Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

711results about How to "Improve combustion stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

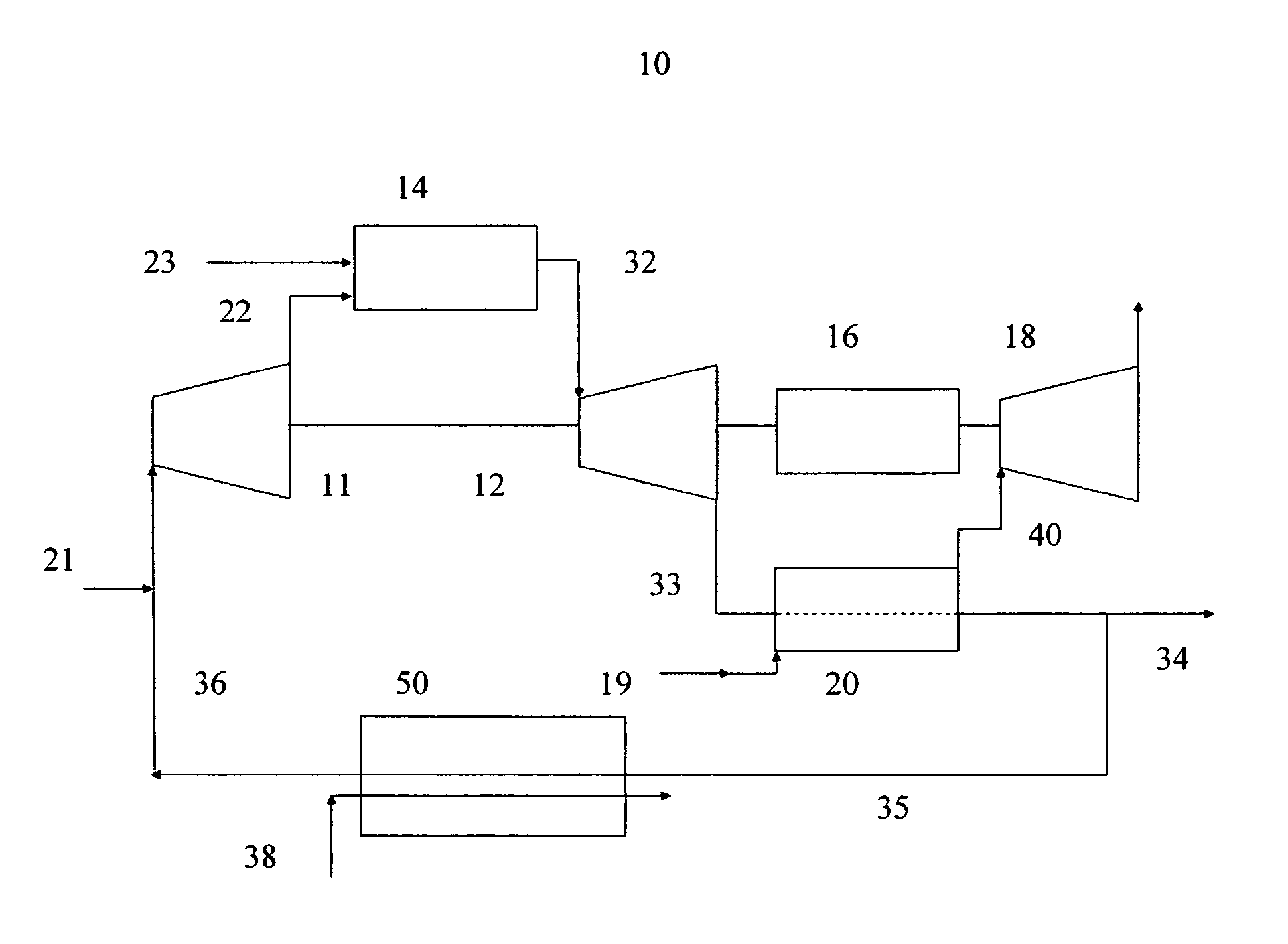

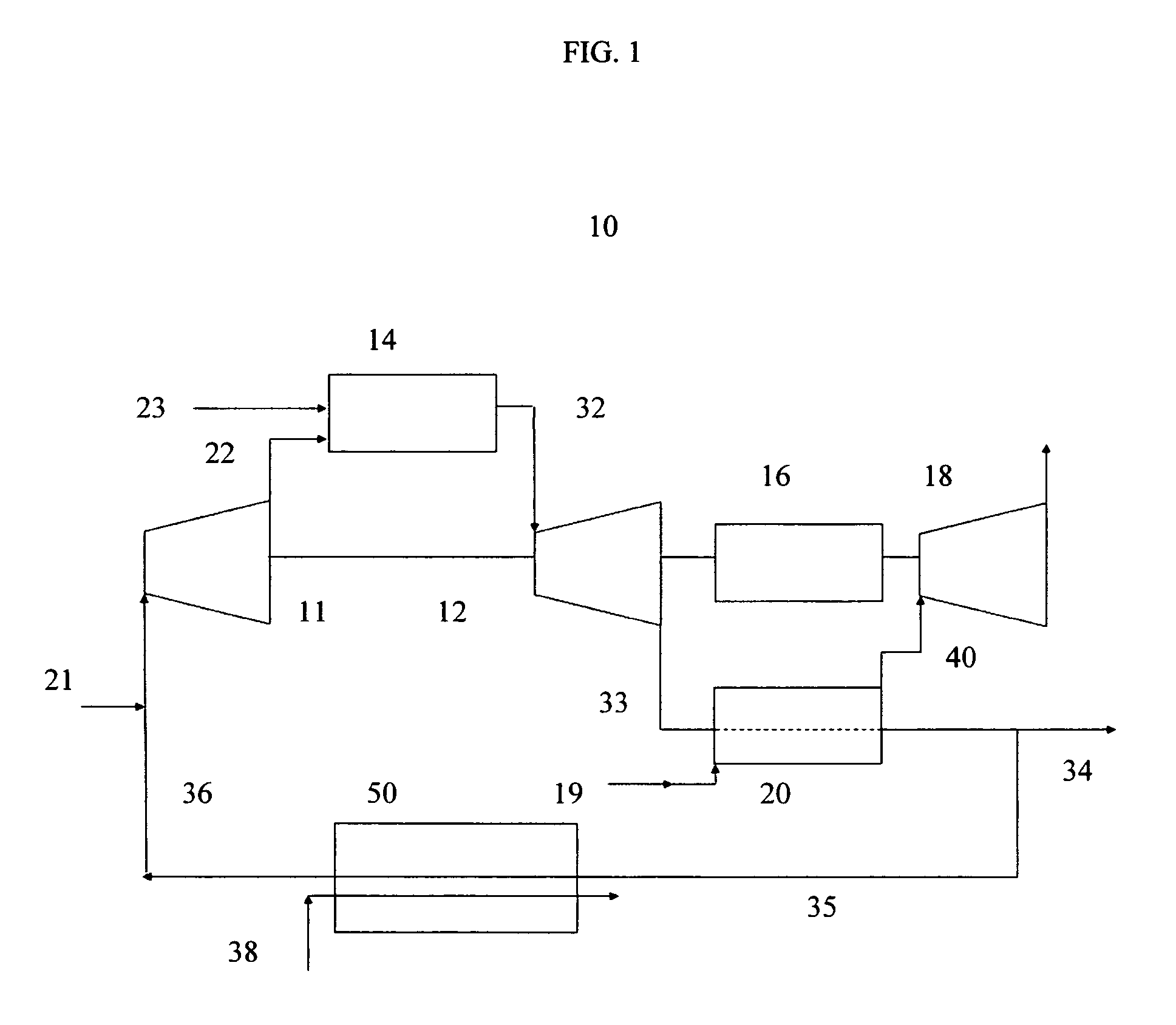

Method for obtaining ultra-low NOx emissions from gas turbines operating at high turbine inlet temperatures

ActiveUS7765810B2Improve combustion stabilityEasy to controlTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustion chamberEquivalence ratio

A method of lowered NOx combustion is taught wherein the kinetic rate of NOx formation is reduced for a given combustion temperature in a gas turbine combustor. A supply of fuel is provided along with a supply of ambient air in sufficient quantity to form a fuel / air mixture having an equivalence ratio greater than about 0.55 when mixed with the fuel. The fuel / air mixture is mixed with a supply of cooled combustion gases in sufficient quantity such that the oxygen content of the resulting air mixture is less than about 18 percent. The resulting air mixture is then passed into the combustor.

Owner:PRECISION COMBUSTION

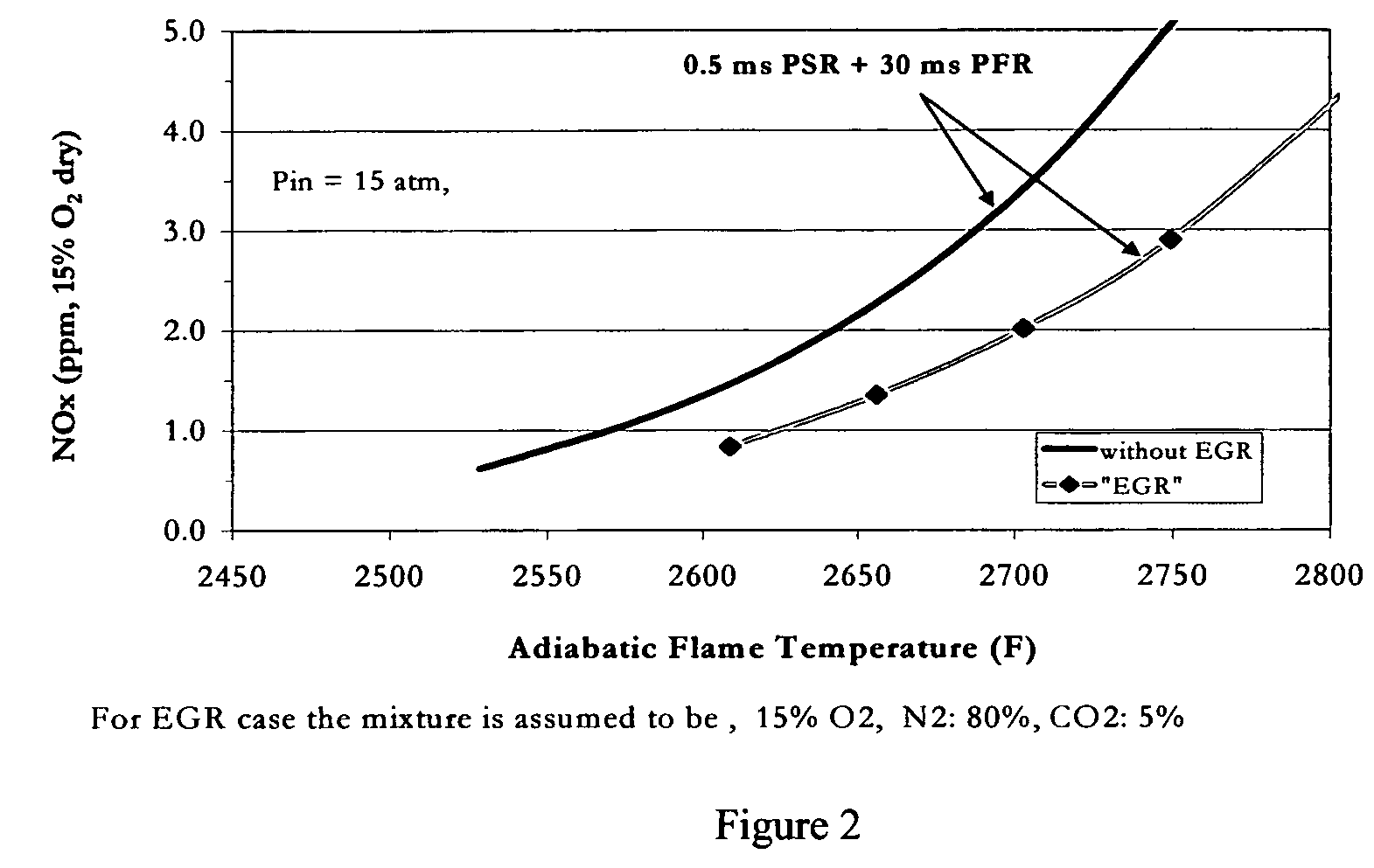

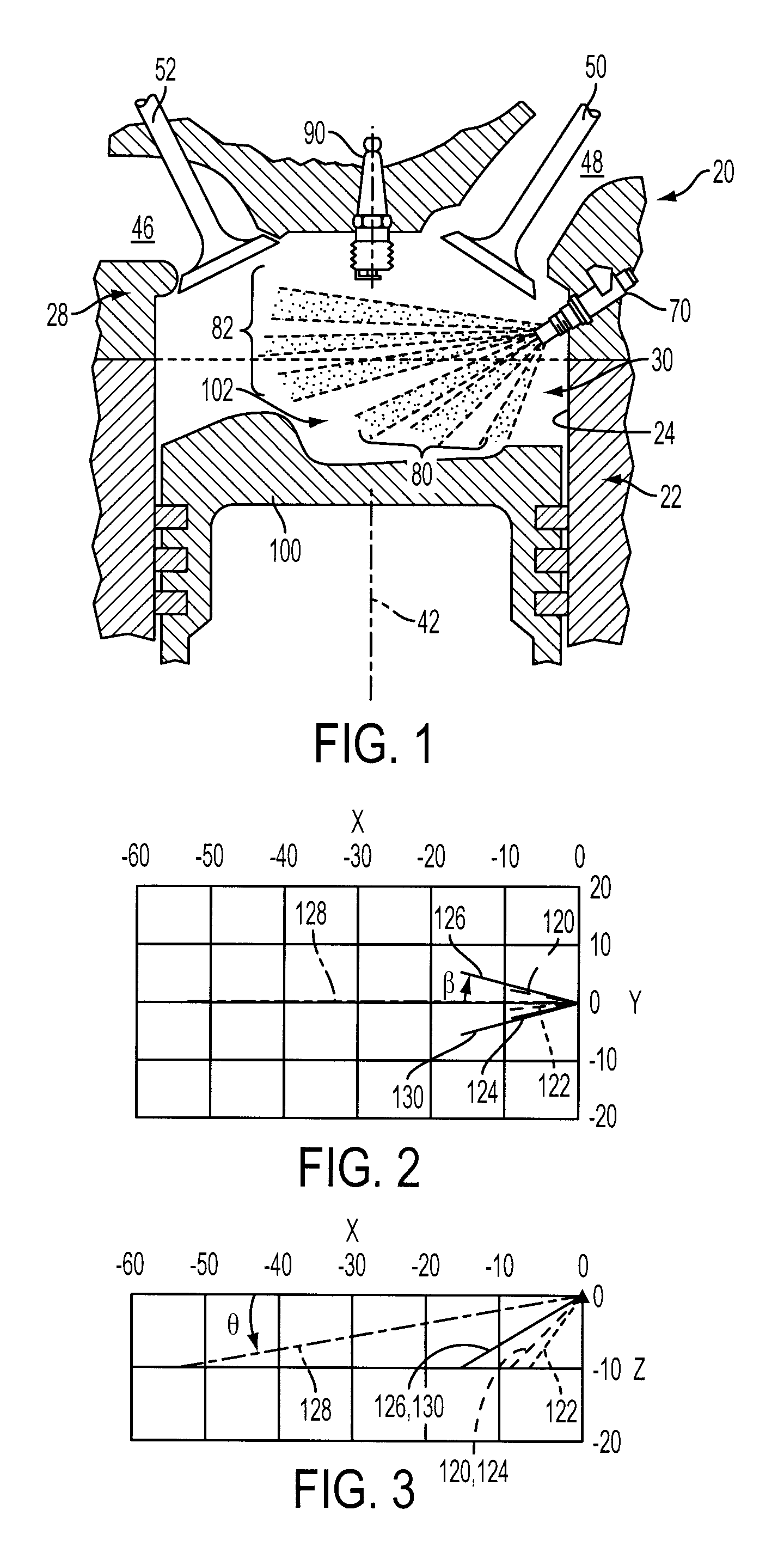

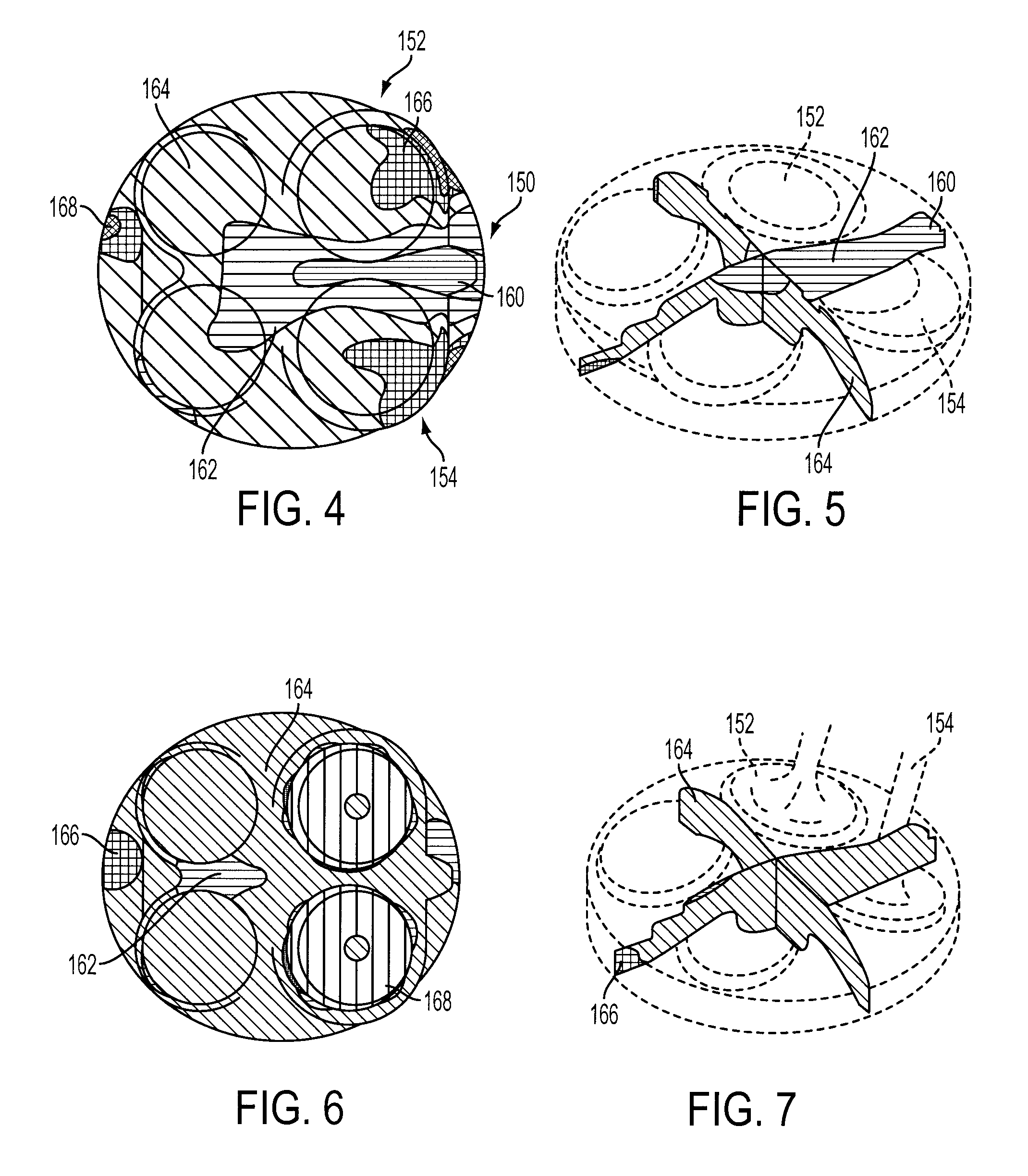

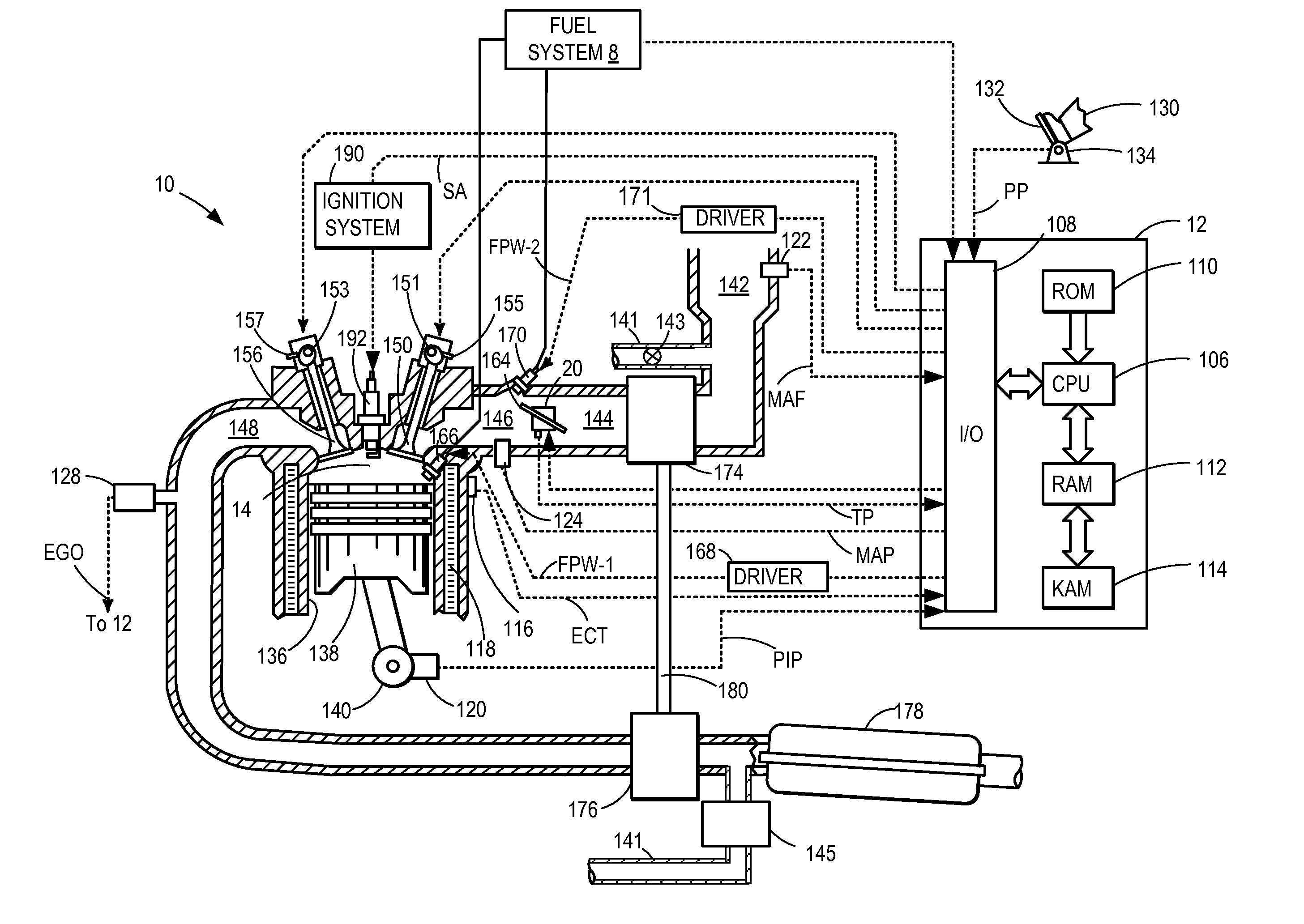

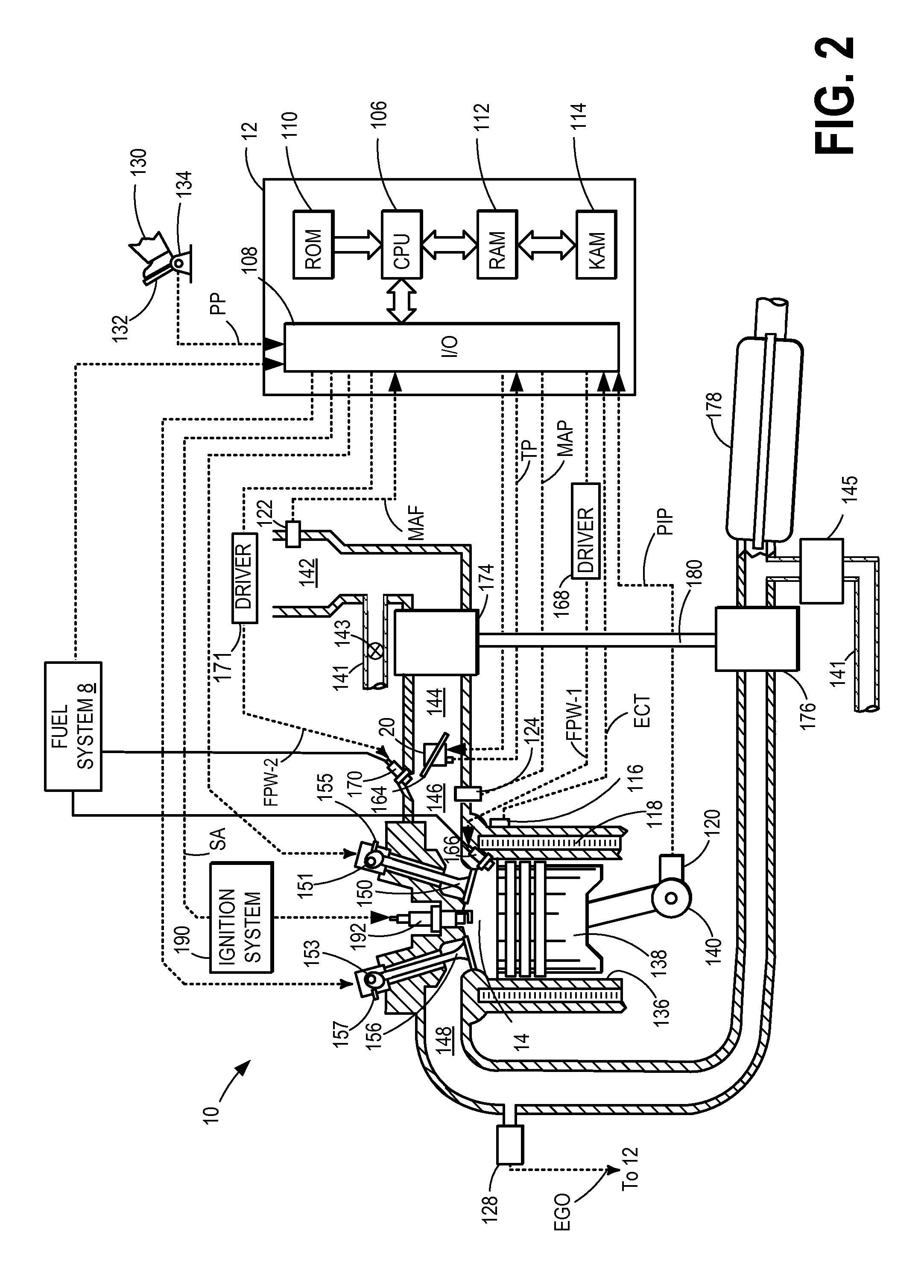

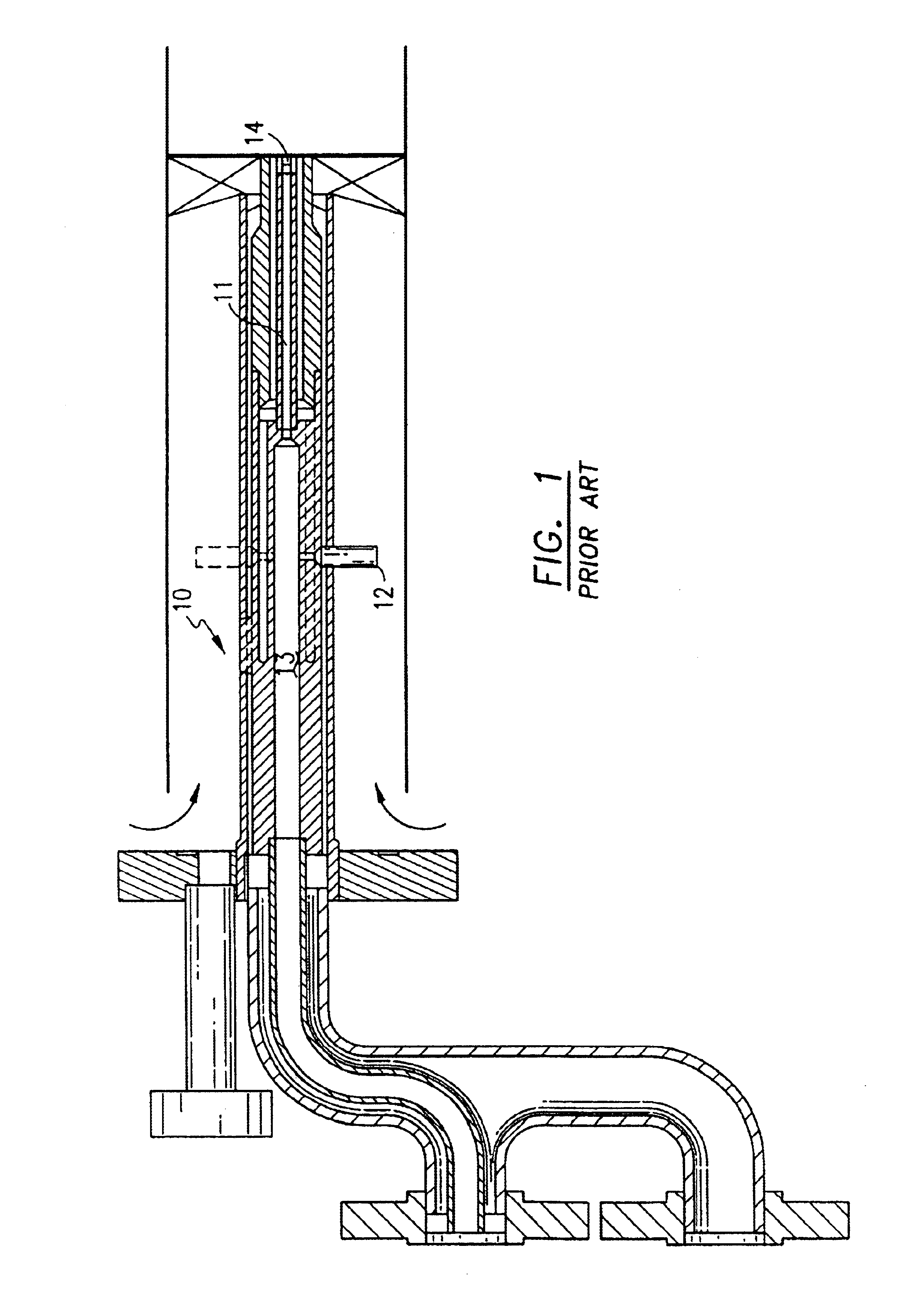

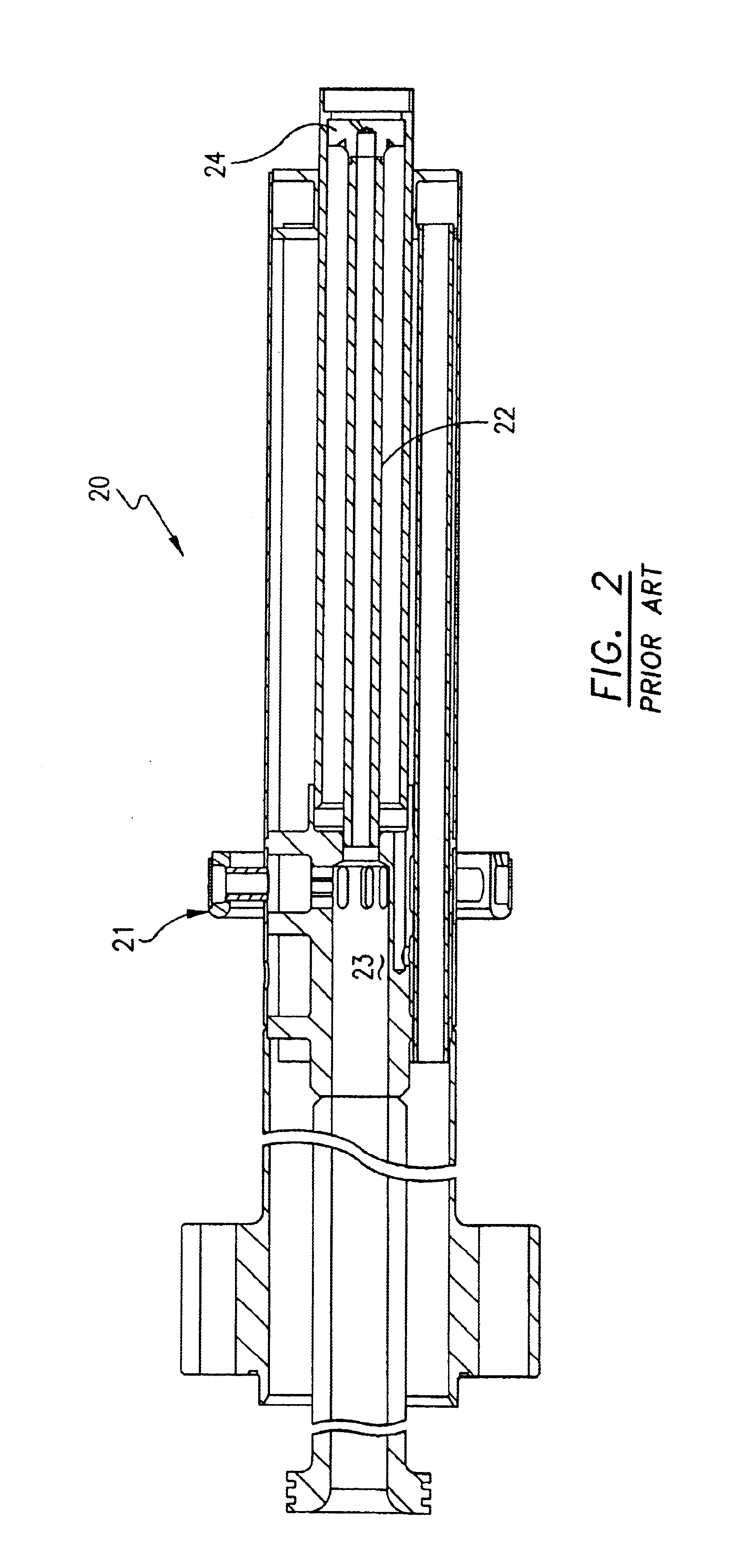

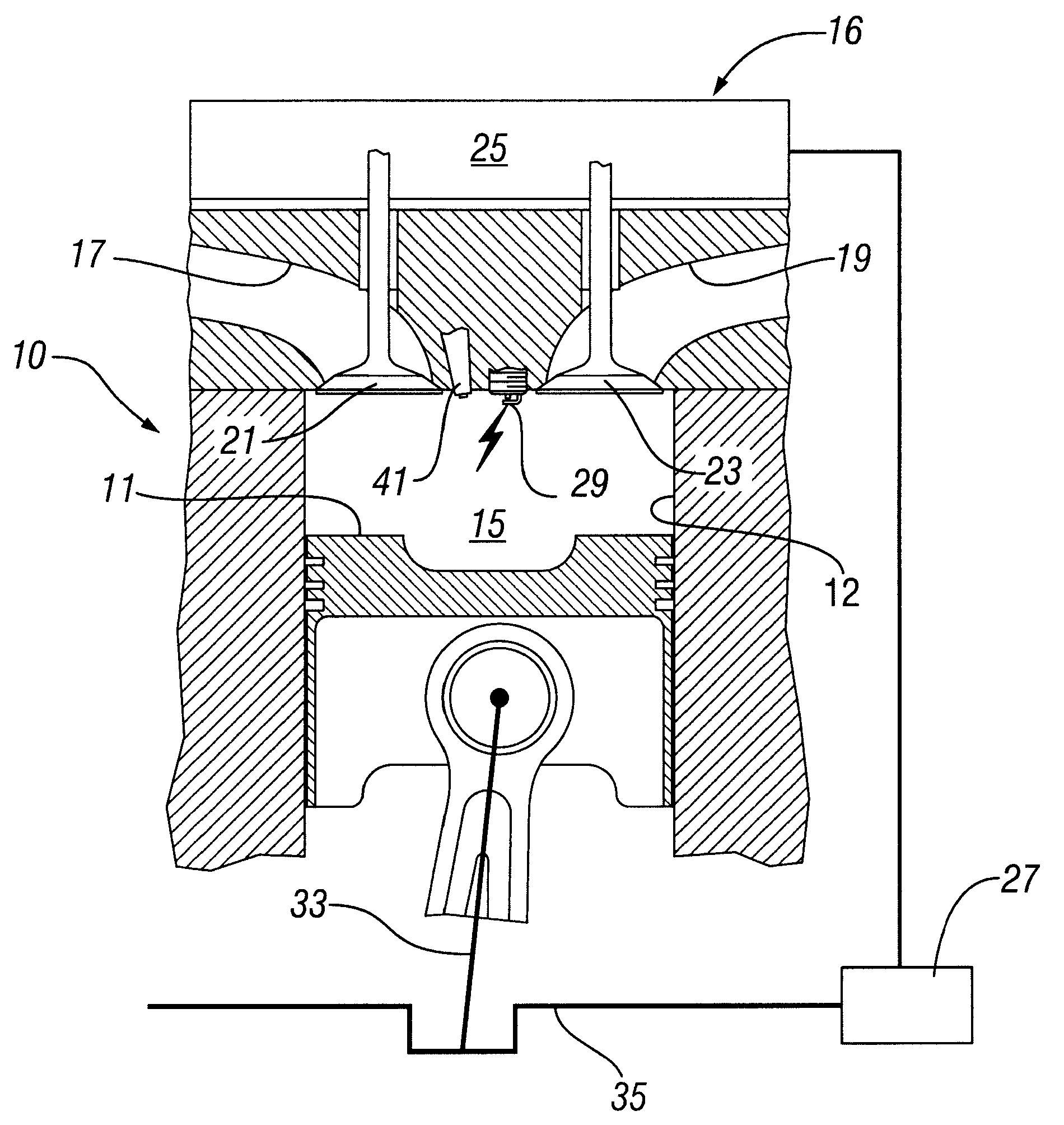

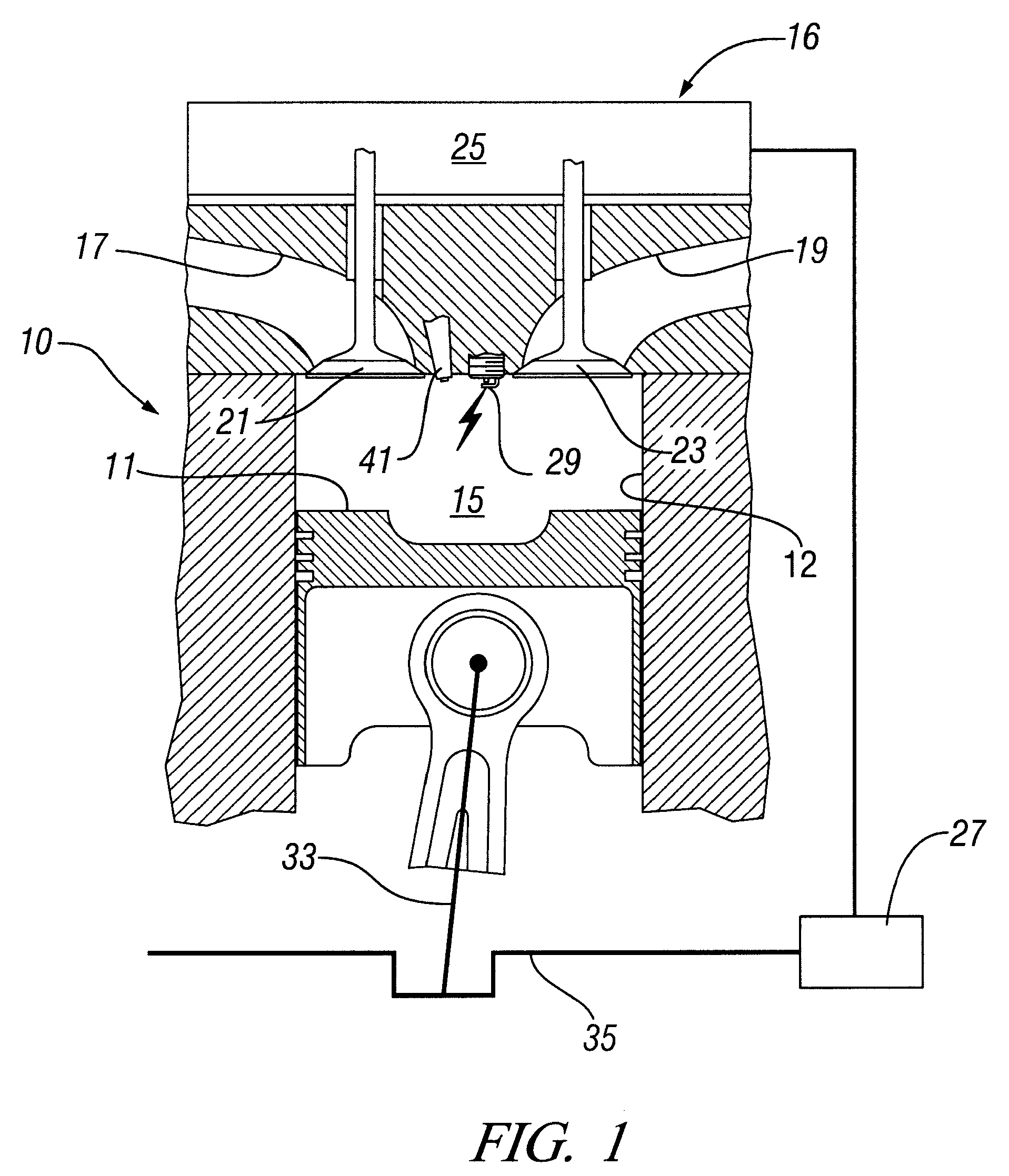

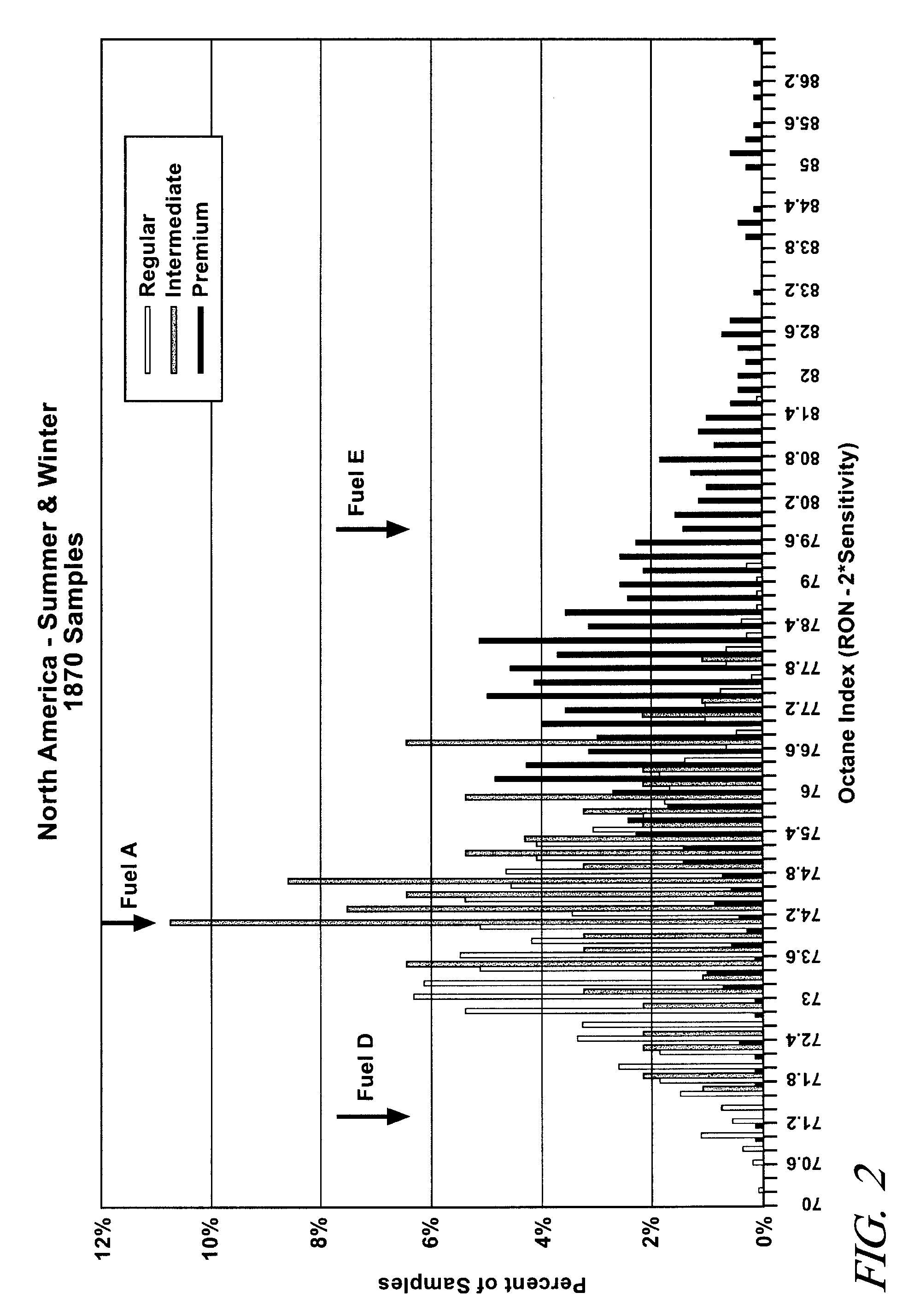

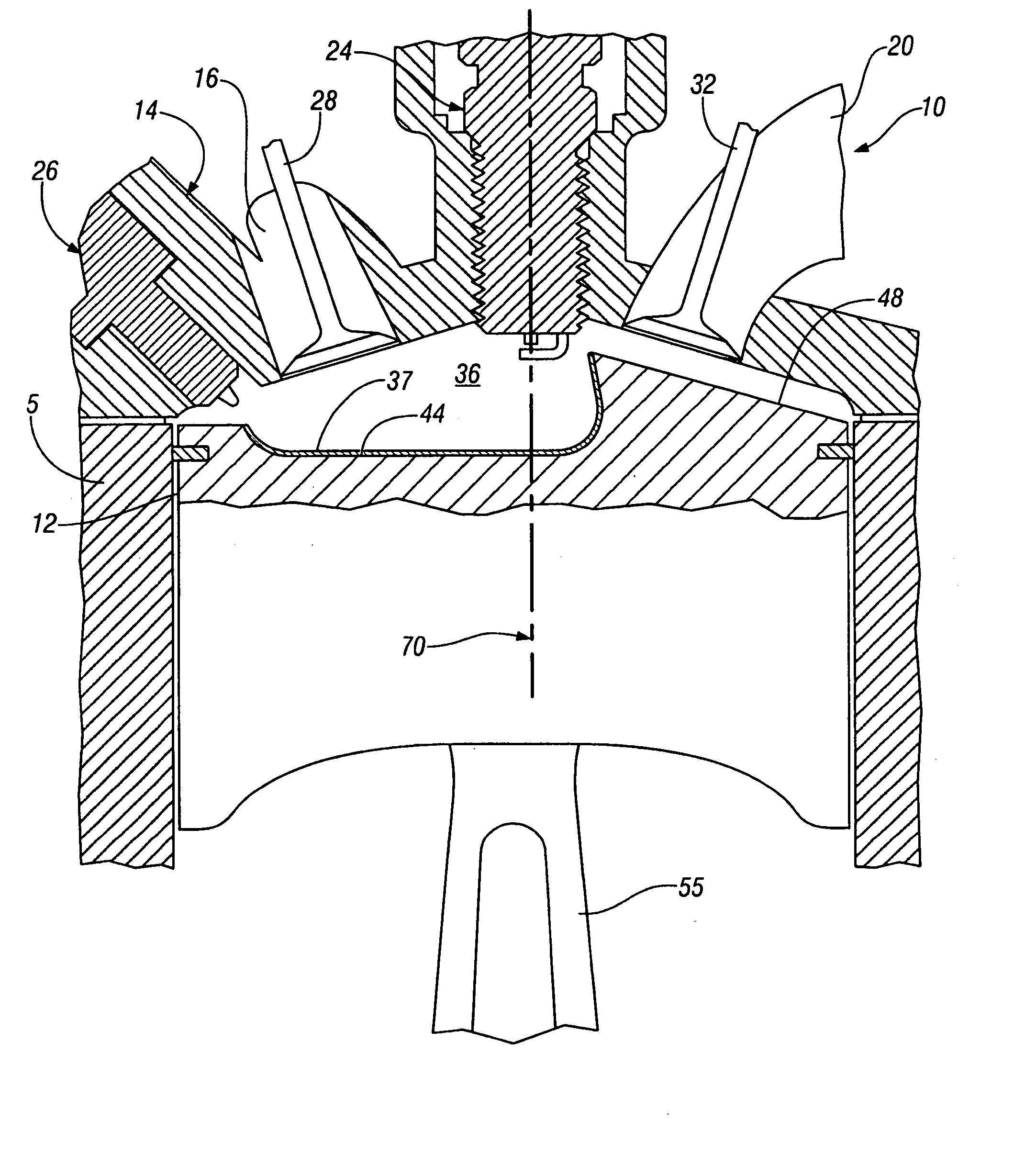

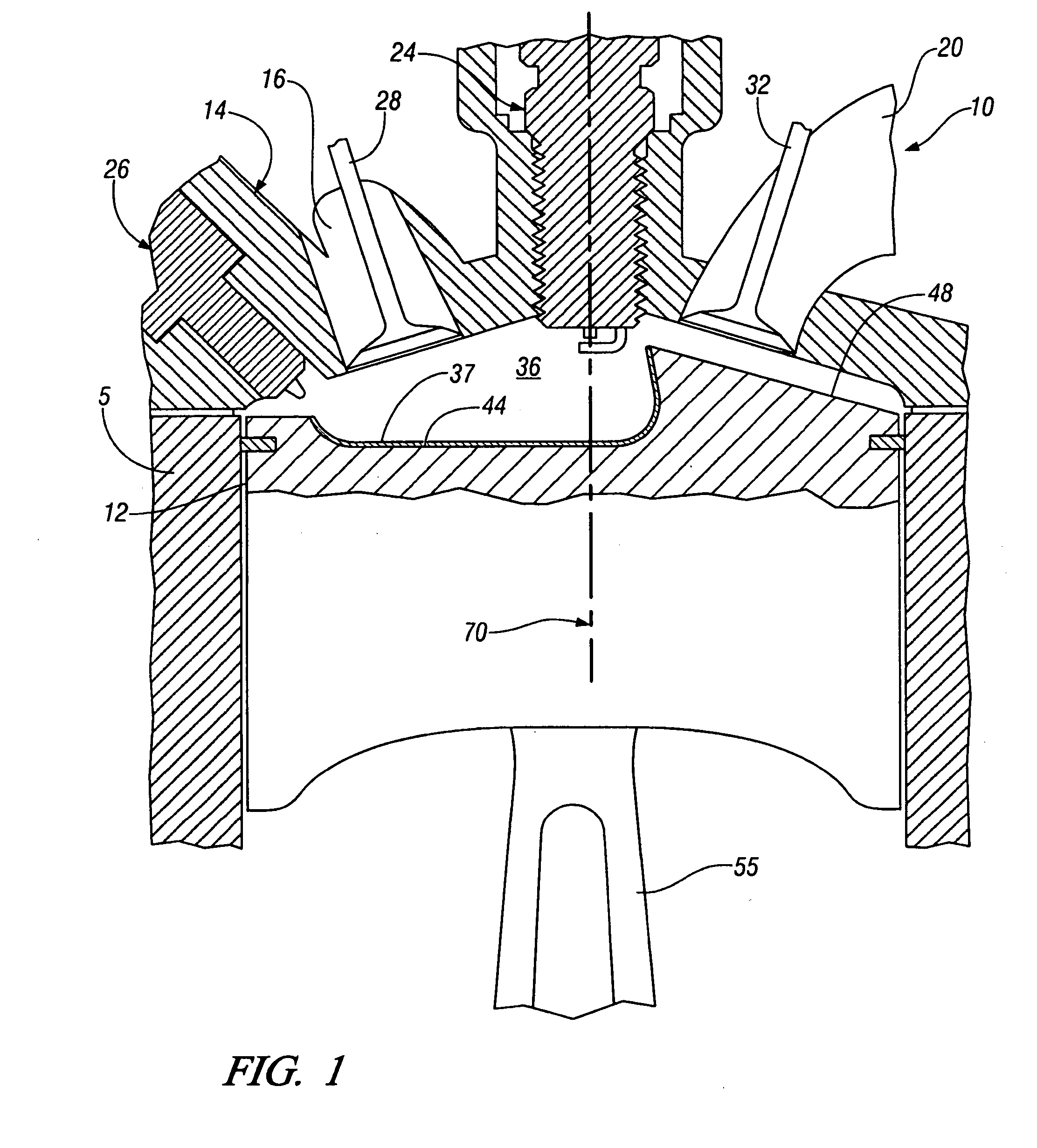

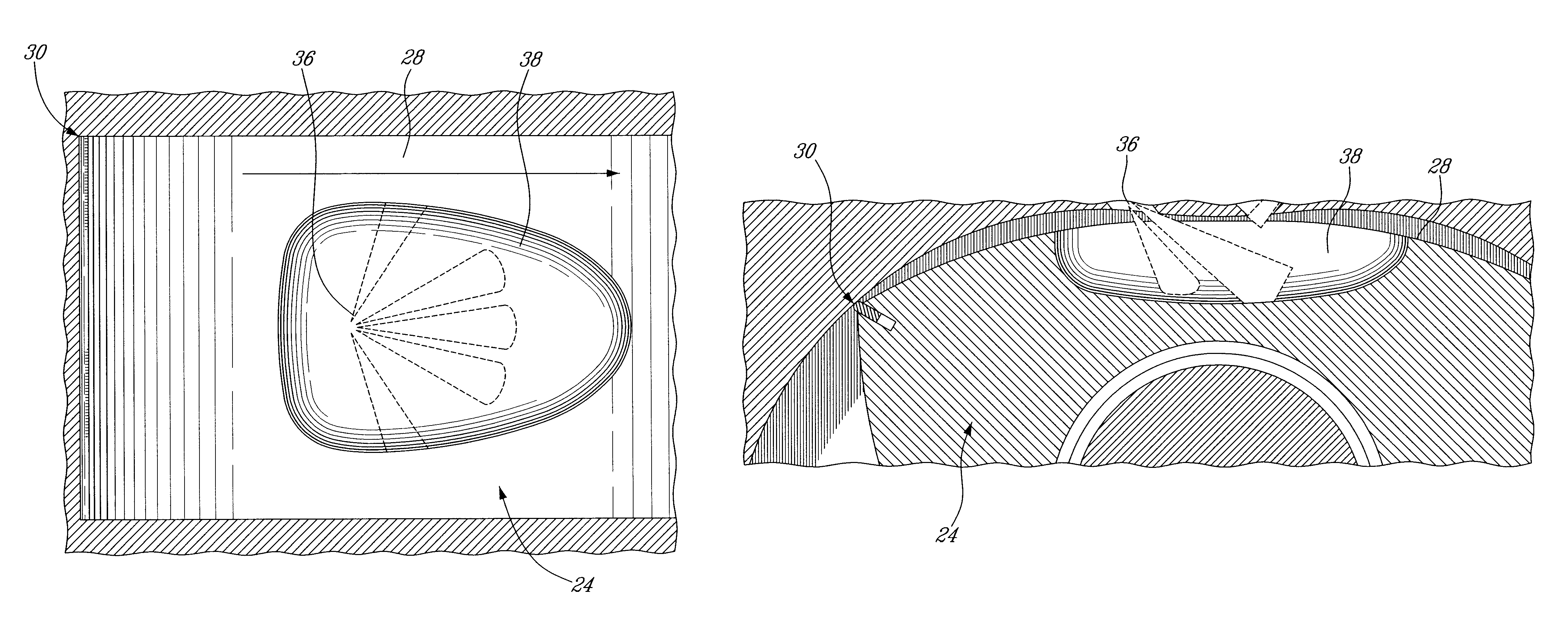

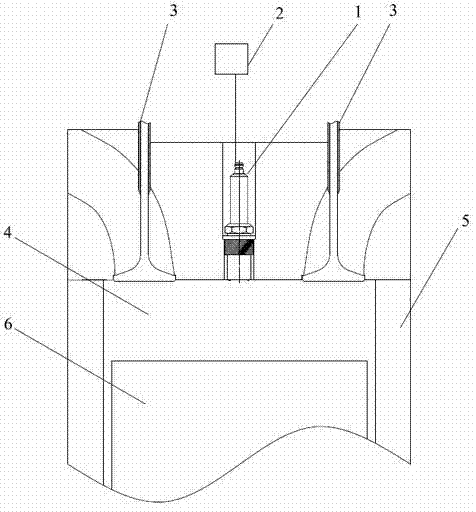

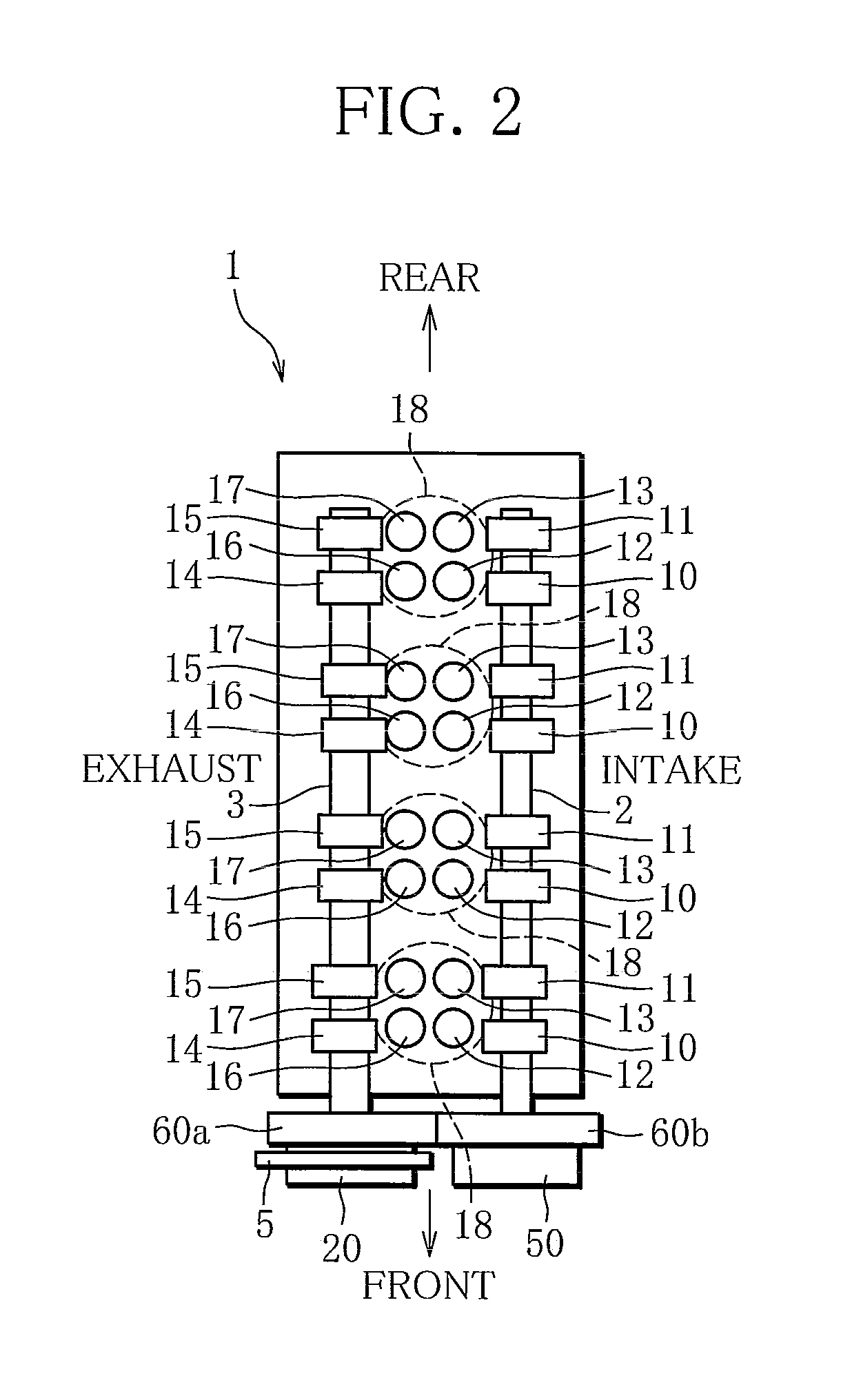

Fuel injector spray pattern for direct injection spark ignition engines

ActiveUS7418940B1Enhanced cold start combustion stabilityReduced cylinder wall wettingInternal combustion piston enginesExhaust valvePiston

A system and method for operating an internal combustion engine include injecting fuel through a plurality of fuel jets of a fuel injector directly into a corresponding cylinder with at least a first plurality jets oriented to primarily support operation in a stratified mode and a second plurality of jets oriented to primarily support operation in a homogeneous mode. The first plurality of jets is oriented to spray fuel generally downward toward the piston bowl and the second plurality of jets is oriented to spray fuel generally across the cylinder toward the exhaust valves. The spray jets reduce or eliminate valve, liner, and piston wetting while providing good mixing in homogeneous mode and good combustion stability for light stratified charge during cold starts to achieve desired targets for feedgas emissions and combustion efficiency.

Owner:FORD GLOBAL TECH LLC

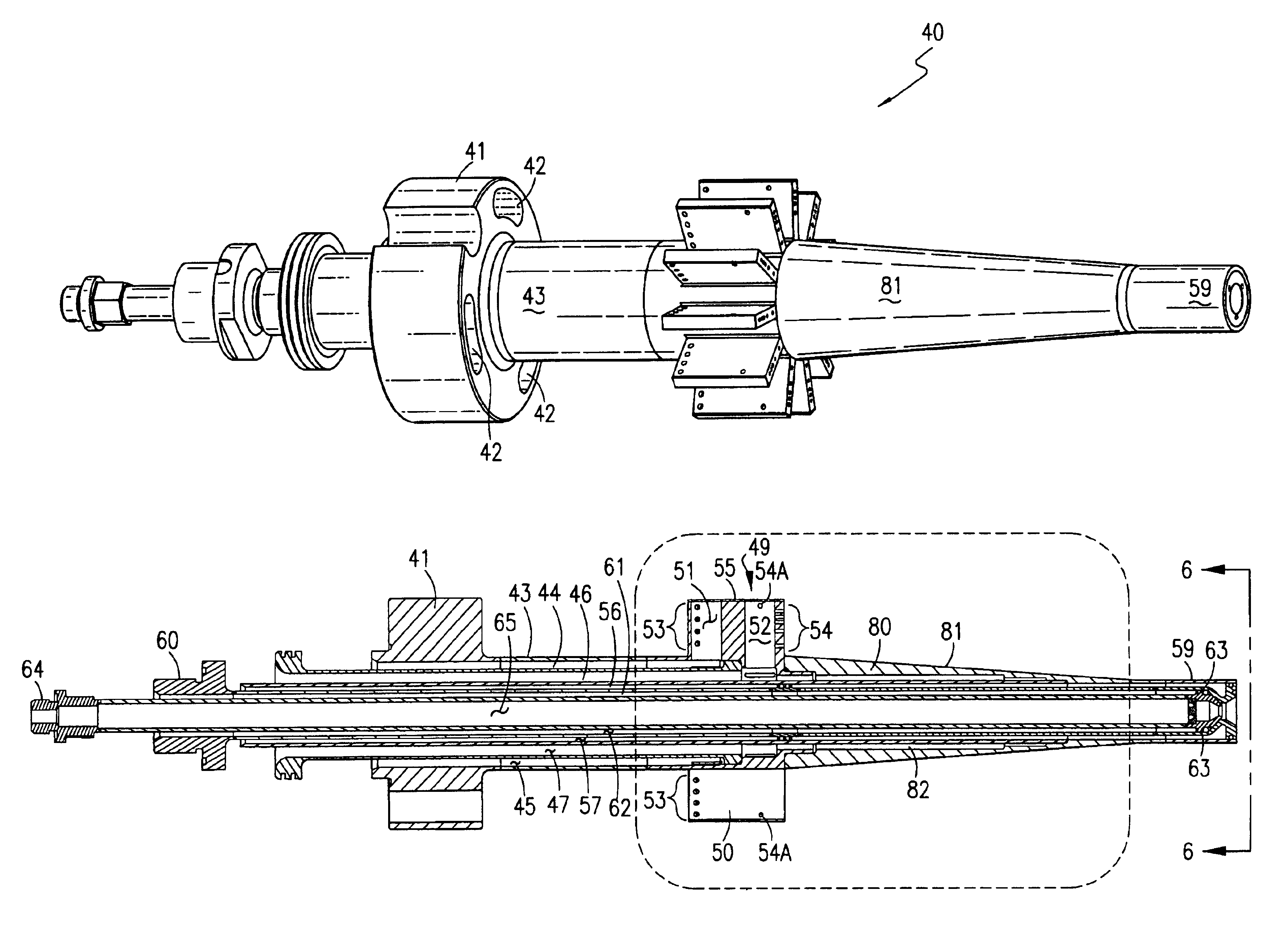

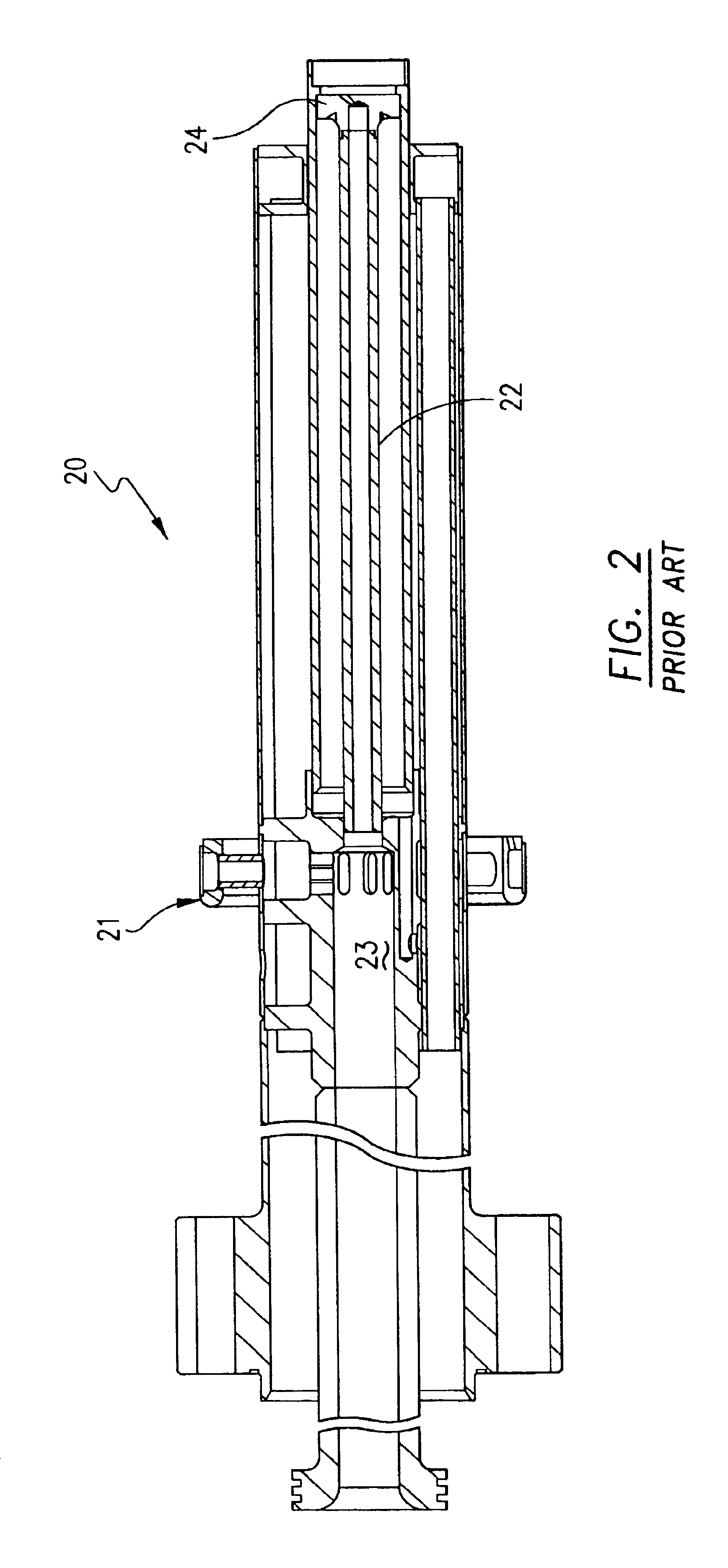

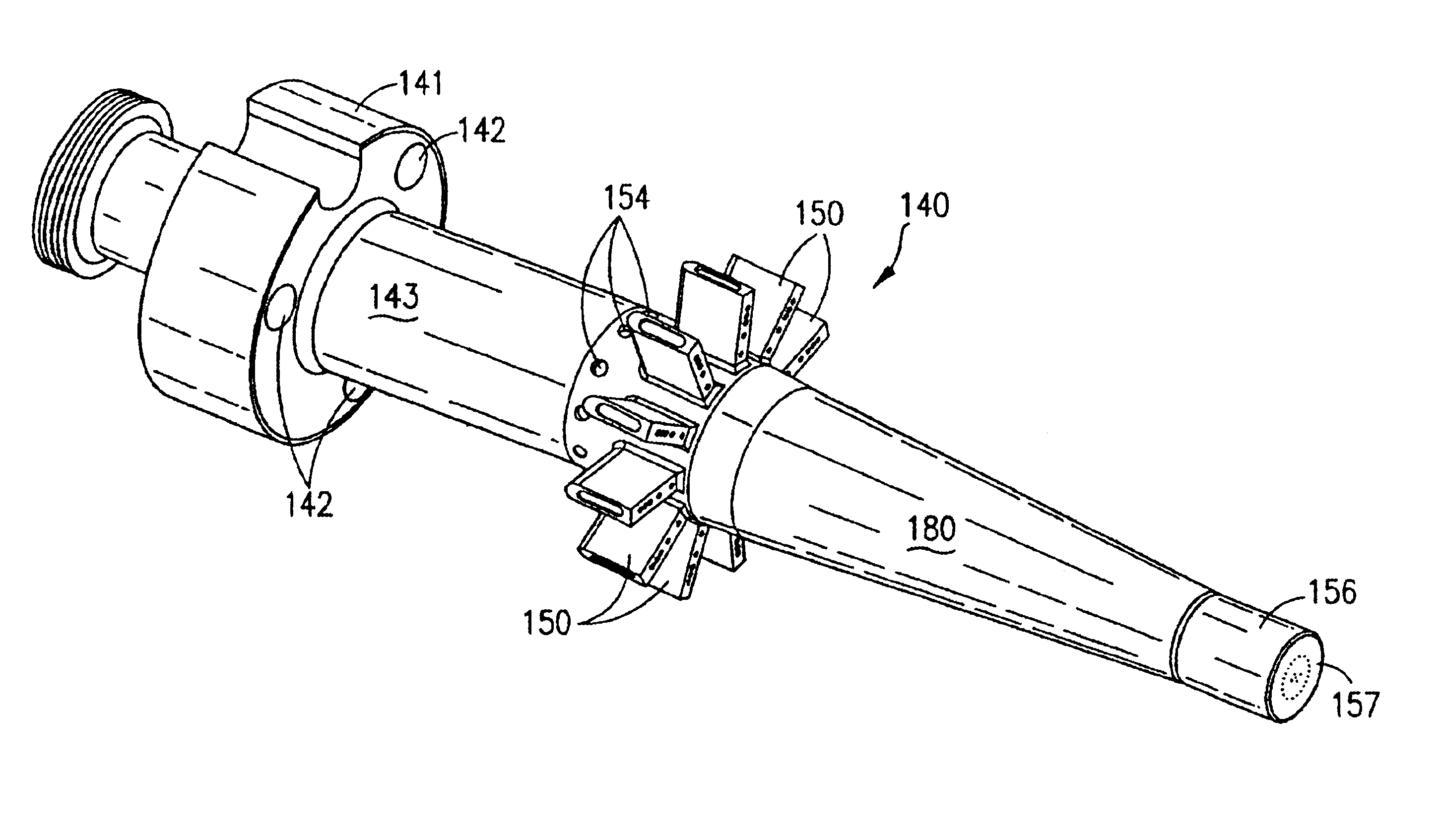

Dual fuel fin mixer secondary fuel nozzle

InactiveUS6915636B2Reduces NOx and other air pollutantUniform profileBurnersBurner safety arrangementsCombustion chamberCombustor

A dual fuel premix nozzle and method of operation for use in a gas turbine combustor is disclosed. The dual fuel premix nozzle utilizes a fin assembly comprising a plurality of radially extending fins for injection of gas fuel and compressed air in order to provide a more uniform injection pattern and homogeneous mixture. The premix fuel nozzle includes a plurality of coaxial passages, which provide gaseous fuel and compressed air to the fin assembly. When in liquid fuel operation, the gas circuits are purged with compressed air and liquid fuel and water pass through coaxial passages to the tip of the dual fuel premix fuel nozzle, where they inject liquid fuel and water into the secondary combustion chamber. An alternate embodiment includes an additional gas fuel injection region located along a conically tapered portion of the premixed fuel nozzle, downstream of the fin assembly. A second alternate embodiment is disclosed which reconfigures the injector assembly and fuel injection locations to minimize flow blockage issues at the injector assembly and simplify fuel nozzle manufacturing.

Owner:ANSALDO ENERGIA SWITZERLAND AG

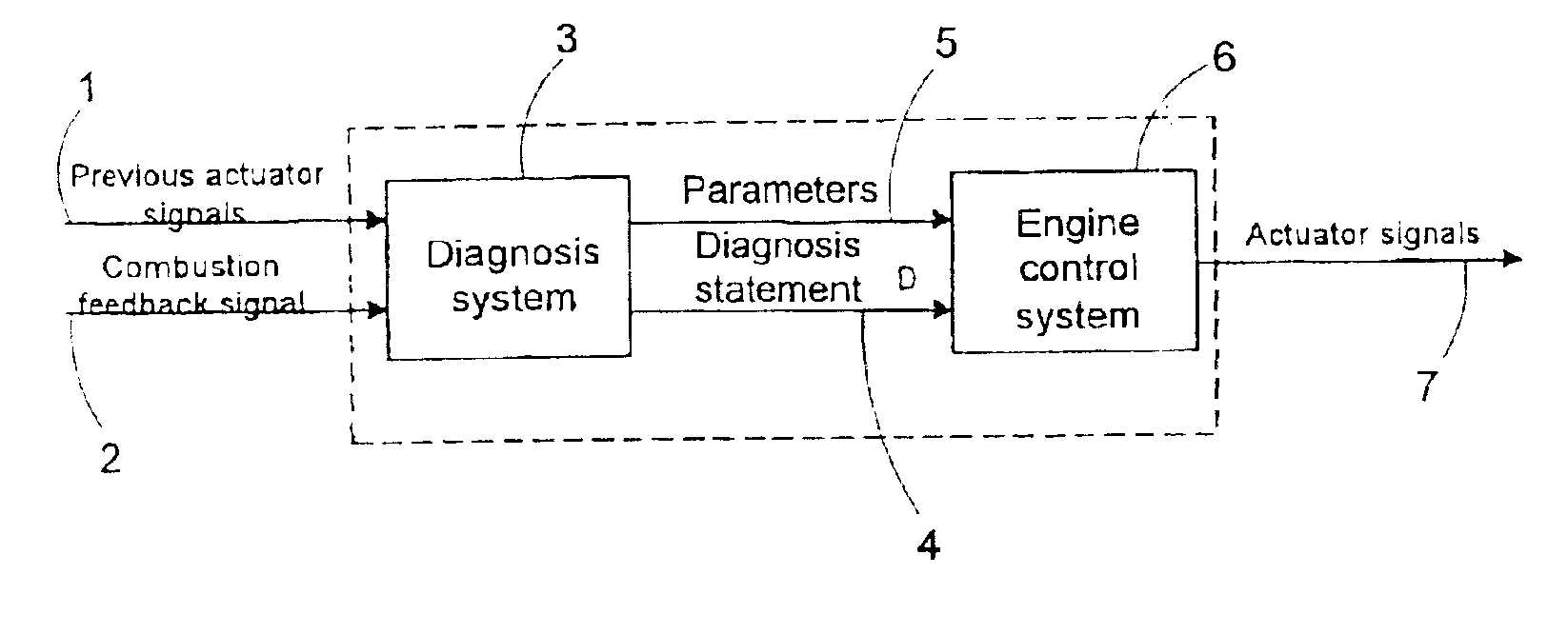

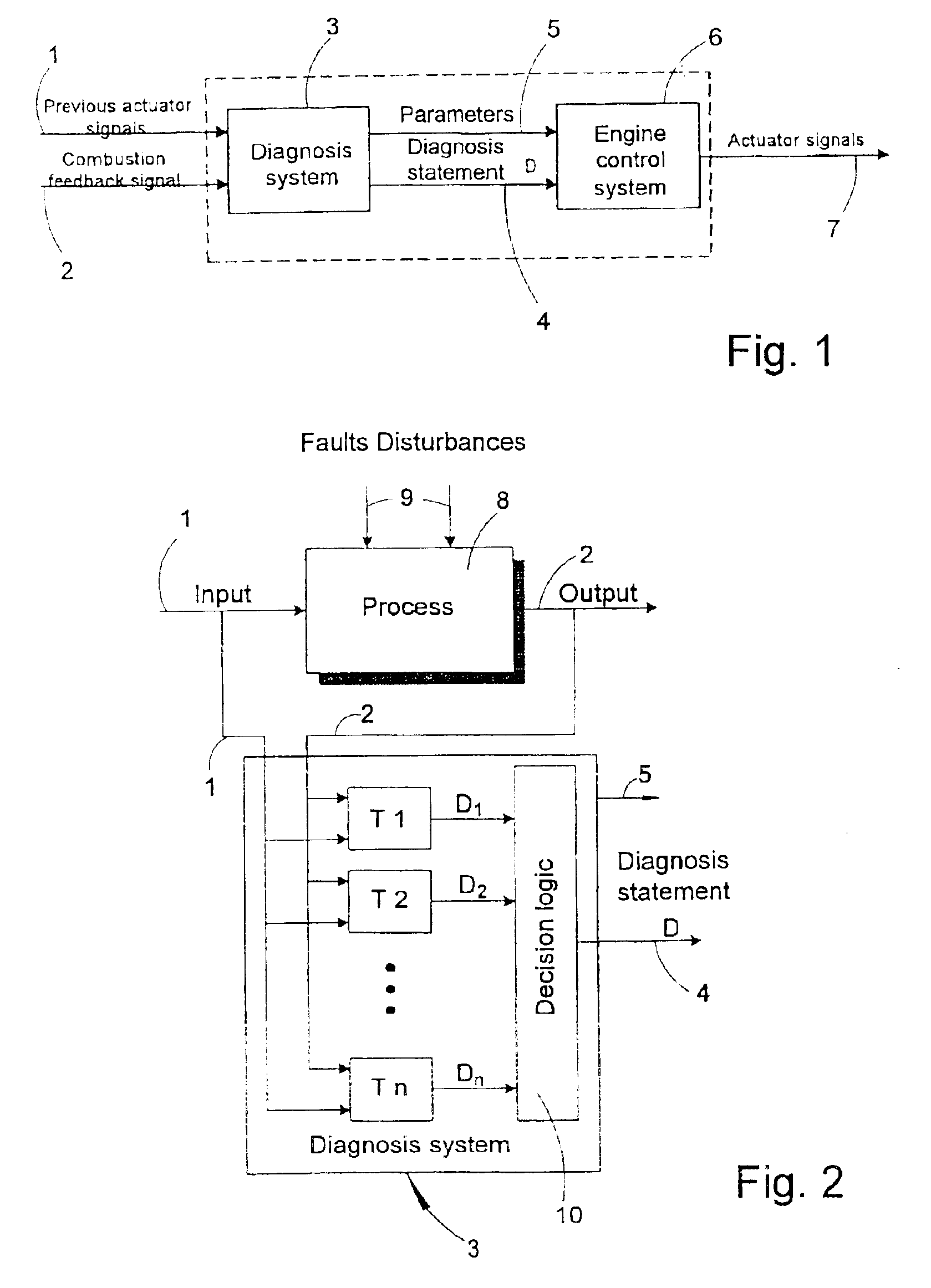

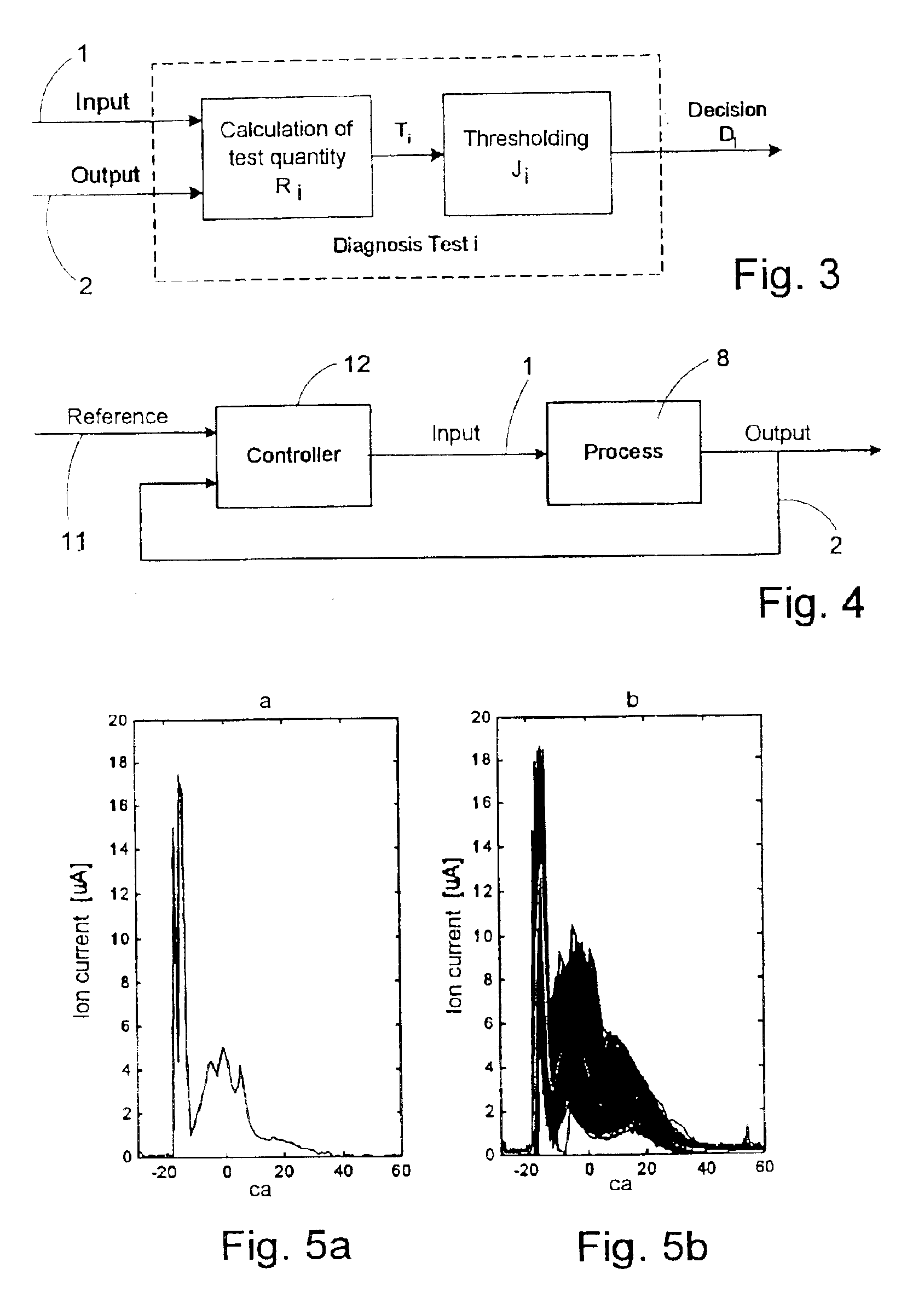

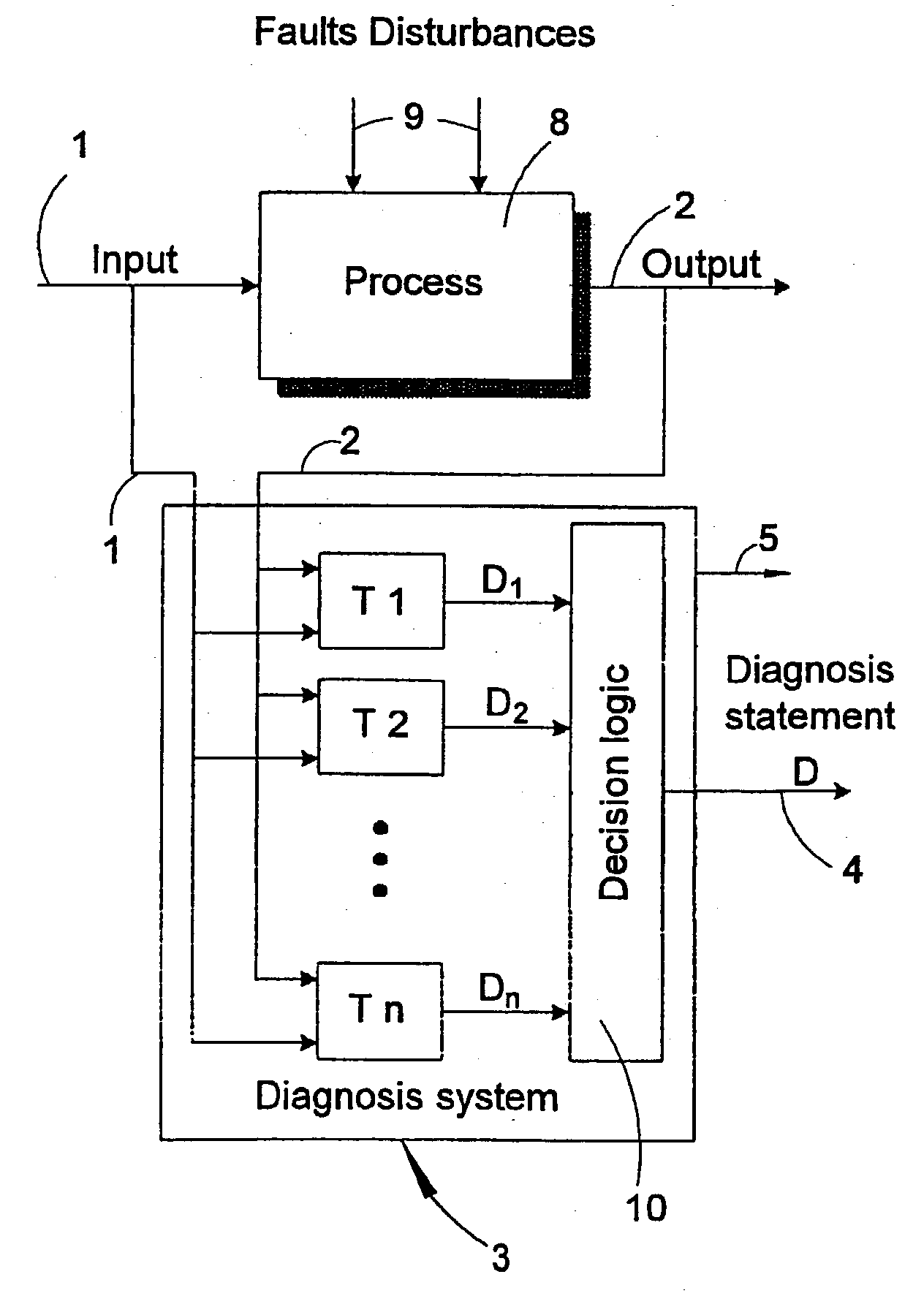

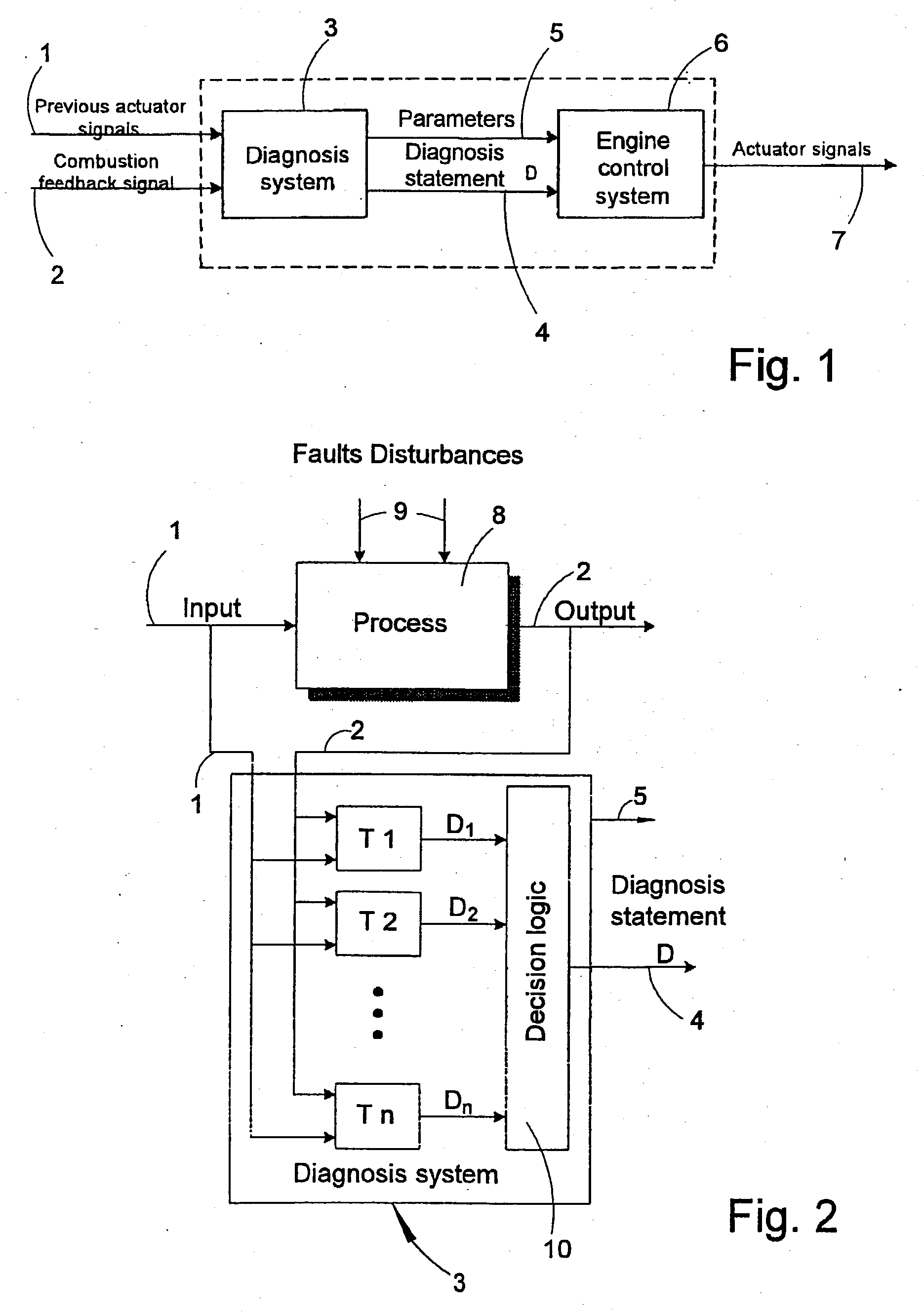

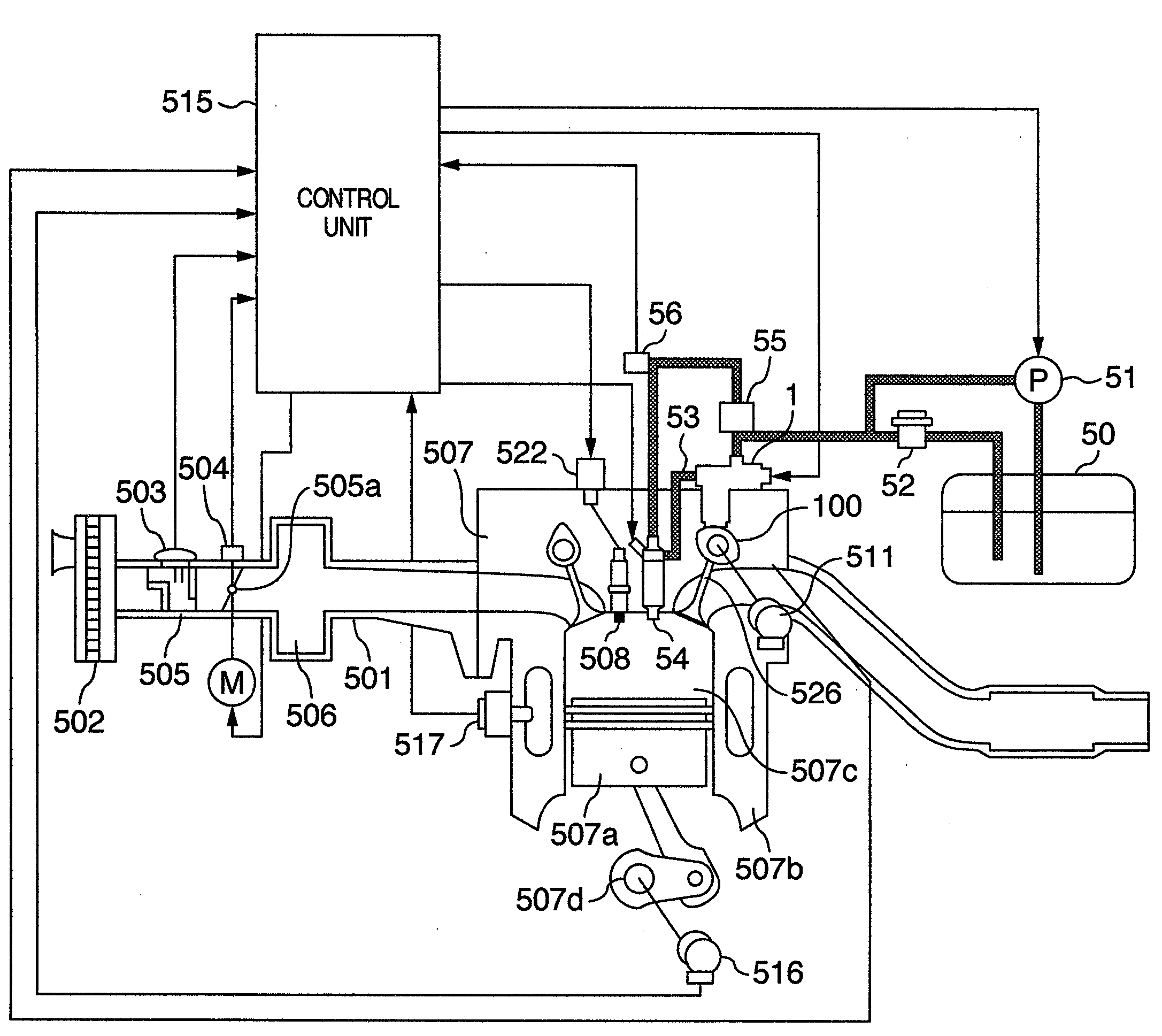

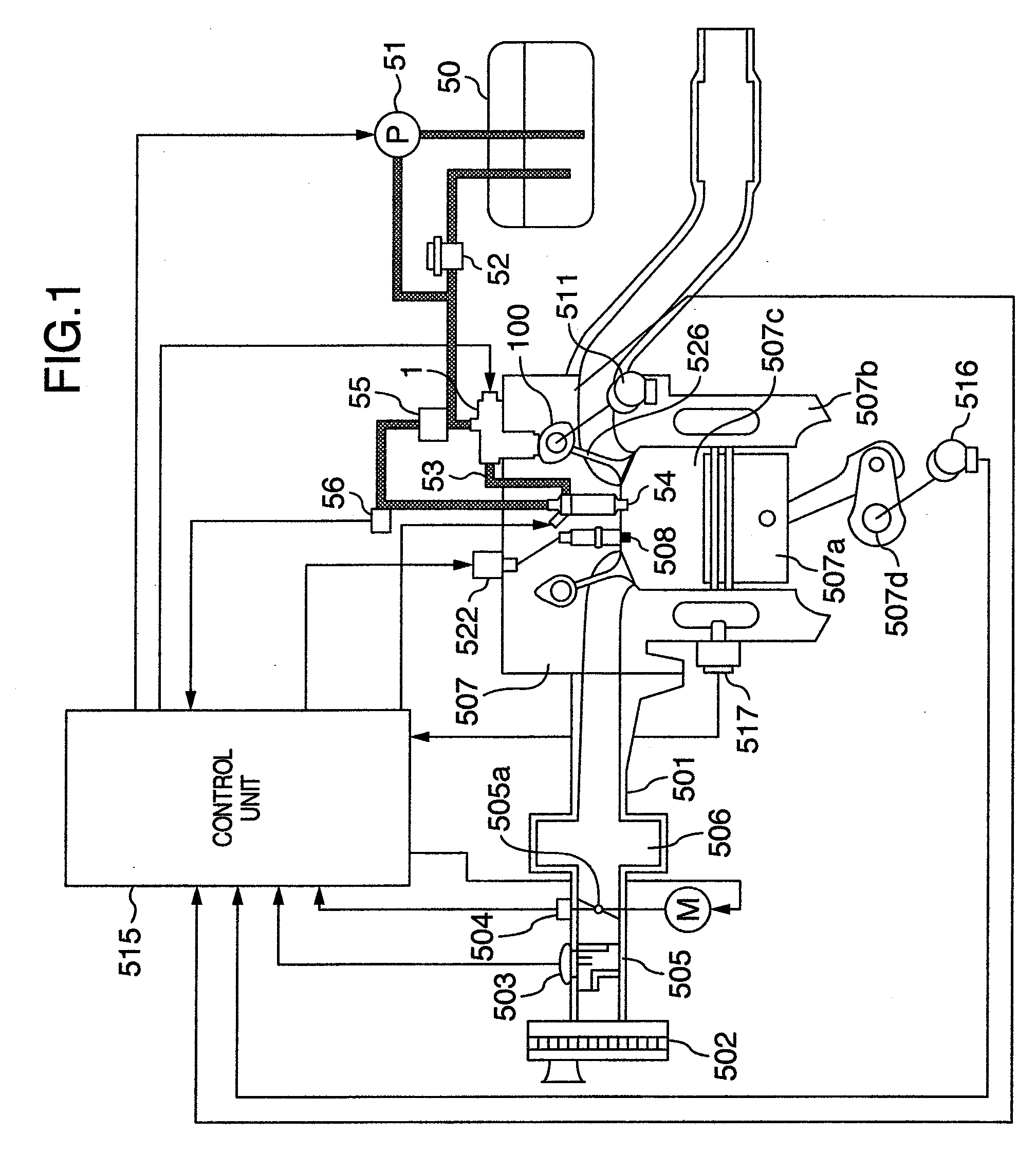

Method in connection with engine control

InactiveUS6827061B2Improve performanceFunction increaseElectrical controlInternal combustion piston enginesCombustionEngine control unit

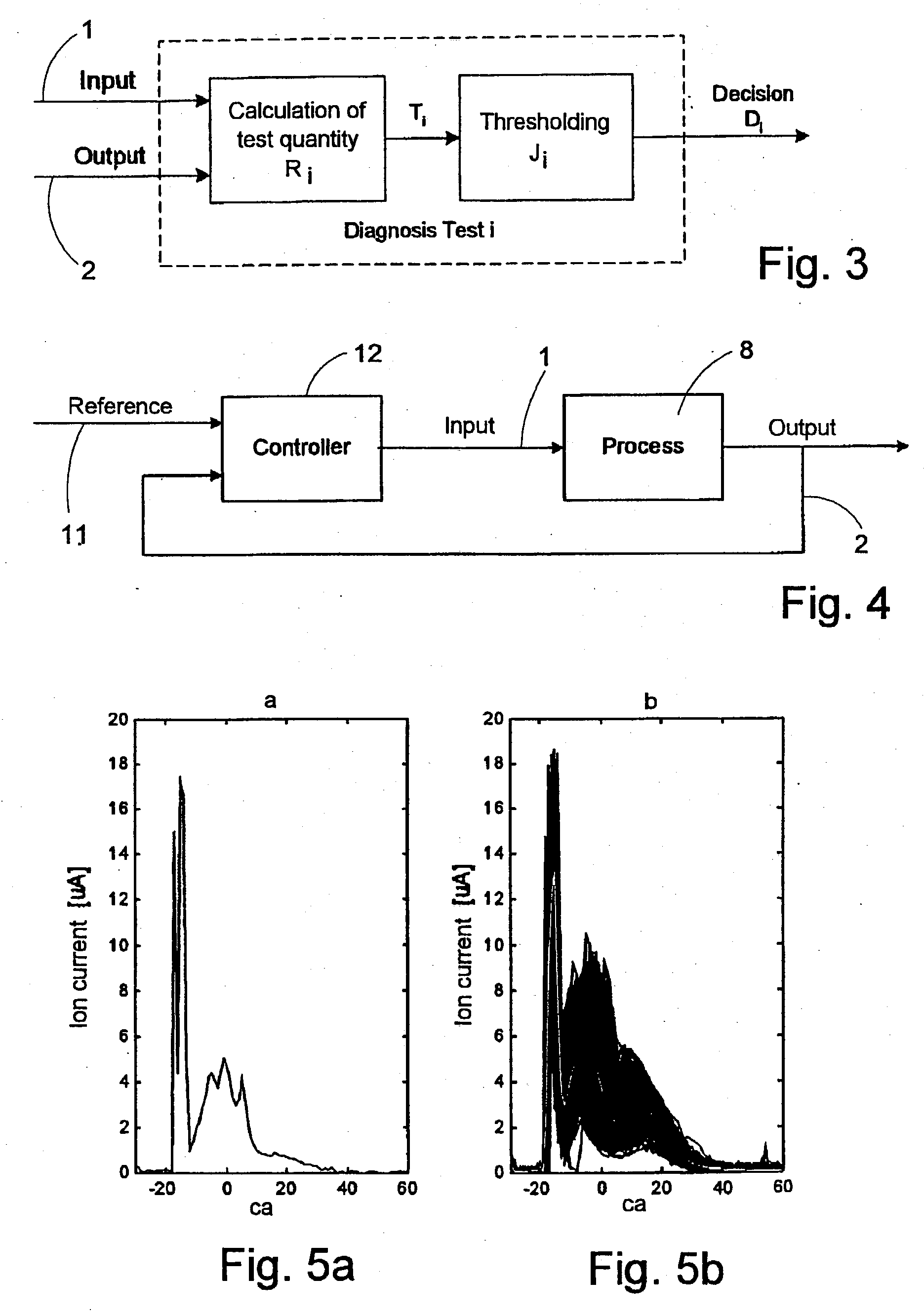

This invention relates to a method in connection with engine control, wherein a combustion feedback signal is derived by measuring one or more combustion related parameters during a chosen time period of a first combustion cycle, for control of a possible fault, wherein at least one reference feature for said parameters has been determined previously, and comparing said measured combustion feed back signal with said reference feature for automatic adaptation of at least one combustion related variable during a forthcoming combustion cycle wherein at least one reference features for each one of at least two different fault situations having been determined previously, and that a diagnosis 3 of said first combustion cycle is performed on the basis of said combustion feedback signal being processed and compared (T1-Tn) with each one of said reference features, the result of which is analysed by a decision logic, whereafter a diagnosis (D) is established by means of which one or more variables in a forthcoming combustion cycle is / are regulated in dependence of the outcome (D) of said diagnosis, thereby achieving fault tolerant engine control.

Owner:ALTRONIC

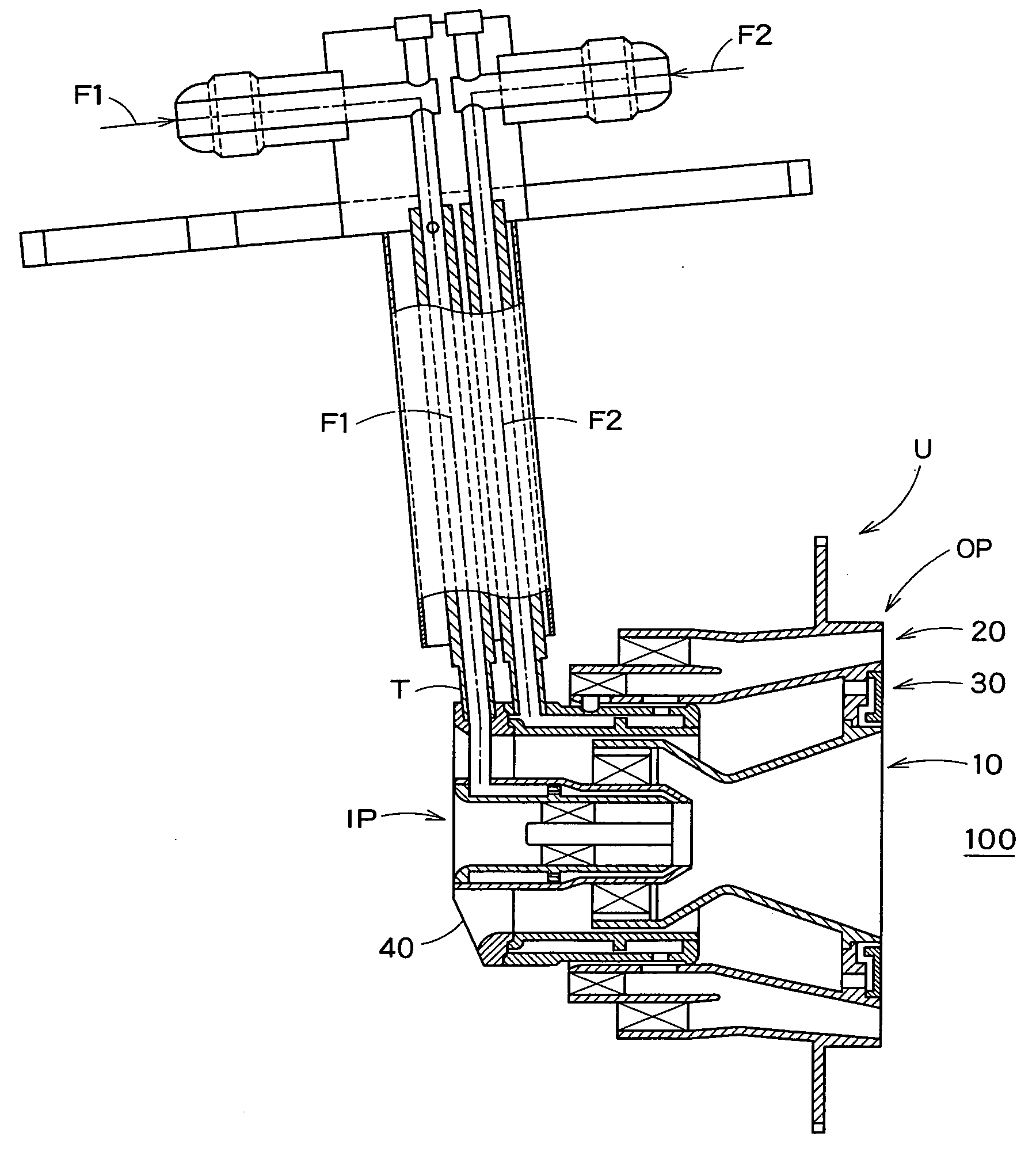

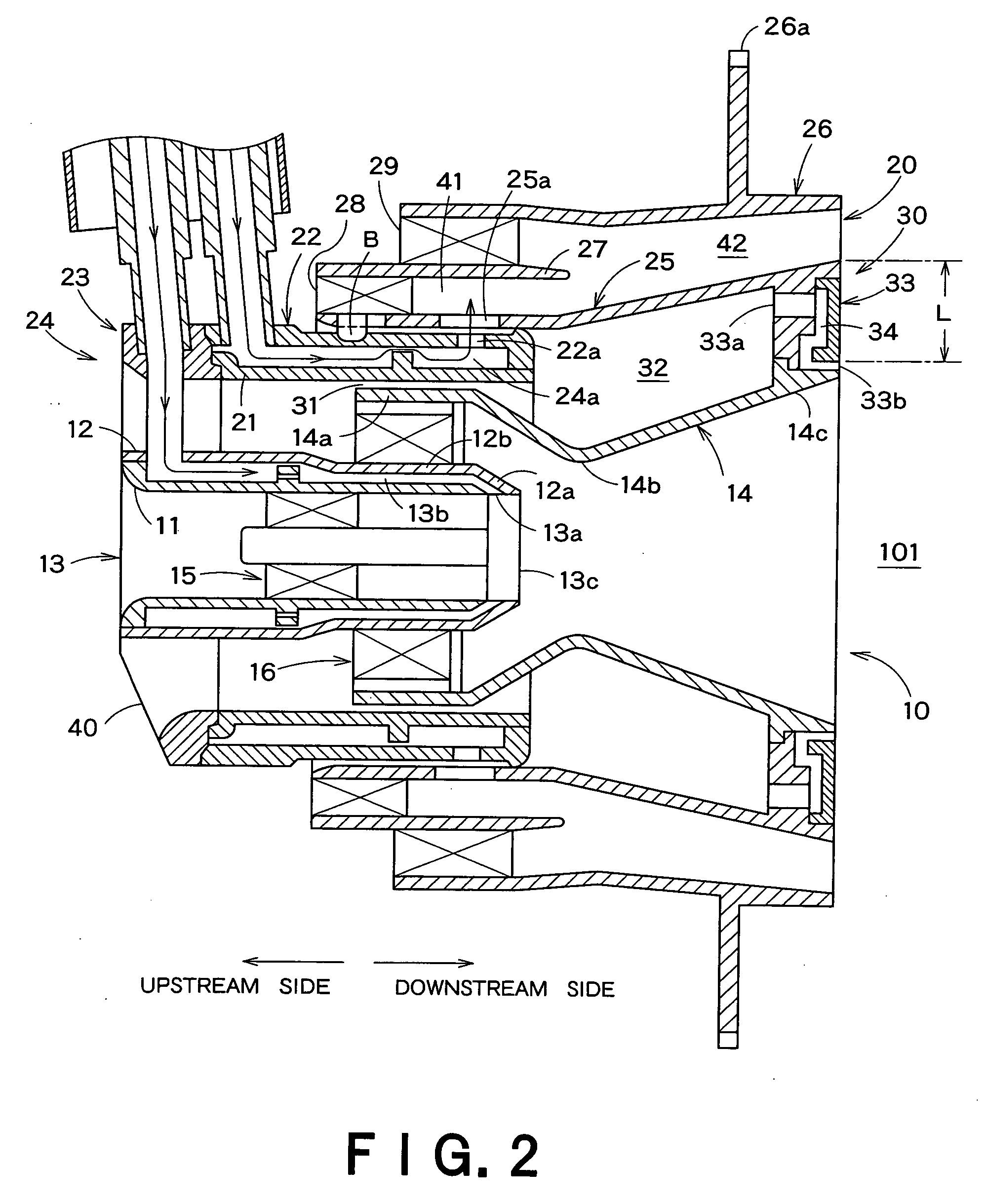

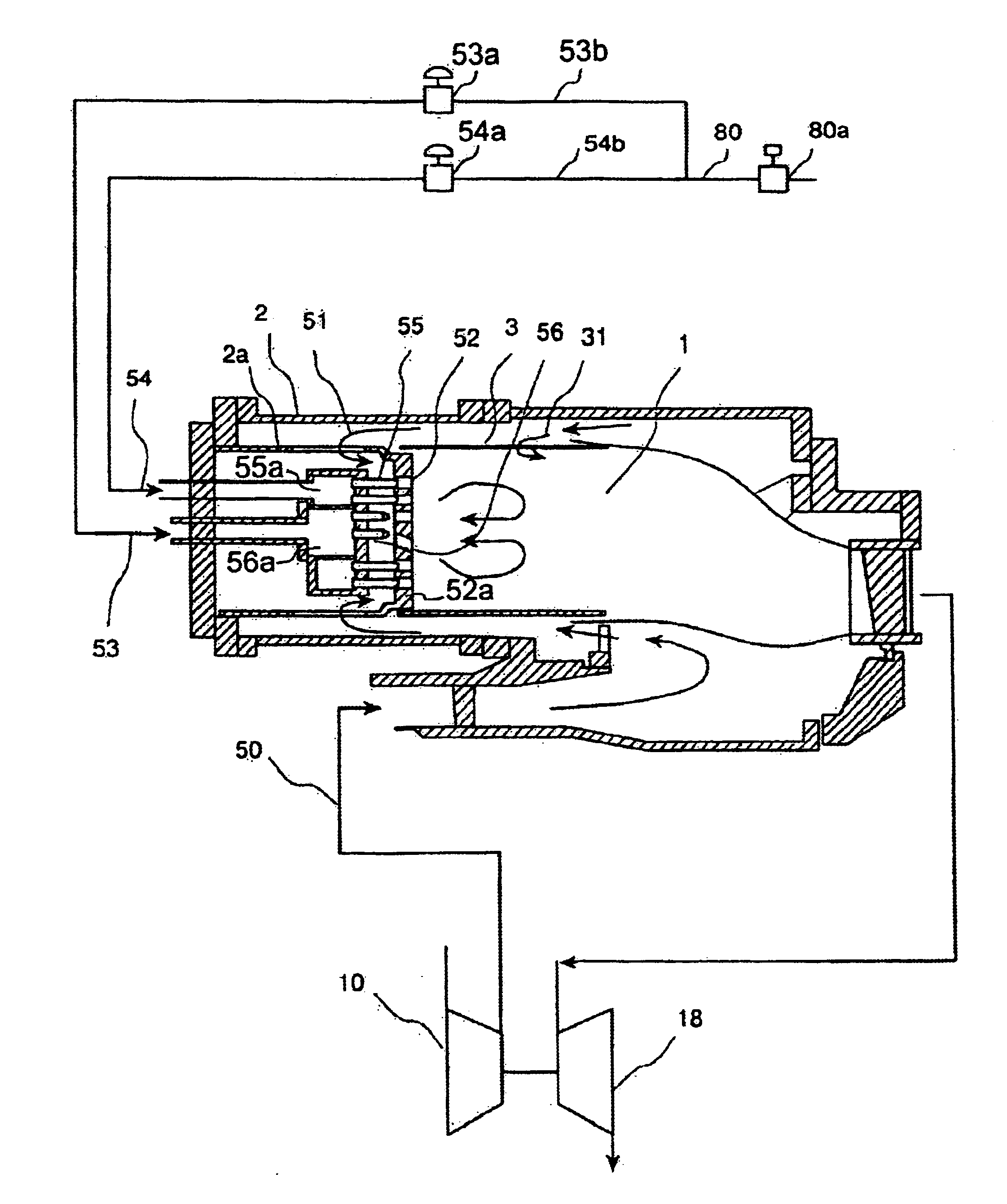

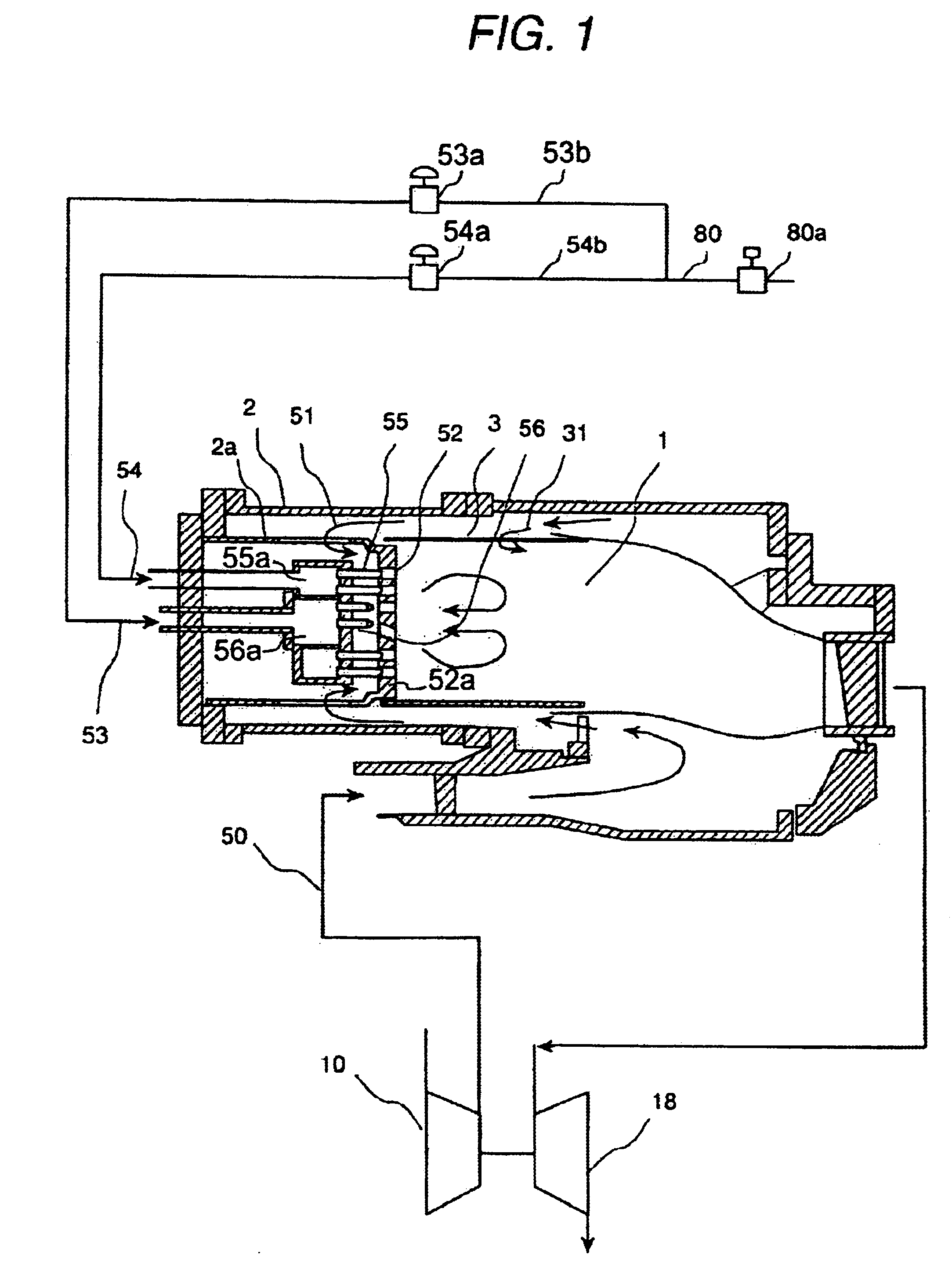

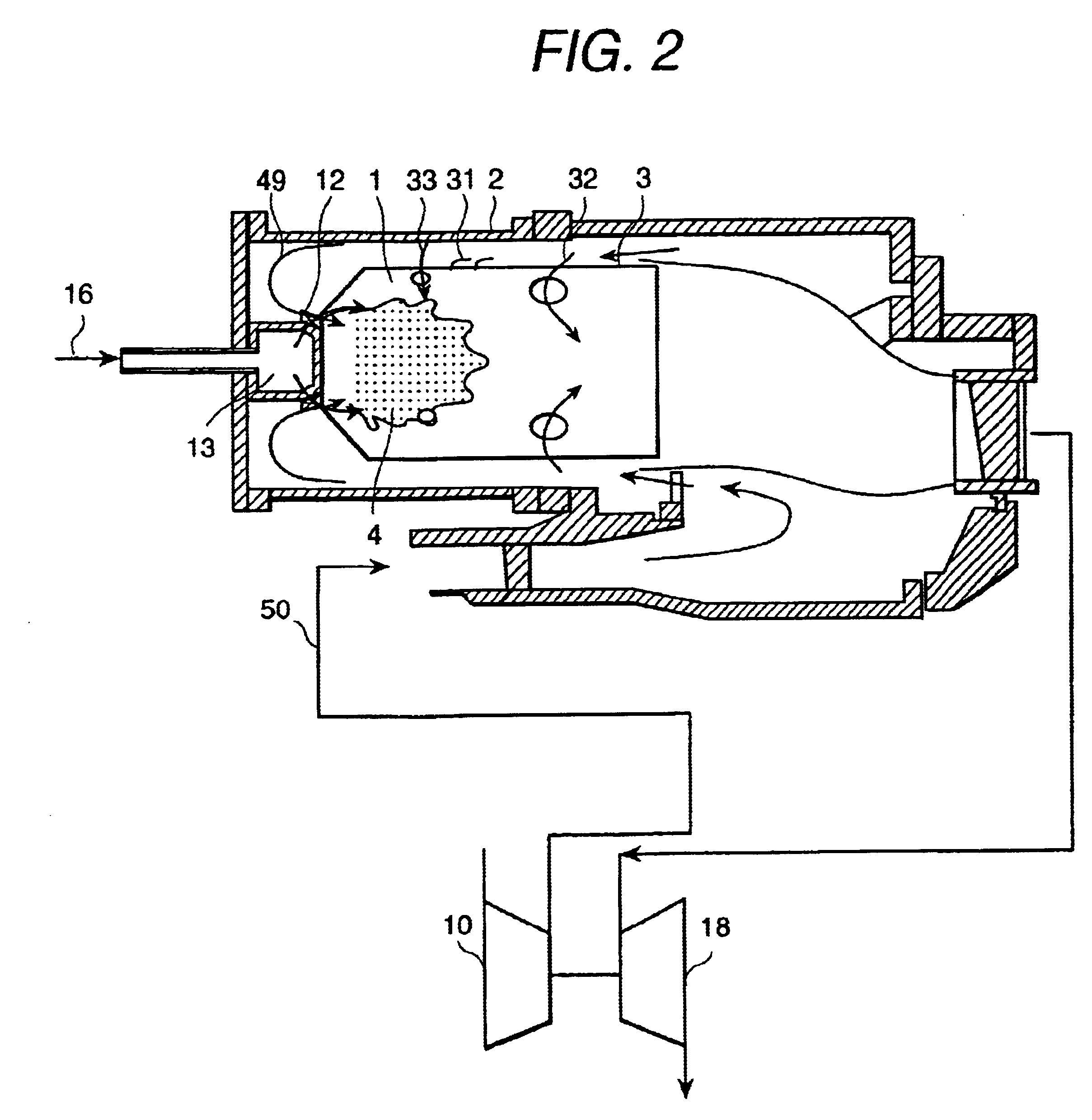

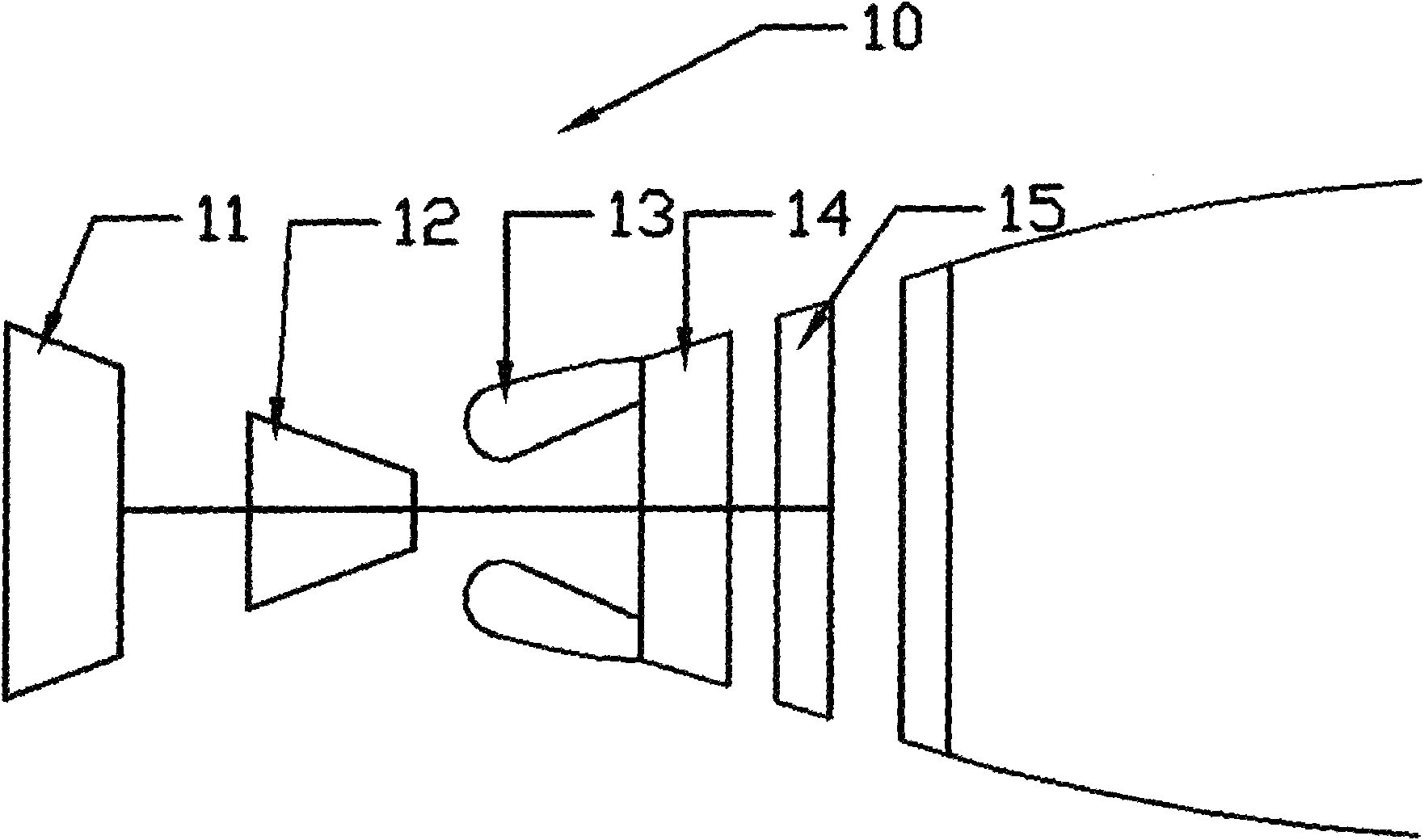

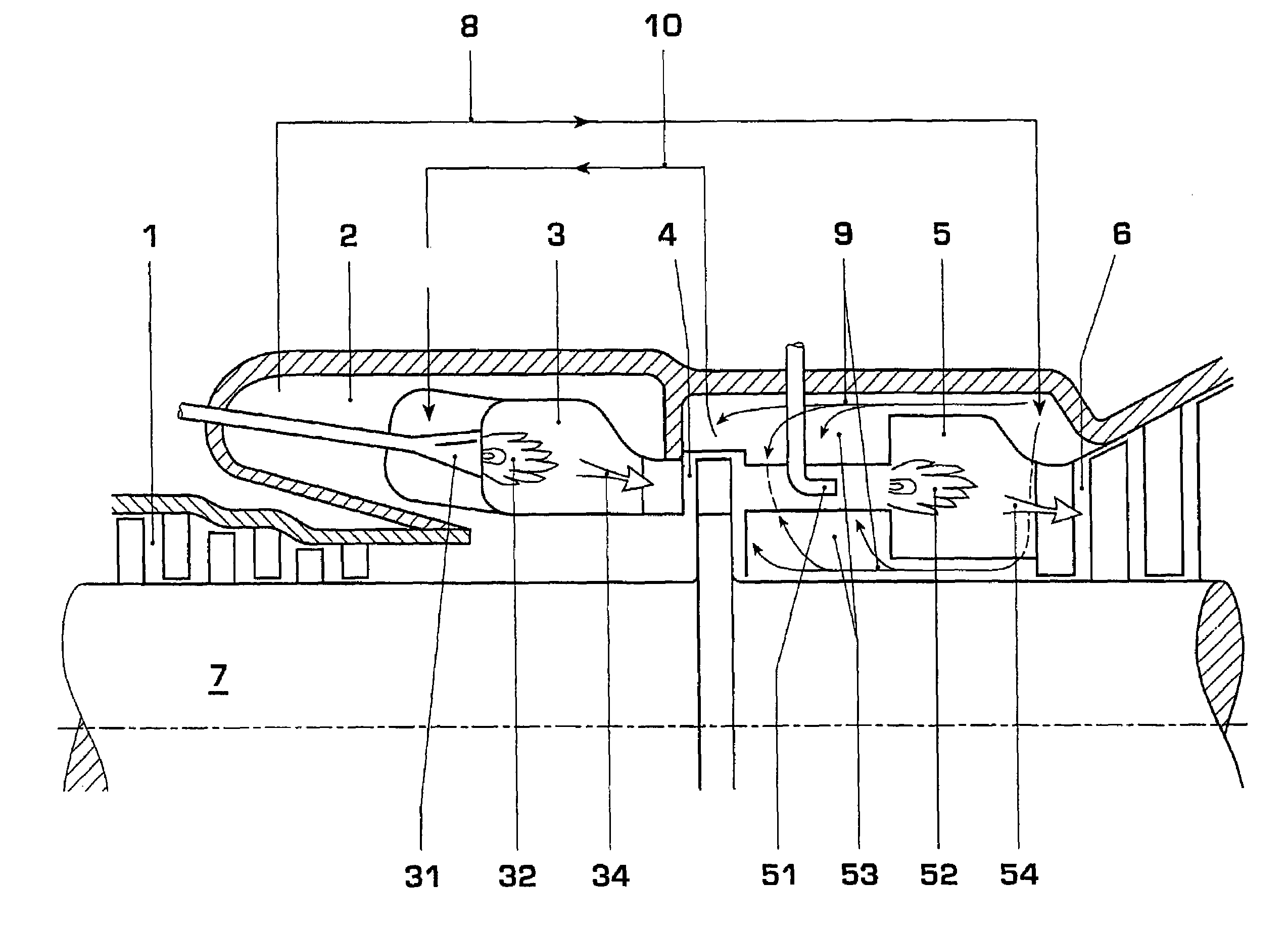

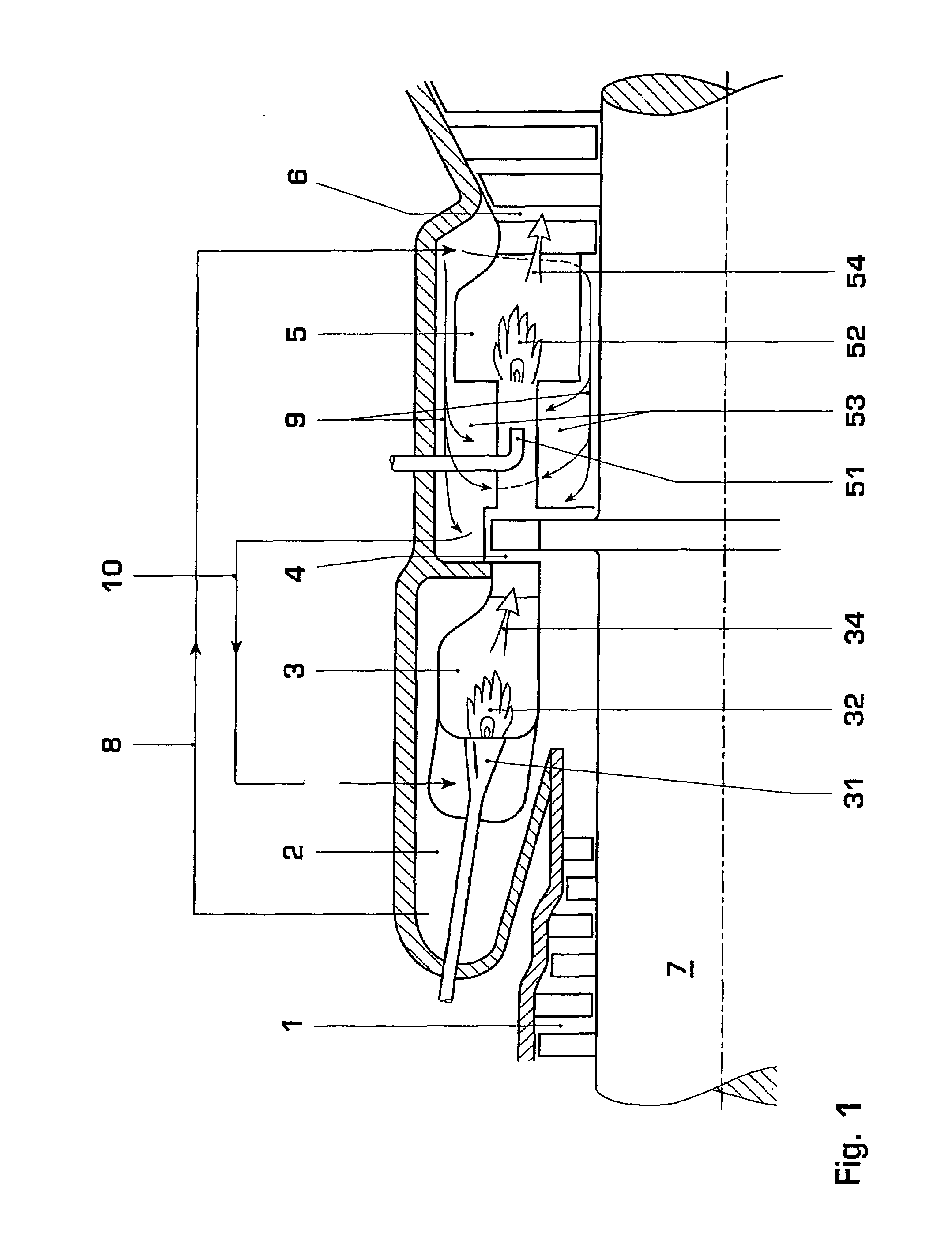

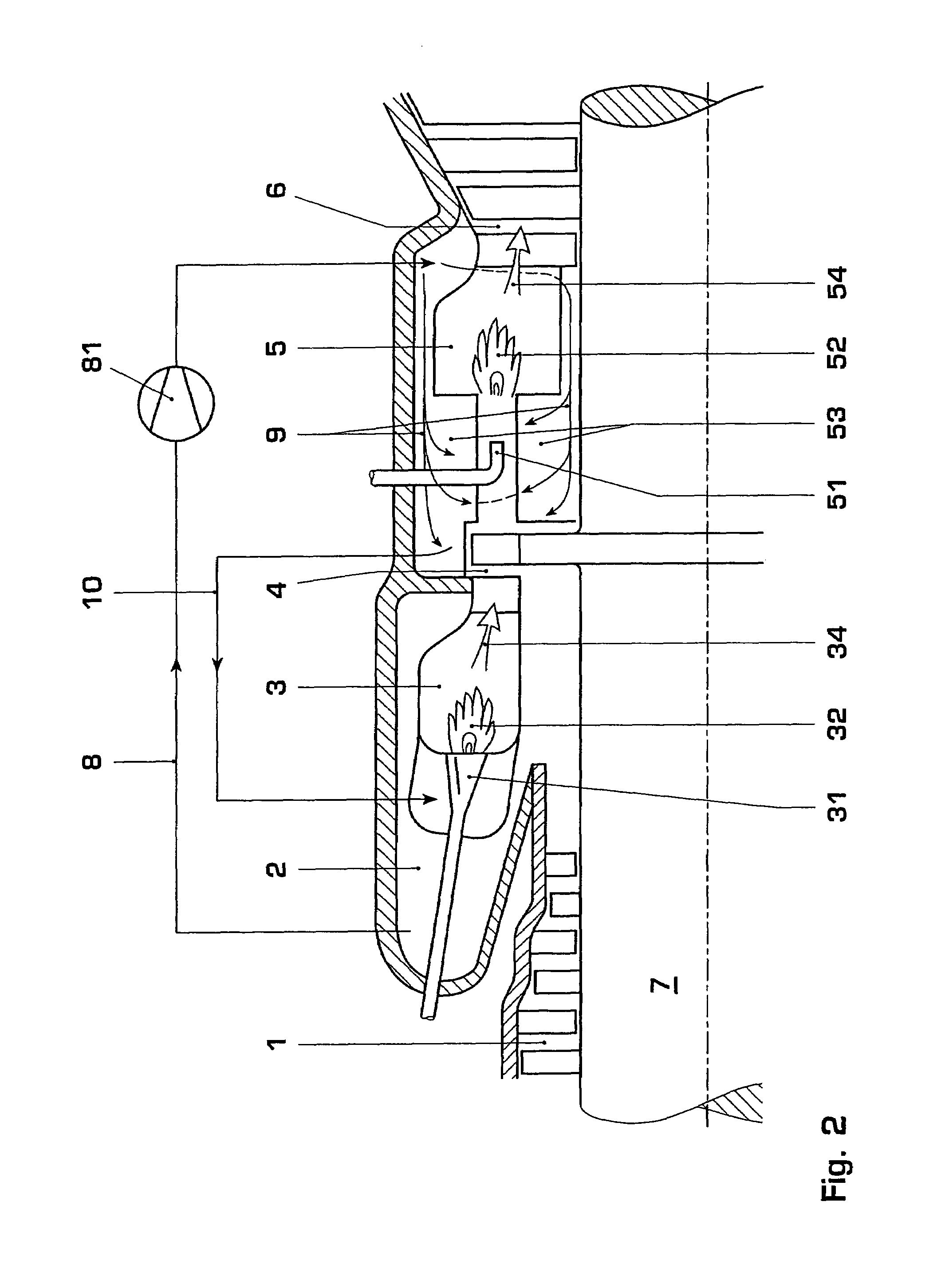

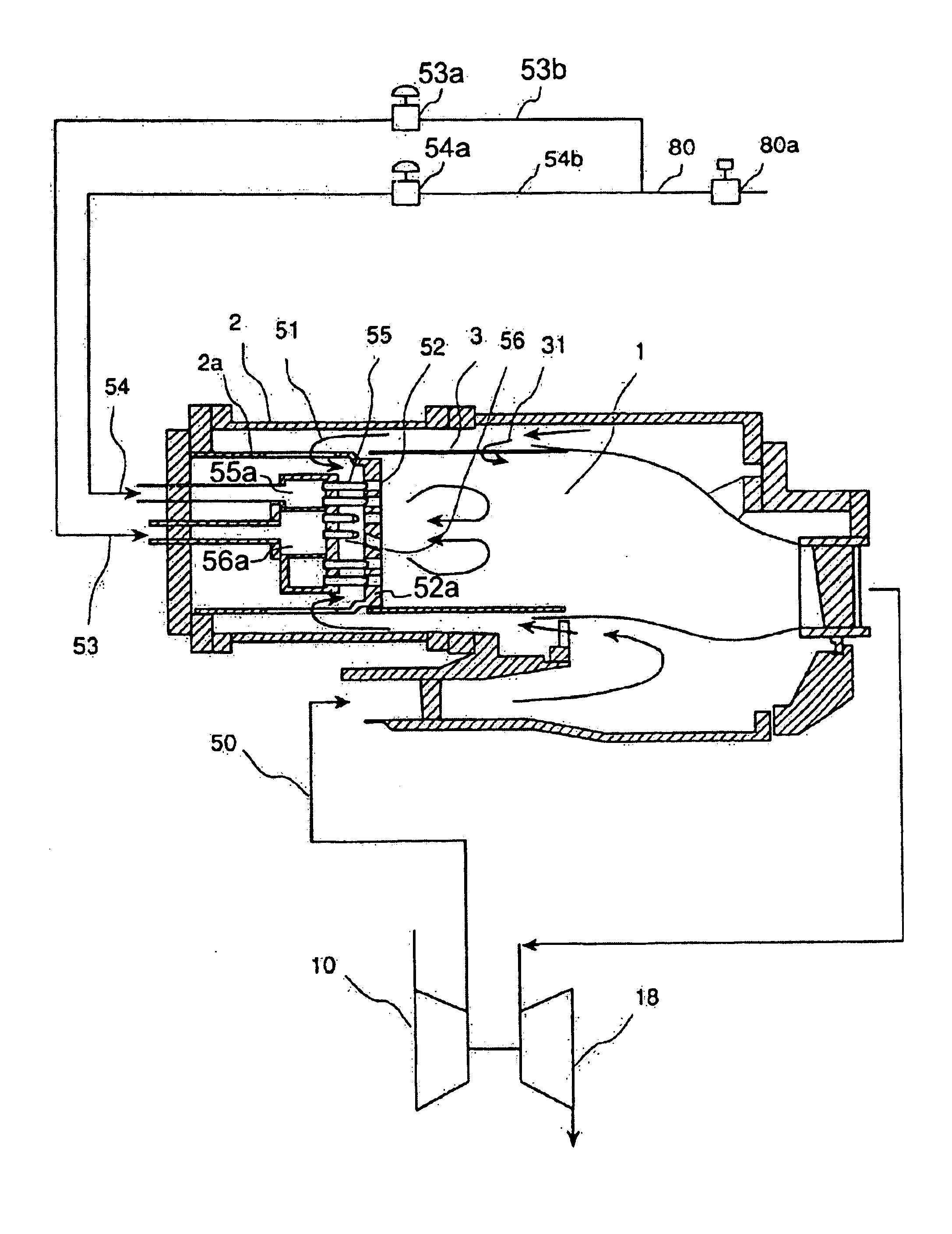

Fuel spraying apparatus of gas turbine engine

ActiveUS20070289305A1Improving flamablenessImproving ignitablenessBurnersContinuous combustion chamberGas turbinesFuel gas

A fuel spraying apparatus of a gas turbine engine includes a first fuel spraying section configured to spray fuel for diffusion combustion and a second fuel spraying section configured to spray fuel for premixed combustion. The second fuel spraying section is disposed so as to surround the first fuel spraying section. The apparatus further includes an air curtain generating section disposed between the first fuel spraying section and the second fuel spraying section. The air curtain generating section configured to generate an air curtain which defines an outer edge of a diffusion combustion area in a combustion chamber.

Owner:KAWASAKI HEAVY IND LTD

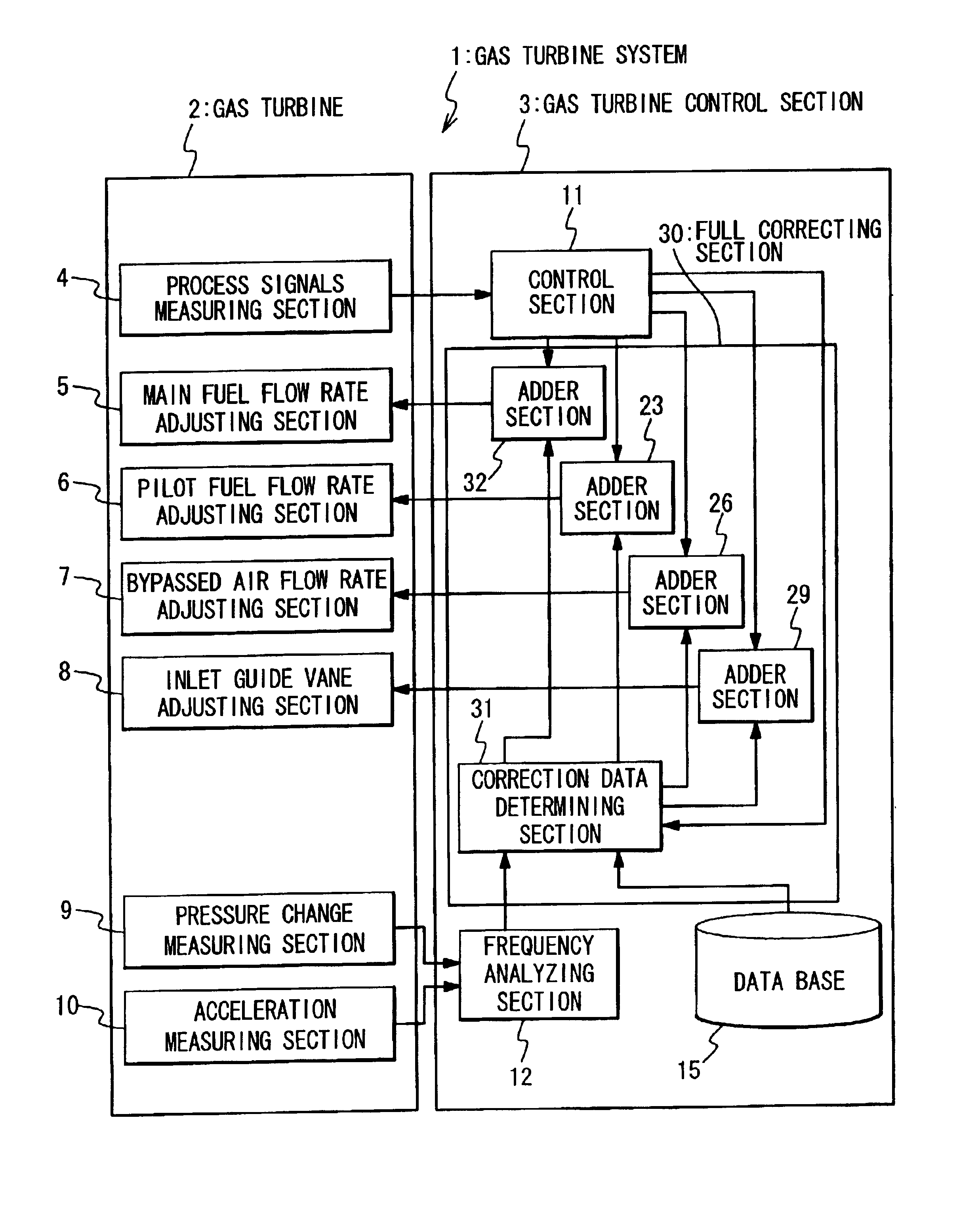

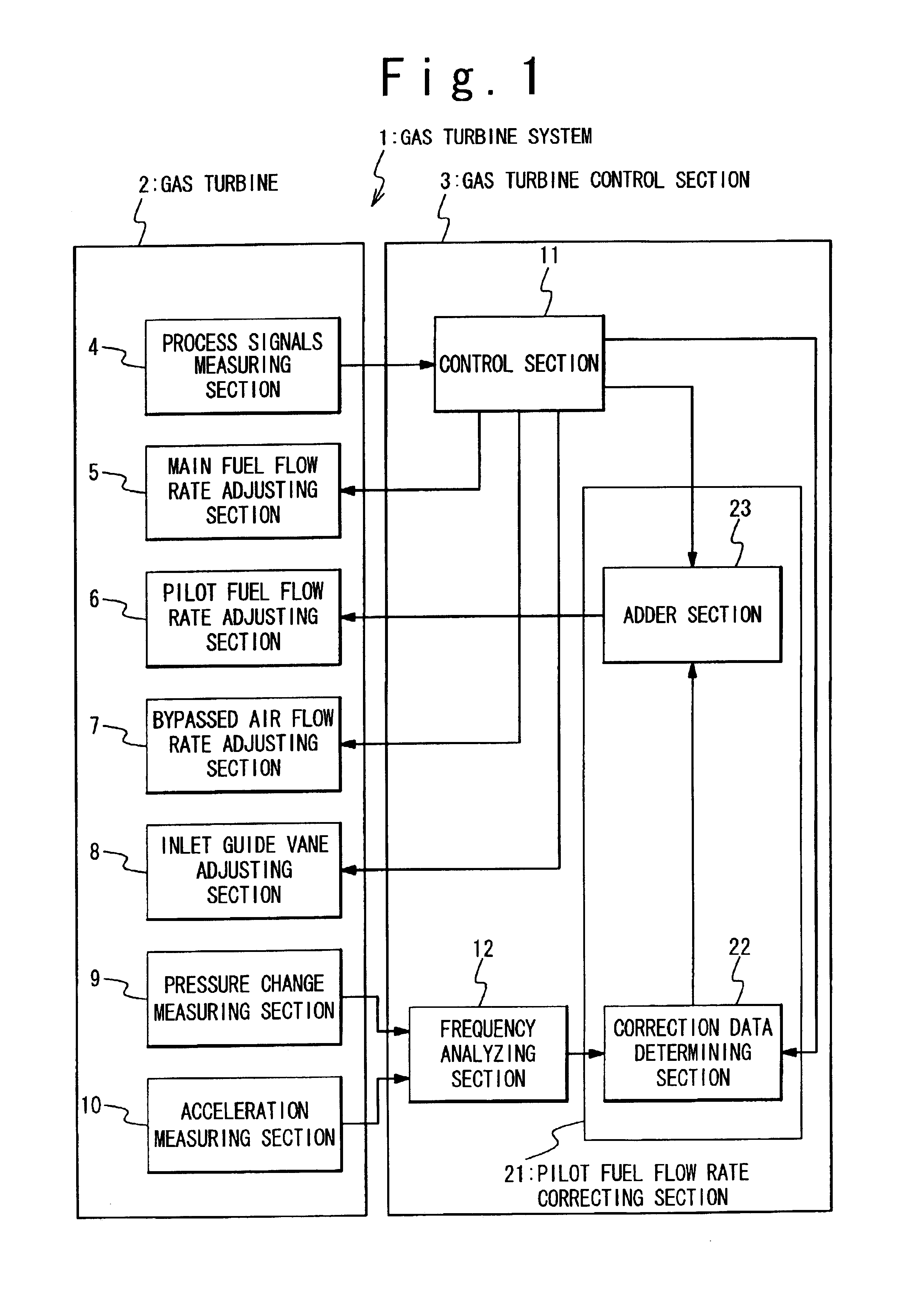

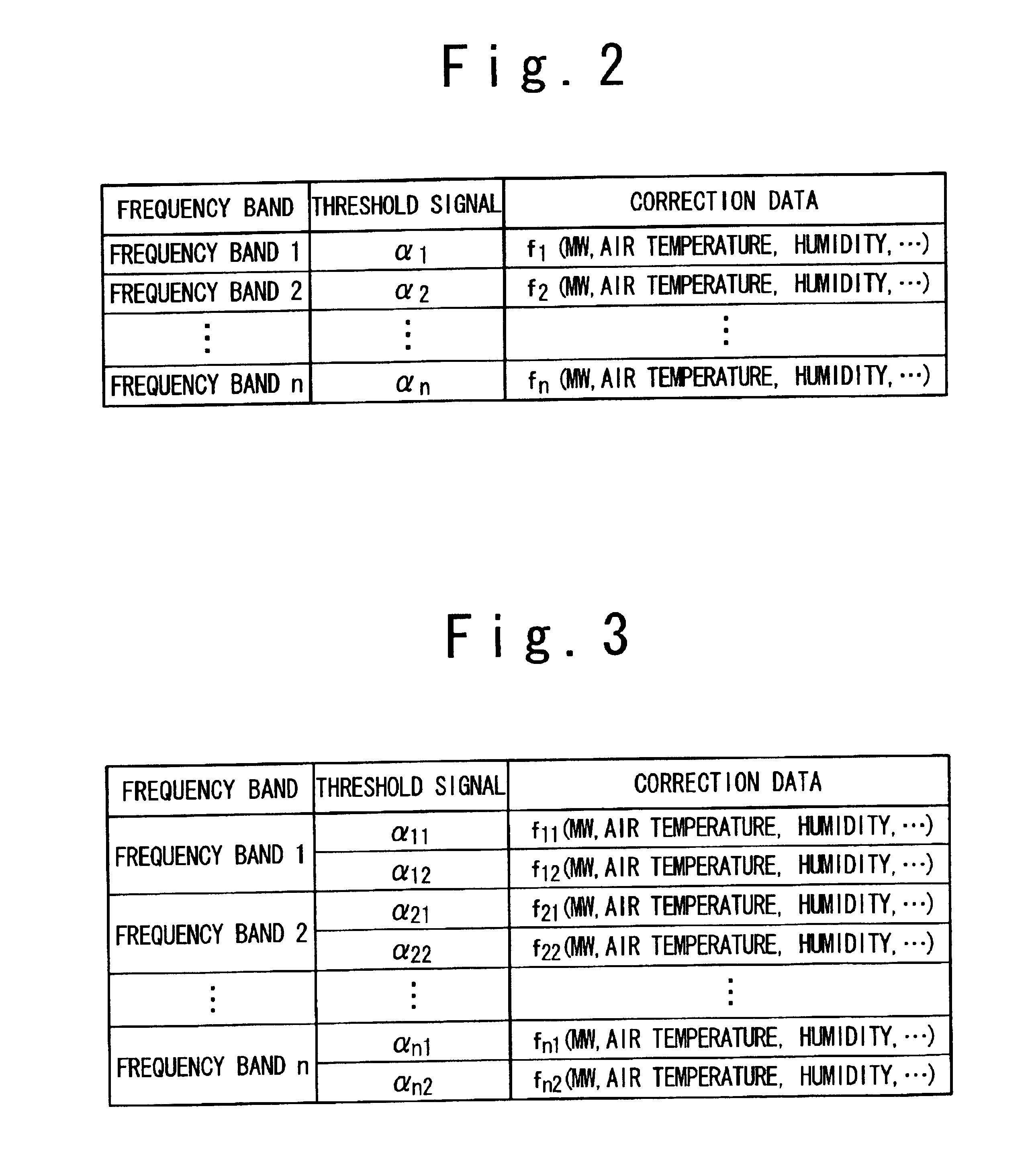

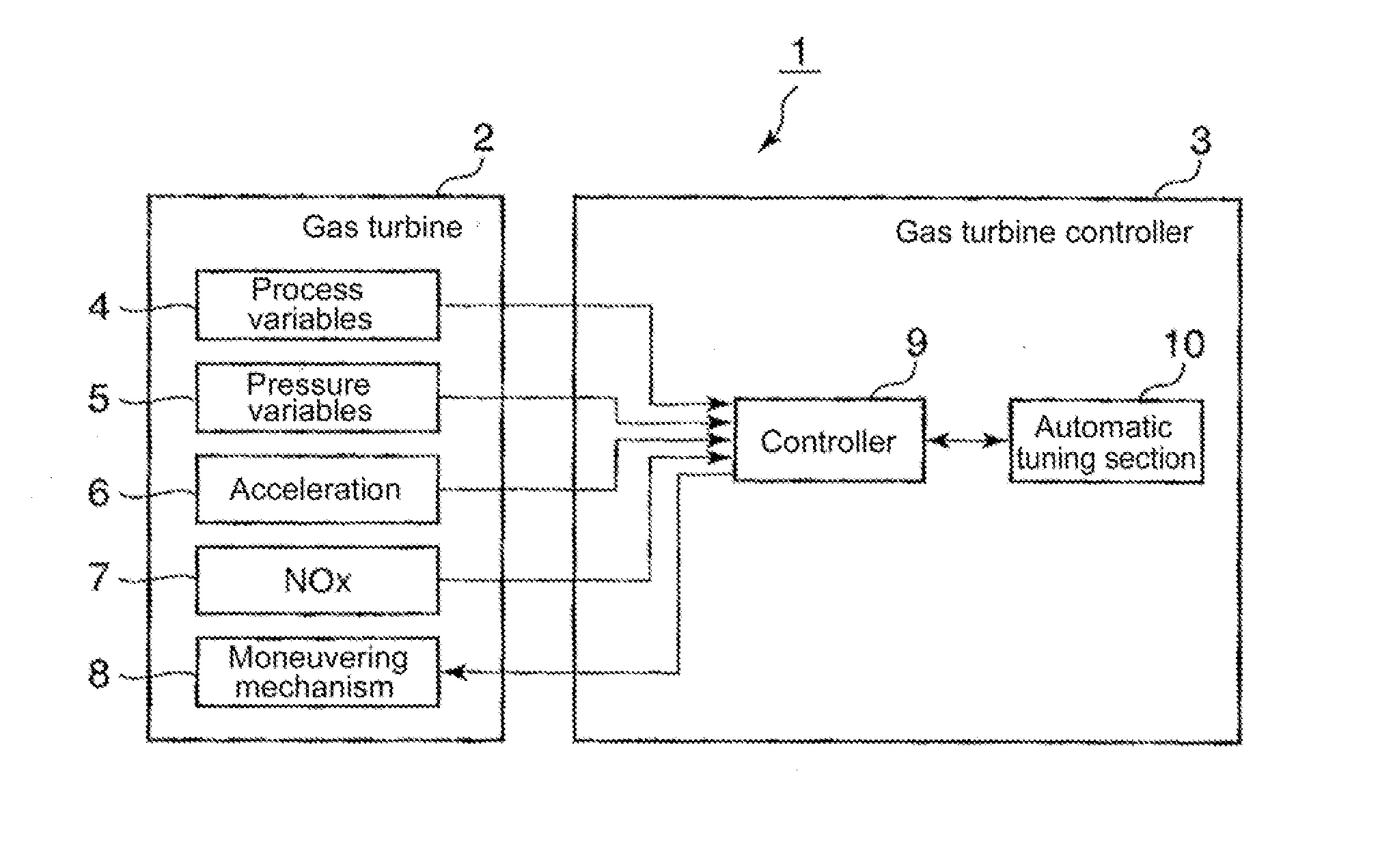

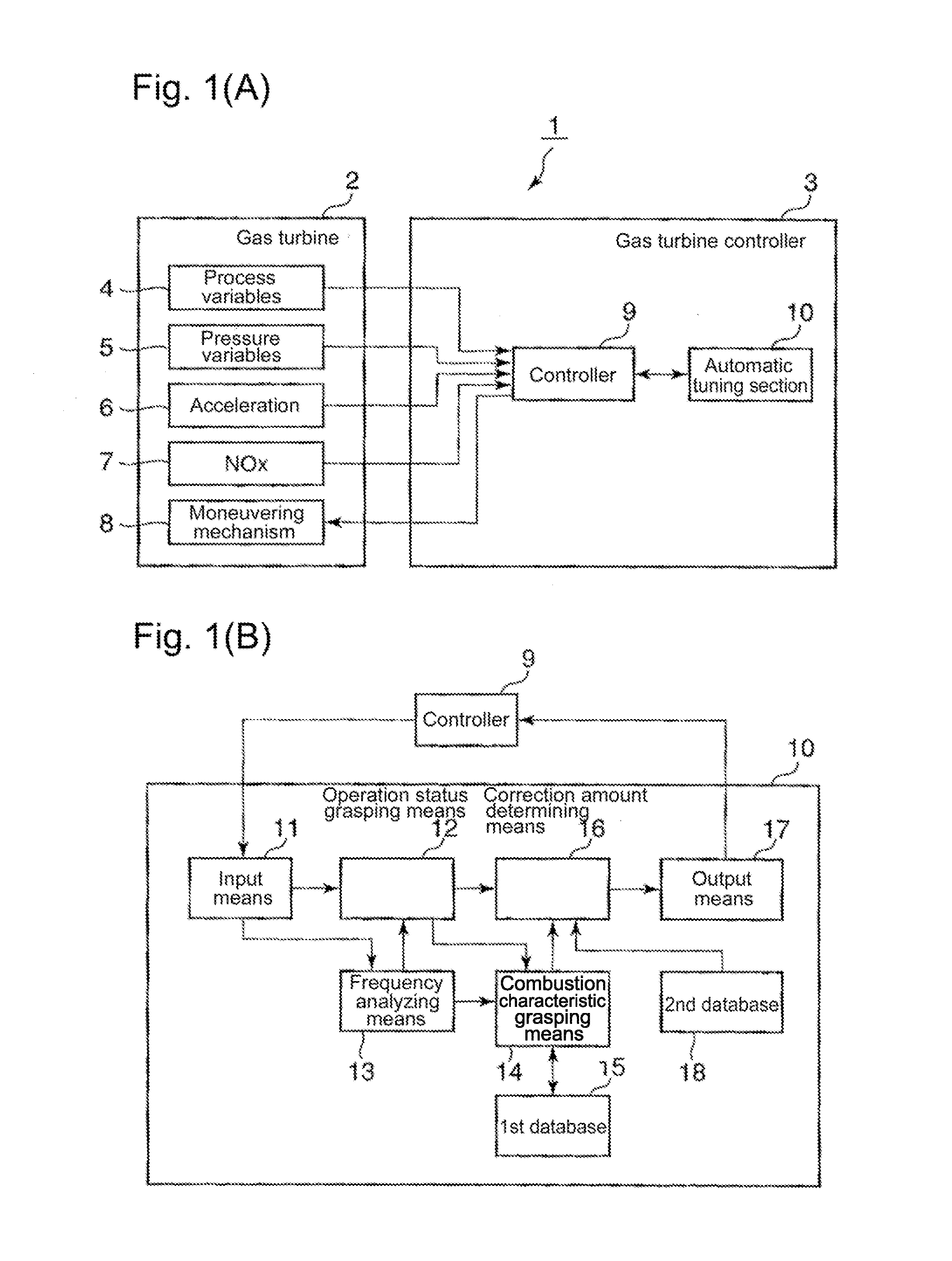

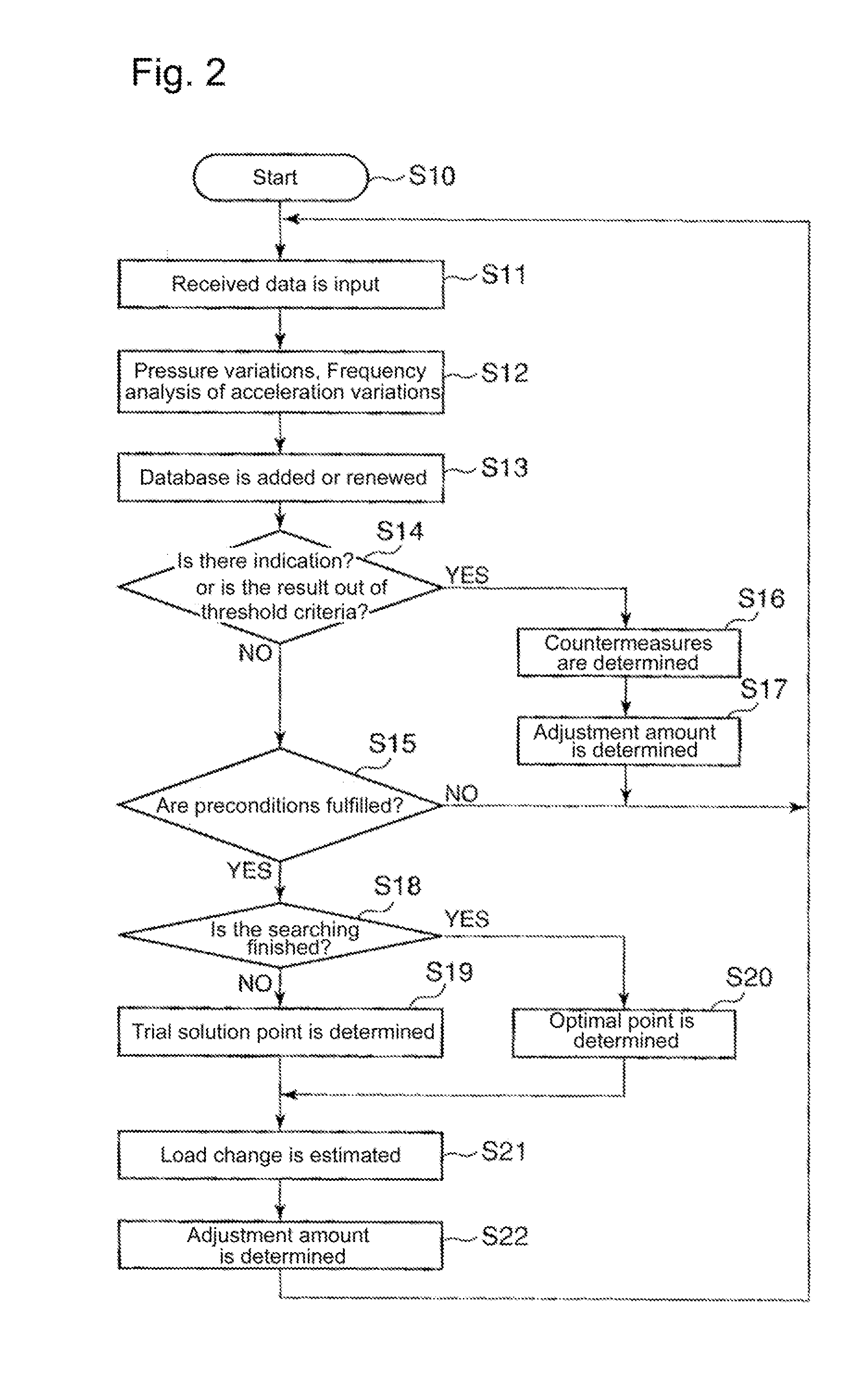

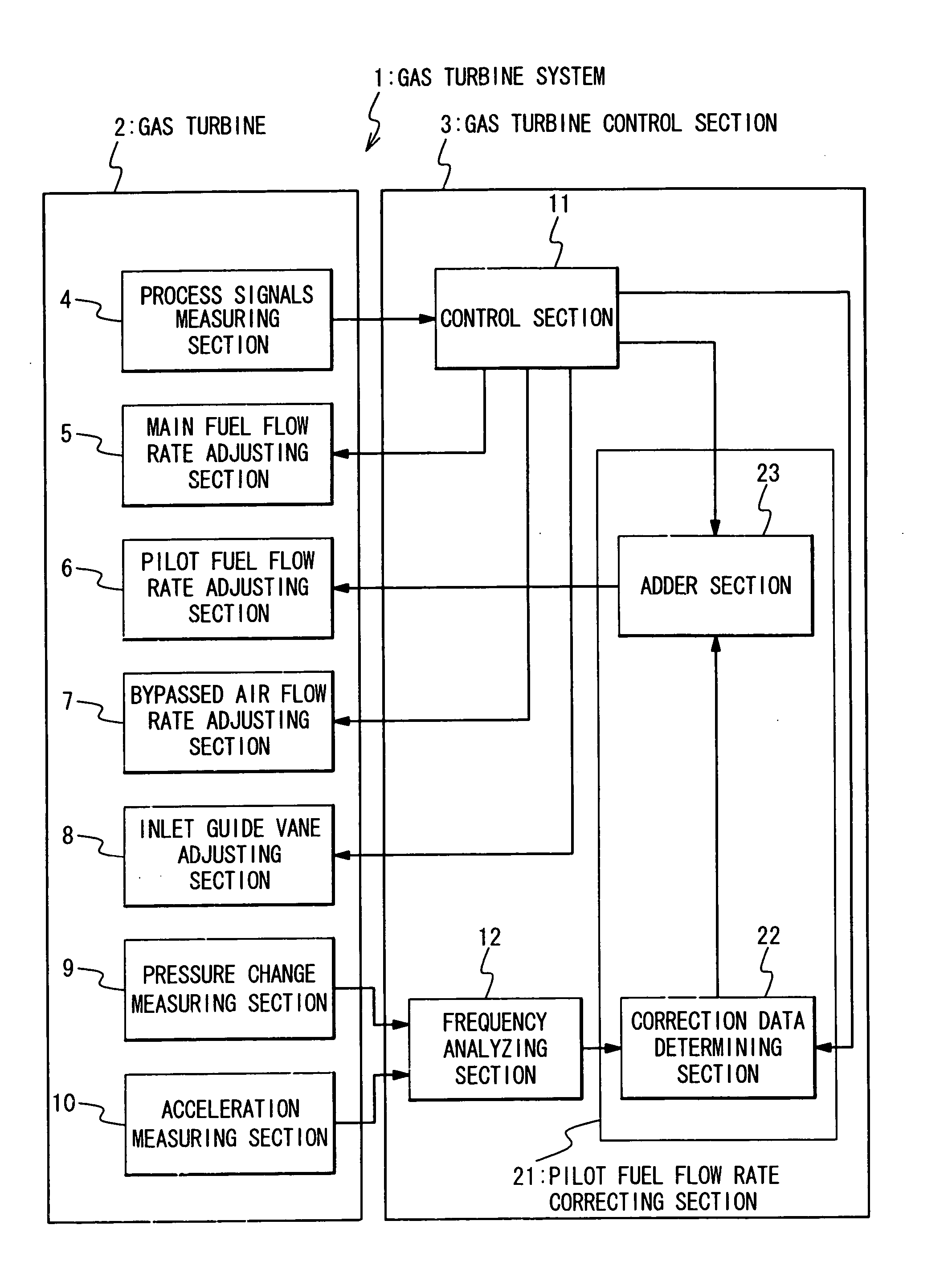

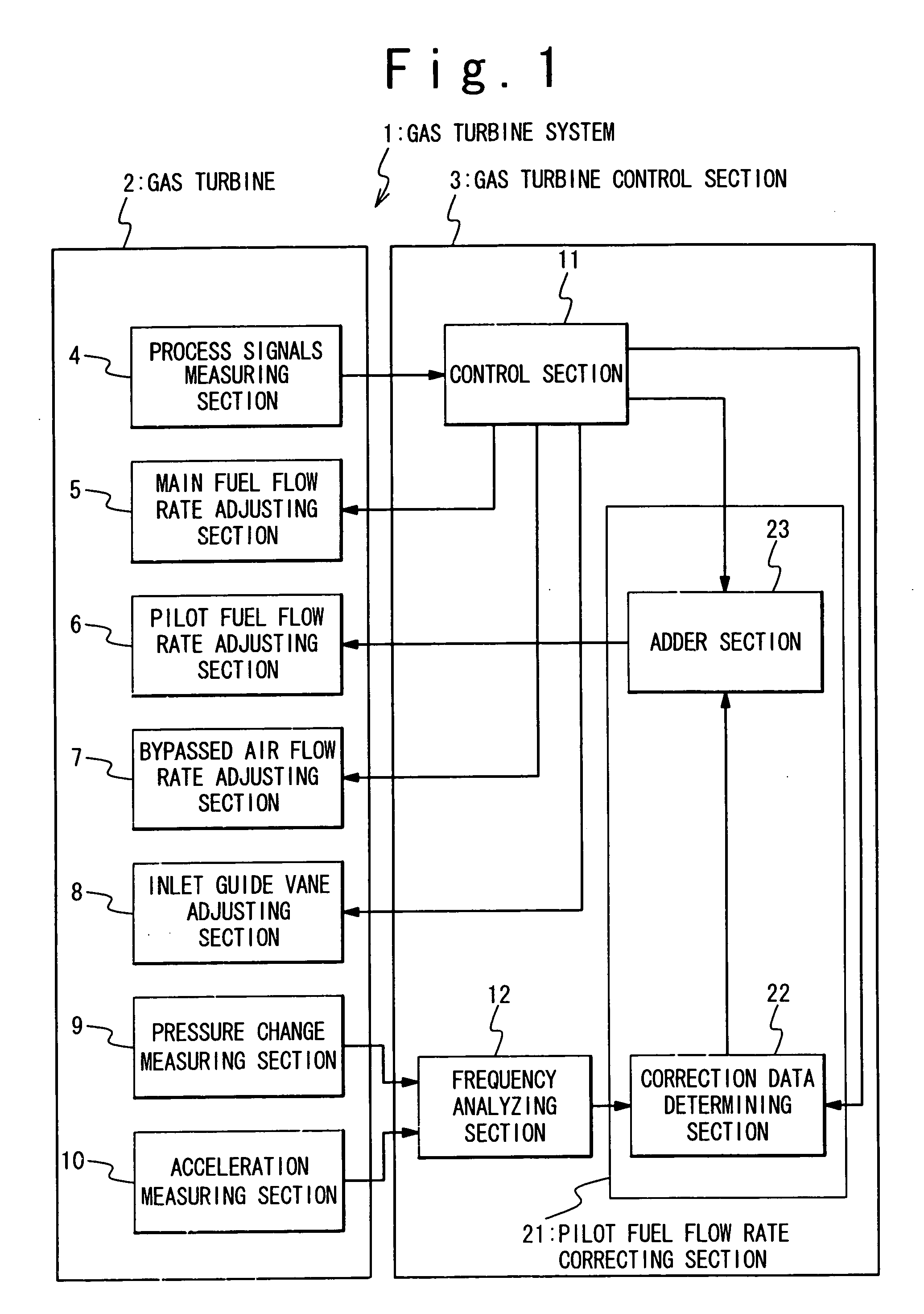

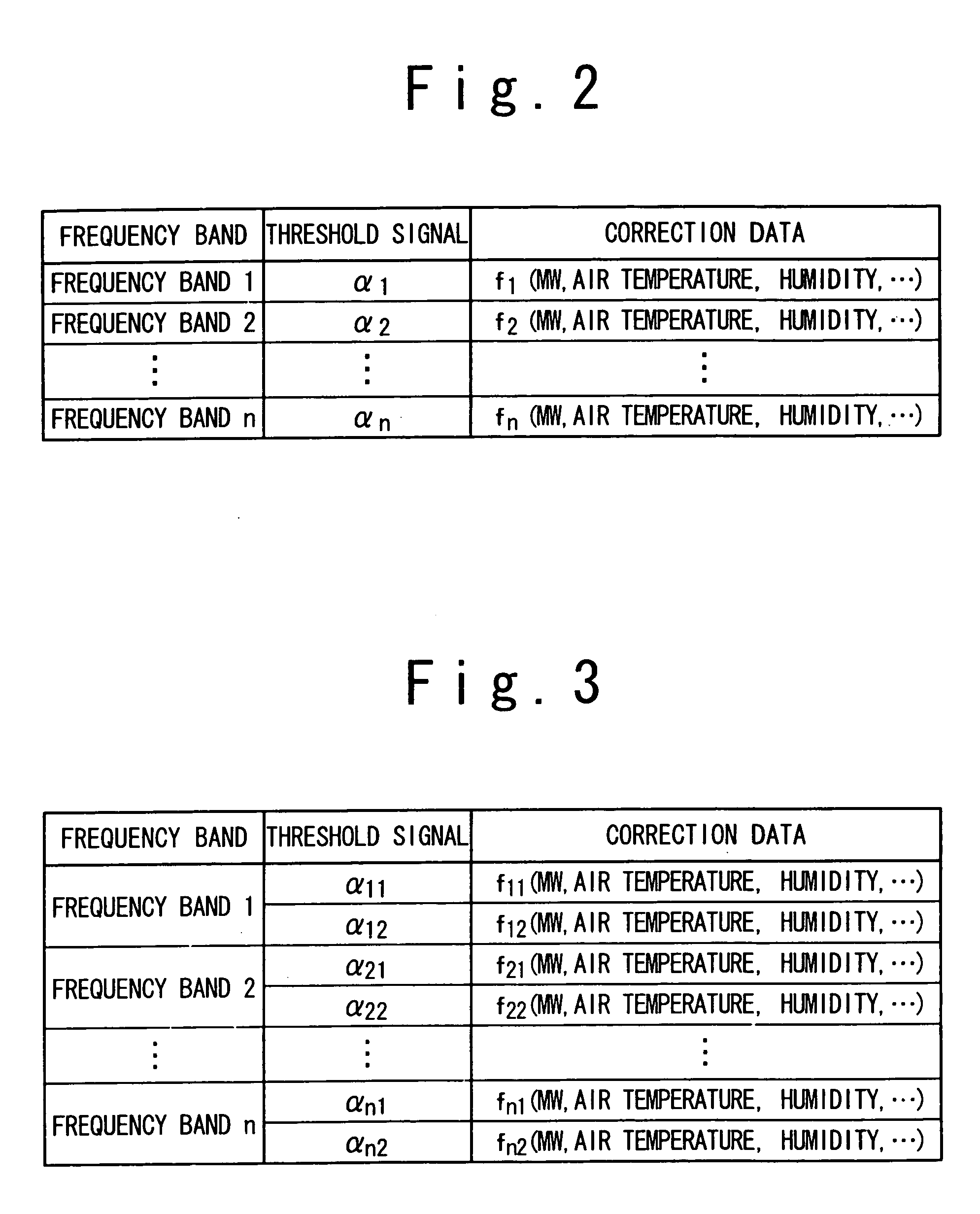

Gas turbine control apparatus and gas turbine system using the same

InactiveUS6955039B2Promote combustionOscillation suppressionContinuous combustion chamberEngine fuctionsCombustorGas turbines

In a gas turbine control apparatus, a frequency analyzing section frequency-analyzes at least one of pressure oscillation in combustors of a gas turbine and acceleration oscillation of each of the combustors and outputs a first frequency analysis result as the result of frequency analysis for a plurality of predetermined frequency bands. A control unit controls at least one of a first fuel flow rate of fuel and a first air flow rate of air based on the first frequency analysis result for the plurality of frequency bands. The fuel and the air are supplied to the gas turbine.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

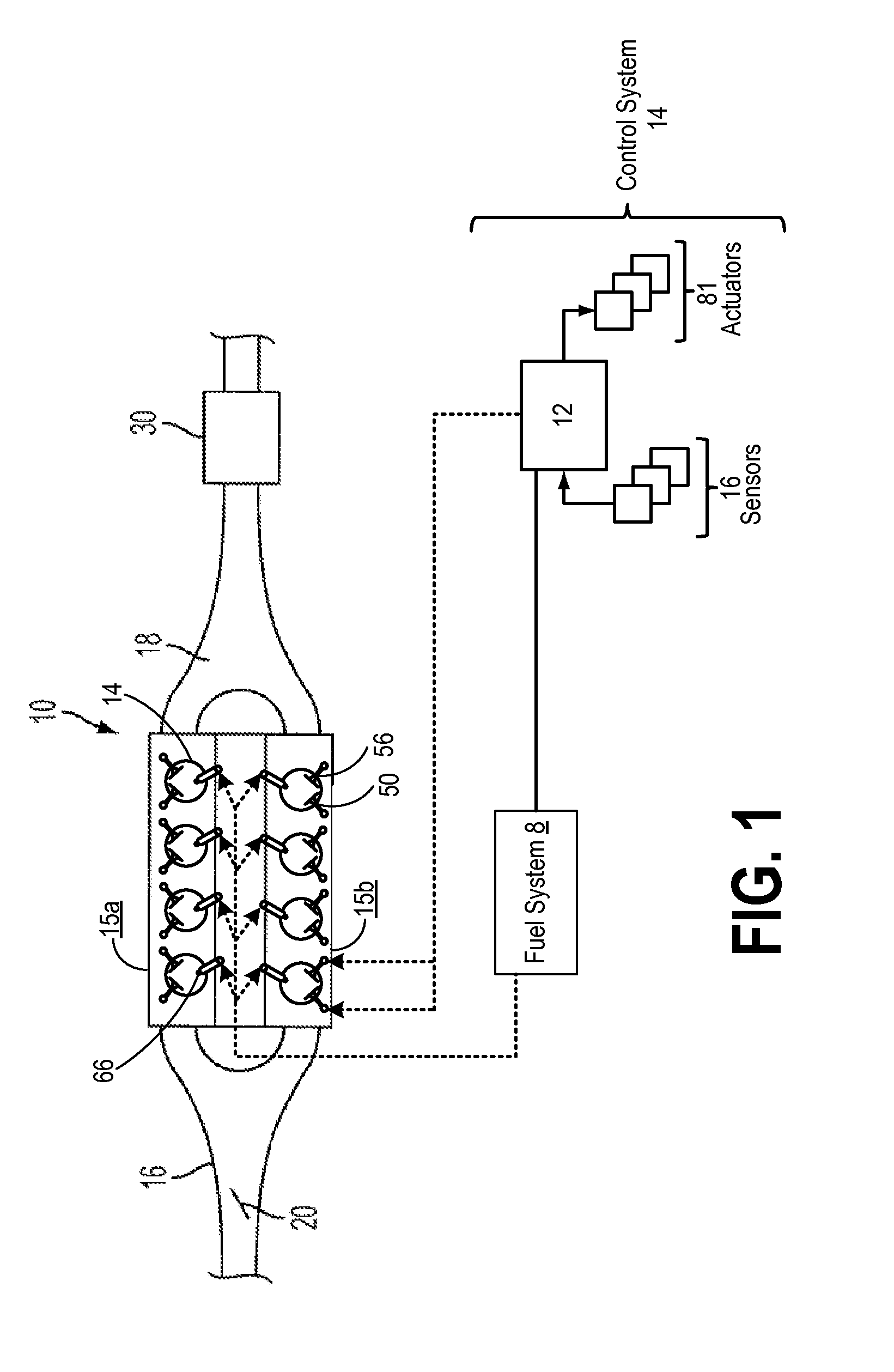

Method and system for particulate matter control

ActiveUS20160115878A1Extending cylinder deactivation benefitImprovement in PM emissionElectrical controlSpeed sensing governorsParticulatesCoolant temperature

Methods and systems are provided for particulate matter control in an engine configured for skip-fire operation. A cylinder pattern selected for selective cylinder deactivation, including a total number of deactivated / active cylinders as well as individual deactivated cylinder identities, may be adjusted based on an engine soot load, or a parameter indicative of engine soot load such as engine coolant temperature. In addition, reactivated engine cylinders may be transiently operated with split fuel injection to raise combustion surface temperatures.

Owner:FORD GLOBAL TECH LLC

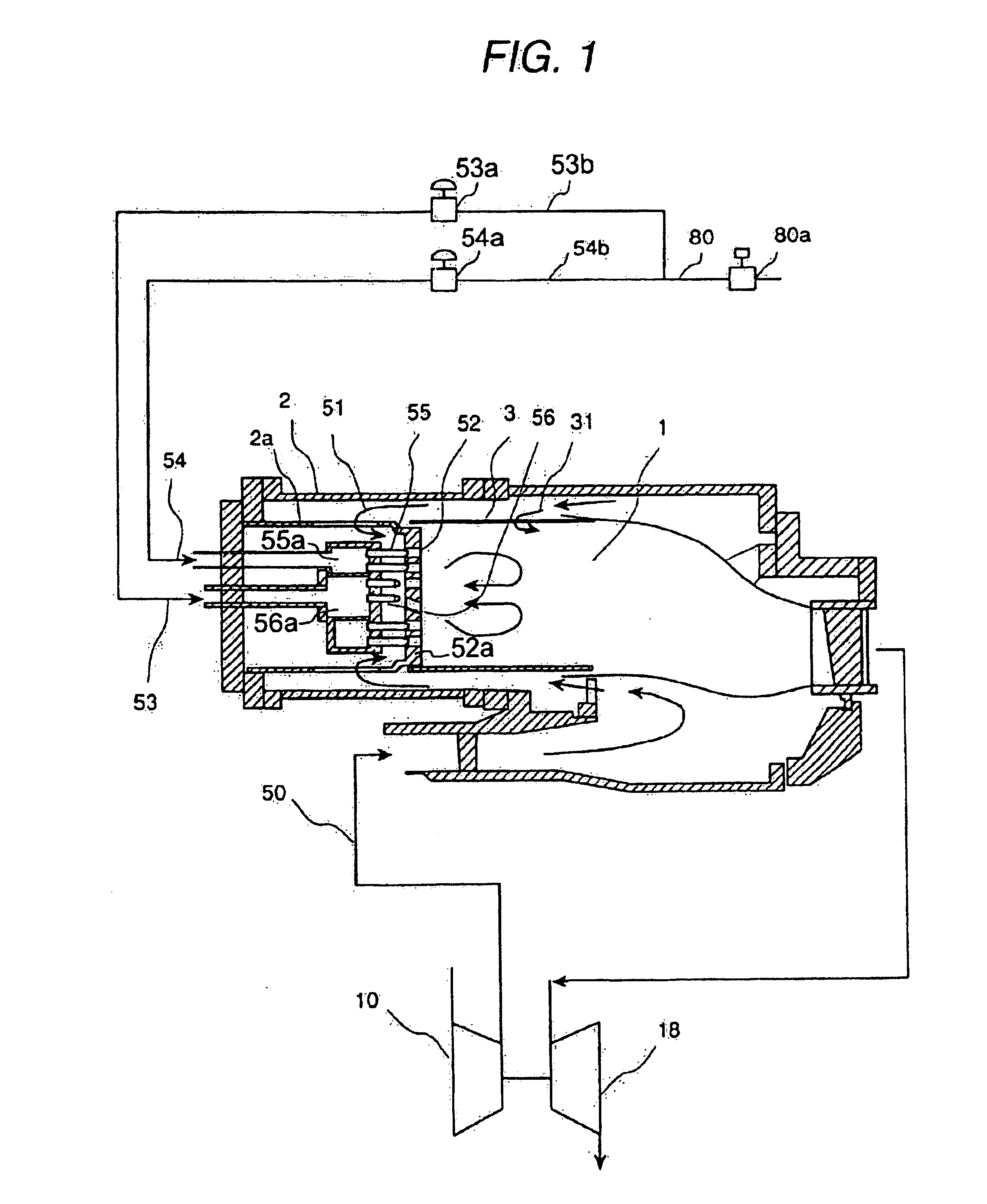

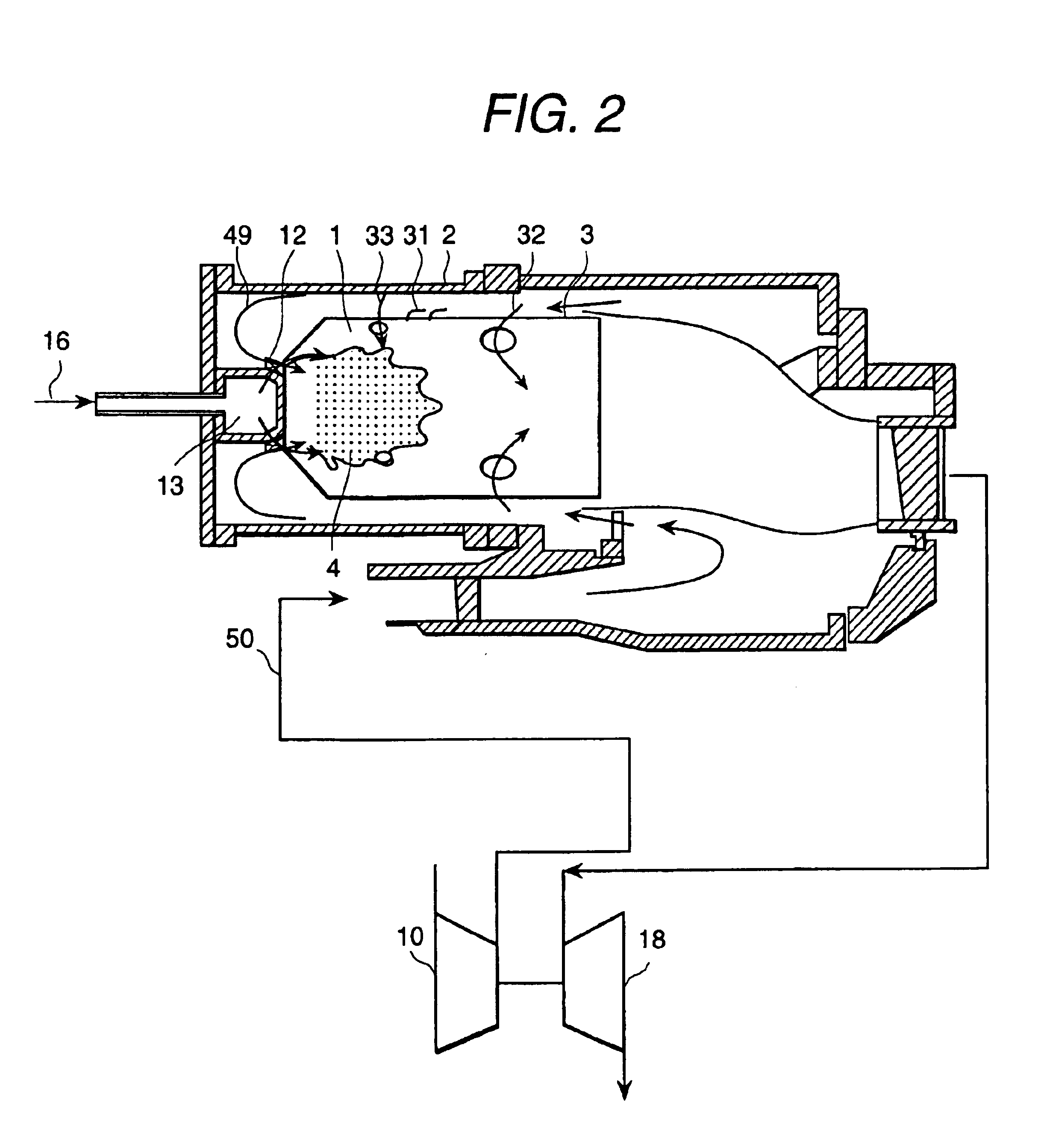

Gas turbine combustor and operating method thereof

InactiveUS6928823B2Low level NOx emissionImprove combustion stabilityContinuous combustion chamberTurbine/propulsion engine ignitionCombustion chamberCombustor

A gas turbine combustor has a combustion chamber into which fuel and air are supplied, wherein the fuel and the air are supplied into said combustion chamber as a plurality of coaxial jets.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

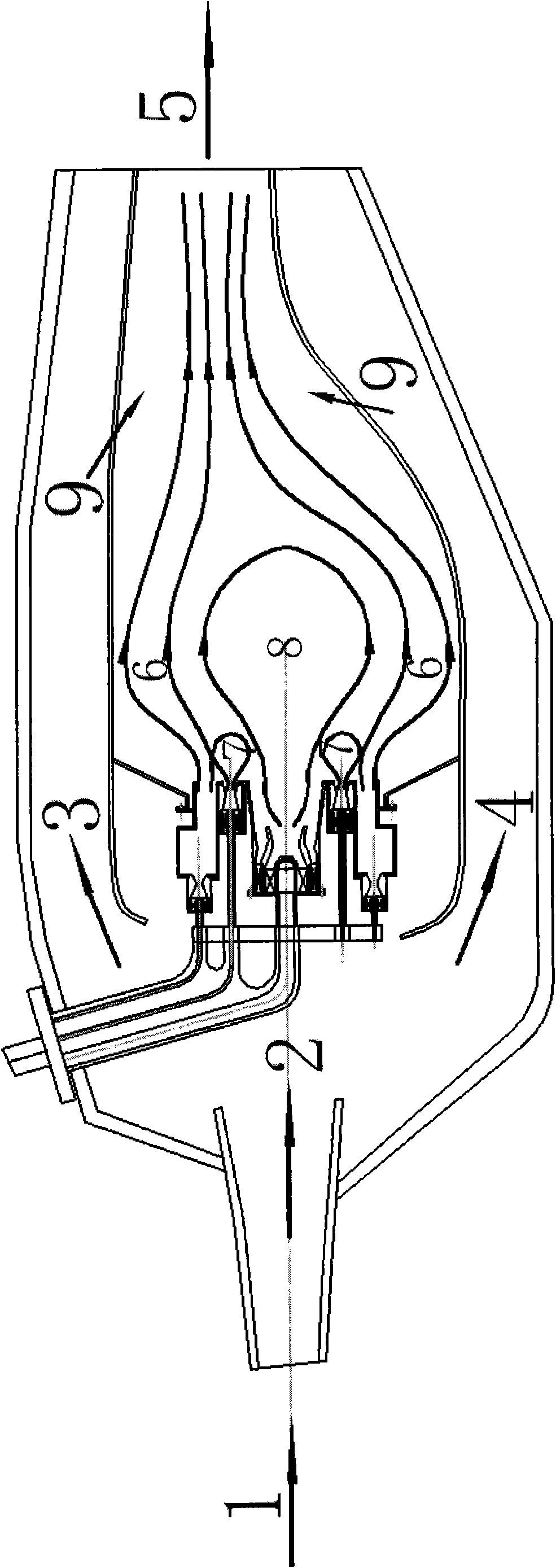

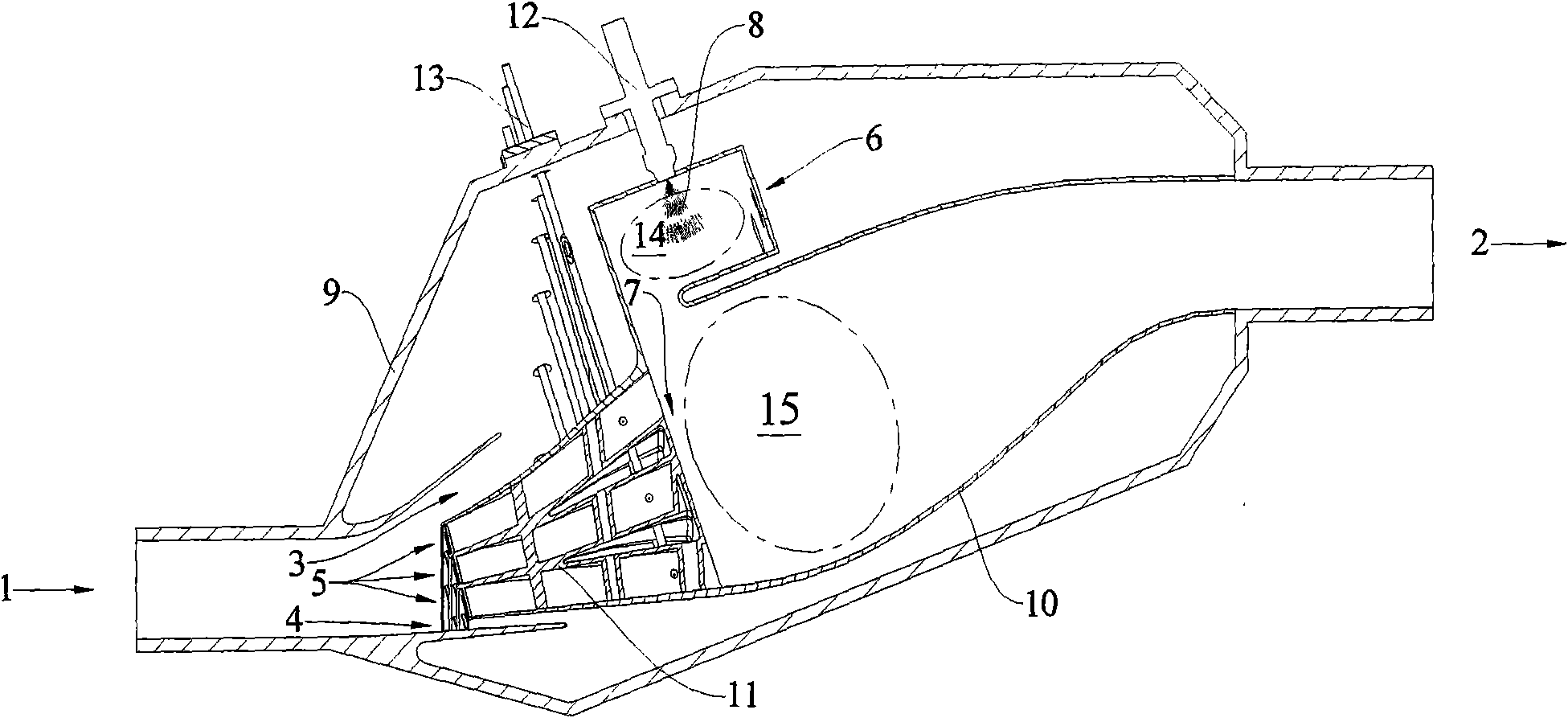

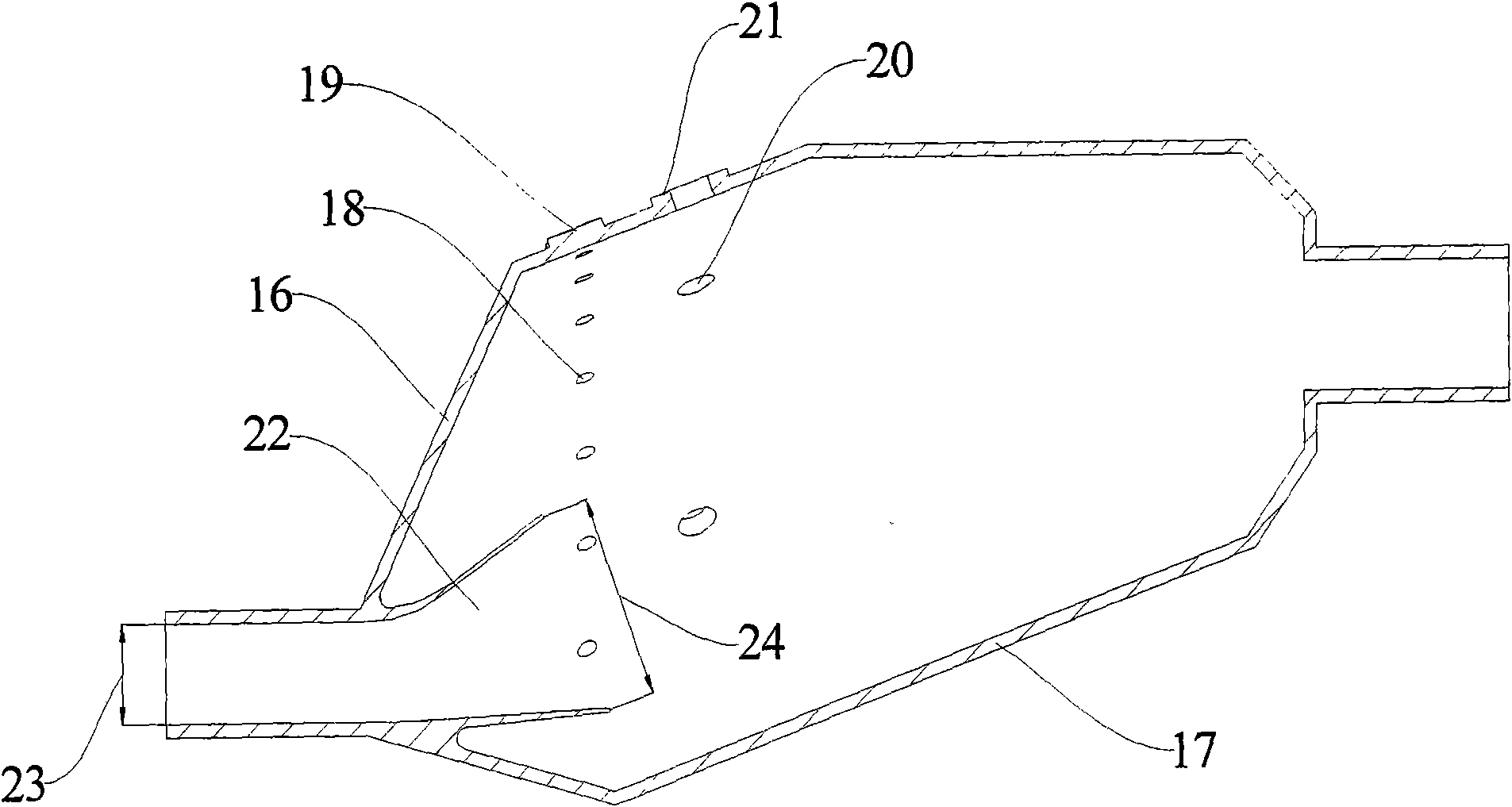

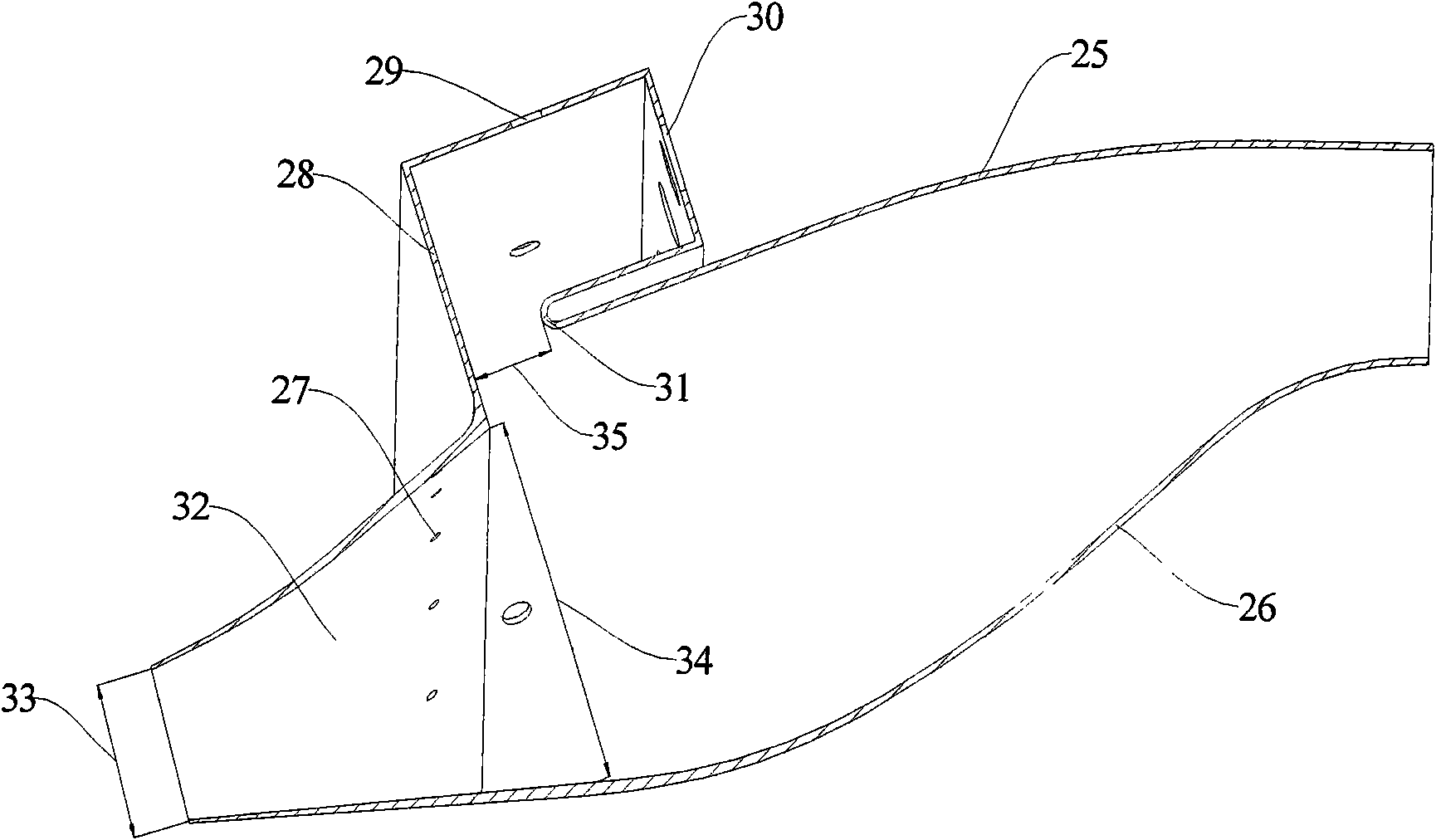

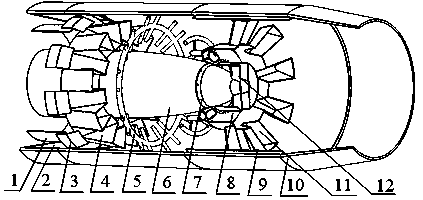

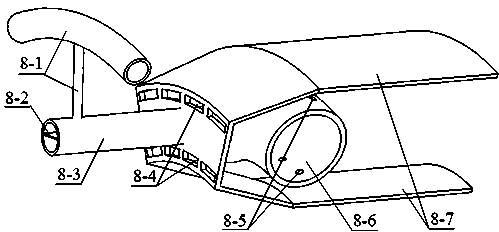

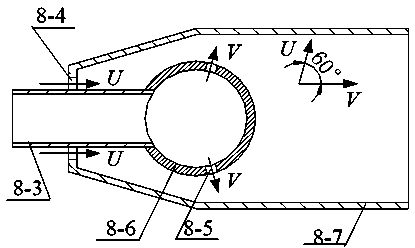

Circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages

InactiveCN102032598AImprove combustion stabilityIncrease the intermediate flame levelContinuous combustion chamberCombustion chamberLow speed

The invention discloses a circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages. The combustion chamber has a single annular cavity structure; a low-pollution combustion organization mode in which air grading is matched with fuel oil grading is adopted; all fuel gas is supplied by a duty stage, a middle stage and a main combustion stage; and fuel oil grading supply proportion is controlled accurately according to the operating condition of an engine and the requirement on stable low-pollution combustion. The duty stage has a combined structure in which two-stage axial spiral flow is matched with a venturi tube, and a formed low-speed reflux region can support stable combustion of the combustion chamber; the middle stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, and a formed middle flame stabilizing stage combustion region is used for intensifying and stabilizing flame in the main combustion stage; and the main combustion stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, so that an oil and gas mixed poor-oil premixing and pre-evaporation combustion mode is intensified and the emission of pollutants is further reduced greatly.

Owner:BEIHANG UNIV

Method in connection with engine control

InactiveUS20030172907A1Improve performanceFunction increaseElectrical controlInternal combustion piston enginesCombustionEngine control unit

This invention relates to a method in connection with engine control, wherein a combustion feedback signal is derived by measuring one or more combustion related parameters during a chosen time period of a first combustion cycle, for control of a possible fault, wherein at least one reference feature for said parameters has been determined previously, and comparing said measured combustion feed back signal with said reference feature for automatic adaptation of at least one combustion related variable during a forthcoming combustion cycle wherein at least one reference features for each one of at least two different fault situations having been determined previously, and that a diagnosis 3 of said first combustion cycle is performed on the basis of said combustion feedback signal being processed and compared (T1-Tn) with each one of said reference features, the result of which is analysed by a decision logic, whereafter a diagnosis (D) is established by means of which one or more variables in a forthcoming combustion cycle is / are regulated in dependence of the outcome (D) of said diagnosis, thereby achieving fault tolerant engine control.

Owner:ALTRONIC

Method of operating an internal combustion engine

ActiveUS20080178836A1Overcome disadvantagesAccelerate emissionsValve arrangementsElectrical controlExternal combustion engineInternal combustion engine

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, comprising during a first mode, bringing the temperature of the combustion chamber to auto-ignition temperature by adjusting engine operating conditions and producing auto-ignition in said combustion chamber without requiring spark from said spark plug; and during a second mode, bringing the temperature of the combustion chamber close to auto-ignition temperature by adjusting engine operating conditions, forming a small cloud of stratified air-fuel mixture near said spark plug, igniting said fuel cloud by a spark form said spark plug, and then causing cylinder pressure to rise, thereby producing auto-ignition at other sites in said combustion chamber wherein said first mode is implemented in a first operating range and said second mode is implemented only in a second operating range where engine speed and load are lower than said first operating range.

Owner:MAZDA MOTOR CORP

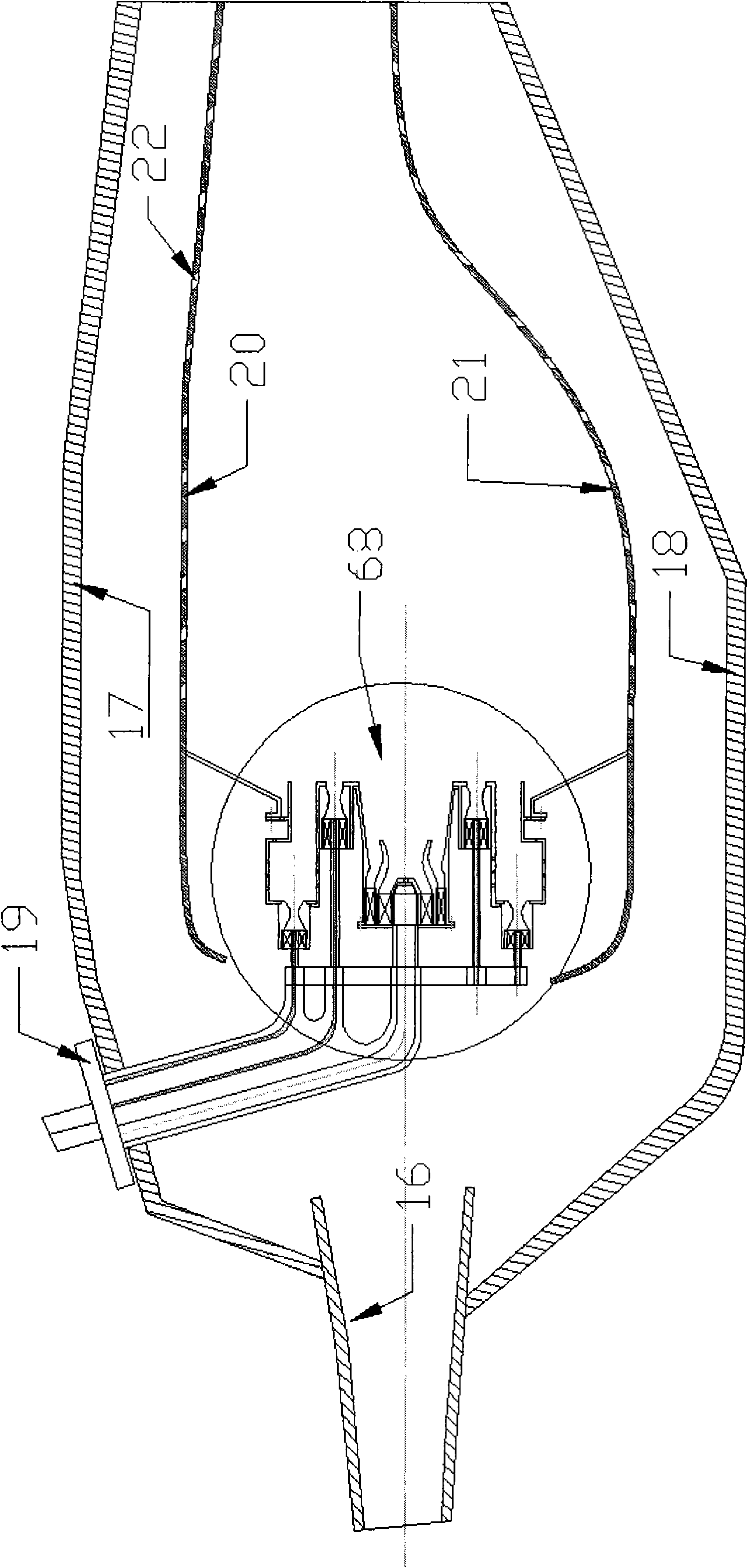

Integrated diffusion oriented combustion chamber

InactiveCN101650038AGuaranteed temperature distributionSimplified matching structureContinuous combustion chamberLow speedCombustion chamber

The invention relates to an integrated diffusion oriented combustion chamber which adopts a full ring combustion chamber structure. The integrated diffusion oriented combustion chamber mainly comprises a crankcase, a combustion liner and an oriented diffuser. The oriented diffuser realizes pneumatic and structural coupling, controls the tangential flow direction and carries out diffusion and speedreduction, and a local return low-speed zone is formed, thereby being good for flame linkage and tangential stable combustion; grading combustion is adopted, and a pre-combustion grade can be selected to work alone and work together with a main pre-combustion grade according to work conditions; the pre-combustion grade utilizes the trapped vortex combustion technology for stable work, goes into amain combustion zone to inflame a main combustion grade through a contraction outlet, and provides a stable ignition source for the main combustion grade; fuel of the main combustion grade is injected to a main combustion grade airflow in the oriented diffuser, atomization evaporation mixing with short distance is realized, and combustible mixture gas with uniform mixing is provided for the maincombustion zone. The invention allows tangential rotational flow of a gas compressor to directly go into the combustion chamber so as to realize tangential highly efficient and stable combustion; in addition, the discharge of pollutants is low, pre-rotation is provided for a turbine, the structure can be simplified, the weight is lightened, and the densification of a gas turbine is realized.

Owner:BEIHANG UNIV

Turbine-based combined cycle engine super-combustion chamber

InactiveCN104019465ASatisfy Advancement RequirementsSolve key technical difficultiesContinuous combustion chamberRamjetGroove width

The invention discloses turbine-based combined cycle engine super-combustion chamber. Key parts of the super-combustion chamber comprise a shunt ring, a rear area-variable deflation valve, a flow guide tongue piece, a square lobe mixer, a first area fuel ejector, a center cone, a second area fuel injection ring, an evaporation tube flame stabilizer, a heat-isolating screen, a super-combustion chamber cylinder, an outer extending groove-width-variable radial flame stabilizer and an inner extending radial flame stabilizer. An internal flow field of the super-combustion chamber is reasonably distributed, the phenomenon of backflow from a punching duct to a turbofan duct can not occur, flow separation can not occur in the square lobe mixer, and the evaporation tube flame stabilizer can achieve soft ignition of the super-combustion chamber. The whole super-combustion chamber is high in mixing efficiency, little in cold flow resistance, high in combustion efficiency, reasonable in temperature distribution, and capable of meeting use requirements in a whole flight envelope of the super-combustion chamber in each work state and the requirement for boost of an turbofan ramjet.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gas turbine control method and device

ActiveUS20110004390A1Improve combustion stabilityAnalogue computers for vehiclesGas turbine plantsCombustorOperant conditioning

Provided is a gas turbine control method and control device whereby a design performance and an operating state based on ideal fuel flow rate and air flow rate simulated at the time of designing can be maintained by preventing an operation deviated from an operating condition that is based on ideal fuel flow rate and air flow rate simulated by initial design values, in a gas turbine control method designed to search optimal operating conditions automatically using control inputs such as a pilot ratio. The gas turbine controller comprises a second database that stores load sensitivity, i.e. the correlation between the load amount of a gas turbine and control inputs such as a fuel flow rate, air flow rate, pilot fuel ratio, and top hat fuel ratio in the gas turbine, wherein the amount of load variation for at least one of control inputs, a fuel flow rate or an air flow rate supplied to a combustor is predicted according to operational conditions obtained by searching using the load sensitivity, regulation is made according to the prediction results, and the regulation results are stored in the second database.

Owner:MITSUBISHI POWER LTD

Gas only fin mixer secondary fuel nozzle

InactiveUS6898937B2Reduces NOx and other air pollutantUniform profileBurnersContinuous combustion chamberCombustorCombustion chamber

A premix fuel nozzle and method of operation for use in a gas turbine combustor is disclosed. The premix fuel nozzle utilizes a fin assembly comprising a plurality of radially extending fins for injection of fuel and compressed air in order to provide a more uniform injection pattern. The fuel and compressed air mixes upstream of the combustion chamber and flows into the combustion chamber as a homogeneous mixture. The premix fuel nozzle includes a plurality of coaxial passages, which provide fuel and compressed air to the fin assembly, as well as compressed air to cool the nozzle cap assembly. An alternate embodiment includes an additional fuel injection region located along a conically tapered portion of the premixed fuel nozzle, downstream of the fin assembly. A second alternate embodiment is disclosed which reconfigures the injector assembly and fuel injection locations to minimize flow blockage issues at the injector assembly.

Owner:H2 IP UK LTD

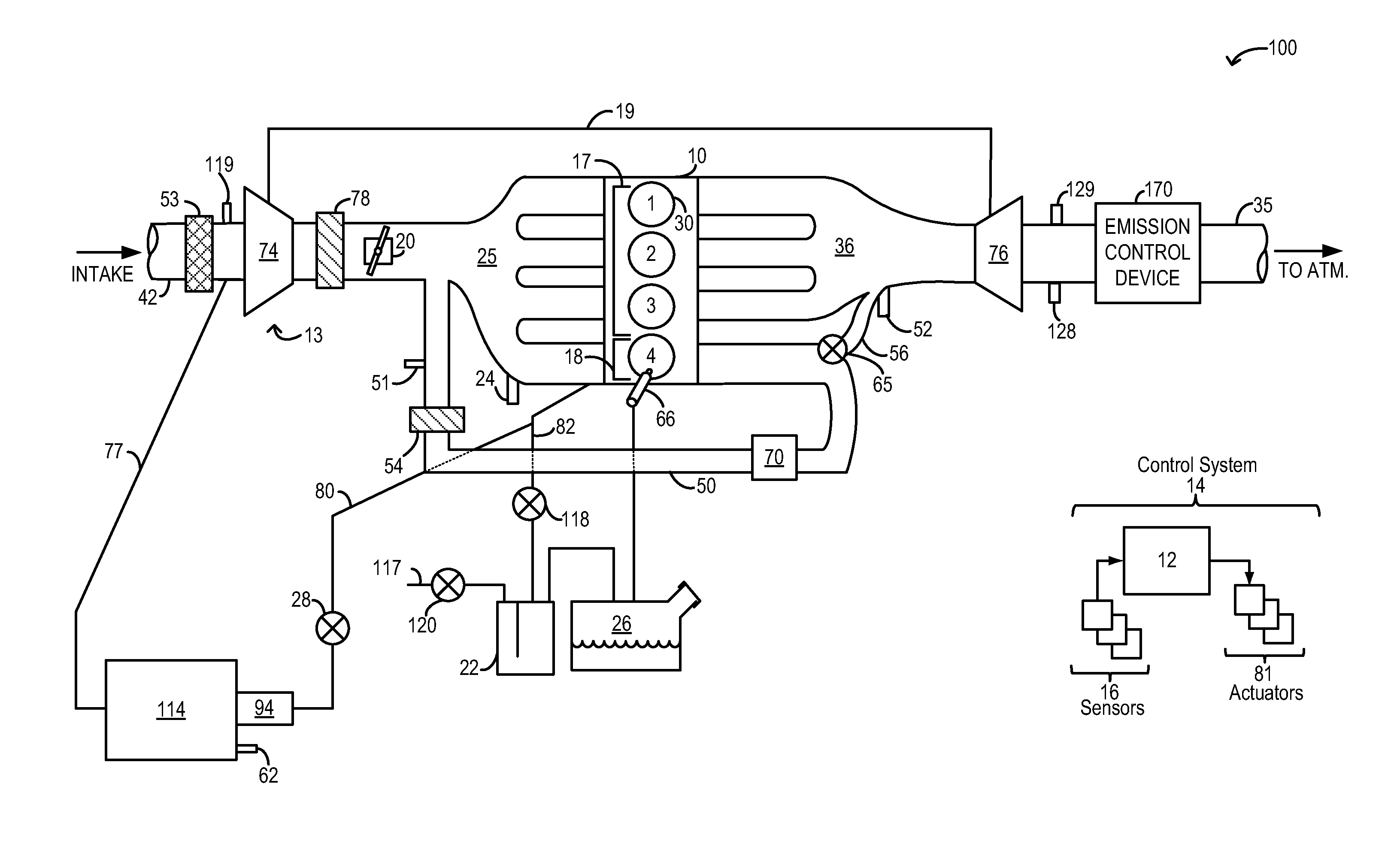

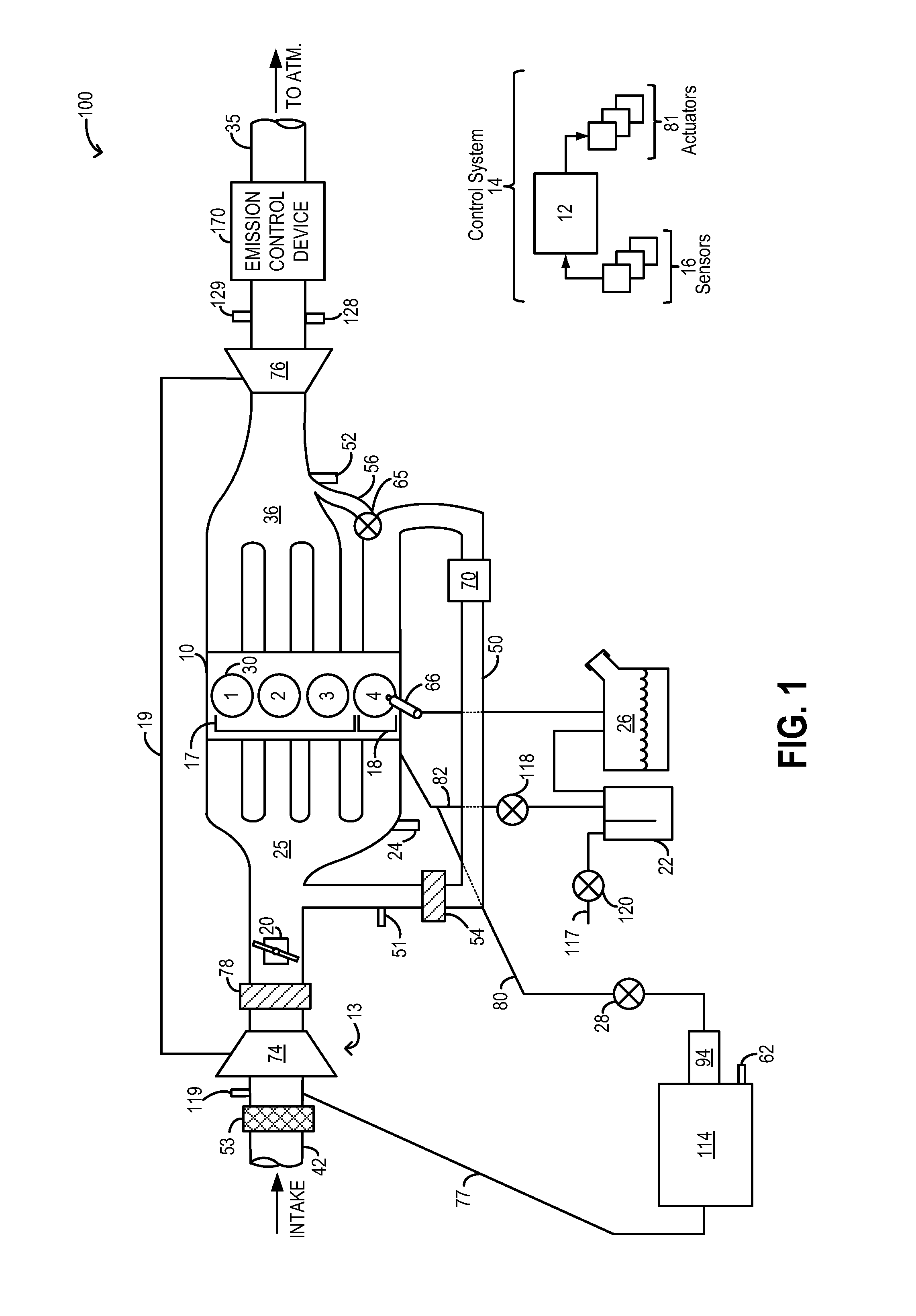

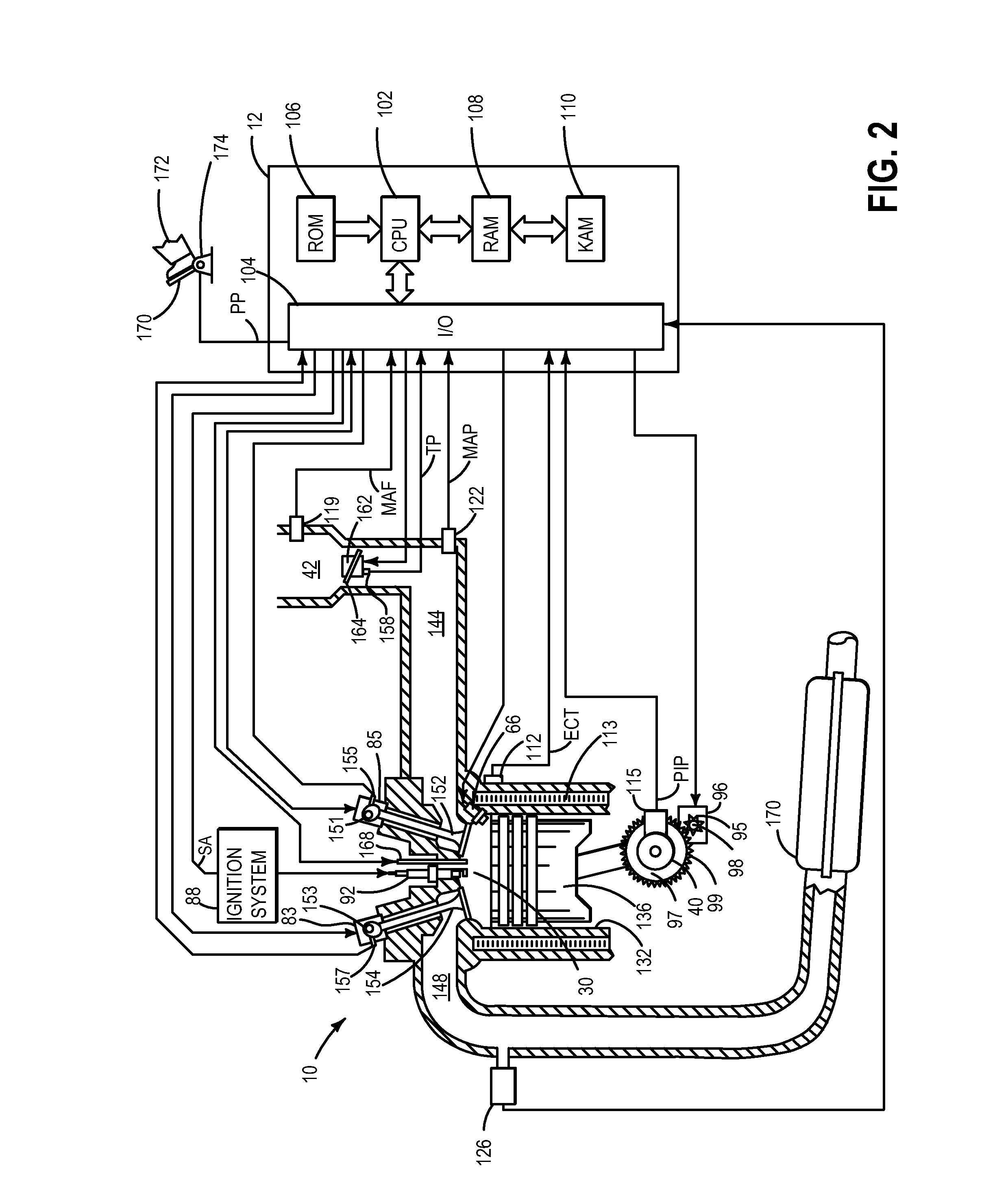

Systems and methods for purge and pcv control

ActiveUS20150337696A1Reliable air-fuel ratio controlImprove toleranceElectrical controlInternal combustion piston enginesEngineeringCrankcase

Methods and systems are provided for improving purge air-fuel ratio control. Fuel vapors from a canister and the crankcase are selectively purged to a group of cylinders and not to remaining engine cylinders. Exhaust is recirculated from the selected group of cylinders to the engine intake wherefrom the EGR is ingested in the remaining engine cylinders and the selected group of cylinders.

Owner:FORD GLOBAL TECH LLC

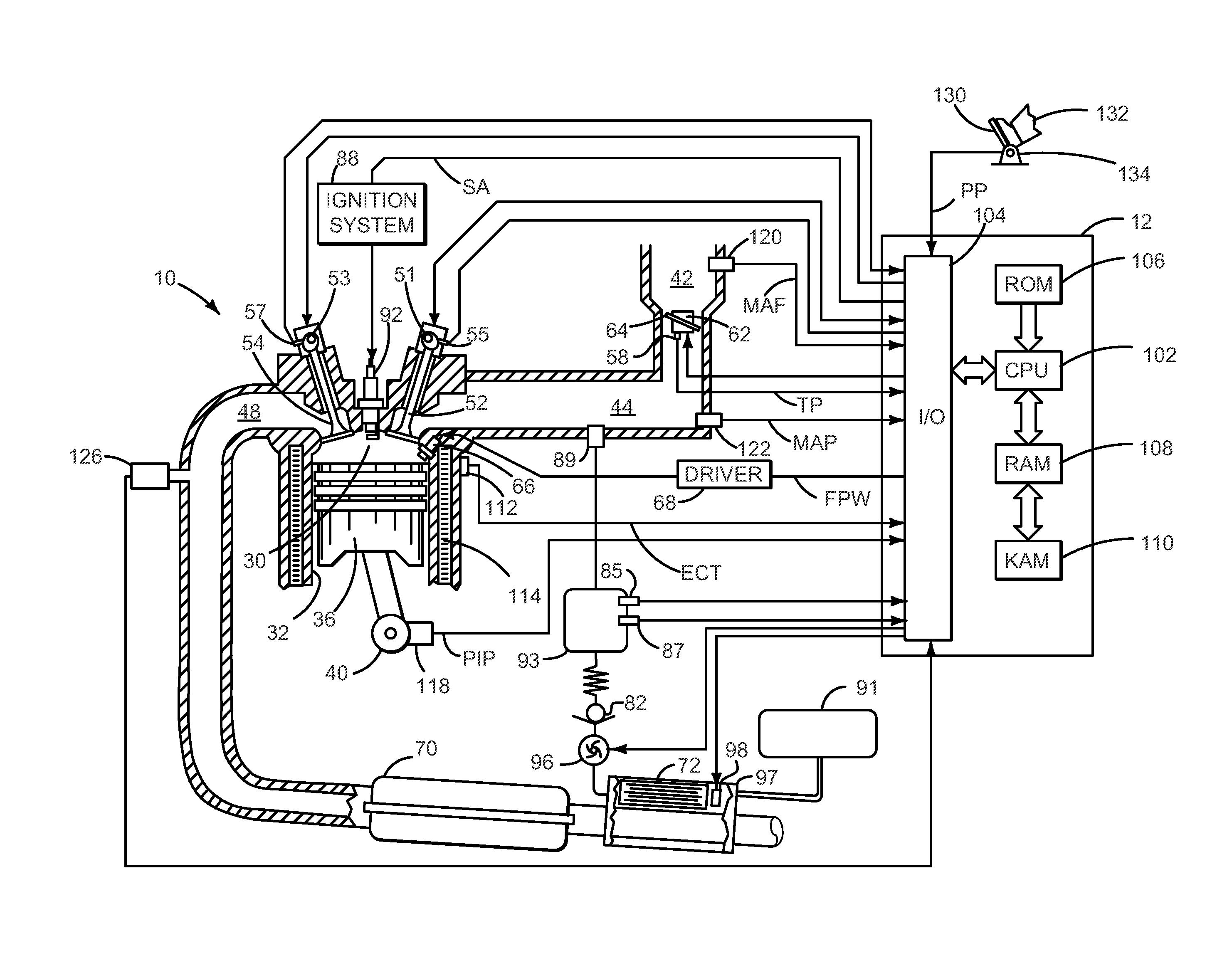

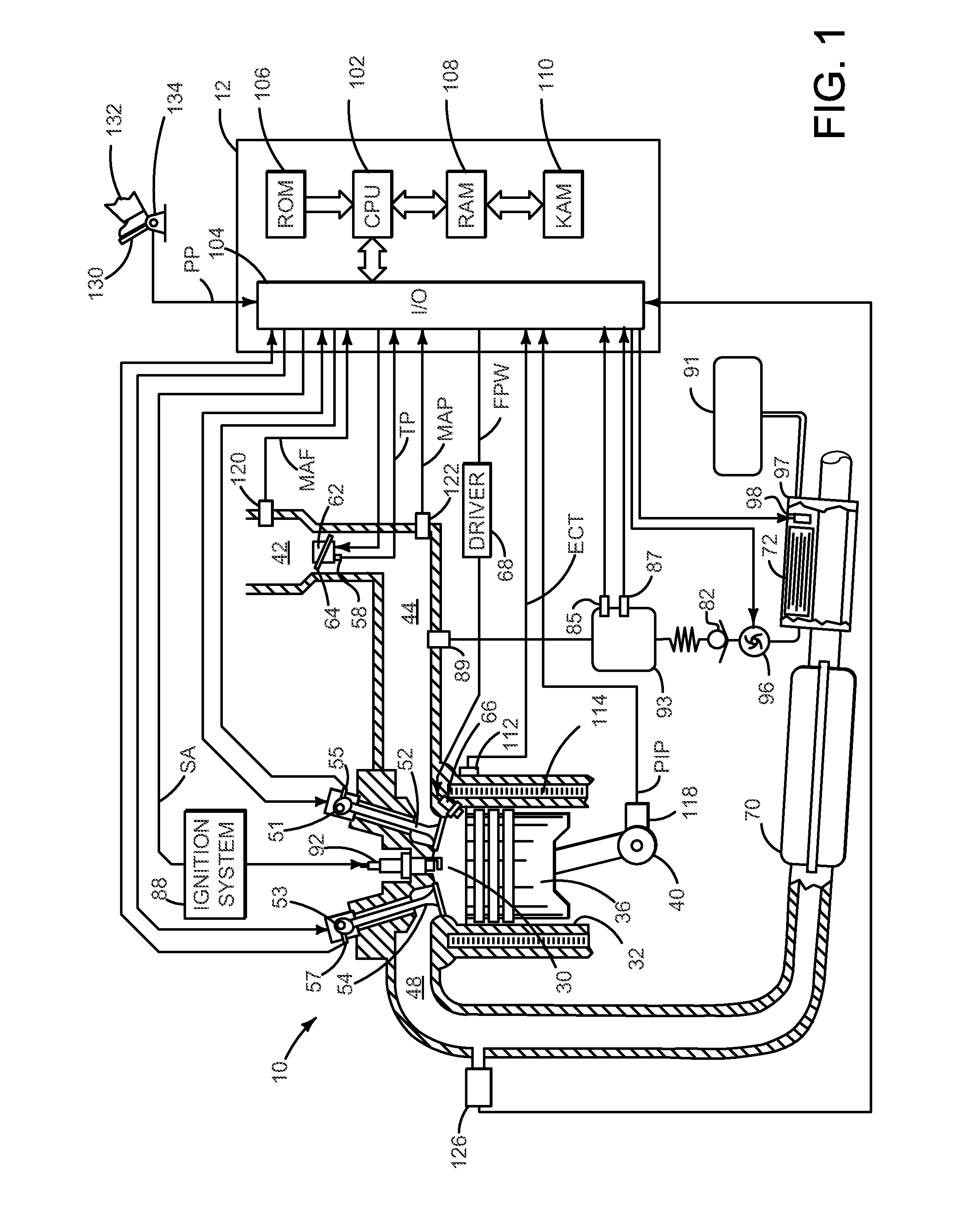

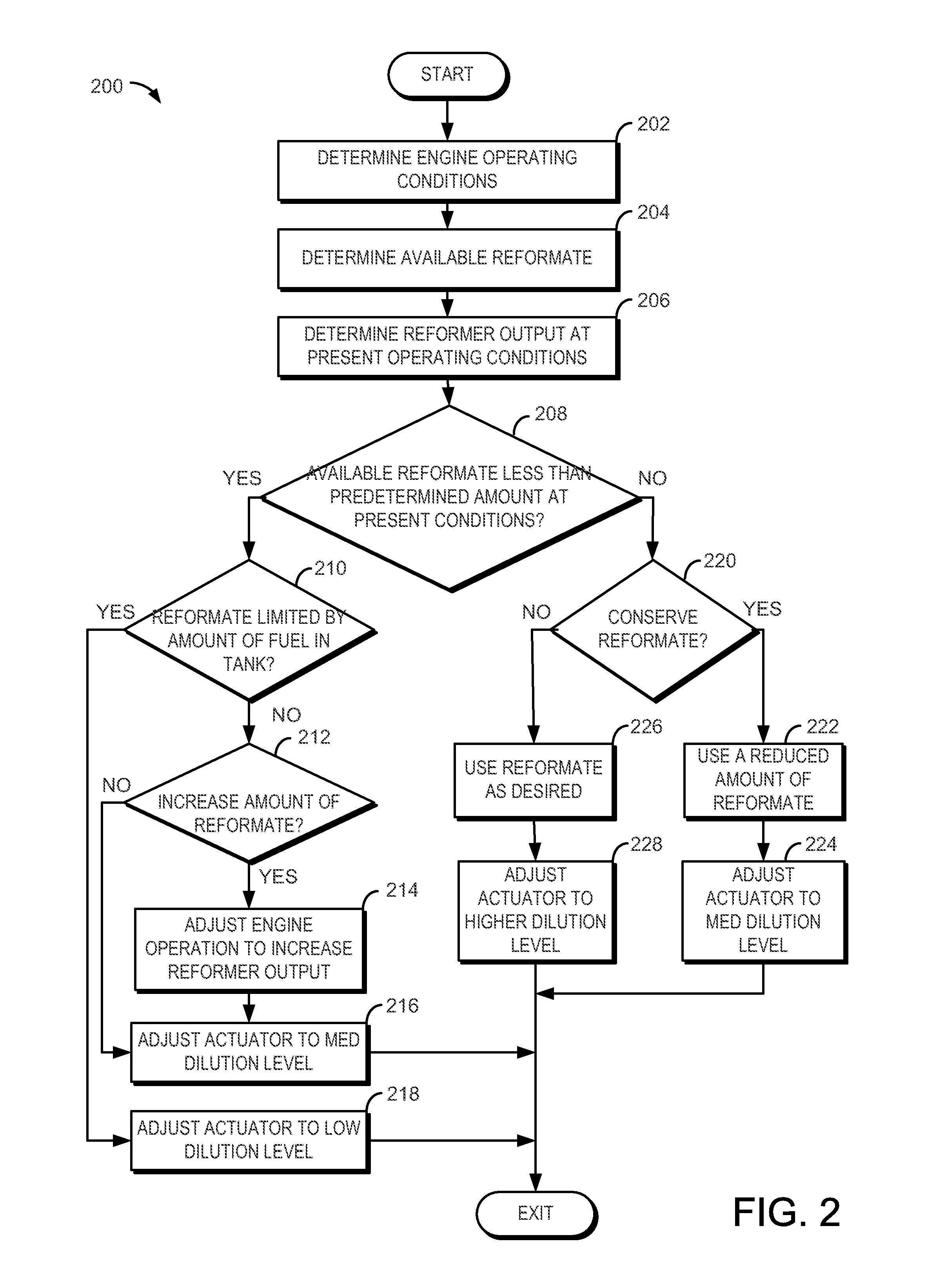

Method for improving transient engine operation

ActiveUS20110132323A1Emission reductionImprove fuel economyValve arrangementsElectrical controlLiquid fuelAutomotive engineering

A method for operating an engine with a fuel reformer is presented. In one embodiment a method for operating an engine by injecting a gaseous fuel and a liquid fuel to at least an engine cylinder is presented. The mixture of an engine cylinder may be diluted with EGR and a fraction of gaseous fuel may be increased relative to a fraction of liquid fuel injected to a cylinder in response to an operator tip-out.

Owner:FORD GLOBAL TECH LLC

Fuel adaptation in a homogeneous charge compression ignition engine

InactiveUS7337762B2Improve combustion stabilityImprove operationValve arrangementsElectrical controlEngineeringMechanical engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

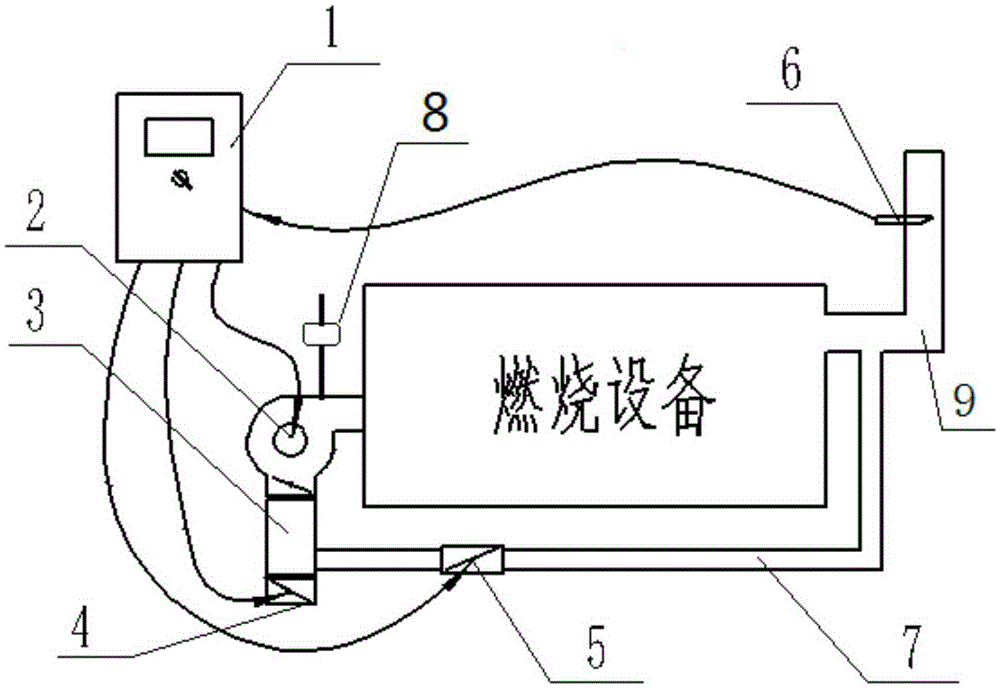

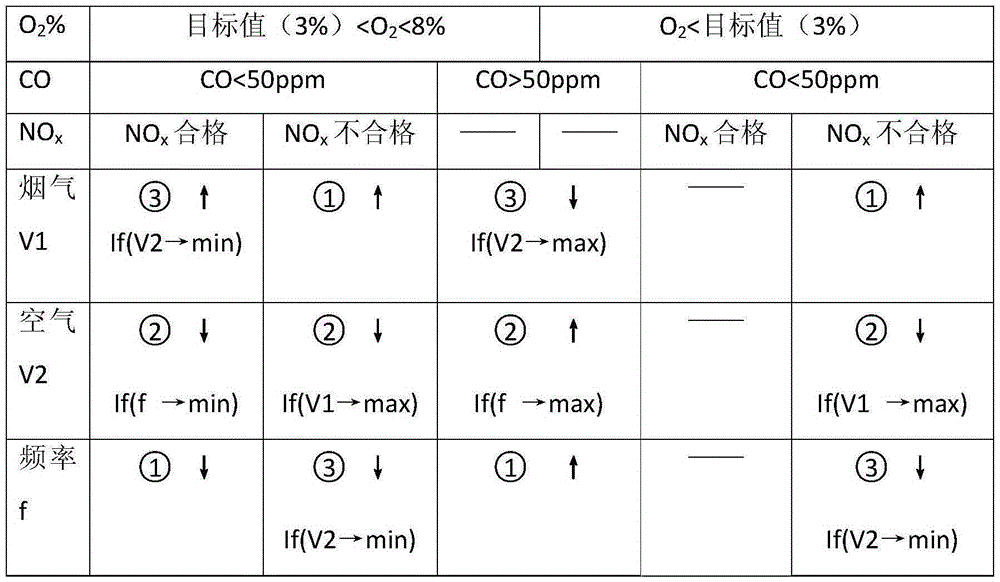

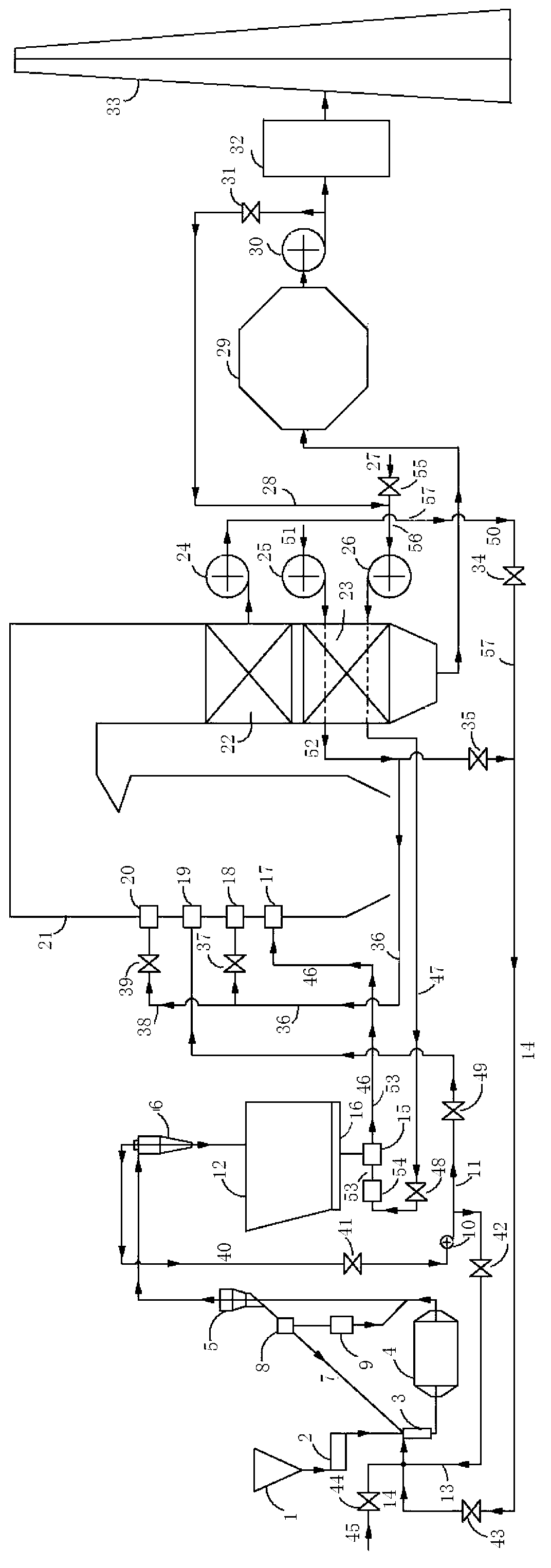

System and method for reducing emission of oxynitride of combustion equipment

ActiveCN105387458AEffective emission controlStable emissionsFuel supply regulationFluegas recirculationAir volumeCombustor

The invention relates to a system for reducing emission of oxynitride of combustion equipment. The system comprises the combustion equipment with a burner and a flue. A gas flow adjusting valve is installed on a pipeline connecting the burner with a gas source. The flue is internally provided with a sensor used for detecting the concentration of gas components. An air inlet of the burner is connected with an air outlet of an air mixer in series. The air mixer is provided with two air inlets, one of the air inlets is connected with a combustion-supporting air pipeline with an air volume adjusting valve, the other air inlet is connected with a smoke gas returning pipeline with a smoke gas returning flow adjusting valve, the other end of the smoke gas returning pipeline is connected with the position, between the combustion equipment and the sensor, of the flue, and an air blower, the air volume adjusting valve, the smoke gas returning flow adjusting valve and the gas flow adjusting valve are controlled by a low-nitrate controller. The invention further relates to a method for reducing emission of the oxynitride of the combustion equipment. The problem that combustion is not stable in the operation process of an existing smoke gas outer circulation system is solved.

Owner:CHONGQING GIENT ENERGY SAVING TECH

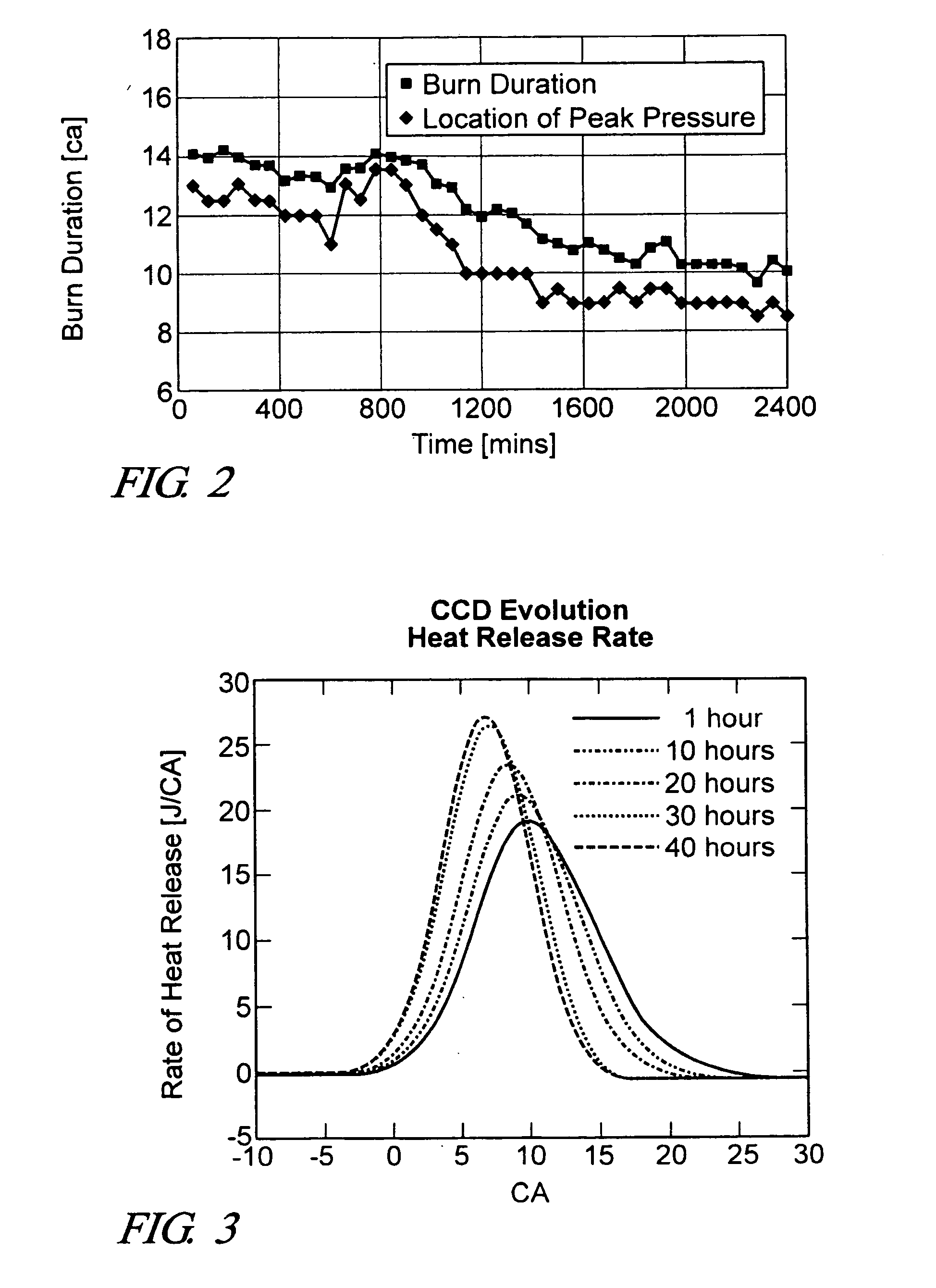

Method to improve combustion stability in a controlled auto-ignition combustion engine

InactiveUS20070084449A1Reduction of combustion variabilityImprove stabilityInternal combustion piston enginesPistonsThermal conductivityMetre/second

A method to control combustion in an HCCI engine, to mitigate effects of combustion chamber deposits is detailed. The method comprises applying a specific surface coating to a combustion chamber surface. The surface coating has thermal properties substantially similar to the combustion chamber deposits. The thermal properties preferably include a) thermal conductivity, b) heat capacity, and c) thermal diffusivity. Applying a surface coating results in a reduction of combustion variability due to variation in combustion chamber deposits, and an improvement on combustion stability at low loads due to reduced heat loss. A preferred thermally insulating surface coating includes thermal parameters of a heat capacity in a range of 0.03×106 J / m3-K to 2.0×106 J / m3-K; a thermal conductivity in a range of 0.25 W / m-K to 2.5 W / m-K; and, a thermal diffusivity in a range of 1×10−7 m2 / s to 8×10−6 m2 / s.

Owner:GM GLOBAL TECH OPERATIONS LLC

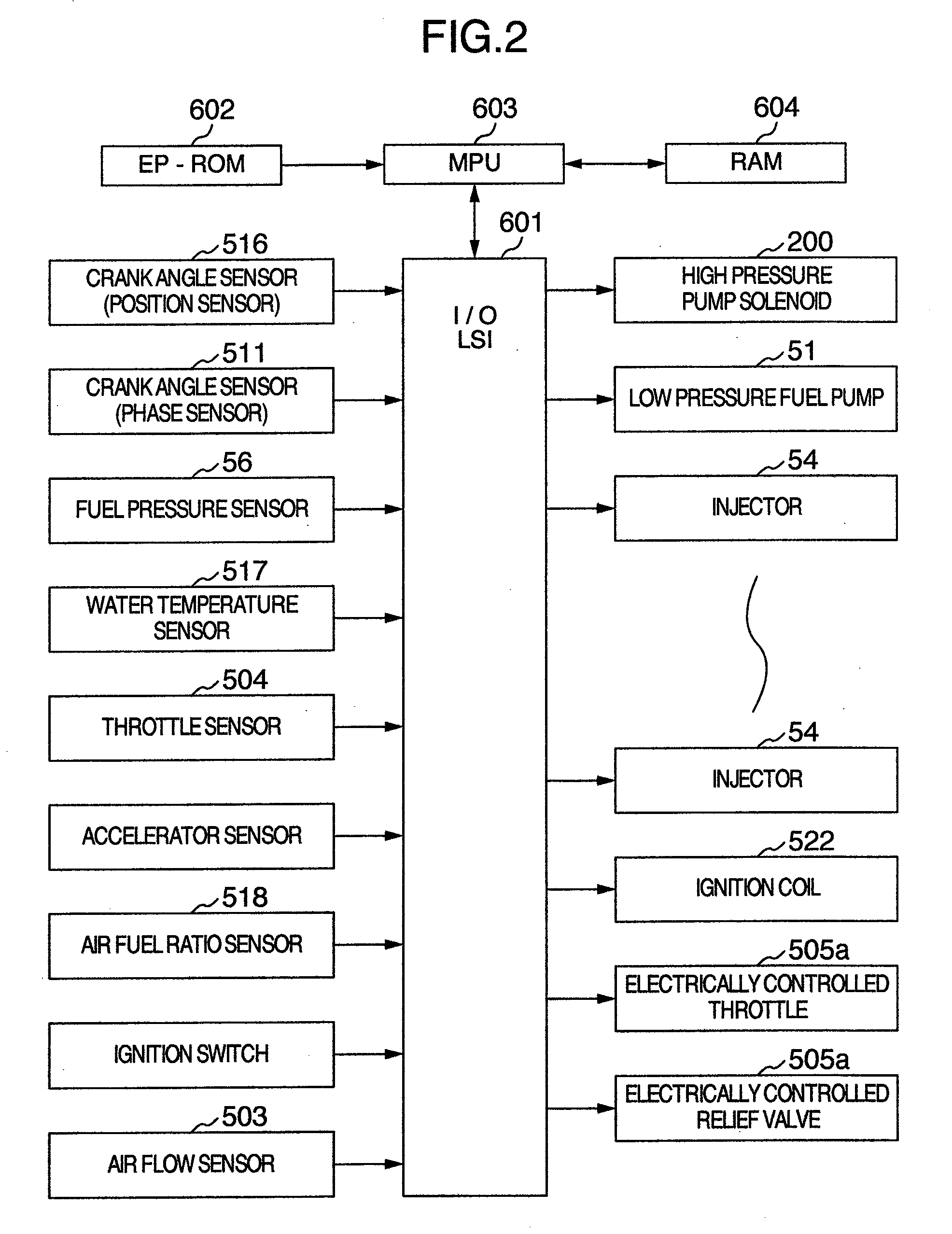

High pressure fuel pump control apparatus for internal combustion engine

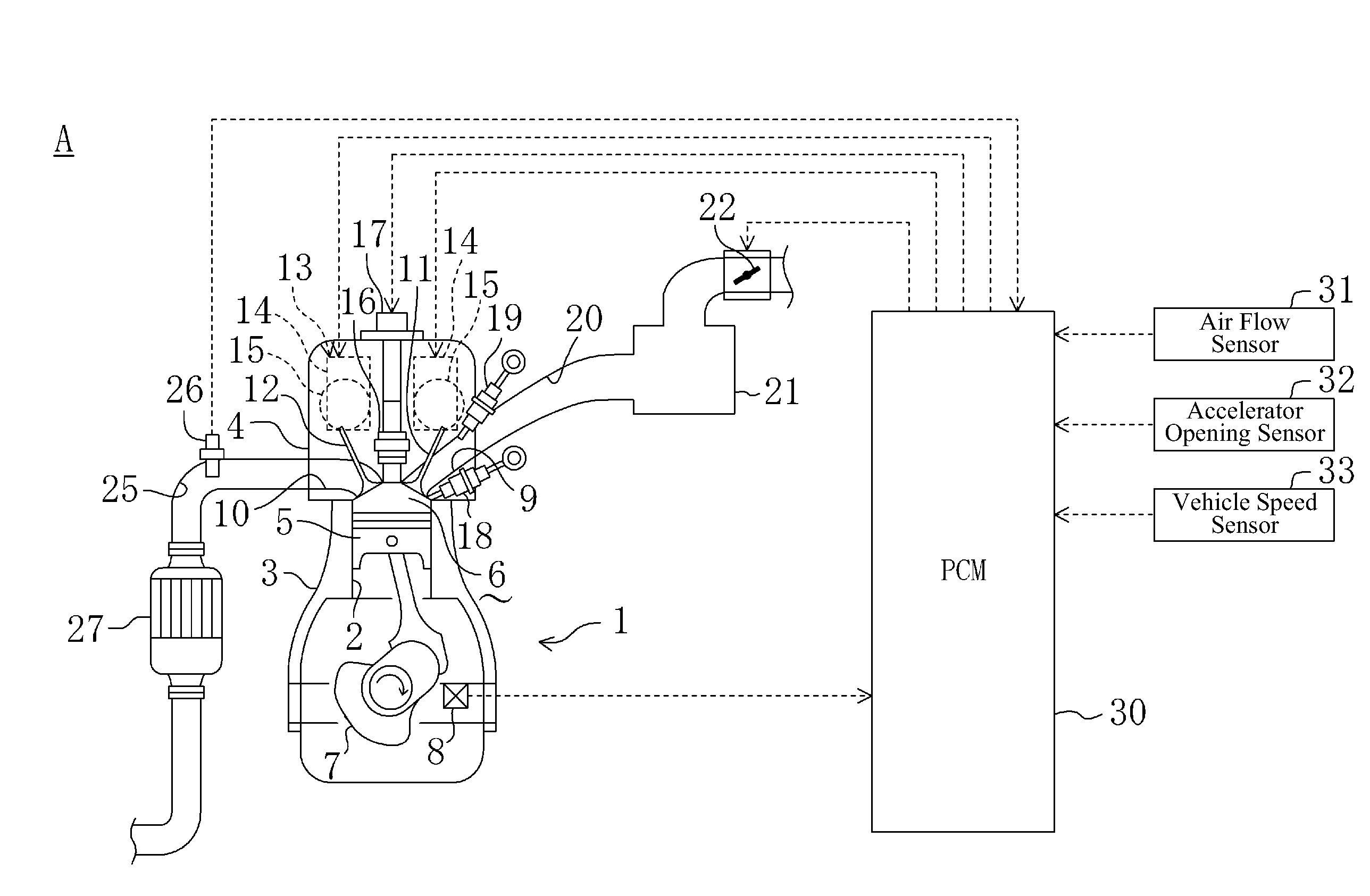

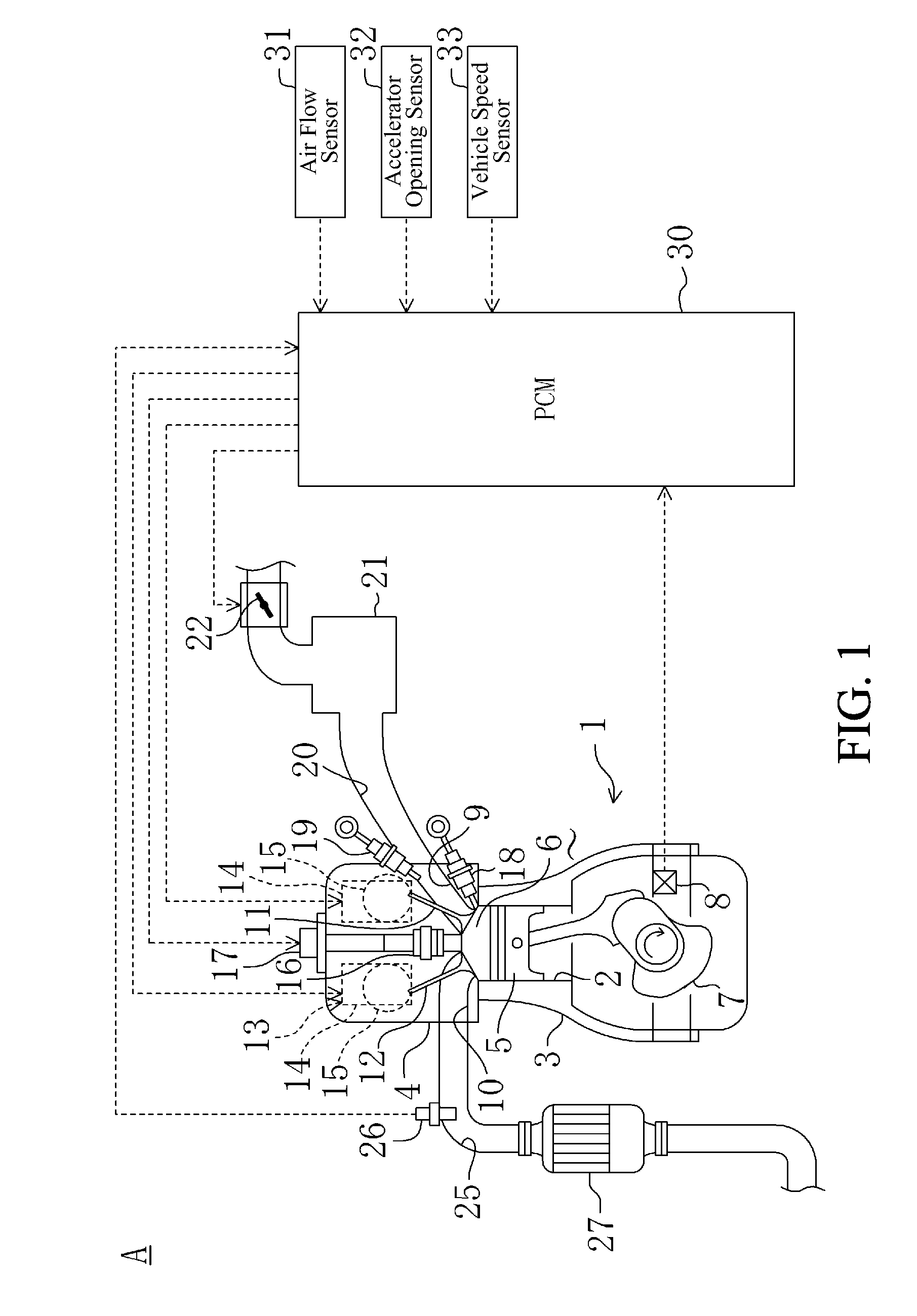

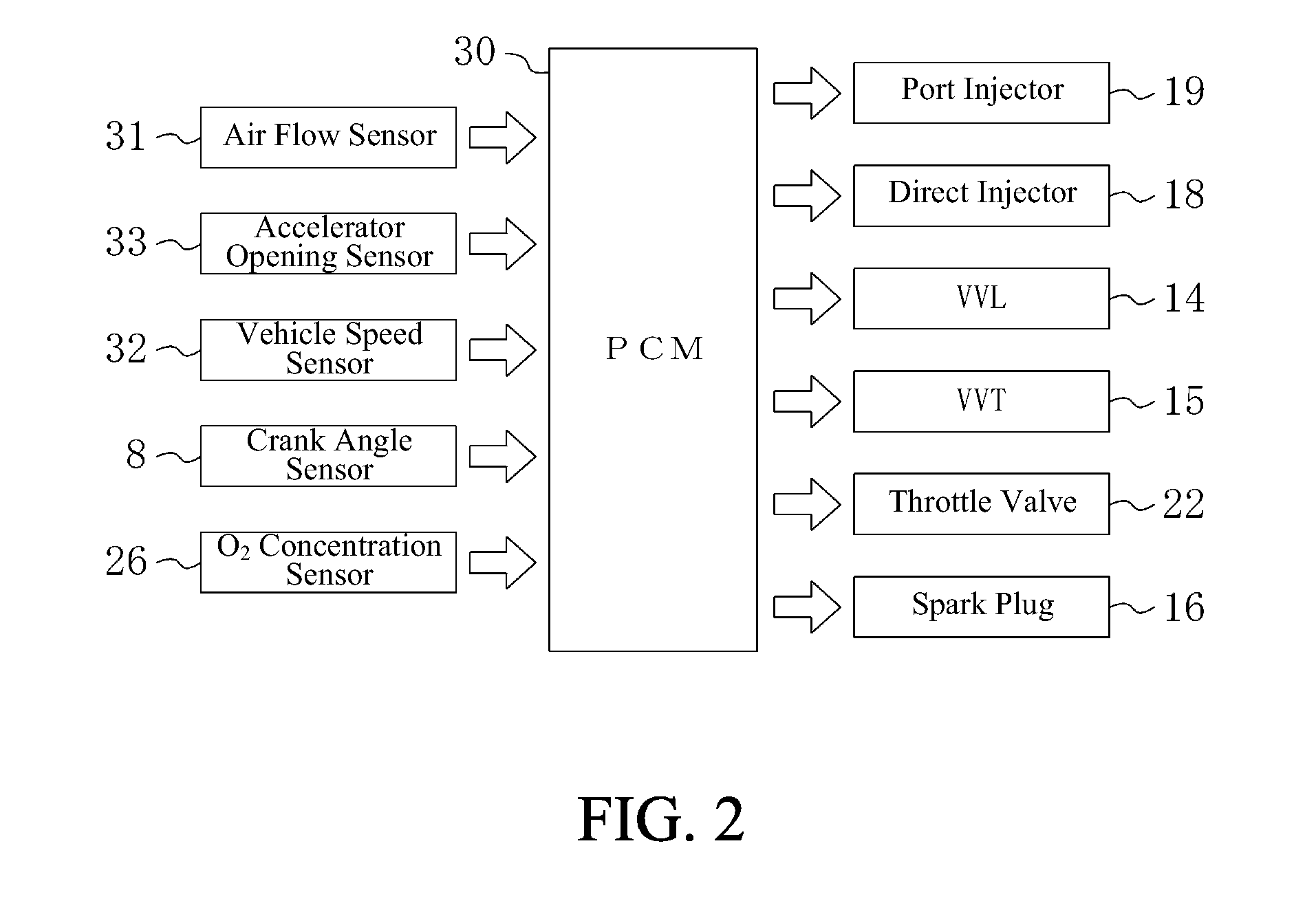

ActiveUS20100082223A1Improve performanceImprovement in emission gas performanceElectrical controlDigital data processing detailsVariable valve timingExternal combustion engine

There is provided a high pressure fuel pump control system for an internal combustion engine which enables fuel pressure control with high precision without being restricted by the number of cylinders of the internal combustion engine or the number of phase sensor signals and the number of cam noses which vertically drives a plunger of a high pressure fuel pump even when a camshaft phase varies by a variable valve timing mechanism by using the high pressure fuel pump with a solenoid valve. The control system has a means which changes an effective stroke by driving the solenoid valve in the high pressure fuel pump, and has a means which changes the drive timing of the high pressure fuel pump based on a cylinder recognition value of the internal combustion engine with the cam angle detecting means as an origin.

Owner:HITACHI ASTEMO LTD

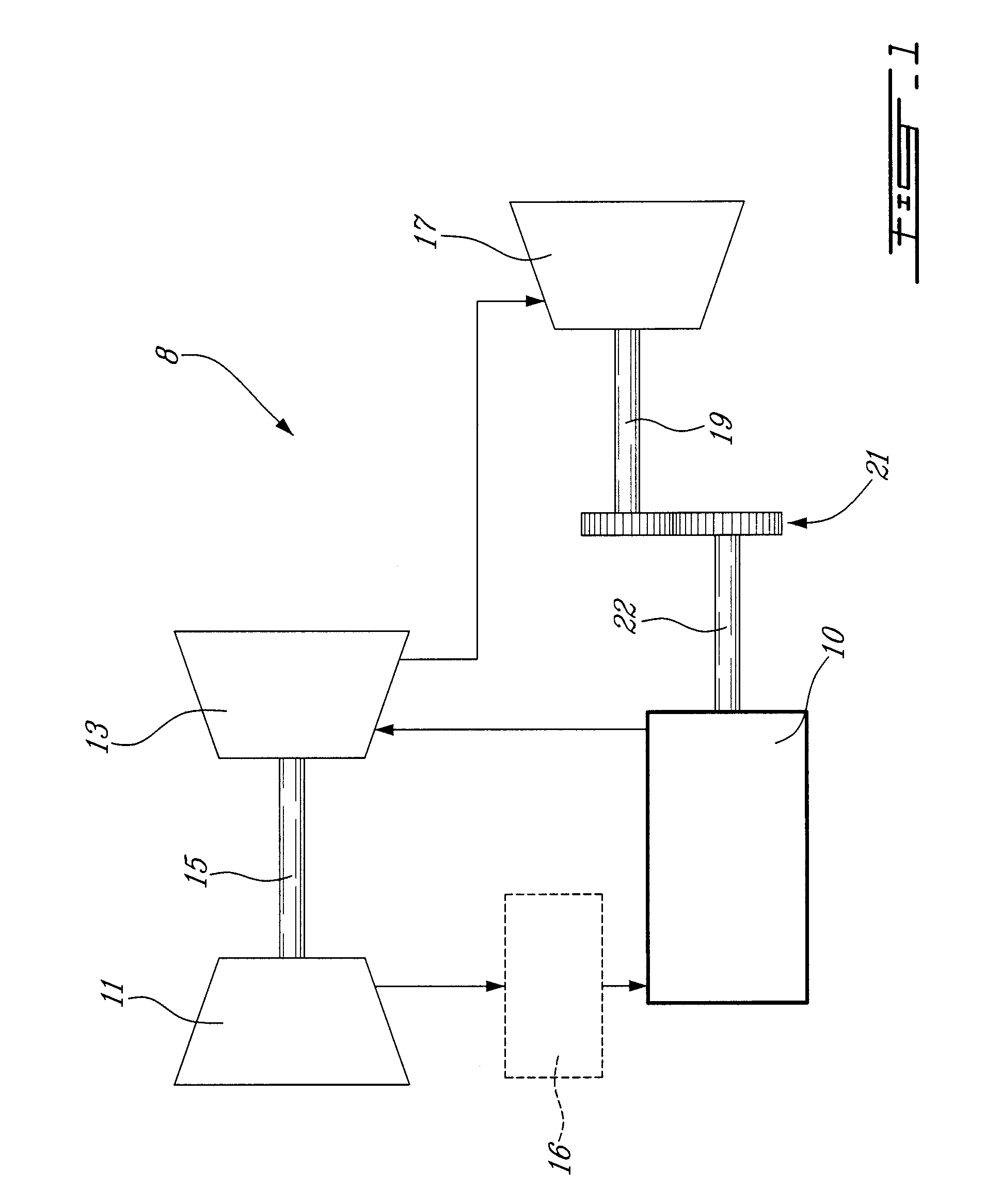

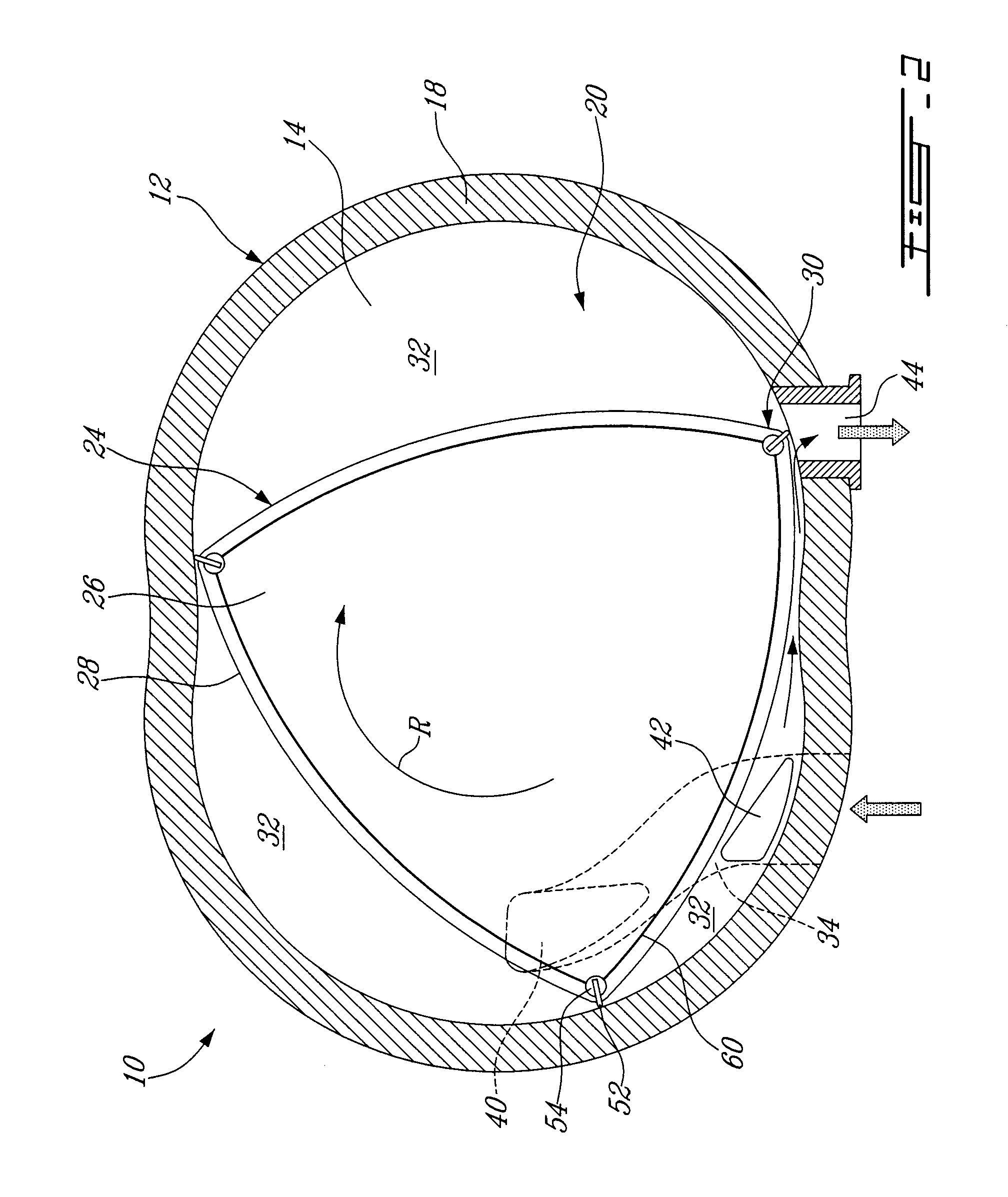

Compound engine system with rotary engine

ActiveUS9027345B2Improve combustion stabilityInternal combustion piston enginesEngine of arcuate-engagement typeRotary engineTurbine

Owner:PRATT & WHITNEY CANADA CORP

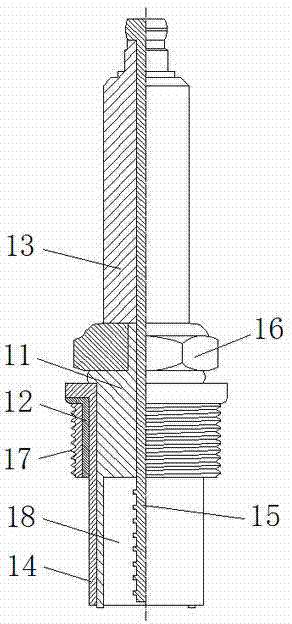

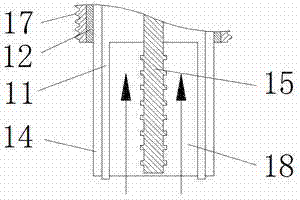

Dielectric barrier discharge non-equilibrium plasma spark plug for internal combustion engine

InactiveCN104779524AImprove combustion stabilityImprove economySparking plugsIonizationExternal combustion engine

The invention discloses a dielectric barrier discharge non-equilibrium plasma spark plug for an internal combustion engine, and belongs to the field of internal combustion engine combustion. An inner electrode of the spark plug is arranged at the center; an ionization cavity is formed in a space between the lower part of a first insulating layer and the lower part of the inner electrode; a bulge is arranged on the surface of the inner electrode positioned in the ionization cavity. A small amount of combustible gas mixture is pressed into the ionization cavity during compression stroke, and the combustible gas mixture is ionized to form non-equilibrium plasma. The formed non-equilibrium plasma has high chemical activity, rushes out from the ionization cavity, enters combustion chamber space, stimulates gas mixture positioned in the combustion chamber space through the high activity of high-energy electron, and begins chain reaction. The non-equilibrium plasma is widely distributed in the combustion chamber space, so that space multi-point ignition is realized. The spark plug can improve the ignition energy of a spark ignited engine, improves the combustion stability and the emission performance of a lean-burn engine, and expands the lean burn limit of the engine, thereby improving the economical efficiency of the engine.

Owner:DALIAN UNIV OF TECH +1

Gas turbine control apparatus and gas turbine system using the same

InactiveUS20050262849A1Promote combustionOscillation suppressionContinuous combustion chamberEngine fuctionsCombustorGas turbines

In a gas turbine control apparatus, a frequency analyzing section frequency-analyzes at least one of pressure oscillation in combustors of a gas turbine and acceleration oscillation of each of the combustors and outputs a first frequency analysis result as the result of frequency analysis for a plurality of predetermined frequency bands. A control unit controls at least one of a first fuel flow rate of fuel and a first air flow rate of air based on the first frequency analysis result for the plurality of frequency bands. The fuel and the air are supplied to the gas turbine.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

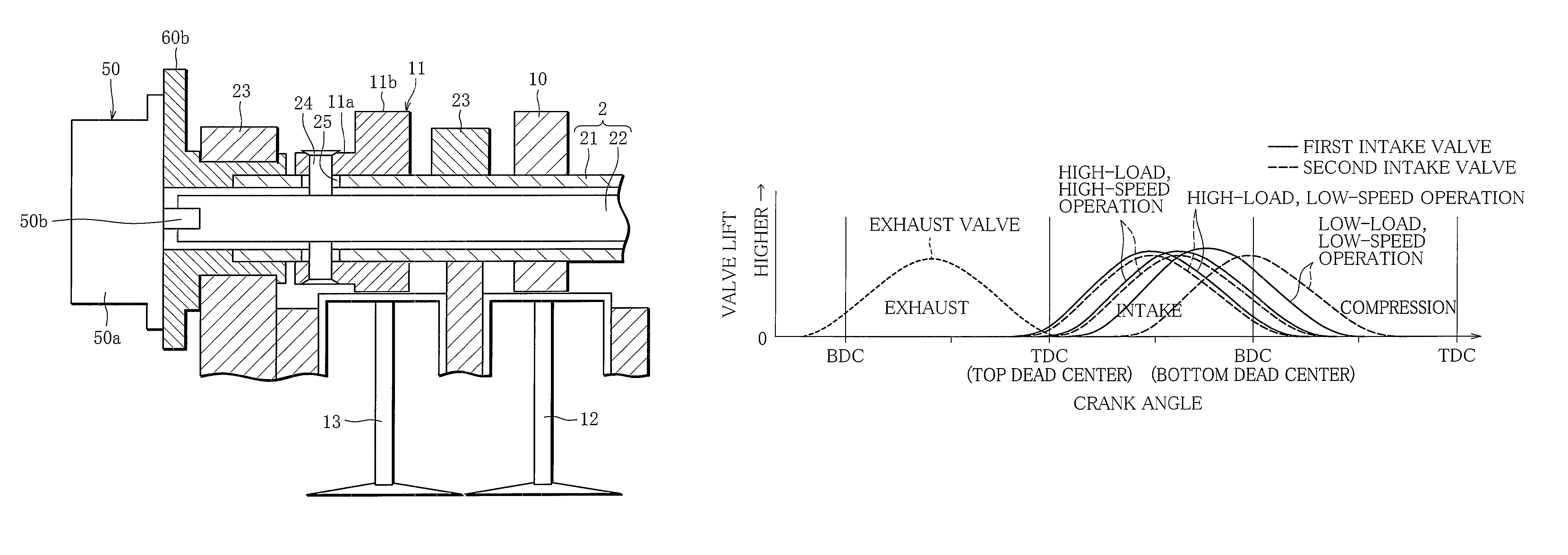

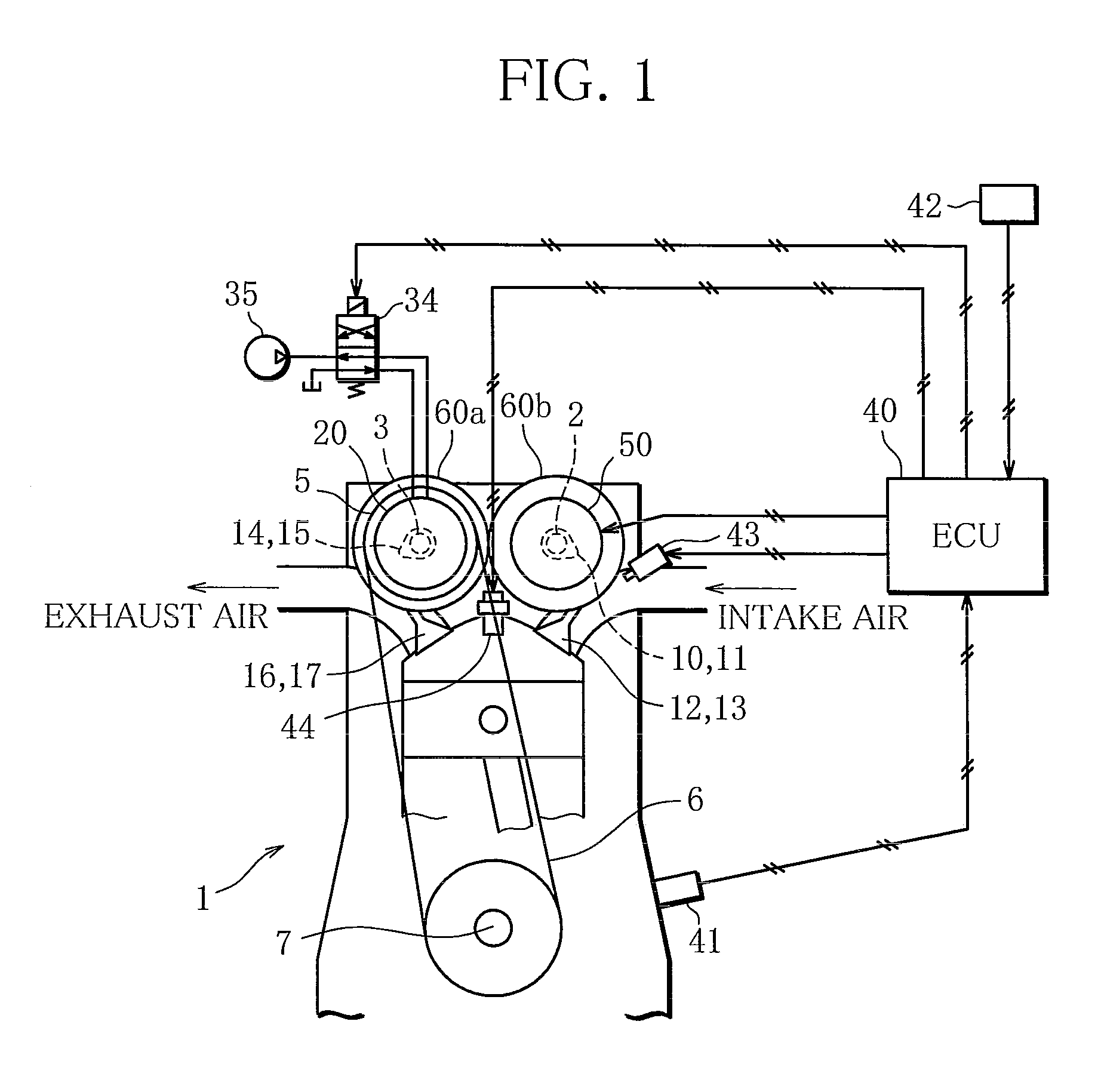

Internal combustion engine with variable valve gear

ActiveUS8235015B2Extended maintenance periodMitigating pumping lossValve arrangementsYielding couplingGear wheelInlet valve

Each cylinder is provided with a first intake valve and a second intake valve, and a first intake cam for driving the first intake valve and a second intake cam for driving the second intake valve are coaxially pivotally supported on an intake camshaft. A first cam phase change mechanism which varies respective phases of the first and second intake cams relative to a crankshaft of the internal combustion engine is combined with a second cam phase change mechanism which varies a phase of the second intake cam relative to the first intake cam. The second cam phase change mechanism is set to have a variable-phase angular range wider than that of the first cam phase change mechanism.

Owner:MITSUBISHI MOTORS CORP

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

Gas turbogroup

ActiveUS7568335B2Improve efficiencySpeed up the flowBurnersContinuous combustion chamberCombustion chamberTurbine

In a gas turbogroup, which comprises a compressor, a first combustion chamber, a first turbine, a second combustion chamber, and a second turbine, the first combustion chamber is arranged downstream of the compressor, the first turbine is arranged downstream of the first combustion chamber, the second combustion chamber is arranged downstream of the first turbine, and the second turbine is arranged downstream of the second combustion chamber, wherein the second combustion chamber has a convectively cooled wall. A cooling air feed line for the second combustion chamber branches from the main flow path of the gas turbogroup downstream of the compressor and upstream of the first combustion chamber. A return line for heated cooling air leads from the second combustion chamber upstream of the first turbine to the main flow path.

Owner:ANSALDO ENERGIA SWITZERLAND AG

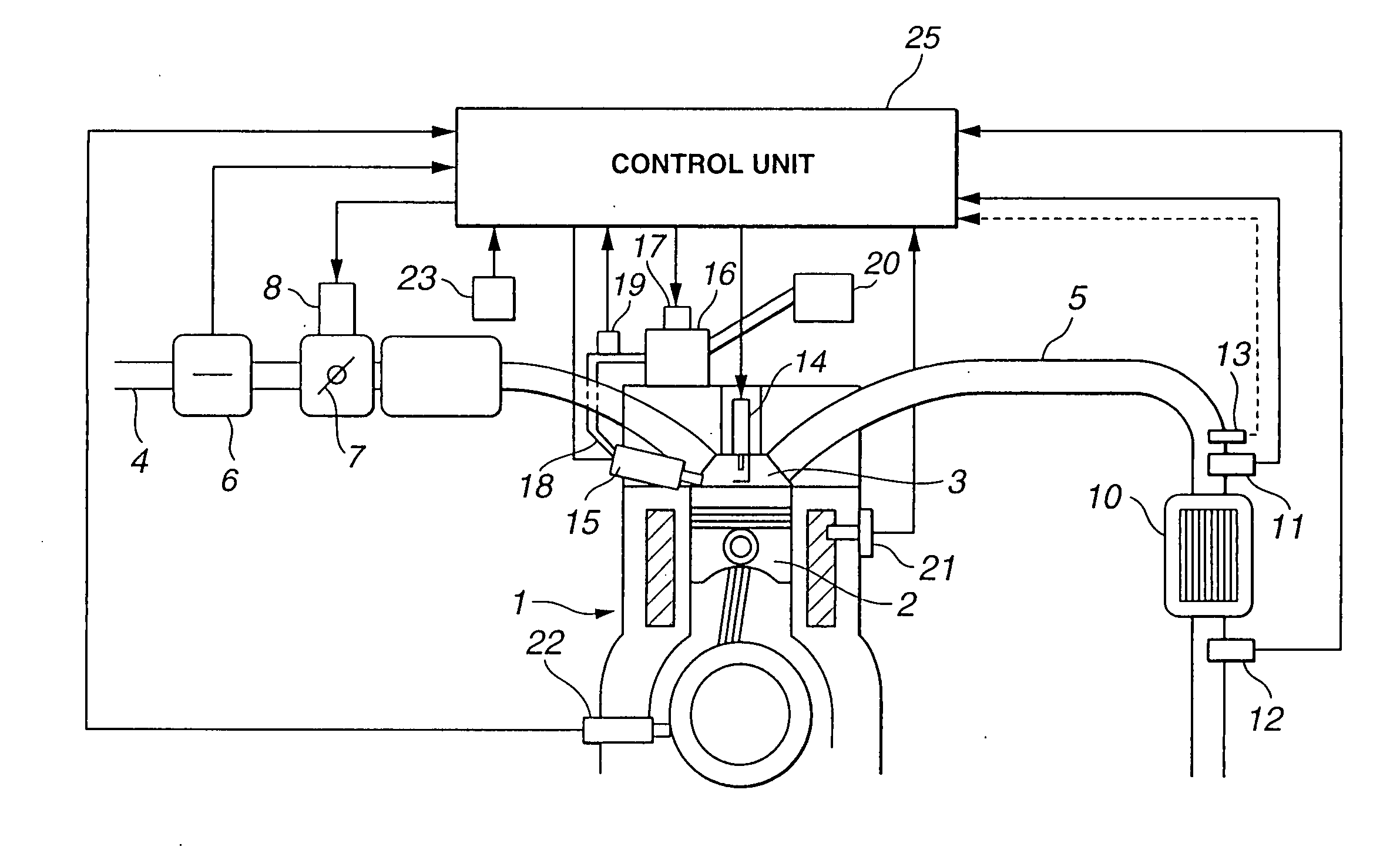

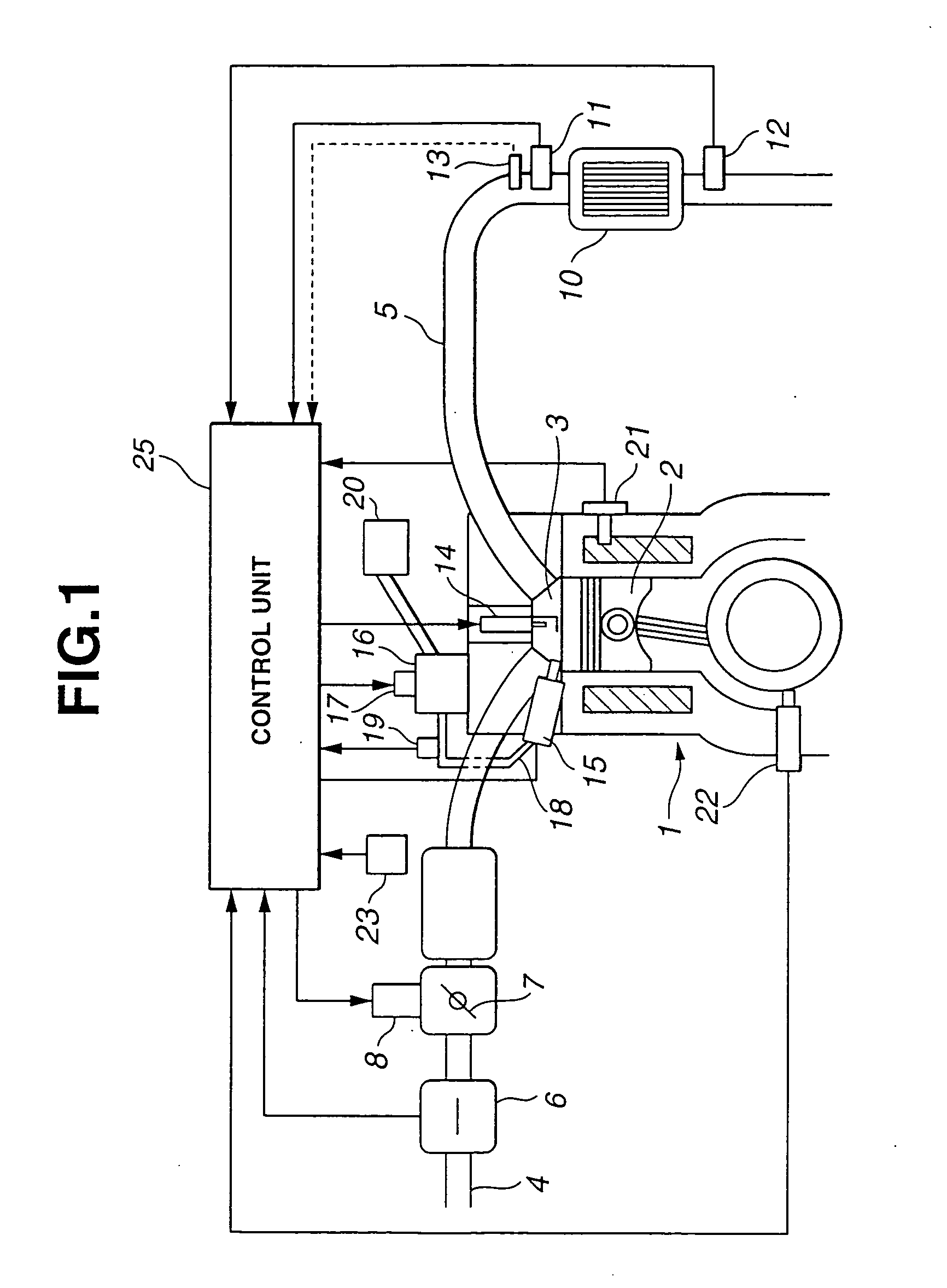

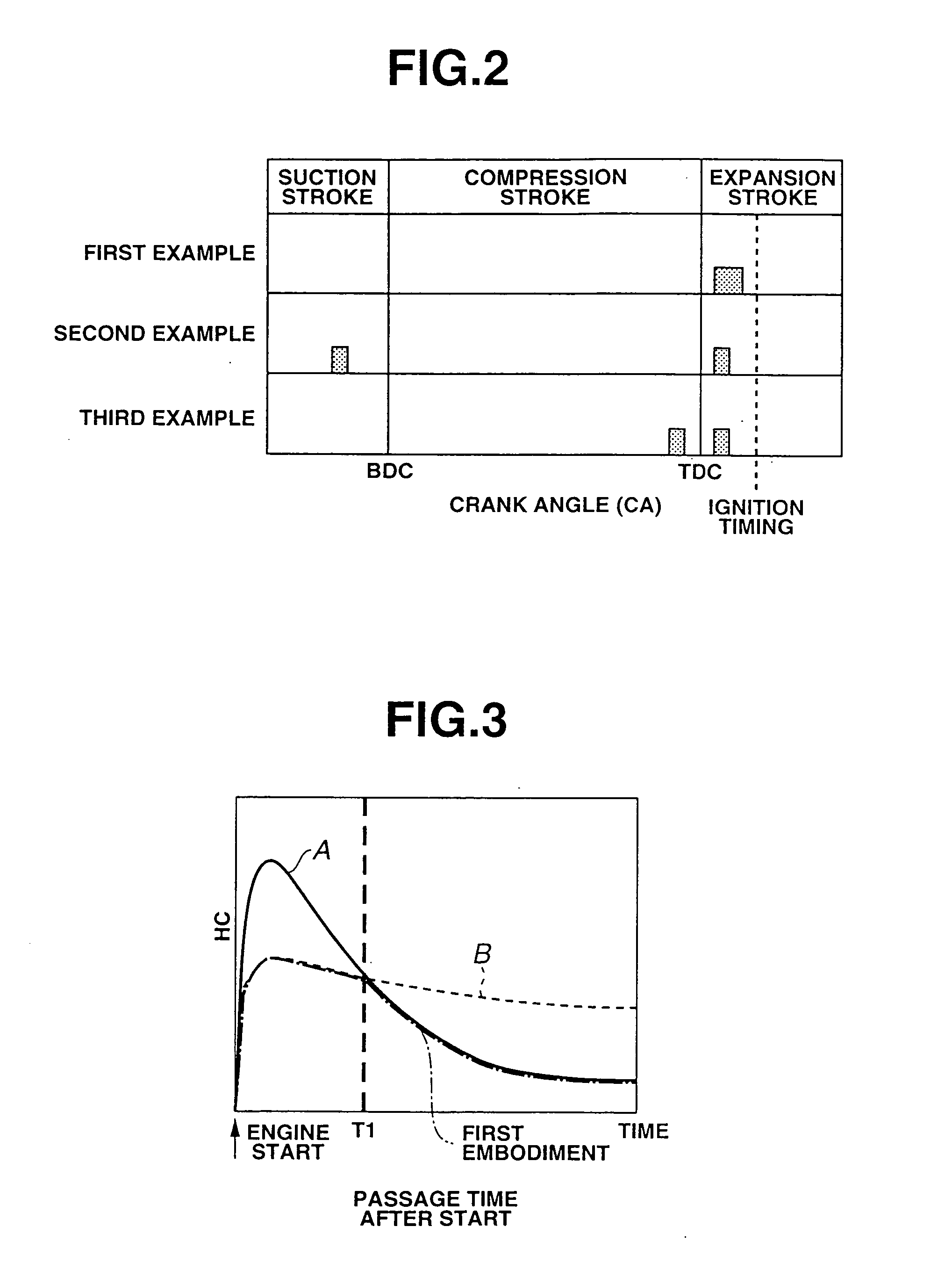

Control method and apparatus for direct injection spark ignited internal combustion engine

ActiveUS20060065235A1Large effect of reducing HCShorten the time intervalElectrical controlInternal combustion piston enginesCombustionTop dead center

In control method and apparatus for a direct injection spark ignited internal combustion engine, the internal combustion engine comprising a fuel injection valve configured to perform an injection of fuel through an engine cylinder and a spark plug, a super retard combustion comprising: an ignition through the spark plug at a timing after a compression top dead center; and at least once fuel injection in which the injection of fuel is started at a timing after the compression top dead center and before the ignition, during a cold start of the engine, is executed, and an execution of the super retard combustion is inhibited for a predetermined interval of time immediately after the cold start of the engine.

Owner:NISSAN MOTOR CO LTD

Gas turbine combustor

InactiveUS6912854B2Emission reductionImprove combustion stabilityContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

Owner:MITSUBISHI HITACHIPOWER SYST LTD

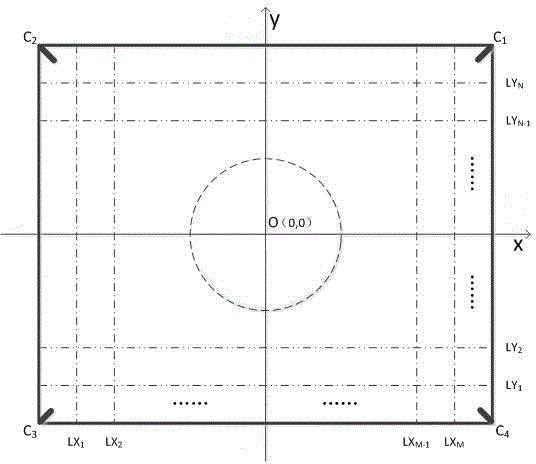

Balance control method for temperature field of utility boiler furnace

InactiveCN103557535AEvenly filledImprove combustion efficiencyCombustion regulationFurnace temperatureProportion integration differentiation

The invention discloses a balance control method for the temperature field of a utility boiler furnace. The balance control method comprises the following steps: (1) building a furnace section reference coordinate system; (2) respectively arranging temperature measurement devices in the cross direction and the longitudinal direction of the furnace section; (3) acquiring the temperature values of all measurement paths; (4) making a fitted curve between the temperature and the coordinates of the furnace section measurement paths; (5) meshing the furnace section; (6) building a two-dimensional temperature field of the furnace section; (7) calculating the center coordinates of the two-dimensional temperature field of the furnace section; (8) adopting a PID (Proportion Integration Differentiation) controller to achieve control correction calculation of the furnace temperature field; (9) calculating the control corrections of the opening degrees of four corner jet fuel air doors of the boiler; (10) implementing the temperature field balance control method in a DCS (Decentralized Control System). The balance control method has the advantages that pulverized coal is sufficiently burnt out during boiler combustion, the flame center is in the center of the furnace, the temperature field of the furnace is uniformly distributed and the combustion efficiency and stability of the furnace are improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com