Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

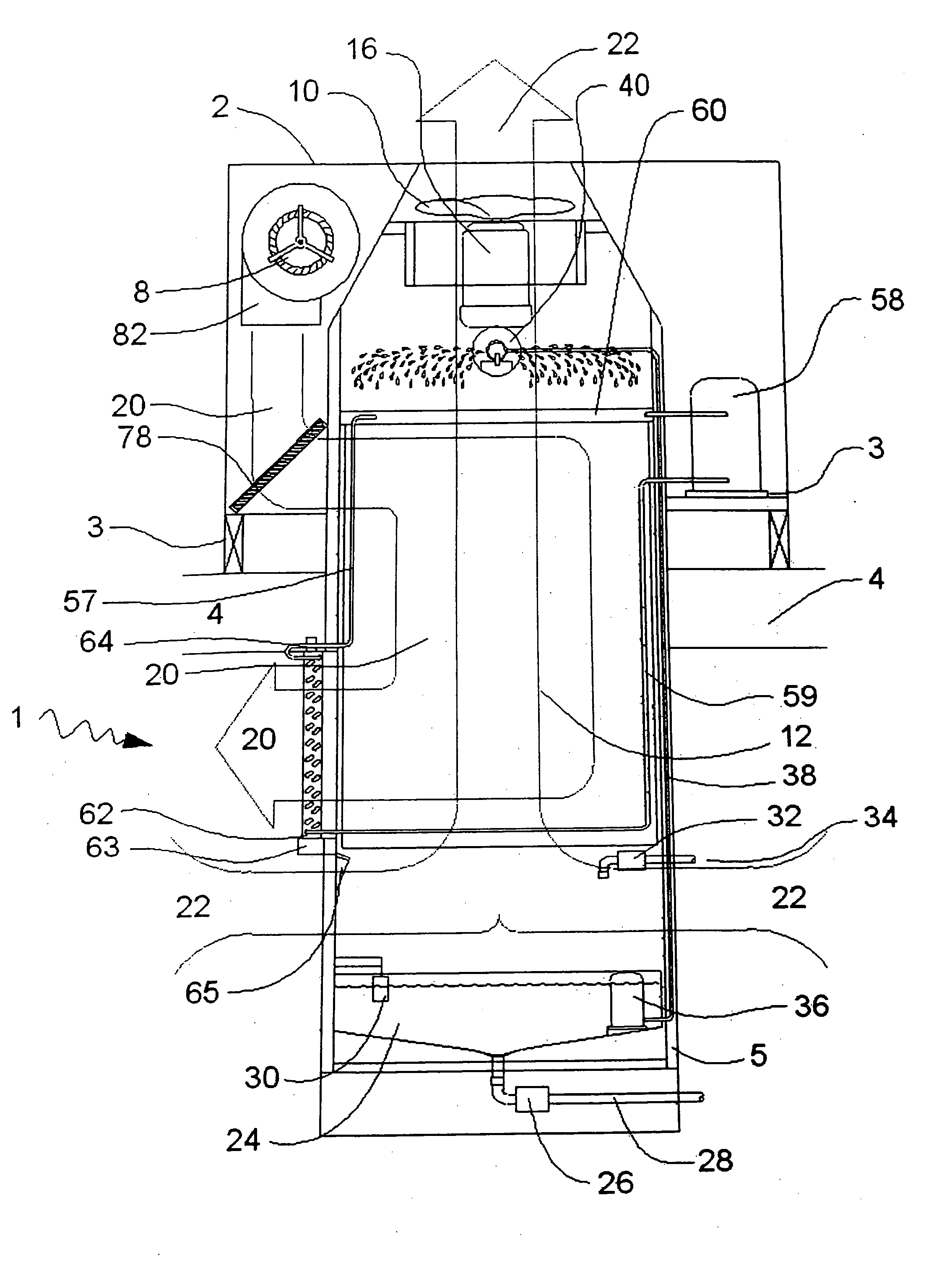

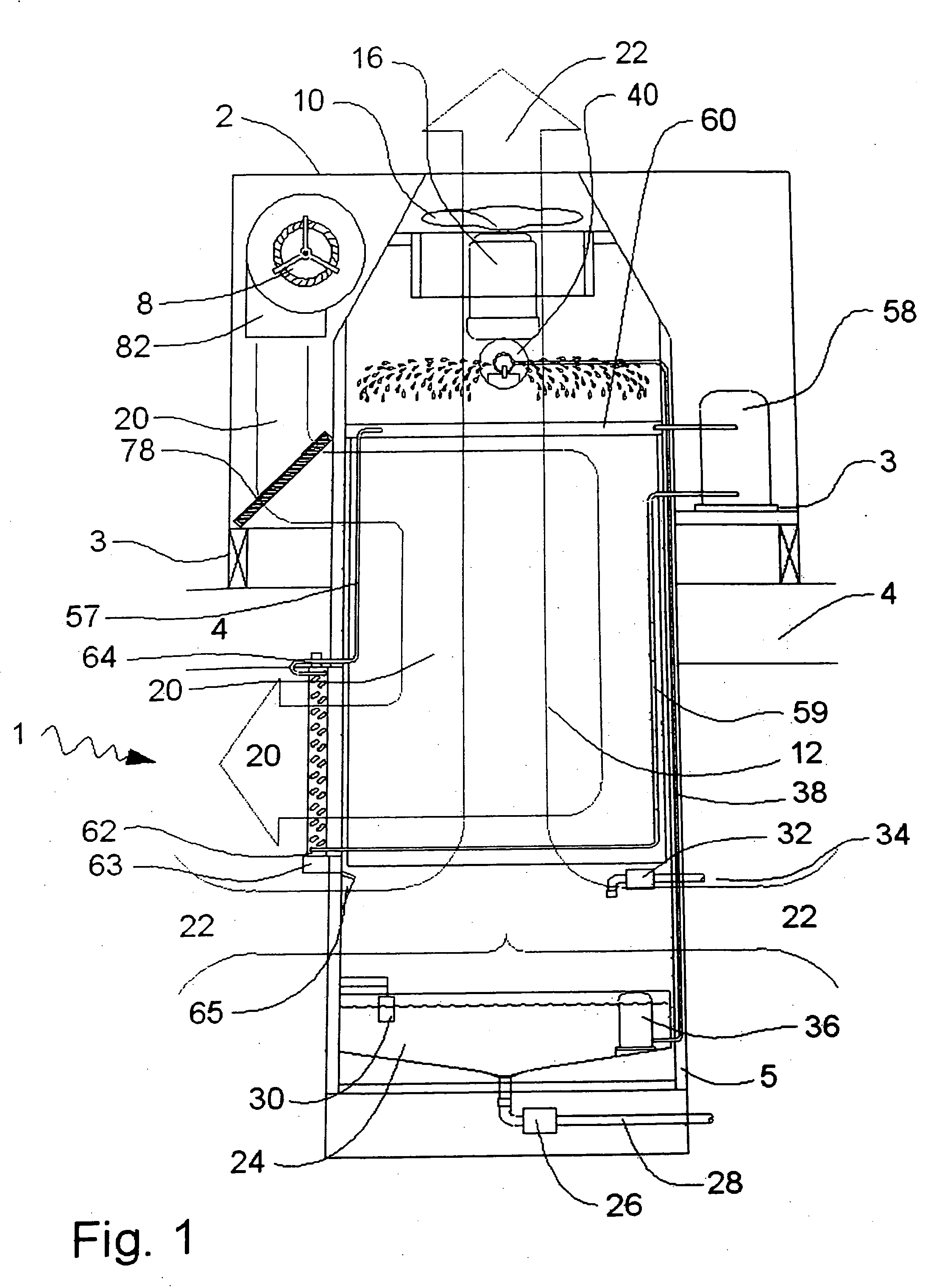

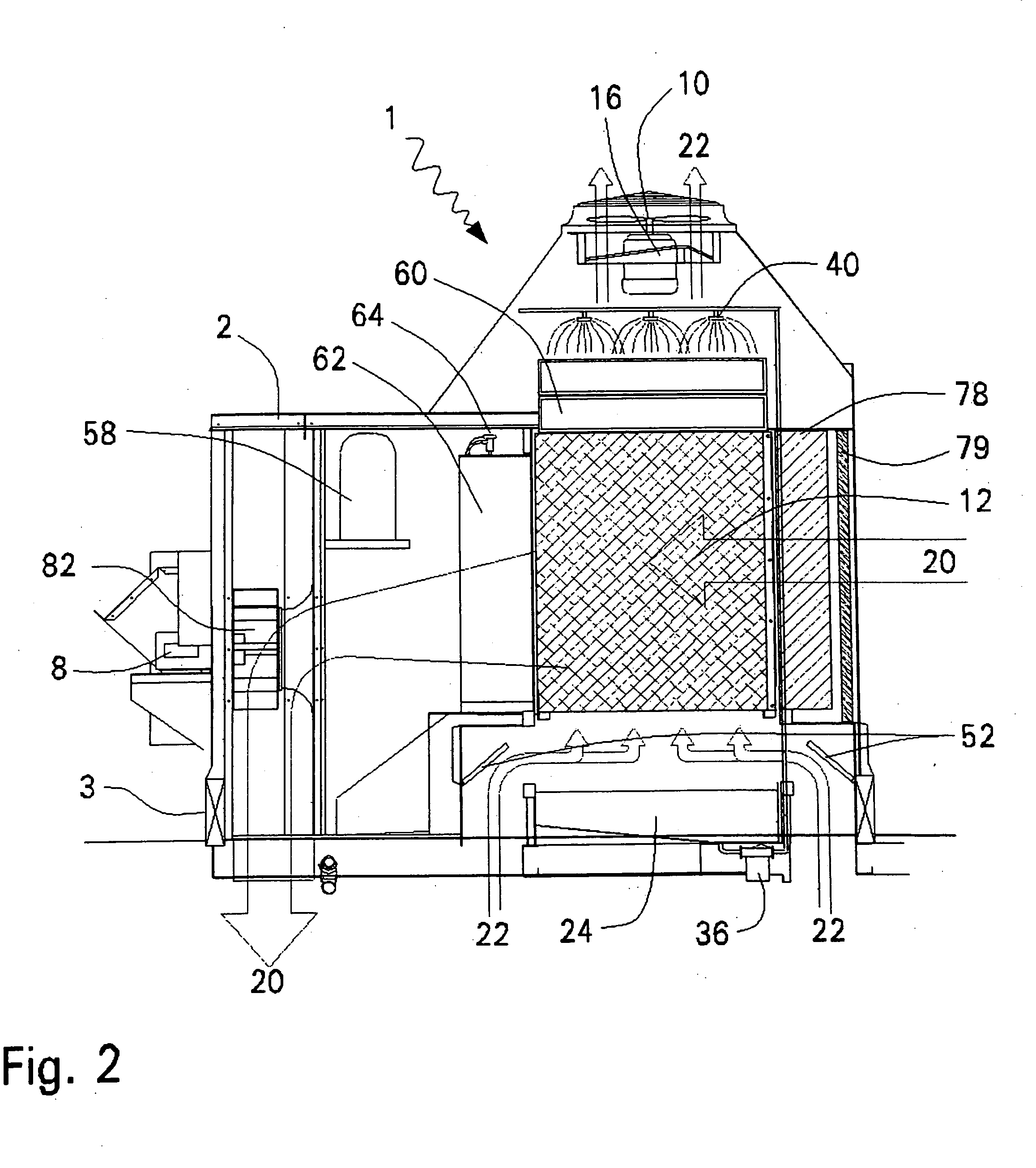

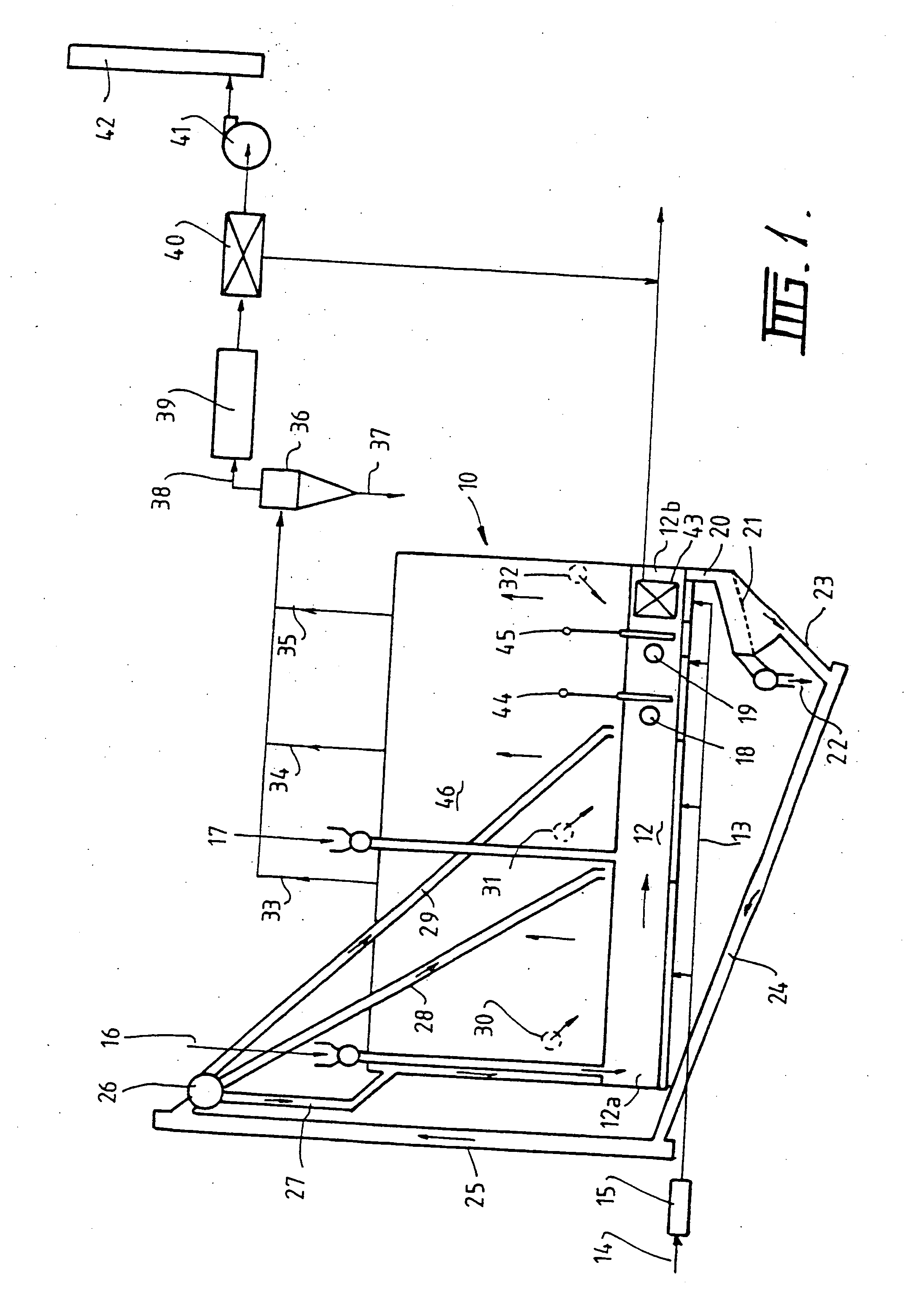

Hydronic rooftop cooling systems

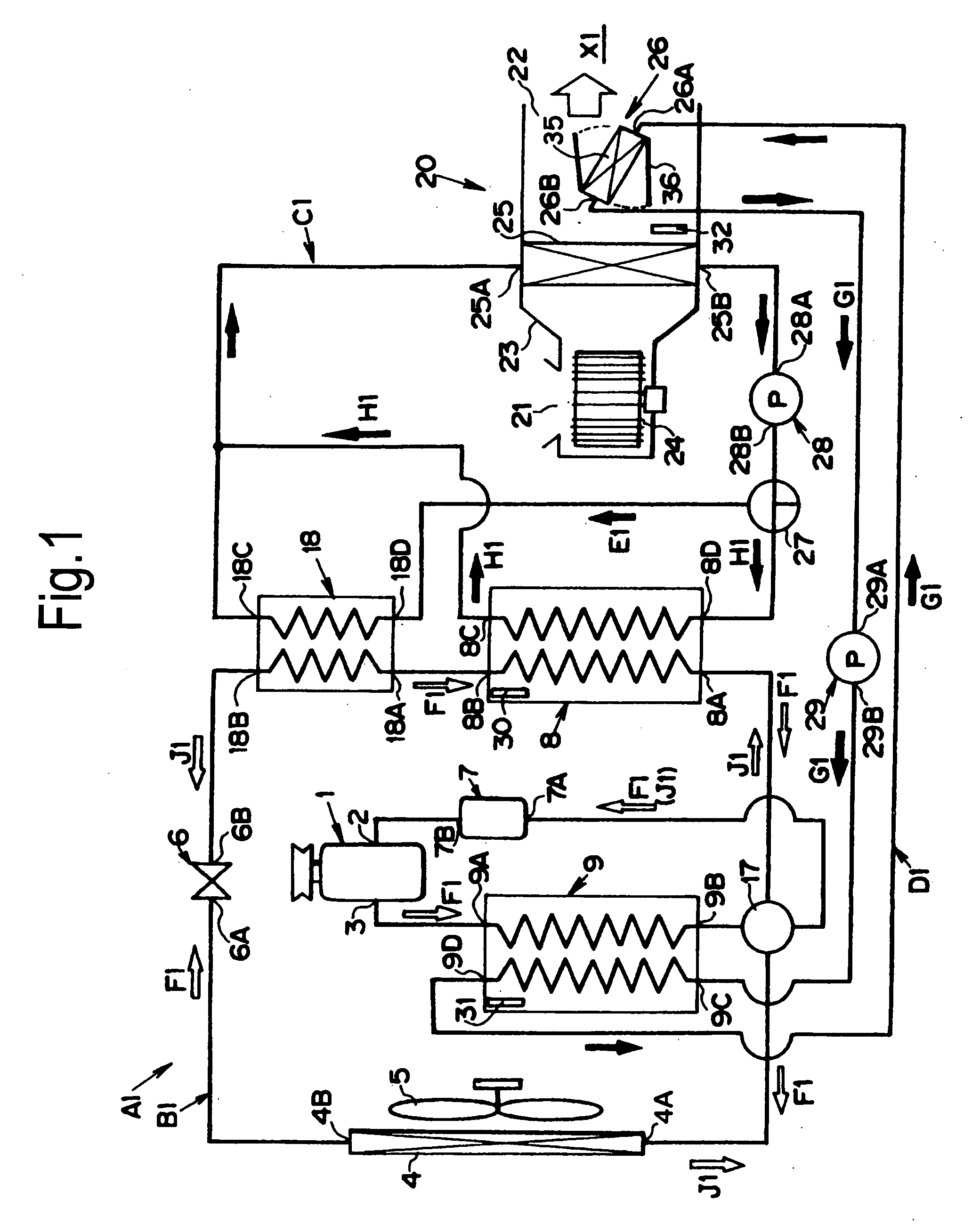

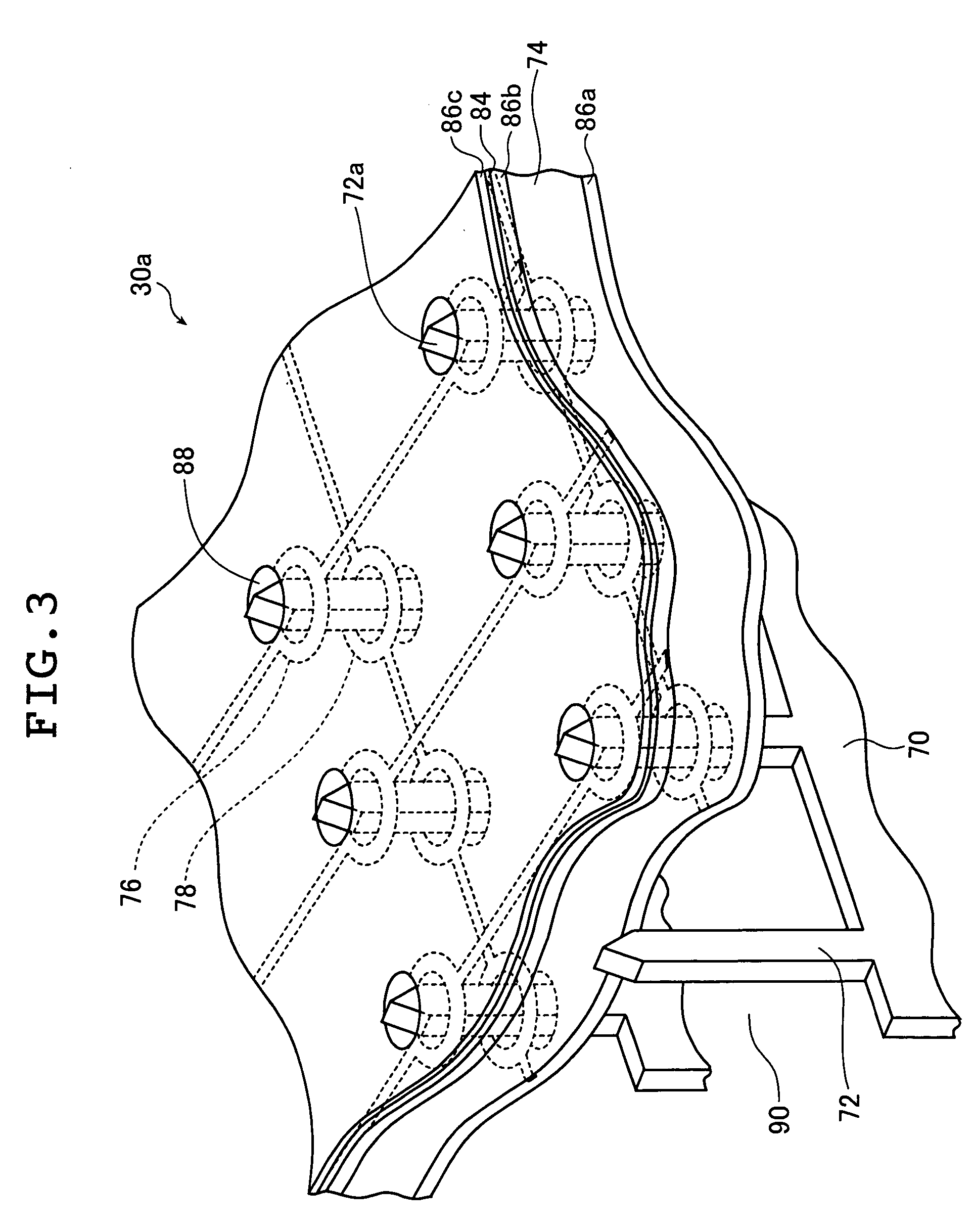

InactiveUS20050056042A1Improve RTU efficiencyEnhanced evaporative cooling effectEnergy recovery in ventilation and heatingHeat recovery systemsAir filterEngineering

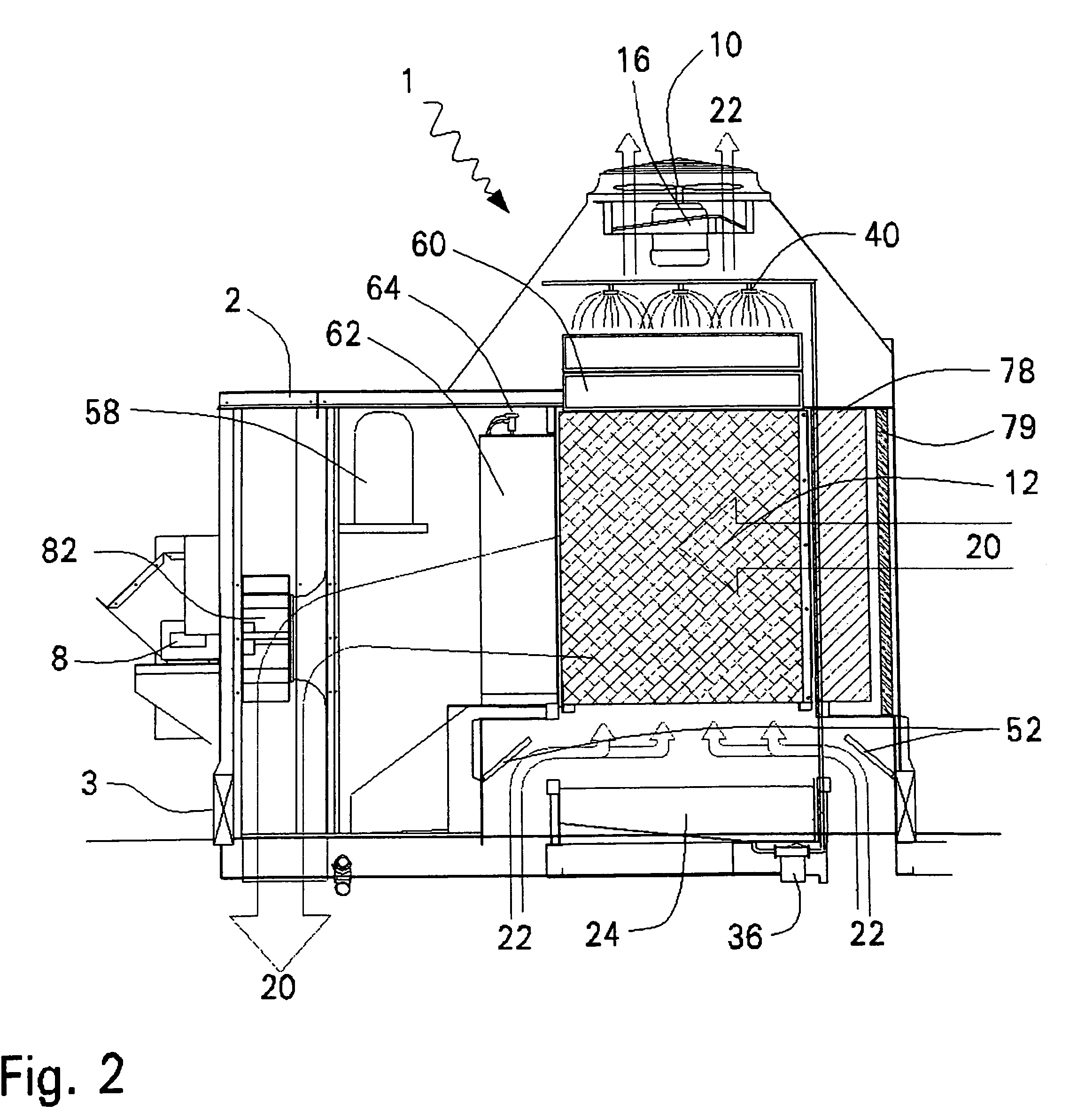

A roof top cooling unit has an evaporative cooling section that includes at least one evaporative module that pre-cools ventilation air and water; a condenser; a water reservoir and pump that captures and re-circulates water within the evaporative modules; a fan that exhausts air from the building and the evaporative modules and systems that refill and drain the water reservoir. The cooling unit also has a refrigerant section that includes a compressor, an expansion device, evaporator and condenser heat exchangers, and connecting refrigerant piping. Supply air components include a blower, an air filter, a cooling and / or heating coil to condition air for supply to the building, and optional dampers that, in designs that supply less than 100% outdoor air to the building, control the mixture of return and ventilation air.

Owner:DAVIS ENERGY GROUP

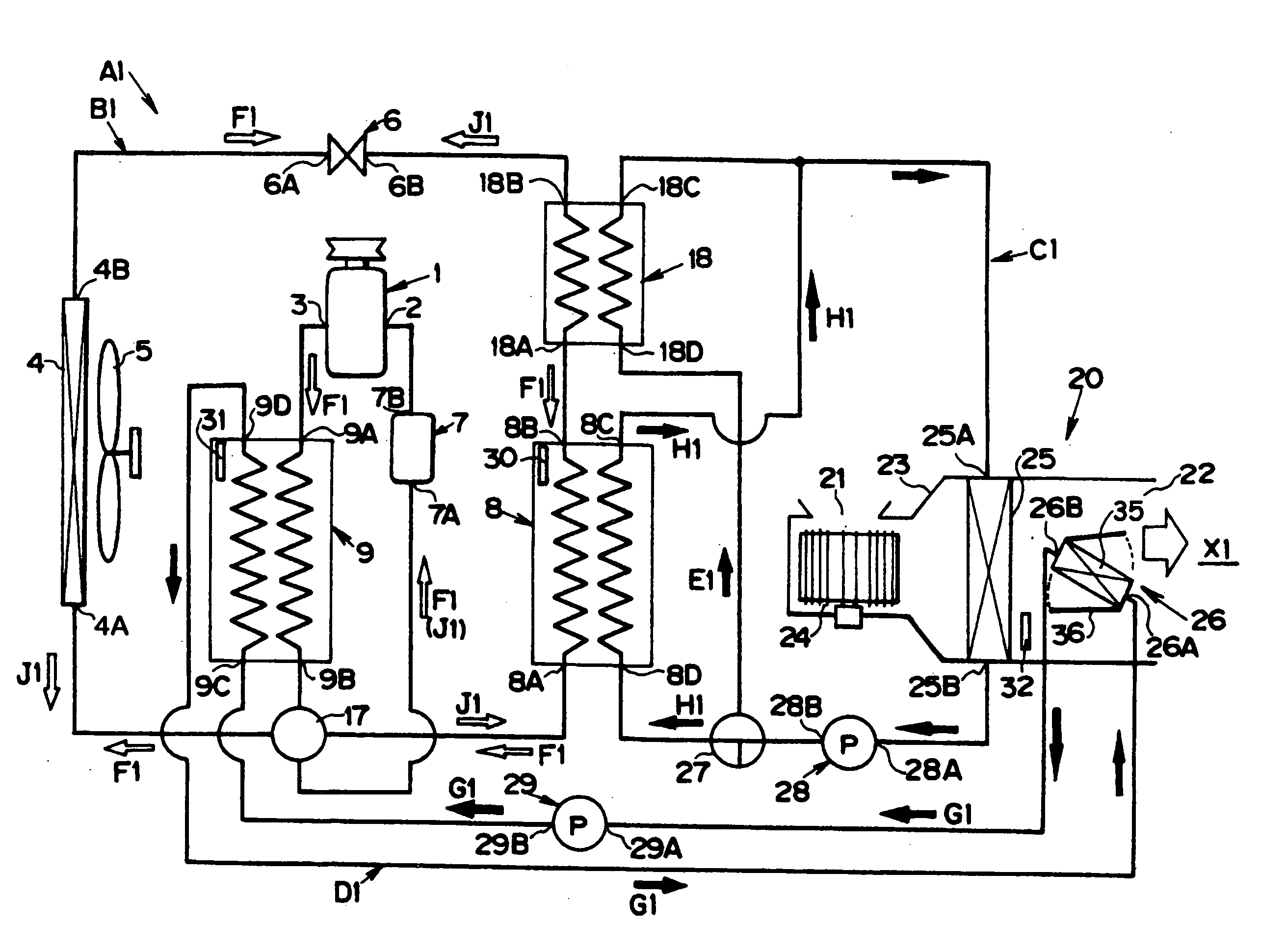

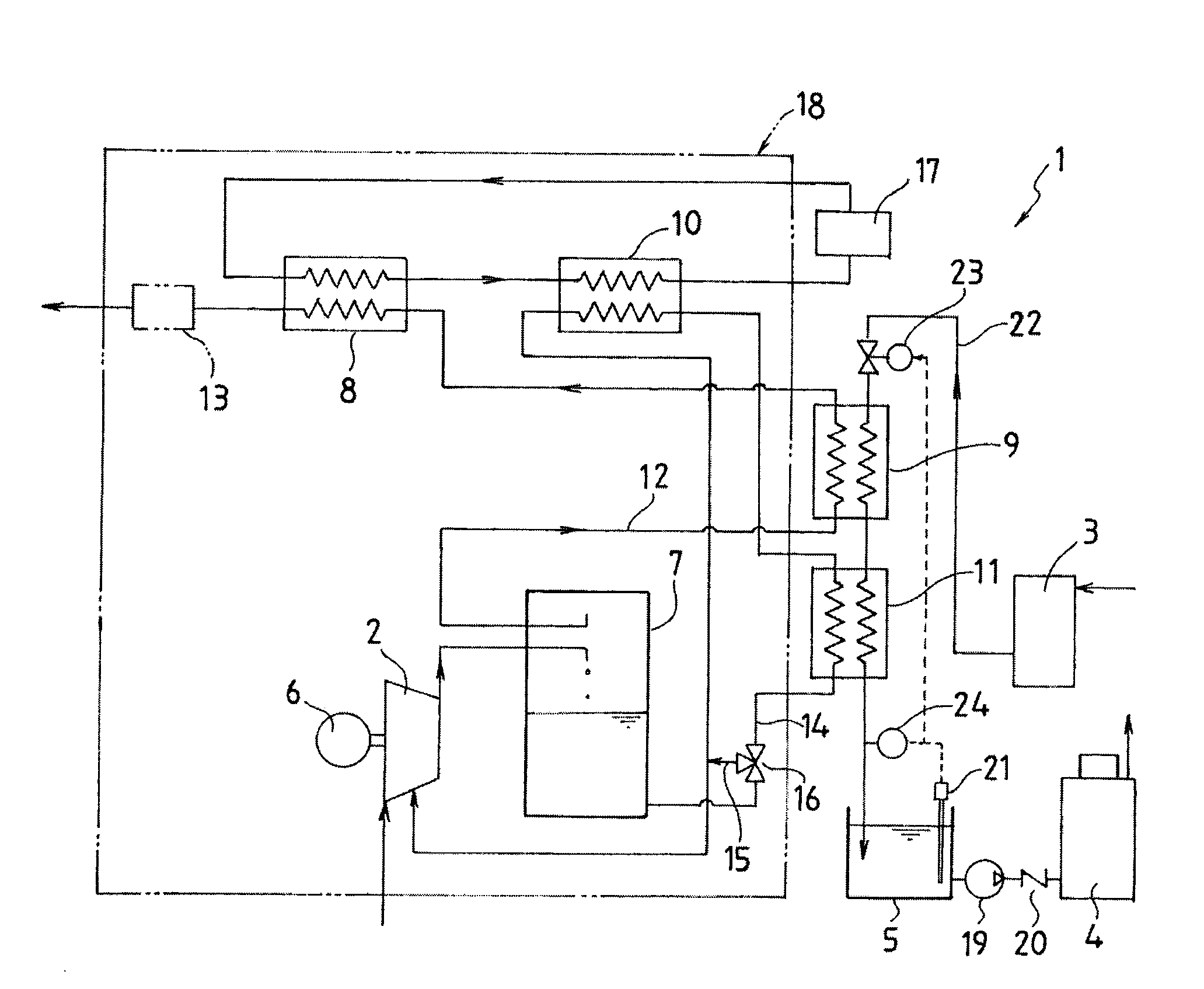

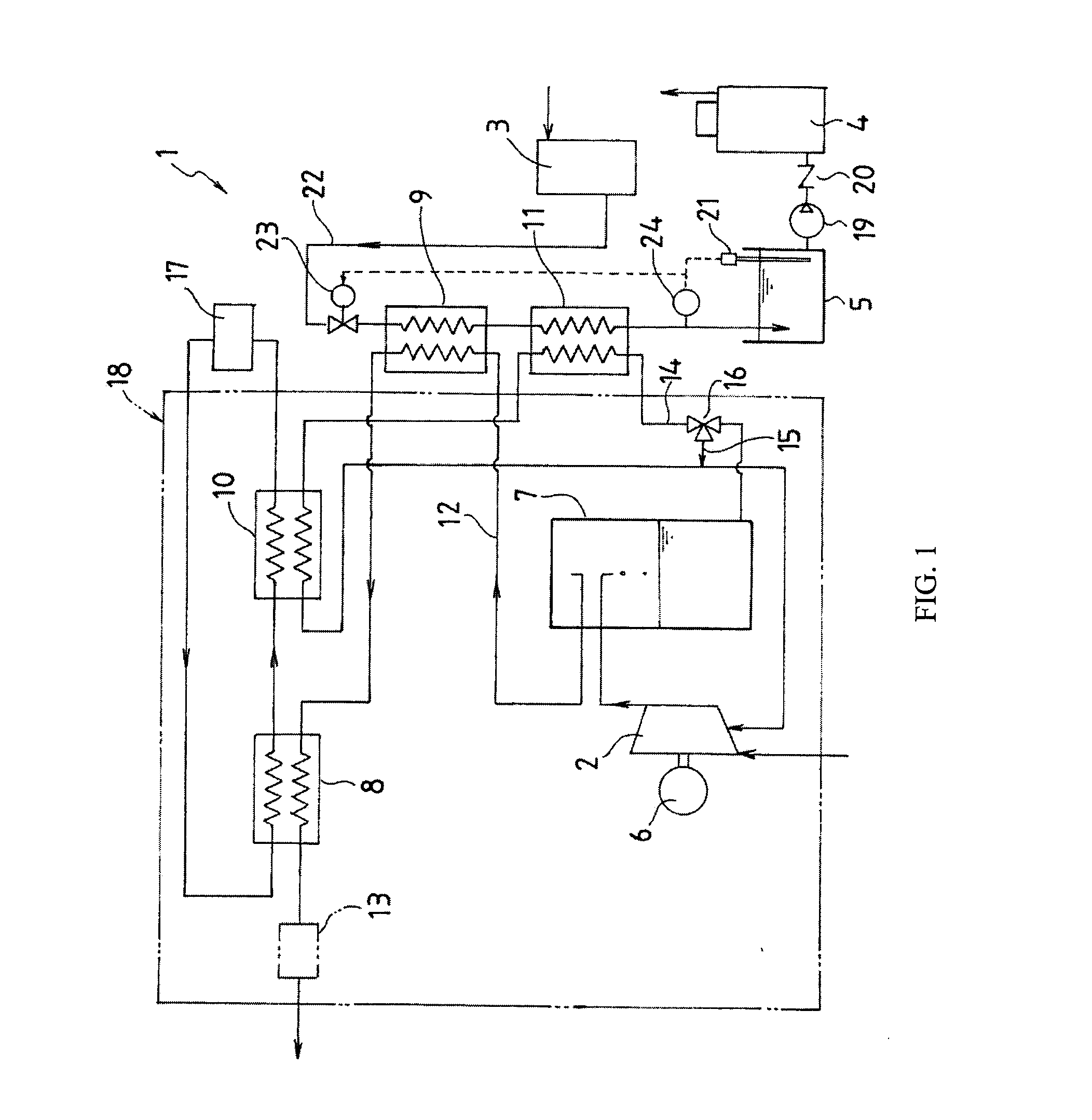

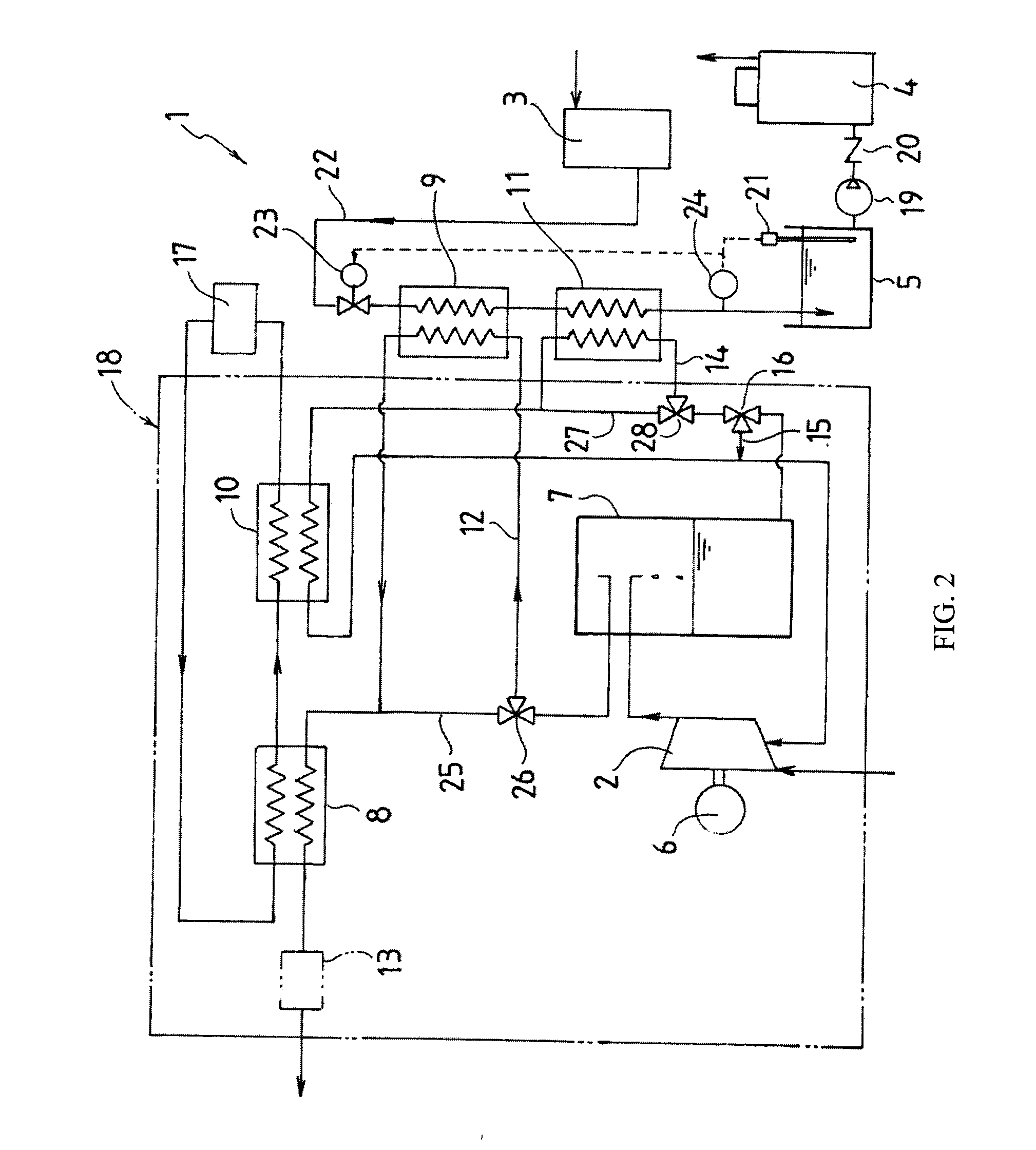

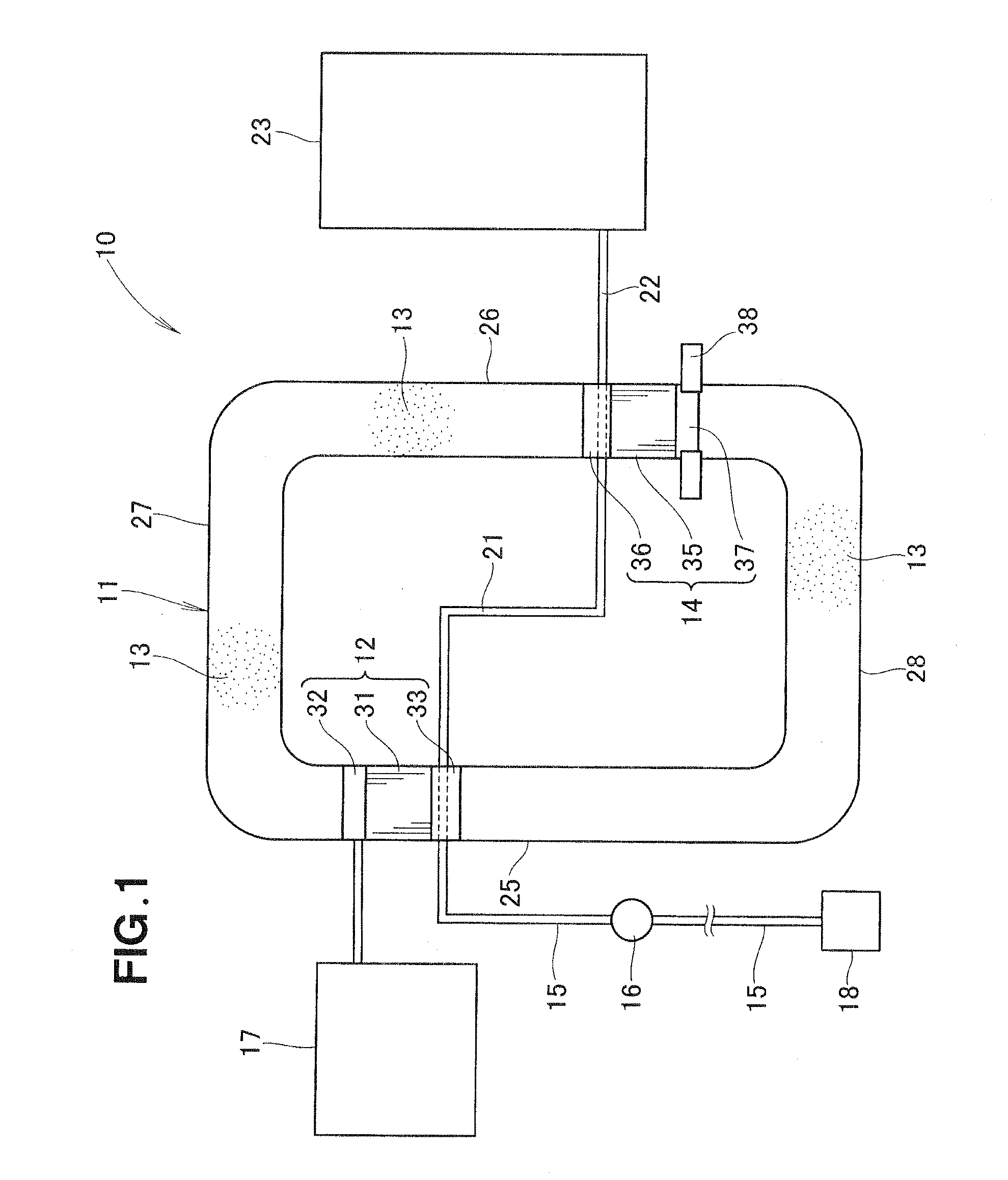

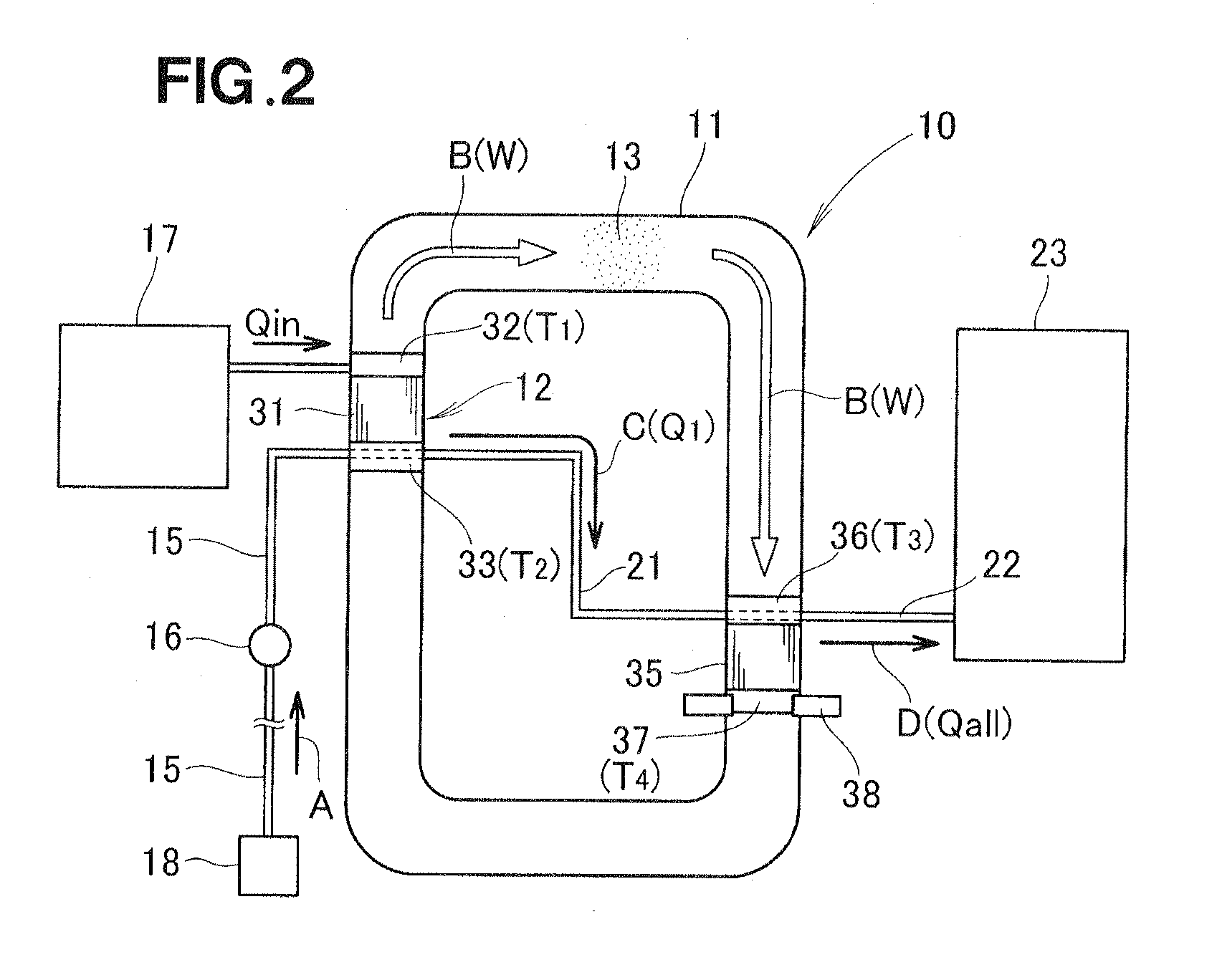

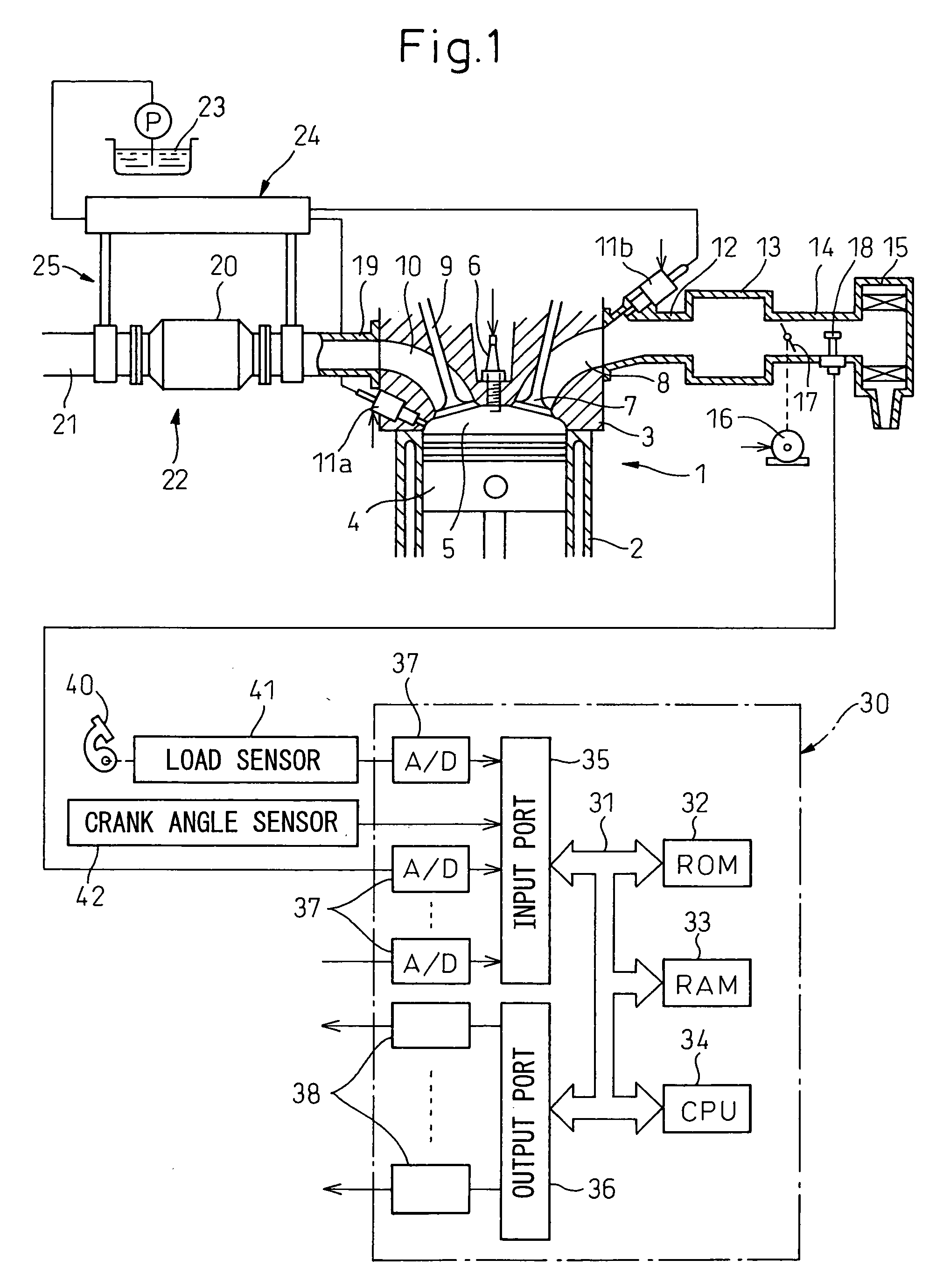

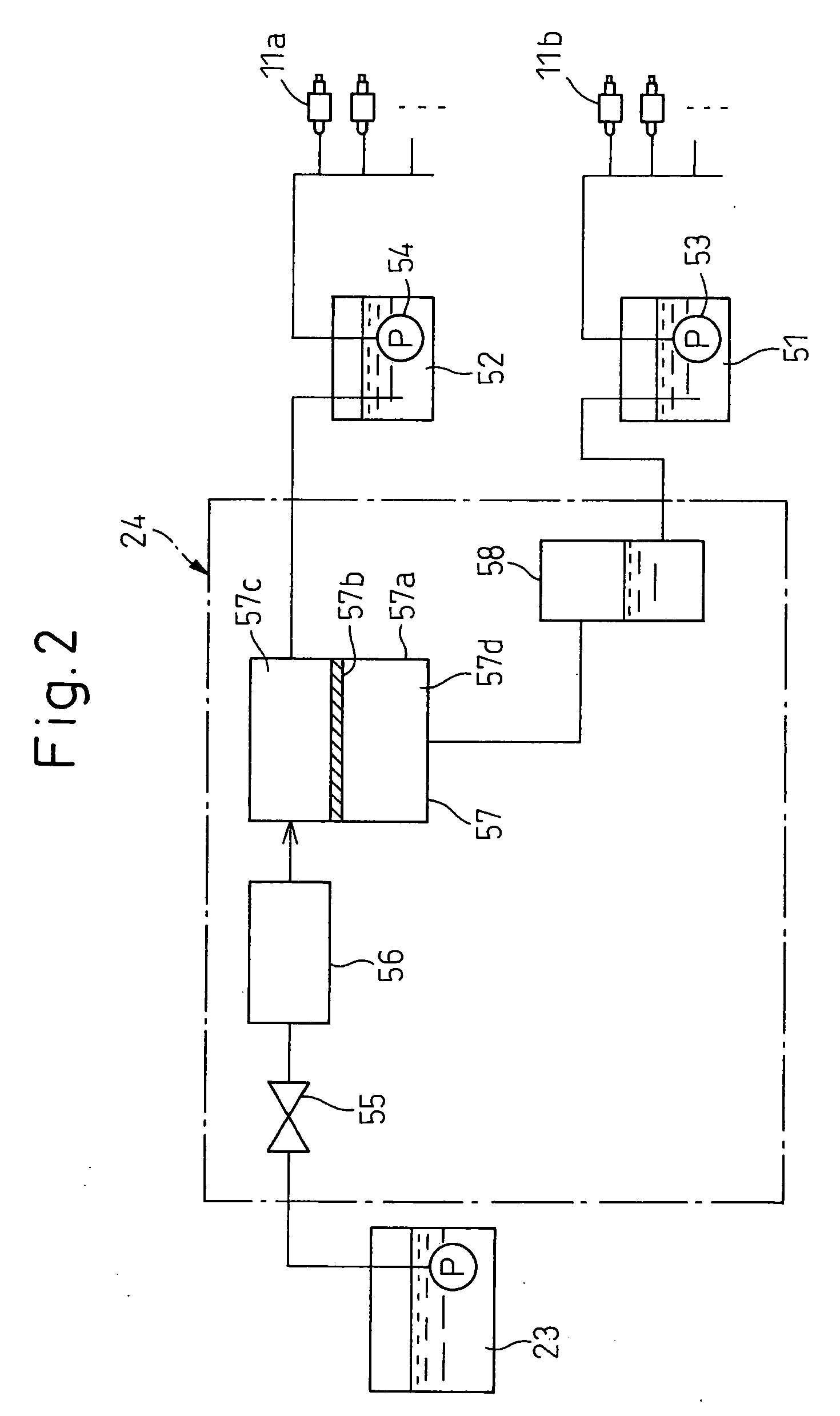

Air conditioning apparatus

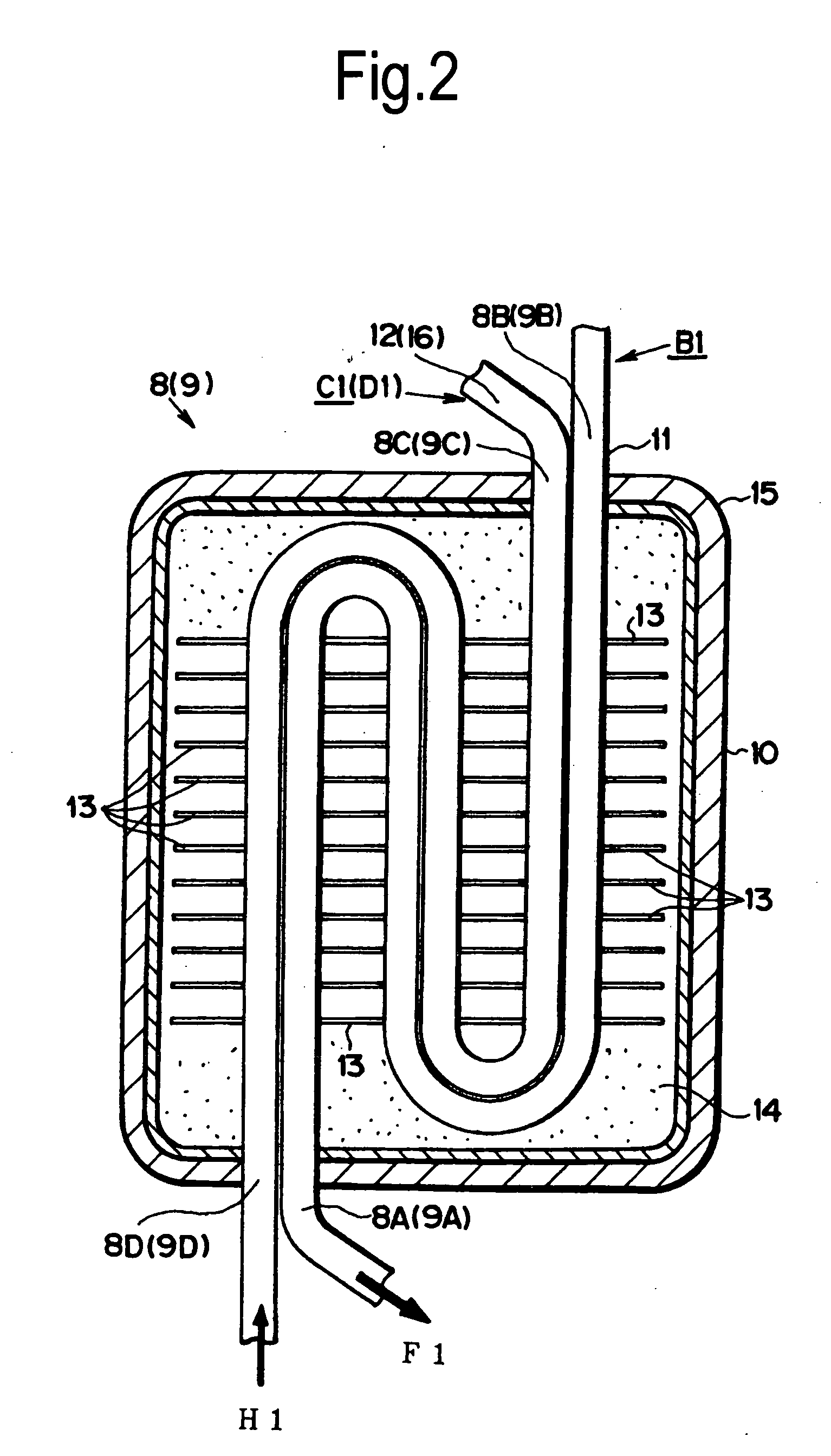

InactiveUS20060032623A1Efficient heat transferImprove heat transfer efficiencyHeat storage plantsDesuperheatersEngineeringHeat exchanger

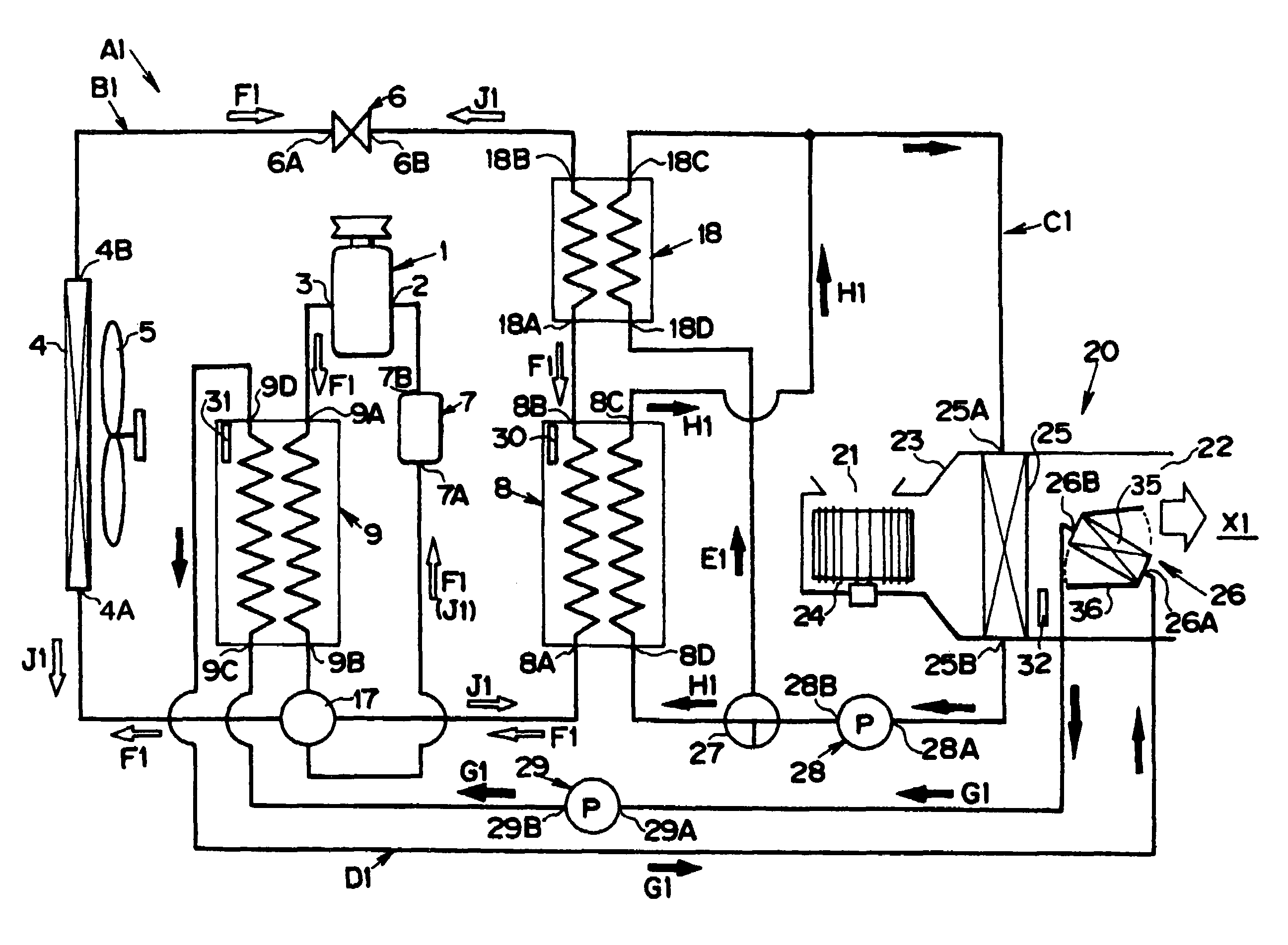

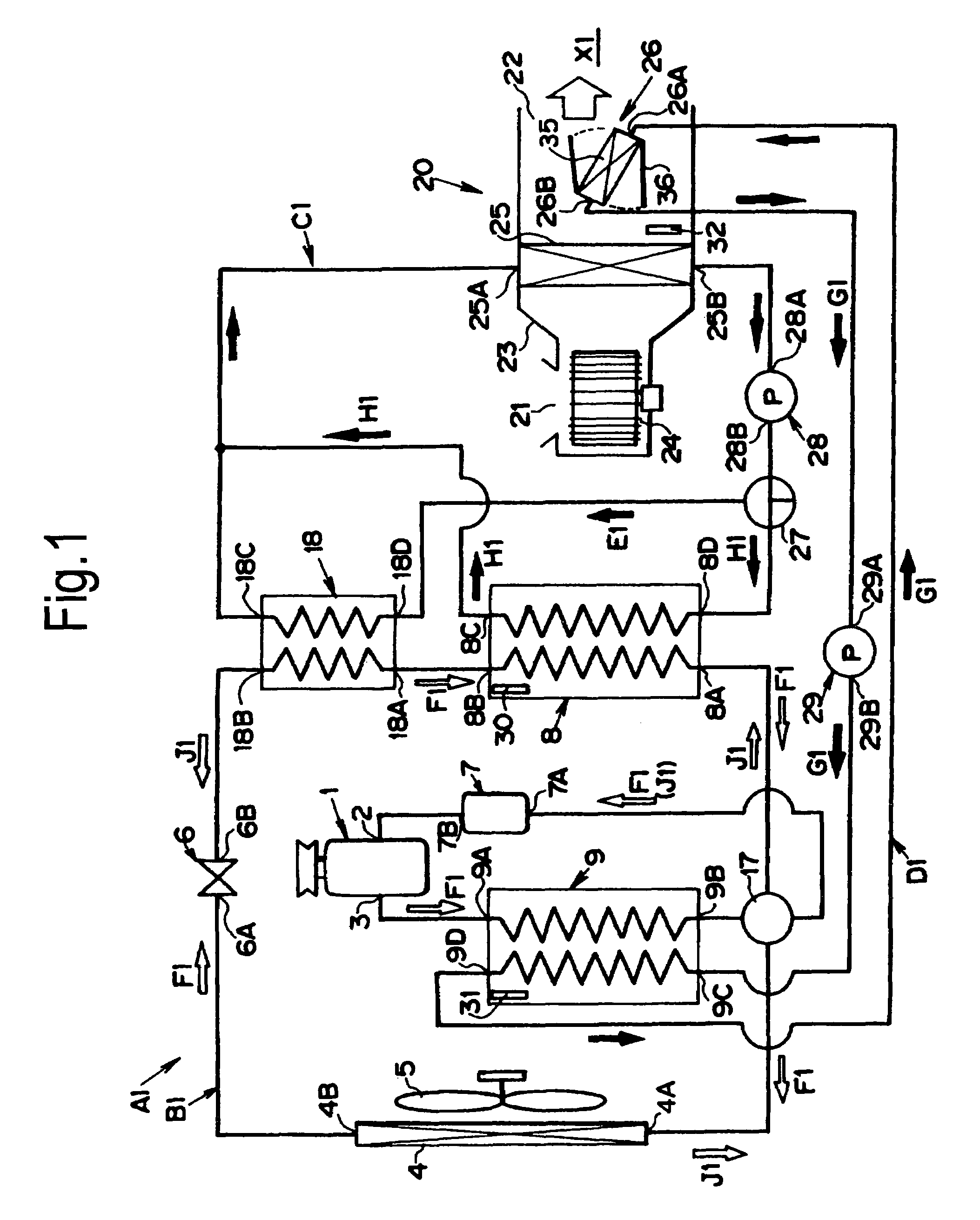

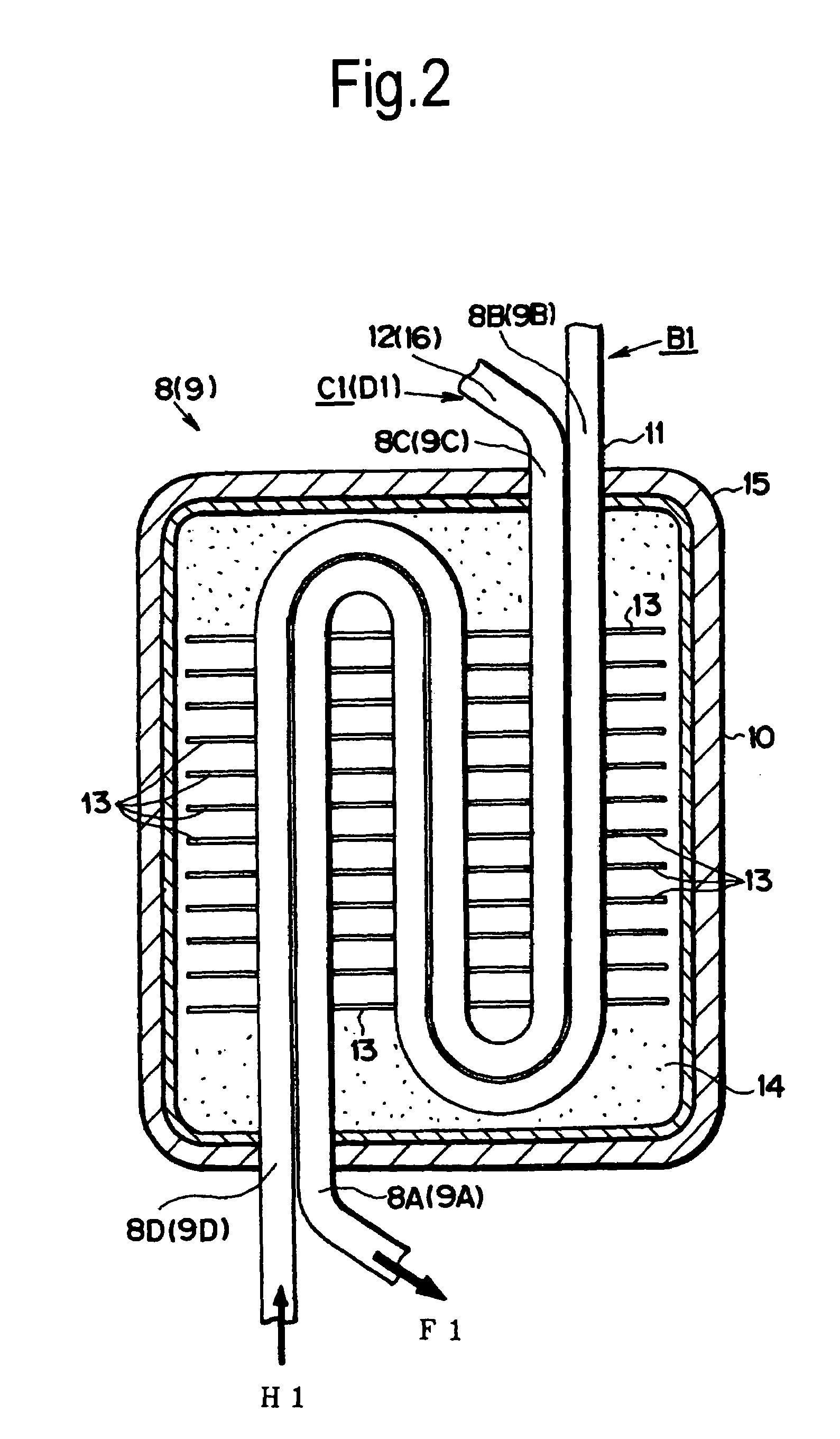

An air conditioning system for cooling or heating an air, and for feeding the heated or cooled air to predetermined portions is characterized by comprising: a first circulating circuit for circulating a first heating medium; a second circulating circuit for circulating a second heating medium; a control unit for controlling the heat for executing heat exchange between the first heating medium and the second heating medium to flow through either the heat exchanger or the first heat storing device. Moreover, an air temperature is controlled by heat of the second heating medium.

Owner:TOYOTA JIDOSHA KK

Hydronic rooftop cooling systems

InactiveUS7322205B2Improve efficiencyEasy to controlEnergy recovery in ventilation and heatingHeat recovery systemsAir filterRefrigerant

Owner:DAVIS ENERGY GROUP

Air conditioning apparatus

InactiveUS7669647B2Increase fuel consumptionImpact engine loadOther heat production devicesHeat storage plantsEngineeringAir conditioning

An air conditioning system for cooling or heating an air, and for feeding the heated or cooled air to predetermined portions is characterized by comprising: a first circulating circuit for circulating a first heating medium; a second circulating circuit for circulating a second heating medium; a control unit for controlling the heat for executing heat exchange between the first heating medium and the second heating medium to flow through either the heat exchanger or the first heat storing device. Moreover, an air temperature is controlled by heat of the second heating medium.

Owner:TOYOTA JIDOSHA KK

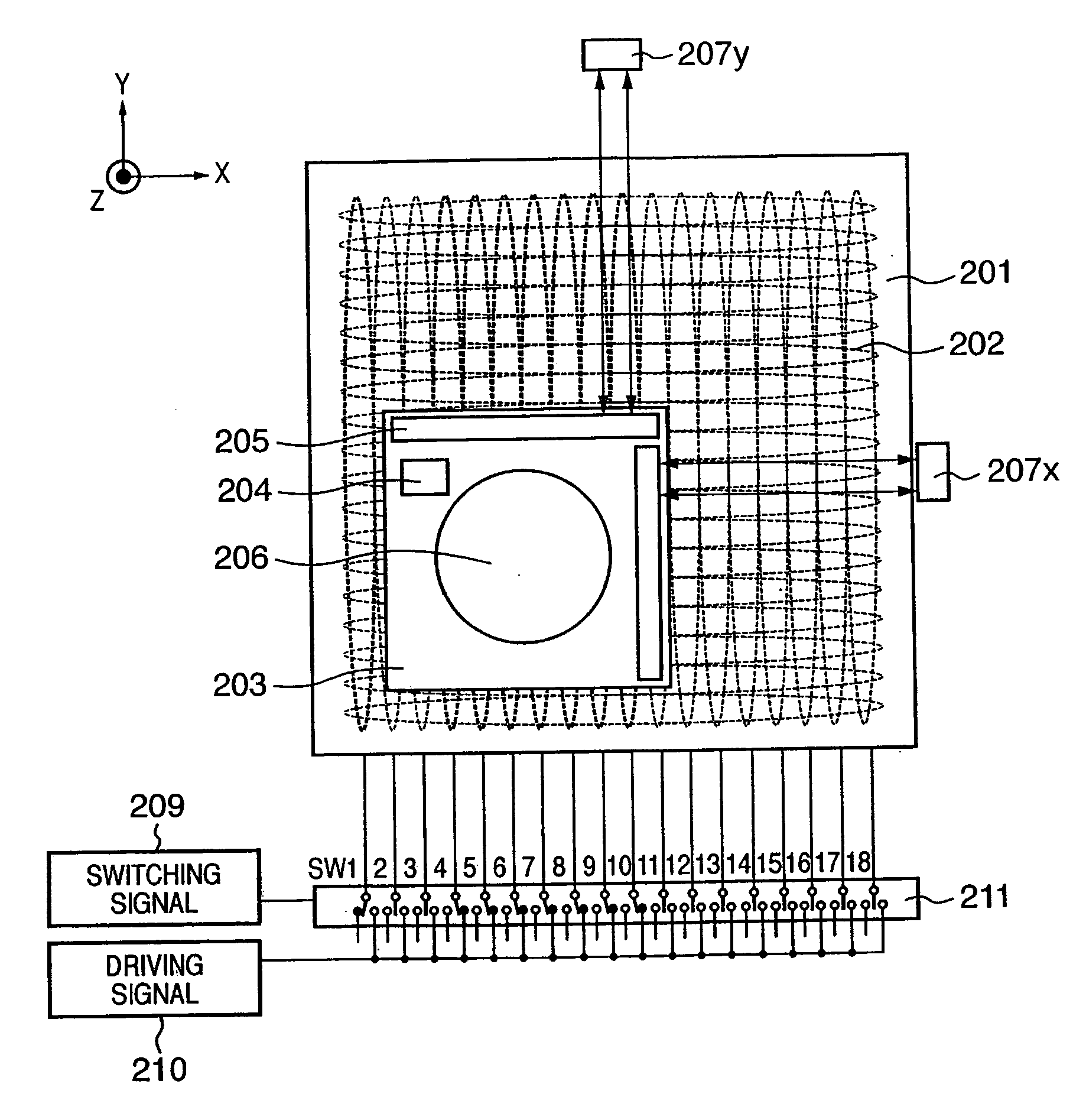

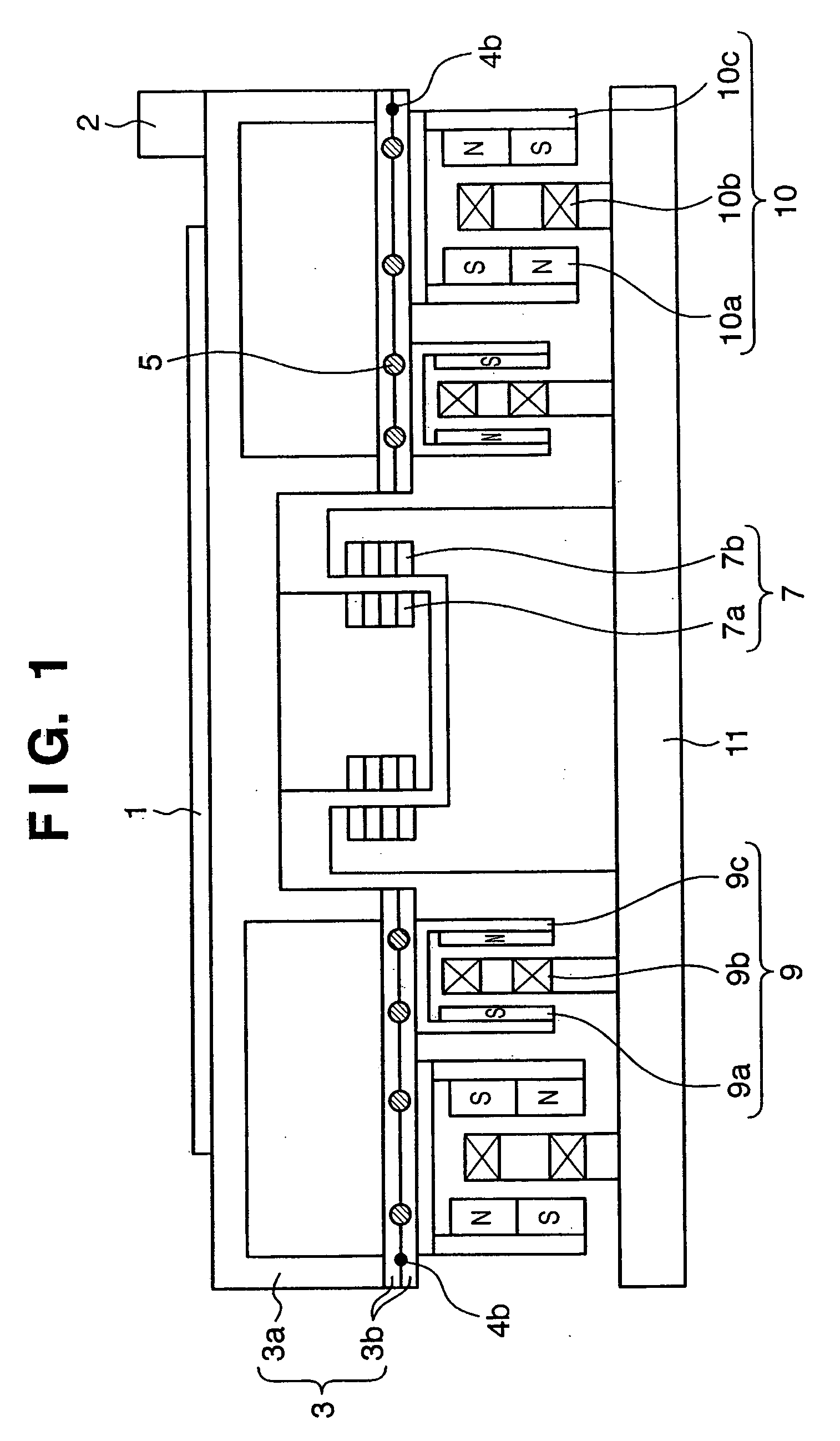

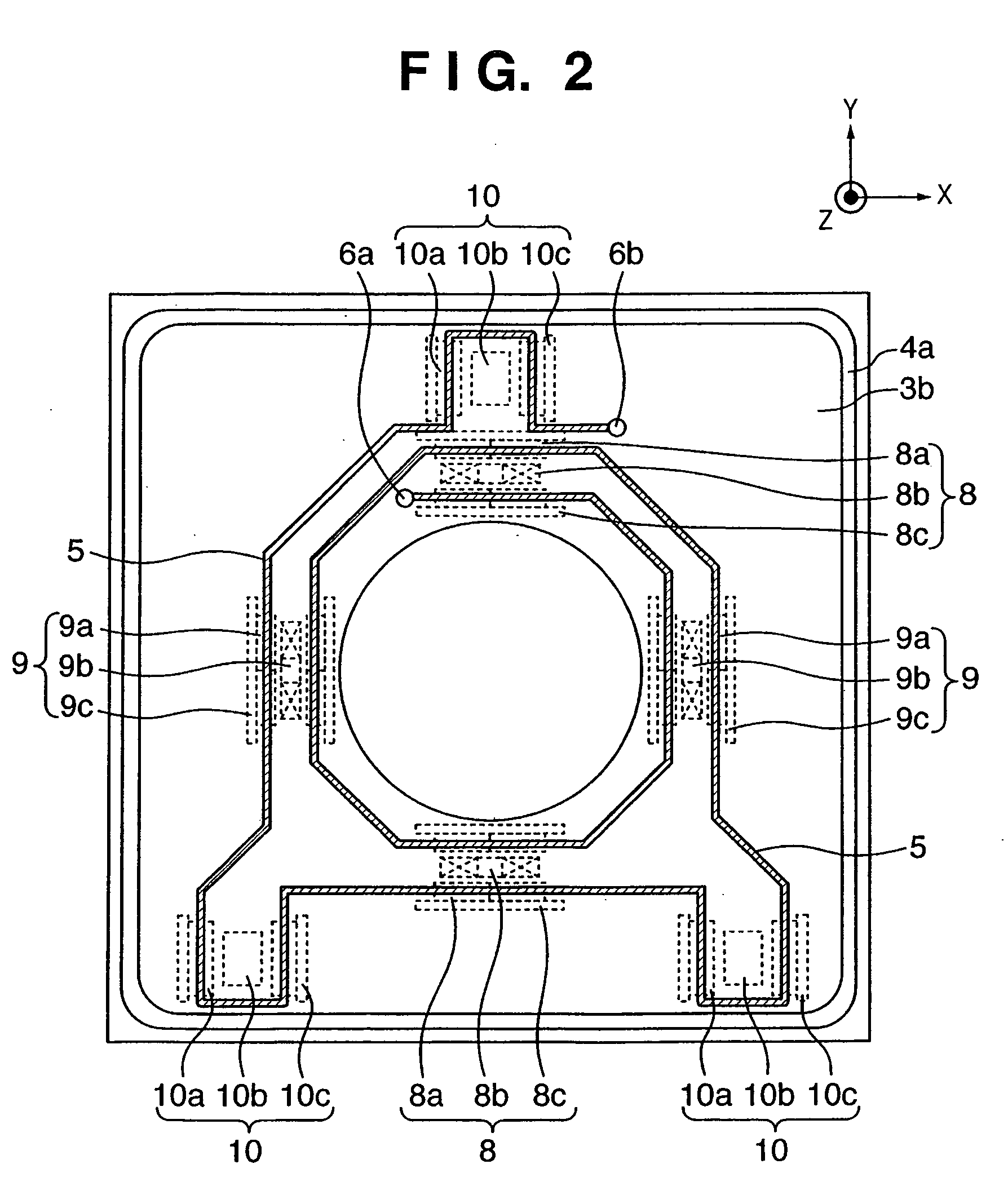

Alignment apparatus, exposure apparatus, and device manufacturing method

InactiveUS20060175993A1Reduce impactPrecise alignmentControl mechanismDC motor speed/torque controlEngineeringLinear motor

An alignment apparatus which moves a object comprises a first structure having a holding member which holds the object, a second structure having a magnet which constitutes a linear motor, the linear motor drives the first and second structure, and a flow passage formed between the holding member and the magnet.

Owner:CANON KK

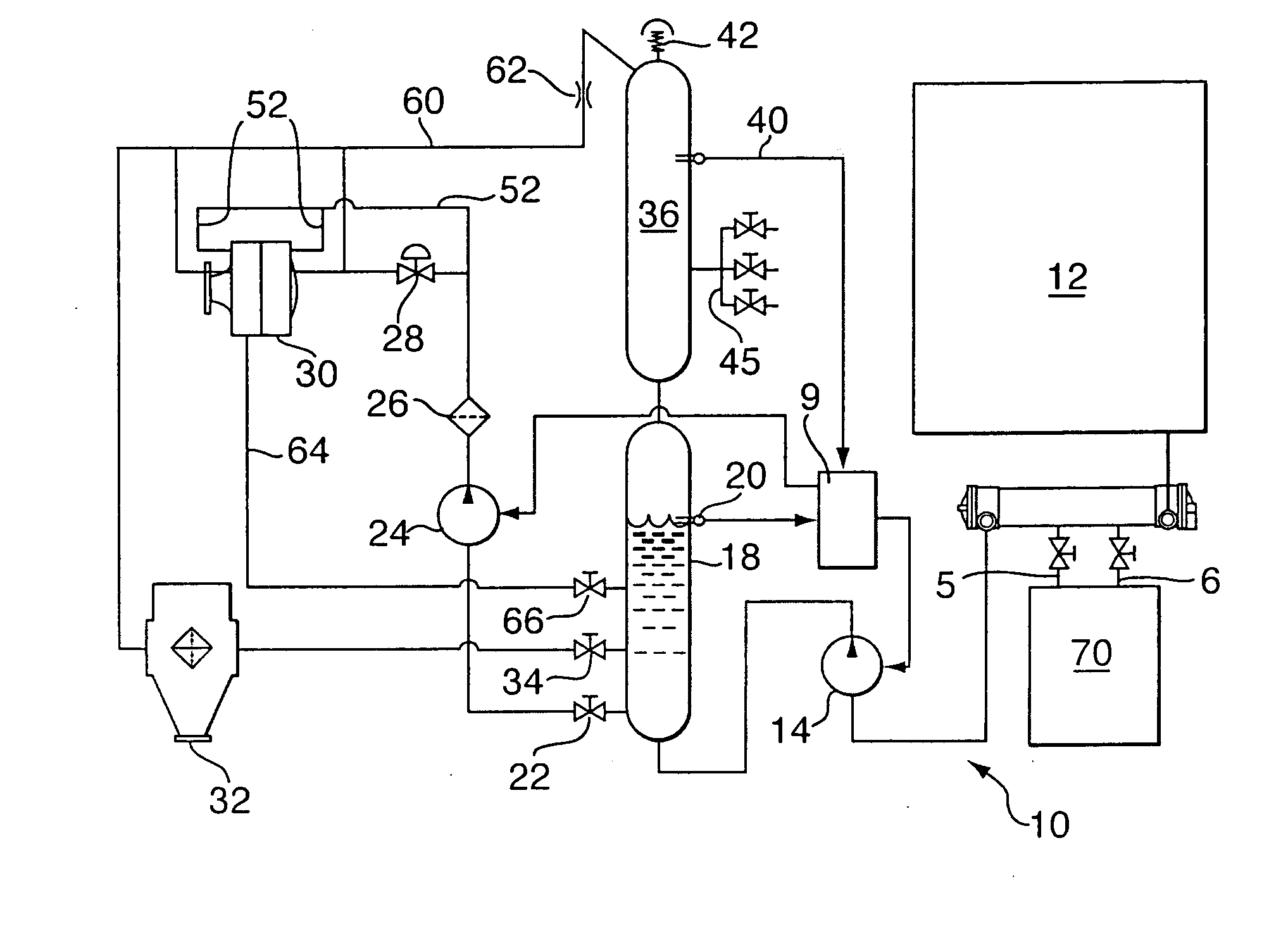

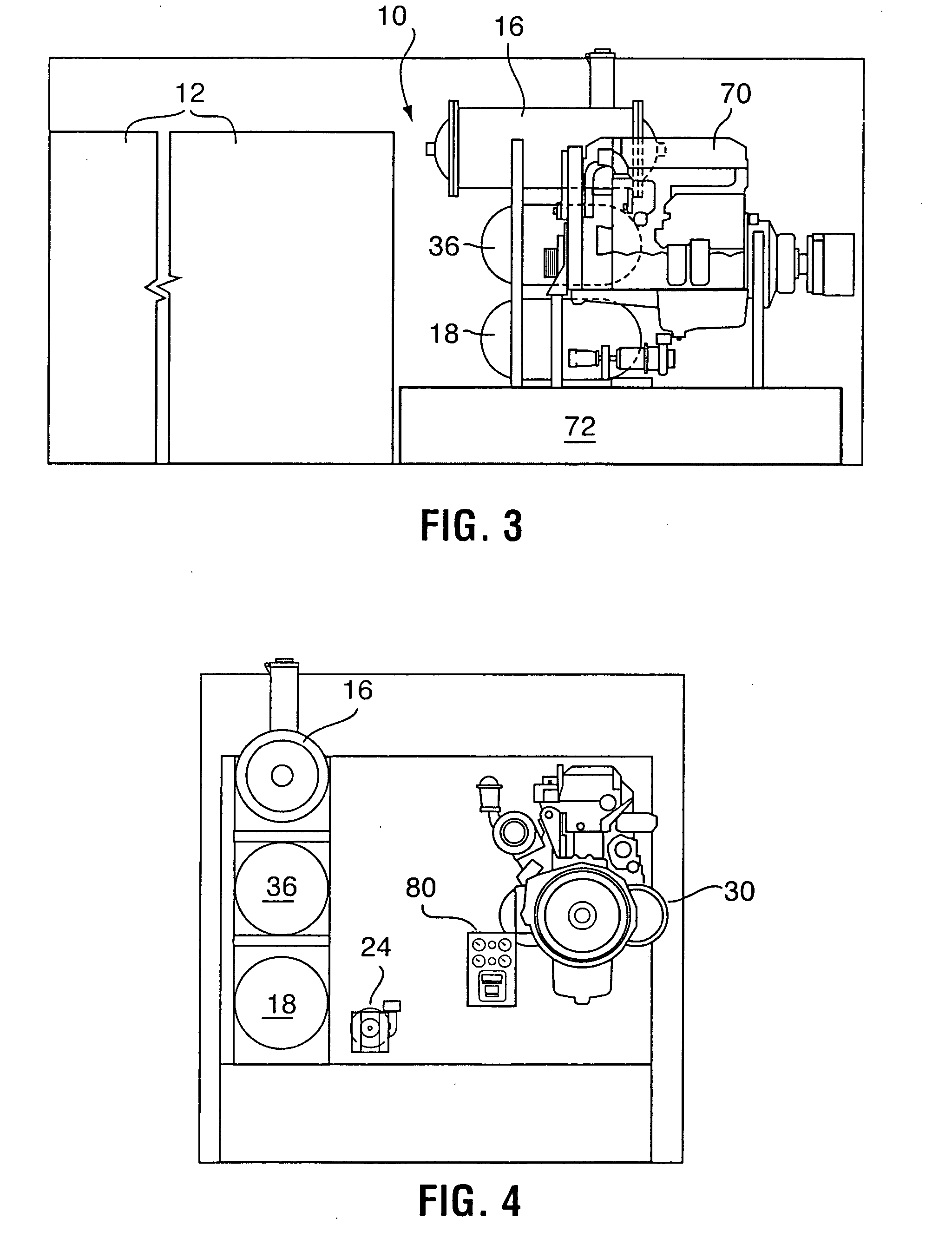

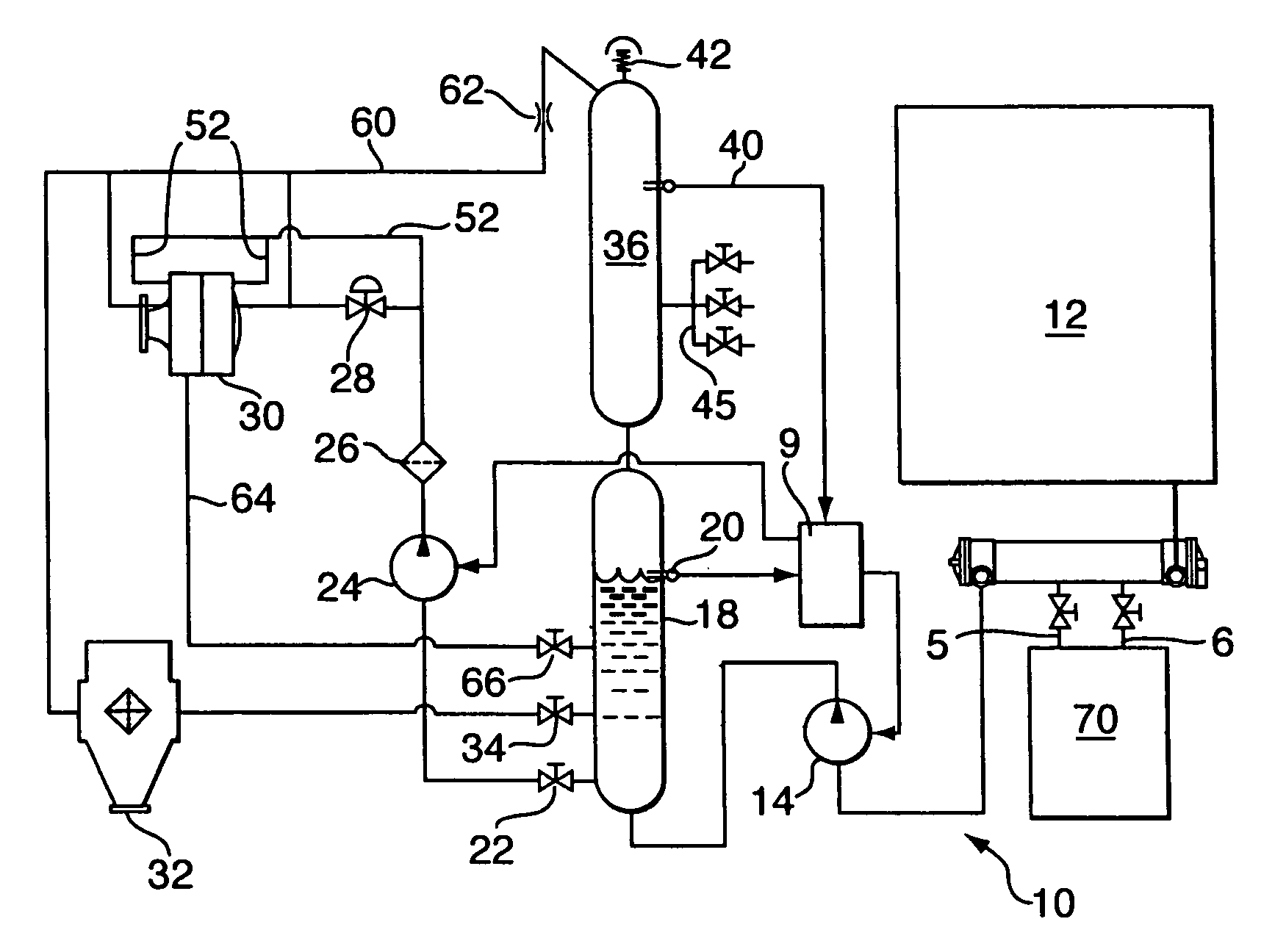

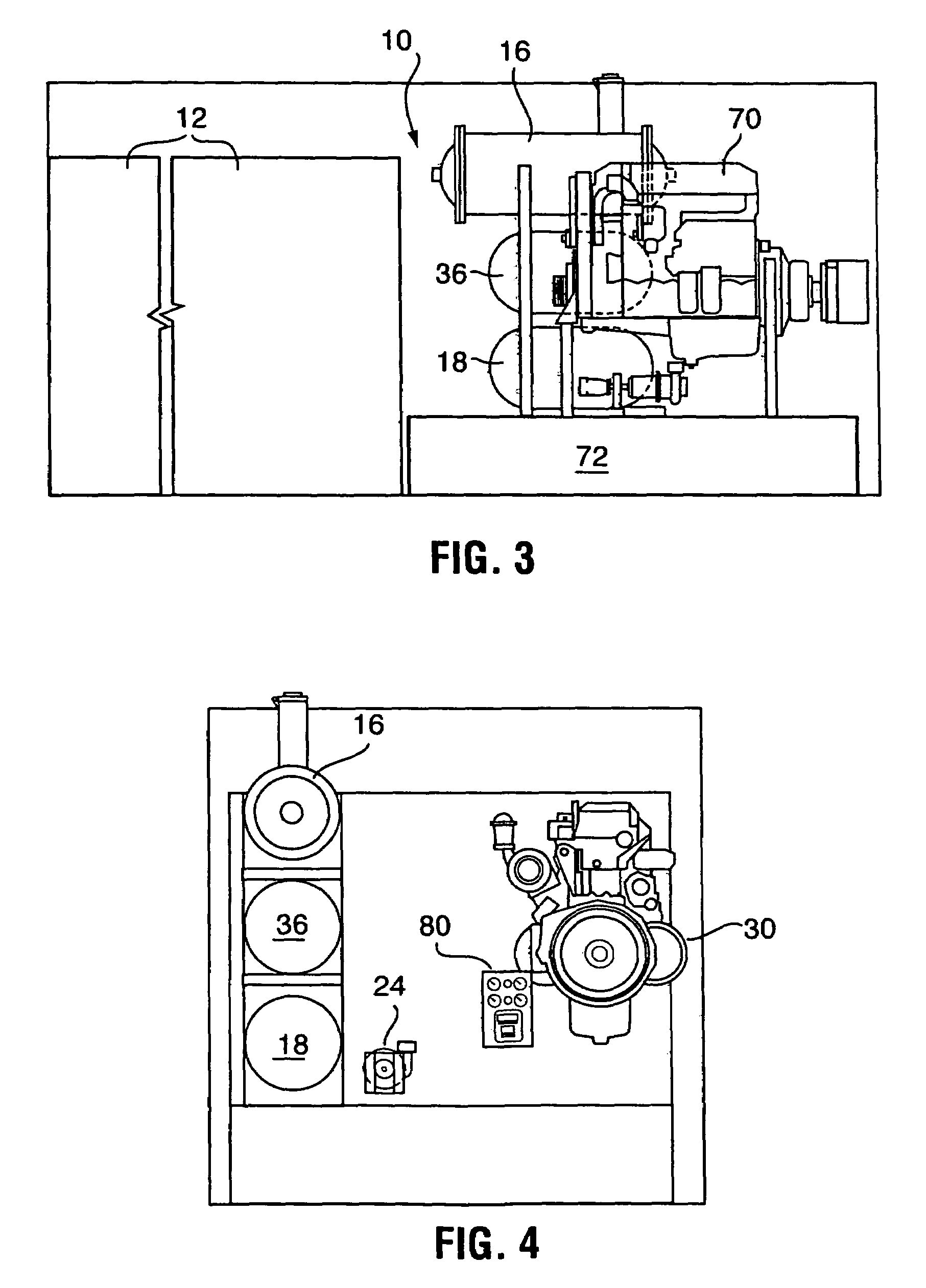

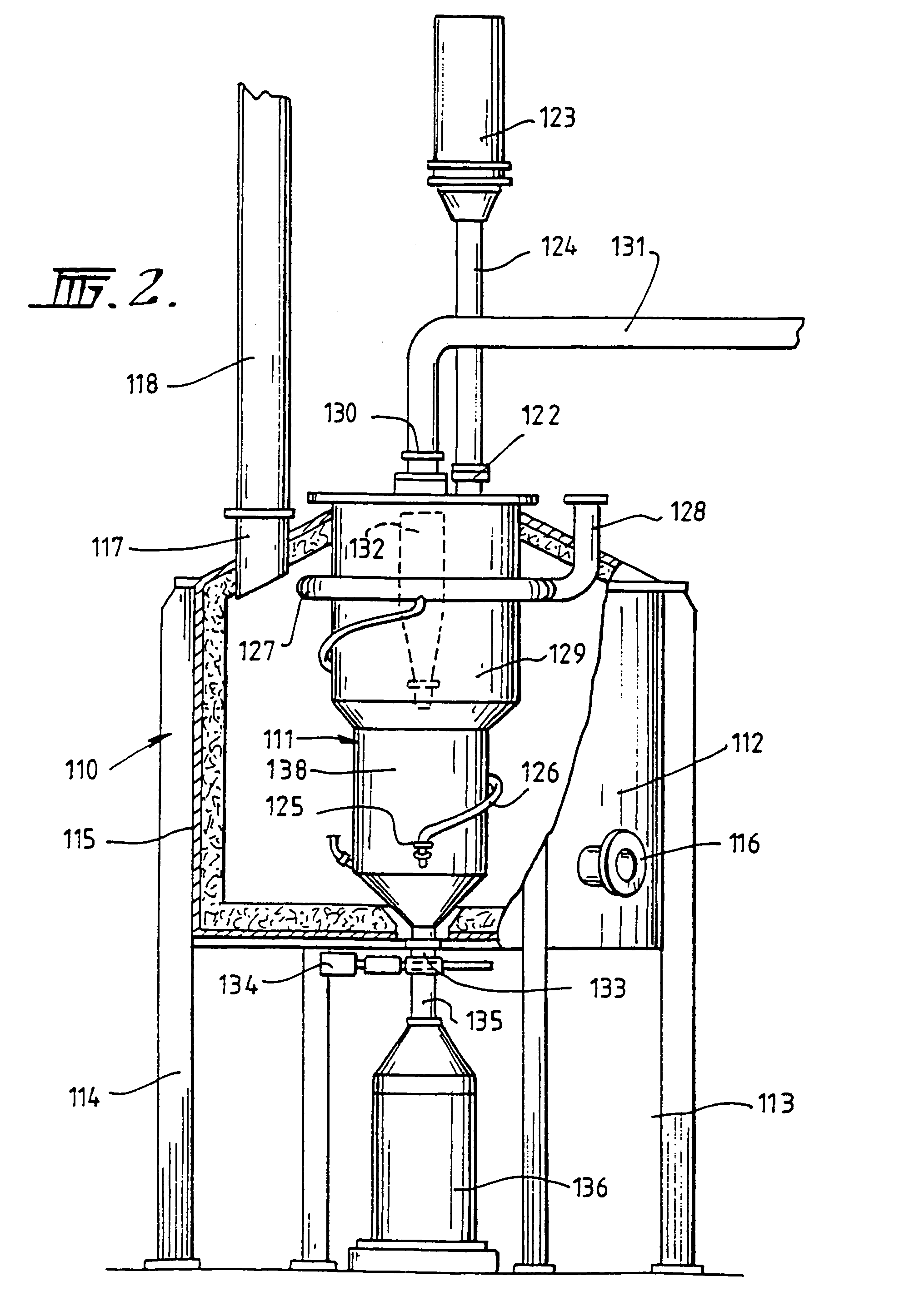

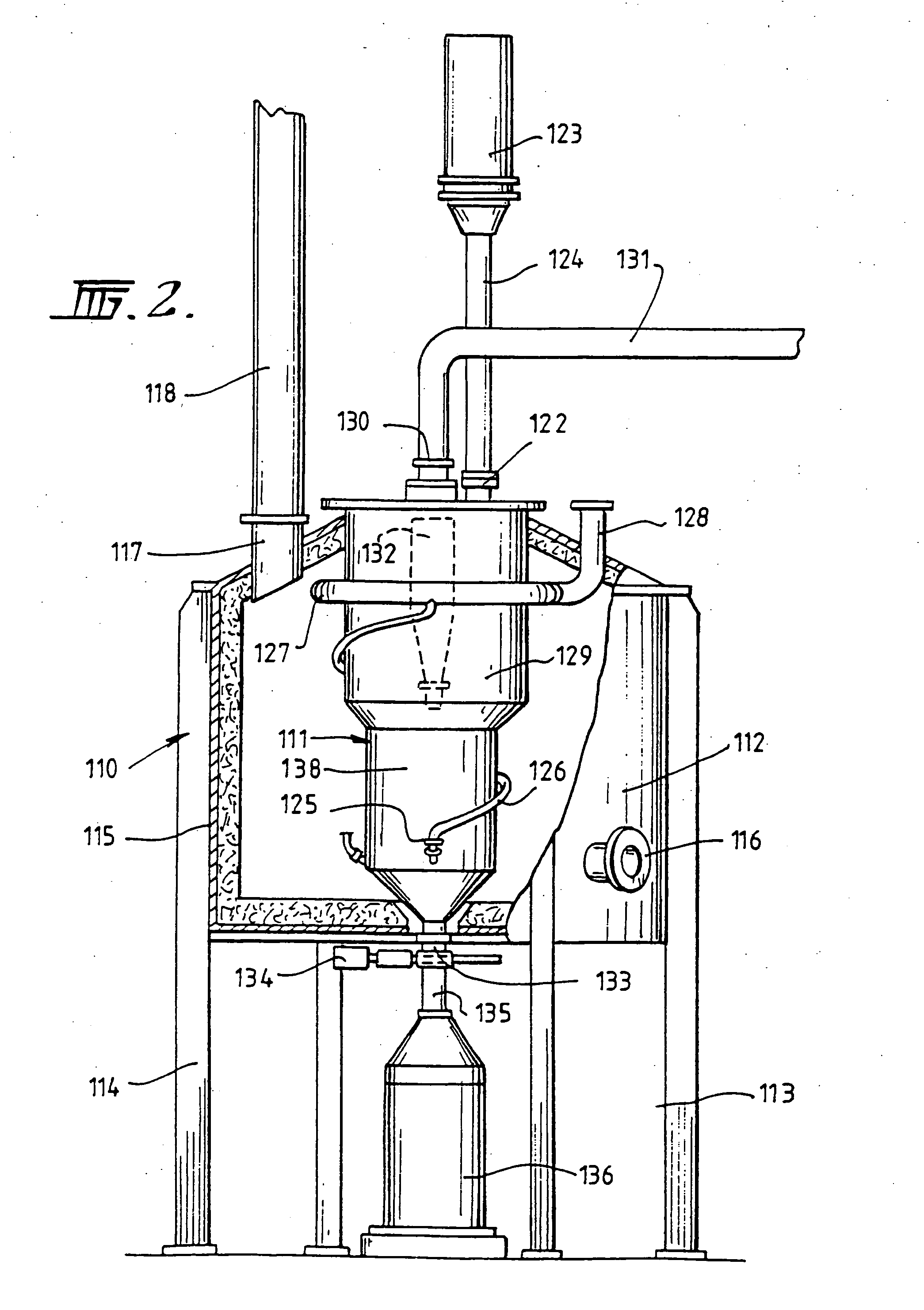

Flameless boiler

InactiveUS20060185621A1Heat recoverySaving weightSteam generation using mechanical energyDomestic stoves or rangesEngineeringFluid pressure

A flameless boiler comprising generator means for generating heat in fluid circulated therethrough by shearing of the fluid; a prime mover drivingly connected to the generator means for shearing of the fluid; a supply reservoir for the fluid; a first pump for circulating the fluid from the supply reservoir to the generator means; and a pressure vessel in fluid communication with the generator means for receiving heated fluid therefrom, the pressure vessel having an outlet for drawing steam therefrom.

Owner:LEADER ENERGY SERVICES

Flameless boiler

InactiveUS7637232B2Heat recoverySaving weightSteam generation using mechanical energyAir-treating devicesEngineeringGenerators (Apparatus)

A flameless boiler comprising generator means for generating heat in fluid circulated therethrough by shearing of the fluid; a prime mover drivingly connected to the generator means for shearing of the fluid; a supply reservoir for the fluid; a first pump for circulating the fluid from the supply reservoir to the generator means; and a pressure vessel in fluid communication with the generator means for receiving heated fluid therefrom, the pressure vessel having an outlet for drawing steam therefrom.

Owner:LEADER ENERGY SERVICES

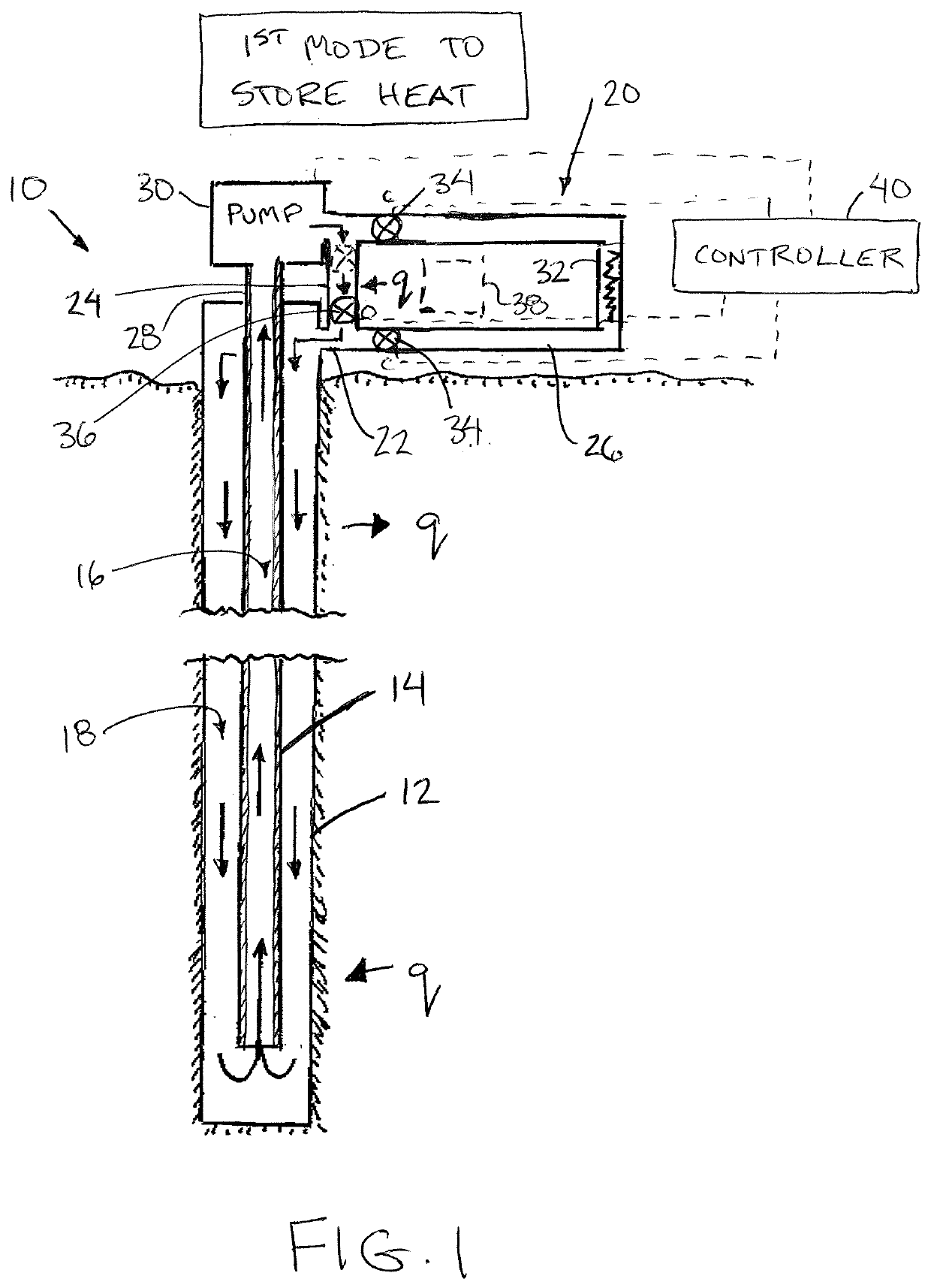

Geothermal system operable between heat recovery and heat storage modes

InactiveUS20200011573A1Reduce heat lossImprove efficiencyCollector components/accessoriesLighting and heating apparatusCold seasonThermodynamics

The geothermal system uses an outer and an inner pipe installed in a single borehole. Cool fluids are pumped down through one pipe and returned to the surface through the other pipe. Subterranean heat increases the temperature of the cool fluid and this heat is returned to the surface where the heated fluid is recovered. The fluid with the heat removed is then pumped back down the borehole to be re-heated. Extra heat recovered from the ground surrounding a lower portion of the borehole is stored in the ground and rock formation surrounding an upper portion of the borehole during warmer seasons to optimize the amount of heat stored in the ground for extraction during colder seasons.

Owner:GRAHAM PETER SAMUEL WINSTON +1

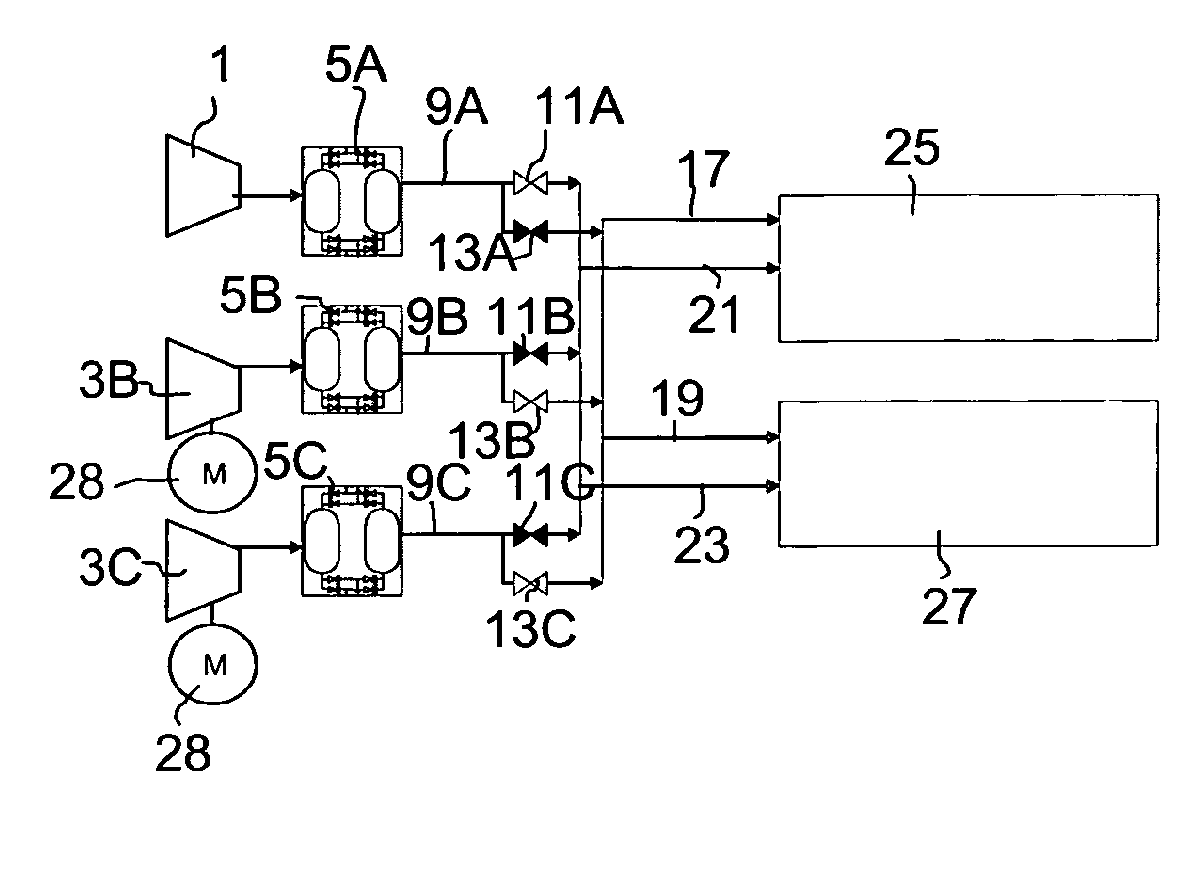

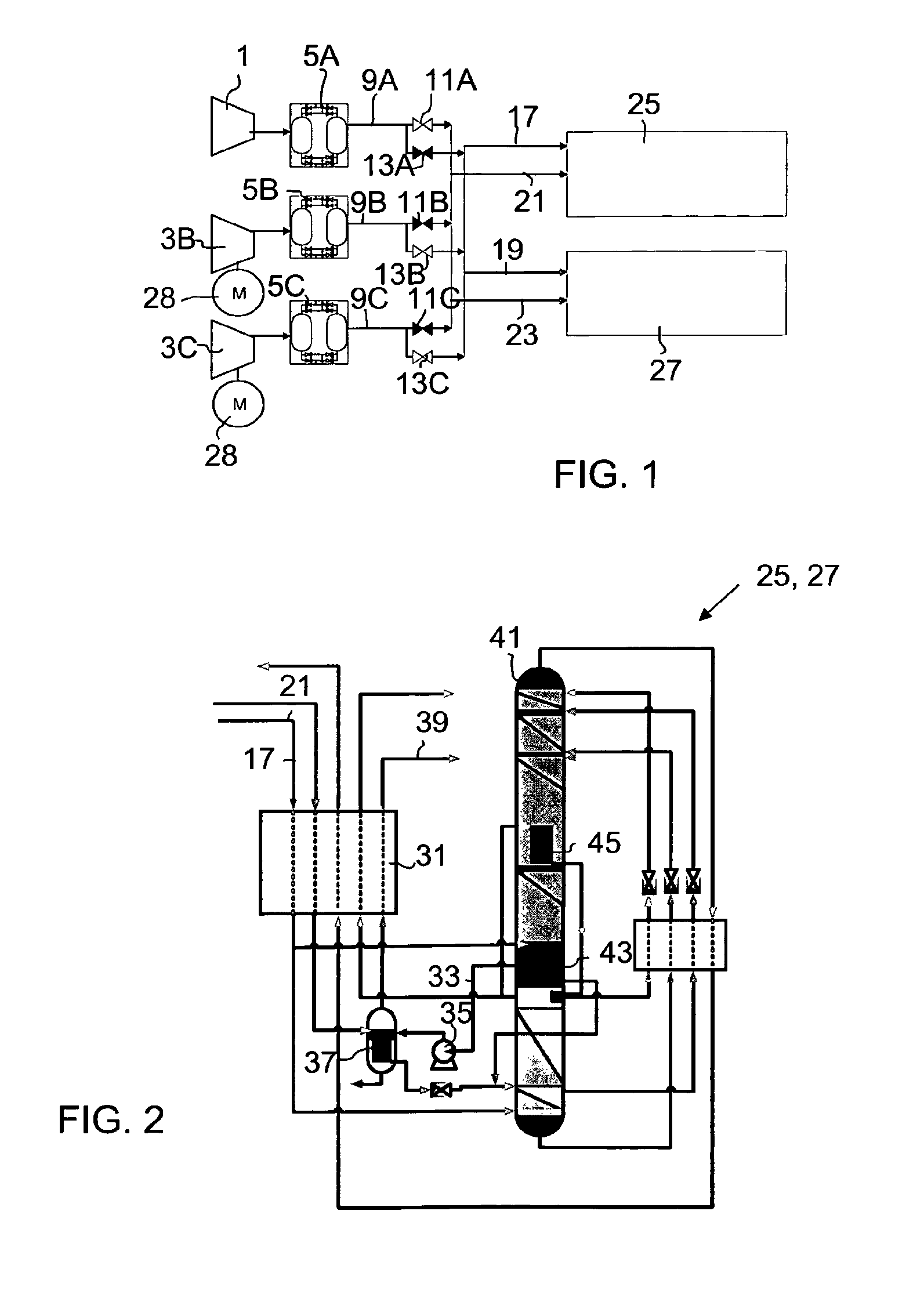

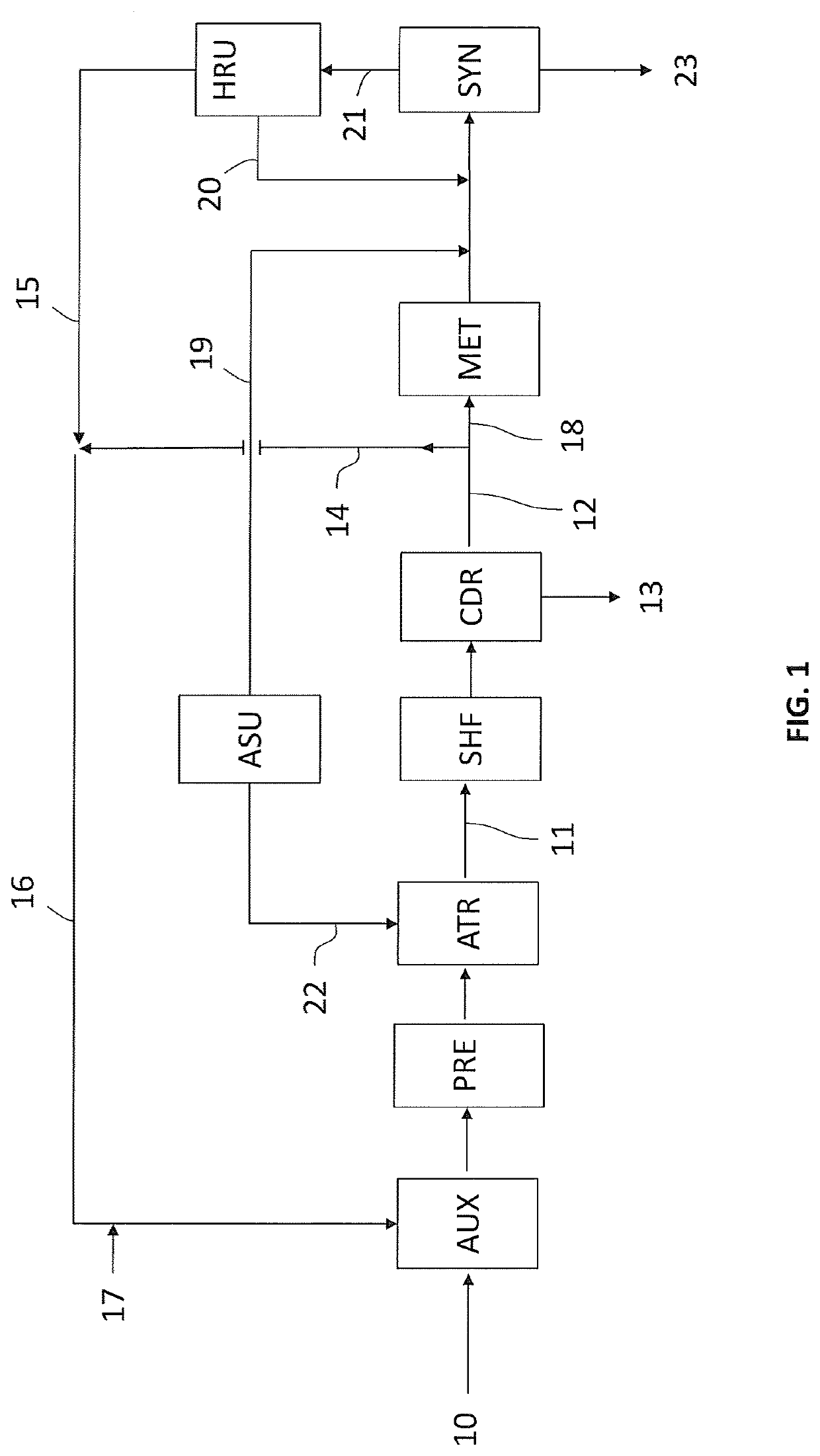

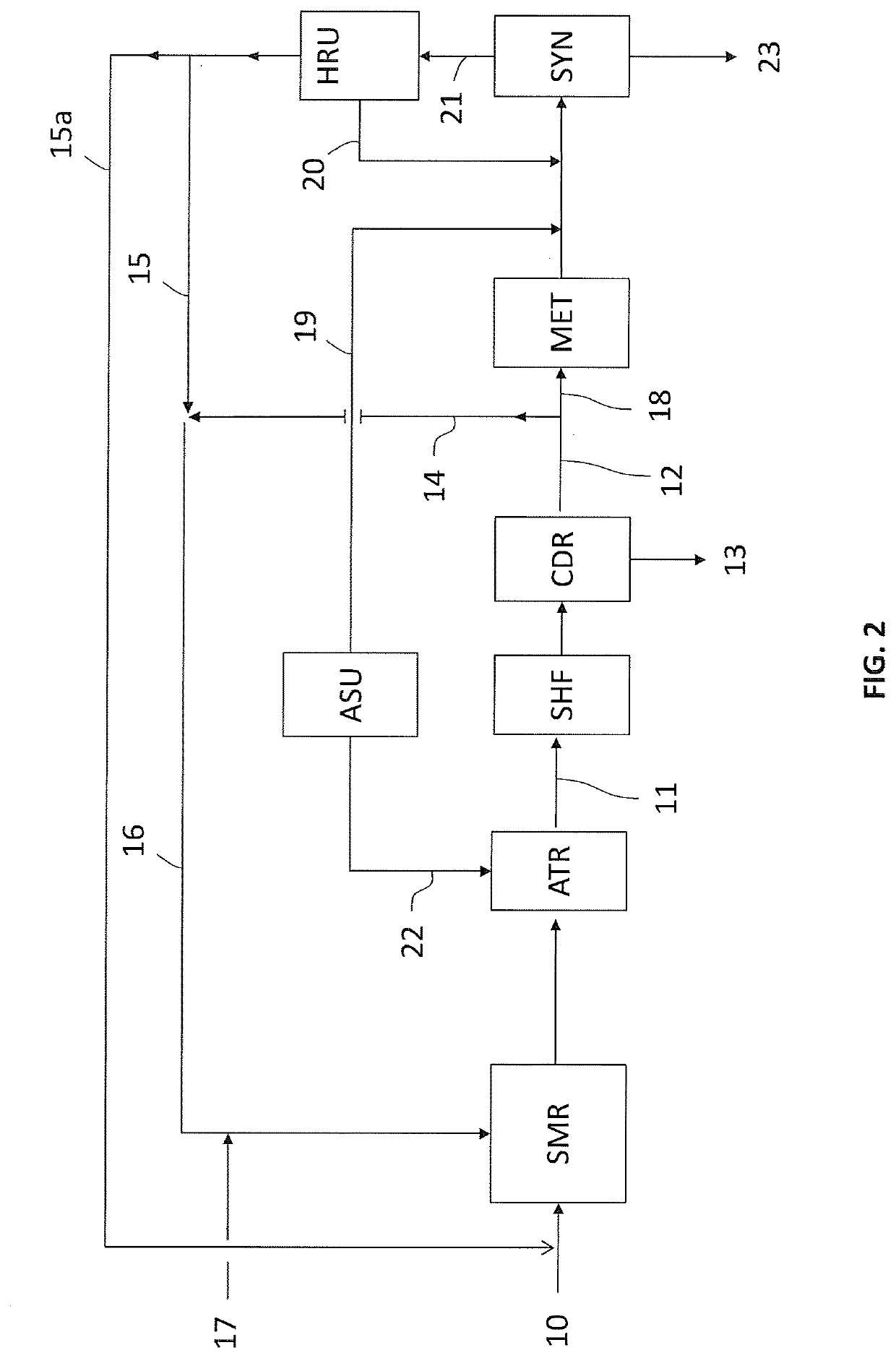

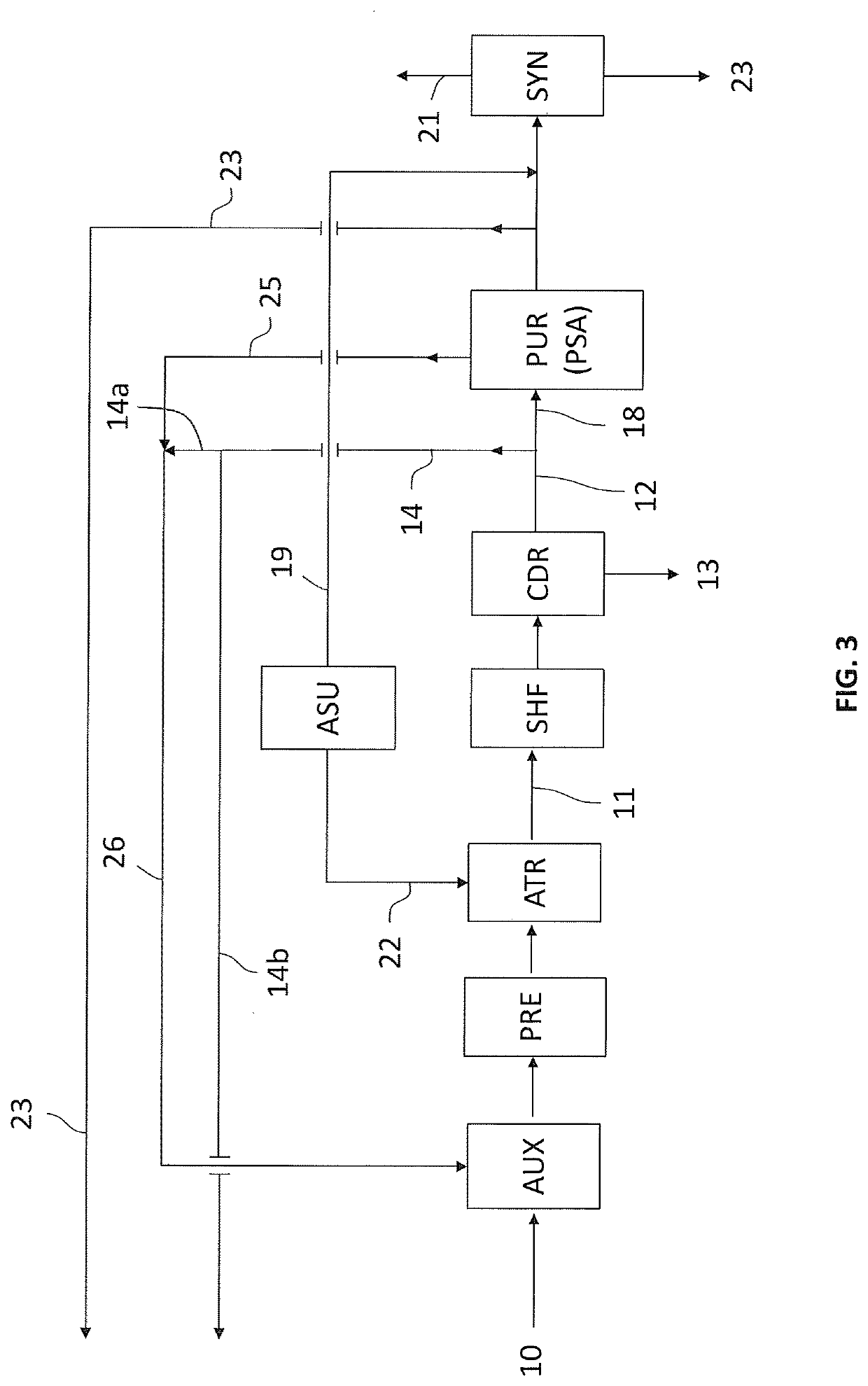

Air separation plant and process operating by cryogenic distillation

An air separation plant is provided that includes a plurality of air compressors, a plurality of air purification units, and one or more cold boxes. In a first mode of operation, a first air compressor is configured to compress air to a higher pressure than a second air compressor. In a second mode of operation, the second air compressor is configured to compress air to a higher pressure than during the first mode of operation.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

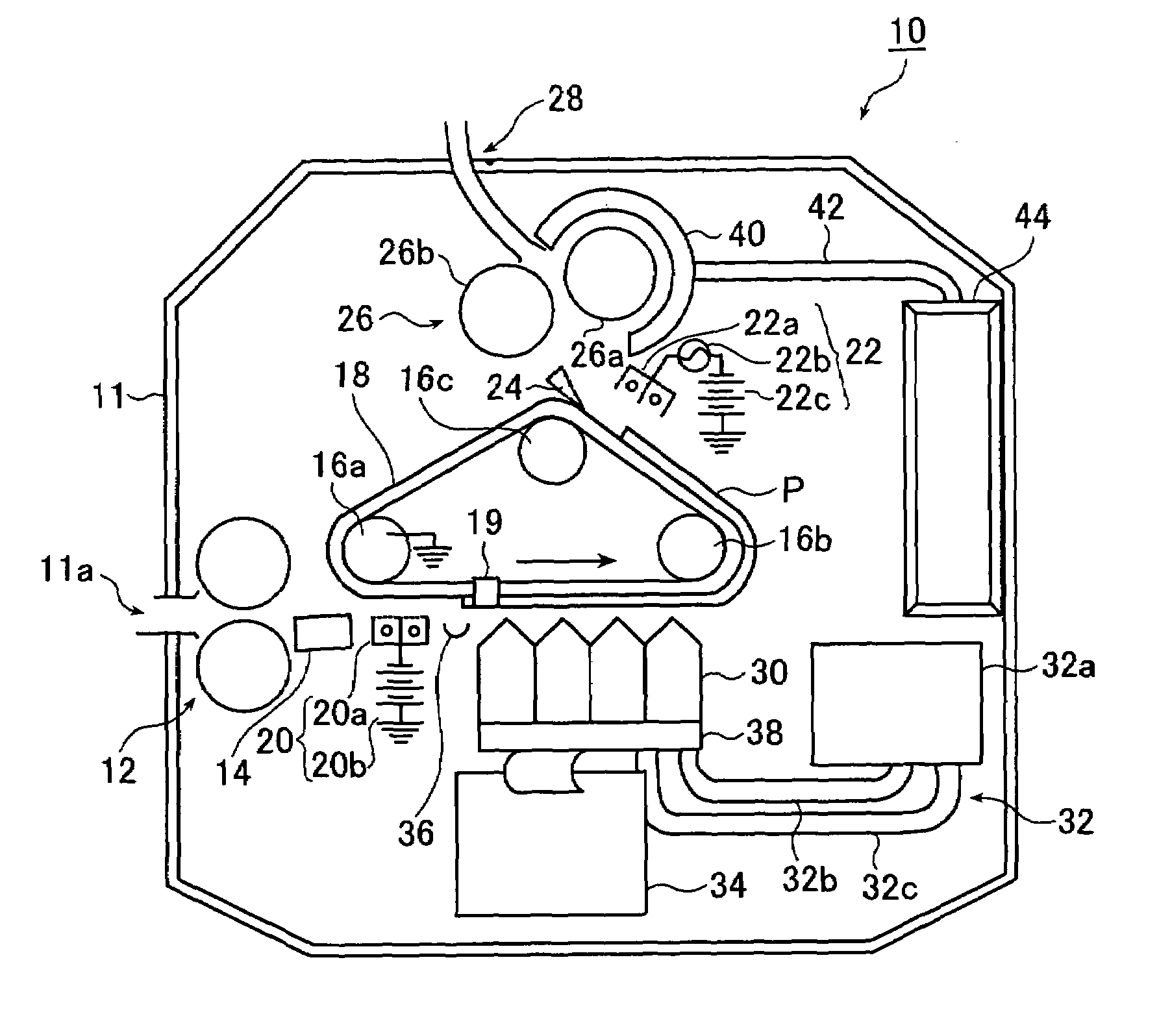

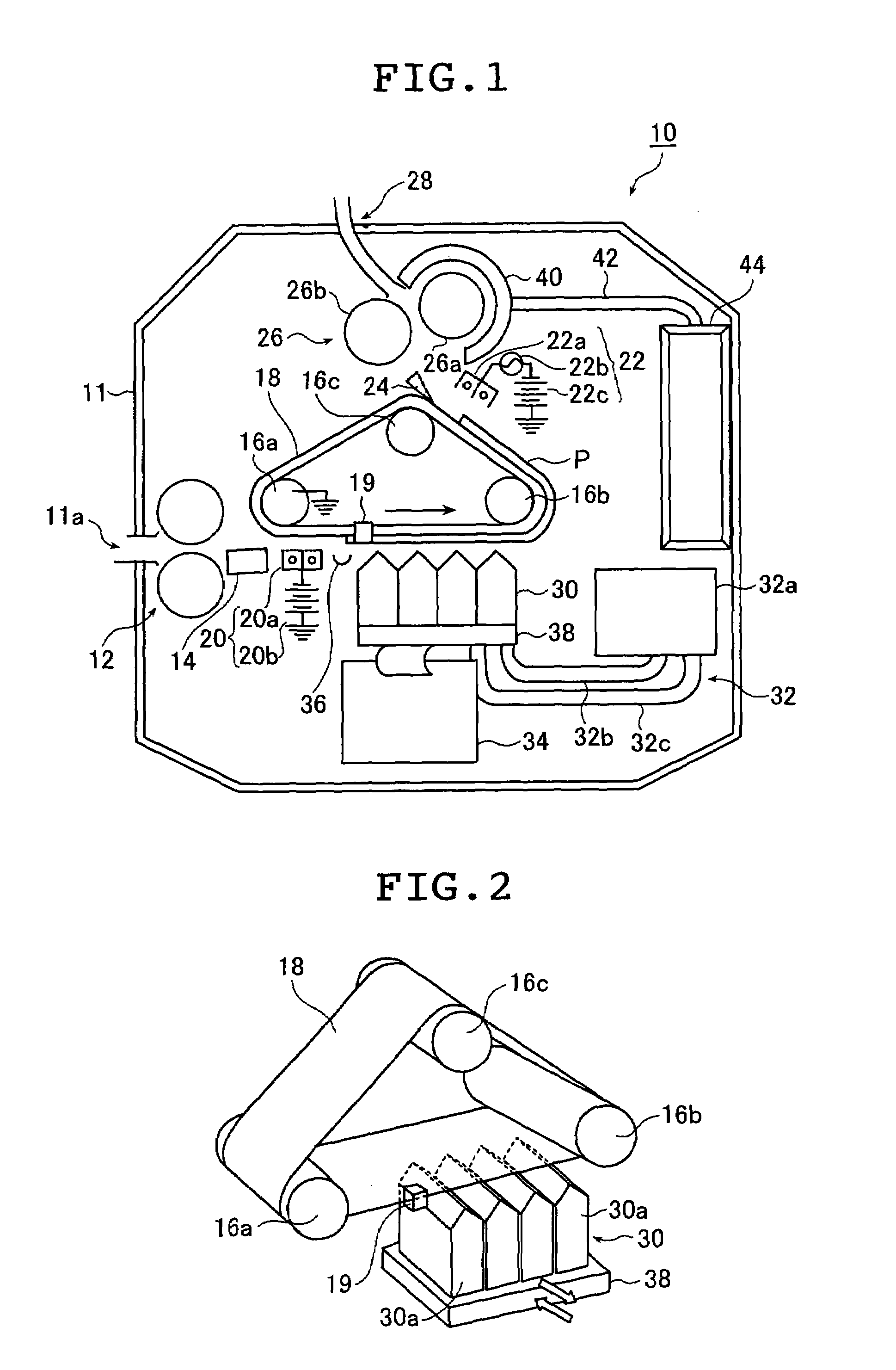

Ink jet recording apparatus

ActiveUS7182454B2Reduce the impactImprove maintainabilityOther printing apparatusImage formationEngineering

The ink jet recording apparatus includes an image forming device for forming an image on a recording medium by ejecting ink containing a solvent and color particles dispersed in the solvent, a fixing device for fixing the image formed on the recording medium by the image forming device, a collecting device for selectively collecting air containing the solvent from an atmosphere in proximity to the fixing device, and a removing device for removing the solvent from the solvent-containing air collected by the collecting device.

Owner:FUJIFILM HLDG CORP +1

Heat recovery system

InactiveUS20120090340A1Heat recoverySteam generation heating methodsCentral heating with accumulated heatEngineeringChiller

A heat recovery system includes a first air cooler for cooling compressed air from a compressor, a first oil cooler for cooling a lubricant from the compressor, and a second air cooler and / or a second oil cooler serving as a heat recovering heat exchanger. The second air cooler heats water with the heat of the compressed air to be fed to the first air cooler. In contrast, the second oil cooler heats water with the heat of a lubricant to be fed to the first oil cooler.

Owner:MIURA COMPANY LIMITED

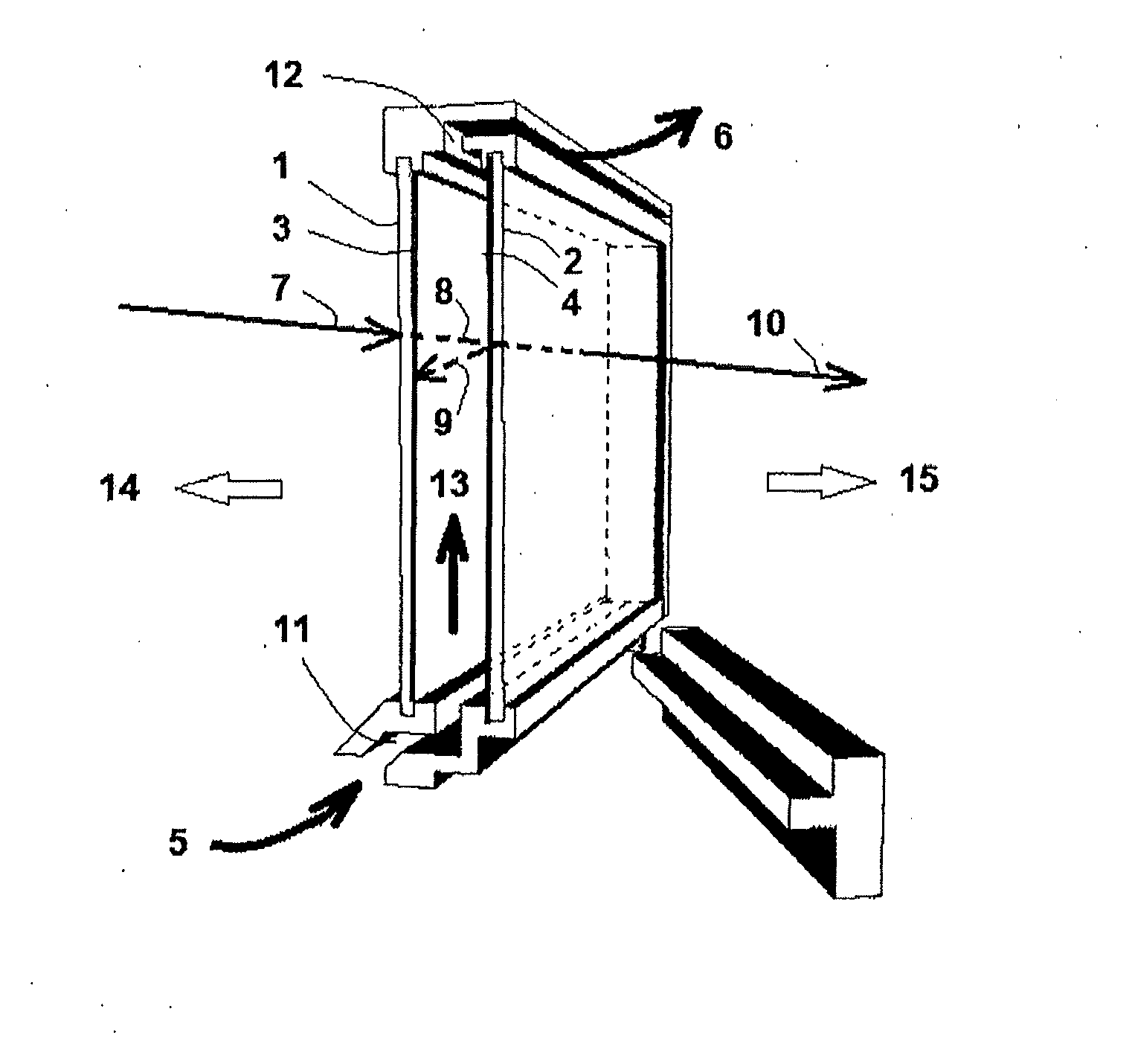

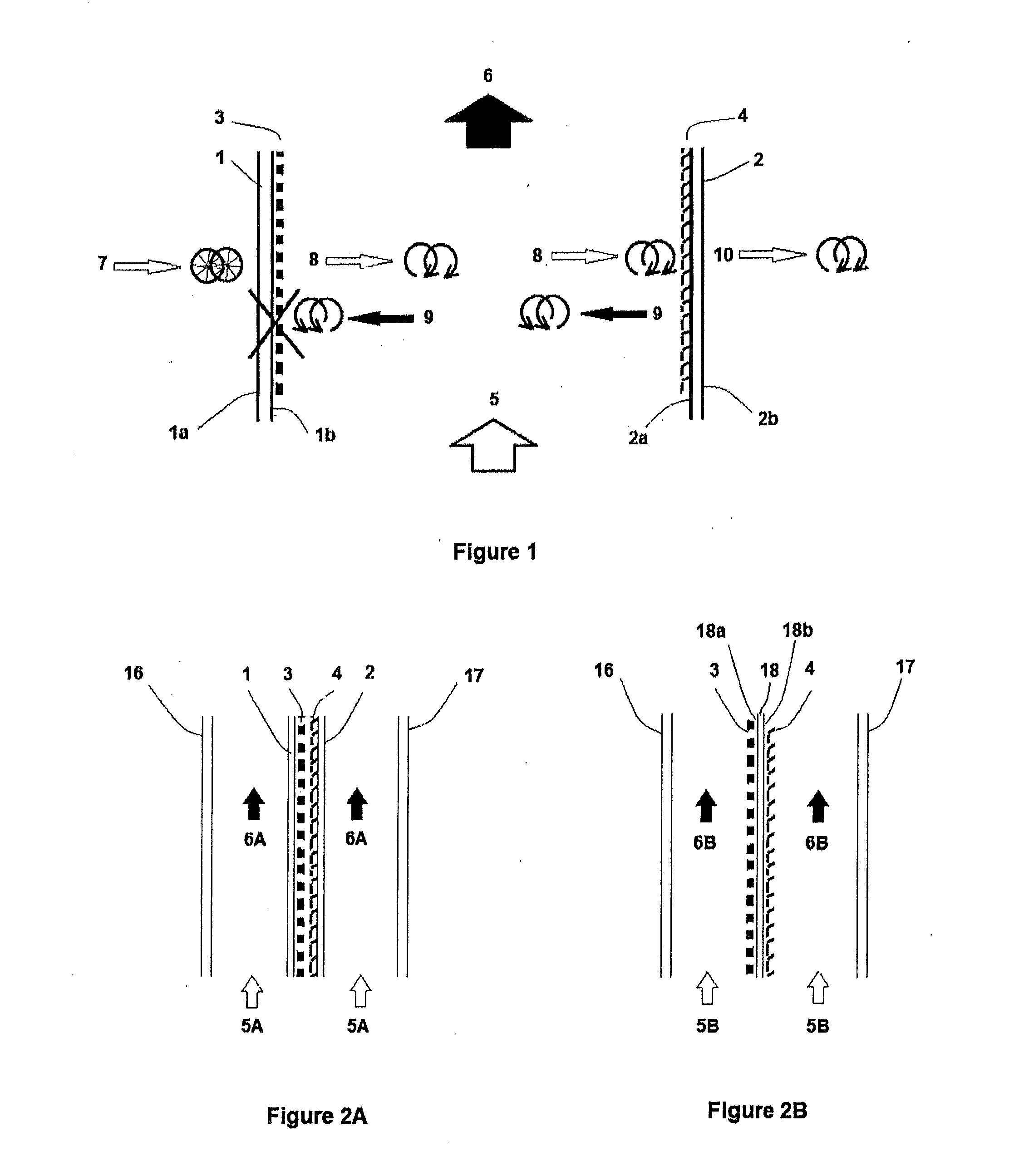

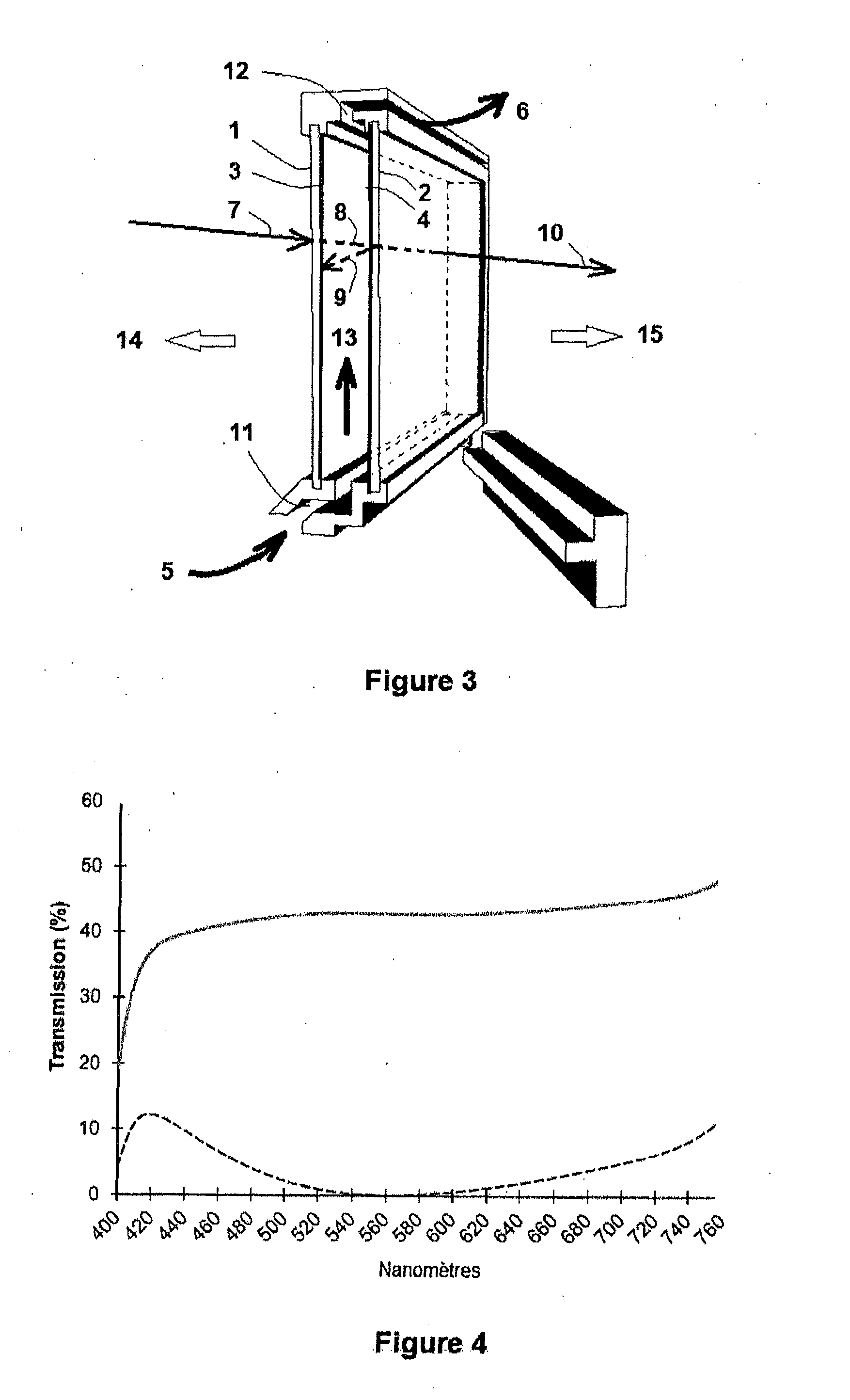

Transparent solar energy collector

InactiveUS20150083195A1Improve efficiencyIncrease degree of collectionSolar heating energySolar heat devicesAir cycleOptoelectronics

The invention concerns a device for collecting infrared solar radiation by heating a circulating blade of air circulating between two transparent glazed walls. The first glazed wall polarises light in a circular manner. The second glazed wall reflects infrared radiation towards the first glazed wall. The infrared radiation which has been reflected has changed polarisation direction and is then absorbed by the first glazed wall which heats up, and in turn heats the circulating blade of air in contact with same.

Owner:SUNPARTNER TECH

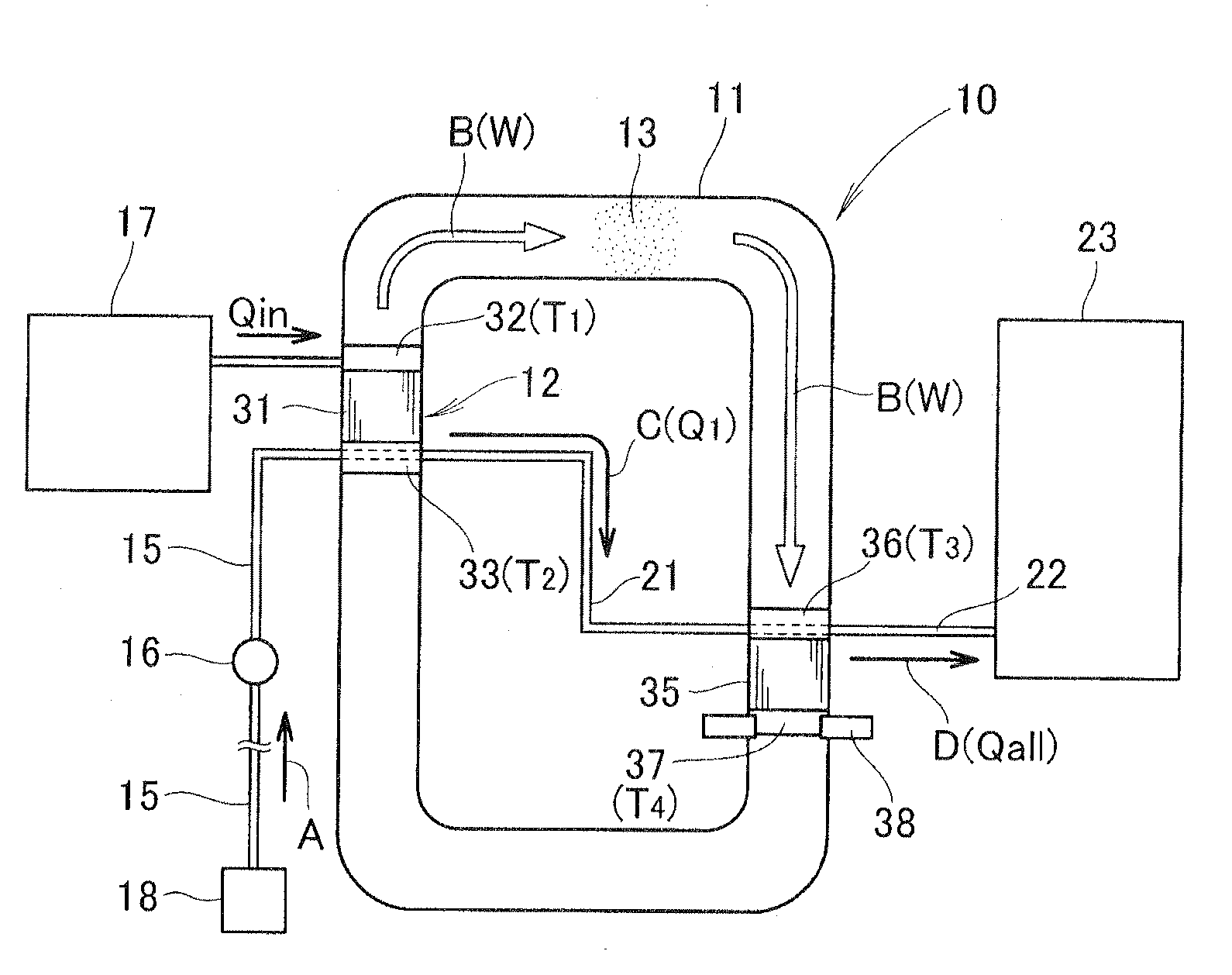

Thermoacoustic engine

InactiveUS20110259003A1Heat recoveryImprove efficiencyStirling type enginesEnergy industryThermoacousticsEngineering

Owner:HONDA MOTOR CO LTD

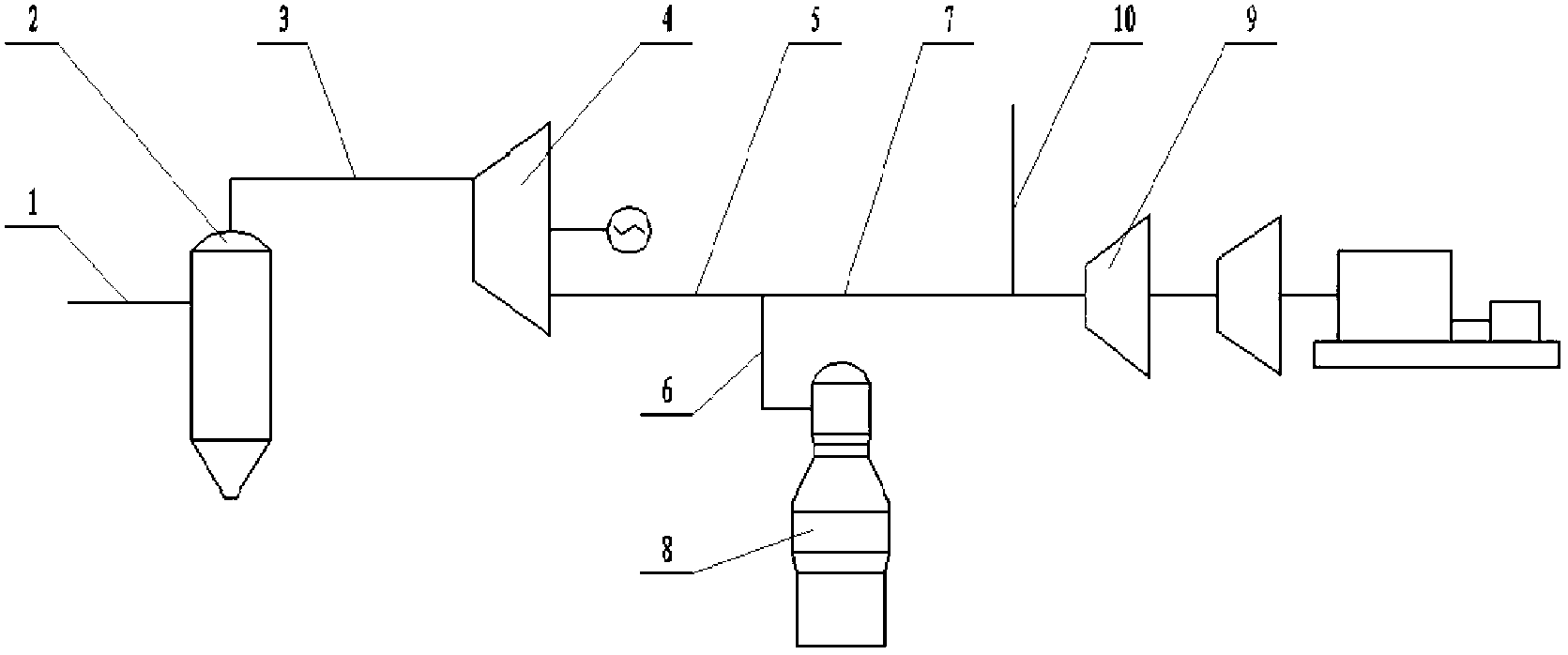

Use method for circulating comprehensive utilization device for blast furnace gas

InactiveCN102703628AEfficient removalHeat recoveryBlast furnace detailsIncreasing energy efficiencyMetallurgyHigh pressure

A use method for a circulating comprehensive utilization device for blast furnace gas belongs to the technical field of utilization of blast furnace gas and comprises the following process steps that: the blast furnace gas exhausted by the top of a blast furnace enters a dry-method bag-type pulse dust removing device from the lower part of an original blast furnace gas pipeline for filtering; the filtered blast furnace gas enters a full-dry type blast furnace gas residual pressure recovering device for reducing the temperature and pressure through a high-pressure net blast furnace gas pipeline; the blast furnace gas subjected to temperature and pressure reduction is inducted out by a low-pressure blast furnace gas pipeline; part of blast furnace gas is induced into the blast furnace gas pipeline through a blast furnace hot blast stove and enters a blast furnace hot blast stove device to finish a heating process; and residual part of blast furnace gas is inducted into the blast furnace gas pipeline through a gas-steam joint power generation device and enters the gas-steam joint circulating power generation device for recovering residual heat and pressure. The use method has the advantages that dust in the blast furnace gas is effectively removed; original pressure energy and heat energy of the blast furnace gas are recovered, the energy is saved, the consumption is reduced and high-efficiency comprehensive utilization of the blast furnace gas is realized.

Owner:BEIJING SHOUGANG INT ENG TECH

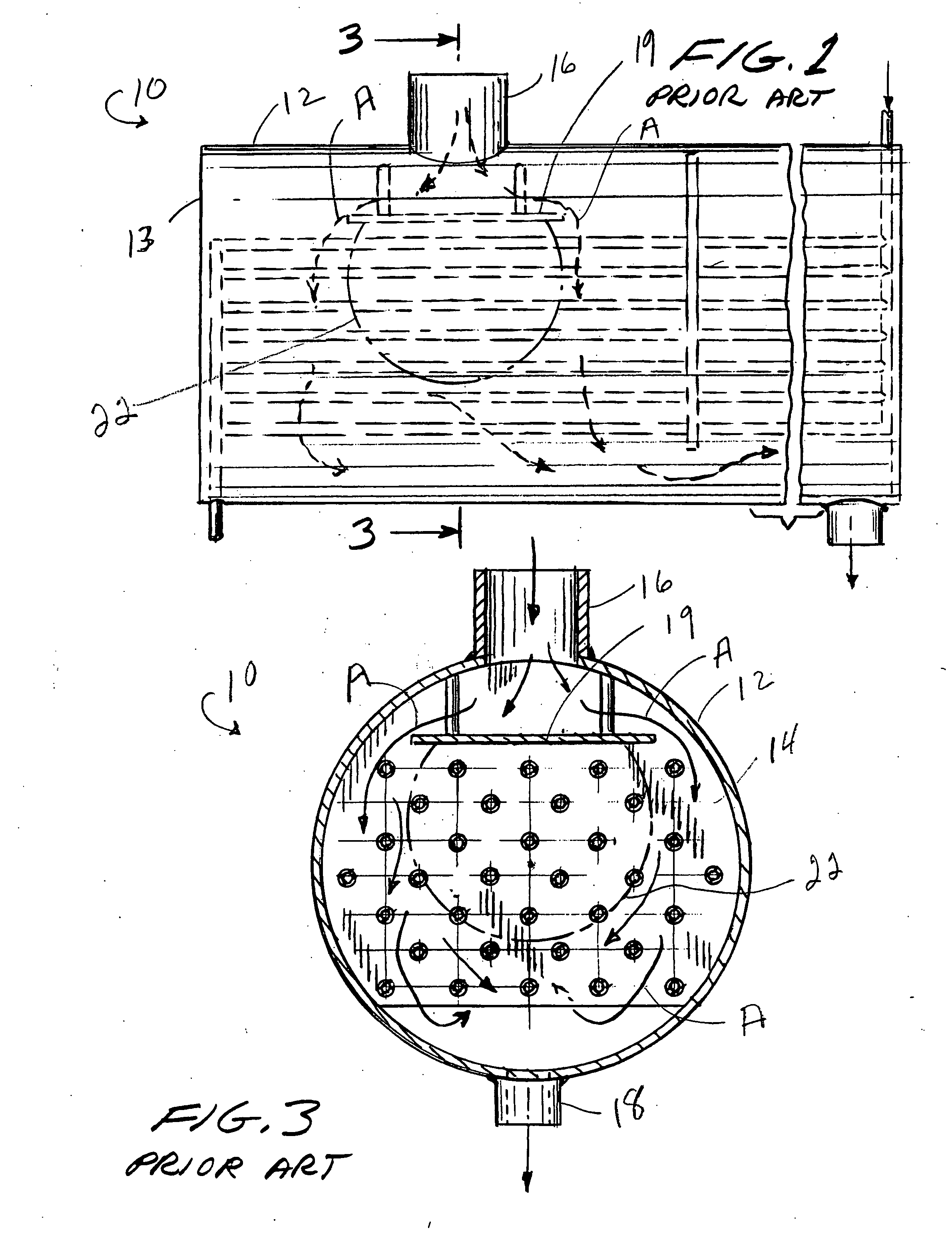

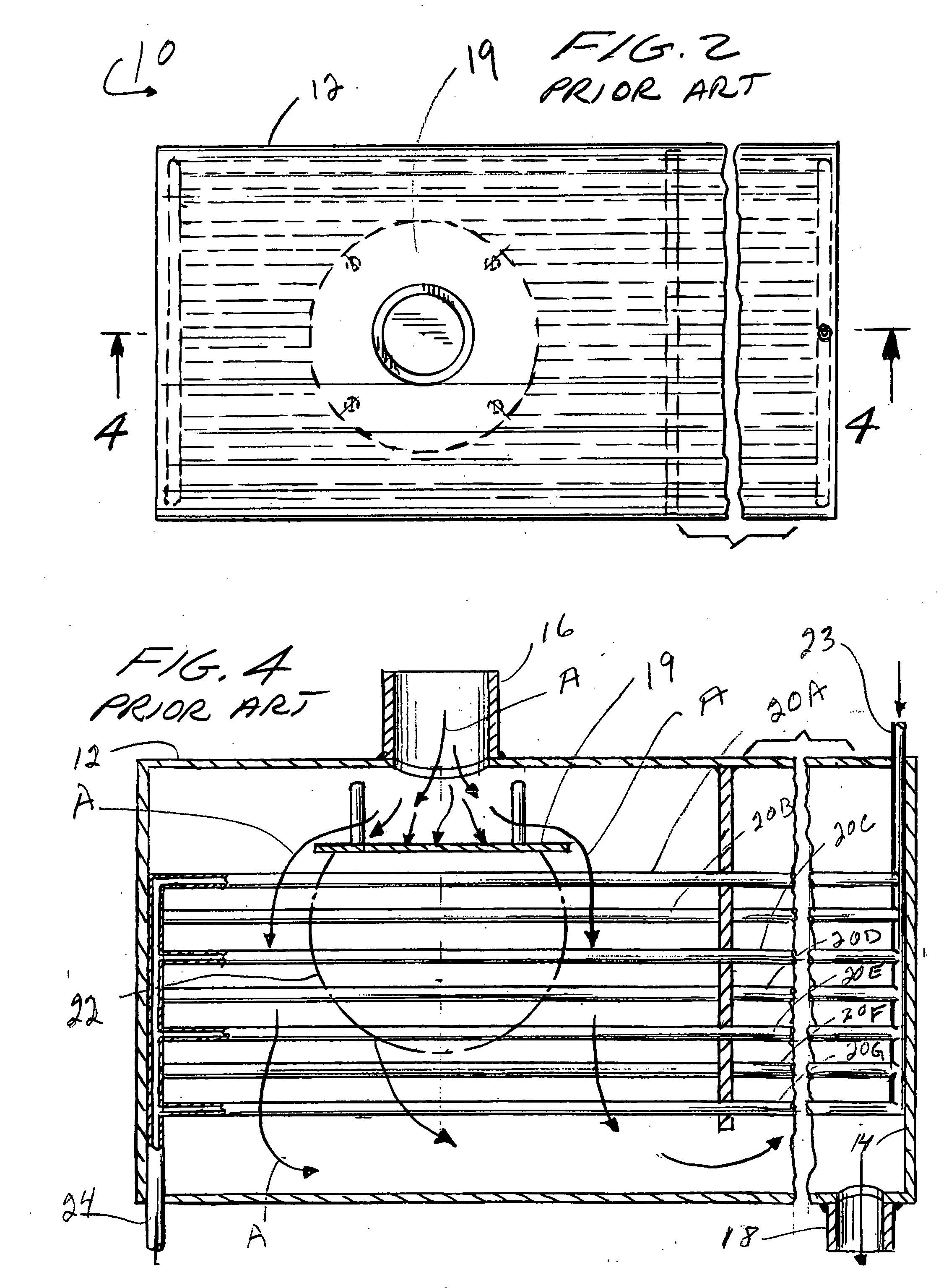

Raised overlapped impingement plate

ActiveUS20090242178A1Reduce dirtImproving shell-side fluid flowCorrosion preventionHeat exchanger casingsInterior spaceEngineering

A heat exchanger for transfer of heat from a first fluid to a second fluid, including: a housing defining an interior space, a plurality of tubes spaced apart from each other, fixed in the housing, and extending in a first direction within the interior space, a first inlet for receiving the first fluid into and through the tubes, and first outlet for discharging the first fluid out of the tubes, a second inlet for receiving the second fluid into the interior space in an inlet flow direction generally transverse of the first direction, and a second outlet for discharging the second fluid out of the interior space, and an impingement plate assembly situated in the interior space of the housing between the second inlet means and the plurality of tubes, with a fouling area defined as the area in the interior space that includes portions of the tubes directly beneath said impingement plate assembly, the impingement plate assembly including: (a) a top plate facing the second inlet, where the top plate lies in a plane generally transverse to the inlet flow direction and onto which the second fluid flow impinges, and (b) a bottom plate fixedly spaced from and generally parallel to and overlying the top plate, the bottom plate defining therethrough an aperture extending from top to bottom thereof.

Owner:SAUDI ARABIAN OIL CO

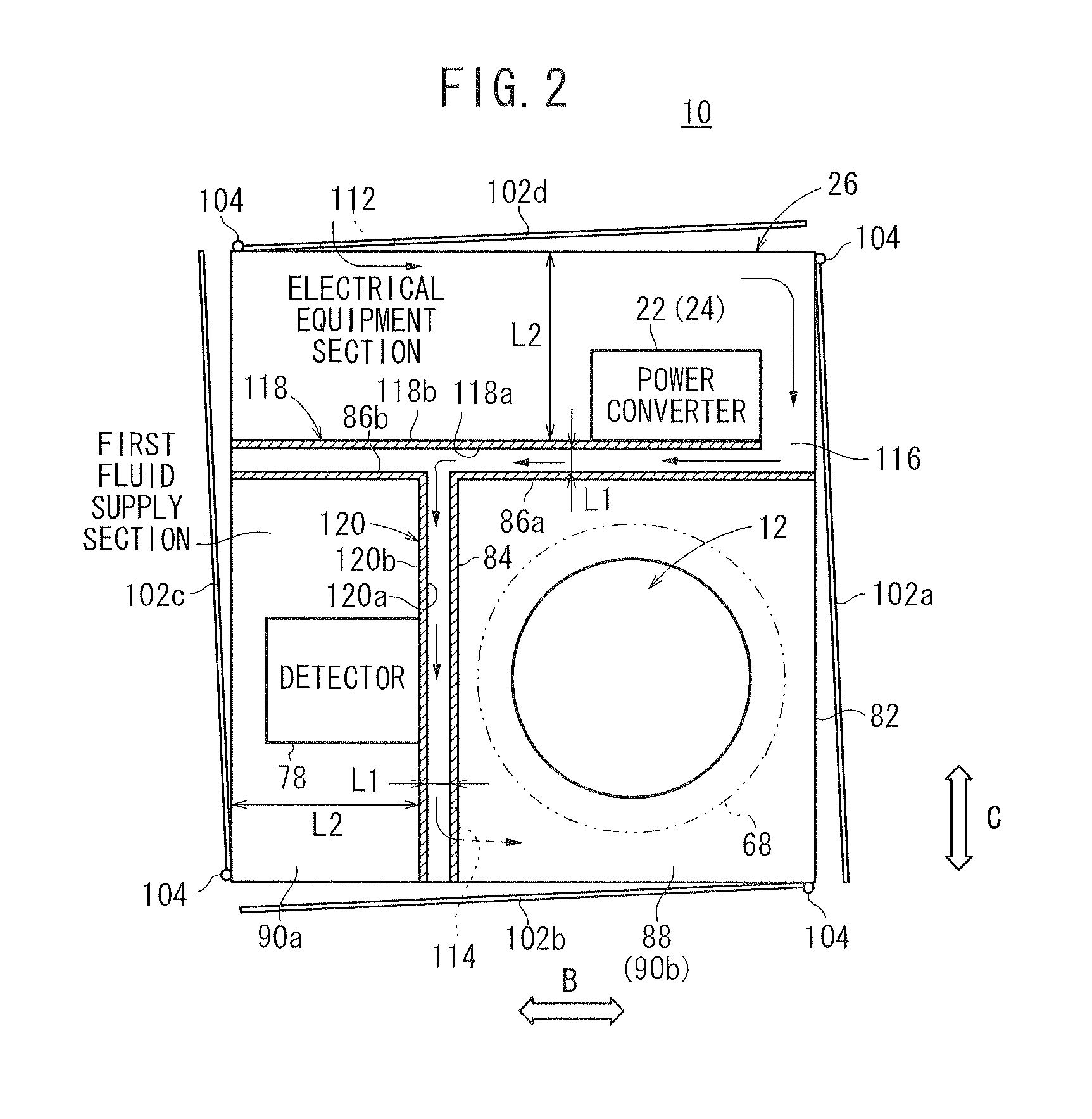

Fuel cell system

ActiveUS20110159391A1Minimize diffusionReliable in operationFuel cell heat exchangeElectrical and Electronics engineeringGas supply

A case configuring a fuel cell system is divided into a module section, a first fluid supply section, a second fluid supply section, and an electric section. The electric section is provided with a first intake vent for intake of an oxidant gas from outside the case into the electric section. The second fluid supply section is provided with a second intake vent for intake of the oxidant gas subjected to intake from the first intake vent, into an oxidant gas supply device. The case is internally provided with first and second internal partitions which generate a bypass path for blocking straight flow of the oxidant gas from the first intake vent to the second intake vent.

Owner:HONDA MOTOR CO LTD

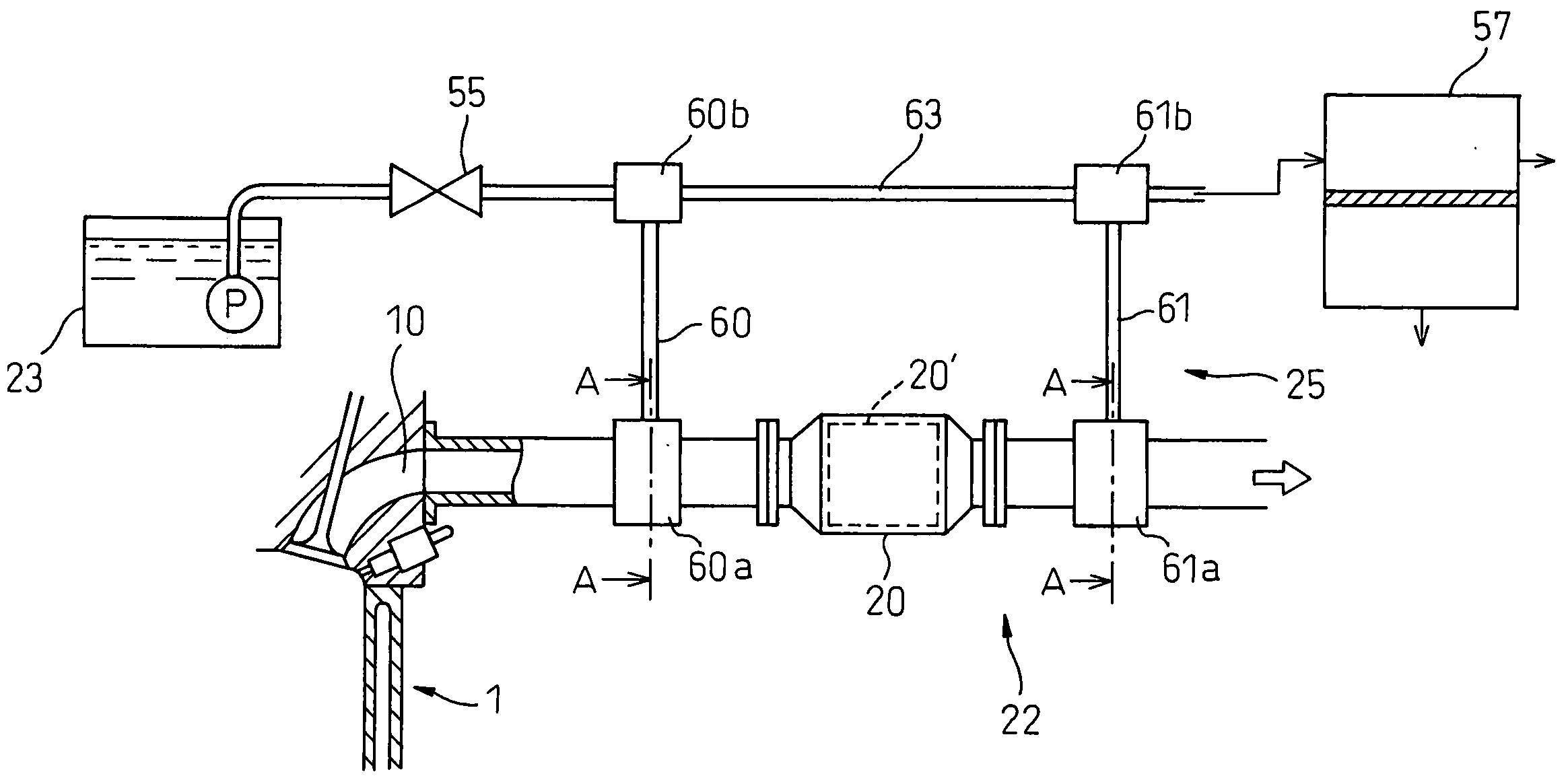

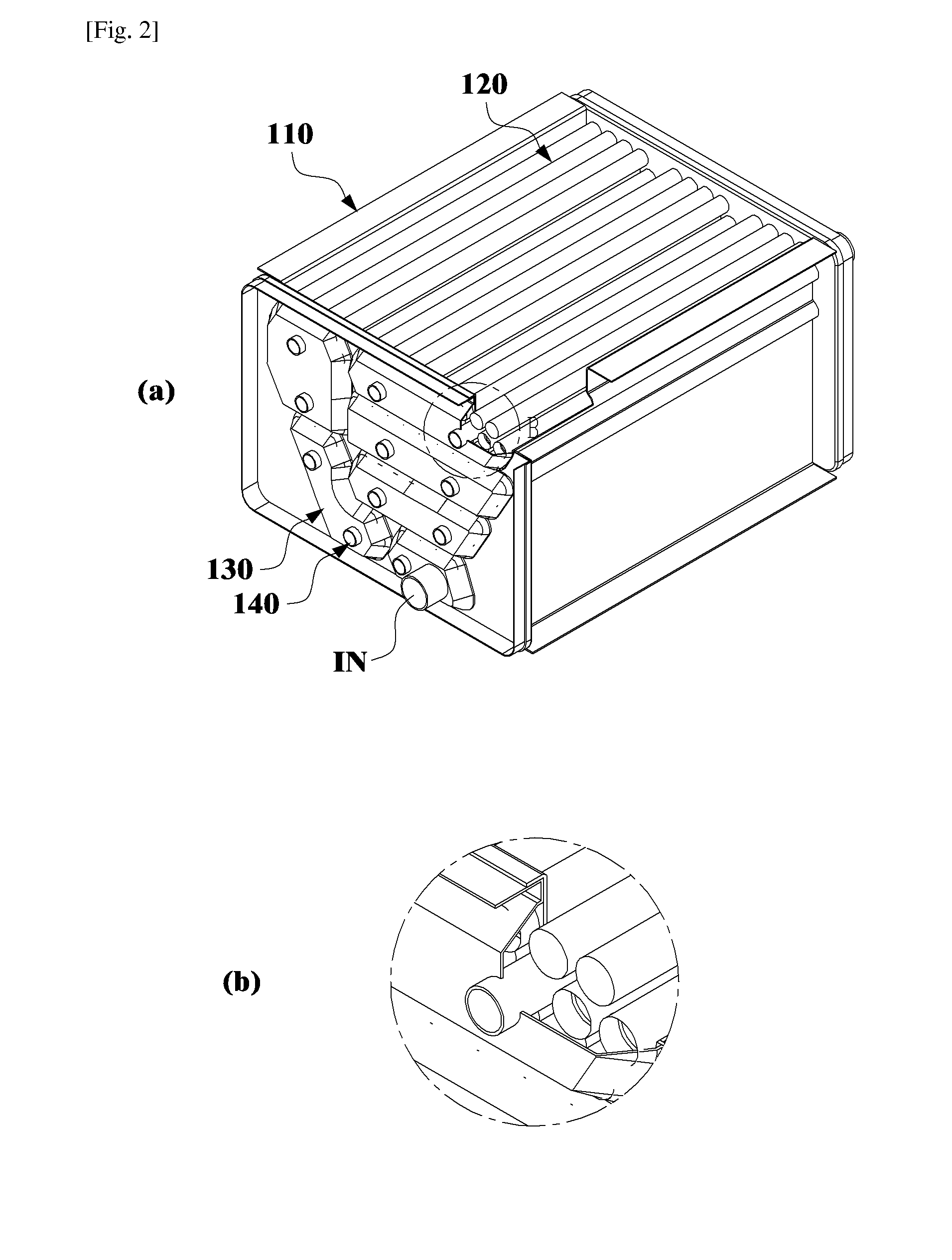

Exhaust heat recovery system

InactiveUS20100154394A1Maintain warm-up performanceHeat recoveryInternal combustion piston enginesRecuperative heat exchangersEngineeringInternal combustion engine

An exhaust heat recovery system 25 provided with a plurality of heat pipes 60, 61 provided with heat recovery parts 60a, 61a and heat exchange parts 60b, 61b. The heat pipes recover heat from exhaust gas exhausted from an internal combustion engine at the heat recovery parts and transfer this recovered heat to an object to be heated at the heat exchange parts. The heat recovery part 60a of the first heat pipe 60 recovers heat from the exhaust gas at an exhaust purification catalyst 20′ provided in an engine exhaust passage or its upstream side. The heat recovery part 61b of the second heat pipe 61 recovers heat from the exhaust gas at the downstream side of the exhaust purification catalyst. Due to this, there is provided an exhaust heat recovery system which can recover at least a fixed amount of exhaust heat at all times while maintaining a warm-up performance of the exhaust purification catalyst.

Owner:EXXON RES & ENG CO +1

Process for carbonizing wood residues and producing activated carbon

InactiveUS7029273B2Improve heat transfer performancePromote combustionProductsCarbon compoundsActivated carbonFluidized bed

An apparatus and process for preparing activated carbon from a wood or wood residue feedstock using fluidized bed technology. The fluidized bed apparatus has a number of wood residue inlets that allow differing residence times in the fluidized bed apparatus appropriate for the wood or wood residue feedstock to be carbonized. The carbonized material may then be activated to form activated carbon.

Owner:COMMONWEALTH SCI & IND RES ORG

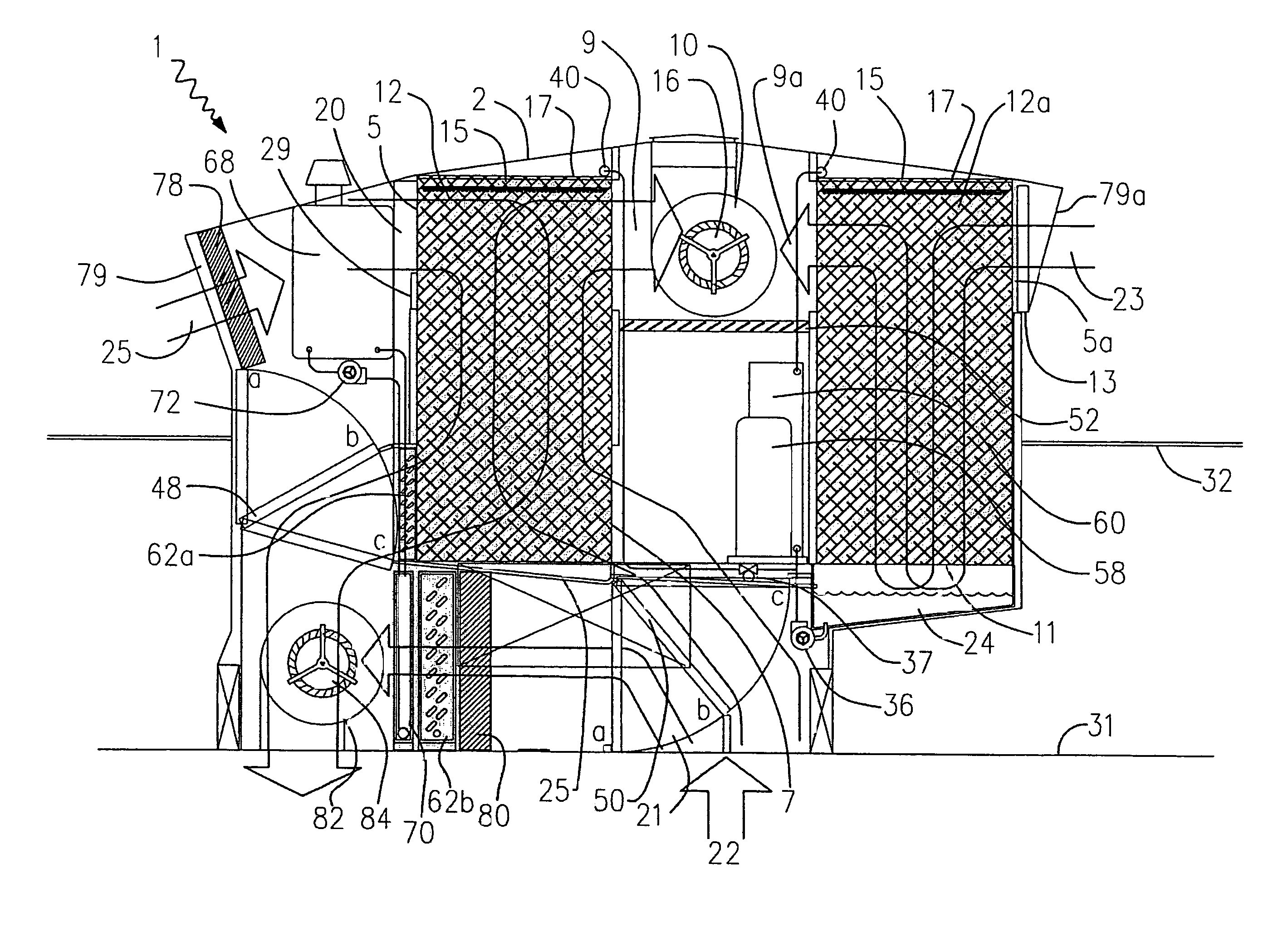

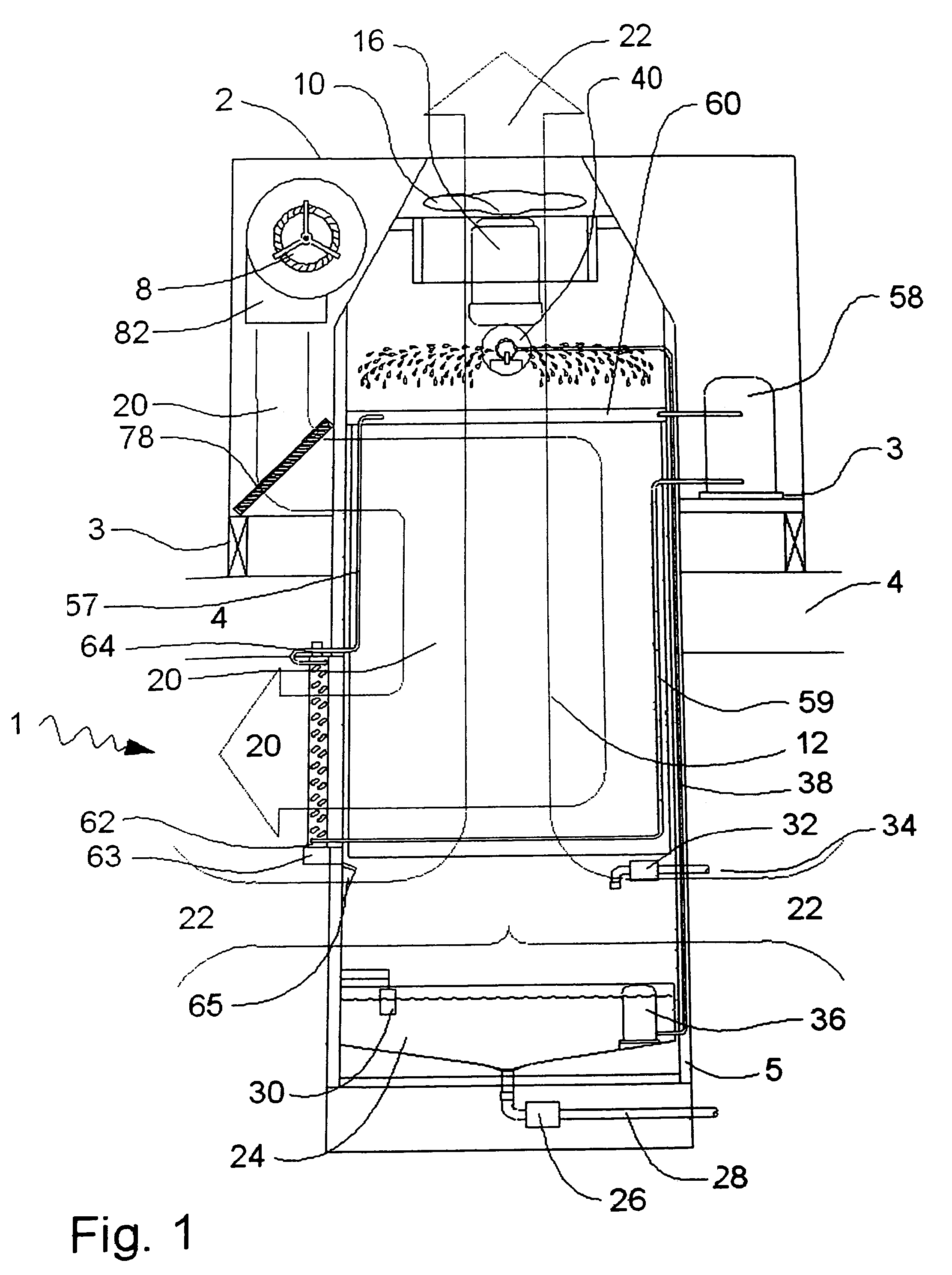

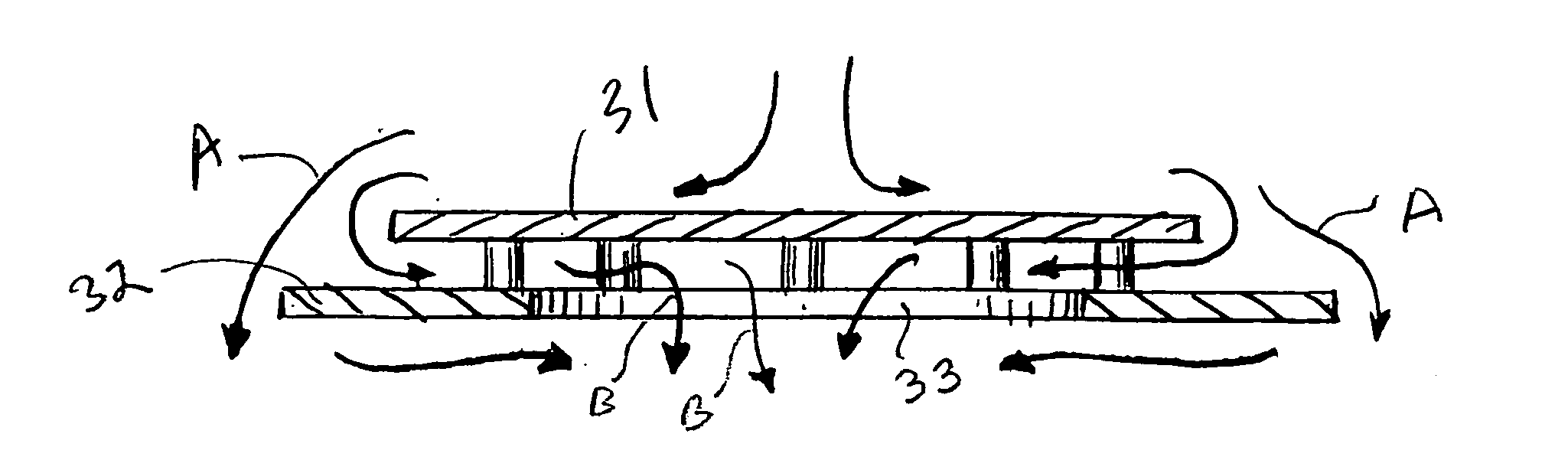

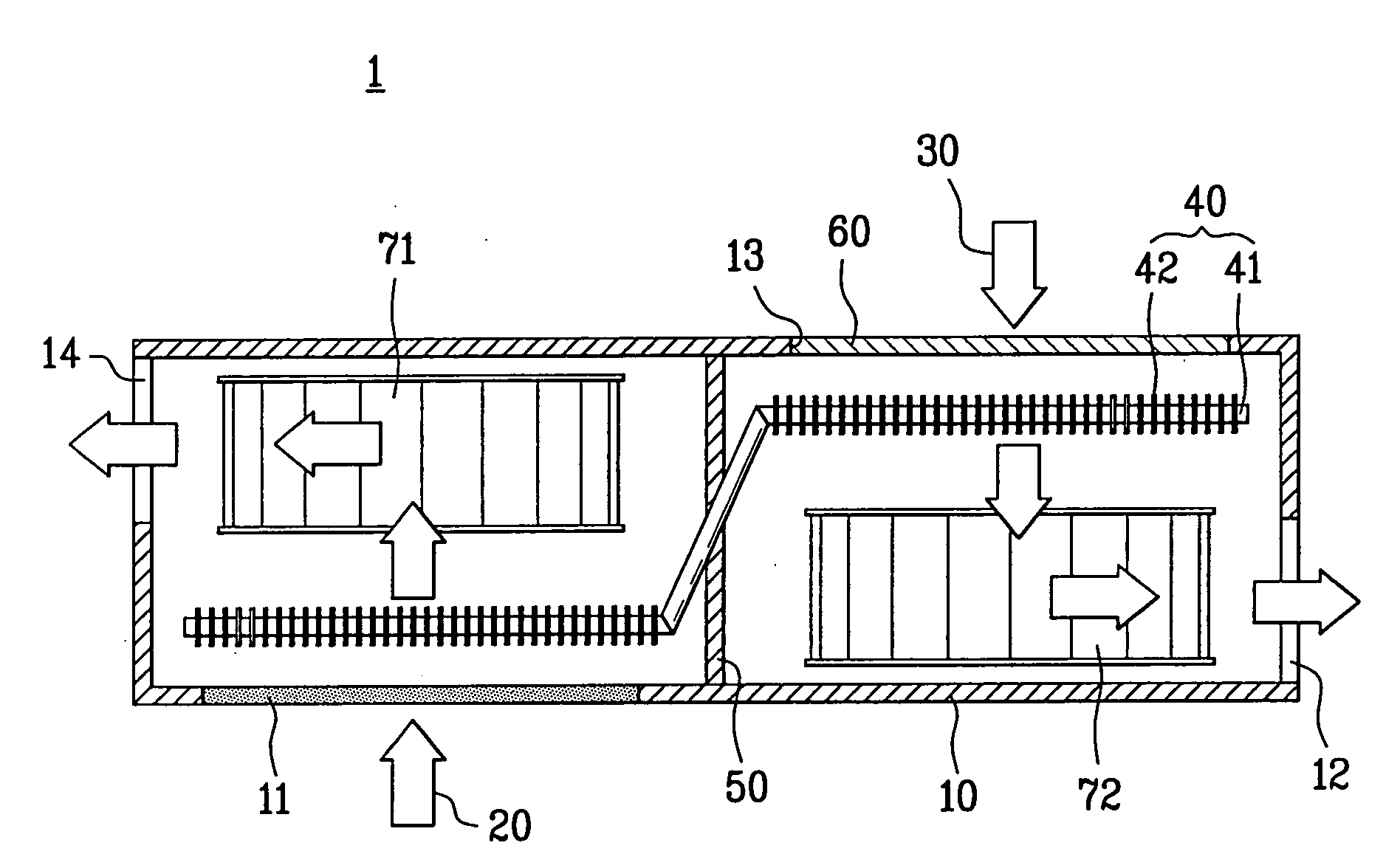

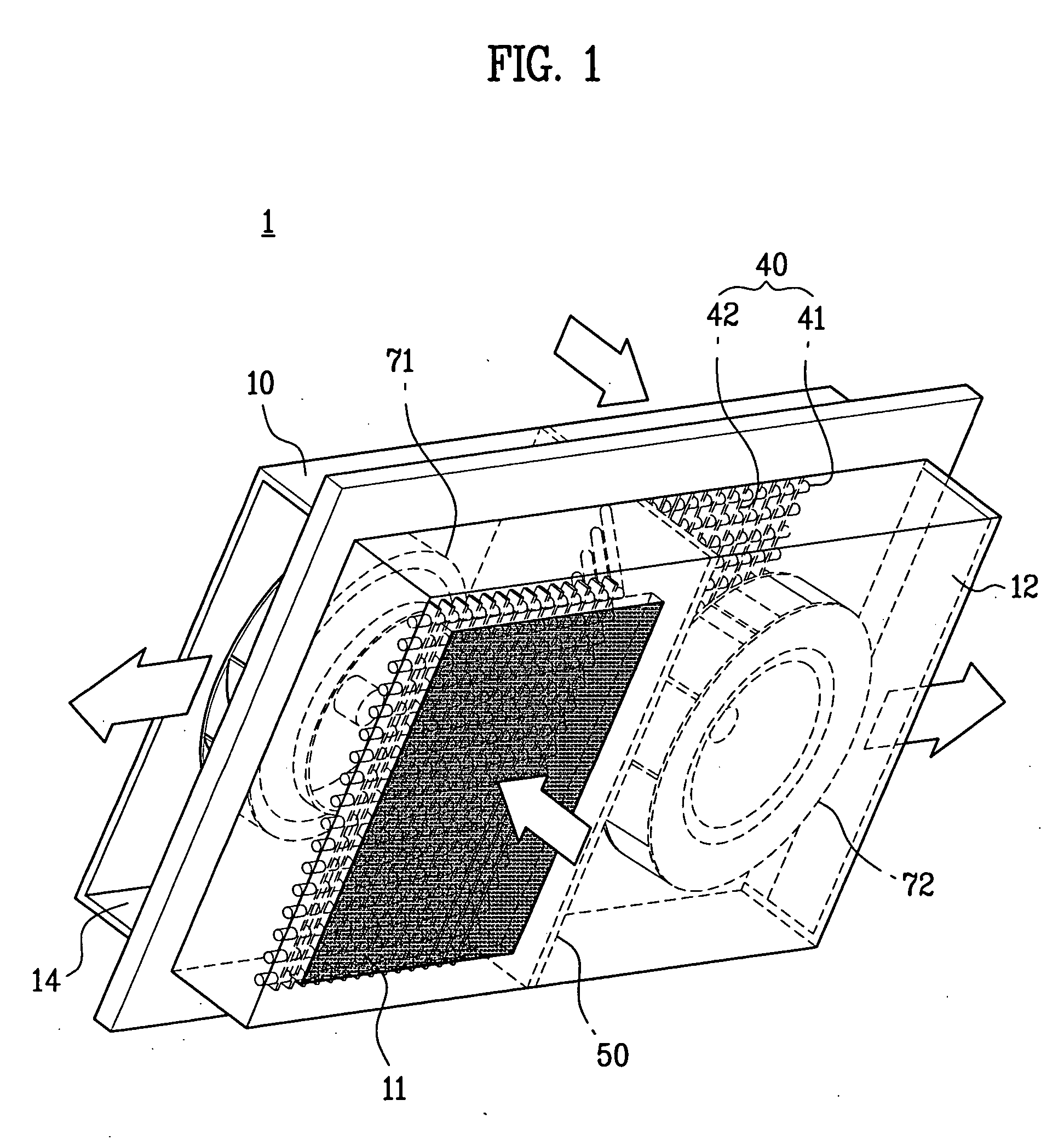

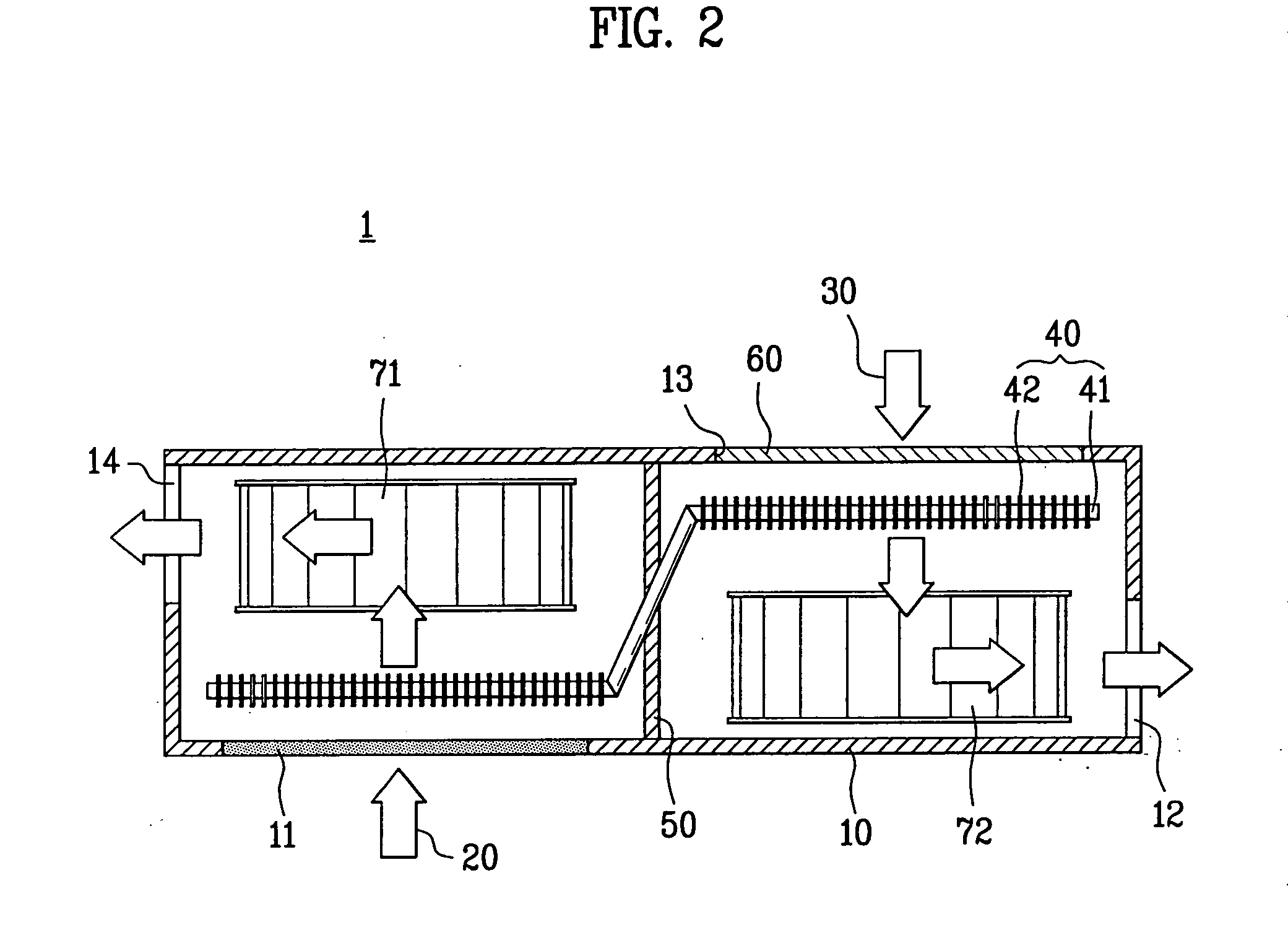

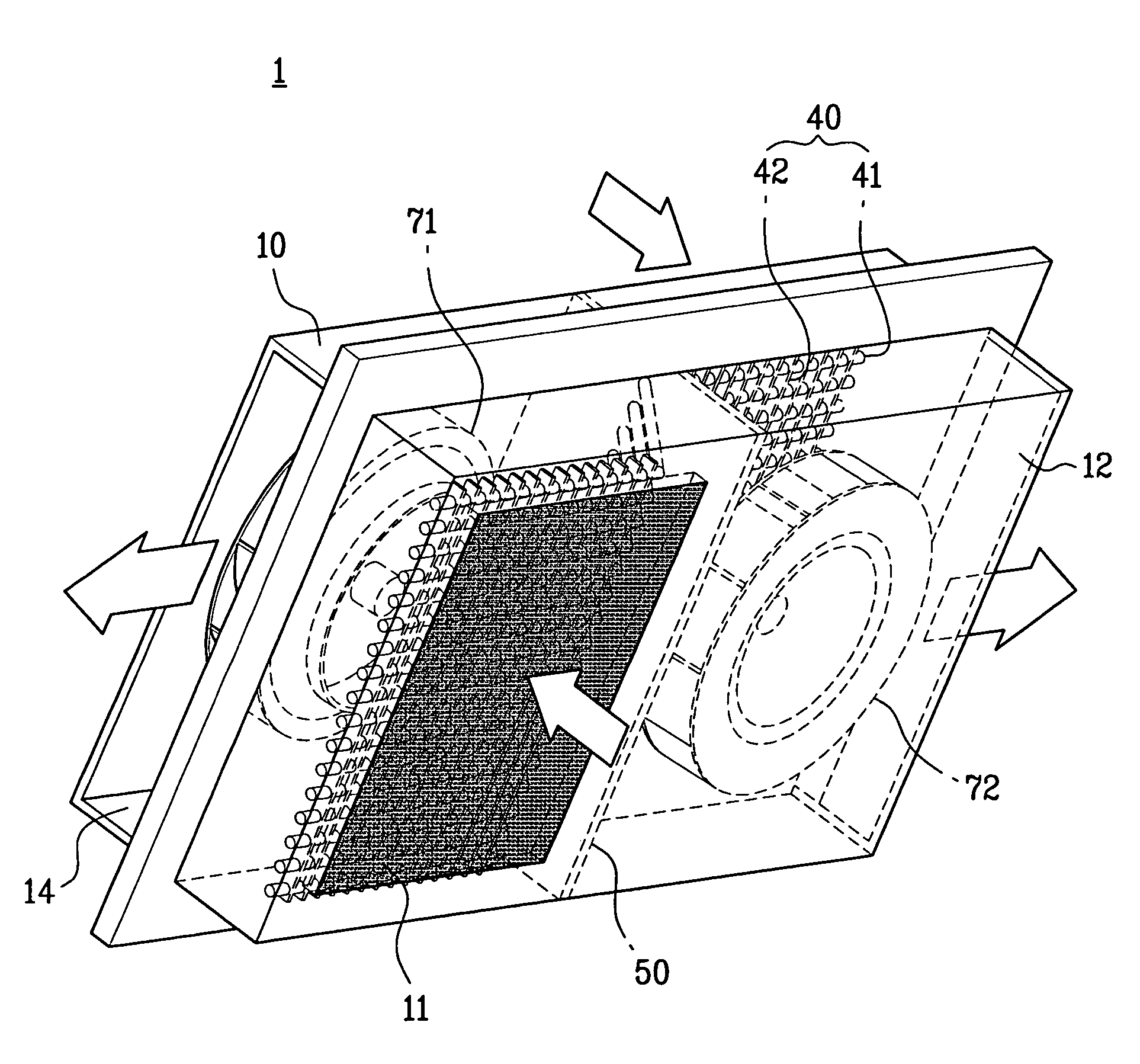

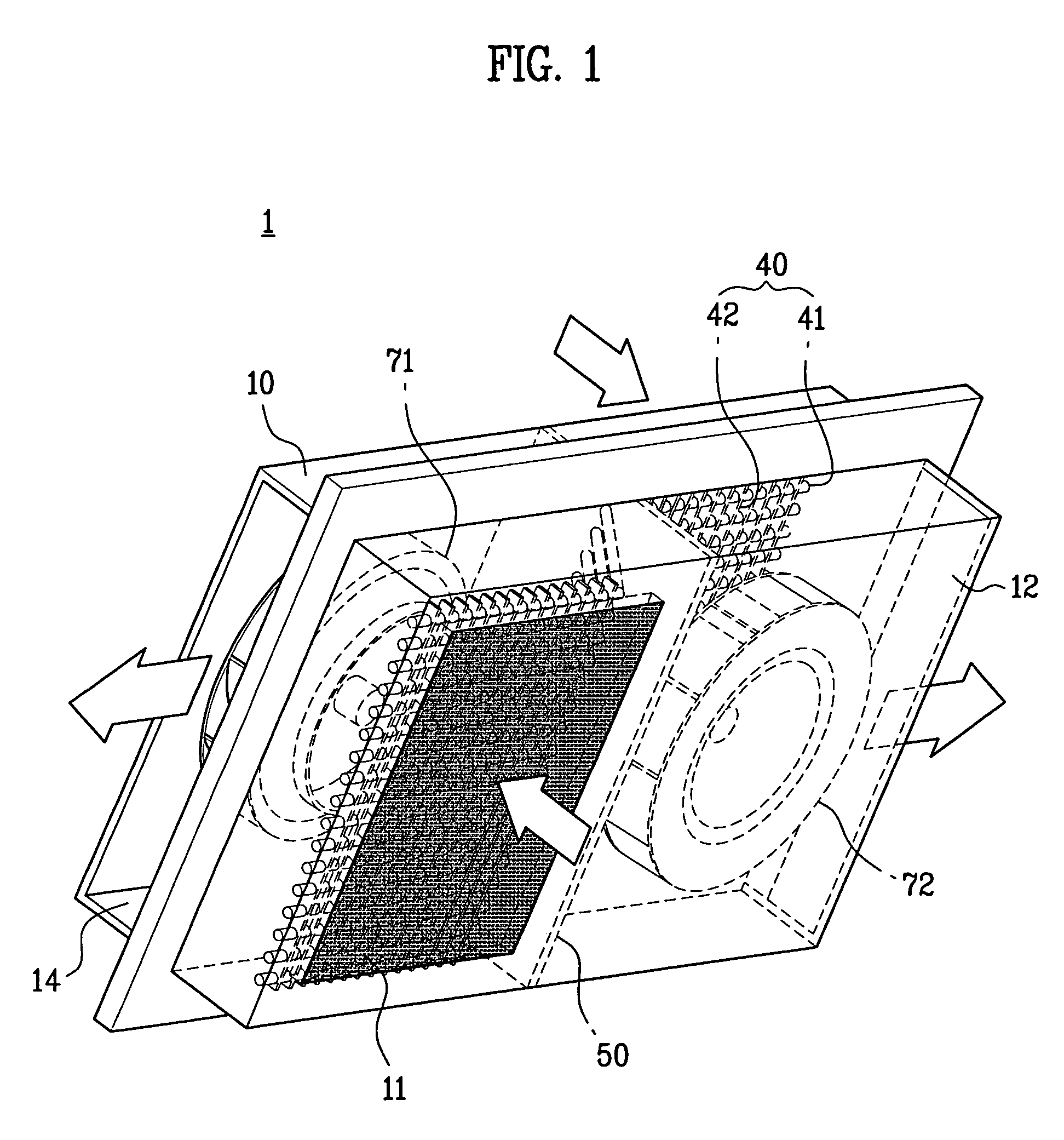

Ventilator

InactiveUS20050263266A1Easy to installHeat recoveryPump componentsHeating and ventilation casings/coversThermal energyWorking fluid

Ventilator including a case having a first flow passage and a second flow passage therein, at least one fan in the case for supplying room air to a room through the first flow passage, and guiding outdoor air to the room through the second flow passage, and a heat exchanger in the case, the heat exchanger having a working fluid therein for repeating evaporation (heat absorption) and condensing (heat dissipation) by a temperature difference of the air flowing through the first flow passage and the second flow passage, for making the air flowing through the first flow passage and the air flowing through the second flow passage to heat exchange, thereby providing a ventilator which is thin, can be installed conveniently, and can recover a thermal energy from room air, and reduce a pressure loss and noise.

Owner:LG ELECTRONICS INC

Ventilator

InactiveUS7322401B2Easy to installHeat recoveryPump componentsHeating and ventilation casings/coversThermal energyWorking fluid

Ventilator including a case having a first flow passage and a second flow passage therein, at least one fan in the case for supplying room air to a room through the first flow passage, and guiding outdoor air to the room through the second flow passage, and a heat exchanger in the case, the heat exchanger having a working fluid therein for repeating evaporation (heat absorption) and condensing (heat dissipation) by a temperature difference of the air flowing through the first flow passage and the second flow passage, for making the air flowing through the first flow passage and the air flowing through the second flow passage to heat exchange, thereby providing a ventilator which is thin, can be installed conveniently, and can recover a thermal energy from room air, and reduce a pressure loss and noise.

Owner:LG ELECTRONICS INC

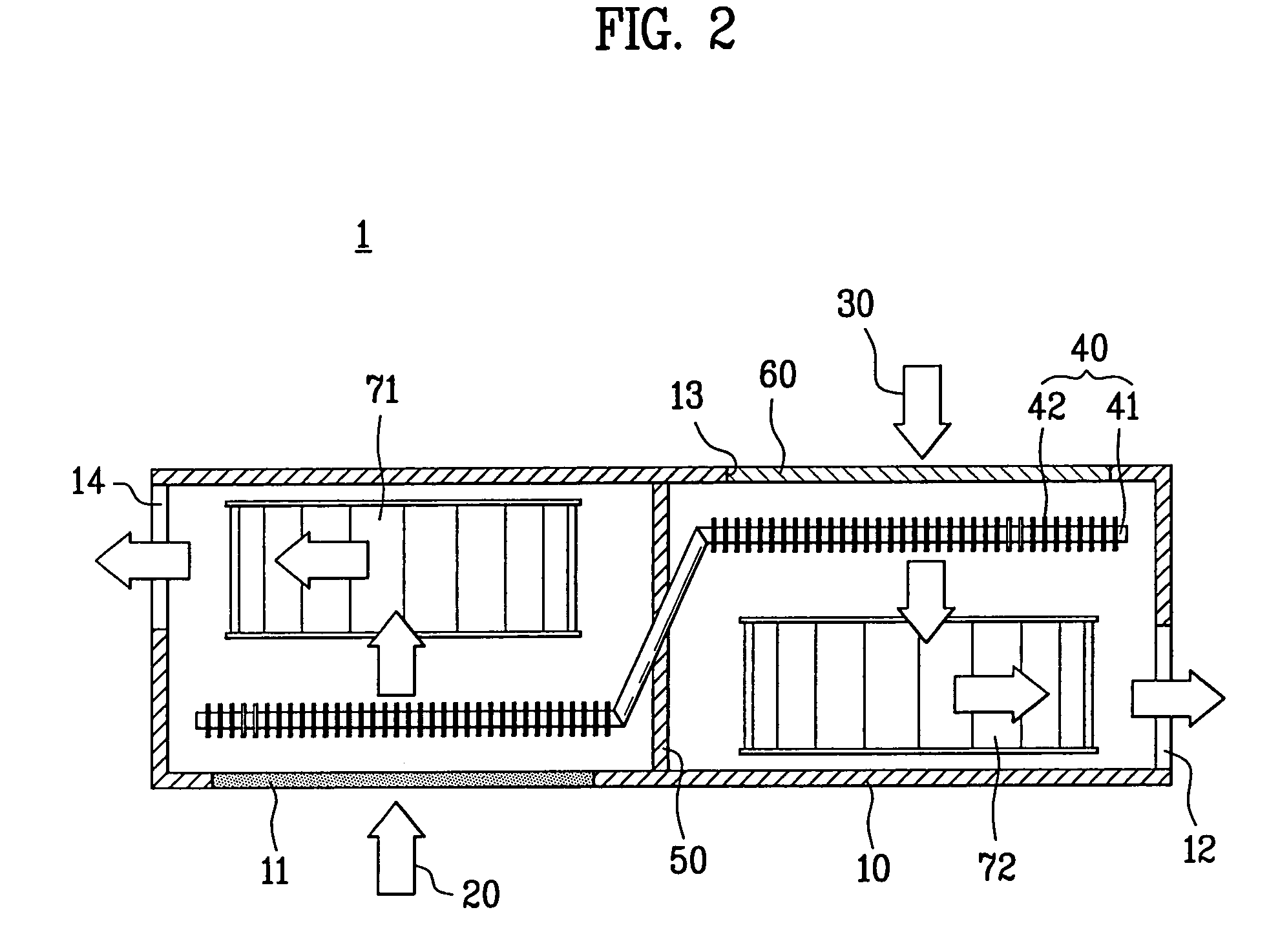

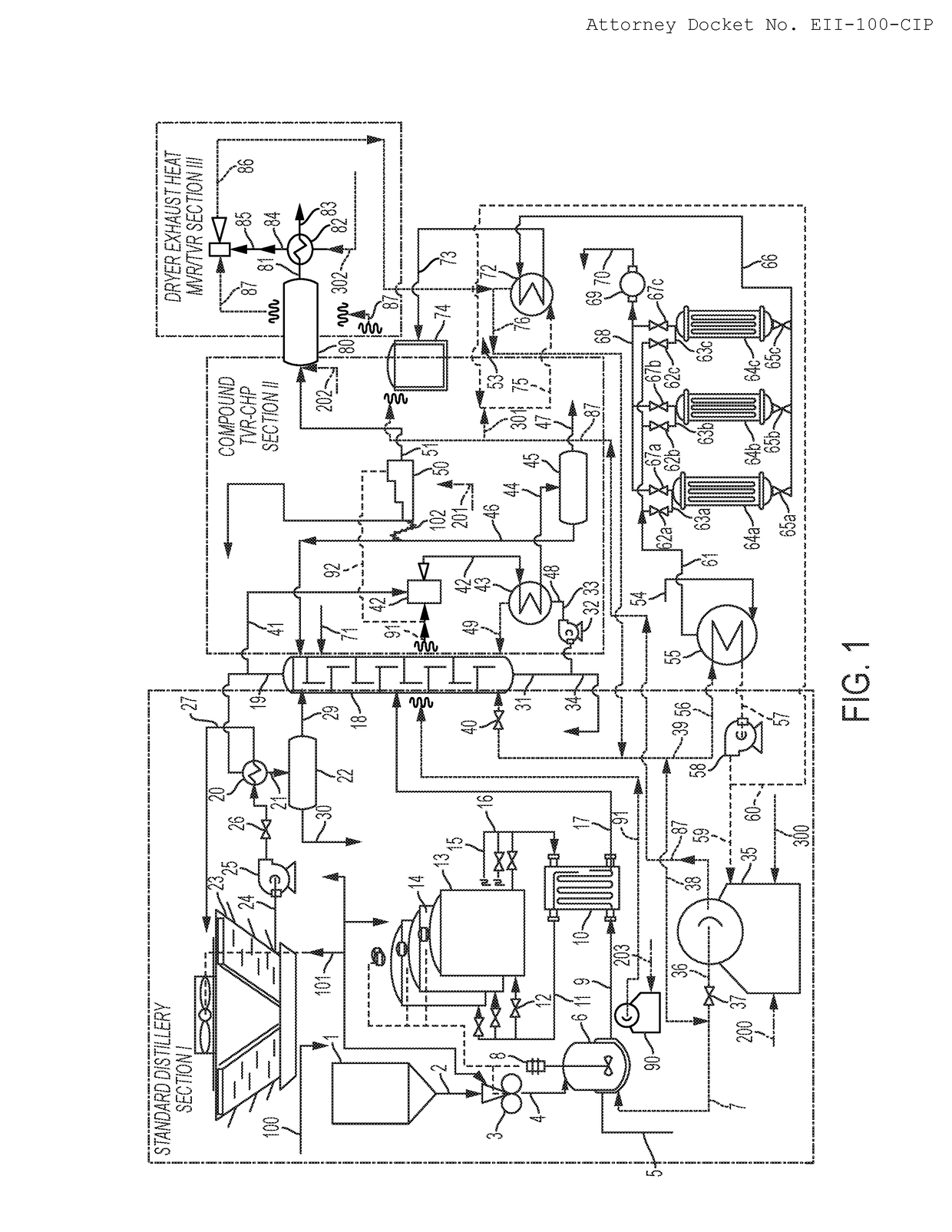

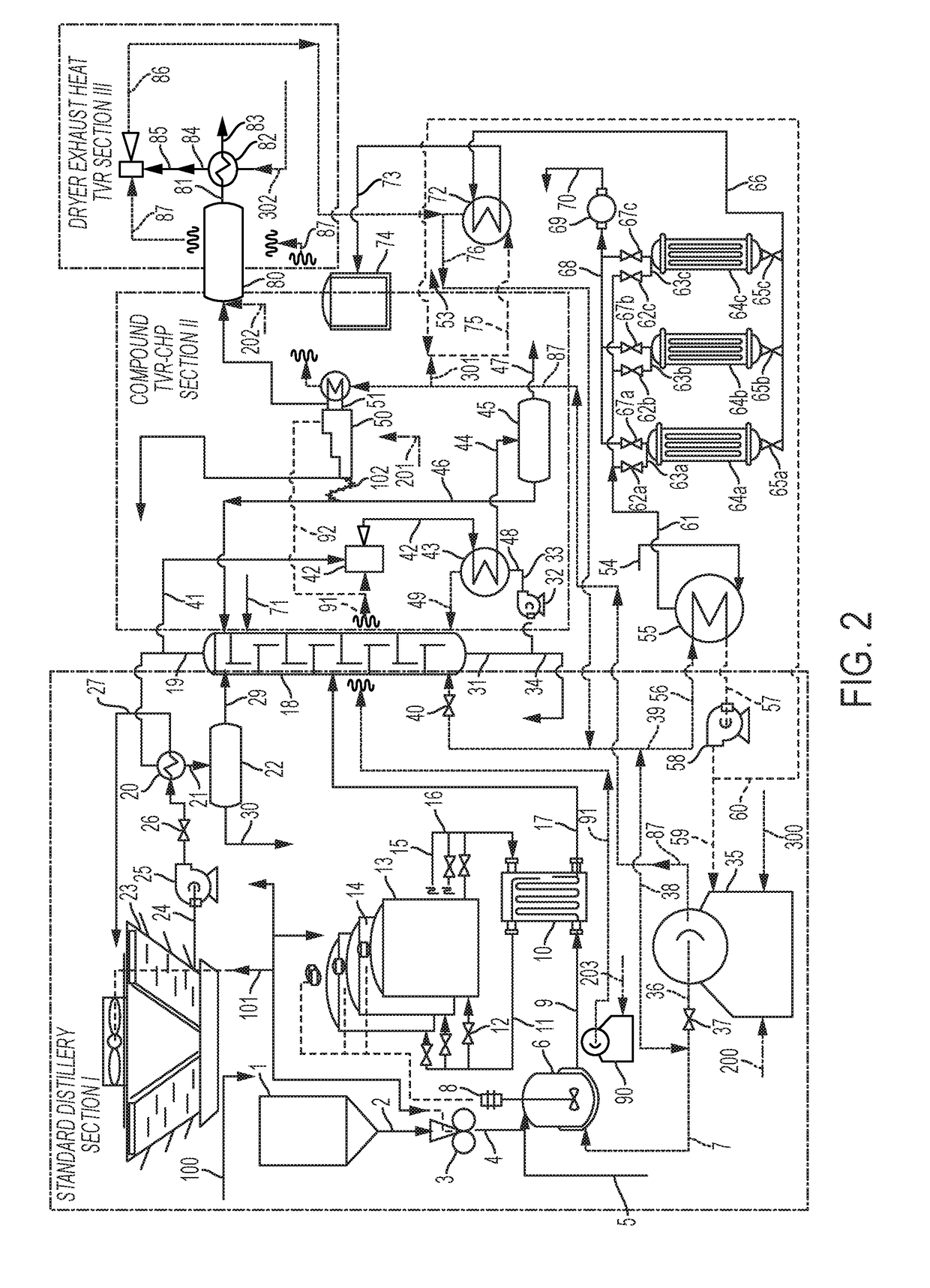

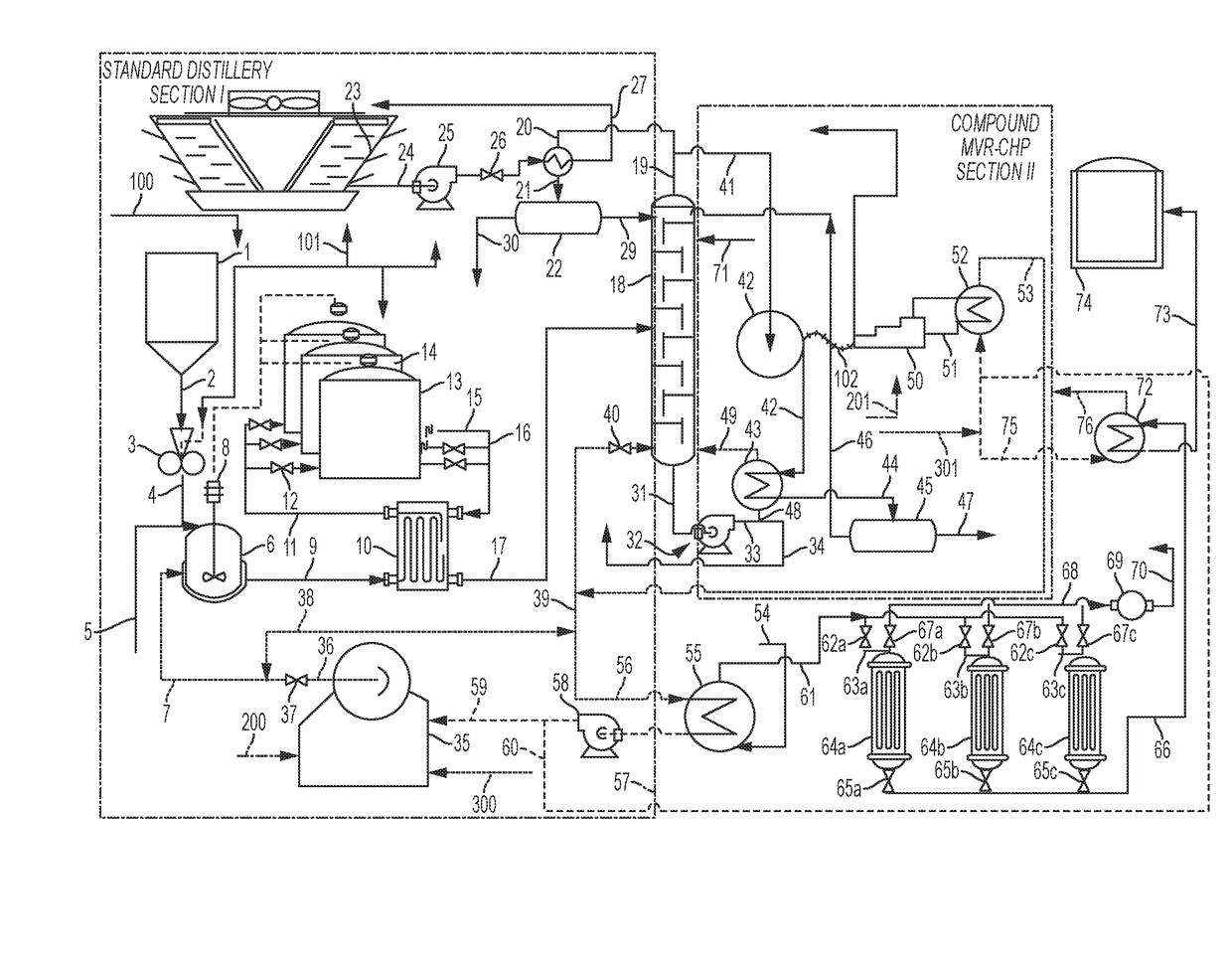

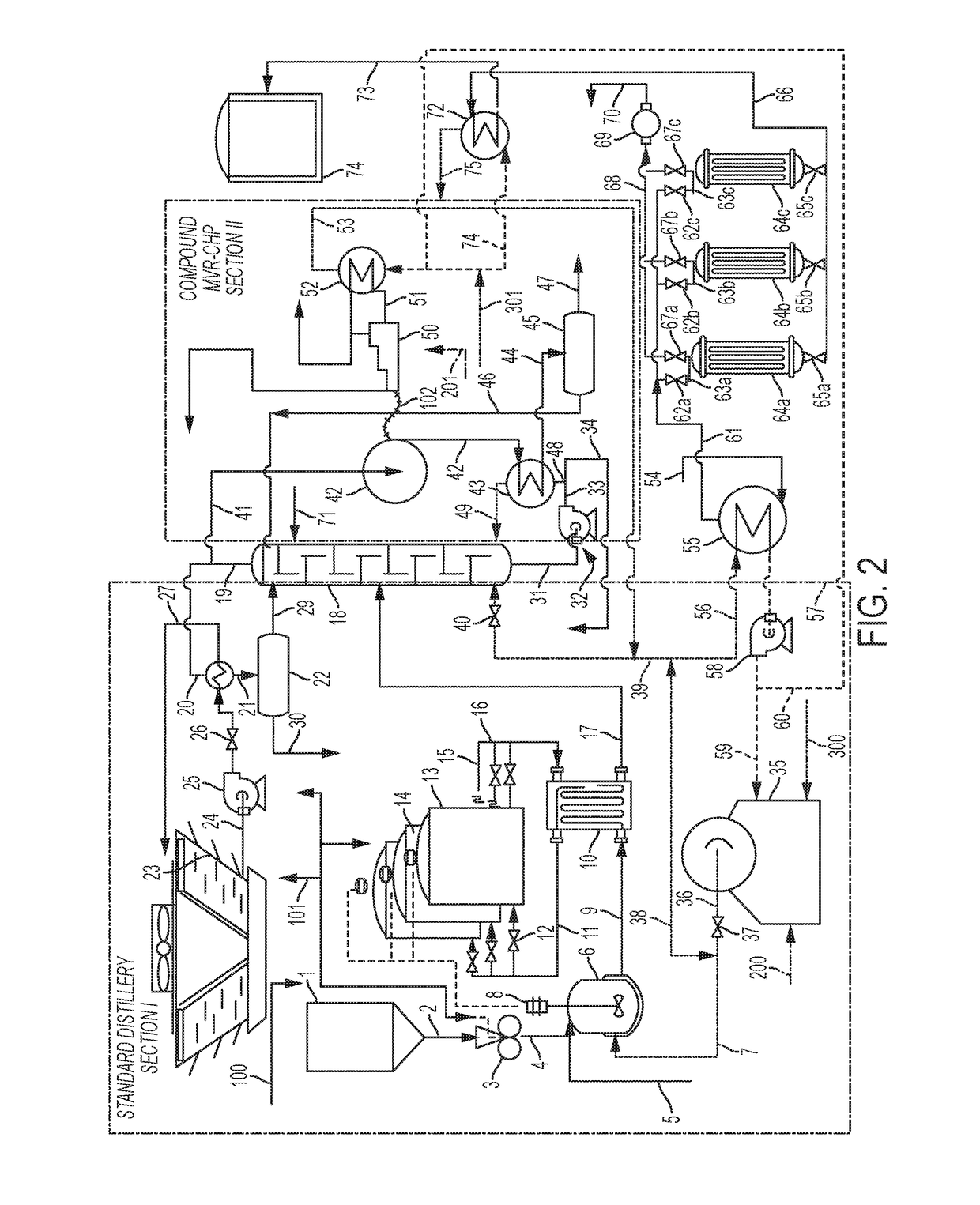

Energy-efficient systems including vapor compression for biofuel or biochemical plants

ActiveUS20180028934A1Reduce usageRecover latent heatFermented solutions distillation/rectificationEvaporation with vapour compressionThermal energyDistillation

Processes and systems are provided to compress vapors produced in distillation and recover the heat of condensation through vapor compression and to derive mechanical, thermal, and electrical energy from a combined heat and power system, while maintaining the plant's original ability to operate. The plant's existing distillation system, steam generation, and electrical demand determine the design basis for the retrofit system that is targeted at an optimized combination of energy usage, energy cost, and environmental impact. Vapor compression (by mechanical vapor recompression and / or thermal vapor recompression) minimizes the total energy usage. Optionally, combined heat and power provides a means of converting energy between fuel, electricity, and thermal energy in a manner that best complements plant requirements and energy economics and minimizes inefficiencies and energy losses.

Owner:ENERGY INTEGRATION INC

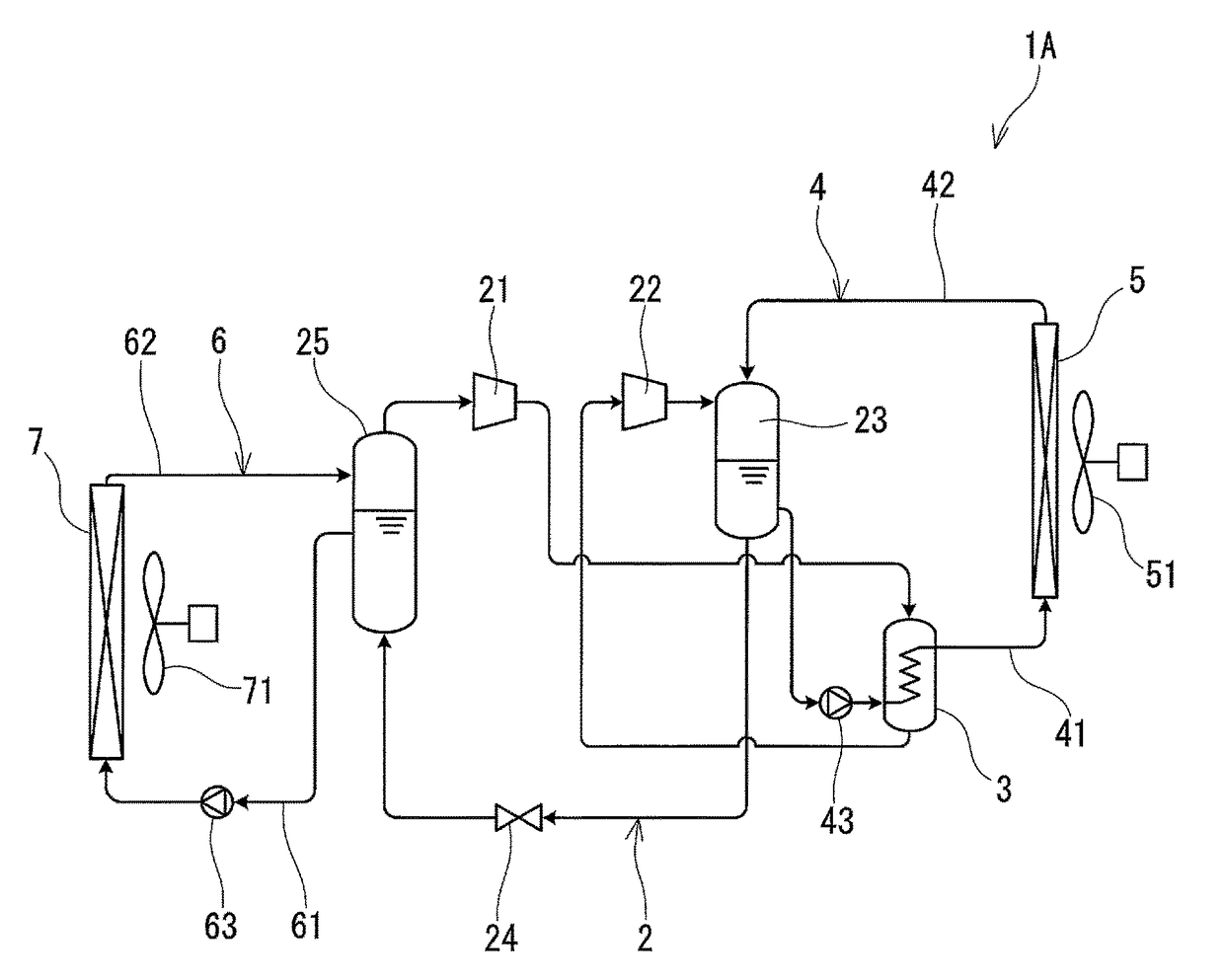

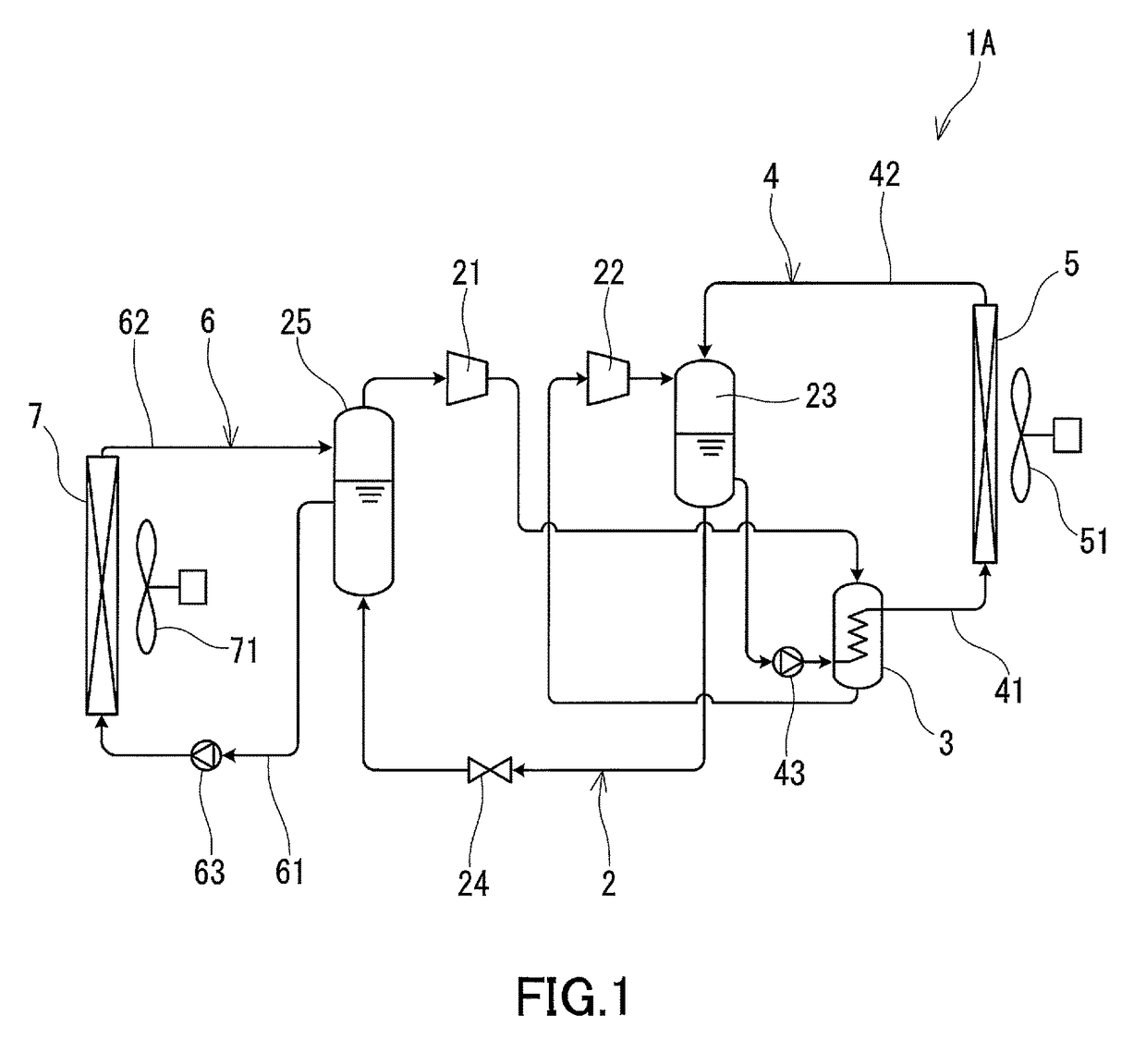

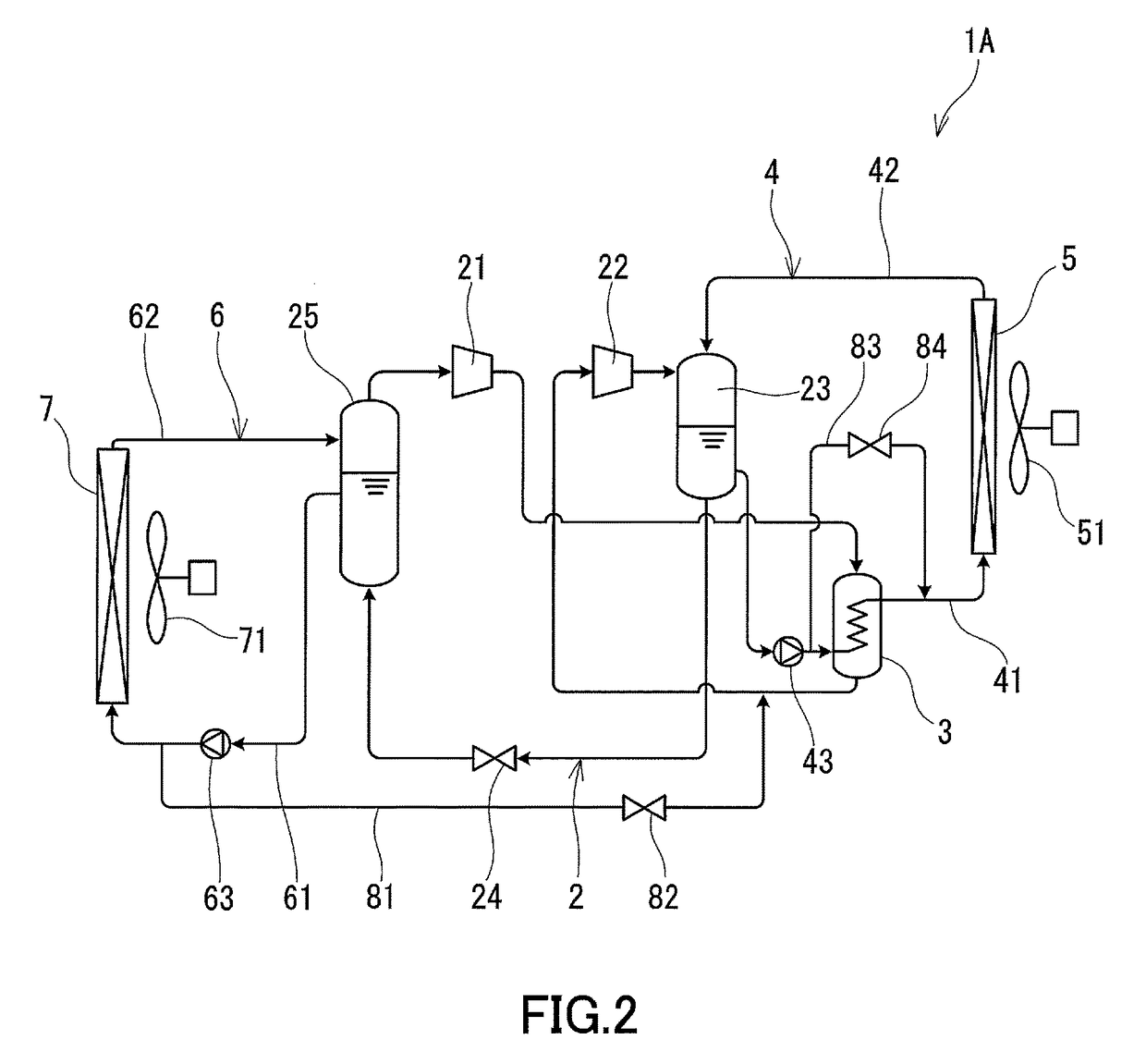

Refrigeration device

InactiveUS9719699B2Reduce heat lossHeat recoveryCompression machines with non-reversible cycleFluid circulation arrangementEngineeringRefrigeration

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

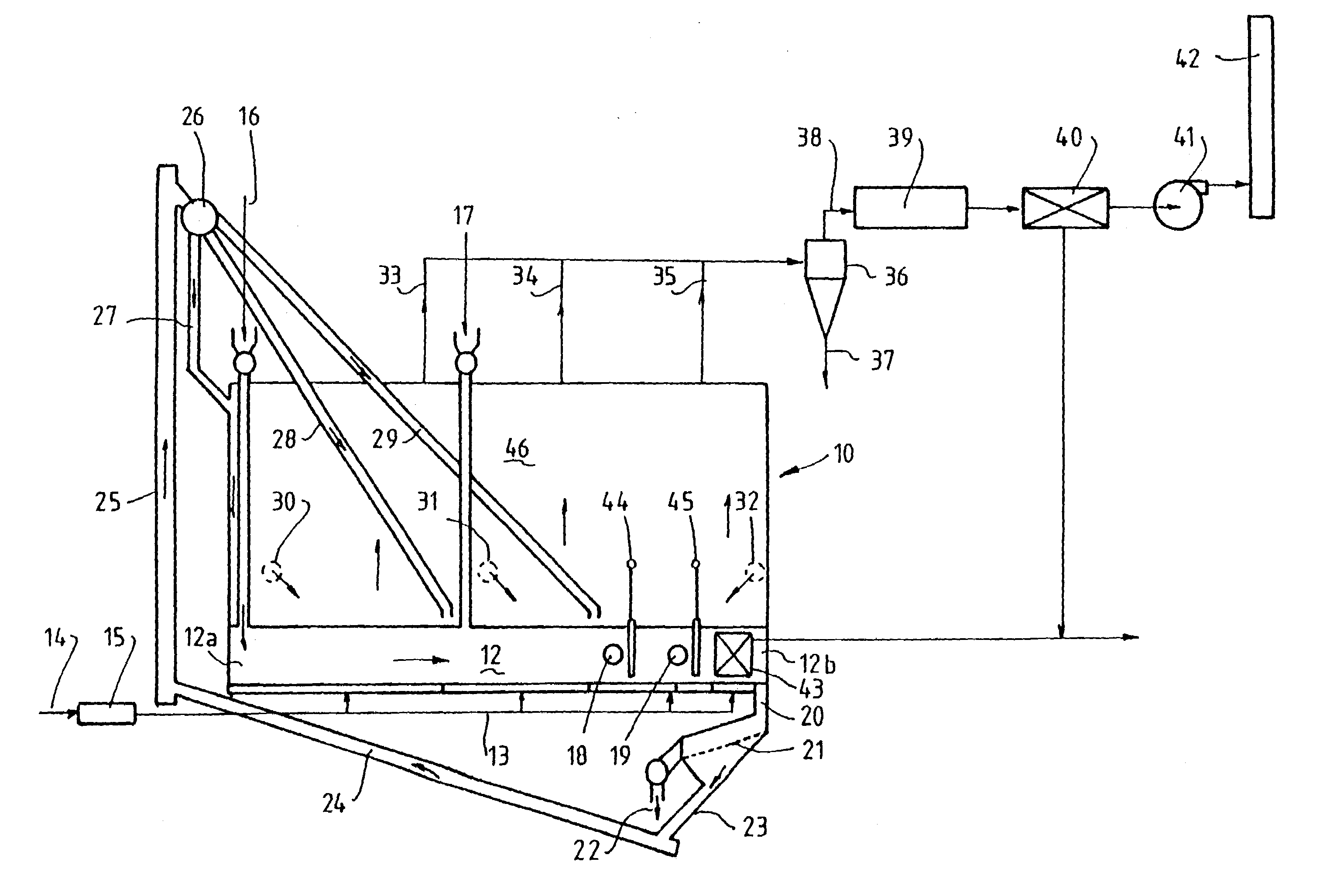

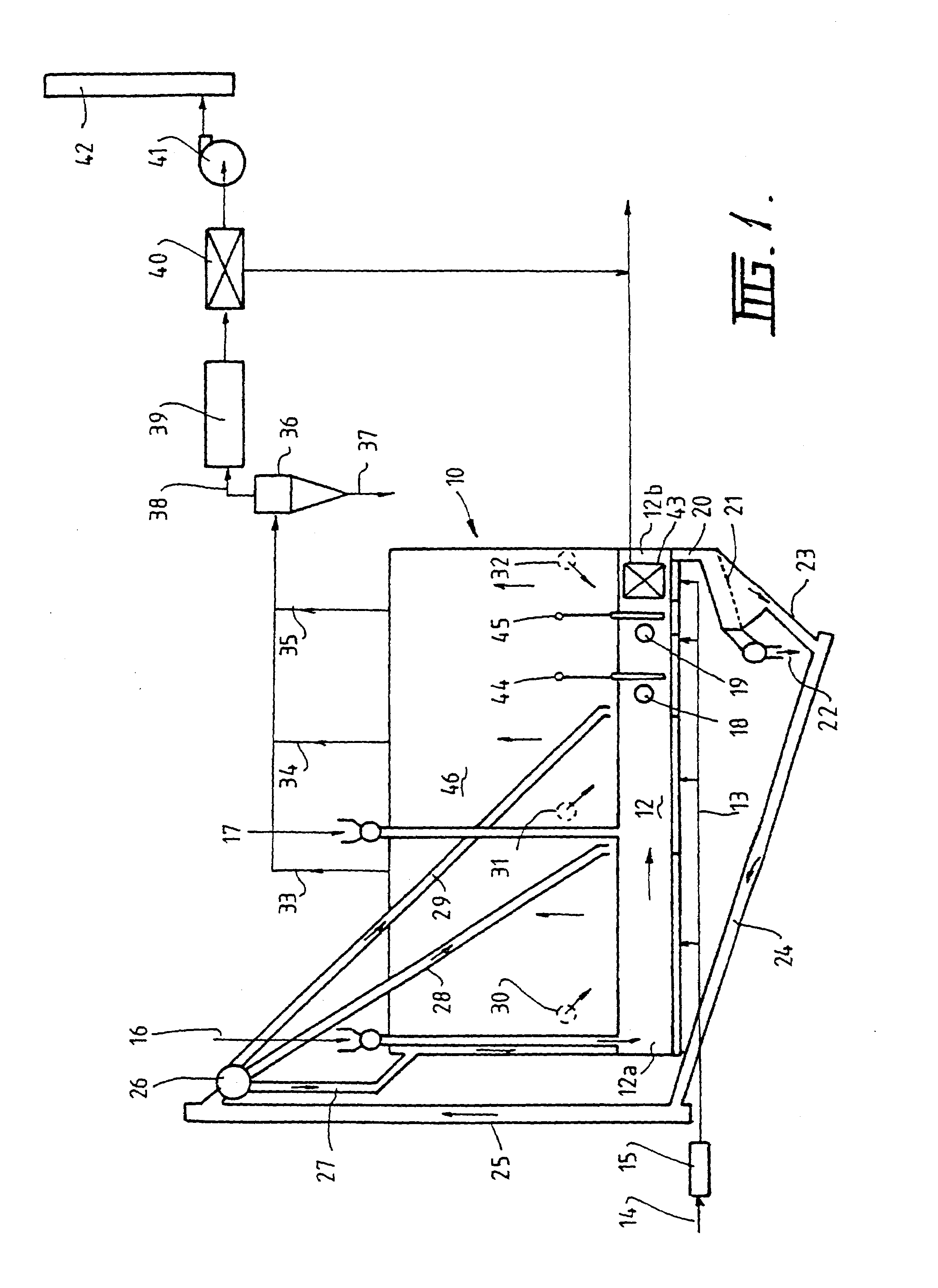

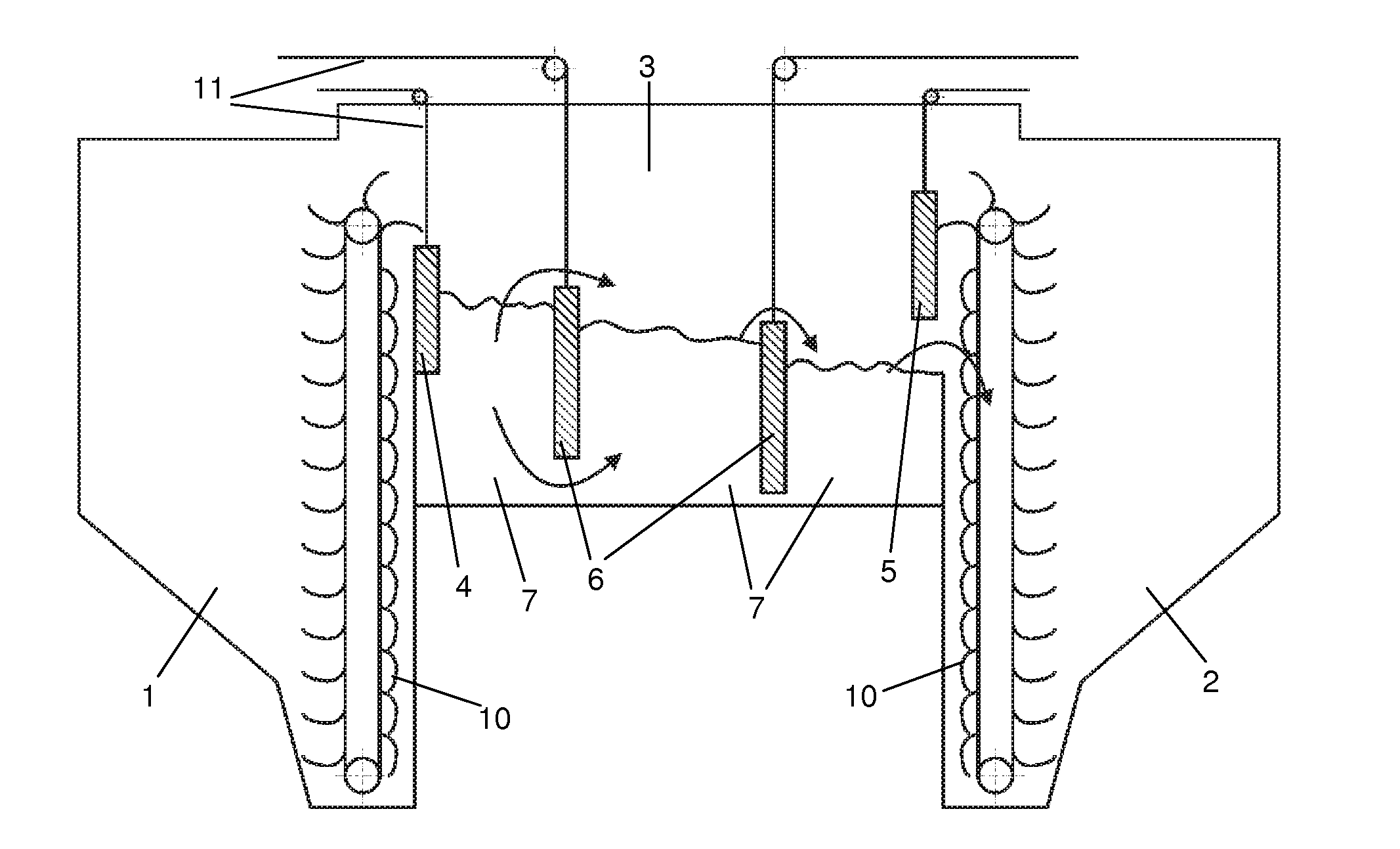

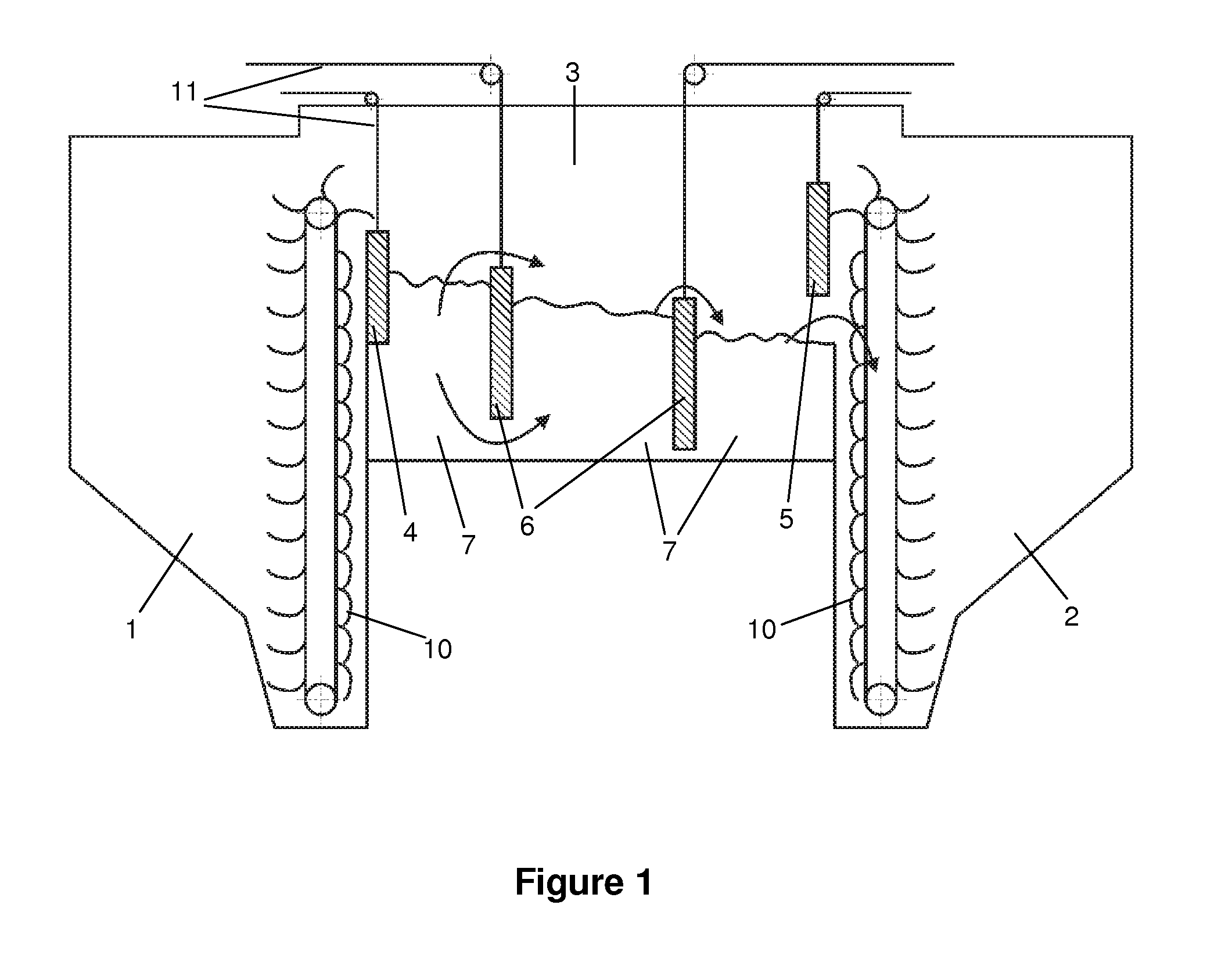

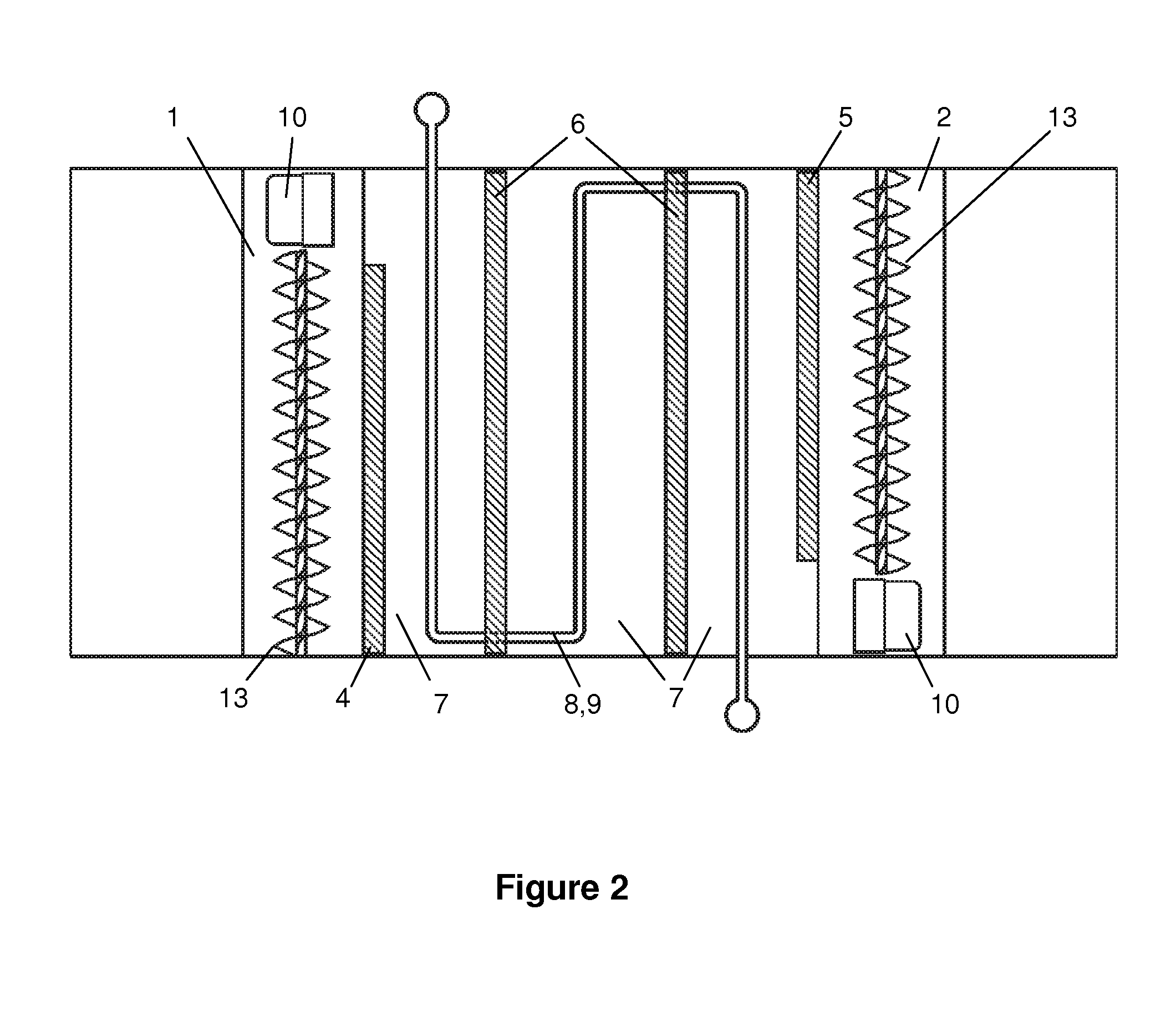

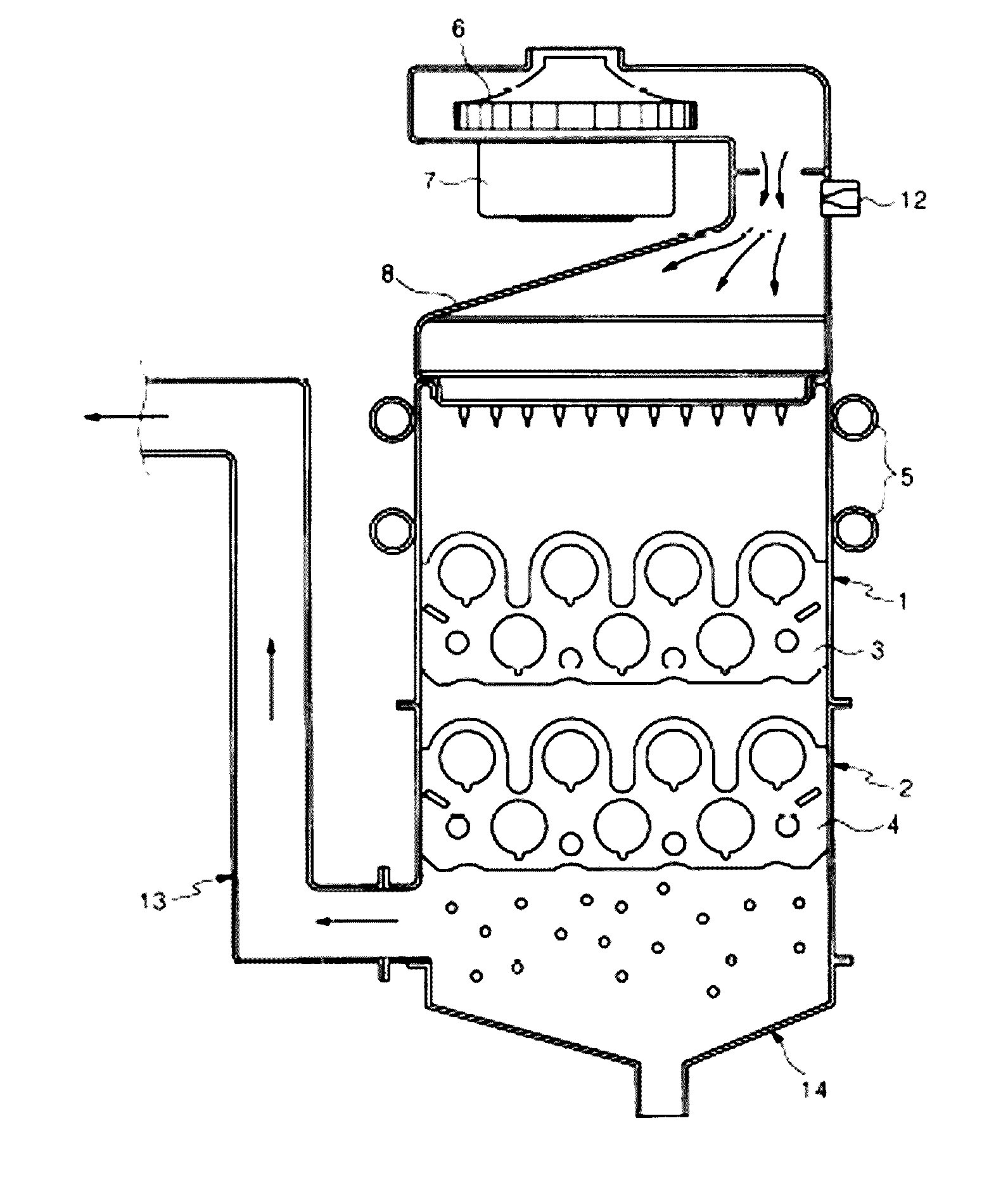

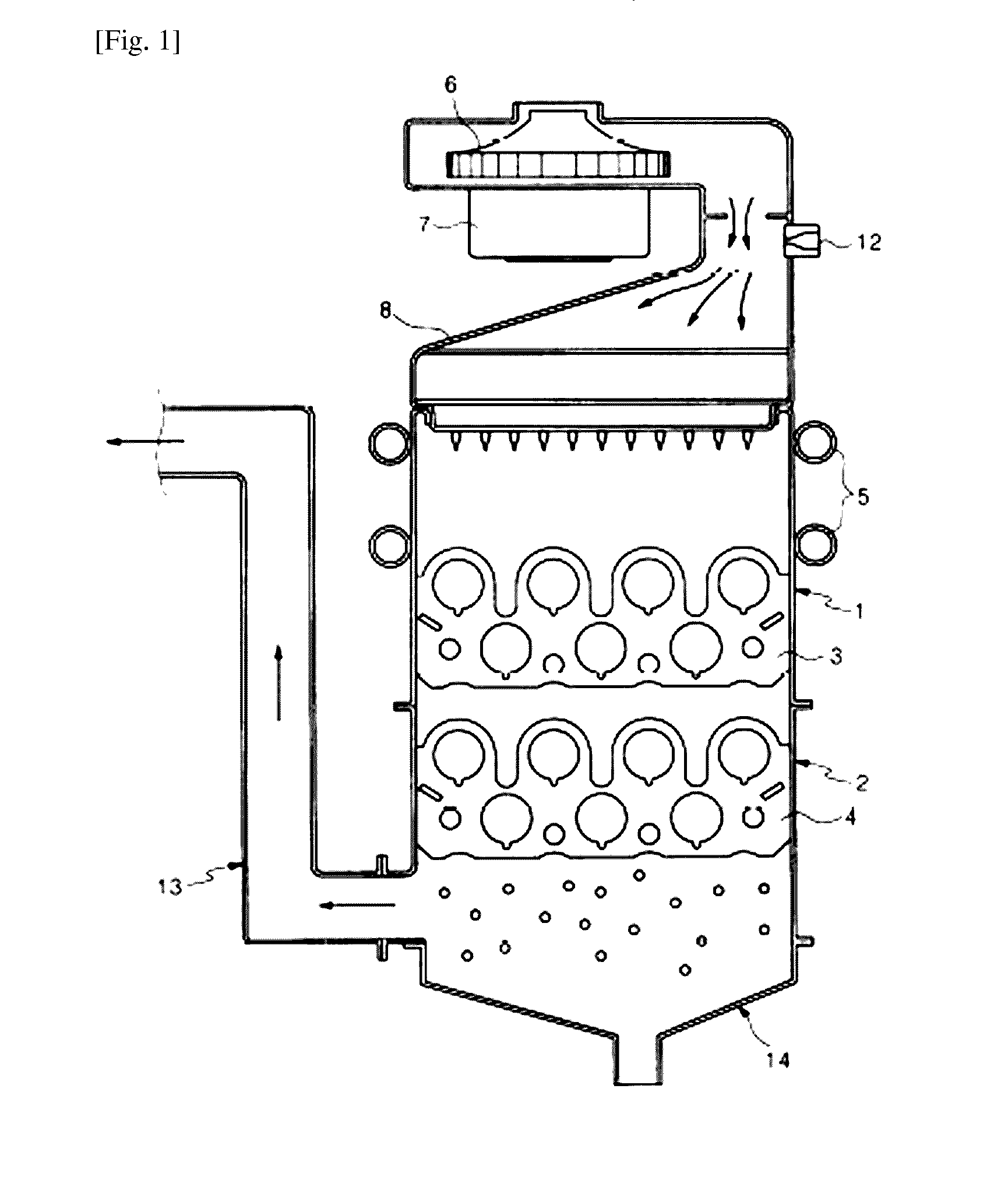

Heat storage system

ActiveUS20130220306A1Increase energy yieldDesign economySolar heating energySolar heat devicesFluidized bedTransport medium

The invention relates to a heat storage system using sand as a solid heat storage medium, characterized in that it comprises the following components: a storage tank (1) for cold sand; a storage tank (2) for hot sand; a fluidized bed heat exchanger (3) arranged therebetween, which is separated from the storage tanks (1, 2) by weirs (4, 5) and divided into a plurality of chambers (7) by weirs (6), wherein the weirs (4, 5, 6) are arranged as a combination of overflow and underflow weirs; wherein means (8) for transferring heat from a heat source to the sand fluidized therein as well as means (9) for transferring heat from the sand fluidized therein to a heat transport medium are provided in the chambers (7) of the heat exchanger (3); and at least one blower (14) positioned underneath the heat exchanger (3) for fluidizing the sand.

Owner:VIENNA UNIVERSITY OF TECHNOLOGY

Process for the synthesis of ammonia with low emissions of co2in atmosphere

ActiveUS20200055738A1Substantial elimination and zeroing of CO emissionHeat recoveryHydrogen productionHydrogen/synthetic gas productionSyngasEnvironmental engineering

Process for the synthesis of ammonia from natural gas comprising conversion of a charge of desulphurized natural gas and steam, with oxygen-enriched air or oxygen, into a synthesis gas, and treatment of the synthesis gas with shift reaction and decarbonation, wherein a part of the CO2-depleted synthesis gas, obtained after decarbonation, is separated and used as fuel fraction for one or more furnaces of the conversion section, and the remaining part of the gas is used to produce ammonia.

Owner:CASALE SA

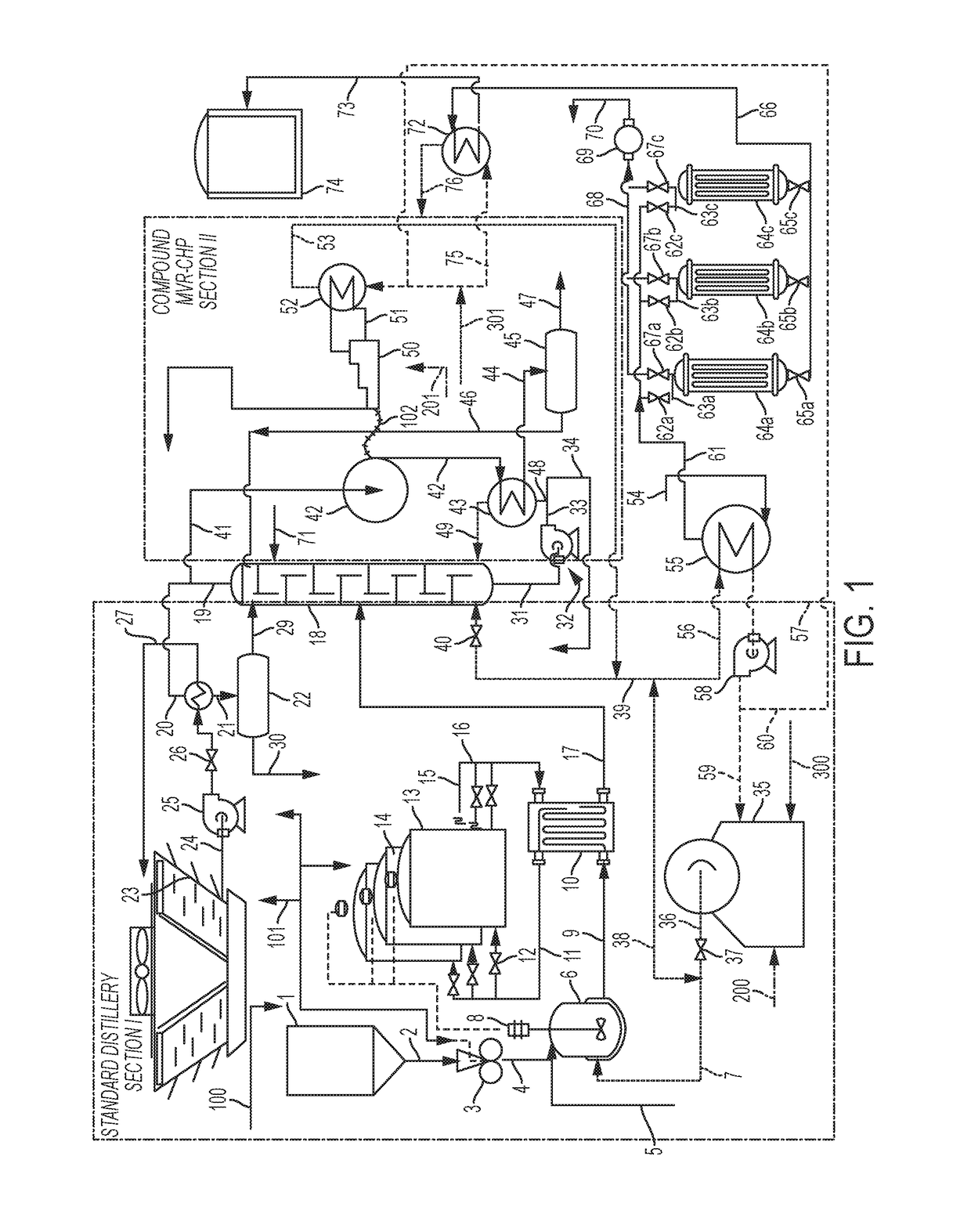

Energy-efficient systems including combined heat and power and mechanical vapor compression for biofuel or biochemical plants

ActiveUS20170274297A1Reduce energy costsProcess energy is not minimizedFermented solutions distillation/rectificationEvaporation with vapour compressionThermal energyDistillation

Processes and systems are provided to compress vapors produced in distillation and recover the heat of condensation through mechanical vapor compression and to derive mechanical and electrical energy from a combined heat and power system, while maintaining the plant's original ability to operate. The plant's existing distillation system, steam generation, and electrical demand determine the design basis for the retrofit system that is targeted at an optimized combination of energy usage, energy cost, and environmental impact. Mechanical vapor compression minimizes the total energy usage. Combined heat and power provides a means of converting energy between fuel, electricity, and thermal energy in a manner that best complements plant requirements and energy economics and minimizes inefficiencies and energy losses.

Owner:ENERGY INTEGRATION INC

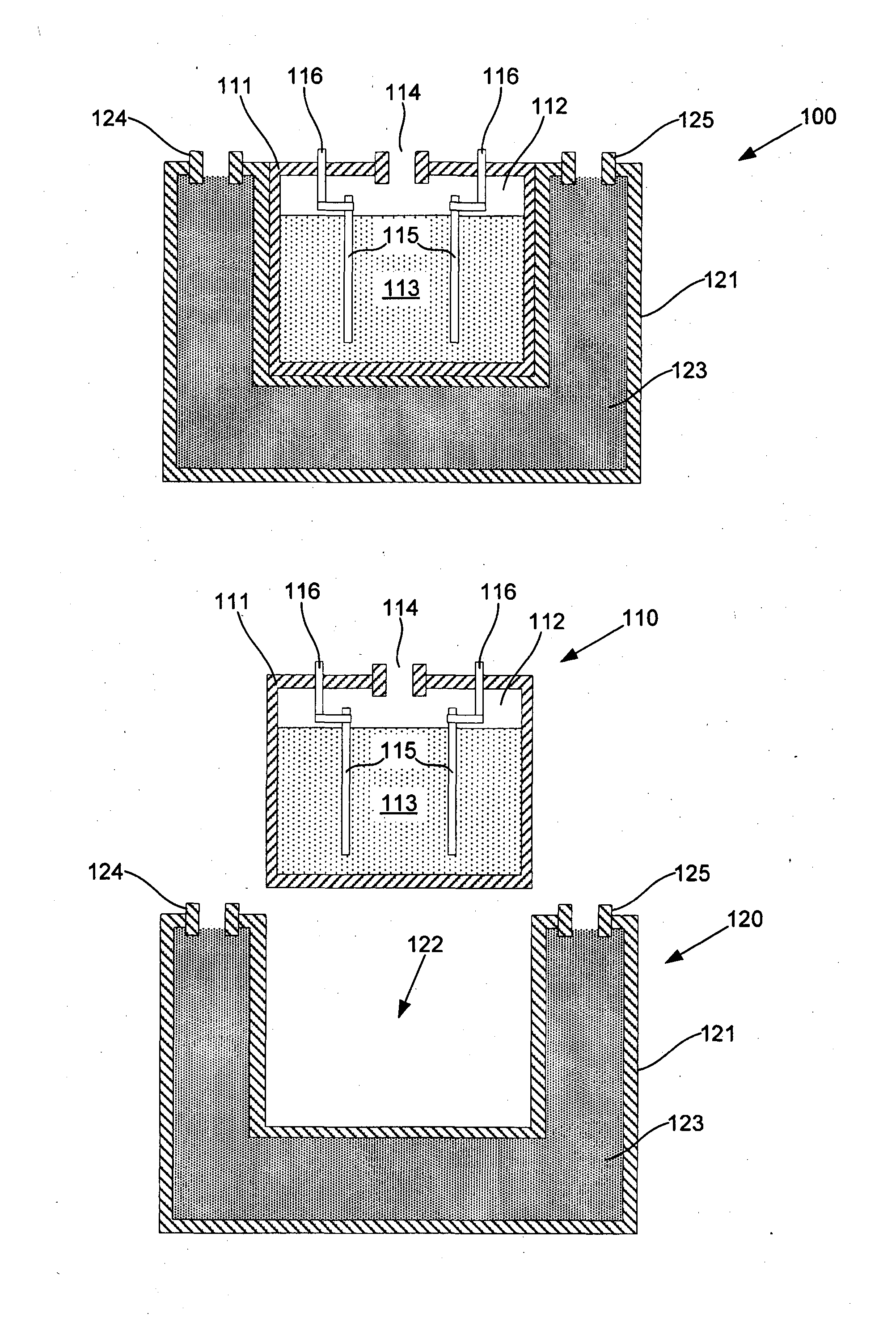

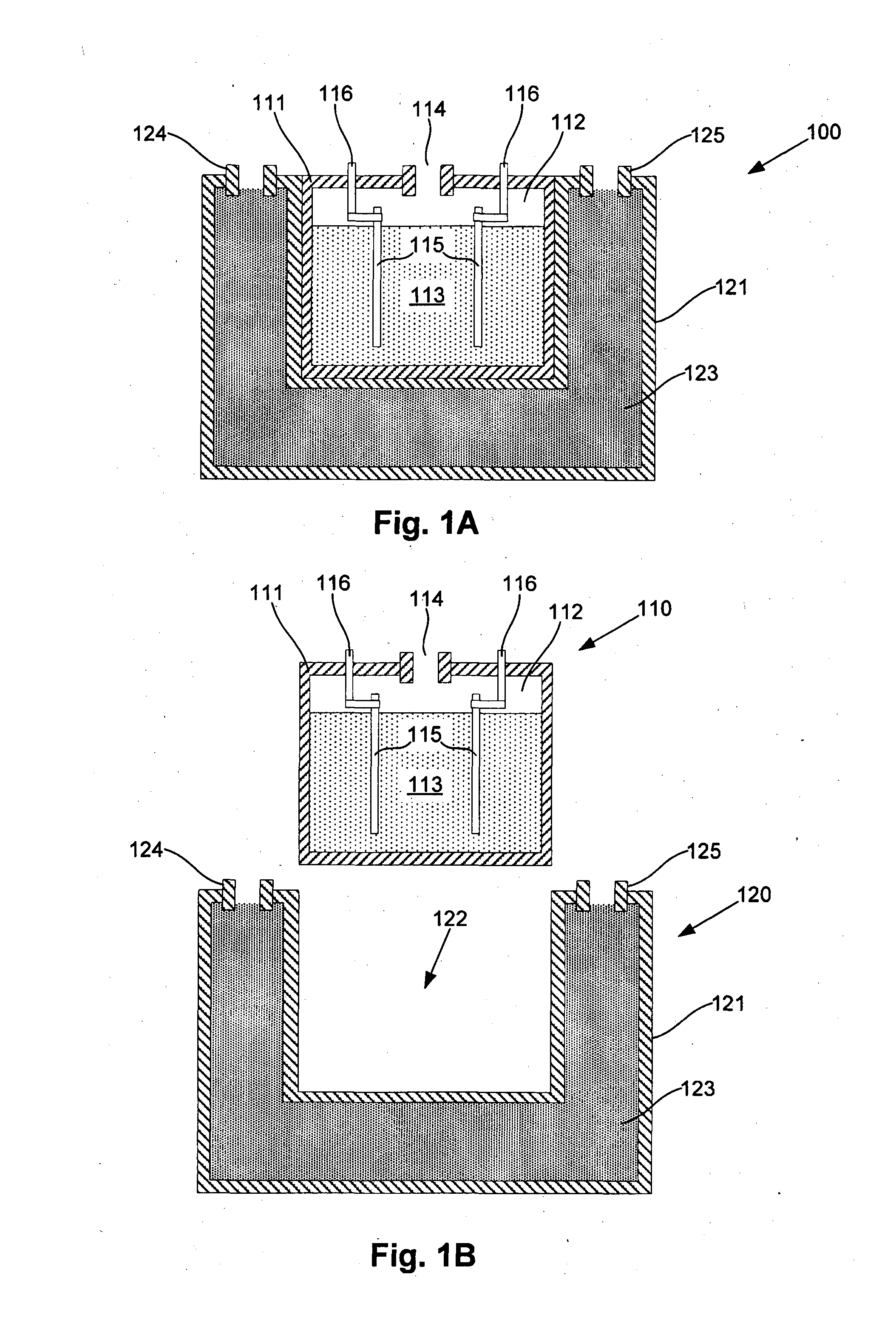

Condensation heat exchanger having dummy pipe

ActiveUS20150241130A1Stable flowRecover latent heatFluid heatersThermal insulationWater cyclingEngineering

A condensation heat exchanger having dummy pipes is provided in which a plurality of condensation heat exchange pipes are connected by means of water housings so as to recover latent heat while the water is circulating, and, by having the dummy pipes, penetrating the water housings, arranged in between the condensation heat exchange pipes, the pressure applied to the water housings is distributed and smooth flow of water is facilitated.

Owner:KITURAMI BOILER

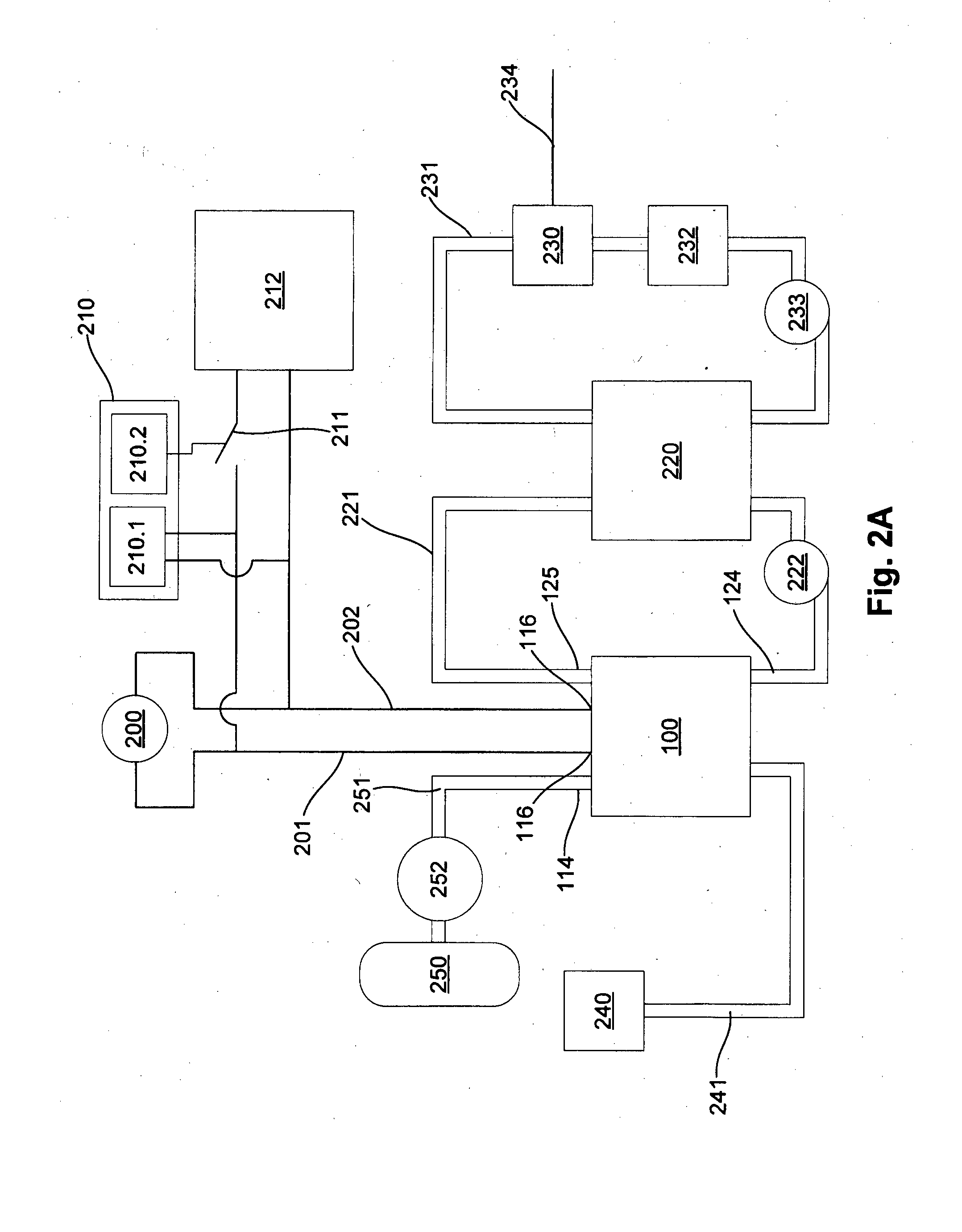

Electrolysis apparatus

InactiveUS20150211131A1Enhance pyroelectric effectGood effectCellsEnergy inputElectrolysisElectrical battery

Apparatus for performing electrolysis and generating heat, the apparatus including an electrolysis cell including, a cell housing defining an electrolyte cavity, the electrolyte cavity containing an electrolyte in use, a plurality of substantially parallel spaced apart electrode plates provided within the electrolyte cavity, the electrode plates defining at least one anode and at least one cathode at least partially submersed within the electrolyte in use, at least two connectors, which in use are connected to an electrical power supply thereby allowing an electrical current to be supplied to the electrolyte to thereby perform electrolysis and heating of the electrolyte, at least one cell outlet in fluid communication with the electrolyte cavity, the at least one cell outlet being coupled to a heat recovery module in use and at least one cell inlet allowing electrolyte to be supplied to the electrolyte cavity.

Owner:GAMIKON

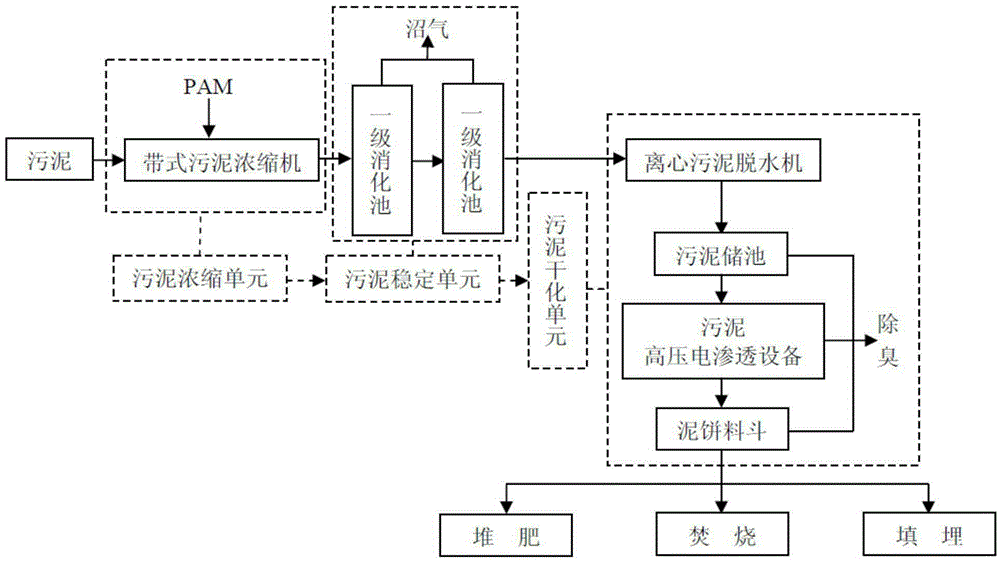

Sludge drying system

ActiveCN105399293AReduce moisture contentIncrease moisture contentSludge treatment by de-watering/drying/thickeningWater contaminantsSludge cakeReagent

The invention discloses a sludge drying system, comprising a sludge concentrating unit, a sludge stabilizing unit and a sludge drying unit which are connected in sequence, wherein the sludge concentrating unit comprises a belt sludge concentrator which is provided with a PAM adding device, the sludge stabilizing unit is provided with a medium-temperature sludge anaerobic digestion tank which is provided with a biogas outlet, the sludge drying unit comprises a sludge centrifugal dehydrator, a sludge storage tank, a sludge high-voltage electro-osmosis unit and a sludge cake hopper which are connected in sequence, the sludge high-voltage electro-osmosis unit is provided with a deodorizing device, and the sludge cake hopper is connected with a composting device, a burning device and / or a dumping device. The sludge drying system realizes quantitative reduction, harmlessness and recycling of sludge without addition of a reagent.

Owner:BEIJING SOUND ENVIRONMENTAL ENG +1

Process for carbonizing wood residues and producing activated carbon

InactiveUS20050072343A1Improve heat transfer performancePromote combustionProductsReagentsActivated carbonFluidized bed

An apparatus and process for preparing activated carbon from a wood or wood residue feedstock using fluidized bed technology. The fluidized bed apparatus has a number of wood residue inlets that allow differing residence times in the fluidized bed apparatus appropriate for the wood or wood residue feedstock to be carbonized. The carbonized material may then be activated to form activated carbon.

Owner:COMMONWEALTH SCI & IND RES ORG

Heat Exchanger and Water Heater

InactiveUS20070221143A1Heat recoveryAvoid flowSpacing meansBoiler water tubesEngineeringHeat exchanger

A heat exchanger A1 includes a coiled tube 60 including a plurality of loops 60a, and a space 35 surrounded by the coiled tube 60 and having an end closed by a partition 19. The heat exchanger is so designed that combustion gas flows from the space 35 to a combustion gas path 36 by passing through clearances 61 of the loops 60a of the coiled tube 60. The loops 60a are made of a tube having a thickness t1 and a width L1 which is larger than the thickness, so that the amount of heat recovery when the combustion gas passes through the clearances 61 is large. Therefore, the heat exchange efficiency is enhanced while simplifying the overall structure of the heat exchanger A1 and reducing the size of the heat exchanger.

Owner:NORITZ CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com