Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about How to "Overcoming wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

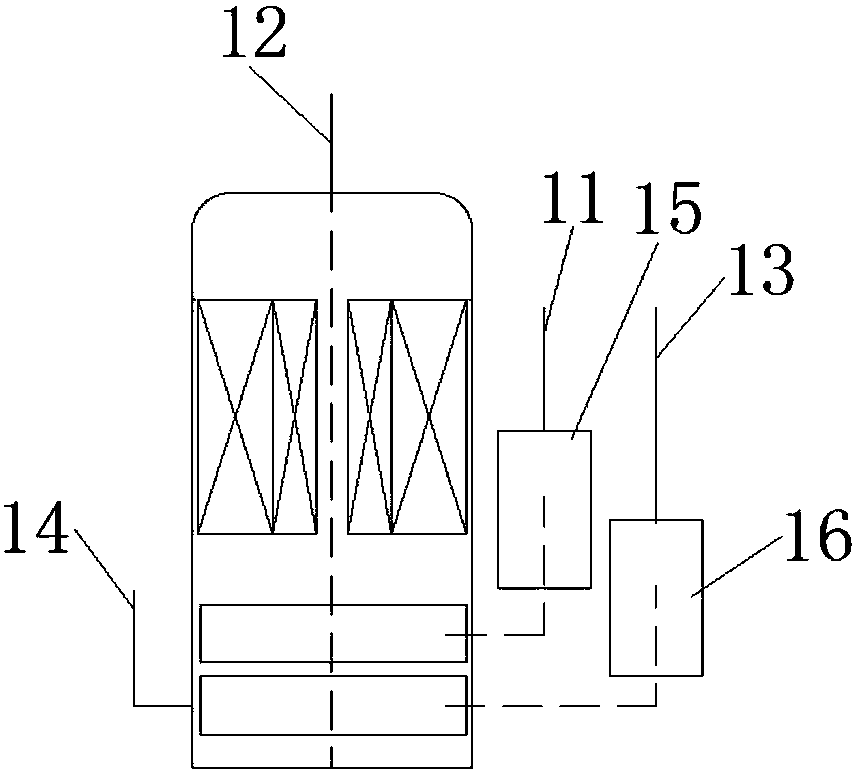

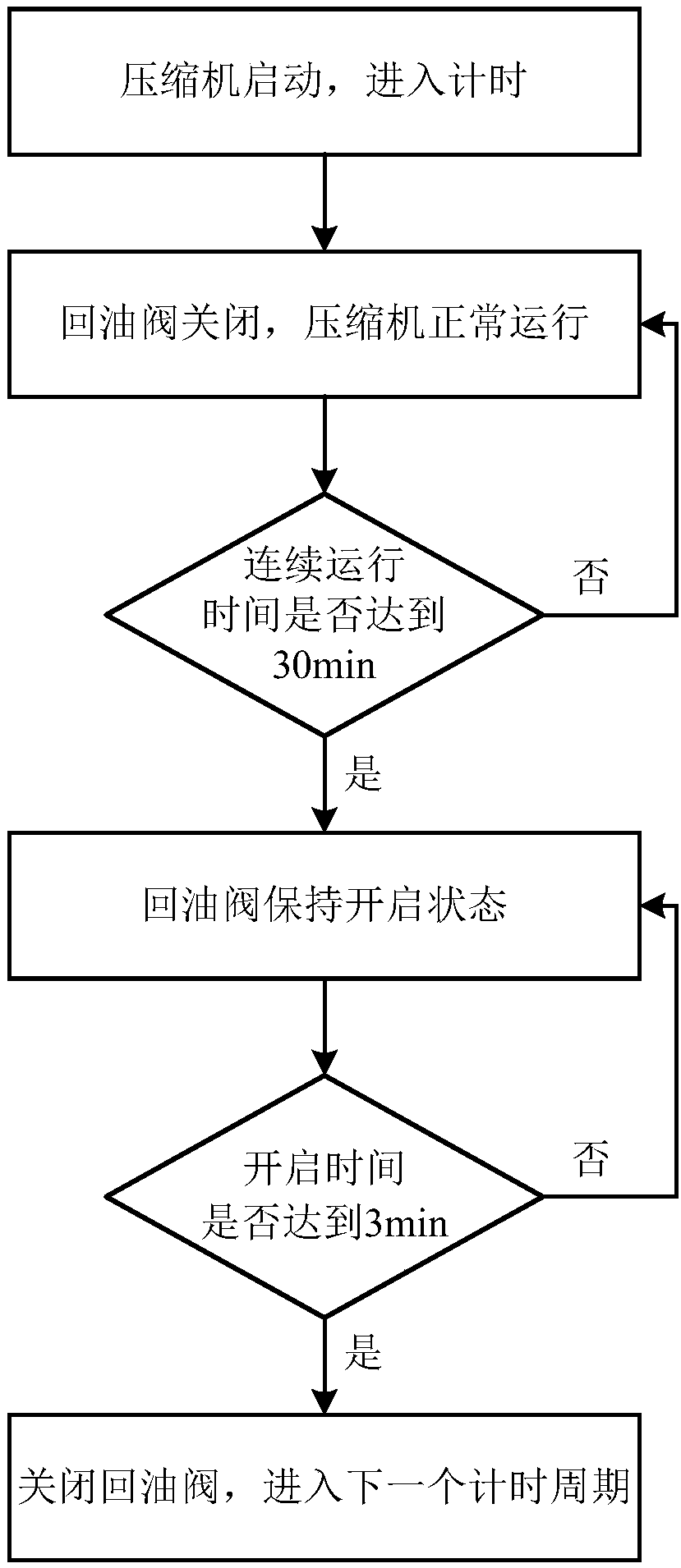

Oil return control device, air conditioning system and oil return control method of air conditioning system

ActiveCN108180680ASolve the problem of excessive exhaust oil discharge rateReduced exhaust oil discharge rateMechanical apparatusFluid circulation arrangementOil separationAir conditioning

The invention discloses an oil return control device, an air conditioning system and an oil return control method of the air conditioning system. The oil return control device comprises an oil separation mechanism and an oil return control assembly, wherein the oil separation mechanism is arranged at an exhaust port of a lower row of exhaust cylinders in a compressor comprising two or more parallel cylinders, and is used for separating and obtaining lubricating oil from exhaust gas of the lower row of exhaust cylinders, and the oil return control assembly is arranged between the oil separationmechanism and an oil pool at the bottom of the compressor, and is used for controlling the lubricating oil to return to the oil pool according to the pressure difference between exhaust ports of thetwo or more exhaust cylinders in the compressor. According to the scheme, the defects that in the prior art, a lower cylinder is prone to wear, short in service life, low in running reliability and the like can be overcome, so that the beneficial effects that the lower cylinder is not prone to wear, long in service life and high in running reliability are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

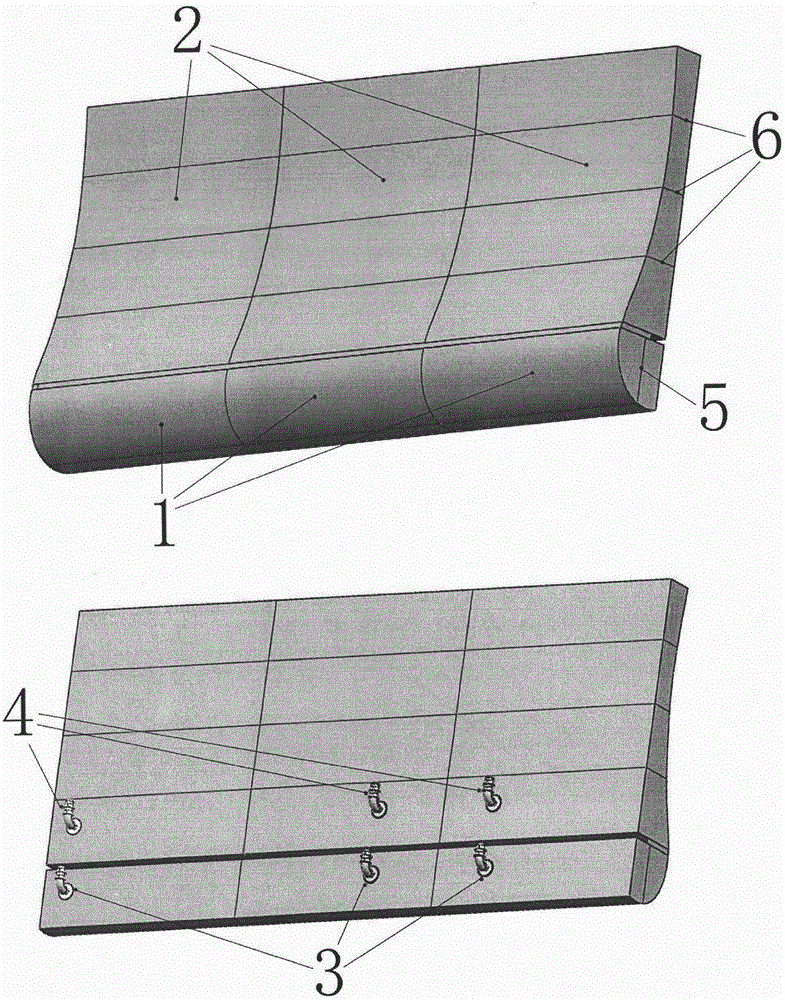

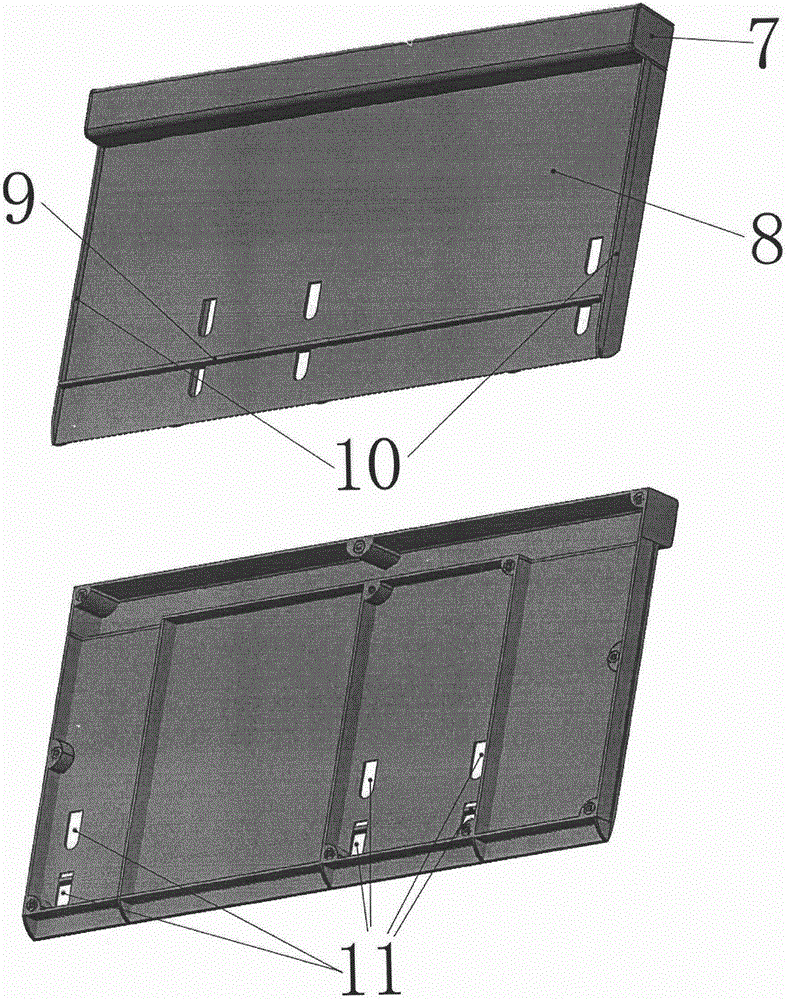

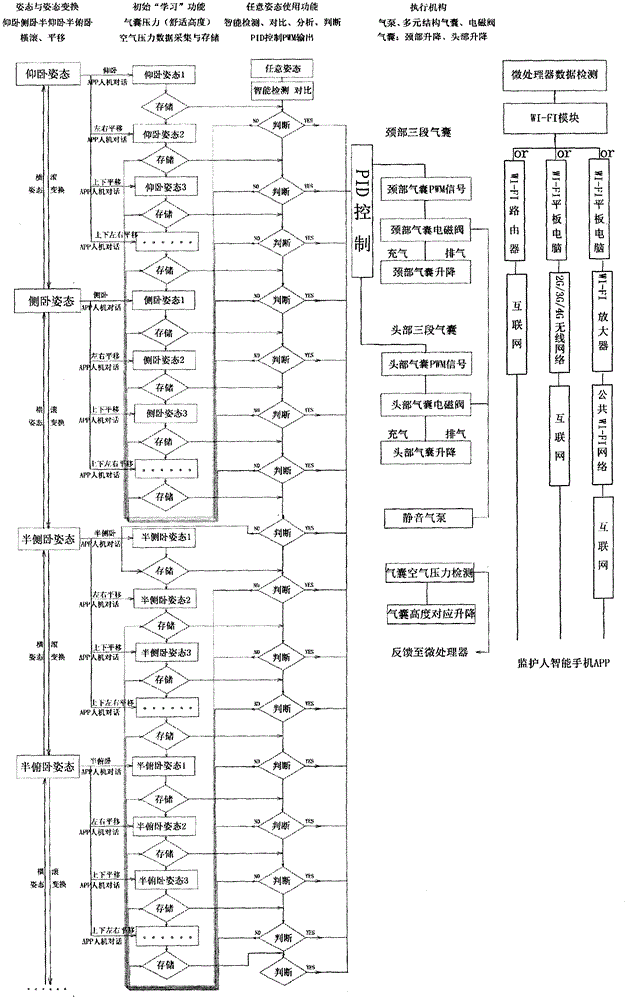

Pillow with intelligent prone position identifying and intelligent height adjusting functions

The invention is a pillow which intelligently recognizes the lying position and intelligently adjusts the height, and belongs to the application of automatic control in necessities of human life. According to the control mechanism of checking every change, adjusting with the posture, changing with the person, the position changes unchanged, the posture changes must be changed, and the timing standby control mechanism, through 6 sets of independent circuits and air circuits, the neck and head airbags of the four lying positions can be adjusted. The combination of pressure and height data is used as the basis for judging the prone position. Through the dialogue between the mobile phone and the pillow, the "learning" data of various postures, neck and head airbag pressures are stored. Using a pillow or rolling, translation, and vacant transformation, according to the control mechanism and algorithm, compare the real-time force data in the airbag with the stored "learning" data, and adjust the neck and head to the corresponding position through circuit and air circuit control The comfort height of the posture. Under the control of the circuit air circuit, the tiled multiple airbags are responsible for the collection and precise lifting of the pressure on the neck and head. The tiled high and low equipment cabins put all the equipment in, realizing "full integration", avoiding dragging and hanging, and making it easy to move and carry.

Owner:陈大庆

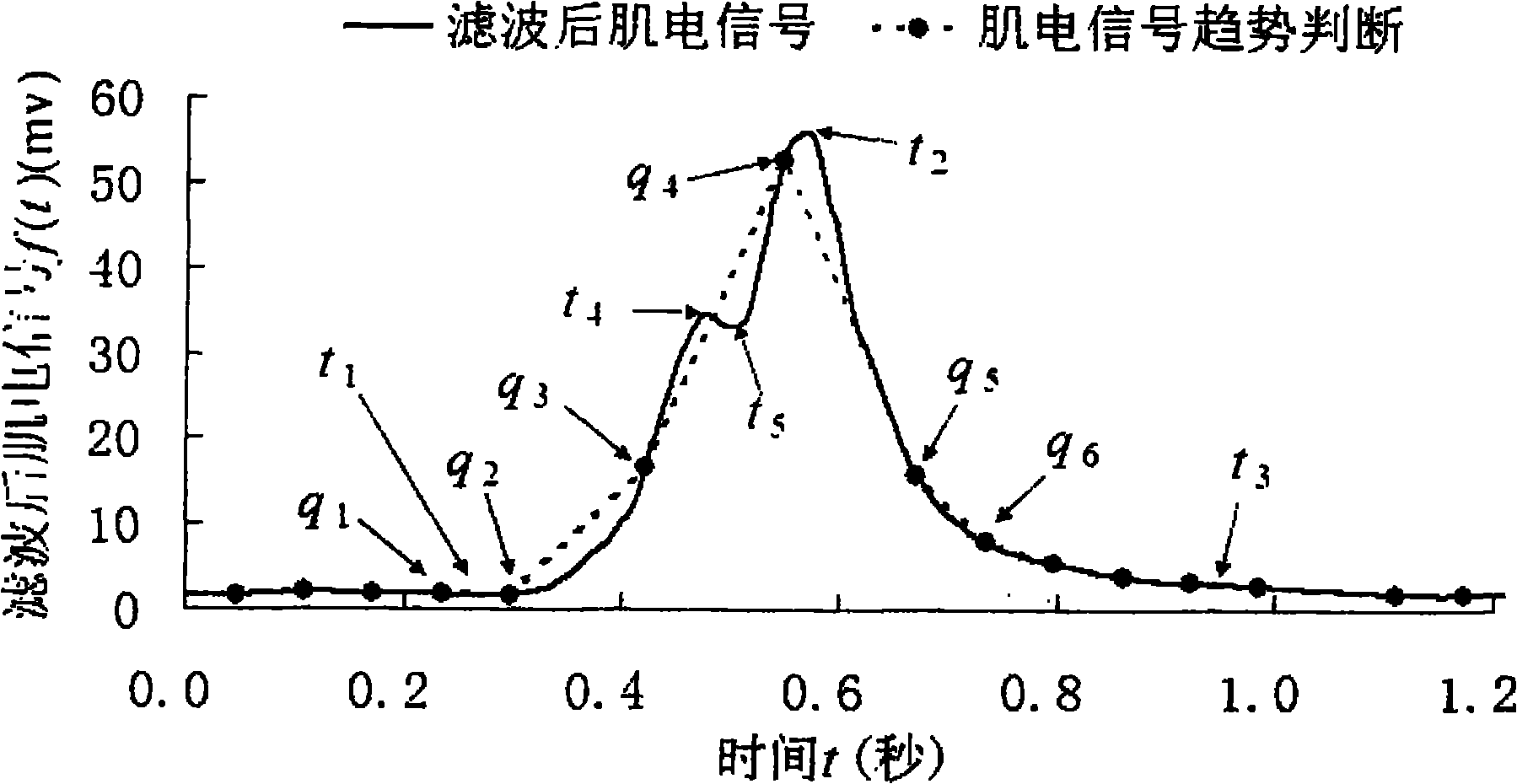

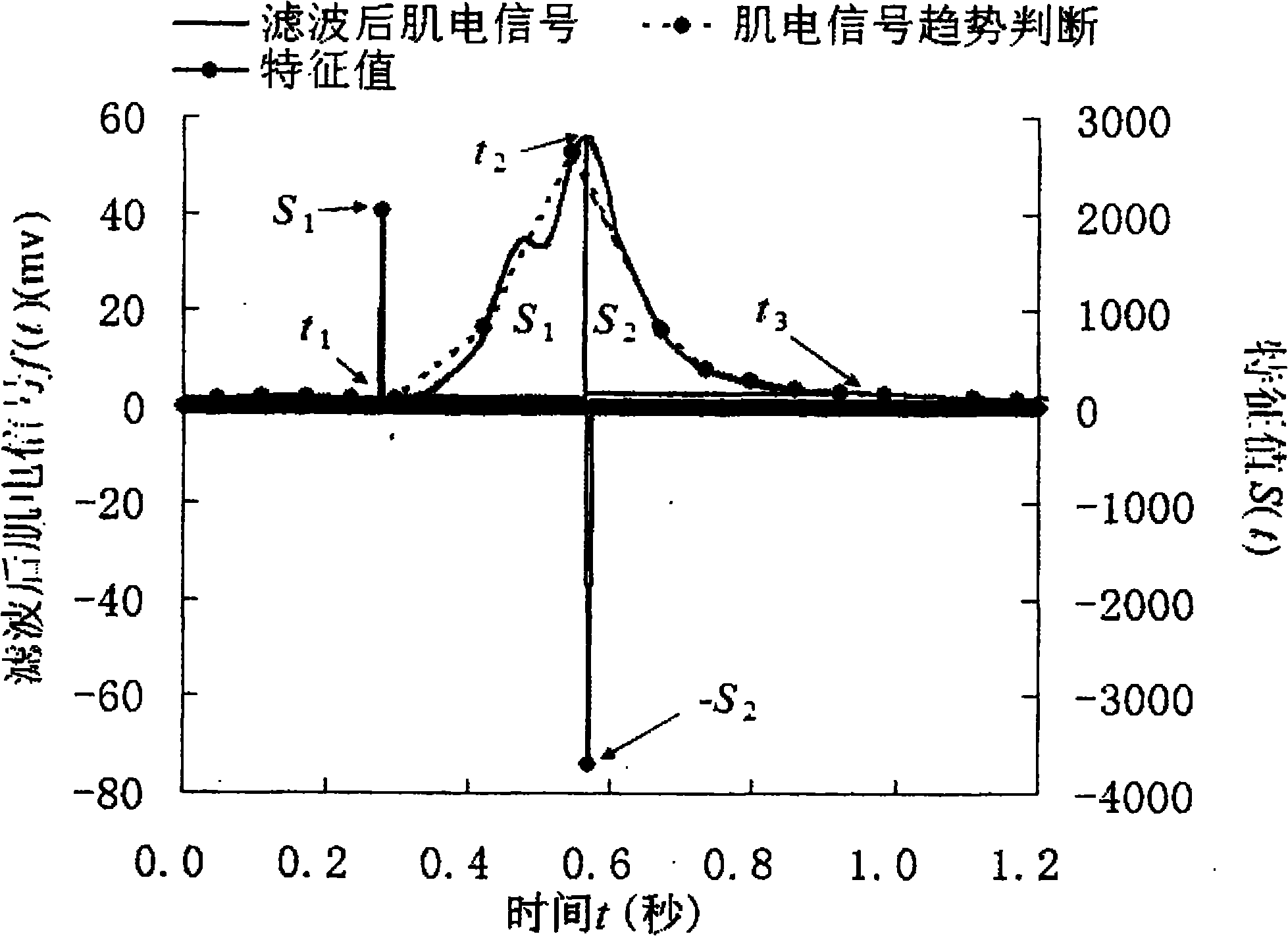

Method for recognizing human walking gait cycle with electromyographic signal

InactiveCN102133103AThere will be no problem of easy wear and tearAccurate expressionDiagnostic recording/measuringSensorsMoving averageAverage filter

The invention discloses a method for recognizing a human walking gait cycle with an electromyographic signal and relates to a method for measuring human limbs movements. The method for recognizing the human walking gait cycle with the electromyographic signal is characterized in that a utilized device comprises a singlechip, an electromyographic signal sensor and a three-point differential input electrocardio electrode based on a segmentation integral algorithm, wherein the electromyographic signal sensor records and processes the electromyographic signal collected by the electromyographic signal sensor to obtain a positive level unstable signal, then the singlechip transfers, moves and calculates an average filter by utilizing a peak-valley segmentation integral algorithm or a simplified algorithm of a peak-valley linear interpolation segmentation integral algorithm to obtain a human walking gait cycle, therefore, the method solves the problems of easy abrasion of a signal sensor of a human movement signal and zero drift of the electromyographic signal sensor and also overcomes the defects that the traditional gait cycle recognizing method is complex and has high equipment price and larger calculation amount. The method for recognizing the human walking gait cycle with the electromyographic signal only needs a single channel signal as an information source and improves the application universality because a plurality of muscles of a person can be selected.

Owner:HEBEI UNIV OF TECH

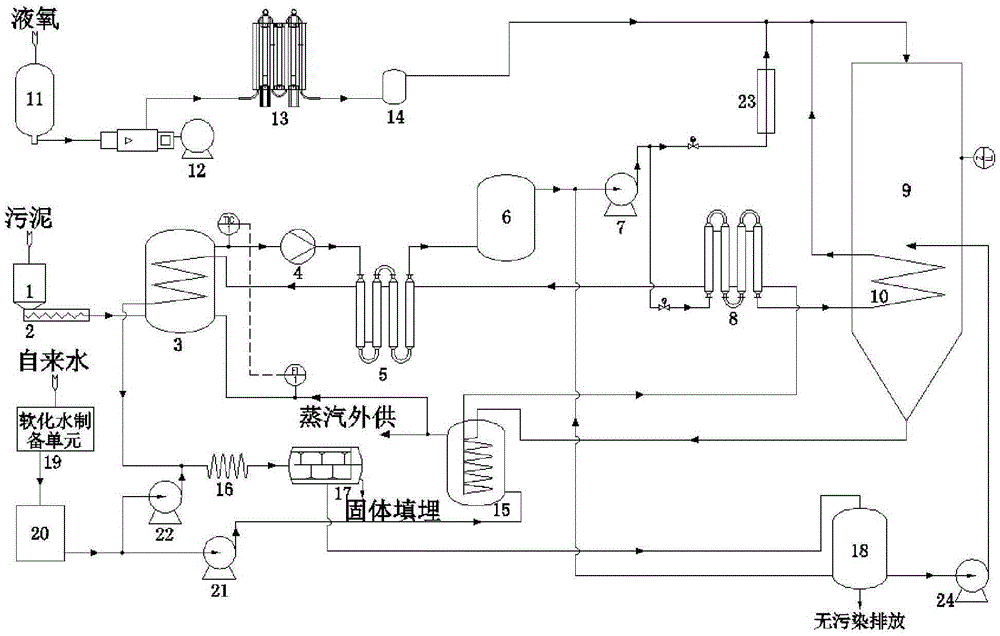

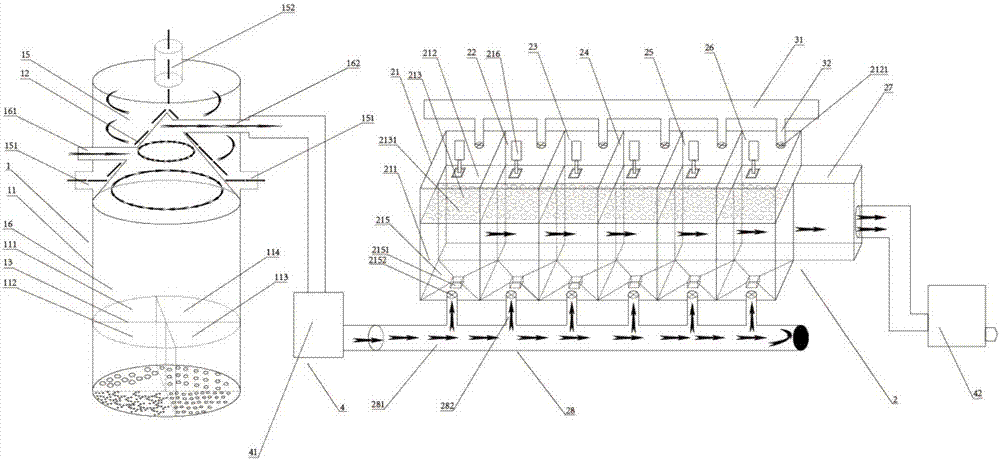

Supercritical water oxidation treatment system and supercritical water oxidation treatment system process for high-concentration dyeing sludge

InactiveCN105293856AChange trafficPrecise regulation of pressure dropSludge treatment by oxidationHigh concentrationTransformer

The invention provides a supercritical water oxidation treatment system and a supercritical water oxidation treatment system process for high-concentration dyeing sludge. After the high-concentration dyeing sludge is ground, the particle sizes of insoluble particles are reduced, and high-flow-speed suspension conveying can be realized; the sludge is further subjected to pyrohydrolysis, cell walls are broken and the viscosity is remarkably reduced; the sludge can be stably conveyed through a high-pressure diaphragm pump and enters into a heat exchanger for preheating, so that the required temperature is reached; subsequently, the sludge and oxygen jointly enter into an inlet in the upper part of a reactor, materials completely react in the up-down flowing process, organic matters are degraded and inorganic salts are separated out; the inorganic salts are secondarily dissolved by the cooling of a small amount of reacted clean fluid introduced from an inlet in the upper part of a third heat exchanger and sludge at the inner pipe side of a fourth heat exchanger; materials flow out of a cone base at the lower part of the reactor for heating soften water to generate steam and preheating the materials; cooled and reacted fluid is decompressed through coarse adjustment of a capillary step-down transformer and fine conditions of flow; decompressed fluid is separated through a pipeline filter to obtain a solid which is finally collected into a liquid collecting tank.

Owner:山川丽(苏州)环保科技有限公司

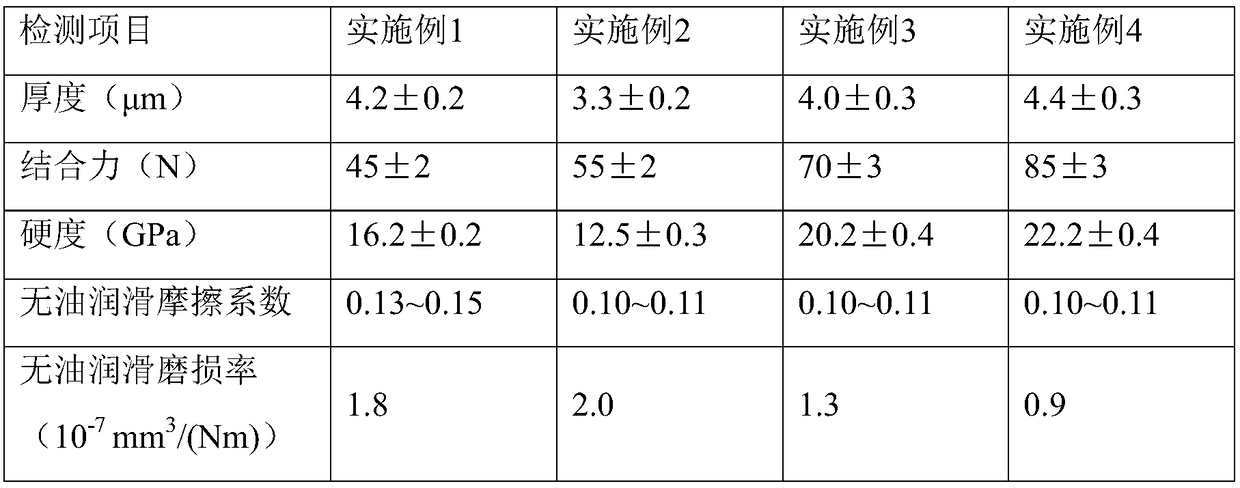

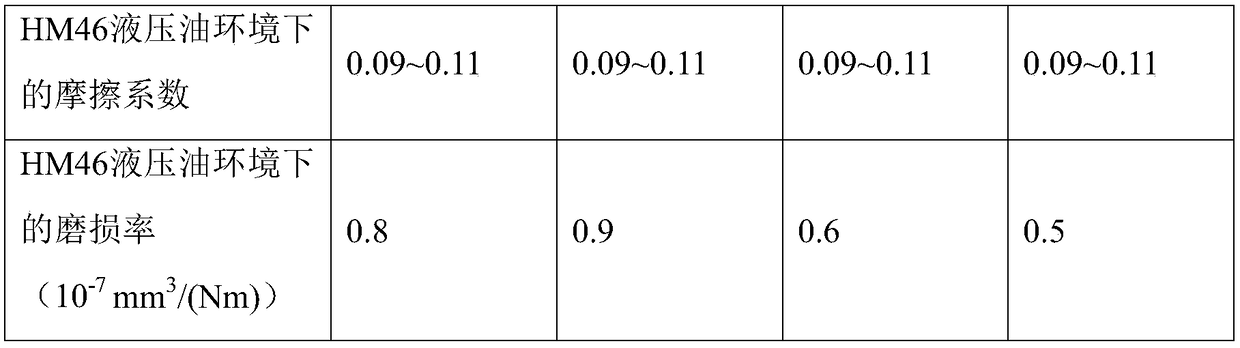

Surface anti-impact abrasion-resisting lubricating composite coating for hydraulic valve rod and preparation method thereof

ActiveCN109023362AExtended service lifeIt has the treatment effect of impact resistance, wear resistance and lubrication integrationVacuum evaporation coatingSputtering coatingFriction reductionComposite function

The invention discloses a surface anti-impact abrasion-resisting lubricating composite coating for a hydraulic valve rod. The coating is composed of a gradient transition layer, a composite multifunctional layer and an amorphous carbon top layer which are sequentially arranged on the surface of a substrate in a stacked mode front bottom to top, and the total thickness is controlled to be 3.0-5.0 microns. The invention further provides a preparation method of the composite coating, the gradient transition layer is prepared through the magnetron sputtering technology or the arc ion plating technology, the composite multifunctional layer is prepared through the magnetron sputtering technology, and the amorphous carbon top layer is prepared through the magnetron sputtering technology or the plasma chemical vapor deposition technology. The surface hardness of the surface anti-impact abrasion-resisting lubricating composite coating for the hydraulic valve rod is larger than or equal to 12 GPa, the friction coefficient is lower than 0.15, high hardness, high toughness, abrasion resistance and friction reduction are integrated, the coating can be better applied to severe working conditions, high-reliability and long-life operation of the hydraulic valve rod is achieved, the coating-plating process is simple, and application value is large.

Owner:中国人民解放军空军勤务学院

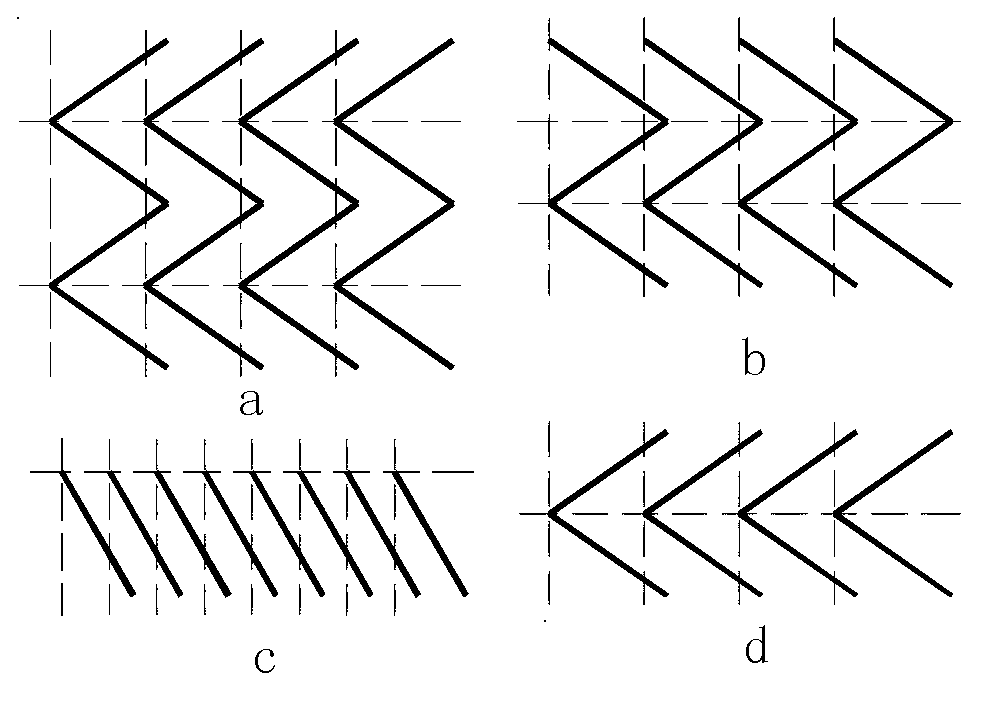

Method for manufacturing drag reduction surface

InactiveCN101402446AReduce pressure loss along the wayLow flow resistanceDecorative surface effectsChemical vapor deposition coatingAviationFlow resistivity

The invention belongs to the technical field of micro-nanometer manufacturing and relates to a method for manufacturing the surface with resistance reduction. Micron level structure arrays in alternate arrangement are designed and manufactured on the surface of a silicon substrate, a silicon dioxide substrate, an engineering plastic substrate or a metal substrate; an ultraviolet stamping photoetching technology is used as a transferring means; a template can be repeatedly used; a fluorination process is used as a surface treatment means to obtain a microstructure substrate with the function of resistance reduction; and the microstructure surface of the substrate has quite low surface energy. The method can be used for the surface of a device for a micro-electromechanical system, and can reduce the surface friction and abrasion as well as the invalidation of adhesion under a microscale; the method can be used for the surface of a conveying pipeline and a microflow device, can reduce the on-way pressure loss of a fluid in a micro-passage and the flow resistance of the fluid, and can increase flow speed; and the method can be used in aviation, spaceflight, navigation, traffic transportation and other fields, and can reduce energy consumption and consequently save energy.

Owner:XI AN JIAOTONG UNIV

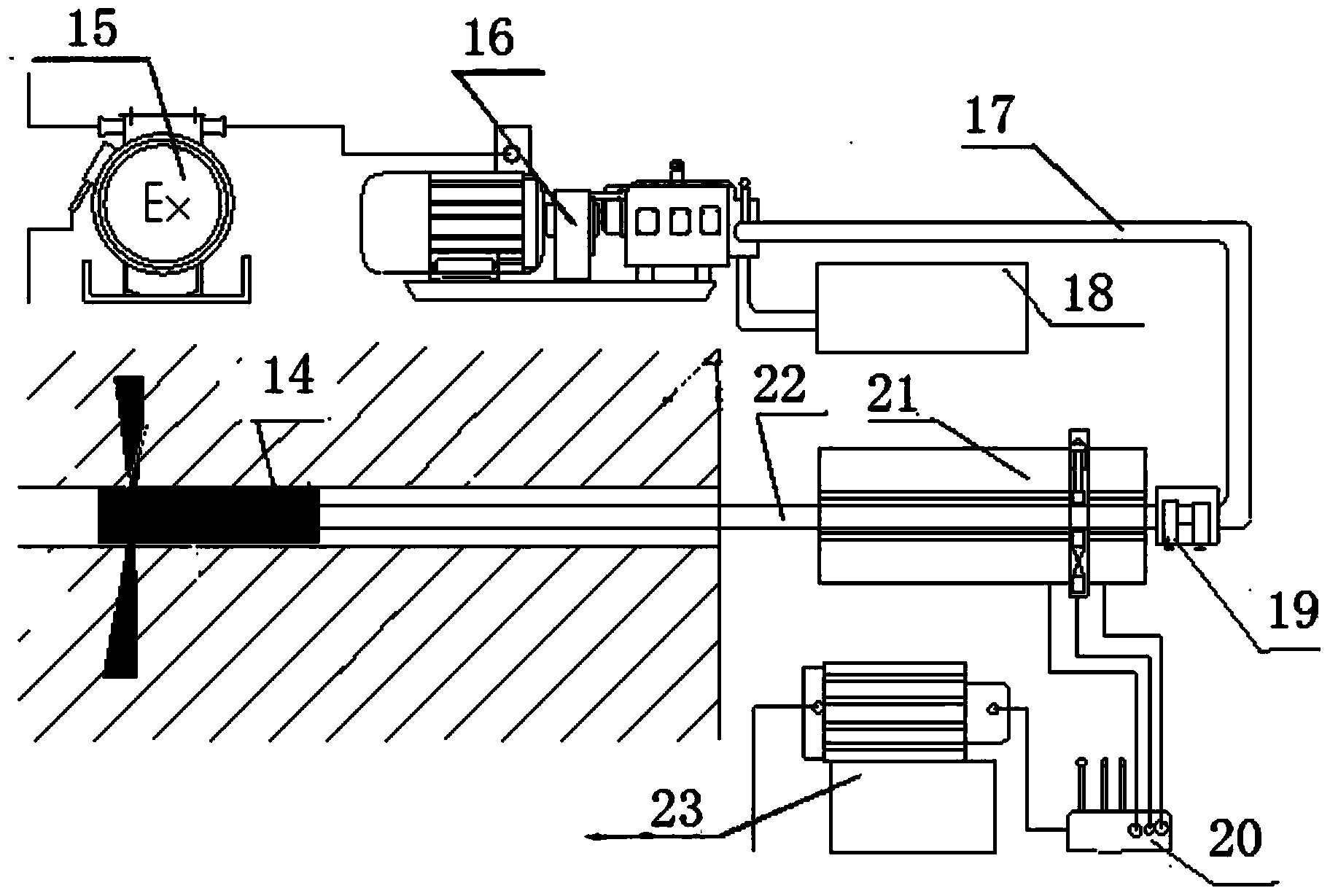

High-pressure water drilling and cutting integrated machine

The invention discloses a high-pressure water drilling and cutting integrated machine comprising a propeller, wherein the propeller is provided with a high-pressure drill rod; the front end of the high-pressure drill rod is provided with a mining drilling and cutting integrated drill bit; a water inlet of the propeller is connected with a high-pressure rubber hose through a rotary water faucet; the other end of the high-pressure rubber hose is connected with a water pump; the water pump is respectively connected with a water tank and an explosion-proof switch; the propeller is also connected with a propeller controller and is controlled by the propeller controller; the propeller is also connected with a propeller motor; the mining drilling and cutting integrated drill bit can be used for realizing the automatic switching of cutting and drilling working states according to the condition that the water filled into an inner cavity is high-pressure water or low-pressure water. The high-pressure water drilling and cutting integrated machine is capable of realizing the drilling and cutting integration, simple and reliable in drilling and cutting switching operation, free of adding grinding materials, and capable of realizing pure water cutting.

Owner:张晓银

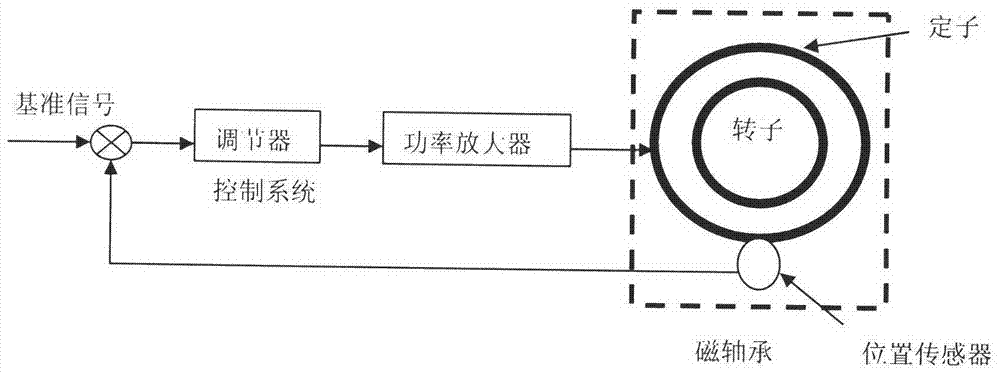

Active electromagnetic bearing impeller pump

InactiveCN104514726AOvercoming wear and tearOvercome tightnessPump componentsPump installationsCorrosion resistantImpeller

The invention discloses an active electromagnetic bearing impeller pump. The active electromagnetic bearing impeller pump is mainly composed of a radial direction electromagnetic bearing rotor, a stator, a thrust bearing, a sensor and a bracket thereof, an impeller and a pump shell. The bearing seat and the impeller are made as an integrated body, the impeller (rotor) of the pump is embedded with the soft magnetic material (magnetic steel and the like) with good permeability, the pump shell (stator) is provided with a coil, which is connected with the electric current for generating the rotating magnetic field, driving the impeller for rotating and realizing the action of the pump. Another magnetic bearing (in radial direction and axial direction) is used for rotating and locating the main shaft and stopping the displacement in radial direction and axial direction. The rotor is soaked in the medium for rotating; the surface contacting the fluid is covered by the corrosion-resistant material, so that the pump has no sealing element of any type inside. The active electromagnetic bearing impeller pump is simple in function, the defect of the common impeller pump, which is easily worn and required to be sealed can be greatly overcome and the active electromagnetic bearing impeller pump has good application prospect.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

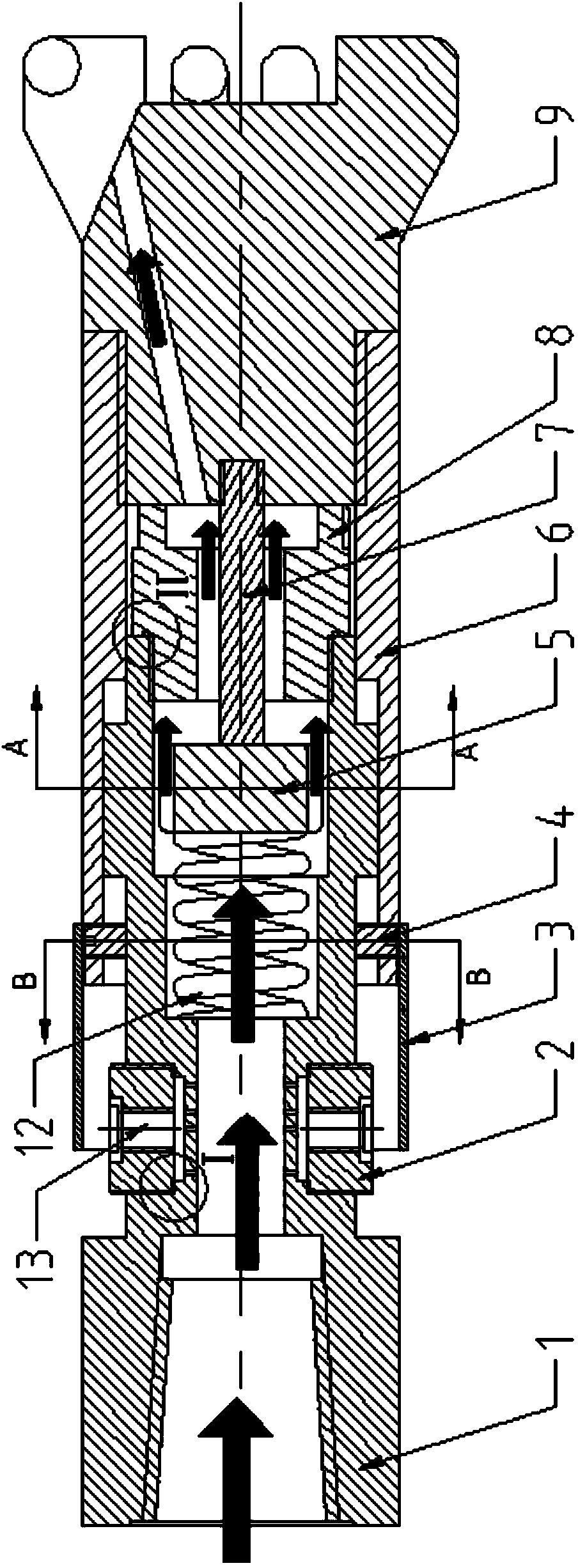

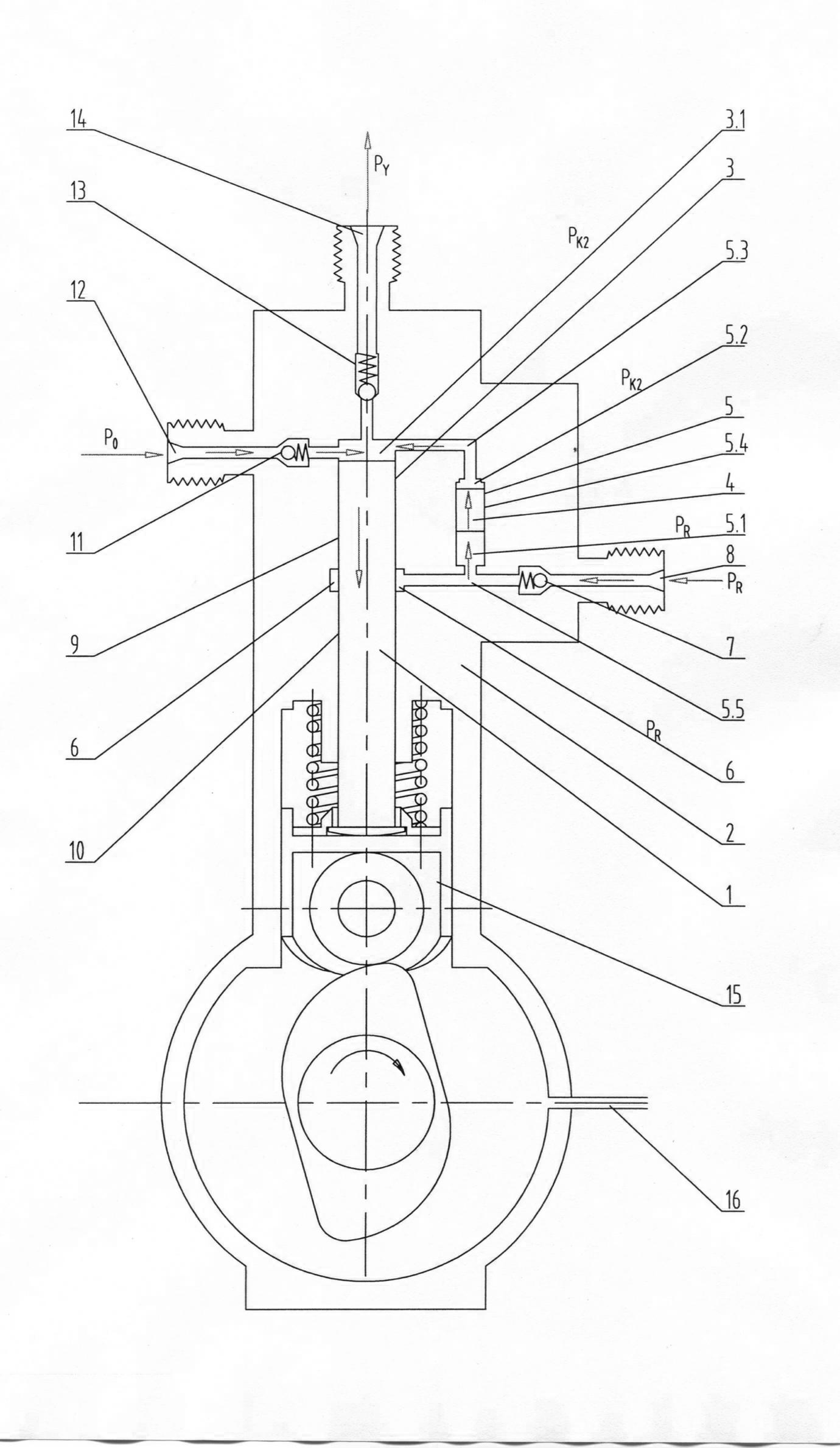

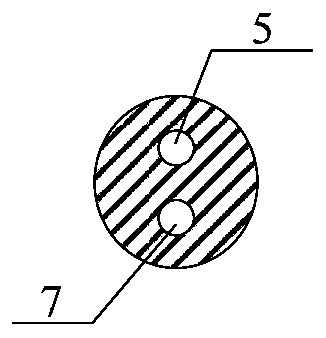

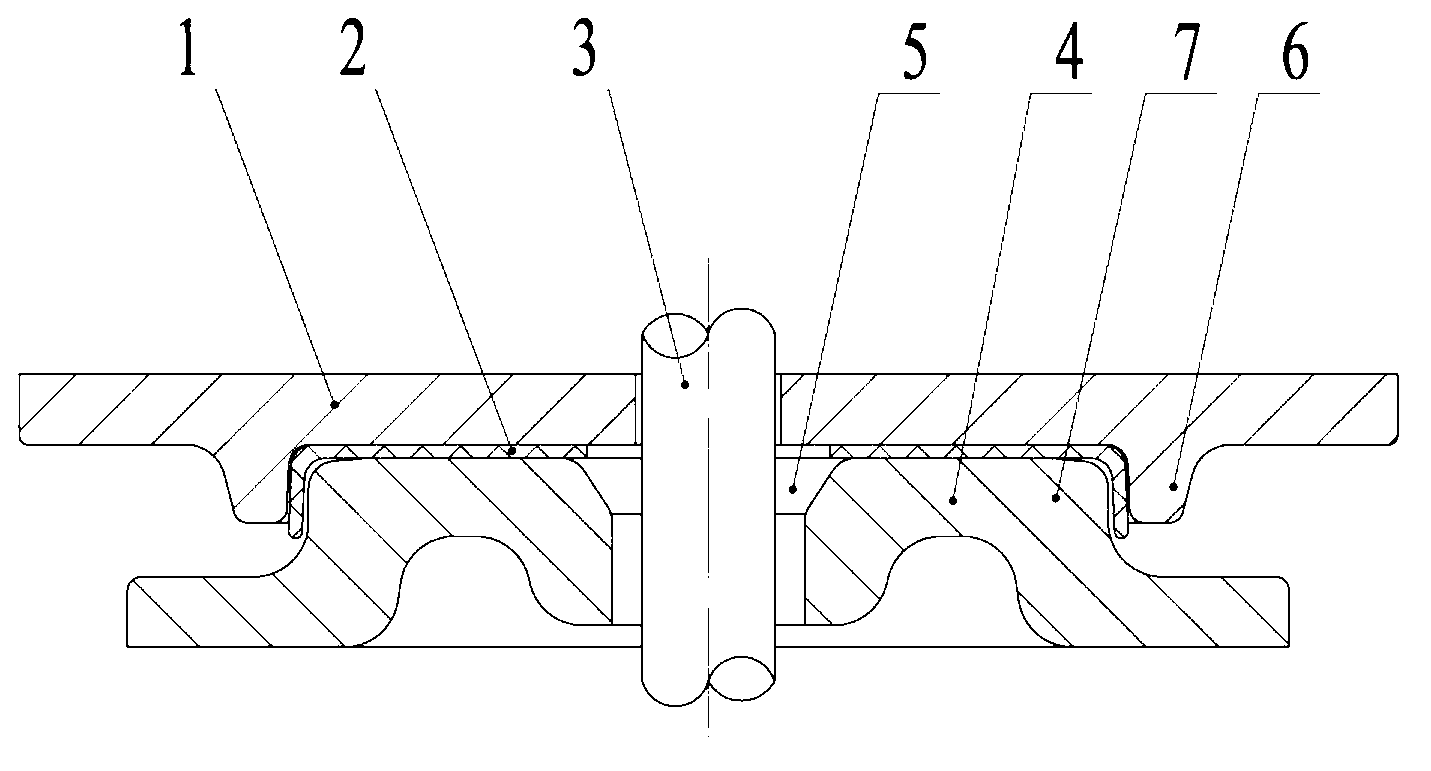

A sealing and lubricating structure for the plunger of an ultra-high pressure plunger pump

ActiveCN102287367AOvercoming wear and tearGuaranteed lubrication effectPositive displacement pump componentsLiquid fuel engine componentsPlunger pumpLubrication

The invention relates to a sealing lubrication structure for a plunger of an ultrahigh pressure plunger pump. The sealing lubrication structure mainly comprises a plunger, a cylinder, a pressure transfer oil cylinder and a free piston arranged in the pressure transfer oil cylinder. The free piston divides the pressure transfer oil cylinder into a pressure transfer cavity and a lubricating oil cavity. The sealing lubrication structure is characterized in that: an annular sealing oil groove formed on a working cylinder hole separates a plunger annular microgap between the plunger and the working cylinder hole into upper and lower plunger annular microgaps; when the plunger ascends to pump oil, the pressure of ultrahigh pressure fuel oil in a pump cavity is transferred to the annular oil groove through an oil duct, the pressure transfer cavity, the free piston, the lubricating oil cavity and a three-way oil duct, so that the pressure of the pump cavity is equal to that of the annular sealing oil groove; and a small amount of lubricating oil leaks from the annular sealing oil groove through the lower plunger annular microgap, and under the action of the pressure of the fuel oil in the pump cavity, the free piston descends to supplement the leaked lubricating oil to keep the pressure of the lubricating oil in the annular sealing oil groove at the lower end of the annular microgap equal to that of the fuel oil in the pump cavity at the upper end so as to effectively prevent the fuel oil from leaking through the annular microgap and overcome the wear between the plunger and the working cylinder hole.

Owner:上海夏雪科技有限公司

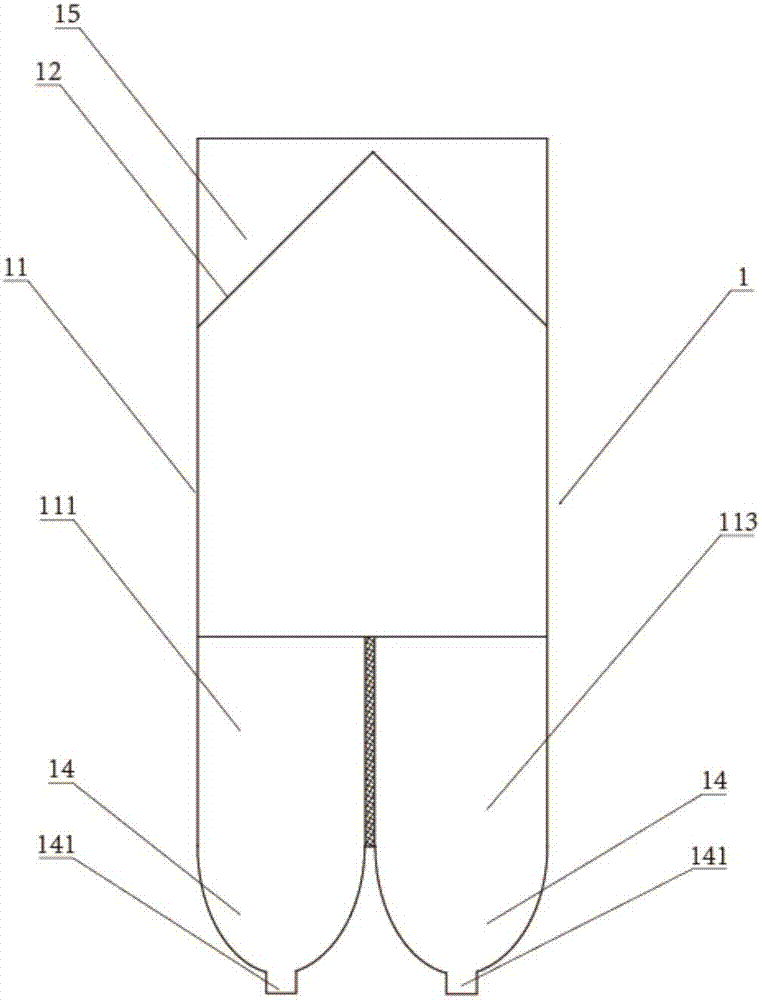

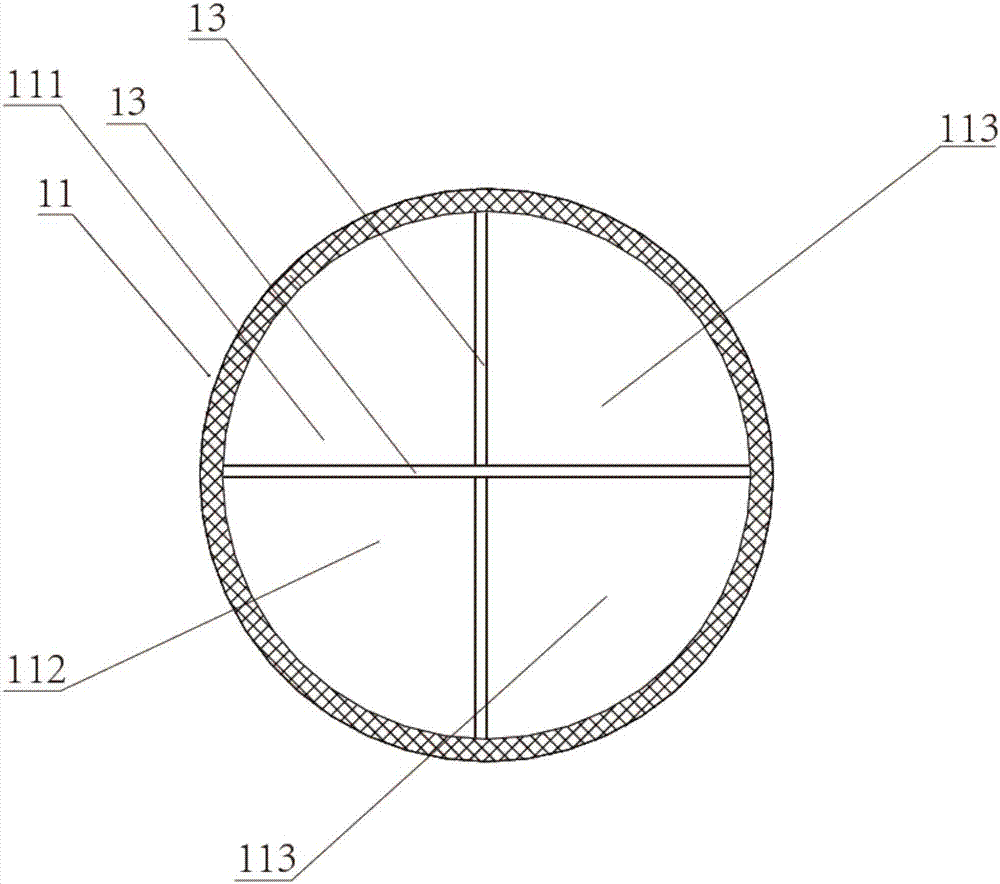

Storage tank type classified sorting system with dust removal function

ActiveCN107309100APrevent affecting operationExtended service lifeCombination devicesDispersed particle filtrationCold airCyclone

The invention discloses a storage tank type classified sorting system with a dust removal function. The system comprises a storage tank type classified sorting device and a warm induced air device. The storage tank type classified sorting device comprises a tank body, an inverted-funnel-shaped cyclone portion and four partition plates. The inverted-funnel-shaped cyclone portion is arranged on the upper portion of the tank body. The outer side wall of the inverted-funnel-shaped cyclone portion and upper space of the tank body form an airtight heat exchange cooling chamber. The heat exchange cooling chamber is provided with a cold air inlet and a hot air outlet. The inner side wall of the inverted-funnel-shaped cyclone portion and the middle space of the tank body form a cyclone classified sorting chamber. The cyclone classified sorting chamber is provided with an air inlet and an air outlet. The partition plates are arranged on the lower portion of the tank body to divide a bottom cavity of the tank body into four fan-shaped cavities. The arm induced air device is used for forming continuous circulation airflow having a negative pressure sucking effect. The design is scientific and reasonable, classified screening and dust removal are carried out during material storage, the production procedures are simplified, and the production efficiency and quality of expanded perlite are improved.

Owner:广东盛达穗南环保科技有限公司

Production process of acrylic fiber/biological fiber yarn-dyed flocked blended fabric

InactiveCN104695110AOvercoming wear and tearOvercoming the defects of easy wearFibre treatmentWoven fabricsHemp fiberCotton fibre

The invention discloses a production process of acrylic fiber / biological fiber yarn-dyed flocked blended fabric. Wefts and warps are made from, by weight, 35 to 60 parts of pupa protein fiber, 16 to 45 parts of Lyocell bamboo fiber, 40 to 90 parts of acrylic fiber, 30 to 60 parts of other biological fibers, 20 to 45 parts of natural fiber, 8 to 15 parts of bamboo fiber, 60 to 95 parts of cotton fiber and 8 to 18 parts of superfine-denier polyester; the other biological fibers include one of or a combination of any of modal fiber, bamdal fiber, corn fiber, chitosan fiber, Shengma fiber, rose fiber and milk fiber. A tentering and setting step adopts the speed of 25 to 50m / min and 1 to 3% of overfeeding. A raising and shearing step adopts controlled raising tension 4.5 to 5 kg, raising speed 12 to 15m / min, shearing tension 4 to 5 kg, speed 9 to 11m / min, and a distance from a cutting edge to the fabric being 0.36 to 0.81 mm. An air washing step adopts control temperature 115 to 125 DEG C, and 3 to 5g / L of 98% softener containing silicone oil is added.

Owner:SUZHOU CHENHENG WEAVING

Digital controlled high-pressure micronizer

InactiveCN1600435AEasy to operateImprove work efficiencyGrain treatmentsElectric machineryEngineering

A numerally controlled high-pressure pulverizing for ore is composed of machine frame, cylindrical cover with air inlet volute, airflow pressure releasing hole and feeding hopper, grinding ring, mainshaft driven by motor, shovel and its holder, centrifugal grinding roller and its holder, and powder fineness analyzer.

Owner:杨金国

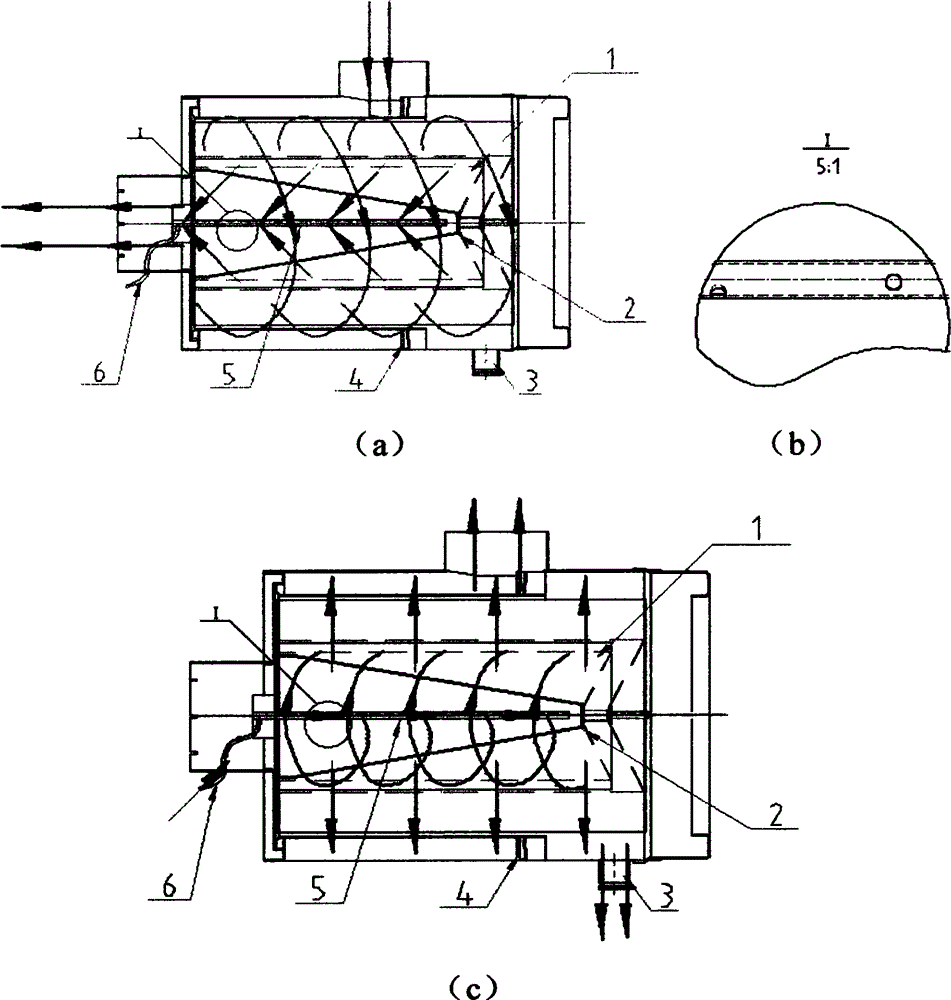

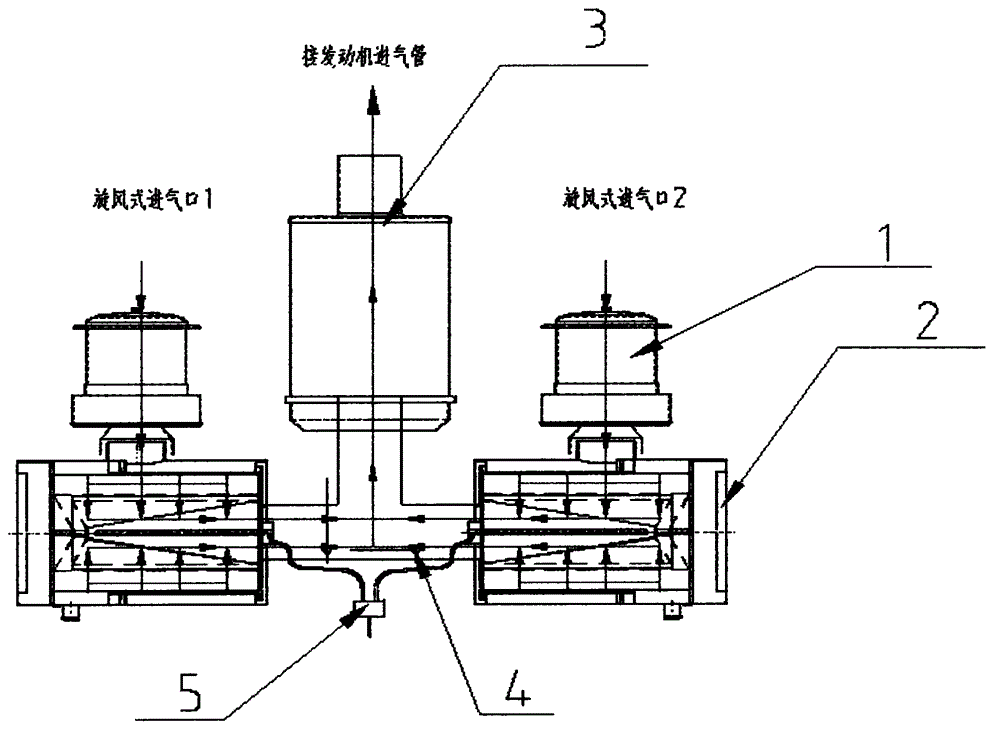

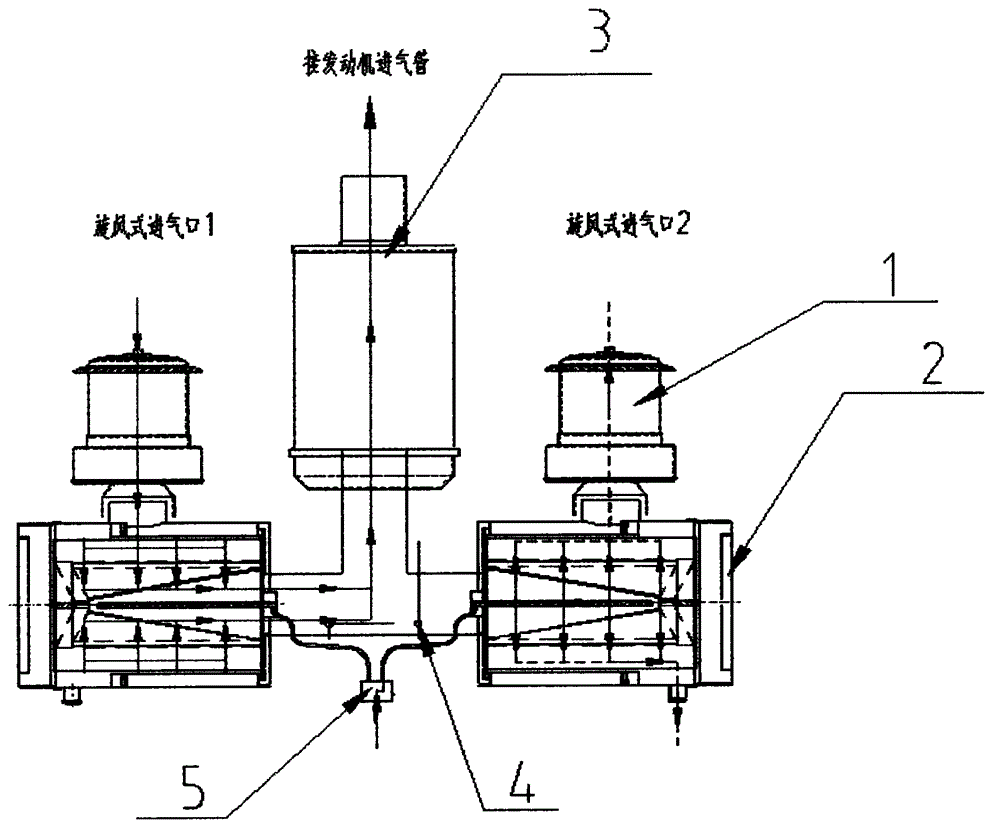

Whirlwind reverse blowing type self-cleaning air filter device

InactiveCN104454259AExtended service lifeOvercome high fuel consumptionMachines/enginesAir cleaners for fuelAir filterOil consumption

The invention discloses a whirlwind reverse blowing type self-cleaning air filter device. The whirlwind reverse blowing type self-cleaning air filter device comprises a shell, a whirlwind air exhaust device, a filter element fastening support, a dry-type filter element assembly, an air pipe and an air inlet, wherein the shell is arranged horizontally, the whirlwind air exhaust device is horizontally arranged at the center position in the shell, the filter element fastening support and the dry-type filter element assembly are located in the shell and arranged around the whirlwind air exhaust device in a matched mode from inside to outside, the air pipe is arranged at one end of the shell and is communicated with the whirlwind air exhaust device, and the air inlet is formed in the top of the shell. The air pipe can be connected with an air intake pipe of an engine. The whirlwind reverse blowing type self-cleaning air filter device can overcome the defects that in the prior art, oil consumption is high, the engine is prone to abrasion and the engine is short in service life, thereby achieving the advantages that oil consumption is low, the engine is not prone to abrasion and the engine is long in service life.

Owner:赵永胜

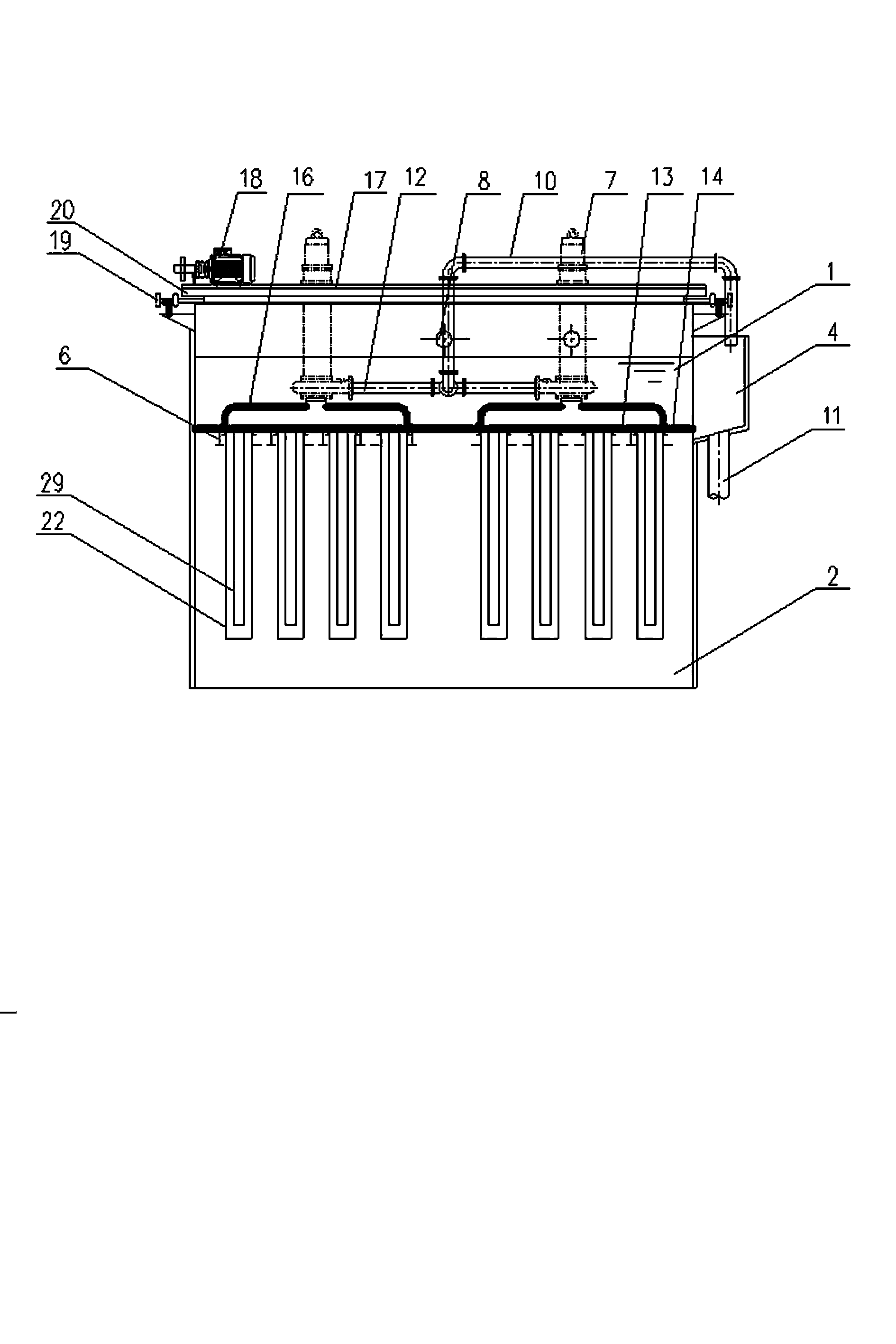

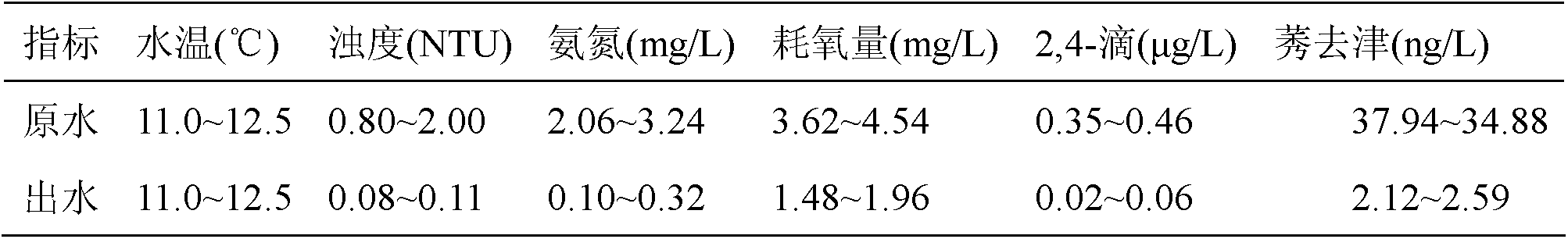

Filter-cloth filter for water treatment

ActiveCN103520972AOvercoming wear and tearGravity filtersStationary filtering element filtersVehicle framePolyvinyl chloride

The invention relates to a filter-cloth filter for water treatment. A filter body consists of a raw water area, a filtered clean water area, an output water area, a mud storage tank, a water inlet pipe, a water outlet pipe, a mud discharge pipe and the like; a filter element of filter main body equipment consists of filter cloth, a center pipe, a filter cloth bracket, a filter element flange, a flange washer, a flange hoop and the like; back-flushing equipment mainly consists of a suction water pump, a suction disc, a mud suction trunk pipe, a mud suction branch pipe, a vehicle frame and the like. The raw water area is positioned above the filtered clean water area, and the raw water area and the filtered clean water area are separated by a PVC (polyvinyl chloride) plate and a stainless steel plate; the upper end of the filter element is communicated with the raw water area through a water inlet of the center pipe, and the top end of the filter element flange is level with the top end of the PVC plate; the center pipe has double effects of pumping the bottom sediment of the filter element while performing flow guide and back-flushing; protection edges are arranged around a suction port of the suction disc, and elastic sealing rings are mounted. Compared with other filter-cloth filters, the filter-cloth filter provided by the invention has three major advantages of no underwater power equipment, no contact with the filter cloth in back-flushing and few valves.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

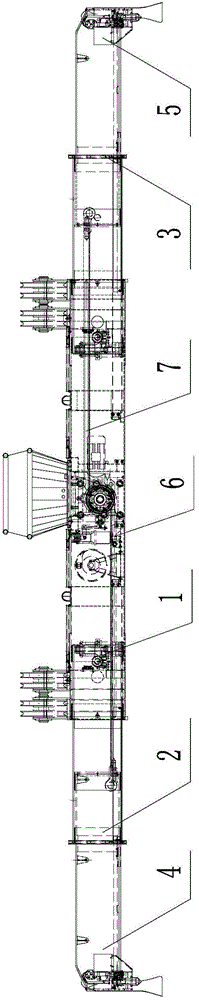

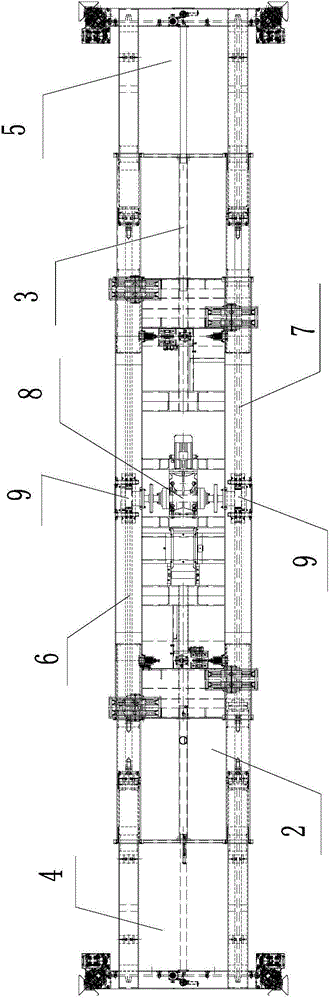

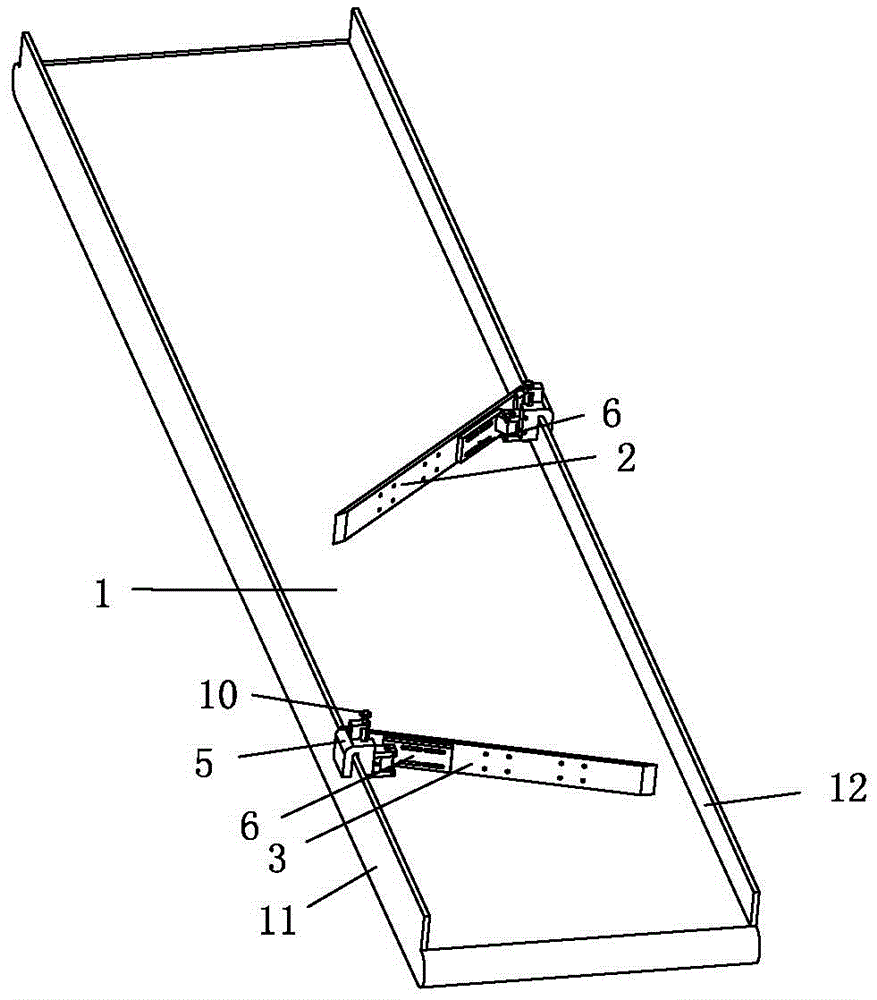

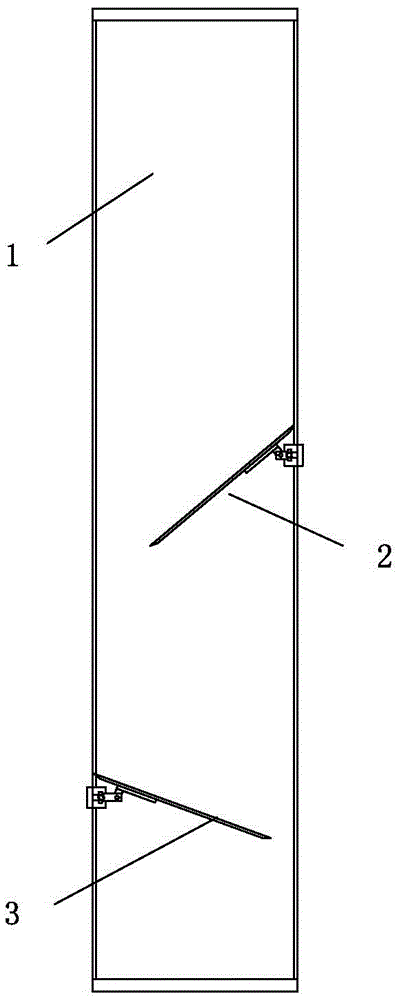

Telescopic mechanism of pinion-and-rack container spreader

ActiveCN104692229AReasonable designEasy maintenanceLoad-engaging elementsFriction gearingsEngineeringReducer

The invention relates to a telescopic mechanism of a pinion-and-rack container spreader. The telescopic mechanism comprises a main beam, a front middle beam, a rear middle beam, a front end beam and a rear end beam, wherein the front middle beam is arranged at the front end of the main beam, the rear end of the front middle beam is connected with the main beam by plugging and in telescopic fit with the front end of the main beam, the front end beam is arranged at the front end of the front middle beam and in telescopic fit with the front middle beam; the rear middle beam is arranged at the rear end of the main beam, and the front end of the rear middle beam is connected with the mean beam by plugging and in telescopic fit with the rear end of the main beam; the rear end beam is arranged at the rear end of the rear middle beam and in telescopic fit with the rear middle beam; and the maim beam is provided with a motor and a motor reducer, and a gear and rack drive mechanism is arranged between the motor reducer and the end beam. The gear and rack drive mechanism is reasonable in design, and convenient to maintain. The defects such as oil leak, high failure rate, complex and difficult maintenance and the like of hydraulic telescopic container spreaders are overcome.

Owner:张家港市盛达冶金吊具制造有限公司

Well drilling method sinking ultrasonic measurement instrument

The invention discloses an ultrasonic meter for shaft sinking by boring, which comprises a downhole tool subsystem, a subsystem above the shaft, a computer subsystem, a depth instrument subsystem, a winch subsystem and an oscillograph subsystem. The invention is characterized in that: a conversion transducer is provided with a constant pressure casing; liquid medium is stored in the constant pressure casing; the conversion transducer is arranged in the liquid medium; the constant pressure casing is made of nylon polyester; the characteristic of the liquid medium is coupled with the material and structure of the constant pressure casing. The invention can form a liquid medium environment in a constant state around the proximity of the transducer. No matter how deep the downhole tool in the meter is lowered under the ground, the transducer can touch the liquid medium which keeps constant all along. Accordingly, the pressure of the conversion transducer is kept constant, and is not changed with difference of the mud specific gravity and pressure of different measuring depths. In this way, the stability and the reliability are significantly improved.

Owner:SHANDONG UNIV OF SCI & TECH

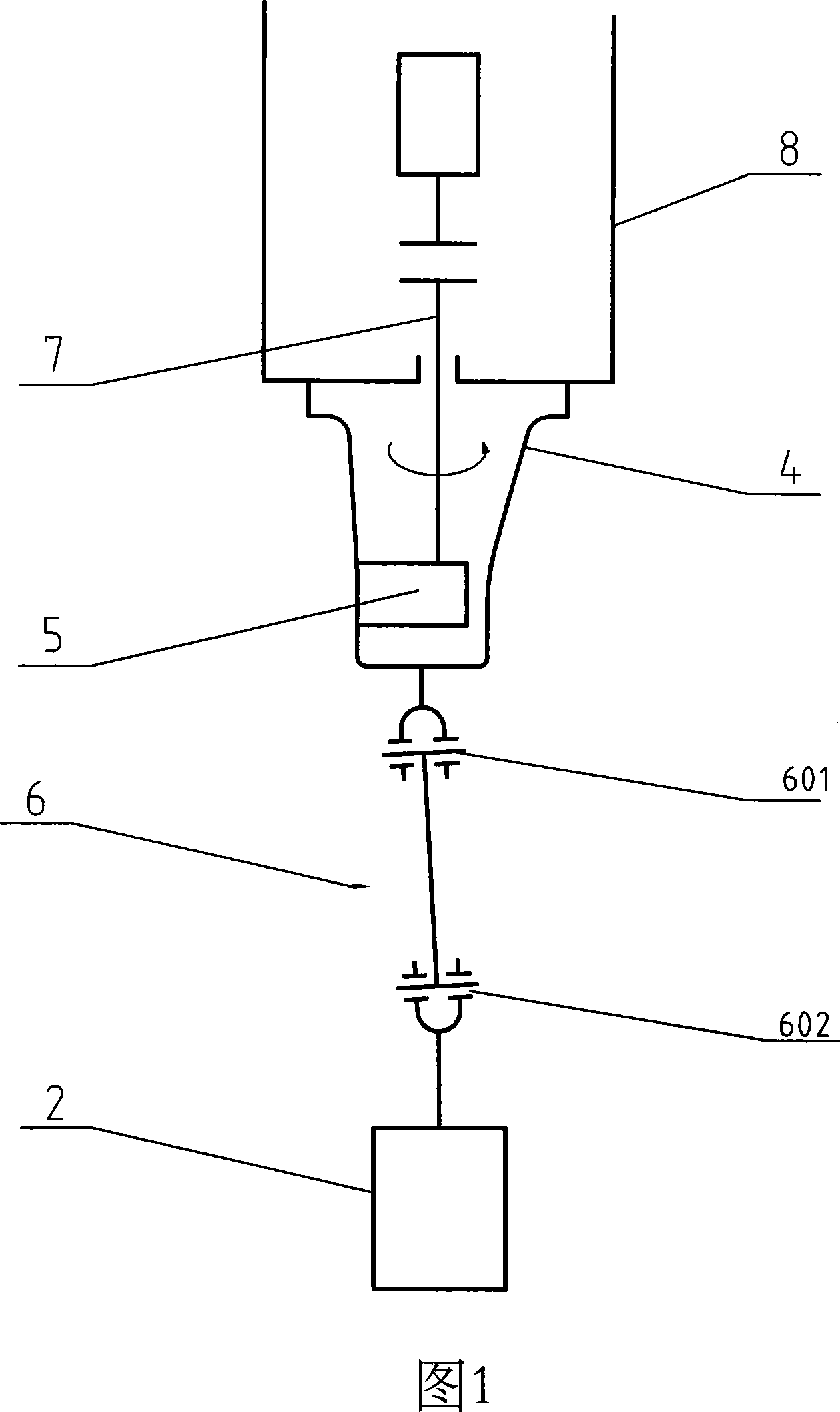

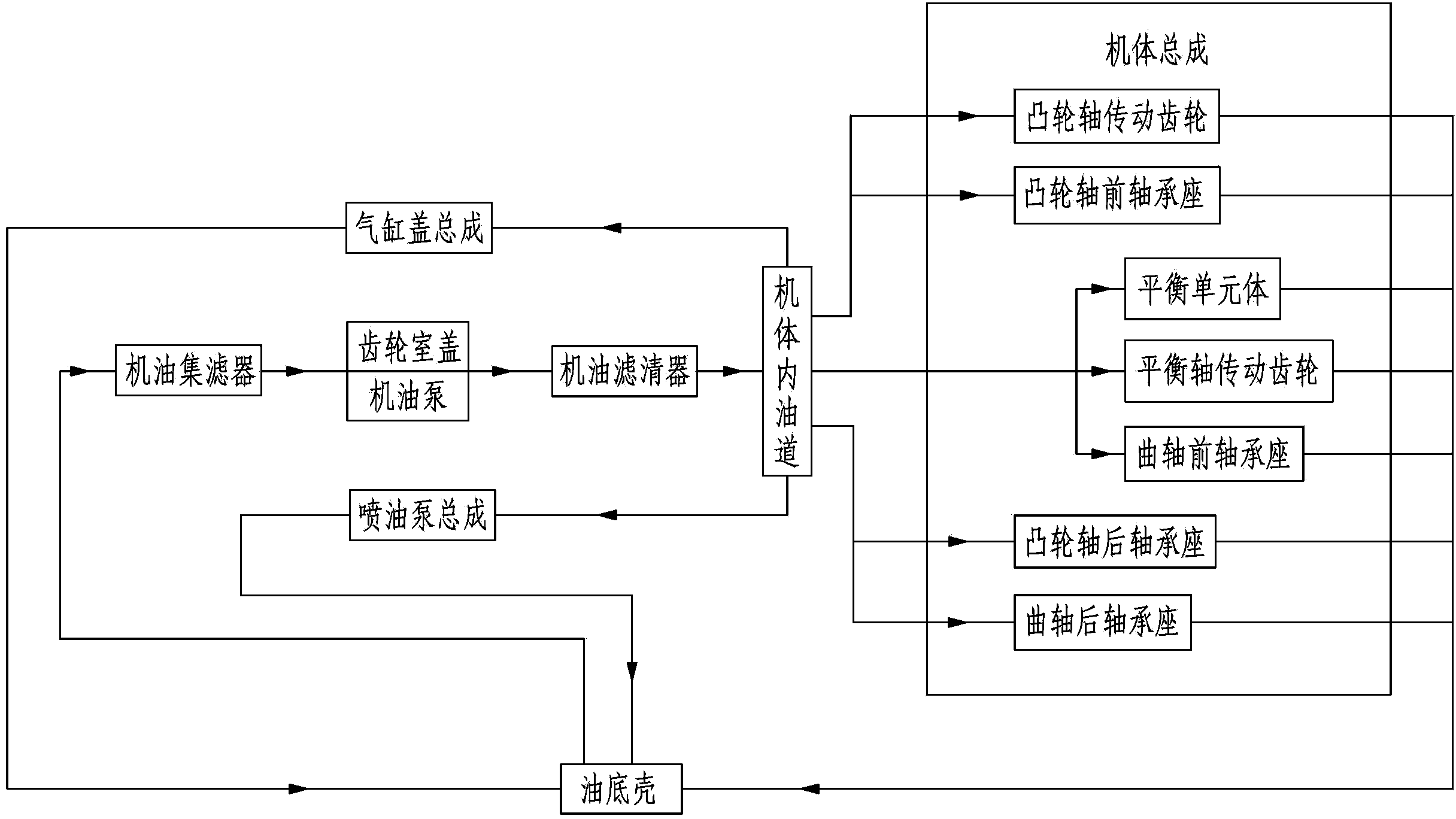

Forced lubricating system of single cylinder diesel

InactiveCN103437851AClean and adequate forced circulation lubricationOvercoming wear and tearMachines/enginesPressure lubrication with lubrication pumpLubricationOil temperature

The invention discloses a forced lubricating system of a single cylinder diesel. The forced lubricating system comprises an oil sump and an oil pump, wherein the oil sump is used for storing oil and cooling, the oil pump is arranged in a gear chamber cover, the oil sump is internally provided with an oil strainer, the oil is sucked by the oil pump through the oil strainer, an outlet of the oil pump is connected with an oil filter, the oil which is filtered by the oil filter can be respectively and forcedly delivered to an oil spray pump assembly, an air cylinder cover assembly and an engine body assembly after entering into an oil duct in an engine body, and oil return ports of the oil spray pump assembly, the air cylinder cover assembly and the engine body assembly are all communicated with the oil sump. According to the forced lubricating system disclosed by the invention, clear, full and forced circulating lubrication of the oil in the diesel is realized through the action of the oil pump and the oil filter, the phenomena of untimely abrasion, bearing bush hugging, cylinder scuffing and the like, which are caused by existing splash lubrication, of each moving piece of the diesel are overcome, the lubrication oil loss of a transmission gear set is avoided, the gear mesh noise and the oil temperature are reduced, the abrasion resistance of each moving piece is increased, and the service life of each moving piece is prolonged.

Owner:常州亚美柯机械设备有限公司

Drilling measuring system and method for detecting height of water flowing fracture zone through water pressure

ActiveCN110107284ASimple measuring principleReduce measurement errorSurveyConstructionsFracture zoneWater flow

The invention discloses a drilling measuring system and method for detecting the height of a water flowing fracture zone through the water pressure. According to the drilling measuring system and method, a drill bit body is drilled into a down-hole roadway through a drilling measuring mechanism to conduct drilling till a hole exceeds the highest position where the water flowing fracture zone is located, after drilling is completed, a drill is withdrawn, in the drill withdrawing process, the height of the water flowing fracture zone is detected, measuring is conducted every time a water injection drill rod is withdrawn by the unit length, according to the change of water level elevation values obtained by a drilling measuring drill bit at different measuring point positions in the hole, therange of the water flowing fracture zone is judged, and the water flowing fracture zone is a zone with the water level elevation values changing along with the depth of the measuring point positionsin the hole. Drill withdrawing and detection are conducted synchronously, the labor amount is reduced, the labor intensity of a worker is lowered, and the detecting efficiency is improved; and the drilling measuring system and method are suitable for detection of the fracture development law of overburden strata with the medium hardness or above, and the good detection effect can still be achievedunder the condition that weak overburden strata or faults are more prone to hole collapse compared with developing zones and the like.

Owner:扎赉诺尔煤业有限责任公司

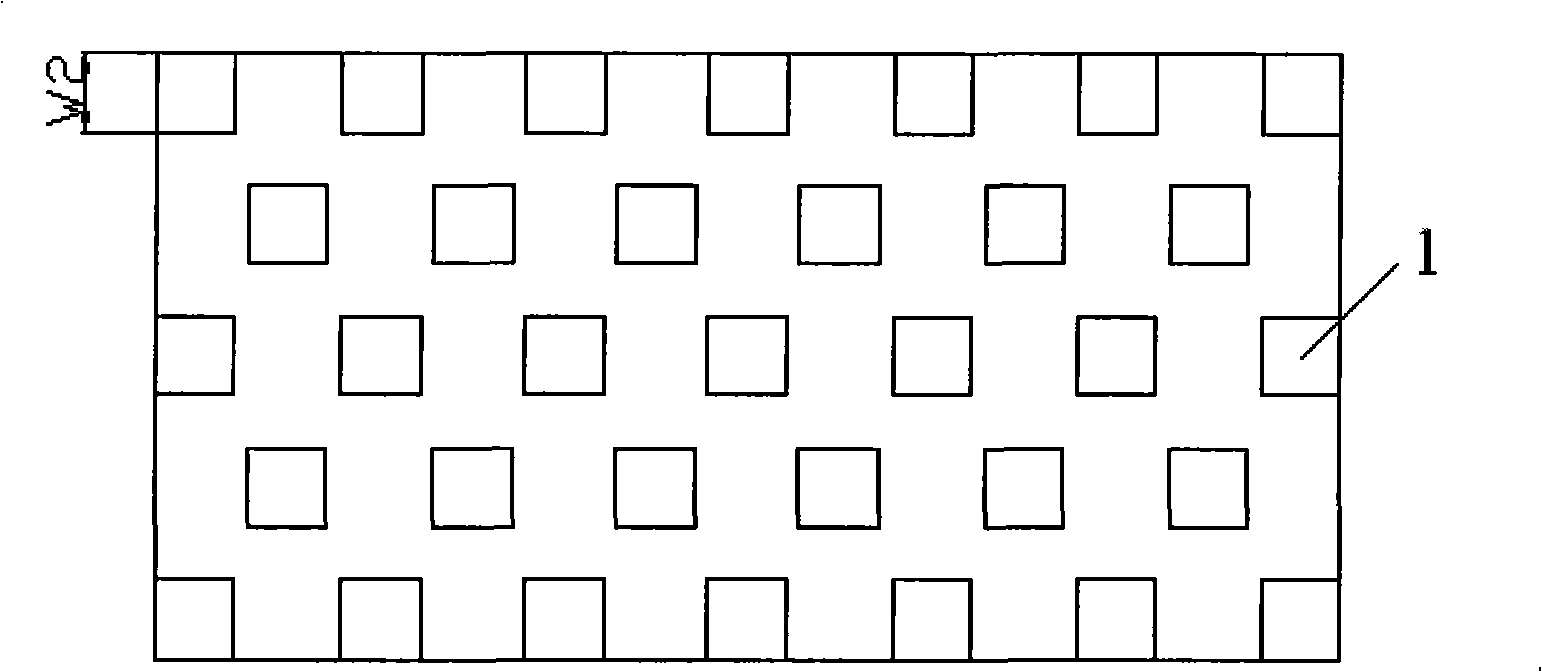

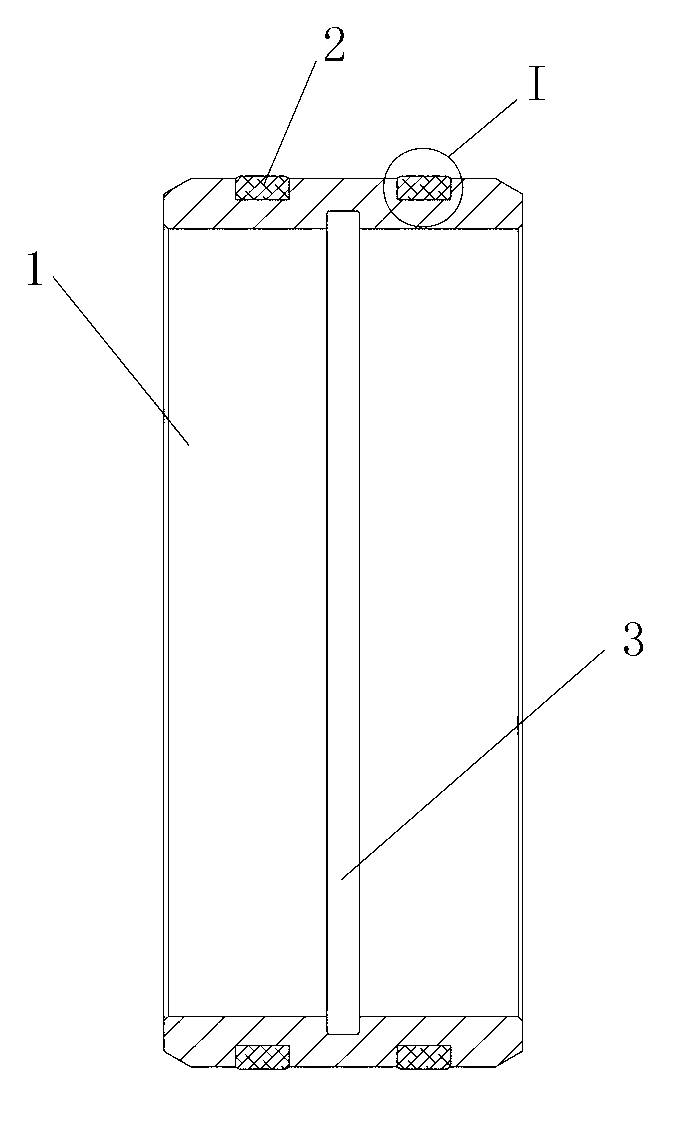

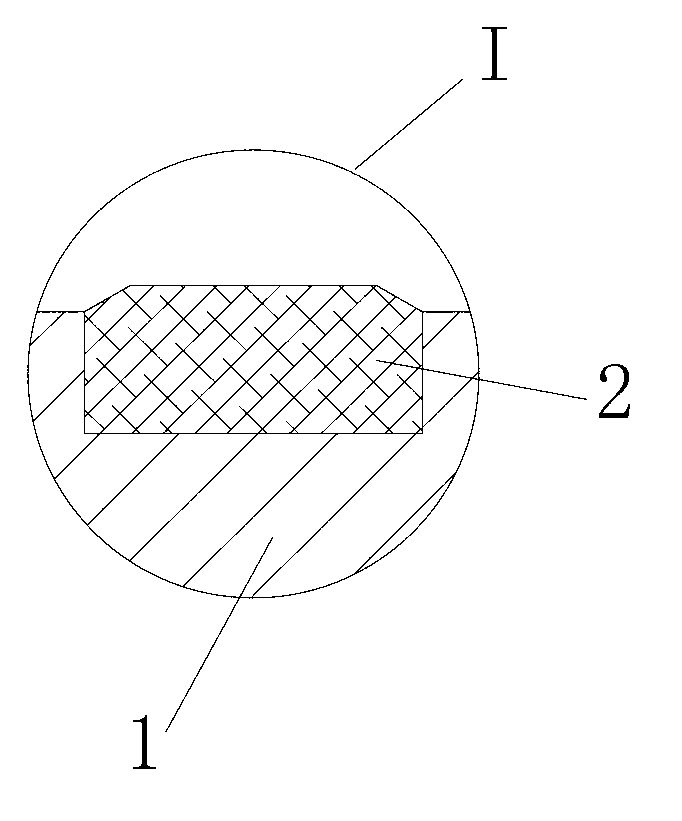

Gap sensor calibration system of magnetic-levitation train

ActiveCN101825428ACompact structureLow costUsing electrical meansTesting/calibration of speed/acceleration/shock measurement devicesElectrical and Electronics engineeringMagnetic levitation

The invention discloses a gap sensor calibration system of a magnetic-levitation train, comprising a base (1), a sensor clamp (2), a vertical driving unit (3), a control mechanism and a track (8), wherein the sensor clamp (2) is used for installing a gap sensor to be calibrated; the track (8) is arranged on the base (1); the sensor clamp (2) is fixed on the vertical driving unit (3); the track (8) is arranged just above the sensor clamp (2); the base (1) is provided with a horizontal driving unit (4); the vertical driving unit (3) is fixed on the horizontal driving unit (4) and is driven to move along a horizontal direction by the horizontal driving unit (4); the track (8) is provided with more than one seam (83); and the control mechanism is respectively connected with the vertical driving unit (3), the horizontal driving unit (4) and the gap sensor to be calibrated. The invention has simple structure, low cost, fastness, effectiveness, high reliability and convenient maintenance.

Owner:NAT UNIV OF DEFENSE TECH

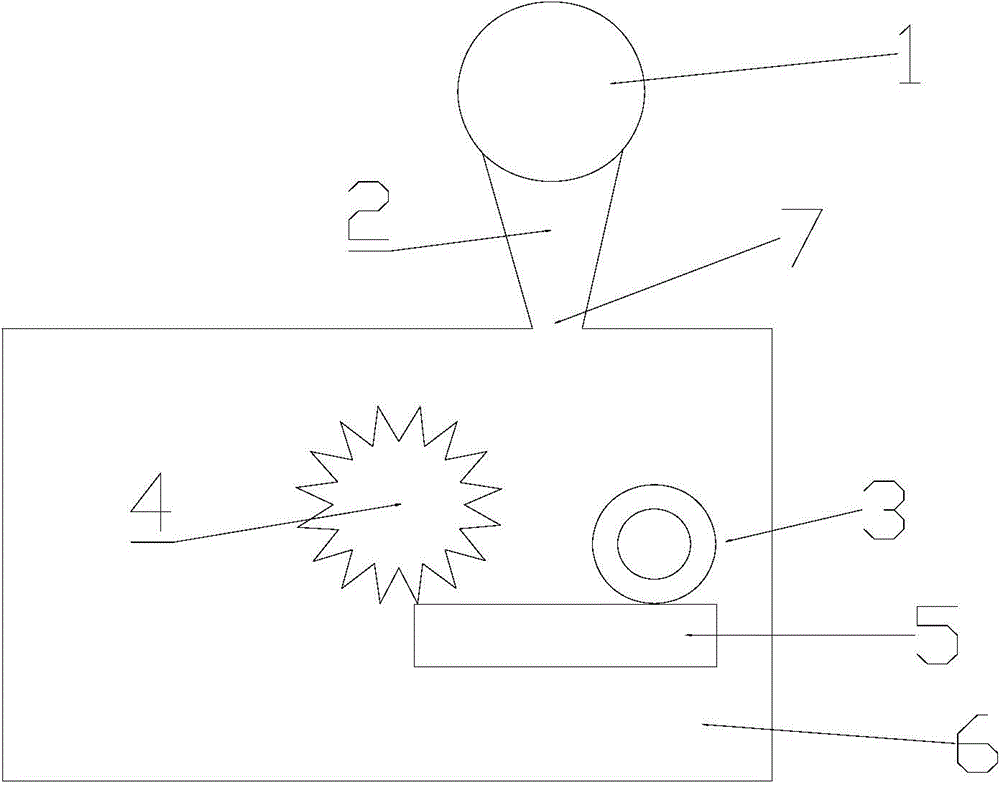

Grain cutting machine

InactiveCN104943014AReduce rust rateExtended service lifeCoatingsAgricultural engineeringWind direction

The invention discloses a grain cutting machine. The grain cutting machine comprises a tooling mechanism, a cooling draught fan (1), an air inlet duct (2) and a grain cutting machine body (6). The tooling mechanism is arranged in the grain cutting machine body (6). An air inlet (7) is formed in the grain cutting machine body (6). The air inlet (7) is communicated with one end of the air inlet duct (2). The other end of the air inlet duct (2) is communicated with the cooling draught fan (1). The wind direction flowing into the grain cutting machine body (6) of the air inlet duct (2) corresponds to the tooling mechanism. The grain cutting machine solves the problems that a knife edge of the grain cutting machine is prone to wear, and the aging speed of a rubber roll is high, and the service life of the grain cutting machine is prolonged effectively.

Owner:WUHU XINNING NEW MATERIAL SCI & TECH CO LTD

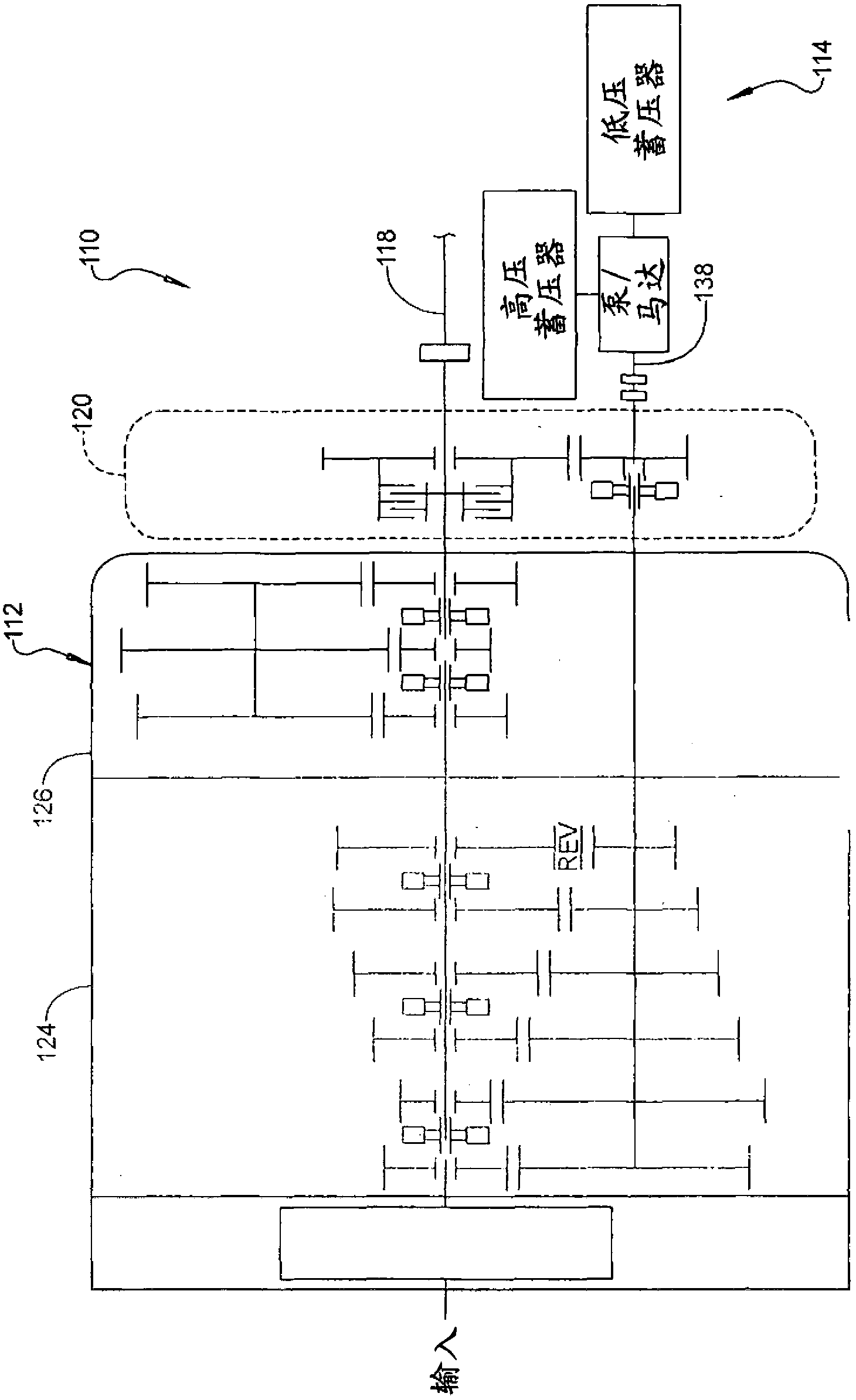

Adapter for connecting a countershaft transmission with a hydraulic launch assist system

InactiveCN102741078AOvercoming wear and tearImprove good performanceMechanical apparatusGas pressure propulsion mountingAutomatic transmissionDrivetrain

Owner:EATON CORP

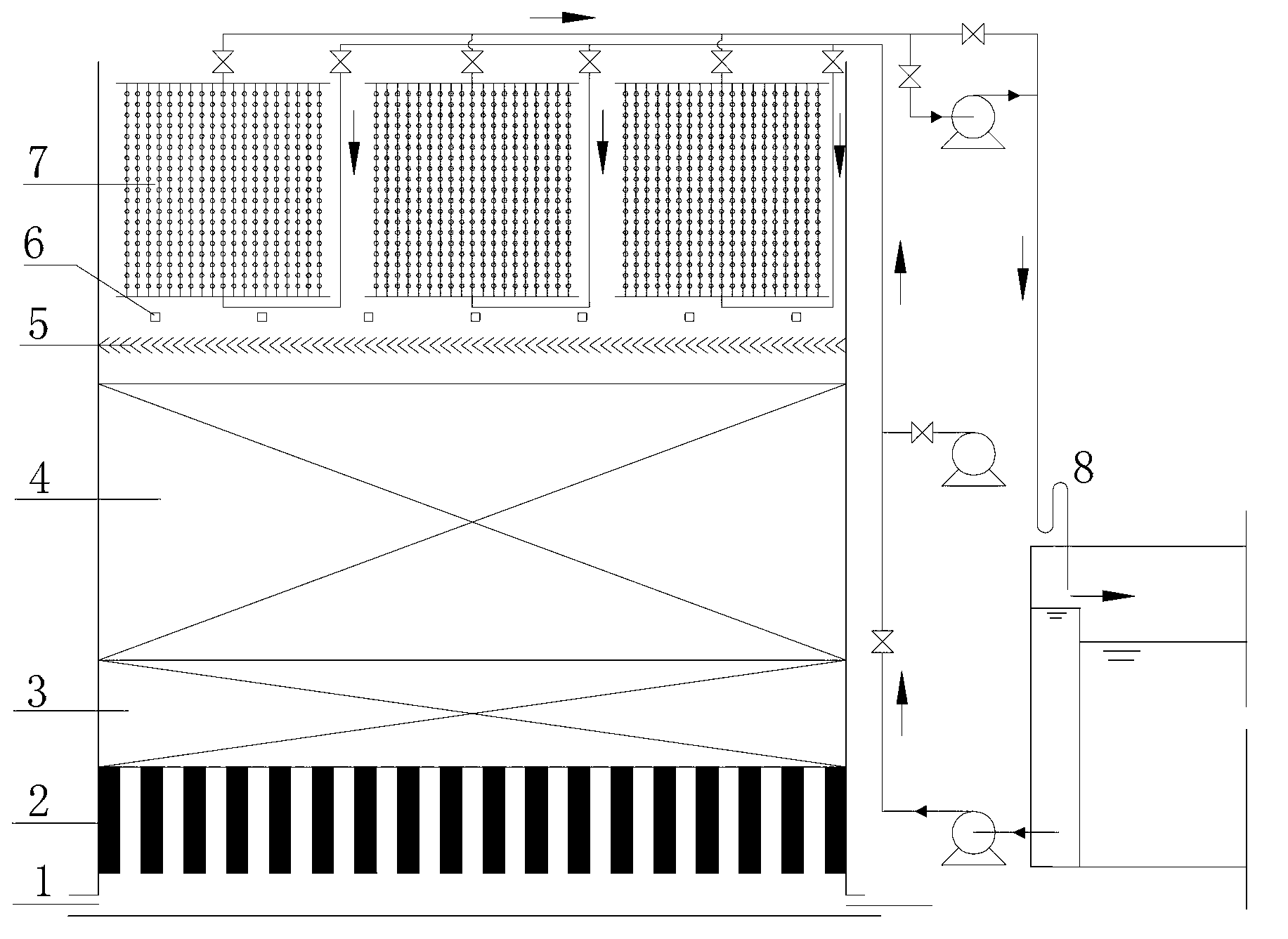

Upward-flowing fluidization biofilter coupled with negative pressure membrane

ActiveCN103253760ARealize purificationAvoid wear and tearBiological water/sewage treatmentSuspended particlesParticulates

The invention relates to a biofilter and discloses an upward-flowing fluidization biofilter coupled with a negative pressure membrane, for solving the technical problems of an existing biofilter, such as poor filtering effect on suspended particles, planktons, benthonic animals and microorganism residues in water bodies, as well as high turbidity of treated water. The upward-flowing fluidization biofilter comprises a water inlet, a water distribution layer, a supporting layer, a filling layer, an anti-interference cantboard, an air floatation releaser and a negative pressure membrane assembly. According to a water treatment process, inlet water passes through the upward-flowing biofilter, is filtered by the negative pressure membrane in an upper clear water area and is naturally siphoned by using a siphon tube to discharge water, and thus a water treatment process is finished. The method can be used for effectively removing organic pollutants, natural organic matters, ammonia nitrogen and other pollutants out of water, the loss of biological matters is reduced, a wear damage effect of particles, such as filler, on membranes is avoided, and the plugging effect of biological metabolites and biological cells on the membranes is also avoided.

Owner:HARBIN INST OF TECH

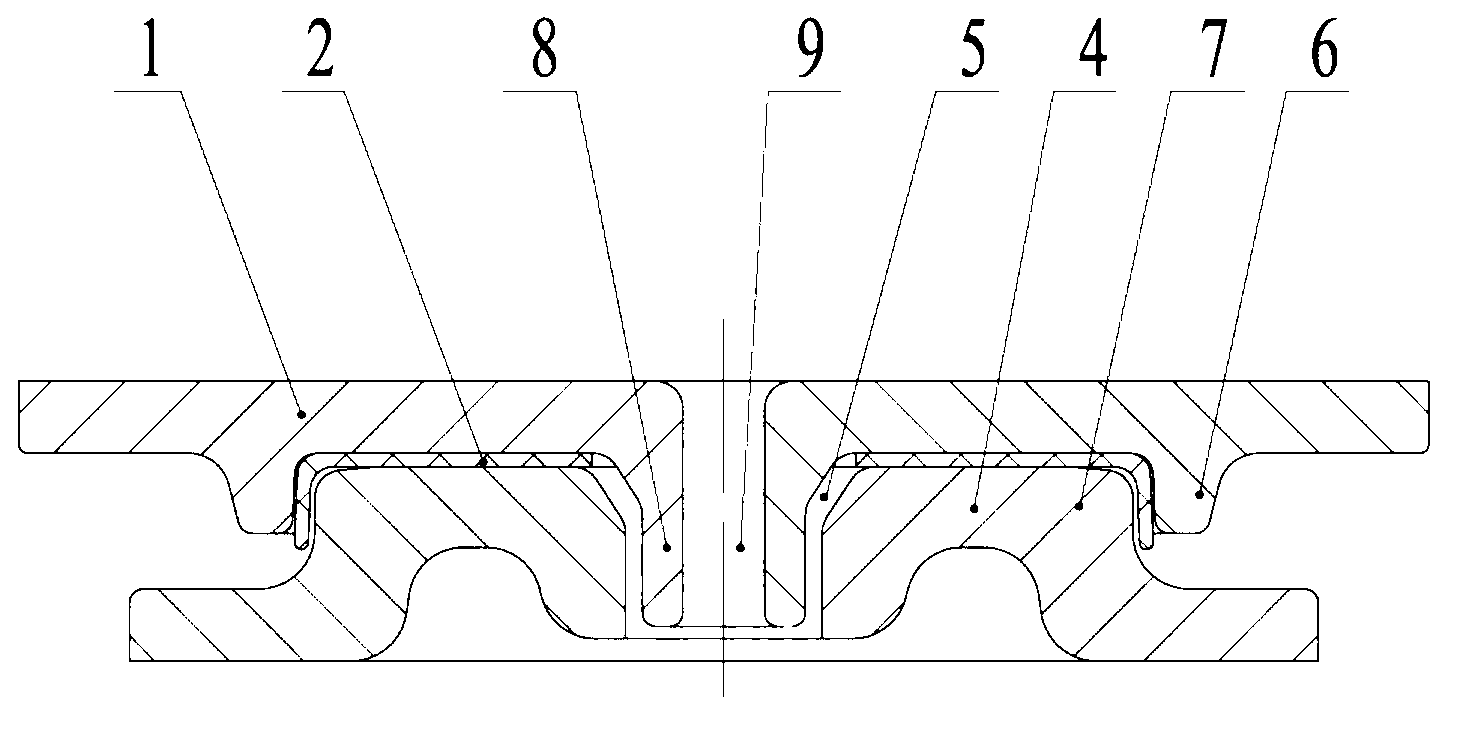

Anti-sedimentation center plate structure for railway vehicles

ActiveCN102795236AAvoid enteringOvercoming wear and tearBogie-underframe connectionsEngineeringSedimentation

The invention discloses an anti-sedimentation center plate structure for railway vehicles, which comprises an upper center plate and a lower center plate, wherein the edge of the upper center plate is provided with a bulge I, the middle of the upper center plate is provided with a groove, the middle of the lower center plate is provided with a bulge II, the groove of the upper center plate is matched with the bulge II of the lower center plate, a center-plate abrading disc with a central hole is arranged between the groove of the upper center plate and the bulge II of the lower center plate, the middles of the upper center plate and the lower center plate are respectively provided with a central hole, the upper part of the central hole of the lower center plate is provided with a tapered hole, and the diameter of the tapered hole is greater than the diameter of the central hole of the upper center plate. The center plate structure disclosed by the invention is simple in structure and manufacturing process and low in cost; and water and sand can be prevented from entering the center plate structure and being sedimentated in the lower center plate, water from vehicle bodies can be drained, and the steering resistance moment of a vehicle is not affected, thereby solving the problem that sand and rainwater occurring in windy, sandy and rainy areas are sedimentated in the center plates of vehicles.

Owner:CRRC SHANDONG CO LTD

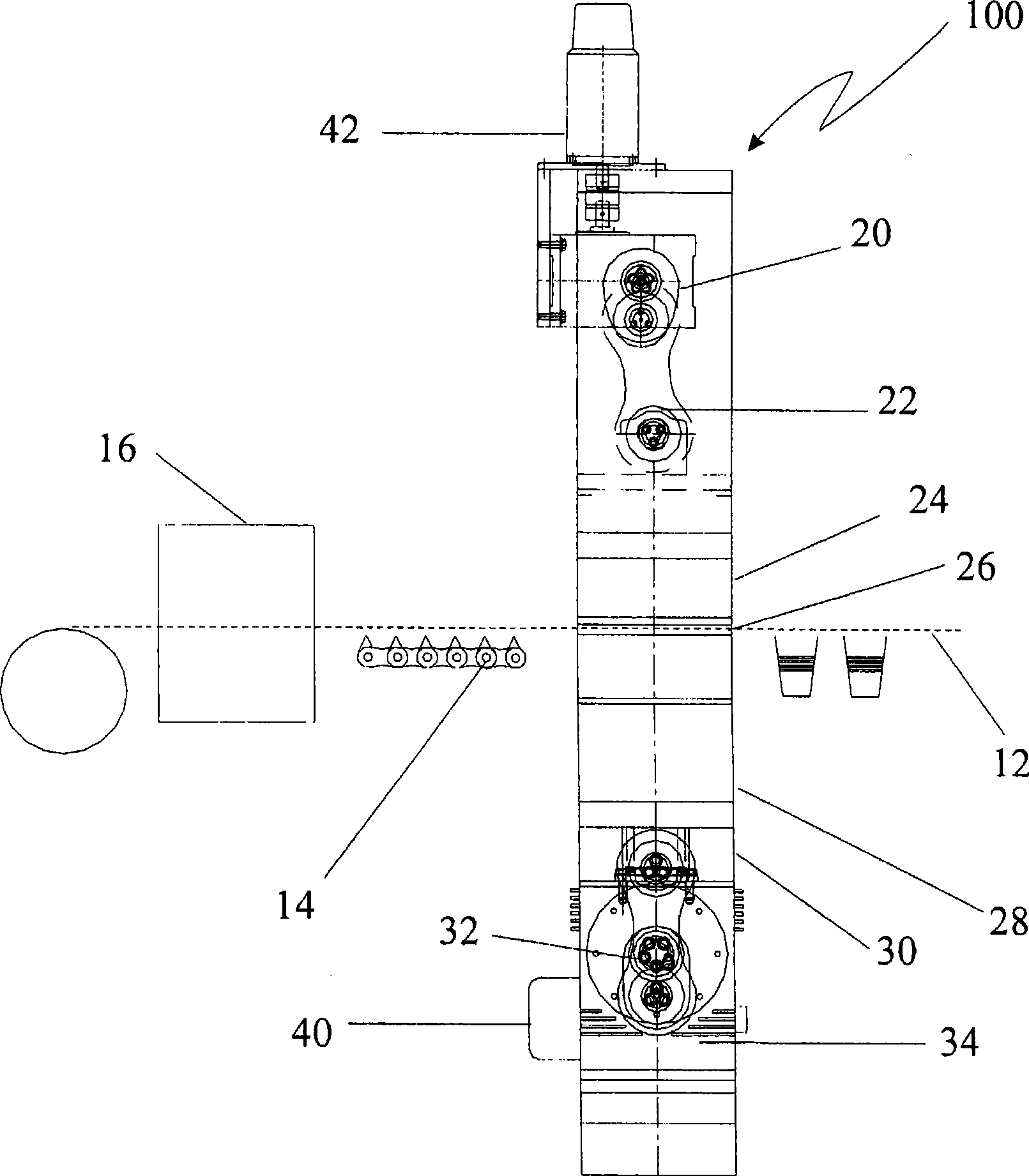

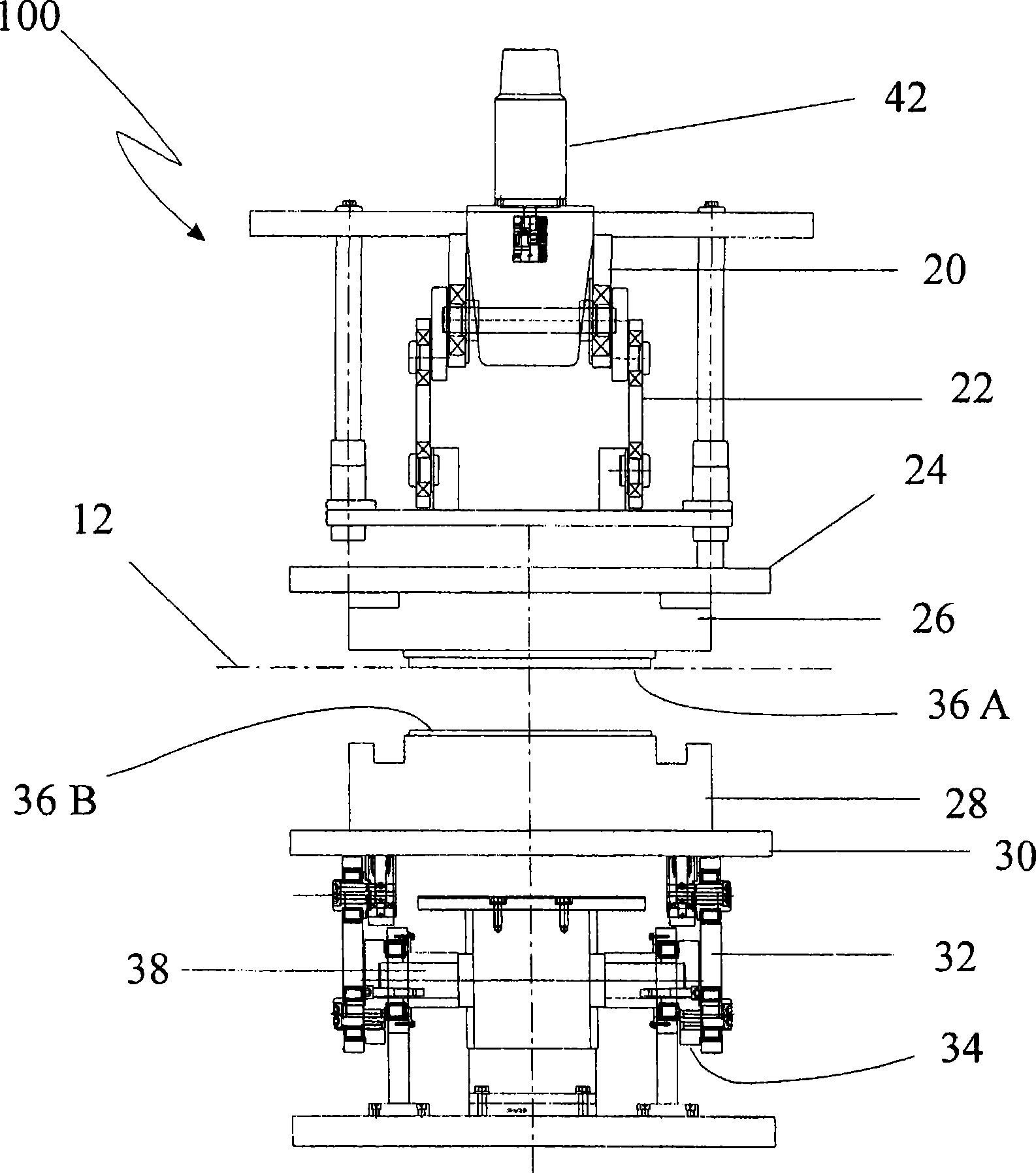

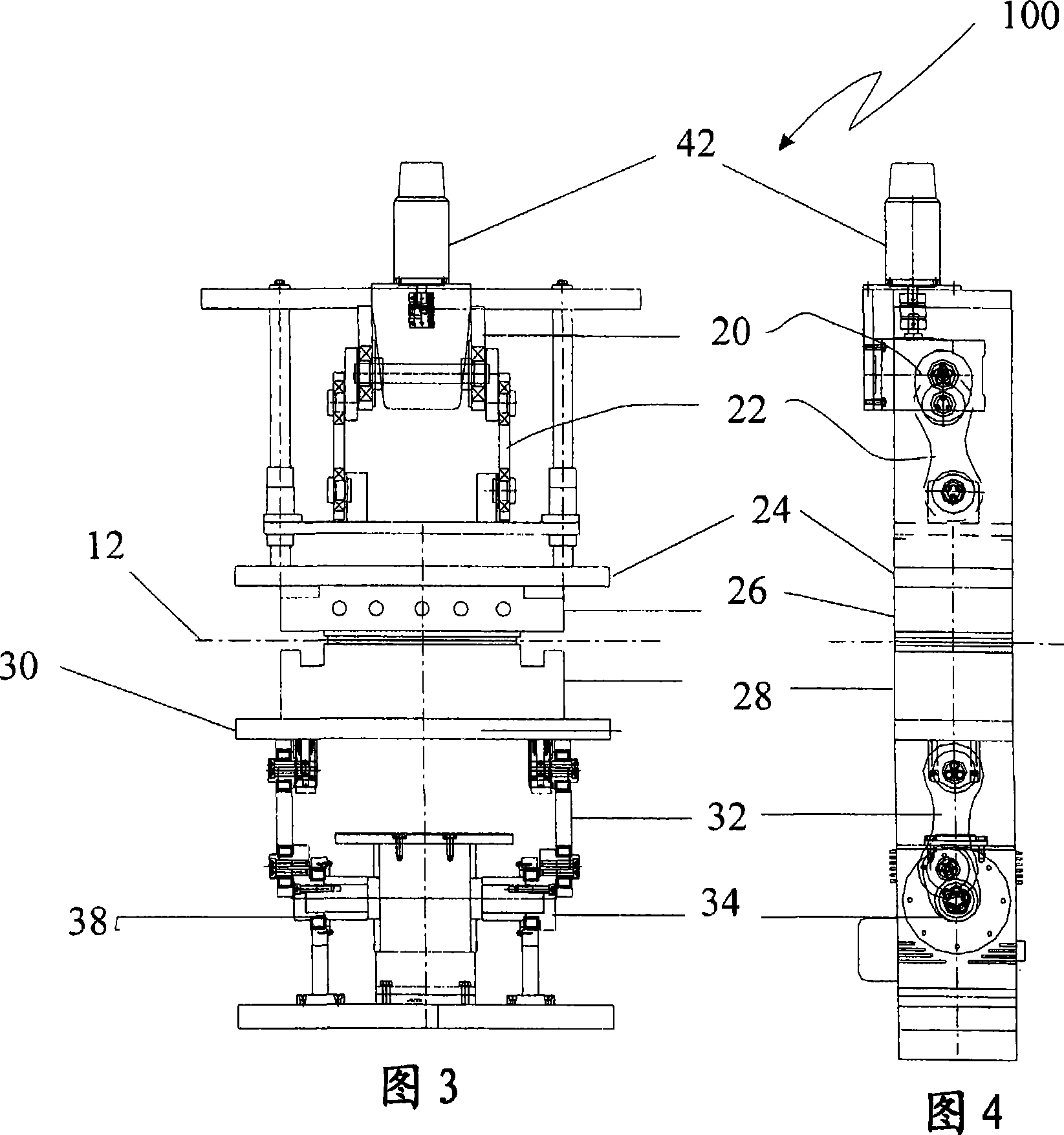

Thermal forming of molded piece

The invention relates to a thermoforming machine which comprises a framework; a first pressure plate and a second pressure plate which are disposed on the framework at an interval; a male mould and a complementary female mould disposed on each pressure plate respectively; an in-mould cutting element with a complementary profile provided in the mould; two drive devices cooperating with each pressure plate and being used for moving the pressure plates to a first movement position for clamping plate material, a second movement position for stretching and forming the plate material, a third movement position for cutting the plate, and a fourth movement position for forming the mould-opening configuration; and a part for ejecting and forming from the mould cavity in the mould-opening configuration and a ejection device of the cut plate. The drive device comprises a prime motor; a spline unit connected to the prime motor; and a link rod positioned between the spline unit and each pressure plate to drive the movement.

Owner:WAND PARKER IND

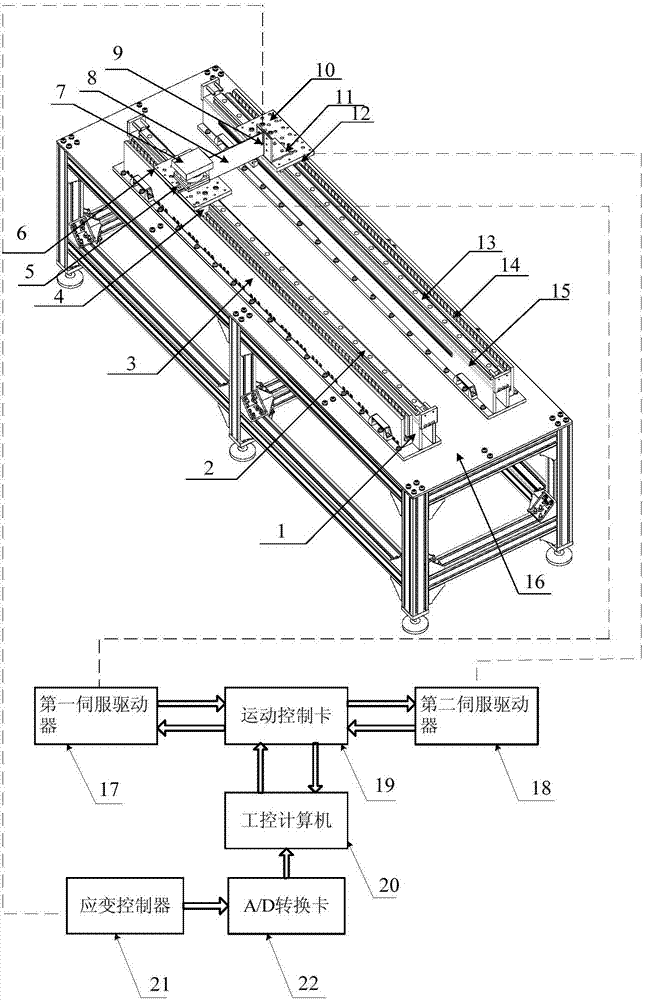

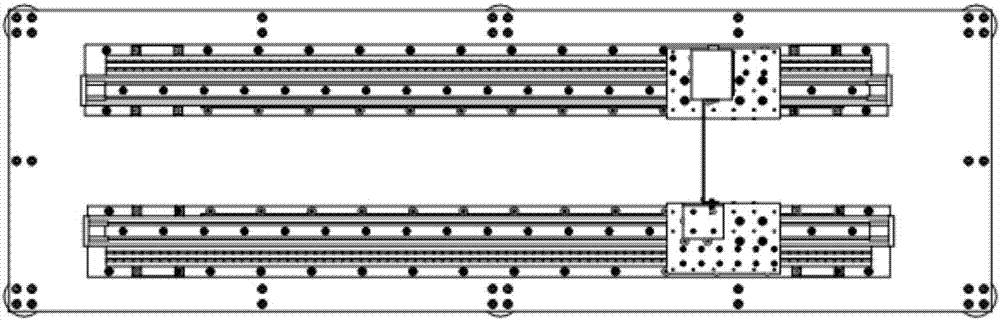

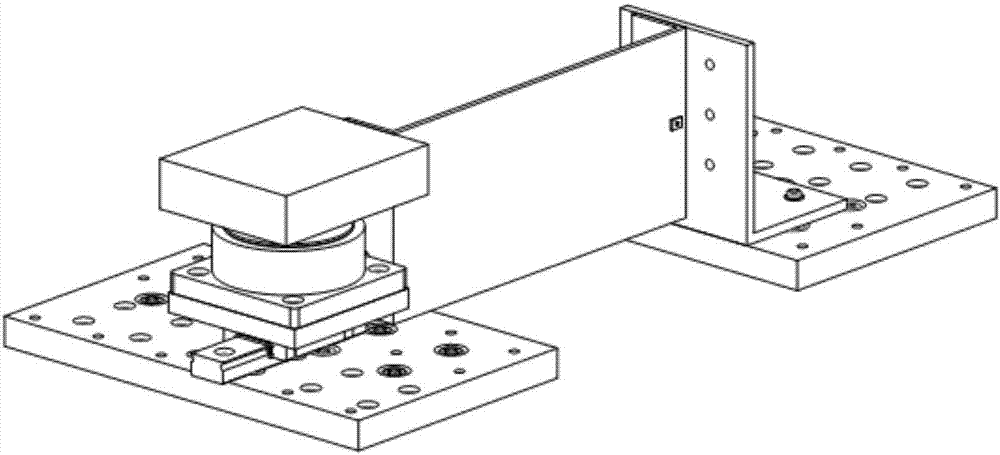

Dual linear motor driven synchronization tracking control device and method

ActiveCN107222144AOvercoming wear and tearOvercome due to gear backlashElectronic commutation motor controlAC motor controlControl engineeringElectric machinery

The invention discloses a dual linear motor driven synchronization tracking control device and method. The device comprises a linear motor drive part, a strain detection part and a drive control part. The linear motor drive part comprises two linear motor drive devices which are completely identical in structure. The two linear motor drive devices are fixed on an experiment table in parallel and respectively comprise a linear motor, a linear guide rail, a slide block and a base. The strain detection part comprises a thin steel plate, a rotating shaft and a strain gauge. The drive control part comprises a servo driver, a motion control card, an industrial control computer, a strain controller and an A / D conversion card. Static and dynamic measurement can be performed by using the strain gauge so as to have the advantages of high sampling frequency and fast response speed, and the synchronization situation between two platforms can be monitored in real time.

Owner:SOUTH CHINA UNIV OF TECH

Fine processing machine tool for foods

The invention discloses a fine processing machine tool for foods. The fine processing machine tool is in direct contact with a mixture of a solvent and an additive for a mixture of a food material, isopropyl acetate and isobutyl acetate and is made of stainless steel which is 0Cr18Ni12Mo2Ti, wherein the content of C is less than or equal to 0.08%, the content of Cr is 16-19%, the content of Ni is 11-14%, the content of Mo is 1.80-2.50%, and the content of Ti is 5 times as much as that of C and is less than or equal to 0.7%. The machine tool is suitable for finely machining the food material and is favorable in wear resistance, convenient to clean and capable of avoiding polluting food raw materials.

Owner:常熟市新洲机械制造厂

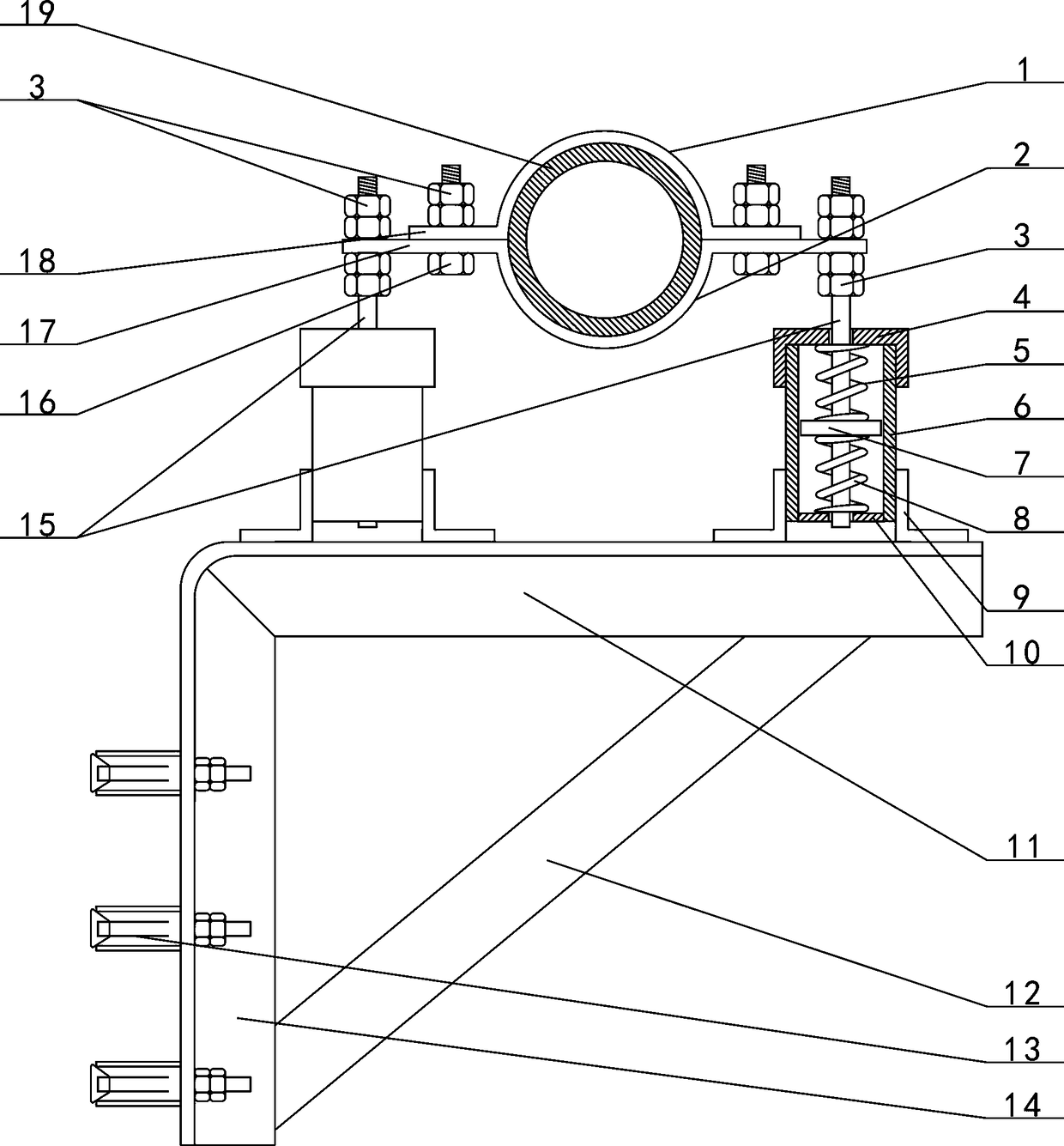

Wall damping device for ethylene glycol antimony raw material conveying pipeline

InactiveCN108386618AReduce wearOvercoming wear and tearPipe supportsNon-rotating vibration suppressionMechanical engineeringEthylene glycol

The invention discloses a wall damping device for an ethylene glycol antimony raw material conveying pipeline, and relates to a damping support for a pipeline. A tripod is fixed on a wall body throughan expansion bolt (13), the two sides of the upper part surface of a tripod cross beam (11) are provided with cylinder bodies (6) correspondingly, partition plates (7) are arranged on the lower partouter edges of two damping rods (15), the partition plate of each damping rod is arranged in the middle in each of the two cylinder bodies correspondingly, the upper ends and the lower ends of lower springs (8) sleeving the lower parts of the damping rod partition plates are abutted against the bottom plates of the partition plates and the bottom plates of the cylinder bodies (10), the upper endsand the lower ends of upper springs (5) sleeving the upper parts of the damping rod partition plates are abutted against upper covers (4) at the upper ends of the cylinder bodies and the partition plates correspondingly, the upper ends of the two damping rods are connected with the outer ends of two long side plates (17) of a hoop correspondingly, and the hoop is used for fixing a pipeline (19). According to the device, the partition plates clamped by the upper springs and the lower springs are used for forming a flexible support, the flexible support for the pipeline is obtained, and the abrasion of the pipeline is effectively reduced.

Owner:平湖市超越时空图文设计有限公司

Automatic pouring gate separation device

Owner:GERRESHEIMER MEDIAL PLASTIC SYST DONGGUAN CO LTD

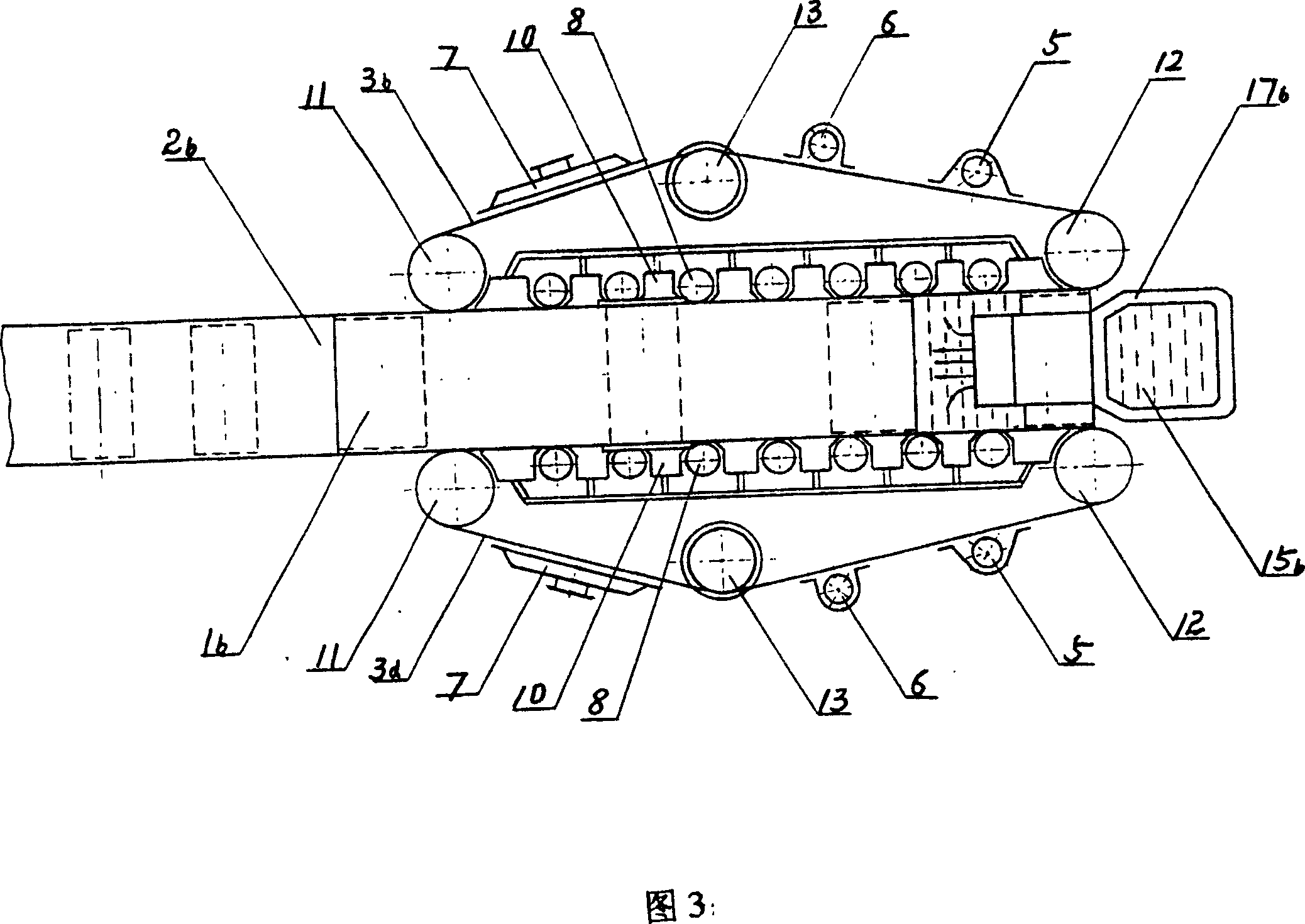

Continuous casting machine for stainless compound steel plate strip blank

The invention relates to a stainless steel clad plate billet conticaster. It belongs to a continuous casting device in the art of metallurgical industry. The device can be characterized in that: it comprises three synchronous circulating mobile steel band crystallizers A, B and C, which are Y- type equipped, the lower cooling steel band 2 of crystallizer A being common with the right-side cooling steel 2c of the crystallizer C, and the lower cooling steel band 2b of crystallizer B being common with the left-side cooling steel 2d of the crystallizer C. After the strand being forged by from multigroup flexible guiders, multigroup steam- water spray devices and traction roller which are under the crystallizer C, the clad plate billet is aligned to horizontality by a blending guider and a smoothing roll, and then is sent to shearer to be sheared into a definite length or sent to continuous rolling mill to roll down. The merit is characterized in that: it improves the production efficiency of the conticaster, and guarantees the quality of strand and rolled metal.

Owner:李铁铎

Sealing ring used for tieback plug

ActiveCN103016731AOvercoming wear and tearOvercoming Extrusion DamageEngine sealsEngineeringMechanical engineering

Owner:TIANJIN ANTON PETROLEUM MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com