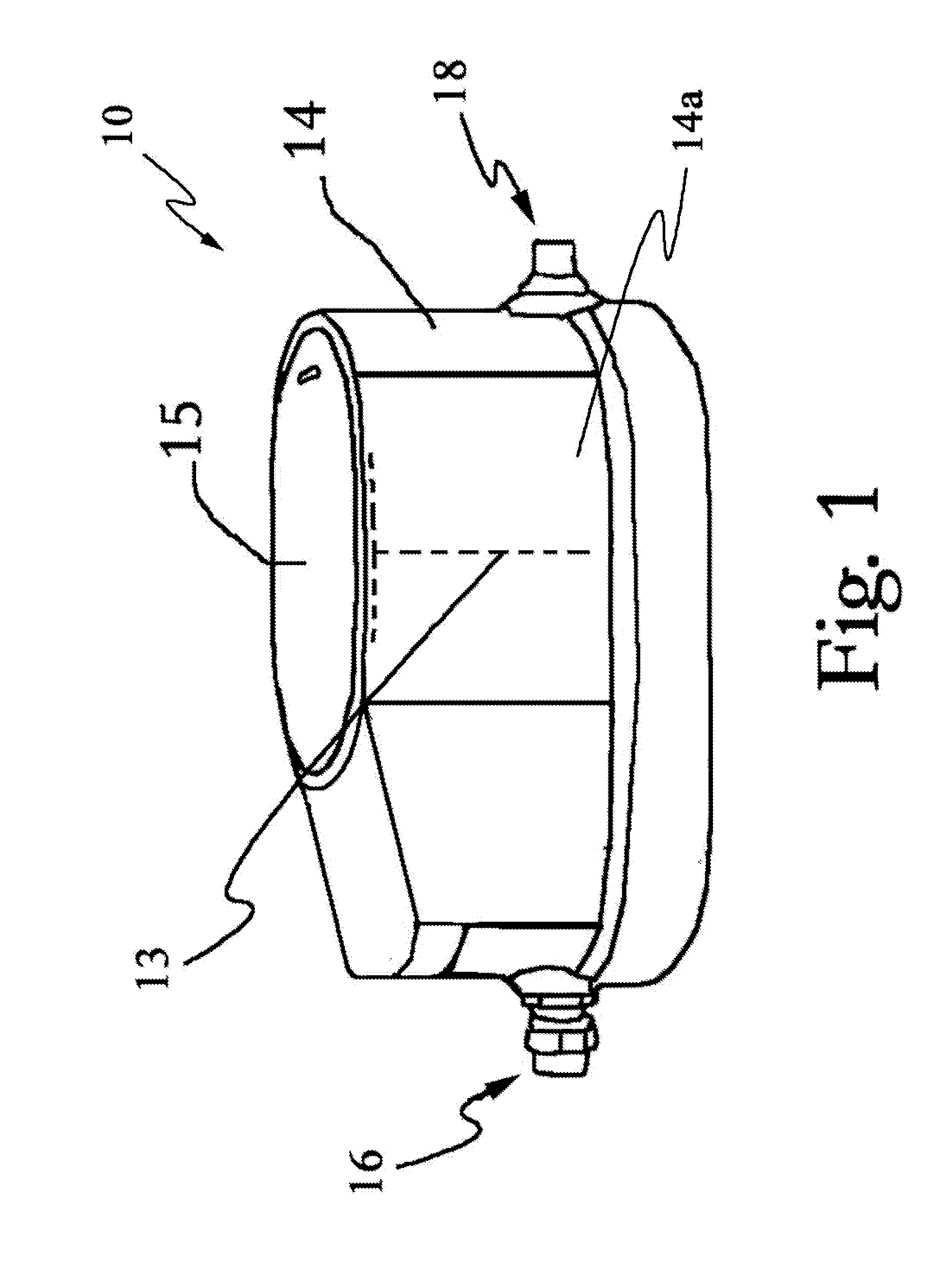

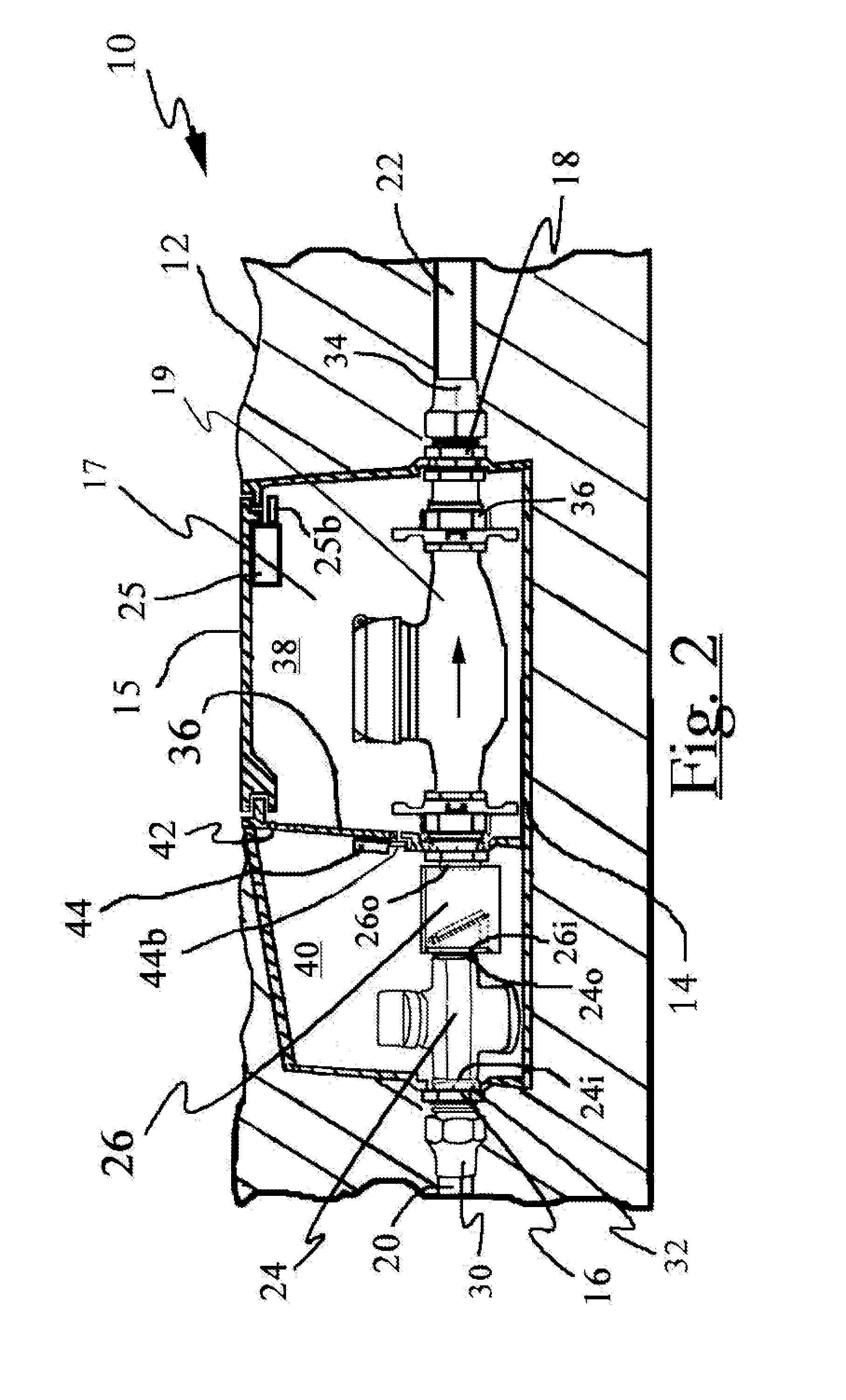

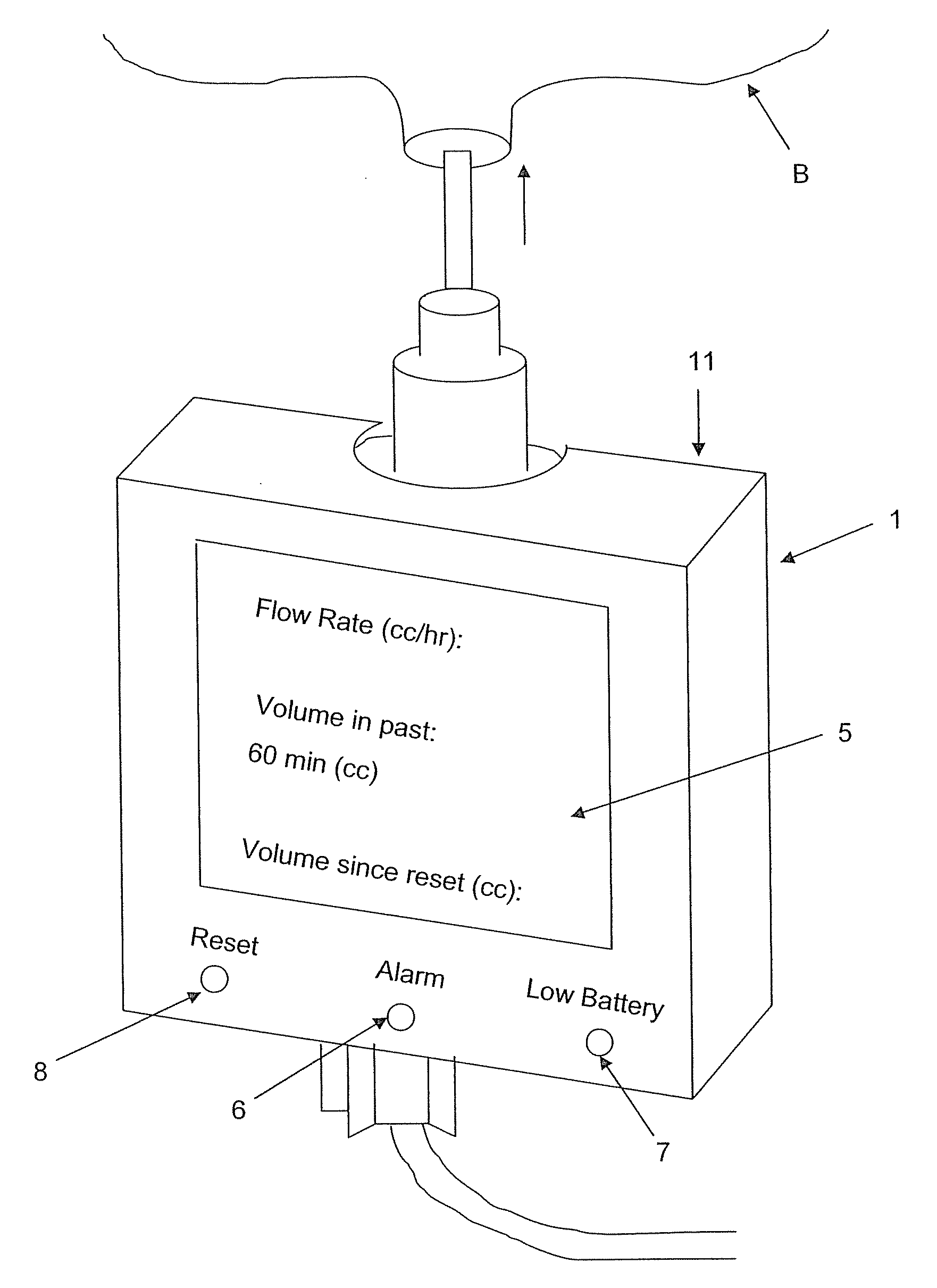

Automated intravenous monitoring device

InactiveUS20100309005A1Drug and medicationsVolume/mass flow measurementDisplay deviceComputer science

An automated intravenous (IV) monitoring device is provided comprising a sensor for sensing drips passing through an IV drip chamber, a processing unit for calculating the total infused volume over a predetermined period of time, and a display for displaying the total infused volume. The IV monitoring device preferably also calculates and displays the flow rate of the drips. Additionally, an alarm can be activated if the flow rate drops below a predetermined value. A method of providing data pertaining to IV drips being infused into a body is also disclosed.

Owner:WARNER TOD H +1

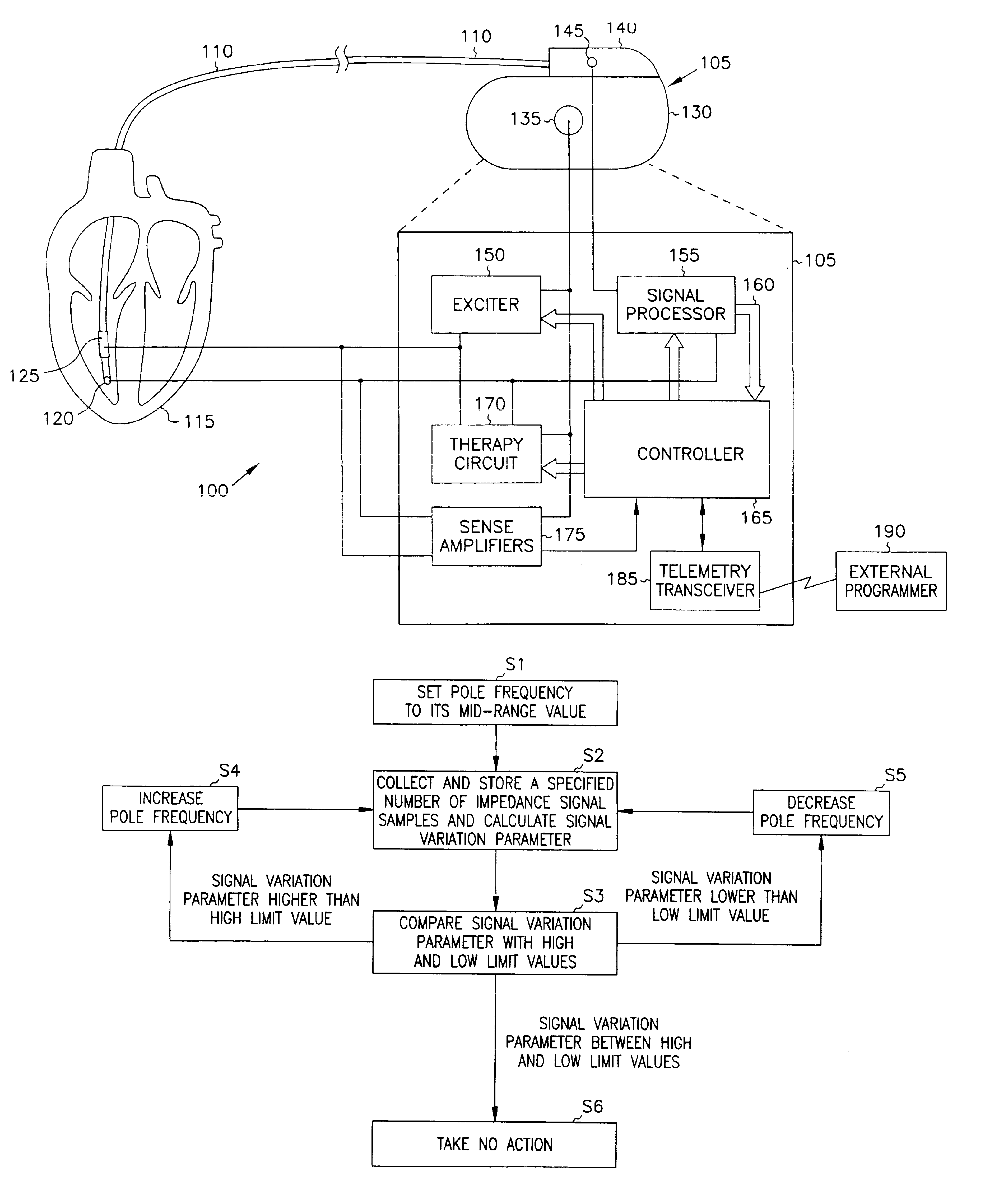

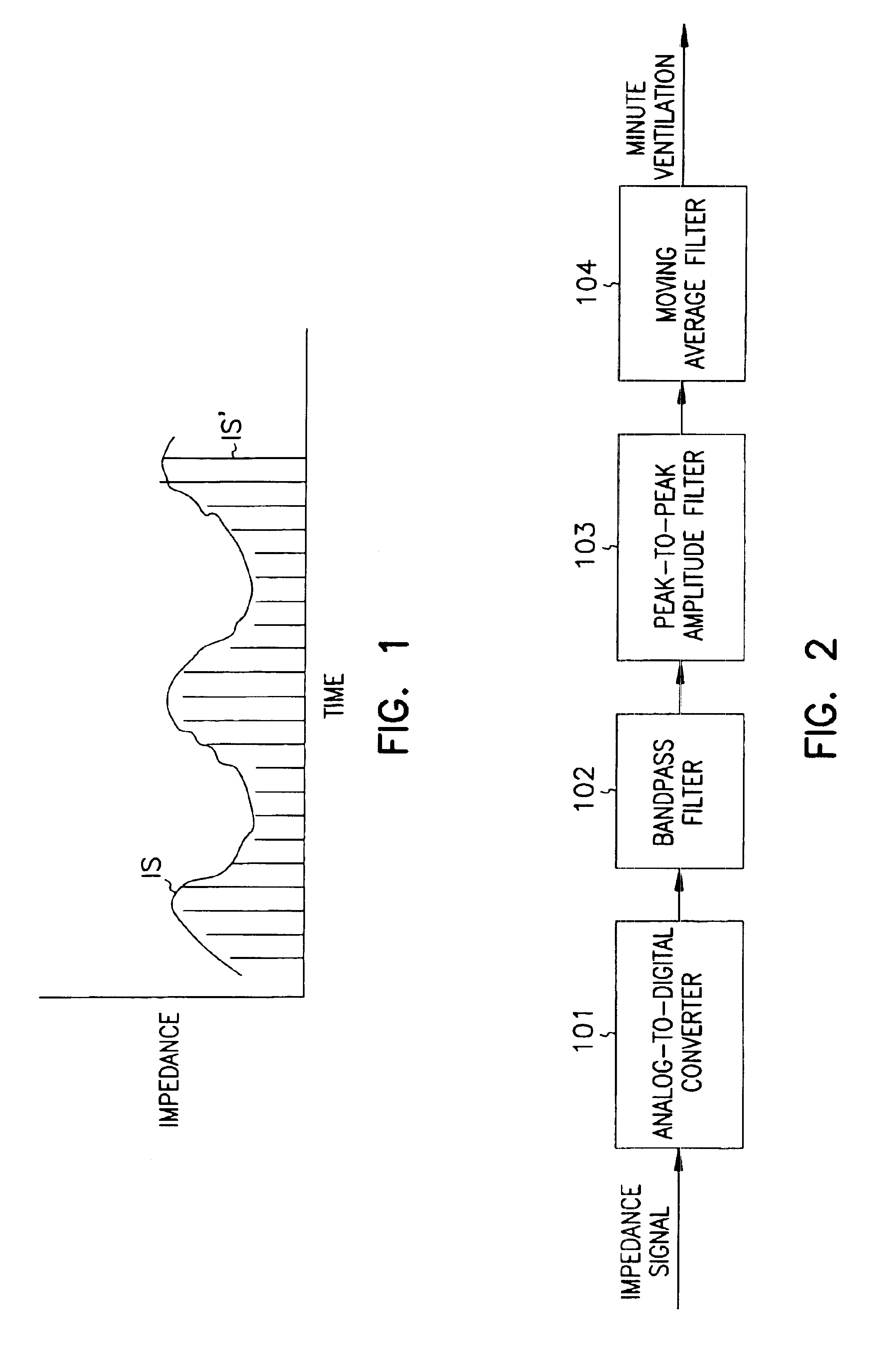

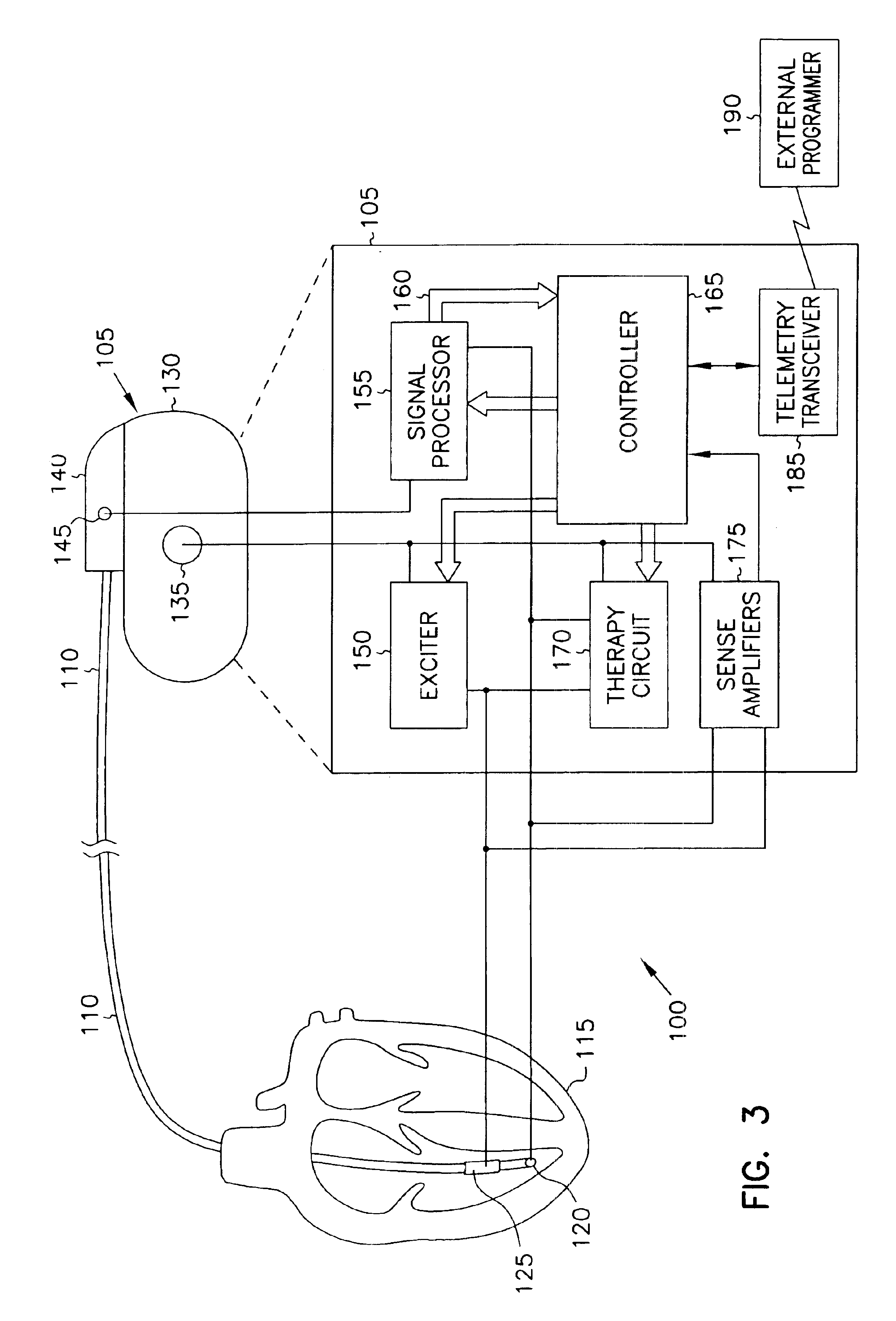

Minute ventilation sensor with automatic high pass filter adjustment

A minute ventilation sensing device in which transthoracic impedance is measured to generate an impedance signal from which a ventilation signal is derived, where the ventilation signal is proportional to minute ventilation. An adaptive high pass filter is used to filter the impedance signal into a ventilation band. The pole frequency of the high pass filter is adjusted in accordance with changes in a calculated signal variation parameter.

Owner:CARDIAC PACEMAKERS INC

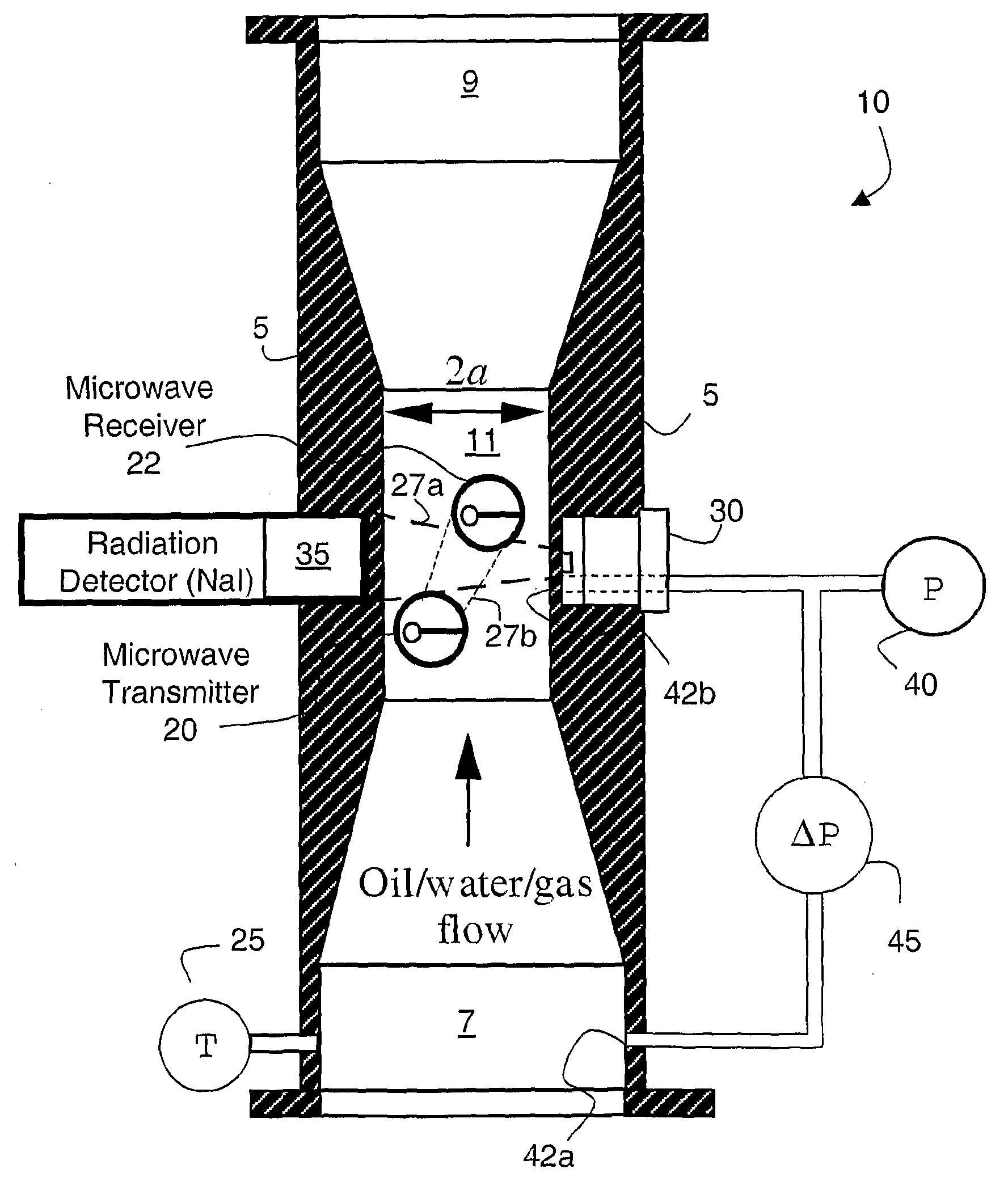

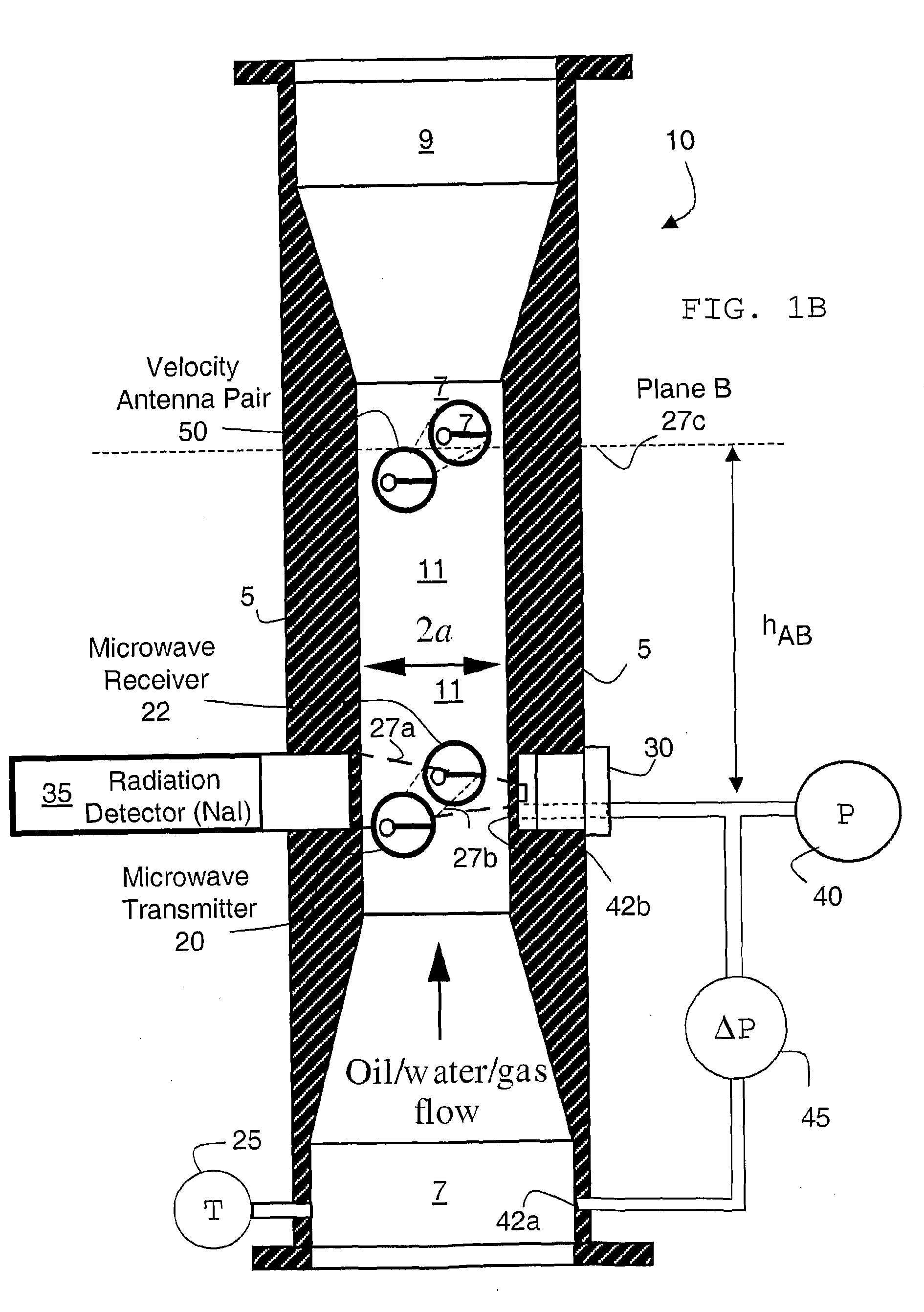

Systems and Methods For Measuring Multiphase Flow in a Hydrocarbon Transporting Pipeline

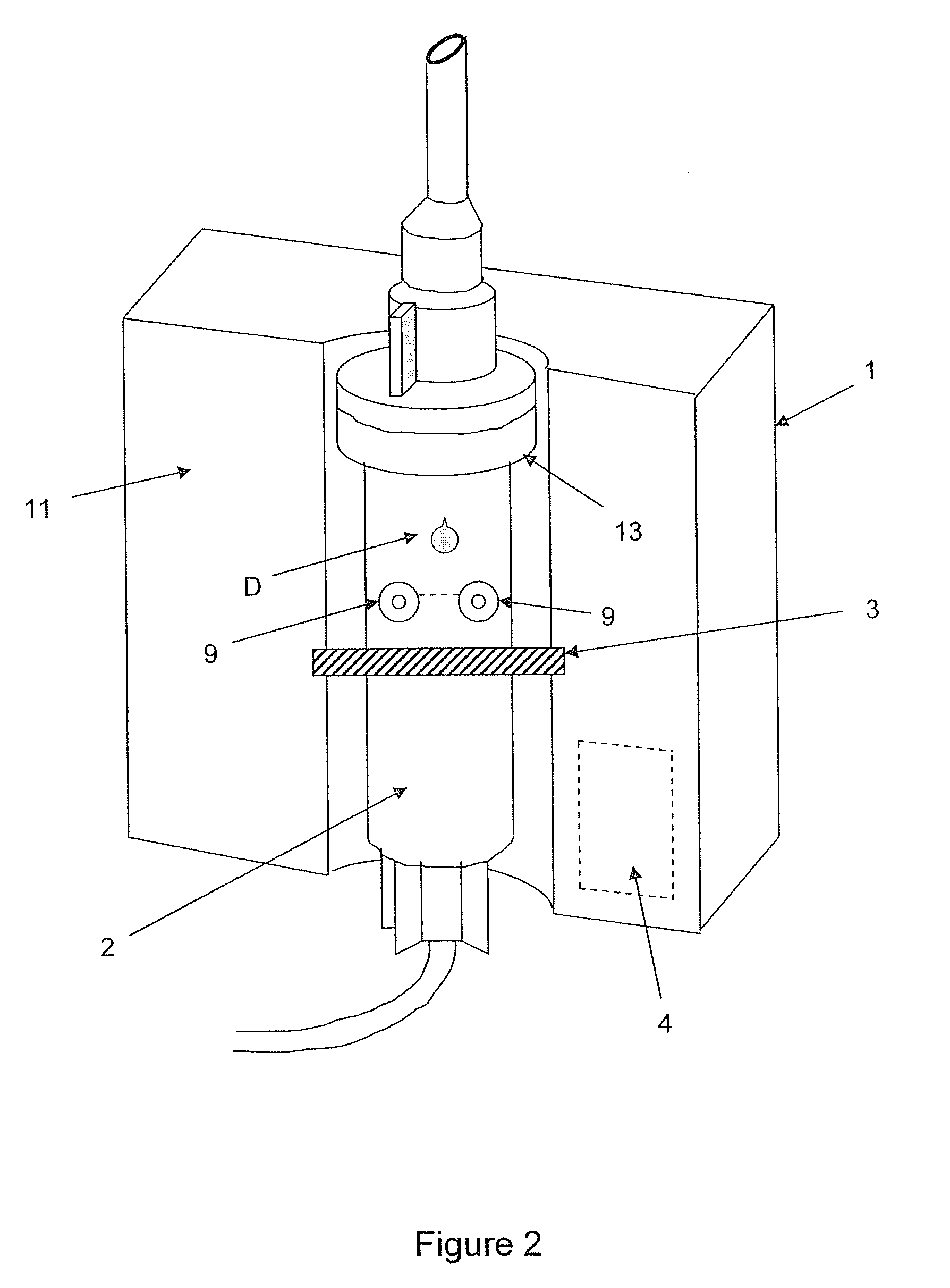

ActiveUS20080319685A1Material analysis using microwave meansMaterial testing goodsLow activityPressure difference

This disclosure relates in general to methods and systems for measuring multiphase flows in a pipeline using a combination of venturi, microwave and radiation techniques, where the pipeline is configured to transport hydrocarbons. More specifically, but not by way of limitation, certain embodiments of the present invention provide methods and systems in which low activity radiation sources may be used in combination with one or more microwave transmitter-receiver pairs and pressure differential sensors to measure the flow rates and fractions of phases in multiphase flows in a pipeline, such as may be encountered in producing hydrocarbon wells. Additionally, other embodiments of the present invention provide for the arrangement of one or more microwave transmitter-receiver pairs, one or more radiation source-detector pairs and / or one or more pressure sensor ports in the same cross-section of the throat of a venturi to measure multiphase flow in a hydrocarbon transporting pipeline.

Owner:SCHLUMBERGER TECH CORP

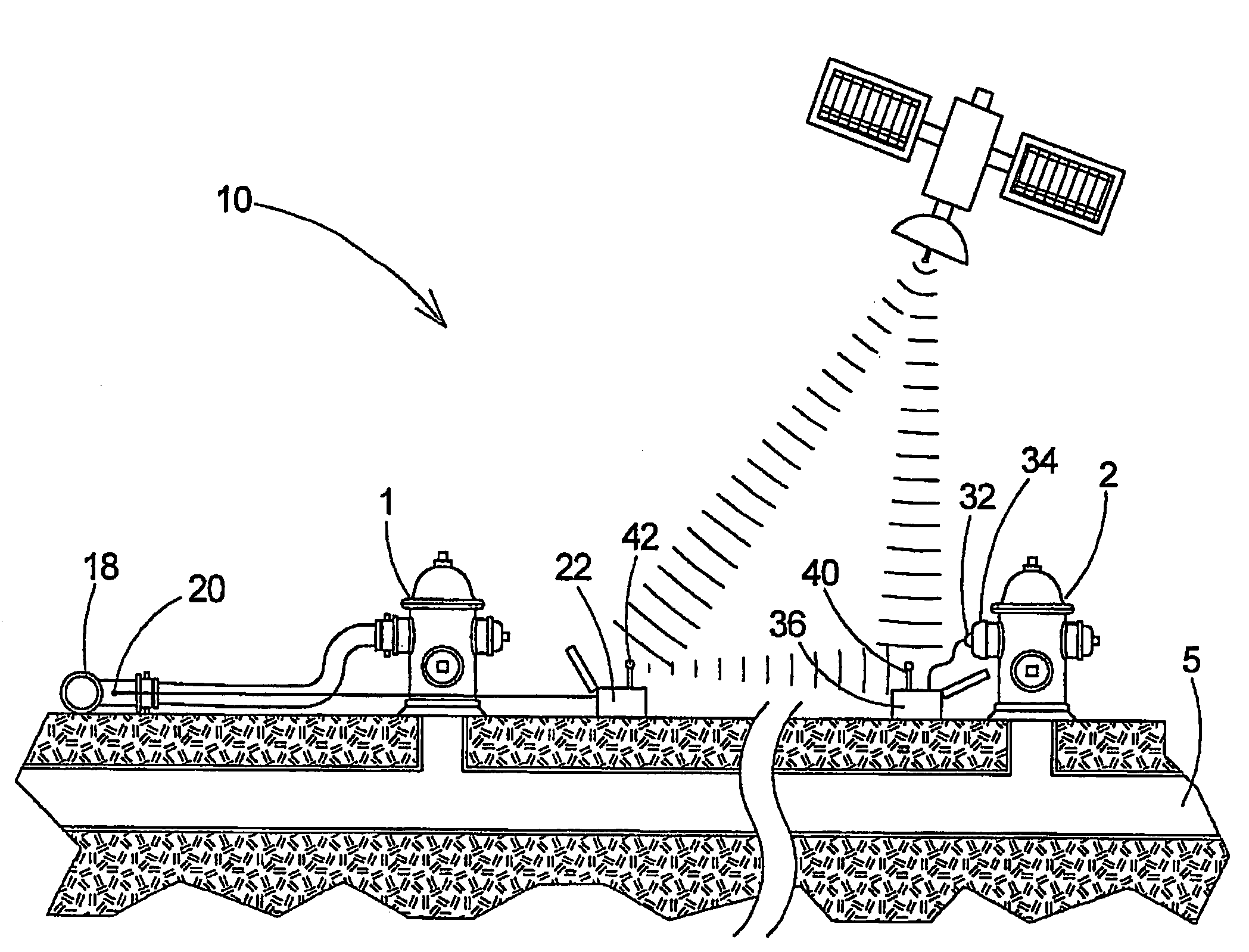

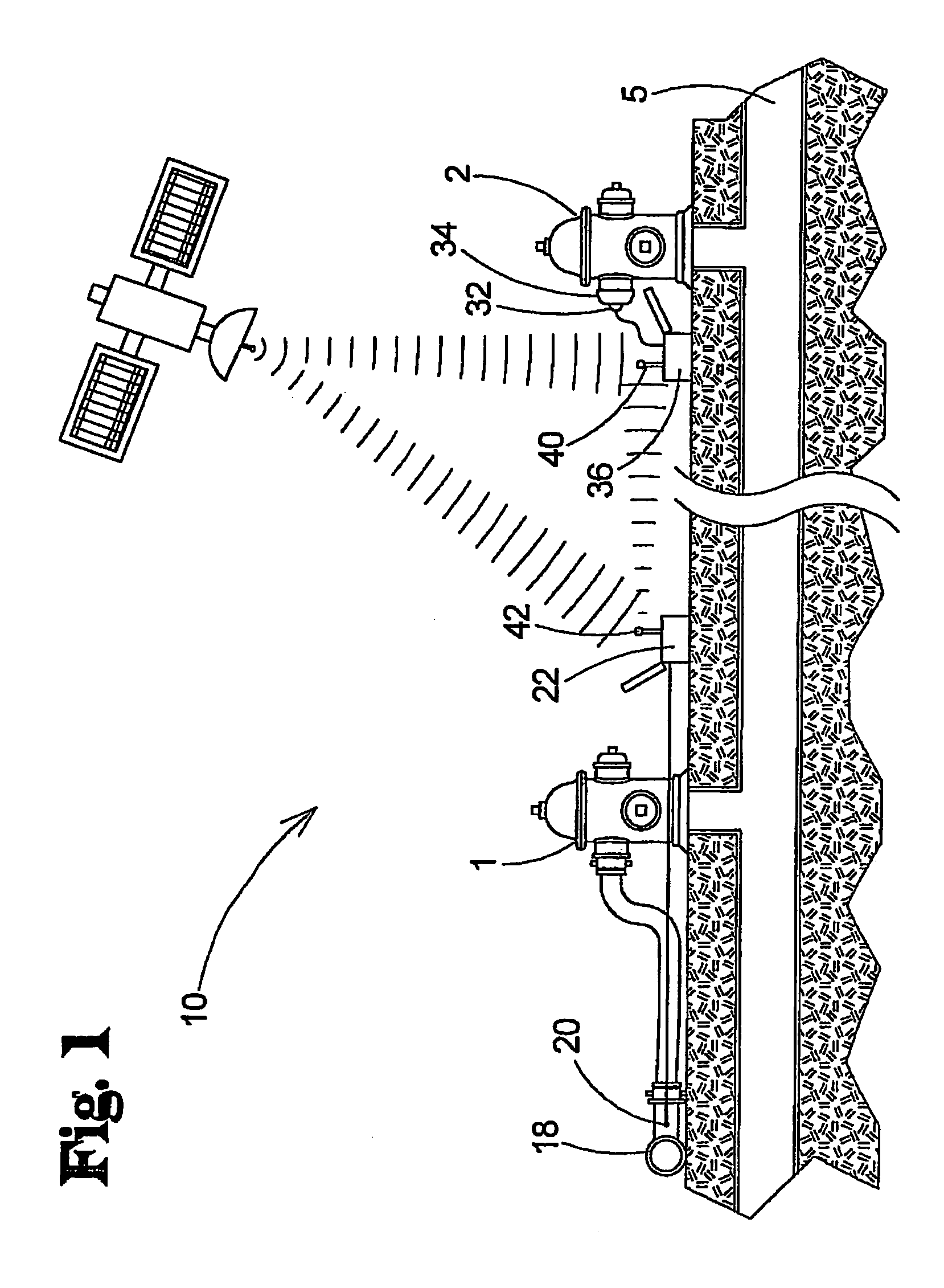

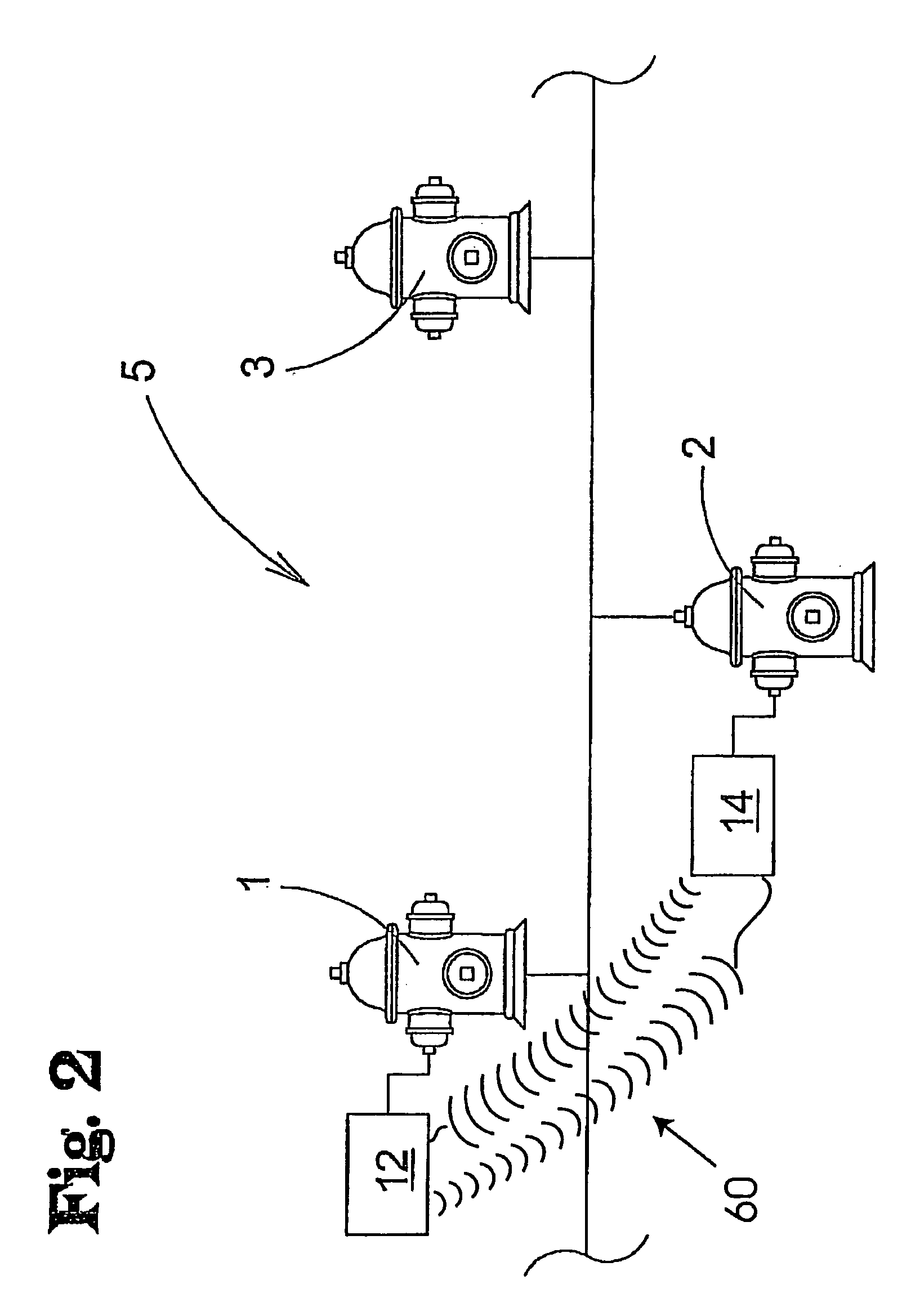

Flow testing system for fluid networks

ActiveUS20080281534A1Way accurateEasy to useVehicle testingAerodynamic testingEngineeringData transmission

An apparatus, system, method and kit for testing fluid flow and pressure is provided. The apparatus, system, method and kit include or include the use of a flow unit which is configured to measure flow rate and / or flow velocity when interfaced with a flow valve or hydrant and a pressure unit configured to measure at least residual pressure when interfaced with a test valve or hydrant. At least one of the units is configured to wirelessly send data transmissions to the other unit which is configured to receive such transmissions.

Owner:HURCO TECH

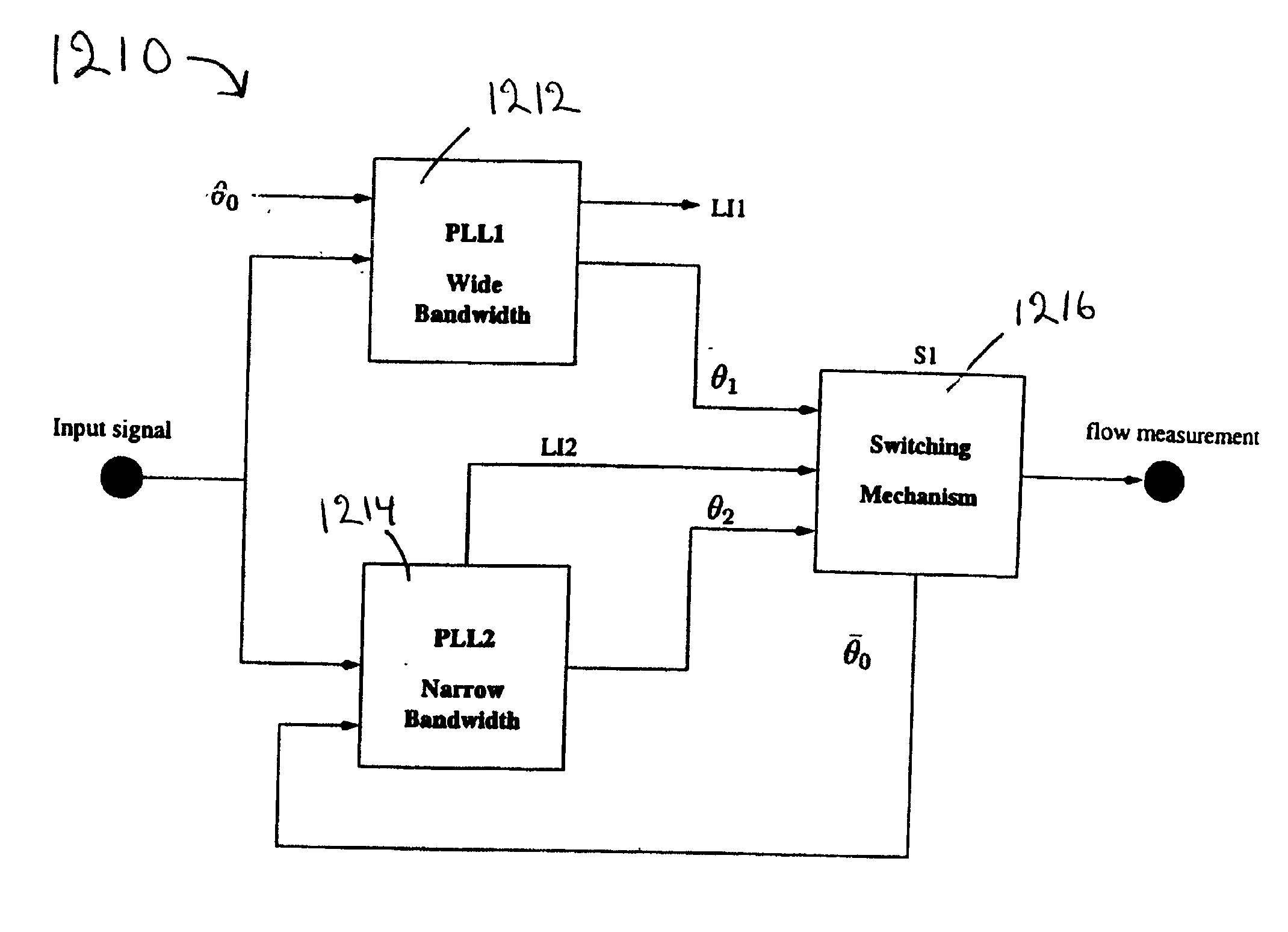

Vortex flowmeter

InactiveUS20020129661A1Improve accuracyIncrease speedElectrical measurementsVolume/mass flow by dynamic fluid flow effectEngineeringBand width

A process variable transmitter, implemented in a dual PLL structure, includes a first PLL having a first bandwidth producing a first output signal, and a second PLL having a second bandwidth narrower than the first bandwidth of the first PLL. The first and second PLLs are operable to lock into a frequency of an input signal and produce first and second output signals, respectively. The second PLL is operable to lock into the frequency of the input signal with greater accuracy and greater immunity to noise than the first PLL. A switch is operable to switch an output signal of the process variable transmitter between the first output signal and the second output signal.

Owner:SCHNEIDER ELECTRIC SYST USA INC

Method for determining pump flow without the use of traditional sensors

ActiveUS7945411B2Testing/calibration apparatusProcess and machine controlOperating pointMuller's method

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

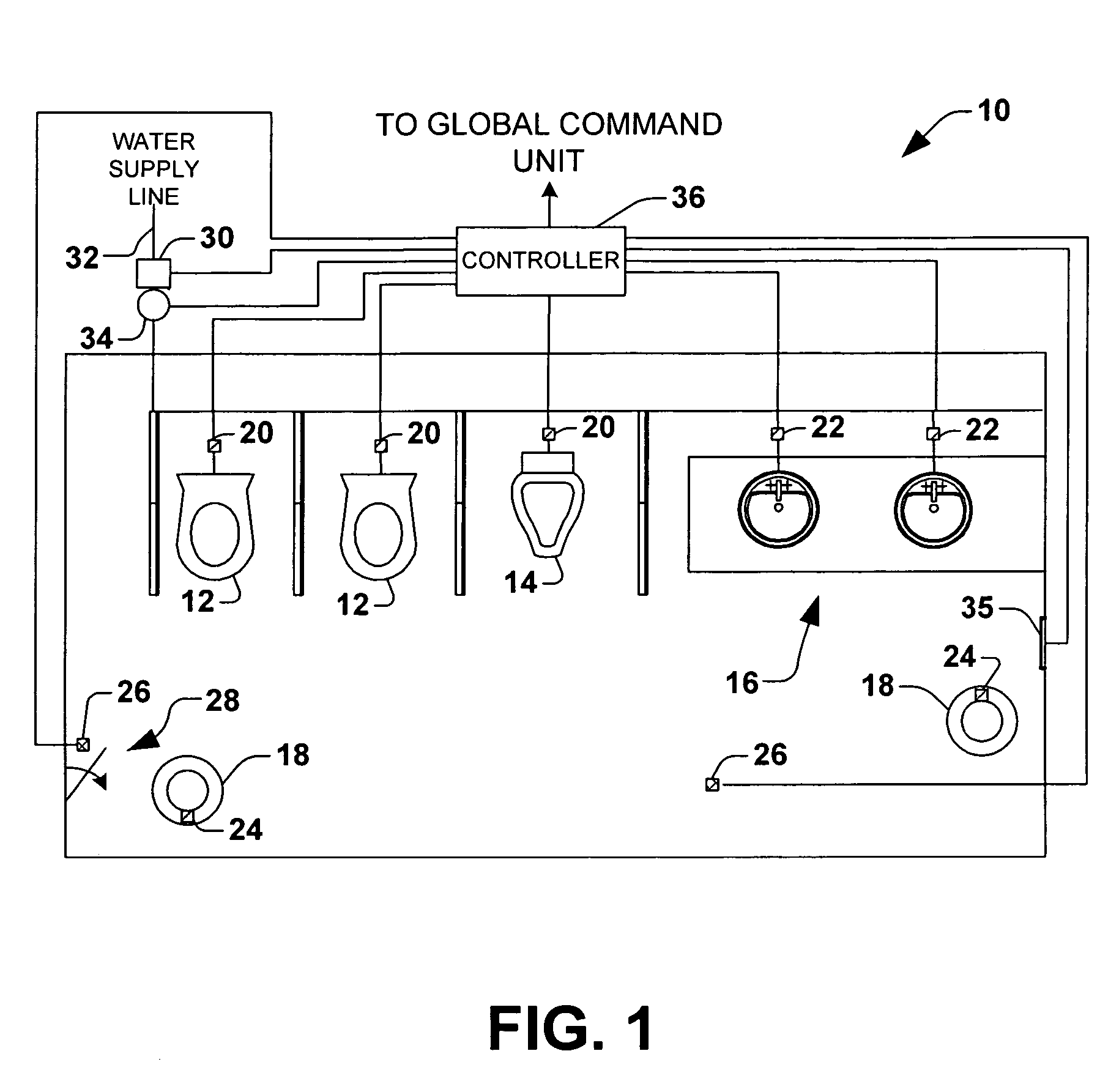

System for the monitor and control of rest rooms

The present invention is directed to a rest room control system including one or more sensors configured to monitor or control a function associated with the rest room. The system also includes a controller operably coupled to the one or more sensors, and configured to receive data therefrom associated with the function, and communicate a status condition associated with the function in response thereto.

Owner:SLOAN VALVE COMPANY +1

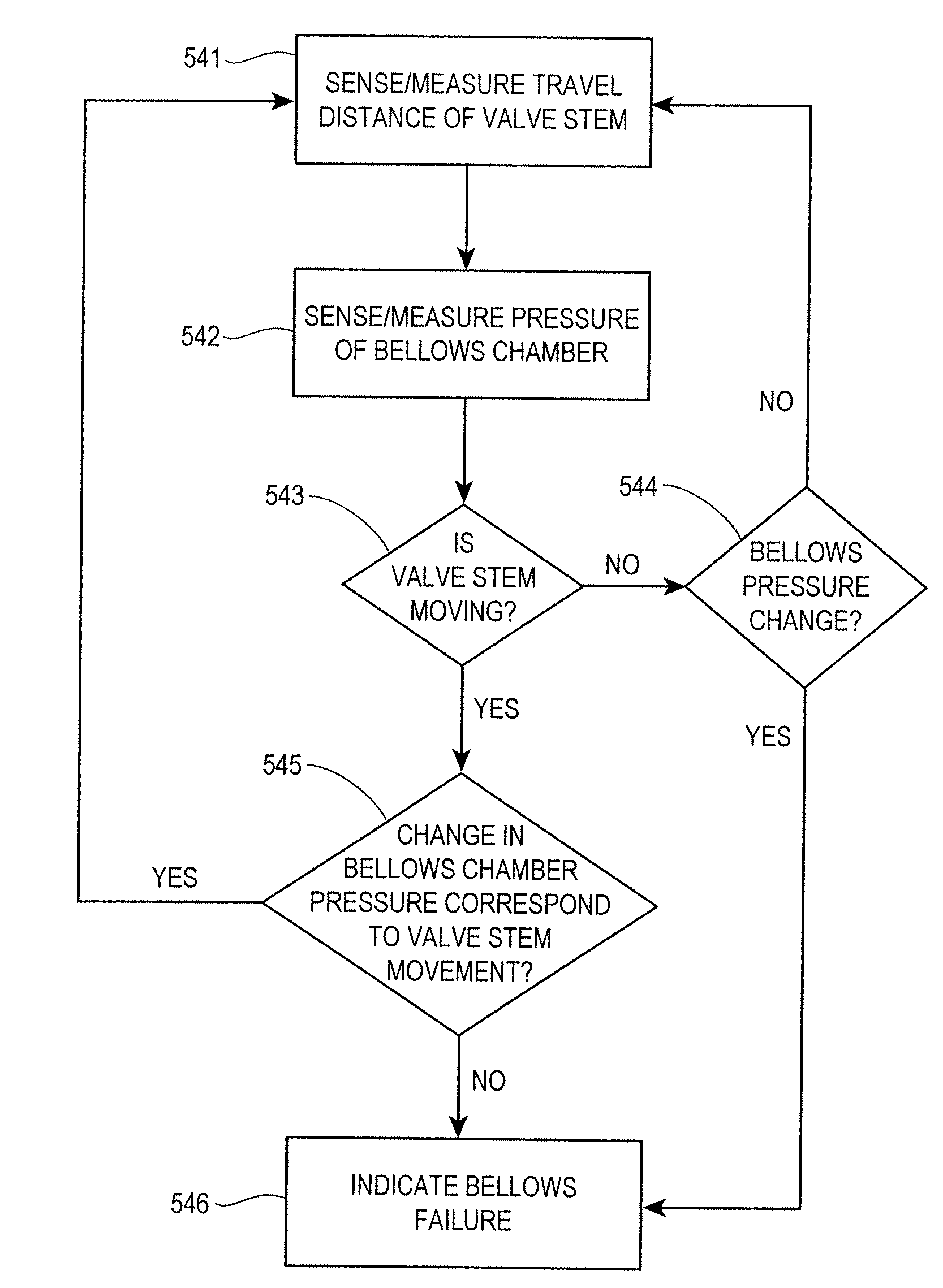

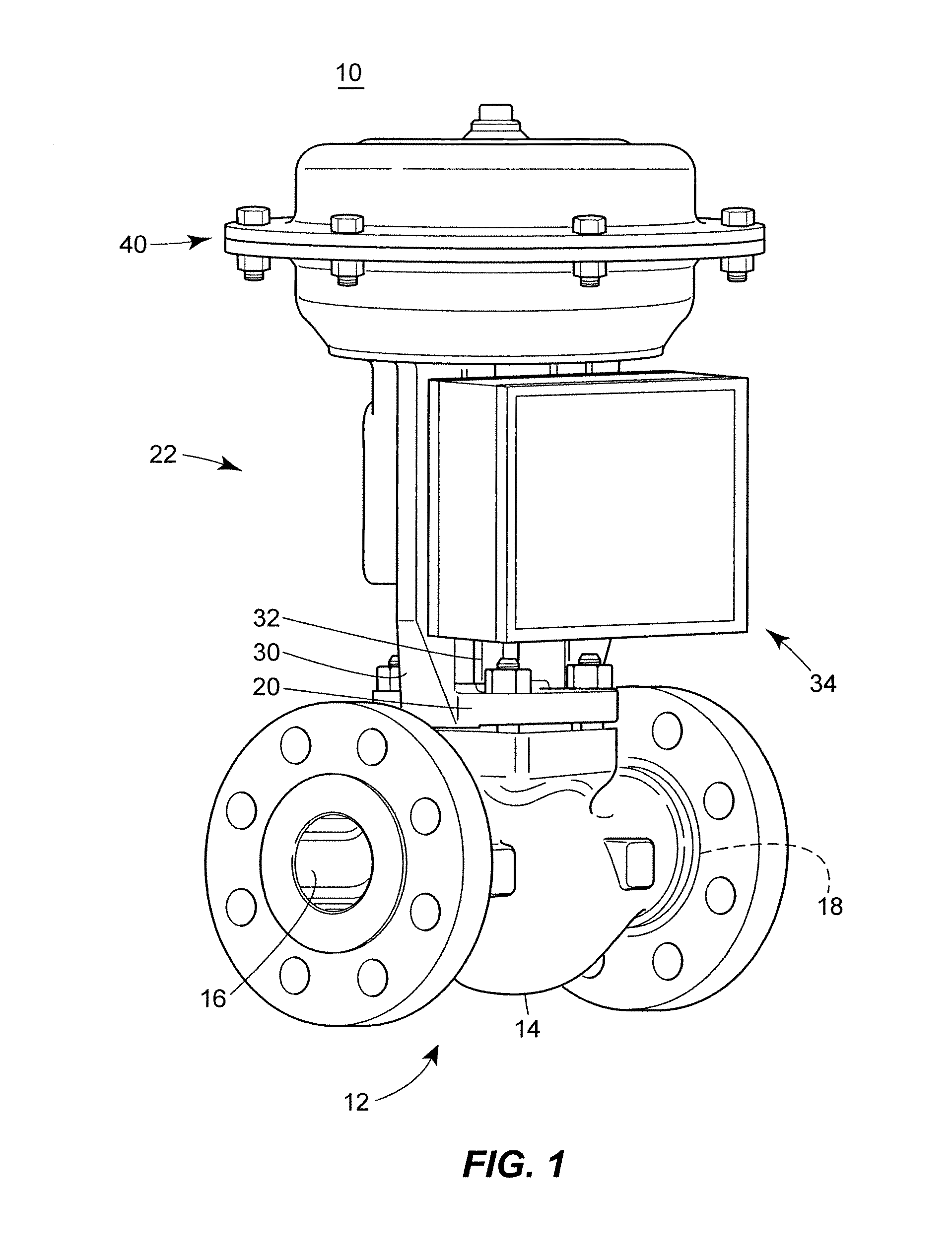

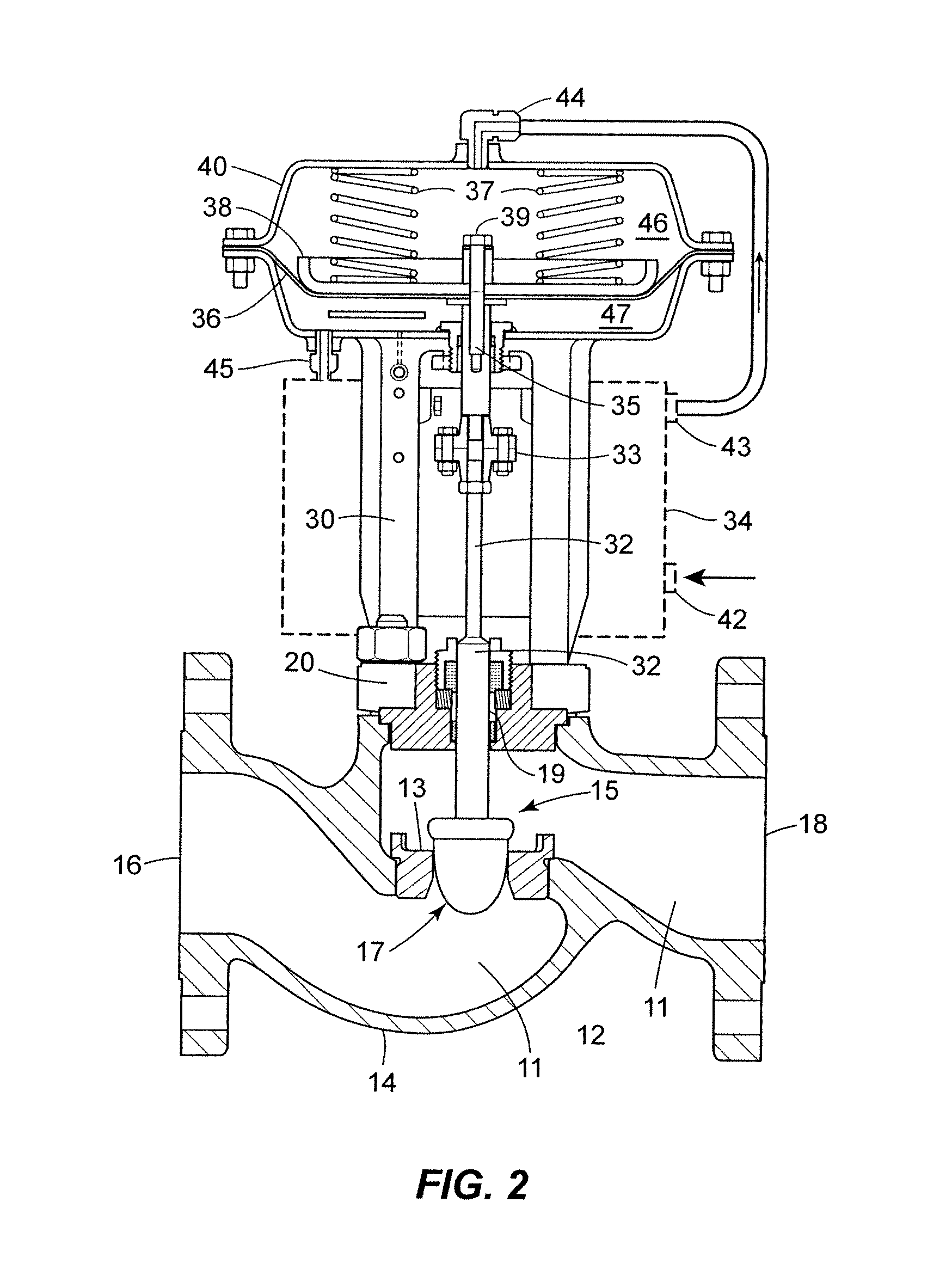

Diagnostic method for detecting control valve component failure

The claimed method and system identifies faults and / or deterioration of components in a process control valve. The system may use different sensor combinations to provide the necessary data to compute irregular component integrity. Alerts may be generated to indicate potential component integrity problems. In particular, the system may detect potential deterioration and / or faults in actuator springs, pneumatic tubing and piping, and bellows seals. The claimed system may be communicatively coupled to a process control network to provide a more elaborate alarm system. Moreover, additional statistical methods may be used to refine the detection accuracy of the system.

Owner:FISHER CONTROLS INT LLC

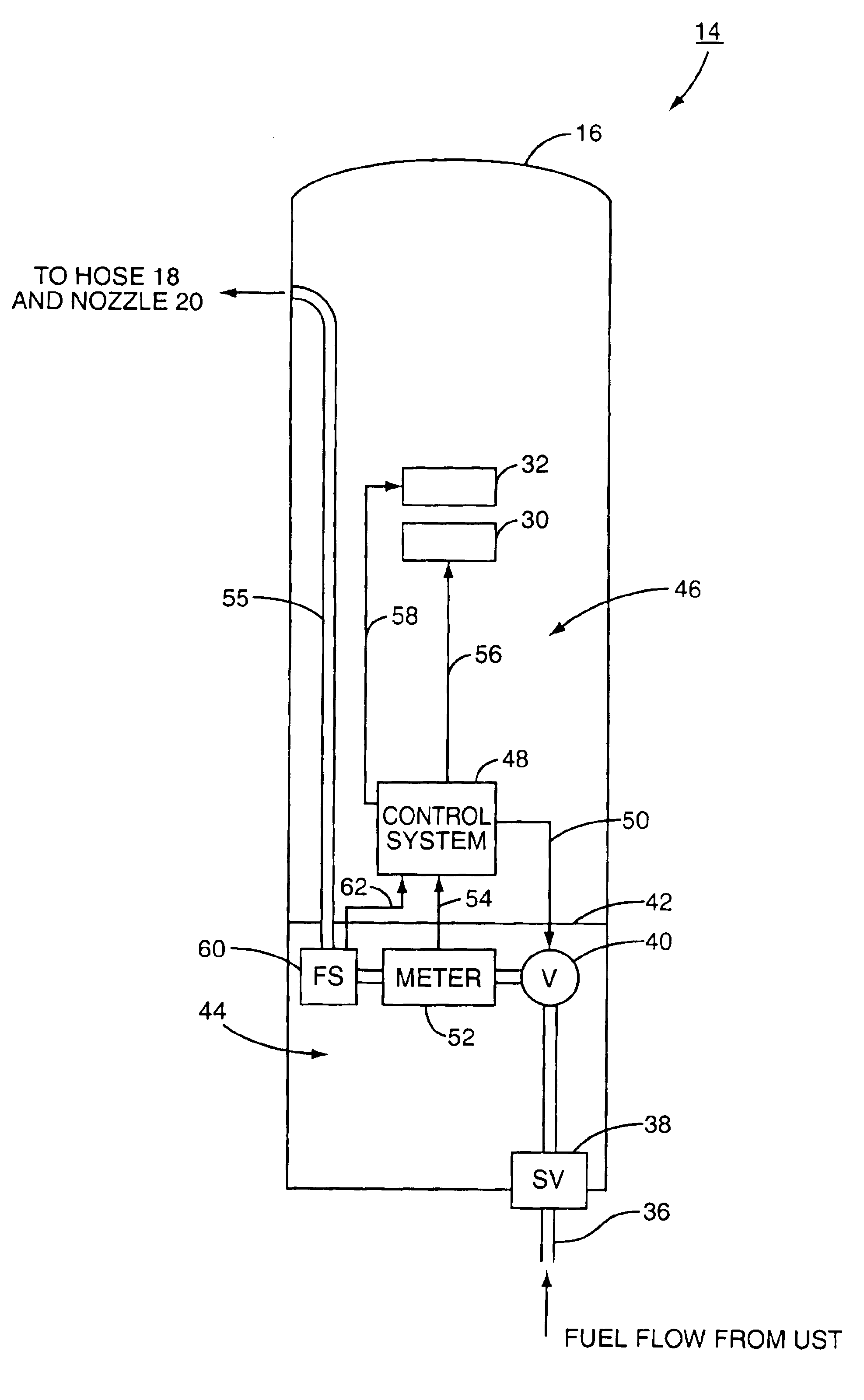

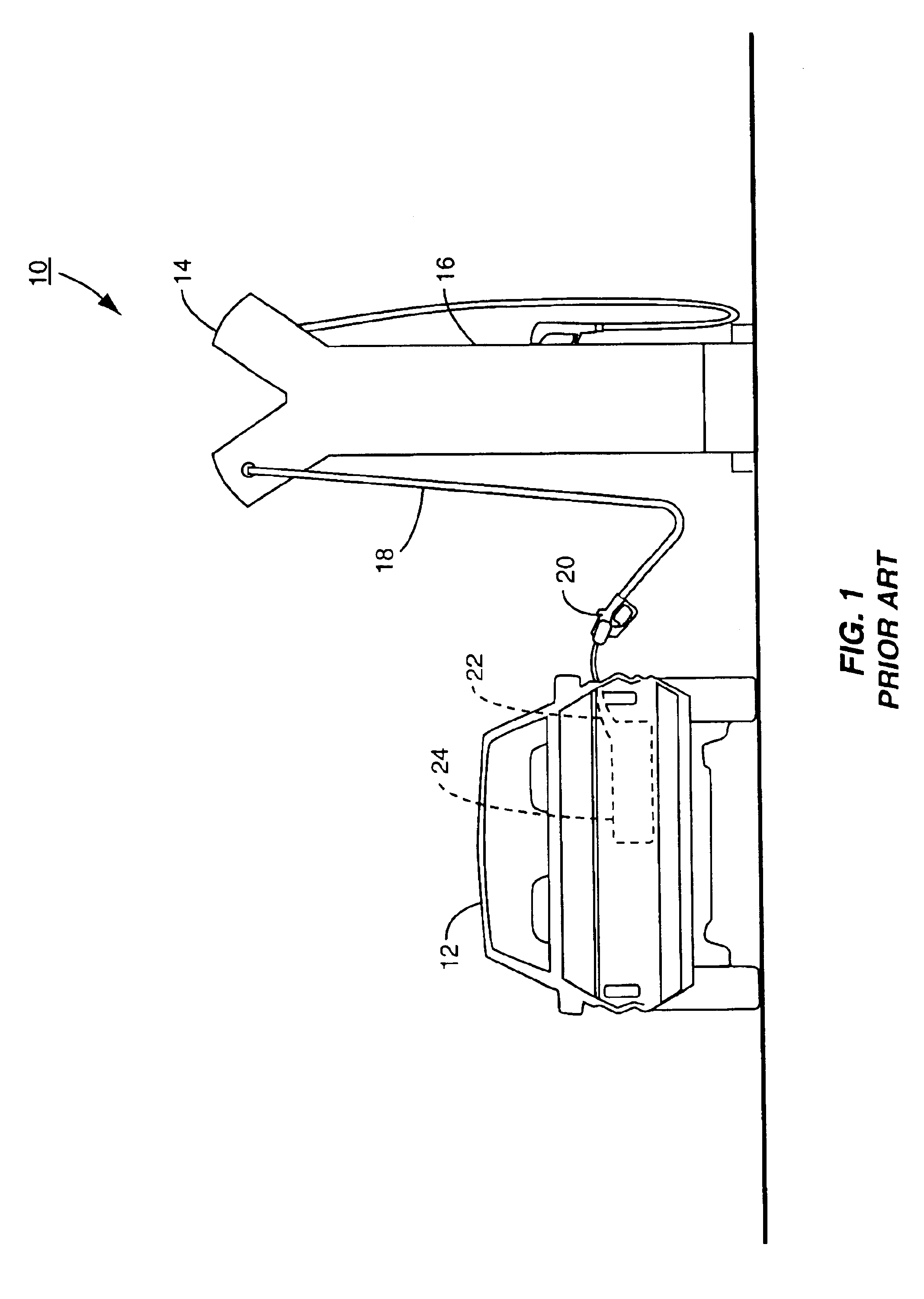

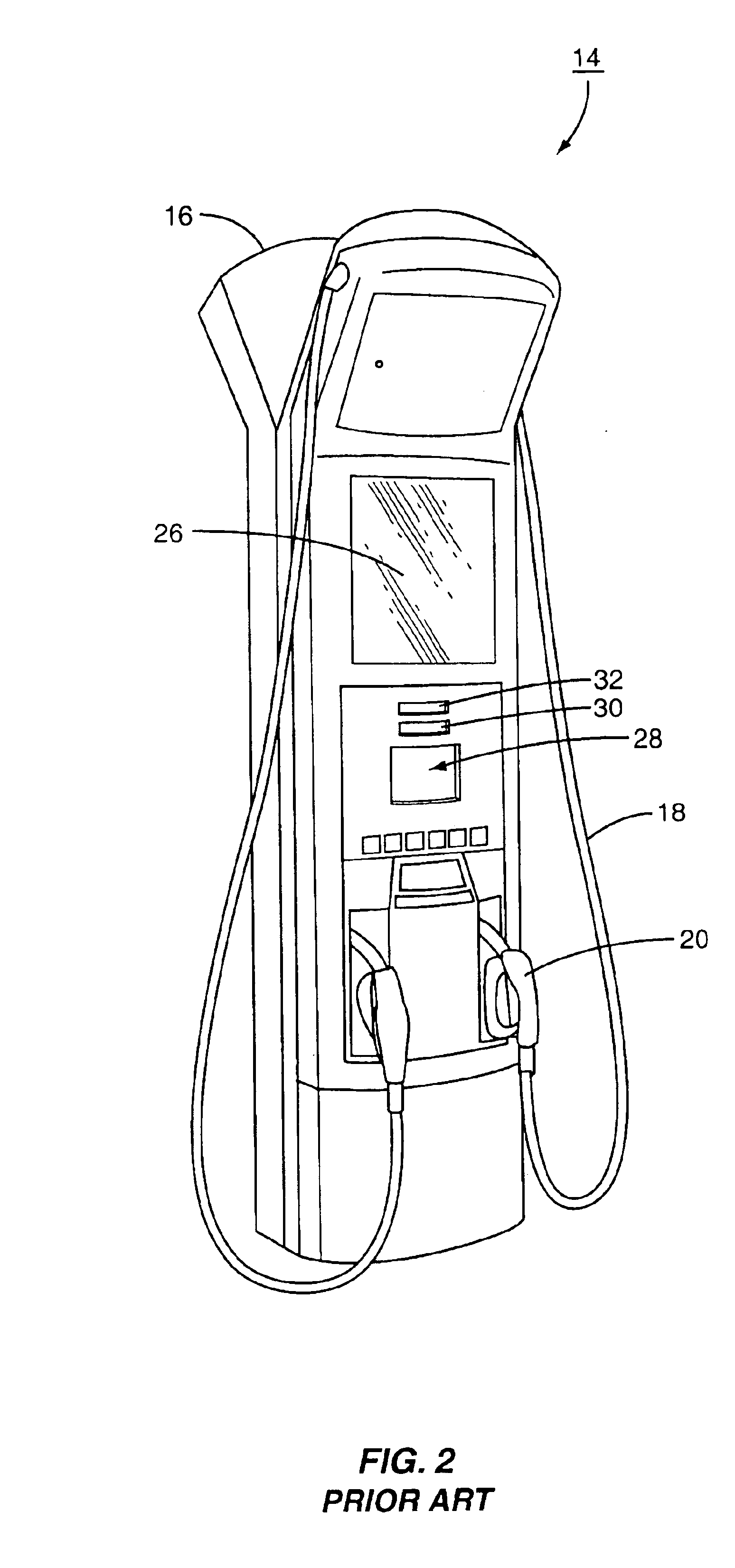

Fuel dispenser fuel flow meter device, system and method

ActiveUS6935191B2Accurate measurementImproper chargingValve arrangementsLiquid transferring devicesCombined useEngineering

A flow switch used on conjunction with a fuel flow meter in a fuel dispenser to determine when fuel flow rate signals form a fuel flow meter should be ignored in the calculation of flow rate and / or volume of fuel dispensed. An inferential fuel flow meter may be used as the fuel flow meter. The inferential fuel flow meter may be a turbine flow meter that comprises one or more turbine rotors that rotate in response to fuel flow flowing through the turbine flow meter. The turbine rotors may continue to generate pulses even when fuel is no longer flowing. A flow switch determines when fuel is actually flowing and fuel is not actually flowing. The flow switch is described as either a single poppet or dual poppet flow switch in examples described herein.

Owner:GILBARCO +1

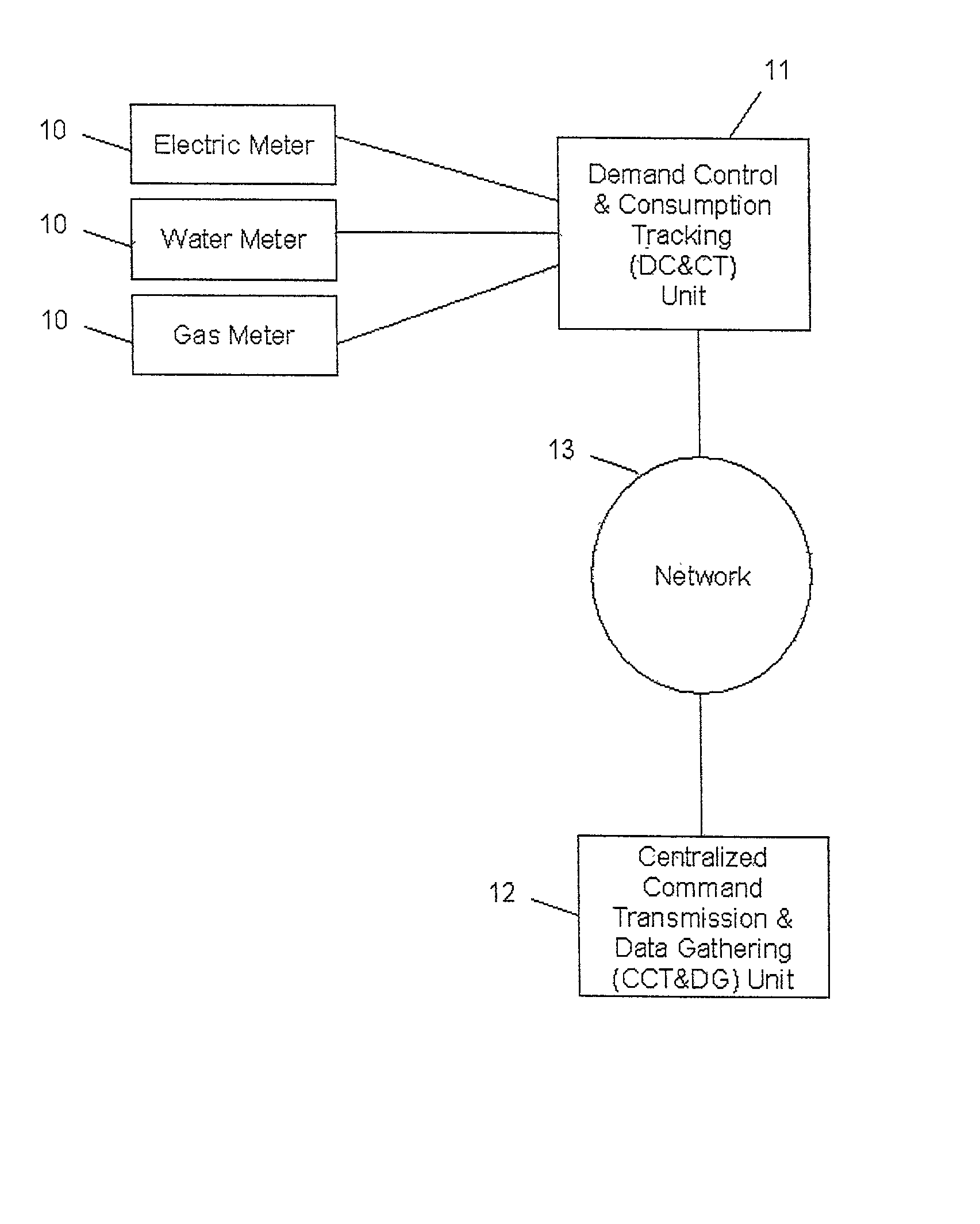

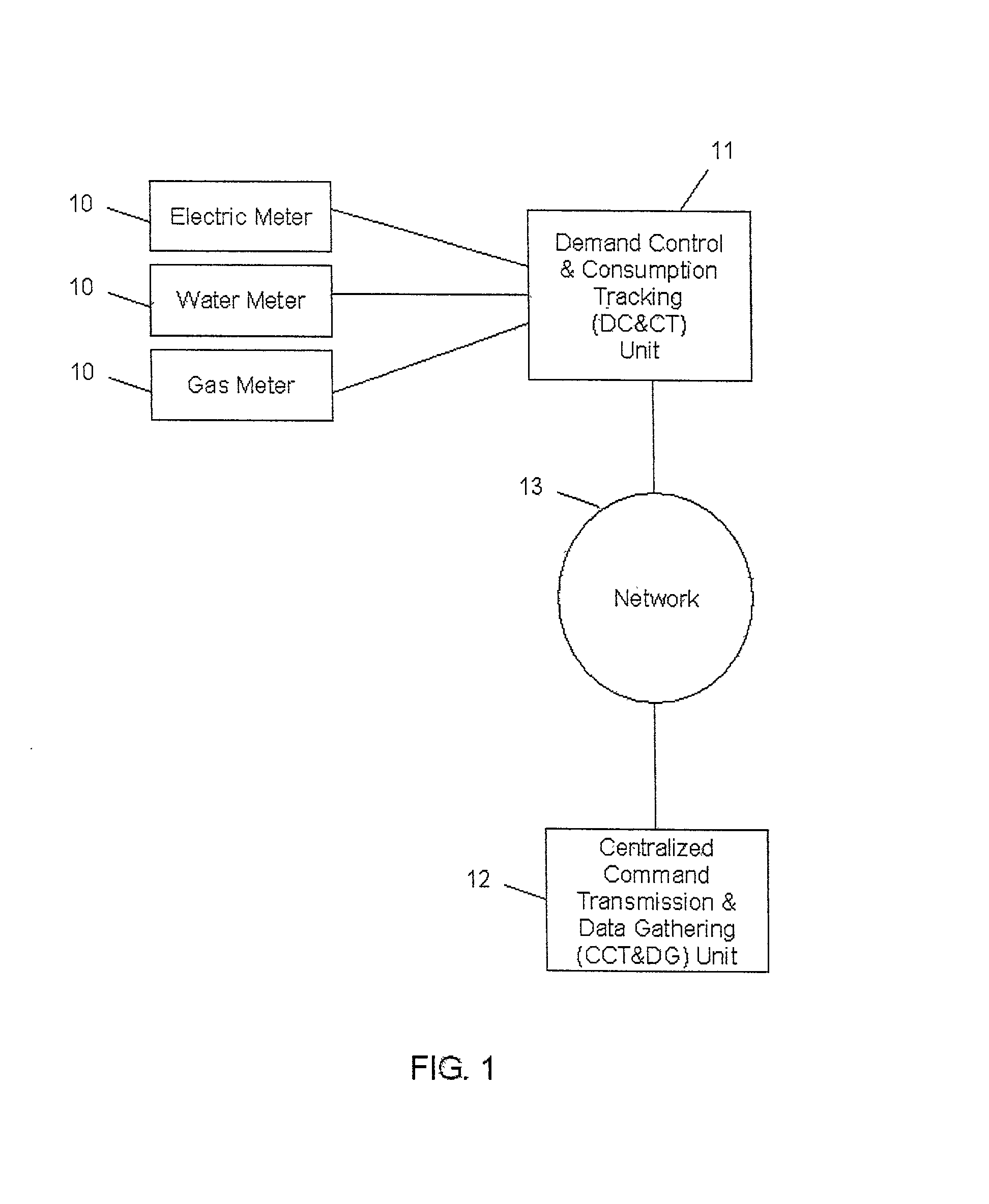

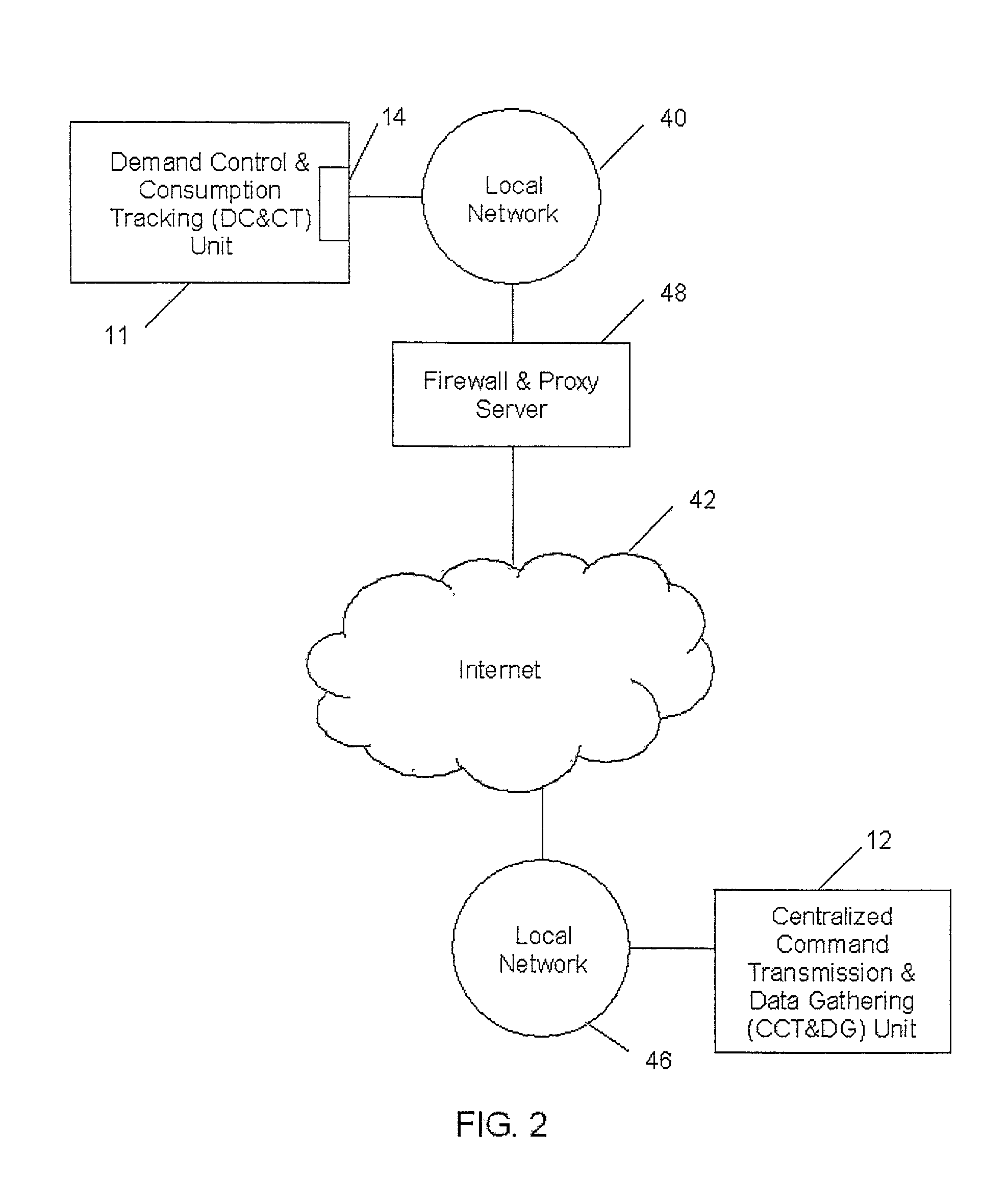

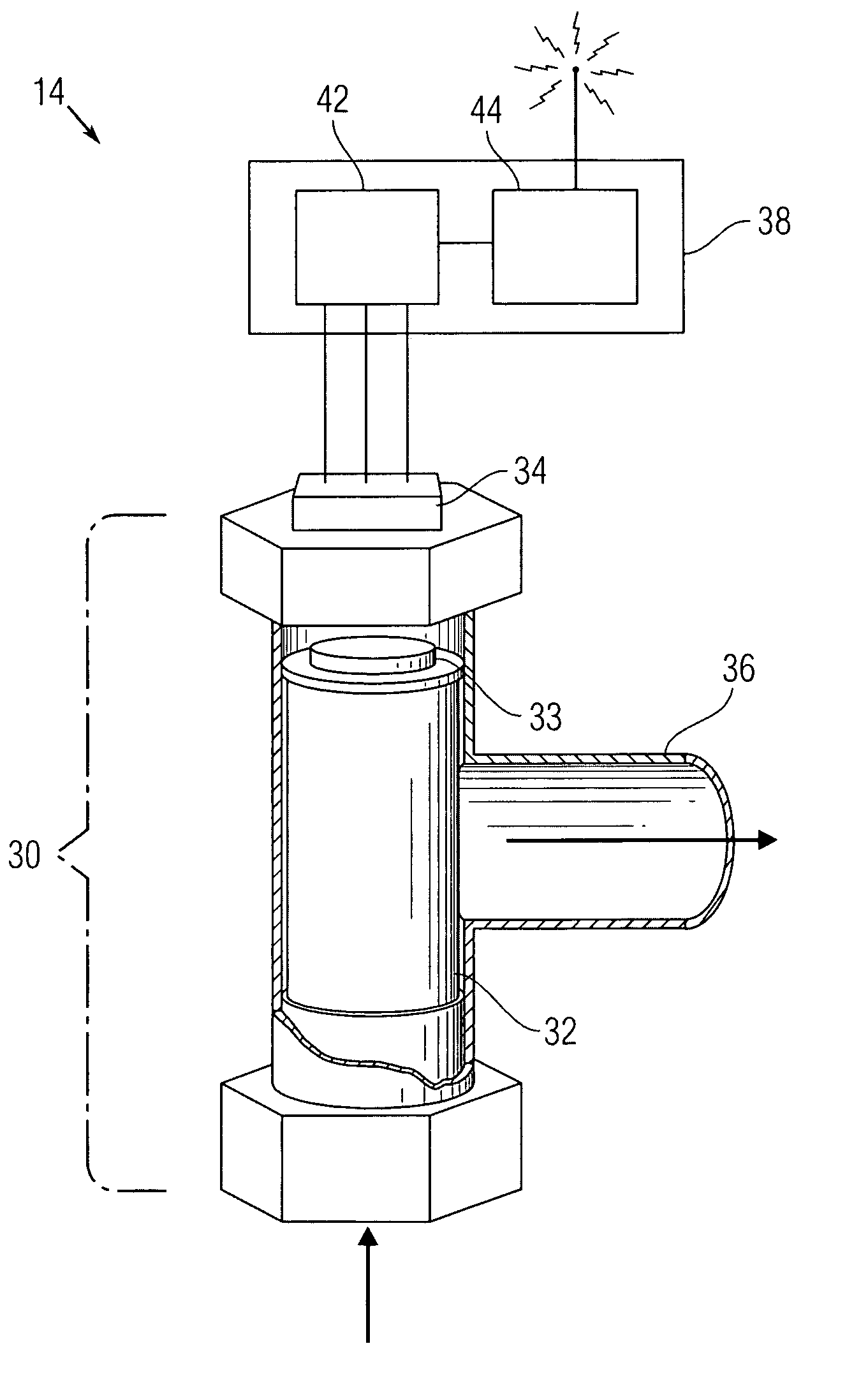

Utility monitoring and control systems

InactiveUS20020082748A1Facilitates/permits communicationLevel controlVolume/mass flow measurementControl systemCollection system

A method of communication useful in remote utility demand control systems, automated utility data gathering systems and combined utility demand control and data systems is disclosed. Also disclosed is an utility remote demand control and / or automated data gathering system. Different methods of communications between a utility demand control and consumption tracking unit, which is connected to different utility consuming devices, on the one hand, and a centralized command transmission and data gathering unit, on the other hand, are described. The communication between these units includes at least one computer information network.

Owner:INTERNET ENERGY SYST INC IES

Wireless water flow monitoring and leak detection system, and method

Owner:WATER CENTS

Popular searches

Fluid pressure measurement by mechanical elements Machines/engines Container/cavity capacity measurement Level indicators Lubrication indication devices Volume/mass flow by differential pressure Special data processing applications Wind motor supports/mounts Variable speed operation control Wind energy generation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com