Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2938 results about "Plate fin heat exchanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plate-fin heat exchanger is a type of heat exchanger design that uses plates and finned chambers to transfer heat between fluids. It is often categorized as a compact heat exchanger to emphasise its relatively high heat transfer surface area to volume ratio. The plate-fin heat exchanger is widely used in many industries, including the aerospace industry for its compact size and lightweight properties, as well as in cryogenics where its ability to facilitate heat transfer with small temperature differences is utilized.

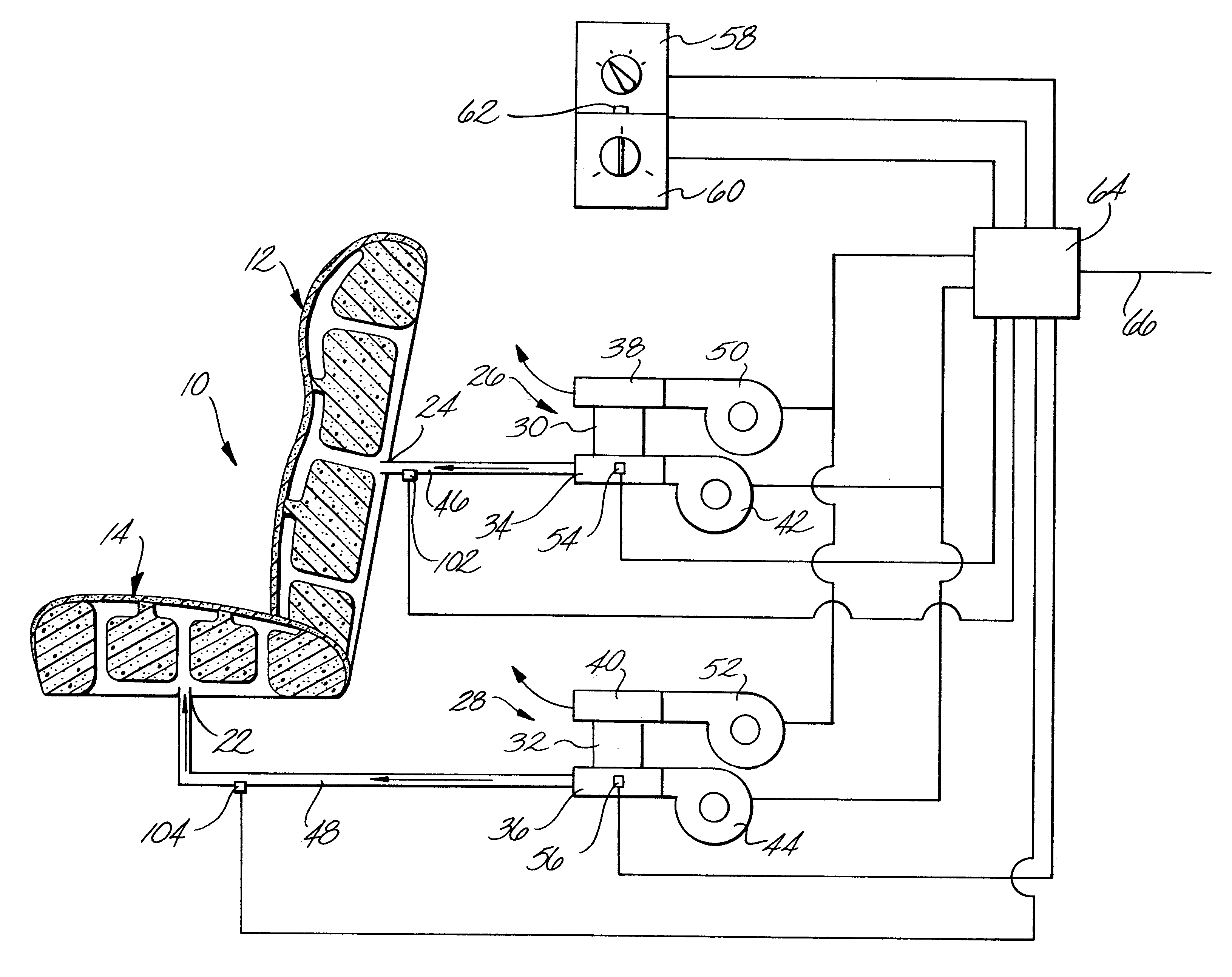

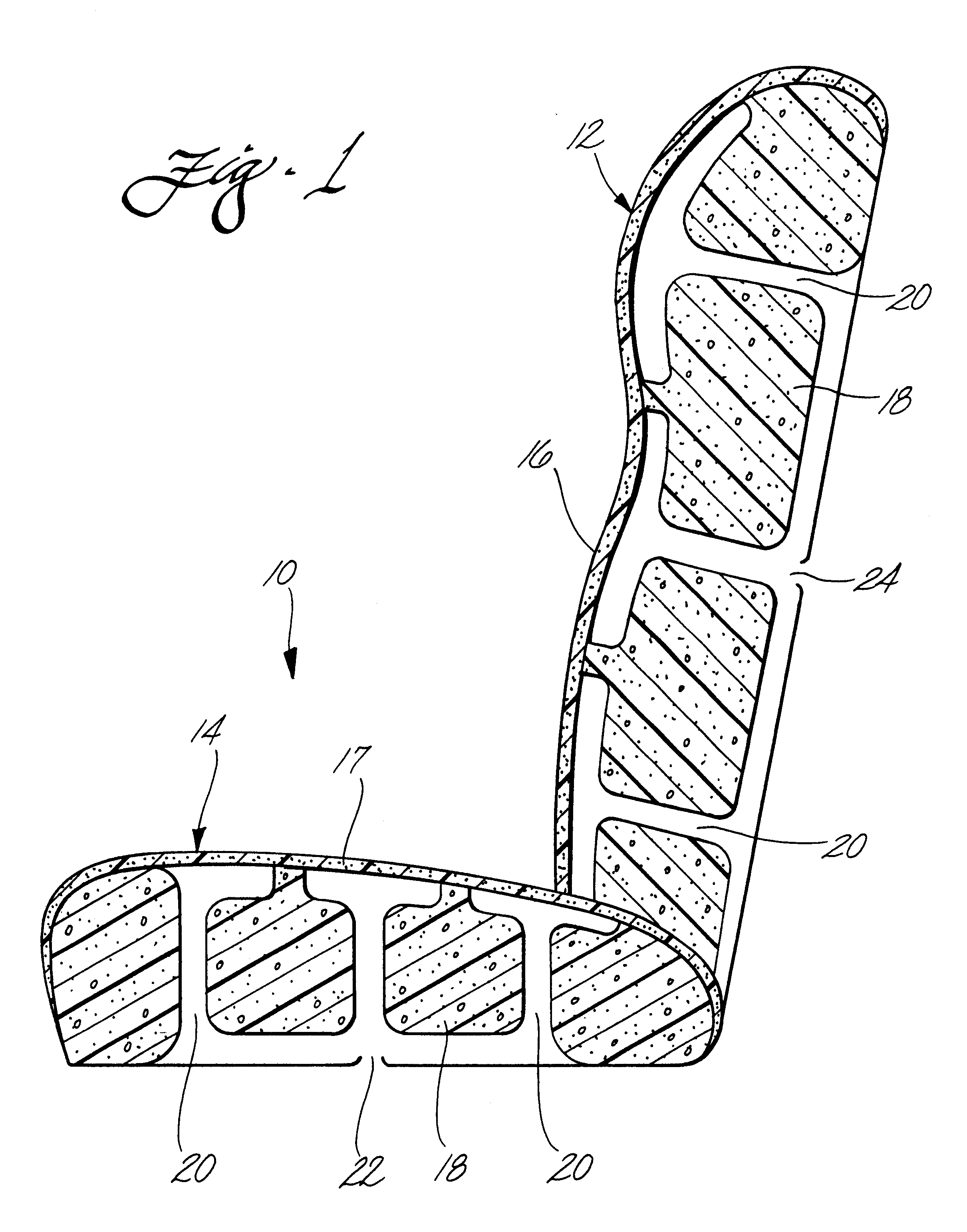

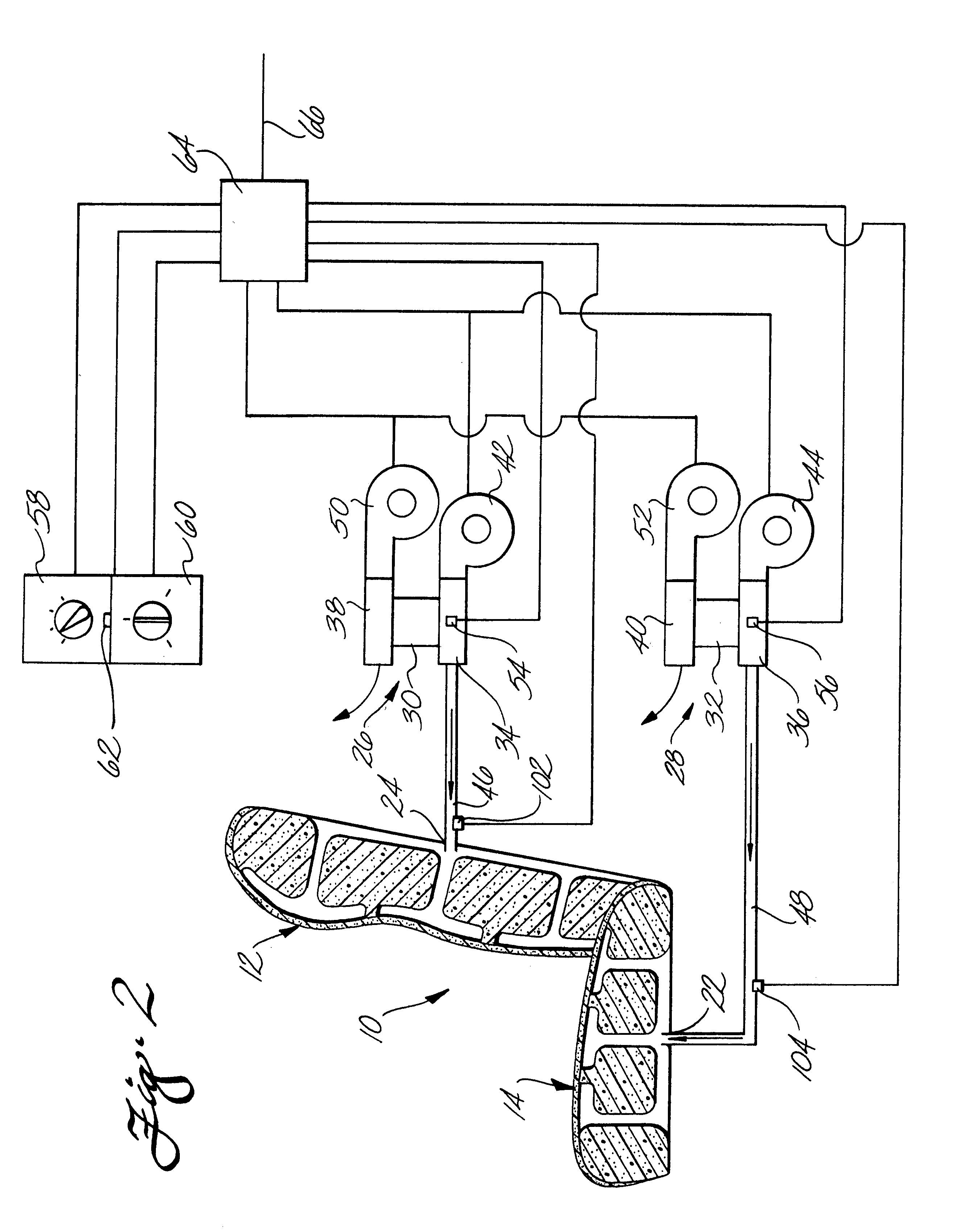

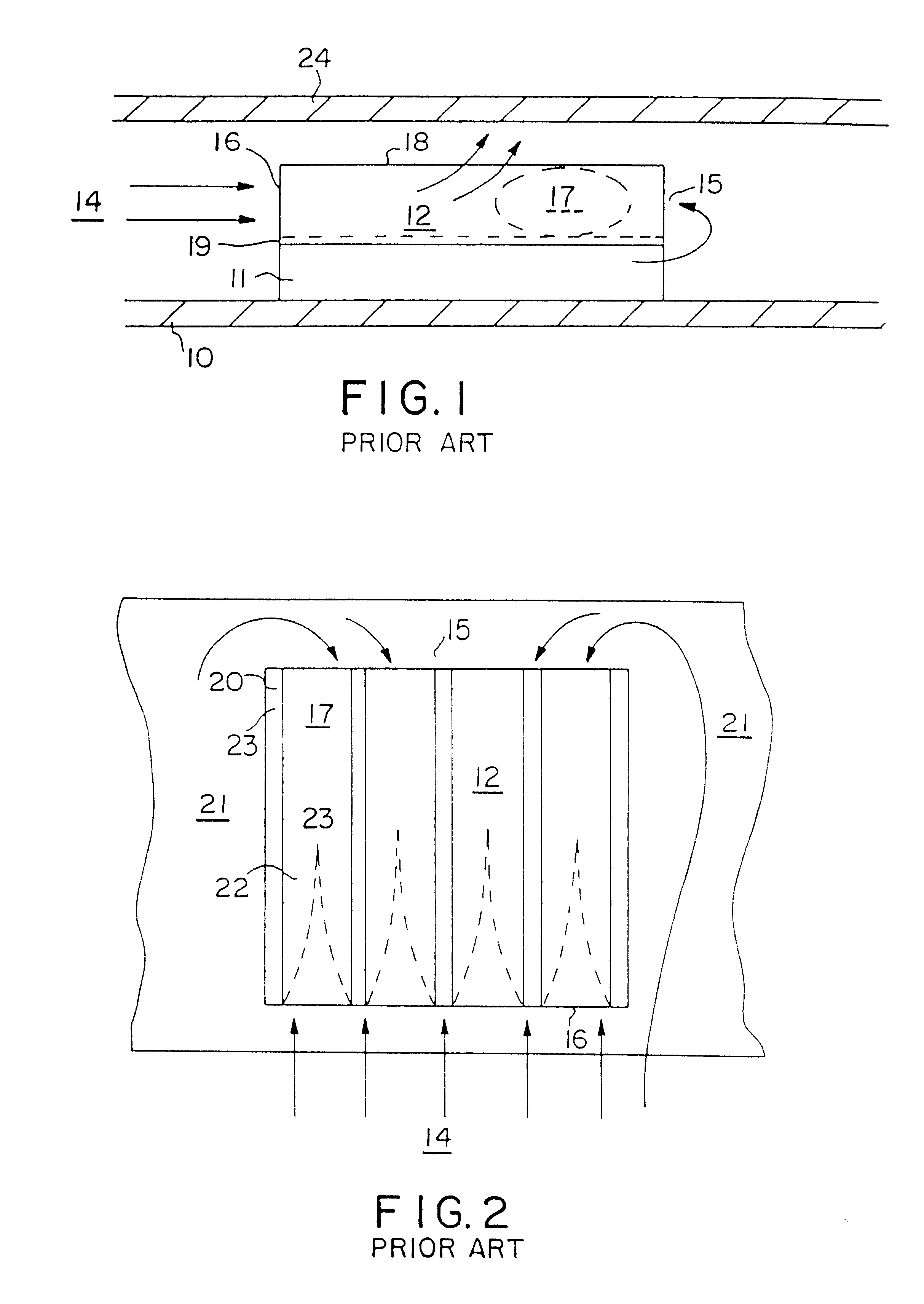

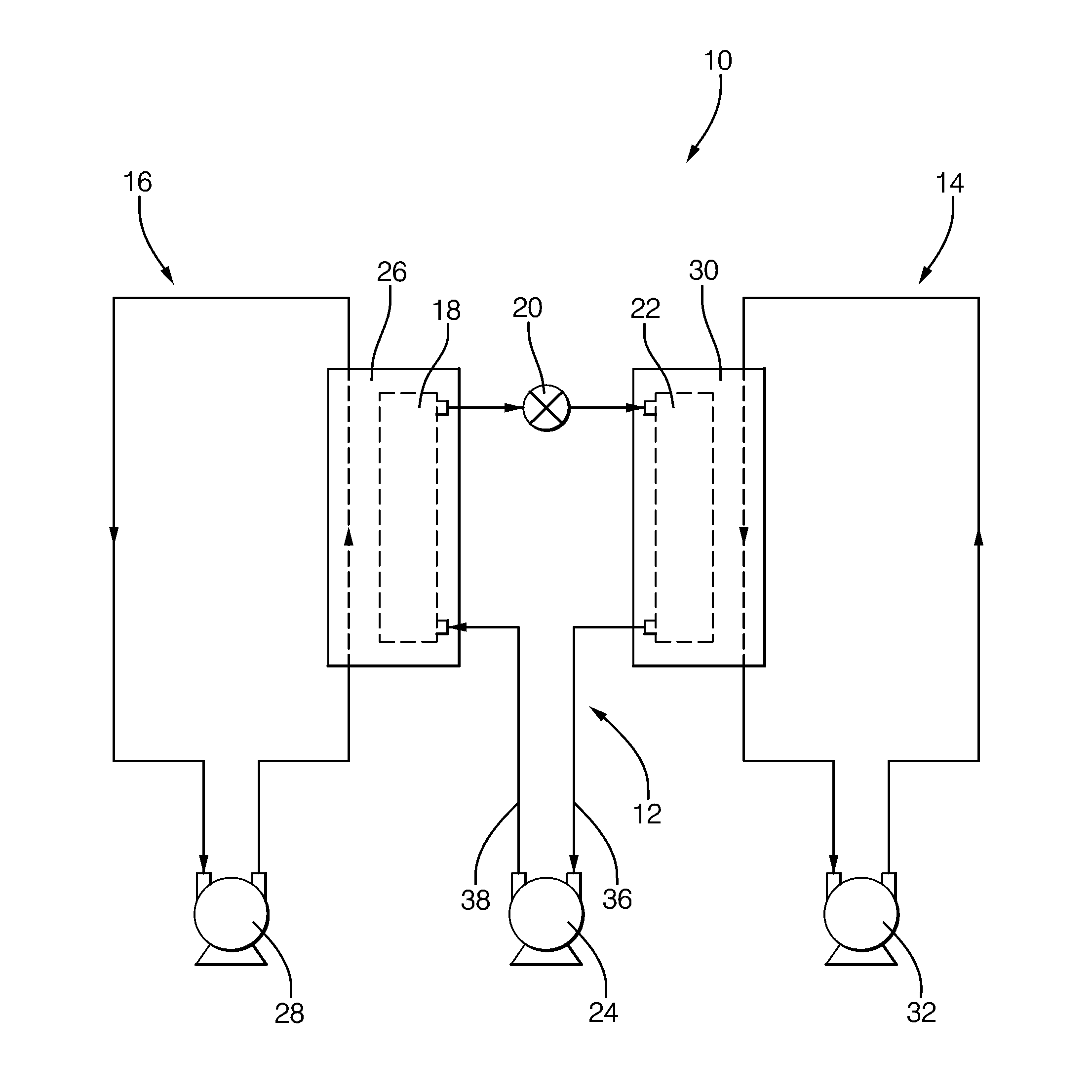

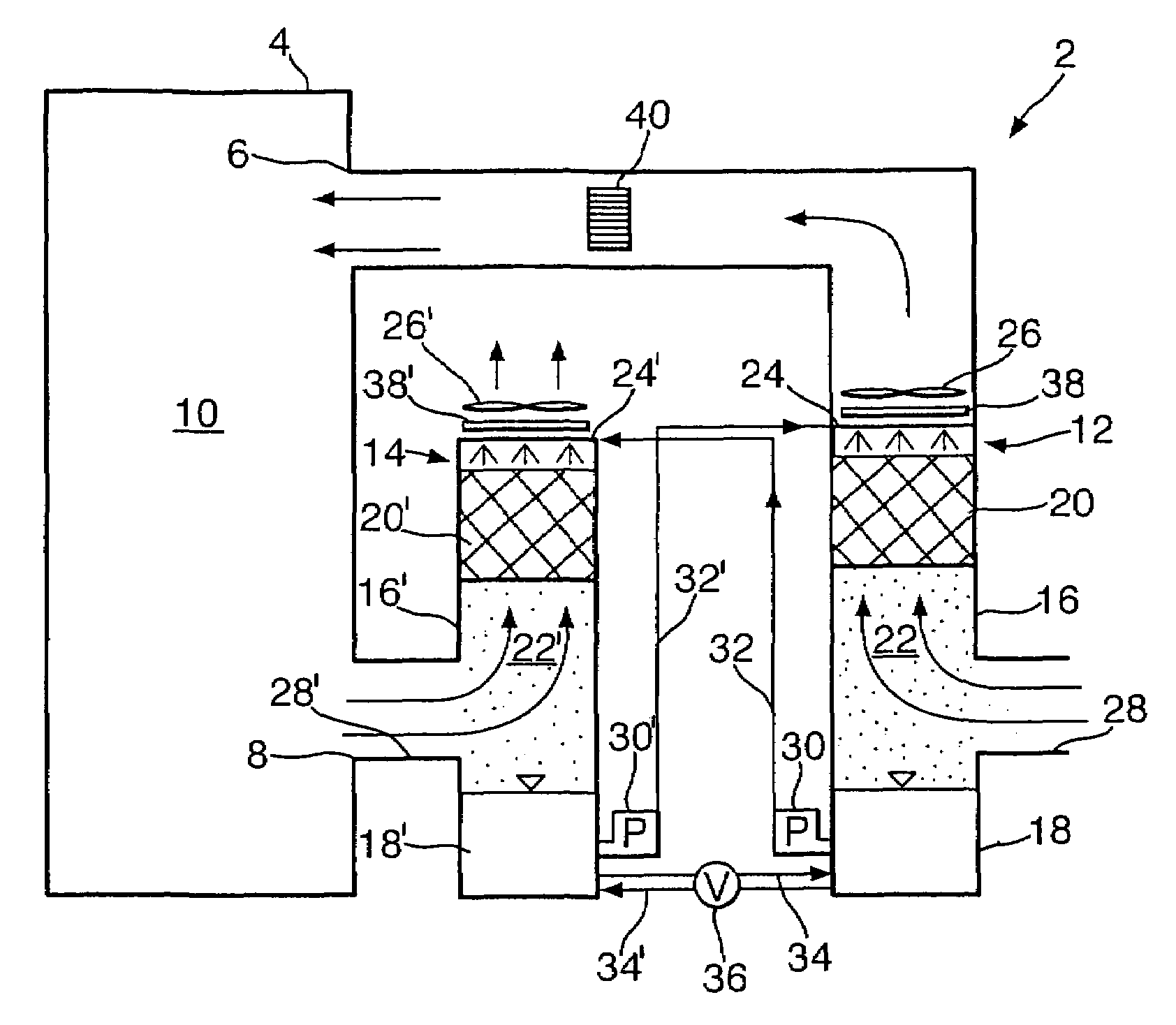

Variable temperature seat climate control system

InactiveUSRE38128E1Minimizing possible occupant discomfortLimited powerAir-treating devicesSeat heating/ventillating devicesAuto regulationControl system

A temperature climate control system comprises a variable temperature seat, at least one heat pump, at least one heat pump temperature sensor, and a controller. Each heat pump comprises a number of Peltier thermoelectric modules for temperature conditioning the air in a main heat exchanger and a main exchanger fan for passing the conditioned air from the main exchanger to the variable temperature seat. The Peltier modules and each main fan may be manually adjusted via a temperature switch and a fan switch, respectively. Additionally, the temperature climate control system may comprise a number of additional temperature sensors to monitor the temperature of the ambient air surrounding the occupant as well as the temperature of the conditioned air directed to the occupant. The controller is configured to automatically regulate the operation of the Peltier modules and / or each main fan according to a temperature climate control algorithm designed both to maximize occupant comfort during normal operation, and minimize possible equipment damage, occupant discomfort, or occupant injury in the event of a heat pump malfunction.

Owner:GENTHERM INC

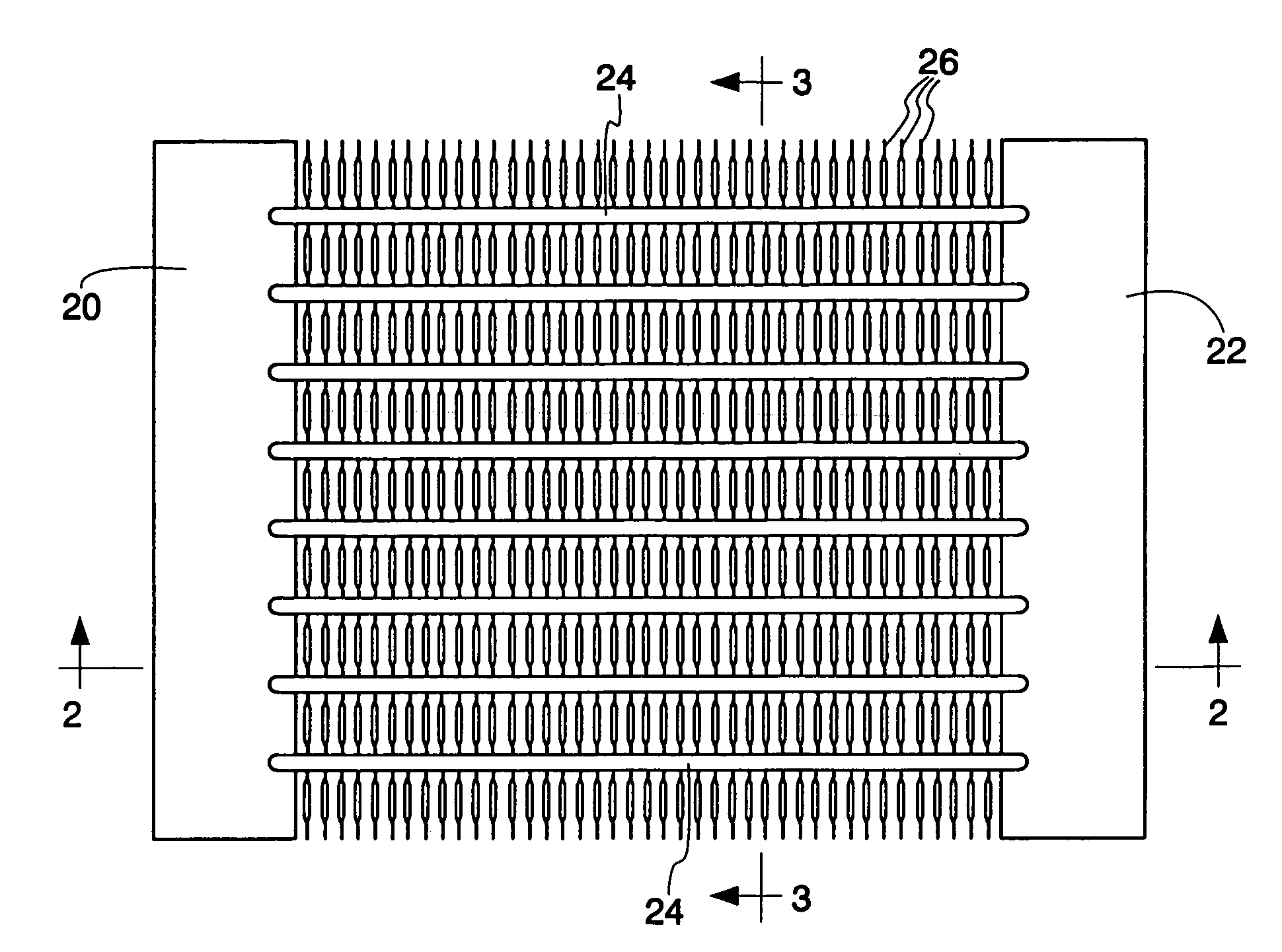

Heat exchanger

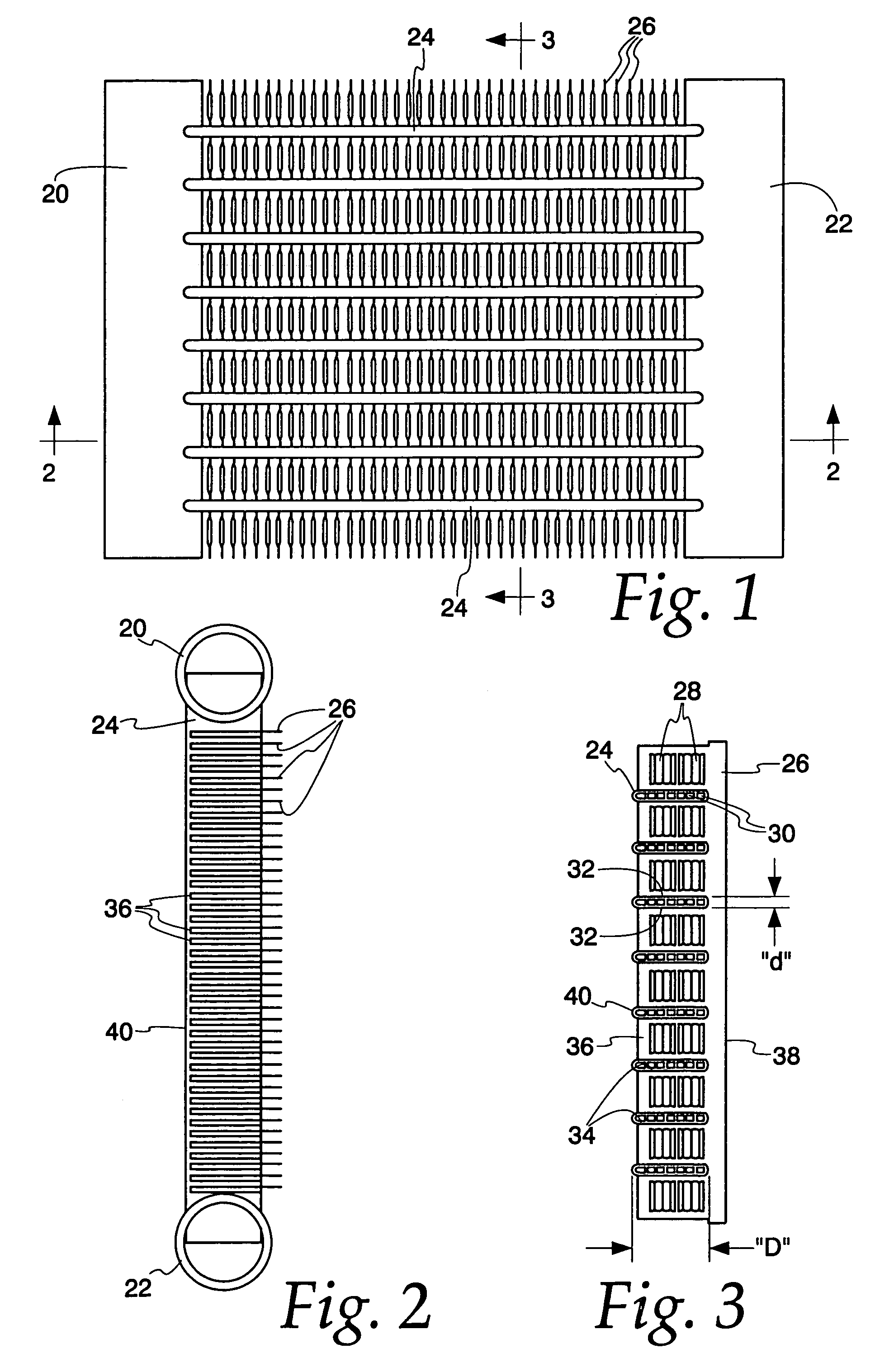

InactiveUS6964296B2Eliminate requirementsImprove relationshipSoldering apparatusHeat exhanger finsEngineeringMechanical engineering

Heat exchange inefficiencies found in round tube plate fin heat exchangers are eliminated in an aluminum heat exchanger that includes first and second headers (20), (22) and at least one flattened tube (24), (70) extending between the headers (20), (22). A plurality of generally parallel tube runs are defined and each has opposite edges. A plurality of plate fins (26), (50) are arranged in a stack and each has a plurality of open ended slots (34), one for each run of the tubes (24), (70). Each of the tube runs (24), (70) is nested within corresponding slots (26) and the fins (26), (50) with one of the edges (40) of the tube runs extending outwardly of the corresponding fin (34). The assembly is brazed together.

Owner:MODINE MFG CO

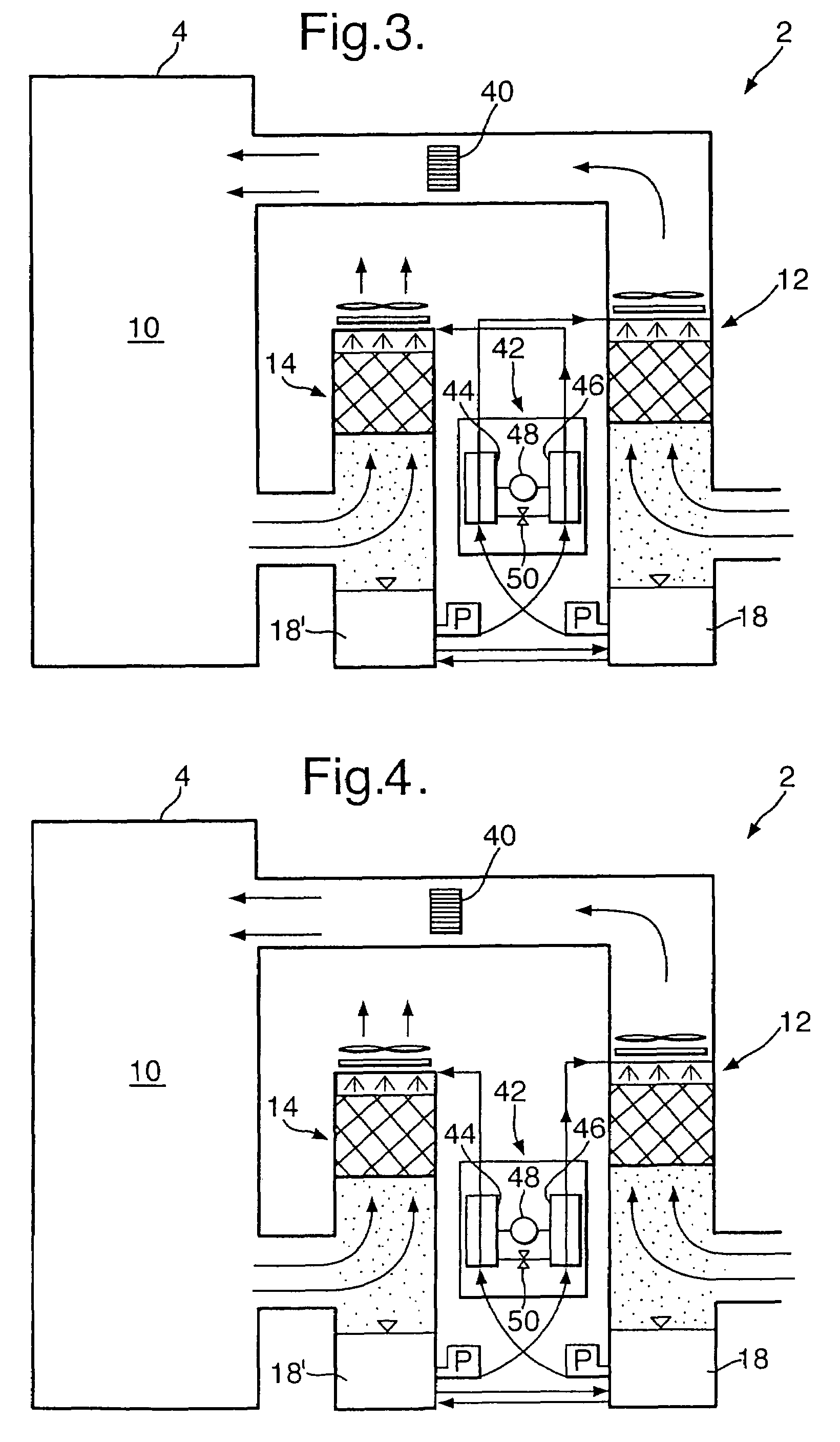

Large temperature-difference central heating system

ActiveCN101231004ALarge heating temperature differenceImprove delivery capacityHeat recovery systemsLighting and heating apparatusElectricityExternal energy

The invention relates to a central heating system with large temperature difference, which belongs to the energy field. The system comprises a steam turbine, a condenser, a steam absorption heat pump, a steam-water heat exchanger, a hot water absorption heat pump, a water-water heat exchanger as well as a connecting pipe and accessories. The invention is characterized in that the temperature difference of the heat net supply is large, and is about one time higher than the conventional heat net operation, thus the transmission capacity of the heat net is greatly increased, and at the same time, no heat preservation and thermal stress compensation problems exist as the backwater temperature of the heating is low, thereby reducing the investment of the backwater pipeline network and the whole pipeline network; the steam turbine is utilized to discharge steam and preheat the backwater of the large heat net, and circulating cooling water is utilized to be taken as the low level heat energy of the absorption heat pumps. The invention has the advantages that the residual heat produced in the electricity generating process of a power plant is recycled to the greatest extent as much as possible, the combination mode of the hot water absorption heat pump and the water-water heat exchanger is adopted at the end to heat the hot water of the secondary heat net supply, and the temperature difference of the supply-water and the backwater of the large heat net are increased, at the same time, the heat net does not need external energy to be the driving force.

Owner:TSINGHUA UNIV +1

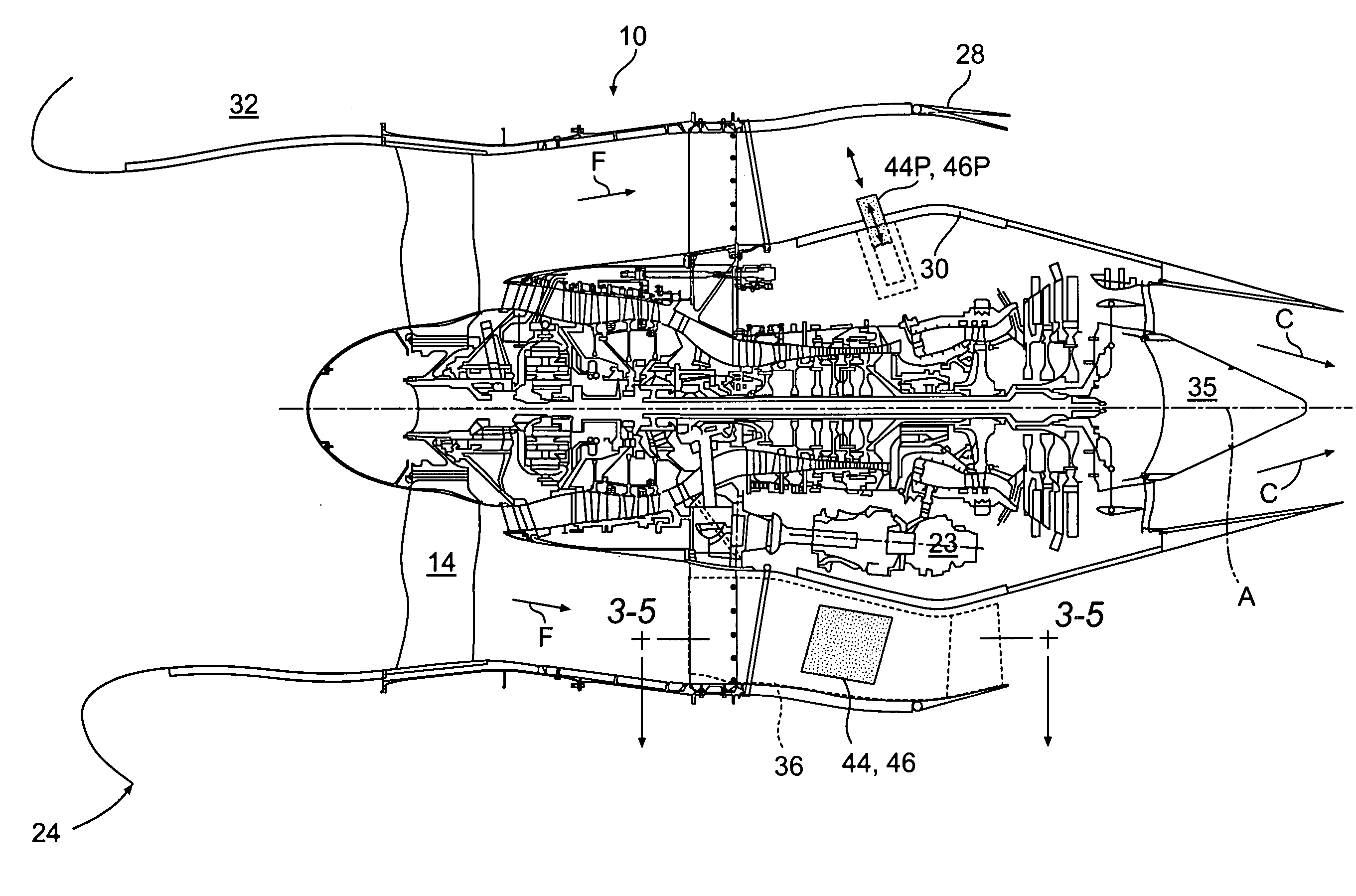

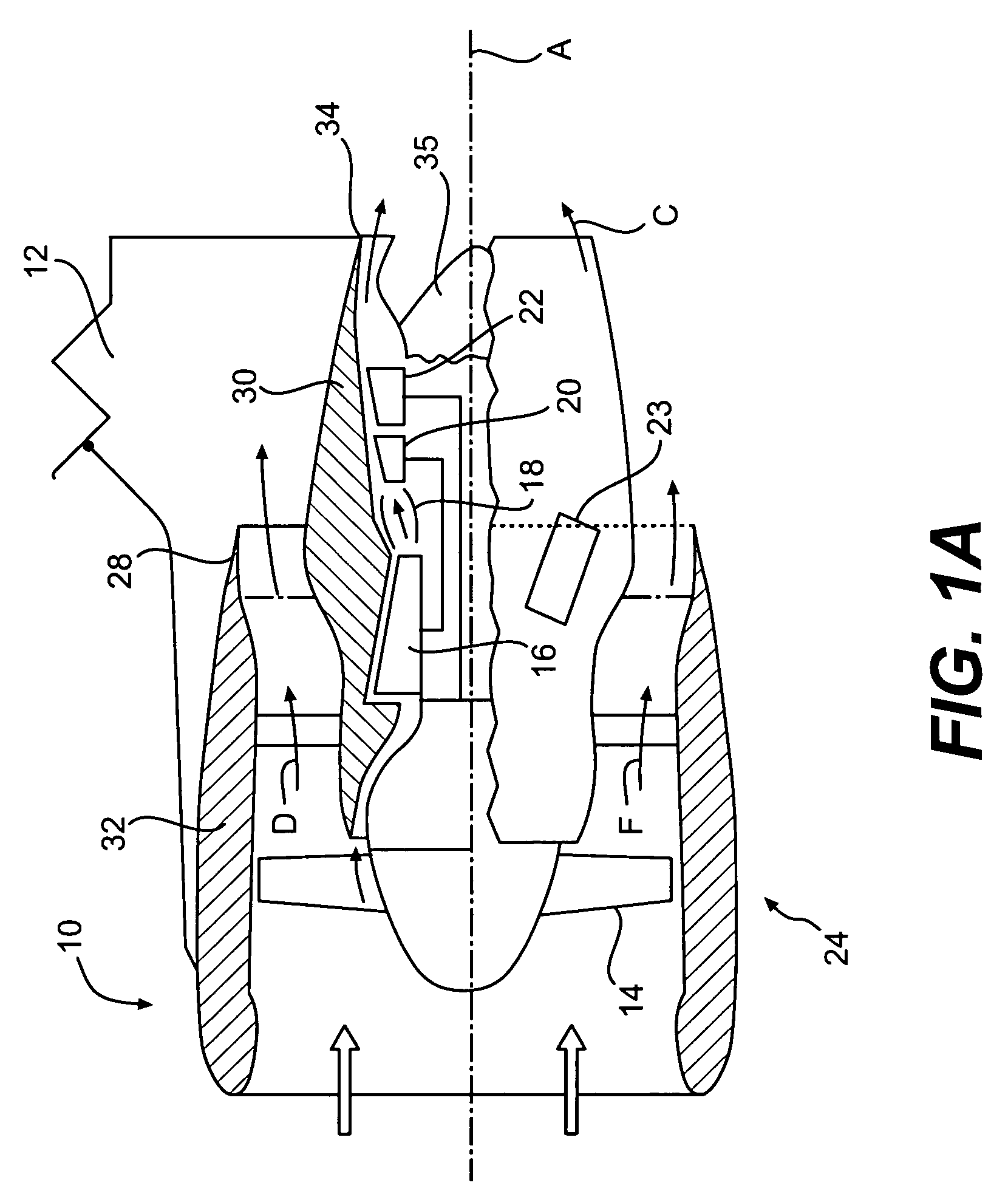

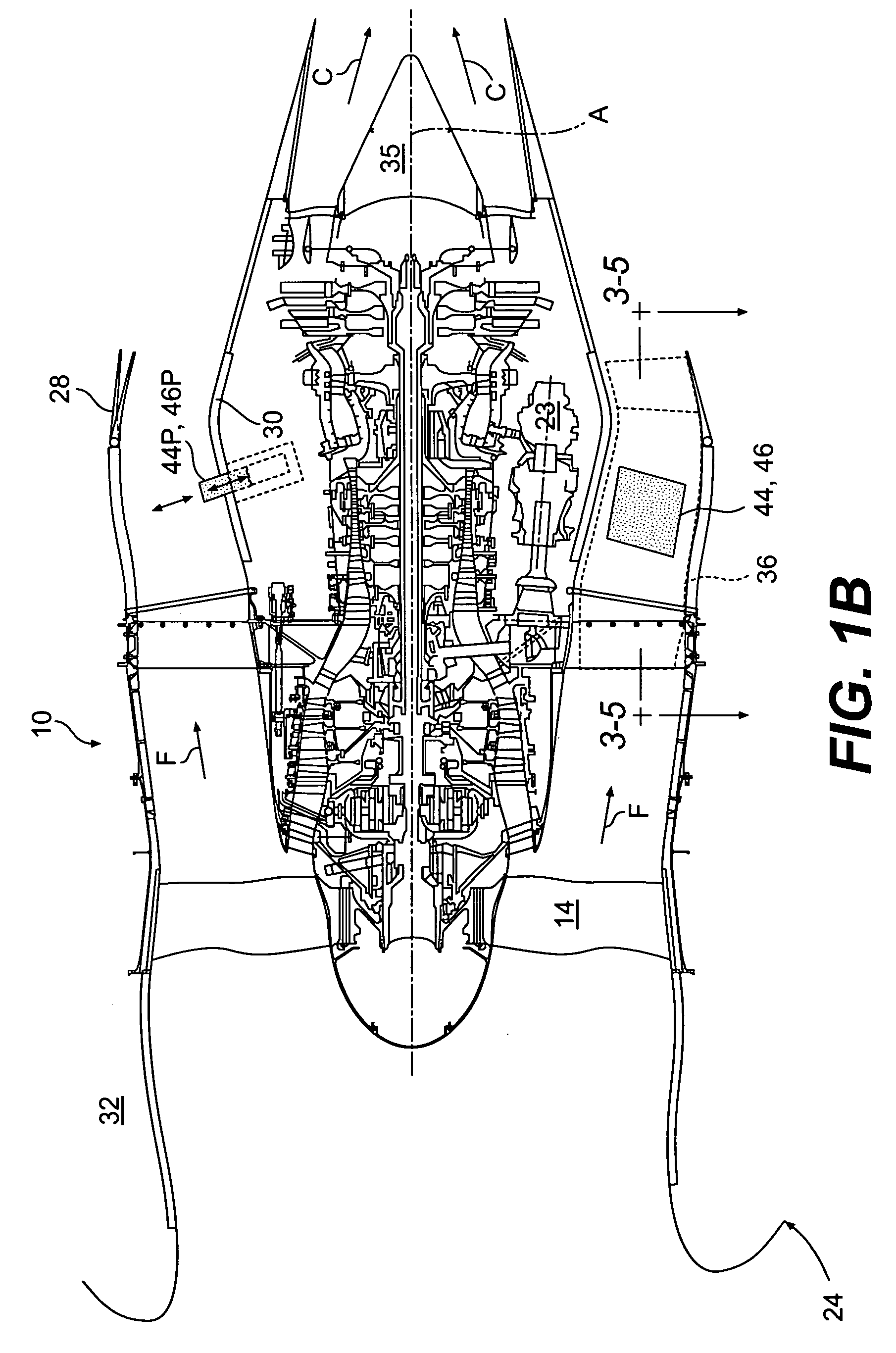

Thermal management system with thrust recovery for a gas turbine engine fan nacelle assembly

InactiveUS20080028763A1Reduces thrust lossesSize reduction requirementsEngine fuctionsEfficient propulsion technologiesNacelleHeat rejection

A thermal management system locates a separate engine heat exchanger and generator heat exchanger into an engine nacelle pylon that is split to provide independent control of both a generator cooling circuit and an engine cooling circuit. A variable exhaust nozzle is provided downstream of each heat exchanger as each has different thermal and heat rejection requirements such that intake air is minimized and maximum thrust is produced in response to the current generator load and engine heat rejection.

Owner:UNITED TECH CORP

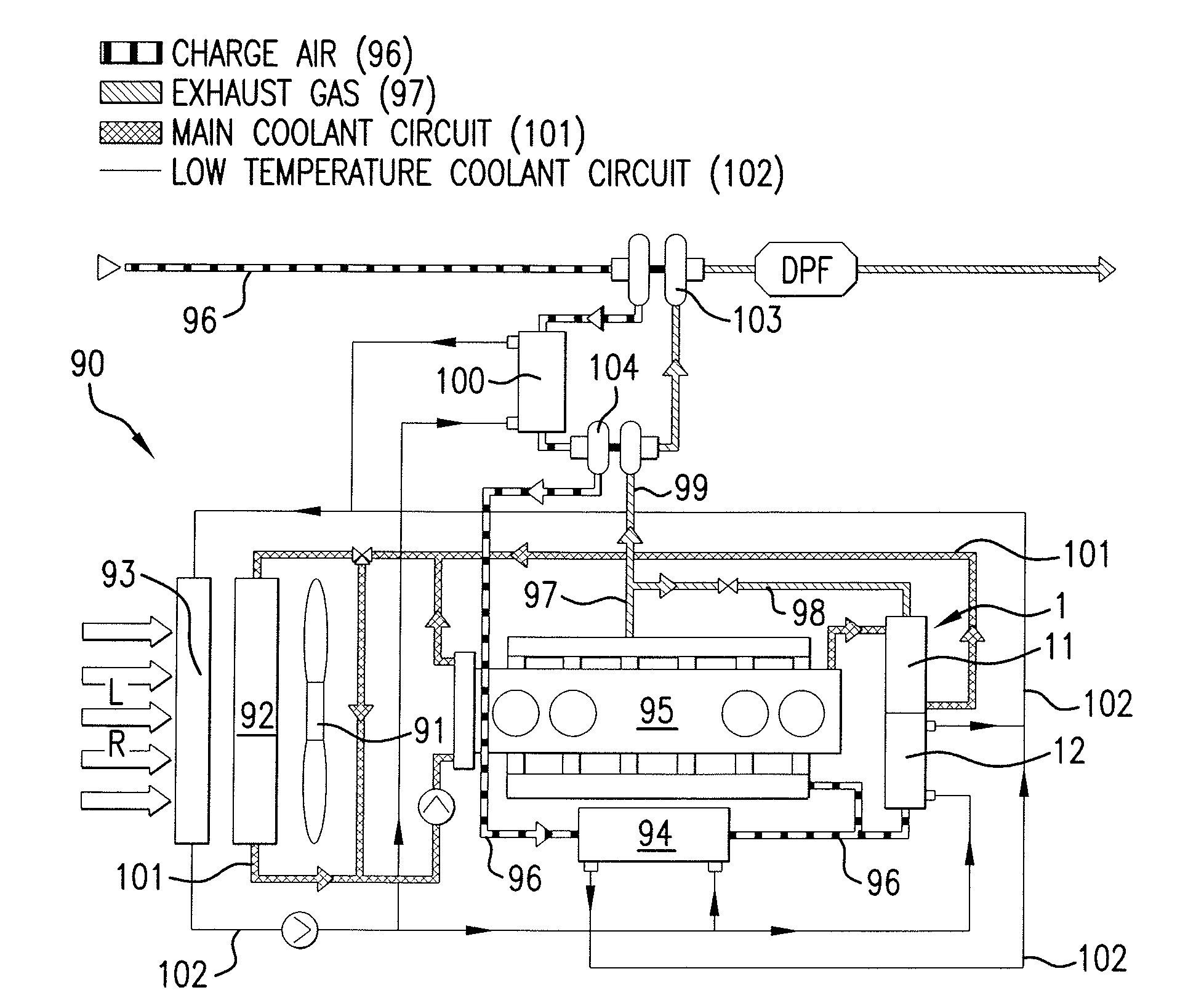

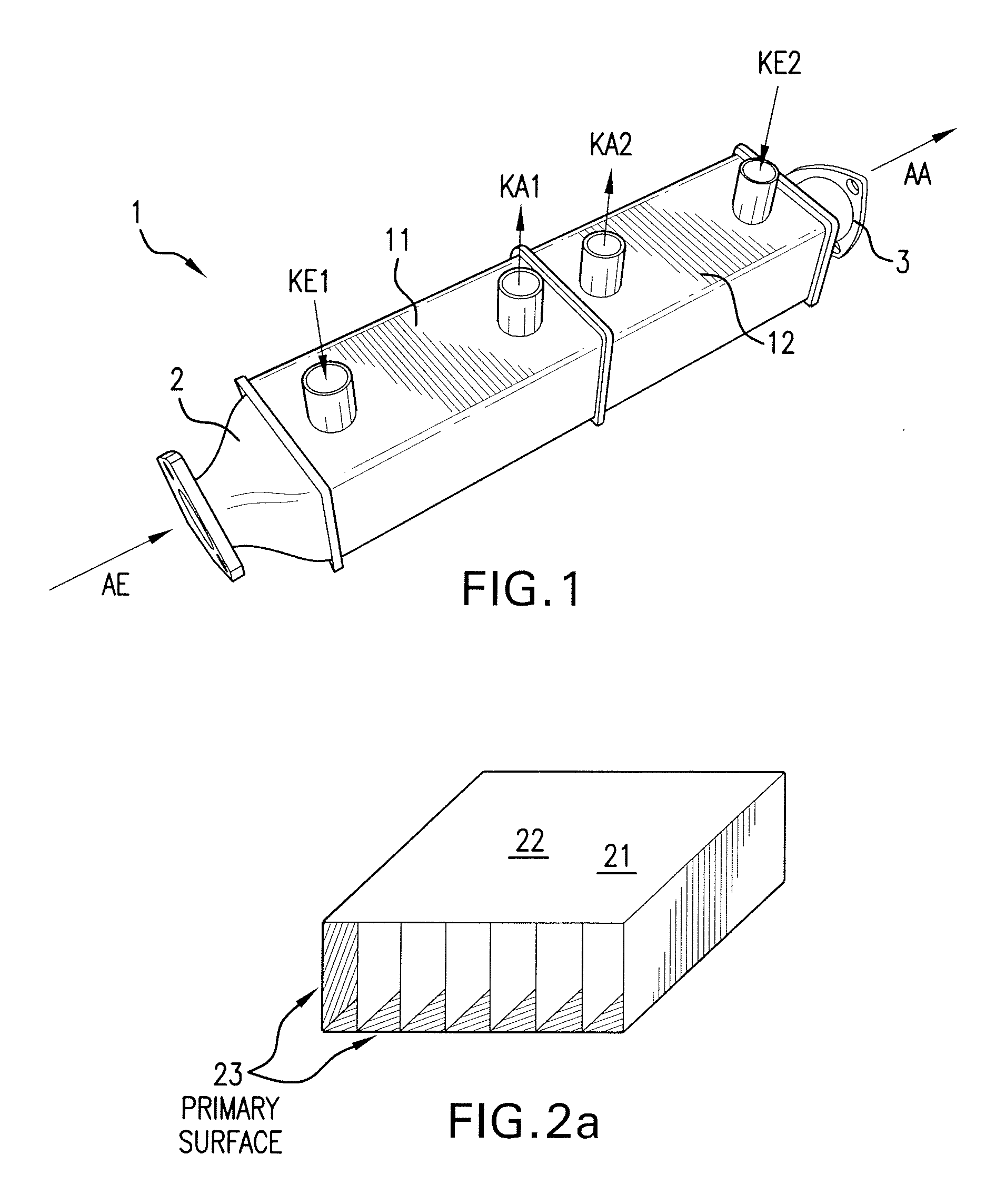

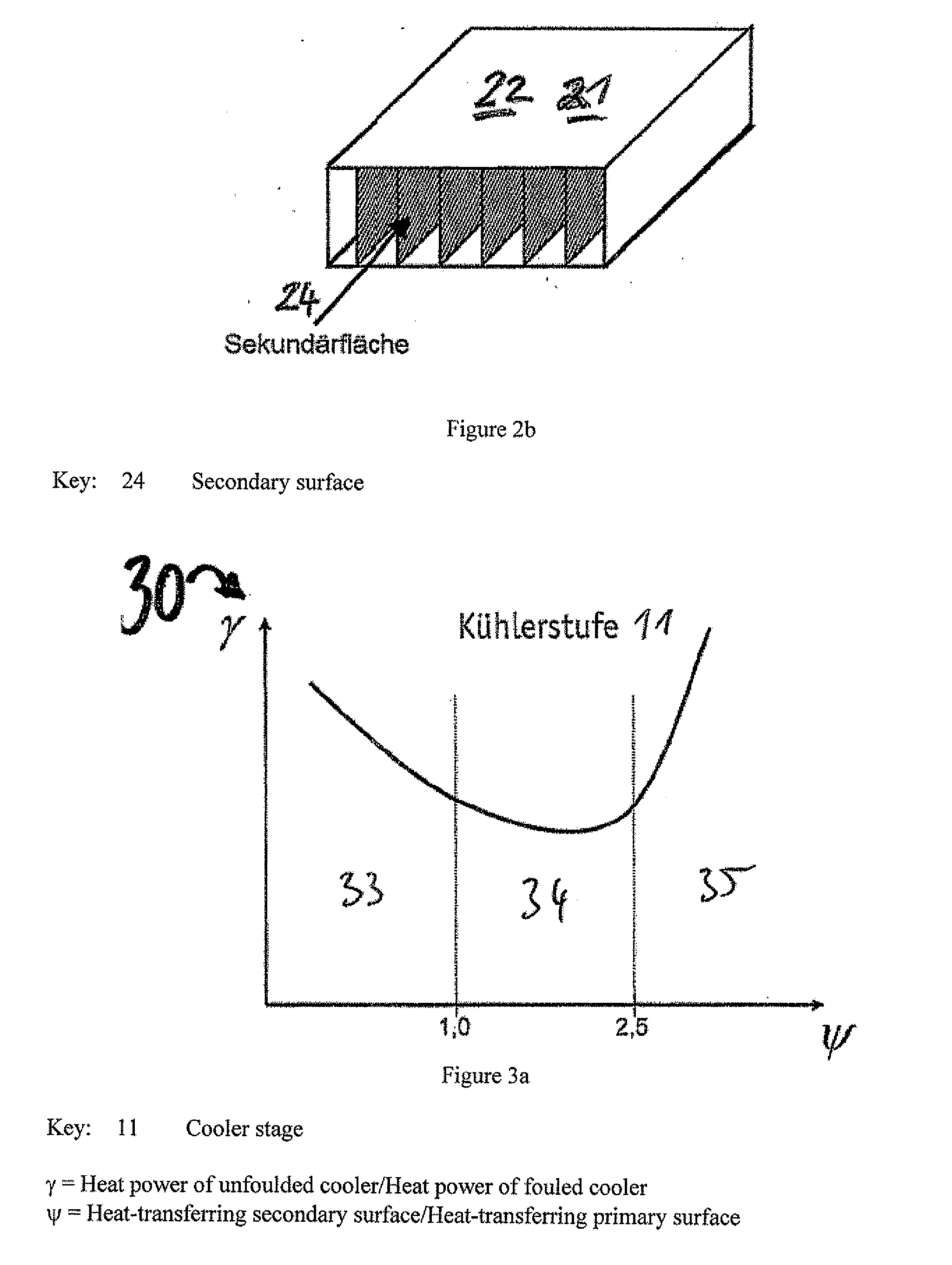

Heat exchanger for exhaust gas cooling; method for operating a heat exchanger; system with a heat exchanger for exhaust gas cooling

InactiveUS20080264609A1Prevent scalingLower performance requirementsNon-fuel substance addition to fuelInternal combustion piston enginesCoolant flowExhaust fumes

A heat exchanger, in particular for cooling the exhaust of a motor vehicle internal combustion engine, is disclosed, the heat exchanger comprising a first partial heat exchanger with at least one first flow channel through which a medium to be cooled is to flow and at least one third flow channel through which a first coolant is to flow, at least one second partial heat exchanger with at least one second flow channel through which a medium to be cooled is to flow and at least one fourth flow channel through which a second coolant is to flow, wherein the at least one first flow channel and the at least one second flow channel are fluidly connected, and the at least one first flow channel and the at least one second flow channel have at least one first specific heat transfer surface and at least one second heat transfer surface, wherein second specific heat transfer surface area, divided by first specific heat transfer surface area, yields a quotient (ψ), the at least one first flow channel having a larger quotient (ψ) than second flow channel.

Owner:BEHR GMBH & CO KG

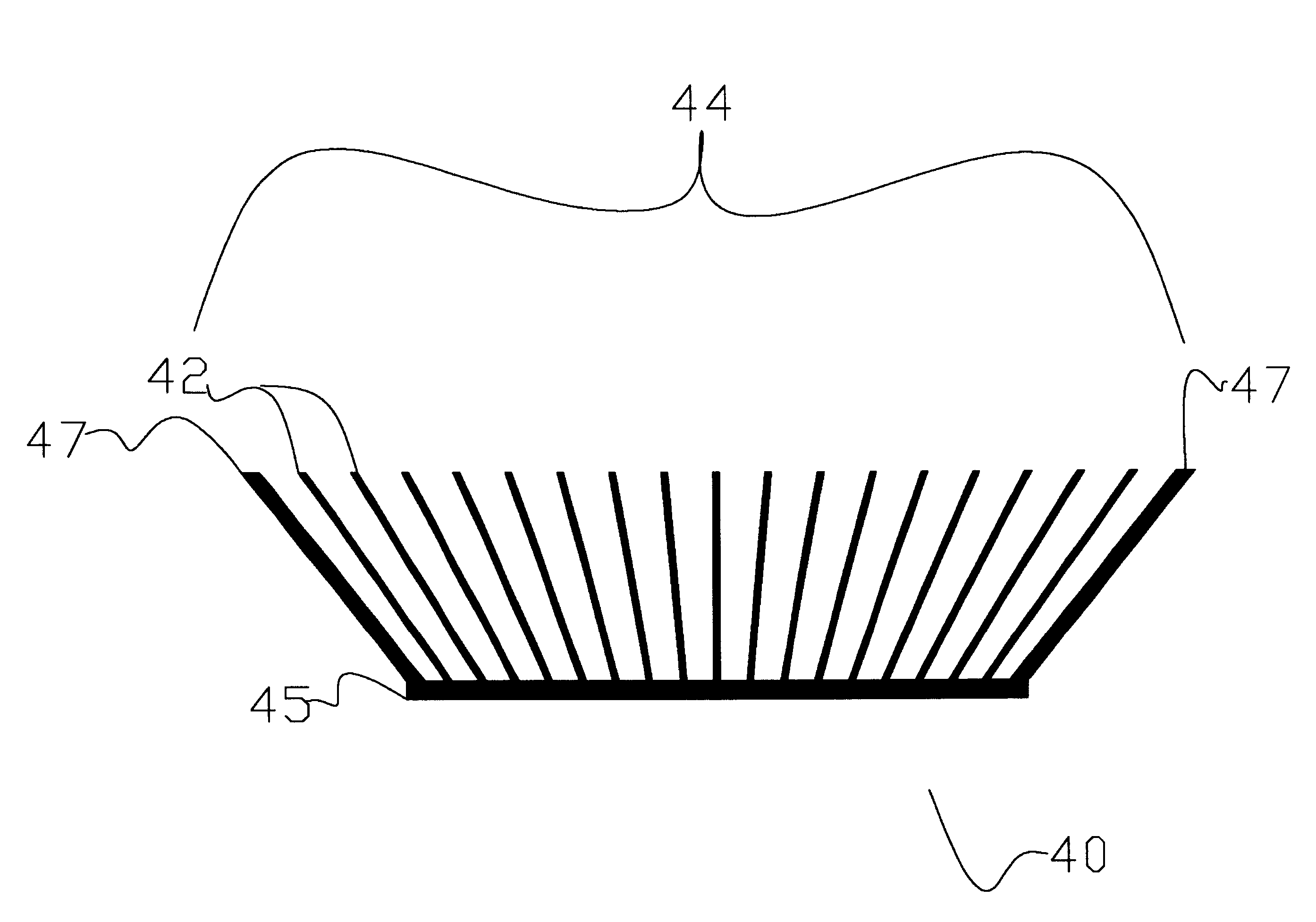

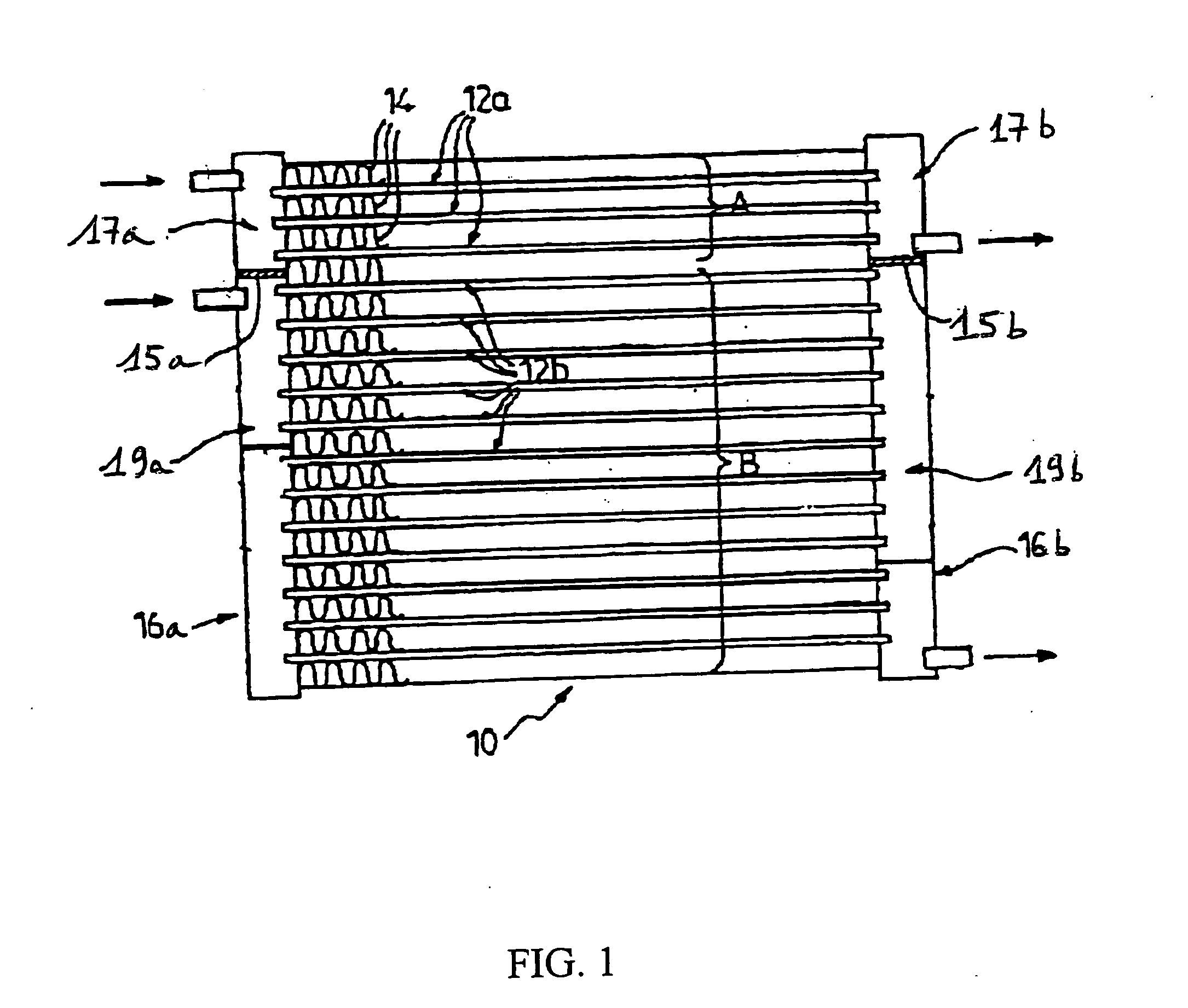

High performance fan tail heat exchanger

InactiveUS6308771B1Increased control volumeOptimize volumeSemiconductor/solid-state device detailsSolid-state devicesAcute angleEngineering

A novel plate fin heat exchanger adapted for high and low velocity fluid flows for dissipating heat from a heat generating component. The heat exchanger comprises an array of fins being affixed to and in thermal communication with a thermally conductive base, wherein the fins are arranged in a fan tail configuration for minimizing flow bypass, and further providing reduced thermal resistance for fluid passing through the fin field. The fins are affixed to and in thermal communication with the base at an acute angle, such that the effective width of the array of fins exceeds the width of the base. The enlarged effective width of the fin array in comparison to conventional heat exchanger provides an increased volume for fluid flow, thereby allowing a greater volume of fluid to enter the fin field and a greater surface area of plate fins for cooling the fluid passing through the heat exchanger. In addition, the heat exchanger comprises a fin density of at least ten fins per inch or greater of base length thereby providing a narrow channel heat exchanger with a fan tail. The aspect ratio of the individual channels between the fins, as compared to parallel fins affixed perpendicular to the base through an extrusion method, generates a reduced pressure drop across the heat exchanger. Accordingly, the heat exchanger of the present invention expands the envelope of cooling performance provided by fluid flow over an array of thermally conductive plates.

Owner:ADVANCED THERMAL SOLUTION

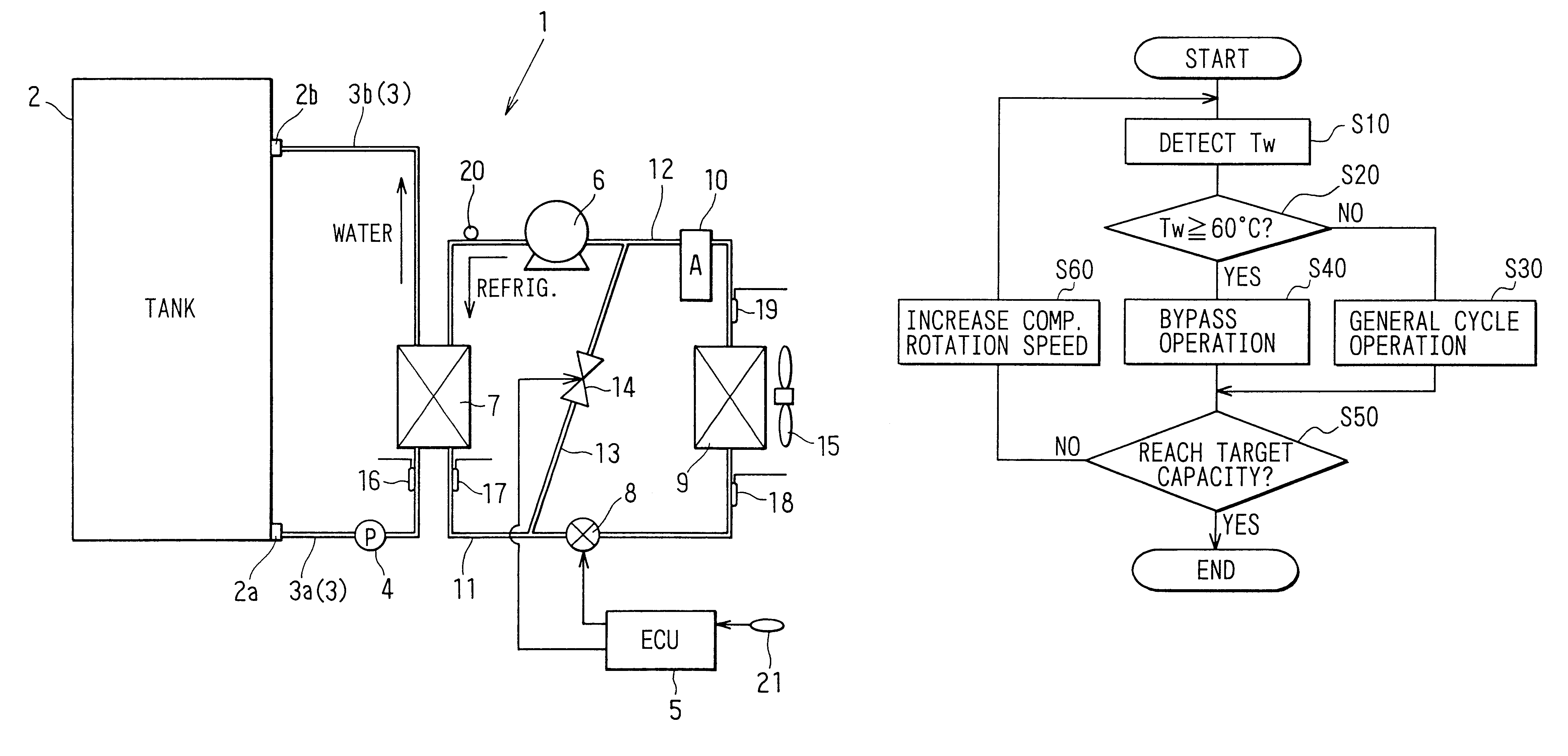

Heat-pump water heater

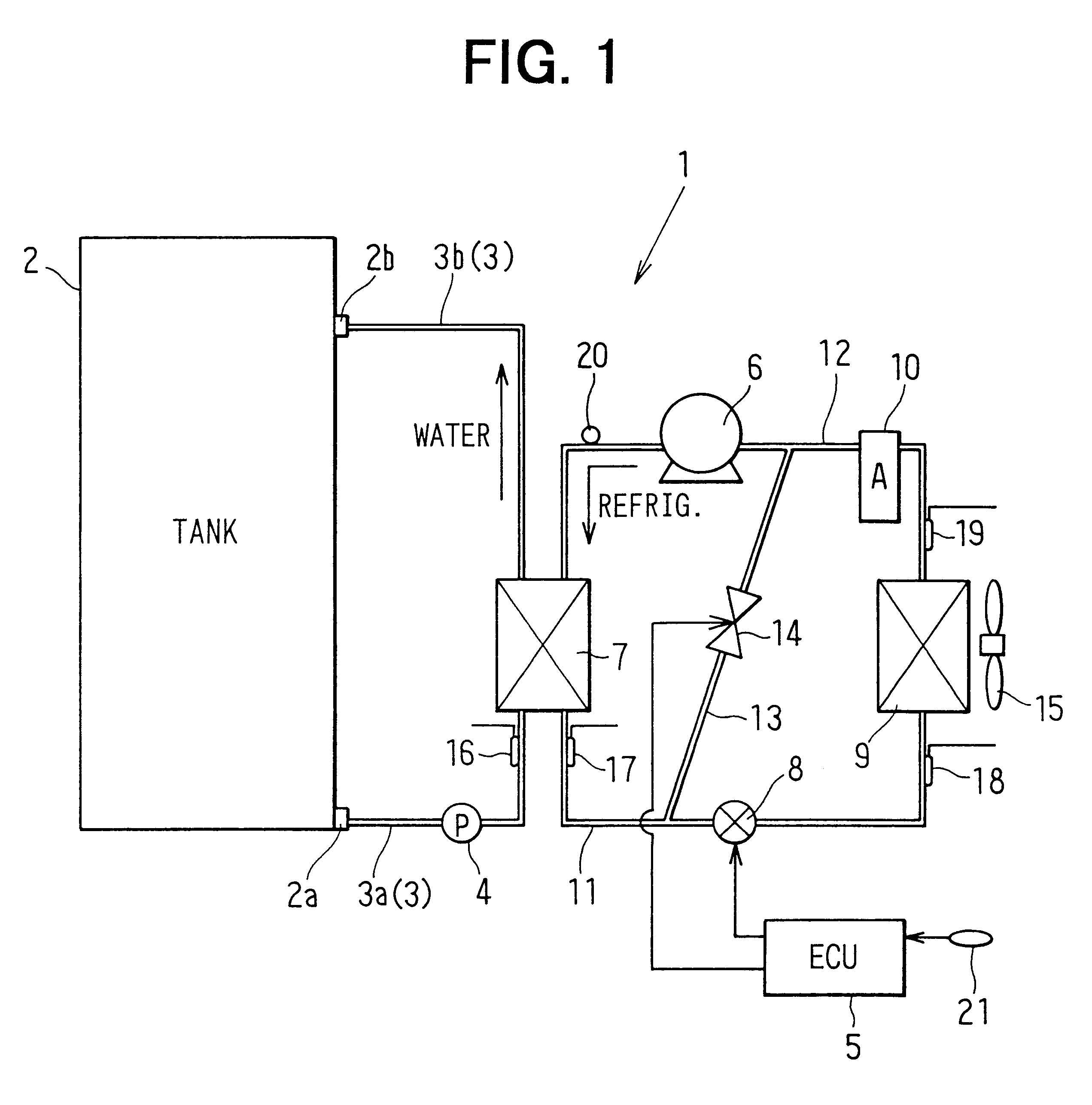

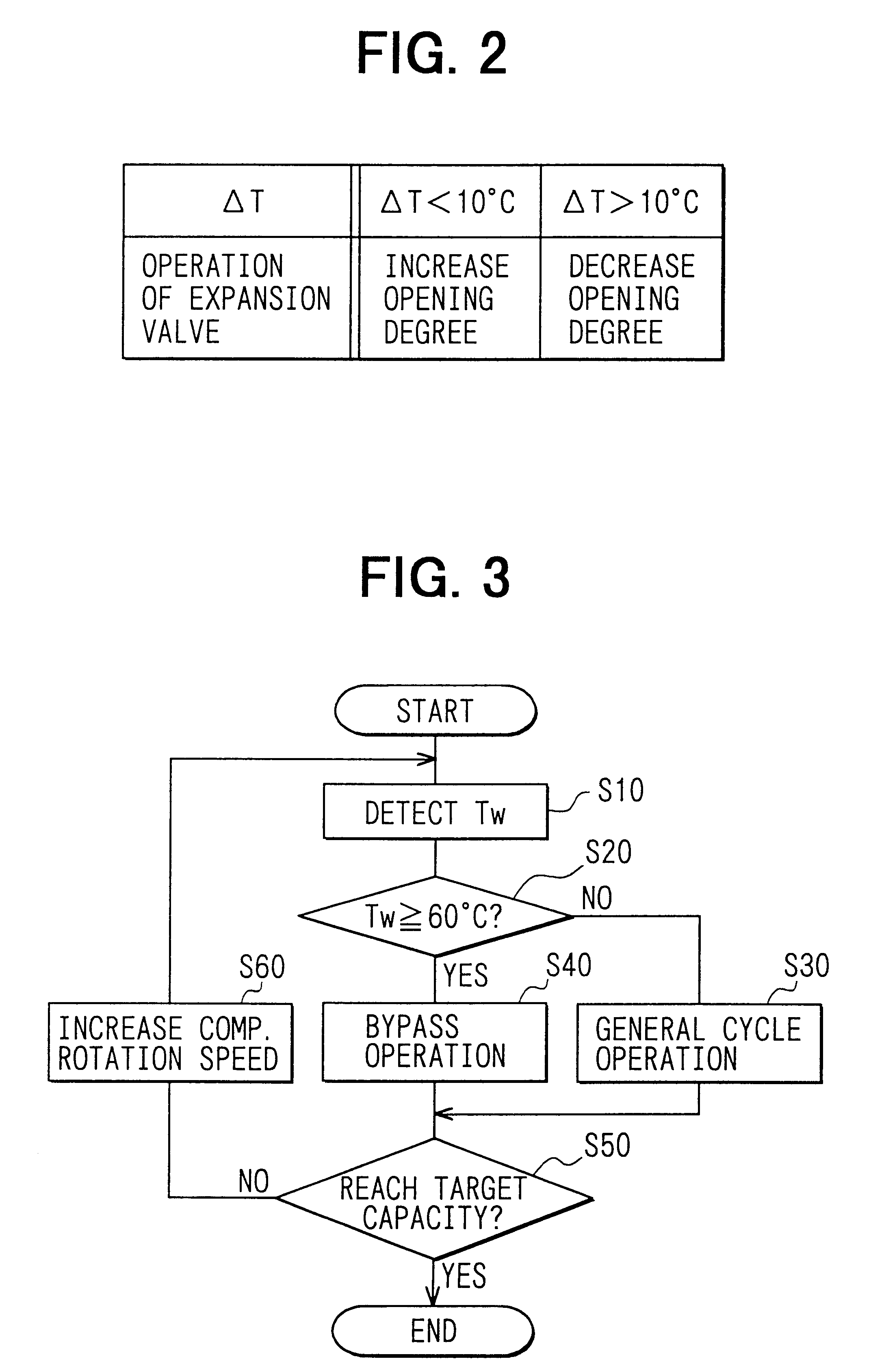

InactiveUS6467288B2Controlled heatingImprove heat pump efficiencyMechanical apparatusHeat pumpsEngineeringRefrigerant

In a heat-pump water heater, a control unit has a heat-radiation determining means for determining a heat radiation from refrigerant to outside air in an air heat exchanger based on a water temperature flowing into a water heat exchanger, and the control unit selectively performs a general cycle operation and a bypass operation in accordance with a determination result of the heat-radiation determining means. That is, when the water temperature flowing into the water heat exchanger is lower than 60° C., the general cycle operation is performed. On the other hand, when the water temperature is equal to or higher than 60° C., the bypass operation is performed.

Owner:DENSO CORP +2

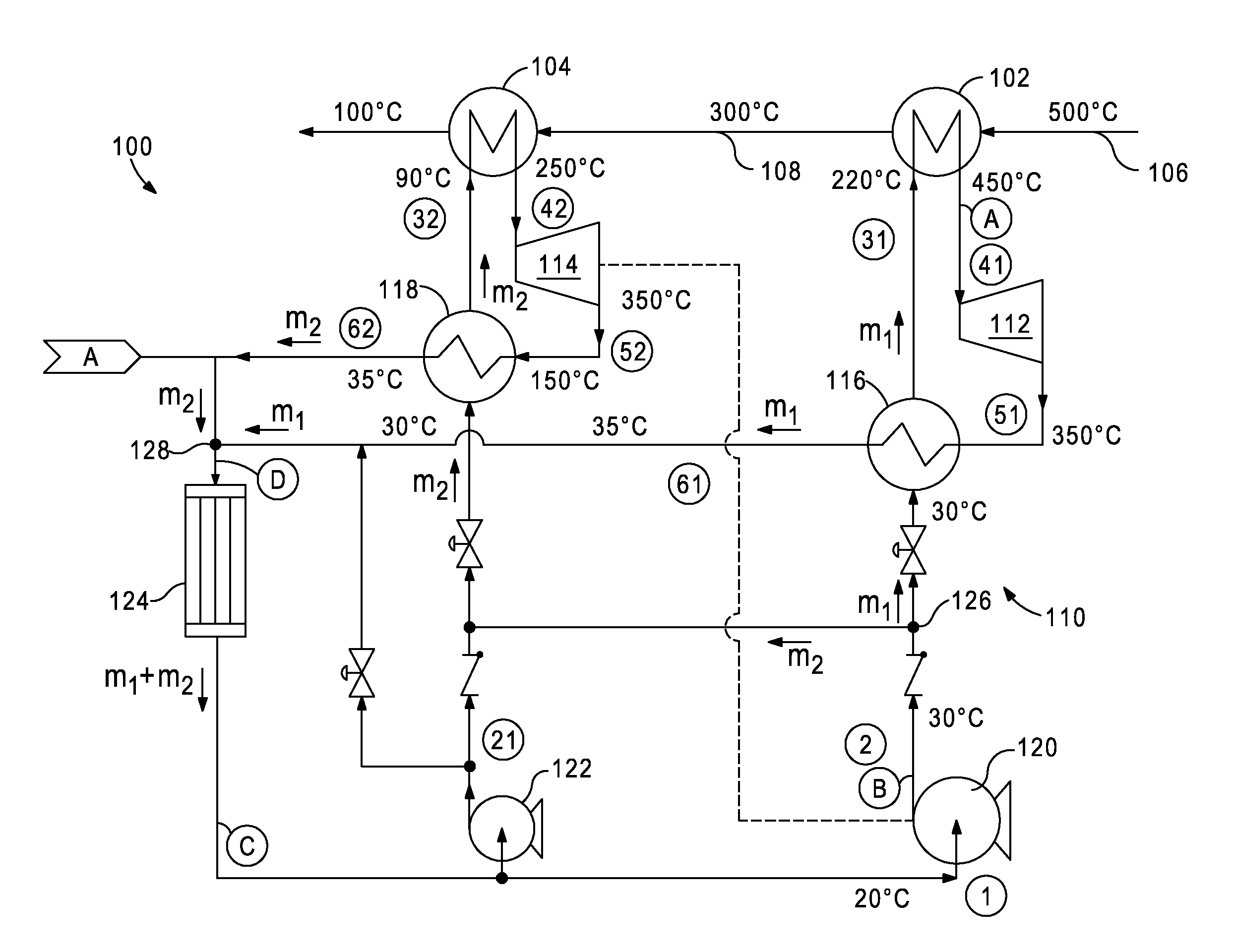

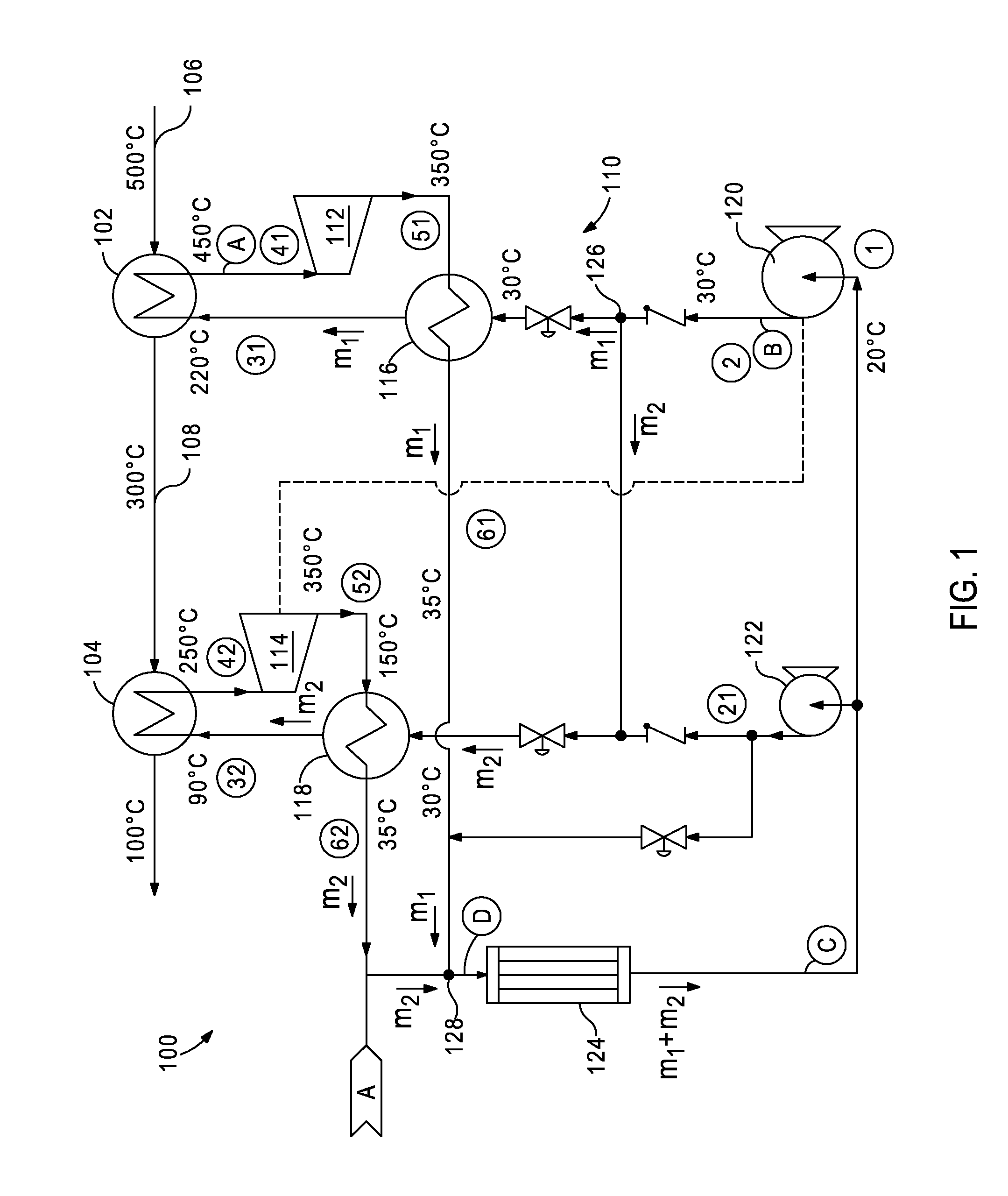

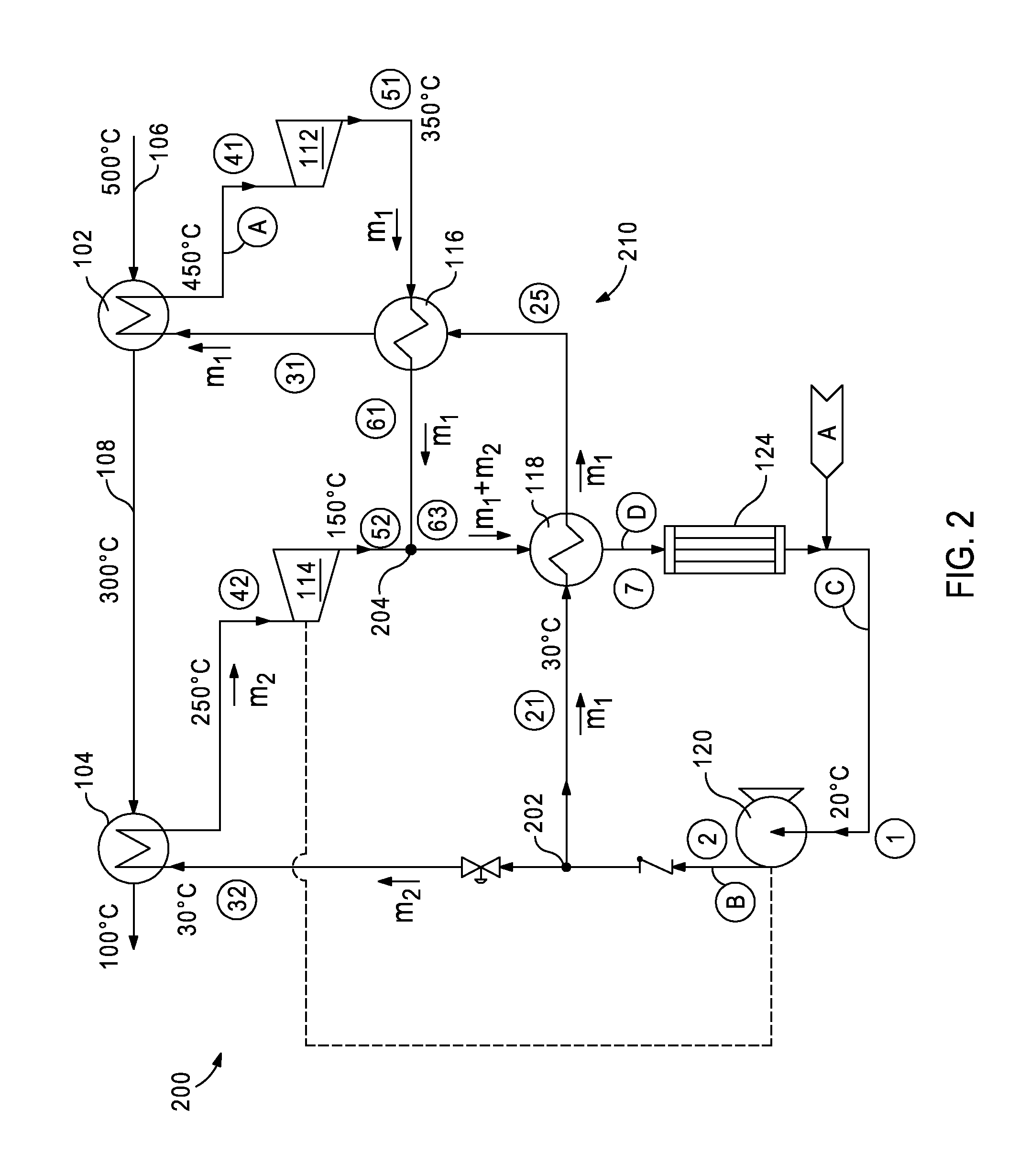

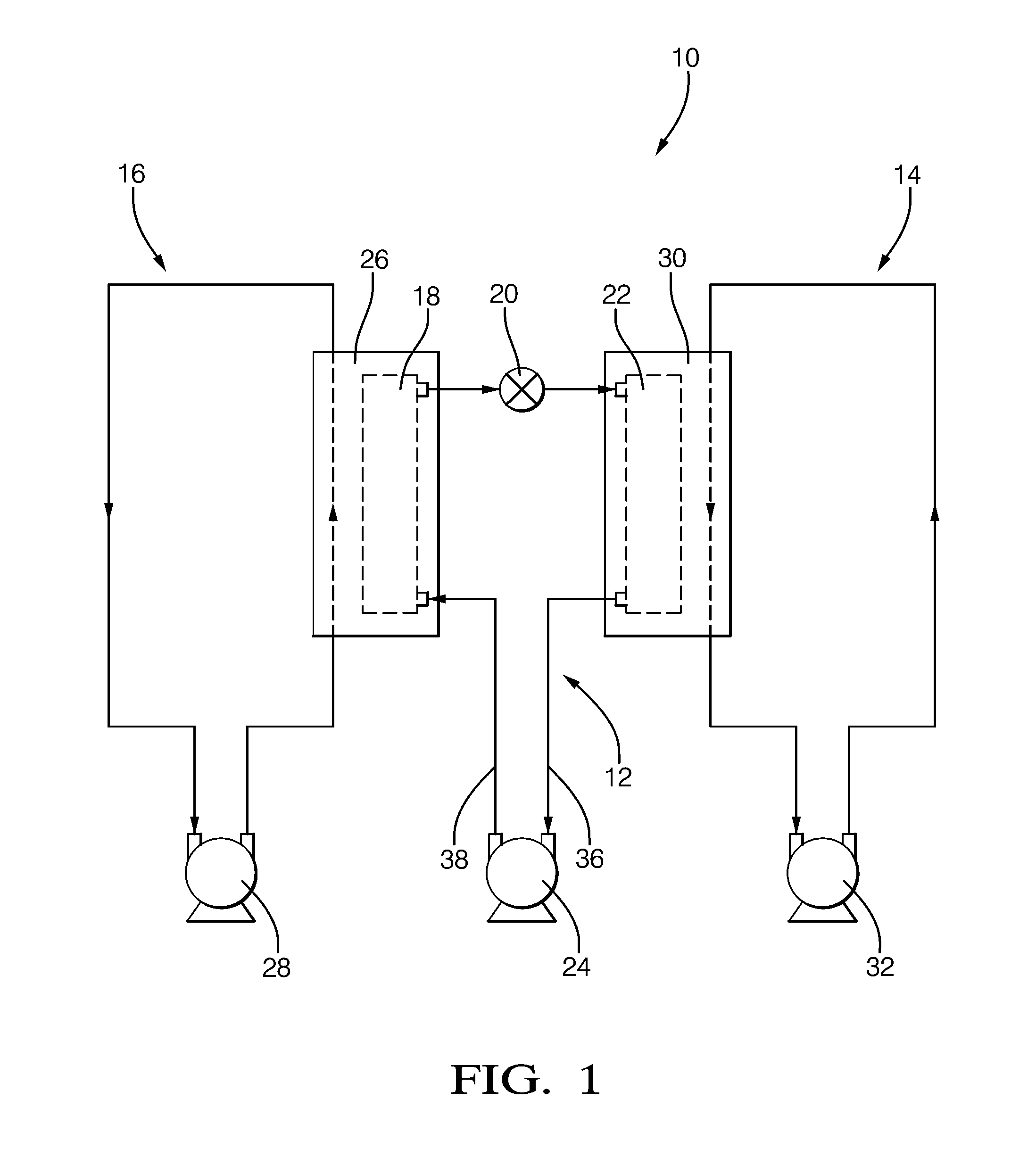

Parallel cycle heat engines

Waste heat energy conversion cycles, systems and devices use multiple waste heat exchangers arranged in series in a waste heat stream, and multiple thermodynamic cycles run in parallel with the waste heat exchangers in order to maximize thermal energy extraction from the waste heat stream by a working fluid. The parallel cycles operate in different temperature ranges with a lower temperature work output used to drive a working fluid pump. A working fluid mass management system is integrated into or connected to the cycles.

Owner:ECHOGEN POWER SYST

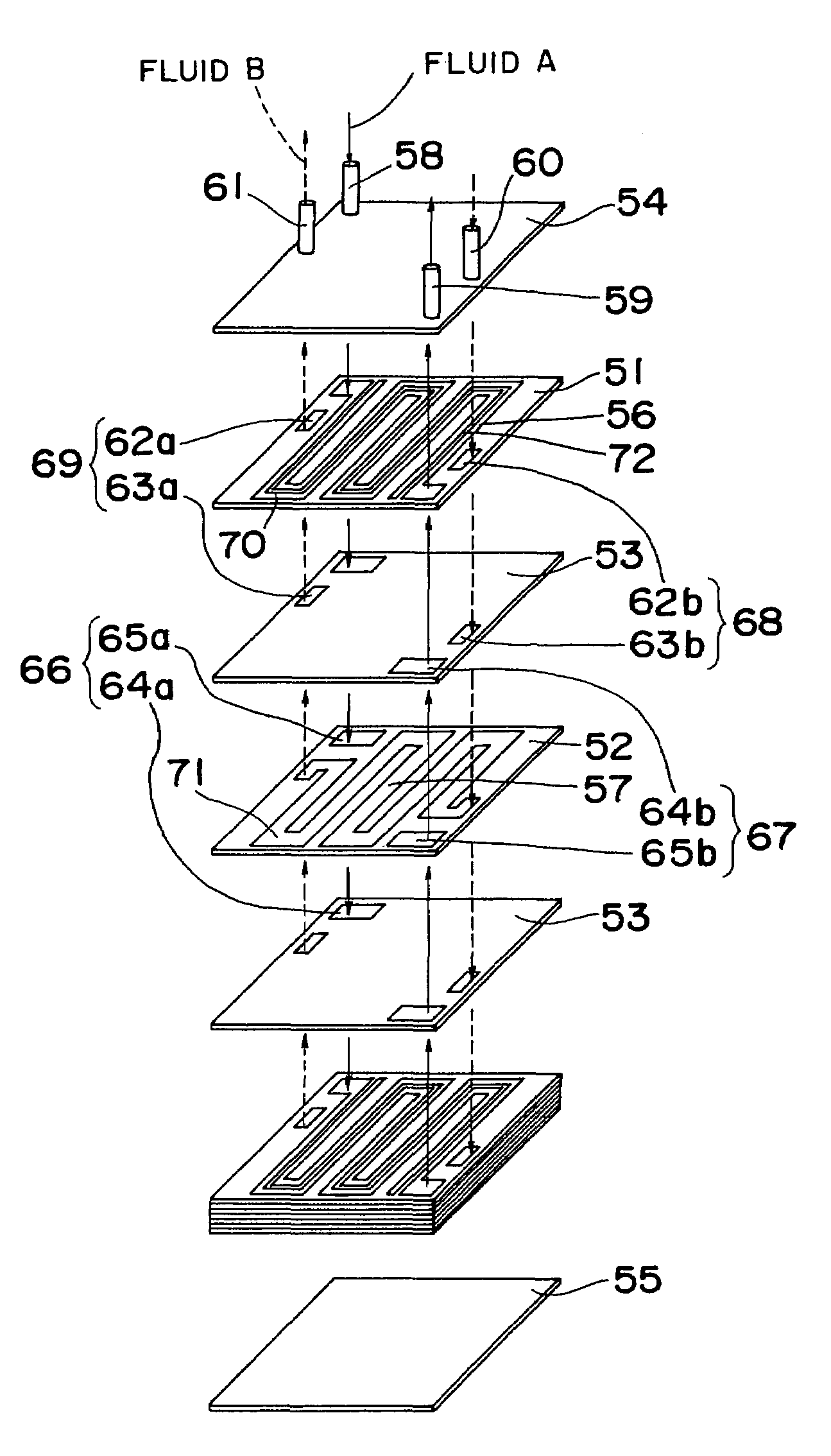

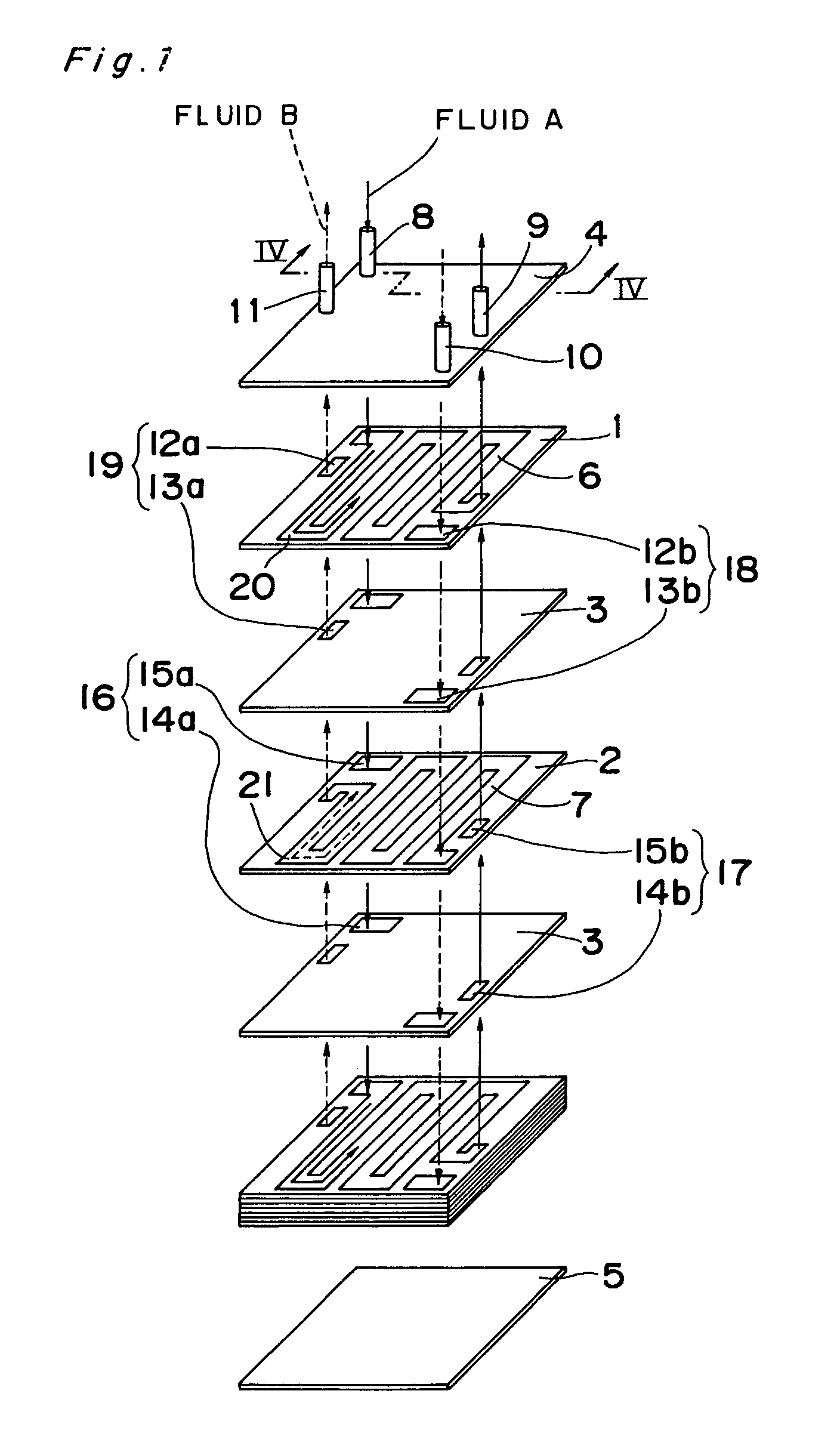

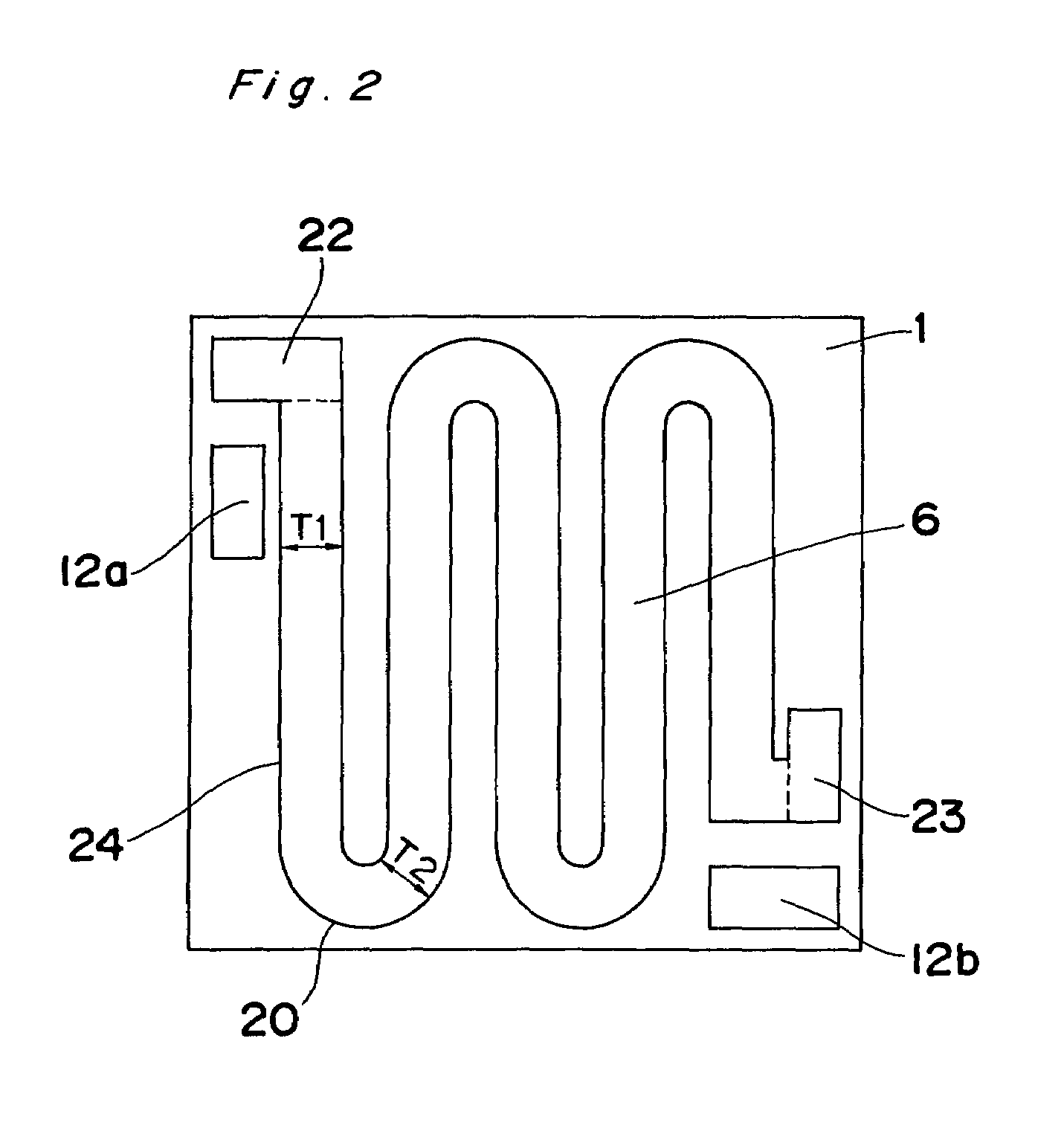

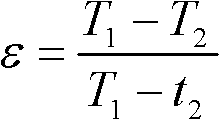

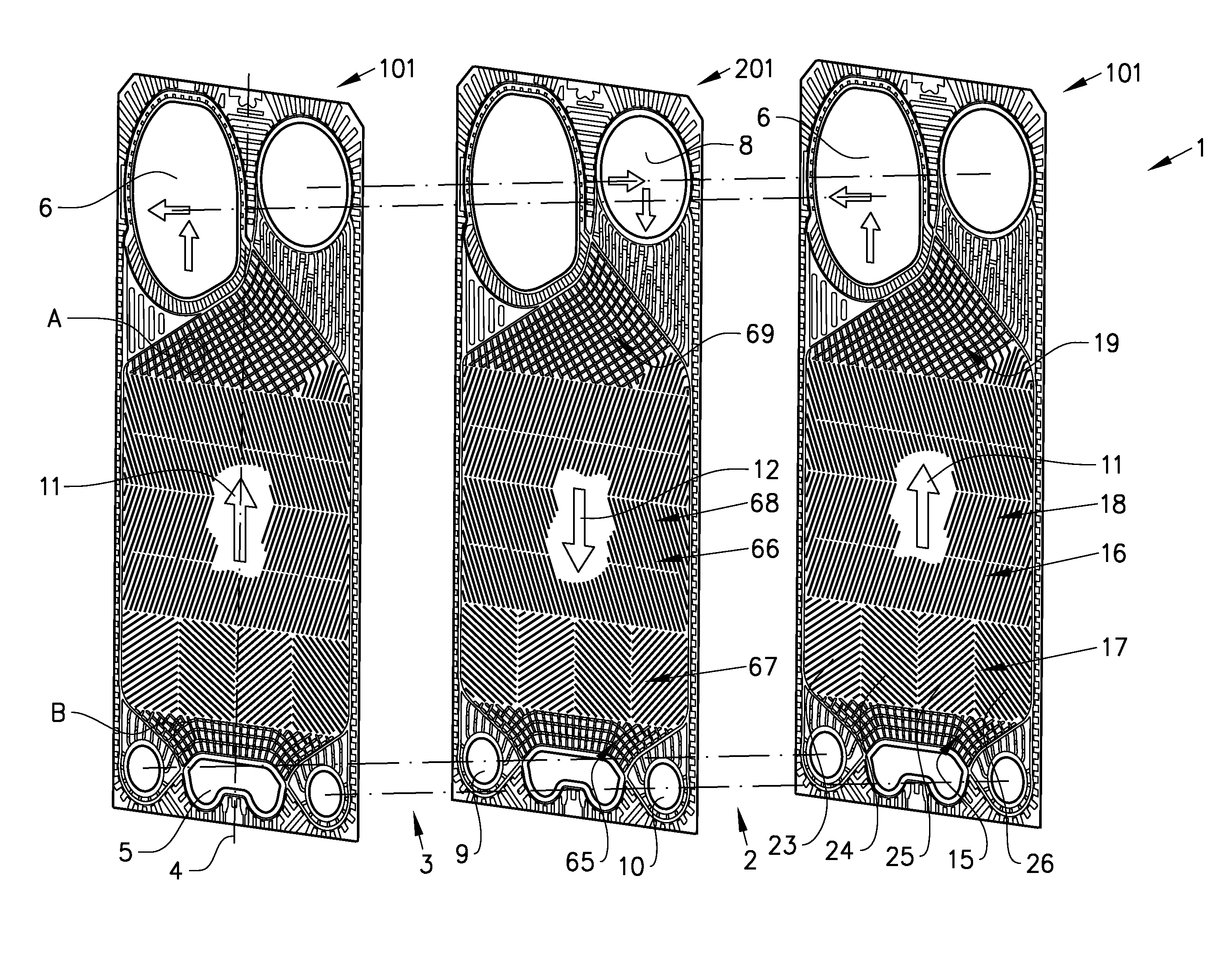

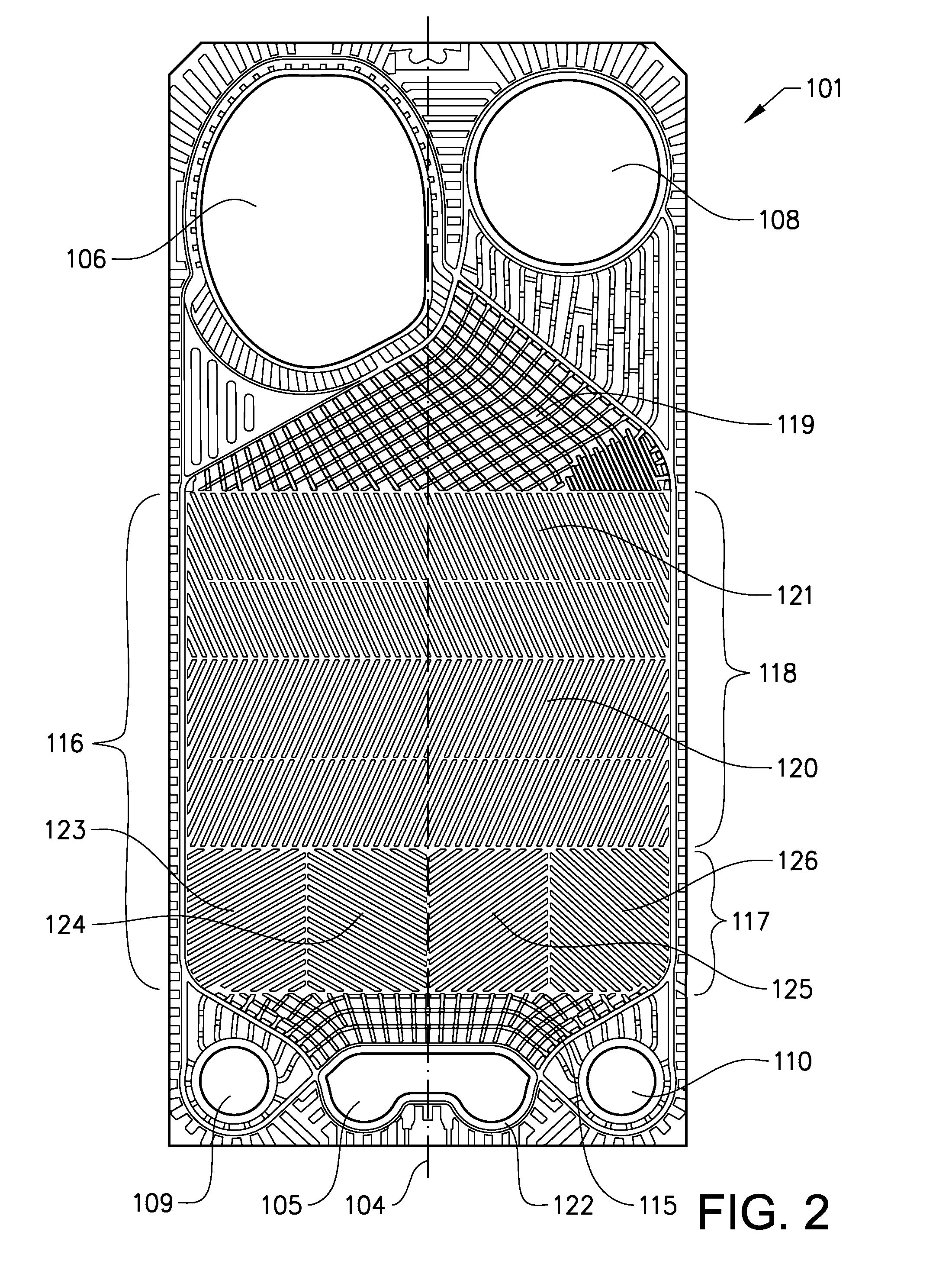

Plate type heat exchanger and method of manufacturing the heat exchanger

InactiveUS6959492B1Smooth connectionReliable and reliableHeat transfer modificationWelding apparatusEngineeringHeat transfer efficiency

A plate heat exchanger includes a plurality of plates sandwiched between a pair of end plates. Each of the plurality of plates has two passageways defined therein that are not in fluid communication with each other. Alternatively, some of the plurality of plates have a passageway, while some of the remaining plates have another passageway. Two fluids flow through the two passageways in a countercurrent fashion. Because the countercurrent flows are superior in heat transfer efficiency, it is possible to enhance the performance and reduce the size of the plate heat exchangers.

Owner:CONSOL SYST +1

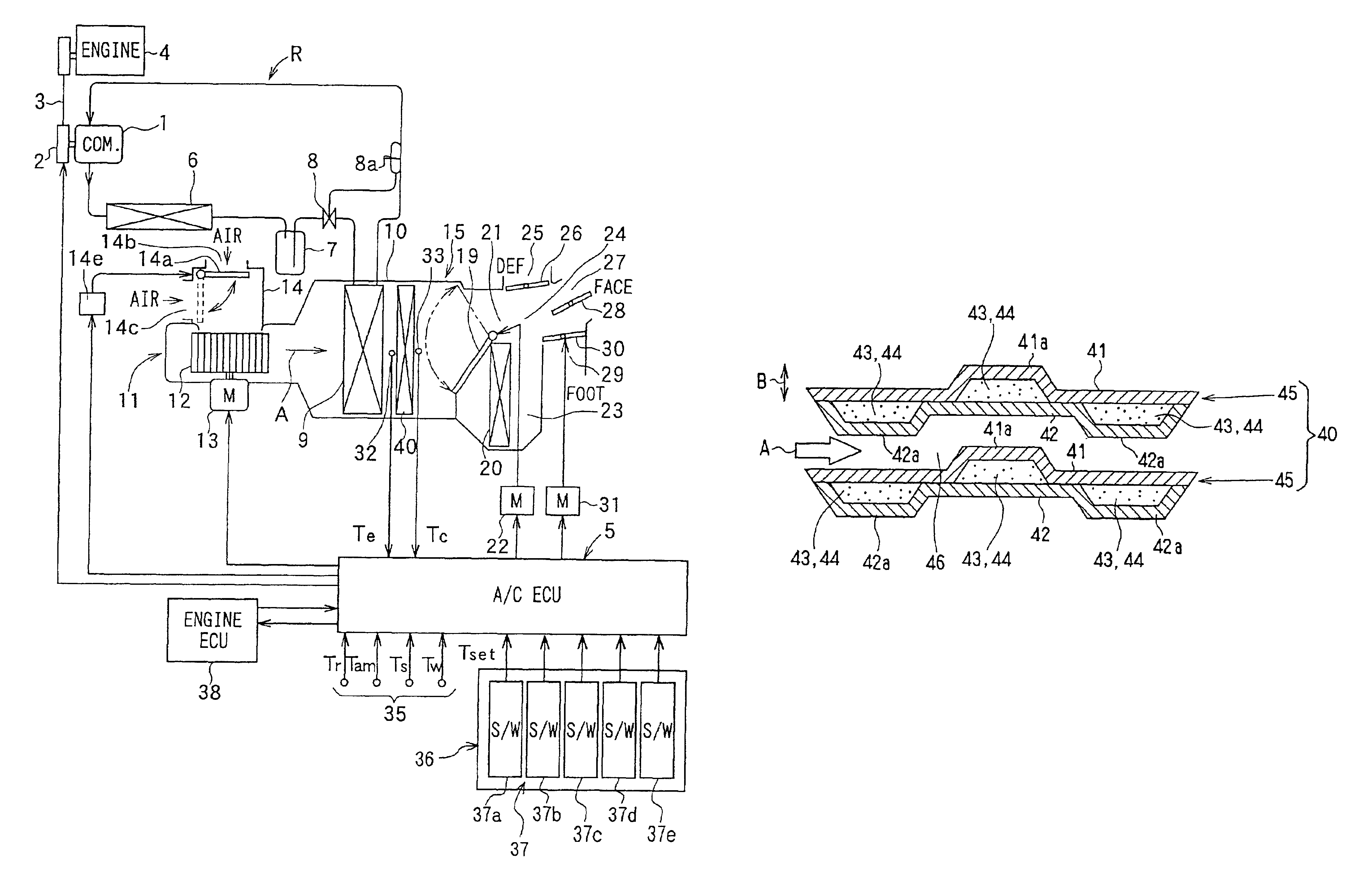

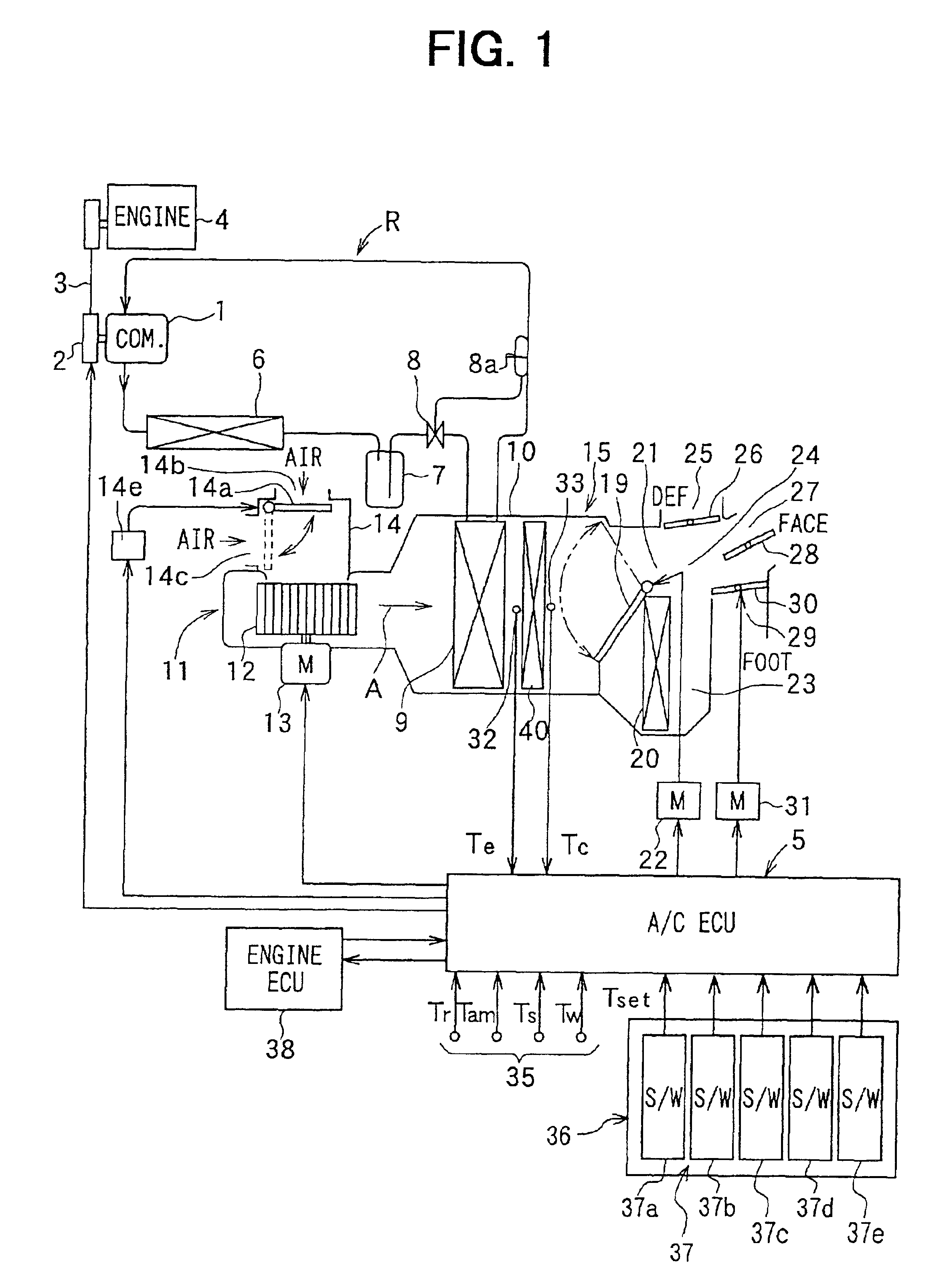

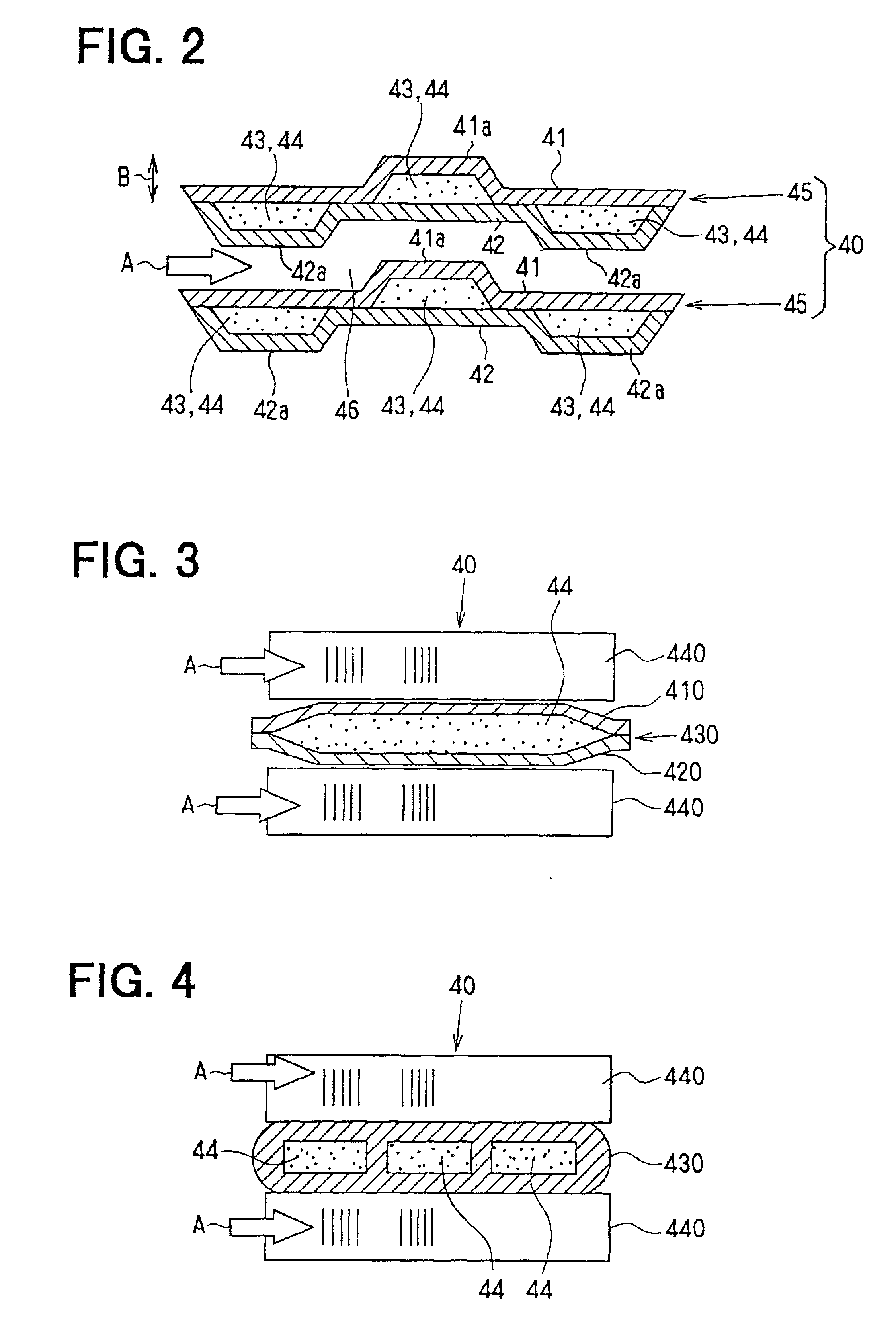

Vehicle air conditioning system with cold accumulator

InactiveUS6854513B2Get stableSimple structureAir-treating devicesRailway heating/coolingCold airEngineering

In a vehicle air conditioning system, a cold accumulator is disposed between a downstream air side of a cooling heat exchanger and an upstream air side of a heating heat exchanger to be cooled by cold air having passed through the cooling heat exchanger. Further, the cold accumulator is disposed at the upstream air side of an air mixing door.

Owner:DENSO CORP

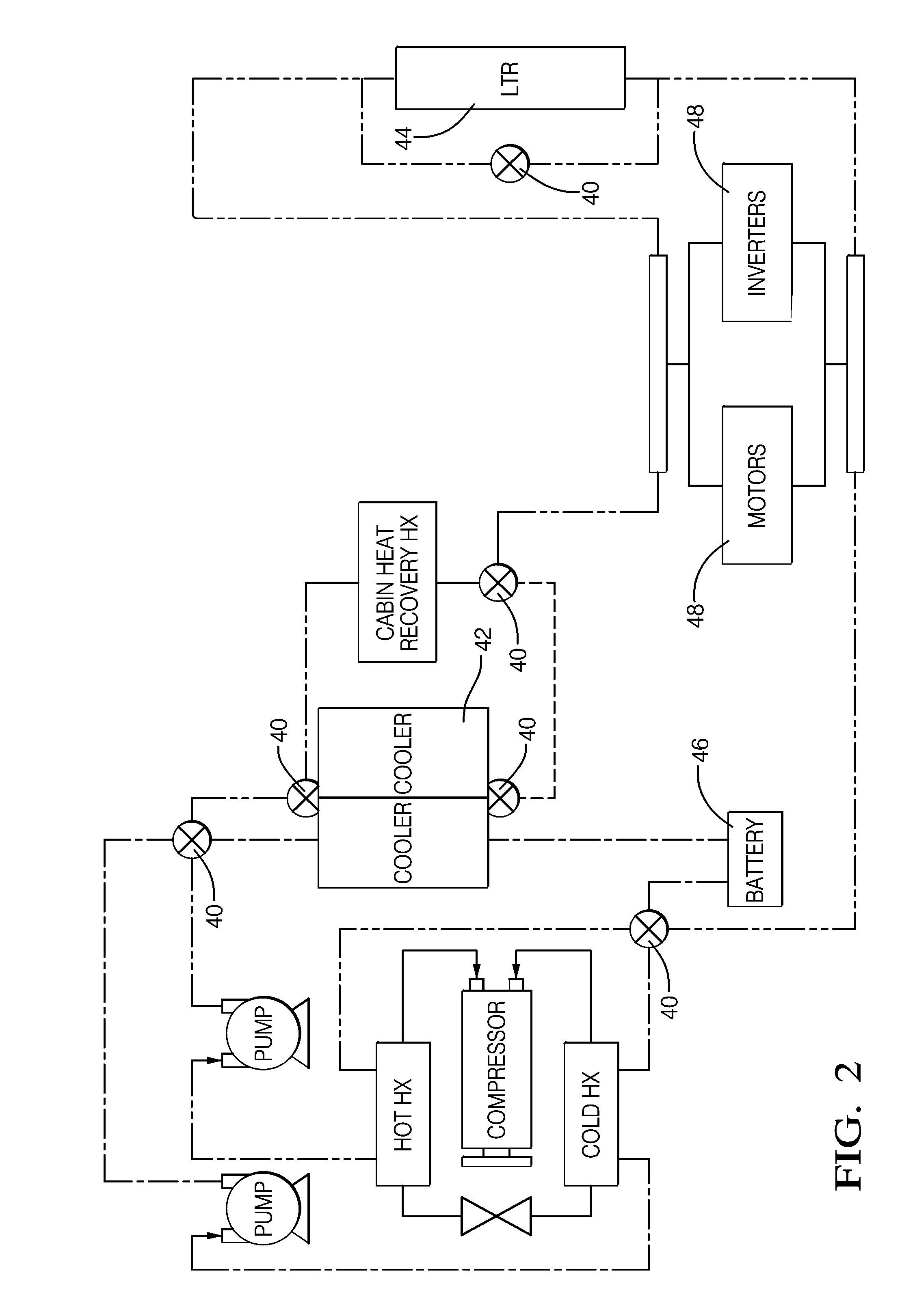

Plate-type heat pump air conditioner heat exchanger for a unitary heat pump air conditioner

ActiveUS20120210746A1Increase temperatureHeat pumpsCompression machines with non-reversible cycleCold sideThermal energy

A plate-type heat exchanger having a first heat exchanger portion configured to receive a refrigerant flow and a hot side coolant flow having a lower temperature than the refrigerant flow, a second heat exchanger portion configured to receive the refrigerant flow exiting from the first heat exchanger portion and a cold side coolant flow having a higher temperature than the refrigerant flow exiting from the first heat exchanger portion, and an internal heat exchanger portion sandwiched between the first heat exchanger portion and the second heat exchanger portion. The refrigerant flow through the plate type heat exchanger is in non-contact thermal communication with the hot side coolant flow and the cold side coolant flow. The cold side coolant flow transfers heat energy to the refrigerant, which in turn transfer that heat energy to the hot side coolant flow.

Owner:MAHLE INT GMBH

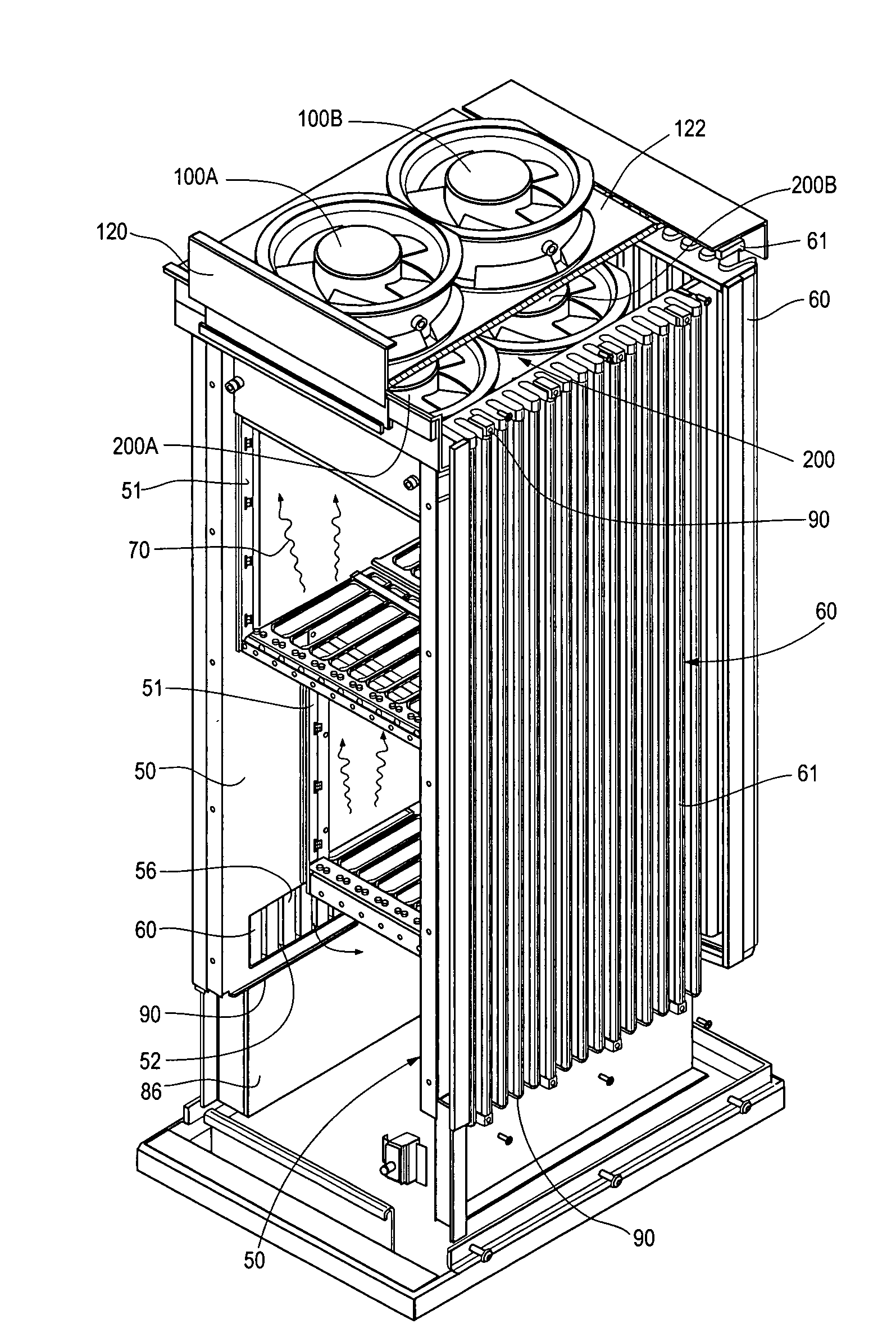

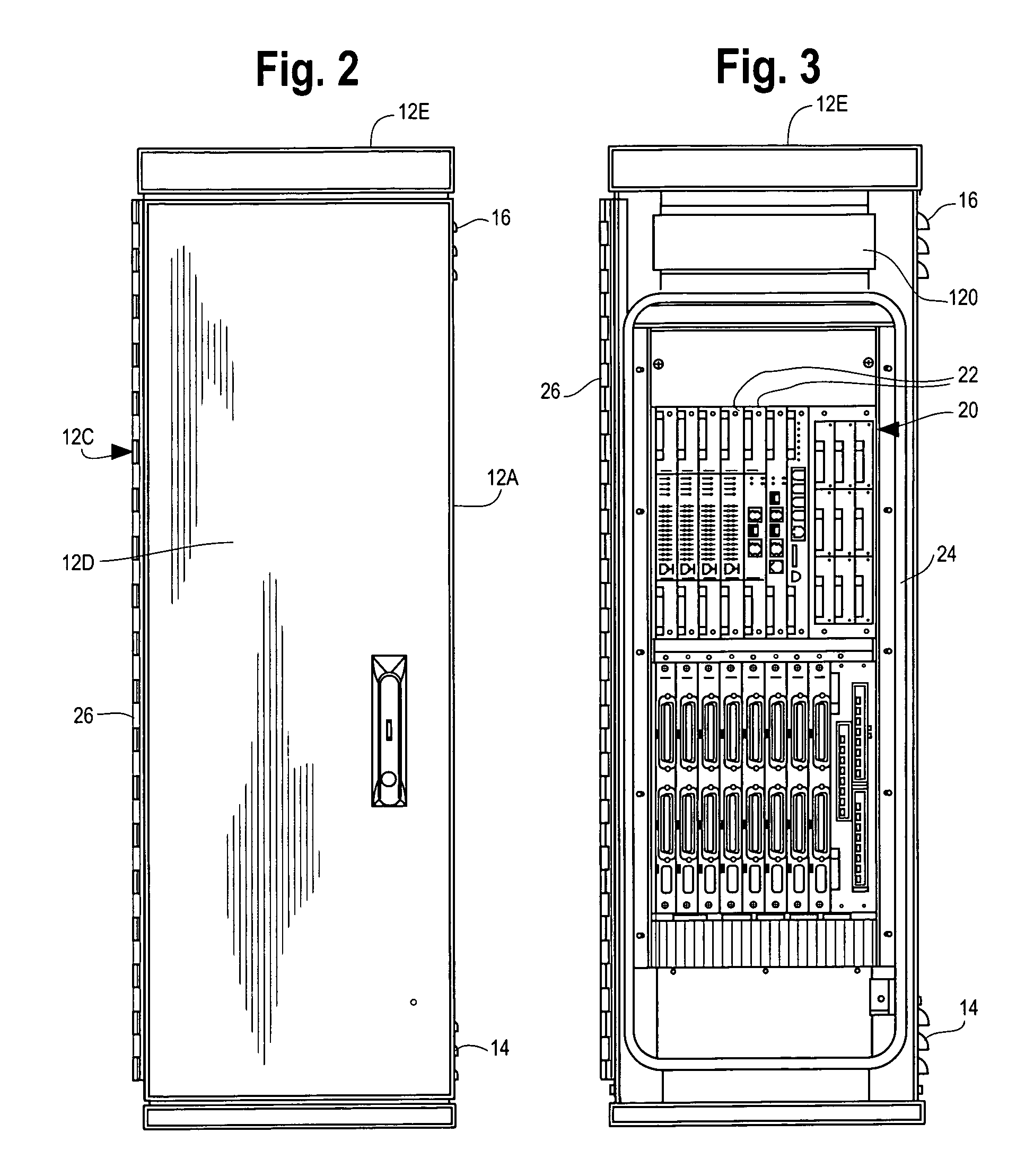

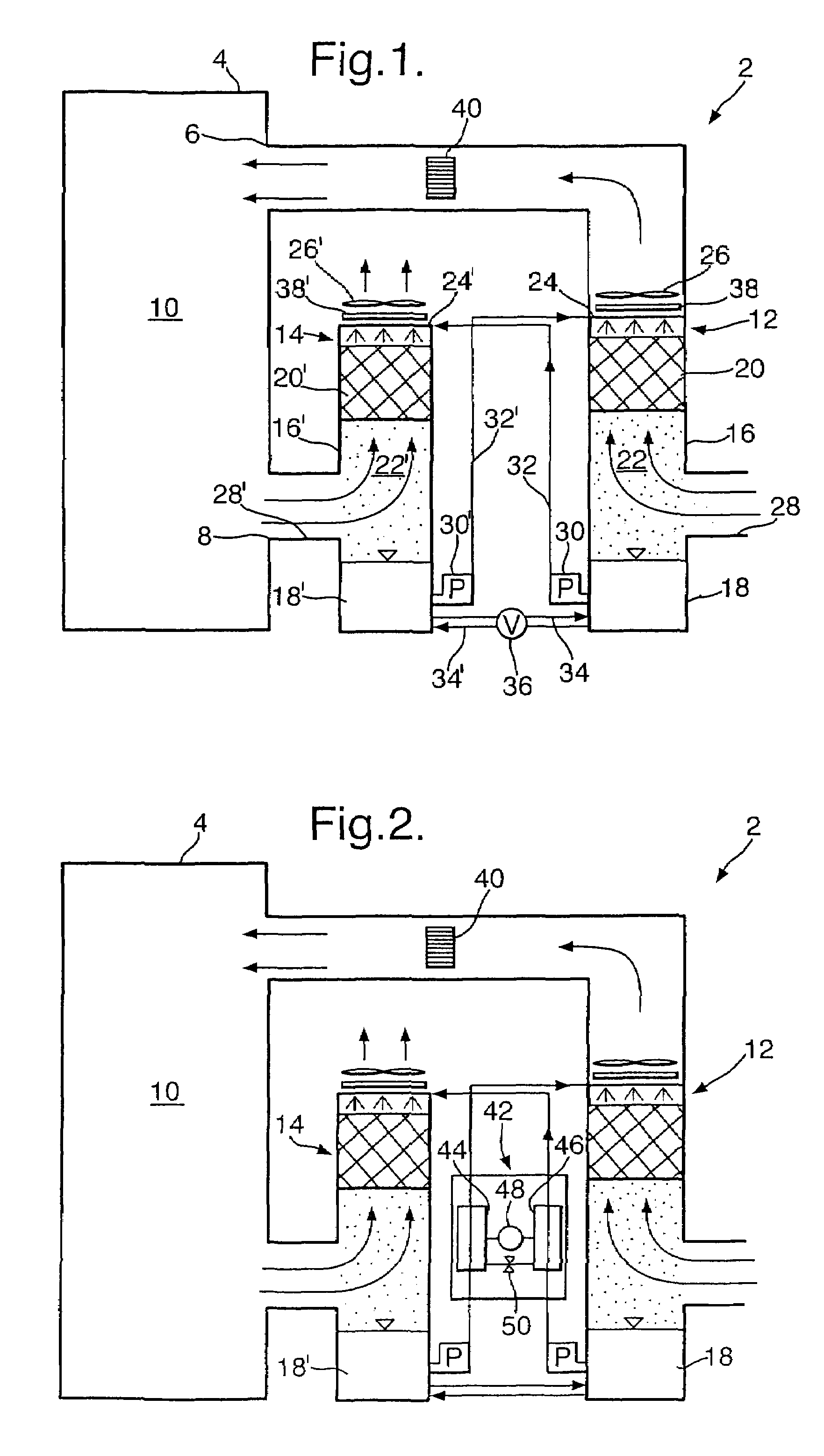

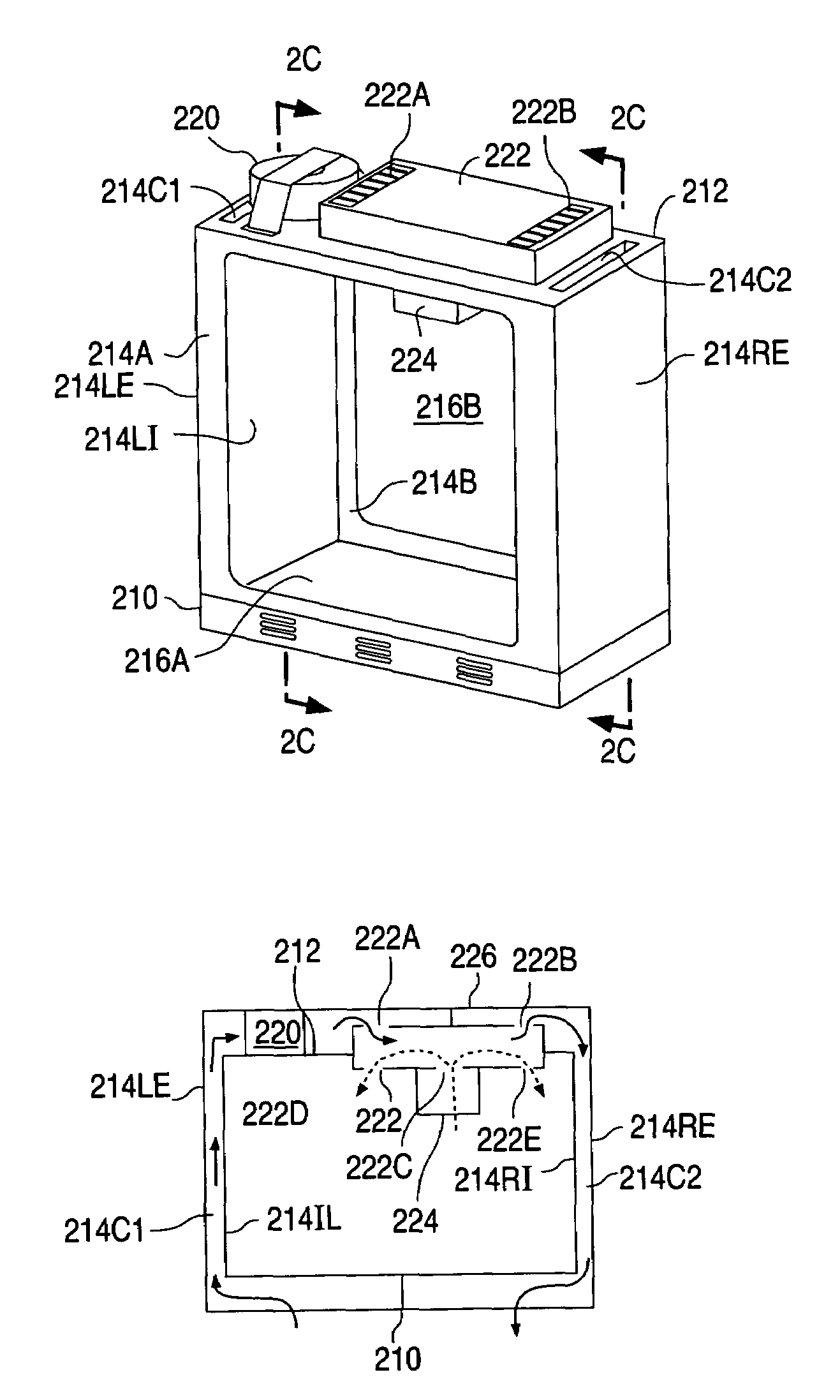

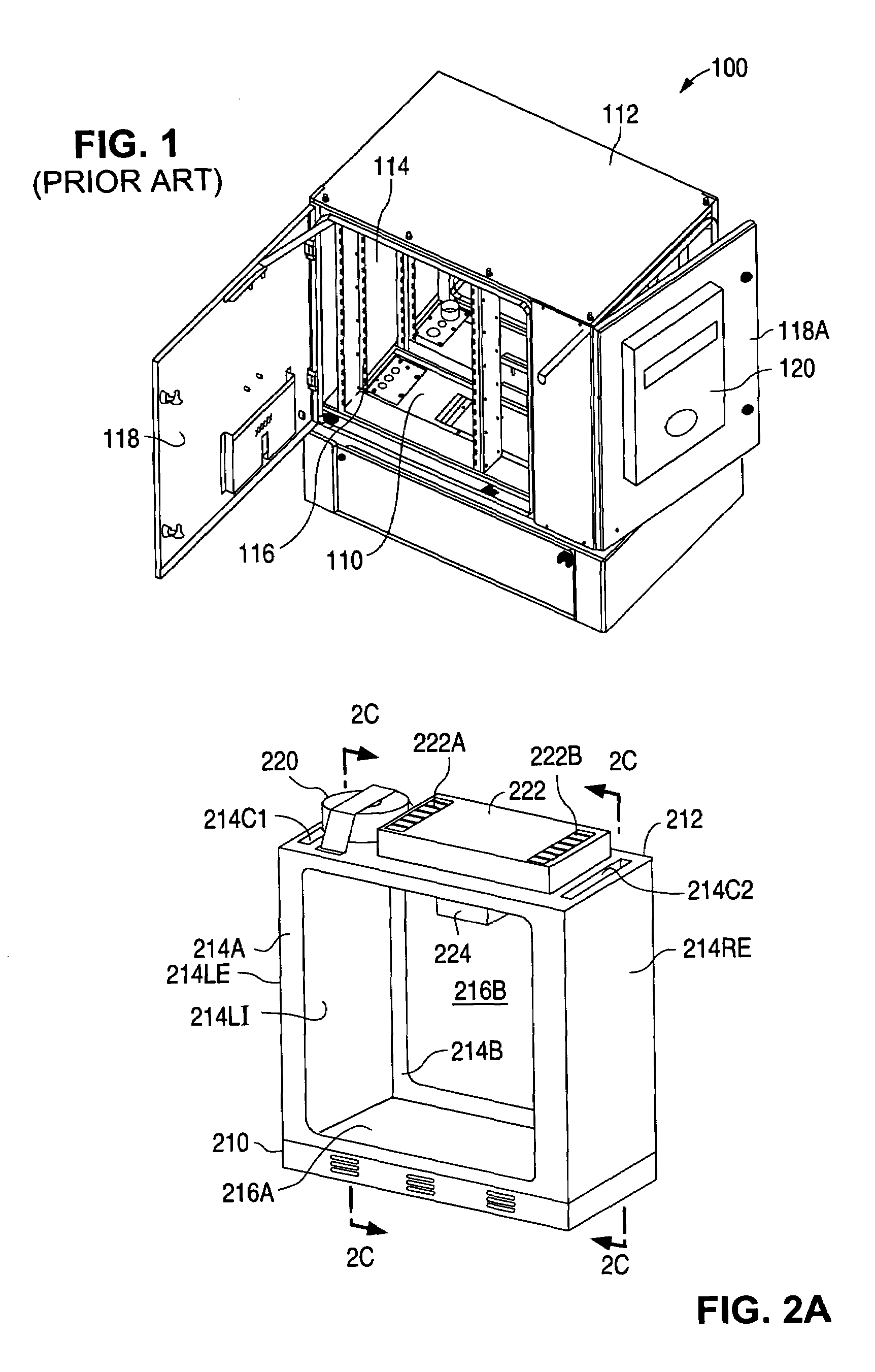

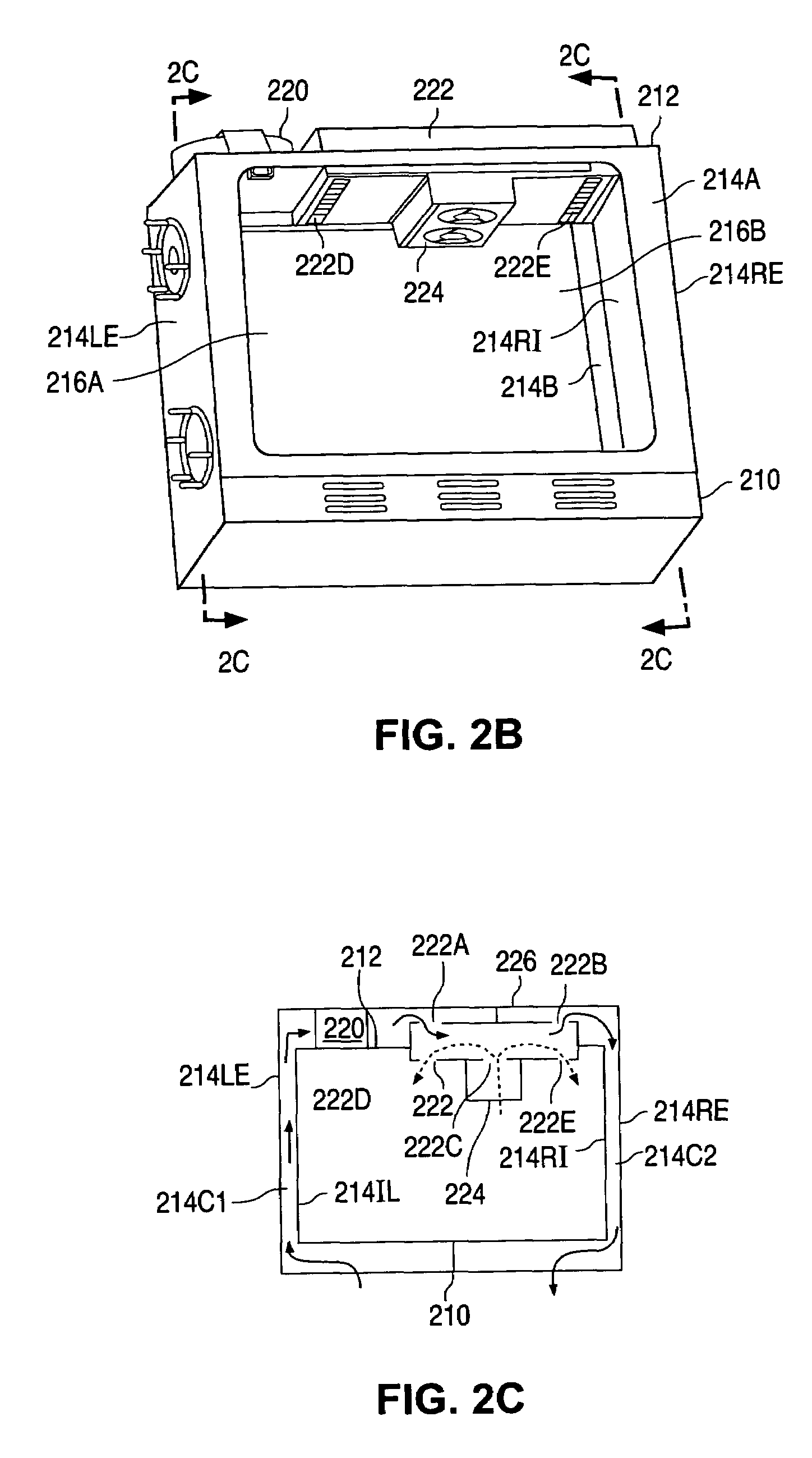

Electronics cabinet with internal air-to-air heat exchanger

ActiveUS7245485B1Increase surface areaImprove heat transfer performanceDigital data processing detailsCooling/ventilation/heating modificationsAir cycleEngineering

An enclosure has a set of panels forming an outer peripheral skin. A heat exchanger wall is placed within the panels. A first fan arrangement circulates ambient air into a space within the panels and along the exterior surface of the heat exchanger wall and back into the environment. A second fan arrangement circulates air contained within the enclosure against the interior surface of the heat exchanger wall. Heat is transferred through the heat exchanger wall to the ambient air circulated by the first fan. An inner wall is placed adjacent to the interior surface of the heat exchanger wall. The space between the inner wall and the heat exchanger wall forms a space for the air within the interior of the enclosure to circulate by the second fan. The heat exchanger wall provides a barrier isolating the ambient air from the air within the enclosure, preventing dust, humidity and pollutants to enter into the interior of the cabinet in the space surrounding the electronic components.

Owner:UTSTARCOM INC

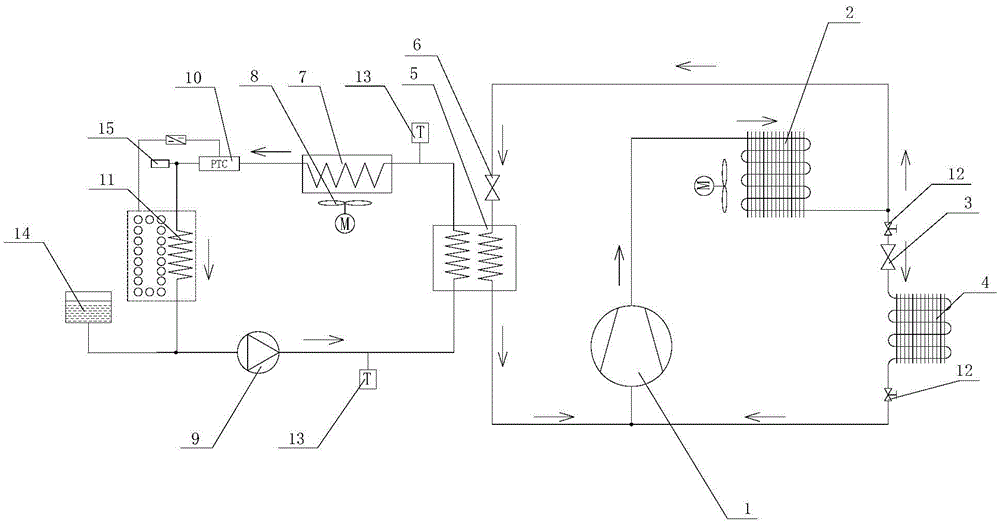

Vehicle air-conditioner system with battery heat management function

InactiveCN105539067AEffective coolingFully meet cooling needsAir-treating devicesVehicle heating/cooling devicesElectricityHeat management

A vehicle air-conditioner system with a battery heat management function comprises a compressor, a condenser, a first expansion valve and an evaporator. The compressor, the condenser, the first expansion valve and the evaporator are connected in the first flowing direction of a refrigerant to form an air-conditioner refrigeration circulation loop. The vehicle air-conditioner system further comprises a plate heat exchanger, a second expansion valve, an air-water heat exchanger, a fan, a water pump, an electric heater and a battery pack built-in heat exchanger. The fan is arranged on the air inlet side of the air-water heat exchanger. The compressor, the condenser, the second expansion valve and the plate heat exchanger are connected in the second flowing direction of the refrigerant to form a battery cooling low-temperature medium circulation loop. The battery pack built-in heat exchanger, the water pump, the plate heat exchanger, the air-water heat exchanger and the electric heater are connected in the water circulation direction to form a battery temperature adjusting medium circulation loop. According to the vehicle air-conditioner system, uniform management of the temperature inside a vehicle and the temperature of a battery is achieved, a battery pack is in the better temperature environment all the time during working, and it is ensured that the good refrigeration effect is achieved inside the vehicle.

Owner:TIANJIN SANDEN AUTO AIR CONDITIONING

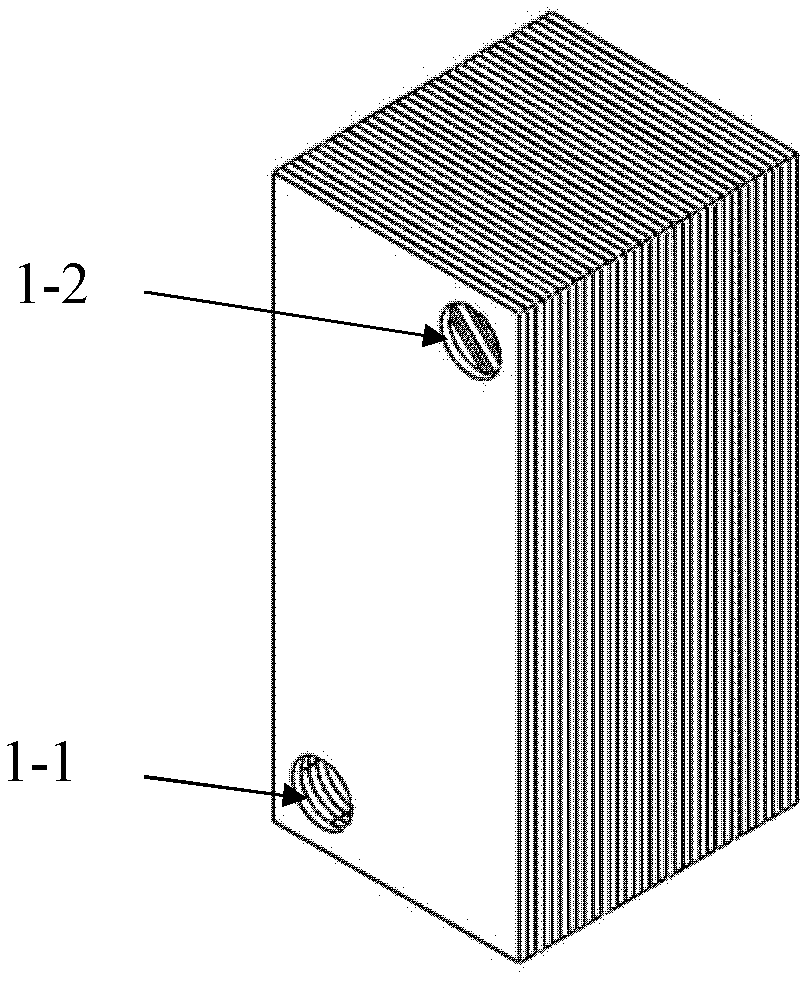

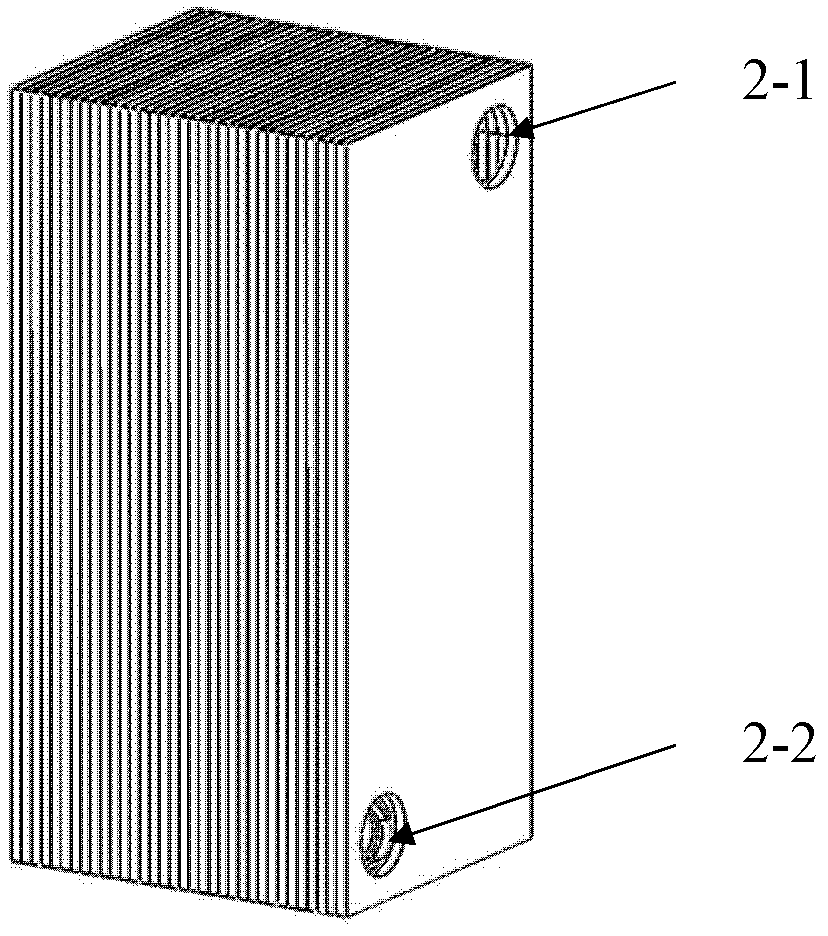

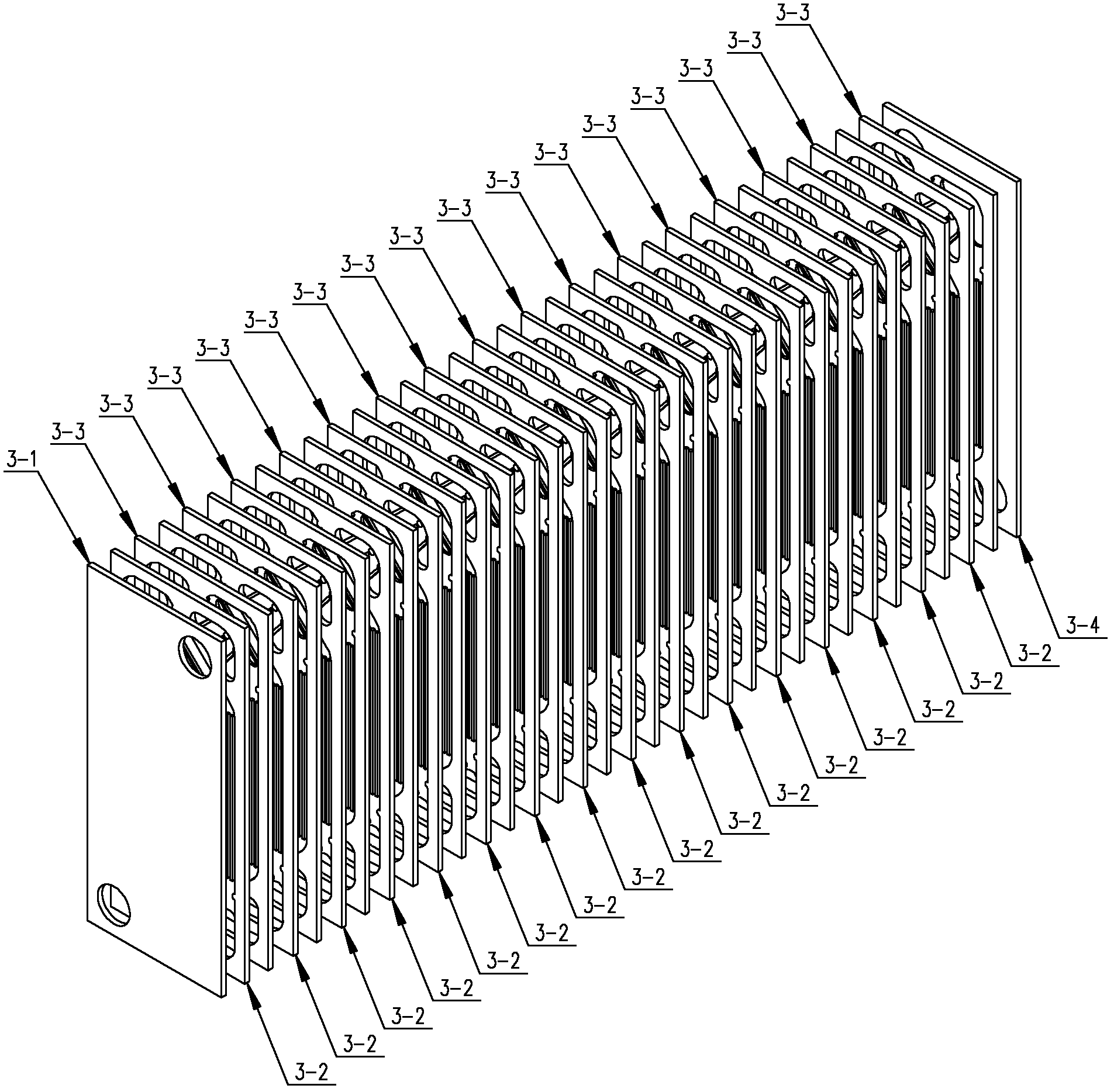

Miniature micro-channel plate-fin heat exchanger

ActiveCN102494547ALaminated elementsStationary plate conduit assembliesMiniaturizationMolecular level

The invention relates to a miniature heat exchanger with a plate-fin micro-channel structure, wherein the miniature heat exchanger can act as a novel sensible heat exchanger or a phase change heat exchanger which is compact in structure, small in volume, high in heat exchange efficiency and high in heat exchange density. According to the embodiment of the invention, the heat exchanger is composed of a plurality of layers of metal thin sheets; one surface of each layer of thin sheet is provided with a micro-channel structure through an etching method, and the other surface of each layer of thin sheet is of a plane structure; and the plane side of one metal thin sheet and the micro-channel side of another metal thin sheet are overlapped and pressed together, thus the plate-fin micro-channel structure is formed. According to the heat exchange quantity requirement, multiple layers of thin sheets are laminated, and molecular-level combination among metal layers can be formed through a vacuum diffusion welding method, thus all the thin sheets are connected into a whole, and a complete heat exchanger is formed. According to the invention, the miniaturization difficulties of the heat exchanger and a refrigerator device can be solved.

Owner:BEIHANG UNIV

Flue gas total-heat recovery device of gas boiler

ActiveCN101769594AEmission reductionImprove protectionEnergy efficient heating/coolingAir heatersPlate fin heat exchangerAir temperature

The invention relates to a flue gas total-heat recovery device of a gas boiler, belonging to the thermotechnical field. In the invention, the temperature of the flue gas exhausted by the gas boiler can be reduced to lower than 40 DEG C by a gas-water heat exchanger and a mixing cooler, then the cooled flue gas is directly supplied for an air-source heat pump water heater for generating the hot water, and the sensible heat and the latent heat in the flue gas can be totally recovered. Most CO2 and NOx in the flue gas can be absorbed by condensed water in the cooling process, thereby reducing the emission of harmful gas. The device comprises the gas-water heat exchanger, the mixing cooler and the heat pump water heater and is characterized in that the flue gas at 150-200 DEG C is cooled to lower than 90 DEG C by the gas-water heat exchanger and then can be cooled to lower than 40 DEG C in the mixing cooler, and the cooled flue gas can serve as heat source to directly enter an evaporator of the air-source heat pump water heater for heat exchange. The invention solves the problems of frosting and low efficiency of the air-source heat pump water heater due to low temperature in winter in the North while recovering the residual heat of the flue gas of the gas boiler at the same time; meanwhile, the emission of the harmful gas in the flue gas of the gas boiler can be reduced, thereby realizing energy saving and emission reduction.

Owner:北京浩特沃特广告有限公司

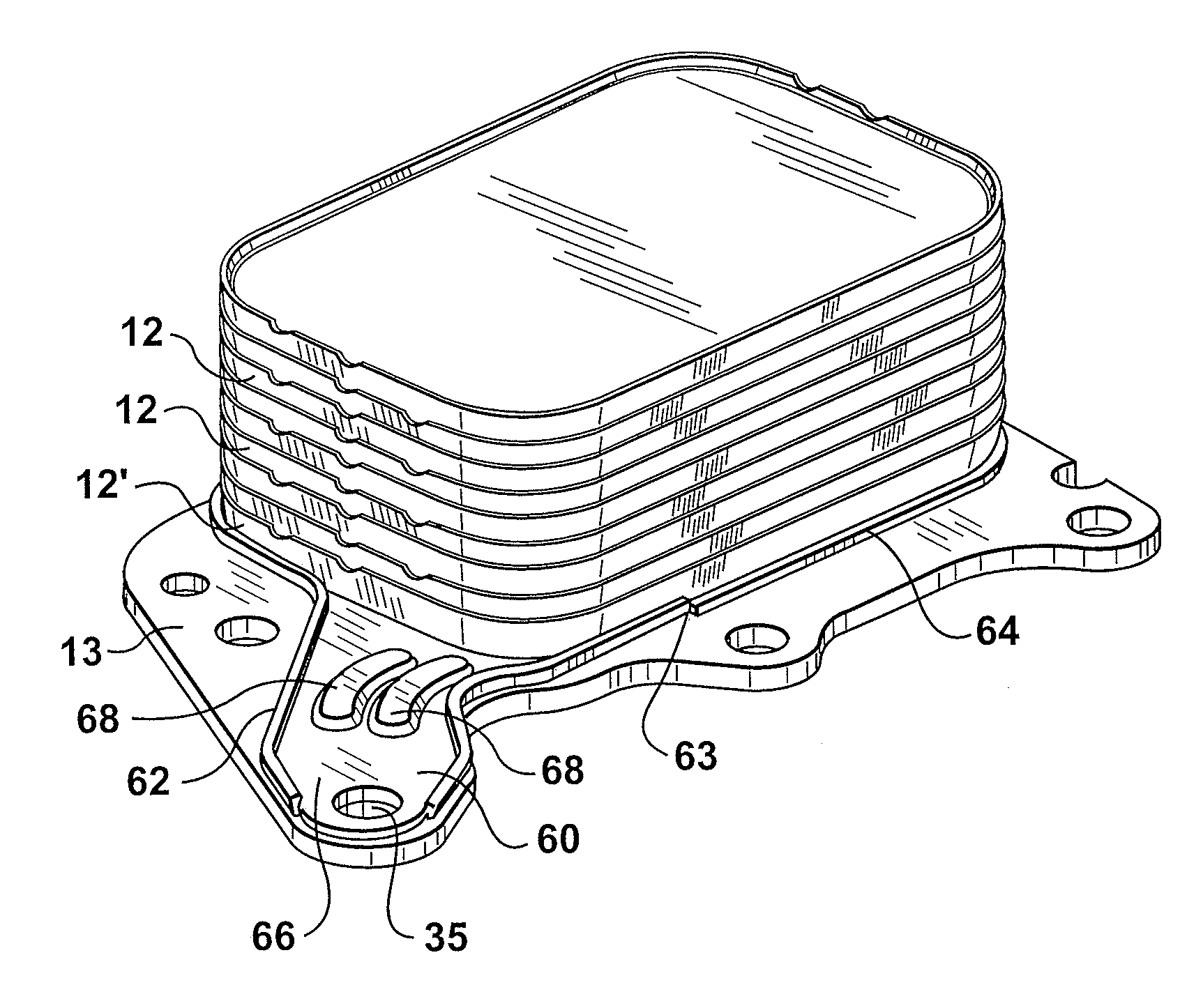

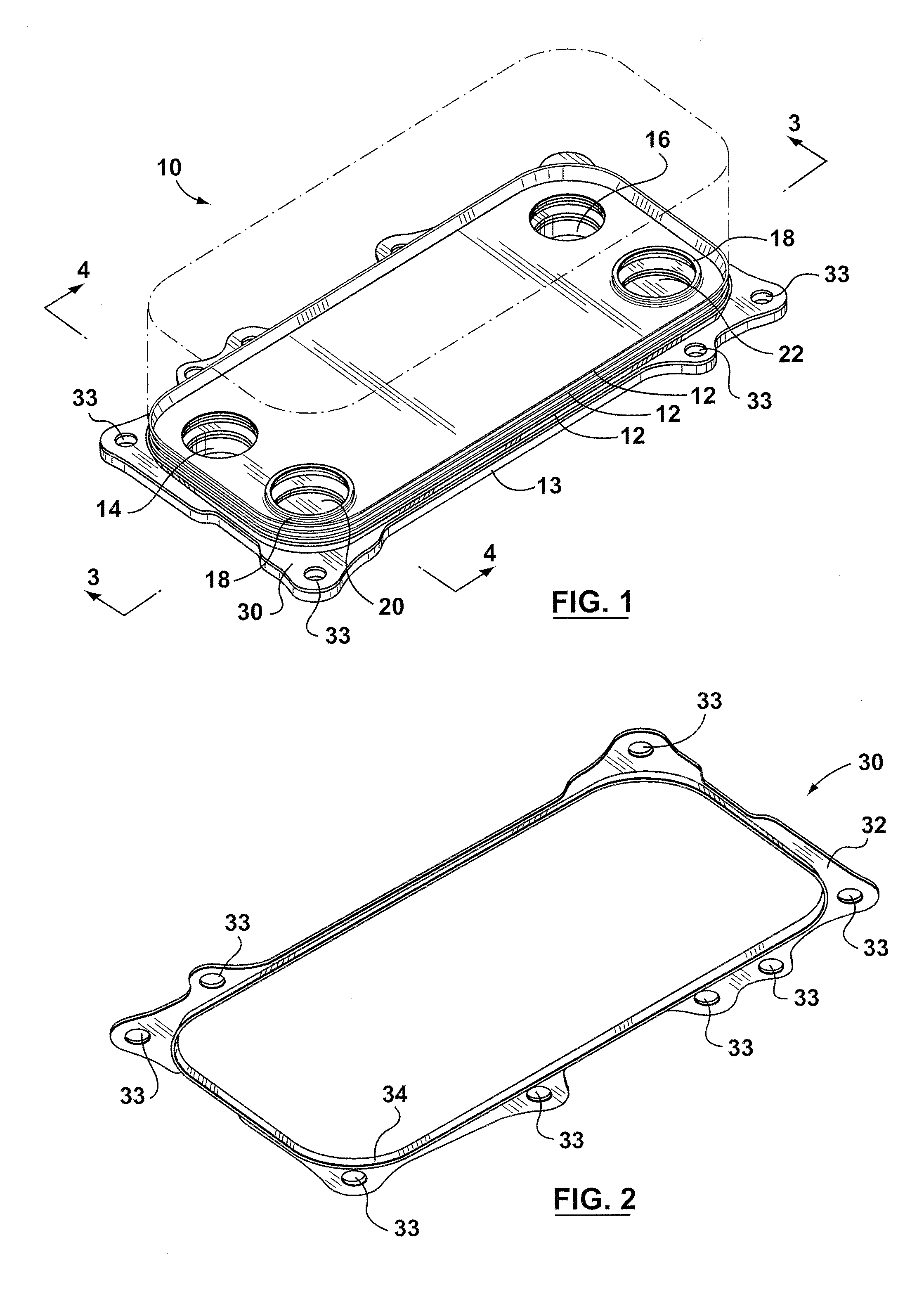

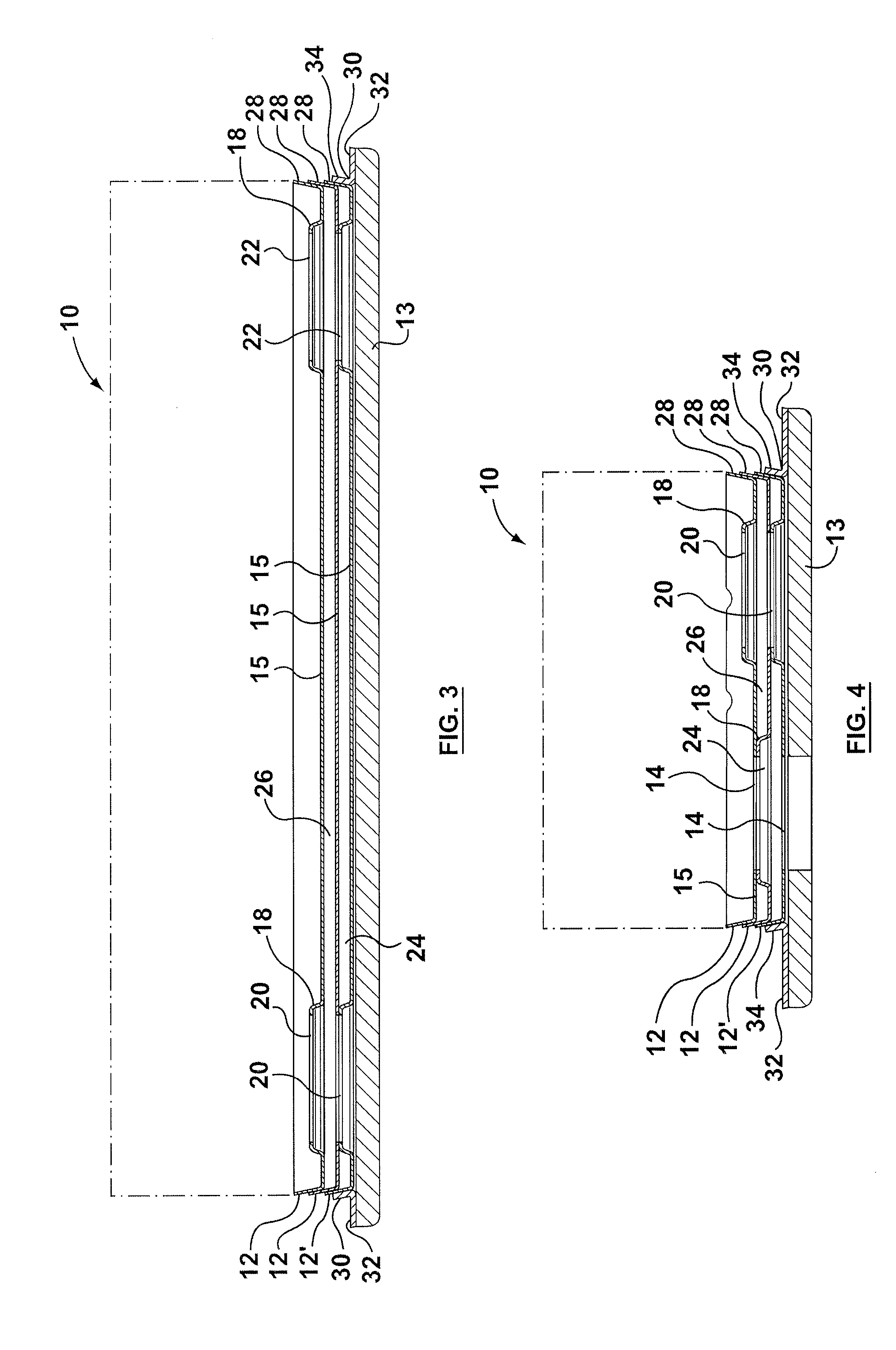

Reinforcement for dish plate heat exchangers

A reinforcing element for a heat exchanger of the type having nested dish plates with inclined, peripheral, overlapping walls, where at least one of the nested dish plates is attached to a mounting plate, the mounting plate extending beyond the outer periphery of the walls of the nested dish plates. The reinforcing element has a base flange attached to the mounting plate extending beyond the outer periphery of the walls of the nested dish plates. The reinforcing element also has a peripheral flange located in parallel, overlapping engagement with the inclined peripheral wall of the at least one dish plate attached to the mounting plate.

Owner:DANA CANADA CORP

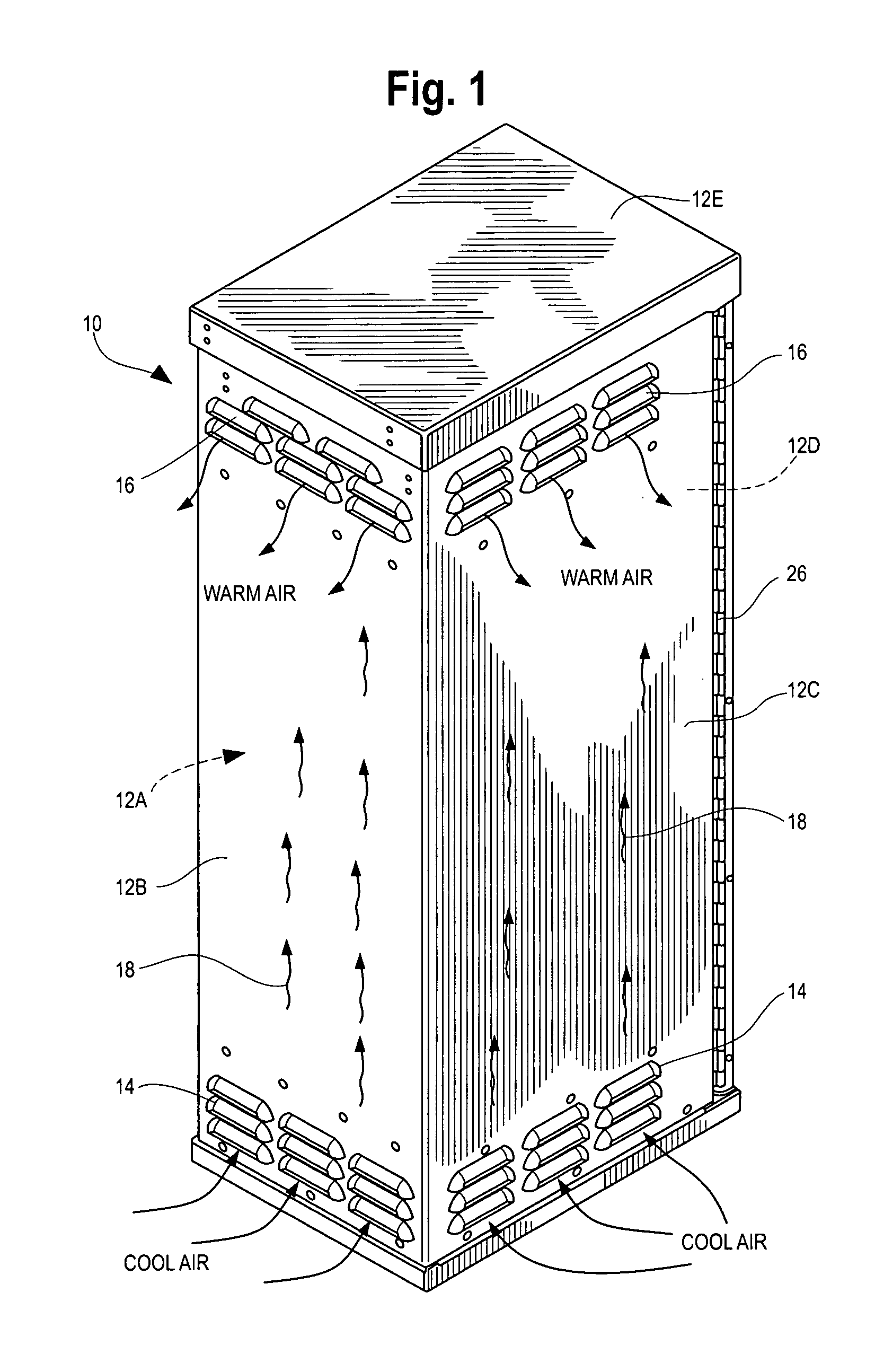

Air conditioning system and methods

An air conditioning system for conditioning the space within an enclosure having at least one inlet and one outlet, the system comprising first and second liquid / air heat exchangers; the first heat exchanger having an opening for receiving fresh air from the environment and for propelling the fresh air through the first heat exchanger to exchange heat with the liquid before it is entered into the enclosure, and the second heat exchanger having an opening for receiving air from the enclosure and for propelling it through the second heat exchanger to exchange heat with the liquid before it is expelled into the atmosphere. There are also provided methods for air-conditioning an enclosed space and for evaporation of industrial wastes.

Owner:AGAM ENERGY SYST

Air separation system for generating liquid oxygen and liquid nitrogen

This kind of air separation system obtaining liquid oxygen and liquid nitrogen at least includes an air separator mainly consisting of a fractionating tower and at least includes an equipment for recovering cold energy of liquefied natural gas mainly consisting of an liquefied natural gas heat exchanger, which still includes main heat exchanger, liquid-oxygen heat exchanger and liquid-nitrogen liquid air subcooler; oxygen is drawn out from the underpart of the upper column on the fractionating tower, and cools and liquefied in the liquid-oxygen heat exchanger as the liquid oxygen products; after nitrogen from the top of the upper column passes through a liquid-nitrogen liquid air subcooler and is reheated by main heat exchanger, some nitrogen enters into liquefied-natural-gas heat exchanger to recool and exchange heat to become high pressure nitrogen through primary compression and pressurization at least. And through throttling expansion and air-liquid separator, nitrogen and liquid nitrogen participate in recycling and other nitrogen as liquid-nitrogen products; energy consumption is reduced notably after using actually, power consumption which produces liquid oxygen of 1kg is 0.39kwh, while the power consumption of the traditional equal air separator is 1.0 to 1.25kwh, which is 2.4 to 3 times than the separator. And it is easy to popularize and apply.

Owner:HANGZHOU HANGYANG

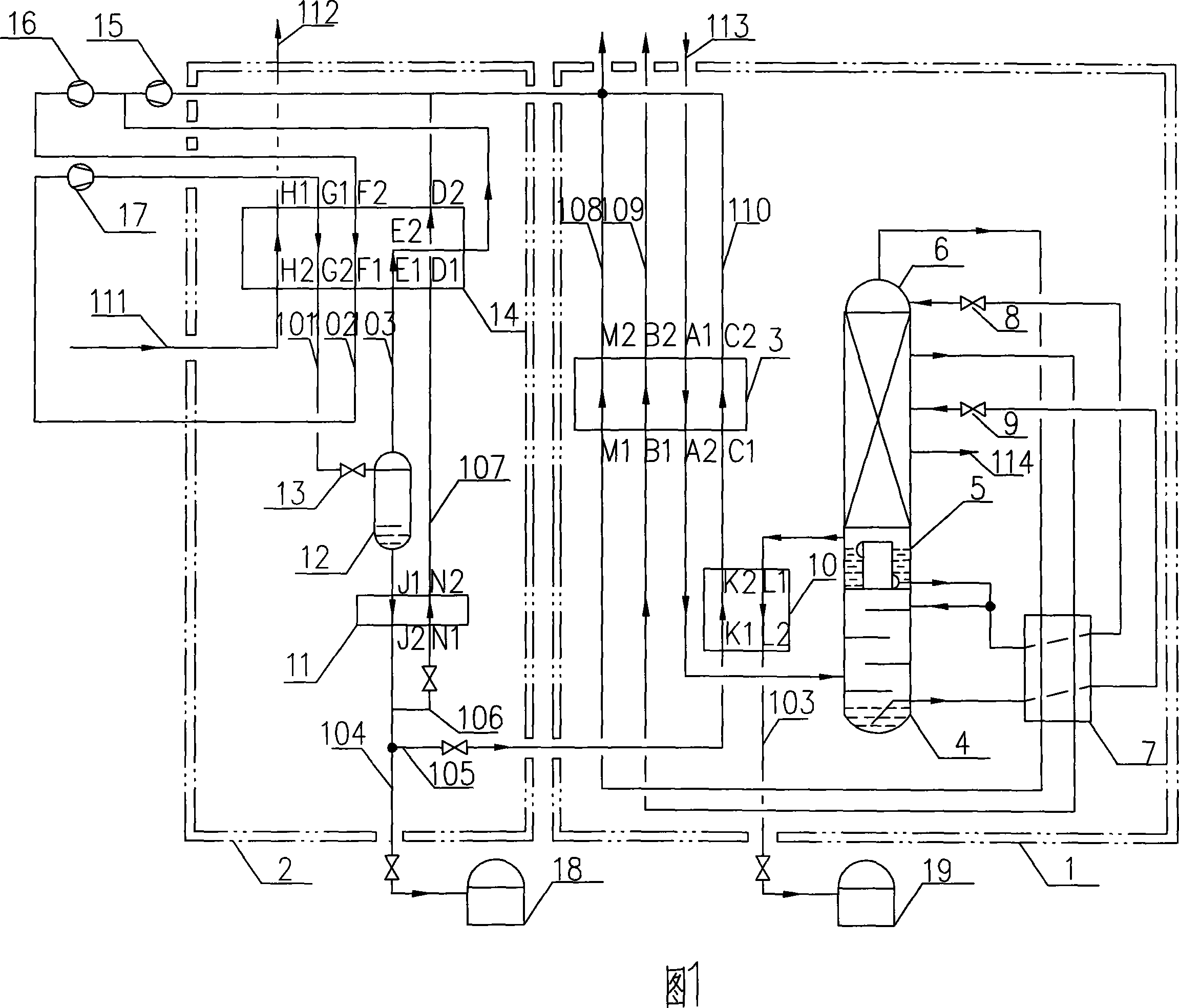

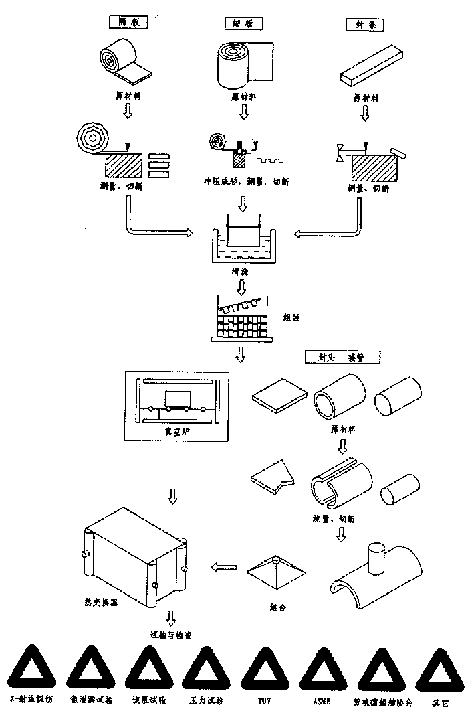

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

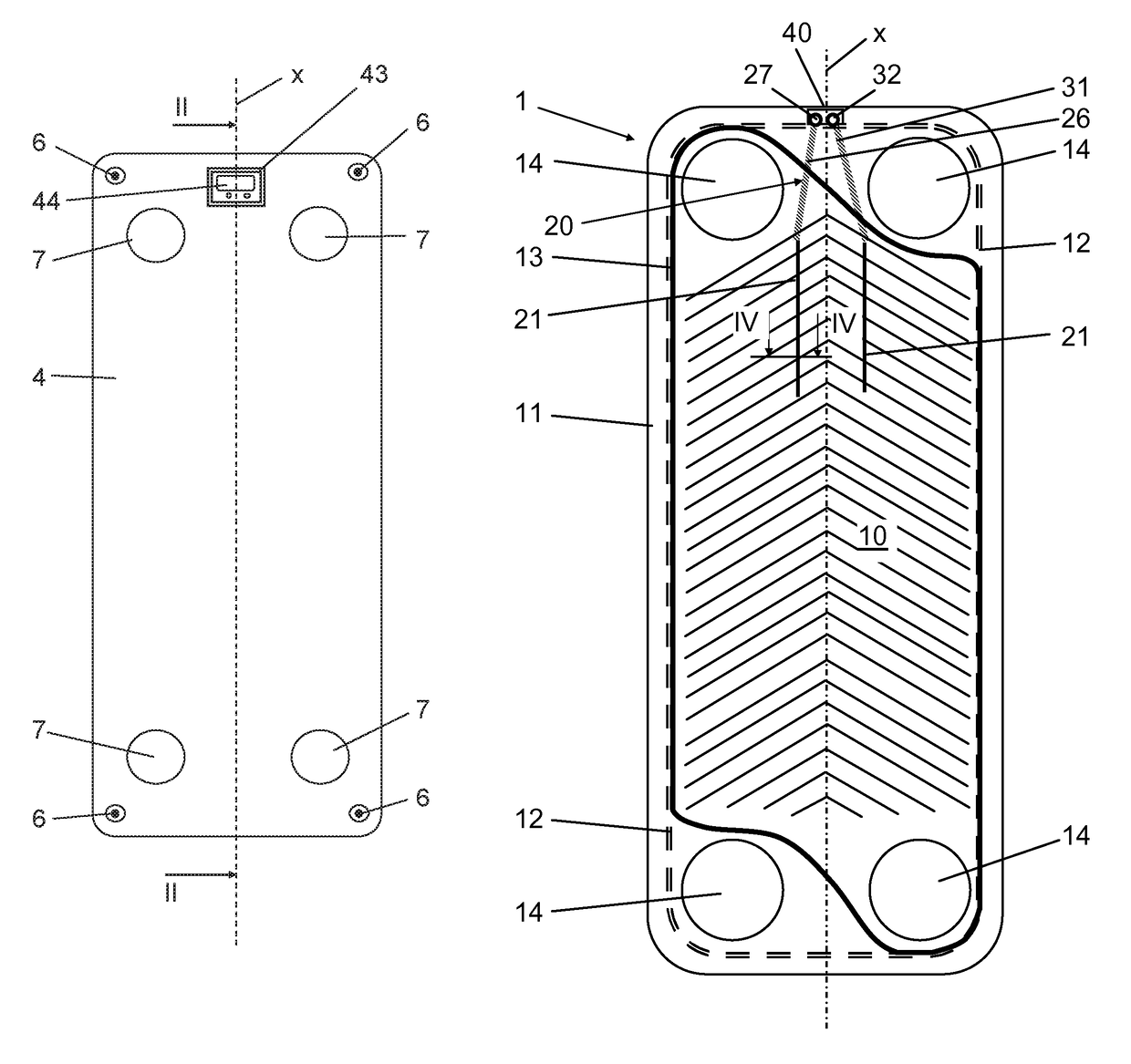

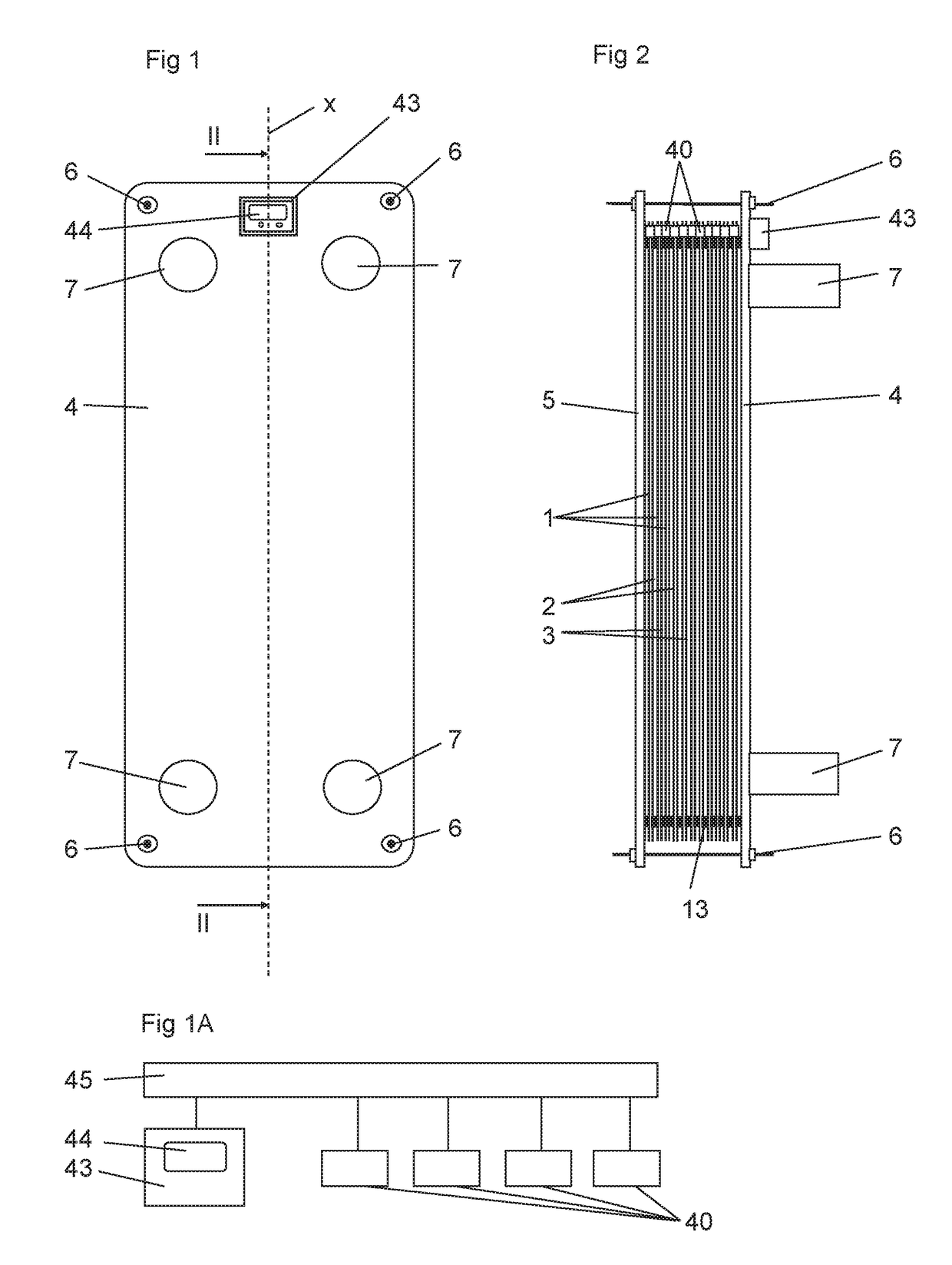

Heat exchanger plate and a plate heat exchanger with insulated sensor internal to heat exchange area

ActiveUS9739546B2Raise the possibilityDetection of leakageDetection of fluid at leakage pointAir-treating devicesDouble wallEngineering

A plate heat exchanger includes a heat exchanger plate having a heat transfer area and an edge area, extending around the heat transfer area. The heat exchanger plate is a double wall plate formed by two adjoining plates compressed to be in contact with each other. A sensor configured to sense at least one parameter and to produce a signal depending on the parameter includes a sensor probe that is provided between the adjoining plates.

Owner:ALFA LAVAL CORP AB

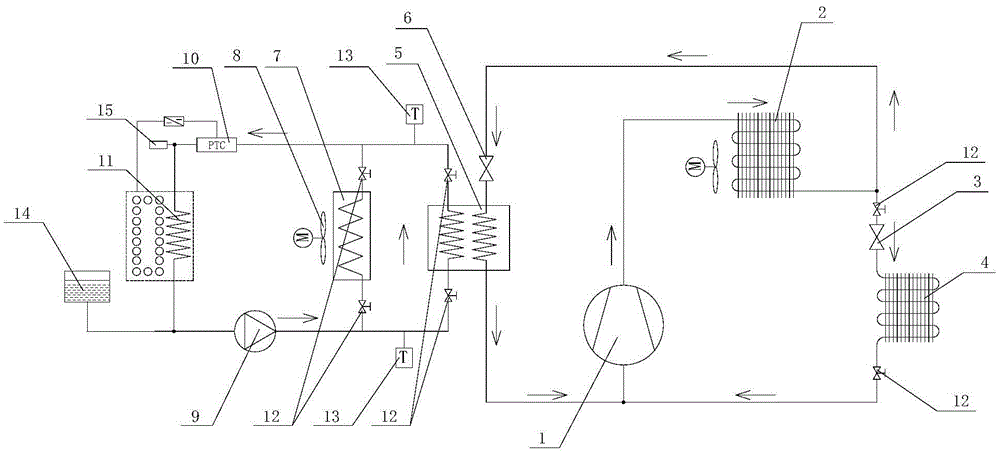

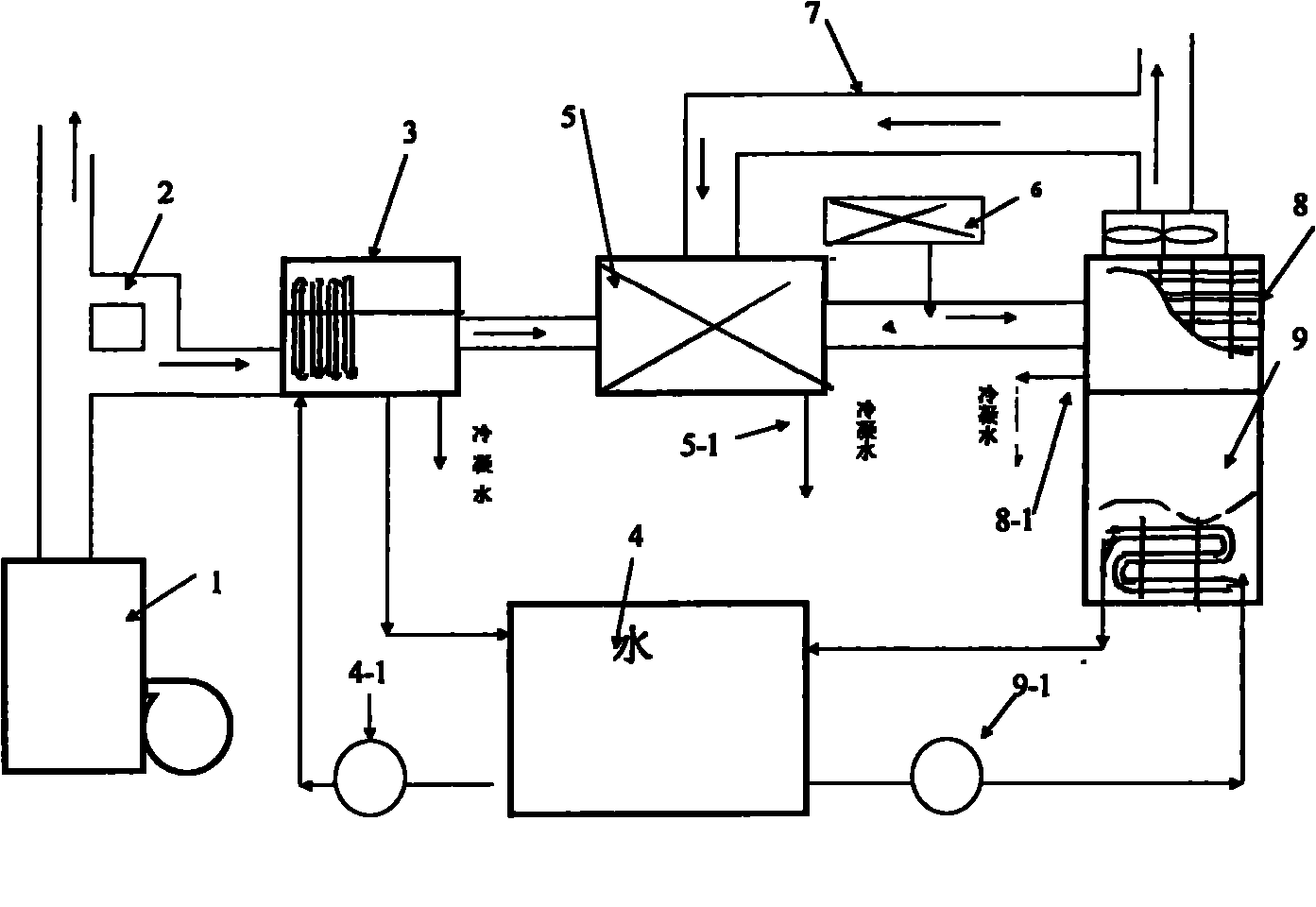

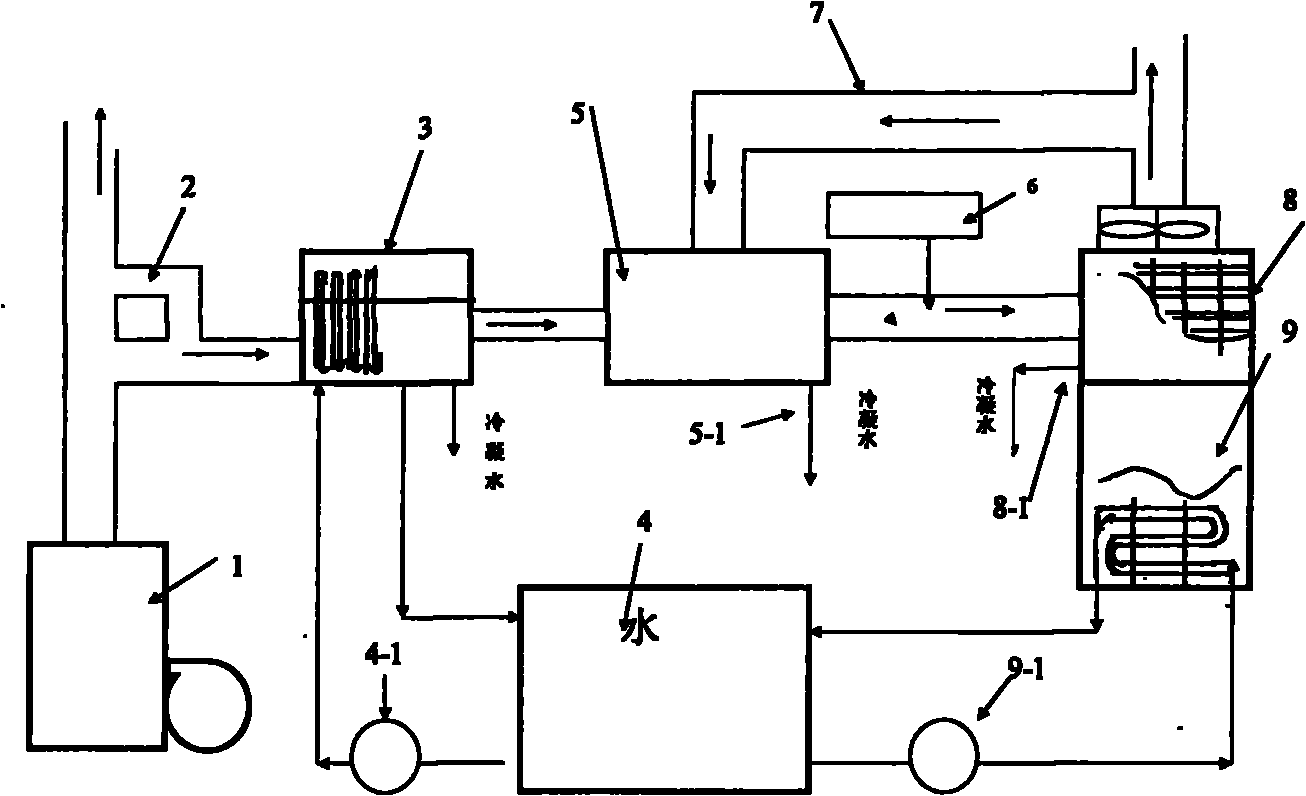

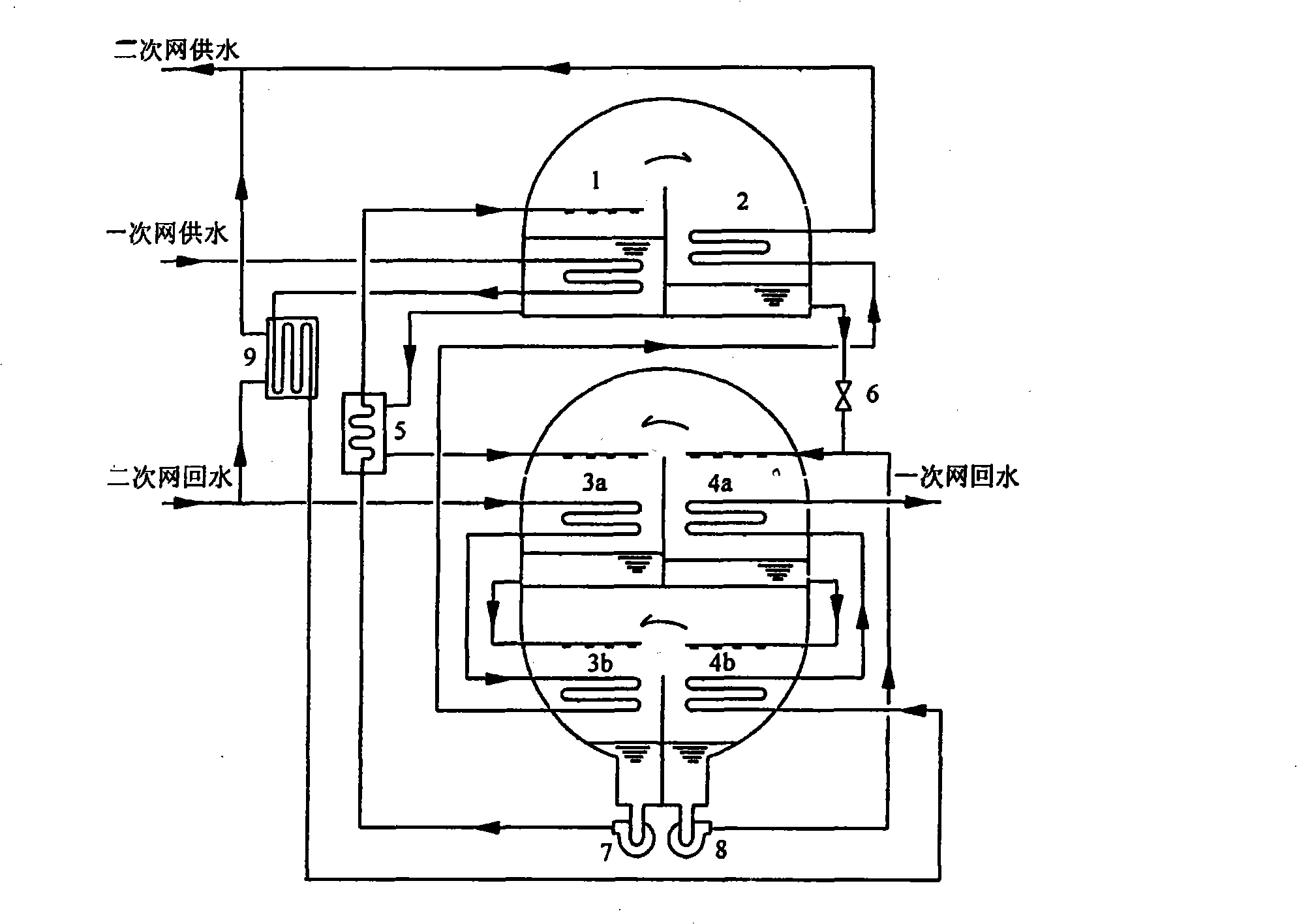

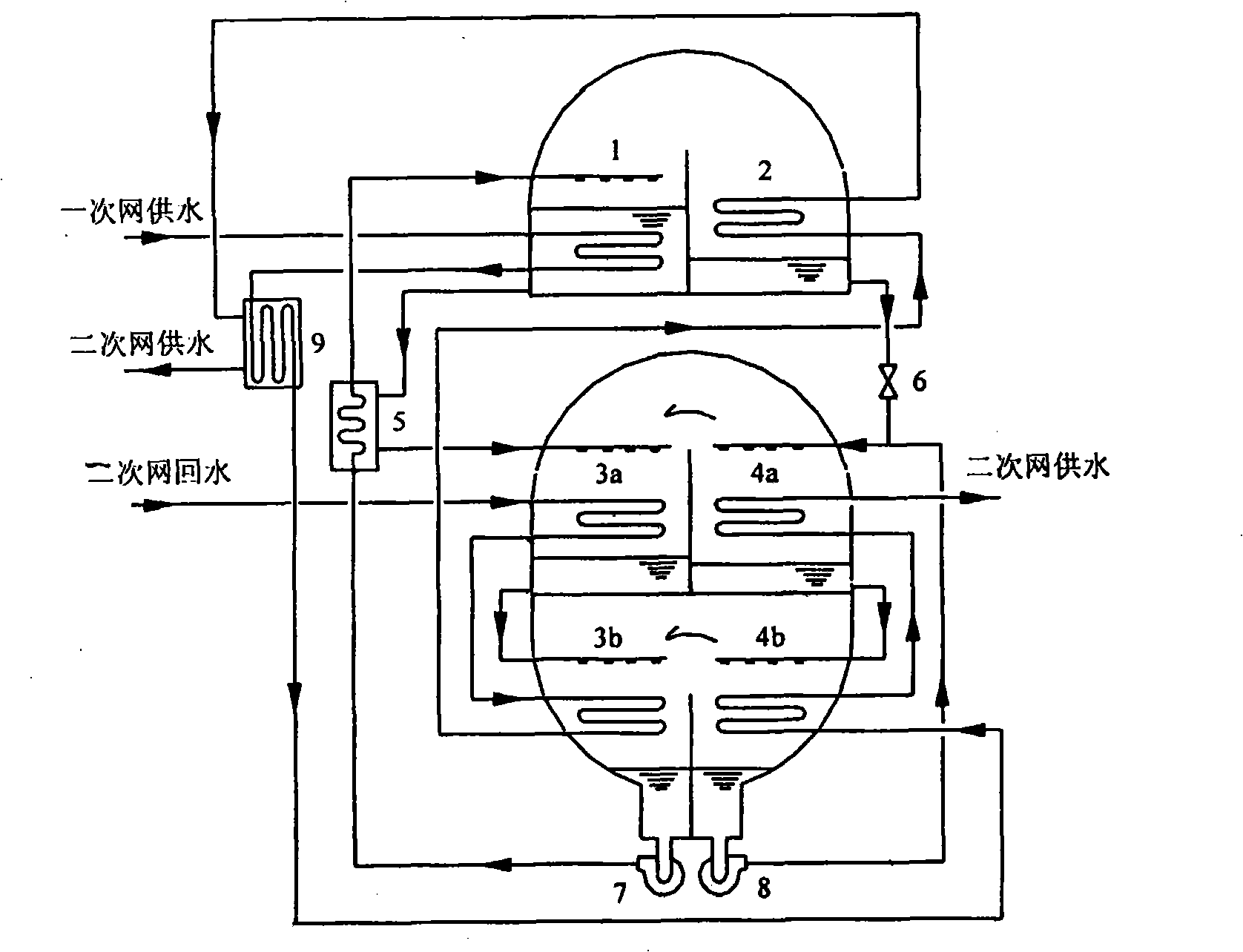

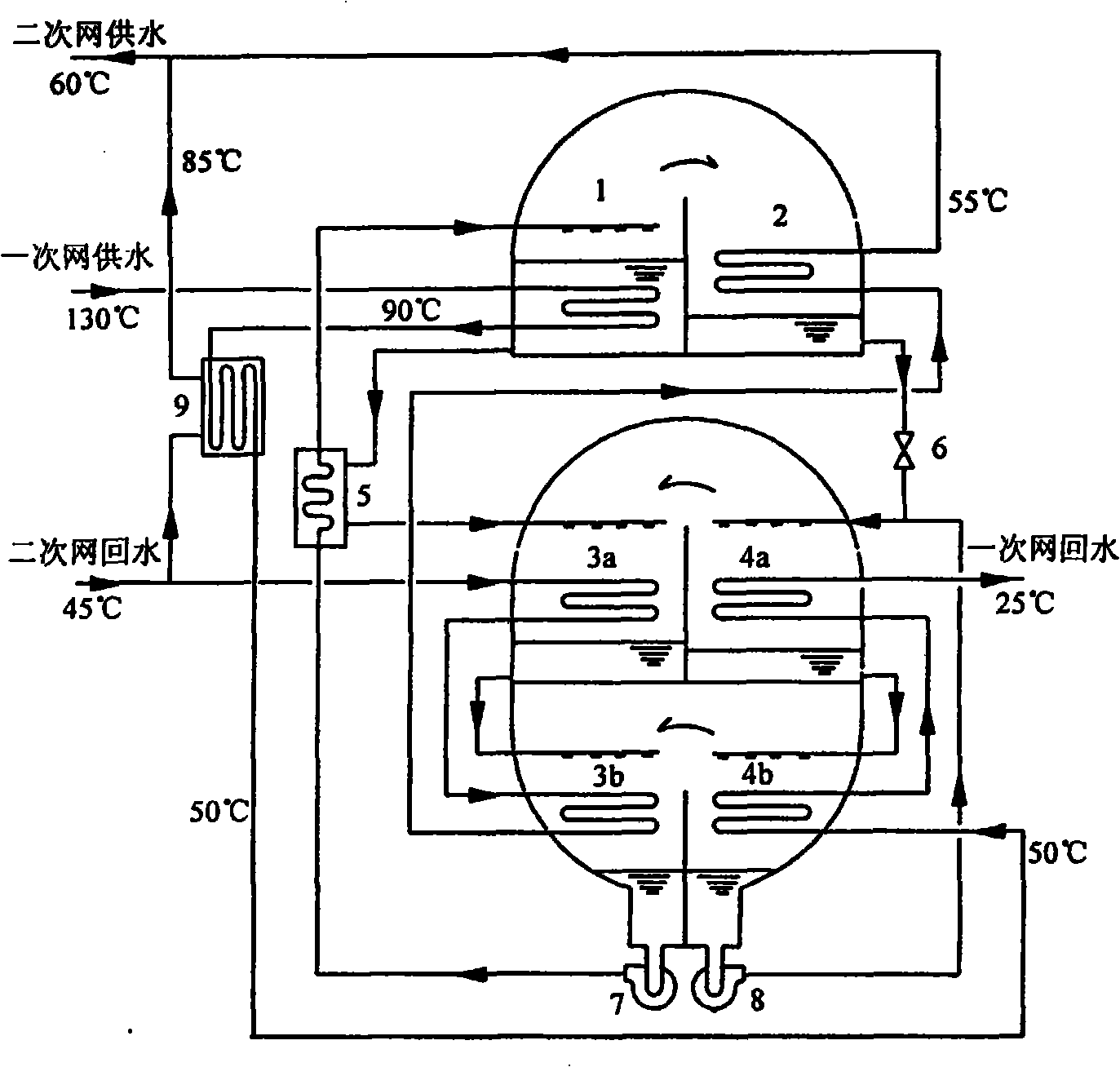

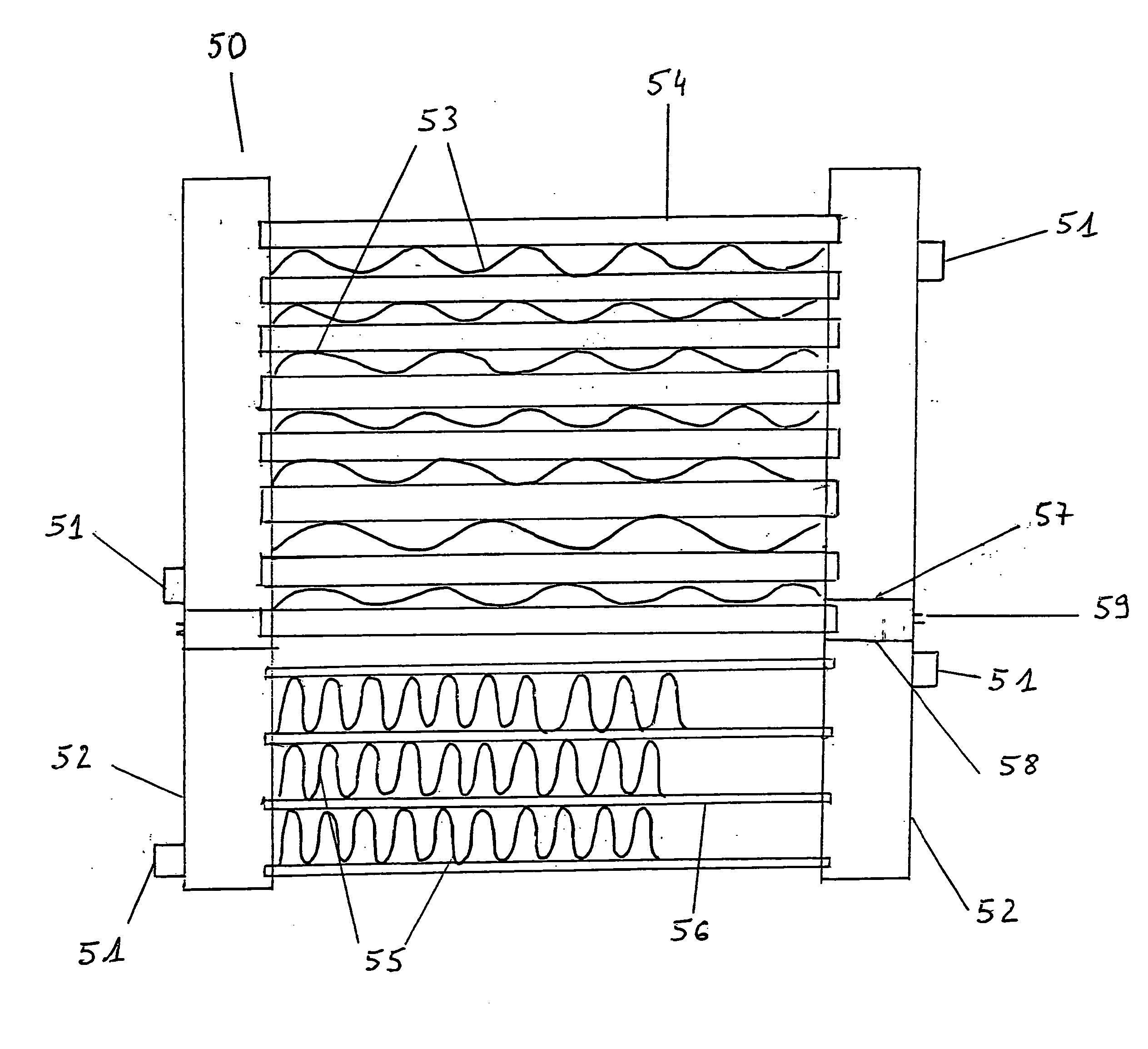

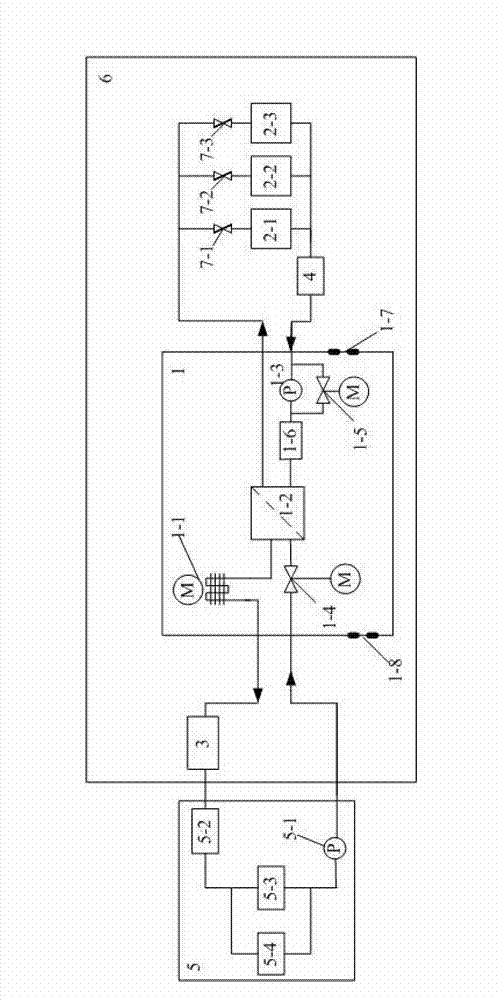

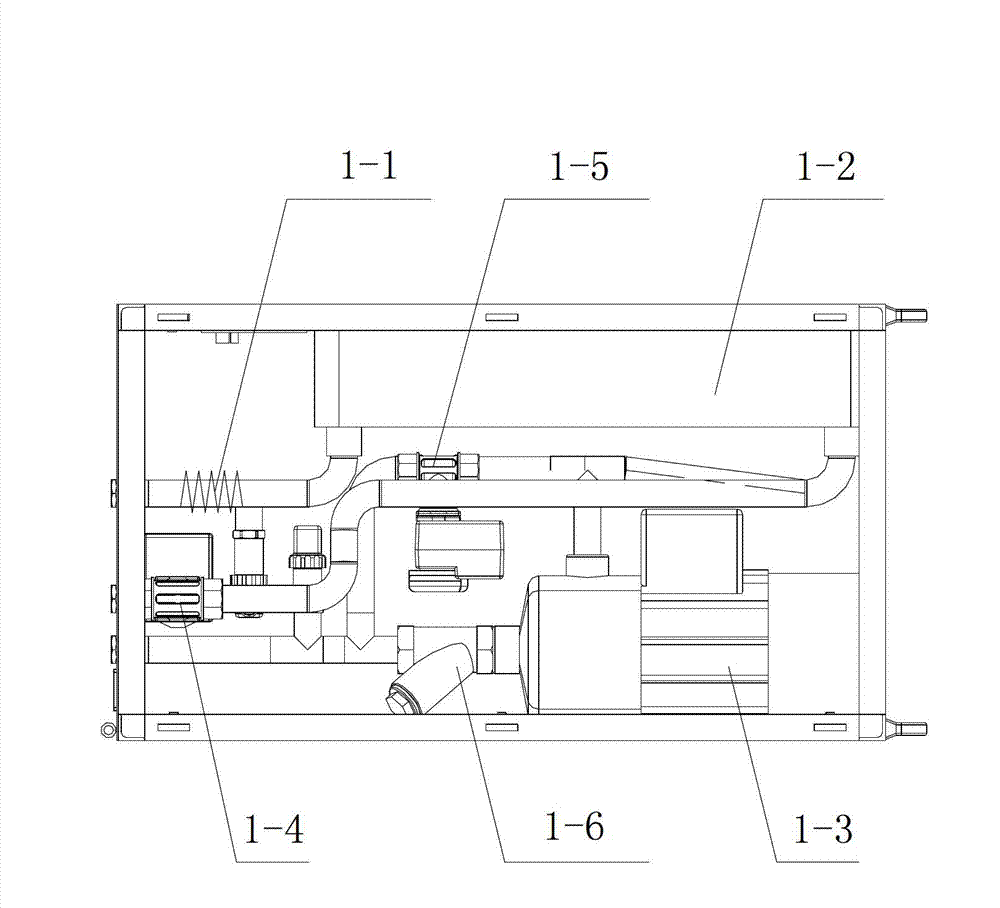

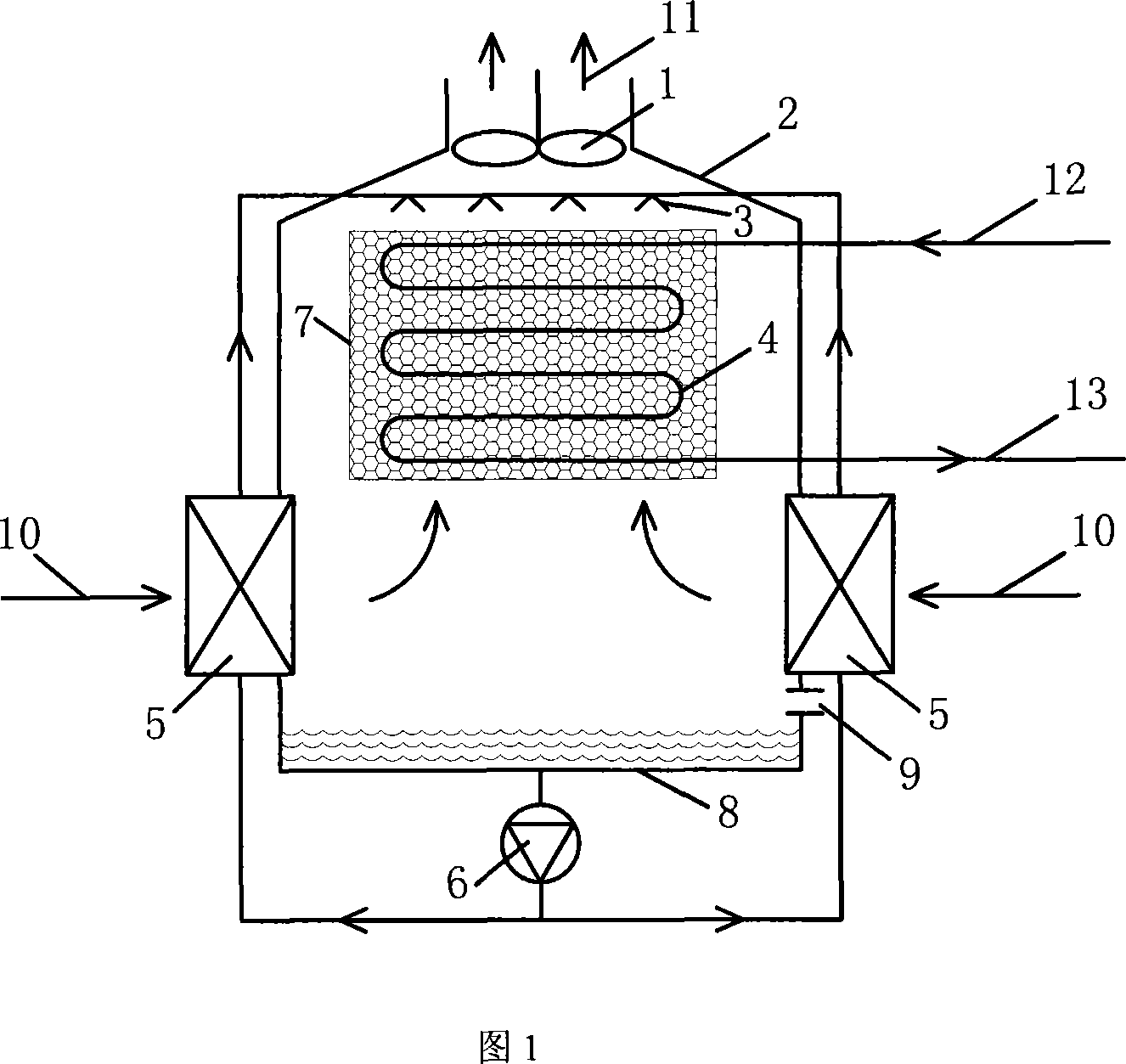

Integral type absorption type heat exchange machine unit

ActiveCN101329117ALower return water temperatureReduce initial investmentHeat pumpsClimate change adaptationThermal energyEvaporation

The invention relates to an integrated absorption heat-exchanging unit, belonging to the field of the heating and hot water supply devices and comprising a hot-water absorption heat-exchanger and a normal water-water heat exchanger which are combined, wherein, the hot-water absorption heat-exchanger adopts the means of two-level evaporation and two-level absorption. The unit comprises a generator, a condenser, a low-pressure absorber, a high-pressure absorber, a low-pressure evaporator, a high-pressure evaporator, a solution heat exchanger, a throttle device, a solution pump, a water-water heat exchanger and various connecting pipes and accessories. The invention can effectively reduce the backwater temperature of a first-time network of a collective heating system, thus greatly raising the temperature difference of between hot water supply and backwater of the first-time network, further greatly reducing the initial investment to the pipeline system and the power cost of the pump running, creating conditions for utilizing the low-quality heat energy even waste heat, etc., enhancing the comprehensive energy utilization efficiency of the system and reducing the heat supply cost.

Owner:北京华源泰盟节能设备有限公司

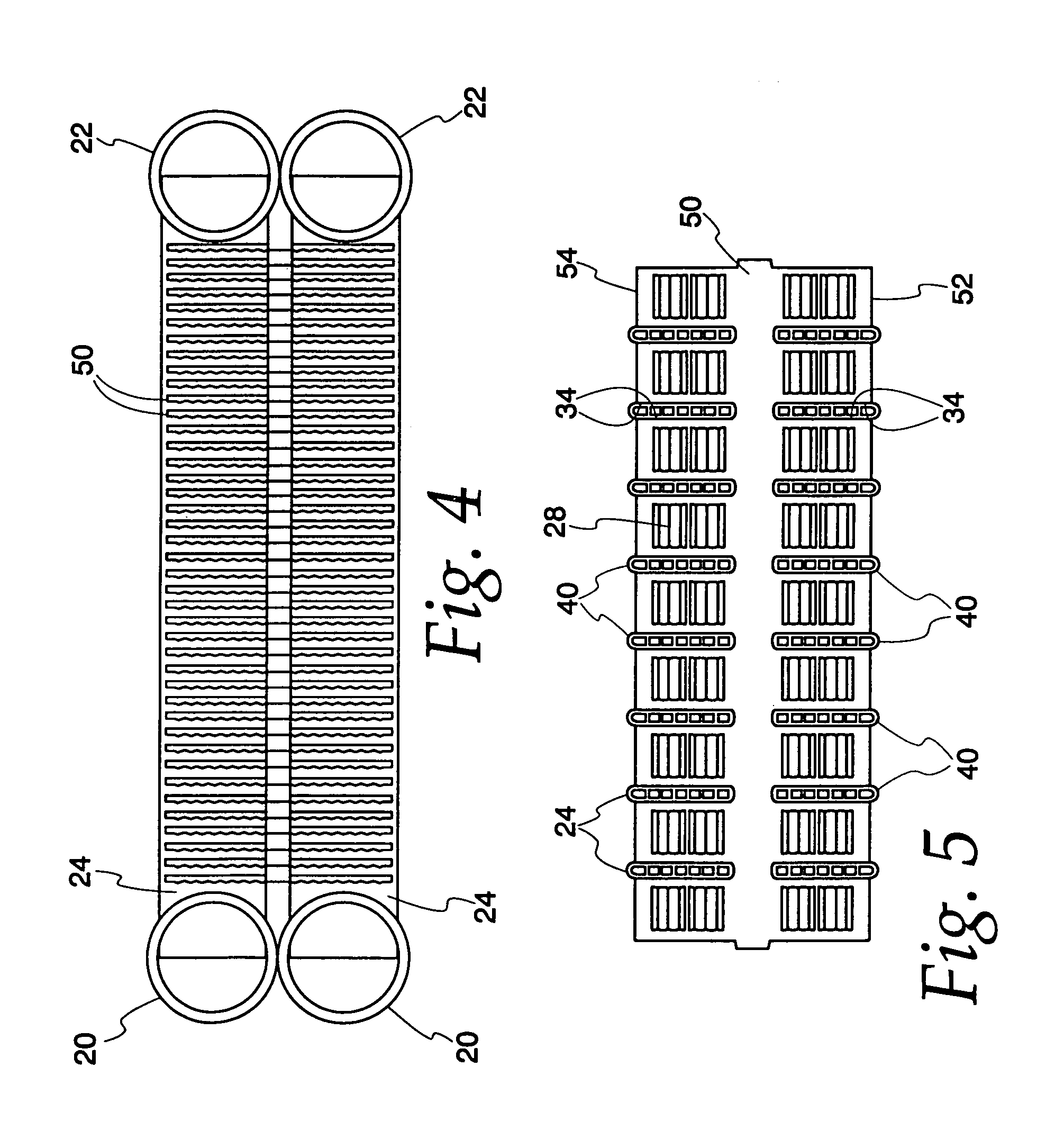

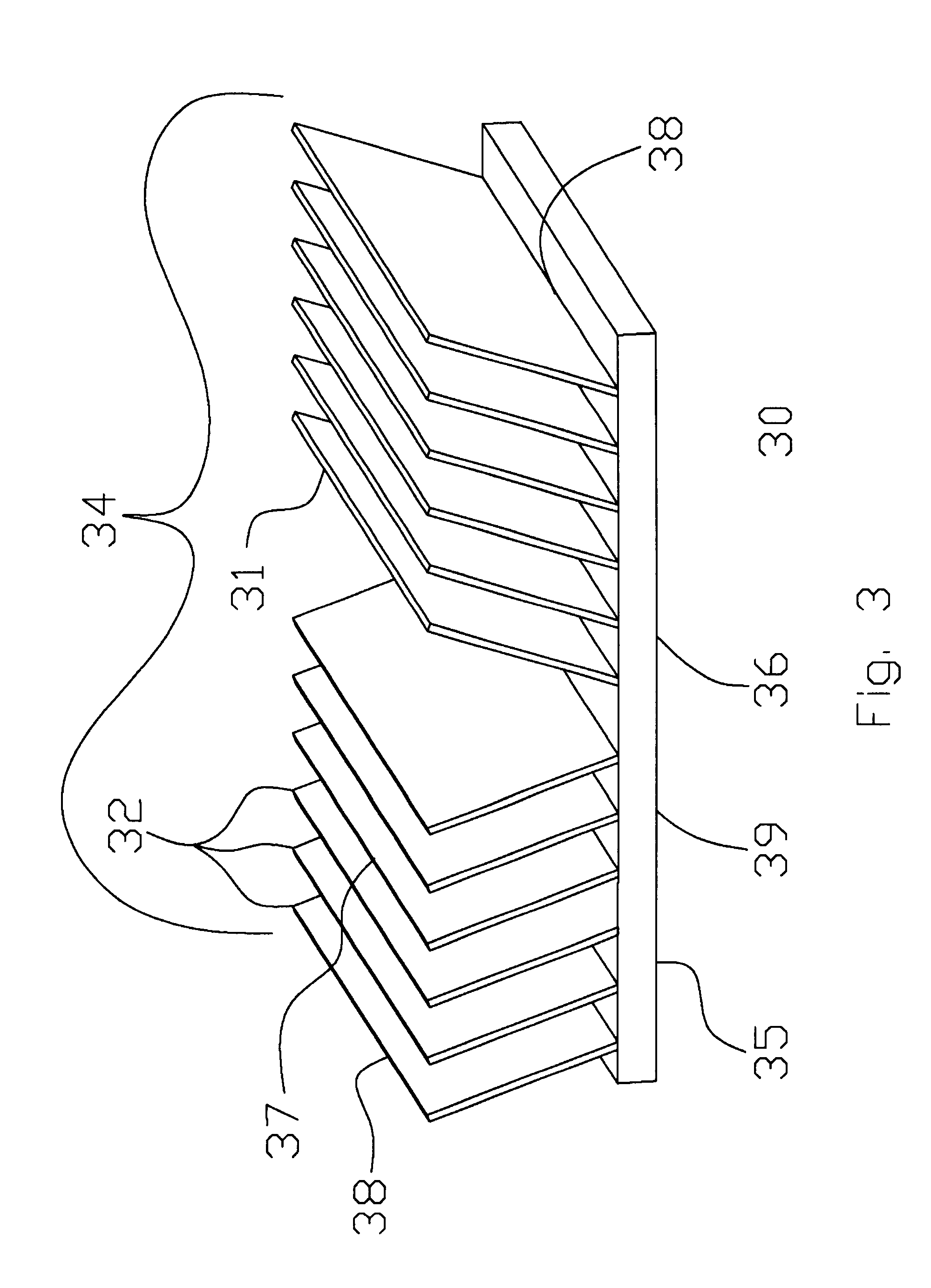

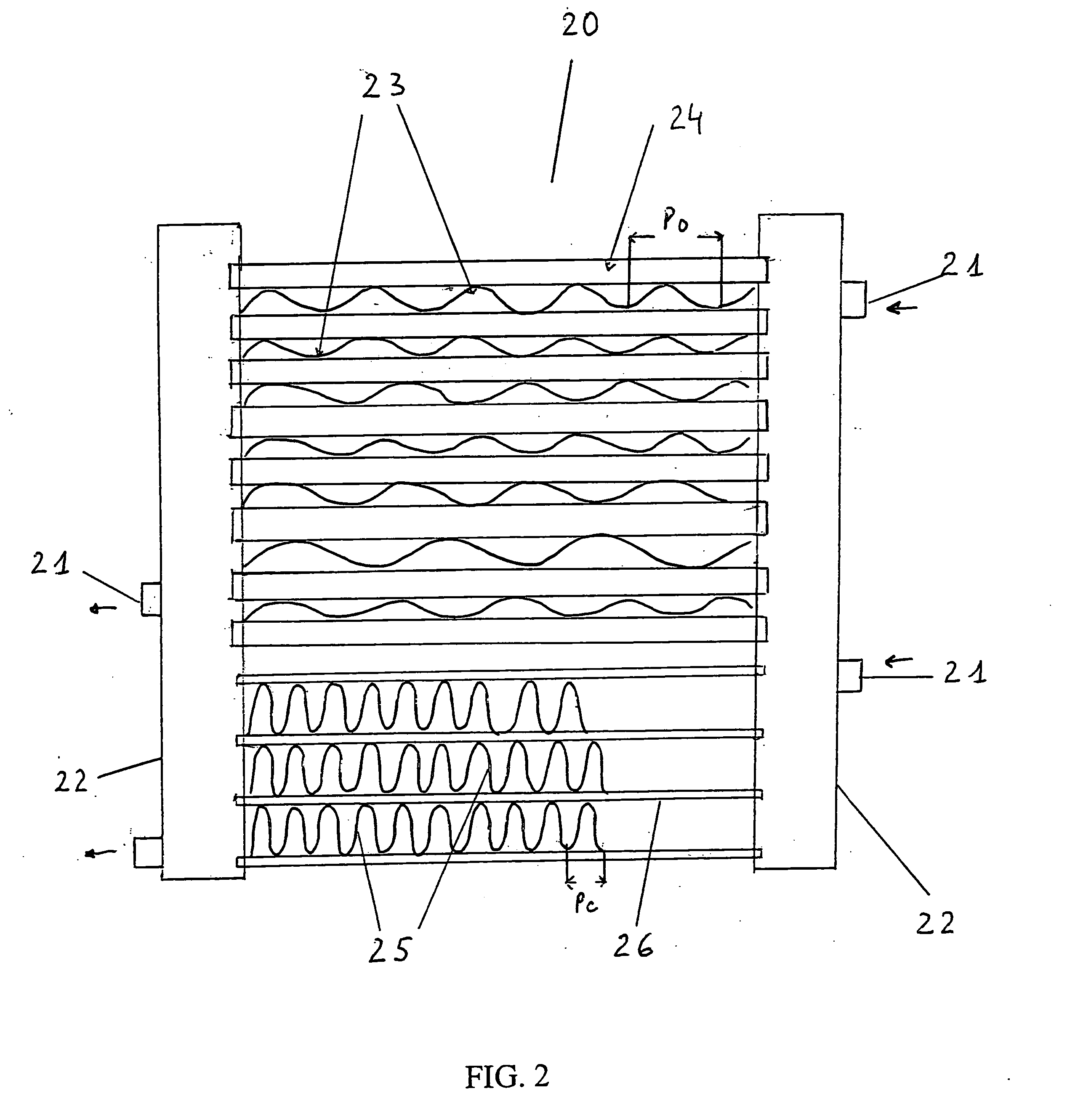

Multi-type fins for multi-exchangers

ActiveUS20050257921A1Improve heat exchange efficiencyFunction increaseSafety devices for heat exchange apparatusHeat exhanger finsEngineeringPlate fin heat exchanger

The present invention relates to optimized designs of heat exchangers, and, in particular, heat exchangers and assemblies comprising multi-exchangers or combo coolers comprising different heat exchanger parts or elements, and fins or separators of different types and / or characteristics on the different tube parts of the heat exchanger results. The two part heat exchanger is capable of being traversed by different fluids, and fins differ in characteristics, such as height and pitch, to increase overall heat exchanger efficiency.

Owner:VALEO INC

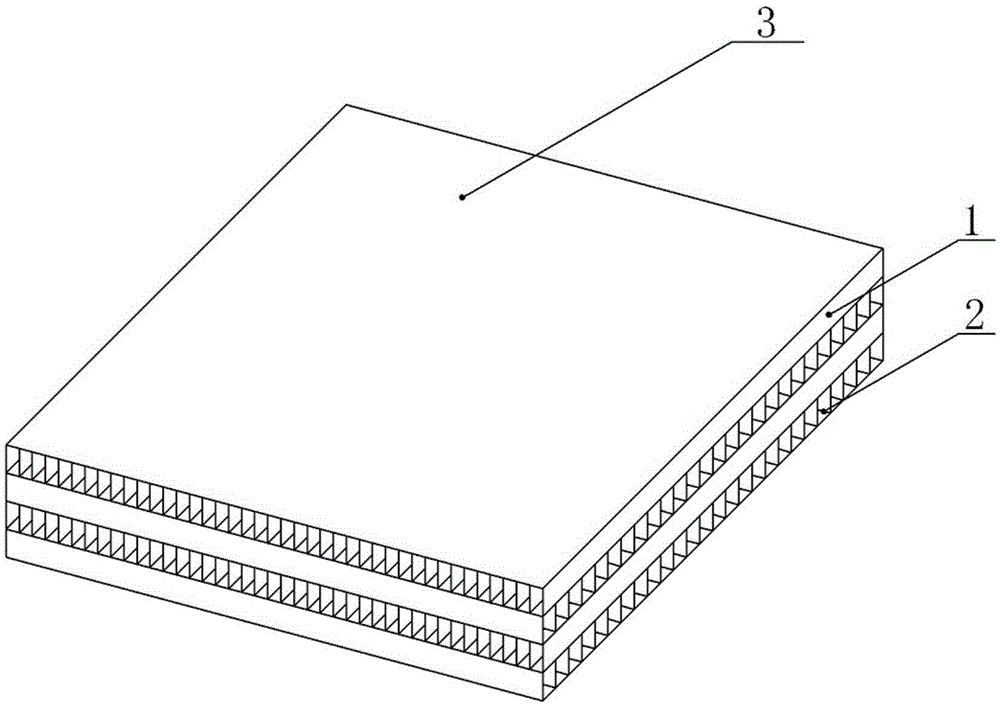

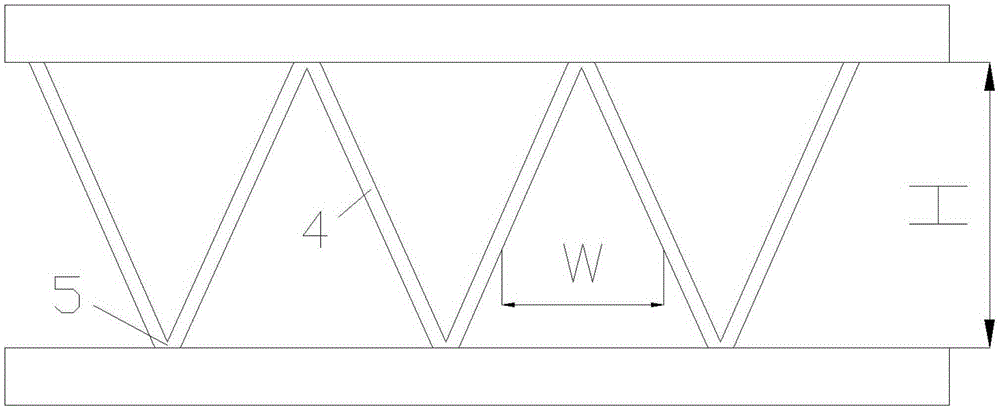

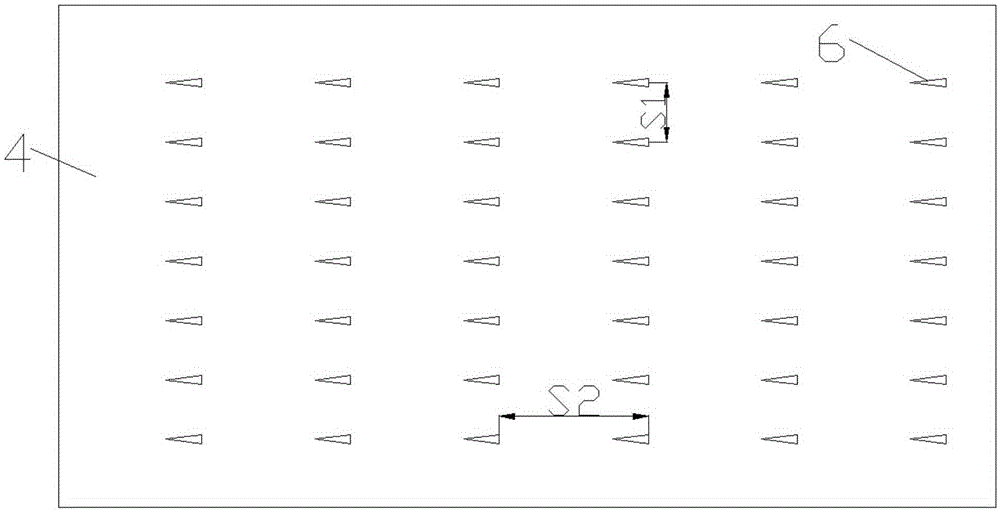

Triangular convex-stab-shaped plate-fin heat exchanger used for condensation of non-azeotropic multi-component mixture

ActiveCN105258535AOvercoming the problem of low heat transfer efficiencyImprove heat transfer efficiencyLaminated elementsStationary plate conduit assembliesBoiling pointParallel plate

The invention provides a triangular convex-stab-shaped plate-fine heat exchanger used for condensation of a non-azeotropic multi-component mixture. The plate-fin heat exchanger comprises parallel plates; fins are arranged between the plates; the fins comprise inclined parts inclining towards the plates; convex stabs are machined on the inclined parts in a stamping mode, so that fluid on the two sides of the inclined part circulates through holes formed in the inclined parts in a stamping mode, and the convex stabs extend outwards in the flowing direction of the mixture from the inclined parts. The novel triangular convex-stab-shaped plate-fine heat exchanger is suitable for being used in condensation of the non-azeotropic multi-component mixture, so that condensation of the non-azeotropic multi-component mixed medium is achieved, the heat exchange efficiency is improved, and the fluid flowing resistance is reduced.

Owner:SHANDONG UNIV

Server cabinet cooling system

InactiveCN103052304ASimple structureRealize modular productionCooling/ventilation/heating modificationsNuclear engineeringLiquid storage tank

The invention discloses a server cabinet cooling system which comprises a liquid cooling tank arranged in a server cabinet, a water-cooled heat sink in the server cabinet, an air radiator in the cabinet, a first liquid storage tank and an outdoor external cooling system, wherein the liquid cooling tank comprises a finned heat exchanger, a plate-type heat exchanger and a first water pump which are integrated in a tank; the hot water side of the plate-type heat exchanger, the first water pump, the first liquid storage tank and the water-cooled heat sink in the server cabinet are connected into a first circulation loop by virtue of pipelines; and the external cooling system, the air radiator in the cabinet, the finned heat exchanger and the cold water side of the plate-type heat exchanger are connected into a second circulation loop through pipelines. The server cabinet cooling system is simple in structure, realizable in modular production and convenient in installation, can be used for not only respectively cooling each server cabinet without local heat gathering, but also avoiding outputting heat into the cabinet, is high in cooling efficiency, and can be used for achieving an energy-saving effect.

Owner:GUANGZHOU GOALAND ENERGY CONSERVATION TECH

Cabinet with an environmentally-sealed air-to-air heat exchanger

Owner:TELLABS PETALUMA

Indirect evaporation type cooling/condensing device

InactiveCN101169299AOutlet temperature dropsRealize energy-saving operationEvaporators/condensersTrickle coolersCooling towerEvaporation

An indirect evaporating cooling / condensing device comprises a blower, a shell body, a spraying machine, a dividing wall type heat exchanger, a wind inlet, a water pump and a water collecting plate, and an air-water heat exchanger which is arranged on the wind inlet. The water pump pumps water from the water collecting plate and sends to the water channel of the air-water heart exchanger, cools the environmental air inducted from the wind inlet enters the spraying machine after being cooled; the water which flows out from the spraying machine is sprayed on the outer surface of the dividing wall type heat exchanger, the water flows back to the water collecting plate depending on the gravity; and the cooled medium which enters into the dividing wall type heat exchanger from the entrance is cooled by the water sprayed from the spraying machine and then flow out from the cooled medium exit. The invention not only can be used as the enclosed type cooling tower, but also can be used as the evaporating type condenser; and compared with the prior art, the utility model can make the temperature of the out flowing liquid of the liquid with single-phase much lower in winter, and also can reduce the condensing temperature of the refrigerating and the chemical liquid system; the utility model has cooling / condensing function for the whole year and is useful for the energy saving running of air-conditions, refrigerating and chemical systems.

Owner:TSINGHUA UNIV

Method for producing aluminum plate-fin heat exchanger

InactiveCN1943973AHigh strengthLow strength, good cleaning qualityDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesShielding gasNitrogen

The process of producing aluminum plate-fin heat exchanger includes the steps of blanking, washing, mounting, brazing, argon arc welding and pressure test. The present invention adopts numerically controlled lathe with high machining precision for blanking; ultrasonic washing for high washing efficiency and high washing quality; continuous high purity nitrogen protected brazing for high brazing quality; and argon arc welding with welding robot for high welding quality and high production efficiency.

Owner:管保清 +1

Method for brazing compact efficient titanium alloy plate-fin heat exchanger

InactiveCN101623785AAvoid misalignmentEnsure brazing qualitySoldering apparatusHeat exchange apparatusTitaniumLeakage test

The invention relates to a method for brazing a compact efficient titanium alloy plate-fin heat exchanger, which adopts an amorphous titanium based brazing filler metal brazing titanium alloy with lower melting point which is between 820 and 840 DEG C, wherein the optimum clearance of the amorphous titanium based brazing filler metal brazing titanium alloy is between 20 and 90 microns, the optimum brazing temperature is between 850 and 900 DEG C, the optimum brazing time is between 10 and 15 minutes, the heating rate before soaking a workpiece is between 10 and 15 DEG C per minute, the heating rate for brazing after the soaking is 15 DEG C per minute, the cooling rate for the brazing filler metal to become solid from liquid is not less than 15 DEG C per minute, and a vacuum system only can be closed when the temperature is below 150 DEG C. Through strict selection and purchase of materials, precise part machining, careful part cleaning, brazing filler metal arrangement according to a process, precise assembling and clamping, and performing brazing according to a stated brazing process, a helium gas leakage test shows that the integral leakage of the product is 9*10<-8>PaM<3> / S which is in accordance with the standard requirement.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

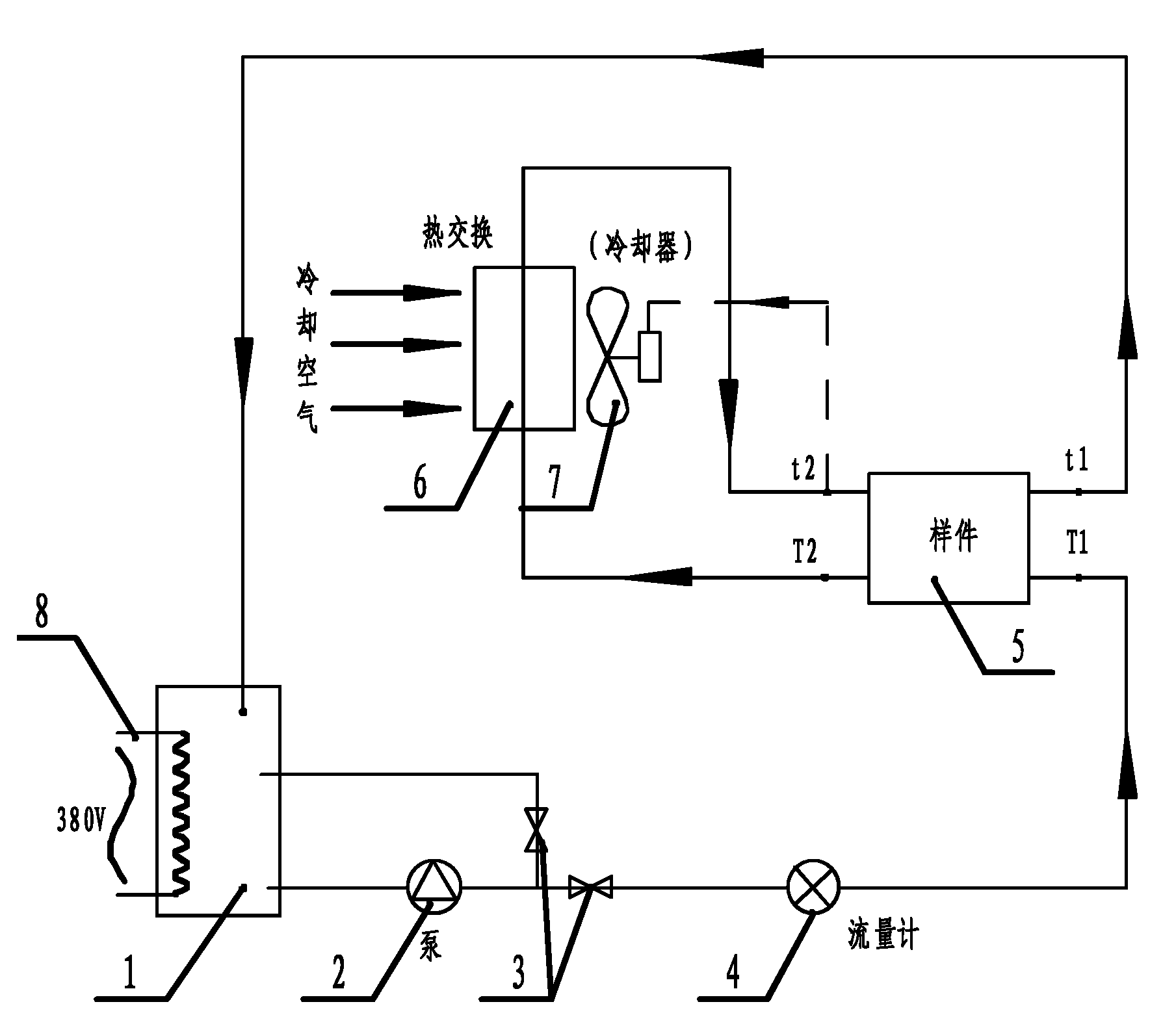

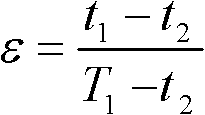

Method and device for testing heat transfer performance of fin surface of plate-fin heat exchanger

ActiveCN102135511AHigh measurement accuracyFew measurement parametersMaterial heat developmentMeasurement deviceLiquid medium

The invention discloses a method and a device for testing heat transfer performance of a fin surface of a plate-fin heat exchanger. The device comprises a heating container, a pump, a valve, a flow meter, an experiment sample, a cooler used for cooling liquid, a connecting pipeline, a liquid medium, a data acquisition instrument and a computer by which a circulation loop is formed. Heat transfer thermal resistance of one side is separated by testing the flow of the liquid medium passing through the heat exchanger and the temperature of four inlets / outlets in real time and utilizing the principle of equal surface thermal resistance of a high-temperature side and a low-temperature side and thermal resistance separation, and a functional relation between the high-temperature side and the low-temperature side is further obtained by calculating heat transfer coefficient h of the fin surface and flow Reynolds number Re according to structural parameters and serves as basic data for design and calculation of the heat exchanger; moreover, a functional relation obtained from new fins serves as a reference and a basis for comparing and judging mould abrasion, service life and mould repair and is simultaneously used for comparing performance difference among the fins with different structural parameters. The method has the advantages of few measurement parameters, simple measurement device and high measurement accuracy.

Owner:ZHEJIANG YINLUN MACHINERY

Heat Exchanger

ActiveUS20110139419A1Increase flow resistanceLow flow resistanceHeat exhanger finsHeat transfer modificationEvaporationEngineering

The invention refers to a plate heat exchanger where the heat exchanger comprises a first flow channel between a first plate and a second plate, and where the flow channel comprises a first distribution passage, a heat transfer passage and a second distribution passage, where the heat transfer passage is vertically divided in a lower and an upper heat transfer passage and where the lower heat transfer passage is horizontally divided in a plurality of adjacent heat transfer zones, where the intermediate angle between the ridges and grooves in any of the heat transfer zones of the lower heat transfer passage is at least 30° larger than the intermediate angle of the upper heat transfer passage. The advantage of the invention is that an improved heat exchanger is provided, having an increased thermal performance and an improved evaporation capacity.

Owner:ALFA LAVAL CORP AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com