Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Improve washing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

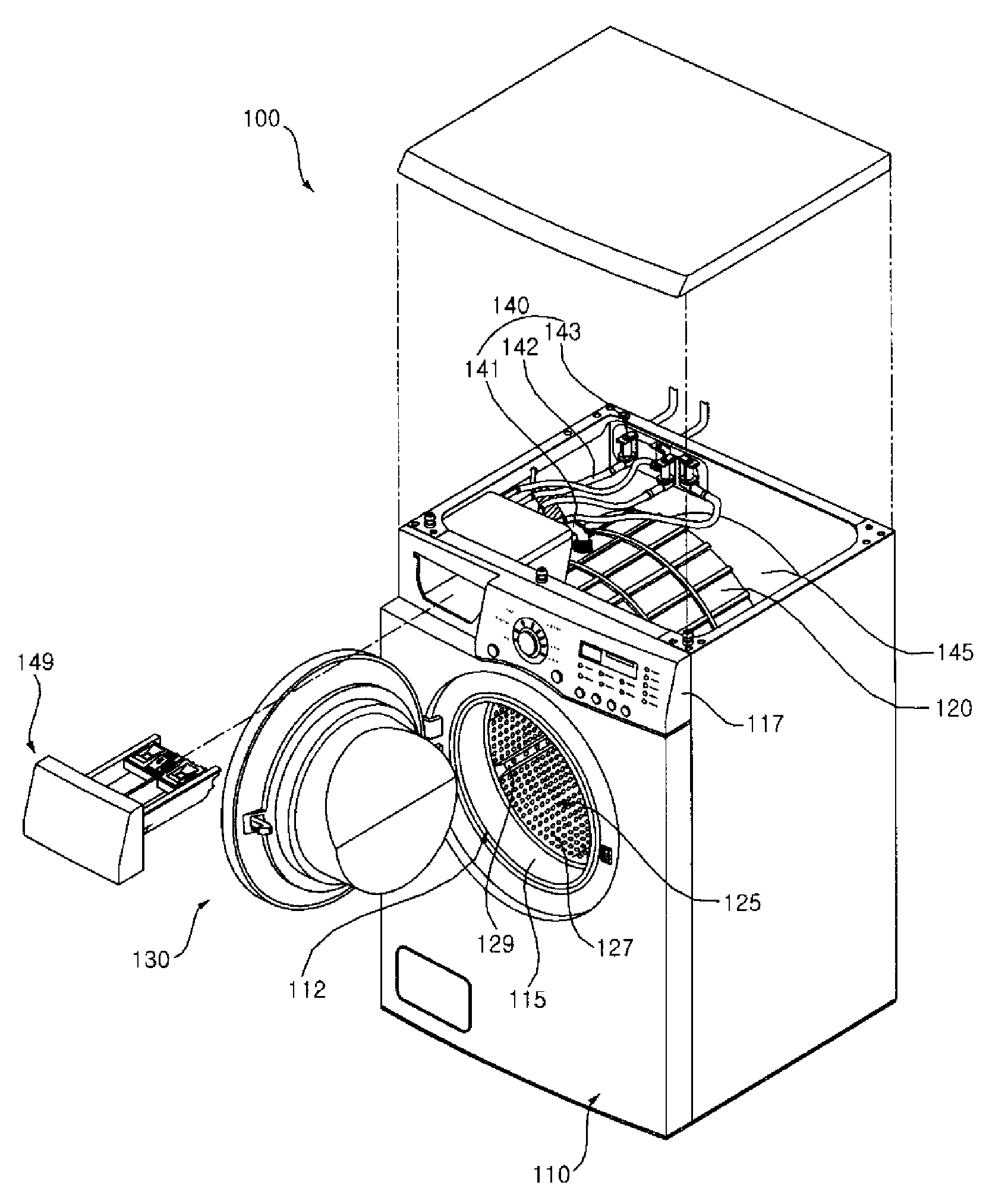

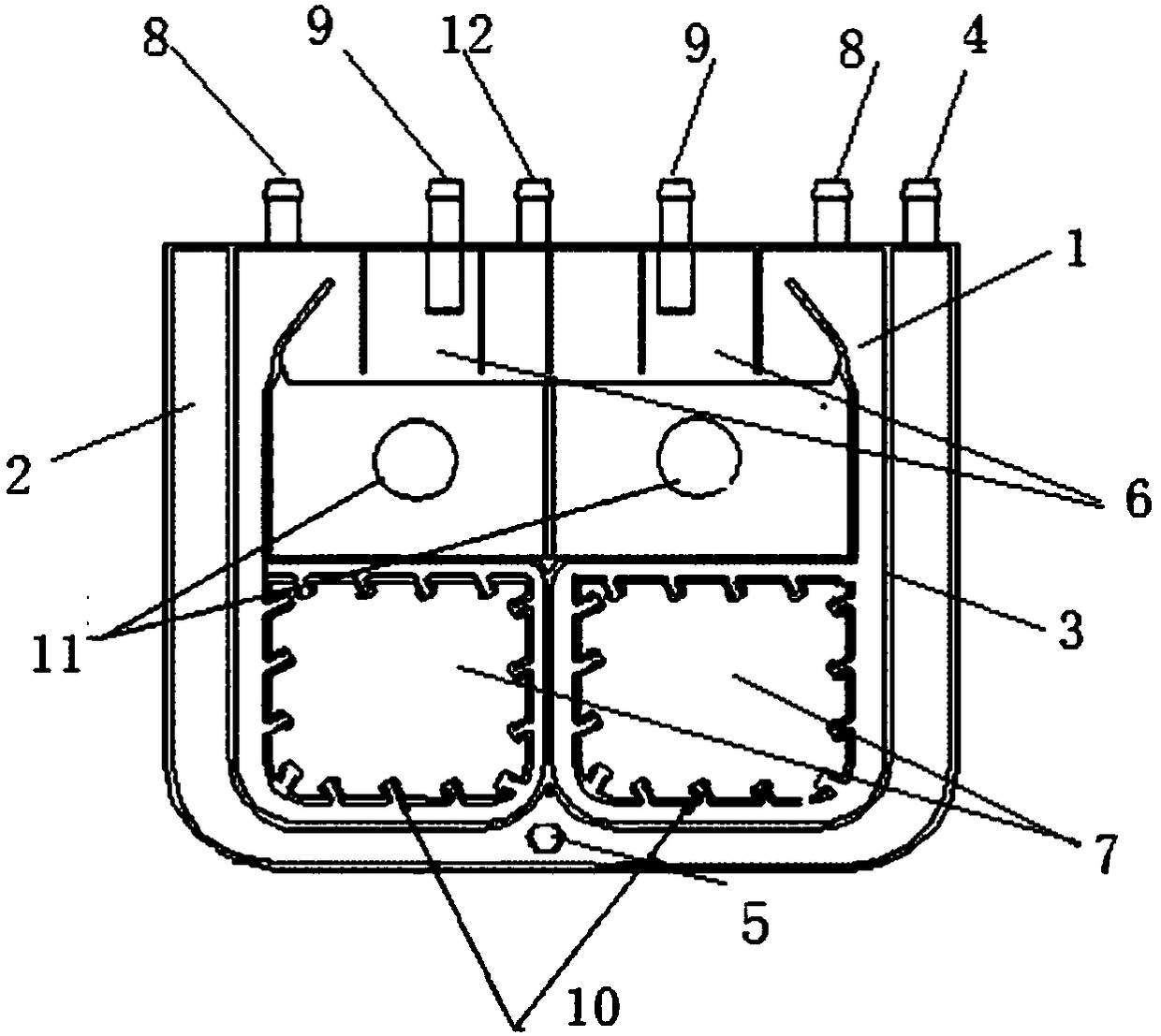

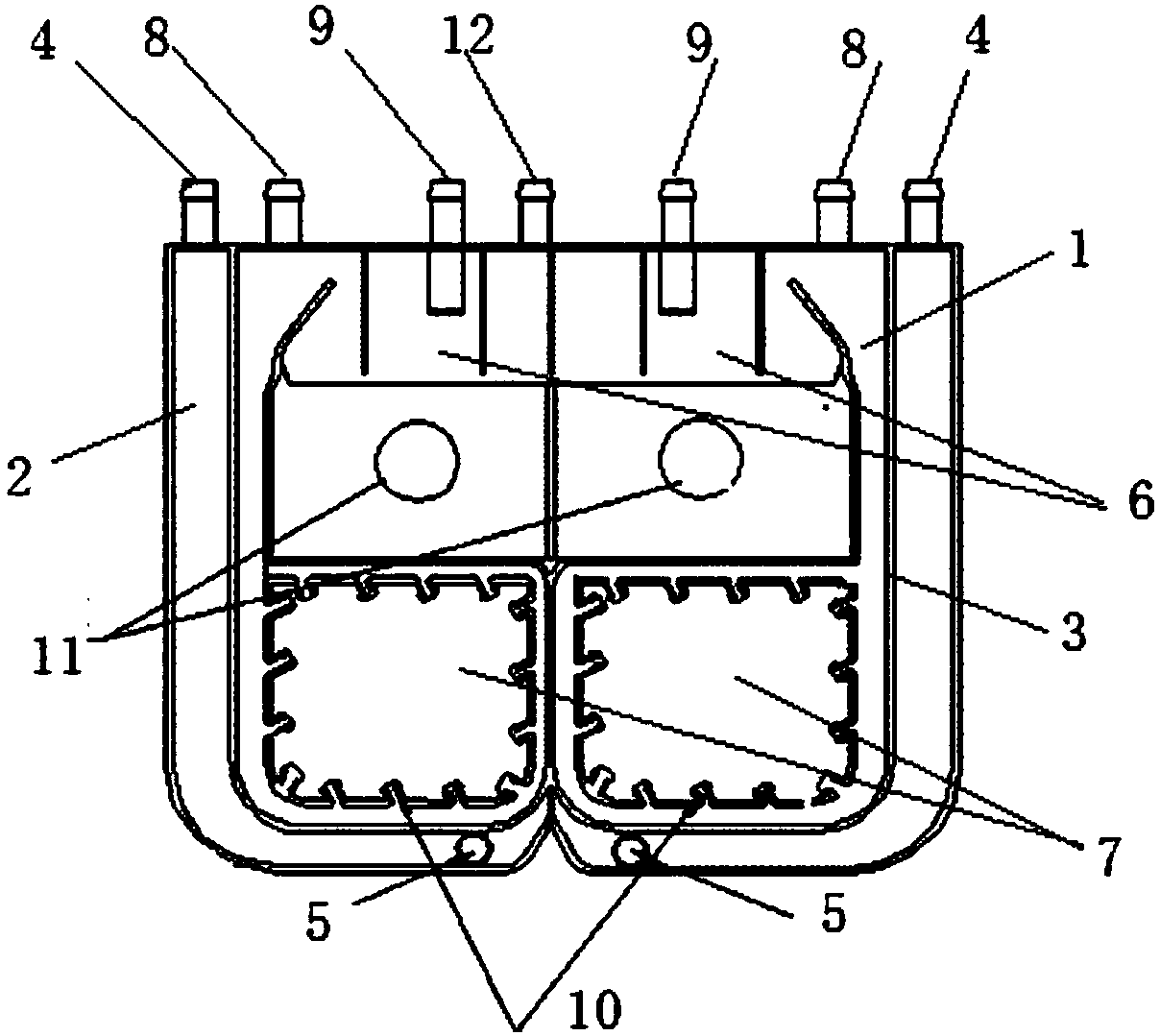

Drum-type washing machine

ActiveUS7251963B2Prevent leakageAvoid water pollutionOther washing machinesWashing machine with receptaclesWaste managementGasket

A drum-type washing machine employs a gasket water draining hose to enable used water to be discharged via the drainpipe, immediately following a washing or rinsing step. The drum-type washing machine includes a cabinet having a door; a tub for containing water, the tub having an entrance corresponding to the door of the cabinet; a gasket, connecting the door of the cabinet to the entrance of the tub, to prevent water contained in the tub from leaking outside the tub, the gasket having a first orifice provided at a bottom point thereof; a drainpipe, communicating with the tub, to discharge water contained in the tub, the drainpipe having a second orifice provided at one side thereof; and a water draining hose, communicating the first orifice with the second orifice, to discharge water via the drainpipe.

Owner:LG ELECTRONICS INC

Washing mode of washing machine and fully automatic washing machine

InactiveCN1986942ASignificant comprehensive benefitsImprove washing qualityWashing machine with receptaclesTextiles and paperReduction driveReciprocating motion

A washing mode of washer is characterized by that an axially reciprocating pressure disc is arranged in a washing drum for generating both bidirectionally rotary water stream and axially reciprocating pressure water stream to flush, beat and press the object to be washed. A full-automatic washer with said washing mode is composed of an external drum, an internal drum, a speed reducer or speed-reducing clutch with output axle and axle sleeve, a waving wheel or bottom plate, and an axially reciprocating pressure disc unit in said internal drum.

Owner:ANHUI JULONG TRANSMISSION TECH

Method and apparatus for treating laundry

InactiveUS20100306927A1Improve user satisfactionPrecision therapyControl devices for washing apparatusDry-cleaning apparatus for textilesEngineeringLaundry

A laundry treatment method and apparatus are provided. The laundry treatment method includes (a) choosing one of a first operating course in which a set of operating conditions are determined based on the weight of laundry and a second operating course in which the operating conditions are determined based on a plurality of operating variables; and (b) treating the laundry according to whichever of the first and second operating courses is chosen.

Owner:LG ELECTRONICS INC

Compound enzyme preparation for improving jeans clothes washing effect and application of preparation

ActiveCN109652988AImprove washing effectImprove washing qualityDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsEnzymeWater washing

The invention discloses a compound enzyme preparation for improving jeans clothes washing effect and an application of the preparation. The compound enzyme preparation comprises liquid desizing compound enzyme and powder enzyme wash compound enzyme. By the aid of the compound enzyme preparation, washing effects of the jeans clothes can be improved, washing quality of the jeans clothes can be improved, and the preparation solves the problems of poor figure effect, severe dye coloring and reddish color light of a fabric surface of a traditional jeans washing.

Owner:WUHAN SUNHY BIOLOGICAL

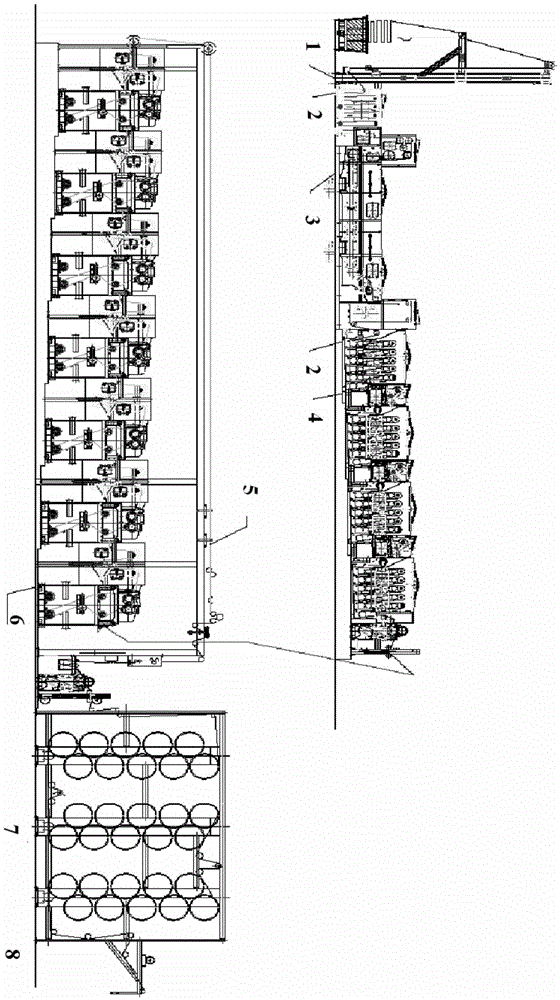

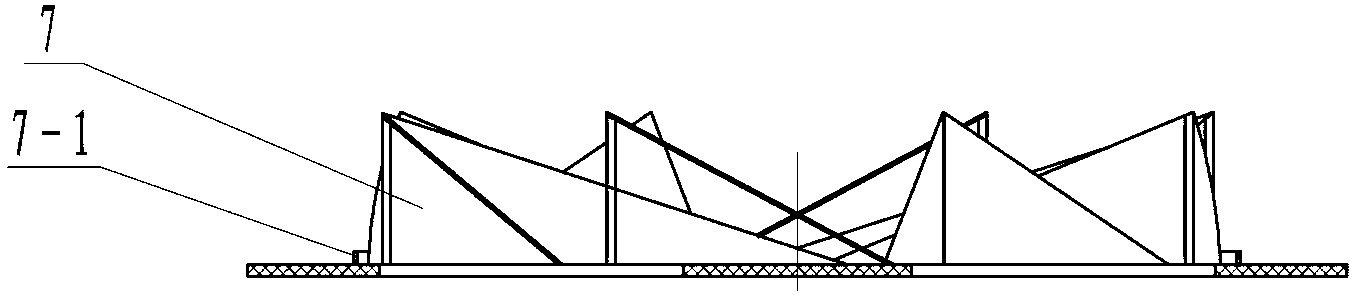

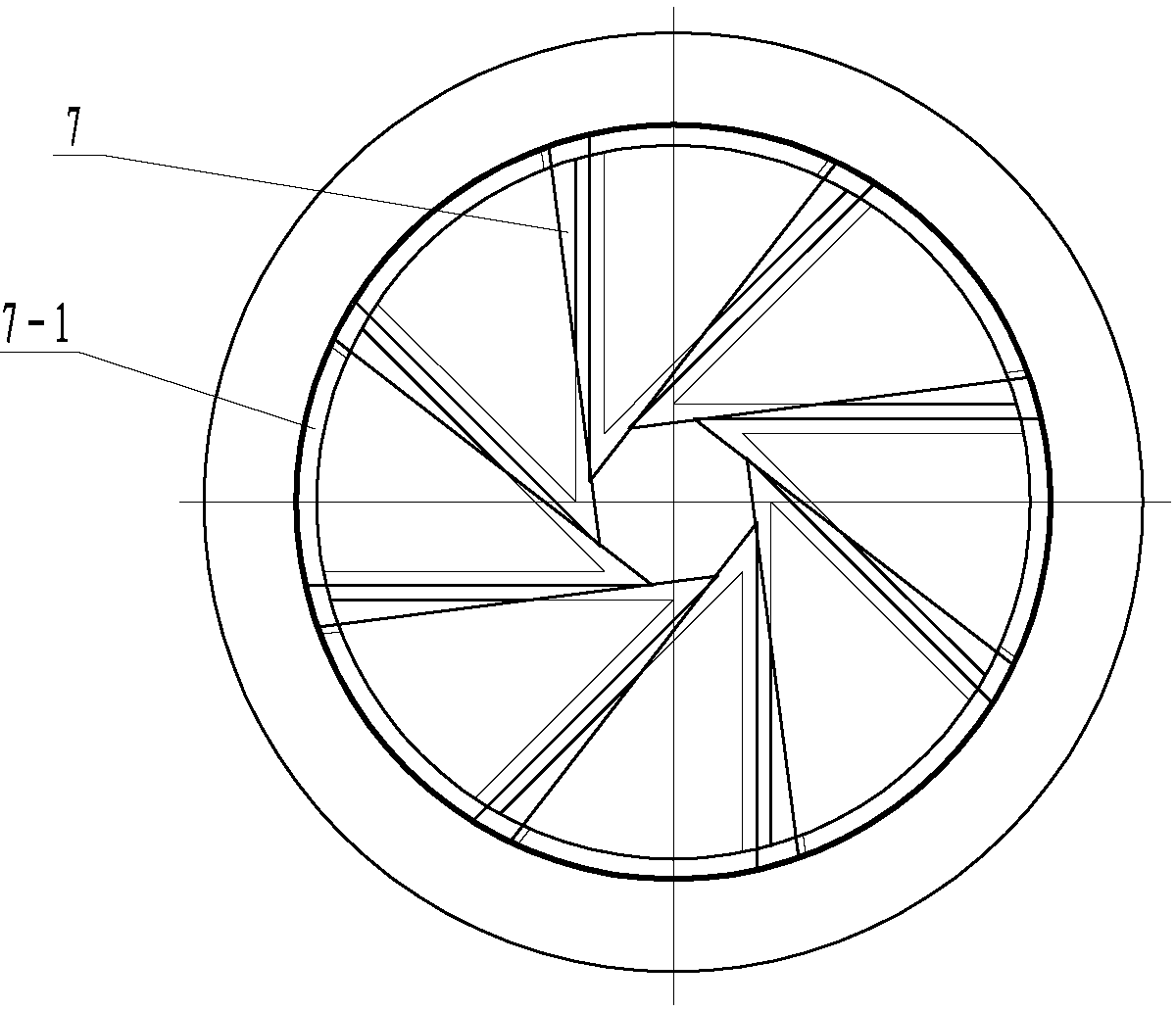

High-efficiency open-width rope washing machine

ActiveCN105603658AAchieve complexImprove washing qualityLiquid/gas/vapor roped fabric treatmentEngineeringMechanical engineering

The invention discloses a high-efficiency open-width rope washing machine. The high-efficiency open-width rope washing machine comprises a cloth feeding frame, a washing tank, a padder, a washing chamber, a door-shaped tension frame, a spraying steam chamber, an open-width processing device, a dryer and a cloth discharging device. The cloth feeding frame is provided with an edge guide, and the cloth feeding frame, the washing tank, the padder, the steam chamber, the washing chamber, the open-width processing device, the dryer for drying and the cloth discharging device are arranged in sequence. The tension frame is used for adjusting cloth tension in a whole operation process. The high-efficiency open-width rope washing machine has the advantages that washing quality of printed and dyed products is guaranteed, washing fastness is improved, and fabric handfeel is improved.

Owner:YUYUE HOME TEXTILE

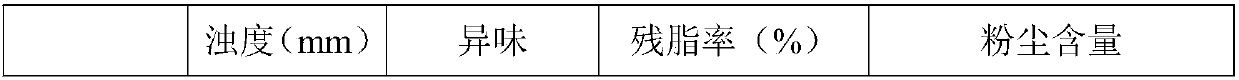

Method for preparing high pure graphite with steam heating

The invention relates to a graphite purifying craftwork, in particular relates to a method for purifying the natural graphite with the heating of the vapor, which overcomes the weaknesses of the prior graphite purifying method that the craftwork is complicated, the energy consumption is large, the adopted devices are complicated, and the production cost is high, so that a method adopting the heating of the vapor to purify the graphite is provided. Through the heating of the vapor, the acid solution is reacted with the foreign matters in the graphite, and the foreign matters in the graphite are removed through the procedures such as washing, mixing, spin-dry, drying and the like. The method has low production cost, short flowing procedures, simple device and convenient operation; the content of the fixed carbon in the graphite that is purified can reach 99.99 percent to 99.995 percent.

Owner:QINGDAO HENSEN GRAPHITE

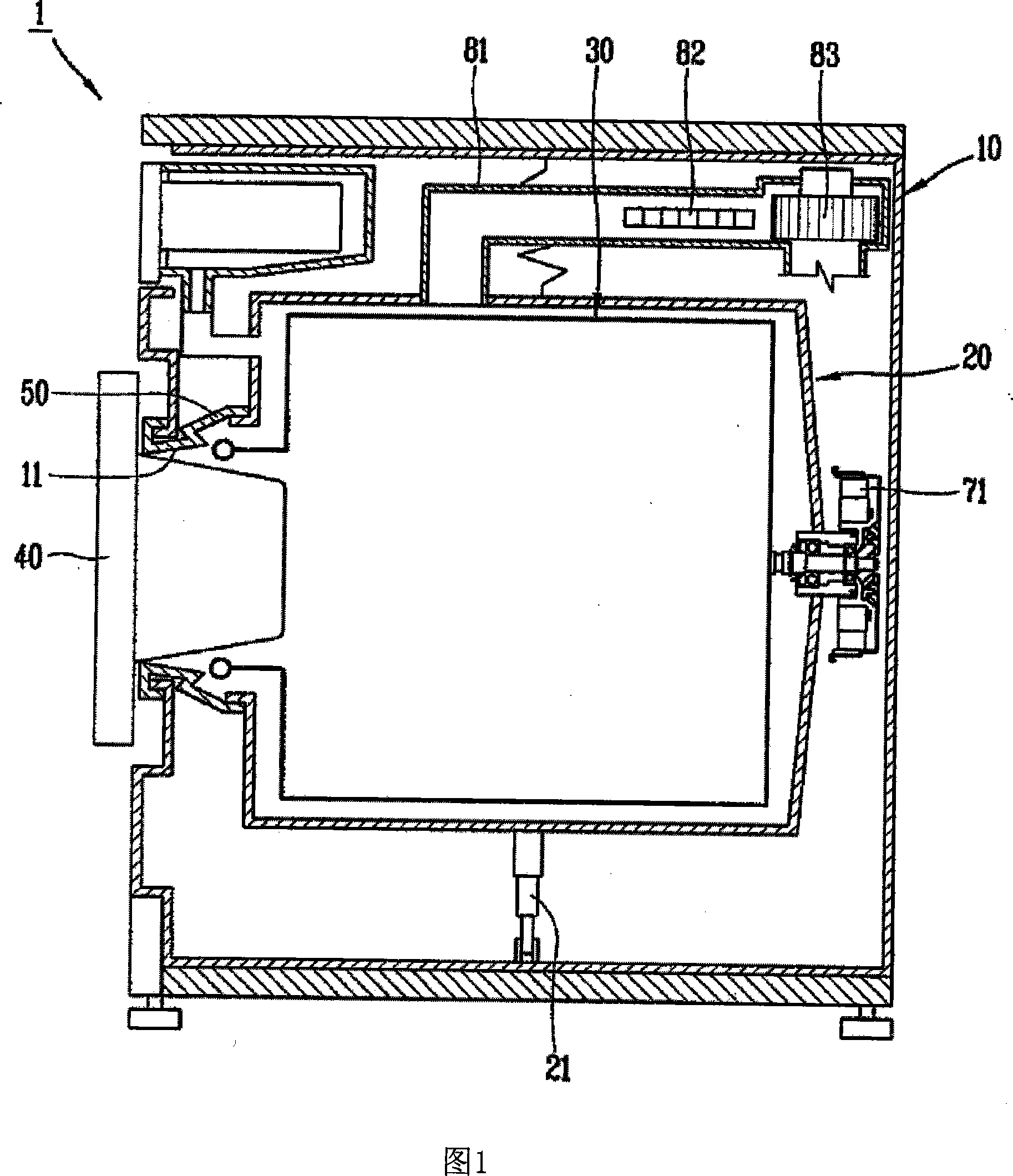

Seal ring moisture removing method for washing drying dual-purpose drum washing machine

InactiveCN101187122AAvoid mildew and smellAvoid it happening againOther washing machinesControl devices for washing apparatusDual purposeSewage

The invention relates to a method for eliminating the humidity of a seal ring used in a washing and drying two-proposal roller washing device. The invention consists of a shell; a door for opening and closing the inlet of the shell; an outer drum arranged inside the shell; a rotary roller arranged at the inner side of the outer drum; a seal ring arranged between the inlet and the door for sealing the gap between the door and the outer drum; a hot-air feeding pipeline arranged inside the seal ring and used for feeding hot air to the inside of the roller through the upper side space of the outer drum; and a drying and heating assembly arranged inside the hot-air feeding pipeline. The invention is characterized by comprising a selective program of eliminating the humidity of the seal ring or not and a program of eliminating the humidity of the seal ring. The invention can effectively prevent the mildew or smell due to residual sewages in advance. The invention provides a method for eliminating the humidity of a seal ring used in a washing and drying two-proposal roller washing device.

Owner:NANJING LG PANDA APPLIANCES

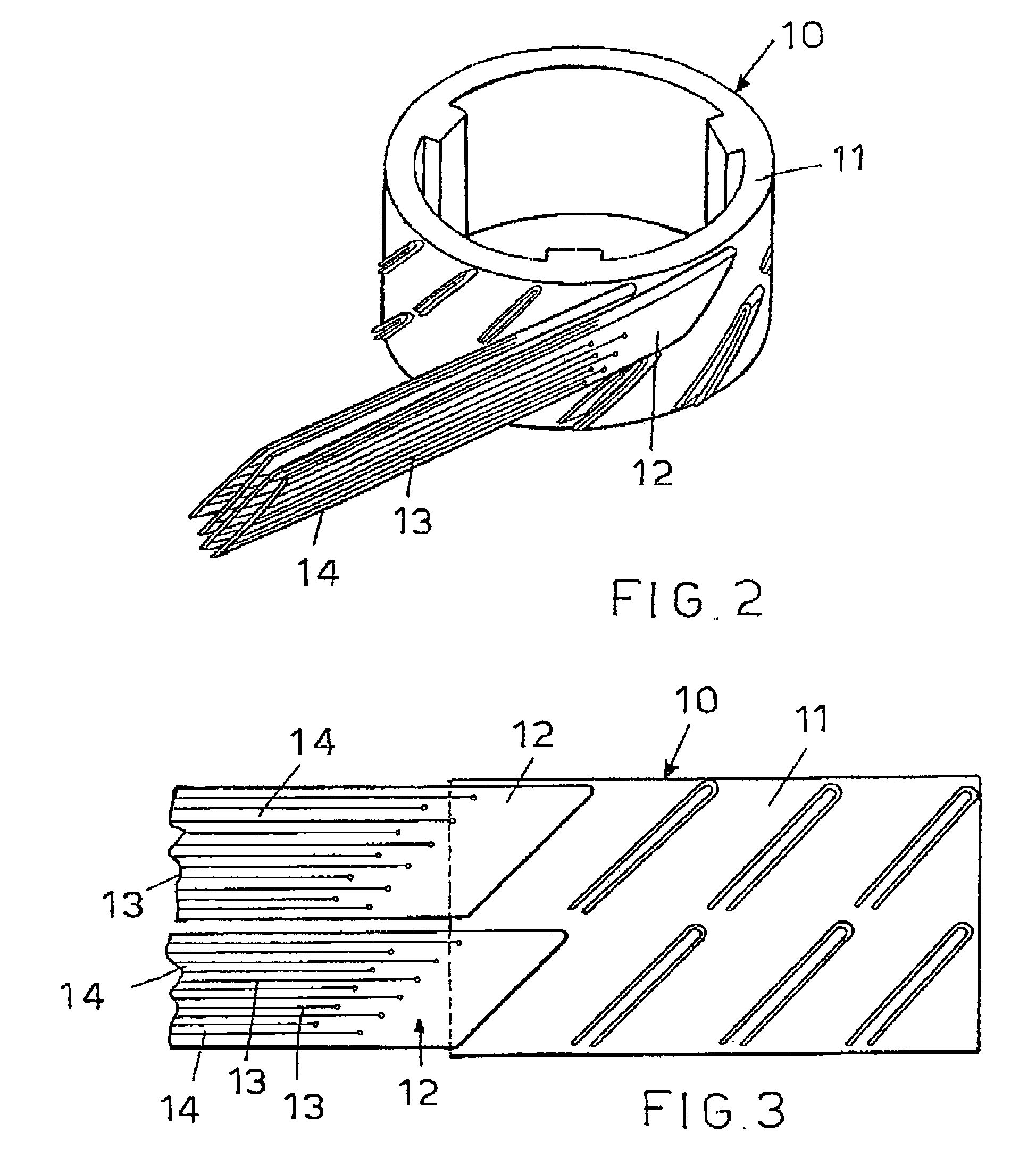

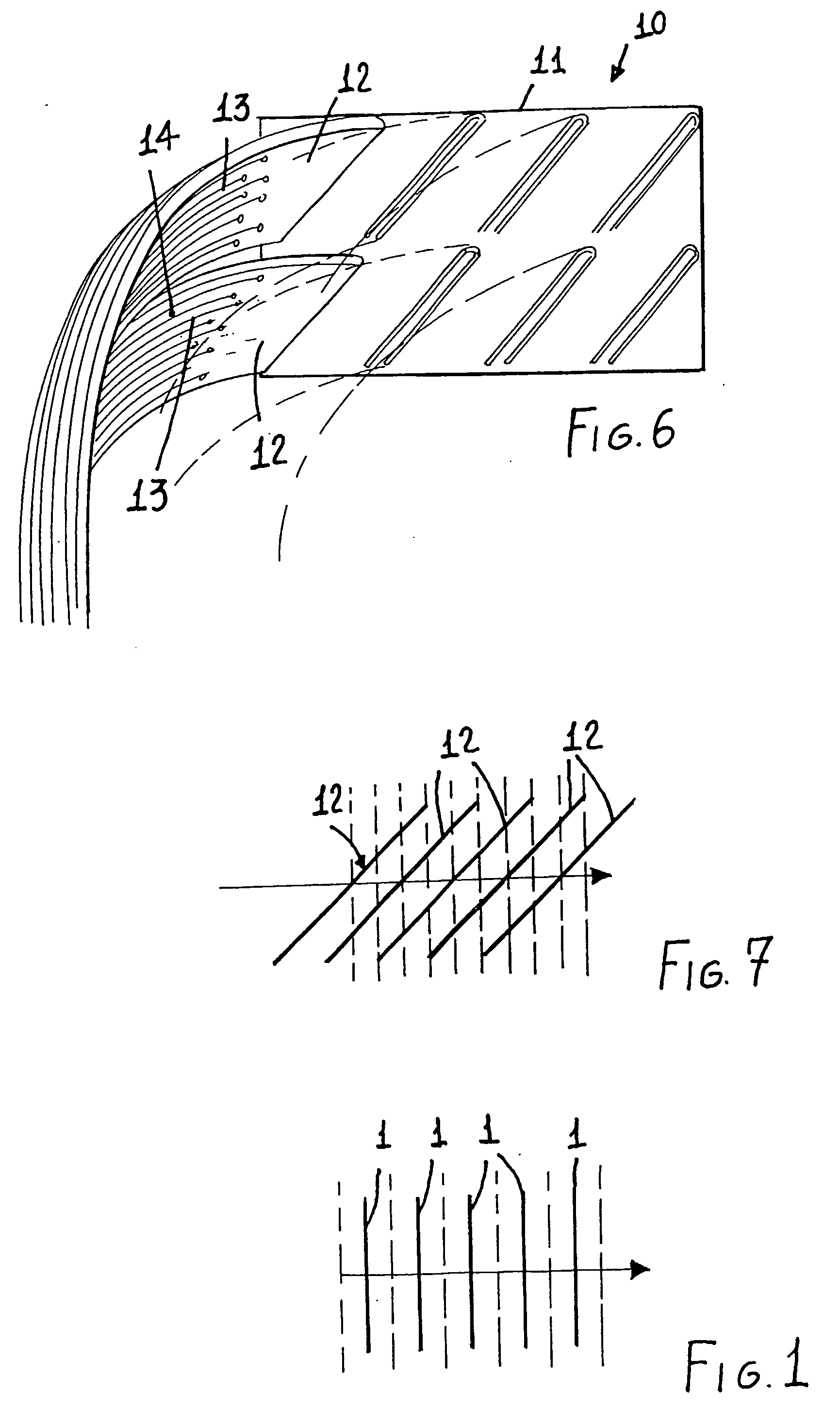

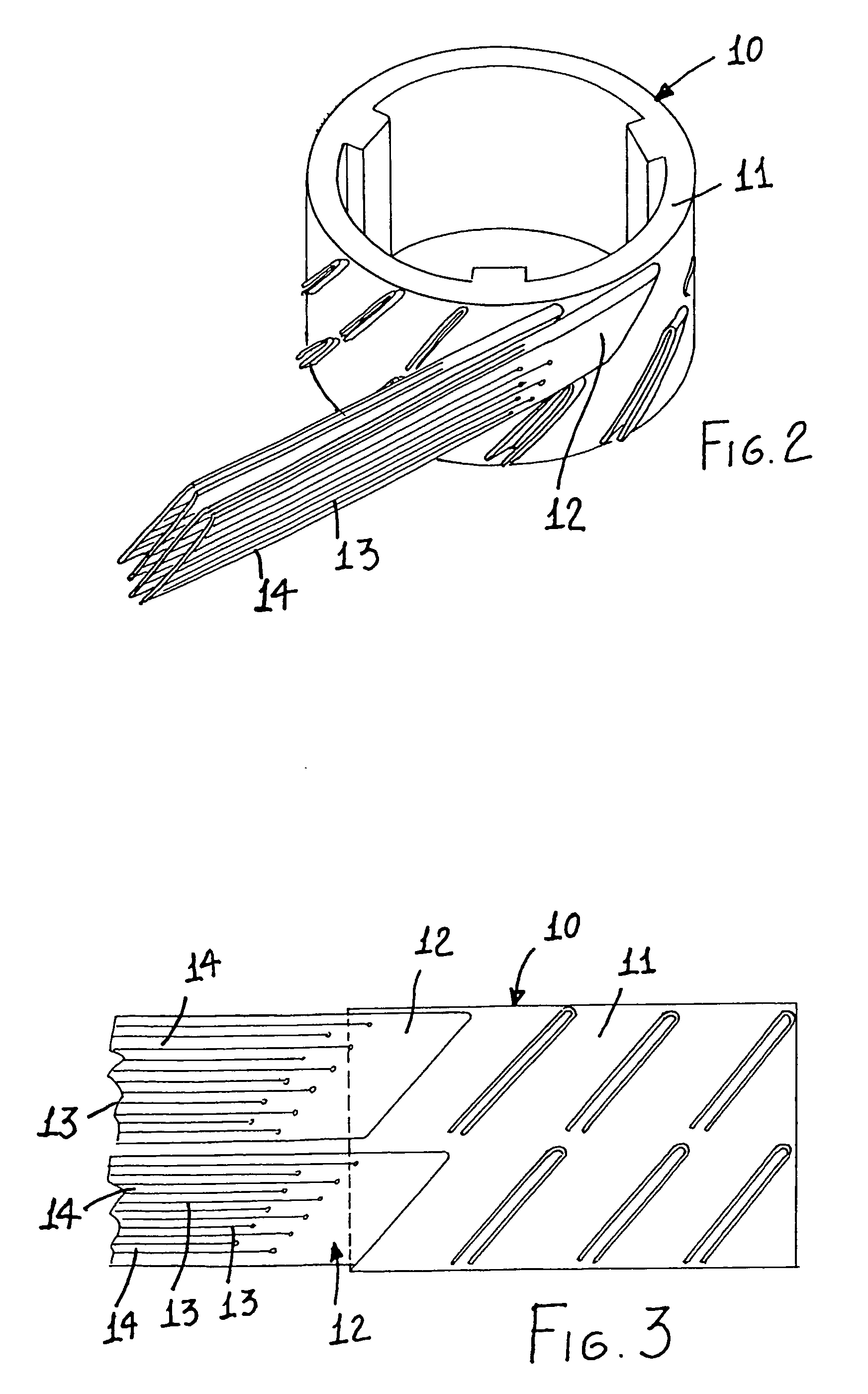

Washing brush for automatic motor vehicle washing systems

ActiveUS7743454B2Improve washing qualityReduce in quantityLiquid surface applicatorsLiquid processingEngineeringMechanical engineering

Owner:FAVAGROSSA EDOARDO SRL

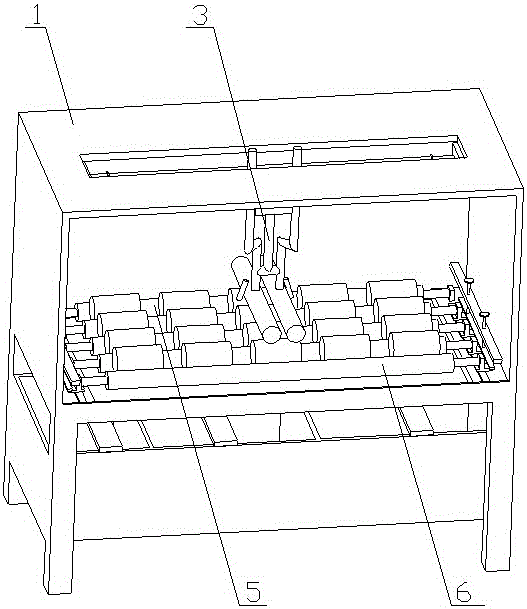

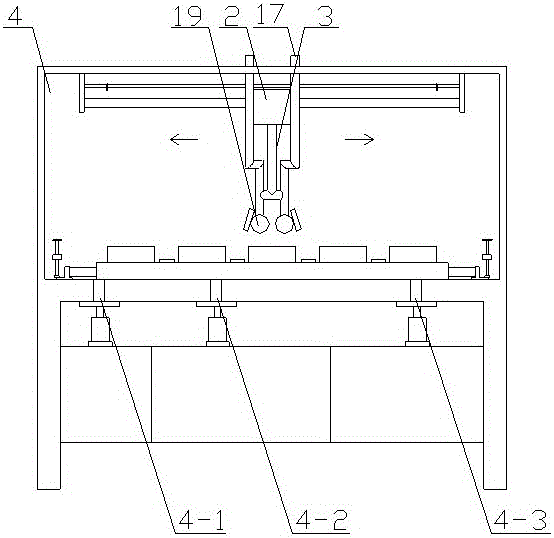

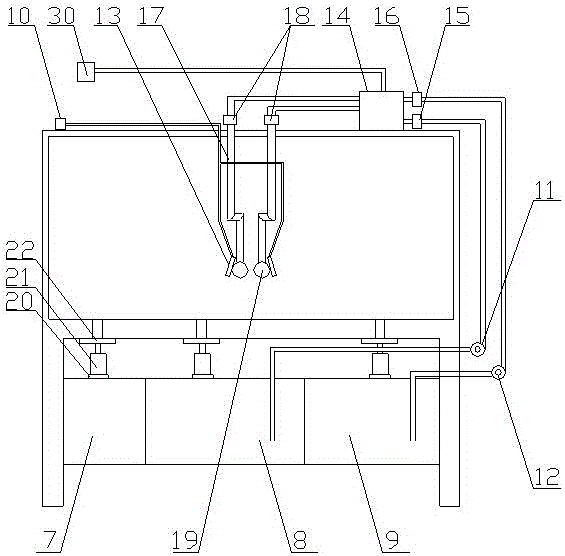

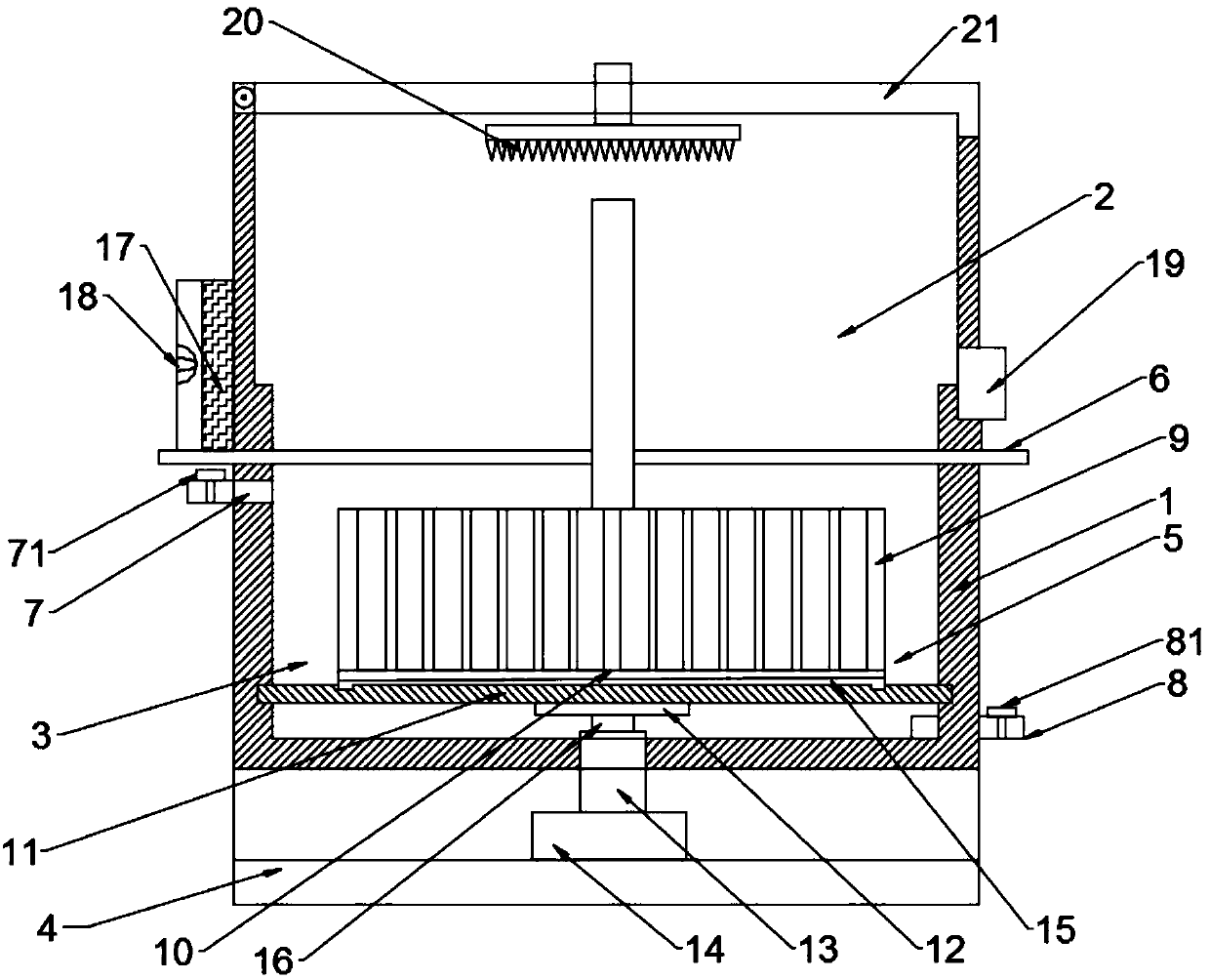

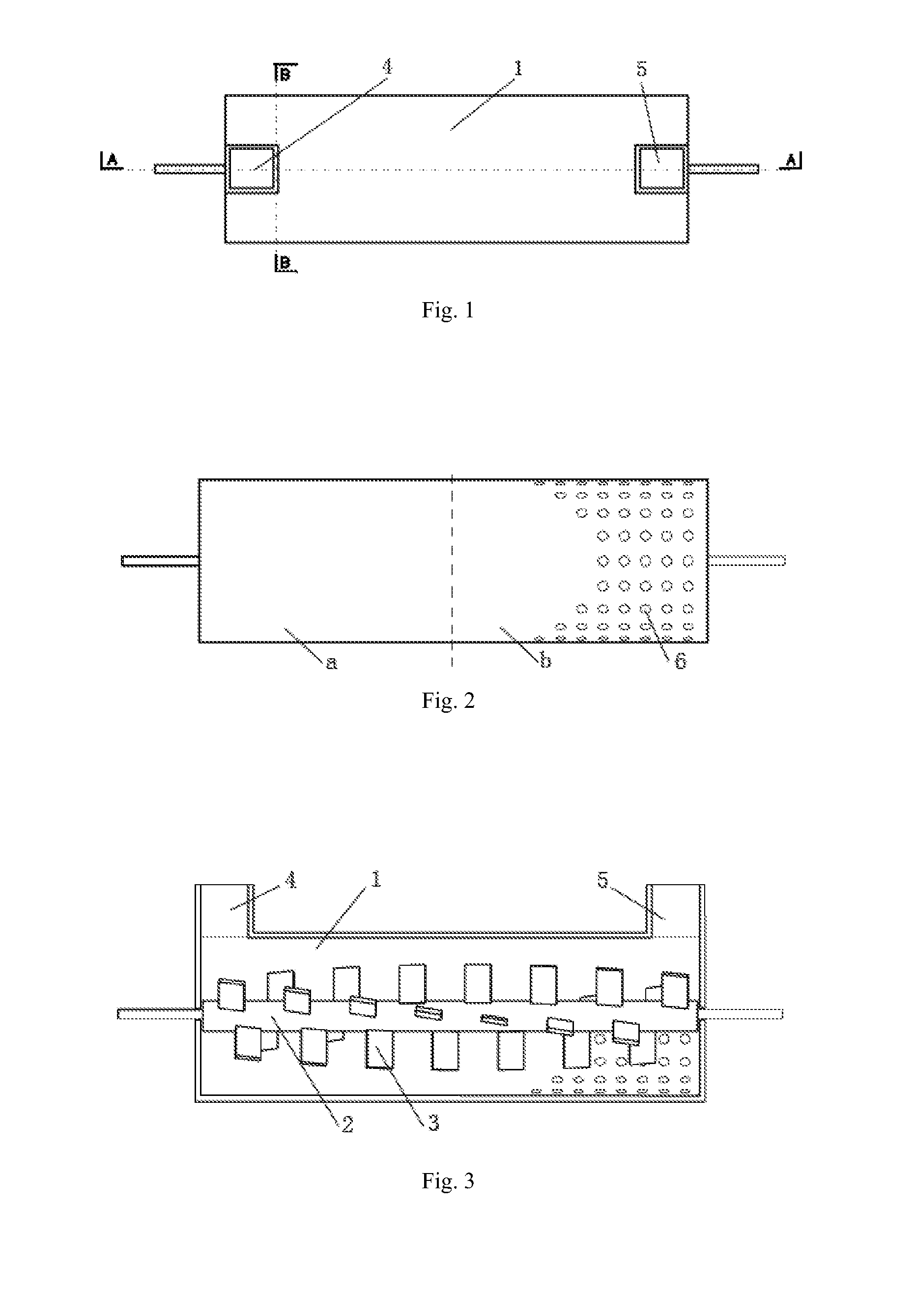

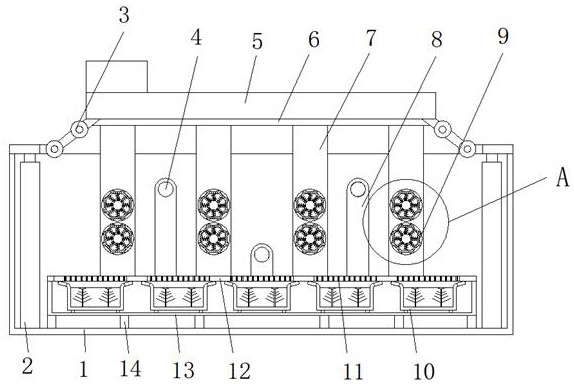

Full automatic cleaning machine for vacuum switch tubes

A full automatic cleaning machine for vacuum switch tubes is characterized by comprising a rack (1), a single-axis reciprocating machine (2), a fixed hanging rod (3), a transmission supporting mechanism and a circulatory spraying system. The transmission supporting mechanism comprises a driving roller (5), a set of driven rollers (6) and a motor. The circulatory spraying system comprises a waste water groove (7), an acid water groove (8), an alkali water groove (9), a high-pressure pump (10), an acid water pump (11), an alkali water pump (12), a pair of spraying nozzles (13), a multi-channel joint (14), an acid solenoid valve (15), an alkali solenoid valve (16), a pair of water outlet pipes (17), a pair of water outlet solenoid valves (18), a pair of stored water spraying pipes (19) and three switch mechanisms. The full automatic cleaning machine for the vacuum switch tubes has the advantages that the cleaning machine has the functions of water washing, acid washing and alkali washing, wherein the acid water and the alkali water can be recycled, so that the production cost is reduced; the cleaning machine can control the washing order and process of the water washing, the acid washing and the alkali washing by the solenoid valves, so that the cleaning requirements of the ceramic vacuum switch tubes in different production stages can be met and the degree of automation is high.

Owner:HUBEI XINSHIQI ELECTROCERAMICS TECH CO LTD

Plastic waste gas washing tower

InactiveCN103230736AExtended service lifeImprove corrosion resistanceDispersed particle separationLiquid wastePlastic waste

The invention belongs to the technical field of waste gas purification equipment, and in particular relates to a plastic waste gas washing tower. The plastic waste gas washing tower comprises a tower body, a waste gas inlet, a waste gas outlet, more than one tower plate, a filler spraying device and observation holes, and is characterized in that overall corrugated fillers are respectively arranged on the tower plate; a swirl plate is arranged on the top tower plate of the tower body; an annular catch tray is arranged at the lower part of the swirl plate; a swirl plate waste liquid outlet is formed in the side surface of the tower body; a lower tower plate waste liquid outlet is formed in the center at the bottom of the tower body; and the spraying device consists of long spraying pipes with nozzles and short spraying pipes with nozzles, which are uniformly and alternately arranged in the circumferential direction of the tower body. The plastic waste gas washing tower has the advantages of high corrosion resistance, ageing resistance, reasonable structure, stable performance, large processing capacity, small system resistance, convenience for mounting, no maintenance, long service life and the like.

Owner:ALIBEI PLASTIC STORAGE TANK ANSHAN

Cleaning and drying all-in-one machine for hardware accessories

InactiveCN107900019AImprove washing efficiencyImprove washing qualityDrying gas arrangementsCleaning using liquidsCushioningEngineering

The invention discloses an integrated cleaning and drying machine for hardware accessories, which comprises: a box body, a drying box, a washing box, a friction damping pad and a washing device, the drying box is located at the upper part of the box body, the washing box is located at the lower part of the box body, The dry box and the washing box are separated by a plugboard. The washing box is composed of a liquid inlet, a liquid outlet, a washing container, a rotating seat, a lifting seat, a motor and a threaded rod. The rotating seat and the threaded rod are slidably connected by a slide rail, and the lifting seat It is slidingly connected with the rotating seat through a circular track, the circular track is set on the lifting seat, the lifting seat is slidingly connected with the box body, the motor is set at the bottom of the box body, and the drying box is composed of electric heating wire, fan, spray device, box cover Composed of vent holes and friction damping pads at the bottom of the box. The invention reduces the collision wear during the cleaning process of the hardware fittings, increases the washing efficiency, can rinse the residual washing liquid on the surface of the hardware fittings after washing, and then dries them. The structure is simple and reasonable, and it is easy to operate.

Owner:WUXI WEI KELAI TECH CO LTD

Device for washing and drying of gray fabric

InactiveCN107142638AReduce wrinklingAvoid wrinklesLiquid/gas/vapor removalStretchingMotor driveMechanical equipment

The invention discloses a gray cloth washing and drying device, which belongs to the field of textile processing machinery and equipment. The invention includes a transmission bracket, a cloth feeding roller, a cloth washing tank, a cloth guide roller, a cloth guiding motor, a cloth supporting roller, a cloth drying roller, a cloth outlet roller and a cloth outlet motor, and the cloth guide motor drives the cloth guide roller. A pickling solution for gray cloth is installed, and a cloth washing roller is connected horizontally in the cloth washing tank, and a lifting plate is installed in the lifting bracket to slide vertically, the output end of the lifting cylinder is connected to the upper side of the lifting plate, and the two ends of the cloth supporting roller are respectively Rotate the lifting plates connected to both sides of the transmission bracket, the cloth drying roller is horizontally connected to the other side above the transmission bracket, the two ends of the cloth drying roller are respectively equipped with heat conduction oil pipes, and the cloth outlet roller is horizontally connected to the lower side of the transmission bracket. The invention has a reasonable structural design, can quickly and efficiently wash and dry the gray cloth during the transmission process, improves the efficiency and quality of gray cloth production and processing, and meets the needs of production and use.

Owner:张帼威

Detergent putting device, washing machine with device and control method

InactiveCN108252032AAvoid secondary pollutionKeep clean and hygienicOther washing machinesControl devices for washing apparatusWater flowPulp and paper industry

The invention discloses a detergent putting device, a washing machine with the device and a control method. The device comprises a first cavity used for containing a clothing treating agent, tap waterpasses through the first cavity to wash the clothing treating agent into an outer cylinder of the washing machine, the device further comprises a second cavity isolated from the first cavity, and thetap water passes through the second cavity and is directly injected into the outer cylinder of the washing machine. The invention provides new water inlet design, a water inlet cavity is additionallyformed in the putting device of the washing machine, different water inlet cavities are selected according to the washing process, and when rinsing is conducted, final rinsing inlet water passes through a softener or tenderizer containing part in the first cavity and enters the outer cylinder of the washing machine; for rinsing before final rinsing, when water enters, the water flows into the cylinder directly through the second cavity, and the problem that due to the fact that detergent cannot be washed out thoroughly, secondary contamination is caused is avoided. Meanwhile, the detergent putting device is detachable, a user can clean away residual detergent in time or regularly, a detergent box is kept clean and sanitary, and the washing quality is effectively improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

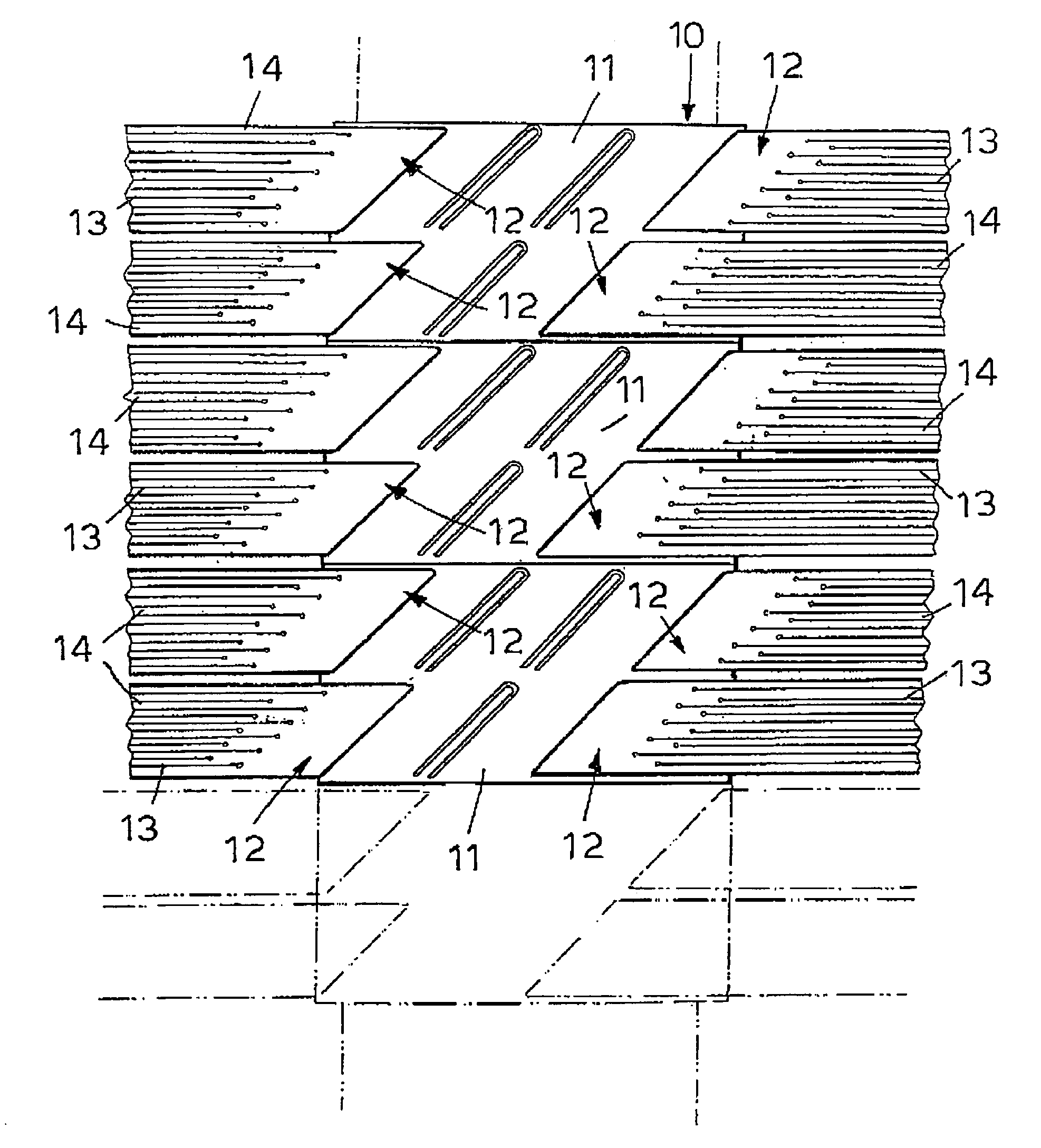

Washing brush for automatic motor vehicle washing systems

ActiveUS20060064835A1Improve washing qualityReduce in quantityLiquid surface applicatorsLiquid processingEngineeringMotorized vehicle

The present invention relates to a washing brush for automatic motor vehicle washing systems, comprising a cylindric body on the side outer surface thereof are provided a plurality of bands defining the cleaning elements of the brush. The main feature of the invention is that the band or strip elements extend on the side surface of the cylindric body along direction which are inclined with respect to the axial direction.

Owner:FAVAGROSSA EDOARDO SRL

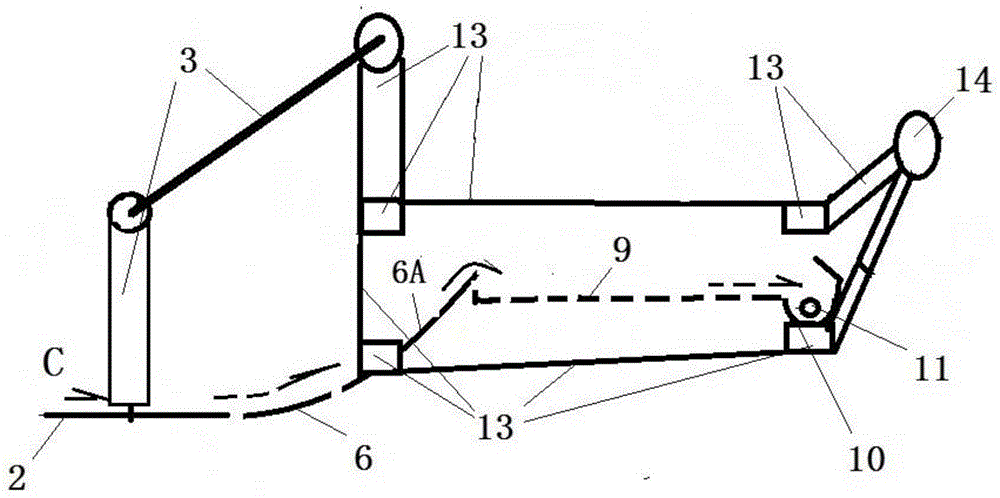

Method for digging water chestnuts by rotary cutting and digger employing same

The invention relates to a method for digging water chestnuts by rotary cutting and a digger employing the same. The method includes the steps: a water chestnut soil layer is divided into an upper soil seedling layer and a lower soil water chestnut layer, the upper soil seedling layer and the lower soil water chestnut layer are cut and divided by rotary cutting and forward movement of two upper and lower cutting wheels, with forward movement of a digging collector, and the upper soil seedling layer enters a digging blade and is discharged from an upper passage into a furrow behind the digging blade; the lower soil water chestnut layer enters a water chestnut collection passage of the digging blade, after screening, water chestnuts and soil are separated, and the broken soil falls into the furrow behind the digging blade through meshes; the water chestnuts obtained by screening enter a product collector. Therefore, automatic digging and collecting of water chestnuts is achieved.

Owner:吴润秀

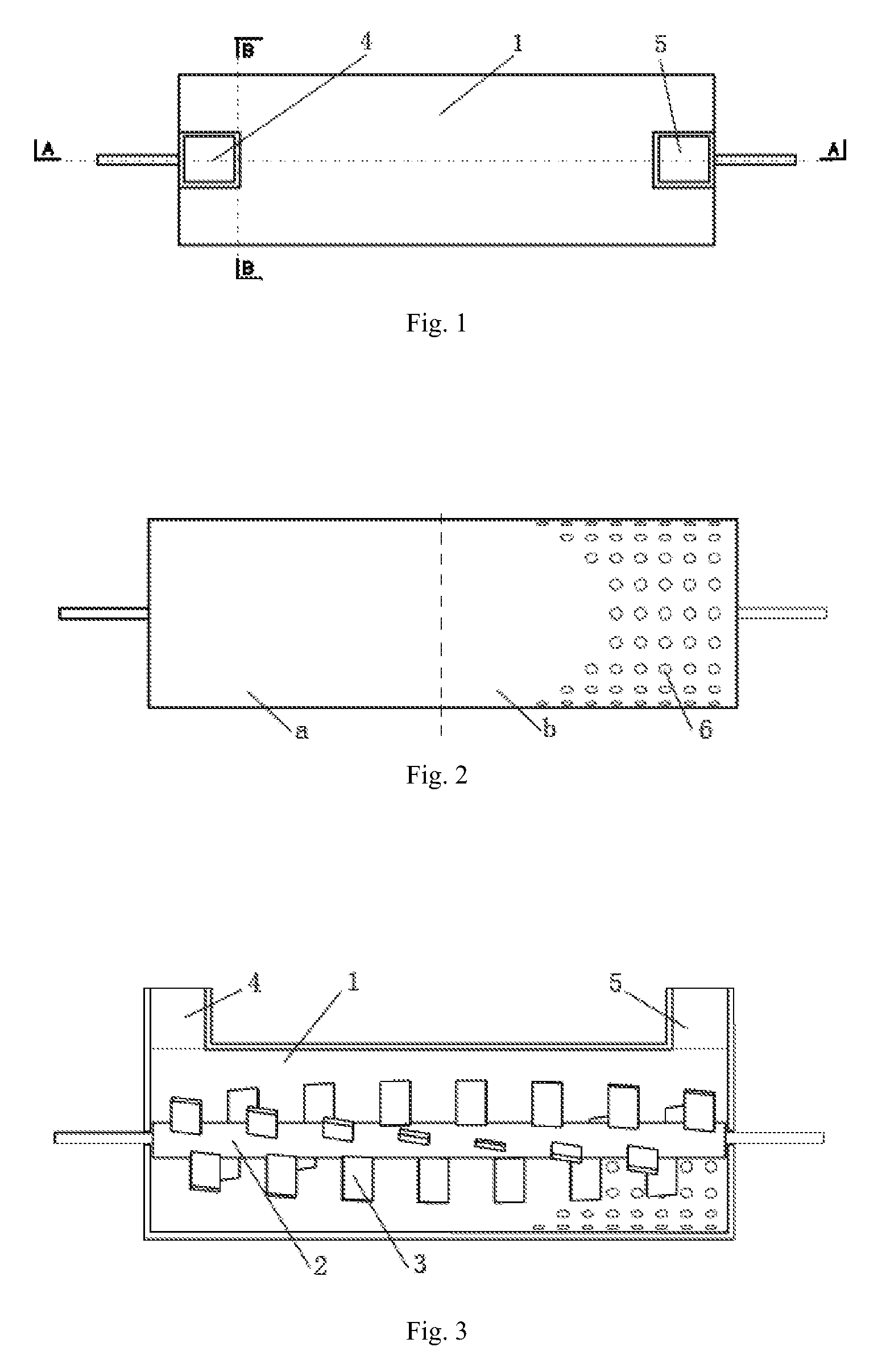

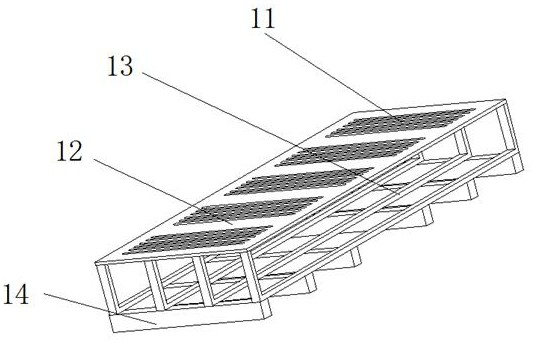

Multi-Functional Rubbing and Separating Device Used for Washing Waste Plastics

ActiveUS20140213159A1Improve washing effectEfficiently attachedEdge grinding machinesSievingRubbingRecycled products

Provided is a multi-functional rubbing and separating device, comprising a main body, a rotating axle and lapping blades; wherein a feeding port is disposed on one end of the main body and a discharge port is disposed on another end; the rotating axle and lapping blades are disposed inside said main body; the lapping blades are distributed on outer cylindrical surface of the rotating axle; and multiple through-holes are disposed on an sidewall of the main body. The multi-functional rubbing and separating device herein is added between a flotation tank and a washing tank, which can effectively improve the washing quality for waste plastics, thereby separating waste plastics and impurities more thoroughly and improving the quality of recycled products.

Owner:FENG YUBIN

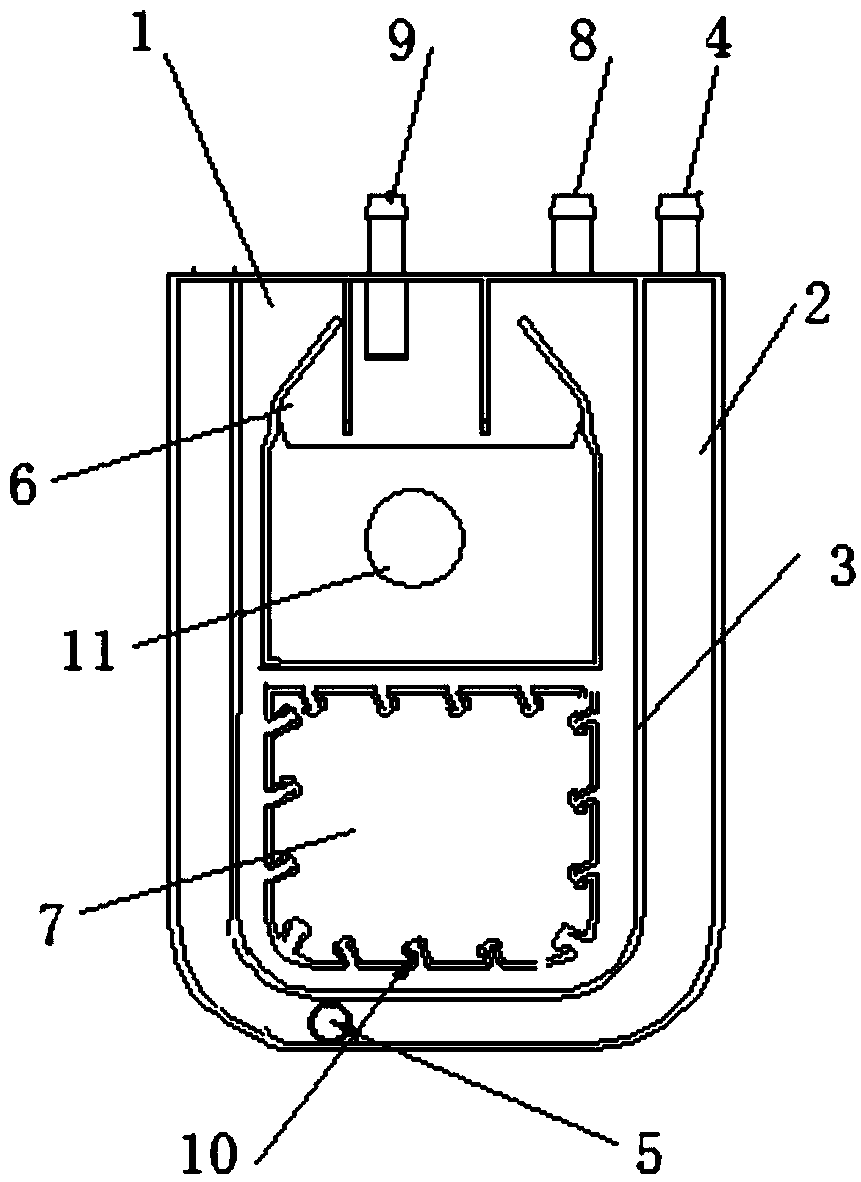

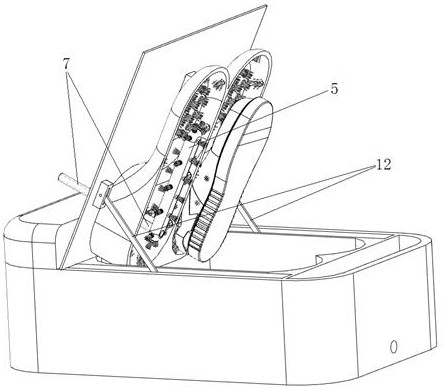

Water-saving drying and washing integrated shoe washing machine and method

InactiveCN111839416ASolve the disadvantages of non-separation and pollutionReduce the amount of waterFootwear cleanersWater savingSewage

A shoe washing machine comprises a machine cover and a box body. When the machine cover and the box body are tightly closed, a cleaning cabin with the outer contour of shoes is formed in the machine cover and the box body, and shoe outer brushes are arranged on the inner surface of the cleaning cabin; shoe inner brushes are arranged in the cleaning cabin, are connected with the output end of a transmission device, are in a hook shape and are used for hanging shoes and driving the shoes to vibrate in the cleaning cabin; water injection pipes are further arranged in the cleaning cabin, and whenthe shoes are hung on the shoe inner brushes, water outlets of the water injection pipes are located in the shoe; a water outlet is formed in the bottom part of the cleaning cabin and is connected with a drainage pump. The shoe washing machine is more comprehensive in washing range, has the advantages of being cleaner in washing and high in washing quality, and can prevent sewage for washing solesfrom polluting other parts.

Owner:SHAANXI UNIV OF SCI & TECH

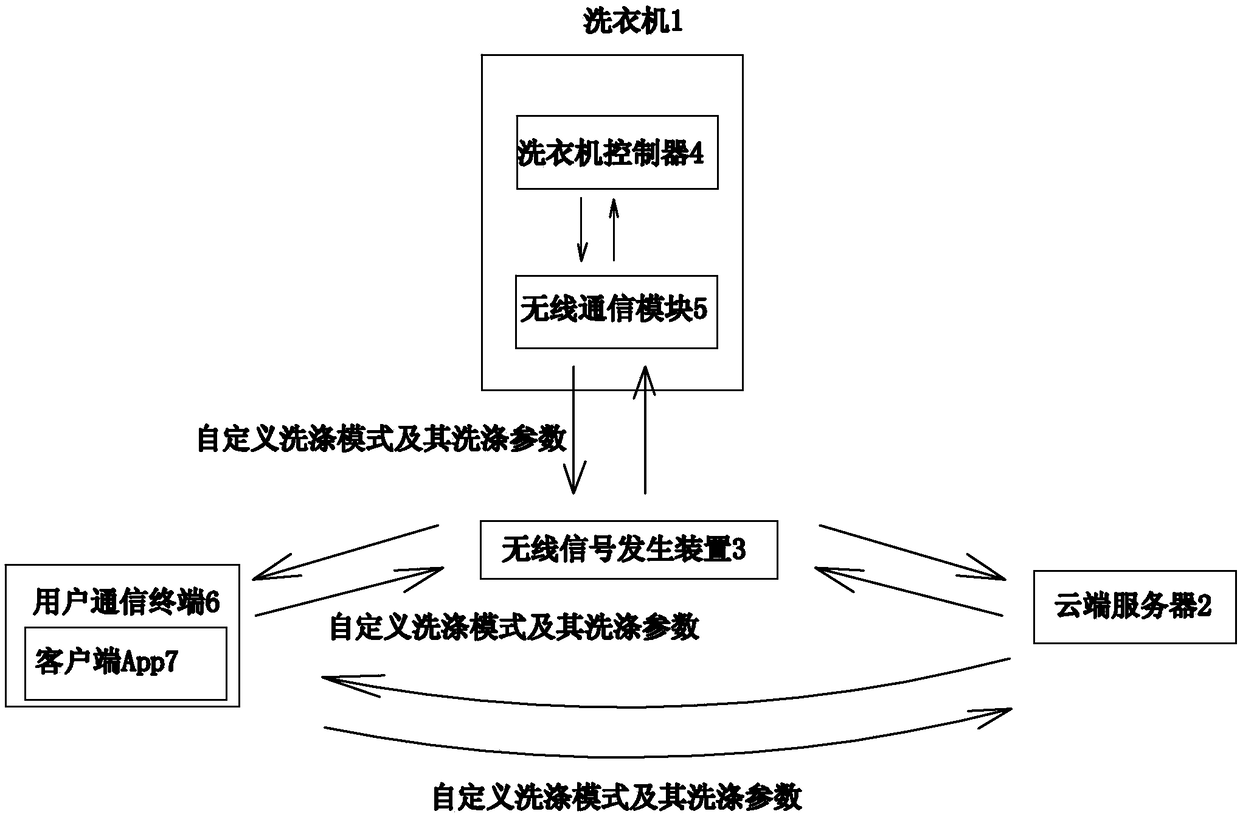

Customizing method for intelligent washing machine washing mode

InactiveCN108642797AFlexible useImprove user experienceControl devices for washing apparatusTextiles and paperElectricityMachine control

The invention relates to a customizing method for an intelligent washing machine washing mode. The method comprises the following steps that 1, a user starts an intelligent washing machine and a wireless signal generation device, and the washing machine is connected with a wireless network through a wireless communication module; 2, the user sets a customized washing mode and washing parameters ofthe customized washing mode on a client App on the mobile communication terminal of the user; 3, the client App uploads the customized washing mode to a washing machine controlled for storage; 4, thewashing machine controller controls an intelligent washing machine to run according to the washing parameters of the customized washing mode. Accordingly, by setting the customized washing mode on the washing machine, the intelligent washing machine can run according to the set customized washing mode, and then the various washing requirements of the user are met. According to the method, convenience is brought to operation, the phenomenon that the user uses the washing machine incorrectly can be reduced, and water and electricity waste is avoided.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

Multi-functional rubbing and separating device used for washing waste plastics

Provided is a multi-functional rubbing and separating device, comprising a main body, a rotating axle and lapping blades; wherein a feeding port is disposed on one end of the main body and a discharge port is disposed on another end; the rotating axle and lapping blades are disposed inside said main body; the lapping blades are distributed on outer cylindrical surface of the rotating axle; and multiple through-holes are disposed on an sidewall of the main body. The multi-functional rubbing and separating device herein is added between a flotation tank and a washing tank, which can effectively improve the washing quality for waste plastics, thereby separating waste plastics and impurities more thoroughly and improving the quality of recycled products.

Owner:FENG YUBIN

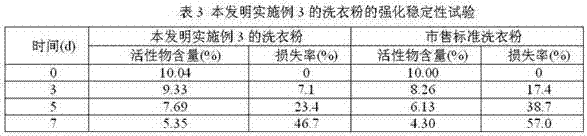

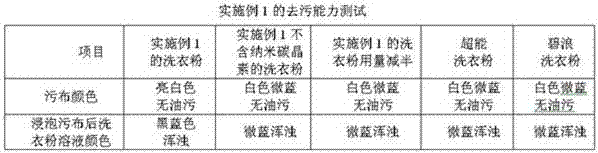

Washing powder easy in white washing and preparation method thereof

InactiveCN109652226AEliminate scalingRestore colorInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsFatty alcoholSodium salt

The invention discloses washing powder easy in white washing. The washing powder includes, by weight, 3-5 parts of LAS sodium salt, 8-12 parts of fatty alcohol polyoxyethylene ether, 1.5-4 parts of peroxide, 0.1-0.4 part of bio-enzyme, 10-18 parts of sodium carbonate, 30-50 parts of EDTA tetrasodium, 0.8-1.3 parts of an anti-redeposition agent, and 2-5 parts of sodium sulfate. Through the component arrangement of the LAS sodium salt, the fatty alcohol polyoxyethylene ether, the peroxide, the bio-enzyme, the sodium carbonate, the EDTA tetrasodium, the anti-redeposition agent and the sodium sulfate, the washing powder can eliminate fouling generated by calcium and magnesium ions except for a function of normal washing, the color and luster of fabrics can be recovered, and the washing powdercan add a sterilization and disinfection function.

Owner:广州丽高生物科技有限公司

Method for improving weather resistance of decorative base paper titanium dioxide

ActiveCN107500348AReduce concentrationIncrease concentrationTitanium dioxideWeather resistancePotassium

The invention provides a method for improving weather resistance of decorative base paper titanium dioxide, and belongs to the technical field of decorative base paper titanium dioxide. The control is performed through salt treatment and calcination. The method comprises the following steps of A, using bleached slurry as raw materials; adding titanium dioxide sol into the raw materials; controlling the addition to meet the requirement that the proportion of TiO2 in the titanium dioxide sol to TiO2 in metatitanic acid is 2 to 6 percent; performing water washing; diluting the slurry subjected to water washing into 300 to 400g / L TiO2 slurry; B, adding potassium and phosphorus solution with the K2O / P2O5 ratio being 1.3 to 4.0 into the diluted slurry; performing stirring; adding aluminum-containing compound solution according to the Al2O3 to TiO2 proportion being 0.3 to 0.9 percent; performing stirring; C, performing pressurized filtering on the slurry material treated by the step B until the filter cake solid content is 45 to 55 percent; C, roasting the filter cake in the step C for 8 to 10h at the roasting temperature of 200 to 950 DEG C. Through the control on the salt treatment and roasting processes, the primary product weather resistance of the decorative base paper titanium dioxide is improved; the weather resistance of the decorative base paper titanium dioxide is further improved.

Owner:HEBEI MILSON TITANIUM DIOXIDE

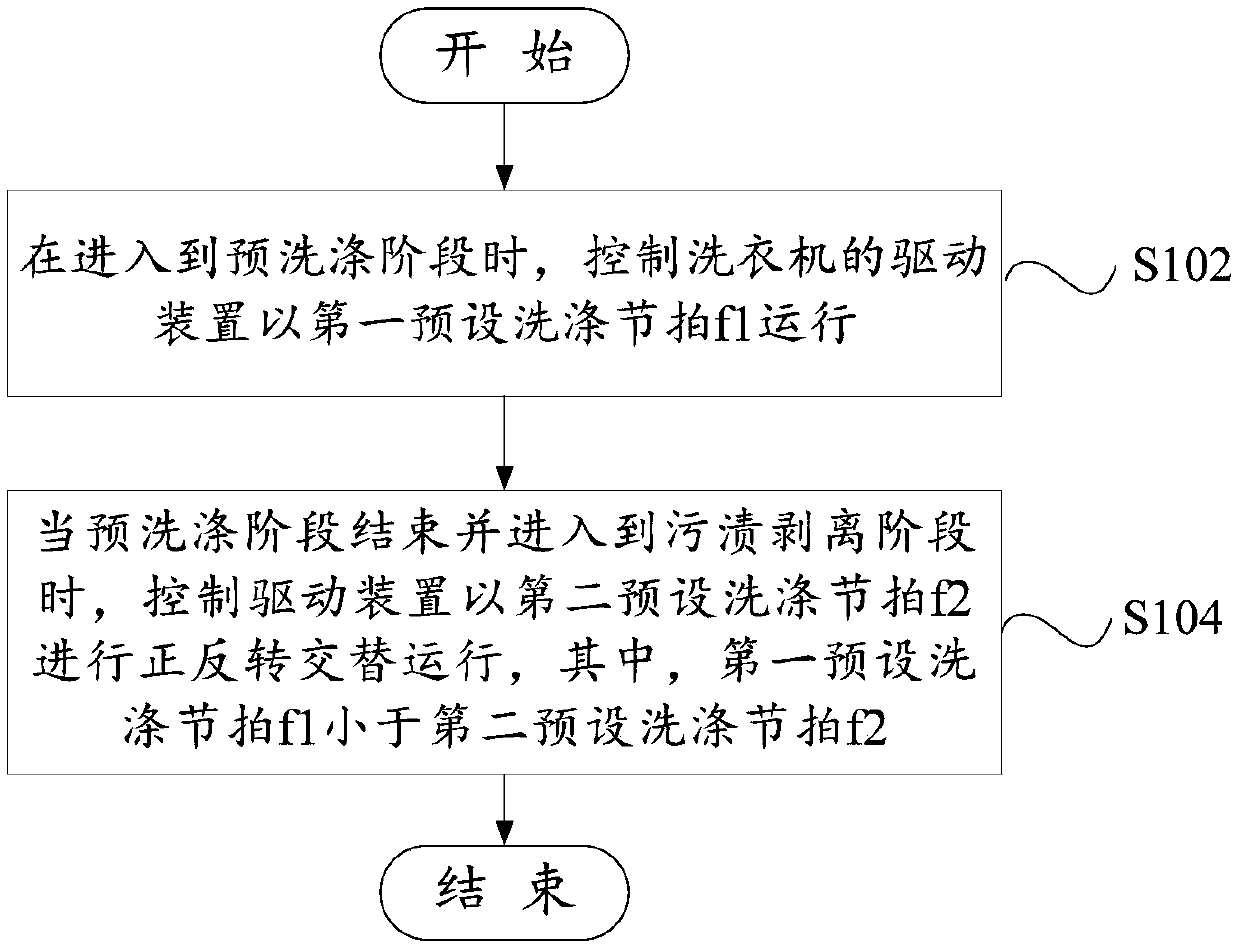

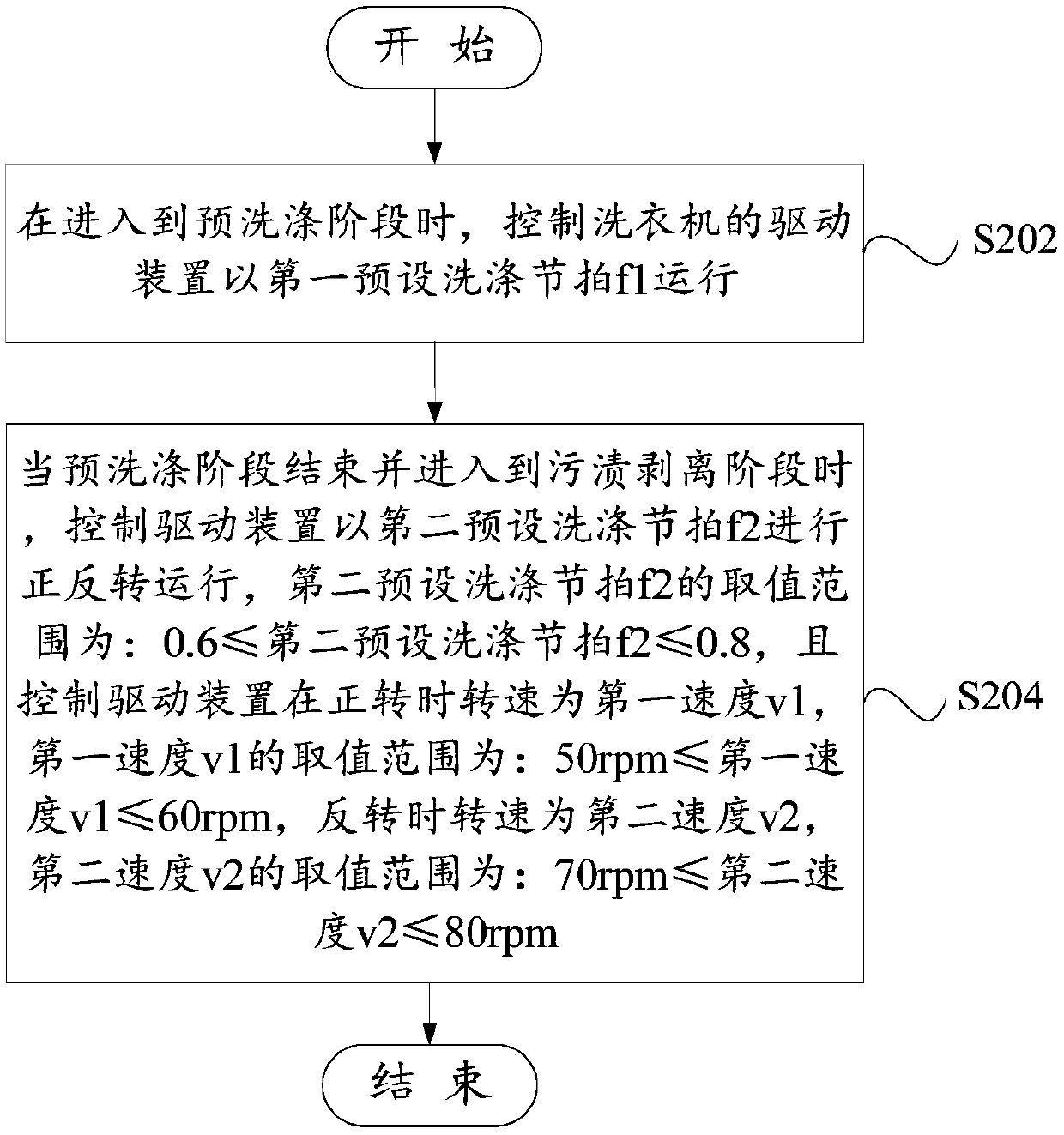

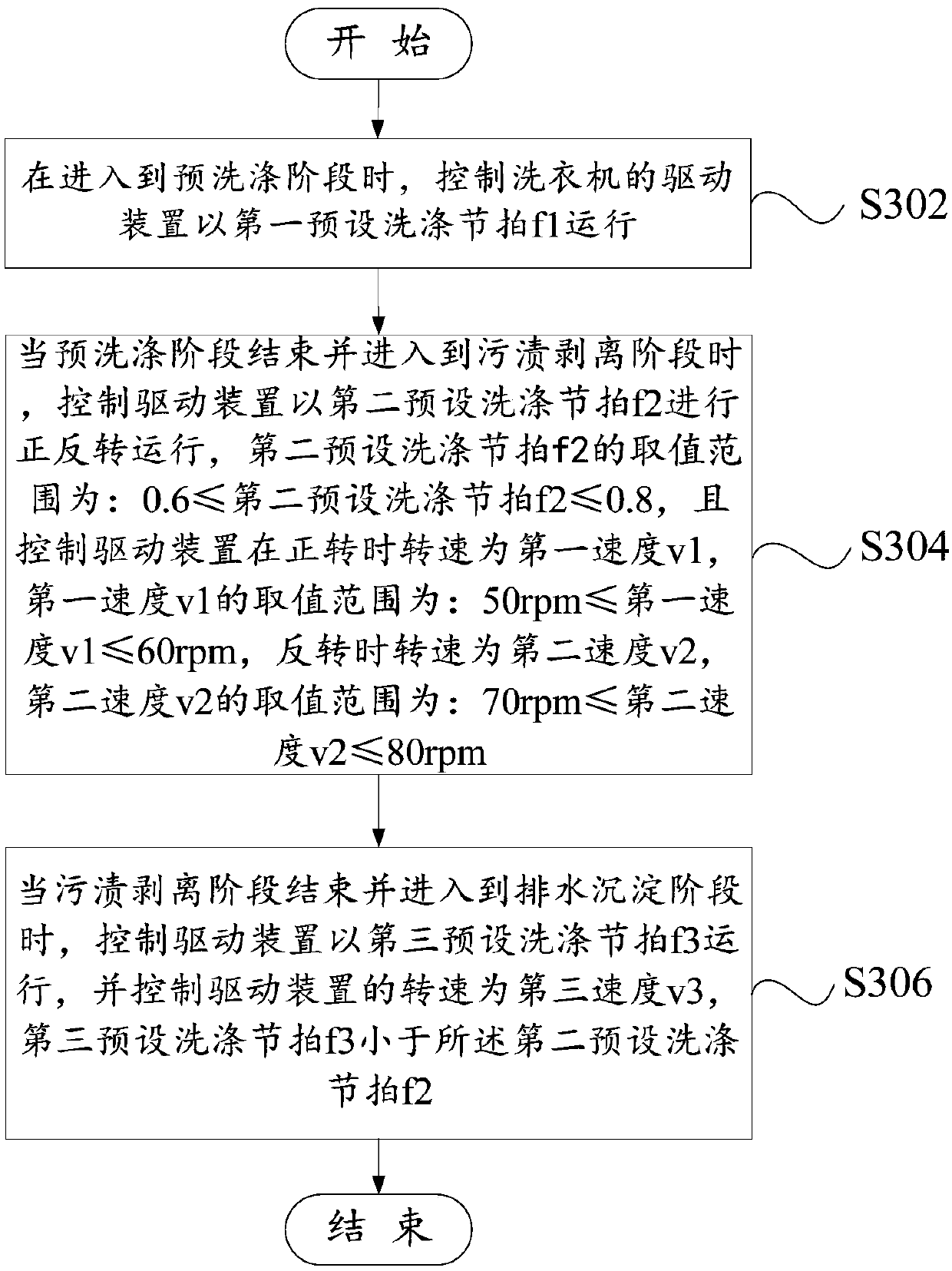

Control method and system of washing machine, computer equipment and storage medium

ActiveCN110344206AFully infiltratedAchieving a slight rolloverControl devices for washing apparatusTextiles and paperProcess engineeringPre washing

The invention provides a control method and system of a washing machine. The control method comprises the following steps: when entering a pre-washing stage, controlling a driving device of the washing machine to operate at a first preset washing beat f1; and when the pre-washing stage is finished and the washing machine enters a stain stripping stage, controlling the driving device to perform forward and reverse rotation alternate operation at a second preset washing beat f2. The first preset washing beat fl is smaller than the second preset washing beat f2. In the pre-washing stage, the driving device of the washing machine is controlled to operate at the first preset washing beat f1. First, the driving device gently operates the washing machine to sufficiently wet clothes, then the washing machine enters the stain stripping stage to control the driving device to perform forward and reverse rotation alternate operation at the second preset washing beat f2 which is larger than the first preset beat f1, namely, the washing beat of the driving device is increased in the stain stripping stage, and a folded unexpanded portion is sufficiently stretched. The control method of the washing machine of the invention is directed to the characteristics of sportswear. The wearing life of the sportswear is prolonged, and the wearing experience of the sportswear is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Granular activated charcoal washing equipment

ActiveCN110117012AReduce wearImprove washing efficiencyCarbon compoundsTemperature controlWater filter

The invention discloses granular activated charcoal washing equipment. The equipment comprises a tank body, an upper sealing head and a lower sealing head, wherein the upper sealing head and the lowersealing head are arranged at the upper and lower ends of the tank body; the upper sealing head is provided with a feeding port, a clear water inlet, an acid liquid port, a circulating water inlet, aliquid level detecting port, a liquid level control device and a purifying device, wherein the liquid level control device is connected to the liquid level detecting port and used for quantifying an acid liquid, and the purifying device is disposed above the feeding port and used for receiving dust and acid vapor; the middle of the side wall of the tank body is provided with a temperature detecting port used for being connected to a temperature control device, the lower portion of the side wall of the tank body is provided with a steam pipe extending into the tank body, and the outer end of the steam pipe is connected with a steam generator; a discharge port is formed in the center of the bottom of the lower sealing head and internally provided with an electric valve, and the lower sealinghead is also provided with an aeration port and at least one water filtering device used for separating granular activated charcoal from black waste water, wherein the aeration port is connected to ahigh-pressure air aerator. In summary, the equipment has the advantages that the control degree is high, the washing efficiency is high, sufficient washing is achieved, the wearing degree of activated charcoal particles is low, manpower is saved, energy is saved, and the environment is protected.

Owner:江苏哈特尔碳材料科技有限公司

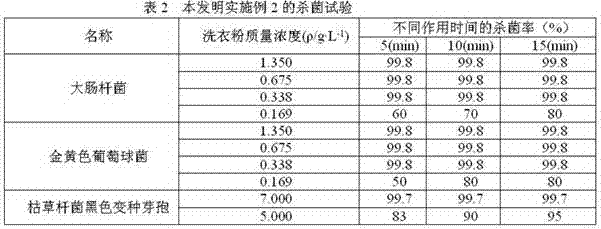

A down feather dedusting agent and a preparing method thereof

InactiveCN108034517AEffective anti-wrinkleEfficient killingNon-ionic surface-active compoundsOrganic detergent compounding agentsCarboxylic saltCoconut oil

A down feather dedusting agent and a preparing method thereof are disclosed. Raw materials of the dedusting agent include, by weight, 3-5 parts of poly(vinylbenzyltrimethyl ammonium), 6-10 parts of sodium polyoxyethylene alkyl ether carboxylate, 2-6 parts of coconut oil diethanolamide, 0.5-1 part of almondamidopropylamine oxide, 2-5 parts of sodium dodecylsulfate, 3-6 parts of di(tallowcarboxyethyl)hydroxyethyl methyl ammonium methylsulfate, 1-2 parts of sodium citrate, 2-4 parts of deacetylchitin, 3-5 parts of tea oil, 20-40 parts of deionized water and 8-12 parts of an antibacterial agent. The dedusting agent effectively reduces dirt in down feather, maintains good compliance of the down feather, does not destroy protein fibers of the down feather substantially, and can kill bacteria propagated on down feather.

Owner:东隆家纺股份有限公司

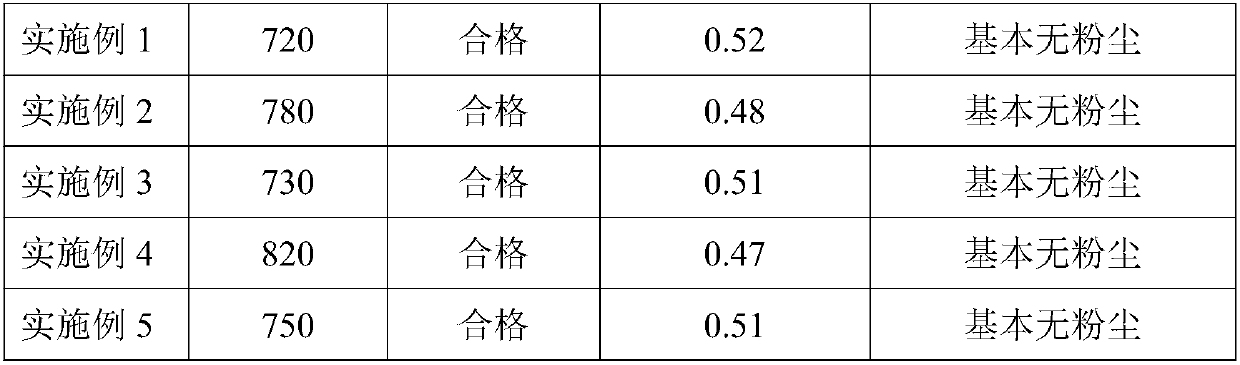

Ejecting circulating device and technical method for alkali soaking tank of bottle washing machine

ActiveCN102825043AImprove washing effectGuaranteed washing qualityHollow article cleaningWater flowSpray nozzle

The invention discloses an ejecting circulating device and a technical method for an alkali soaking tank of a bottle washing machine. The ejecting circulating device comprises a circulating pump which is respectively connected with an internal alkali tank and an external alkali tank of the alkali soaking tank of the bottle washing machine through a circulating pump inlet pipeline and a circulating pump outlet pipeline; alkali liquid is circulated based on the connection among the pump, the pipelines, the internal alkali tank and the external alkali tank; a circulating pump outlet is connected to the bottom of the external alkali tank through the pipeline, and is connected with a corresponding ejecting pipeline in the external alkali tank, wherein the ejecting pipeline is arranged at the bottom of the external alkali tank, and corresponds to a container bottle inlet; the alkali liquid of the internal alkali tank is ejected through a nozzle on the ejecting pipeline under the effect of the circulating pump, so as to form a circulating stream; and labels separated from container bottles and floating in the alkali liquid flow to a label removing net above the internal alkali tank based on the principle of water flowing. The alkali liquid is served as an ejecting medium, so that the labels deposited in the bottom of the tank can flow, the alkali liquid in the alkali soaking tank is circulated, and further, the washing efficiency and quality can be ensured.

Owner:湖南珠江啤酒有限公司

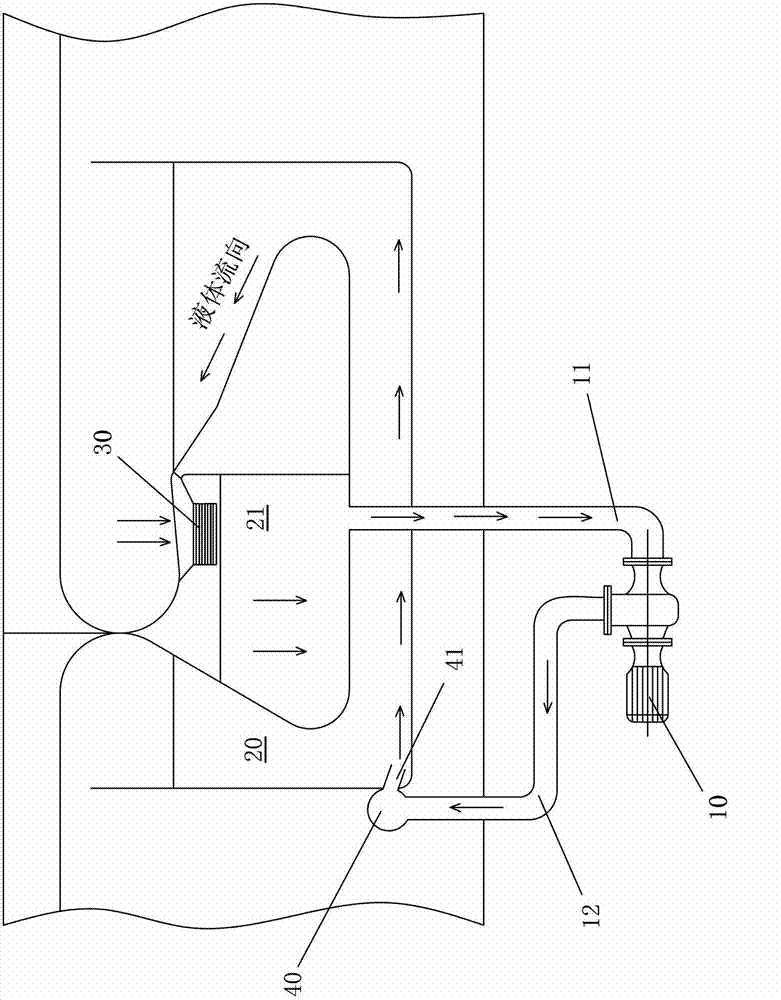

High-low pressure combined method for extracting black liquor

InactiveCN1752339AHigh extraction rateIncrease concentrationPulp liquor regenerationBlack liquorCombined method

The method for extracting black liquor includes the following steps: after the black pulp is produced by digestion, making the black pulp be passed through blow tank, series-connecting two pulp-pressing machines, utilizing high-pressure to extract black liquor, making outlet pulp of pulp-pressing machine be passed through series-connected pulp chest, then series-connecting horzontal ban-type vacuum pulp-washing machine, using hot water to wash pulp, and utilizing low-pressure to extract black liquor.

Owner:冯长祯 +1

Washing powder containing nano carbon crystal grains

InactiveCN107012012AReduce pollutionSimplify the washing processInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWhitening AgentsLotion

The invention discloses washing powder containing nano carbon crystal grains and belongs to the technical field of daily supplies. The washing powder comprises, by weight percentage, 1-15% of anionic surfactant, 1-5% of nonionic surfactant, 1-10% of macromolecule washing aid, 0.1-2% of sodium carboxymethyl cellulose, 5-20% of sodium carbonate, 8-15% of sodium silicate, 1.3-2.8% of caustic soda liquid, 20-60% of anhydrous sodium sulfate, 0.05-0.5% of whitening agent, 0.1-1% of biological enzyme, 0.1-0.4% of essence, 5-15% of 4A zeolite and 1-10% of modified nano carbon crystal grains. The washing powder has the advantages that the washing powder has effects of ultrastrong decontaminating and sterilizing, washing and sterilizing are completed at the same time, a washing process is simplified greatly, washing time is saved, a good washing effect can be achieved under a cold water condition, the washing powder is unlimited by region geographic positions and temperature and is wide in application range and low in pollution to environments.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Emulsifier and preparation method thereof

InactiveCN108913379ASimple production processSimple methodOrganic detergent compounding agentsSurface-active detergent compositionsAlcoholPolyethylene glycol

The invention discloses a preparation method of an emulsifier. The preparation method comprises the following steps: a, heating deionized water to a certain temperature; b, adding fatty alcohol polyoxyethylene ether, polyethylene glycol, isoether alcohol and Kathon into the deionized water treated in the step a under a stirring state; adding Kaisone again after the solution in the step b reacts tobe clear and transparent to obtain the emulsifier. The preparation method disclosed by the invention has a simple process, only needs stirring, and has very good economic benefit and practicability.Through addition of the obtained emulsifier into washing liquid, the permeability of the washing liquid can be improved, the surface tension of the washing liquid can be reduced, grease can be emulsified, greasy dirt can be loosened, the washing ability of the washing liquid can be improved, and heavy oil dirt on the tools, table cloth and napkin can be effectively removed.

Owner:杭州白鹭清洁剂厂

Dishwasher control method and dishwasher

InactiveCN110464271AImprove quality of experienceImprove washing qualityTableware washing/rinsing machinesSoftware engineeringControl unit

The invention belongs to the field of dishwashers, and particularly relates to a dishwasher control method and a dishwasher. After a washing program is selected, a control unit inquires whether the washing program needs to be adjusted or not. If yes, the washing program is adjusted according to an adjusting method. If not, the washing program is directly executed. The washing period of the dishwasher is adjusted through user feedback. The interaction of the dishwasher with the user is increased. The washing experience and the washing quality of the dishwasher are improved. The washing processparameters of the dishwasher are adjusted according to the personalized difference of the user and the dietary habits of the user.

Owner:QINGDAO HAIER DISHWASHER

Starching device for producing linen for painting and calligraphy

ActiveCN111764073AImprove convenienceFully contactedTextile treatment machine arrangementsTextile treatment carriersMechanical engineeringHydraulic pressure

The invention discloses a starching device for producing linen for painting and calligraphy, relates to the technical field of producing linen for painting and calligraphy, and aims to solve the problem that cloth needs to be stretched and stirred manually in the process of washing and starching, as a result, a large amount of labor is caused to laborers. The starching device specifically comprises a starching pool, wherein hydraulic oil cylinders are fixedly installed at the four corners of the bottom inner wall of the starching pool, a movable frame is fixedly installed among the top ends ofthe four hydraulic oil cylinders, a plurality of connecting frames of rectangular tubular structures are fixedly installed on the two sides of the bottom of the movable frame, movable plates are fixedly installed between the bottom ends of the connecting frames, and a conveying mechanism is installed between every two adjacent connecting frames through a sealed bearing. The starching device is easy and convenient to starch and improves the convenience of washing and starching work of the linen, traction is carried out at the end of the cloth, the cloth is conveyed by the conveying mechanismsin the starching device, the cloth is turned inside the starching pool for multiple times by arranging turning rollers, so the cloth is in full contact with starching liquid, and the washing and starching efficiency of the cloth is improved.

Owner:南京秦邦吉品农业开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com