Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

335 results about "Heat rejection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

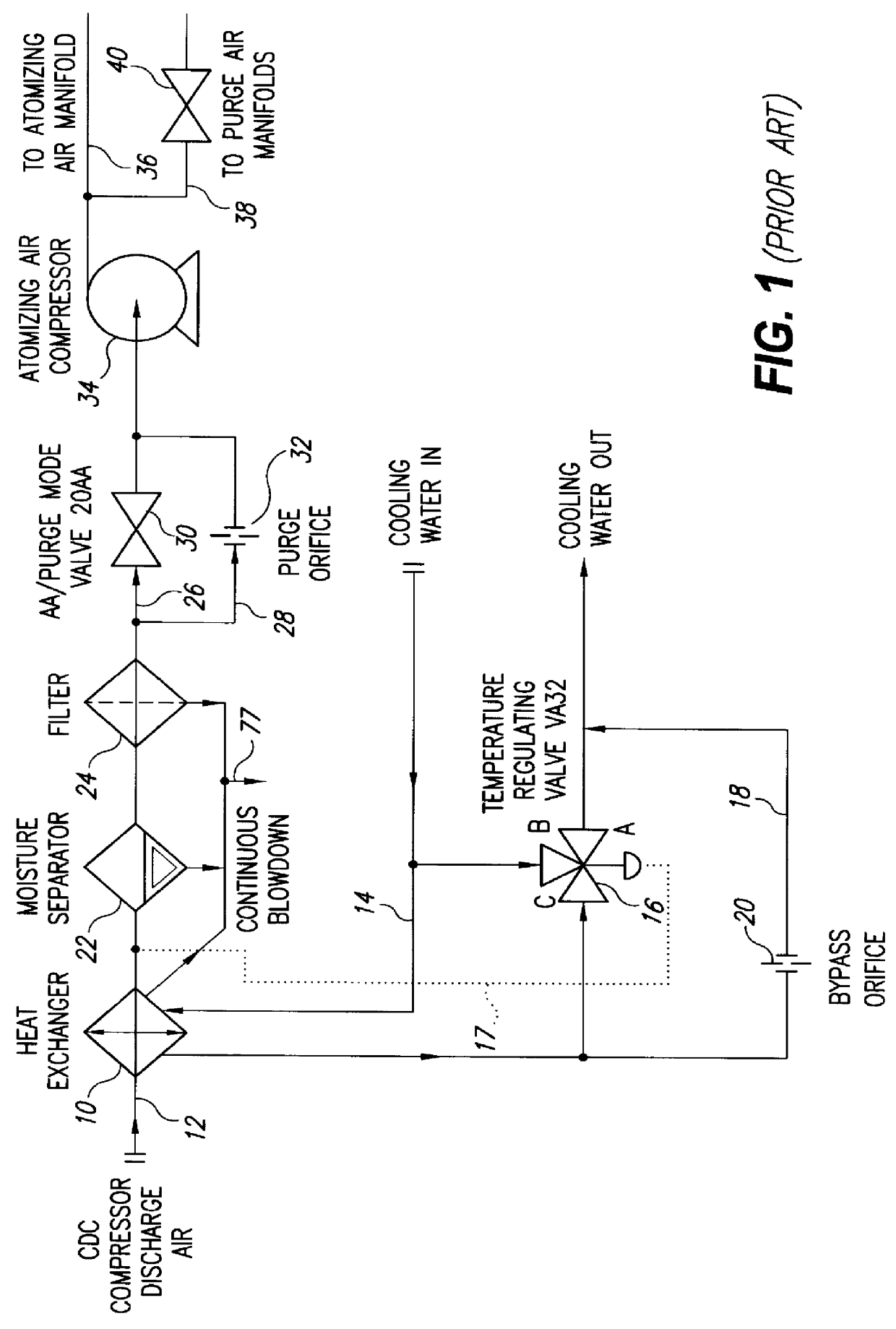

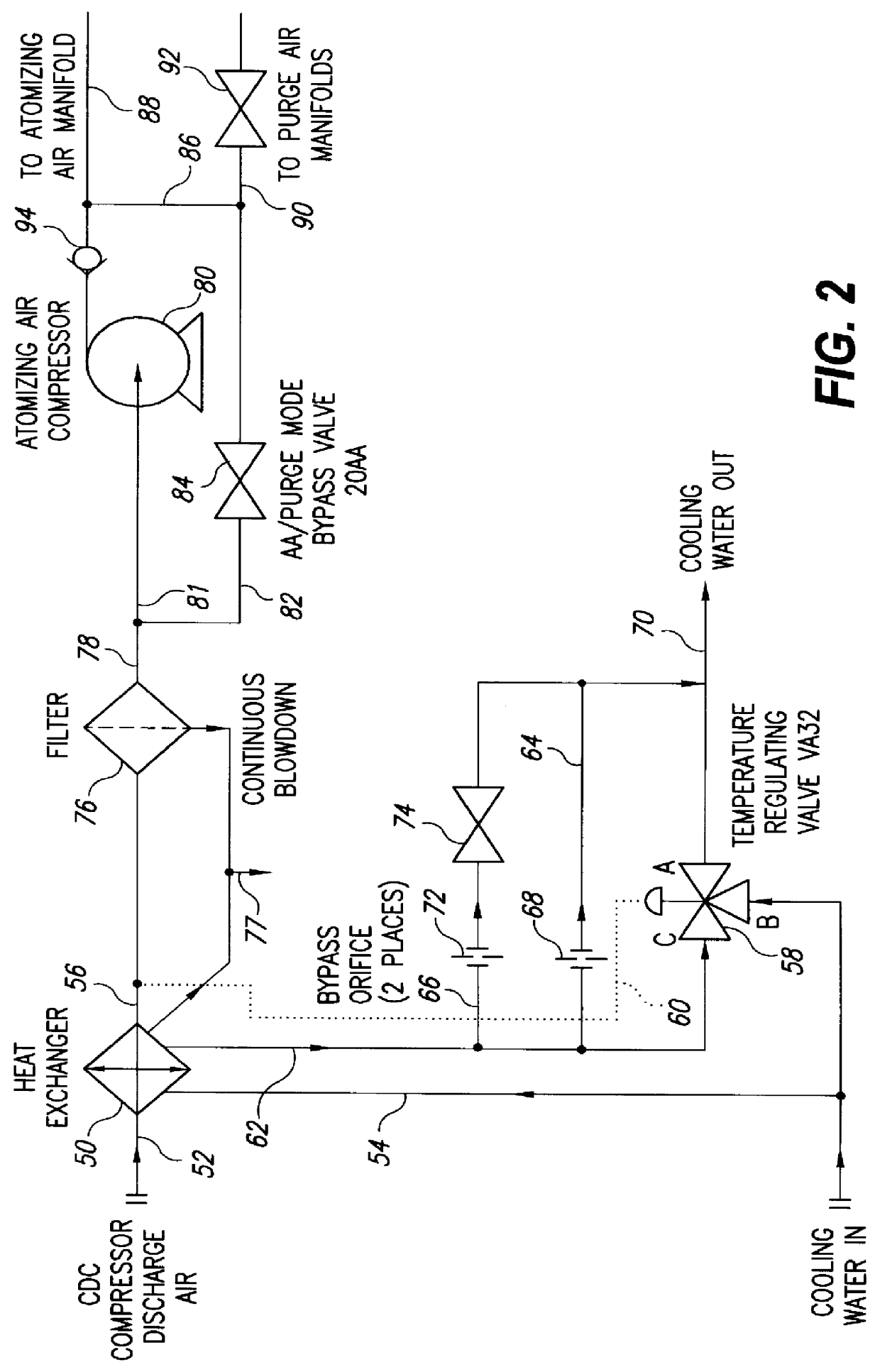

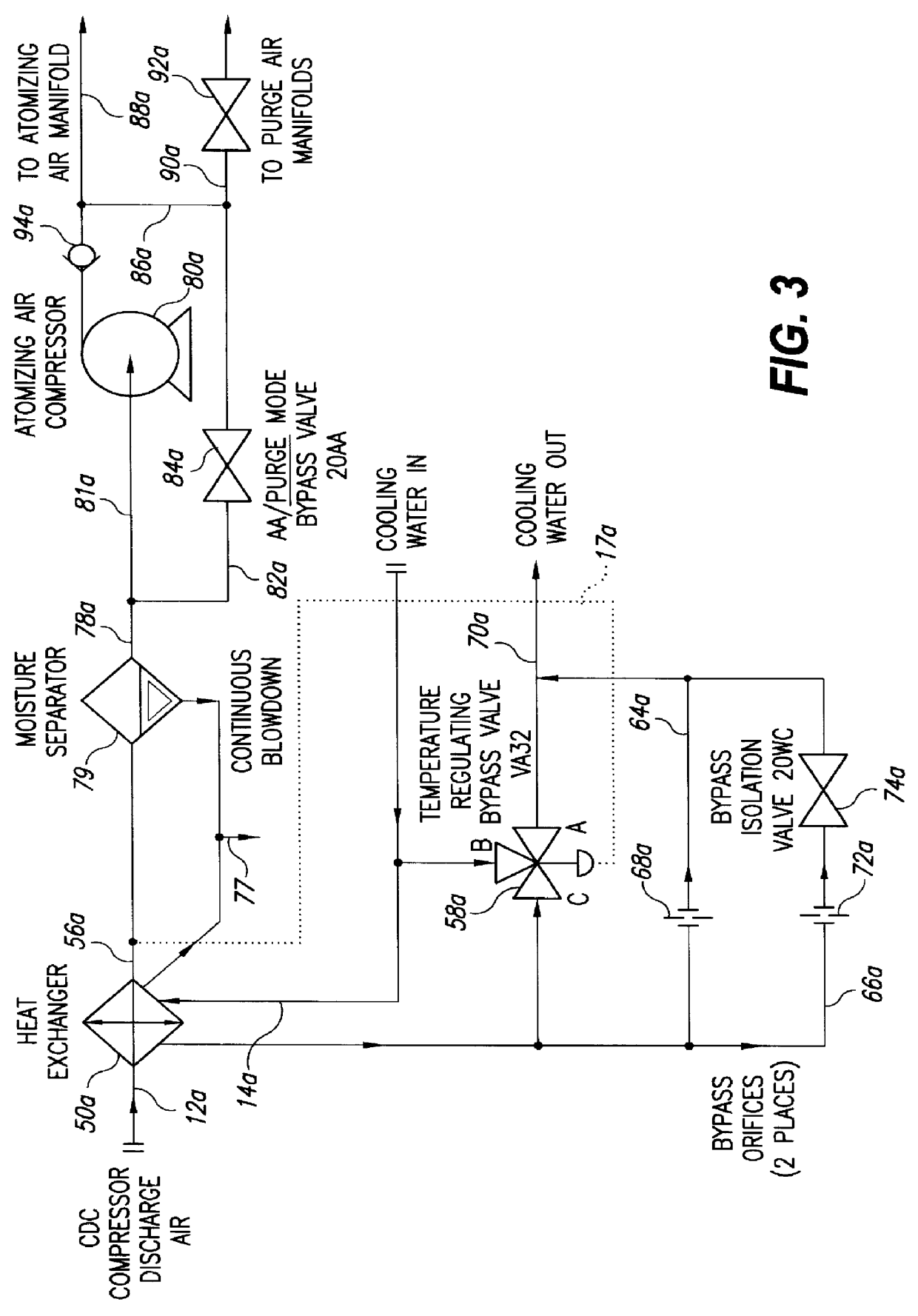

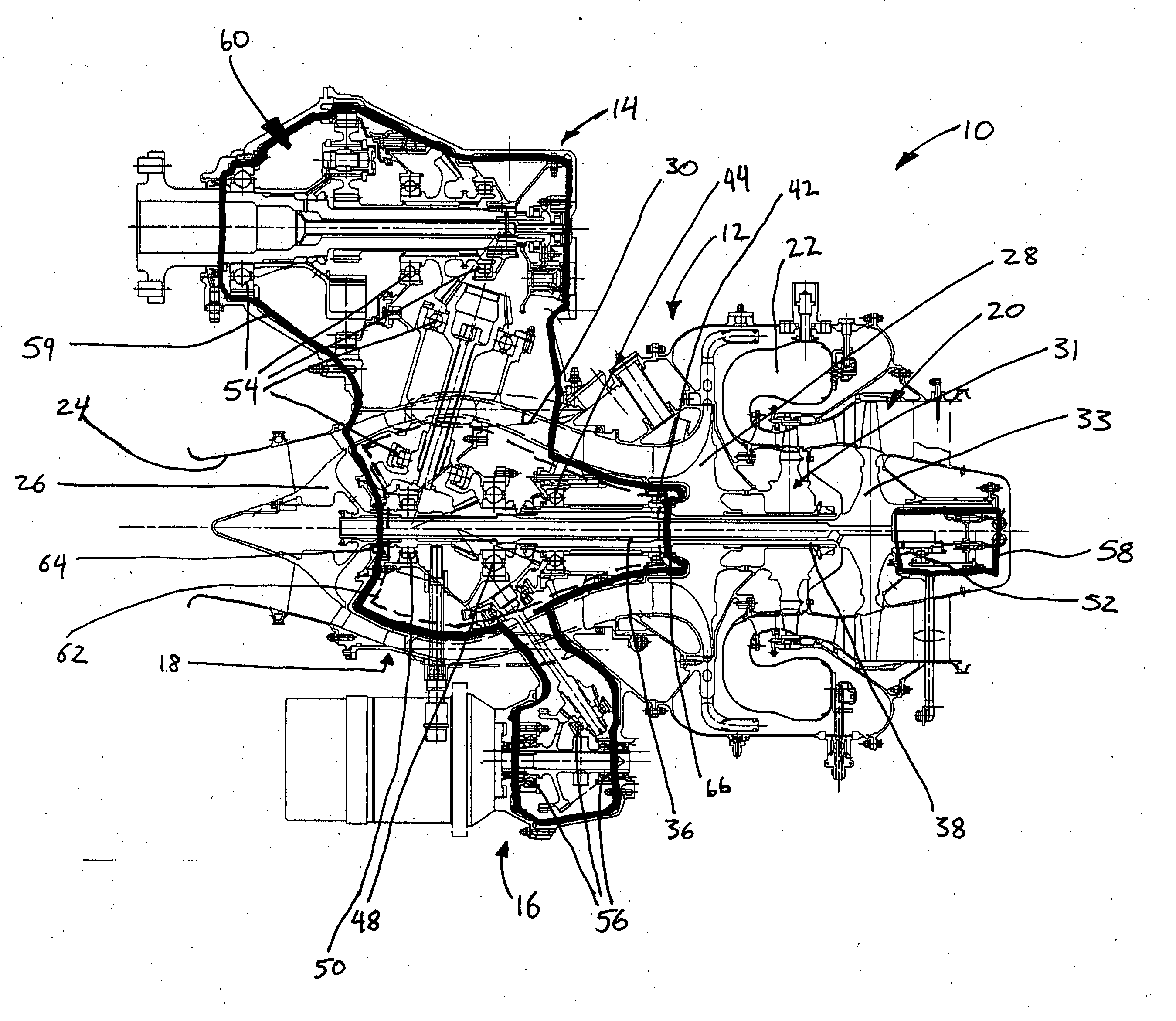

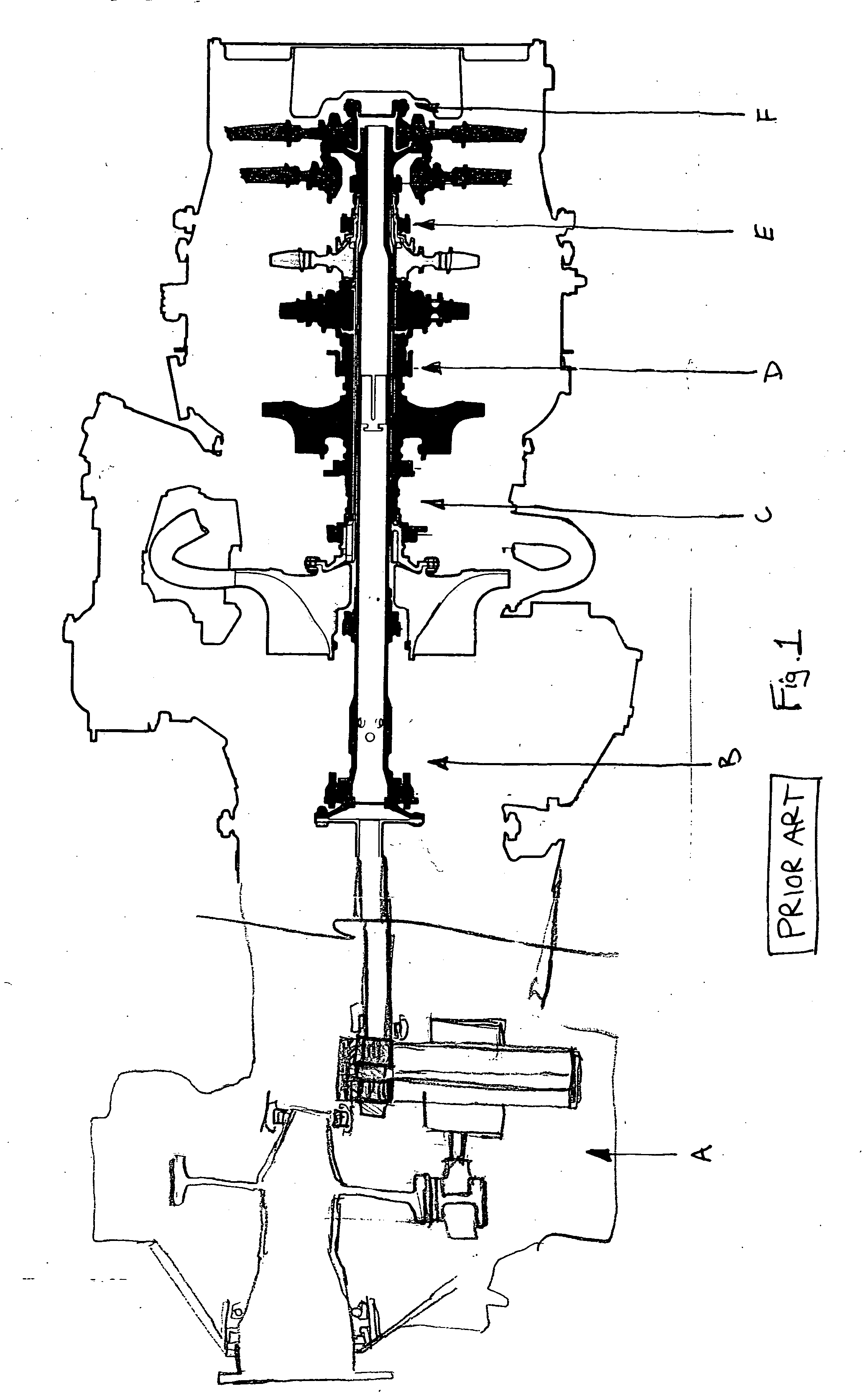

Dual orifice bypass system for dual-fuel gas turbine

InactiveUS6145318AReduce trafficAvoid heat buildupBurner safety arrangementsBurnersCombustorHeat rejection

Compressor discharge air flows through a heat exchanger in heat exchange relation with cooling water and is supplied at reduced temperature in atomizing air and purge modes to combustors in a dual-fuel gas turbine. The heat exchanger has a pair of bypass passages in parallel with a temperature regulating valve controlling flow of water through the heat exchanger in response to the temperature of the compressor discharge air exiting the heat exchanger. Should the flow control valve close in response to low temperature of the compressor discharge air, in the air atomizing mode, the bypass passages with orifices therein provide a minimum protective flow of cooling water to the heat exchanger. In the purge mode where only half the air flow and heat rejection is required in the heat exchanger and the flow control valve closes, a bypass valve in one of the bypass passages closes to enable reduced flow of cooling water through the heat exchanger.

Owner:GENERAL ELECTRIC CO

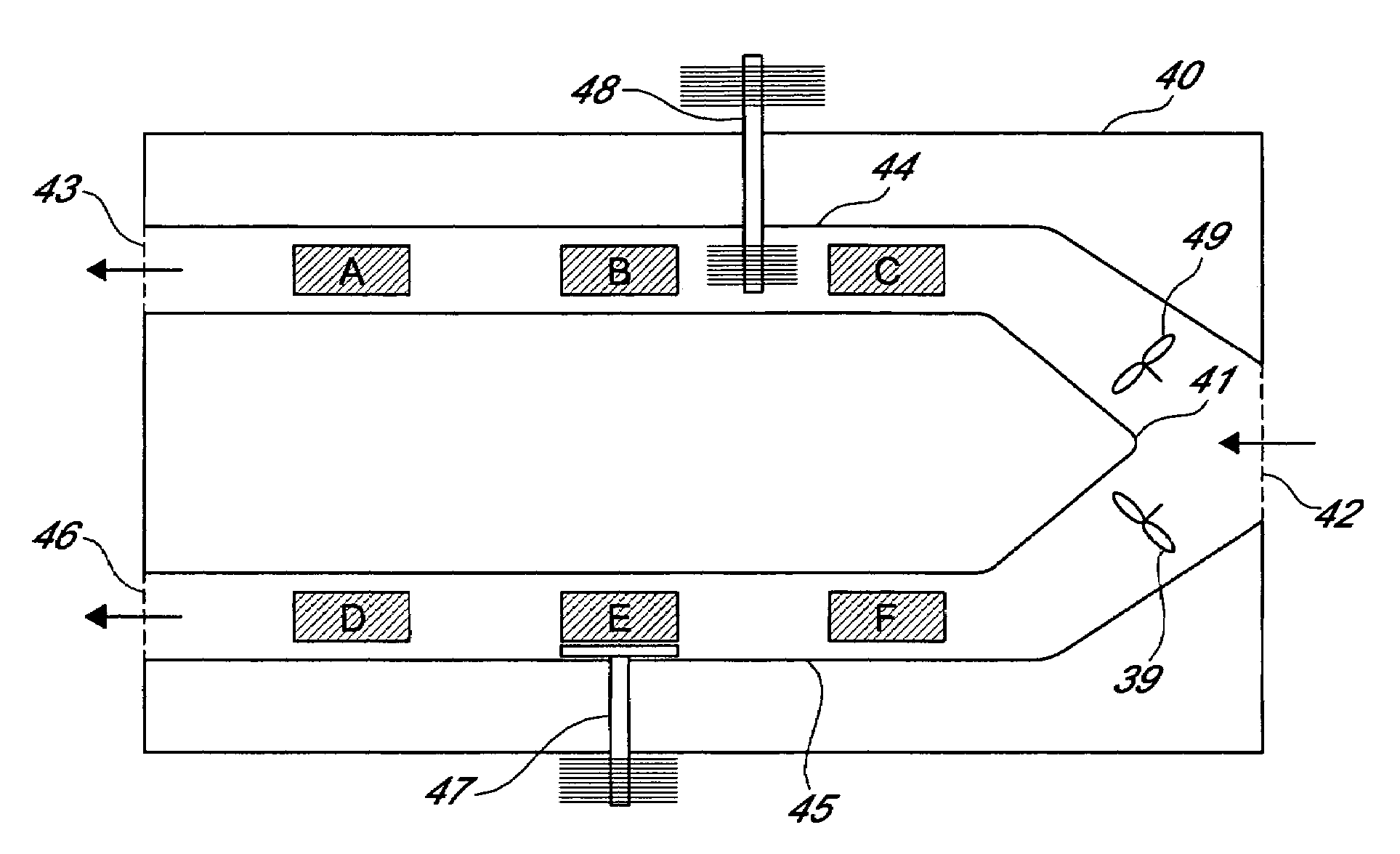

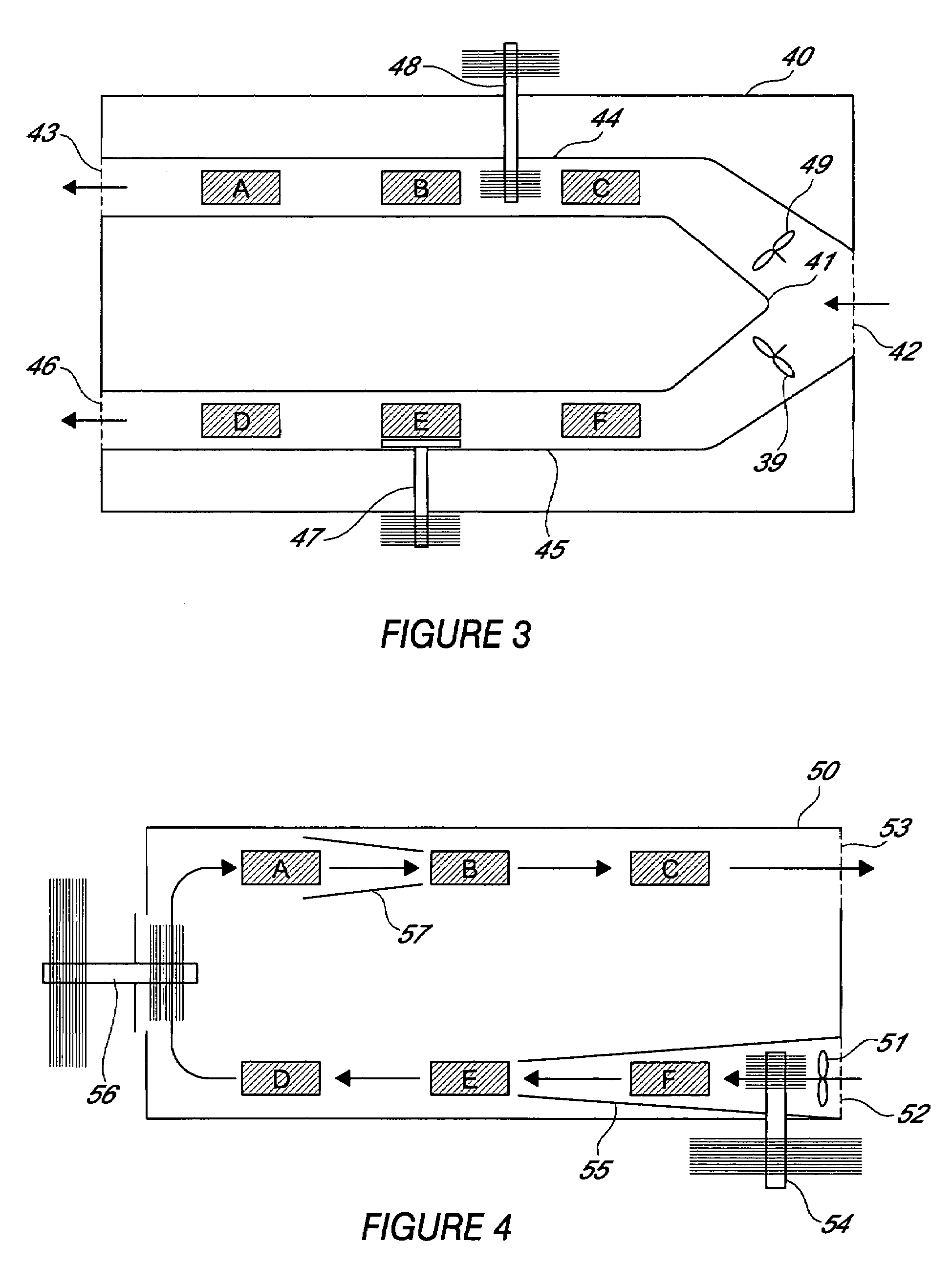

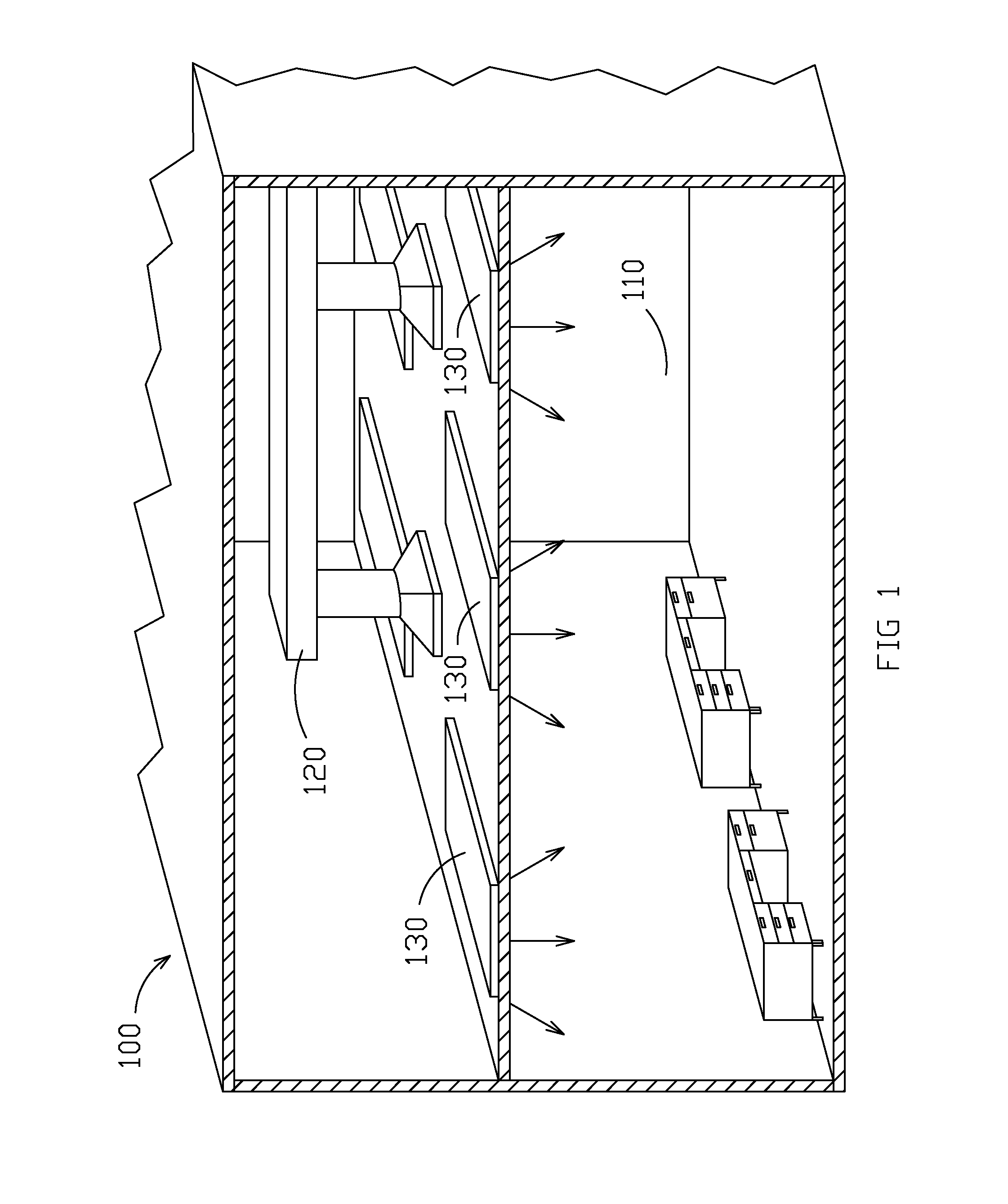

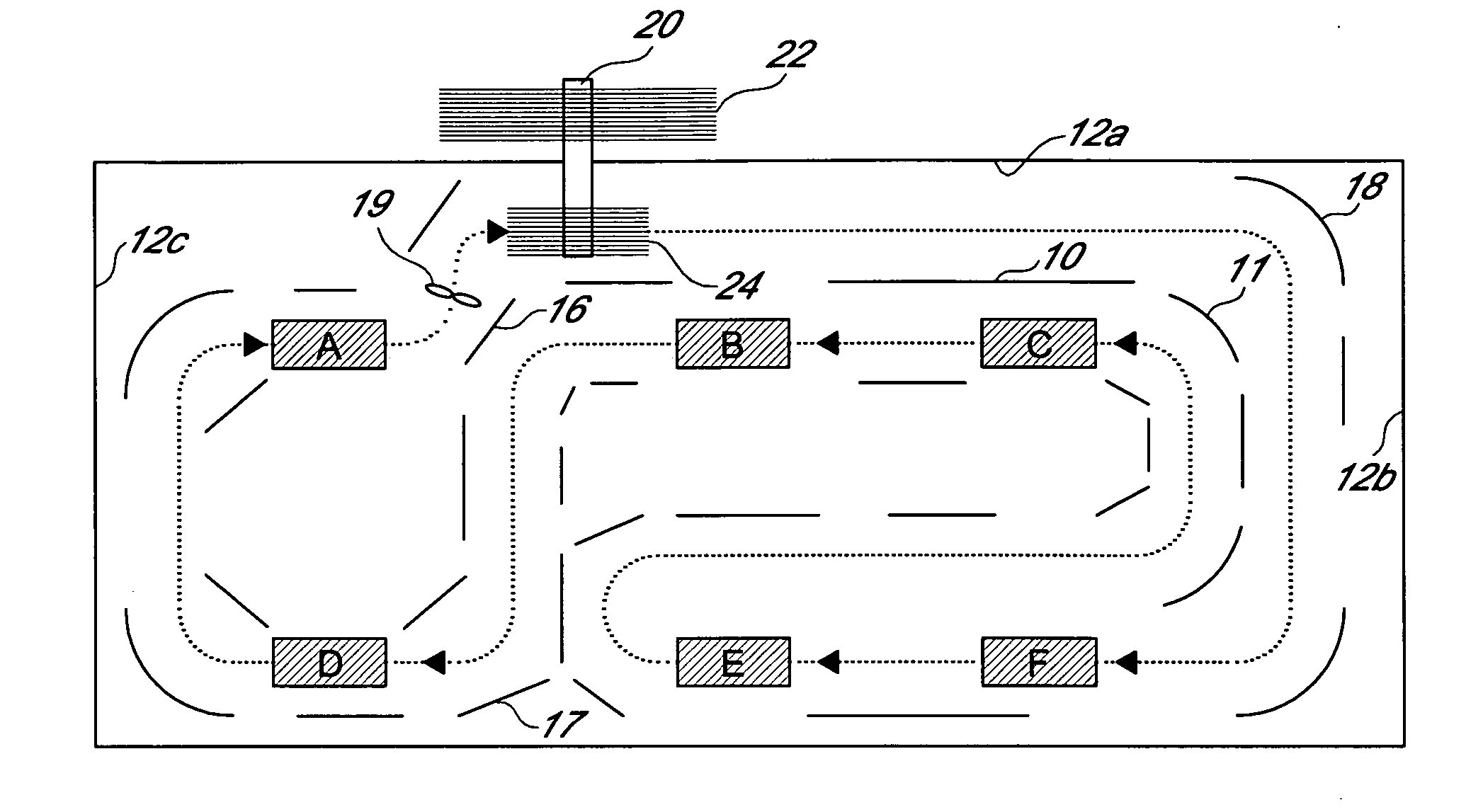

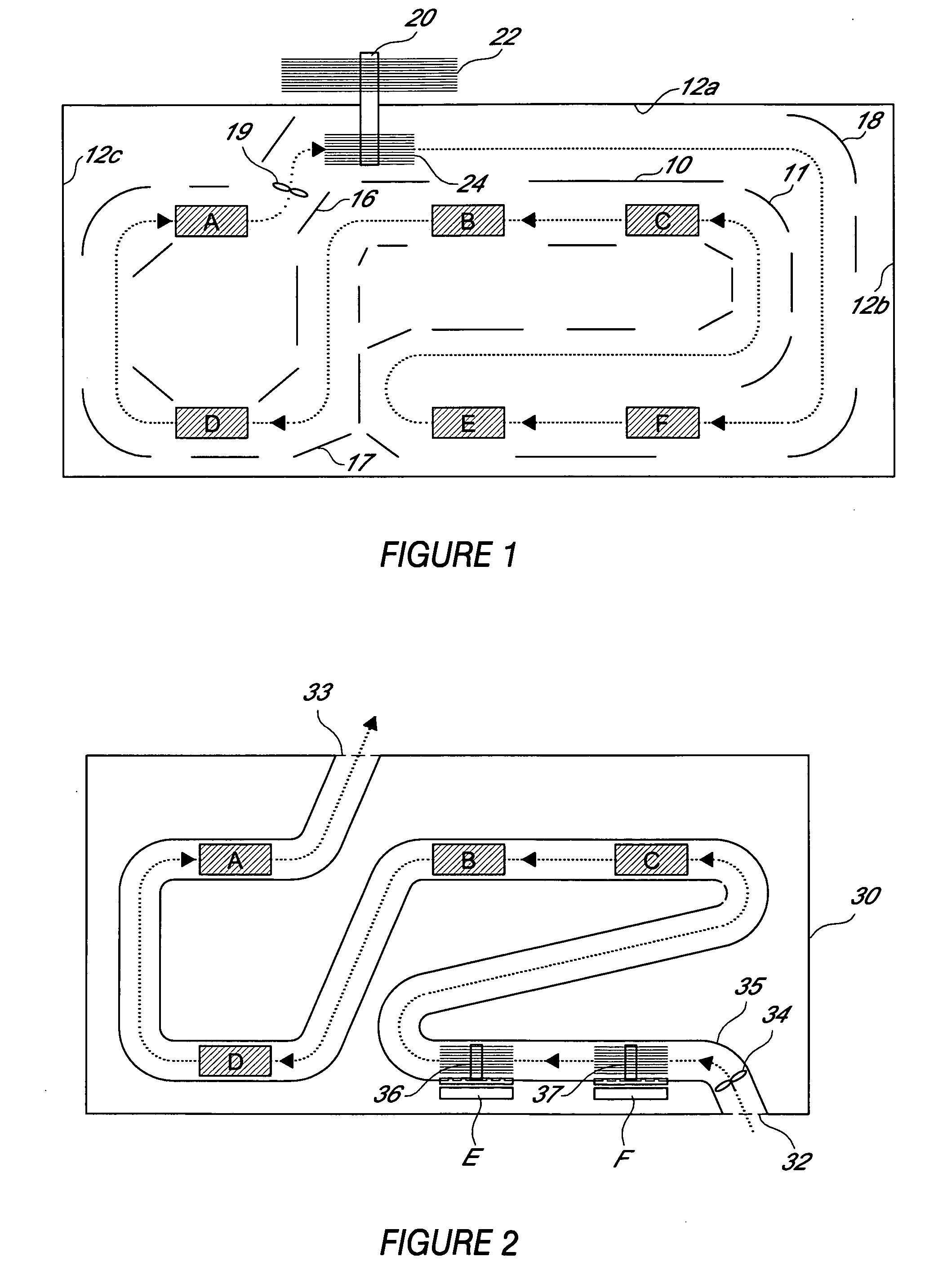

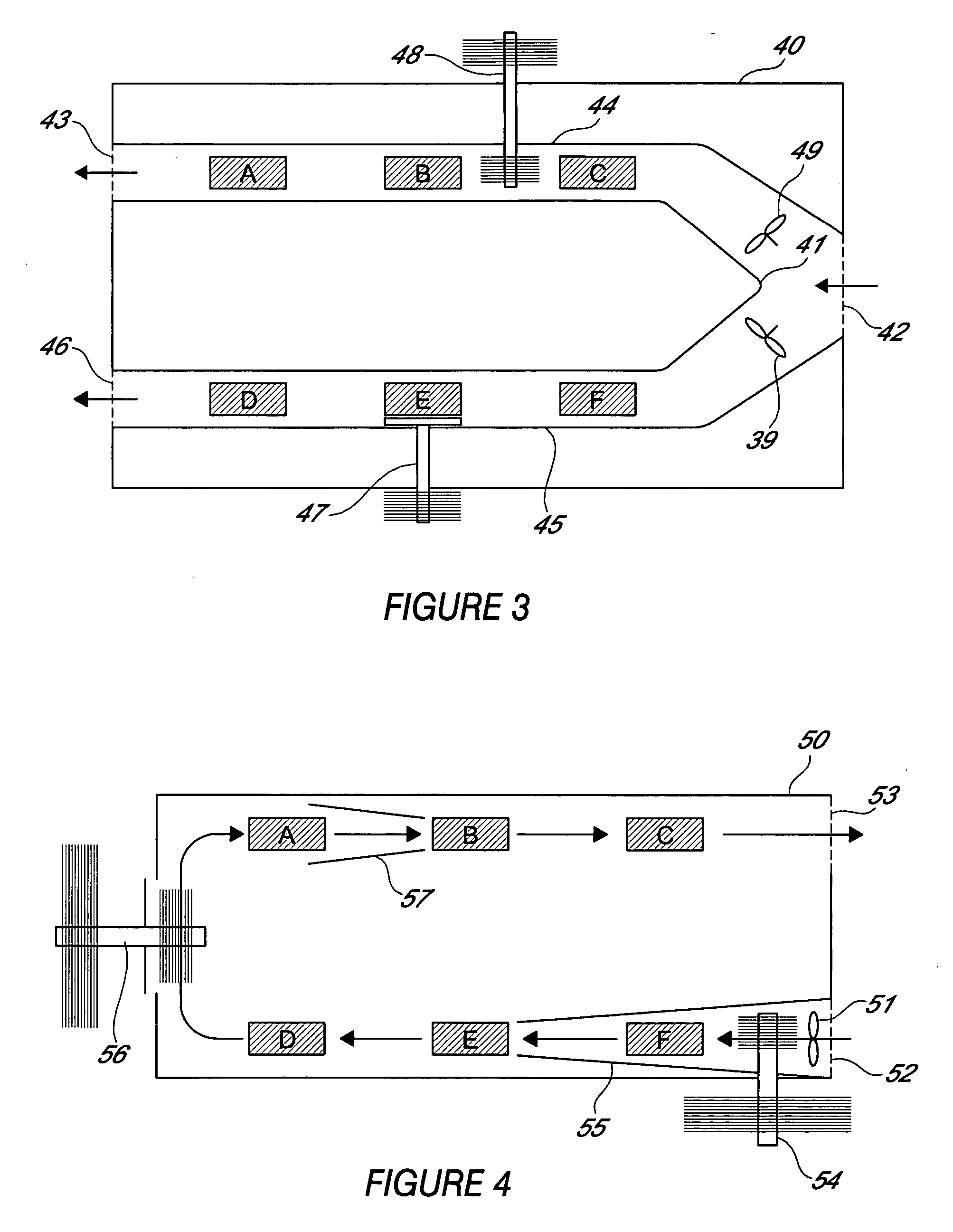

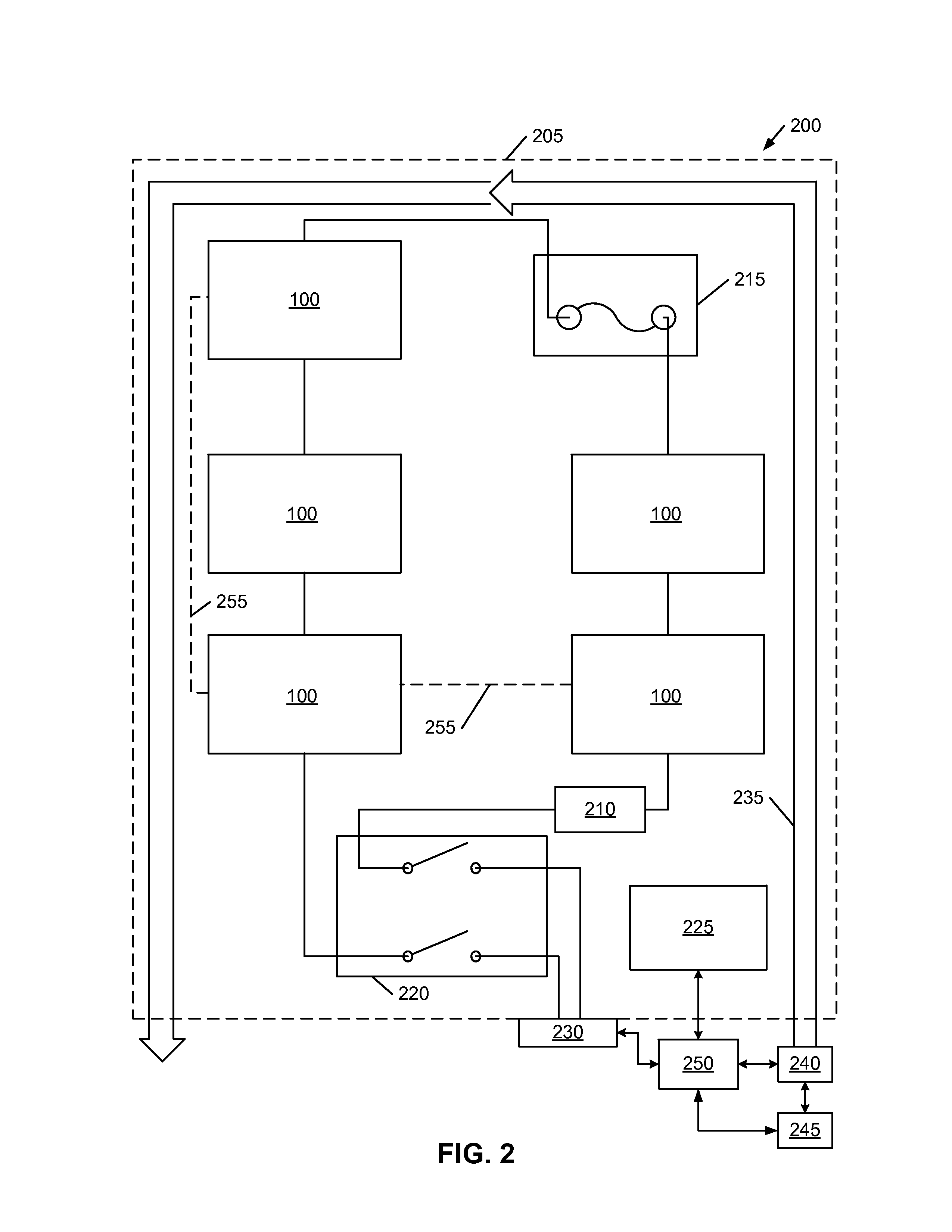

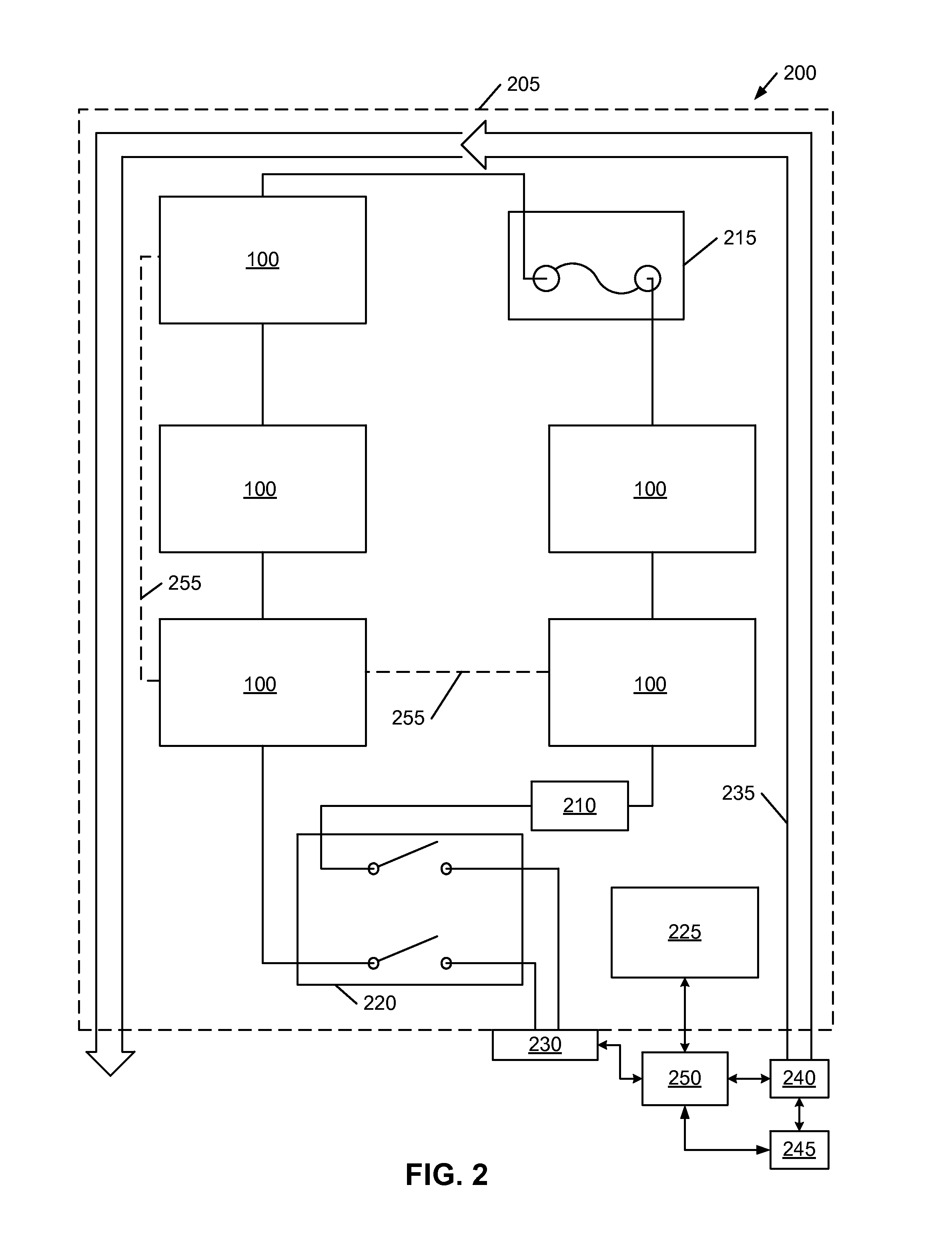

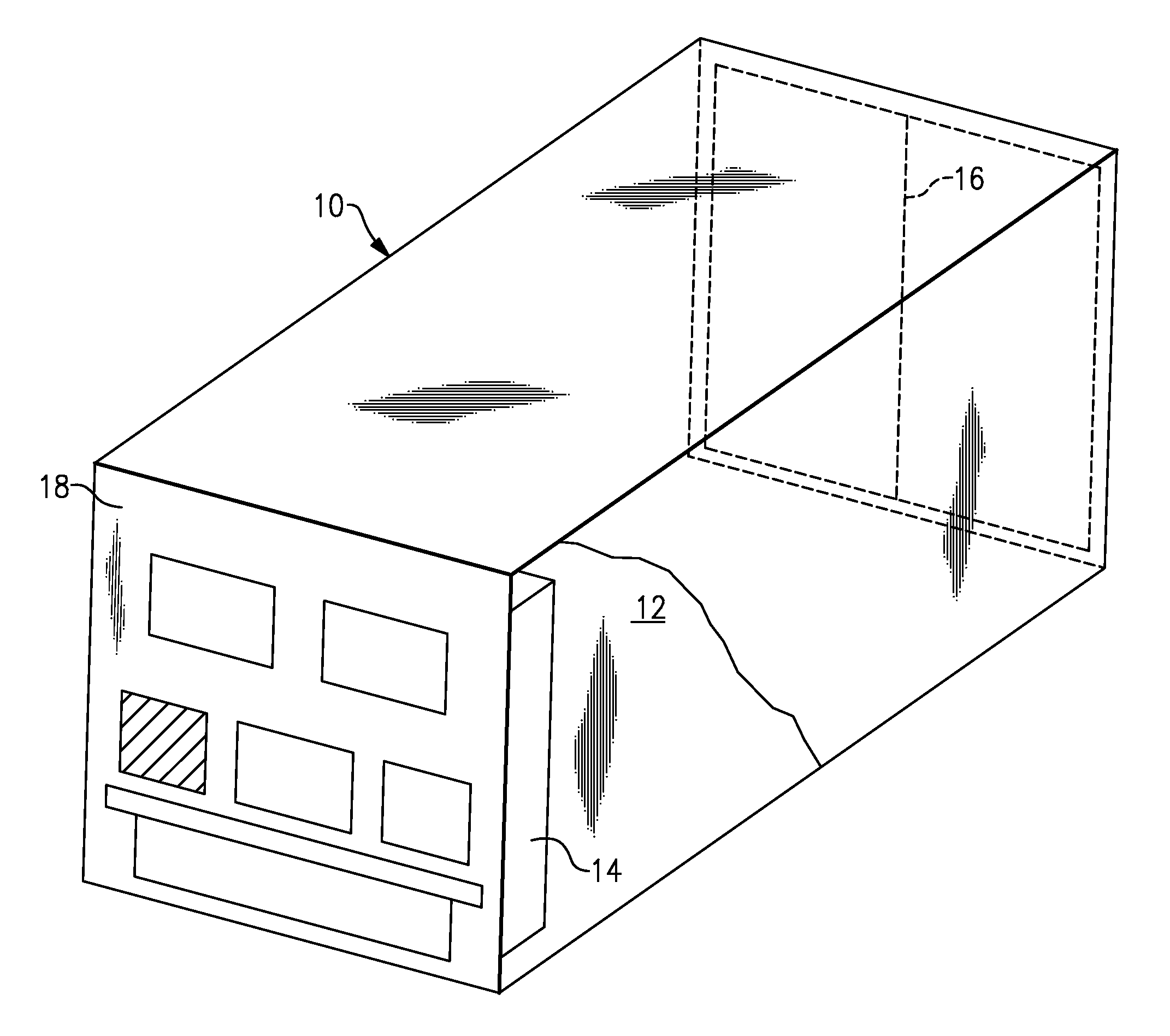

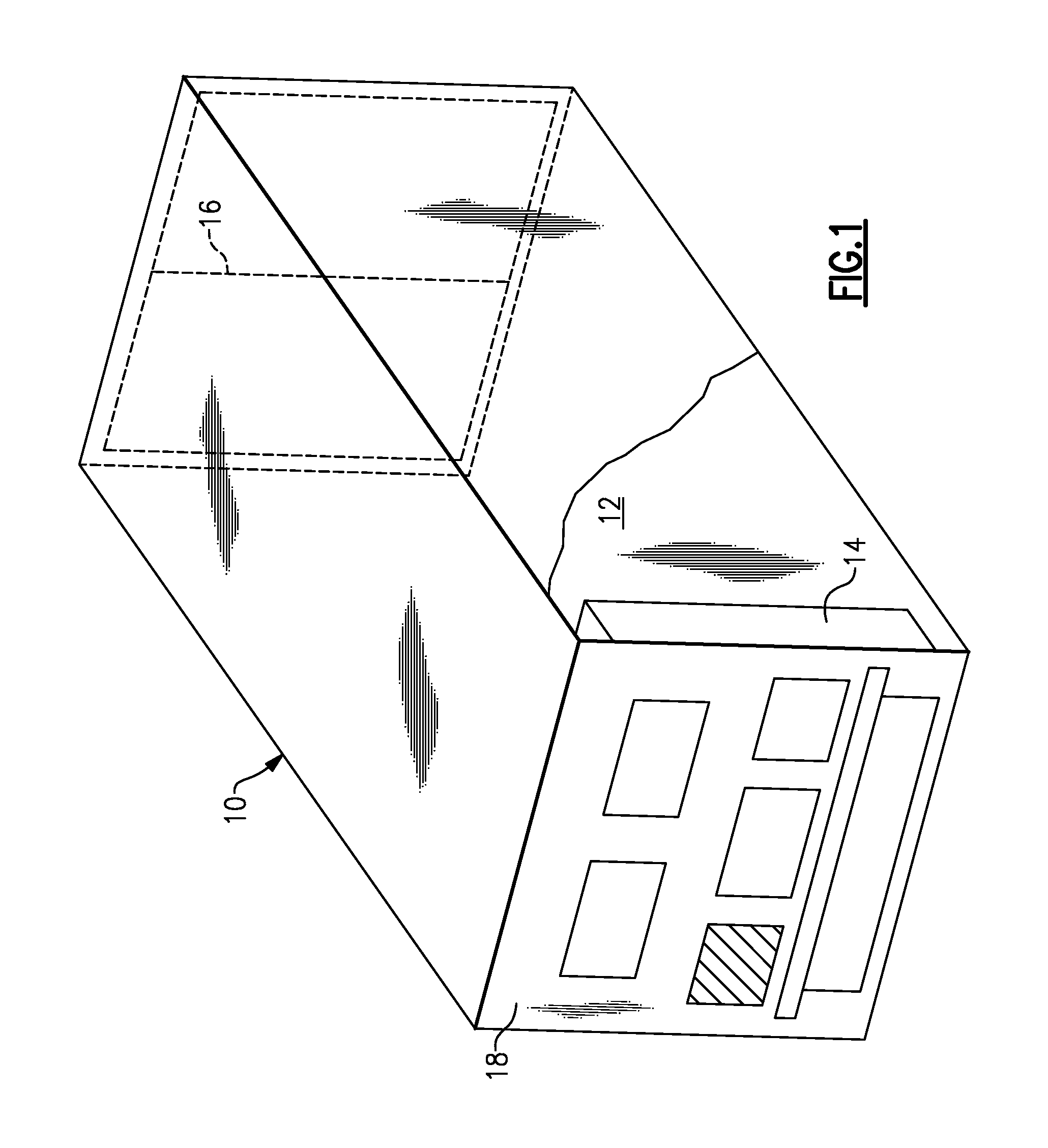

Apparatus and method for cooling electronics and computer components with managed and prioritized directional air flow heat rejection

An apparatus and method of cooling a plurality of electronic components in a housing using one or more fans cooperating with baffles or ducts for directing a stream of air sequentially to the components or heat exchangers for the components. Direction of the air stream to the components is based on predetermined cooling prioritization of the plurality of components.

Owner:ROCKY RES INC

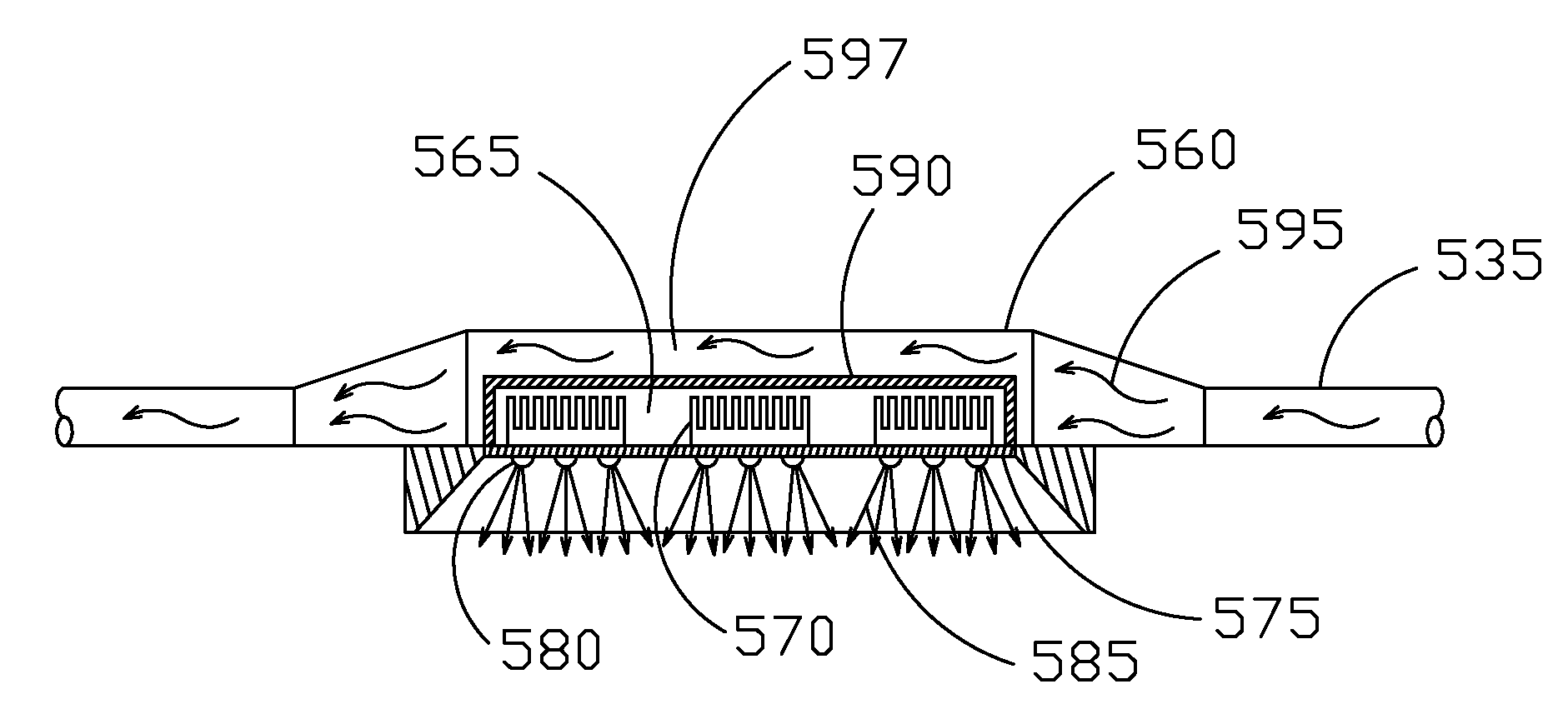

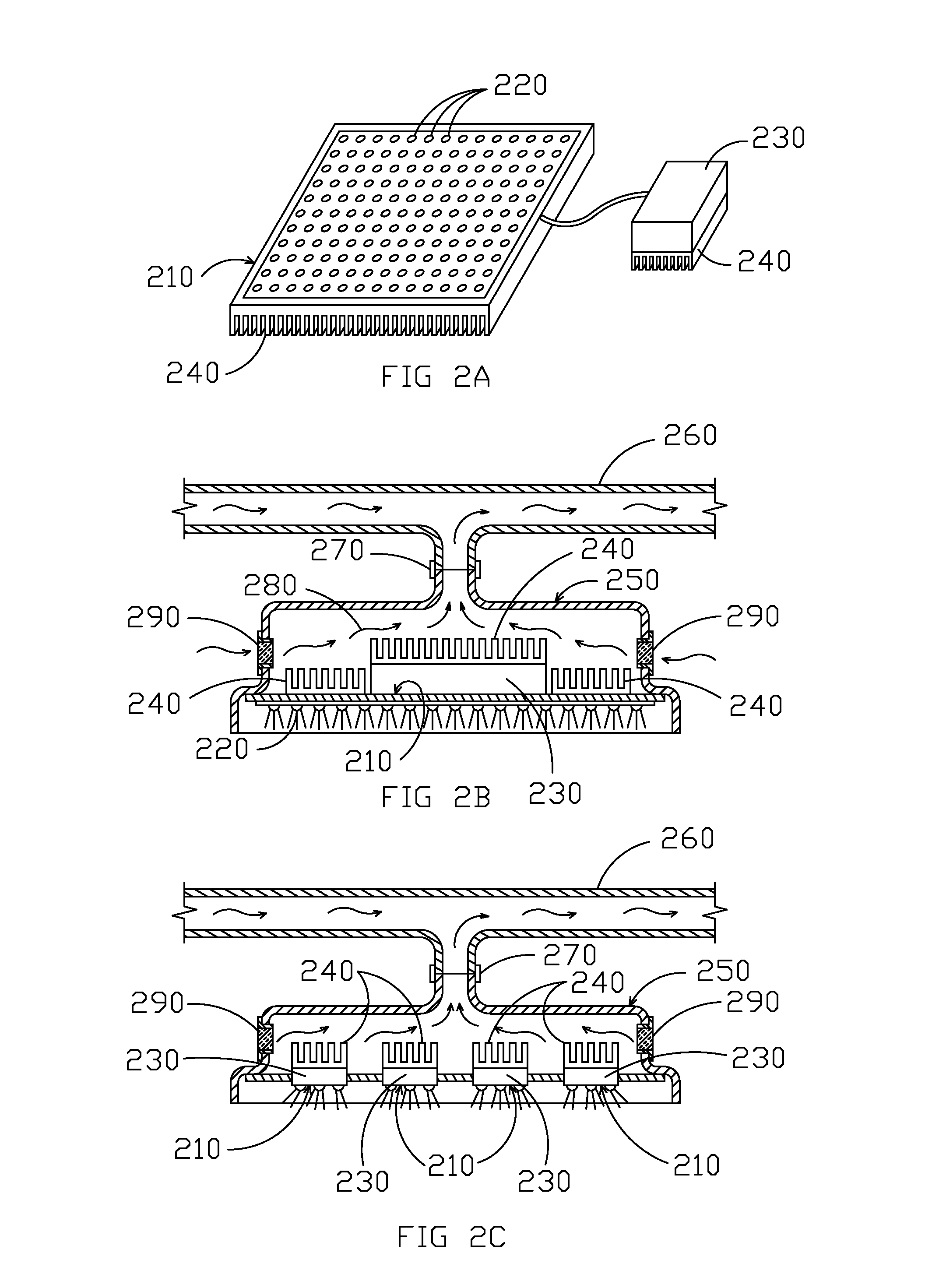

Solid state light fixture with cooling system with heat rejection management

ActiveUS8651704B1Increase operating powerReduce in quantityPlanar light sourcesMechanical apparatusSemiconductor materialsElectrical battery

Systems and methods for solid-state light source heat management are provided. A solid-state light source, e.g. having one or more LEDs, can be mounted within an enclosure. In some embodiments, a heat sink associated with semiconductor material and / or power electronics can be placed on a separate side of the enclosure that is thermally insulated or separated from the state-light source. The enclosure can include a first side or portion that allows light from the solid-state-light source (e.g., LEDs) to pass through to a target area. A fluid transfer conduit may be connected to the second side or portion of the enclosure for passing a fluid (e.g., air, water, coolant, etc.) across the heat sink to transport heat generated by the power electronics and / or semiconductor material away. The heated fluid can then be routed to, as examples, an HVAC system, a vent, water heating systems, heat exchanger systems, and / or storage systems (e.g., batteries).

Owner:MUSCO

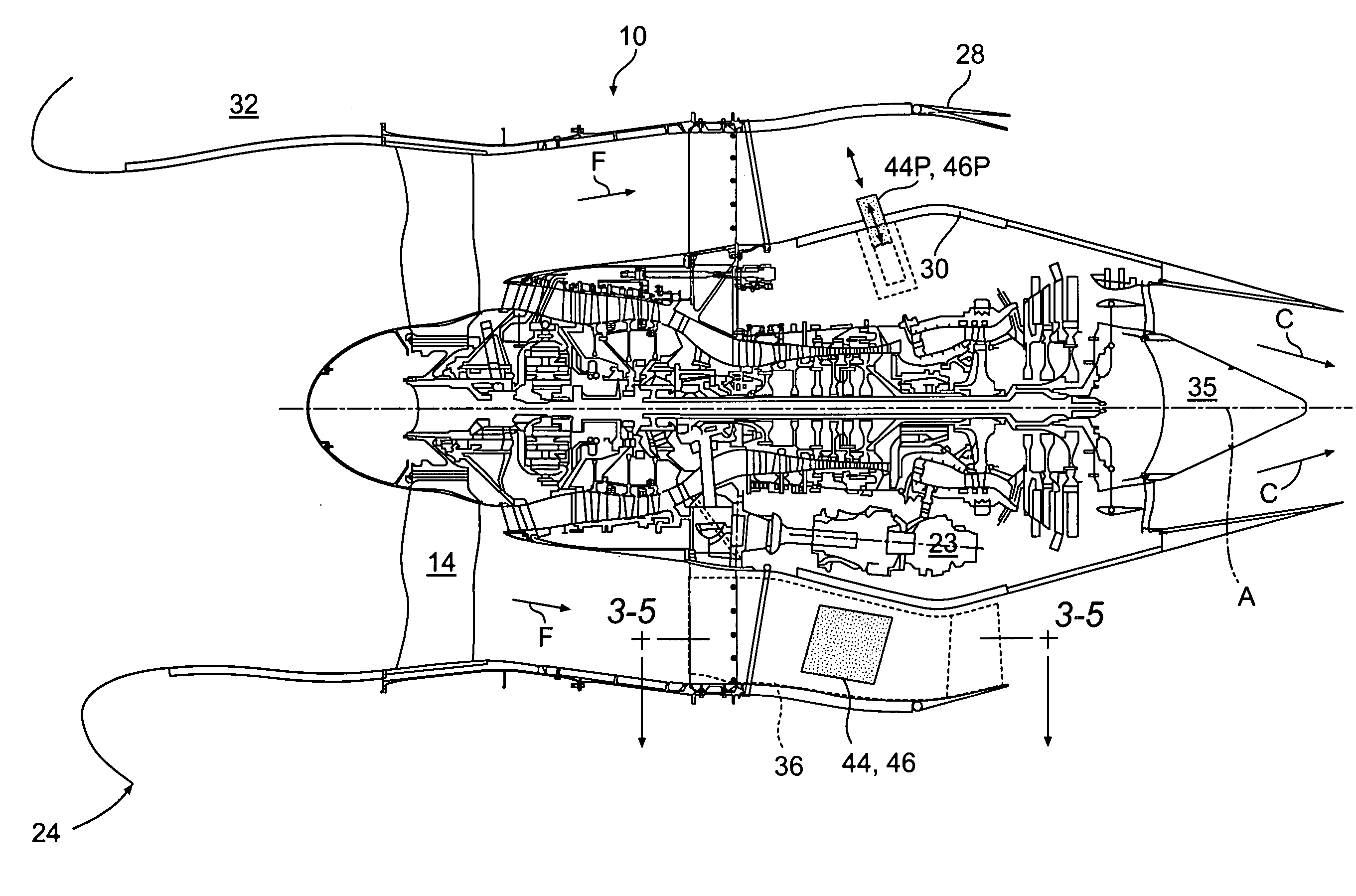

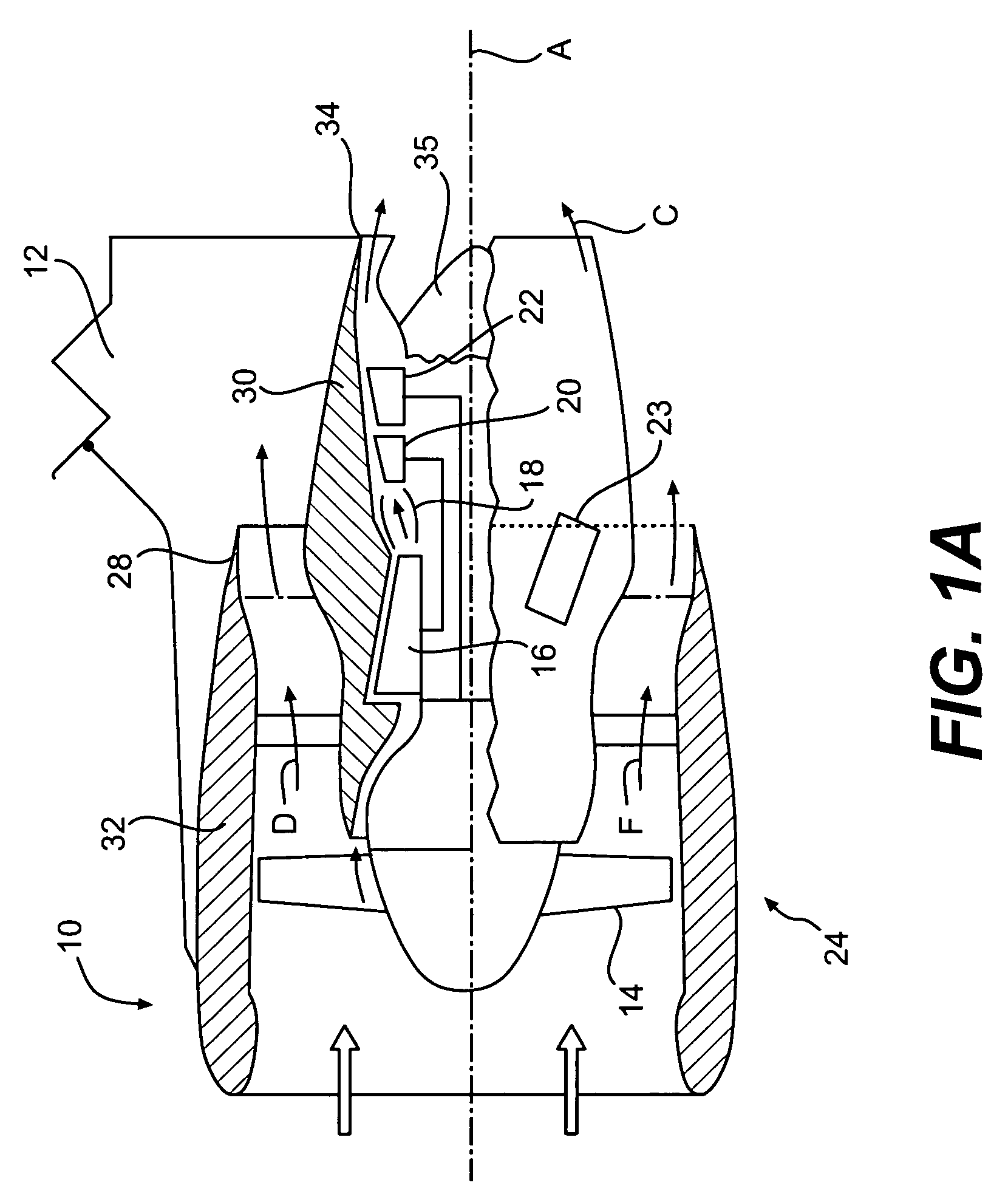

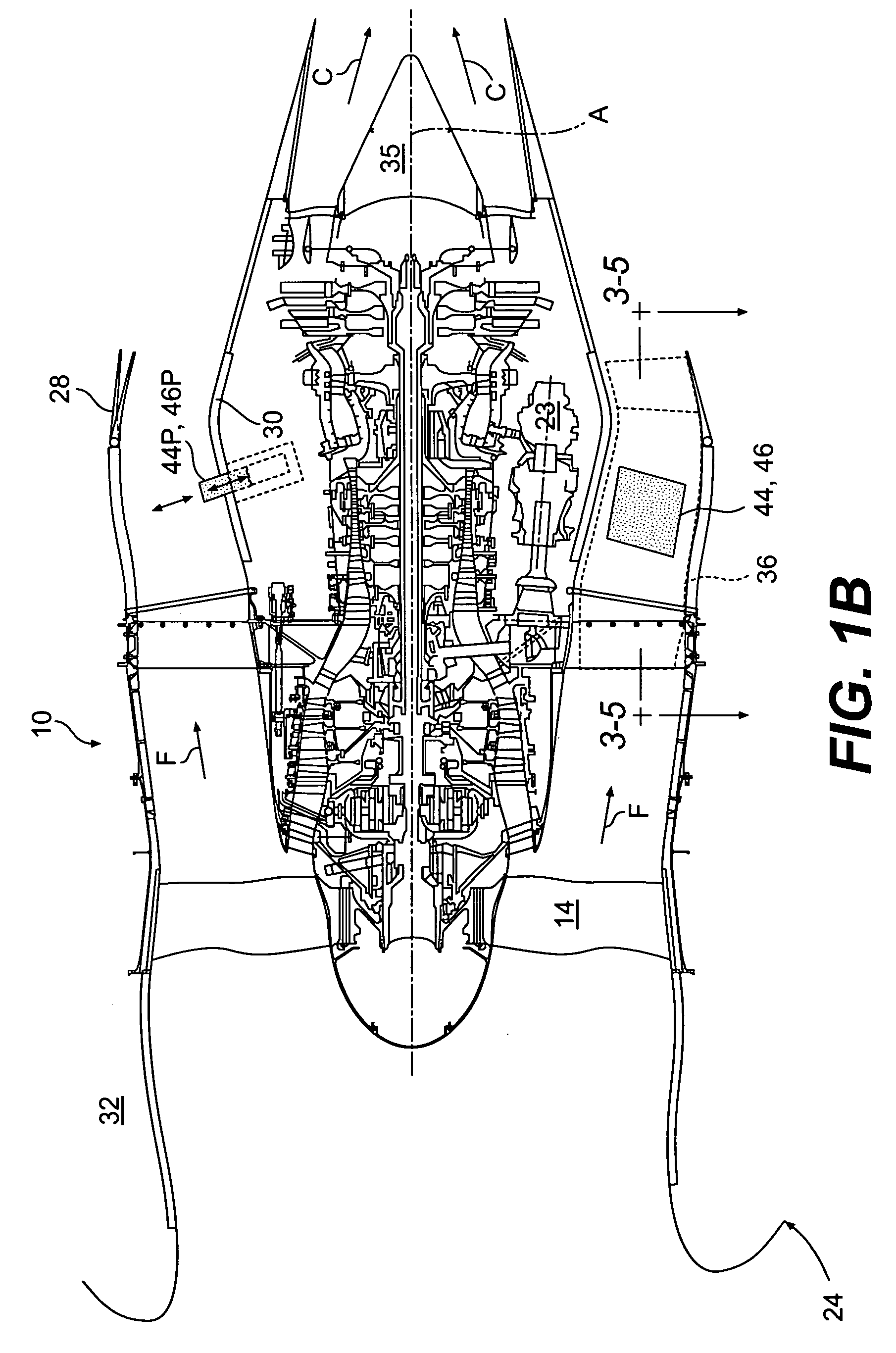

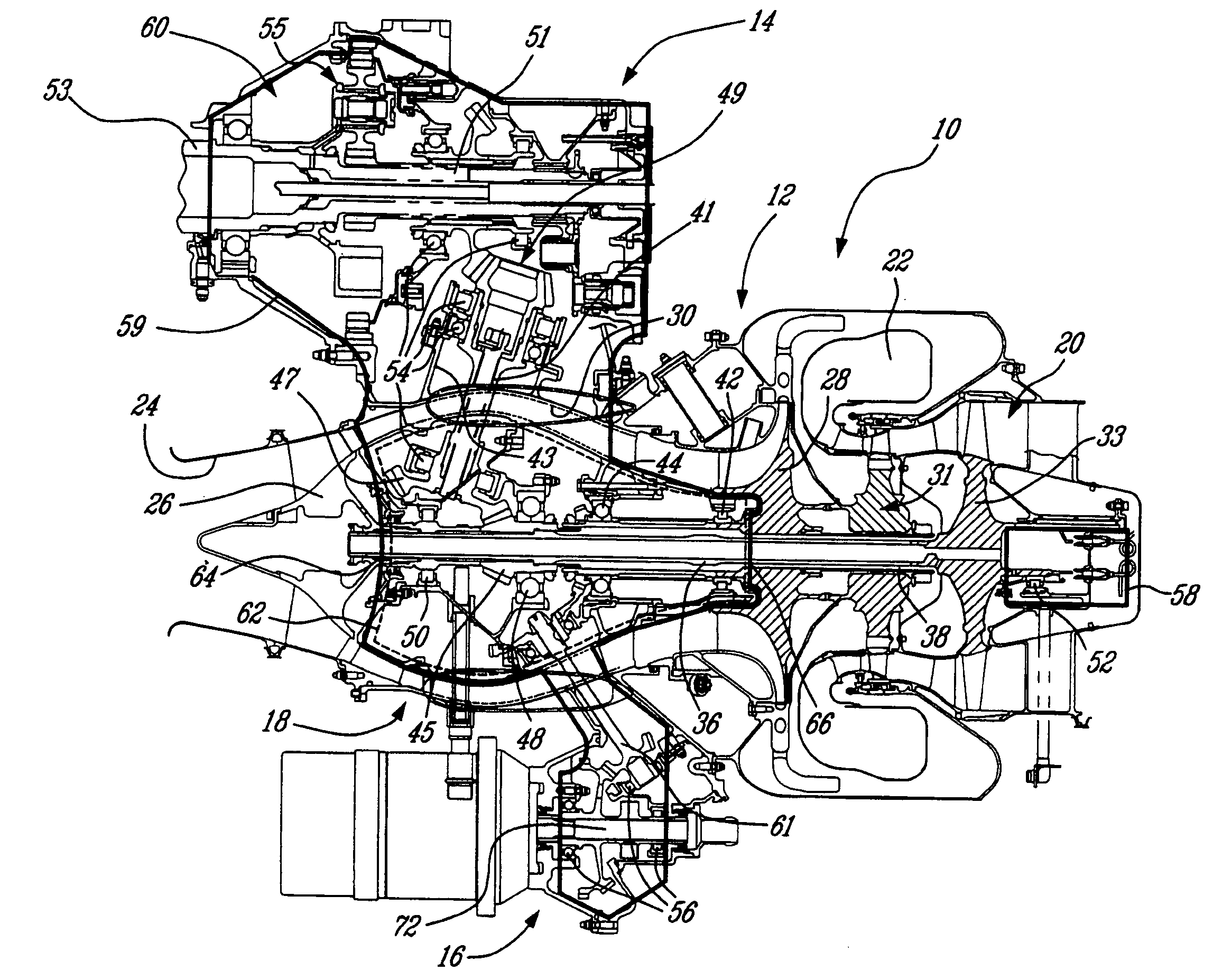

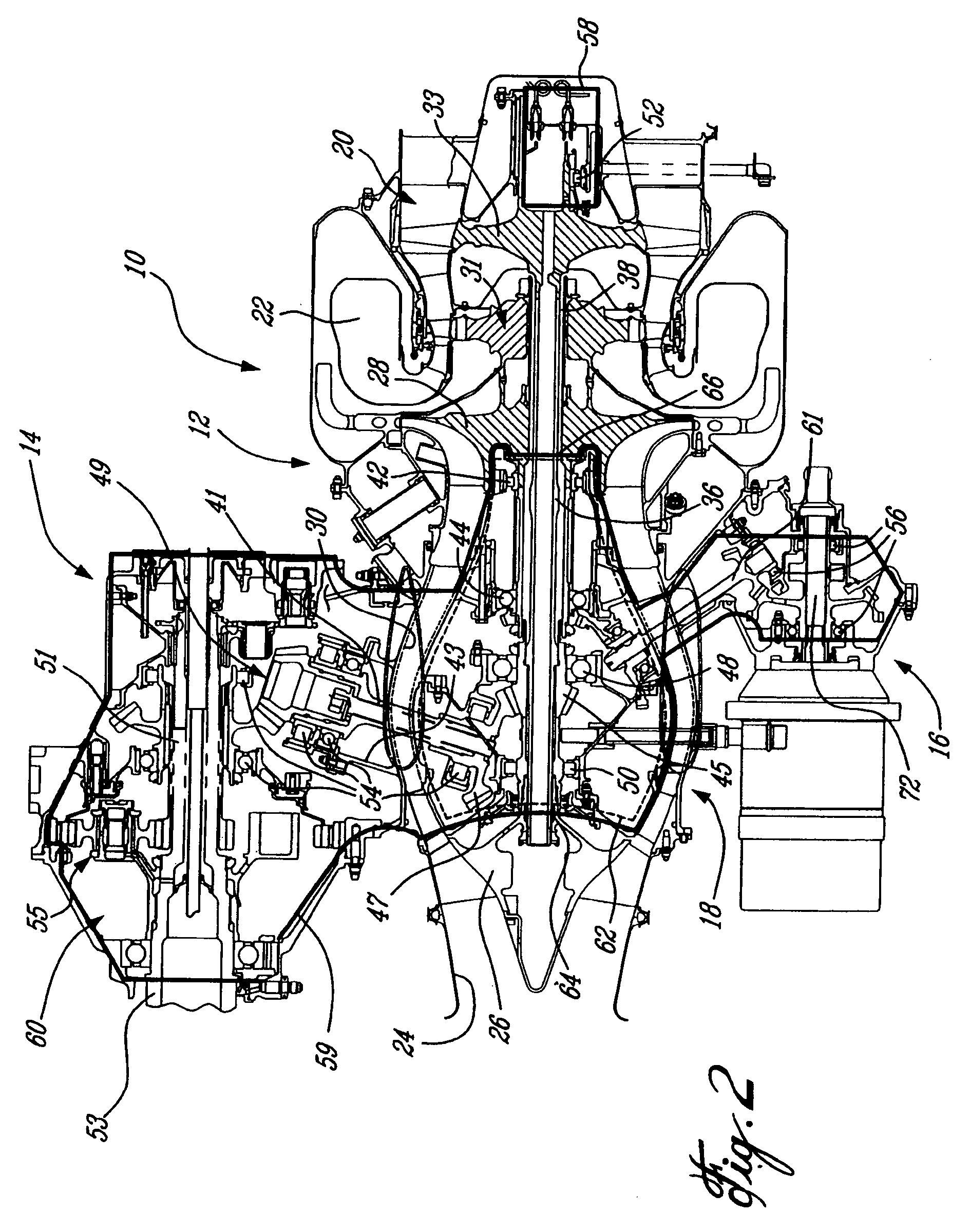

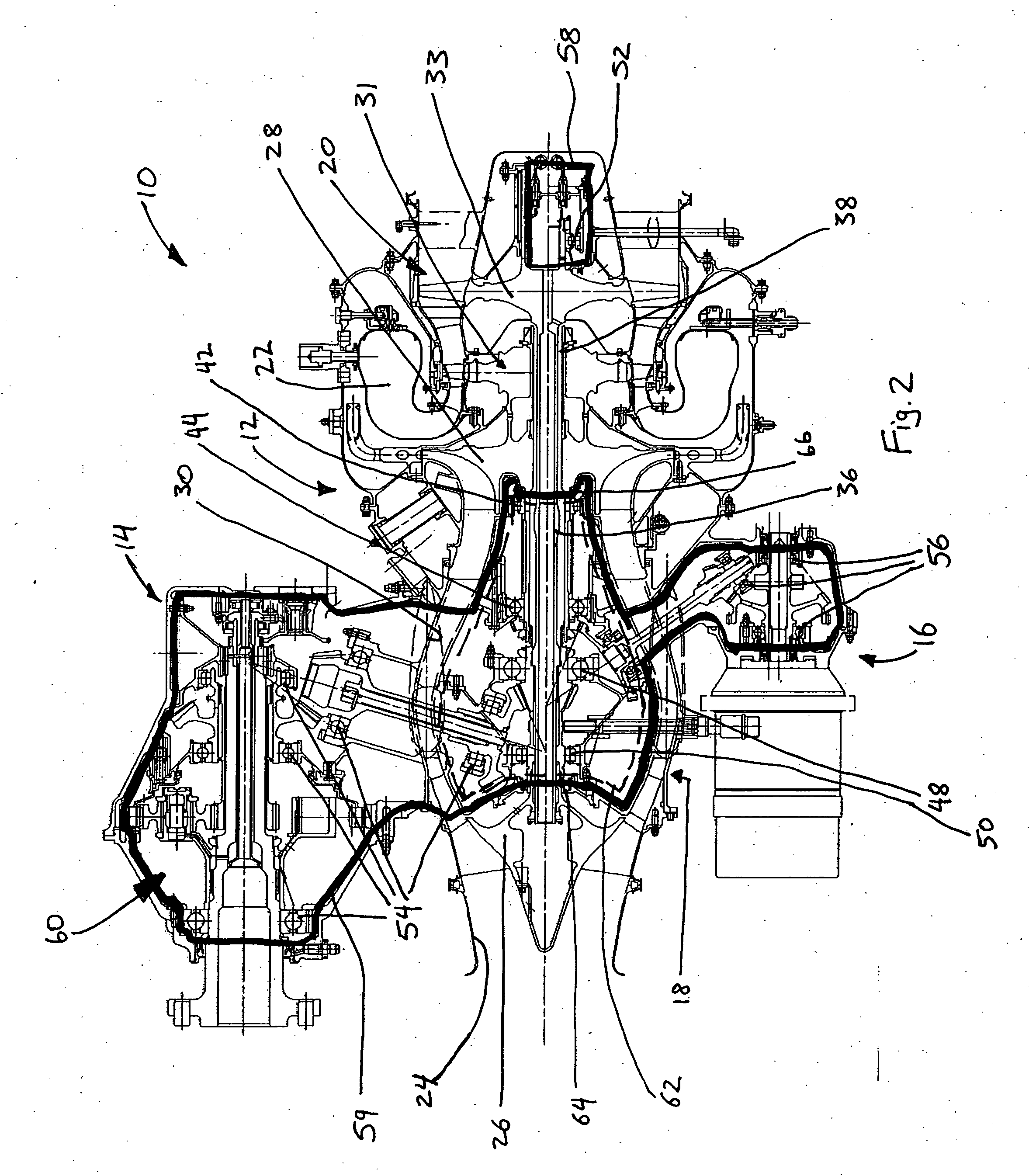

Thermal management system with thrust recovery for a gas turbine engine fan nacelle assembly

InactiveUS20080028763A1Reduces thrust lossesSize reduction requirementsEngine fuctionsEfficient propulsion technologiesNacelleHeat rejection

A thermal management system locates a separate engine heat exchanger and generator heat exchanger into an engine nacelle pylon that is split to provide independent control of both a generator cooling circuit and an engine cooling circuit. A variable exhaust nozzle is provided downstream of each heat exchanger as each has different thermal and heat rejection requirements such that intake air is minimized and maximum thrust is produced in response to the current generator load and engine heat rejection.

Owner:UNITED TECH CORP

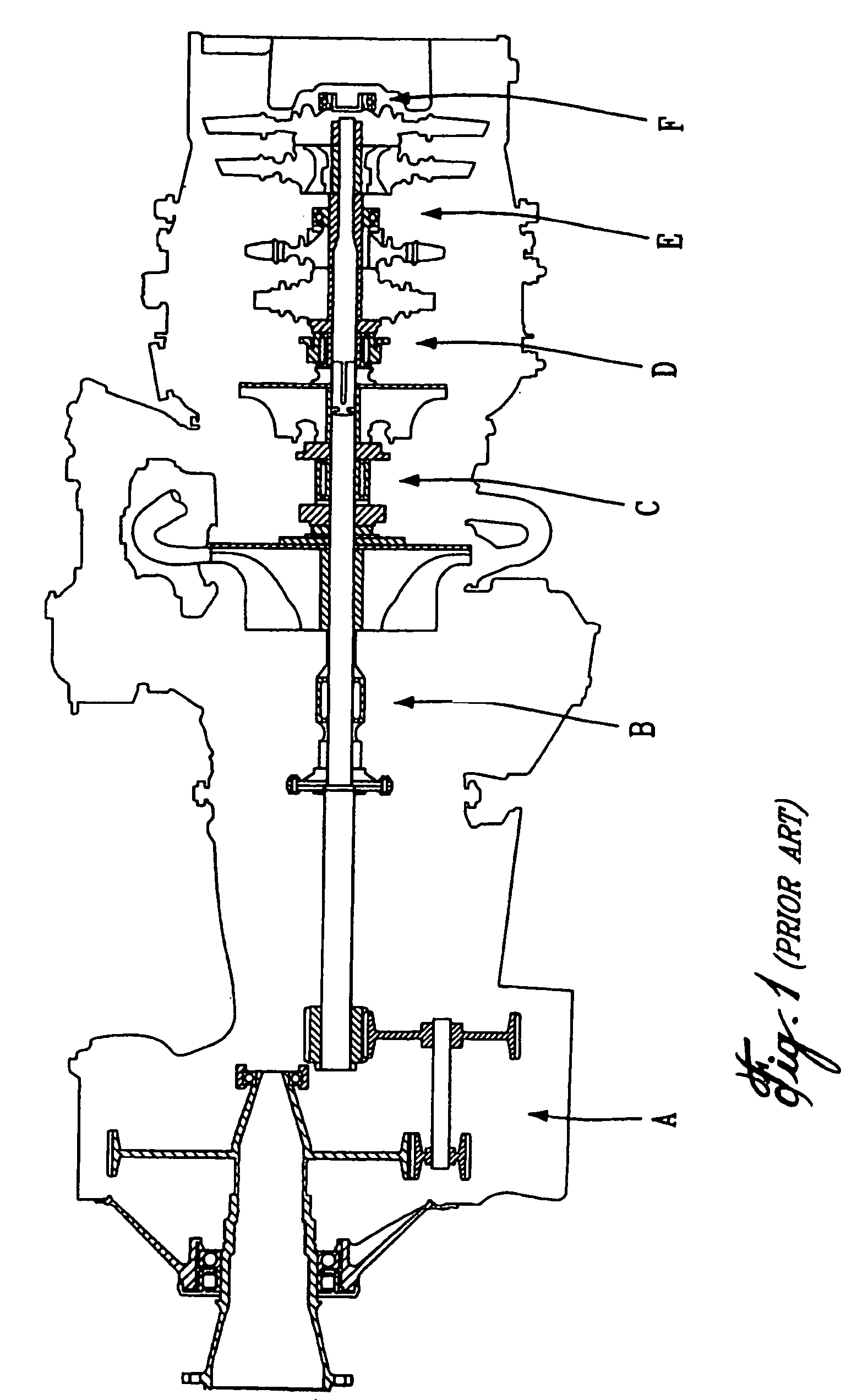

Gas turbine engine architecture

A gas turbine engine having an oil cavity architecture and bearing placement which reduce heat rejection and oil system complexity by enclosing the reduction gearbox bearings and at least the shaft bearings supporting the high pressure shaft in the same oil cavity.

Owner:PRATT & WHITNEY CANADA CORP

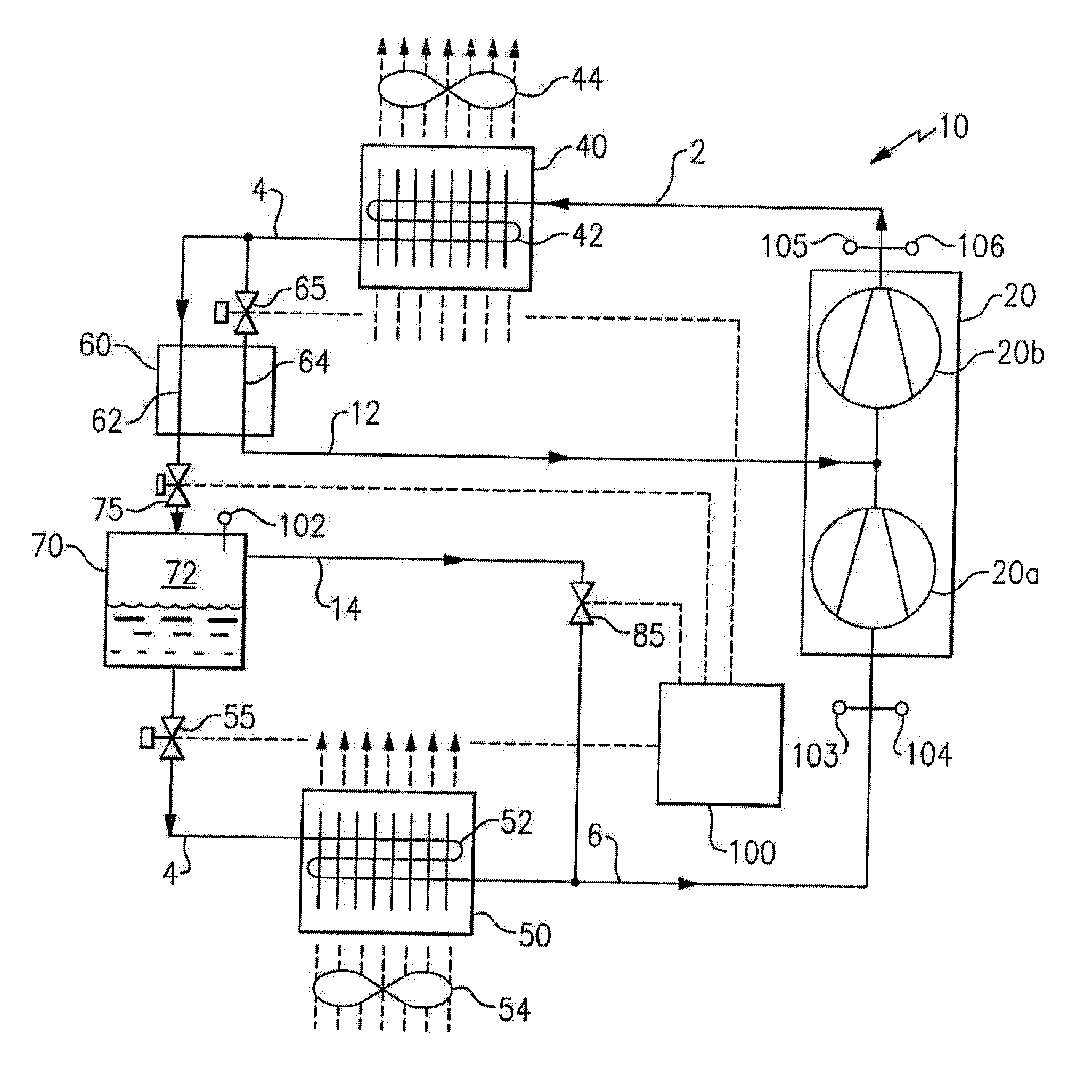

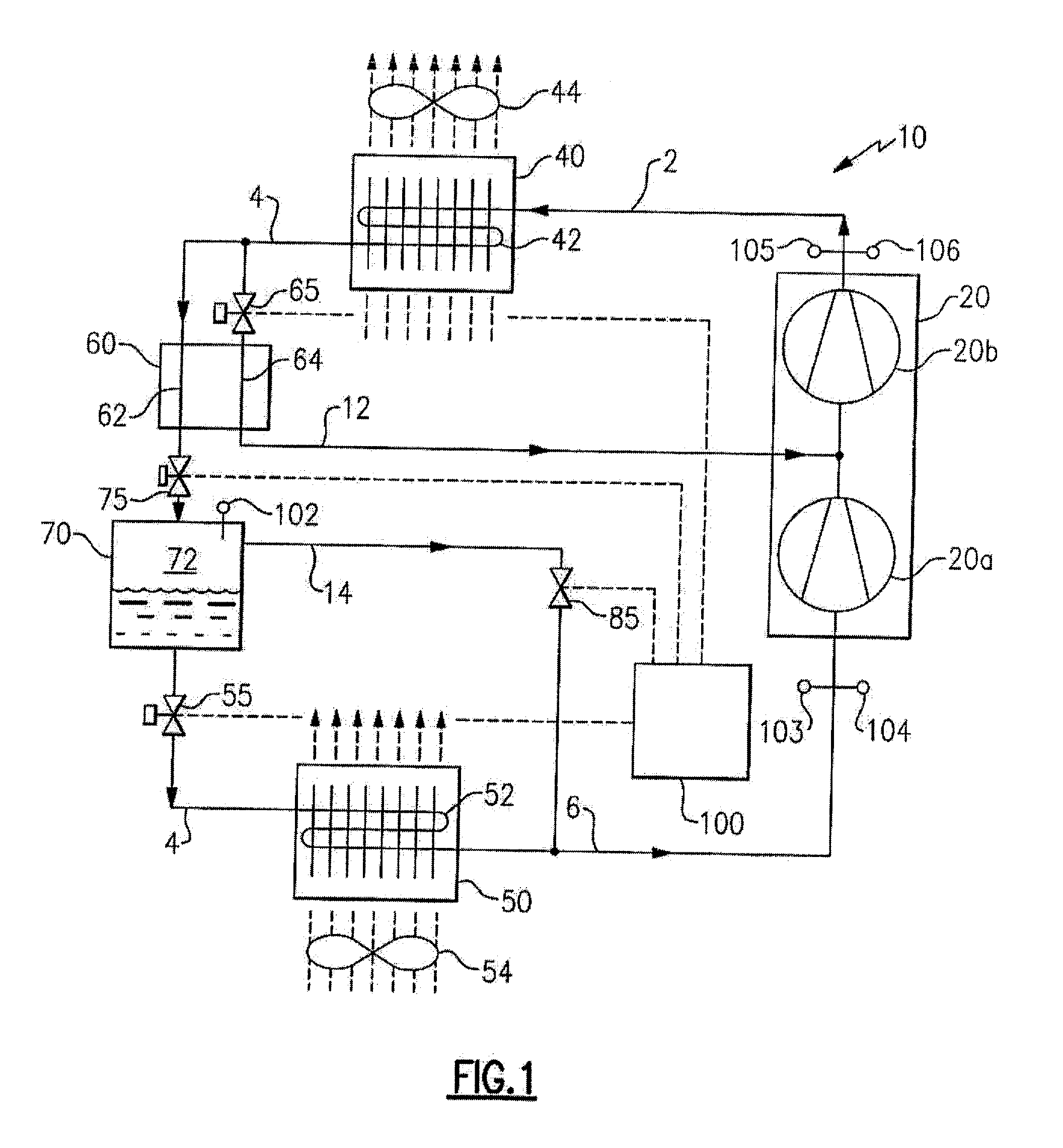

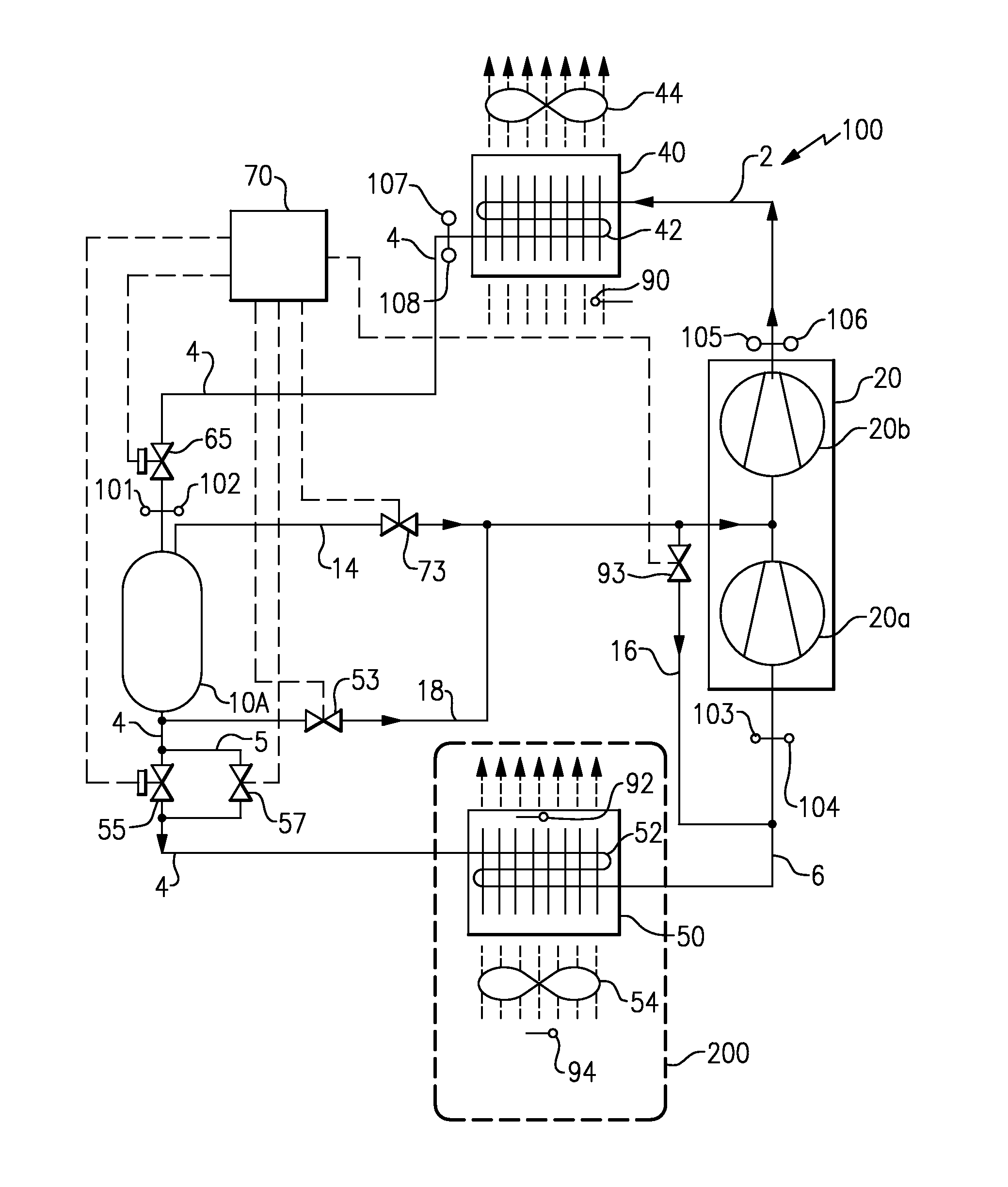

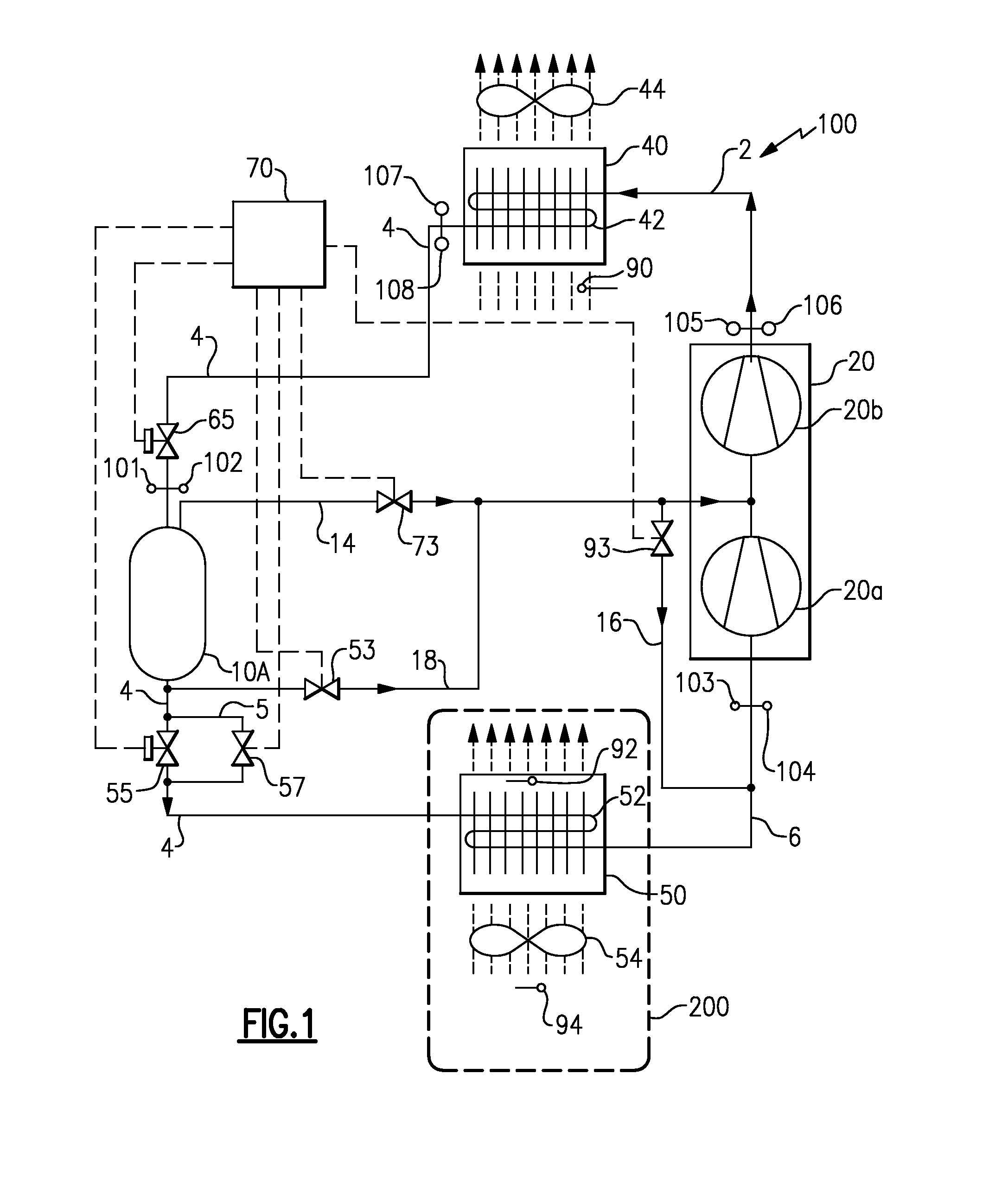

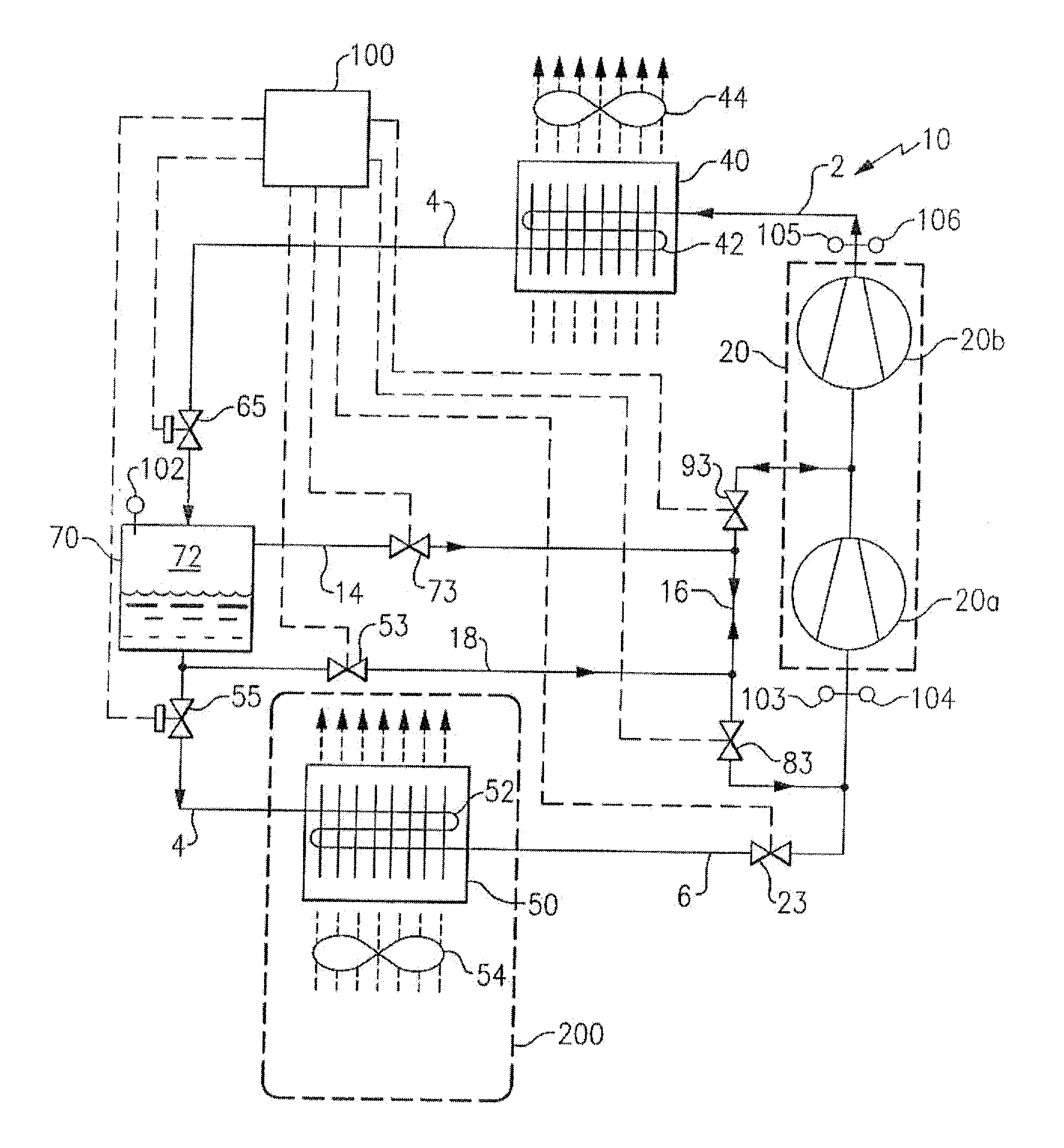

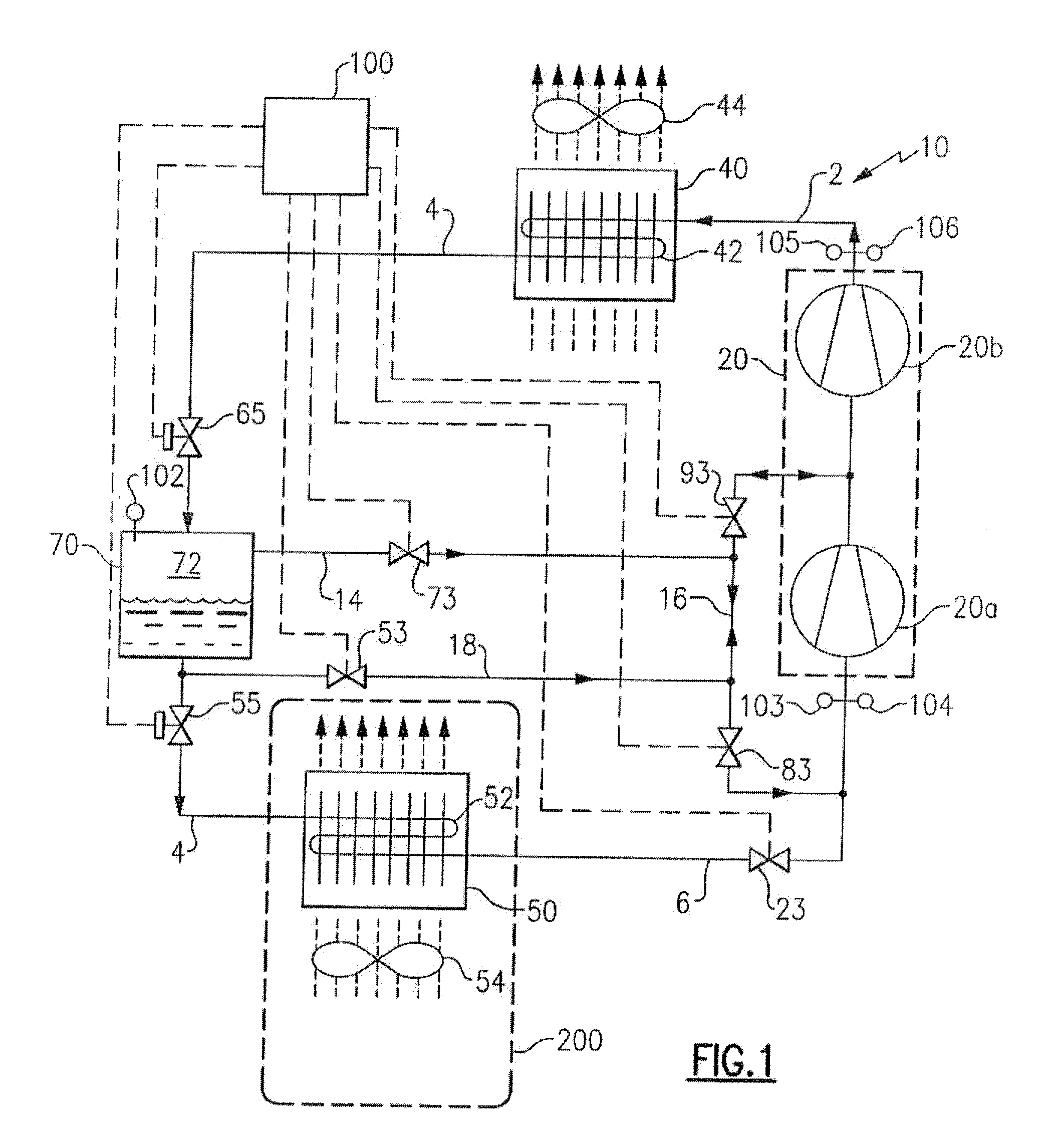

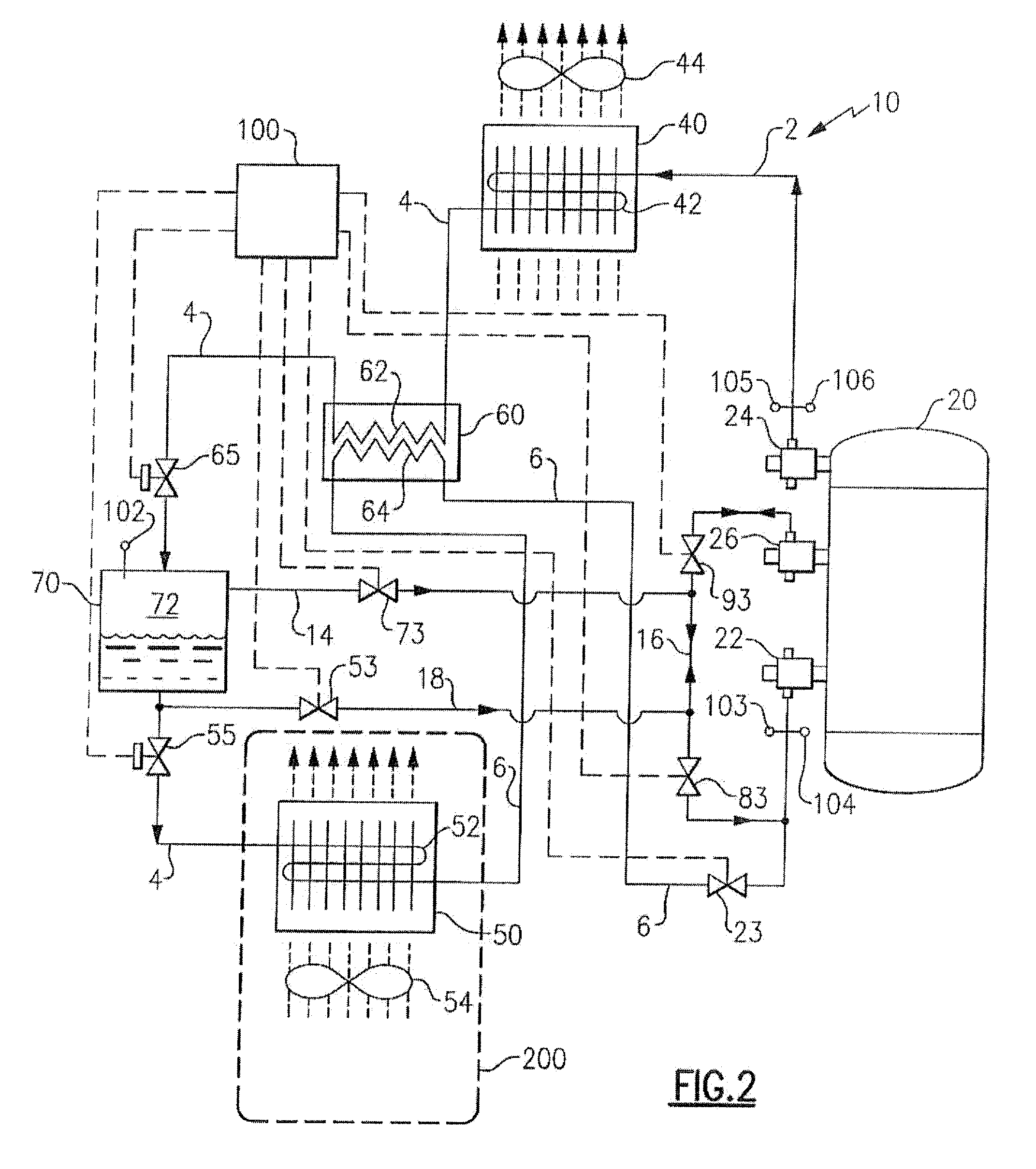

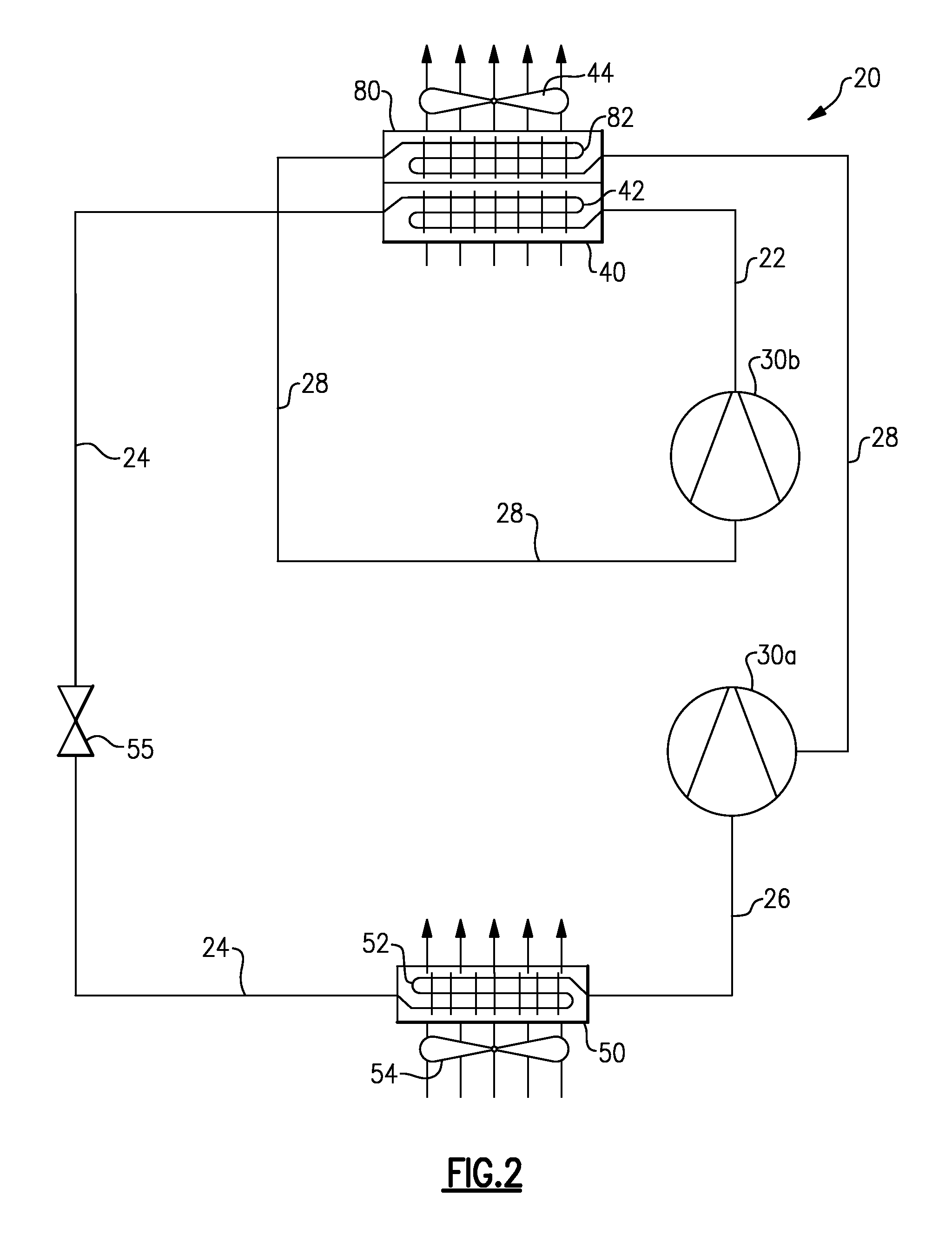

Transcritical refrigerant vapor compression system with charge management

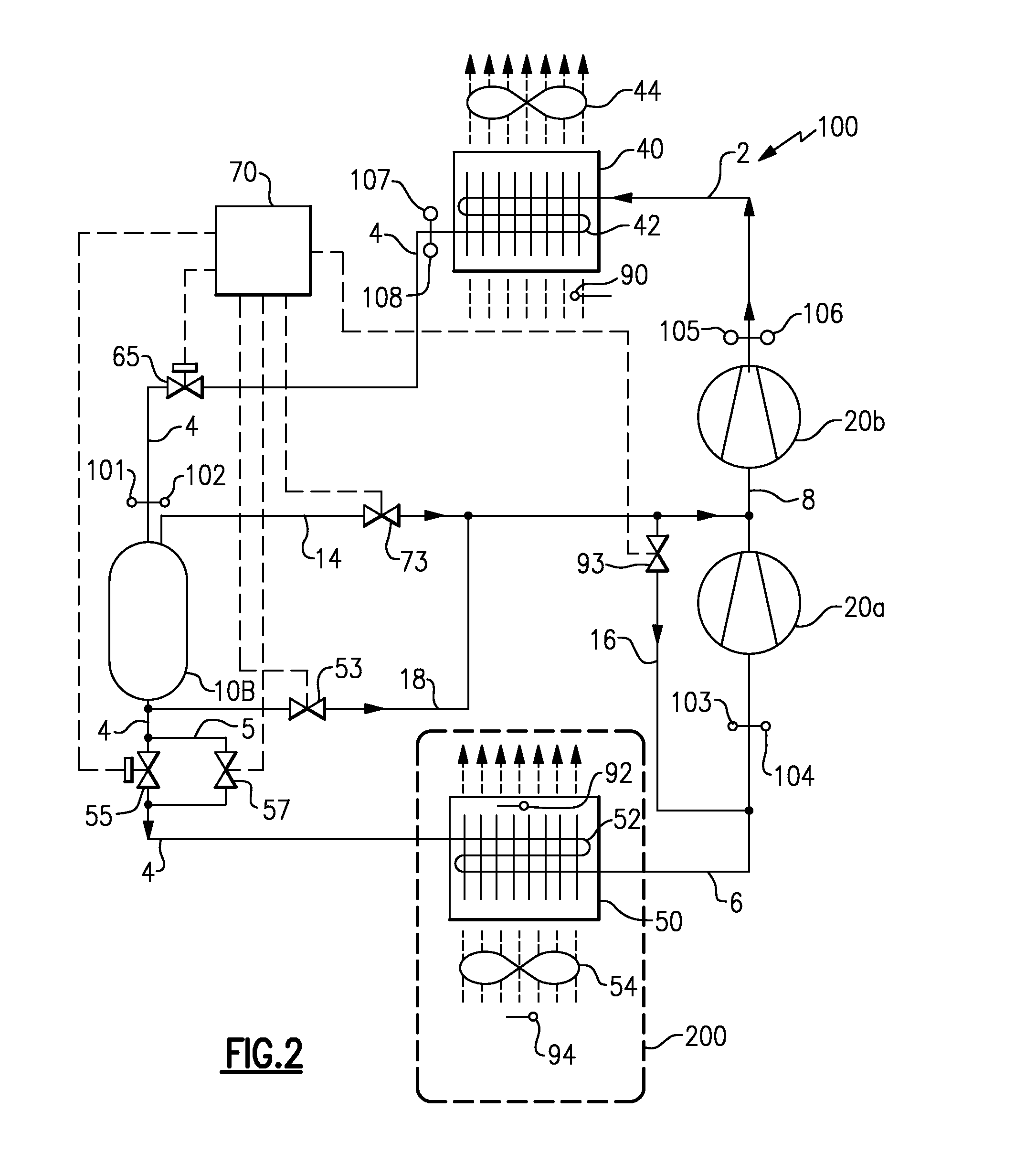

InactiveUS20100132399A1Increase refrigerantCompression machines with non-reversible cycleVehicle heating/cooling devicesHeat rejectionEngineering

A refrigerant vapor compression system includes a refrigerant-to-refrigerant heat exchanger economizer and a flash tank disposed in series refrigerant flow relationship in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. A primary expansion valve is interdisposed in the refrigerant circuit upstream of the refrigerant heat absorption heat exchanger and a secondary expansion valve is interdisposed in the refrigerant circuit upstream of the flash tank. The flash tank functions as a refrigerant charge storage reservoir wherein refrigerant expanded from a supercritical pressure to subcritical pressure separates into liquid and vapor phases. A refrigerant vapor bypass line is provided to return refrigerant vapor from the flash tank to the refrigerant circuit downstream of the refrigerant heat absorption heat exchanger. The primary expansion valve and a flow control valve interdisposed in the refrigerant vapor bypass provide refrigerant charge management.

Owner:CARRIER CORP

Refrigerant vapor compression system with flash tank economizer

A refrigerant vapor compression system includes a flash tank disposed in series refrigerant flow relationship in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. A primary expansion valve is interdisposed in the refrigerant circuit upstream of the refrigerant heat absorption heat exchanger and a secondary expansion valve is interdisposed in the refrigerant circuit upstream of the flash tank. A refrigerant vapor line is provided to direct refrigerant vapor from the flash tank to an intermediate pressure stage of the compression process. A refrigerant-to-refrigerant heat exchanger operates to transfer heat from refrigerant flowing through the primary refrigerant circuit to refrigerant flowing through the refrigerant vapor line.

Owner:CARRIER CORP

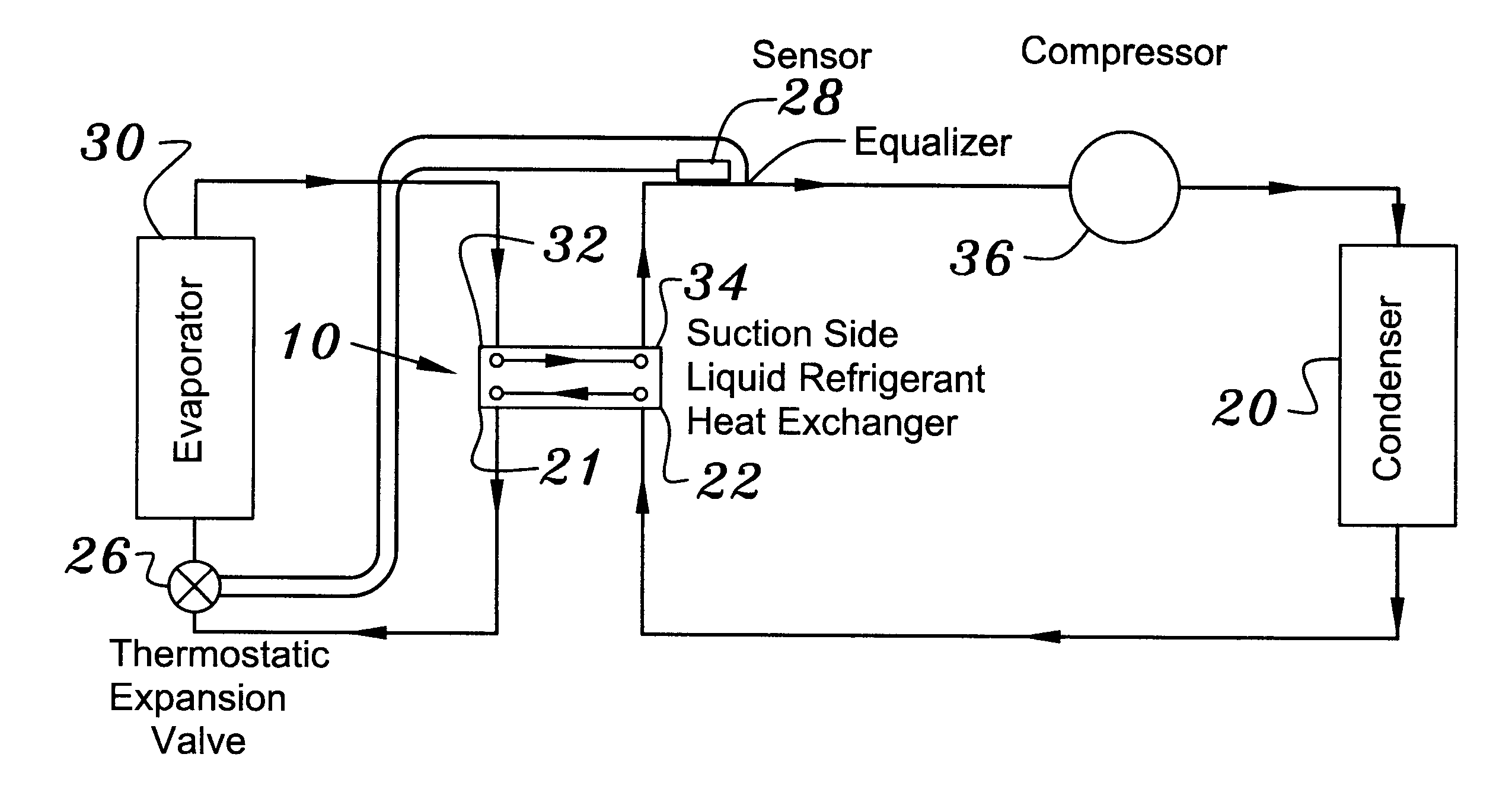

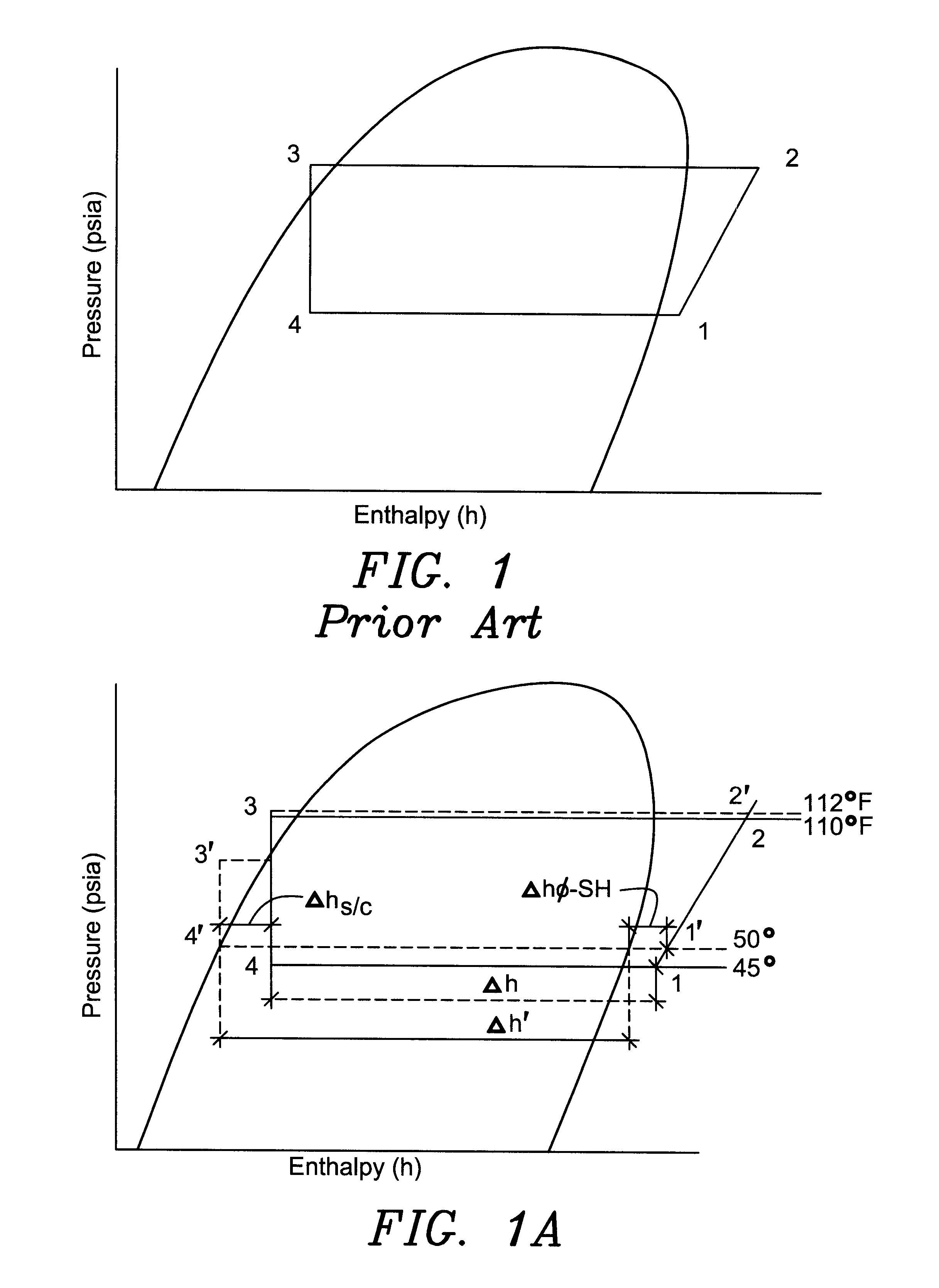

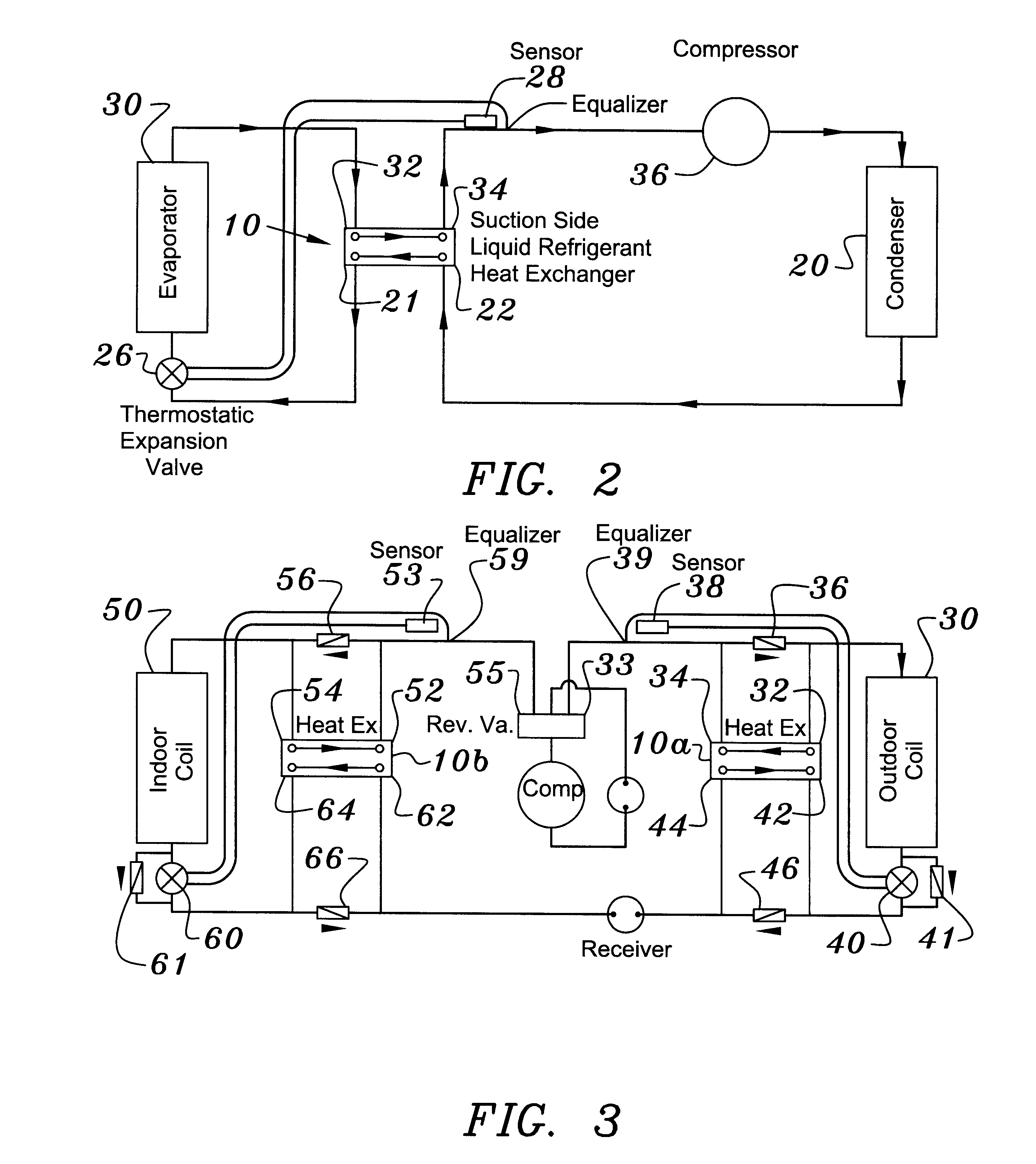

Flash gas and superheat eliminator for evaporators and method therefor

InactiveUS6460358B1Comprehensive understandingImprove cooling effectMechanical apparatusFluid circulation arrangementHeat rejectionFlash-gas

A low pressure suction side refrigerant to liquid refrigerant heat exchanger, located in the refrigeration circuit in such a way that the sensor (and external equalizer tube, if applicable) is located downstream of the low pressure refrigerant outlet of the heat exchanger, provides for effectively eliminating both the superheat and flash gas loss regions of the evaporator which in turn increases the mass flow through the evaporator and increases the refrigerating capacity of the evaporator at very little increase in compressor power thereby providing for increased system efficiency for refrigerating or cooling purposes. On the heating side, heat rejection capacity of a heat pump is increased even more dramatically because of the heat reclaim of the flash gas loss heat, which provides for even greater efficiency increases for heating applications.

Owner:OLIVE TREE PATENTS 1 +1

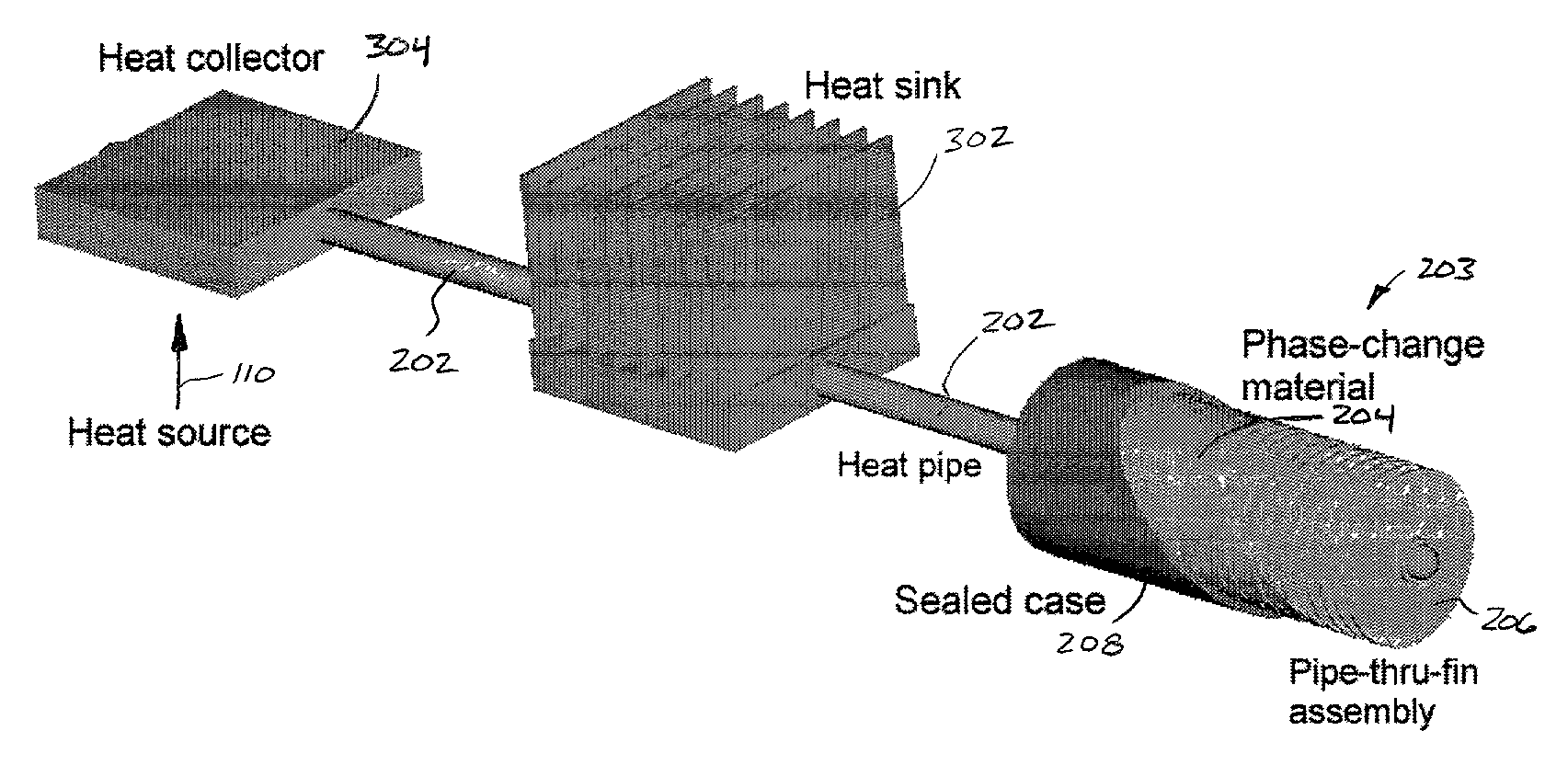

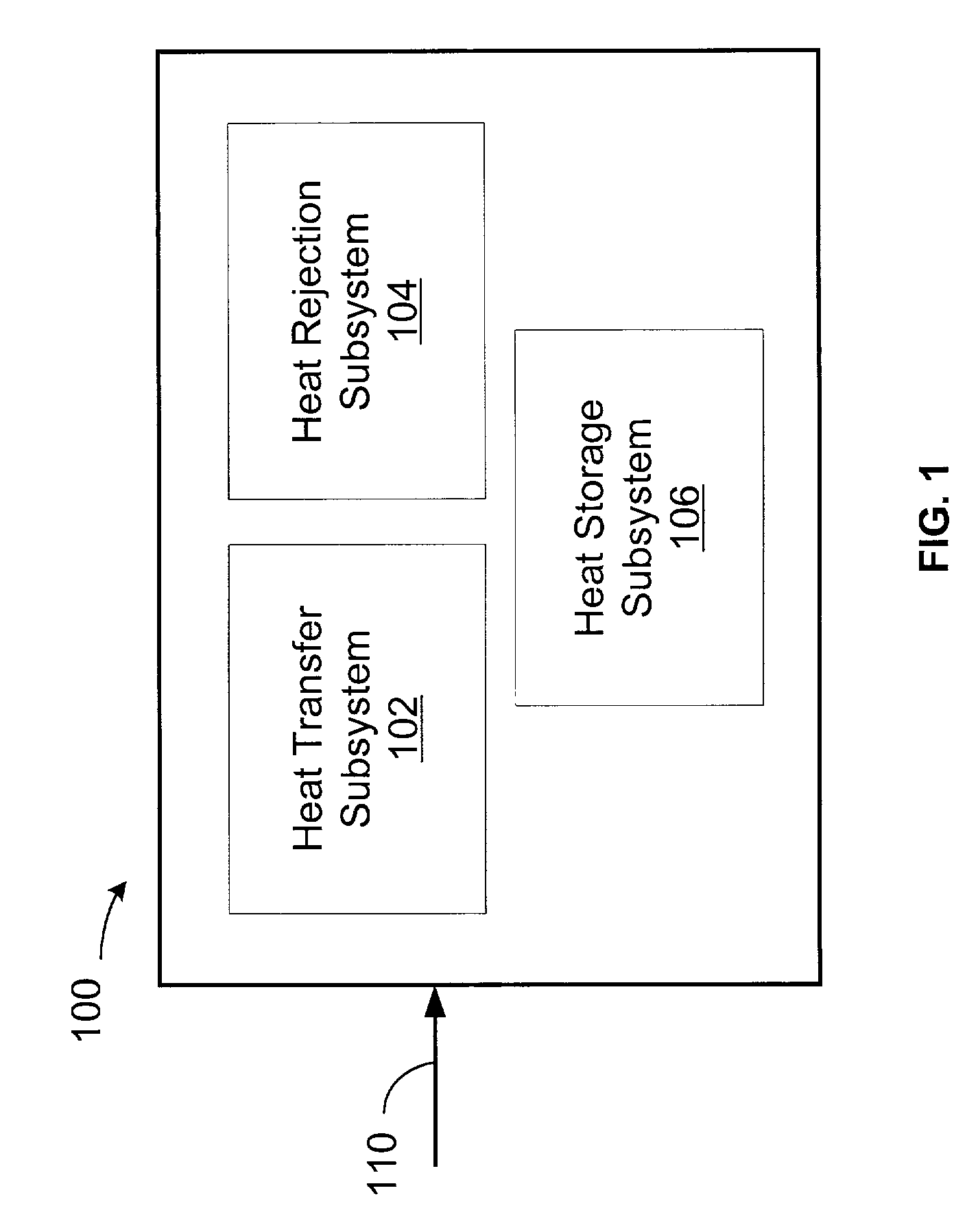

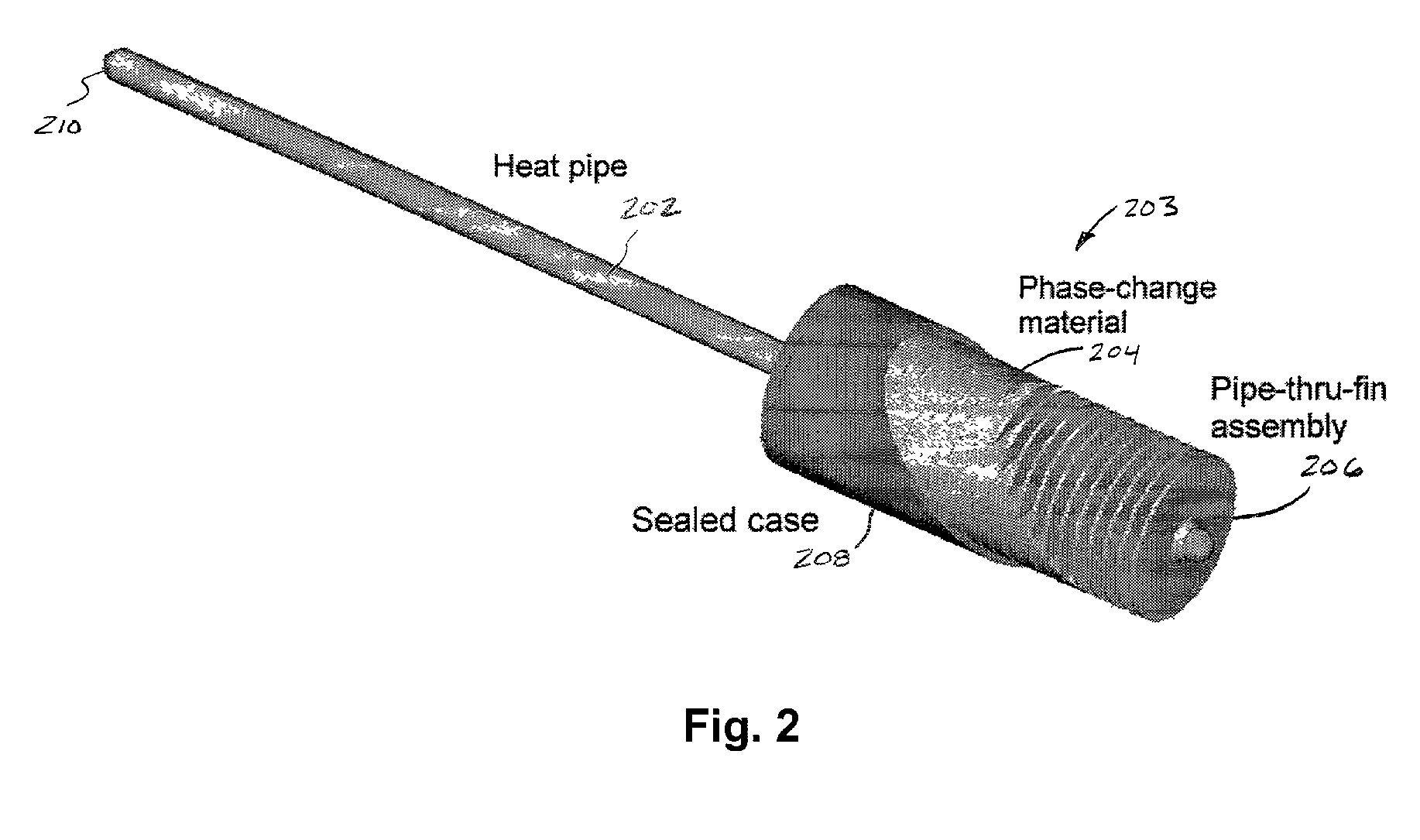

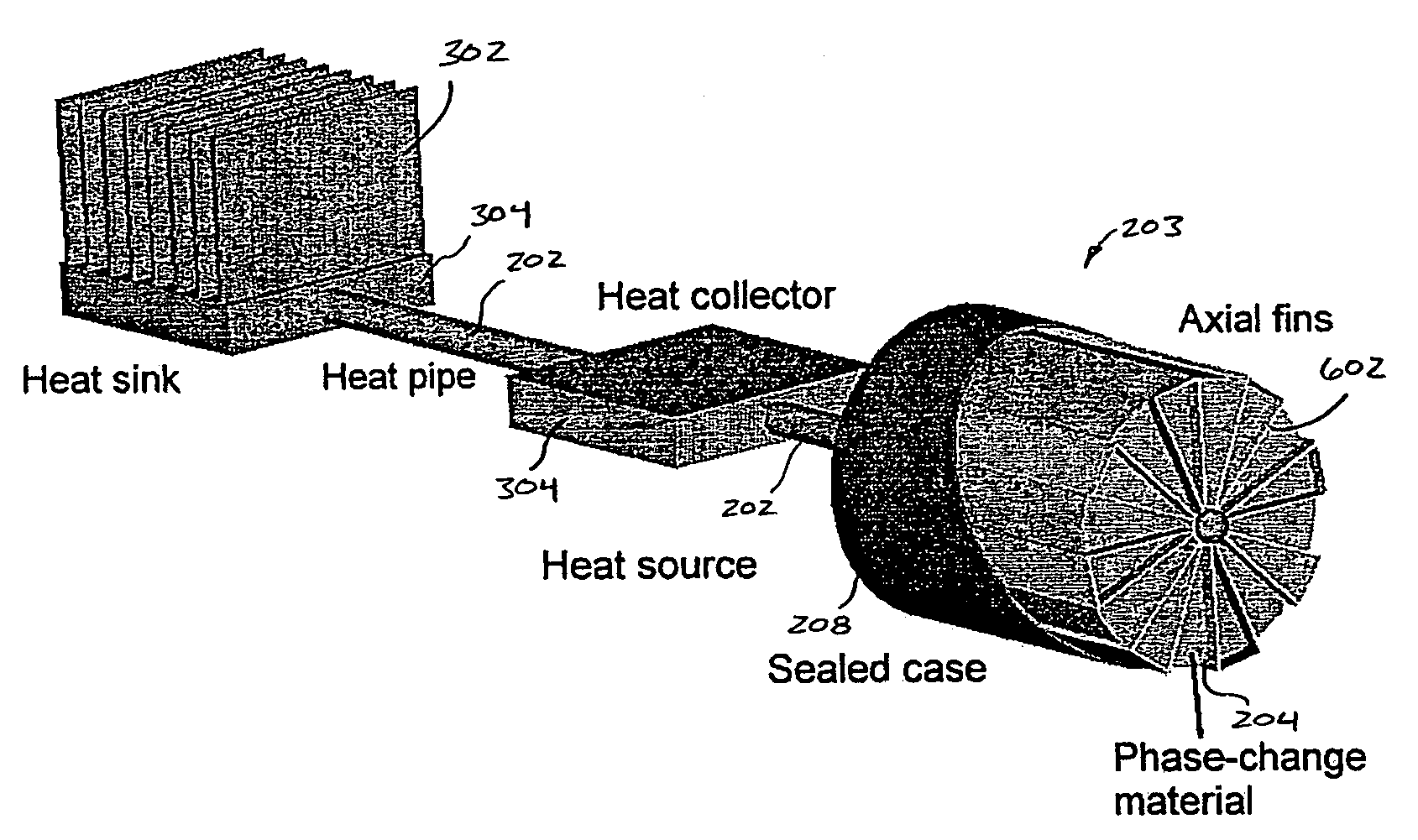

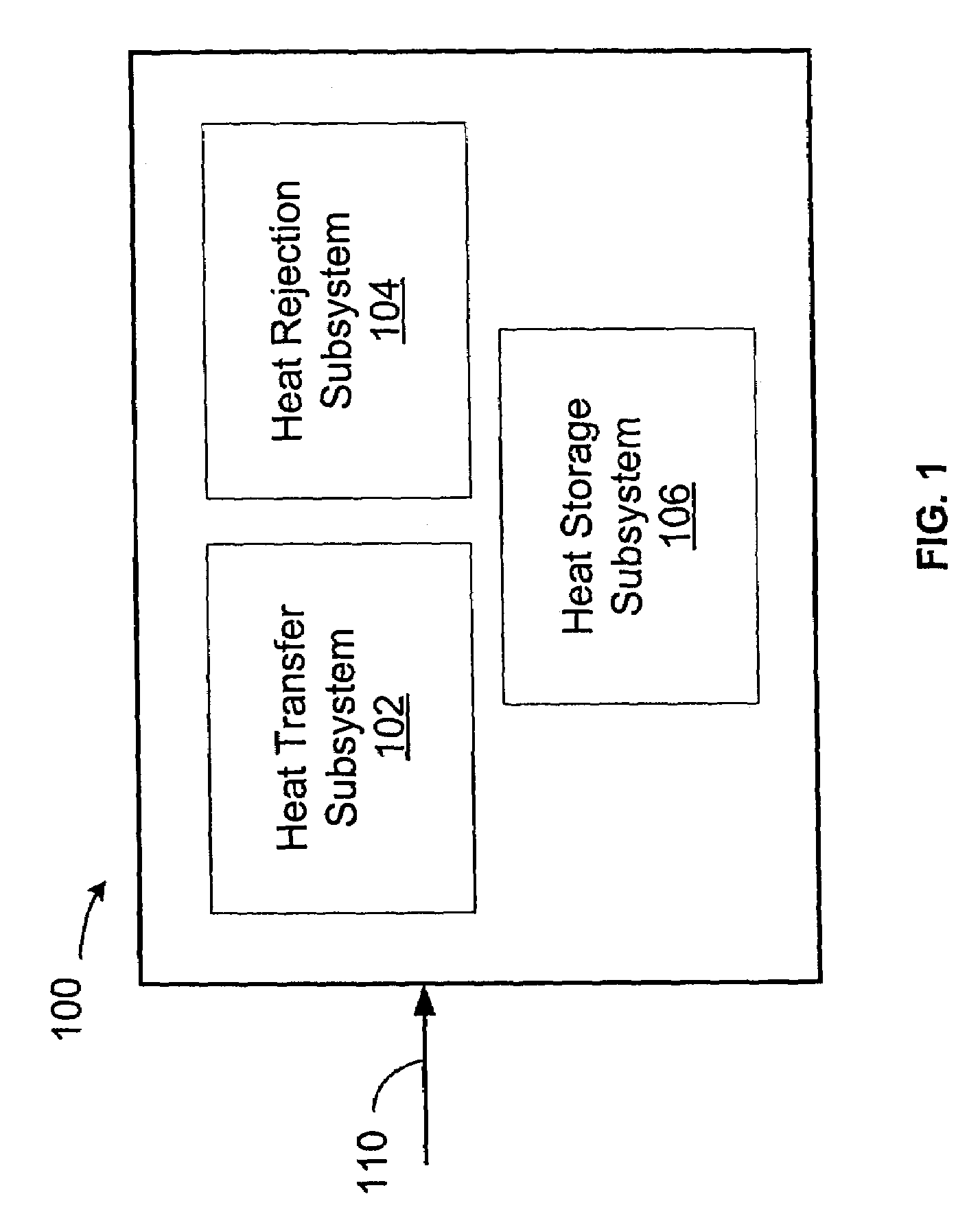

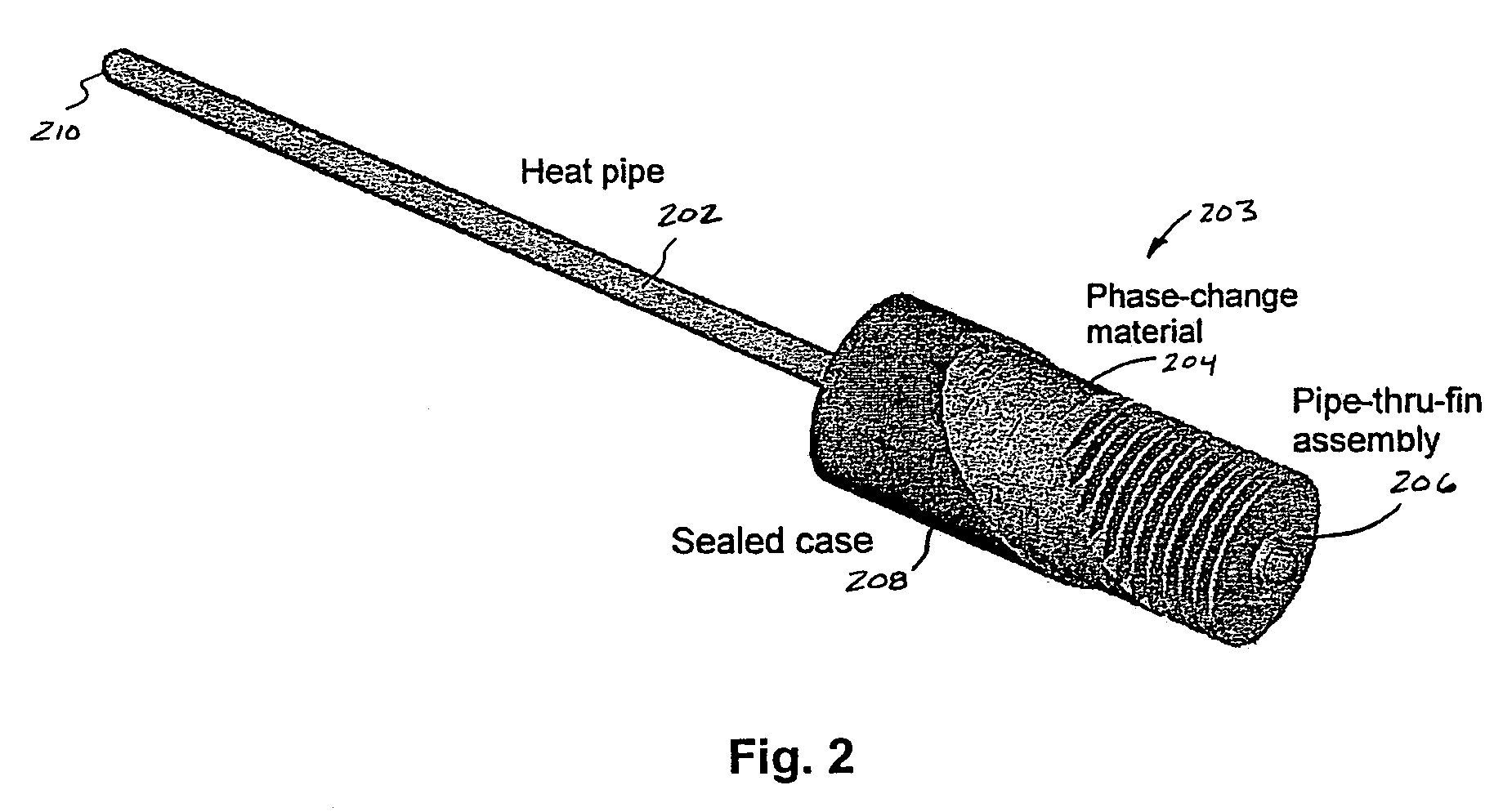

Phase-change heat reservoir device for transient thermal management

InactiveUS6997241B2Good flexibilitySmall sizeCentral heating with accumulated heatHeat storage plantsHeat rejectionThermal solution

A heat transfer system is presented for managing thermal transients, thus providing engineers greater flexibility in designing thermal solutions for applications subject to transient heat-generation. A heat reservoir device for managing a heat input subject to transient conditions includes a heat transfer subsystem having a first end and a second end, where the first end is thermally coupled to the heat input; a heat storage subsystem coupled to the second end of the heat transfer subsystem, where the heat storage subsystem comprises a phase change material responsive to the transient conditions. The excess heat load during transient operation is temporarily absorbed by the latent heat of fusion when the phase change material changes its phase from solid to liquid. Subsequently, the absorbed heat can be released back to the ambient via a heat rejection subsystem. This allows engineers to design smaller heat sinks capable of accommodating given transient conditions. This results in heat sinks which are lower cost and smaller size, or which reduce the requirement to provide higher airflow, thereby also decreasing cost and noise, and increasing reliability.

Owner:ENERTRON INC

Liquid vapor separation in transcritical refrigerant cycle

A refrigerant vapor compression system includes a flash tank disposed in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. The flash tank has a shell defining an interior volume having an upper chamber, a lower chamber and a middle chamber. A first fluid passage establishes fluid communication between the middle chamber and the upper chamber and a second fluid passage establishing fluid communication between the middle chamber and the lower chamber. An inlet port opens to the middle chamber. A first outlet port opens to the upper chamber and a second outlet port opens to the lower chamber.

Owner:CARRIER CORP

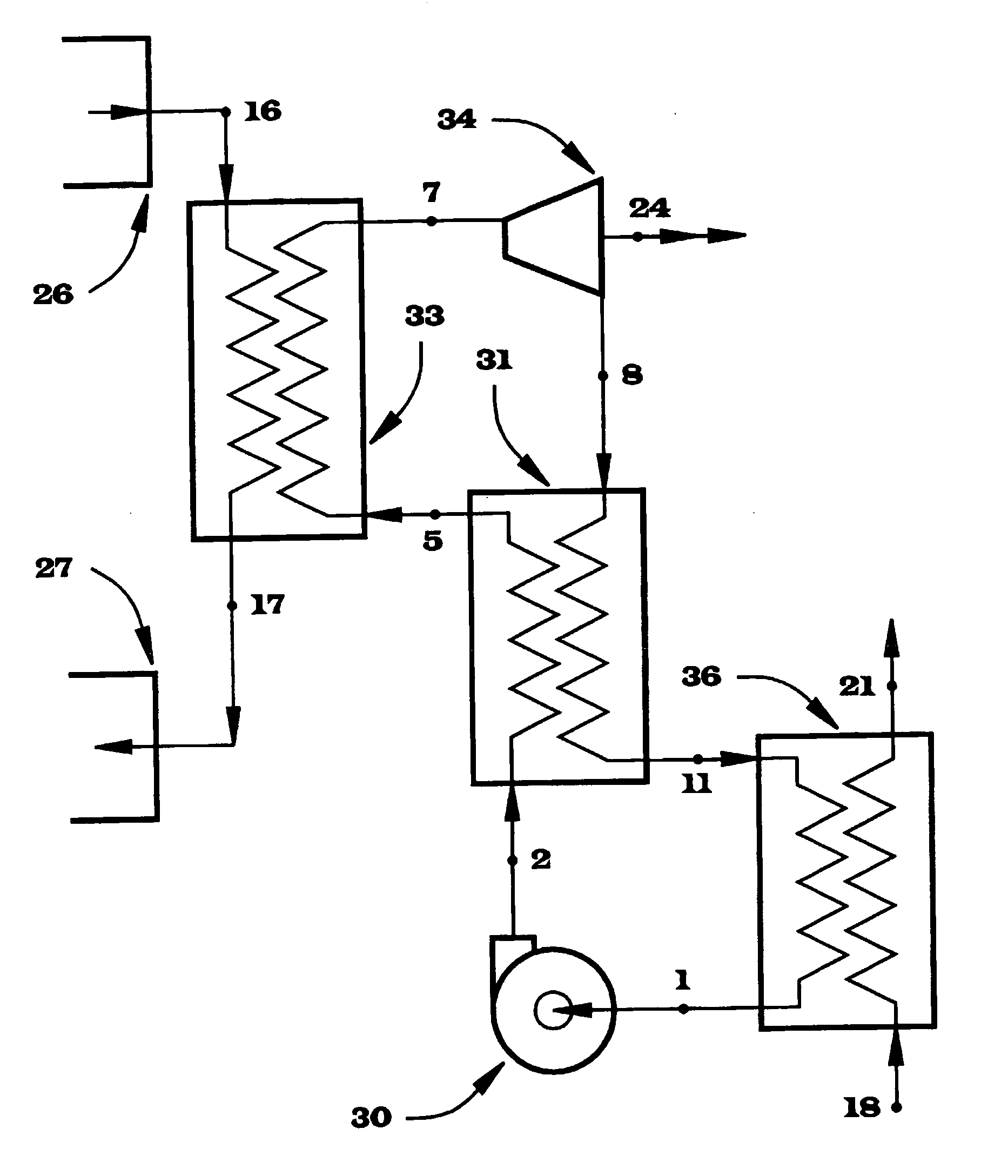

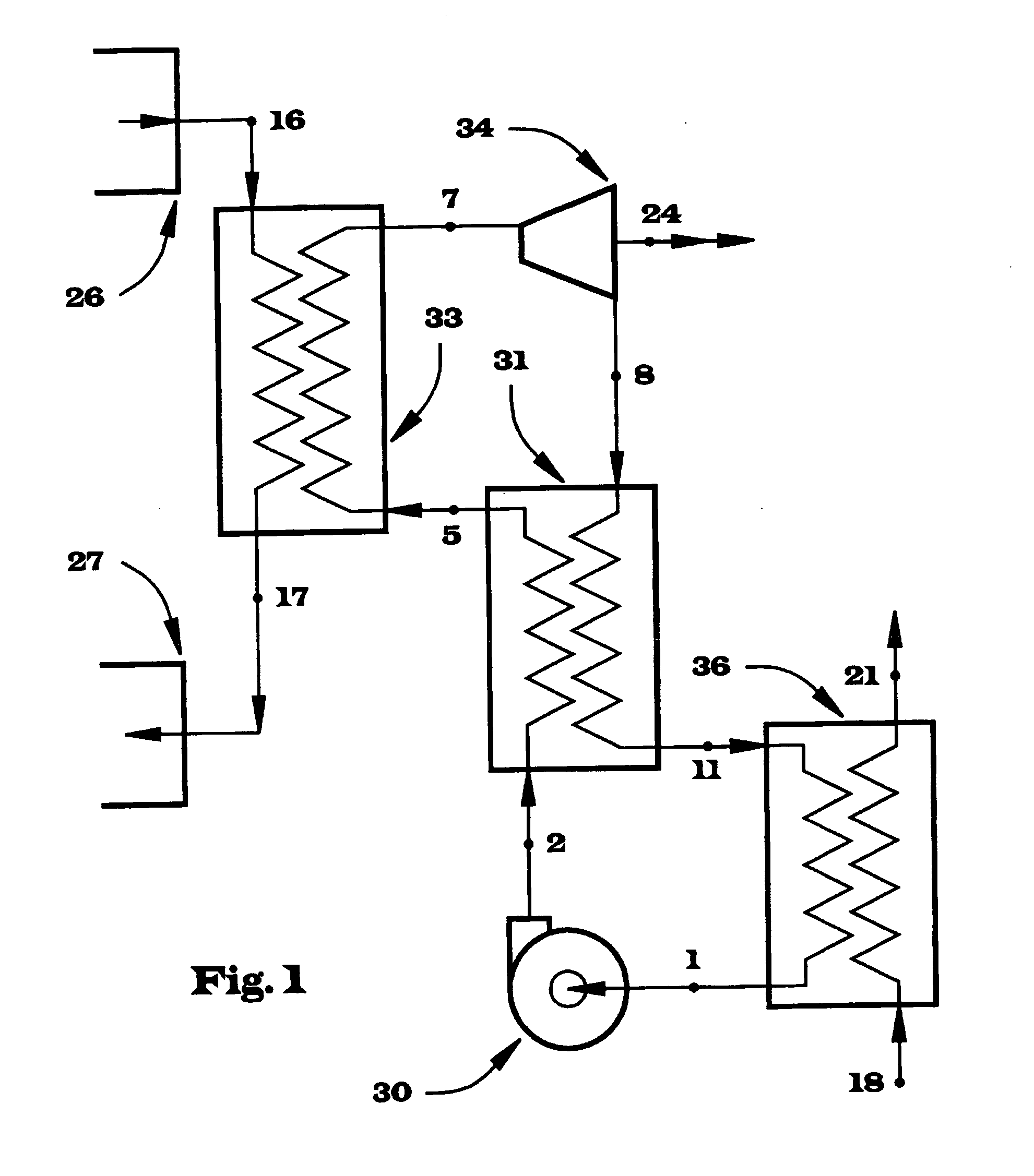

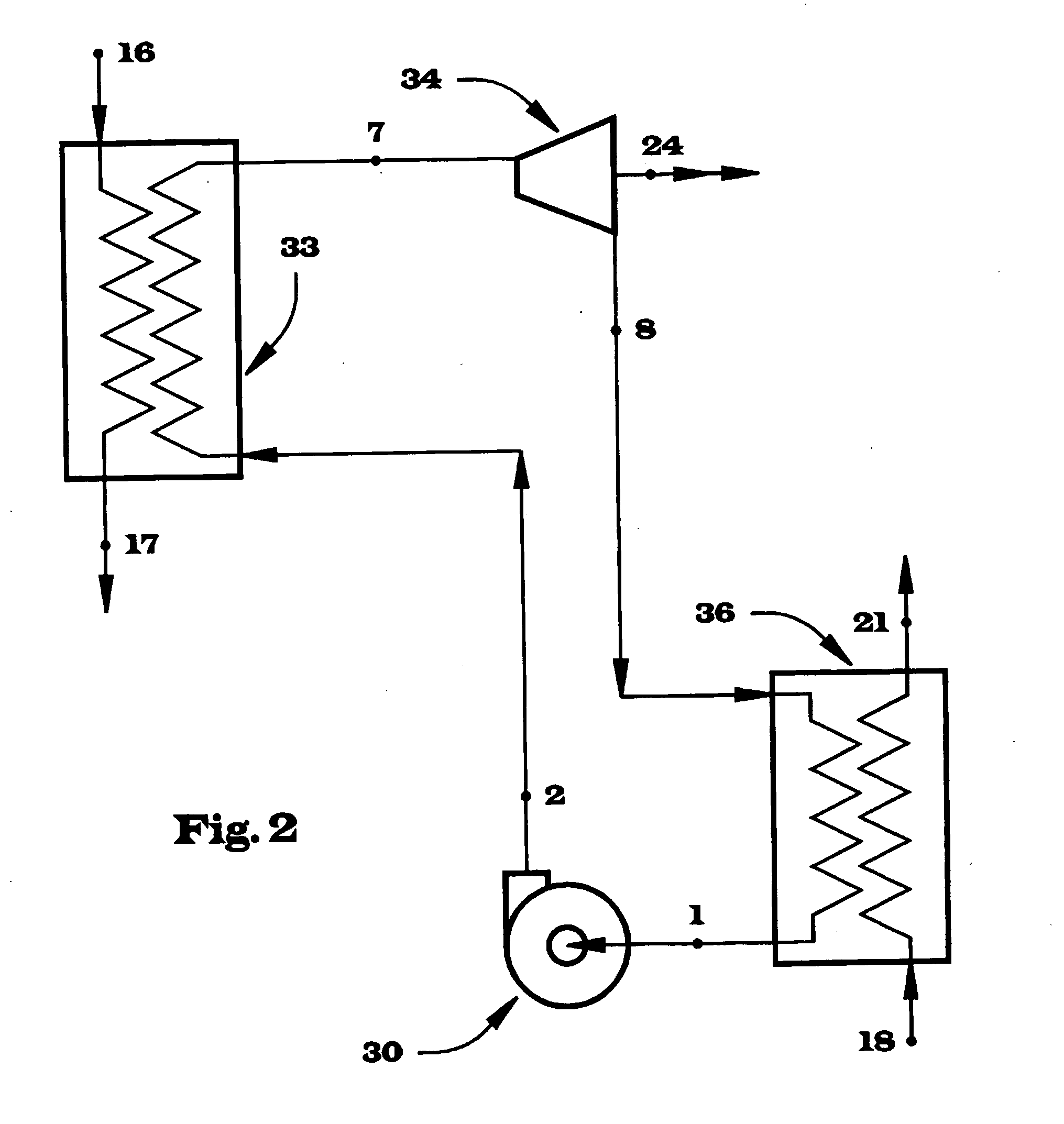

Method of converting energy

The invention provides a method of converting heat energy to a more usable form using a multi-component working fluid mixture that contains ammonia and water. The working fluid is operated in a thermodynamic cycle that includes liquid compression (30), vaporization (33), expansion through a turbine (34) and condensing (36). The multi-component fluid varies in temperature during phase change allowing for the use of counter-flow heat exchangers for the heater (33), cooler (36), recuperator and pre-heater (32). Significant recuperation is possible due to the temperature change during phase change. A pre-heater (32) can be applied to ensure only single-phase vapour exists within the heater. The invention can be used in conjunction with a biomass combustor or with waste flue gas from an existing industrial process. The coolant exits at a temperature sufficient to allow use in external heating applications or to minimize the size of external heat rejection equipment

Owner:SMITH & WESSON

Phase-change heat reservoir device for transient thermal management

InactiveUS7191820B2Good flexibilitySmall sizeHeat storage plantsSemiconductor/solid-state device detailsHeat rejectionThermal solution

Owner:ENERTRON INC

Apparatus and method for cooling electronics and computer components with managed and prioritized directional air flow heat rejection

ActiveUS20060087810A1Digital data processing detailsIndirect heat exchangersHeat rejectionEngineering

An apparatus and method of cooling a plurality of electronic components in a housing using one or more fans cooperating with baffles or ducts for directing a stream of air sequentially to the components or heat exchangers for the components. Direction of the air stream to the components is based on predetermined cooling prioritization of the plurality of components.

Owner:ROCKY RES

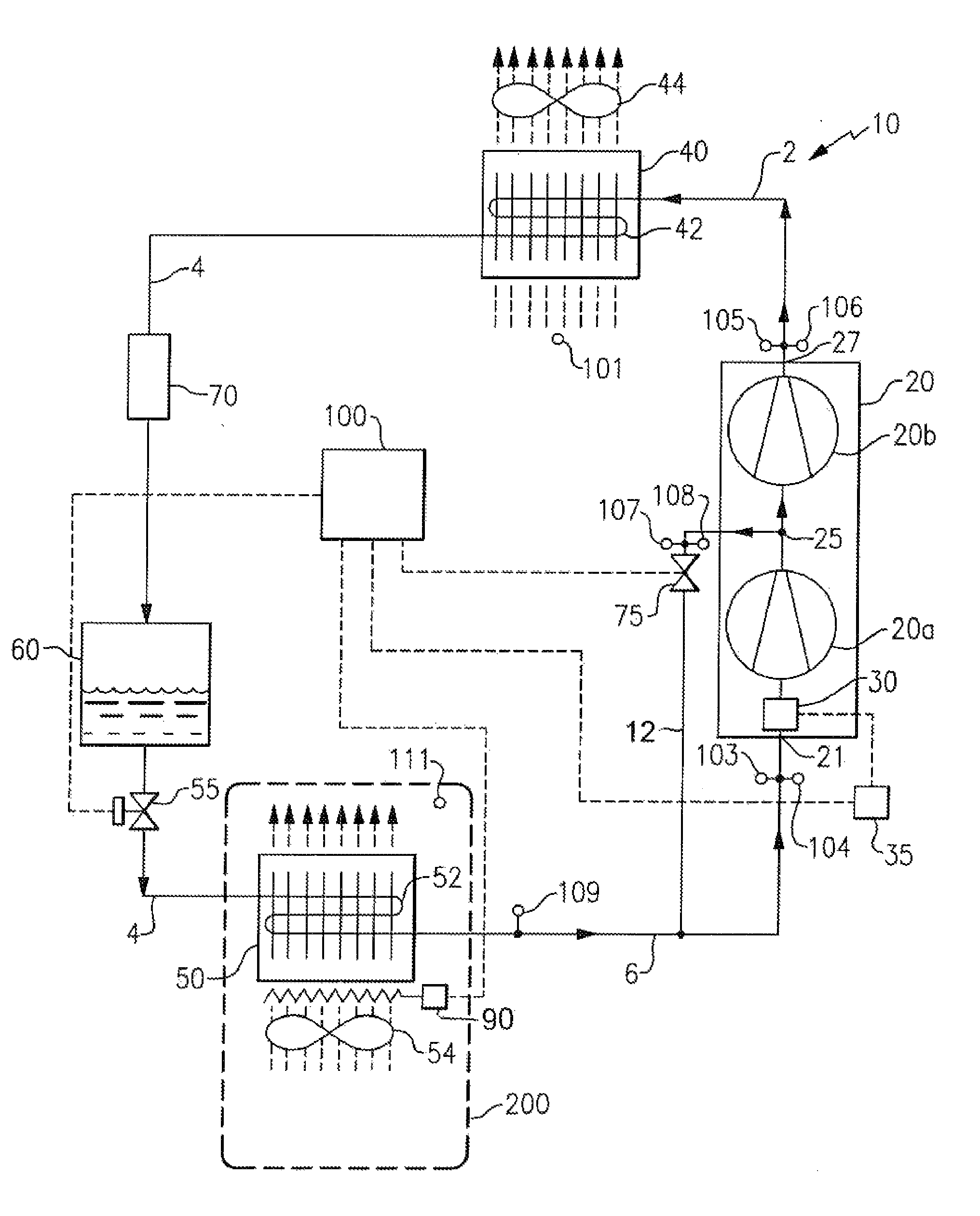

Refrigerant vapor compression system and method of transcritical operation

A refrigerant vapor compression system includes a flash tank economizer defining a separation chamber is disposed in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. A primary expansion valve is interdisposed in the refrigerant circuit in operative association with and upstream of the refrigerant heat absorption heat exchanger and a secondary expansion valve is interdisposed in the refrigerant circuit in operative association and upstream of the flash tank economizer. A refrigerant vapor injection line establishes refrigerant flow communication between an upper portion of the separation chamber and an intermediate pressure stage of the system's compression device and a suction pressure portion of the refrigerant circuit. A refrigerant liquid injection line establishes refrigerant flow communication between a lower portion of said separation chamber and an intermediate pressure stage of the compression device and a suction pressure portion of the refrigerant circuit.

Owner:CARRIER CORP

Carbon dioxide refrigerant vapor compression system

ActiveUS20110138825A1Maintenance operationCompression machines with non-reversible cycleEfficient regulation technologiesLine tubingHeat rejection

A carbon dioxide refrigerant vapor compression system and method of operating that system are provided. The refrigerant vapor compression system includes a compression device, a flash tank receiver disposed in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger, and a compressor unload circuit including a refrigerant line establishing refrigerant flow communication between an intermediate pressure stage of the compression device and the refrigerant circuit at a location downstream of the refrigerant heat absorption heat exchanger and upstream of a suction inlet to the compression device, and a unload circuit flow control device disposed in said unload circuit refrigerant line. In response to at least one system operating parameter sensed by at least one sensor, the controller selectively positions the unload flow control device to maintain the refrigerant vapor compression system operating below a preselected high pressure limit.

Owner:CARRIER CORP

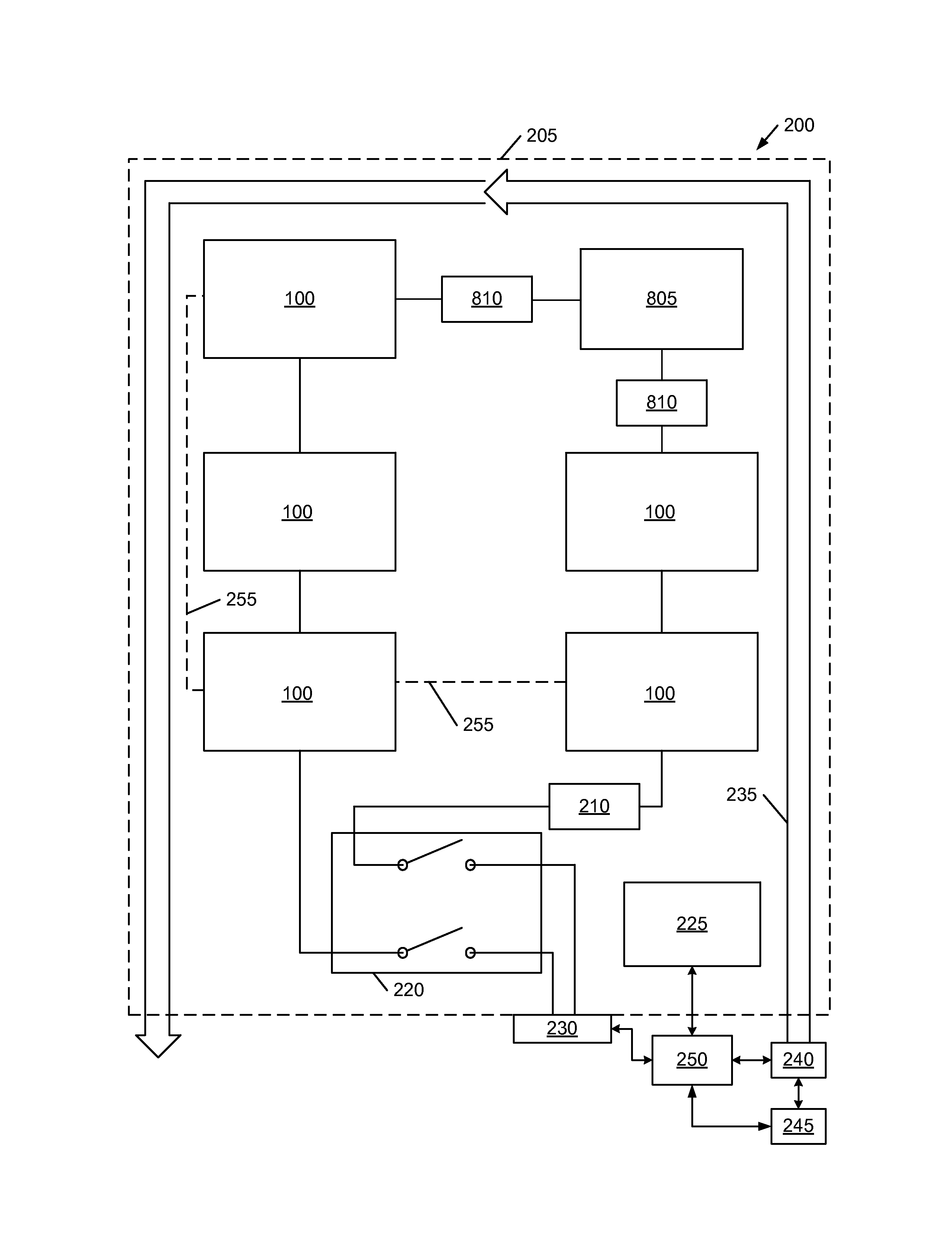

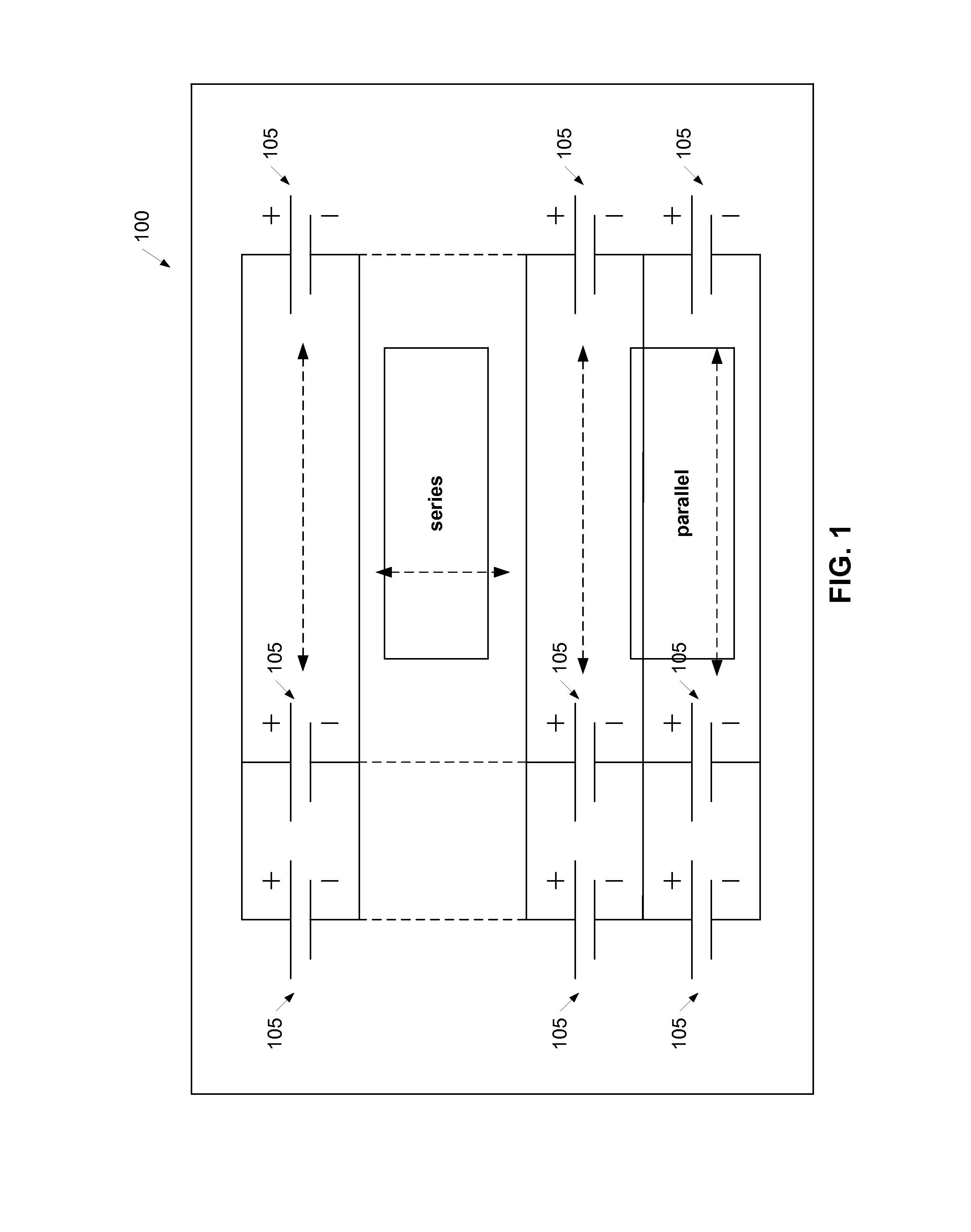

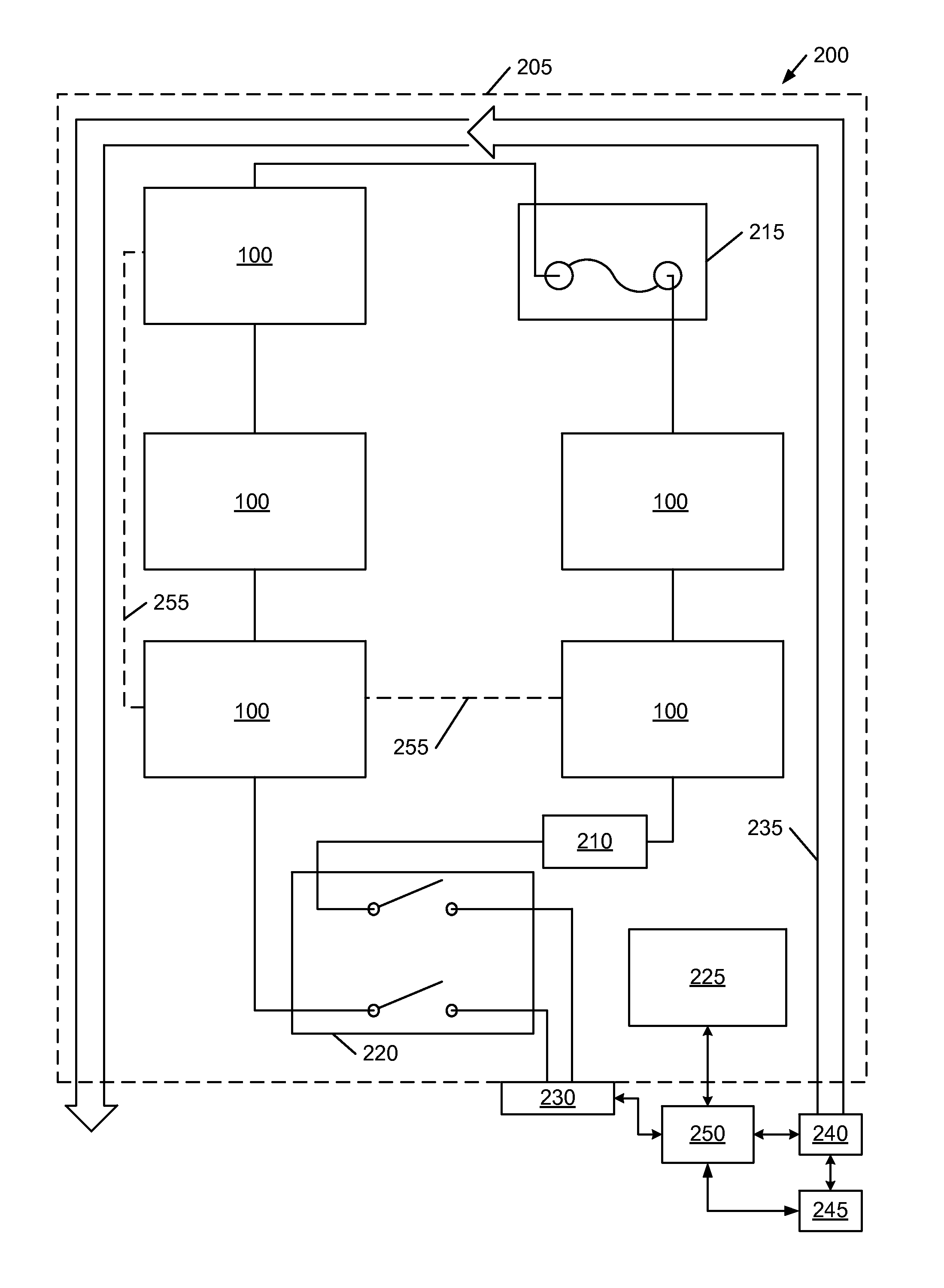

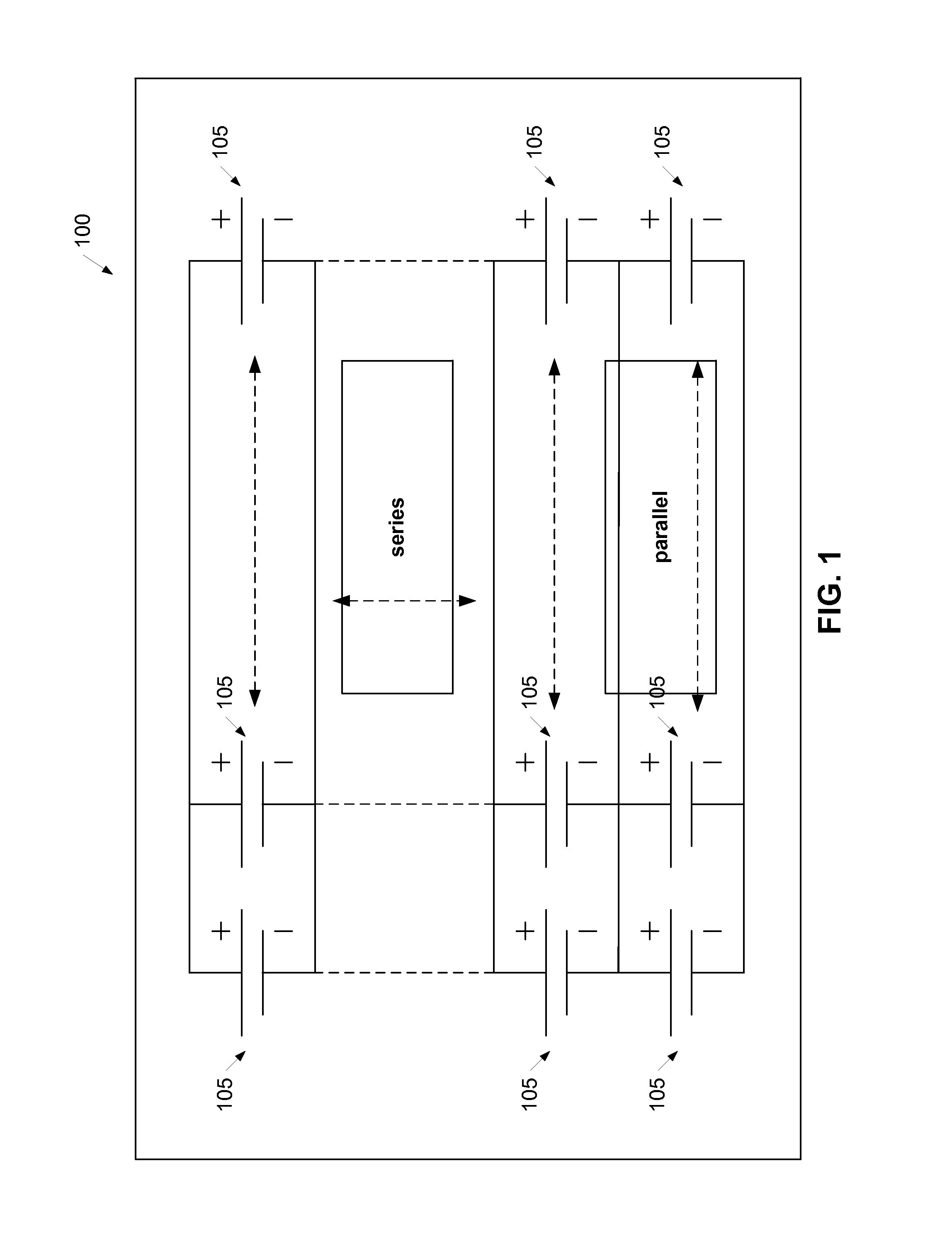

Battery module with integrated thermal management system

ActiveUS20130196184A1Improve manufacturabilityImprove thermal efficiencyCell temperature controlSecondary cells charging/dischargingLow voltageHeat rejection

A controller identifies a condition of a hazardous internal short by comparing patterns of series element voltages to the last known balance condition of the series elements. If the loaded or resting voltage of one or more contiguous series elements uniformly drop from the previously known condition by an amount consistent with an over-current condition, an over-current internal short circuit fault is registered. The desired response is to prevent the affected series elements from heating to a hazardous temperature by summoning the maximum heat rejection capability of the system until the short ceases and the affected elements cool, the cooling function is no longer able to operate due to low voltage, or the affected series string has drained all of its energy through the short. Also includes are responses that allow the battery pack to continue to power the cooling system even though it may enter an over-discharged state.

Owner:TESLA INC

Method to optimize chiller plant operation

A chiller plant which produces chilled water for airconditioning, or an industrial process and which is comprised of chillers, cooling fluid pumps, and cooling towers with electrical motor drives uses a substantial amount of energy. A method that coordinates the operation of the cooling tower, cooling fluid pumps, and refrigeration machines so that the chiller plant operates at a higher overall efficiency thus reducing the power usage has been developed and is presented herein. The flow rate of the cooling fluid pumps are controlled to maintain a precise temperature difference across the refrigerant condenser. The cooling tower fans are controlled by comparing the cooling fluid temperature and the cooling fluid flow rate to selected design parameters. The heat rejection rate is measured for each chiller in the chiller plant and operating set points are established for each operating chiller to provide the optimum operation for best energy efficiency.

Owner:CHILLER PLANT OPTIMIZATION LLC

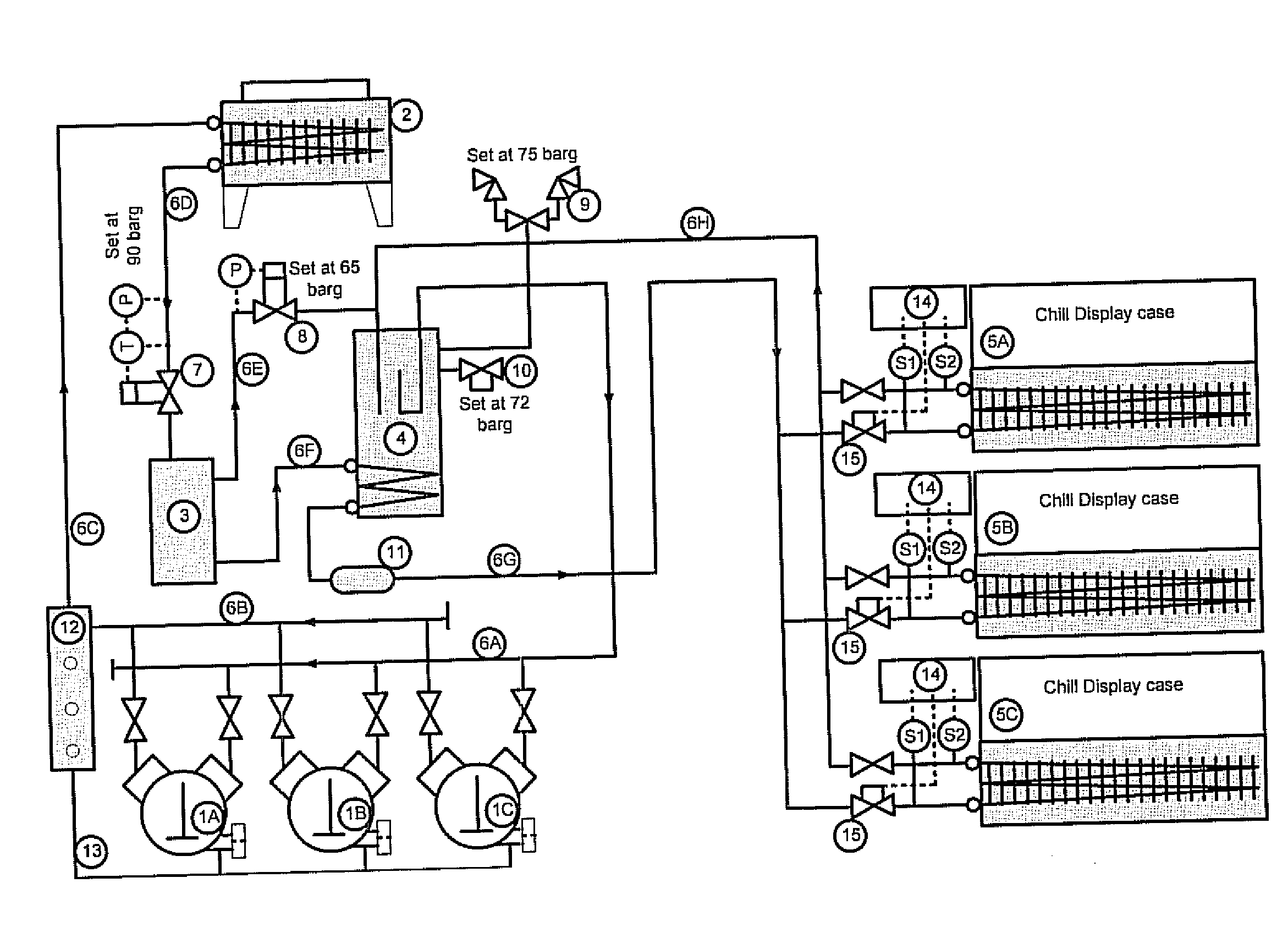

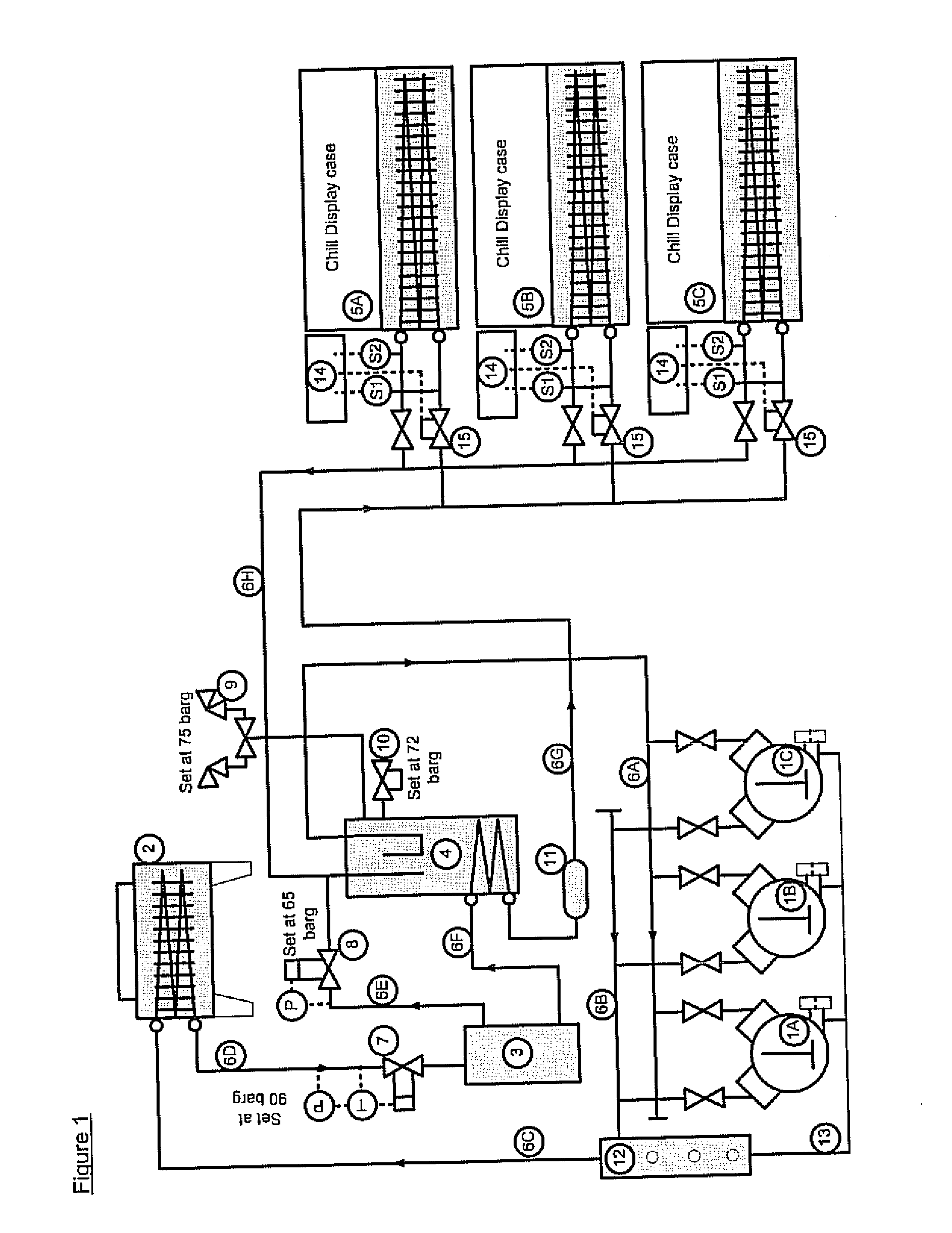

Refrigeration system

InactiveUS20100199707A1Increase pressureNot to damageMechanical apparatusCompression machines with non-reversible cycleAutomatic controlExhaust valve

A refrigerating system comprises a compressor (1A, 1B, 1C), a heat rejection device (2), an expansion device (15), an evaporator (5A, 5B, 5C) and a receiver (4), capable of operating with the compressor discharge higher than the critical pressure of the refrigerant; wherethe flow outlet from the heat rejection device is regulated by a pressure control valve (7),the pressure downstream of the pressure control valve is regulated by a gas vent valve (8),the refrigerant flow to the evaporator is further regulated by an automatic control device (41, 52, 14) at the inlet to the evaporator, andthe automatic control device being set to permit intermittent flow of liquid refrigerant to the receiver during normal operation of the system.The refrigerant may be carbon dioxide, which may operate under transcritical pressures e.g. 80 to 120 bar absolute. The receiver acts as a trap for any liquid from the evaporator and ensures that the gas flow to the compressor suction is dry.

Owner:STAR REFRIGERATION

Detection of over-current in a battery pack

ActiveUS20130179012A1Reduce riskExcessive thermal conditionLevel controlTemperatue controlLow voltageHeat rejection

A controller identifies a condition of a hazardous internal short by comparing patterns of series element voltages to the last known balance condition of the series elements. If the loaded or resting voltage of one or more contiguous series elements uniformly drop from the previously known condition by an amount consistent with an over-current condition, an over-current internal short circuit fault is registered. The desired response is to prevent the affected series elements from heating to a hazardous temperature by summoning the maximum heat rejection capability of the system until the short ceases and the affected elements cool, the cooling function is no longer able to operate due to low voltage, or the affected series string has drained all of its energy through the short. Also includes are responses that allow the battery pack to continue to power the cooling system even though it may enter an over-discharged state.

Owner:TESLA INC

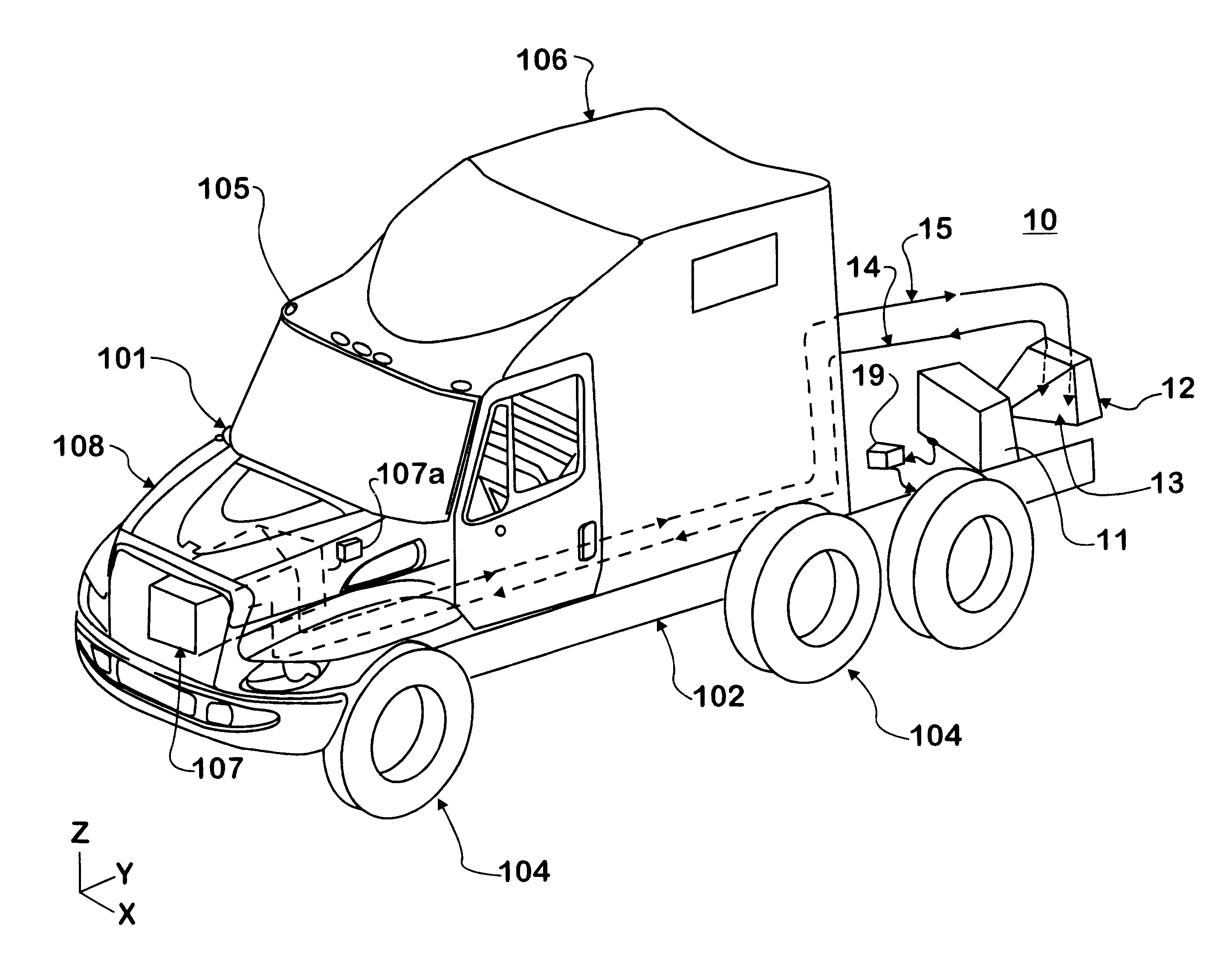

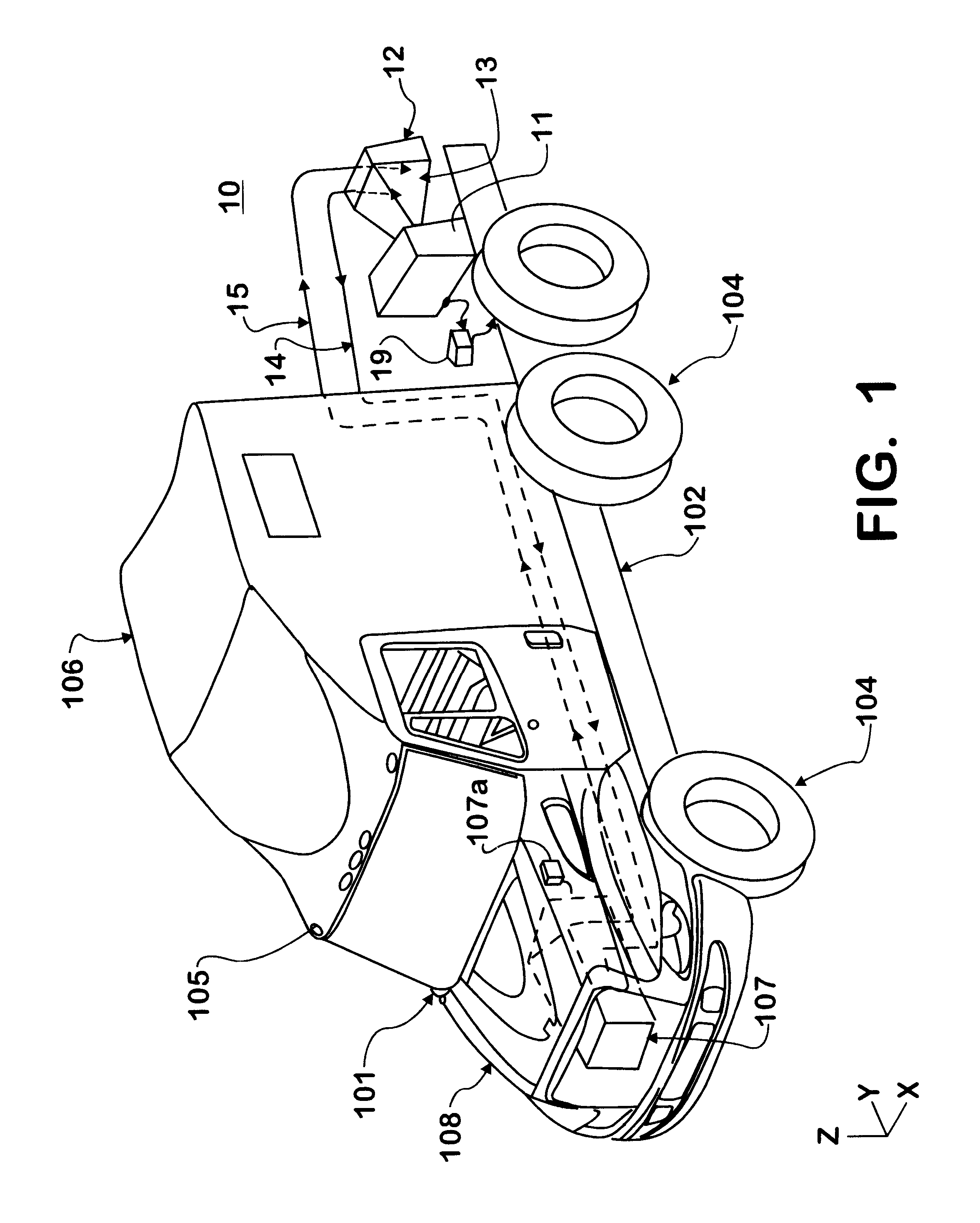

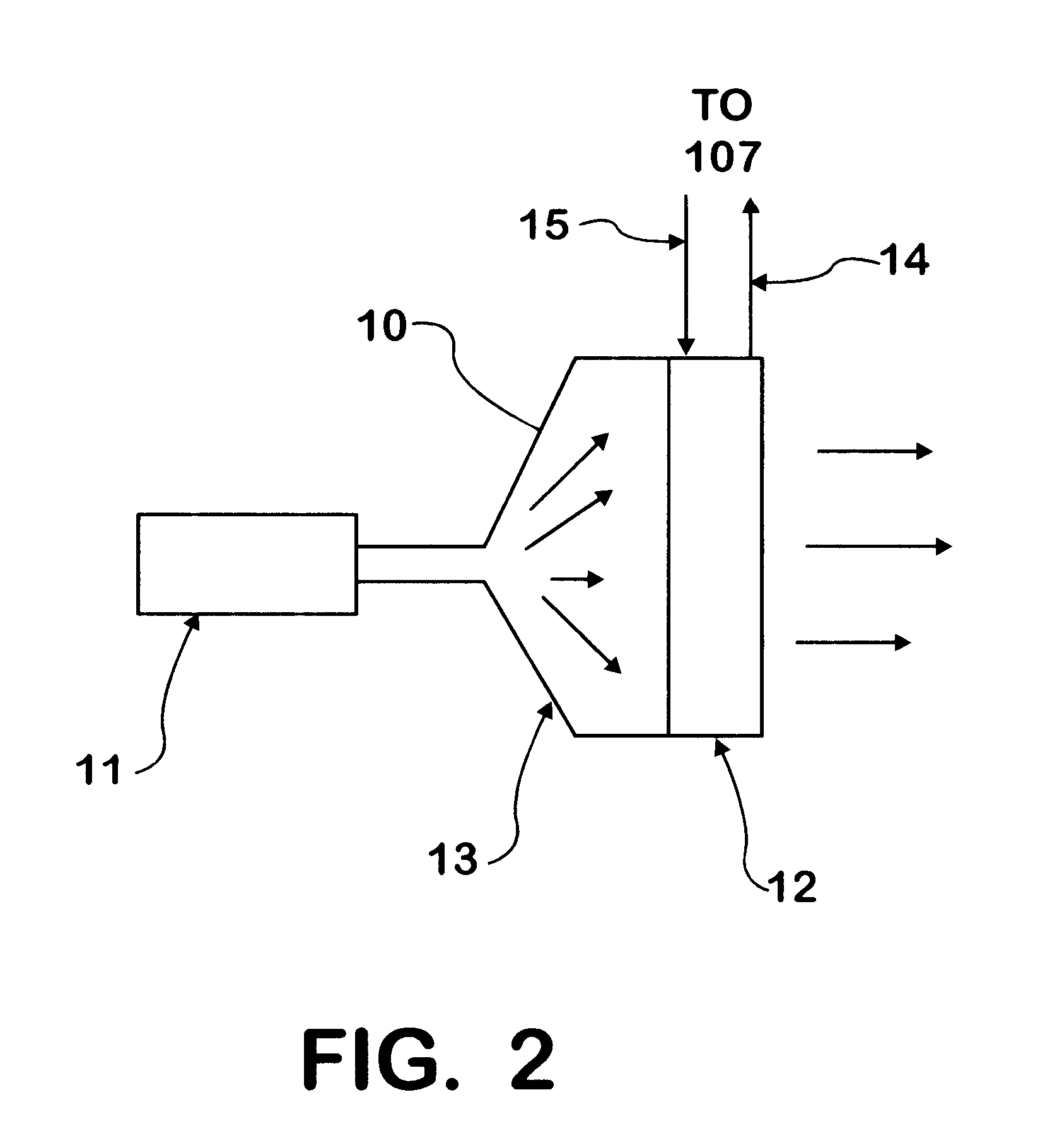

Vehicle engine cooling system without a fan

A vehicle cooling system for a mobile vehicle consists of three essential parts. These are a compressed air reservoir, a heat exchanger and a duct connecting the reservoir and the heat exchanger. On demand, the compressed air will be released to the duct and will expand (as the end connected to the reservoir is expected to be lower in cross-sectional area compared to the end connected to the face of the heat exchanger). This expansion will lead to the reduction in air temperature. This helps in increasing the heat rejection capacity of the cooling system. The colder air passes through the heat exchanger and carries away the heat. This air exits from the other end of the heat exchanger into the environment. A fan is optional to operate behind the heat exchanger to help draw the air though it. The compressed air may originate in the vehicle air system for operating air brakes found on medium and heavy-duty trucks or the compressed air may originate from a separate air compressor. The system may be located in various locations on the vehicle due to the lack of reliance on ram air caused from vehicle movement.

Owner:INT TRUCK & ENGINE CORP CANADA

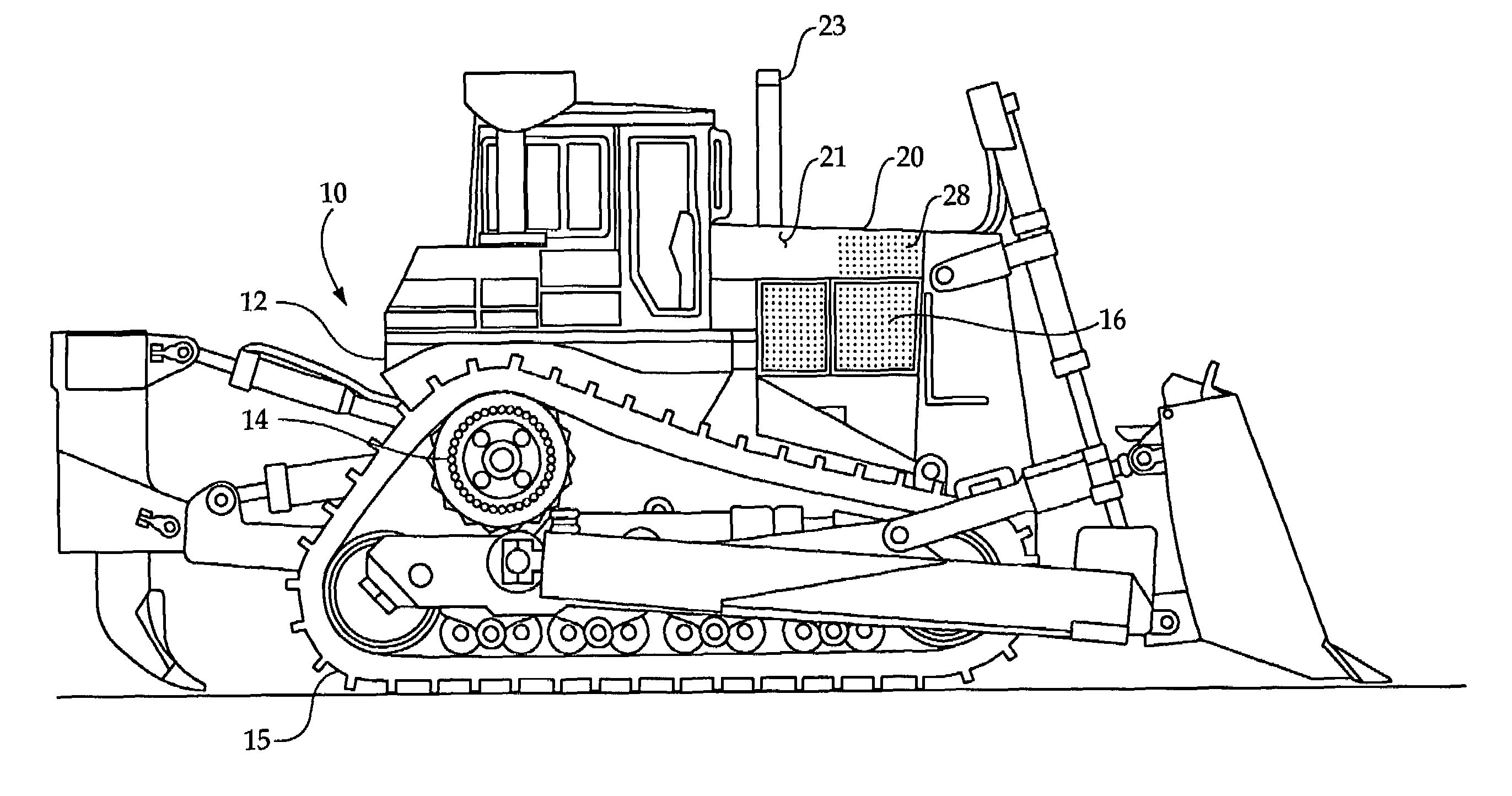

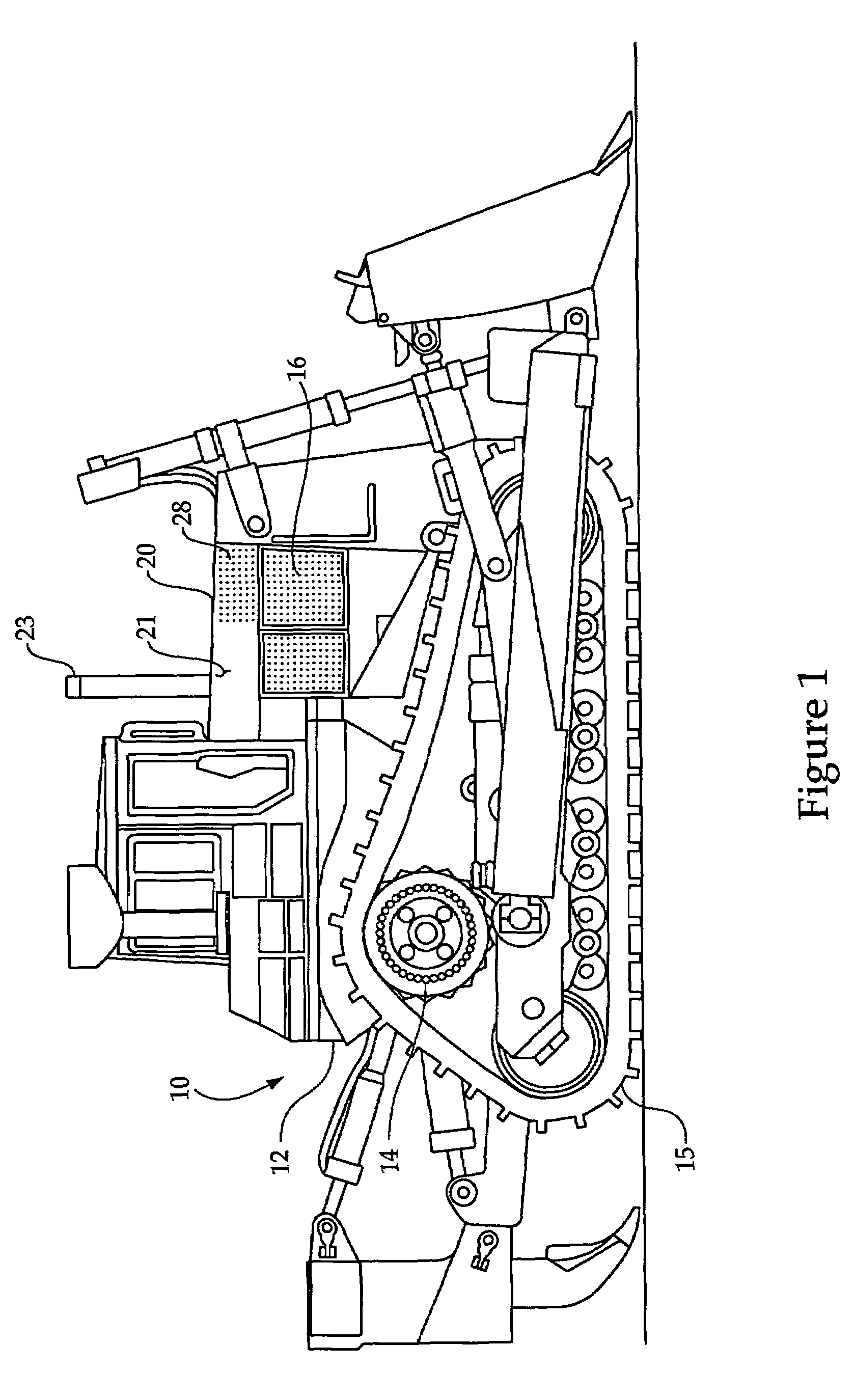

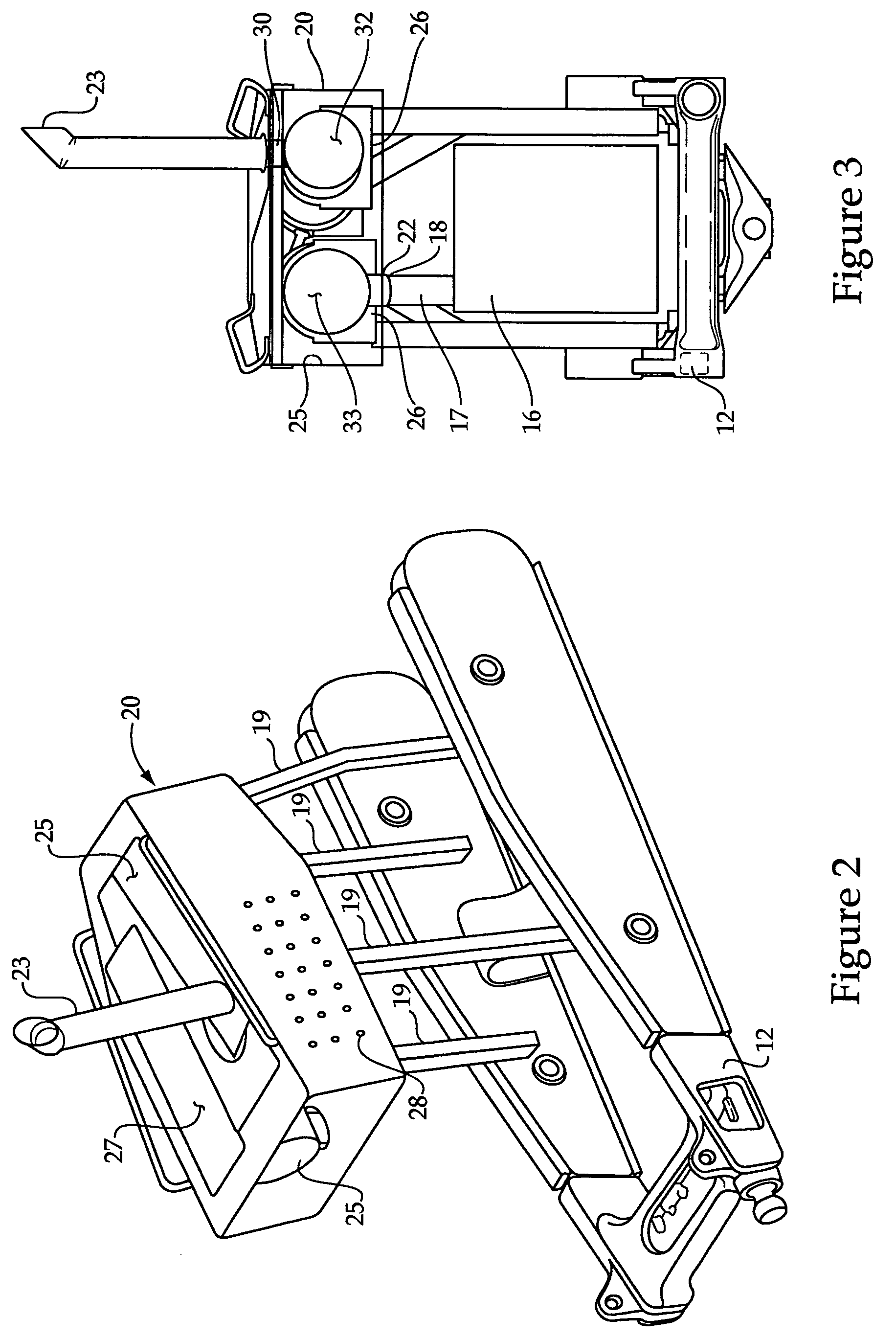

Engine hood assembly enclosure with exhaust aftertreatment device integrated therein, and machine using same

A hood assembly for a machine includes an enclosure within which at least one exhaust aftertreatment device is mounted. The engine hood assembly may be preassembled so that the exhaust aftertreatment system is integrated into the enclosure. This may allow the hood assembly to be assembled to the machine and the exhaust aftertreatment system mated to an exhaust pipe from the engine as a unit while the machine is being built on an assembly line. The engine hood assembly may include ventilation openings to assist in heat rejection from the engine compartment and from the exhaust aftertreatment devices. The hood assembly of the present disclosure finds particular application in assisting large track type tractors in meeting ever more stringent exhaust emission requirements without extensive and expensive redesign alternatives.

Owner:CATERPILLAR INC

Gas turbine engine architecture

ActiveUS20050132693A1Optimize architectureGas turbine plantsEfficient propulsion technologiesHeat rejectionHigh pressure

A gas turbine engine having an oil cavity architecture and bearing placement which reduce heat rejection and oil system complexity by enclosing the reduction gearbox bearings and at least the shaft bearings supporting the high pressure shaft in the same oil cavity.

Owner:PRATT & WHITNEY CANADA CORP

Detection of over-current shorts in a battery pack using pattern recognition

ActiveUS8618775B2Reduce riskExcessive thermal conditionLevel controlTemperatue controlPower flowLow voltage

A controller identifies a condition of a hazardous internal short by comparing patterns of series element voltages to the last known balance condition of the series elements. If the loaded or resting voltage of one or more contiguous series elements uniformly drop from the previously known condition by an amount consistent with an over-current condition, an over-current internal short circuit fault is registered. The desired response is to prevent the affected series elements from heating to a hazardous temperature by summoning the maximum heat rejection capability of the system until the short ceases and the affected elements cool, the cooling function is no longer able to operate due to low voltage, or the affected series string has drained all of its energy through the short. Also includes are responses that allow the battery pack to continue to power the cooling system even though it may enter an over-discharged state.

Owner:TESLA INC

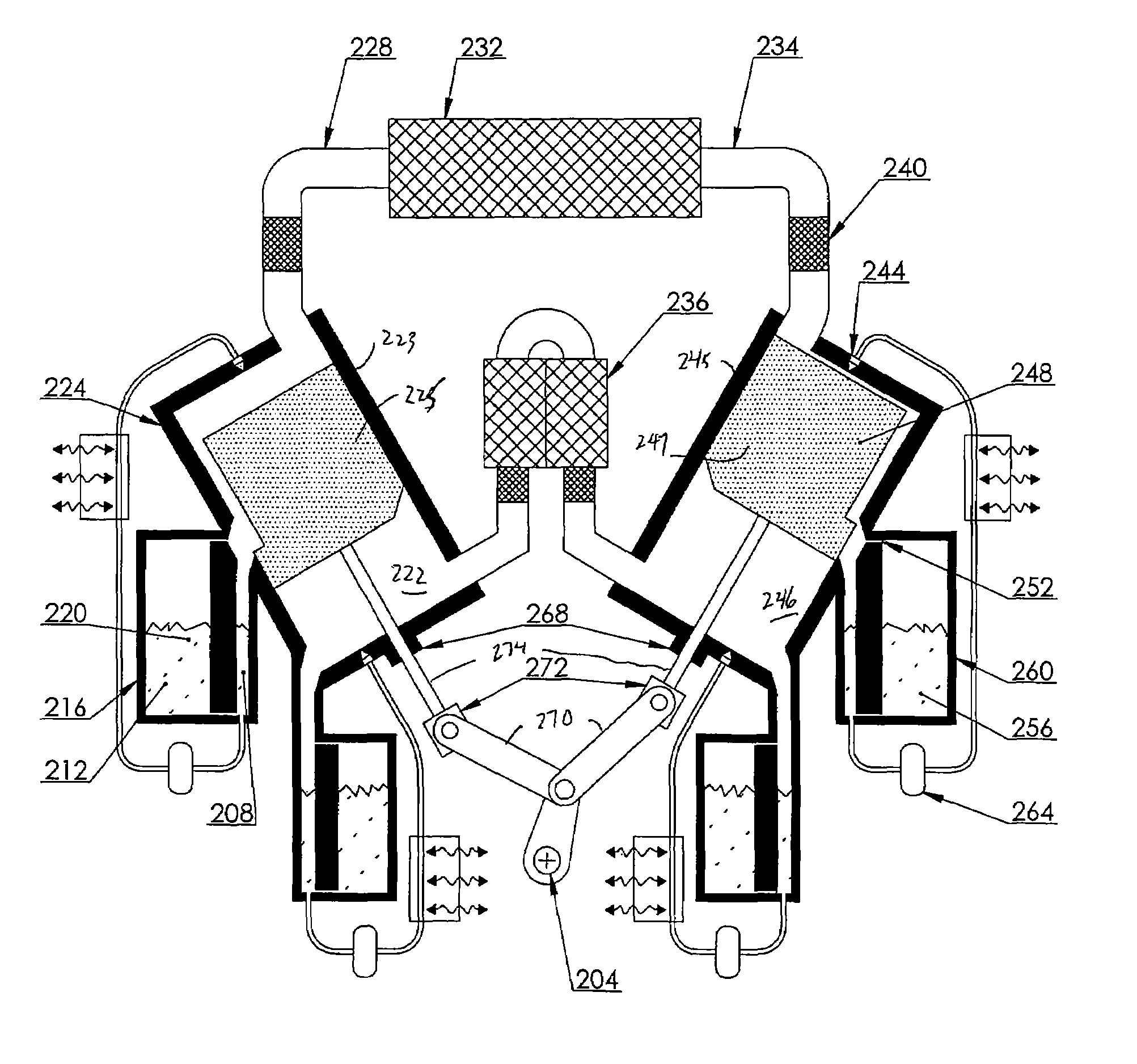

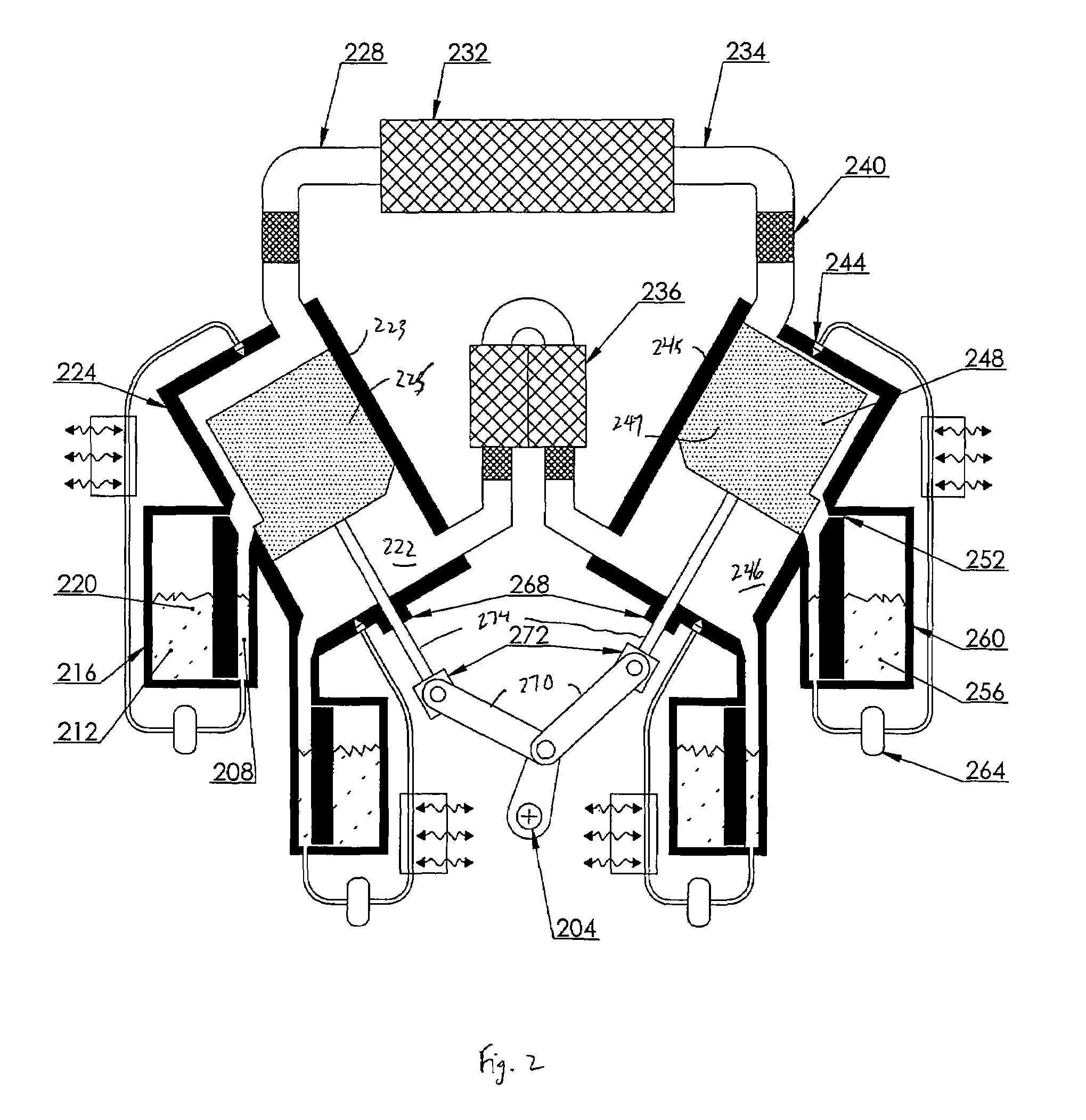

Direct contact thermal exchange heat engine or heat pump

InactiveUS7694514B2Compression machinesClosed-cycle gas positive displacement engine plantWorking fluidHeat rejection

Systems and methods for operating a thermodynamic engine are disclosed. The systems and methods may effect cyclic motion of a working fluid between hot and cold regions of a thermodynamic engine and inject a dispersible material into the working fluid at the hot or cold region during a heat-addition or heat-rejection process. The system and methods may also evacuate the dispersible material from the hot or cold region.

Owner:COOL ENERGY

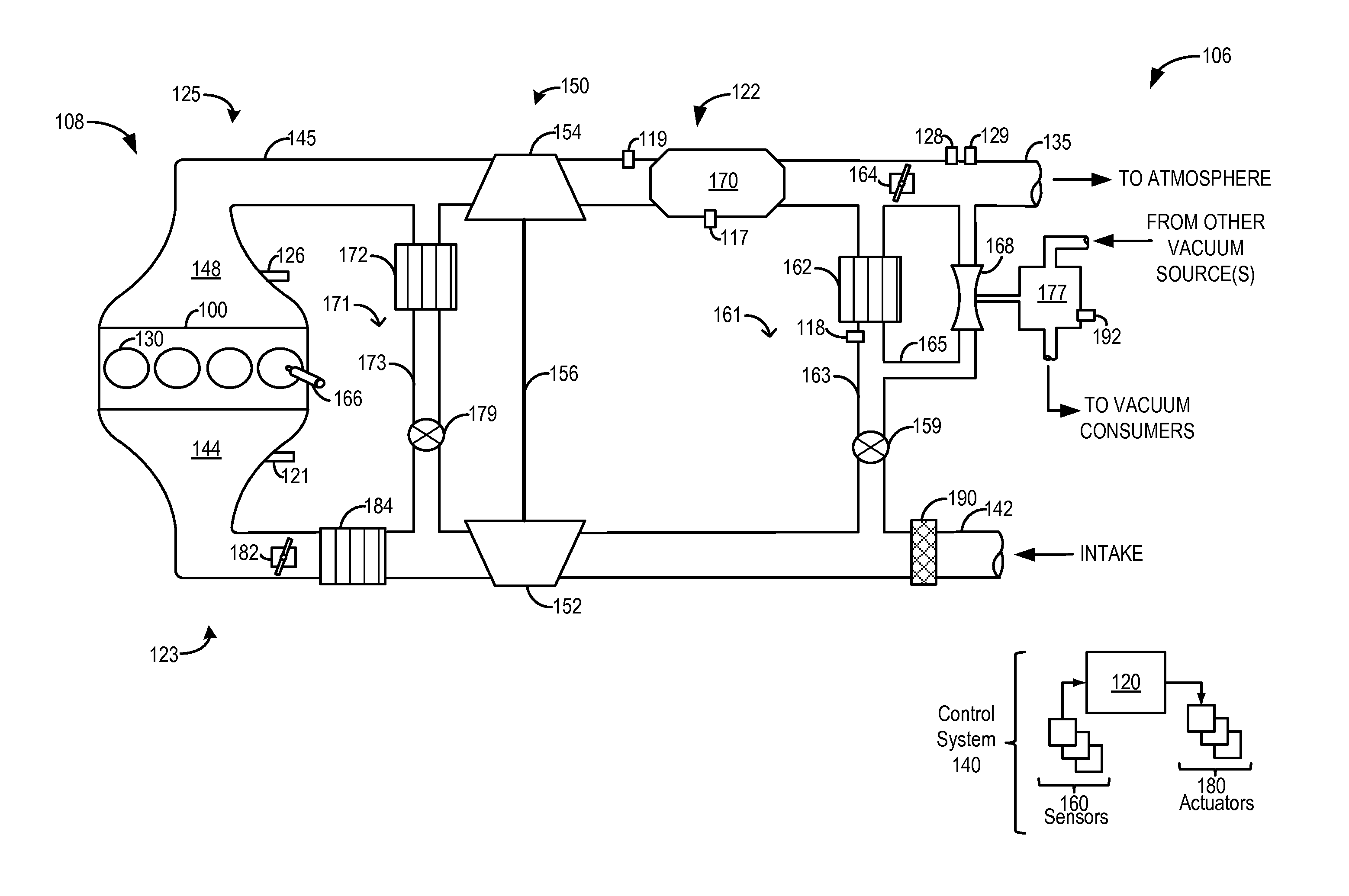

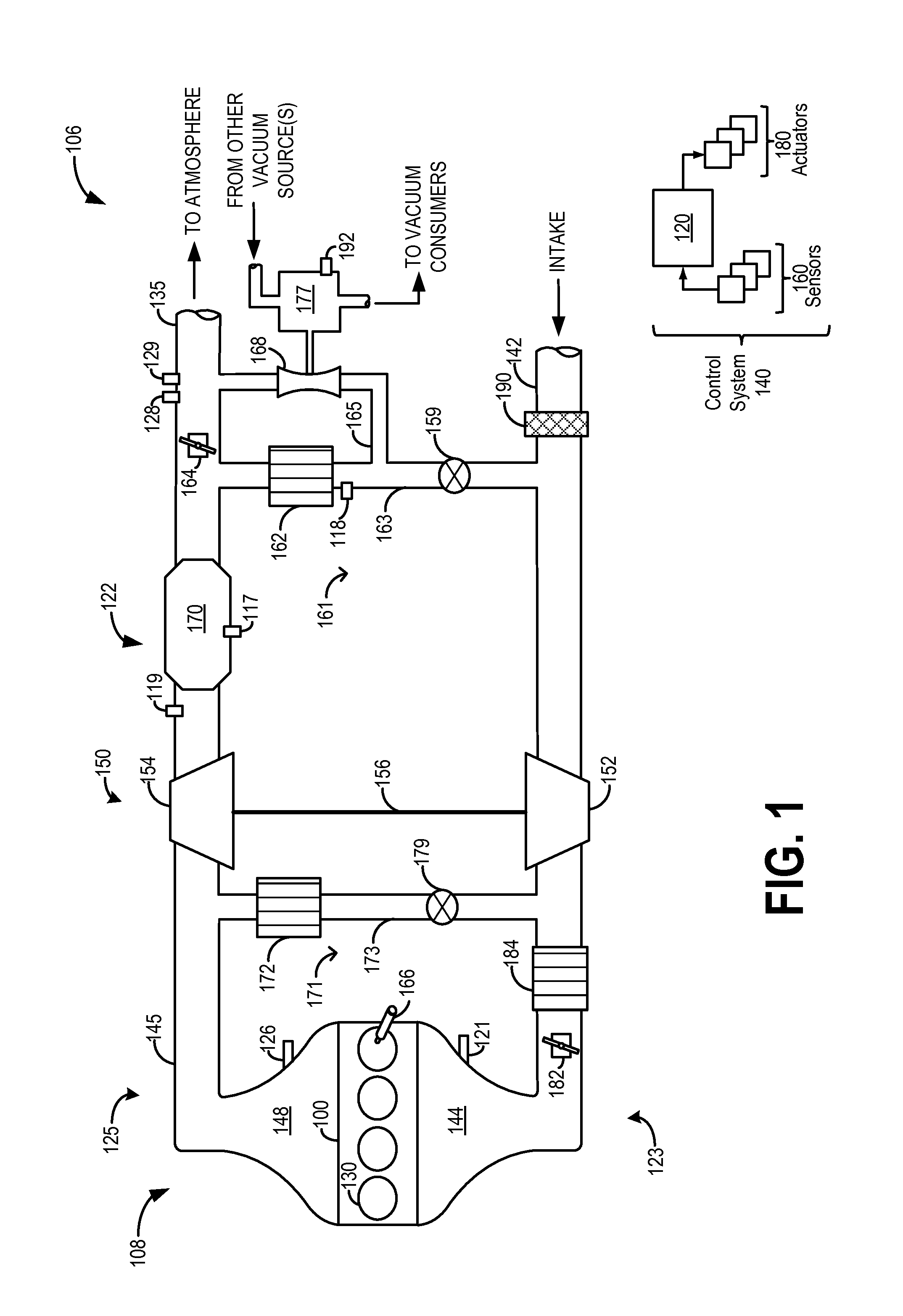

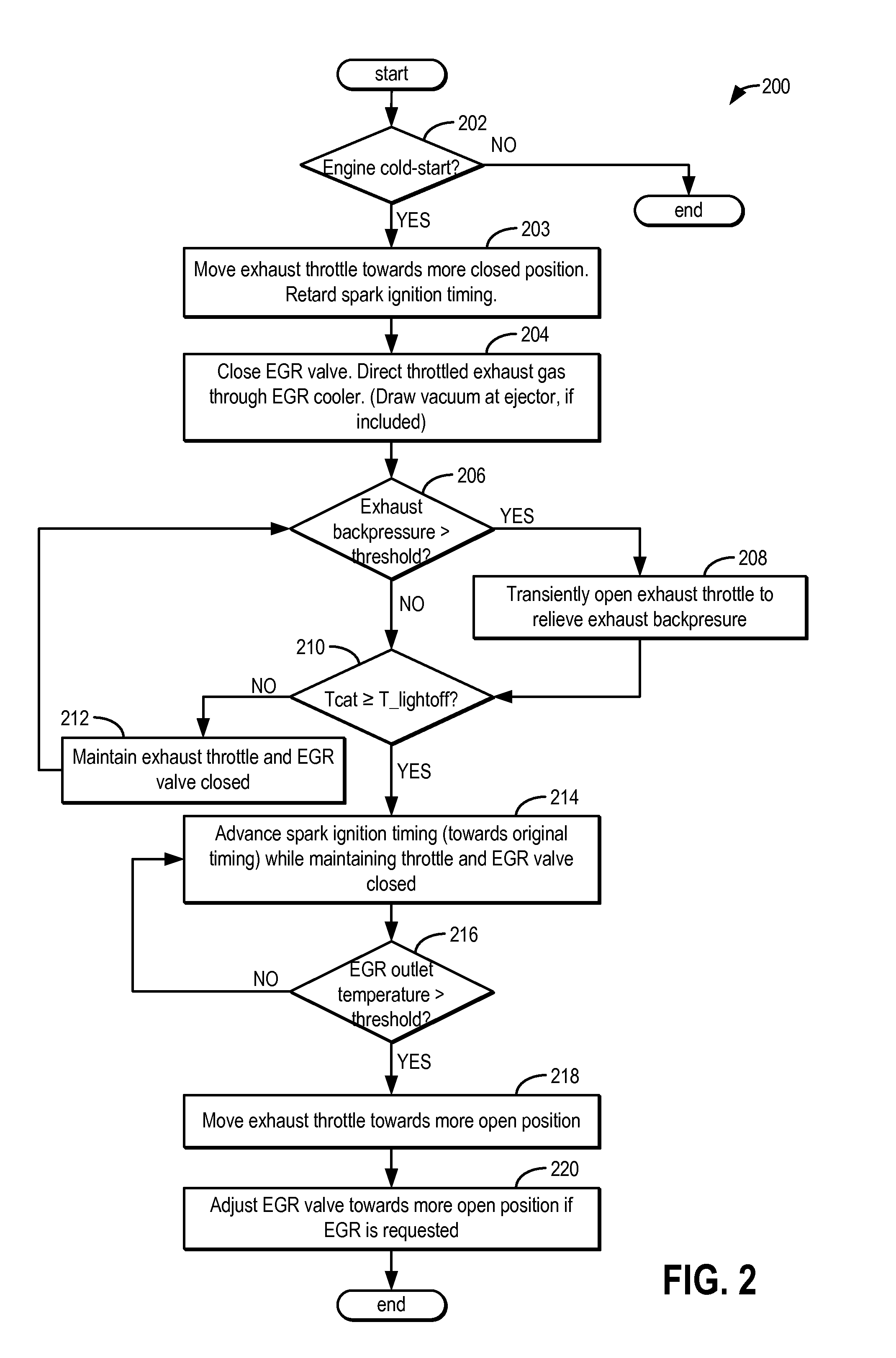

Method and system for catalyst temperature control

ActiveUS20140196454A1Vehicle exhaust qualityQuality improvementElectrical controlInternal combustion piston enginesTemperature controlHeat rejection

Methods and systems are provided for controlling and coordinating control of a post-catalyst exhaust throttle and an EGR valve to expedite catalyst heating. By closing both valves during an engine cold start, an elevated exhaust backpressure and increased heat rejection at an EGR cooler can be synergistically used to warm each of an engine and an exhaust catalyst. The valves may also be controlled to vary an amount of exhaust flowing through an exhaust venturi so as to meet engine vacuum needs while providing a desired amount of engine EGR.

Owner:FORD GLOBAL TECH LLC

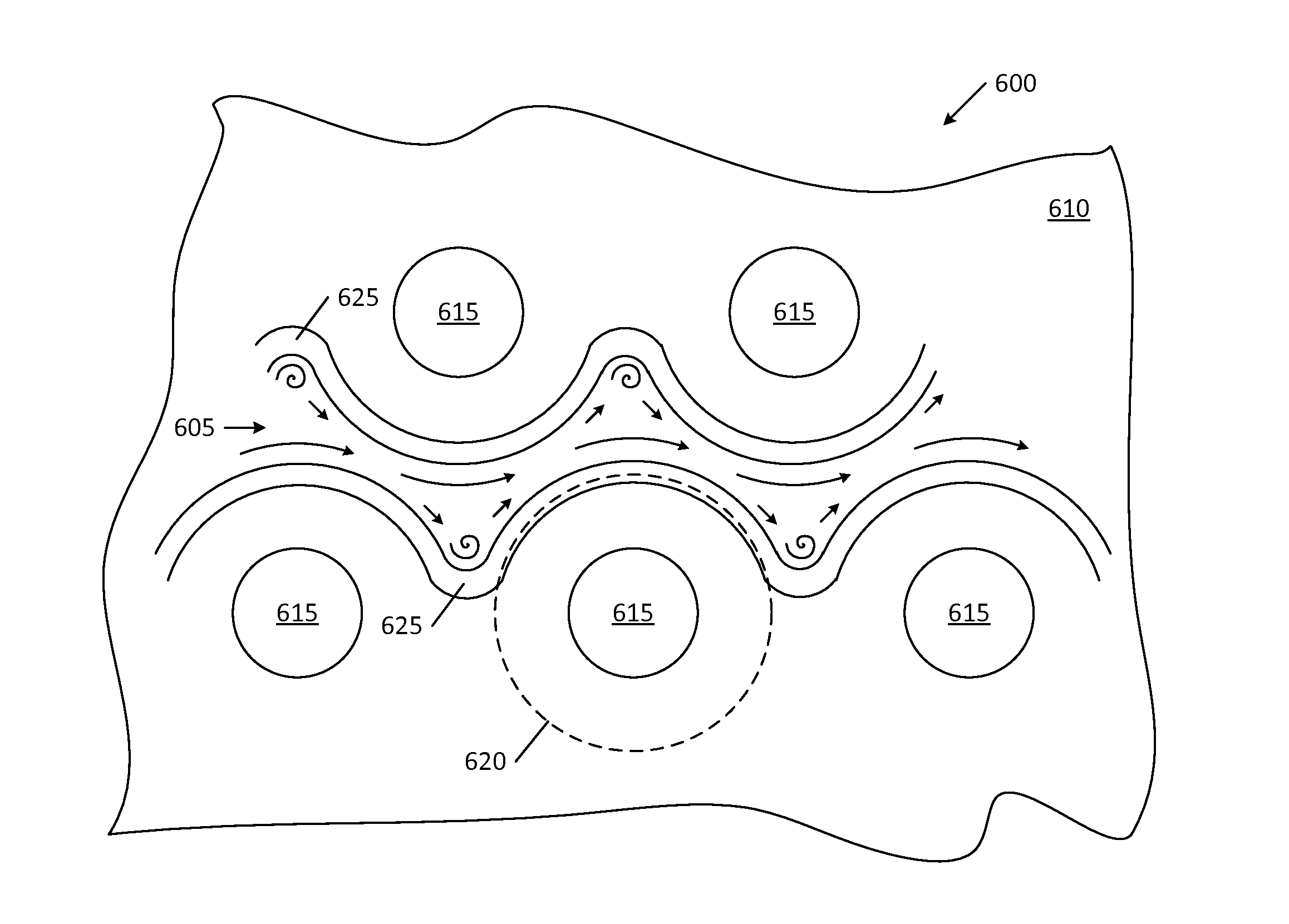

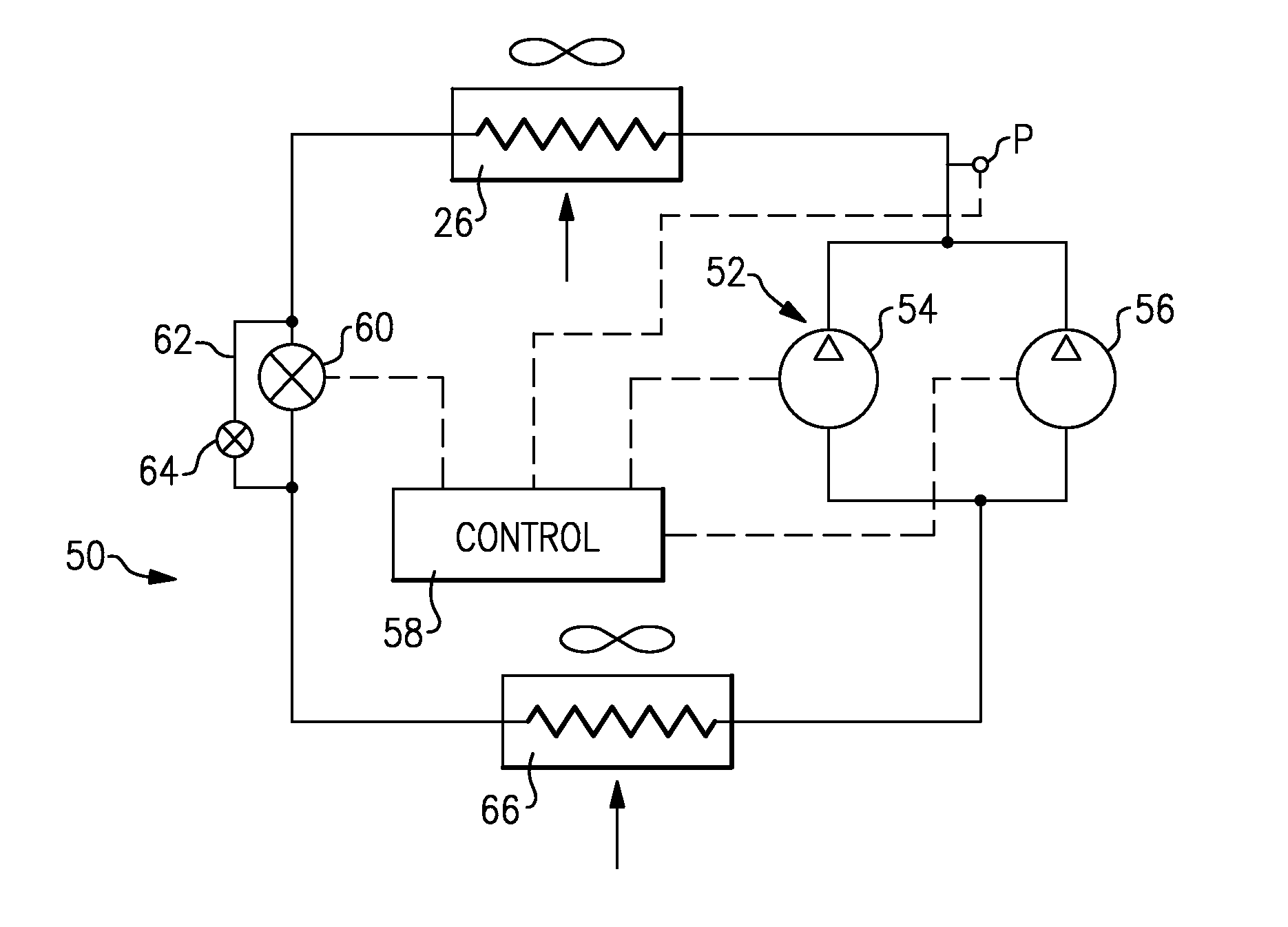

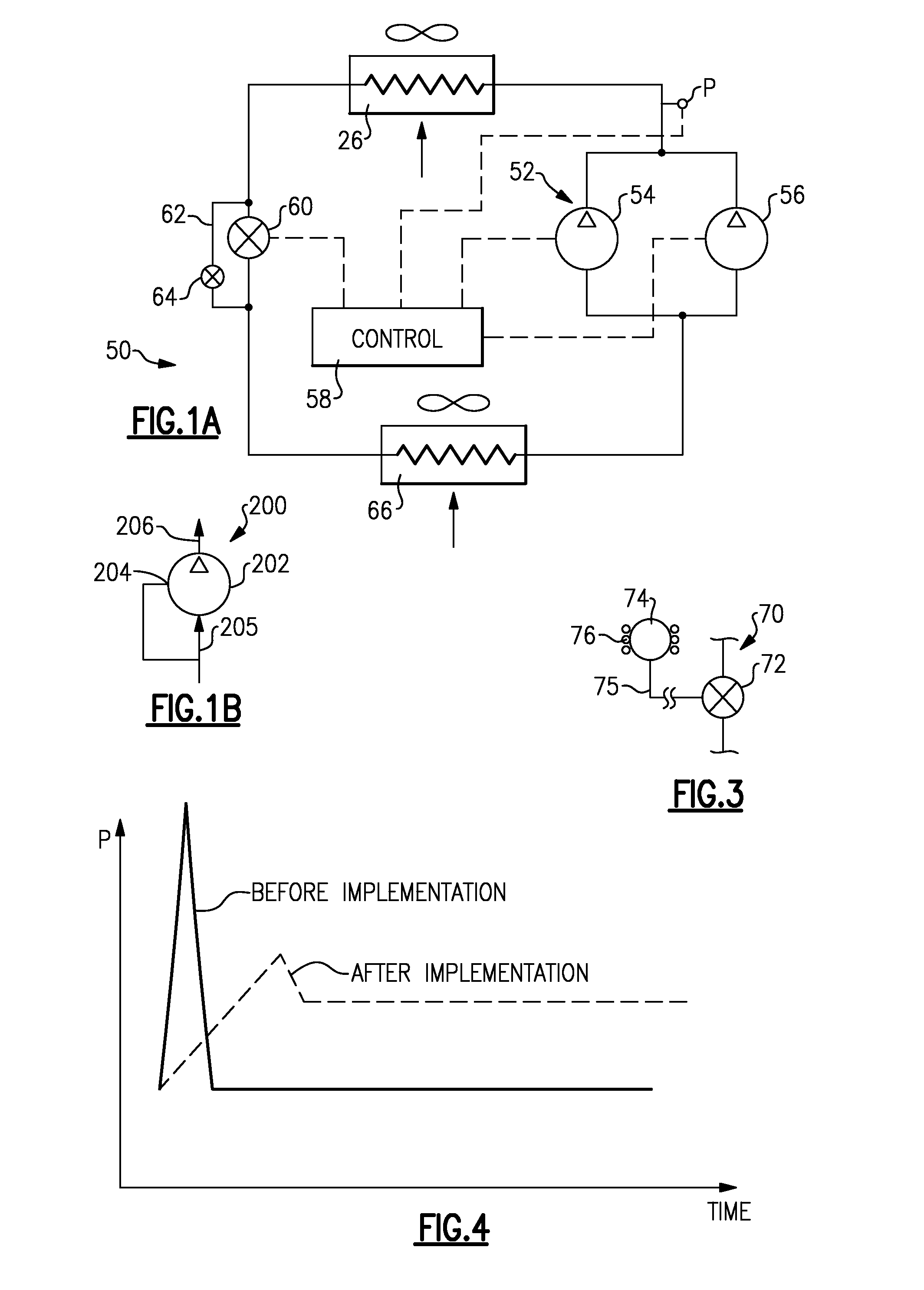

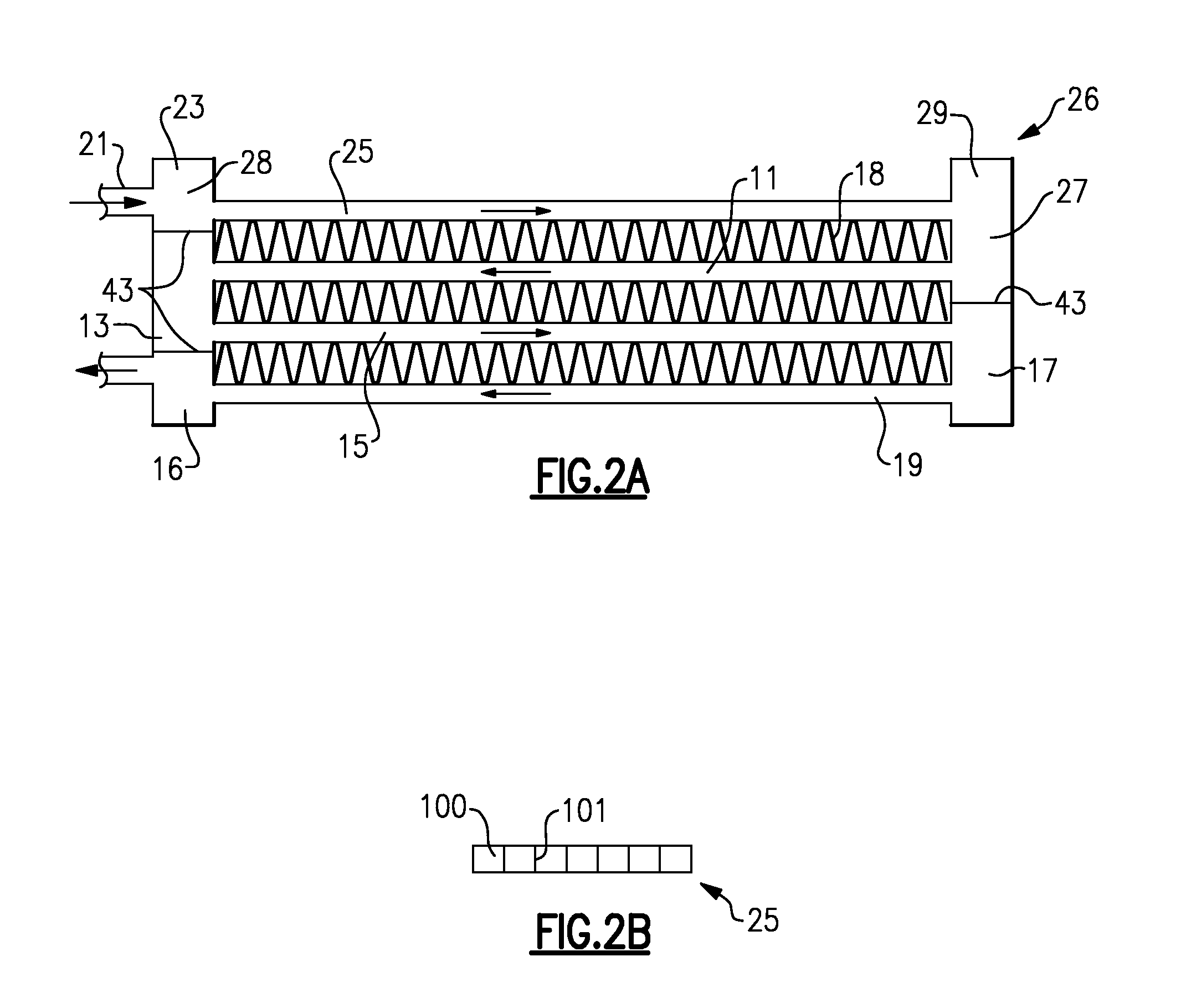

Pressure spike reduction for refrigerant systems incorporating a microchannel heat exchanger

ActiveUS20120167602A1Reduce pressure spikeCompression machines with non-reversible cycleEfficient regulation technologiesHeat rejectionEngineering

A refrigerant system includes at least one compressor (54, 56) that compresses refrigerant and delivers it downstream to a heat rejection heat exchanger (26). The heat rejection heat exchanger is a microchannel heat exchanger. Refrigerant passes from the heat rejection heat exchanger downstream to an expansion device (60), from the expansion device through an evaporator (66), and from the evaporator back to the at least one compressor. A control (58) operates at least one compressor and the expansion device to reduce pressure spikes at transient conditions.

Owner:CARRIER CORP

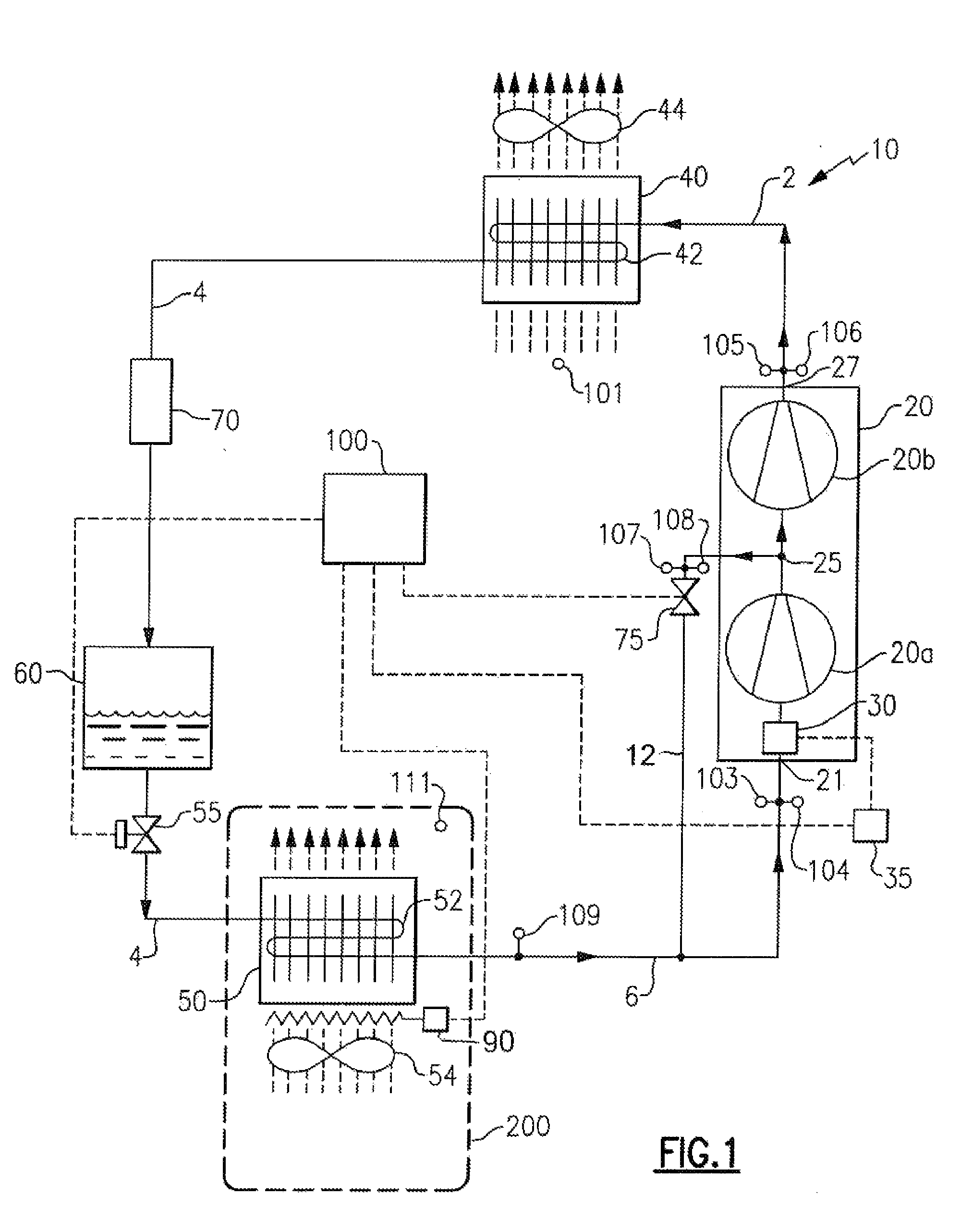

Refrigerant vapor compression system with intercooler

ActiveUS20130031934A1Improve energy efficiencyImprove cooling effectCompression machines with non-reversible cycleStationary tubular conduit assembliesHeat rejectionCompression device

A refrigerant vapor compression system includes a compression device having at least a first compression stage and a second compression stage, a refrigerant heat rejection heat exchanger disposed downstream with respect to refrigerant flow of the second compression stage, and a refrigerant intercooler disposed intermediate the first compression stage and the second compression stage. The refrigerant intercooler is disposed downstream of the refrigerant heat rejection heat exchanger with respect to the flow of a secondary fluid. A second refrigerant heat rejection heat exchanger may be disposed downstream with respect to refrigerant flow of the aforesaid refrigerant heat rejection heat exchanger, and a second refrigerant intercooler may be disposed intermediate the first compression stage and the second compression stage and downstream with respect to refrigerant flow of the aforesaid refrigerant intercooler.

Owner:CARRIER CORP

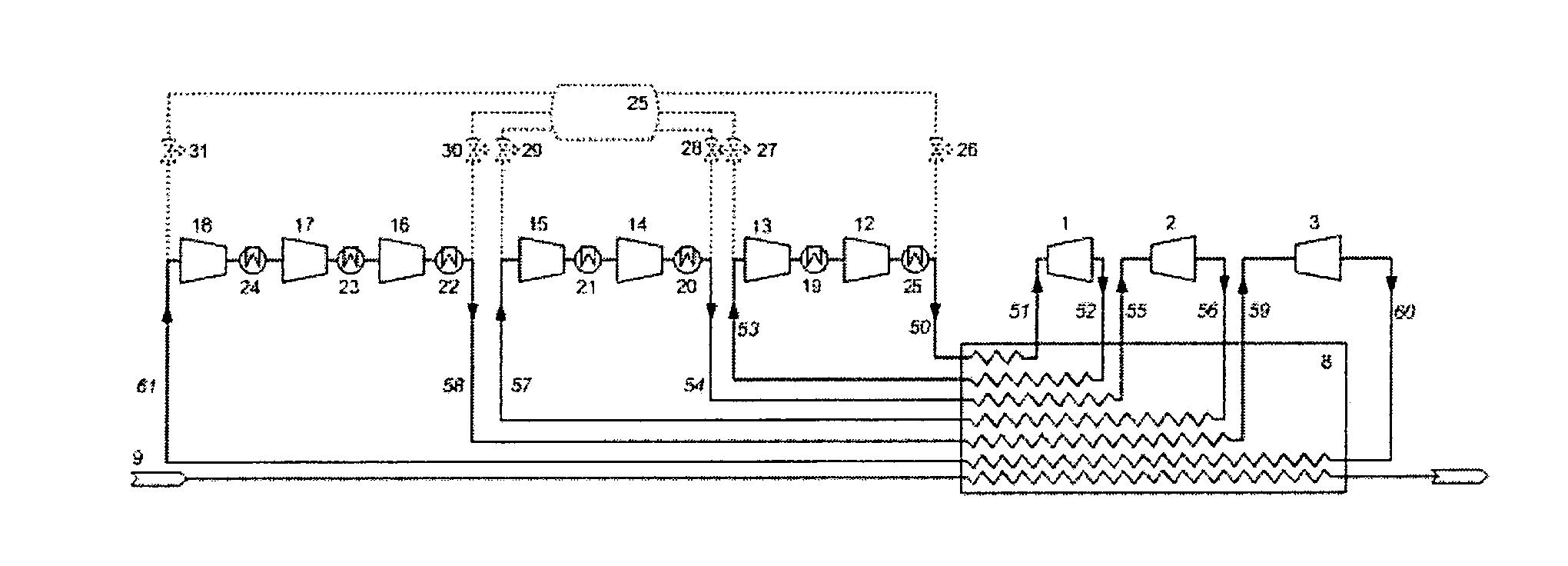

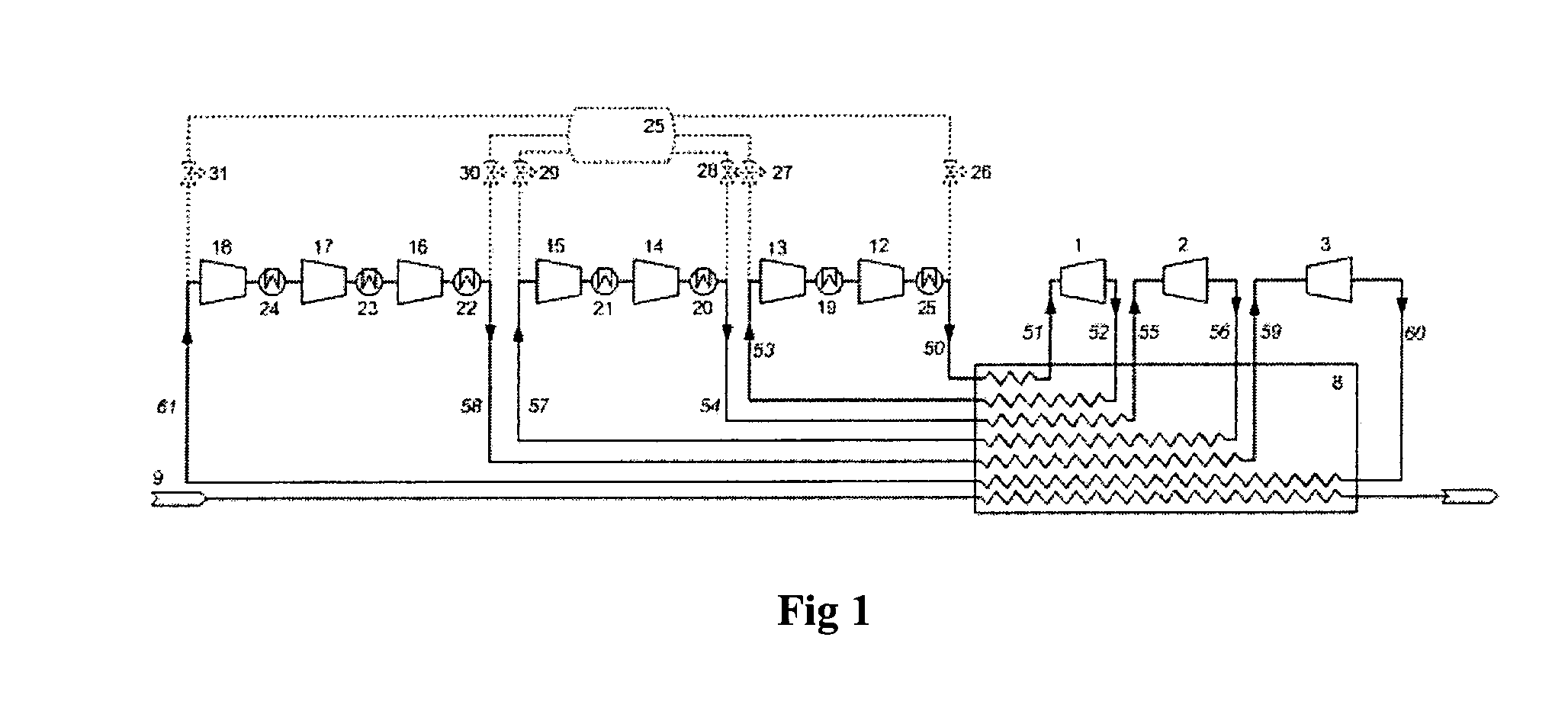

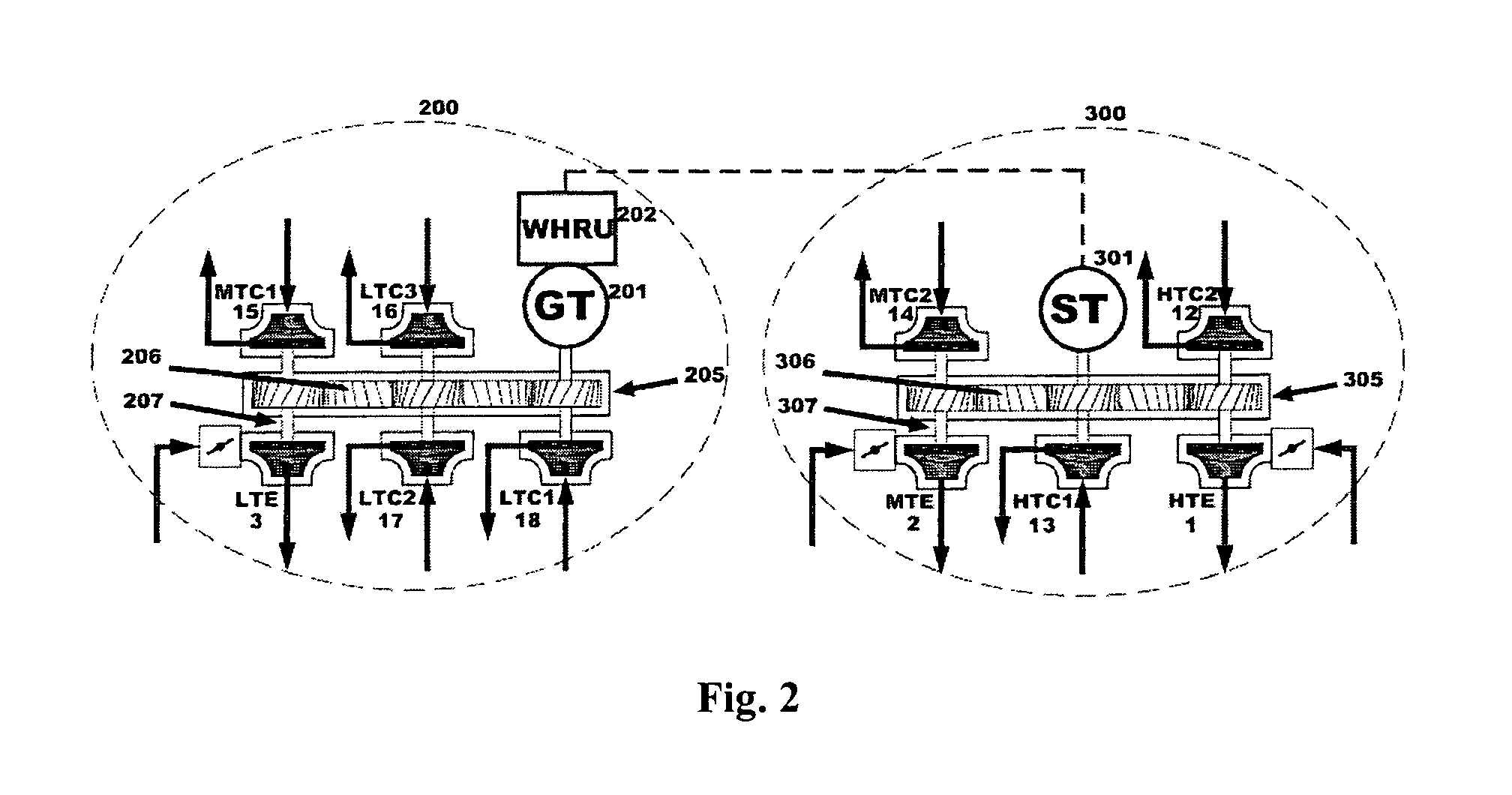

System for combined cycle mechanical drive in cryogenic liquefaction processes

InactiveUS20110209496A1Reduce operating costsReduce fuel requirementsSolidificationLiquefactionHeat rejectionNatural gas

A system for producing liquefied and sub-cooled natural gas by means of a refrigeration assembly using a single phase gaseous refrigerant comprises at least two expanders; a compressor assembly; a heat exchanger assembly for heat absorption from natural gas; and a heat rejection assembly, in which the expanders are arranged in expander loops and the refrigerant to the respective expander is served in a compressed flow by means of the compressor assembly having compressors or compressor stages enabling adapted inlet and outlet pressures for the respective expander. According to the present the expanders and compressors assembly are assembled in two mechanically connected compressor and expander packages of which one is driven by a gas turbine and the other is driven by a steam turbine, the steam primarily being generated by exhaust gases from the gas turbine in a waste heat recovery unit, and in that the expanders and compressors assemblies are distributed between the two compressor and expander packages to optimize the steam utilization and to balance the power generated by the gas turbine and the steam turbine.

Owner:HAMWORTHY OIL & GAS SYST AS

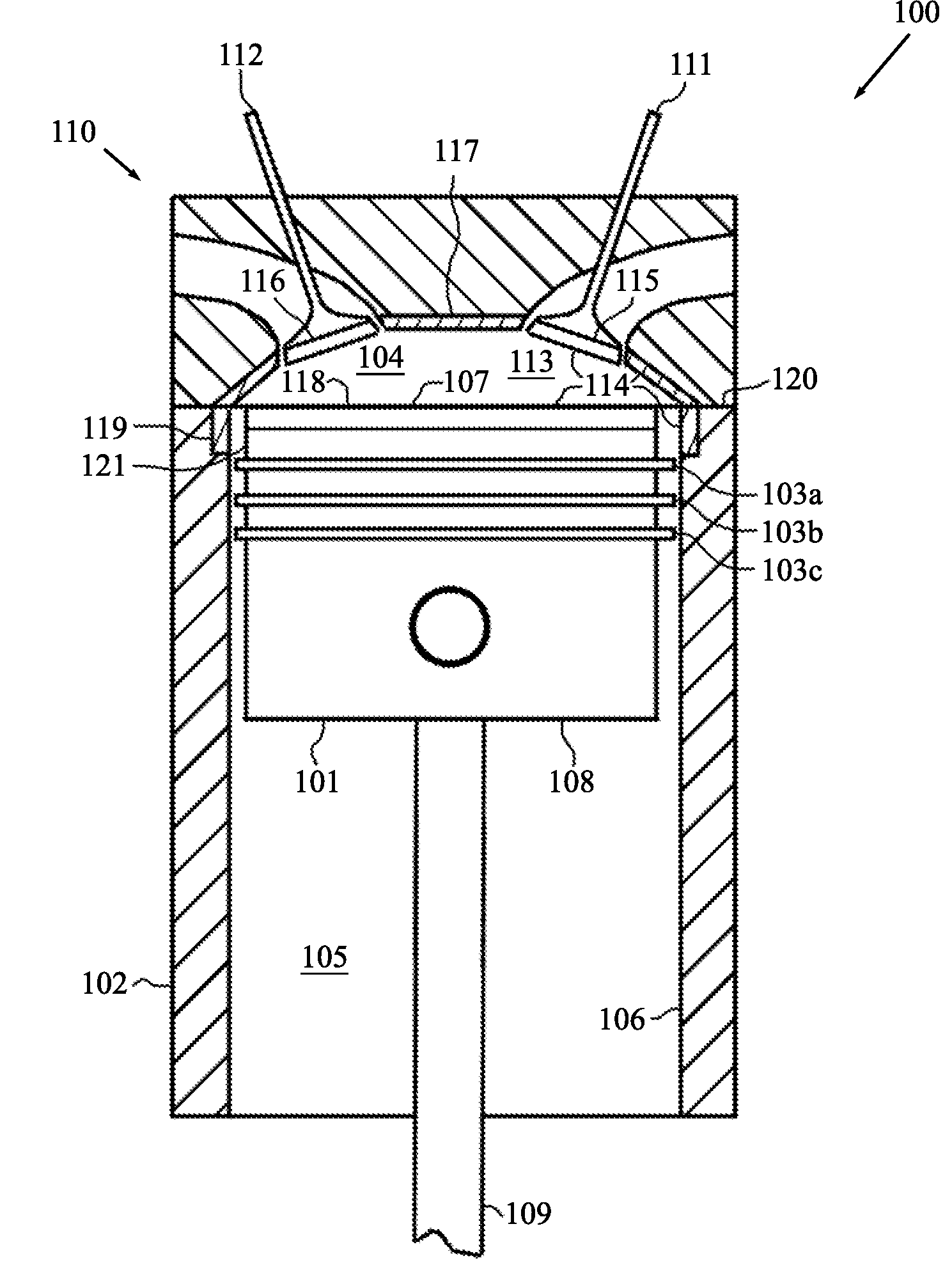

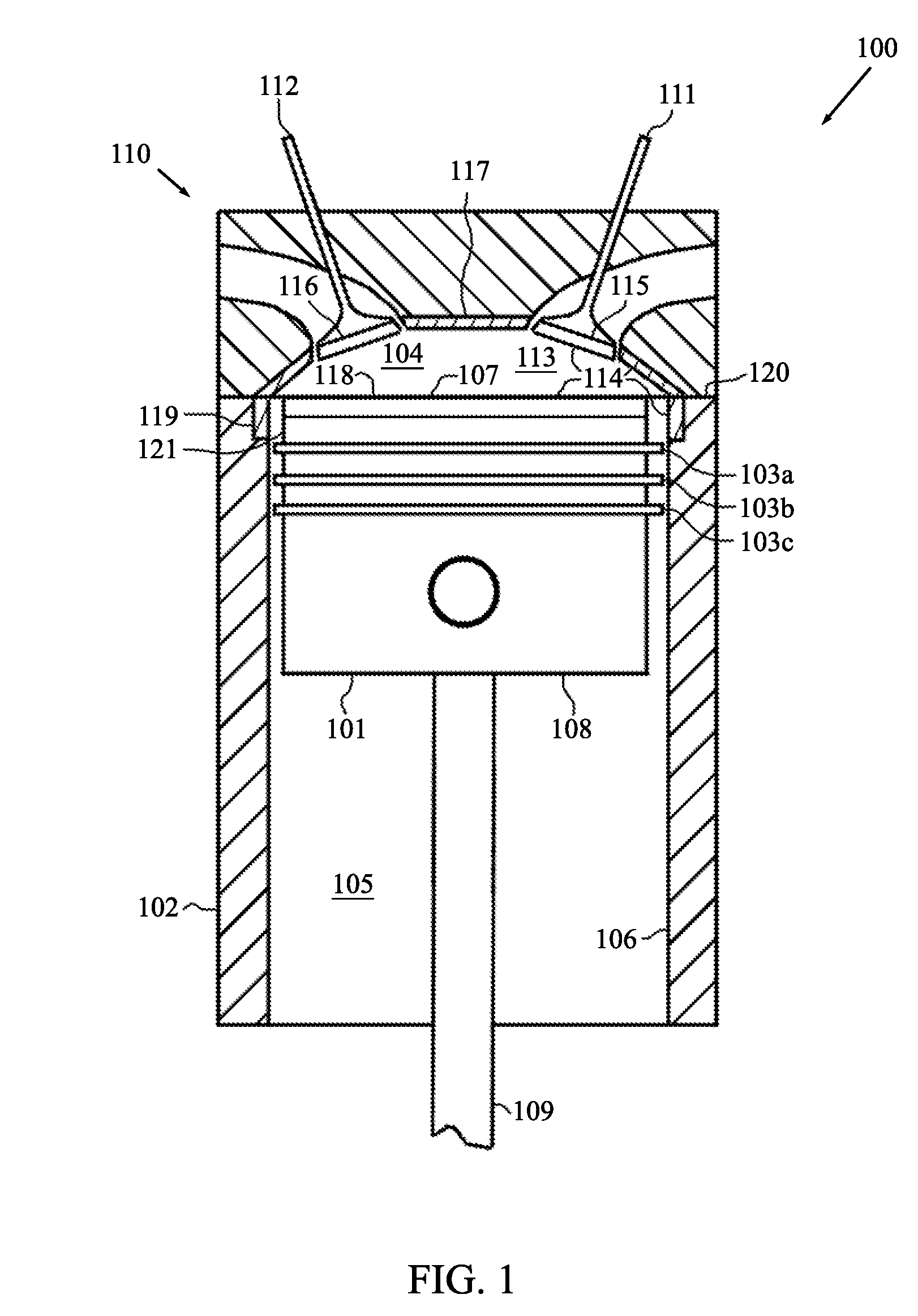

Low heat rejection high efficiency internal combustion engine

InactiveUS20090071434A1Improve efficiencyLow heat rejection rateCasingsInternal combustion piston enginesExternal combustion engineVariable valve timing

An internal combustion engine including a low thermal capacity, low thermal conductivity insulating liner is provided. The insulating liner may be positioned to line the combustion chamber and a portion of the cylinder wall. The insulating liner may comprise a high aspect morphology sintered ceramic material and may further include a surface coating. The internal combustion engine may be a four-stroke diesel engine with variable valve timing operating using an asymmetric cycle. Through the asymmetric cycle and insulative properties of the insulating liner, the heat loss of the disclosed internal combustion engine is significantly less than that of a similar conventional internal combustion engine, resulting in significant efficiency improvements.

Owner:DWIGHT ENGINE TECHNOLGIES

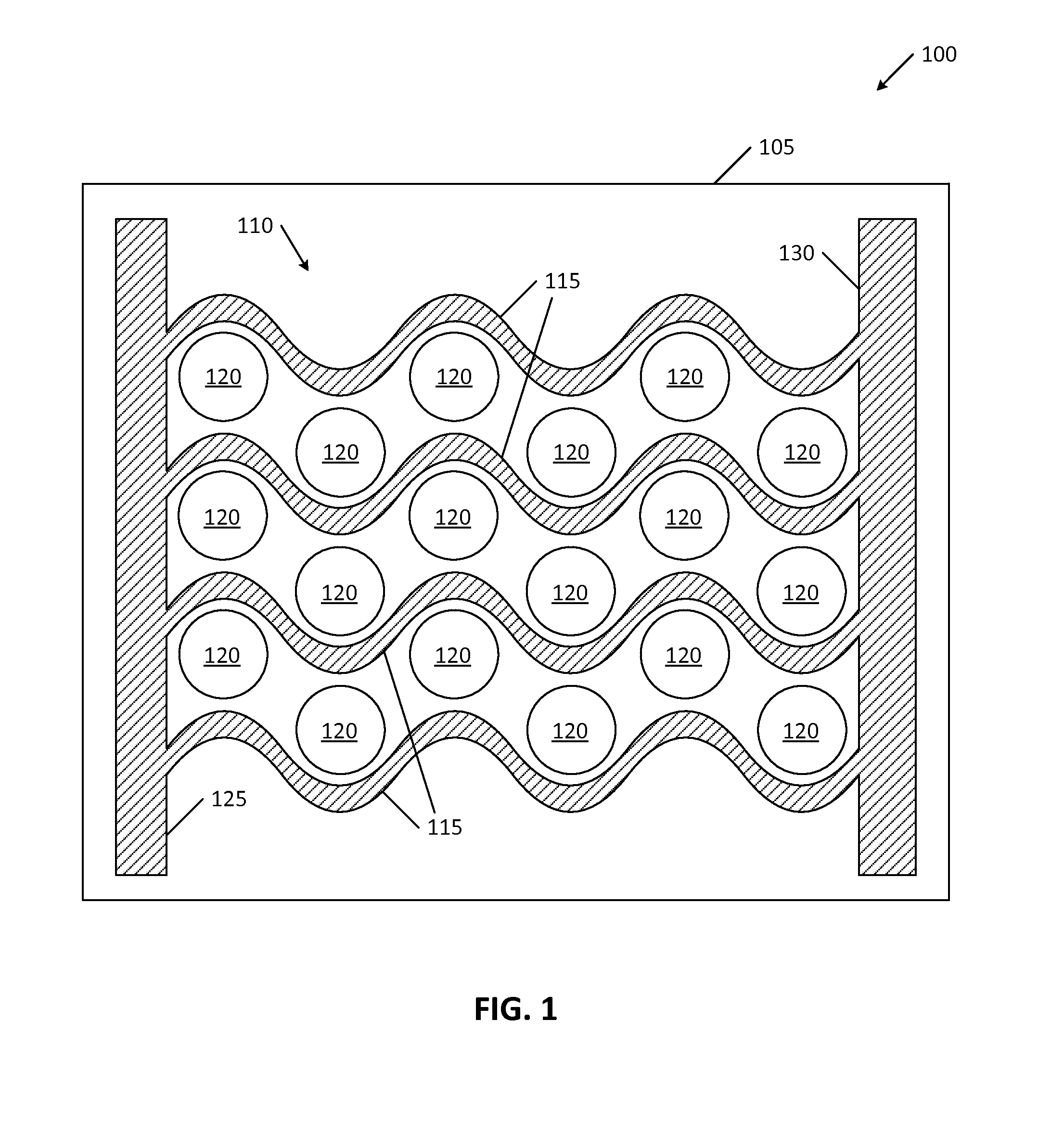

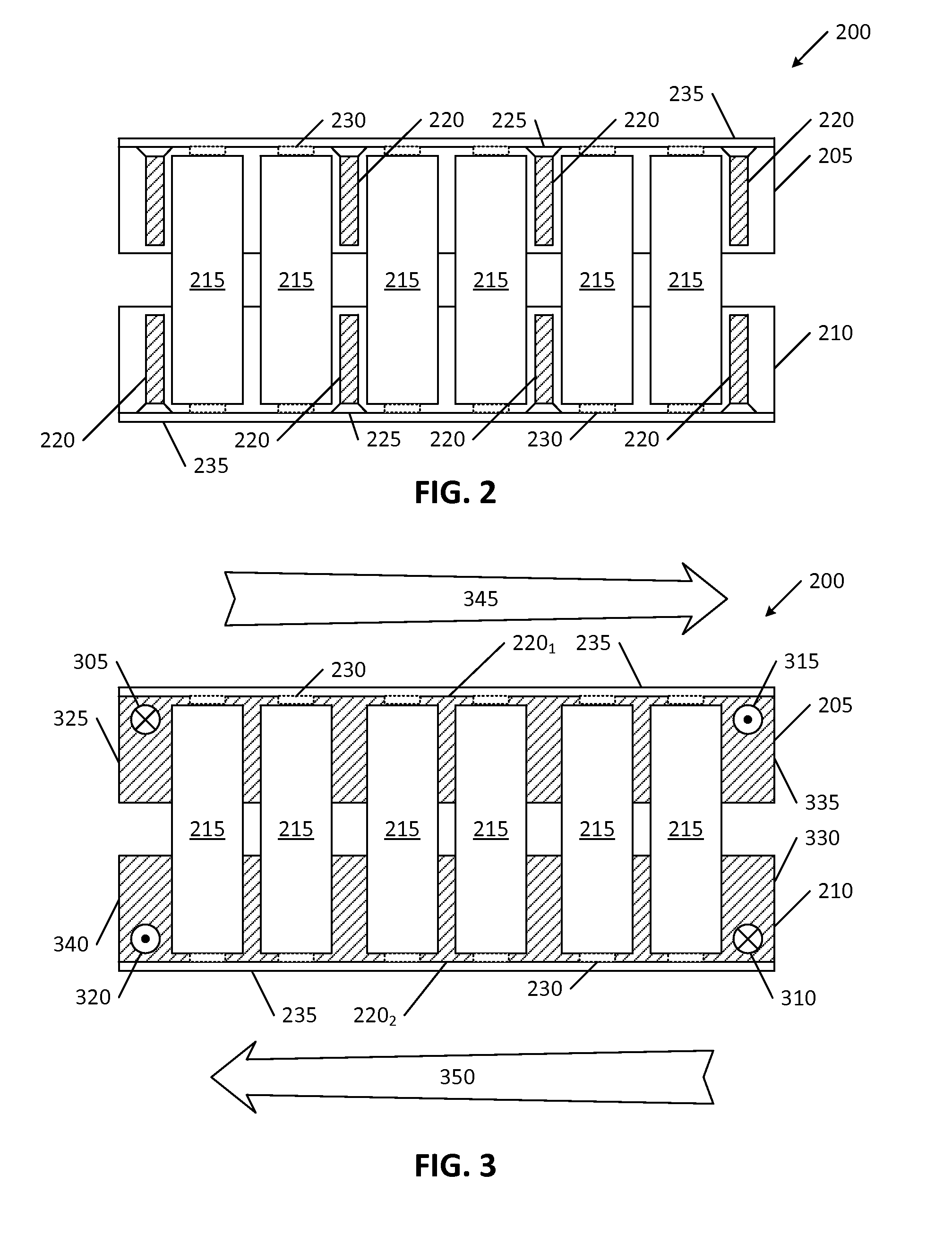

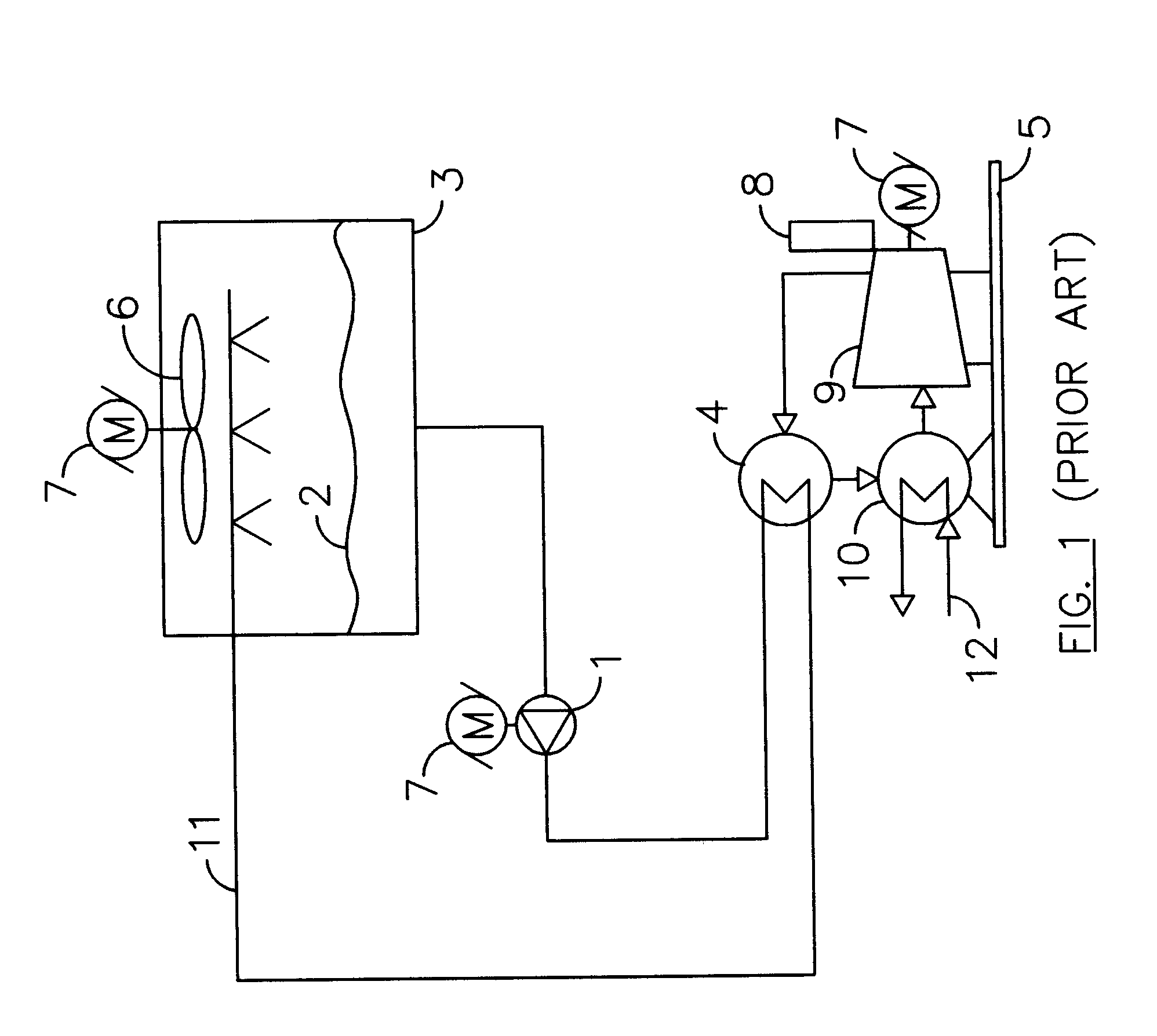

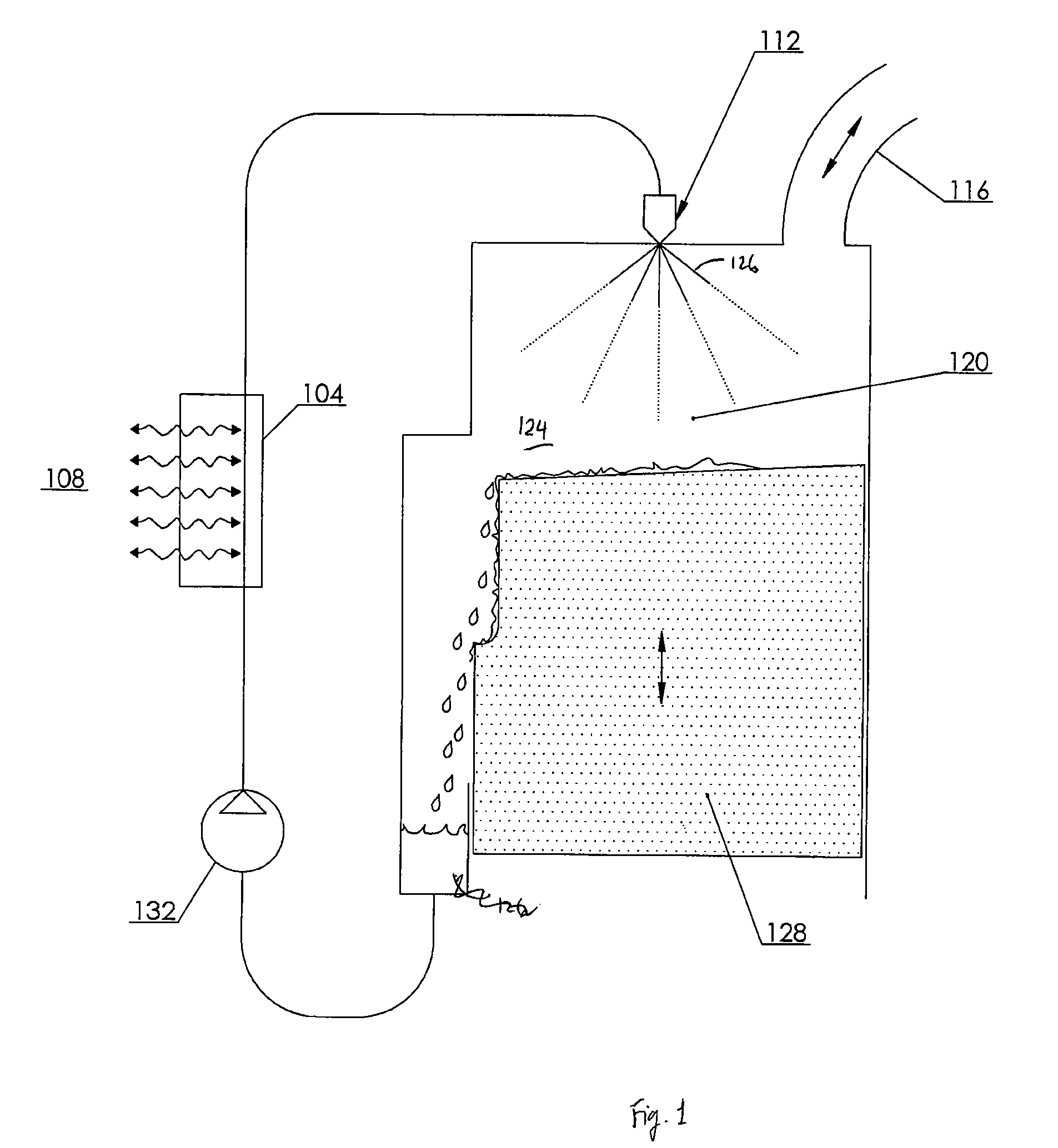

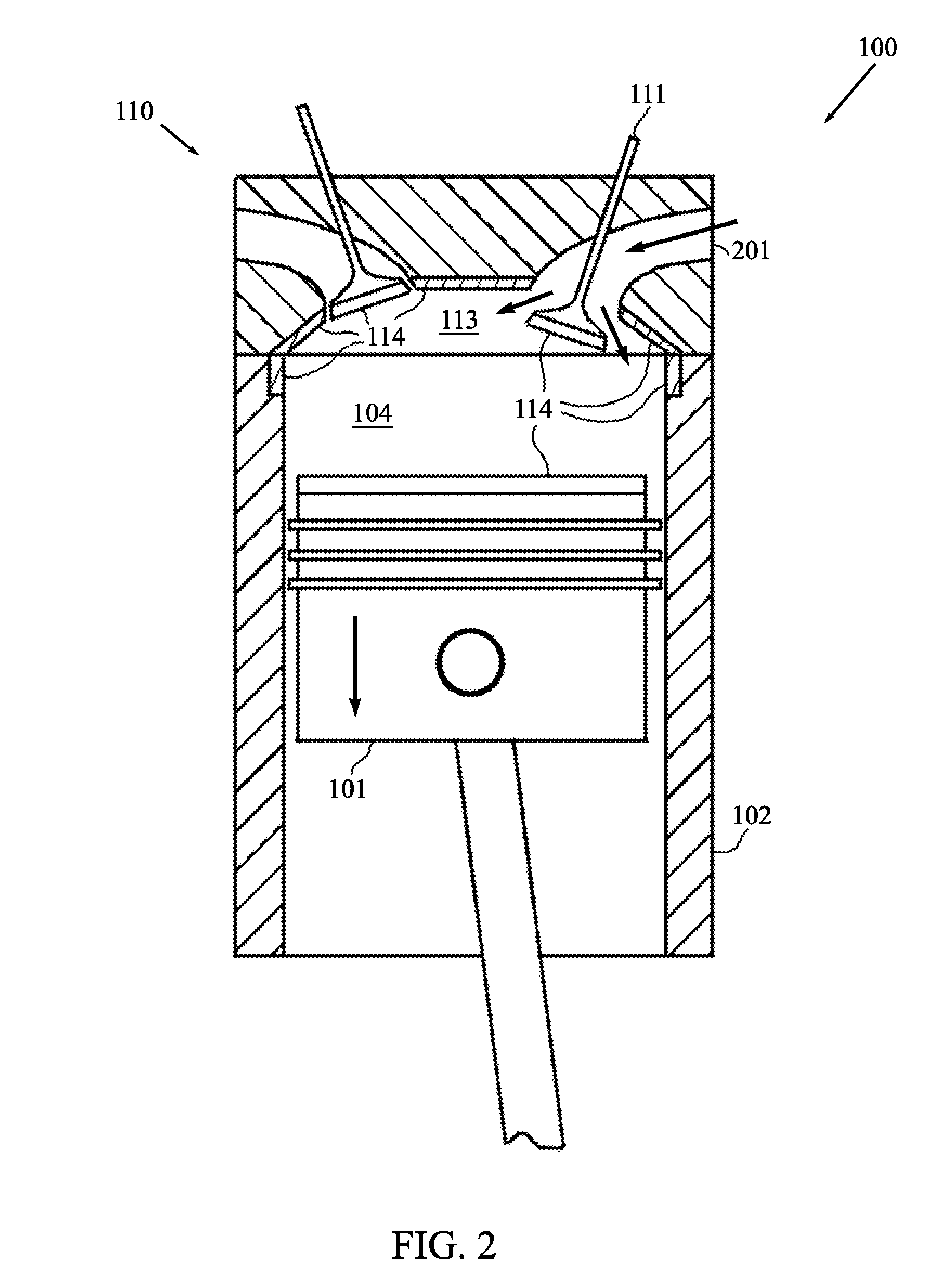

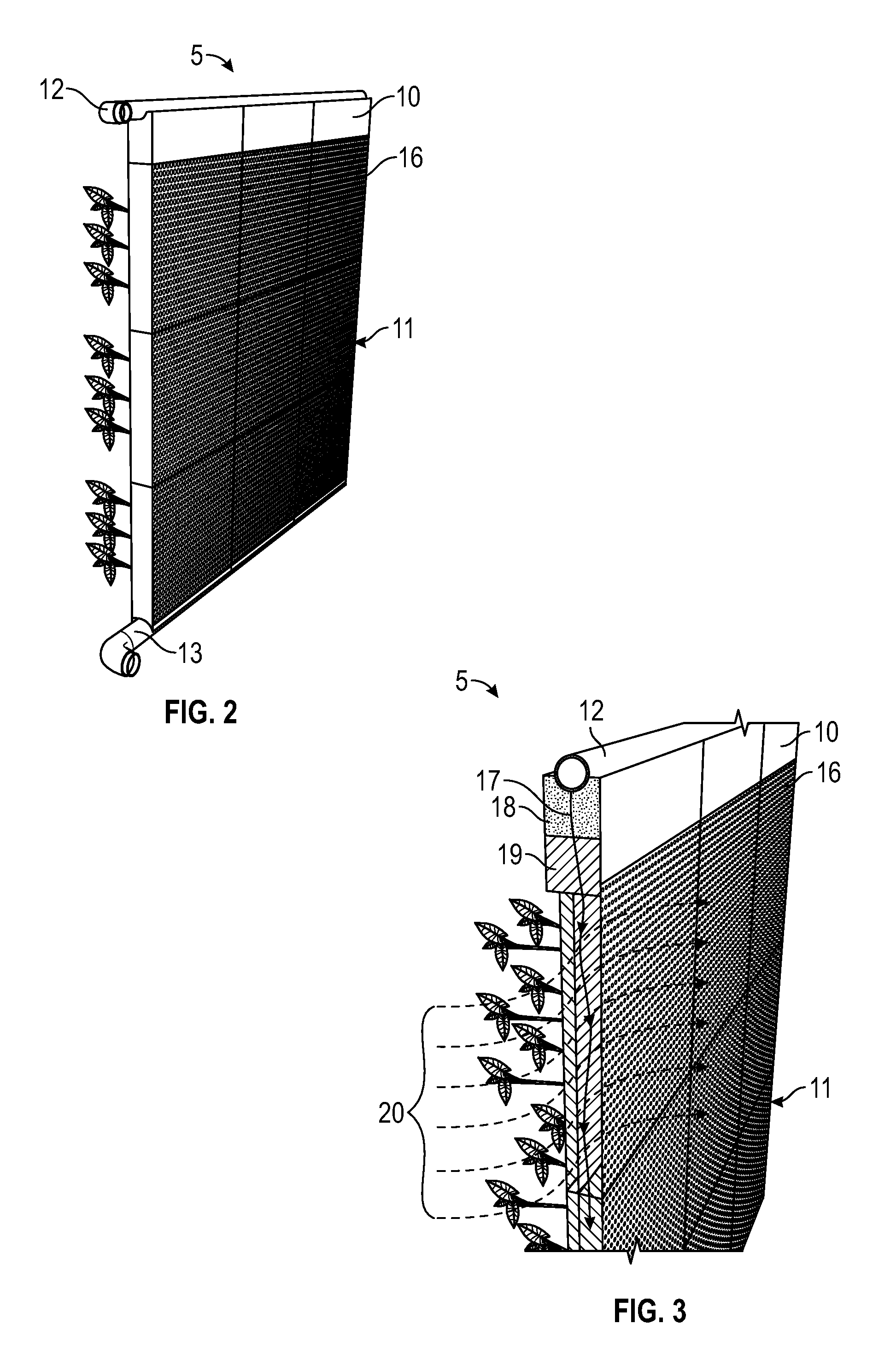

Modular Living Green Wall System to Provide Heat Rejection

InactiveUS20150289452A1Facilitates rejection/heat exchangeEasy maintenanceSelf-acting watering devicesWatering devicesPorous substrateWarm water

Modular living green wall systems are provided that supply water-cooled heat rejection for building cooling, power generation, industrial, chemical, and other processes that rely on heat rejection to the ambient environment for their efficient operation. Warm water from the process requiring heat rejection is circulated vertically through channels of porous media of the system and is cooled by evaporative and / or convective heat transfer to the ambient air that flows over and / or through the porous media across or counter to the water flow direction. Cool water leaving the system is piped to a heat exchanger of the process to provide the requisite cooling and is returned warm to the modular green wall system to complete the circulation loop. Modular living green wall systems may be assembled using plant modules and water treatment modules that are nested together to form continuous porous vertical water flow channels and a water recirculation system. The plant modules may consist of an inner porous media layer and an exposed porous substrate layer attached to each other and a stackable module housing. The water treatment module may be housed in a compatible stackable housing containing horizontal layers of filtration media. These modules are stacked in an interlocking manner and may be attached to an existing building support structure or alternatively be used to form a free standing living green wall.

Owner:YALE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com