Storage-type super-low nitric oxide system in coal fired boiler coal mill

A technology for nitrogen oxide and coal-fired boilers, which is applied in the direction of combustion methods, combustion equipment, fuel supply, etc., can solve the problems of large investment in SCR out-of-stock devices, reduction of nitrogen oxide emissions, living environment pollution, etc., so that it is not easy to explode, The effect of reducing nitrogen oxide emissions and reducing coal fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

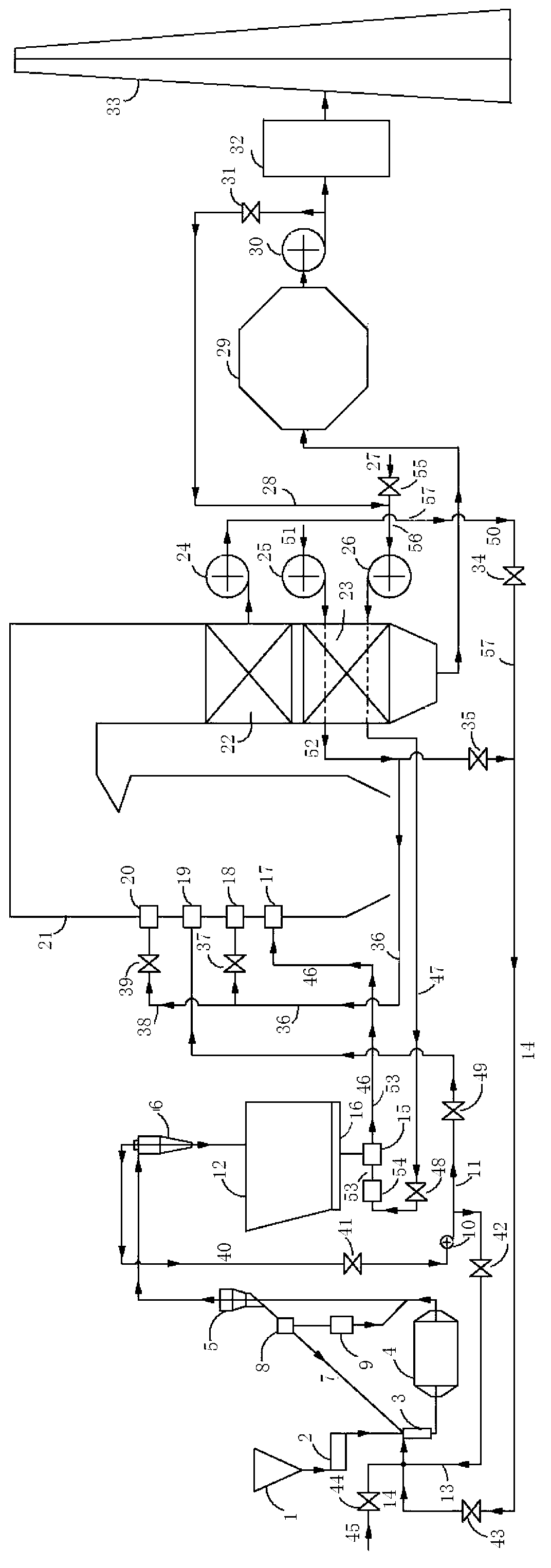

[0027] The medium-storage super low-nitrogen combustion system of the coal pulverizer of the coal-fired boiler includes high-temperature flue gas recirculation technology, ultra-fine coal powder preparation technology and low-nitrogen combustion technology. The high-temperature flue gas recirculation technology adopts the powder feeding technology of cold furnace smoke heated by the air preheater and the hot air plus high temperature furnace smoke drying technology of the pulverizing system: the so-called powder feeding technology of cold furnace smoke heated by the air preheater, that is, from the induced draft fan 30 The cold furnace smoke is extracted from the outlet flue, and led to the inlet of the primary fan 26 through the cold furnace smoke pipe 28. After mixing with the cold air at the inlet of the primary fan 26, it is heated by the air preheater 23, so that the temperature of the cold furnace smoke rises, and the temperature of the hot furnace smoke rises. Enter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com