Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3033 results about "Coal fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pollutant emission control sorbents and methods of manufacture

InactiveUS20070122327A1Small particle sizePromotes Hg-captureGas treatmentOther chemical processesSorbentFlue gas

Sorbents for removal of mercury and other pollutants from gas streams, such as a flue gas stream from coal-fired utility plants, and methods for their manufacture and use are disclosed. The methods include mixing sorbent substrate particles with a sulfide salt and a metal salt to form a metal sulfide on the outer surface of the sorbent particles.

Owner:BASF CATALYSTS LLC

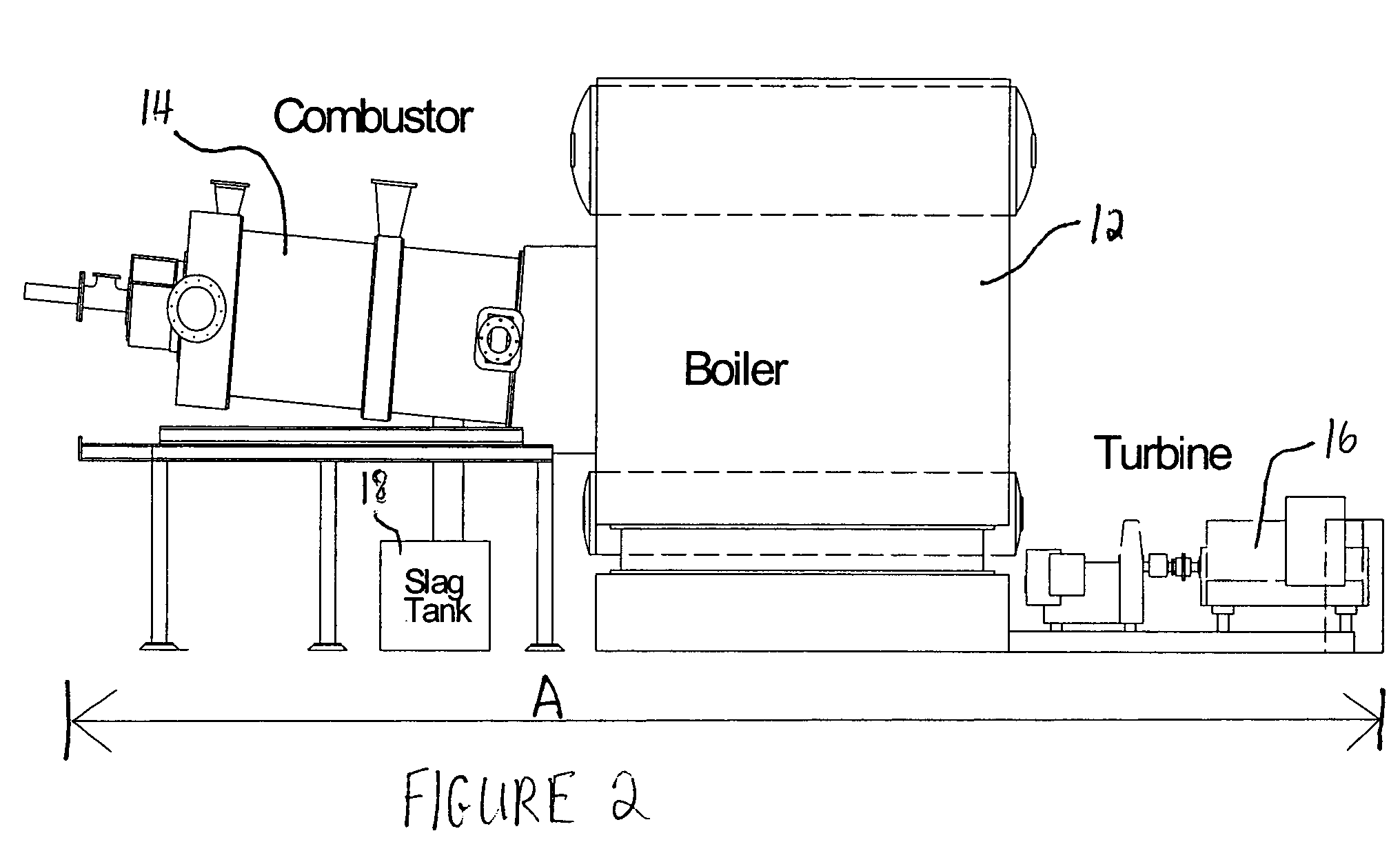

Production of hydrogen and removal and sequestration of carbon dioxide from coal-fired furnaces and boilers

InactiveUS7282189B2Increase ratingsValue maximizationOrganic chemistryNitrogen compoundsHydrogenProcess engineering

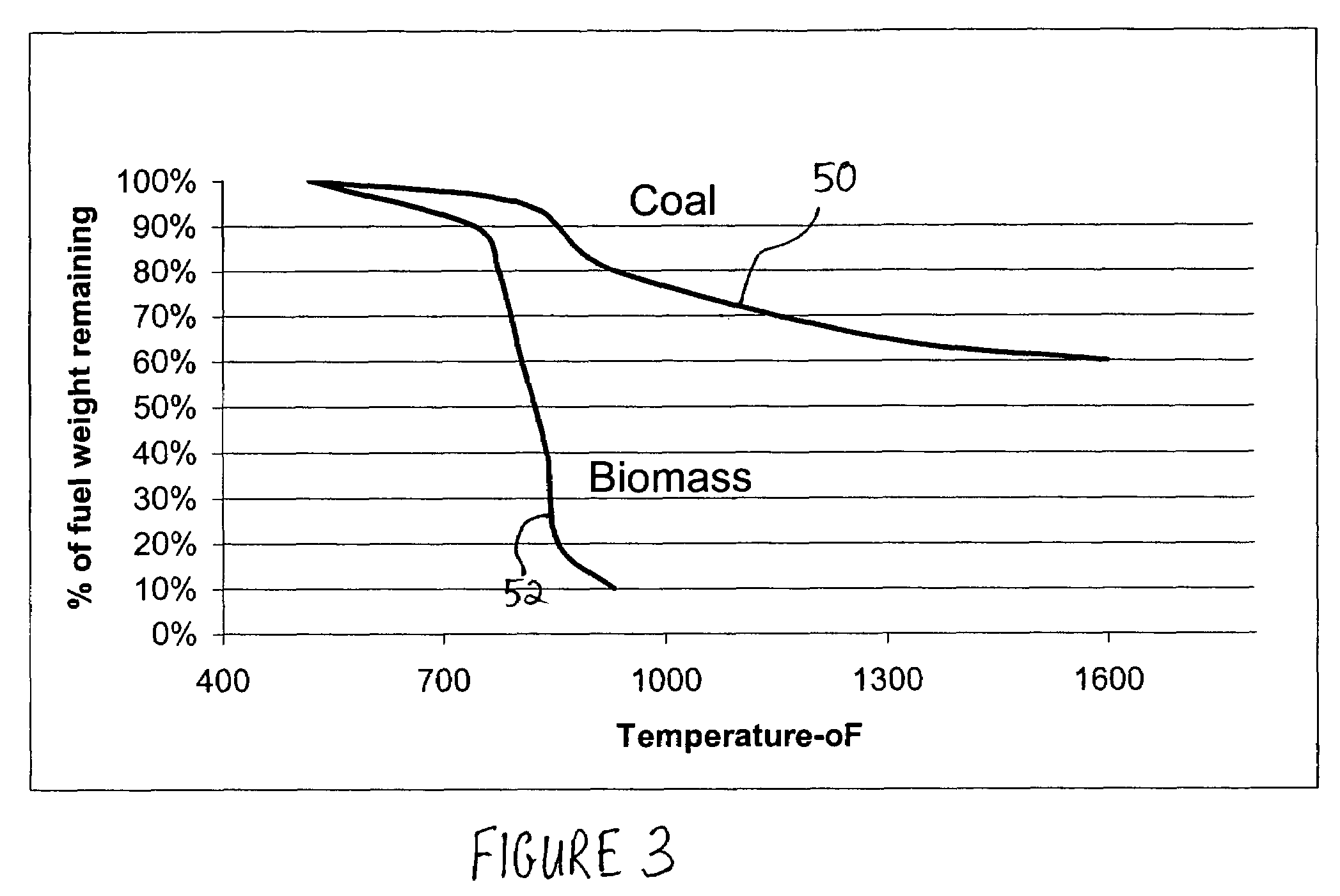

Methods for reducing and eliminating carbon dioxide from the emissions of solid fuel fired power plants, particularly coal fired power plants, and to sequester the carbon dioxide, typically by using existing equipment. In some embodiments, the methods involve pyrolyzing the solid fuel to remove volatile matter and using the volatile matter to produce hydrogen. Additionally, the methods may involve burning the solid fuel or pyrolized solid fuel at very fuel rich stoichiometric conditions. Sequestration may include the production of a carbon dioxide-containing solution and the pumping of the solution into the ground, particularly in areas high in limestone.

Owner:ZAUDERER BERT

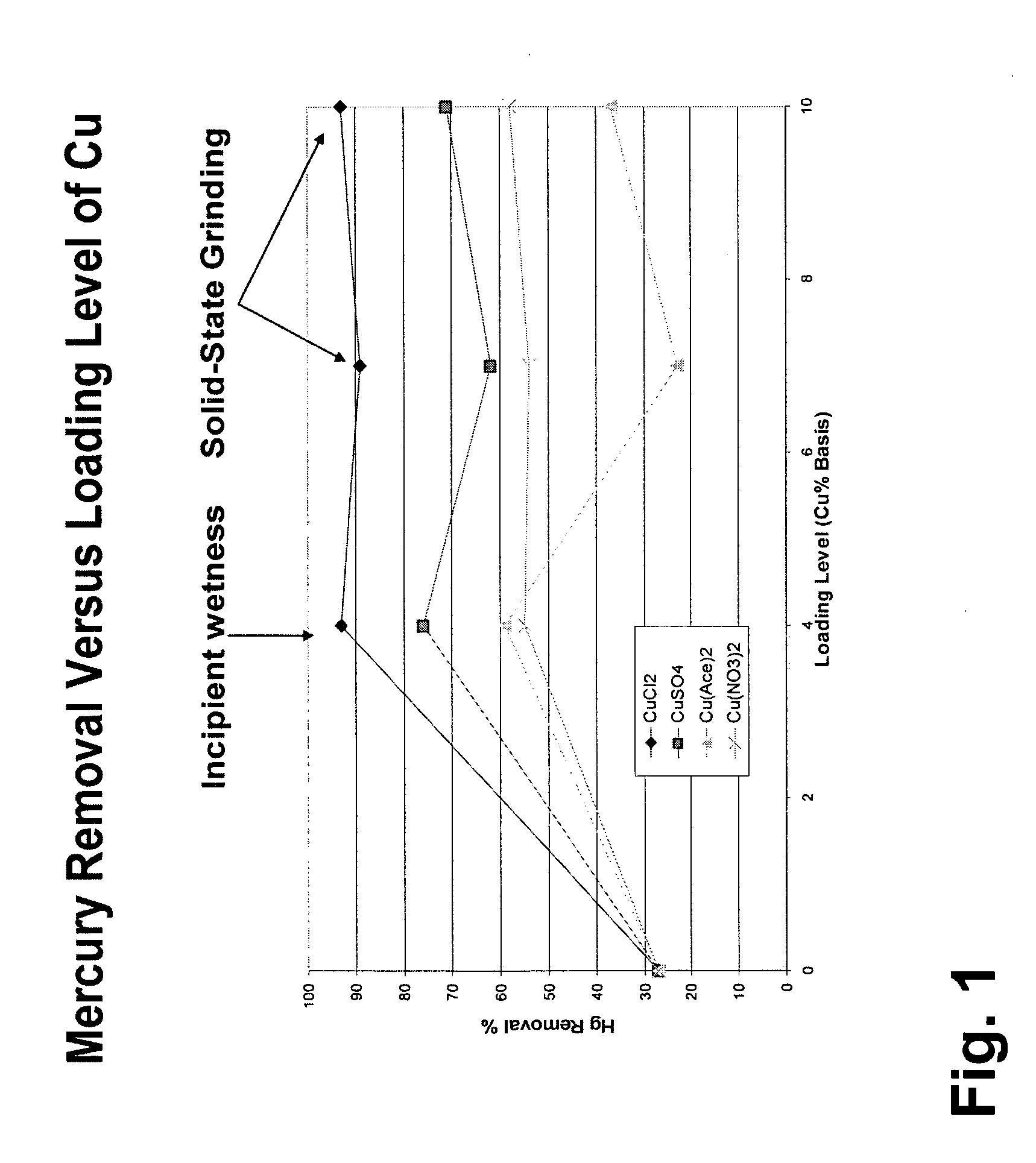

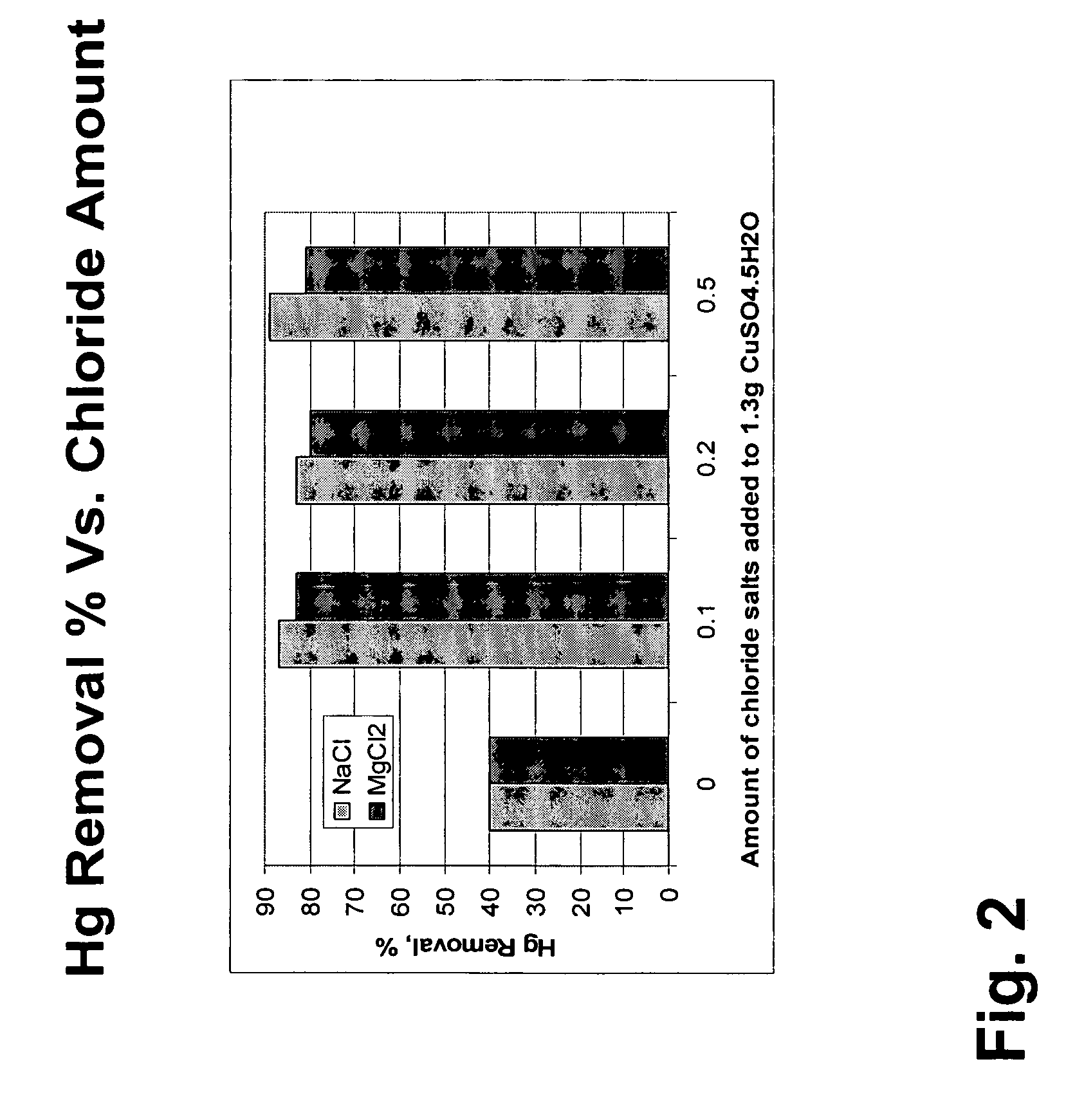

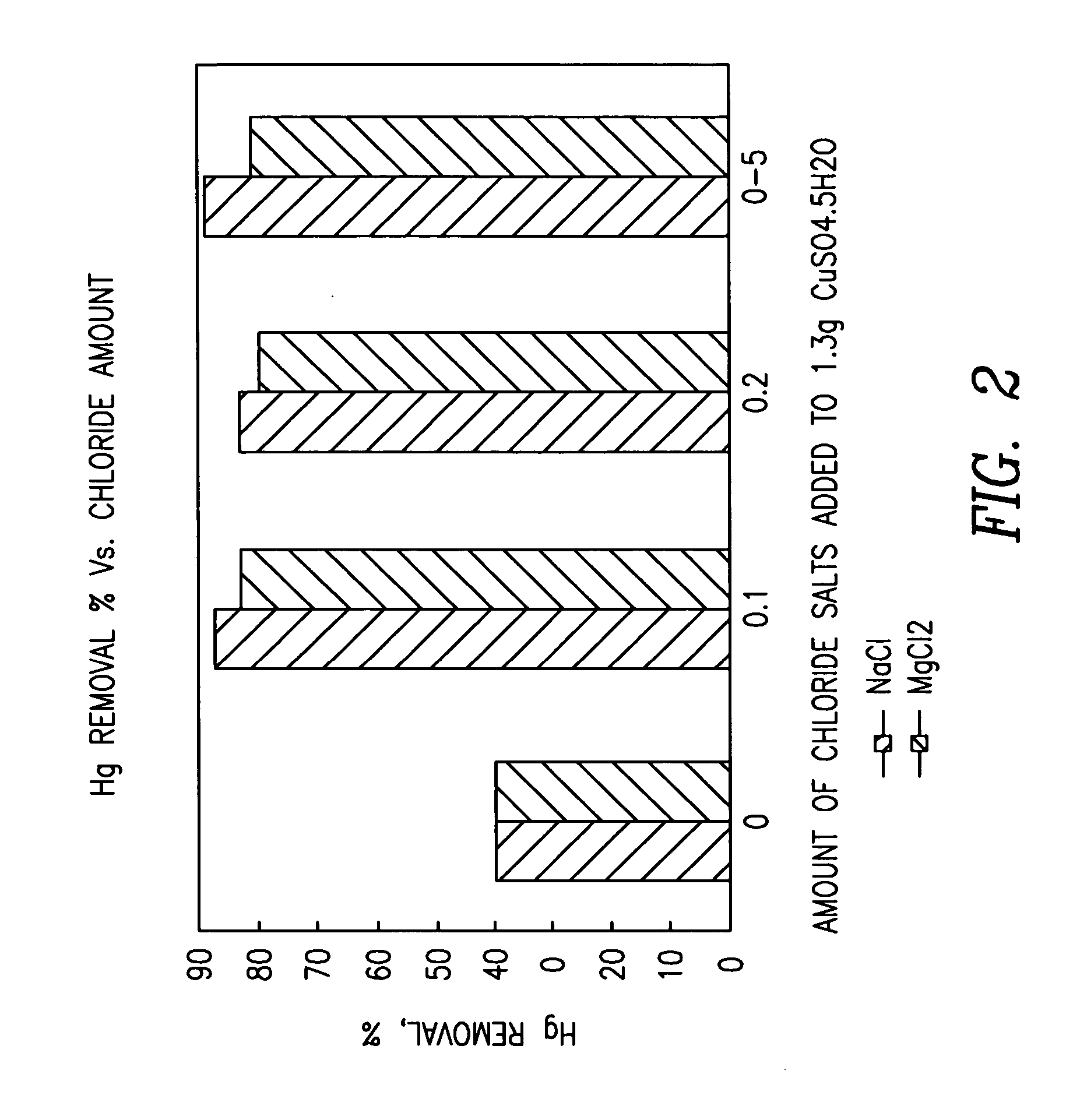

Compositions and methods for removing mercury from mercury-containing fluids

InactiveUS20070140940A1Facilitate mercury removalThe material is lowGas treatmentDispersed particle filtrationSodium BentoniteSorbent

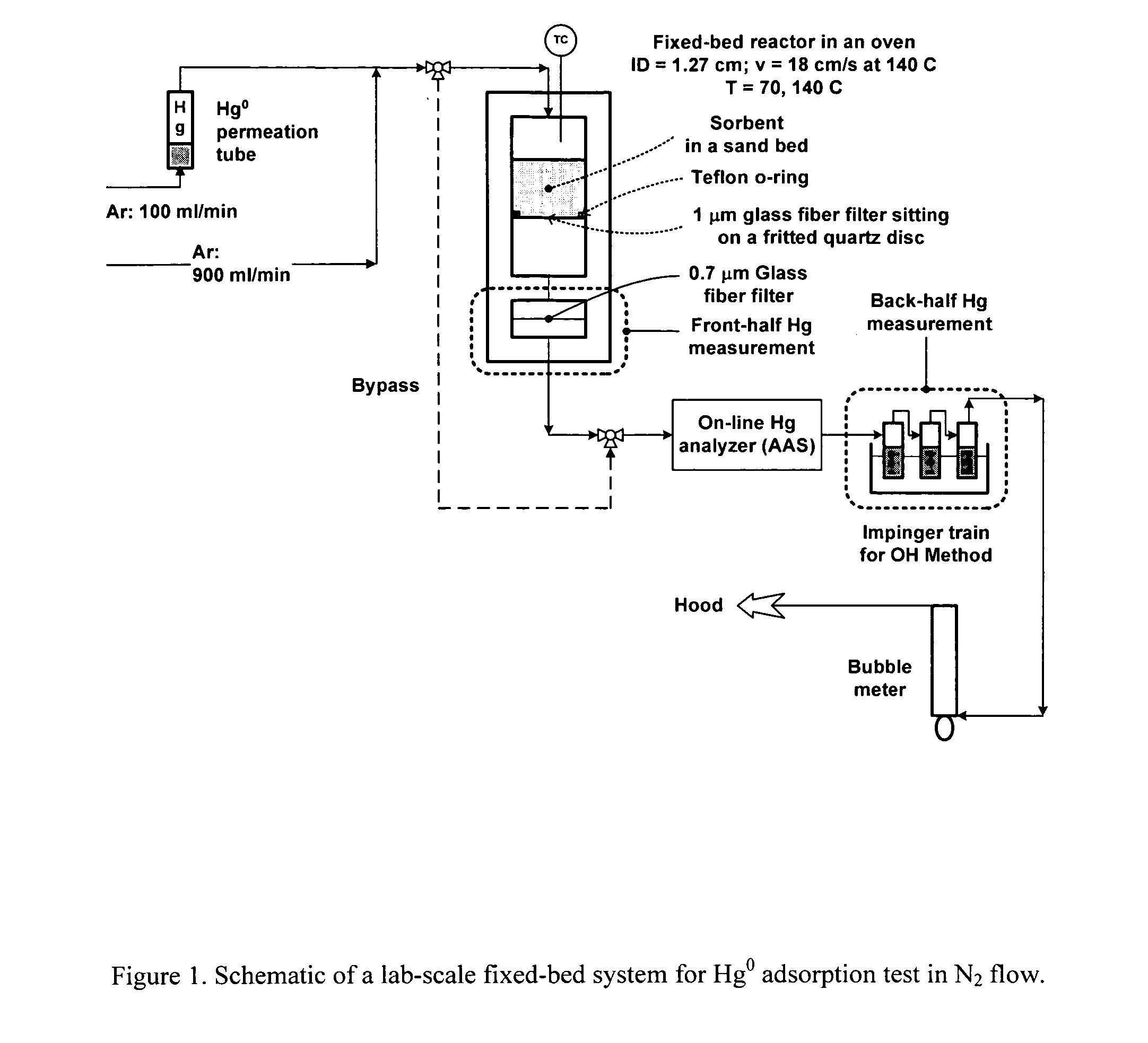

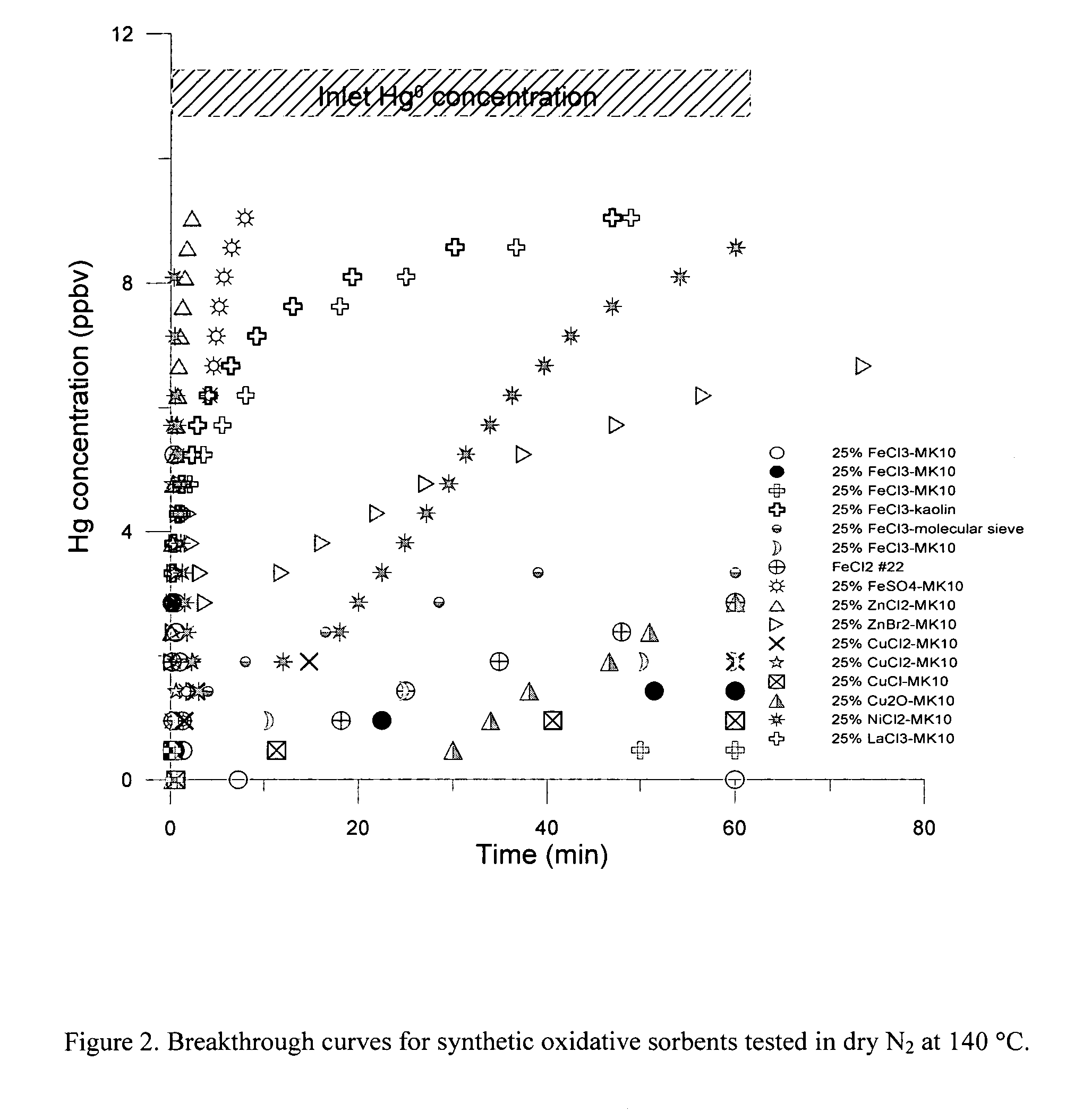

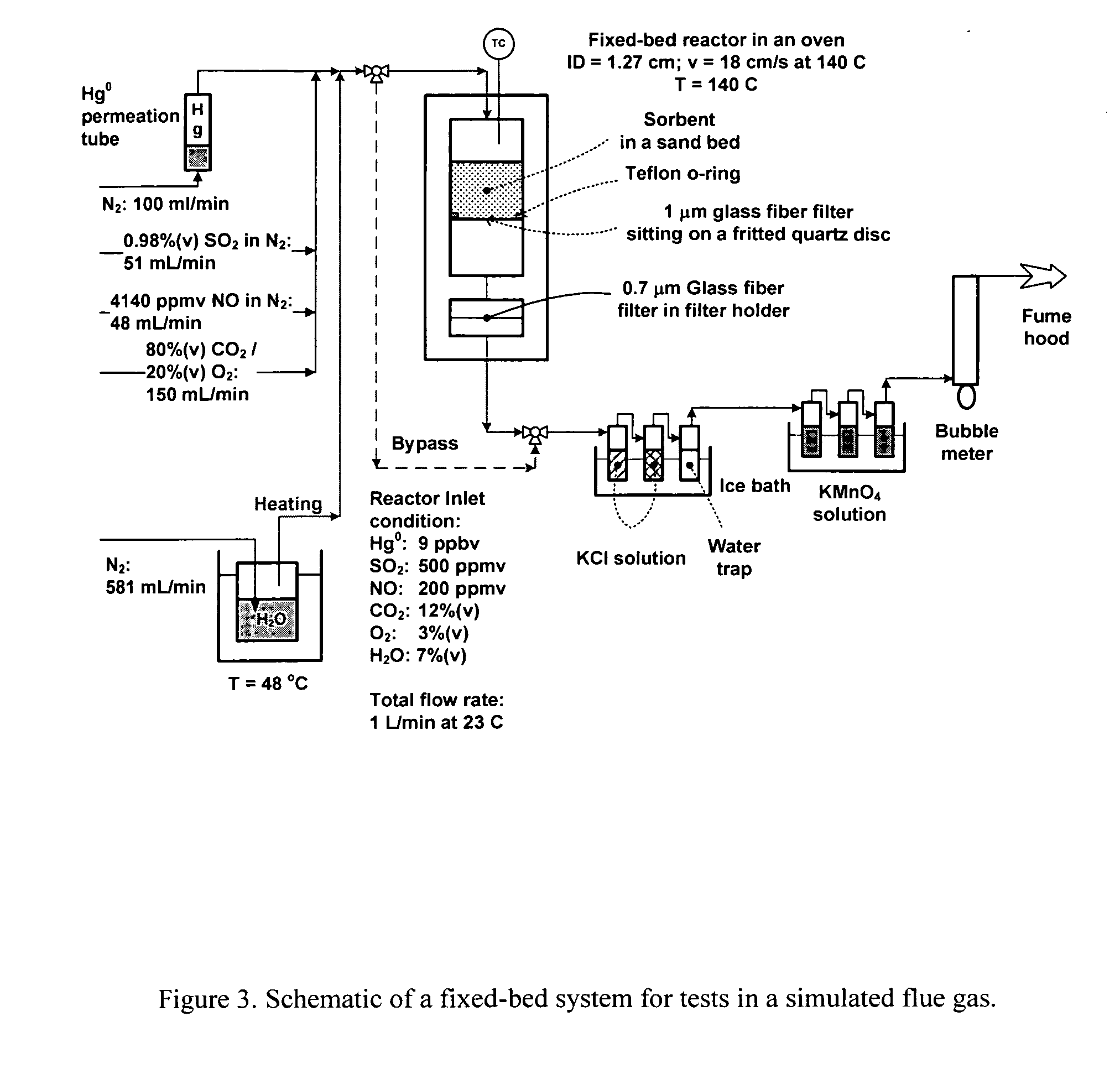

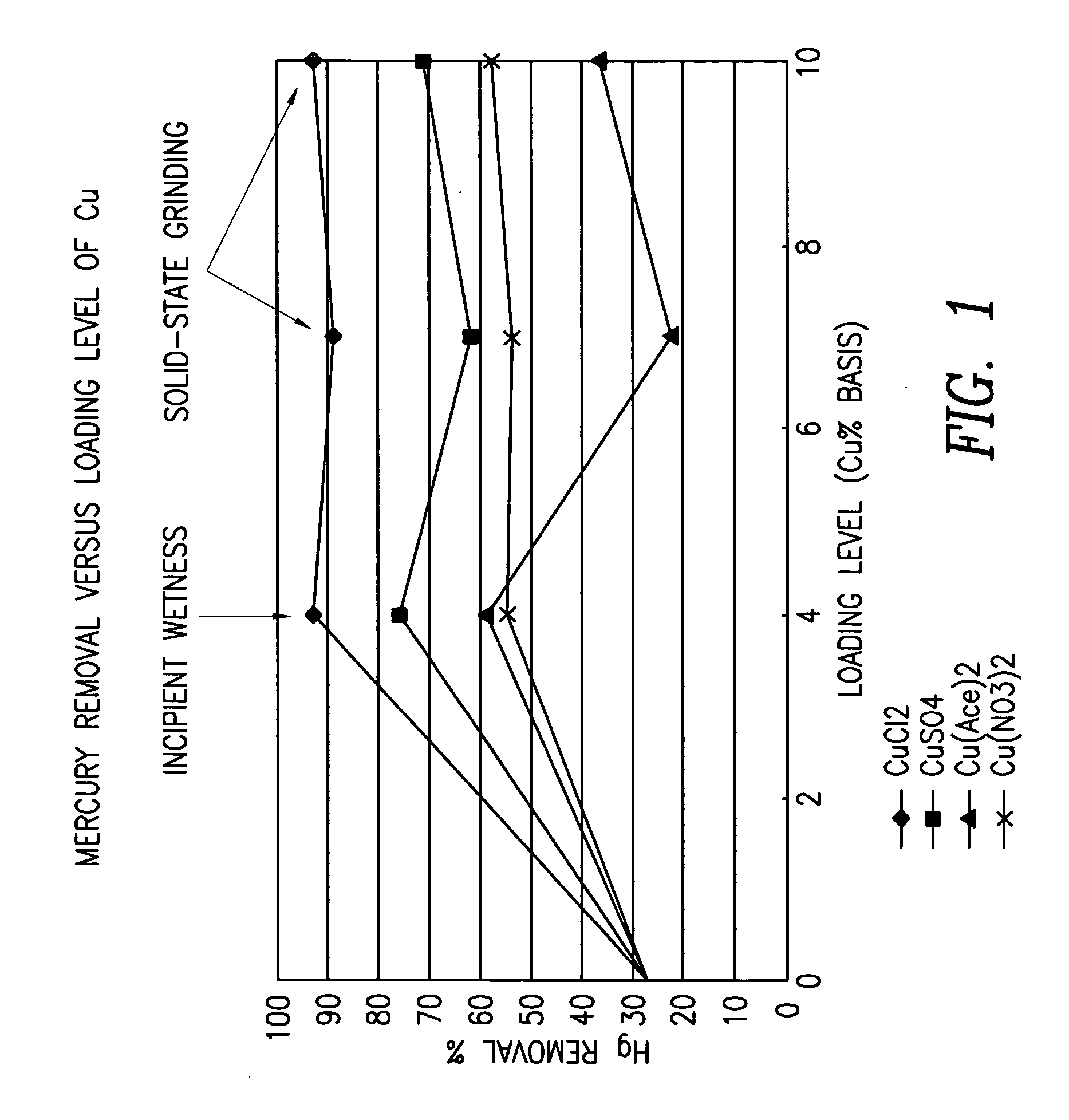

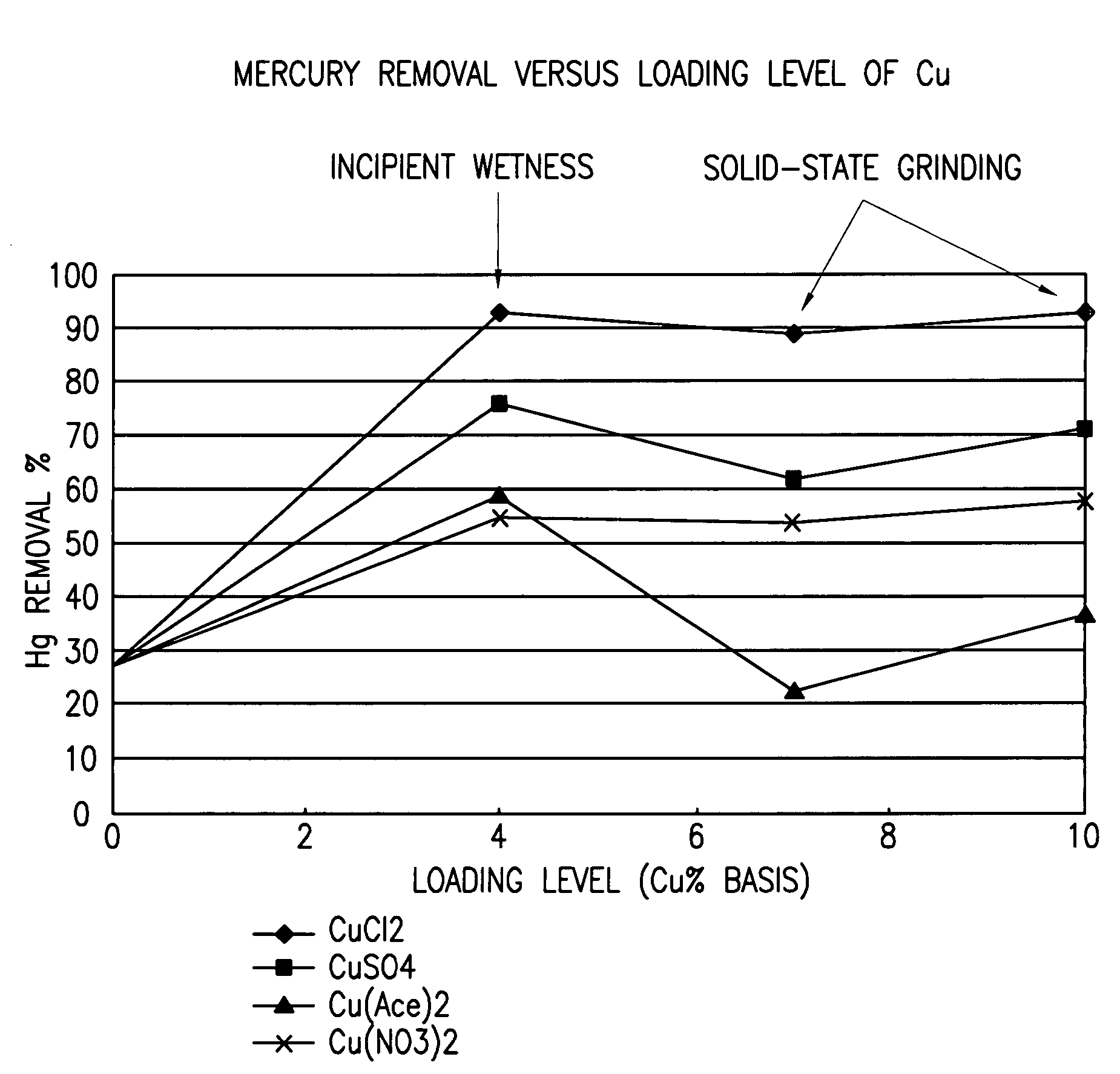

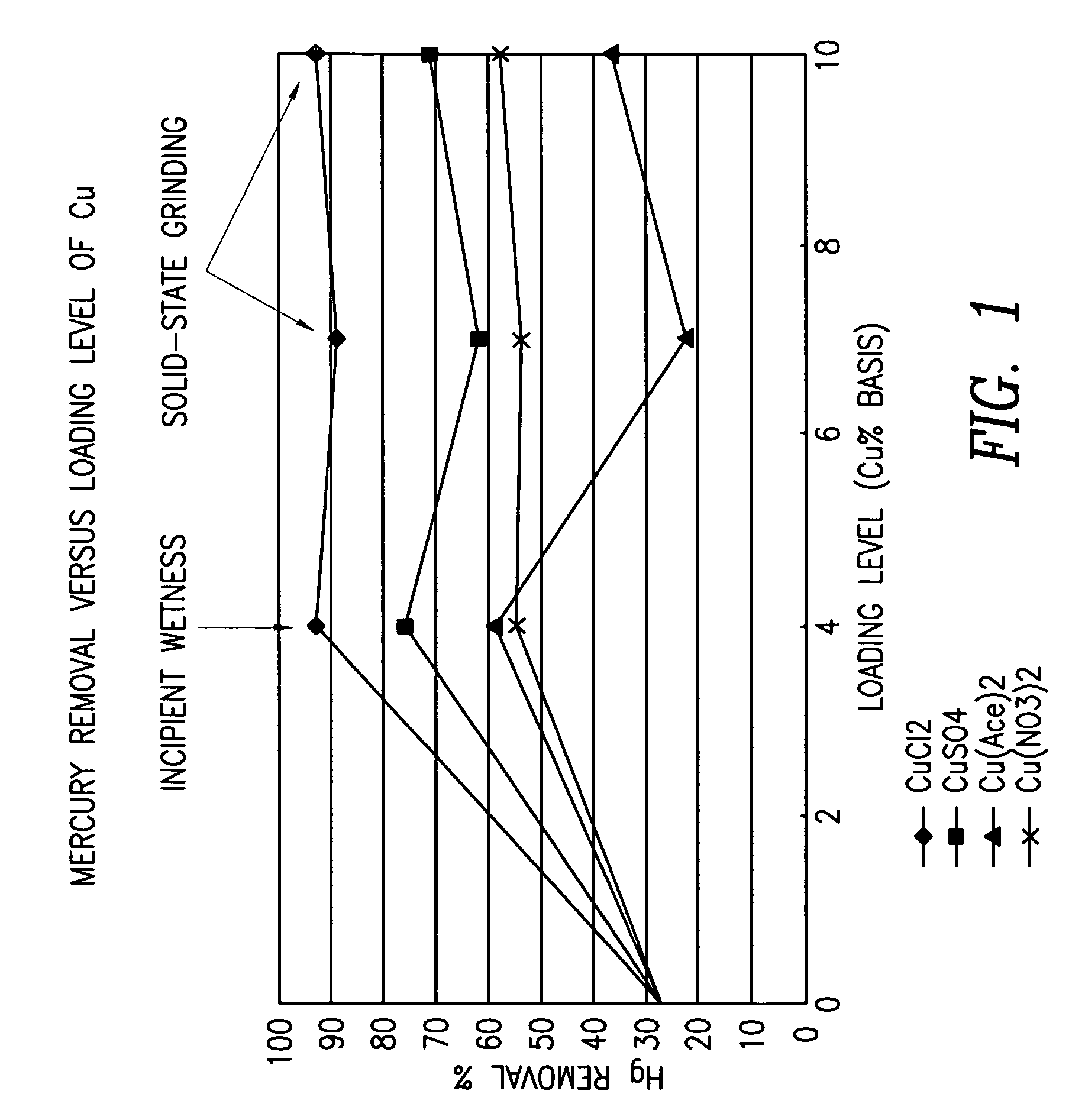

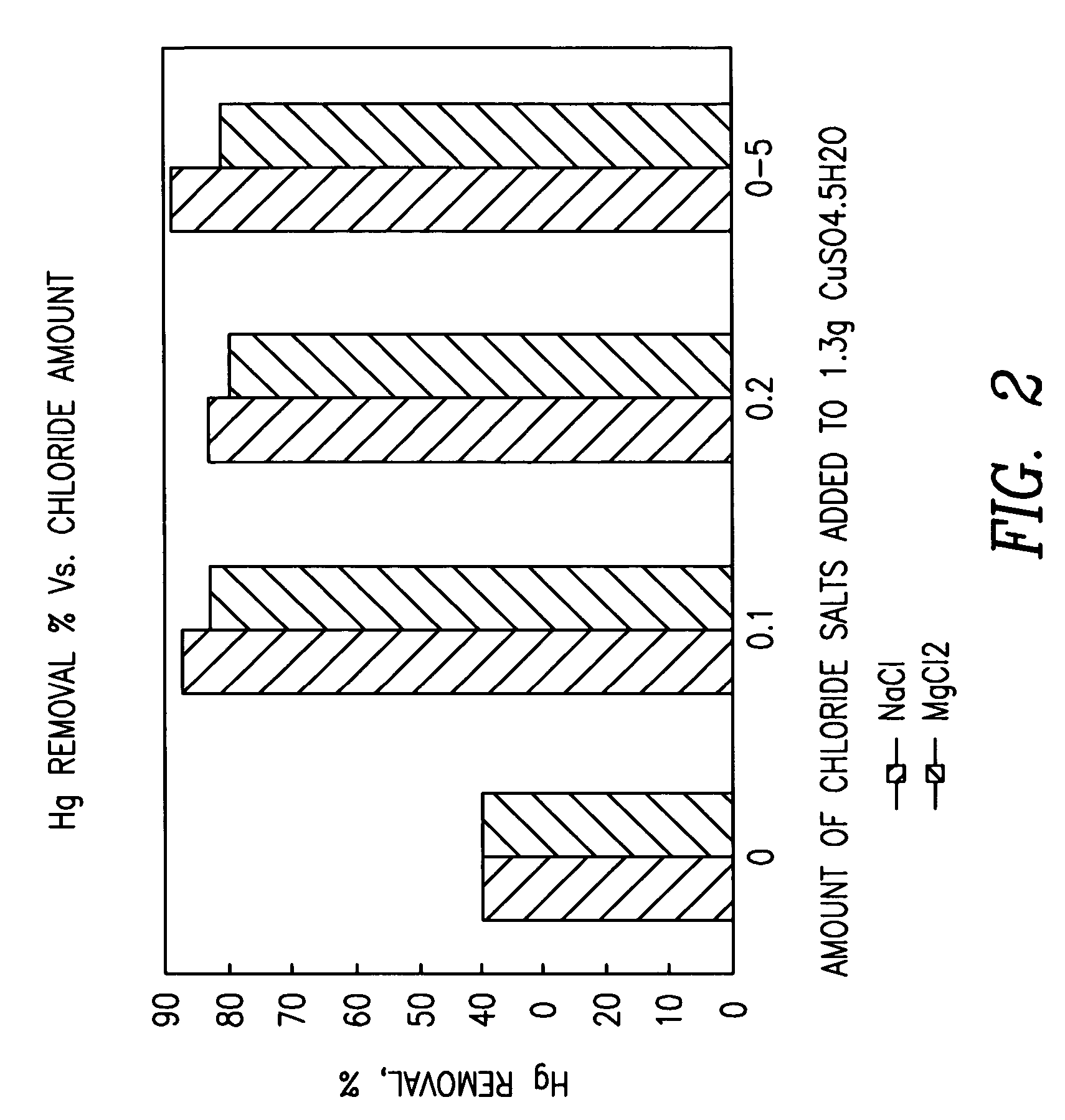

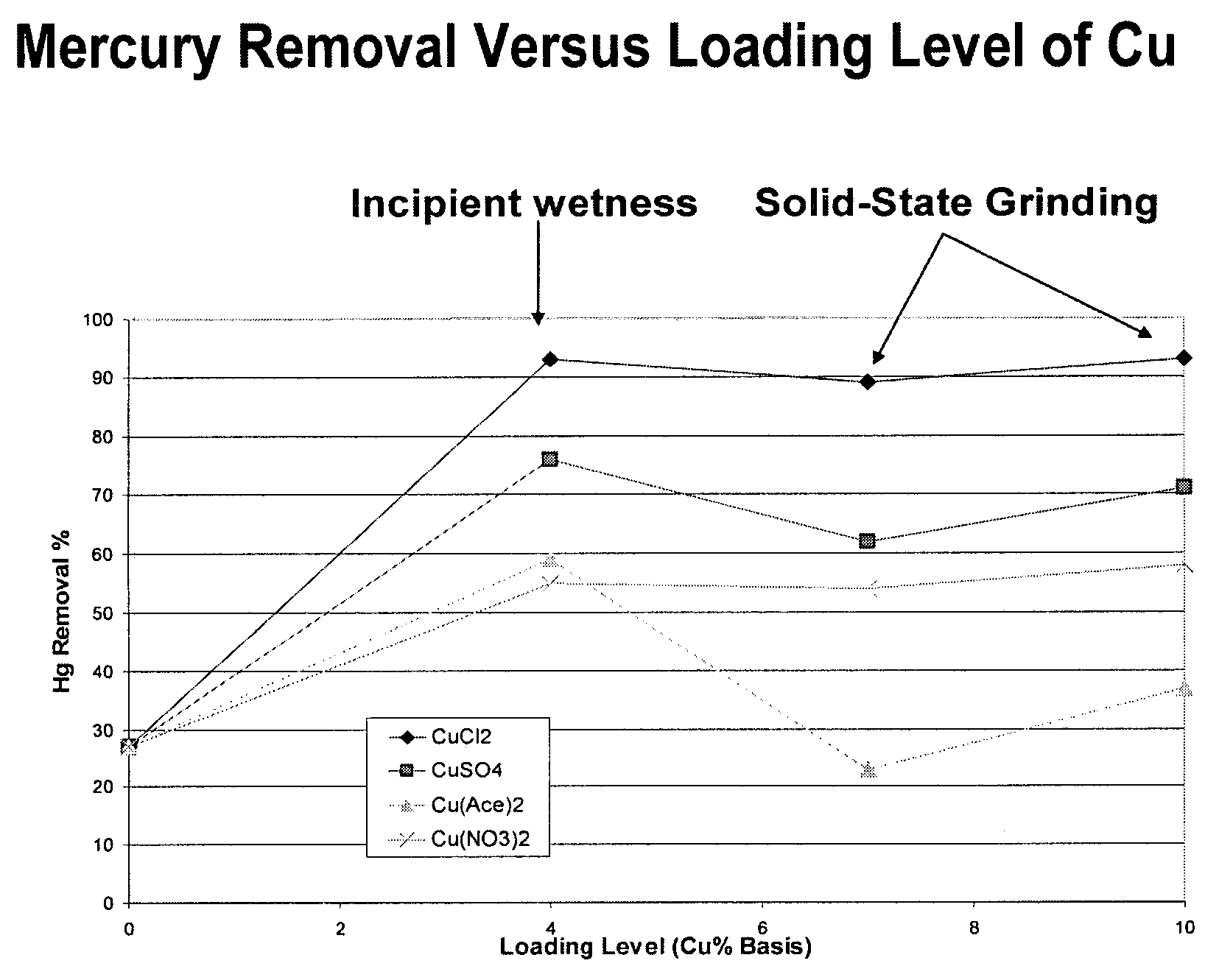

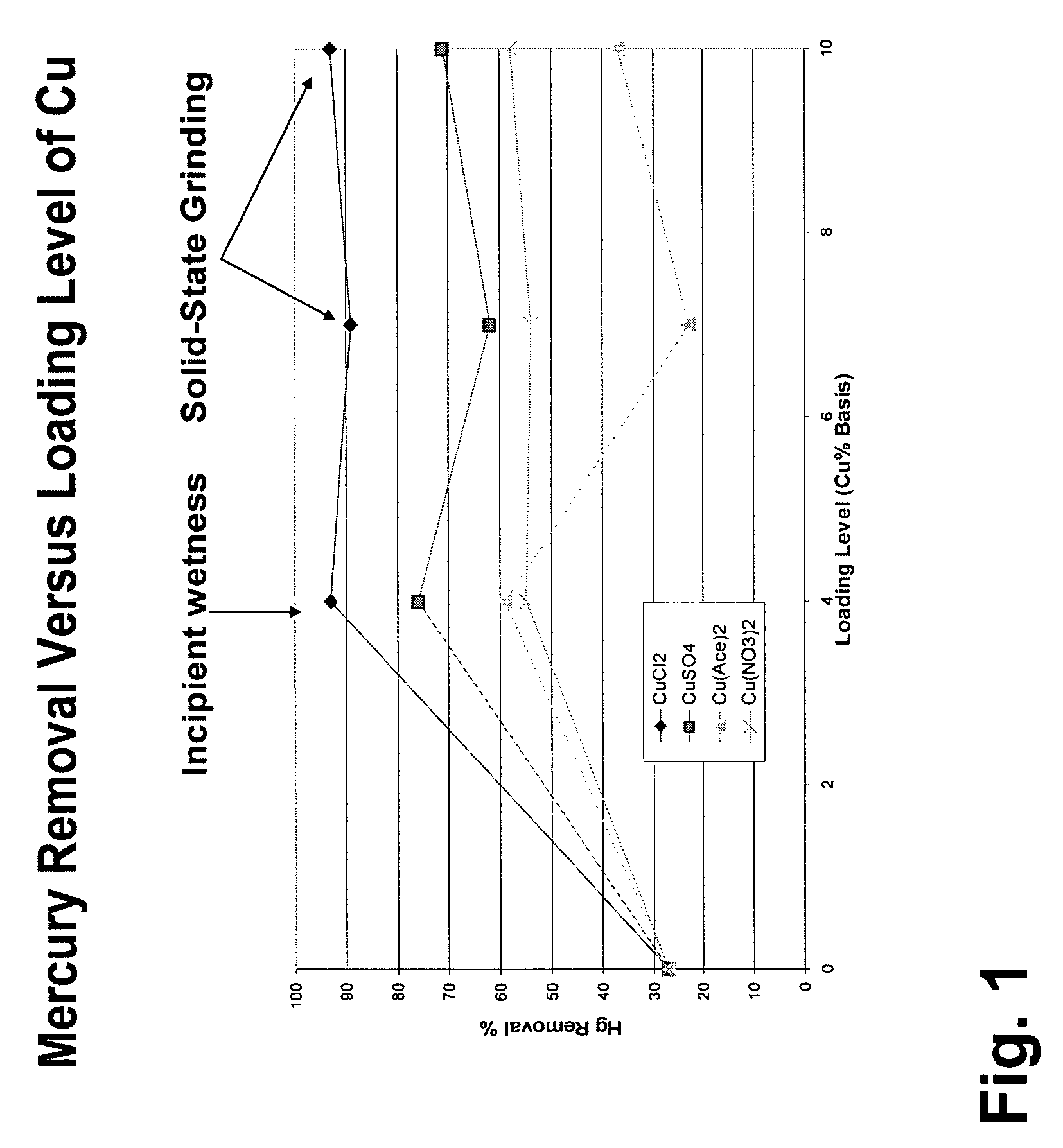

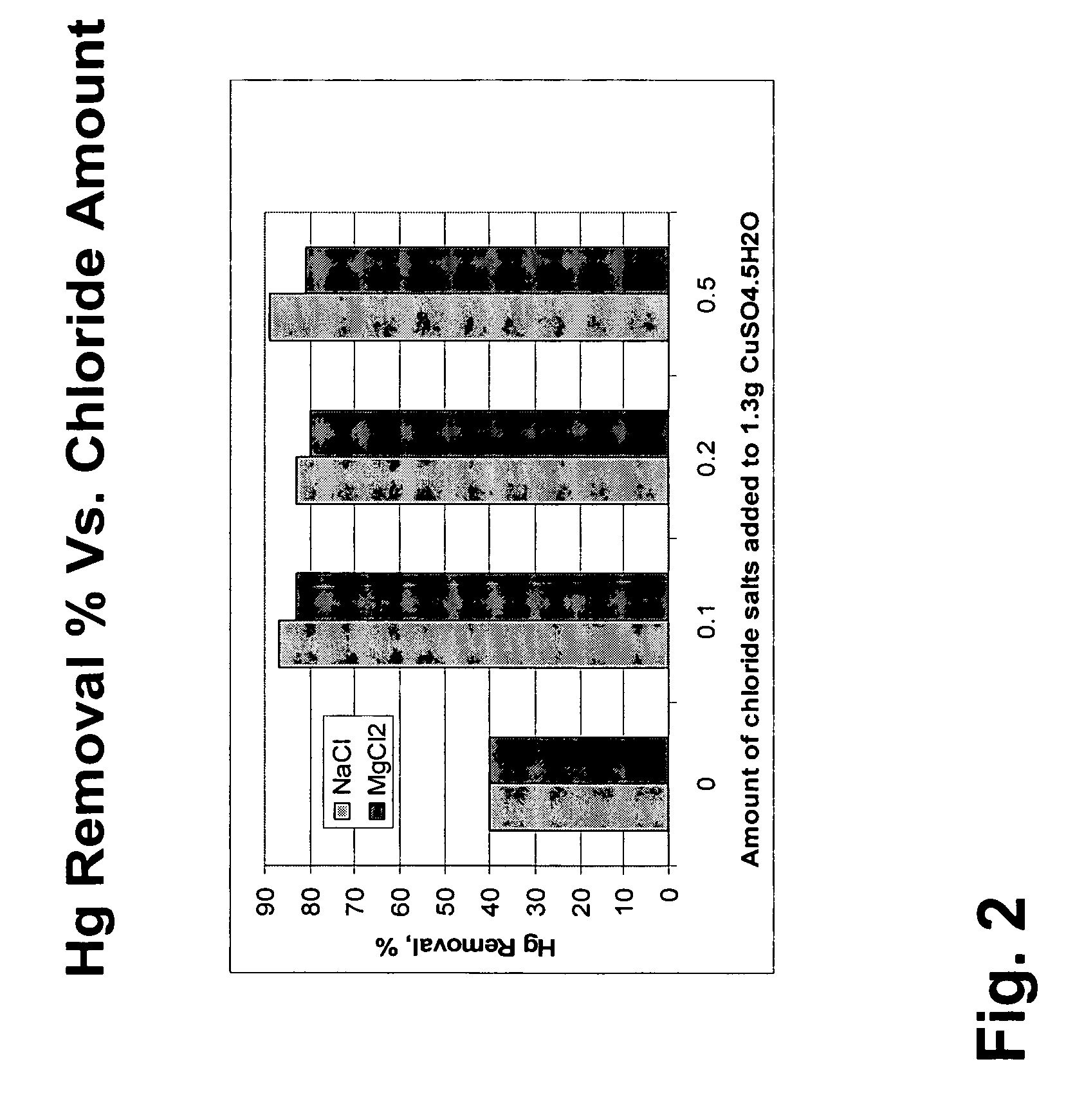

Oxidative sorbents are provided for adsorbing elemental or oxidized mercury from mercury-containing fluids such as flue gas from a coal-burning power utility or the like at a temperature range of about 50 to 350 ° C. The method of preparing and using the oxidative sorbents is also provided. The oxidative sorbent compositions include one or more silicates capable of cation exchange with a plurality of active metal cations and their counter anions. The silicates may include those selected from clays such as montmorillonite, laumonite, bentonite, Mica, vermiculite and kaolinite, and from silica gels, natural and synthetic molecular sieves, zeolites, and ashes from stoker- and pulverized coal-fired boilers. The one or more oxidative metal halides and / or sulfates may be selected from the group consisting of CuCl, CuBr, CuCl2, CuBr2, CuSO4, FeCl2, FeCl3, FeSO4, Fe2(SO4)3, ZnCl2, ZnBr2, NiCl2, and NiSO4. The oxidative sorbents may also include activated carbon.

Owner:U S ENVIRONMENTAL PROTECTION AGENCY UNITED STATES OF AMERICA THE AS REPRESENTED BY THE ADMINISTATOR

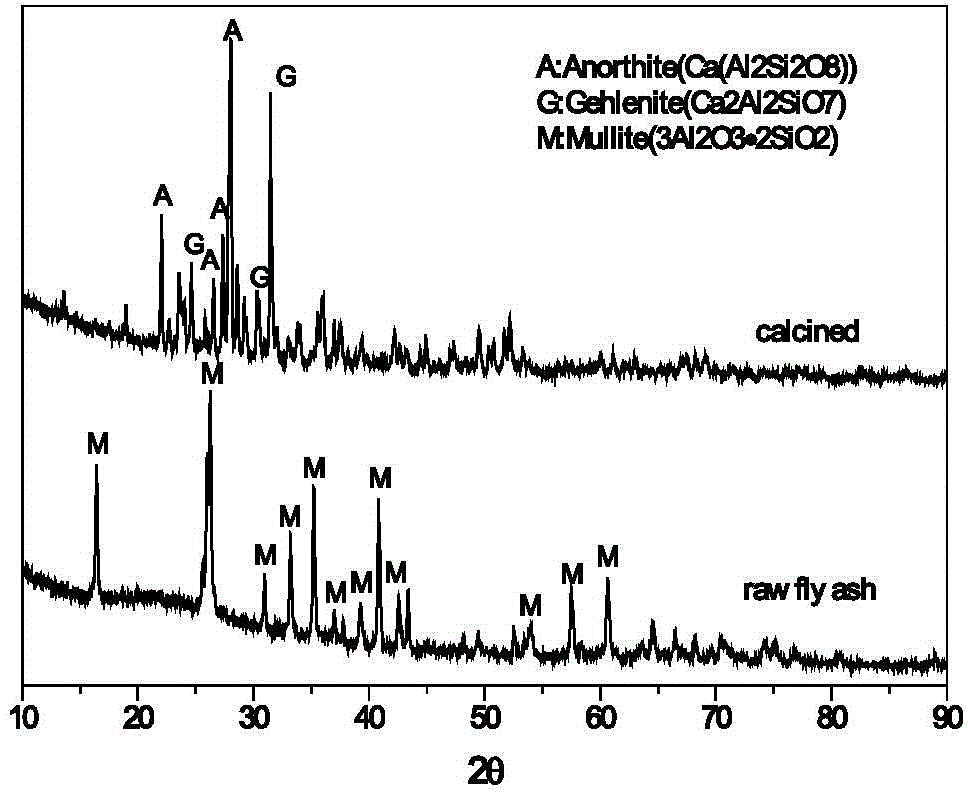

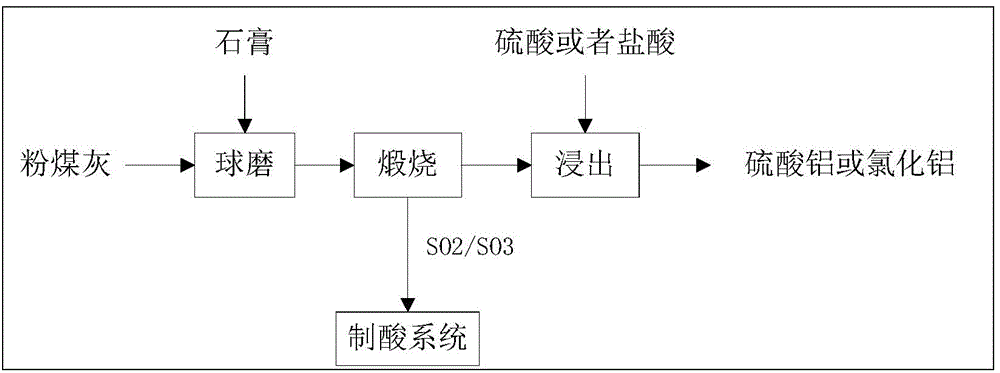

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

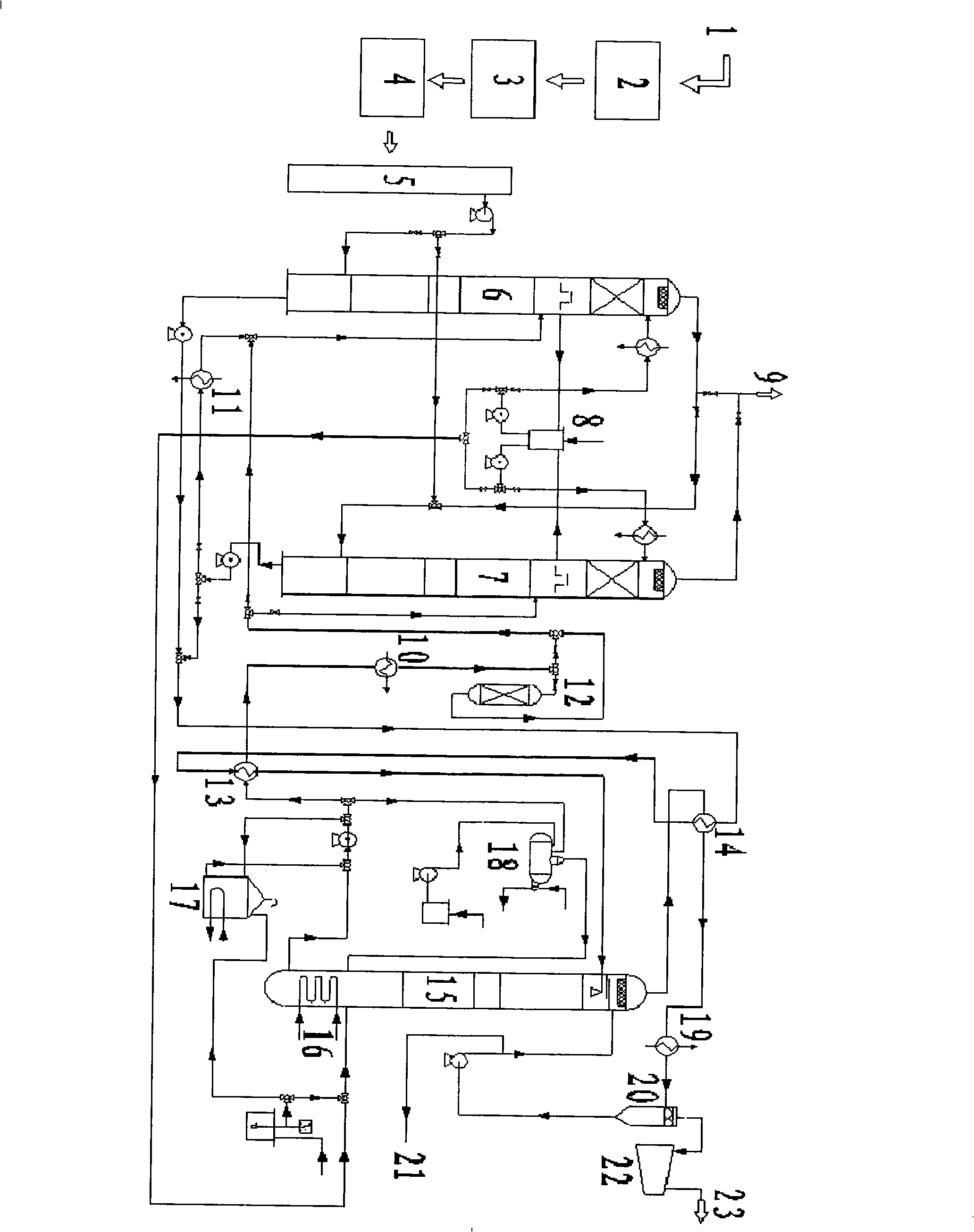

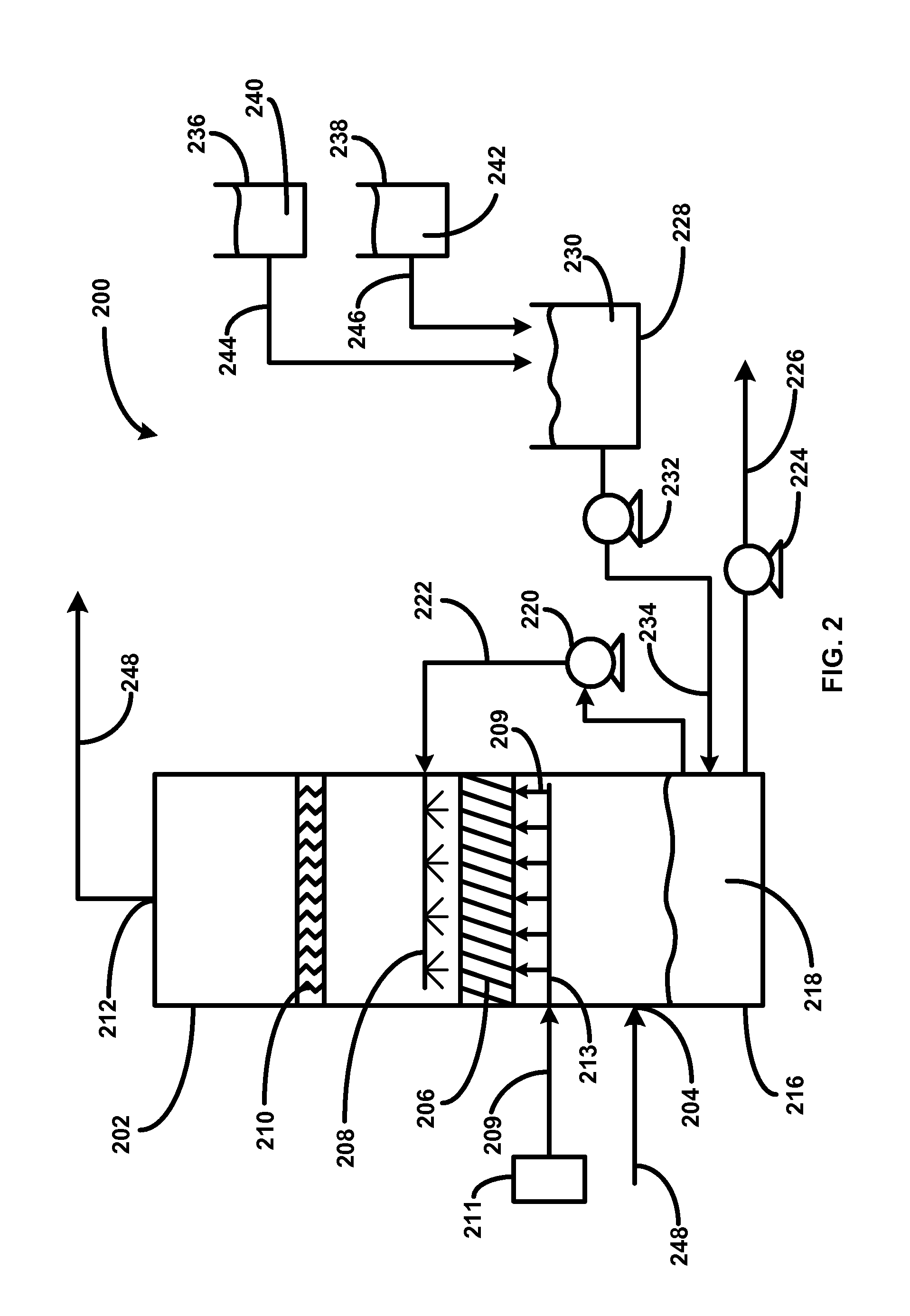

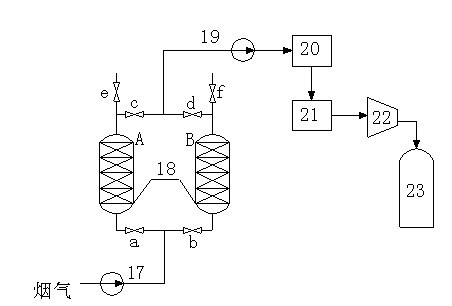

Method and apparatus for collecting carbonic anhydride in coal-fired plant flue gas

The invention provides a method and a device for collecting carbon dioxide in smoke gas of a coal-fired power plant. The device consists of a smoke gas pretreatment system, absorption towers, a regeneration tower, an exhaust scrubbing system, a solution heating recoverer, a product gas processing system (comprising a condenser, a gas-liquid separator and a compressor). The device is integrated with the prior smoke gas purification device of the coal-fired power plant, and is provided with a high-efficiency whirlcone and a chemical absorption system, so that mass carbon dioxide gas exhausted from a coal-fired boiler can be collected, and the emission of greenhouse gas can be reduced; the special arrangement of double absorption towers ensures more flexible operation of a collecting system, and improves the operational reliability; an absorption solution reclaiming process reduces the consumption of the solution; the arrangement of a lean-rich solution heat exchanger and a product gas rich solution heat exchanger reduces the energy consumption of the collecting system; and the steam consumption can be effectively reduced by adopting a built-in solution boiling unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

Methods of manufacturing bentonite pollution control sorbents

InactiveUS20070119300A1Small particle sizeLiquid surface applicatorsGas treatmentSodium BentoniteSorbent

Methods of manufacturing bentonite sorbents for removal of pollutants including mercury from gas streams, such as a flue gas stream from coal-fired utility plants are disclosed. The methods include mixing bentonite sorbent particles with a sulfide salt and a metal salt to form a metal sulfide on the outer surface of the bentonite sorbent particles.

Owner:BASF CATALYSTS LLC

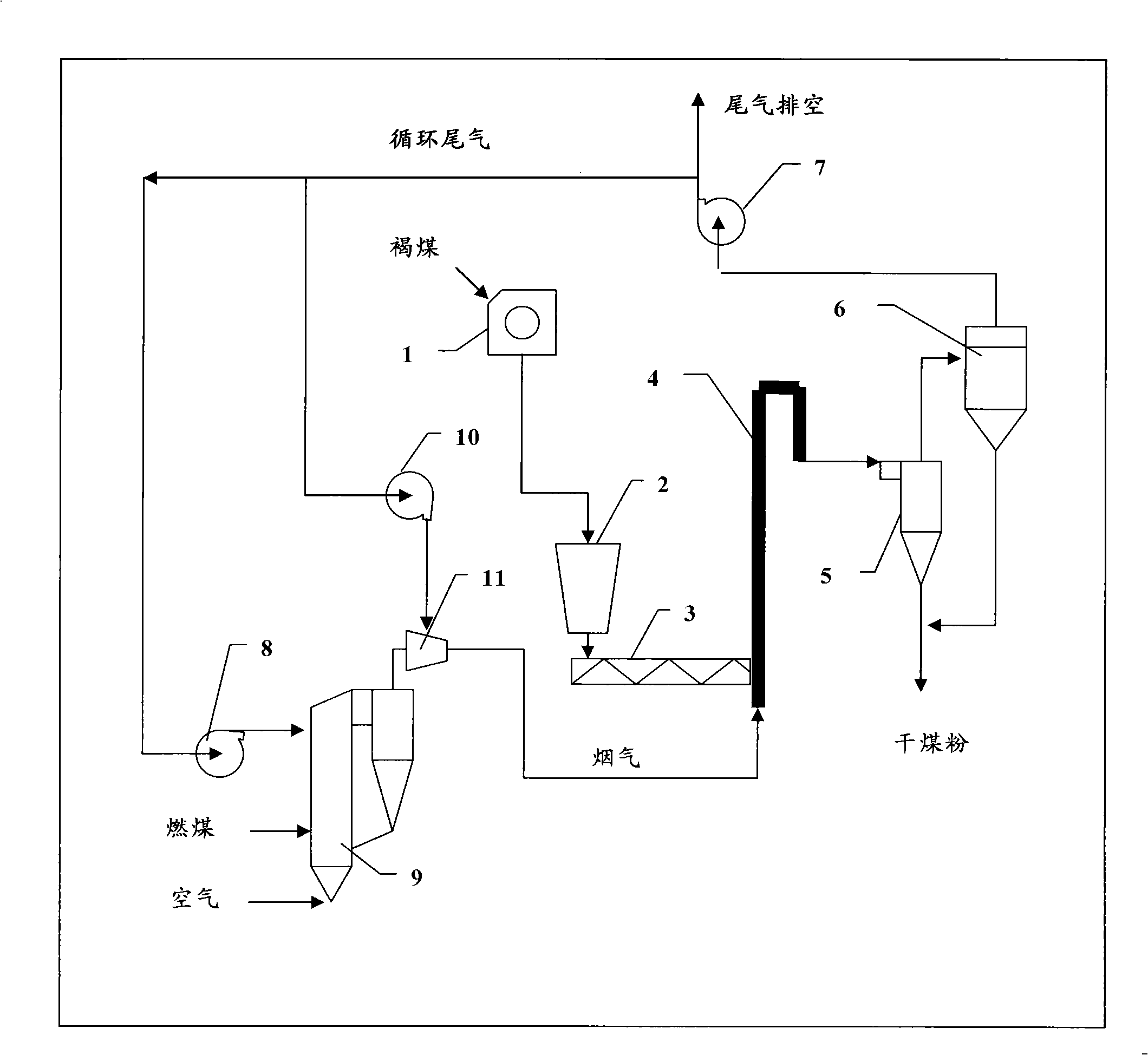

Low rank coal high temperature flue gas drying method and device

The invention relates to a method of high-temperature flue gas drying, which is particularly suitable for drying long flame coal, brown coal or other low rank coal. The coal-fired high-temperature flue gas is used to dry flammable and explosive coal types, such as brown coal in the direct contact method; therefore, the method has less gas exhaust, high thermal efficiency and high drying speed. The internal water content of the dried coal is obviously reduced, and the heating power of the dried coal is greatly increased. The invention also relates to the device using the method.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

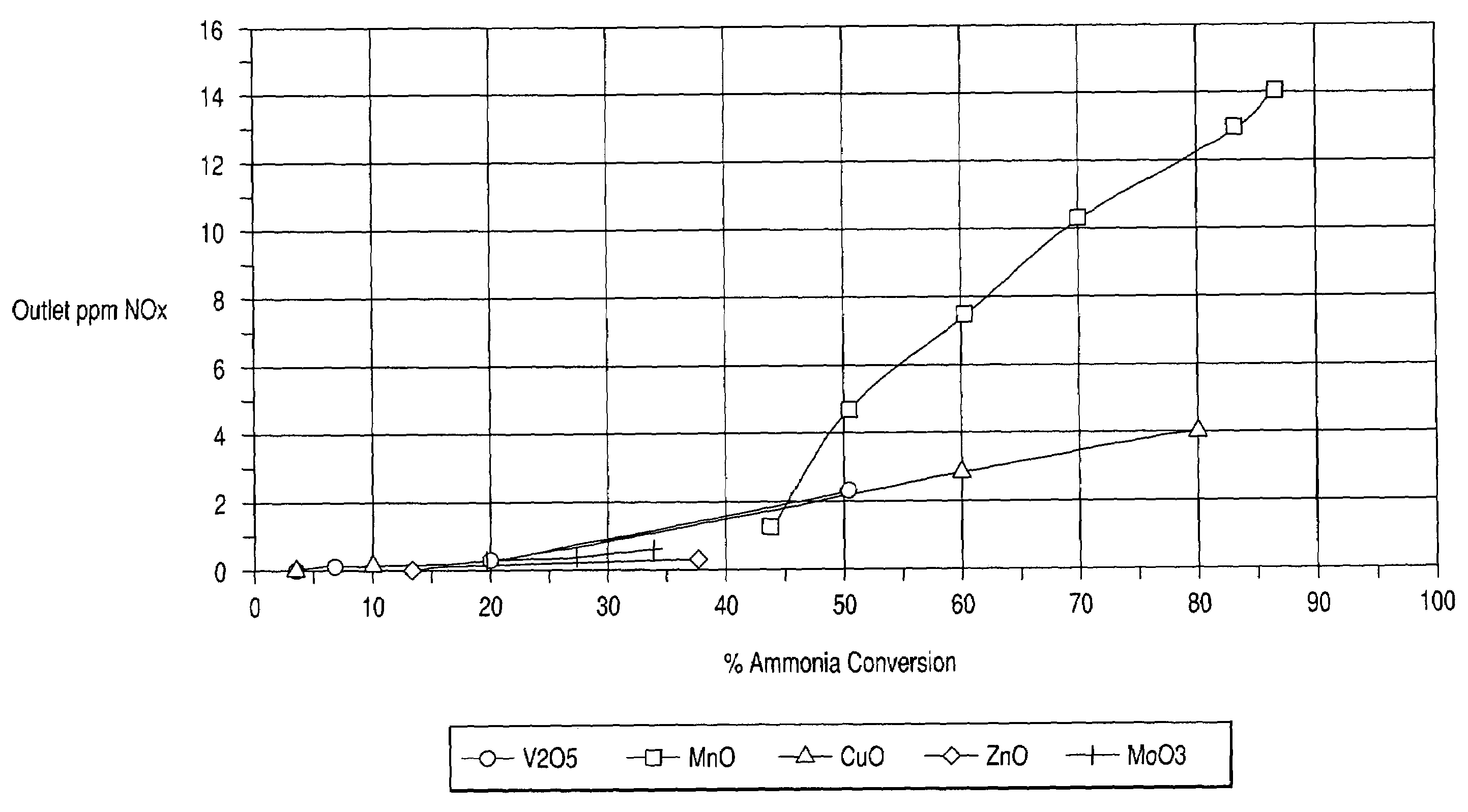

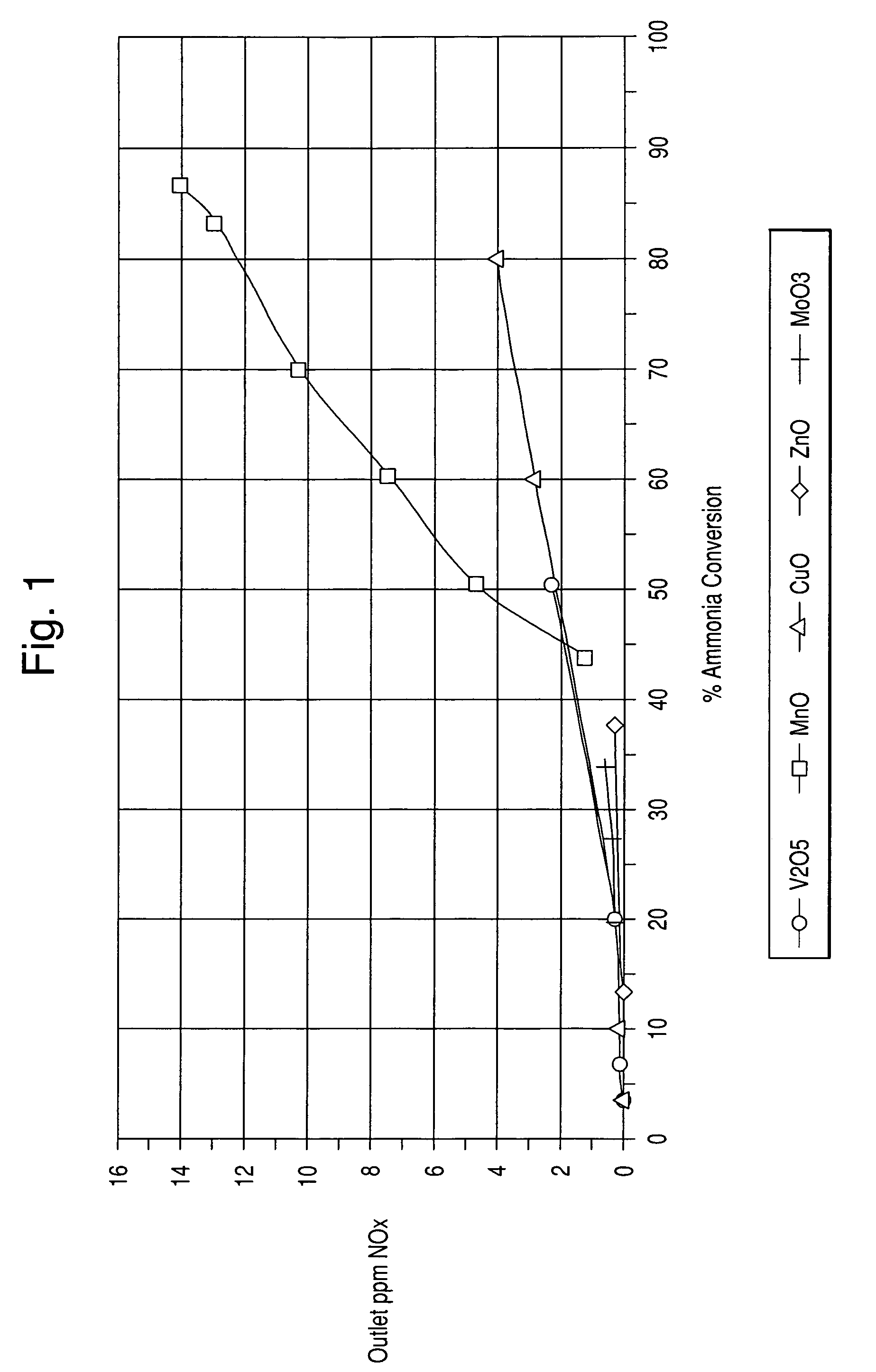

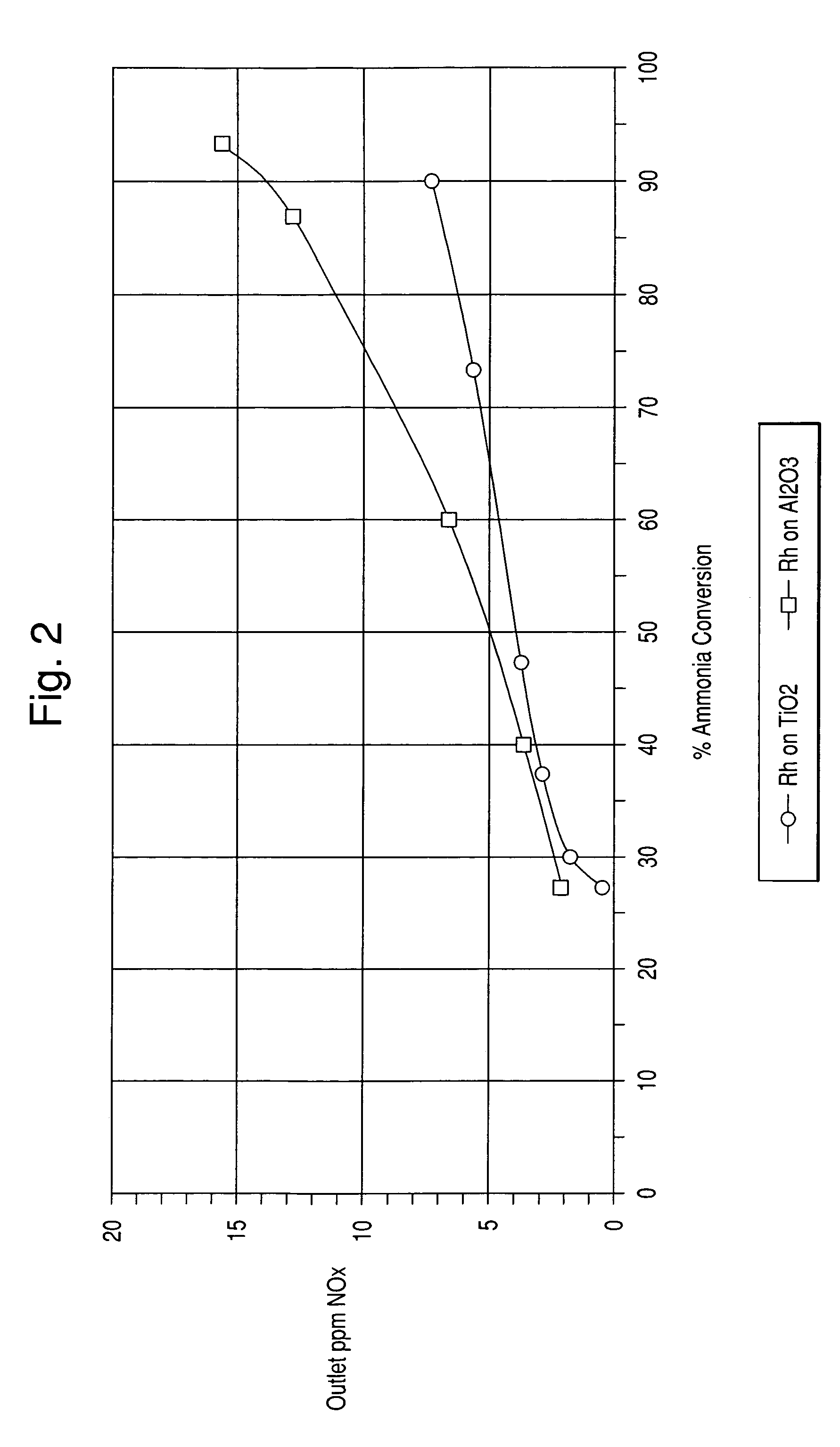

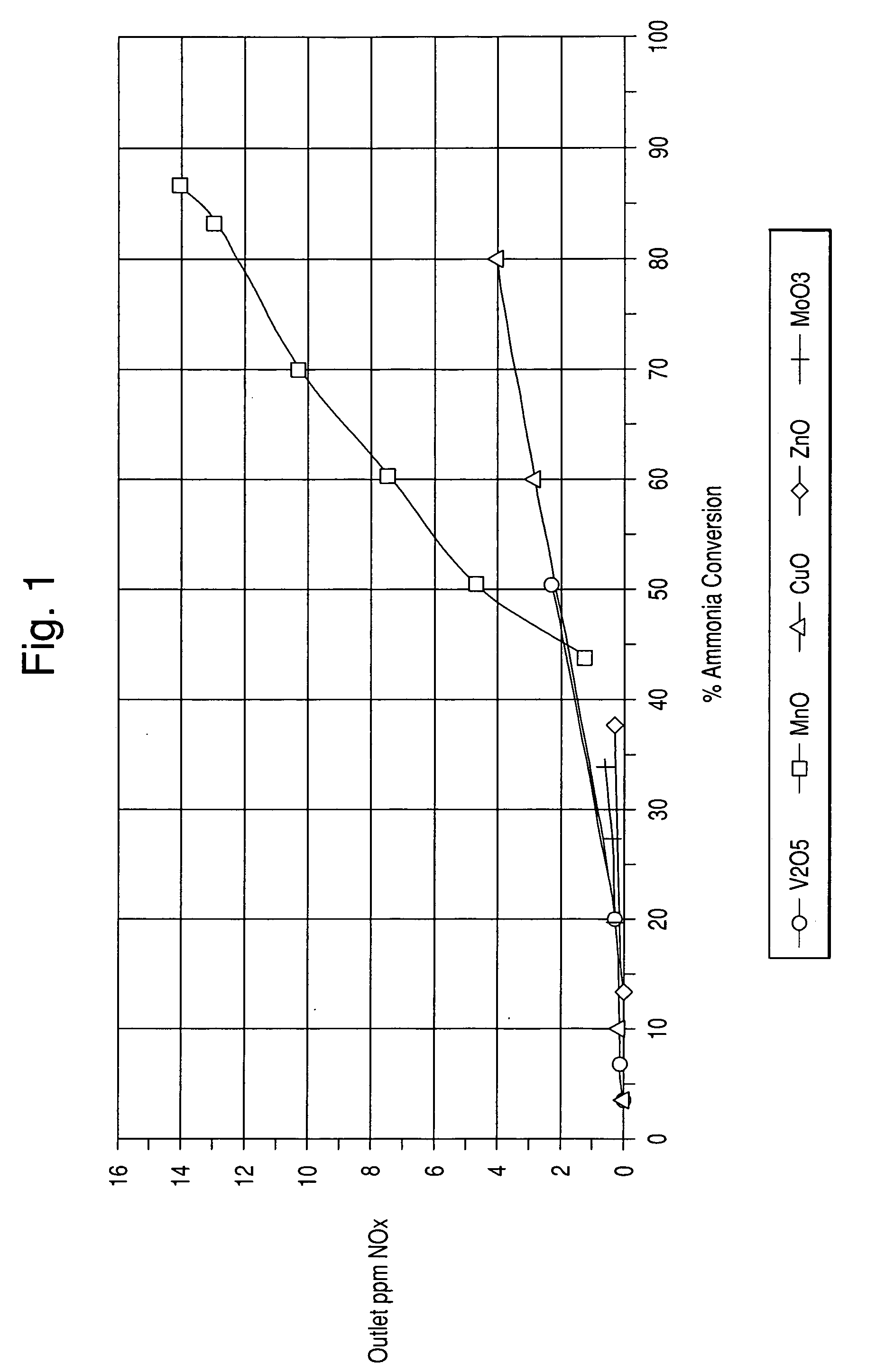

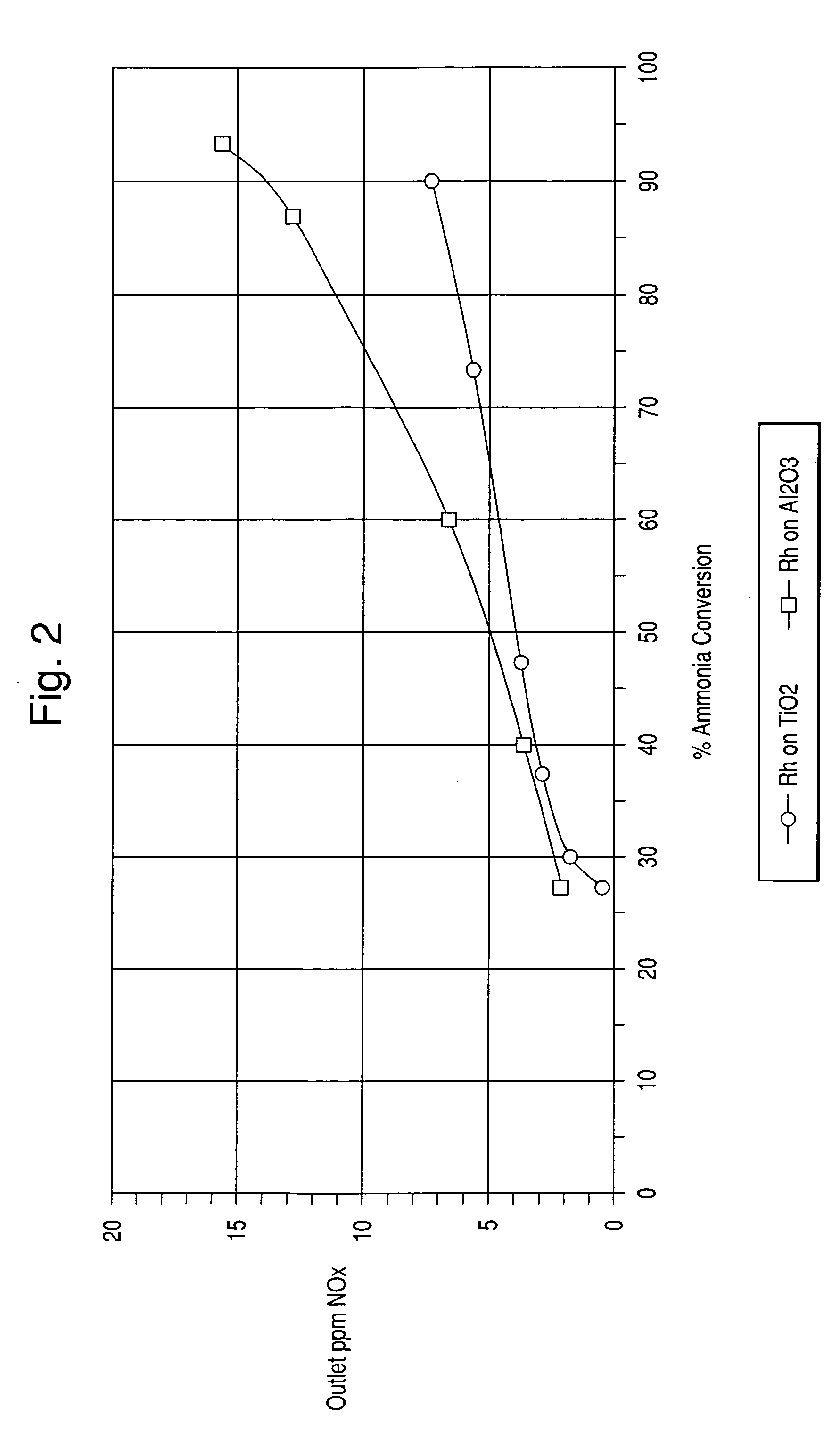

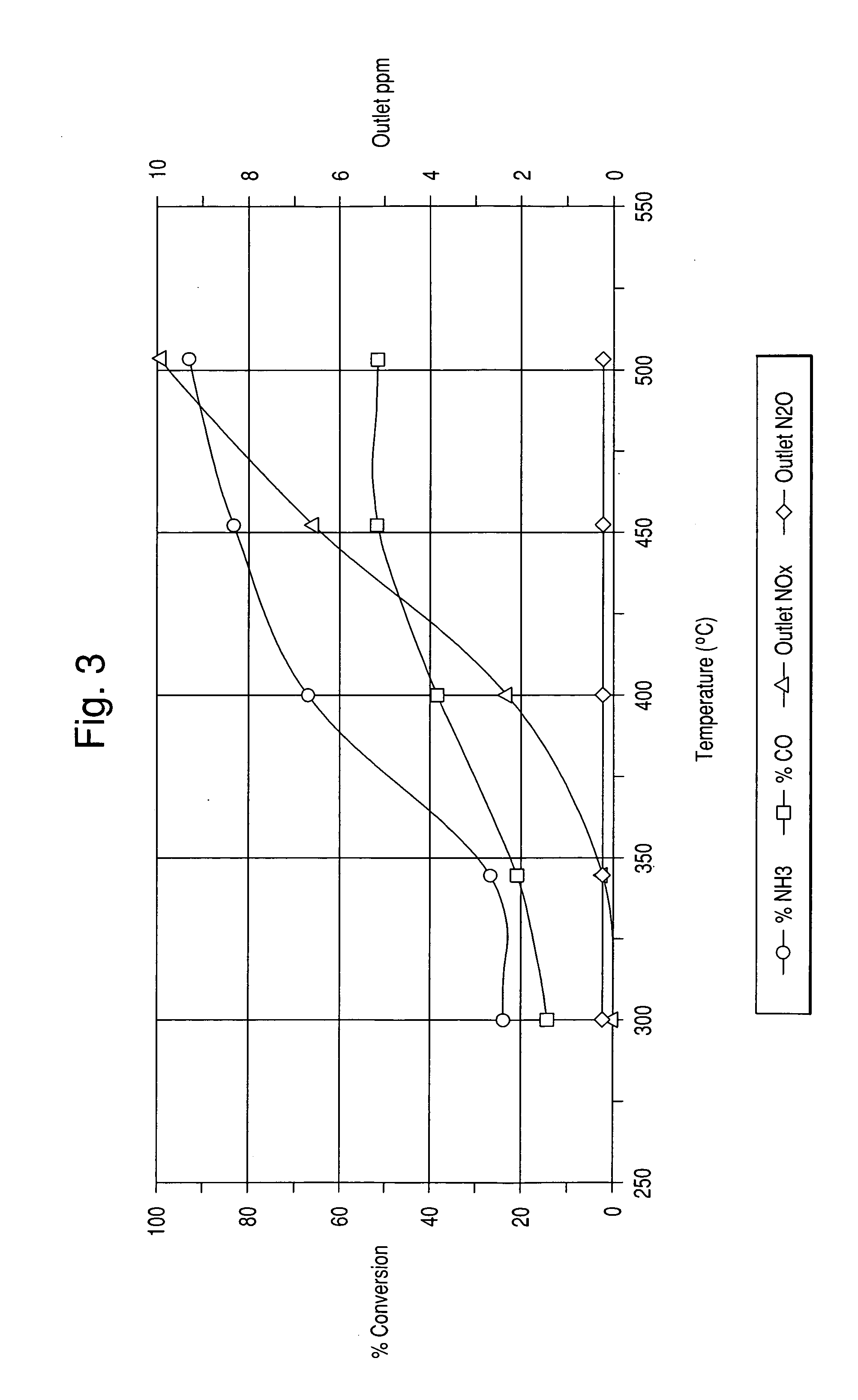

Ammonia oxidation catalyst for the coal fired utilities

InactiveUS7393511B2Undesirable emission levelNo sulfurCyanogen compoundsNitrogen compoundsSulfur dioxideCarbon monoxide

A process is described that removes by oxidation the excess ammonia (NH3) gas from flue gases that have been subjected to selective catalytic reduction (SCR) of oxides of nitrogen (NOx) by ammonia injection. The inventive process incorporates a secondary catalyst of precious metal and vanadia on a metal oxide such as titania to catalyze the oxidation of both ammonia and carbon monoxide (CO) while maintaining sulfur dioxide (SO2) levels.

Owner:BASF CATALYSTS LLC

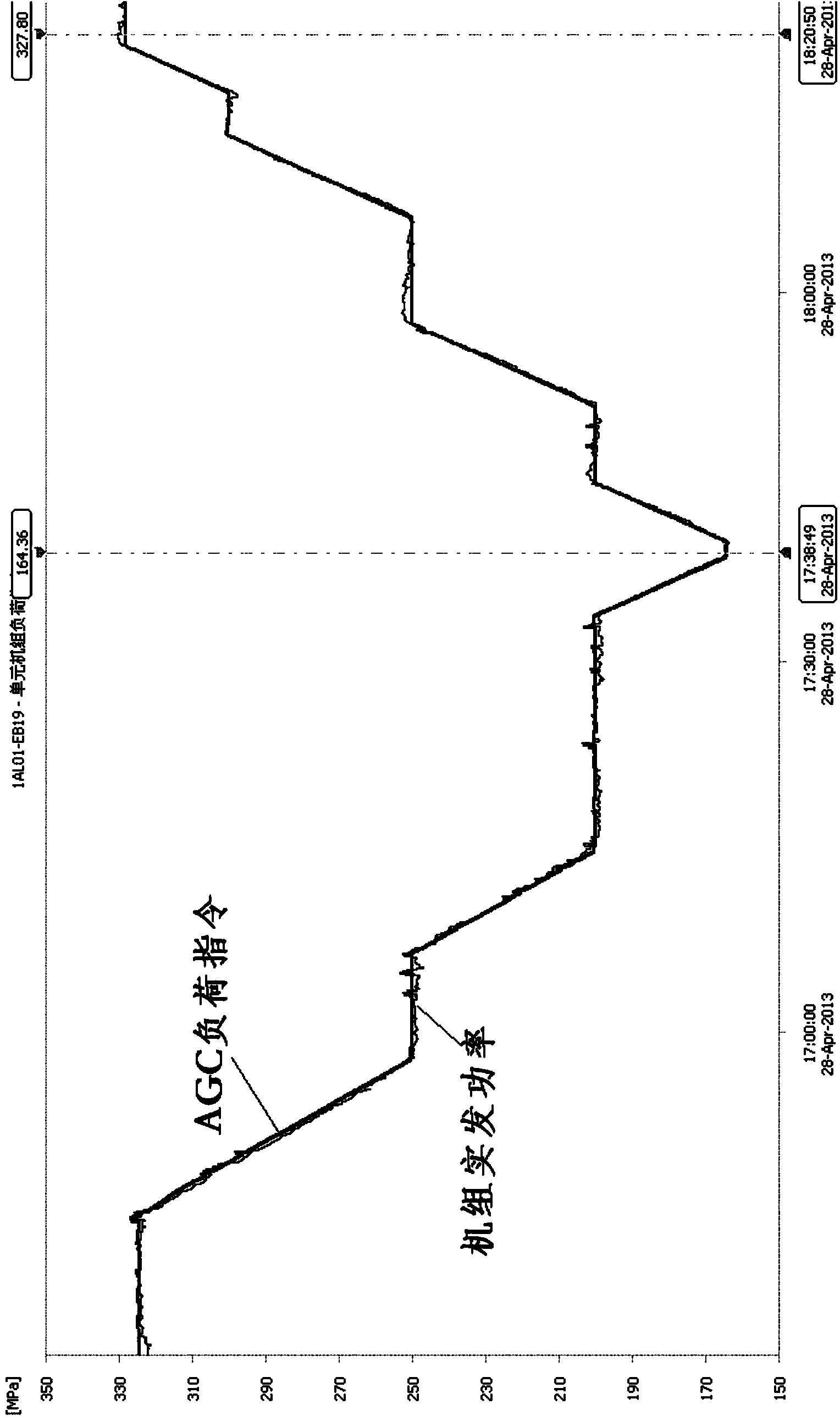

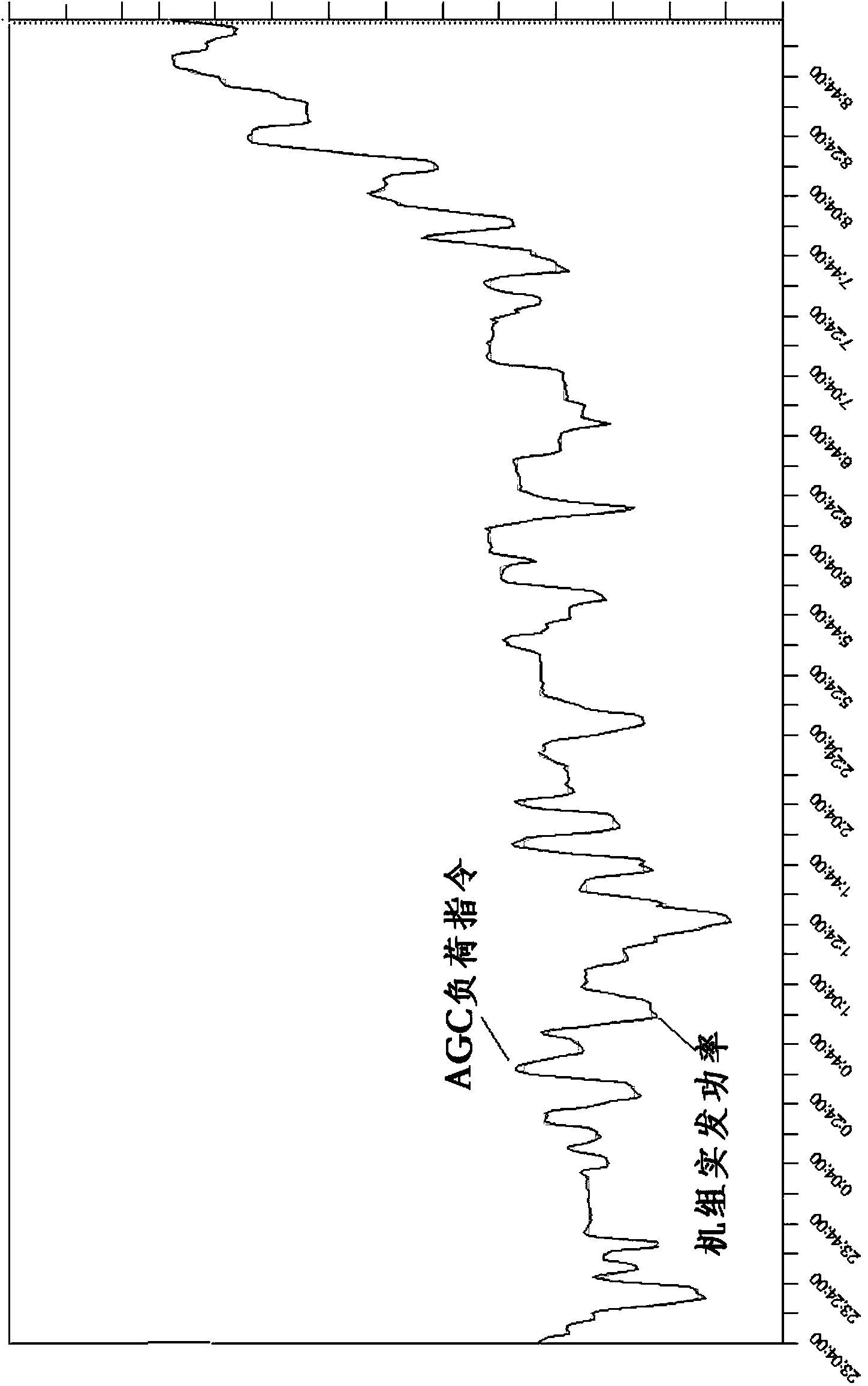

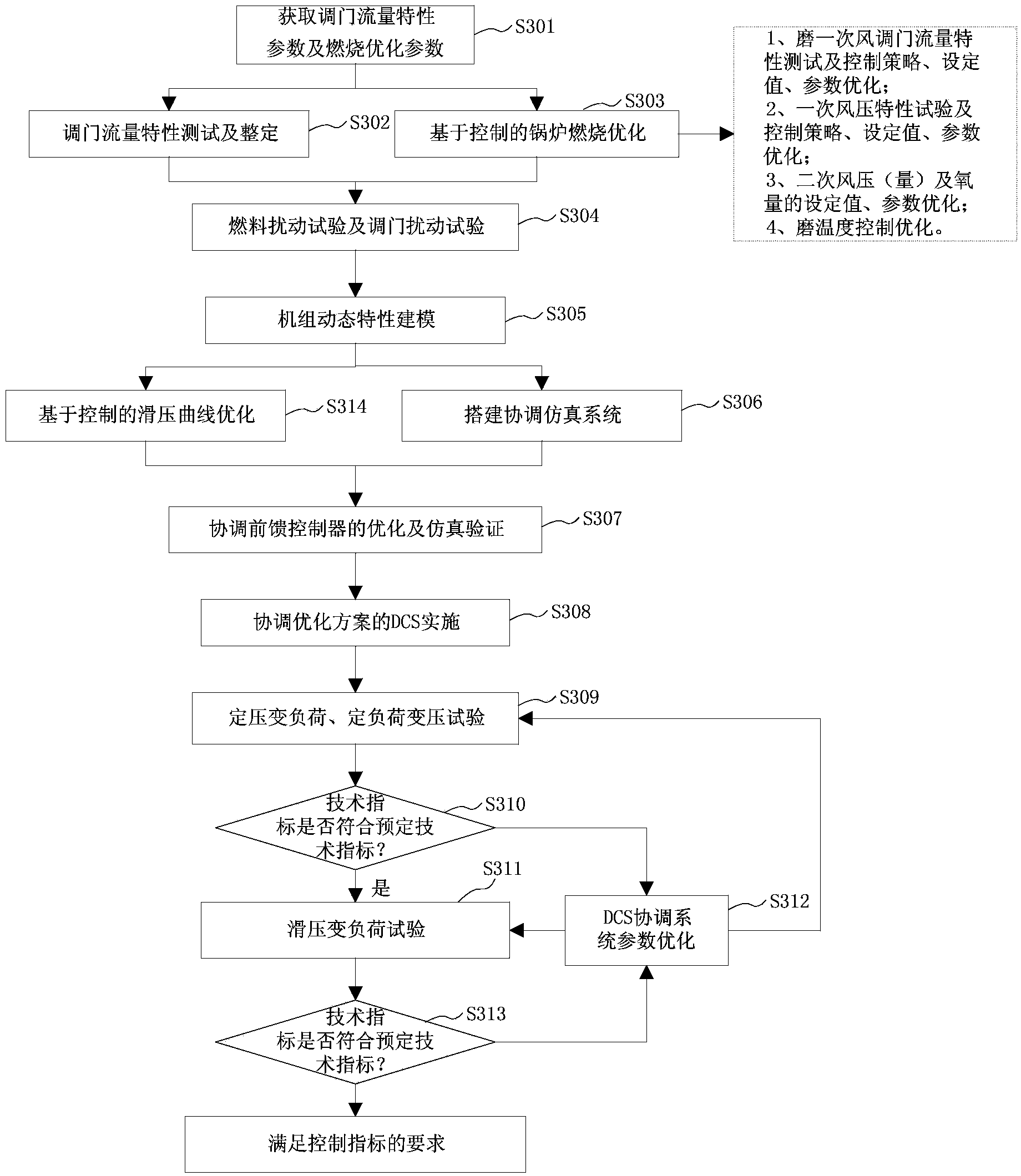

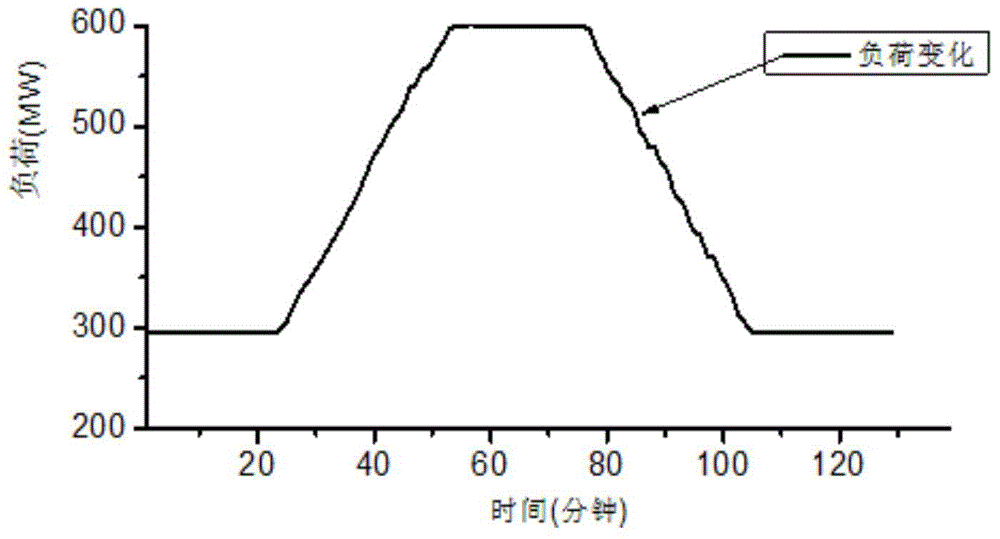

Integral optimization method and system for automatic power generation system of coal-fired unit

ActiveCN103513640AImprove variable load capacityImprove adaptabilityProgramme total factory controlSteam pressureDynamic models

The invention provides an integral optimization method and system for an automatic power generation system of a coal-fired unit. The method comprises the steps of carrying out control valve flow characteristic test and adjustment according to control valve flow characteristic parameters, carrying out combustion optimization on a wind and smoke subsystem and a combustion subsystem, carrying out a fuel disturbance test and a control valve disturbance test to generate typical test parameters, using the typical test parameters to generate a dynamic unit model, constructing a coordinating simulation system according to a coordinating controller and the dynamic unit model, using the dynamic unit model to optimize a feedforward controller and carry out simulation verification on the coordinating simulation system simultaneously, carrying out DCS configuration and parameter debugging in the simulation system, carrying out a constant-voltage slide-voltage variable-load test and a constant-load voltage-transformation test to generate technical indexes of the variable-load rate, the variable-load accuracy, variable-load response time and the main steam pressure accuracy, judging whether the technical indexes meet the preset technical indexes, and if on yes judgment, carrying out a slide-voltage variable-load test to enable the coal-fired unit to operate normally.

Owner:STATE GRID CORP OF CHINA +1

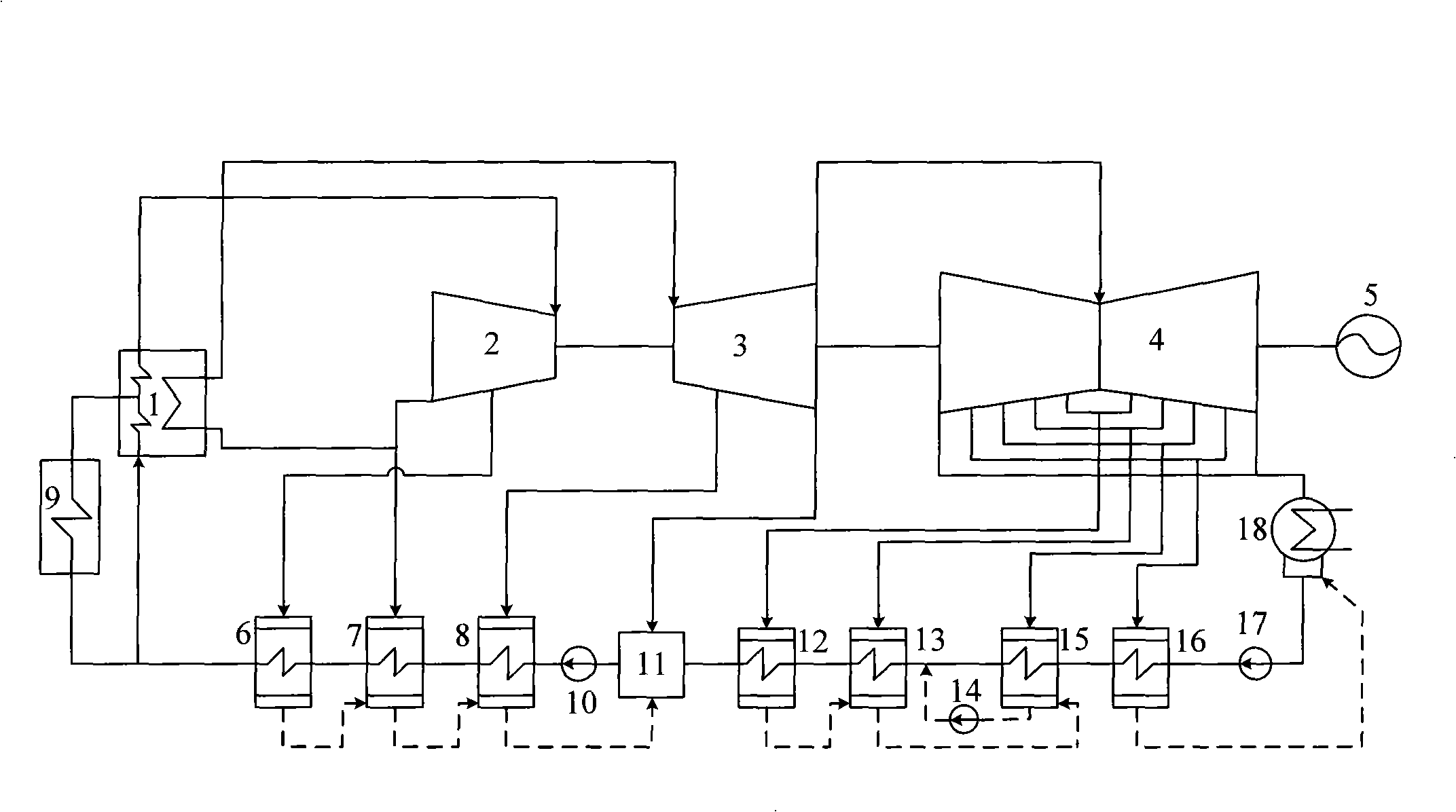

Solar energy and coal-burning unit combined thermal power generation system

InactiveCN101270675AHigh thermal efficiencyImprove thermal efficiencySteam engine plantsDeaeratorEngineering

The invention relates to a generating system, in particular to the heat generating system consisting of a solar heat collector and a coal-fired unit. The heat generating system adopts solar energy to take the place of the partial coal-fired heat energy of a coal-fired unit boiler. A condenser, an extraction pump, a low pressure heater, a deaerator, a water-feeding pump, a high pressure heater and the heat collector, a coal burning boiler and a steam turbine that are connected in parallel are connected in series. The steam turbine drives the generator and discharges gas into the condenser. Condensed water flows into a heater from the condenser to be heated up and pressurized, is deoxidized by the deaerator, then goes through the solar heat collector to be heated to be saturated vapor and goes into the coal burning boiler or directly goes into the coal burning boiler to become the steam with high temperature and high pressure. And then the steam goes into the steam turbine for applying work to drive the generator to generate electricity. The extracted steam of the steam turbine goes into each heater to finish thermodynamic cycle. The thermal efficiency of solar thermal power generation is improved, investment in the trough solar electrical energy generation of single paraboloid is reduced and the coal consumption of the coal-fired unit is decreased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

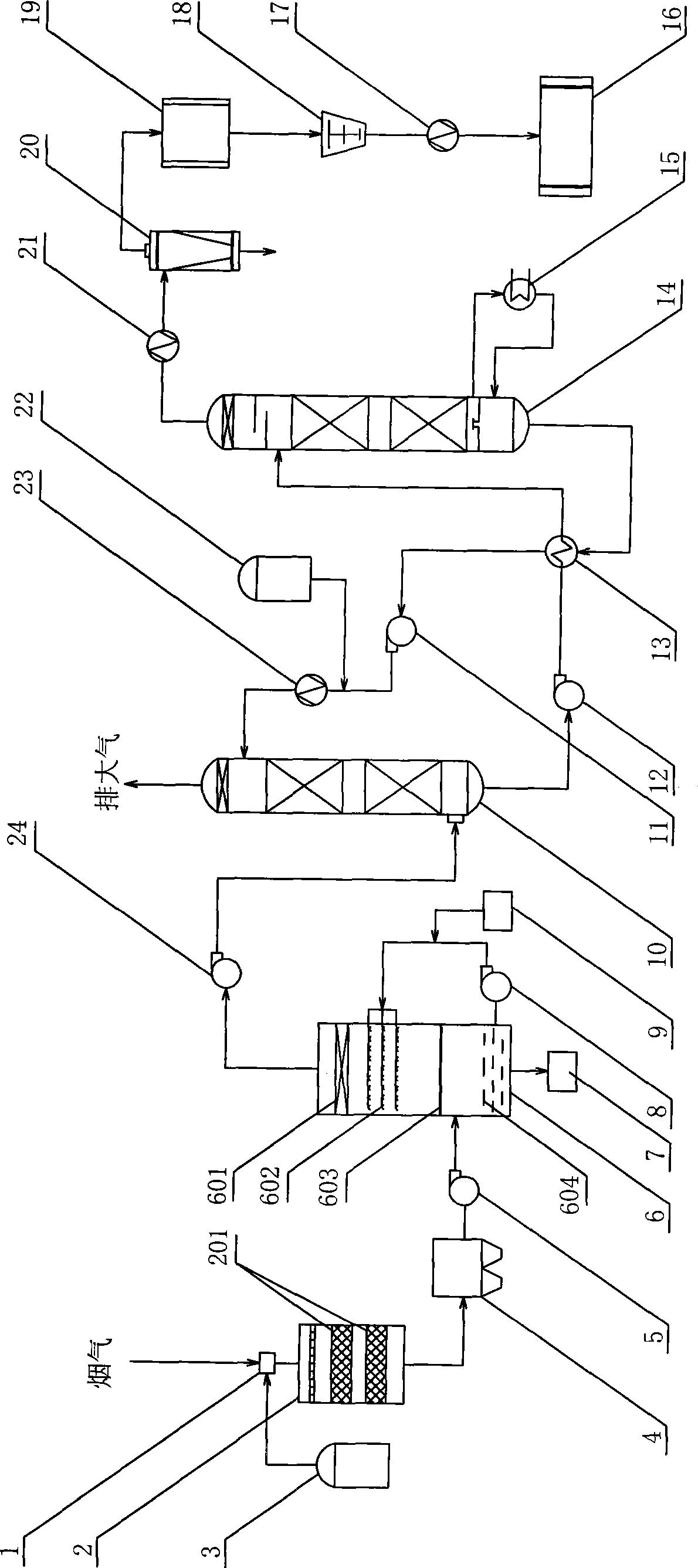

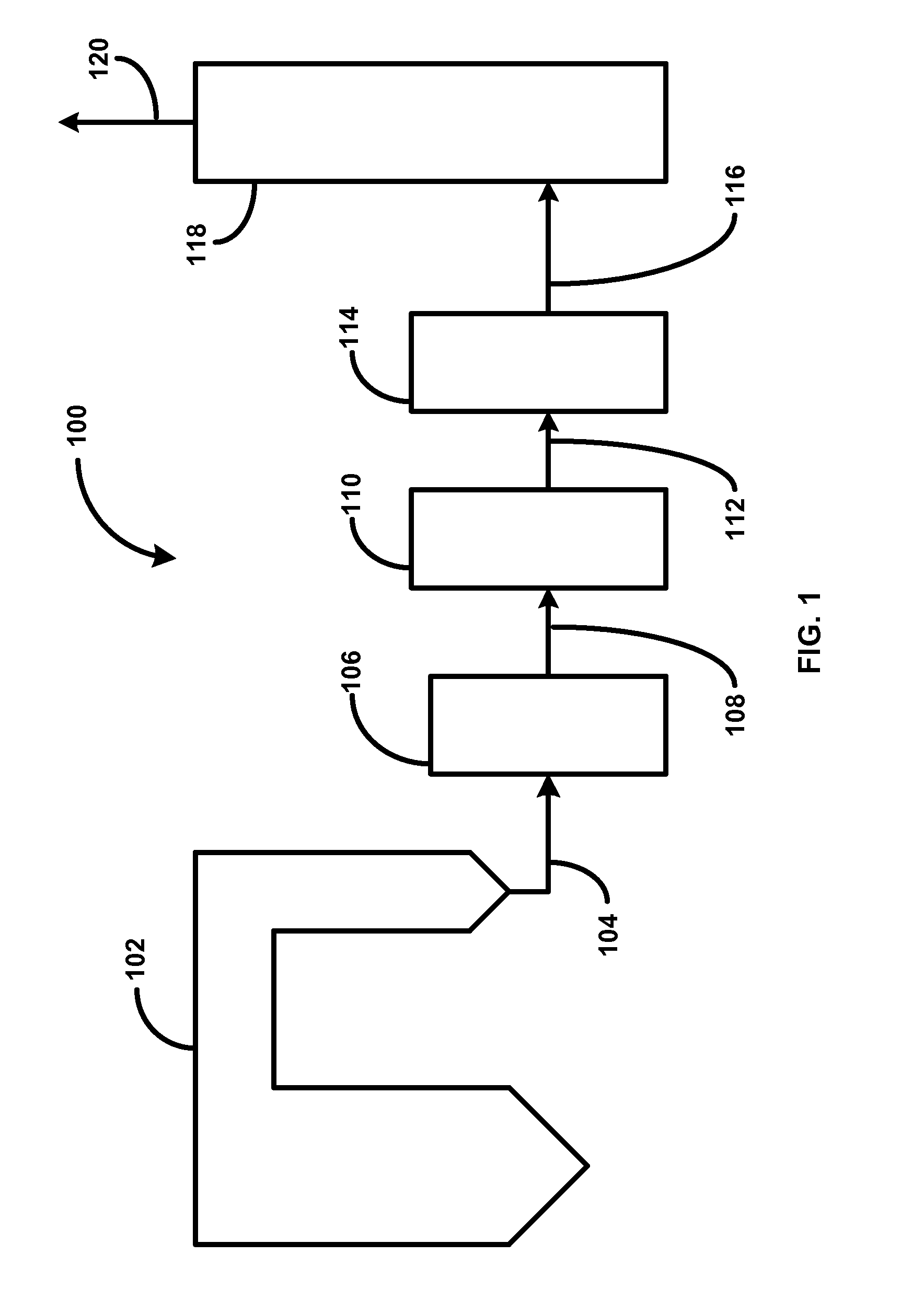

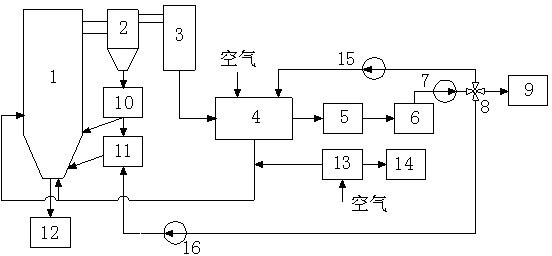

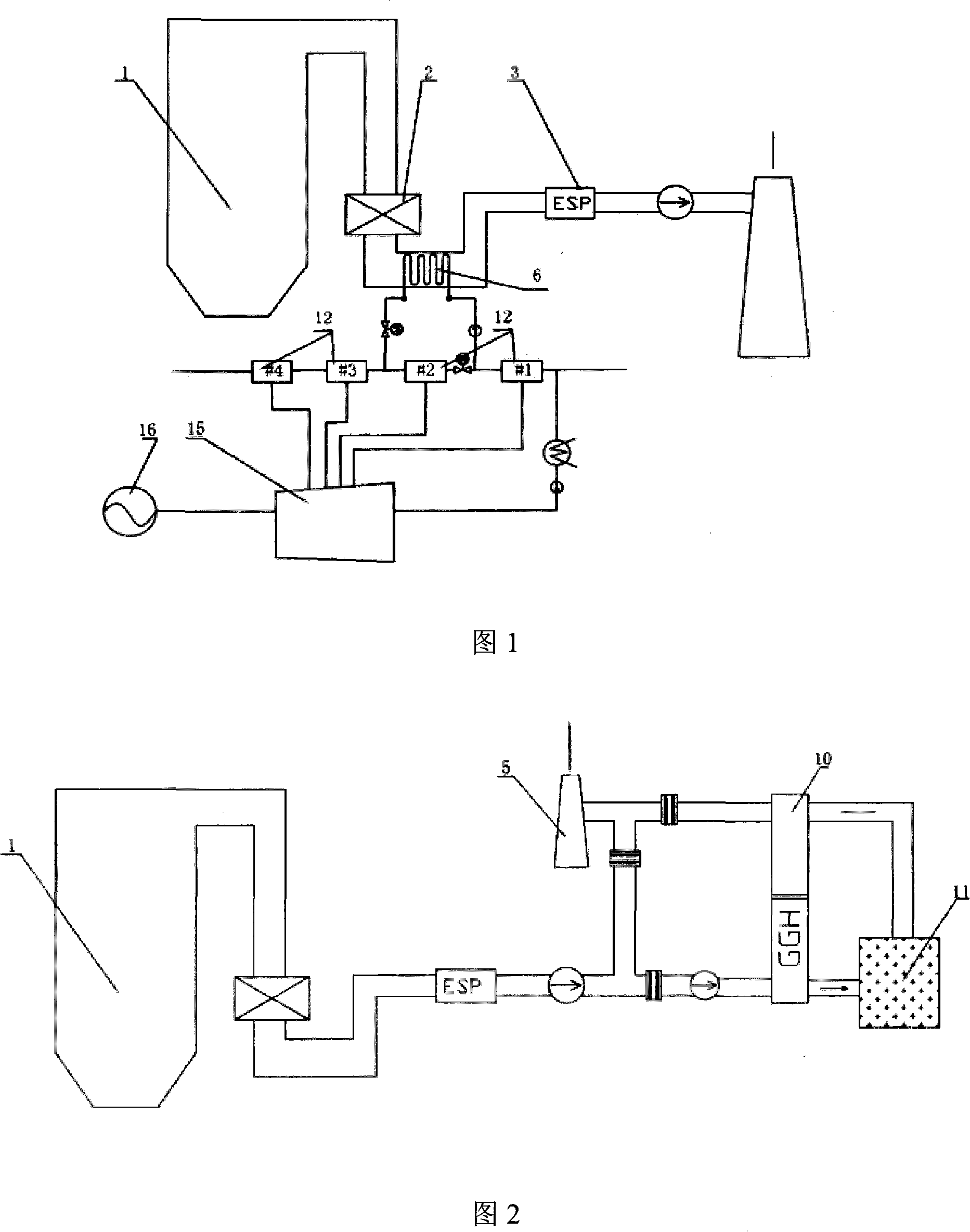

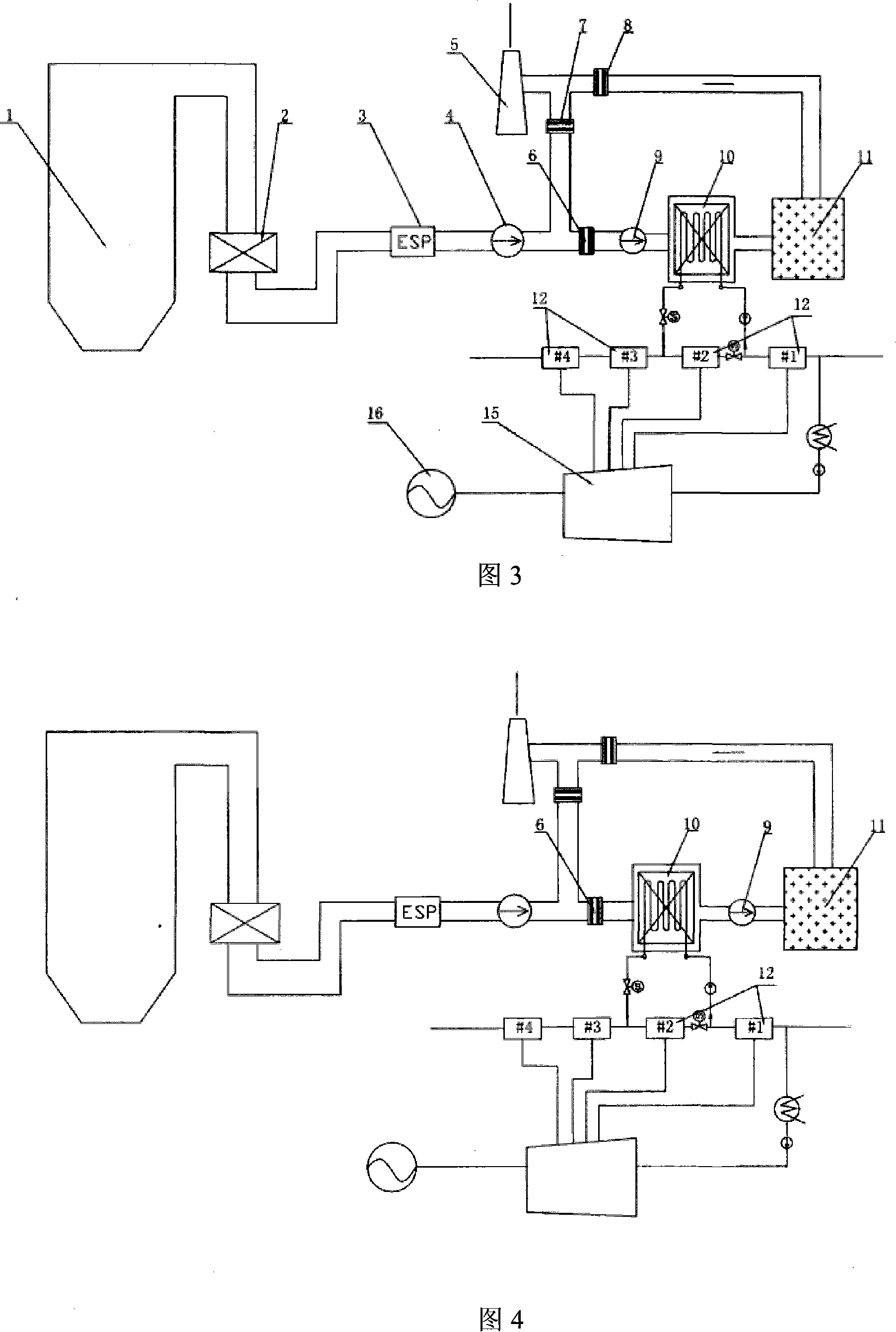

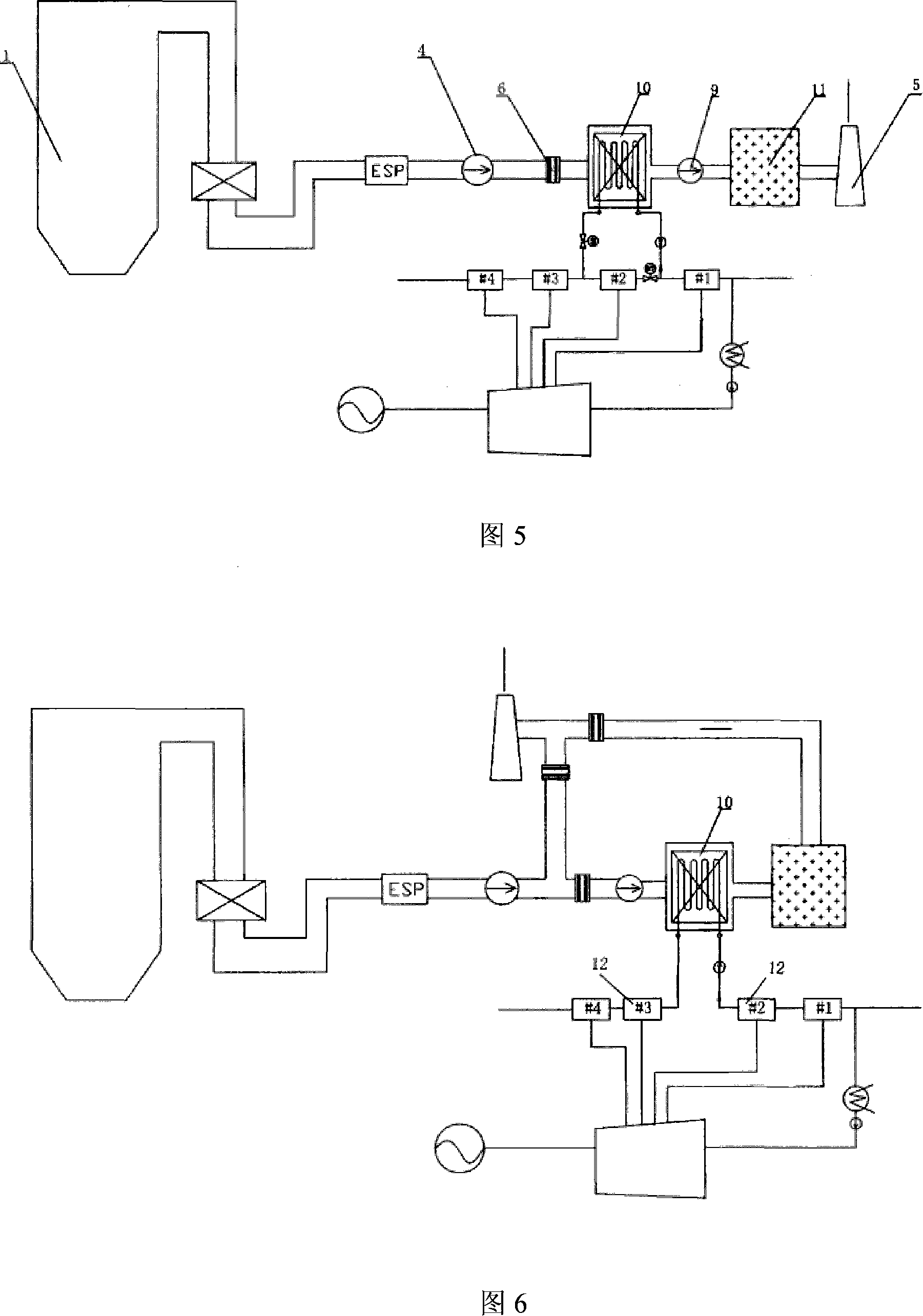

Multi-pollutant removing technique and device of fuel coal smoke

InactiveCN101422691ALow flow resistanceReduce investmentProductsCarbon compoundsHigh concentrationDecarburization

The invention discloses a removal technology of removing coal-fired flue gas pollutants and a device thereof. The technology is as follows: an SCR denitration method is first used for removing NOX in the flue gas; then a dust collector is used for removing dusts and ash particles in the flue gas; then a wet calcium-based desulphurization method is used for removing SO2 in the flue gas; then an MEA decarburization process is used for absorbing the SO2 in the flue gas; simultaneously, a pregnant solution of a generated alkanolamine solution is heated, analyzed and regenerated and the generated barren solution of the alkanolamine solution is continuously and cyclically used; and the analyzed CO2 gas with high concentration is produced to be liquid carbon dioxide of industrial grade with high purity after being cooled, gas-liquid separated, dried, compressed and condensed. The device consists essentially of an SCR denitration reactor, the dust collector, a wet calcium-based desulphurization reactor, an MEA decarburization absorption tower, a regeneration tower, a gas-liquid separator, a dryer, a compressor, a condenser and the like which are connected with each other by pipes. The device has simple and compact overall design, low investment and operation costs, and stable and reliable work and can conduct classified integration processing and highly efficient simultaneous removal on every pollutant in the coal-fired flue gas.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

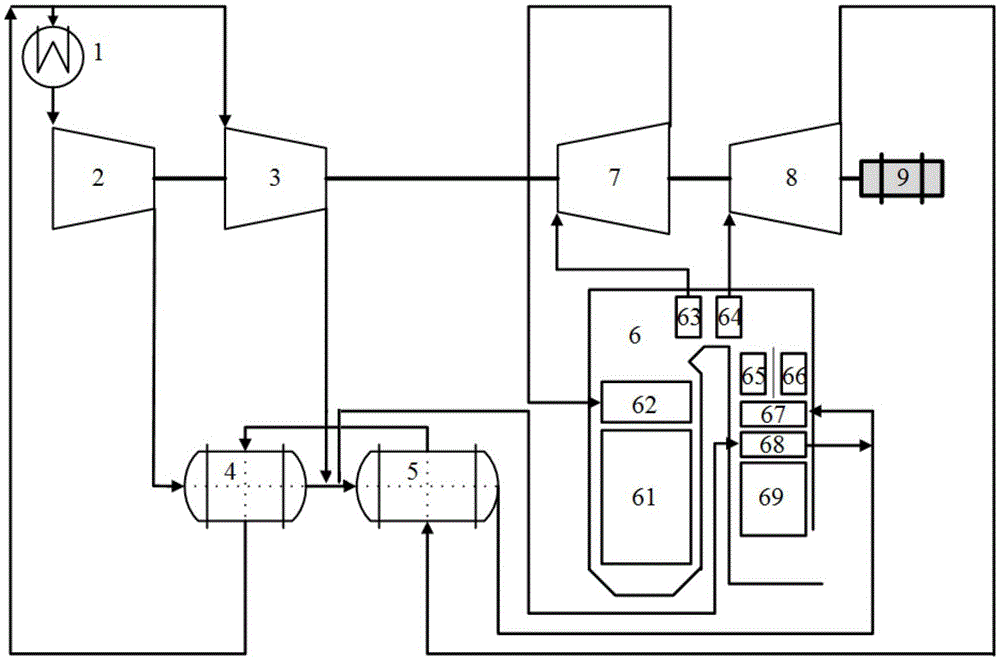

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas

InactiveCN101816886APromote regenerationSolve pollutionDispersed particle separationAir quality improvementMass ratioSorbent

The invention provides a method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas. The method comprises the following steps: dedusting and cooling the coal-fired flue gas containing SO2, NOx and CO2; leading the gas into an adsorbent for saturated adsorption at the adsorption temperature of 50-100 DEG C and the adsorption pressure of 50-10000Pa; evacuating the coal-fired flue gas, desorbing the adsorbent by means of pressure reduction or temperature rise, and then repeatedly using; leading the desorbed gas into ammonia water for absorption treatment, wherein, the mass ratio of the ammonia water to the mixed gas containing SO2, NOx and CO2 is 2-6:1, the absorption temperature is 30-50 DEG C, and the absorption pressure is 5000-12000Pa; and recycling the gas to generate ammonium sulfate, ammonium nitrate and ammonium carbonate. The method can achieve simultaneouse desulfuration, denitration and decarbonization, and has small investment, low cost and low energy consumption; and the method can be widely applied to purification treatment of SO2, NOx and CO2 in the waste gas discharged from fixed fire coal sources such as thermal power plants, smelting plants, oil refinery, chemical plants and the like.

Owner:KUNMING UNIV OF SCI & TECH

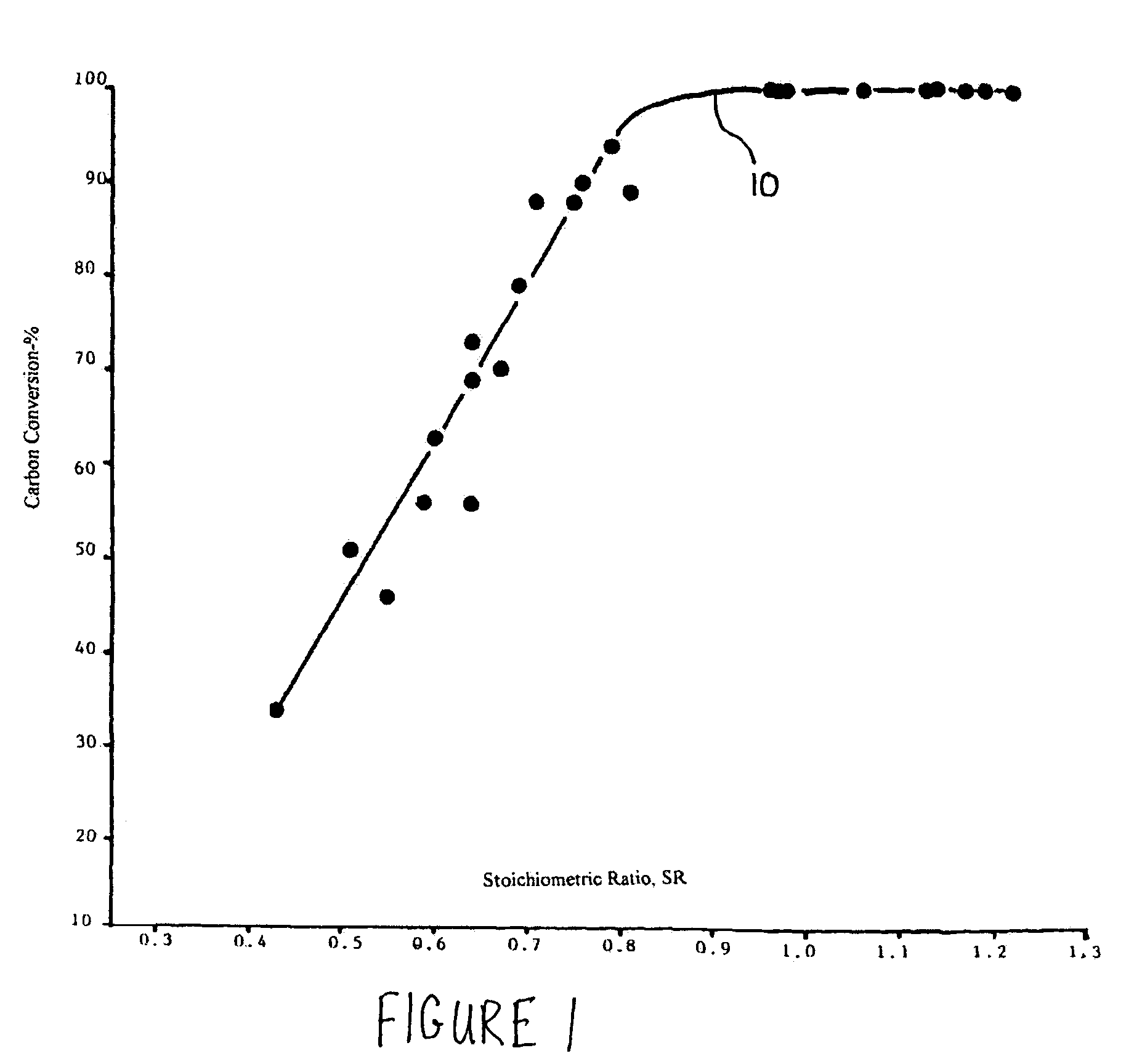

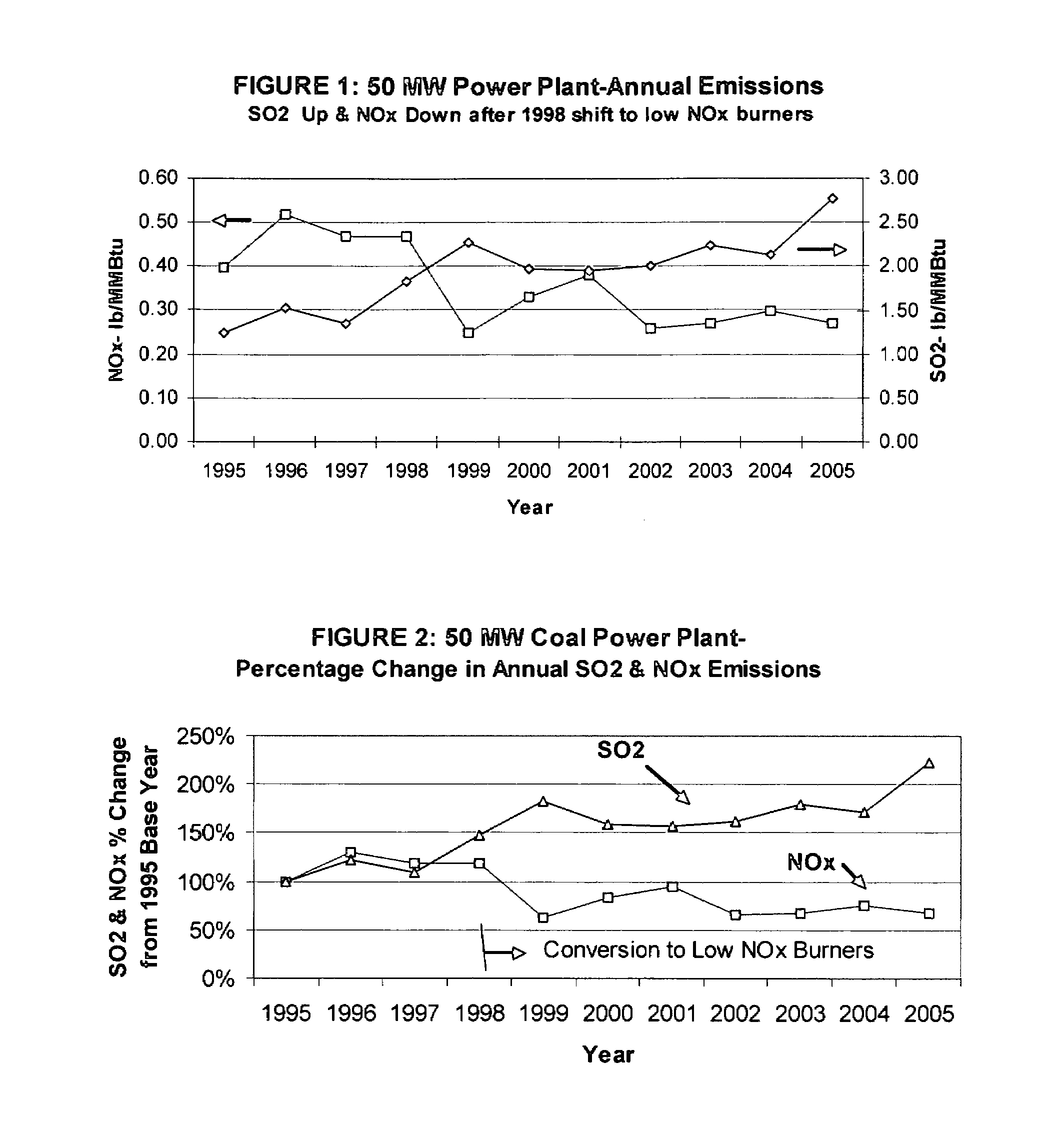

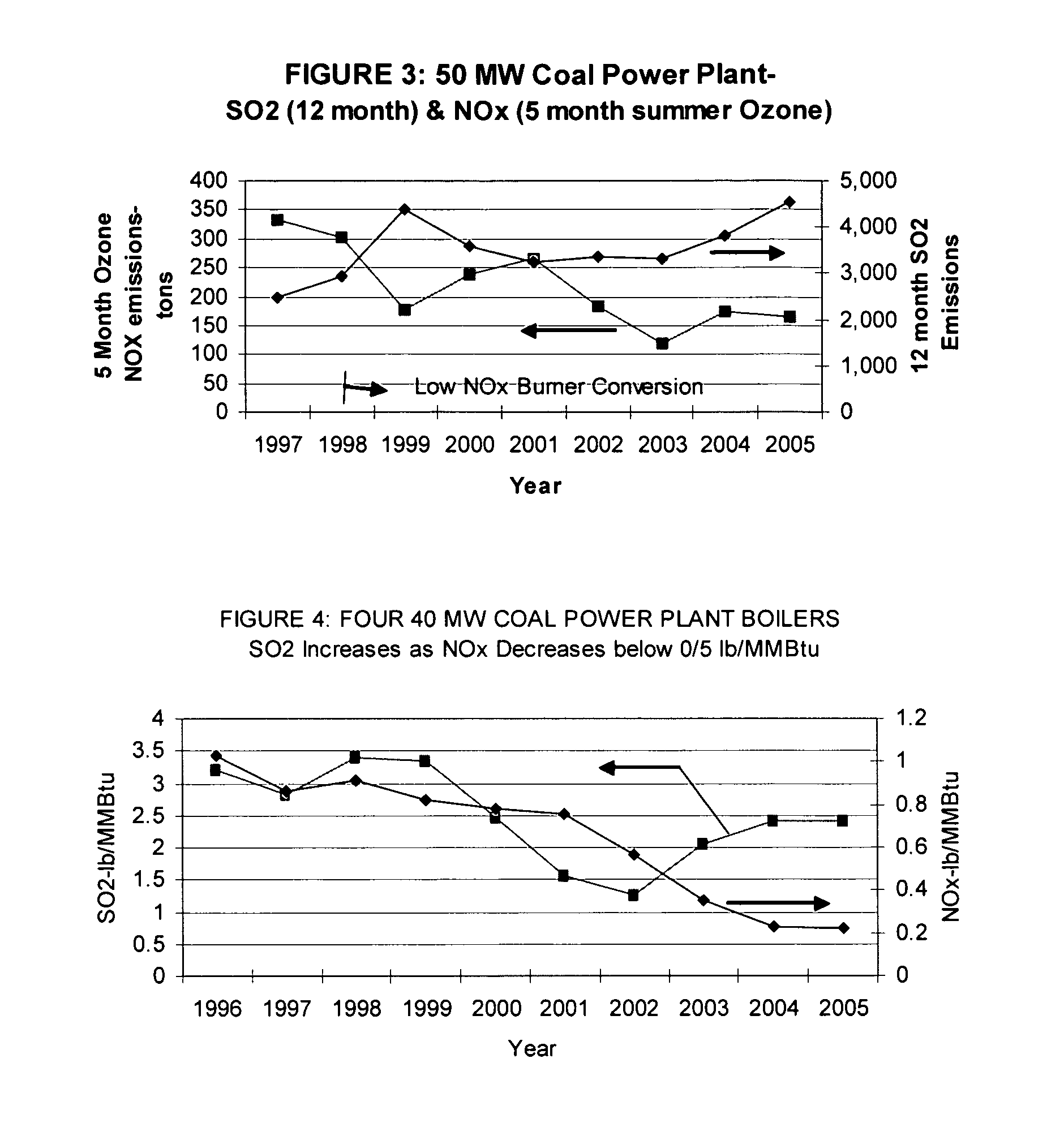

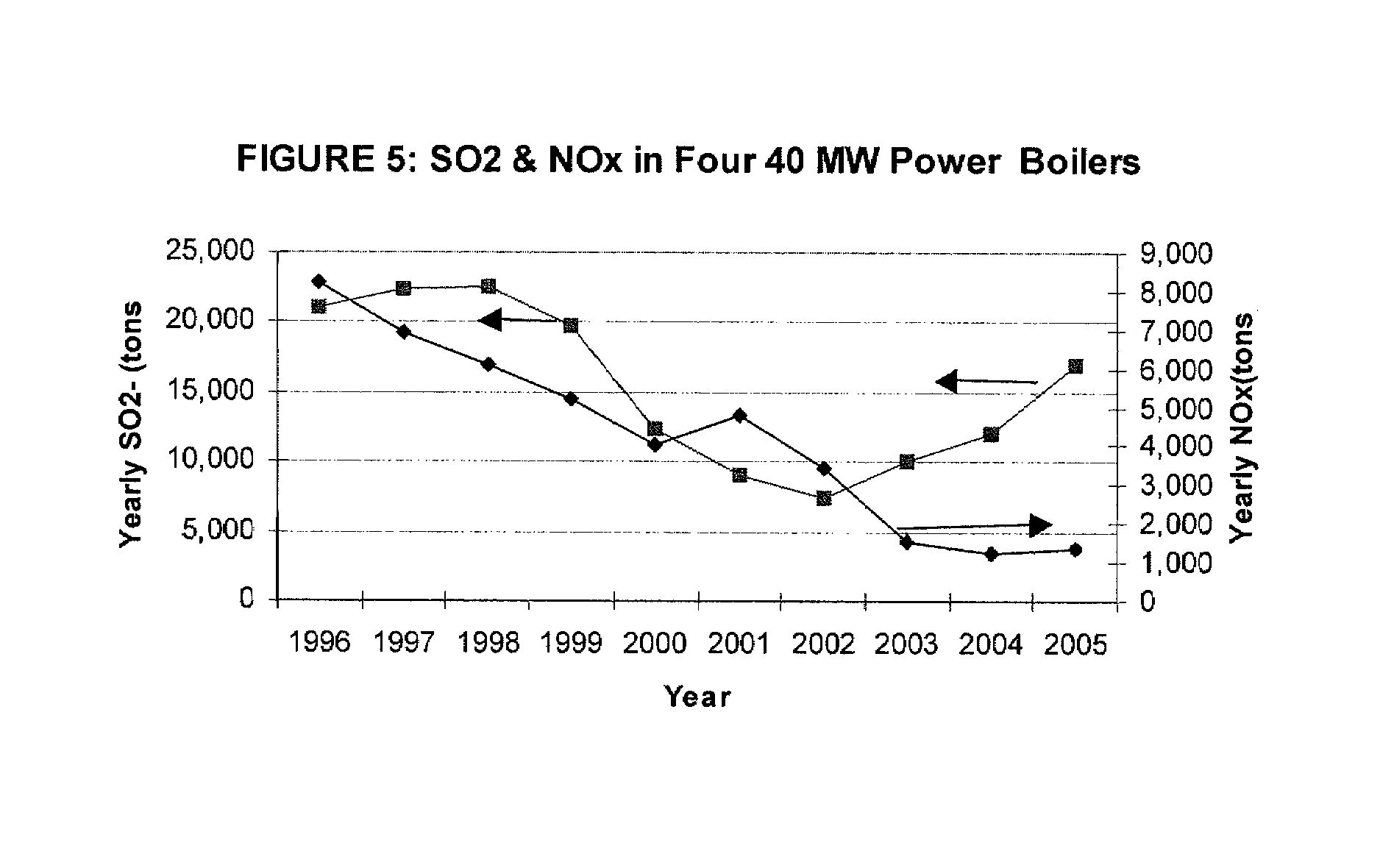

Technical and economic optimization of combustion, nitrogen oxides, sulfur dioxide, mercury, carbon dioxide, coal ash and slag and coal slurry use in coal fired furnaces/boilers

InactiveUS7553463B2Minimal equipment costLow costNitrogen compoundsUsing liquid separation agentParticulatesWater use

Methods by which new or used boilers or furnaces ranging from small industrial to the largest utility units that are designed for coal or oil or natural gas or shredded waste or shredded biomass firing can substantially improve their technical operation and sharply reduce their capital and operating costs by implementing component modifications and process steps that (a) minimize the adverse impacts of coal ash and slag on boiler surfaces and particulate emissions thereby also facilitating the use of oil or gas designed boilers for coal firing, (b) drastically reduce the loss of water used to transport coal in slurry form to power plants, (c) essentially eliminate the combined total nitrogen oxides (NOx), sulfur dioxide (SO2), mercury (Hg), trace metals, and carbon dioxide (CO2) emissions, (d) separate and permanently sequester carbon dioxide released during combustion and (e) improve the coal and solid fuel combustion efficiency.

Owner:ZAUDERER BERT

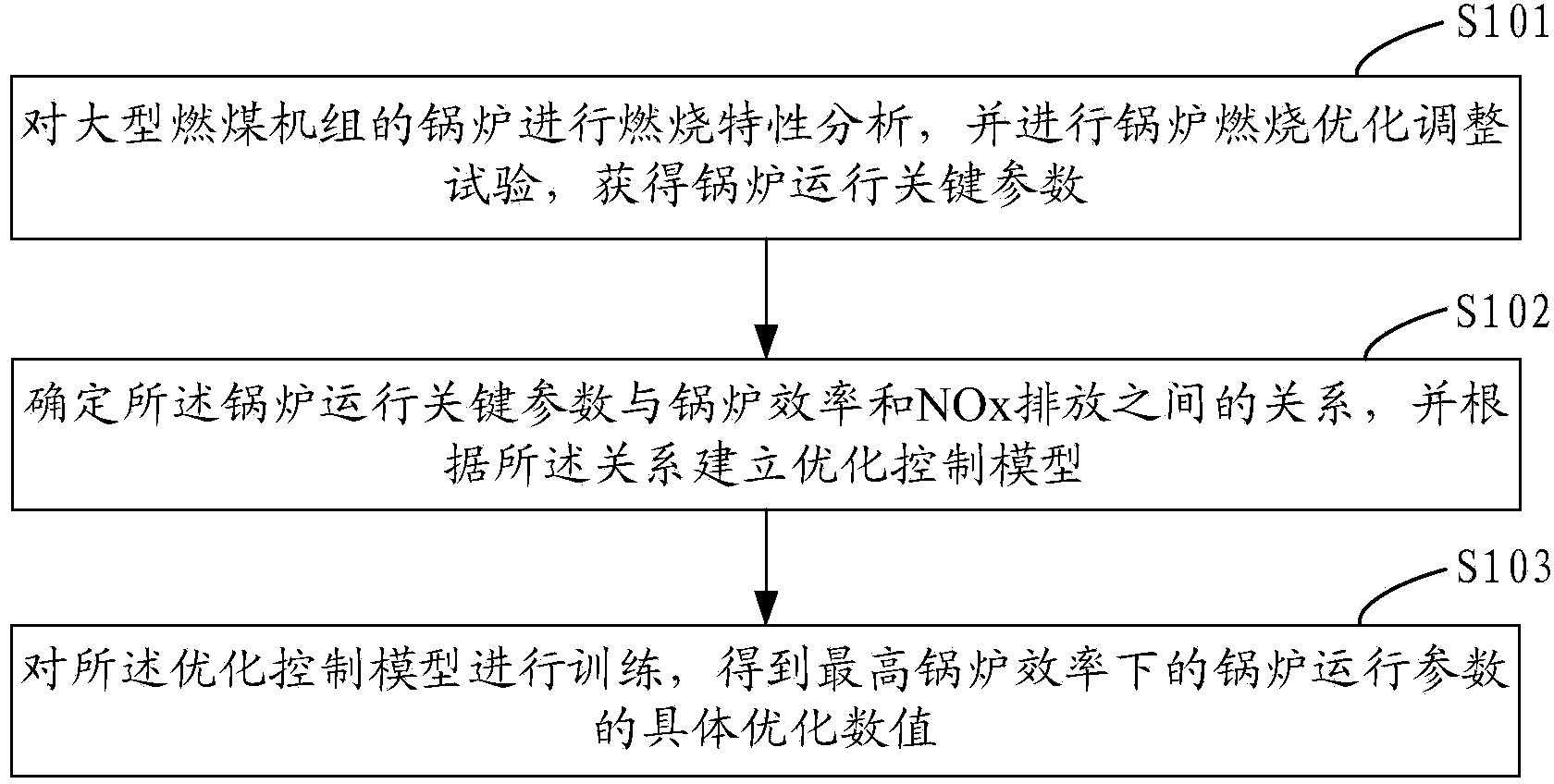

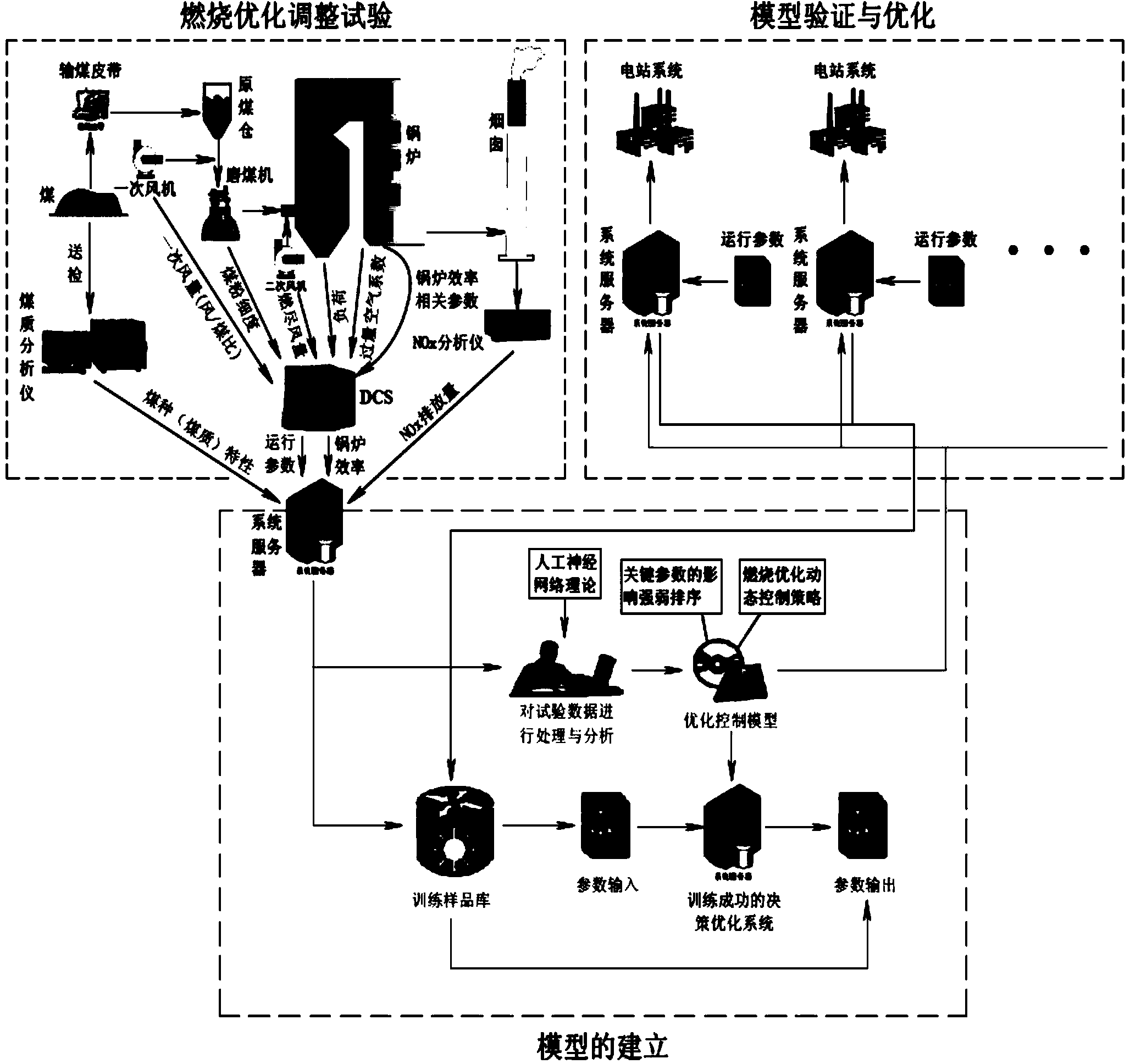

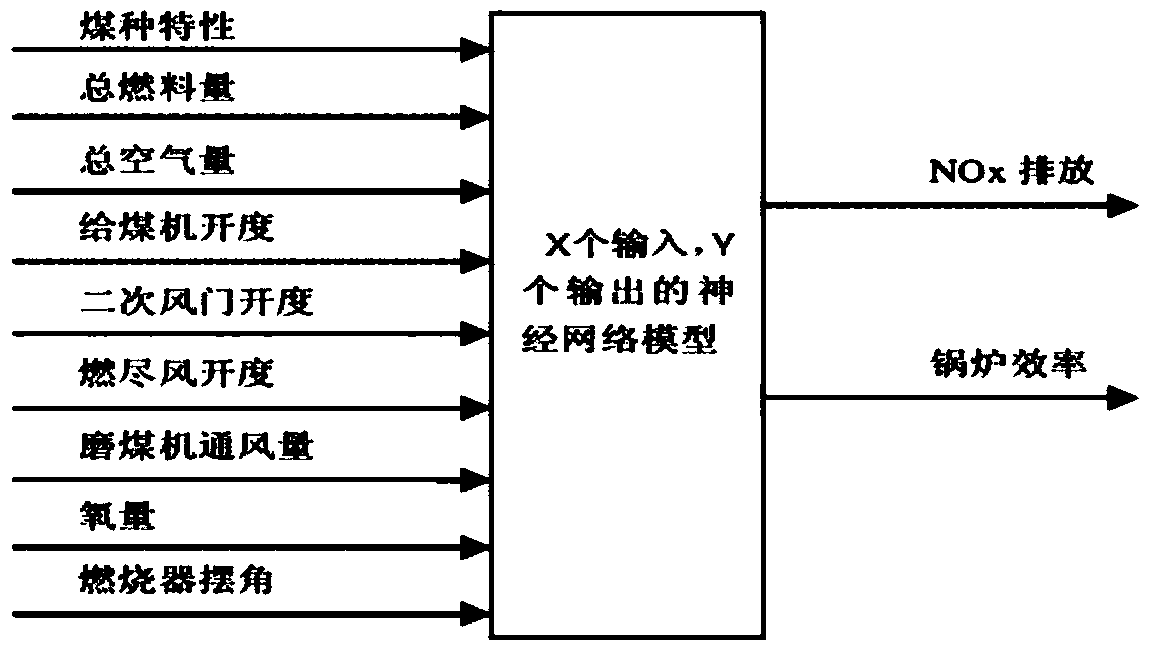

Large coal-fired unit online monitoring and optimal control system and implementation method thereof

InactiveCN103759290AImprove efficiencyHigh power consumptionBoiler controlCombustion regulationOptimal control systemProcess engineering

The invention provides a large coal-fired unit online monitoring and optimal control system and an implementation method thereof. The method includes the steps of analyzing combustion characteristics of a boiler of a large coal-fired unit, and performing boiler combustion optimization and adjustment test to acquire boiler operation key parameters; determining a relation of the boiler operation key parameters to boiler efficiency and NOx emission, and establishing an optimal control model according to the relation; training the optimal control model to obtain specific optimal values of boiler operation parameters under highest boiler efficiency. The large coal-fired unit online monitoring and optimal control system and the implementation method thereof have the advantages that boiler efficiency is improved on the premise of guaranteeing low NOx emission and operational economy of power plants is effectively improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

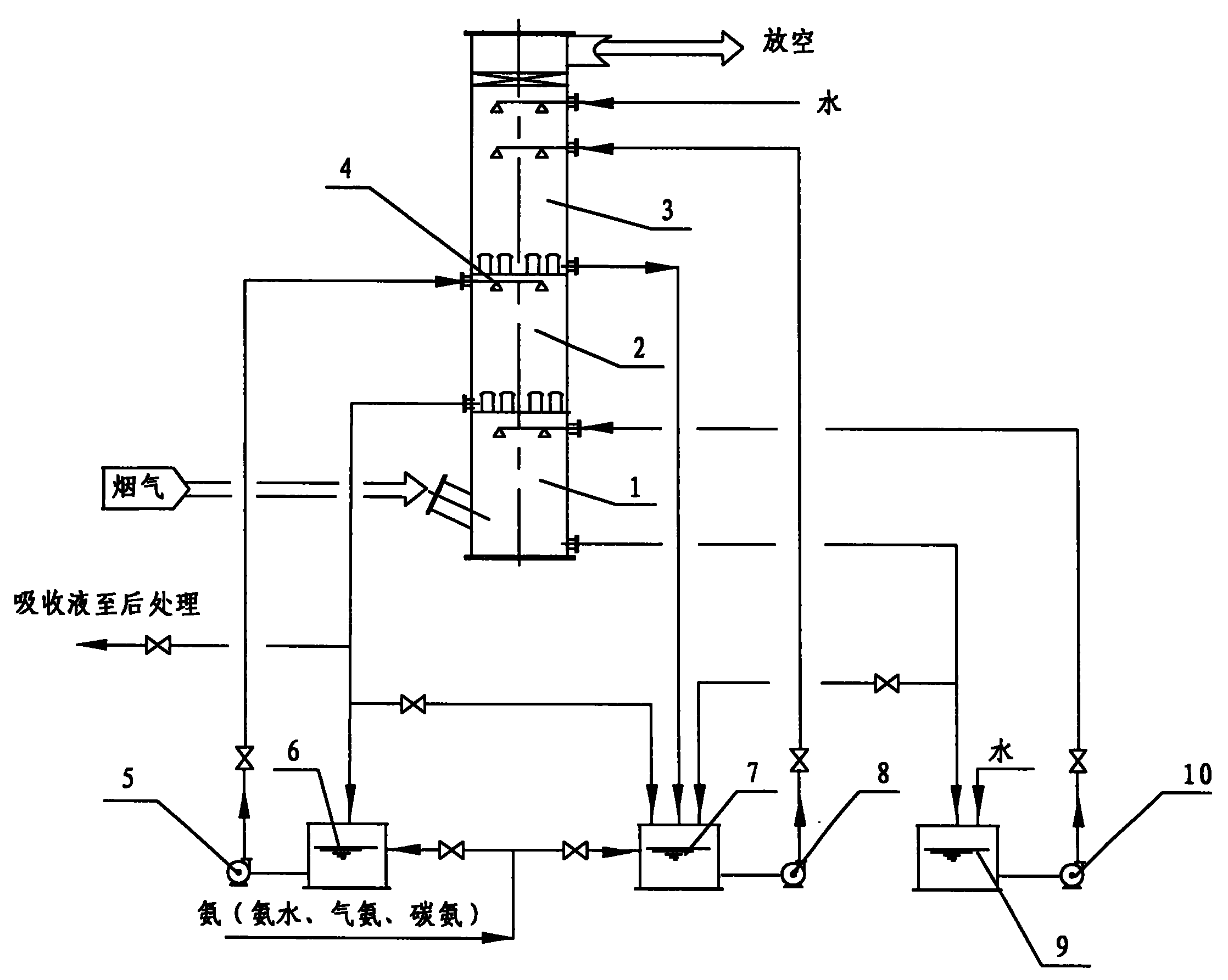

Fuel coal smoke low oxidation rate desulfur method

InactiveCN1283346CGuaranteed desulfurization effectGuaranteed total desulfurization efficiencyDispersed particle separationFlue gasTower

The invention belongs to the environmental protection technology, and relates to a method for recycling sulfur dioxide in flue gas of a coal-fired boiler, in particular to a method for desulfurization of coal-fired flue gas with a low oxidation rate. Its treatment process and parameters in the desulfurization tower are: a. Cool down and remove dust, spray and wash the flue gas entering the tower with water first, so that the temperature of the flue gas will drop to 40-50°C within 2-3 seconds; b. For the first level of absorption, use the ammonium salt absorption solution with a concentration of 500-650g / l and a pH value of 5.2-6.2 for spray absorption; c. For the second-level absorption, use a concentration of 300-500g / l and a pH value of 5.4 ~6.5% ammonium salt absorption liquid is sprayed and absorbed; d. Washing and defogging the flue gas after absorption treatment, eluting the absorption liquid entrained in the flue gas and emptying it. The invention can reduce the oxidation rate in the ammonia desulfurization process and improve the utilization value of by-products.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Ammonia oxidation catalyst for the coal fired utilities

InactiveUS20060182676A1Reduce ammonia concentrationLower emission levelsCyanogen compoundsNitrogen compoundsNitrogen gasSulfur dioxide

A process is described that removes by oxidation the excess ammonia (NH3) gas from flue gases that have been subjected to selective catalytic reduction (SCR) of oxides of nitrogen (NOx) by ammonia injection. The inventive process incorporates a secondary catalyst of precious metal and vanadia on a metal oxide such as titania to catalyze the oxidation of both ammonia and carbon monoxide (CO) while maintaining sulfur dioxide (SO2) levels.

Owner:BASF CATALYSTS LLC

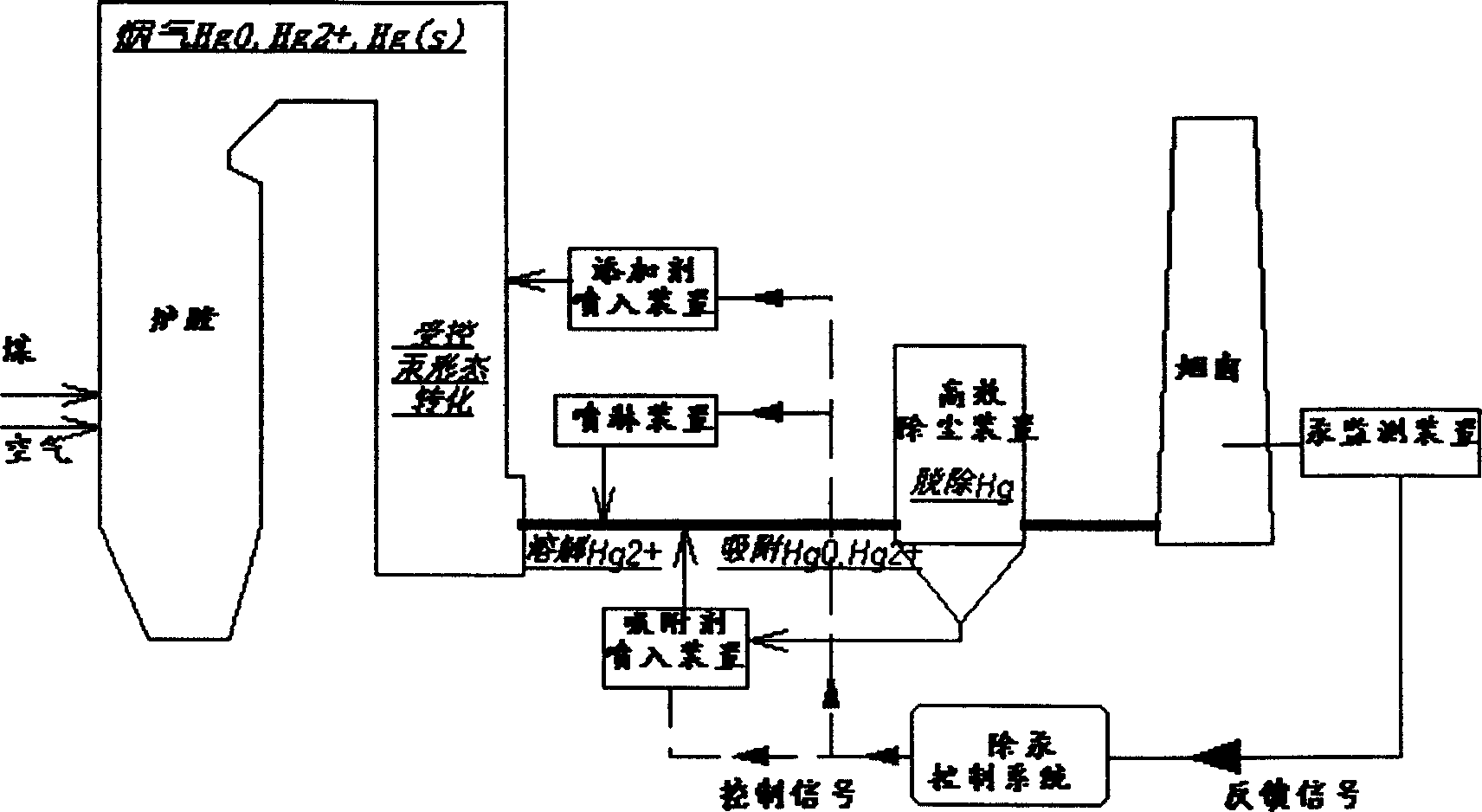

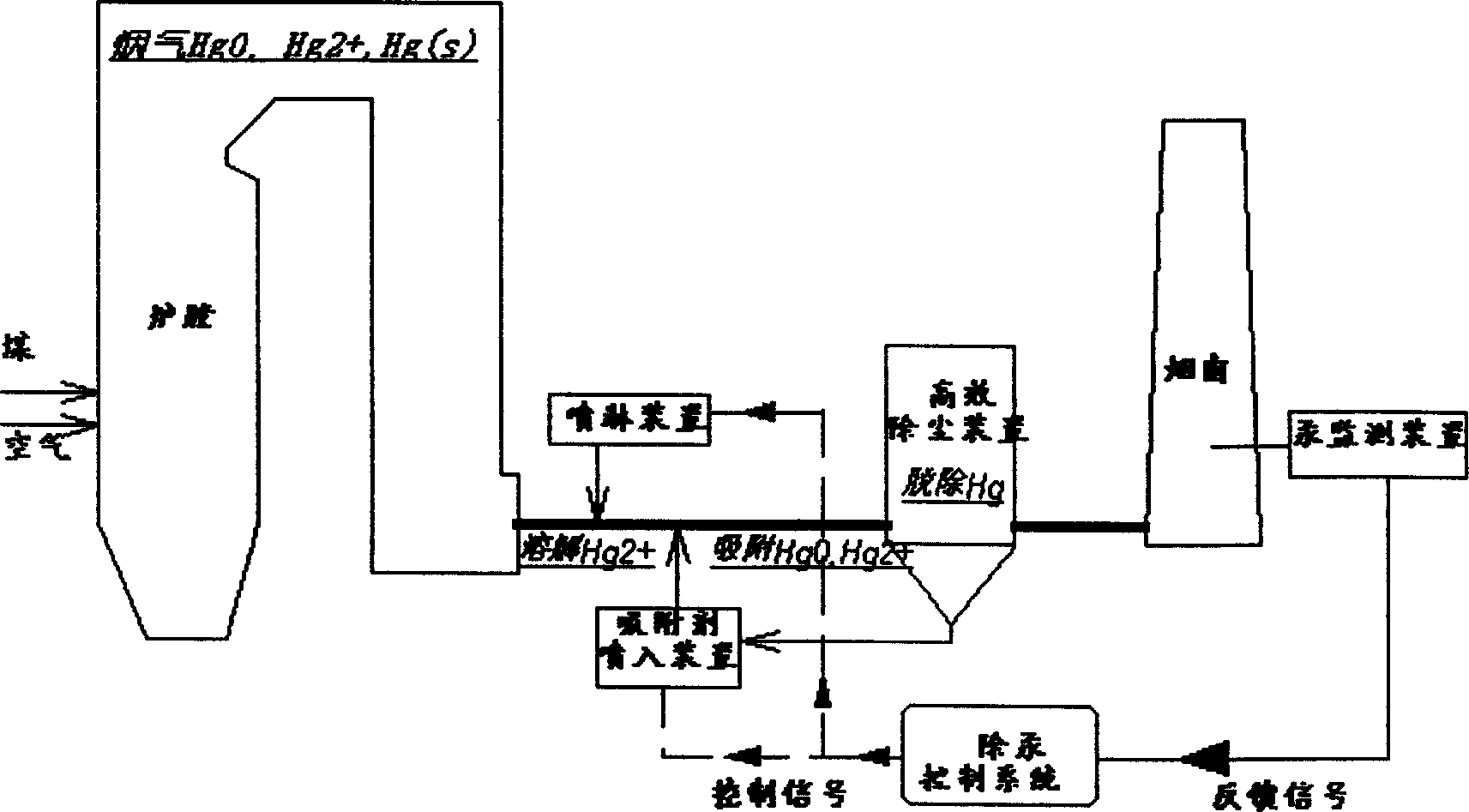

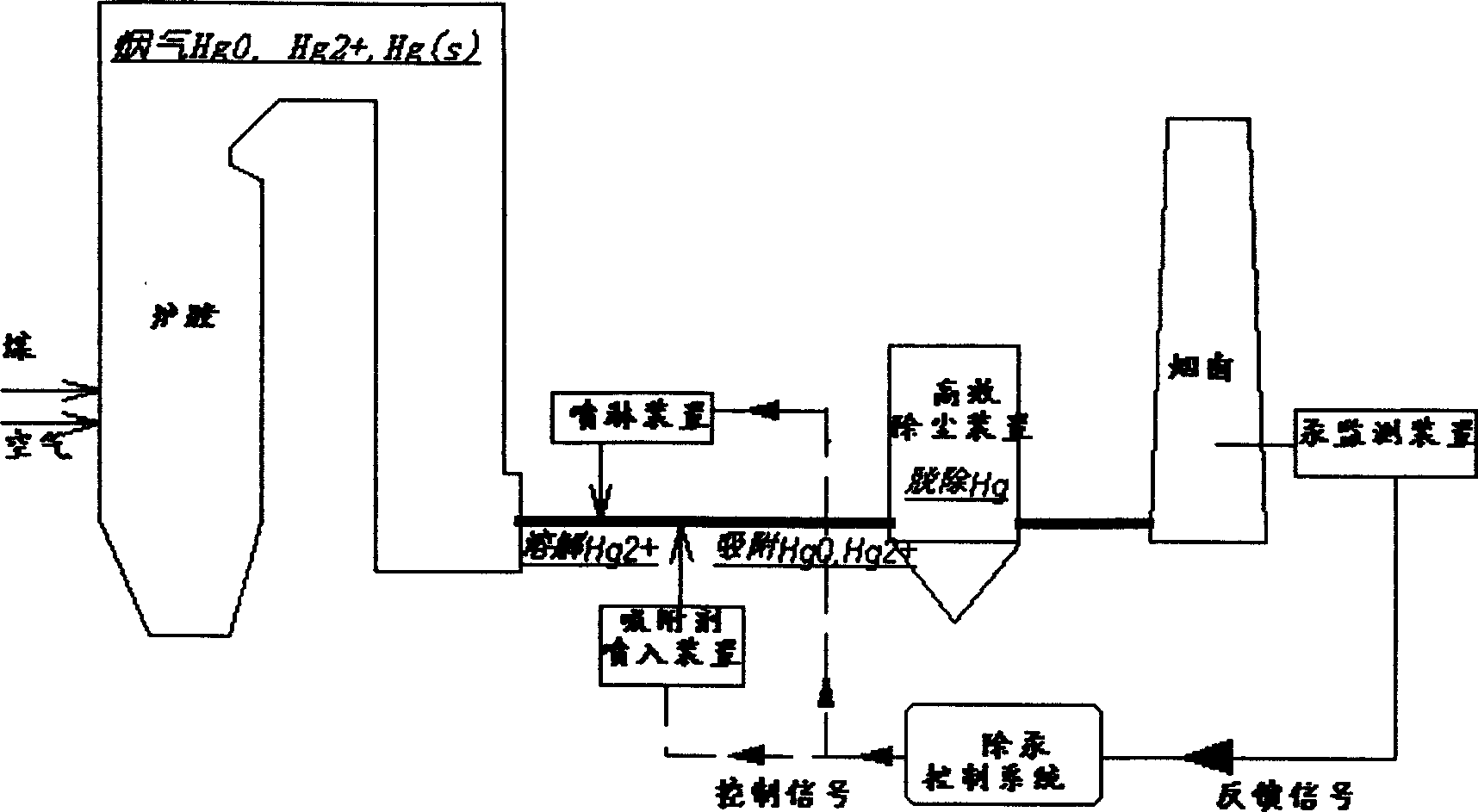

Coal-fired mercury discharge control method based on semi-dry process

InactiveCN1488423AEasy to controlImprove adsorption efficiencyDispersed particle separationElectricitySorbent

The invention discloses a kind of coal mercury discharging control method which is based on semi-drying method. Sprays additive into the boiler smoke, oxidizes the elemetary mercury into mercuric oxide easy to remove; then sprays liquid including oxidant into smoke and oxidizes the mercury, and the temperature is decreased and forms the low temperature for high efficiency absorption; sprays absorption agent into cooled smoke, eliminates the mercuric oxide and mercury; the solid particle containing mercury is collected through electricity deduster or baggage dedusting device. The invention reduces the cost of operation.

Owner:ZHEJIANG UNIV

Methods of manufacturing bentonite pollution control sorbents

InactiveUS7578869B2Small particle sizeGas treatmentLiquid surface applicatorsSodium BentoniteSorbent

Methods of manufacturing bentonite sorbents for removal of pollutants including mercury from gas streams, such as a flue gas stream from coal-fired utility plants are disclosed. The methods include mixing bentonite sorbent particles with a sulfide salt and a metal salt to form a metal sulfide on the outer surface of the bentonite sorbent particles.

Owner:BASF CATALYSTS LLC

Method and Apparatus for the Removal of Carbon Dioxide from a Gas Stream

The invention provides methods and apparatuses for removing carbon dioxide from a gas stream. In particular, the invention provides methods and apparatuses for absorbing carbon dioxide from a coal-fired boiler flue gas stream using an absorbing solution and for regeneration of an alkaline component used in the absorbing solution. In one embodiment, the invention provides a method for removing carbon dioxide from a gas stream by contacting a gas stream containing carbon dioxide with an alkaline liquid stream; absorbing at least a portion of the carbon dioxide into the alkaline liquid stream to produce absorbed carbon dioxide; and catalyzing a reaction of the absorbed carbon dioxide to a form of carbonate.

Owner:FLUEGEN

Reduction of coal-fired combustion emissions

ActiveUS20060034743A1Efficiently and economically capturedReduce in quantityUsing liquid separation agentSolid fuel pretreatmentBruciteMagnesite

A process for mitigation of fouling deposits within a combustion zone, capturing of toxic metal emissions, and reduction of visible sulfur emissions attributable to sulfuric acid mist during coal combustion. SO3 formed during coal combustion is reduced by the addition to the coal of raw, unprocessed magnesium-containing minerals such as magnesite ore or brucite ore. The minerals are pulverized to a fine particle size and combined with pulverized coal to provide a mixture of the particles. The mixture is combusted and the ore particles calcine and decrepitate to very fine magnesium oxide particles that have a significant particle surface area. The magnesium oxide particles react with the SO3 produced during combustion of the coal and also capture toxic metals to reduce the quantity of undesirable stack discharge components.

Owner:PREMIER MAGNESIA

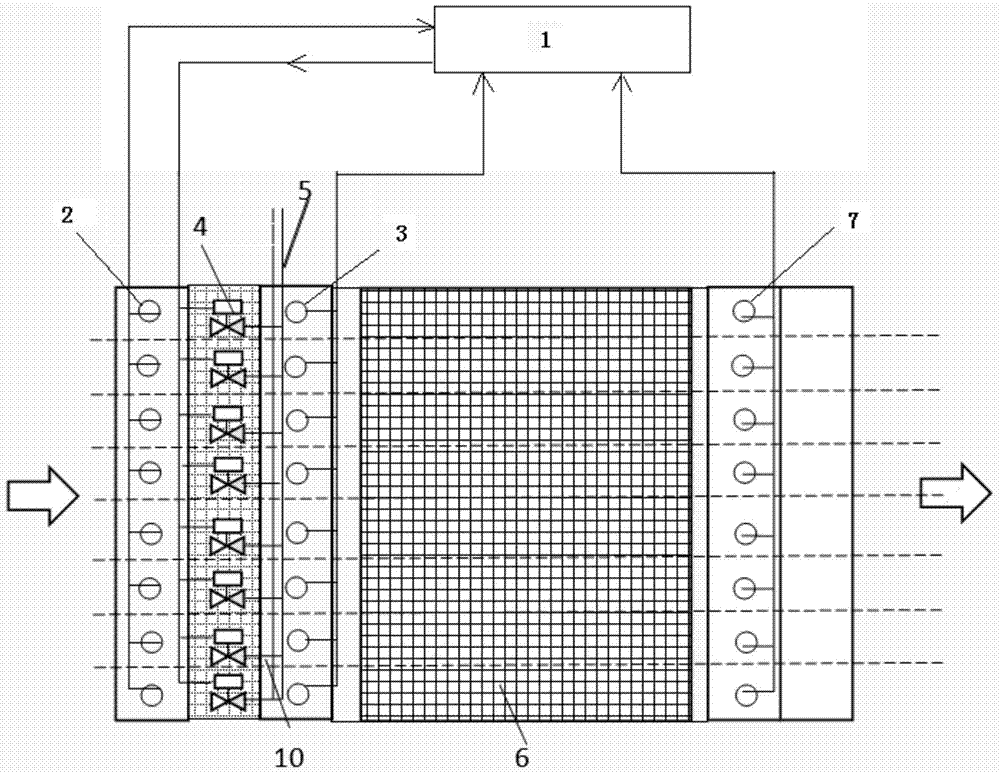

Online detecting, soot blowing and optimal energy-saving method for large coal-fired boiler

InactiveCN101034009AAccurate calculationSave fuelRadiation pyrometryBoiler indication operationsEngineeringSoot

This invention relates to a energy-saving method of large coal burning boiler's on-line measuring and soot blowing optimizing. The feature lays: the invention takes new developed HTAS procedure as main, combine with TTURTHERM procedure and infrared fume pyroscope, to form a integrated system that is able to accuracy and significance monitor and count large boiler heating surface cleanness degree, so to realize soot blowing-optimizing and energy-saving.

Owner:SHANGHAI POWER EQUIP RES INST

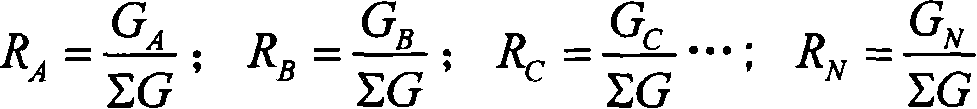

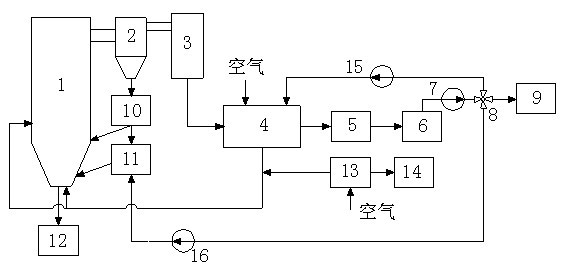

Coal-fired boiler SCR (Selective Catalytic Reduction) denitration control method and system

ActiveCN104226110AReduce consumptionAvoid cloggingControlling ratio of multiple fluid flowsDispersed particle separationFlue gasControl system

The invention relates to a coal-fired boiler SCR denitration control method and system. The method includes the steps of monitoring the molar ratio of ammonia and nitrogen in each section in real time before flue gas enters a catalyst, regulating ammonia injection branch pipe remote electric control regulating valves corresponding to each section to control ammonia supply amount of each section in real time according to a preset molar ratio of ammonia and nitrogen, and keeping the actually measured molar ratio of ammonia and nitrogen to be identical to the preset molar ratio of ammonia and nitrogen so as to prevent excessive ammonia injection and ensure even concentration distribution of nitric oxides at a denitration system outlet.

Owner:河南合众电力技术有限公司

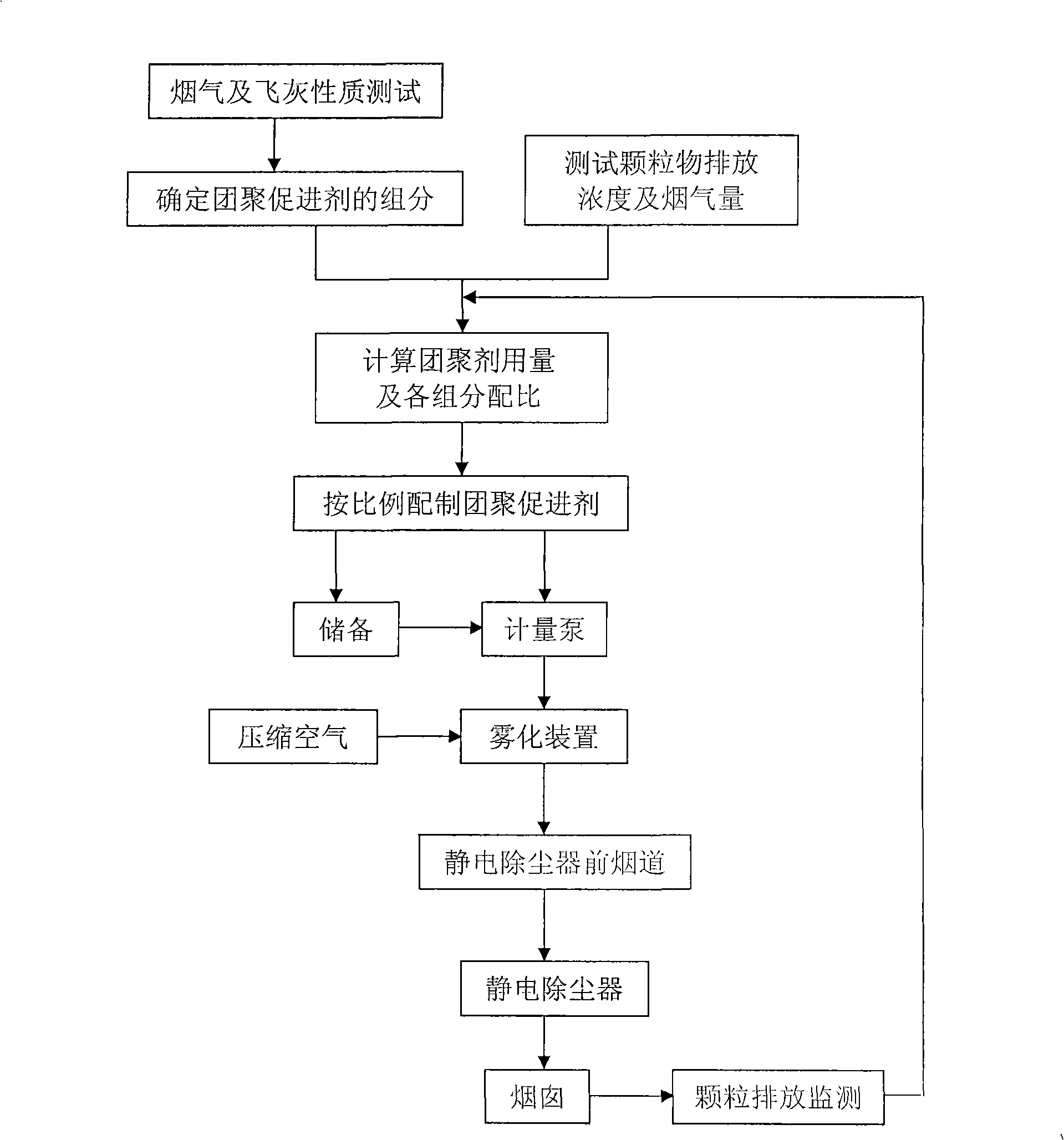

Coal-fired ultrafine grain chemical agglomeration promotor

ActiveCN101513583AWide variety of sourcesEasy to synthesizeAuxillary pretreatmentElectrostatic separationInorganic saltsWater soluble

The invention discloses a coal-fired ultrafine grain chemical agglomeration promotor which comprises the components based on mass percent: 0.001-0.2% of surface active agent, 0.0001-0.01% of water-soluble high molecular compound, 0.001-0.05% of inorganic salt additive and the rest of water. The invention can effectively promote ultrafine grains to agglomerate, improve the removal efficiency of a static precipitator for the ultrafine grains and high specific resistance flying ash, and reduce the soot emission and the charges for disposing pollutant of enterprises. The agglomeration promotor has the components with wide source, economical price, environmental protection, simple synthetic process, easy operation and no environmental pollution.

Owner:武汉天空蓝环保科技有限公司

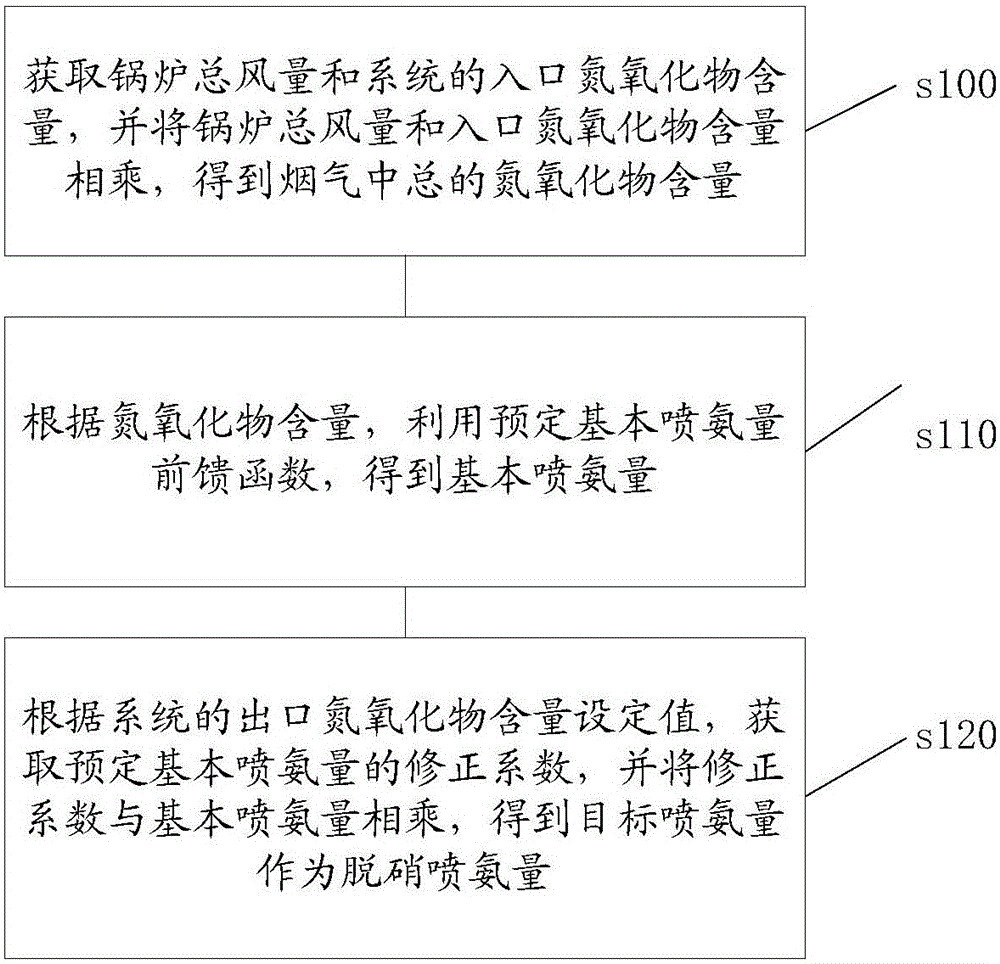

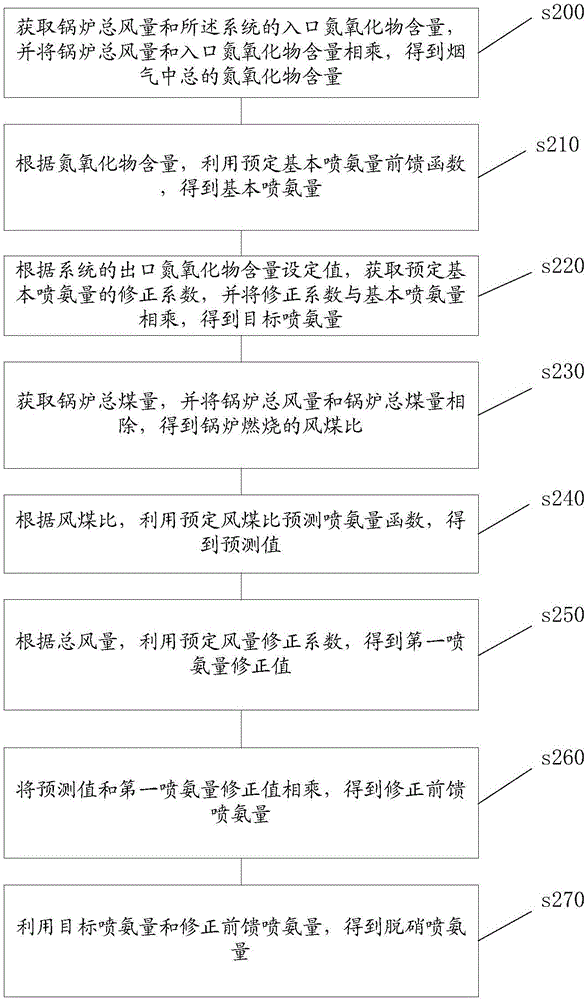

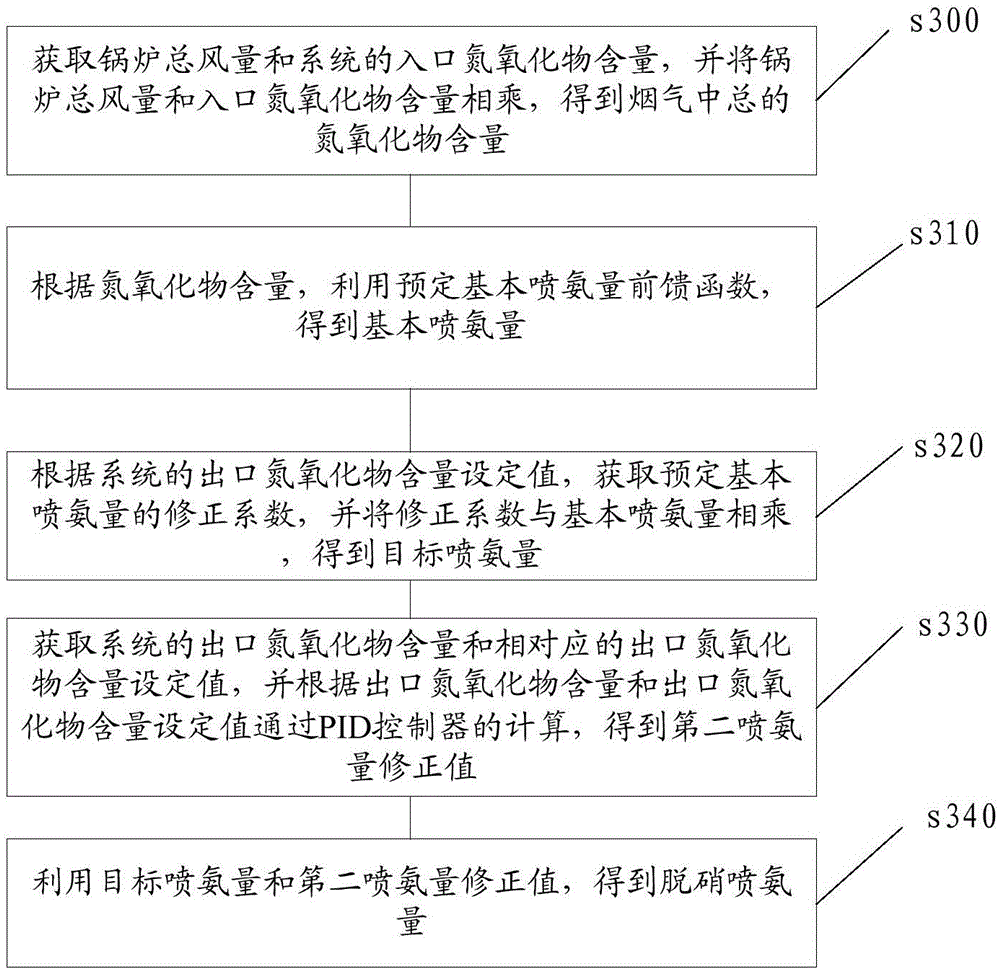

Denitration spraying ammonia automation control method and system

ActiveCN105137760AAccurate measurementChange the amount of ammonia injection in advanceDispersed particle separationAdaptive controlAir volumeFlue gas

The invention discloses a denitration spraying ammonia automation control method which is applied to a coal-fired boiler SCR system. The method comprises the following steps of acquiring a total air volume of a boiler and an entrance nitric oxide content of the system, and multiplying the total air volume of the boiler by the entrance nitric oxide content of the system so as to obtain a total nitric oxide content in a flue gas; according to the nitric oxide content, using a predetermined basic spraying ammonia amount feedforward function to obtain a basic spraying ammonia amount; according to an entrance nitric oxide content set value of the system, acquiring a correction coefficient of the predetermined basic spraying ammonia amount, multiplying the correction coefficient by the basic spraying ammonia amount so as to obtain a target spraying ammonia amount, and taking the target spraying ammonia amount as a denitration spraying ammonia amount. By using the method, a theoretical spraying ammonia amount can match an actual-needed spraying ammonia amount; a probability of excess emission of nitric oxide and an environmental protection risk brought by the excess emission can be reduced; and negative effects and economic losses brought by excessive spraying ammonia are decreased.

Owner:HUANENG PINGLIANG POWER GENERATION CO LTD

Improvement method for selective catalytic reduction flue gas denitrification and ammonia injection control system

ActiveCN104826492AEasy to controlSimple structureDispersed particle separationControl signalOptimal control

The invention provides an improvement method for a selective catalytic reduction flue gas denitrification and ammonia injection control system. An optimal control station is introduced into an original flue gas denitrification and ammonia injection control system. In an optimal control station module, parameters affecting coal fired boiler NOx generation amount and an original PID controller output ammonia injection amount control signal, and a dynamic neural network, an output sensitivity method is utilized to construct neuron in hidden layer, through comprehensive learning of the PID controller and the introduced parameters, and according to the output amount of the PID controller and the introduced parameters affecting boiler NOx generation amount, integrated computation is carried out to form dynamic compensation control quantity. In denitrification and ammonia injection amount control logic, the original PID controller is taken as the main controller, and the dynamic neural network ammonia injection amount prediction controller is adopted as the revision controller so as to obtain the adjustment amount of optimal ammonia injection amount, thus promoting reliable and economical operation of the denitrification system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and system

InactiveCN102425789ALow costZero pollution dischargeSolidificationFluidized bed combustionProcess engineeringPollution

The invention discloses a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction system for solving the problem of low-cost CO2 emission reduction of an industrialized coal-fired boiler. A micro oxygen rich combustion mode using mixed gas of air, oxygen and recycled smoke as a combustion aid is adopted, wherein the mixed gas contains about 25 percent of oxygen, 30 to 40 percent of recycled smoke and the balance of air; and in the micro oxygen rich combustion mode, the concentration of the CO2 gas in the generated smoke is 30 to 40 percent, and the CO2 in the smoke is removed by adopting a physical adsorption technology. The invention also provides a system device for implementing the method. By considering oxygen making cost, energy consumption and optimal comprehensive effect of separating CO2 by physical adsorption and combining the micro oxygen rich concept and the circulating fluidized bed combustion technology, desulfuration, denitration, decarburization and zero pollution emission at lower cost can be realized. The invention has the advantages of good economic efficiency, simple process, low energy consumption, high automation degree in operation process and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

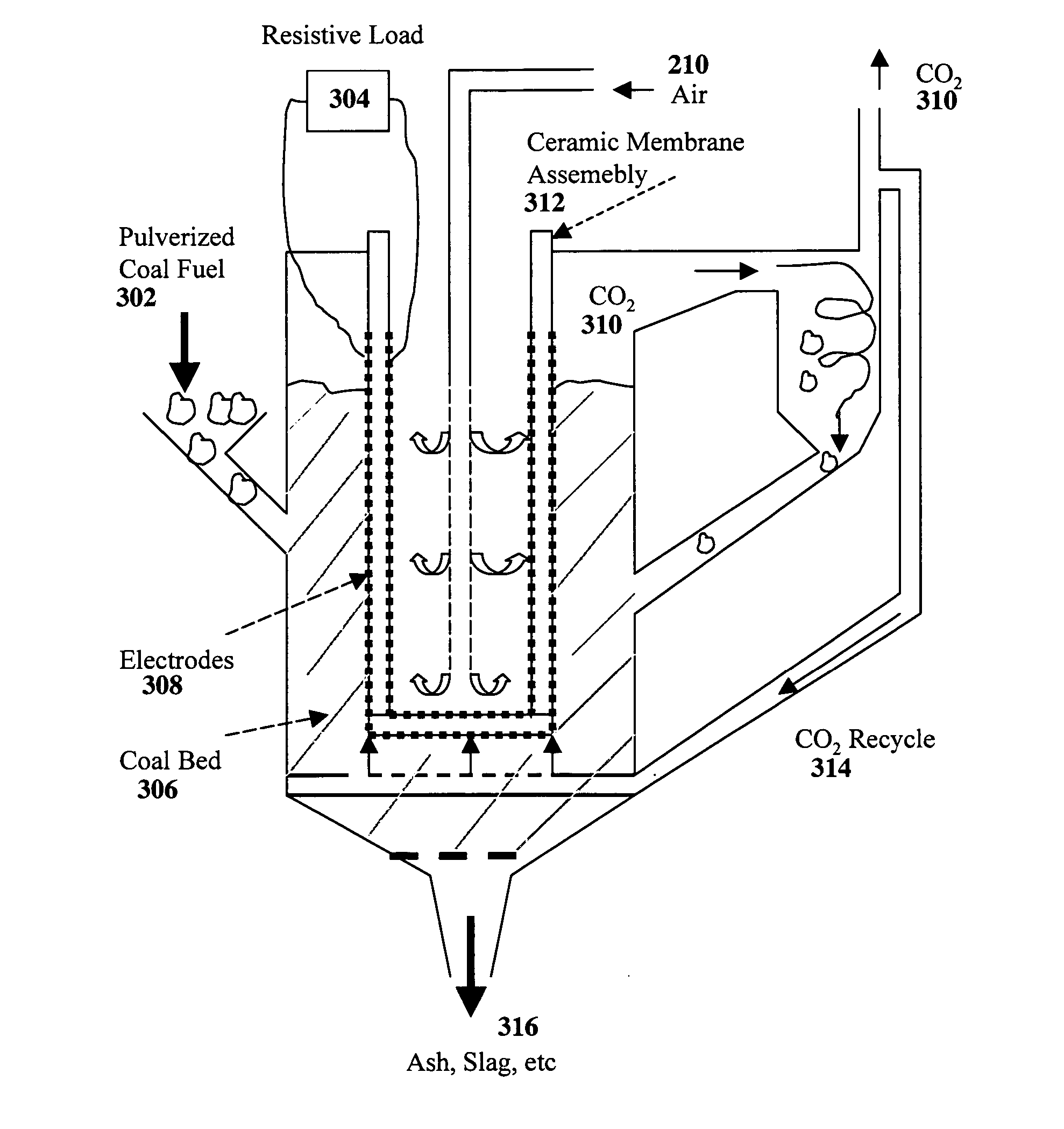

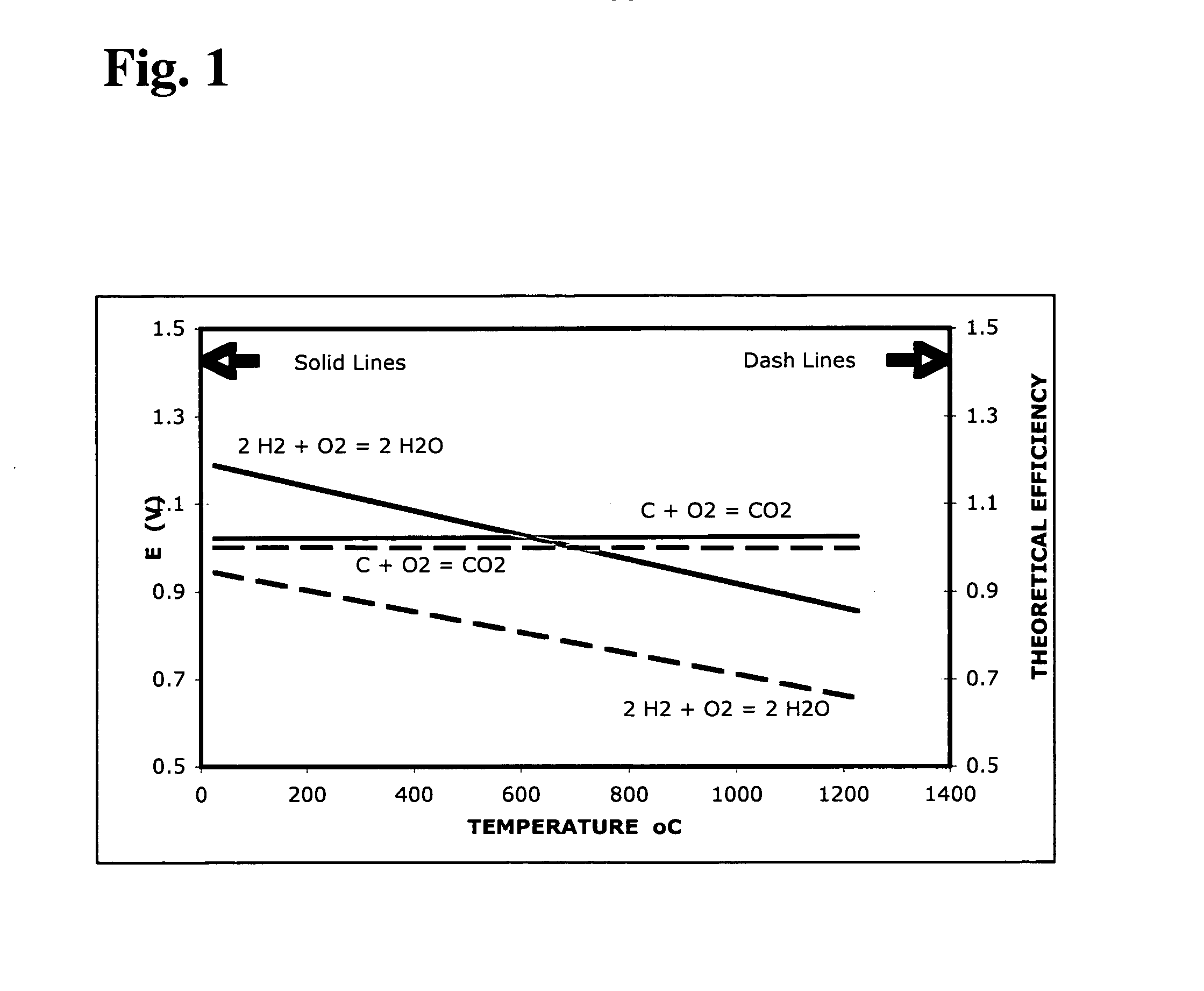

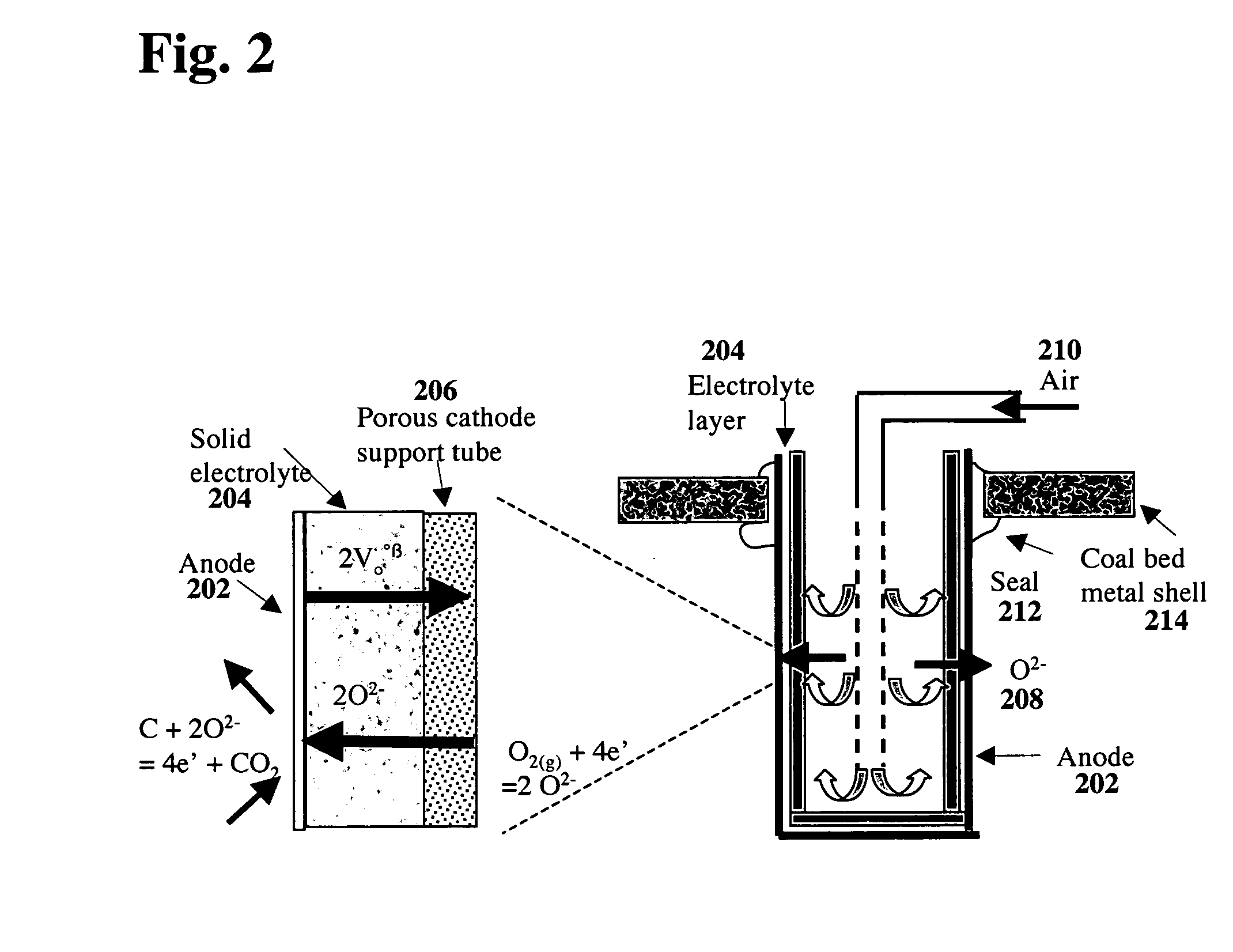

High temperature direct coal fuel cell

The invention relates to direct conversion of coal into electricity in a high temperature electrochemical generator in a single step process. This novel concept promises nearly doubling the conversion efficiency of conventional coal-fired processes and offering near-zero emissions. The improved efficiency would mean that nearly half as much coal is mined and transported to the power plant, and half the greenhouse gases and other pollutants such as sulfur, mercury and dioxins are produced. It also offers several crucial distinctions from conventional coal-burning processes. Since the process does not involve the combustion of coal in air, it does not involve nitrogen and hence generates practically no NOx. Accordingly, there is also no latent heat lost to nitrogen. In this process, the oxygen necessary to oxidize coal is supplied through an ion selective ceramic membrane electrolyte. The resultant product stream primarily consists of CO2 and, hence, it is easier and cheaper to capture and sequester, compared to waste streams from conventional combustion processes where CO2 ordinarily constitutes about 15-20% of the flue stream, in which case it may first be separated from other constituents before sequestration.

Owner:TURGUT GUR

Desulfurize flue gas waste heat recovery system used in fire coal electric generating set

InactiveCN101140072AImprove utilizationOvercoming wear and tearLighting and heating apparatusCombustion technology mitigationThermal energyInlet channel

The invention discloses a desulfurization flue gas waste heat recovery system for a coal-fired generator set, which comprises at least a gas-water heat exchanger for exchanging heat energy between gas state and liquid state, a flue gas inlet channel and a flue gas outlet channel respectively independently communicated with the gas-water heat exchanger, and a condensation water inlet pipeline and a condensation water outlet pipeline; a flue gas inlet of the gas-water heat exchanger is communicated with a rear flue gas channel of a boiler flue gas dust remover in the coal-fired generator set; a flue gas outlet of the gas-water heat exchanger is communicated with the flue gas inlet of a desulfurization absorption tower in a desulfurization system; a condensation water inlet and a condensation water outlet of the gas-water heat exchanger can be in sereies or parallel with at least a first-stage low-pressure heater of a regenerative system. The desulfurization flue gas waste heat recovery system provided in the invention has the advantages of the high waste heat utilization ratio, saving energy and water, the obvious discharge reducing benefit and the high comprehensive utilization degree of abandoned resources.

Owner:SHANGHAI WAIGAOQIAO NO 3 POWER GENERATION

Pollutant emission control sorbents and methods of manufacture

InactiveUS7704920B2Small particle sizePromotes Hg-captureGas treatmentOther chemical processesSorbentFlue gas

Sorbents for removal of mercury and other pollutants from gas streams, such as a flue gas stream from coal-fired utility plants, and methods for their manufacture and use are disclosed. The methods include mixing sorbent substrate particles with a sulfide salt and a metal salt to form a metal sulfide on the outer surface of the sorbent particles.

Owner:BASF CATALYSTS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com