Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

342 results about "Cloth filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Developed for use in Bangladesh, the cloth filter is a simple and cost-effective appropriate technology method for reducing the contamination of drinking water. Water collected in this way has a greatly reduced pathogen count - though it will not necessarily be perfectly safe, it is an improvement for poor people with limited options. Filtering water to free it from micro-organisms has been an age-old practice among Jains who carefully remove the micro-organisms in the cloth through filtered water in order to follow doctrine of Ahimsa or non-violence, preventing pain to any living creature.

Methods and apparatus for treating water and wastewater employing a cloth disk filter

ActiveUS20120091065A1Eliminate needEliminateSedimentation separationMembrane filtersCloth filterSuspended solids

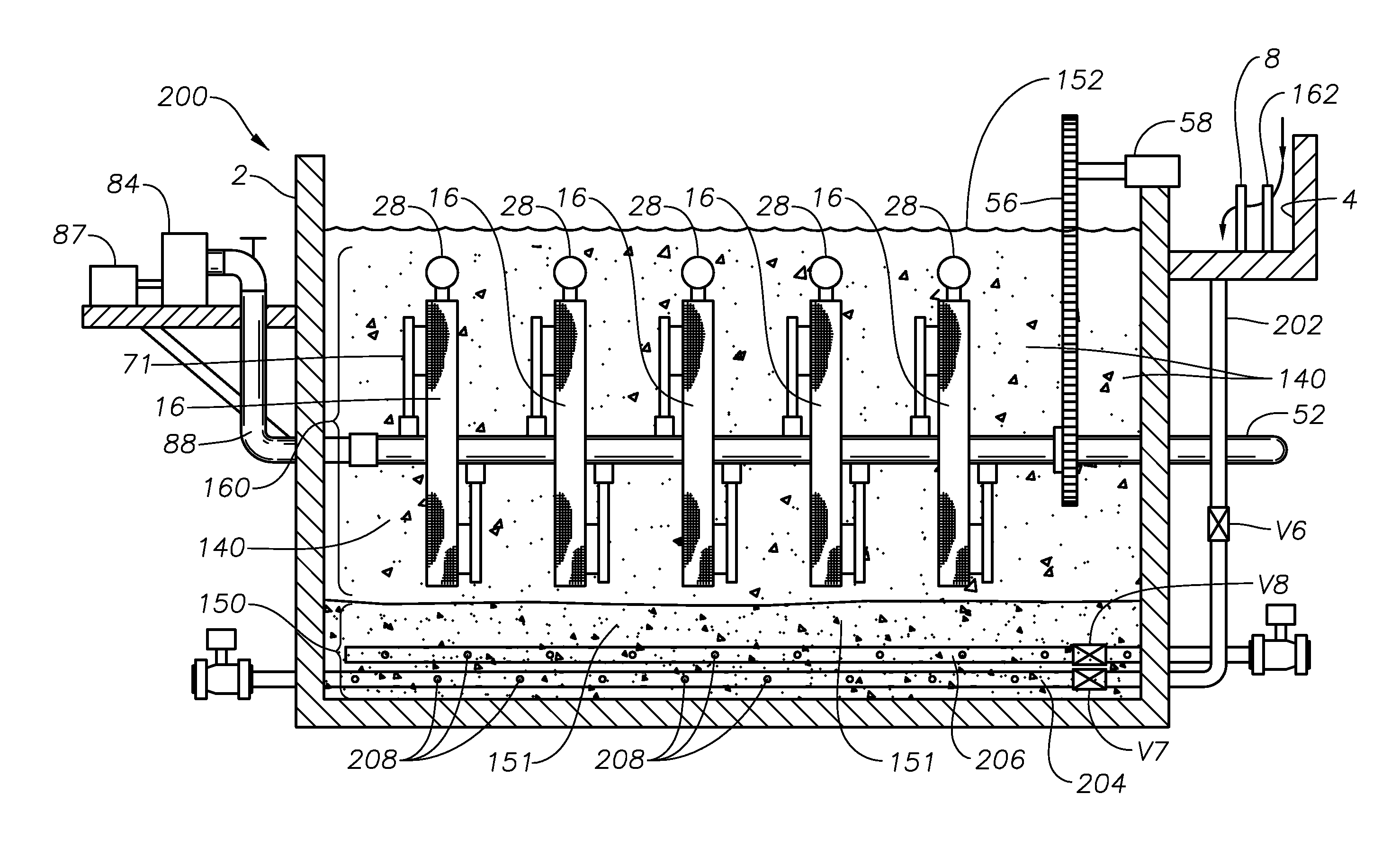

Methods and apparatus for treating water and wastewater include the step of flowing a suspended solids stream generally upward through a sludge blanket region of a cloth disk filter vessel, thus forming a partially treated effluent composition and a solids-enriched sludge blanket. The partially treated effluent composition is allowed to flow generally upward to a cloth filter zone in the vessel after contacting the sludge blanket. The methods include flowing the suspended solids stream through one or more distribution headers positioned in the sludge blanket. An option is to provide a sludge concentration zone in the sludge blanket region, allowing sludge to flow into the sludge concentration zone to form concentrated sludge. Other methods and apparatus include backwash assemblies that backwash substantially the entire filter cassette surfaces, with or without use of a sludge blanket zone. Either the backwash assemblies or filter cassettes move in the latter methods and apparatus.

Owner:ALFA LAVAL ASHBROOK SIMON HARTELY INC

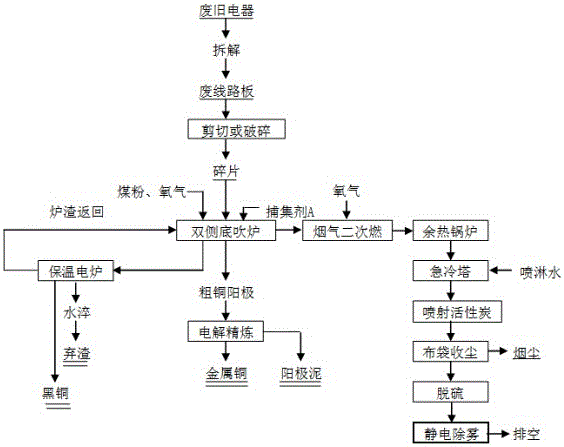

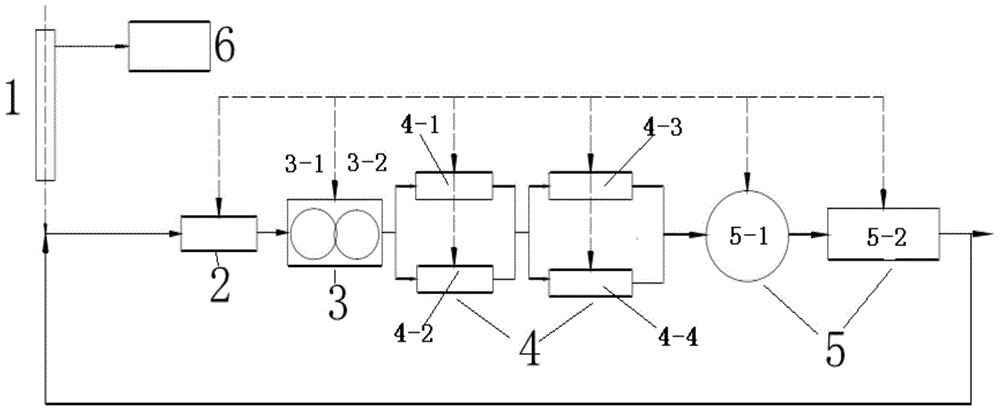

Complete equipment and method for extracting and purifying precious metals from waste circuit boards

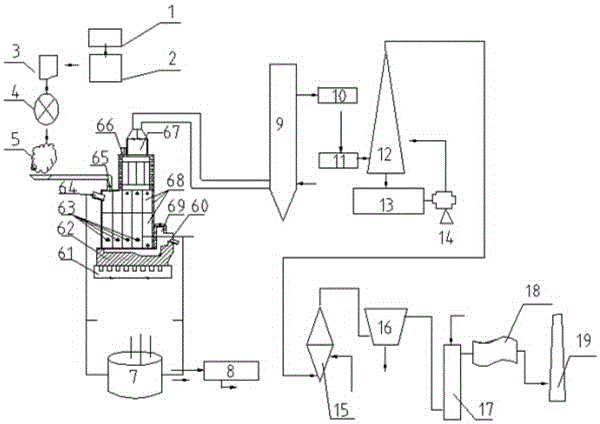

ActiveCN106086415AComponent adaptabilitySimple preparationProcess efficiency improvementPrinted circuit boardQuenching

The invention discloses complete equipment and a method for extracting and purifying precious metals from waste circuit boards. The complete equipment comprises a bottom-blowing furnace, a secondary smoke combustion furnace, an absorption tower, a pulsed jet cloth filter, a wet desulfurization device and an electrostatic precipitation defogging device, and is characterized in that smoke generated by the bottom-blowing furnace is discharged through a flue arranged on the top of the bottom-blowing furnace; the flue communicates with an inlet of the secondary smoke combustion furnace; the secondary smoke combustion furnace communicates with a spraying quenching tower through a smoke waste heat boiler; an outlet of the spraying quenching tower communicates with the pulsed jet cloth filter through the absorption tower; an activated carbon spraying device is arranged inside the absorption tower; the pulsed jet cloth filter communicates with the wet desulfurization device; and the wet desulfurization device communicated with a chimney through the electrostatic precipitation defogging device. Effective separation and respective enrichment and recycle of various metals are achieved, organic substances are used as fuel, and no secondary pollution is generated for the environment. The process procedure is short, and the remarkable economic, environment-friendly and social benefits are achieved.

Owner:江西自立环保科技有限公司

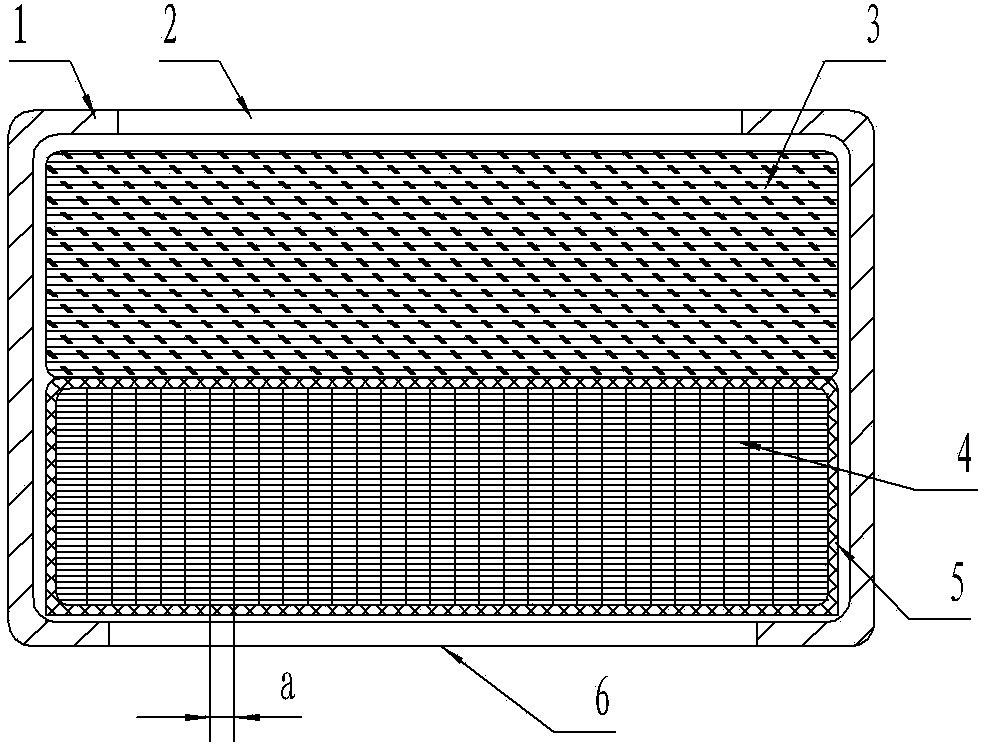

Automotive air-conditioning filter

InactiveCN104043298AEfficient removalEliminate odorDispersed particle filtrationAutomobile air conditioningEngineering

The invention discloses an automotive air-conditioning filter, relating to the technical field of manufacturing of automotive parts. The automotive air-conditioning filter comprises a shell, wherein an air inlet is formed in the top of the shell, an air outlet is formed in the bottom of the shell, a filament non-woven filter cloth filter element is arranged in the shell and is formed by laminating multiple layers of filament non-woven filter cloth, a layer of active carbon filter element is arranged under the filament non-woven filter cloth filter element in the shell and comprises active carbon packaged by non-woven fabrics. Compared with the prior art, the automotive air-conditioning filter has the advantages that the problems that a current automotive air-conditioning filter cannot be used for effectively filtering harmful gas and is poor in filtering effect are solved.

Owner:柳州市够旺贸易有限公司

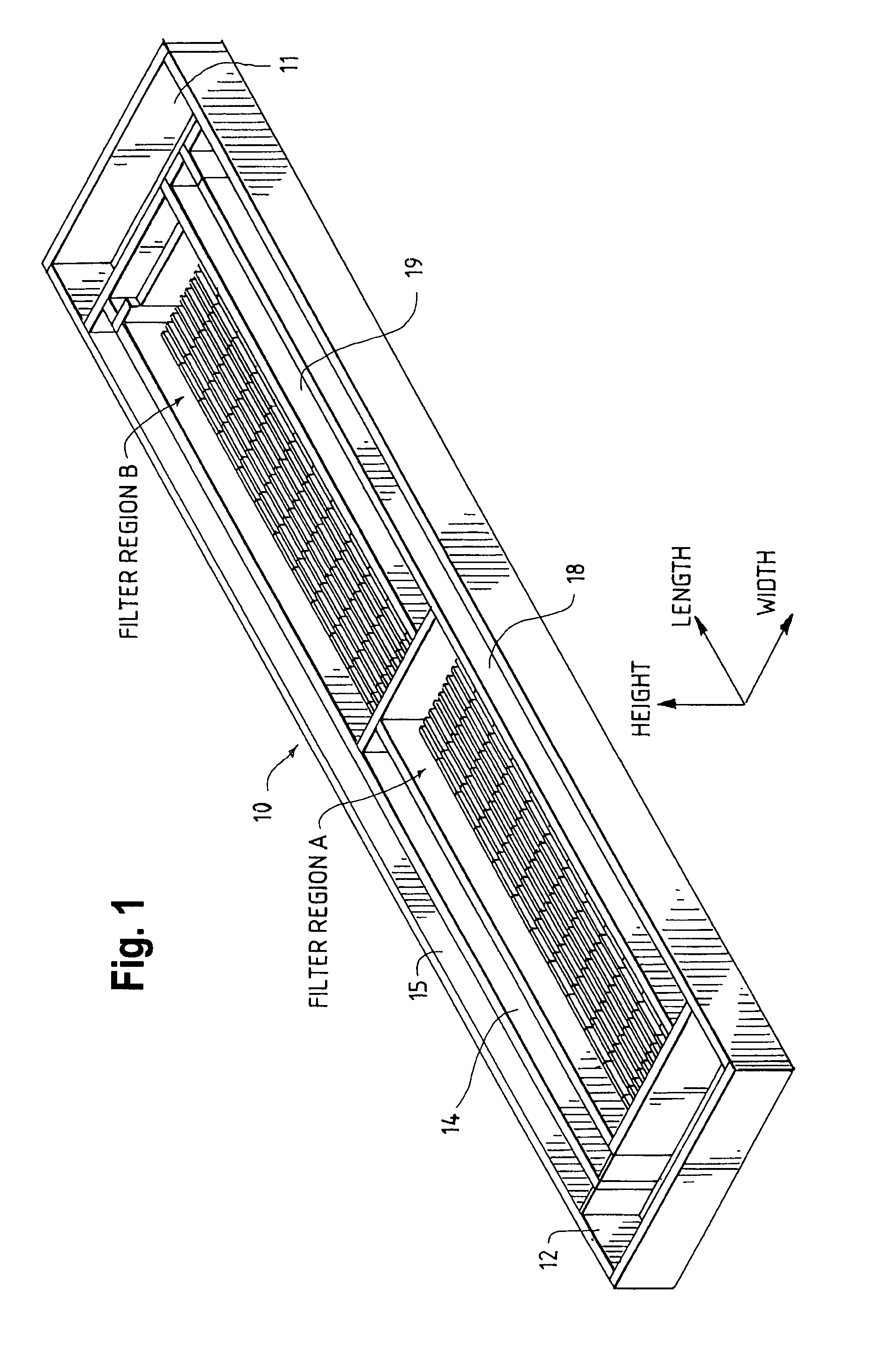

Methods and apparatus for treating water and wastewater employing a cloth disk filter

ActiveUS20130105415A1Reduce and overcome deficiencyImprove backwash efficiencyWater/sewage treatmentMembrane filtersWastewaterEngineering

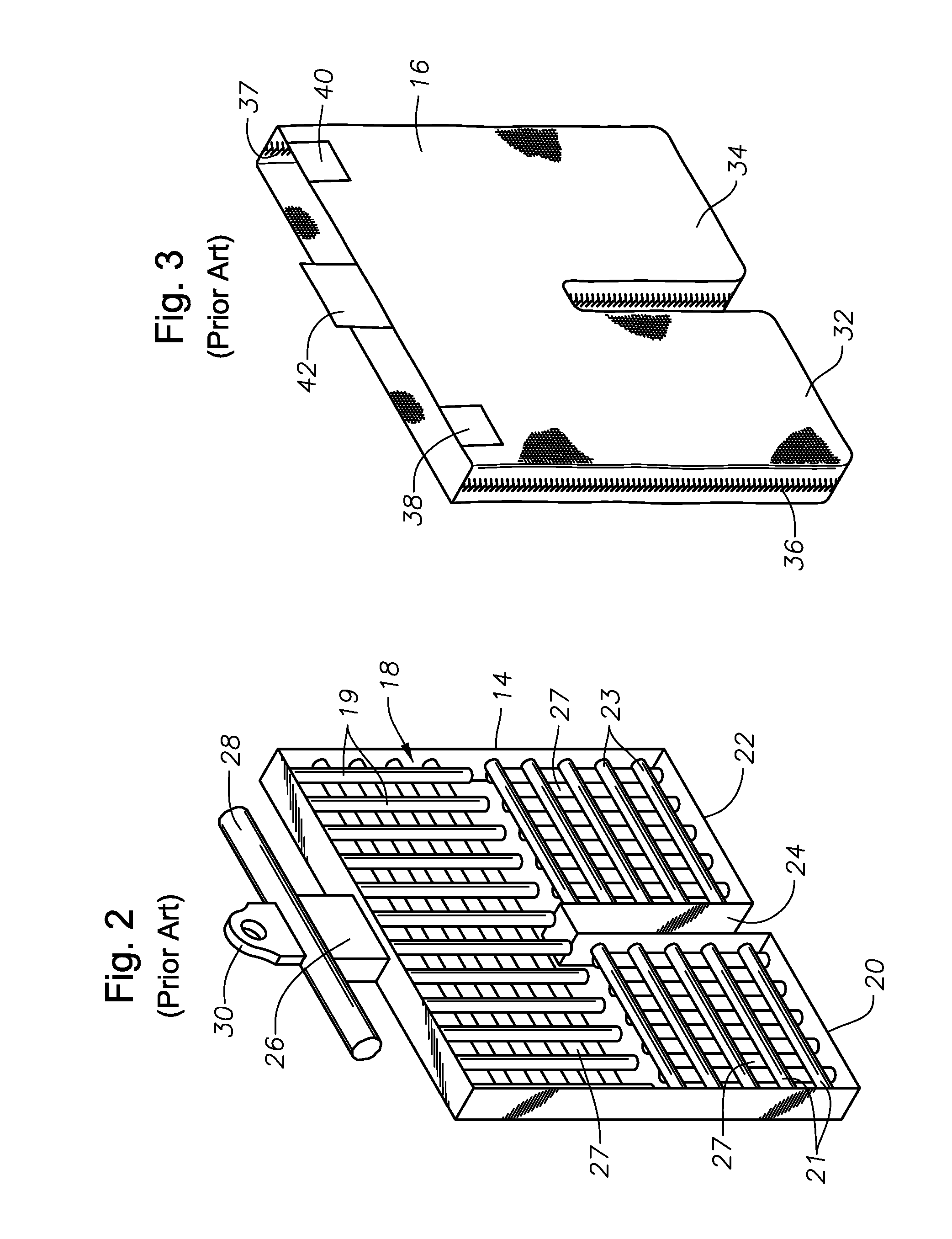

A backwash header for a cloth filter disk includes a body having a length a diameter, first and second ends, a longitudinal axis, and an exterior surface, the body defining at least one internal cavity. The body includes at least one suction slot configured to allow fluids and solids to enter the internal cavity from outside of the exterior surface. A structure is attached to a portion of the exterior surface of the body around and extending away from the suction slot to form a chamber defined by the structure and a portion of the exterior surface near the suction slot. The structure is configured to allow fluids and solids to enter the chamber and then the suction slot and cavity from a material being cleaned. Cloth disk filters and methods of treating water and wastewater using the backwash headers and cloth disk filters.

Owner:ALFA LAVAL CORP AB

Methods and apparatus for treating water and wastewater employing a cloth disk filter

ActiveUS8852445B2Reduce and overcome deficiencyImprove backwash efficiencyWater/sewage treatmentMembrane filtersWastewaterEngineering

A backwash header for a cloth filter disk includes a body having a length a diameter, first and second ends, a longitudinal axis, and an exterior surface, the body defining at least one internal cavity. The body includes at least one suction slot configured to allow fluids and solids to enter the internal cavity from outside of the exterior surface. A structure is attached to a portion of the exterior surface of the body around and extending away from the suction slot to form a chamber defined by the structure and a portion of the exterior surface near the suction slot. The structure is configured to allow fluids and solids to enter the chamber and then the suction slot and cavity from a material being cleaned. Cloth disk filters and methods of treating water and wastewater using the backwash headers and cloth disk filters.

Owner:ALFA LAVAL CORP AB

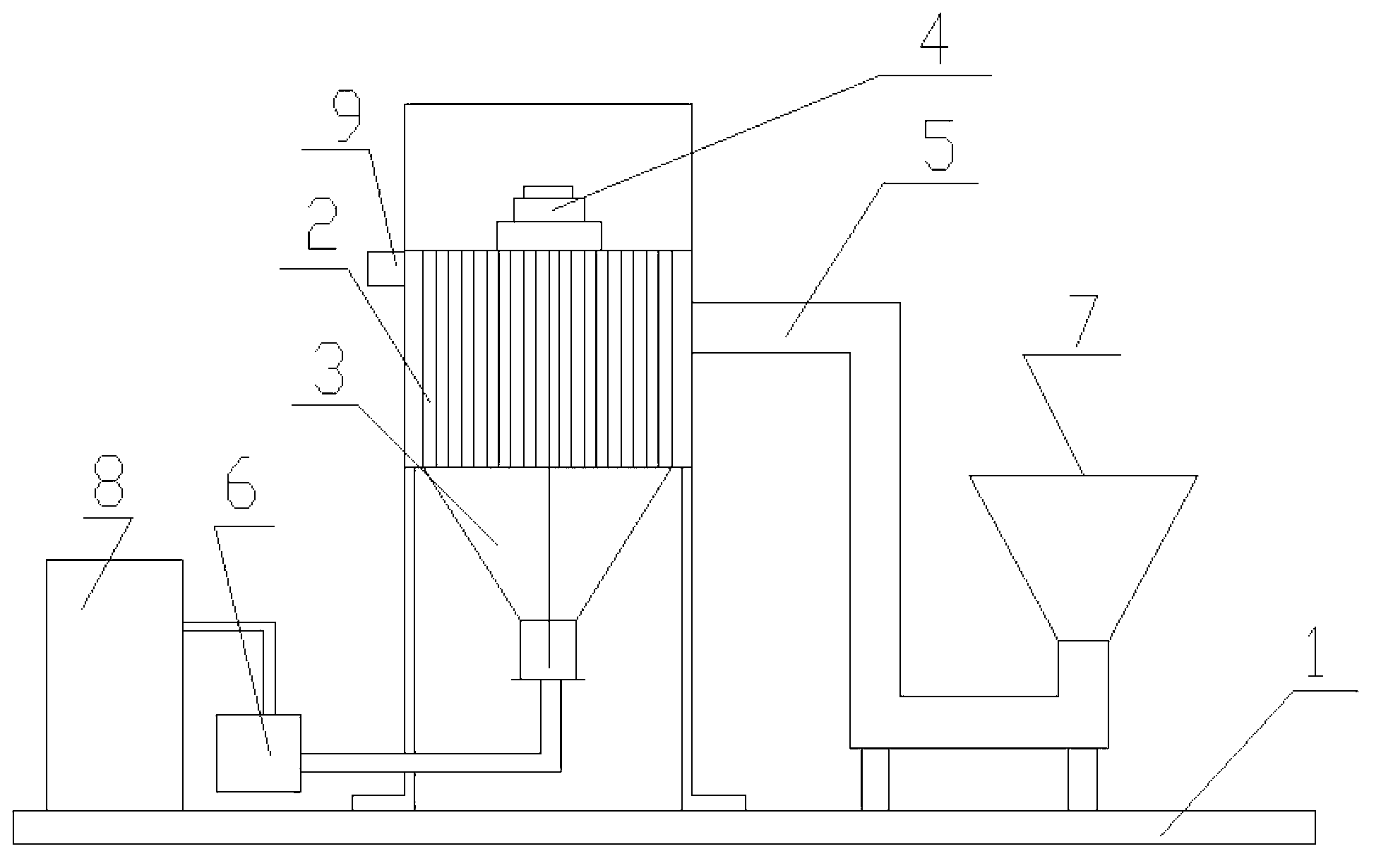

Environment friendly system for smelting copper and copper alloy

The invention belongs to the copper alloy processing field. Aiming at that a larger space is provided between a smelting furnace and a dust cover separated with each other in the prior art, when using partial scrap copper and even the entire scrap copper to smelt copper or copper alloy, the pollution is serious and the useful materials in the dust are wasted, an environmental protection system of copper and copper alloy smelting of the invention is adopted. The useful materials in the dust are recovered, the working environment of smelting is greatly improved and the waste gas exhausted by smelting is superior to the current national industrial waste gas emission standard. The system consists of a smelting furnace (1), a lower gate of the dust cover (2), an upper gate of the dust cover (3), a dust cover (4), a dust collector cyclone (10), a powder collecting box (11), a pipeline (5), a pulsed jet cloth filter (6), a dust box (9), an induced draft fan (8), a vent pipe (7), a slag drop channel (12), a slag connecting box (13) and an operations area (14). The system is also suitable for the environmental protection systems of other nonferrous metal and ferrous metal smelting.

Owner:JINTIAN COPPER GROUP CORP NINGBO +1

Fillet feeding diaphragm filter plate assembly constituted by flat membrane and filter board

InactiveCN101385913AFully filteredImprove cleaning rateFiltration separationBiochemical engineeringSlurry

The invention relates to a corner membrane filter plate assembly which comprises the flat membrane filter plate and the filter cloth filter plate. Both the flat membrane filter plate and the filter cloth filter plate are single-corner feeding through holes and are arranged in cross banding. The corner membrane filter plate assembly has the advantages that: 1. portholes have self-cleaning function, thus being capable of keeping the portholes smooth without obstacles; 2. rapid filter of slurry is realized; 3. a filter cake can be convenient to be washed either in a forward direction or a reverse direction, therefore, the filtering ratio of effective components in filtered slurry is greatly increased, and a feeding pump and a washing pump can share a pump; 4. by adjusting the thickness of a core board, the requirements for the thickness of the filter cake from different materials can be met; 5. a supporting lug boss can be arranged on the membrane filter plate or no supporting lug boss is arranged on the membrane filter plate; 6. no filter cloth is installed on the flat membrane filter plate.

Owner:HANGZHOU XINGYUAN FILTER TECH

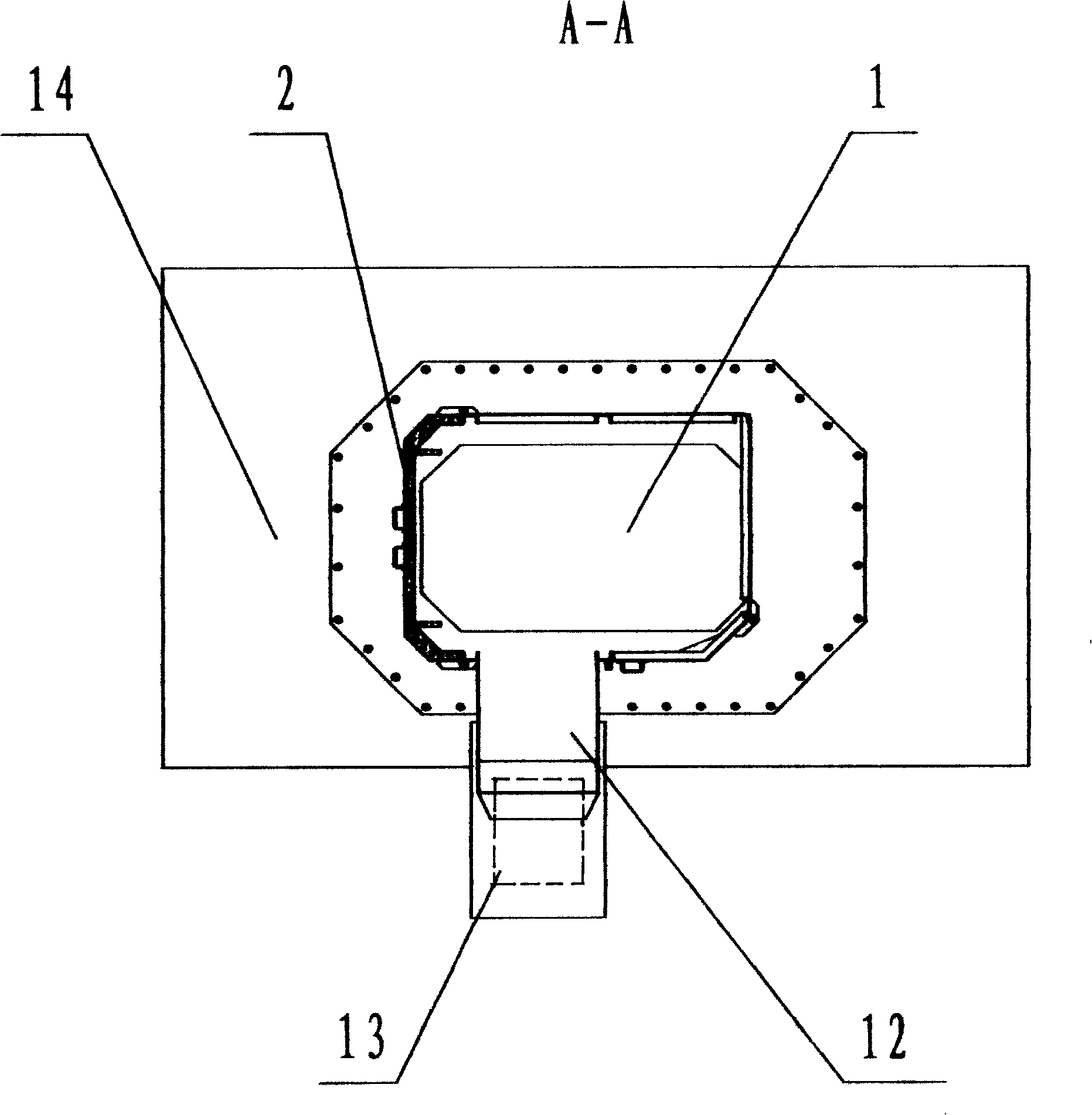

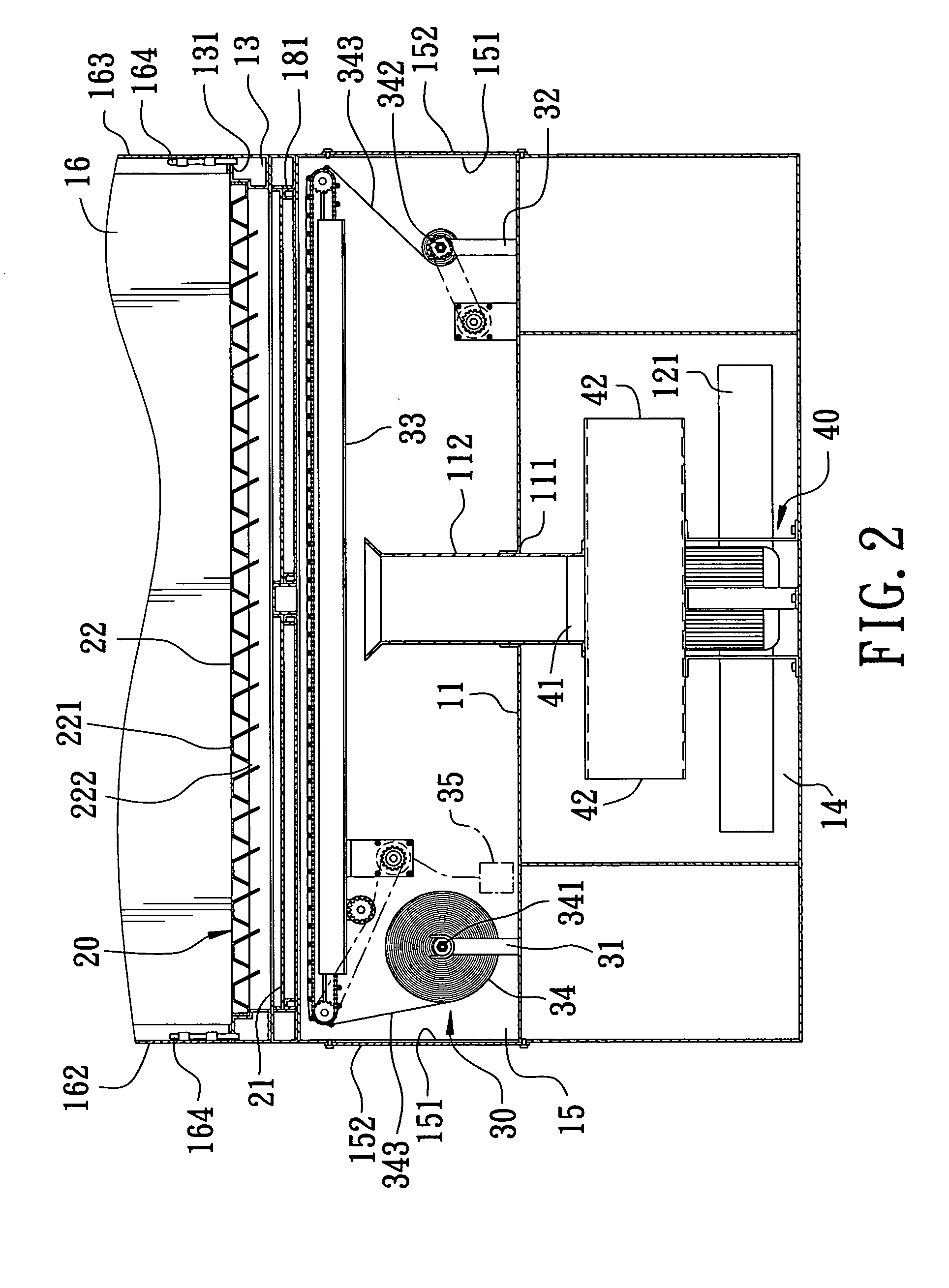

Dust collecting table

InactiveUS20080098896A1Easy to pourDispersed particle filtrationTransportation and packagingFiltrationMechanical engineering

A dust collecting table includes a box divided into a first chamber, a second chamber, a third chamber and a fourth chamber, a spark blocker installed in an upper portion of the second chamber, a movable cloth filter device installed in a lower portion of the second chamber, a blower set in the first chamber, and at least a screening device. As the blower is switched on, air is to be sucked from air inlet gates of the spark blocker to pass through the movable cloth filter device, the blower and the screening device orderly into the atmosphere, blocking sparks completely and achieving an effective filtration.

Owner:CHENG YUAN TAI

Backwash assembly and method having a rotating backwash arm for cleaning cloth filter media

ActiveUS7807050B2Reduce necessityReduce wearWater/sewage treatmentMembrane filtersFiltrationEngineering

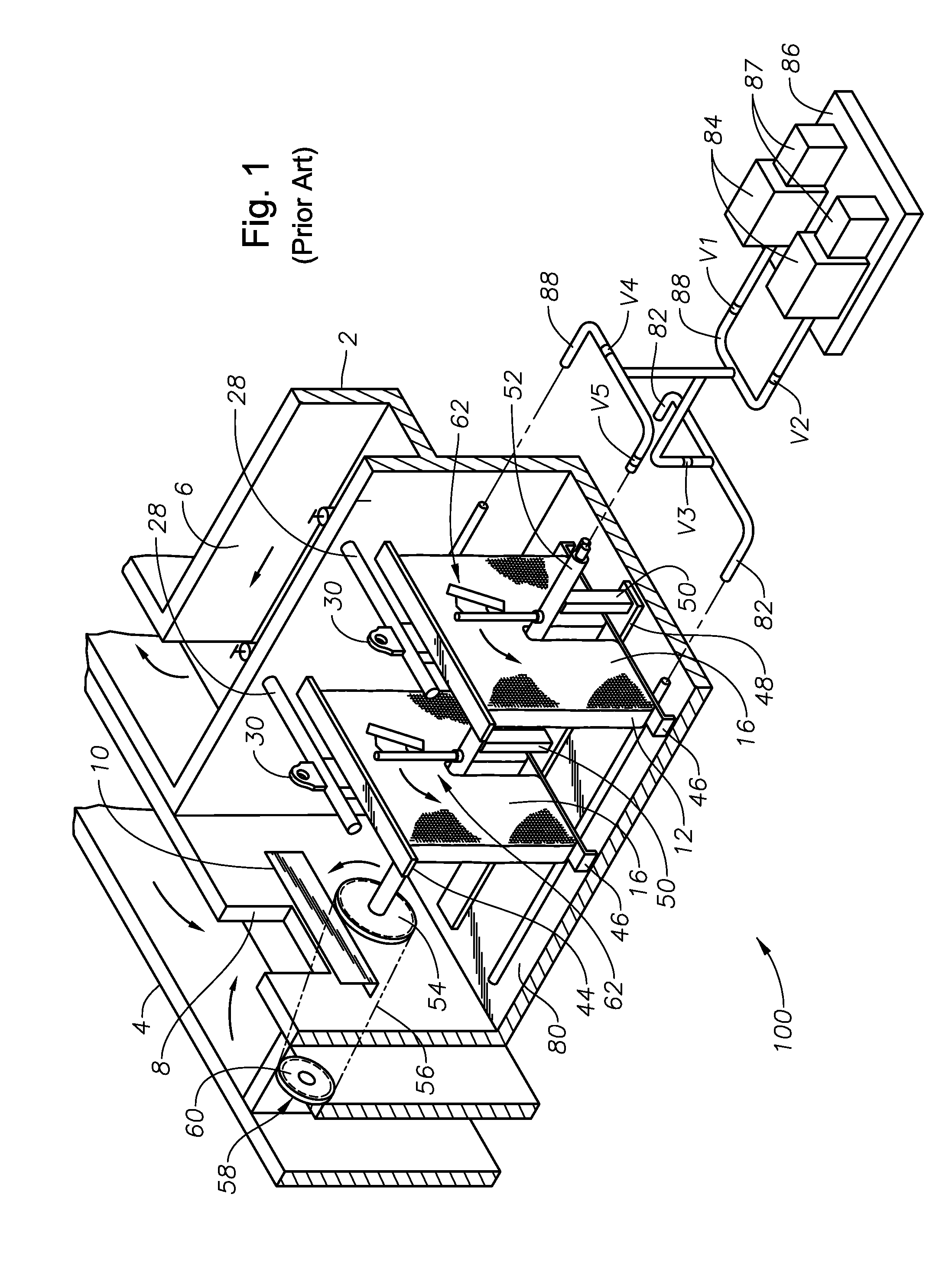

The present invention relates to stationary cloth media filtration systems and devices, as well as processes and devices, including improved cloth media filter backwashing using a rotating backwash arm assembly.

Owner:AQUA AEROBIC SYST

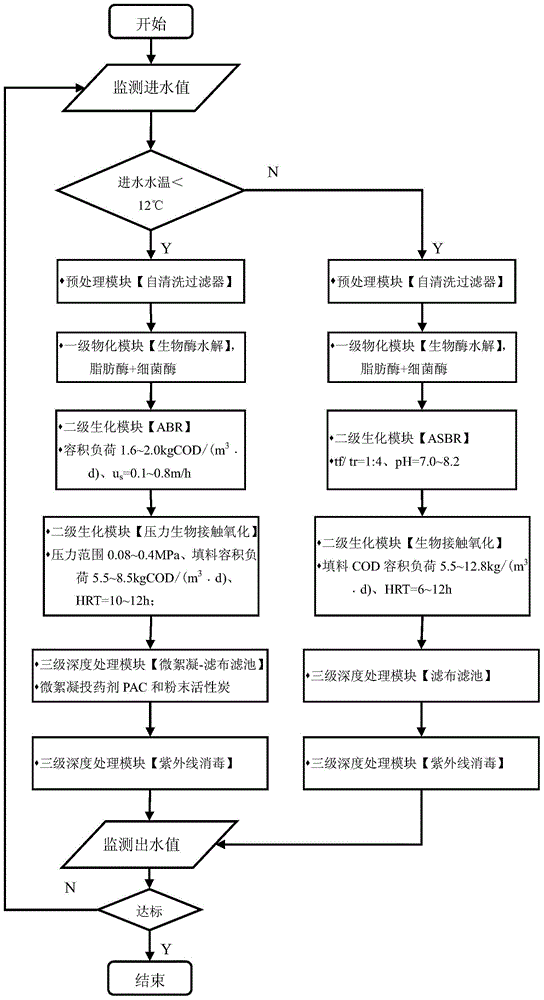

Modularized integrated system and method applicable to treatment of low-temperature livestock and poultry slaughtering waste water in north

ActiveCN104961292AEasy to handleHigh degree of modularityMultistage water/sewage treatmentFlocculationUv disinfection

The invention especially relates to a modularized integrated system and method applicable to treatment of low-temperature livestock and poultry slaughtering waste water in the north, belonging to the technical field of water treatment. The modularized integrated system comprises the following concrete modules: a pre-treating module used for intercepting large pollutants in the livestock and poultry waste water, a primary physicochemical module used for adjusting and biological hydrolysis, a secondary biochemical module and a tertiary in-depth treating module, wherein the secondary biochemical module comprises an anaerobic submodule and an aerobic submodule which are in series connection, and the tertiary in-depth treating module comprises a micro-flocculation submodule, a cloth filter and an ultraviolet disinfection submodule.

Owner:中工能源环保技术(南京)有限公司

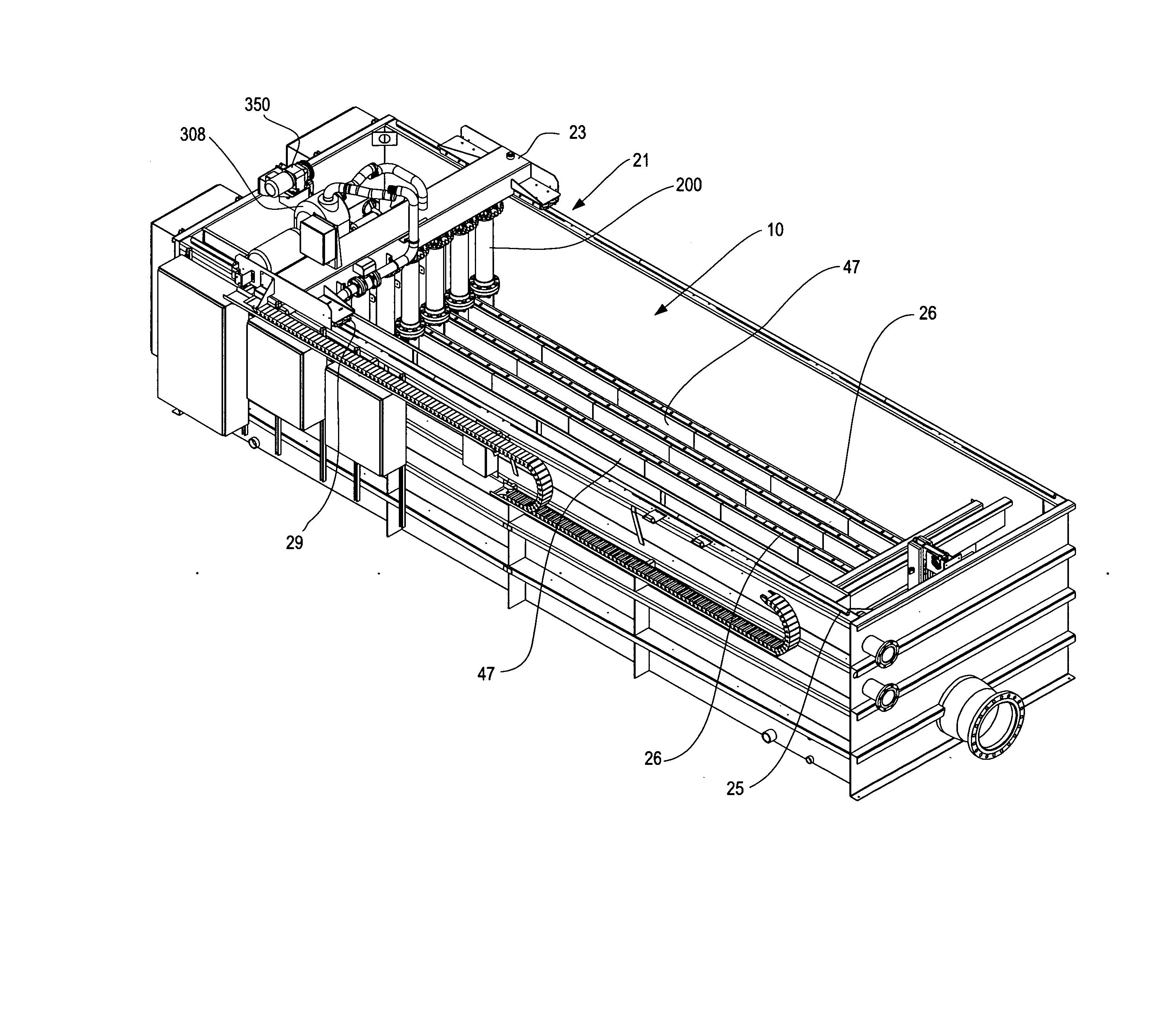

Backwash assembly and method having a rotating backwash arm for cleaning cloth filter media

InactiveUS7833424B1Continuous filtrationQuality improvementWater/sewage treatmentMembrane filtersWaste managementCloth filter

The present invention relates to a method for cleaning cloth filter media supported on a plurality of opposingly-spaced filter plate frames. A backwash assembly (23) moves linearly and includes at least one cylindrical backwash arm (200) that rotates to consecutively clean the media of the spaced filter plate frames.

Owner:AQUA AEROBIC SYST

Quick molding dustproof perforating machine

InactiveCN109773233AEasy to punchHigh precisionMaintainance and safety accessoriesBoring/drilling machinesGlass fiberActivated carbon filtration

The invention discloses a quick molding dustproof perforating machine. The machine comprises a worktable; the bottom of the worktable is fixedly connected with a base; a first support column is fixedly connected to the top of the worktable near the left side; a second support column is fixedly connected to the top of the worktable near the right side; a placing plate is fixedly mounted at the topof the worktable near the center; and a drilling groove is formed in the top of the placing plate near the center. In the quick molding dustproof perforating machine, through cooperative use of an airblower, a nozzle, an induced draft fan, a dust sucking head, a filter water tank, a magnet, a precipitation box, a non-woven cloth filter layer, an active carbon filter layer, a glass fiber filter layer, the placing plate, the drilling groove, a limiting block, a fixed clamping plate and a fixed bolt, when workpieces are perforated by the perforating machine, dust and metal chips can be effectively blown to one side of the dust sucking head, so that the induced draft fan conveniently sucks the dust and the metal chips for treatment to improve the dust preventing and removing effects.

Owner:惠州市丰瑞印刷科技有限公司

Preparation method of nano fiber-needling PTFE base cloth filter material

InactiveCN106149206AImprove filtration efficiencyBlock effectFibre typesElectro-spinningGlass fiberElectrospinning

The invention relates to a preparation method of a nano fiber-needling PTFE base cloth filter material, and belongs to the technical field of electrospinning. The preparation method comprises the following steps: step 1, PTFE base cloth pretreatment; step 2, electrospinning; step 3, superfine nano fiber dispersion liquid preparation; and step 4, composite filter material soaking treatment. In the technical scheme provided by the invention, the PTFE base cloth is prepared by mixing PTFE fibers and PPS fibers, so, compared with the traditional glass fiber mat, the flexibility is better, and the spinnability and durability of the fiber material are relatively greatly improved; the service life is prolonged to 1-2 years compared with eight months of the common glass fiber mat base cloth; and the market prospect is wide.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Discharging and dedusting device on bunker

InactiveCN103230714AImprove work efficiencyImprove filtration efficiencyDispersed particle filtrationBaghouseWorking environment

The invention discloses a discharging and dedusting device on bunker, which comprises a movable unloading trailer and a supporting platform, and the supporting platform is arranged with a cloth bag deduster, a flue-dust retainer, a sound wave ash removing device, a dedusting pipeline and a centrifugal blower fan; the flue-dust retainer is arranged below the cloth bag deduster, and the sound wave ash removing device is arranged above the cloth bag deduster, and the centrifugal blower fan and the flue-dust retainer are communicated, and one end of the dedusting pipeline is provided with an ash suction port which is communicated with an ash outlet of the movable unloading trailer, and the other end of the dedusting pipeline is communicated with the upper part of the cloth bag deduster. When discharging, primary air containing dust enters into a deduster casing from an air inlet of the cloth bag deduster, and an outer filter cloth filters the dust in the primary air containing dust, and the dust adheres to the cloth bag; when the set value is reached, the sound wave ash removing device starts for vibrating and beating the dust which is adhered to the cloth bag, and dust drops into the flue-dust retainer, and is sent to an electric ash discharging and storing apparatus by the centrifugal blower fan for carrying away. The equipment has the advantages of high work efficiency, good filtering efficiency, improved work environment, thereby realizing energy saving and emission reduction without secondary pollution.

Owner:安徽华龙环保技术工程有限公司

Harmless processing system and process for copper powder containing organism and glass fiber

InactiveCN101008050AImprove puritySolve the glass fiber inclusions in hard-to-melt copper powderSolid waste disposalProcess efficiency improvementCooling towerDecomposition

The invention relates to an innocent treatment system for copper powder containing organic matter and fiber glass and the treating process. Said system can not only recover valuable copper, but also can treat organic waste innocently. It is characterized by rational allocation, high purity of recovered copper powder, and thorough treatment of waste material and water gas. The innocent treatment system is characterized in that it is connected by electrode smelter, rotary retort, decomposition combustion tower, cooling tower, waste gas treating tower and jet cloth filter through conduit pipe. The invention can recover copper powder from waste wiring board, covering brass plate and other copper- containing rim leftover and can treat left waste material innocently.

Owner:王威平

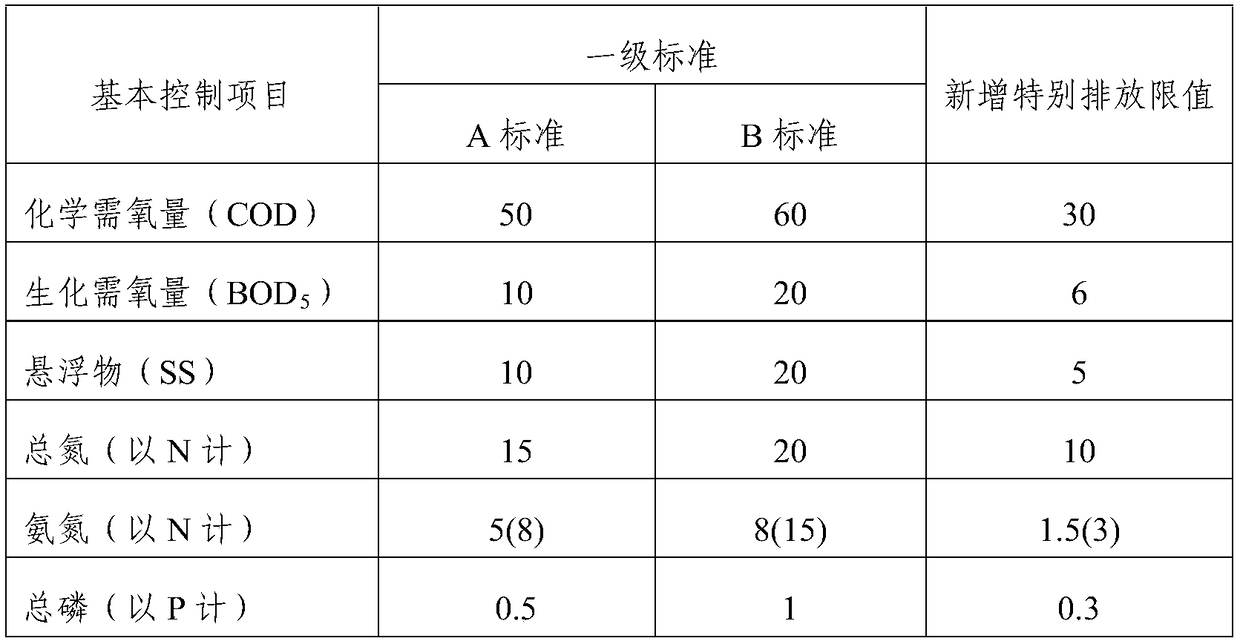

Urban sewage treatment process applicable to quasi-IV class water standard

InactiveCN109133531ASolve the dispute of different mud agesReduce outputSpecific water treatment objectivesTreatment involving filtrationTotal nitrogenLarge particle

The invention provides an urban sewage treatment process applicable to a quasi-IV class water standard. The invention relates to the field of urban sewage treatment, and discloses the sewage treatmentprocess which meets requirements of quasi-IV class water. The sewage treatment process comprises the following steps: urban sewage is treated through primary treatment (mainly through processing units such as coarse and fine grids, a grit chamber, a regulating tank and the like) so that garbage of relatively large particle size, floating matter, suspended solid, sandstone and the like in the sewage can be removed; effluent after the primary treatment enters a multi-stage AO composite IFAS biochemical system to remove most of the organic matter, total nitrogen, total phosphorus and other pollutants; the effluent from IFAS enters a A2O tank, and the effluent from the A2O tank enters a secondary settling tank for solid-liquid separation; supernatant liquid discharged from the secondary settling tank enters a high-speed settling tank, and a phosphorus removal agent and a coagulant are added for reaction and precipitation; the effluent from the high-speed settling tank enters a high-precision filter cloth filter tank, and the sewage is filtered to remove SS; and the effluent enters a disinfection tank for disinfection treatment and is discharged after reaching the quasi-IV class waterstandard.

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

Backwash assembly and method having a rotating backwash arm for cleaning cloth filter media

ActiveUS20080011666A1Continuous filtrationQuality improvementWater/sewage treatmentMembrane filtersFiltrationMechanical engineering

The present invention relates to stationary cloth media filtration systems and devices, as well as processes and devices, including improved cloth media filter backwashing using a rotating backwash arm assembly.

Owner:AQUA AEROBIC SYST

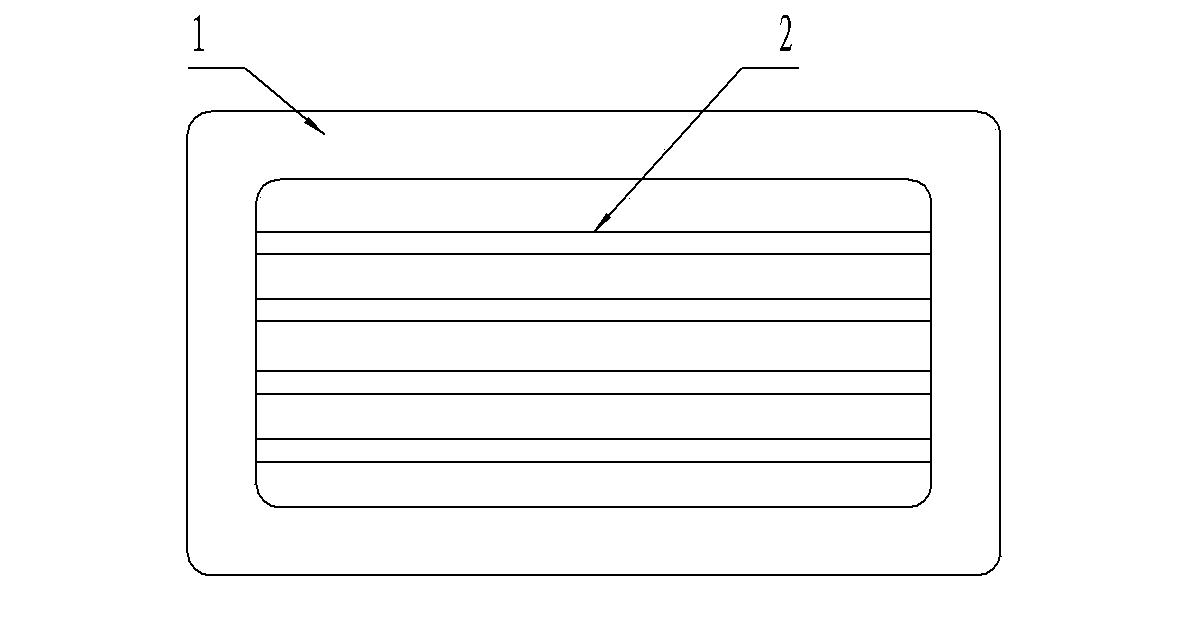

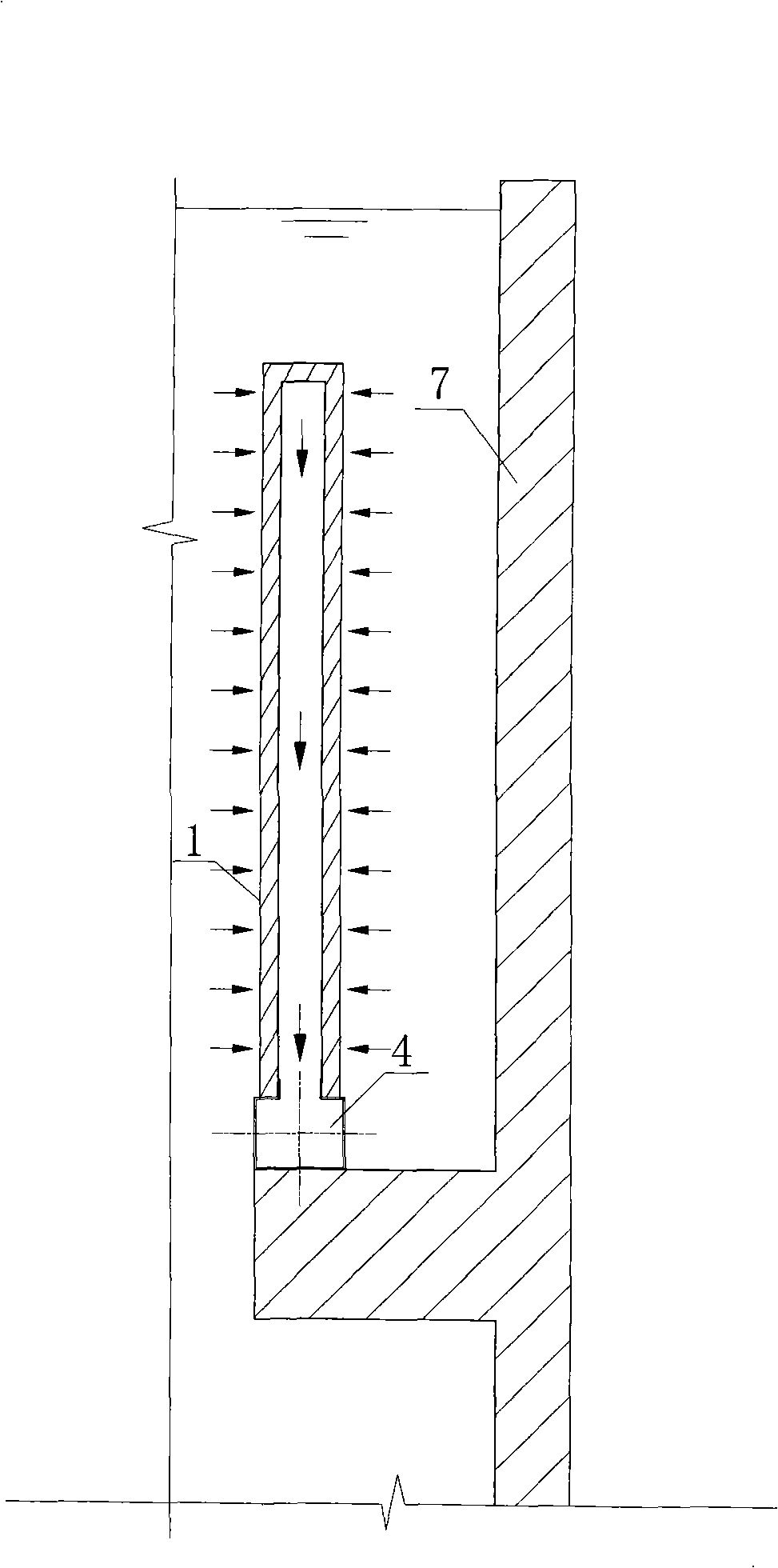

Round subsider micro-filter cloth surface filtration water exit method

InactiveCN101259339AImprove effluent qualityReduce the chromaticity of the waterWater/sewage treatmentSedimentation settling tanksProcess equipmentFiltration

The invention relates to a microfiltration cloth surface filtering water yielding method for a circular sedimentation tank, in which the water yielding is realized by a filtering system that mainly consists of a microfiltration cloth filter board (1) and an automatic cleaning device (2), wherein, the filtering system is provided with a plurality of microfiltration cloth filter boards which surround the periphery of the circular sedimentation tank and carry out the surface filtering of the sewage in the sedimentation tank, thus reducing the concentration of the suspending solids in the sewage to below 10mg / L;when the microfiltration cloth filter board is blocked up, the microfiltration cloth filter board is washed repeatedly by the automatic cleaning device, to resume the filtering function thereof. The method of the invention can improve water quality, and ensure the concentration of the suspending solids in the water to be lower than 10m / L; the method has the advantages of simple structure, convenience of installation and maintenance and low operation cost; and the backwash can be finished automatically and easily; the method can be used by old sewage treatment plant for improving the transformation of the yielding water quality standard and little changes can be done to the original technical equipment and construction; the phosphorus in the sewage can be effectively removed by using jointly with metal salt coagulant; besides, the chroma of the yielding water can also be effectively reduced.

Owner:WUHAN TEXTILE UNIV

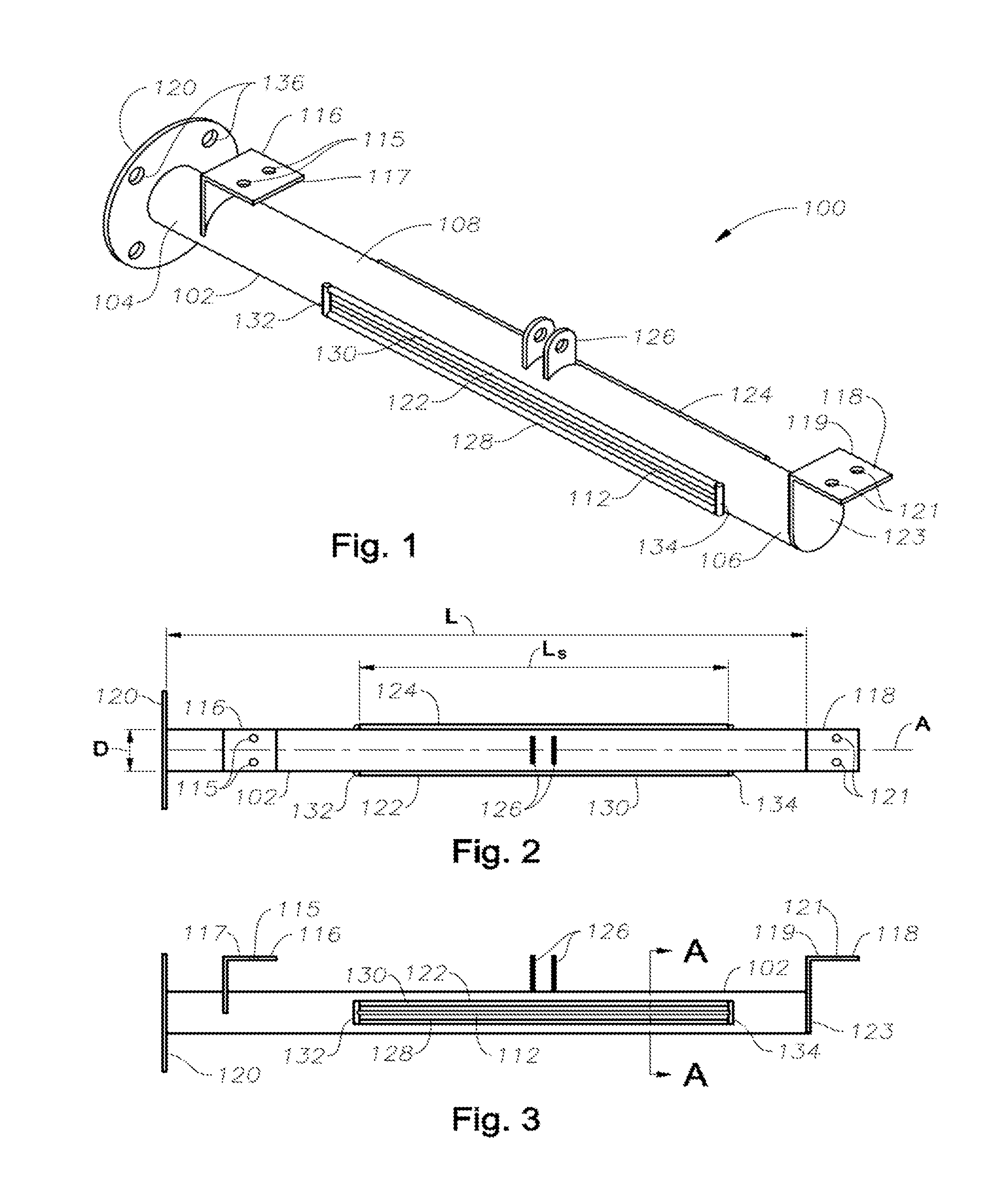

Backwash shoe method and apparatus that increases effective surface area of cloth filter media

ActiveUS10195549B1Increases effective filtration surface areaLow costMembrane filtersSustainable biological treatmentFilter mediaEngineering

Backwash shoes and methods of using backwash shoes are provided to increase the filtration area of a cloth filter media, the backwash shoe having a trailing surface formed from a series of merlons and crenels whereby some of the pile threads of the cloth filter media are compressed toward the support surface of the cloth filter media by the trailing surface and some of the pile threads remain in an extended or straightened position.

Owner:AQUA AEROBIC SYST

Backwash assembly and method having a rotating backwash arm for cleaning cloth filter media

InactiveUS20100300989A1Reduce necessityReduce wearWater/sewage treatmentMembrane filtersFiltrationEngineering

The present invention relates to stationary cloth media filtration systems and devices, as well as processes and devices, including improved cloth media filter backwashing using a rotating backwash arm assembly.

Owner:AQUA AEROBIC SYST

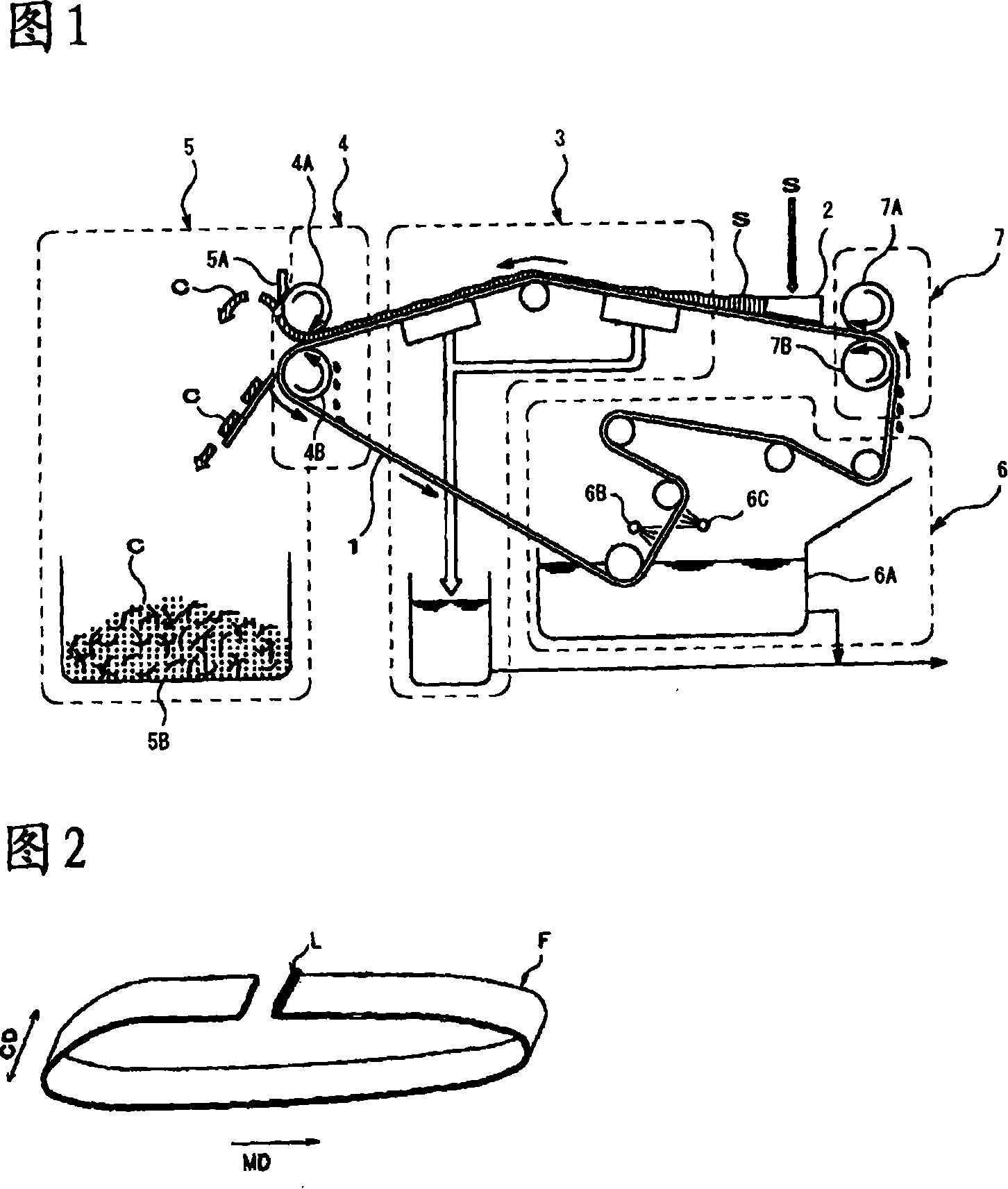

Filter cloth belt of spin-drying sludge and sludge spin-drying device using the same

InactiveCN101091851AEasy and fast hook-upSludge treatment by de-watering/drying/thickeningFibre treatmentSludgePulp and paper industry

The present invention provides a sullage dewatering used jointed cloth filter strip which dewaters the slurry shaped or sullage shaped dewatering object to the cake shaped object that contains lower moisture and can simplify the hanging operation of the sullage dewatering used jointed cloth filter strip and the cloth filter strip type dewatering device. The cloth filter strip type dewatering device is provided with the following components: a sullage dewatering used jointed cloth filter strip, which is used for the cloth filter strip of the cloth filter type dewatering device for dewatering the slurry shaped or sullage shaped dewatering object to the cake shaped object that contains lower moisture, and it is formed by clutching the seam ring of the hatch strip provided with seam rings at the two end parts and traversing the component wire through the formed through hole to joint it; and a dewatering part which does filtering and dewatering to the dewatering object provided on the cloth filter strip by the pressing of the pressuring strip or roller and / or the suction from the lower part of the cloth filter strip; besides, it winds the jointed cloth filter strip and do dewatering to the sullage shaped dewatering object.

Owner:TDE +1

Methods and apparatus for treating water and wastewater employing a cloth filter

ActiveUS20160059156A1Sufficient volumeGradual straightening and relaxing of fiberWater treatment parameter controlSpecific water treatment objectivesWastewaterEngineering

A backwash header for a cloth filter includes a body having a length, a diameter, first and second ends, a longitudinal axis, and an exterior surface, the body defining at least one internal cavity. The body includes at least one suction slot sized to allow fluids and solids to enter the internal cavity from outside of the exterior surface. A structure is attached to a portion of the exterior surface of the body around and extending away from the suction slot to form an open-ended chamber defined by the structure and a portion of the exterior surface near the suction slot. The structure allows fluids and solids to enter the open-ended chamber and then the suction slot and cavity from a material being cleaned. Cloth filters and methods of treating water and wastewater using the backwash headers and cloth filters.

Owner:ALFA LAVAL CORP AB

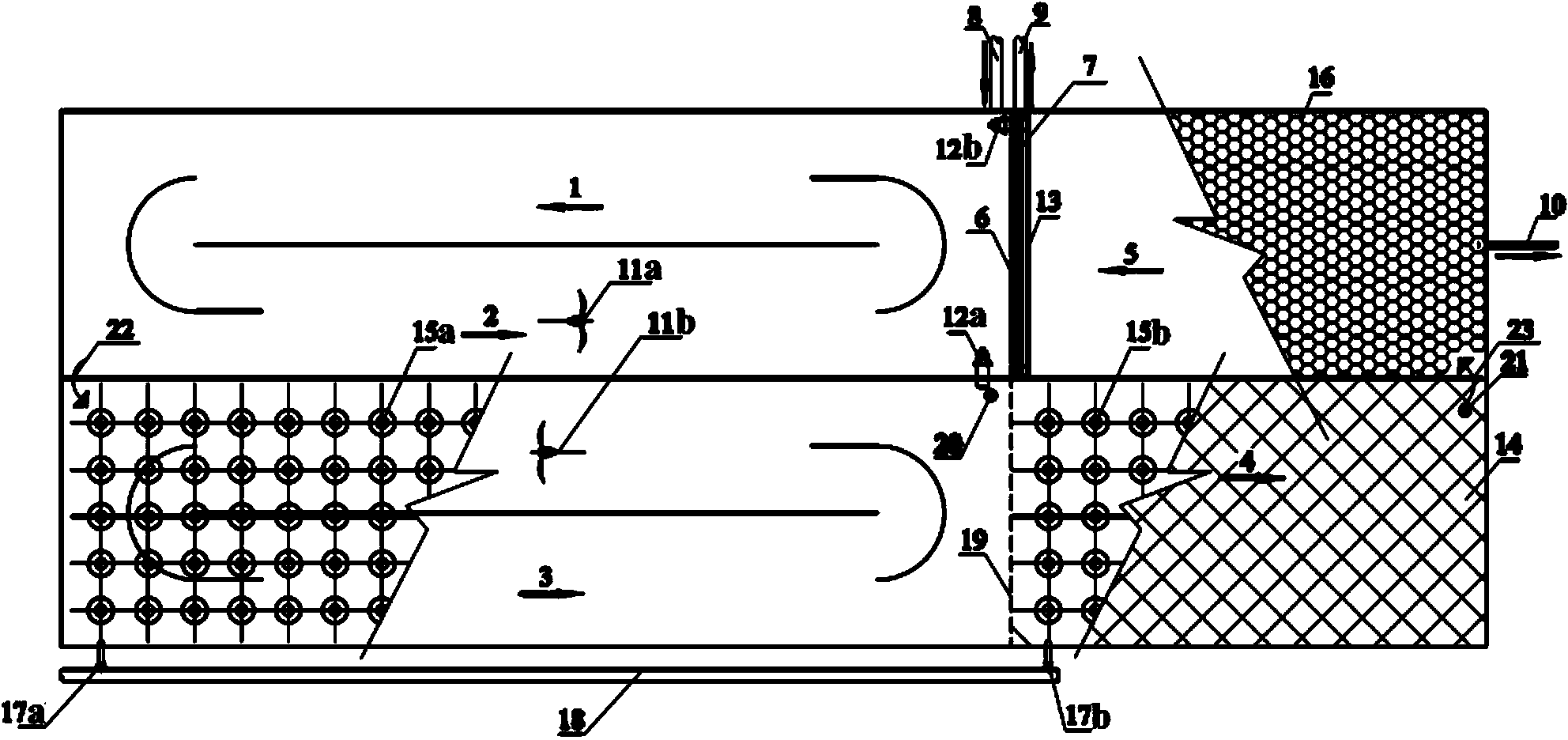

Integrated advanced wastewater treatment device and process

ActiveCN103922527AReduce thicknessReduce volumeMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationGrating

The invention relates to an integrated advanced wastewater treatment device and process. A sludge reflowing pipe is arranged at the bottom of a settling region, wherein one end of the sludge reflowing pipe is connected with a flocculation region, a sludge discharging pipe is arranged at the other end of the sludge reflowing pipe, and a filter cloth filtering region and a disinfecting region are arranged up and down and are adjacent to the settling region. Wastewater enters a mixing region through a wastewater inlet pipe, enters the flocculation region through a first water passing hole after being mixed, and enters the settling region through a second water passing hole after being flocculated; supernate overflows through an effluent weir after sludge and wastewater are separated through settling in the settling region, and enters the filter cloth filtering region after passing through a grating plate, effluent enters the disinfecting region from meshes in the bottom through a wastewater collecting tank after being filtered, and discharged through a wastewater outlet pipe through a third water passing hole after being disinfected, and a sludge part reflows to the flocculating region through a sludge reflowing pipe, and is partially discharged through the sludge discharging pipe. The process provided by the invention is reasonable in procedures; the device is compact in integrated design, saving in occupation area, less in head loss and less in chemical adding amount.

Owner:中清生态环境(宁波)有限公司

Rebalance system and method for wet-process desulfurization water system of heat-engine plant

InactiveCN104667736ASimple structureReasonable designLighting and heating apparatusDispersed particle separationWastewaterWater pipe

The invention relates to a rebalance system and method for a wet-process desulfurization water system of a heat-engine plant. The problem that water of a desulfurization system is deeply saved while a water system of the desulfurization system is rebalanced is not solved. The rebalance system comprises a gypsum carrying water pipe and a desulfurization wastewater pipe and is characterized by further comprising a water pipe for replacing pulping water with filtering water, a water pipe for replacing filter cloth filter cake washing water with the filtering water, and a water pipe for replacing demister washing water with the filtering water, wherein the two ends of the water pipe for replacing the pulping water with the filtering water are connected with a washing filtering water tank and a pulp tank respectively; and the two ends of the water pipe for replacing the filter cloth filter cake washing water with the filtering water are connected with the washing filtering water tank and a filter cloth filter cake respectively. The rebalance method has the characteristics that the filtering water in the filtering water tank is conveyed into the pulp tank by the water pipe for replacing the pulping water with the filtering water and is used for completely or partially replacing the pulping water. According to the rebalance system and method, the deep water saving is carried out on the desulfurization system so that the water system of the desulfurization system is rebalanced.

Owner:HANGZHOU HUADIAN ENERGY ENG

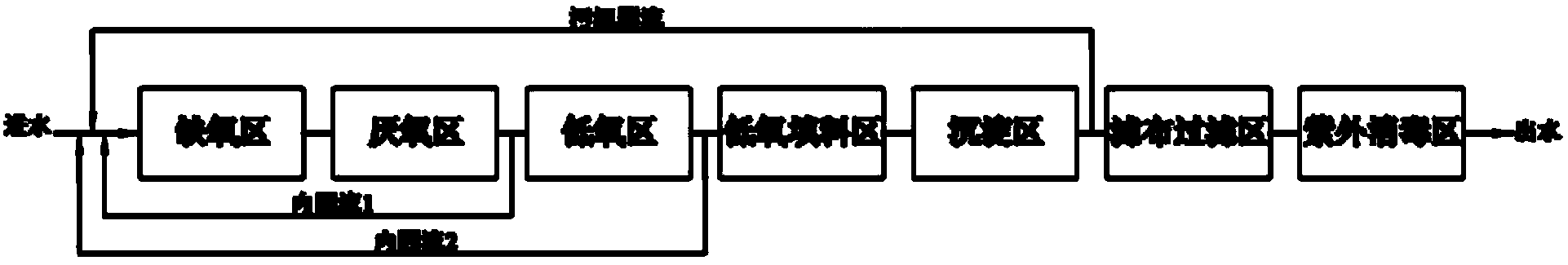

Integrated efficient biological reactor and reaction process thereof

ActiveCN103964633AFull backflowReasonable designMultistage water/sewage treatmentEnergy consumptionBiological reactor

The invention relates to an integrated efficient biological reactor and reaction process thereof. The integrated efficient biological reactor comprises an anoxic zone, an anaerobic zone, a hypoxic zone, a hypoxic filling zone, a precipitation zone, a filter cloth filtering zone and a sterilizing zone. The reactor adopts the integrated structure, is compact in overall design and occupies a small area. With adoption of the reaction process, the sewage treatment is low in energy consumption the efficiency is high, partial nitrification, synchronous nitrification and denitrification and denitrifying phosphorus removal are realized, and the treatment efficiency of nitrogen and phosphorus removal is high.

Owner:中清生态环境(宁波)有限公司

Methods and apparatus for treating water and wastewater employing a cloth disk filter

ActiveUS8778174B2Convenient inspectionEasy to removeMembrane filtersLoose filtering material filtersSludgeSuspended solids

Methods and apparatus for treating water and wastewater include the step of flowing a suspended solids stream generally upward through a sludge blanket region of a cloth disk filter vessel, thus forming a partially treated effluent composition and a solids-enriched sludge blanket. The partially treated effluent composition is allowed to flow generally upward to a cloth filter zone in the vessel after contacting the sludge blanket. The methods include flowing the suspended solids stream through one or more distribution headers positioned in the sludge blanket. An option is to provide a sludge concentration zone in the sludge blanket region, allowing sludge to flow into the sludge concentration zone to form concentrated sludge. Other methods and apparatus include backwash assemblies that backwash substantially the entire filter cassette surfaces, with or without use of a sludge blanket zone. Either the backwash assemblies or filter cassettes move in the latter methods and apparatus.

Owner:ALFA LAVAL ASHBROOK SIMON HARTELY INC

Spreading mechanism and spreading method for organic matter solid waste treatment device

PendingCN110803847AImprove laying qualityImprove laying efficiencySludge treatmentPressesProcess engineeringOrganic matter

The invention provides a spreading mechanism and a spreading method for an organic matter solid waste treatment device. The spreading mechanism comprises a filter cloth filter pressing chamber, a spreading bed and a cloth rolling frame used for providing a filter cloth, a tray capable of moving up and down is arranged in the filter cloth filter pressing chamber, the spreading bed comprises a spreading part capable of moving back and forth, and the cloth rolling frame is arranged between the spreading bed and the filter cloth filter pressing chamber; and the moving direction towards the filtercloth filter pressing chamber is taken as the advancing direction, the spreading part is in a filter cloth spreading state when advancing, and the spreading part is in a material spreading state whenretreating. The single-layer filter cloth is folded and then laid in the filter cloth filter pressing chamber layer by layer when moving back and forth, and material laying is conducted between the two folded layers of the filter cloth, so that the filter cloth spreading quality and the dehydration efficiency are effectively improved.

Owner:中合清源(济南)生态科技有限公司

Backwash assembly and method having a rotating backwash arm for cleaning cloth filter media

InactiveUS20100300957A1Reduce necessityReduce wearMembrane filtersLoose filtering material filtersFiltrationMechanical engineering

The present invention relates to stationary cloth media filtration systems and devices, as well as processes and devices, including improved cloth media filter backwashing using a rotating backwash arm assembly.

Owner:AQUA AEROBIC SYST

Tree barrier hidden danger rapid detection method based on vegetation three-dimensional convex hull and terminal

PendingCN111985496AImprove detection efficiencySmall amount of calculationImage enhancementImage analysisAlgorithmEngineering

The invention discloses a tree barrier hidden danger rapid detection method based on a vegetation three-dimensional convex hull and a terminal. The method comprises the steps that ground points in a power transmission line are filtered based on a cloth filtering algorithm; a power line point cloud is extracted from the power transmission line laser point cloud data of which the ground points are filtered out; vegetation point cloud in the power transmission line laser point cloud data is extracted; three-dimensional reconstruction is performed on the single power line to obtain a vectorizationmodel of the single power line; and the vegetation three-dimensional convex hull is generated through the vegetation point cloud, the distance between the vegetation three-dimensional convex hull andthe power line vector is calculated, tree barrier hidden danger analysis is conducted according to the distance, and a tree barrier hidden danger analysis result is obtained. According to the methodfor calculating the distance between the power line vector and the vegetation three-dimensional convex hull, the calculation amount of the tree line distance is greatly reduced, and the tree barrier hidden danger detection efficiency is greatly improved.

Owner:CHINA SOUTHERN POWER GRID DIGITAL GRID RES INST CO LTD

Stopping degree sensing method of gauze filter

InactiveCN1467013AAvoid damageCan not be discharged smoothlyFiltration separationEngineeringExhaust pipe

A method for sensing the blocked degree of gauze filter features that during baking job, the rotation speed (RPM) of variable exhaust blower is monitored, and when said rotation speed is higher than a reference value to some extent the blocked degree of gauze filter and exhaust pipe can be sensed and a signal is sent to user for scavenging them.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com