Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

697results about How to "Improve cleaning rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

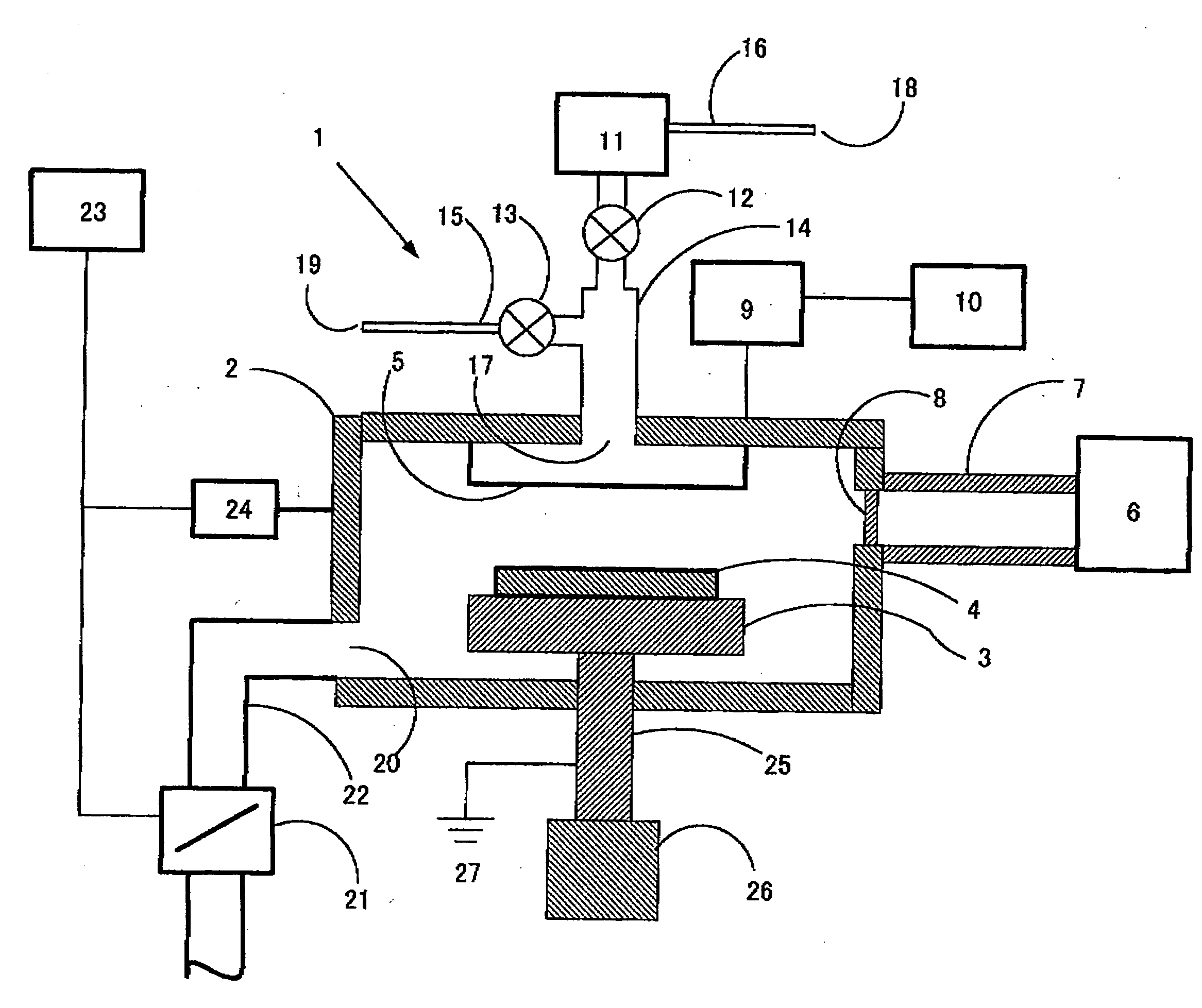

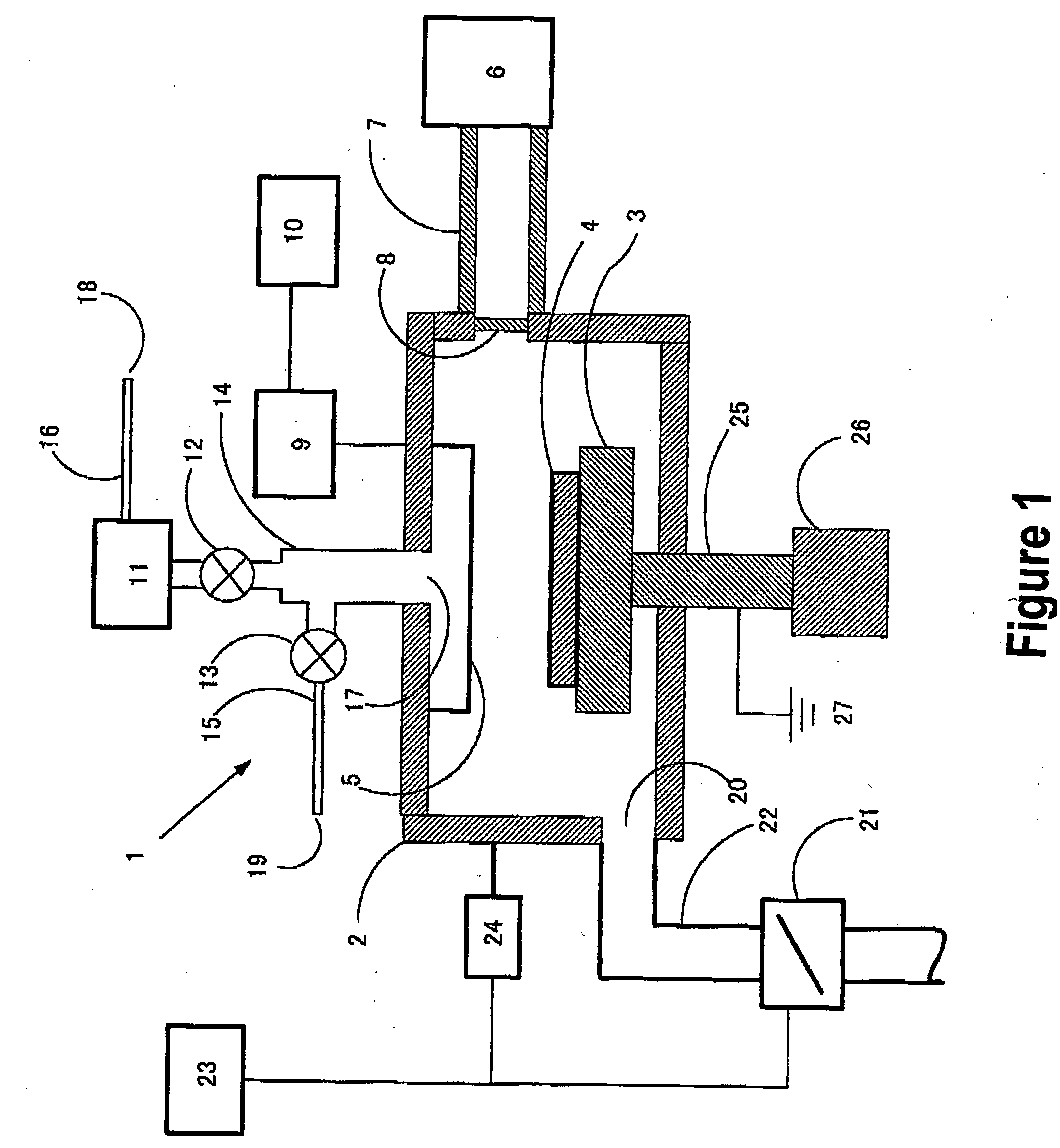

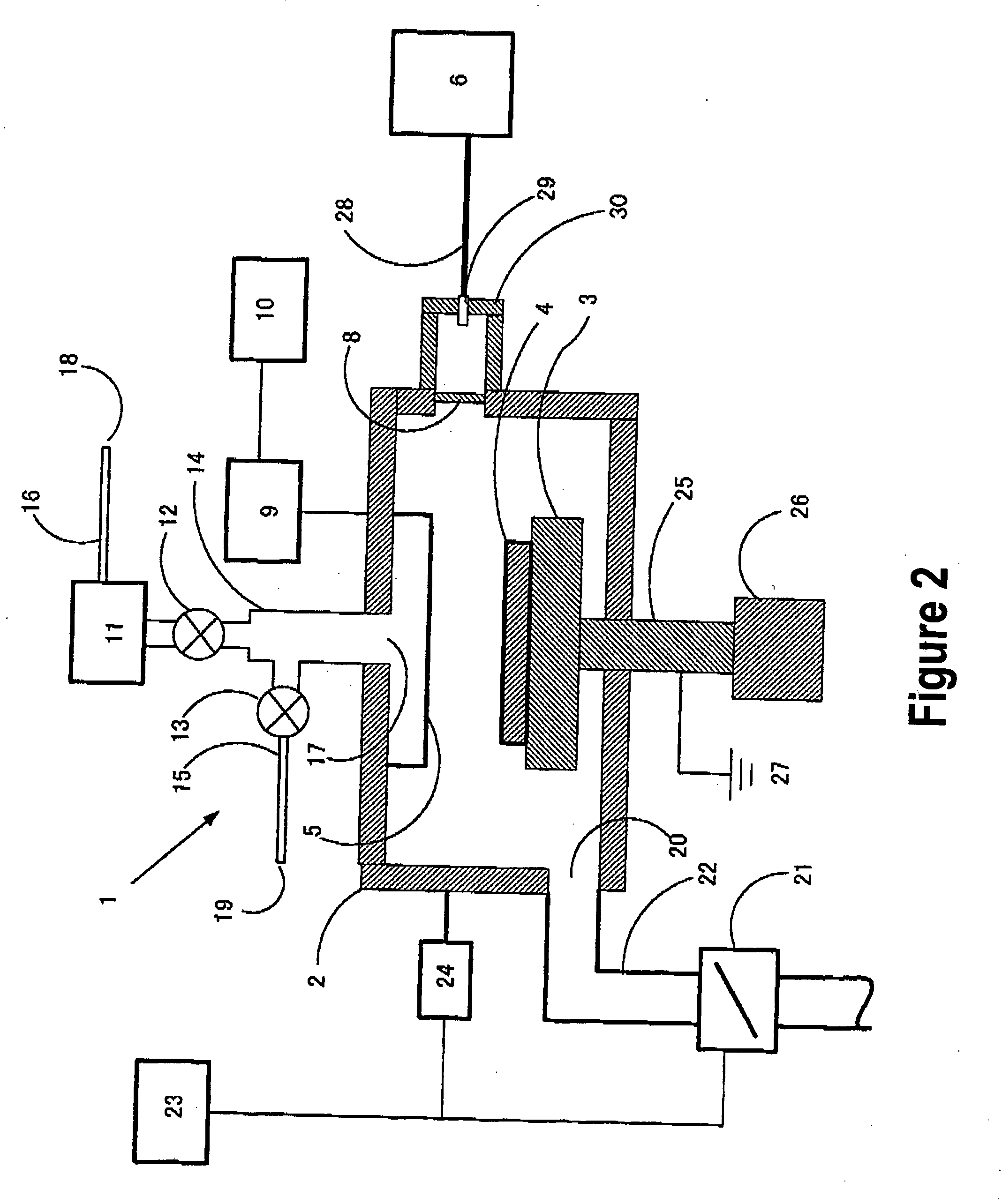

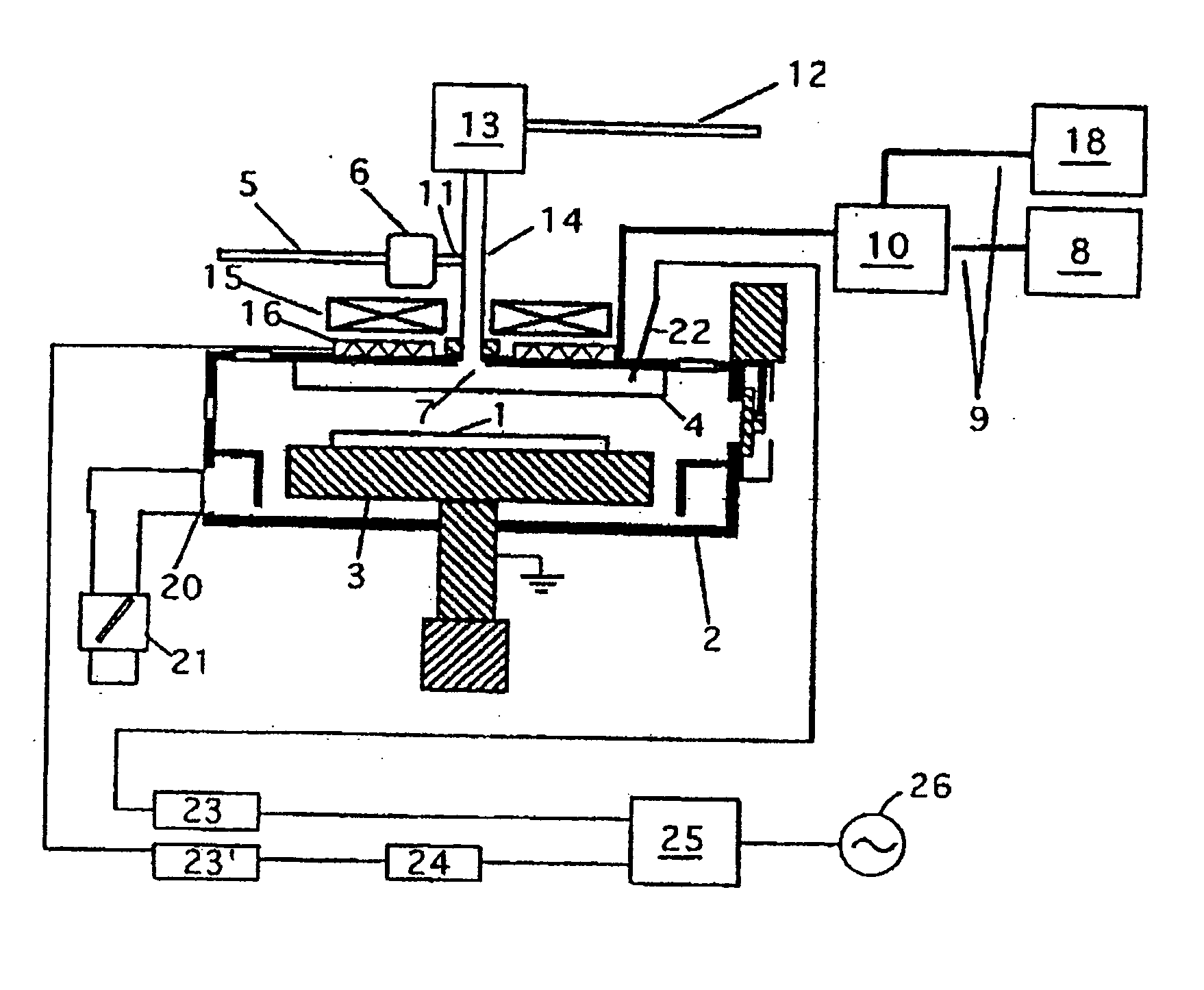

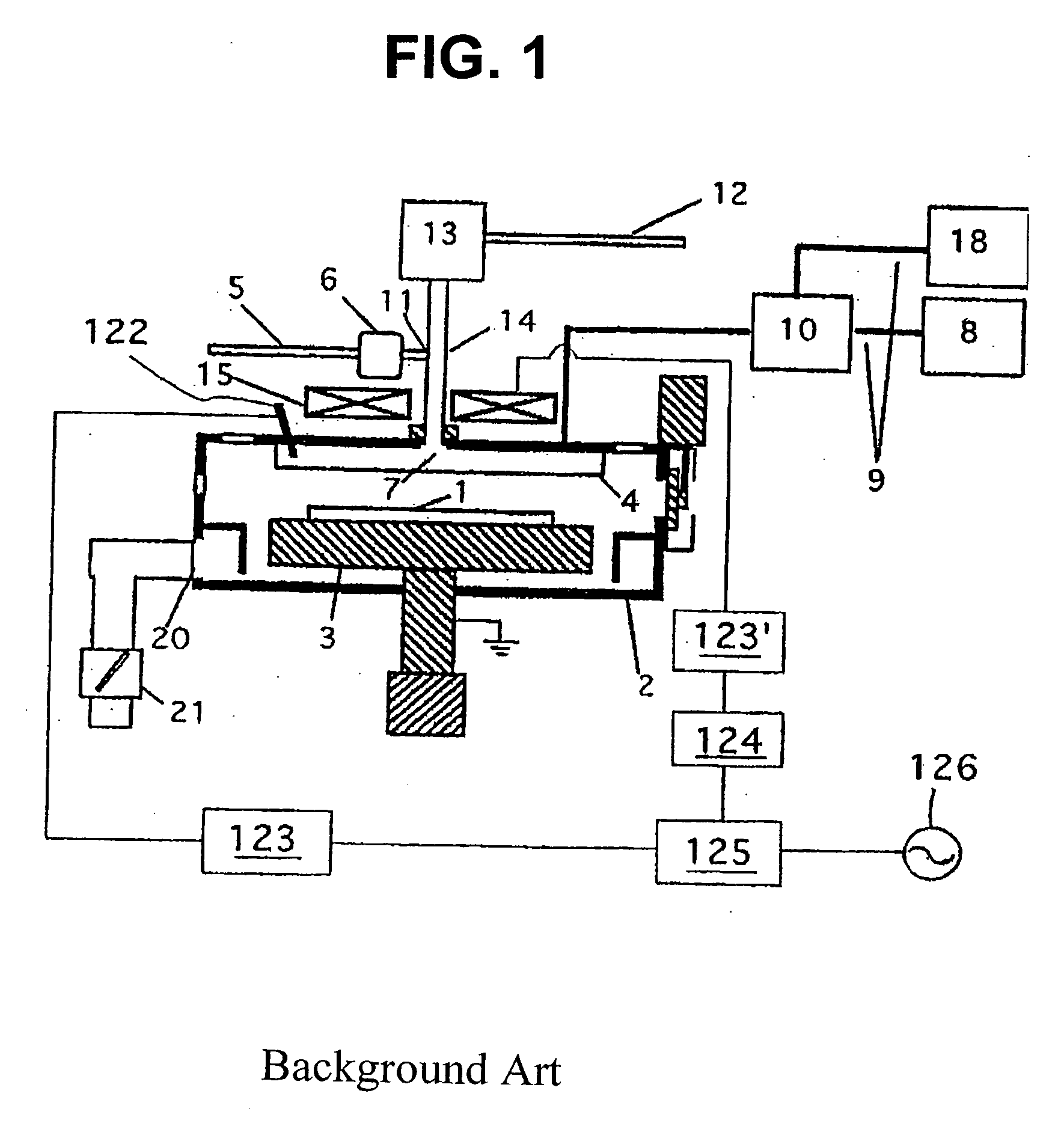

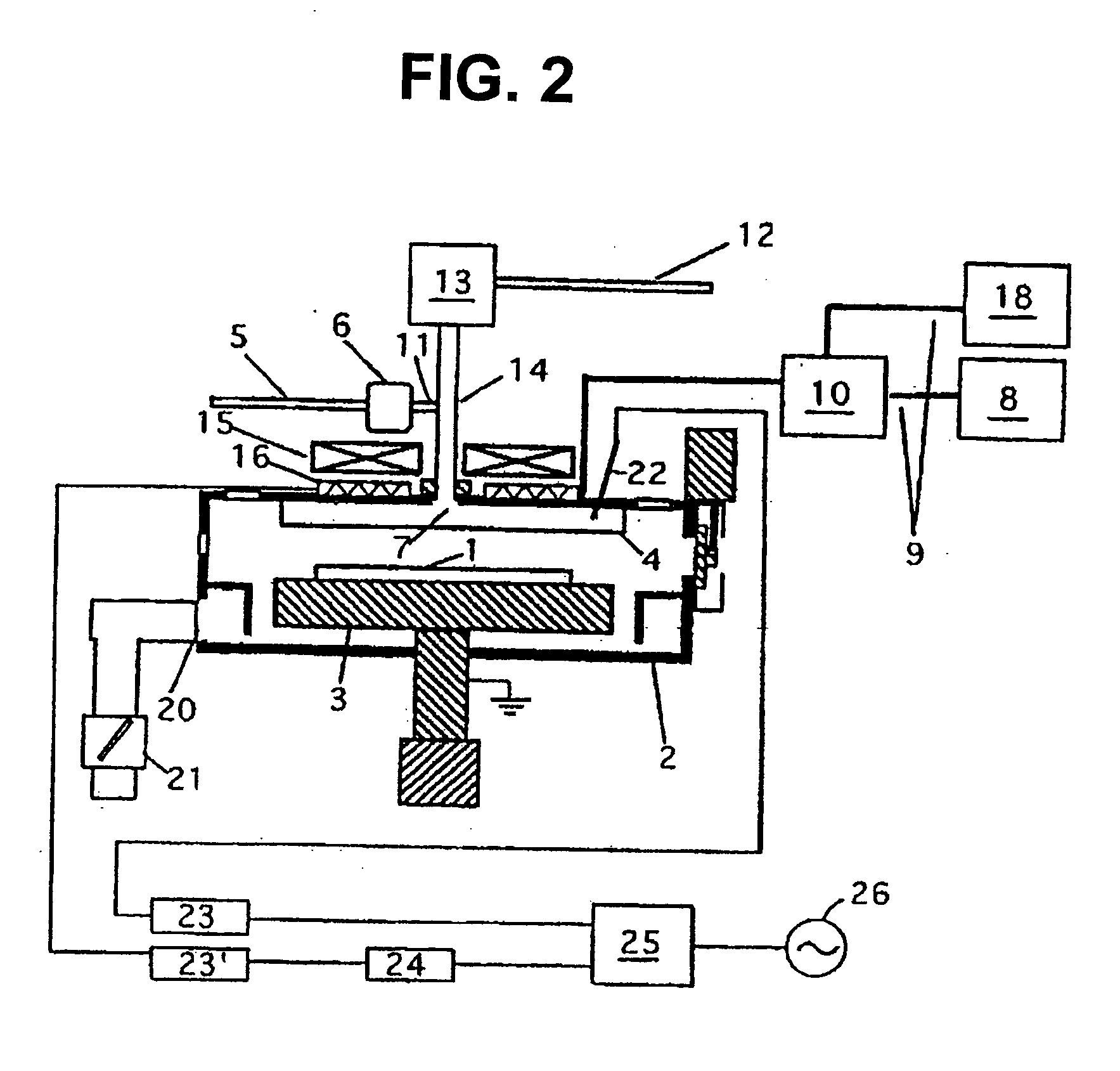

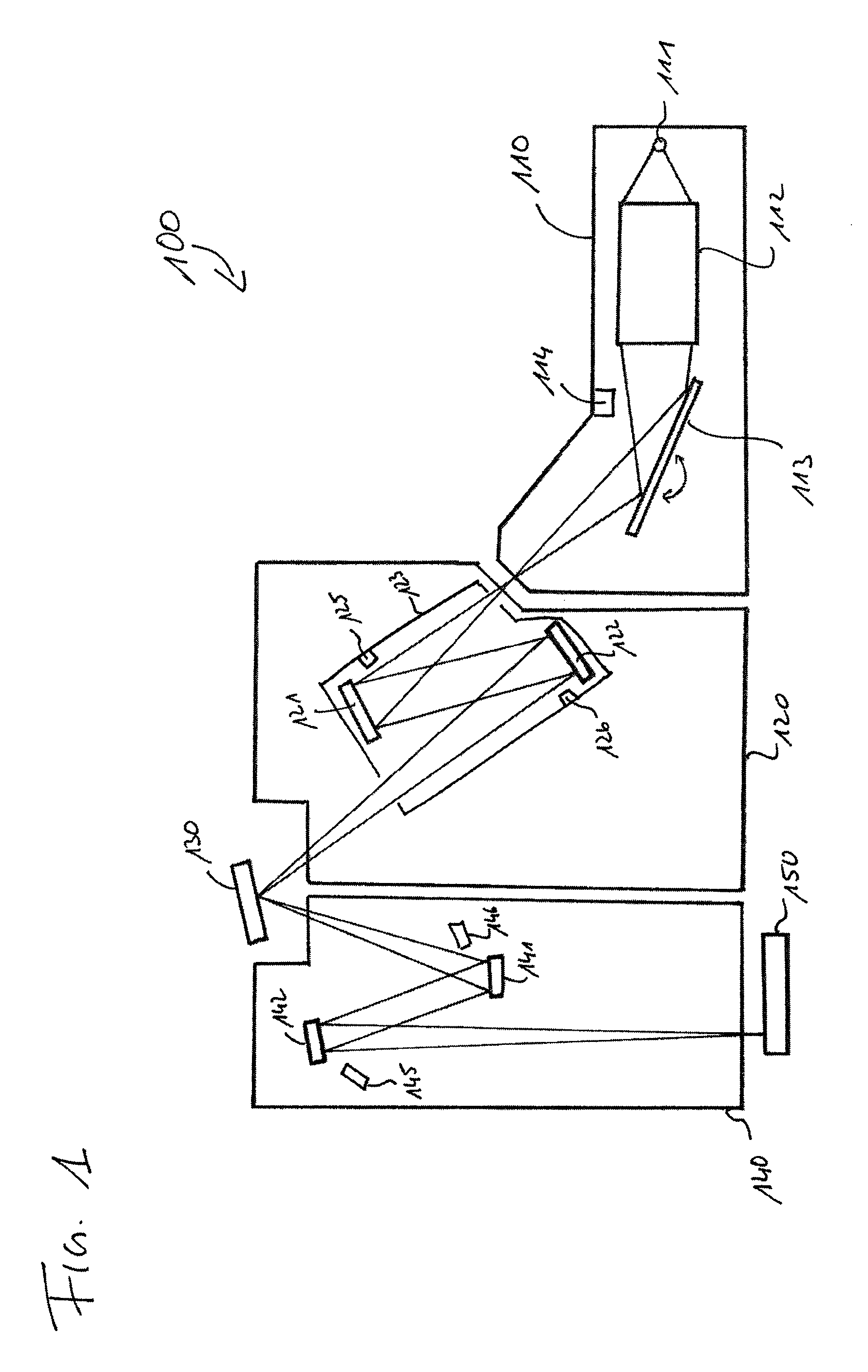

System and method of CVD chamber cleaning

InactiveUS20050178333A1High rateSpeedPretreated surfacesSemiconductor/solid-state device manufacturingPlasma reactorRemote plasma

A thin-film deposition system includes a plasma CVD reactor; a remote plasma chamber; and an electromagnetic wave generator for emitting electromagnetic waves to an interior of the reactor. Unwanted reaction products adhering to an inner surface of the reactor absorb electromagnetic waves are effectively removed.

Owner:ASM JAPAN

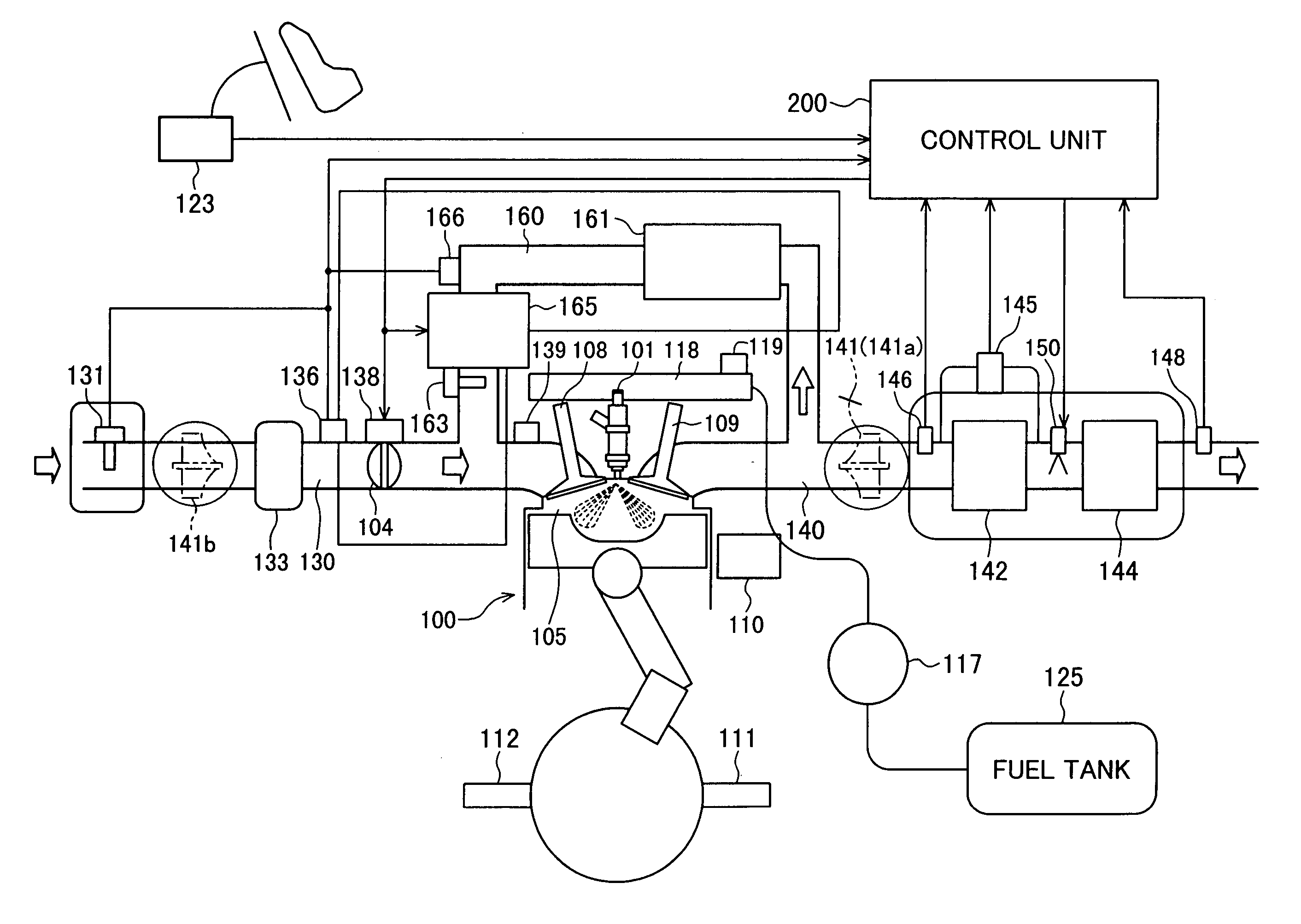

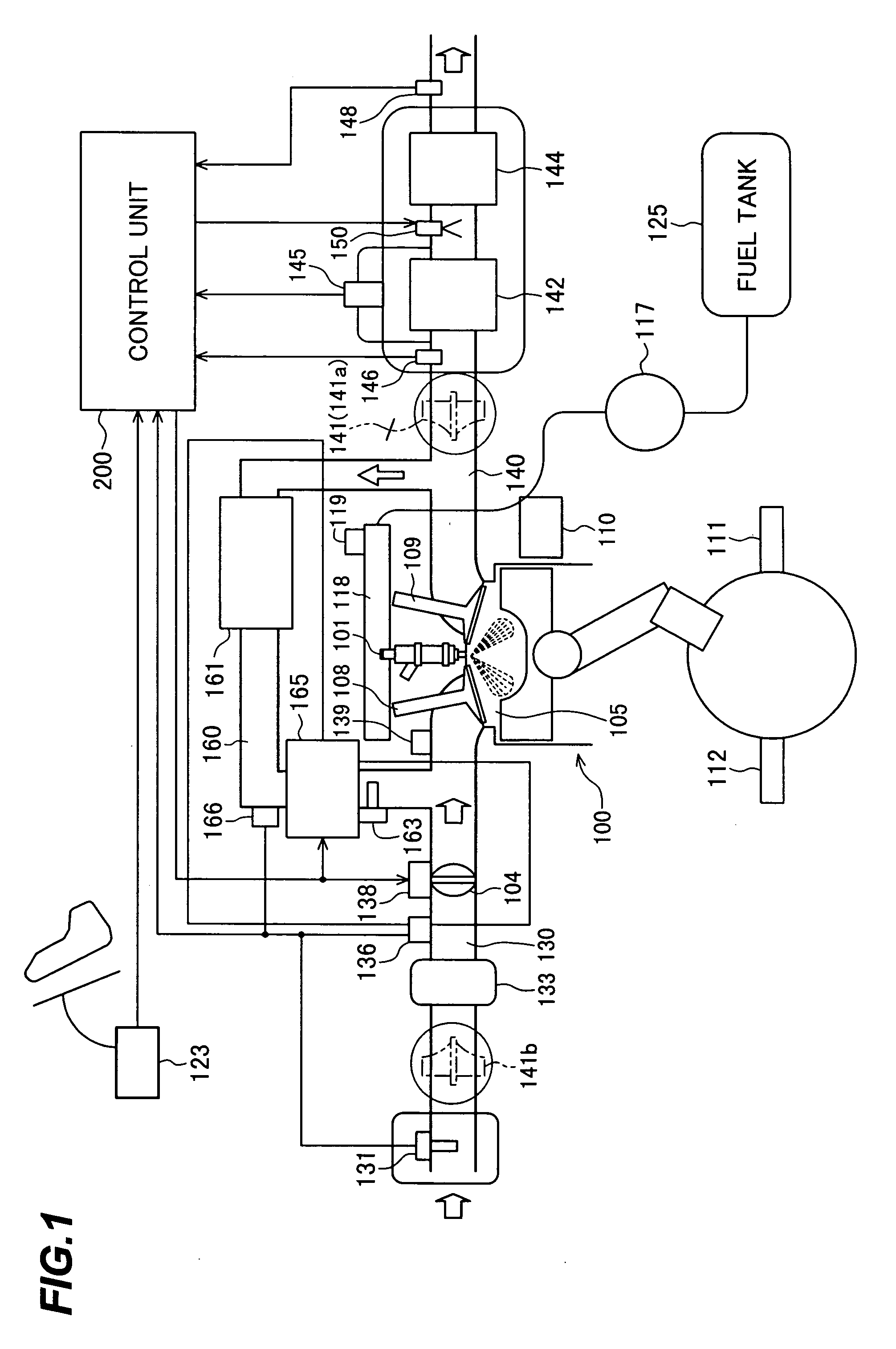

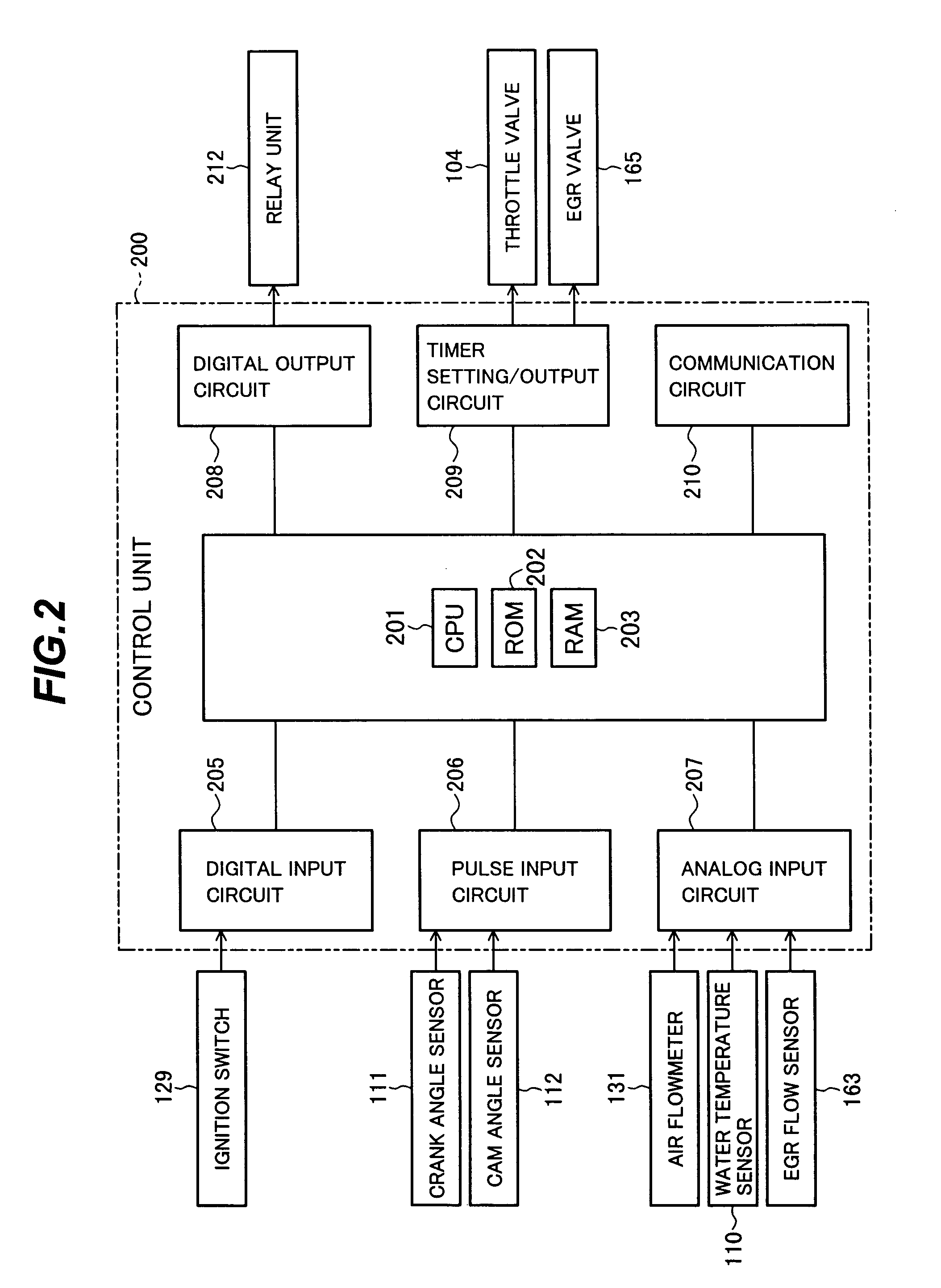

Engine exhaust gas cleaning method and system

InactiveUS20060086080A1Emission reductionReduce cleaning rateElectrical controlNon-fuel substance addition to fuelExhaust fumesEnvironmental engineering

An engine exhaust gas cleaning method and system, which can effectively reduce emission amounts of particular components, such as NOx, contained in exhaust gas by adding an additive, such as urea water or light oil, into an exhaust passage, which is adaptable for a reduction of the cleaning rate caused by deterioration of a catalyst, which can always maintain a high cleaning rate during acceleration and deceleration as well, and which can minimize environmental pollution with use of the additive in the least necessary amount. The engine exhaust gas cleaning system comprises a catalyst for removing a particular component, represented by NOx, contained in exhaust gas of an engine, an additive adding unit for adding, to the exhaust gas, an additive for reducing the particular component represented by NOx, and an EGR amount adjusting unit for adjusting an EGR amount. An addition amount of the additive and the EGR amount are set depending on an operating state and deterioration of the catalyst with time. The catalyst is regenerated when a cleaning capability of the catalyst has reduced to a predetermined value or below.

Owner:HITACHI LTD

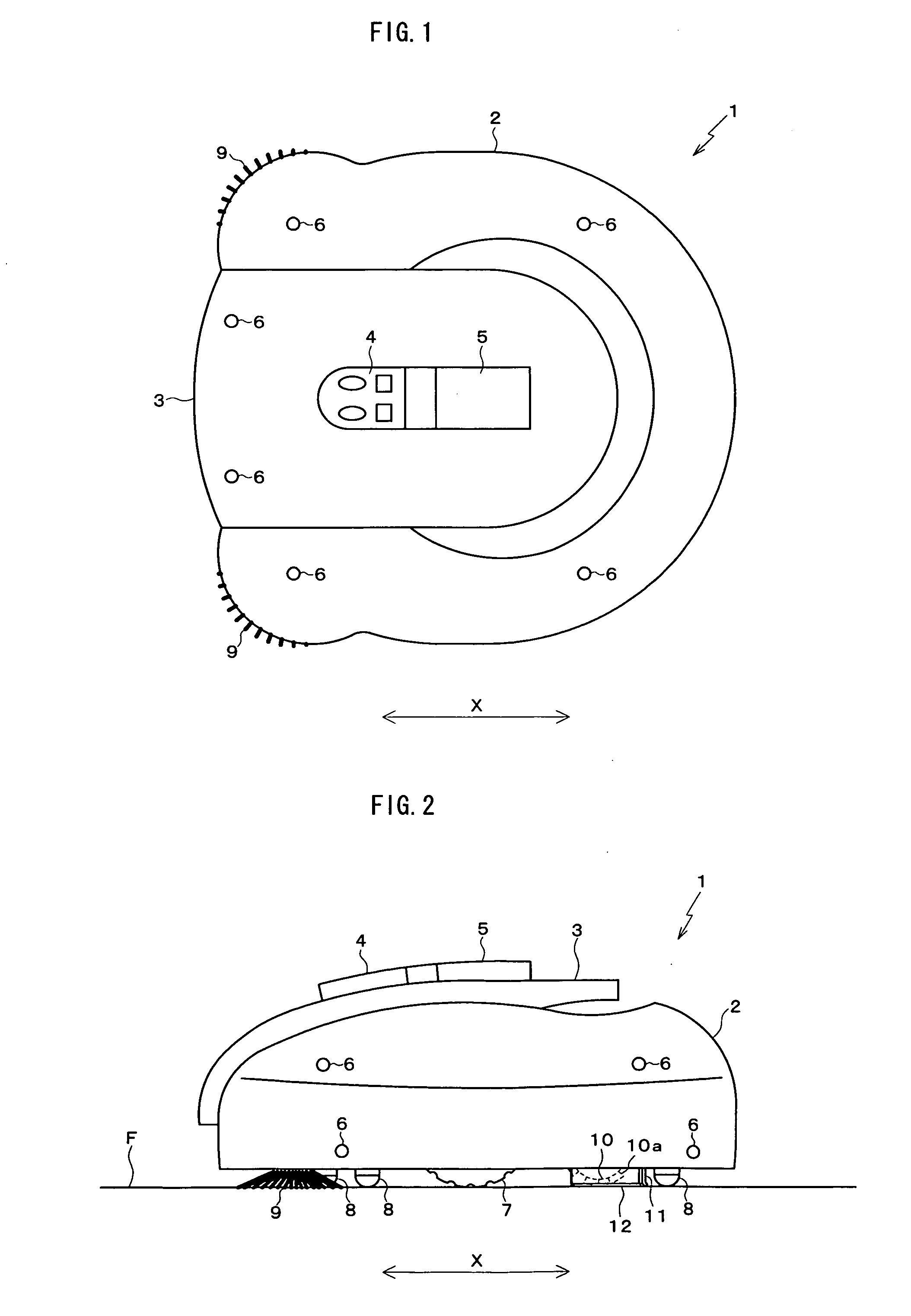

Autonomous electric cleaner and electric cleaner

InactiveUS20060236492A1Improve cleaning rateExclude influenceCarpet cleanersFloor cleanersEngineering

Owner:FUNAI ELECTRIC CO LTD

Food purification apparatus

ActiveCN101336809AFall off quicklyFood Safety GuaranteeClimate change adaptationKitchen equipmentWater savingUltrasonic sensor

A food cleaning device comprises a cleaning water tank, a water pump and an electrolyzed water generator all provided with water inlets and water outlets and connected to form a closed circulation loop by pipelines. An ultrasonic transducer is provided in the water tank. Food can be cleaned safely and effectively by the inventive device with disinfection and pesticide residue removing functions. The invention is provided with advantages of time saving, labor saving, water saving, high cleaning ratio, and body health benefiting, thereby the invention is capable of being widely used by household, school, mess hall, catering industry and vegetable cleaning industry.

Owner:CHINA NAT FOOD PURIFICATION TECH BEIJING CO LTD

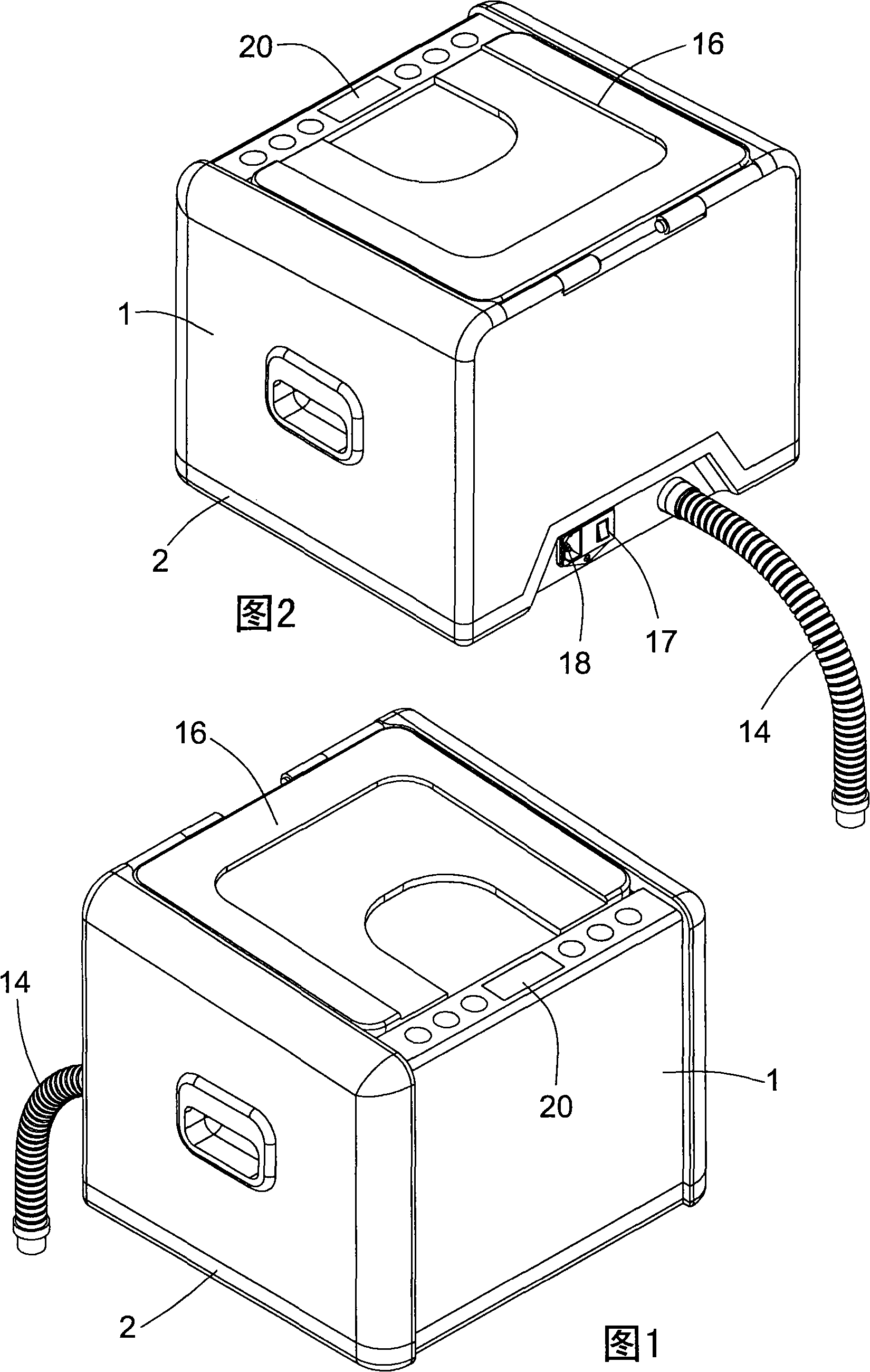

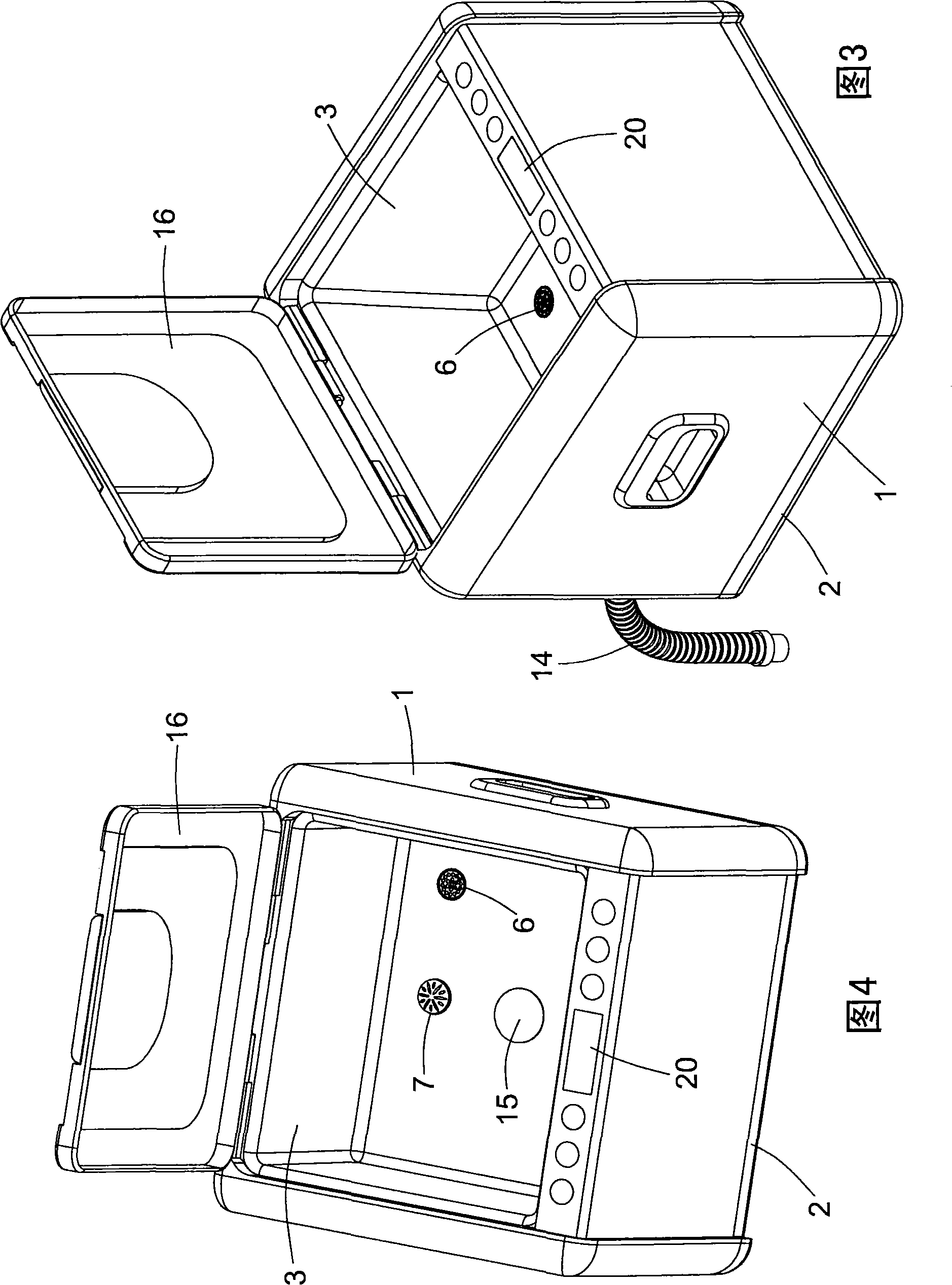

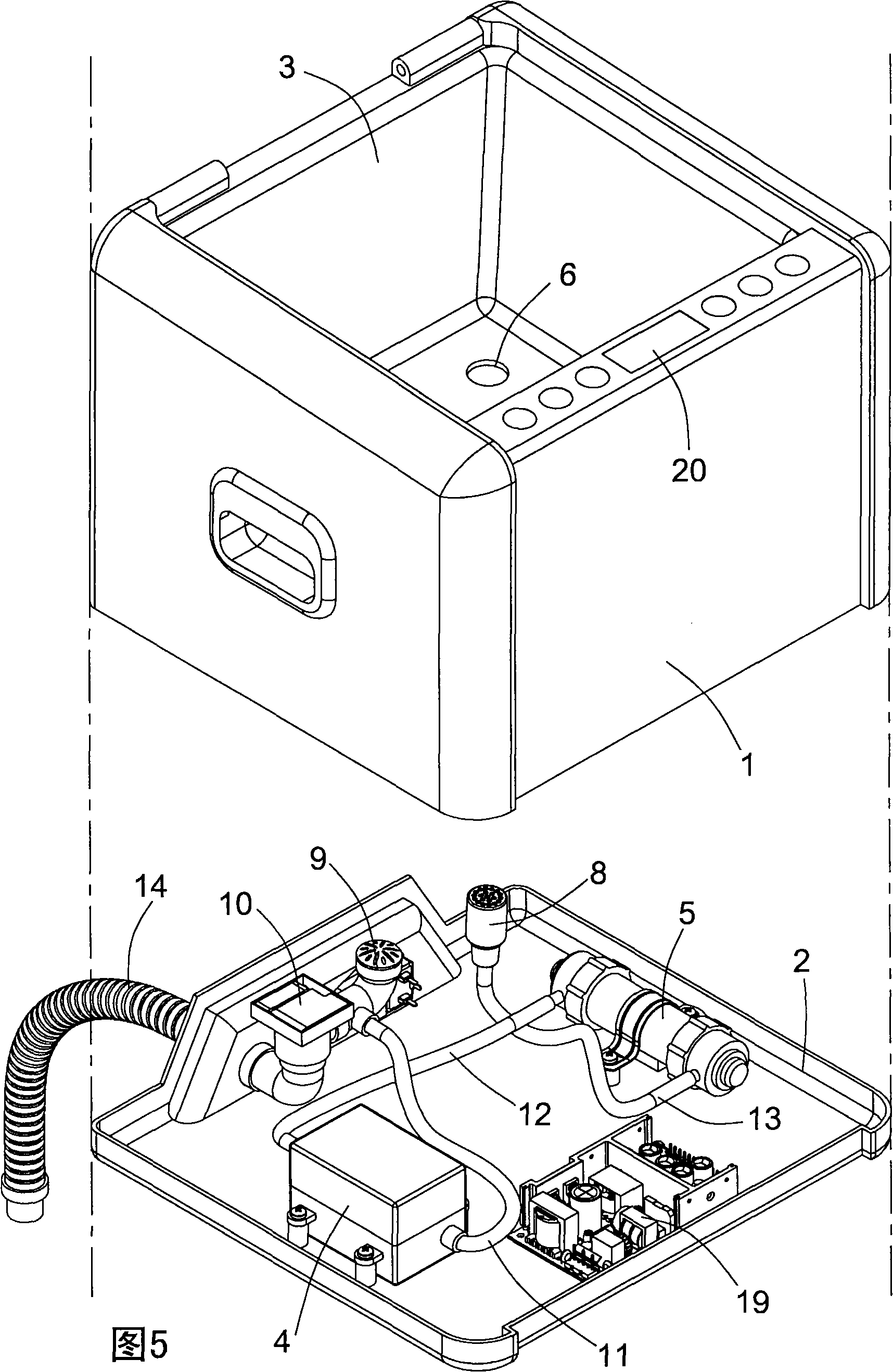

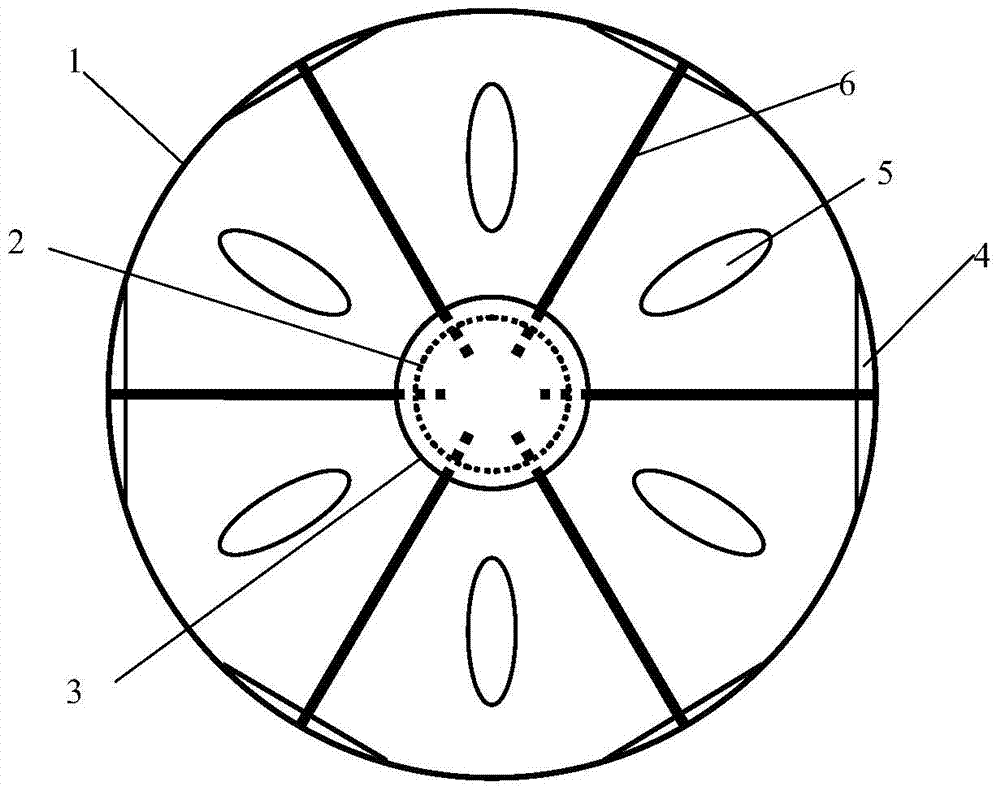

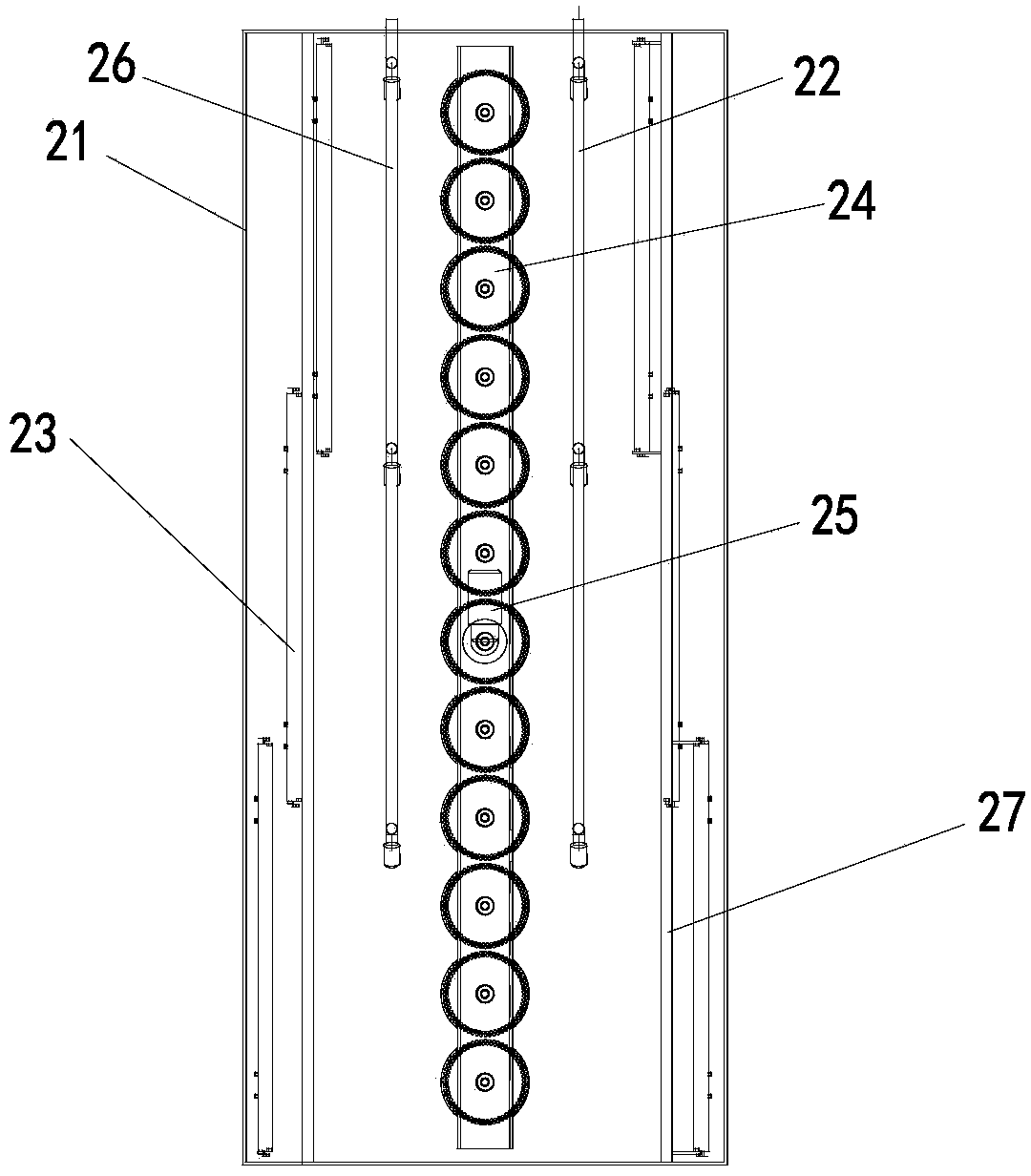

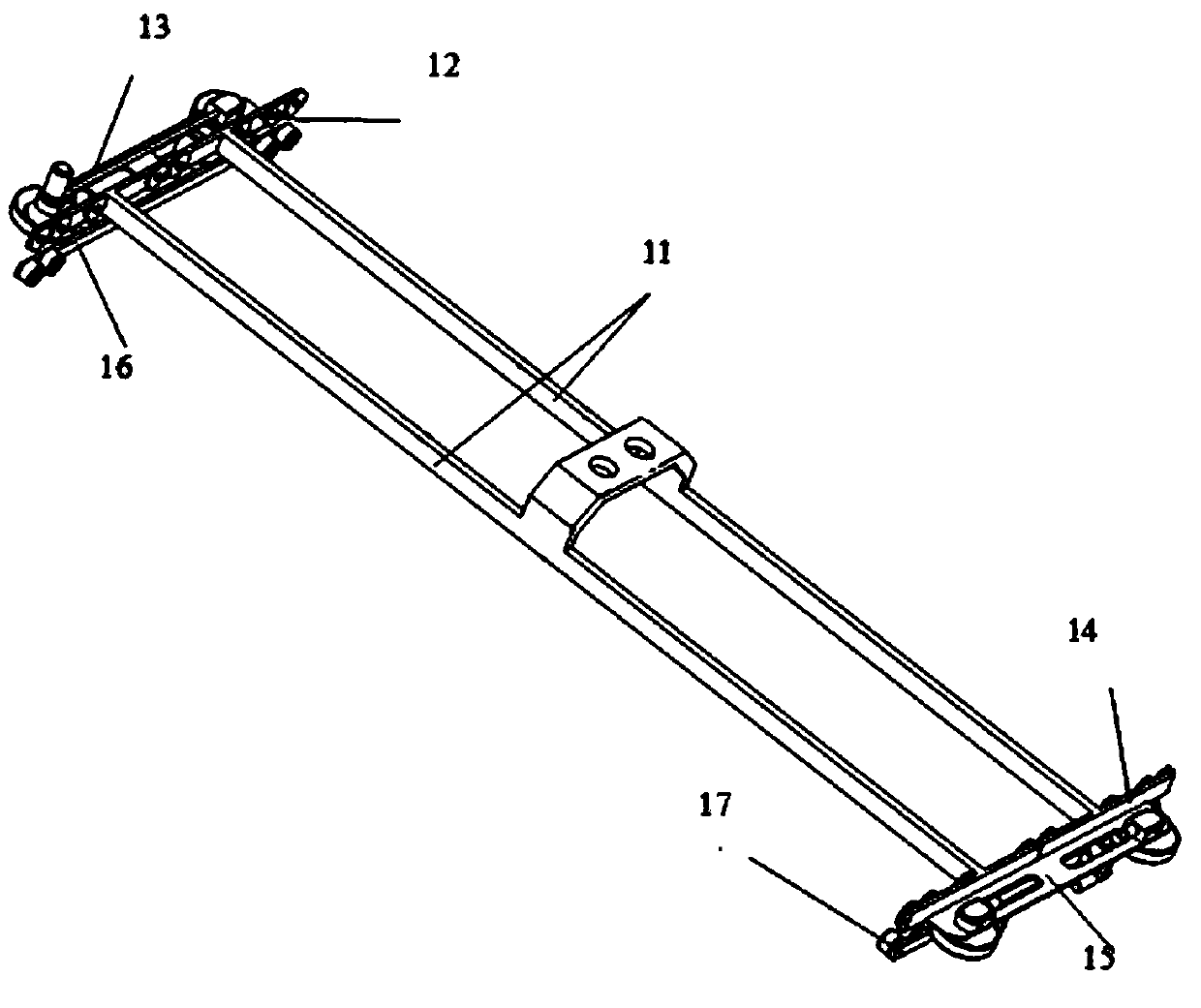

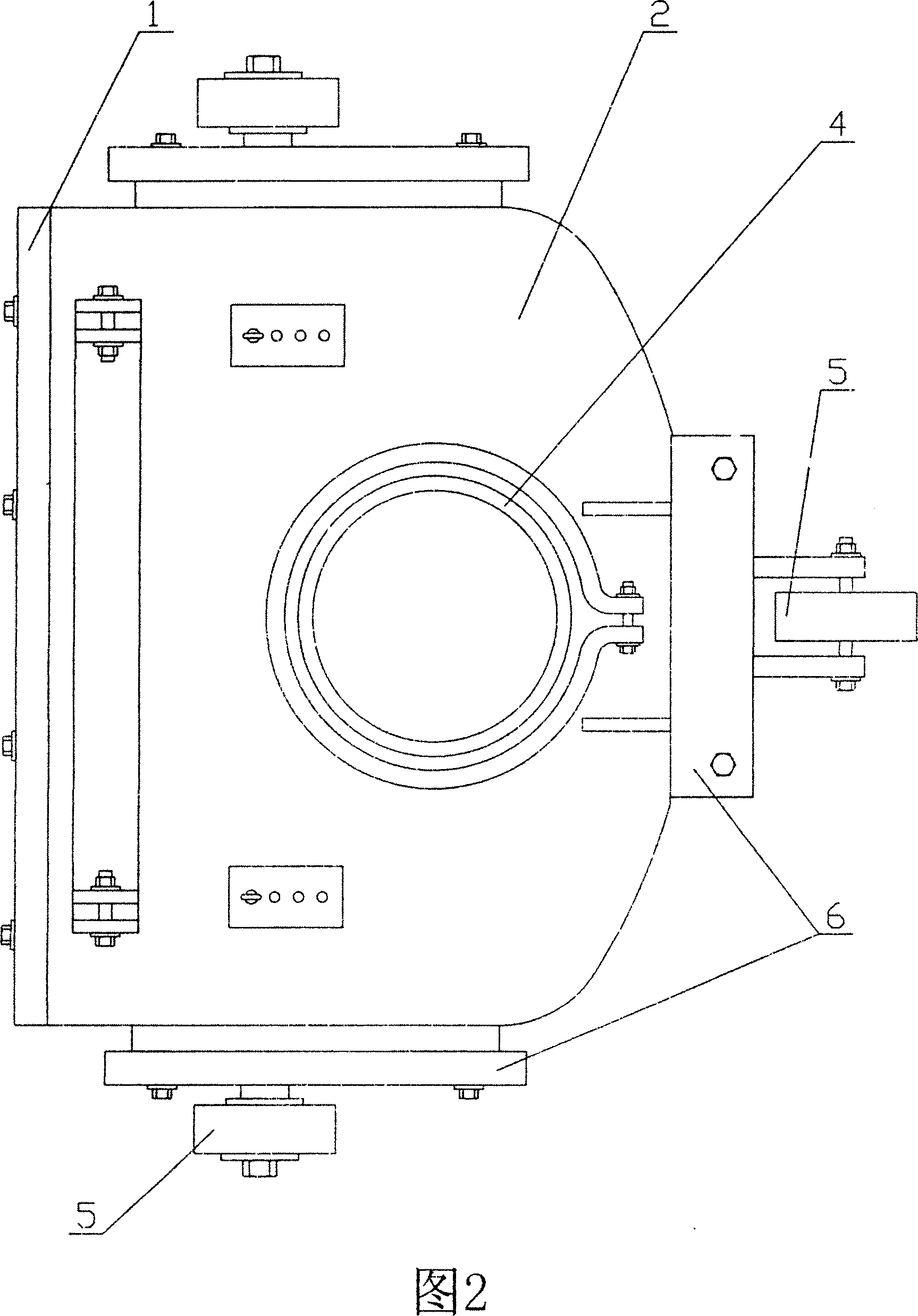

Dish washing machine and spraying arm assembly thereof

ActiveCN104739346AImprove cleaning rateImprove manufacturabilityTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention discloses a dish washing machine and a spraying arm assembly thereof. The spraying arm assembly comprises a fixed gear, a main spraying arm, a mobile gear and an auxiliary spraying arm; the fixed gear is provided with a water inlet; the main spraying arm is connected with the fixed gear and can pivot around the center axis of the fixed gear; a first spraying chamber is formed in the main spraying arm; the outer surface of the main spraying arm is provided with a thrust hole and a plurality of first spraying holes; the mobile gear is connected with the main spraying arm; the mobile gear is meshed with the fixed gear so as to drive the mobile gear to pivot around the center axis of the mobile gear and pivot around the center axis of the fixed gear; the auxiliary spraying arm is connected with the mobile gear and synchronously moves along with the mobile gear; a second spraying chamber is limited in the auxiliary spraying arm; the peripheral surface of the auxiliary spraying arm is provided with a plurality of second spraying holes. According to the spraying arm assembly of the dish washing machine, the change of the spraying arms into the two-dimensional rotation from the one-dimensional rotation can be implemented and accordingly the cleaning rate is improved and the spraying arms are not integrally-formed parts any more, the auxiliary spraying arm can be formed by two separated parts especially, and accordingly the manufacturability is improved and the cost is reduced.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

Self-cleaning method for plasma CVD apparatus

InactiveUS20050242061A1Improve cleaning rateReduce cleaning frequencyElectric discharge tubesDecorative surface effectsCleaning methodsPlasma reaction

A self-cleaning method for a plasma CVD apparatus includes: (a) after unloading an object processed in a reaction chamber, heating a showerhead to a temperature of 200° C. to 400° C.; (b) introducing a cleaning gas into the reaction chamber; and (c) cleaning the reaction chamber by plasma reaction using the cleaning gas.

Owner:FUKUDA HIDEAKI

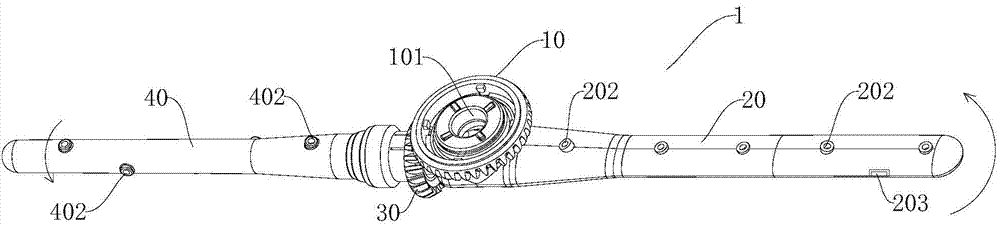

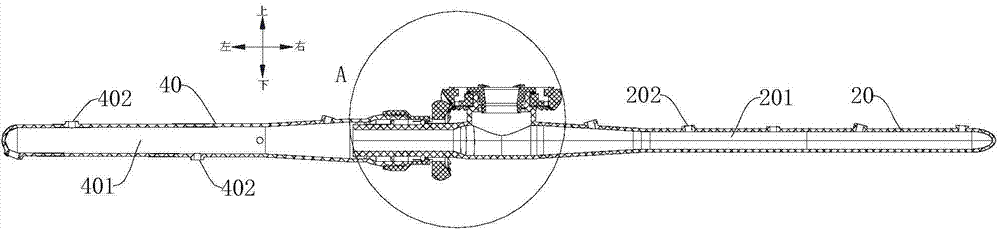

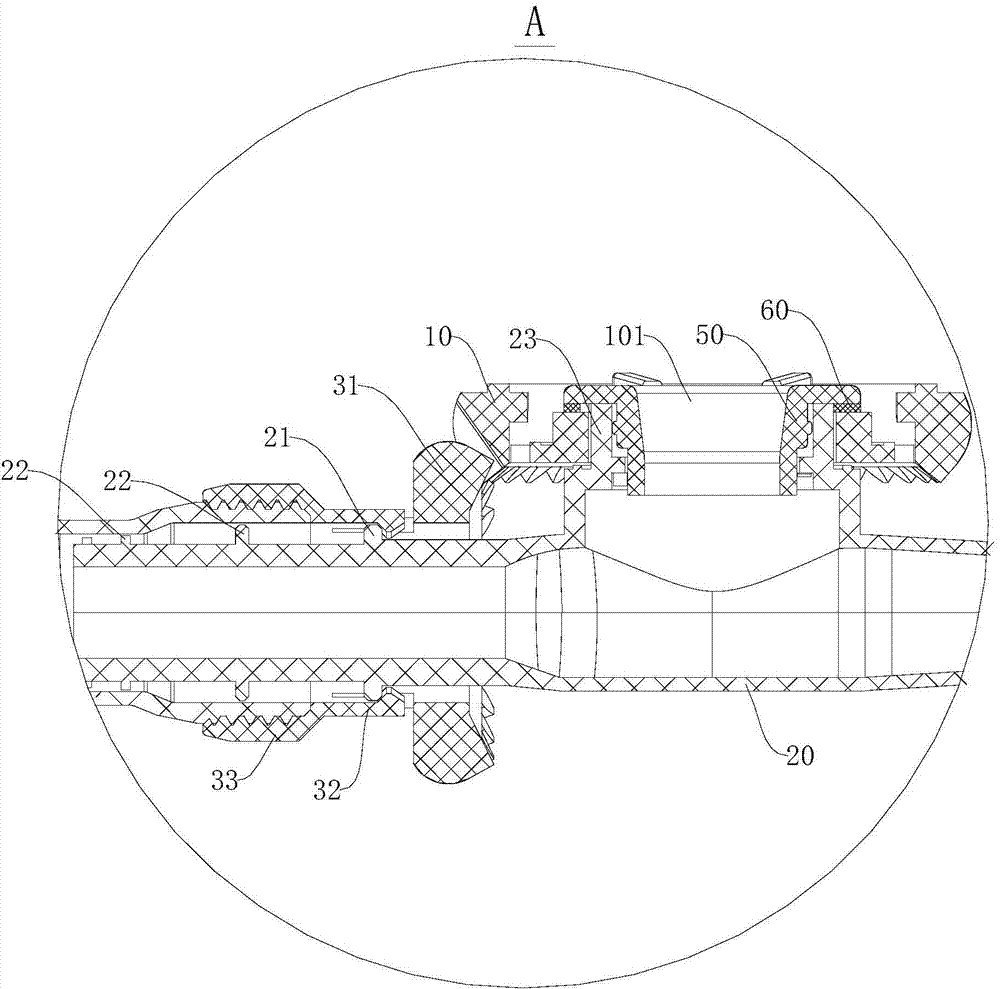

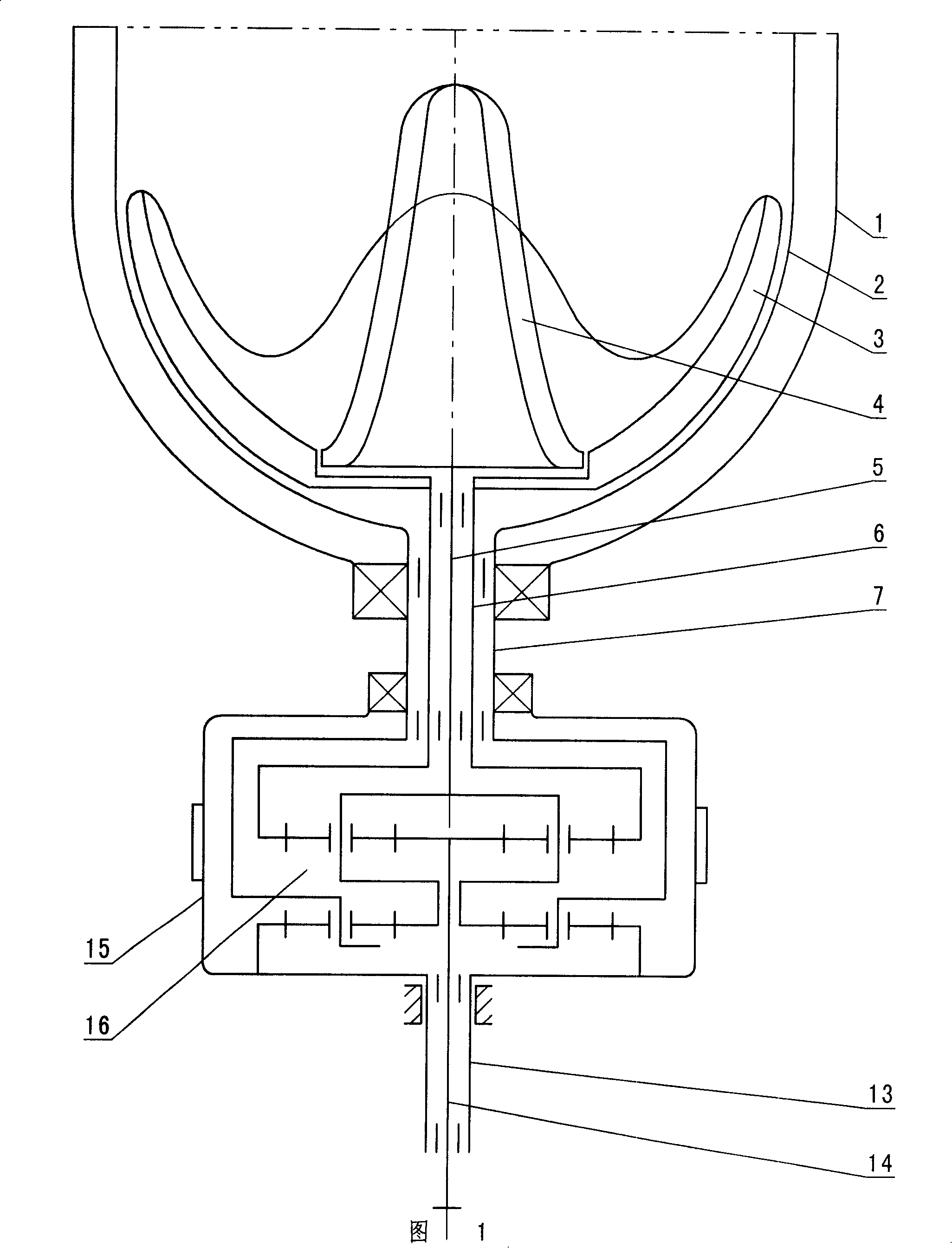

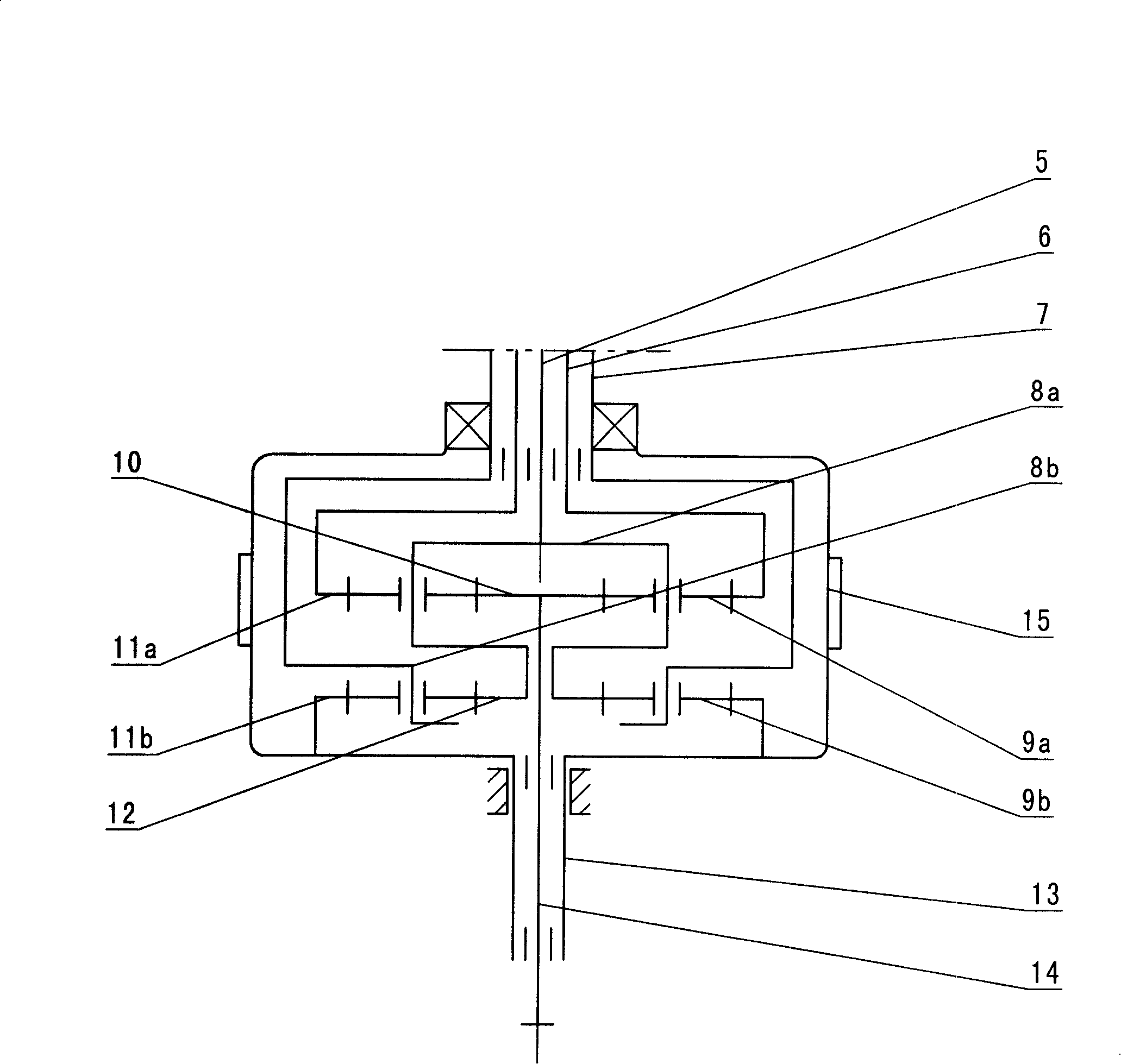

Washing machine deceleration clutch, washing machine and washing mode thereof

ActiveCN101210372ATumble fullImprove cleaning rateToothed gearingsOther washing machinesWater flowClutch

A decelerating clutch of a washer and the washer and a washing mode thereof relates to the technical field of washer. An output shaft of the decelerating clutch includes a small wave wheel shaft, a large wave wheel shaft and an inner barrel shaft, wherein the small wave wheel shaft is supported in the large wave wheel shaft, and the large wave wheel shaft is supported in the inner barrel shaft. By adopting the deceleration mechanism of the decelerating clutch, the invention can simultaneously drive a large wave wheel, a small wave wheel and an inner barrel to rotate. A washer manufactured by using the decelerating clutch comprises a small wave wheel and a large wave wheel, wherein the small wave wheel is fixedly arranged on the small wave wheel shaft and positioned at the middle portion of the large wave wheel; the large wave wheel is fixedly arranged on the large wave wheel shaft; and the inner barrel is fixedly arranged on the inner barrel shaft. The washer manufactured by using the decelerating clutch is operated in such a mode that the small wave wheel, the large wave wheel and the inner barrel make reciprocating rotation in mutually reverse directions at different speeds and different rotation angles by a ratio in two directions to produce complex and crossing shock water flow to scrub and clean the clothes, thus completely rotating the clothes, achieving strong scrubbing force and improving the cleaning rate.

Owner:NINGGUO JULONG IND

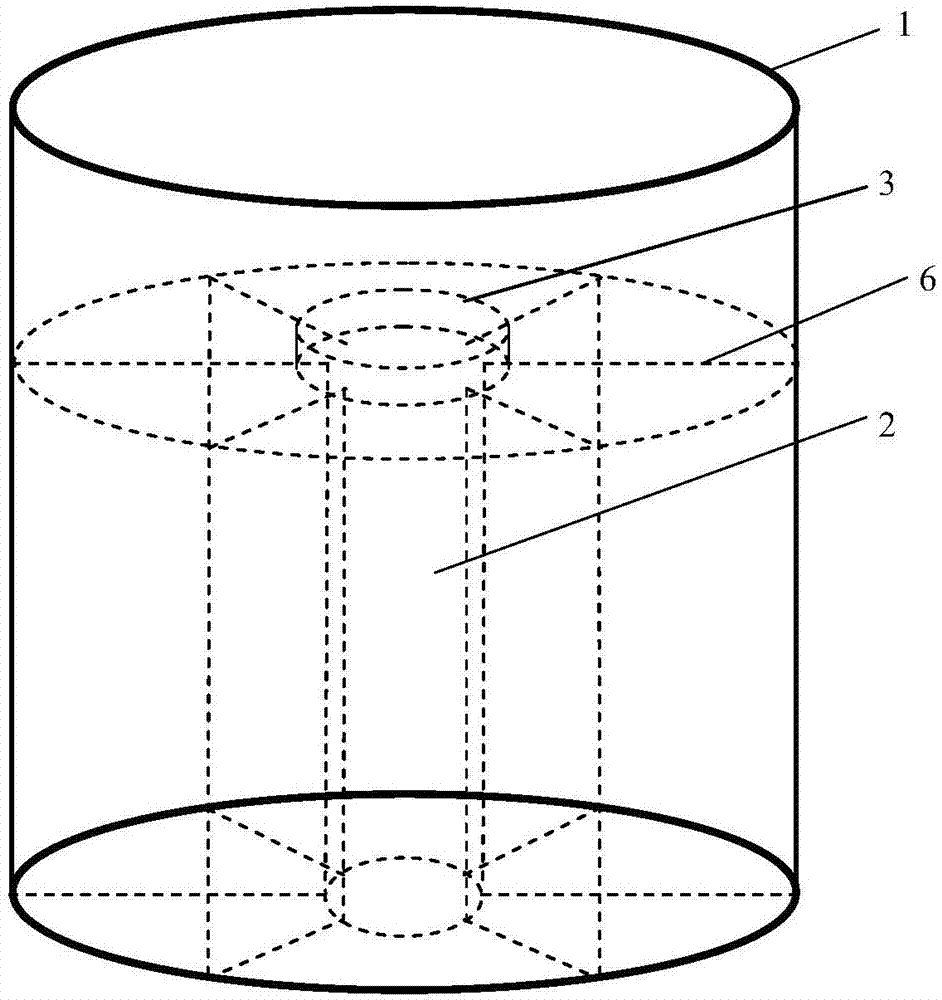

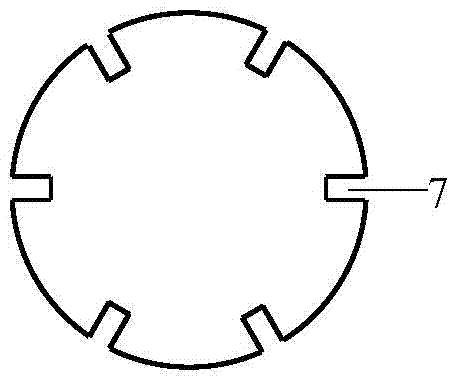

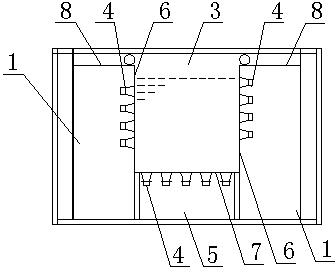

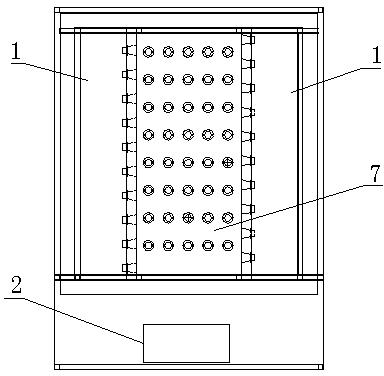

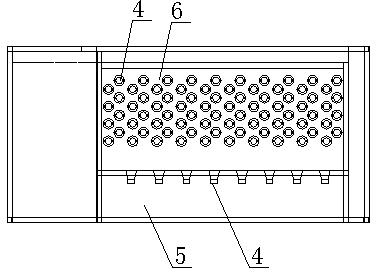

Flapping type washer preventing clothes from intertwining

InactiveCN104278476ACleaning rate and rinse improvementImprove washing effectOther washing machinesWashing machine with receptaclesImpellerMotor drive

The invention discloses a flapping type washer preventing clothes from intertwining and relates to the technical field of electric washer. The washer comprises a wash bucket which is vertically arranged and internally coaxially provided with a cylinder 2 in the fixed manner. A plurality of baffles 6 with holes are vertically arranged between the cylinder 2 and a wash bucket wall 1 along the diameter direction of the wash bucket. The wash bucket is divided into a plurality of wash chambers by the baffles. The clothes are separately placed in the different wash chambers. The inner wall or bottom of the wash bucket is provided with protruded ribs 5. During washing or rinsing, a motor drives the wash bucket to perform forward rotation, pause, reverse rotation and pause in a circulating manner. Thus, the baffles 6 constantly flap the clothes and drive the same to do forward rotation and reverse rotation in the water, and in this way, the clothes are washed cleanly. According to the arrangement, the traditional impeller structure is omitted, and the clothes are separately placed and washed and rinsed without vortex flow; the problem that the clothes are intertwined and extended is solved, and higher washing ratio and better rinsing effect are achieved.

Owner:陈爱文

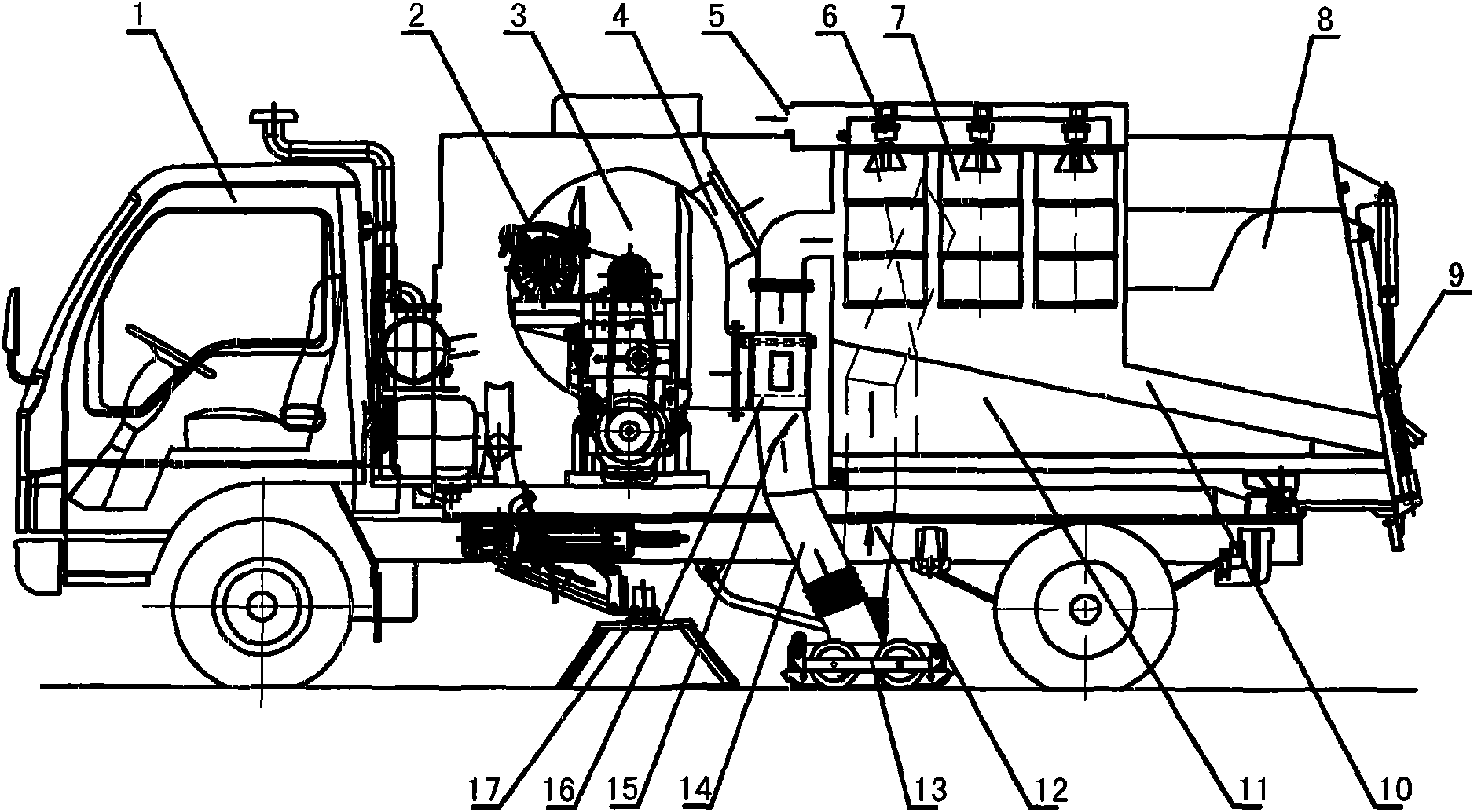

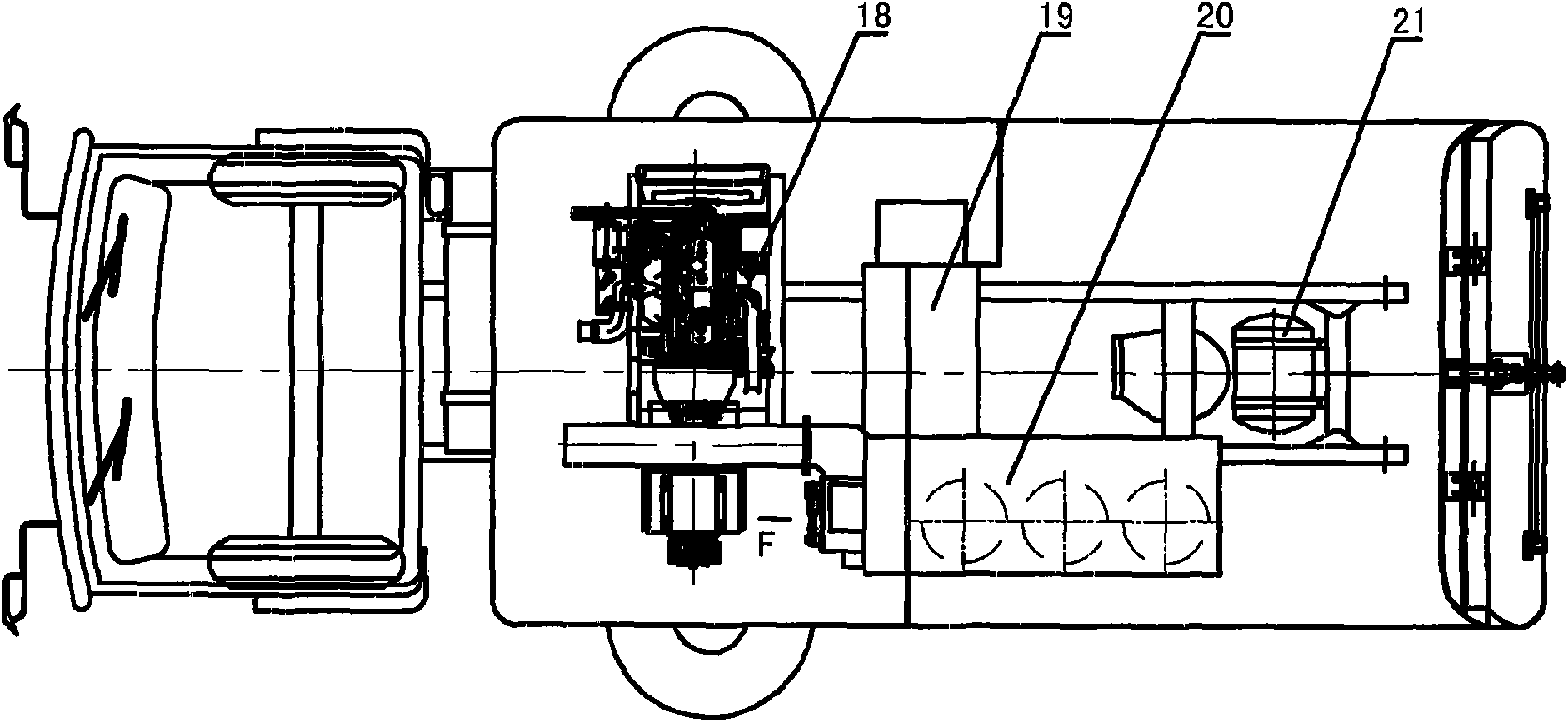

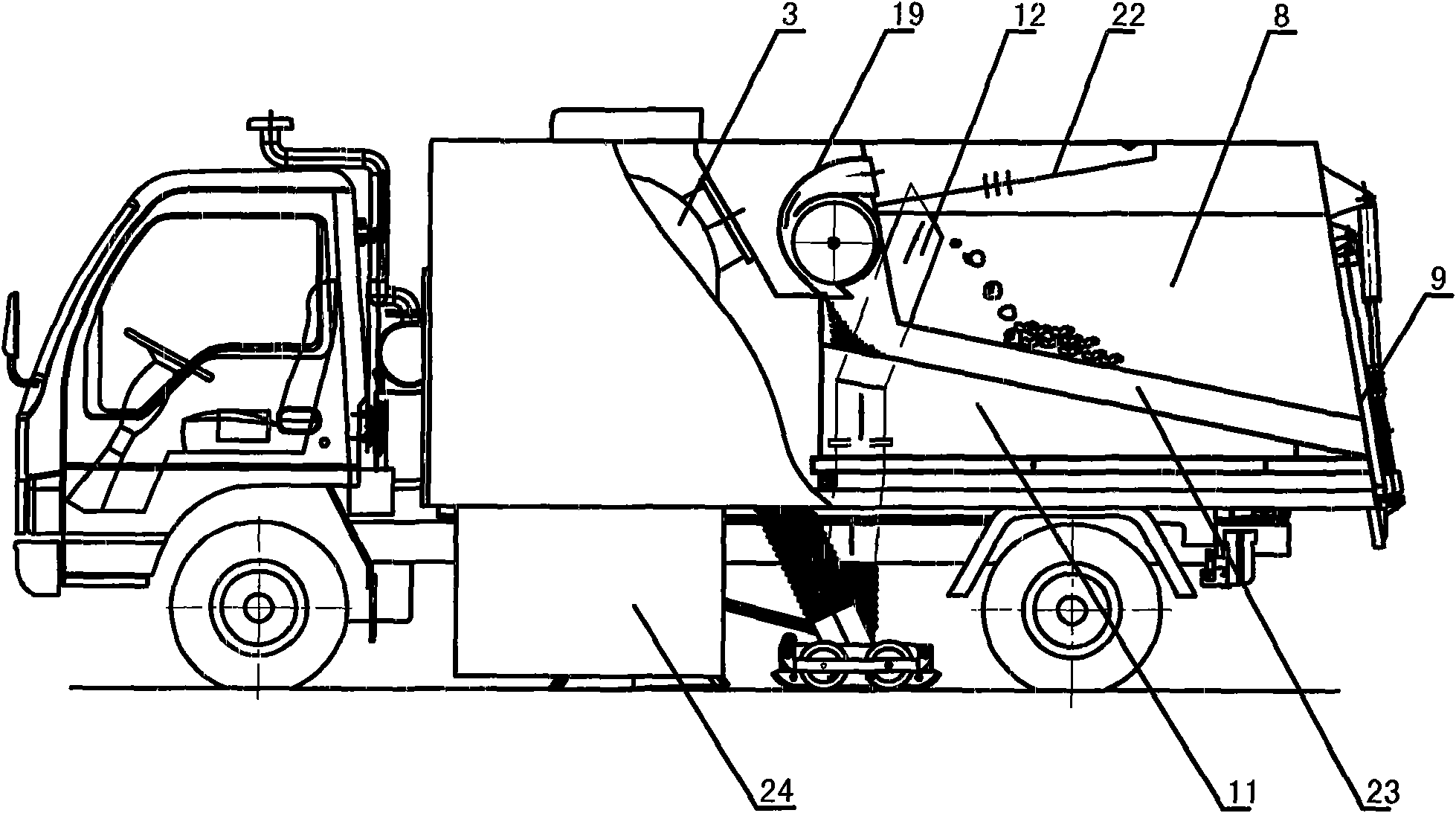

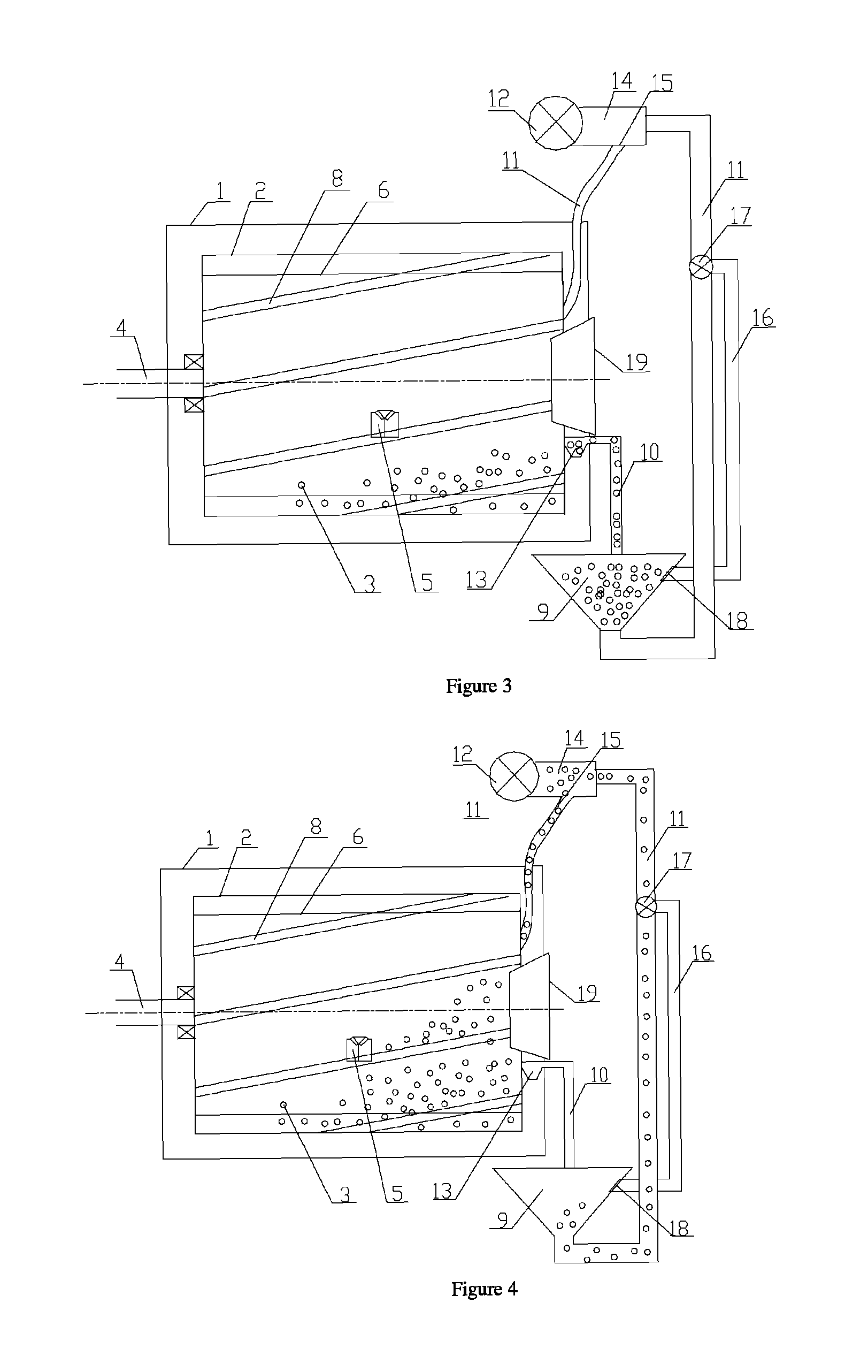

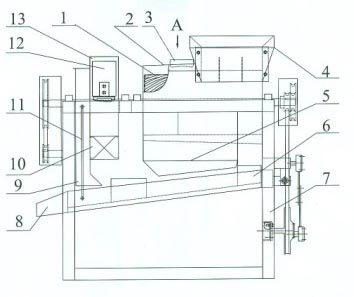

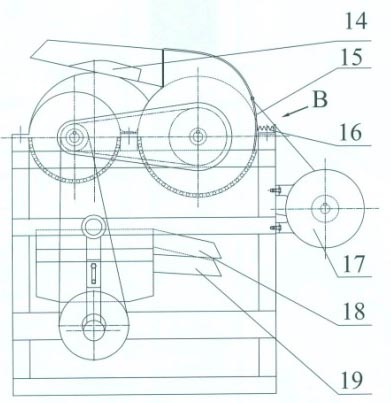

Sweeping and sucking type wet and dry road sweeper

The invention relates to a sweeping and sucking type wet and dry road sweeper, belonging to the special-purpose vehicle technology field. The road sweeper comprises an automobile chassis. A main fan is arranged at the upper part of the beam in the middle of the chassis and a rotary sweeper brush is installed at the lower part. A blowback type suction nozzle is arranged at the back of the rotary sweeper brush. The upper part at the back of the chassis is provided with a dedusting and dust collecting device and a water tank. The water tank is connected with nozzle at the rotary sweeper brush. The dedusting and dust collecting device comprises a dustbin and a dust filtering chamber. One part of the dustbin is communicated with the suction nozzle through a dust pipe and the other part is connected with an air inlet of the centrifugal separator through a filter screen. The air outlet of the centrifugal separator is communicated with the inlet of the main fan. The dust outlet goes to the back door of the dustbin. The outlet of the main fan is communicated with the blowback mouth at the suction nozzle by the blowback pipe and is communicated with the air outlet and the dust filtering chamber. The upper part of the dust filtering chamber is communicated with the air by a filter barrel. The road sweeper can sweep in a dry way or a wet way, is not limited by the climatic condition, combines suction and sweeping, has high cleaning rate, simple structure and easy sanitary tipping.

Owner:AEROSUN CORP

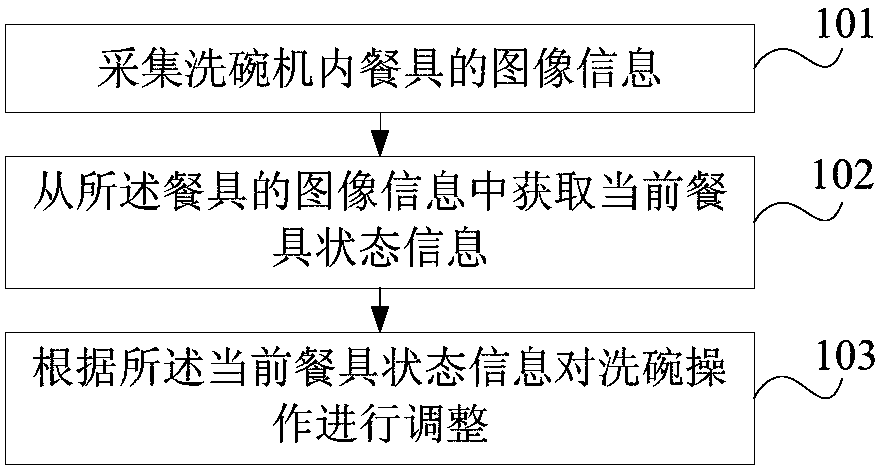

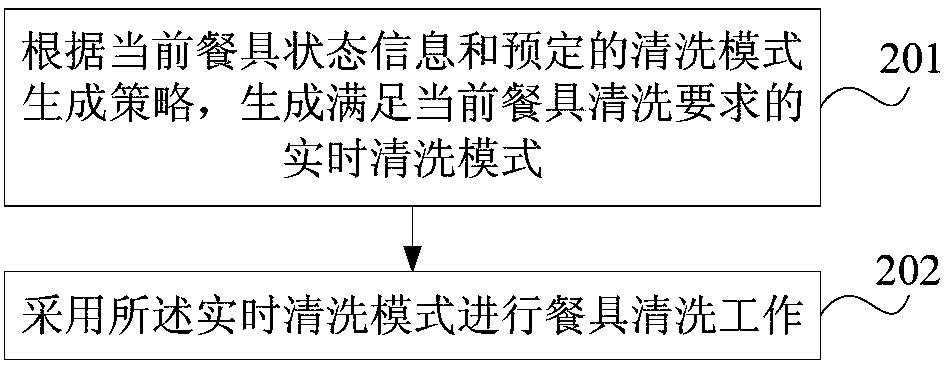

Dish-washing machine control method and device, dish-washing machine and computer readable storage medium

InactiveCN108577730ASolve the cleaning rateSolve efficiency problemsWashing controlling processesHome appliance efficiency improvementMachine controlEnergy consumption

An embodiment of the invention discloses a dish-washing machine control method and device, a dish-washing machine and a computer readable storage medium, relates to the field of intelligent householdelectrical appliances and can solve the problems of low washing rate and working efficiency of existing dish-washing machines. The dish-washing machine control method comprises steps as follows: acquiring image information of tableware in the dish-washing machine; acquiring current tableware state information from the image information of the tableware; adjusting dish-washing operation according to the current tableware state information. The washing rate and washing efficiency of the dish-washing machine can be improved, the cleaning time is saved, energy consumption and water consumption arereduced, and the dish-washing machine control method and device are applicable to various dish-washing machines.

Owner:KINGSOFT

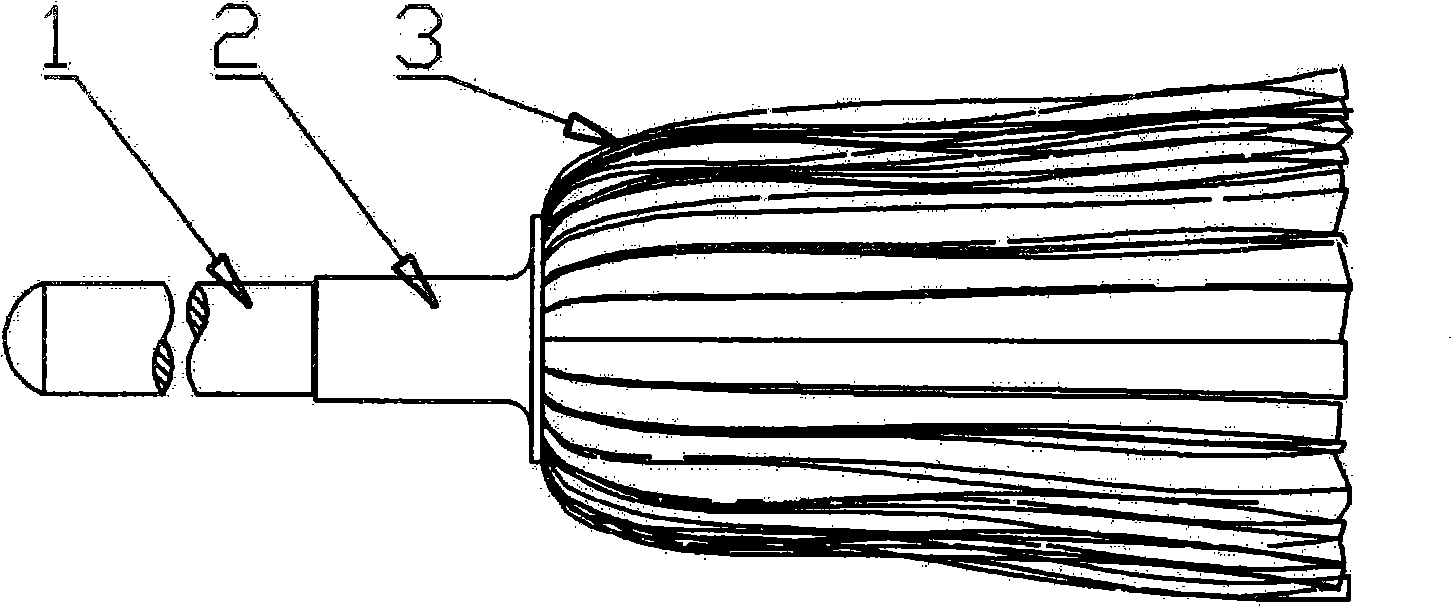

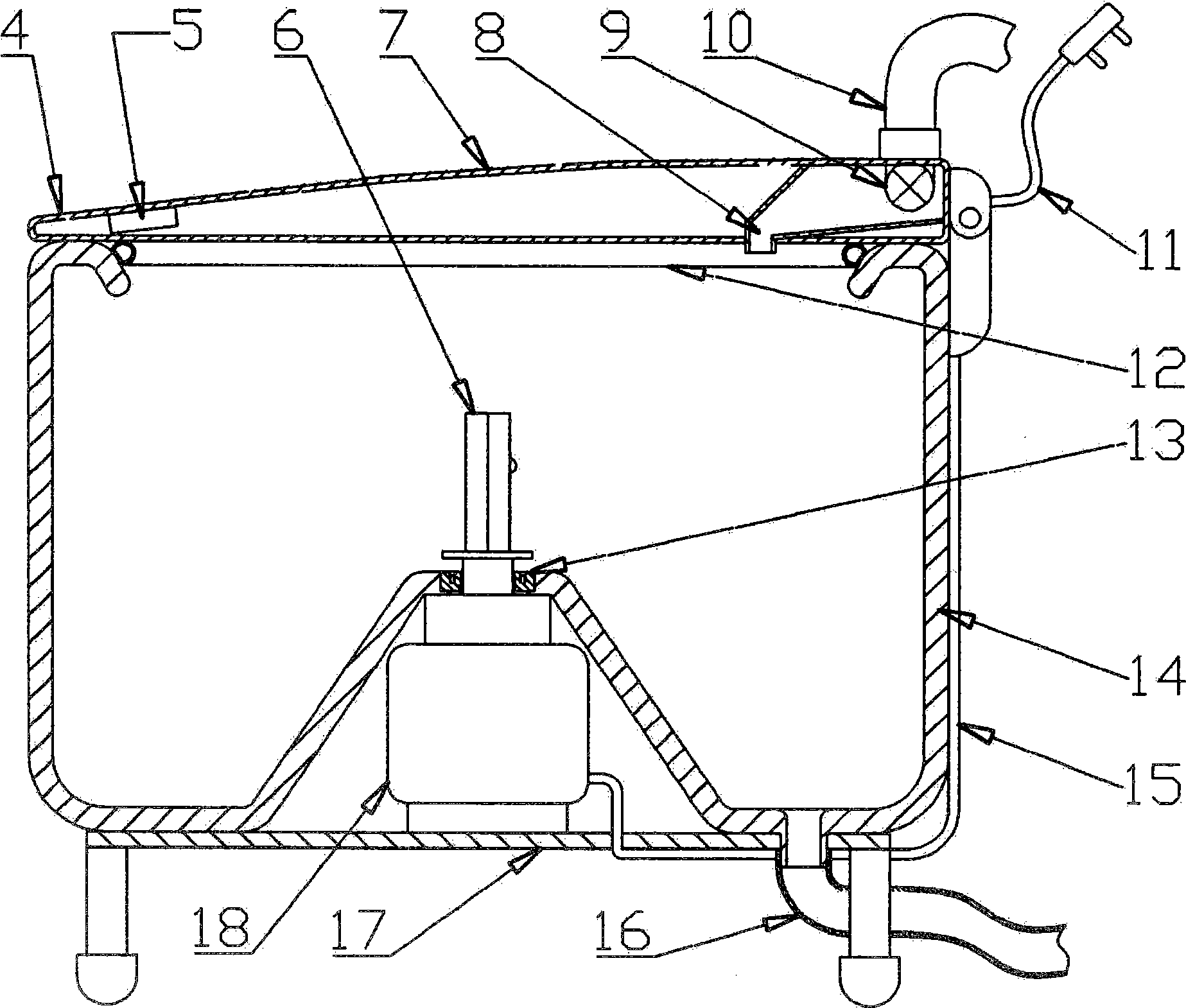

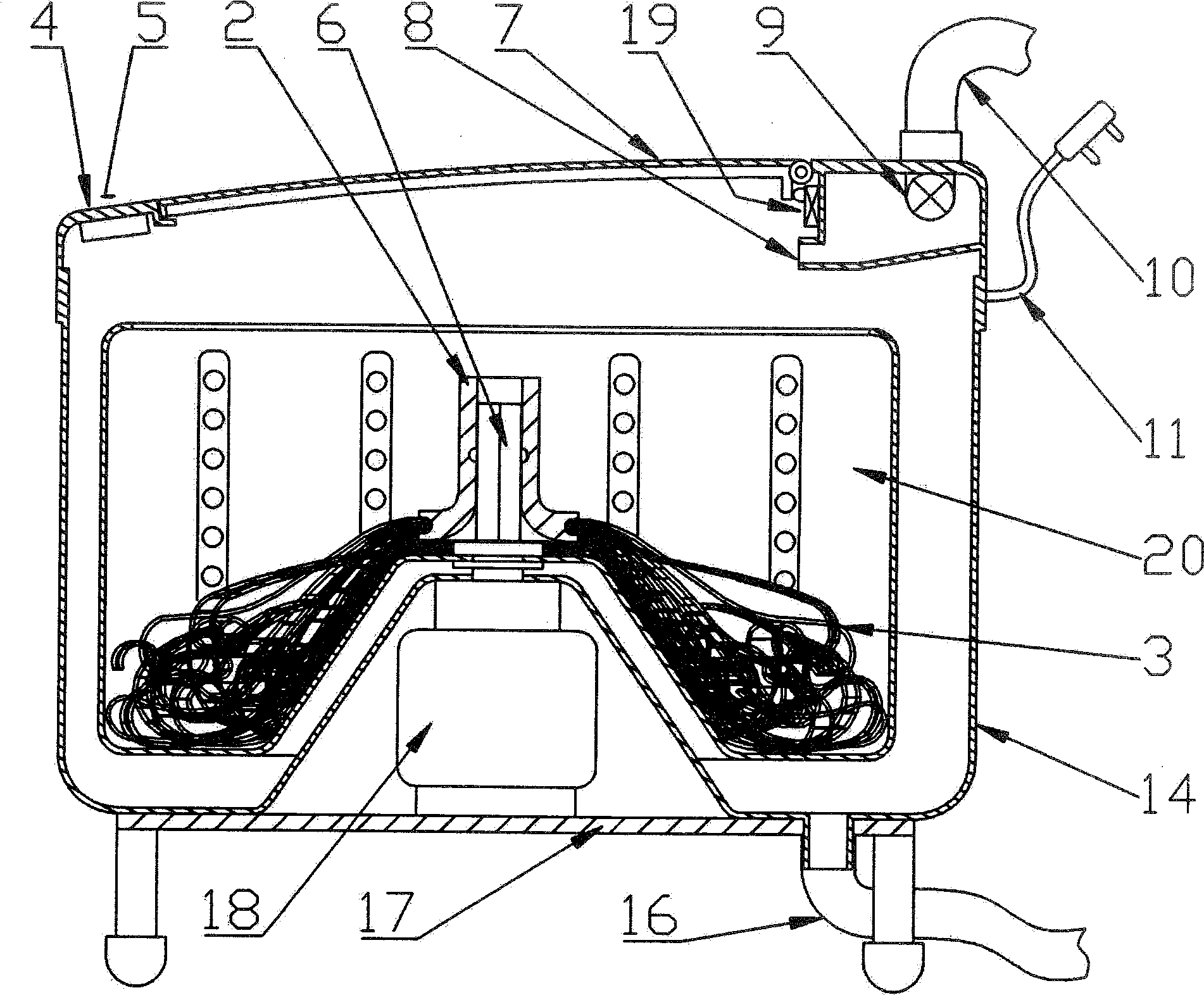

Mop rinsing machine and mop rinsed by mop rinsing machine

The invention discloses a mop rinsing machine and a mop rinsed by the mop rinsing machine. The mop rinsing machine is characterized in that the bottom of the barrel body of the mop rinsing machine is raised in the middle; a motor and a clutch of the motor are arranged between the a base and the barrel body; the output shaft of the motor or the clutch penetrates through the bottom of the barrel body; the output shaft and the barrel body are rotationally sealed; and the output shaft is connected with a raised handle. The mop rinsed by mop rinsing machine comprises a mop handle, a connector and cloth strips; one end of the connector is connected with the mop handle, and the other end is detachably connected with the mop strips at the periphery; the upper end of the connector is provided with a hole or shaft to be matched with the mop handle, and the lower end is provided with an inner hole to be matched with the raise handle of the mop rinsing machine. When a mop is rinsed by the mop rinsing machines, the head of the mop can be arranged on the raised handle of the mop rinsing machine and can rotate synchronously with the raised handle. The mop can be cleanly rinsed and highly dried, has strong soil removal and adsorption capacity and improved cleaning effect, can not cause the floor to be wet and slippery and reduces the labor intensity of workers.

Owner:姜浩

Clothes washing water recycling device, washing method thereof and water-saving clothes washing control method

ActiveCN103835095AImprove cleaning rateSave flushing waterOther washing machinesControl devices for washing apparatusWater savingUltrafiltration

The invention discloses a clothes washing water recycling device, a water-saving clothes washing control method and a washing method of the clothes washing water recycling device. The clothes washing water recycling device comprises a washing cylinder, a circulation water pipeline, a drainage pipeline and an ultrafiltration membrane assembly. The water inlet end of the circulation water pipeline is communicated with a water outlet of the washing cylinder, and the water outlet end of the circulation water pipeline is communicated with a water inlet of the washing cylinder. The ultrafiltration membrane assembly is provided with a water inlet end, a first water outlet end and a second water outlet end. The ultrafiltration membrane assembly is connected to the circulation water pipeline through the water inlet end and the first water outlet end, and a gas conveying device is connected to the water inlet of the ultrafiltration membrane assembly. The circulation water pipeline is further provided with a liquid conveying device, and the drainage pipeline is communicated with the second water outlet end of the ultrafiltration membrane assembly. When much dirt is retained on an ultrafiltration membrane, gas washing is performed on the ultrafiltration membrane, and then water is used for washing. Compared with the manner that only water washing is used, washing water can be saved, and cleaning is better and more thorough.

Owner:HAIER GROUP TECHN R&D CENT +1

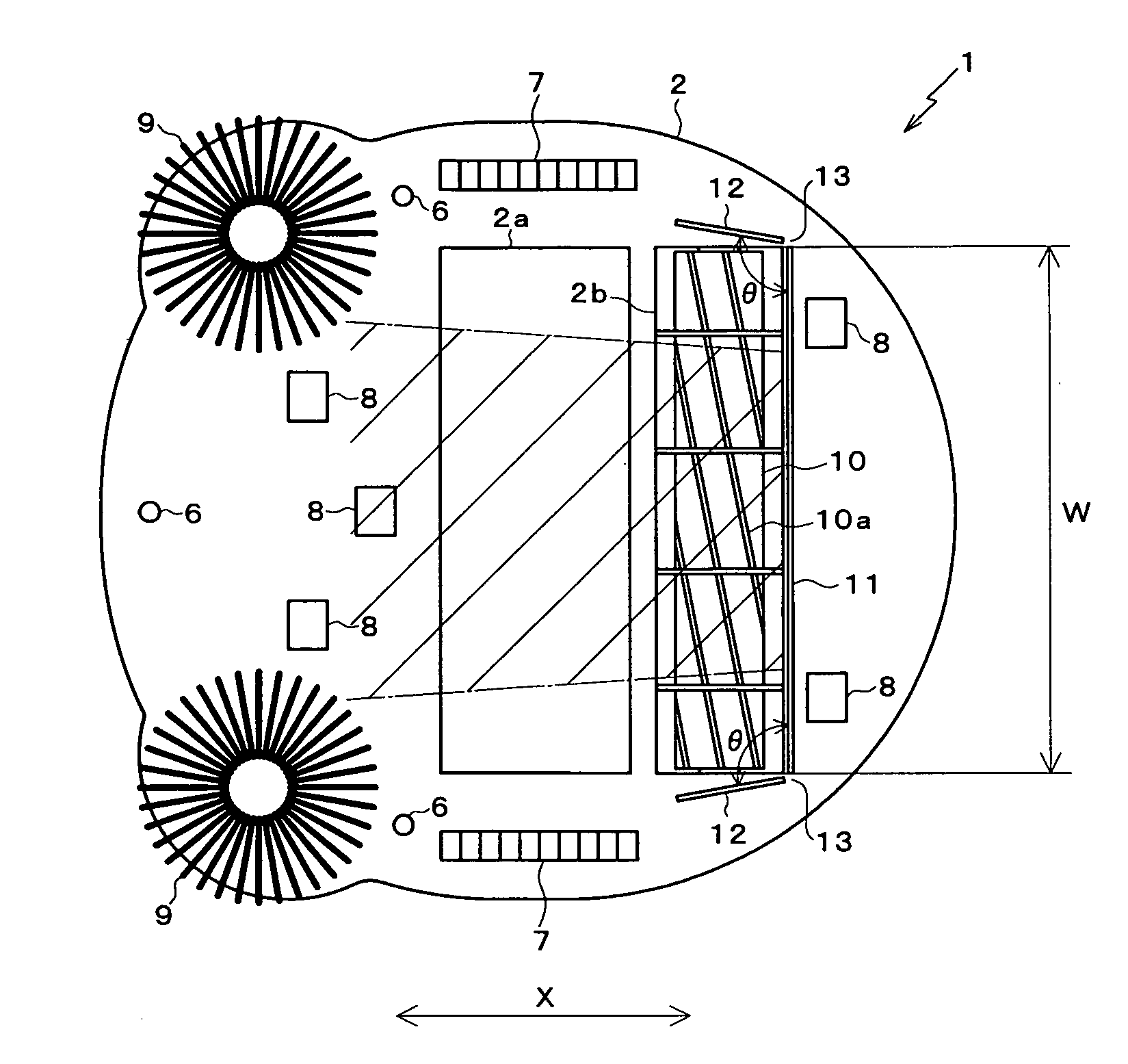

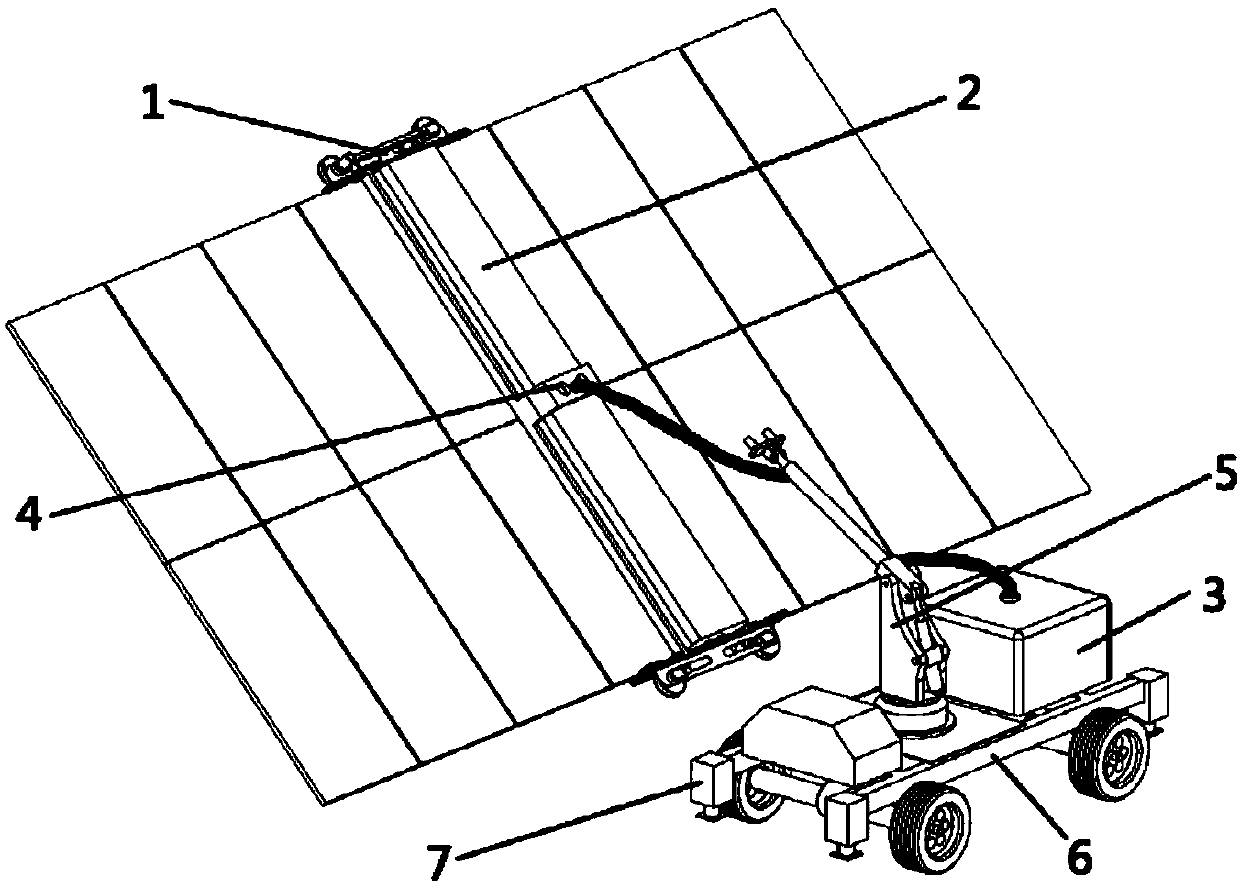

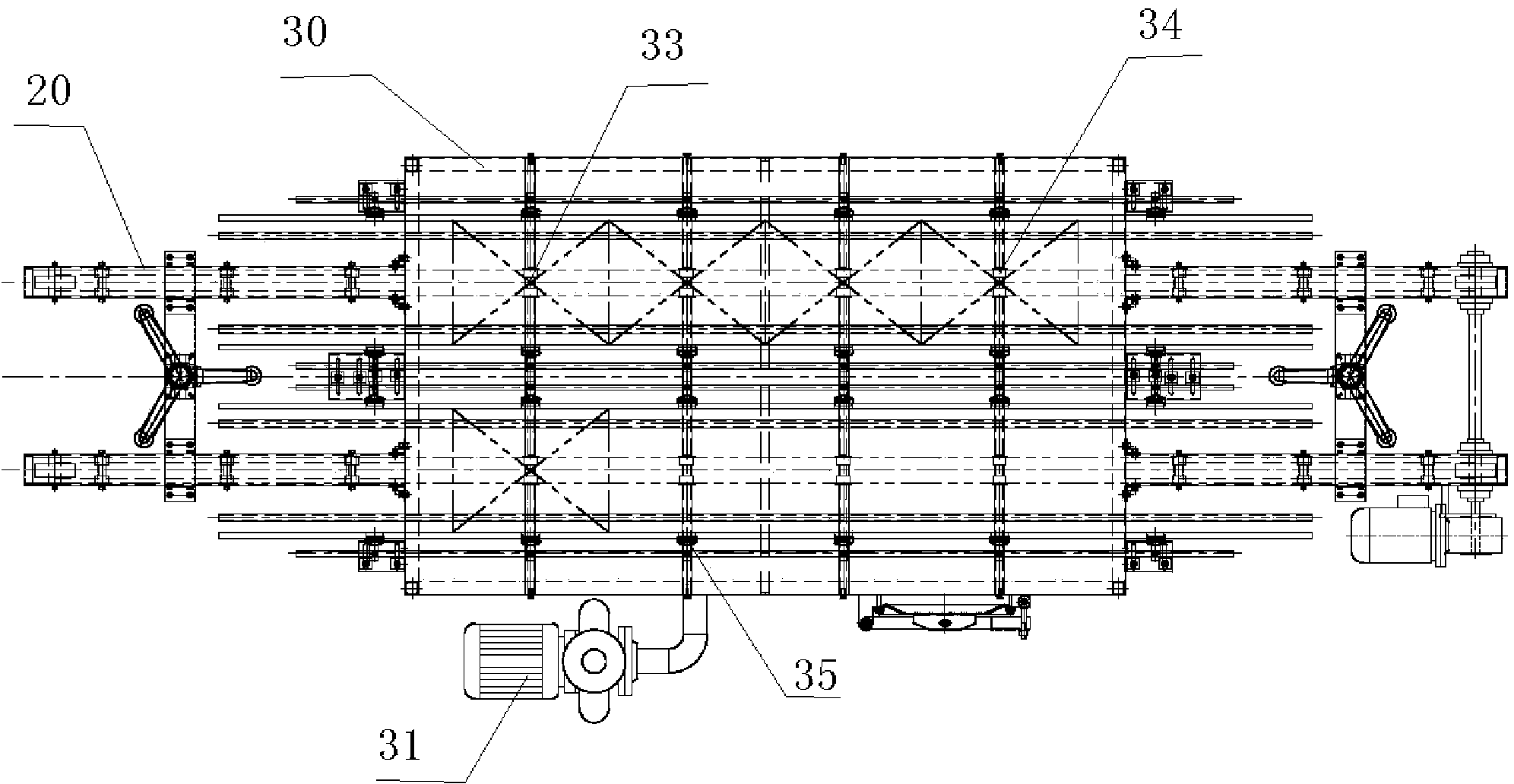

Comprehensive cleaning device for solar power station

InactiveCN104209299AResolution timeSolve efficiency problemsPhotovoltaicsCleaning using toolsPower stationResource saving

The invention discloses a comprehensive cleaning device for a solar power station. The comprehensive cleaning device comprises a walking support, a cleaning unit, a supply unit, a connector and a mechanical arm; the comprehensive cleaning device for the solar power station is used for cleaning solar cell modules quickly and conveniently, has the obvious advantages of time and labor saving effects, low resource consumption and low energy consumption, has more remarkable performance in the aspects of high-efficiency cleaning rate and resource saving effect particularly for cleaning the solar cell modules in a large-scale solar power station, solves the problems of long working time, low efficiency, high cost and the like in the traditional method for cleaning the solar cell modules, and also solves the problems that the traditional vehicle-mounted solar cell module cleaning equipment has a high requirement on place flatness of the solar power station and the cleaning equipment damages the solar cell modules and wastes resources and energy in the process of cleaning the solar cell modules.

Owner:金丹

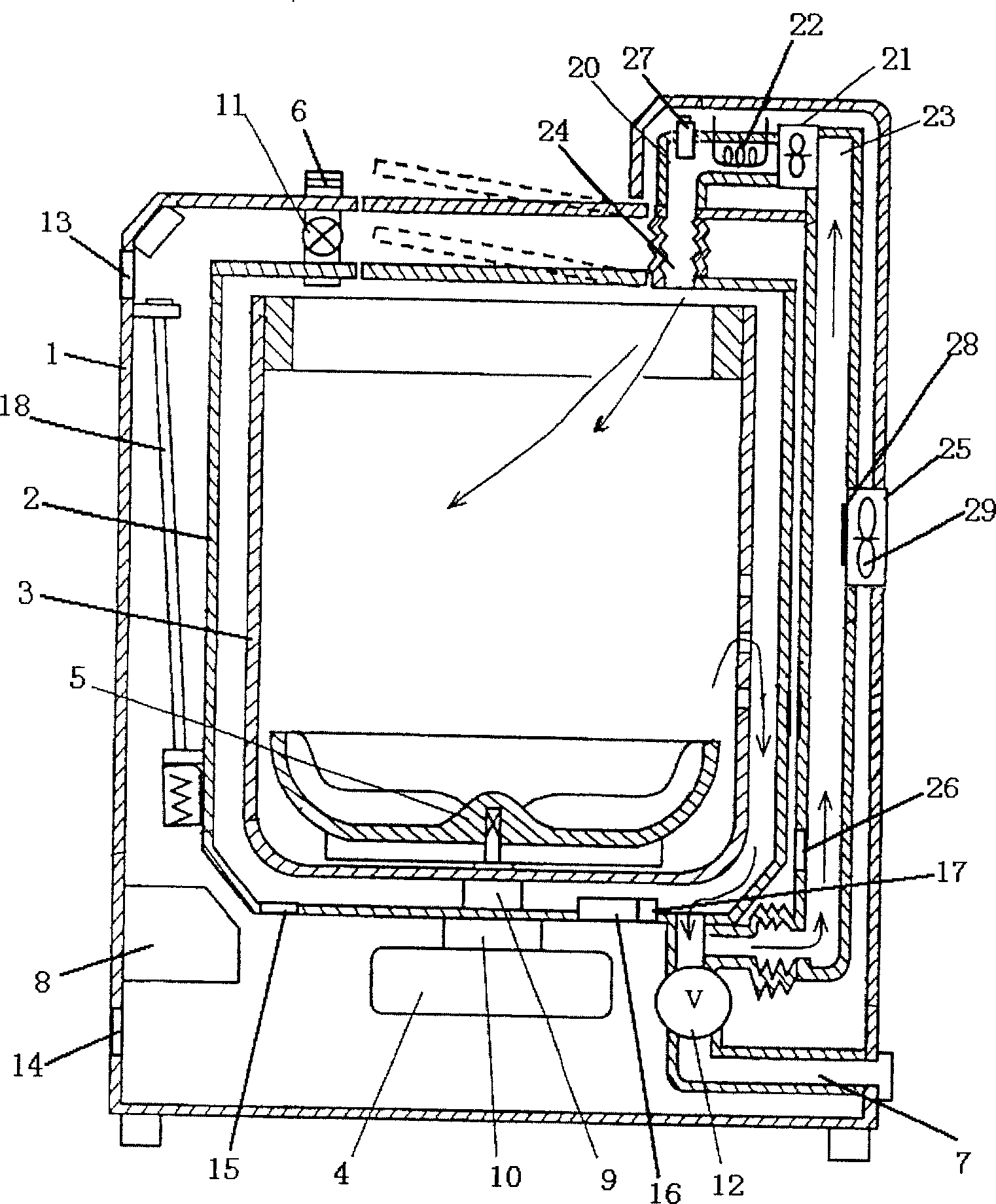

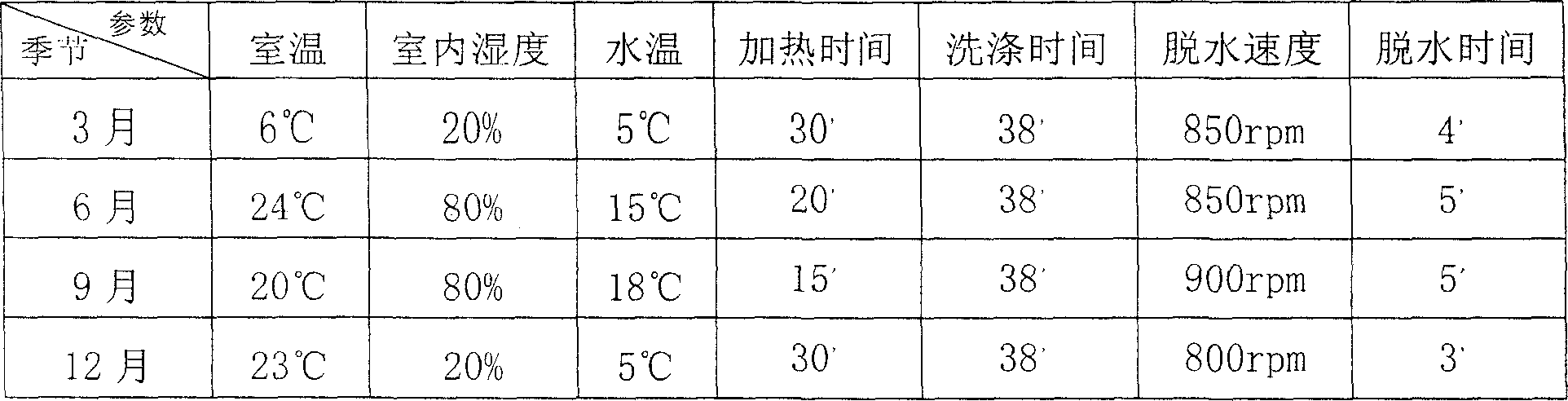

Self-adaptive laundry method and device

ActiveCN1908284AImprove dissolution rateImprove cleaning rateLaundry dryer apparatusWashing machine with receptaclesAutomatic controlProcess engineering

The invention relates to a control method when washing clothes and relative washer, wherein it comprises: (1) when the washer is started, the temperature sensor sends the temperature data to the controller; the humidity sensor sends the humidity data to the controller; (2) when the washer feeds water, the water temperature sensor measures the water temperature, and the controller, based on water temperature decides to add water or not to improve the dissolution rate of detergent, to obtain best washing effect; (3) when the washing and poaching are completed, based on around humidity data, the controller automatically controls the rotation speed and time of dewater process. And said control method comprises a drying process, that after completing washing, poaching, and dewatering, to be automatically set by the controller. The invention can consider different temperatures and humidity to obtain best washing effect.

Owner:HAIER GRP CORP +1

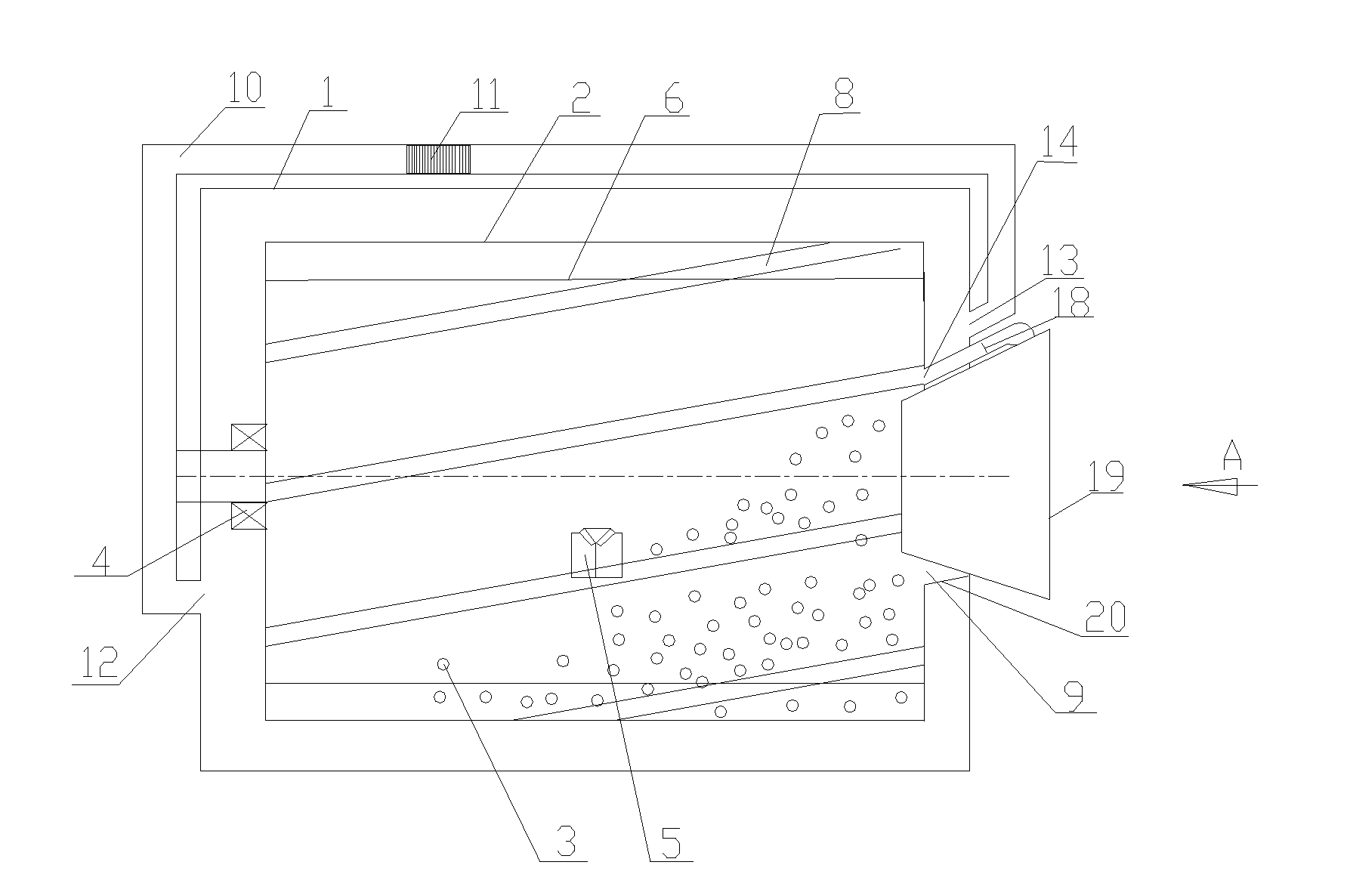

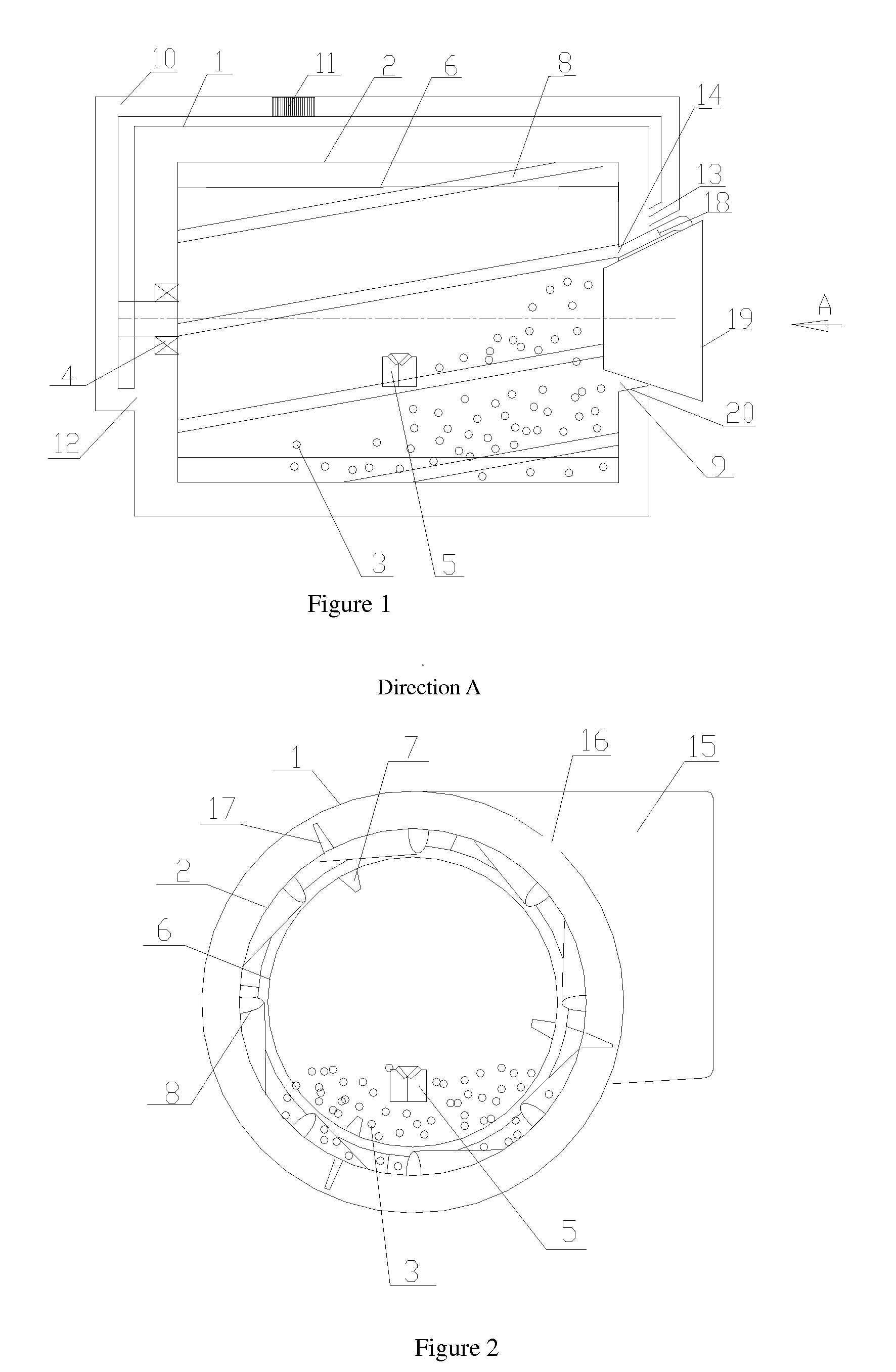

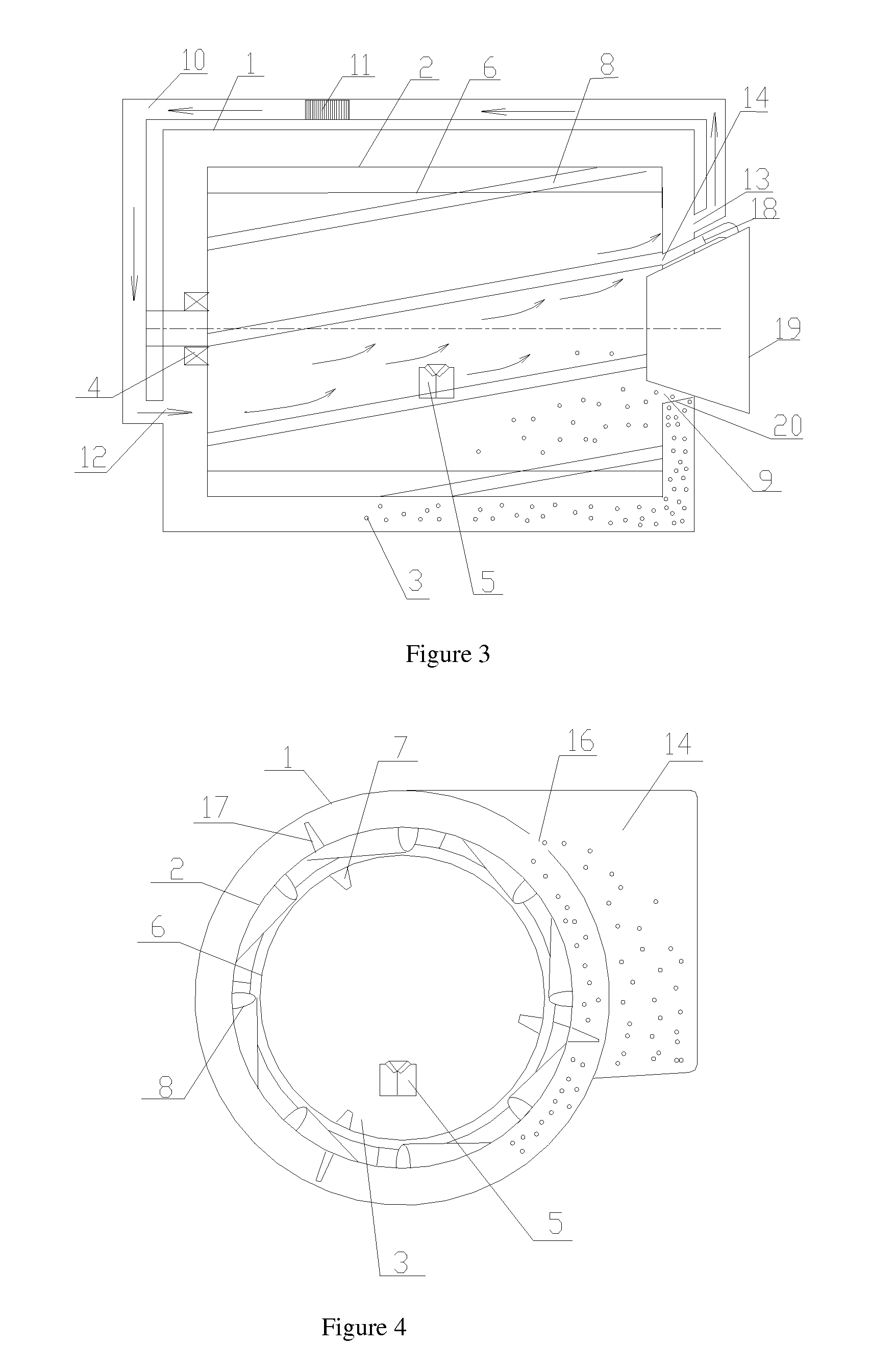

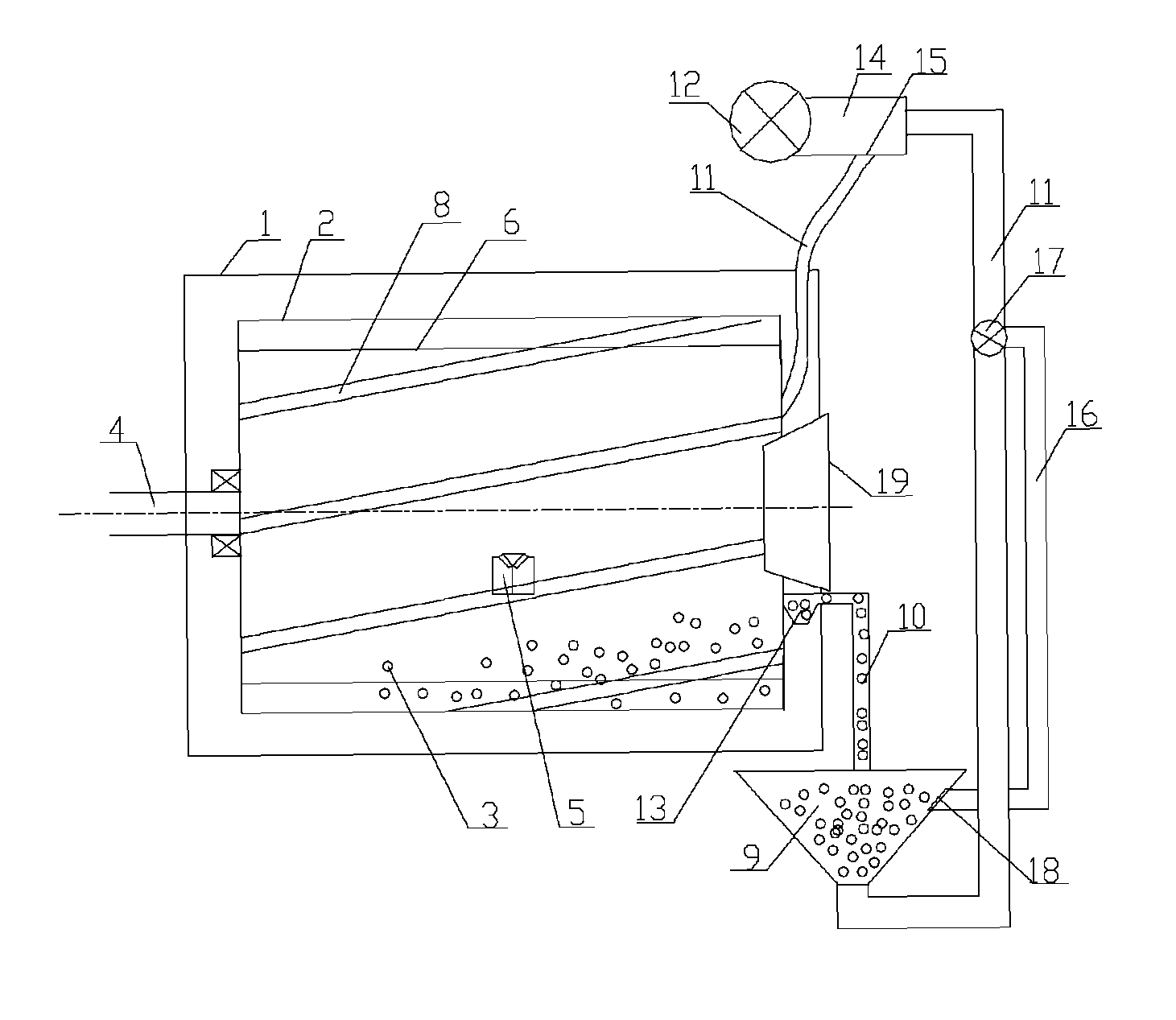

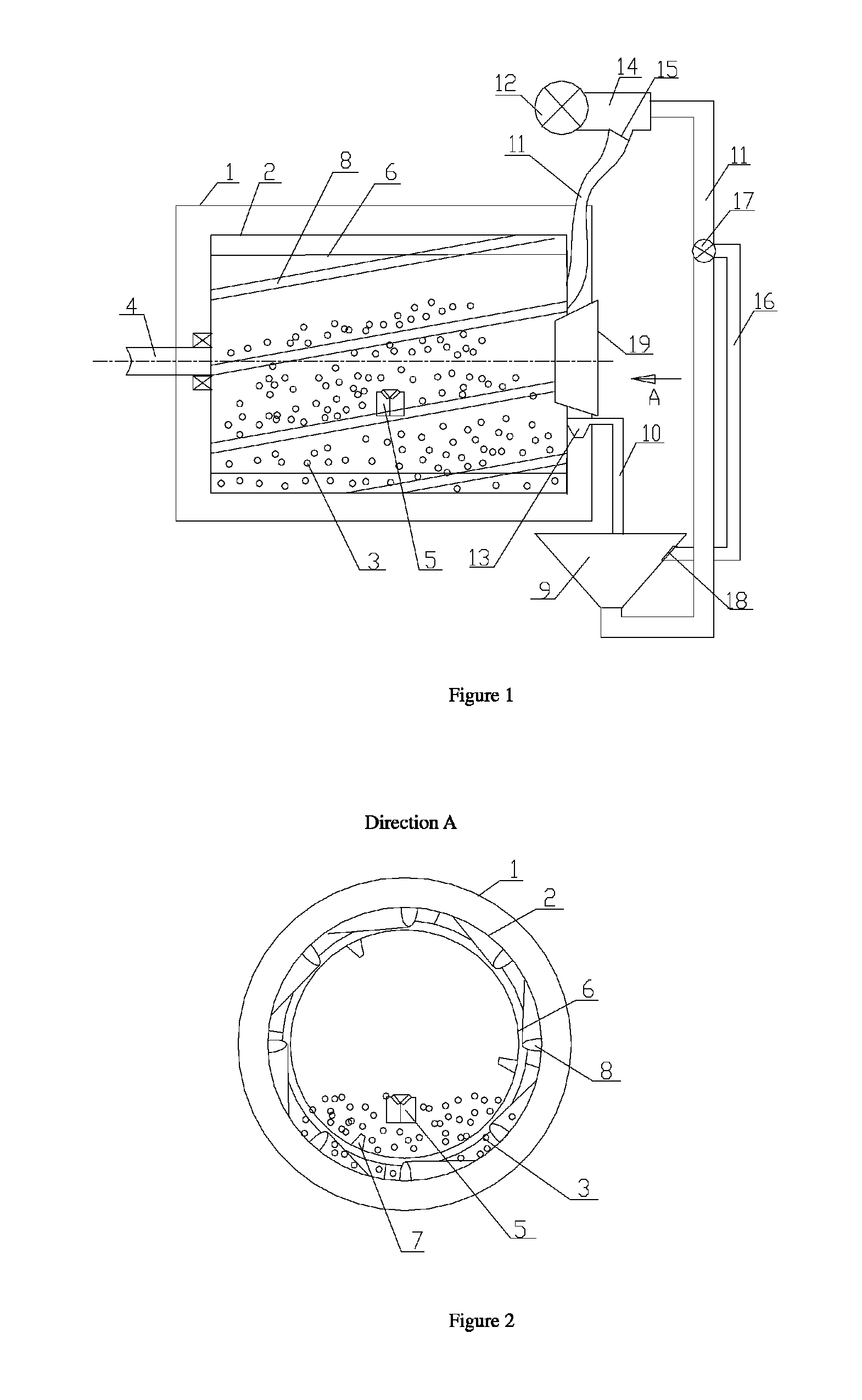

A washing machine and washing method thereof

InactiveUS20140317860A1Simplify the washing processImprove cleaning rateOther washing machinesDetergent compounding agentsAir cycleEngineering

A washing machine and washing method thereof, comprising an inner tub, an outer tub and solid particles as washing medium. The inner tub, whose inner wall is arranged with lifting ribs protruding inward, rotates under the driving power of a driving device. Inside the washing machine, there is an air circulation channel, wherein, a fan is arranged. Both ends of the air circulation channel communicate to the inner tub. A discharge hole for recycling the particles and a feeding hole for putting in the particles are arranged at the front end of the inner tub. When the washing process comes to an end, both the clothes and particles can be dewatered and dehydrated simultaneously, so the washing procedures get simplified. Besides, blowing air towards the inner tub to separate and recycle the particles is conducive to 100% recycling of the particles.

Owner:XEROS LTD

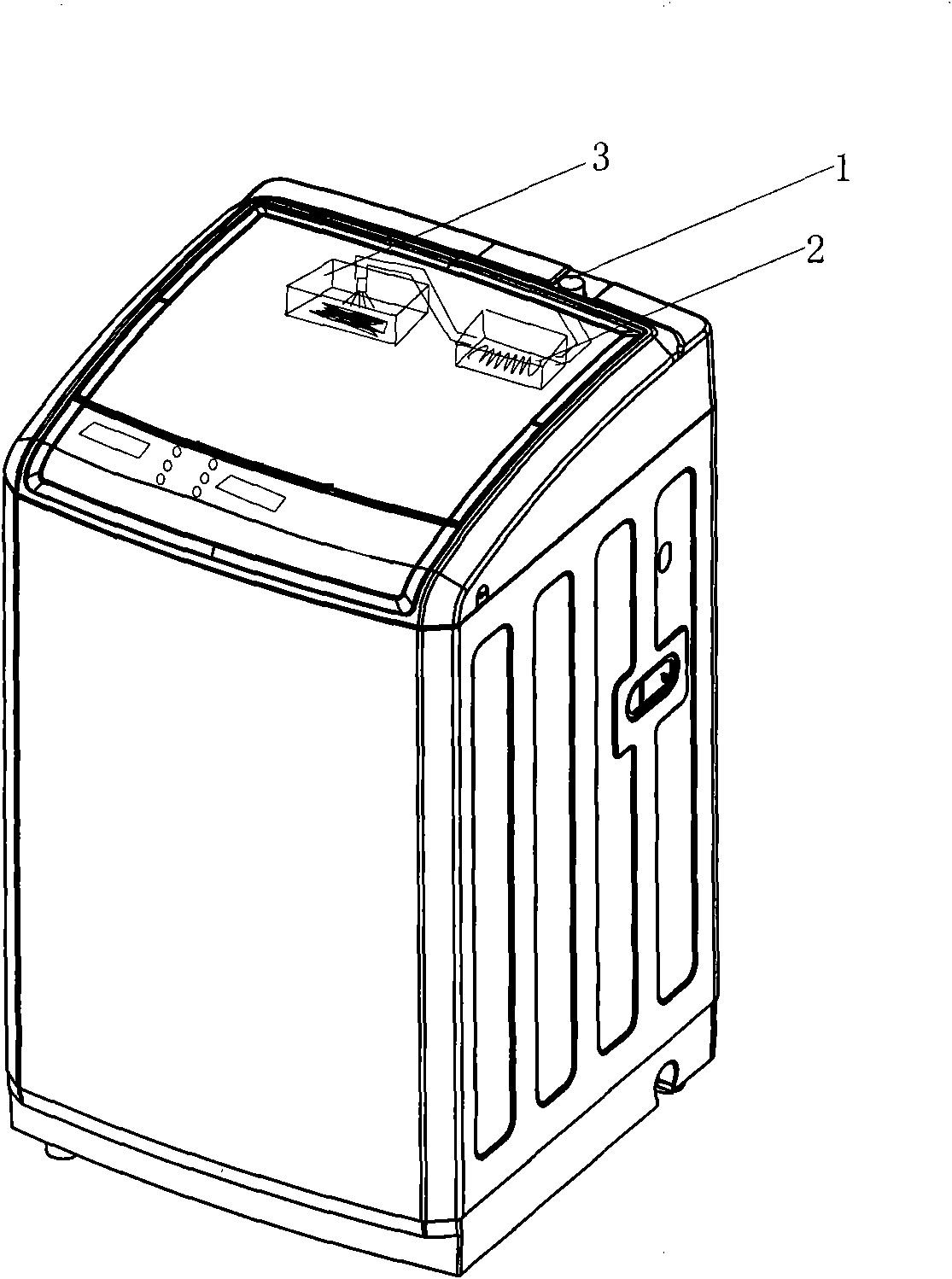

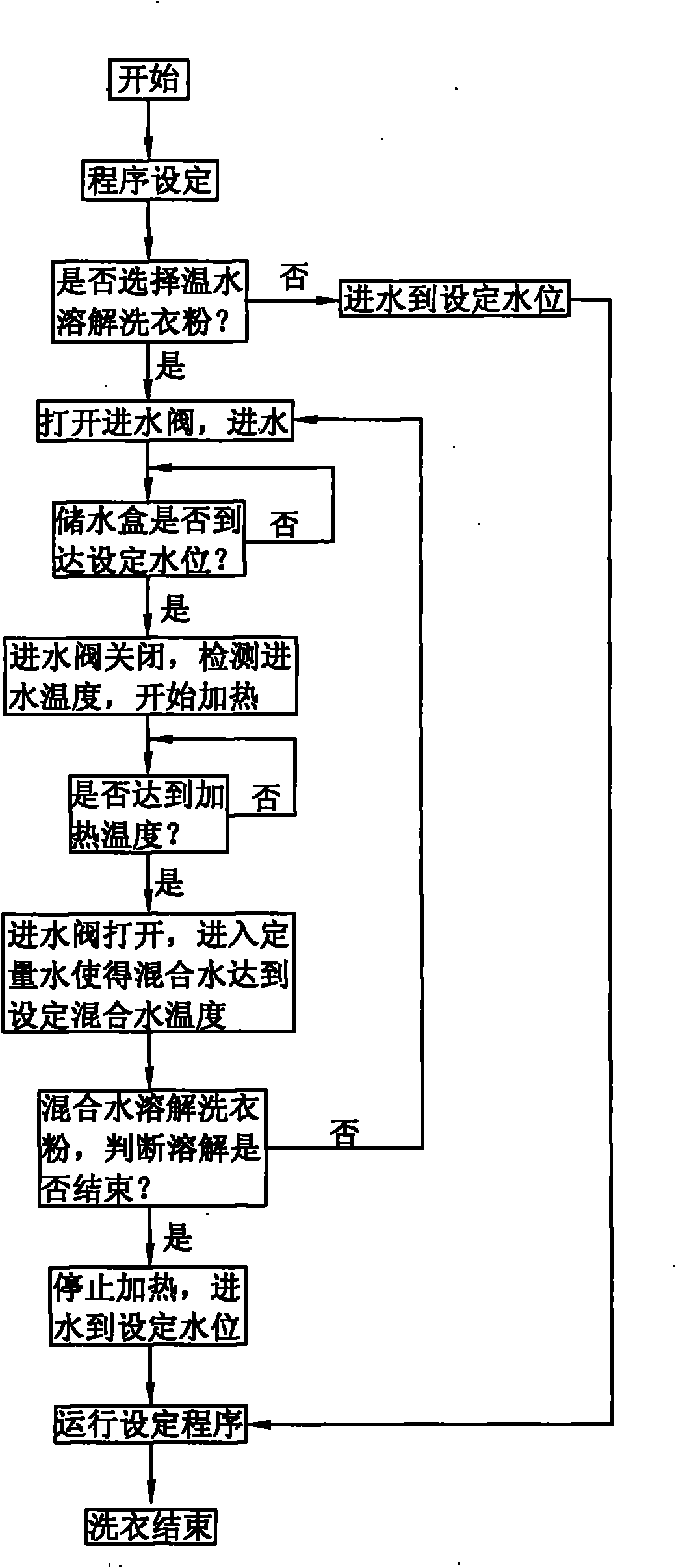

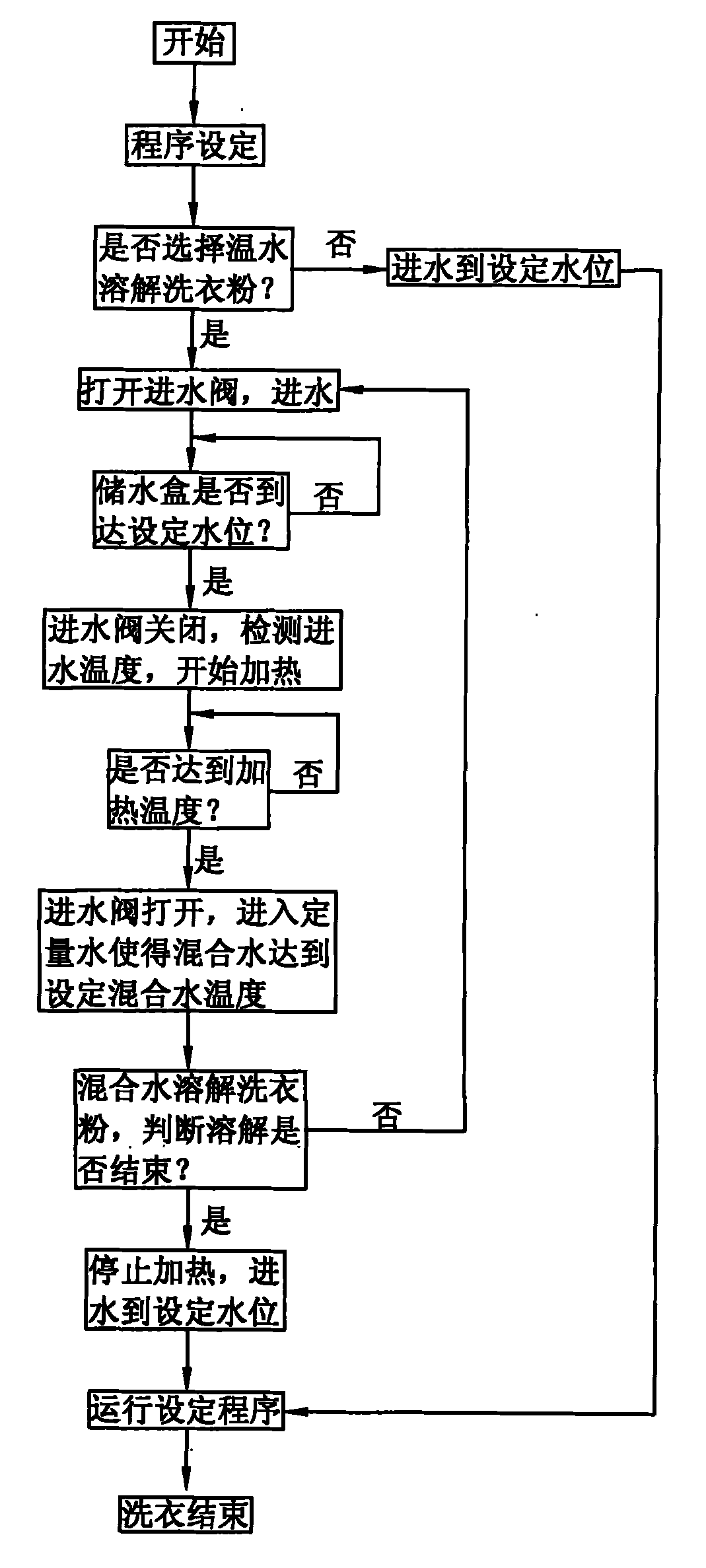

Method for controlling water feeding dissolution of washing powder in washing machine and washing machine thereof

ActiveCN102080323AImprove cleaning rateImprove uniformityOther washing machinesControl devices for washing apparatusWater storageDissolution

The invention discloses a method for controlling water feeding dissolution of washing powder in a washing machine and a washing machine thereof. The washing machine comprises a water feeding valve, a water storage box and a washing powder box, wherein the water storage box is arranged between the water feeding valve and the washing powder box and is communicated with the washing powder box; when the washing powder is dissolved, water is firstly fed into the water storage box to reach a set water level, the water is heated to a set heating temperature after the water feeding temperature is detected, a fixed amount of water is continuously fed according to the relationship of the amount of the heated water in the water storage box, the set heating temperature and the water feeding temperature so that the heated water and the fed water in the water storage box are mixed to generate mixed water with the temperature, suitable for the dissolution of the washing powder; the mixed water simultaneously flows into the washing powder box to dissolve the washing powder sufficiently, washing articles are then uniformly soaked in the washing powder-dissolved water in the manner of internally circulated sprinkling and stirring; and finally, the water is fed to reach the set water level for the purpose of washing, therefore, the cleaning rate and the uniformity of the washing articles are improved.

Owner:HAIER GRP CORP +2

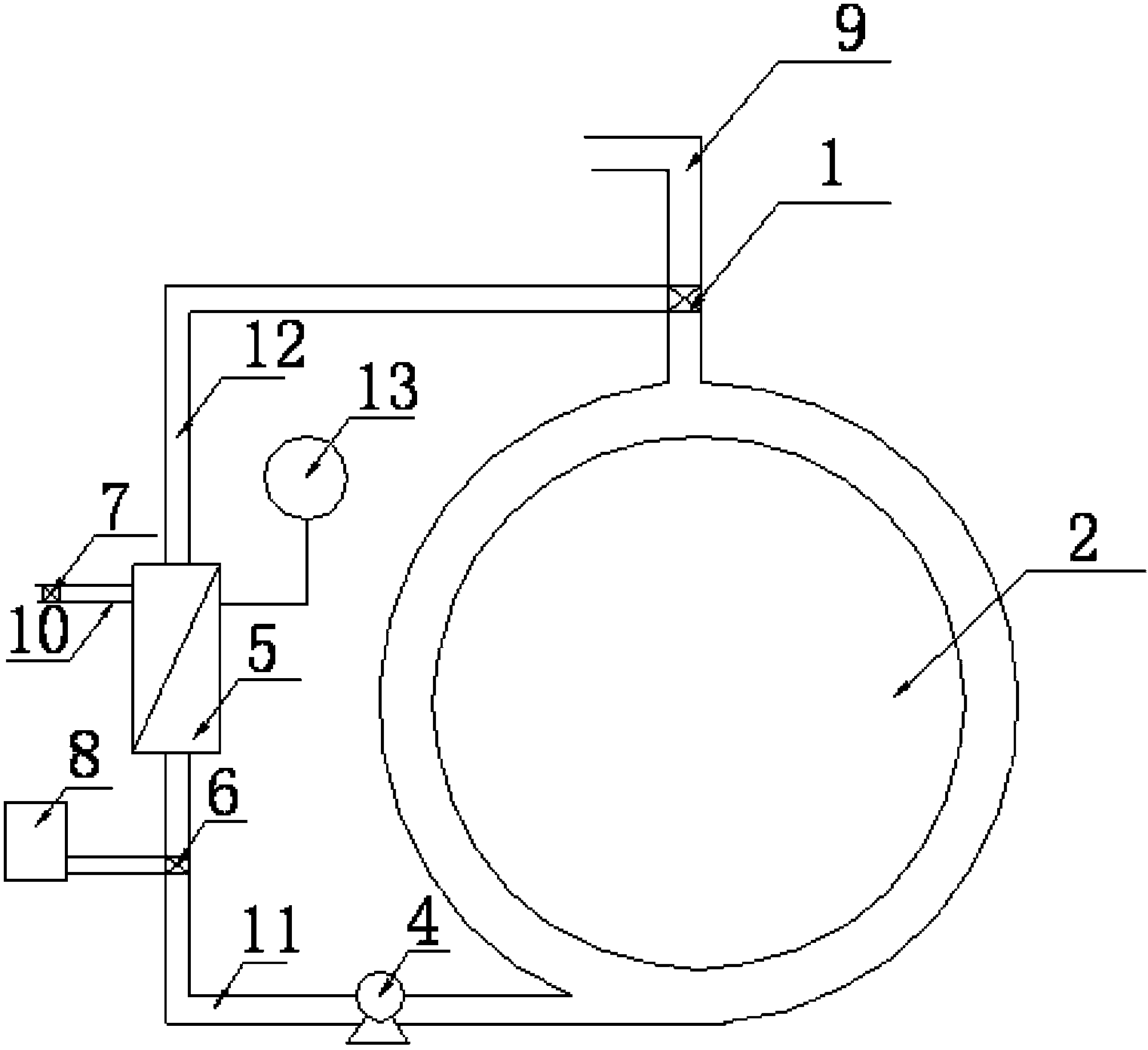

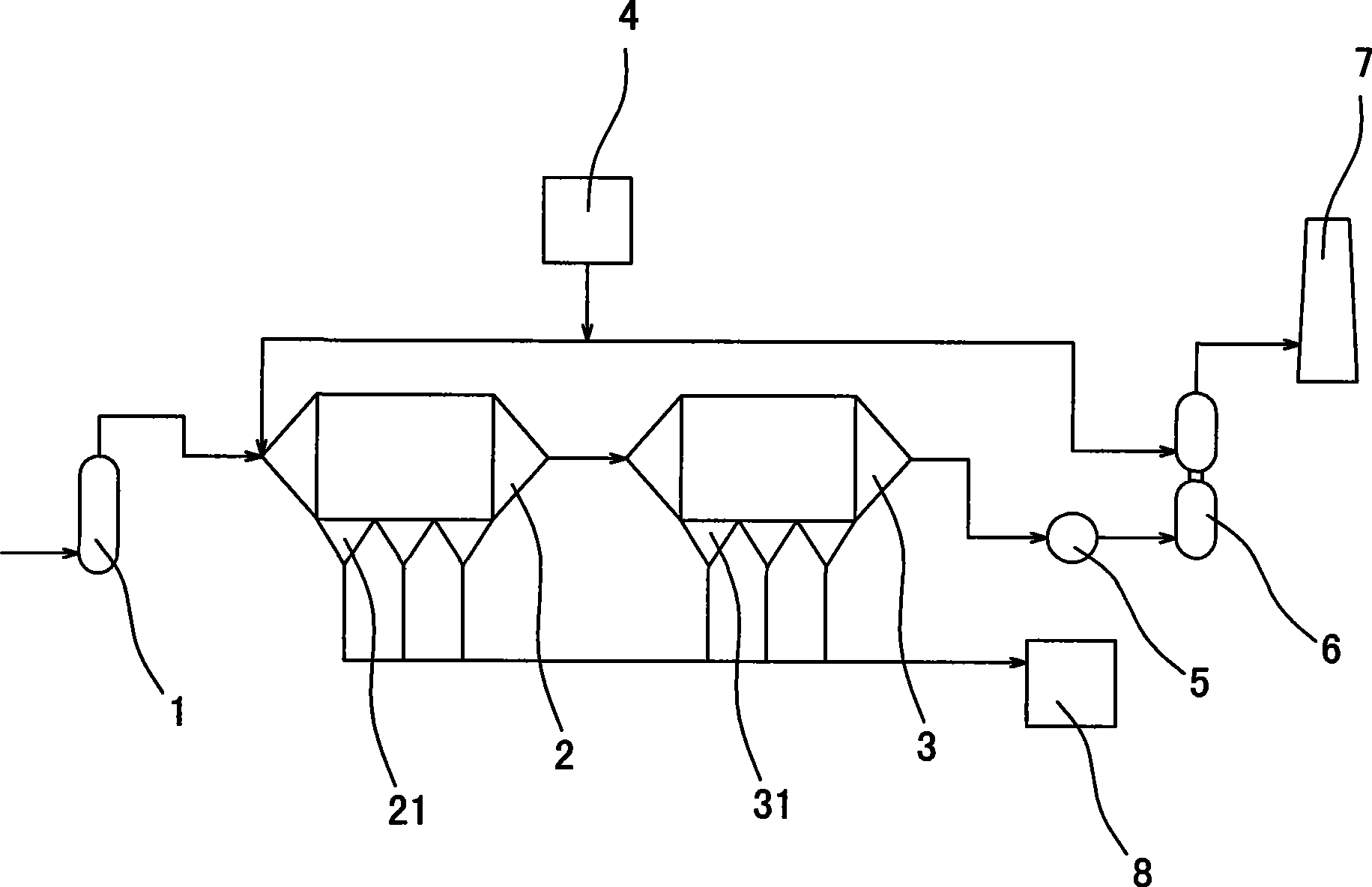

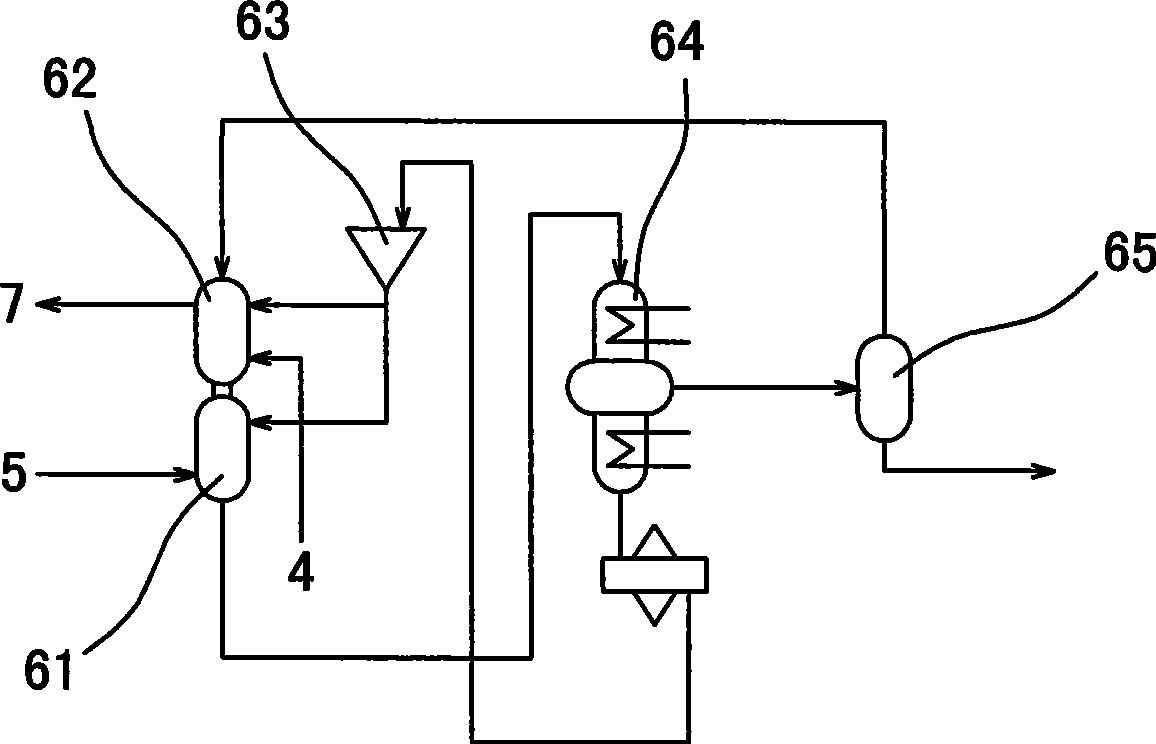

Pulse corona plasma reaction and absorption catalysis desulfurization denitration method and device

InactiveCN101422692AGood economic valueImprove the effect of desulfurization and denitrificationNitrous oxide captureDispersed particle separationFlue gasTower

The invention discloses a desulfurization and denitration method of the reaction, adsorption and catalysis of pulse corona plasma. Flue gas enters a quenching and tempering tower (1); the flue gas after being regulated enters a plasma reactor (2); simultaneously, additive ammonia is added for the desulfurization and denitration; then the flue gas enters a material collector (3) to be collected; the flue gas discharged from the material collector (3) is preheated; and then the flue gas enters an adsorption and catalysis system (6) for the adsorption and catalysis, desulfurization and denitration. The device using the method comprises the quenching and tempering tower (1), the plasma reactor (2), the material collector (3) and an ammonia supplying system (4); the device also comprises a pre-heater (5) and the adsorption and catalysis system (6); and the pre-heater (5) is communicated with an air outlet of the material collector (3) and an air inlet of the adsorption and catalysis system (6). The desulfurization and denitration method of the reaction, adsorption and catalysis of pulse corona plasma enhances the threshing performance without secondary pollution, has simple structure and less investment, and can greatly enhance the capability of domestic dry desulfurization and denitration method of the reaction, adsorption and catalysis of pulse corona plasma.

Owner:袁宝春

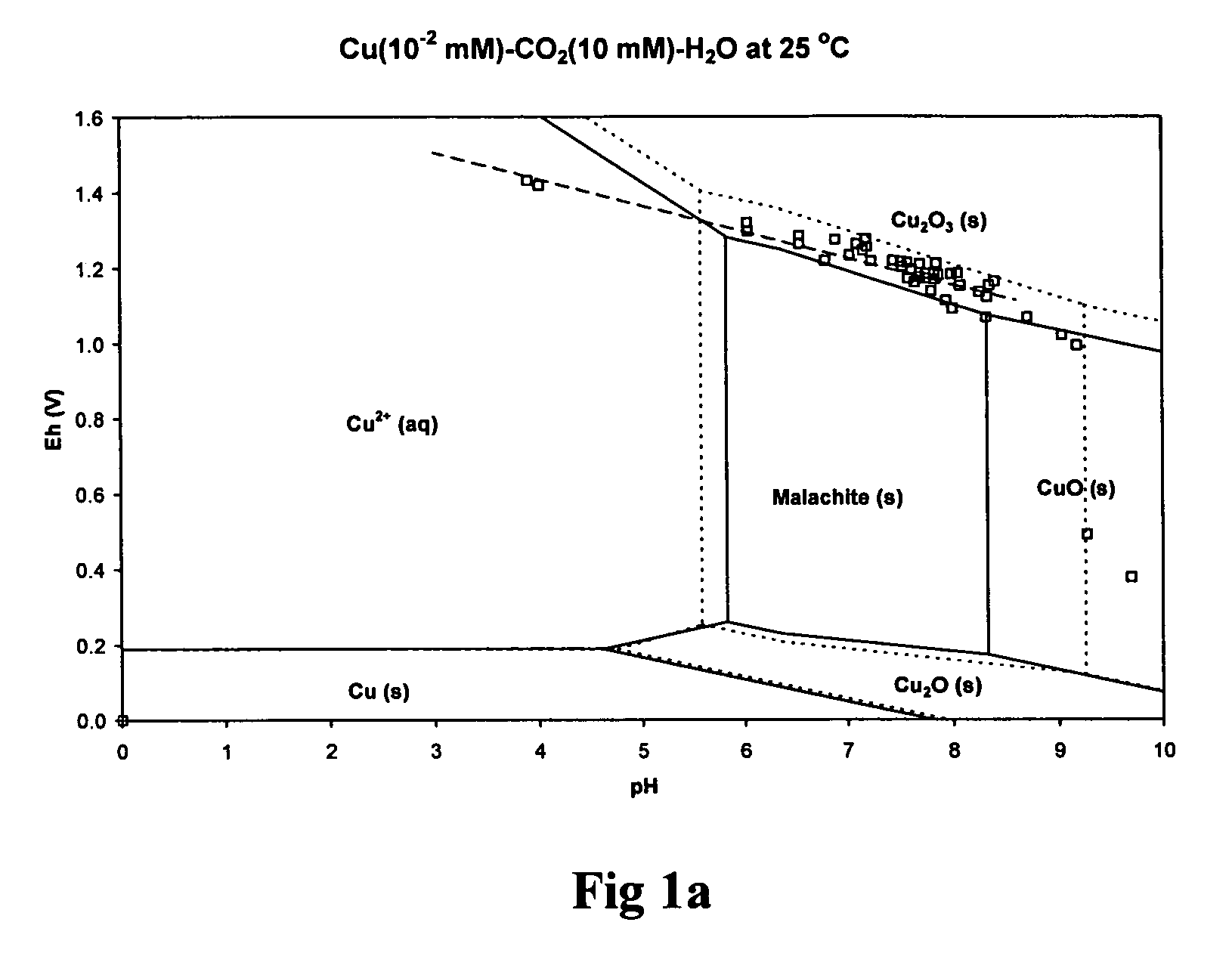

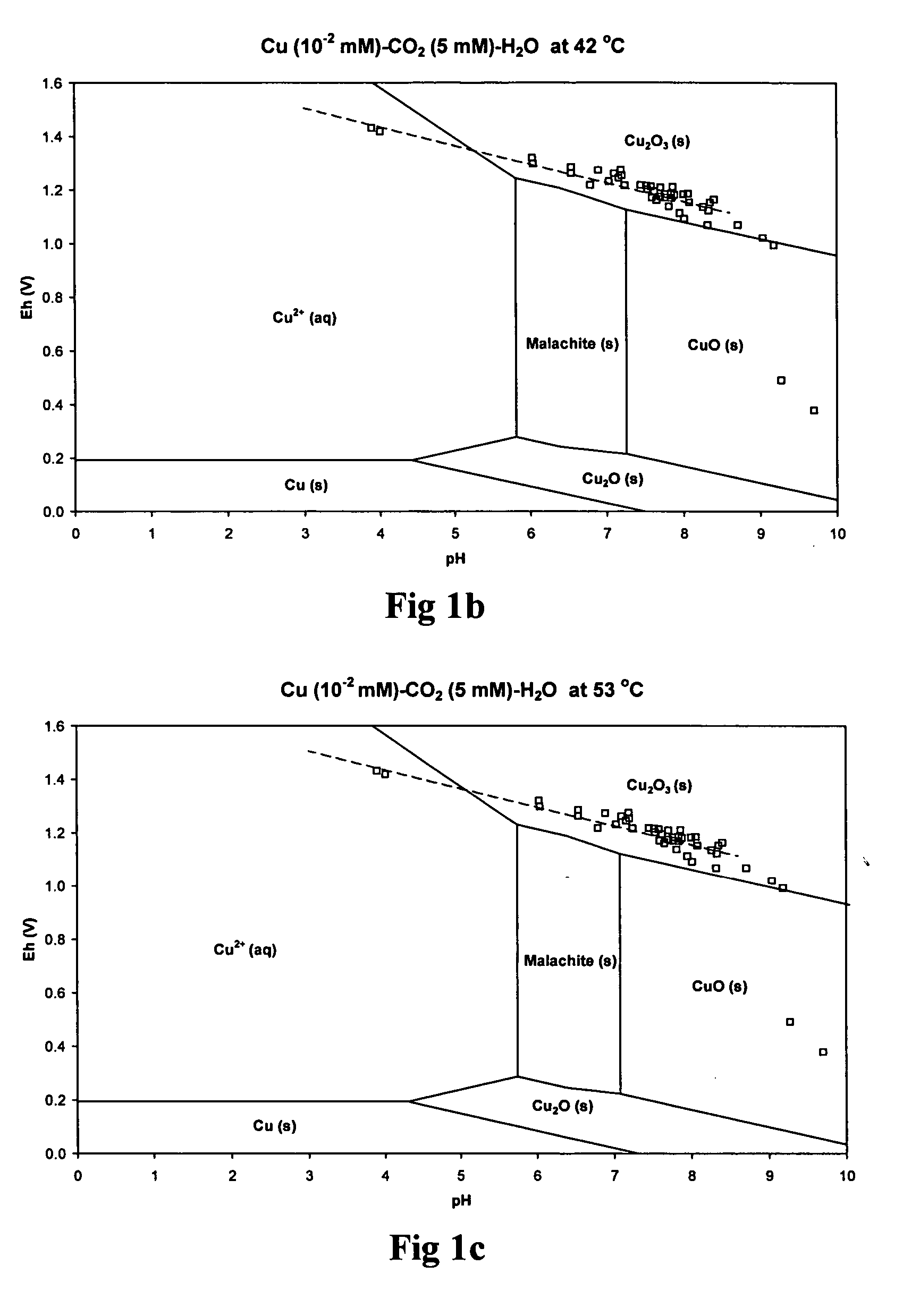

Copper processing using an ozone-solvent solution

InactiveUS20060084260A1Avoid corrosionAccurate removalPhotomechanical apparatusSemiconductor/solid-state device manufacturingDevice materialAlloy

The present invention relates to a method and apparatus for treating materials such as copper or copper based metal alloys, used in fabricating semiconductor devices with an ozone solvent solution and avoiding damage to metals by corrosion. The invention is also applicable to treating of materials such as copper and copper based alloys for the purpose of forming a protective layer on the exposed metal surface for protection of those copper surfaces from damage or corrosion caused by subsequent exposure to other liquid, gas, or plasma environments. This can be achieved by properly selecting the composition of the ozone solvent solution and controlling the pH and ORP of the ozone-solvent solution while avoiding the use of certain chemical constituents in the ozone solvent solution.

Owner:BOYERS DAVID G +1

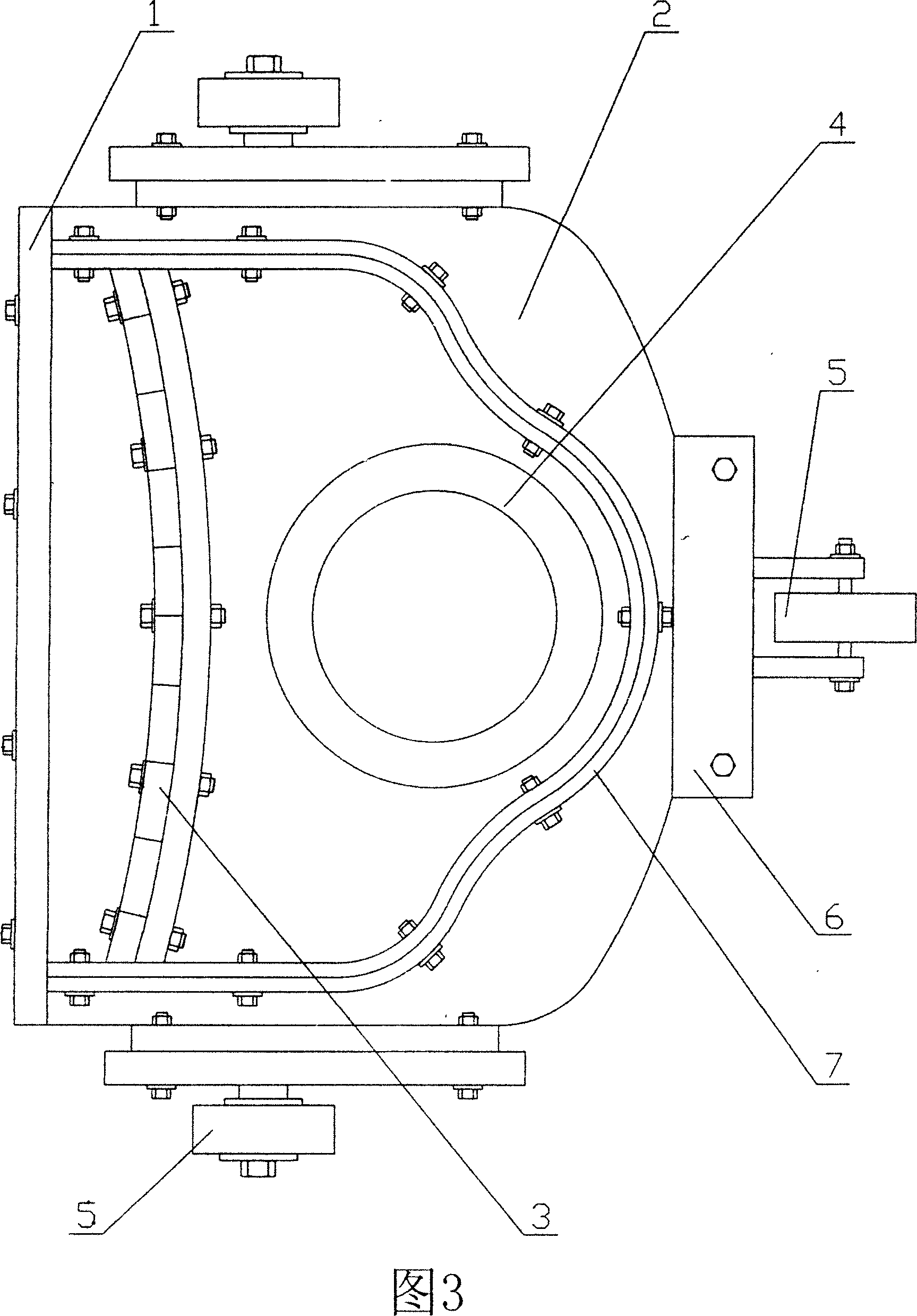

Fillet feeding diaphragm filter plate assembly constituted by flat membrane and filter board

InactiveCN101385913AFully filteredImprove cleaning rateFiltration separationBiochemical engineeringSlurry

The invention relates to a corner membrane filter plate assembly which comprises the flat membrane filter plate and the filter cloth filter plate. Both the flat membrane filter plate and the filter cloth filter plate are single-corner feeding through holes and are arranged in cross banding. The corner membrane filter plate assembly has the advantages that: 1. portholes have self-cleaning function, thus being capable of keeping the portholes smooth without obstacles; 2. rapid filter of slurry is realized; 3. a filter cake can be convenient to be washed either in a forward direction or a reverse direction, therefore, the filtering ratio of effective components in filtered slurry is greatly increased, and a feeding pump and a washing pump can share a pump; 4. by adjusting the thickness of a core board, the requirements for the thickness of the filter cake from different materials can be met; 5. a supporting lug boss can be arranged on the membrane filter plate or no supporting lug boss is arranged on the membrane filter plate; 6. no filter cloth is installed on the flat membrane filter plate.

Owner:HANGZHOU XINGYUAN FILTER TECH

Washing machine and washing machine thereof

InactiveUS9487898B2Simplify the washing processImprove cleaning rateOther washing machinesWashing machine with receptaclesSolid particleMechanical engineering

A washing machine and washing method thereof comprises an inner tub, an outer tub and solid particles as washing medium. The inner tub, of which the inner wall is provided with lifting ribs protruding inward, rotates under the driving power of a driving device. Inside the washing machine, a storage tank for storing particles connects to the inner tub through a discharge channel for recycling particles and a feeding channel for putting in particles, and an air suction device is arranged on the feeding channel. Through alternate clockwise and counter-clockwise rotates of the inner tub, clothes and particles within are overturned in all directions, thus clothes and particles get better blended, and the cleaning rate gets improved. Meanwhile, putting-in and recycling particles through an air suction device is conducive to 100% recycling of particles.

Owner:XEROS LTD

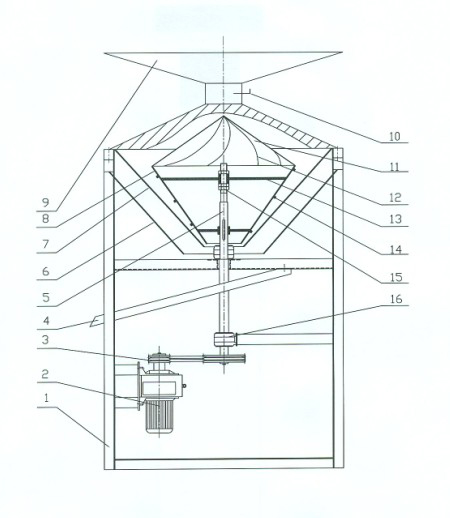

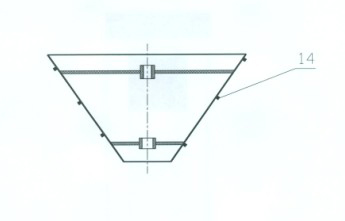

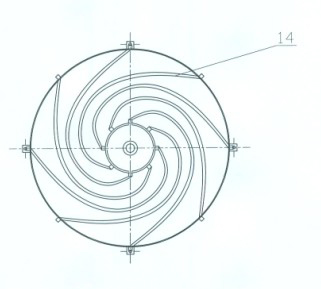

Peanut huller

InactiveCN102028299AEasy to separateAvoid stayingHuskingHullingAgricultural engineeringStructural engineering

The invention relates to a peanut huller which is characterized by comprising a feeding hopper, a rotary drum, a rotary drum shaft, a notch board sieve, a material collecting drum, a material receiving board, a motor and a rack; the exterior of the rotary drum is fixed with an inverted cone-shaped vertical type hollow drum with spiral bulged ribs; the notch board sieve is also in an inverted cone shape; the annular hulling region between the rotary drum and the notch board sieve is gradually contracted from top to bottom; and the upper end of the rotary drum is provided with a cone-shaped uniform distributor with a spiral rib board. The peanut huller has the advantages that a vertical type hulling mode is adopted; the large area of the notch board sieve is effectively utilized and the hulling speed is enhanced so as to enhance the hulling efficiency; the rapid separation of peanuts from the hulling region is realized so as to avoid the peanuts from remaining in the hulling gap; the damage is decreased so as to reduce the damage rate of the peanuts; thus, the peanut huller can automatically adapt to the actual condition of different shape sizes of the peanuts; the hulling damage is lightened, and the completely hulling rate and the hulling efficiency are enhanced; and the hulling gap can be adjustable to adapt to the hulling of the peanuts with different varieties and shape sizes.

Owner:SHENYANG AGRI UNIV

Oil-based drilling fluid shaft completion cleaning fluid and preparation method thereof

The invention relates to the technical field of drilling fluid cleaning fluids, particularly to an oil-based drilling fluid shaft completion cleaning fluid and a preparation method thereof. The oil-based drilling fluid shaft completion cleaning fluid comprises raw materials in percentage by weight as follows: 25%-30% of an organic acid solution, 1%-3% of an emulsifier, 0.5%-0.7% of an organic solvent, 0.5%-2% of a quick penetrating agent, 0.05%-0.1% of a corrosion inhibitor and the balance of base oil. The oil-based drilling fluid shaft completion cleaning fluid is an oil-based cleaning fluid, is an acid-in-oil emulsion, is applied after open hole completion or screen pipe (slotted pipe) completion, can be used for restoring near-wellbore holes between a shaft and a stratum, can be used for opening an oil and gas channel, has the higher cleaning rate, can be used for clearing away substances adhered to the shaft, can be used for dredging a near-wellbore reservoir channel, can be used for washing a screen pipe (slotted pipe) and can be used for protecting an oil-gas bed.

Owner:克拉玛依市金鑫科技有限公司

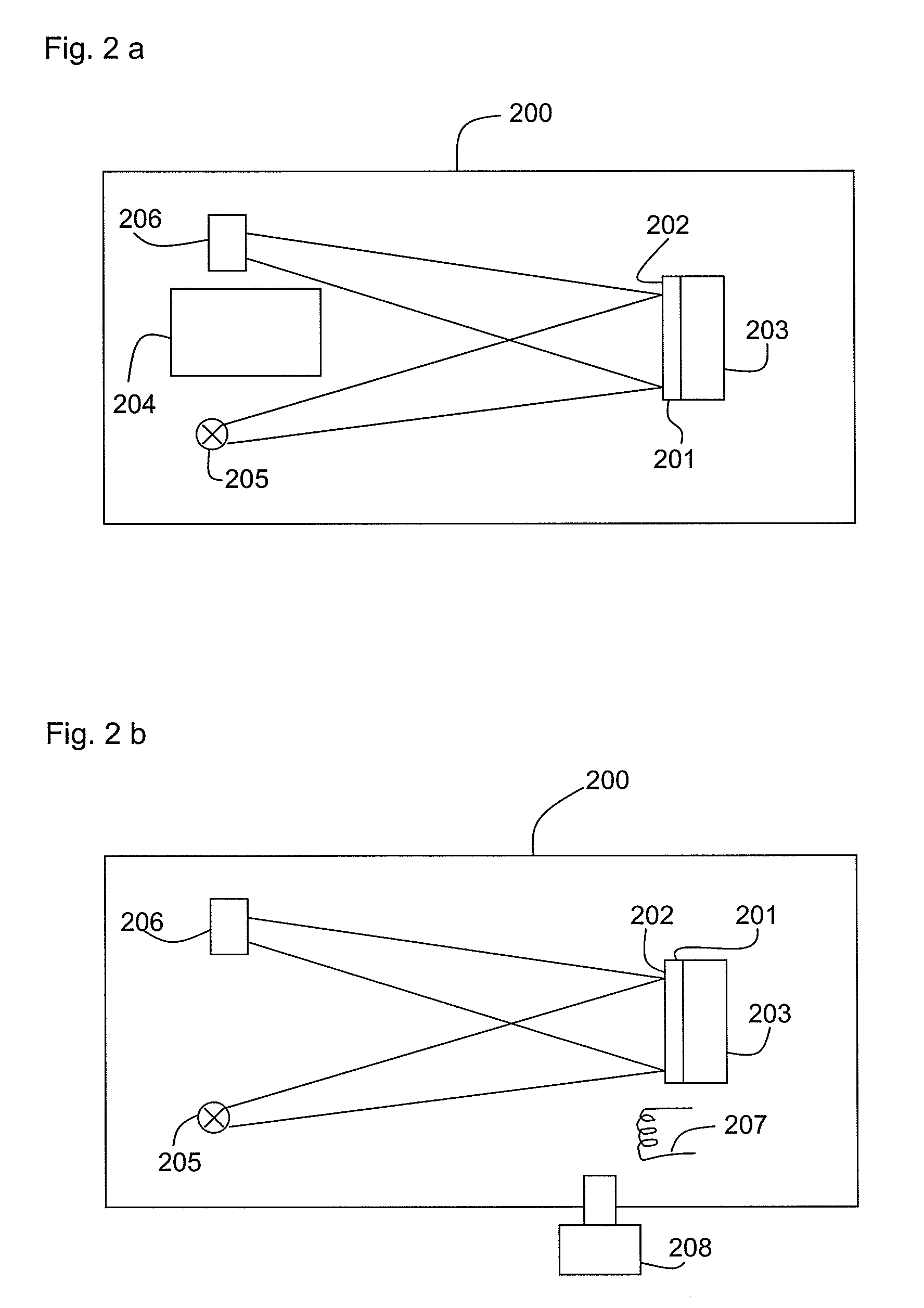

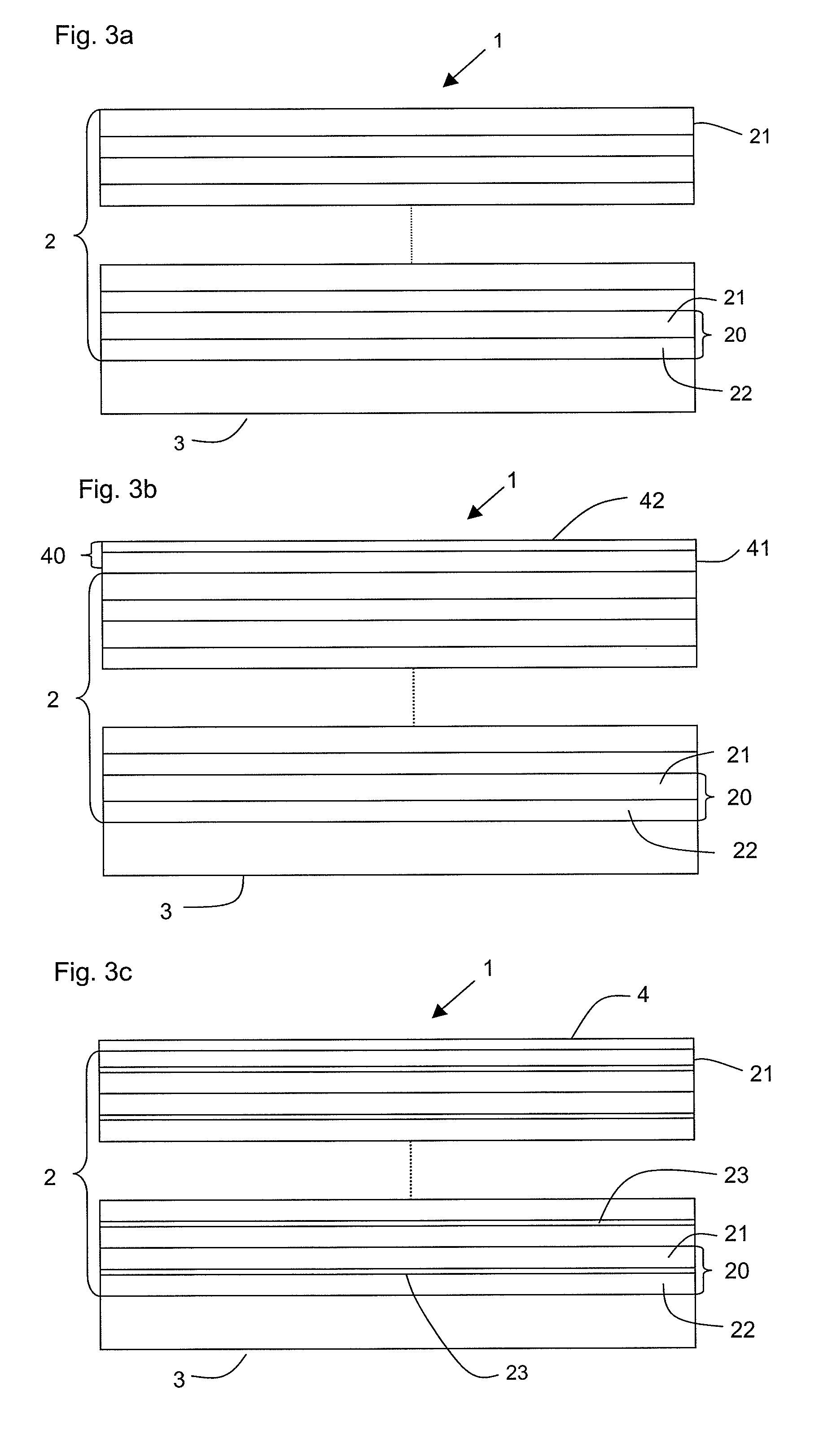

Method and system for removing contaminants from a surface

InactiveUS20100071720A1High cleaning rateEnhance cleaningLighting and heating apparatusPhotomechanical apparatusPollutantDeuterium

Inside a vacuum chamber 200 a cleaning unit 204 provides atomic hydrogen or atomic deuterium for cleaning a surface 202 at a pressure of less than 10−4 Torr or of more than 10−3 Torr. The surface 202 is heated by the heating unit 203 to a temperature of at least 50° C. This allows achieving cleaning rates of more than 60 Å / h. Preferably, the surface 202 is the surface of a multilayer mirror 201 as used in an EUV lithography apparatus.

Owner:CARL ZEISS SMT GMBH

Street sweeper suction nozzle

InactiveCN101012640AReduce the cross-sectional areaIncrease flow rateRoad cleaningEngineeringRoad surface

The invention discloses a sweep and suction nozzle of sweep road car. By using the suction nozzle of sweep road car the clearing quality is good when the road surface is cleared. The clearing rate is improved and the energy consumption can not be added. The using cost need not be added, which comprises suction cylinder 4, seat of suction nozzle 2, rolling wheel 5, rack for rolling wheel 6, rubber baffle 1 and wall board 7 so on. A silicon baffle 3 is set vertically to the seat of suction nozzle 2 in inner cavity of suction nozzle, at the back of rubber baffle 1 and at the front of the lower mouth of suction cylinder 4. Notches with 60mm or so upwards are set on the lower end of baffle in every 30mm. when the sweep road car of sweep and suction works, the lower end of rubber baffle 1 bends so that the section area of air input is decreased and the air speed is increased. After the air enters into the suction nozzle, it flows near the ground for a long distance to pass through the baffle 3, it turns a corner to enter into the suction cylinder 4. The air through the suction nozzle can take garbage with bigger weight, bigger cubage and more quantity into the suction cylinder 4. Finally, it is sent into dustbins.

Owner:赵宏坚

Ultrasonic wave box washing machine

ActiveCN103769402AImprove cleaning rateImprove work efficiencyHollow article cleaningCleaning using liquidsBrush deviceUltrasonic generator

The invention relates to an ultrasonic wave box washing machine, which comprises a soaking box and a spraying cleaning device, wherein a driving chain and a driving wheel which can cyclically rotate are arranged in the soaking box, a plurality of soaking groove frames used for fixing boxes to be cleaned are arranged on the driving chain, an ultrasonic wave generator is arranged below cleaning liquid of the soaking box, a box discharging opening of the soaking box is connected with a box feeding opening of the spraying cleaning device through a conveying support frame, the spraying cleaning device comprises a spraying box, a spraying cleaning machine and a hair brush device, the spraying cleaning machine is arranged in the spraying box, and the hair brush device is used for brushing and washing the box body. The ultrasonic wave box washing machine has the advantages that the box bodies to be cleaned are repeatedly flushed and brushed through the spraying cleaning device after being soaked and being subjected to ultrasonic wave cleaning, the clean washing rate of the box bodies and the work efficiency are greatly improved, in addition, the labor and the work time are saved, the energy consumption and the alkali concentration are greatly reduced, in addition, dirt and alkali liquor attached to the surfaces can be flushed away, the ultrasonic wave box washing machine conforms to the national sanitation standard through one-step cleaning, the cleaning speed is high, the effect is good, and parts are not damaged.

Owner:安第斯新材料科技(浙江)有限公司

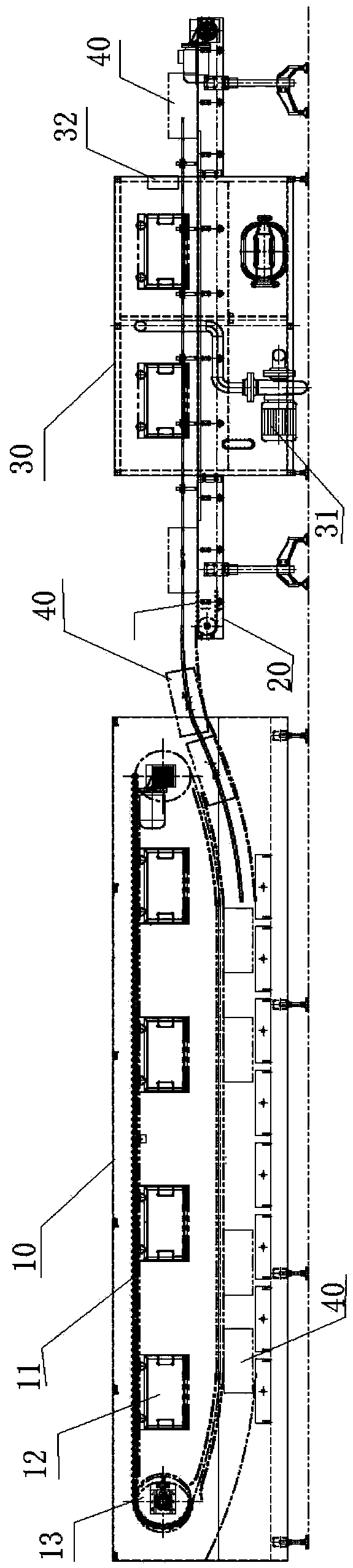

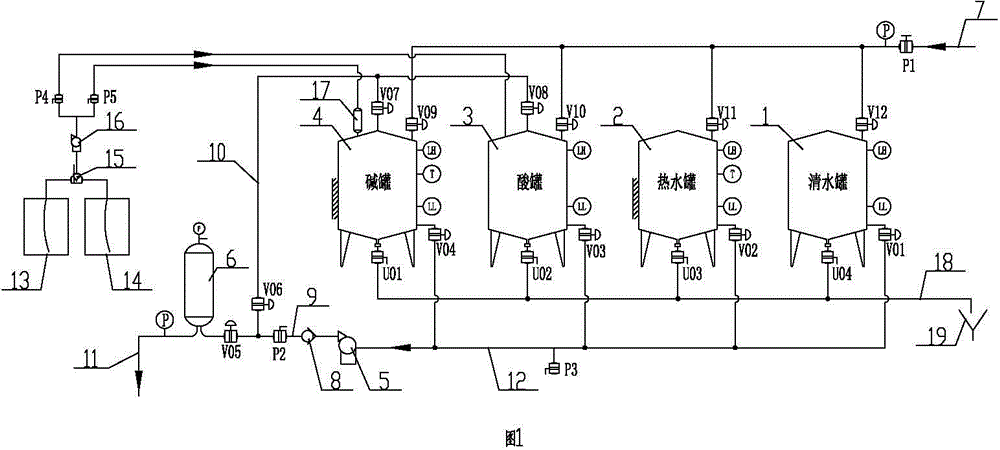

Automatic cleaning device and cleaning method thereof

ActiveCN104096692AReasonable structureEasy to useHollow article cleaningCleaning using liquidsProcess engineeringPneumatic valve

The invention relates to the technical field of automatic cleaning devices for wine production equipment, and discloses an automatic cleaning device and a cleaning method thereof. The automatic cleaning device comprises a clear water pot, a hot water pot, an acid pot, an alkali pot, a cleaning fluid pump, a cleaning fluid filter and an electric cabinet, wherein the upper parts of the clear water pot, the hot water pot, the acid pot and the alkali pot are respectively provided with a pneumatic water inlet valve, and water inlets of the pneumatic water inlet valves are respectively communicated with a water inlet pipe with a water inlet hand valve. The automatic cleaning device is reasonable and compact in structure, convenient to use, higher in cleaning efficiency, time-saving, labor-saving, high in equipment cleaning rate, and capable of reducing the influence of harmful aerial fog on the health of operators during cleaning; equipment can be automatically controlled by the electric cabinet to performing clear water flushing, alkali liquor cleaning, acid liquor cleaning and sterilization, acid or alkali can be added by an acid-alkali adding device, and the acid or alkali in the corresponding pots can be evenly mixed by a fluid circulating pipe and the relevant pneumatic valve, and the device has the characteristics of being safe, labor-saving, simple, convenient and efficient.

Owner:TURPAN LOULAN WINE IND

ultrasonic cleaner

InactiveCN102274838AReduce noiseImprove cleaning rateCleaning using liquidsElectrolysisMegasonic cleaning

The invention discloses an ultrasonic cleaning machine, which comprises a cleaning tank, vibrator chambers are respectively arranged on both sides of the cleaning tank, the cleaning tank and the vibrator chamber are separated by side partitions, several vibrators are respectively arranged on the outer walls of the partitions on both sides, the cleaning tank A bottom vibrator chamber is arranged under the bottom partition, and several vibrators are arranged on the bottom surface of the bottom partition; all the vibrators are connected to the ultrasonic generator. The invention overcomes the defects of high labor intensity and low work efficiency of the existing manual and semi-mechanized cleaning of electrolysis cathode plates, and is suitable for batch cleaning of electrolysis cathode plates and other similar items.

Owner:湘潭大众整流器制造有限公司

Corn thresher

The invention discloses a corn thresher comprising a feeding trough, threshing rollers, a vibrating screen, a cleaning fan, a motor and a rack. The corn thresher is characterized in that a front threshing roller and a rear threshing roller are arranged in parallel; the surface of the front threshing roller is provided with evenly-distributed spiral threshing corrugated tendons; a spiral grid notch board is arranged below the front threshing roller; a machine cover is arranged above the front threshing roller; a buffer cover board is hinged below the feeding windward of the machine cover and is connected with a buffer spring; the surface of the rear threshing roller is provided with spirally-arranged nail teeth; parallel grid notch boards are arranged below the rear threshing roller; and the machine cover is arranged above the rear threshing roller. The corn thresher has the advantages that the corn thresher can directionally feed without impact, flexibly rubs in sequence, threshes differentially by double rollers, has small damage on corn seed particles, has the advantages of high threshing rate, low breakage rate, compact structure, and wide applicability, is convenient to use and adjust, and can simultaneously satisfy requirements on commodity corn threshing and seed corn threshing.

Owner:SHENYANG AGRI UNIV

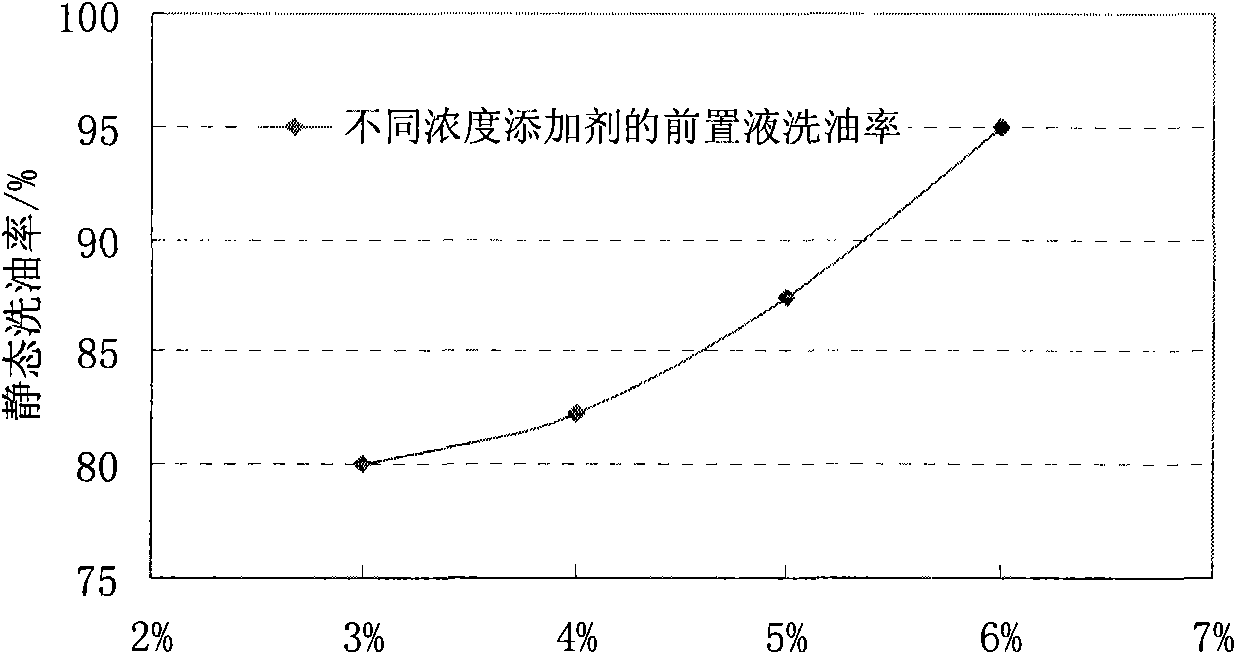

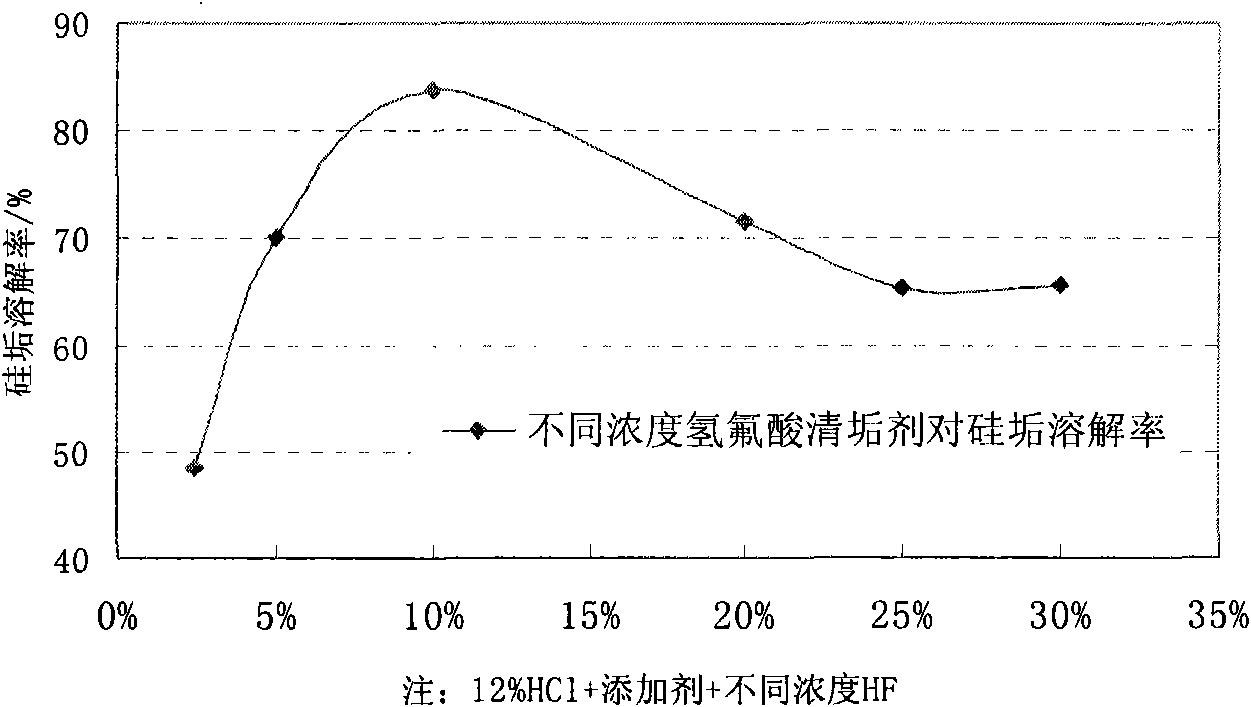

Silicate scale clearing agent for ternary combination flooding extraction well

The invention discloses a silicate scale clearing agent for a ternary combination flooding extraction well. The silicate scale clearing agent consists of prepad fluid and scale clearing main agent. The prepad fluid consists of 6% of additive (SYQ-II) and the balance of water. The additive (SYQ-II) consists of sodium dodecyl benzene sulfonate (ABS), nonyl phenol polyethenoxy ether (OP10) and ethylene glycol monobutyl ether with the ratio of 3:1:2. The scale clearing main agent consists of 12% of hydrochloric acid, 10% of hydrofluoric acid, 2% of glacial acetic acid, 0.2% of citric acid, 0.5% indoor-synthesized imidazoline type corrosion inhibitor (YC-II) and the balance of water. The scale clearing agent achieves a silicate scale clearing rate up to 80%, and can effectively clear silicate scale at an oil well pump cylinder, a rod pipe and other positions and prolong the pump examination period of the extraction well.

Owner:PETROCHINA CO LTD +1

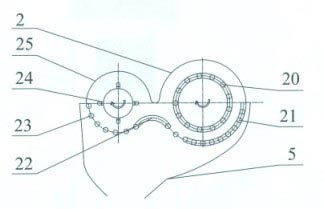

Washing mode of washing machine and fully automatic washing machine

InactiveCN1986942ASignificant comprehensive benefitsImprove washing qualityWashing machine with receptaclesTextiles and paperReduction driveReciprocating motion

A washing mode of washer is characterized by that an axially reciprocating pressure disc is arranged in a washing drum for generating both bidirectionally rotary water stream and axially reciprocating pressure water stream to flush, beat and press the object to be washed. A full-automatic washer with said washing mode is composed of an external drum, an internal drum, a speed reducer or speed-reducing clutch with output axle and axle sleeve, a waving wheel or bottom plate, and an axially reciprocating pressure disc unit in said internal drum.

Owner:ANHUI JULONG TRANSMISSION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com