Filter cloth belt of spin-drying sludge and sludge spin-drying device using the same

A technology of dewatering device and filter cloth belt, which is applied in the fields of dewatering/drying/concentrated sludge treatment, water/sewage treatment, water/sewage treatment equipment, etc. To avoid problems such as detours, to achieve the effect of simple hooking and quick hooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

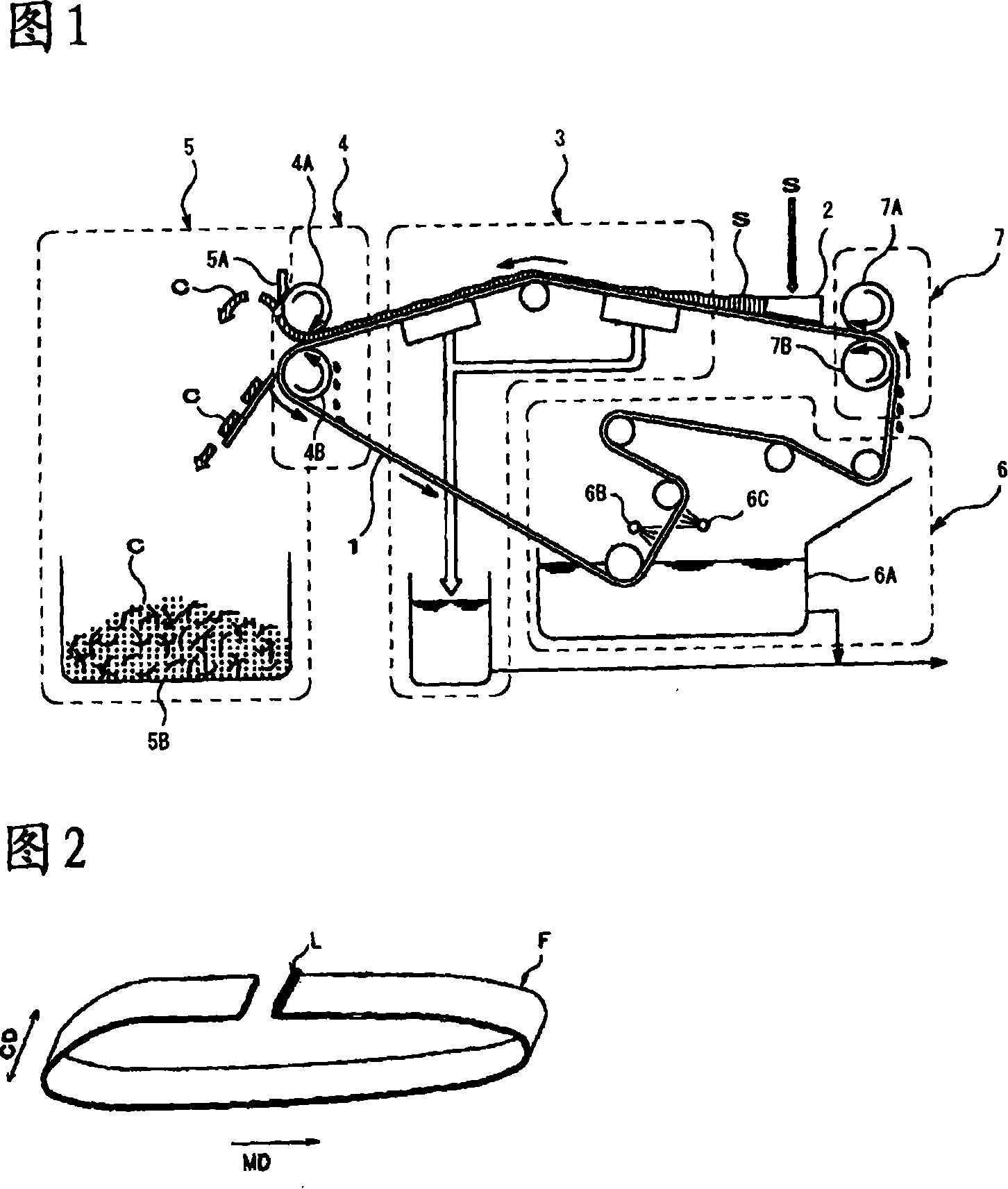

[0038] The filter cloth belt type dehydration device of the present invention is a device that filters a slurry-like or sludge-like object to be dehydrated and treats it into a cake-like shape with a relatively low water content. Examples of the dewatered product include excess sludge in the food industry, product recovery from sludge in the chemical and metal industries, waste, activated excess sludge of sewage, and domestic sewage sludge.

[0039] The basic principle of the filter cloth belt type dehydration device is to filter and dehydrate the dehydrated material supplied to the filter cloth belt by pressing the pressure belt or roller, or by suction from the lower part of the filter cloth belt. The method of dewatering under pressure by sandwiching the material between two filter cloth belts or between the filter cloth belt and the pressure belt; or using a single filter cloth belt, dewatering by the pressing of the roller and the suction from the lower part of the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com