Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Diesel cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Diesel cycle is a combustion process of a reciprocating internal combustion engine. In it, fuel is ignited by heat generated during the compression of air in the combustion chamber, into which fuel is then injected. This is in contrast to igniting the fuel-air mixture with a spark plug as in the Otto cycle (four-stroke/petrol) engine. Diesel engines are used in aircraft, automobiles, power generation, diesel-electric locomotives, and both surface ships and submarines.

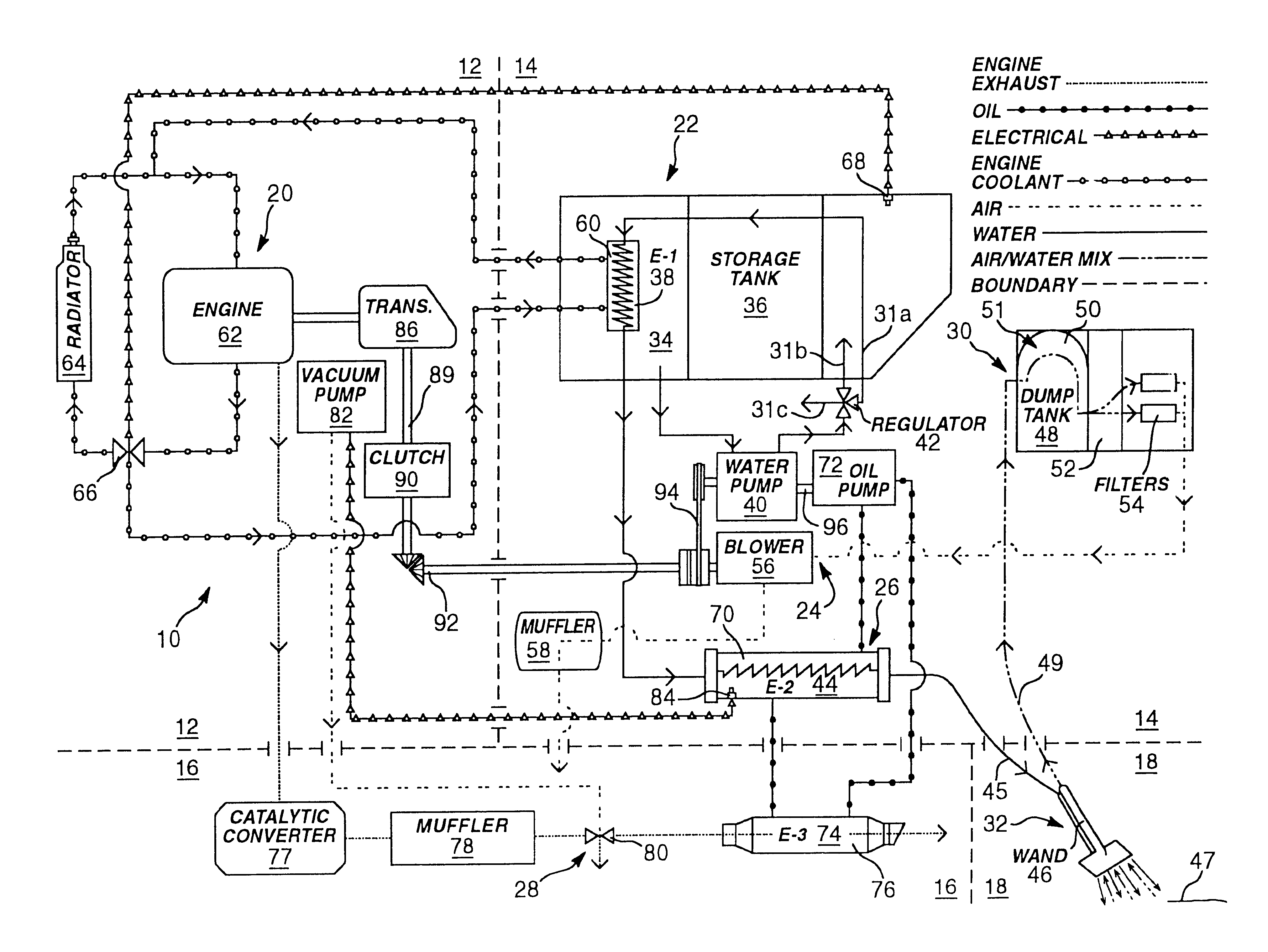

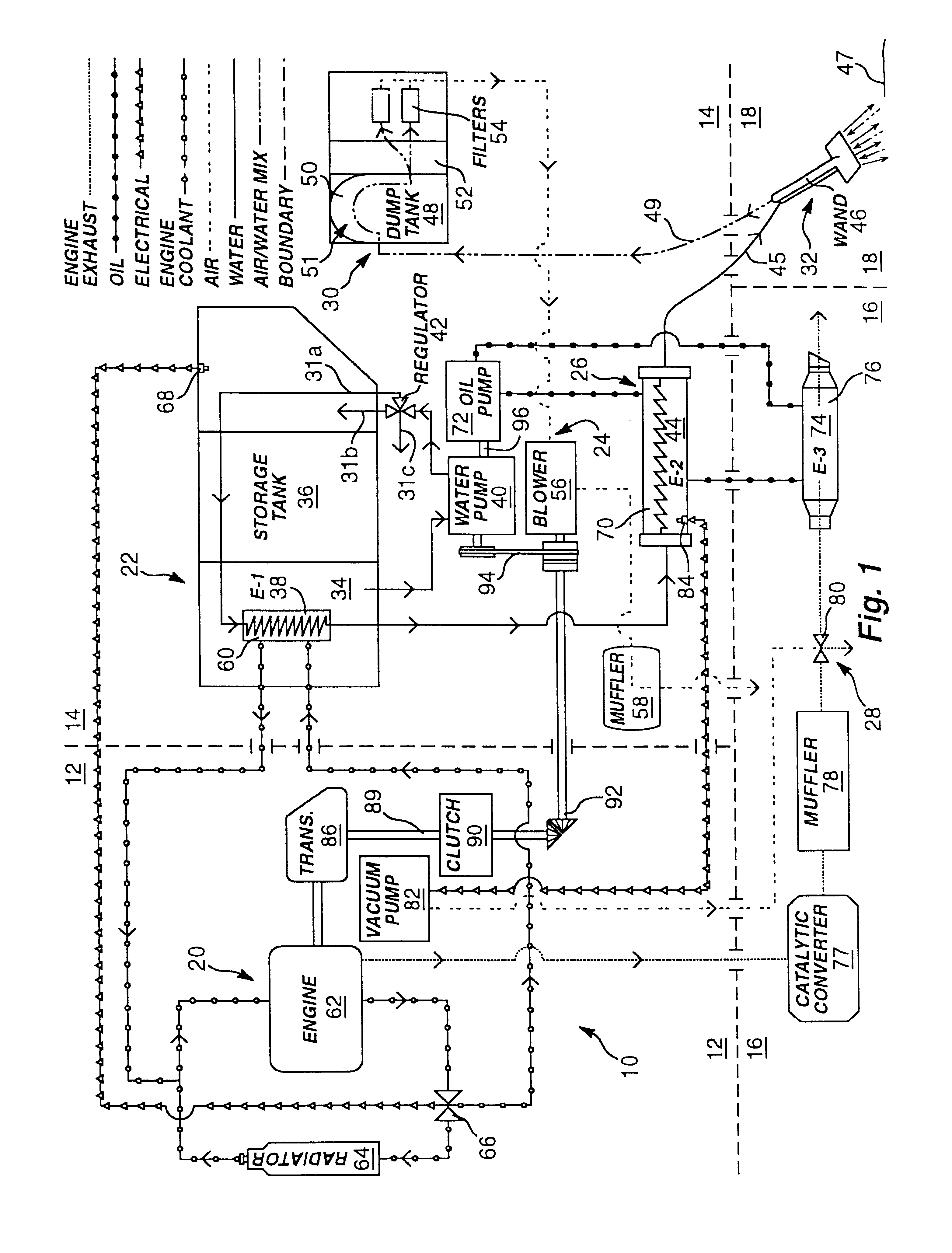

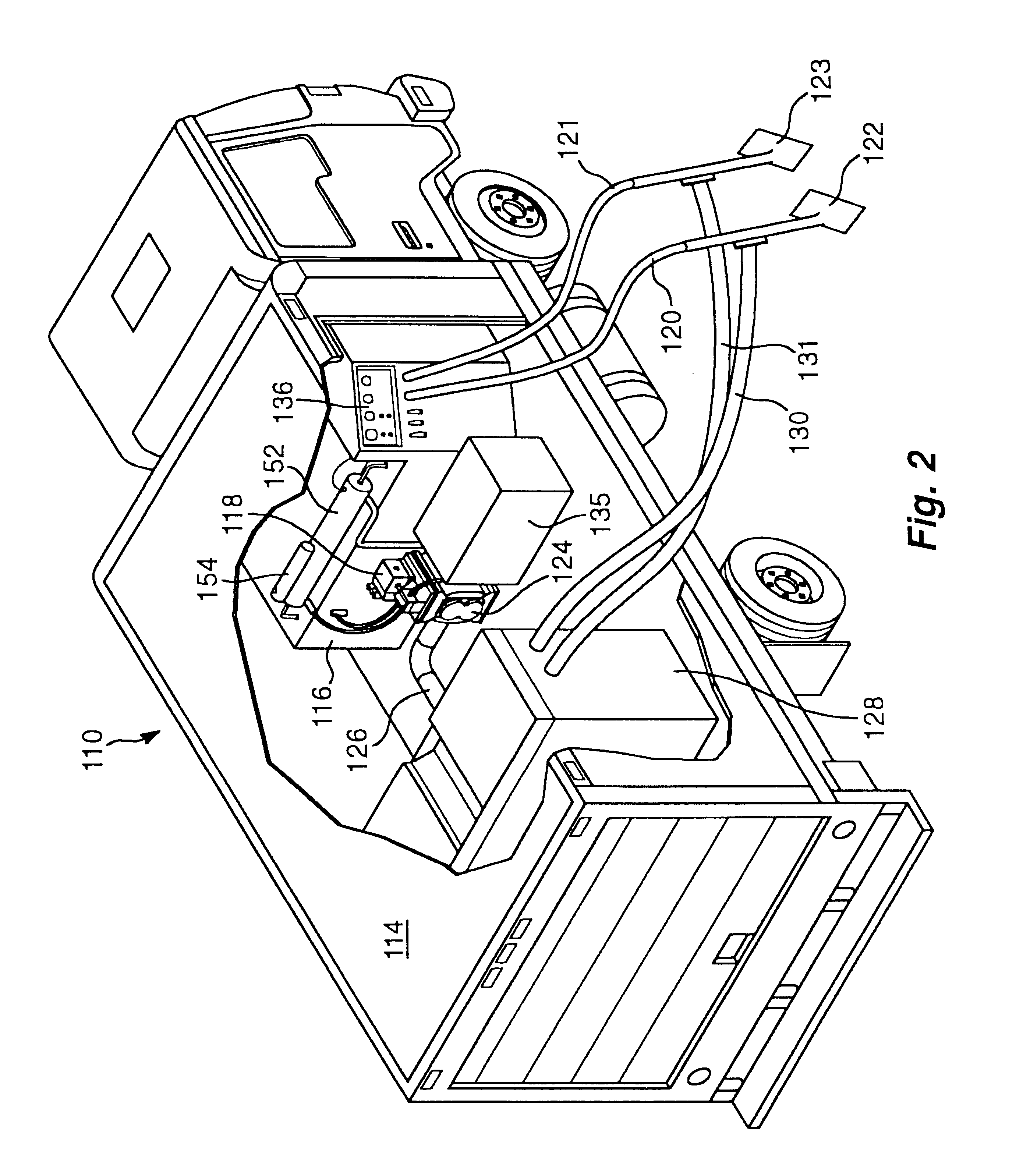

Portable high-temperature, high-pressure washing plant

InactiveUS6675437B1Reliable outputIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersProcess engineeringThermal contact

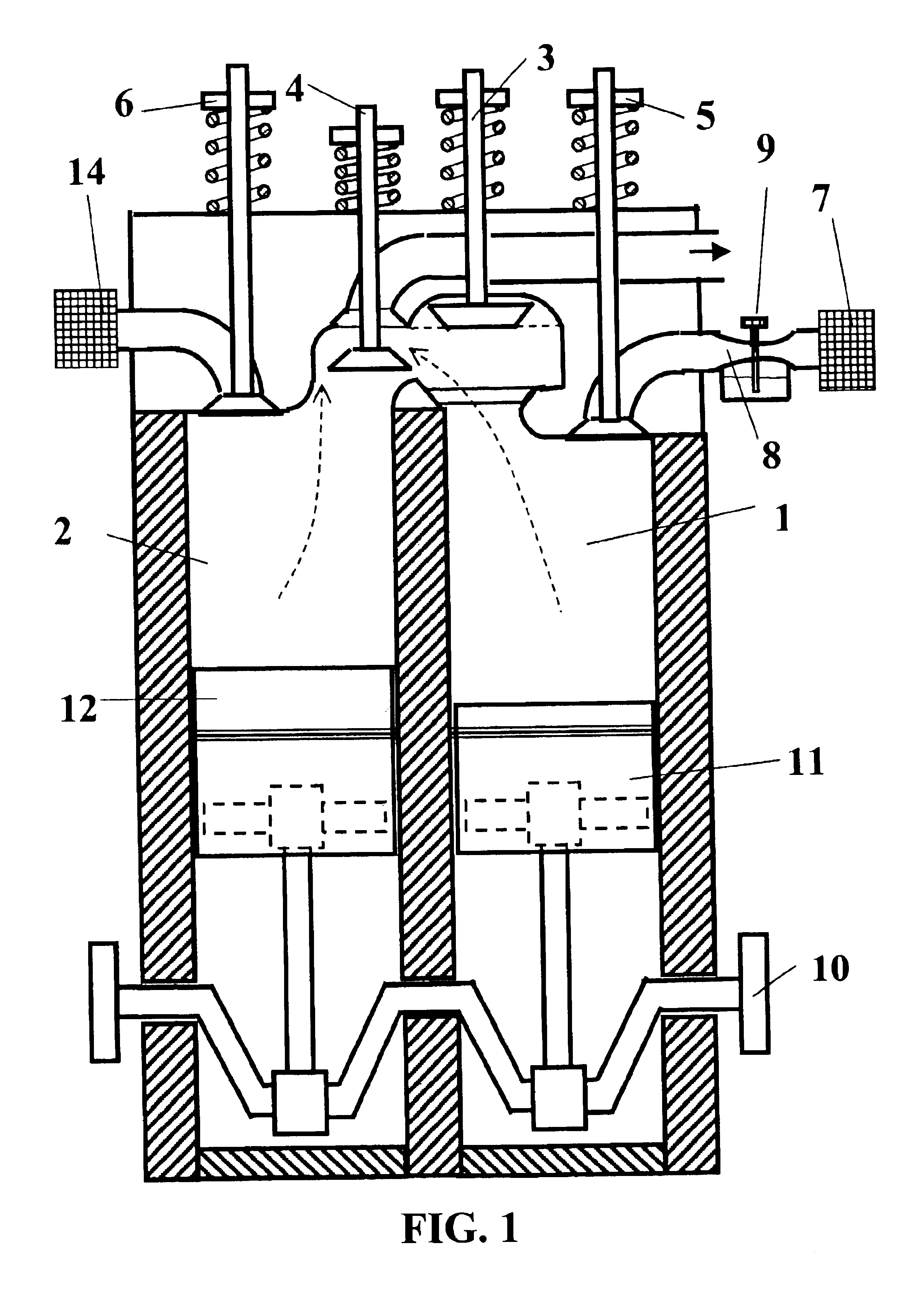

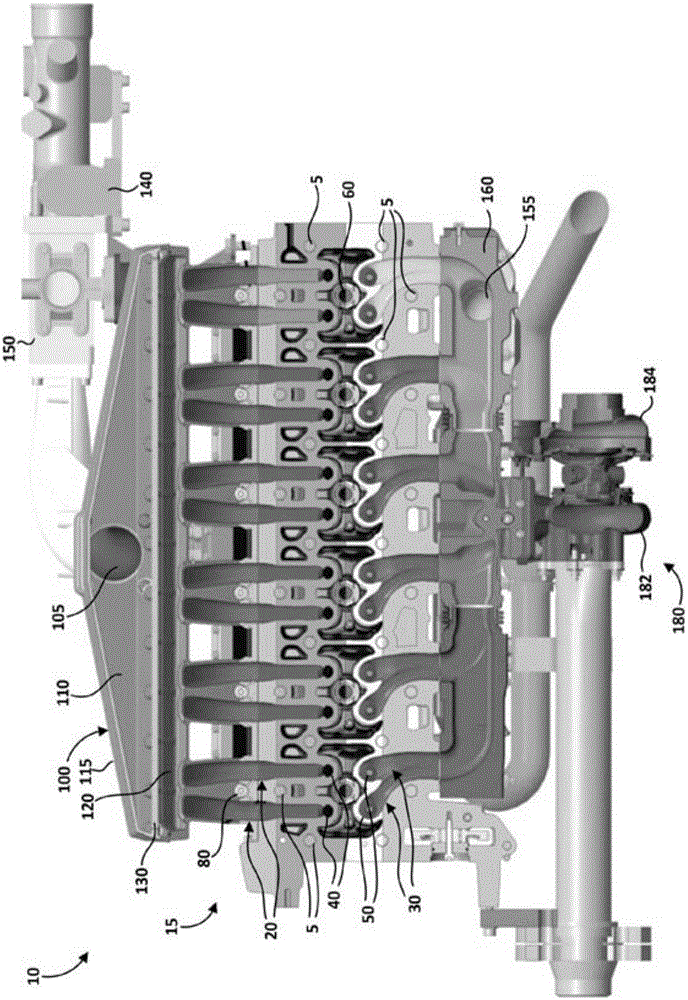

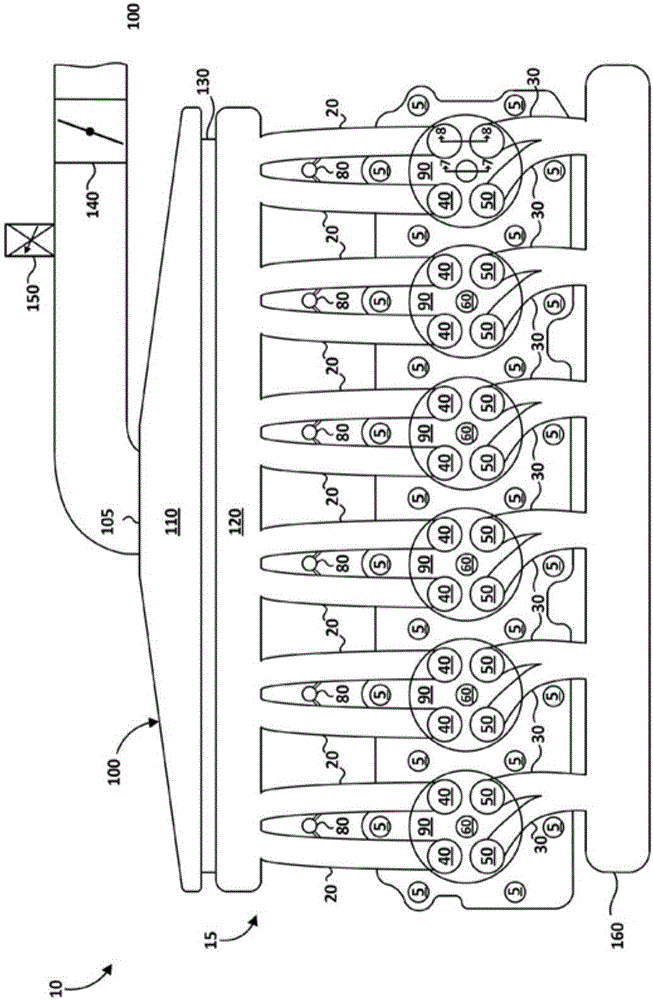

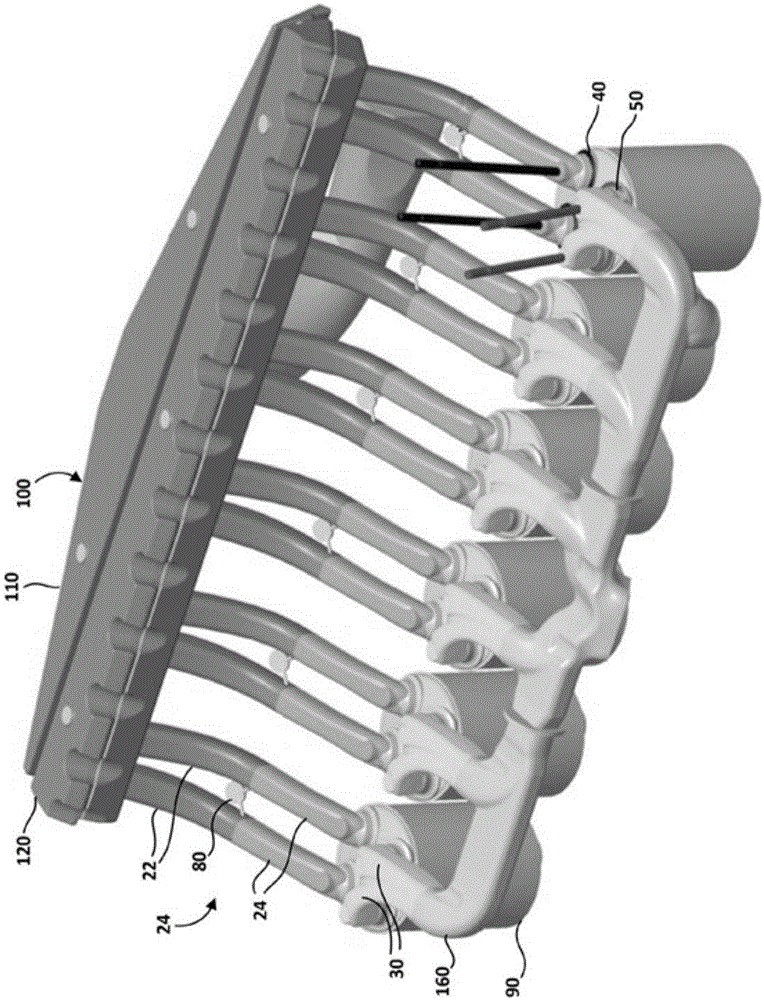

A washing system for high temperature cleaning applications, such as carpet-cleaning, is disclosed that provides a consistent cleaning fluid temperature. The washing system utilizes multiple heat exchangers and multiple heat paths. The heating and power source is provided by a medium duty, diesel cycle engine. Multi-stage heating involves heat transfer from the engine's coolant to the cleaning fluid and heat transfer from the exhaust of the engine to the cleaning fluid via an intermediate medium. The system also includes a fluid clutch used to engage a power takeoff from the engine to operate the pump and blower of the washing plant. A failsafe source cutoff diverts the exhaust flow from thermal contact with an intermediate heat transfer oil.

Owner:BLUE LINE EQUIP

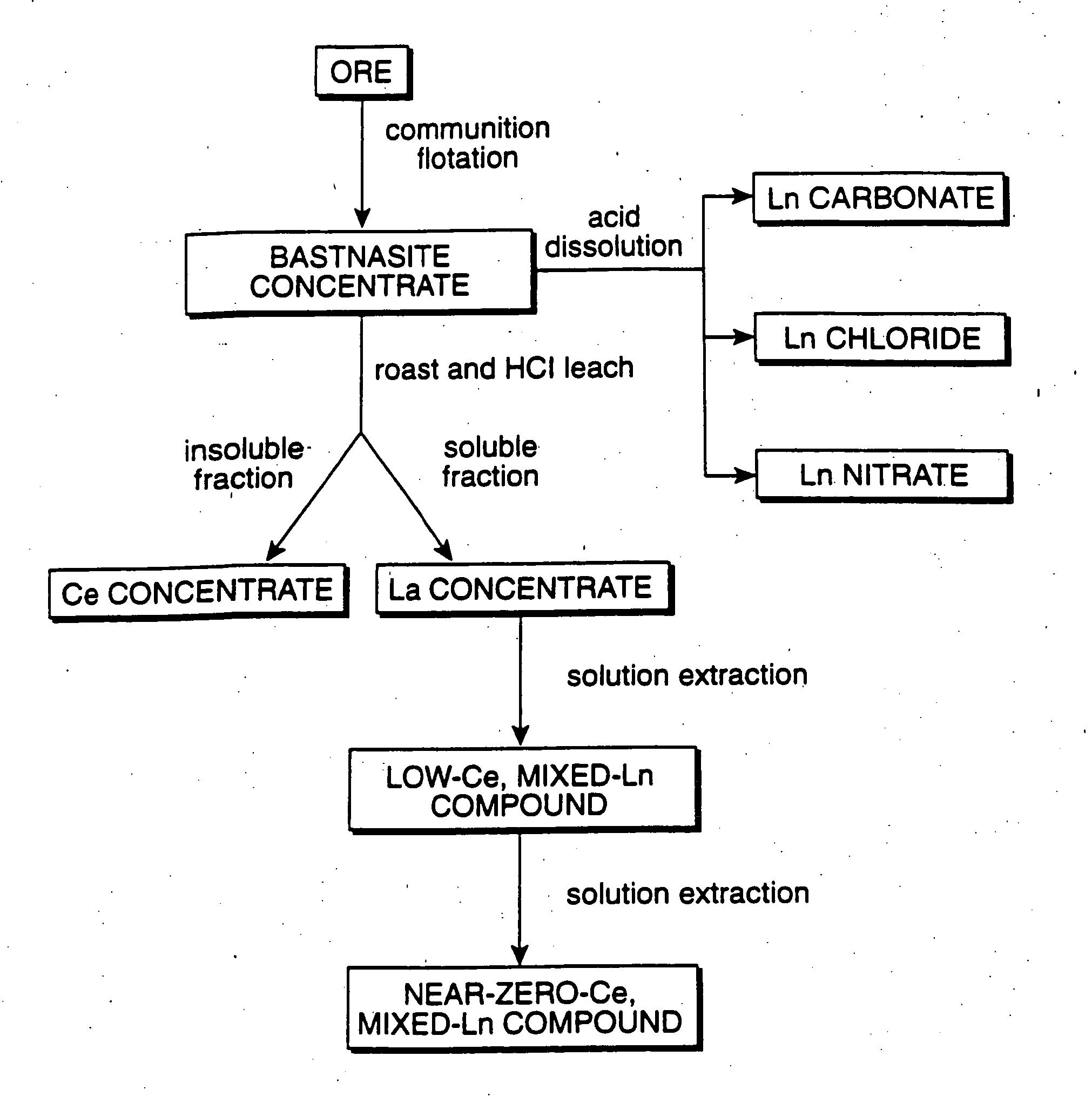

Method of controlling emissions from a diesel cycle internal combustion engine with perovskite-type metal oxide compounds

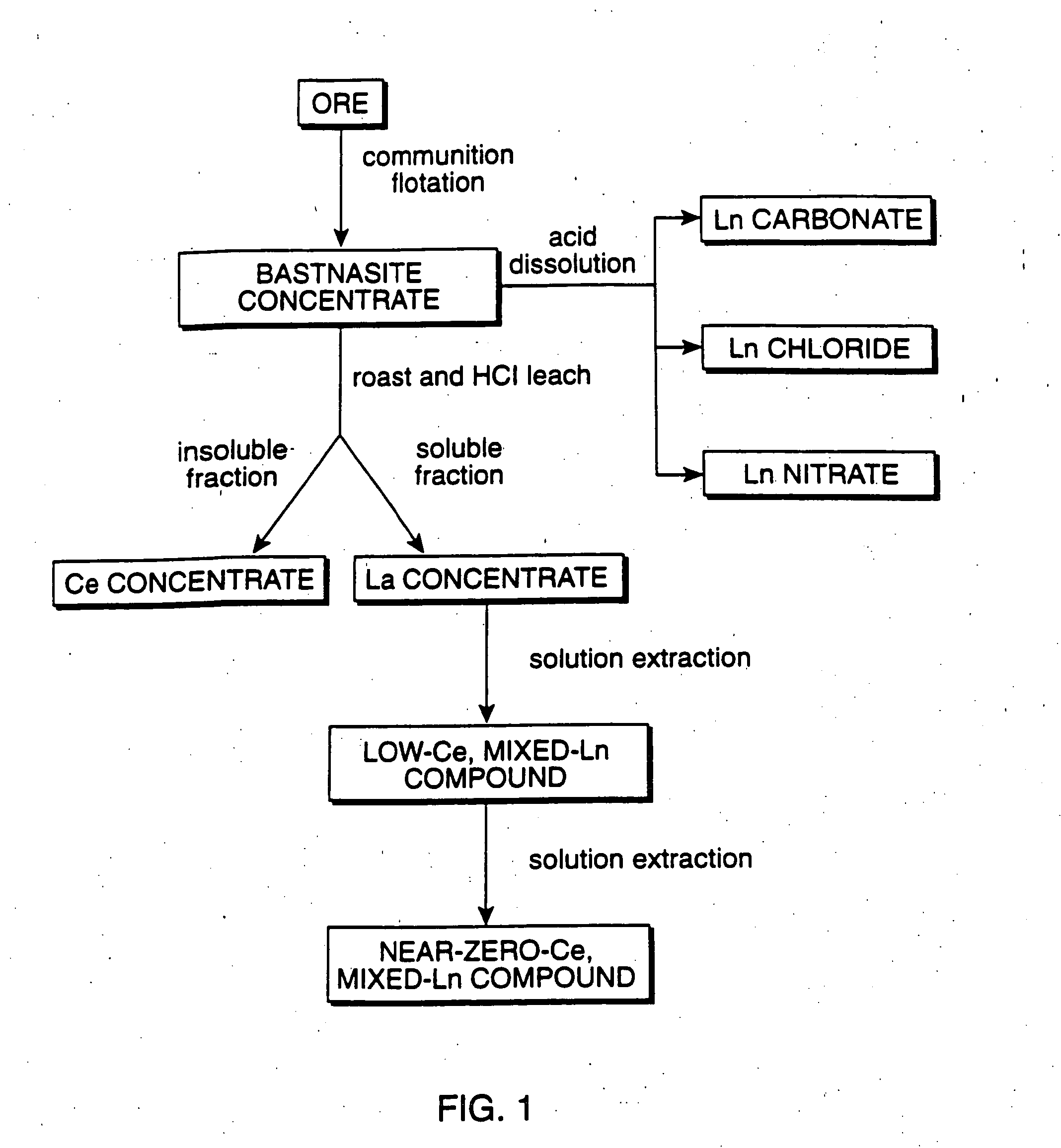

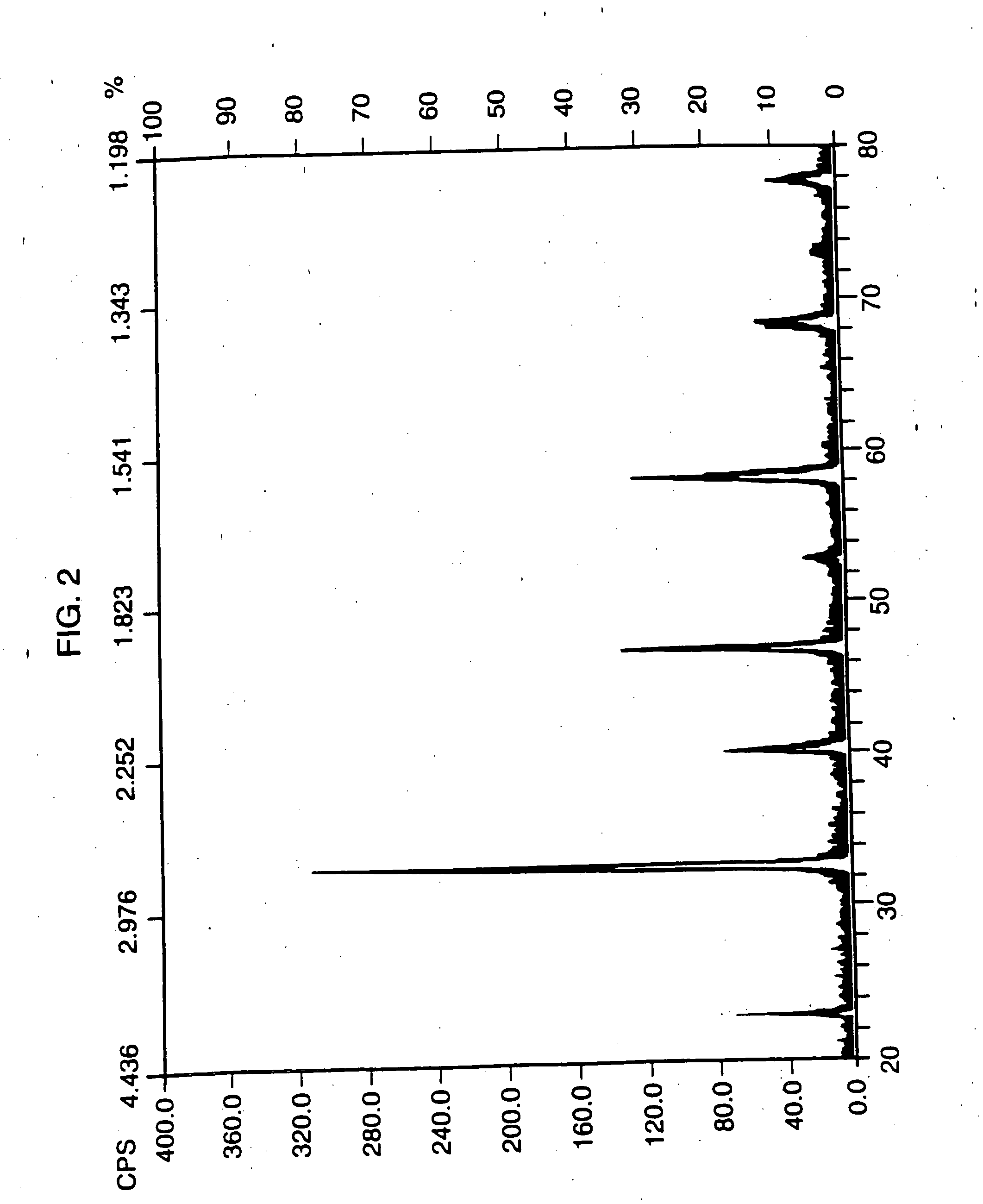

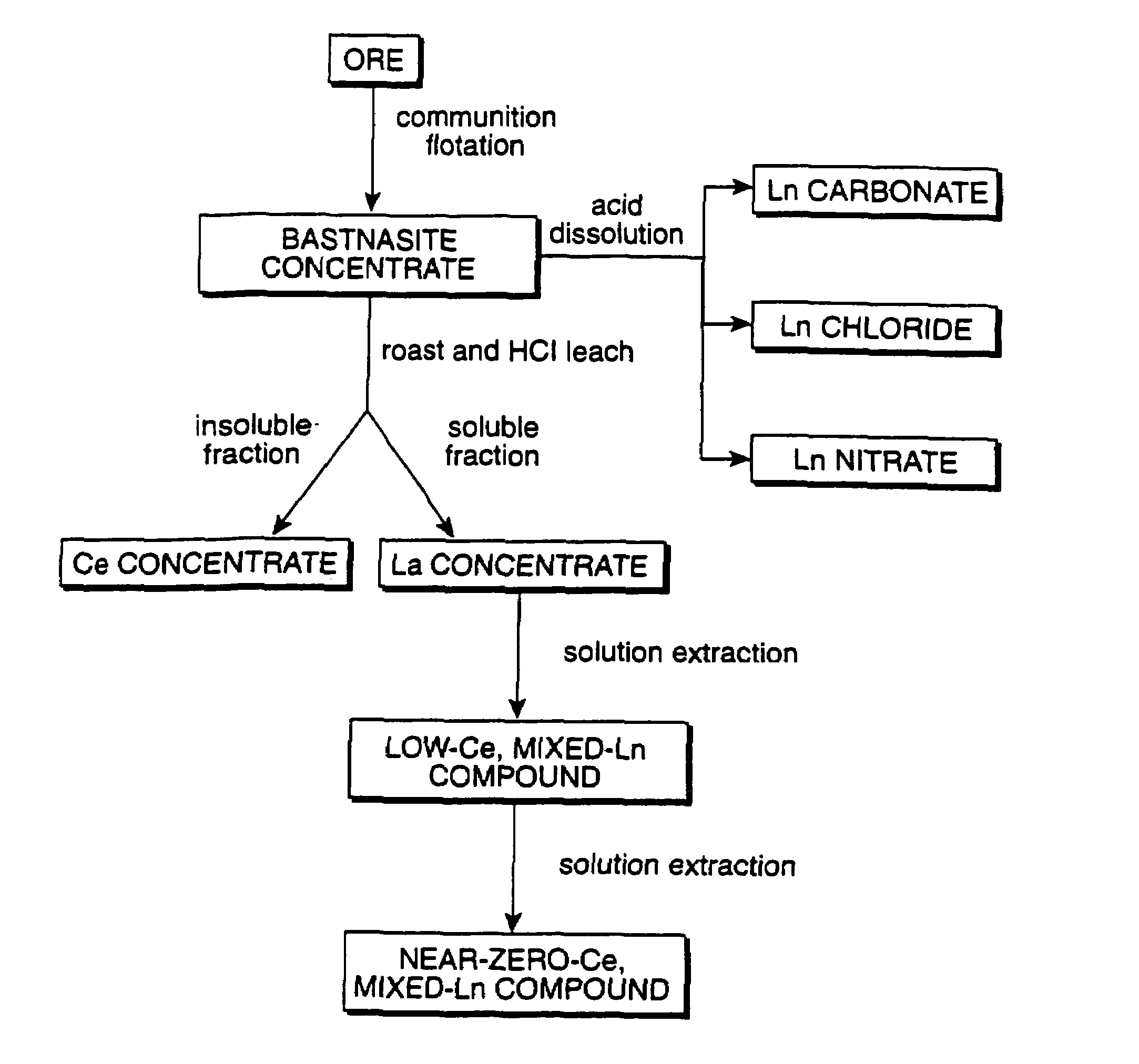

Methods of controlling emissions from a diesel engine are provided. The method includes contacting the emissions with a perovskite-type catalyst consisting essentially of a metal oxide composition represented by the general formula Aa-xBxMOb, in which A is a mixture originally in the form of single phase mixed lanthanides collected from bastnasite; B is a divalent or monovalent cation; M is at least one element selected from the group consisting of M is at least one element selected from the group consisting of elements of an atomic number of from 22 to 30, 40 to 51, and 73 to 80; a is 1 or 2; b is 3 when a is 1 or b is 4 when a is 2; and x is a number defined by 0<x<0.7. The perovskite-type catalyst may be used to oxidize hydrocarbons and carbon monoxide and to control particulate emissions in the diesel exhaust.

Owner:CATALYTIC SOLUTIONS INC

Method of controlling emissions from a diesel cycle internal combustion engine with perovskite-type metal oxide compounds

Methods of controlling emissions from a diesel engine are provided. The method includes contacting the emissions with a perovskite-type catalyst consisting essentially of a metal oxide composition represented by the general formula Aa−xBxMOb, in which A is a mixture originally in the form of single phase mixed lanthanides collected from bastnasite; B is a divalent or monovalent cation; M is at least one element selected from the group consisting of M is at least one element selected from the group consisting of elements of an atomic number of from 22 to 30, 40 to 51, and 73 to 80; a is 1 or 2; b is 3 when a is 1 or b is 4 when a is 2; and x is a number defined by 0<x<0.7. The perovskite-type catalyst may be used to oxidize hydrocarbons and carbon monoxide and to control particulate emissions in the diesel exhaust.

Owner:CATALYTIC SOLUTIONS INC

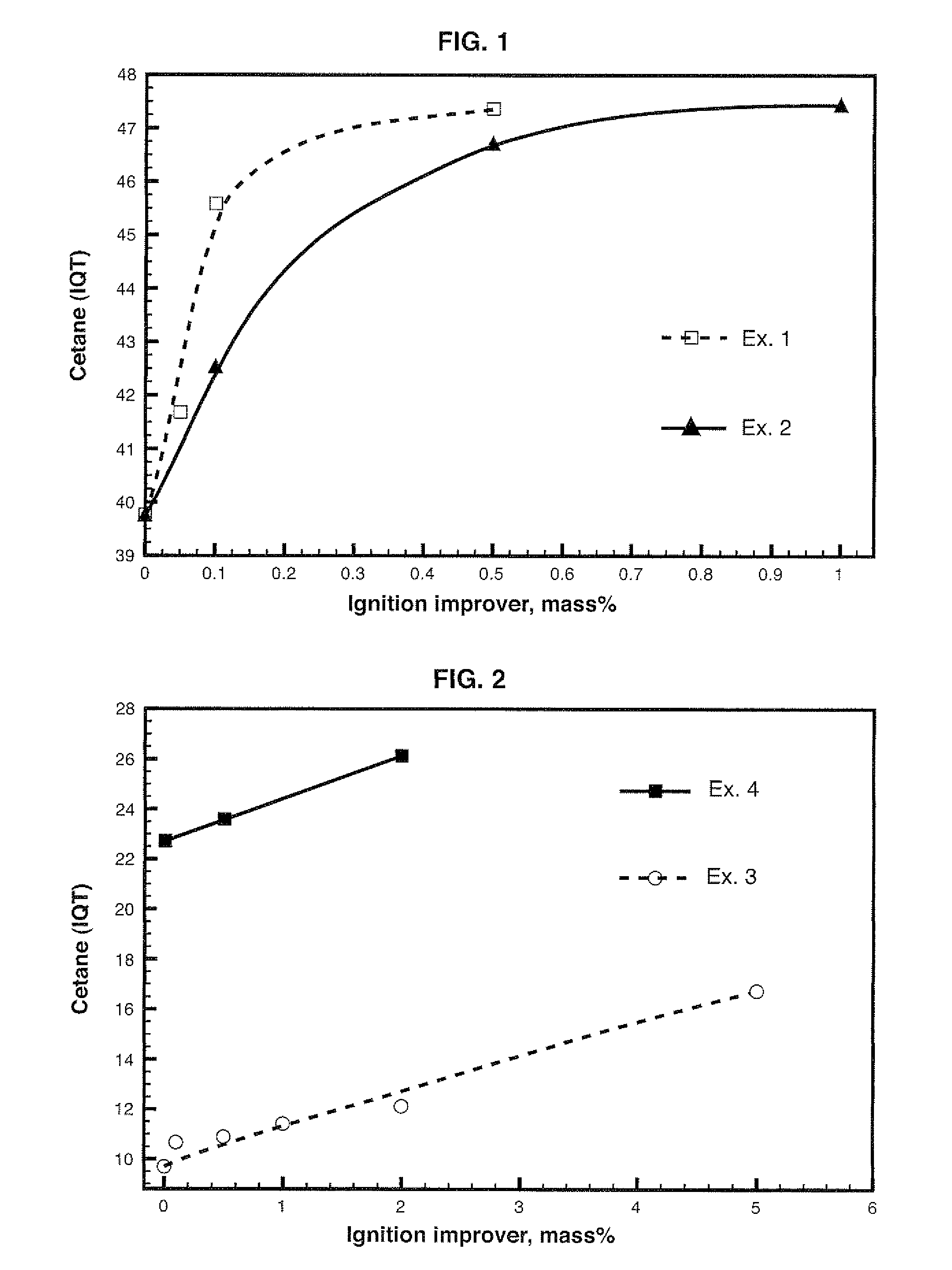

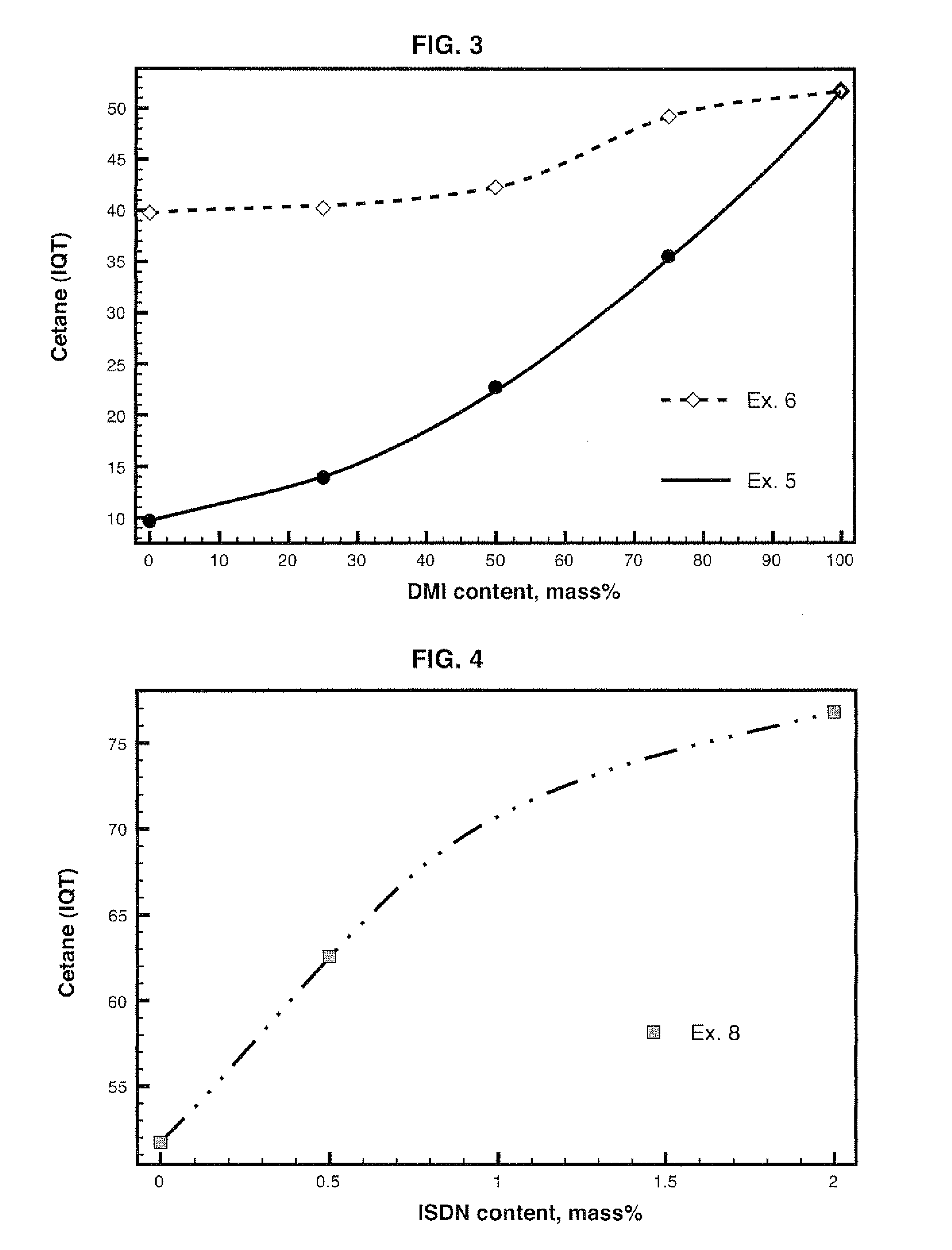

Diesel cycle fuel compositions containing dianhydrohexitols and related products

Diesel cycle fuel compositions are described containing at least one dianhydrohexitol compound according to the general formula 2 and / or itsderived hydrocarbyl ethers or nitric ethers compounds, where the R′ and R″ substituents are both H or one or both of R′ and R″ is alkyl, cycloalkyl or phenyl, or one or both are —NO2. A preferred fuel composition is that containing dimethyl isosorbide (DMI) added or not of isosorbide dinitrate (ISDN) as ignition improver. The dianhydrohexitols compounds form compositions with at least one of the components selected among petroleum-derived diesel fuel, biodiesel, ethanol and water. The mixture of DMI and ISDN has excellent cetane number (IQT). Still, the oxygenated nature of the dianhydrohexitols and related compounds of the fuel compositions inhibits soot formation upon burning of the said Diesel cycle fuel compositions.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

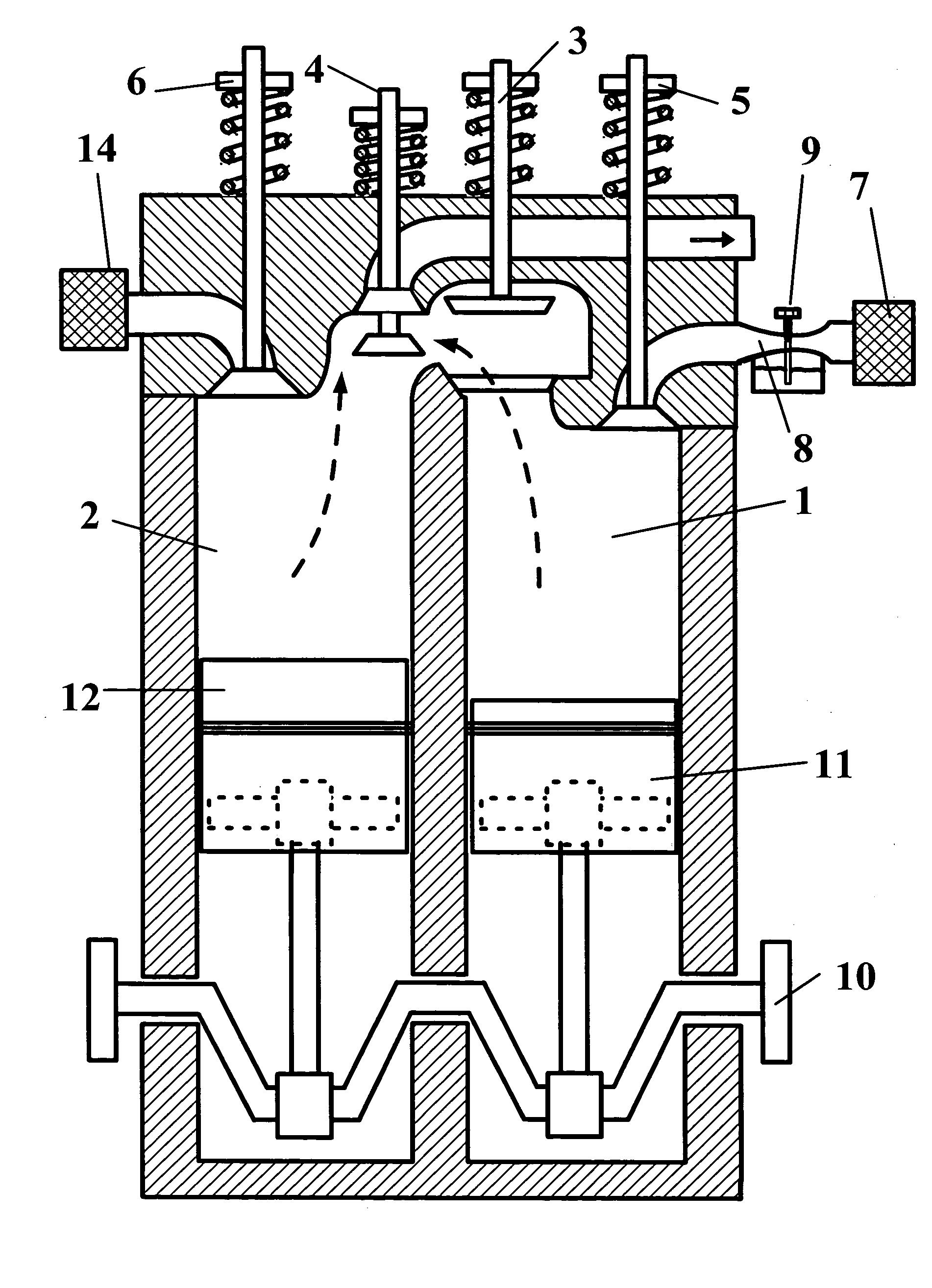

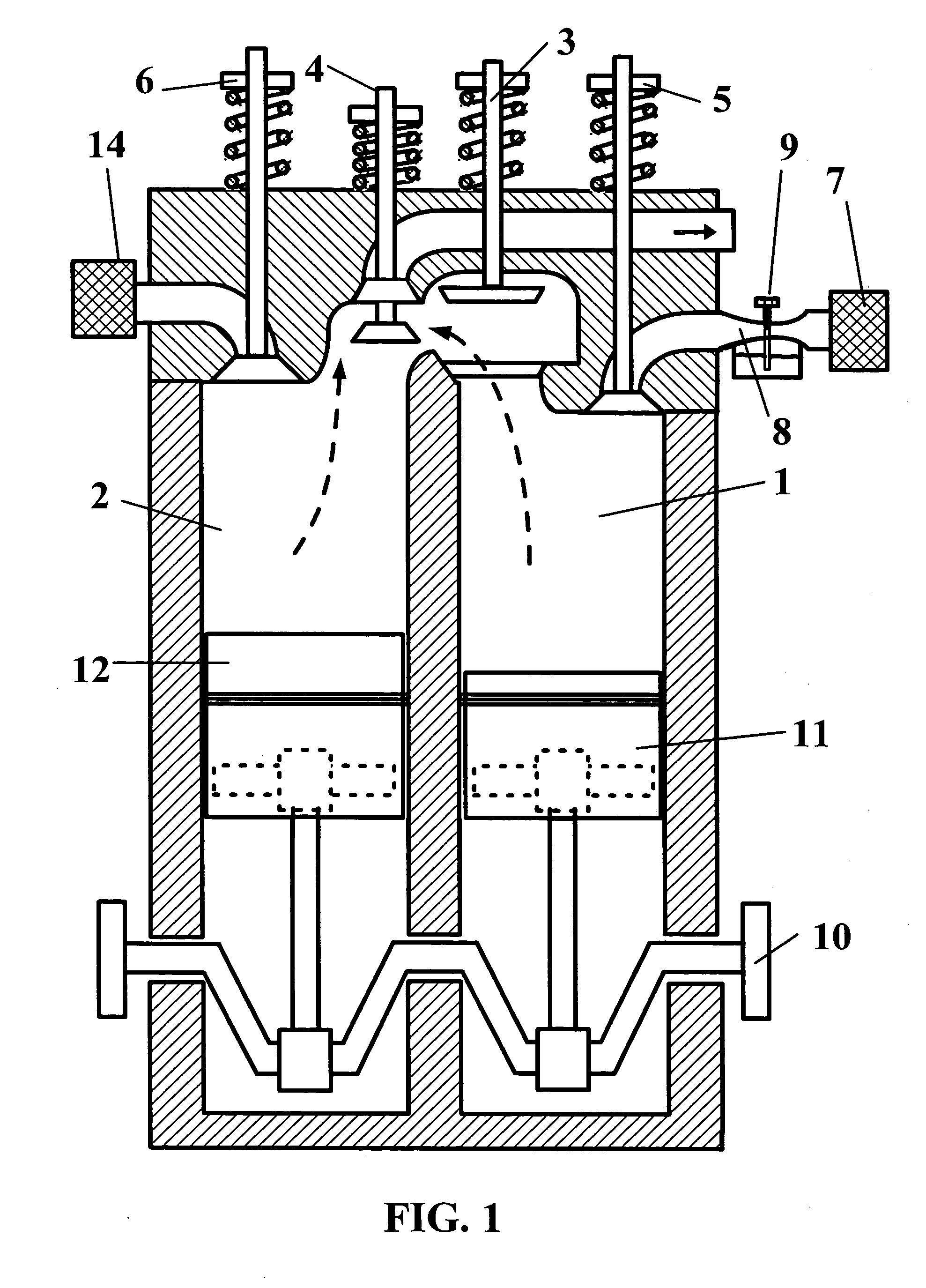

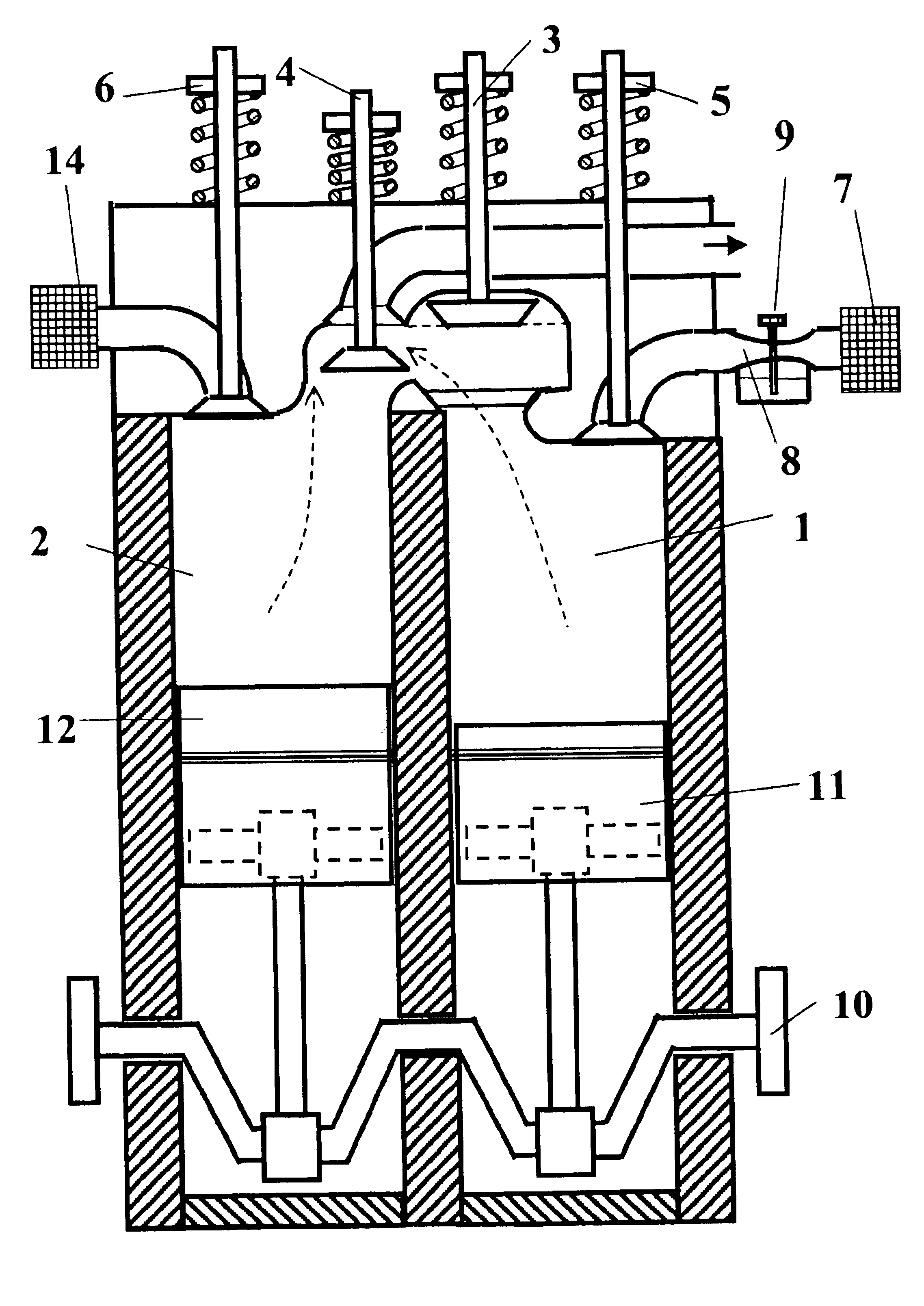

Compression ignition engine by air injection from air-only cylinder to adjacent air-fuel cylinder

InactiveUS6994057B2Higher effective compression ratioImprove reliabilityCombustion enginesEngine controllersDetonationEngineering

Owner:WEST VIRGINIA UNIVERSITY

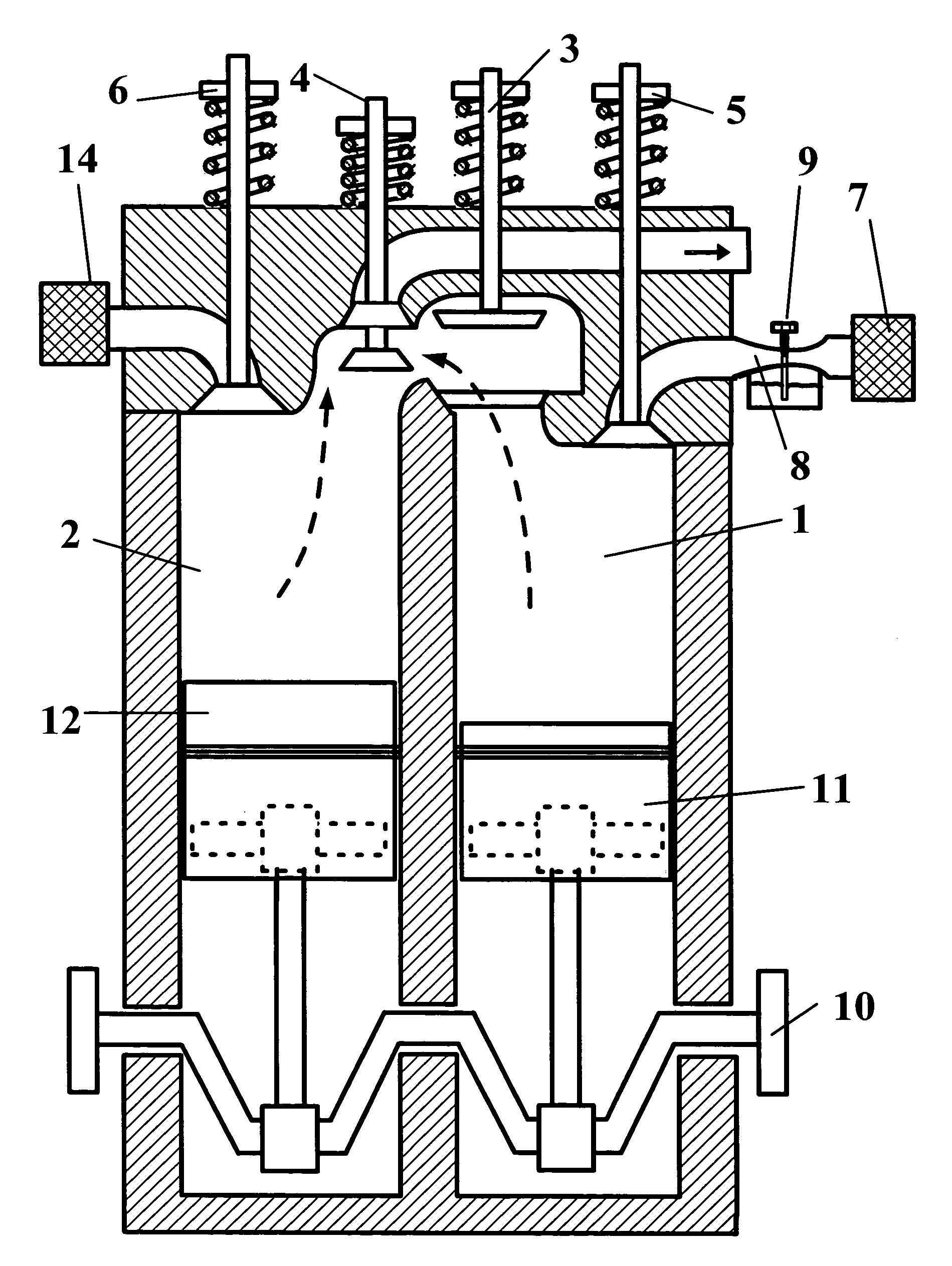

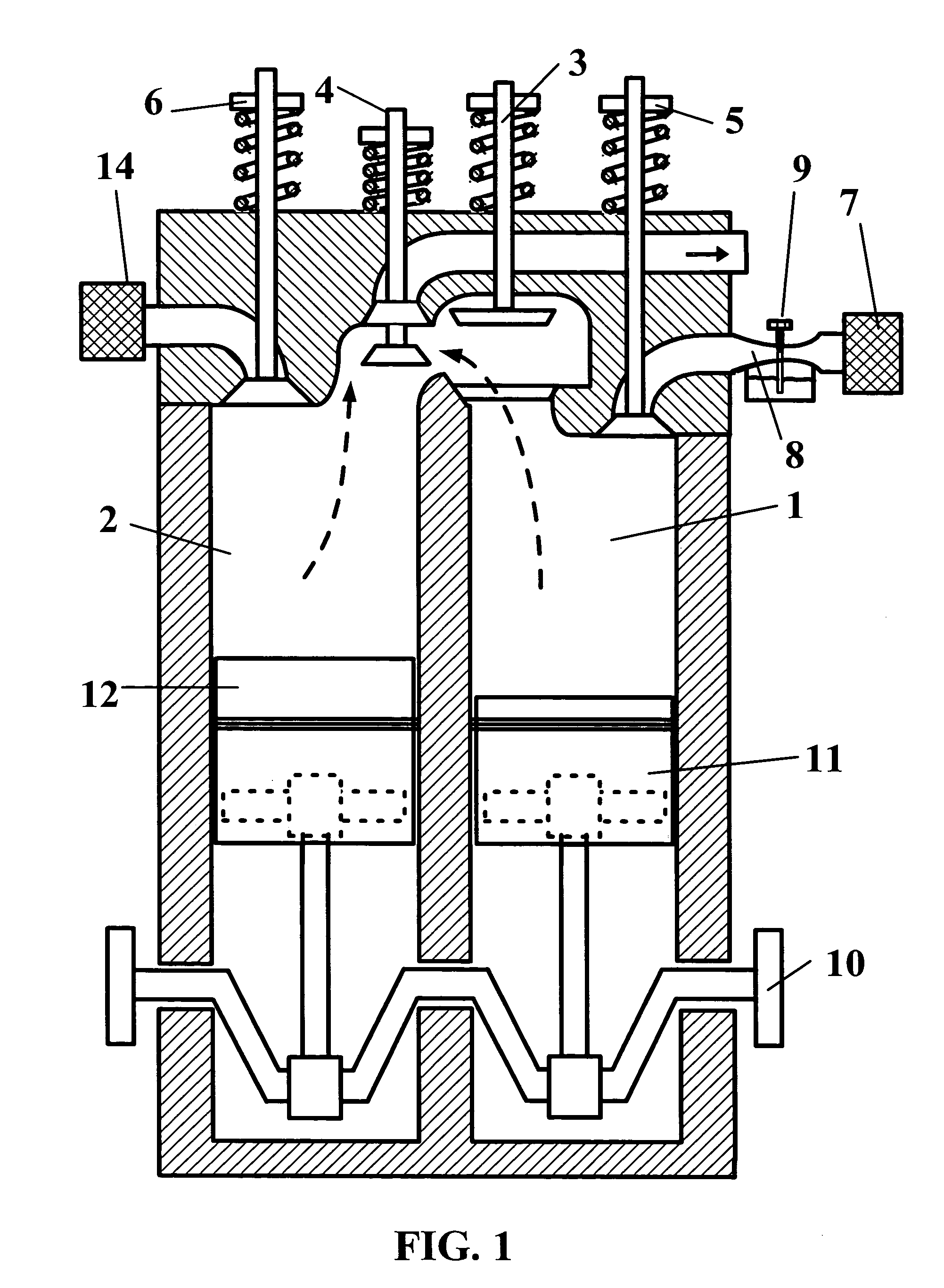

Compression ignition engine by air injection from air-only cylinder to adjacent air-fuel cyliner

InactiveUS20050199191A1More fuel efficientMore reliableCombustion enginesEngine controllersDetonationFuel cells

The herein disclosed IC engine relies on air injection for ignition instead of Otto cycle spark or Diesel cycle fuel injection. One or more adjacent cylinders are connected by a valve, which is opened near the end of their compression strokes so that high-pressure air can inject into the cylinder containing the air fuel mixture, and induce detonation ignition at top dead center. During expansion the cylinder-connecting valve remains open and provides equal pressure on both cylinders, which is substantially higher than possible in Otto cycle. Constant volume heat addition makes this engine also more efficient than Diesel cycle. The absence of spark ignition or high pressure fuel injectors make this engine more economical, more reliable, and scalable down to very small size unlike Diesel fuel injectors which cannot meter small quantities and eliminate the Diesel cold starting problem. Engine can serve as reactor for generating high temperature hydrogen to power high temperature fuel cells.

Owner:WEST VIRGINIA UNIVERSITY

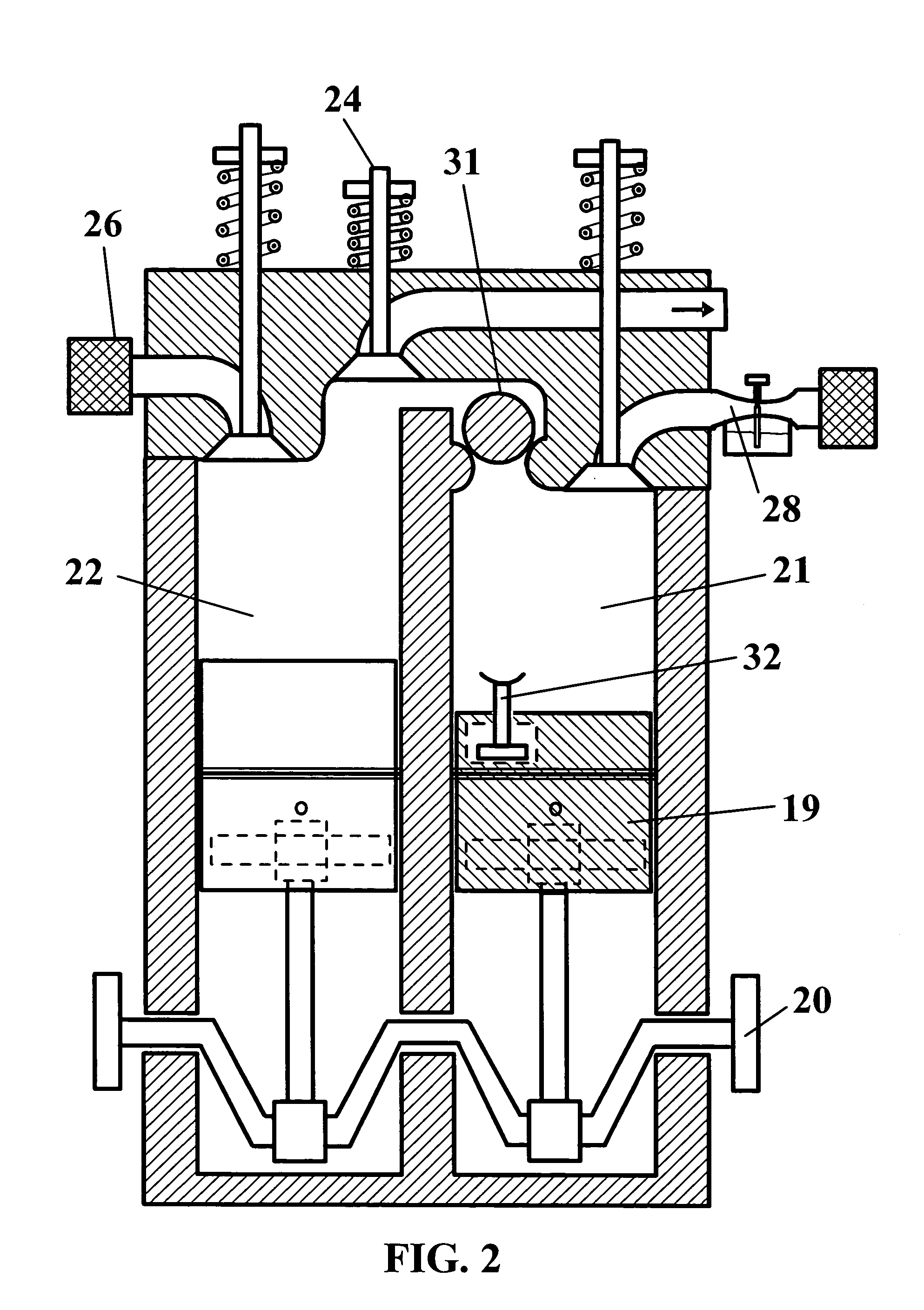

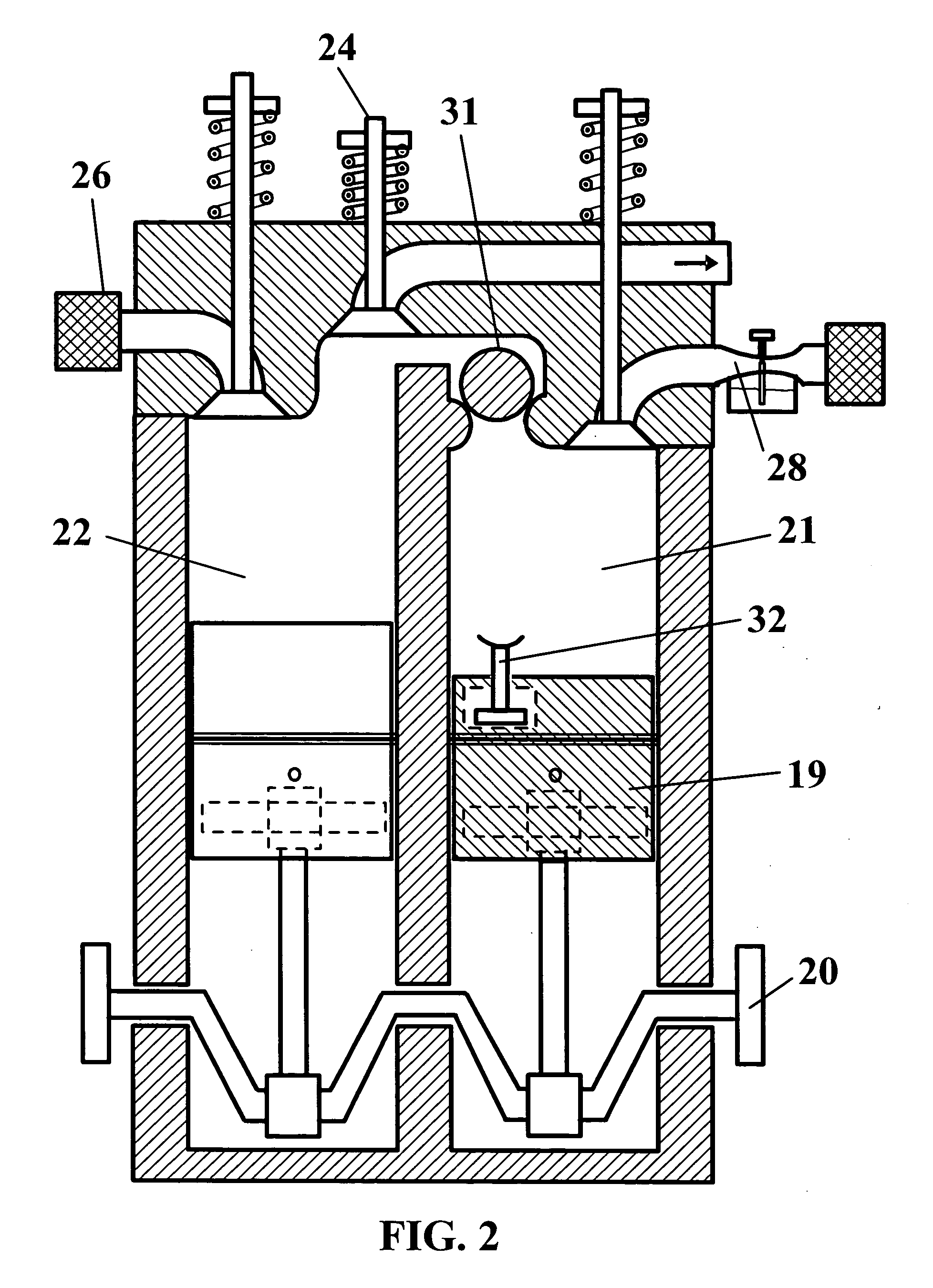

Compression ignition by air injection cycle and engine

InactiveUS6899061B1Improve efficiencyRaise the ratioInternal combustion piston enginesEngine controllersHigh pressureInternal combustion engine

The herein disclosed Compression Ignition By Air Injection (CIBAI) cycle and internal combustion engine has following advantages over Otto and Diesel cycles: higher thermal efficiency and operating like a stratified charge engine on lean mixtures. More reliable by lack off: spark ignition, high-pressure fuel pump and injectors; throttle valve and cold starting problems. Only one valve is required in addition to the usual I.C. engine components. However the CIBAI cycle requires one or more pairs of piston / cylinders to operate together in phase. During the compression stroke a closed cylinder-connecting valve isolates the cylinders. One cylinder compresses an air-fuel mixture to below knock level. The other cylinder compresses only air to high pressure and temperature. Near top dead center, the cylinder-connecting valve opens allowing the high-pressure air to compress, heat and ignite the pre-evaporated air-fuel mixture. This valve remains open during following power stroke and scavenging of exhaust products.

Owner:VOTOLATO LIVING TRUST DATED JUNE 1 1994 AS WHOLLY AMENDED THE +1

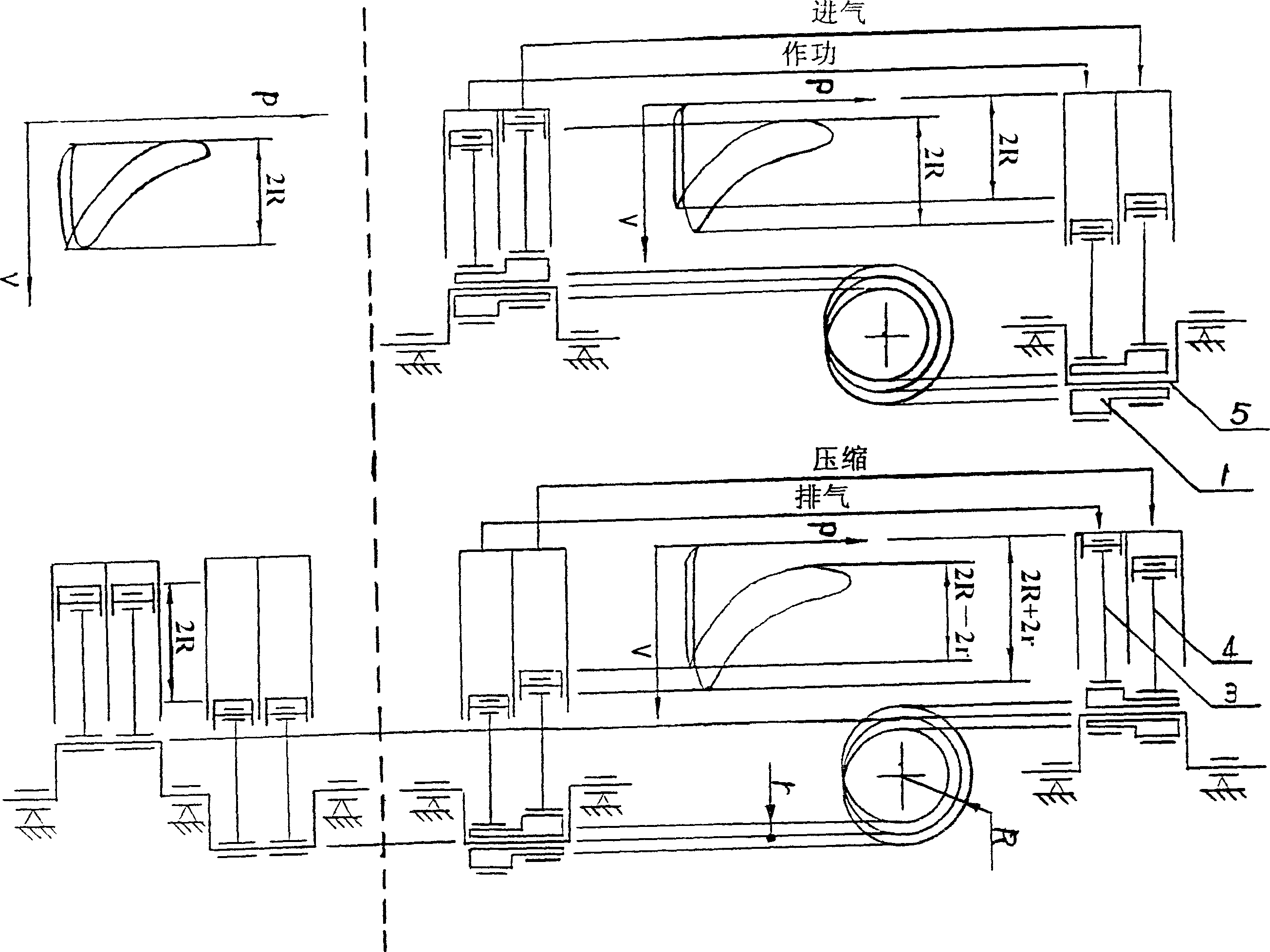

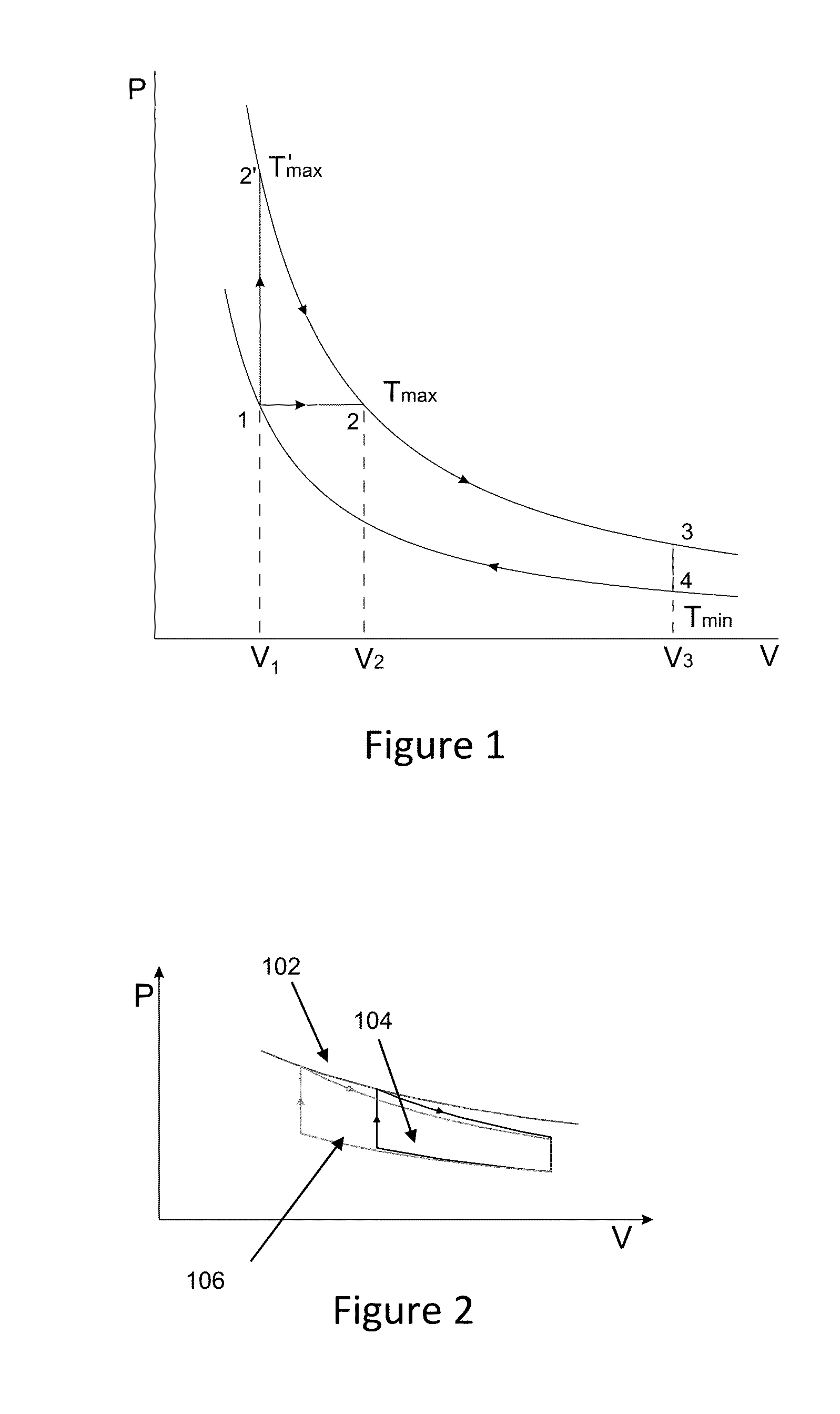

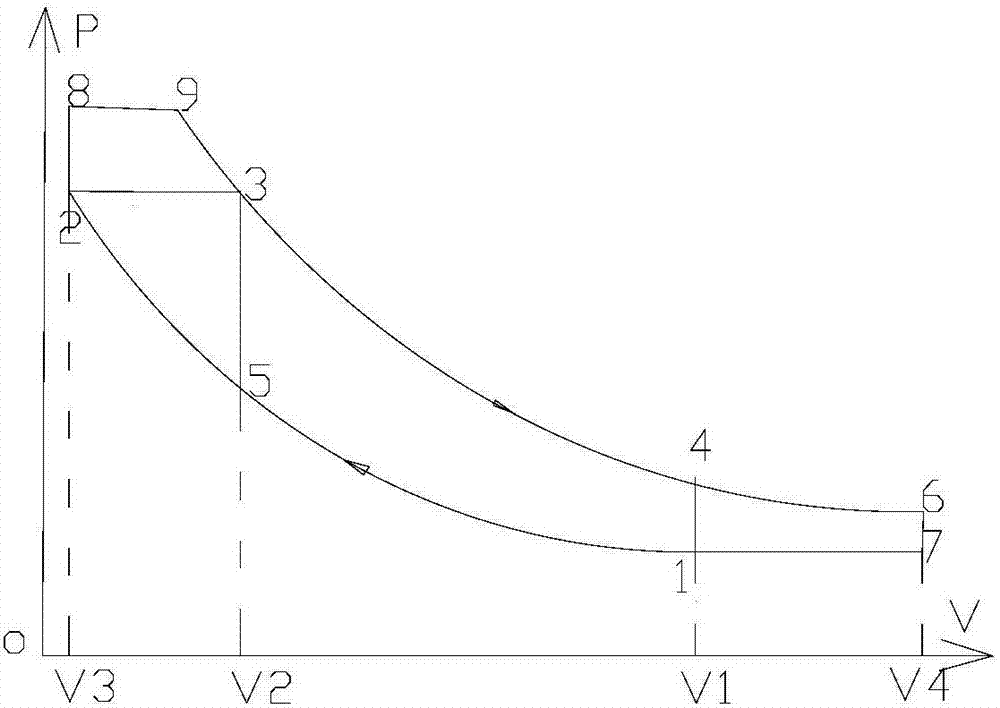

Improvement of Otto cycle, Diesel cycle and Atkinson cycle

InactiveCN1614213AReduce negative work of compressionImprove mechanical efficiencyInternal combustion piston enginesEngine controllersOtto cycleAtkinson cycle

A method for improving the Otto cycle, Diesel cycle and Atkinson cycle is disclosed, which can lower the specific consumption rate of fuel for the reciprocating 4-stroke IC engine and increase its power performance.

Owner:任军

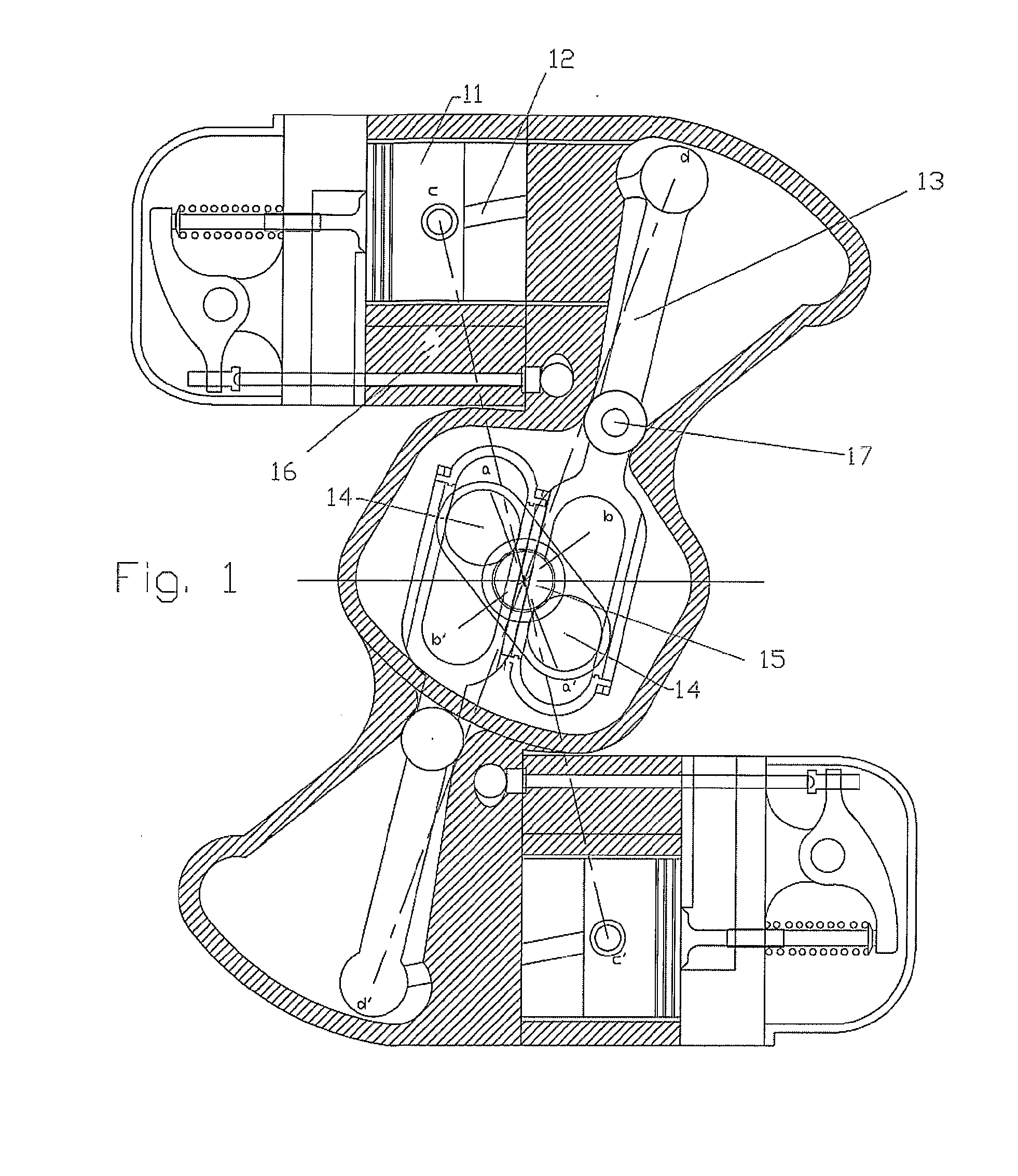

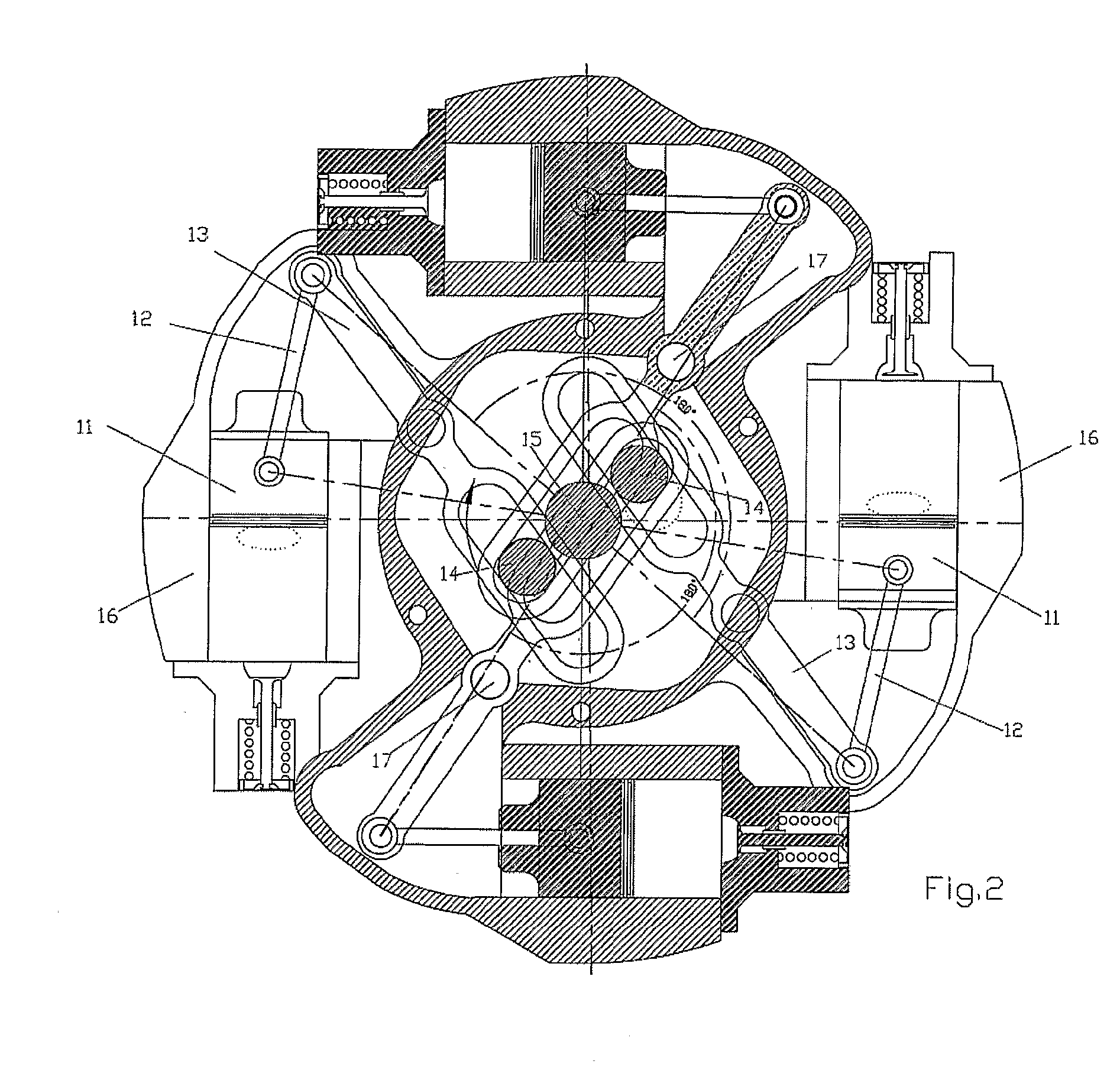

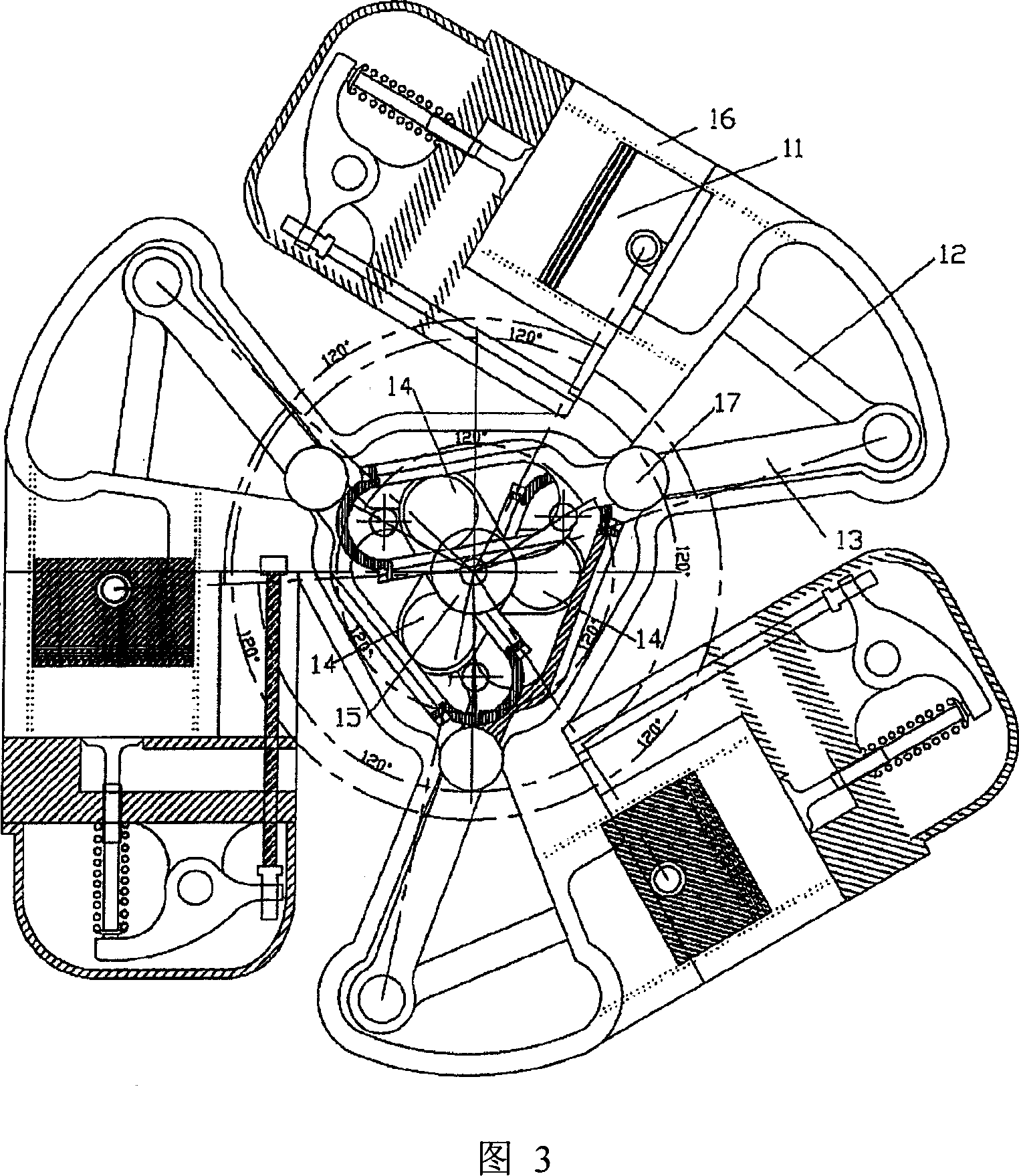

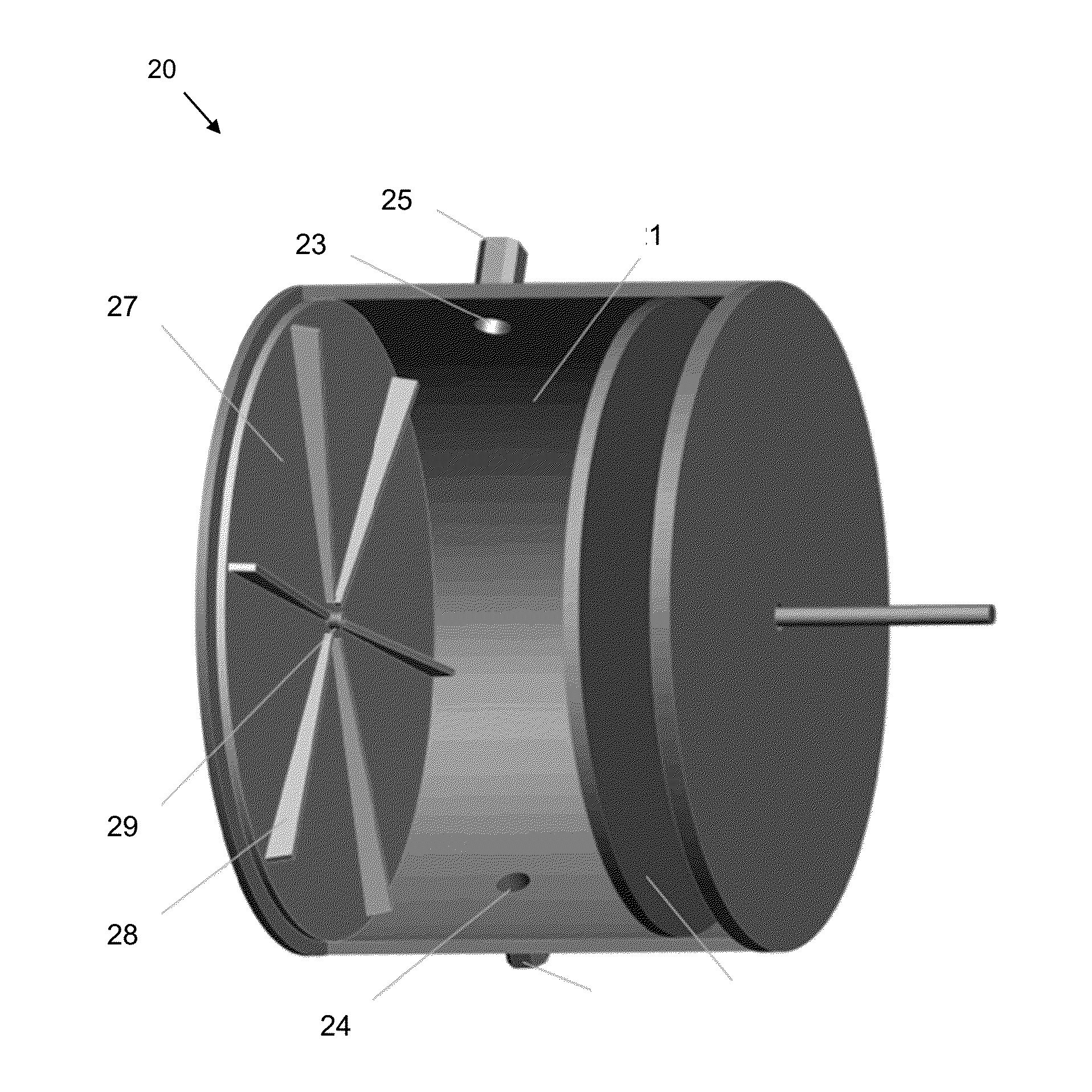

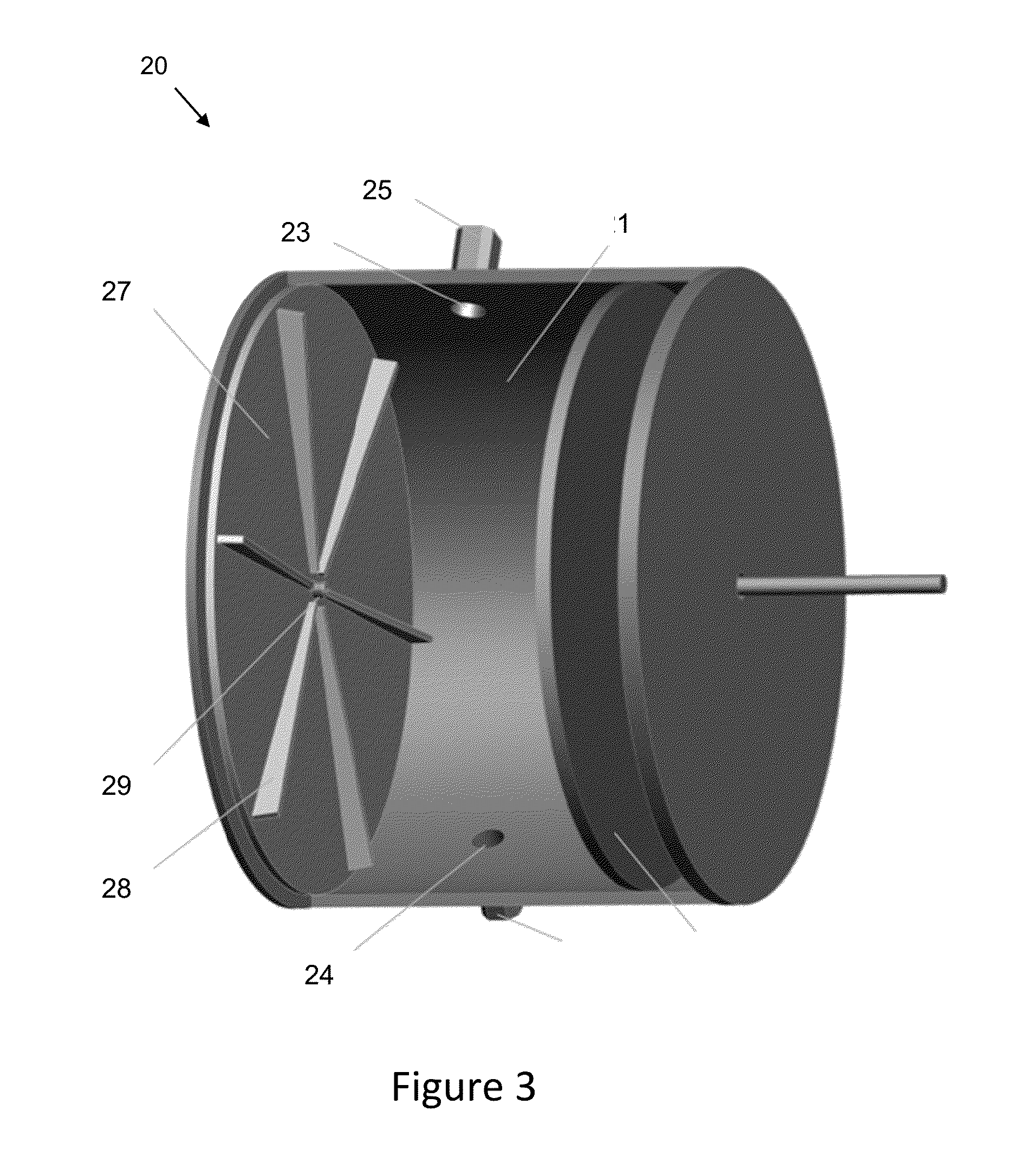

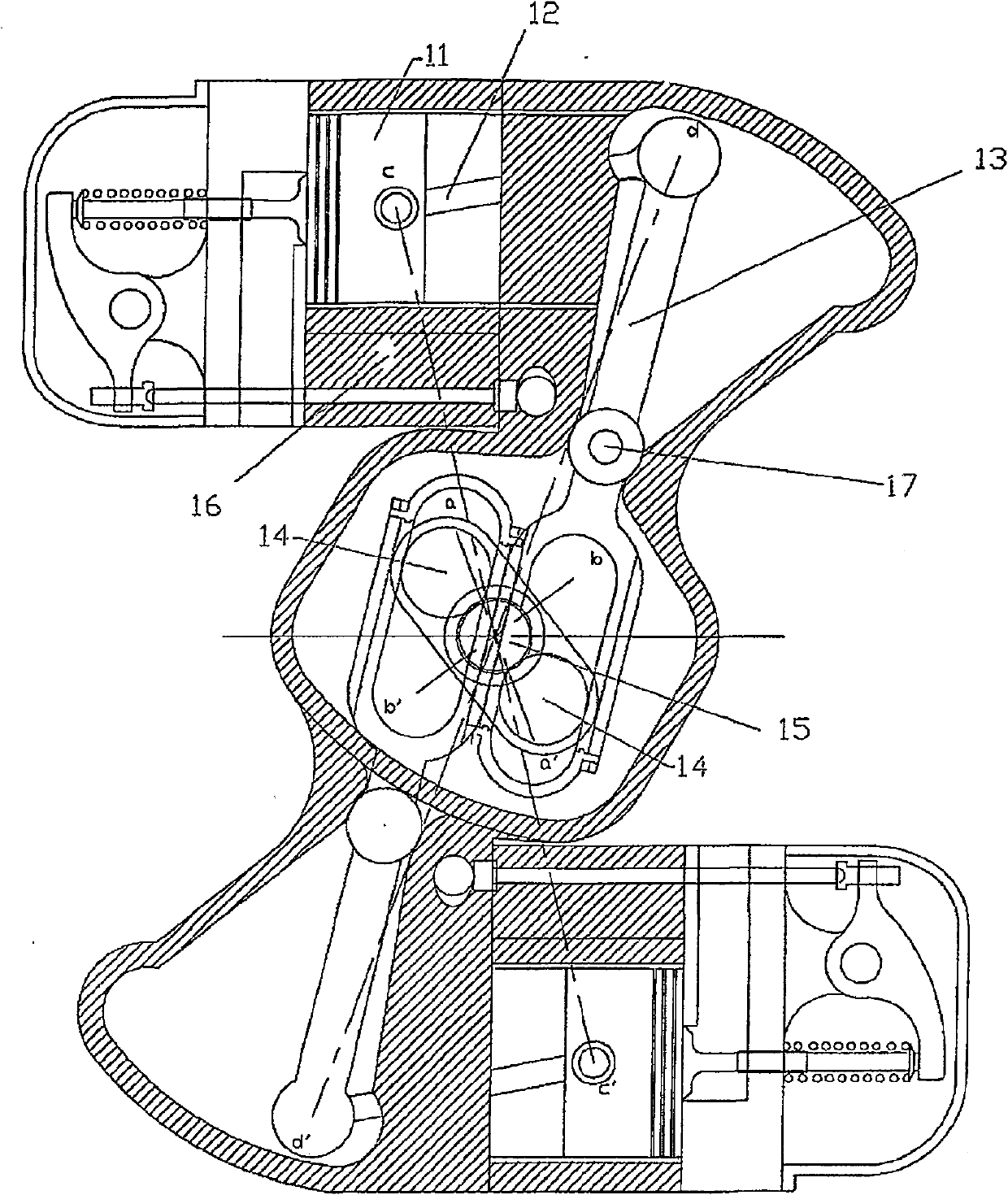

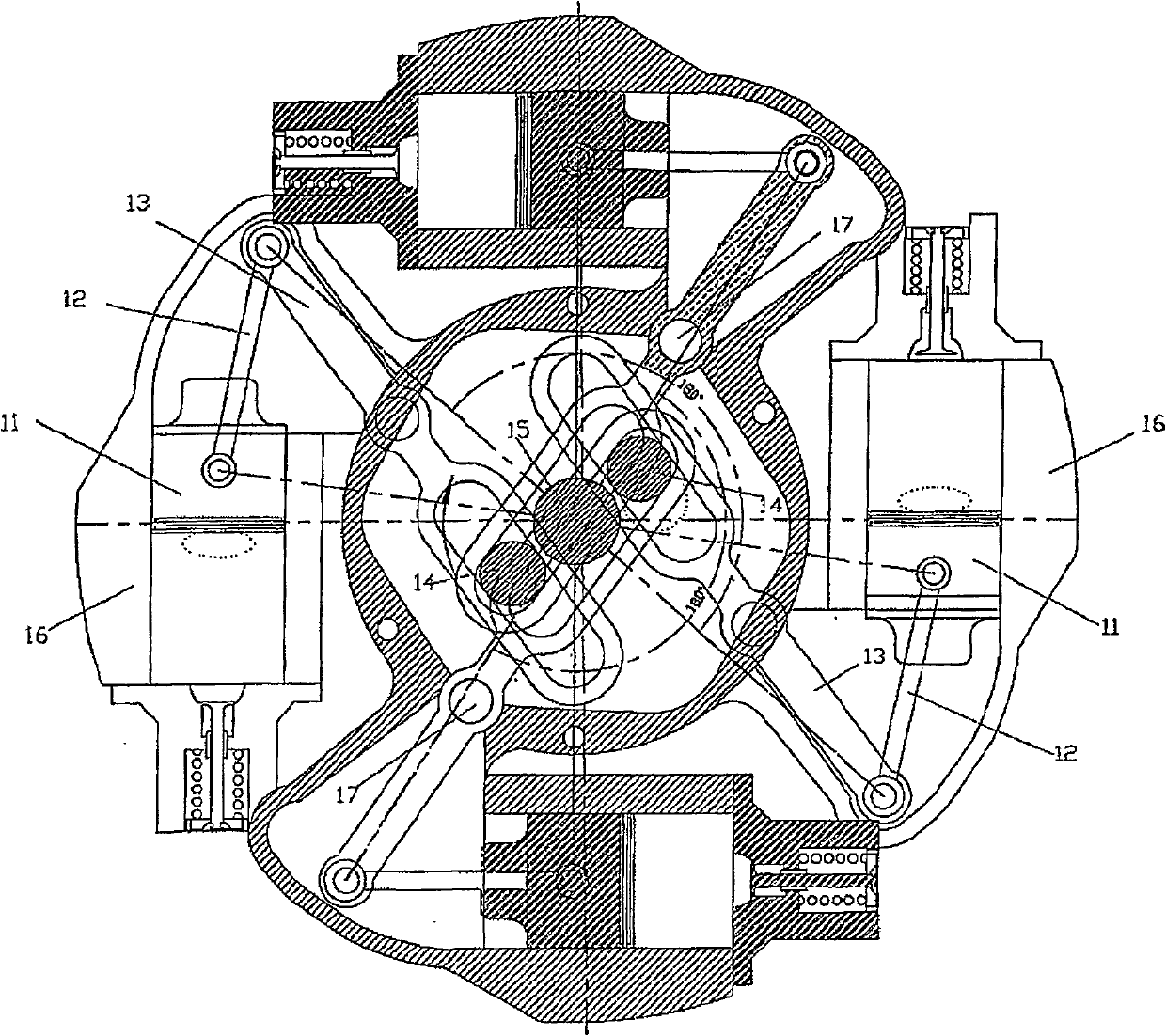

Balanced Rotary Engine

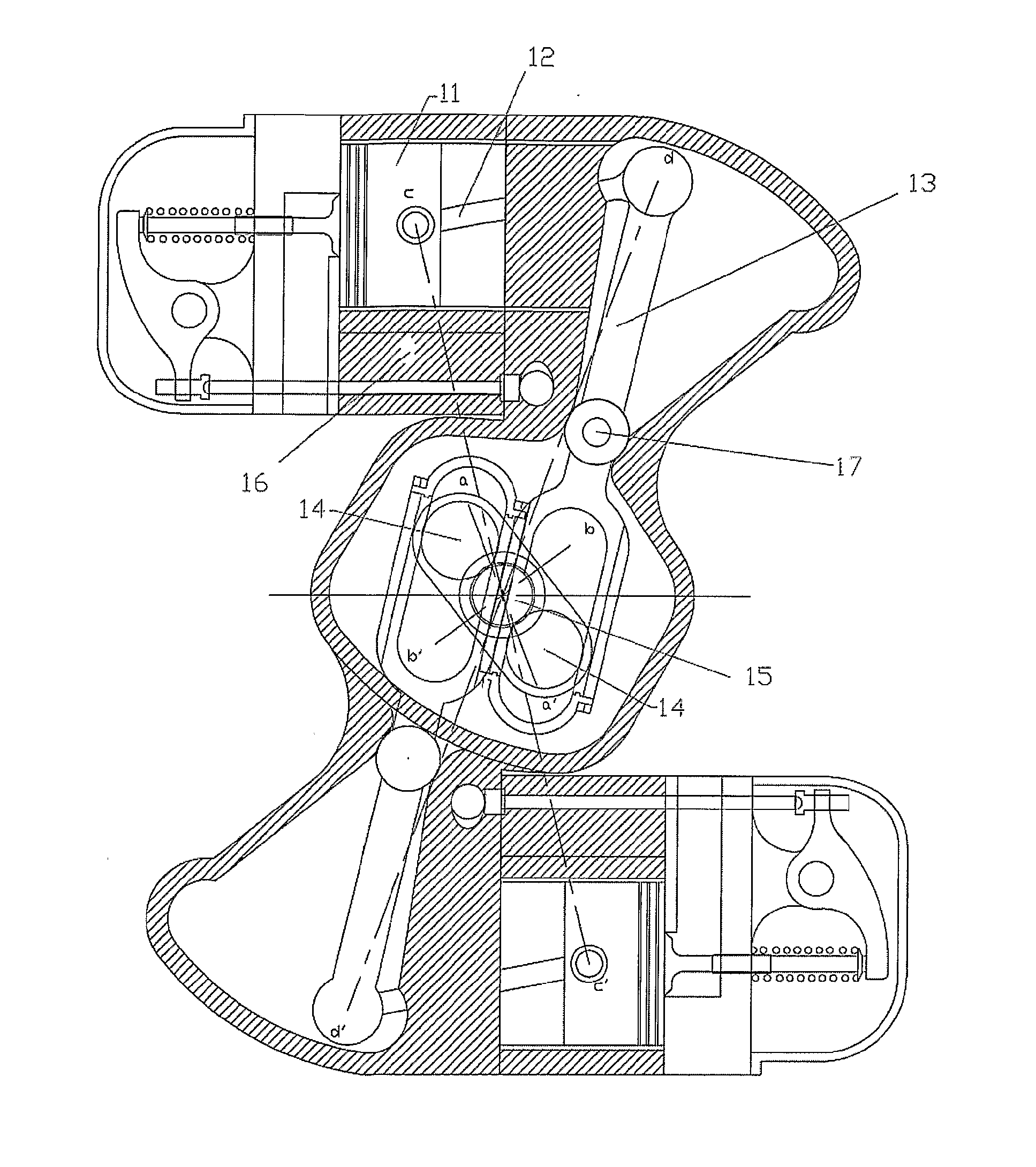

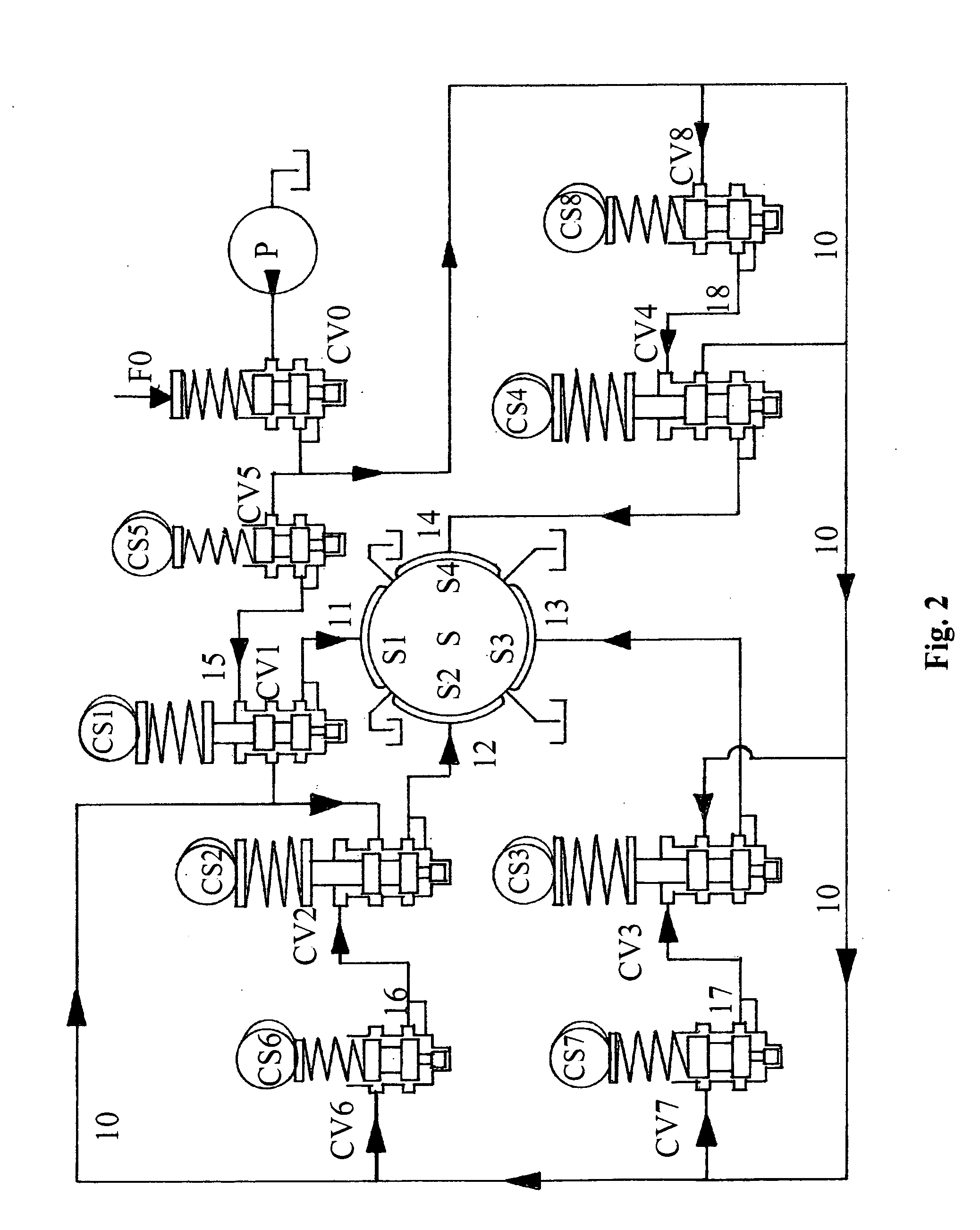

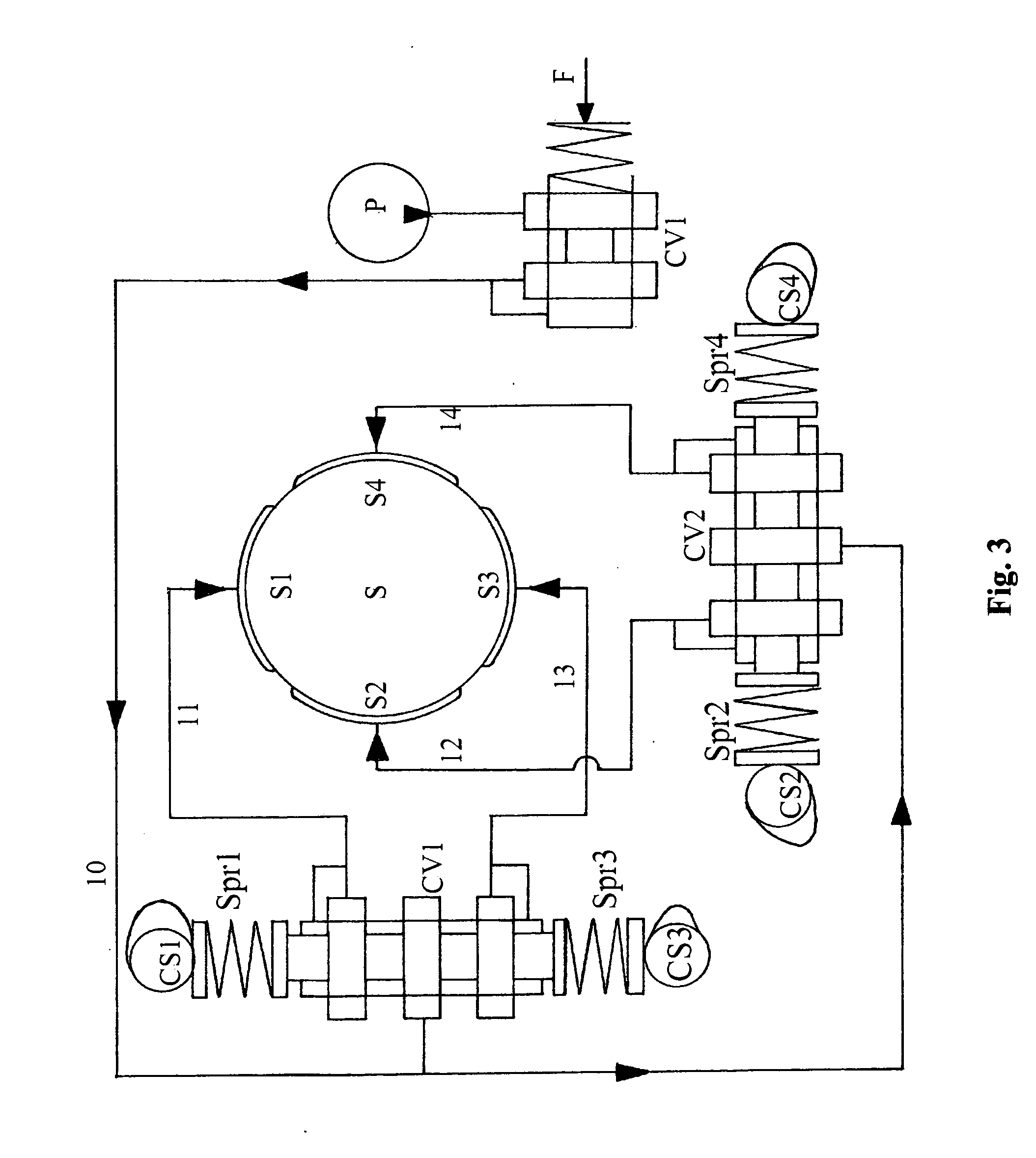

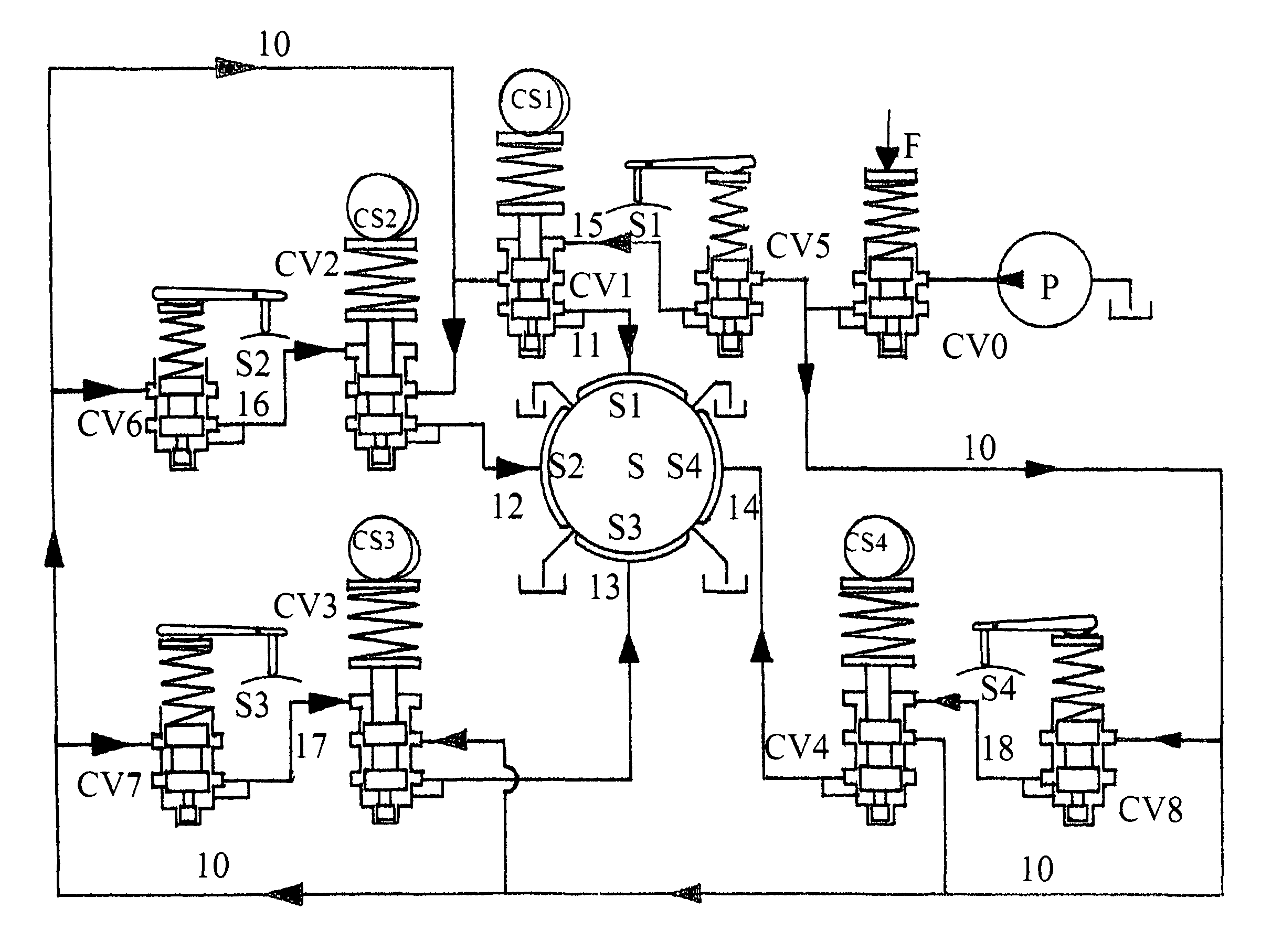

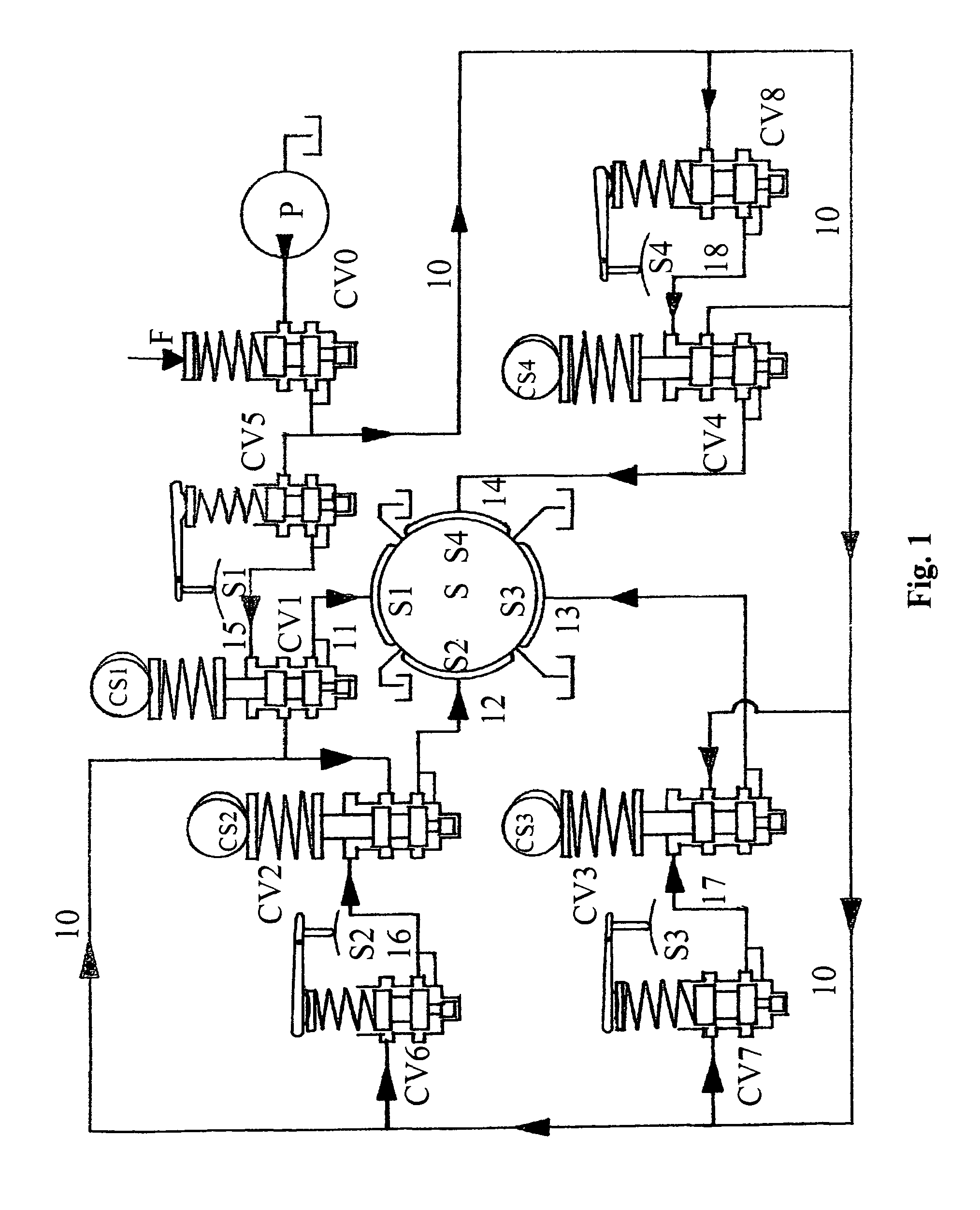

InactiveUS20070227345A1Accelerated dissipationEasy to useEngines with rotating cylindersRotary engineLubrication

The invention relates to a balanced rotary engine consisting of a rotary engine comprising tangential pistons which improve engine performance, facilitate the lubrication of the engine components, enable the use thereof at high revolutions and condition same for two-stroke operation with full use of the combustion chamber, even with mixtures (diesel cycle) which explode spontaneously upon reaching high compressions with a suitable volume. According to the invention, the components are structured such that (i) the engine can also be self-powered and (ii) the air or mixture is drawn directly from the rear of the cylinder and, subsequently, injected into the combustion chamber of said cylinder or of the cylinder adjacent thereto.

Owner:RUIZ MARTINEZ FRANCISCO JAVIER

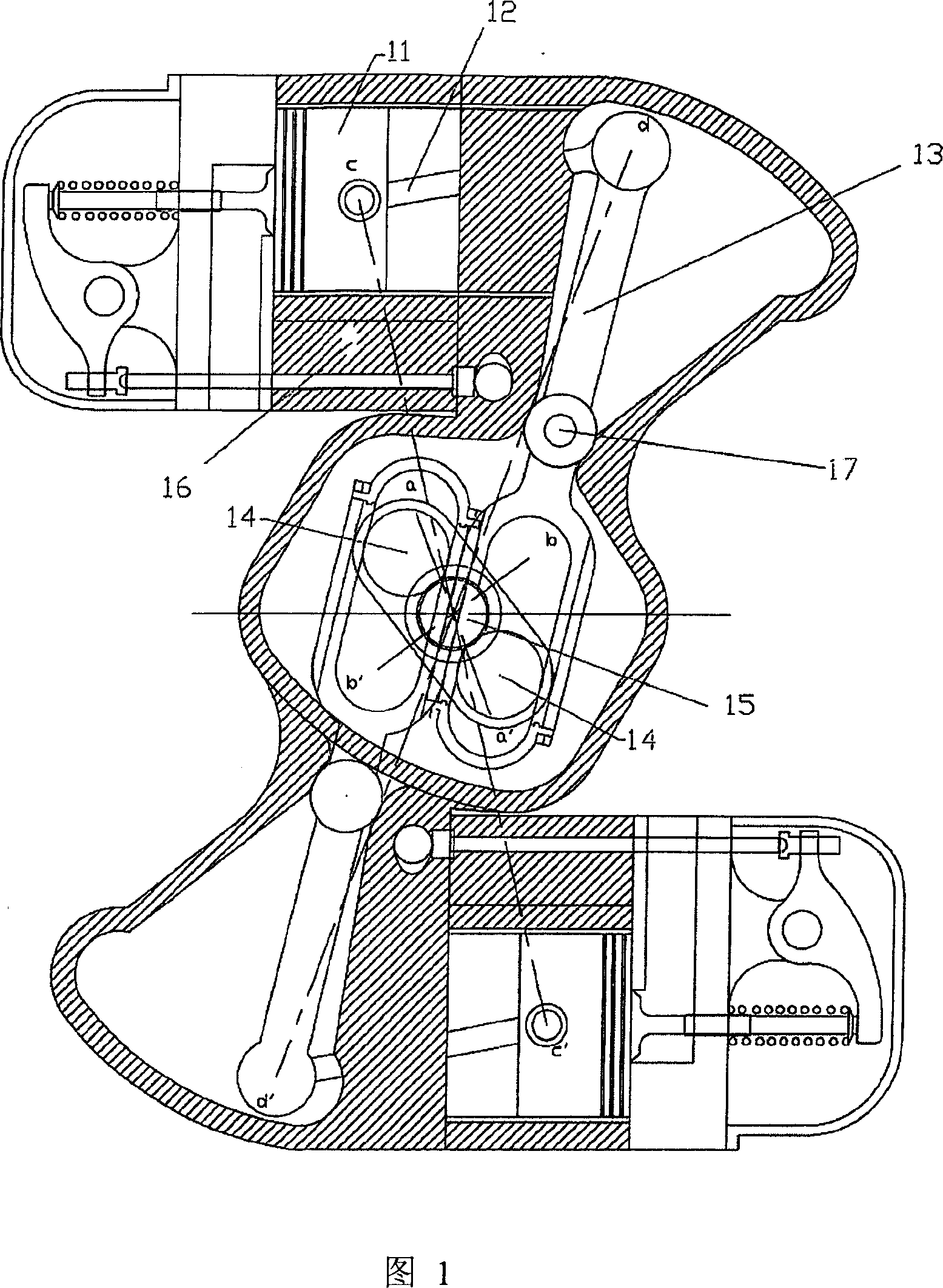

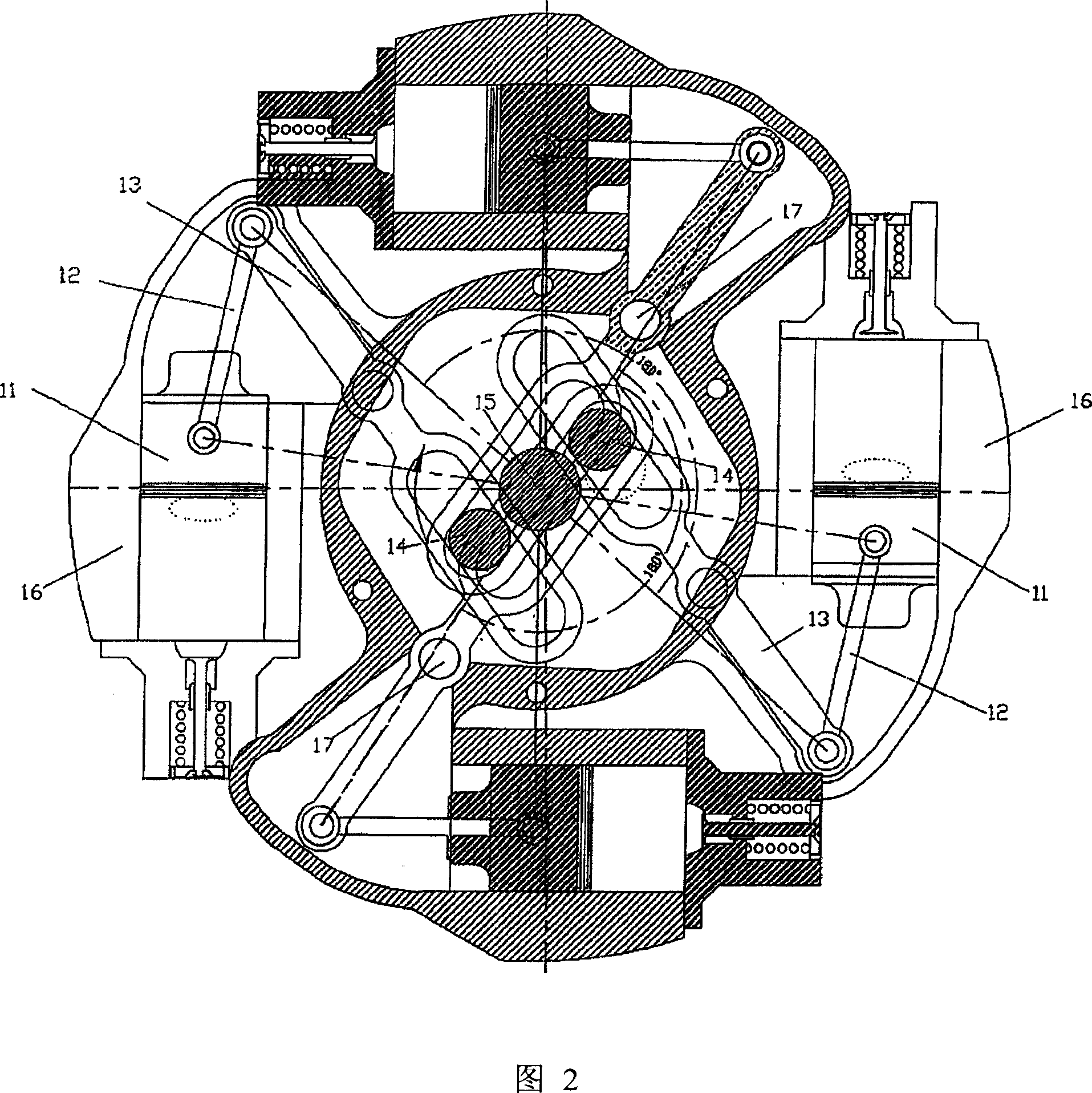

Balanced rotary engine

InactiveCN1950587AEven mass distributionImprove distributionReciprocating piston enginesRotary engineHigh pressure

The invention relates to a balanced rotary engine consisting of a rotary engine comprising tangential pistons which improve engine performance, facilitate the lubrication of the engine components, enable the use thereof at high revolutions and condition same for two-stroke operation with full use of the combustion chamber, even with mixtures (diesel cycle) which explode spontaneously upon reaching high compressions with a suitable volume. According to the invention, the components are structured such that (i) the engine can also be self-powered and (ii) the air or mixture is drawn directly from the rear of the cylinder and, subsequently, injected into the combustion chamber of said cylinder or of the cylinder adjacent thereto.

Owner:弗朗西斯科·哈维尔·路易斯·马丁内兹

Internal combustion engine

An internal combustion engine electrically ignites most of the fuel as it is introduced into the combustion chamber. This design solves the lower efficiency of typical Otto Cycle engines by allowing the use of a full air charge for each power cycle. This design also solves the problem of heavy duty designs required for existing diesel cycle engines by allowing relatively low compression ratios and therefore lighter weight engine designs. The engine design allows a wide range of fuel combustion properties, as it avoids a dependence on flame propagation through a combustible mixture, where fuel combustion properties control evaporation, rate of flame front propagation and the like. The engine design forces the combustion to be initiated as and at the rate the fuel is introduced into the combustion chamber.

Owner:SEELIG HAROLD CRANMER

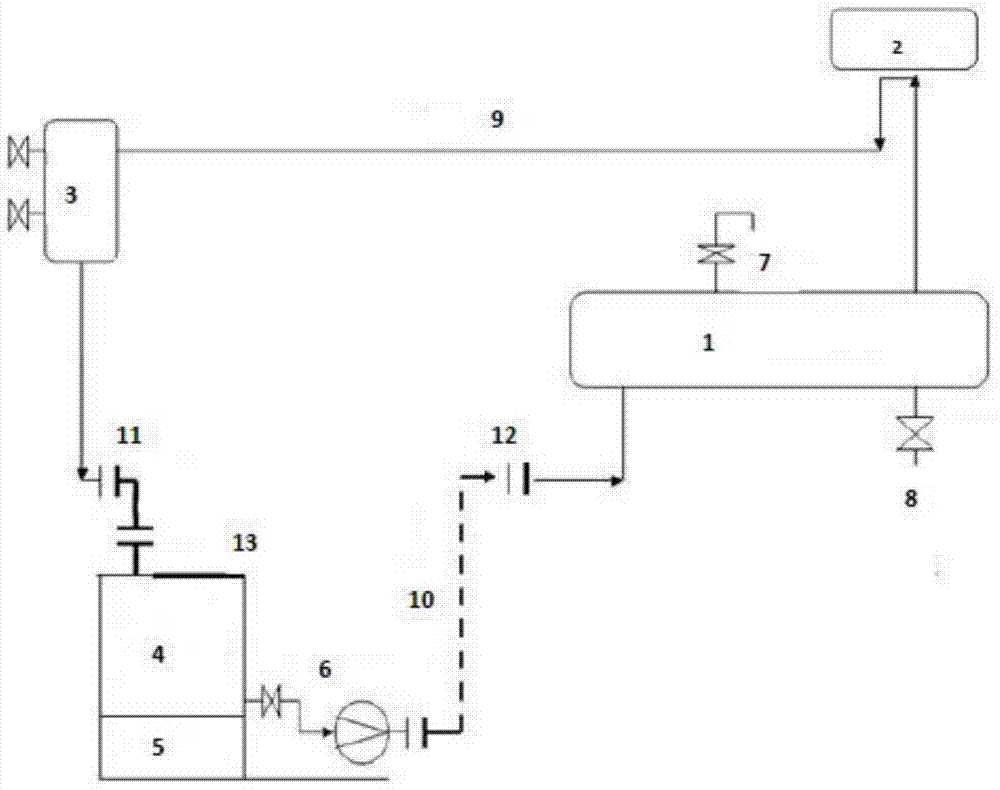

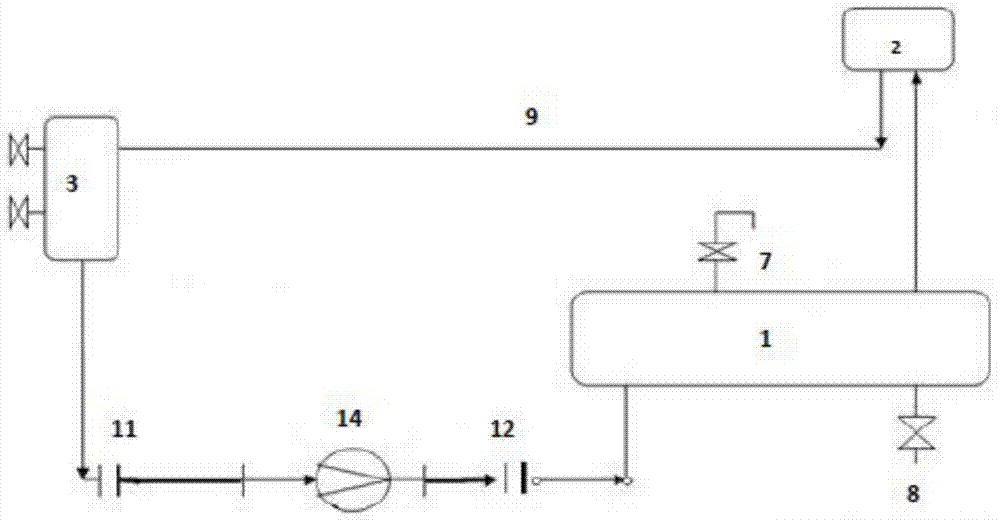

Method for removing sediments in heavy oil pipeline of spare heat medium boiler

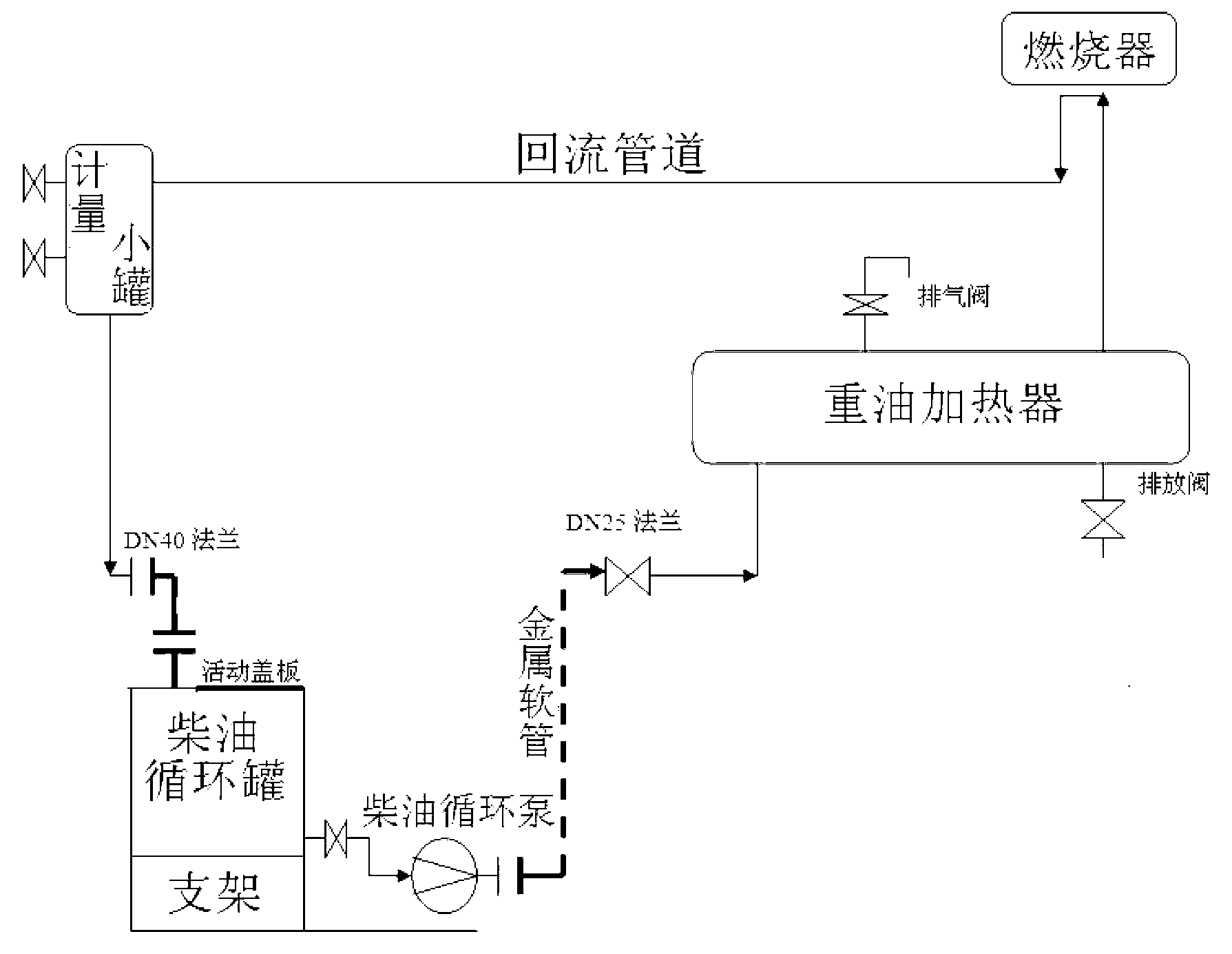

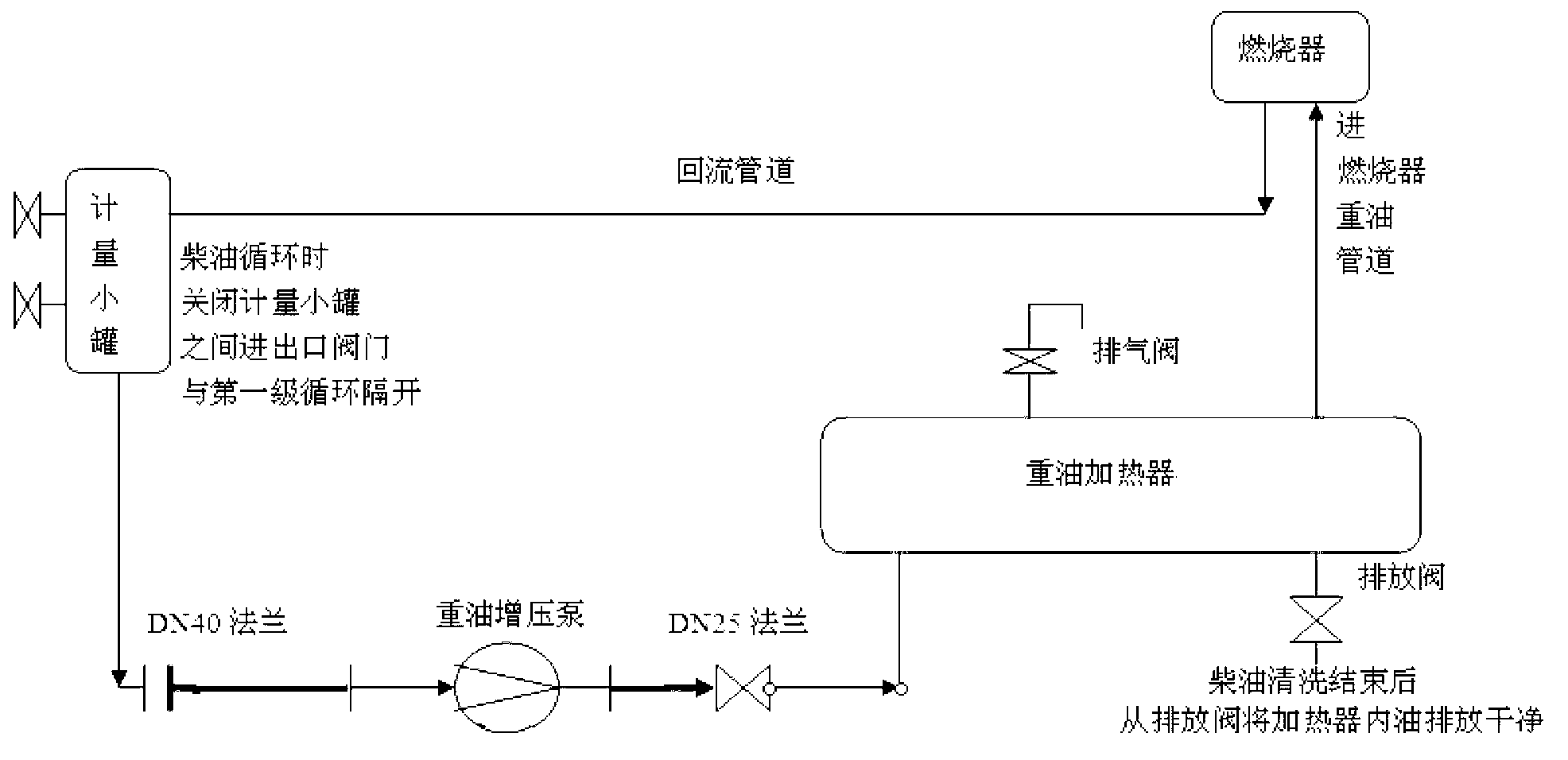

A method for removing sediments in a heavy oil pipeline of a spare heat medium boiler includes the steps of (1) closing an inlet and outlet valve of a heavy oil booster pump, and moving away the heavy oil booster pump; (2) connecting a diesel circulation pump and a diesel cycle collecting tank to a position to which the heavy oil booster pump was connected before so as to form a cycle; (3) opening an inlet valve from the diesel cycle collecting tank to the diesel circulation pump, a reflux valve of a diesel collecting tank, and an inlet and an outlet valves of the original heavy oil booster pump; and (4) starting the diesel circulation pump to enable diesel to reciprocally cycle through the diesel circulation pump, a heavy oil heater, a pipeline and the diesel collection tank for 2-3 hours. The diesel is used for realizing cycling of a small closed system formed by a heavy oil system of a single spare fuel heat medium boiler, and such impurities as oil sludge existing in the pipeline of the spare fuel heat medium boiler and the heater are removed, and thus, unimpeded cycle of the heavy oil pipeline in the spare fuel heat medium boiler is guaranteed, and the spare fuel heat medium boiler can be successfully put into use at any time.

Owner:JIANGSU SHENJIU CHEM FIBER CO LTD

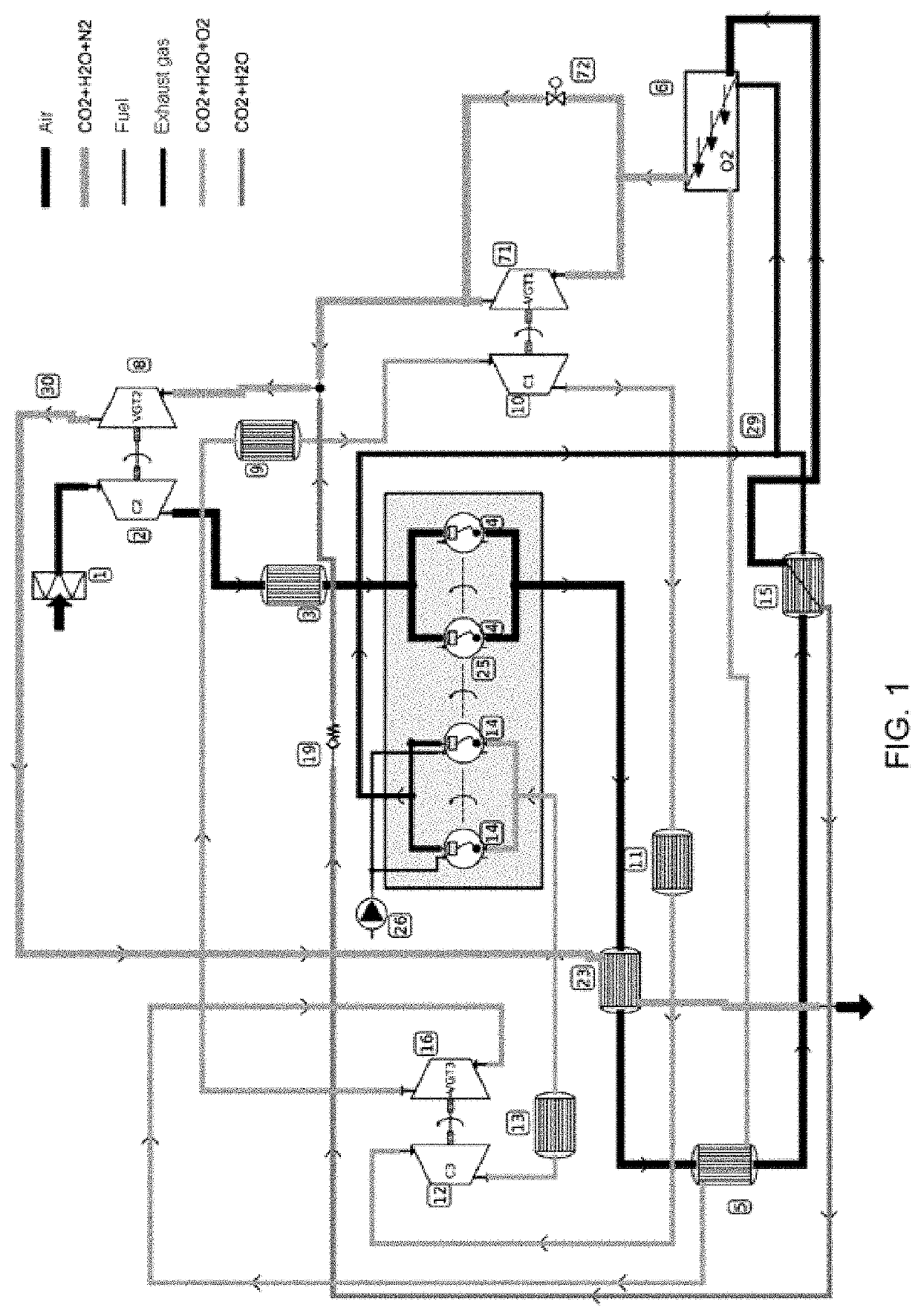

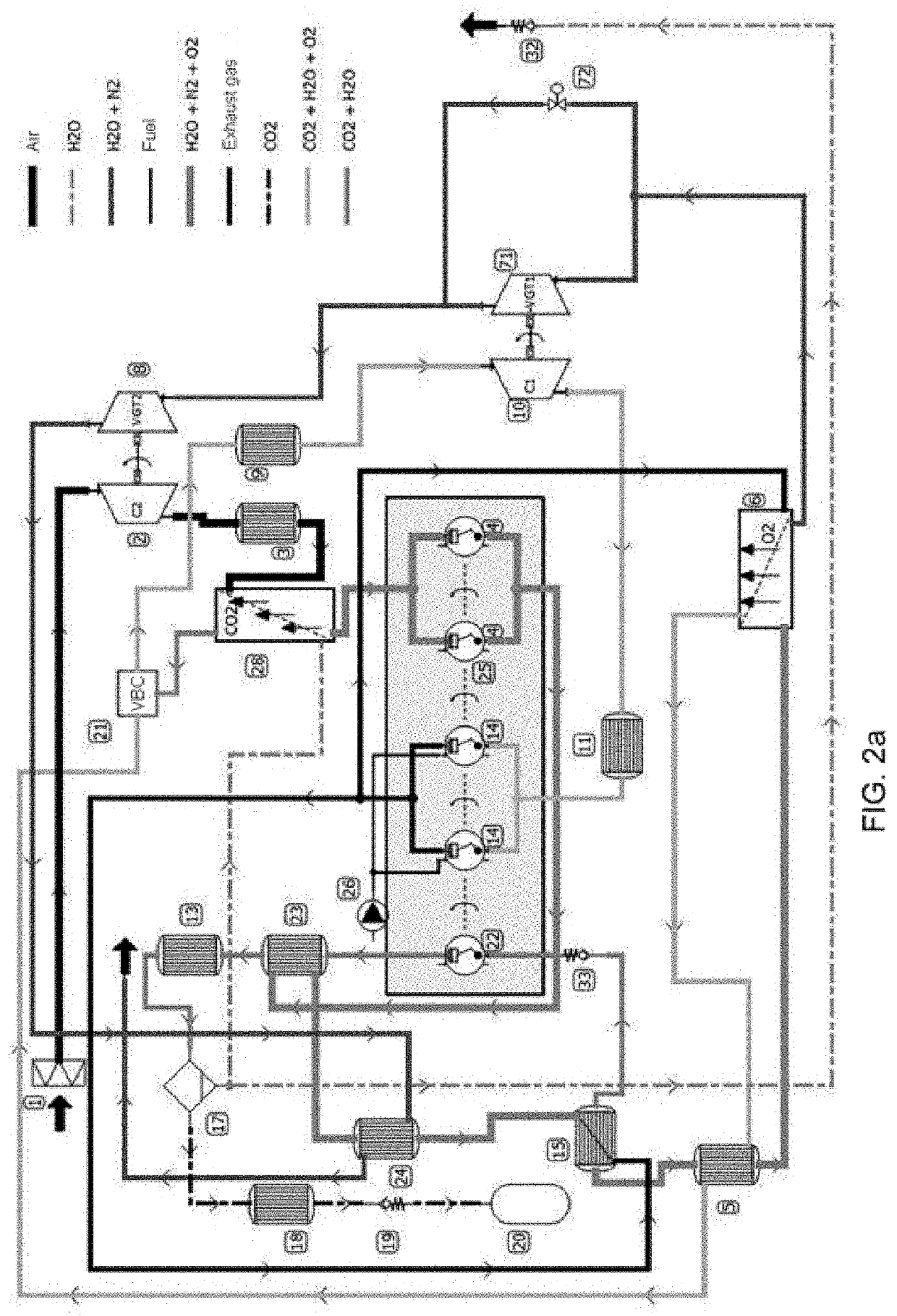

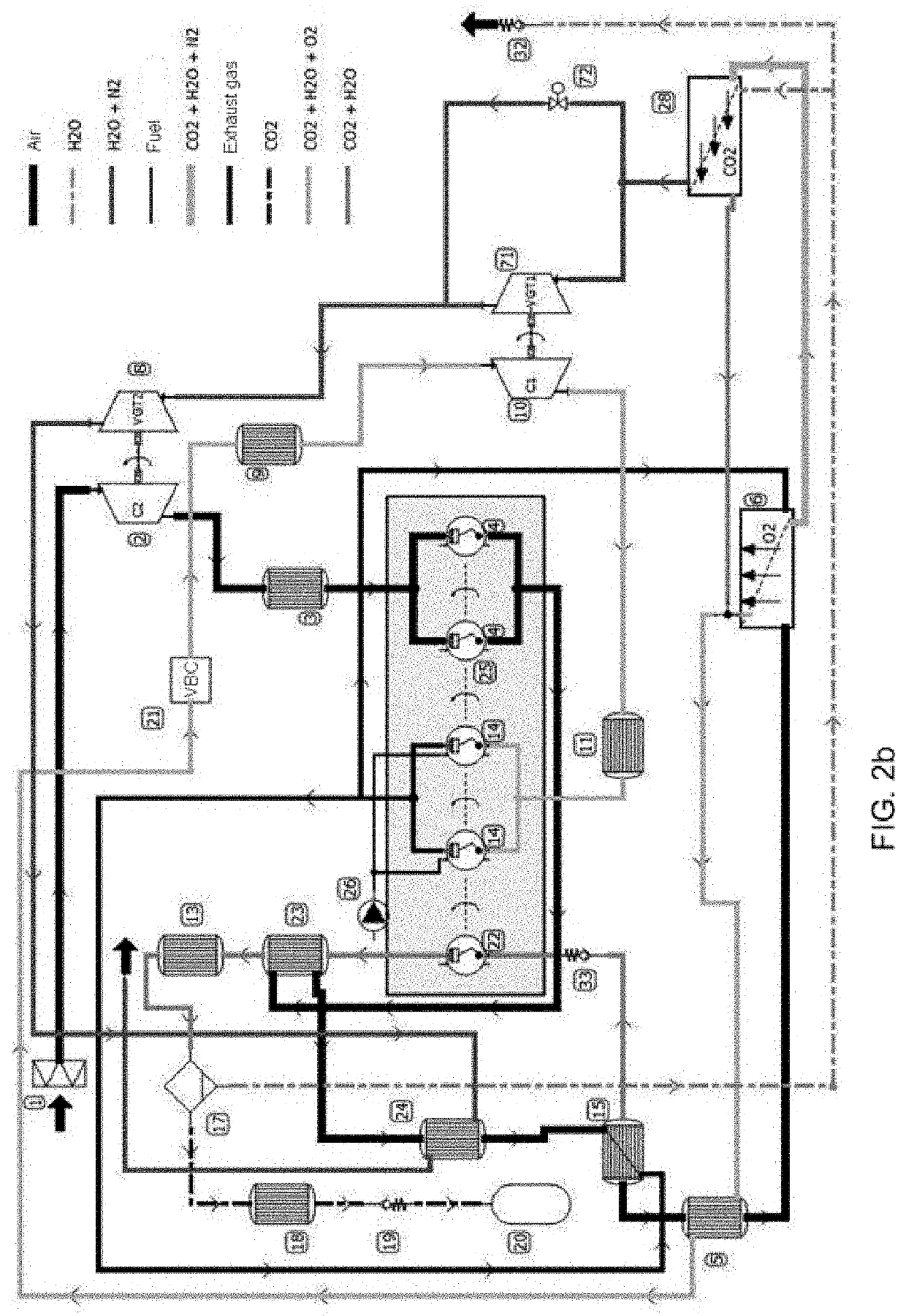

Internal combustion engine and operating method of same

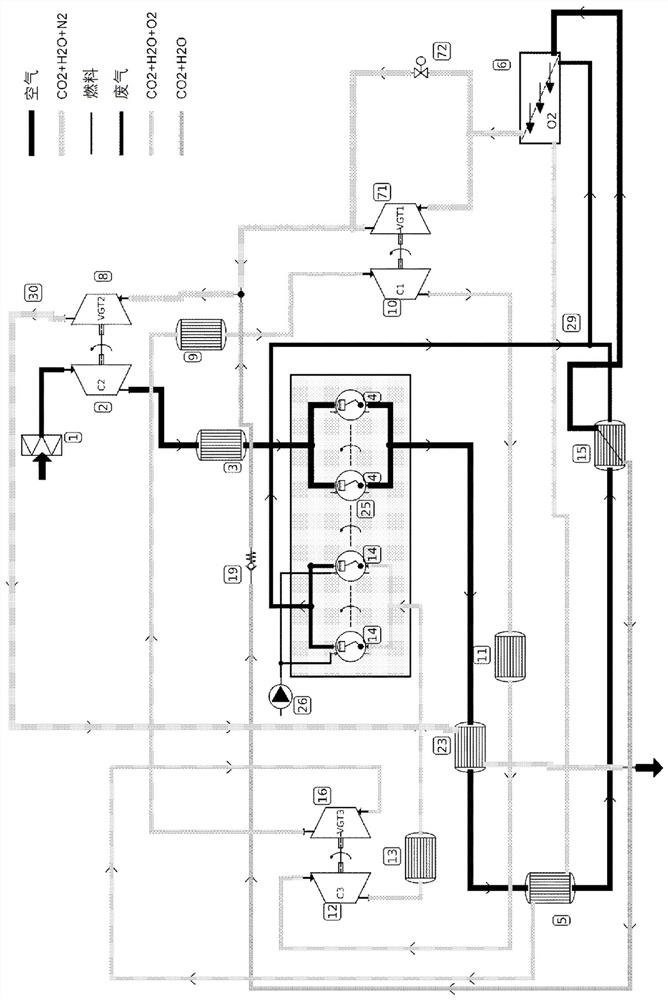

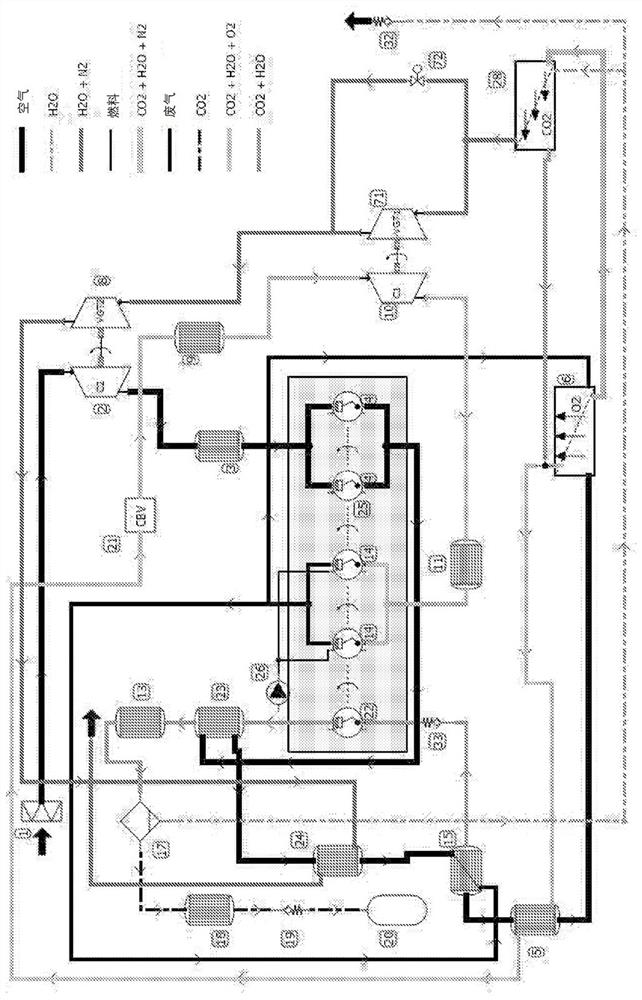

PendingCN113874618AReduce consumptionInternal combustion piston enginesLiquid fuel feedersBrayton cycleOtto cycle

The invention relates to an internal combustion engine that comprises a first Brayton cycle comprising a mixed ionic-electronic conducting (MIEC) membrane that separates the O2 in the air such that the suctioned air current is free from N2; and a second Brayton cycle combined in a binary manner with the first Brayton cycle and nested with a cycle selected from an Otto cycle and a diesel cycle performed by means of oxy-fuel combustion. The second Brayton cycle transmits mechanical energy and thermal energy from exhaust gases to the first Brayton cycle. The first Brayton cycle provides to the second Brayton cycle compressed O2 from the MIEC membrane. By means of the present engine, the NOx emission of into the atmosphere, caused by the separation of N2 in the MIEC membrane, is prevented.

Owner:UNIV POLITECNICA DE VALENCIA +1

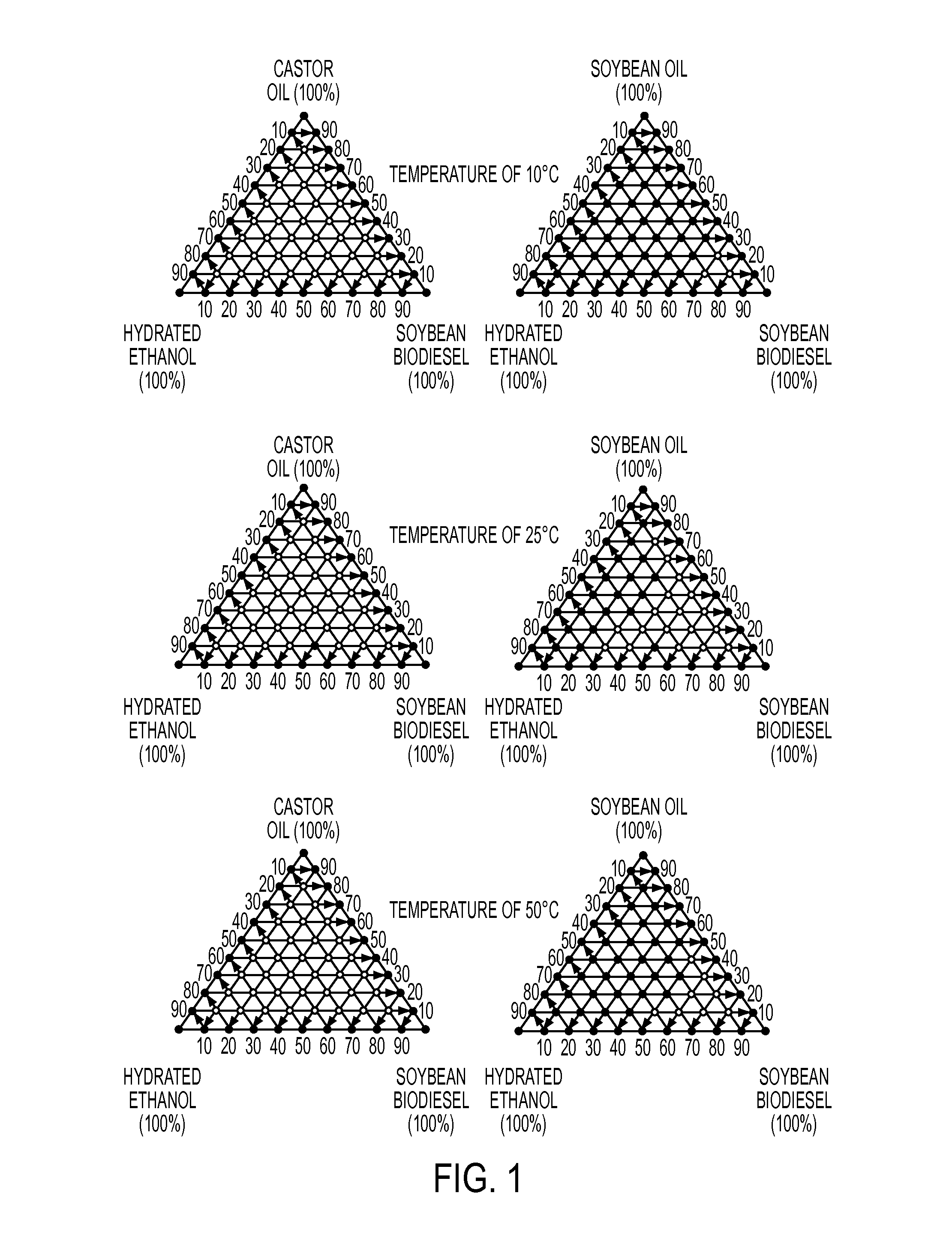

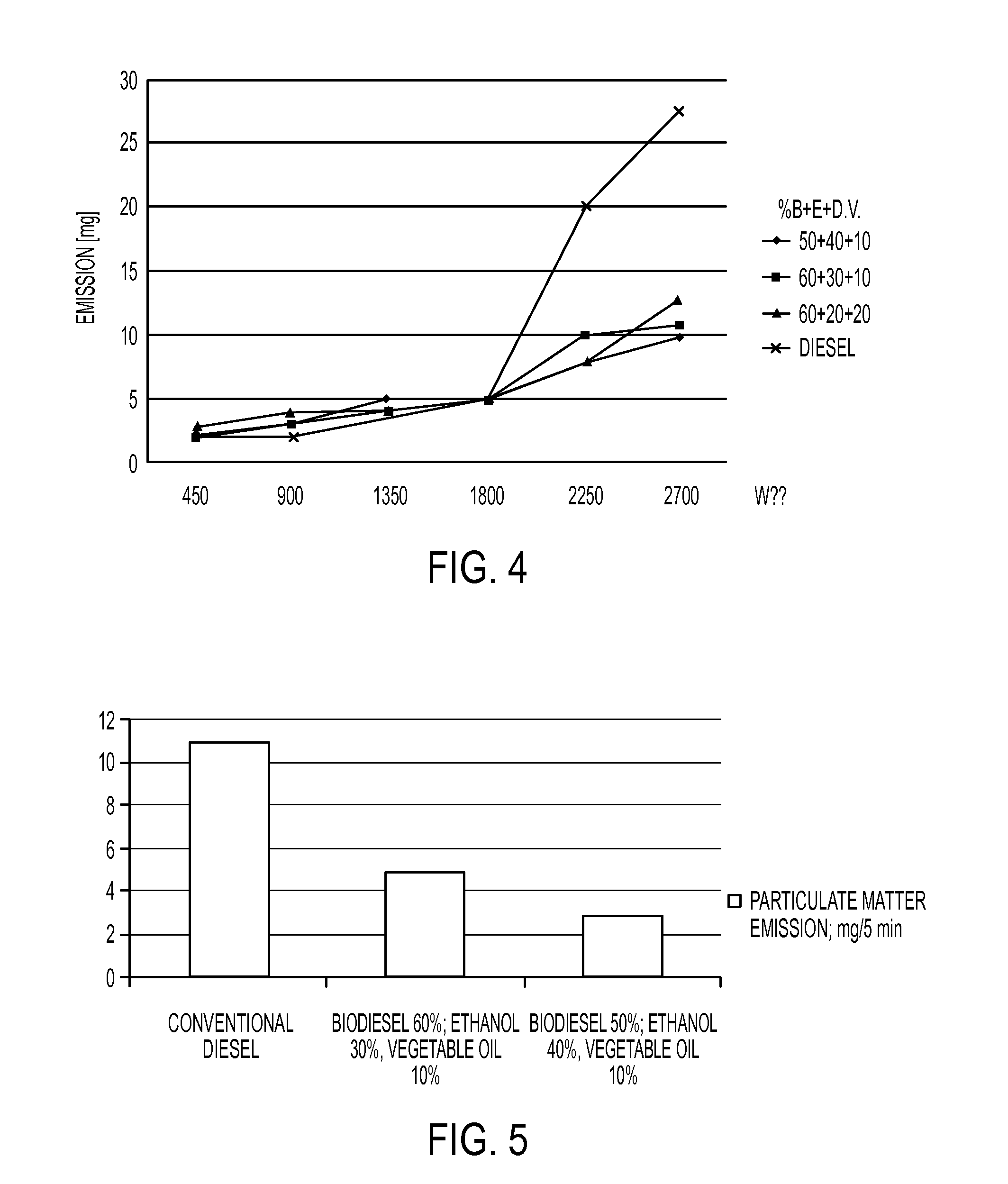

Ternary fuel compositions containing biodiesel, plant oil and lower alcohols for feeding diesel-cycle motors

InactiveUS20130269240A1Shorten ignition delayLow pour pointBiofuelsLiquid carbonaceous fuelsVegetable oilPetroleum

Fuel compositions based on biodiesel, lower alcohols and plant oil for feeding Diesel cycle engines, enabling more perfect burning, less emission of pollutants and less formation of internal deposits of impurities onto the inner surface of engines. Since the blends exhibit density similar to that of diesel oil, as well as chemical affinity for the latter (since it contains biodiesel, which performs the function of co-solvent), the present invention also relates to compositions of quaternary blends, that is, junction of the ternary blends proposed (biodiesel, lower alcohol and vegetable oil) with petroleum diesel in the most varied proportions. The preferred embodiment of this invention provides the replacement of fuel of non-renewable source (diesel oil) by others of renewable source, which are natural, non-toxic, biodegradable and that have excellent technical performance.

Owner:EMPRESA BRASILEIRA DE PESQUISA AGROPECUARIA EMBRAPA

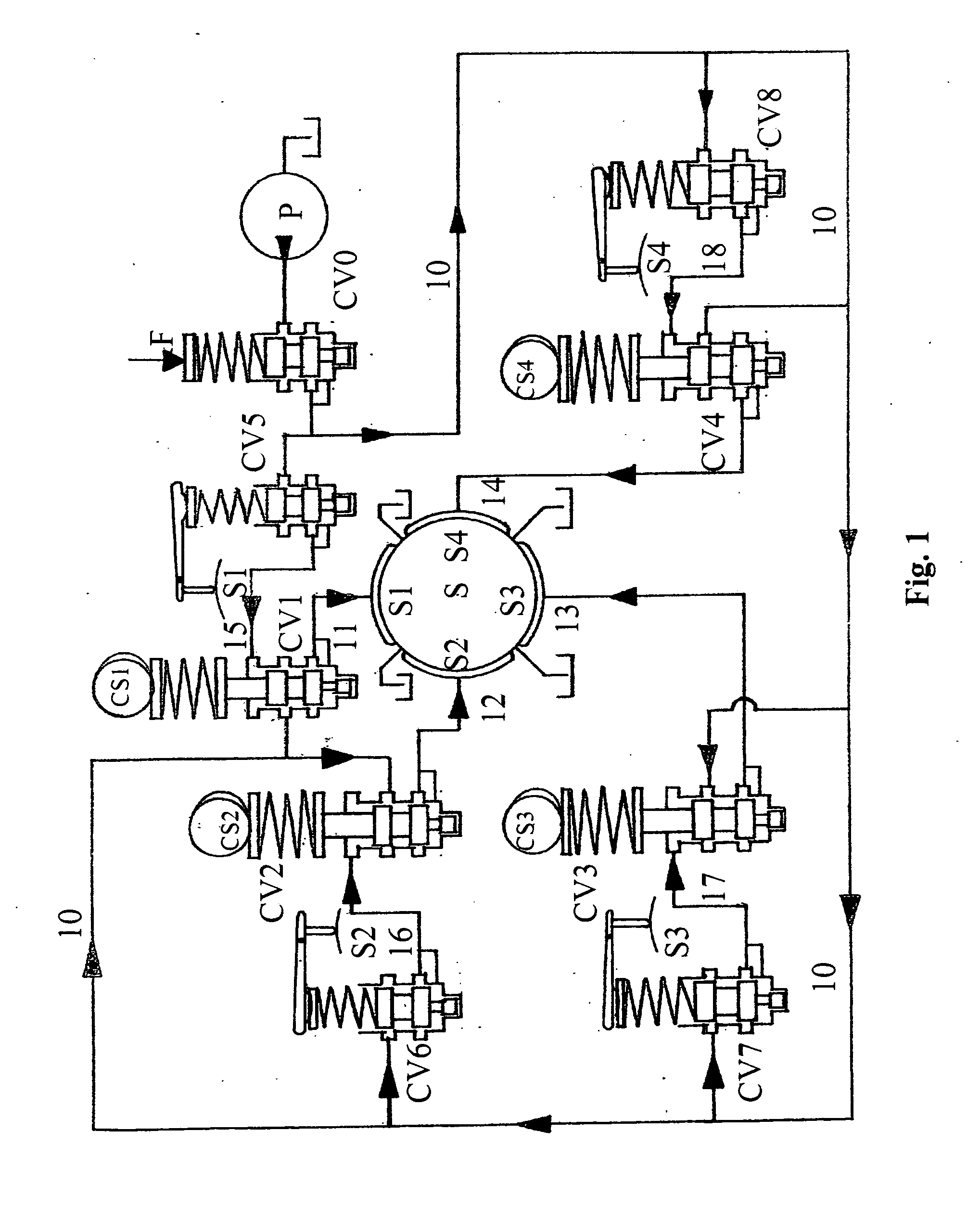

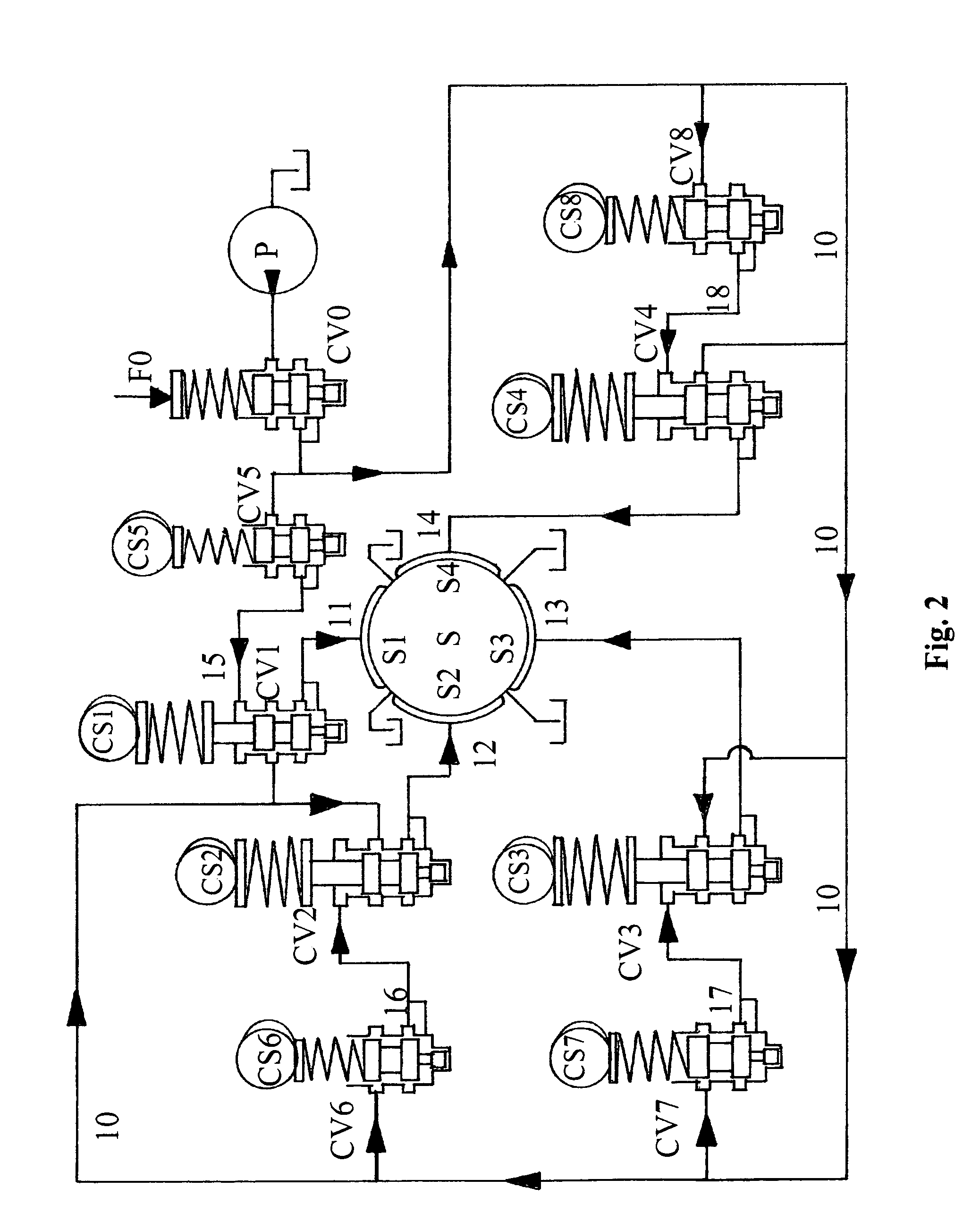

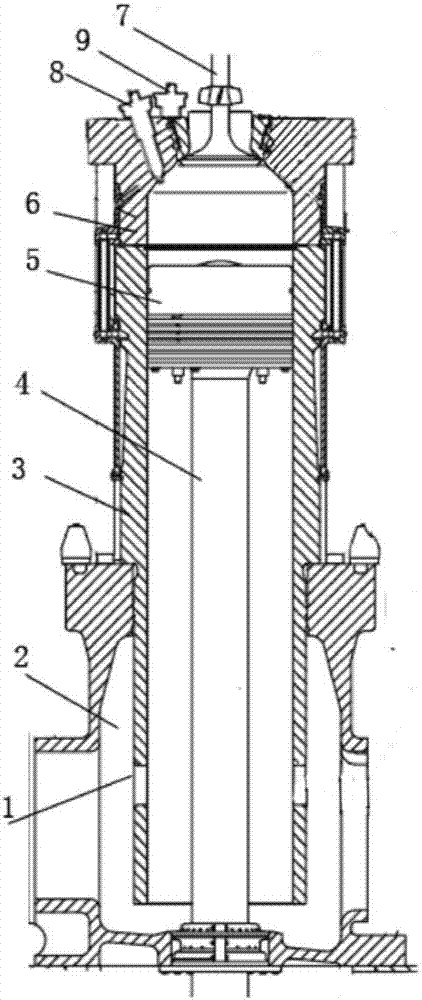

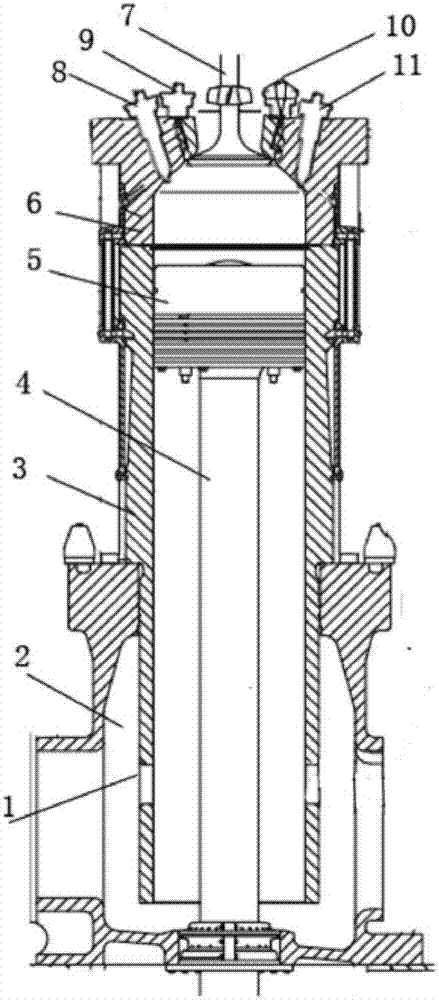

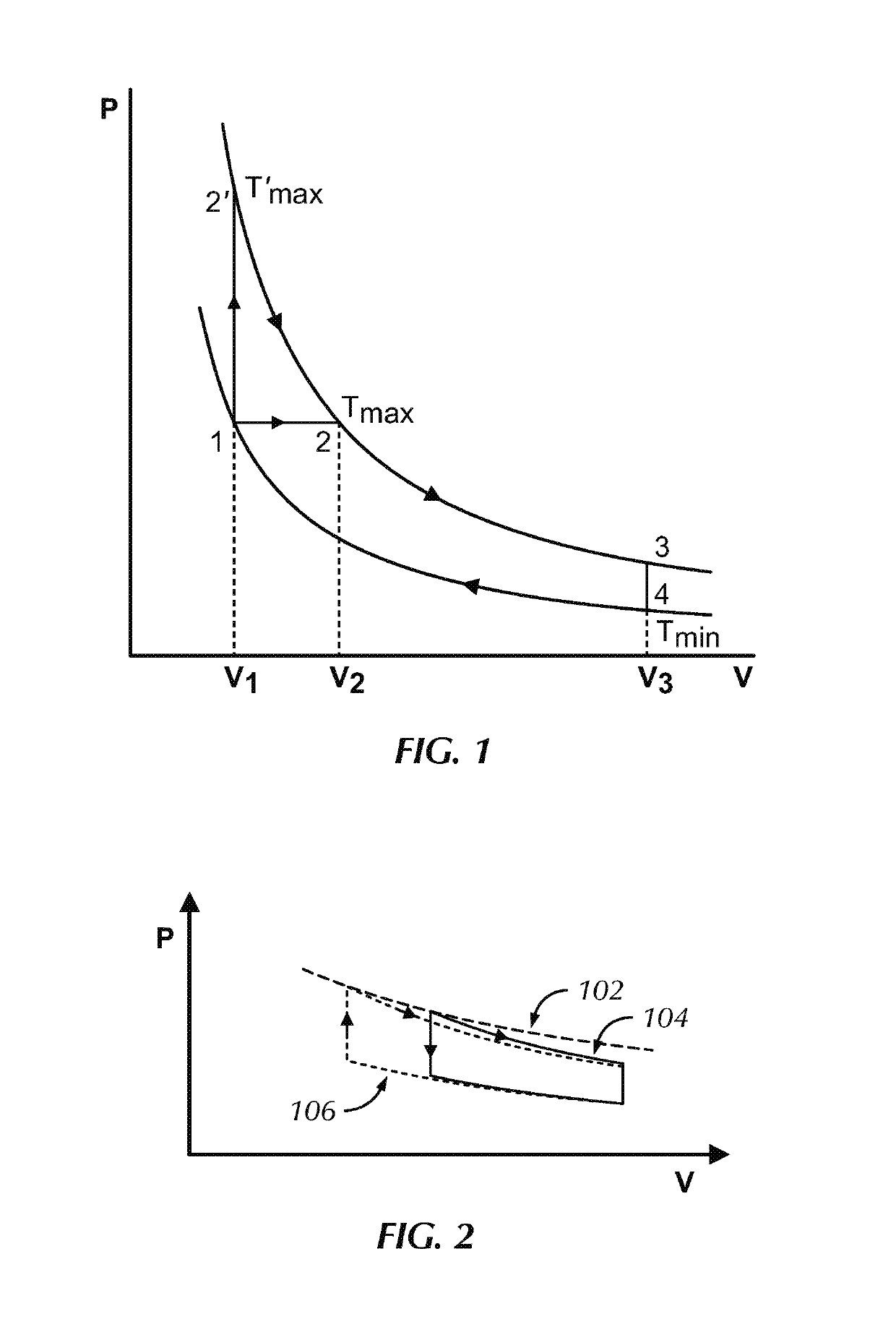

Active hydrostatic bearing, particularly for internal combustion reciprocating engines, a fluid handling system associted therewith, and method

InactiveUS20120020597A1Efficient methodIncrease loadLiquid cushion bearingsHomogeneous charge compression ignitionDetonation

This invention relates to bearings, and more specifically is directed to active hydrostatic bearings destined for large heavily loaded reciprocating internal combustion engines, like ultra high compression ratio Diesel cycle engines, and homogeneous charge compression ignition (HCCI) and detonation engines working on stoichiometric fuel / air mixture. A fluid handling system therefore, method and apparatus are also disclosed.

Owner:OLEDZKI WIESLAW JULIAN

Diesel cycle fuel compositions containing dianhydrohexitols and related products

Diesel cycle fuel compositions are described containing at least one dianhydrohexitol compound according to the general formula 2 and / or itsderived hydrocarbyl ethers or nitric ethers compounds, where the R′ and R″ substituents are both H or one or both of R′ and R″ is alkyl, cycloalkyl or phenyl, or one or both are —NO2. A preferred fuel composition is that containing dimethyl isosorbide (DMI) added or not of isosorbide dinitrate (ISDN) as ignition improver. The dianhydrohexitols compounds form compositions with at least one of the components selected among petroleum-derived diesel fuel, biodiesel, ethanol and water. The mixture of DMI and ISDN has excellent cetane number (IQT). Still, the oxygenated nature of the dianhydrohexitols and related compounds of the fuel compositions inhibits soot formation upon burning of the said Diesel cycle fuel compositions.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Active hydrostatic bearing, particularly for internal combustion reciprocating engines, and a fluid handling system associated therewith

InactiveUS8523445B2Increase loadMinimal internal frictionLiquid cushion bearingsHomogeneous charge compression ignitionDetonation

Owner:OLEDZKI WIESLAW JULIAN

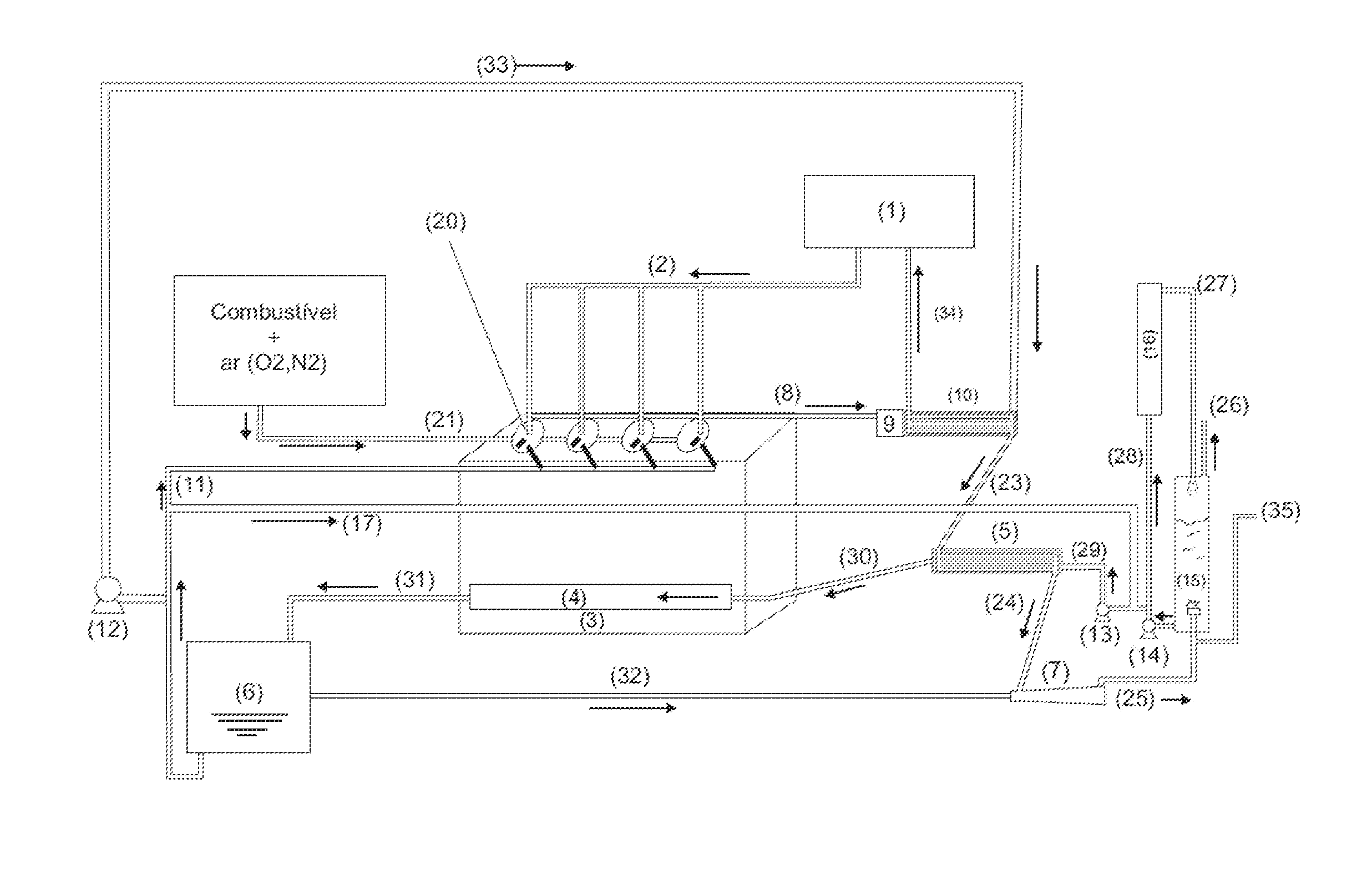

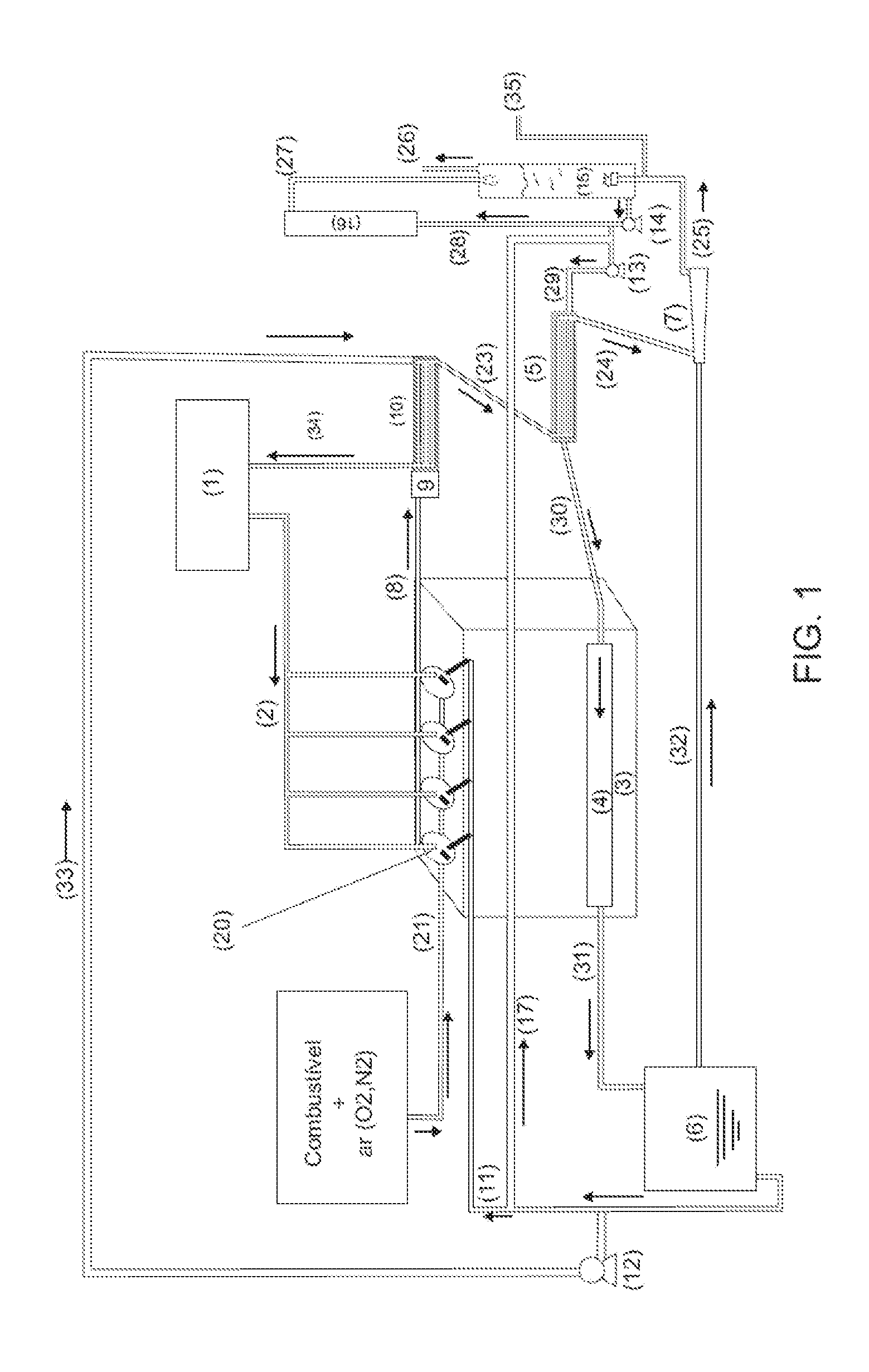

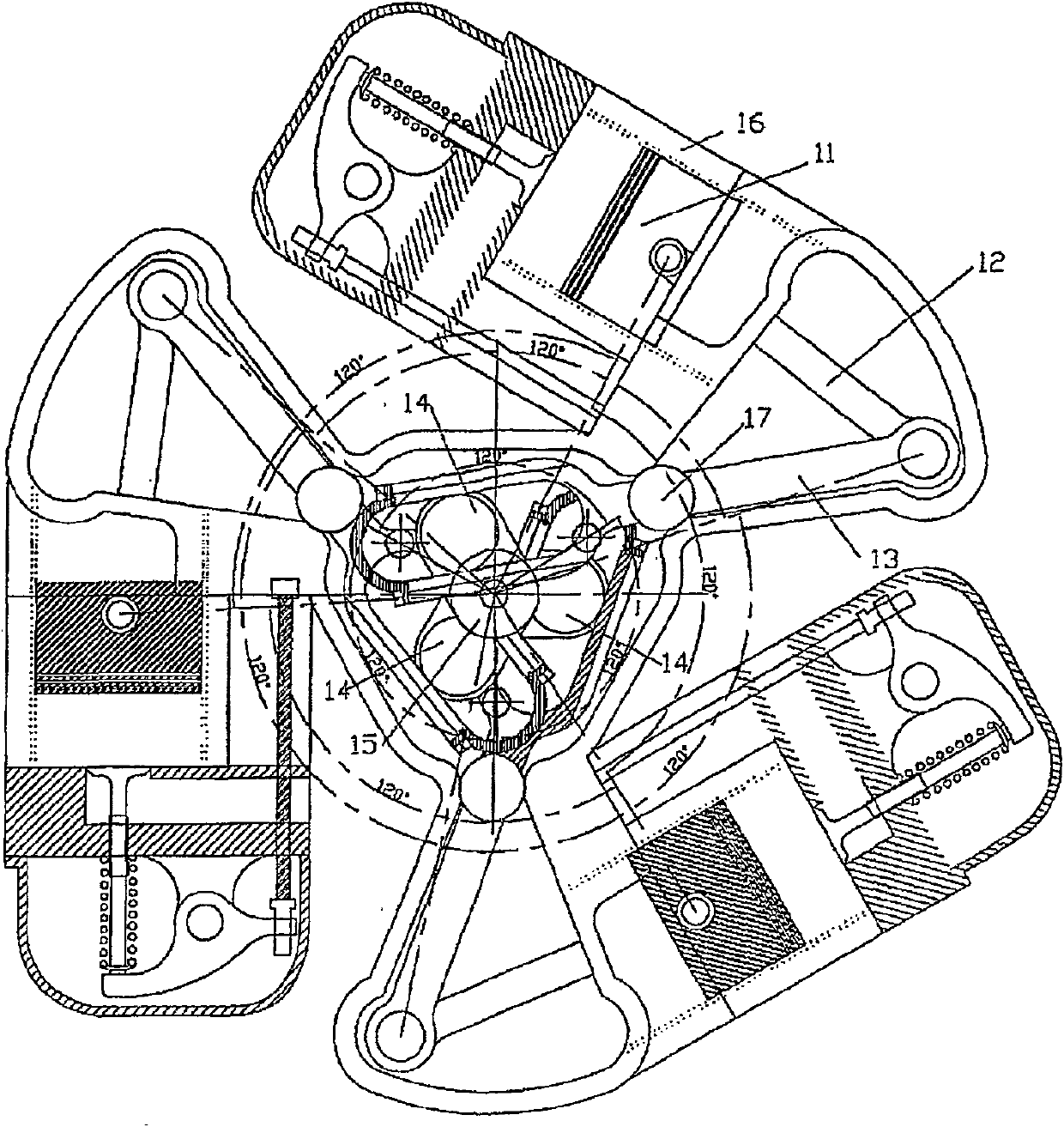

Combined cycle combustion engine process and combined cycle combustion engine

InactiveUS20160273392A1Internal combustion piston enginesEngine operationsInternal pressureOtto cycle

The invention describes an Otto cycle or Diesel cycle internal combustion engine assembled with an energy and water recovery systems to Rankine cycle. In the first innovation, the high pressure steam, preferably above critical pressure, is injected in combustion chamber (20) in the end of compression (C) stroke reducing the combustion temperature and increasing internal pressure in the cylinder.

Owner:SAKAI MASSAO

Otto and diesel cycles employing spinning gas

An internal combustion engine is disclosed and includes a main cylinder and main piston that are relatively axially displaceable along a main axis to define a variable volume main working chamber. At least one valve is configured to admit air and fuel into the working chamber forming an air / fuel mixture. The main cylinder is configured to cause the air / fuel mixture in the main cylinder to spin rapidly enough to cause a substantive change in the heat capacity of the air / fuel mixture creating a spinning air / fuel mixture. The main cylinder and main piston are configured to compress the spinning air / fuel mixture to create an ignitable spinning air / fuel mixture. The spinning air / fuel mixture is ignited and the main cylinder and main piston are configured to extract mechanical energy from the ignited spinning air / fuel mixture. An exhaust valve is configured to exhaust combustion products from the main working chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Method for operating low-speed marine engine in variable thermodynamic cycle mode

InactiveCN107061028AGuaranteed reliabilityGuaranteed economyInternal combustion piston enginesEngine controllersLow speedEmission standard

The invention discloses a low-speed marine gas engine. When a ship navigates outside an emission control area, the engine works by using fuel oil or fuel gas under the diesel cycle. When the ship navigates in the emission control area, the engine works by using fuel gas under the Otto cycle. Thus, low-temperature homogeneous lean burn is realized, and emission is reduced and meets the third phase of IMO emission standard. The low-speed marine gas engine realizes a variable thermodynamic cycle mode and burning optimization by adopting the combination of various technologies. Fuel gas injection and exhaust timing are adjusted through an electronic control system, and fuel homogeneous premixing is realized through a fuel gas injection valve structure or layout change; the compression ratio is reduced to prevent knocking through a variable valve, and the air-fuel ratio is regulated to realize lean burn through a variable nozzle ring or an exhaust gas bypass technology; and the rated power of the low emission mode of the engine is properly reduced to prevent knocking. By the method, the engine has the advantages of a high pressure gas fuel engine and a low pressure gas fuel engine at the same time.

Owner:王艺澄

Method for removing sediments in heavy oil pipeline of spare heat medium boiler

Owner:JIANGSU SHENJIU CHEM FIBER CO LTD

Gaseous fuel combustion apparatus for an internal combustion engine

InactiveCN106164440AInternal combustion piston enginesFuel supply apparatusExternal combustion engineOtto cycle

Diesel-cycle engines are known to have greater power, torque and efficiency compared to Otto-cycle engines of like displacement. When the fuel is a gaseous fuel, such as natural gas, a pilot fuel (such as diesel) is normally required to assist with ignition in a gaseous fuelled Diesel-cycle engine. It would be advantageous to reduce the power, torque and efficiency gap between a Diesel-cycle engine and a gaseous fuelled Otto-cycle engine. A combustion apparatus for a gaseous fuelled internal combustion engine comprises a combustion chamber defined by a cylinder bore, a cylinder head and a piston reciprocating within the cylinder bore. A diameter of the cylinder bore is at least 90 mm and a ratio between the diameter and a stroke length of the piston is at most 0.95. There is at least one intake passage for delivering a charge to the combustion chamber, and at least one intake valve is configured in the cylinder head and cooperates with the intake passage to create a predominant tumble flow motion in the combustion chamber.

Owner:WESTPORT POWER

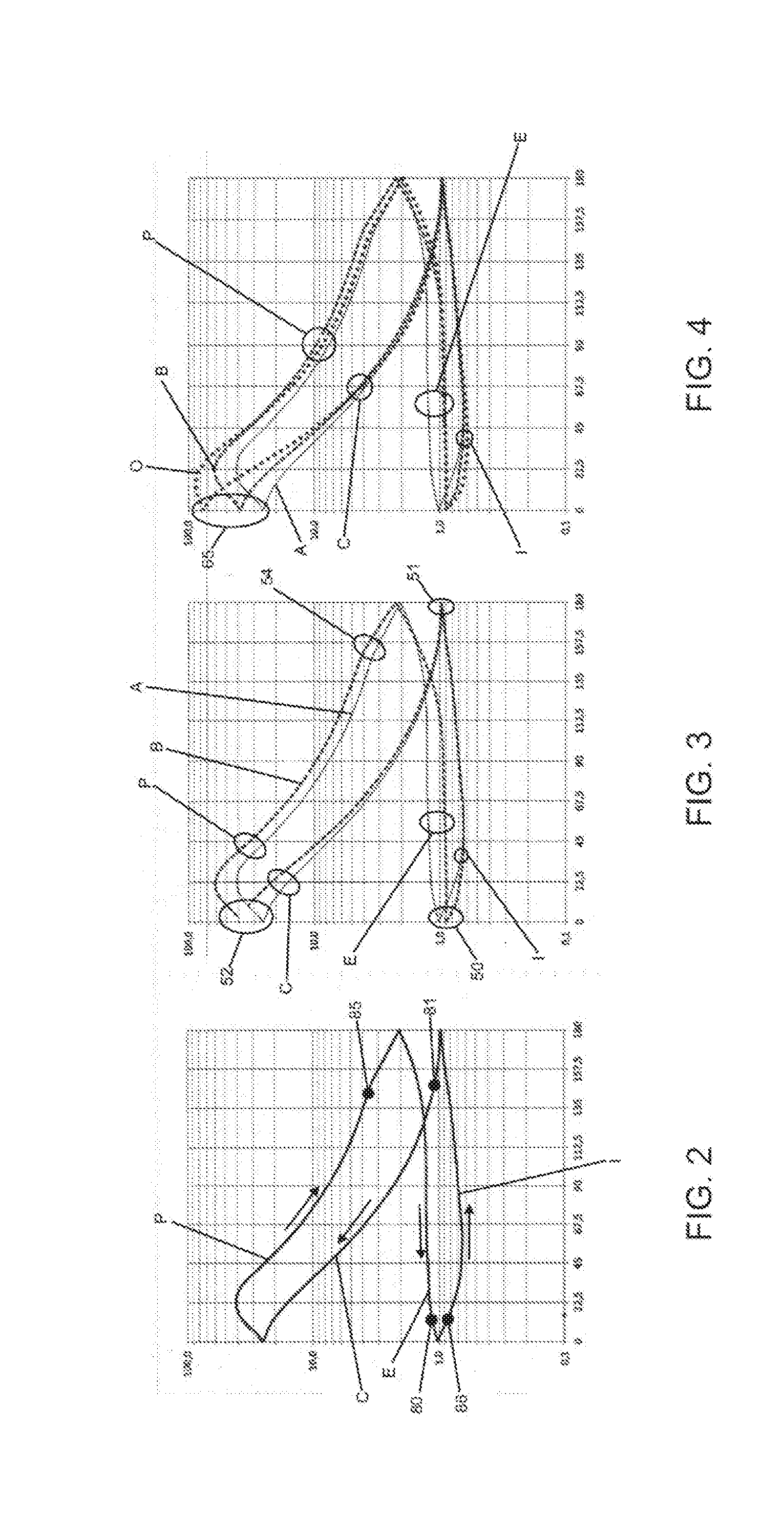

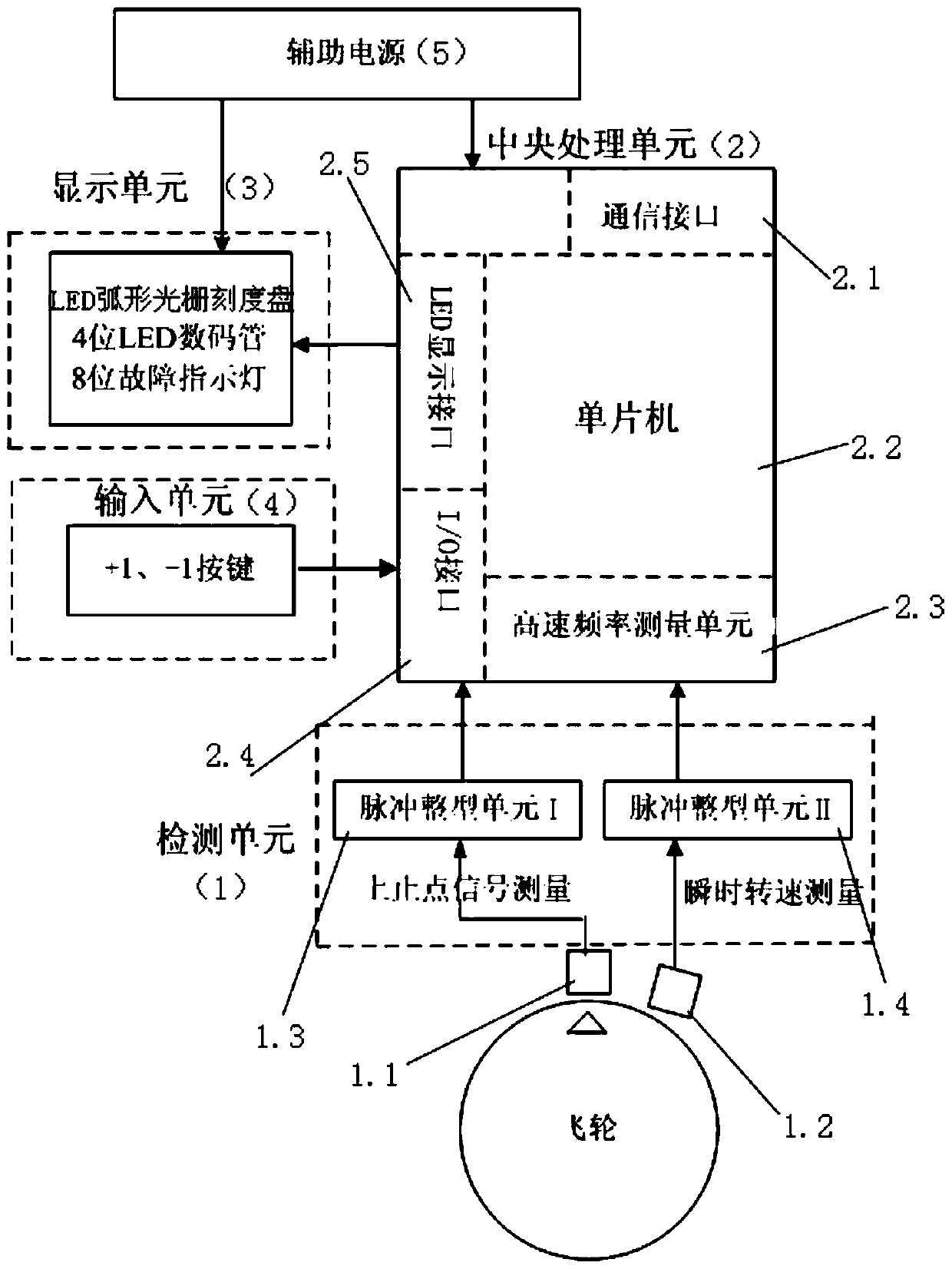

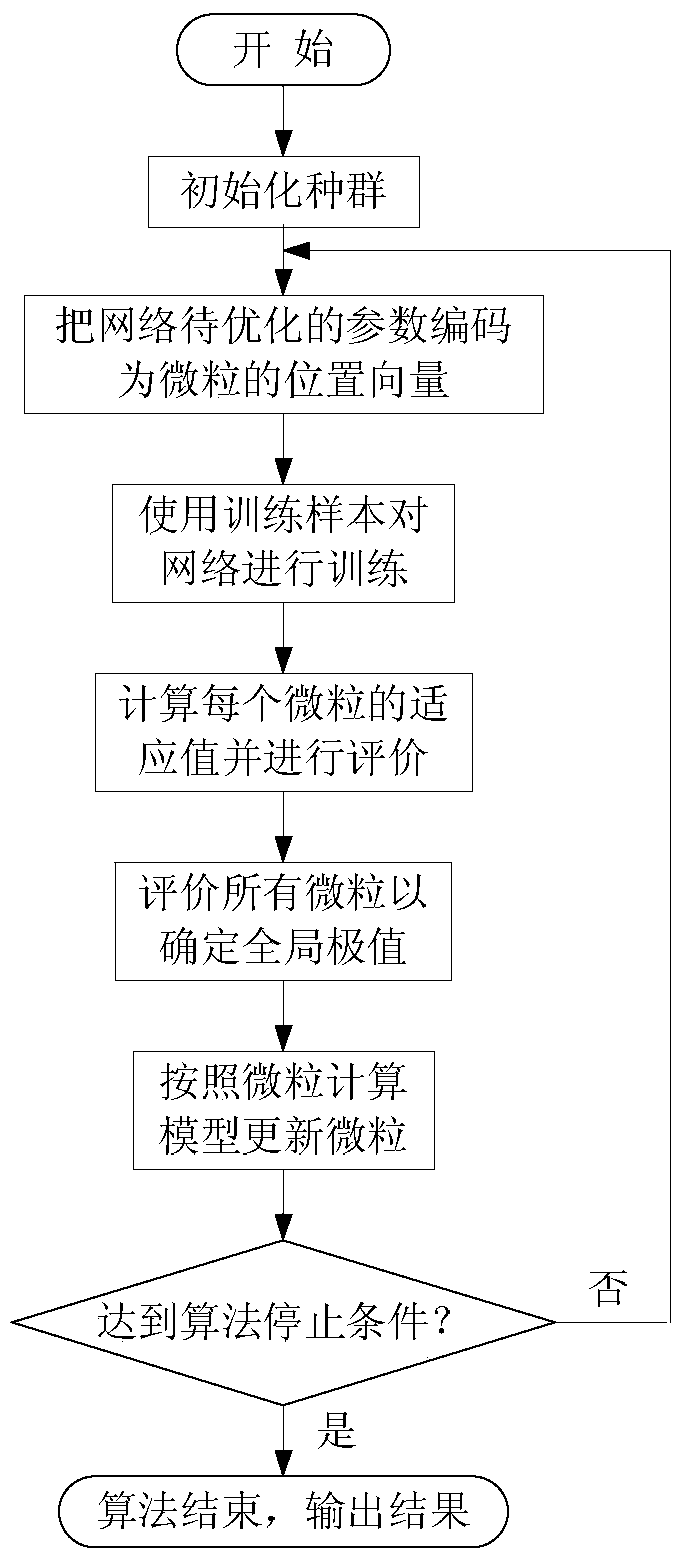

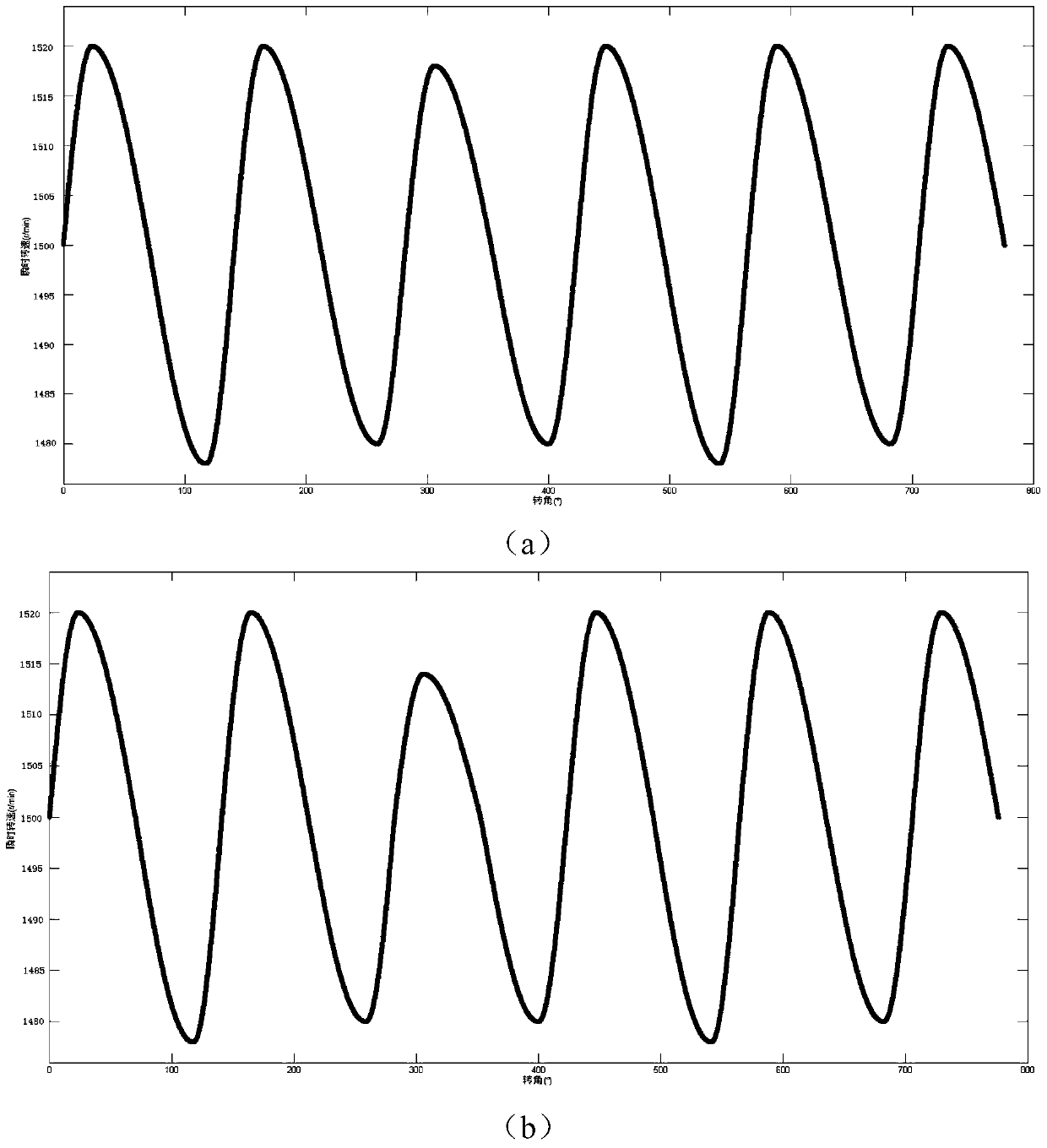

Device and method for instantaneous speed measurement and cylinder flameout fault diagnosis of diesel engine

ActiveCN105736140BRealize flameout fault diagnosisRealize parameter settingLinear/angular speed measurementMachines/enginesFlameoutTooth number

The invention relates to the field of diesel engine fault diagnosis, and discloses a diesel engine instantaneous rotational speed measurement and cylinder flameout fault diagnosis device and method. The device mainly comprises a detection unit, a central processing unit, a display unit, an input unit and an auxiliary power supply, wherein the detection unit detects and acquires a instantaneous rotational speed signal and a top dead center signal of a diesel engine flywheel; the central processing unit calculates the instantaneous rotational speed according to the received signals, performs cylinder flameout fault diagnosis based on a PSO-BP diesel engine cylinder flameout fault recognition algorithm, determines the position of the fault cylinder, and sends the position information to the display unit, wherein the algorithm rapidity meets the utilization requirement of a test instrument based on an embedded mobile computing platform; the input unit inputs the flywheel tooth number of the diesel engine; and the auxiliary power supply supplies power to all the modules. According to the device, the rotational speed is accurately measured, and the cylinder flameout fault judgment is correct; and the device is utilized in large and medium diesel engines, tests the instantaneous rotational speed of the diesel engines on line, accurately diagnoses the diesel engine cylinder flameout faults, and can achieve digital measurement and remote monitoring management.

Owner:CHONGQING TELECOMMUNICATION INSTITUTE +1

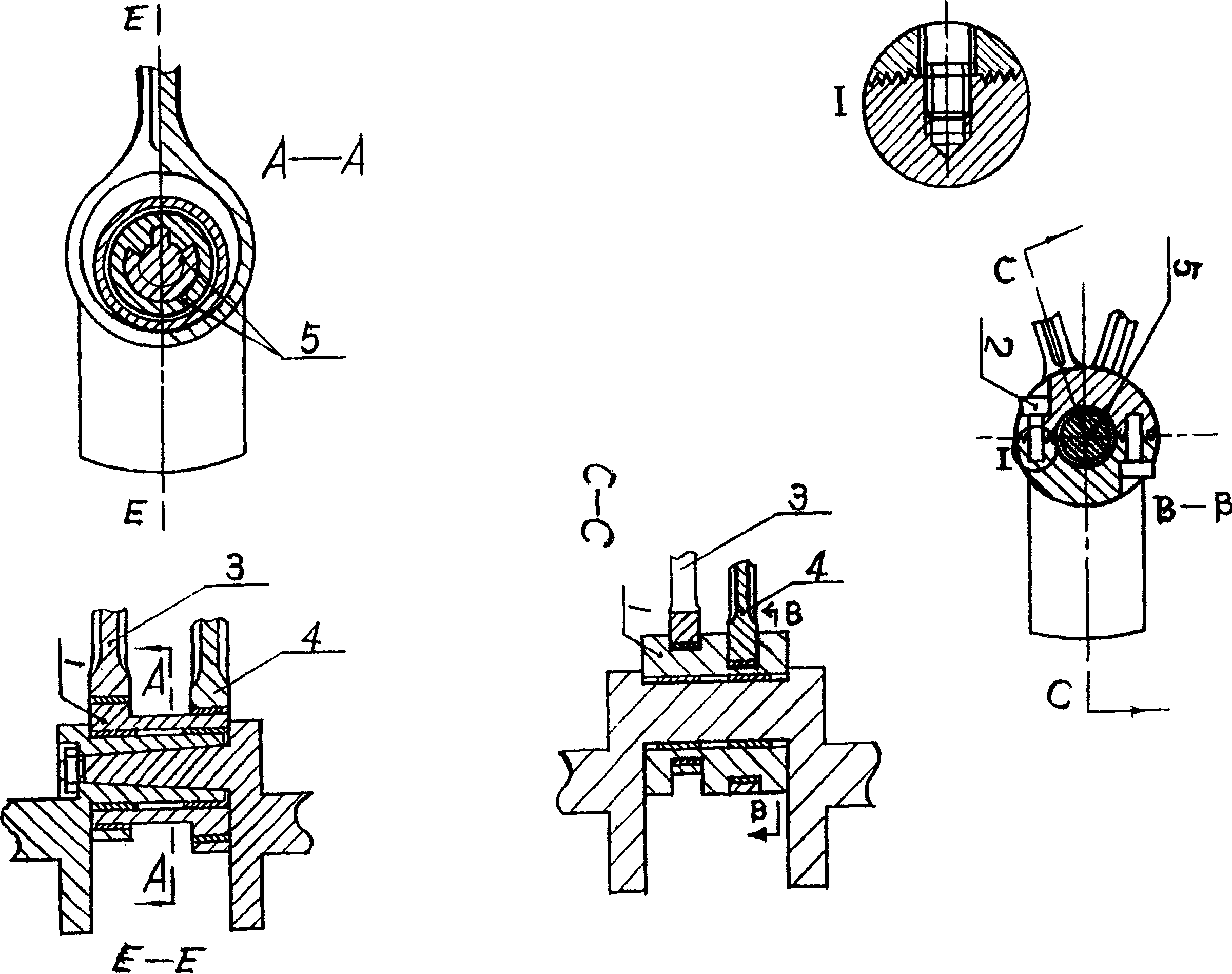

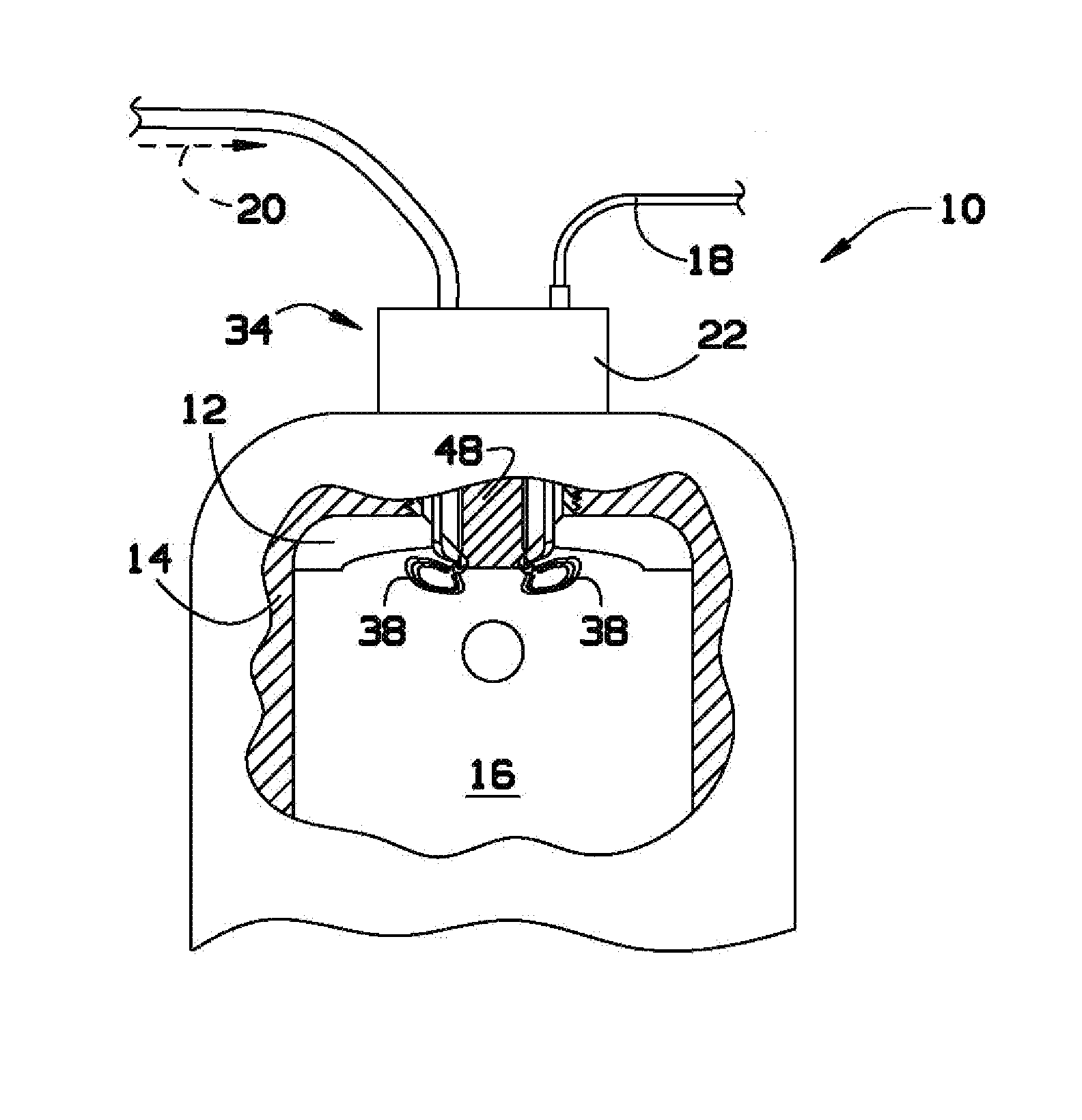

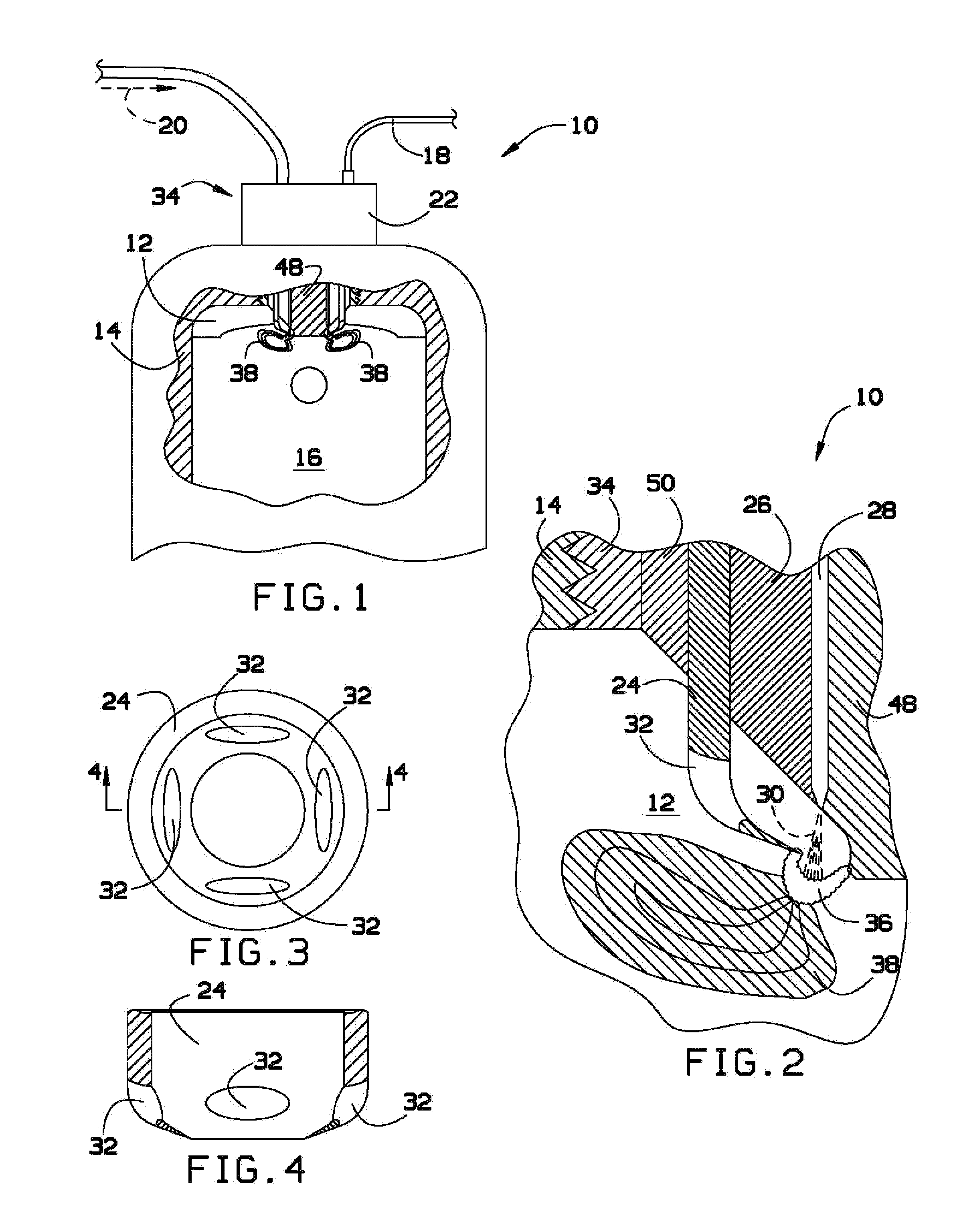

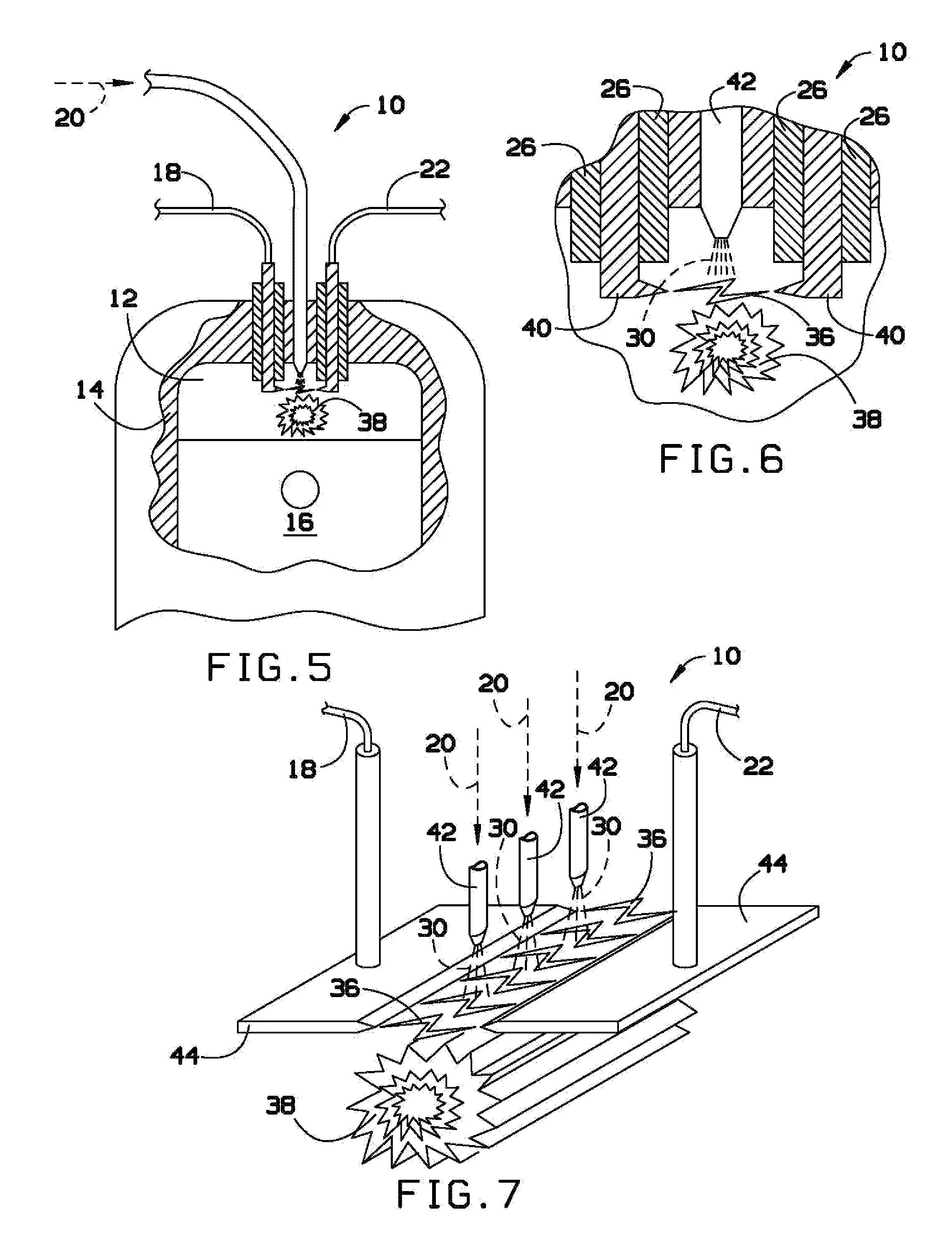

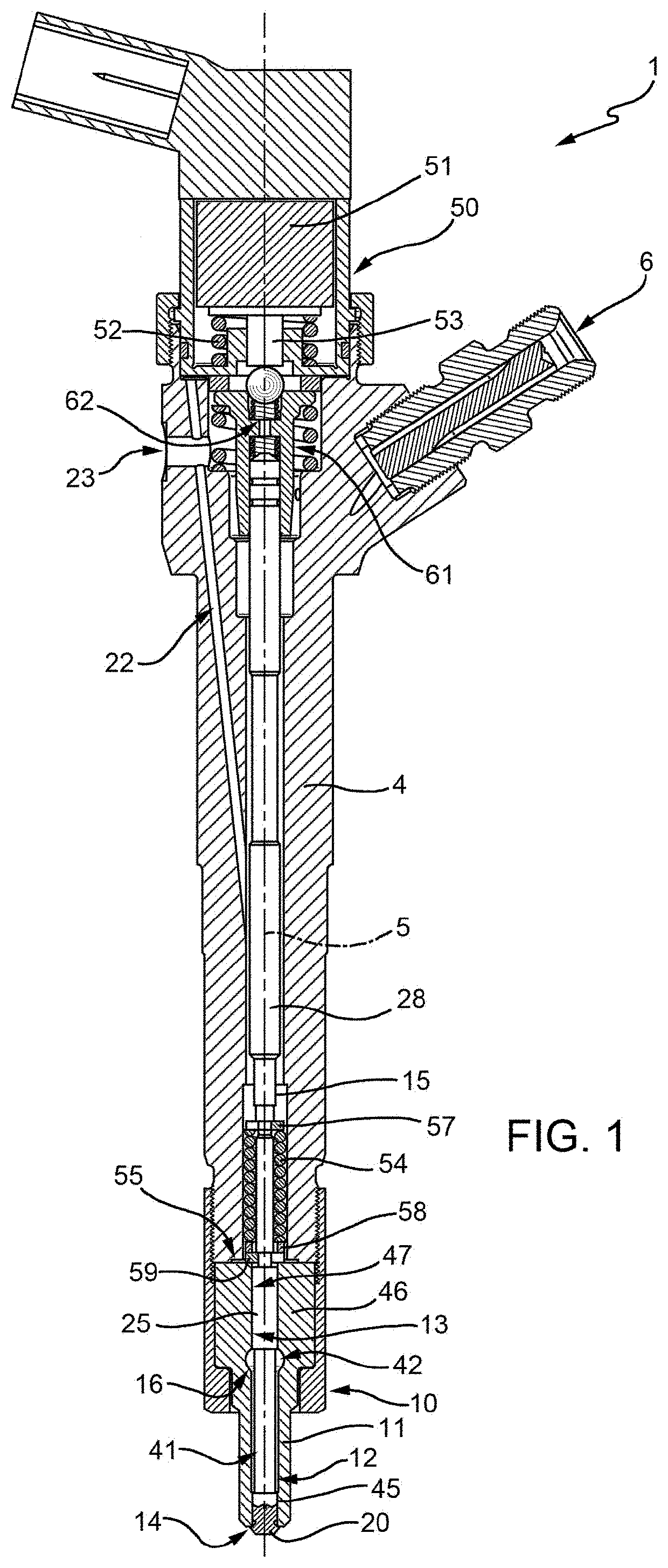

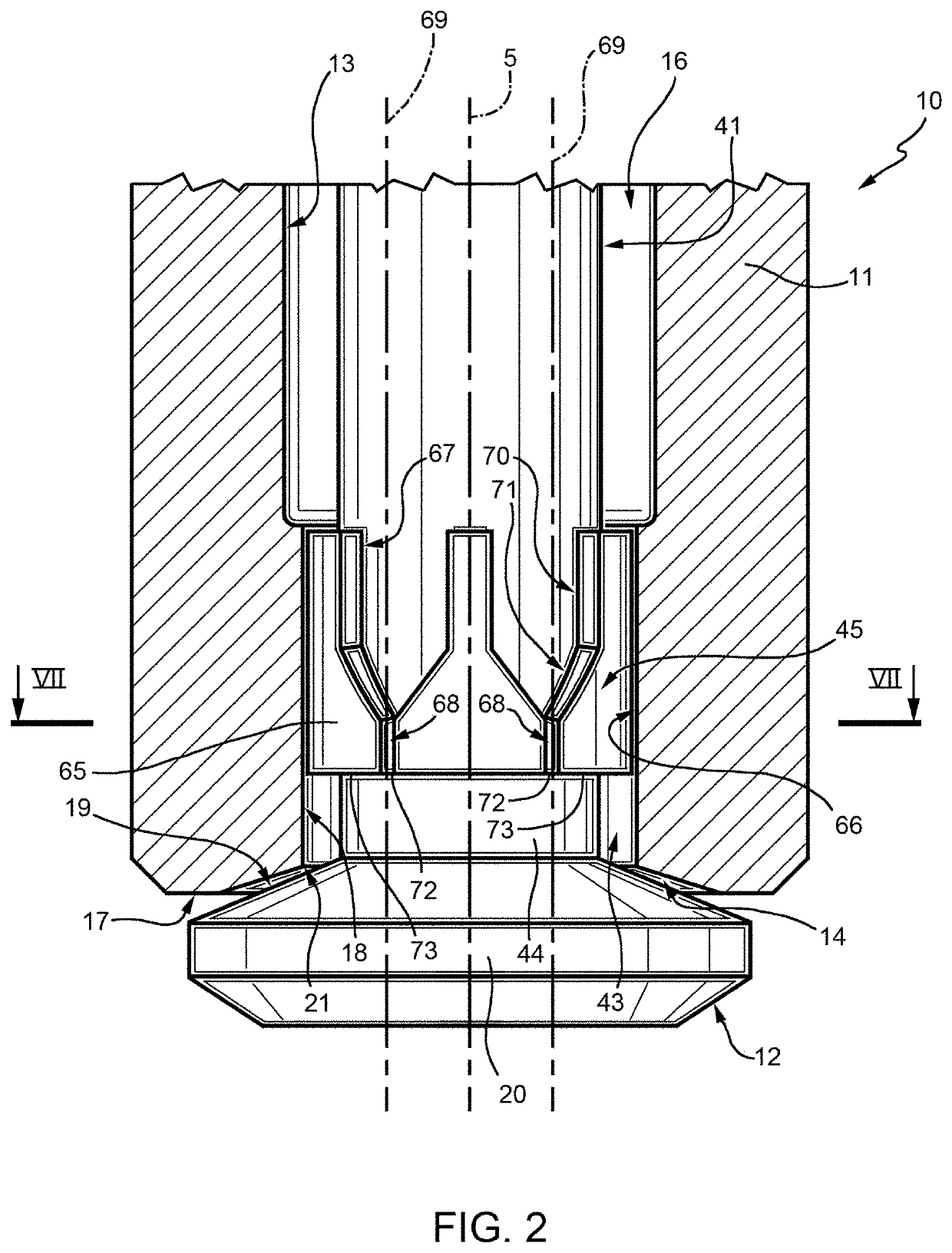

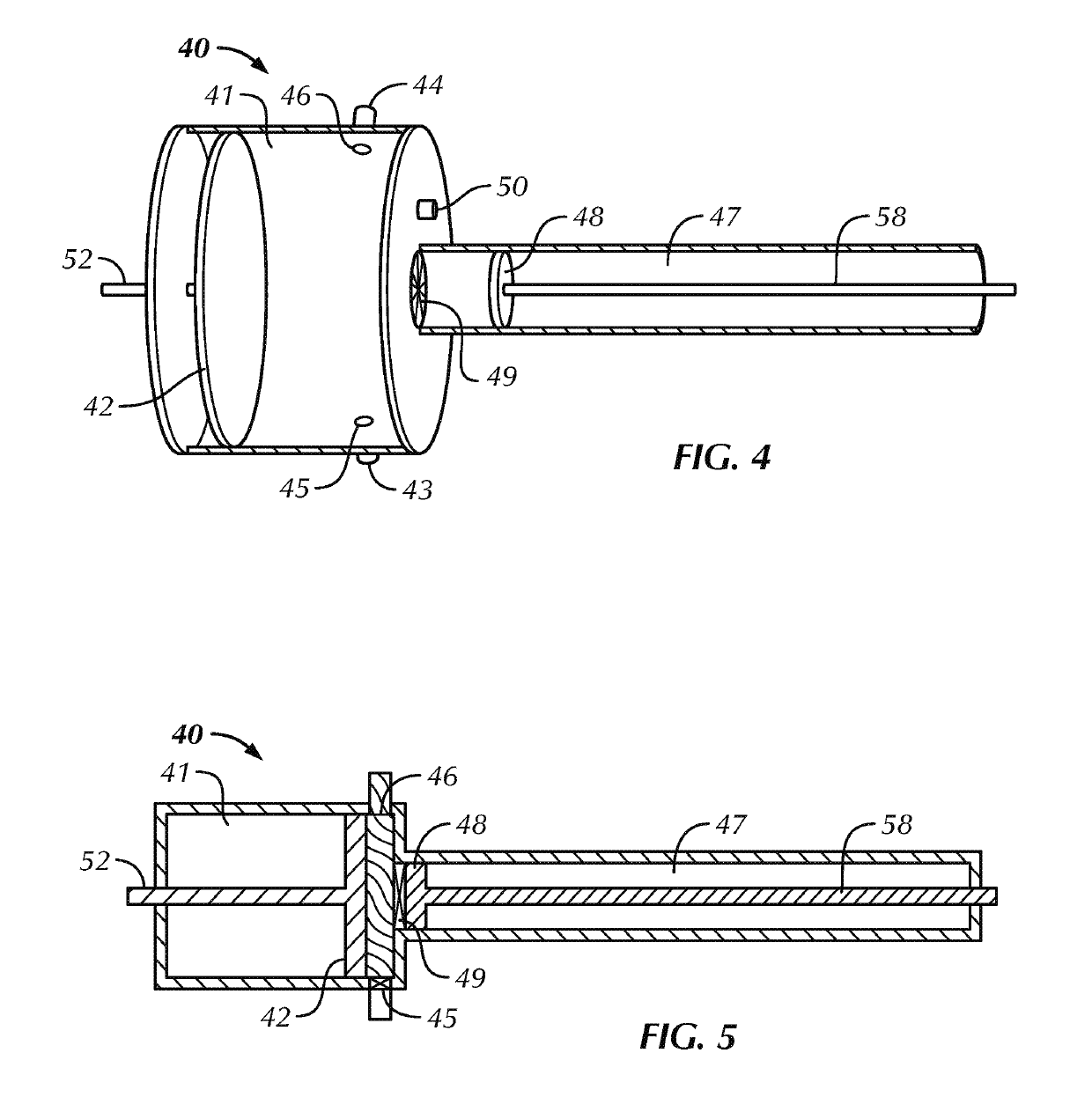

Fuel electro-injector atomizer, in particular for a diesel cycle engine

An atomizer of a fuel electro-injector is equipped with a nozzle and a valve needle having a head, which is coupled to a sealing seat of the nozzle, and stem, which engages an inner seat of the nozzle; the stem and the nozzle define an annular passageway with a chamber that axially terminates at the sealing seat; the stem has an intermediate portion coupled in an axially sliding manner in the inner seat and defining a plurality of channels, the outlets of which are arranged on the annular chamber; the sealing seat and the head of the valve needle define a discharge section, which is annular and has a width that increases as the opening stroke of the valve needle proceeds; the ratio between the depth and the outer chord of the minimum cross-section of the channels is greater than or equal to two.

Owner:CENT RICERCHE FIAT SCPA

Biodiesel production method

The present invention relates to a process for obtaining a mixture of fatty acid esters, suitable as a combustible or fuel in diesel cycle engines, comprising: a) the obtaining of a microbial biomass with a triglyceride content equal to or greater than 20% by dry weight, by means of the use of an oleaginous microorganism using glycerin as a carbon source; and b) the conversion of the triglycerides contained in the biomass obtained in step a) into a mixture of fatty acid esters. The invention likewise relates to said oleaginous microorganism, to a process for its selection and to polynucleotides obtained therefrom.

Owner:NEOL BIOSOLUTIONS

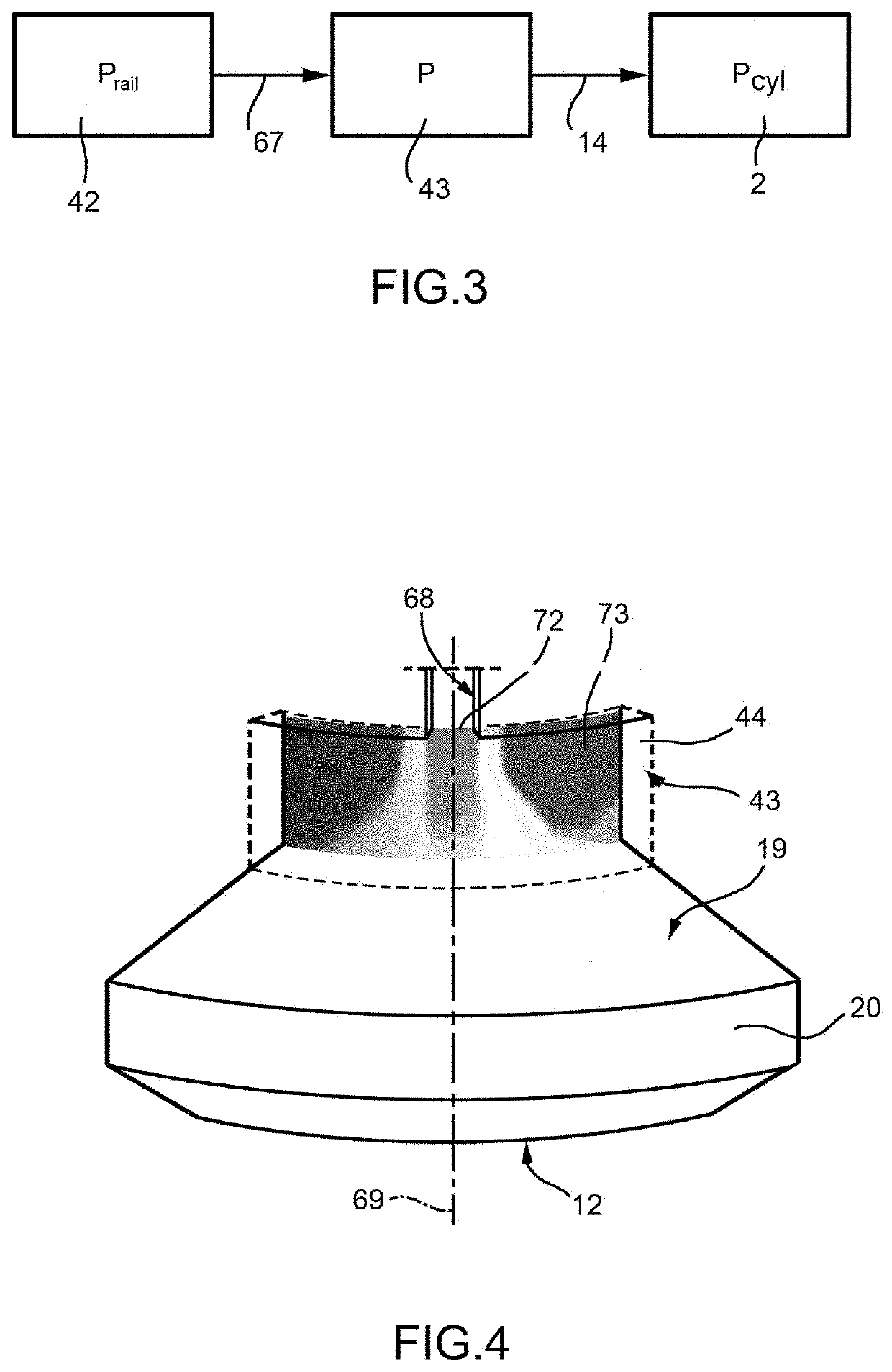

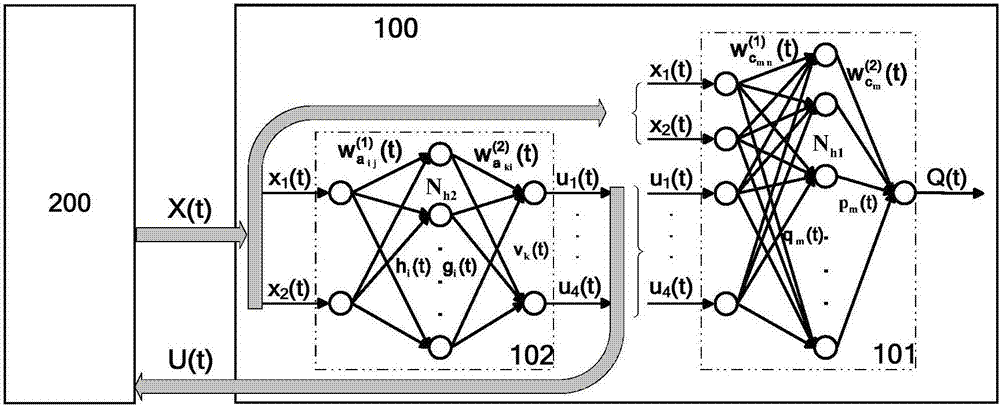

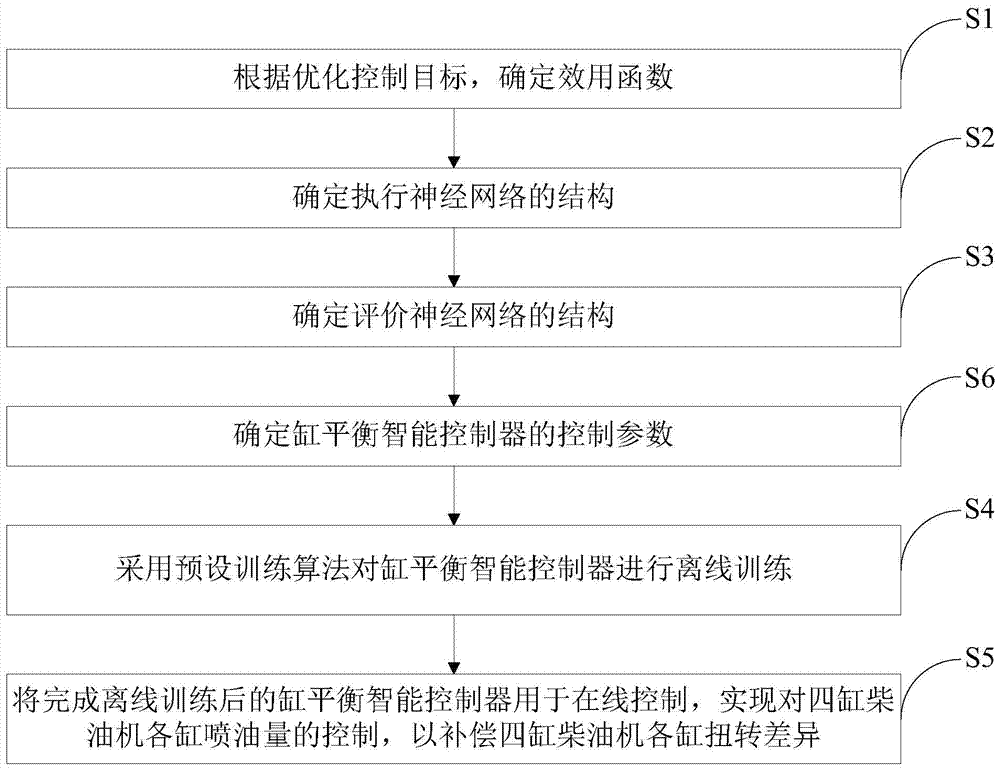

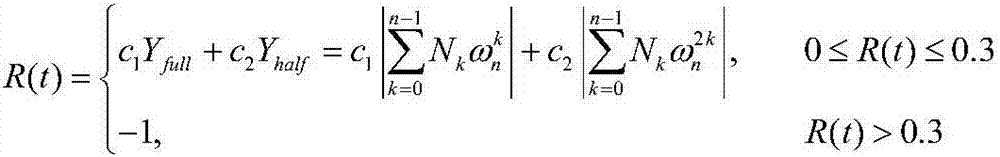

A Diesel Engine Cylinder Balance Intelligent Adjustment Algorithm Based on Approximate Dynamic Programming

ActiveCN105443259BFast iterative convergence performanceElectrical controlMachines/enginesIntelligent Diesel EngineDynamic planning

The invention discloses an intelligent diesel engine cylinder balance adjusting algorithm based on approximate dynamic planning. The instant rotation speed of a four-cylinder diesel engine is sampled, the modulus sum being zero of first-order harmonic waves and second-order harmonic waves of discrete Fourier transform results of rotation speed data on a working circulation of the diesel engine serves as an optimization objective, a utility function is designed, input and output control variables are selected, an approximate dynamic planning controller is designed, and through learning, the oil spray amount of four cylinders of the diesel engine is self-adaptively adjusted to compensate for the torque differences of the cylinders, so that the four periodical waveforms on the working circulation of the diesel engine tend to be identical, and the rotation characteristic is stable. By the adoption of the algorithm, the oil spray amount of the cylinders of the diesel engine can be intelligently adjusted within a certain range to compensate for the rotation speed differences, caused by uncertain factors such as device differences, parameter changes, aging and abrasion, of the cylinders, and therefore the cylinder balancing effect is self-adaptively improved.

Owner:无锡科铭新汽车电子系统有限公司

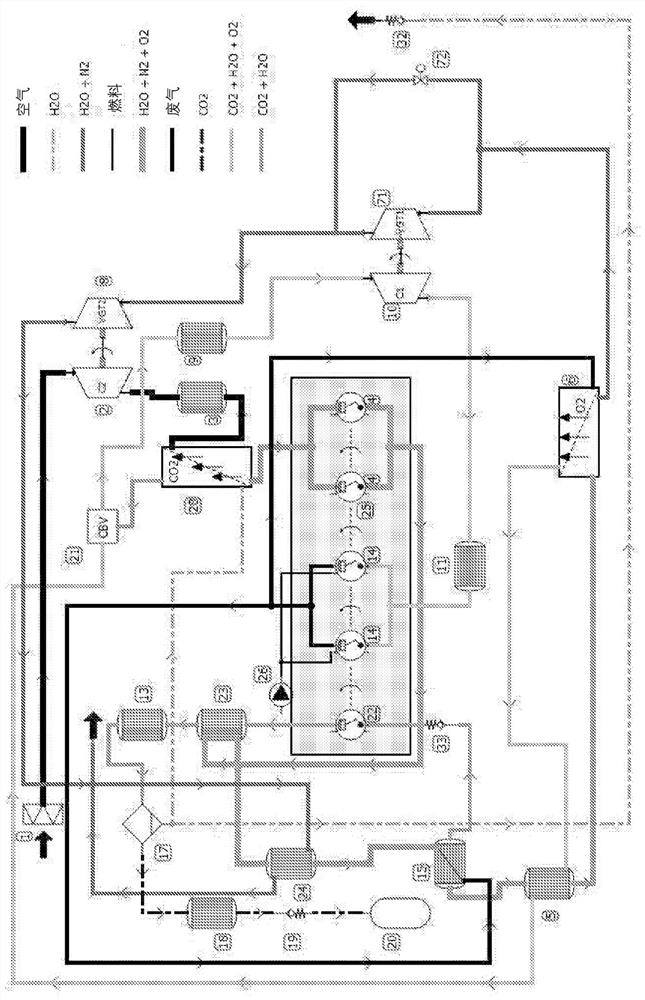

Internal combustion engine and operating method of same

ActiveUS20220178333A1Reduce pollutionReduces, orInternal combustion piston enginesLiquid fuel feedersBrayton cycleOtto cycle

The invention relates to an internal combustion engine that comprises a first Brayton cycle comprising a mixed ionic-electronic conducting (MIEC) membrane that separates the O2 from the air such that the suctioned air current is free from N2; a second Brayton cycle combined in a binary manner with the first Brayton cycle and nested with a cycle selected from an Otto cycle and a diesel cycle performed by means of oxy-combustion. The second Brayton cycle transmits mechanical energy and thermal energy from exhaust gases to the first Brayton cycle. The first Brayton cycle provides to the second Brayton cycle compressed O2 from the MIEC membrane. By means of the present engine, the NOx emission into the atmosphere is prevented by the separation of N2 in the MIEC membrane.

Owner:UNIV POLITECNICA DE VALENCIA +1

Medium pressure hydrocracking and catalytic cracking combined process for producing low sulfur diesel oil

InactiveCN1202218CSolve hydro-upgradingHydrocarbon oil crackingTreatment with hydrotreatment processesProcess engineeringDiesel cycle

The invention provides a reverse sequence medium-pressure hydrocracking-catalytic cracking combined process for producing clean fuel through circular refining of high-sulfur catalytic diesel oil, which is used to process heavy hydrocarbon materials to obtain middle distillates and provide hydrogenated materials for FCC units. The feature of the process is the reverse sequence medium oil hydrocracking process under the one-pass operation mode, that is, the raw material first passes through the cracking section and then passes through the refining section to produce wide-distillation diesel oil and hydrogenated unconverted oil used as feed to the downstream FCC unit. In particular, the feature of the process is to provide a cycle refining of FCC diesel, that is, to circulate the FCC diesel components back to the hydrorefining reactor for further refining to produce ultra-low sulfur clean diesel components in a maximum amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

Balanced rotary engine

InactiveCN100593078CEven mass distributionImprove distributionMachines/enginesRotary engineHigh pressure

The invention relates to a balanced rotary engine consisting of a rotary engine comprising tangential pistons which improve engine performance, facilitate the lubrication of the engine components, enable the use thereof at high revolutions and condition same for two-stroke operation with full use of the combustion chamber, even with mixtures (diesel cycle) which explode spontaneously upon reachinghigh compressions with a suitable volume. According to the invention, the components are structured such that (i) the engine can also be self-powered and (ii) the air or mixture is drawn directly from the rear of the cylinder and, subsequently, injected into the combustion chamber of said cylinder or of the cylinder adjacent thereto.

Owner:弗朗西斯科·哈维尔·路易斯·马丁内兹

Otto and diesel cycles employing spinning gas

An internal combustion engine is disclosed and includes a main cylinder and main piston that are relatively axially displaceable along a main axis to define a variable volume main working chamber. At least one valve is configured to admit air and fuel into the working chamber forming an air / fuel mixture. The main cylinder is configured to cause the air / fuel mixture in the main cylinder to spin rapidly enough to cause a substantive change in the heat capacity of the air / fuel mixture creating a spinning air / fuel mixture. The main cylinder and main piston are configured to compress the spinning air / fuel mixture to create an ignitable spinning air / fuel mixture. The spinning air / fuel mixture is ignited and the main cylinder and main piston are configured to extract mechanical energy from the ignited spinning air / fuel mixture. An exhaust valve is configured to exhaust combustion products from the main working chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com