Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167results about "Desuperheaters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

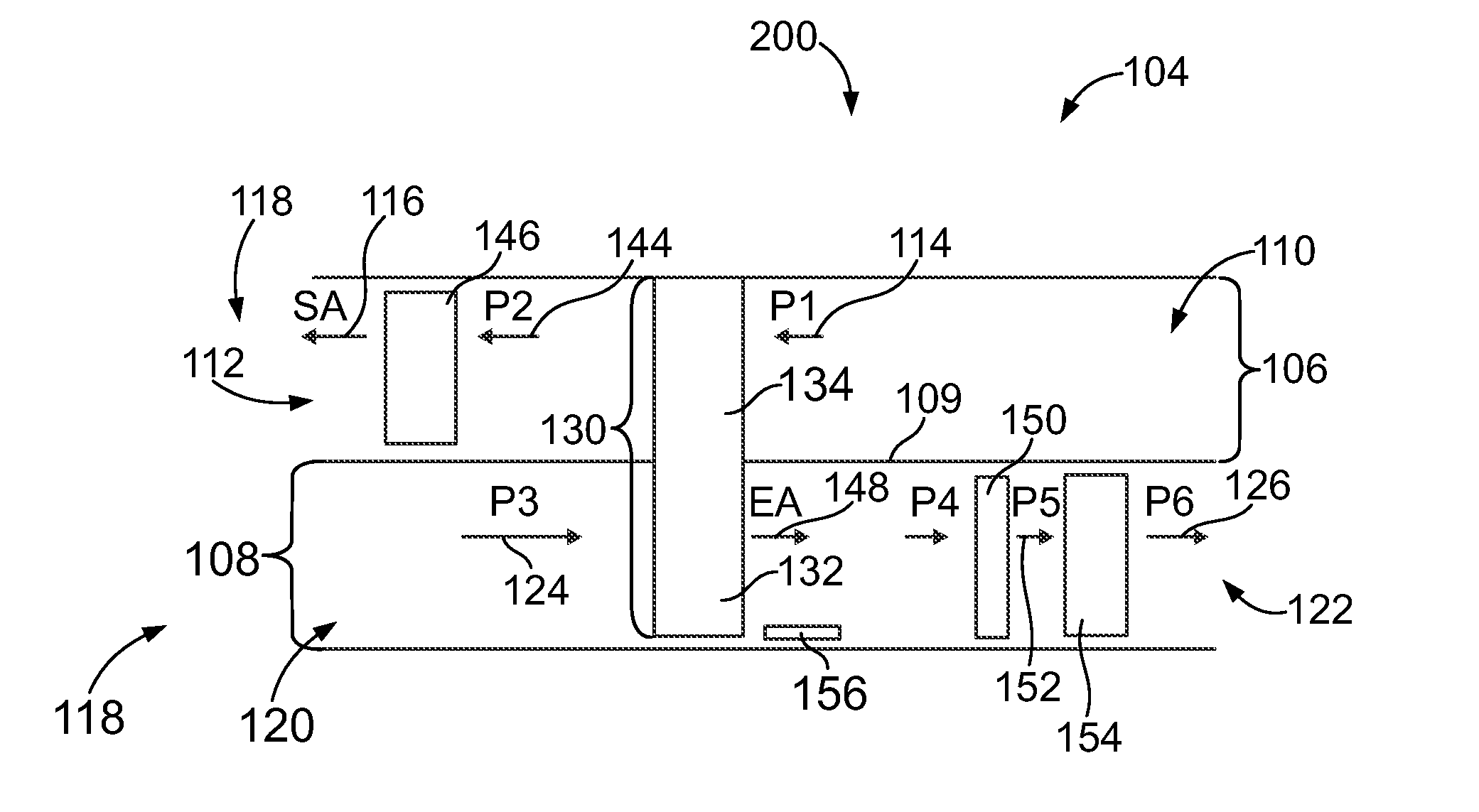

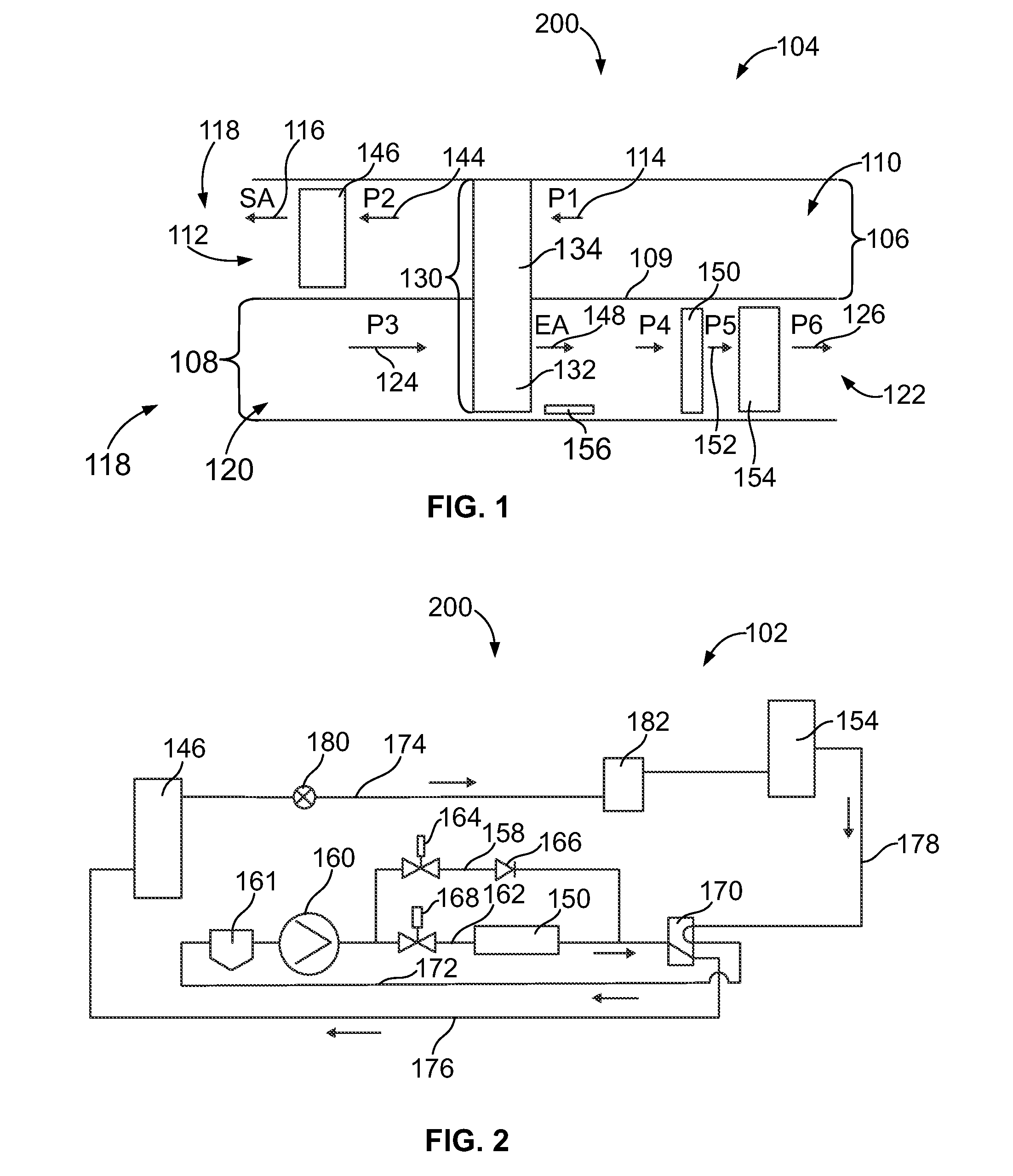

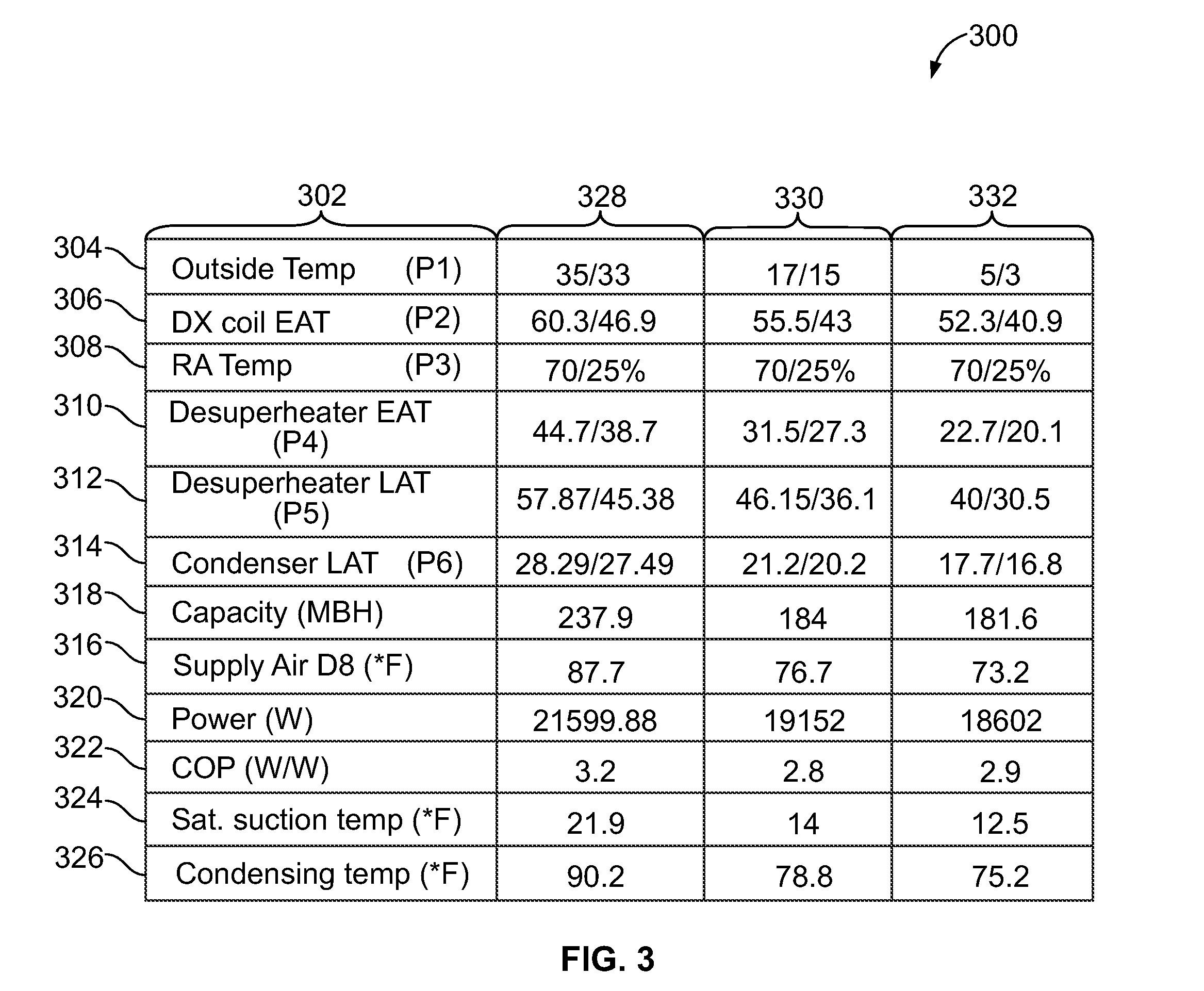

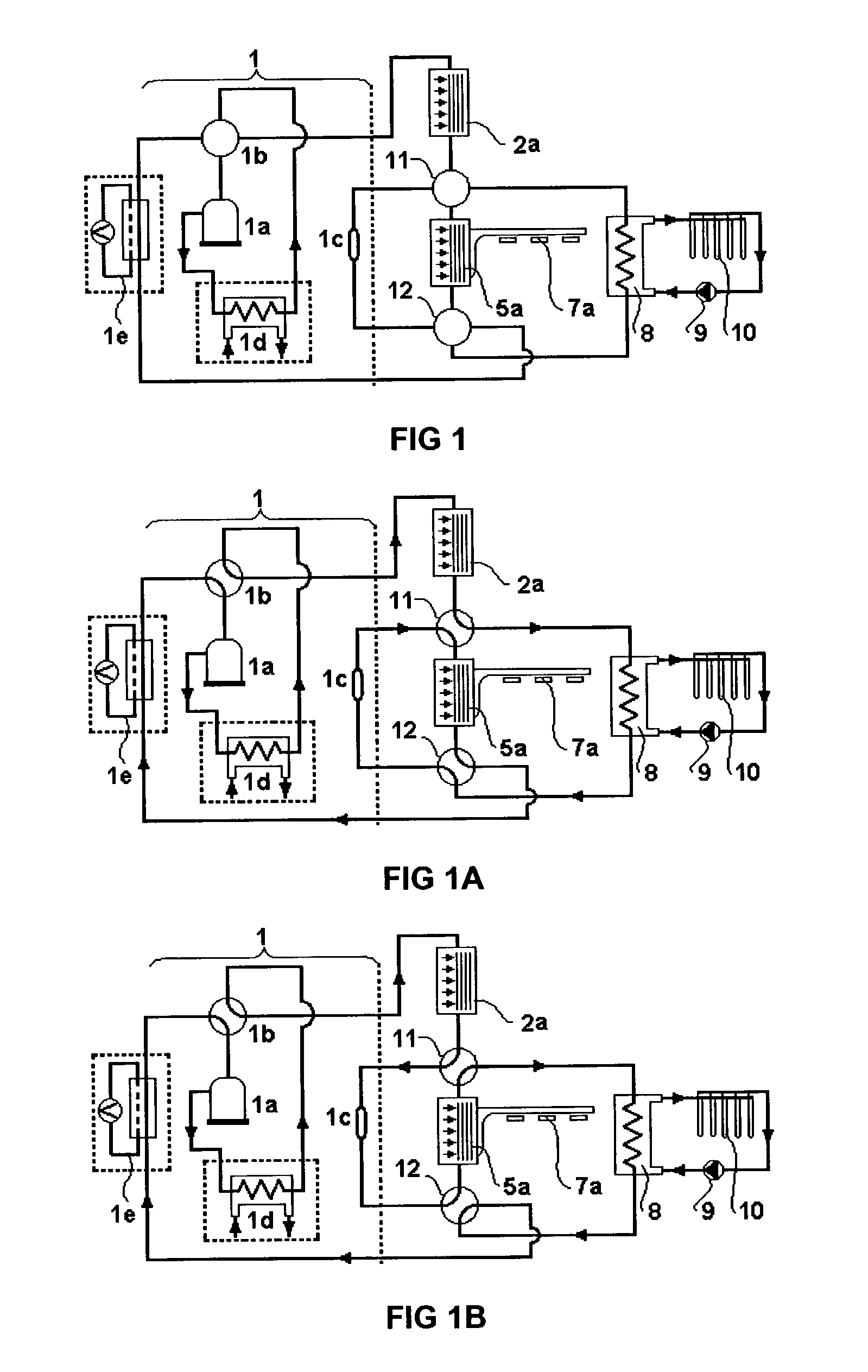

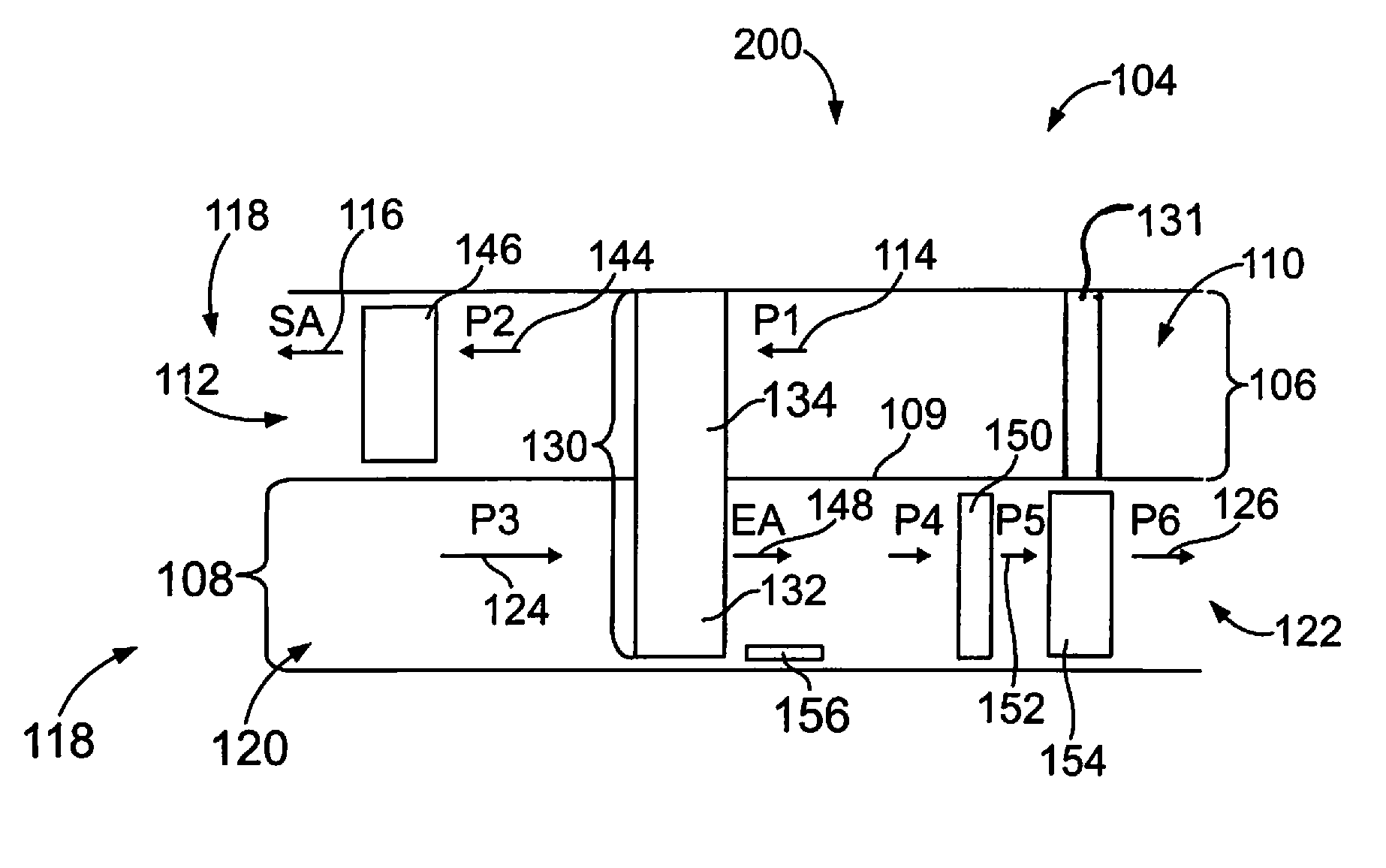

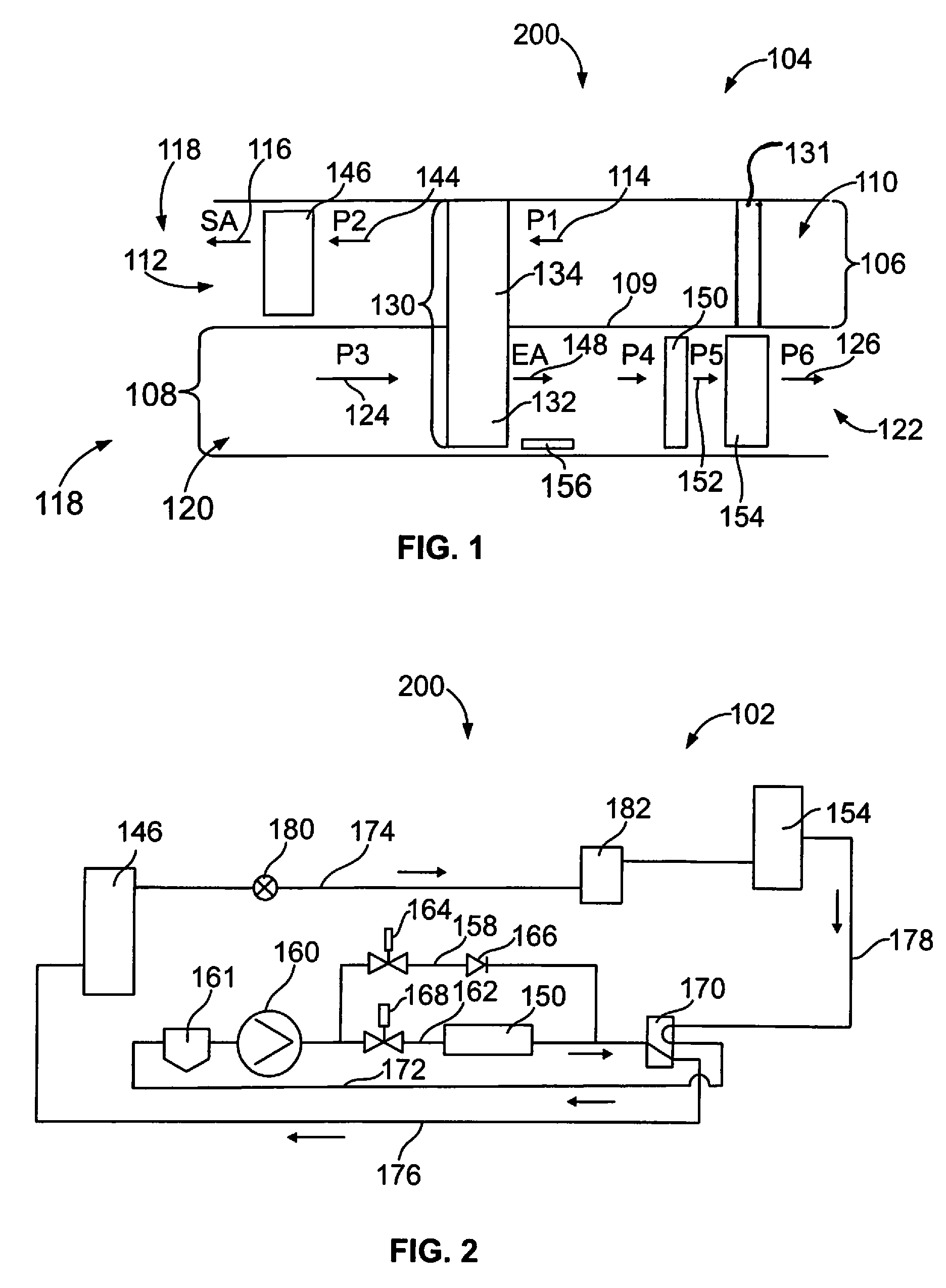

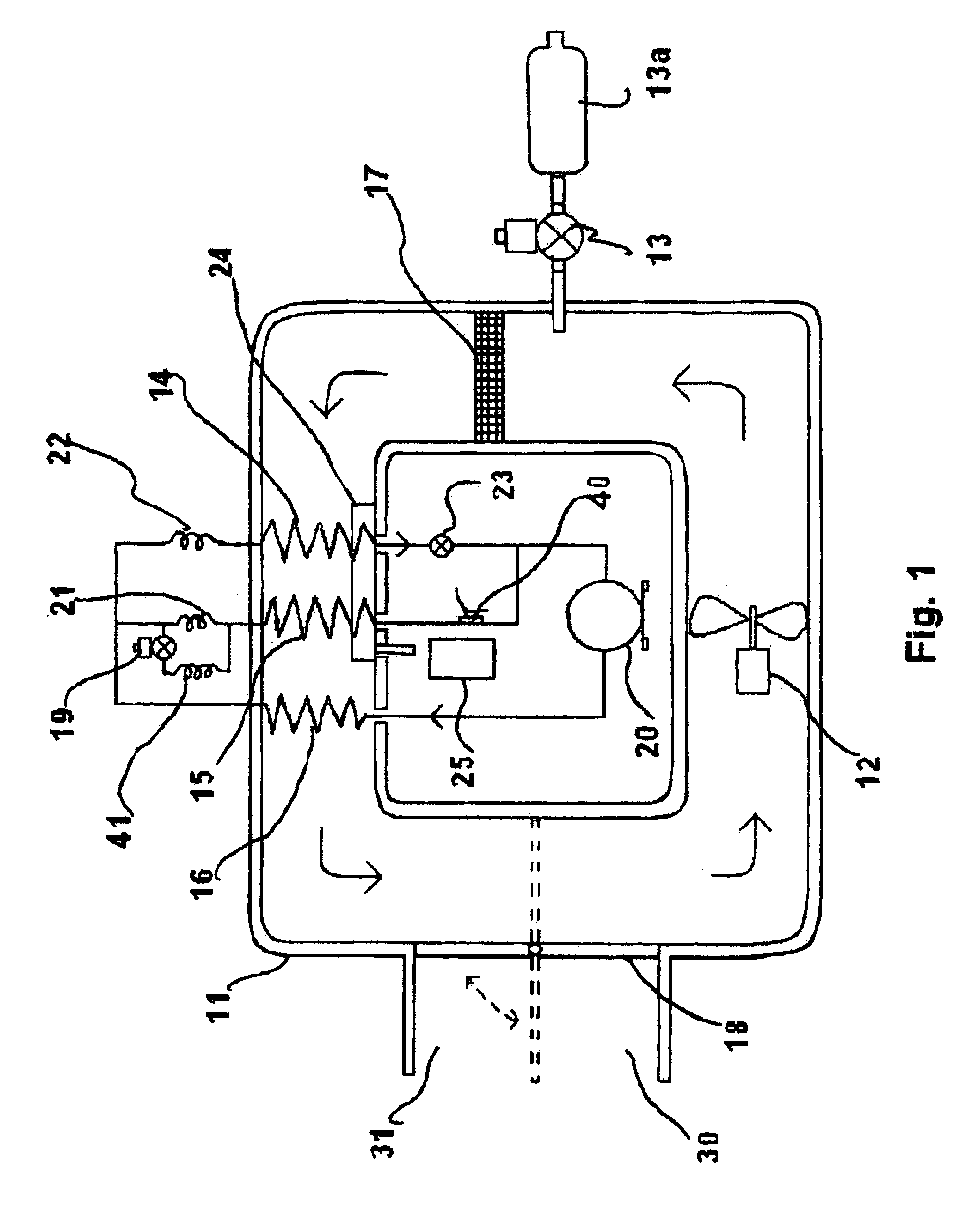

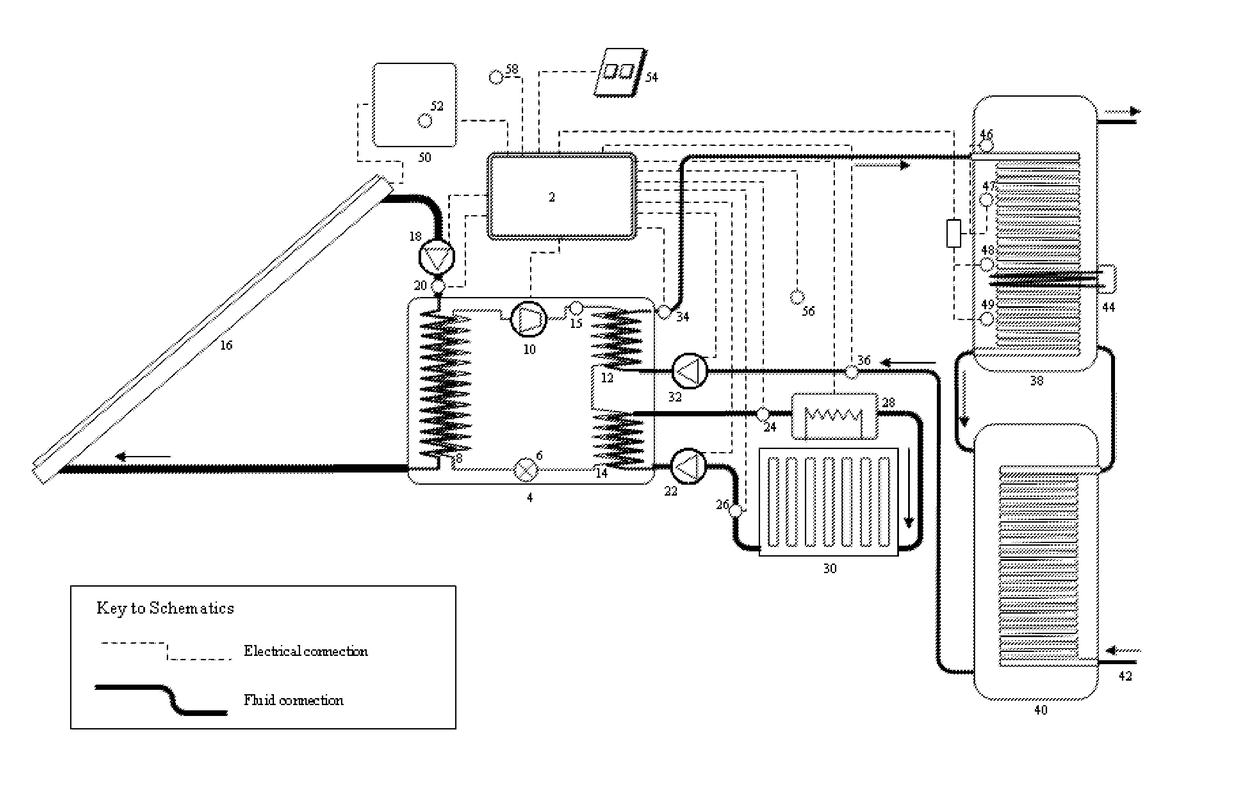

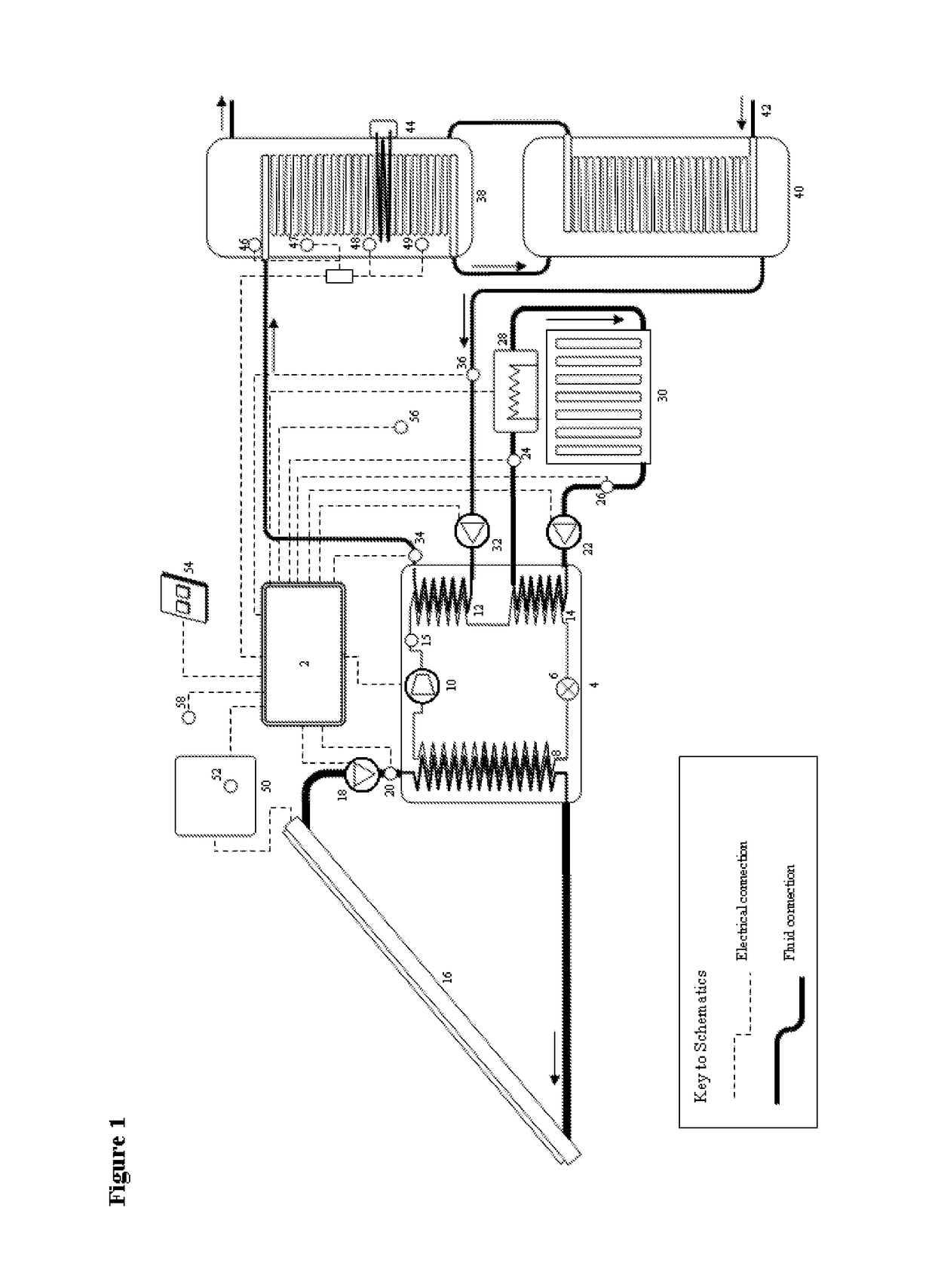

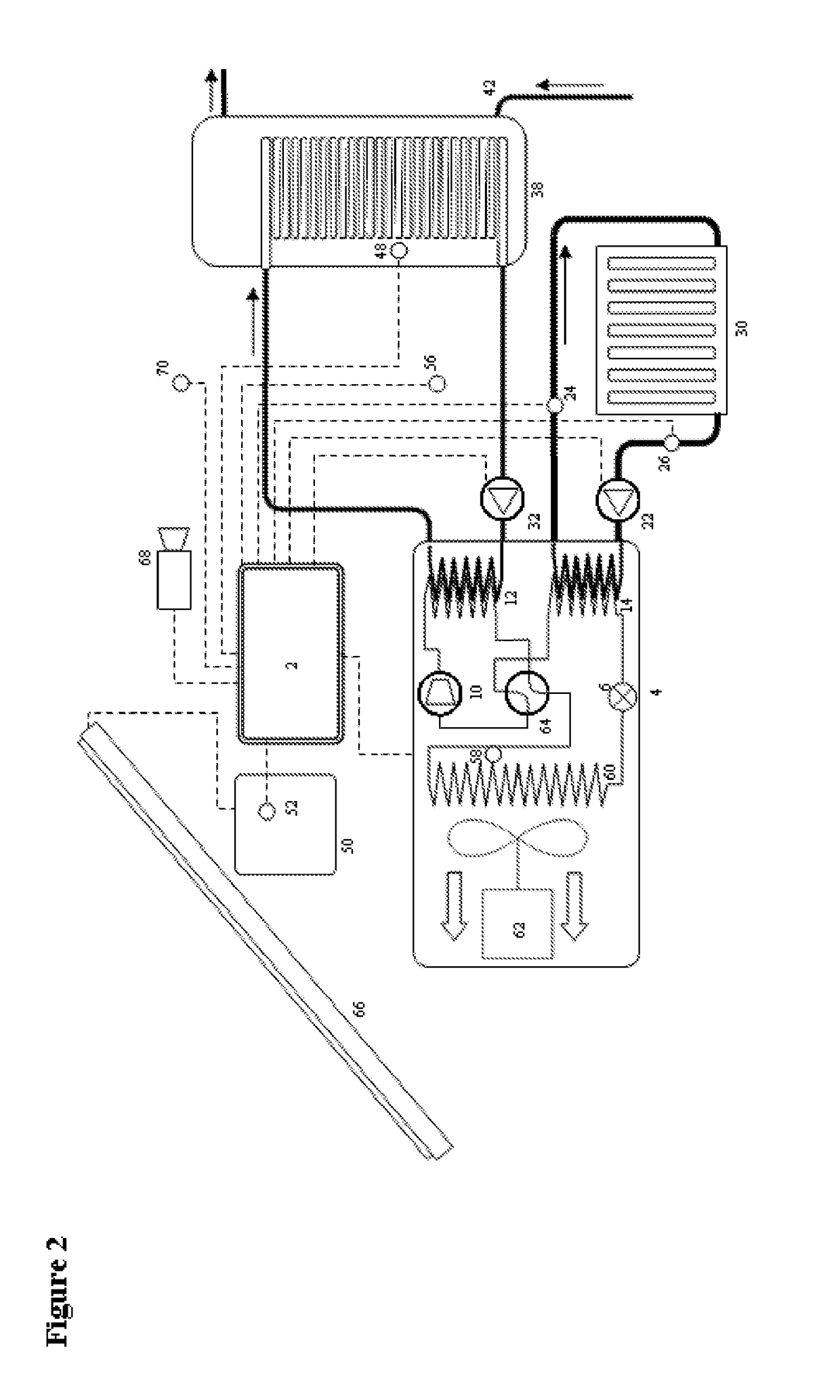

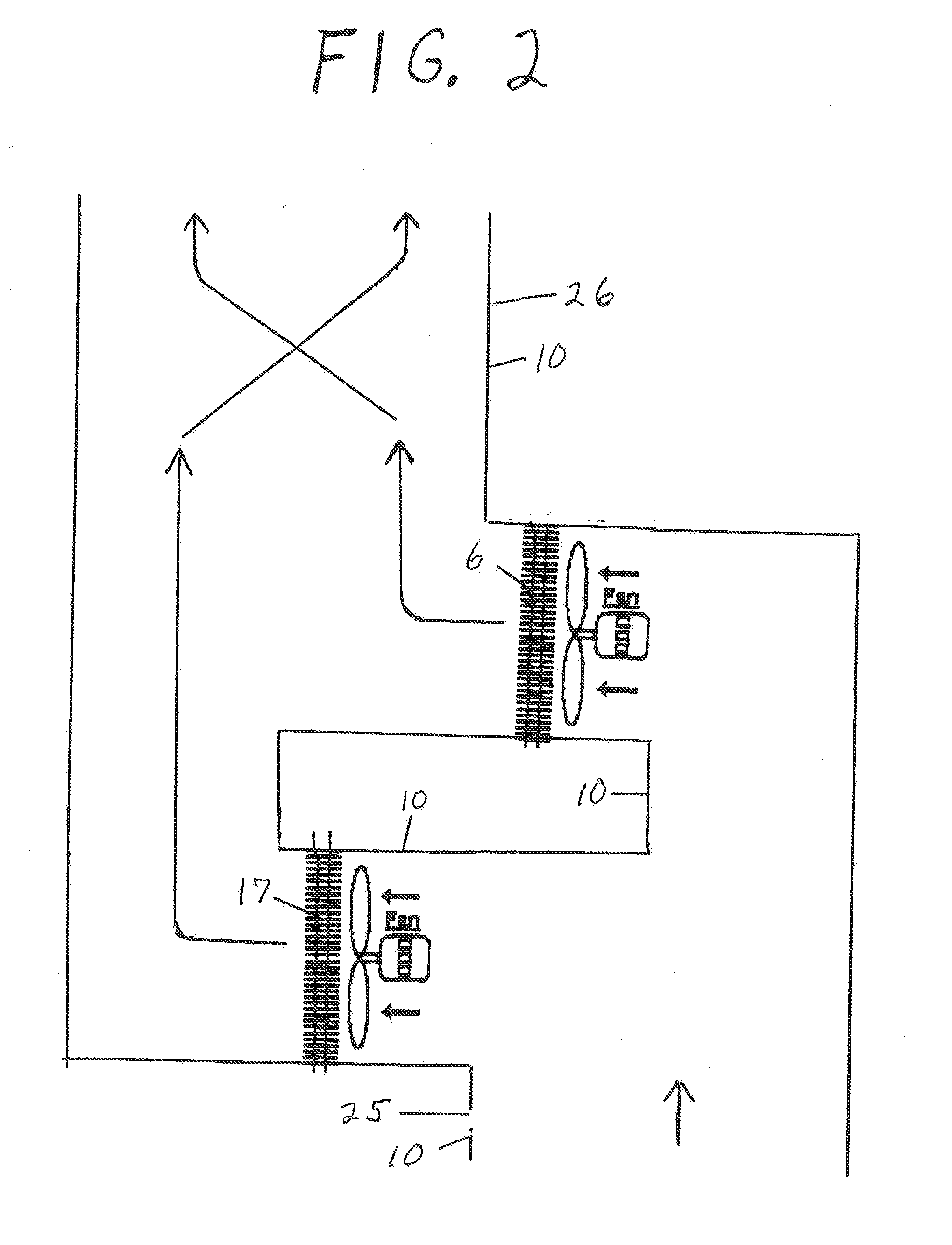

Heat pump system having a pre-processing module

ActiveUS20120180505A1Avoid frostImprove regeneration efficiencyEnergy recovery in ventilation and heatingMechanical apparatusComputer moduleEnergy recovery

A heat pump system is operable in winter mode and / or summer mode, and may be selectively operated in a defrost mode or cycle. The system includes an energy recovery module that receives and conditions air in a regeneration air channel. A pre-processing module is positioned downstream of the energy recovery module. The pre-processing module receives and heats air from the energy recovery module. A regeneration air heat exchanger is positioned downstream of the pre-processing module. The regeneration air heat exchanger receives and conditions air from the pre-processing module. The pre-processing module heats the air from the energy recovery module to increase efficiency of the regeneration air heat exchanger. During the defrost mode, a loop of regeneration air may be recirculated between the supply air channel and the regeneration air channel in order to defrost the regeneration air heat exchanger.

Owner:NORTEK AIR SOLUTIONS CANADA INC

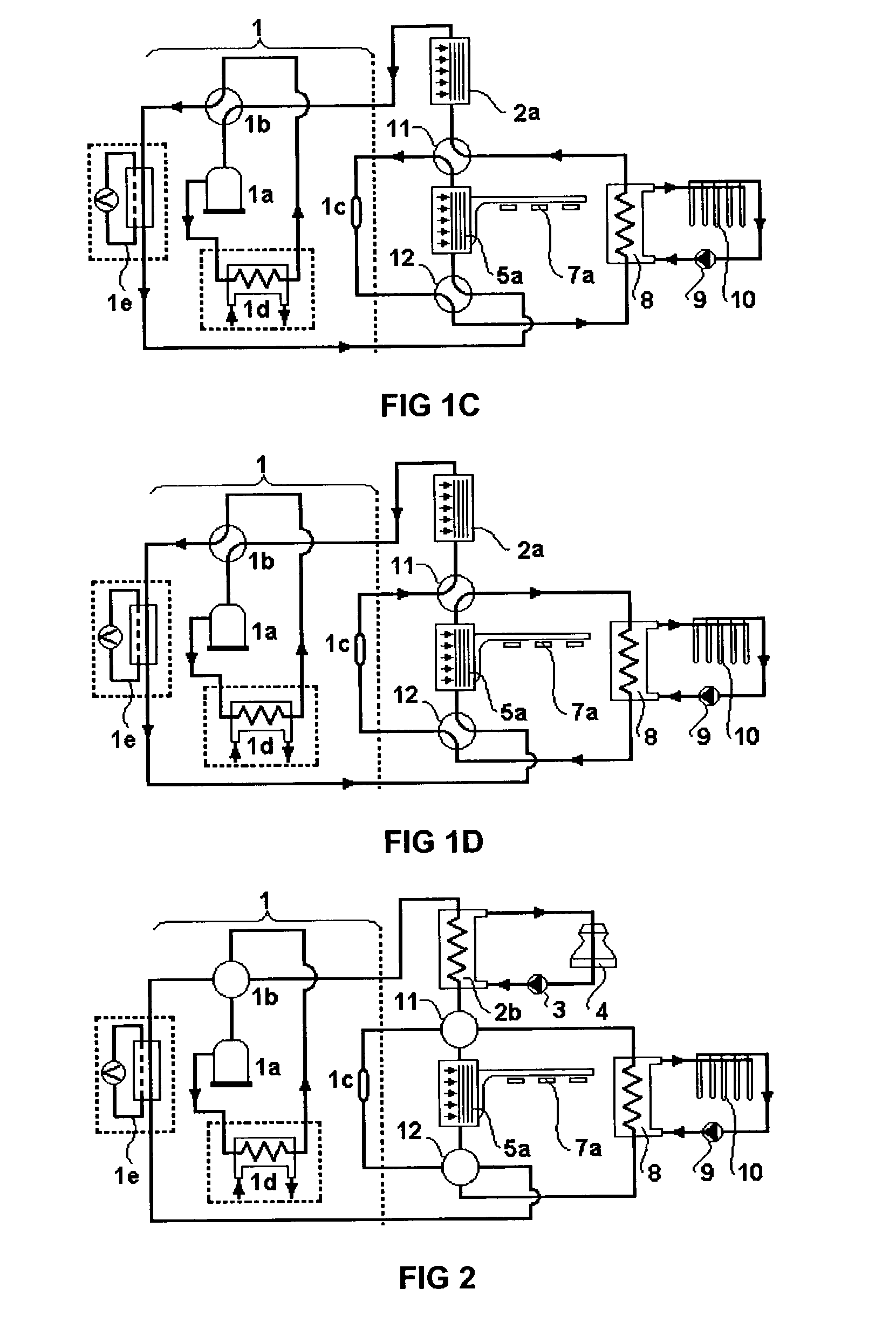

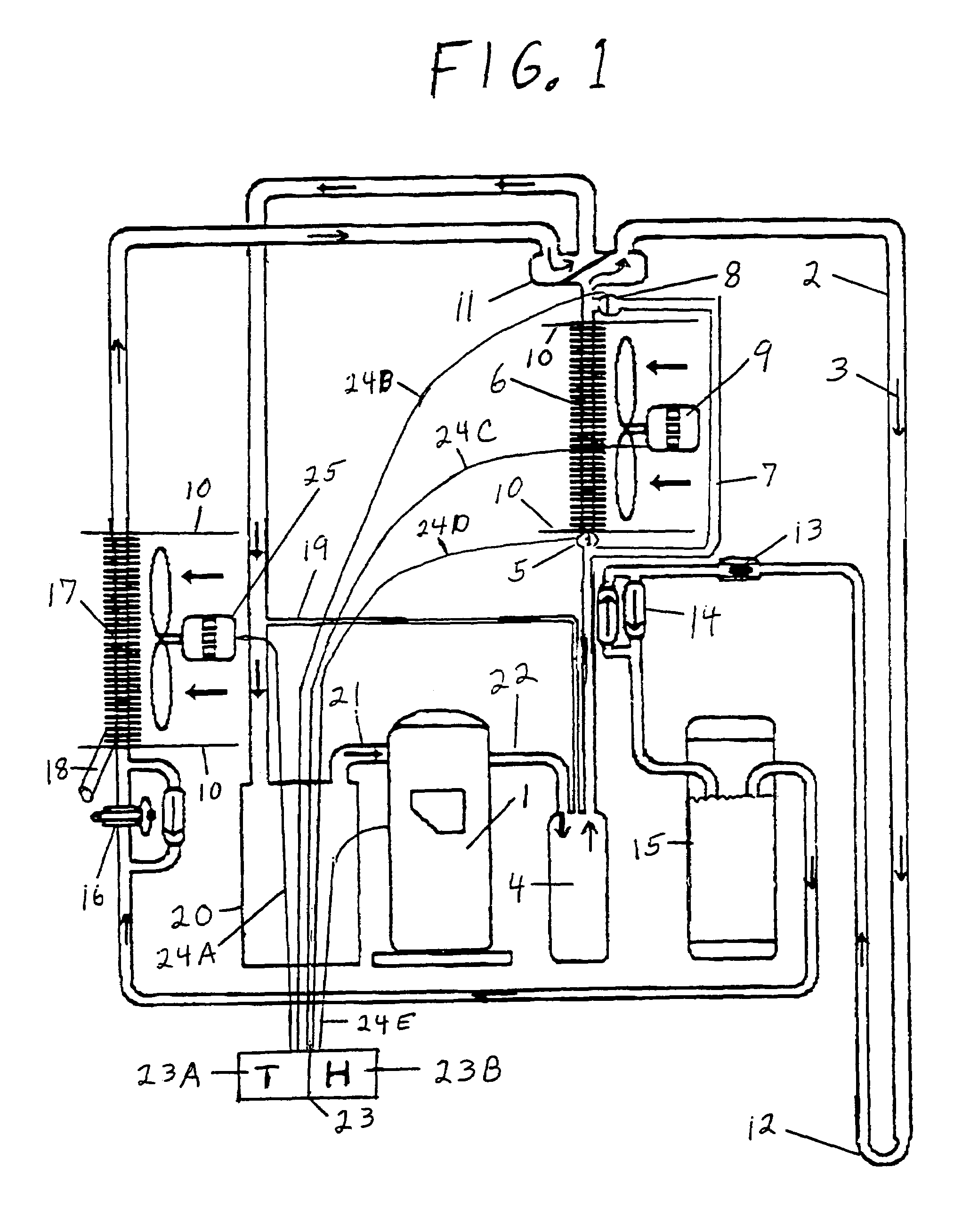

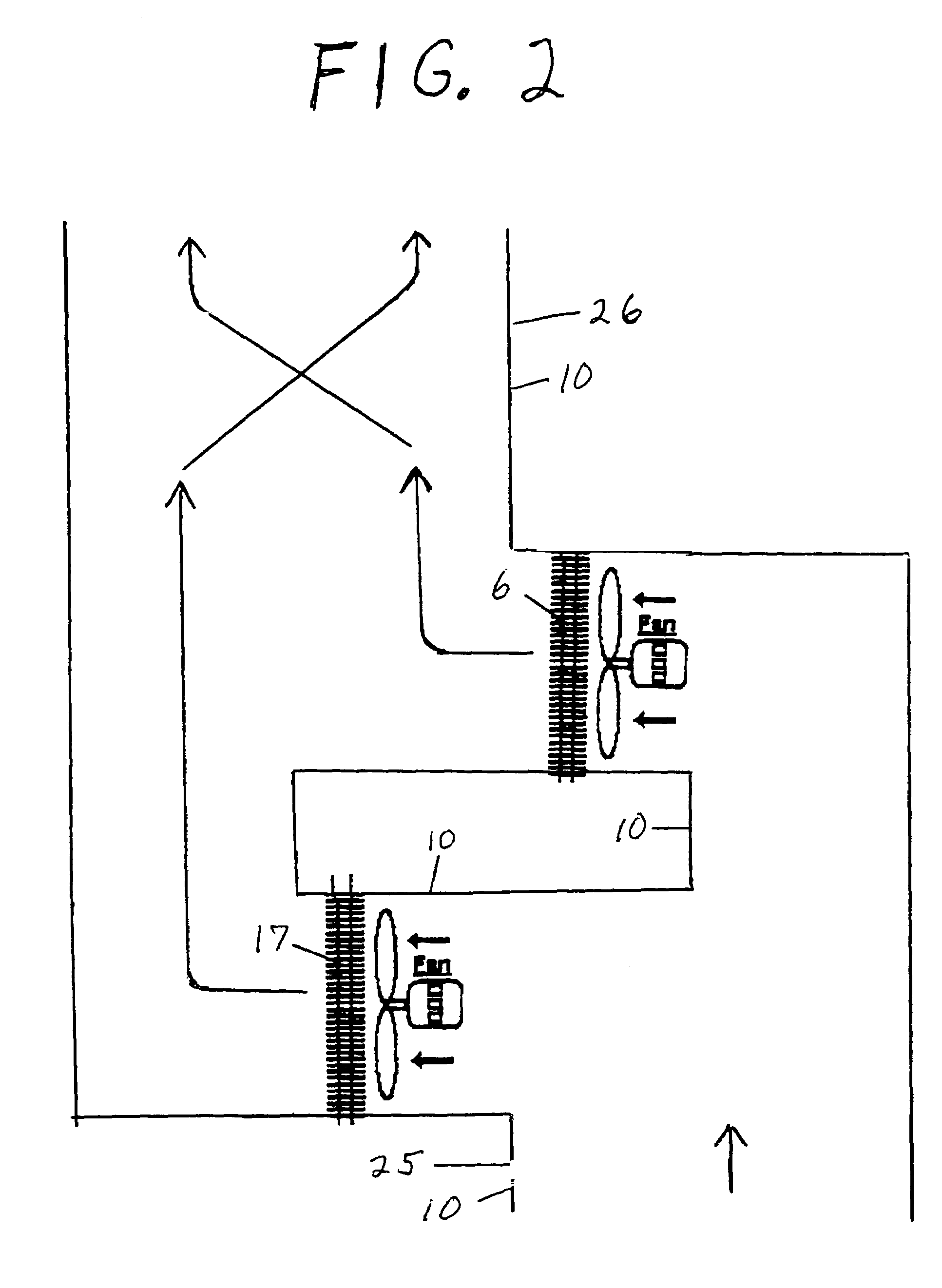

Heat pump/direct expansion heat pump heating, cooling, and dehumidification system

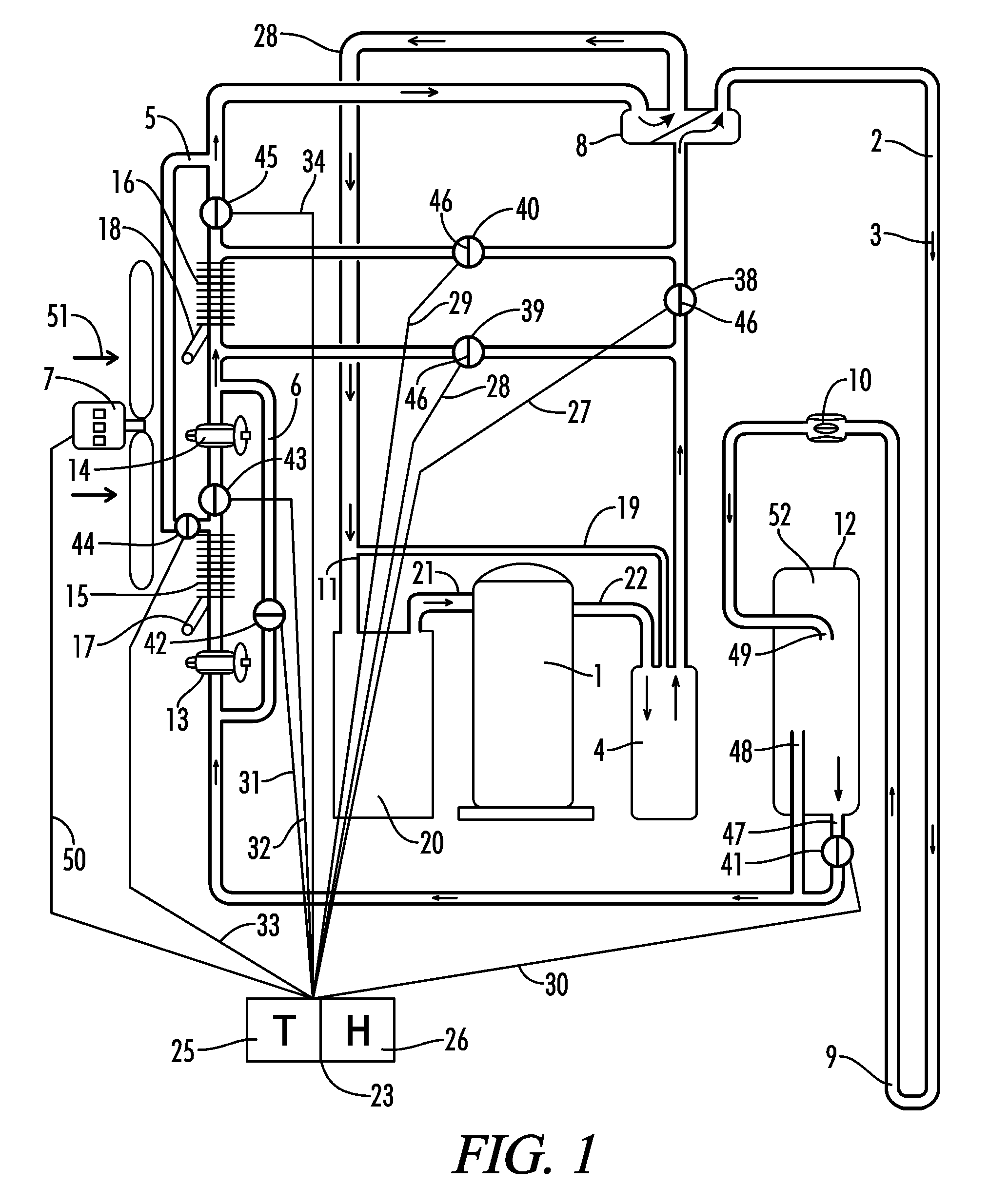

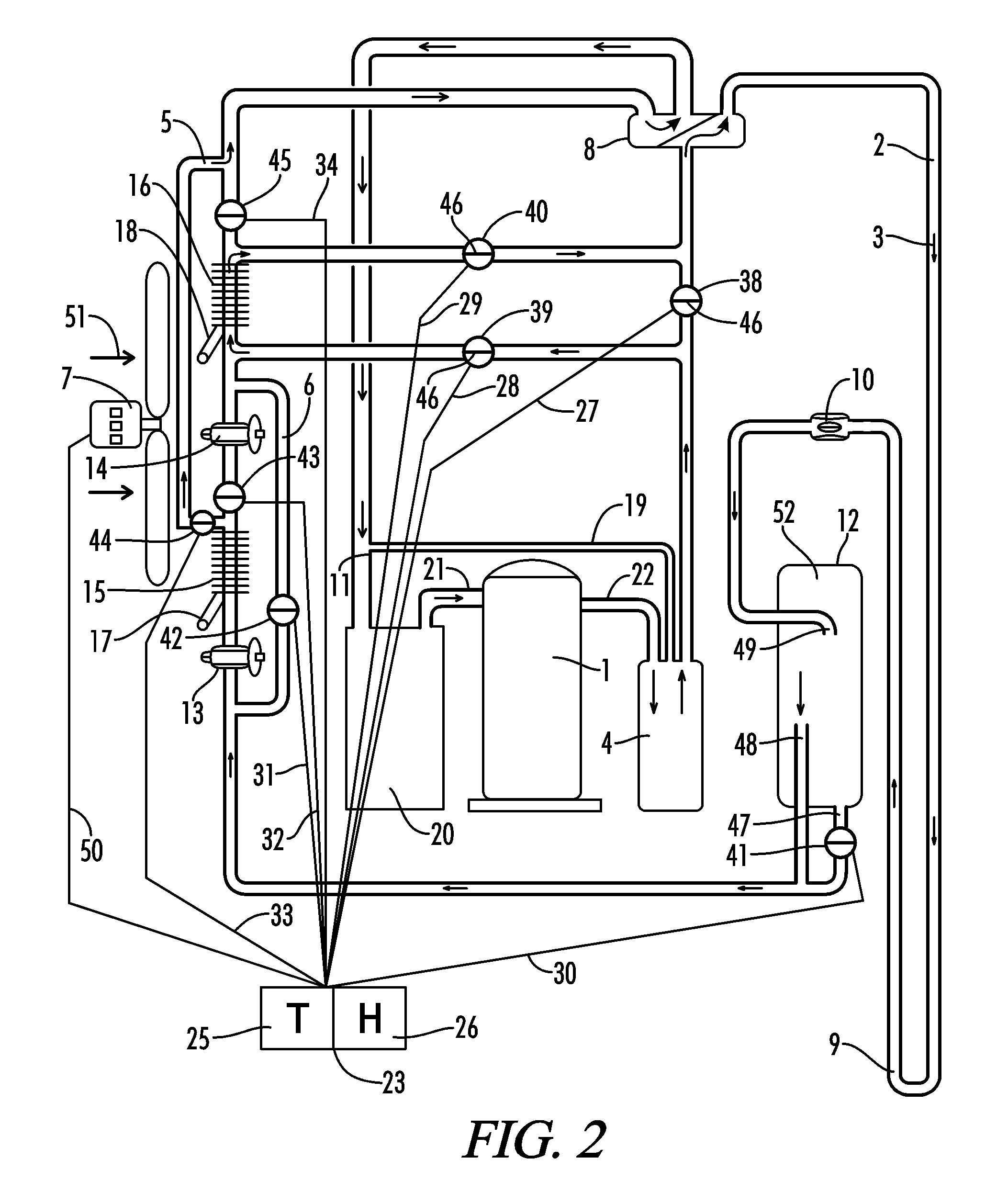

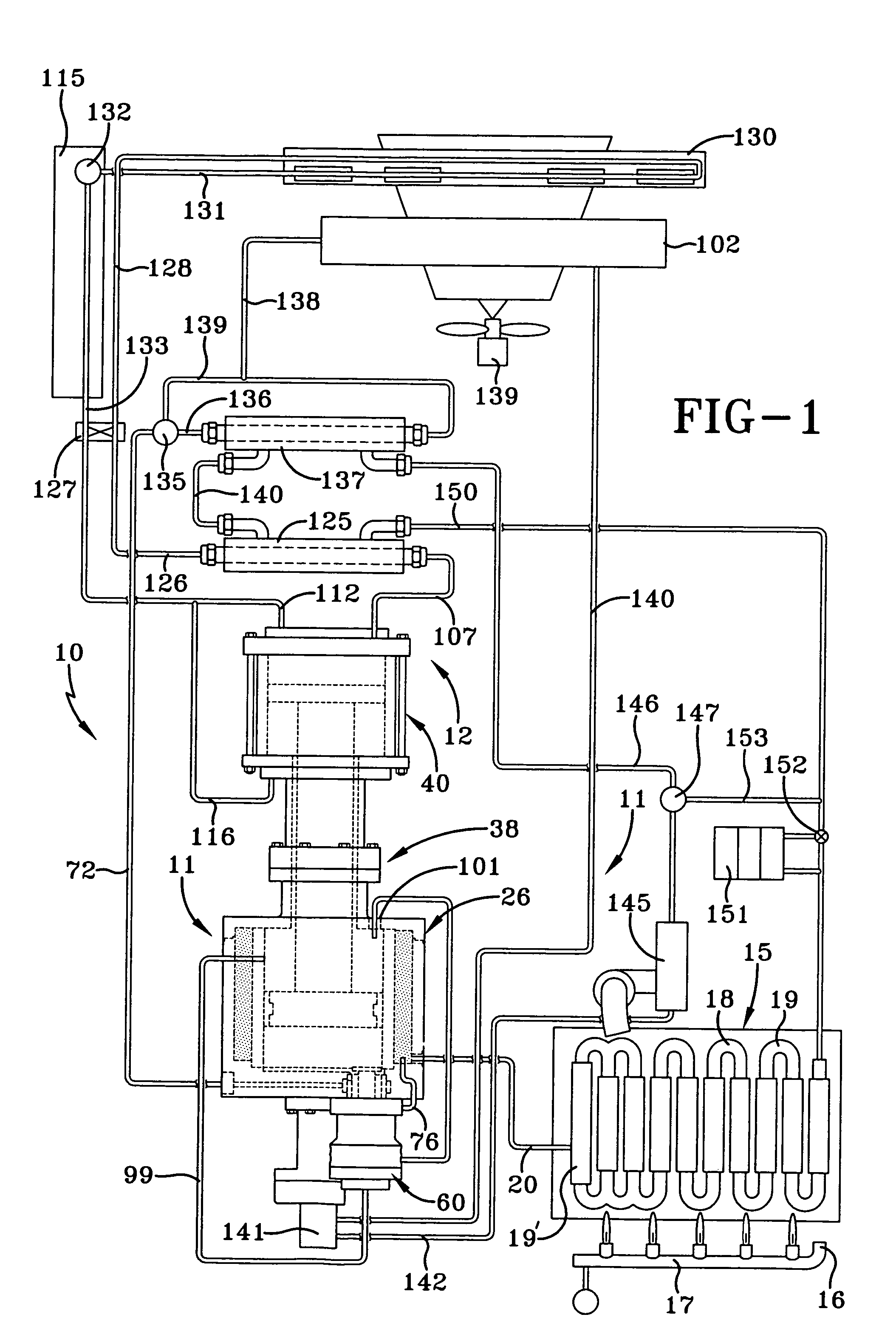

InactiveUS7591145B1Ensure maximum refrigerant charge efficiency levelIncrease capacityHeat pumpsEvaporators/condensersWater source heat pumpSolenoid valve

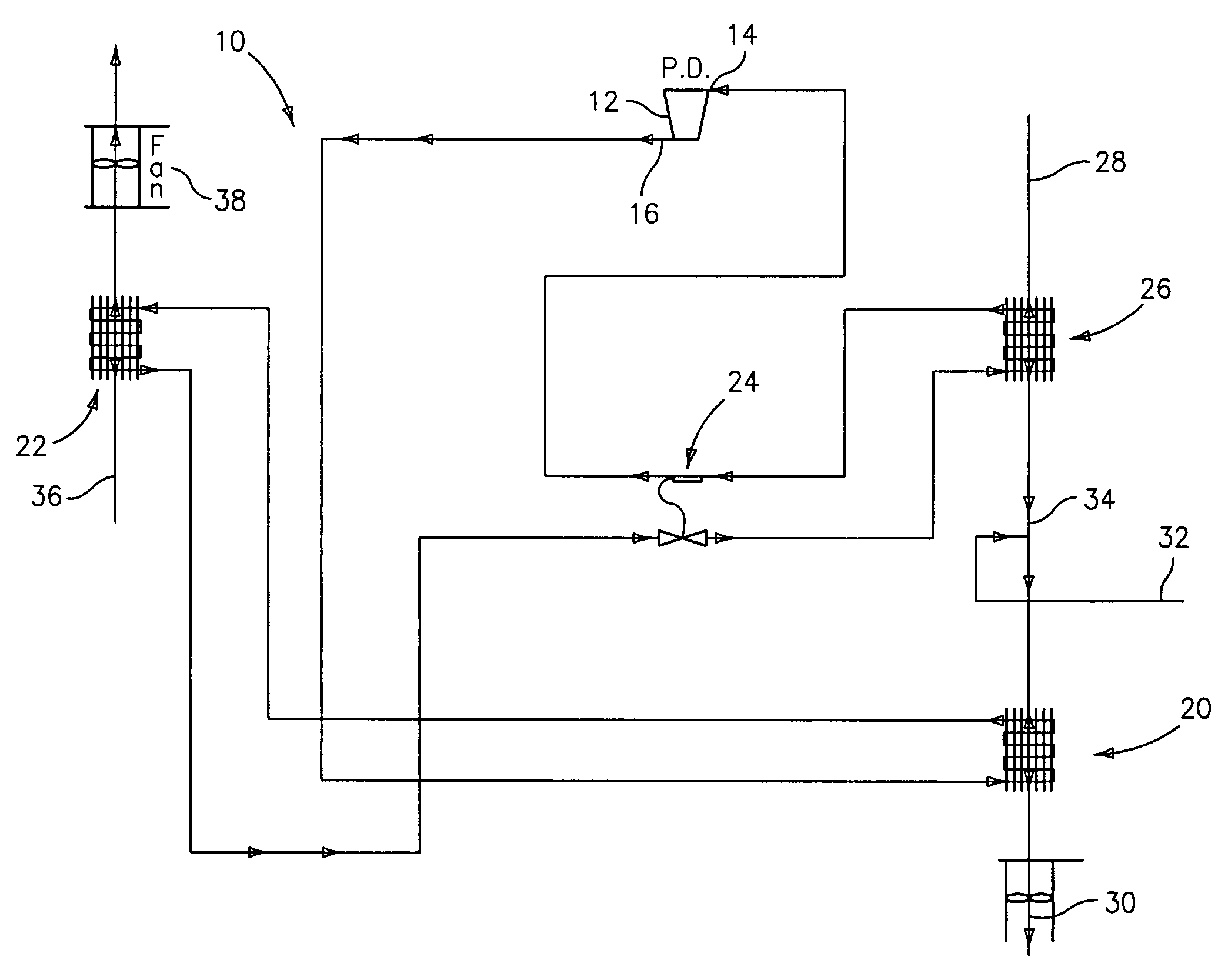

A heat pump heat pump system, operating with an R-410A refrigerant, comprised of at least one of an air source heat pump system, a water source heat pump system, and a direct expansion heat pump system, preferably for use in a Deep Well Direct Expansion heat pump system, which incorporates a three-mode receiver and an interior air handler, with at least one fan, with such air handler comprised of a combination of two sets of refrigerant to air heat exchange tubing / interior air heat exchange means, with by-pass lines and solenoid valves to facilitate system operation in the desired operational mode, all enabling optimum system performance in one of the desired heating mode, cooling mode, and dehumidification mode of system operation, as controlled by at least one of a thermostat / humidistat.

Owner:EARTH TO AIR SYST

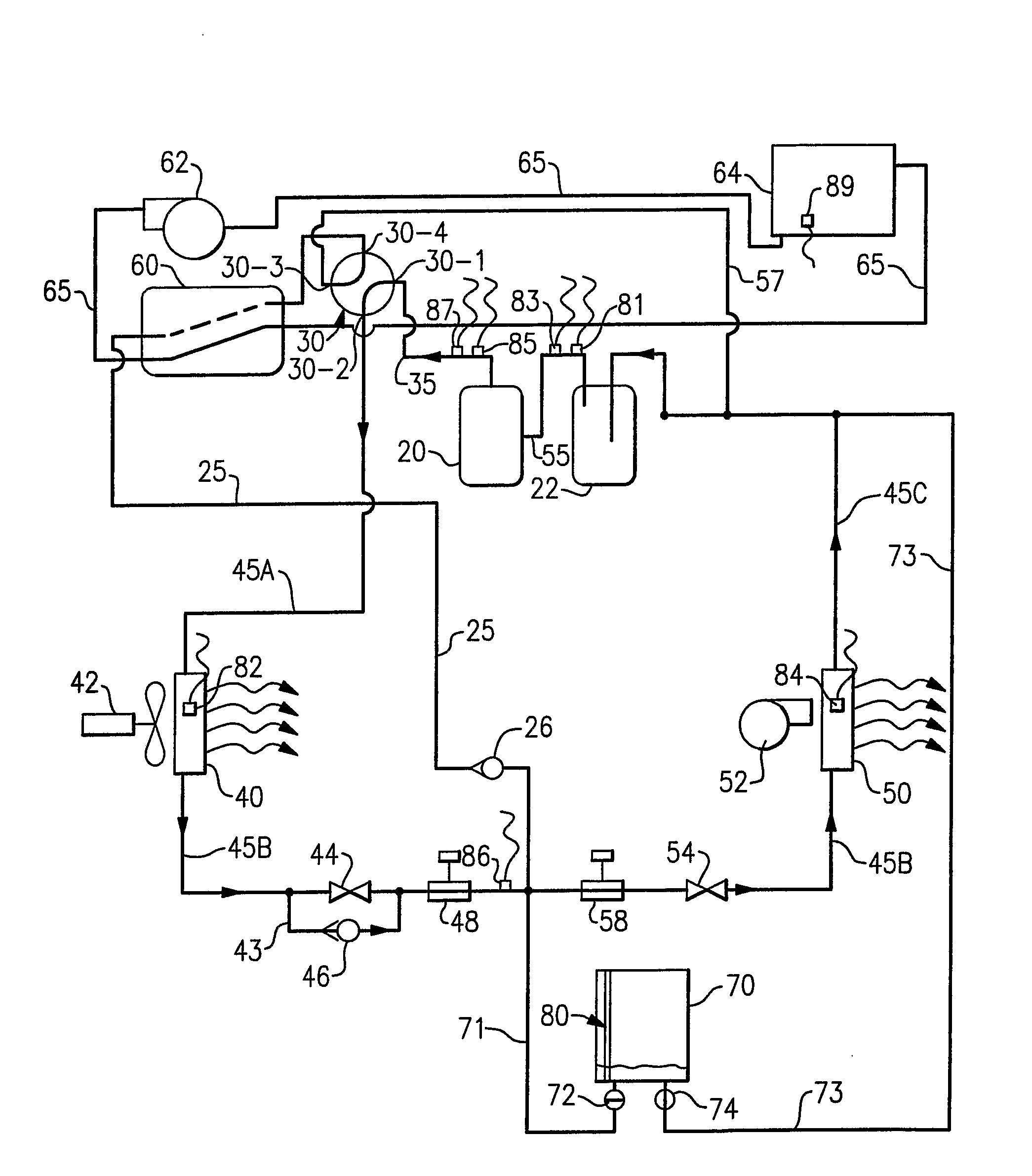

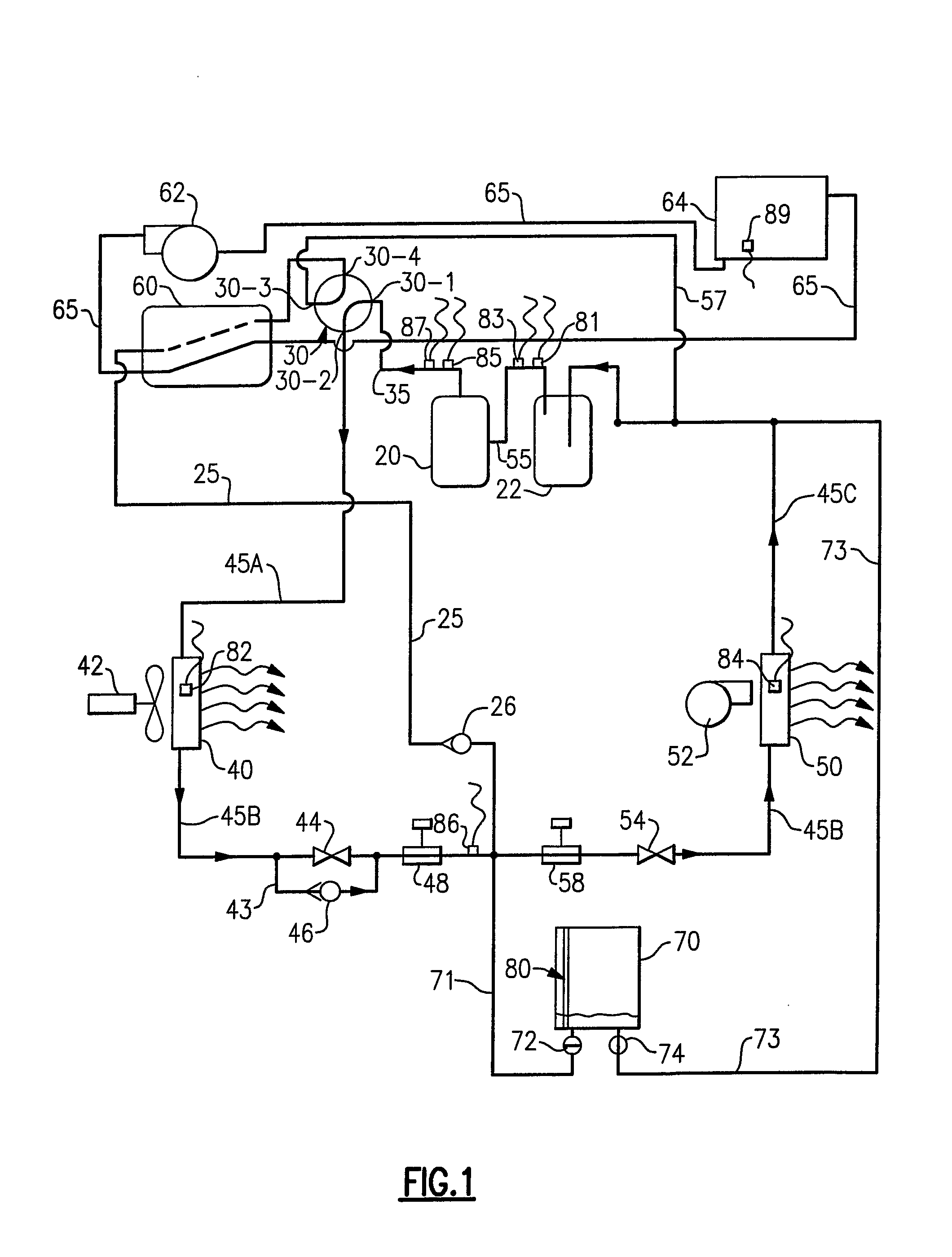

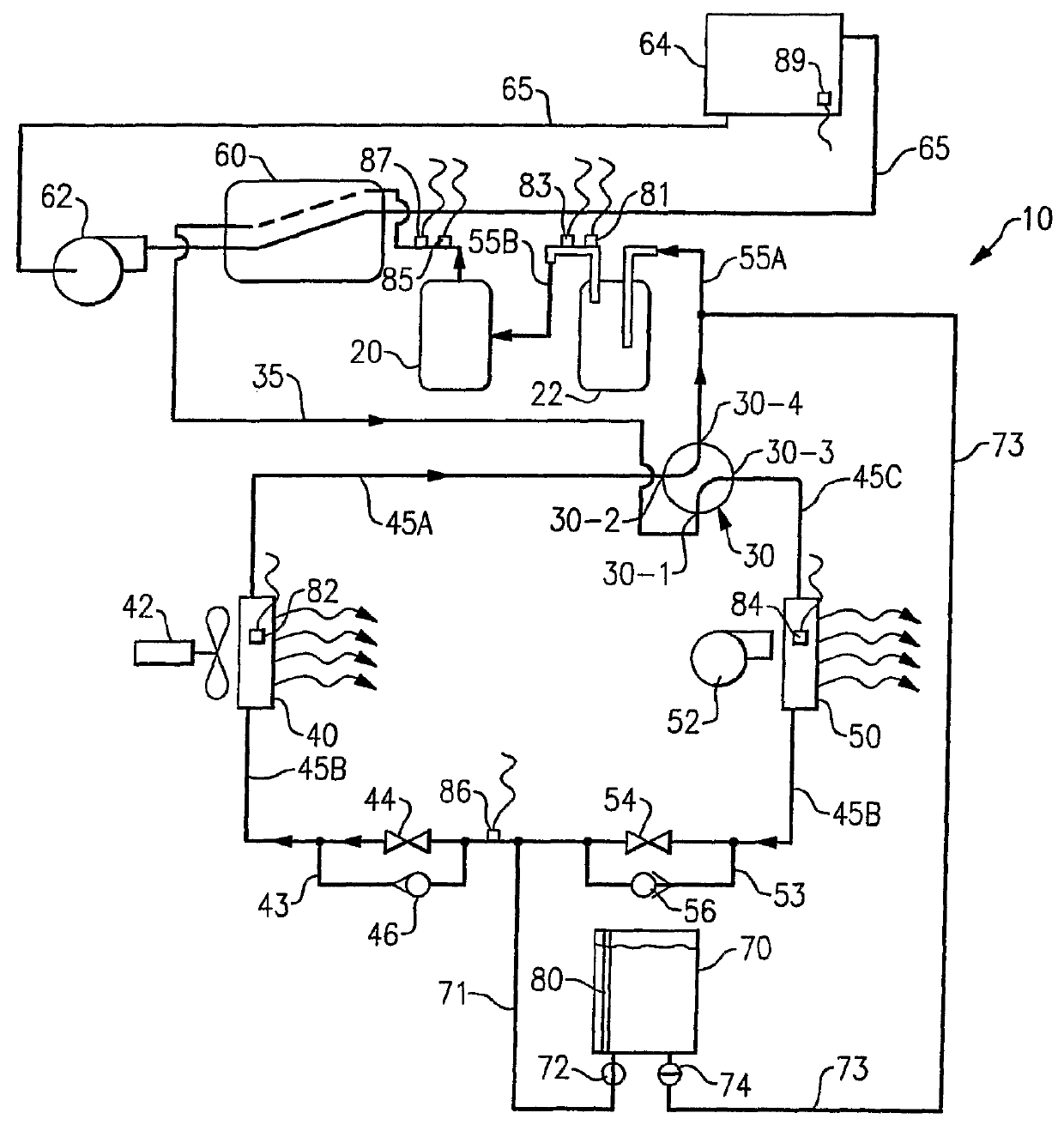

Refrigerant System With Water Heating

InactiveUS20080197206A1Improved refrigerant charge controlCentral heating with accumulated heatDesuperheatersCharge controlEngineering

A heat pump system (10) includes a compressor (20), a reversing valve (30), an outdoor heat exchanger (40) and an indoor heat exchanger (50) coupled via refrigerant lines (35, 45) in a conventional refrigeration circuit, and a refrigerant-to-water heat exchanger (60). In the air cooling with water heating mode, the air heating with water heating mode and the water heating only mode, water from a water reservoir (64), such as a storage tank or swimming pool, is passed through heat exchanger (60) in heat exchange relationship with refrigerant passing through an additional refrigerant line (27) that establishes a fluid flow path through the heat exchanger (60) into the refrigerant circuit intermediate the outdoor heat exchanger (40) and indoor heat exchanger (50). A refrigerant reservoir (70) may be provided for use in refrigerant charge control.

Owner:CARRIER CORP

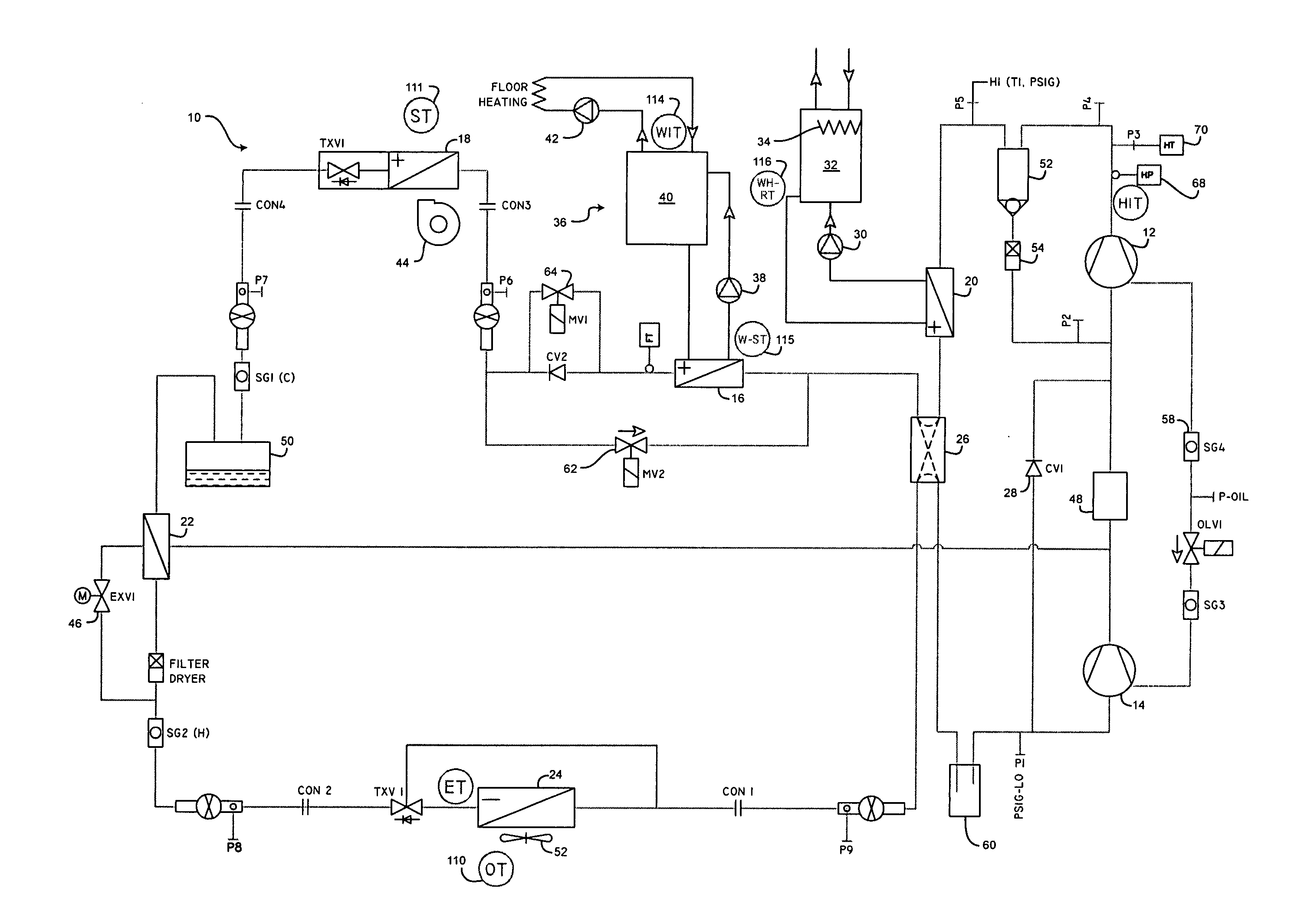

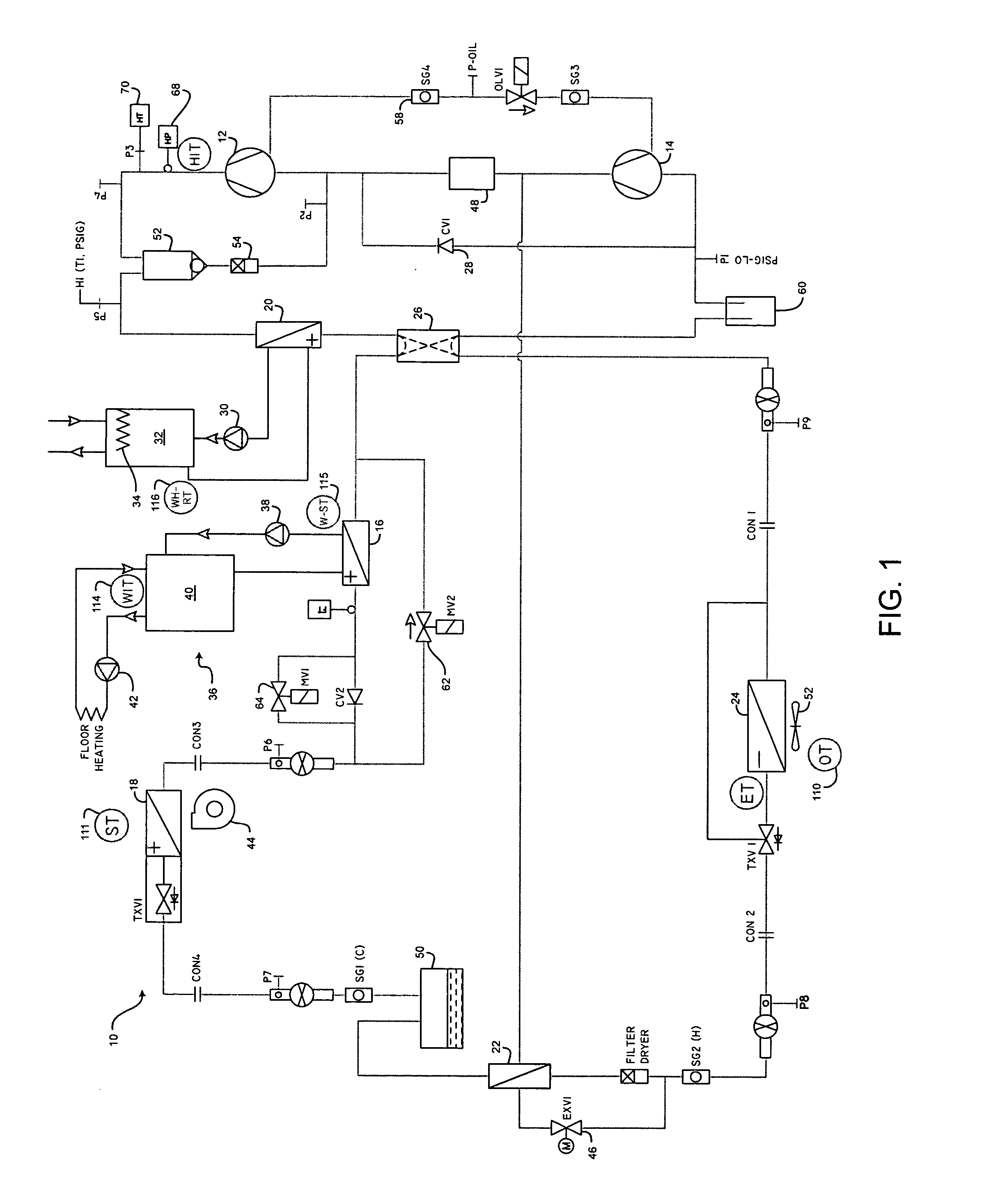

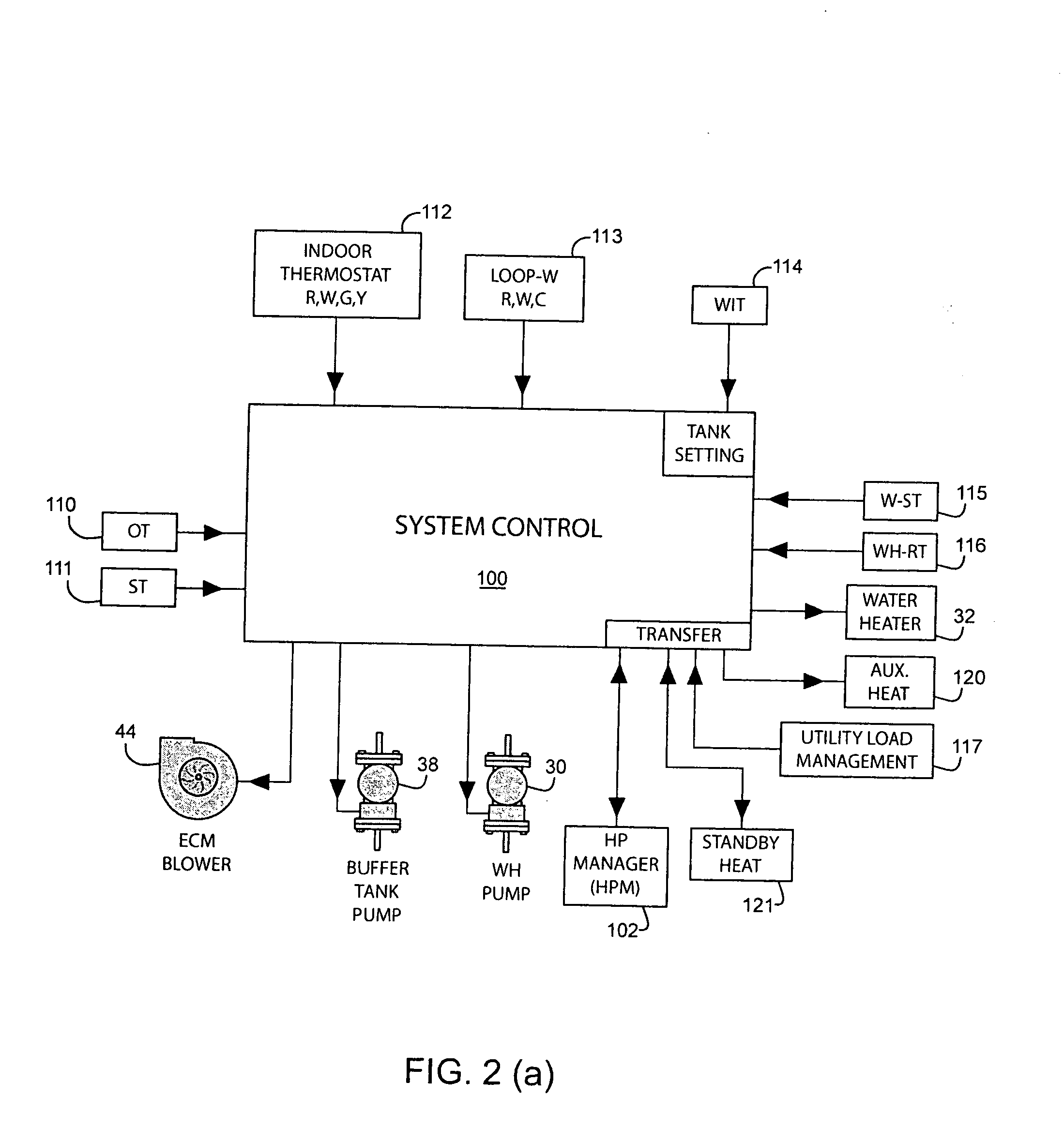

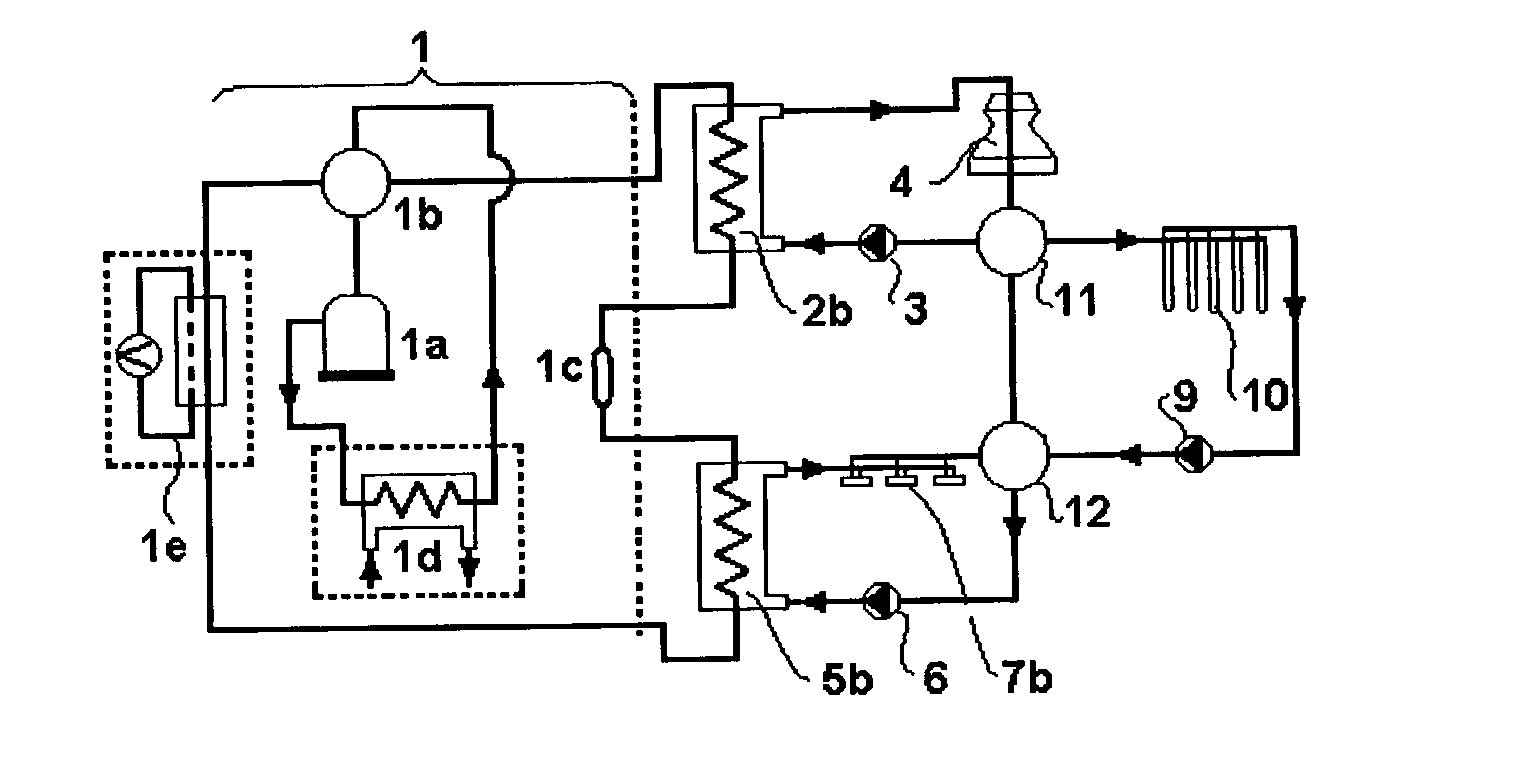

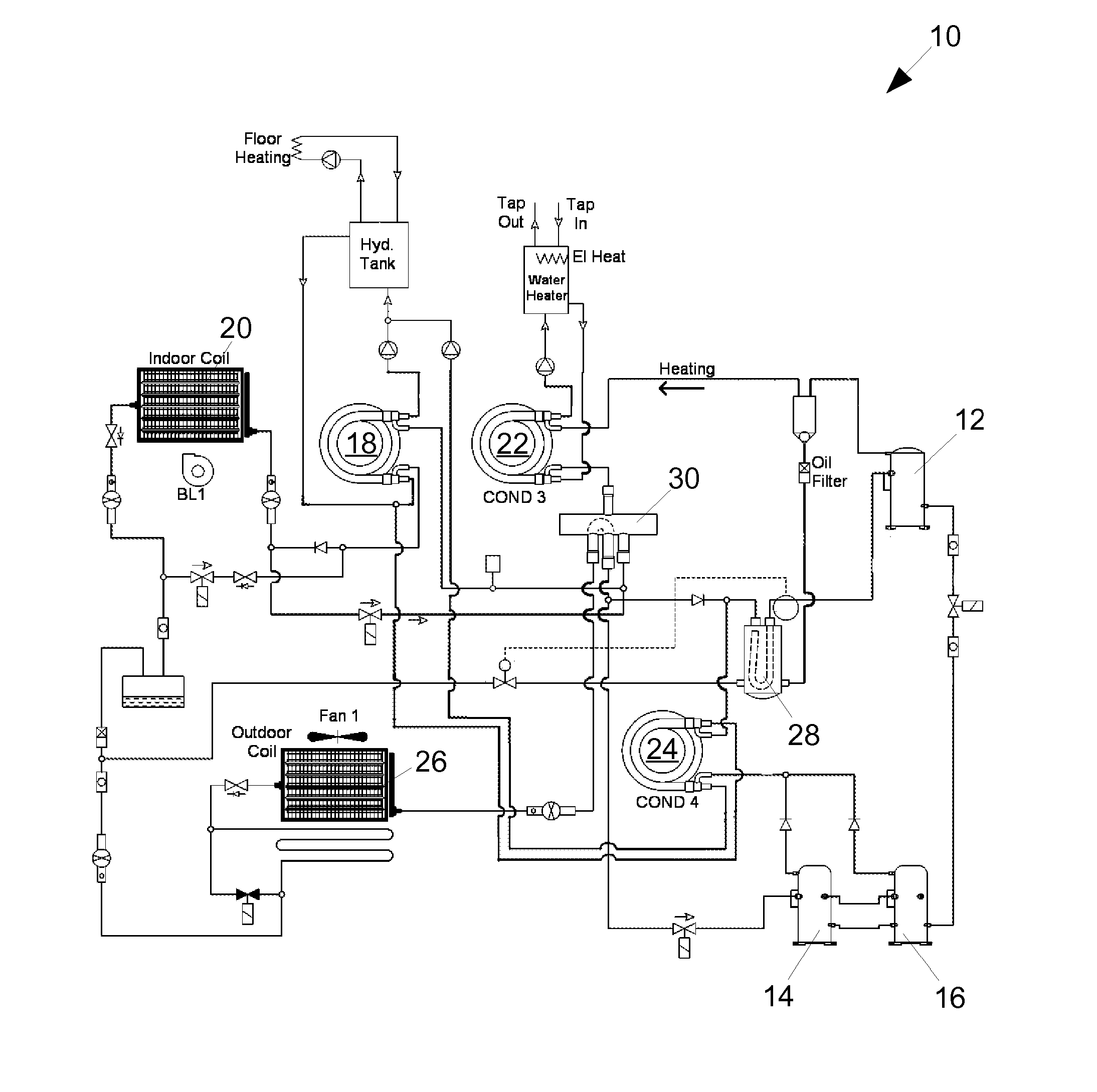

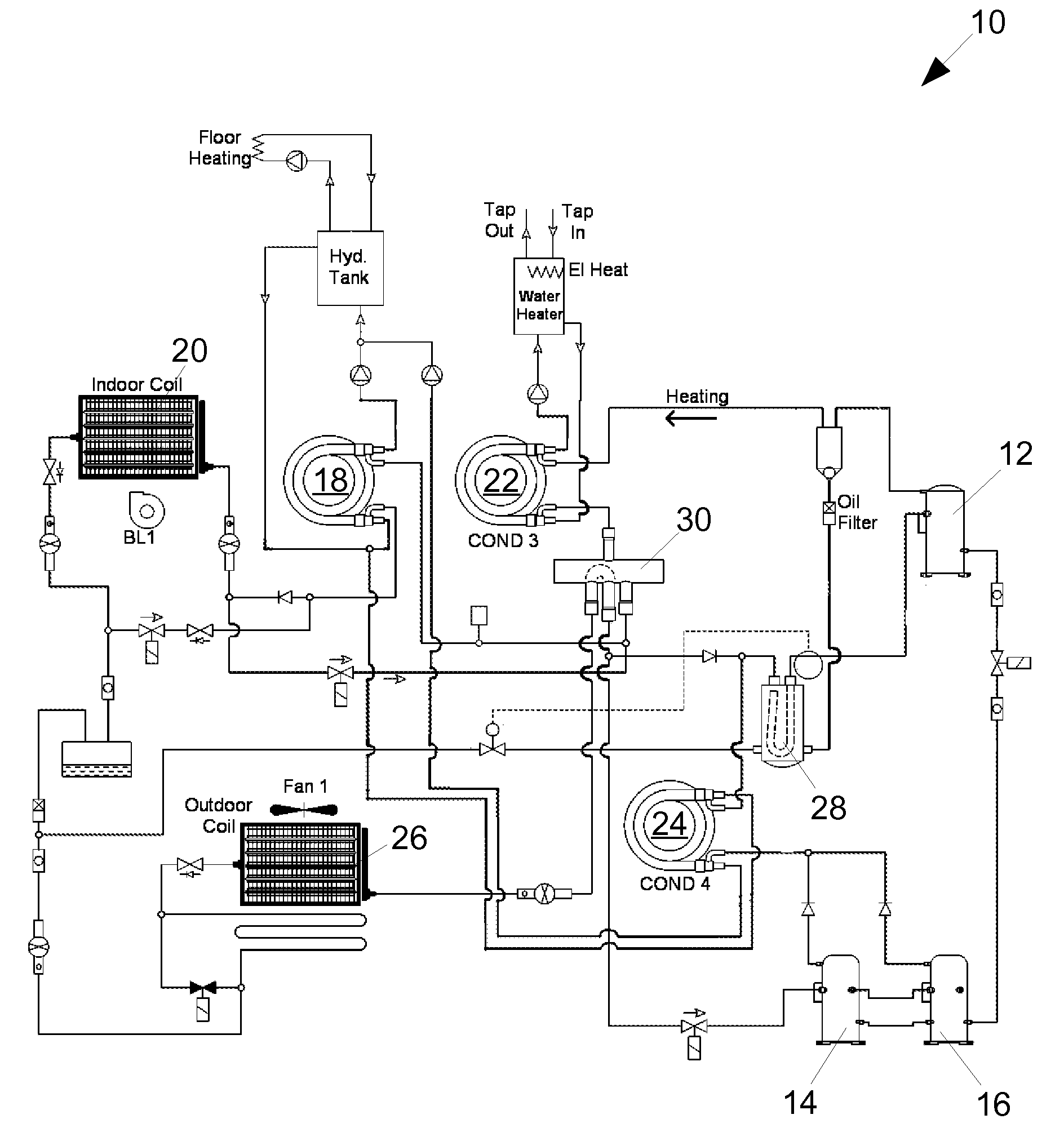

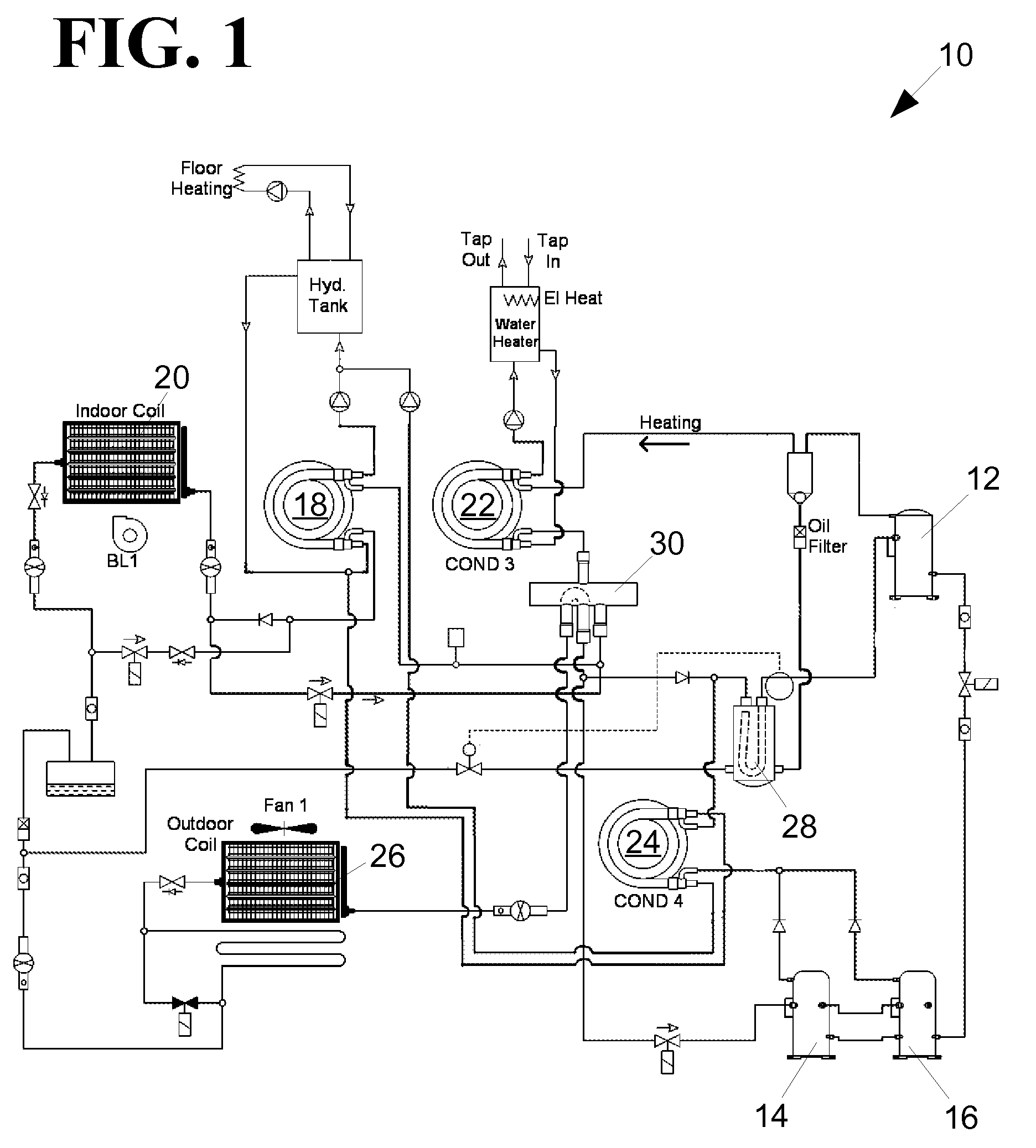

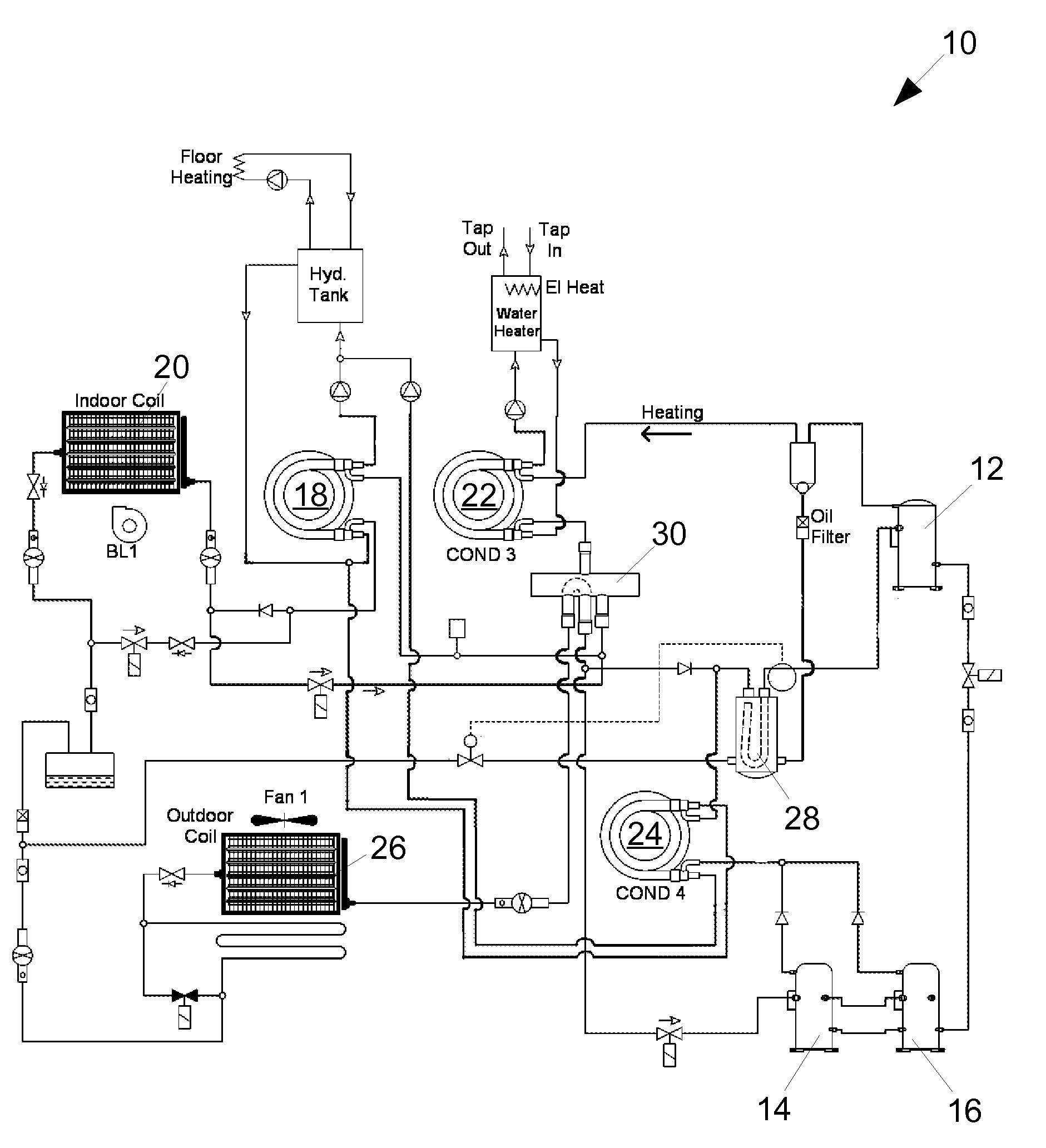

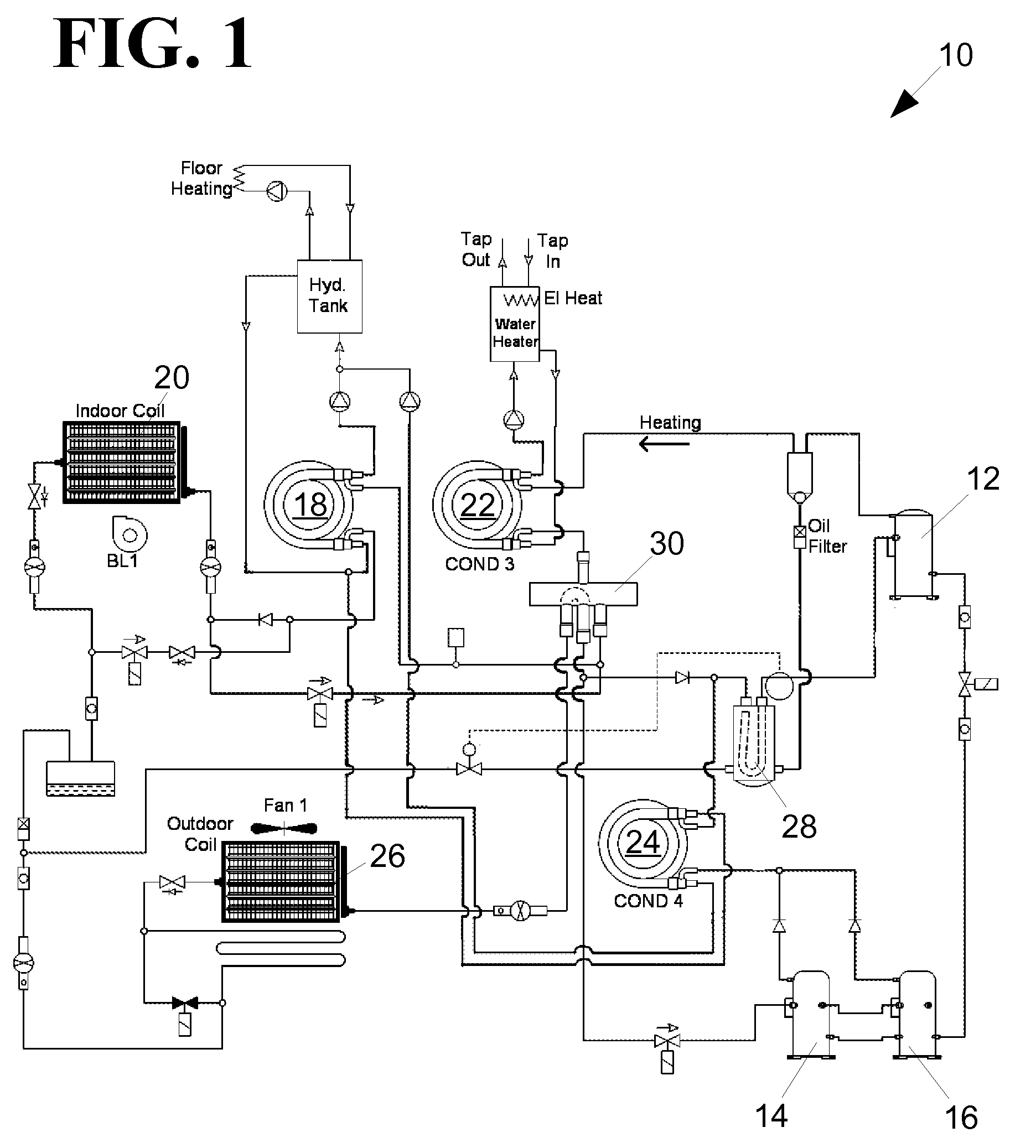

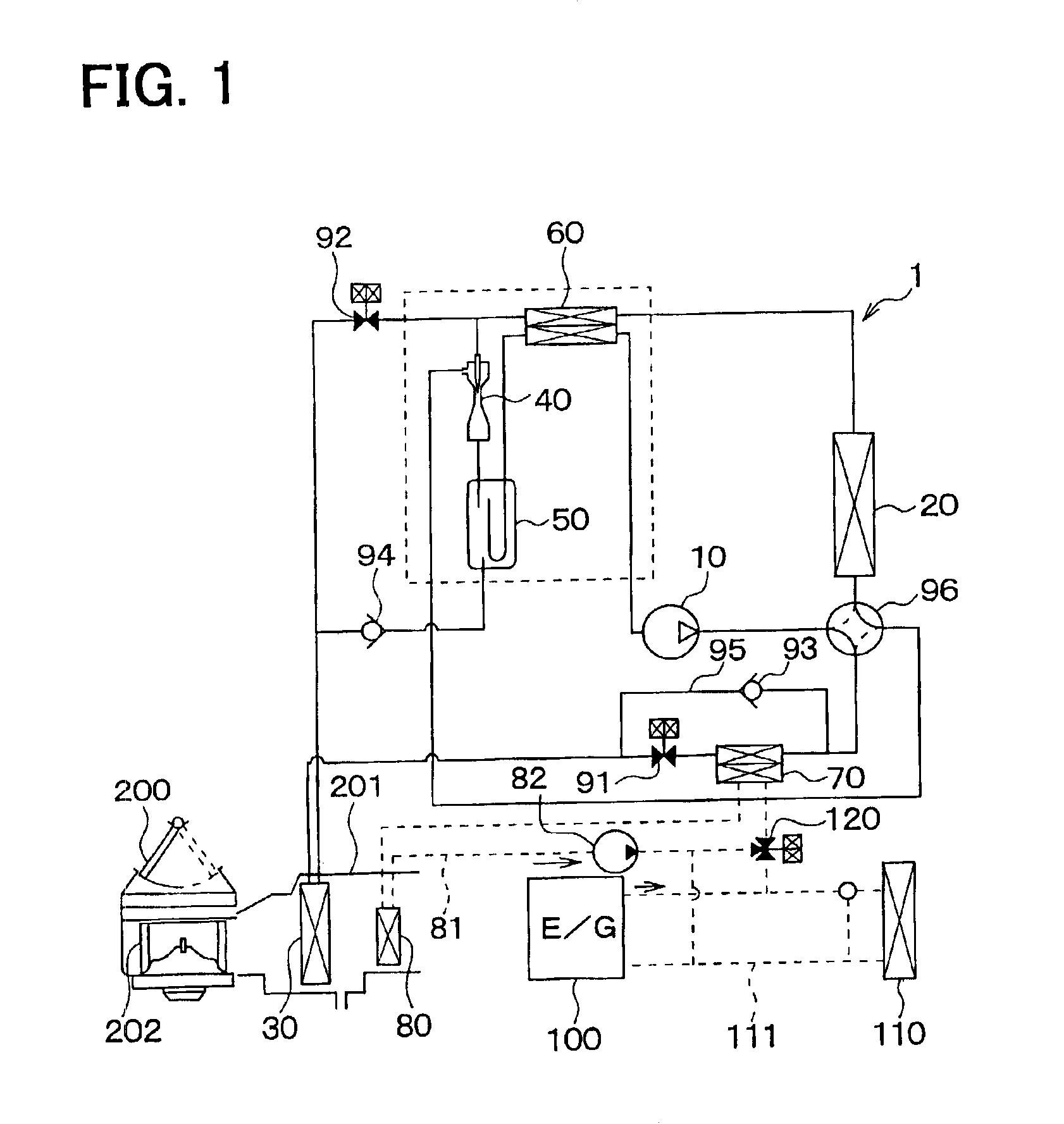

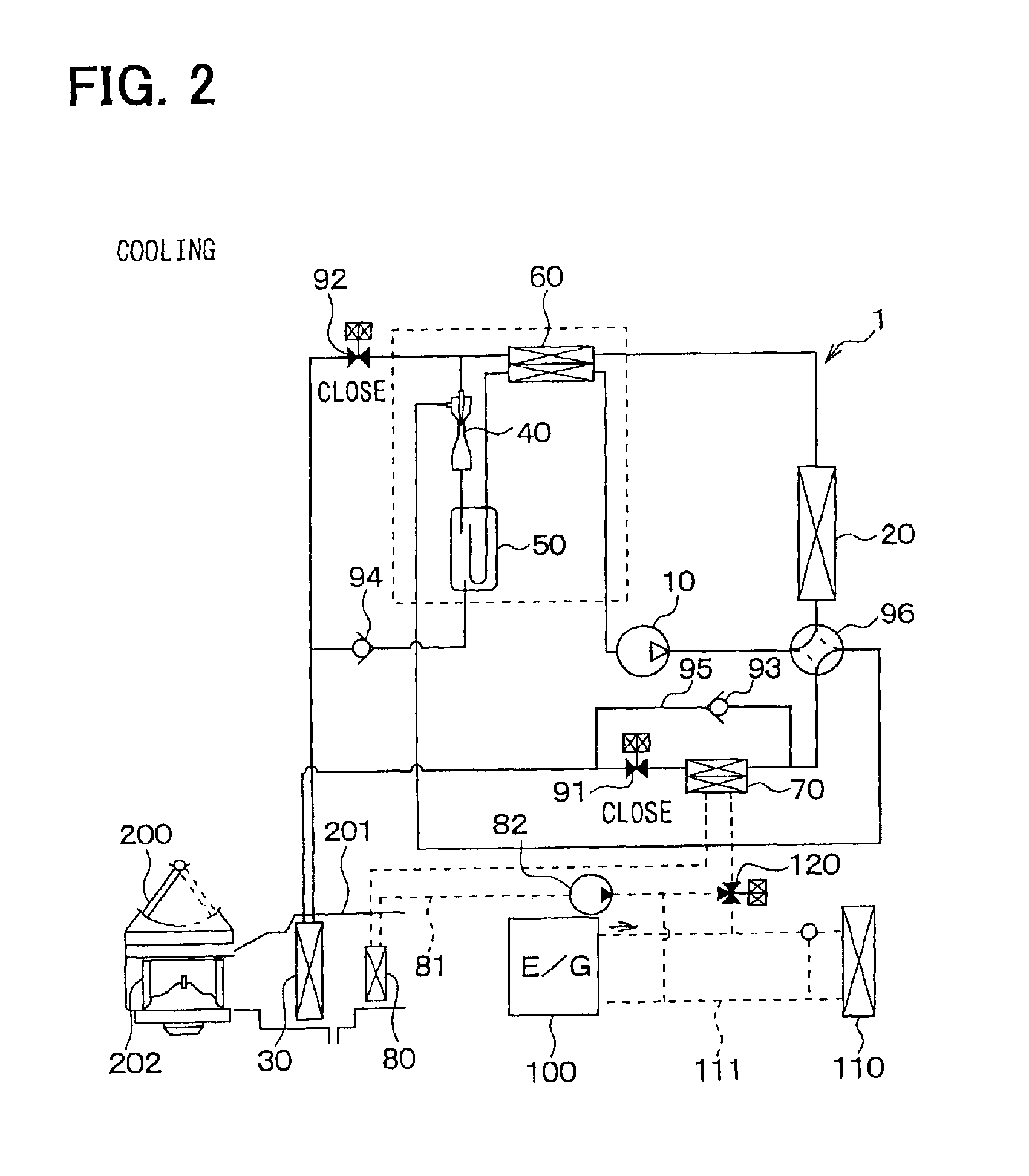

Heat pump system and controls

InactiveUS20080098760A1Improve the heating effectEasy transferCompression machines with non-reversible cycleEvaporators/condensersForced-airEngineering

A heat pump system is disclosed that utilizes one or two compressors and multiple heat exchangers to provide forced air heating, radiant heating and / or water heating for an interior space. A controller directs energy to these multiple system outputs to provide maximum comfort, effectively utilize any excess energy, address fluctuations in energy output, prevent unsafe operating conditions and avoid intermittent compressor operation. The system may provide energy for a water heater in both heating and cooling mode, and control operation of the water heater to utilize system energy whenever possible and avoid use of a conventional water heater heating element. Load Management Control is also provided so that the system may be shut down remotely by a utility company.

Owner:ELECTRO IND

Recoverable ground source heat pump

Recoverable Ground Source Heat Pump system with energy storage function which uses and stores off-peak-hours electricity to maintain the ground medium temperature to ensure the efficient operation of the system during on-peak electricity hours. The release and receiving of energy is accomplished through the ground heat exchanger by flowing the fluid through different routings of the circulation loop using reversing vales. Space heating and cooling is assured while the underground medium temperature is recovered. The heat pump system of the invention has less initial investment compared to conventional ground source heat pump and ice energy storage cooling systems; requires less ground space; provide operating energy cost savings; assures performance of operation; and avoids using antifreeze solution in the ground circulation fluid that may cause environmental, safety and erosion problems.

Owner:XU YUNSHENG

Heat pump dehumidification system

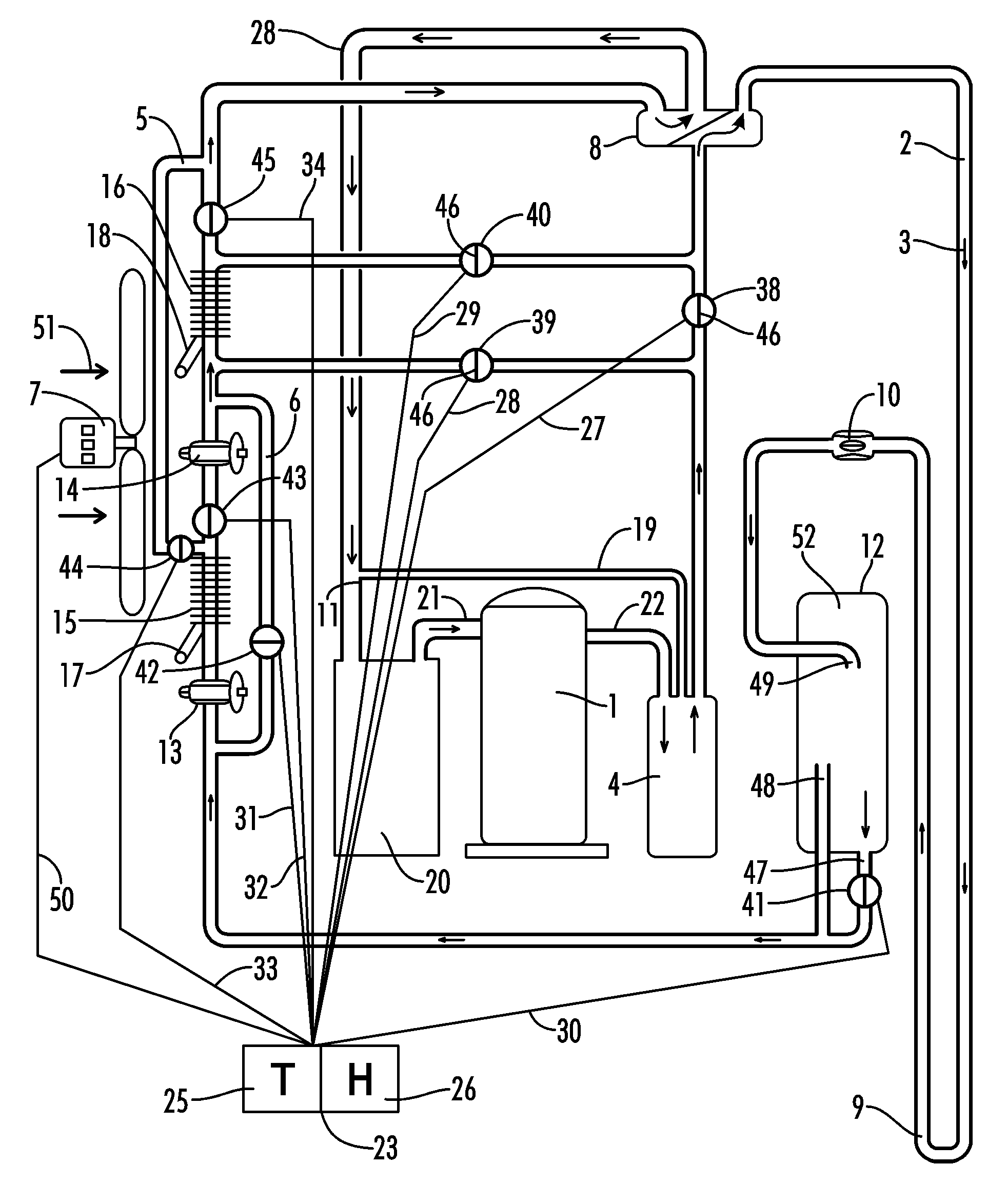

ActiveUS7191604B1Easy to doEnhanced cooling/dehumidification/heatingHeat pumpsDesuperheatersWater source heat pumpWater source

A heat pump dehumidification system comprised of one of an air source heat pump system, a water source heat pump system, and a direct expansion heat pump system, with an extra interior air heat exchange means situated between the system's compressor's hot refrigerant gas discharge side and the exterior heat exchange means, for activation and use in conjunction with the system's primary interior air heat exchange means, located between the exterior heat exchange means and the system's compressor's refrigerant gas suction side, when operation in a dehumidification mode is desired absent sensible cooling, and optimum design sizes for both interior air exchange means while the system is operating in one of a dehumidification mode, a cooling mode, and a heating mode.

Owner:EARTH TO AIR SYST

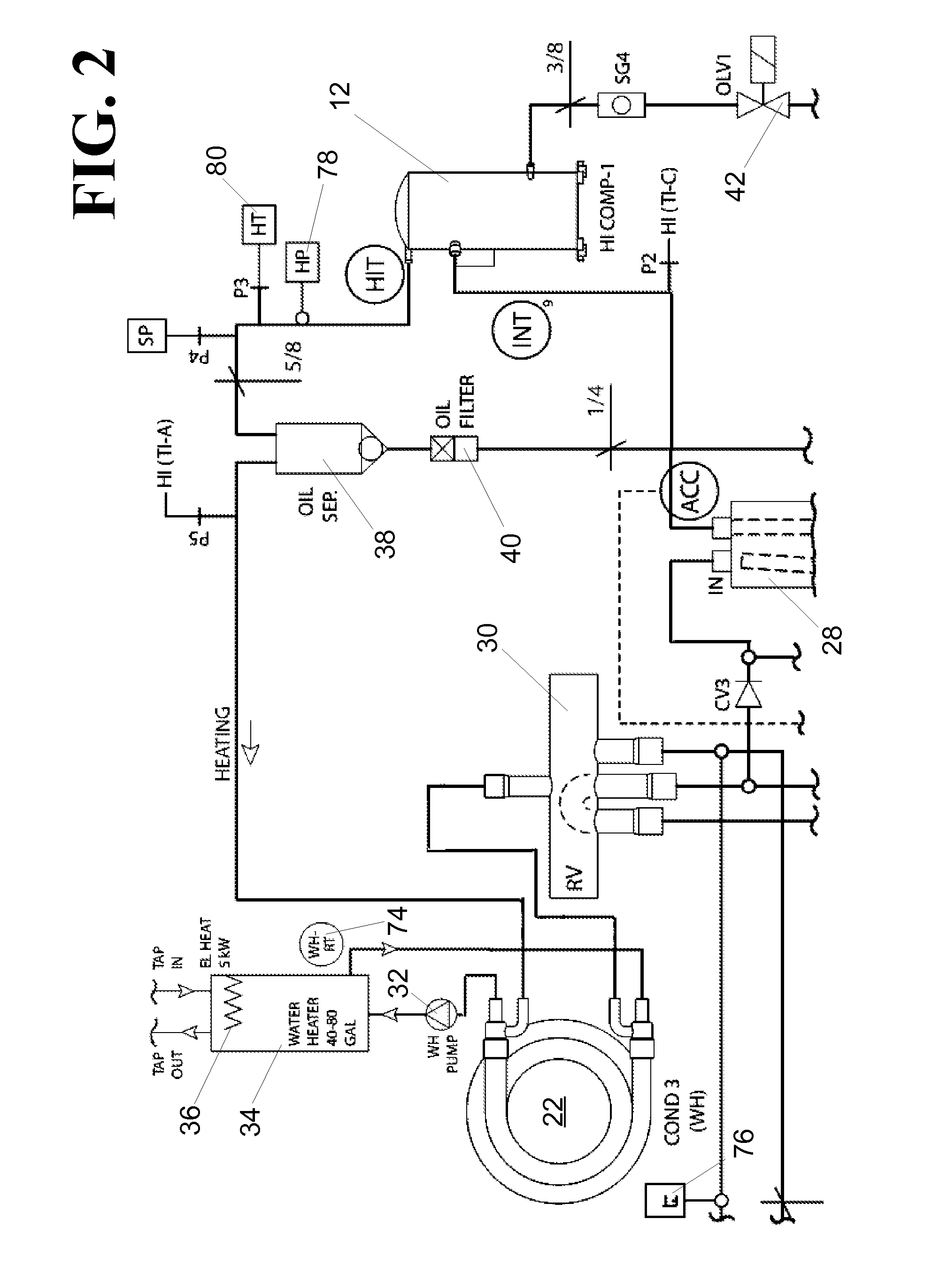

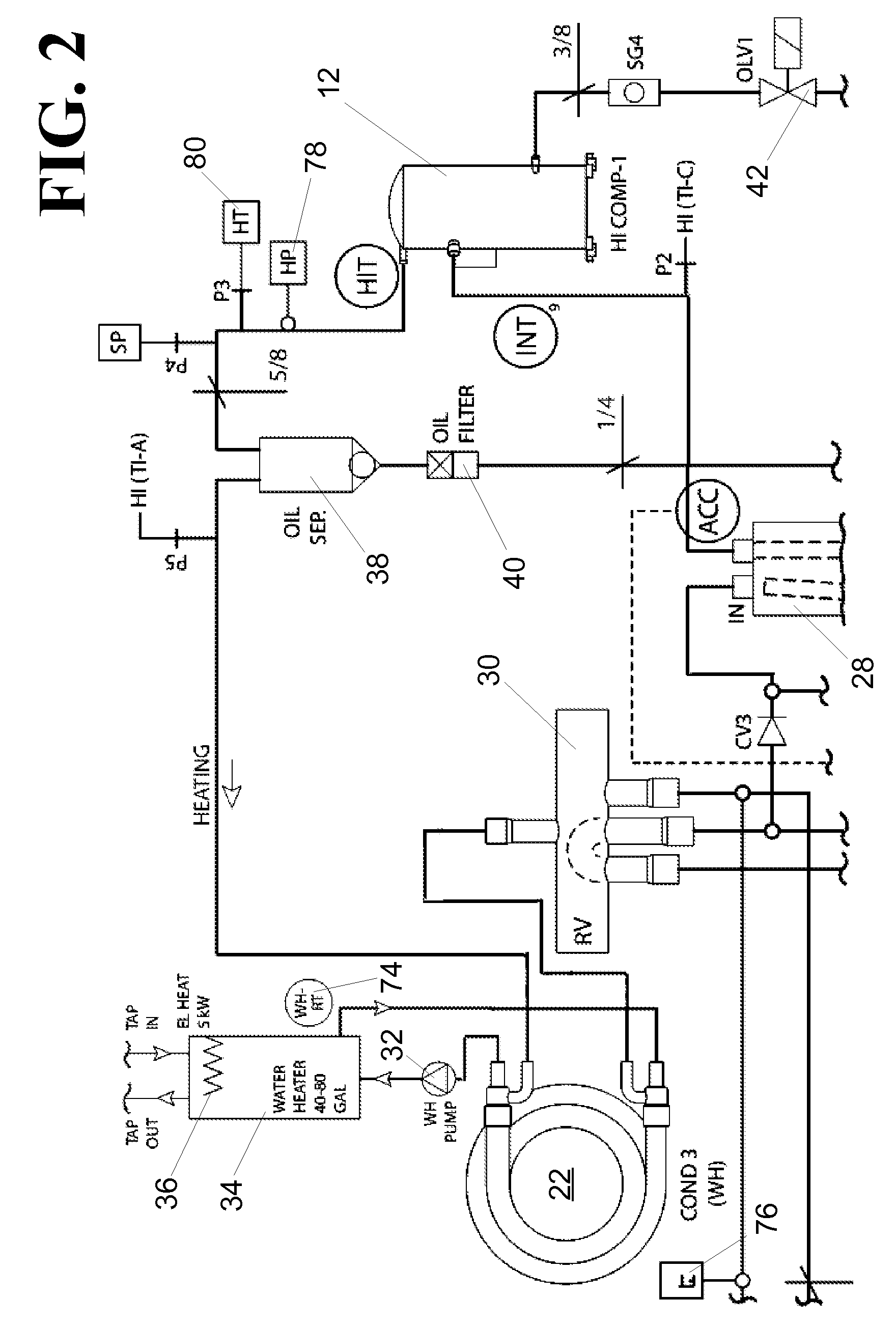

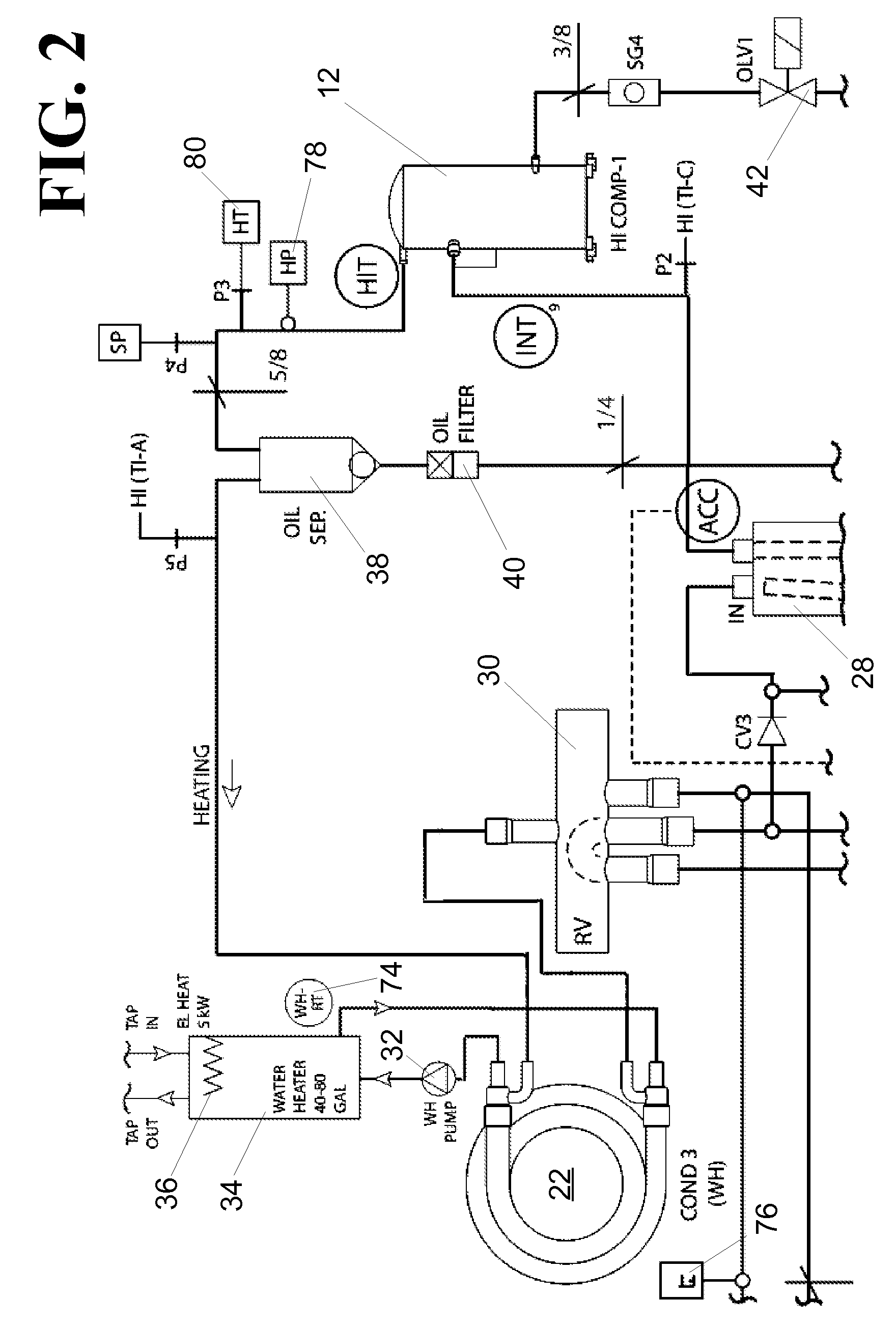

Heat pump with accumulator at boost compressor output

InactiveUS20080041072A1Improve the heating effectEasy transferEvaporators/condensersDesuperheatersEngineeringRefrigerant

A heat pump system is disclosed that utilizes an accumulator fluidly connected between a boost compressor output and a primary compressor input. The accumulator is multifunctional in that it allows the refrigerant from the boost compressor to be cooled with refrigerant from other parts of the system if necessary. The accumulator also serves to receive and cool the oil separated from the refrigerant near the output of the primary compressor. A method for distributing oil among the compressors is also disclosed.

Owner:ELECTRO IND

Air conditioning apparatus

InactiveUS7669647B2Increase fuel consumptionImpact engine loadOther heat production devicesHeat storage plantsEngineeringAir conditioning

An air conditioning system for cooling or heating an air, and for feeding the heated or cooled air to predetermined portions is characterized by comprising: a first circulating circuit for circulating a first heating medium; a second circulating circuit for circulating a second heating medium; a control unit for controlling the heat for executing heat exchange between the first heating medium and the second heating medium to flow through either the heat exchanger or the first heat storing device. Moreover, an air temperature is controlled by heat of the second heating medium.

Owner:TOYOTA JIDOSHA KK

Heat pump with forced air heating regulated by withdrawal of heat to a radiant heating system

InactiveUS20080276638A1Easy transferImprove the heating effectSpace heating and ventilation safety systemsSpace heating and ventilation control systemsThermal energyCirculator pump

A heat pump system is disclosed that utilizes a variable speed hydronics pump to selectively divert heat energy from a forced air heating system to a hydronics radiant heating system. By actively controlling the speed of the withdrawal of heat, the temperature of the forced air output may be maintained while maximizing the amount of heat delivered by the efficient hydronics system. The heat pump system also actively controls the blower of the forced air system. To reduce the frequency of the compressors cycling on and off, a tank may be used to store and dispense heat if the hydronics system is not of sufficient size.

Owner:ELECTRO IND

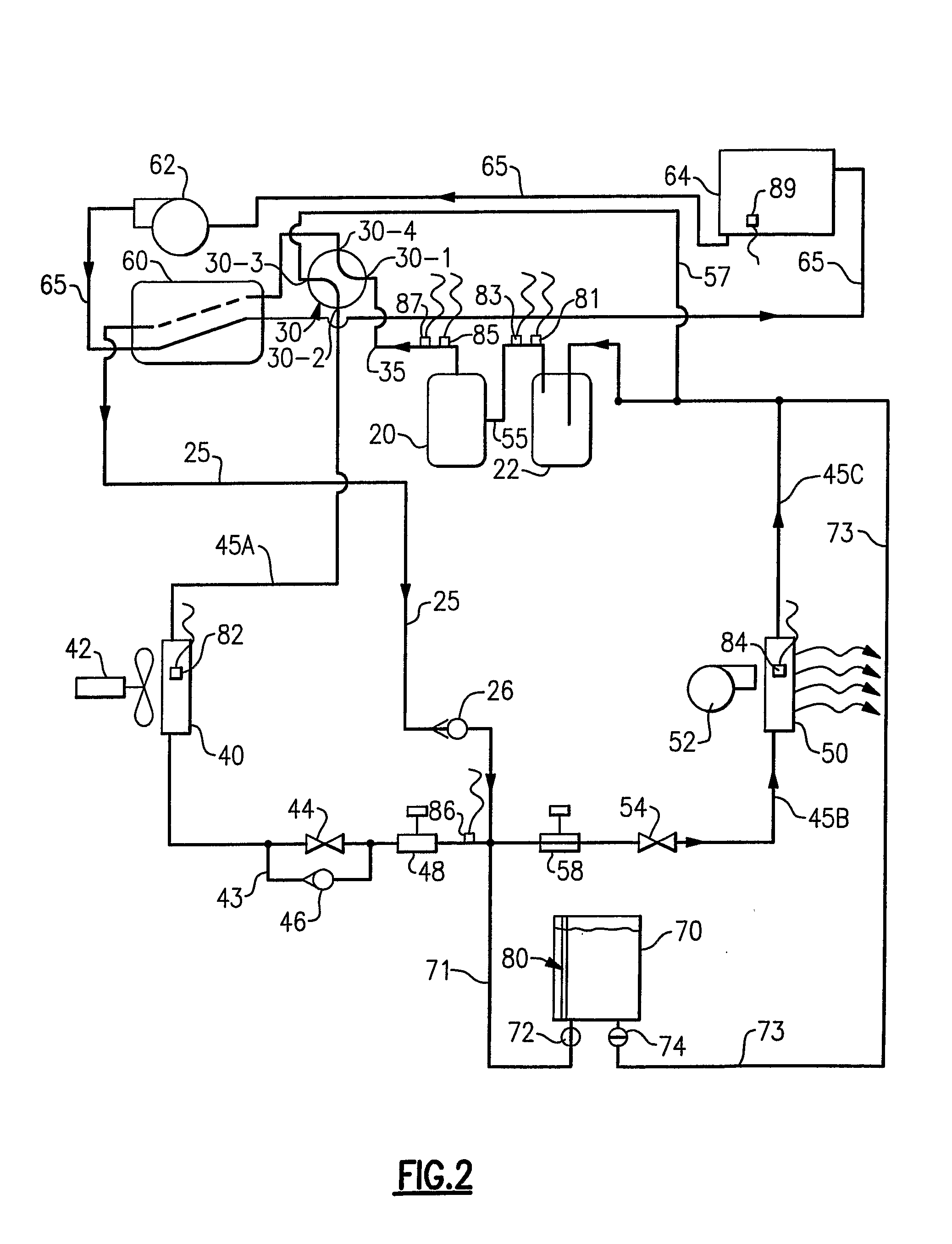

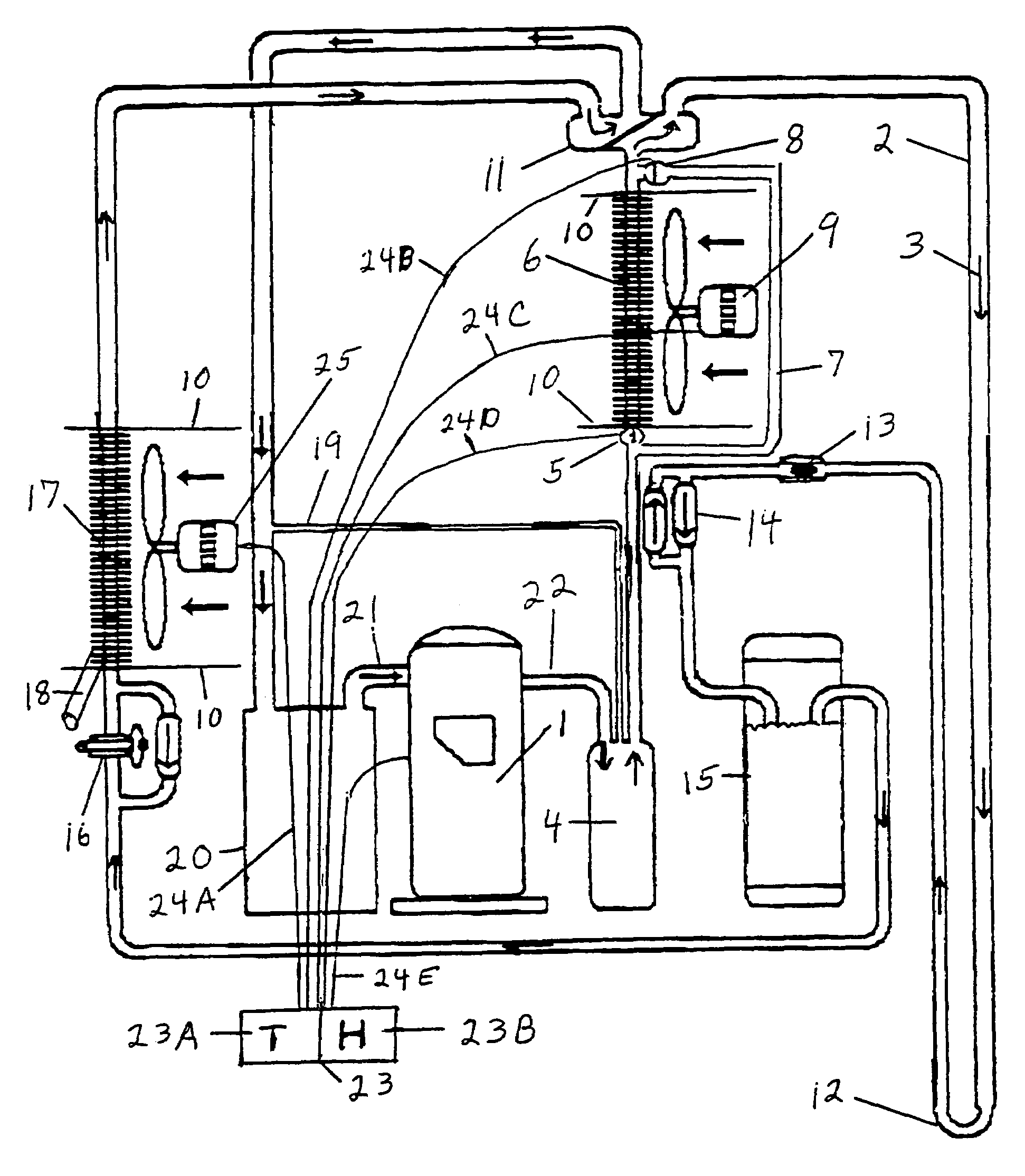

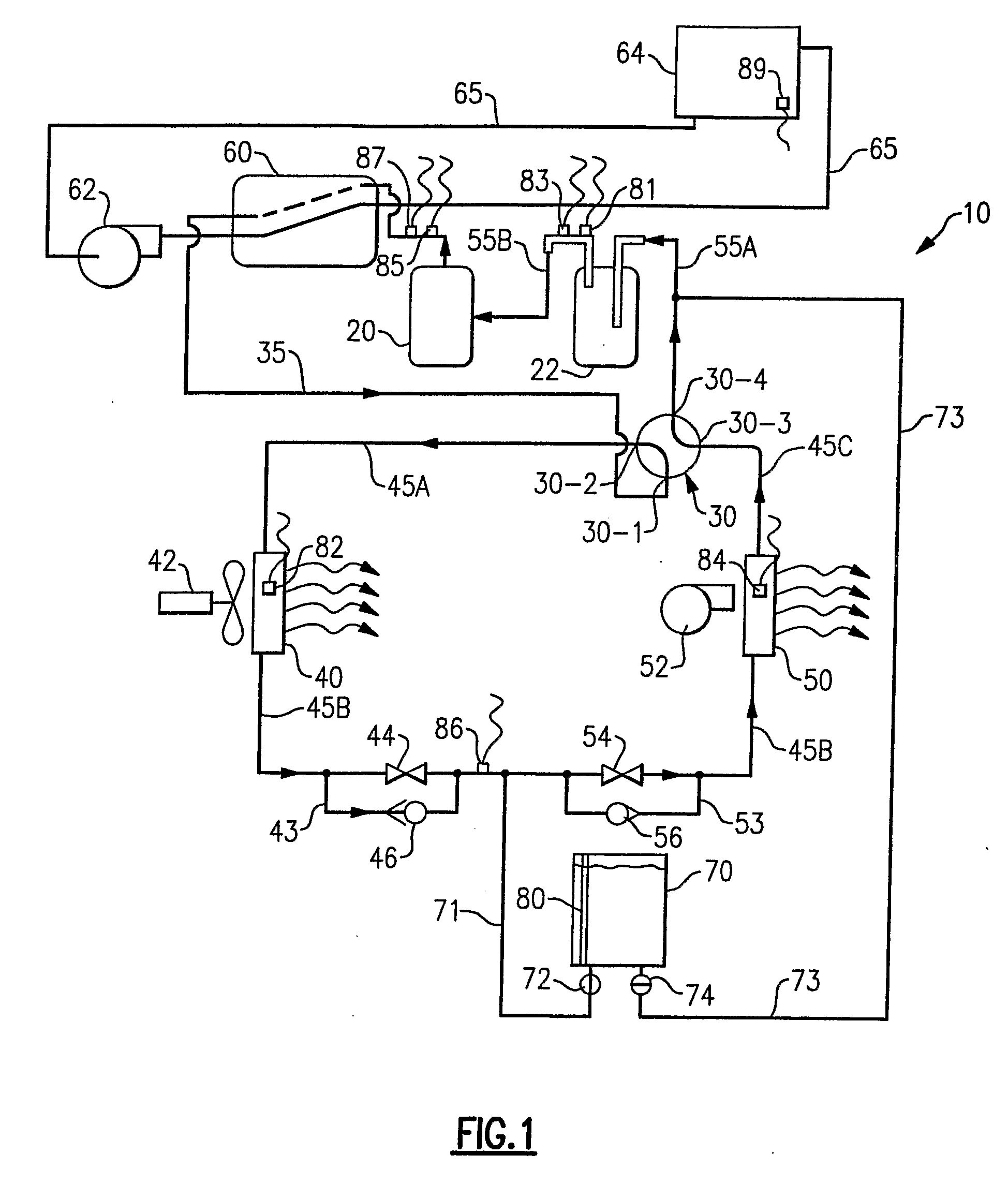

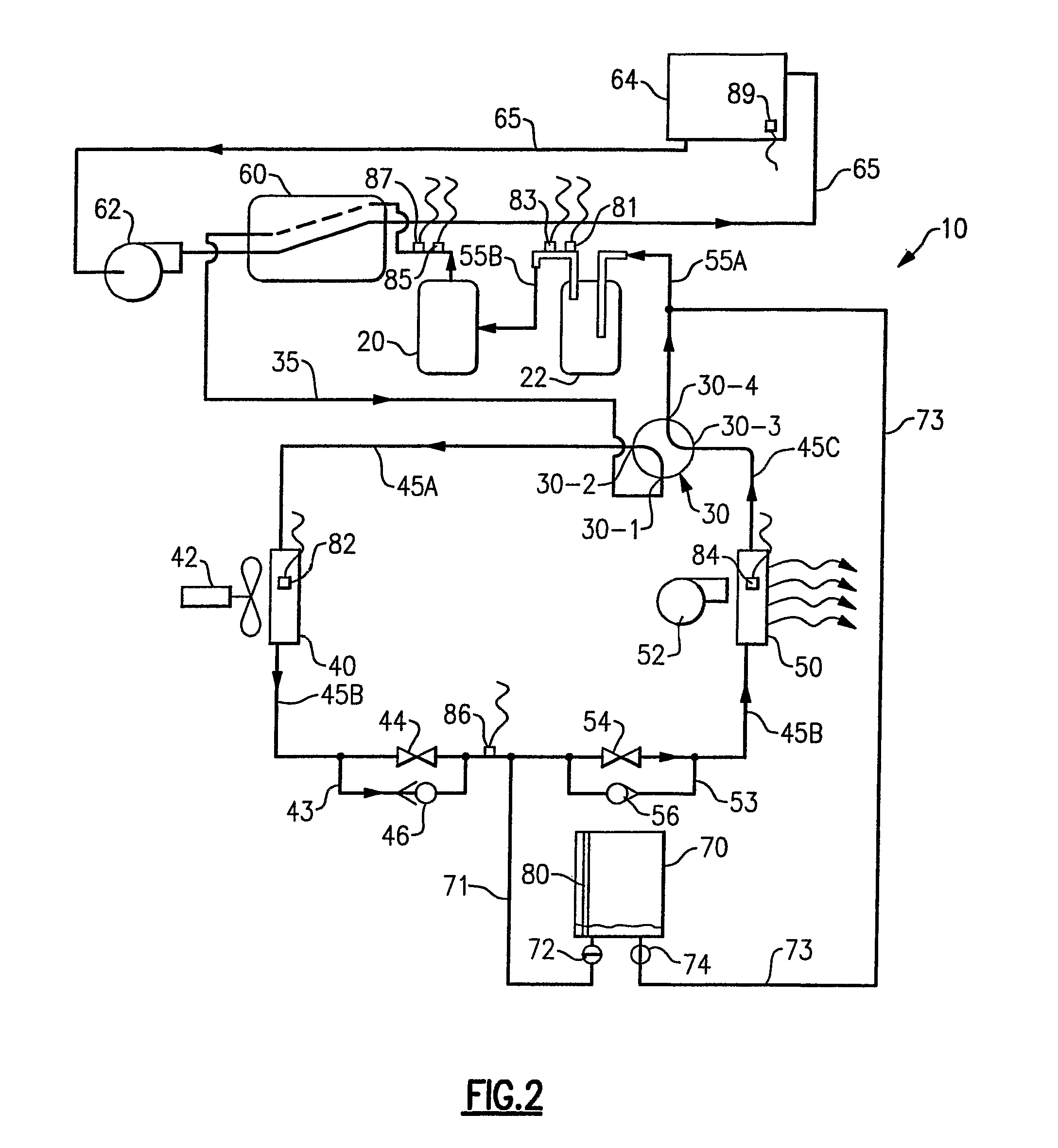

Heat Pump System with Auxiliary Water Heating

InactiveUS20080190130A1Improved refrigerant charge controlLevel controlDesuperheatersCharge controlEngineering

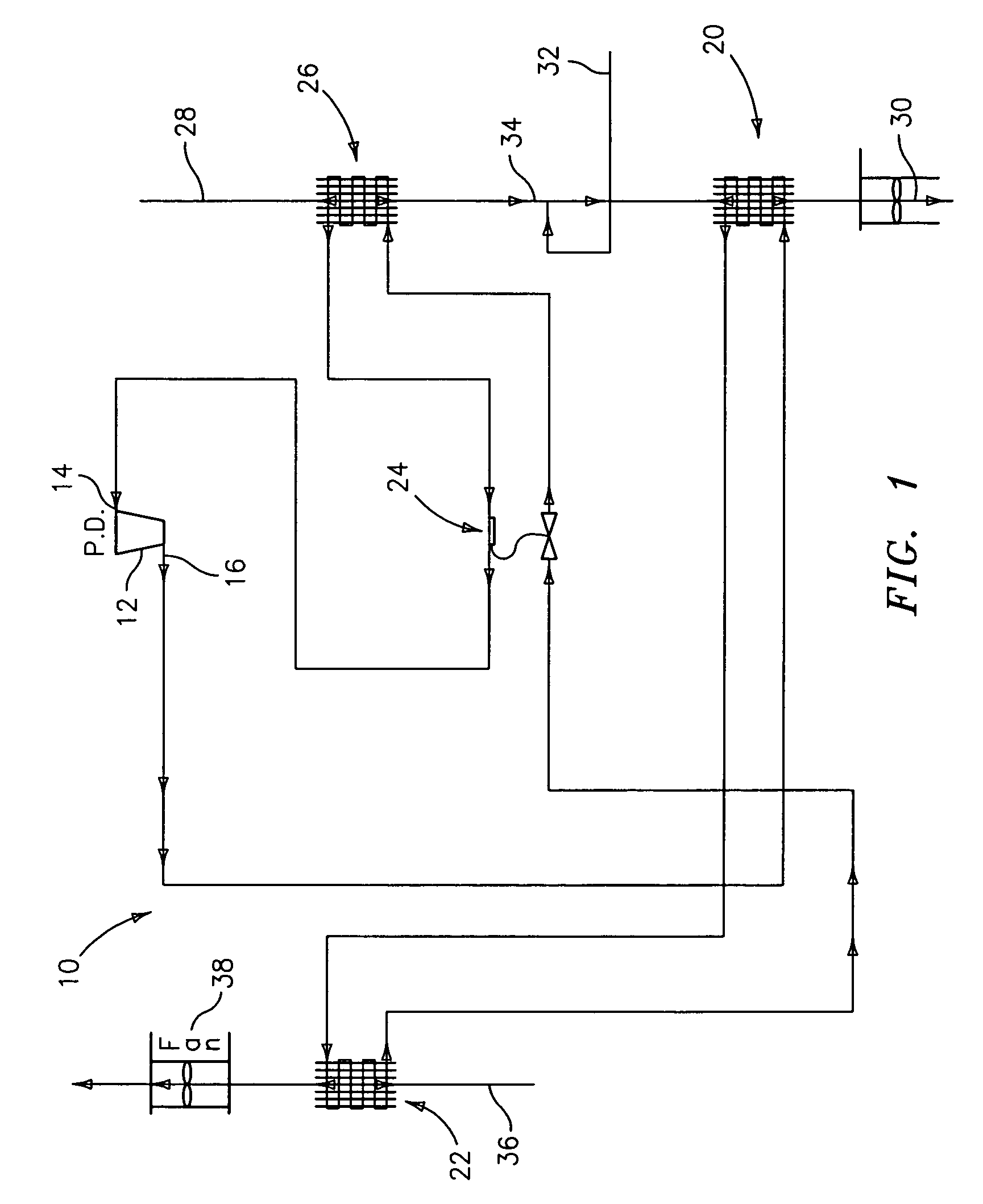

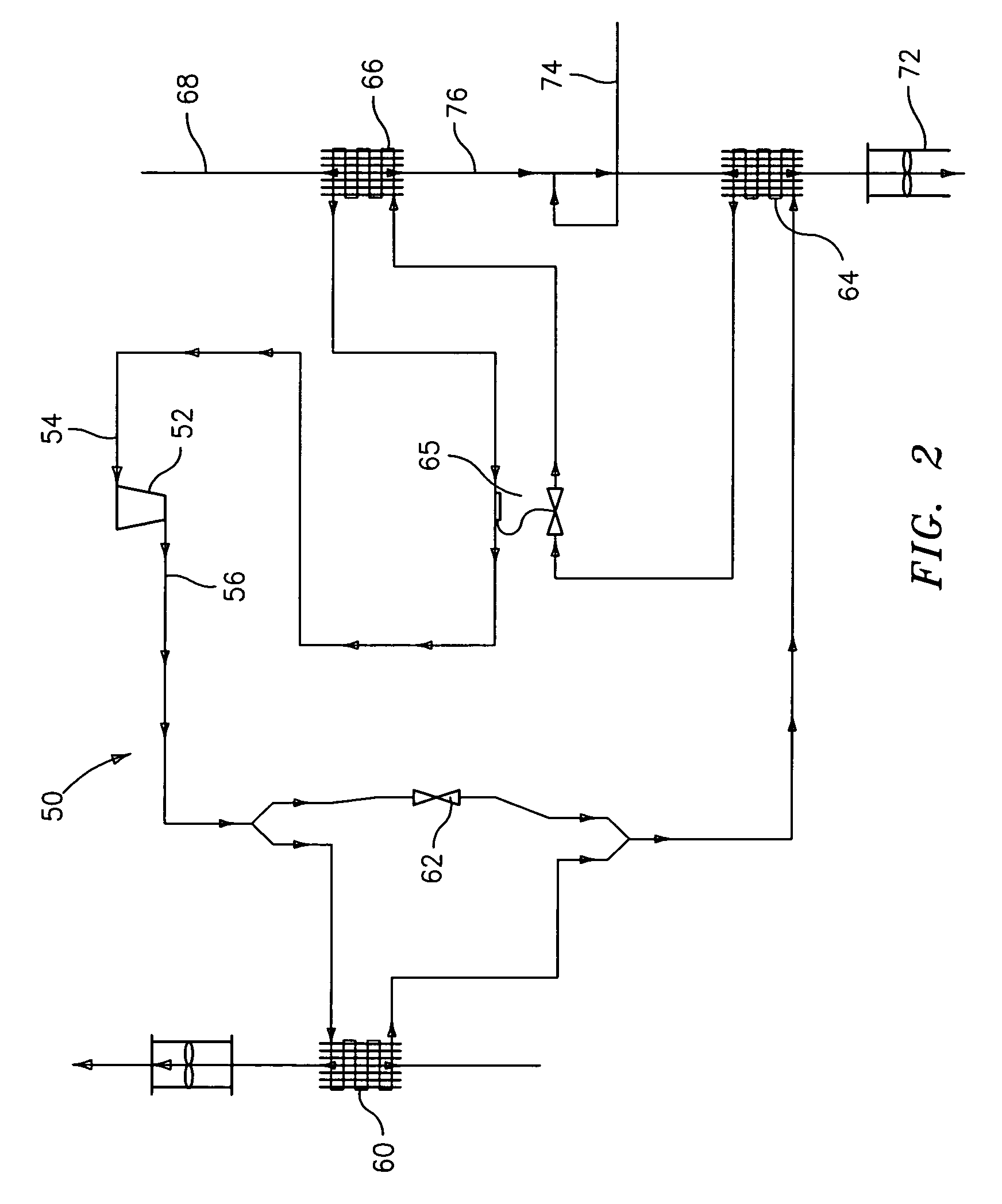

A heat pump system (10) includes a compressor (20), a reversing valve (30), an outdoor heat exchanger (40) and an indoor heat exchanger (50) coupled via refrigerant lines (35, 45, 55) in a conventional refrigeration circuit, and a refrigerant-to-water heat exchanger (60). In the air cooling with water heating mode, the air heating with water heating mode and the water heating only mode, water from a water reservoir (64), such as a storage tank or swimming pool, is passed through heat exchanger (60) in heat exchange relationship with refrigerant passing through line (35). A refrigerant reservoir (70) may be provided for use in refrigerant charge control. A refrigerant line (71) couples reservoir (70) to the refrigerant circuit intermediate the outdoor and indoor heat exchangers for directing liquid refrigerant into the reservoir (70) and a refrigerant line (73) couples the refrigerant circuit upstream of the suction inlet to the compressor (20) for returning refrigerant to the refrigerant circuit. A controller (100) controls flow into and from the refrigerant reservoir (70) through selective opening and closing of control valve (72) in line (71) and control valve (74) in line (73).

Owner:CARRIER CORP

Heat pump system

InactiveUS7003964B2Operation efficiency can be improvedImprove efficiencyInternal combustion piston enginesHeat recovery systemsWorking fluidEngineering

A heat pump system (10) including a heat generator (15), a heat engine (26) supplied with heat engine working fluid (18) by the heat generator (15) having a heat engine cylinder chamber (34), a heat engine piston (32), and a heat engine piston rod (35), a preheating chamber (31) employing the heat engine working fluid (18) to heat the heat engine cylinder chamber (34), a compressor (40) driven by the heat engine (26) employing compressor working fluid having a compressor cylinder chamber (46), a compressor piston (44), and a compressor piston rod (47), a spacer (50) separating and joining the heat engine piston rod (35) and the compressor piston rod (47), a sealing assembly (38) associated with the spacer (50) separating the heat engine working fluid (18) and the compressor working fluid, and a valve assembly (60) communicating with the heat engine cylinder chamber (34) and controlling the ingress and egress of heat engine working fluid (18) to the heat engine (26).

Owner:SOLOMON FRED D

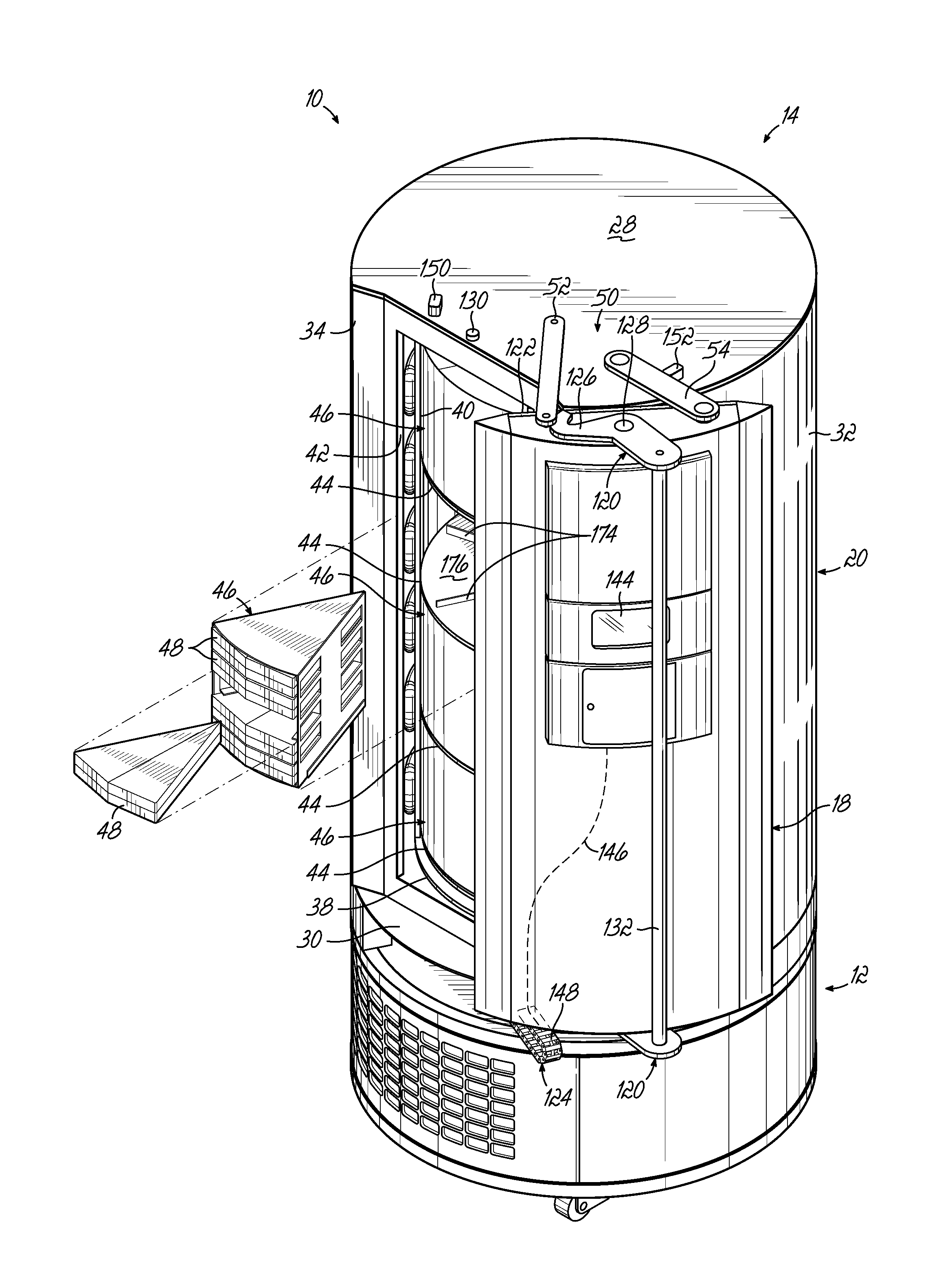

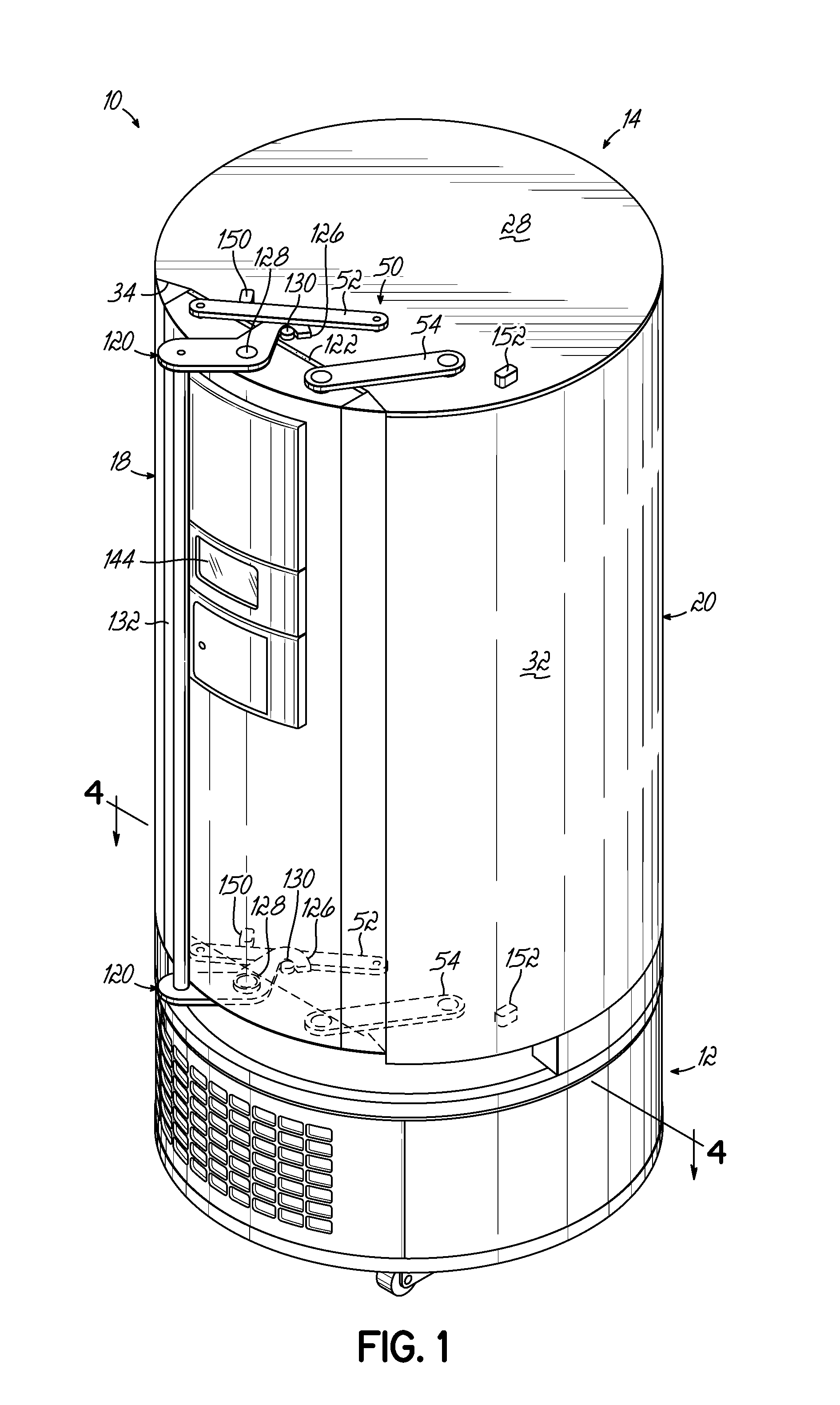

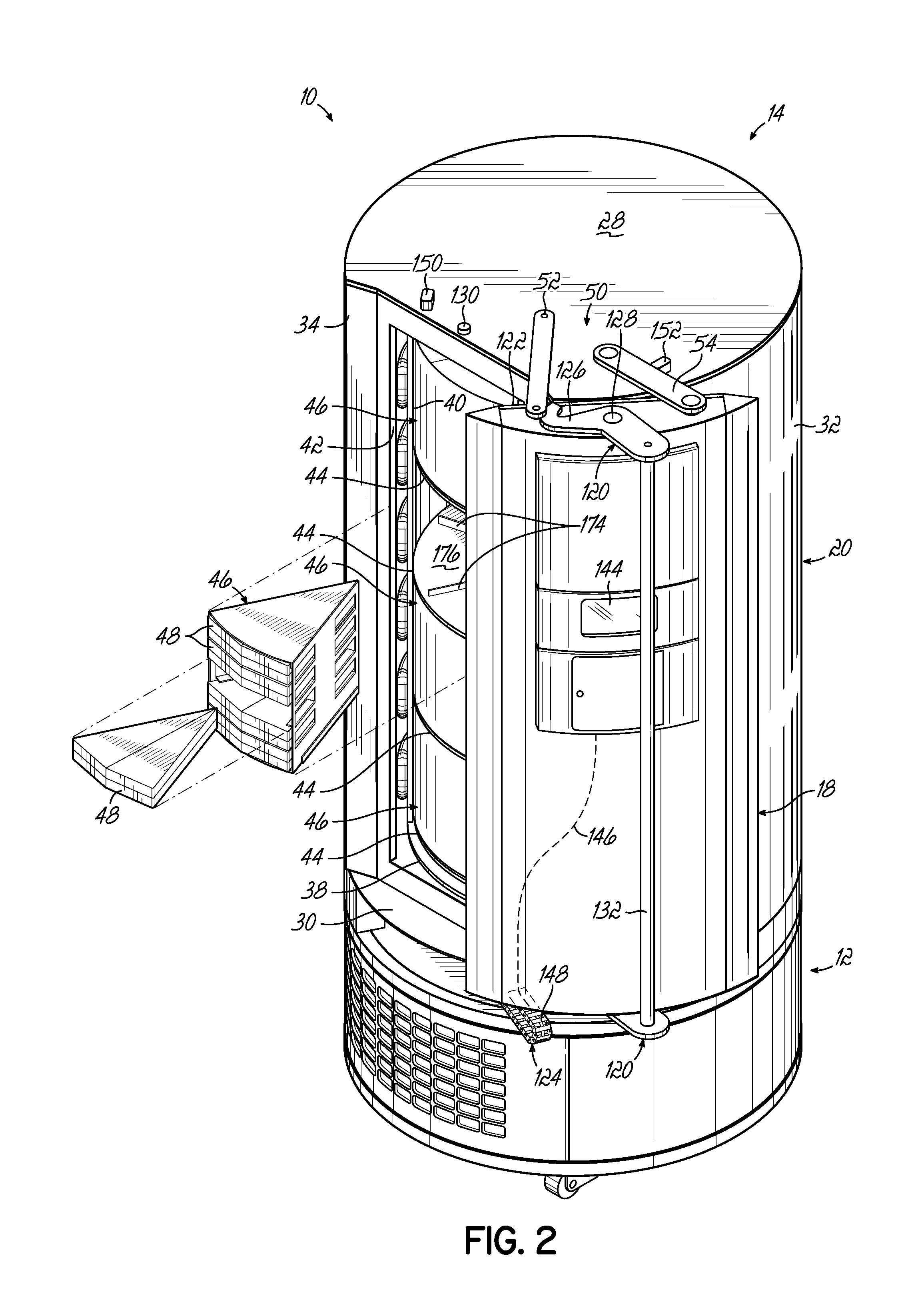

High performance freezer having cylindrical cabinet

InactiveUS20130199232A1Increase storage configuration and capacityDomestic refrigeratorsDesuperheatersEngineeringRefrigeration

A high performance freezer includes a deck and a cabinet supported above the deck and having a cabinet housing defining a generally cylindrical shape. The freezer includes a door supported by the cabinet housing that moves between open and closed positions by sliding or pivoting generally along the side wall of the cabinet. The freezer further includes a refrigeration system mounted at least partially within the deck and partially within the cabinet to refrigerate an inner chamber of the freezer. The cylindrical shape of the cabinet enables rotation of shelves within the inner chamber and a maximized storage space with a minimal floor space required.

Owner:THERMO FISHER SCI ASHEVILLE

Heat pump system

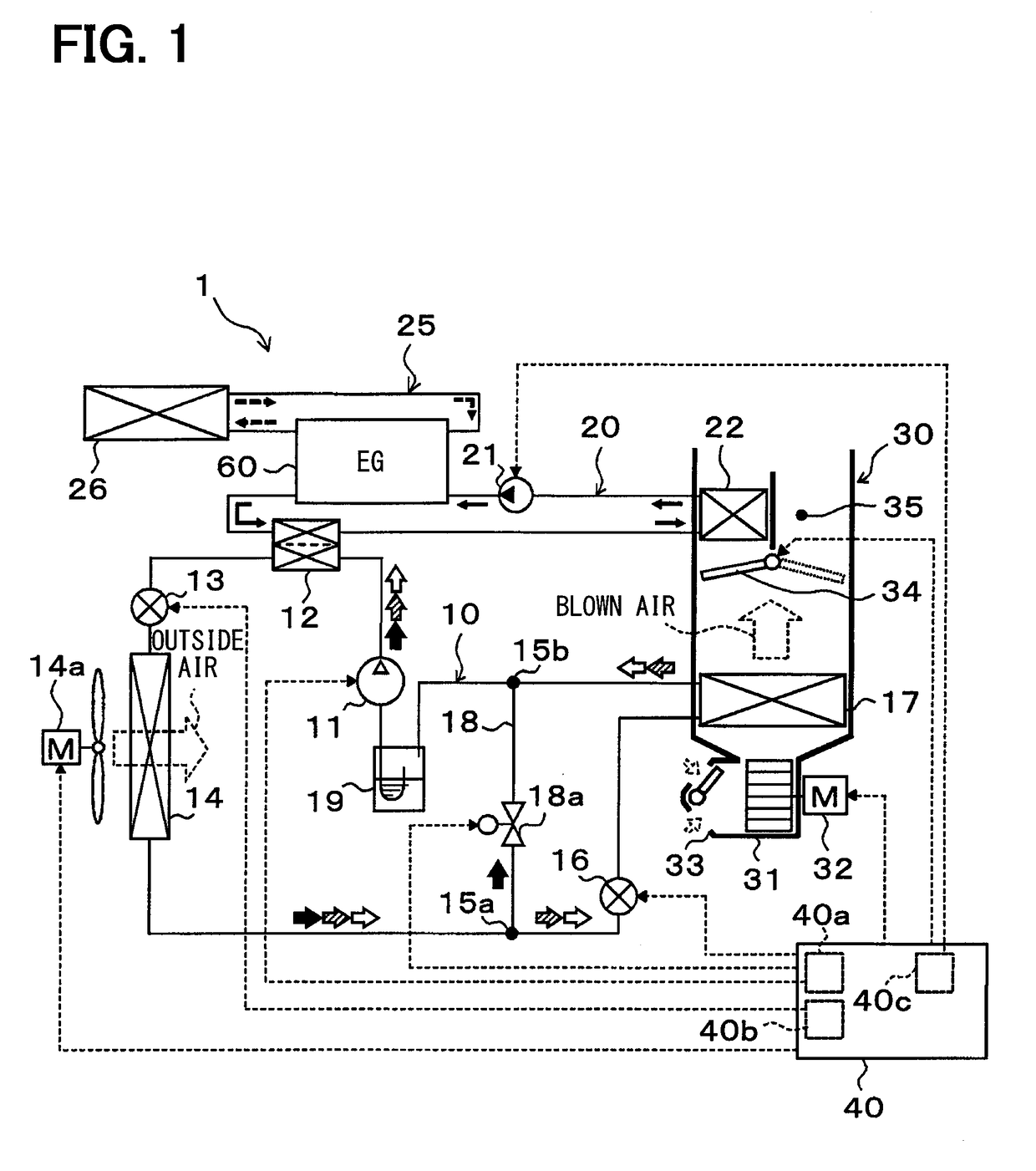

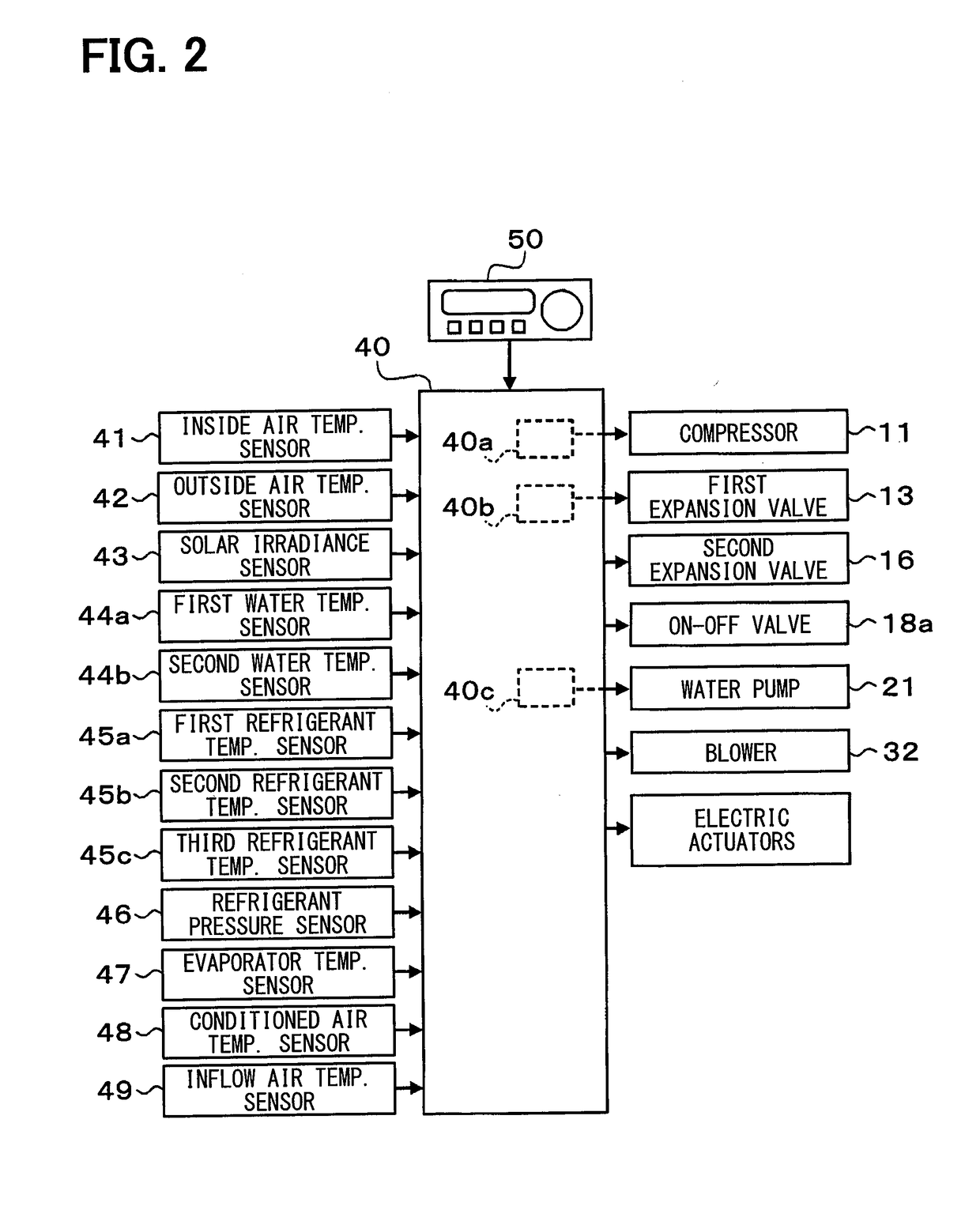

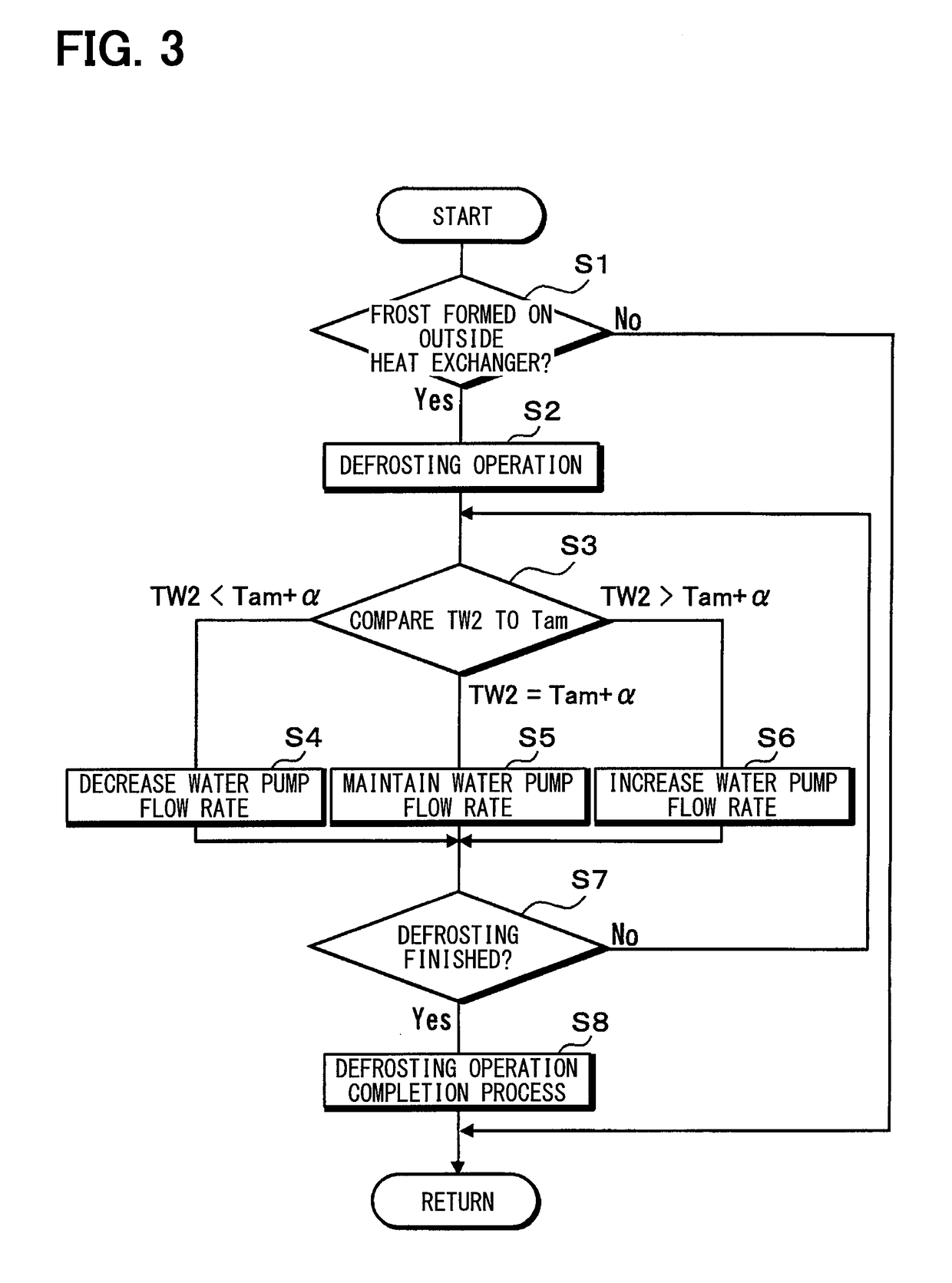

ActiveUS20190030992A1High degree of opennessSuppress temperature decreaseAir-treating devicesMechanical apparatusFrostEngineering

A heat pump system includes a heat pump cycle, a heat medium circulation circuit, and a refrigeration cycle device. The refrigeration cycle device is configured to perform a defrosting operation when a frost formation determiner determines that frost is formed. A throttle opening degree controller is configured to increase an opening degree in the defrosting operation. A pumping capacity controller is configured to increase a pumping capacity in the defrosting operation with increase of a required heating capacity required for heating a heating target fluid, the pumping capacity controller increasing the pumping capacity such that heat of refrigerant discharged from a compressor is transferred to heat medium in a first heat exchanger within a range in which a temperature of the refrigerant flowing into an outside heat exchanger is capable of melting the frost formed on the outside heat exchanger.

Owner:DENSO CORP

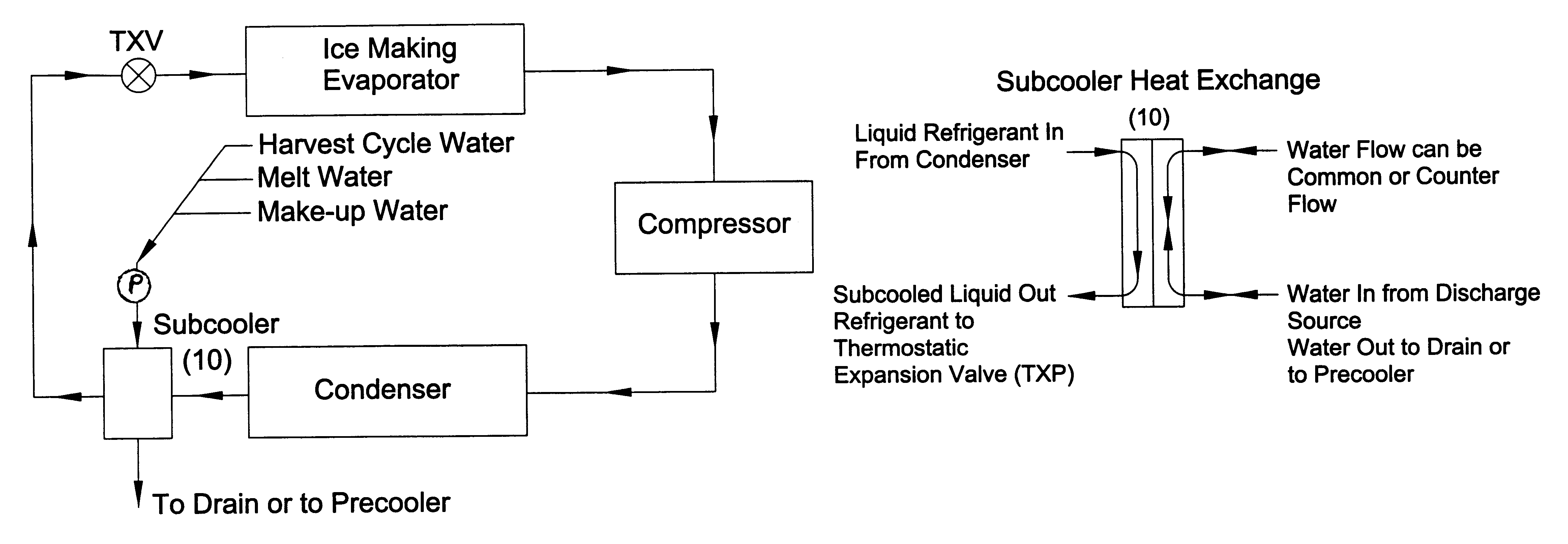

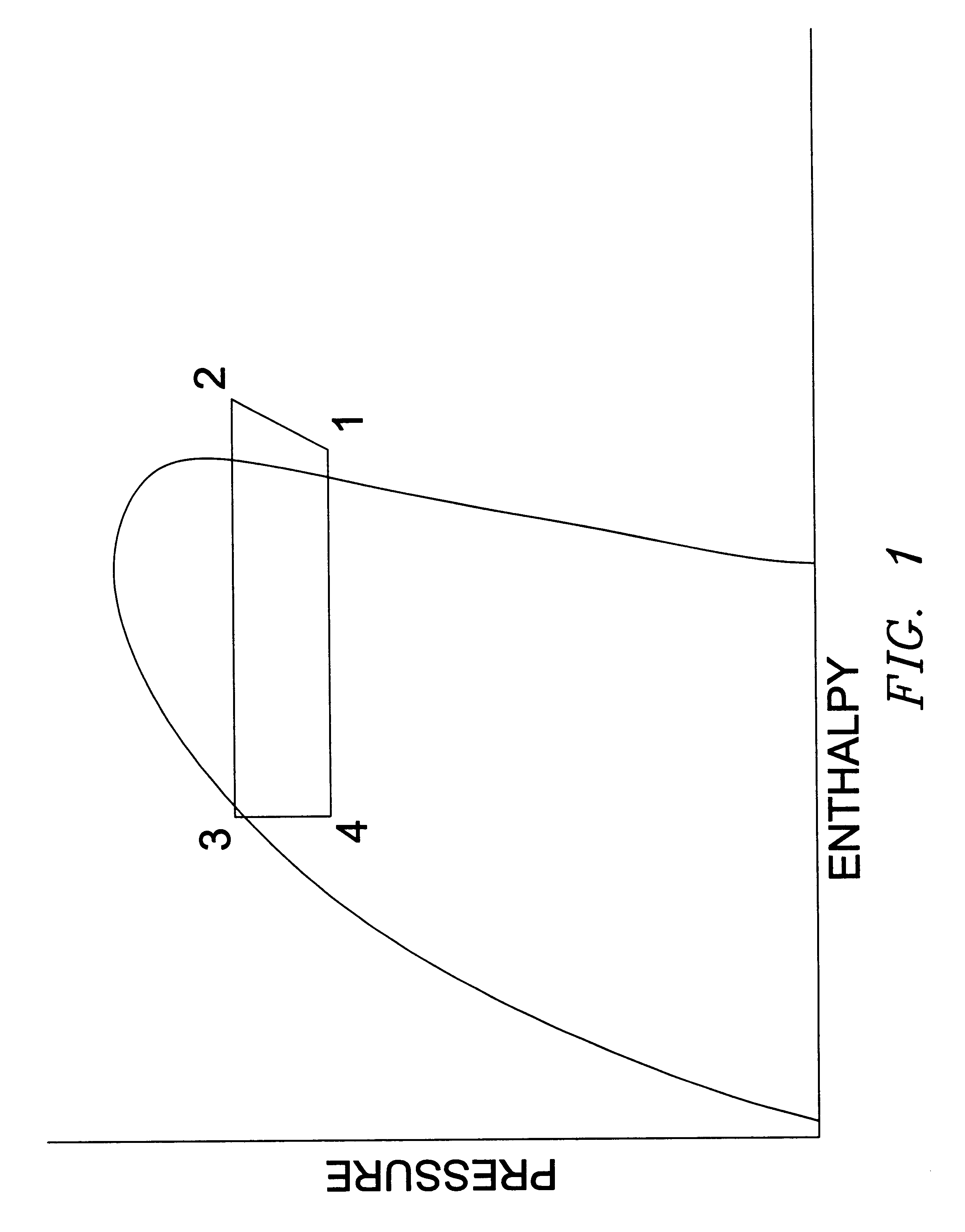

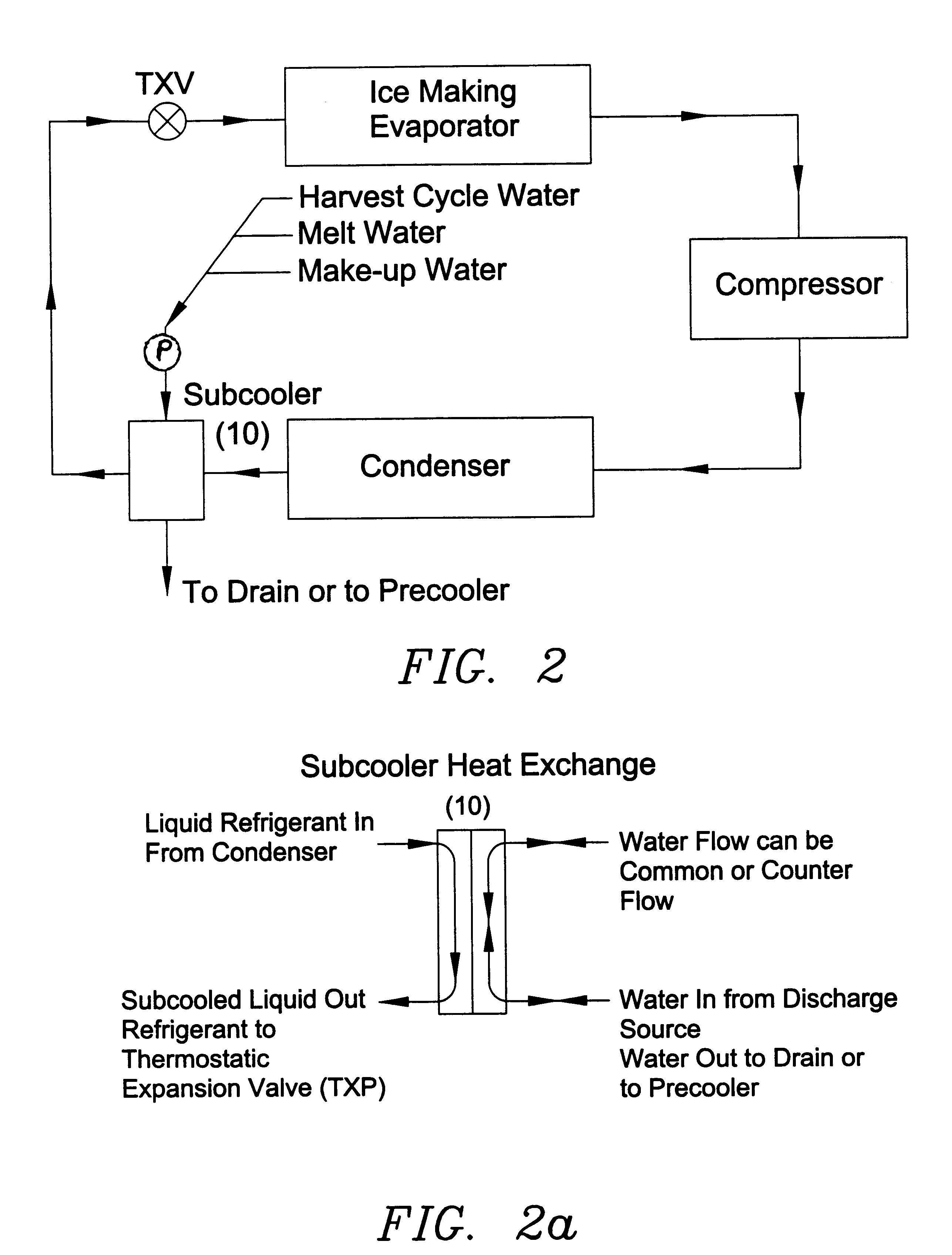

Utilization of harvest and/or melt water from an ice machine for a refrigerant subcool/precool system and method therefor

InactiveUS6237359B1Comprehensive understandingReduce heat dissipationSkin implantsFood processingCounter flowWater discharge

A system for providing liquid refrigerant subcooling, subsequent to that subcooling accomplished by the primary condenser of an ice machine, by means of utilizing cold harvest and / or melt water discharge from said ice machine. The subcooler is connected in fluid communication with the output of a pump that pumps stored ice machine discharge water to directly flow through the subcooler from a bottom portion to a top portion in a counter-flow direction and then to discharge such that the subcooler utilizes the pumped and flowing cold discharge water from the ice machine for providing maximum available subcooling to the liquid refrigerant of said ice machine

Owner:OLIVE TREE PATENTS 1 +1

Heat pump system having a pre-processing module

ActiveUS8915092B2Avoid frostImprove regeneration efficiencyMechanical apparatusDesuperheatersComputer moduleEnergy recovery

Owner:NORTEK AIR SOLUTIONS CANADA INC

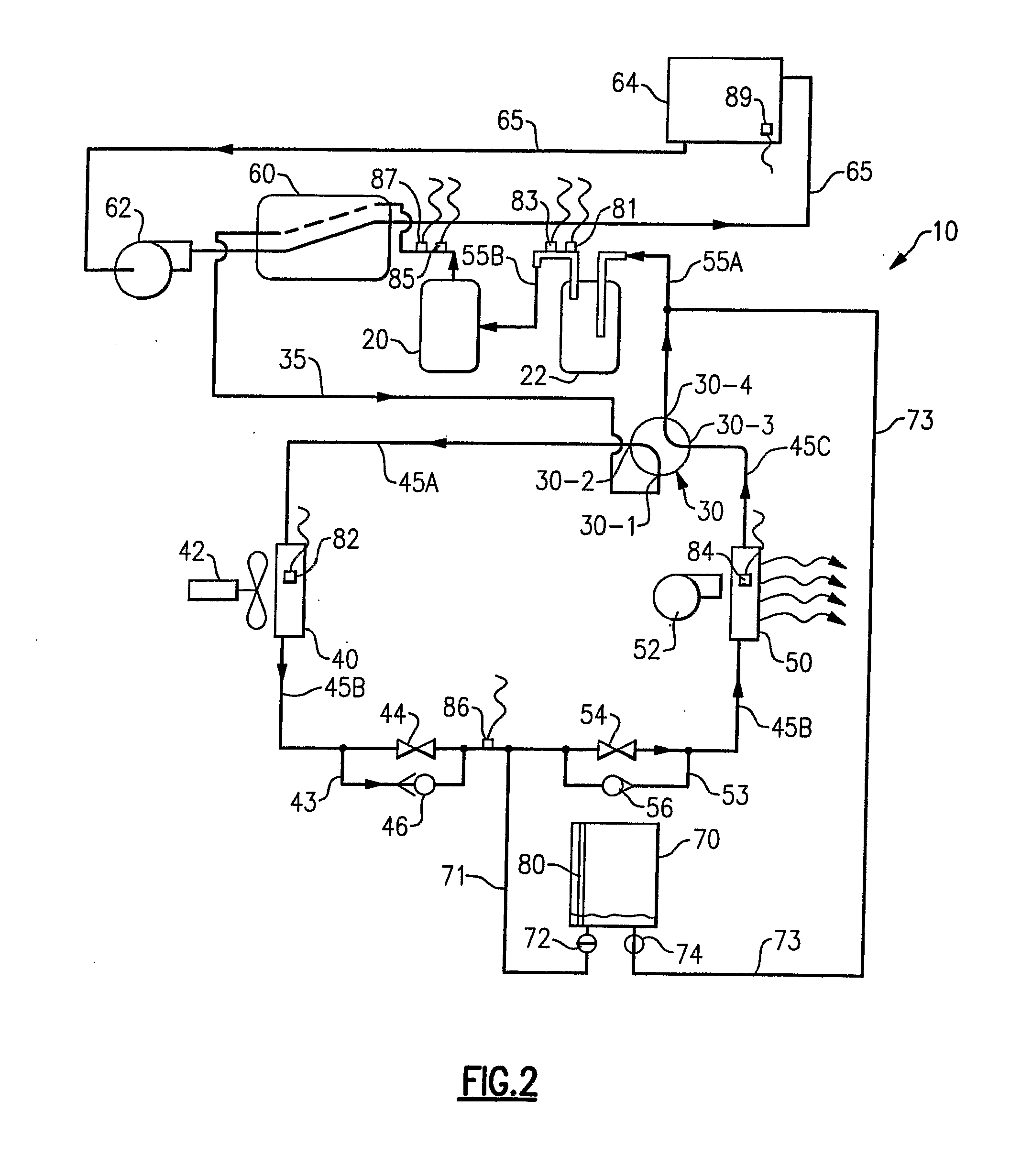

Heat pump system with auxiliary water heating

InactiveUS8220531B2Improved refrigerant charge controlLevel controlDesuperheatersEngineeringHeat pump

A heat pump system (10) includes a compressor (20), a reversing valve (30), an outdoor heat exchanger (40) and an indoor heat exchanger (50) coupled via refrigerant lines (35, 45, 55) in a conventional refrigeration circuit, and a refrigerant-to-water heat exchanger (60). In the air cooling with water heating mode, the air heating with water heating mode and the water heating only mode, water from a water reservoir (64), such as a storage tank or swimming pool, is passed through heat exchanger (60) in heat exchange relationship with refrigerant passing through line (35). A refrigerant reservoir (70) may be provided for use in refrigerant charge control. A refrigerant line (71) couples reservoir (70) to the refrigerant circuit intermediate the outdoor and indoor heat exchangers for directing liquid refrigerant into the reservoir (70) and a refrigerant line (73) couples the refrigerant circuit upstream of the suction inlet to the compressor (20) for returning refrigerant to the refrigerant circuit. A controller (100) controls flow into and from the refrigerant reservoir (70) through selective opening and closing of control valve (72) in line (71) and control valve (74) in line (73).

Owner:CARRIER CORP

Multipurpose adiabatic potable water production apparatus and method

ActiveUS7121101B2Safe to drinkReduce energy costsMechanical apparatusGeneral water supply conservationAir cycleWater vapor

Apparatus and methods for transforming water vapor into potable water by using a vapor compression refrigeration system which includes first and second cooling elements disposed in a closed loop air passage duct that provides a continuous air circulation pattern driven by a fan or similar device. Water is introduced into the circulating air and undergoes adiabatic cooling followed by two stage cooling, first at a temperature below the dew point and then at a lower temperature at or below freezing. Water is collected from the air in each step and the air is thereafter heated back up by the condensing element of the refrigeration system enabling it to absorb more water vapor at the point of introduction. The air is recirculated and processed as above to permit cyclical water recovery.

Owner:SKYWATER INT LLC

Dual temperature heat pump system

InactiveUS20170211862A1Improve performanceImprove system flexibilityHeat pumpsFuel heating with wind energyProcess engineeringMajor and minor

A heating system includes a heat pump that provides heat to a major fluid circuit and a minor fluid circuit for performing different heating operations. The system includes a power source having a variable cost and a controller configured to regulate flow of the major and minor fluid circuits to perform the heating operations. The controller is configured to receive information regarding the variable cost of the power source and distribute flow between the major and minor fluid circuits to perform the heating operations to minimize the electricity cost. The combined enhanced demand regulation and enhanced output regulation amplifies the total heat output and power consumption while permitting greater use of a power source of varying cost (e.g. PV)—thereby minimizing overall daily operating cost.

Owner:SHARP KK

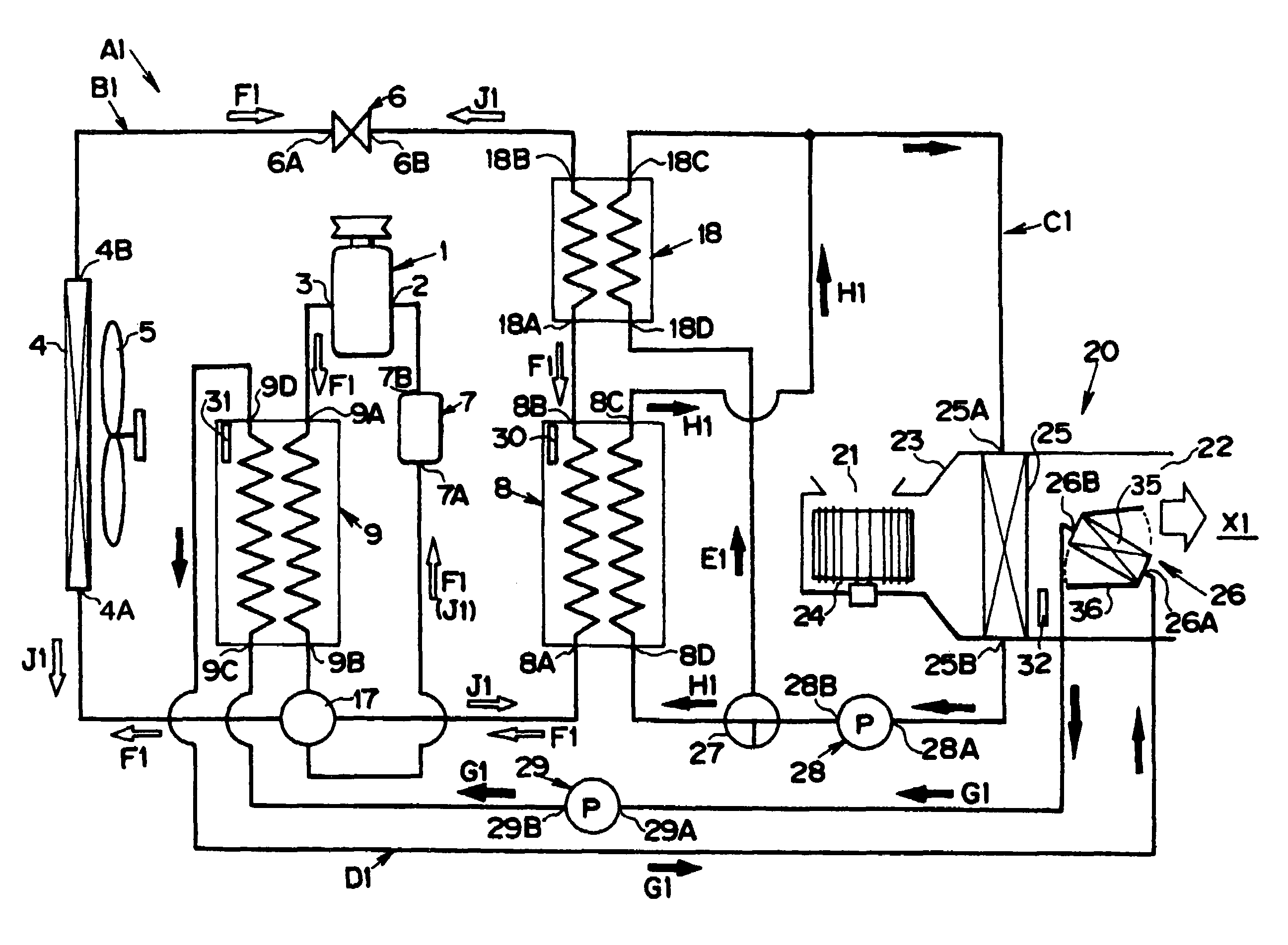

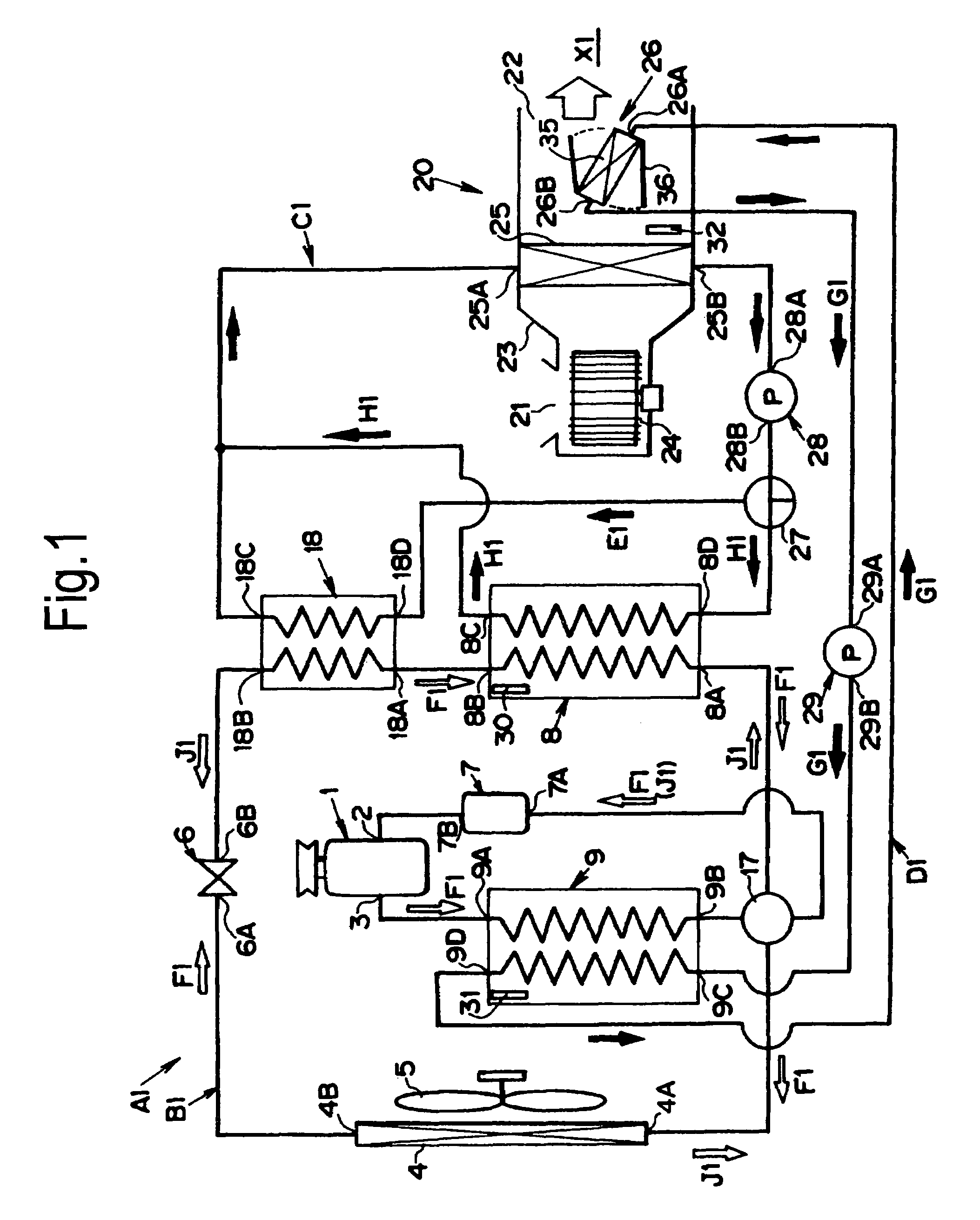

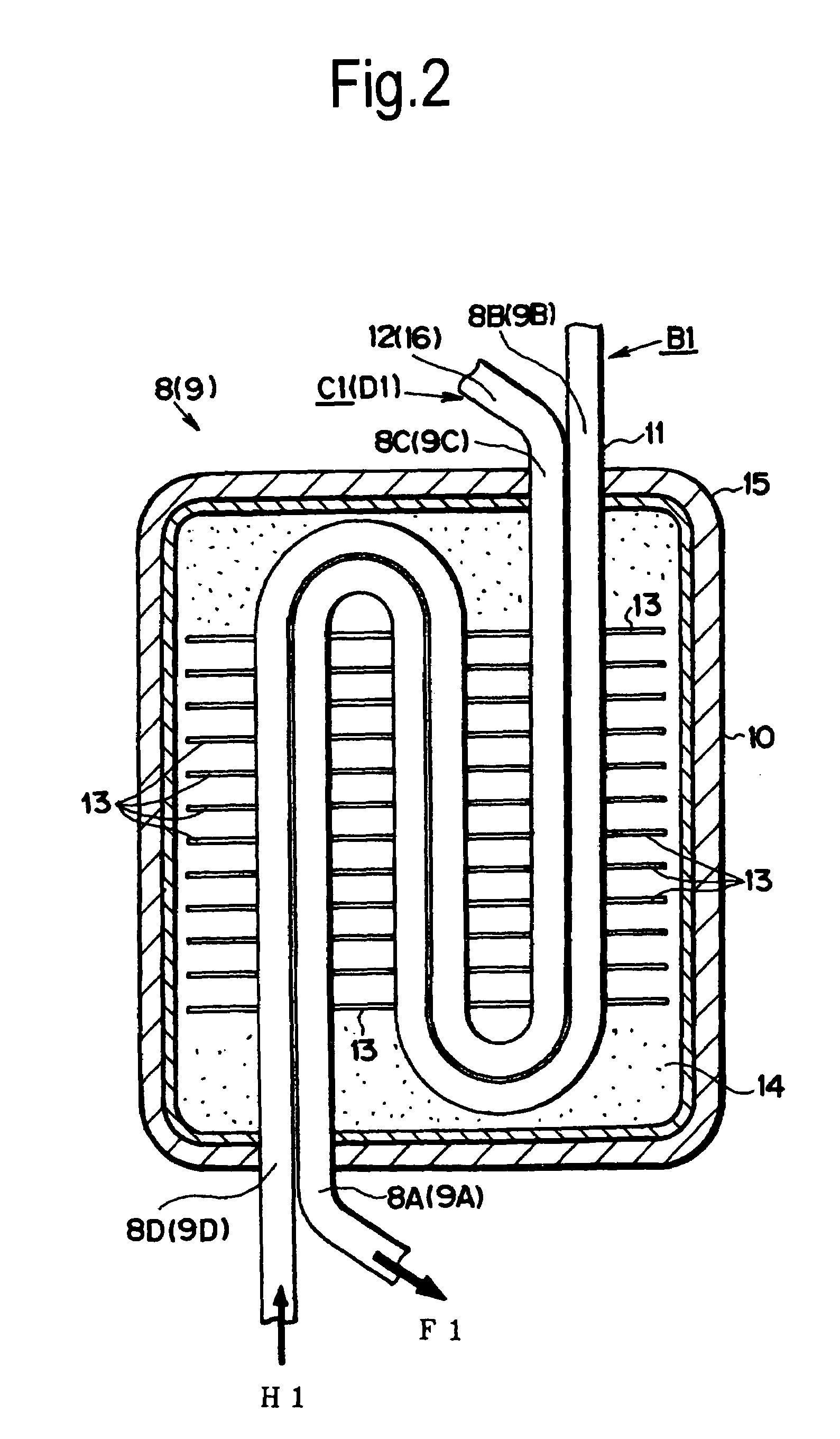

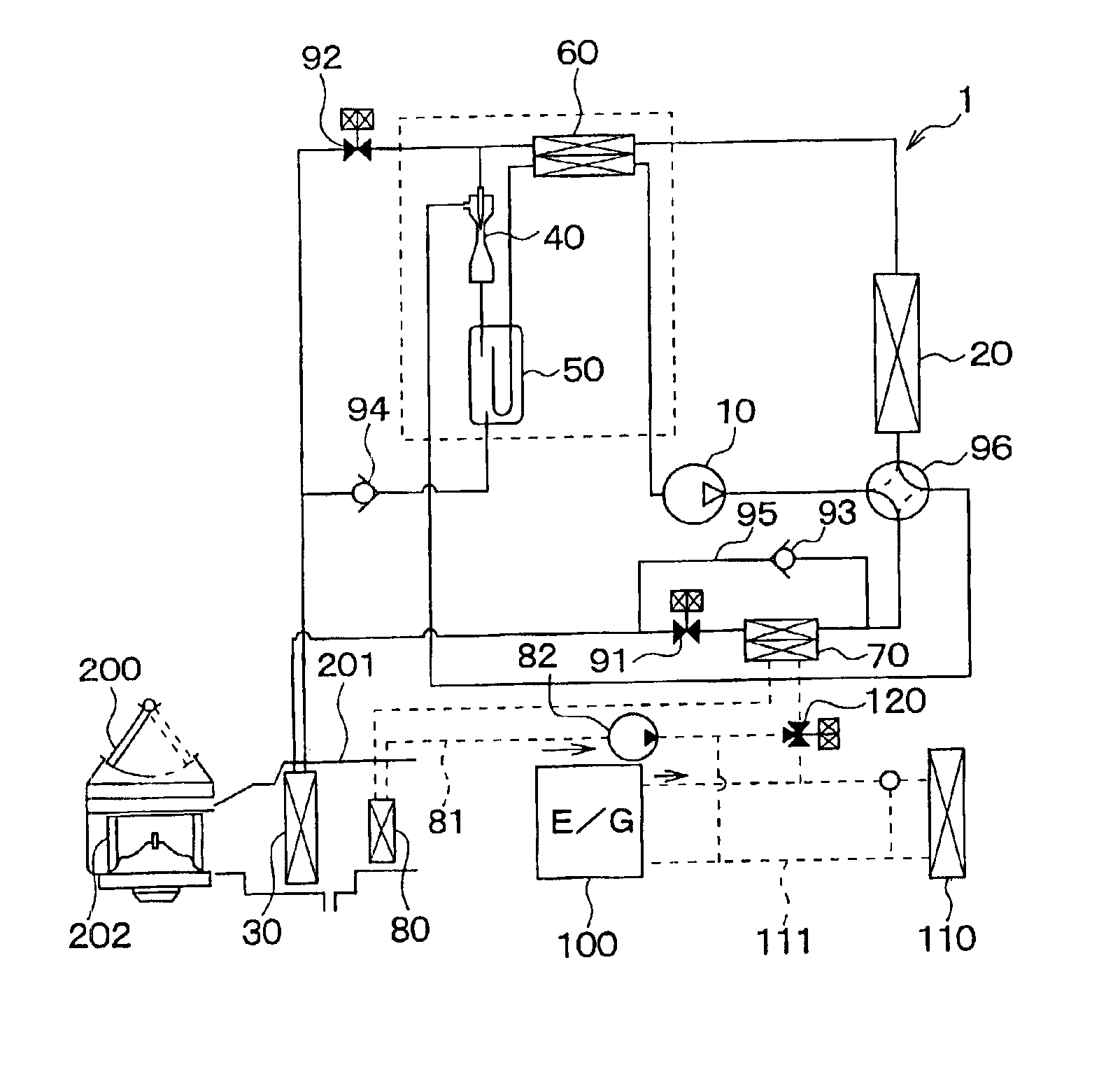

Cogeneration system

InactiveUS20060037352A1Maximize absorptionPreventing compressor malfunctionHeat pumpsInternal combustion piston enginesElectricityFour-way valve

A cogeneration system including an engine, which drives a generator to generate electricity, a cooling / heating unit, which comprises at least one compressor, a four-way valve, an outdoor heat exchanger, an expansion device, and an indoor heat exchanger, to establish a heat pump type refrigerant cycle, a cooling water heat supplier to supply heat of cooling water used to cool the engine to a suction side of the compressor of the cooling / heating unit and to pre-heat air passing through the outdoor heat exchanger, and a discharge-side refrigerant over-heater to supply heat of exhaust gas discharged from the engine to a discharge side of the compressor. In accordance with the cogeneration system, it is possible to maximize absorption of the waste heat of the engine while preventing compressor malfunction, and thus, to increase the refrigerant condensing temperature of the indoor heat exchanger and the refrigerant pre-heating temperature of the outdoor heat exchanger. Thus, an enhancement in heating performance is achieved.

Owner:LG ELECTRONICS INC

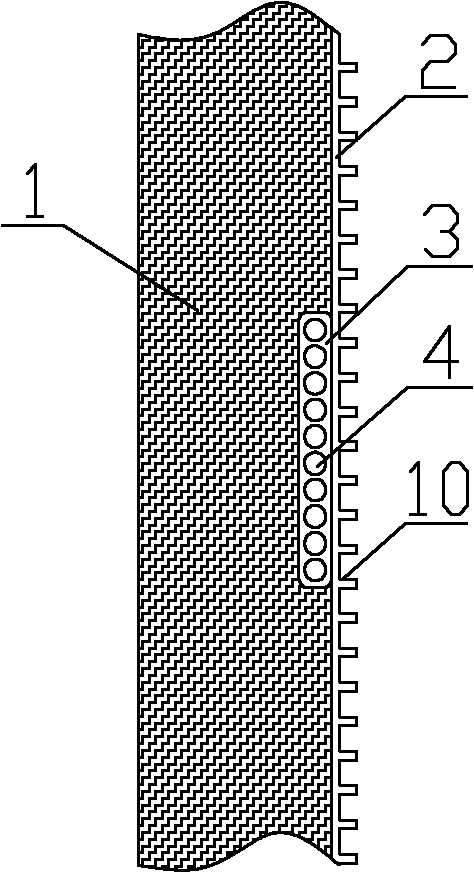

Condenser

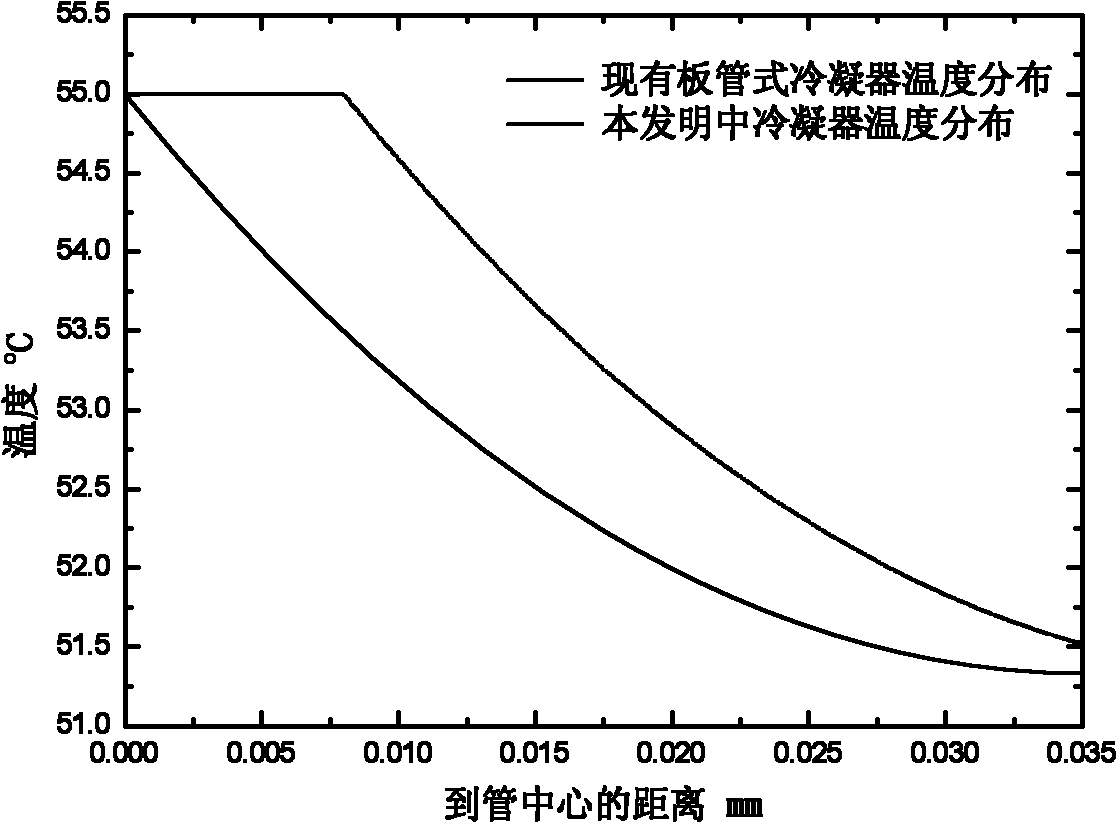

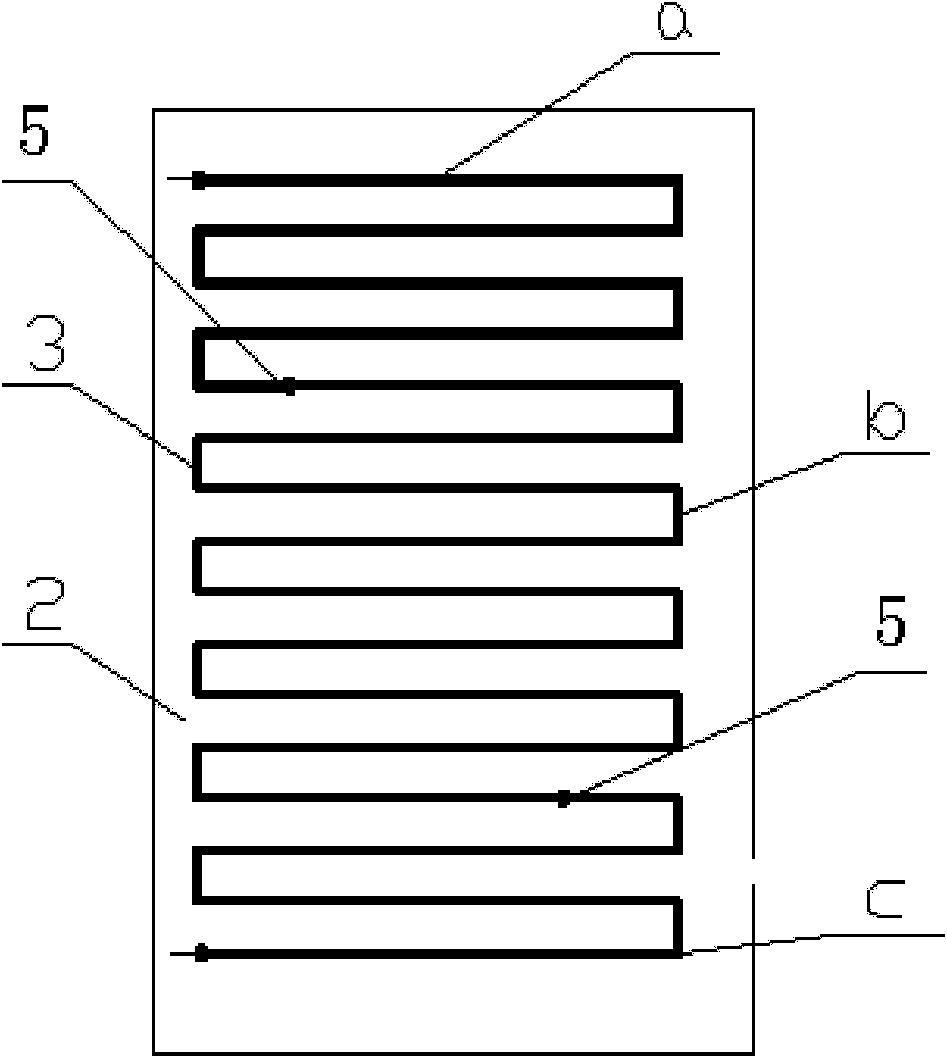

InactiveCN102052807AIncrease temperatureImprove the overall heat transfer coefficientThermal insulationEvaporators/condensersFlow resistivityMaterial consumption

The invention discloses a condenser which is composed of a porous micro through heat exchange flat tube, a corresponding connecting header and a heat dissipation back plate arranged at one side of the heat exchange flat tube. In the invention, the structure is compact, the heat exchange efficiency is high, the aluminum flat tube is adopted, thus the condenser is more advantageous than the existing copper heat exchange tube in the aspect of economical efficiency, and the condenser is suitable for the fields such as refrigeration, chemical engineering, energy source, heat exchange and the like. The condenser is characterized in that on the one hand, since the porous micro channel flat tube structure is adopted, the coefficient of heat transfer in the tube is improved, and simultaneously the flow resistance of a refrigerant in the tube is reduced; and on the other hand, the contact type of the condenser and the side wall of the heat dissipation back plate is surface contact, so that contact thermal resistance is reduced, the average temperature of the side wall of the heat dissipation back plate is improved, and the heat exchange between the side wall of the back plate and the ambient air is strengthened, namely the condensing effect is strengthened, thus, when the lengths of pipes are the same, the quantity of the condenser can be increased, or when the heat exchange quantities are the same, the length of the pipes can be reduced, therefore the condenser is more compact, simultaneously the material consumption is reduced, and the condenser has a certain advantage in the aspect of economical efficiency.

Owner:XI AN JIAOTONG UNIV

Refrigerant charge control in a heat pump system with water heater

A heat pump system includes a compressor, a reversing valve, an outdoor heat exchanger and an indoor heat exchanger in a circuit, and a refrigerant-to-water heat exchanger. In the air cooling with water heating mode, the air heating with water heating mode and the water heating only mode, water from a water reservoir is passed through refrigerant-to-water heat exchanger. A refrigerant reservoir may be provided for use in refrigerant charge control. A refrigerant line (71) couples reservoir to the refrigerant circuit intermediate the outdoor and indoor heat exchangers for directing liquid refrigerant into the reservoir and a refrigerant line (73) couples the refrigerant circuit upstream of the suction inlet to the compressor for returning refrigerant to the refrigerant circuit. A controller controls flow into and from the refrigerant reservoir through selective opening and closing of control valve (72) in line (71) and control valve (74) in line (73).

Owner:CARRIER CORP

Heat pump with forced air heating regulated by withdrawal of heat to a radiant heating system

InactiveUS7849700B2Easy transferImprove the heating effectSpace heating and ventilation safety systemsSpace heating and ventilation control systemsThermal energyCirculator pump

Owner:ELECTRO IND

Refrigerant charge management in a heat pump water heater

Heat pumps that heat or cool a space and that also heat water, refrigerant management systems for such heat pumps, methods of managing refrigerant charge, and methods for heating and cooling a space and heating water. Various embodiments deliver refrigerant gas to a heat exchanger that is not needed for transferring heat, drive liquid refrigerant out of that heat exchanger, isolate that heat exchanger against additional refrigerant flowing into it, and operate the heat pump while the heat exchanger is isolated. The heat exchanger can be isolated by closing an electronic expansion valve, actuating a refrigerant management valve, or both. Refrigerant charge can be controlled or adjusted by controlling how much liquid refrigerant is driven from the heat exchanger, by letting refrigerant back into the heat exchanger, or both. Heat pumps can be operated in different modes of operation, and segments of refrigerant conduit can be interconnected with various components.

Owner:NORTEK GLOBAL HVAC

Heat Pump Dehumidification System

InactiveUS20070151280A1Reduce stepsReduce heat transferHeat pumpsDesuperheatersWater source heat pumpWater source

A heat pump dehumidification system comprised of one of an air source heat pump system, a water source heat pump system, and a direct expansion heat pump system, with an extra interior air heat exchange means situated between the system's compressor's hot refrigerant gas discharge side and the exterior heat exchange means, for activation and use in conjunction with the system's primary interior air heat exchange means, located between the exterior heat exchange means and the system's compressor's refrigerant gas suction side, when operation in a dehumidification mode is desired absent sensible cooling, and optimum design sizes for both interior air exchange means while the system is operating in one of a dehumidification mode, a cooling mode, and a heating mode.

Owner:EARTH TO AIR SYST

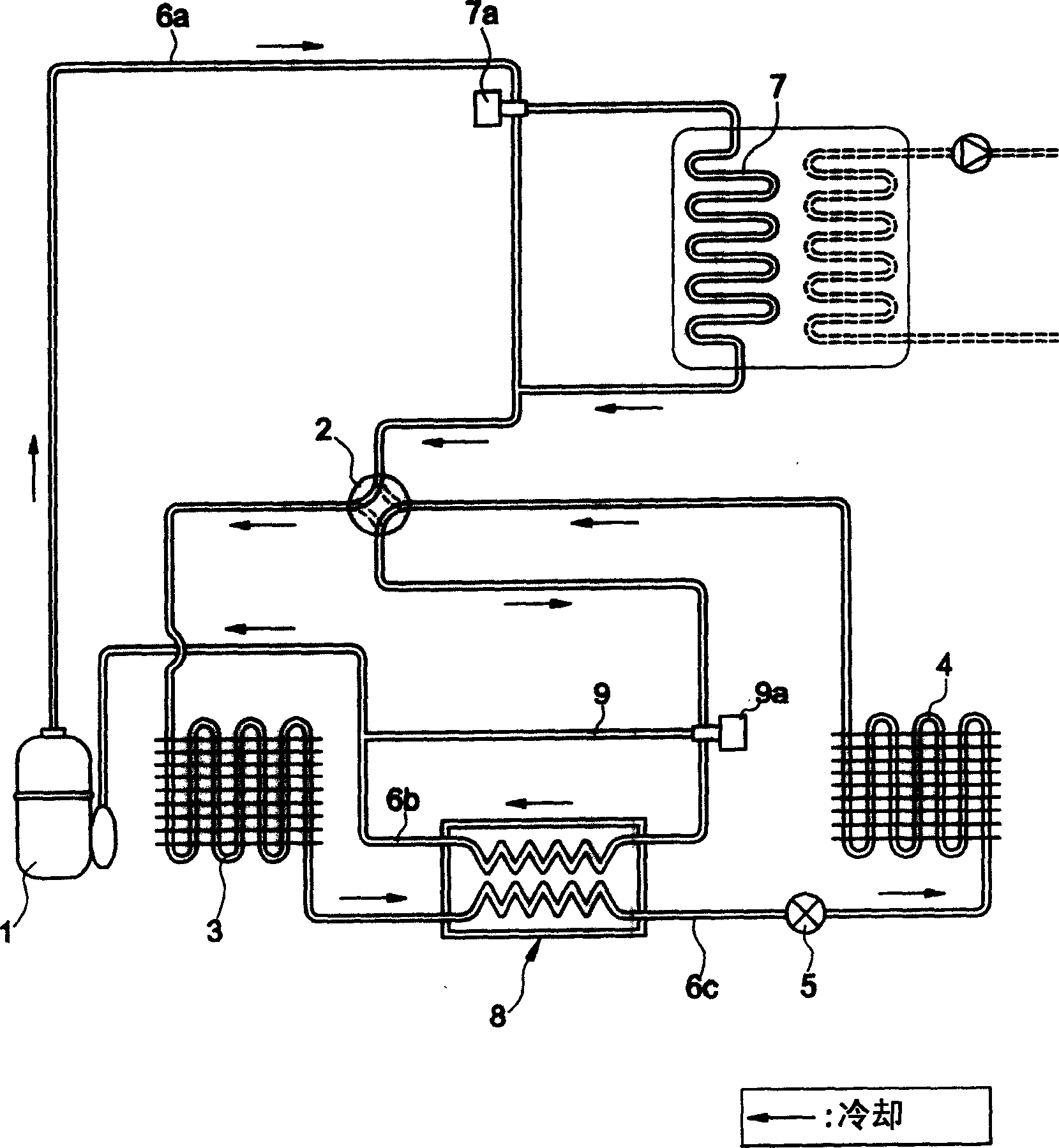

Vehicle air conditioner with ejector refrigerant cycle

InactiveUS6935421B2Effective coolingEfficient heatingMechanical apparatusDesuperheatersEngineeringHigh pressure

An air conditioner includes a compressor for compressing refrigerant, an exterior heat exchanger for performing heat exchange between refrigerant and outside air, an interior heat exchanger for performing heat exchange between the refrigerant and air to be blown into the compartment, an ejector for decompressing high-pressure refrigerant, a heater core for heating air using a high-temperature fluid as a heating source, and a fluid-refrigerant heat exchanger that heats the fluid flowing to the heater core using high-temperature refrigerant discharged from the compressor as a heating source. In a dehumidifying and heating operation, refrigerant in the interior heat exchanger absorbs heat from air so that the air is cooled and dehumidified, and the dehumidified and cooled air can be further heated in the heater core by indirectly using the heating source from the high-temperature refrigerant.

Owner:DENSO CORP

Heating and cooling system

A heating and cooling system for preventing the deterioration of heating efficiency generated due to a subsidiary heat exchanger used to increase cooling efficiency. The heating and cooling system includes a compressor for compressing a refrigerant, an indoor heat exchanger for heat-exchanging the refrigerant with indoor air, an outdoor heat exchanger for heat-exchanging the refrigerant with an outdoor air, a four-way valve disposed at an outlet of the compressor for selectively discharging the refrigerant to one of the indoor and outdoor heat exchangers according to heating and cooling modes, an expansion valve for decompressing and expanding the refrigerant, an inlet refrigerant pipe for guiding the refrigerant drawn into the compressor, a subsidiary heat exchanger disposed in the inlet refrigerant pipe for heat-exchanging the refrigerant passing through the inlet refrigerant pipe and the refrigerant passing through a connection refrigerant pipe in the cooling mode so as to control the temperature of the refrigerant drawn into the compressor, and a bypass refrigerant pipe for allowing the refrigerant drawn into the compressor to bypass the subsidiary heat exchanger and then to be directed into the compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

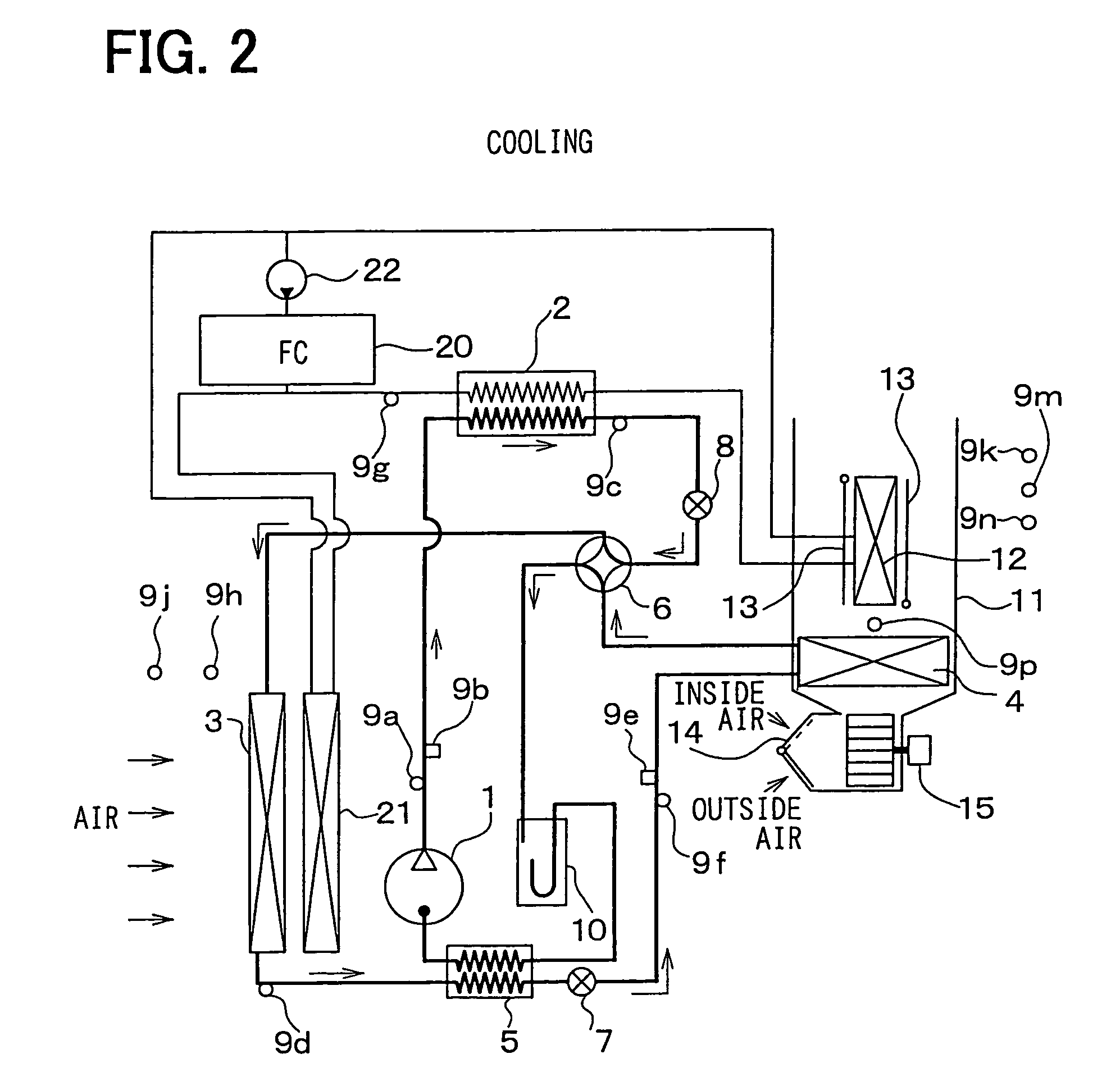

Air conditioner with dehumidifying and heating operation

ActiveUS6966197B2Improve the heating effectEffective absorptionAir-treating devicesMechanical apparatusEngineeringRefrigerant

When a dehumidifying and heating operation is set in an air conditioner, refrigerant is circulated from a compressor to the compressor through a first exterior heat exchanger, a decompression device, an interior heat exchanger, an another decompression device, an inner heat exchanger and a second exterior heat exchanger, in this order. Further, by controlling a throttle opening degree of the another decompression device, a refrigerant temperature in the interior heat exchanger can be set higher than that in the second exterior heat exchanger. Thus, even when the interior heat exchanger is controlled to a temperature to be not frosted, heat can be absorbed from outside air in the second exterior heat exchanger. Accordingly, when an outside air temperature is low, by setting the dehumidifying and heating operation, air to be blown into a compartment can be dehumidified while sufficiently increasing heating capacity.

Owner:DENSO CORP

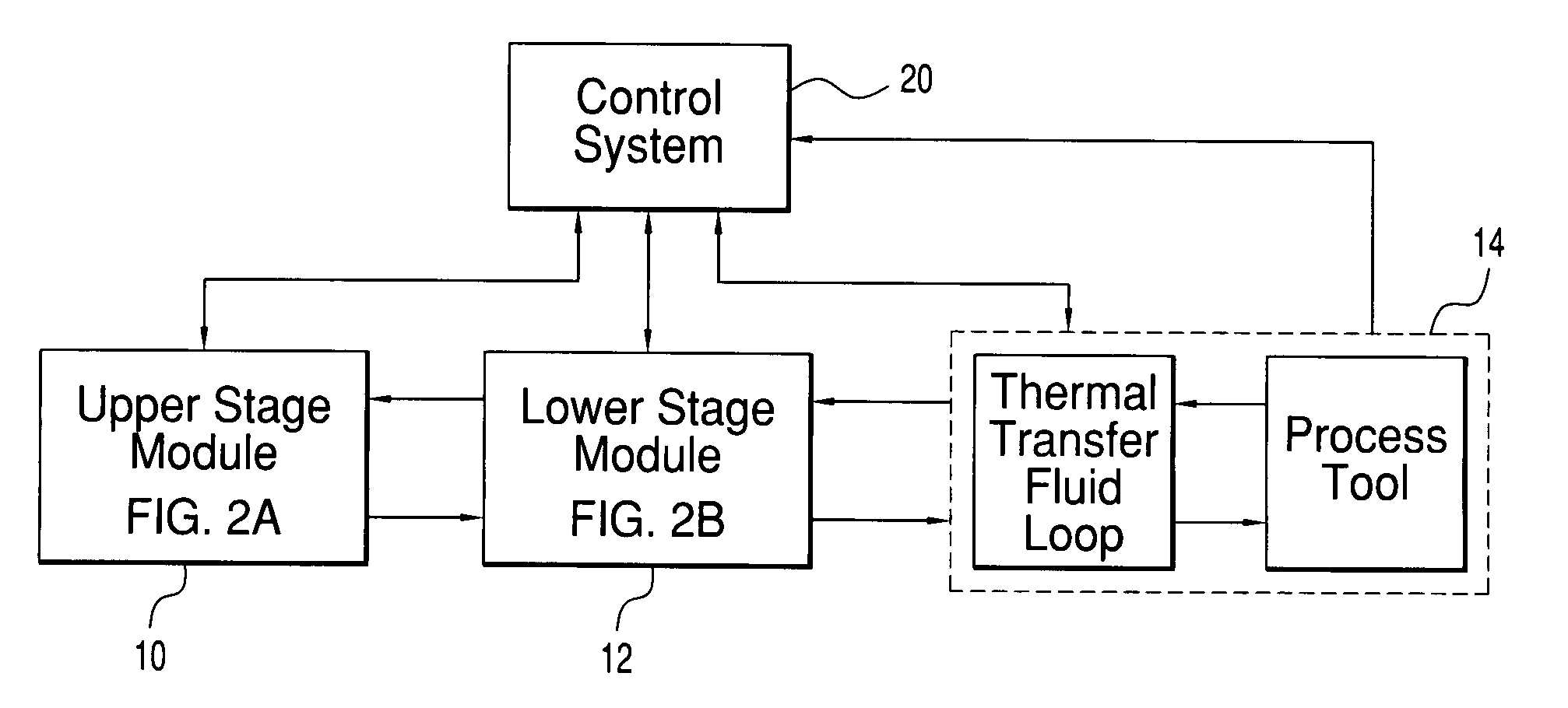

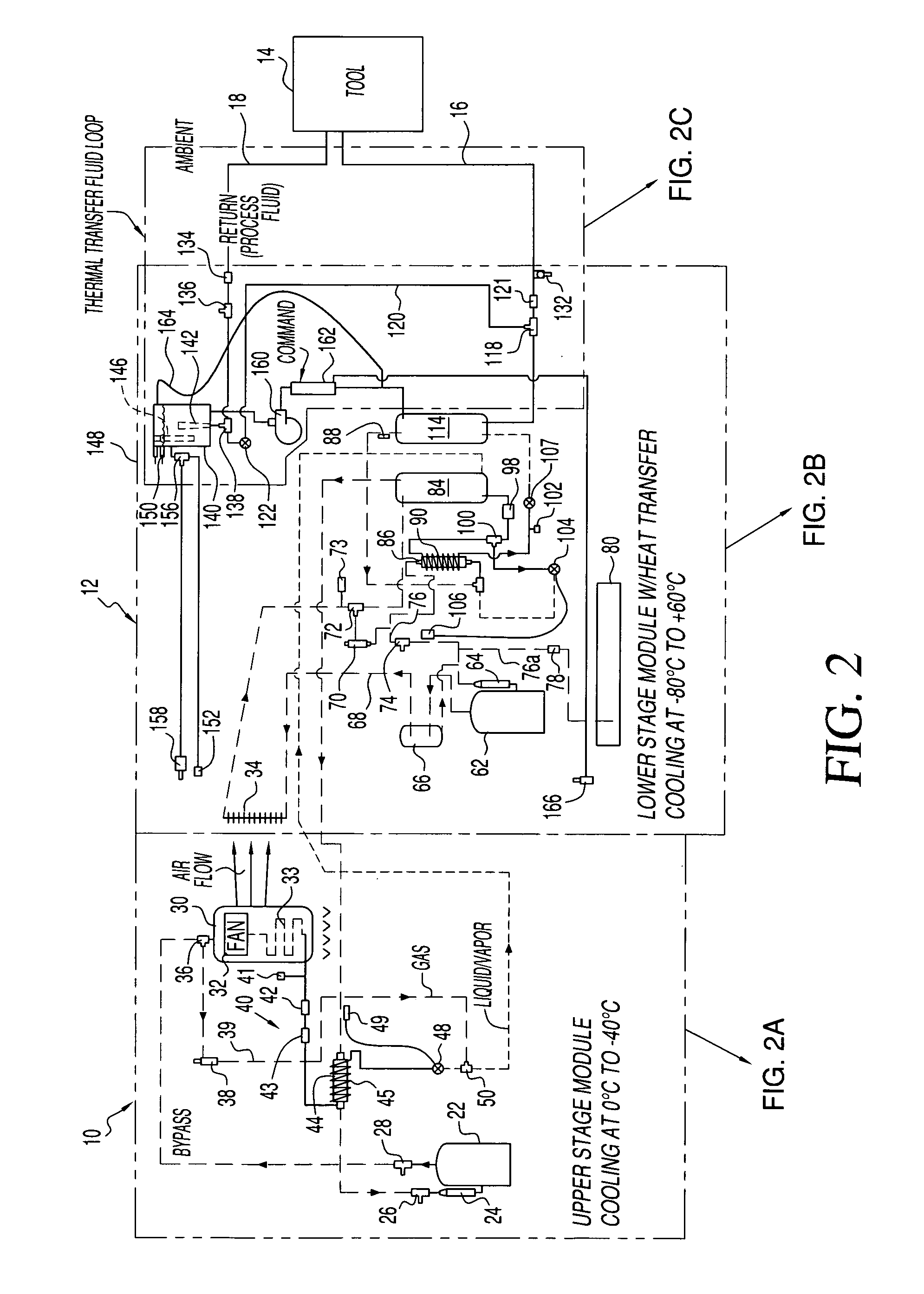

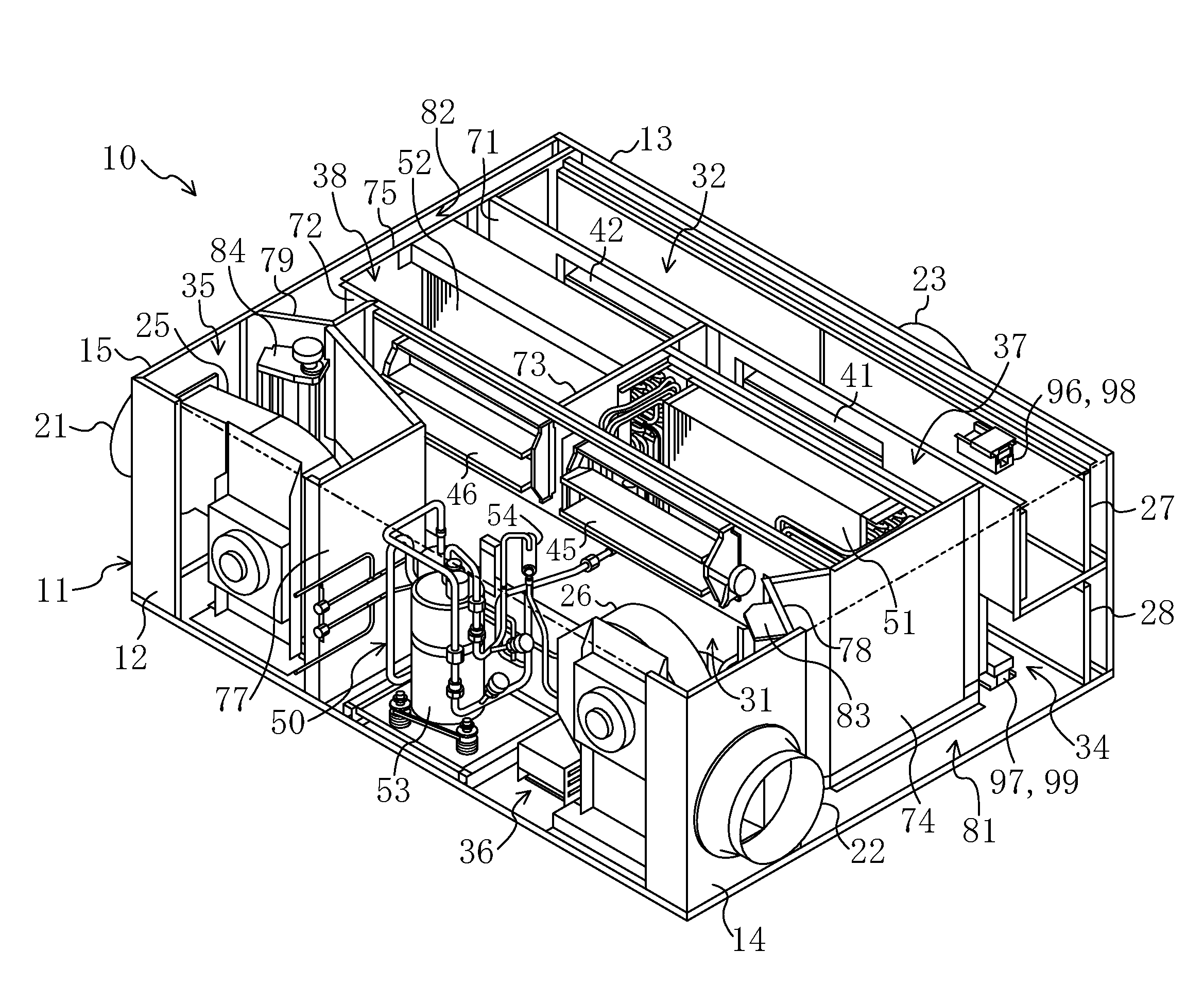

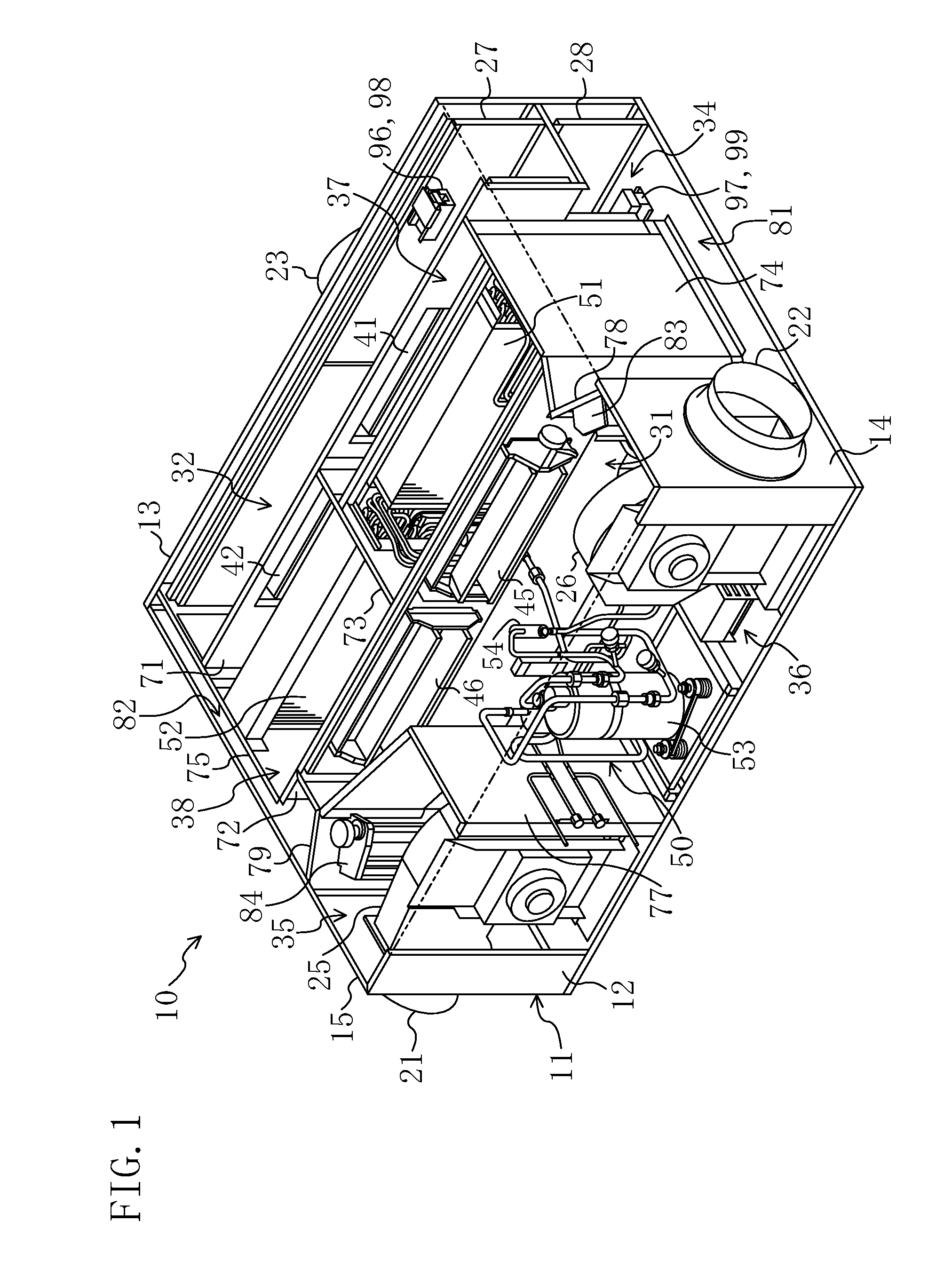

Thermal control systems for process tools requiring operation over wide temperature ranges

ActiveUS6993918B1Extended service lifeImprove reliabilityDesuperheatersCompression machines with cascade operationEnergy transferLow load

A system and method for maintaining the temperature of a thermal transfer fluid at a selectable level within a wide temperature range, so as to operate a process tool in a chosen mode employing at least two cascaded stages, each operating with a different fluid in a separate refrigeration cycle. By interrelating energy transfers between parts of upper and lower stages, thermal efficiency is maximized and a smooth continuum of temperature levels can be provided. The refrigerants advantageously have vaporization points below and above ambient, for upper and lower stages respectively, and employs the upper stage for a constant refrigeration capacity, controlling the final temperature with the lower stage. The system allows for a further extension of range because the thermal transfer fluid can be heated for some process tool modes as the refrigeration cycles are run at low loads.

Owner:BE AEROSPACE INCORPORATED

Humidity control apparatus

InactiveUS20110192182A1Avoid loweringLimit to energy conservationGas treatmentDispersed particle separationEngineeringVapor-compression refrigeration

A humidity control apparatus includes a refrigerant circuit (50) which has a compressor (53), a main electric-operated expansion valve (55), and a first adsorption heat exchanger (51) and a second adsorption heat exchanger (52) on which adsorbent for adsorbing moisture in air is supported, and in which refrigerant reversibly circulates to perform a vapor compression refrigeration cycle. In the humidity control apparatus, refrigerant circulation in the refrigerant circuit (50) is reversibly switched to alternately perform an adsorption process and a recovery process with the adsorbent in the adsorption heat exchangers (51, 52), and the humidity of air passing through the adsorption heat exchangers (51, 52) is adjusted. The refrigerant circuit (50) is provided on an upstream side of the adsorption heat exchanger (51, 52) in a recovery air flow, and includes an auxiliary heat exchanger (61) configured to preheat recovery air to be supplied to the adsorption heat exchanger (51, 52), and a refrigerant adjusting mechanism (62) configured to adjust an amount of refrigerant flowing into the auxiliary heat exchanger (61).

Owner:DAIKIN IND LTD

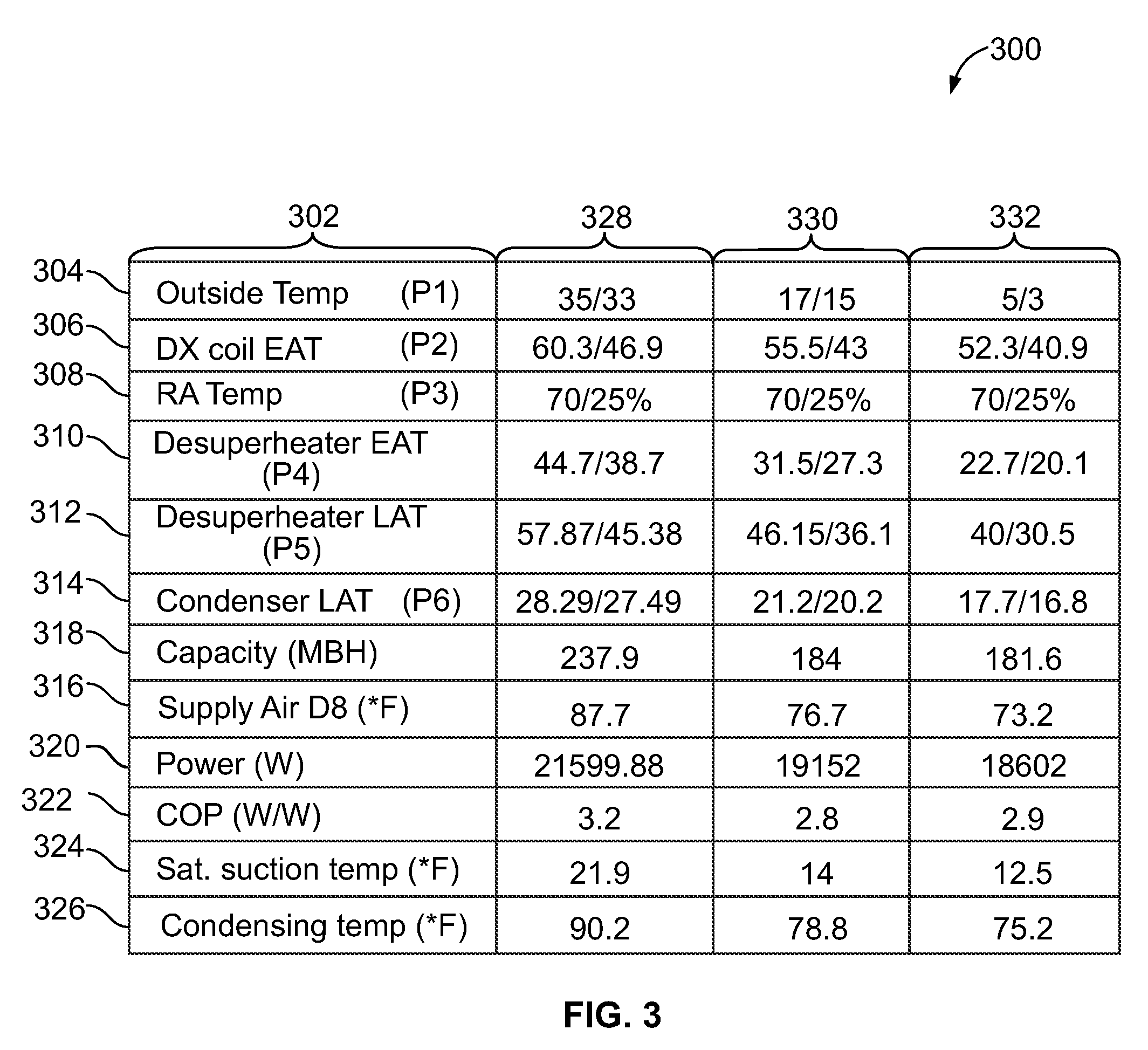

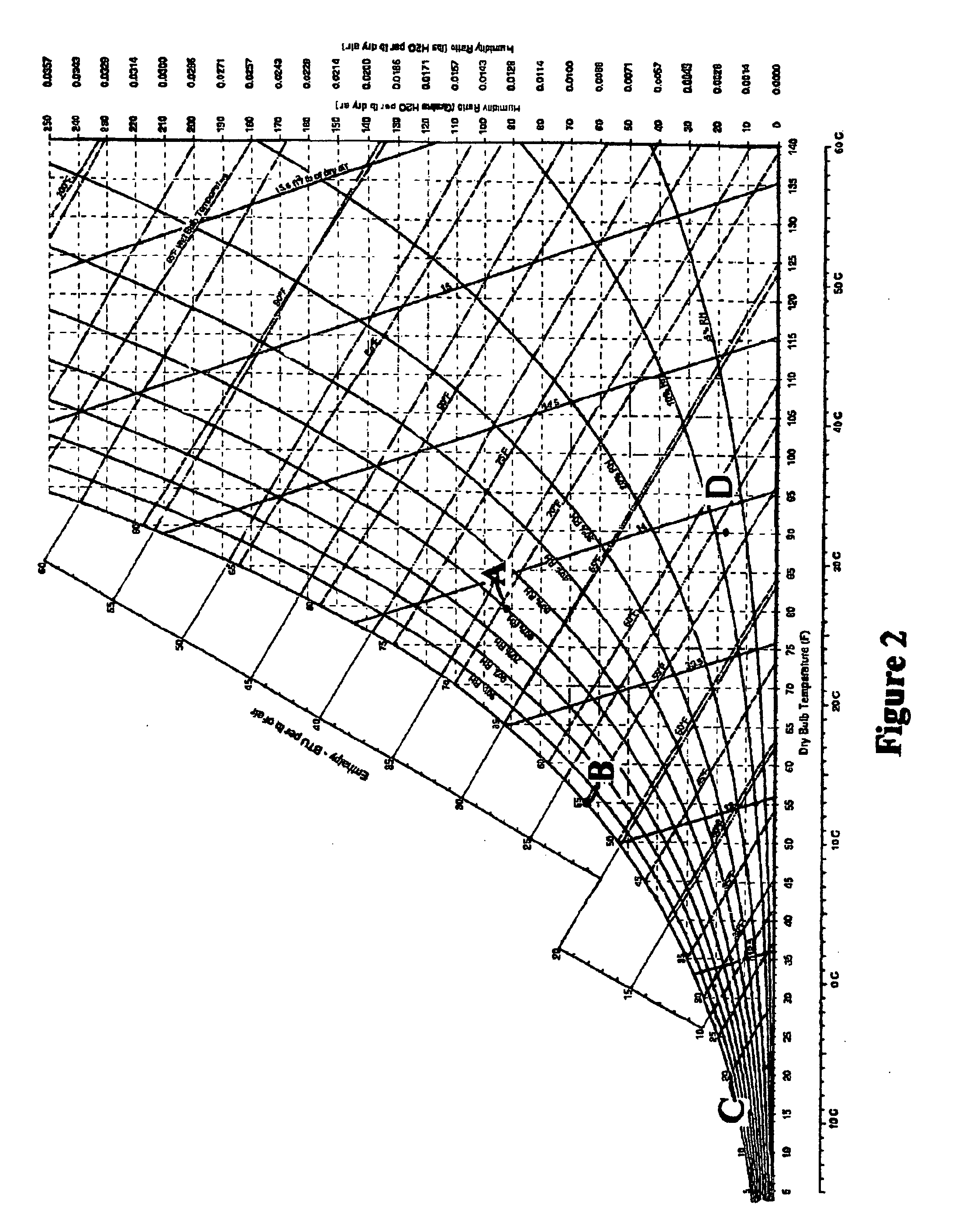

Control scheme and method for dehumidification systems at low ambient conditions

ActiveUS6955057B2Improve dehumidification effectBoost of latent capacityCompression machines with non-reversible cycleCompression machines with several condensersProcess engineeringRefrigerant

A method for operating a vapor compression system includes the steps of providing a vapor compression system having a compressor circuit including a compressor having an inlet port and an outlet port, a circuit incorporating the compressor, a condenser, an evaporator and an expansion device for sequentially generating a cooling refrigerant for cooling a stream of air so as to provide a dehumidified cooled stream of air, and a reheat refrigerant for heating the dehumidified cooled stream of air to provide a reheated dehumidified stream of air; controlling discharge pressure from the compressor outlet so as to increase discharge pressure from the compressor outlet. Furthermore, system dehumidification performance is improved in terms of latent capacity boost, undesired sensible capacity reduction, latent efficiency enhancement, and recovery of supply air temperature to a desired level.

Owner:CARRIER CORP

Popular searches

Hot-air central heating Space heating and ventilation details Compression machines with reversible cycle Defrosting Efficient regulation technologies Refrigeration safety arrangement Cooling fluid circulation Air conditioning systems Temperature control using electric means Heating and refrigeration combinations

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com