Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86 results about "Otto cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

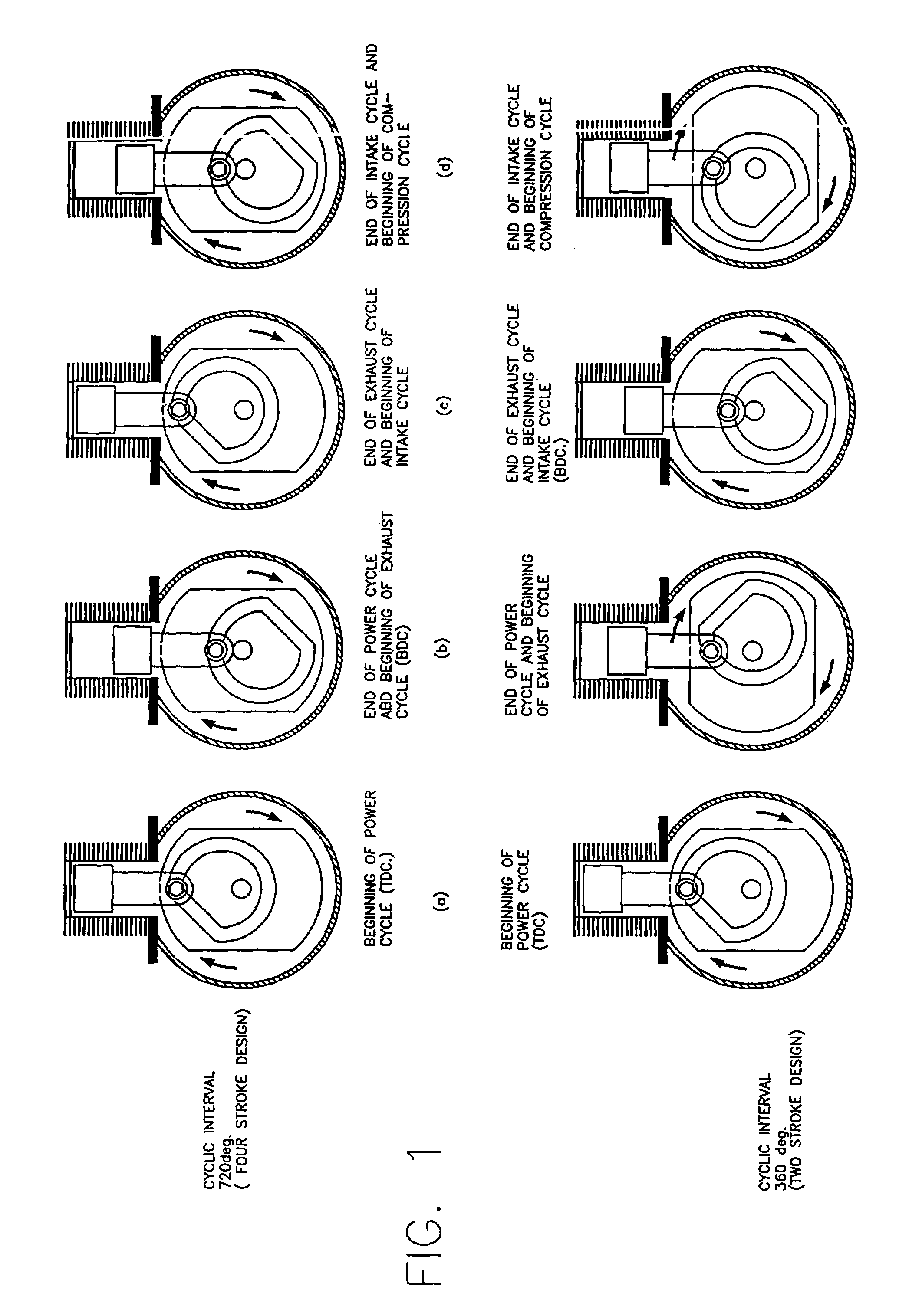

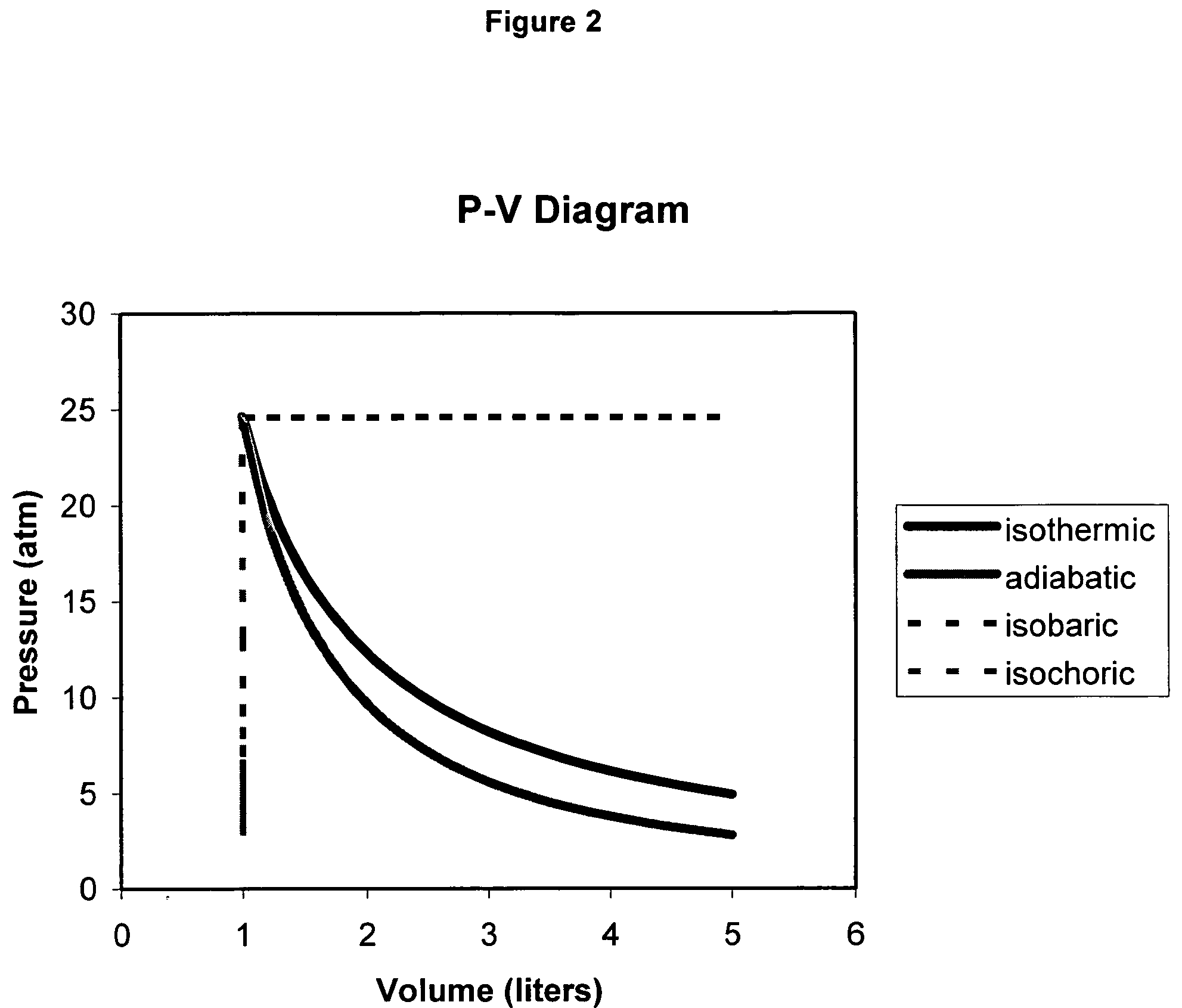

An Otto cycle is an idealized thermodynamic cycle that describes the functioning of a typical spark ignition piston engine. It is the thermodynamic cycle most commonly found in automobile engines. The Otto cycle is a description of what happens to a mass of gas as it is subjected to changes of pressure, temperature, volume, addition of heat, and removal of heat. The mass of gas that is subjected to those changes is called the system. The system, in this case, is defined to be the fluid (gas) within the cylinder. By describing the changes that take place within the system, it will also describe in inverse, the system's effect on the environment. In the case of the Otto cycle, the effect will be to produce enough net work from the system so as to propel an automobile and its occupants in the environment.

Steam Combustion Engine

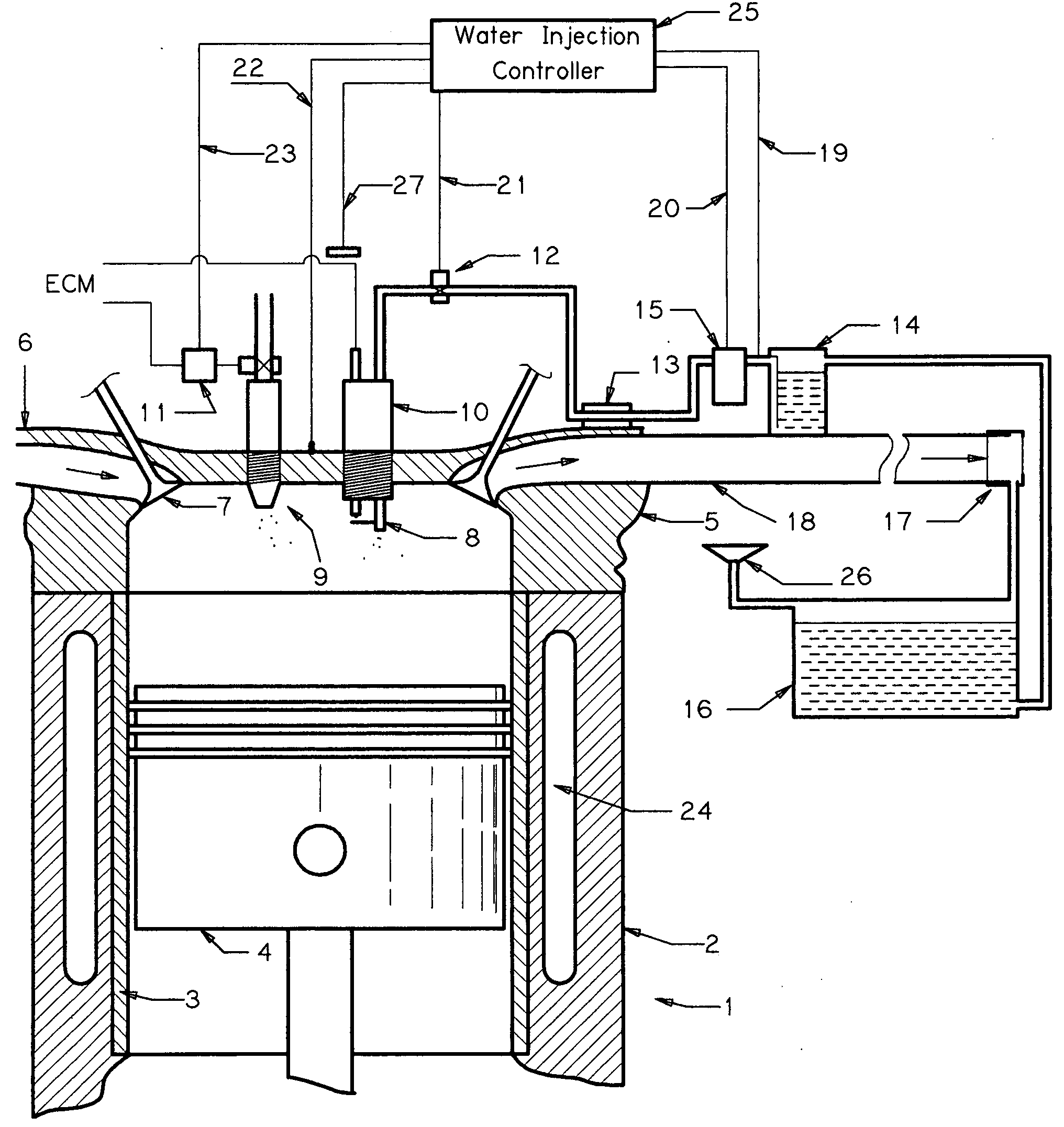

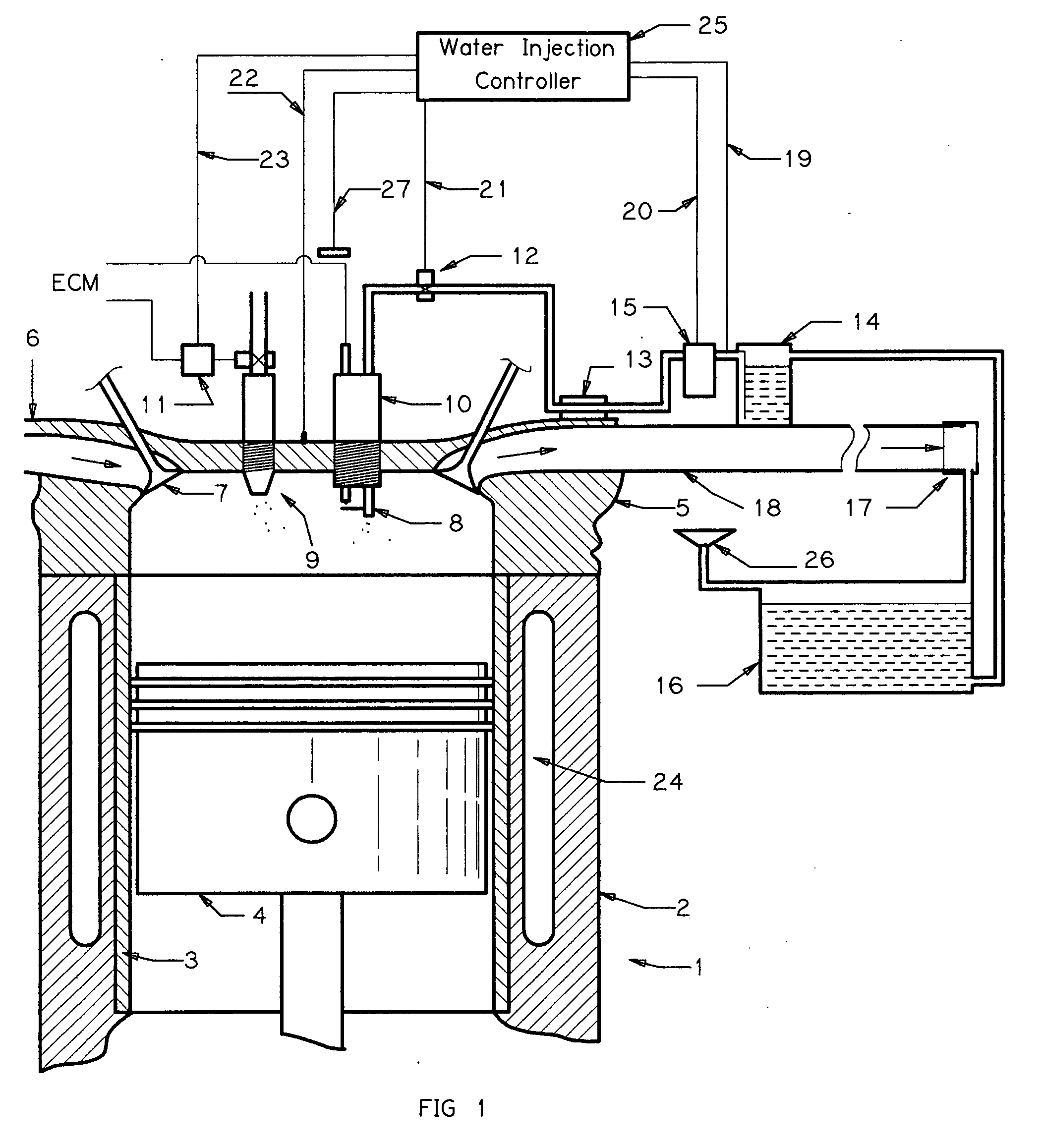

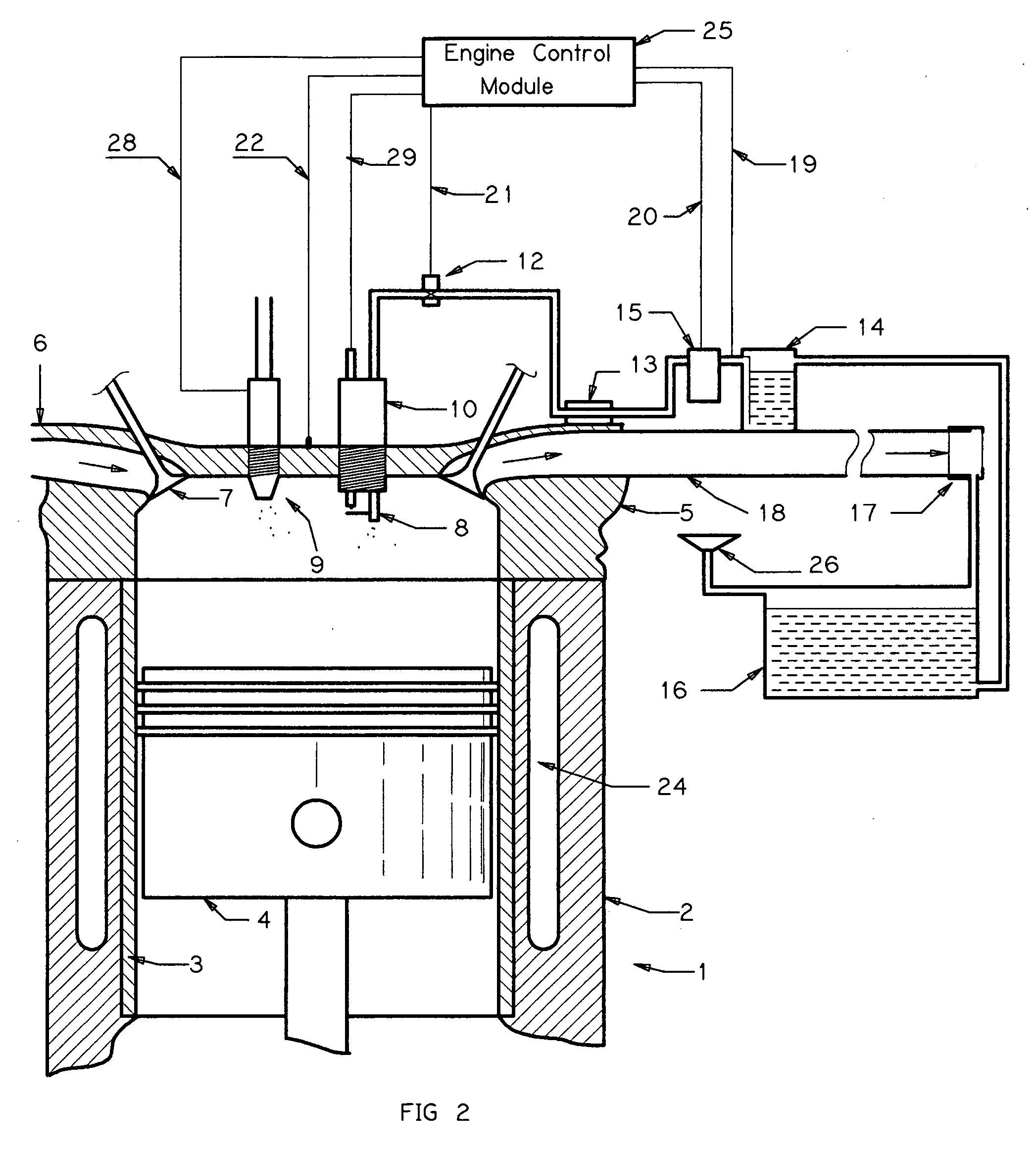

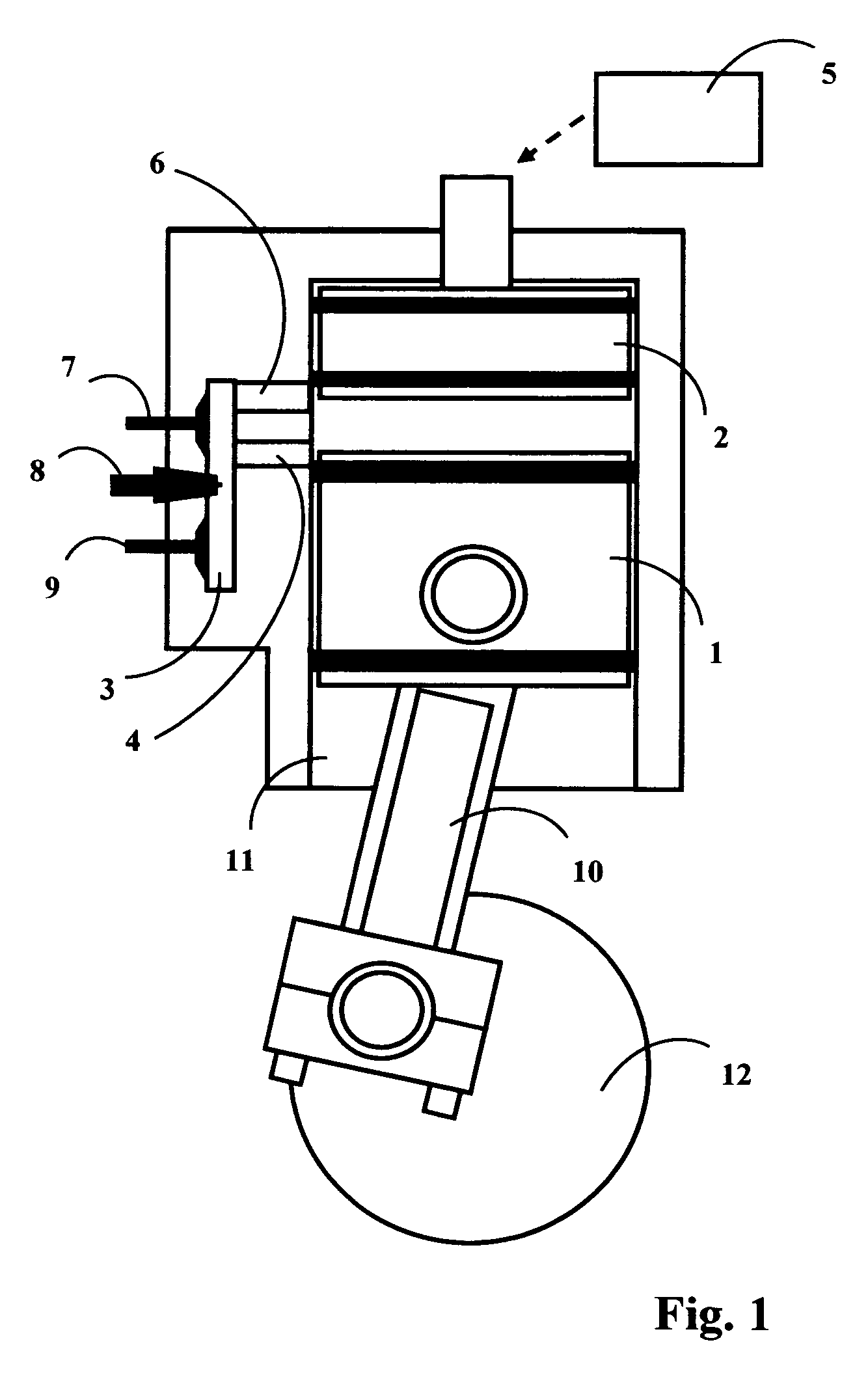

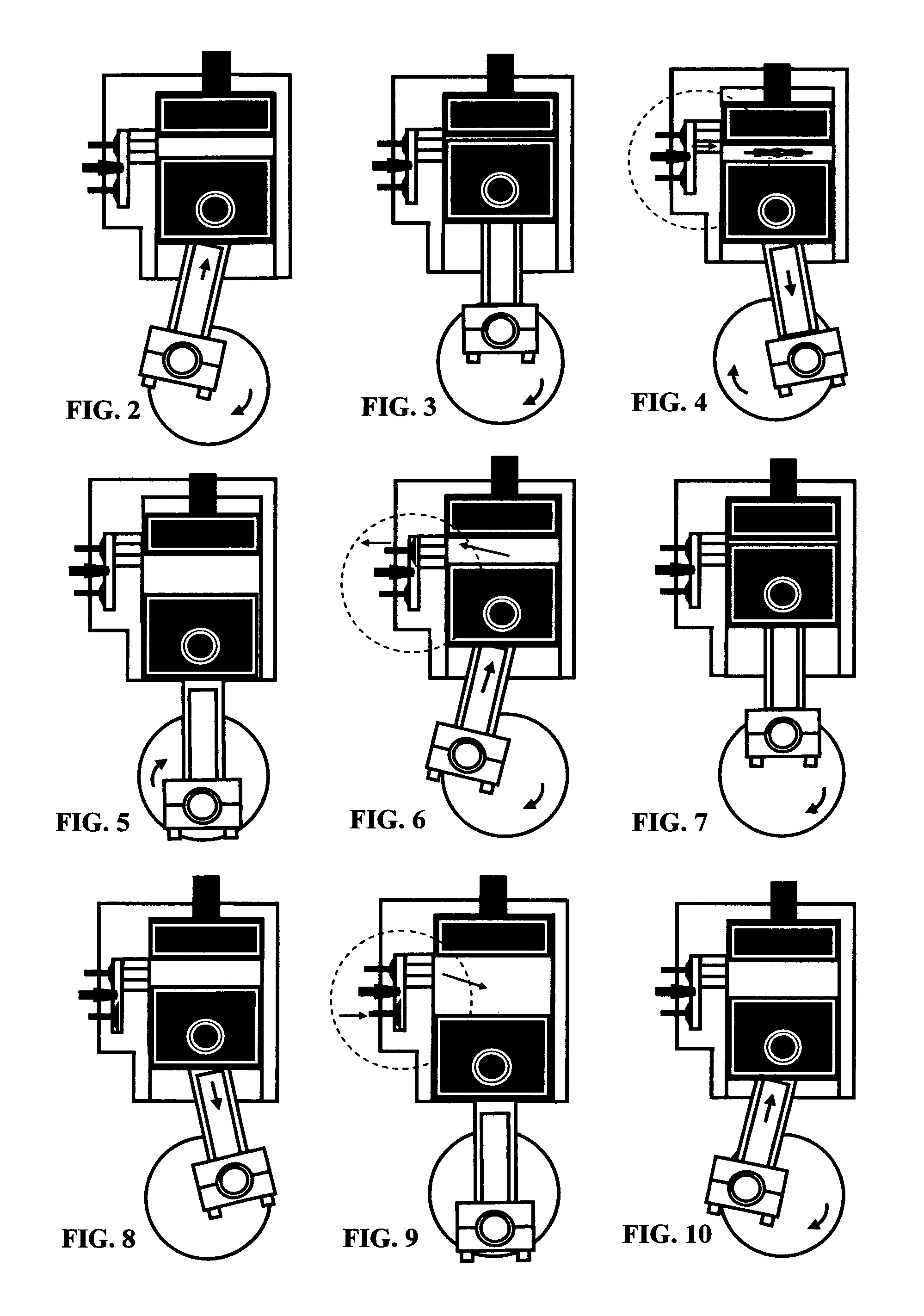

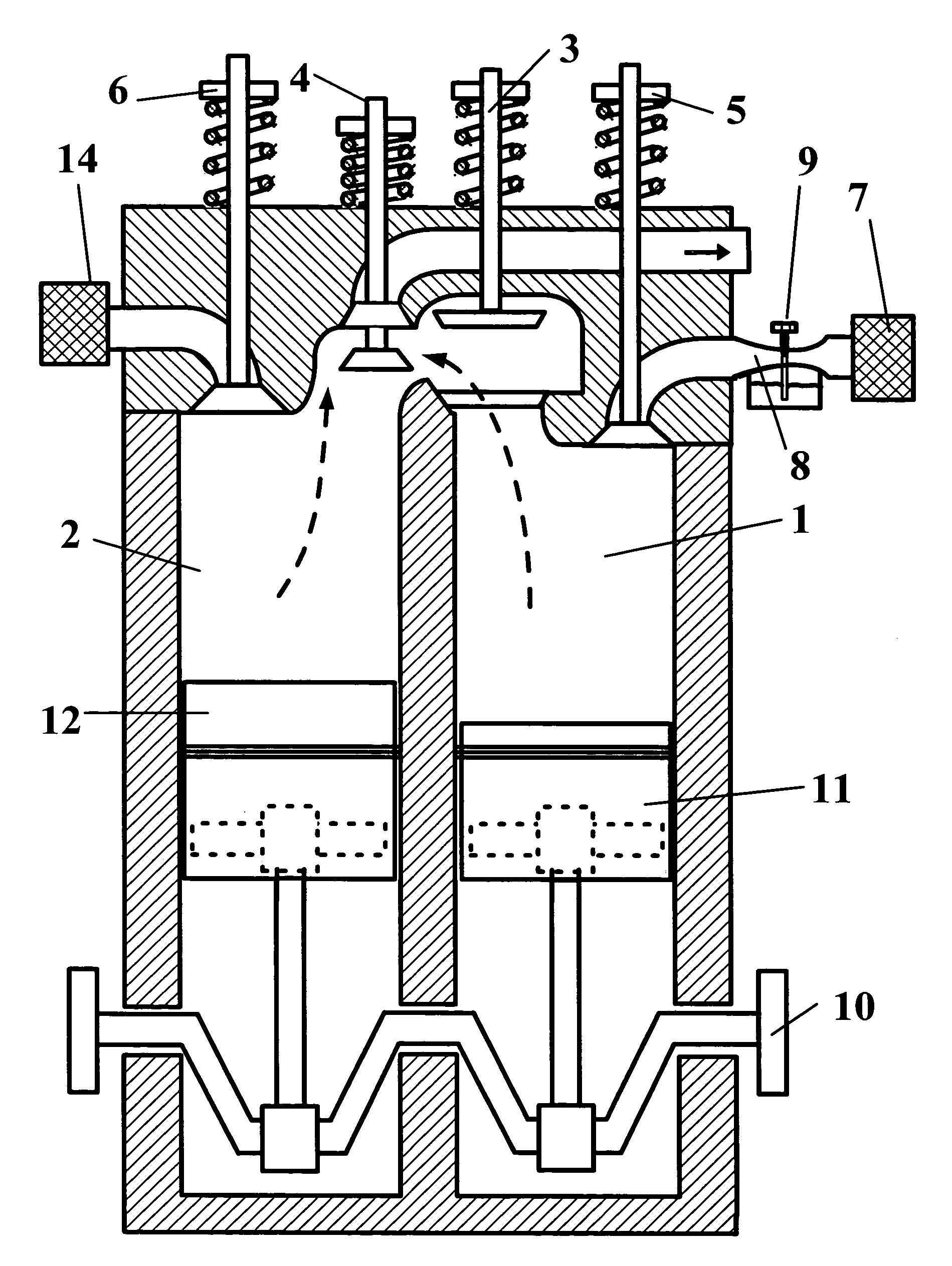

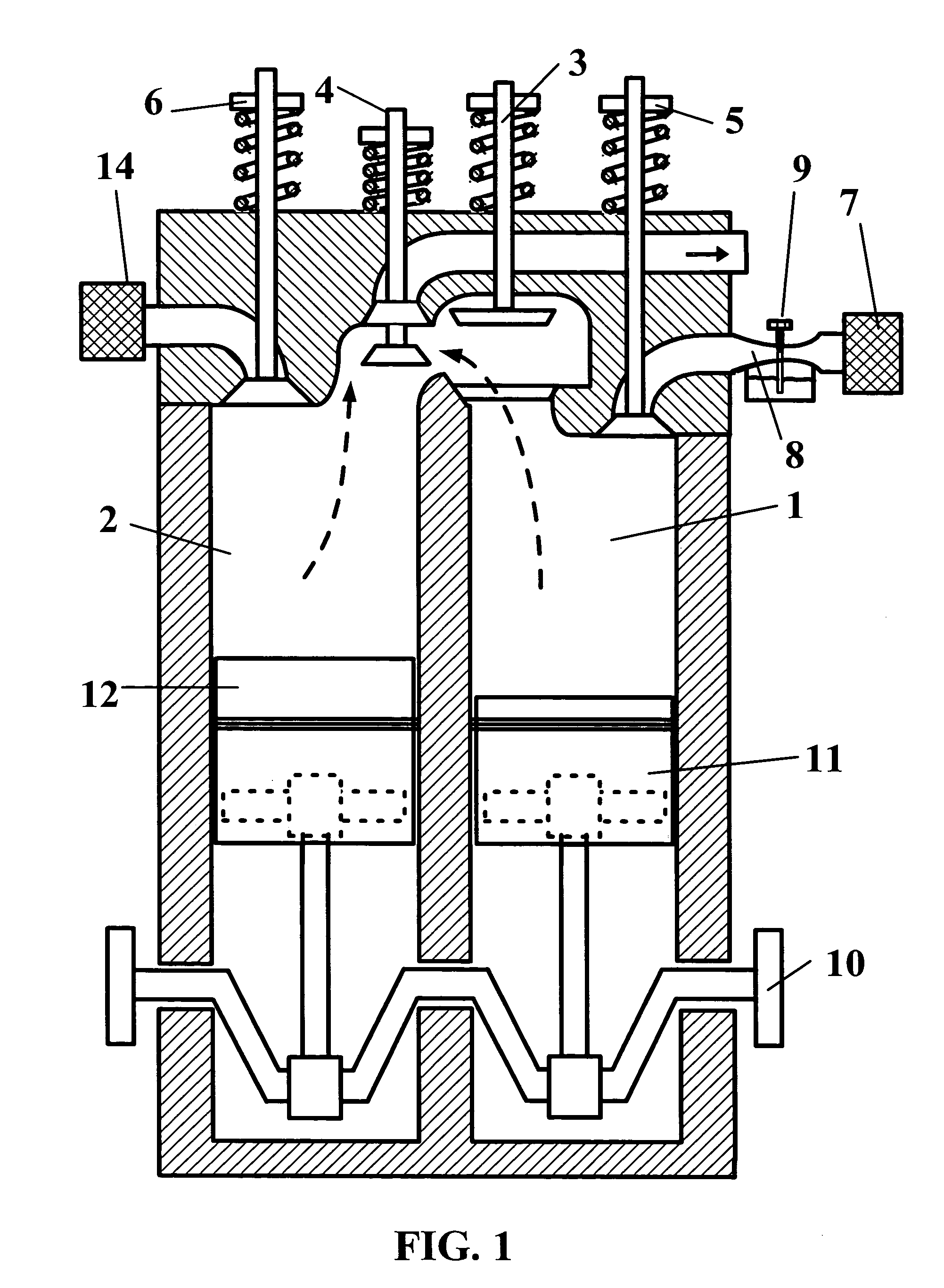

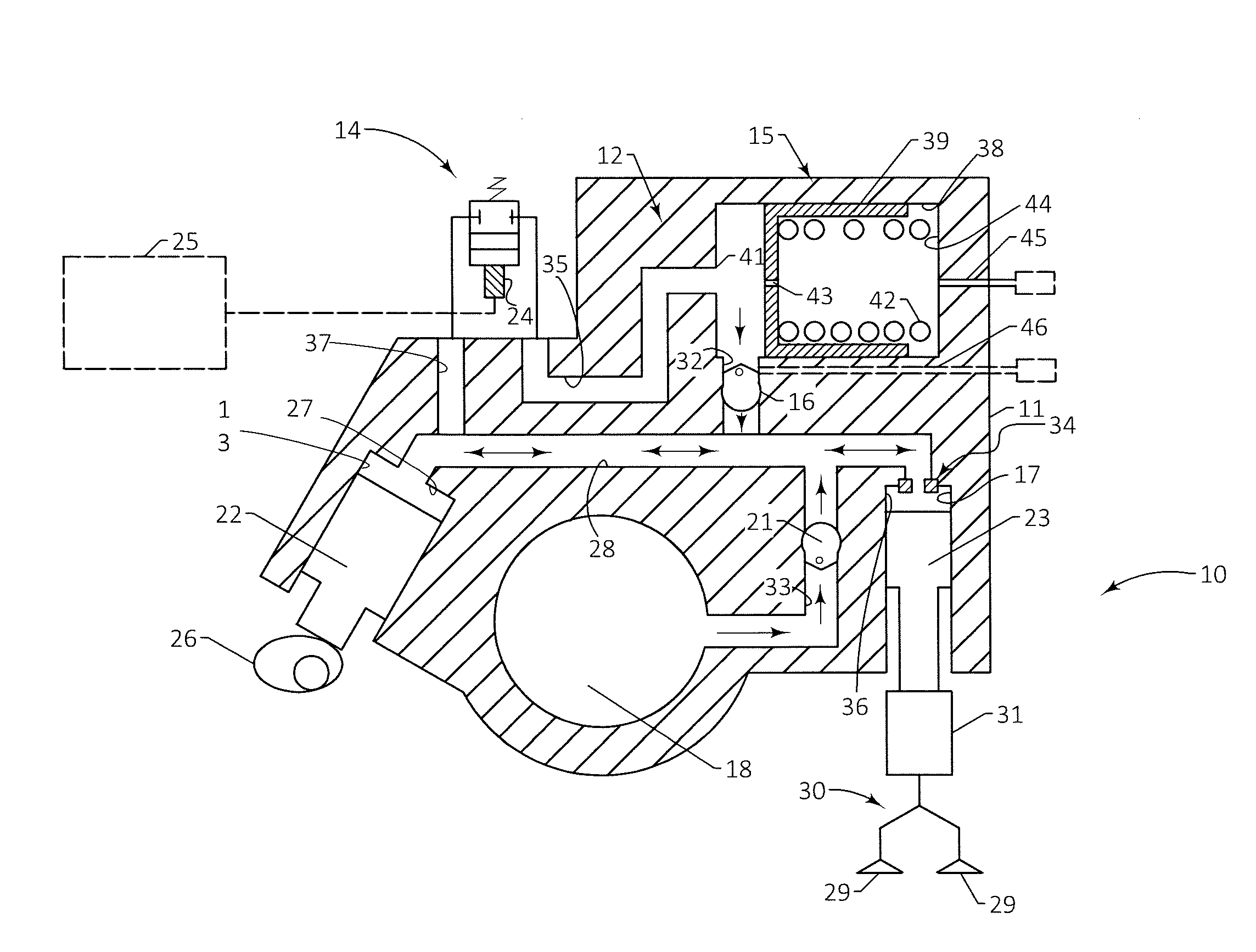

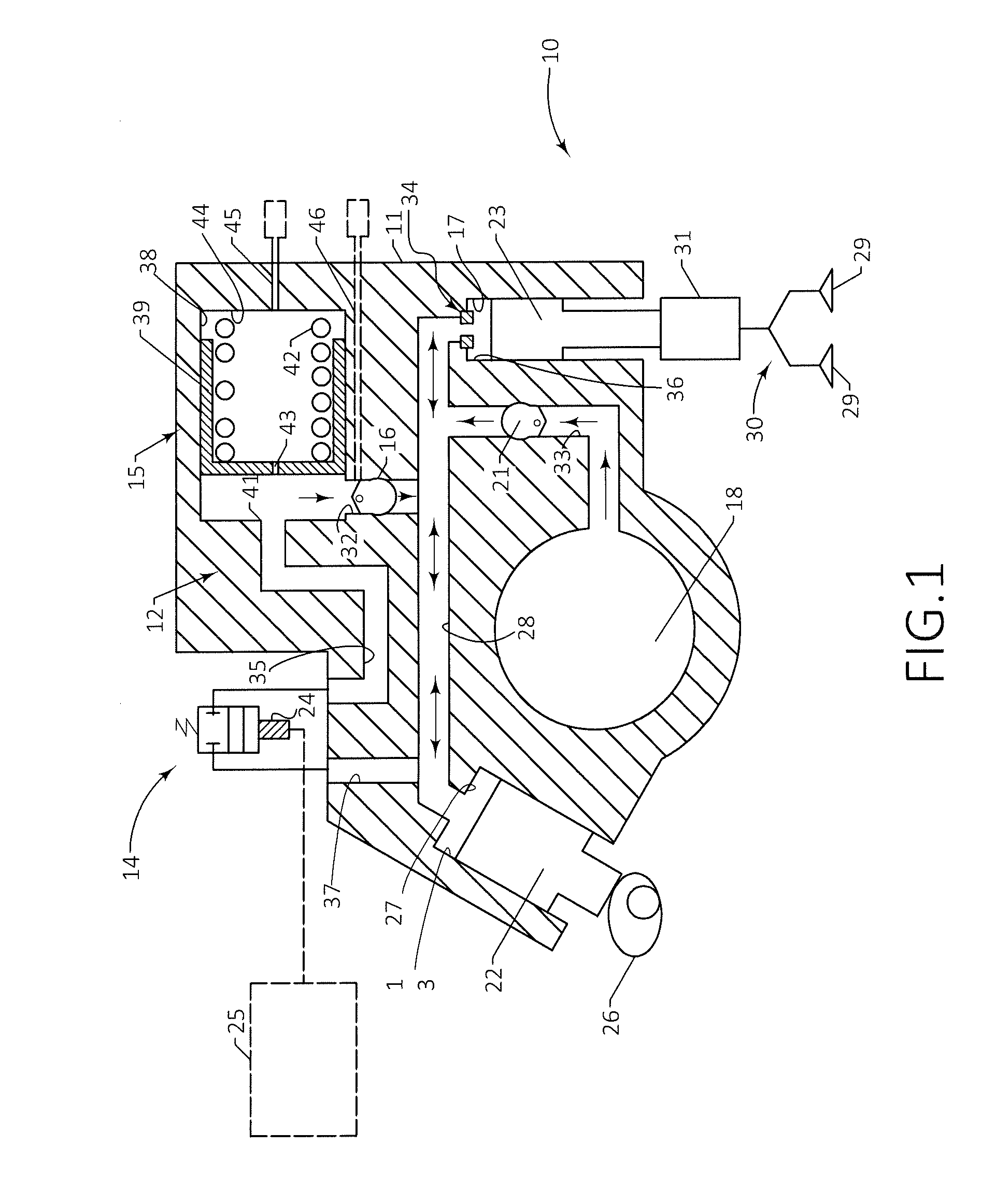

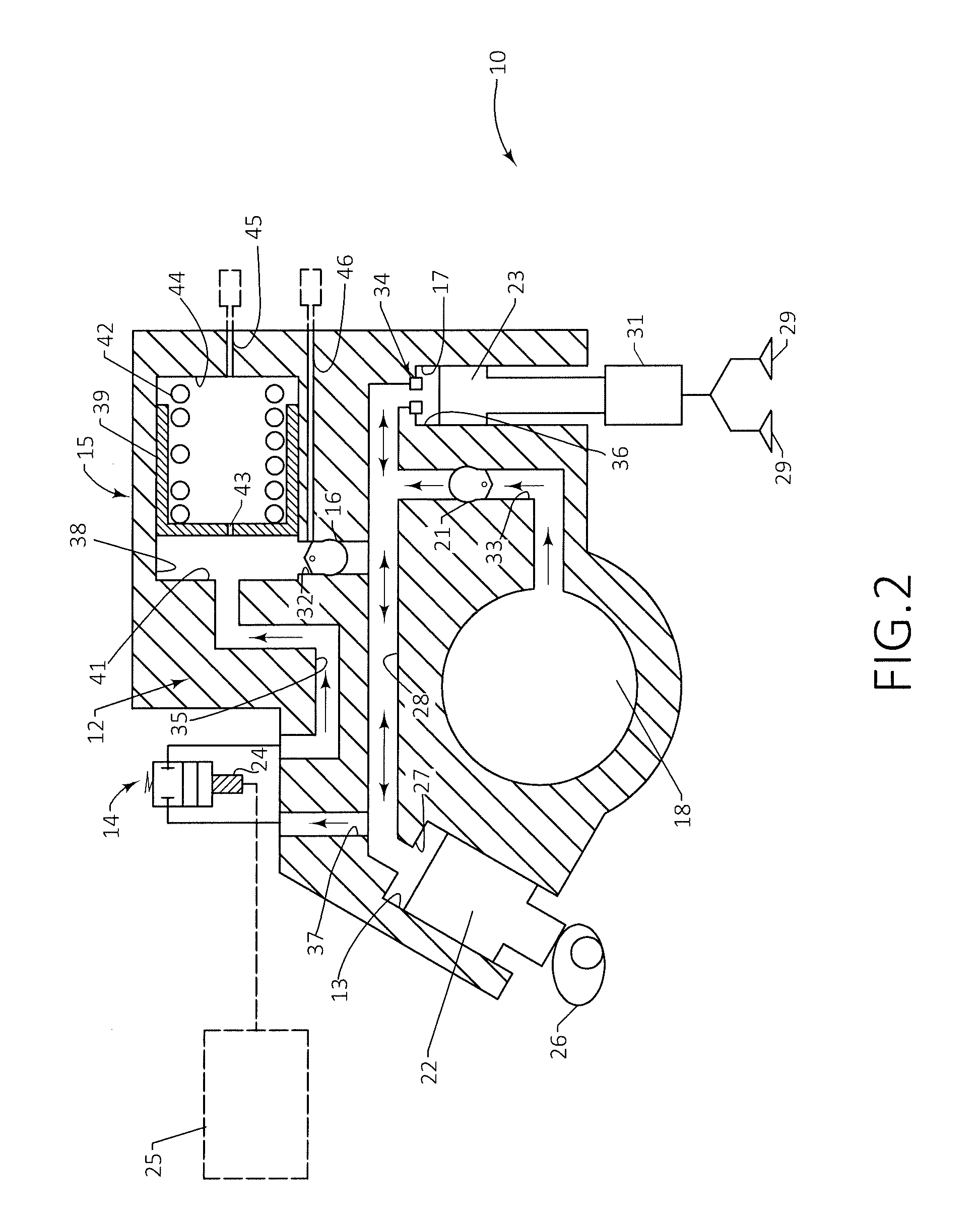

InactiveUS20100077986A1Improve fuel efficiencyFuel injection amount is reducedNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberOtto cycle

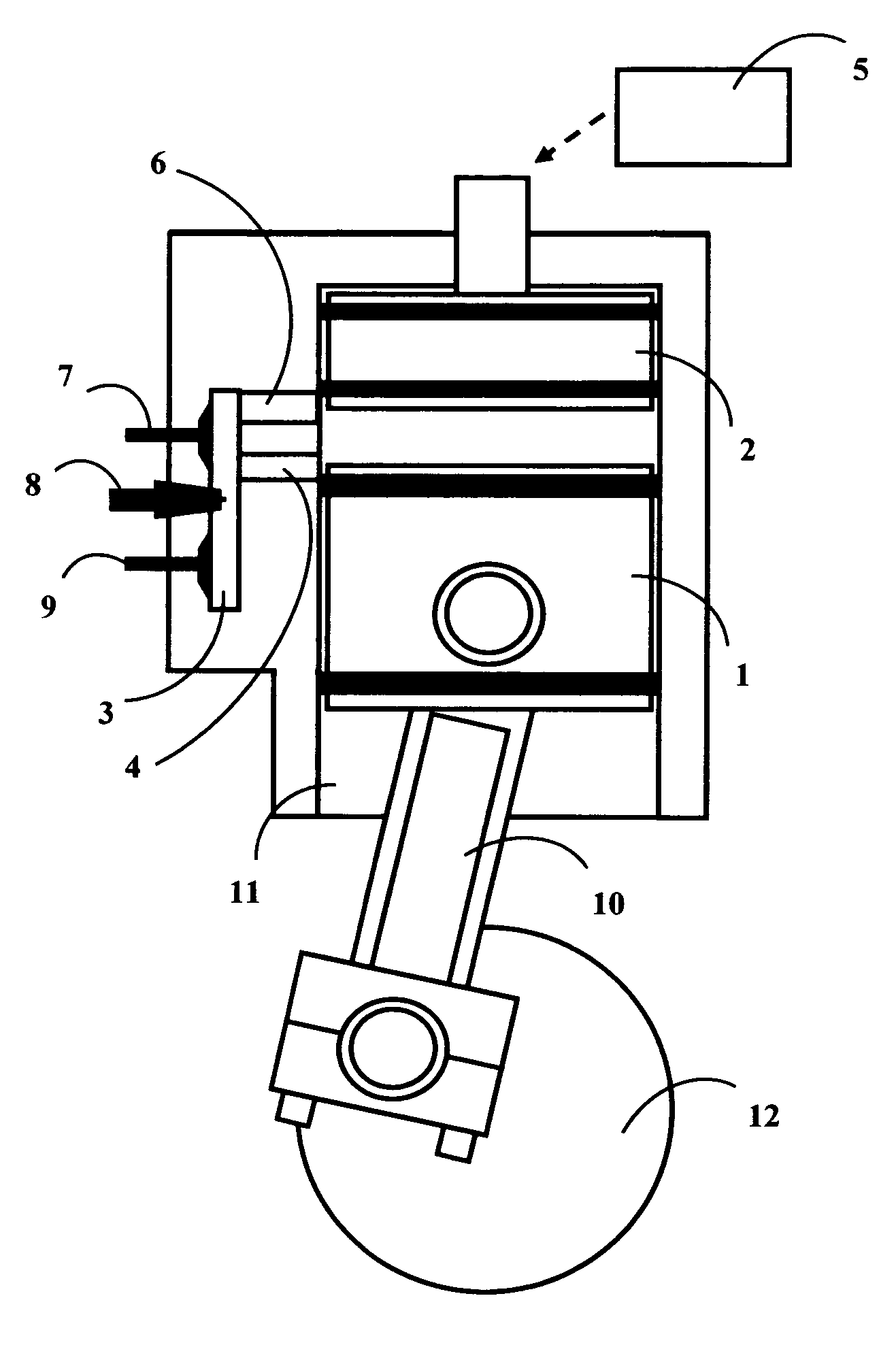

A steam combustion engine is improved from a conventional internal combustion engine by replacing spark plugs with water injection spark plugs, which inject small amount of boiling water into combustion chamber at the beginning of the fuel burning cycle if the engine temperature reaches preset limit. A steam combustion engine controller monitors the temperature of the engine, intercepts and alters fuel injection signal, turns on and off water injection solenoid at the right timing with the right amount. The apparatus can convert conventional vehicle into a steam combustion engine vehicle, reducing fuel consumption and emission by taking advantage of the waste heat and turning water into steam to generate extra useful work. This steam combustion engine can reach 40% efficiency instead of 20% in existing internal combustion engine. This apparatus can be used in any Otto cycle combustion engines found in electric generators, lawn mower, etc besides in most vehicles.

Owner:CHEN JACK YAJIE

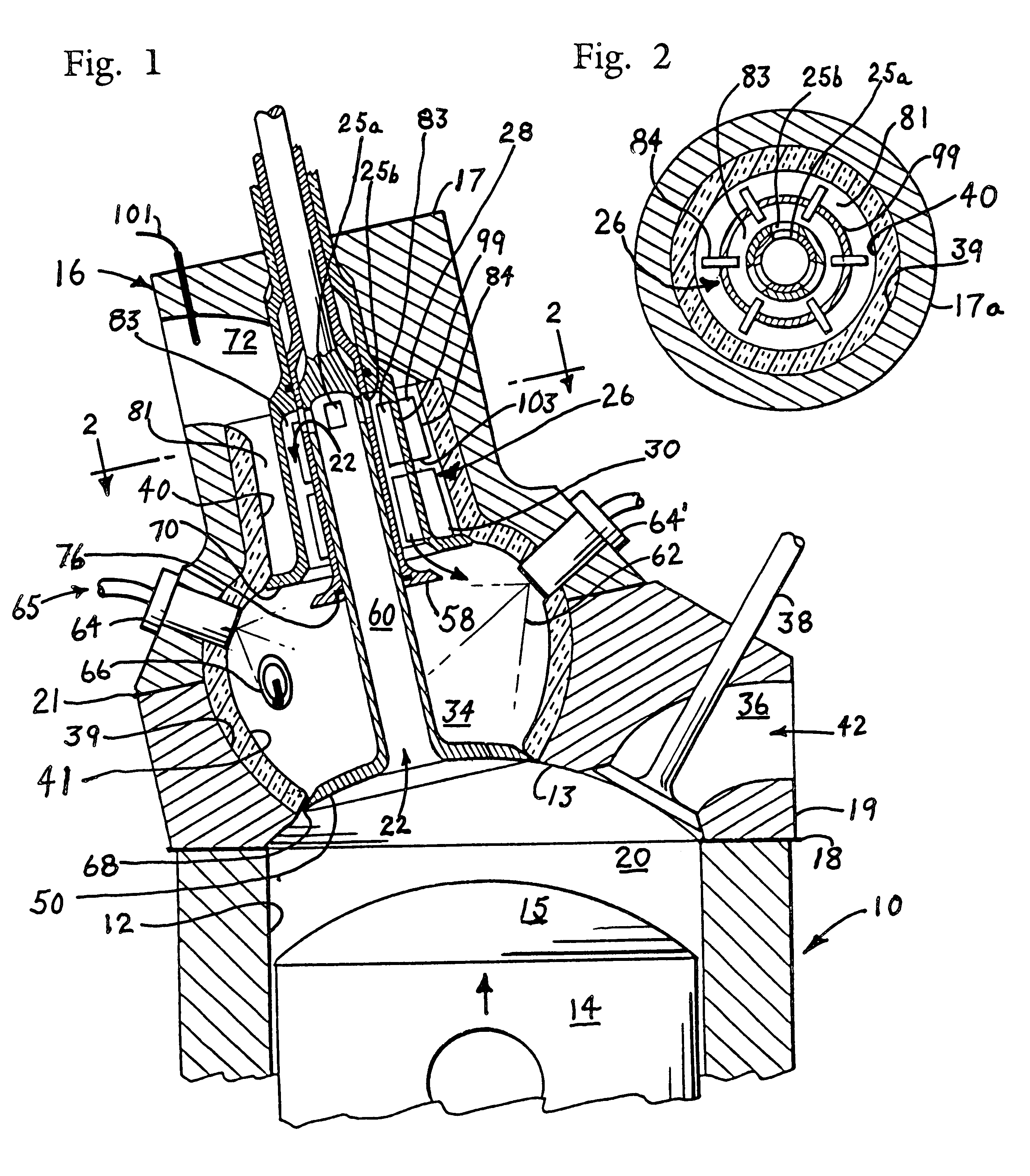

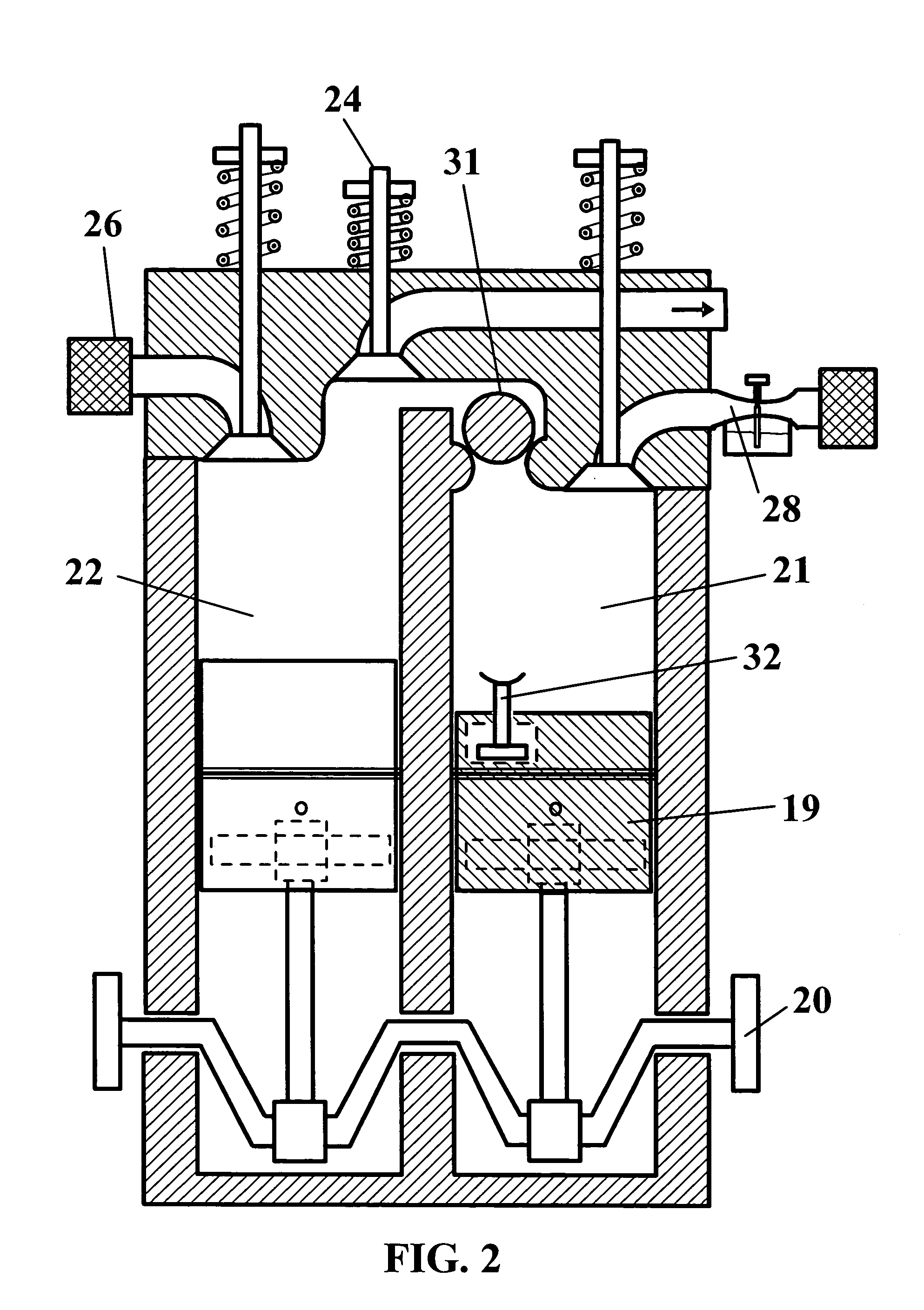

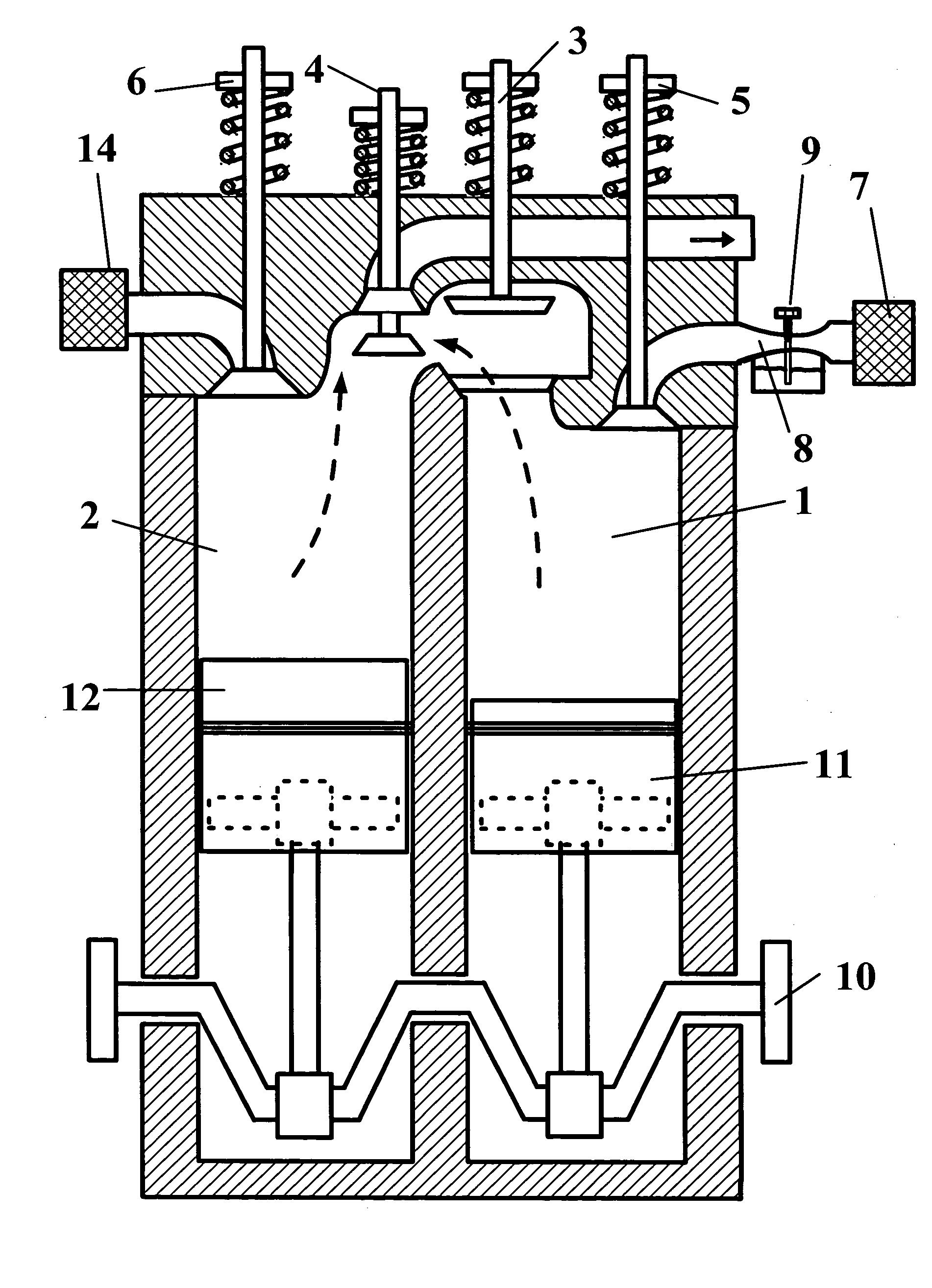

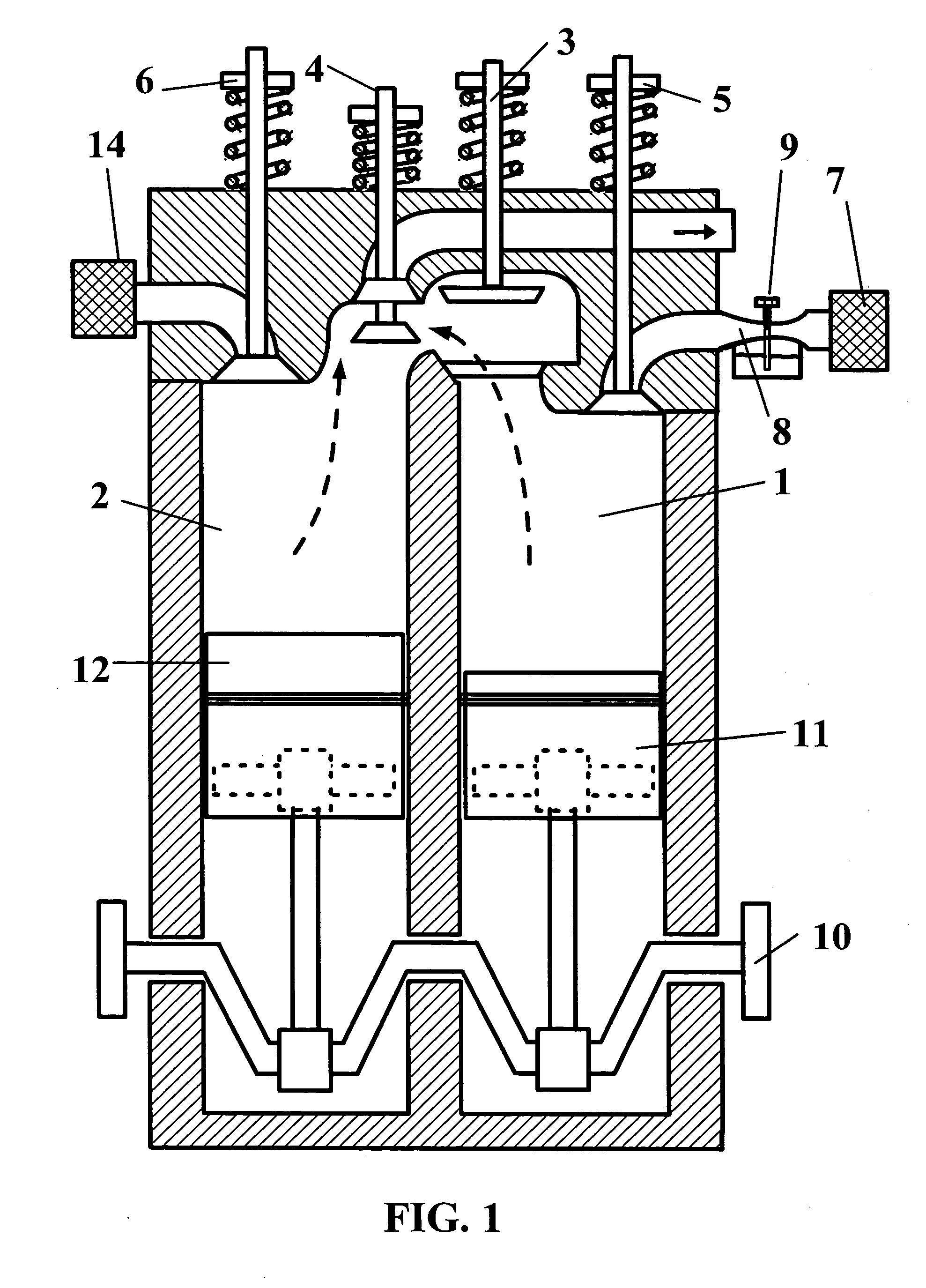

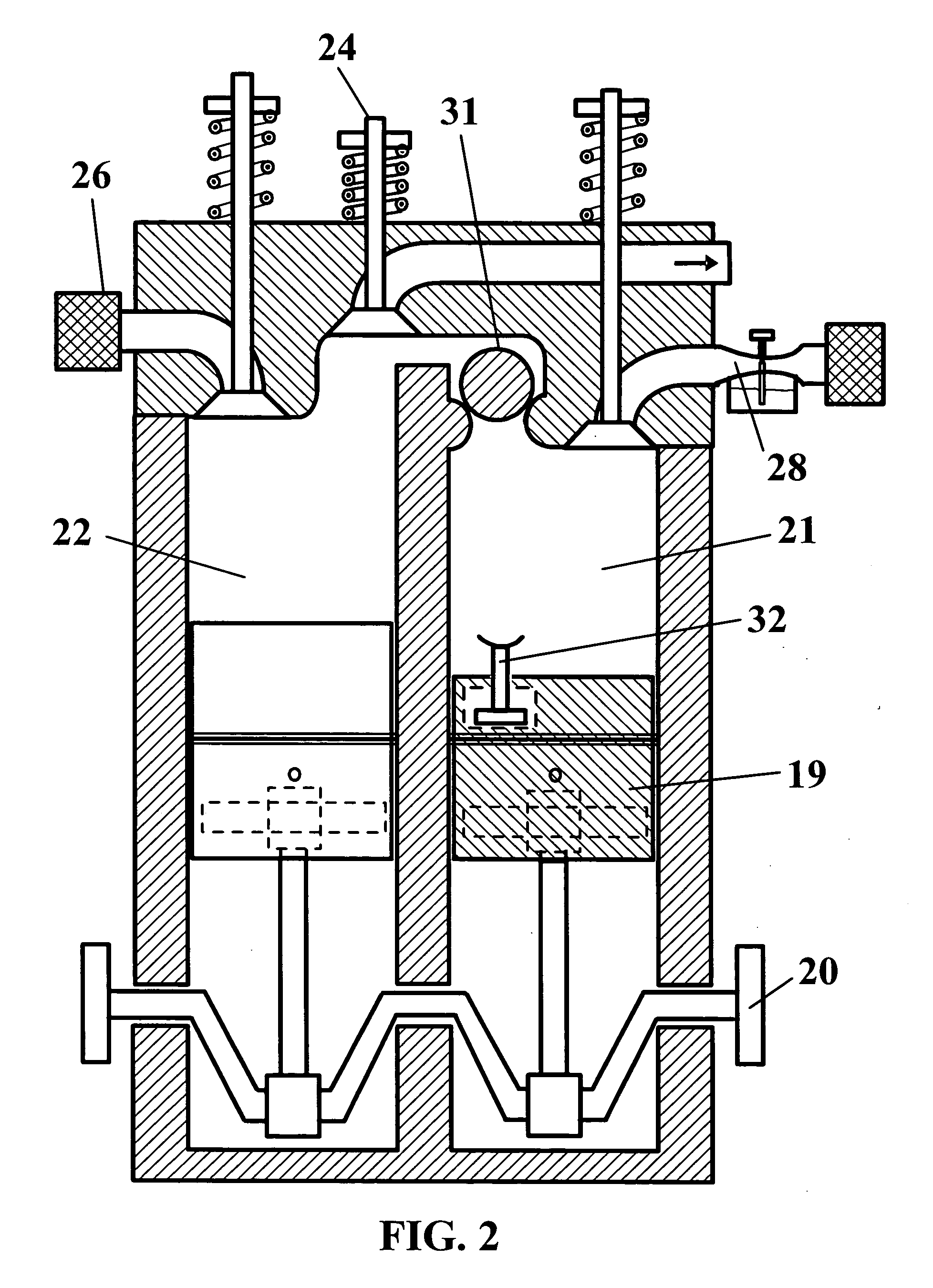

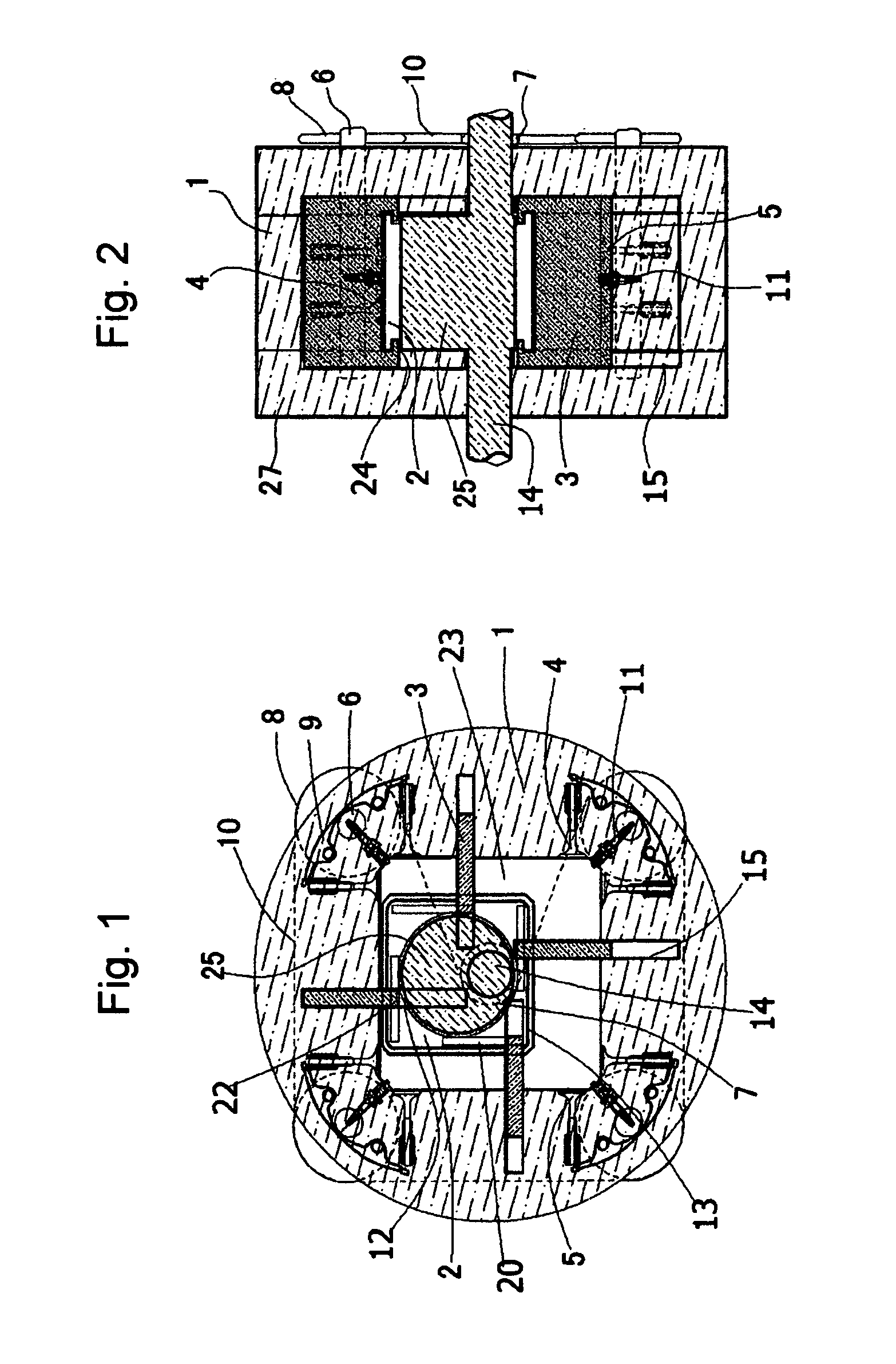

Four-stroke internal combustion engine with recuperator in cylinder head

InactiveUS6340013B1Prevent leakageQuick mixInternal combustion piston enginesCylinder headsThermal energyCommon Duct

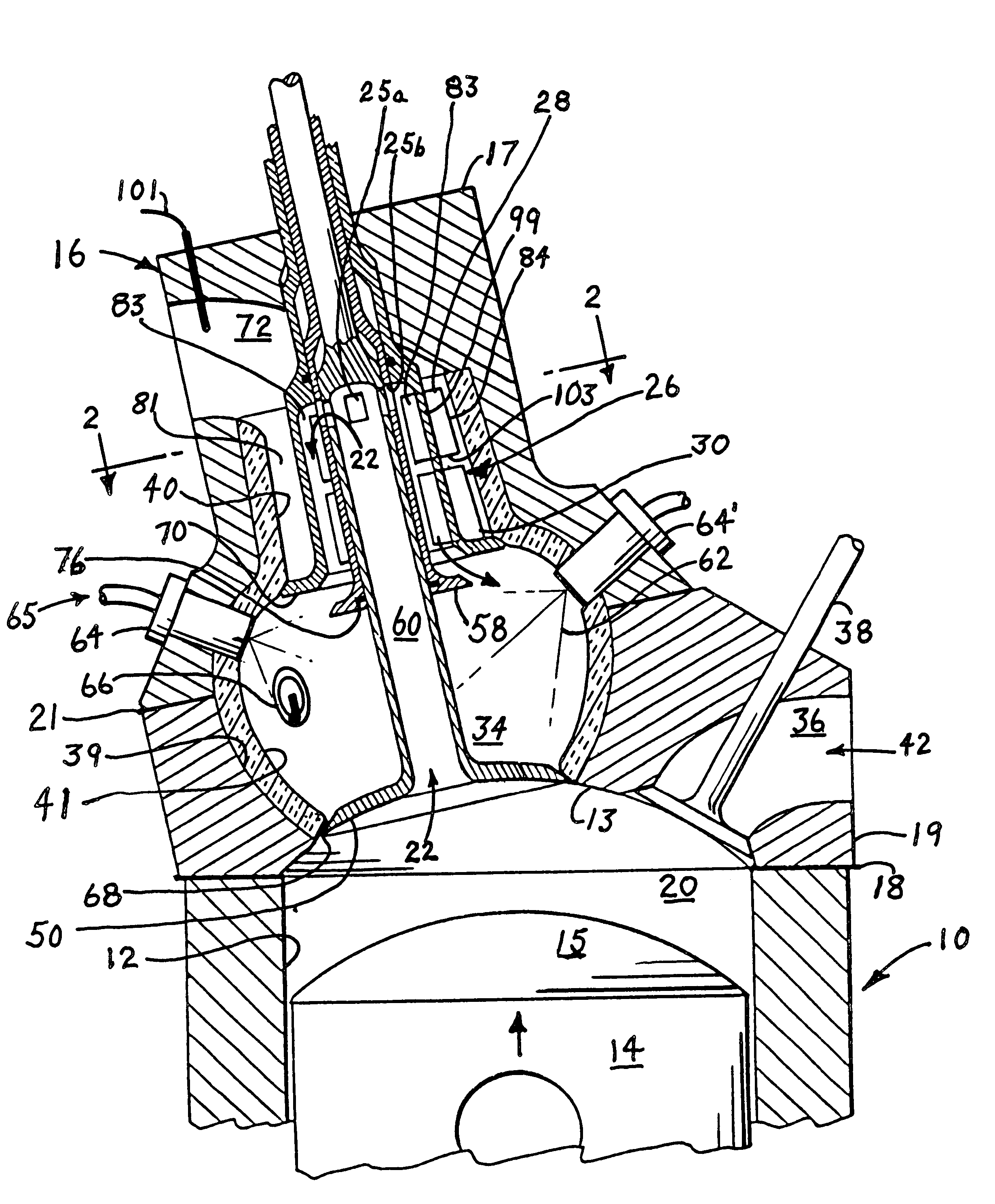

A recuperating four-stroke internal combustion engine obtains improves Carnot efficiency by use of a new and novel cylinder head which captures thermal energy normally thrown away in the exhaust and re-introduces it to the working cycle. This result, long sought by others, has been achieved by incorporating within the head a compact internal recuperative heat exchanger in series with a combustion chamber or pre-chamber. A recuperator-protecting valve segregates the recuperator from hot combustion gases until the gases reach maximum expansion in the cylinder. Recuperators of both common-duct and seperated-duct design are described, the separated duct recuperator permitting higher recuperator temperature and increased efficiency and a reduction in the number of valves necessary to control gas flow. A preferred embodiment employs four valves per cylinder unit, a separated duct recuperator, and an insulating liner that surrounds both the combustion chamber and the recuperator. A similar prototype recuperative engine has demonstrated that recuperation can reduce exhaust temperature as much as 600° Rankine below that attainable in an equivalent Otto Cycle engine.

Owner:BRITTON RICHARD BERKELEY

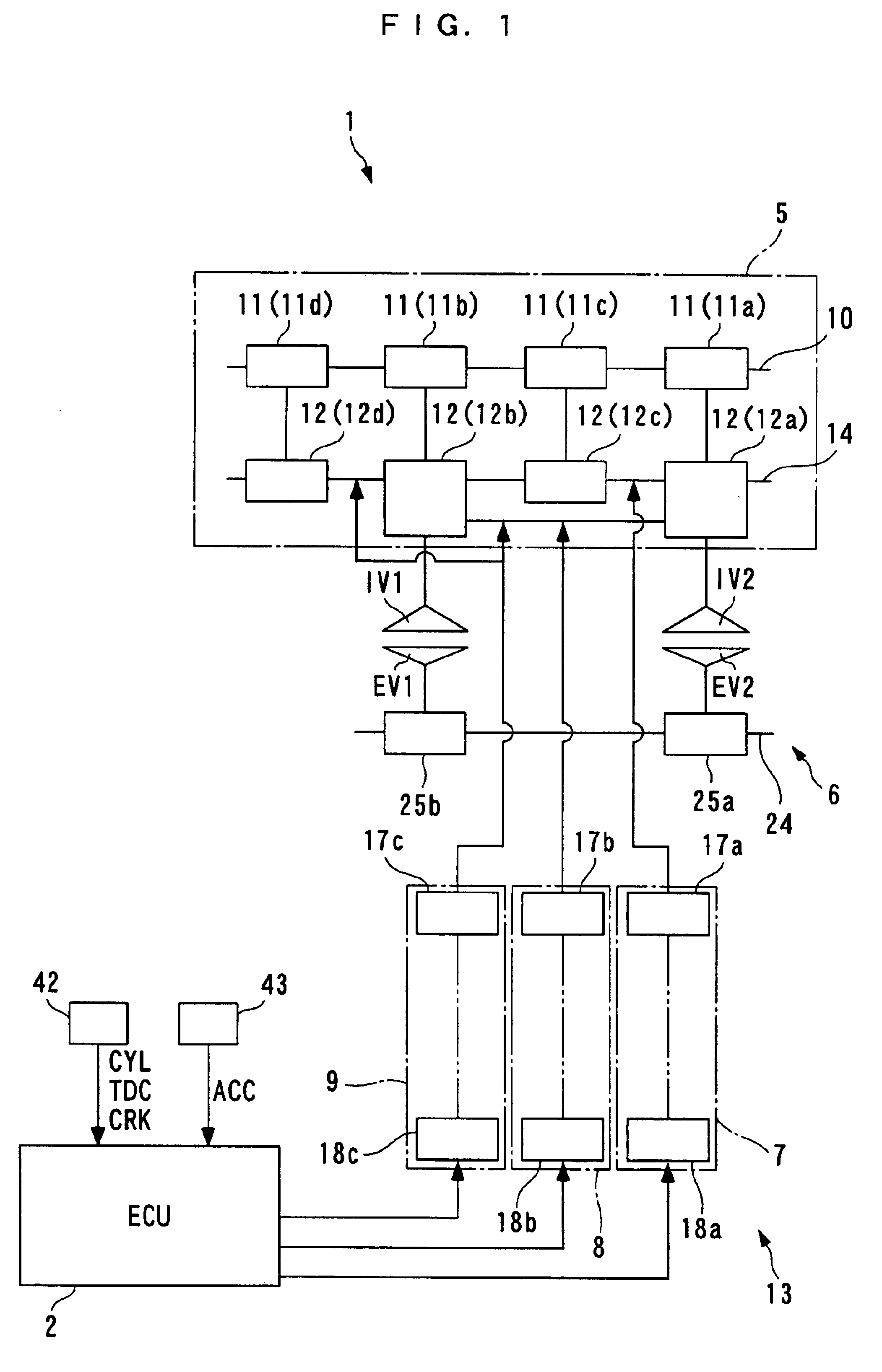

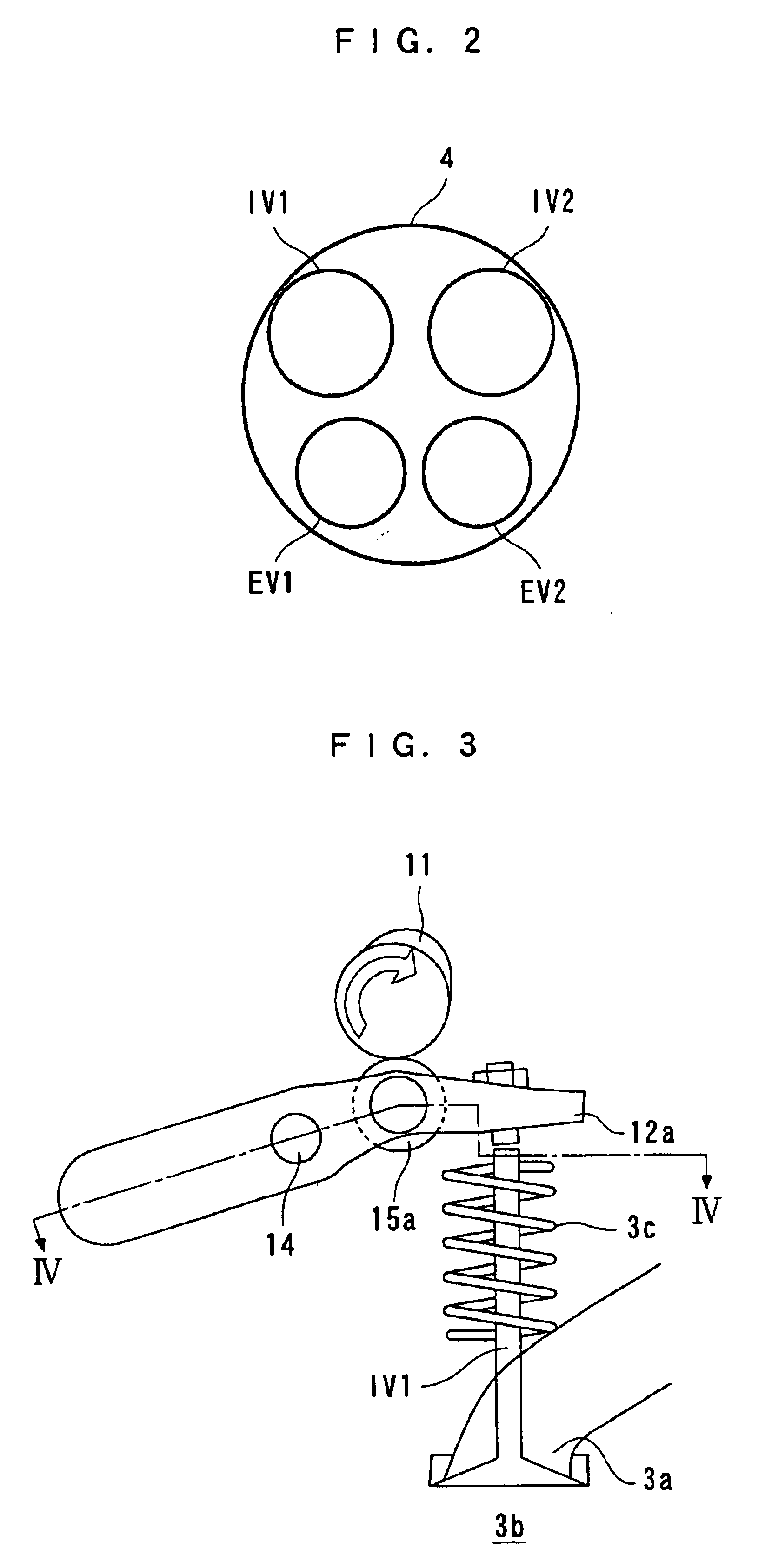

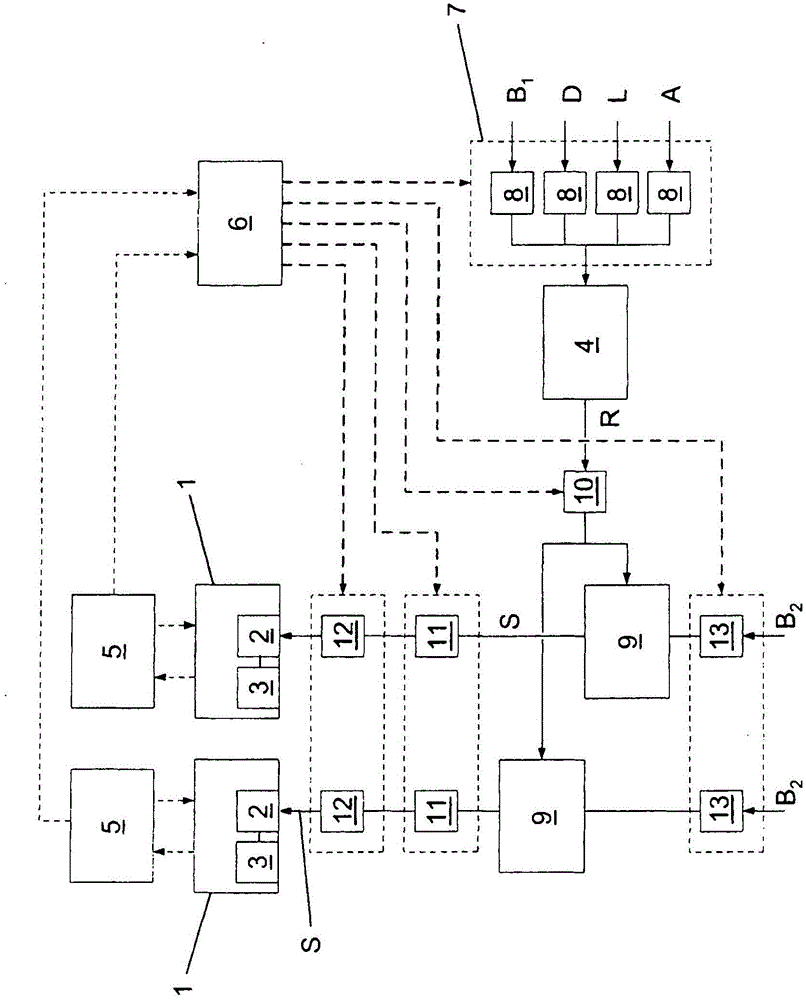

Control system for internal combustion engine

InactiveUS20050000480A1Emission reductionQuick activationElectrical controlInternal combustion piston enginesControl systemOtto cycle

A control system for an internal combustion engine, which is capable of reducing exhaust emissions during and after the start of the engine. A control system is capable of changing the valve-closing timing of intake valves relative to the valve-opening timing thereof as desired using a variable intake valve actuation assembly. The control system includes an ECU. The ECU sets a target auxiliary intake cam phase to a start value that sets the valve-closing timing of the intake valves to retarded-closing timing, during starting of the engine, and to a catalyst warmup value that sets the same to timing closer to timing in the Otto cycle operation, during catalyst warmup control after the start of the engine.

Owner:HONDA MOTOR CO LTD

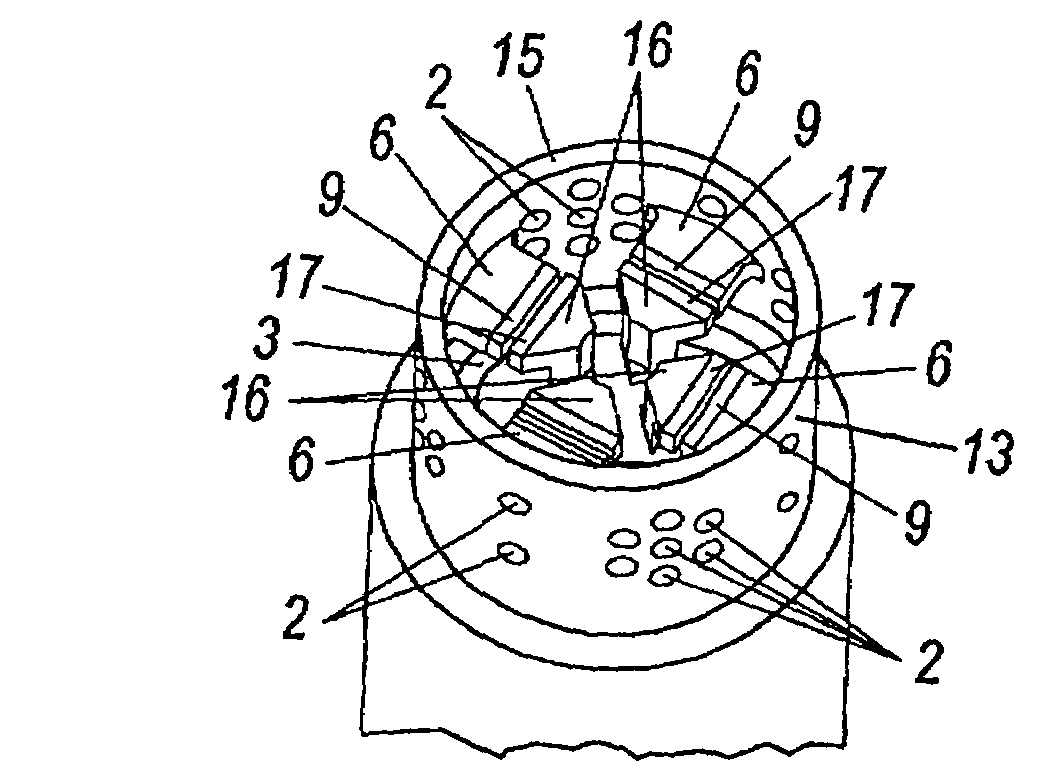

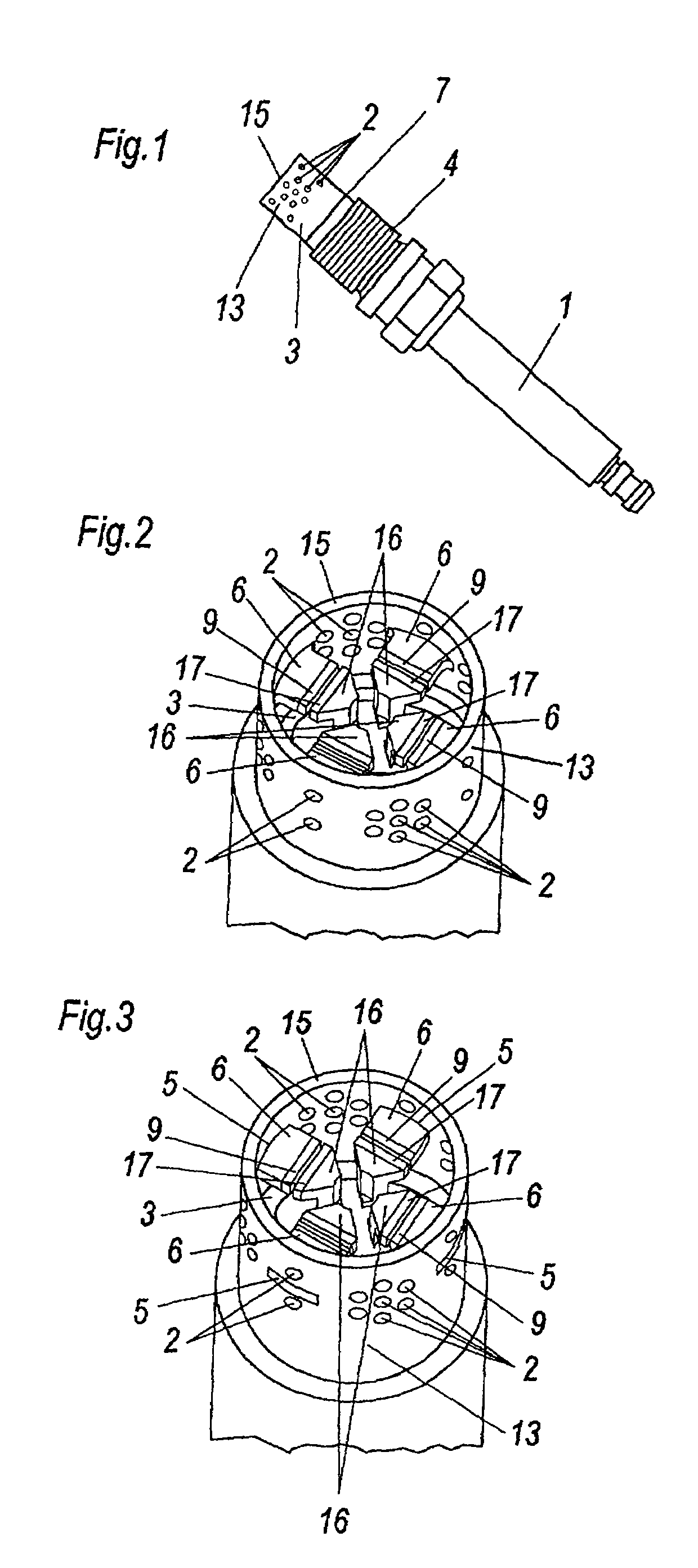

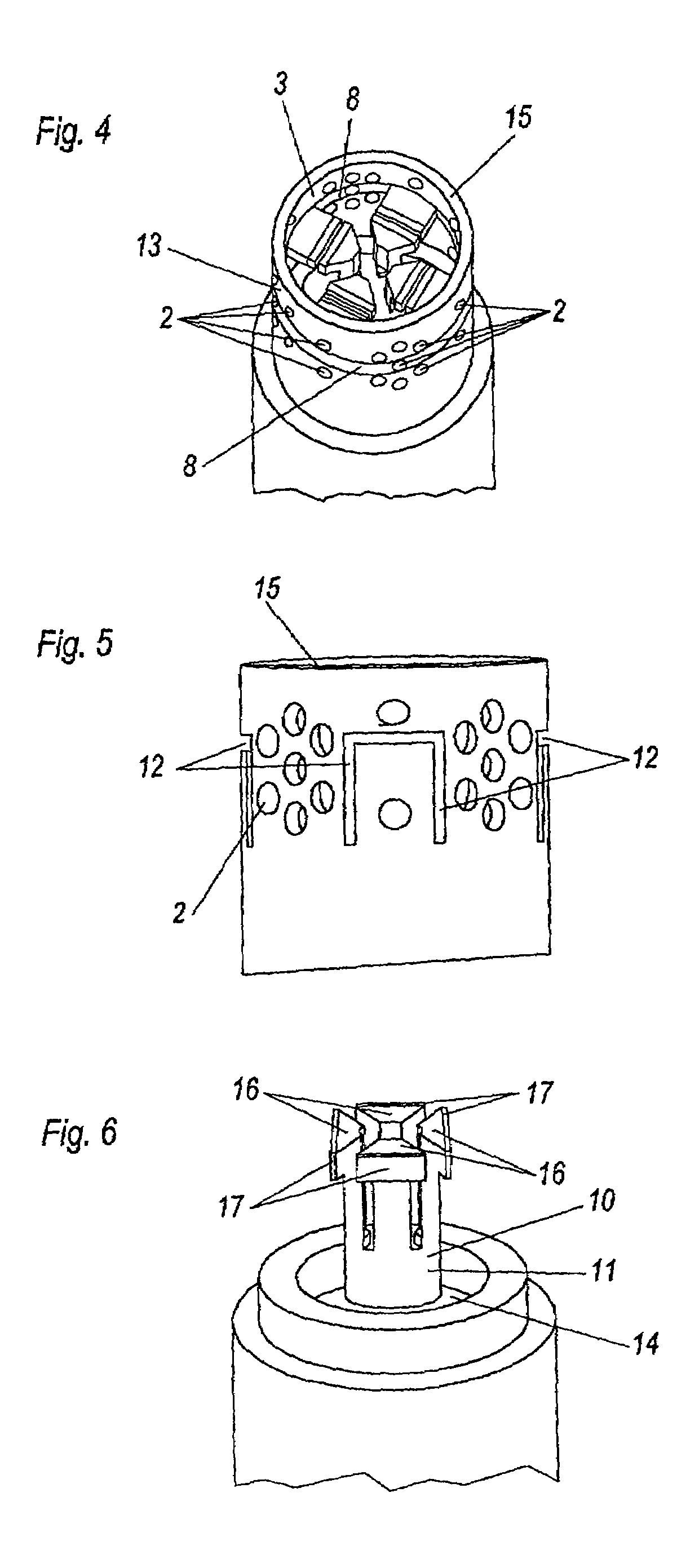

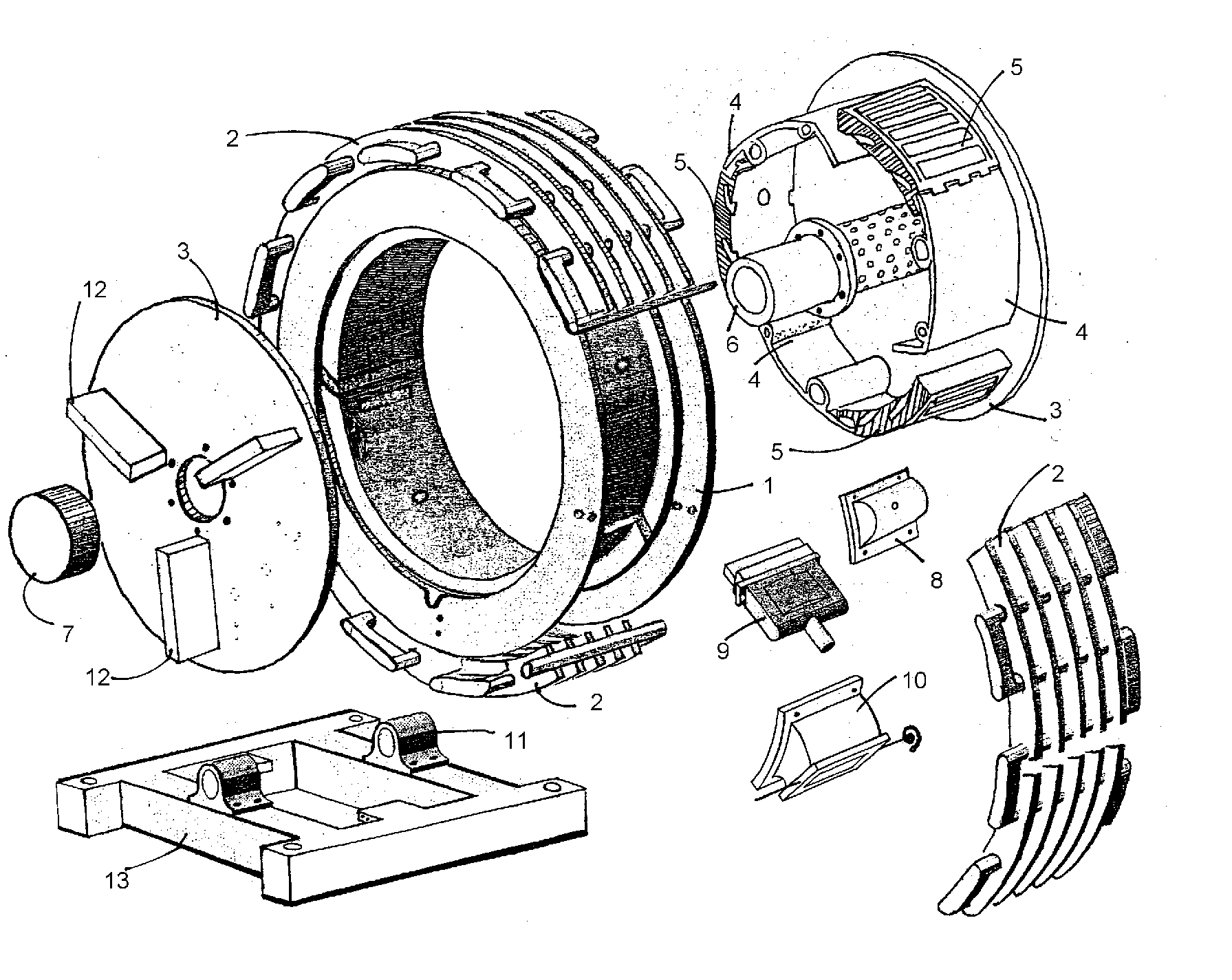

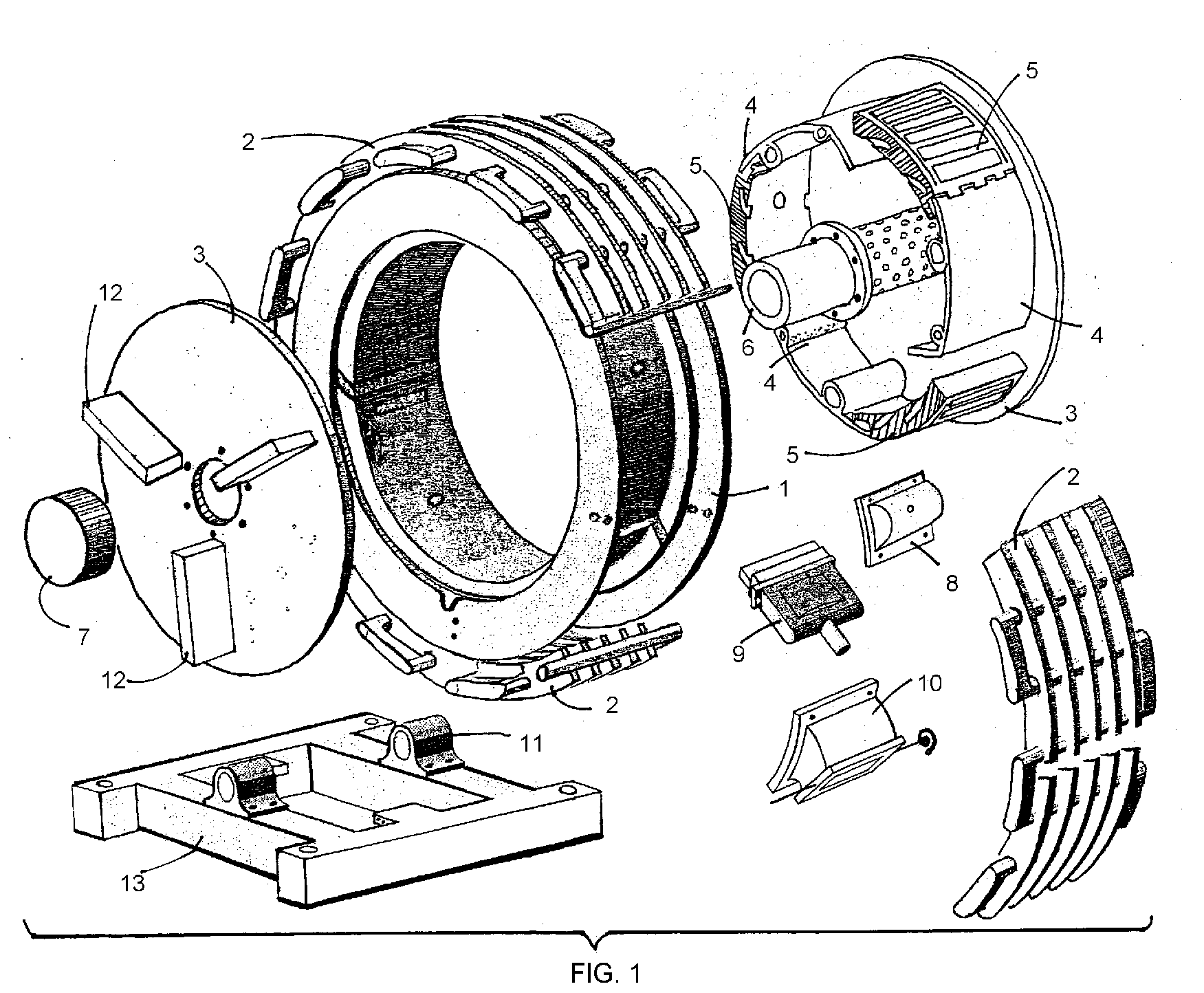

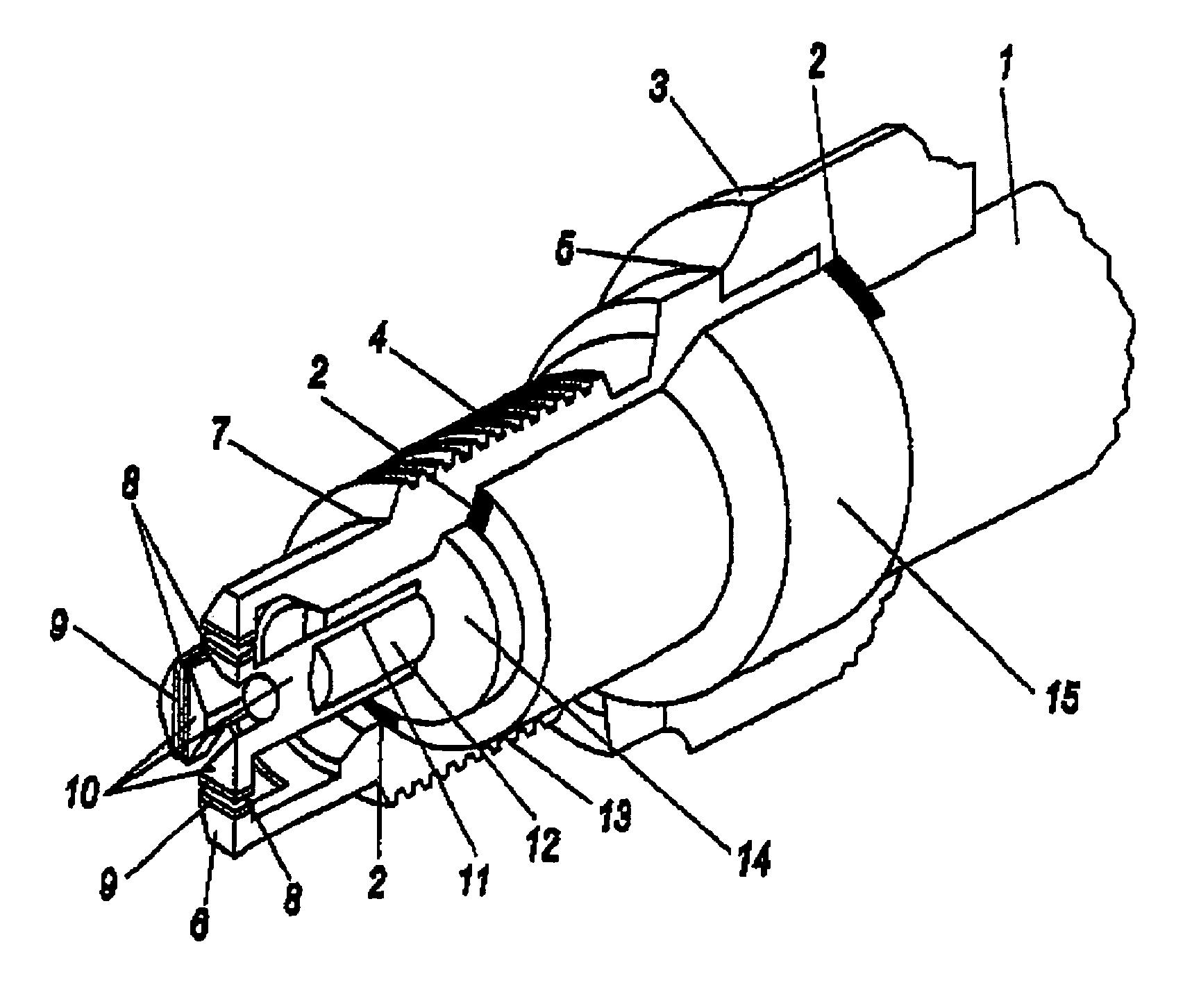

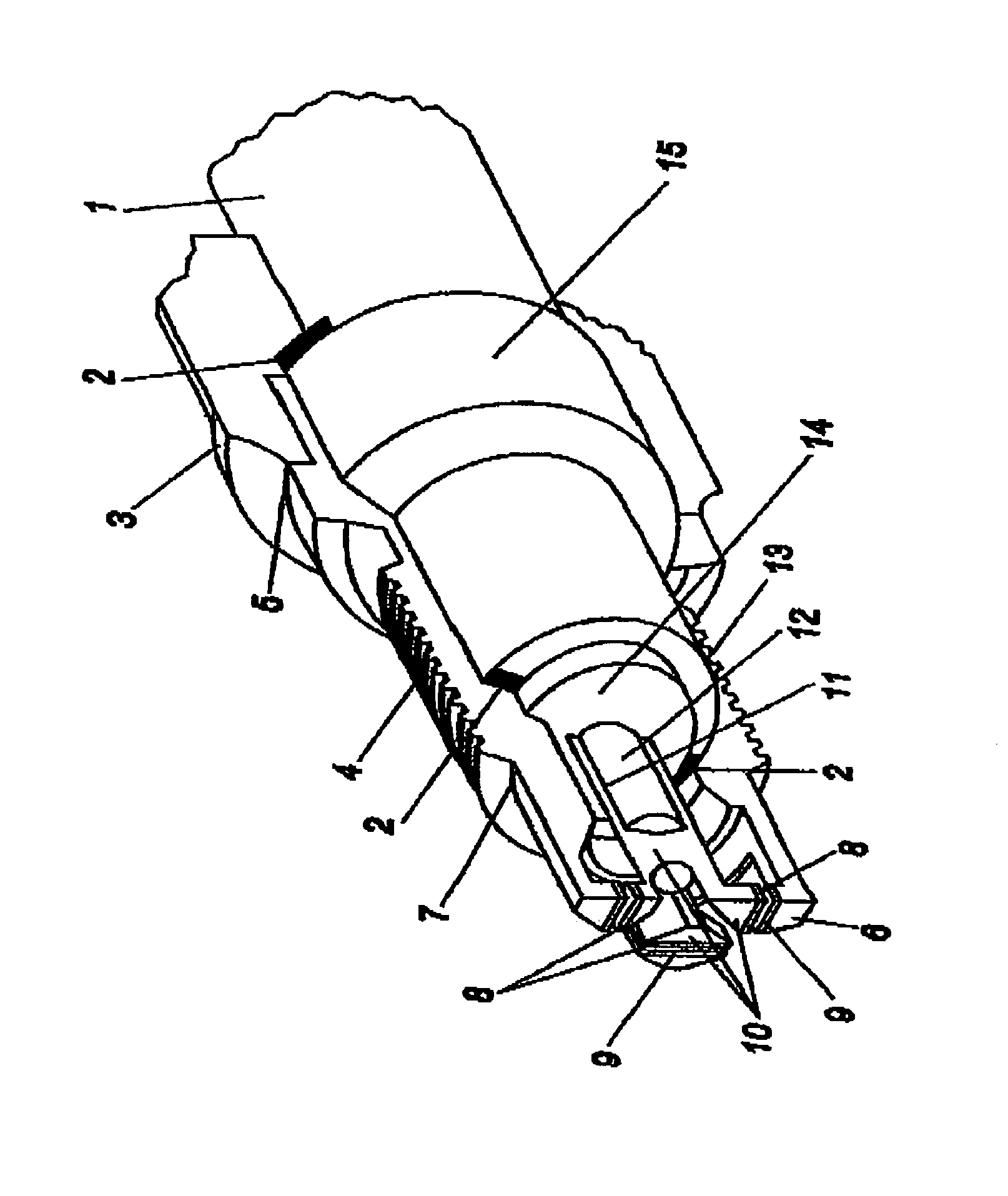

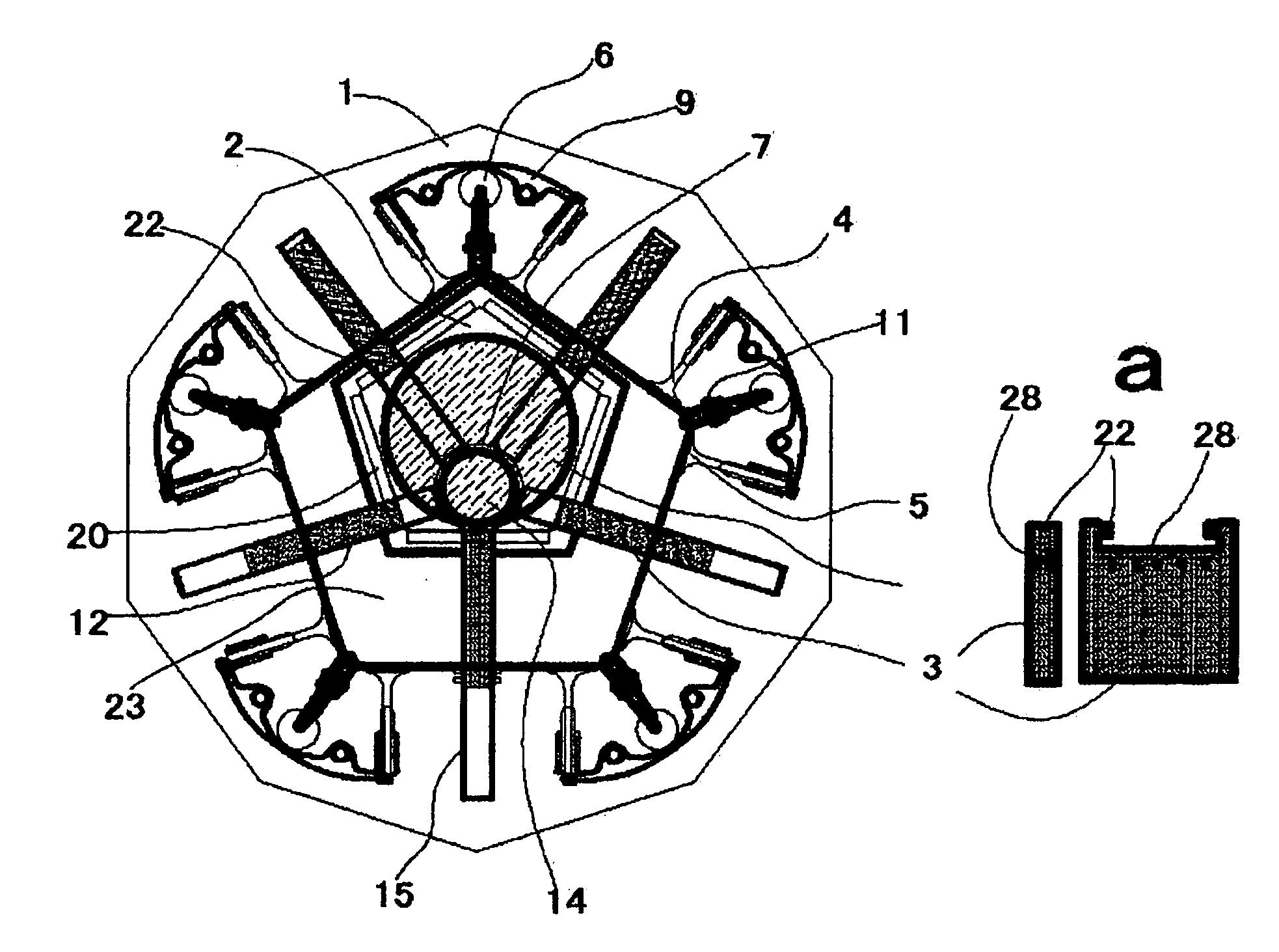

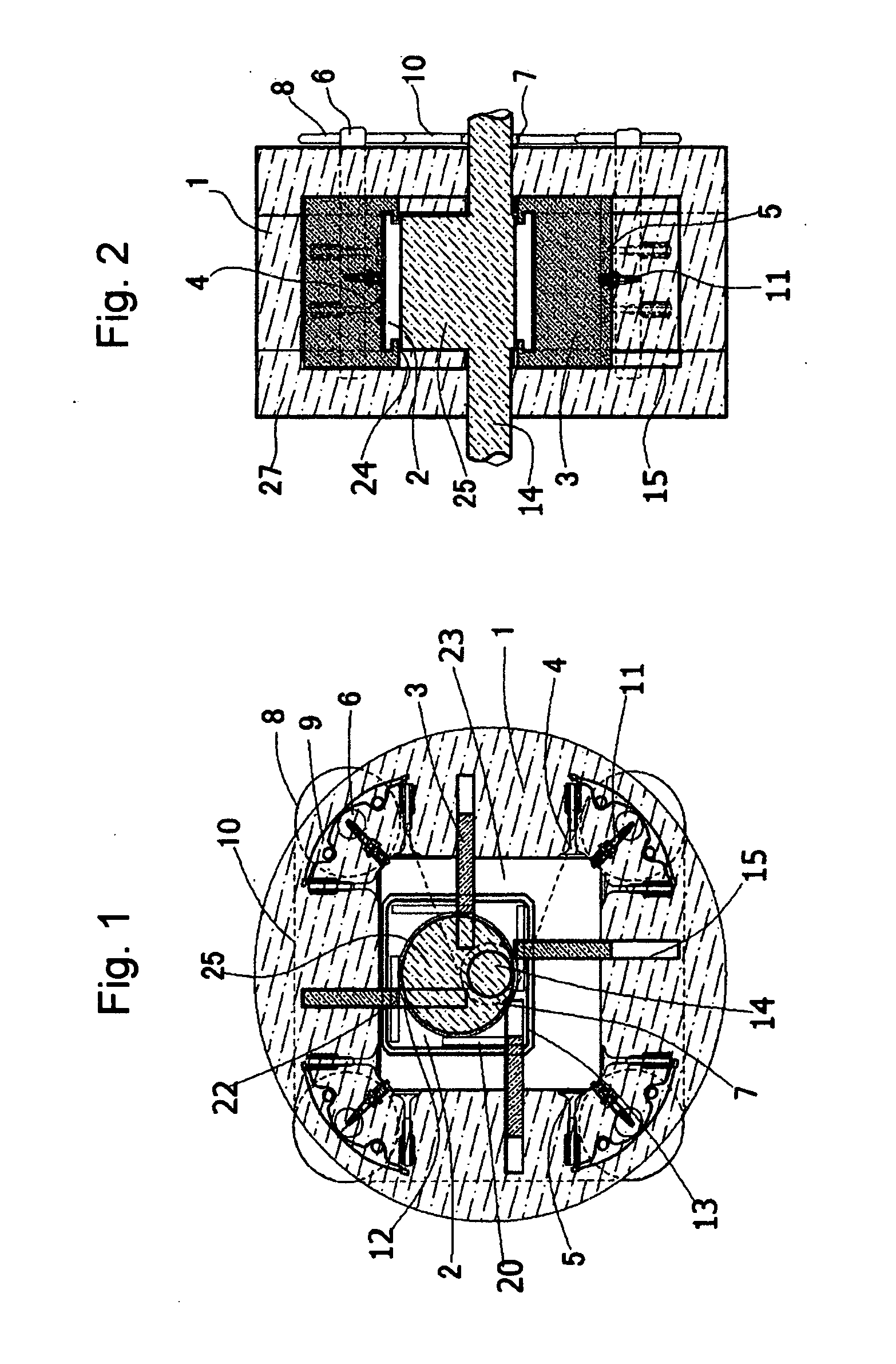

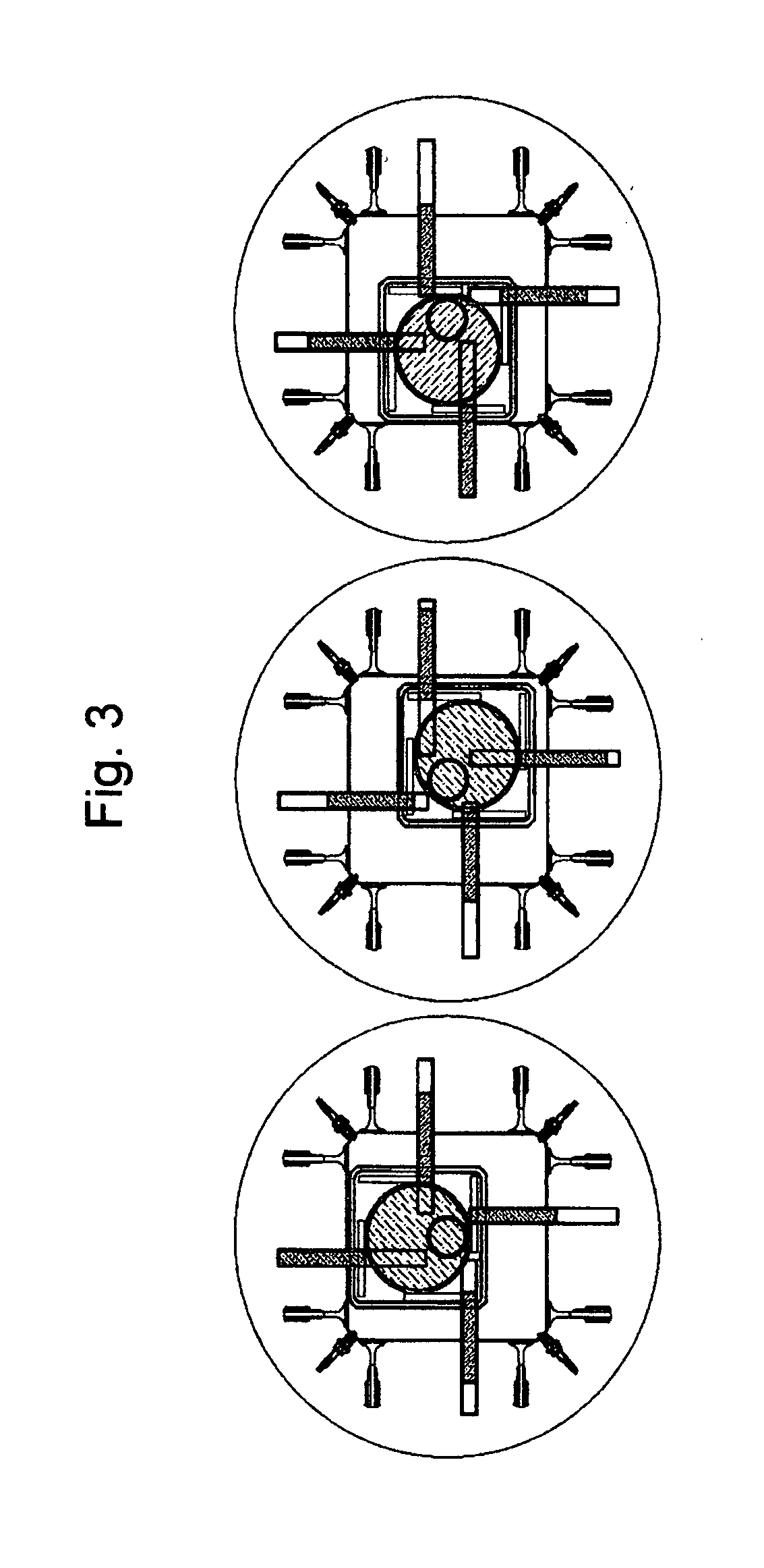

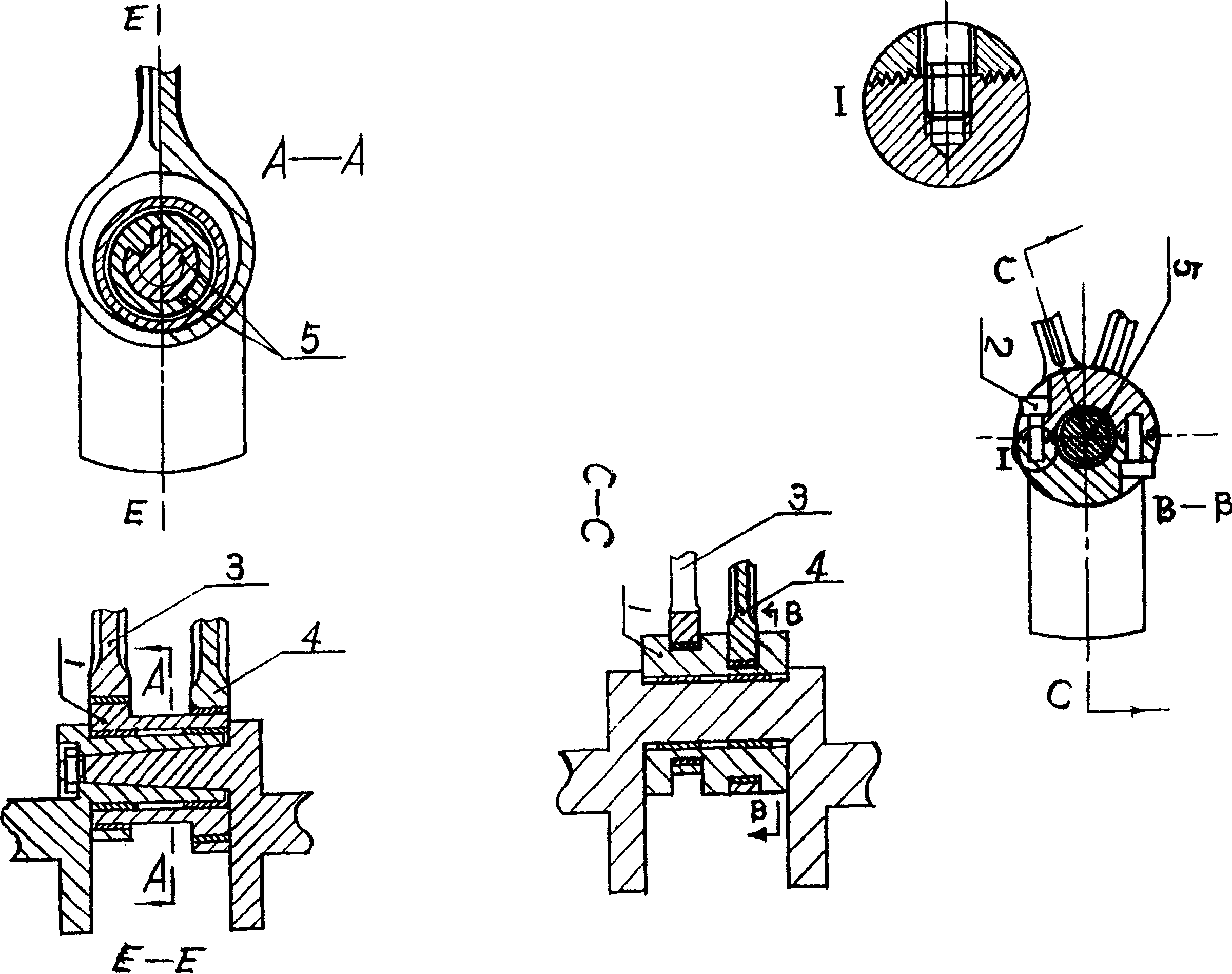

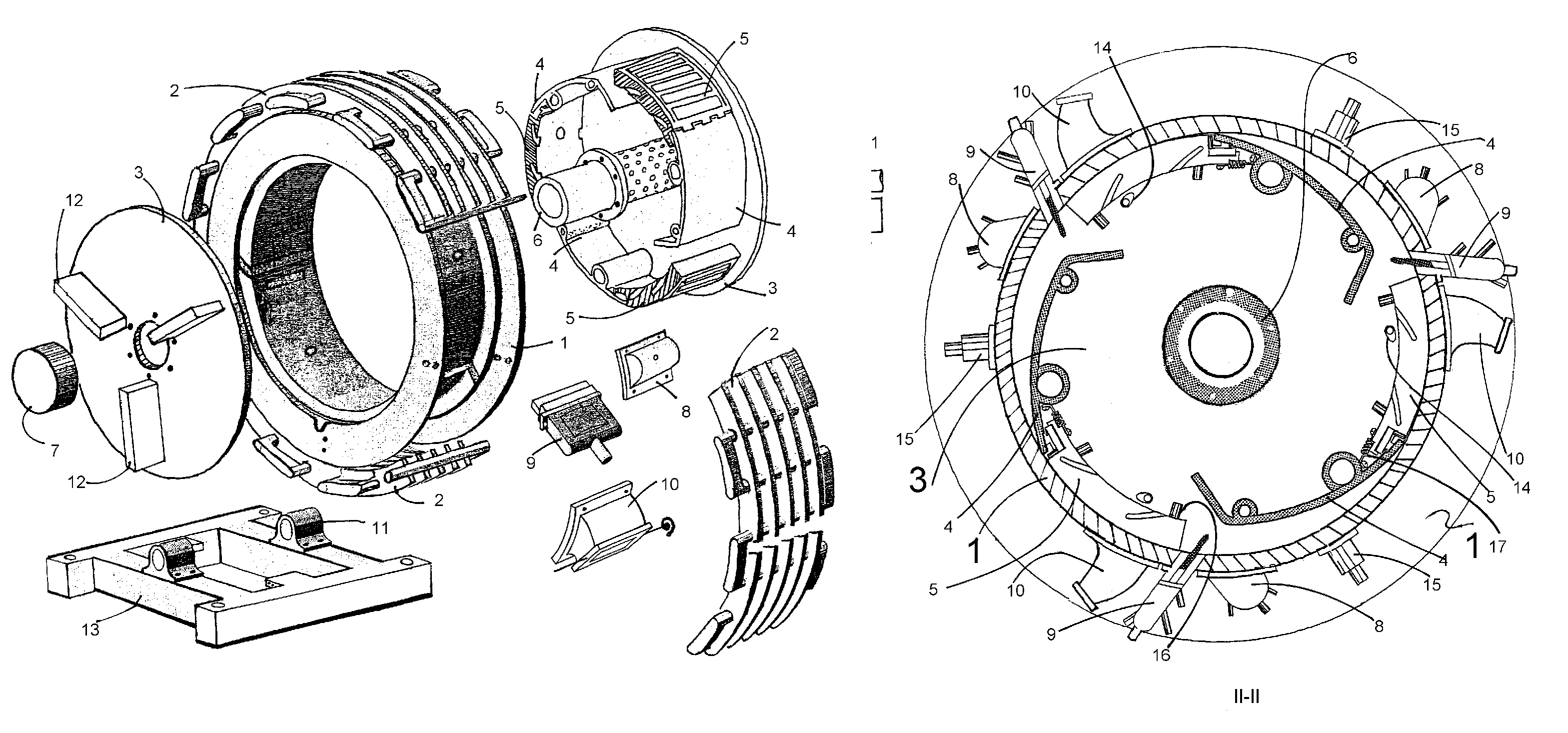

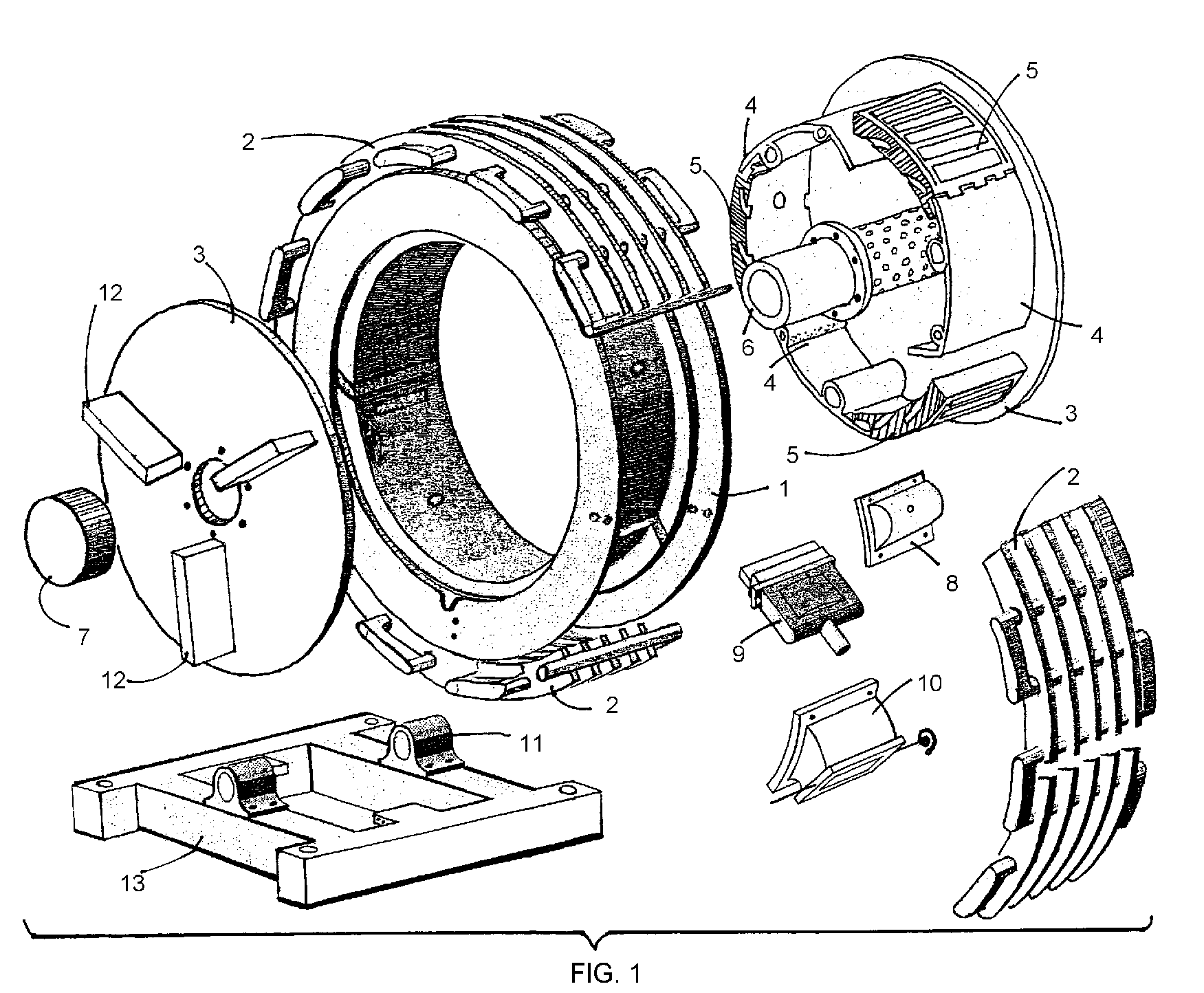

Spark plug of an internal combustion engine

ActiveUS7615914B2Extended service lifeCheap productionFuel injection apparatusMachines/enginesOtto cycleExternal combustion engine

A spark plug of an internal combustion engine, in particular for use in Otto-cycle gas engines, comprising an insulator body, a base central electrode, at least one ground electrode and at least one swirl chamber, wherein the electrodes of the spark plug are surrounded by a wall, which in particular is in the form of a surface of a cylinder, of the swirl chamber, wherein at least one ground electrode carrier arrangement (8) with a plurality of inwardly facing, preferably flat ground electrodes (9) or a plurality of ground electrode carriers (6) each with inwardly facing, preferably flat ground electrodes (9) is or are arranged at the wall (13) of the swirl chamber (3).

Owner:GE JENBACHER

Dimethyl ether (DME) enhanced gasoline engine

InactiveUS20110100323A1Minimizes possibility of misfireUse minimizedElectrical controlInternal combustion piston enginesAlcoholOtto cycle

An engine having DME pilot ignition is disclosed. DME Pilot ignition creates far more energy than a conventional spark plug, thus minimizes the possibility of misfire in the engine map. DME injection can be used in a number of ways. In one embodiment, DME injection replaces the conventional spark plug in an Otto cycle engine. In another embodiment, DME injection is used in addition to spark ignition to minimize the use of DME. In this embodiment, DME injection is only used during those portions of the engine map where misfire may occur, or during those times when a misfire sensor detects misfire. DME injection can also be used in conjunction with alcohol boosting in other embodiments.

Owner:ETHANOL BOOSTING SYST LLC

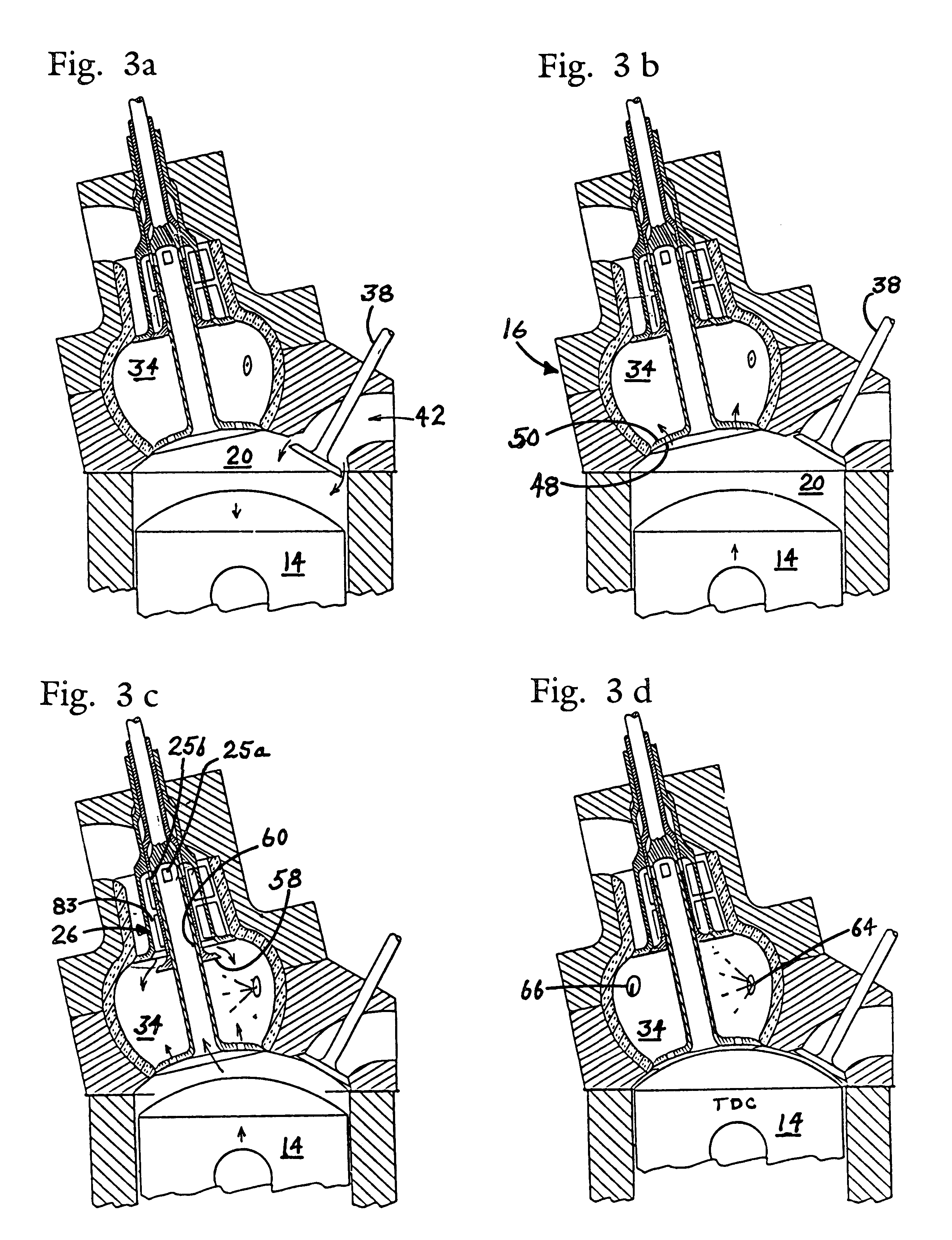

Internal combustion engine with sidewall combustion chamber and method

InactiveUS7387093B2Improve effectiveness and efficiencyLess complexInternal combustion piston enginesReciprocating piston enginesCombustion chamberTop dead center

An internal-combustion, reciprocating-piston engine operating on the Otto cycle and associated method are provided where a sidewall combustion chamber is employed that is capable of receiving highly-compressed air or a mixture of any gas and fuel from a cylinder while a main piston is positioned at or near top-dead-center in the cylinder, and where the sidewall combustion chamber is also capable of temporarily storing a highly-compressed air or a mixture of any gas and fuel before sending and re-injecting an ignited or burning mixture of highly-compressed air or a mixture of any gas and fuel into the same cylinder between the main piston and the displacer-piston when the main piston is located in the cylinder at an optimum position for receiving and transferring energy or forces.

Owner:HACSI JAMES SCOTT

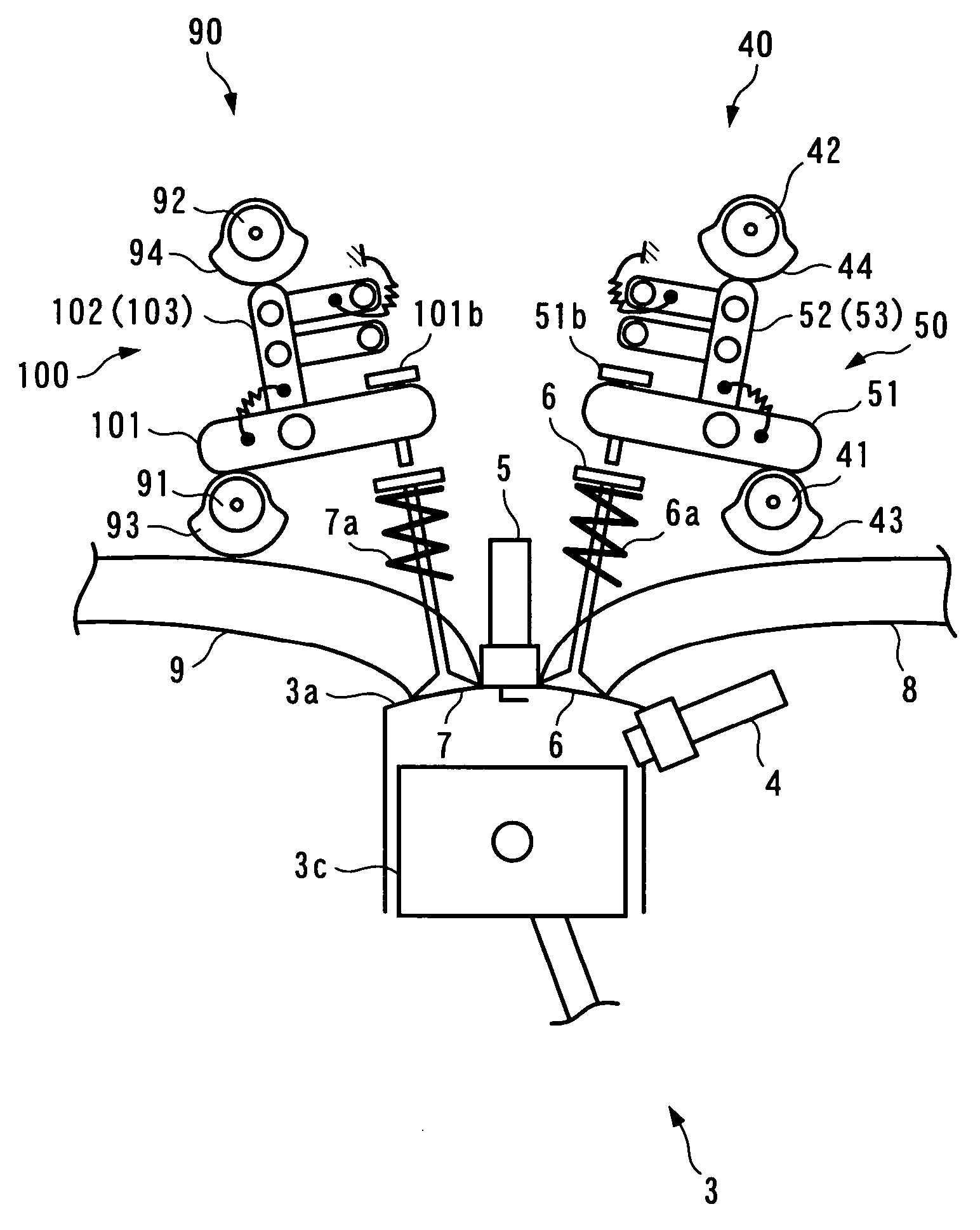

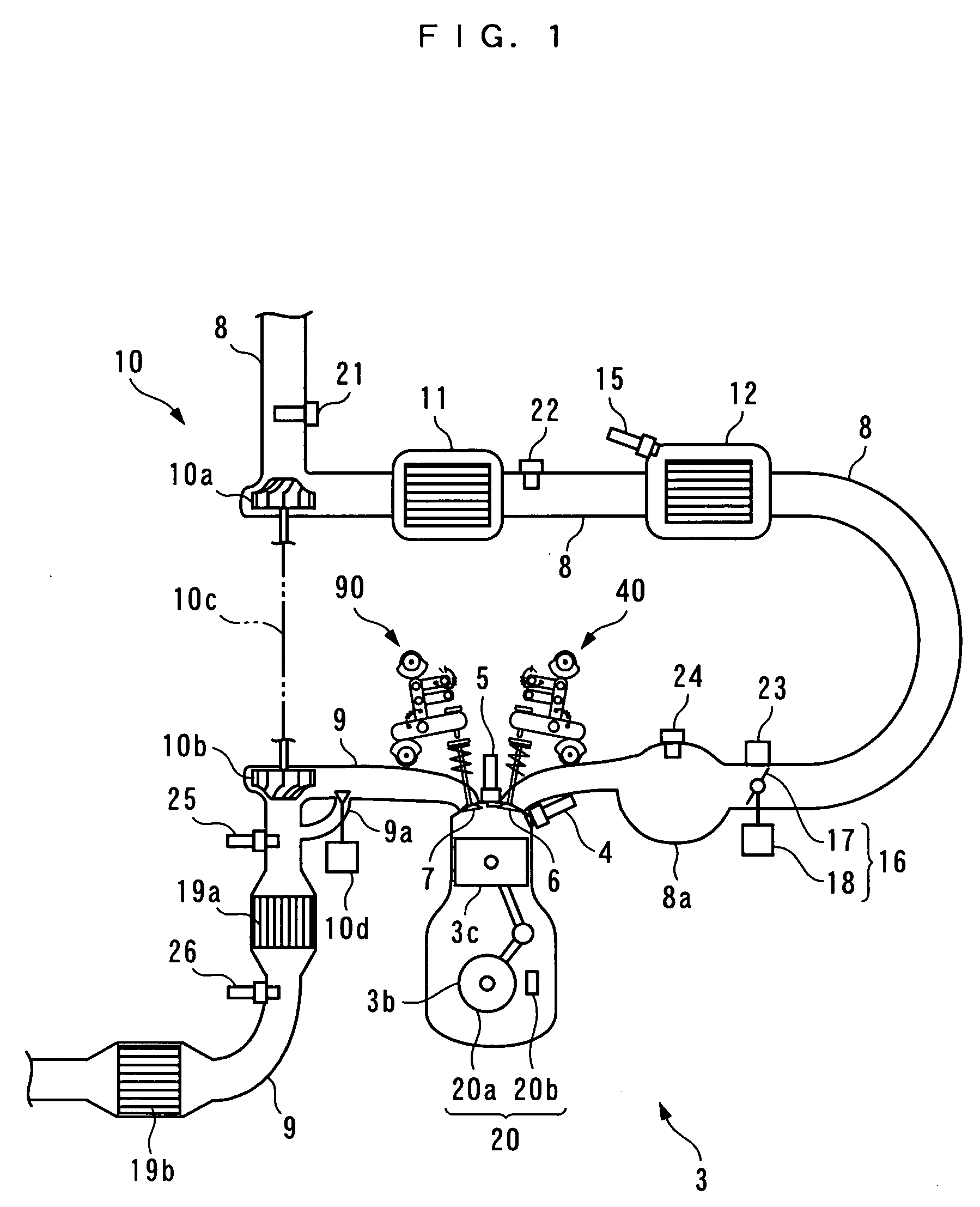

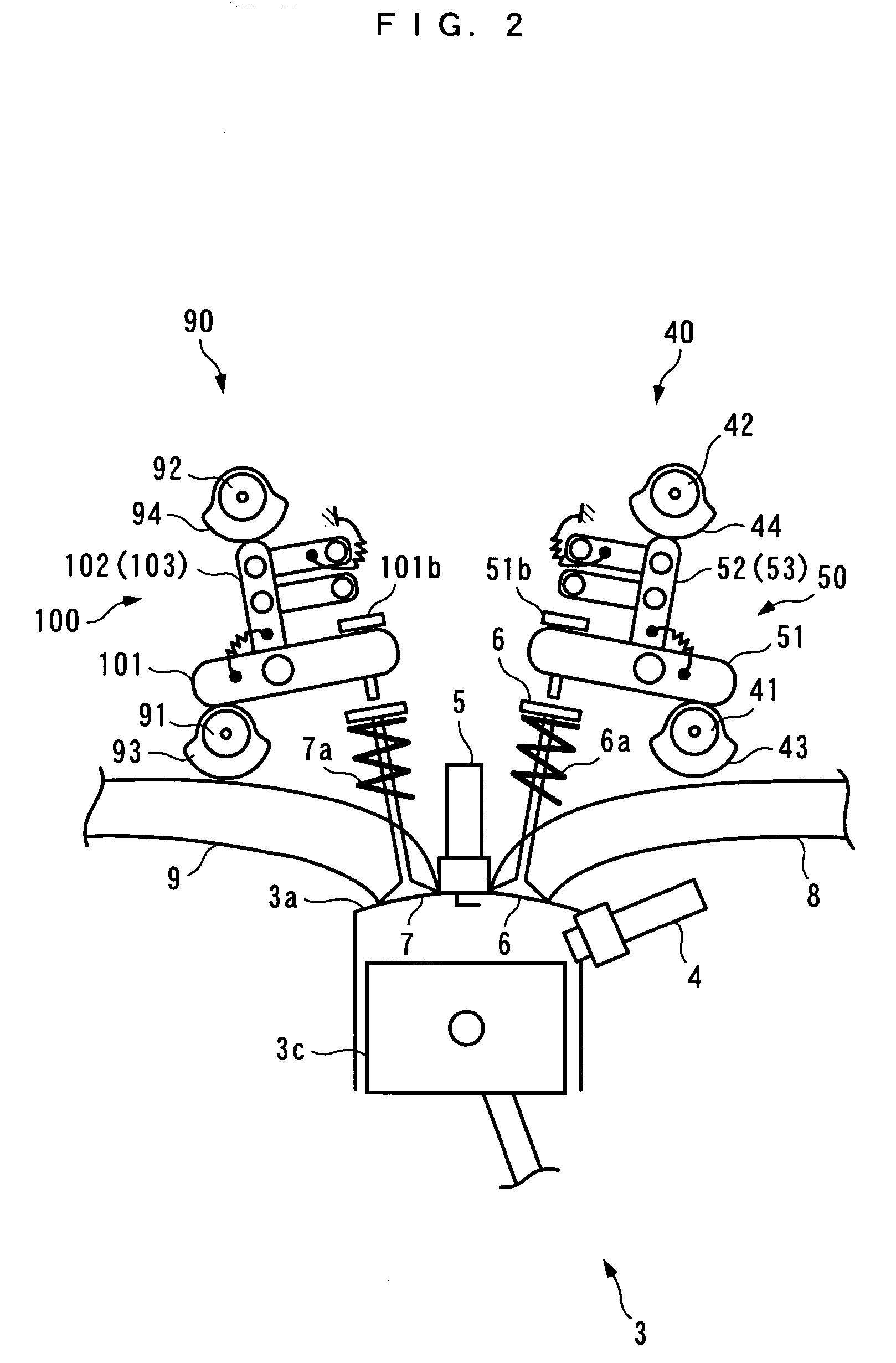

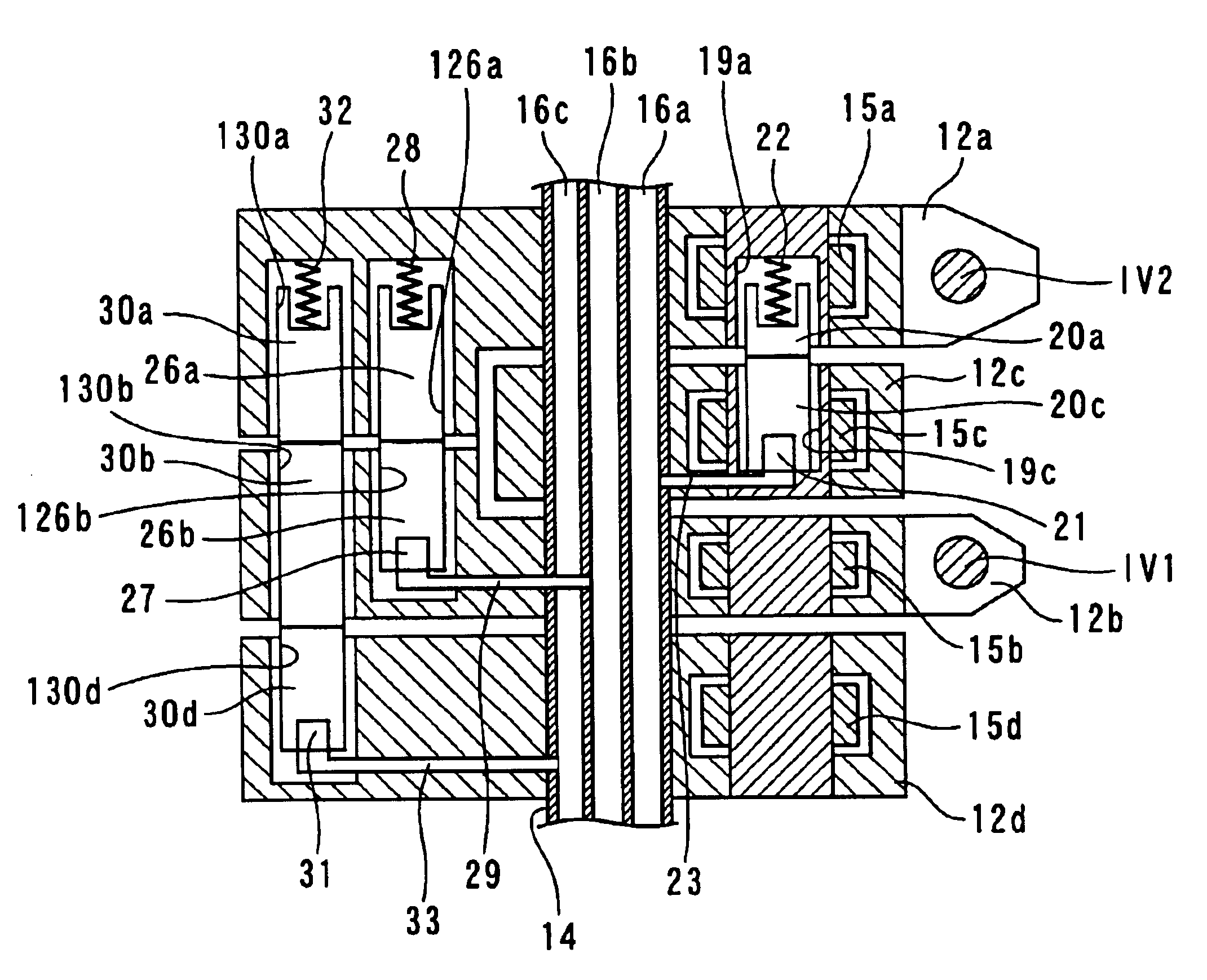

Valve actuating apparatus for internal combustion engine

InactiveUS6837199B2Stable combustionImprove fuel economyValve arrangementsElectrical controlExternal combustion engineLow load

A valve actuating apparatus for an internal combustion engine selectively operating in the normal Otto cycle or the Miller cycle is provided which enables the engine to achieve stable combustion and improved fuel economy during cruising or in a low-load engine operating region. A delayed-closing cam for Miller cycle operation and a normal cam having a cam profile for earlier valve-closing timing of the intake valve than a cam profile of the delayed-closing cam are provided on a camshaft. A cam profile-switching mechanism switches between the delayed-closing cam and the normal cam, for opening and closing the intake valve. An ECU controls the switching mechanism such that when a detected operating condition of the engine indicates starting or idling, the intake valve is operated by the normal cam, and when the detected operating condition indicates cruising, the intake valve is operated by the delayed-closing cam.

Owner:HONDA MOTOR CO LTD

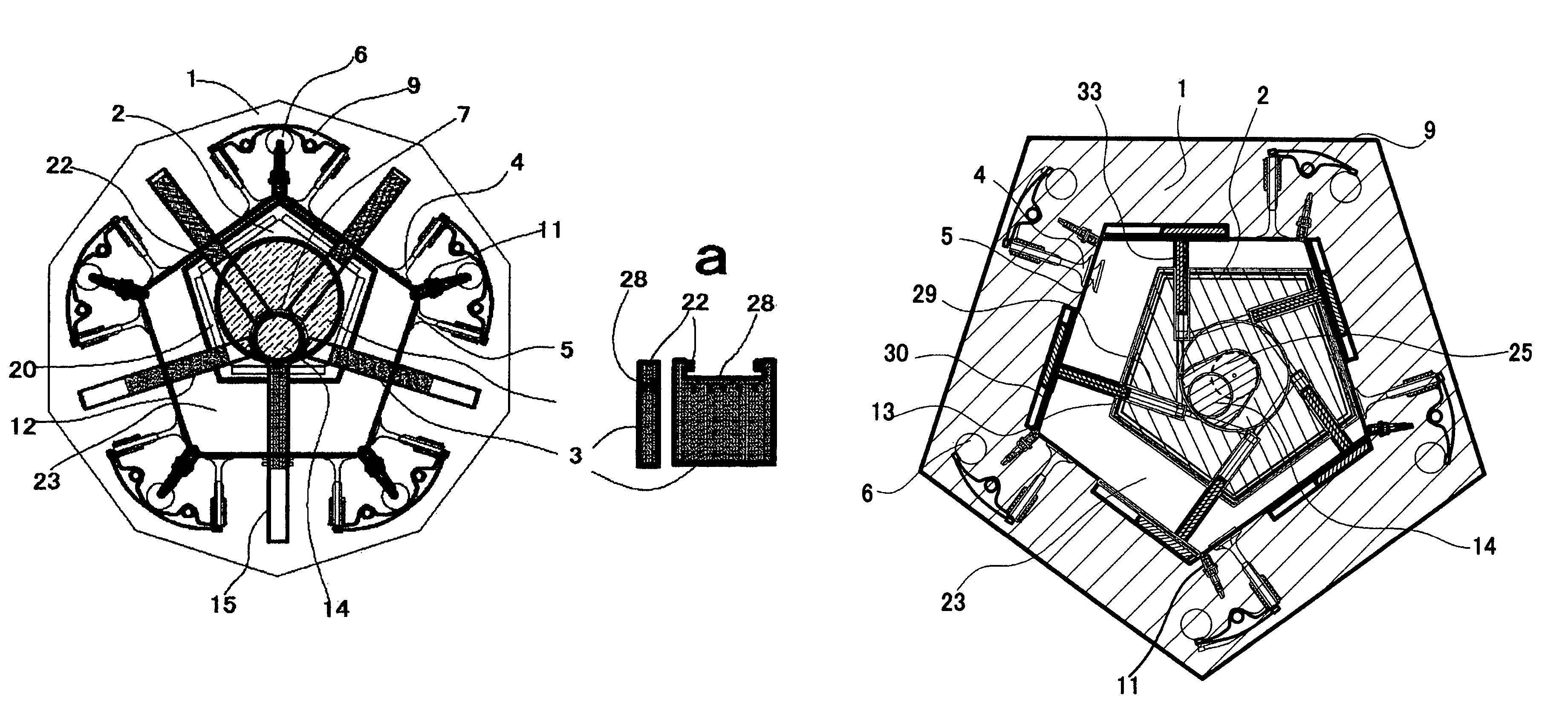

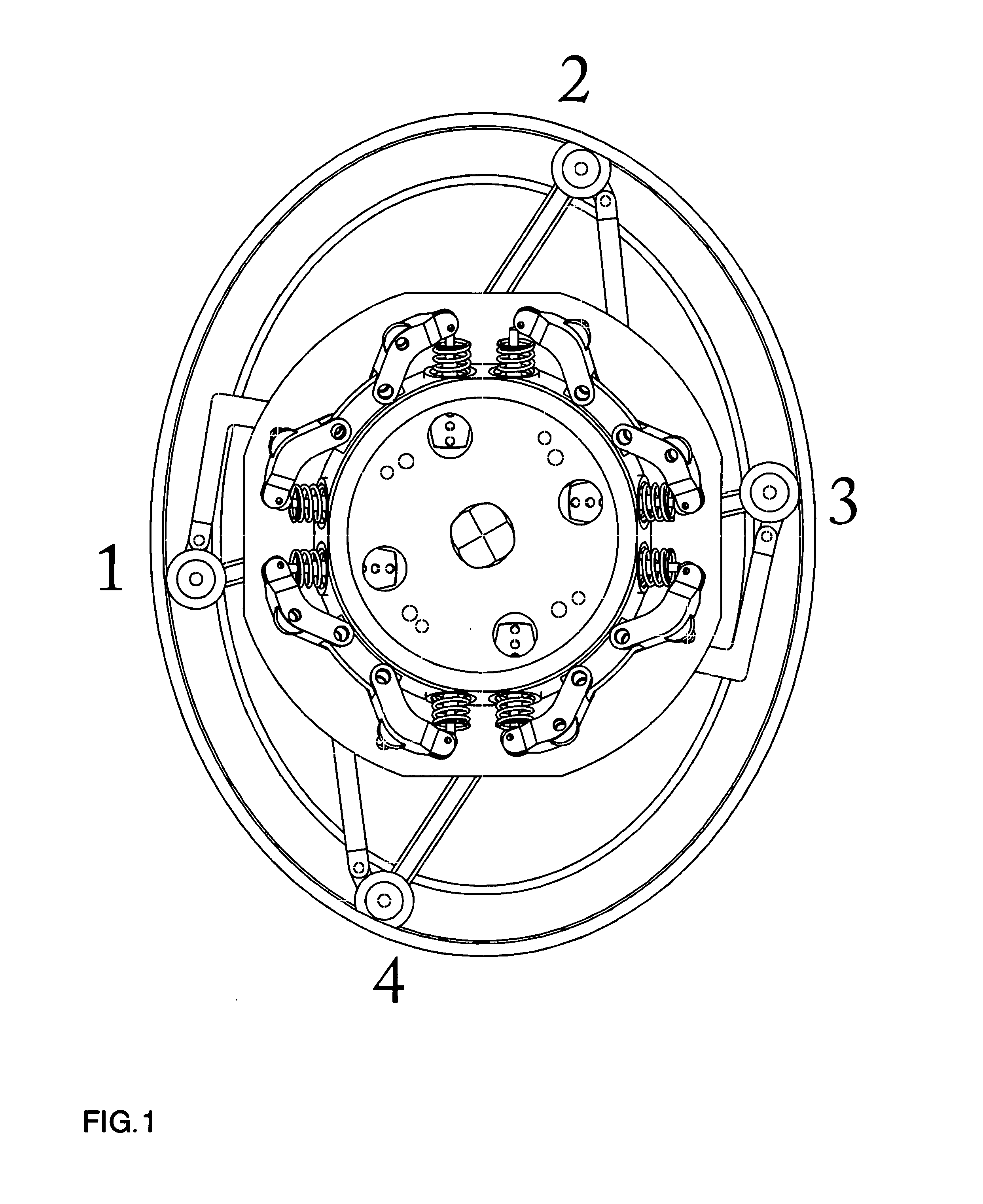

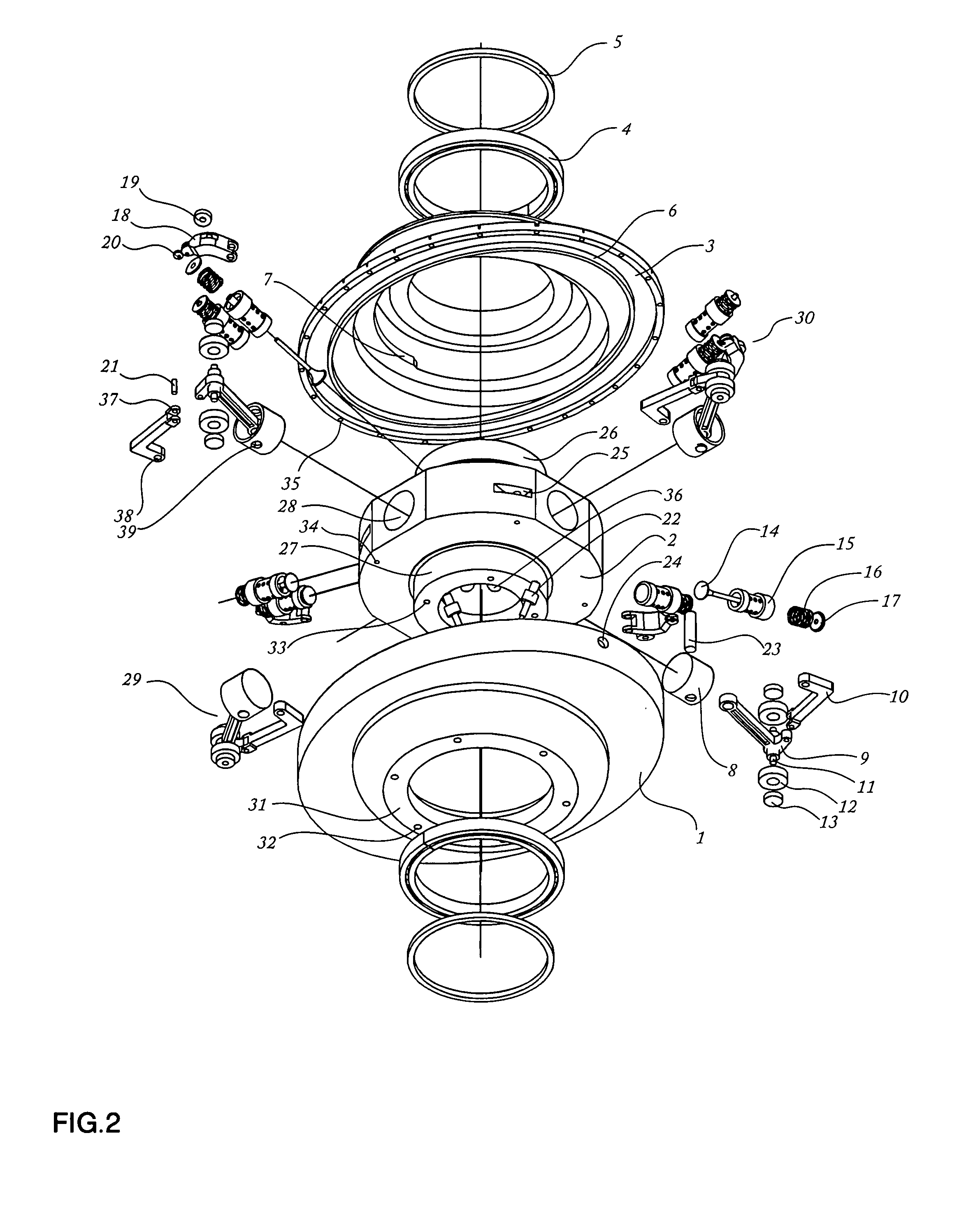

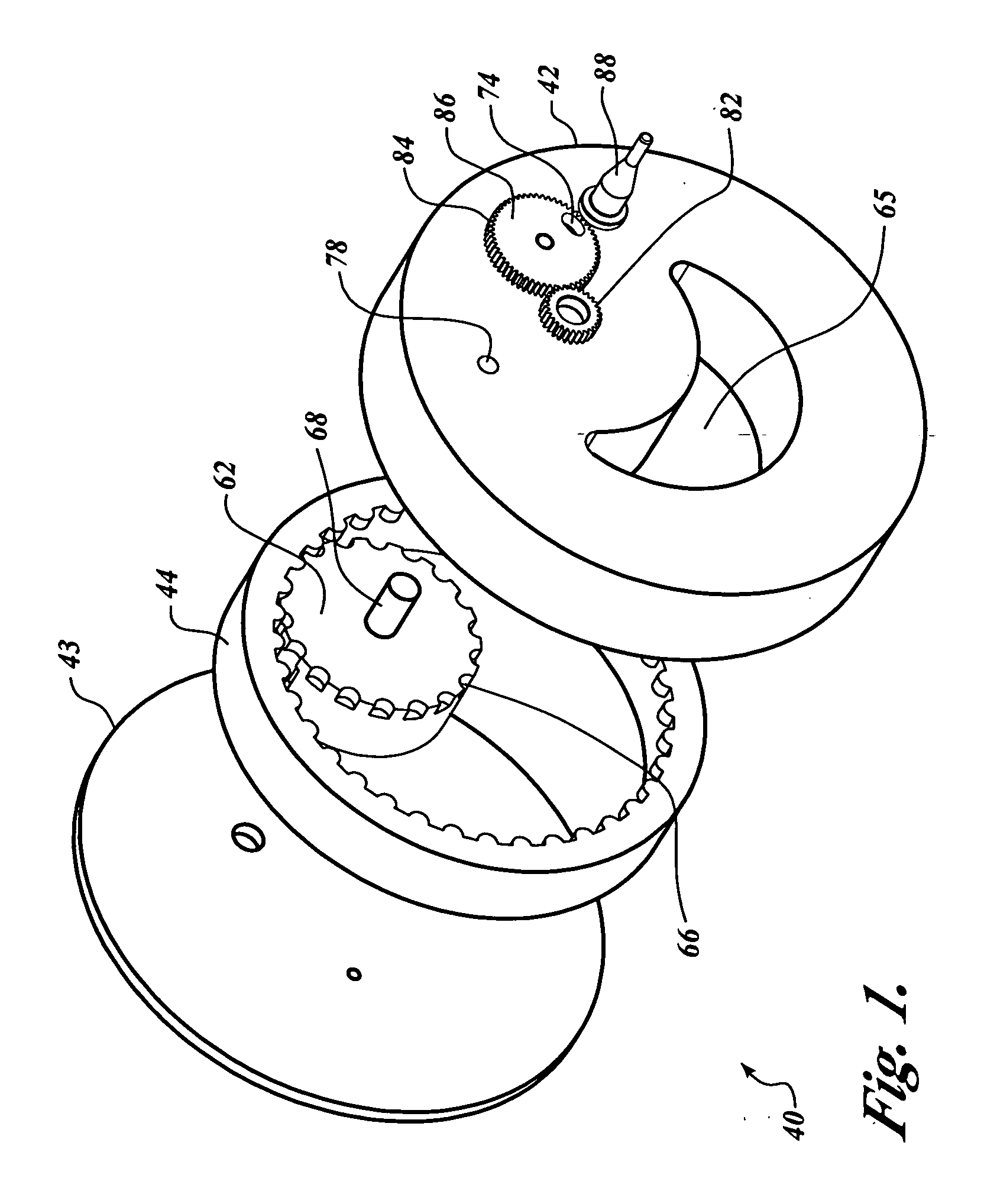

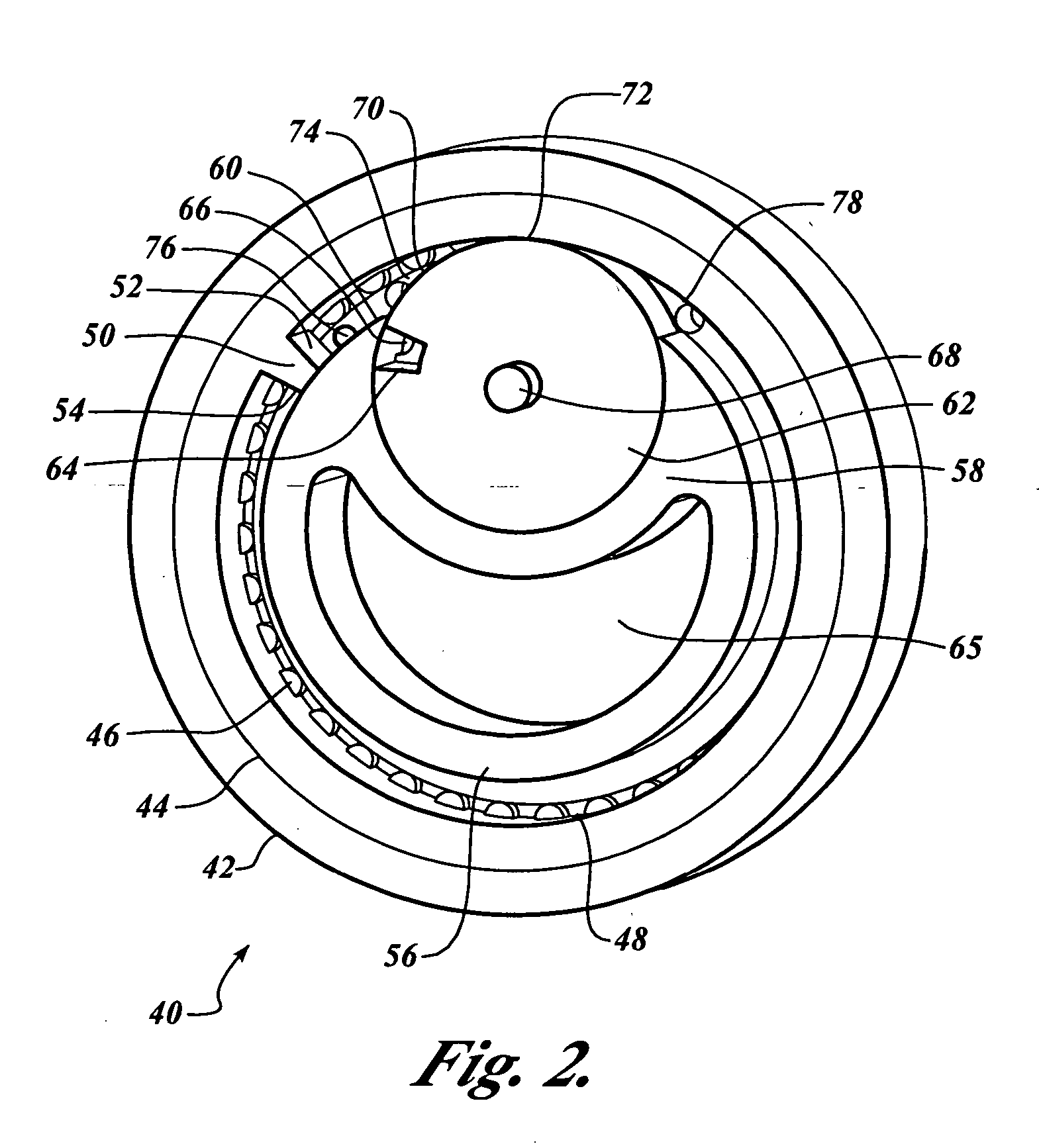

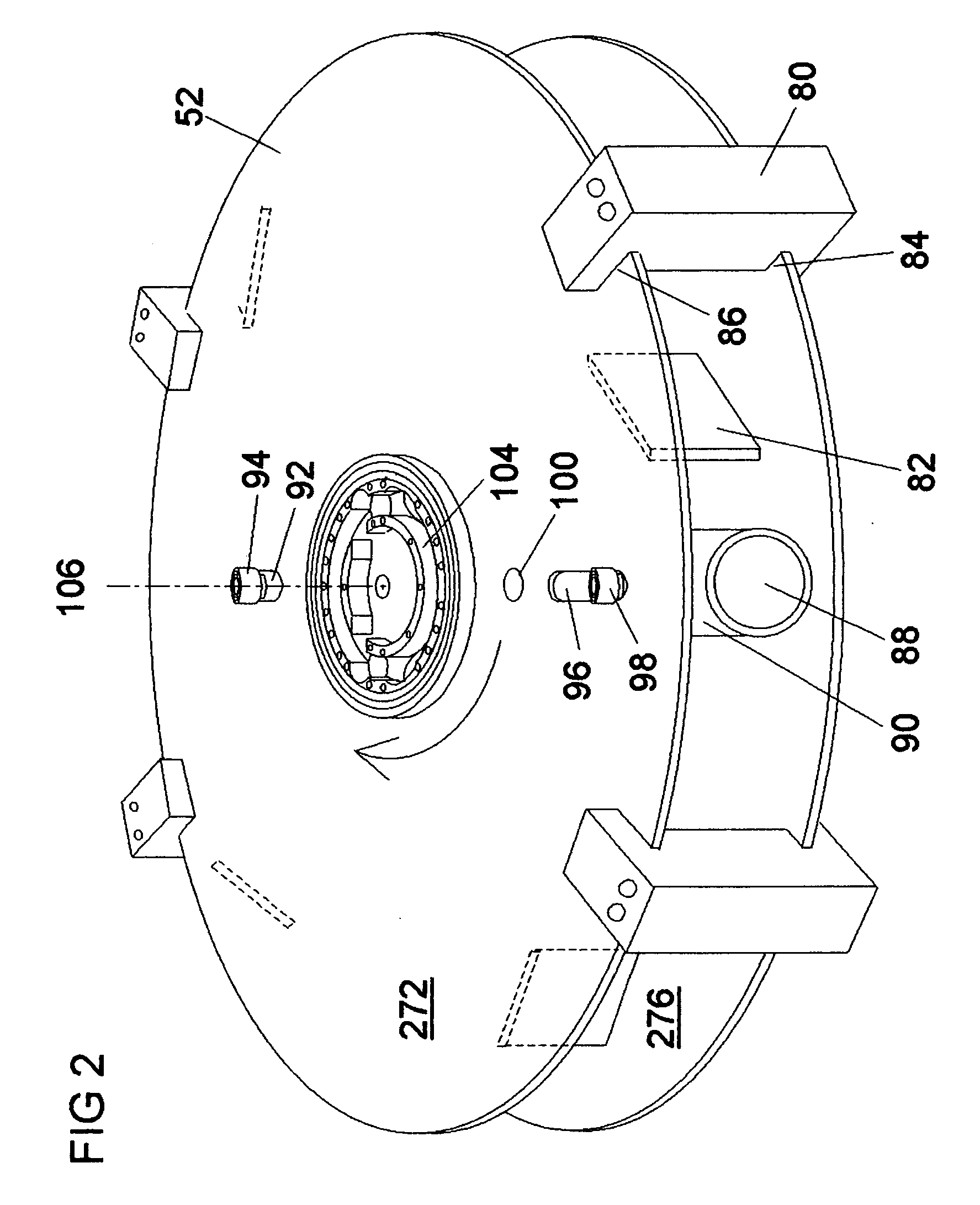

Modular Rotary Engine

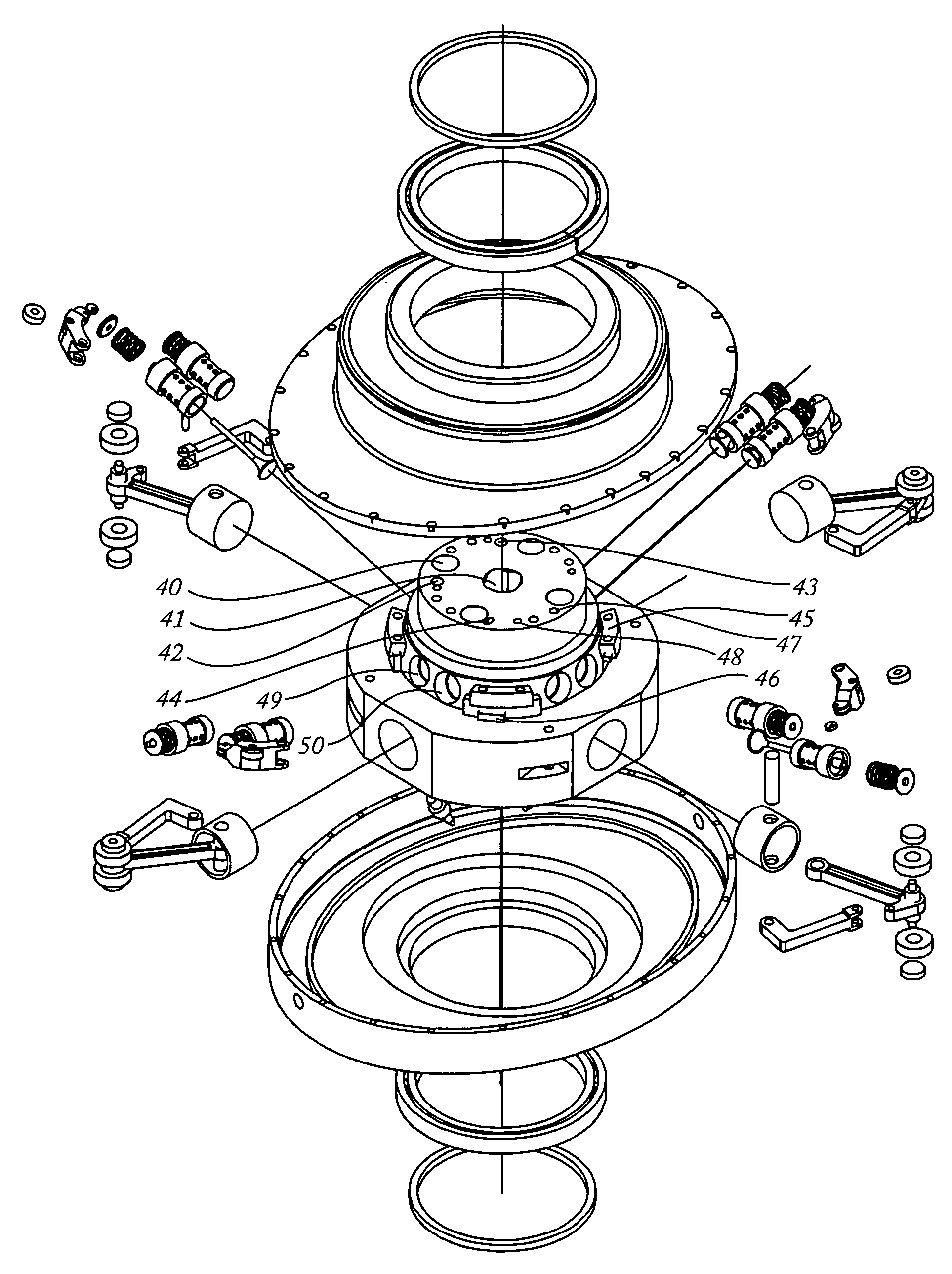

InactiveUS20070084434A1Low reciprocating massReduce distanceInternal combustion piston enginesOscillating piston enginesExternal energyEngineering

An internal combustion rotary engine, self cooled, totally concentric and symmetric, dynamically variable compression ratio, capable of developing multiple Otto cycles in each rotation, by means using modules, composed mainly by a solenoid gate valve and three chambers operating at the rotor periphery, producing at low RPM, torsion of value near close at theoretical limit. High power / weight ratio, which increases substantially when number of modules increase, without drive shaft length increase; plus reduced internal friction, is a truly saver fuel machine; with volumetric asymmetry ratio between expansion and compression chambers, and that compression chambers working at beginning of the cycle at normal atmospheric pressure, it gives a fast rise pressure peak, because of the almost wedged form of that chambers. Proper for many types of combustion and class of fuels, including hydrogen, liquefied propane gas and efficient use of air compressed as external energy supply. Excels in aircraft use.

Owner:LEON ENRIQUE HALUY

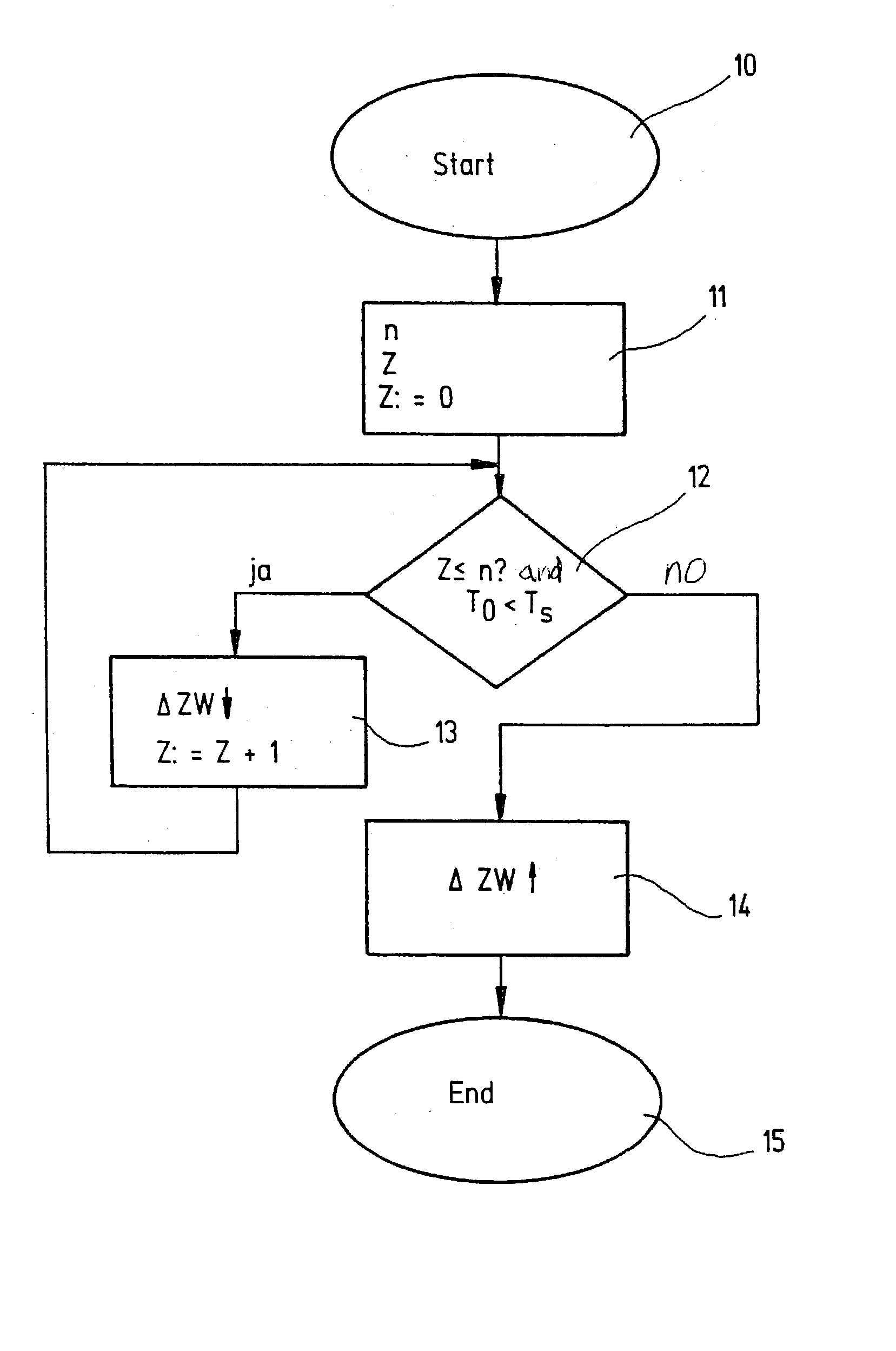

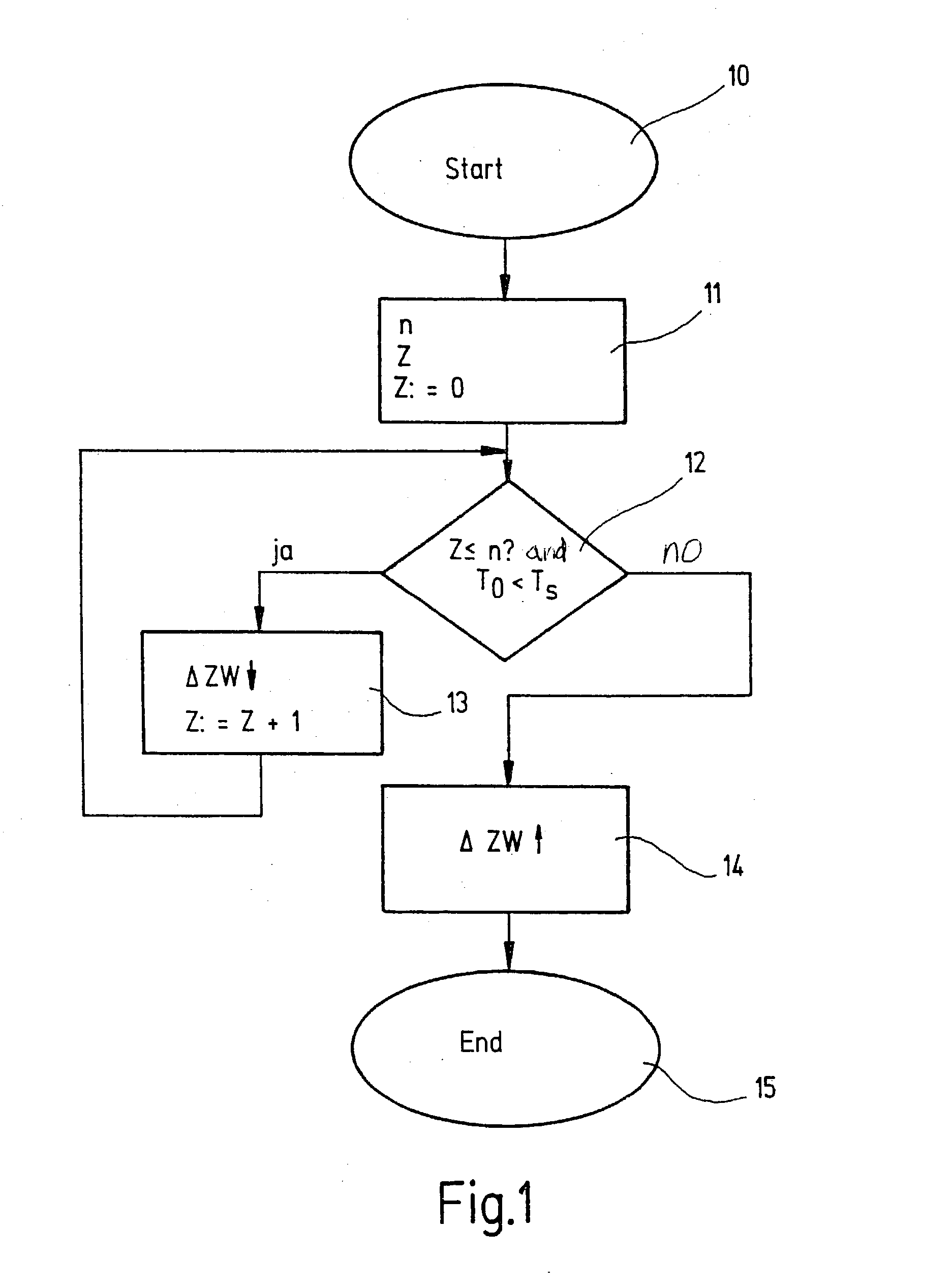

Method for operating an otto-cycle internal combustion engine with fuel injection on a cold start

InactiveUS20030075152A1Small torqueIncrease rotation speedElectrical controlInternal combustion piston enginesSpark-ignition engineOtto cycle

A method is provided for operating a spark ignition internal combustion engine having fuel injection at a cold start. The method retards the spark angle to a cold start value at least for the first combustion in at least one cylinder of the internal combustion engine during a cold start phase, the fuel injected into the cylinder being brought to combustion, and the method sets the spark angle to normal, to end the cold start phase.

Owner:ROBERT BOSCH GMBH

Compression ignition engine by air injection from air-only cylinder to adjacent air-fuel cylinder

InactiveUS6994057B2Higher effective compression ratioImprove reliabilityCombustion enginesEngine controllersDetonationEngineering

Owner:WEST VIRGINIA UNIVERSITY

Compression ignition engine by air injection from air-only cylinder to adjacent air-fuel cyliner

InactiveUS20050199191A1More fuel efficientMore reliableCombustion enginesEngine controllersDetonationFuel cells

The herein disclosed IC engine relies on air injection for ignition instead of Otto cycle spark or Diesel cycle fuel injection. One or more adjacent cylinders are connected by a valve, which is opened near the end of their compression strokes so that high-pressure air can inject into the cylinder containing the air fuel mixture, and induce detonation ignition at top dead center. During expansion the cylinder-connecting valve remains open and provides equal pressure on both cylinders, which is substantially higher than possible in Otto cycle. Constant volume heat addition makes this engine also more efficient than Diesel cycle. The absence of spark ignition or high pressure fuel injectors make this engine more economical, more reliable, and scalable down to very small size unlike Diesel fuel injectors which cannot meter small quantities and eliminate the Diesel cold starting problem. Engine can serve as reactor for generating high temperature hydrogen to power high temperature fuel cells.

Owner:WEST VIRGINIA UNIVERSITY

Nagata cycle rotary engine

InactiveUS7757658B2Internal combustion piston enginesEngine of arcuate-engagement typeExhaust valveExternal combustion engine

Owner:NAGATA SUMIYUKI +1

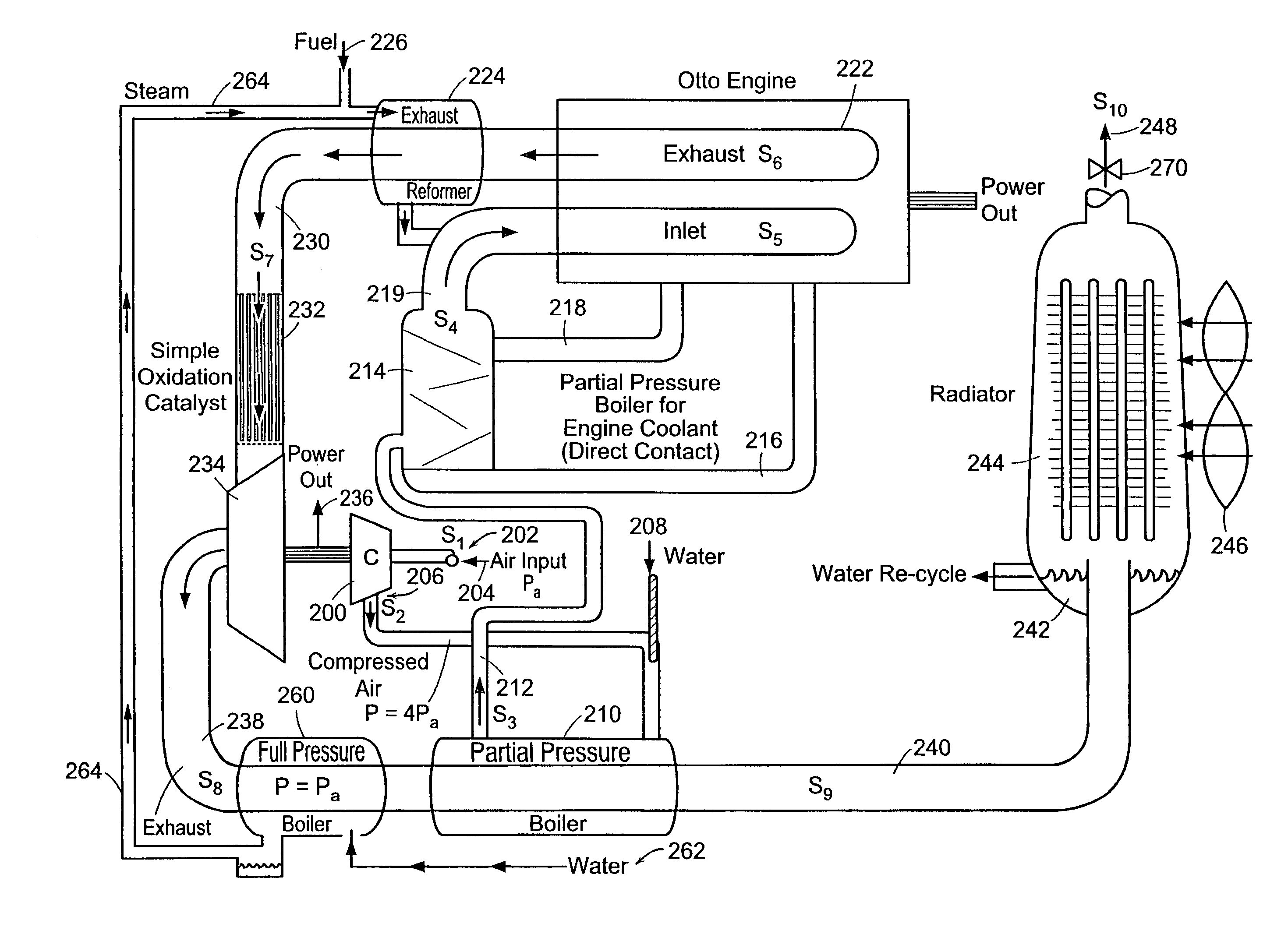

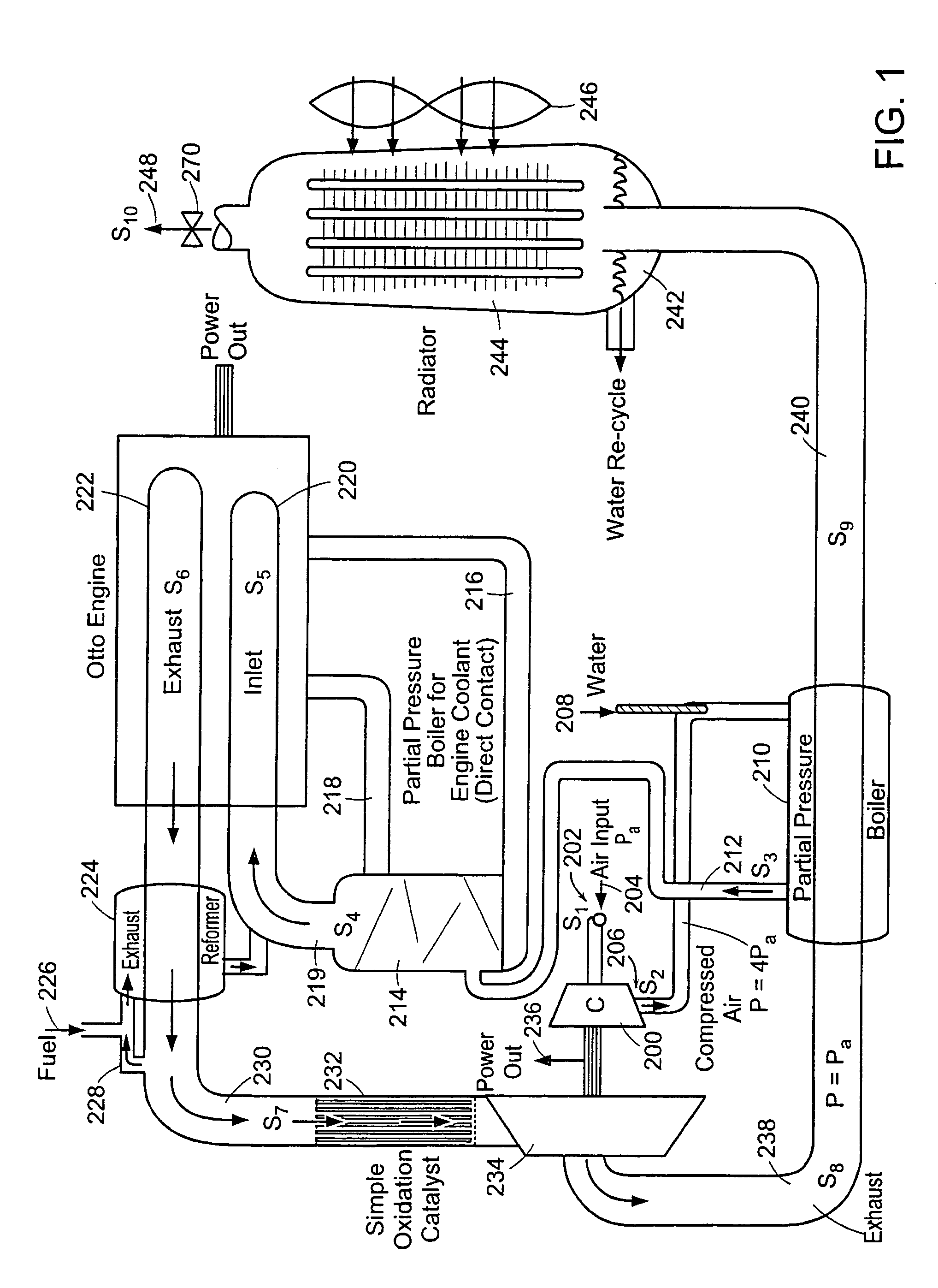

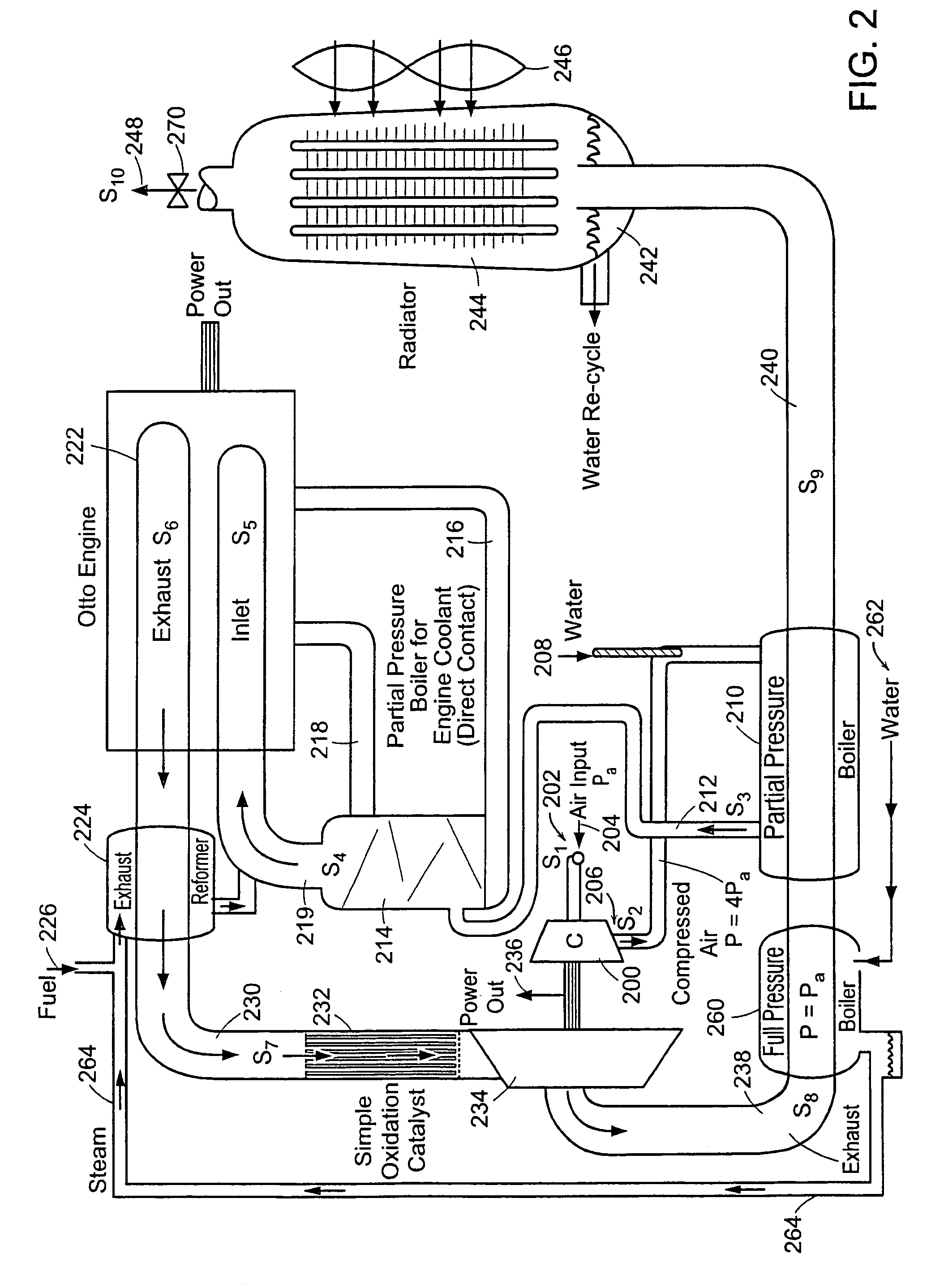

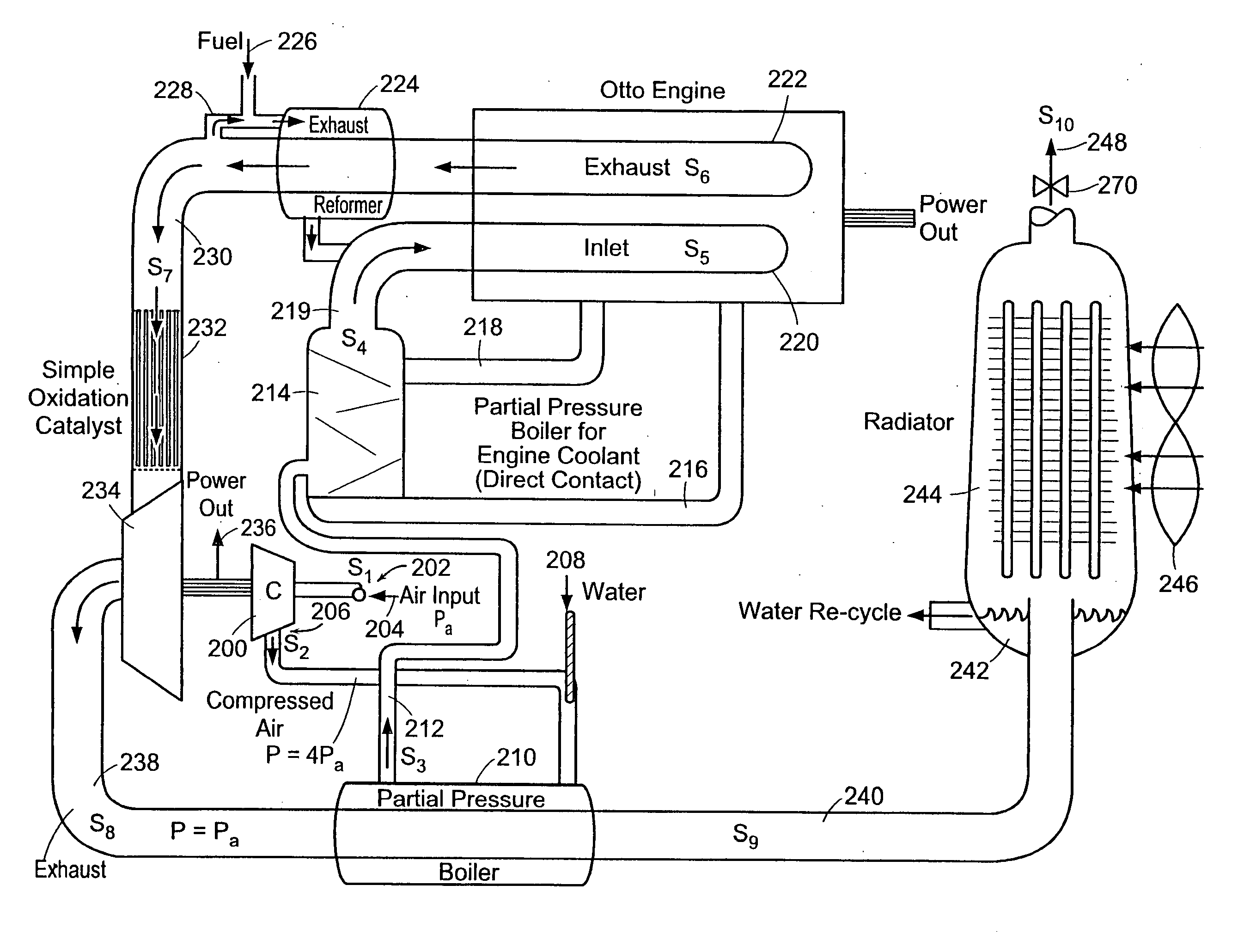

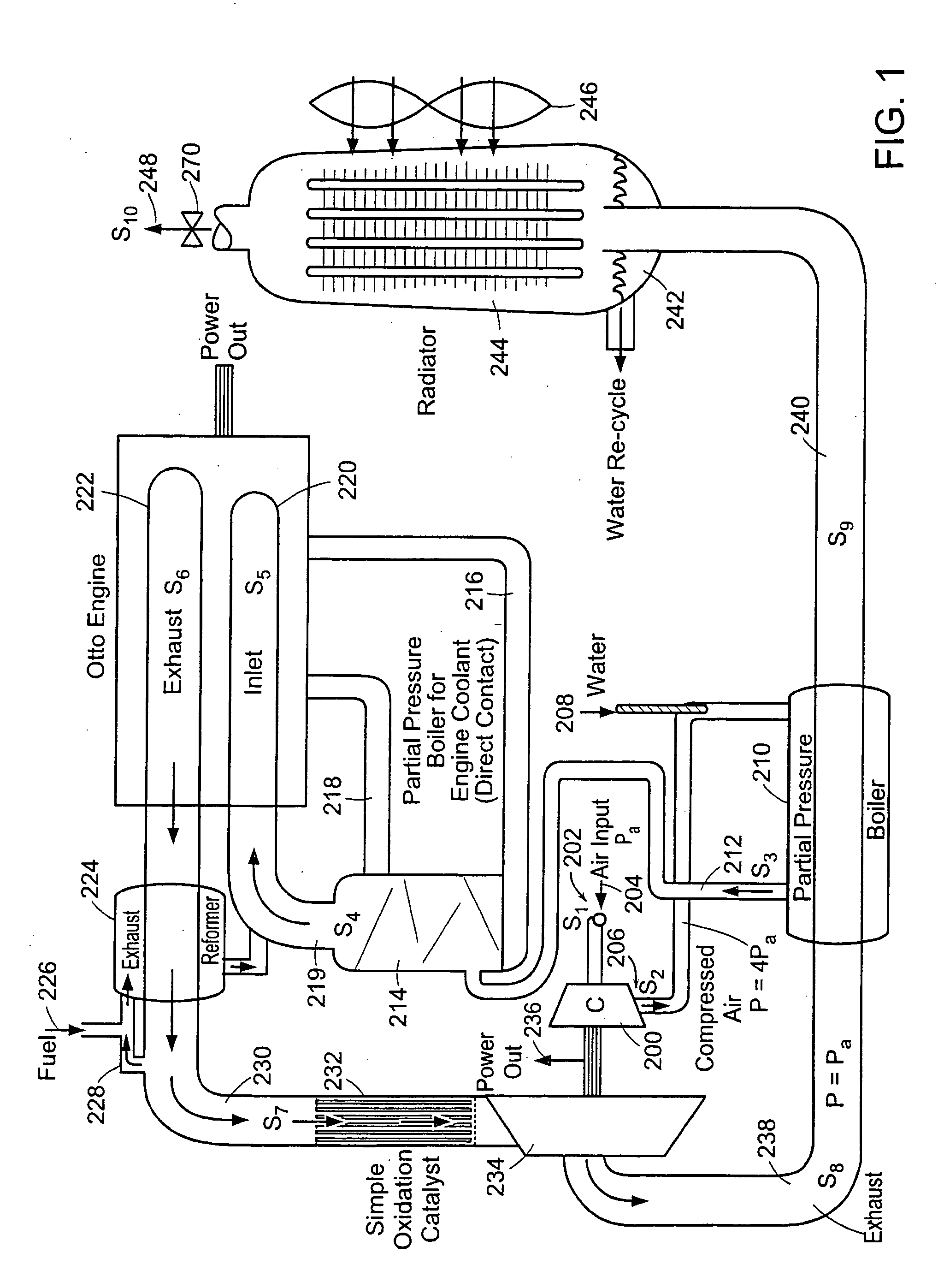

High-efficiency otto cycle engine with power generating expander

InactiveUS7062915B2Improve efficiencyEasy to implementReciprocating combination enginesInternal combustion piston enginesHydrogenFront propagation

High-efficiency combustion engines, including Otto cycle engines, use a steam-diluted fuel charge at elevated pressure. Air is compressed, and water is evaporated into the compressed air via the partial pressure effect using waste heat from the engine. The resultant pressurized air-steam mixture then burned in the engine with fuel, preferably containing hydrogen to maintain flame front propagation. The high-pressure, steam-laden engine exhaust is used to drive an expander to provide additional mechanical power. The exhaust can also be used to reform fuel to provide hydrogen for the engine combustion. The engine advantageously uses the partial pressure effect to convert low-grade waste heat from engine into useful mechanical power. The engine is capable of high efficiencies (e.g. >50%), with minimal emissions.

Owner:MICROERA POWER INC

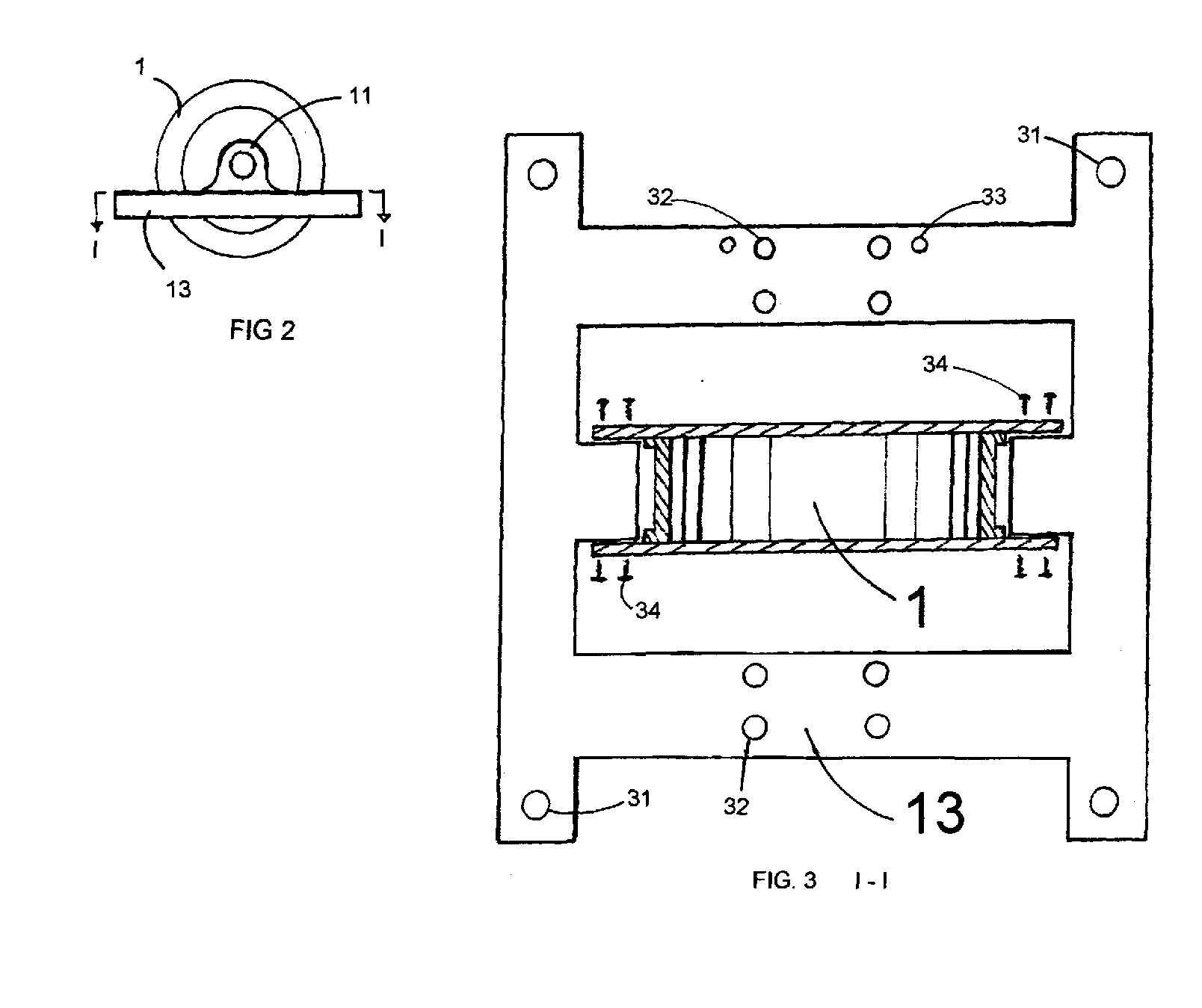

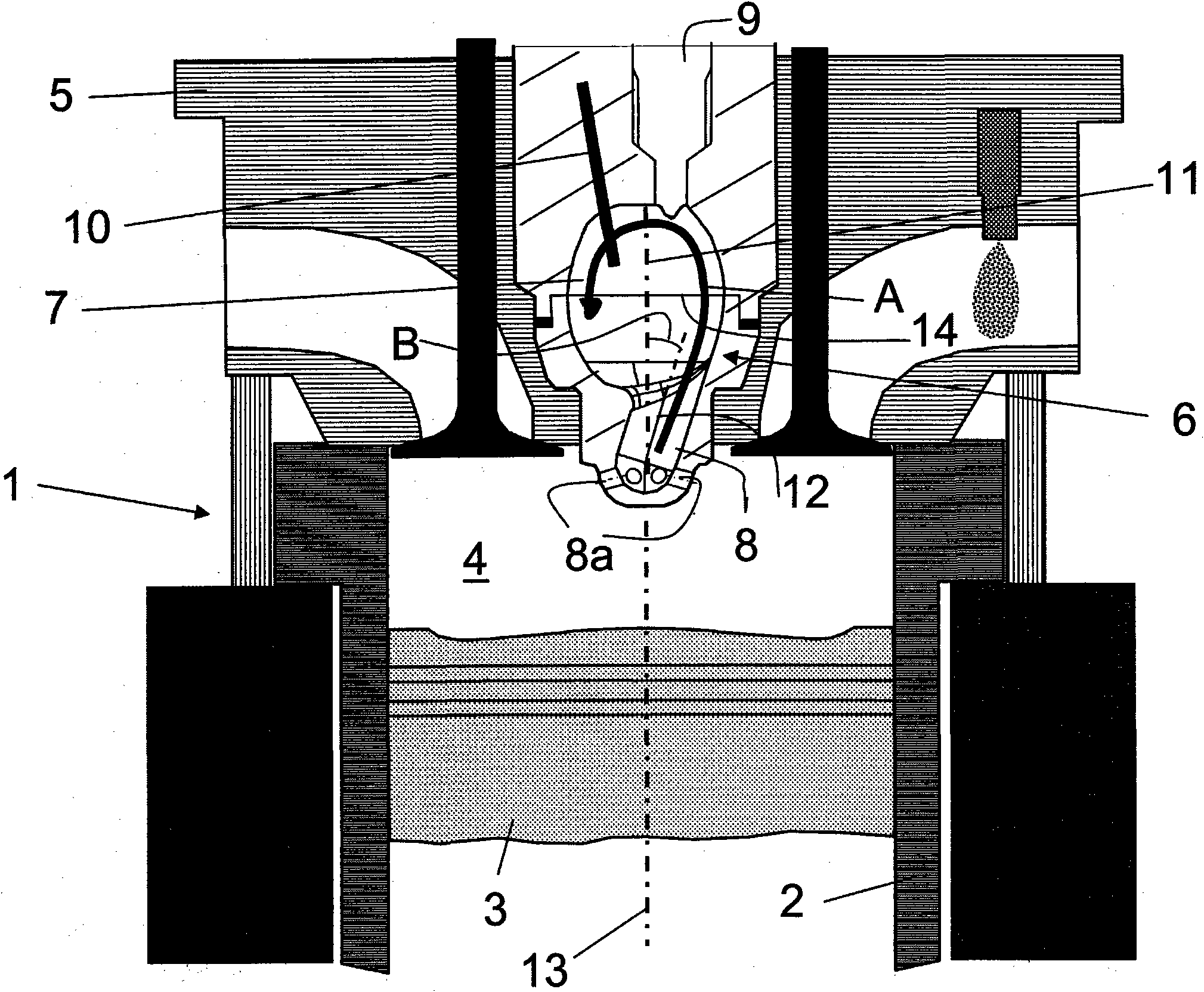

Pre-chamber arrangement

InactiveCN101960114AEfficient cycleQuick mixInternal combustion piston enginesFuel injection apparatusCombustion chamberOtto cycle

The invention relates to a pre-chamber arrangement for a cylinder (1) of an internal combustion engine fitted for premixed combustion (Otto cycle), the pre- chamber arrangement including a first chamber (7) for mixing and igniting of the fuel and a second chamber (8) of substantially smaller volume for communication between the first chamber (7) and the main combustion chamber (4) of the cylinder (1), the first chamber (7) being provided with pilot injection means (9) and having a chamber top substantially opposite to the second chamber (8). The first chamber (7) has substantially oval shape with curved walls between the chamber top and the second chamber (8). The second chamber (8) is asymmetrically positioned with regard to the first chamber (7) so as to provide a tumble flow motion (A) in the first chamber (7) for the gaseous fuel pressed from the main combustion chamber (4) and guided by curved wall of the first chamber (7) towards and past the fuel of pilot injection means (9) to be ignited.

Owner:WARTSILA FINLAND OY

Spark plug of an internal combustion engine

InactiveUS6992426B2Good reliable ignitionEasy to useSparking plugs manufactureCombustion chamberOtto cycle

A spark plug of an internal combustion engine, in particular for use in Otto-cycle gas engines, having an insulator body, at least one fixed ground electrode carrier arrangement and at least one fixed central electrode carrier, wherein a spark plug housing having at least two parts encloses the insulator body, wherein the spark plug housing has a lower housing portion and an upper housing portion, wherein at least the combustion chamber-side part of the insulator body is pressure-resistantly, preferably completely, enclosed by the lower housing portion jointly with the upper housing portion.

Owner:JENBACHER

Nagata cycle rotary engine

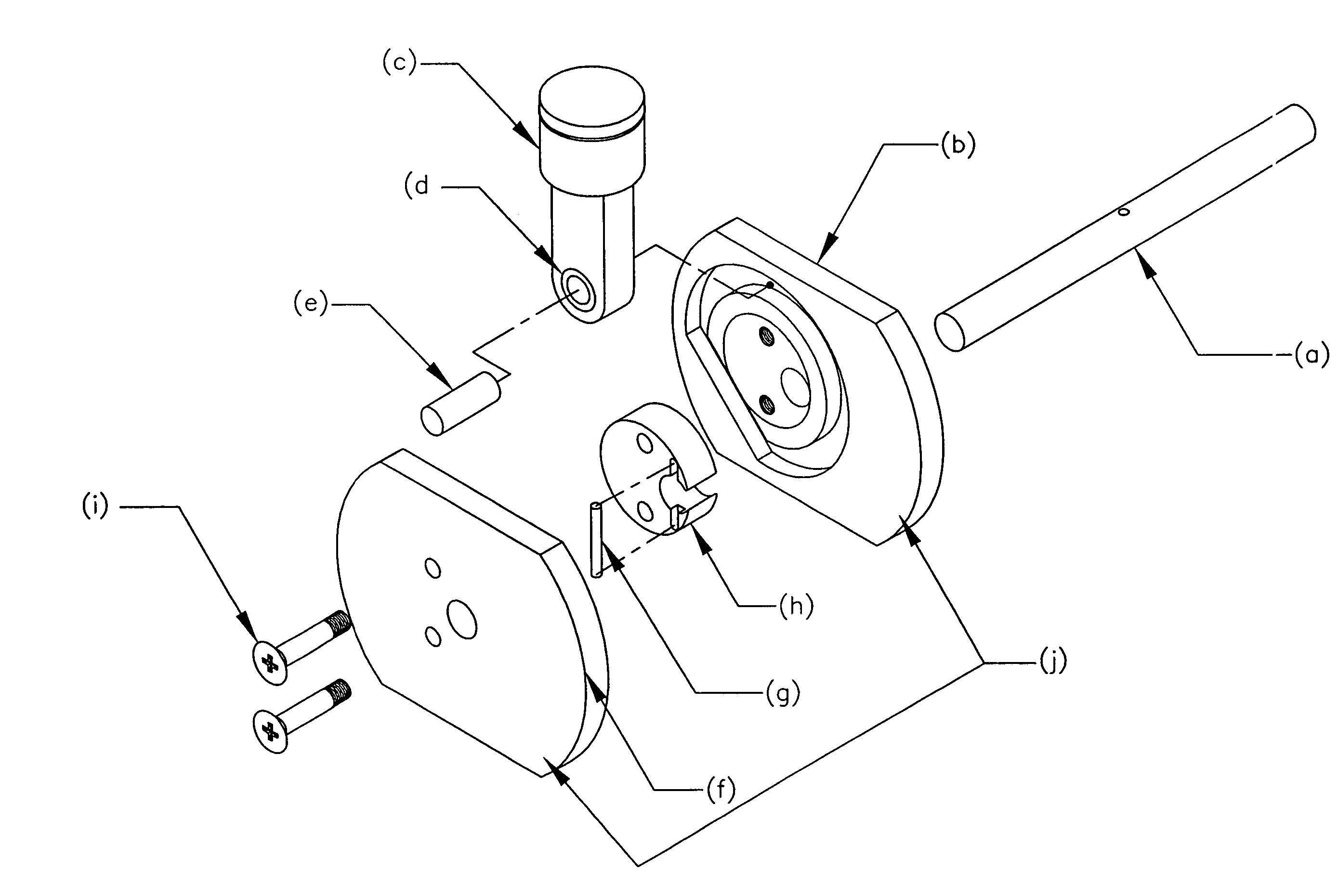

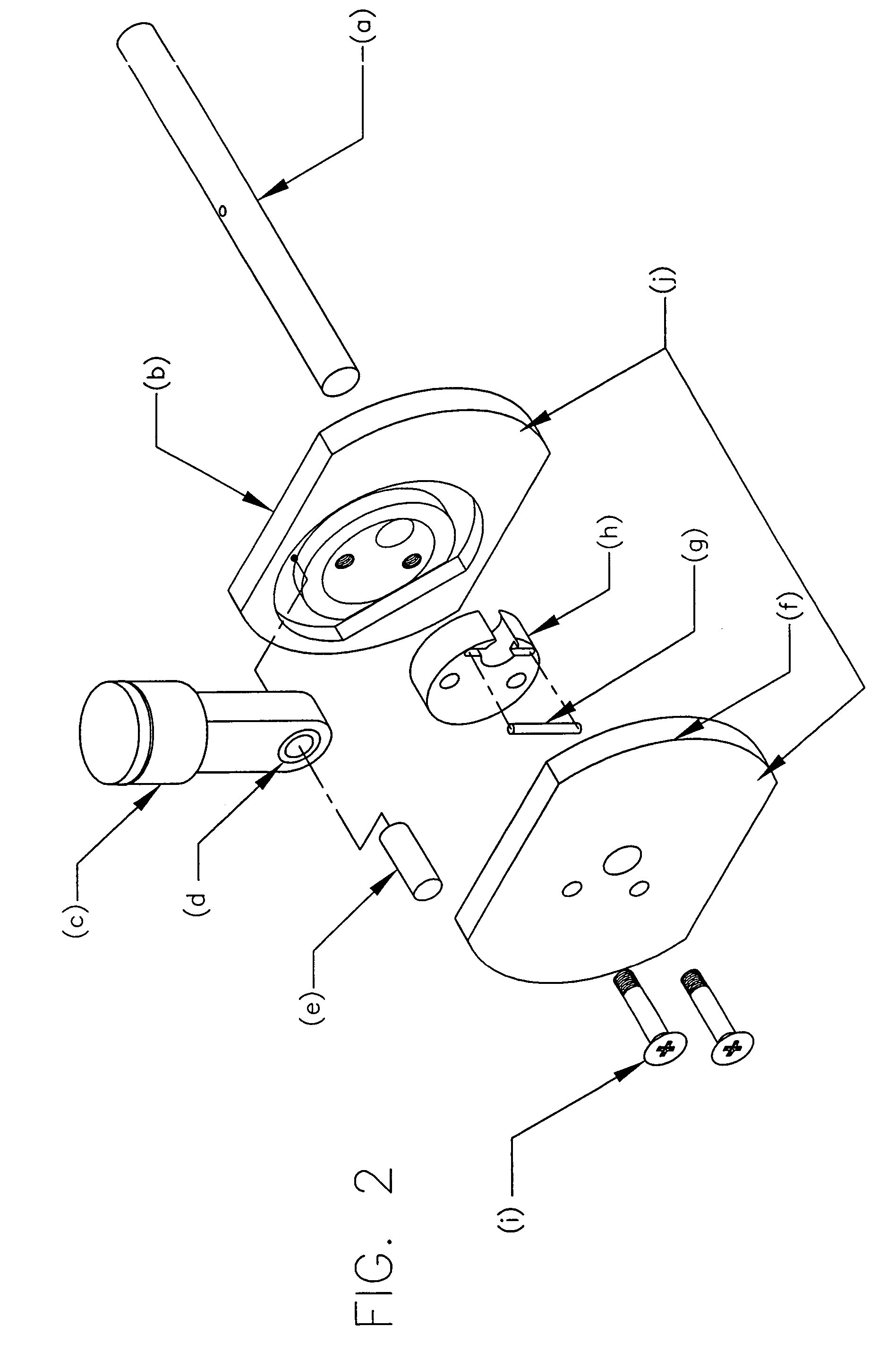

InactiveUS20070215094A1Superior gas mileageImprove performanceInternal combustion piston enginesEngine of arcuate-engagement typeCombustion chamberExhaust valve

An internal combustion rotary engine using vanes to create separate combustion chambers within the engine and capable of performing all four strokes of the Otto cycle (intake, compression, combustion and exhaust) in each separate combustion chamber. Each Otto cycle is completed in a 180-degree rotation with all four strokes of the Otto cycle being completed in 720 degrees. An intake and exhaust valve system tightly controls the flow of the air / fuel mixture into each separate combustion chamber.

Owner:NAGATA SUMIYUKI +1

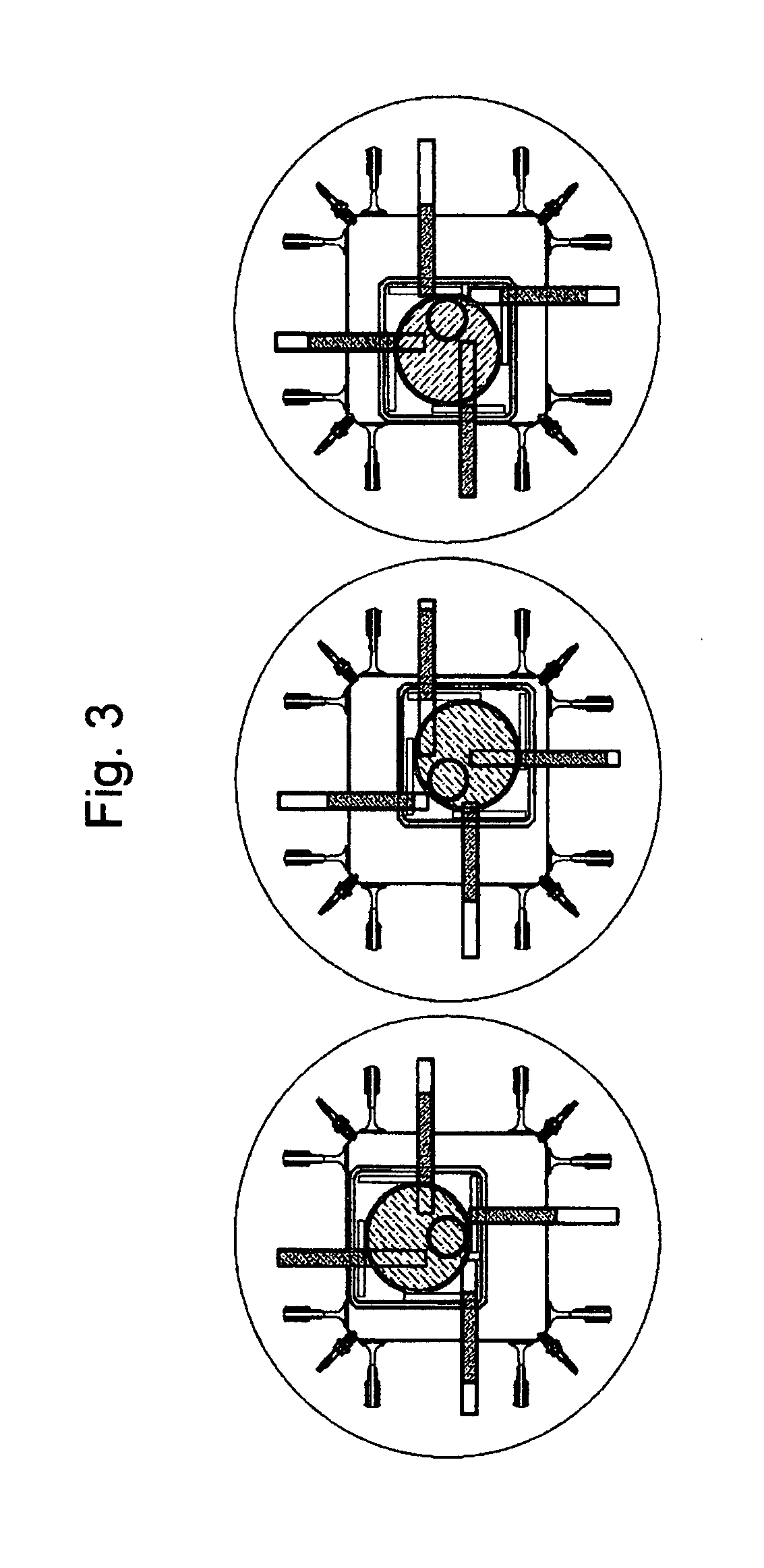

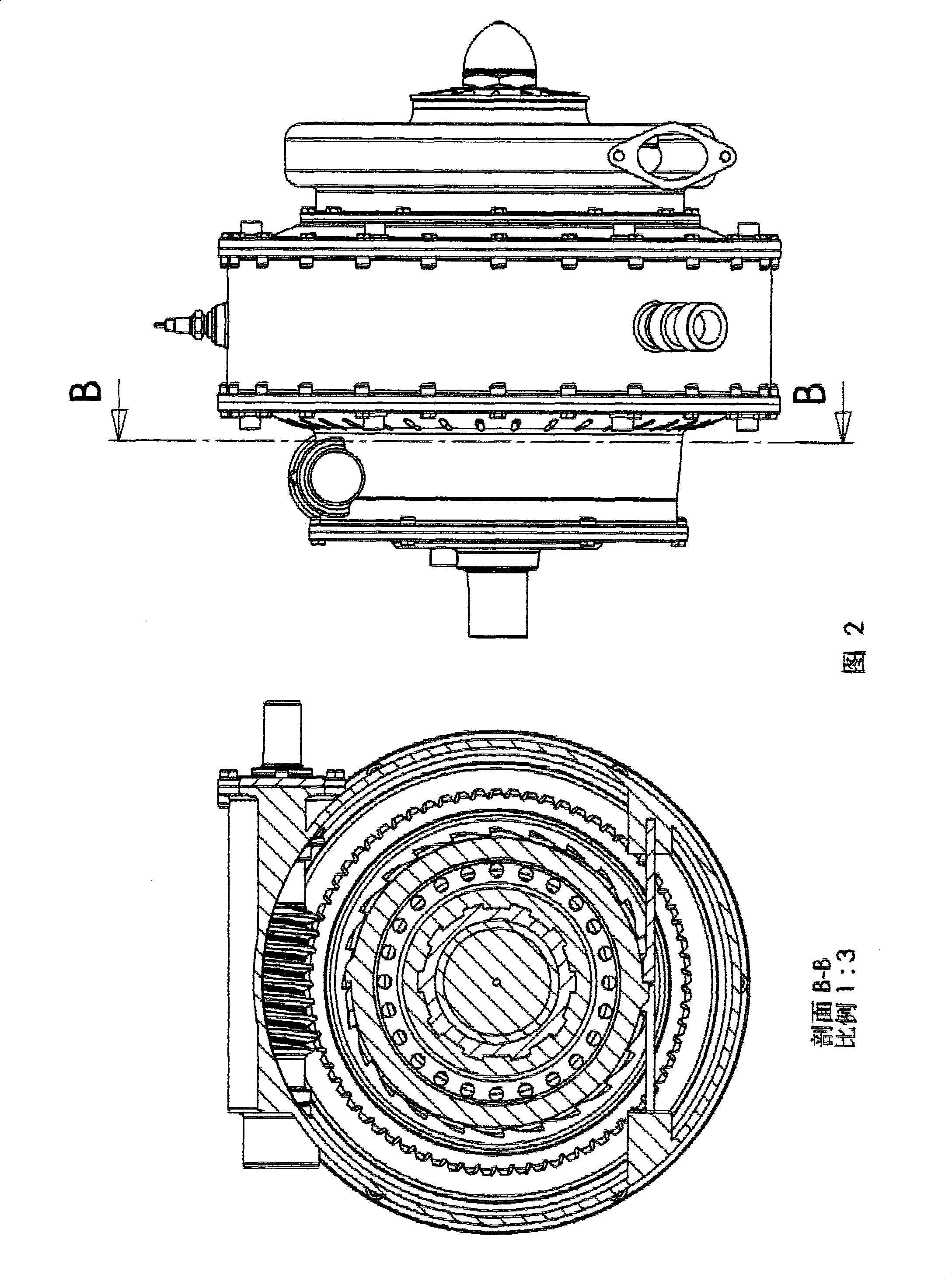

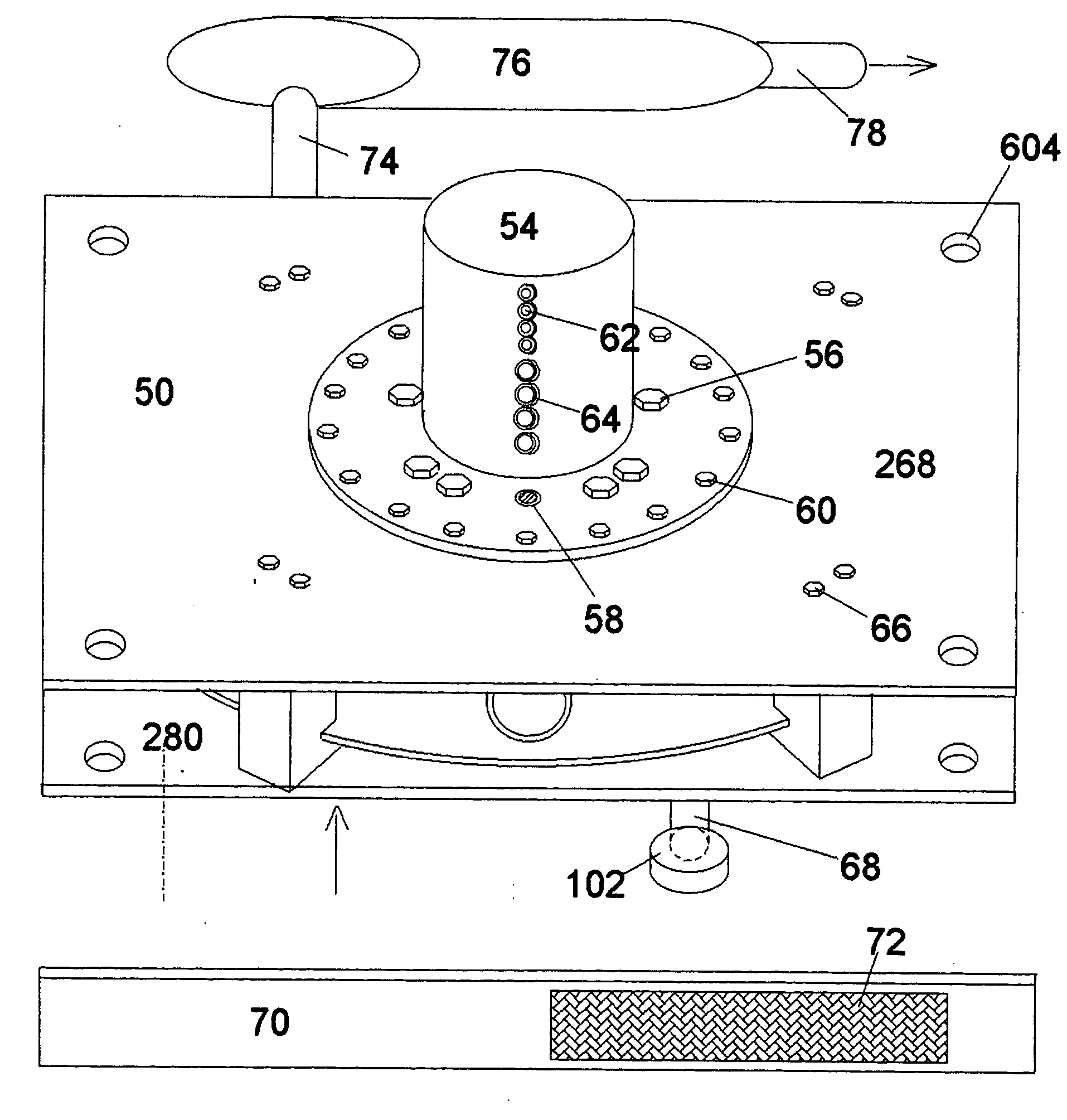

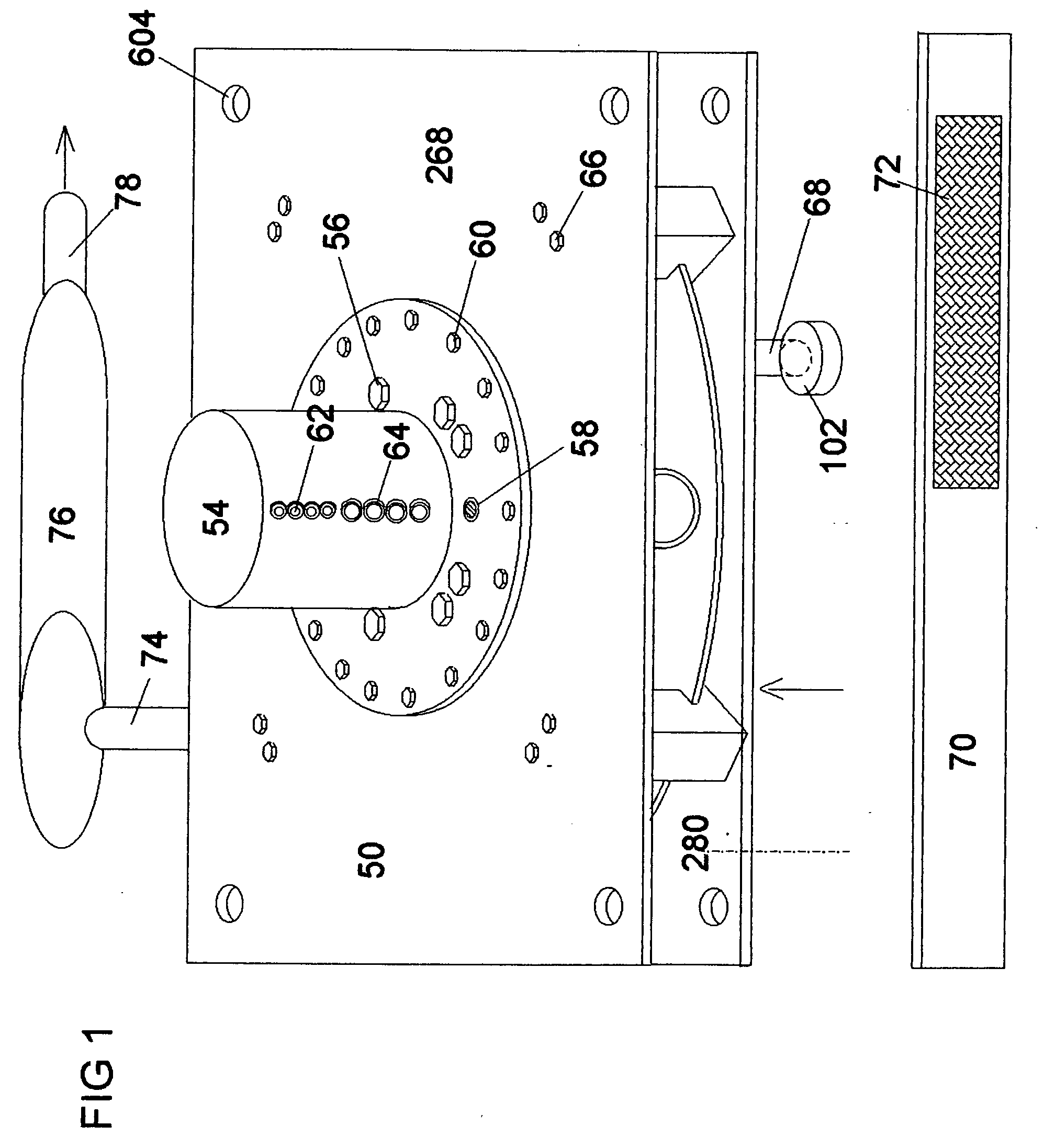

Low speed valveless horizontally opposed piston rotary internal combustion engine

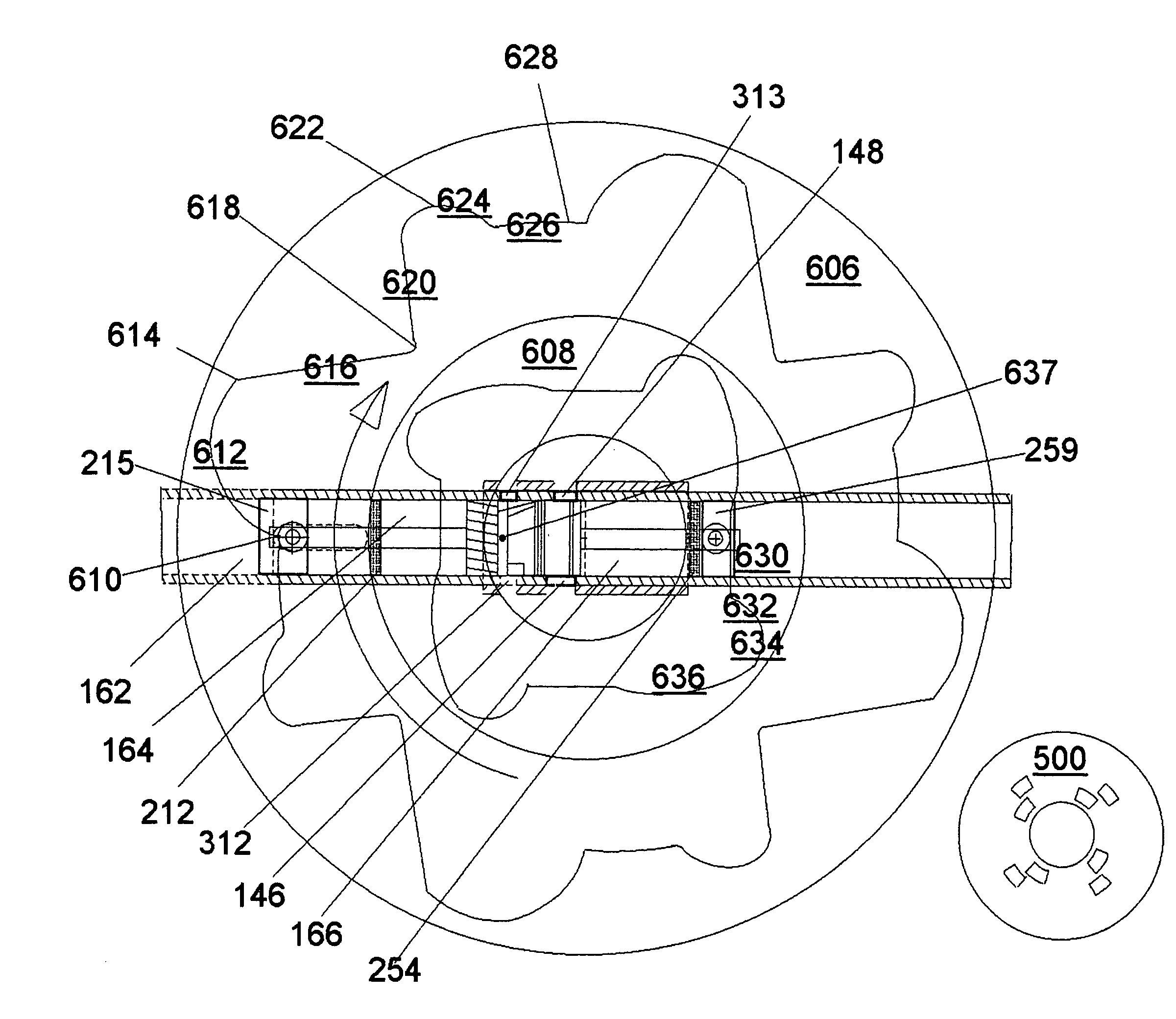

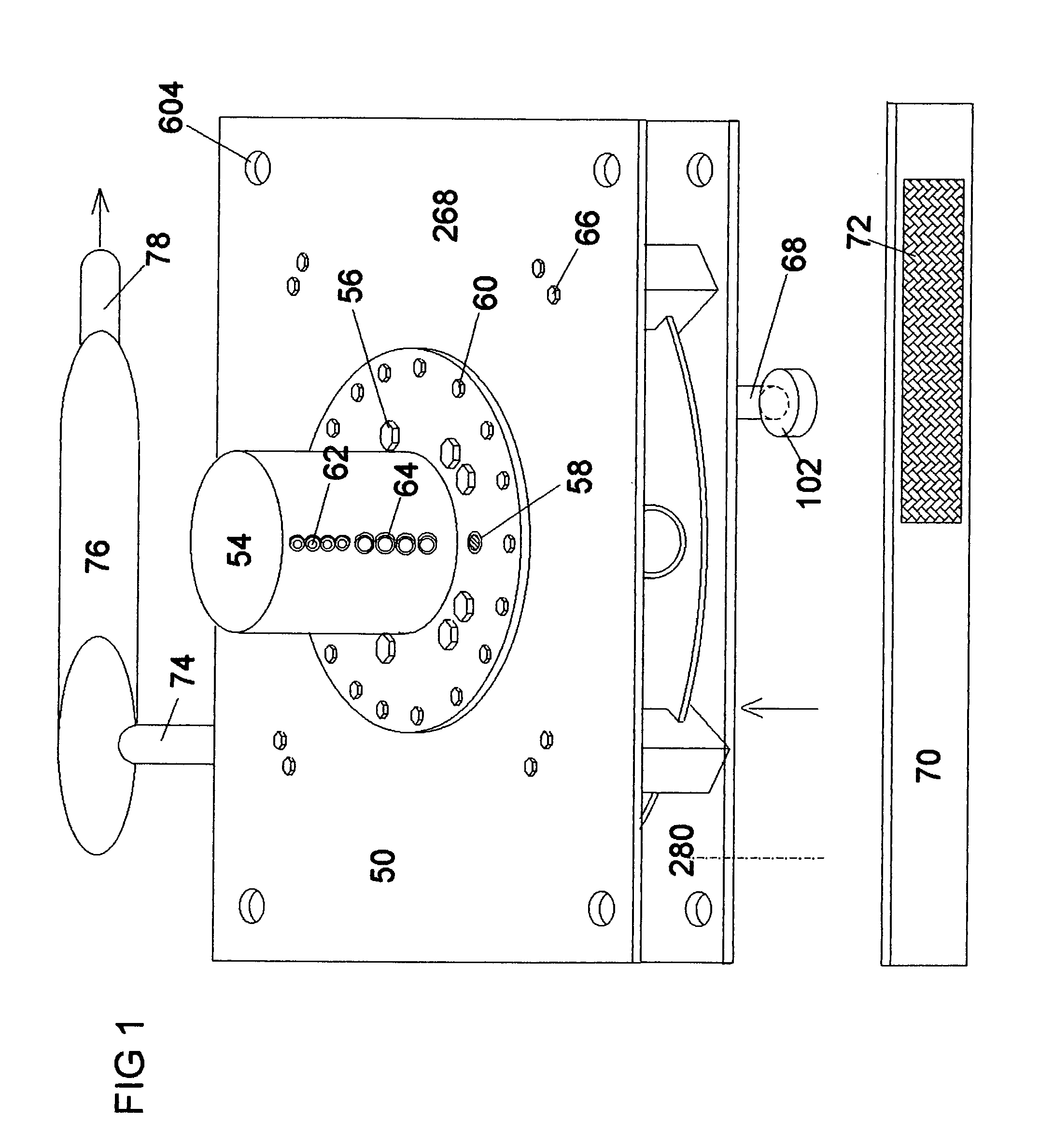

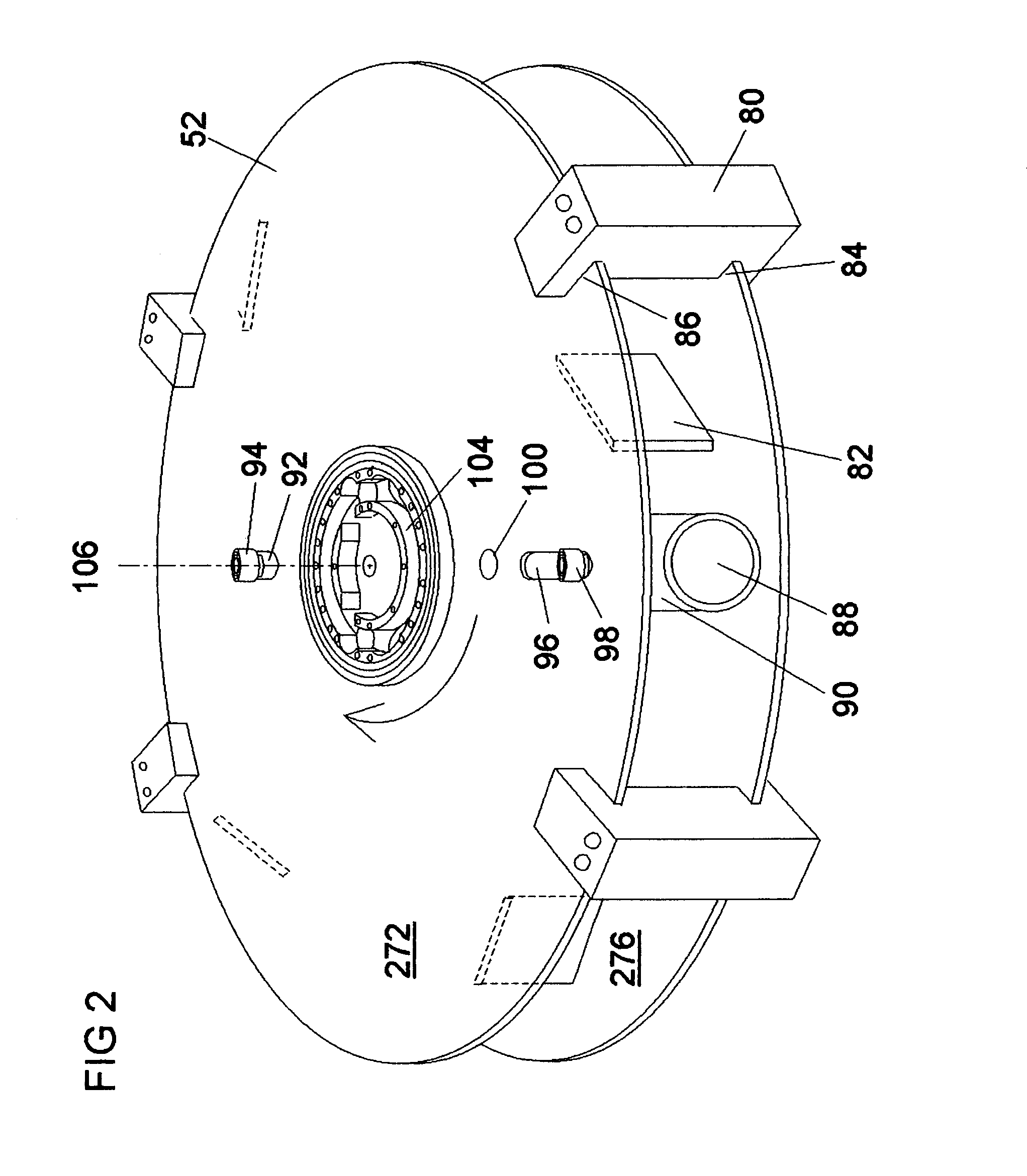

InactiveUS7938097B2Reduce designIncreased torque outputInternal combustion piston enginesEngines with rotating cylindersLow speedDrive shaft

Presented is a very low speed, high torque, horizontally opposed, rotary, valveless, Otto cycle piston engine producing four power strokes per revolution, the engine consisting of a fixed engine case assembly having upper and lower plates, the engine rotor assembly having upper and lower plates, sandwiching a single, closed ended cylinder assembly, the cylinder containing intake and exhaust-intake ports, independently reciprocating power and head pistons, each piston being reciprocally controlled by its vertically projecting piston bearing sets contacting respective sets of upper and lower, inner and outer peripheral cam plates, the engine being thus rotated, the cylinder being lubricated by a sealed, recirculating air-oil mist system, the engine rotor assembly having a lower, vertically projecting gear box housing containing a gas porting cap, a vertical drive shaft, two counter rotating output shafts, intake and exhaust pipes, and an exhaust gas filter canister.

Owner:SPARLING JAMES DOUGLAS

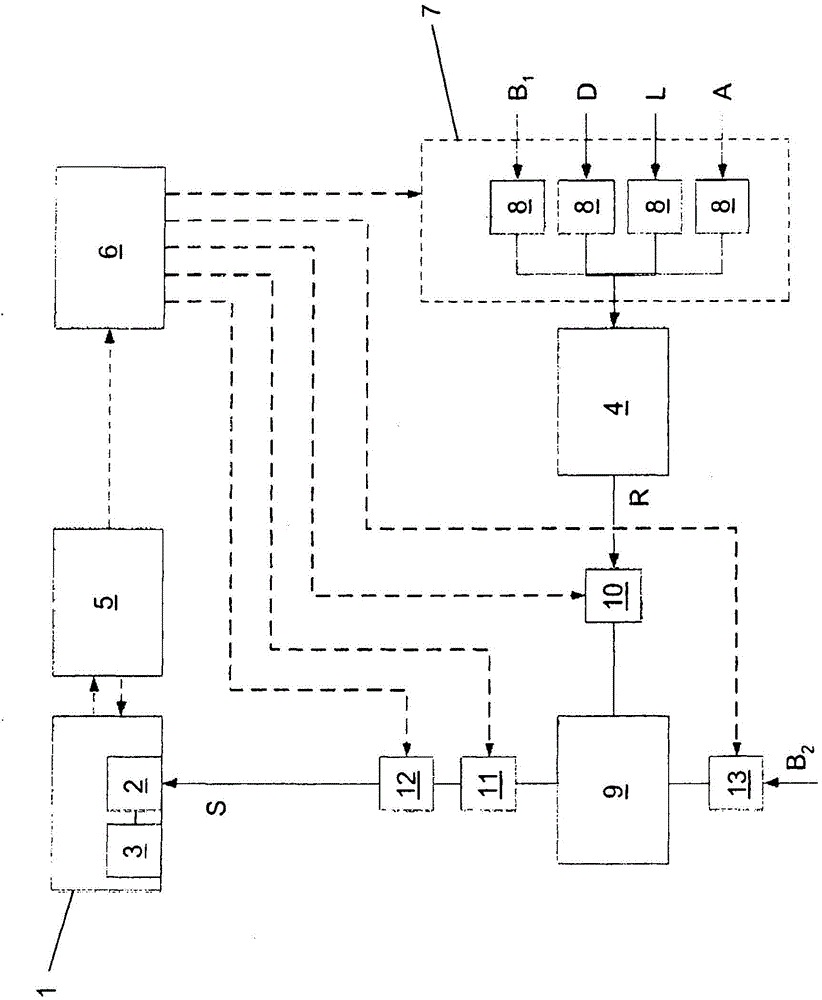

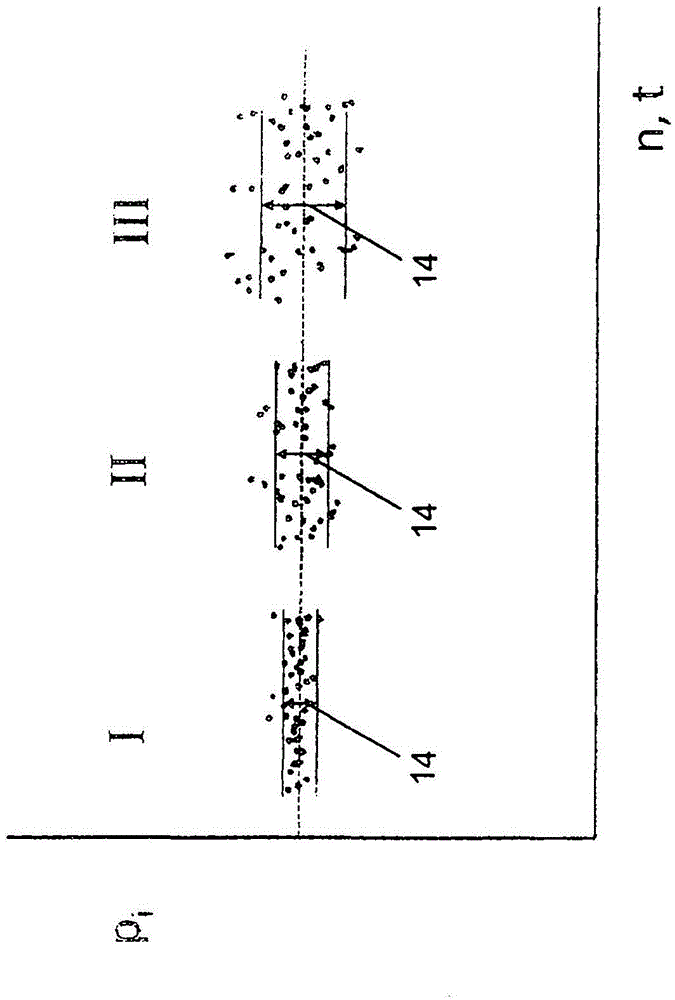

Method for operating at least one precombustion chamber-fired internal combustion engine

InactiveCN103958865AImprove combustion characteristicsBest chemical compositionElectrical controlInternal combustion piston enginesChemical compositionOtto cycle

The invention relates to a method for operating at least one precombustion chamber-fired internal combustion engine (1), in particular a stationary gas Otto cycle engine, having a pilot chamber (2) and a main combustion chamber (3) associated with the precombustion chamber (2), wherein a gas mixture is fed to the precombustion chamber (2) as flushing gas (S), wherein a synthesis gas (R) generated in a fuel reformer (4) and a fuel (B2) from a fuel source are fed to the flushing gas (S) and wherein a fuel (B1) and at least one further substance stream (D, L, A) are fed to the fuel reformer (4) for the reforming process, wherein at least one operating parameter of the at least one internal combustion engine is monitored, wherein in accordance with a change in the at least one operating parameter the chemical composition of the flushing gas (S); is modified by changing the mass stream of the at least one further substance stream (D, L, A).

Owner:GE JENBACHER

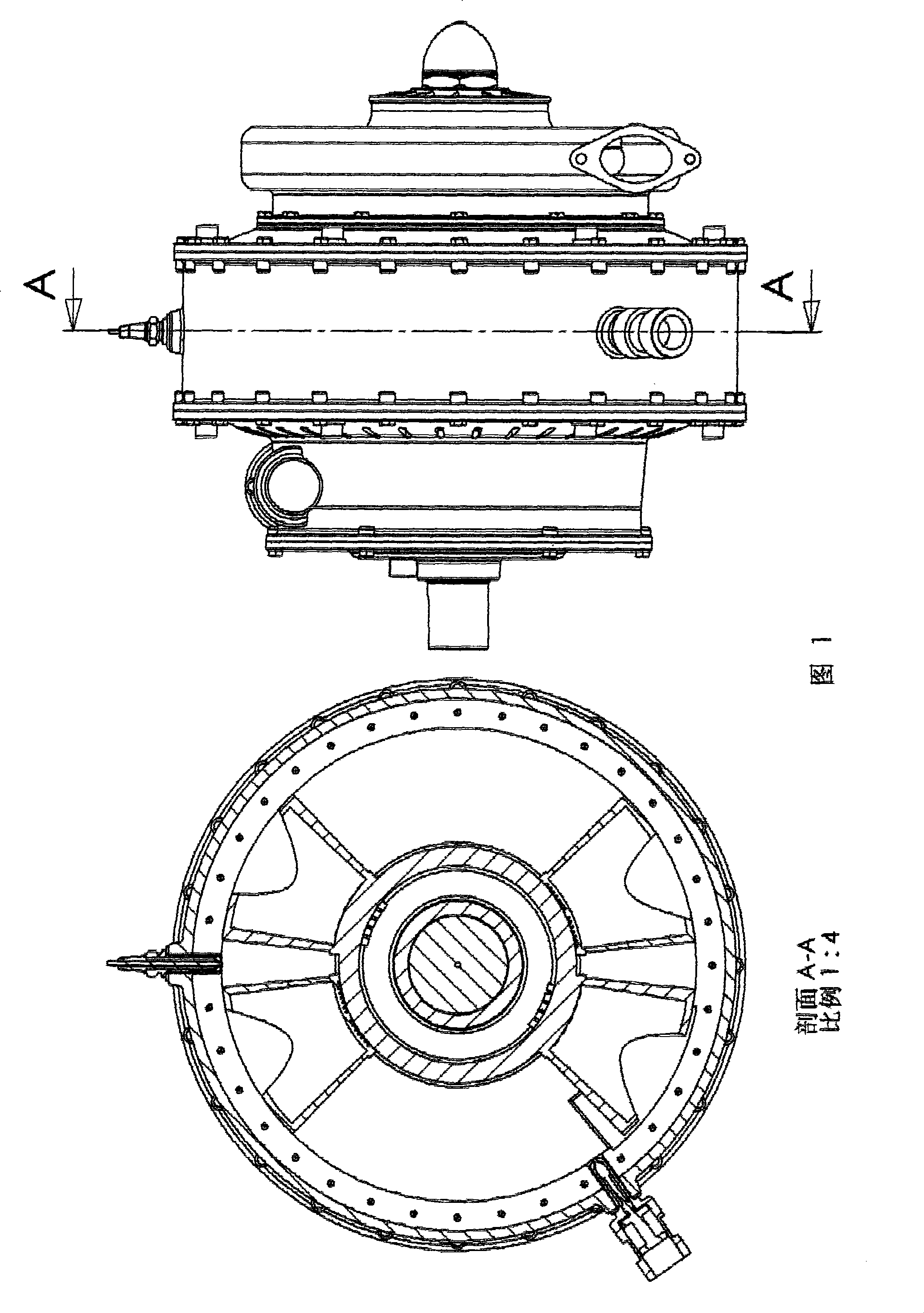

Pneumatic air distributing engine

InactiveCN101363360AImprove sealingPlay a sealing roleInternal combustion piston enginesEngineeringConstant angular velocity

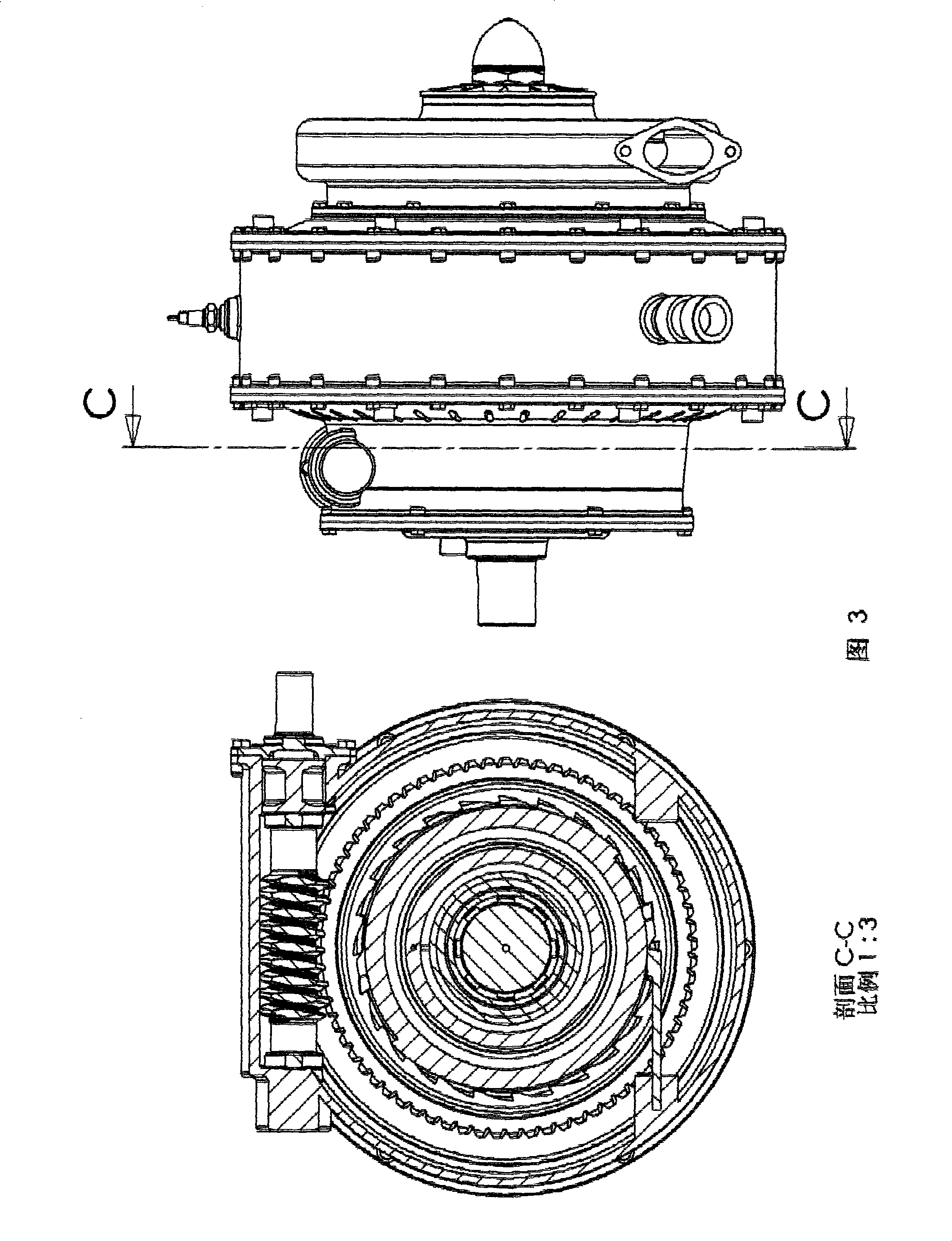

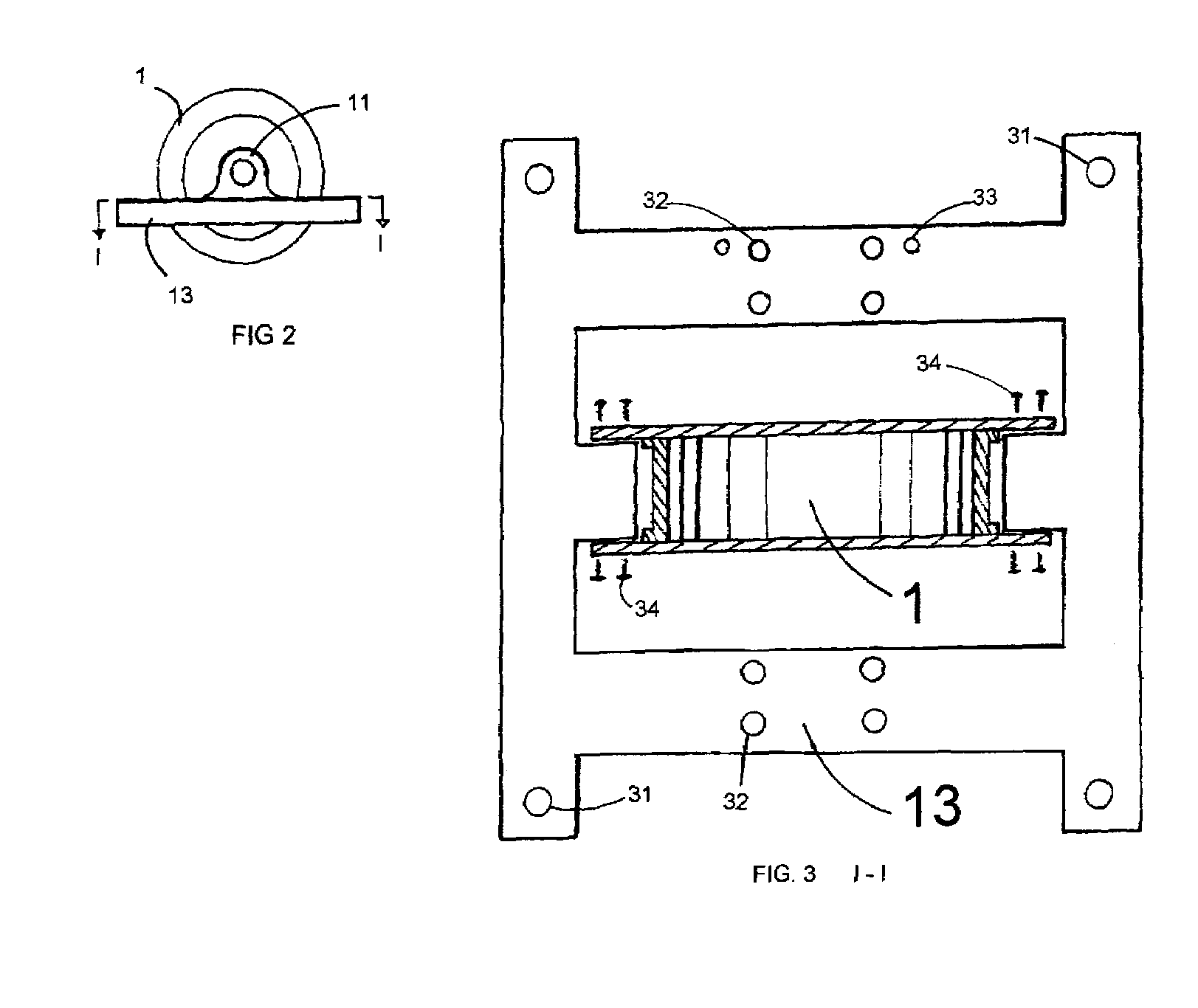

The invention relates to a pneumatic air distribution engine which can significantly improve thermal efficiency and reduce pollution emission, production cost as well as maintenance expense. By adopting the novel pneumatic air distribution technology, the pneumatic air distribution engine can drive a piston to do rotation with variable angular velocity or with constant angular velocity by relying on gas pressure and a control mechanism, thus meeting the basic requirements of the Otto cycle in the way of changing the motion property of the key components of the engine. The pneumatic air distribution engine adopts high-temperature resistant structure ceramics as the high-temperature resistant components of the engine, abandons a sealing system and a valve structure of the traditional engine, simplifies a cooling and lubricating system and is simpler in structure and cheaper in price than any traditional engines. By adopting two transduction ways, namely, piston way and turbine way, the pneumatic air distribution engine has extremely high volumetric efficiency, combustion efficiency, mechanical efficiency as well as thermal efficiency when working under the condition of high temperature, high speed and high compression ratio, and shows the characters of the existing shaft power engine such as low fuel consumption, low emission, low production cost and little maintenance. Diagram 1 is the front view (omitted in appendix) of the engine, and A-A is the sectional view thereof.

Owner:蔡盛龙

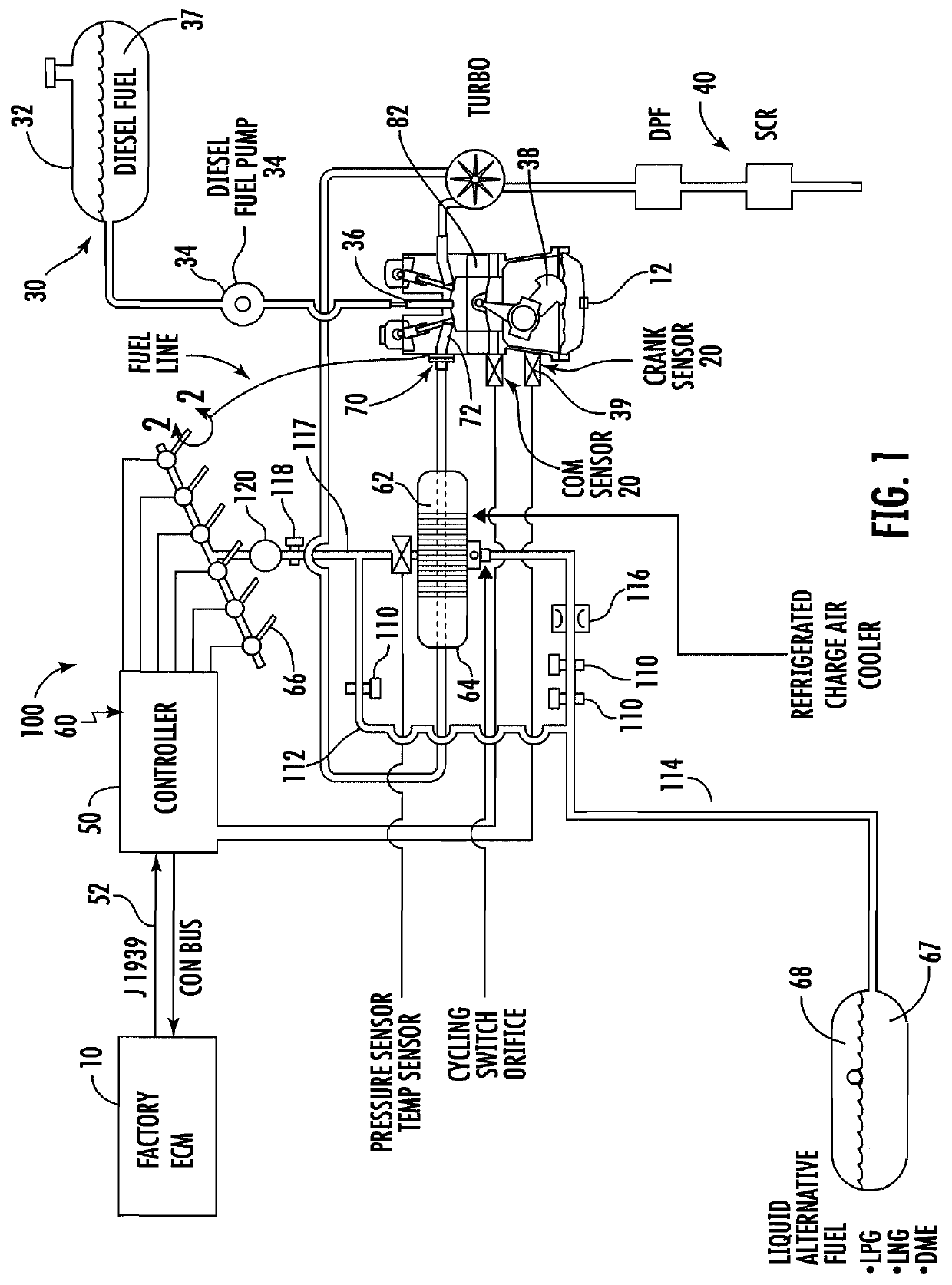

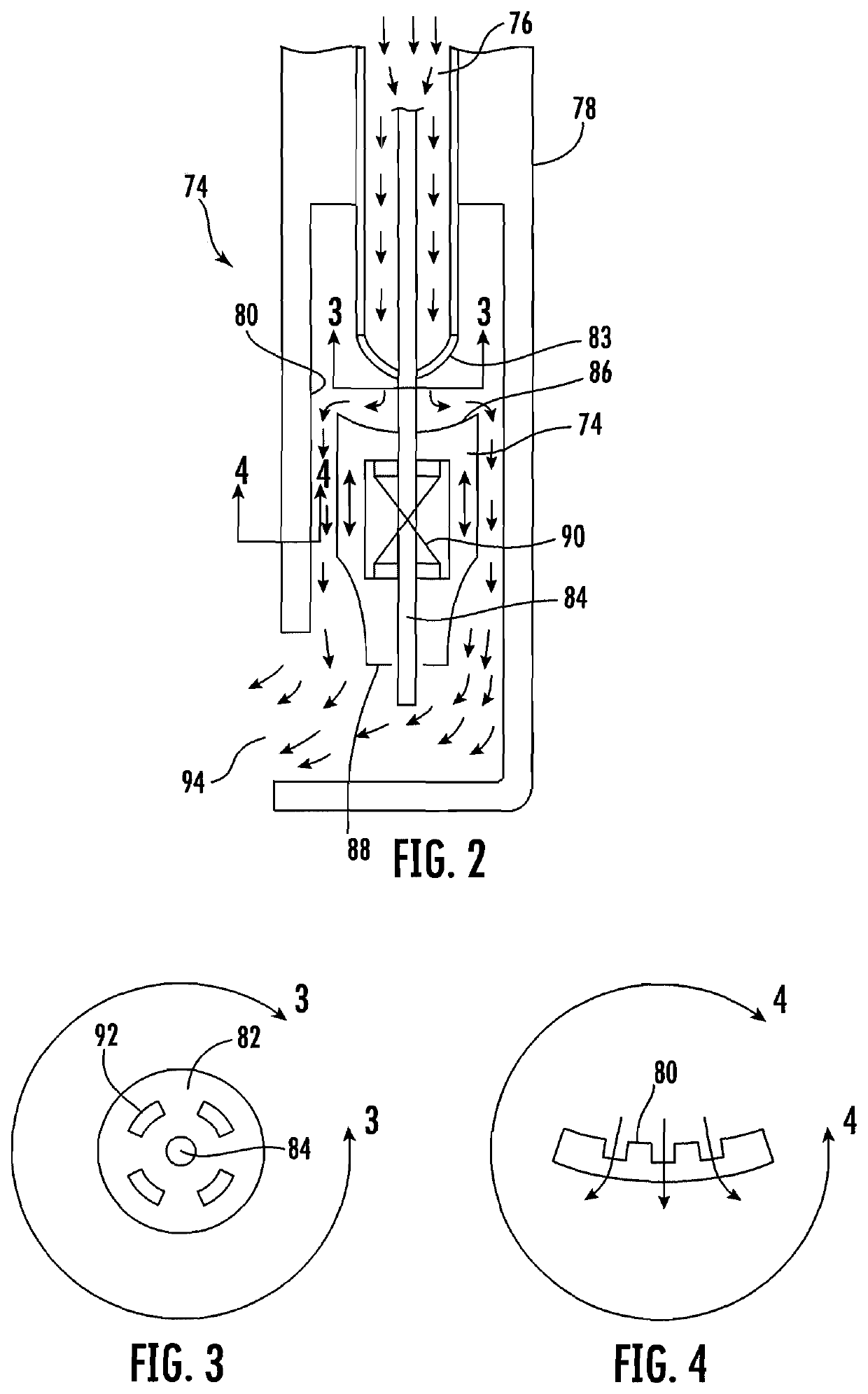

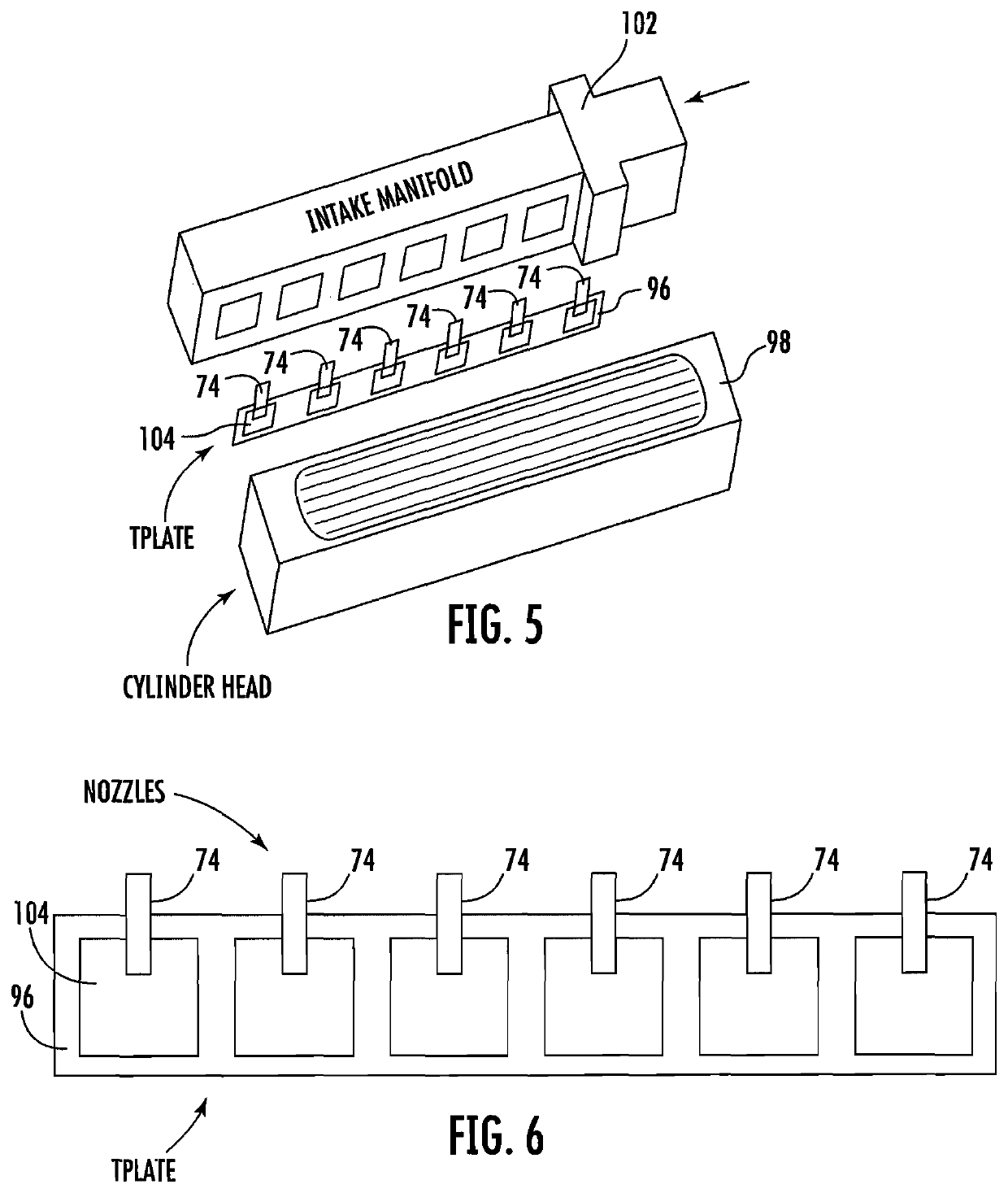

Dual fuel injection system for optimizing fuel usage and minimizing slip for diesel engines

ActiveUS10890106B2Improve efficiencyReduce slippageElectrical controlInternal combustion piston enginesOtto cycleLiquid fuel

The invention involves a system and method for providing a liquid fuel or a liquid and gaseous fuel to a diesel or Otto cycle engine for operation of the engine. The system includes a primary electronic control module (ECM), which monitors engine sensors and contains a first three-dimensional fuel map for the liquid fuel. A second ECM is connected for bi-directional transfer of information to the first ECM, the second ECM contains a second three-dimensional fuel map for delivery of the gaseous fuel through a secondary gaseous fuel injection assembly. The bi-directional communication between the two ECMs while monitoring the engine sensors allows both ECMs to “learn” an efficient fuel map for delivery of both fuels in the same cycle for improved efficiency, reduction in slip and lower emissions.

Owner:DYNAMIC FUEL SYST

Intake Valve Closure Control for Dual-Fuel Engines

ActiveUS20150345347A1Avoid flowAvoid communicationInternal combustion piston enginesNon-mechanical valveControl flowOtto cycle

A system and a method for actuating intake valves of an internal combustion engine. The system includes a hydraulic circuit including a master cylinder, a control valve, an accumulator, a first one-way valve and a slave cylinder. The slave cylinder accommodates a slave piston, which is coupled to the intake valves. The control valve is disposed upstream of the accumulator for controlling flow from the hydraulic circuit to the accumulator. The first one-way valve is disposed downstream of the accumulator for permitting flow from the accumulator to the hydraulic circuit and for preventing flow from the hydraulic circuit to the accumulator without first passing through the control valve. The control valve has an open position that provides communication between the hydraulic circuit and the accumulator for a Miller cycle or Miller-like cycle operation. The control valve also has a closed position that prevents communication between the hydraulic circuit and the accumulator during Otto cycle operation.

Owner:CATERPILLAR INC

Continuous Otto piston elliptical engine

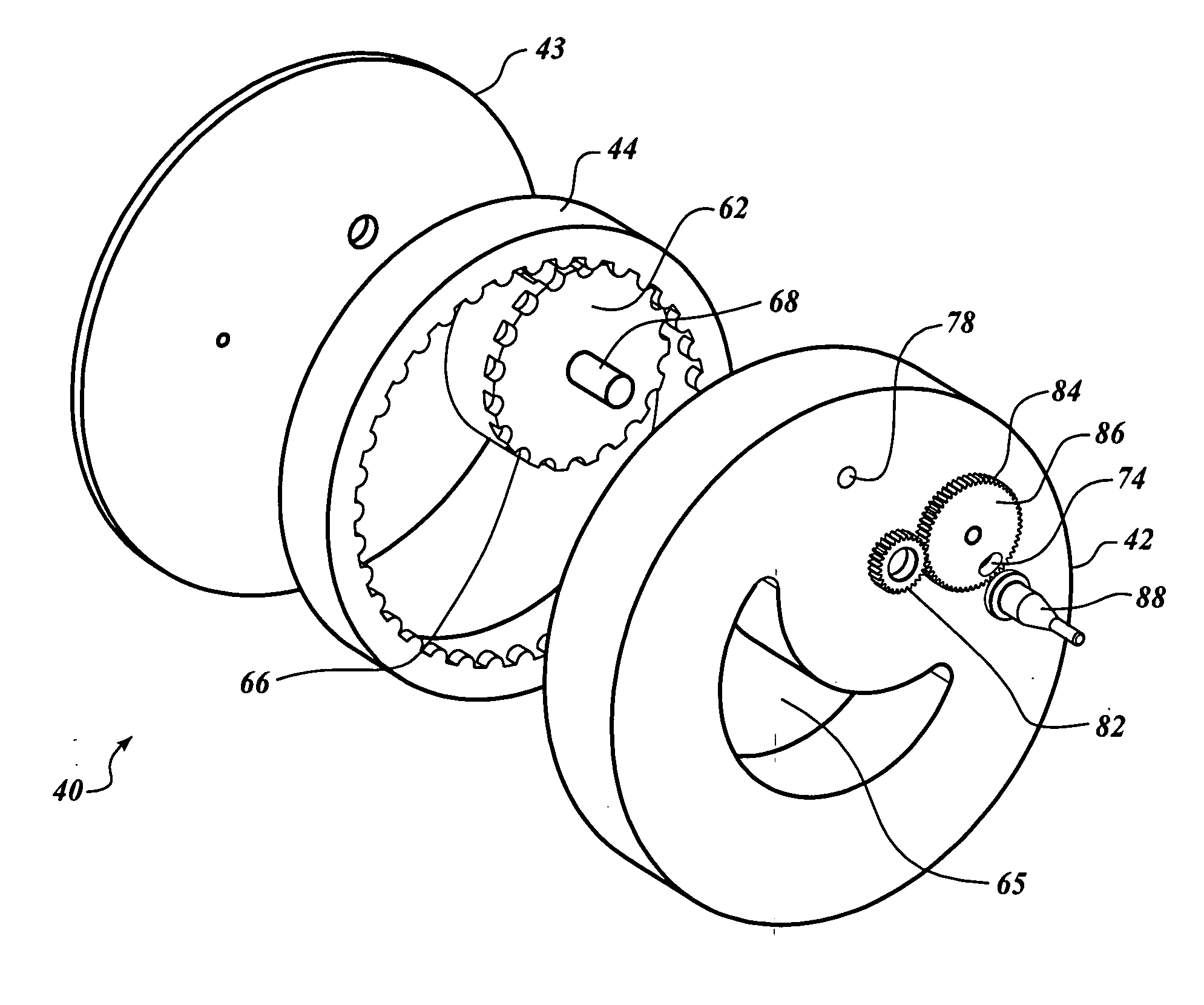

InactiveUS20090038565A1Reduce volumeLubrication of auxillariesInternal combustion piston enginesContact formationOtto cycle

A continuous Otto piston elliptical engine including cylinder and ellipse, where the cylinder includes:i. an X shape layout of the common Otto cycle pistons in a single block,ii. a coolant inlet port and a coolant outlet port (Part Nos. 42 and 43, FIG. 3),iii. where lubrication of pistons is done by the lubricating liquid splashed by the connecting arms, guide arm and the up down movement of the pistons themselves (Part No. 29, FIG. 2),iv. conventional spark plugs are placed in the cylinder (Part No. 36, FIG. 2),v. there is a contact between the guiding arm and the connecting rod which make an arc trace which force the ellipse to rotate (Part No. 29, FIGS. 2), andvi. the holes the sparkplug cables pass through (Part No. 32, FIG. 2).

Owner:TAWFIQ KHALAF

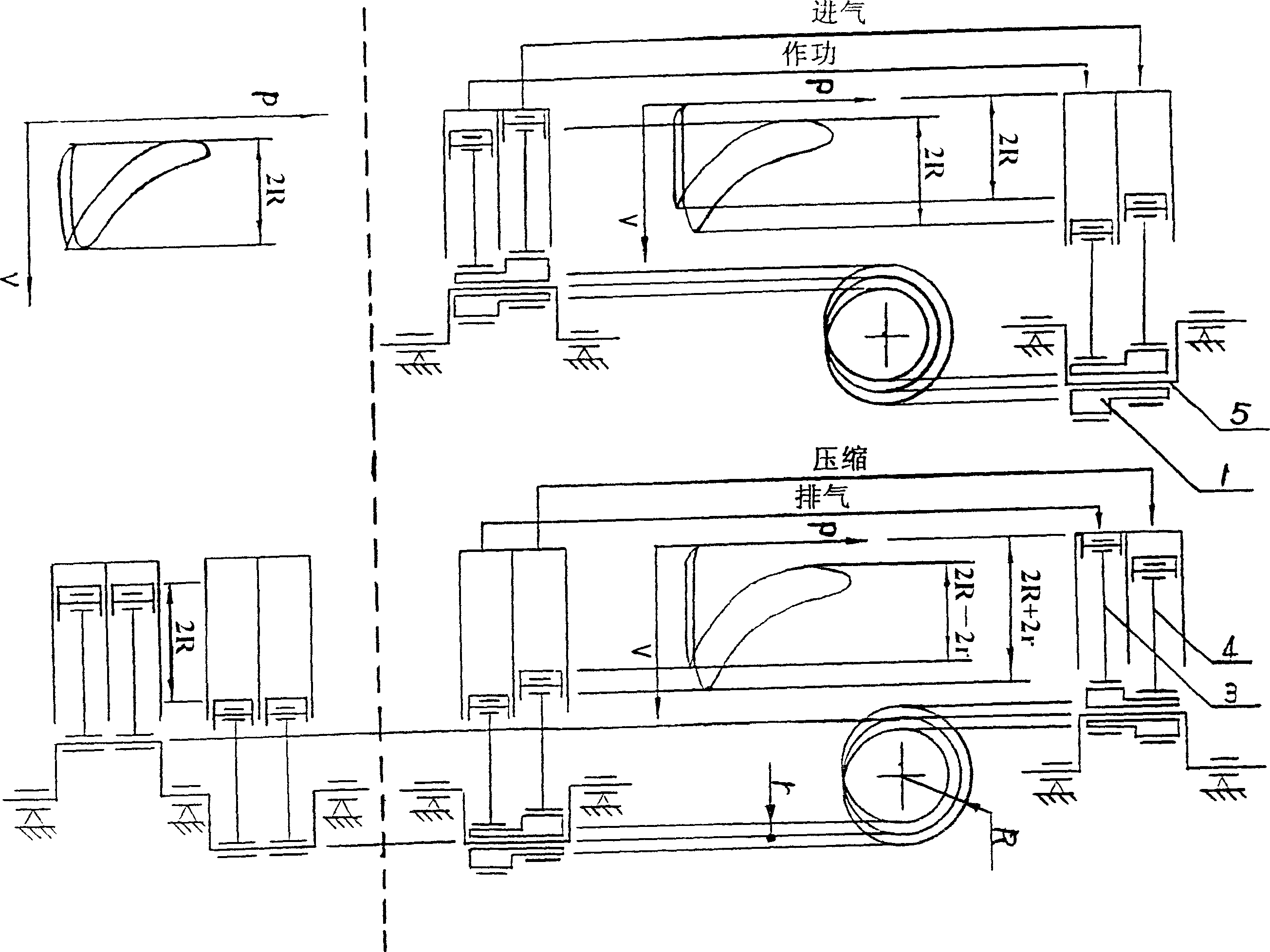

Improvement of Otto cycle, Diesel cycle and Atkinson cycle

InactiveCN1614213AReduce negative work of compressionImprove mechanical efficiencyInternal combustion piston enginesEngine controllersOtto cycleAtkinson cycle

A method for improving the Otto cycle, Diesel cycle and Atkinson cycle is disclosed, which can lower the specific consumption rate of fuel for the reciprocating 4-stroke IC engine and increase its power performance.

Owner:任军

Dynamic journal engine

ActiveUS7121252B2Valid conversionIncreased complexityConnecting rodsReciprocating piston enginesPower cycleOtto cycle

Owner:JOHNSON MELISSA T

Rotary machine and thermal cycle

InactiveUS20050284440A1Avoid pressure lossHigh power outputInternal combustion piston enginesEngine of intermeshing engagement typeGas compressorOtto cycle

A rotary machine having a housing with rotary components disclosed within. The rotary machine is configurable as an internal combustion rotary engine, an external combustion rotary engine, a gas compressor, a vacuum pump, a liquid pump, a drive turbine, or a drive turbine for expandable gases or pressurized liquids. The combustion engine employs a new thermal cycle—eliminating the Otto cycle's internal compression of the combustion products as part of the cycle. The new combustion thermal cycle is intake, expansion and exhaust.

Owner:DUNCAN RONNIE J

Low speed valveless horizontally opposed piston rotary internal combustion engine

InactiveUS20100024763A1Low costOperational reliability can be loweredInternal combustion piston enginesLow speedDrive shaft

Presented is a very low speed, high torque, horizontally opposed, rotary, valveless, Otto cycle piston engine producing four power strokes per revolution, the engine consisting of a fixed engine case assembly having upper and lower plates, the engine rotor assembly having upper and lower plates, sandwiching a single, closed ended cylinder assembly, the cylinder containing intake and exhaust-intake ports, independently reciprocating power and head pistons, each piston being reciprocally controlled by its vertically projecting piston bearing sets contacting respective sets of upper and lower, inner and outer peripheral cam plates, the engine being thus rotated, the cylinder being lubricated by a sealed, recirculating air-oil mist system, the engine rotor assembly having a lower, vertically projecting gear box housing containing a gas porting cap, a vertical drive shaft, two counter rotating output shafts, intake and exhaust pipes, and an exhaust gas filter canister.

Owner:SPARLING JAMES DOUGLAS

High-efficiency otto cycle engine with power generating expander

InactiveUS20050217268A1Improve efficiencyGood synergistic effectReciprocating combination enginesInternal combustion piston enginesHydrogenFront propagation

High-efficiency combustion engines, including Otto cycle engines, use a steam-diluted fuel charge at elevated pressure. Air is compressed, and water is evaporated into the compressed air via the partial pressure effect using waste heat from the engine. The resultant pressurized air-steam mixture then burned in the engine with fuel, preferably containing hydrogen to maintain flame front propagation. The high-pressure, steam-laden engine exhaust is used to drive an expander to provide additional mechanical power. The exhaust can also be used to reform fuel to provide hydrogen for the engine combustion. The engine advantageously uses the partial pressure effect to convert low-grade waste heat from engine into useful mechanical power. The engine is capable of high efficiencies (e.g. >50%), with minimal emissions.

Owner:MICROERA POWER INC

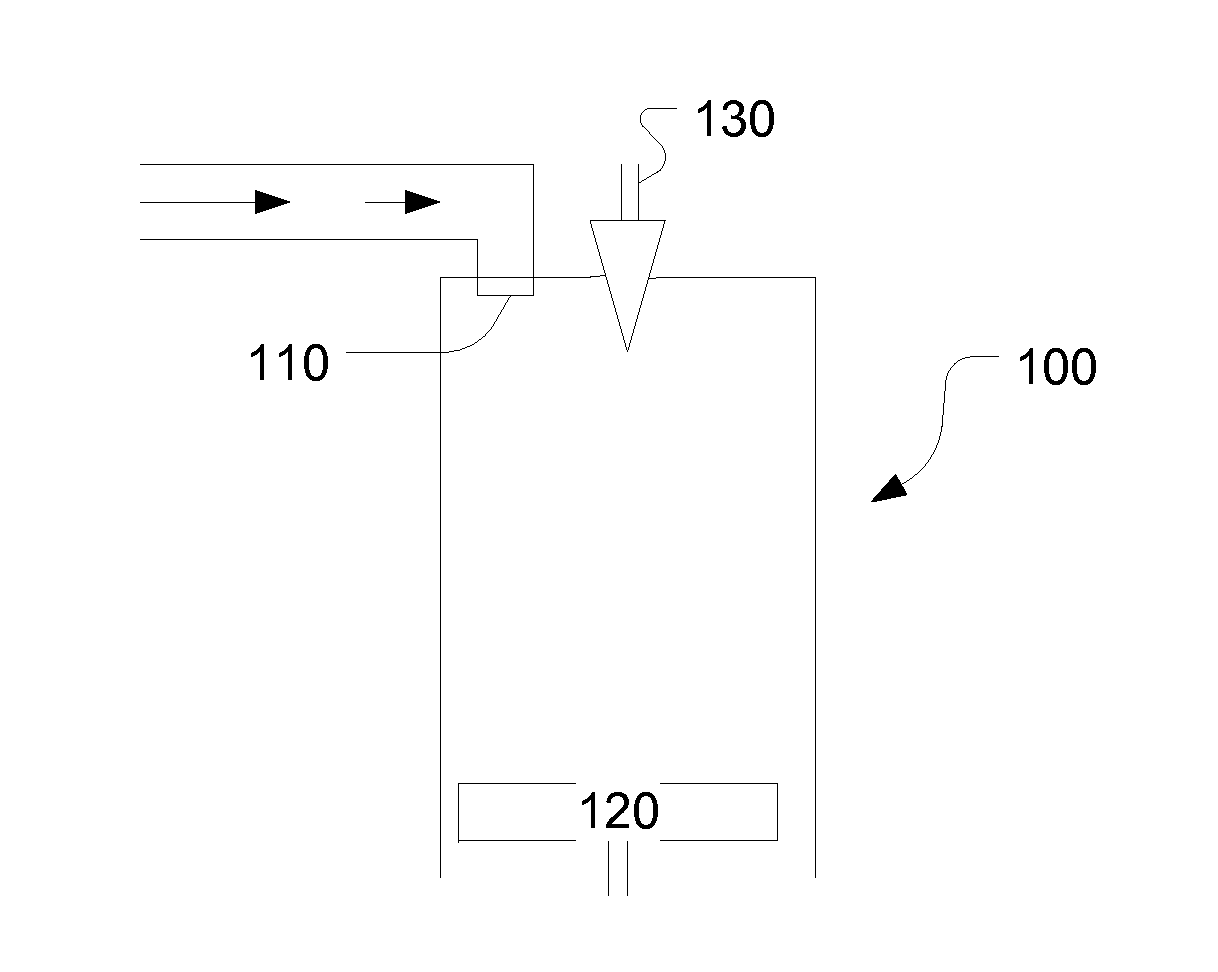

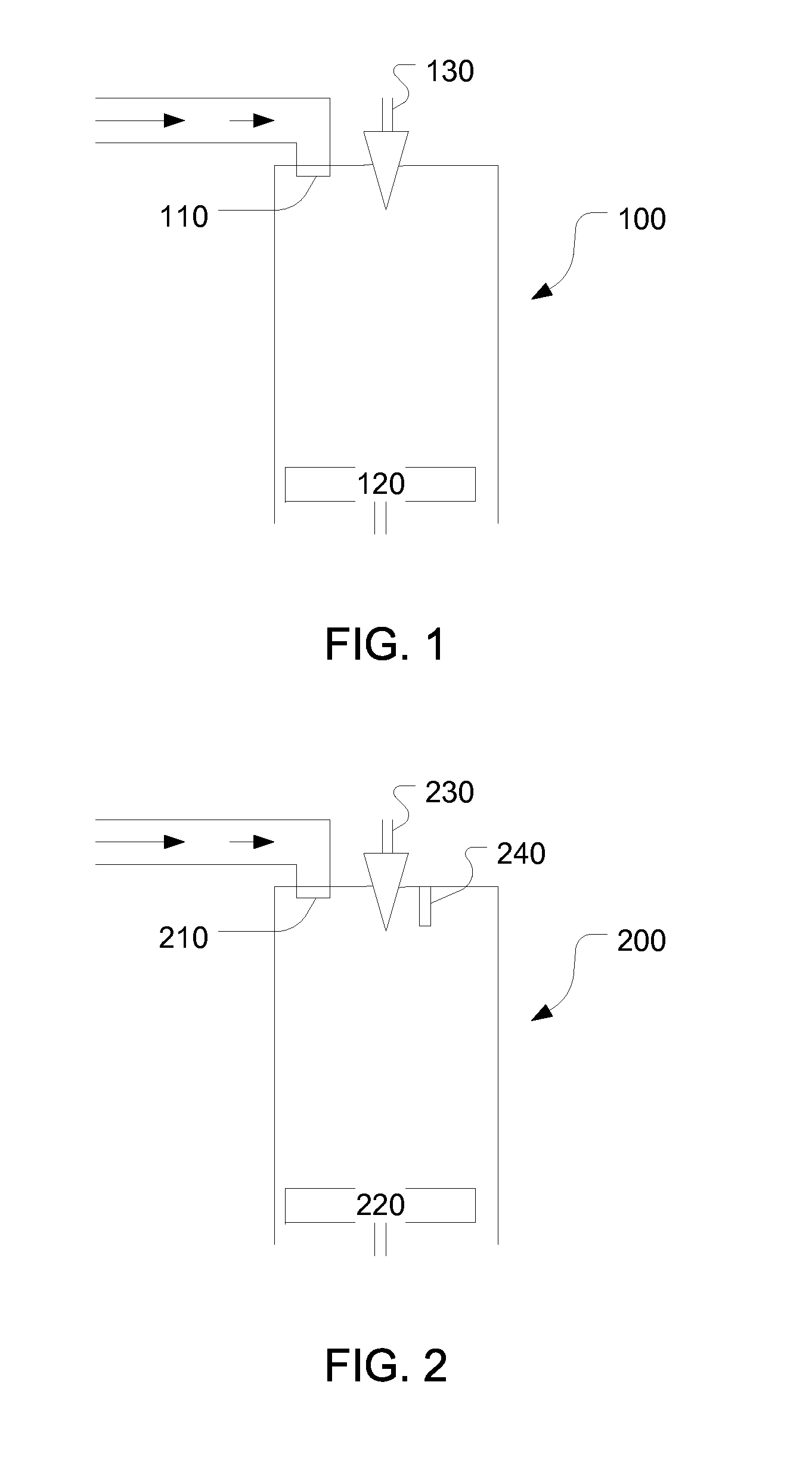

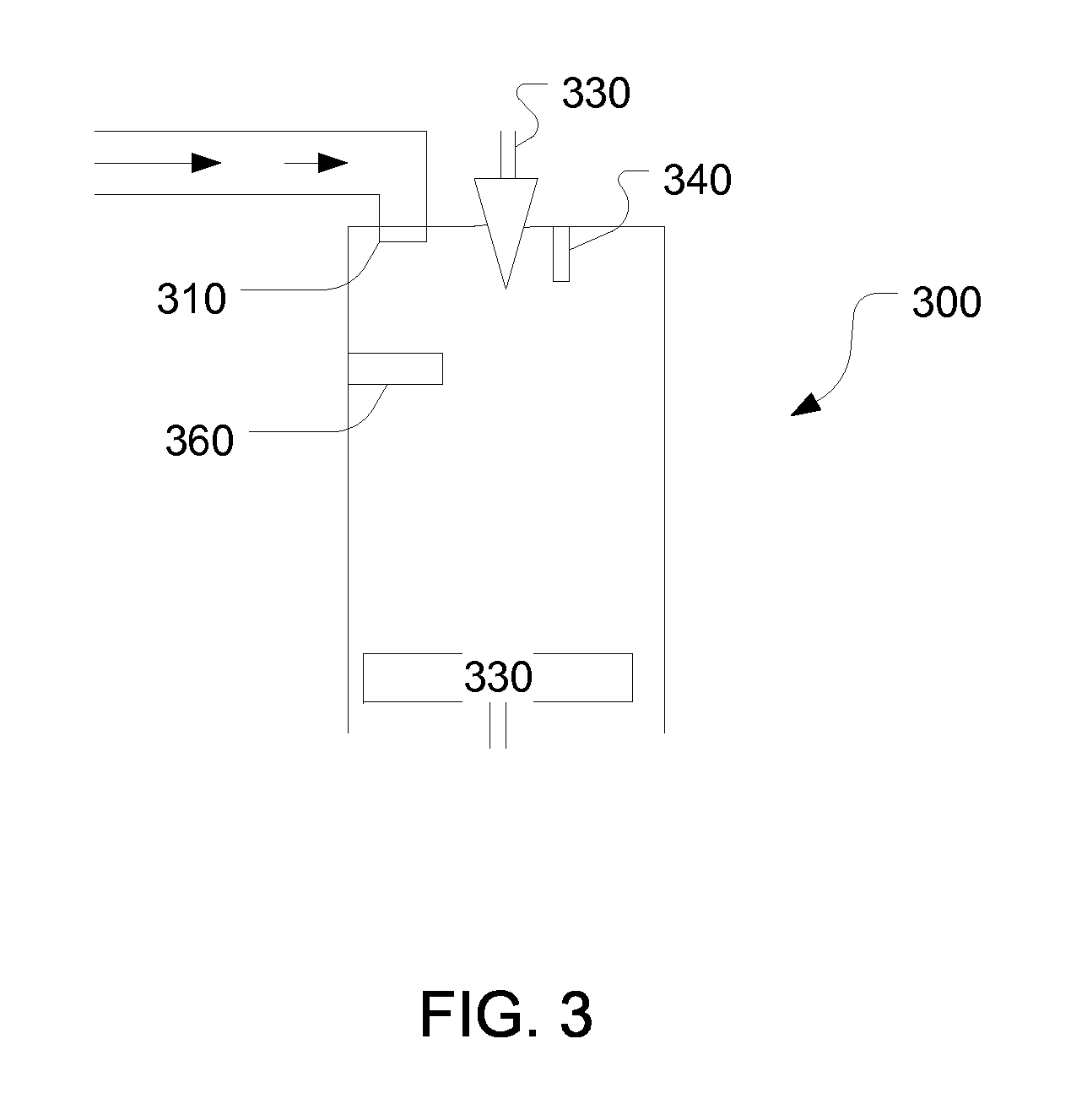

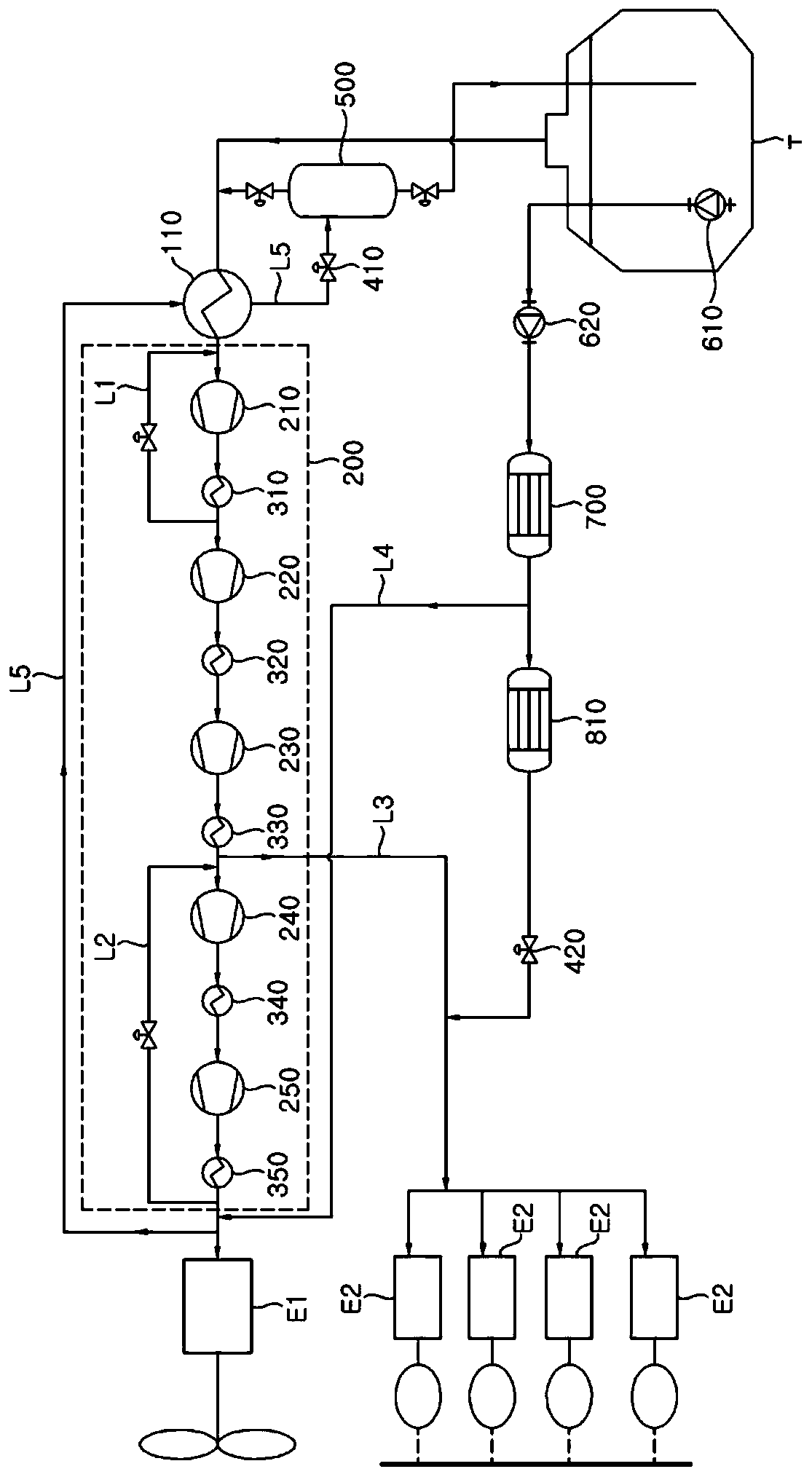

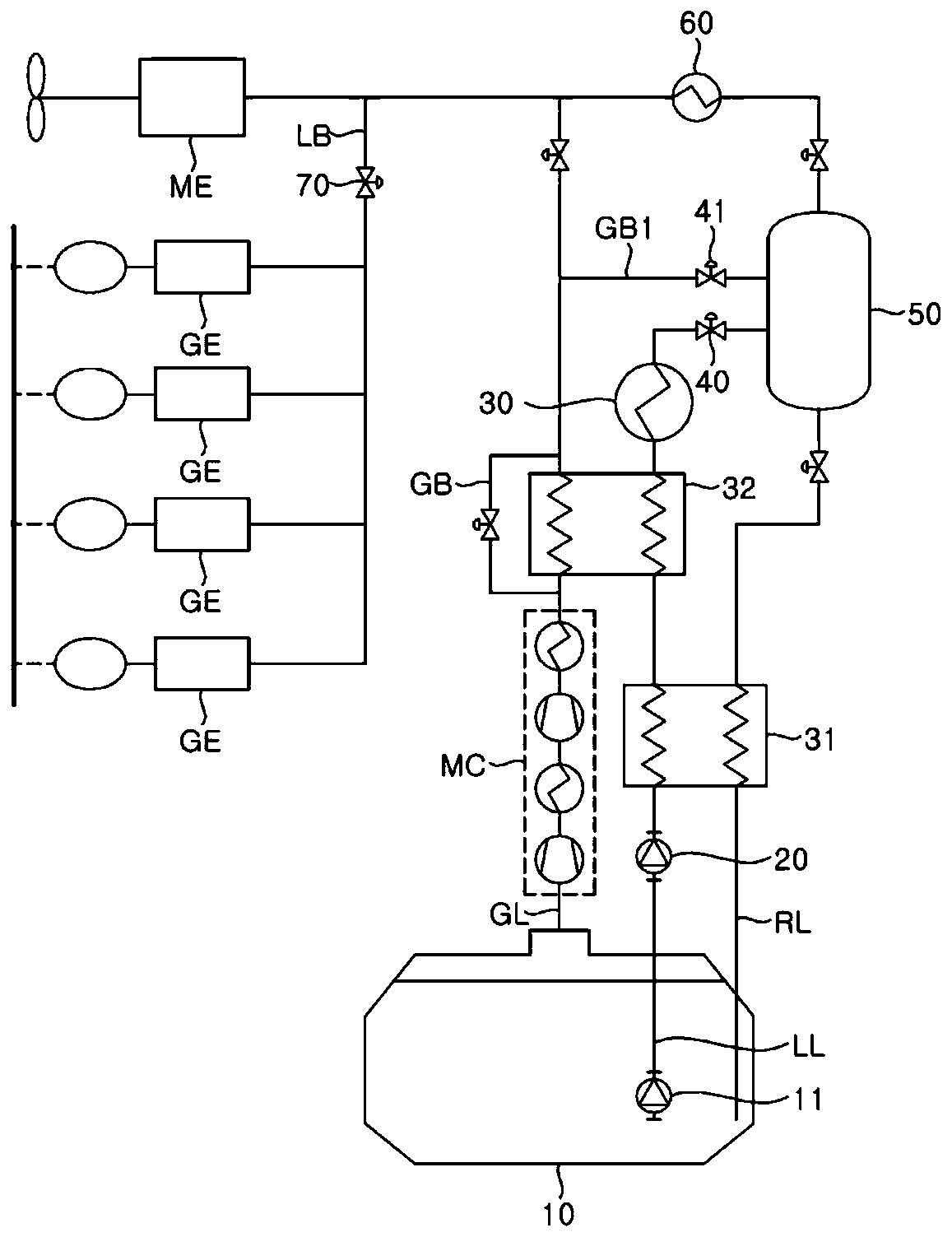

System and method for supplying fuel in liquefied natural gas fueled ship

ActiveCN110248866AEnsure methane numberReduce operating costsNon-fuel substance addition to fuelInternal combustion piston enginesThermodynamicsVapor–liquid separator

The present invention relates to a system and a method for supplying a fuel in a liquefied natural gas fueled ship to which an engine using liquefied natural gas as a fuel is applied, wherein a pump and a regasification facility are used to supply a liquefied natural gas fuel, without the aid of a compressor, in compliance with fuel supply conditions of the engine. A system for supplying a fuel in a liquefied natural gas fueled ship according to the present invention comprises: an Otto cycle engine using liquefied natural gas as a fuel and operating according to an Otto cycle; a high-pressure pump for compressing liquefied natural gas which has been discharged from a storage tank; a gasifier for gasifying the liquefied natural gas which has been compressed by the high-pressure pump; an expansion valve for expanding the natural gas which has been gasified by the gasifier; and a gas-liquid separator for separating gas and liquid from a gas-liquid mixture formed by the expansion valve, wherein the liquid separated in the gas-liquid separator is recovered into a storage tank, the gas separated in the gas-liquid separator is supplied as a fuel for the Otto cycle engine, thereby adjusting the methane number of a natural gas fuel supplied to the Otto cycle engine.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

Modular rotary engine

InactiveUS7343894B2Reduce quality problemsReduce distanceInternal combustion piston enginesOscillating piston enginesExternal energyHydrogen

Owner:LEON ENRIQUE HALUY

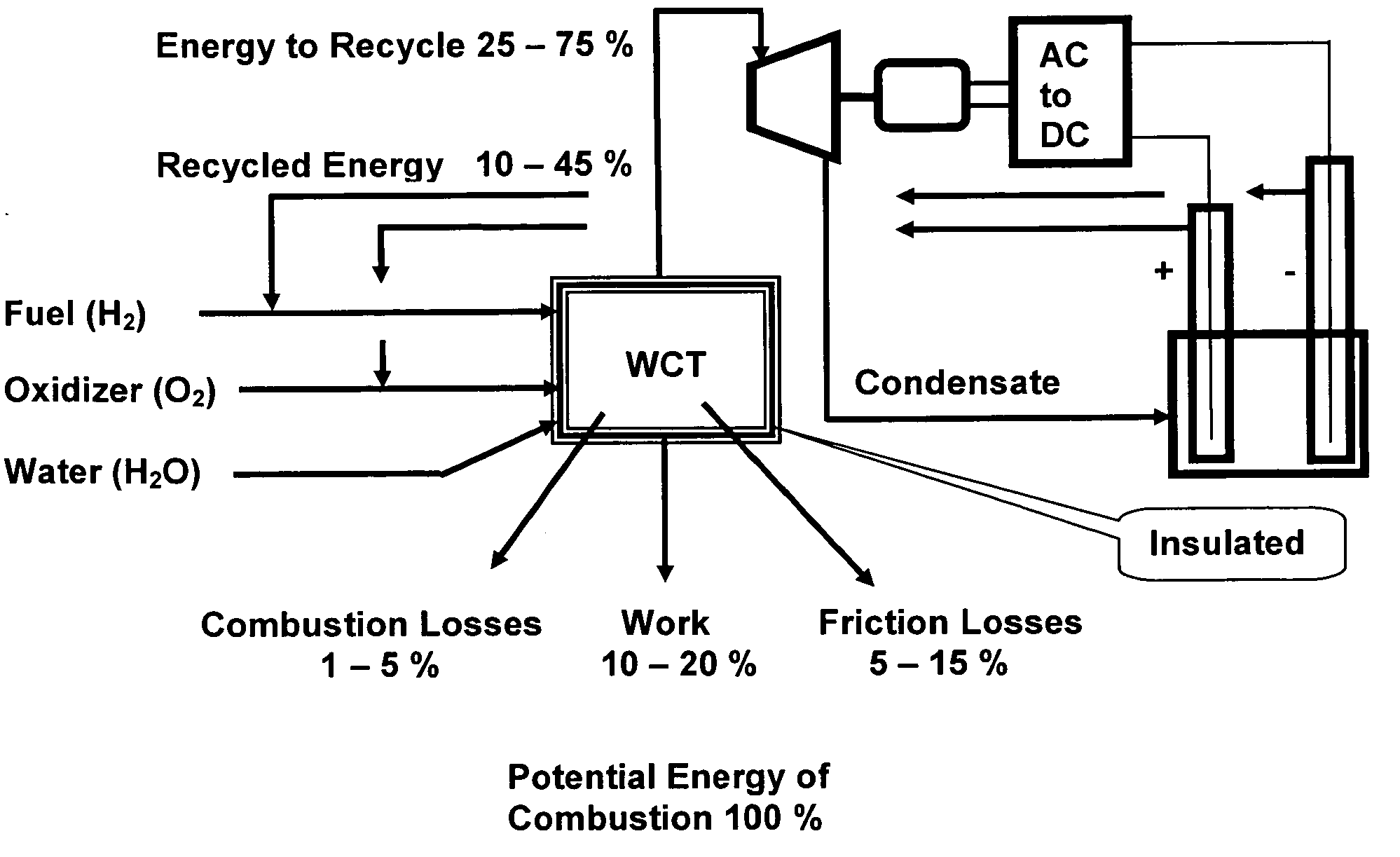

Space engine including the haase cycle with energy recovery cooling

InactiveUS20110061612A1Efficient and effectiveImprove effectivenessElectrical controlSteam generation heating methodsHydrogenOtto cycle

The instant invention relates to improved methods, systems, processes and apparatus (means) for the combustion of hydrogen (H2) with oxygen (O2), wherein the H2 and O2 are obtained from at least one storage tank or obtained by electrolysis of water (H2O). The instant invention is based upon the chemistry of H2O incorporating H2 as the fuel and O2 as the oxidizer. The instant invention relates to combustion, wherein the thermodynamics of the Otto Cycle are improved providing improved combustion efficiency and power output, thereby producing the Haase Cycle. The instant invention relates to means of liquefaction unit for storage of said H2 and / or of said O2 in applications which are at an altitude above the surface of the earth (space applications). Finally, the instant invention relates to applications of producing mechanical or electrical energy, as well as improved H2 and / or O2 storage in space applications.

Owner:HAASE RICHARD ALAN +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com