Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Realize continuous casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency continuous casting method of structure-controllable closed cell foam aluminum ingot

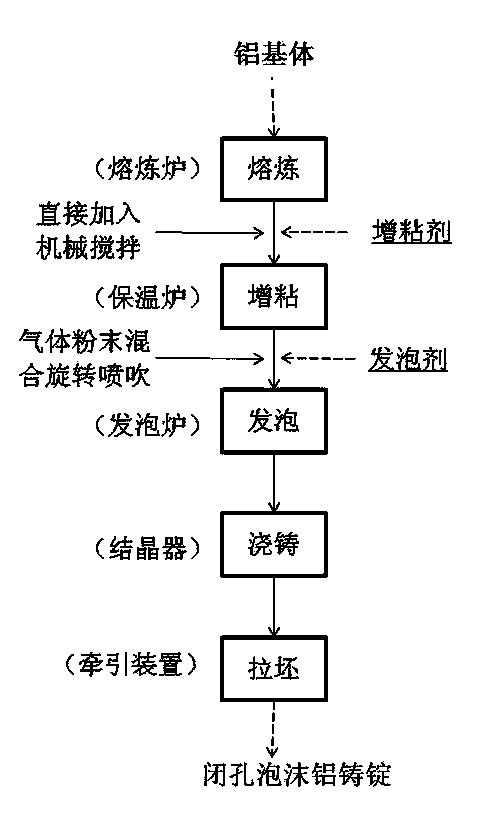

The invention discloses a high-efficiency continuous casting method of controllable structure-controllable closed cell foam aluminum ingot, belonging to the technical field of continuous porous metal preparation. According to the method, the decomposition control on a foaming agent in a melting body is realized by changing the treatment means of the foaming agent, the continuous production not only greatly improves the production efficiency but also solves the problem of bubble-free layers during static casting, and the continuous production of the closed cell foam aluminum ingot is achieved by controlling the casting temperature, the casting speed and the cooling intensity in a continuous casting process; the sizes and the shapes of bubbles in an aluminum substrate are controlled by adding foaming agents which have different types, different additive amounts and different particle sizes and are subjected to different pretreatments, and a control method of the porous structure is relatively high in realizability and relatively meets the requirements on the product diversity in actual application. The method is simple in process and low in cost, achieves the continuous casting, greatly improves the production efficiency, relatively meets the industrialized requirements and can be used for efficiently and continuously preparing large-sized closed cell foam aluminum ingot.

Owner:DALIAN UNIV OF TECH

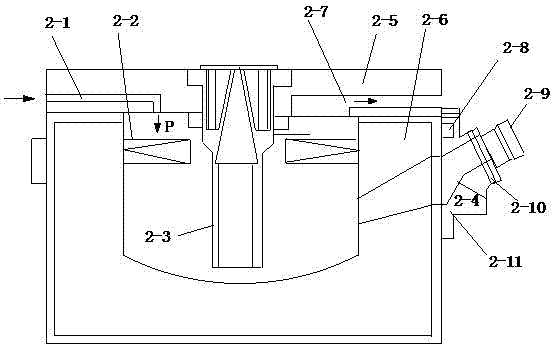

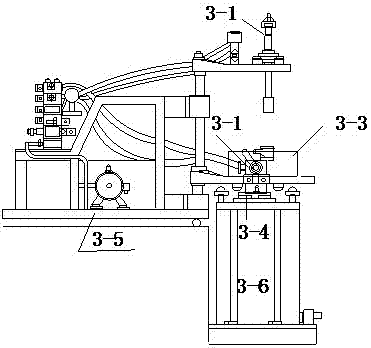

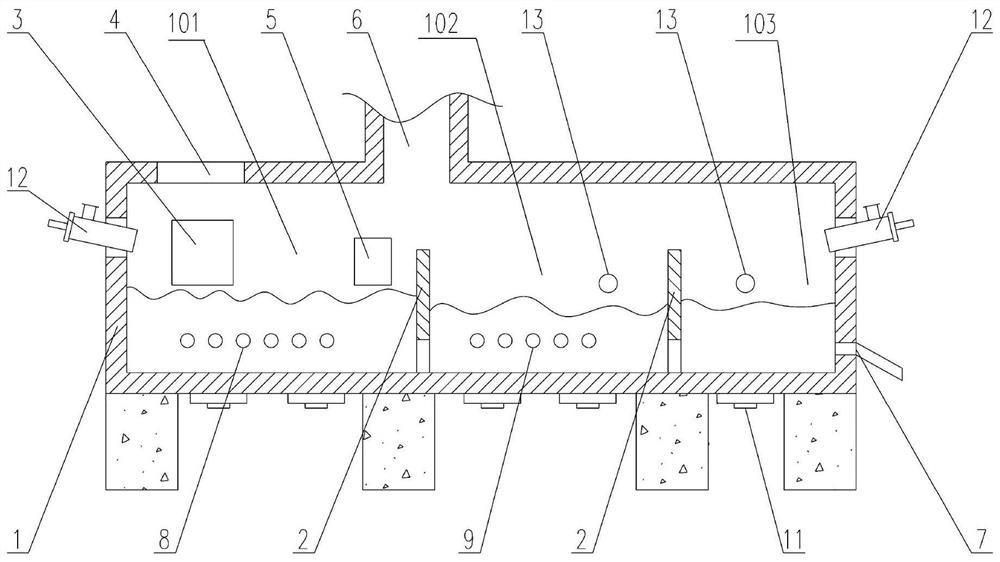

Automatic production line technology and equipment for low-pressure casting of aluminum alloy

The invention belongs to the technical field of metal casting equipment, and particularly relates to full automatic continuous casting production equipment and technology for low-pressure casting of aluminum and aluminum alloy. The equipment consists of a smelting furnace (1), a low-pressure heat preserving furnace (2), a wheel type multi-platform casting machine (3), an automatic part-taking mechanical arm (4), an automatic dedusting-spraying-cooling three-in-one mechanical arm (5), an automatic conveyor and liquid level pressuring device (6), a temperature control cabinet (7) and a control panel (8). By adopting a numerical control multi-station and timing-sequence-sharing continuous casting technology, the raw material is fed into the smelting furnace, and is automatically transported into the heat preserving furnace after being smelted, and molten aluminum is injected into metal molds on the wheel type multi-platform casting machine under the control of the liquid level pressuring device, so that a product can be formed. A plurality of molds and corresponding mold disassembly / assembly mechanisms are arranged on the wheel type multi-platform casting machine, and the working procedures such as the casting, the shape keeping, the mold disassembling, the part taking, the cleaning-spraying-cooling, the mold assembling and the like in the process of the low-pressure casting can be completed on different stations at different times when the wheel type multi-platform casting machine rotates, so that the continuous and quantitative automatic production of the aluminum alloy cast parts can be realized.

Owner:ZHEJIANG SANRUI INTERNAL COMBUSTION ENGINE PARTS

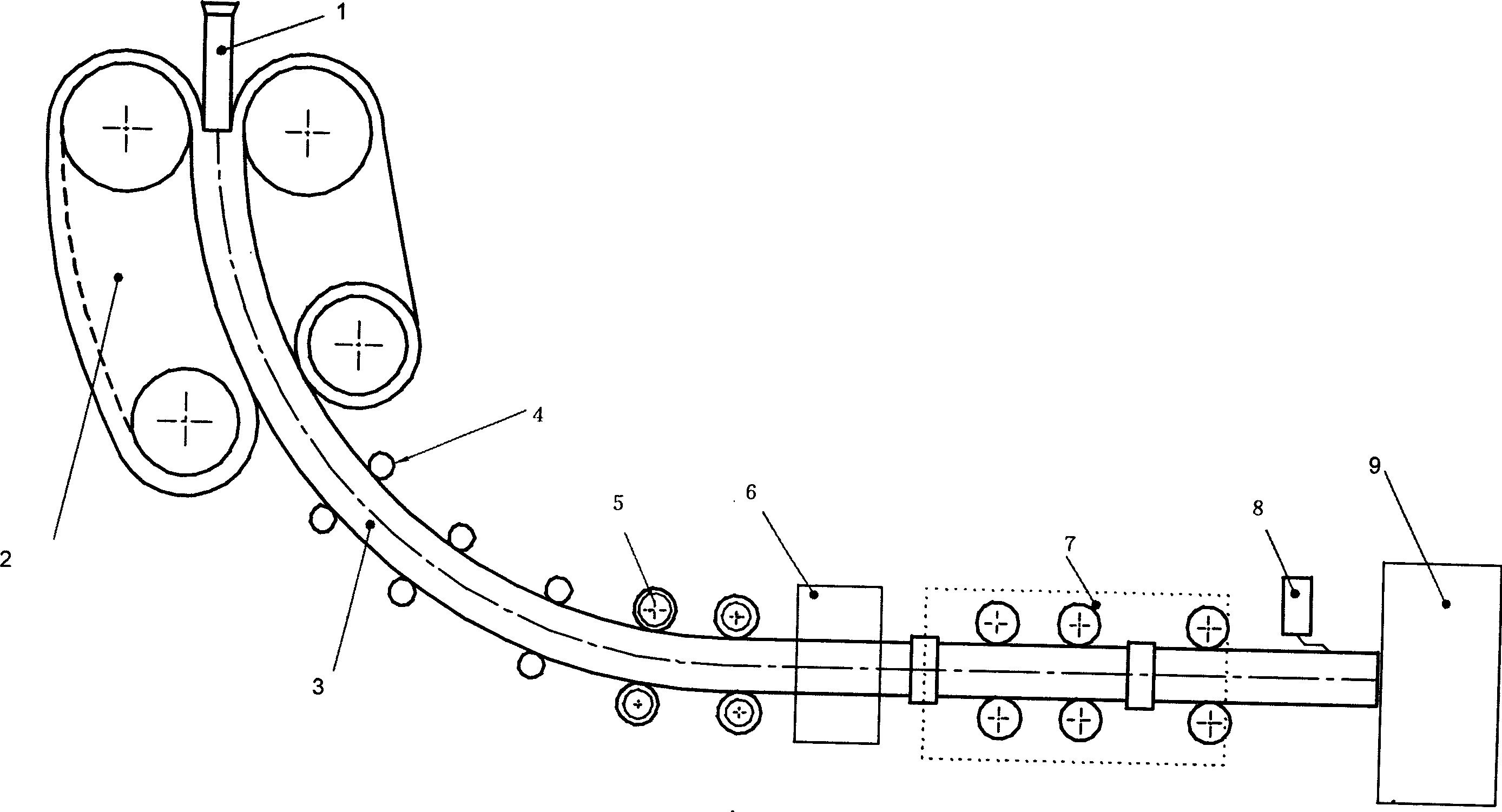

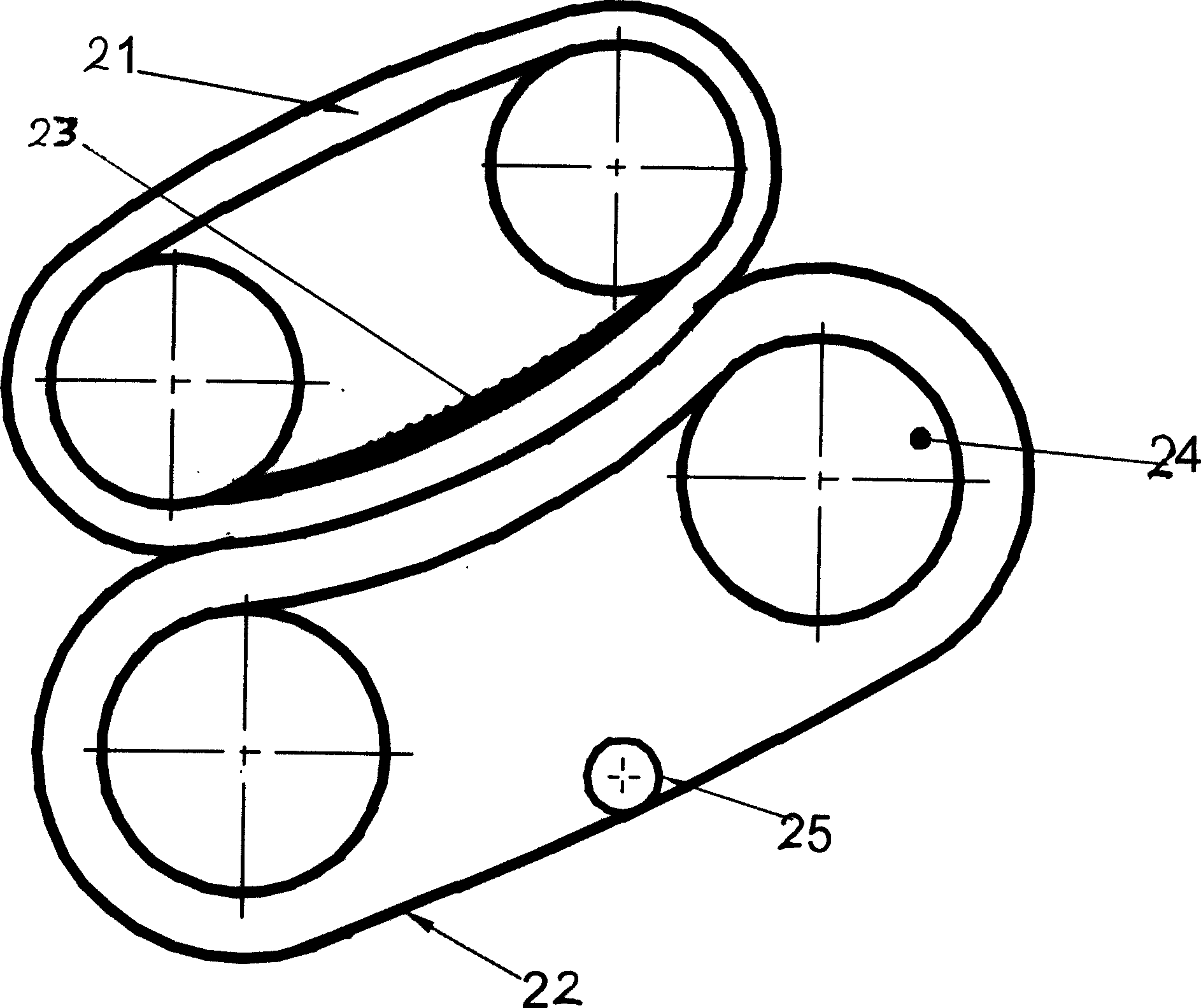

Amorphous alloy double-belt type continuous casting machine and continuous casting method thereof

The invention discloses an amorphous alloy double-belt type continuous casting machine and a continuous casting method thereof. The double-belt type continuous casting machine comprises a rack, an upper belt part and a lower belt part; the upper belt part and the lower belt part are both fixed to the rack; the upper belt part comprises a heating roller, a first supporting device, a second supporting device, a first tensioning device, a driven device and an upper steel belt; the lower belt part comprises a first distance adjusting device, a second distance adjusting device, a third distance adjusting device, a second tensioning device, a driving device and a lower steel belt; the portion, between the first tensioning device and the heating roller, of the upper belt steel and the portion, between the first distance adjusting device and the second distance adjusting device, of the lower belt steel form a molten pool used for containing amorphous alloy liquid; an inclined plane is formed between the upper steel belt and the heating roller, and two tangent lines tangential with a rotating roller of the driven device; another inclined bevel is formed between the lower steel belt and three tangent lines tangential with a rotating roller of the first distance adjusting device, the second distance adjusting device and the third distance adjusting device; and the two inclined planes areparallel to each other, and a coagulation area is formed between the two planes.

Owner:YANSHAN UNIV

Continuous casting and rolling productive technology for figured steel

InactiveCN1541783ARealize continuous castingRealize the integrated production of casting and rollingMetal rolling arrangementsSlagIntegrated production

The continuous special-steel casting and rolling production process is combination of ultrahigh speed near-finish continuous casting technology and new generation steel rolling technology and can realize automatic whole-line control. It has high production efficiency, low power consumption and compact technological process; no need of protecting slag and lubricant during continuous casting, and synchronous motion of the crystallizer and billet casing. Starter head is used to block the bottom of the crystallizer during starting the continuous casting machine, and the billet casing demolded from the crystallizer is cooled in two sections and fed with holding roller to rolling and straightening machine for direct rolling. The present invention has compact technological process, reasonable matter flow and environment friendship and may be used in integrated production of special steel.

Owner:LAIWU IRON & STEEL GRP

Method for controlling center porosity defect of bearing steel

InactiveCN102784800ARealize continuous castingPrevent water clogging problemsRoll mill control devicesMetal rolling arrangementsPorosityCooking & baking

The invention provides a method for controlling a center porosity defect of bearing steel. Continuous casting adopts a weak cold system and low superheat and low drawing speed, a tundish adopts soft fire and automatic baking, electromagnetic stirring current intensity and frequency of a crystallizer are controlled, the heating charging temperature is smaller than 850 DEG C, the temperature of a soaking zone ranges from 1200 DEG C to 1220 DEG C, the heating total time is larger than or equal to 5 hours, high reduction rolling is adopted, the first two rolling reduction is controlled between 70mm and 80mm, and finished products are piled in a mode that multiple tanks are continuously piled in each steel tanks. By means of the method, continuous casting of the bearing steel can be achieved, slag blocking and control of oxygen content of tapping in the smelting process of a converter are not needed, special top slag modification treatment is avoided when refining is performed, the problem of water port blockage caused by impurities of the bearing steel can be effectively avoided, quality level of macrostructures of the bearing steel is greatly improved, inherent quality and using performance of bearing steel are improved, and the quality qualified rate of the bearing steel is increased.

Owner:ANGANG STEEL CO LTD

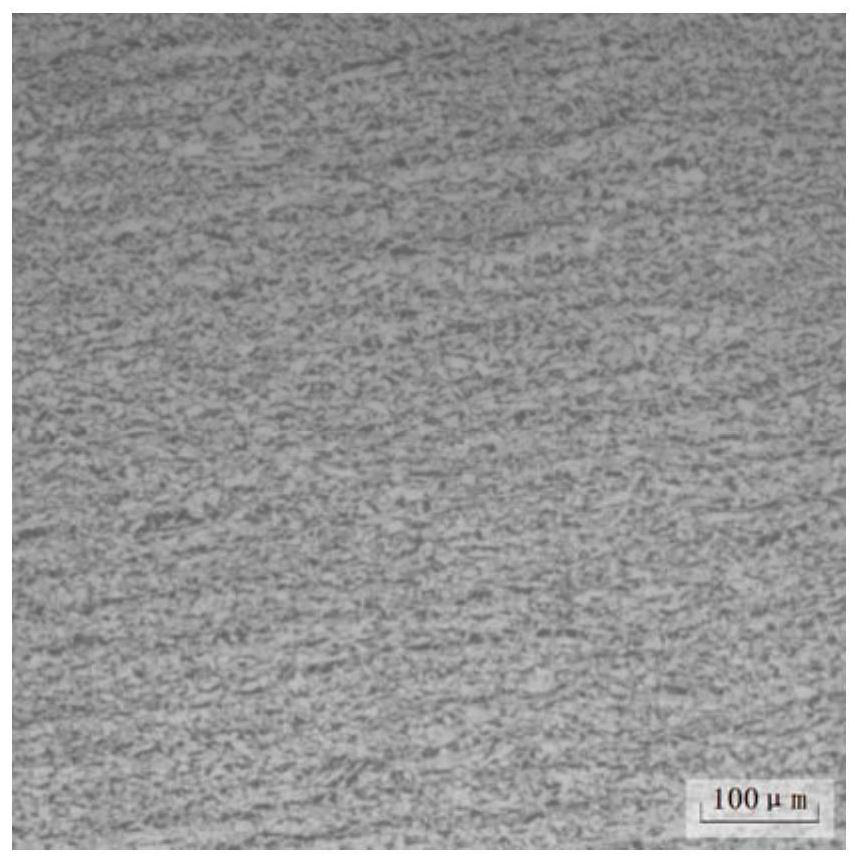

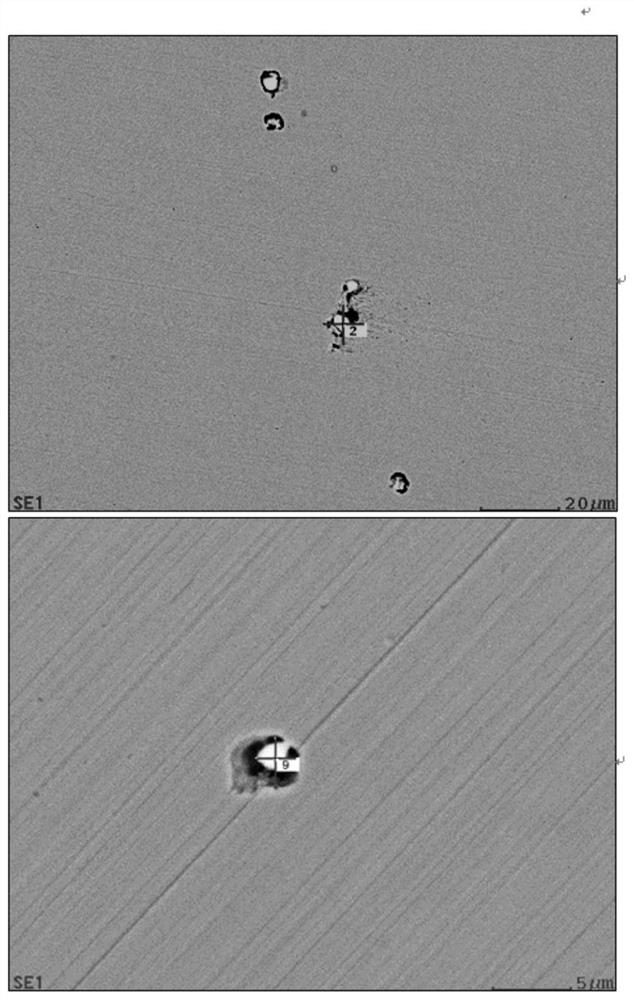

Rare earth treated low-cost high-toughness low-temperature pressure vessel steel plate and production method thereof

The invention provides a rare earth treated low-cost high-toughness low-temperature pressure vessel steel plate and a production method thereof. The rare earth treated low-cost high-toughness low-temperature pressure vessel steel plate comprises the following components: 0.10-0.16% of C, 1.20-1.60% of Mn, 0.20-0.50% of Si, less than or equal to 0.020% of P, less than or equal to 0.005% of S, 0.015-0.025% of Nb, 0.010-0.020% of Ti, 0.020-0.040% of Alt, 0.0020-0.0040% of La+Ce, less than or equal to 20 ppm of O, the balance of Fe and unavoidable inclusions. Through the microalloy elements Nb andTi and trace rare earth alloy, the low-temperature toughness of steel is further improved. Rare earth steel is produced by strictly controlling the O content and the S content of molten steel, the Cacontent in the molten steel is kept at a high level through calcium treatment in the later period of smelting, continuous casting and batch production of the rare earth steel are achieved, and the problem that the rare earth steel is unstable in performance is solved.

Owner:新余钢铁股份有限公司

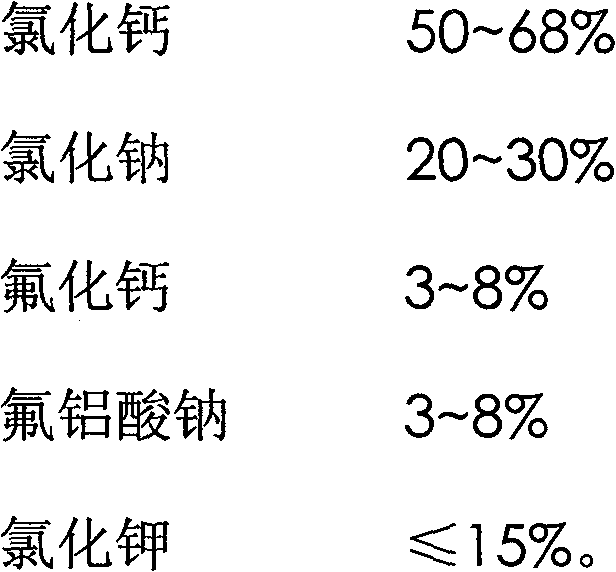

Covering agent for smelting copper alloy

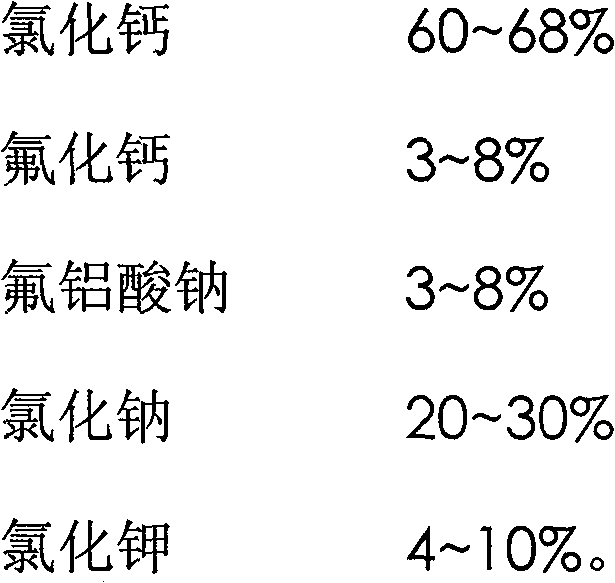

The invention discloses a covering agent for smelting copper alloy, which is prepared by adopting the mixture of calcium chloride, potassium chloride, sodium chloride, sodium fluoaluminate and calcium fluoride; one layer of favourable protective layer with the thickness of 5-80 mm is formed on the surface of smelting furnace solution so as to effectively prevent oxygen in air outside a molten pool from entering and avoid oxidation burning loss of alloy elements in the smelting process, and the covering agent has the action of thermal insulation. The covering agent of the invention can ensure that copper alloy requiring vacuum smelting can be smelted under the atmospheric environment. The covering agent of the invention is suitable for smelting copper alloy, such as copper zirconium, copper chromium, copper magnesium, copper chromium zirconium and the like which contain oxidizable elements, and is suitable for ingot blank casting, vertical continuous casting, horizontal continuous casting, up-drawing continuous casting and the like.

Owner:SHENYANG NONFERROUS METALS PROCESSING CO LTD

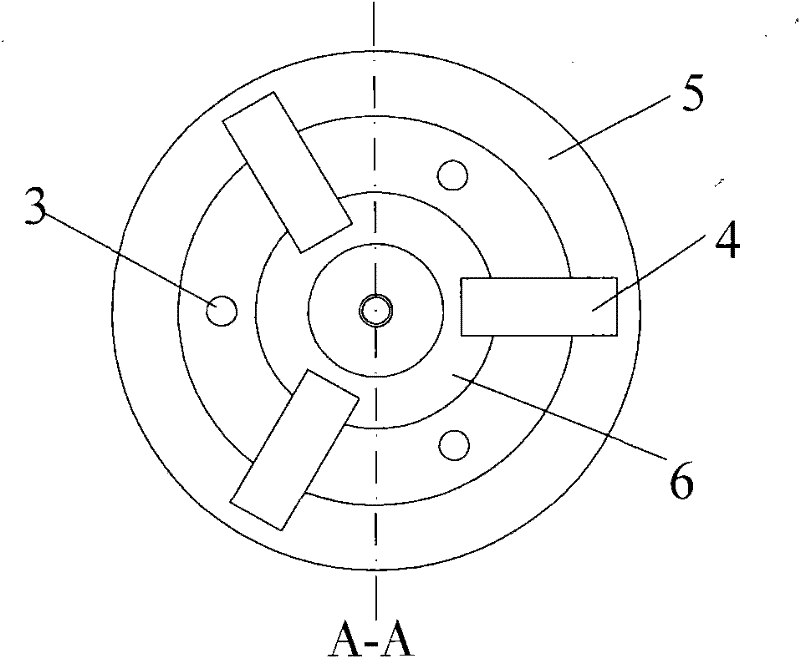

Radial functional gradient composite material casting device and method

The invention relates to a radial functional gradient composite material casting device and method, and belongs to the field of metal-based gradient composite material preparation. The casting deviceis composed of a smelting crucible, an electromagnetic induction coil, an electromagnetic separation runner, a casting mold, a cooling device and a traction mechanism. The device is simple in structure, convenient to operate and maintain and wide in application range, structural / functional adjustable functional gradient composite materials can be industrially produced in batches, the content of awild phase is increased in a gradient manner from the center to the surface in the radial direction, the size is uniform, distribution is continuous, the gradient is controllable, and the matching degree with a base body is high. The preparation method is short in technological process, high in production efficiency and high in material structure / function designability.

Owner:UNIV OF SCI & TECH BEIJING

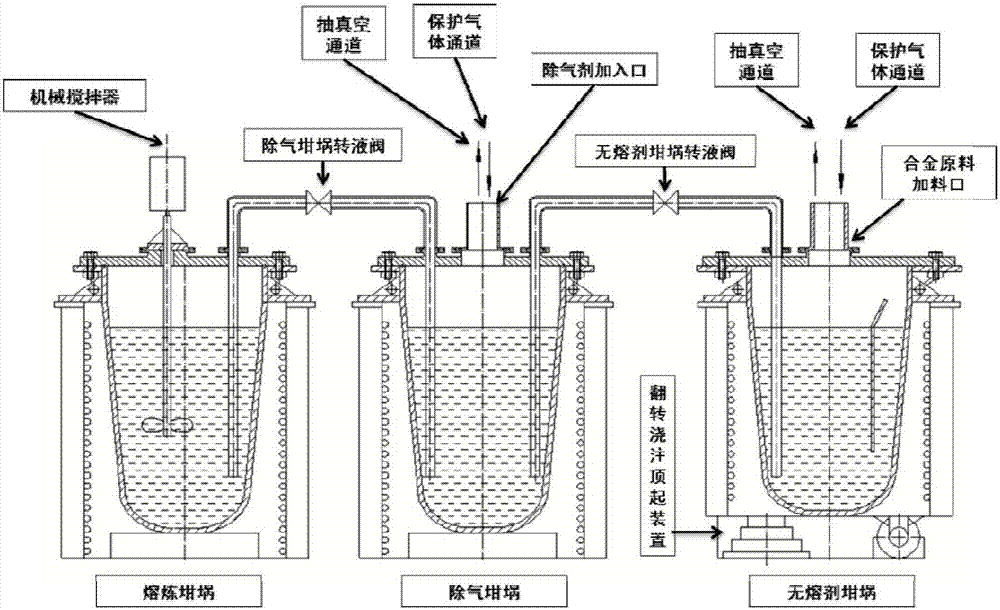

Continuous smelting and casting method of high-quality zirconium-containing magnesium alloy

The invention provides a continuous smelting and casting method of high-quality zirconium-containing magnesium alloy. The continuous smelting and casting method comprises the three continuous steps of high-density solvent refining for impurity removal, zero-impurity drag-in type degassing treatment and solvent-free efficient alloying, wherein rapid separation of a pure magnesium melt and slag is achieved through the high-density solvent refining for impurity removal, then degassing treatment is conducted on the refined pure magnesium melt by adding a zero-impurity drag-in paraffin-graphite degassing agent, finally the alloying is completed by adding a zinc element, magnesium-zirconium intermediate alloy subjected to isothermal forging deformation treatment and magnesium-rare earth intermediate alloy subjected to isothermal forging deformation treatment in a solvent-free crucible, and casting and forming of the high-quality zirconium-containing magnesium alloy melt are completed in a tilt rotating mode of the crucible. The continuous smelting and casting method meets the component ageing sensibility and high melt quality requirements of the zirconium-containing magnesium alloy, and the continuous smelting and casting method of the high-quality zirconium-containing magnesium alloy is low in inclusion content and low in melt gas content and capable of efficiently utilizing alloy elements and achieving continuous smelting and casting.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Short-flow continuous forming device for tin-bismuth alloy welding wire and forming method

InactiveCN105598168AShort production processProduction Facility SavingsMetal rolling arrangementsBismuth preparationMelting heat

The invention discloses a short-flow continuous forming device for a tin-bismuth alloy welding wire. The short-flow continuous forming device comprises a melt heat-preserving furnace, a heat-preserving plate with a casting hole, a guide wheel, a water atomizer, a guide rod and a rolling mill, wherein the heat-preserving plate with the casting hole is fixedly connected to the side face of the melt heat-preserving furnace; the water atomizer is arranged on an upper part behind the casting hole; the rolling mill is positioned behind the casting hole; the guide rod is inserted into the casting hole, and is arranged on a traction machine; the guide rod passes through the guide wheel. By adopting the short-flow continuous forming device for the tin-bismuth alloy welding wire and a forming method provided by the invention, show-flow machining of the tin-bismuth alloy welding wire which is difficult to form is realized, and the production process is shortened remarkably.

Owner:JIANGXI UNIV OF SCI & TECH

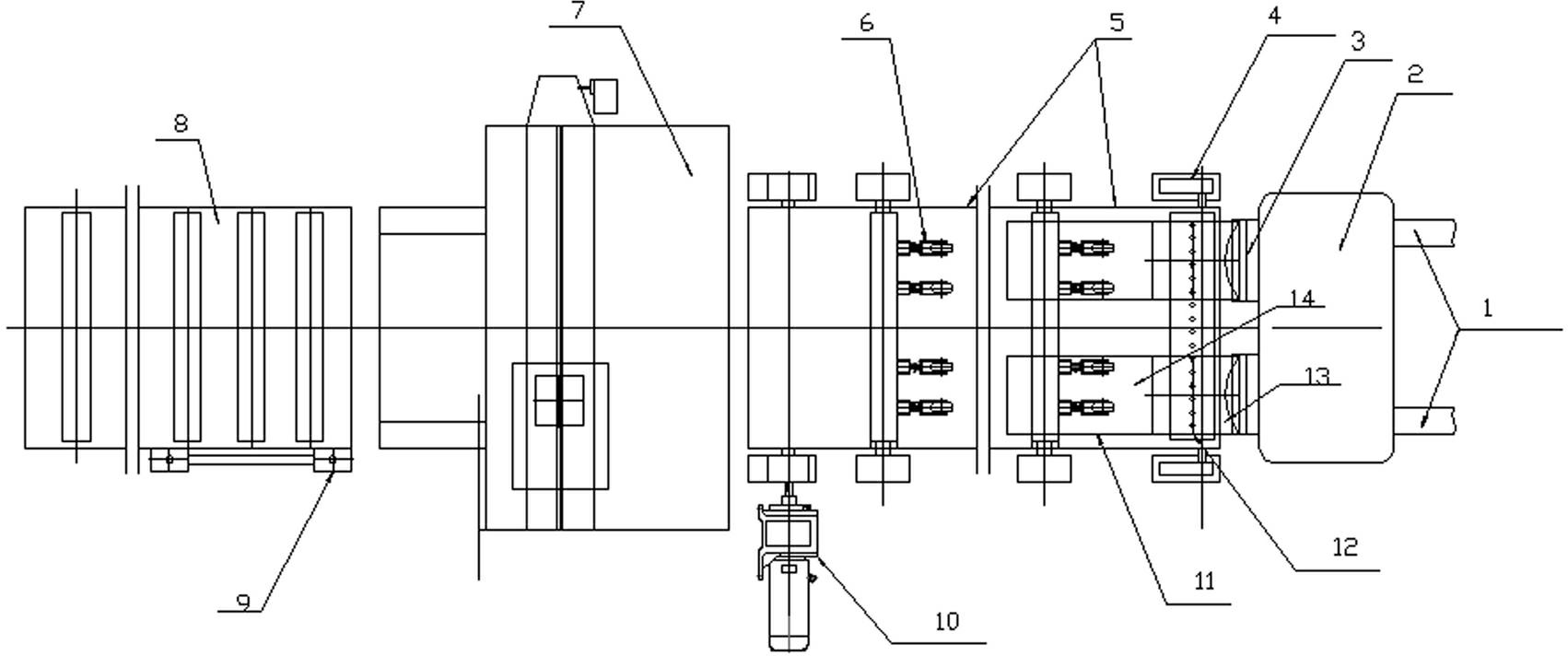

Aluminum alloy low pressure casting automatic production line technology and equipment

The invention belongs to the technical field of metal casting equipment, and particularly relates to full automatic continuous casting production equipment and technology for low-pressure casting of aluminum and aluminum alloy. The equipment consists of a smelting furnace (1), a low-pressure heat preserving furnace (2), a wheel type multi-platform casting machine (3), an automatic part-taking mechanical arm (4), an automatic dedusting-spraying-cooling three-in-one mechanical arm (5), an automatic conveyor and liquid level pressuring device (6), a temperature control cabinet (7) and a control panel (8). By adopting a numerical control multi-station and timing-sequence-sharing continuous casting technology, the raw material is fed into the smelting furnace, and is automatically transported into the heat preserving furnace after being smelted, and molten aluminum is injected into metal molds on the wheel type multi-platform casting machine under the control of the liquid level pressuring device, so that a product can be formed. A plurality of molds and corresponding mold disassembly / assembly mechanisms are arranged on the wheel type multi-platform casting machine, and the working procedures such as the casting, the shape keeping, the mold disassembling, the part taking, the cleaning-spraying-cooling, the mold assembling and the like in the process of the low-pressure casting can be completed on different stations at different times when the wheel type multi-platform casting machine rotates, so that the continuous and quantitative automatic production of the aluminum alloy cast parts can be realized.

Owner:ZHEJIANG SANRUI INTERNAL COMBUSTION ENGINE PARTS

Continuous casting process of nickel coated copper composite materials

The invention provides a continuous casting process of nickel coated copper composite materials. The continuous casting process comprises the following steps of smelting copper and nickel and performing heat preservation on a copper and nickel solution in a heat preservation furnace; step 2, performing nickel pipe forming which comprises enabling the nickel solution to pass through a graphite crystallizer to form a nickel pipe, wherein a graphite core of the graphite crystallizer is in a hollow shape; step 3, hollowly pouring the copper solution into the formed nickel pipe through the graphite core in a rotating magnetic field environment simultaneously, maintaining the billet drawing speed to be 50 to 60 millimeters every minute and the cooling water temperature to be 20 to 50 DEG C in the process of horizontal continuous casting, enabling the current frequency of an alternating induction coil to be 18 to 30 Hz and the current intensity of the alternating induction coil to be 100 A when the rotating magnetic field is applied and obtaining nickel coated copper continuous casting billet; step 4, performing oxidation cleaning; step 5, performing surface treatment; step 6, performing storage. According to the continuous casting process of the nickel coated copper composite materials, the nickel coated copper wires are firm in combination, the production process is simple, the wastewater is not produced in the production process, and the environment-friendly effect is achieved.

Owner:江苏华旺科技有限公司

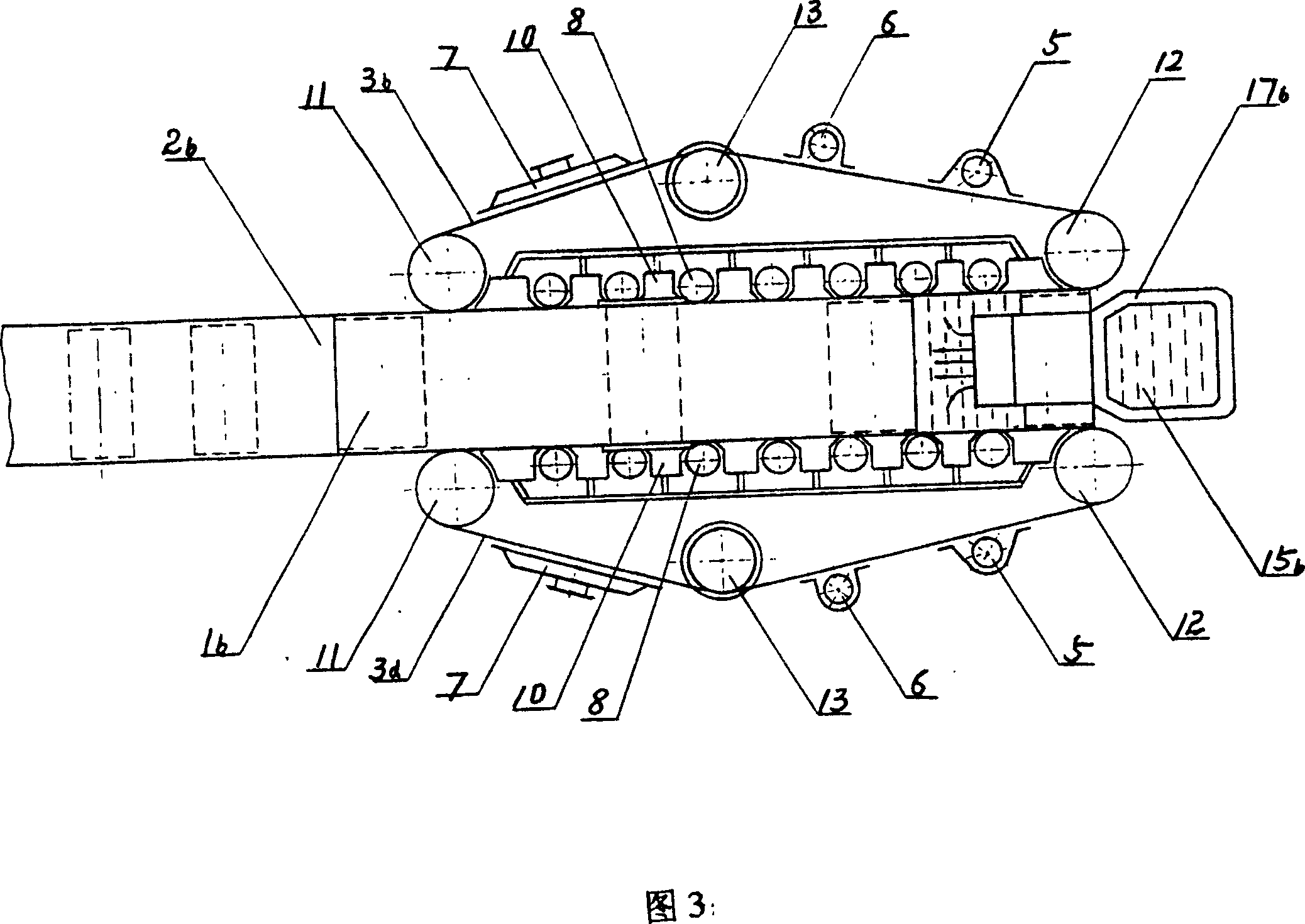

Continuous casting machine for stainless compound steel plate strip blank

The invention relates to a stainless steel clad plate billet conticaster. It belongs to a continuous casting device in the art of metallurgical industry. The device can be characterized in that: it comprises three synchronous circulating mobile steel band crystallizers A, B and C, which are Y- type equipped, the lower cooling steel band 2 of crystallizer A being common with the right-side cooling steel 2c of the crystallizer C, and the lower cooling steel band 2b of crystallizer B being common with the left-side cooling steel 2d of the crystallizer C. After the strand being forged by from multigroup flexible guiders, multigroup steam- water spray devices and traction roller which are under the crystallizer C, the clad plate billet is aligned to horizontality by a blending guider and a smoothing roll, and then is sent to shearer to be sheared into a definite length or sent to continuous rolling mill to roll down. The merit is characterized in that: it improves the production efficiency of the conticaster, and guarantees the quality of strand and rolled metal.

Owner:李铁铎

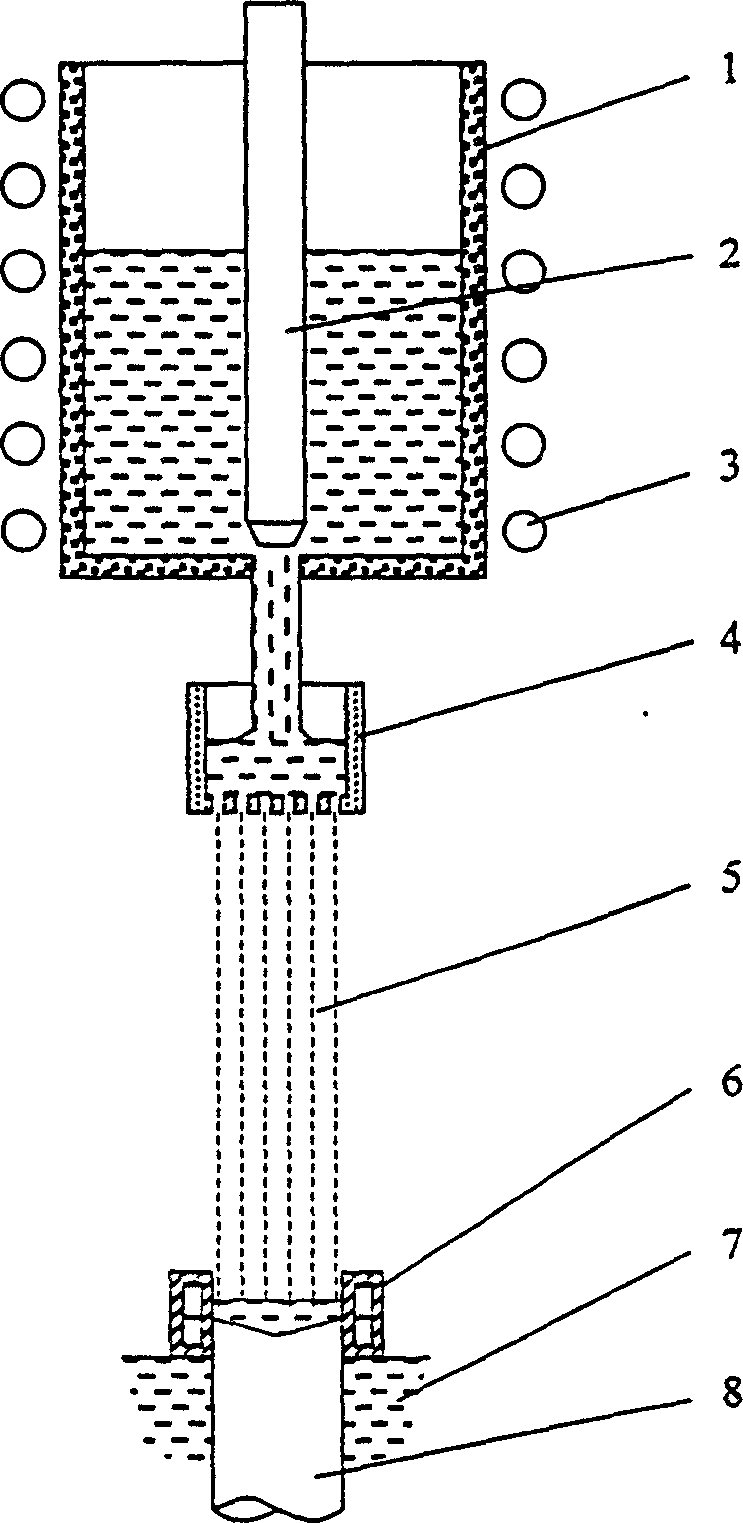

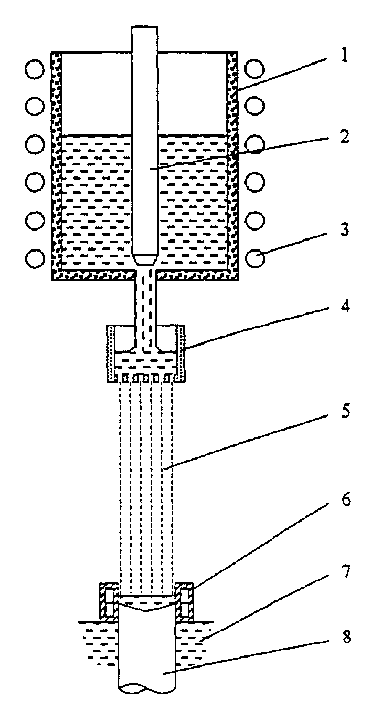

Copper, chrome, titanium and zirconium alloy rod and continuous preparing method thereof

The invention discloses a method for upward traction continuous preparing of a copper, chrome, titanium and zirconium alloy rod. Fine copper and a copper chrome alloy raw material are placed into a crucible, are covered with charcoal, and are heated to be not lower than 1180 DEG C + / -5 DEG C and not higher than 1200 DEG C + / -5 DEG C, after an alloy is fused, copper titanium and copper zirconium alloy raw materials are added into the crucible and are subject to heat preservation and standing for not longer than 1 min, and the melt temperature is measured; and after melt reaches 1180 DEG C-(10*chrome mass percent+50*titanium mass percent+100*zirconium mass percent) DEG C, (the chrome mass percent in the alloy is not lower than 0.2 and not higher than 0.7, the titanium mass percent is not lower than 0.05 and not higher than 0.1, the zirconium mass percent is not lower than 0.05 and not higher than 0.2, and the balance is copper and impurities) the alloy is subject to upward continuous traction, and a continuous length copper, chrome, titanium and zirconium alloy rod material is obtained and rolled. According to the method, upward traction continuous casting of a copper rod by 100 m or above can be achieved, and the scale production and application prospect is achieved.

Owner:JIANGXI UNIV OF SCI & TECH

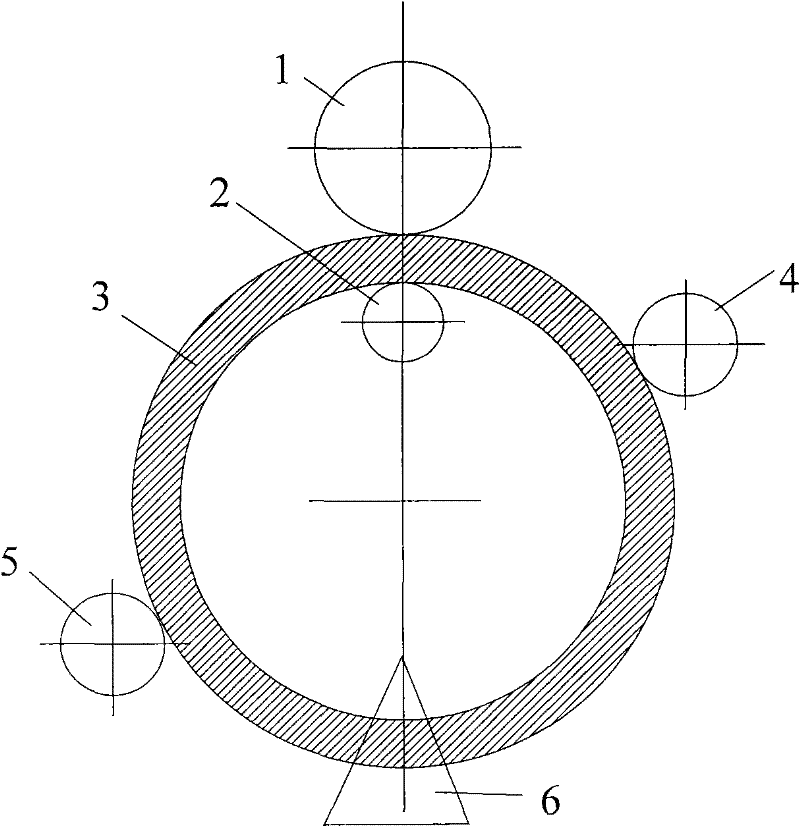

Short-flow preparation process for thick-wall ring piece and thick-wall tube piece

The invention belongs to the field of high-end equipment manufacturing, in particular to a hollow-ingot-continuous-casting-manufacturing-technology-based short-flow preparation process for a highly compact and purely purified thick-wall ring piece and a highly compact and purely purified thick-wall tube piece. The raw blanks of the thick-wall tube piece and the thick-wall ring piece are produced by a hollow ingot continuous casting technology, and the thick-wall ring piece and the thick-wall tube piece are produced by a ring roller machine and a forging press. Generally, the thick-wall ring piece and the thick-wall tube piece which have a large diameter is prepared from solid steel ingot by the steps of upsetting, punching, drawing-out, chambering and the like, the process is complex, themanufacturing period is long, and the heating frequency is high. The hollow steel ingot prepared by the technology has the characteristics of high compactness and purity degree, and provides high-quality raw materials for the high-end ring piece and the high-end tube piece. Through the hollow ingot continuous casting, the steps of upsetting and punching are saved, and the large-diameter tube piece and the large-diameter ring piece can be prepared only by the steps of drawing-out and chambering, the manufacturing period is greatly shortened, the heating frequency is reduced, and the short-flowmanufacturing of the high-end ring piece and the high-end tube piece is realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Covering agent applicable to smelting of copper alloy containing easily oxidized alloying elements and application of covering agent

The invention belongs to the technical field of copper alloy machining, and relates to a covering agent applicable to smelting of a copper alloy containing easily oxidized alloying elements, and application of the covering agent. The coving agent consists of the following components in mass percent: 50-80% of sodium borate and 20-50% of cullet, wherein the sodium borate and the cullet are added respectively, and the cullet is added firstly, and then the sodium borate is added with the time interval not less than 10 min. Through the covering agent, vacuum smelting can be replaced by common smelting, the copper alloy containing easily oxidized alloying elements can be smelted by a common electric induction furnace, large-size ingot castings can be easily prepared and continuously cast, and the alloy quality of the copper alloy subjected to smelting is better. The covering agent related to the invention has the characteristics of low cost, environmental protection and energy conservation.

Owner:洛阳双瑞达特铜有限公司

Broad-width horizontal multiple continuous casting device

The invention relates to a broad-width horizontal multiple continuous casting device, which comprises a tundish and a horizontal chain plate-type aluminum and aluminum alloy continuous casting machine, wherein, the tundish is used for casting; a crystallizer with a water jacket, a horizontal chain scraper conveyor, an ingotting hold-down device, a dummy ingot device, a synchronous saw-cutting mechanism and a floating roller way are arranged in the horizontal chain plate-type aluminum and aluminum alloy continuous casting machine; in addition, the breadths of the tundish for casing and the horizontal chain plate-type aluminum and aluminum alloy continuous casting machine are not less than 1.5 to 6.5 m. The broad-width horizontal multiple continuous casting device widens the breadths of a traditional aluminum and aluminum alloy chain plate casting machine and the tundish for casing to more than 1.5 m, and correspondingly changes the aspects of aluminum feeding manner, the ingotting hold-down device, a synchronous saw-cutting device and the like at the same time, so that the broad-width horizontal multiple continuous casting can be achieved, and the production efficiency can be improved greatly.

Owner:王建军

A method and device for continuously preparing particle-reinforced metal matrix composites

Owner:KUNMING UNIV OF SCI & TECH

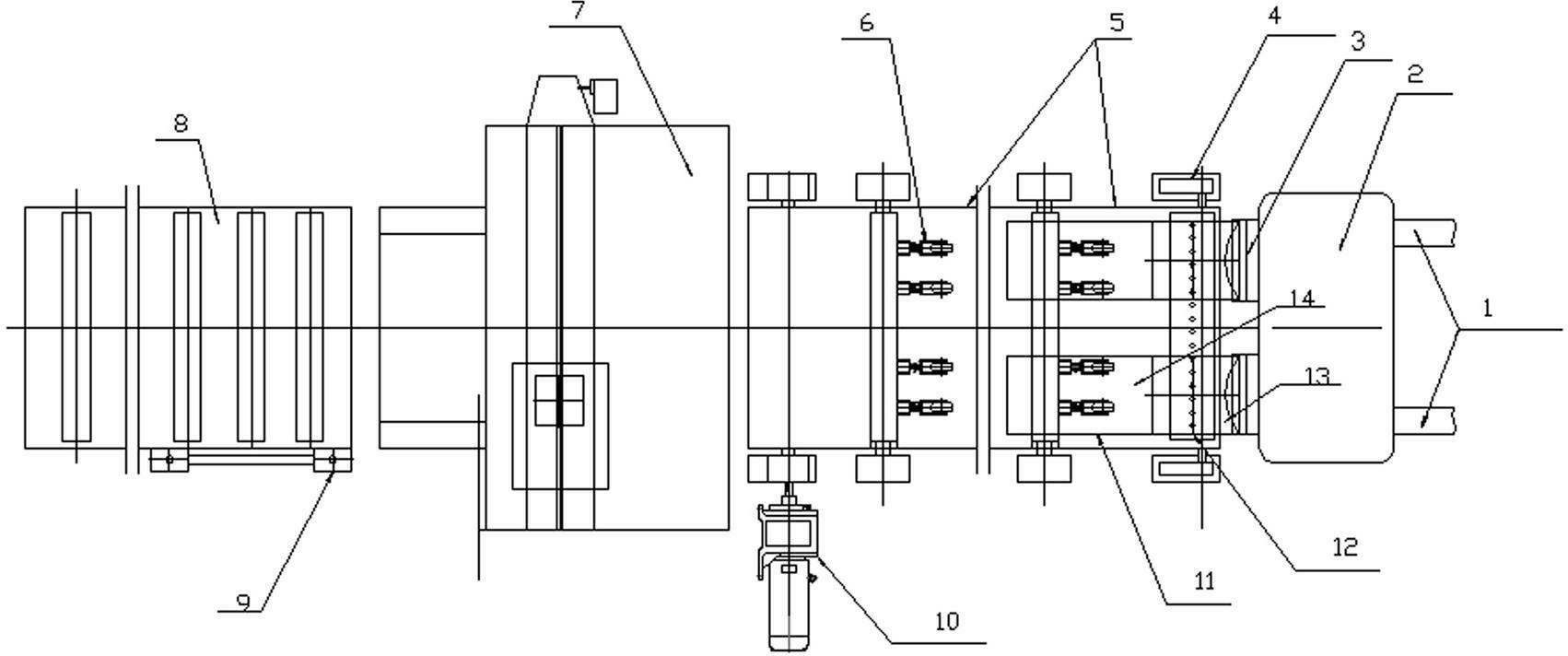

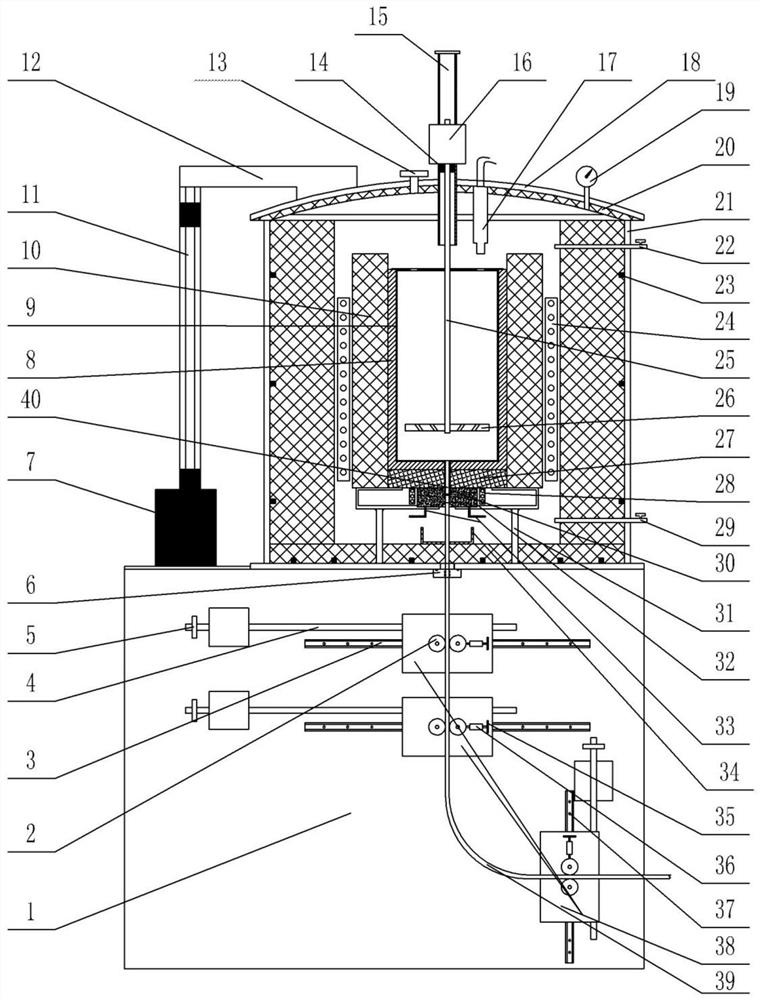

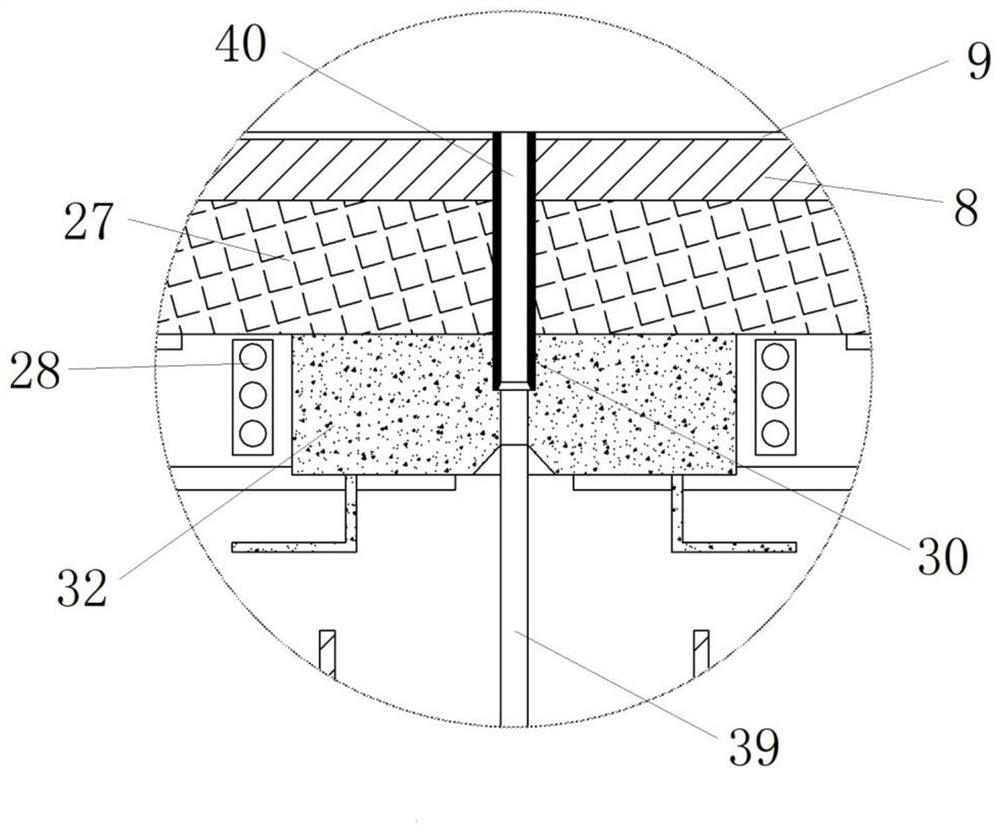

Vacuum vertical continuous casting machine for high-temperature metal and alloy

ActiveCN113385650ARealize continuous castingUniform compositionProcess efficiency improvementExhaust valveCrucible

The invention provides a vacuum vertical continuous casting machine for high-temperature metal and alloy. The continuous casting machine comprises a vacuum device, a smelting device, a heat preservation device, a crystallization forming device and a traction device. The vacuum device comprises a furnace body and an upper cover body, wherein an exhaust valve and an air inlet valve are arranged on the furnace body; the smelting device comprises a crucible, wherein the crucible is arranged in the furnace body, a heating coil is arranged on the periphery of the crucible, a stirring motor is arranged on the upper cover body, an output shaft of the stirring motor is connected with a stirring rod, and the lower end part of the stirring rod is connected with a stirrer; a discharge hole is formed in the lower part of the crucible; the crystallization forming device comprises a crystallizer, coolers and a heater, the crystallizer is arranged in the peripheral direction of a discharging port in the lower portion of the crucible, and the coolers are arranged on the periphery of the crystallizer; a heater is arranged at the periphery of the cooler; the traction device comprises traction wheels which are arranged in pairs.

Owner:HENAN POLYTECHNIC UNIV +1

Aluminum guide rod forming device

The invention relates to an aluminum guide rod forming device, in particular to an aluminum guide rod casting device. The aluminum guide rod casting device comprises a melting furnace, and is characterized in that the lower part of the melting furnace is connected with a filtering box, and the rear part of the filtering box is sequentially connected with crystallizers, an endless conveyor belt and a synchronous saw. The aluminum guide rod casting device provided by the invention has the advantages as follows: the structure is simple; the problems of low one-step casting yield, length limitation and the like of aluminum guide rods are solved; the investment is low; the efficiency is high; the technological operation is convenient; the technological conditions are easy to control; continuous casting can be realized; the yield is high; the product quality is stable; the defects of gas pore, slag inclusion and the like of ingots are few; and the electric conductivity is excellent.

Owner:QINGTONGXIA ALUMINUM GRP

Stepped cooling and continuous casting method of massive amorphous alloy

The large block amorphous alloy stepwise cooling continuous casting method includes: firstly, melting alloy material in crucible, heating to above melting point, heat-insulating, then removing plunger of crucible to make molten alloy flow out from cast gate of crucible bottom portion and flow into lower liquid flow disperser, quickly-cooling the dispersed fine-small molten alloy flow to about nasal tip temp. Tn of nucleation C curve, then pouring the low-temp. molten alloy into casting mould, further cooling to below vitrification point and condensing to obtain the invented amorphous alloy whose mechanical and physicochemical properties are identical to that of copper mould heavy cast amorphous material.

Owner:SHANGHAI JIAO TONG UNIV

Amorphous alloy continuous casting machine and continuous casting method thereof

PendingCN113118403ARealize continuous castingGuarantee the surface quality of the slabMetallic materialsAlloy

The invention discloses an amorphous alloy continuous casting machine and a continuous casting method thereof, and relates to the technical field of metal material casting. The amorphous alloy continuous casting machine comprises a rack, multiple moving blocks, a molten pool, a sealing mechanism and a driving mechanism. A guide rail is arranged on the inner side of the rack, the multiple moving blocks are movably arranged on the guide rail, and the moving blocks are in power connection with the driving mechanism. The molten pool is arranged above one end of the rack, and the sealing mechanism is arranged above the rack and located at the tops of the multiple moving blocks. A rectangular casting cavity formed by the moving blocks and a steel belt realizes continuous casting of amorphous alloys with different specifications. The moving blocks and the steel belt move synchronously, so that the surface quality of an amorphous alloy cast blank is guaranteed. Solidification and output of amorphous alloys are completed in the casting cavity, the device structure is simple, and space is saved. Melt moves in the casting direction while being cooled and solidified in the casting cavity, continuous casting is achieved, and therefore the continuously-cast amorphous alloys are obtained. The moving blocks are mutually independent and are convenient to replace and disassemble when problems occur.

Owner:YANSHAN UNIV

A high-efficiency continuous casting method for closed-cell aluminum foam ingot with controllable structure

The invention discloses a high-efficiency continuous casting method for a closed-cell foamed aluminum ingot with a controllable structure, which belongs to the technical field of continuous preparation of porous metals. This method achieves the decomposition control of the foaming agent in the melt by changing the treatment method of the foaming agent. The continuous production not only greatly improves the production efficiency, but also solves the problem of no foam layer in the static casting. The pouring temperature, pouring speed and cooling intensity realize the continuous production of closed-cell aluminum foam ingots. This method controls the size and shape of the bubbles in the aluminum matrix by adding foaming agents of different types, different amounts, different particle sizes, and different pretreatments. The control method of the pore structure has higher feasibility and is more in line with reality. Requirements for product diversity in applications. The method is simple in process and low in cost, realizes continuous casting, greatly improves production efficiency, and is more in line with industrial requirements. The method can continuously prepare large-sized closed-cell foamed aluminum ingots with high efficiency.

Owner:DALIAN UNIV OF TECH

Cooling device for aluminum alloy casting processing equipment

ActiveCN112045155BRealize continuous castingRealize automatic unloadingWater storage tankEngineering

The invention belongs to the field of casting, especially a cooling device for aluminum alloy casting processing equipment. The following proposal is proposed, which includes a water storage tank and a fixing plate. The middle position of the plate is rotatably connected with a rotating column, and the bottom end of the rotating column is fixedly connected with a transmission disc located below the fixed plate. There are four transmission holes arranged in a circular array on the edge of the transmission disc. The top of the water storage tank is installed with a An electric motor, the output shaft of the motor is connected with a swing piece, the top side of the swing piece is fixedly connected with a sliding block slidingly connected with the transmission hole, the top end of the rotating column is fixedly connected with a mounting plate, and four rings are fixedly connected on the mounting plate The casting mold arranged in an array is provided with a plurality of casting wells arranged in an annular array on the casting mold, and the casting wells pass through the mounting plate. The invention can realize the continuous casting of the aluminum alloy rod, and realize the secondary cooling in the casting process, the cooling speed is fast, and the processing efficiency is high.

Owner:东莞安兴五金压铸有限公司

A continuous refining process of blister copper by fire method

The invention provides a crude copper pyrogenic process continuous refining technology. The technology comprises the steps that crude copper is added into an adding oxidation area, and copper liquid is obtained through fusion; oxidizing gas is introduced into the copper liquid, impurity elements in the copper liquid are oxidized to generate oxidation refining slag, and the oxidation refining slagis discharged at regular intervals; the oxidized copper liquid flows into a reducing area; a reducing agent is added into the reducing area, the oxidized copper liquid is subjected to a reducing reaction; and the reduced copper liquid flows into a casting area, wherein the adding oxidation area, the reducing area and the casting area are isolated through isolation walls, communicate mutually in the bottoms and are located in a furnace body. The crude copper pyrogenic process continuous refining technology has the advantages of being low in energy consumption, environmentally friendly, high inautomation level, high in production efficiency and the like, crude copper continuous feeding and anode copper continuous casting can be achieved, oxidation and reducing processes are simultaneously carried in the operation process, operation time can be shortened, the equipment utilization rate is improved, the smog amount and smog ingredients are stable, and concentrated treatment and waste heatrecycling can be achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION

A kind of magnesium alloy thick plate continuous production equipment and process

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

A continuous refining device for blister copper by fire method

The invention provides a crude copper fire continuous refining device comprising a furnace body and a floss hole formed in the top of the furnace body. The furnace body is internally provided with a charging oxidation zone, a reduction zone and a casting zone which are partitioned through partition walls, but the bottoms of the charging oxidation zone, the reduction zone and the casting zone communicate mutually; and the reduction zone is located between the charging oxidation zone and the casting zone. The crude copper fire continuous refining device has the advantages of lower energy consumption, environmental friendliness, high automation level, high production efficiency and the like; crude copper continuous feeing and anode copper continuous casting can be achieved, the oxidation andreduction processes are conducted simultaneously during running, the operation time can be shortened, the utilization rate of the crude copper fire continuous refining device is increased, meanwhile,the flue gas volume and the flue gas ingredient are stable, centralized treatment can be achieved, and waste heat is recycled.

Owner:CHINA ENFI ENGINEERING CORPORATION

Casting process of clay cylinder

InactiveCN102756091AMeet the use requirementsLess investmentFoundry mouldsFoundry coresMetalComposite material

The invention discloses a casting process of a clay cylinder. The casting process of the clay cylinder includes following steps: manufacturing a metal mould of the clay cylinder; preparing a manufacturing tool; arranging a sprue gate, a riser and an air outlet on the mould; placing resin sand into the metal mould to mould the resin sand; patching the molded resin sand mould and painting the surface of the mould; arranging and assembling the resin sand mould; lifting a box of the resin sand mould; placing a sprue cup on the sprue gate of the mould, and placing a riser cup on the riser of the mould; and casting melted iron into a cavity of the resin sand mould by the aid of a crane ladle for grey chiller casting. The casting process of the clay cylinder has the advantages of high accuracy, saving in materials, simple steps, and improved production efficiency.

Owner:陆宝庆

A method for continuous melting and casting of high-quality zirconium-containing magnesium alloy

The invention provides a continuous smelting and casting method of high-quality zirconium-containing magnesium alloy. The continuous smelting and casting method comprises the three continuous steps of high-density solvent refining for impurity removal, zero-impurity drag-in type degassing treatment and solvent-free efficient alloying, wherein rapid separation of a pure magnesium melt and slag is achieved through the high-density solvent refining for impurity removal, then degassing treatment is conducted on the refined pure magnesium melt by adding a zero-impurity drag-in paraffin-graphite degassing agent, finally the alloying is completed by adding a zinc element, magnesium-zirconium intermediate alloy subjected to isothermal forging deformation treatment and magnesium-rare earth intermediate alloy subjected to isothermal forging deformation treatment in a solvent-free crucible, and casting and forming of the high-quality zirconium-containing magnesium alloy melt are completed in a tilt rotating mode of the crucible. The continuous smelting and casting method meets the component ageing sensibility and high melt quality requirements of the zirconium-containing magnesium alloy, and the continuous smelting and casting method of the high-quality zirconium-containing magnesium alloy is low in inclusion content and low in melt gas content and capable of efficiently utilizing alloy elements and achieving continuous smelting and casting.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Rare earth treatment Low -cost high toughness Low -temperature pressure vessel steel plate and its production method

The rare earth-treated low-cost, high-toughness, low-temperature pressure vessel steel plate and a production method thereof provided by the invention are composed of: C0.10-0.16%, Mn1.20-1.60%, Si0.20-0.50%, P≤0.020%, S ≤0.005%, Nb: 0.015-0.025%, Ti: 0.010-0.020%, Alt: 0.020-0.040%, La+Ce: 0.0020-0.0040%, O≤20ppm, the rest are Fe and inevitable inclusions. The low temperature toughness of steel is further improved by microalloying elements Nb, Ti and trace rare earth alloys. The rare earth steel is produced by strictly controlling the content of O and S in the molten steel. In the later stage of smelting, the Ca content in the molten steel is kept at a high level by calcium treatment. Stability issue.

Owner:新余钢铁股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com