Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1953 results about "Composite filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

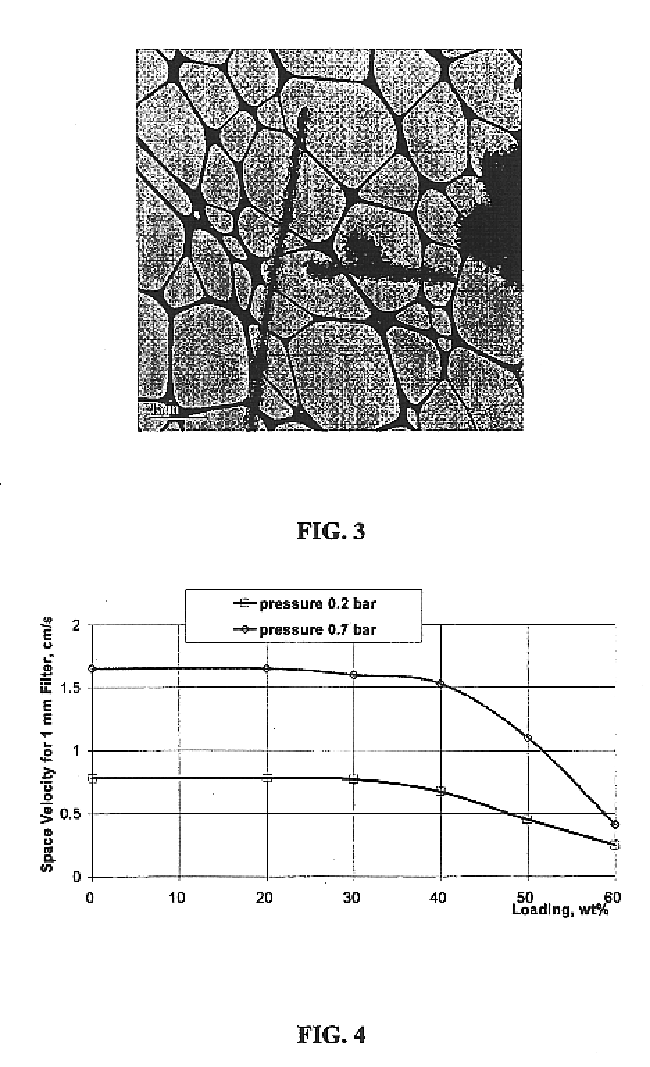

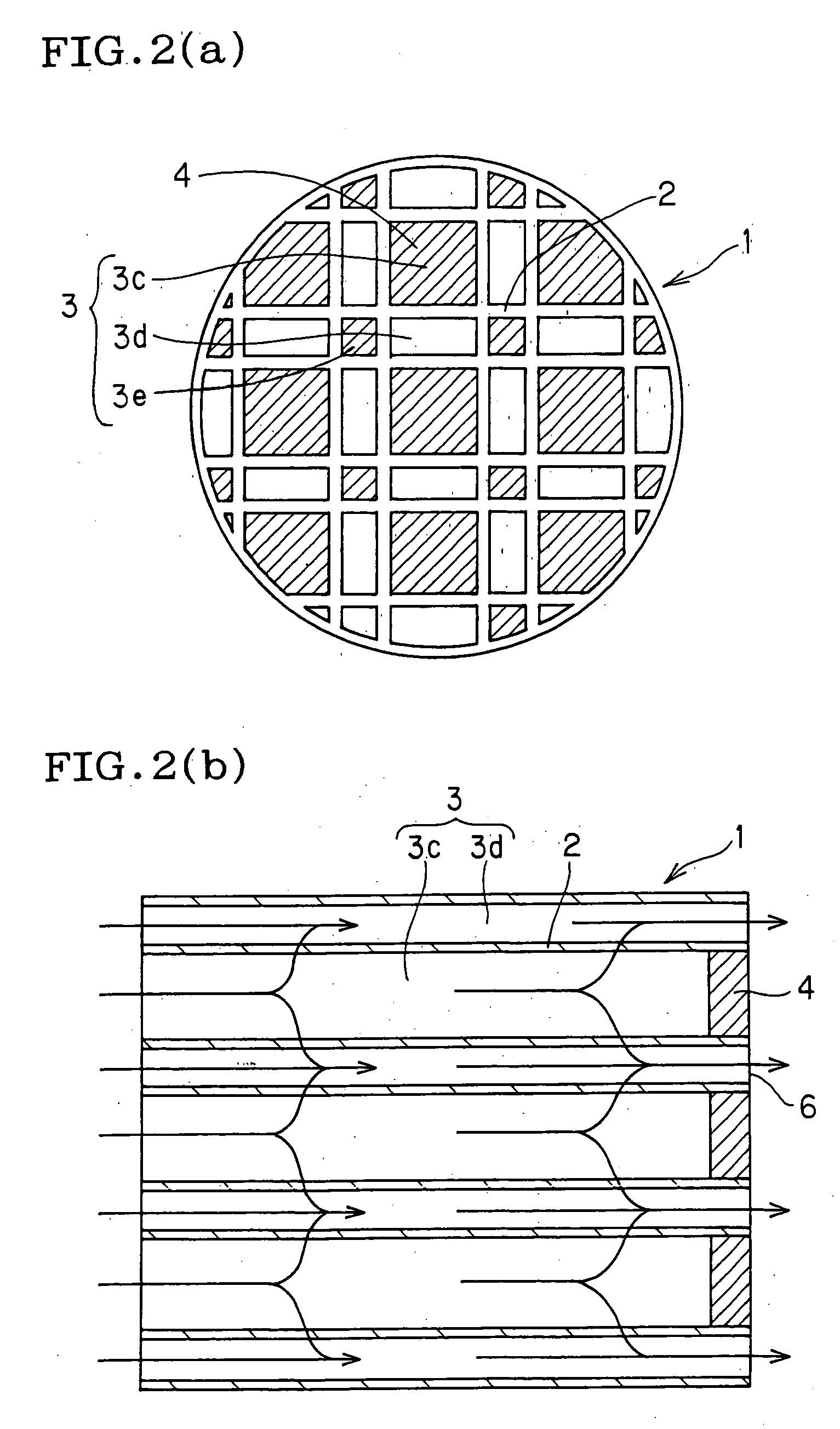

Nanosize electropositive fibrous adsorbent

InactiveUS6838005B2Improve the immunityEfficient precipitationIon-exchanger regenerationLoose filtering material filtersFiberParticulates

Aluminum hydroxide fibers approximately 2 nanometers in diameter and with surface areas ranging from 200 to 650 m2 / g have been fount to be highly electropositive. When dispersed in water they are able to attach to and retain electronegative particles. When combined into a composite filter with other fibers or particles they can filter bacteria and nano size particulates such as viruses and colloidal particles at high flux through the filter. Such filters can be used for purification and sterilization of water, biological, medical and pharmaceutical fluids, and as a collector / concentrator for detection and assay of mirobes and viruses. The alumina fibers are also capable of filtering sub-micron inorganic and metallic particles to produce ultra pure water. The fibers are suitable as a substrate for growth of cells. Macromolicules such as proteins may be separated from each other based on their electronegative charges.

Owner:ARGONIDE CORP

Integrated nanofiber filter media

A filter media is formed from electrospun fine fibers and coarse fibers which are entangled and integrated together into a single fiber composite filter media layer.

Owner:CLARCOR INC

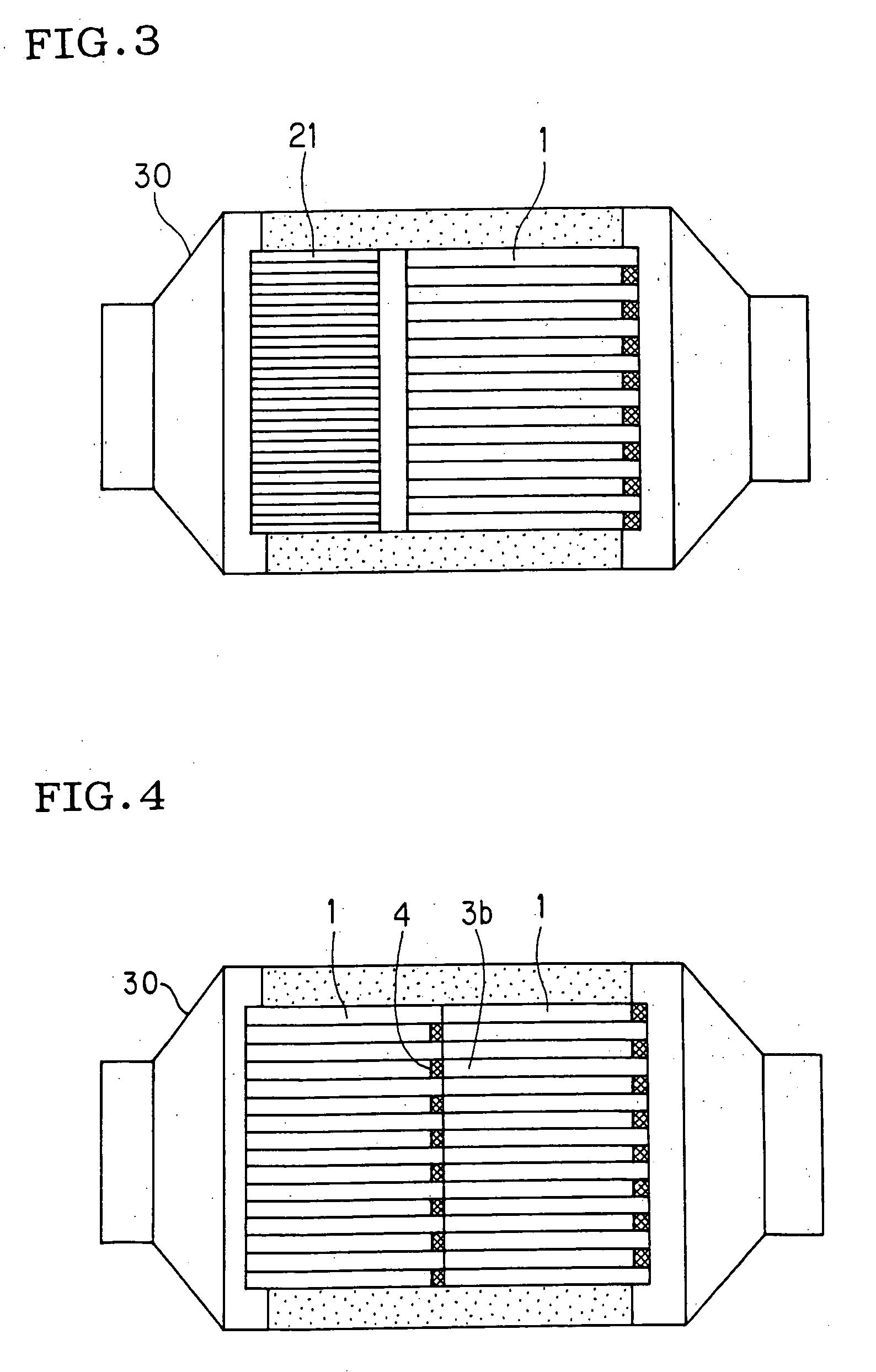

Honeycomb filter and exhaust gas purification system

A honeycomb filter comprises a honeycomb structure having a large number of through channels formed in the axial direction and partitioned by porous partition walls, wherein specified through channels are plugged only on one end face at the same side out of two end faces. This honeycomb filter shows less pressure loss, and is hardly clogged with solids that cannot be extinguished by combustion such as ash, iron oxide, and the like. Furthermore, an unwanted discharge of particulates deposited in through channels of the filter in a larger amount due to pulsation even under conditions that the exhaust gas from an engine greatly pulsates can be effectively suppressed. This filter is also usable as an element for exhaust gas purification system, or a part of composite filter in addition to the use for an exhaust gas purification filter for gasoline engines. The production method therefor is also disclosed.

Owner:NGK INSULATORS LTD

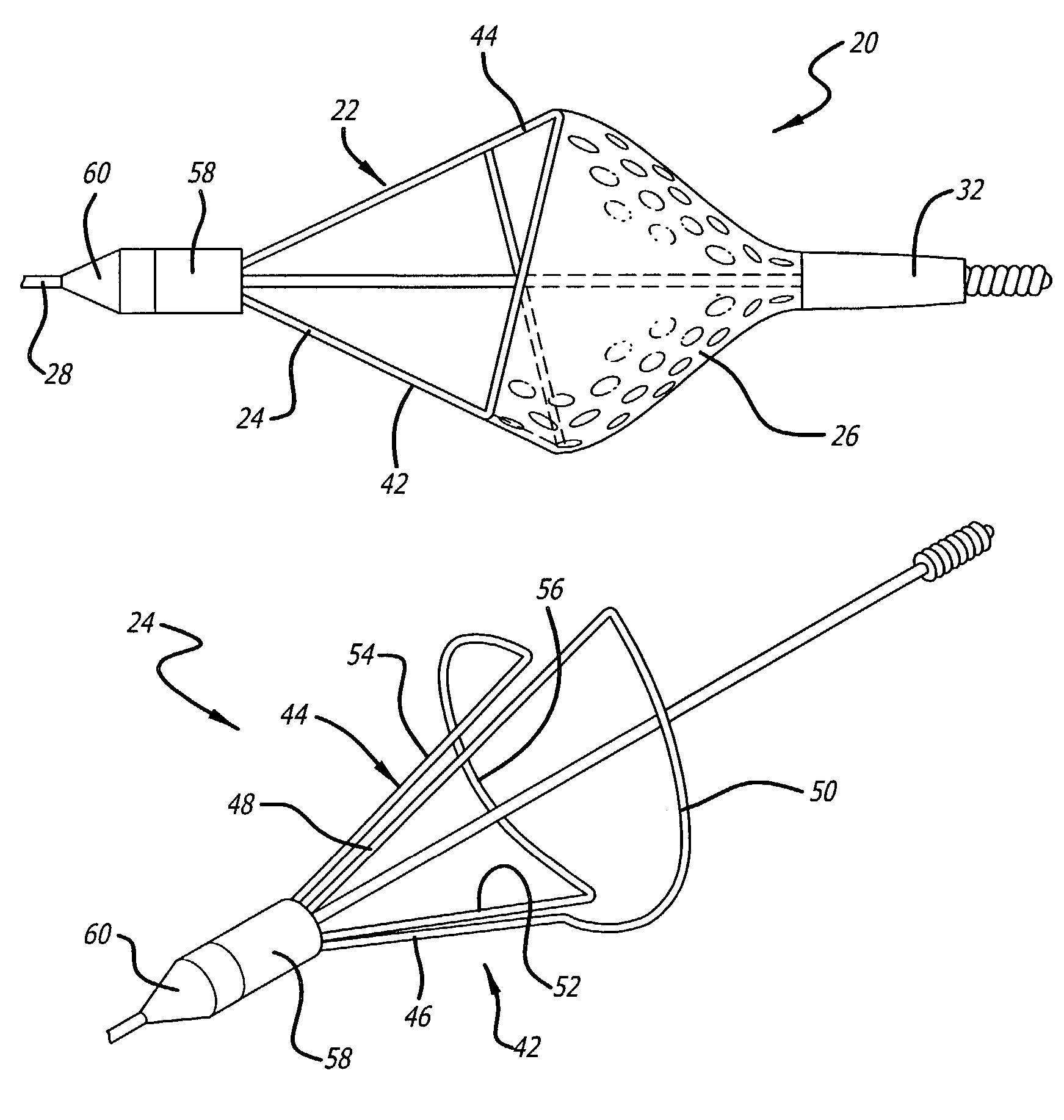

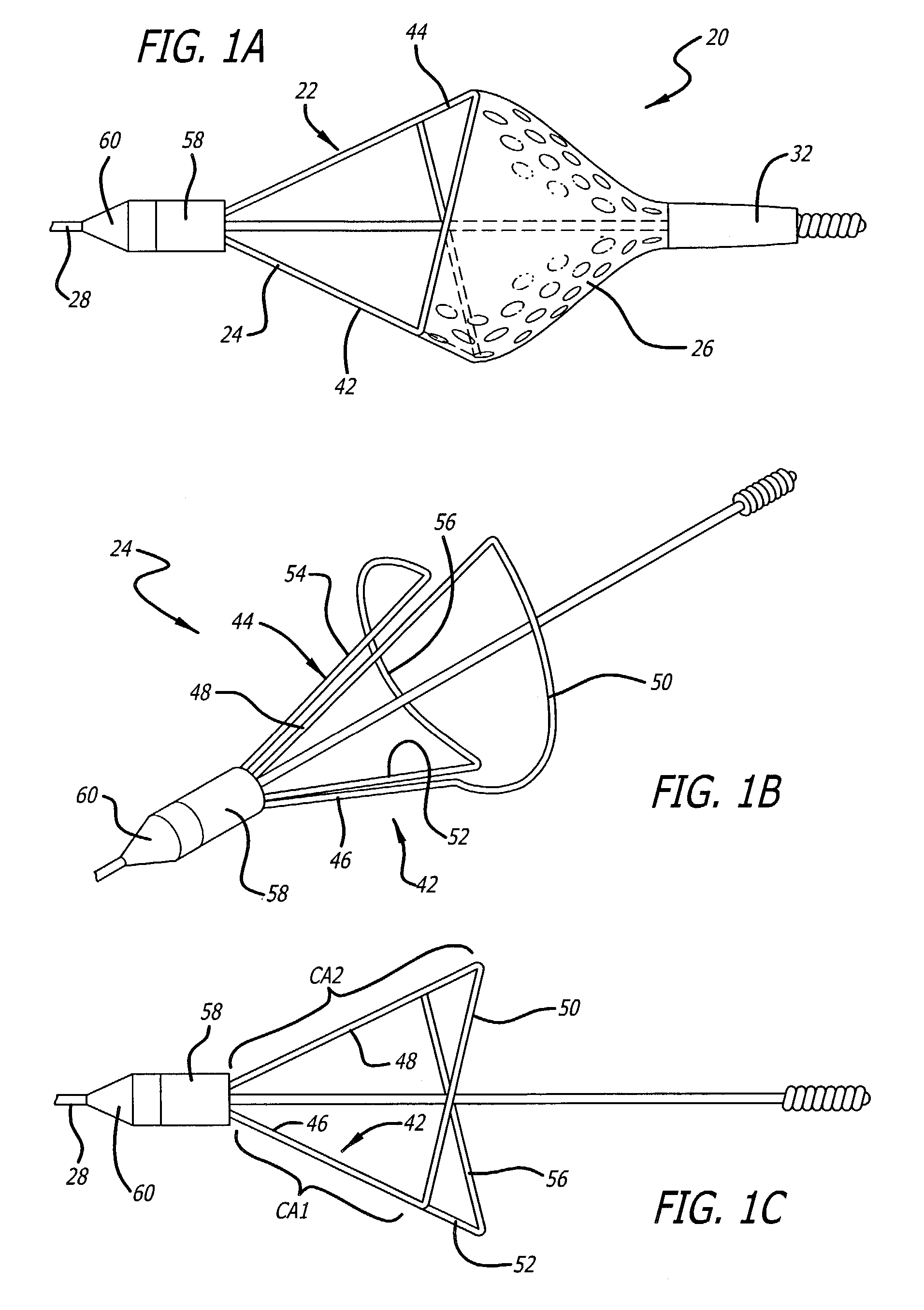

Embolic filtering devices

An expandable frame for an embolic filtering device used to capture embolic debris in a body vessel includes a first half frame having a first control arm connected to a second control arm by a partial loop and a second half frame having a first control arm connected to a second control arm by a partial loop. The partial loops cooperatively form a composite loop for attachment of a filtering element which will expand in the body vessel to capture embolic debris entrained in the fluid of the vessel. The lengths and positioning of the first and second control arms of each half frame can be varied to create an expandable frame which conforms to the size and shape of the body vessel in which the filtering device is deployed. Additionally, the radius of the partial loops, along with the length of the arc of the partial loops, can be varied on each of the frames to create a composite filtering assembly that can easily adapt to the size and shape of the body vessel. Additionally, the control arms of the half frames can be disposed either proximally or distally of the composite loop to create a distinct filtering structure.

Owner:ABBOTT CARDIOVASCULAR

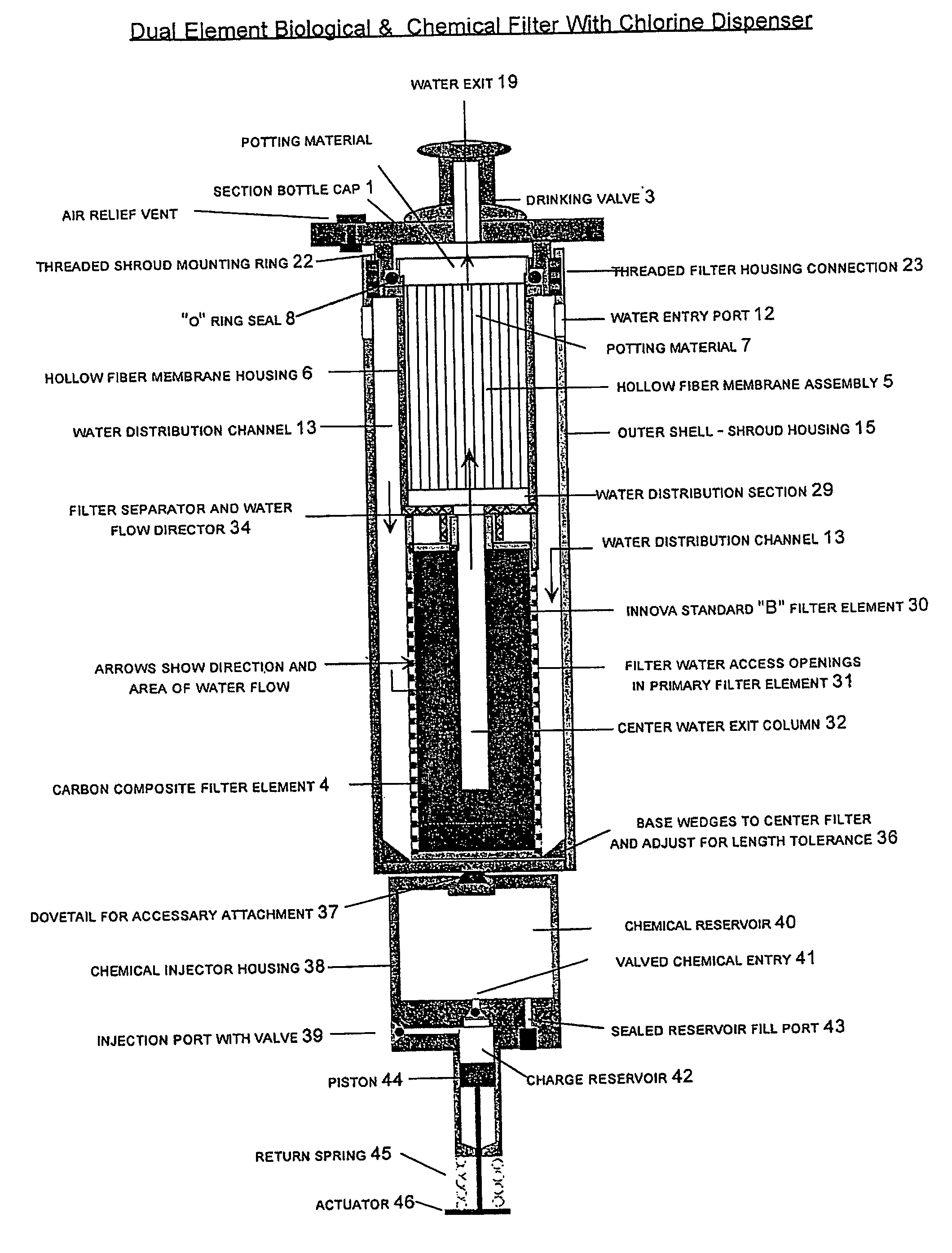

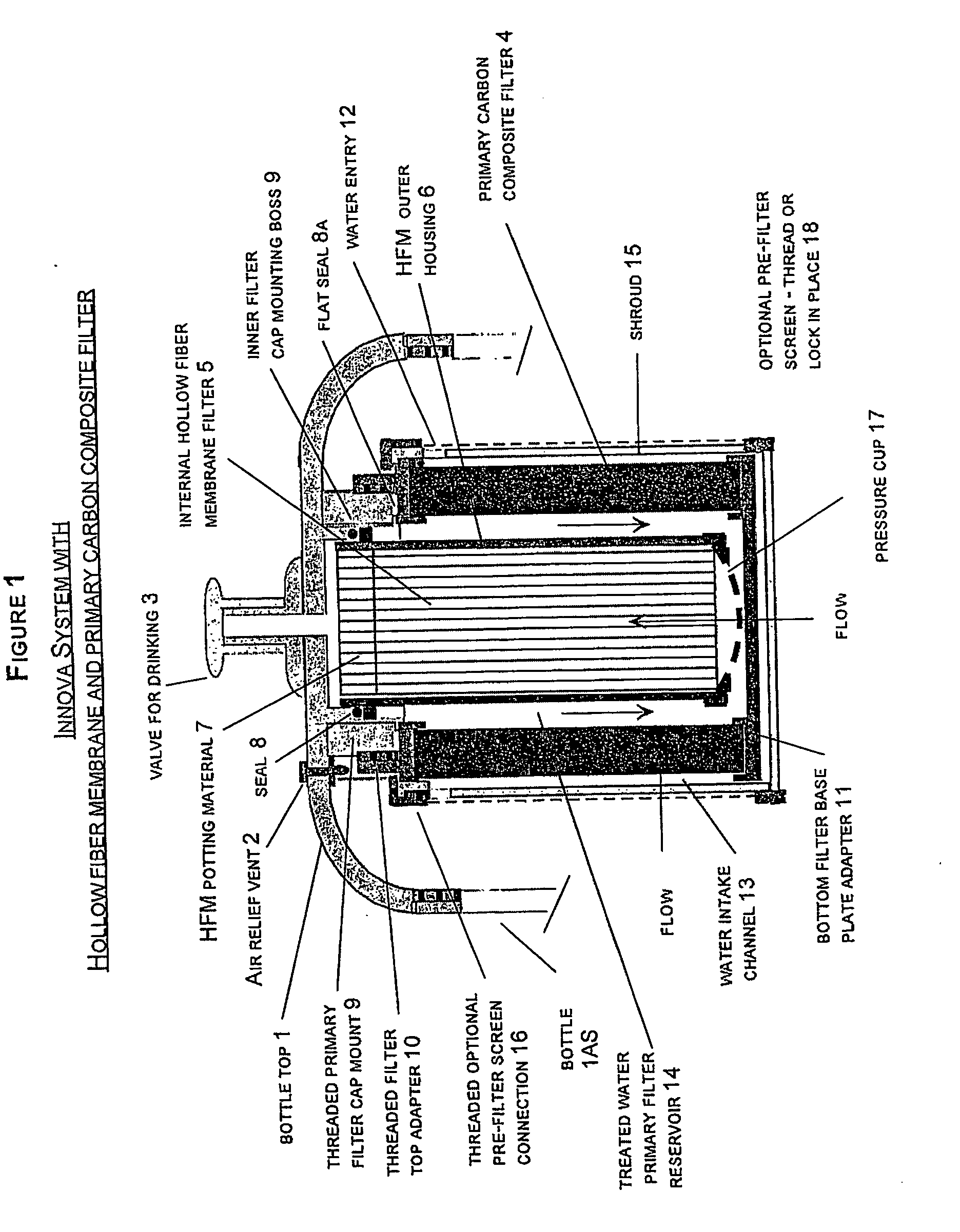

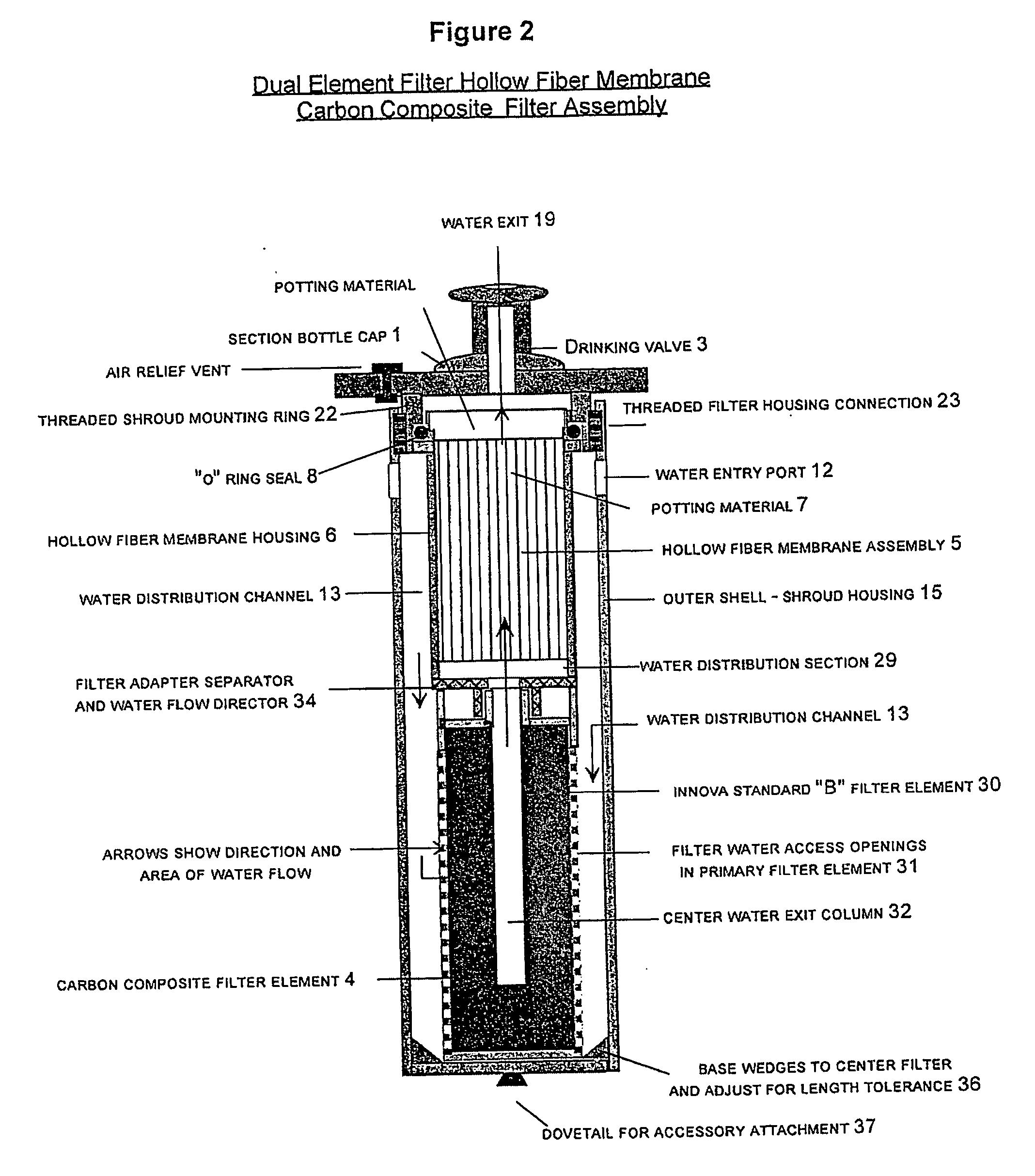

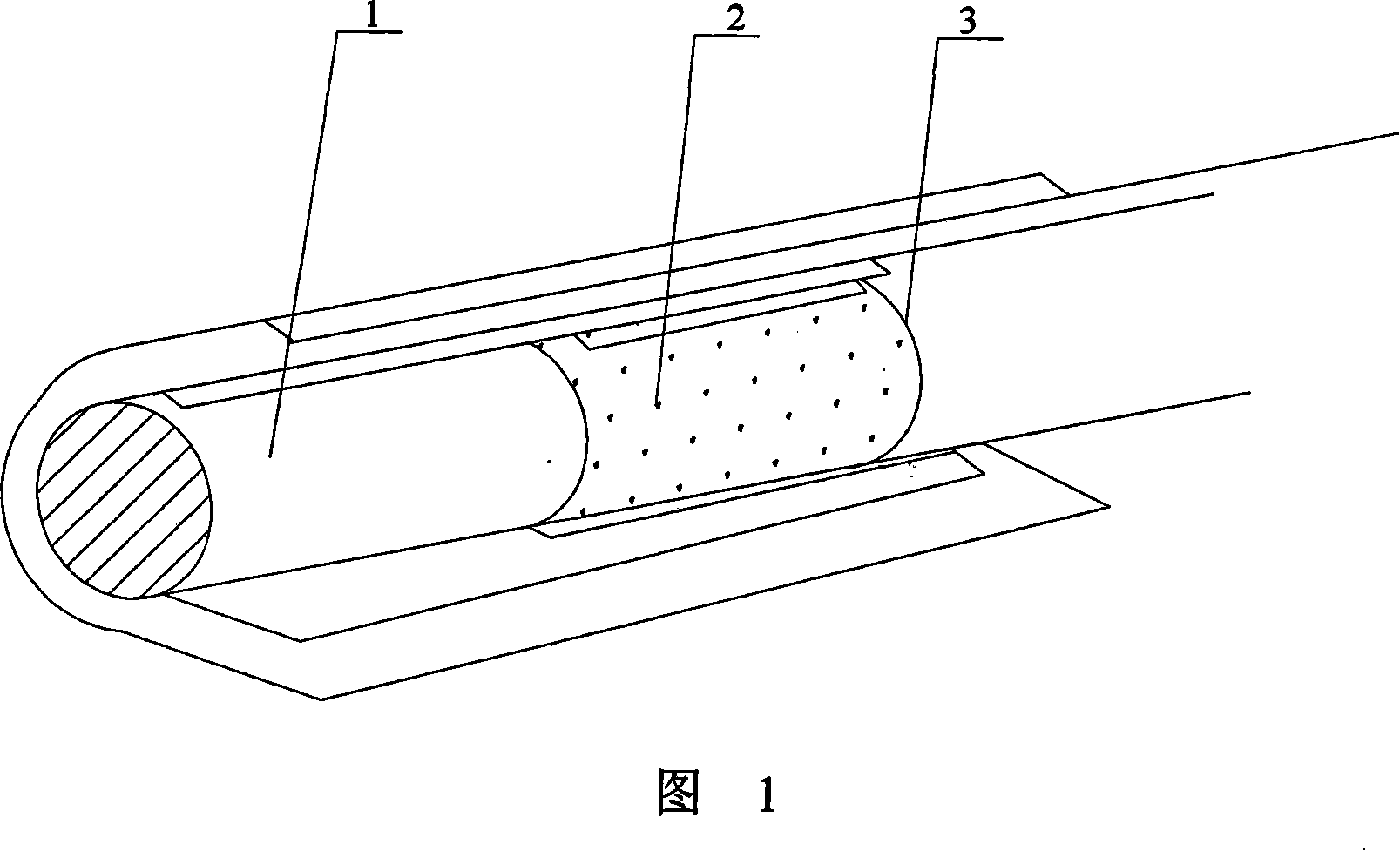

Hollow fiber membrane filters in various containers

InactiveUS20050035041A1Eliminate the problemAvoid accumulationTravelling sacksUltrafiltrationCarbon compositesWater filter

A water filter cooperable with a water container includes both a carbon composite filter (30) and a bundle of micro porous hollow fiber membranes (5) in fluid communication with the carbon composite filter (30). An influent side of the hollow fiber membrane (5) is continuously immersed in water whereby air is prevented from being reintroduced to the hollow fiber membrane (5).

Owner:INNOVAPURE WATER

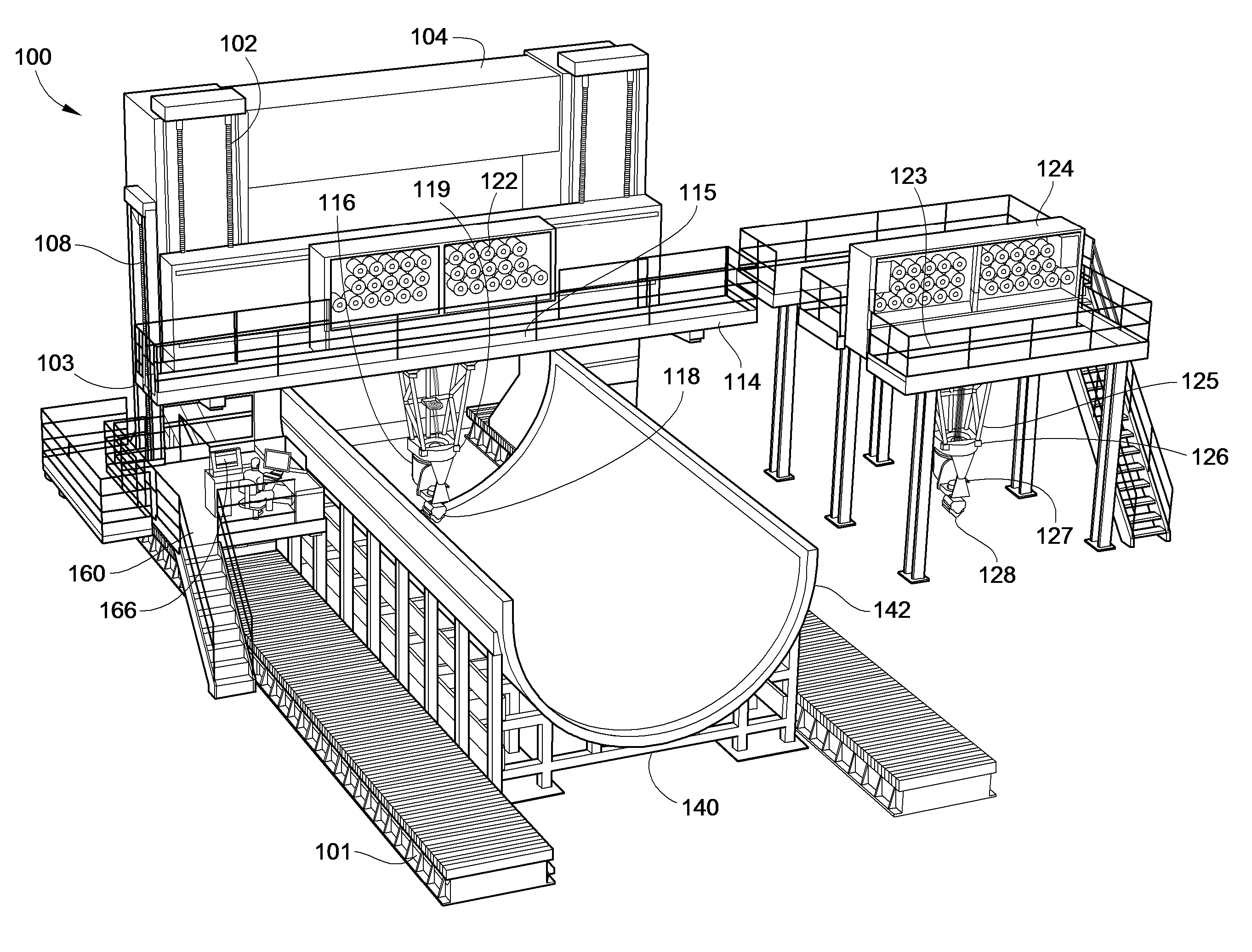

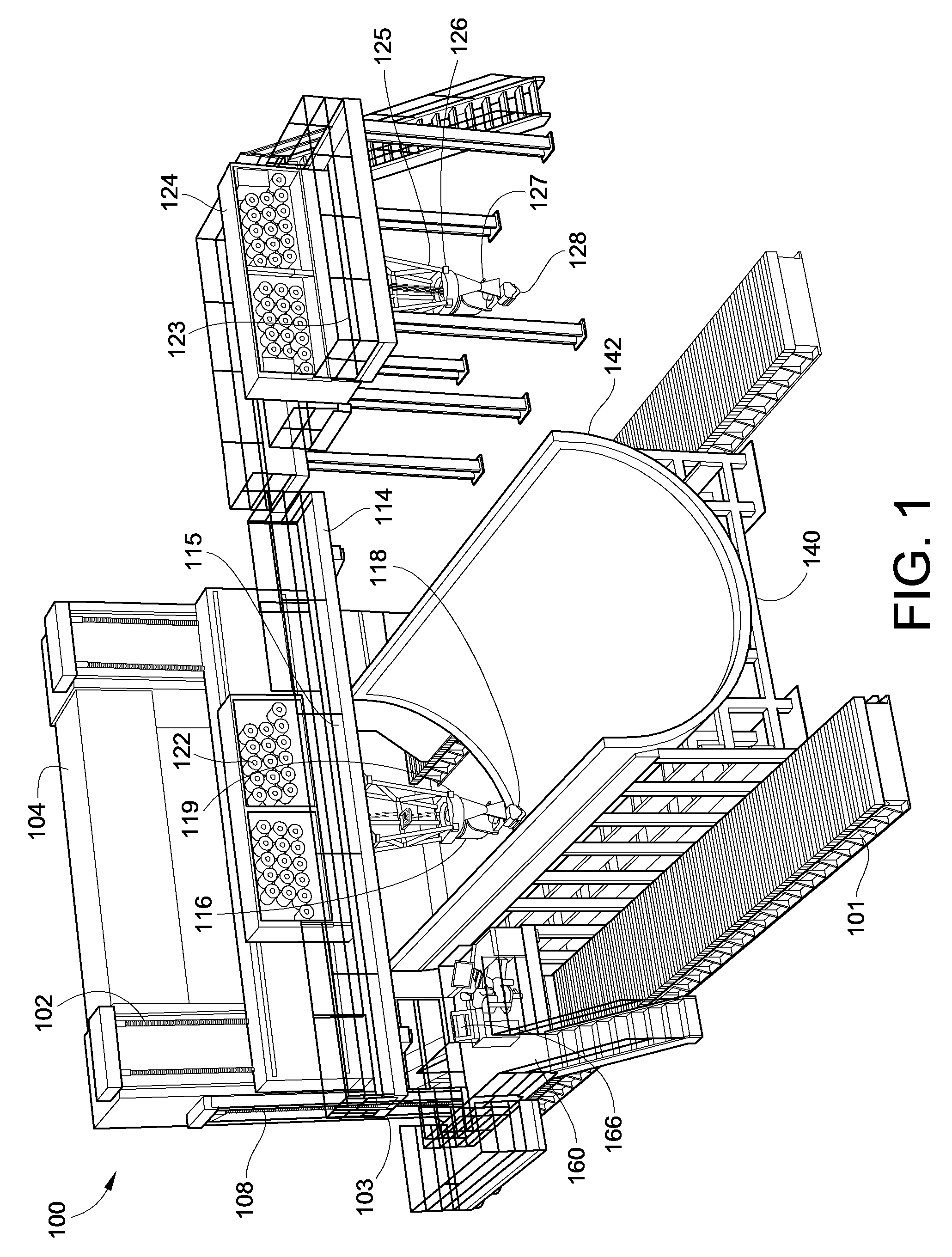

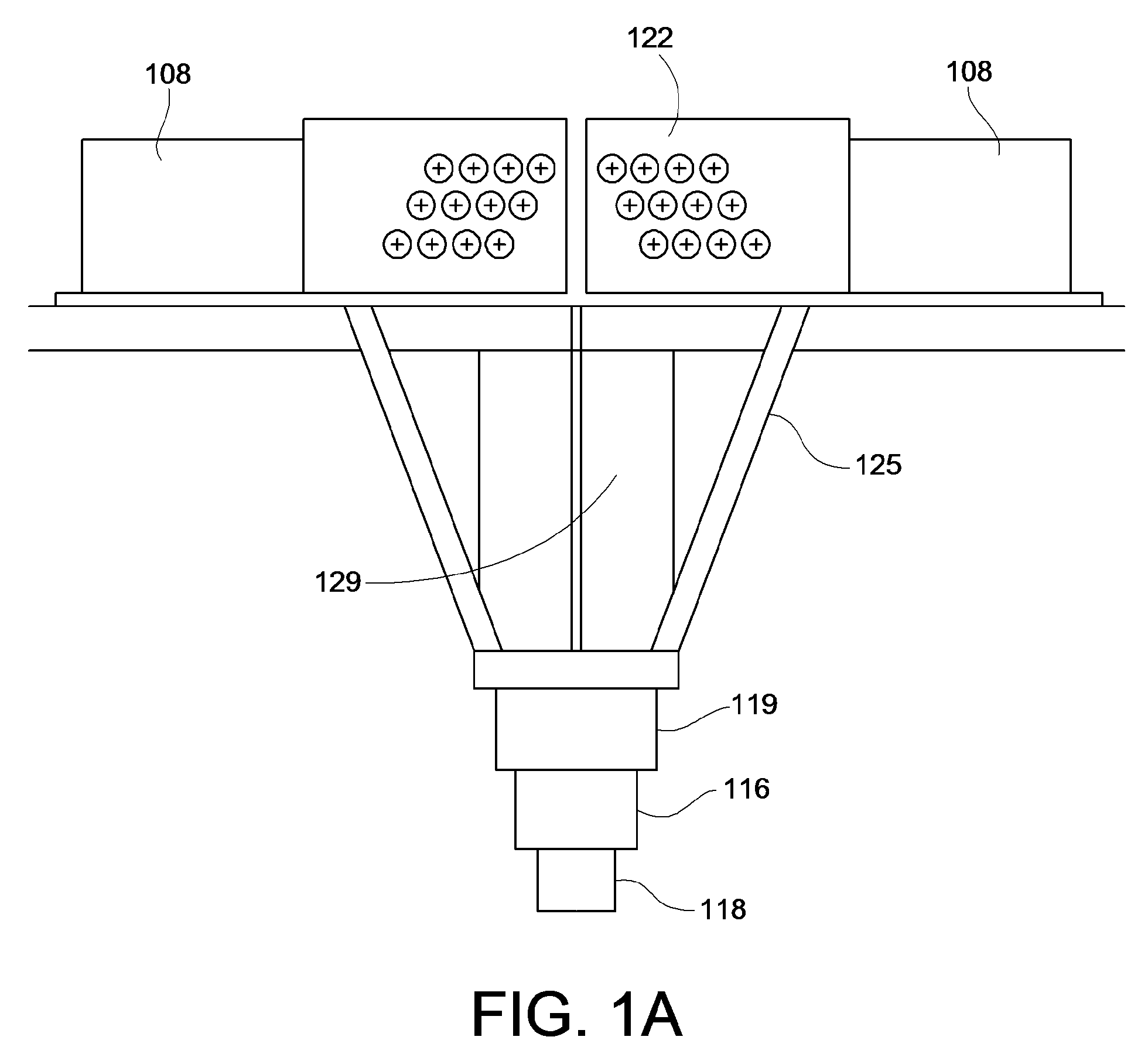

Fiber placement machine platform system having interchangeable head and creel assemblies

Owner:INGERSOLL MACHINE TOOLS

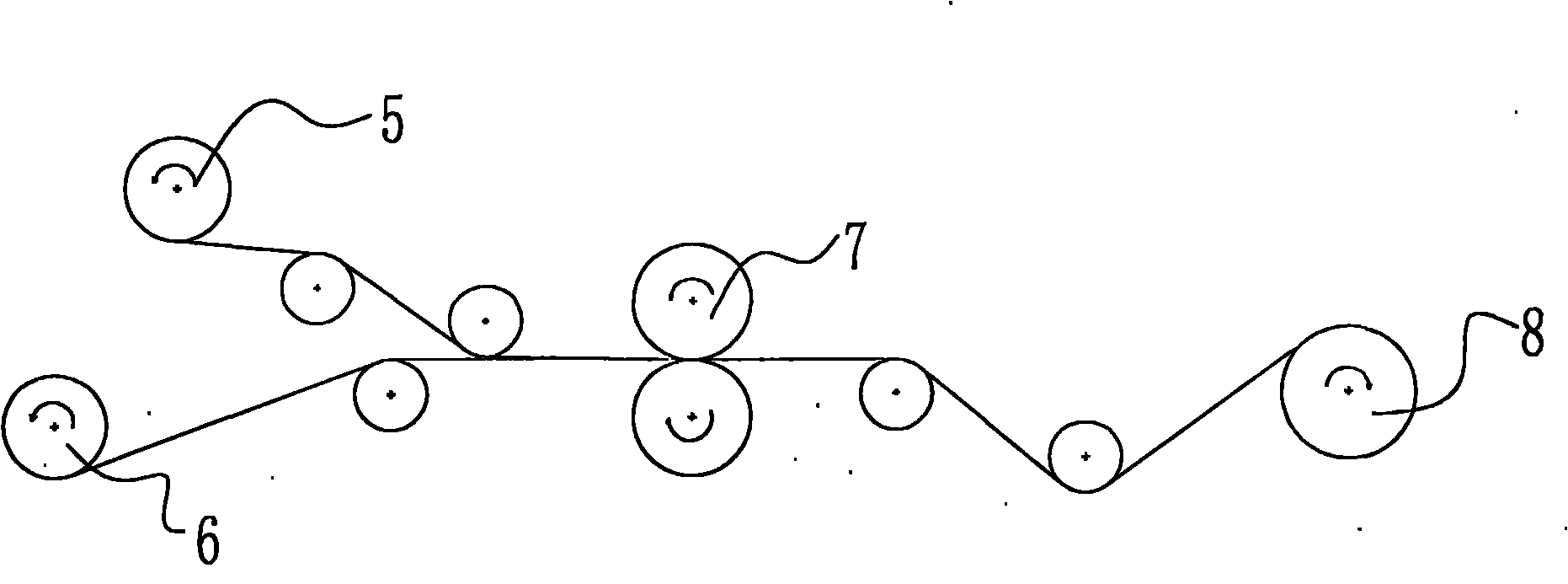

Composite filter membrane with multidimensional pore structure and preparation method thereof

ActiveCN103894077APotential for industrial production application promotionEffective filteringSemi-permeable membranesFiberElectrospinning

The invention provides a composite filter membrane with a multidimensional pore structure and a preparation method thereof. The composite filter membrane comprises nonwoven base cloth and a porous composite nanofiber layer, wherein the nonwoven base cloth and the porous composite nanofiber layer are composited in a manner of hot rolling, and the porous composite nanofiber layer is prepared from a polymer and an additive. The preparation method comprises the following steps: adding the additive into a spinning solution solvent, carrying out ultrasonic treatment to achieve homodisperse, then adding the polymer, and stirring at room temperature until the solution is clear and transparent. A multiple-nozzle electrostatic spinning device is used for electrostatic spinning, and the obtained porous composite nanofibers are directly deposited on the surface of the nonwoven cloth and are composited through a subsequent hot rolling device. The composite filter membrane combines the advantages of common filter materials and nanofiber filter materials, has a good filtering effect, a simple production process and low production cost and is easy to realize large scale production.

Owner:JIANGNAN UNIV

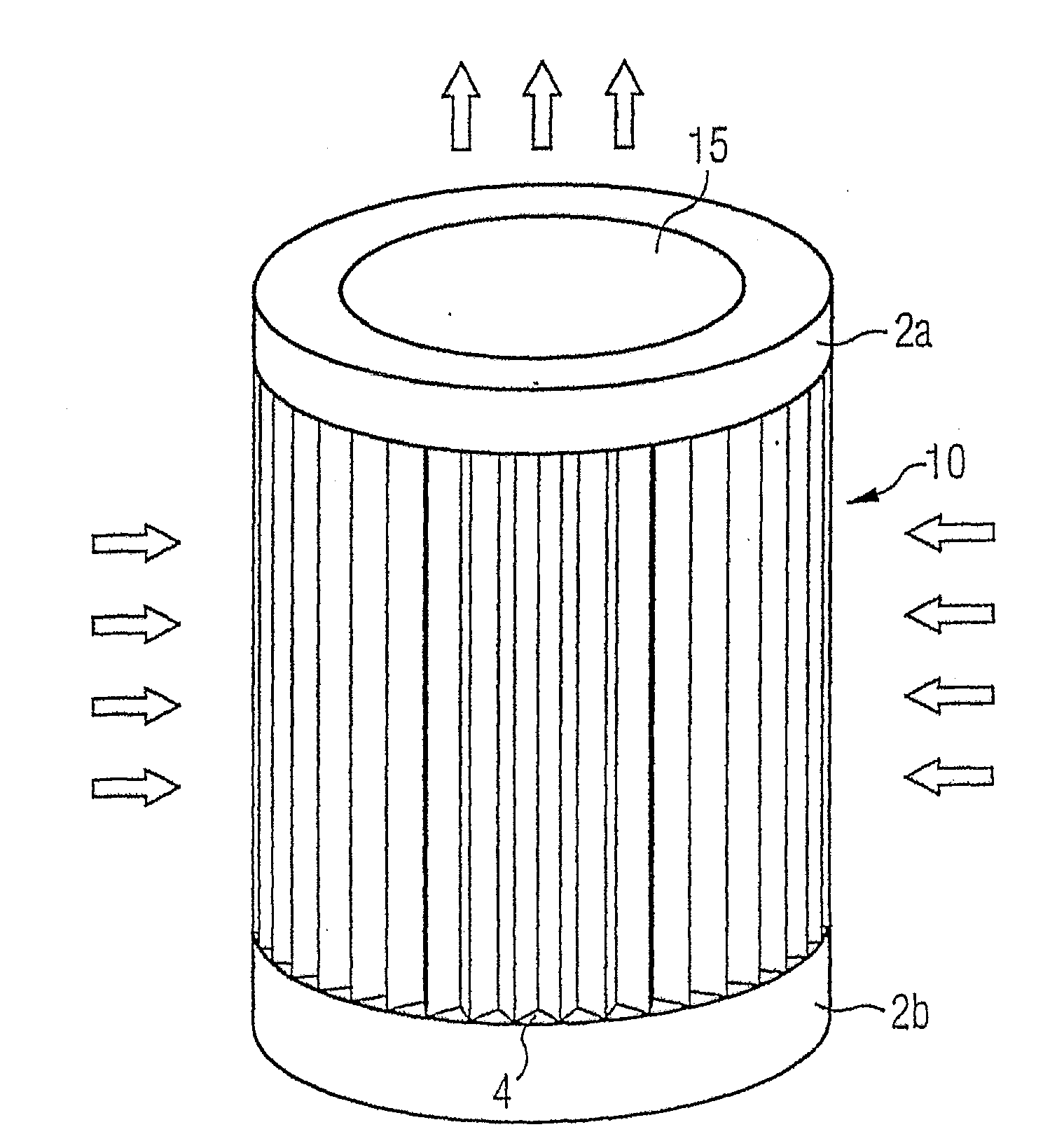

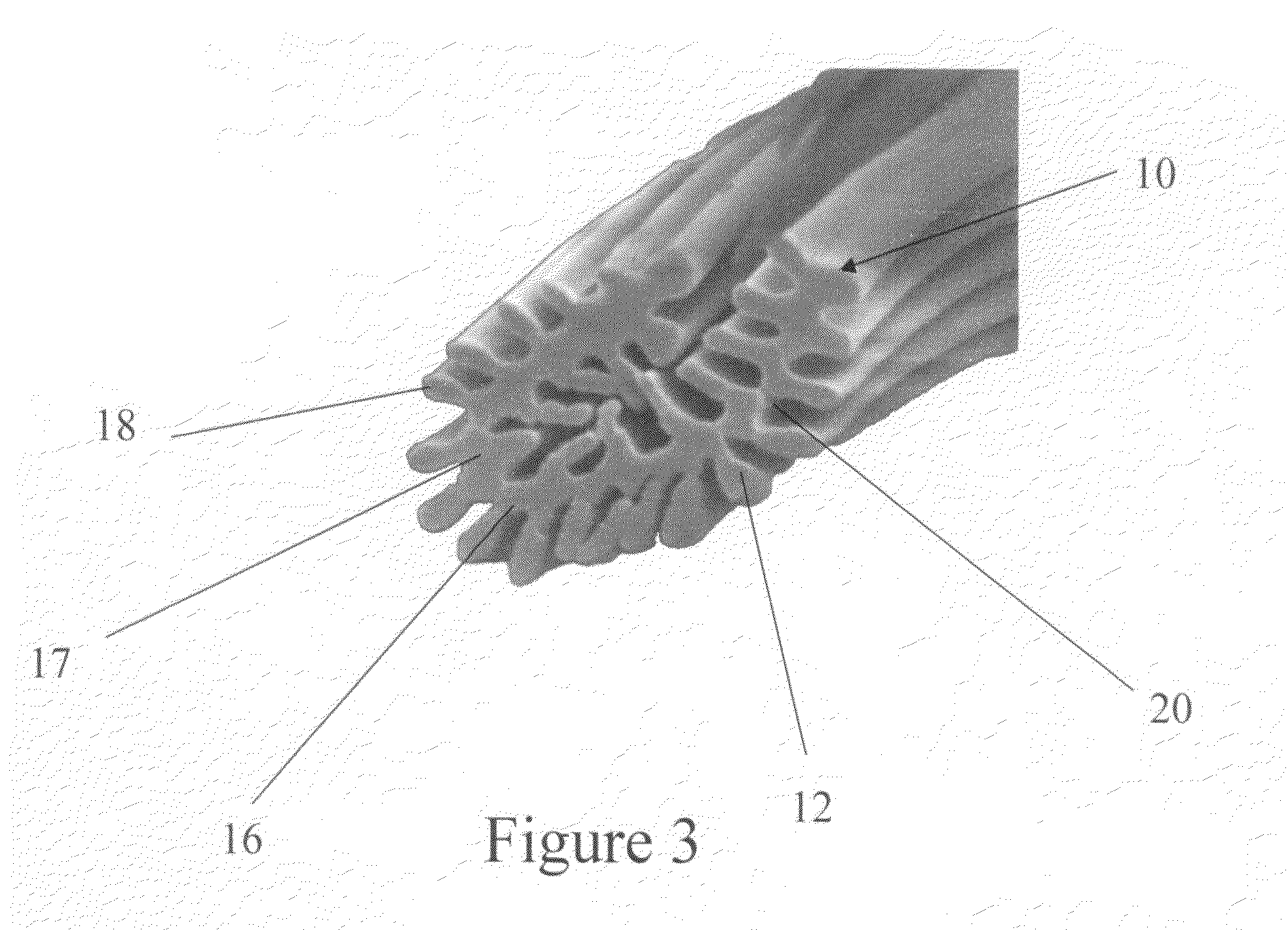

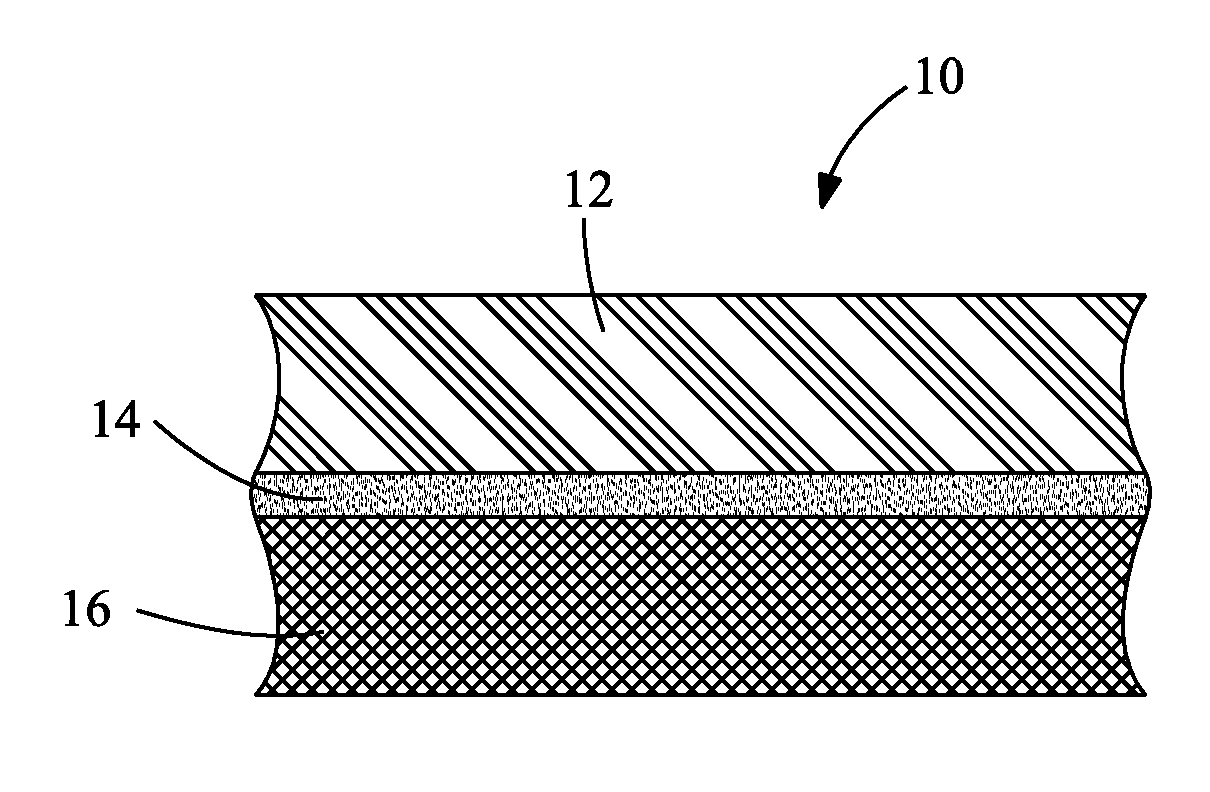

Turbine Air-Intake Filter

InactiveUS20090266048A1Improve filtering effectSimple wayGas treatmentDispersed particle filtrationFiberFiltration

A turbine air-intake filter for removal of particles from an air stream entering a gas turbine comprises a composite filter media (10) being made from a membrane filtration layer (20) comprising a porous polymeric membrane, such as porous polytetrafluoroethylene (ePTFE), and at least one depth filtration media layer (18) comprising fibers, such as a melt blown web, and being disposed on an upstream side of the membrane filtration layer (20) relative to a direction of gas flow through the filter. The fibers of the depth filtration media layer (18) have an electrostatic charge. The ePTFE membrane is preferably made from a blend of a PTFE homopolymer and a modified PTFE polymer.

Owner:SCHWARZ ROBERT

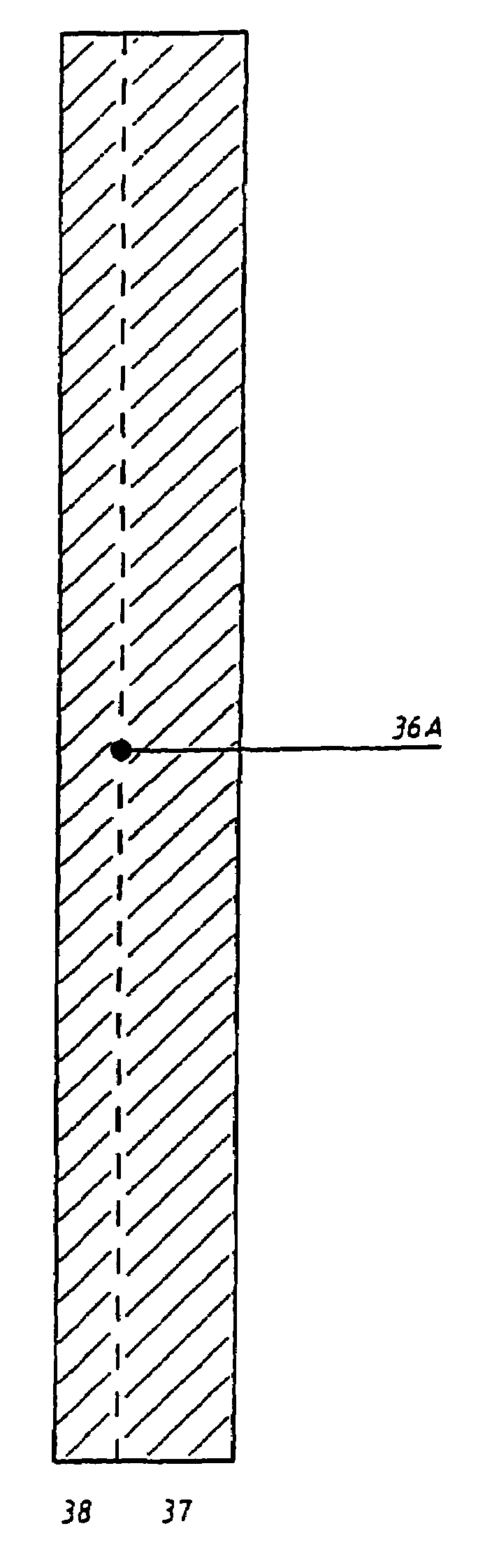

Composite filter and method of making the same

InactiveUS7094270B2Lower overall pressure dropExtended service lifeCombination devicesDispersed particle filtrationFiberFiltration

The invention refers to a composite filter for filtering a stream of ambient air including at least one non-prebonded upstream tier and one non-prebonded downstream tier, wherein the ratio of absolute pore volume of upstream tier to downstream tier RAPV>2, and the absolute projected fiber coverage of upstream tier and of downstream tier APFC>95%. Further, the invention refers to a method of making such a composite filter including the steps of (a) laying down a filtration material onto a support to form the upstream non-prebonded tier, (b) depositing onto the upstream tier the downstream non-prebonded tier, and (c) bonding the tiers to form a composite filter having a unitary stratified structure.

Owner:EUROLIFTERS HLDG NV

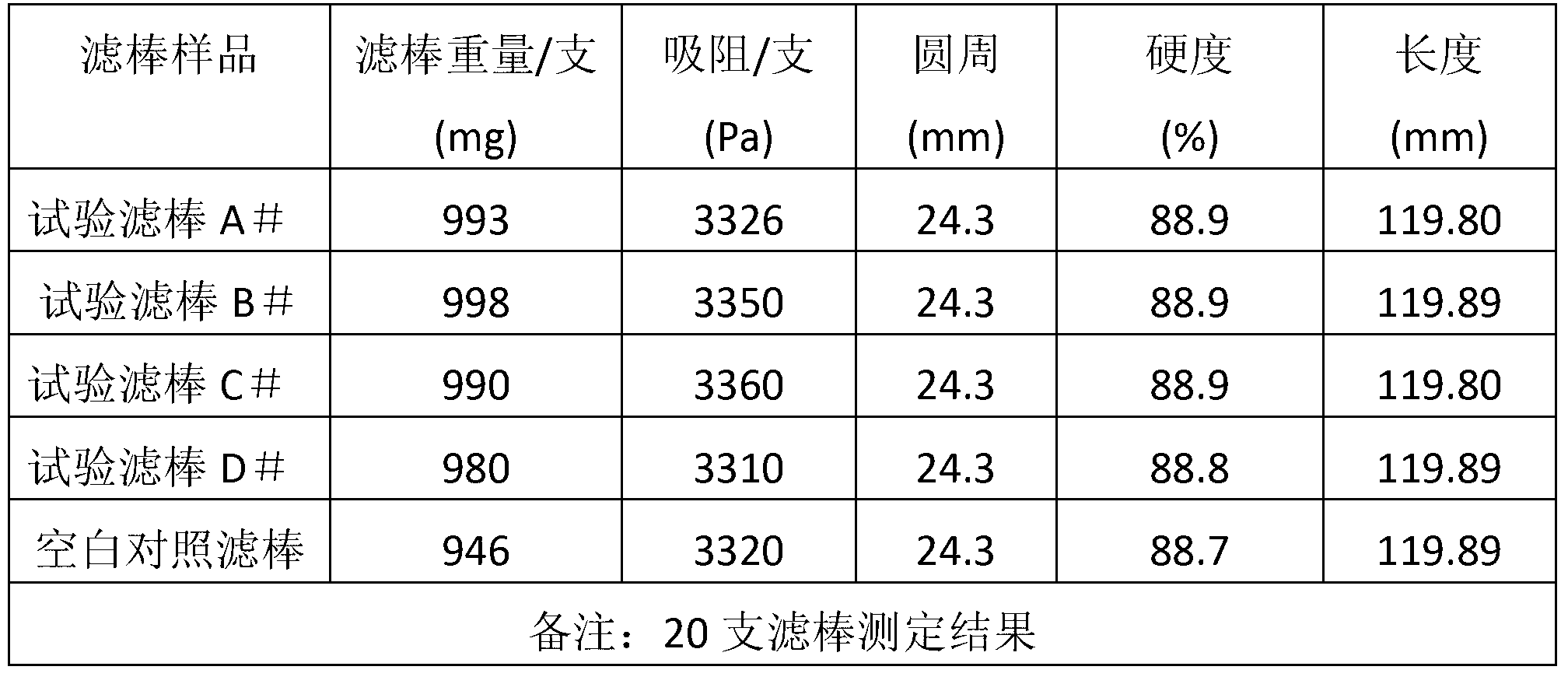

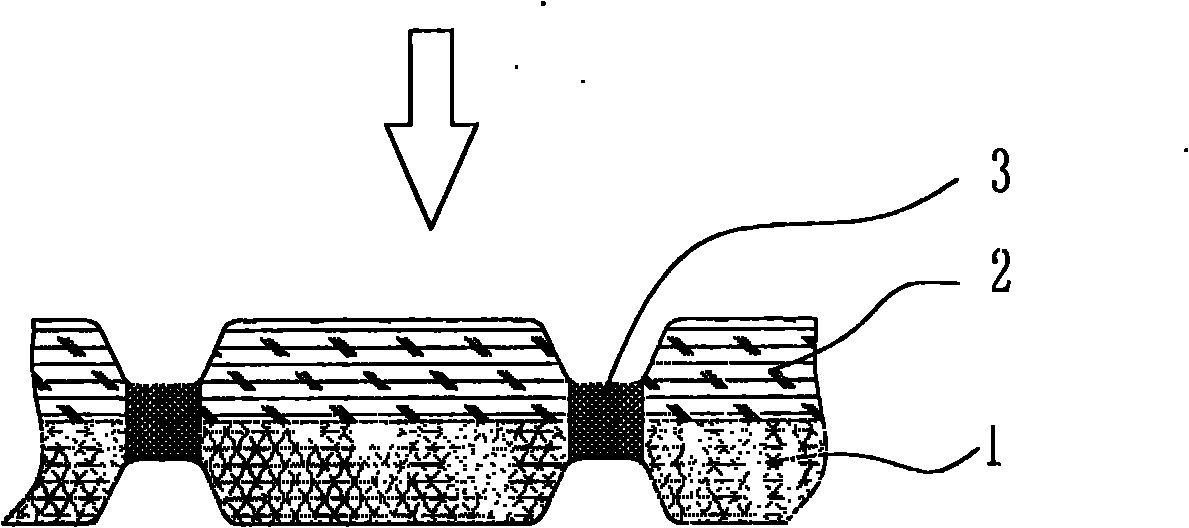

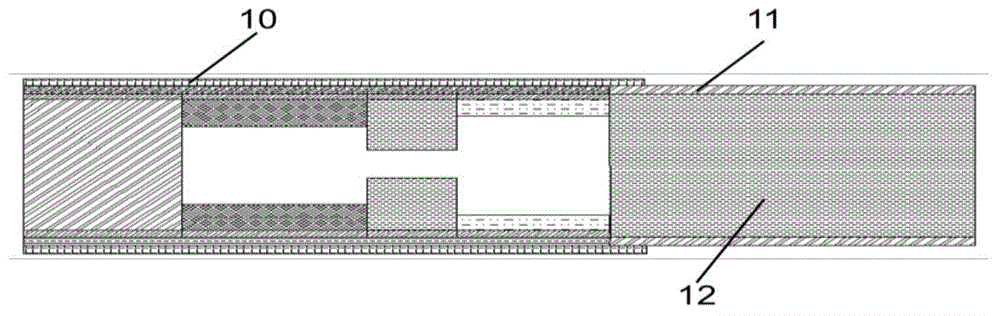

Filtering material for cigarette filter tip and its preparation method

ActiveCN101103845AEasy to shapeConducive to the manufacture of cigarettesTobacco preparationTobacco treatmentEconomic benefitsTar

The invention discloses a filter material for cigarette filter and the preparation method. Based on the expanded cabo particles from <The Preparation Method of an Expanded Cabo Particles and Relevant Equipment> (Application No.: 200710065892.3), the expanded cabo particles are extracted, shaped and selected as so to become the required filter material. The filter material utilizes the waste in the cigarette production, which not only has significant economic benefits, but also is not necessary to be recycled, and will not cause the abrasion of equipment and affect the sensory quality of cigarette. The filter material is uniformly arranged on the filter tows so as to make a composite filter; as the composite is applicable to the cigarette, the smell of the cigarette will be more clear and soft, and the tar and nicotine content in the smoke gas can be reduced effectively. The invention has the advantages that: the operation is simple; the effect is remarkable, therefore the invention has a good applicable prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

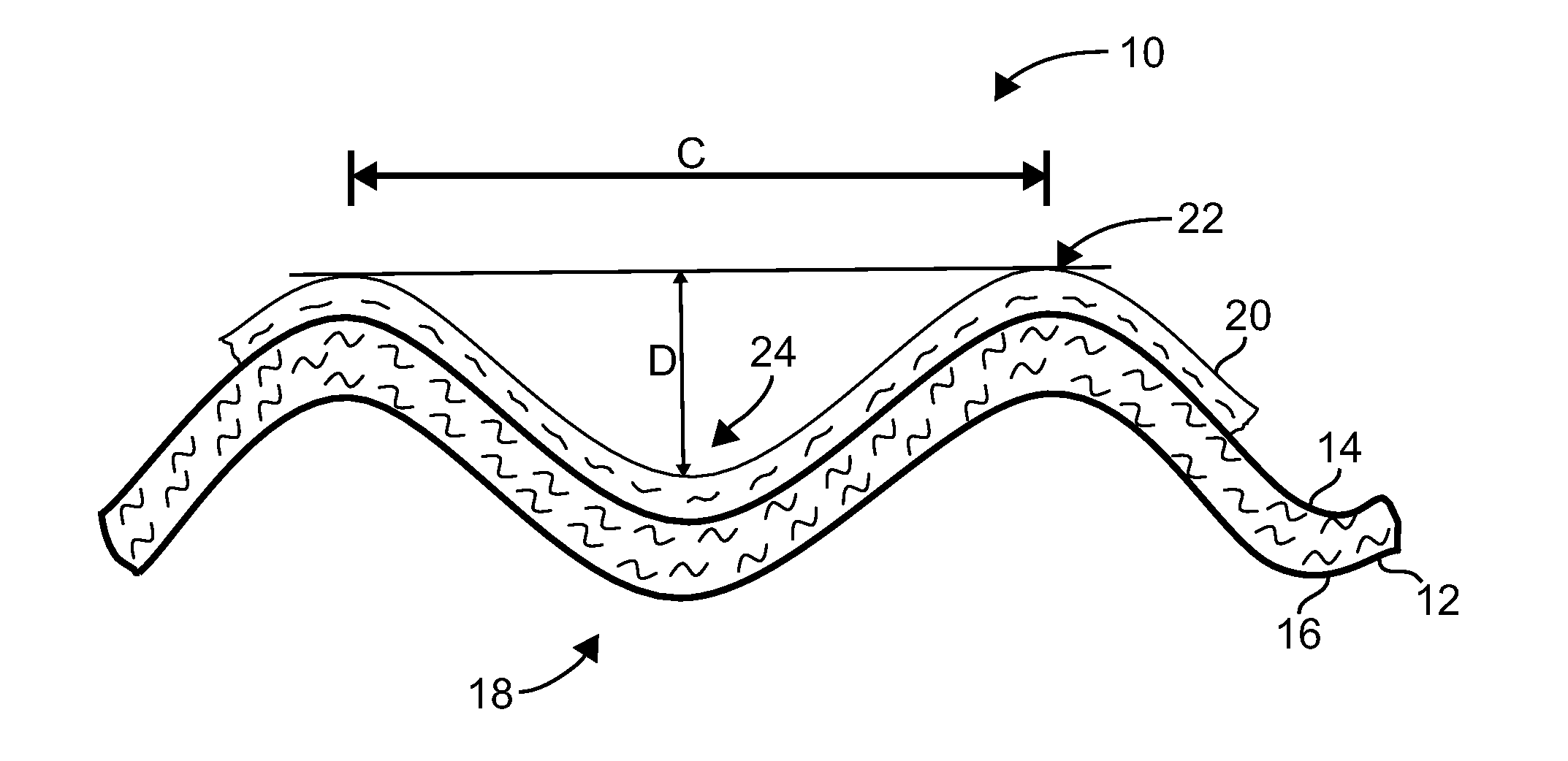

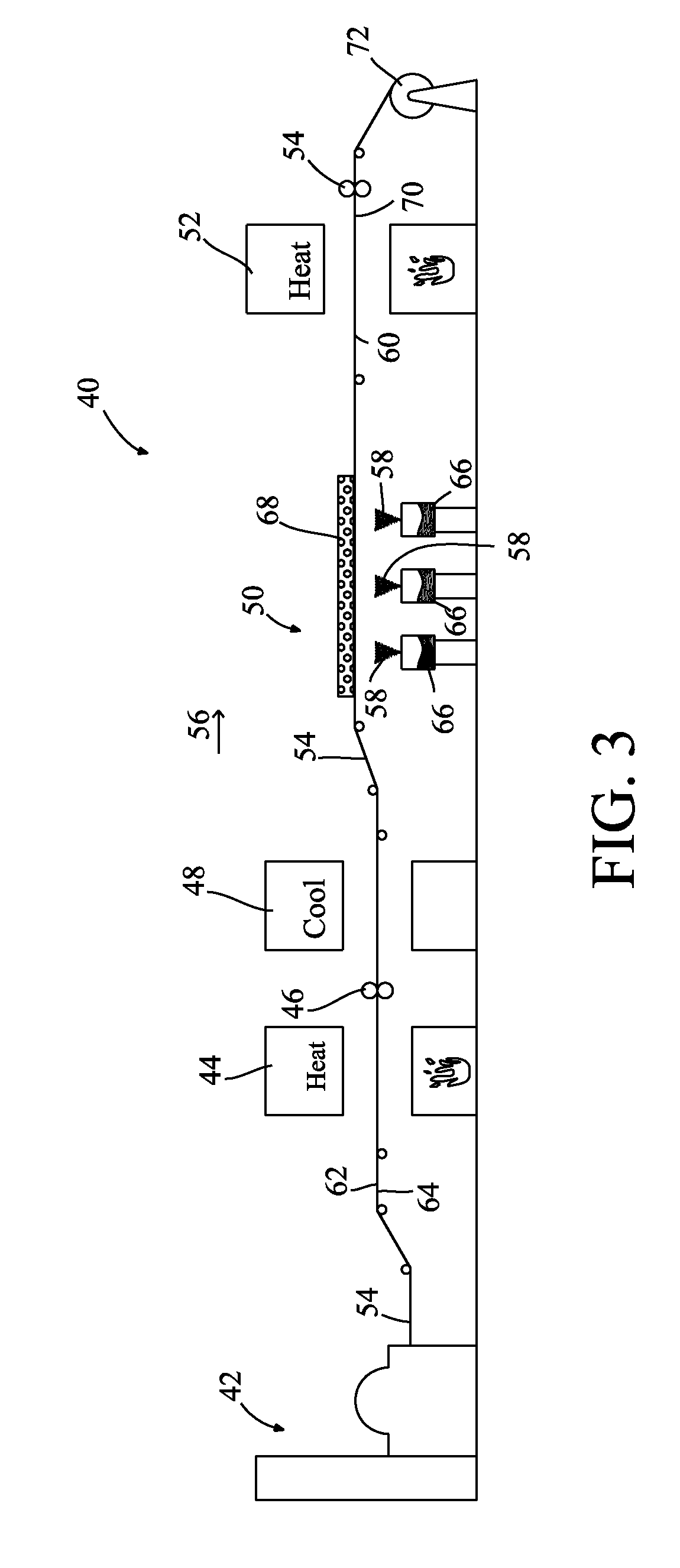

Composite filter media and methods of manufacture

A composite filter media structure is provided. In an exemplary embodiment, the composite filter media structure includes a corrugated base substrate that includes a nonwoven synthetic fabric formed by a dry-laid process that corrugates the base substrate during the forming process. The composite filter media structure also includes a nanofiber membrane deposited on at least one side of the base substrate by an electro-blown spinning process.

Owner:EI DU PONT DE NEMOURS & CO +1

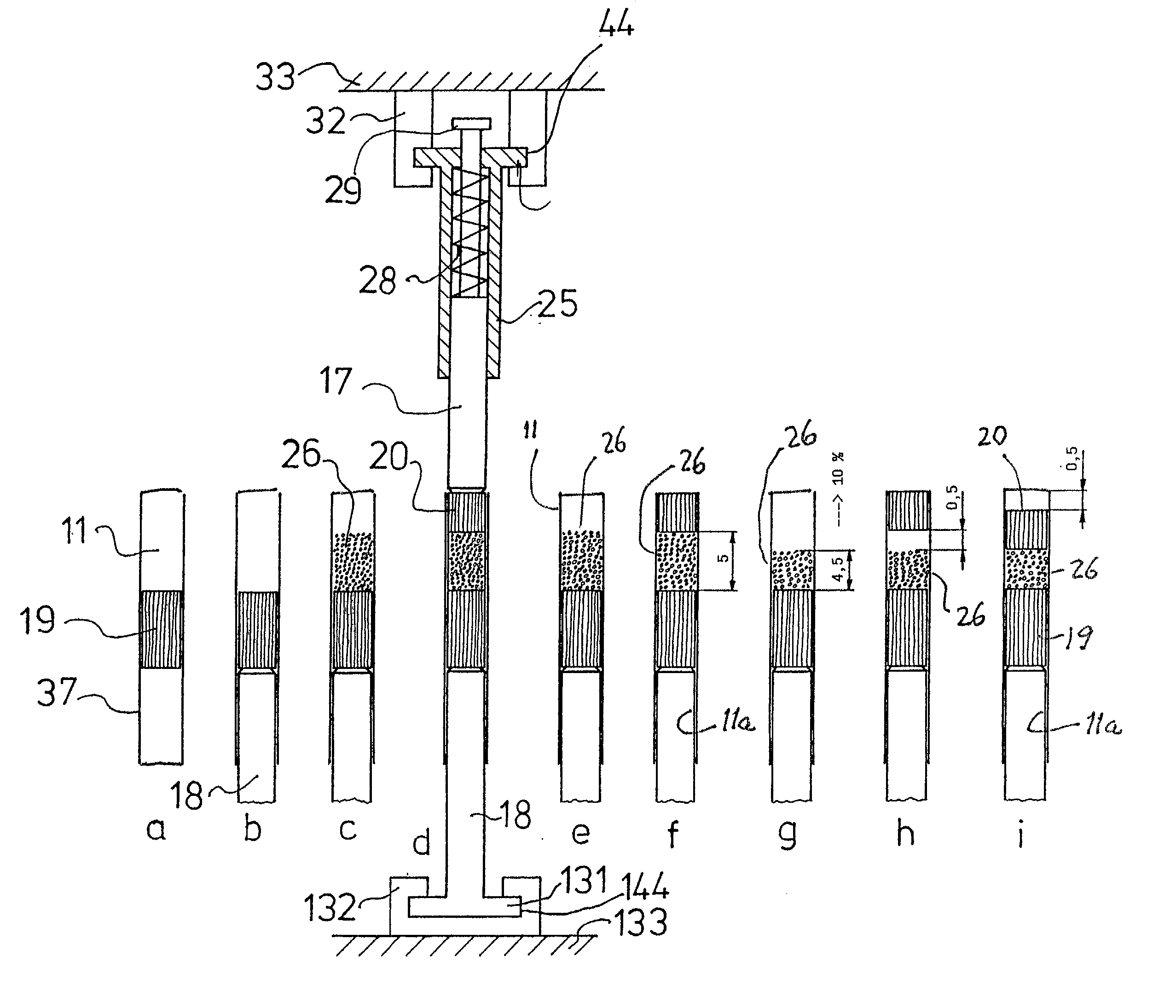

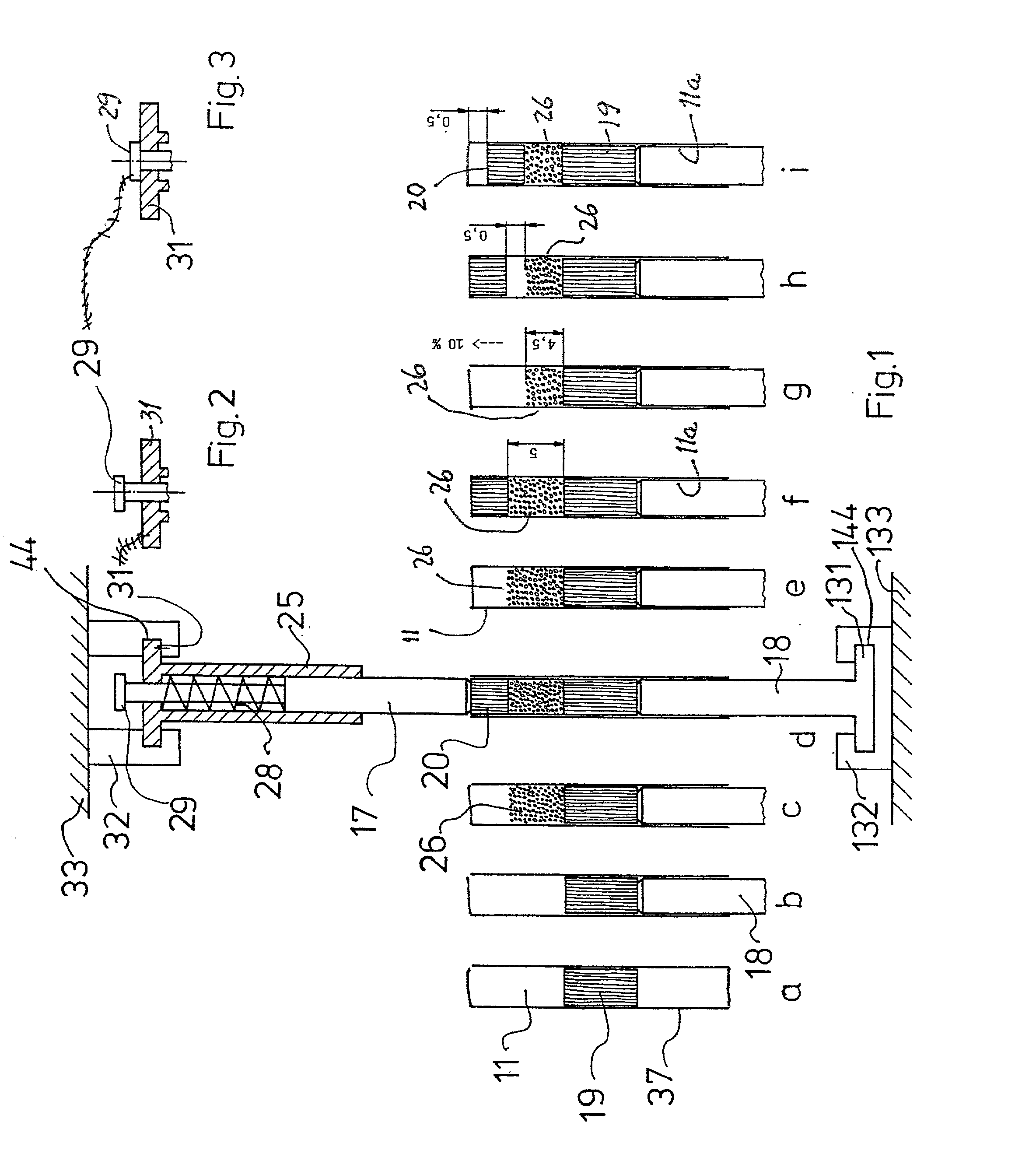

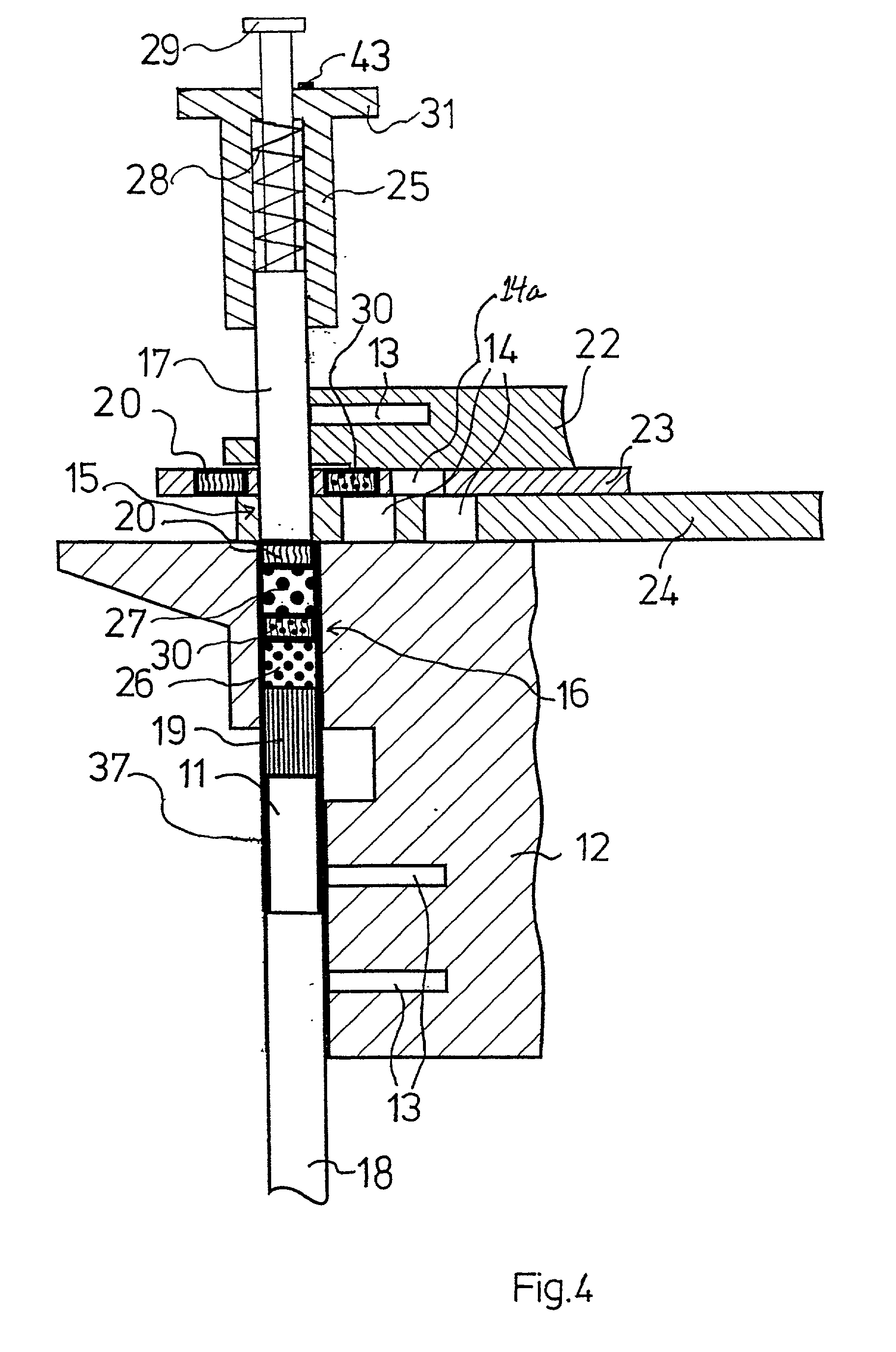

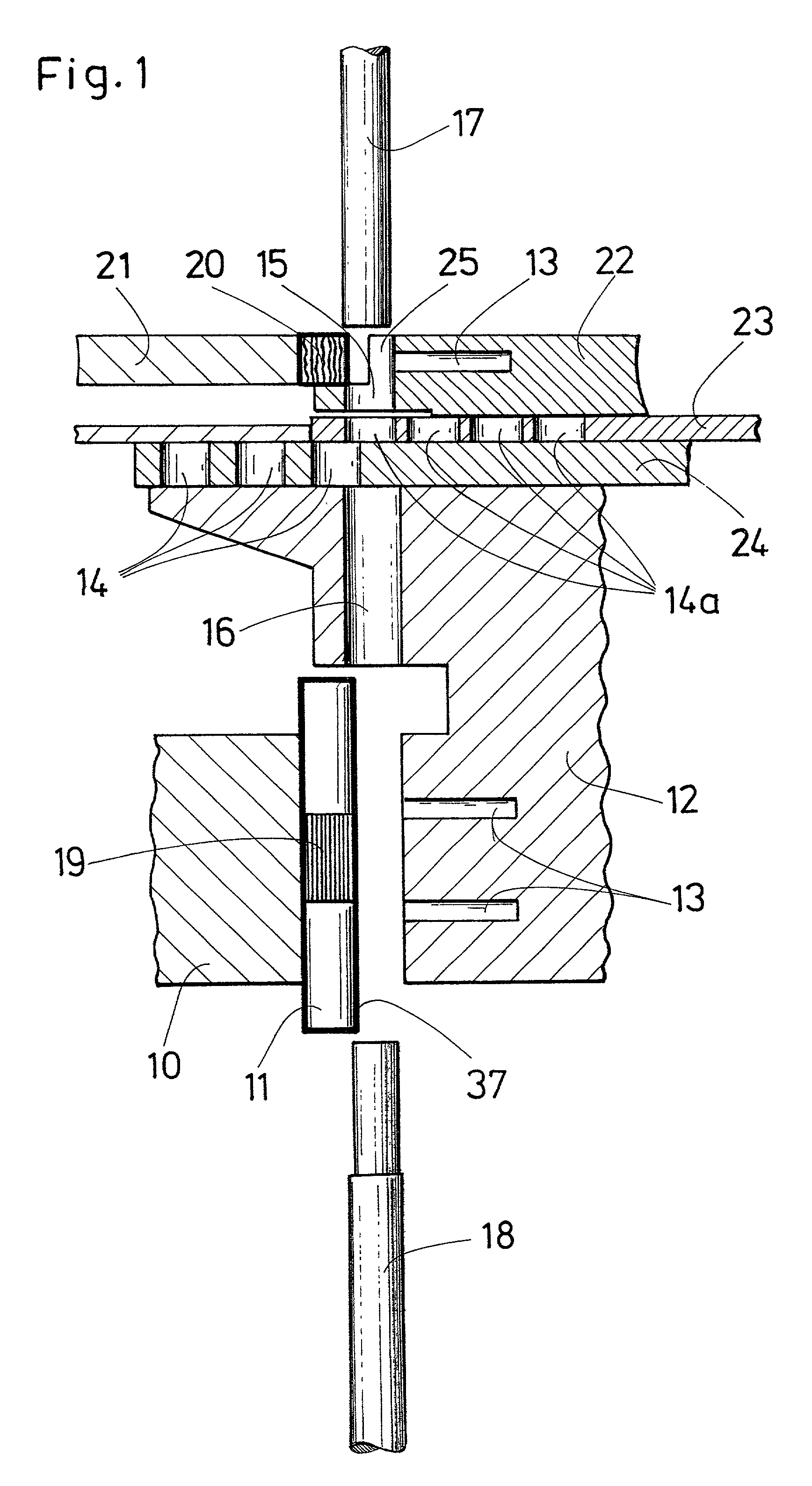

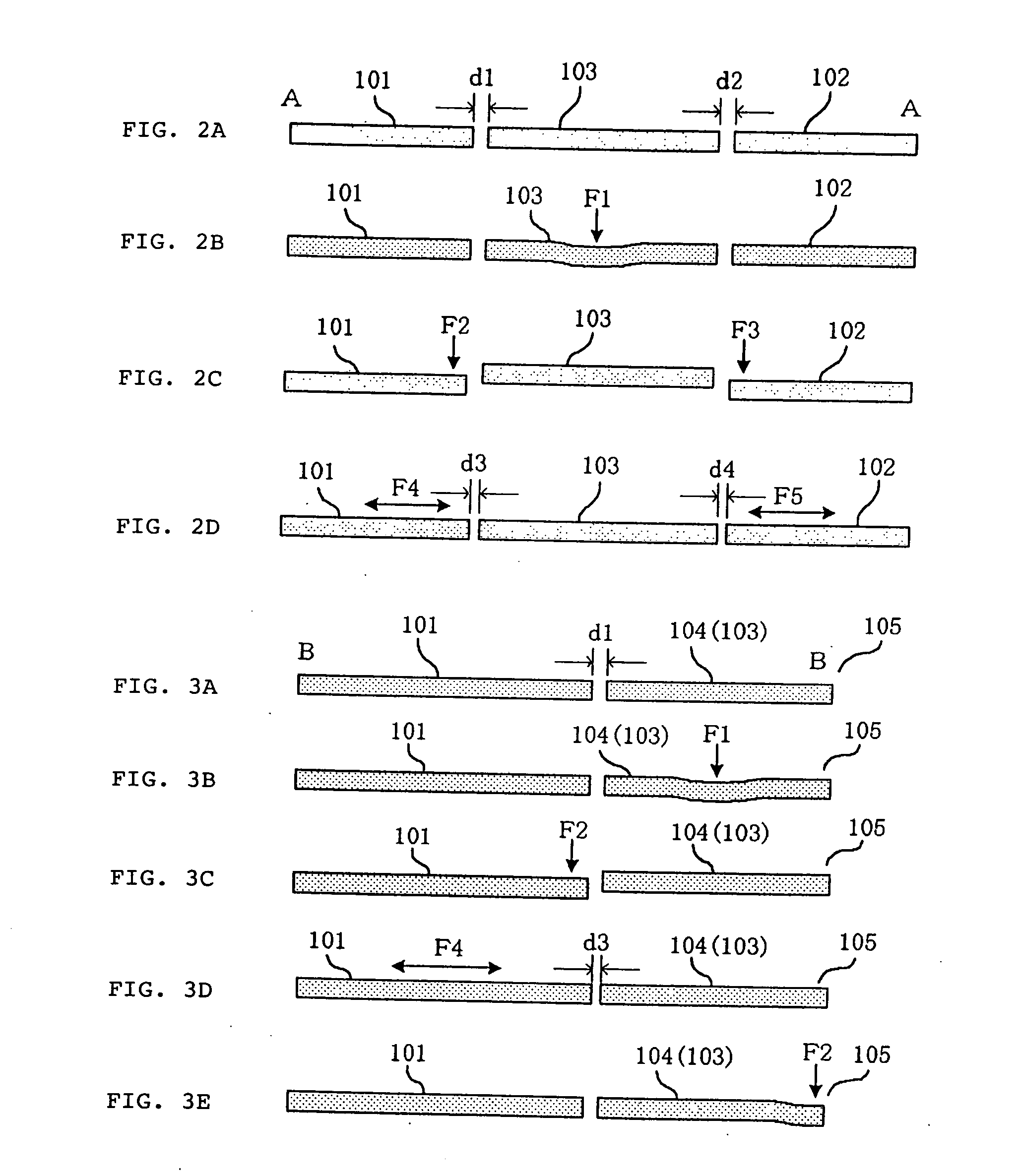

Machine for making filter mouthpieces for rod-shaped smokers' products

InactiveUS20020119873A1Simple and inexpensive modificationPaper/cardboard wound articlesCigarette manufactureEngineeringComposite filter

A machine for making composite filter mouthpieces for cigarettes or the like has a conveyor serving to transport a series of upright tubes of paper or the like past a vertically movable plunger which serves to introduce into successive tubes alternating plugs or wads of filter material and batches of flowable granular and / or pulverulent filter material. If the extent to which the plunger descends into a registering tube is outside of a predetermined range, the tube contains an excessive quantity or less than the required quantity of filter material. This is detected by one or more sensors which causes or cause ejection of the respective tube from the path for acceptable filter mouthpieces. A compensating device cooperates with the plunger to allow for proper confinement of flowable filter material against rattling between a pair of filter plugs if the quantity of such flowable filter material in a tube is below an optimum value.

Owner:HAUNI MASCHINENBAU AG

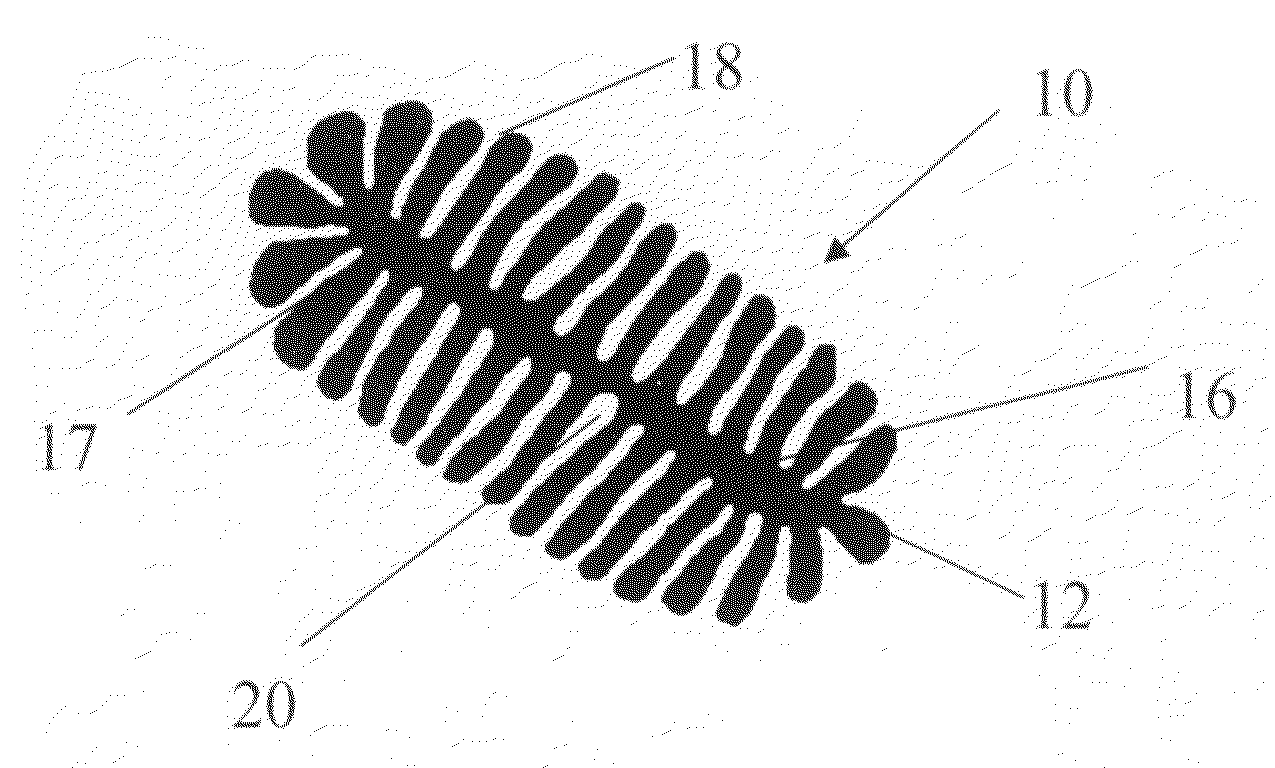

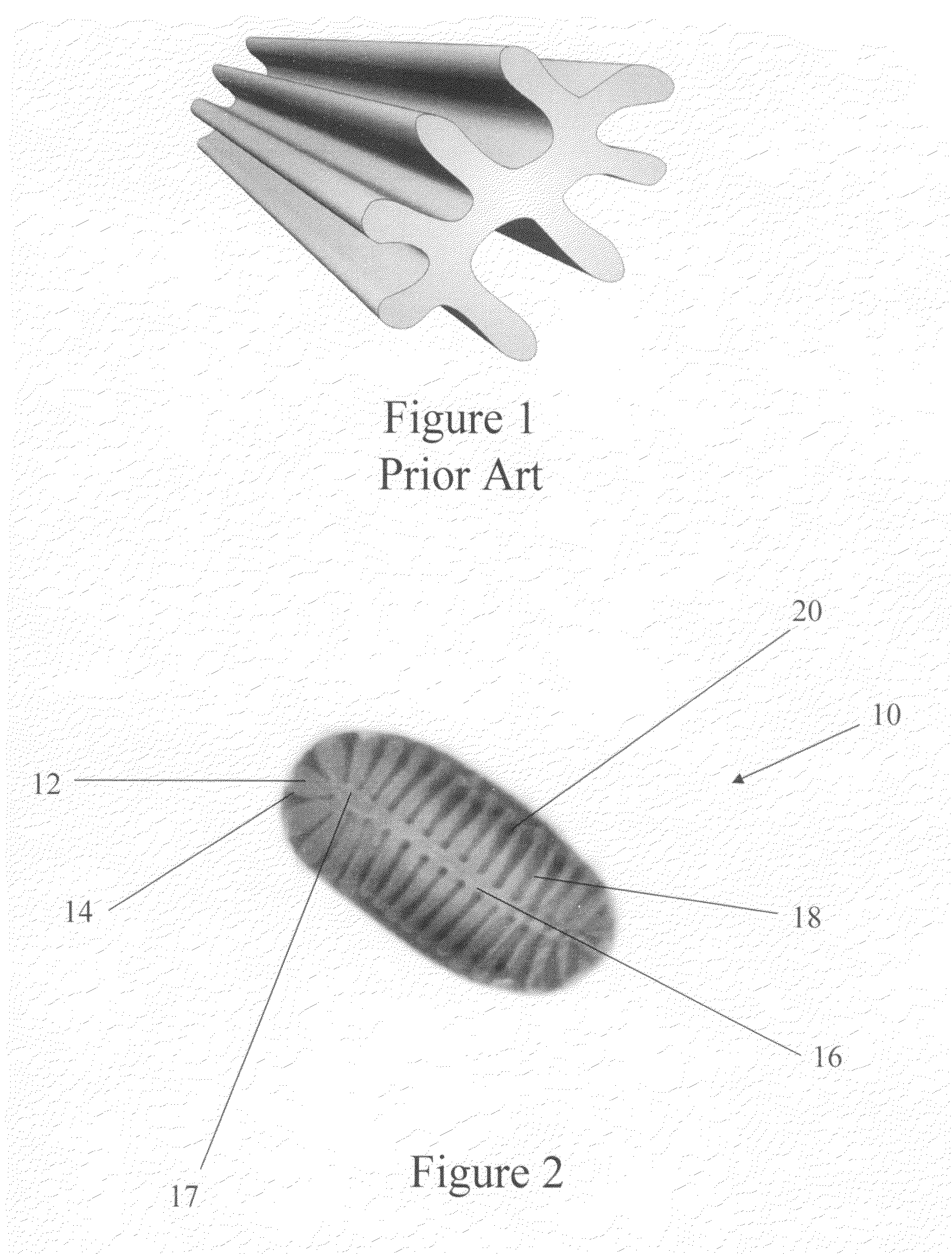

Composite filter media with high surface area fibers

ActiveUS20080105612A1Increased durabilityPromote absorptionOrnamental textile articlesFilament/thread formingComposite mediaPolymer science

The present invention is directed to a high surface area fibers and an improved filter composite media made from the same. More specifically, the composite media preferably comprises a winged-fiber layer having high surface area fibers for increased absorption and strength and a meltblown layer for additional filtration. In one preferred embodiment the high surface area fibers have a middle region with a plurality of projections that define a plurality of channels, which increases the surface area of the fiber. In one preferred embodiment, the high surface area fiber has a specific surface area of about 140,000 cm2 / g or higher and a denier of about 1.0 to about 2.0. The high surface area fiber of the present invention is made using a bicomponent extrusion process using a thermoplastic polymer and a dissolvable sheath.

Owner:ALLASSO IND +1

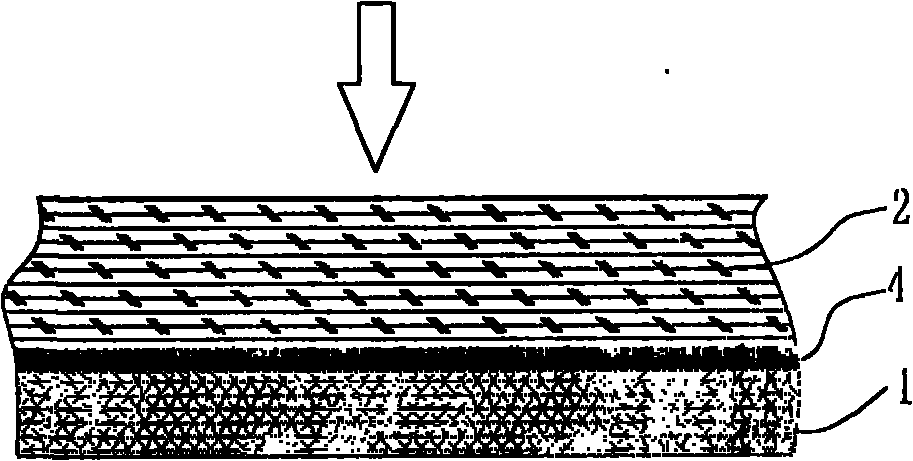

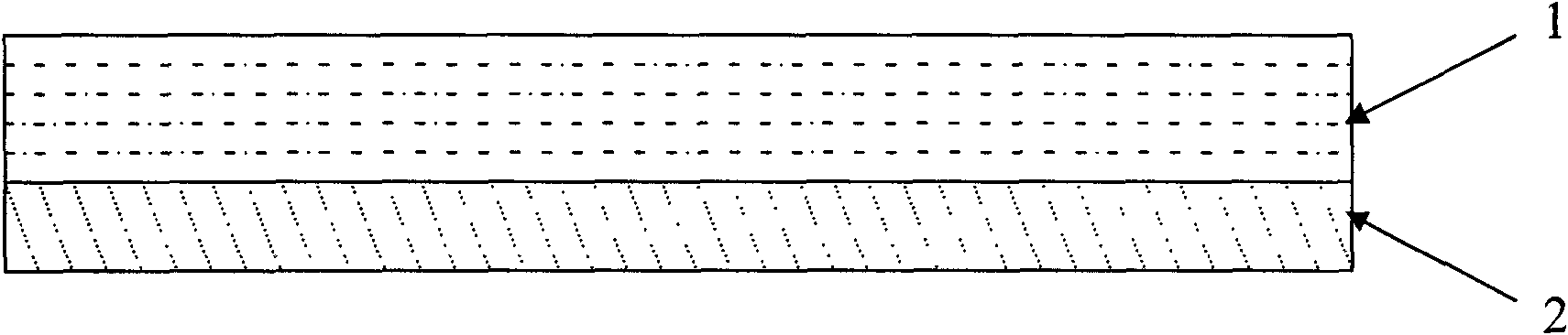

High temperature resistant P.T.F.E. coated filter material

ActiveCN1768912AAvoid cloggingExcellent "surface filter" characteristicsSemi-permeable membranesSynthetic resin layered productsTetrafluoroethyleneGlass fiber

The invention relates to a high temperature-resistant polytetrafluoroethylene tectorial filter material, belonging to the improvement on present polytetrafluoroethylene composite filter material, which comprises a glass fiber base cloth and a polytetrafluoroethylene surface film. It is characterized in that: first using after-treatment agent to process the dipping process on the glass fiber base cloth, then processing the high-temperature heat compression on the polytetrafluoroethylene surface film. The invention uses film forming emulsifier, fluorine silane coupling agent and fluoroplymer emulsion to form a film on the glass fiber base cloth, which can improve the effects of anti-soil, oil-proof and preservation, and it can have fusion combination with expanded micro-pore polytetrafluoroethylene film in the condition of high-temperature heat compression, to effectively solve the problem of hard fusion combination between inorganic material of glass fiber and organic inertia material of polytetrafluoroethylene to significantly improve the fastness between them.

Owner:中材科技膜材料(山东)有限公司

Composite filter and method of making the same

The invention refers to a composite filter for filtering a stream of ambient air comprising at least one non-prebonded upstream tier and one non-prebonded downstream tier, wherein the ratio of absolute pore volume of upstream tier to downstream tier RAPV>2, and the absolute projected fiber coverage of upstream tier and of downstream tier APFC>95%. Further, the invention refers to a method of making such a composite filter comprising the, steps of (a) laying down a filtration material onto a support to form the upstream non-prebonded tier, (b) depositing onto the upstream tier the downstream non-prebonded tier, and (c) bonding the tiers to form a composite filter having a unitary stratified structure.

Owner:EUROLIFTERS HLDG NV

Basalt fiber high temperature compositing filter material

InactiveCN101053718AImprove high temperature resistanceMeeting the needs of the high temperature filtration industryFiltration separationThermal energyIndustrial gas

The invention provides a basalt fibre high-temperature composite filter material. The high-temperature composite filter material is formed by weaving or needling, using the basalt fibre or the mixture of basalt fibre and other high temperature material which is one or more of the glass fibre, stainless-steel fibre and ceramic fibre. The invention can effectively improve the resistance to high temperature of filter material, extending the useful life, and also recycle heat energy, which saves energy source, has a excellent filter effect, and meet the need in the industry of industrial gases filter in high temperature.

Owner:江苏正大森源集团

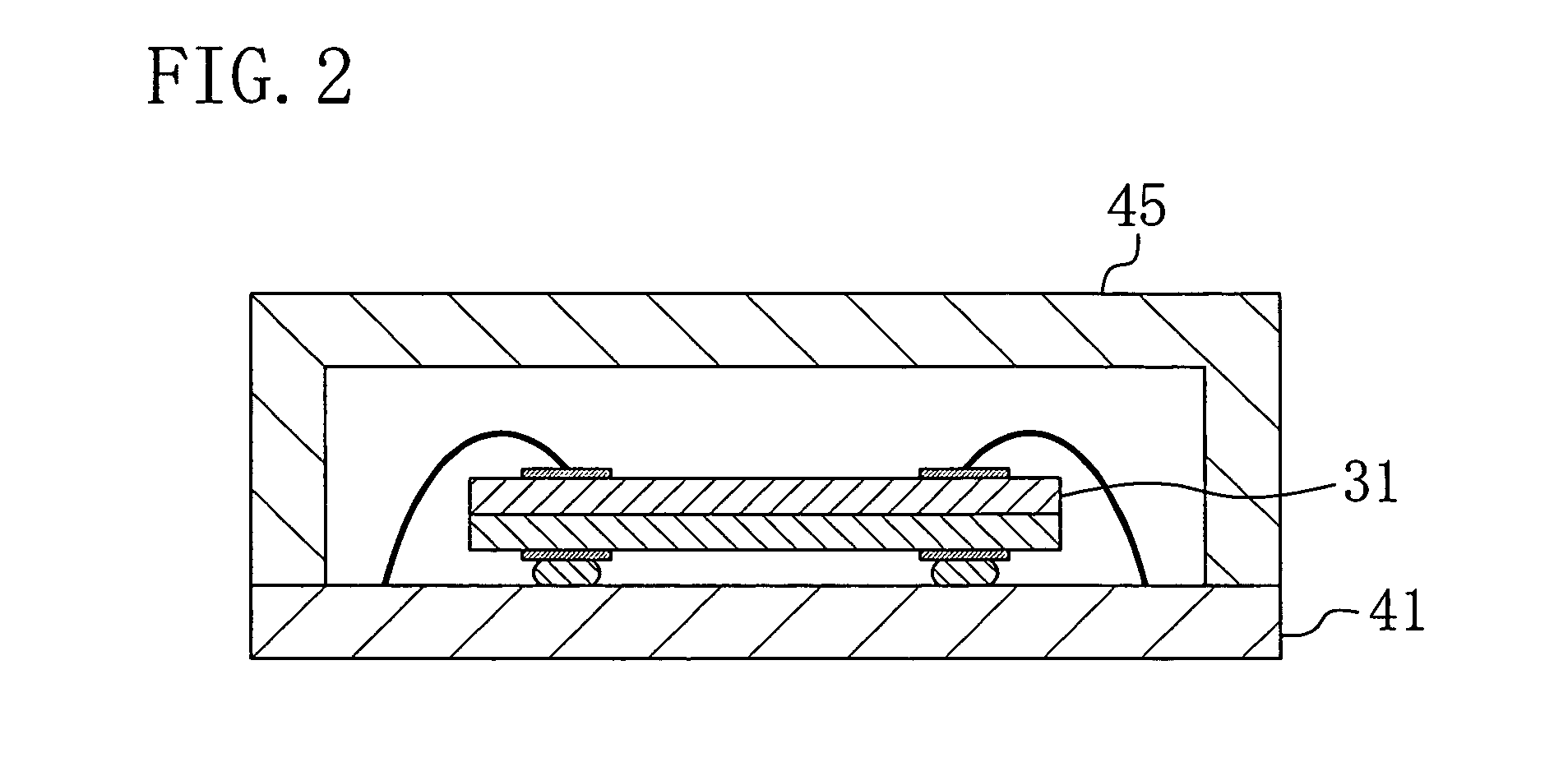

Composite filter chip

InactiveUS20070080757A1Reduce filter areaImpedence networksSolid-state devicesEngineeringComposite filter

A composite filter chip includes a stacked chip made by stacking a first chip and a second chip. The first chip has a first filter circuit formed on the main surface thereof. The second chip has a second filter circuit formed on the main surface thereof.

Owner:PANASONIC CORP

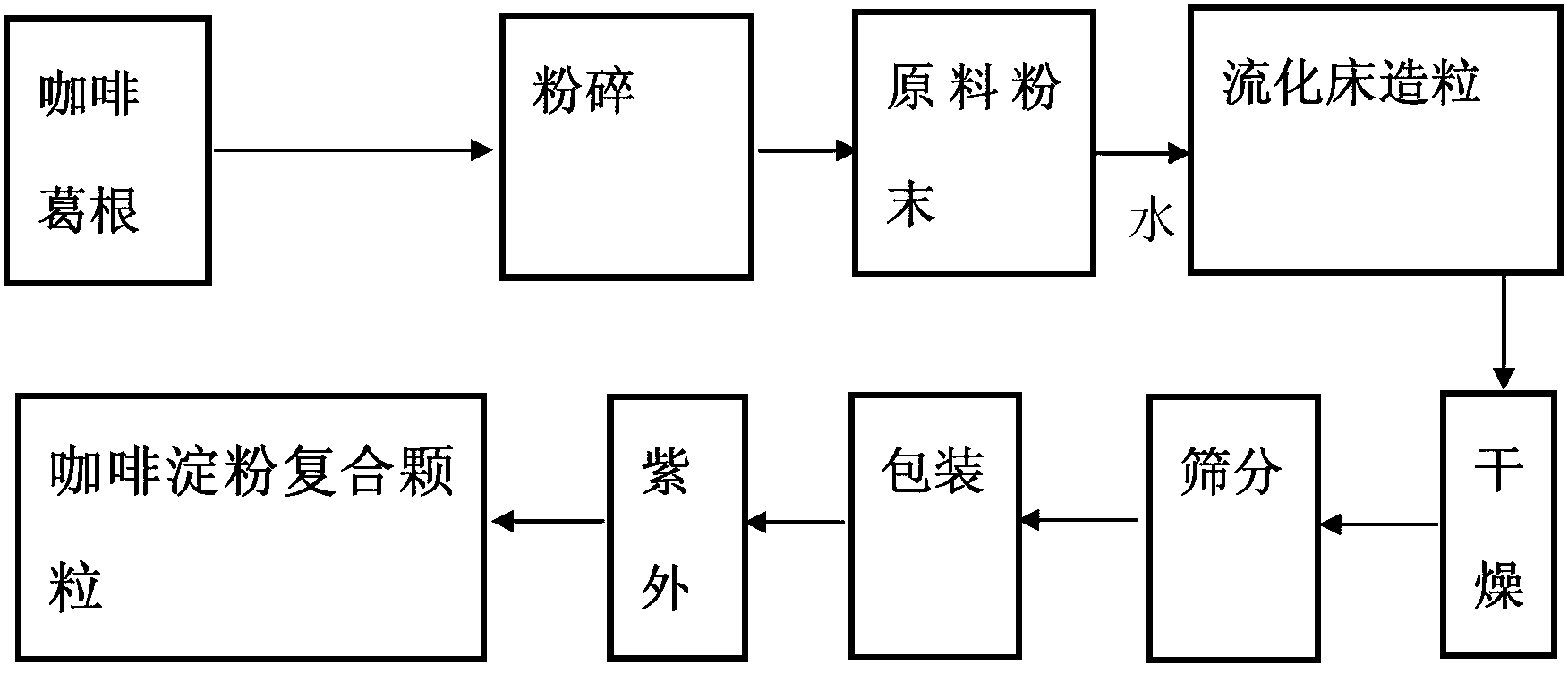

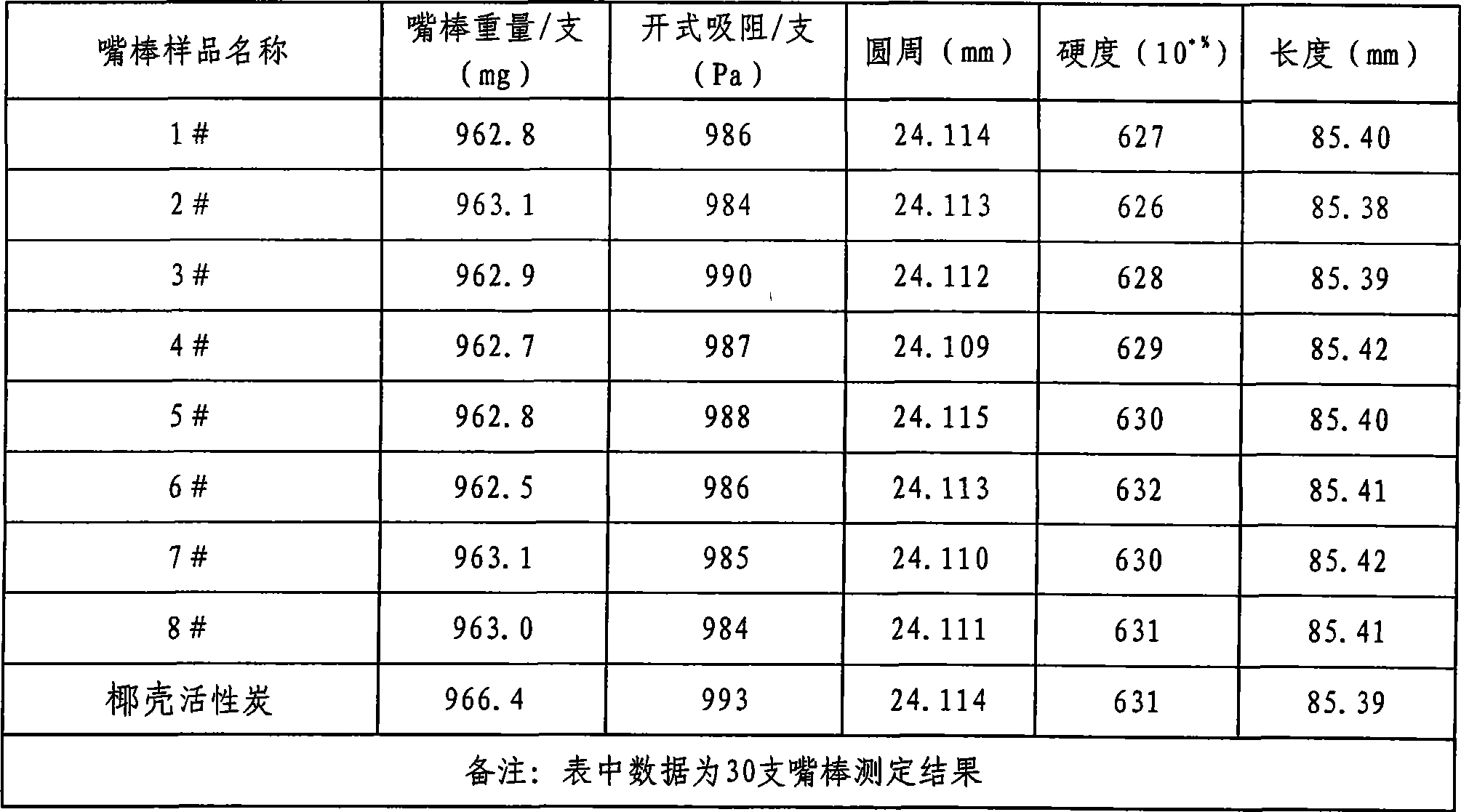

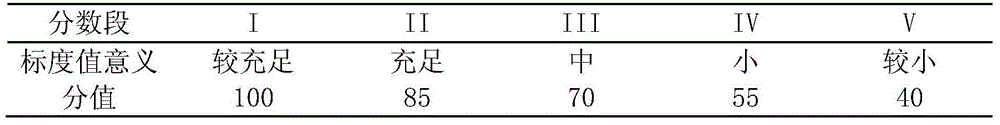

Preparation method of coffee-starch composite particles and application of coffee-starch composite particles in cigarette filter

ActiveCN103271443AHigh strengthStable coffee aromaTobacco smoke filtersComposite filterCigarette filter

The invention discloses a preparation method of coffee-starch composite particles and the application of the coffee-starch composite particles in a cigarette filter. The preparation method includes mixing and smashing coffee and the root of kudzu vine according to a certain proportion; pelleting through a fluidized bed and a pelletizer, drying and sifting; obtaining the composite particles containing coffee and starch, high in strength and stable in coffee fragrance. The composite particles can be loaded into cigarette filter sticks to make into binary composite filter sticks to be rolled into cigarettes. Sensory evaluation shows that by adding the composite particles containing the coffee and the starch into the filter sticks, smoke irritancy can be lowered, aroma quality of smoke can be improved, aroma quantity of the smoke can be increased, cigarette smoking quality can be improved, and characters and styles of strong-flavor cigarettes can be formed.

Owner:CHINA TOBACCO GUANGXI IND

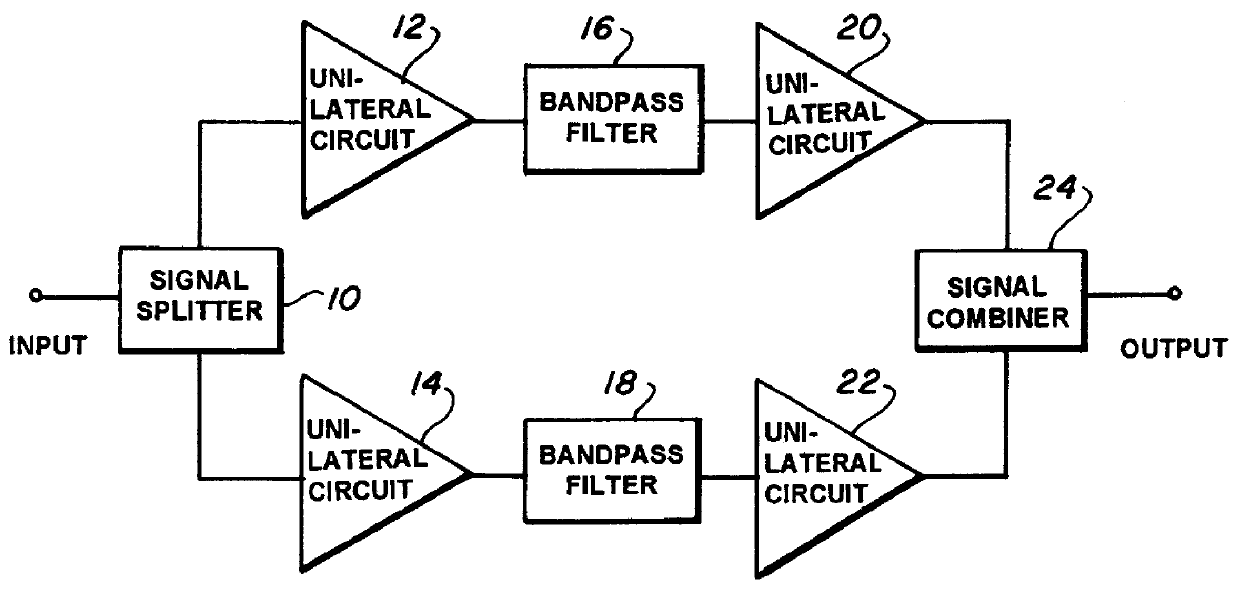

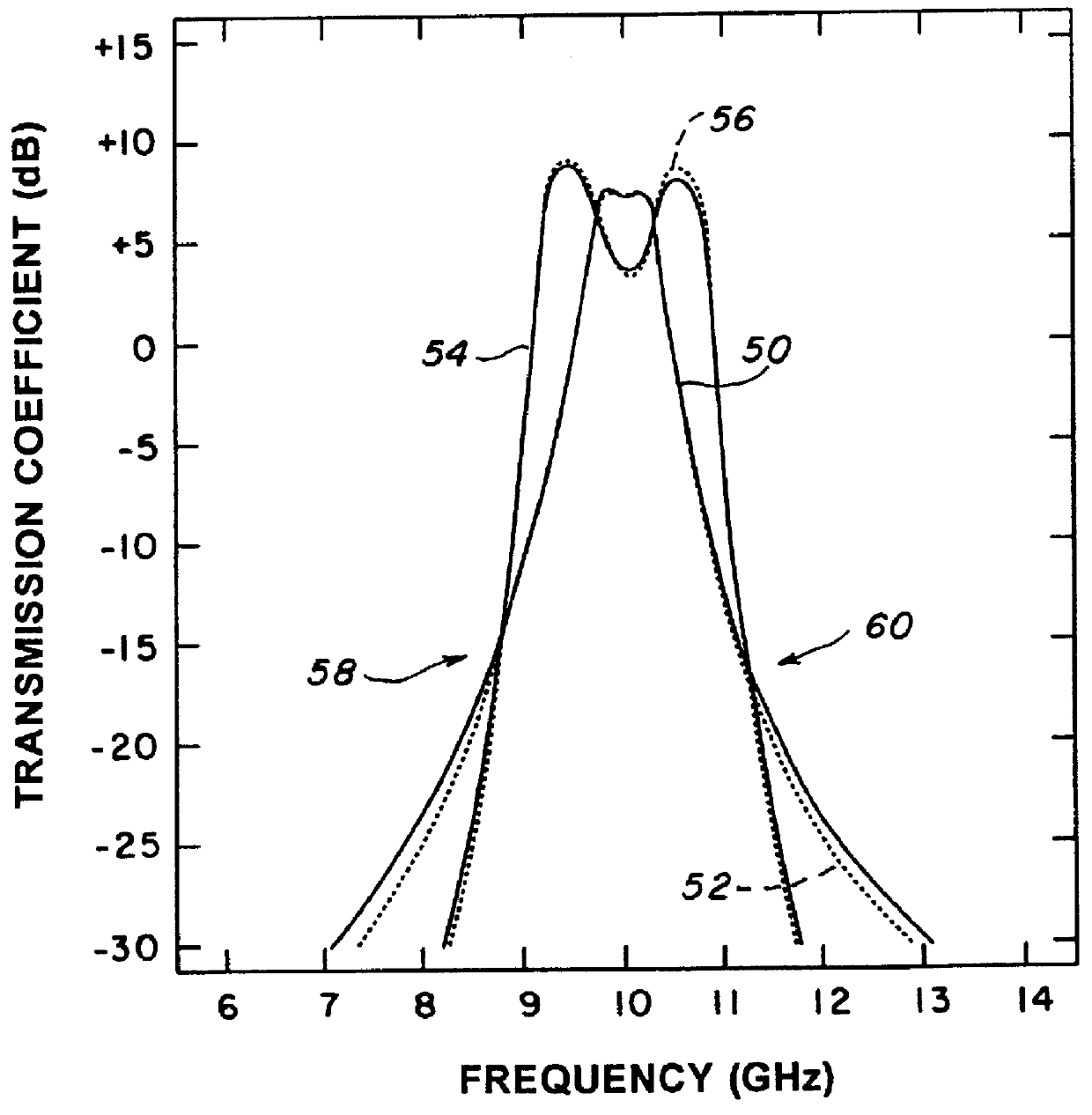

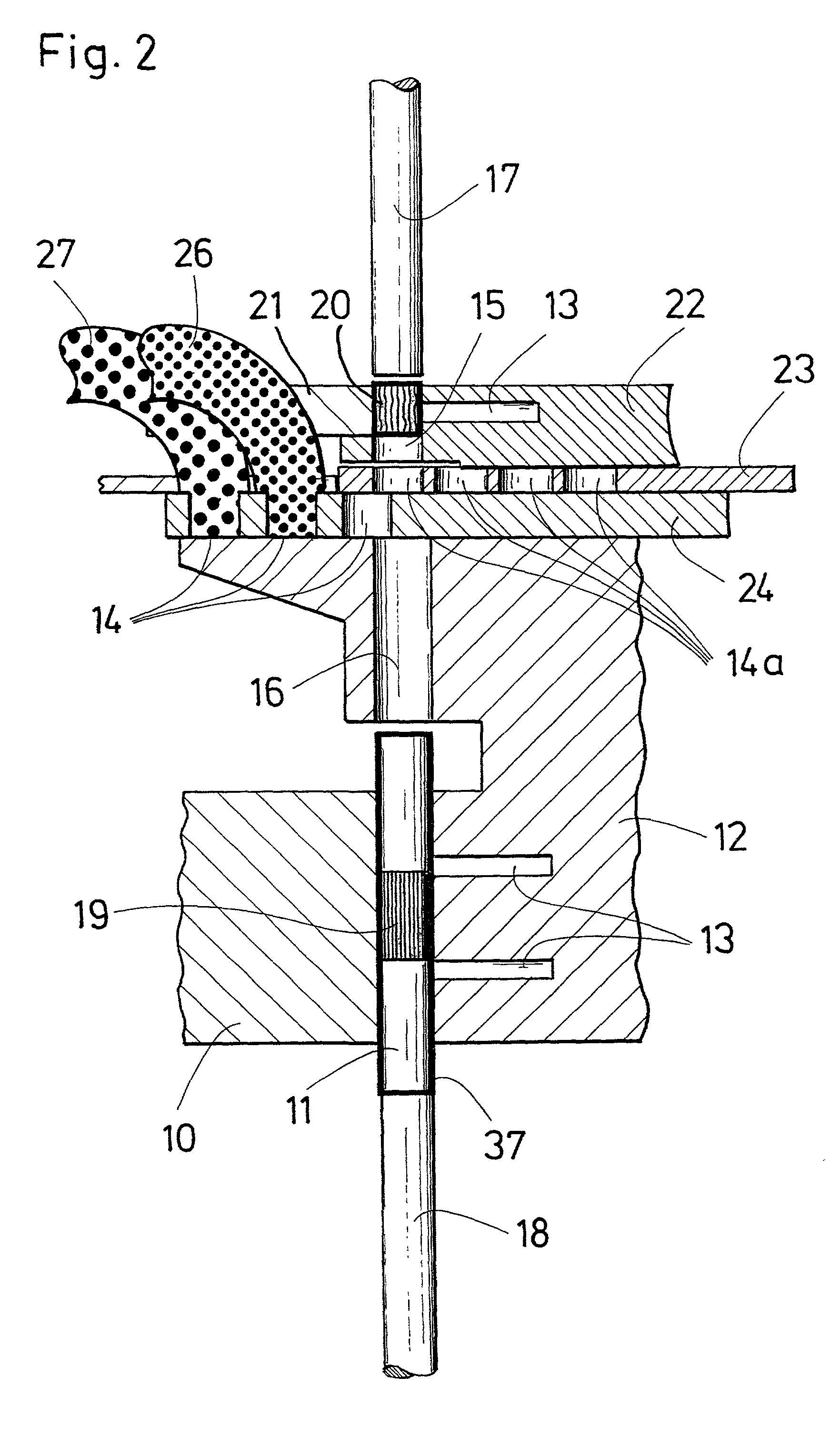

Microwave channelized bandpass filter having two channels

InactiveUS6107898AMultiple-port networksAmplifiers wit coupling networksBandpass filteringPhase splitter

A channelized active bandpass filter having only two branches which provide respective frequency-selective feed-forward signal paths. The two signal paths have overlapping frequency response bands such that the combination of the two paths provides a composite filter with a bandpass response. The two branches may be provided with bandpass transfer characteristics of different orders and shapes, such as a second-order response and a fourth-order response. Two-way signal splitting and combining to define the two channels may be performed with in-phase splitters and combiners, for example, or diplexer circuits, each composed of two bandpass filters with different characteristics but overlapping frequency responses and preferably approximately equal center frequencies. Combinations of the two splitting and combining arrangements are also usable.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Nano photocatalyst-active carbon fiber composite filter medium

ActiveCN101804275AImprove adsorption capacityPlays the role of immobilizing and binding nanoparticlesFiltration separationFiberCarbon fibers

The invention belongs to the technical field of air filter materials, and particularly relates to a nano photocatalyst-active carbon fiber composite filter medium. The nano photocatalyst-active carbon fiber composite filter medium is characterized in that the filter medium consists of a nano photocatalyst-active carbon fiber non-woven fabric and a filter base material, wherein the nano photocatalyst-active carbon fiber non-woven fabric comprises the following components in percentage by weight: 0.5 to 1.0 percent of nano photocatalyst, 1.0 to 4.0 percent of nano active carbon and 95 to 98.5 percent of carrier resin. The filter medium enables organic molecular aerosol which cannot be trapped by a conventional efficient filter layer to be quickly adsorbed by active carbon grains of nano carbon fiber, has the properties of tolerating water washing and holding carbon grains, and can be combined and used with various efficient filter media calendared by other materials. In addition, the filter can be placed in the sun or under an ultraviolet lamp to perform illumination and regeneration after adsorbed saturation, and the service life of the whole filter can be greatly prolonged.

Owner:HANGZHOU FILTECH INTELLIGENT CO LTD

Method and arrangement for producing compound filters

InactiveUS7004896B2Increase productionPaper/cardboard wound articlesCigarette manufactureEngineeringComposite filter

Owner:HAUNI MASCHINENBAU AG

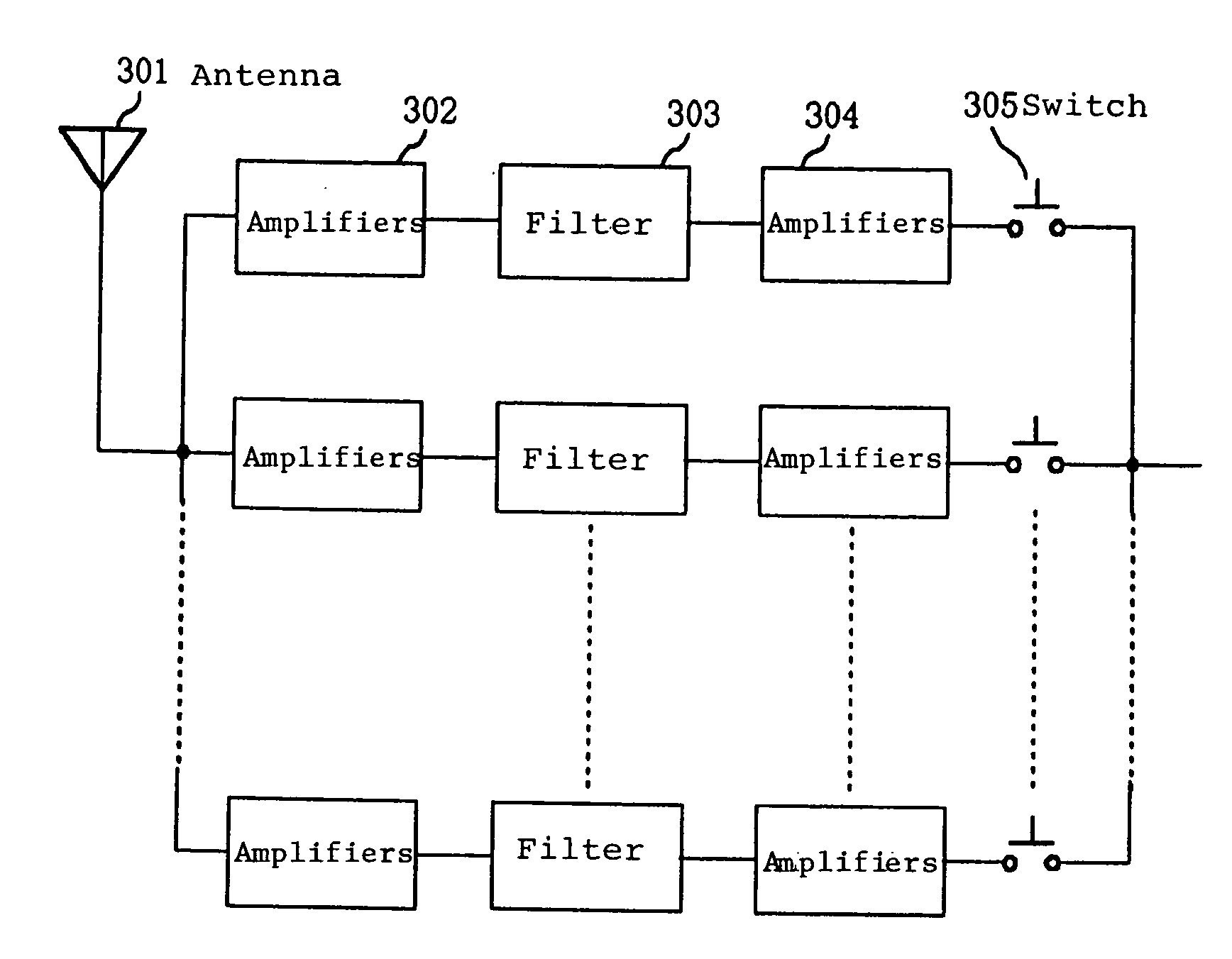

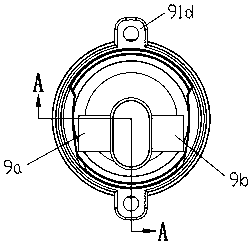

Filter and composite filter, filter assembly, integrated circuit chip and electronic device which contain same, and frequency characteristic changing method therefor

ActiveUS20070082642A1Improve performanceSatisfactory characteristicImpedence networksTransmissionDual modeFilter bank

A dual-mode acoustic wave resonator (7a) having a resonance mode inter-coupler (6) is disposed across narrow voids (4, 5) from an input electrode (2) and an output electrode (3). They are supported for vibrations on a substrate by conductive posts (27, 28, 29) and a power supply pad (3). Opposing electrodes (10, 11, 21, 23) are formed below the input and output electrodes (2, 3), resonator (7a), and resonance mode inter-coupler (6) across narrow gaps. As a voltage of a power supply (25) is changed, a distortion of the resonator (7a) changes due to an electrostatic force, causing a change in the center resonance frequency. As voltages of power supplies (16, 17) are changed, distortions of the input and output electrodes (2, 3) change to cause a change in the opposing areas of end faces of the input and output electrodes to the resonator (7a). This causes a change in the situation of exchanging energy between the input and output electrodes and the resonator (7a) to change the external Q-value. As the voltage of the power supply (25) is changed, a distortion of the inter-coupler (6) changes to cause a change in the coupling coefficient between the resonance modes.

Owner:NEC CORP

Multi-component filter media with nanofiber attachment

Owner:CLARCOR INC

Macroporous and microporous hybrid starch granule and preparation method and application thereof

InactiveCN101531779AHigh specific surface areaHigh selective adsorption capacityTobacco smoke filtersPolymer scienceCyclodextrin

The invention discloses a macroporous and microporous hybrid starch granule and a preparation method and an application thereof; wherein, the method comprises the following steps: mixing the macroporous starch with pore diameter ranging from 0.5umm to 1.5umm with microporous starch with pore diameter ranging from 6A degree to 6.5 A degree according to the weight proportion of 0.5-4;1; then wetting, microwave drying, crashing and sifting are carried out on the mixture, thus obtaining the hybrid starch granule; the additive is superior to single modified cornstarch granule (YSQ) or beta- cyclodextrin (HH) in terms of absorption property; dualistic or ternary composite filter prepared by adding the additive to a filter element of a cigarette filter can effectively reduce delivery volume of tar, phenol, hydrocyanic acid and carbon monoxide in smoke gas and improve organoleptic quality of the cigarette, effectively improve sensory comfort of the cigarette, enhance intensity of cigarette aroma, thus enjoying good application prospect.

Owner:YUNNAN RES INST OF TOBACCO SCI

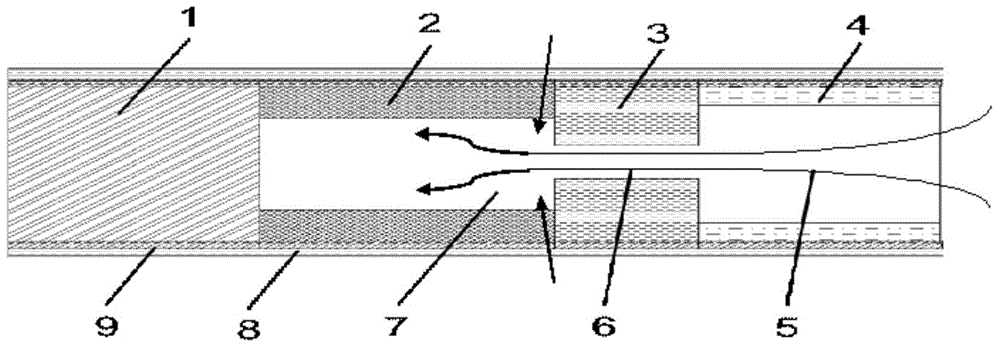

Composite filter tip for heating type non-combustion cigarette

InactiveCN104921296AReduce the temperatureLess irritatingCigar manufactureTobacco smoke filtersCombustionComposite filter

The invention relates to a composite filter tip for a heating type non-combustion cigarette. The composite filter tip comprises a solid filter (1), a first hollow filter or first cavity (2), a second hollow filter (3) and a third hollow filter or third cavity (4) which are connected in sequence, wherein a fourth cavity (7) is formed in the hollow portion of the first hollow filter or first cavity (2), a sixth cavity (5) is formed in the hollow portion of the third hollow filter or third cavity (4), the fourth cavity (7) and the sixth cavity (5) are in airflow communication through a fifth cavity (6) located in the hollow portion of the second hollow filter (3), and the diameter of the fifth cavity (6) is smaller than that of the fourth cavity (7) and that of the sixth cavity (5). The composite filter tip has a smoke mixing function, a smoke response time shortening function and other functions and has the advantages of being capable of increasing the smoke amount of the heating type non-combustion cigarette, reducing smoke temperature, improving the smoking sensory quality of the heating type non-combustion cigarette and the like.

Owner:CHINA TOBACCO YUNNAN IND

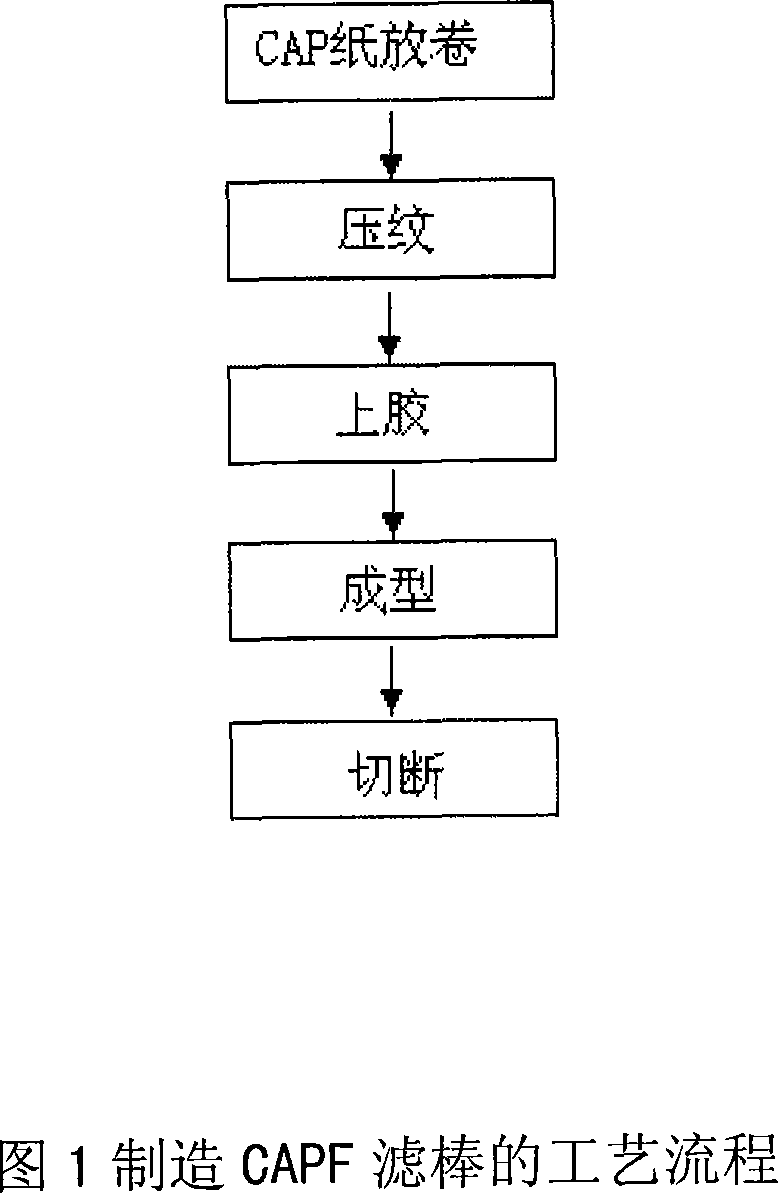

Producing technique of filter tip bar for filling material including acetate fibre paper to cigarette

The present invention relates to cigarette filter tip making technology, and is especially one kind of cigarette filter tip with cellulose acetate paper as the filling and filtering material. The cellulose acetate paper filter tip may be filter tip made of cellulose acetate paper or composite filter tip made of composite material with cellulose acetate paper. During the formation of the cellulose acetate paper filter tip, triglycreyl acetate or other cellulose acetate is applied as the plasticizer, and the filter tip may be 'cured' or 'non-cured'.

Owner:NANTONG CIGARETTE FILTER +1

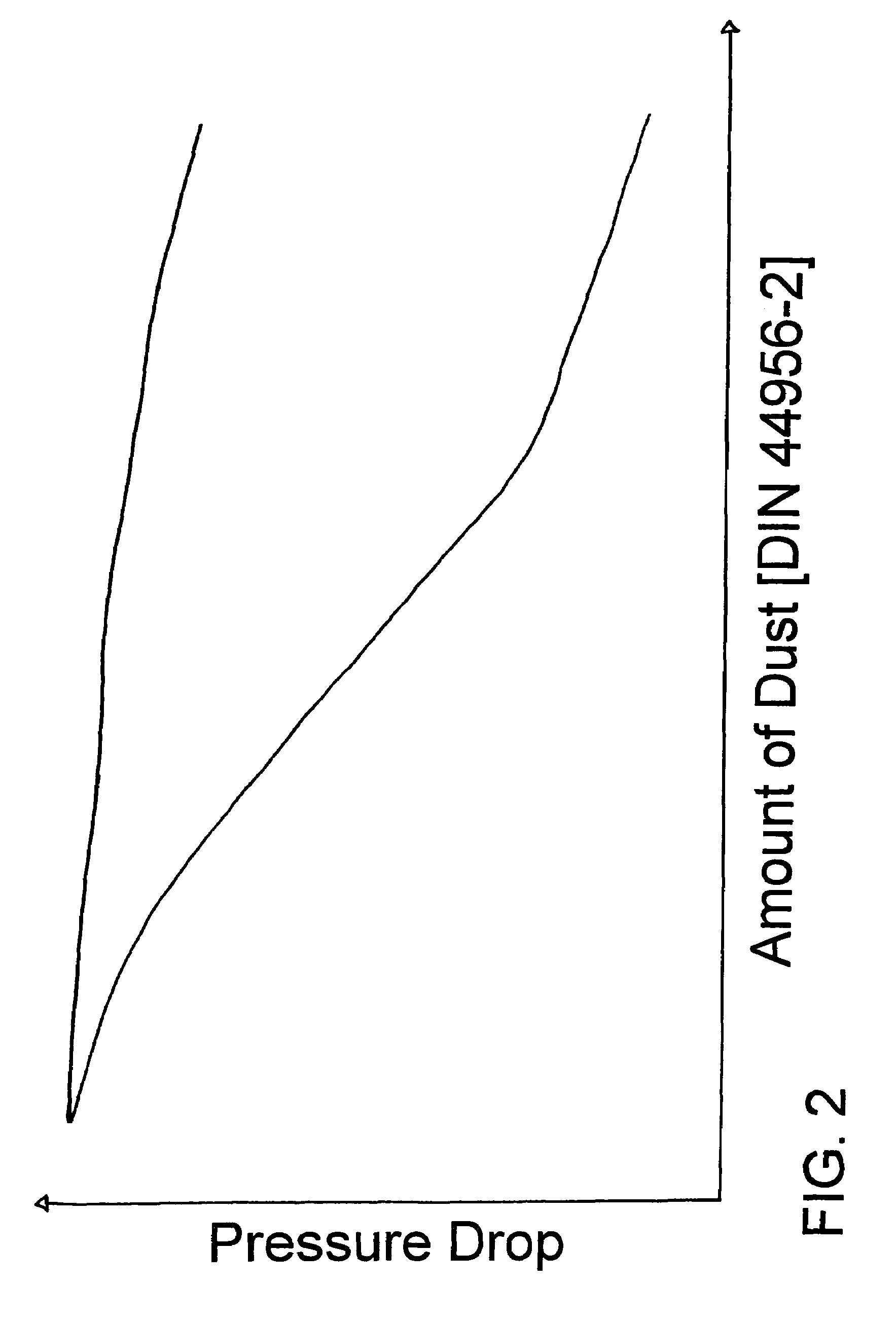

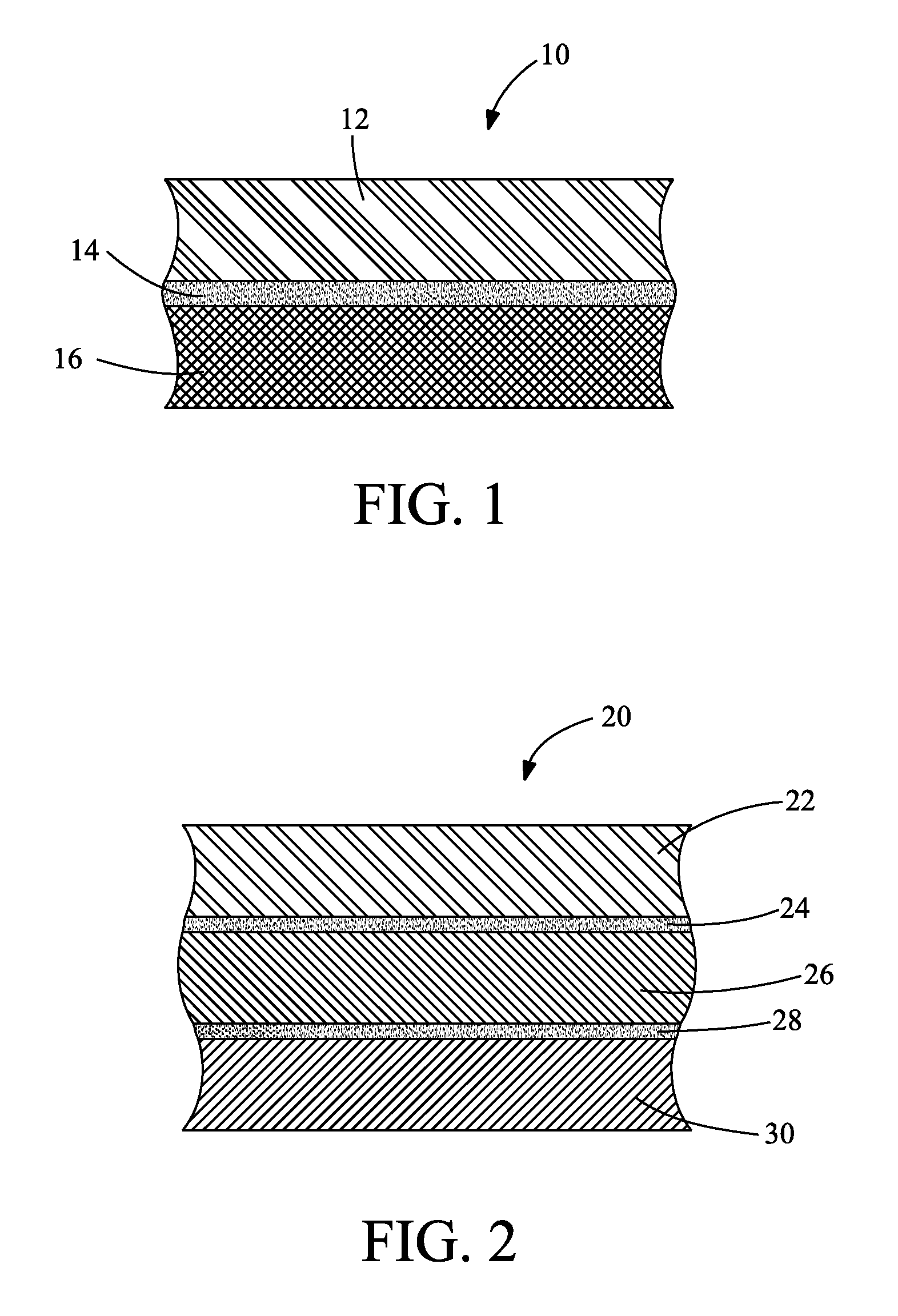

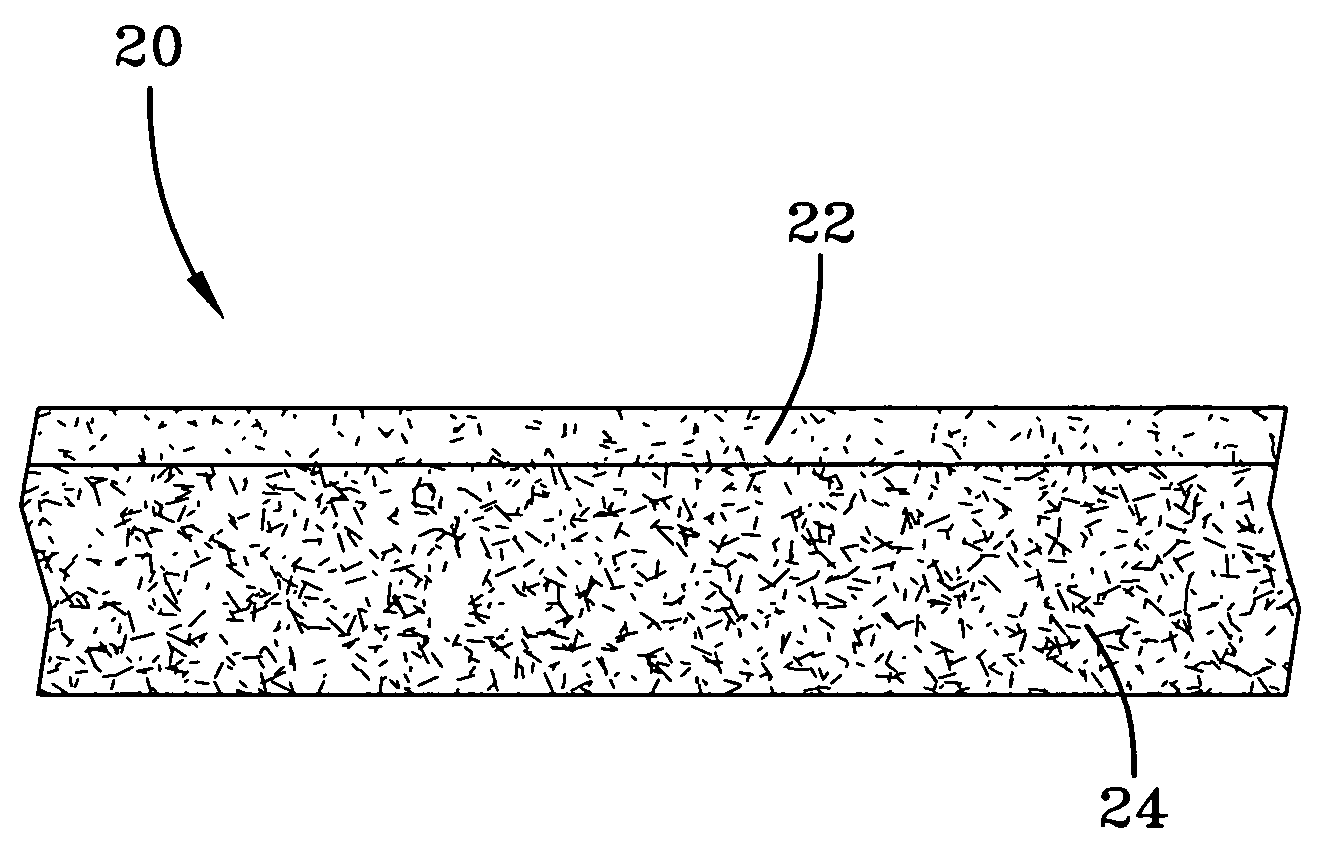

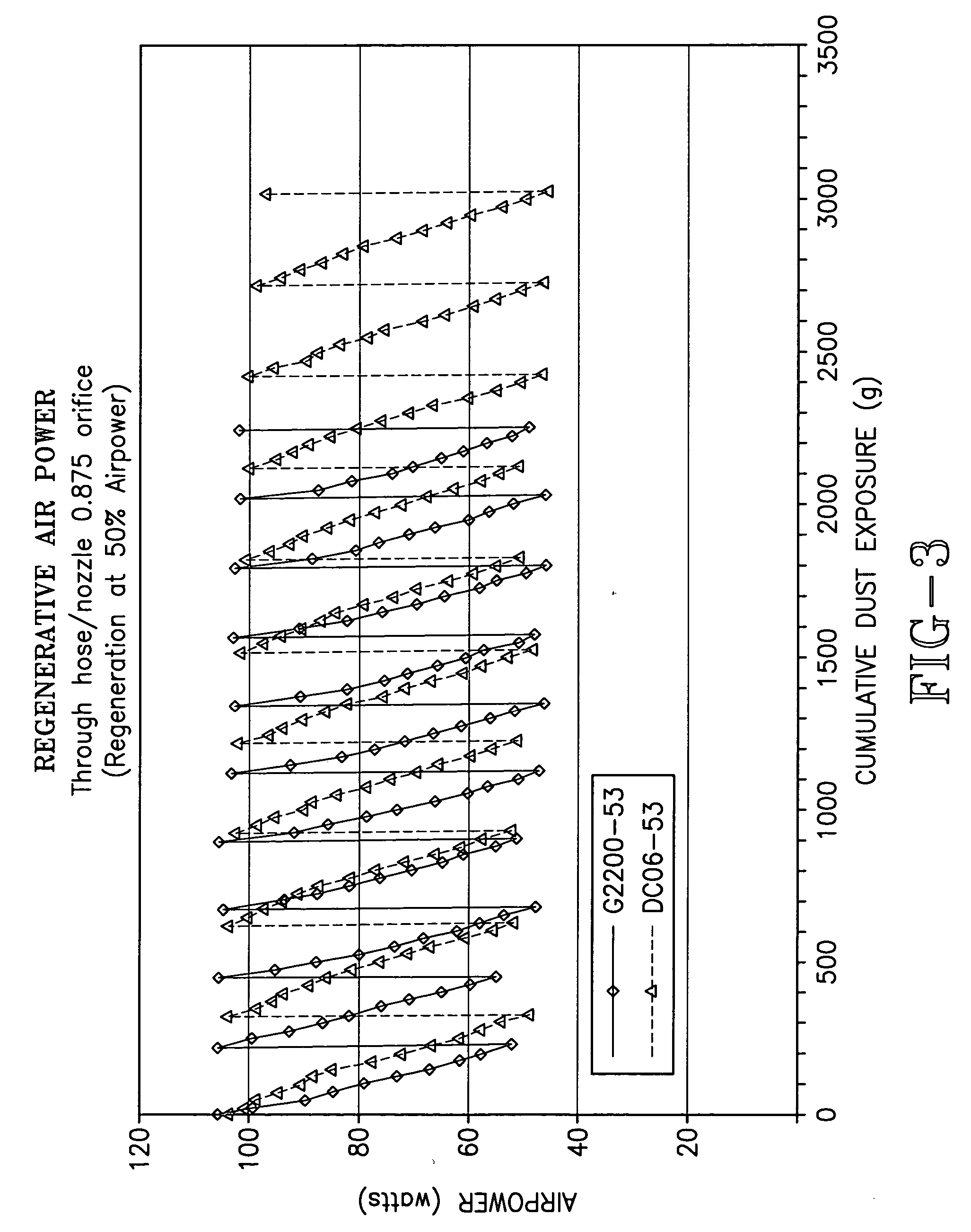

Composite filter media

InactiveUS20060060085A1Enhance dust releasing propertyImprove regenerative abilityCombination devicesDispersed particle filtrationComposite mediaFilter media

A composite filter media having excellent dust-releasing properties provided with a first layer of non-woven synthetic fibers having one outer surface hot calendered to increase smoothness and carrying a coating of a hydrophobic material which lowers surface tension and at least a second layer of non-woven synthetic fibers laminated to the downstream side of said first layer. A backing layer may be included to provide additional support to the first and second layer if desired. The second layer may include an electrostatic charge to increase filter efficiency at a reduced pressure drop across the composite media.

Owner:COLUMBUS INDS

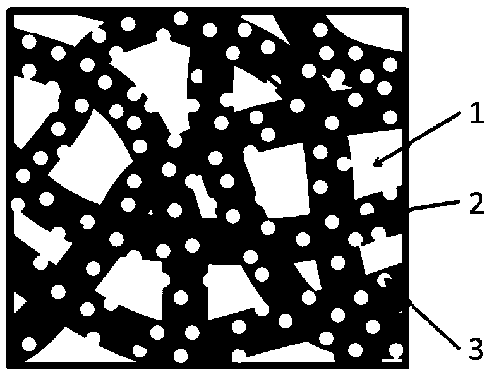

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

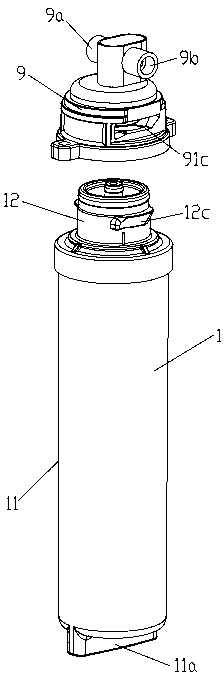

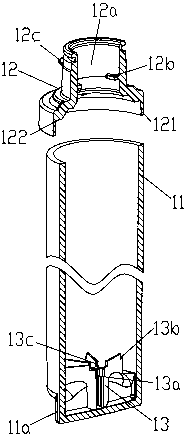

Composite filter element and adapter thereof

ActiveCN103071334ASmall diameterSolution volumeMembrane filtersLoose filtering material filtersActivated carbonComposite filter

The invention discloses a composite filter element and an adapter thereof. The composite filter element comprises a filter element housing body comprising a filter element housing and a filter element housing cover, wherein the filter element housing body is internally provided with a PP (Propene Polymer) cotton filter element and an active carbon filter element; a connection gland is spaced between the PP cotton filter element and the activated carbon filter element; the PP cotton filter element is clamped and sleeved with a PP cotton head; the PP cotton head is connected with a filter element divider provided with a water inlet sub-channel and a water outlet sub-channel; a location support is integrally arranged on a bottom wall of the filter element housing body; a partition is arranged on the location support in a seating manner, and forms a purified water chamber with the bottom wall of the filter element housing body; a purified water conduit for communicating the water outlet sub-channel with the purified water chamber is arranged in the centers of the PP cotton filter element and the activated carbon filter element in a penetrating manner; the periphery surface of the connection gland and an internal wall of the filter element housing body are subjected to liquid sealing and matched with the PP cotton head and the PP cotton filter element to form a water inlet chamber and a primary filter chamber that are communicated with the water inlet sub-channel; the filter element housing cover is provided with a self-closing filter element connection seat provided with a water inlet connector and a water outlet connector; and the water inlet connector and the water outlet connector are in ejection connection with and are communicated with the water inlet sub-channel and the water outlet sub-channel respectively after opening.

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

High temperature resistance basalt fiber composite filter material and preparation method thereof

InactiveCN101612496AStable structureHigh filtration precisionLayered productsFiltration separationFiltrationPore diameter

The invention relates to a high temperature resistance basalt fiber composite filter material and a preparation method thereof; the composite filter material comprises basalt fiber base fabric and high-performance fiber mesh in a weight ratio of 7:1-2:1; the preparation method comprises the following steps: forming high-performance fiber mesh on the basalt fiber base fabric, combining and strengthening the material more by spunlaced process, hot rolling the material, then soaking the material in water repellent oil-proofing agent, sizing and obtaining the finished product. The filter material of the invention has the advantages of stable structure, high filtration accuracy, small bore diameter, concentrated pore diameter distribution and high temperature resistance, can bear 450 DEG C of instantaneous high temperature and can be used stablely for long time below 280 DEG C.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com