Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1190 results about "Fluid temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

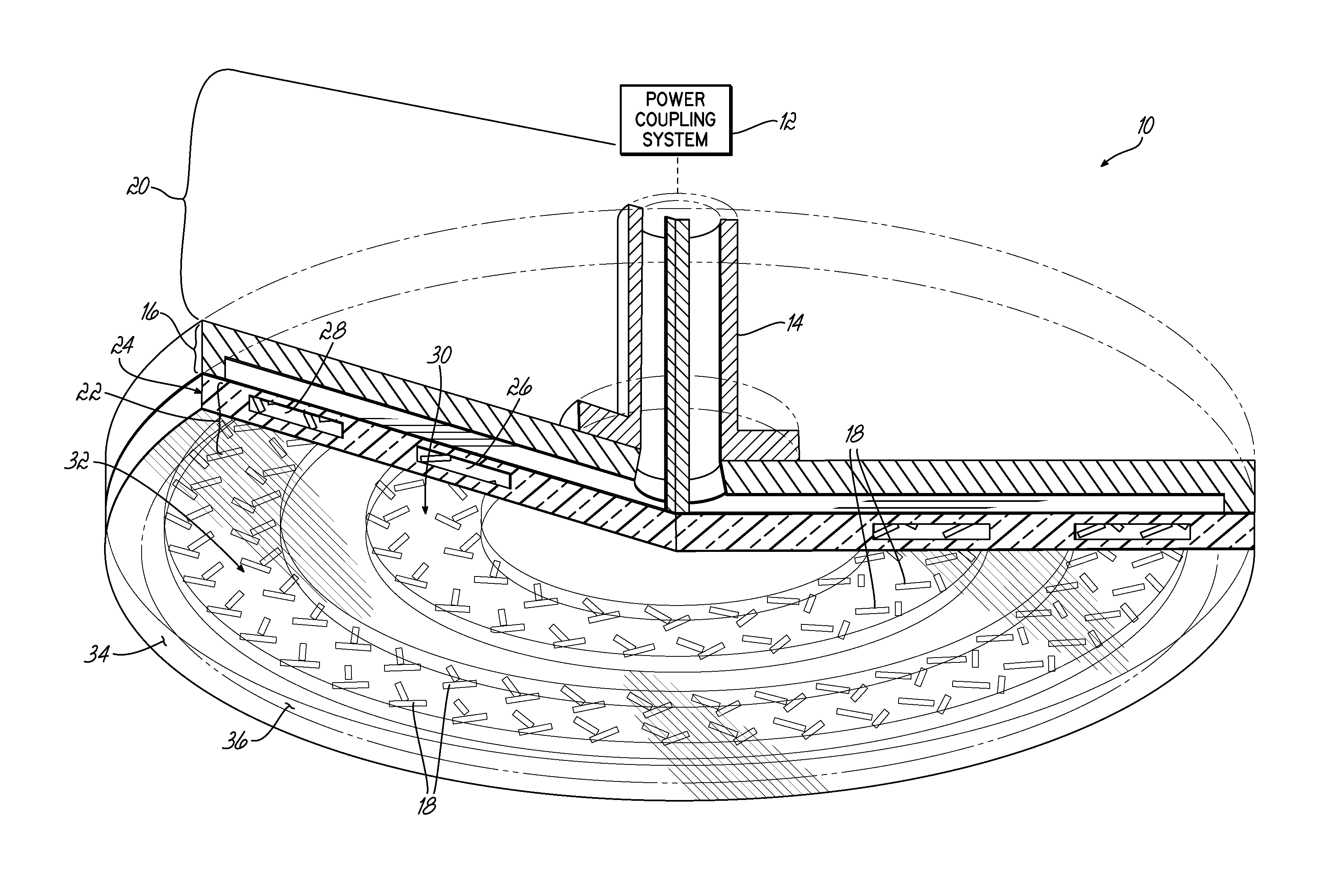

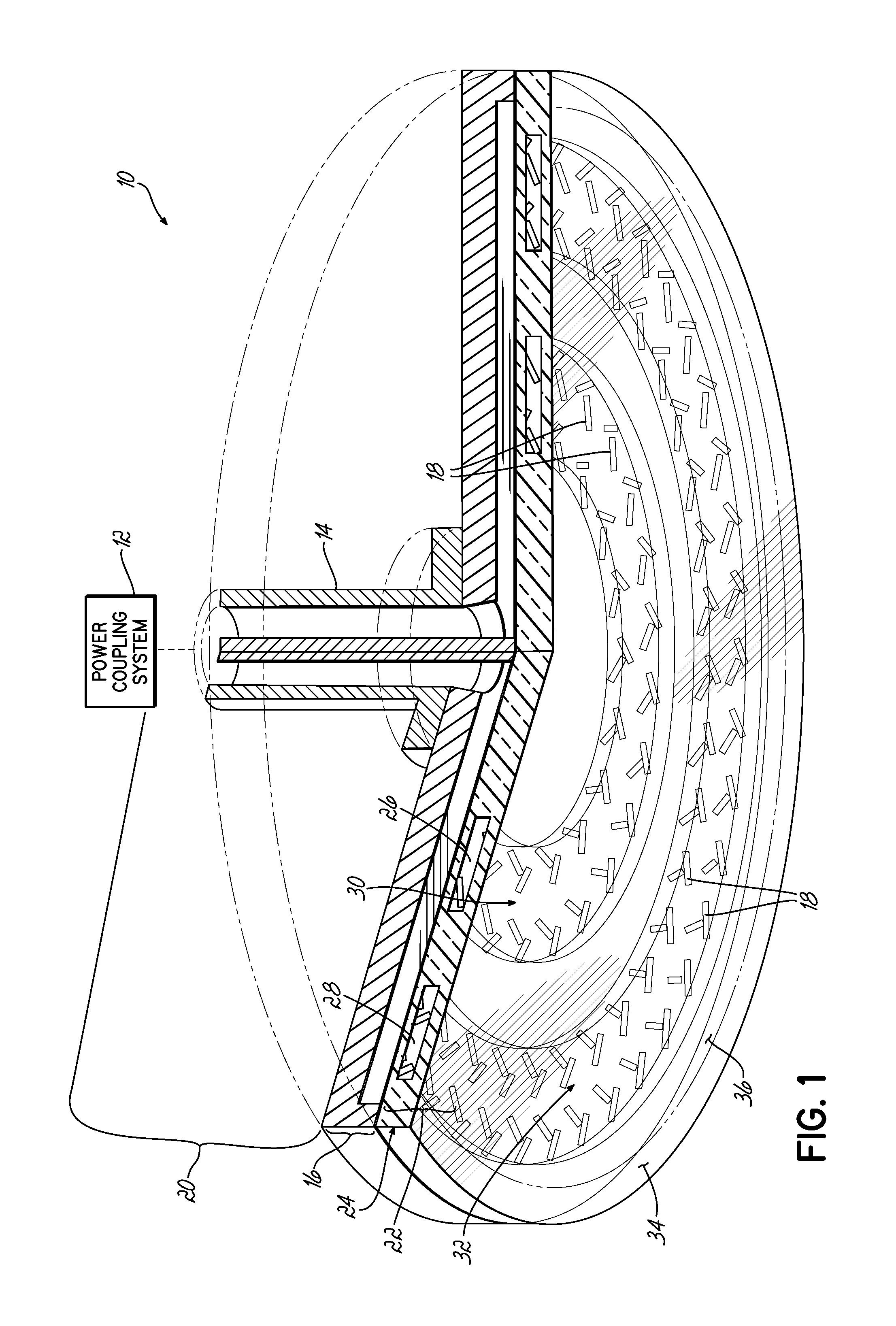

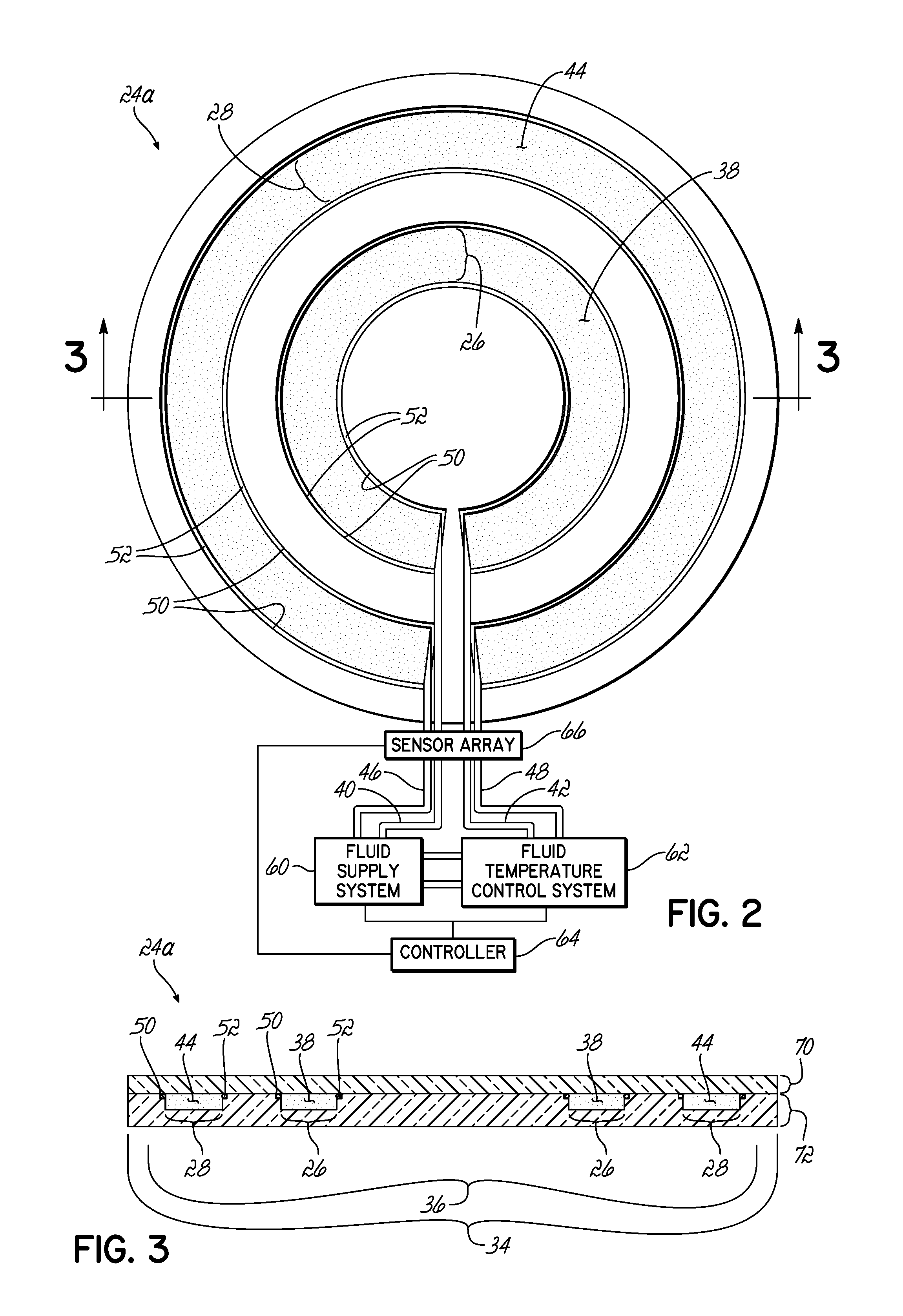

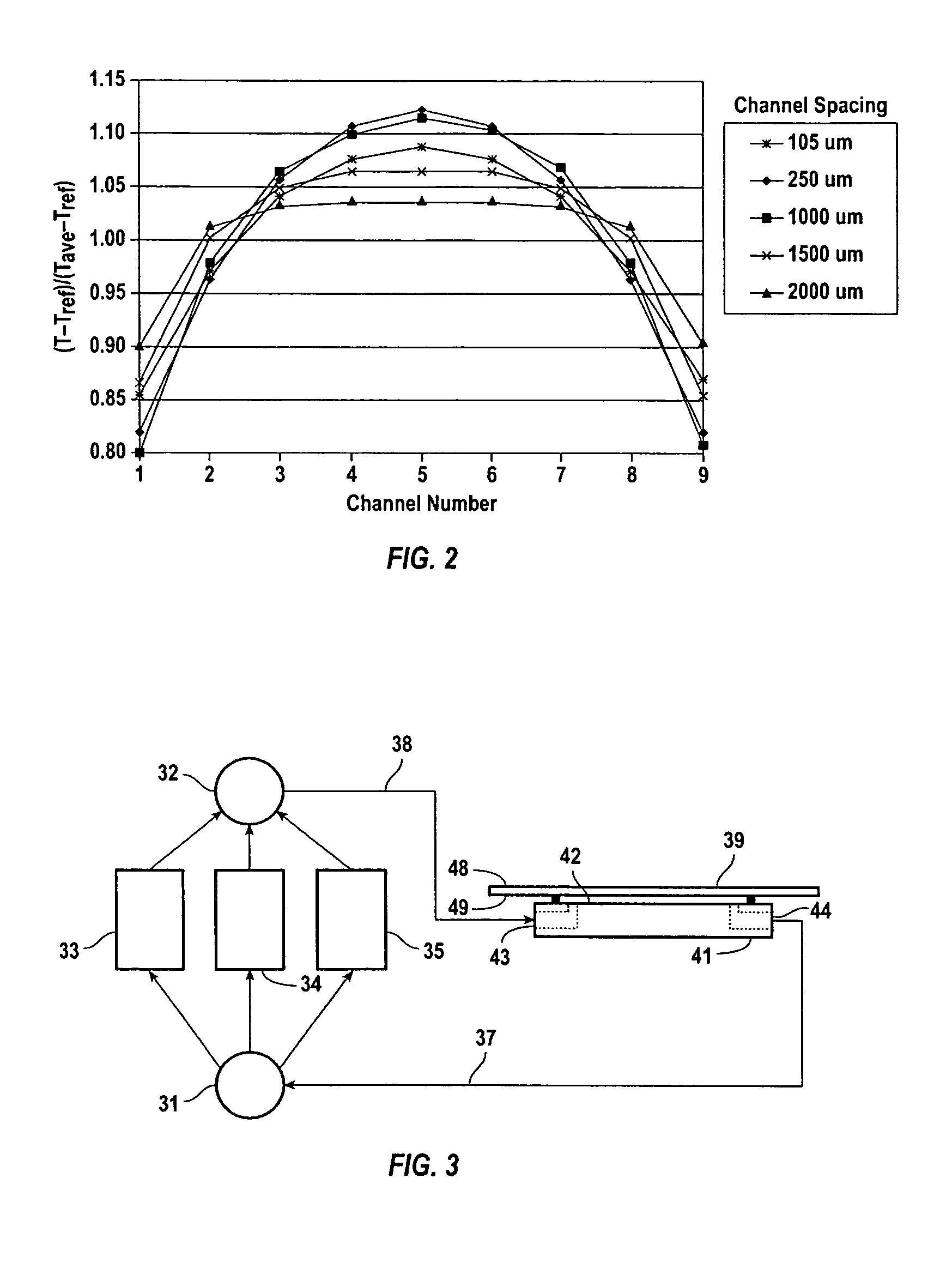

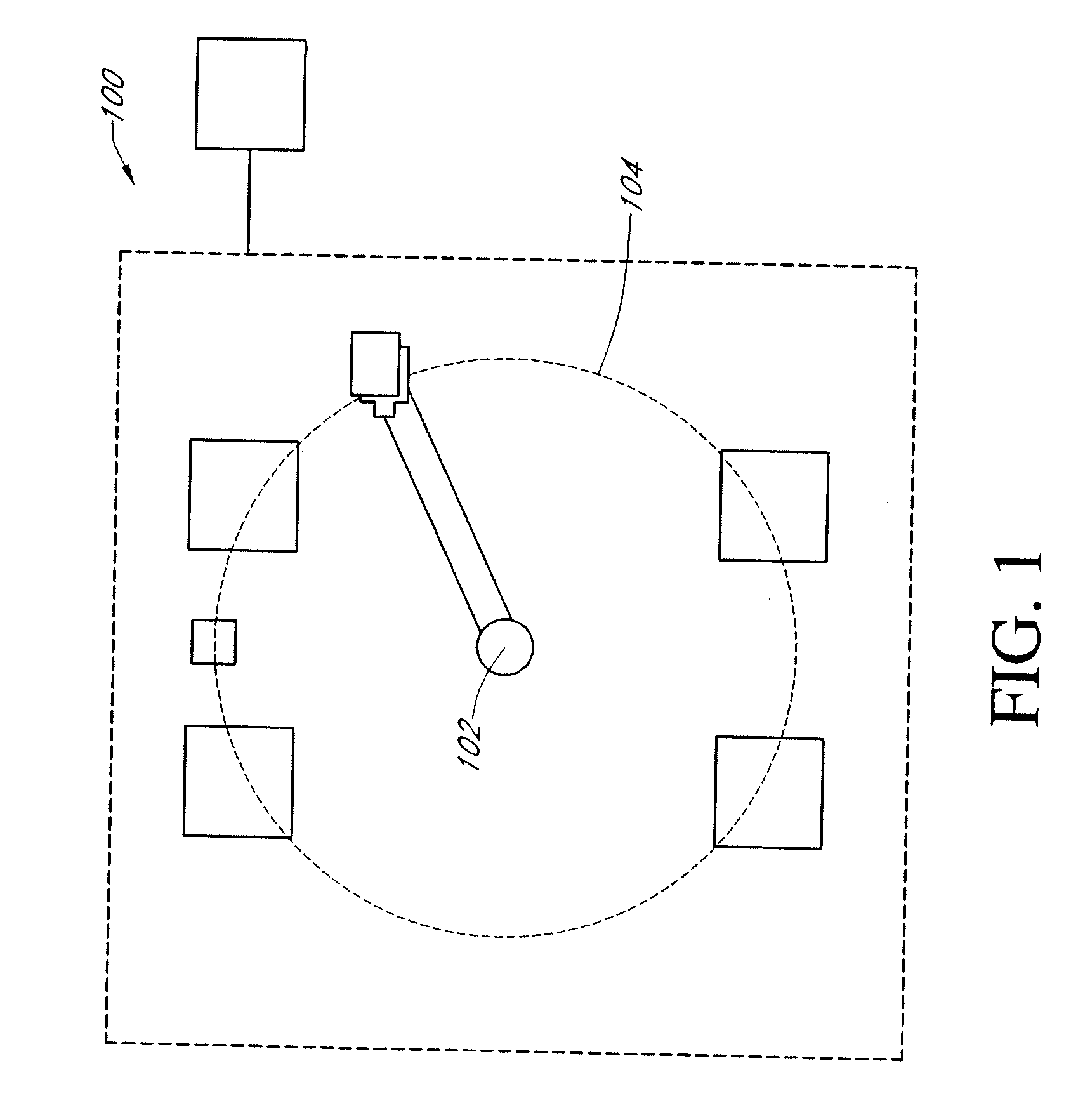

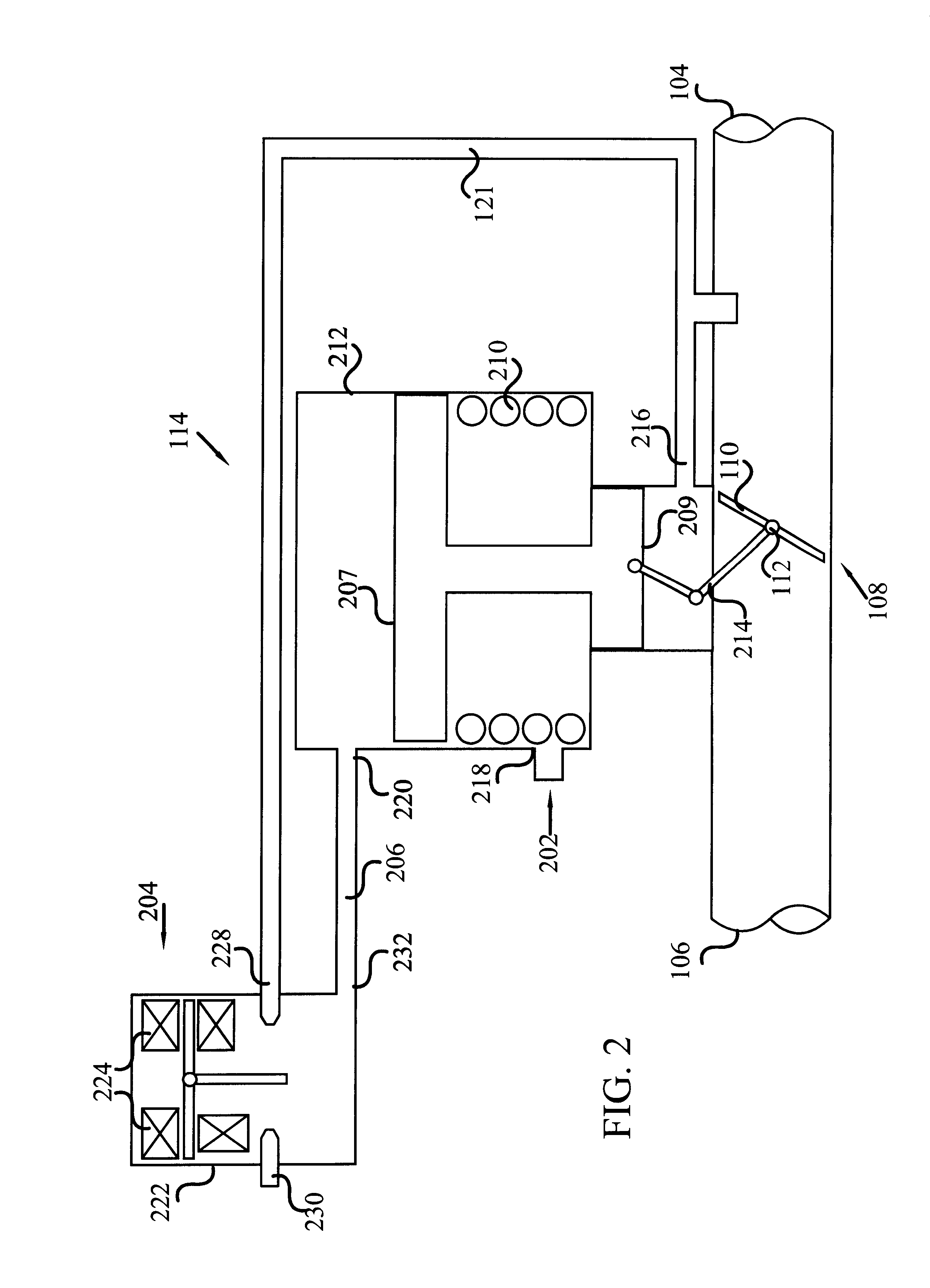

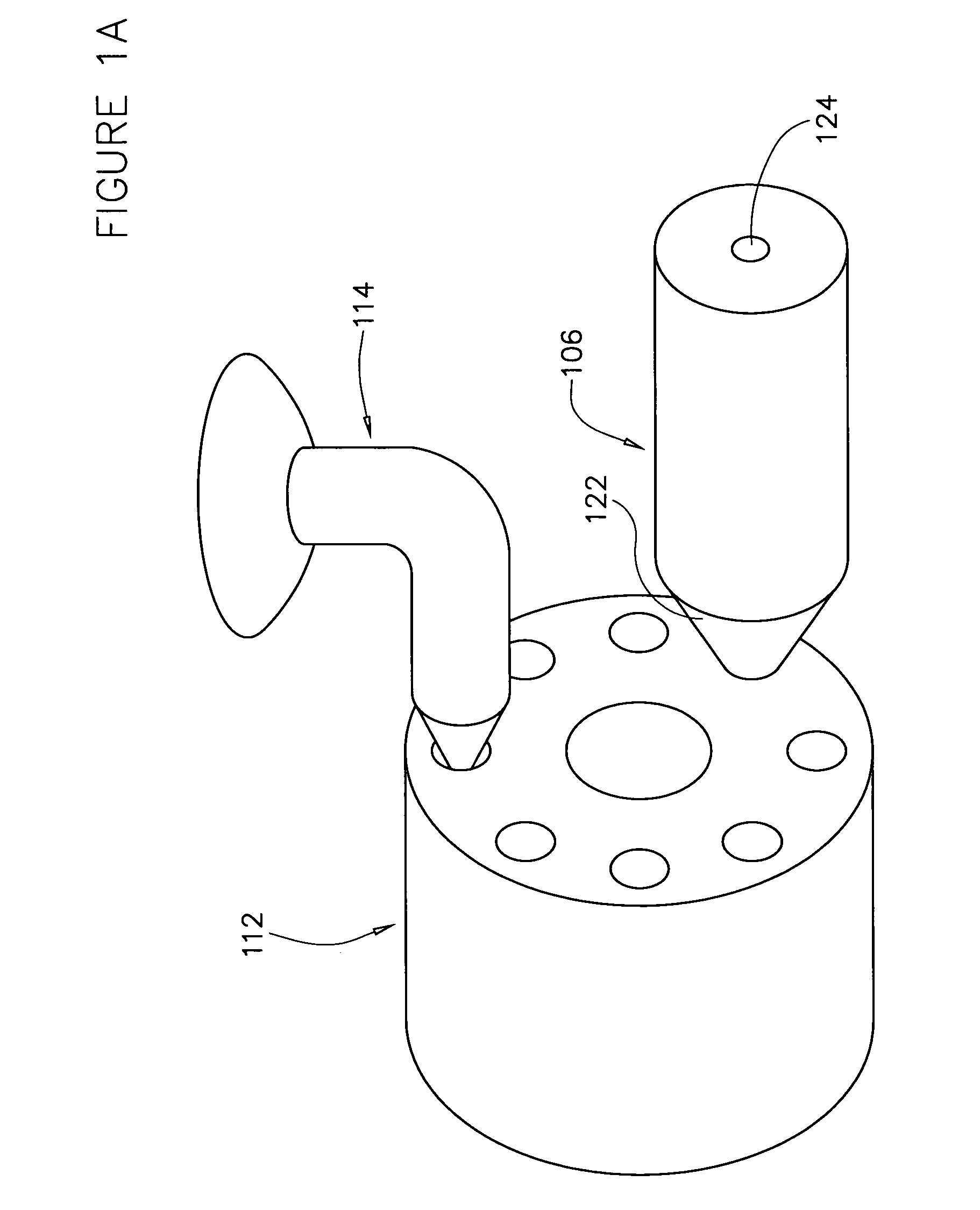

Control of uniformity in a surface wave plasma source

A surface wave plasma source (SWPS) is disclosed, having an electromagnetic (EM) wave launcher including a slot antenna configured to couple EM energy in a desired EM wave mode to a plasma by generating a surface wave on a plasma surface of the SWPS adjacent the plasma. The SWPS also includes a dielectric window positioned below the slot antenna, having a lower surface and the plasma surface. The SWPS further includes an attenuation assembly disposed between the slot antenna and the plasma surface. The attenuation assembly includes a first fluid channel substantially aligned with a first arrangement of slots in the slot antenna, and is configured to receive a first flow of a first fluid at a first fluid temperature. The SWPS finally includes a power coupling system coupled to the EM wave launcher and configured to provide EM energy to the EM wave launcher for forming the plasma.

Owner:TOKYO ELECTRON LTD

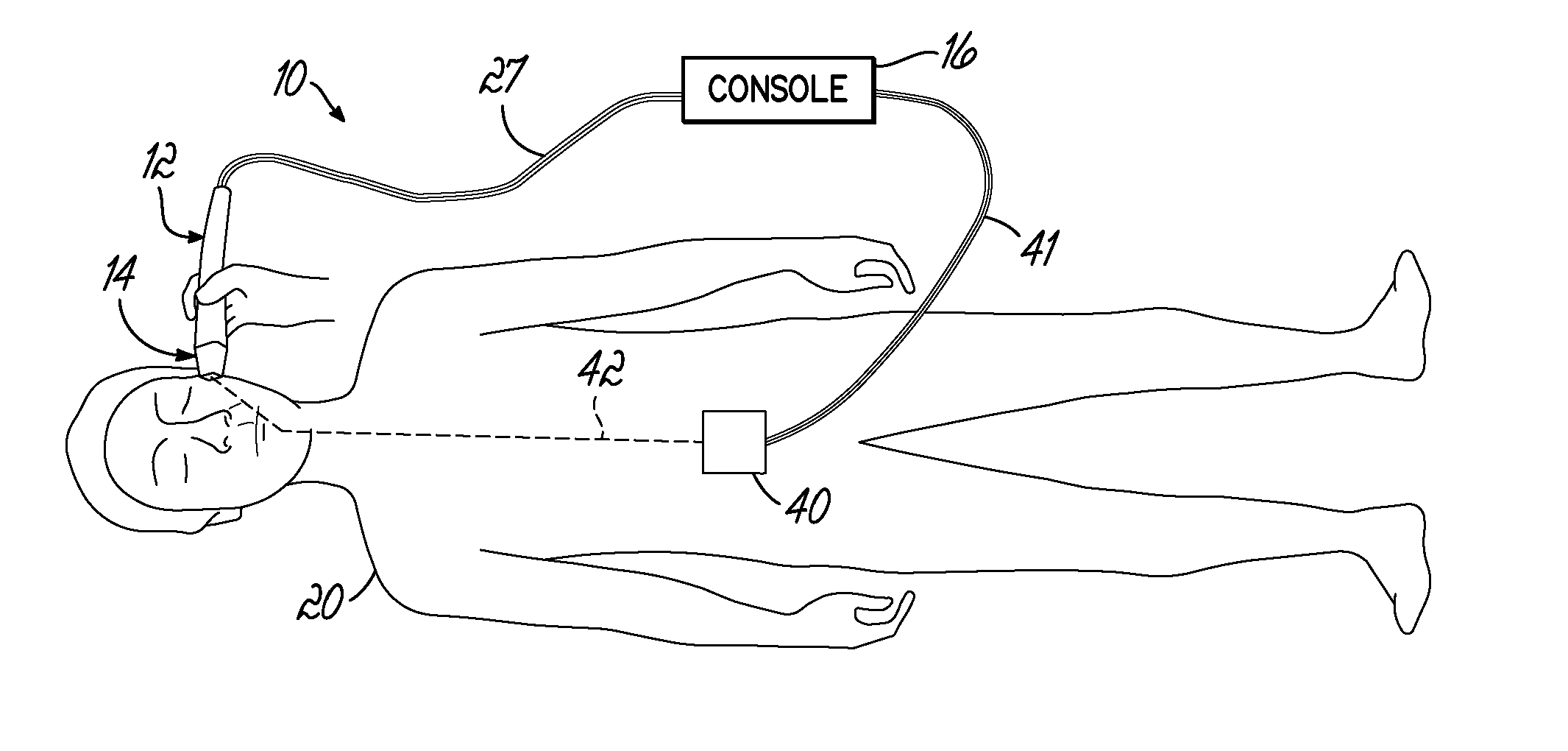

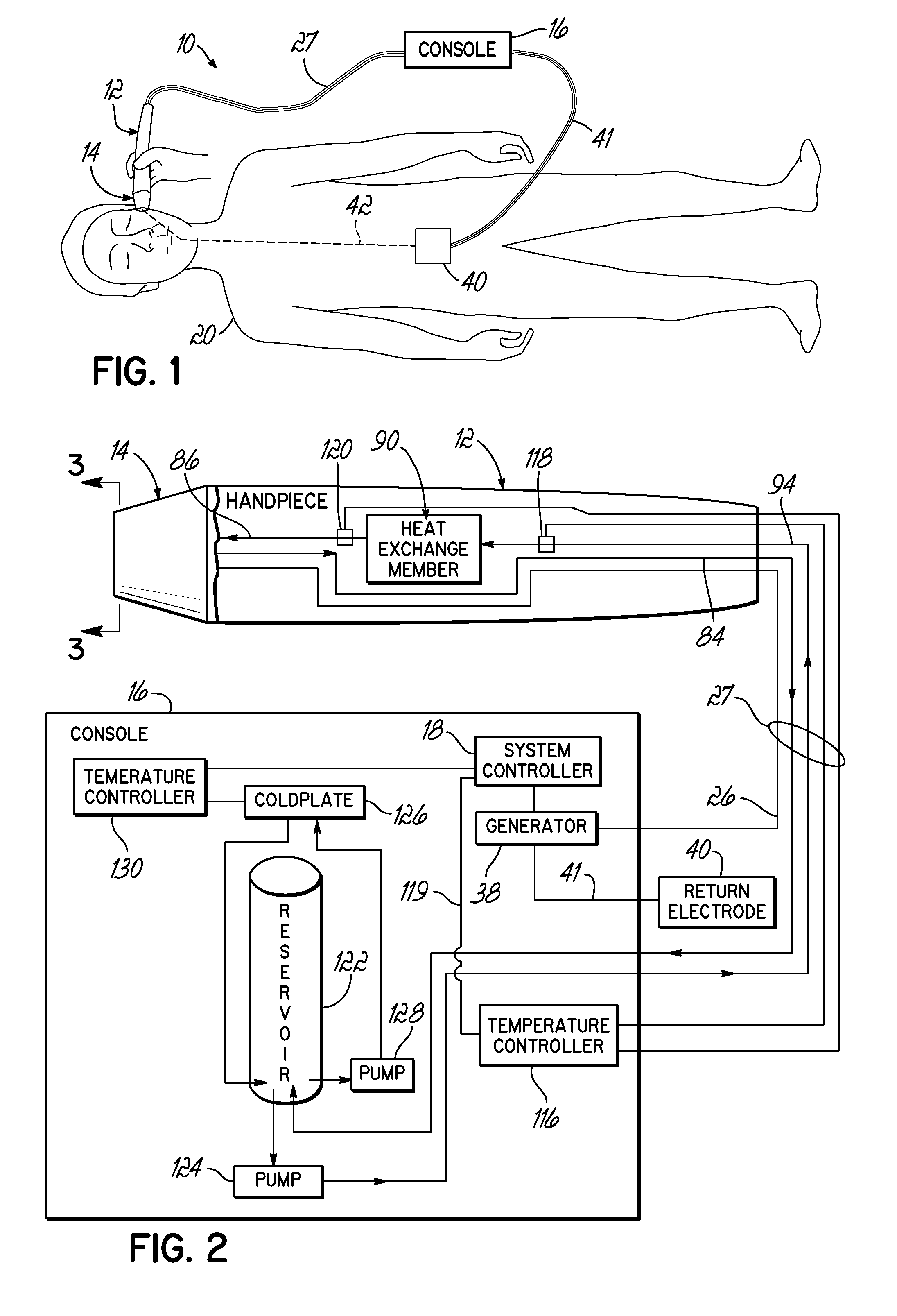

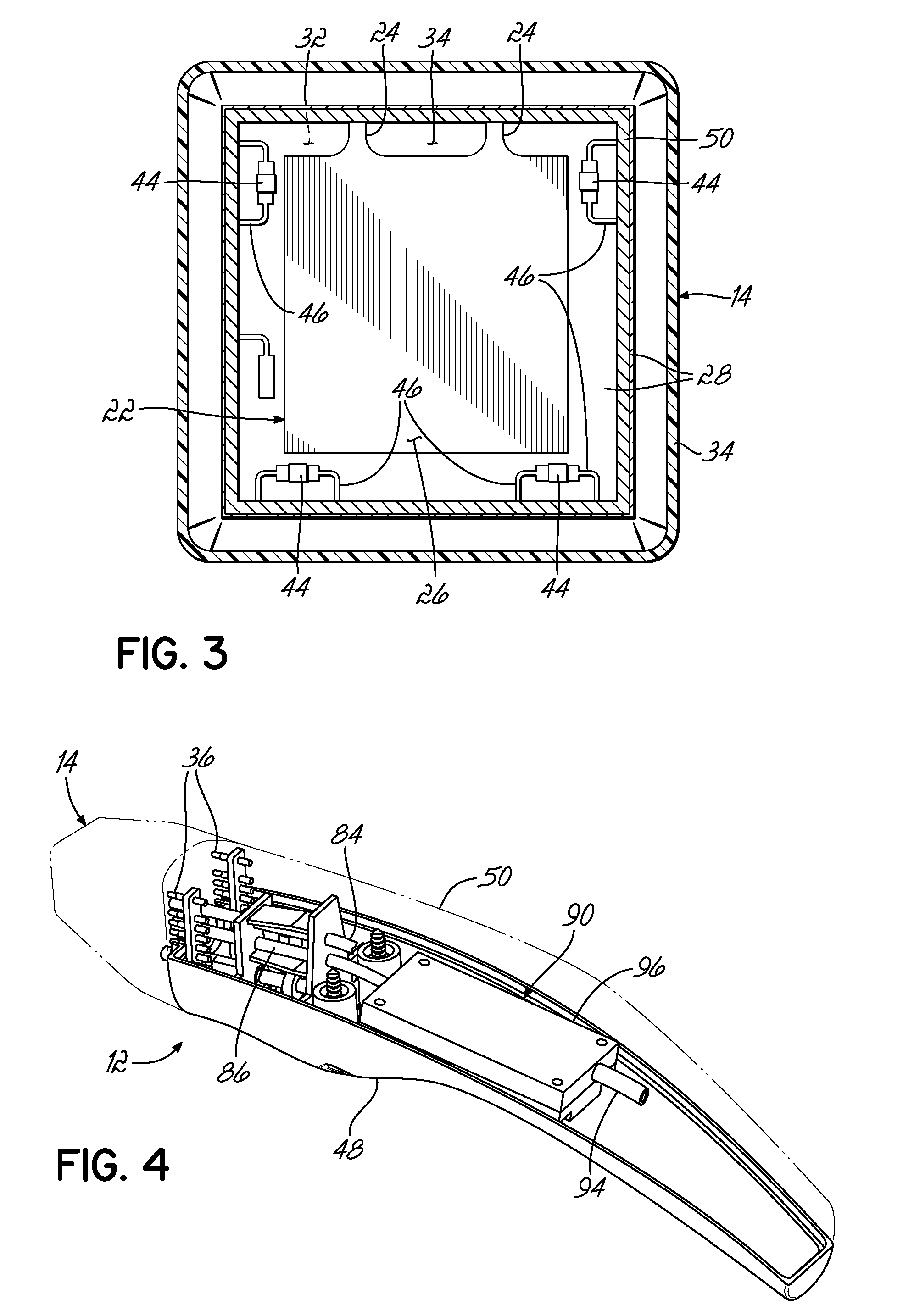

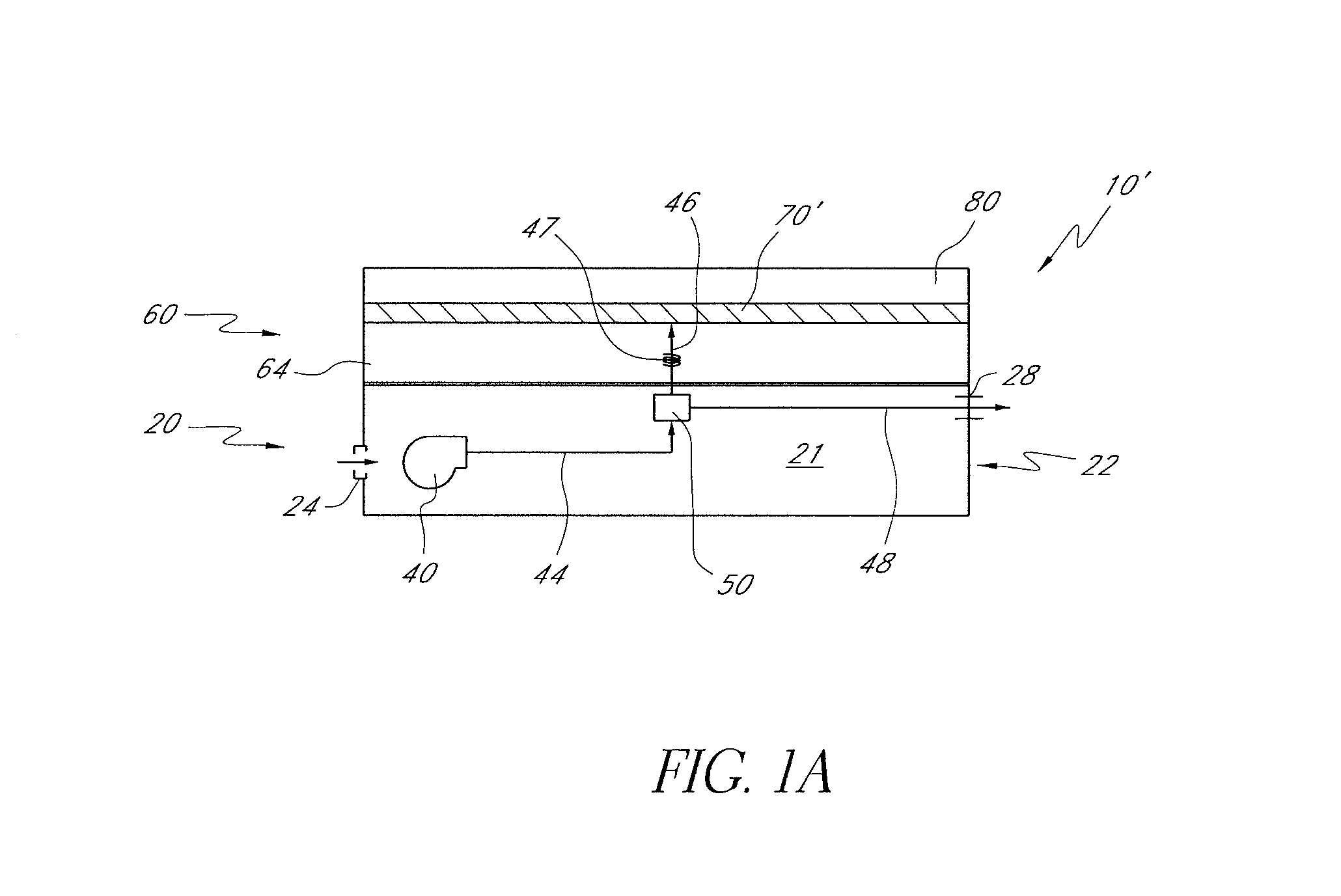

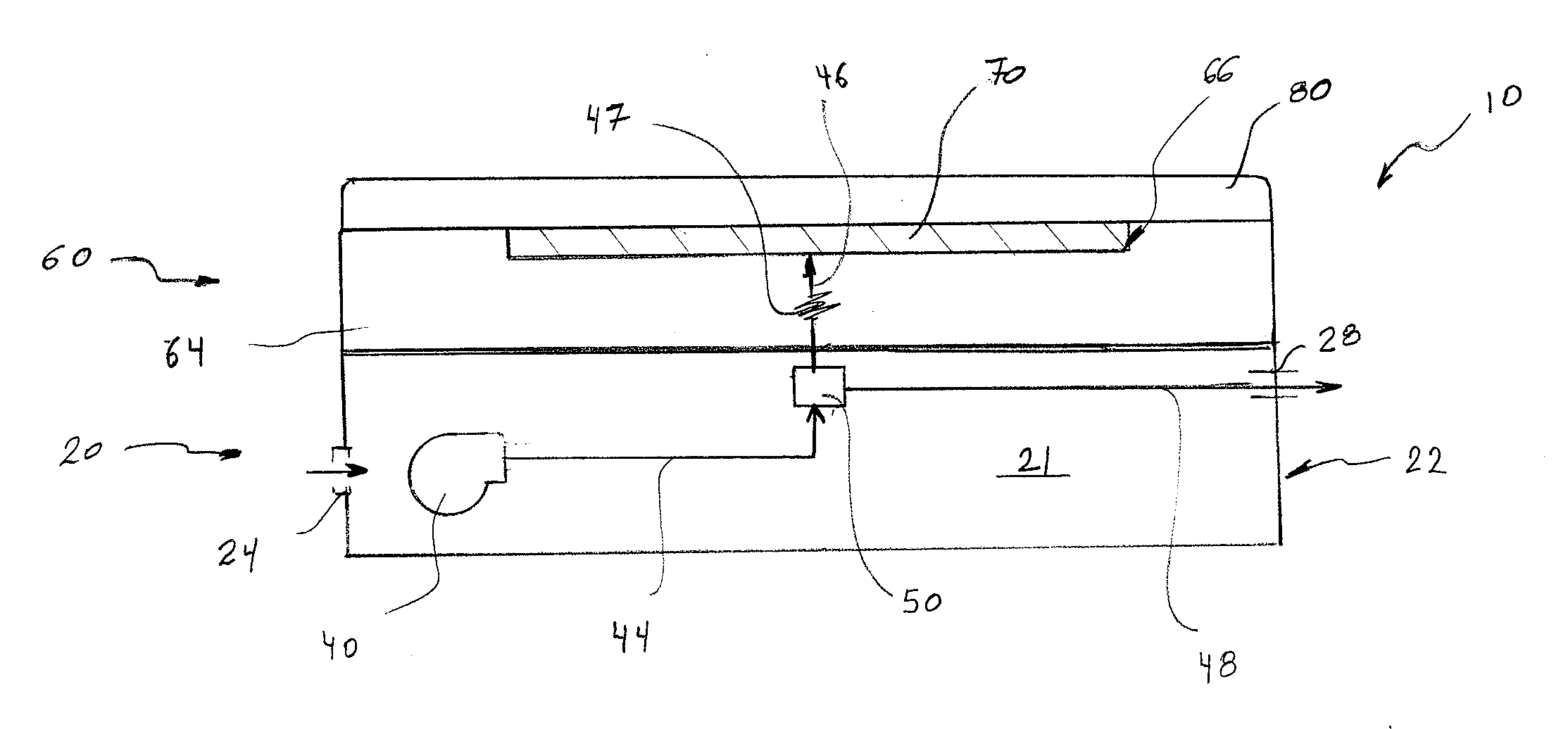

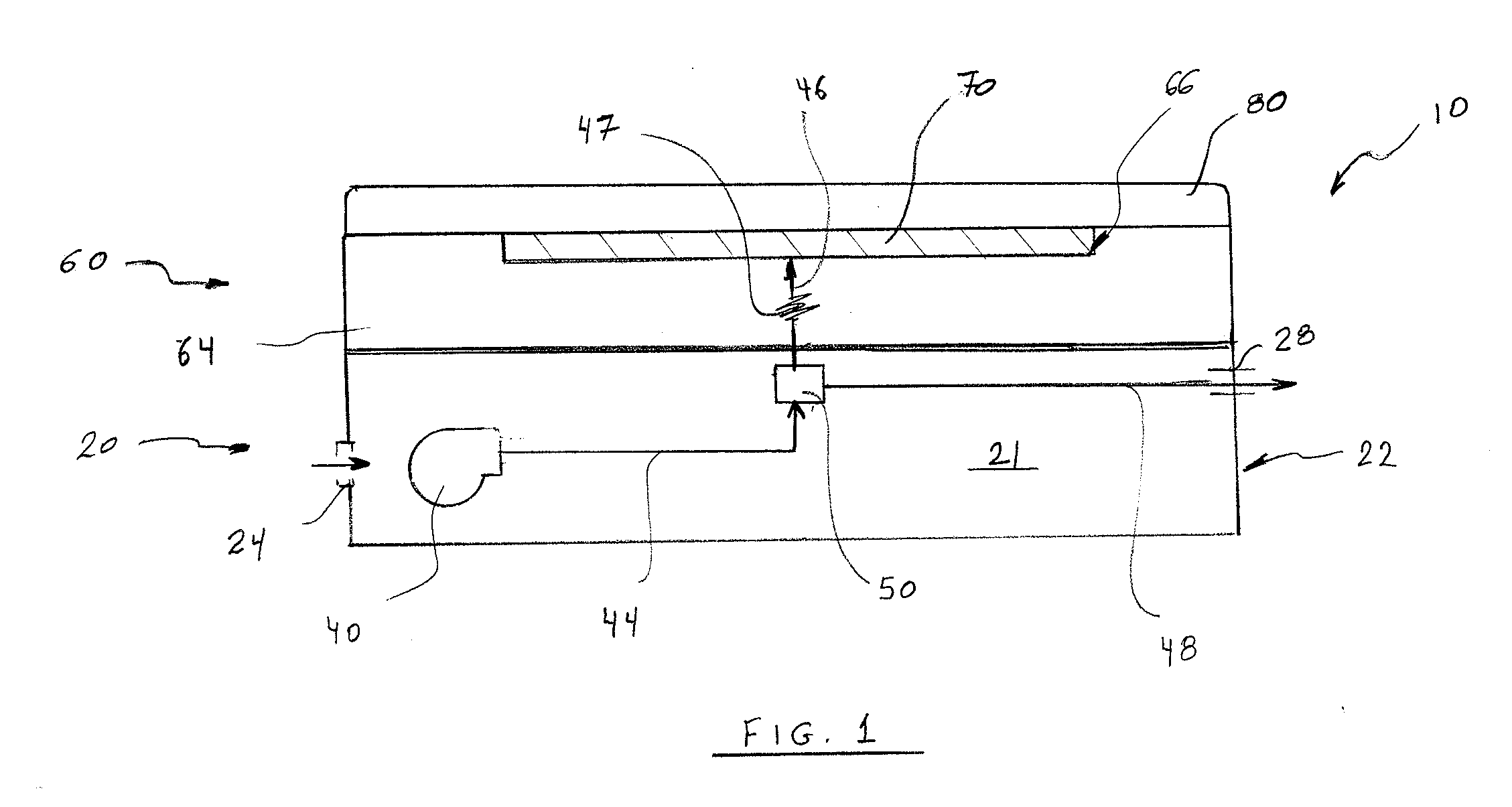

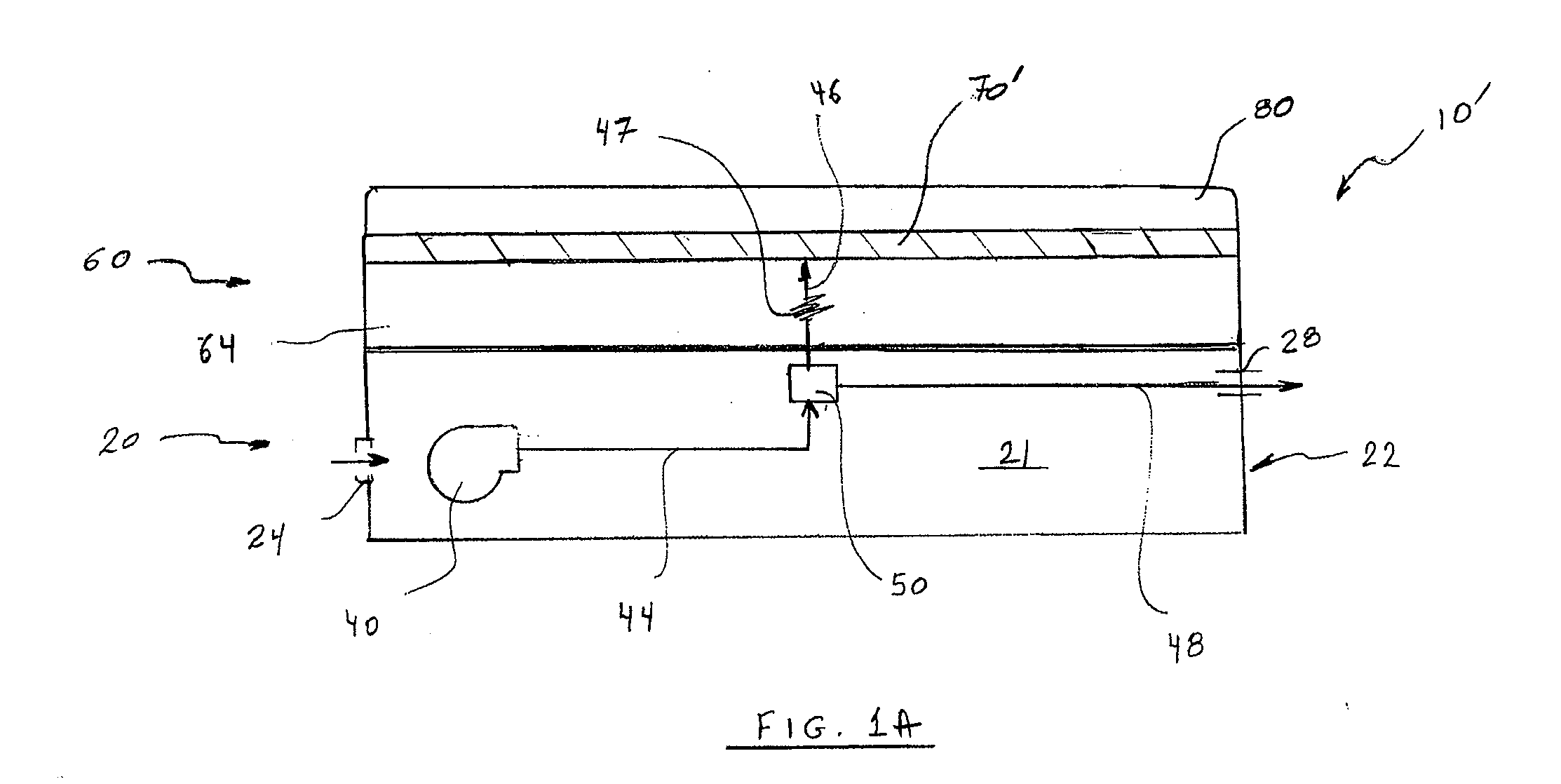

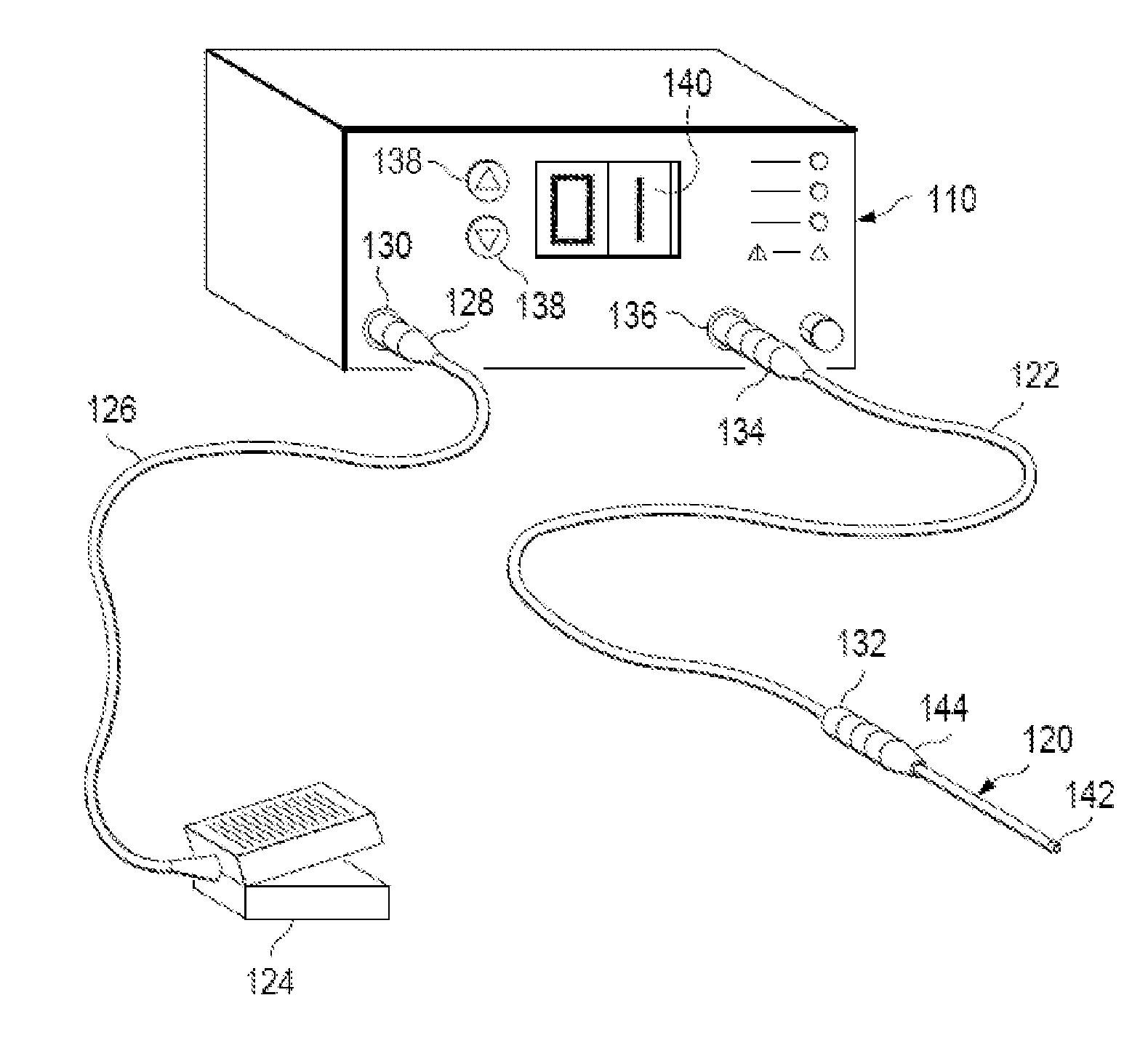

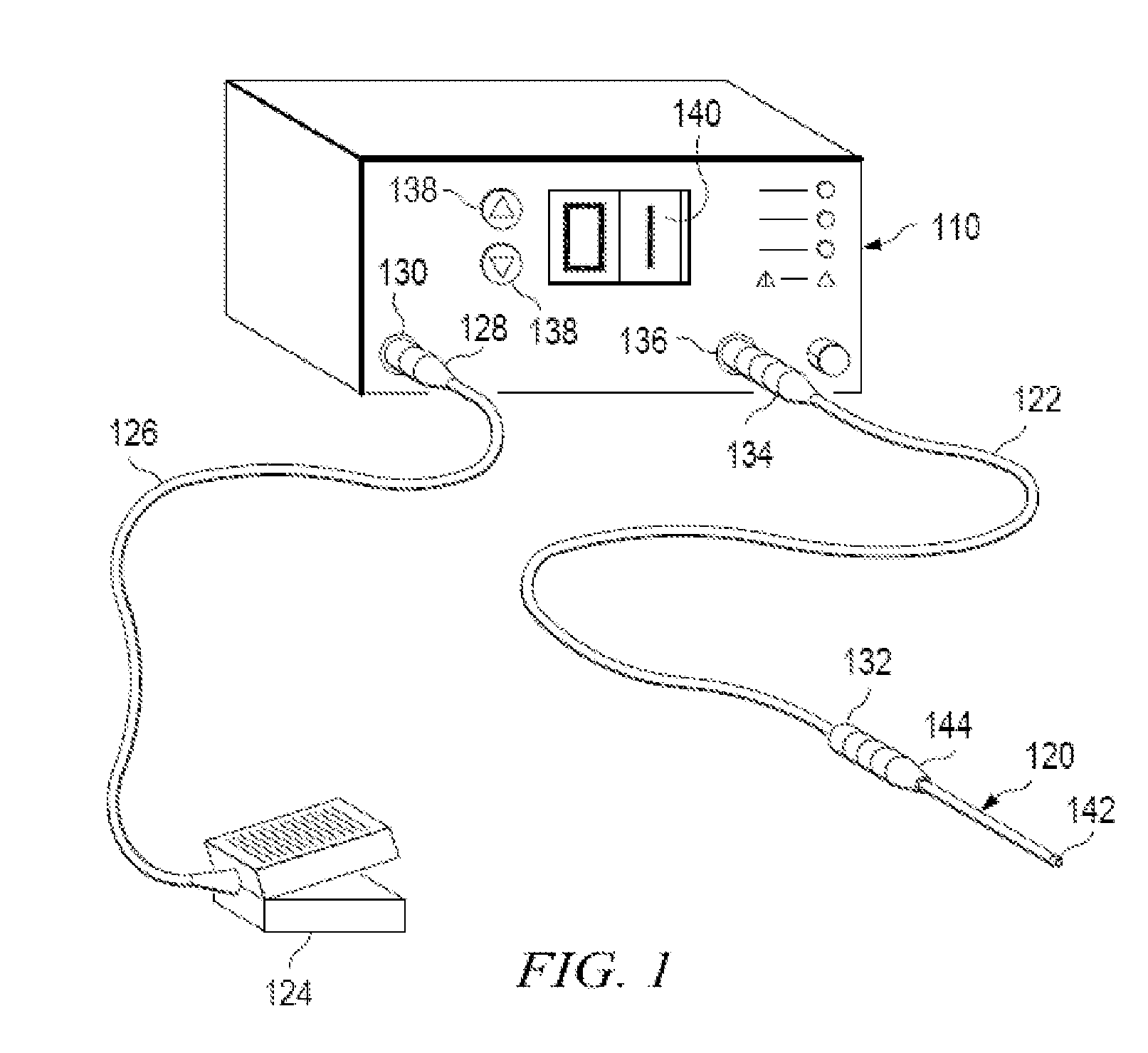

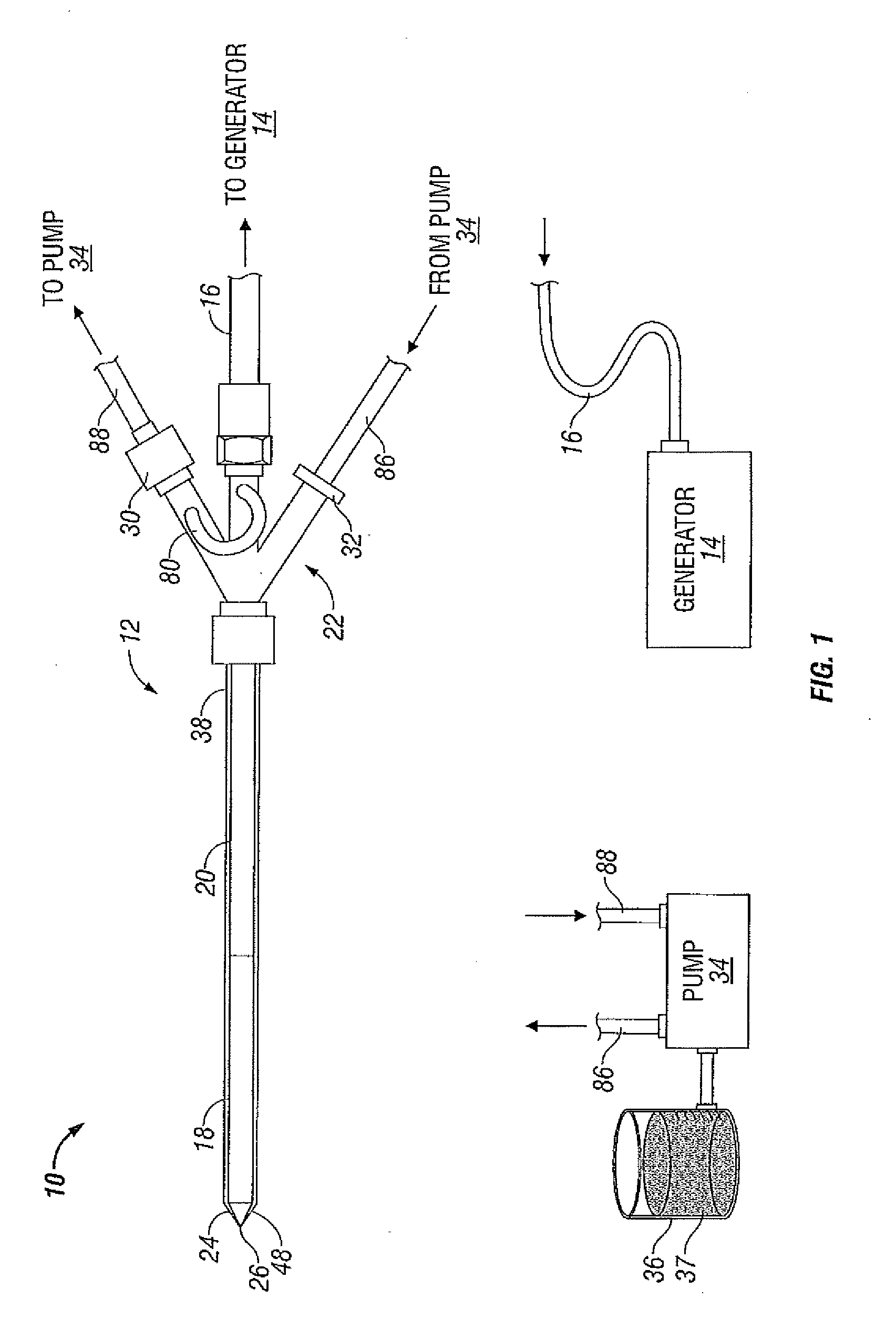

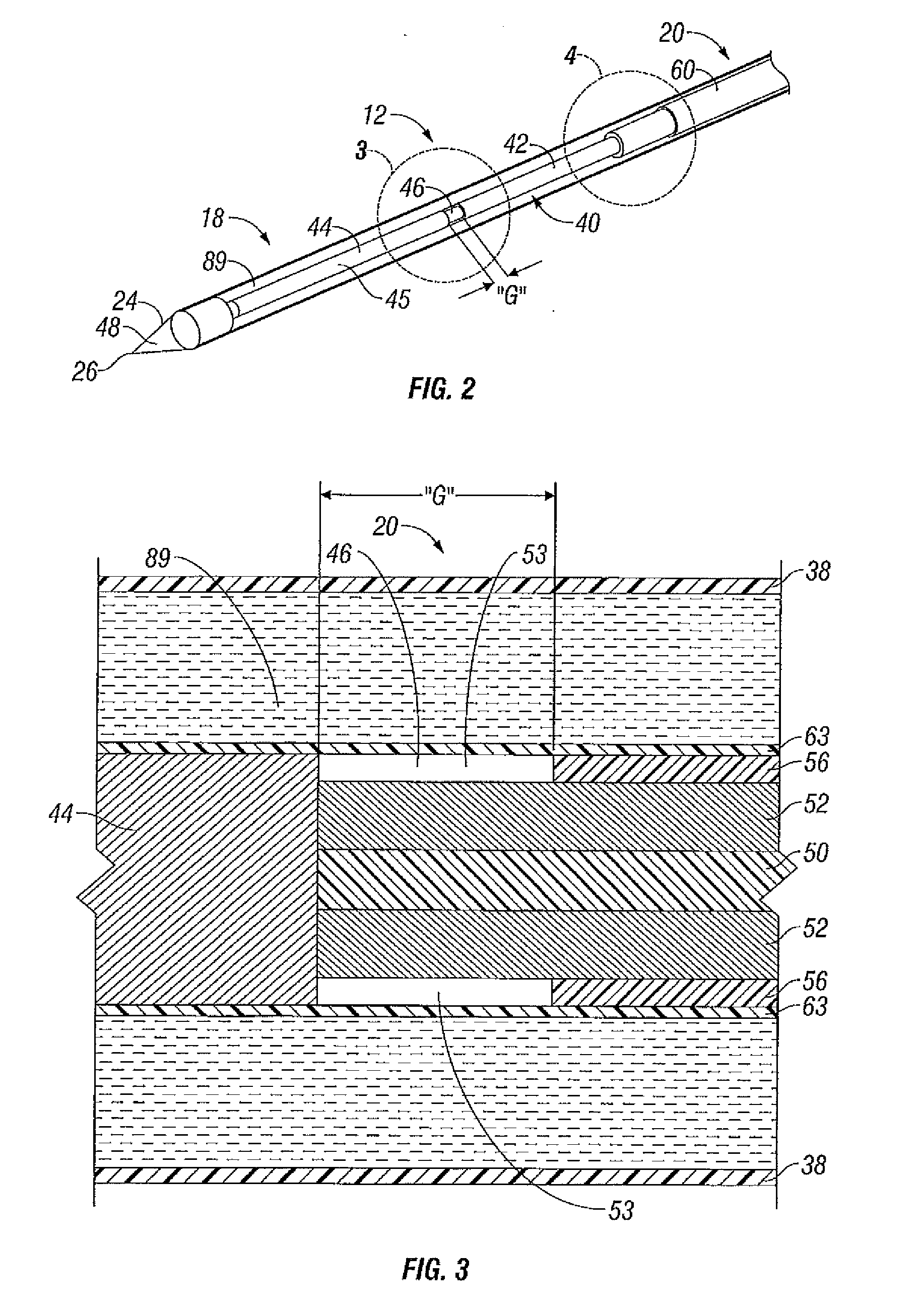

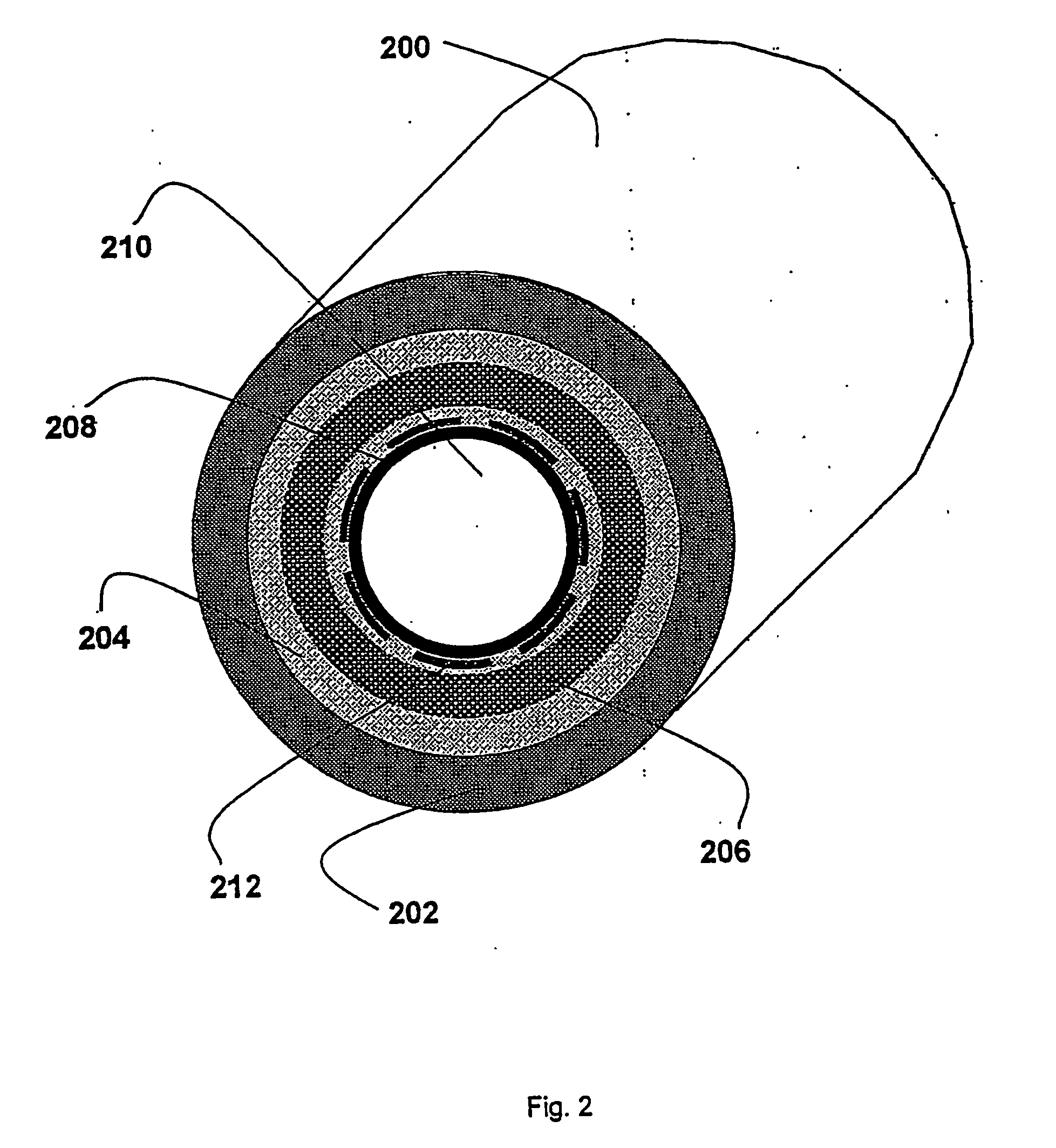

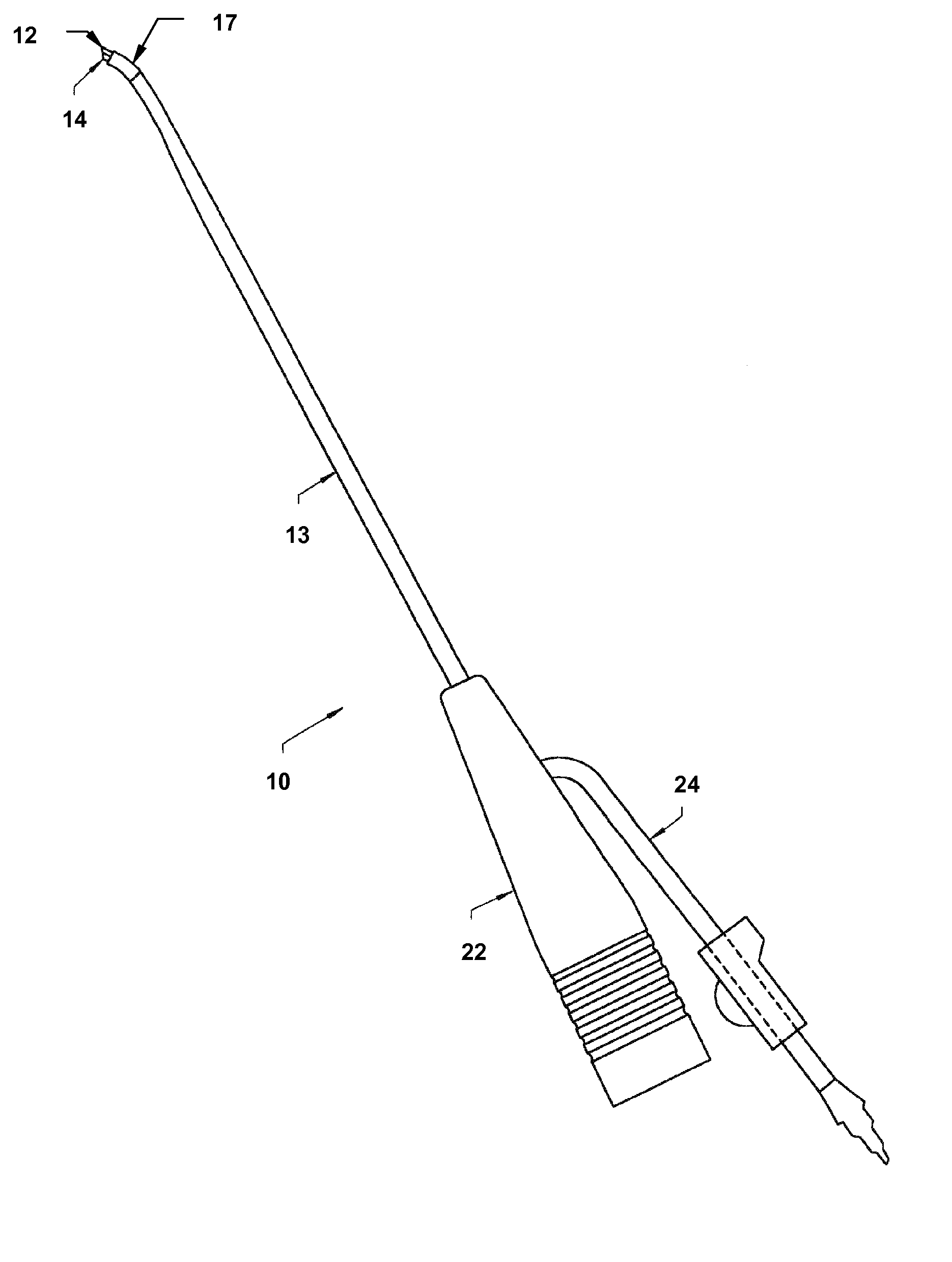

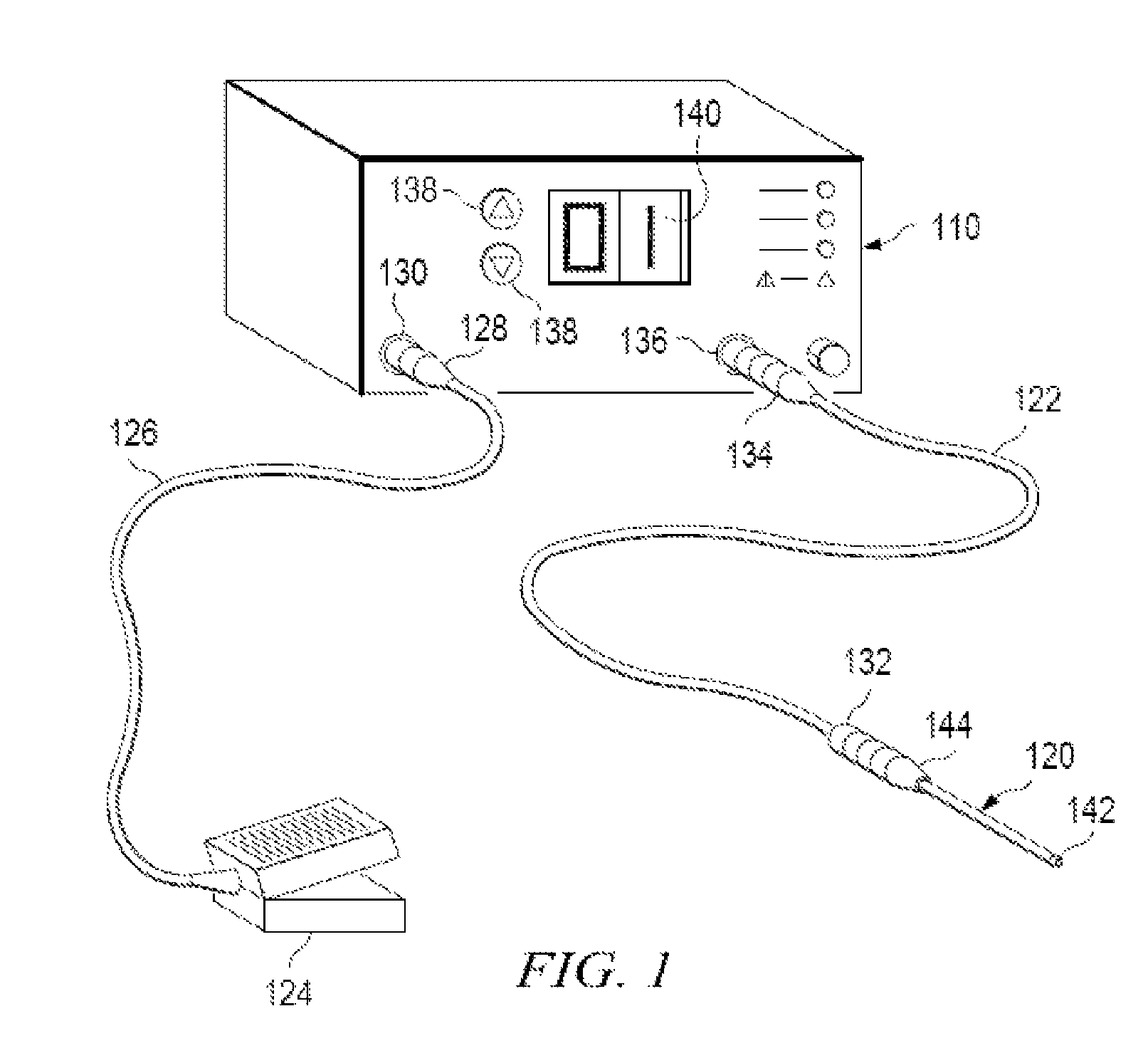

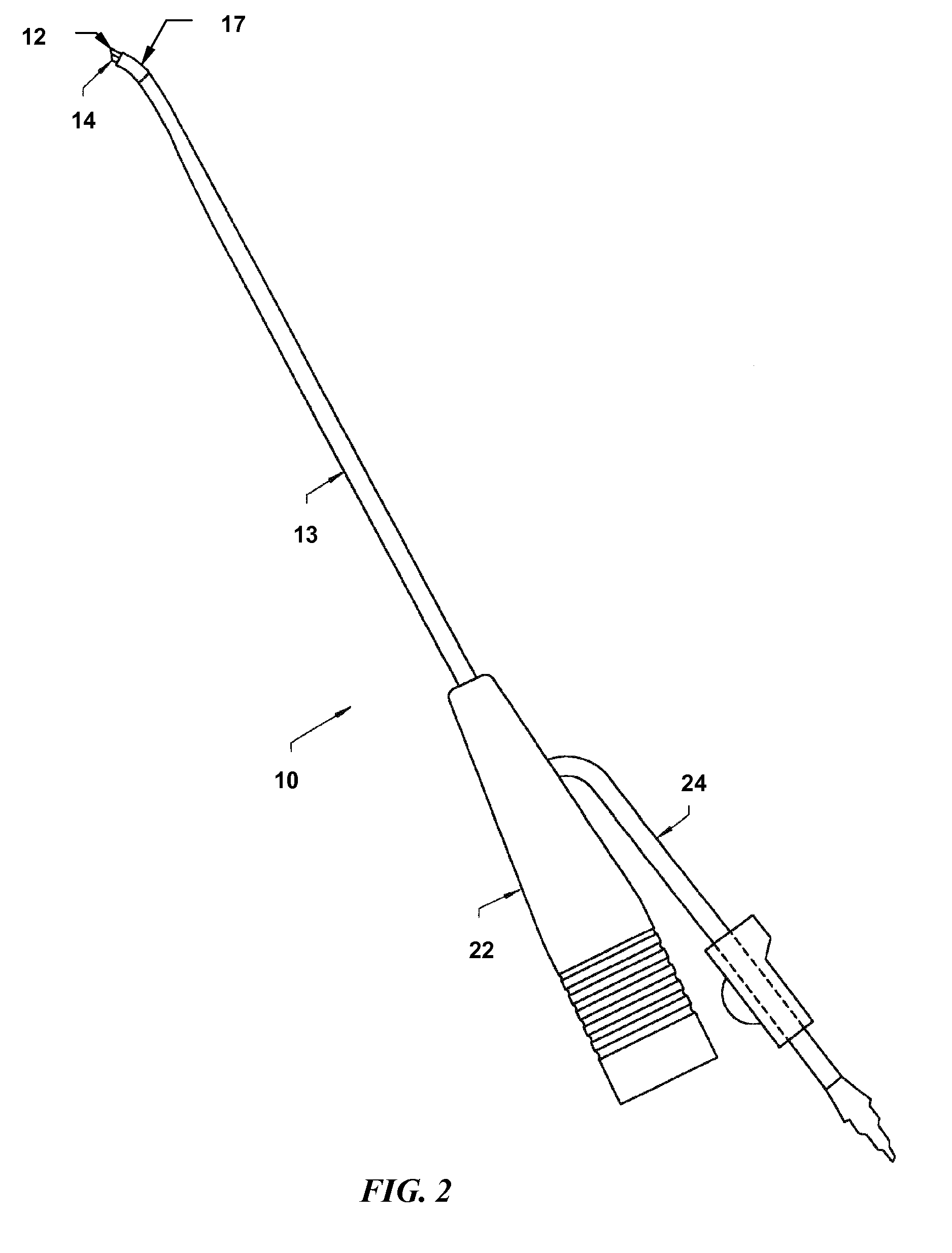

Apparatus and methods for cooling a treatment apparatus configured to non-invasively deliver electromagnetic energy to a patient's tissue

InactiveUS20090149930A1Surgical instruments for heatingLight therapyClosed loopElectromagnetic shielding

Apparatus and methods for delivering electromagnetic energy to a patient's tissue. The treatment apparatus includes a closed-loop cooling system that cools the energy delivery device. The fluid forced to flow in the closed-loop cooling system is chilled to a first temperature at a location remote from the energy delivery device and is warmed to a higher second temperature near the energy delivery device. This promotes better control over the fluid temperature at the energy delivery device.

Owner:THERMAGE INC

Air conditioned bed

A climate controlled bed comprises a cushion member having an outer surface comprising a first side for supporting an occupant and a second side, the first side and the second side generally facing in opposite directions. In some embodiments, the cushion member includes one or more recessed areas along its first side or its second side. In one embodiment, the bed further includes a support structure having a top side configured to support the cushion member, a bottom side and an interior space generally located between the top side and the bottom side, the top side and the bottom side of the support structure generally facing in opposite directions, a flow conditioning member that may be at least partially positioned with the recessed area of the cushion member, an air-permeable topper member positioned along the first side of the cushion member and a fluid temperature regulation system. The fluid temperature regulation system includes a fluid transfer device, a thermoelectric device and a conduit system generally configured to transfer a fluid from the fluid transfer device to the thermoelectric device. The fluid temperature regulation system is configured to receive a volume of fluid and deliver it to the flow conditioning member and the topper member.

Owner:SLEEP NUMBER CORP

Air conditioned bed

A climate controlled bed comprises a cushion member having an outer surface comprising a first side for supporting an occupant and a second side, the first side and the second side generally facing in opposite directions. In some embodiments, the cushion member includes one or more recessed areas along its first side or its second side. In one embodiment, the bed further includes a support structure having a top side configured to support the cushion member, a bottom side and an interior space generally located between the top side and the bottom side, the top side and the bottom side of the support structure generally facing in opposite directions, a flow conditioning member that may be at least partially positioned with the recessed area of the cushion member, an air-permeable topper member positioned along the first side of the cushion member and a fluid temperature regulation system. The fluid temperature regulation system includes a fluid transfer device, a thermoelectric device and a conduit system generally configured to transfer a fluid from the fluid transfer device to the thermoelectric device. The fluid temperature regulation system is configured to receive a volume of fluid and deliver it to the flow conditioning member and the topper member.

Owner:SLEEP NUMBER CORP

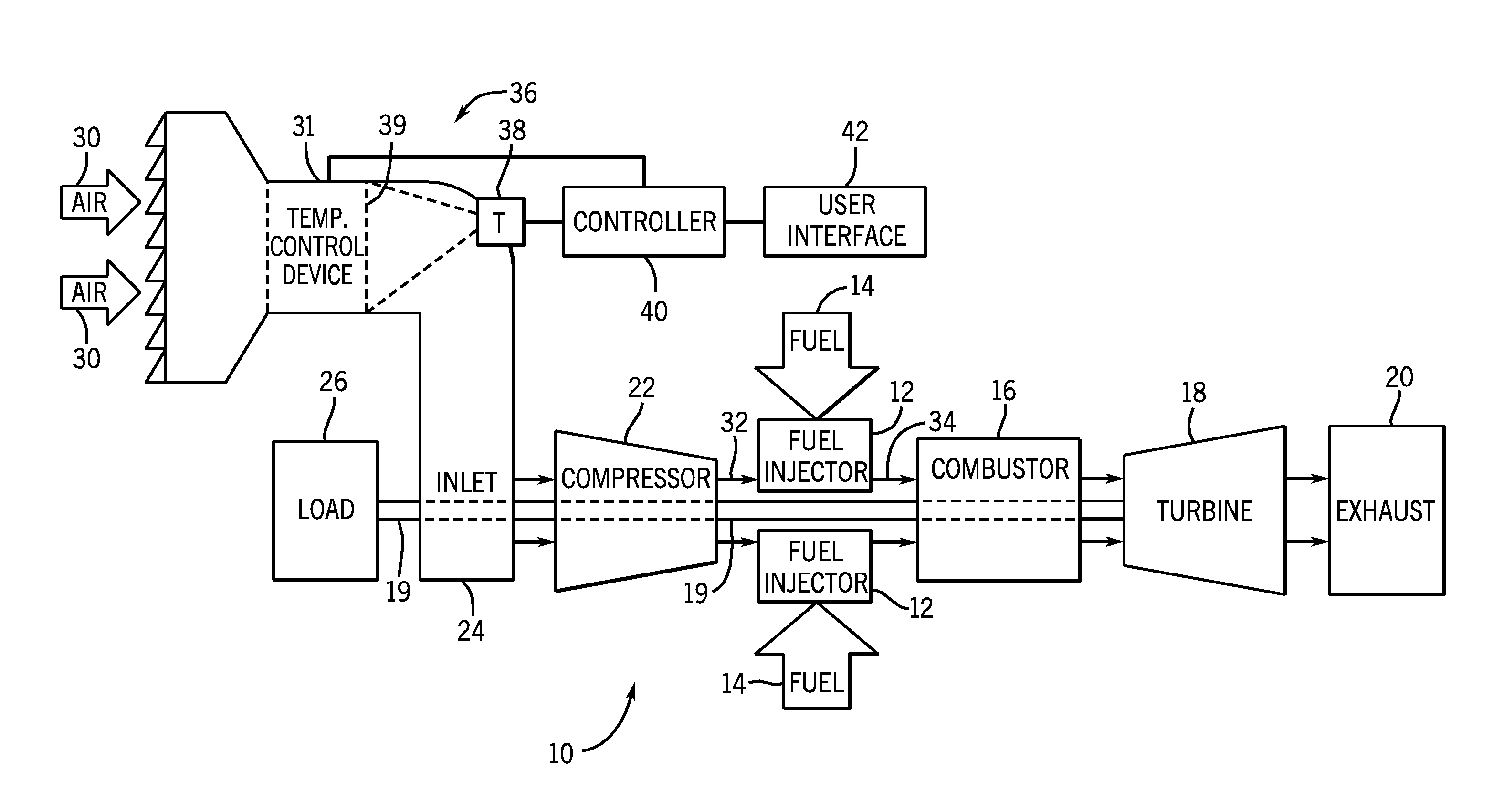

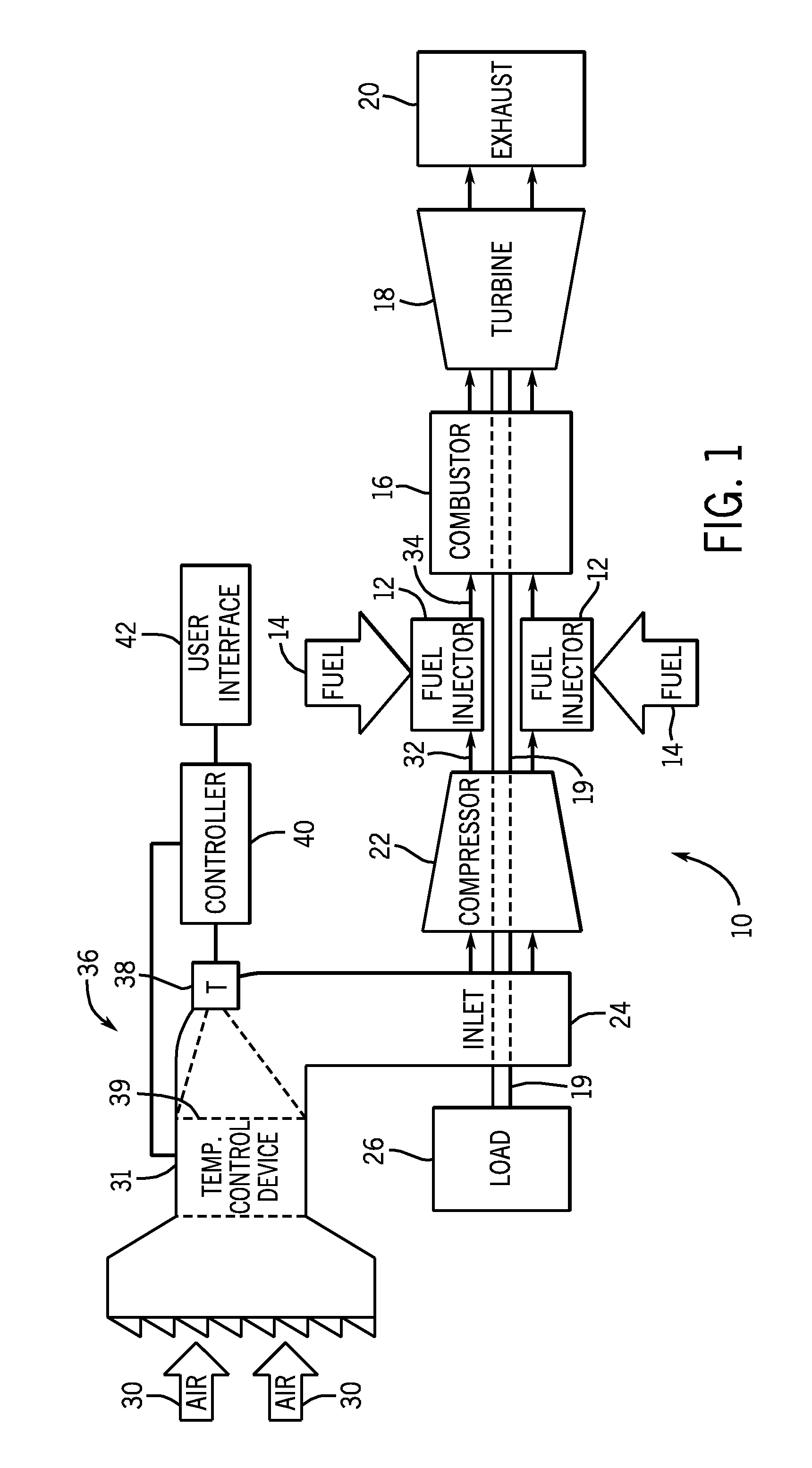

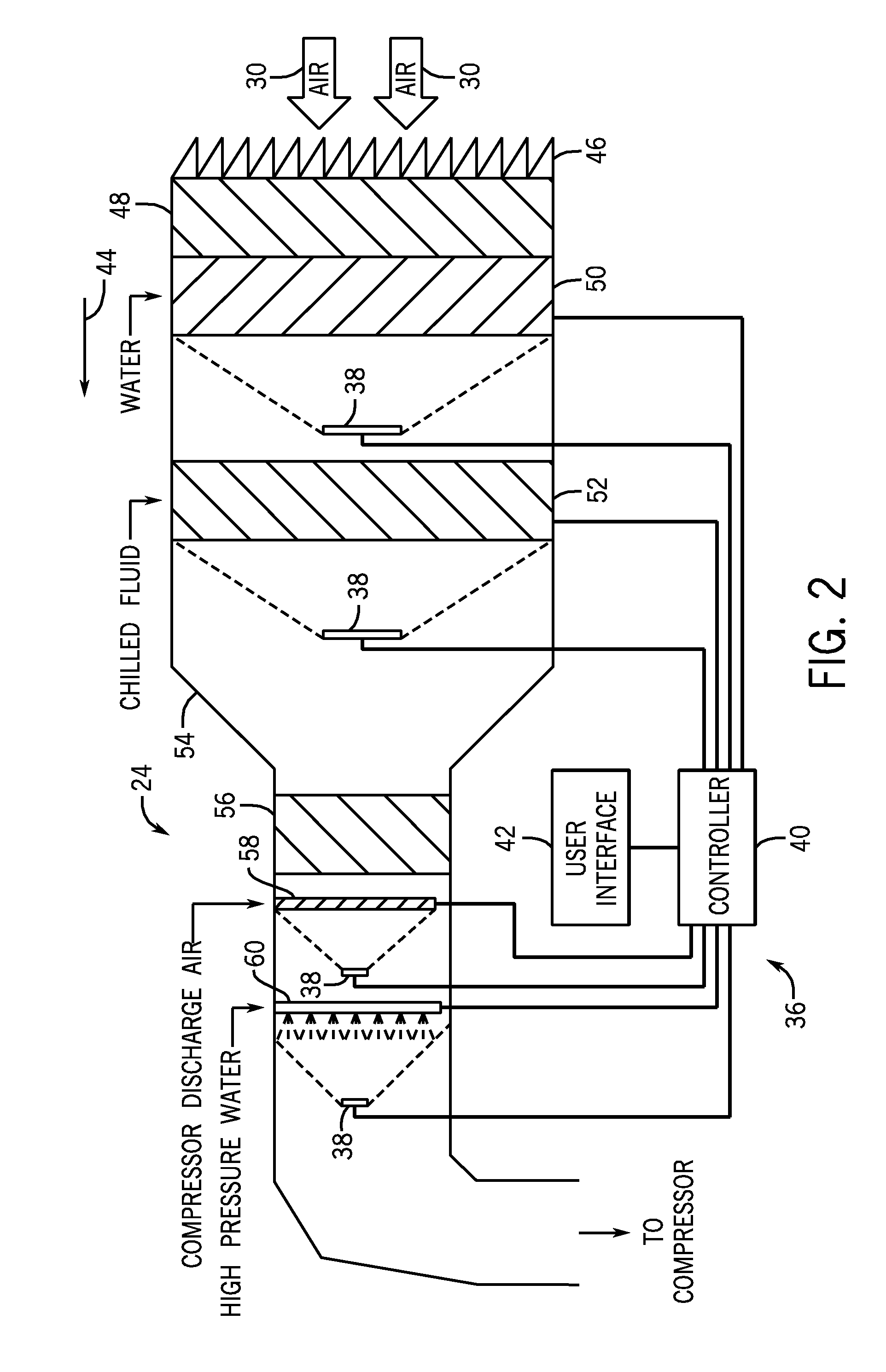

System and method for adjusting compressor inlet fluid temperature

InactiveUS20110265443A1Continuous combustion chamberPump componentsTemperature controlDetector array

A system includes a radiation detector array directed toward a fluid flow into a compressor. The radiation detector array is configured to output a signal indicative of a two-dimensional temperature profile of the fluid flow. The system also includes a controller communicatively coupled to the radiation detector array. The controller is configured to detect a temperature variation across the fluid flow based on the signal, and to adjust a parameter of a temperature control device to compensate for the detected temperature variation.

Owner:BHA ALTAIR

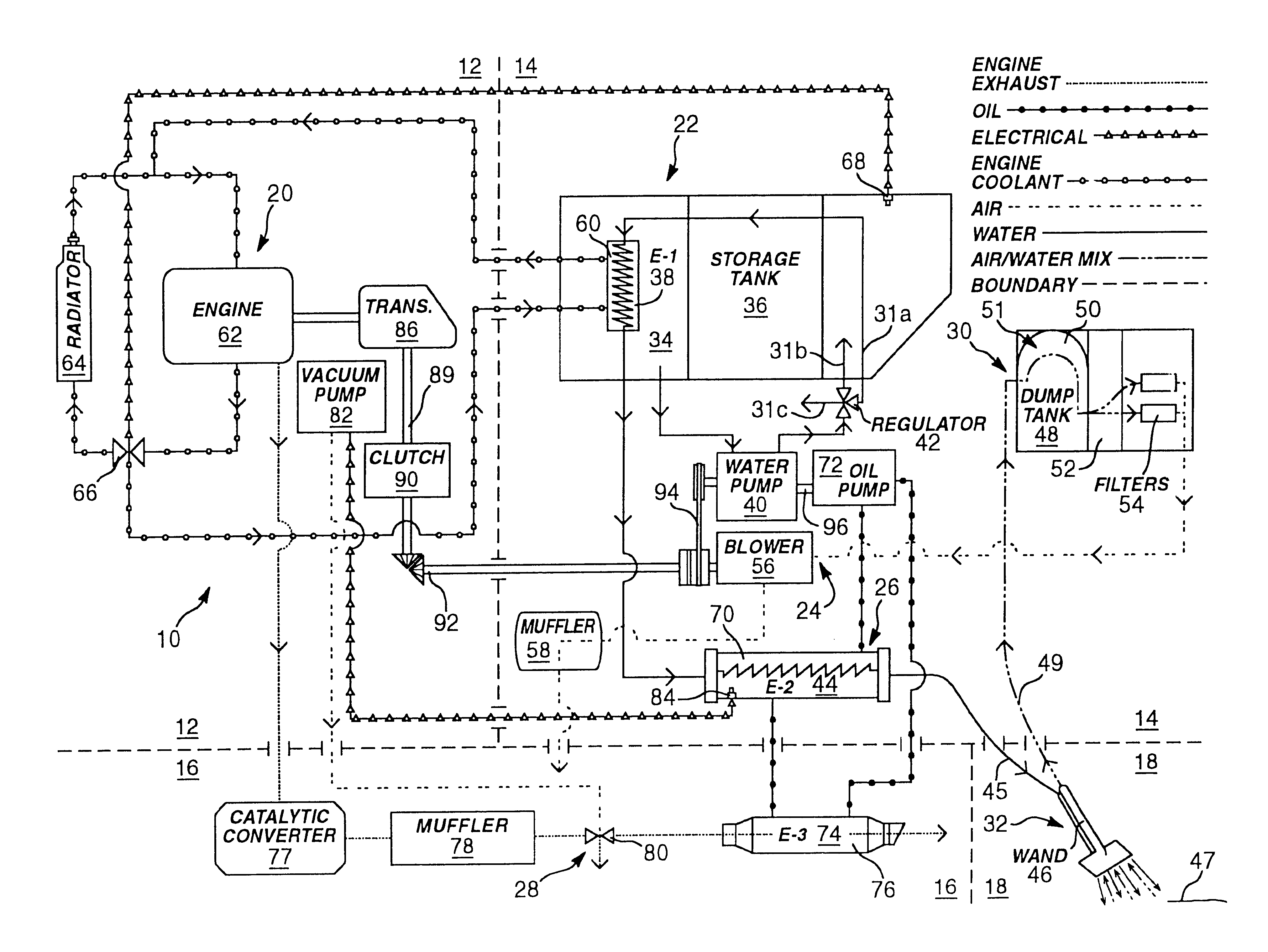

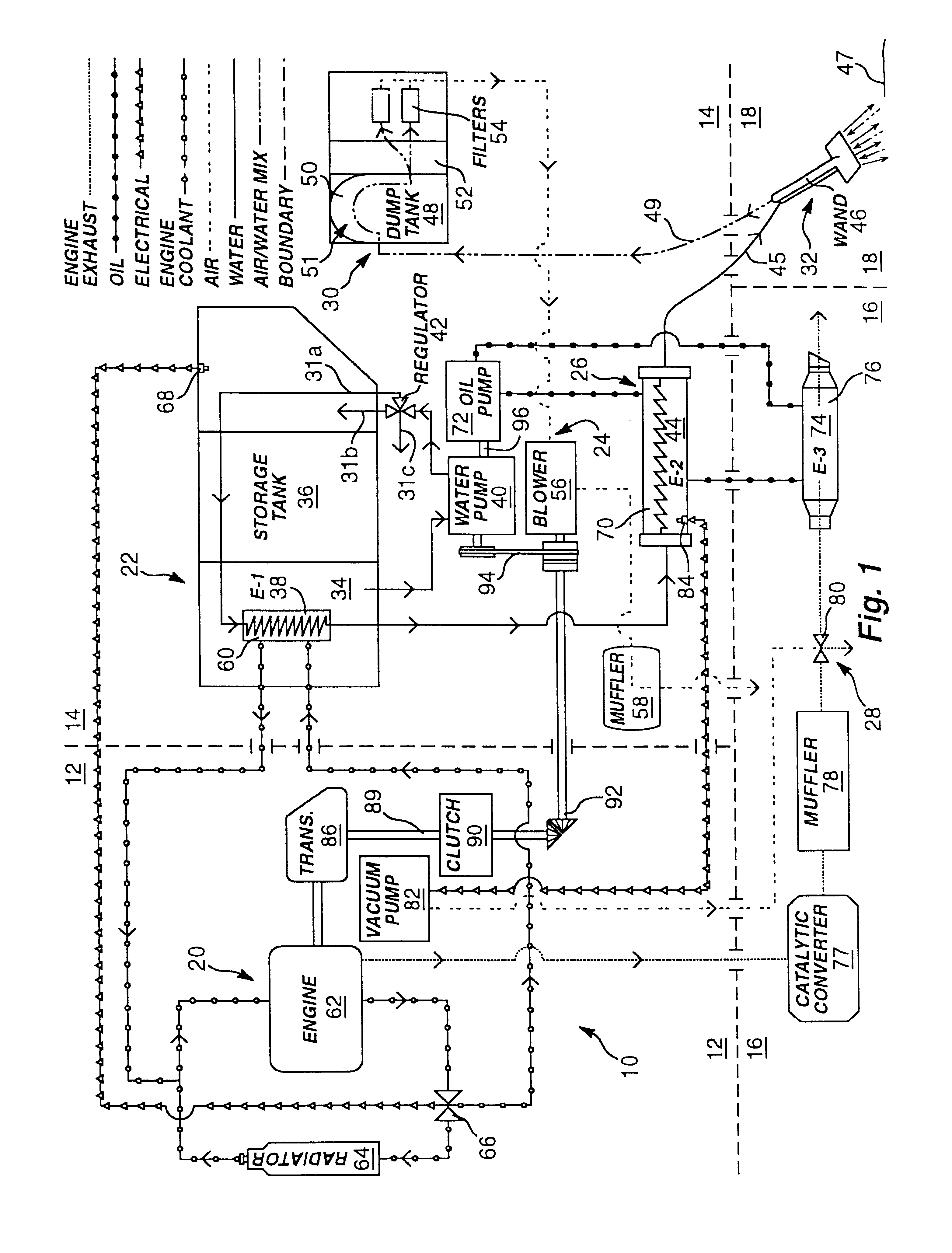

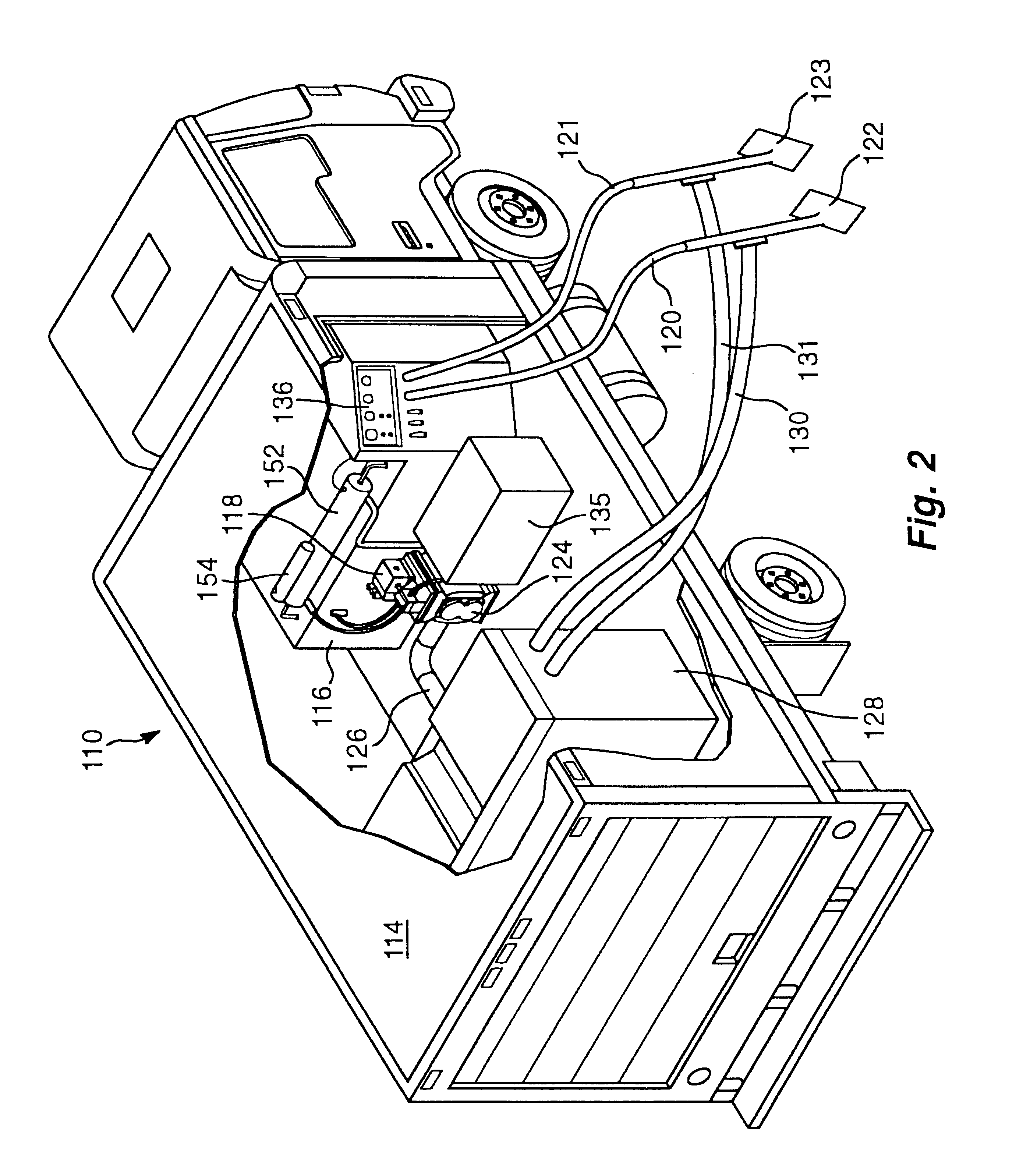

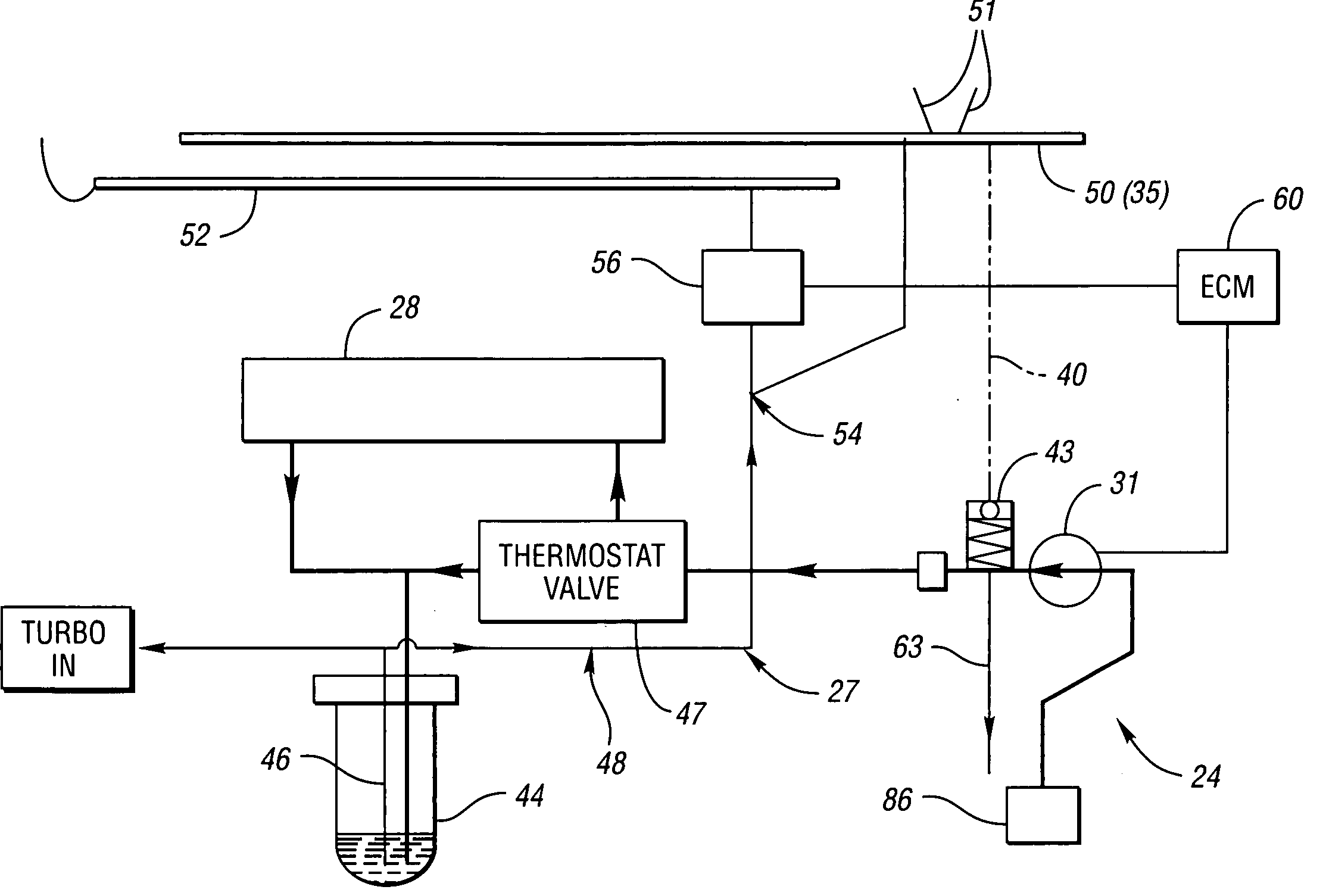

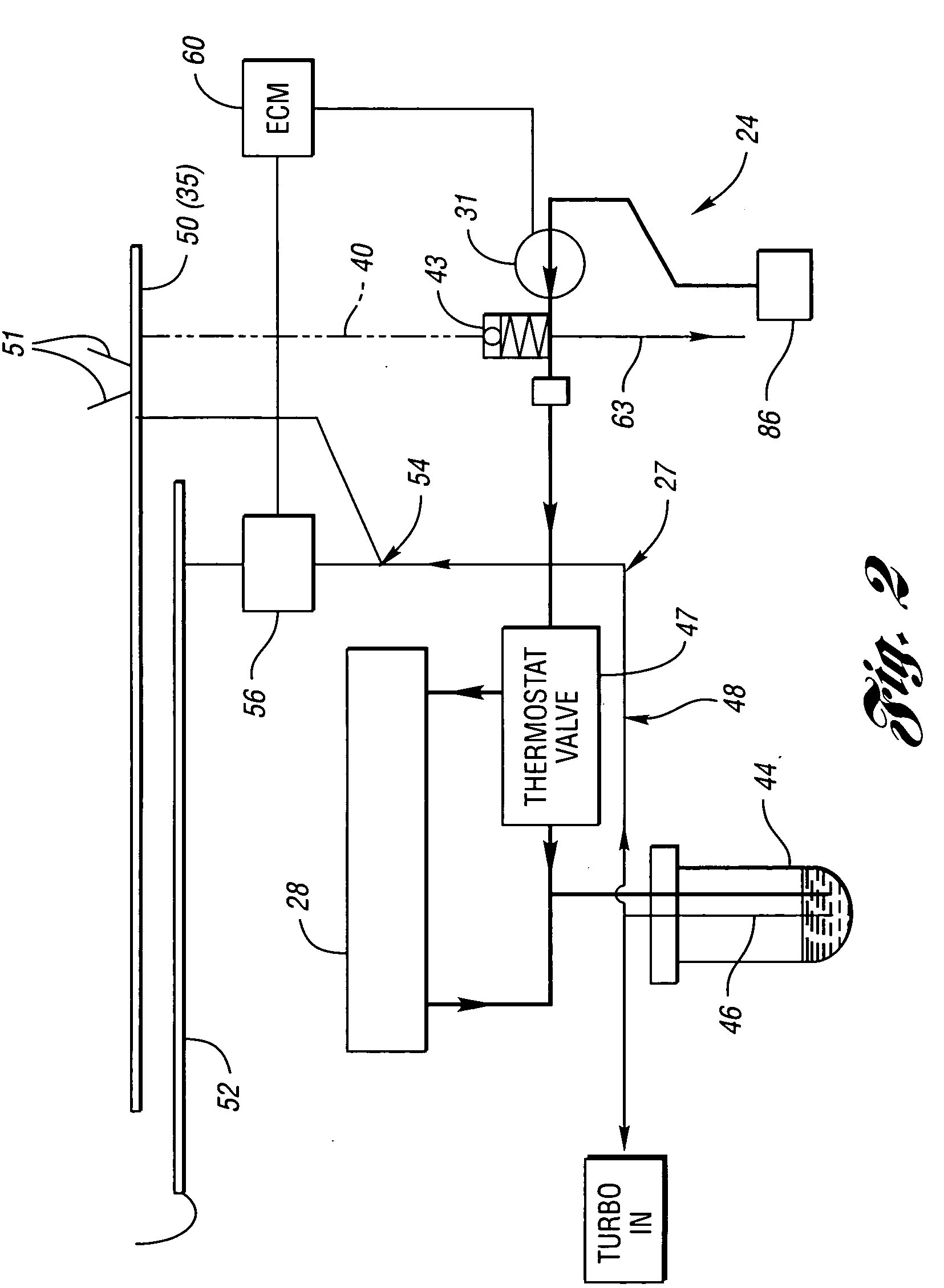

Portable high-temperature, high-pressure washing plant

InactiveUS6675437B1Reliable outputIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersProcess engineeringThermal contact

A washing system for high temperature cleaning applications, such as carpet-cleaning, is disclosed that provides a consistent cleaning fluid temperature. The washing system utilizes multiple heat exchangers and multiple heat paths. The heating and power source is provided by a medium duty, diesel cycle engine. Multi-stage heating involves heat transfer from the engine's coolant to the cleaning fluid and heat transfer from the exhaust of the engine to the cleaning fluid via an intermediate medium. The system also includes a fluid clutch used to engage a power takeoff from the engine to operate the pump and blower of the washing plant. A failsafe source cutoff diverts the exhaust flow from thermal contact with an intermediate heat transfer oil.

Owner:BLUE LINE EQUIP

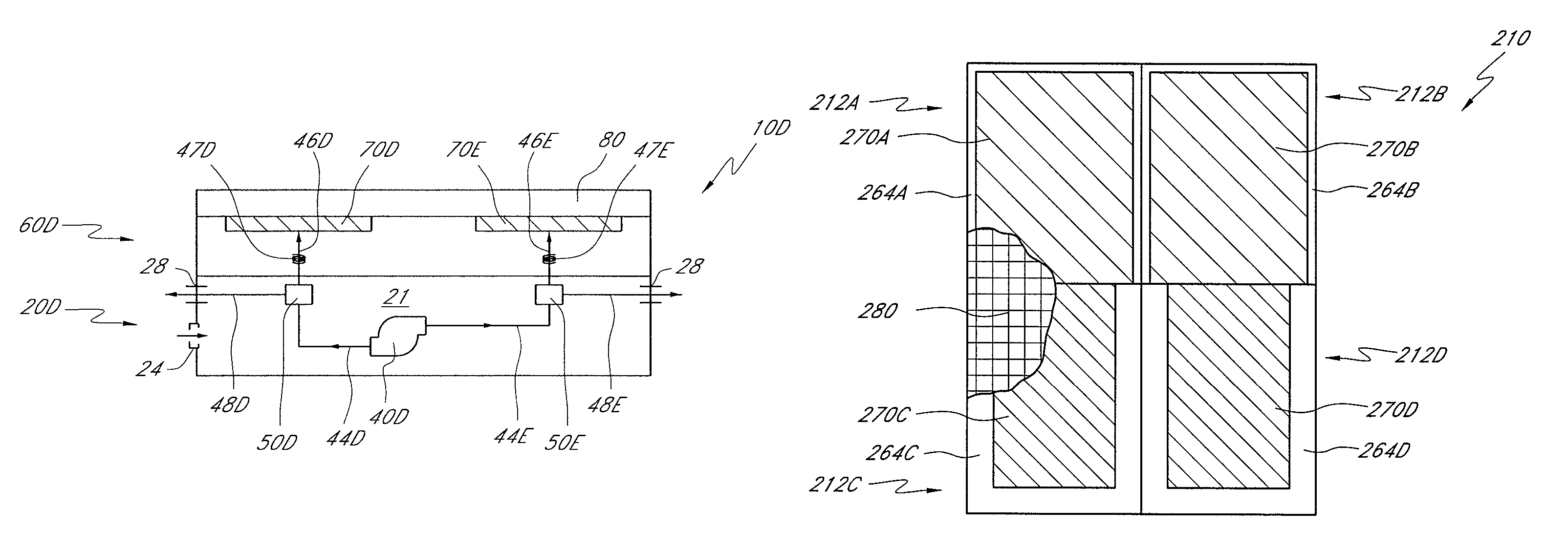

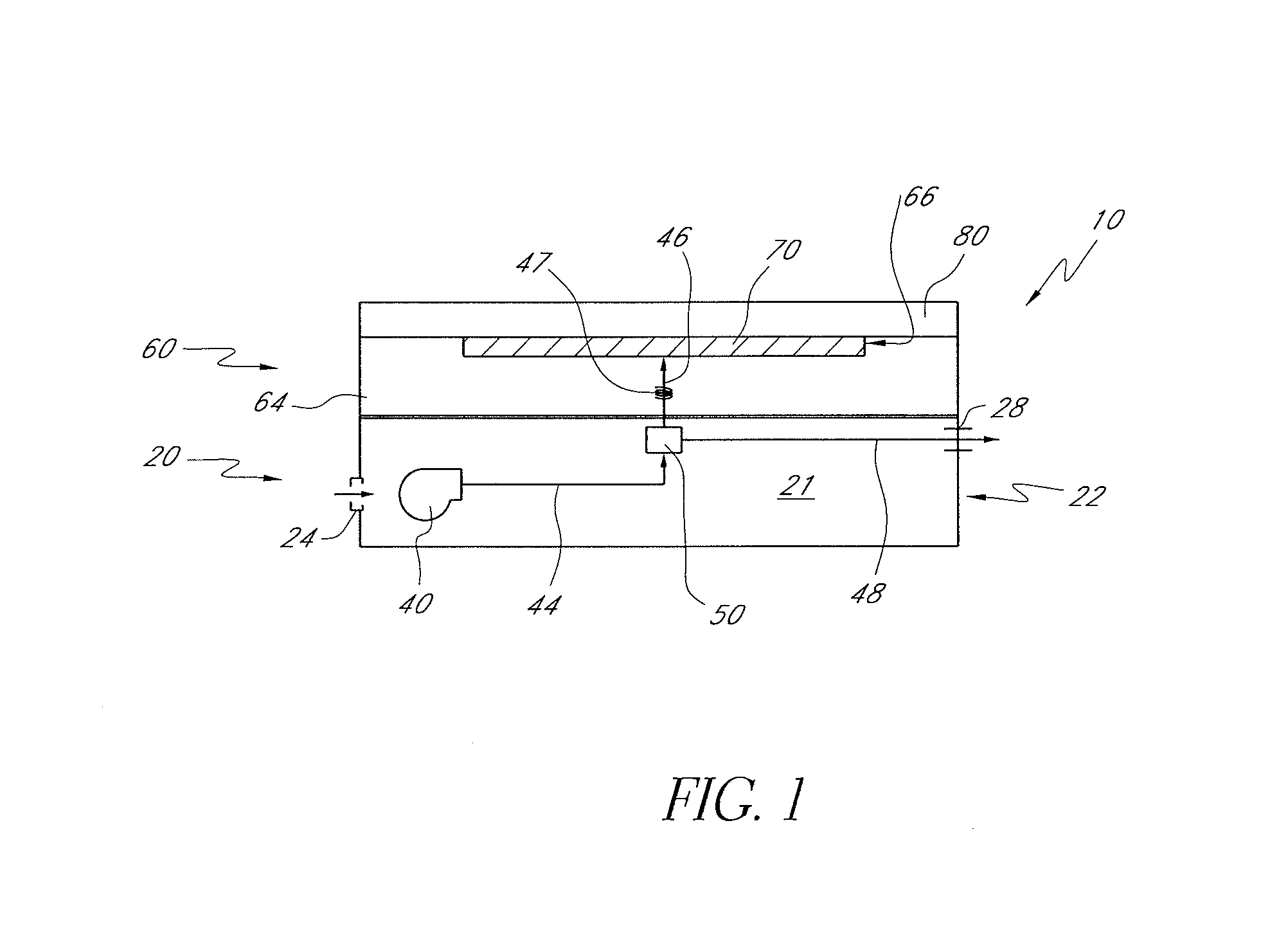

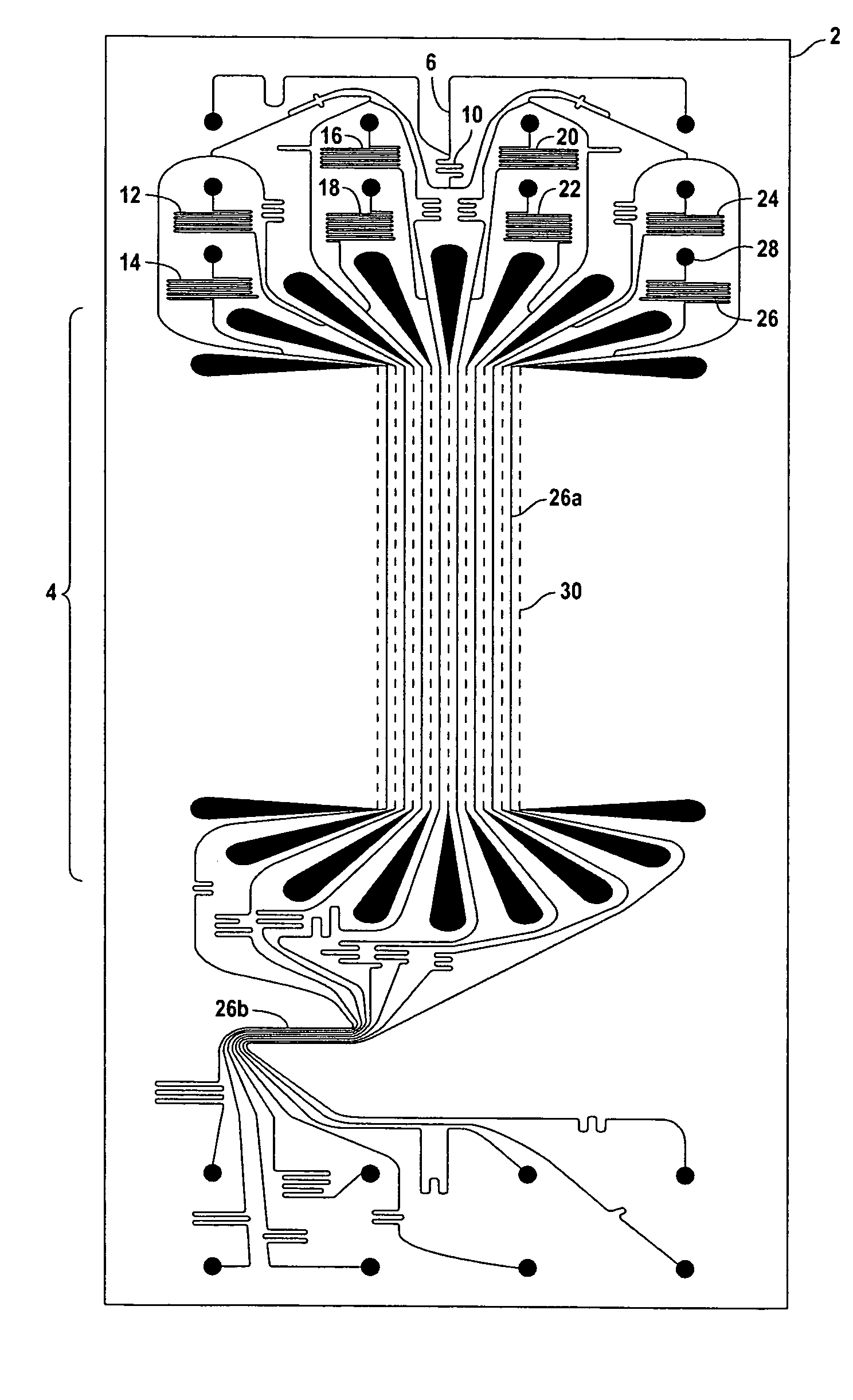

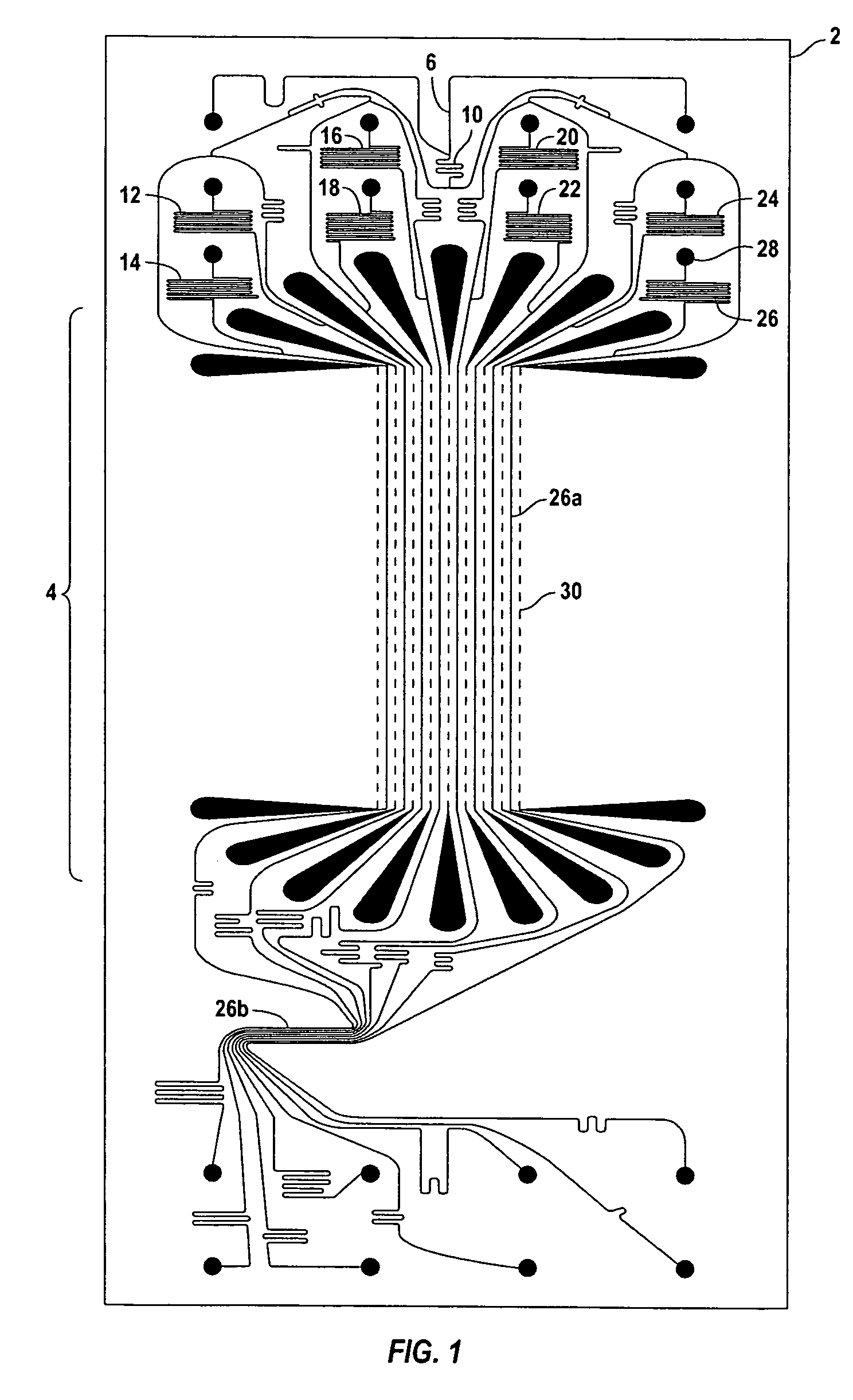

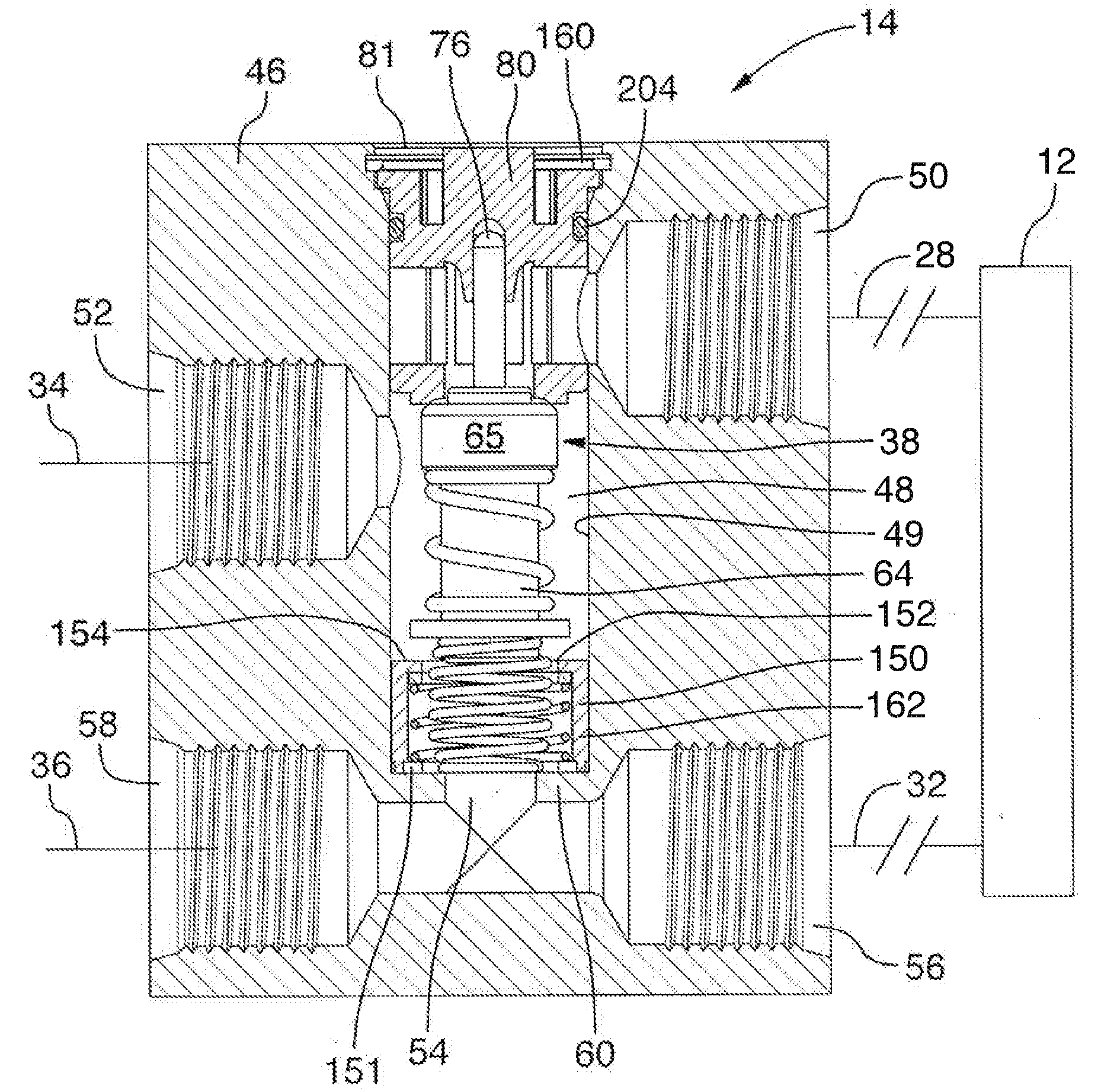

Method and apparatus for improved temperature control in microfluidic devices

InactiveUS7440684B2Easy to unifyImprove heat transfer performanceBioreactor/fermenter combinationsBiological substance pretreatmentsElectrical resistance and conductanceTemperature control

A microfluidic system and method for employing it to control fluid temperatures of fluids residing within microchannels of a microfluidic device. The microfluidic device is provided with a top layer and a bottom layer and microchannels configured therebetween. Temperature of the fluid within the microchannels is controlled in various ways including the use of electrical resistive heating elements and by providing zones located in contact with the top and bottom layers of the microfluidic device for circulating heat transfer of fluid therein.

Owner:CAPLIPER LIFE SCI INC

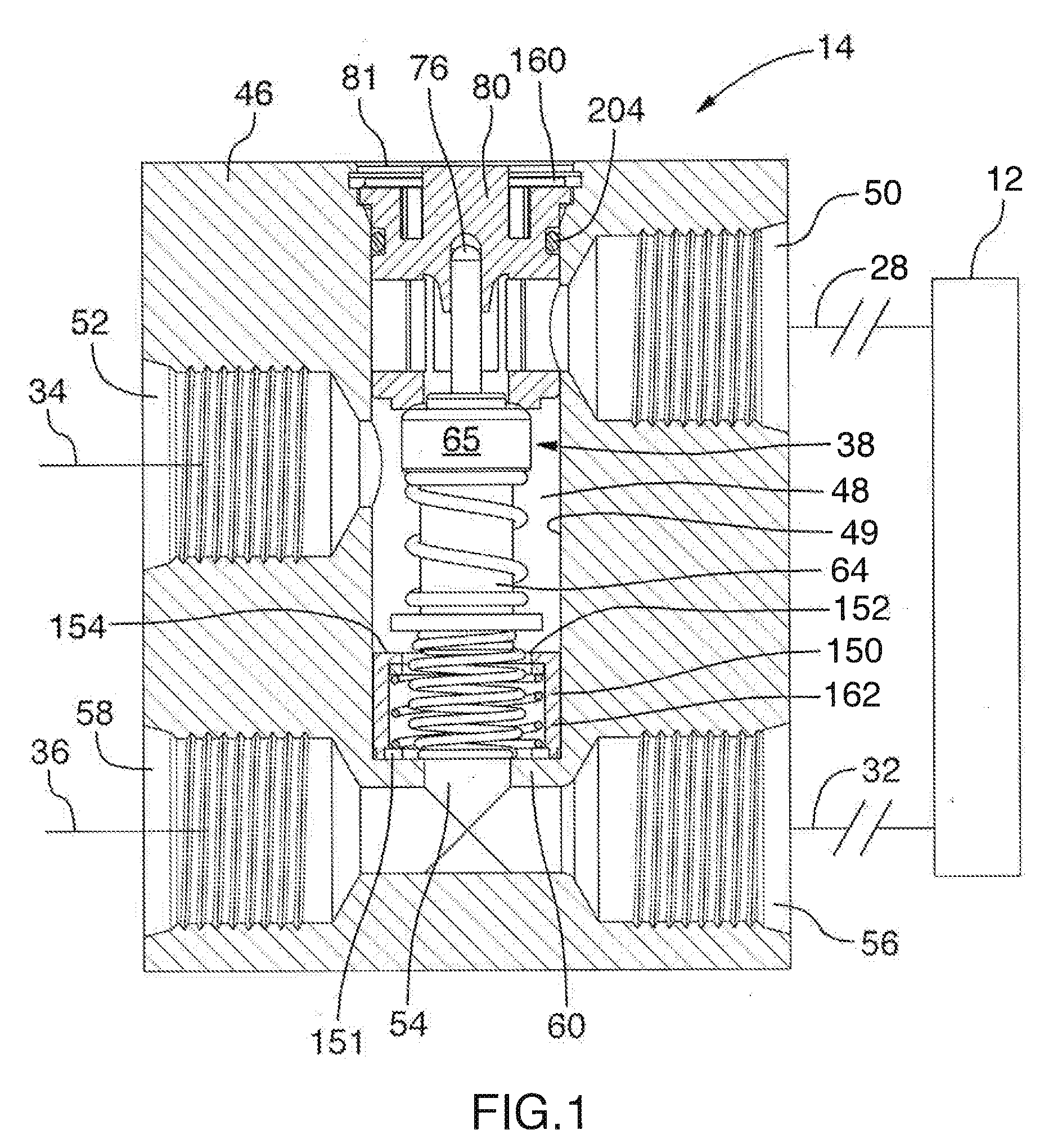

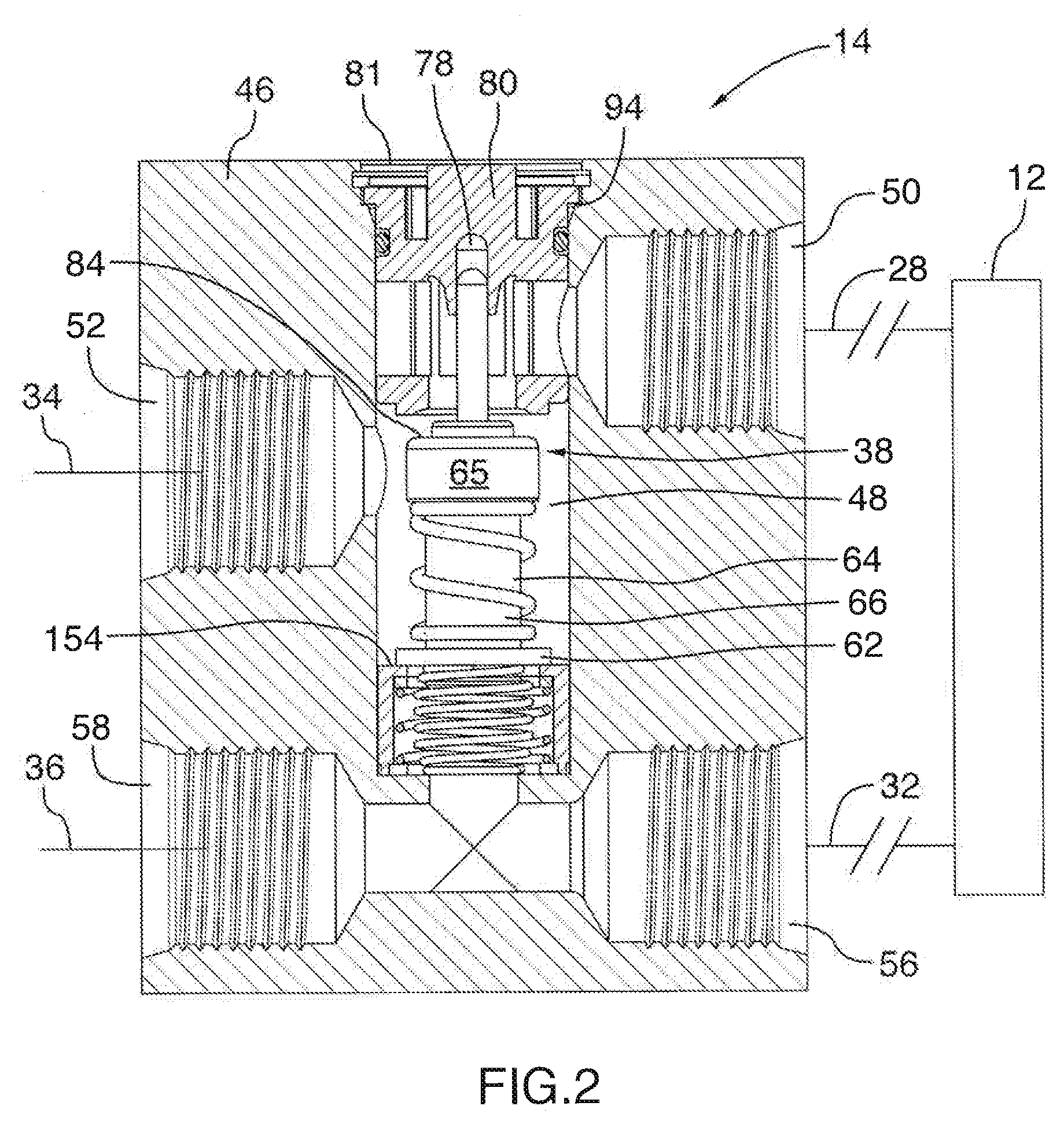

Thermal bypass valve with pressure relief capability

ActiveUS20100126594A1Relieve excessive stressIncrease dependenceTemperature control without auxillary powerOperating means/releasing devices for valvesEngineeringActuator

A by-pass valve for a heat exchanger circuit that includes a cooler has a chamber and ports for flow of fluid into and out of this chamber. A thermally sensitive actuator is mounted in the chamber and can extend or retract in dependence on its body temperature as influenced by temperature of the fluid. A by-pass valve seat is arranged in a valve housing along with a by-pass valve member movable by the actuator into or out of engagement with the seat. A relief valve is mounted in the chamber and has a relief valve member movable between closed and open positions in order to close or open pressure relief ports. This relief valve member is biased towards the closed position. Excessive pressure build up in an end section of the chamber causes the relief valve member to move to its open position.

Owner:DANA CANADA CORP

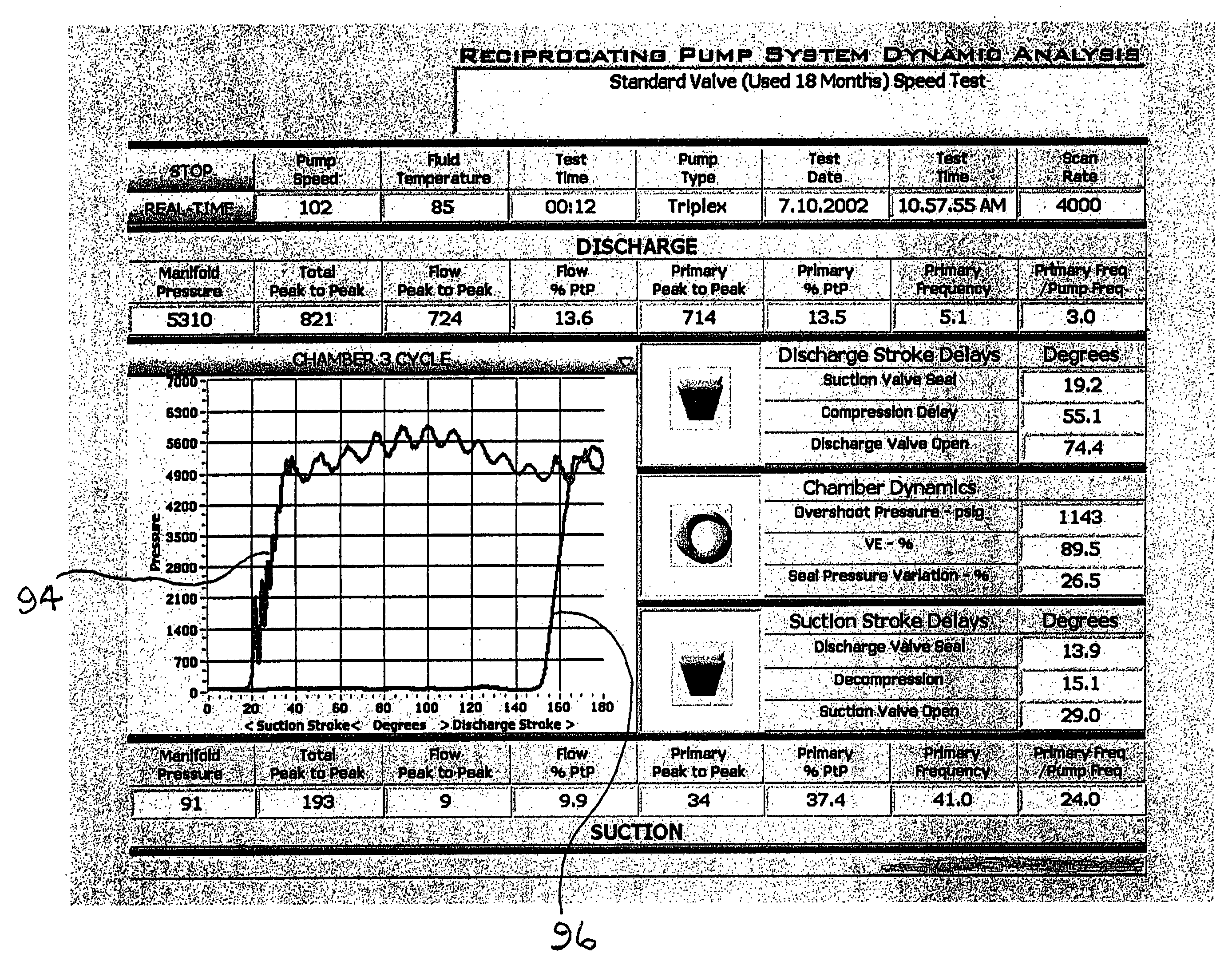

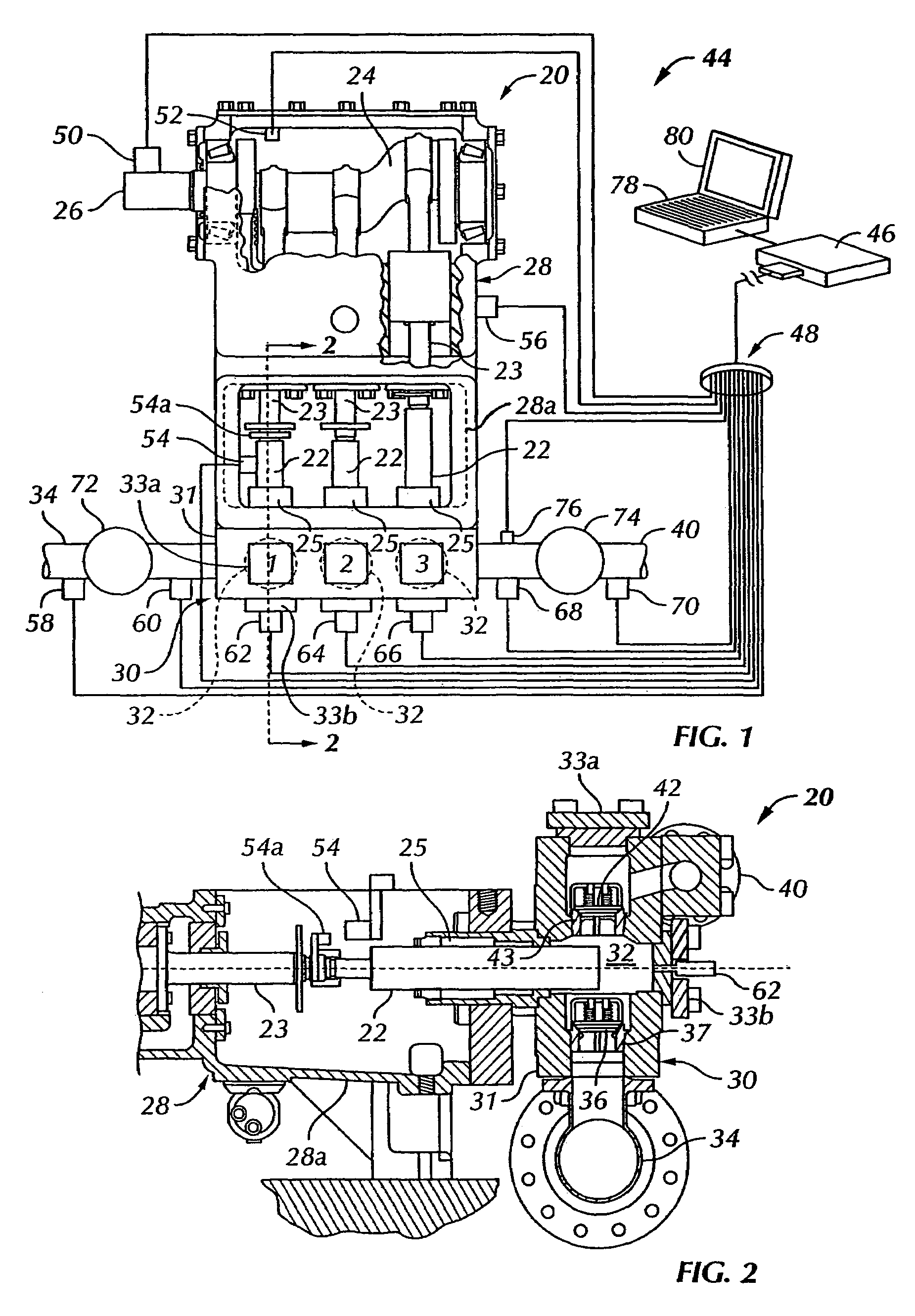

System and method for power pump performance monitoring and analysis

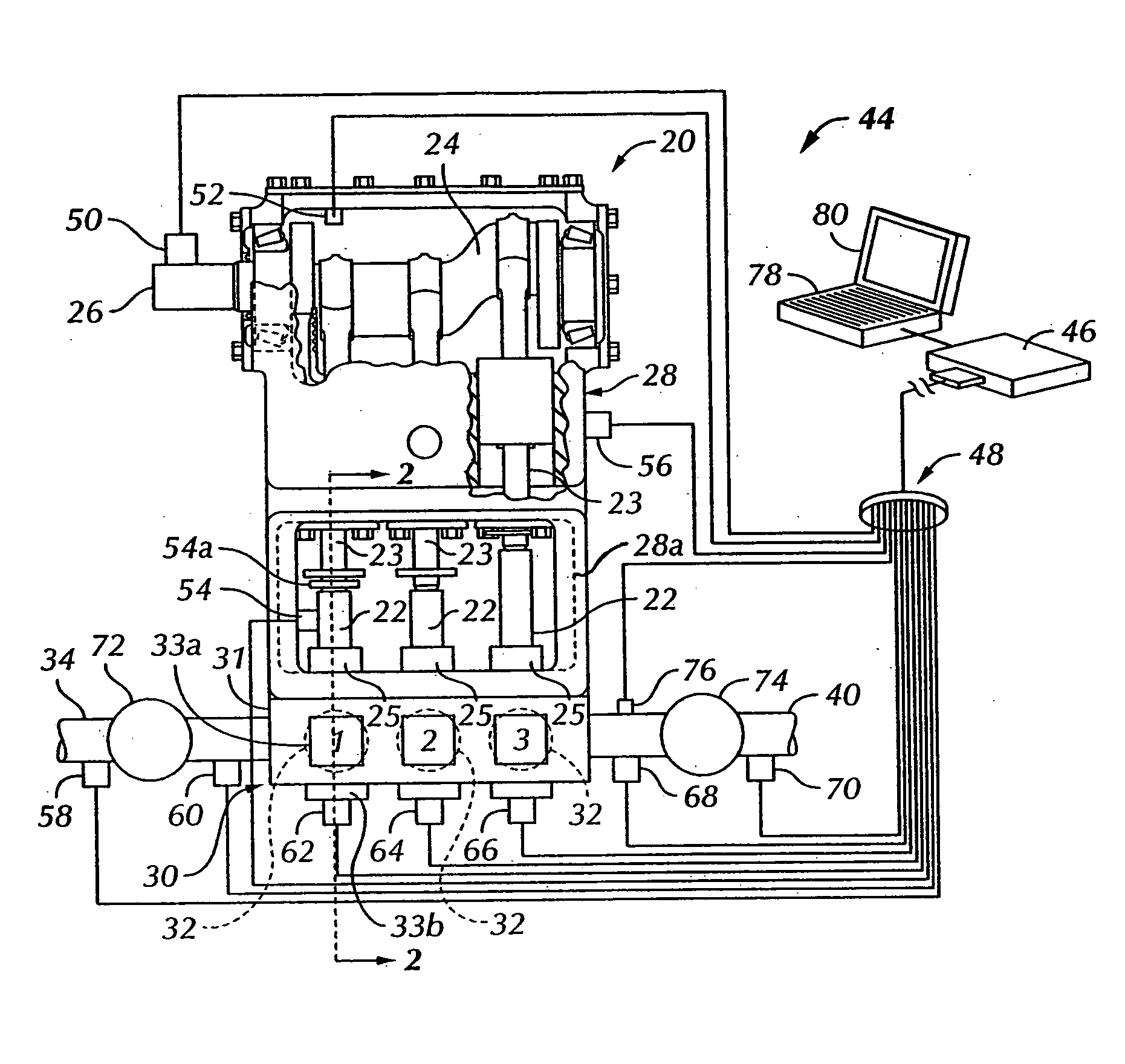

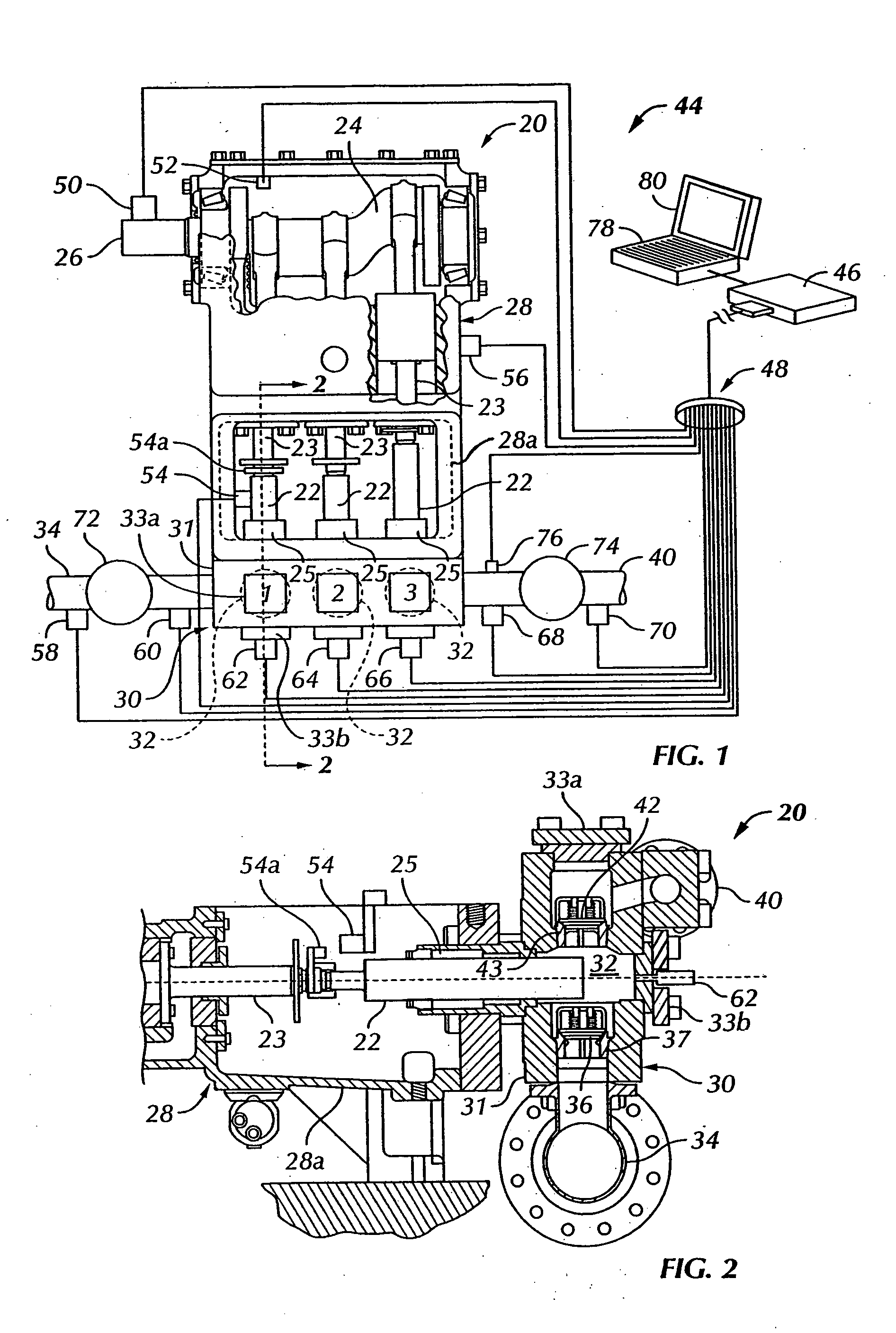

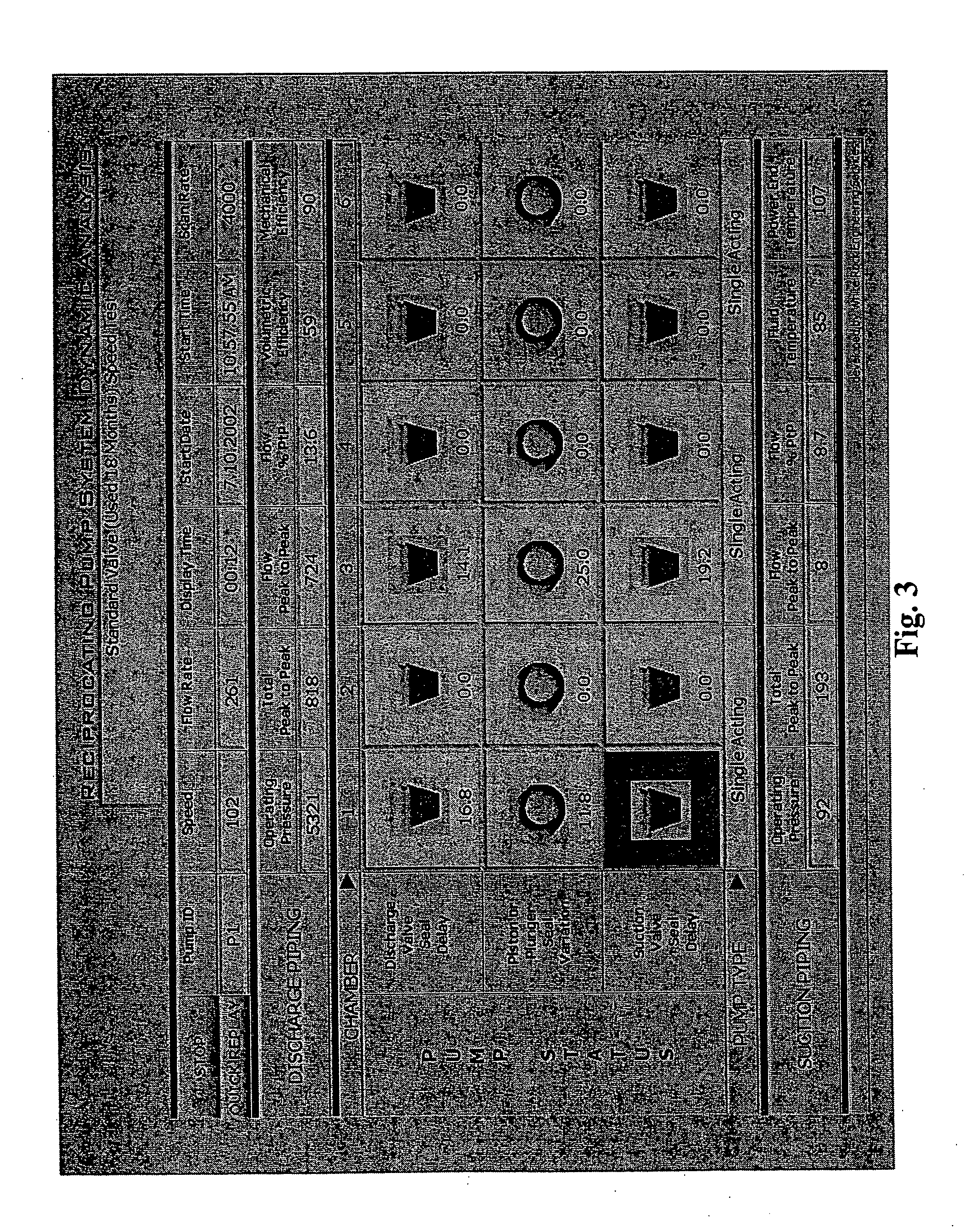

InactiveUS20050180868A1Easy to useEasy to provideTime indicationProgram control using stored programsDisplay deviceEngineering

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

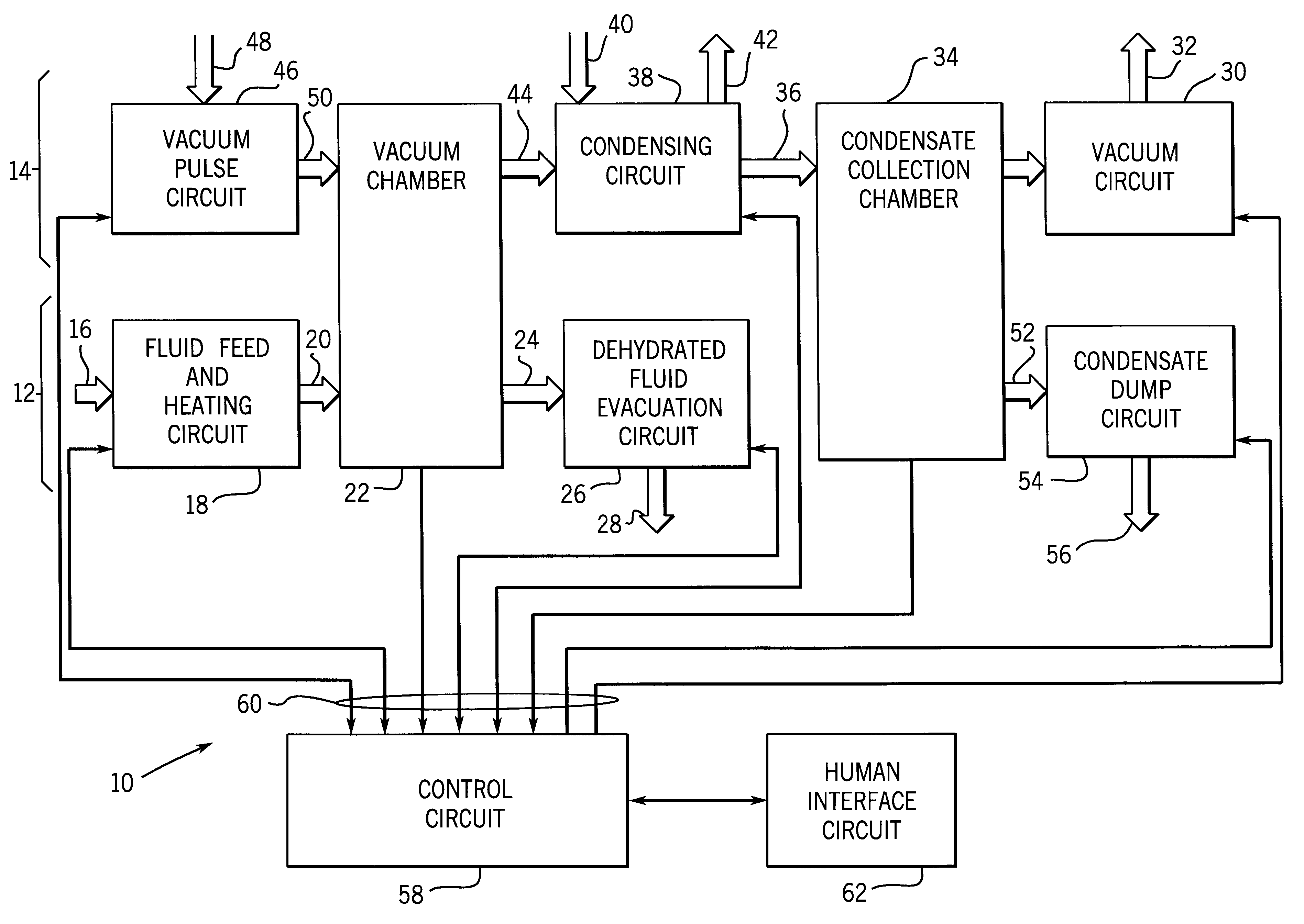

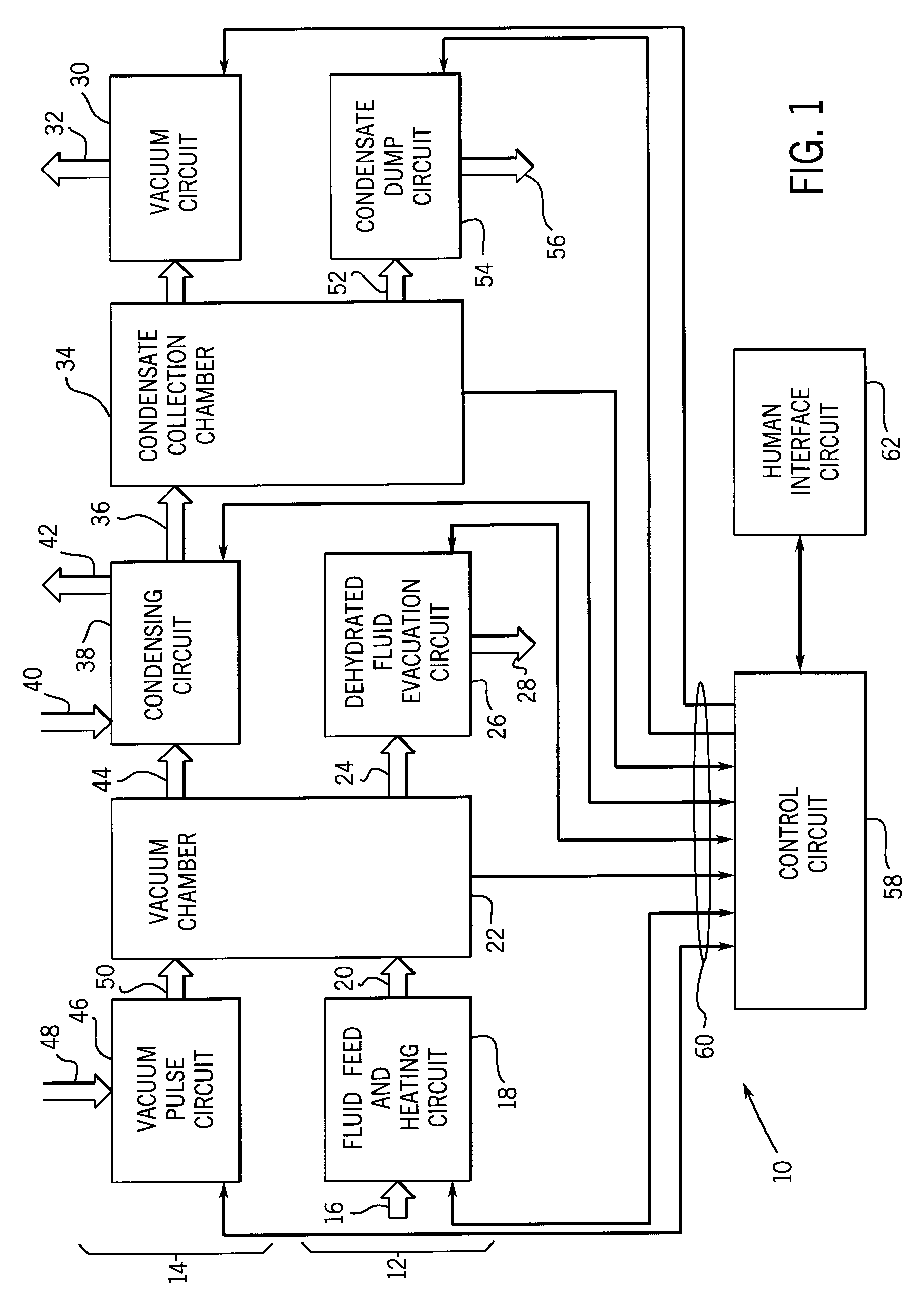

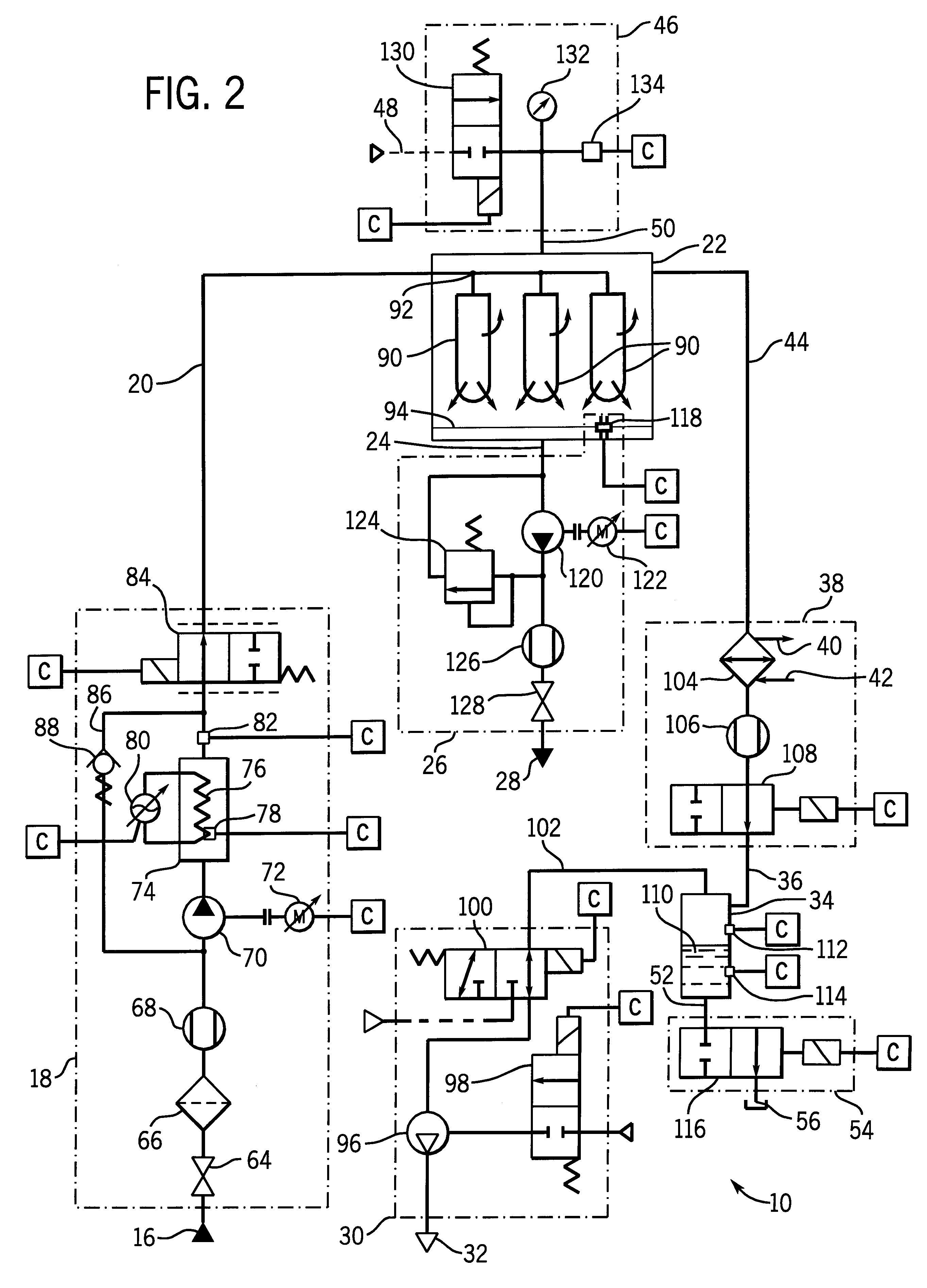

Apparatus for dehydrating oil

InactiveUS6224716B1Distillation regulation/controlEvaporation with vapour compressionVacuum pressureClosed loop

A system for dehydrating lubricating and hydraulic fluids includes a heating circuit and circuitry for creating a vacuum. The heating circuitry introduces a stream of heated fluid into a vacuum chamber in which a partial vacuum is drawn by the vacuum circuit. Aqueous components of the fluid stream are flashed in the vacuum chamber by virtue of the elevated temperature and reduced pressure. Dehydrated fluid is then collected and evacuated from the vacuum chamber. Vapor from the vacuum chamber, including the aqueous components of the fluid stream are collected, condensed and separately evacuated. The heating circuit limits surface temperature of a heating element in a closed-loop manner to avoid degradation of the fluid. The fluid stream is introduced into the vacuum chamber or is recirculated through the heating circuit to maintain a desired level of fluid temperature in a closed-loop manner. The system includes circuits for evacuating dehydrated fluid in a closed-loop manner and for automatically discharging condensate. The technique avoids undesirable foaming of dehydrated fluid within the vacuum chamber. A vacuum pulsing circuit is provided for periodically pulsing vacuum pressure within the vacuum chamber to aid in flashing aqueous components from the heated fluid stream.

Owner:OILQUIP

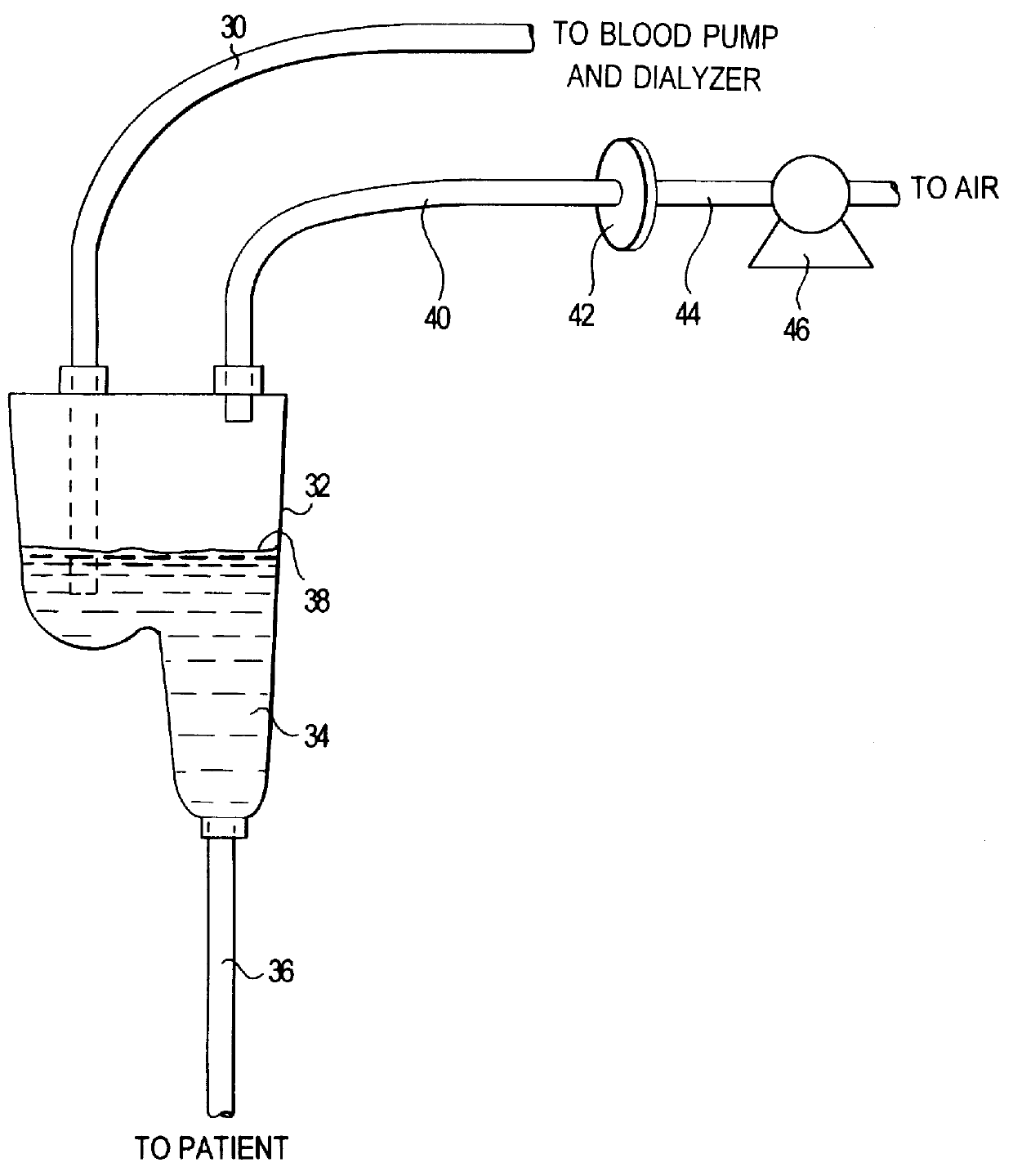

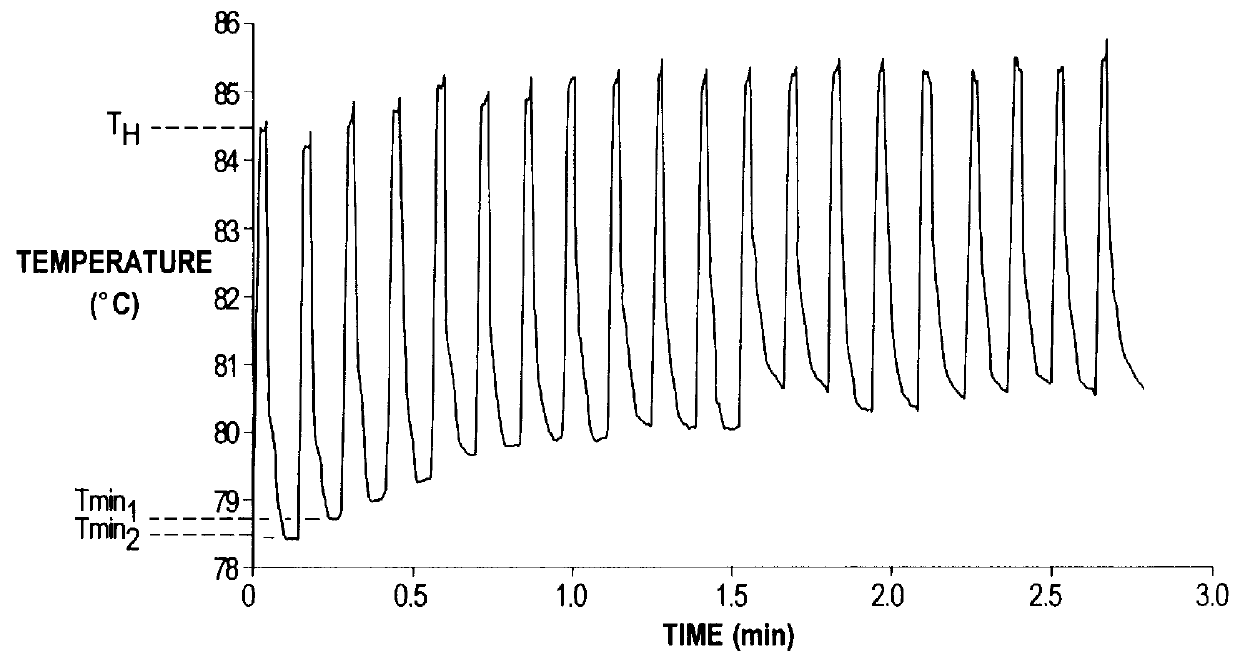

Disinfection of dead-ended lines in medical instruments

A method of disinfection of a dead-ended fluid line in a medical instrument such as a dialysis machine is described. The method comprises introducing a heated fluid into the fluid line, allowing the fluid to remain in the line for an experimentally determined optimal dwell period, removing the fluid from the fluid line, and then repeating the cycle for a time period sufficient to achieve a disinfection of the fluid line. The optimum dwell period and frequency for exchanging the heated fluid is determined so that the heated fluid is left resident in the line to exert a cidal effect but not so long that the it cools to the point of being ineffective, nor changed so frequently that that the time spent with no hot water resident in the line begins to detract (e.g., unduly prolong) the disinfection process. A representative cycle is introducing water at a temperature of about 85 degrees C, allowing it to reside in the fluid line for about 10 seconds, withdrawing the water, and then reintroducing water at 85 degrees C. The process continues for 1-2 hours. Variation from the representative cycle will be expected based on parameters such as the degree to which disinfection is to be achieved, the length and diameter of the fluid line, the temperature of the fluid, the ambient temperature, the presence of elements in the fluid line that contribute to heat loss, the material used for fluid line tubing, and whether the fluid comprises water or a disinfection solution such as a dilute citric acid solution. The optimum dwell period and frequency of the cycles can be determined experimentally from the teachings described herein.

Owner:BAXTER INT INC +2

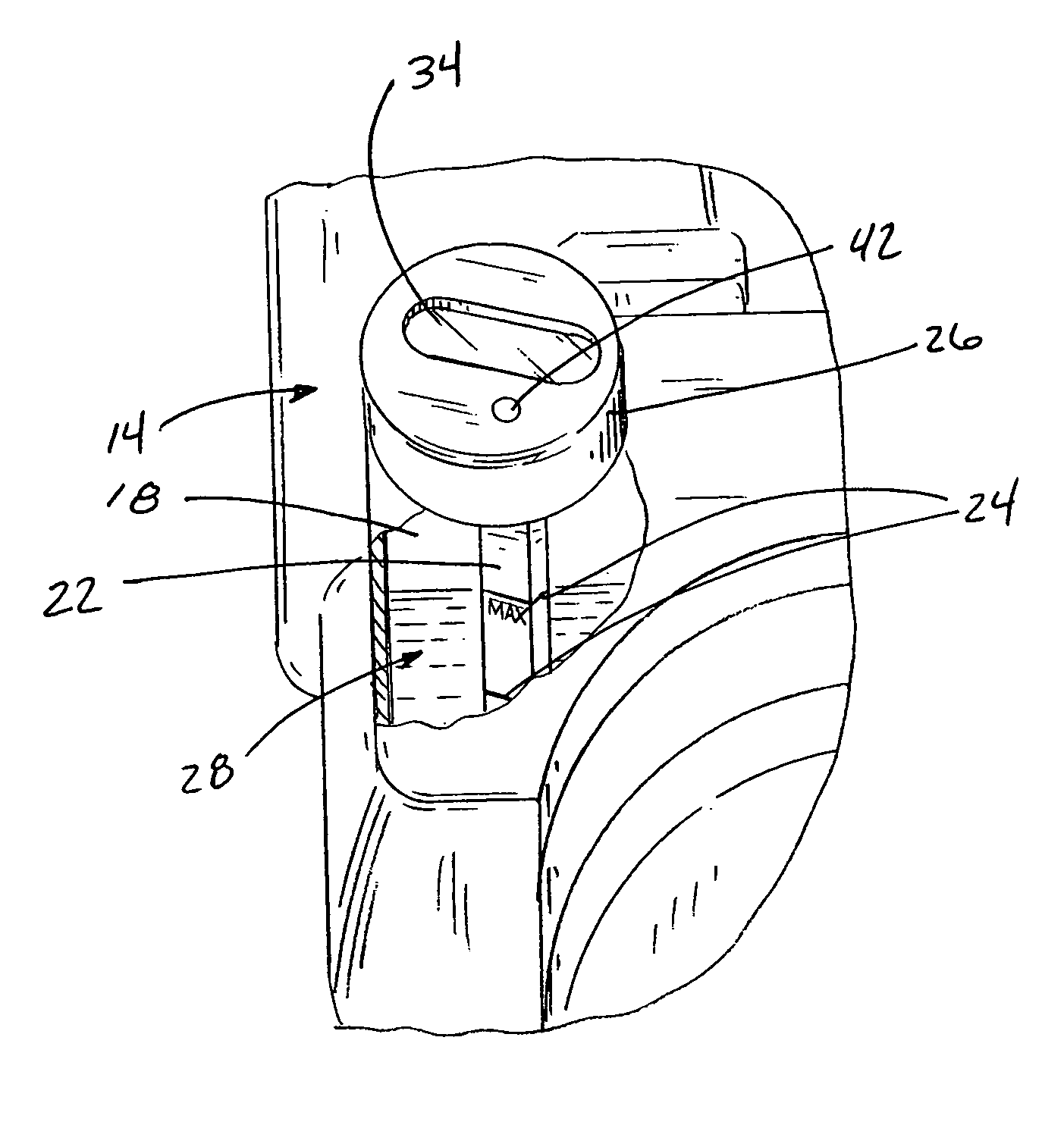

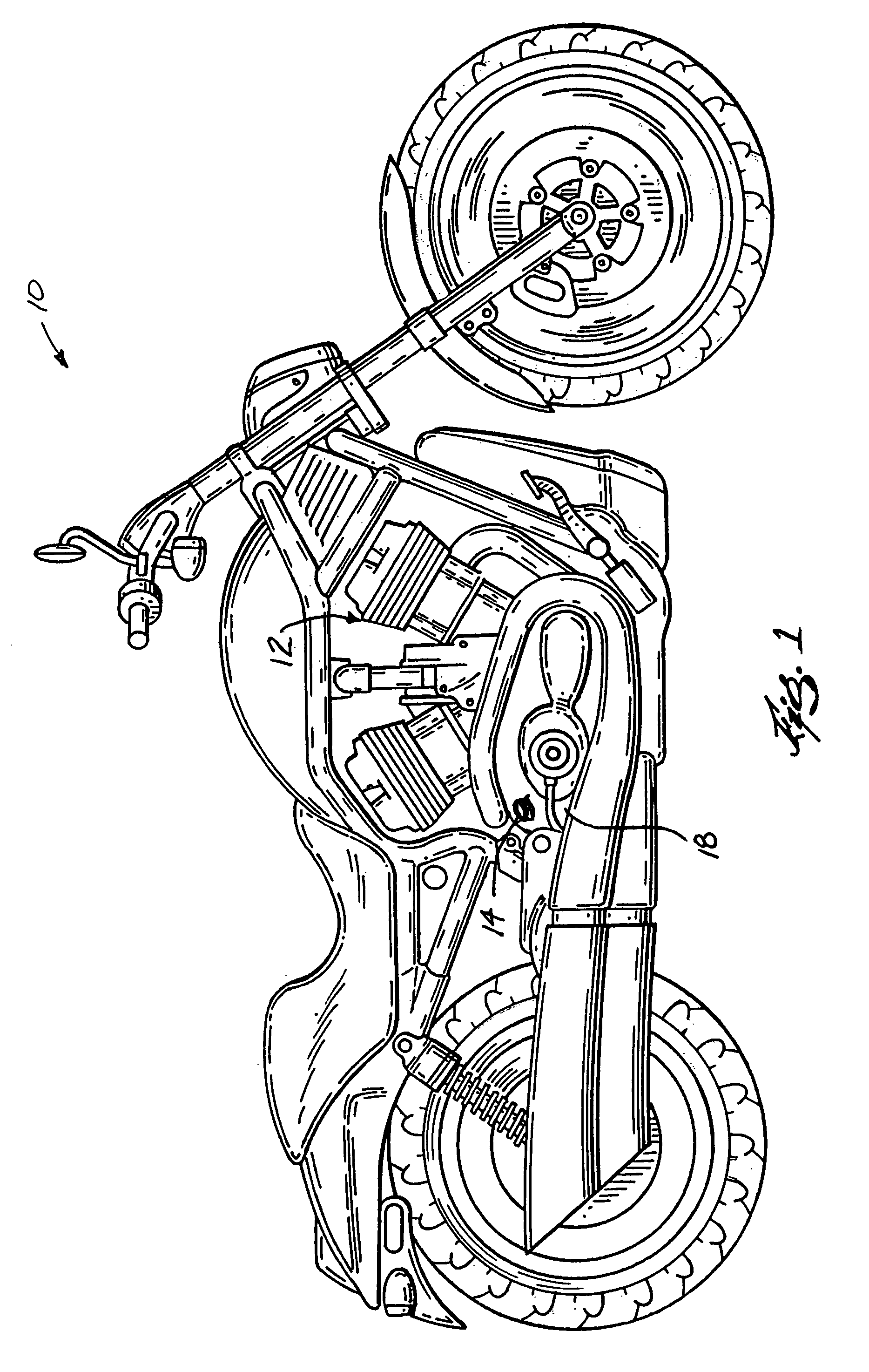

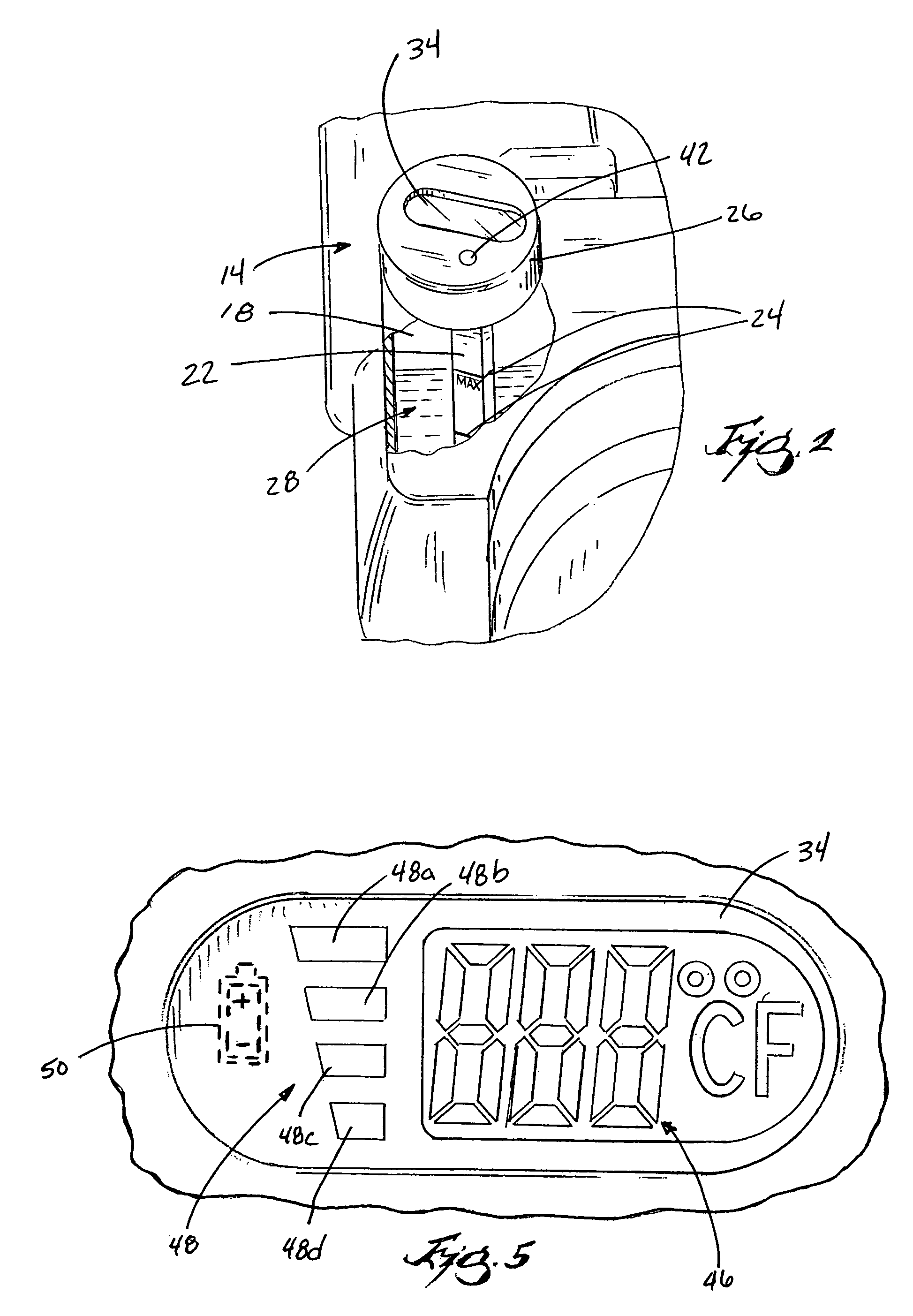

Apparatus for indicating oil temperature and oil level within an oil reservoir

Owner:HARLEY DAVIDSON MOTOR COMPANY GROUP INC

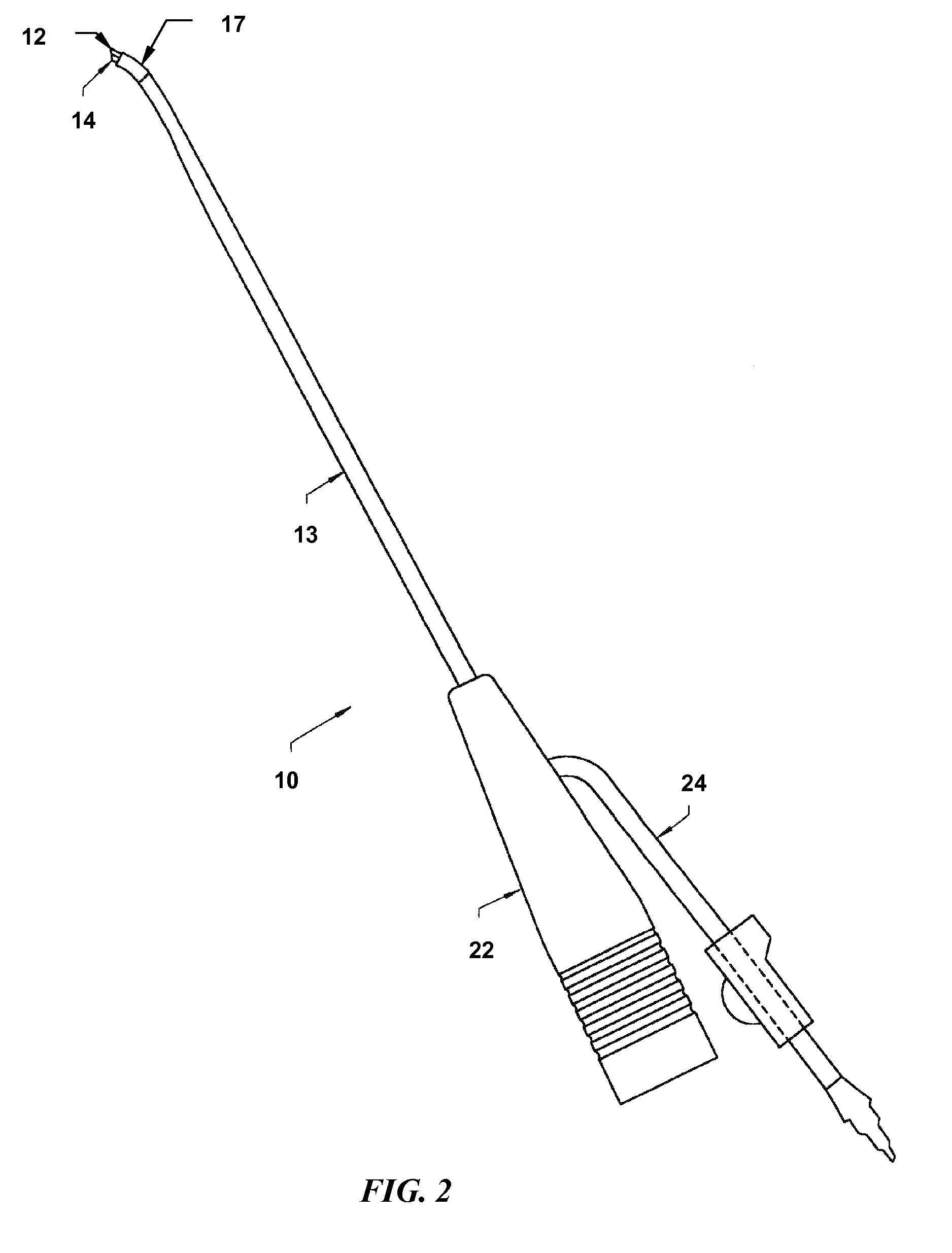

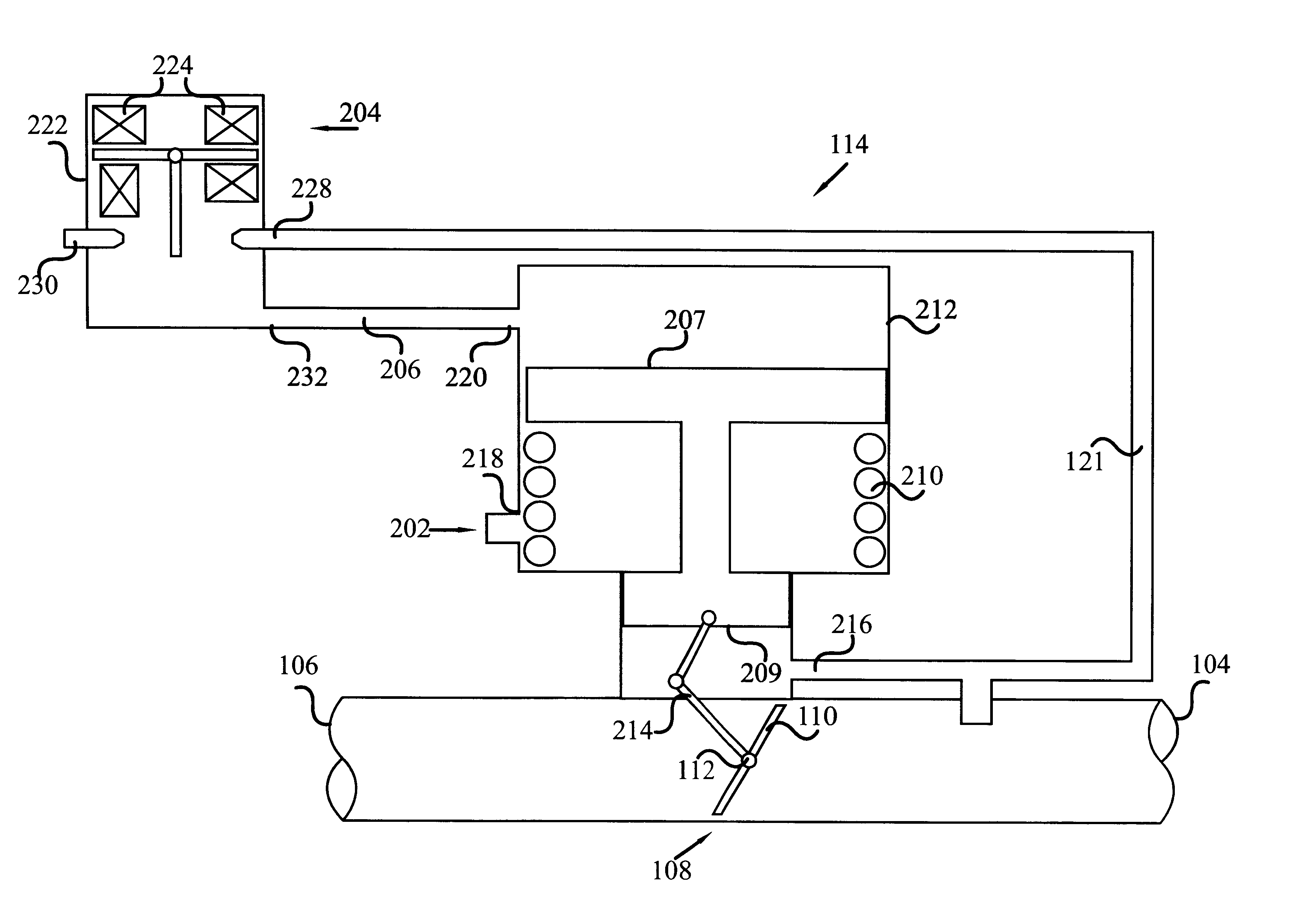

Systems and methods for limiting joint temperature

ActiveUS20100152724A1Reduce the risk of injuryReduce and eliminate temperature influenceDiagnostic recording/measuringSensorsTarsal JointFluid temperature

Joint temperature monitoring and control systems and methods are described herein in which the temperature of a fluid within a body or joint space is determined and / or monitored despite the energy generated during treatment by an ablation probe. One or more temperature sensors are positioned along the probe proximally of the electrode assembly and measure the temperature of an electrically conductive fluid without being overly influenced by the surgical effect occurring proximate the electrode assembly. The controller coupled to the probe can also be configured to set temperature limits and treatment times as well as moderating joint temperature by altering the electrically conductive fluid flow.

Owner:ARTHROCARE

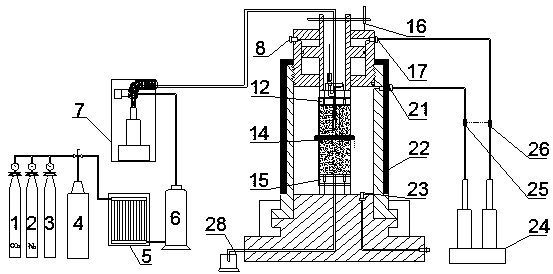

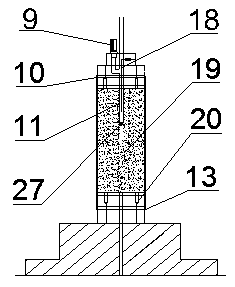

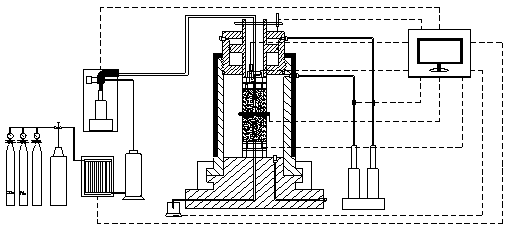

Coal petrography multiphase different fluid three-axis crushing test unit and method

ActiveCN105510142ARealize the effects of fracturingEnables research on the effects of fracturingMaterial strength using tensile/compressive forcesTest comparisonData acquisition

The invention discloses a coal petrography multiphase different fluid three-axis crushing test unit and method and belongs to the technical field of rock and rock mass mechanics and engineering. The unit is composed of a three-axis stress real-time loading system, a multiphase different fluid crushing system, a sealing system, a temperature control system, an acoustic emission monitoring system and a data acquisition system. Different fluid and multiphase crushing test comparison can be conducted on a coal petrography test piece, sensibility of parameters, such as fluid pressurization rate, fluid viscosity, fluid isothermal compressibility and fluid temperature, affecting crushing of the coal petrography test piece can be analyzed under multiple conditions, the change rule of the pressure and temperature of a crushing medium can be precisely recorded in a crushing experiment, acoustic emission events during test piece crushing can be recorded in real time through an assembled micro acoustic emission sensor, and multi-phase fluid seepage tests before and after crushing can also be conducted on the coal petrography test piece.

Owner:TAIYUAN UNIV OF TECH

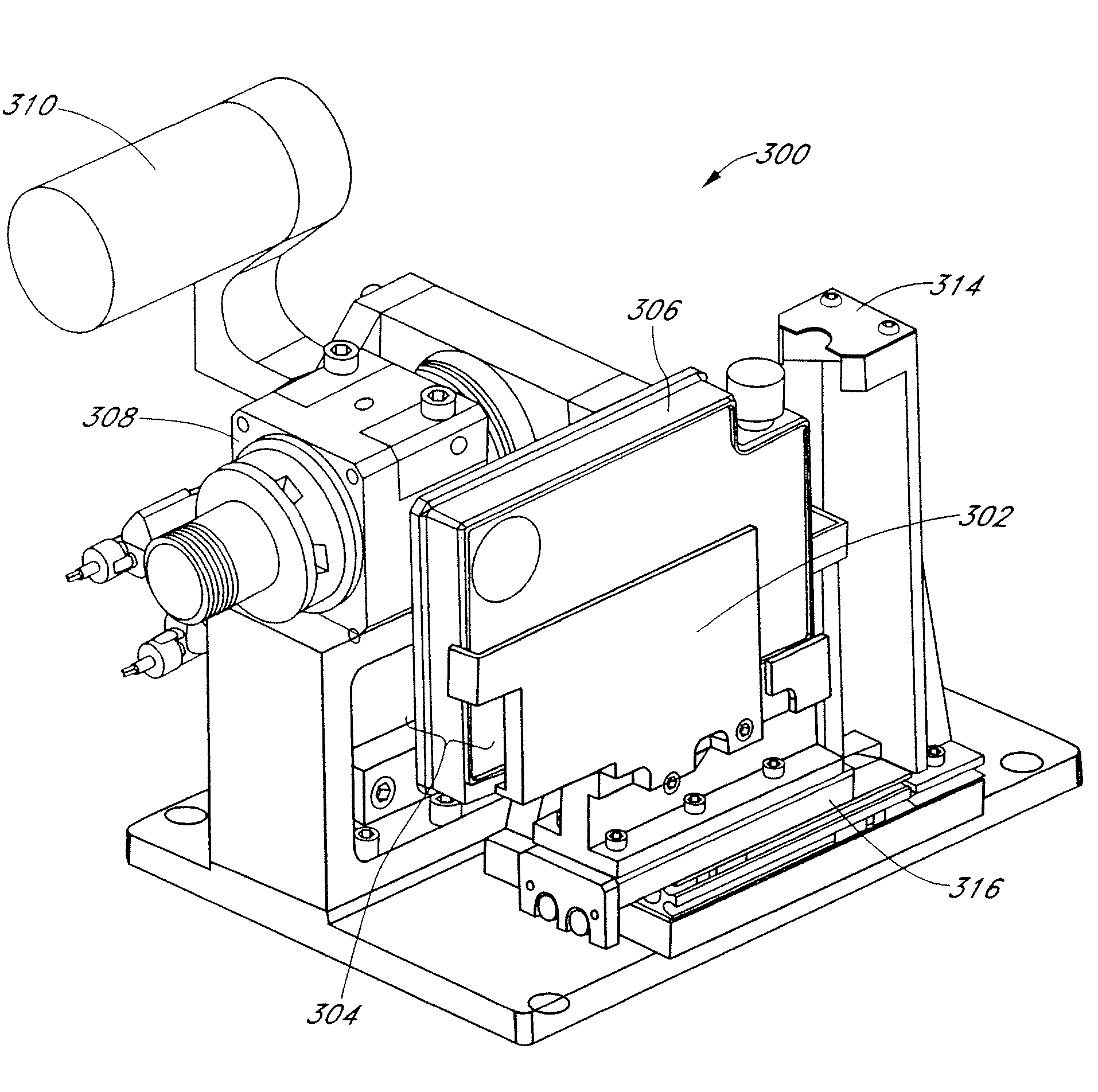

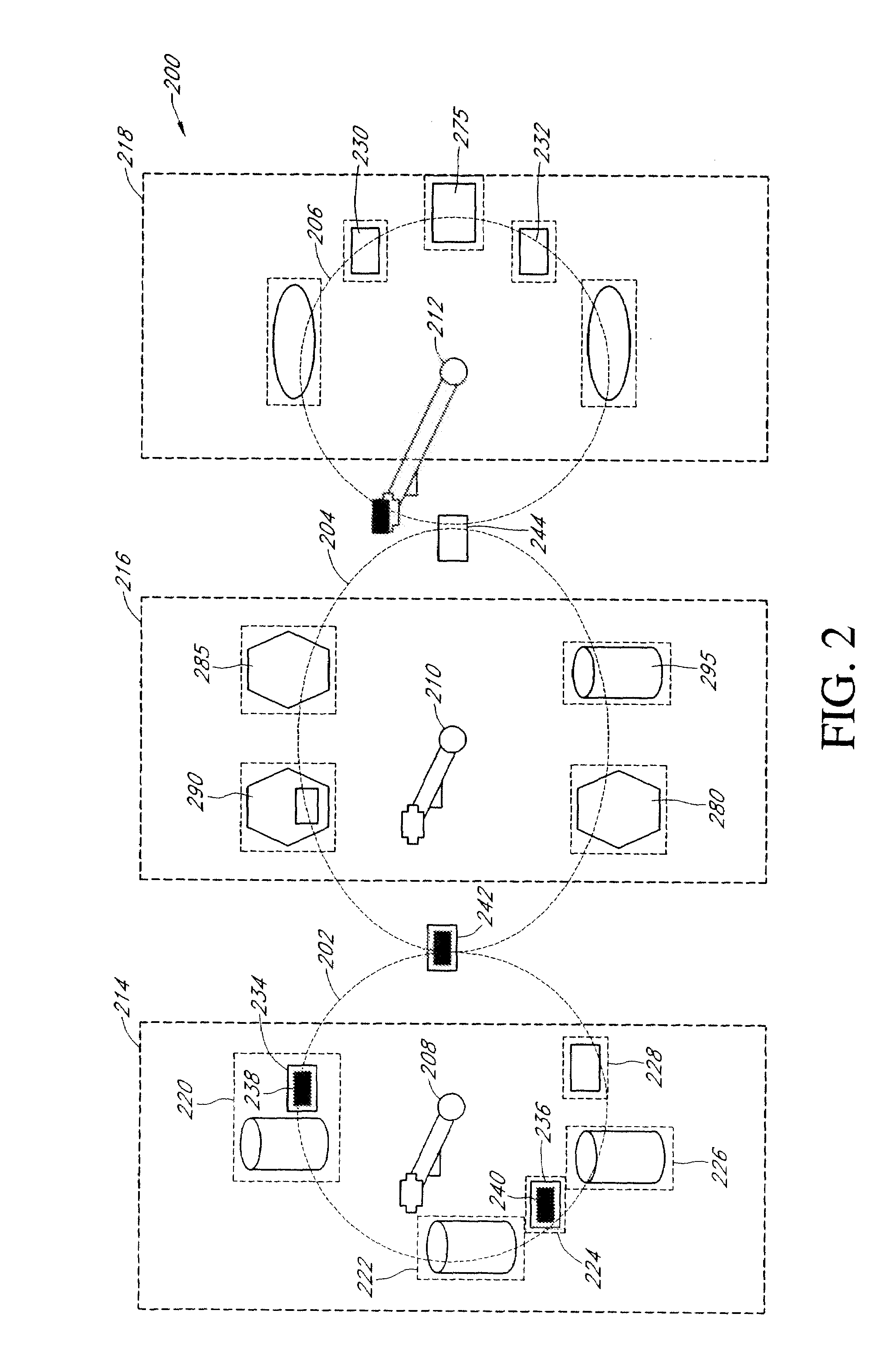

Compound profiling devices, systems, and related methods

InactiveUS20090042281A1Bioreactor/fermenter combinationsSequential/parallel process reactionsEngineeringCell separation

Owner:IRM

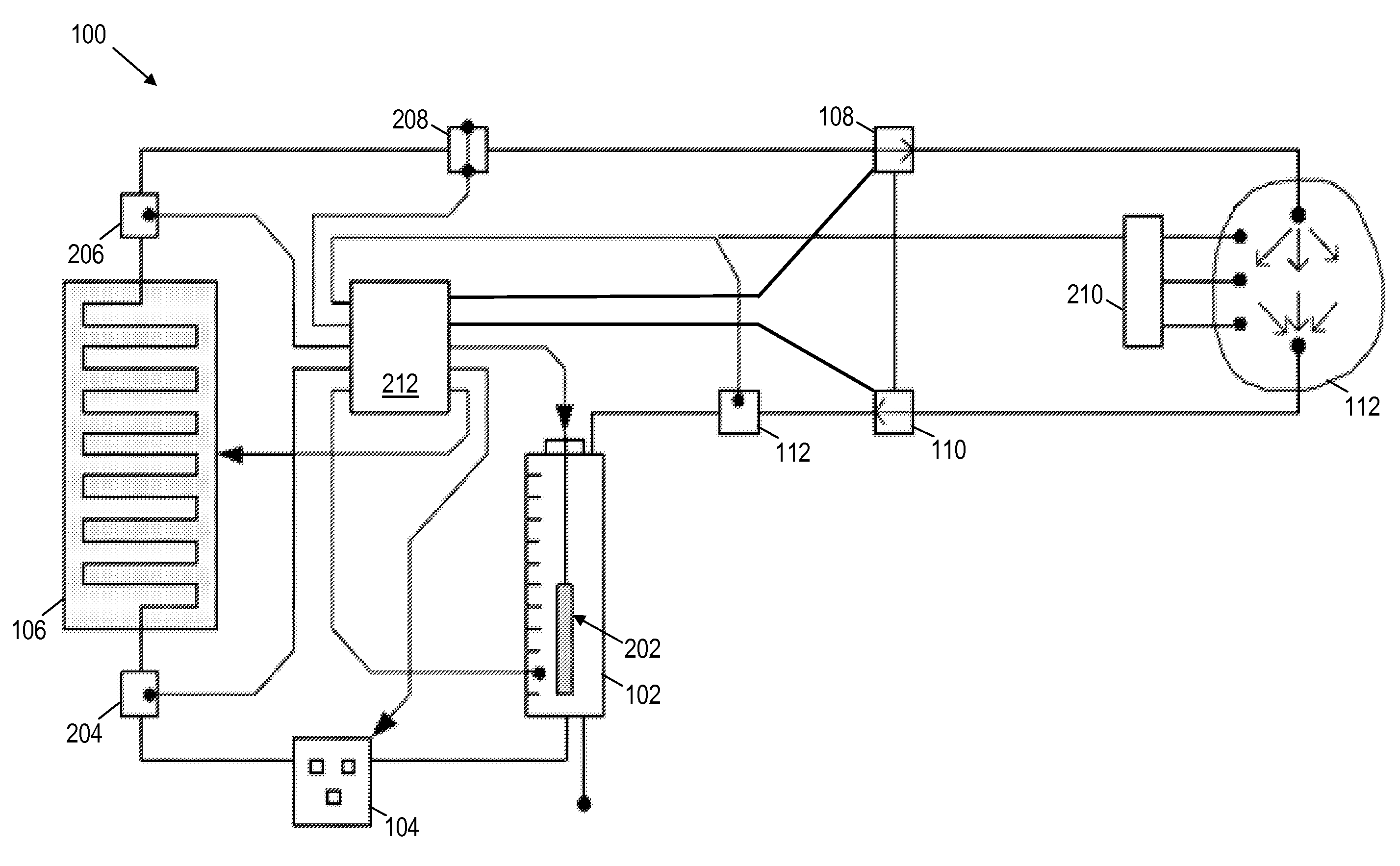

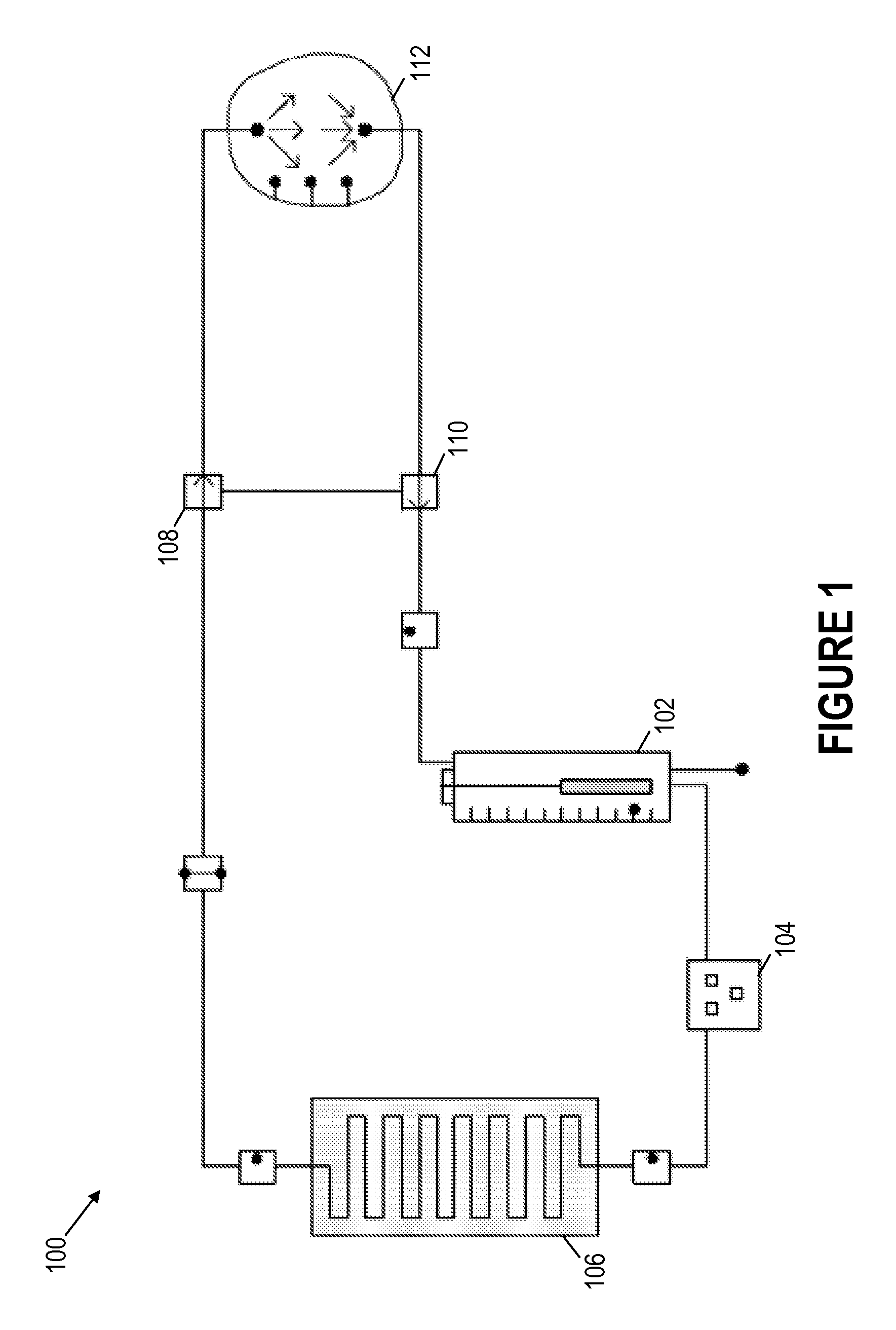

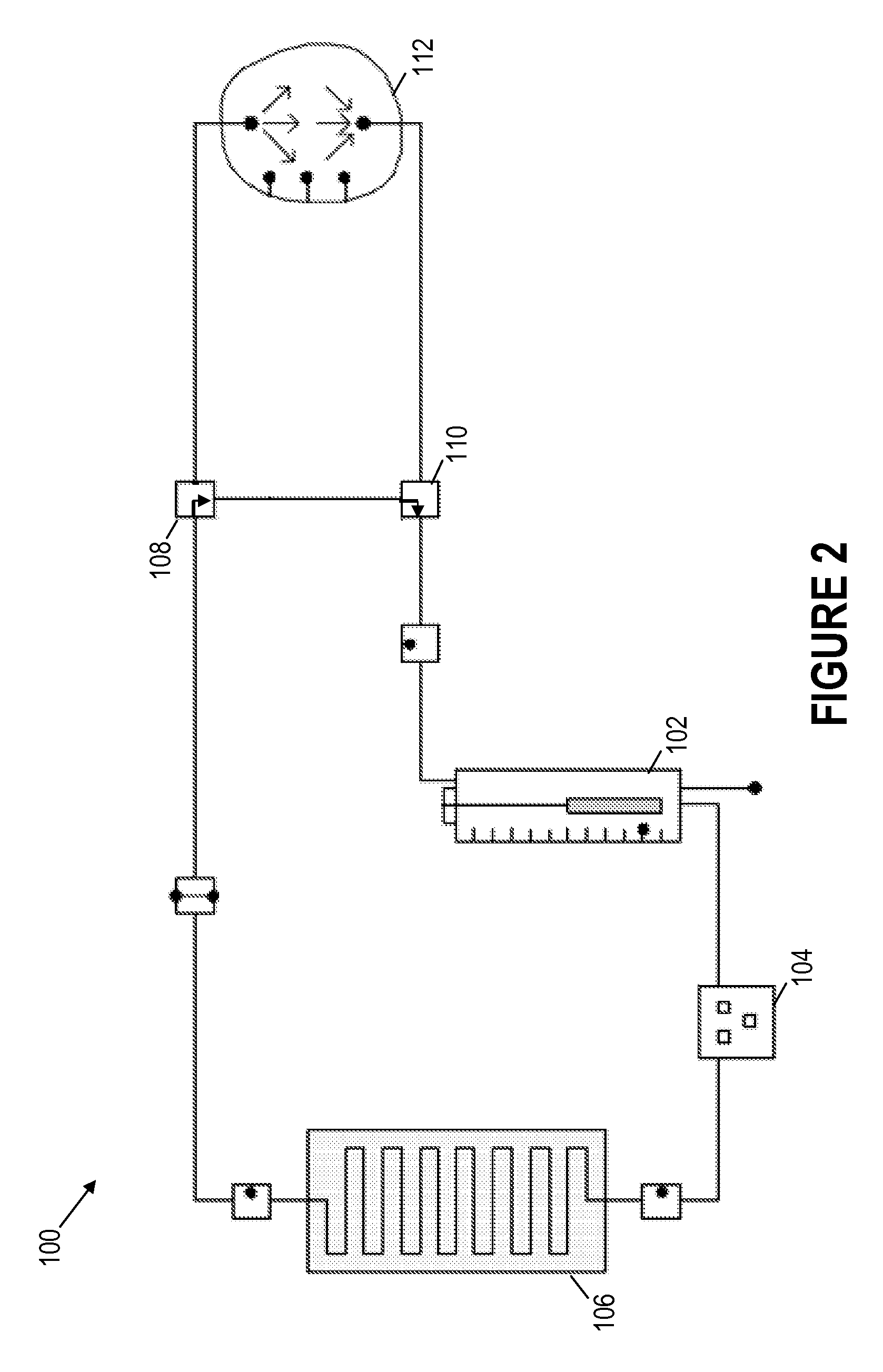

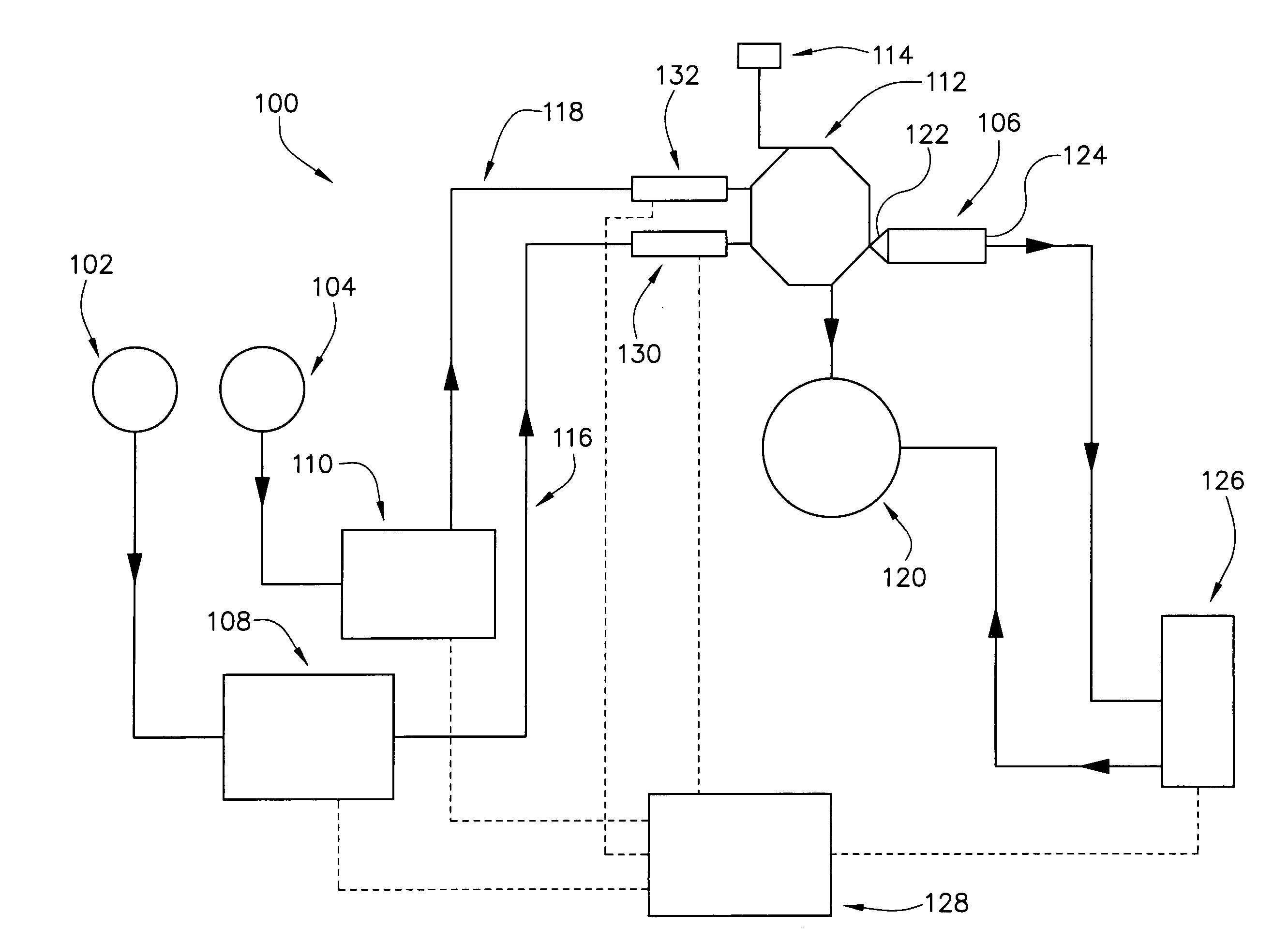

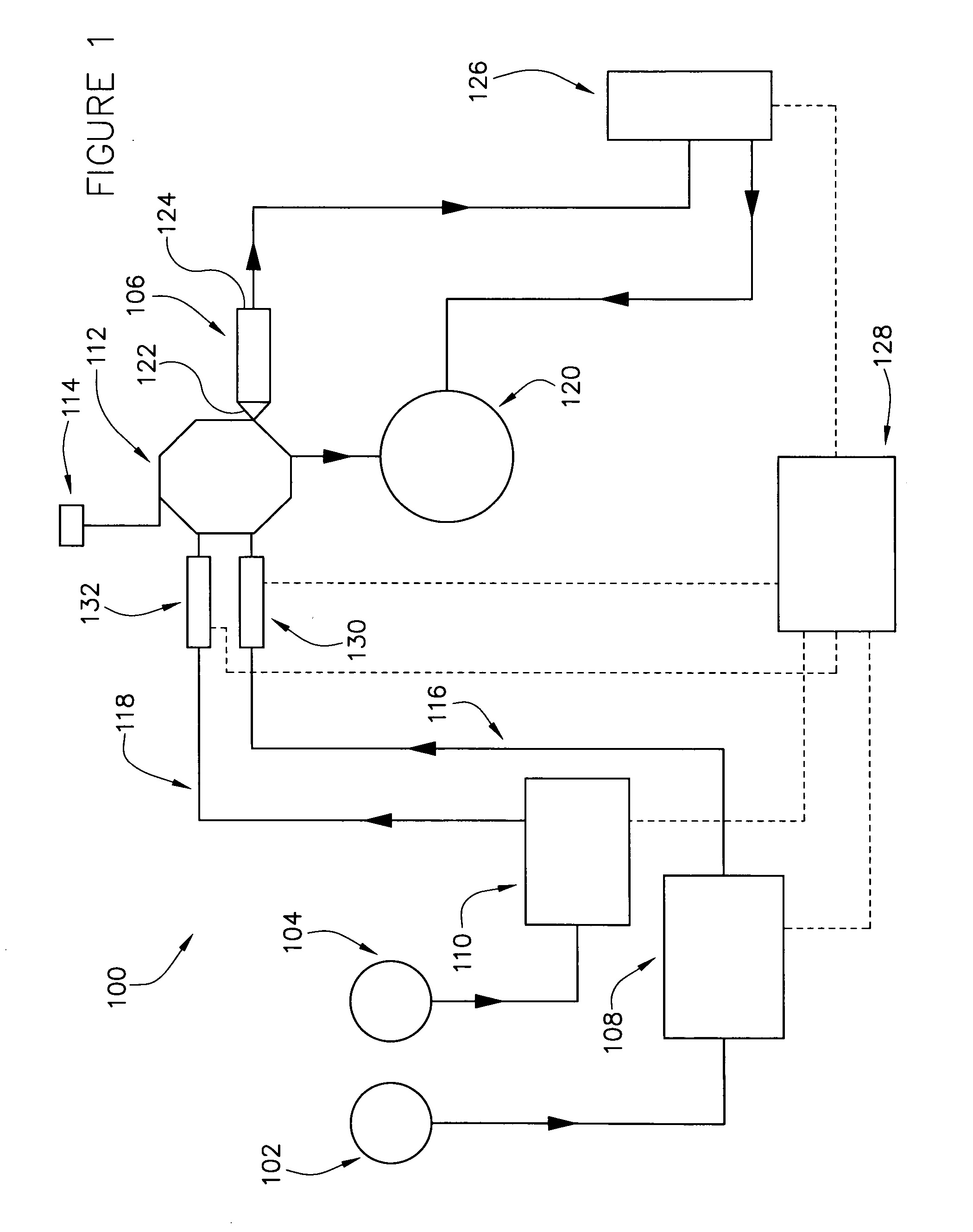

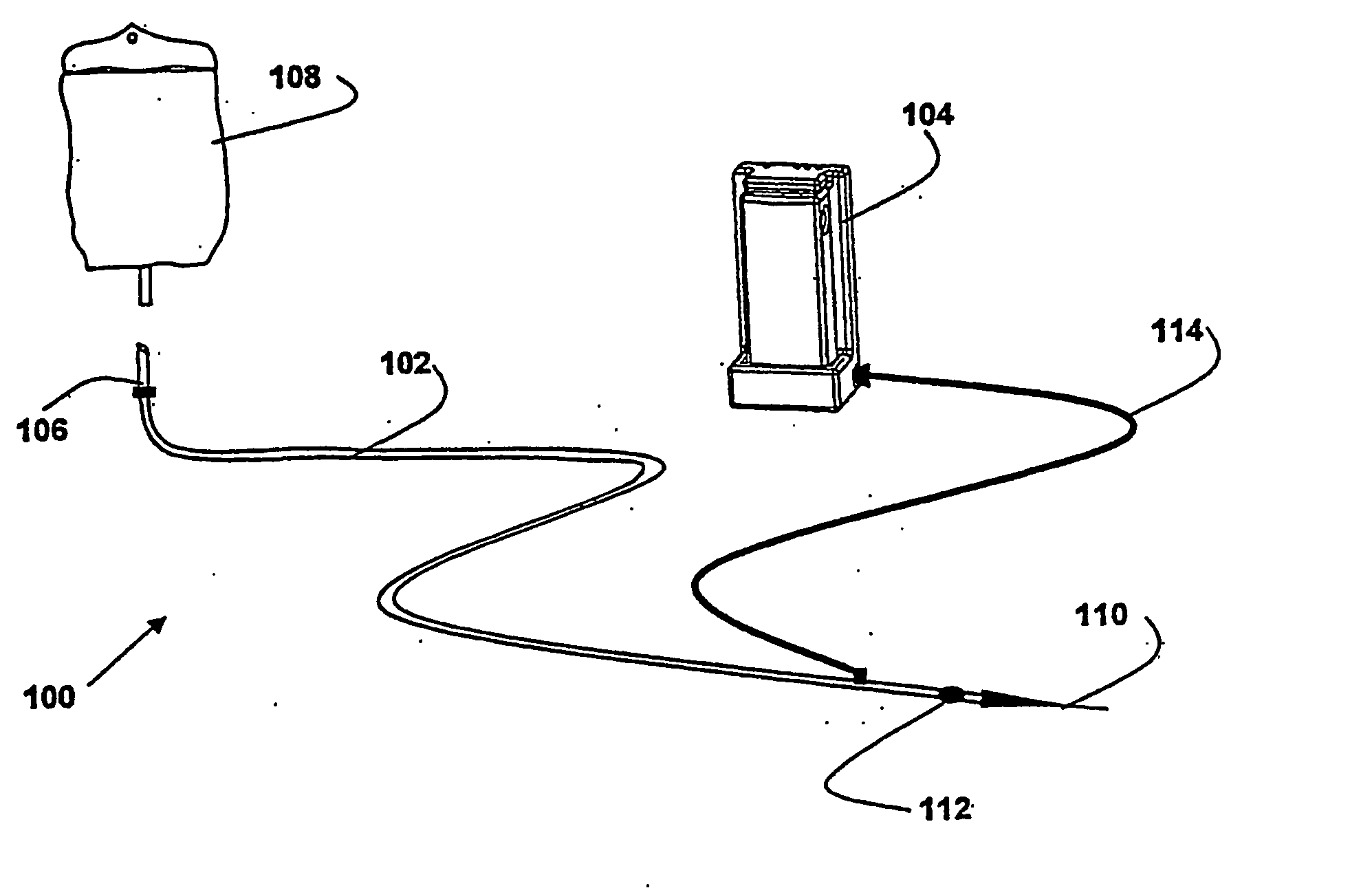

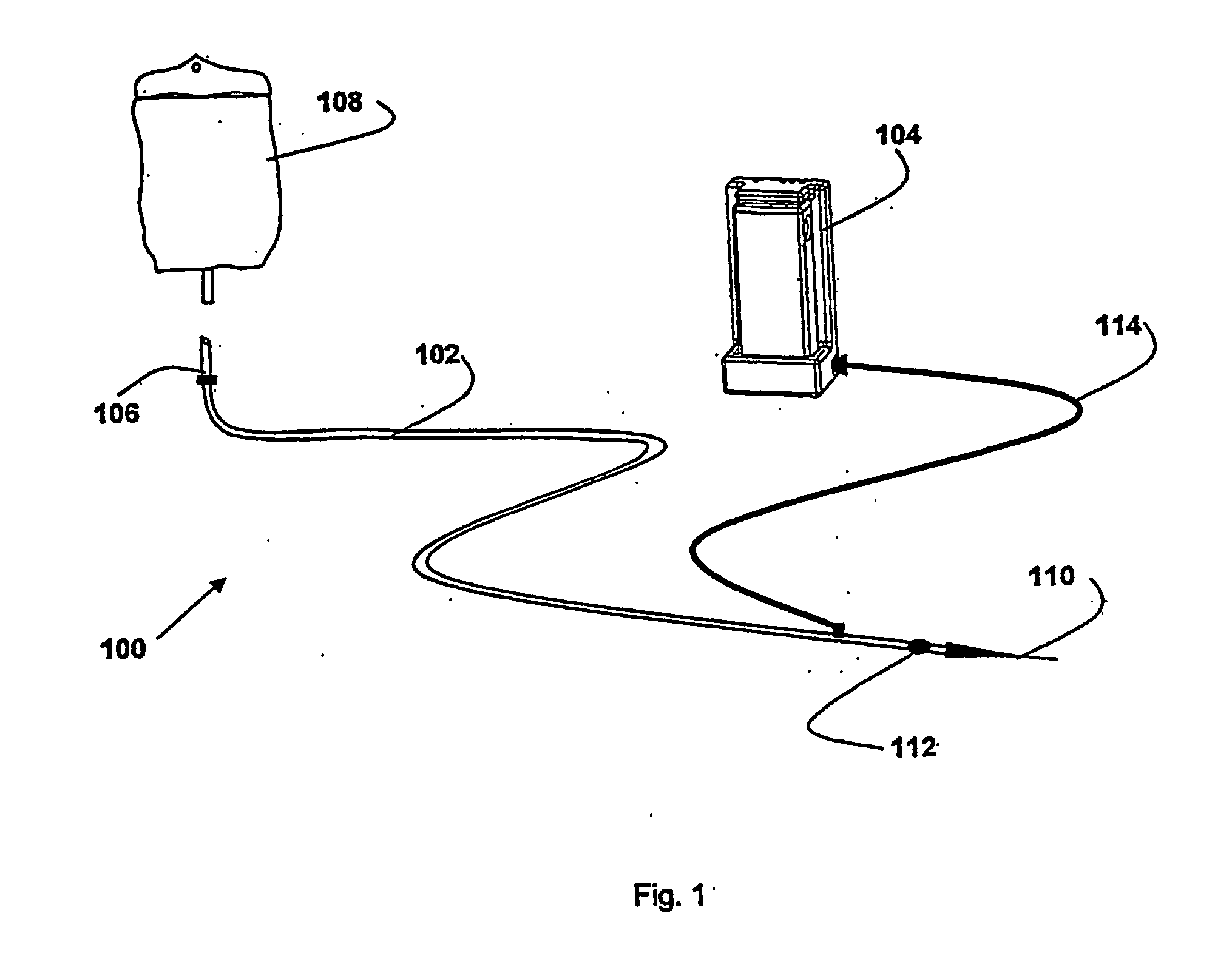

System and method for regulating the temperature of a fluid injected into a patient

A system and method for injecting a fluid into a patient is disclosed. In some embodiments, the system comprises a plurality of sensors that measure a characteristic of the fluid, a first temperature regulator that biases the fluid temperature to a desired temperature range, a second temperature regulator that refines the temperature of the fluid, and logic coupled to the first and second temperature regulators and configured to dynamically adjust the first and second temperature regulators based, at least in part, on feedback from the plurality of sensors.

Owner:DERRICO JOEL BRIAN +1

System and method for power pump performance monitoring and analysis

InactiveUS7623986B2Easy to useEasy to provideTime indicationProgram control using stored programsEngineeringStreamflow

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

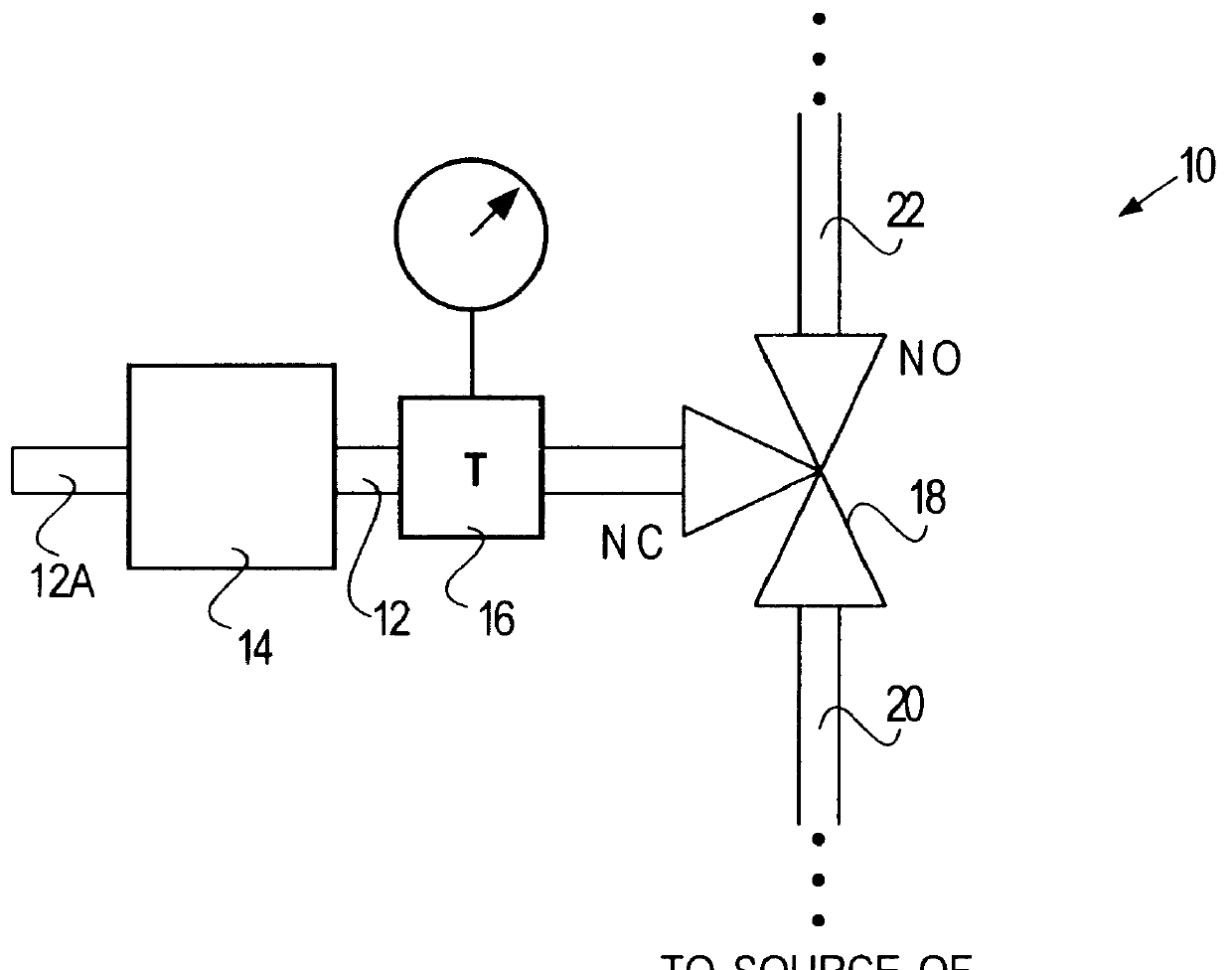

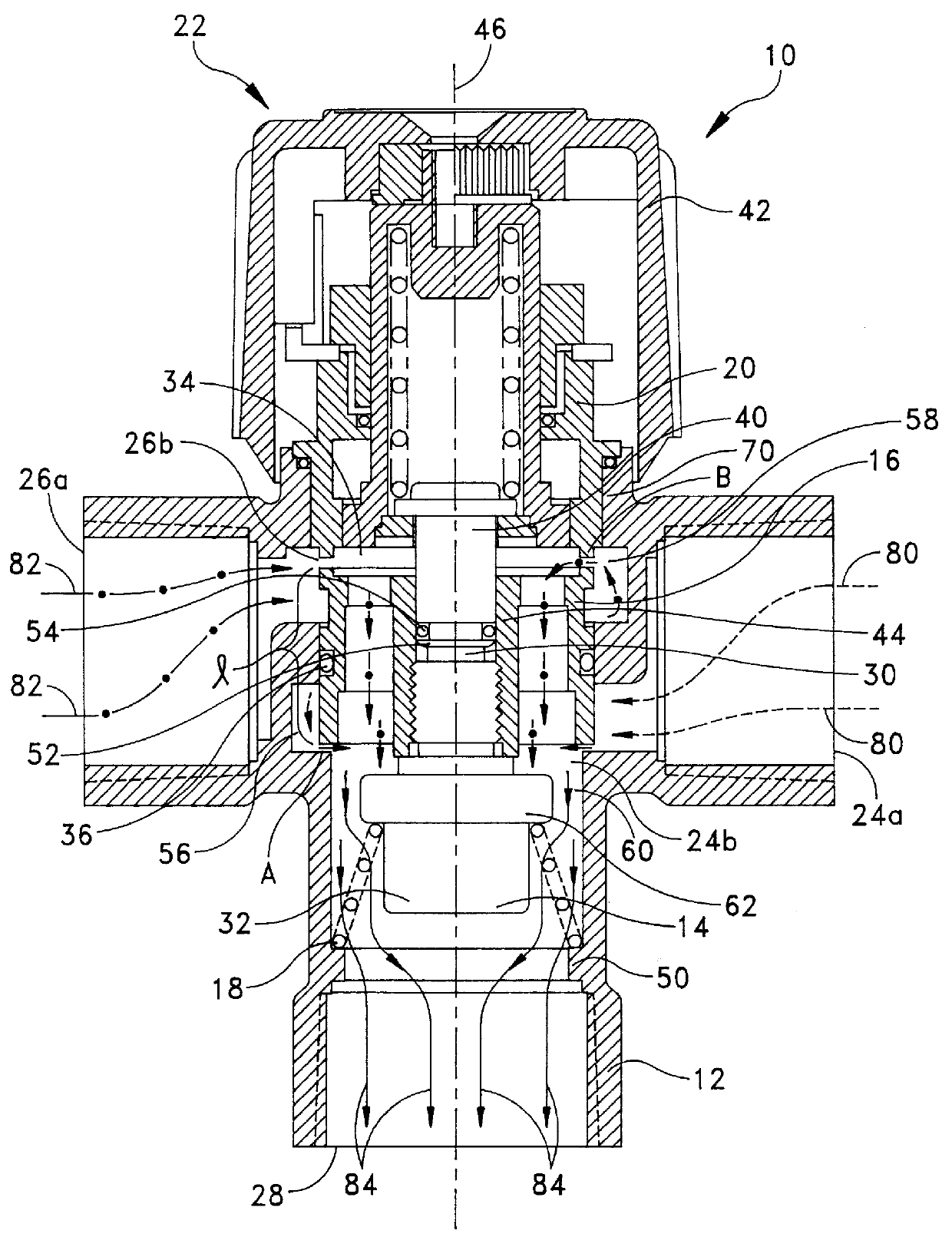

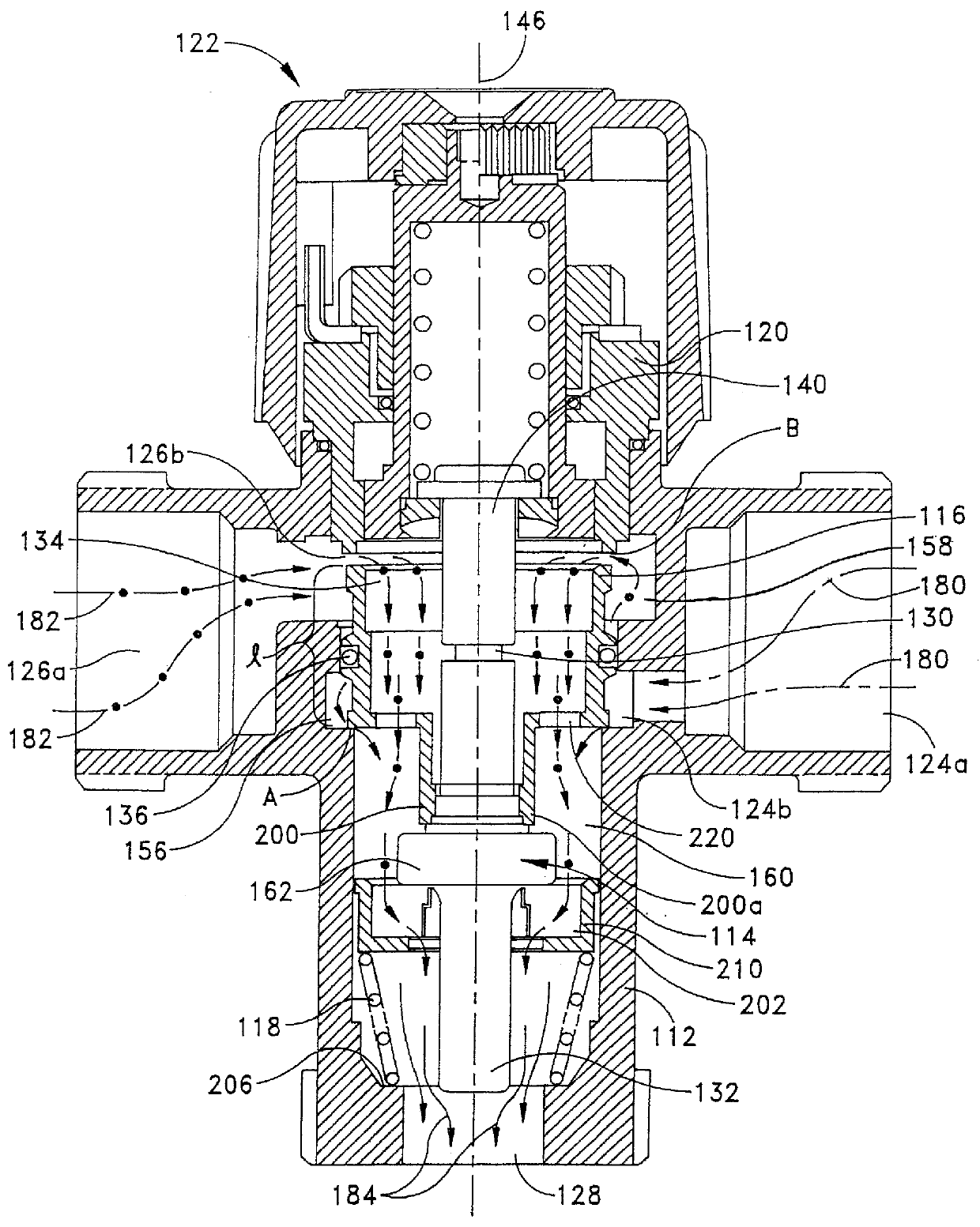

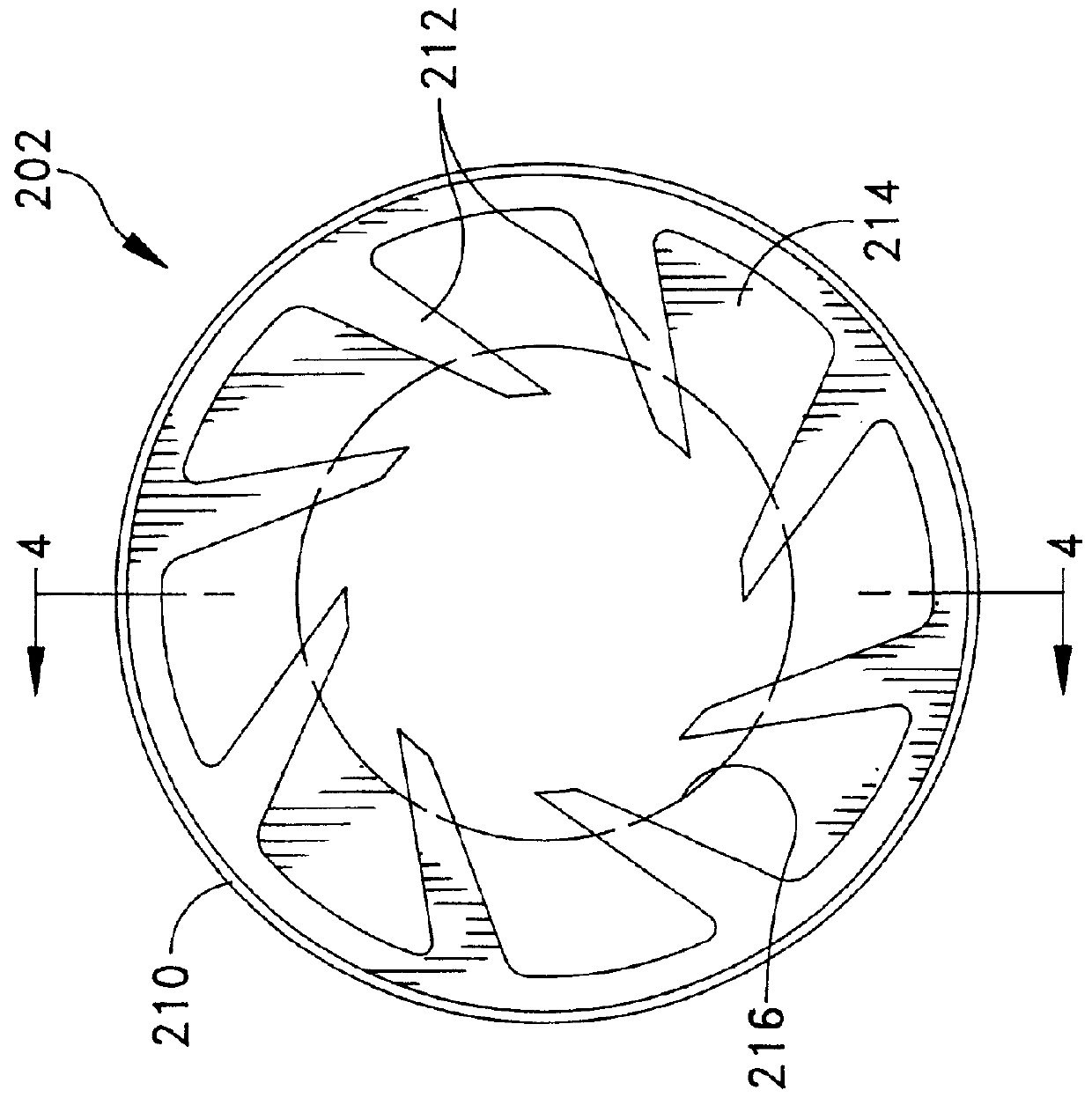

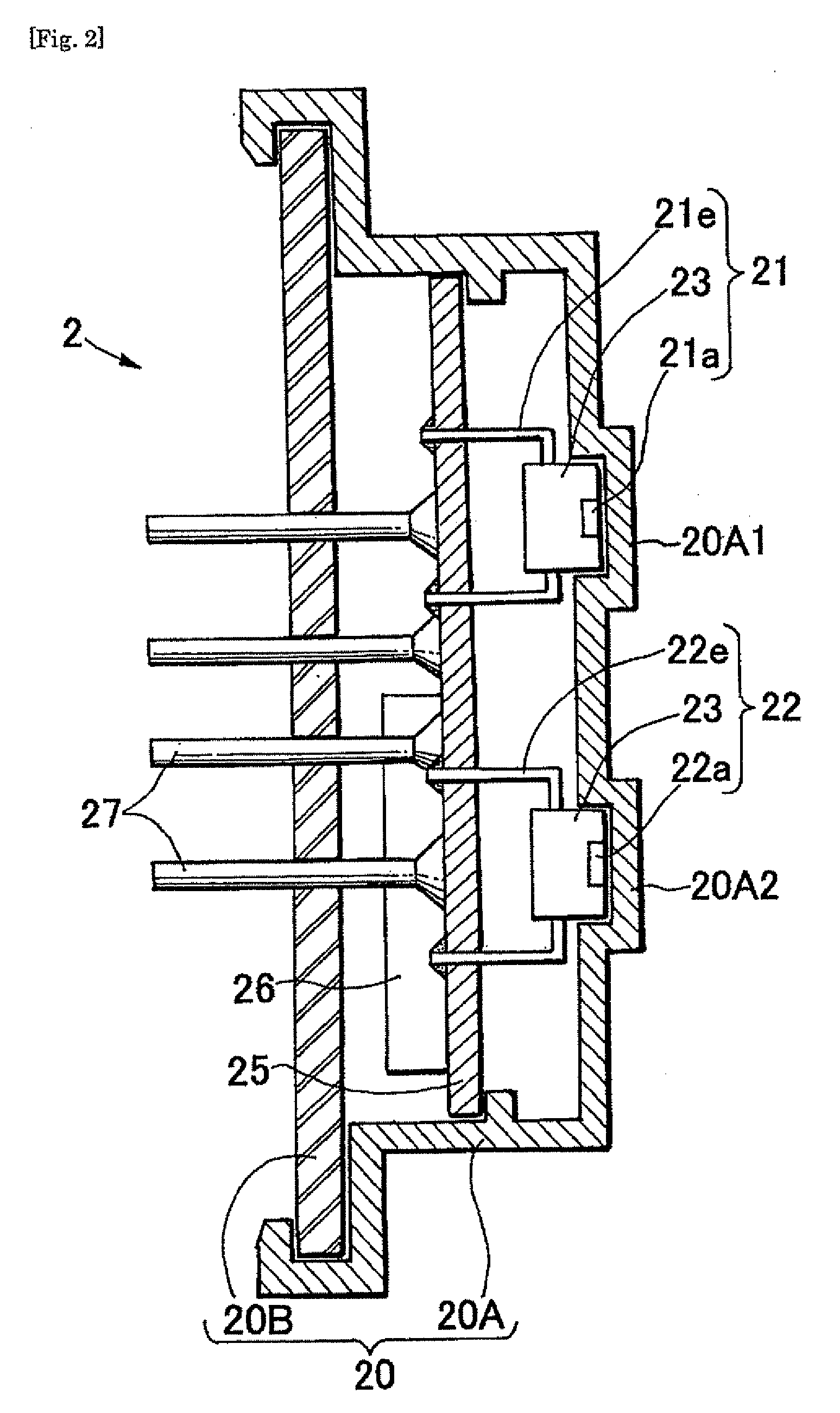

Thermostatic mixing valve

A mixing valve receives fluid from a first source and fluid from a second source and outputs a mixture of the fluids. The mixing valve includes a valve body including a first fluid inlet, a first fluid chamber, a second fluid inlet, a second fluid chamber, and a fluid outlet. The mixing valve further comprises a fluid flow regulator mounted within the housing, wherein a lower surface of the fluid flow regulator is disposed within the first fluid chamber and an upper surface of the fluid flow regulator is disposed within the second fluid chamber. The fluid flow regulator is mounted within the valve body in such a way as to permit movement of the fluid flow regulator along a longitudinal axis of the valve body. The fluid flow regulator includes a central hub which extends below the lower surface into the mixing chambr. A temperature-sensing device is mounted to the central hub of the fluid flow regulator and is constructed and arranged for sensing a temperature of fluid which flows from the mixing chamber to the outlet.

Owner:ADEMCO INC

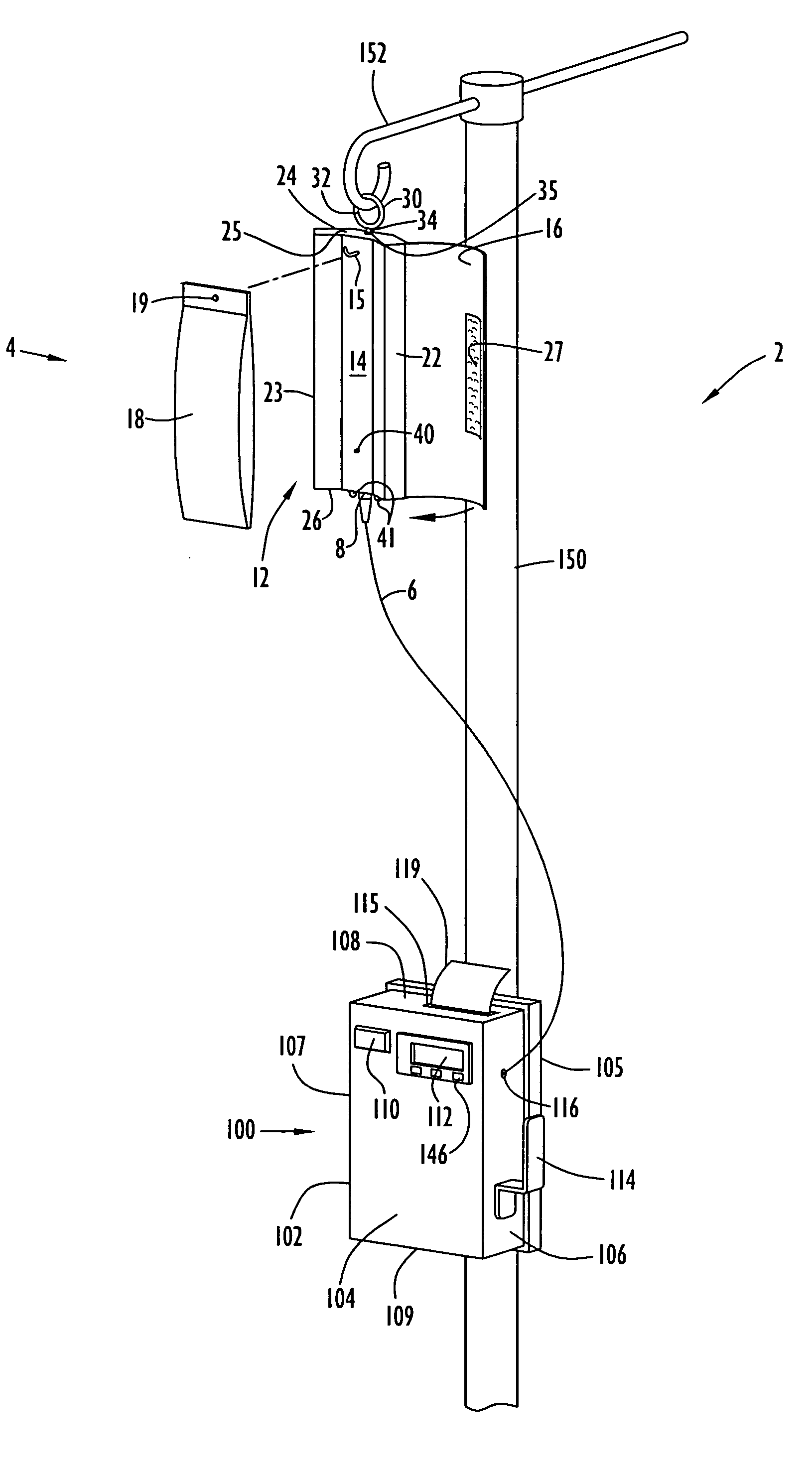

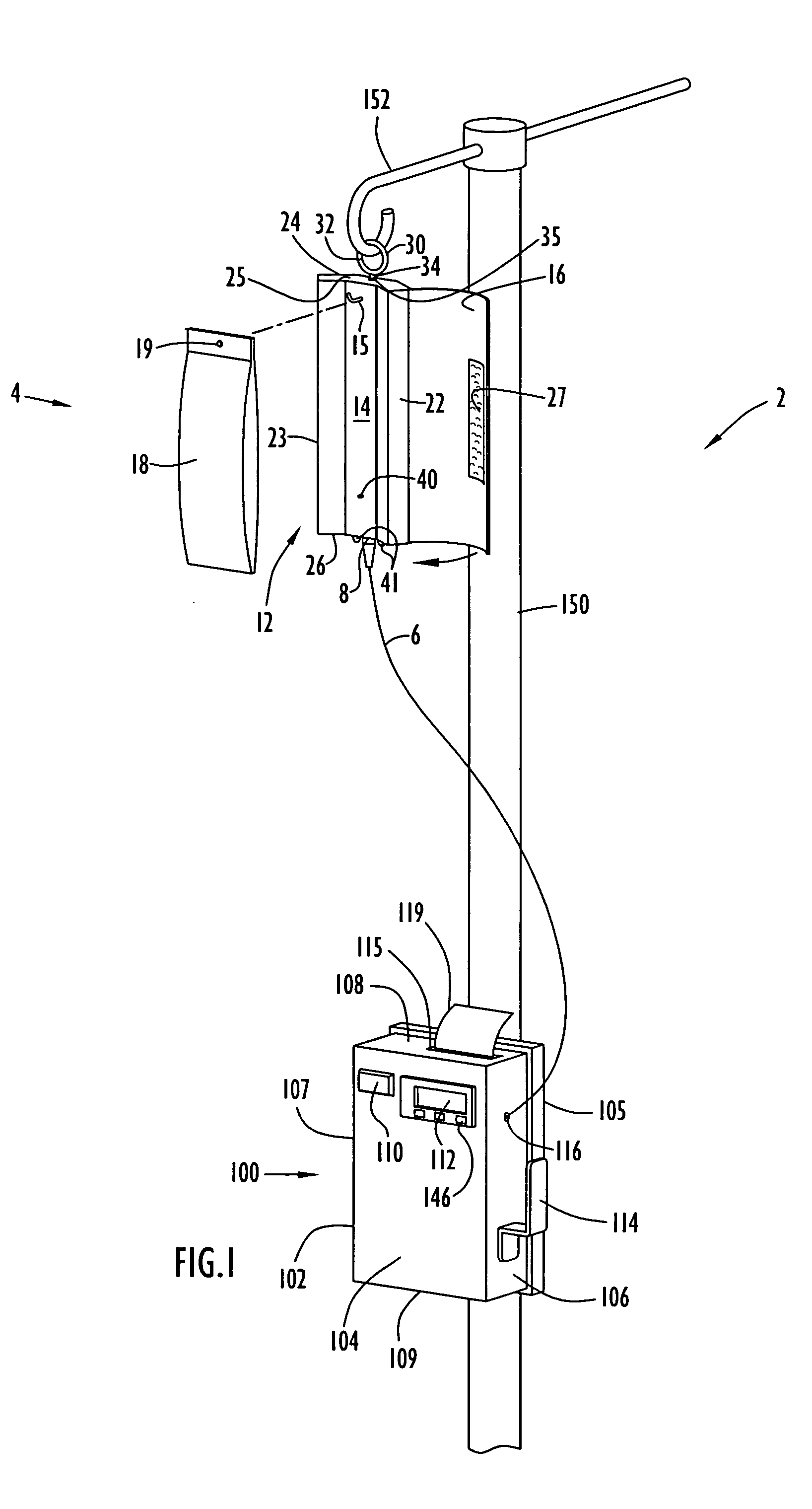

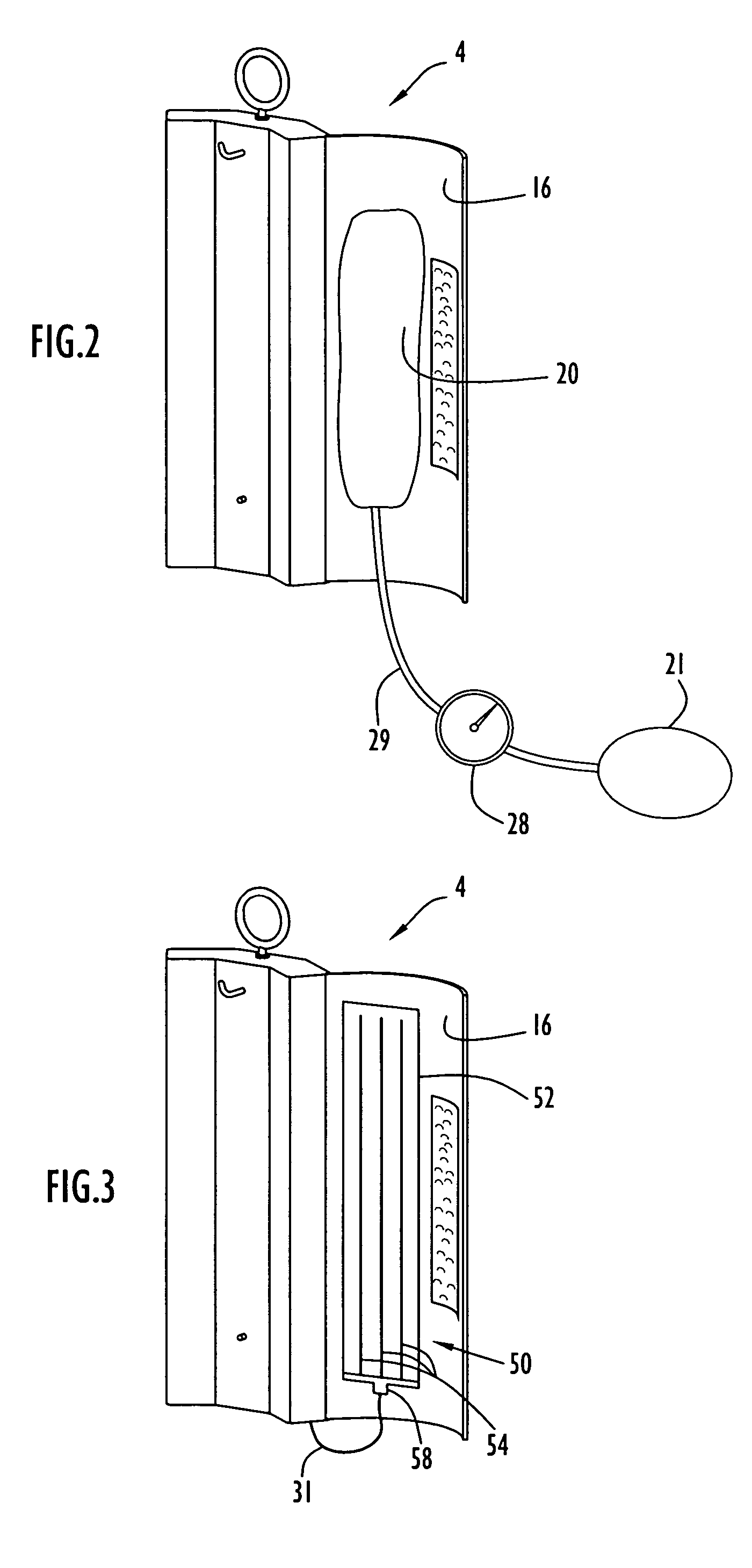

Method and apparatus for controlling temperature of infused liquids

InactiveUS7031602B2Easy access to allFacilitate to visual monitoringDomestic stoves or rangesElectrical heating fuelDisplay deviceIntravenous fluid

A system for controlling the temperature of intravenous fluids according to the present invention includes a heating cabinet and a power supply cabinet. The heating cabinet includes a housing, a flexible cover and a heating plate with a generally curved configuration to uniformly heat a solution container. The cover wraps around the fluid container to secure the solution container against the heating cabinet. The heating cabinet further includes a heating controller to maintain the solution at a desired temperature. The power supply cabinet provides power to the heating cabinet and includes a display for indicating a solution temperature. A secondary power supply may be provided in the heating cabinet to facilitate heating controller operation when the heating cabinet is disengaged from the power supply cabinet. The system further monitors and provides reports of fluid temperature history.

Owner:MEDICAL SOLUTIONS

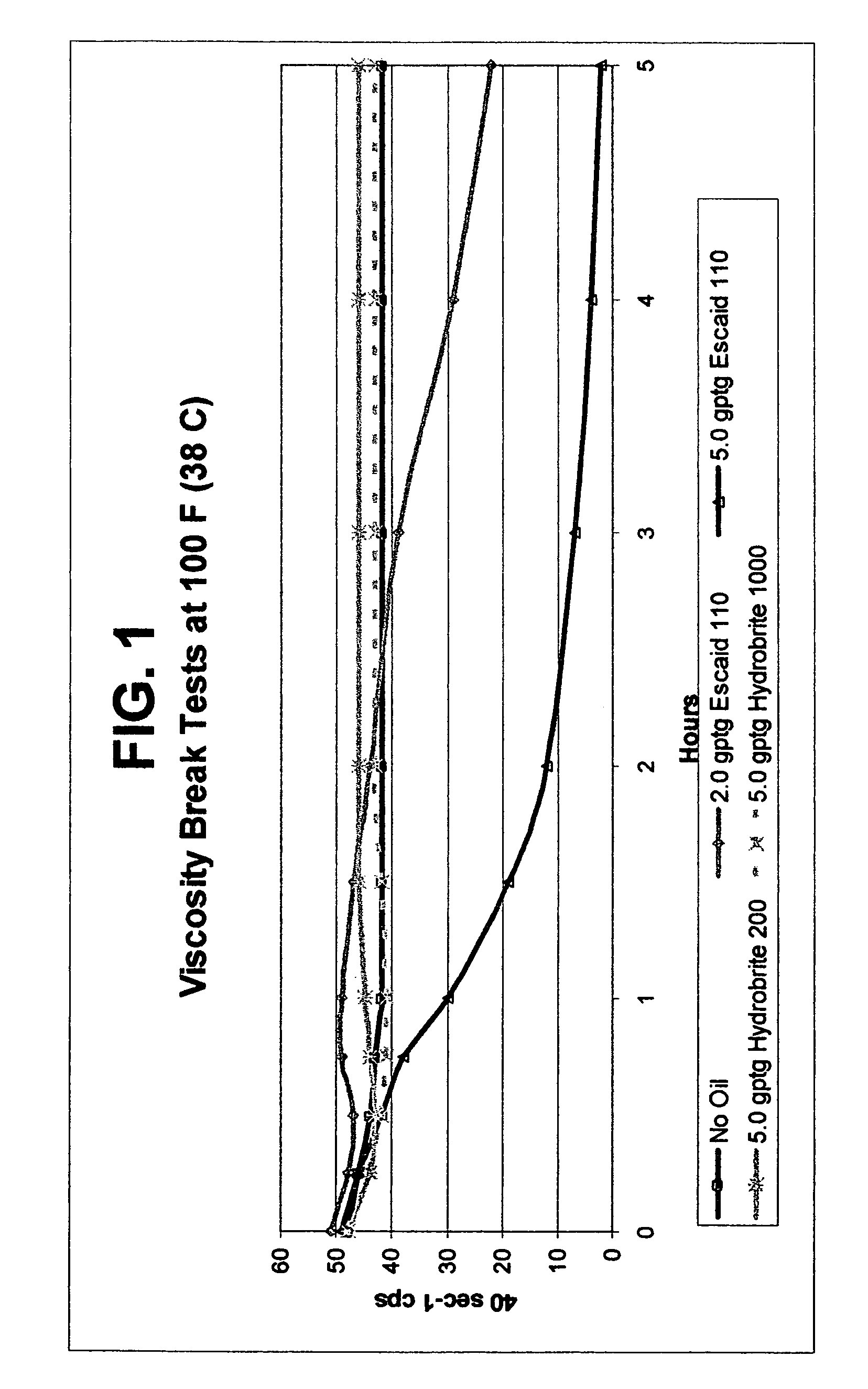

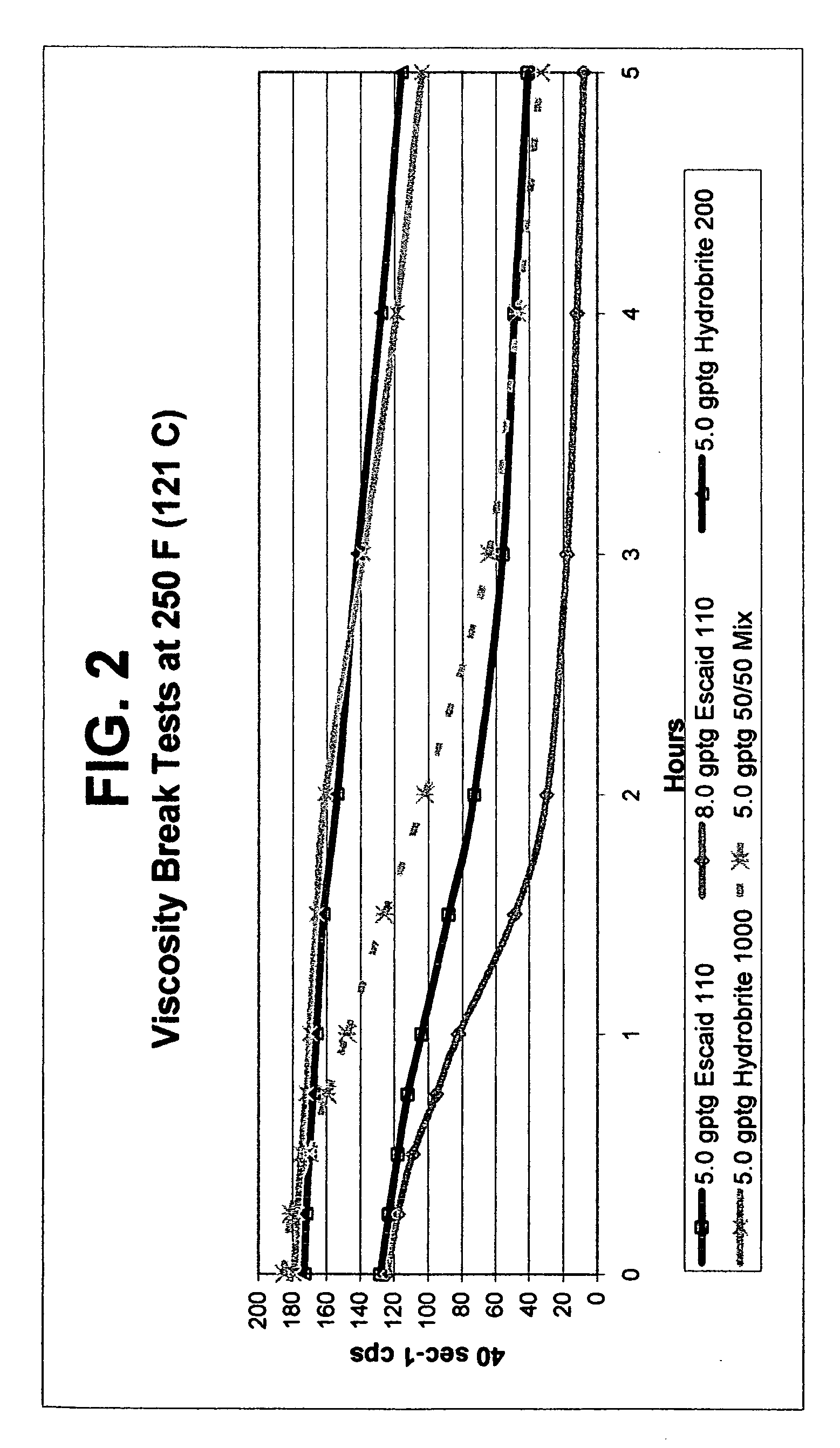

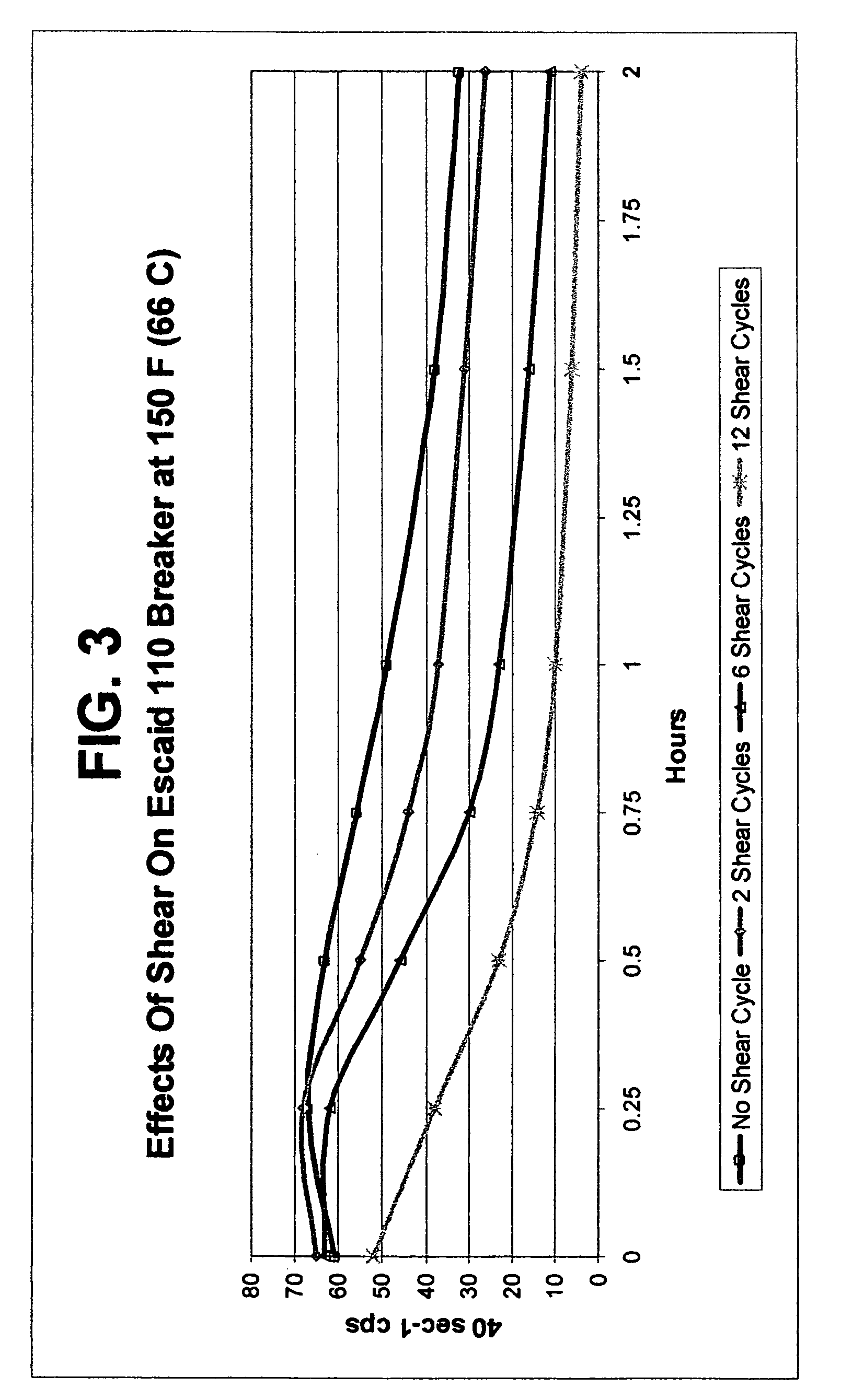

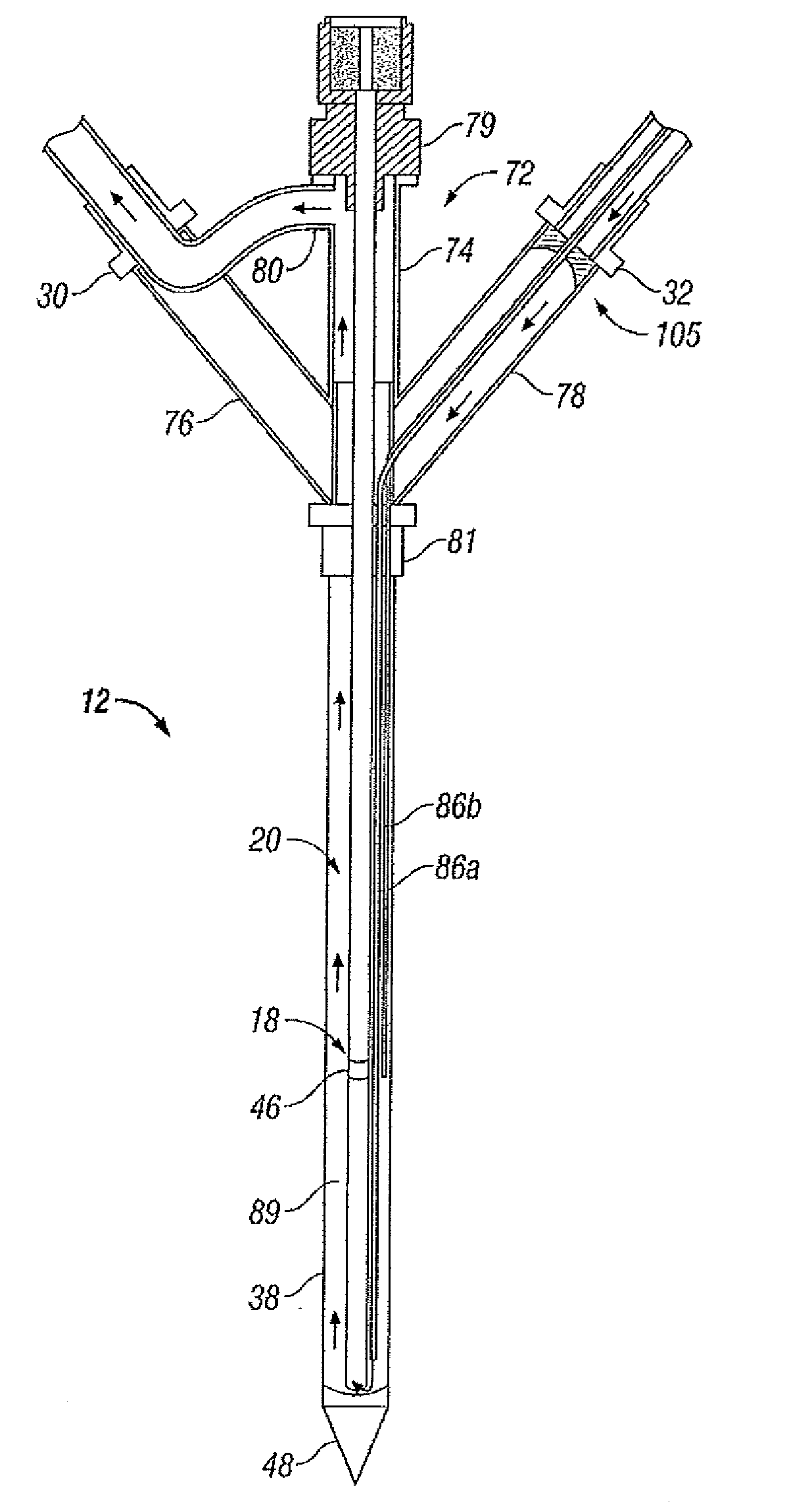

Use of mineral oils, hydrogenated polyalphaolefin oils and saturated fatty acids for breaking ves-gelled fluids

Fluids viscosified with viscoelastic surfactants (VESs) may have their viscosities reduced (gels broken) by the direct or indirect action of a breaker composition that contains at least one mineral oil, at least one polyalphaolefin oil, and / or at least one saturated fatty acid. The breaker may initially be dispersed oil droplets in an internal, discontinuous phase of the fluid. In one non-limiting embodiment, the breaker, e.g. mineral oil is added to the fluid after it has been substantially gelled. The breaking composition is believed to act possibly by rearranging, disaggregating or otherwise attacking the micellar structure of the VES-gelled fluid in a non-spontaneous, rate controlled manner at elevated fluid temperatures. In a specific, non-limiting instance, a brine fluid gelled with an amine oxide surfactant can have its viscosity broken with a light, low viscosity paraffinic mineral oil.

Owner:BAKER HUGHES INC

System and Method for Performing an Ablation Procedure

ActiveUS20110060326A1Heat dissipationReduce the temperatureSurgical needlesSurgical instruments for heatingCooling chamberBiomedical engineering

A method of performing an ablation procedure includes the initial step of supplying a fluid to a cooling chamber defined within an antenna assembly. The method also includes the steps of decreasing the temperature of the fluid to form a solid material and inserting the antenna assembly into tissue. The method also includes the step of supplying energy to the antenna assembly to treat tissue. Residual heat from the antenna assembly transitions the solid material back to the fluid. The method also includes the step of circulating the fluid within the antenna assembly to dissipate heat emanating from the antenna assembly.

Owner:TYCO HEALTHCARE GRP LP

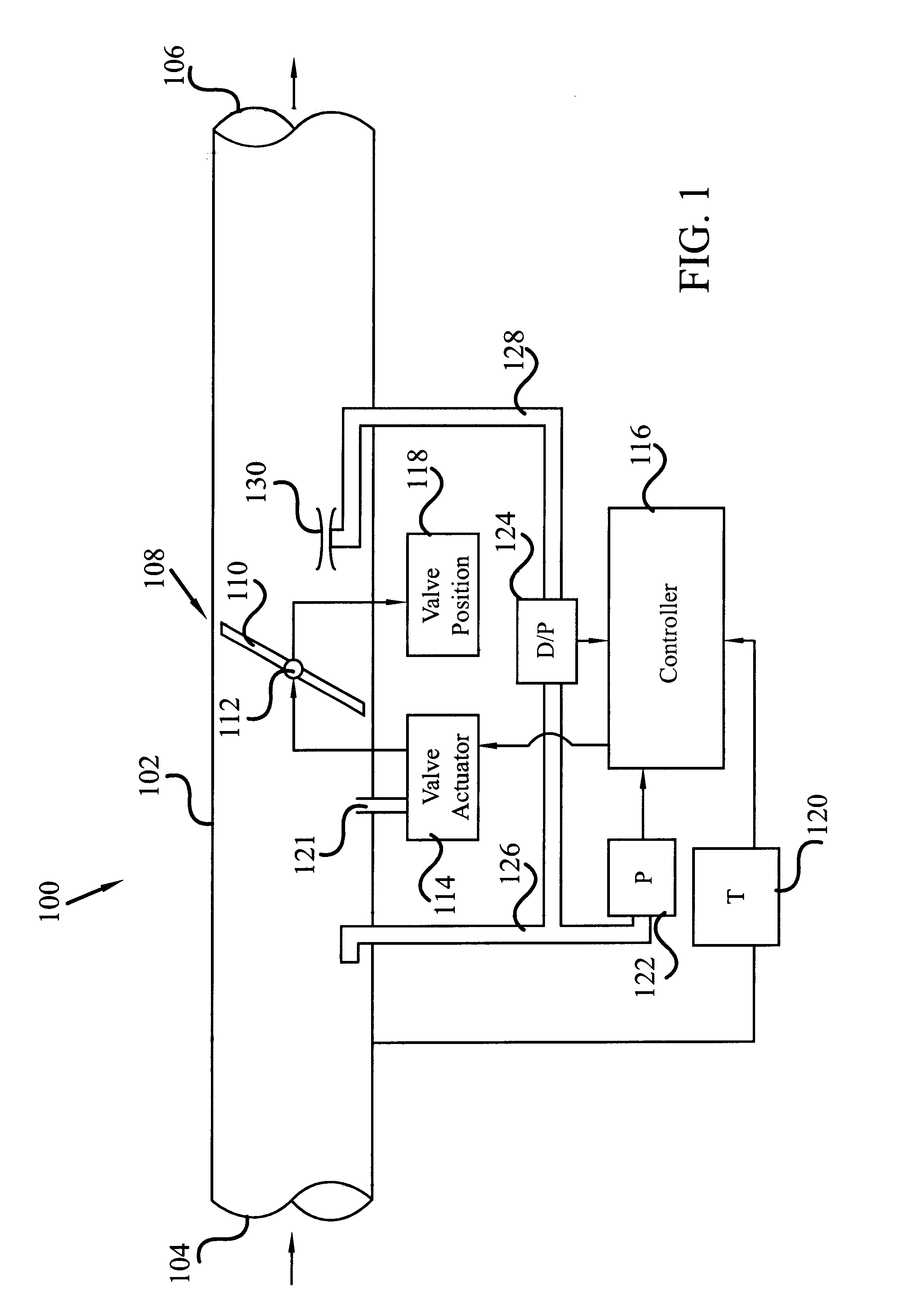

Flow control valve with integral sensor and controller and related method

ActiveUS6892745B2Simple designWide measurement rangeOperating means/releasing devices for valvesFlow control using electric meansDifferential pressureEngineering

A flow control valve assembly, and a method of determining and controlling fluid flow through the valve, that is relatively simple in design, is relatively inexpensive, is accurate, and has a relatively wide measurement range. The flow control valve is relatively compact and includes all of the flow measurement and control components in a single, relatively compact assembly. Such components may include a differential pressure sensor, pressure sensor, a temperature sensor, a position sensor, and a processor. The differential pressure sensor senses differential pressure across the variable area flow orifice. The pressure sensor senses fluid pressure within the valve and supplies a fluid pressure signal. The temperature sensor senses fluid temperature and supplies a fluid temperature signal. The position sensor senses the position of the variable area flow orifice and supplies a position signal. The processor receives the differential pressure signal, the fluid pressure signal, the fluid temperature signal, and the position signal and uses these signals to determine and control fluid flow parameter in the passageway.

Owner:HONEYWELL INT INC

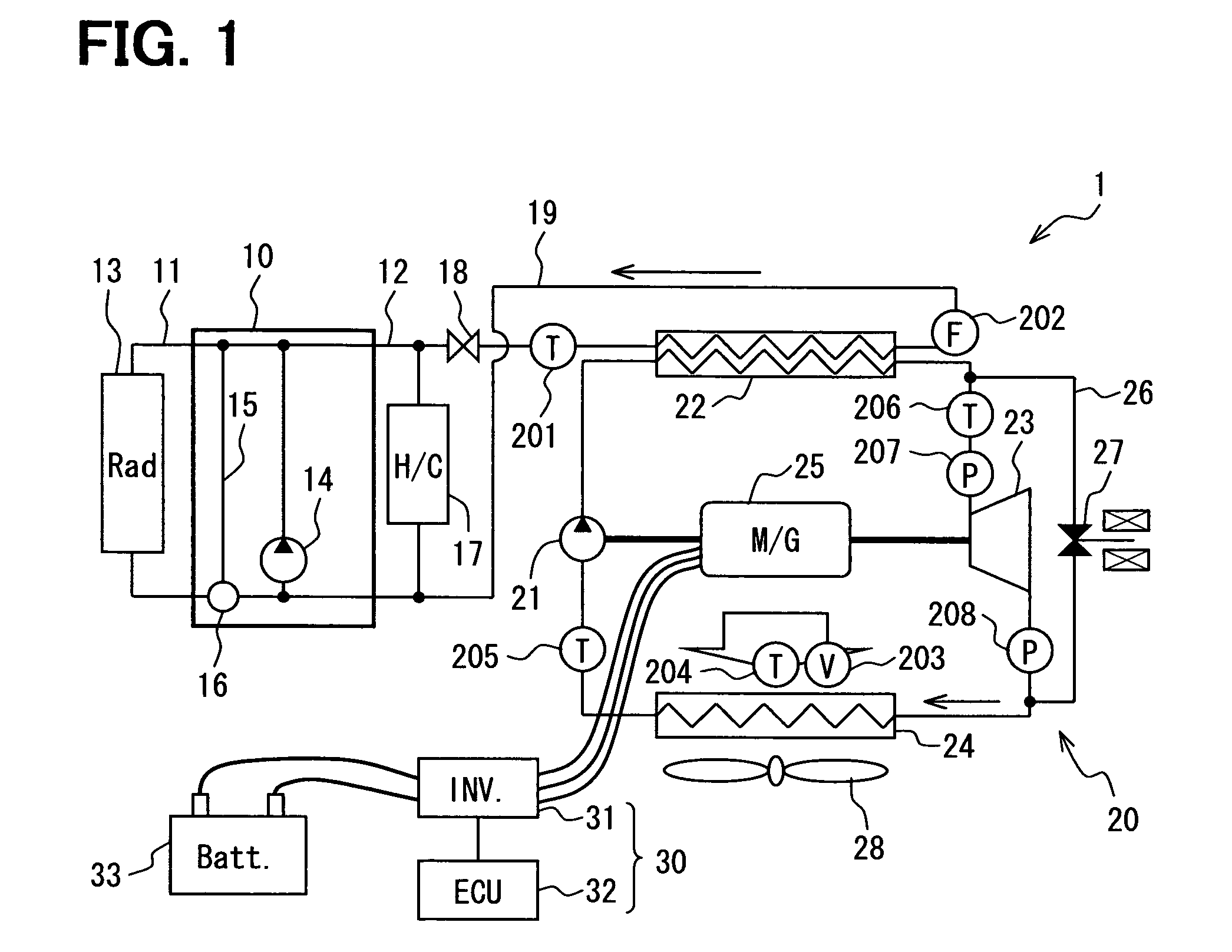

Waste heat recovery apparatus

InactiveUS7950230B2Stably and efficiently recovering powerGuaranteed uptimeInternal combustion piston enginesEngine componentsWorking fluidMechanical energy

A waste heat recovery apparatus including a Rankine cycle which includes a heater for heating an operation fluid by waste heat from a heat-generating device, an expansion unit for converting energy of expansion of the operation fluid flowing out from the heater into mechanical energy, and a condenser for condensing and liquefying the expanded operation fluid, a temperature detector for detecting the temperature of the operation fluid on the inlet side of the expansion unit, a pressure detector for detecting inlet-side pressure of the expansion unit, a pressure detector for detecting outlet-side pressure of the expansion unit, and a control unit. The control unit controls a command rotational speed of the expansion unit based on superheated degree information at the inlet of the expansion unit obtained from the operation fluid temperature and the inlet-side pressure, and pressure information in which the outlet-side pressure is considered.

Owner:DENSO CORP +1

System and method for rapid chromatography with fluid temperature and mobile phase composition control

InactiveUS20060054543A1Easy to separateMinimizing temperature variationIon-exchange process apparatusComponent separationChromatographic separationFraction Collector

The invention relates to liquid chromatography techniques for rapidly characterizing samples, such as polymer solutions, emulsions and dispersions, and to devices for implementing such techniques. The system includes a design that provides the ability to perform chromatographic separations by using mobile phase composition gradients and temperature gradients during separations. The invention accomplishes this by providing mixing zones for a plurality of fluids as well as heated and chilled feeds feeding the fluids to the mixing zones. Additionally, the system provides the ability to analyze separated components with a detector and / or collect separated fractions into vessels of a fraction collector for further separation and / or analysis.

Owner:UNCHAINED LABS

Methods and system for warming a fluid

InactiveUS20070142773A1Control damageEasy to useOther blood circulation devicesMedical devicesProximateLine tubing

The invention is directed generally to a method and system for controlling the temperature of a fluid, i.e., warming or cooling a fluid, and more particularly, to a method and system for warming a fluid to be delivered to the body of a patient. In a preferred embodiment, a method and system for warming a fluid to be delivered into the body of a patient is provided and may include a controller and a fluid delivery-line. The fluid delivery-line may include an insulative tube and a fluid delivery tube positioned within the first tube and for communicating a fluid from a source to a destination. The fluid delivery-line may also include at least one thermal sensor positioned proximate the fluid delivery tube, a heating element positioned proximate the fluid delivery tube and a thermal medium positioned between the first tube and the second tube.

Owner:THERMICS

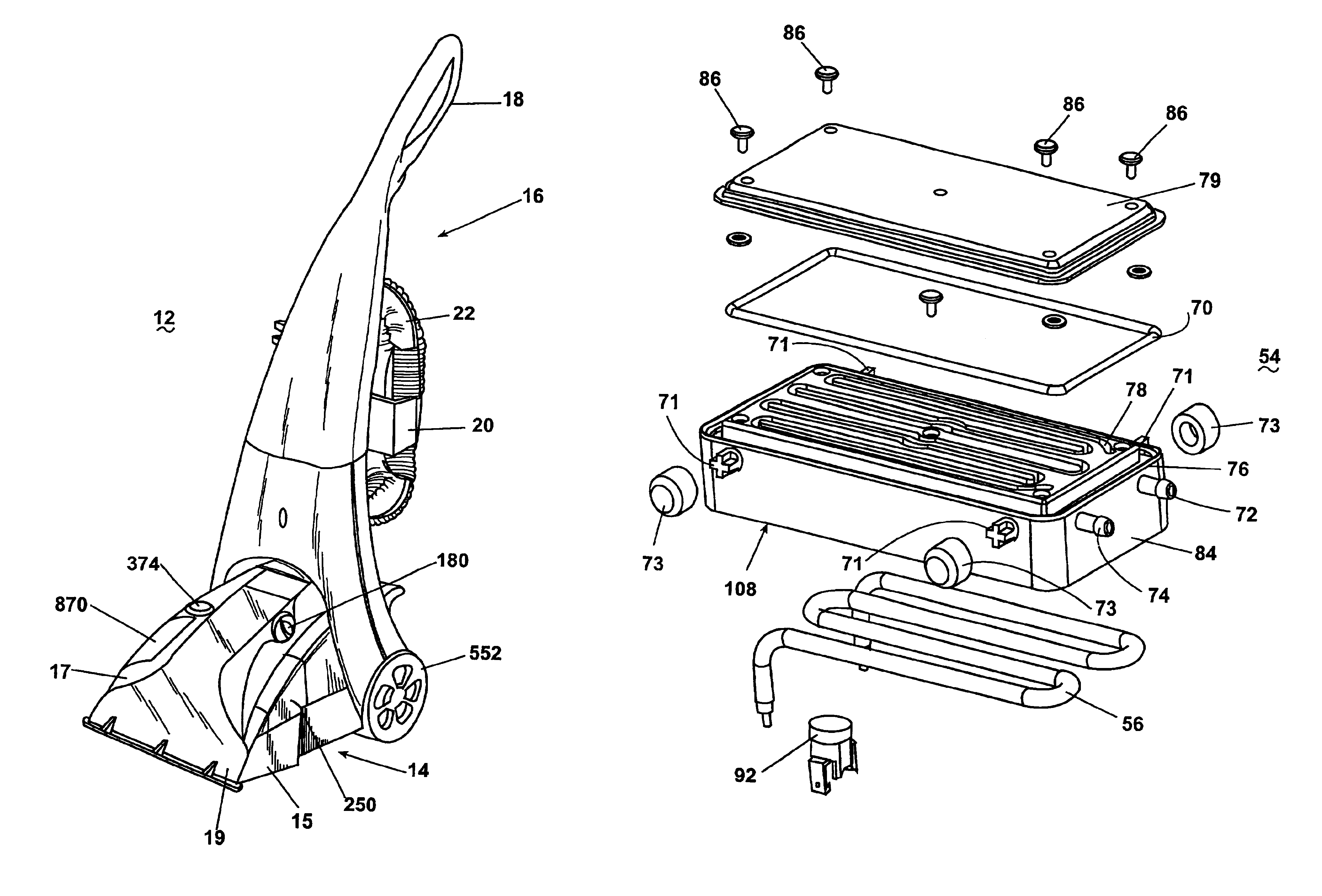

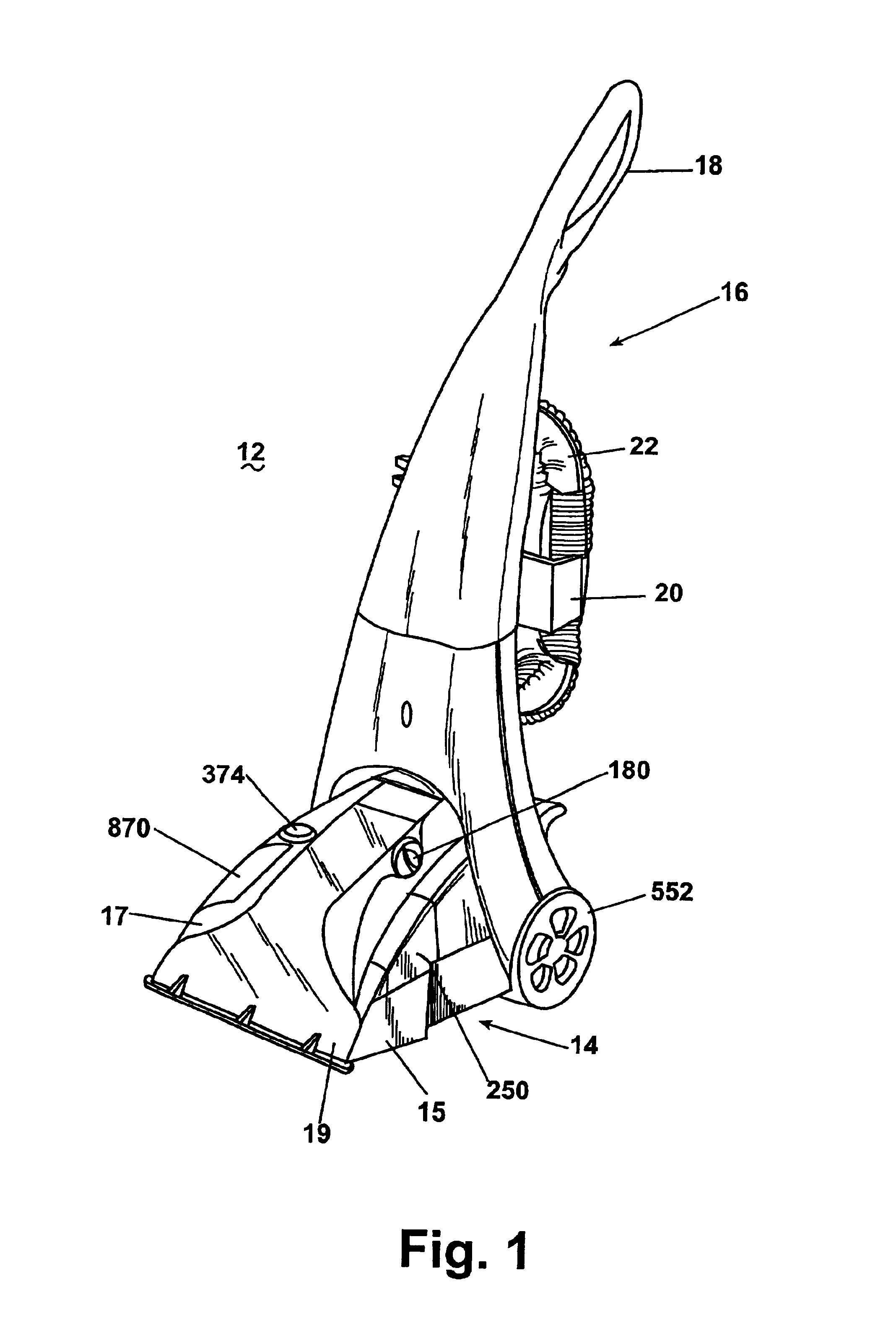

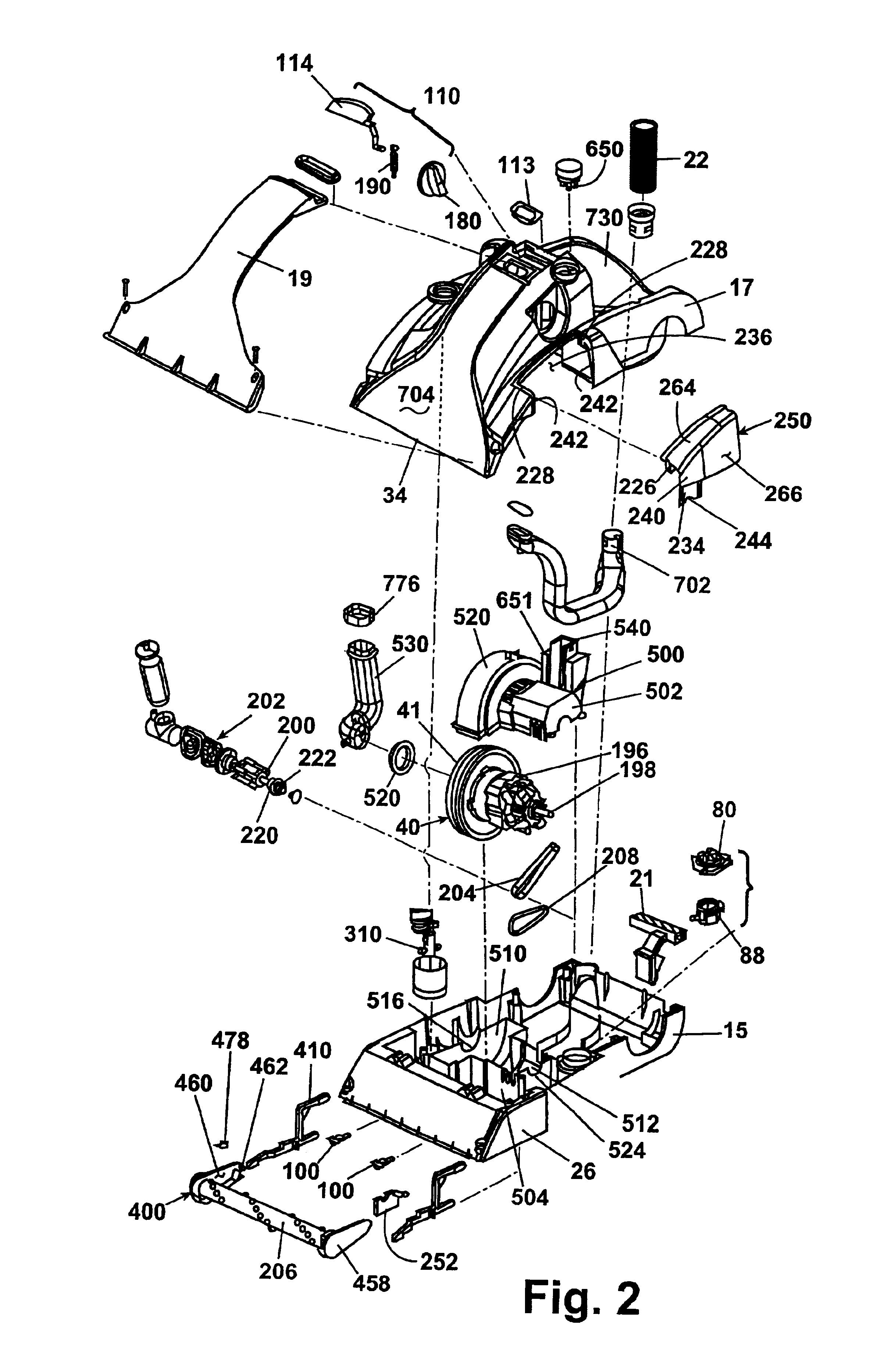

Extraction cleaning with heating

A portable surface cleaning apparatus comprises a fluid dispensing system including at least one fluid supply tank, a dispensing nozzle for applying a cleaning fluid to a surface to be cleaned, and a block heater for heating the fluid to be applied to the surface to be cleaned to a temperature less than boiling; a fluid recovery tank for holding recovered fluid; a suction nozzle; a working air conduit extending between the recovery tank and the suction nozzle; and a vacuum source in fluid communication with the recovery tank for generating a flow of working air from the suction nozzle through the working air conduit and into the recovery tank to thereby recover fluid from the surface to be cleaned.

Owner:BISSELL INC

Systems and methods for limiting joint temperature

ActiveUS8355799B2Reduce and eliminate temperature influenceReduce the risk of injuryDiagnostic recording/measuringSurgical instruments for heatingControl systemMonitoring and control

Joint temperature monitoring and control systems and methods are described herein in which the temperature of a fluid within a body or joint space is determined and / or monitored despite the energy generated during treatment by an ablation probe. One or more temperature sensors are positioned along the probe proximally of the electrode assembly and measure the temperature of an electrically conductive fluid without being overly influenced by the surgical effect occurring proximate the electrode assembly. The controller coupled to the probe can also be configured to set temperature limits and treatment times as well as moderating joint temperature by altering the electrically conductive fluid flow.

Owner:ARTHROCARE

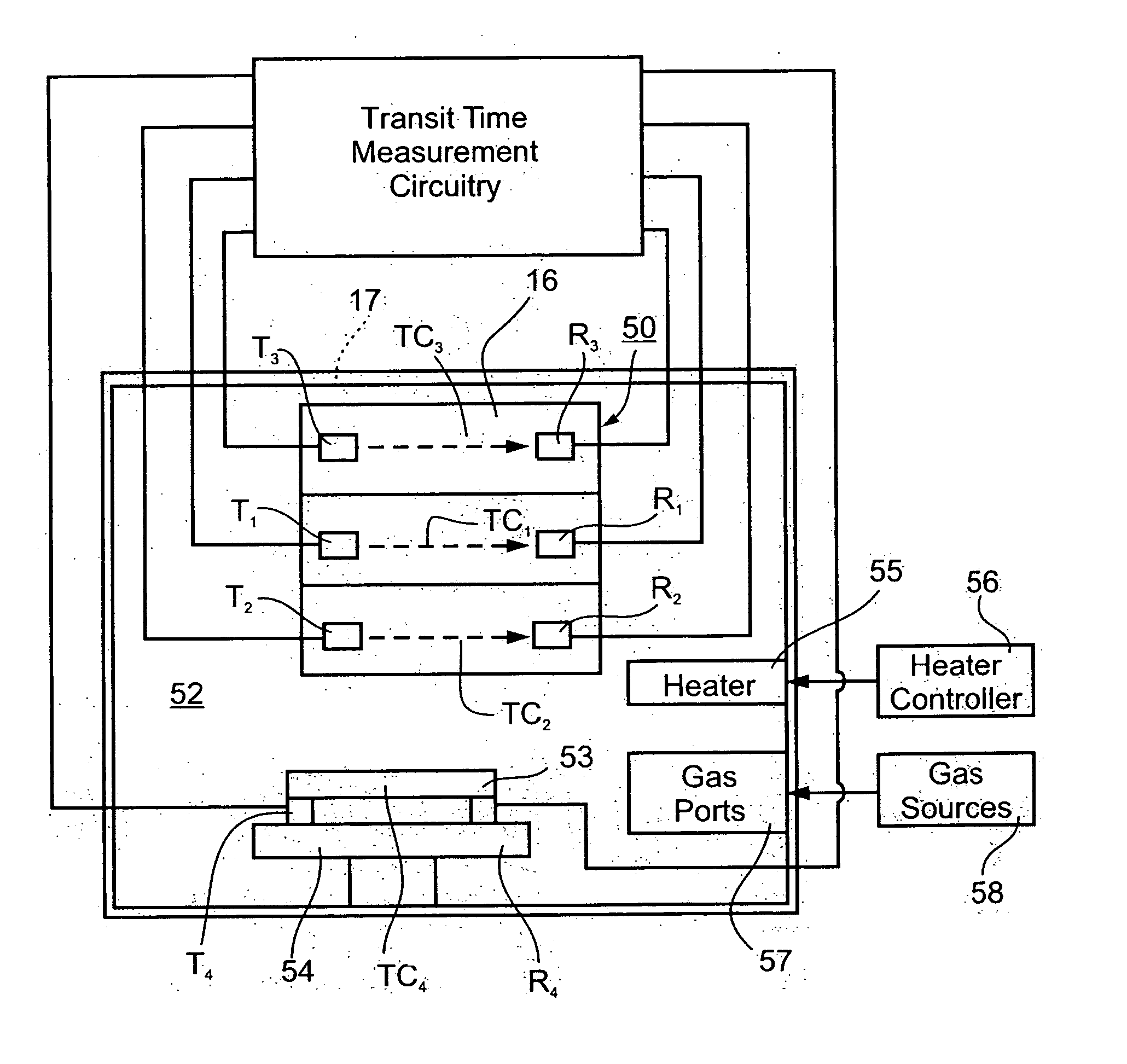

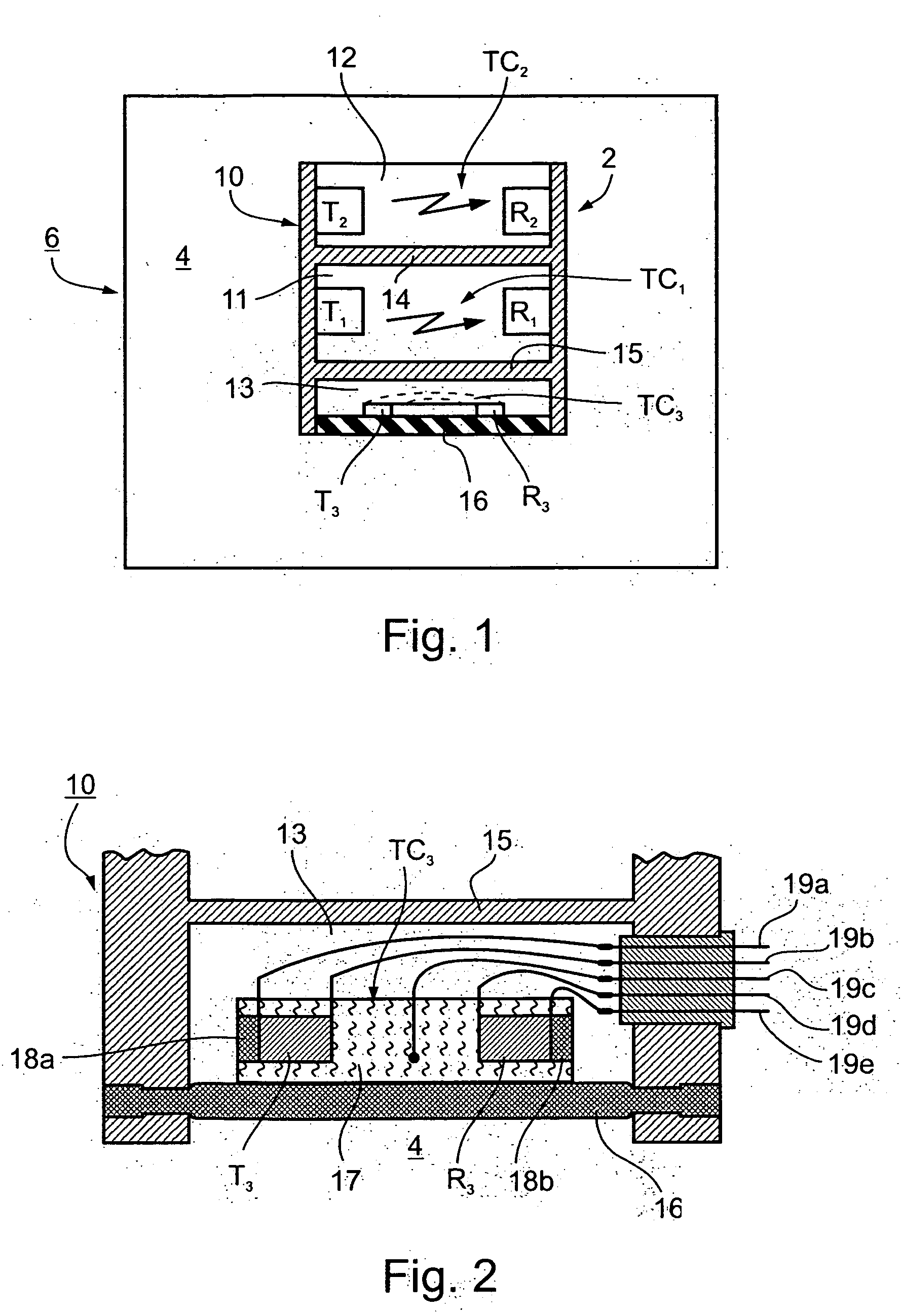

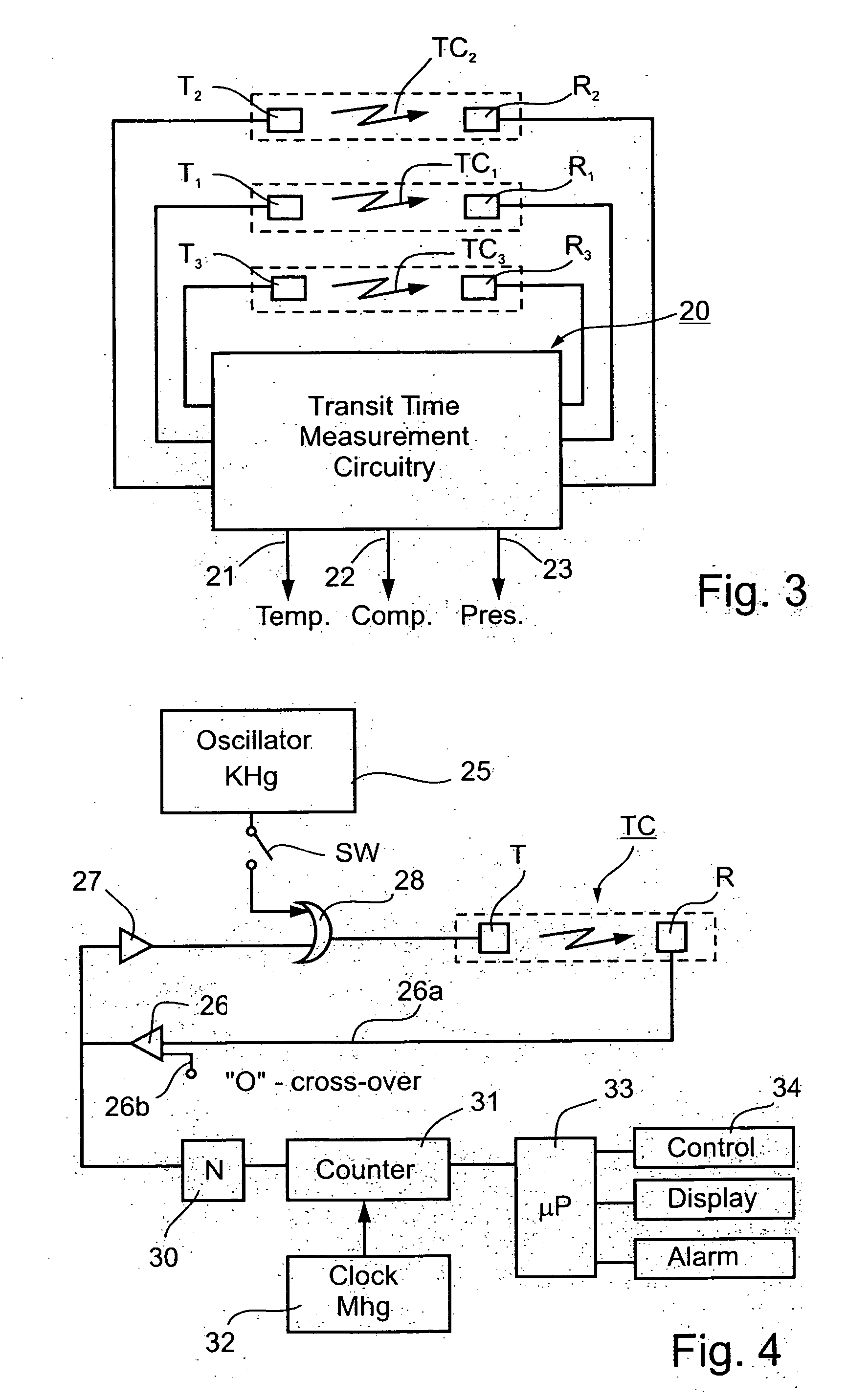

Sensor system for high-precision measurements of temperature, composition, and/or pressure of a fluid

InactiveUS20050252294A1High precision measurementAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic transmissionTransmission channel

A sensor system immersible in an ambient-fluid for sensing at least two conditions of the ambient fluid, includes a sealed chamber filled with a reference fluid of a known composition and / or pressure, and two acoustic transmission channels, one including the reference fluid, and the other including the ambient fluid. Measuring circuitry measures (a) the transit time of an energy wave through one transmission channel to determine the temperature of the fluid within the sealed chamber and thereby the temperature of the ambient fluid; and (b) the transit time of an energy wave through the other transmission channel to determine the composition and / or the pressure of the ambient fluid.

Owner:NEXENSE

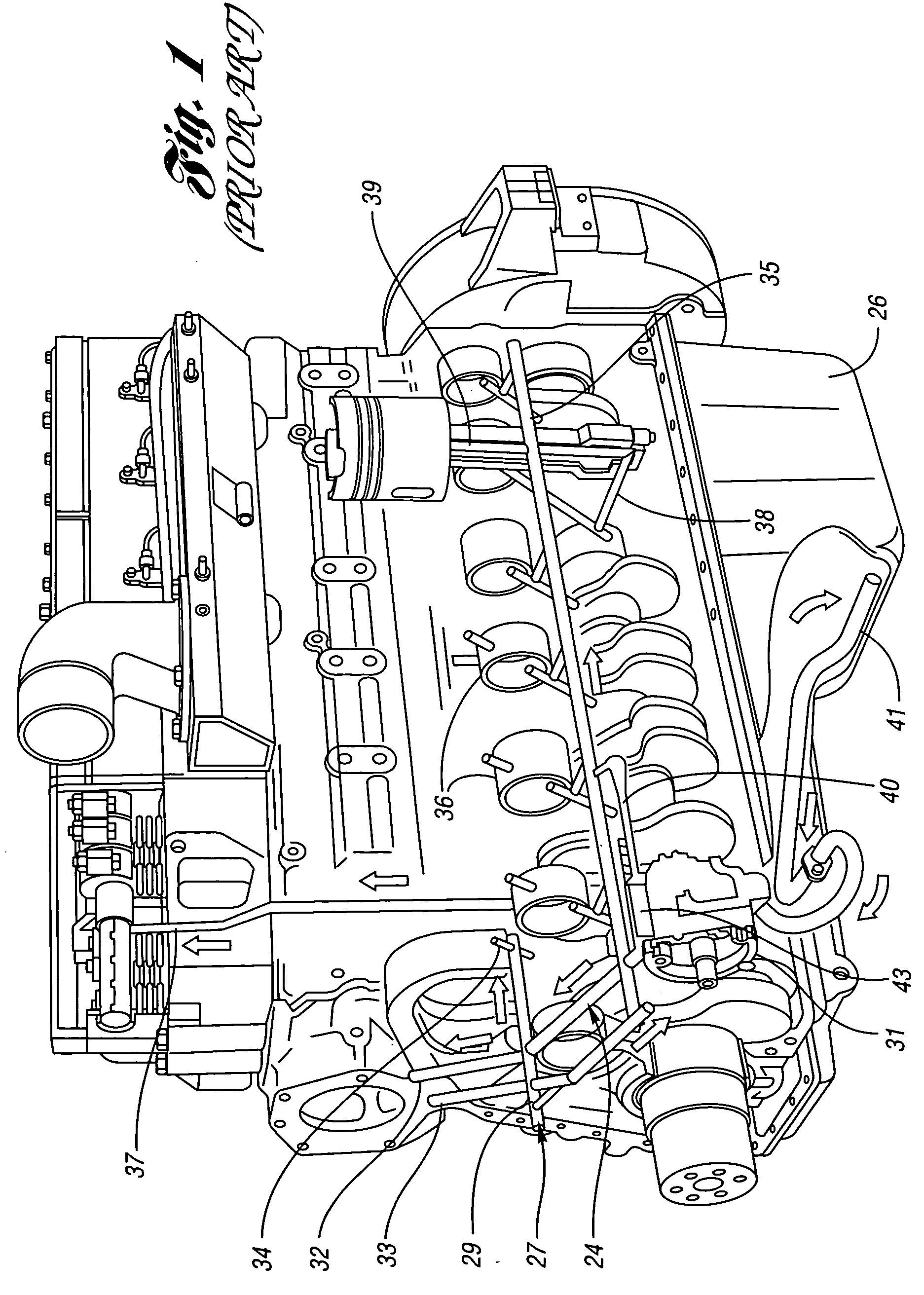

Separate oil gallery for piston cooling with electronic oil flow control

InactiveUS20050120982A1Reduce oil flowSaving in parasitic lossLiquid coolingCoolant flow controlThermal stateOil distribution

An engine oil distribution system for an internal combustion engine includes a main gallery and a separate oil gallery for piston cooling nozzles. The separate gallery may be controlled by a control valve that regulates the oil flow. The oil flow to the separate gallery may be controlled by an electronic control module in accordance with the piston cooling needs, for example, varied as a function of the load applied to the engine, or as a function of engine temperature. Preferably, engine temperature is sensed by coolant fluid temperature, or directly measured metal temperature, correlated to the thermal state of the piston.

Owner:DETROIT DIESEL CORP

Fluid Identification Device and Fluid Identification Method

InactiveUS20100294021A1Solution to short lifeHigh measurement accuracyMeasurement of fluid loss/gain rateMaterial thermal conductivityLiquid temperatureIdentification device

A fluid identification device of long life for identification of a target fluid. The device uses at least two liquid type detection parts each of which is equipped with both of a temperature detector and a heating element, selects electrical conduction to any one of the heating elements, and identifies the target fluid based on a fluid temperature detection signal of the temperature detector in the fluid detection part not including the heating element whose electrical conduction has been selected and an output of the fluid type detection circuit.

Owner:MITSUI MINING & SMELTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com