Use method for circulating comprehensive utilization device for blast furnace gas

A technology of blast furnace gas and blast furnace, which is applied in the field of blast furnace gas cycle comprehensive utilization device, can solve problems such as insufficient heat utilization, lower combustion temperature of combustion system, increase of gas, etc., to avoid early scrapping, increase of combustion temperature, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

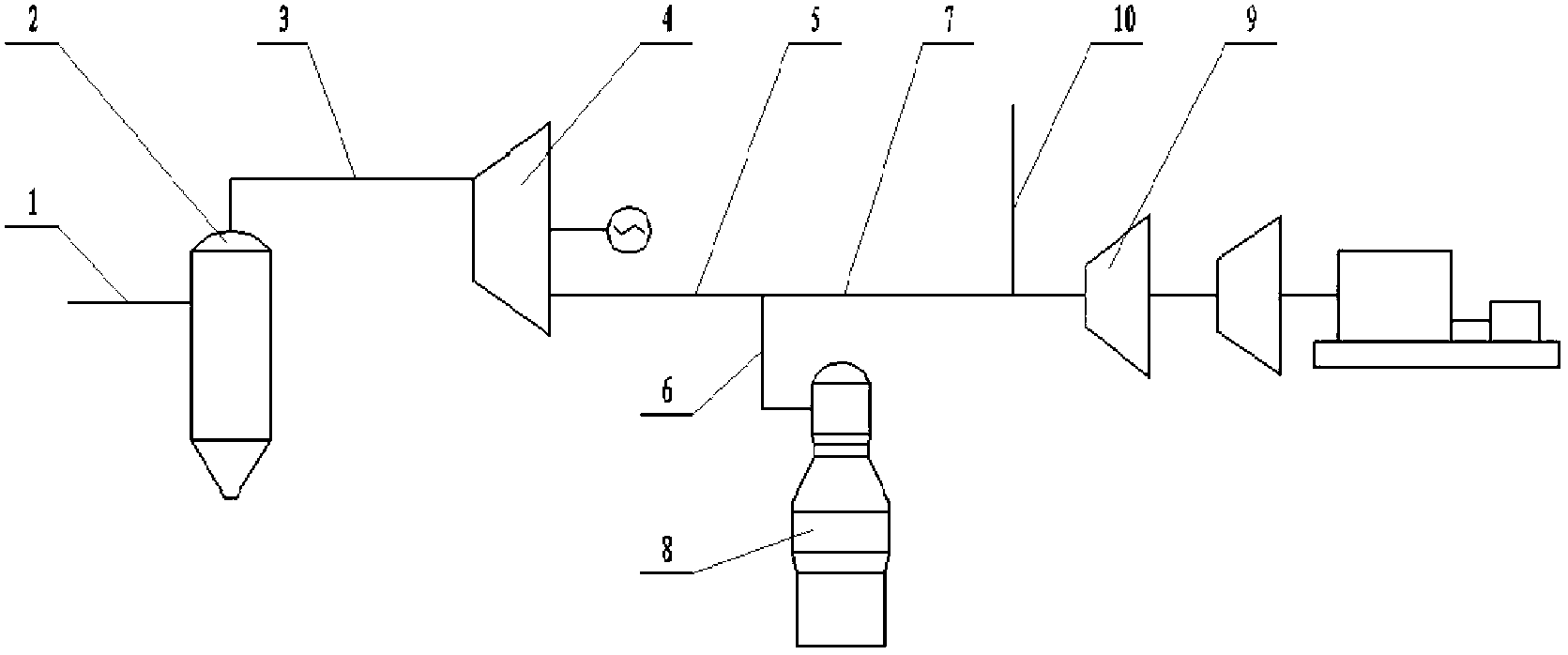

[0022] like figure 1 As shown, a blast furnace gas cycle comprehensive utilization device includes a dry bag type pulse dust removal device 2, a fully dry blast furnace gas residual pressure recovery device 4, a blast furnace hot blast stove device 8, a gas-steam combined cycle power generation device 9, and an original blast furnace gas Pipeline 1, high-pressure clean blast furnace gas pipeline 3, low-pressure blast furnace gas pipeline 5, blast furnace hot blast stove leading blast furnace gas pipeline 6, gas-steam combined cycle power generation device leading blast furnace gas pipeline 7, maintenance and exporting blast furnace gas pipeline 10. The specific process steps and parameters are:

[0023] 1) The blast furnace gas discharged from the top of the blast furnace enters the dry bag pulse dust removal device 2 from the lower part through the original blast furnace gas pipeline 1. The back blowing type of the dry bag pulse dust removal device 2 is pulse type, and it ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com