Pre-chamber arrangement

A technology of pre-chamber and pre-mixed combustion, which is applied in the direction of fuel injection device, charging system, combustion engine, etc. It can solve the problems that cannot be satisfied at the same time, and achieve the effect of reliable pre-chamber ignition, effective combustion and rapid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

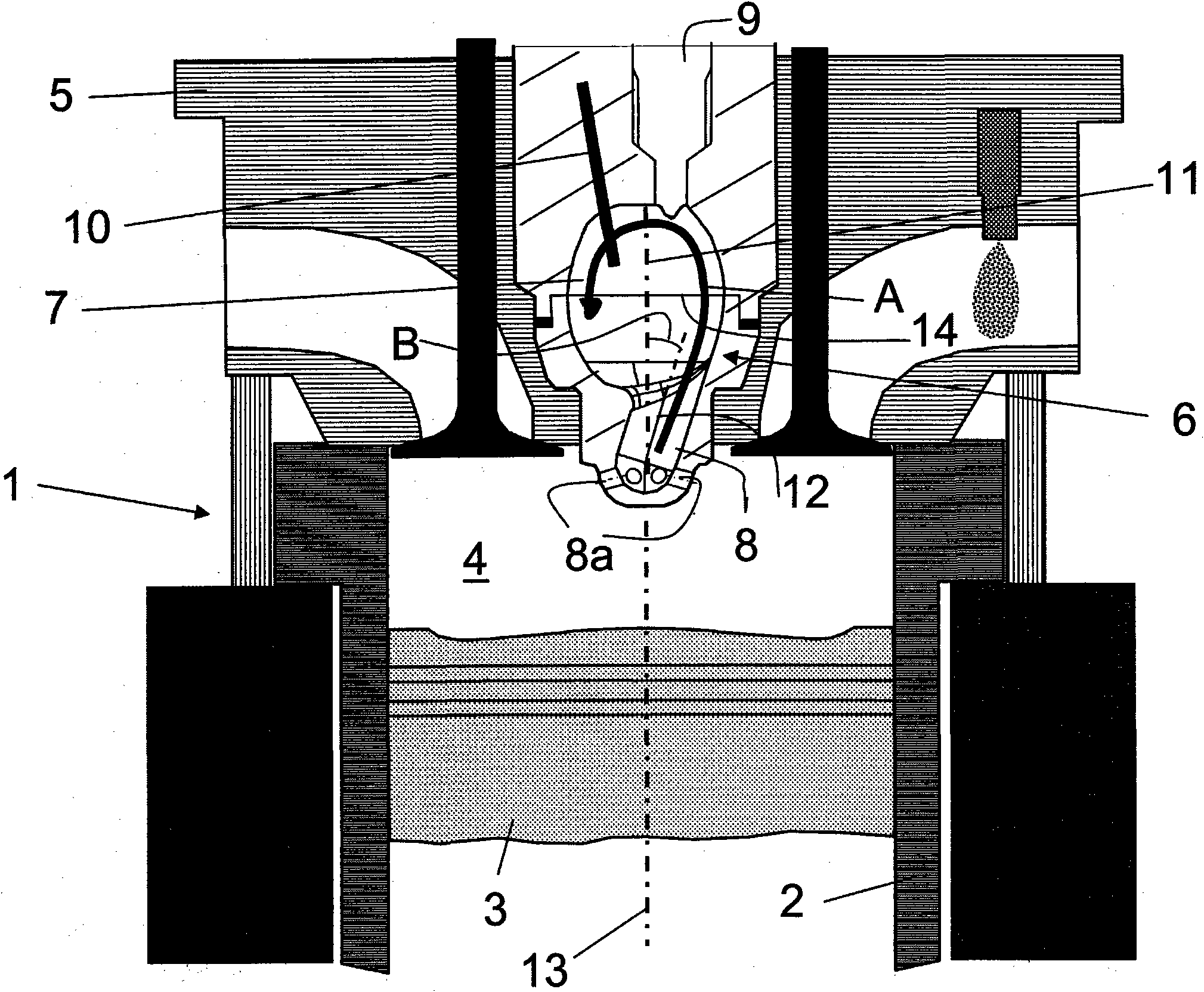

[0016] Reference numeral 1 in the drawings refers to a cylinder of a lean-burn internal combustion engine, which comprises a cylinder liner 2 , a reciprocating piston 3 and a main combustion chamber 4 . The main combustion chamber 4 is delimited in a conventional manner by a cylinder head 5 with inlet and outlet ducts and valves. The cylinder head 5 is additionally provided with a prechamber arrangement 6 comprising a first chamber 7 and a second chamber 8 . The first chamber 7 is provided with injection means 9 for providing pilot injection and optionally with a glow plug 10 . The part of the second chamber 8 facing the main combustion chamber 4 is provided with a plurality of nozzle holes 8 a, which are preferably arranged symmetrically with respect to the main combustion chamber 4 .

[0017] As can be seen from the figure, according to the invention, the first chamber 7 of the prechamber arrangement 6 is of substantially elliptical shape with smoothly curved walls. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com