Wet steam flow instrument and measuring method

A technology of wet steam and flowmeter, which is applied in the direction of mass flow measurement device, indirect mass flowmeter, material moisture content, etc., which can solve the problems of poor measurement accuracy and achieve the effect of high precision of wet steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

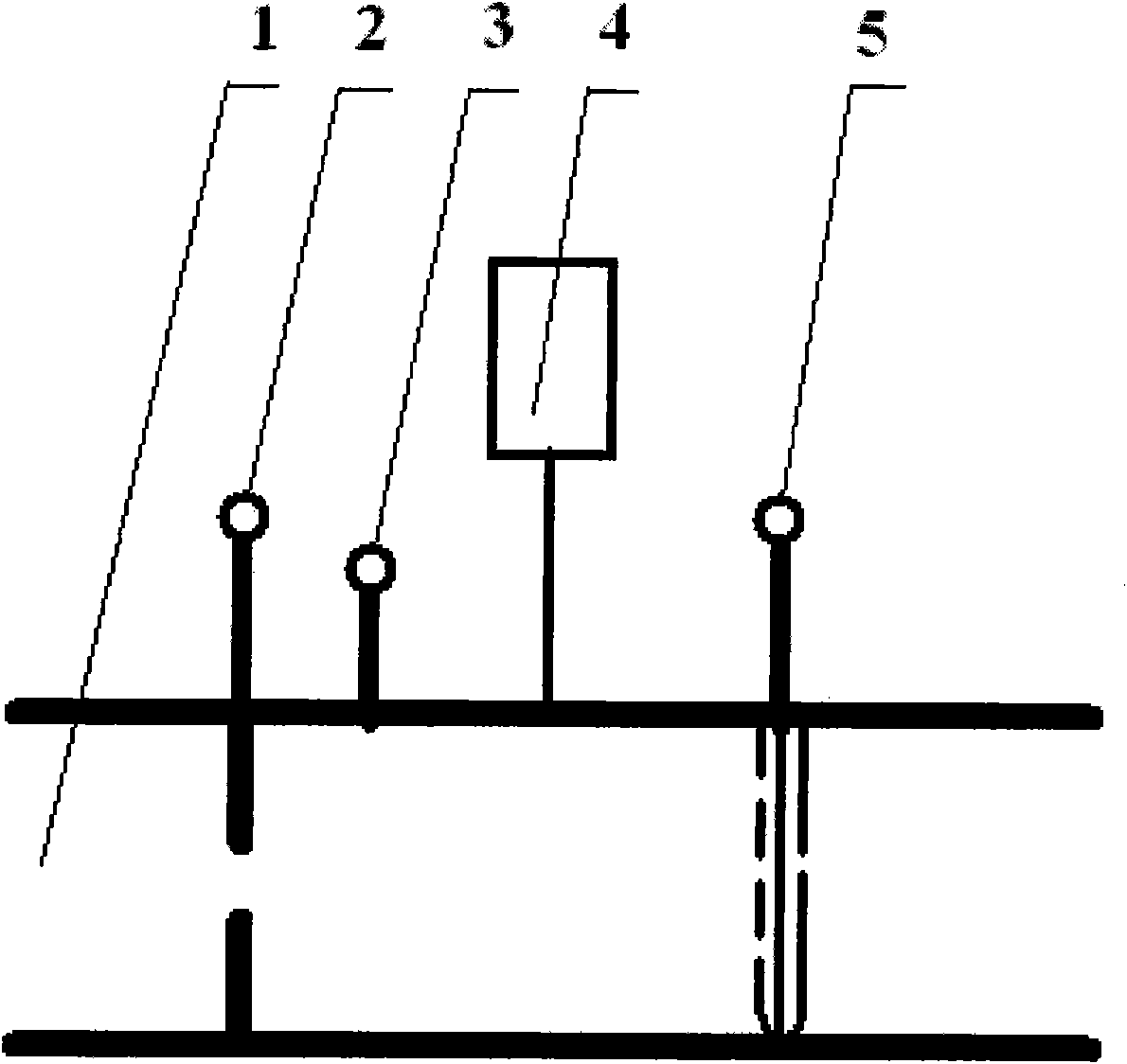

[0022] This embodiment is a wet steam flowmeter, which is used to measure the wet steam flow and dryness in a wet steam pipeline with a wet steam pressure of 15MPa, a wet steam flow of 5-9t / h, and a steam dryness of 60-85%. , where the inner diameter of the wet steam pipeline is 56mm and the wall thickness is 10mm; the flowmeter is an orifice flowmeter, and the flowmeter is a constant velocity tube flowmeter.

[0023] This embodiment includes a wet steam pipeline 1 , an orifice flowmeter 2 , a pressure gauge 3 , a dryness flow processor 4 and an equalizing tube flowmeter 5 . The flow dryness processor has a built-in steam thermal physical property database and a mathematical model of steam flow dryness. The wet steam pipe 1 is a seamless steel pipe made of No. 20 boiler steel with an inner diameter of 56mm, a wall thickness of 10mm, and a length of 1000mm. The orifice flowmeter 2 and the equal velocity tube flowmeter 5 are connected in series on the wet steam pipeline 1, resp...

Embodiment 2

[0037] This embodiment is a wet steam flow meter, which is used to measure the wet steam flow rate and the wet steam flow rate in a wet steam pipeline with a wet steam pressure of 8-18MPa, a wet steam flow rate of 4-10t / h, and a steam dryness of 40-90%. Dryness, wherein, the inner diameter of the wet steam pipeline is 56mm, and the wall thickness is 10mm; the flowmeter is an inner cone flowmeter, and the flowmeter is a thermal flowmeter.

[0038] This embodiment includes a wet steam pipeline 1 , an inner cone flowmeter 2 , a pressure gauge 3 , a dryness flow processor 4 and a thermal flowmeter 5 . The flow dryness processor has a built-in steam thermal physical property database and a mathematical model of steam flow dryness. The wet steam pipe 1 is a seamless steel pipe made of No. 20 boiler steel with an inner diameter of 56mm, a wall thickness of 10mm, and a length of 1000mm. The orifice flowmeter 2 and the equal velocity tube flowmeter 5 are connected in series on the wet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com